Page 1

HP

P4800 G2 SAN Solution for BladeSystem

Maintenance Guide

Abstract

This guide explains how to back up, restore, upgrade, and otherwise maintain the HP P4800 G2 SAN Solution for BladeSystem.

The intended audience is system administrators and technicians with experience managing and repairing networked storage.

For installation and configuration information, see the HP P4800 G2 SAN Solution for BladeSystem Quick Start Guide. For

day-to-day operations, see the HP P4000 SAN Solution User Guide. For late-breaking information, HP recommends that you

read the release notes for the installed software version.

Obtain the latest version of this and other HP P4000 user documents by navigating to the Manuals page of the HP Business

Support Center website:

www.hp.com/support/manuals

In the Storage section, select Disk Storage Systems and then select HP P4000 G2 SAN Solutions.

HP Part Number: AX696-96151

Published: September 2011

Edition: 4

Page 2

© Copyright 2010, 2011 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or omissions contained herein.

Acknowledgments

Microsoft® Windows® is a U.S. registered trademark of Microsoft Corporation.

Warranty

To obtain a copy of the warranty for this product, see the warranty information website:

http://www.hp.com/go/storagewarranty

Revision History

July 2010Revision 1

First edition

November 2010Revision 2

Second edition—Updated with changes for the SAN/iQ software 9.0 release.

March 2011Revision 3

Third edition—Applied branding changes to product and server blade names. The product name changed from P4000 BladeSystem for SAN

Solutions to P4000 G2 SAN Solution for BladeSystem. The server blade changed from the BL460c G6 to the BL460c G7 (G2 server blade). The

G2 server blade name is P4460sb.

September 2011Revision 4

Fourth edition—Changed Quick Restore references from a CD to an .iso image.

Page 3

Contents

1 Overview..................................................................................................5

Hardware components..............................................................................................................5

Hardware configuration.............................................................................................................5

Documentation available...........................................................................................................9

2 Backing up HP P4800 G2 solution configurations.........................................11

Backing up or restoring the Virtual Connect domain configuration.................................................11

Backing up the SAS switch.......................................................................................................12

Backing up remaining HP P4800 G2 solution configurations........................................................12

3 Maintaining the HP P4800 G2 solution.......................................................13

Troubleshooting......................................................................................................................13

Locating the HP P4800 G2 solution warranty entitlement labels....................................................13

Performing field system recovery of the HP P4800 G2 solution......................................................14

Repairing a storage system......................................................................................................17

Upgrading SAN/iQ software...................................................................................................18

Adding capacity to an existing P4800 G2 SAN.........................................................................18

Upgrading firmware................................................................................................................18

4 Removing and replacing the HP P4800 G2 solution components....................20

Additional component removal and replacement instructions........................................................20

Identifying hot pluggable and non-hot pluggable components......................................................20

Replacing the server blade and server blade components............................................................20

Replacing the controller and controller components.....................................................................22

Replacing the VC Flex-10 module..............................................................................................24

Replacing the SAS switch.........................................................................................................24

Replacing a SAS cable............................................................................................................25

Replacing the disk enclosure I/O module...................................................................................26

Replacing the disk enclosure power supply.................................................................................26

Replacing the disk enclosure fan...............................................................................................26

Replacing the disk enclosure hard drive.....................................................................................27

5 Support and other resources......................................................................28

Contacting HP........................................................................................................................28

HP Insight Remote Support software..........................................................................................28

Related information.................................................................................................................29

Rack stability..........................................................................................................................30

Customer self repair................................................................................................................30

A HP P4800 G2 solution cabling..................................................................31

B Regulatory compliance notices...................................................................35

Regulatory compliance identification numbers............................................................................35

Federal Communications Commission notice..............................................................................35

Canadian notice (Avis Canadien).............................................................................................36

European Union notice............................................................................................................36

Japanese notices....................................................................................................................37

Korean notices.......................................................................................................................37

Taiwanese notices...................................................................................................................38

Turkish recycling notice............................................................................................................38

Laser compliance notices.........................................................................................................39

Recycling notices....................................................................................................................41

Contents 3

Page 4

Battery replacement notices.....................................................................................................46

Glossary....................................................................................................50

Index.........................................................................................................51

4 Contents

Page 5

1 Overview

The HP P4800 G2 SAN Solution for BladeSystem (HP P4800 G2 solution) base configuration is

a 2-node SAN consisting of two server blades and one disk enclosure. The server blades run the

SAN/iQ software, and the disk enclosure contains 70 disks. Up to six server blades and three

disk enclosures can be added, for a total of eight blades and four disk enclosures in an 8-node

SAN.

Multiple HP P4800 G2 solutions can be combined into clusters or management groups as part of

the same SAN.

NOTE: In this solution, storage system corresponds to a server blade. There are up to eight

storage systems in the HP P4800 G2 solution.

Hardware components

The HP P4800 G2 solution comprises the following components:

• HP BladeSystem c7000 Enclosure (1)

• Server blades (2 to 8)

• HP 3G SAS BL Switches (2, pass-through modules between the blade enclosure and the disk

enclosures)

• HP disk enclosures (1 per pair of server blades)

• HP Smart Array P700m controller cards (one on each server blade)

• HP VC Flex-10 modules (2, these modules connect to your network)

NOTE: Note: The original P4800 solution uses the HP 4000sb server blade. All information in

this guide applies to both the original and G2 solutions and server blades.

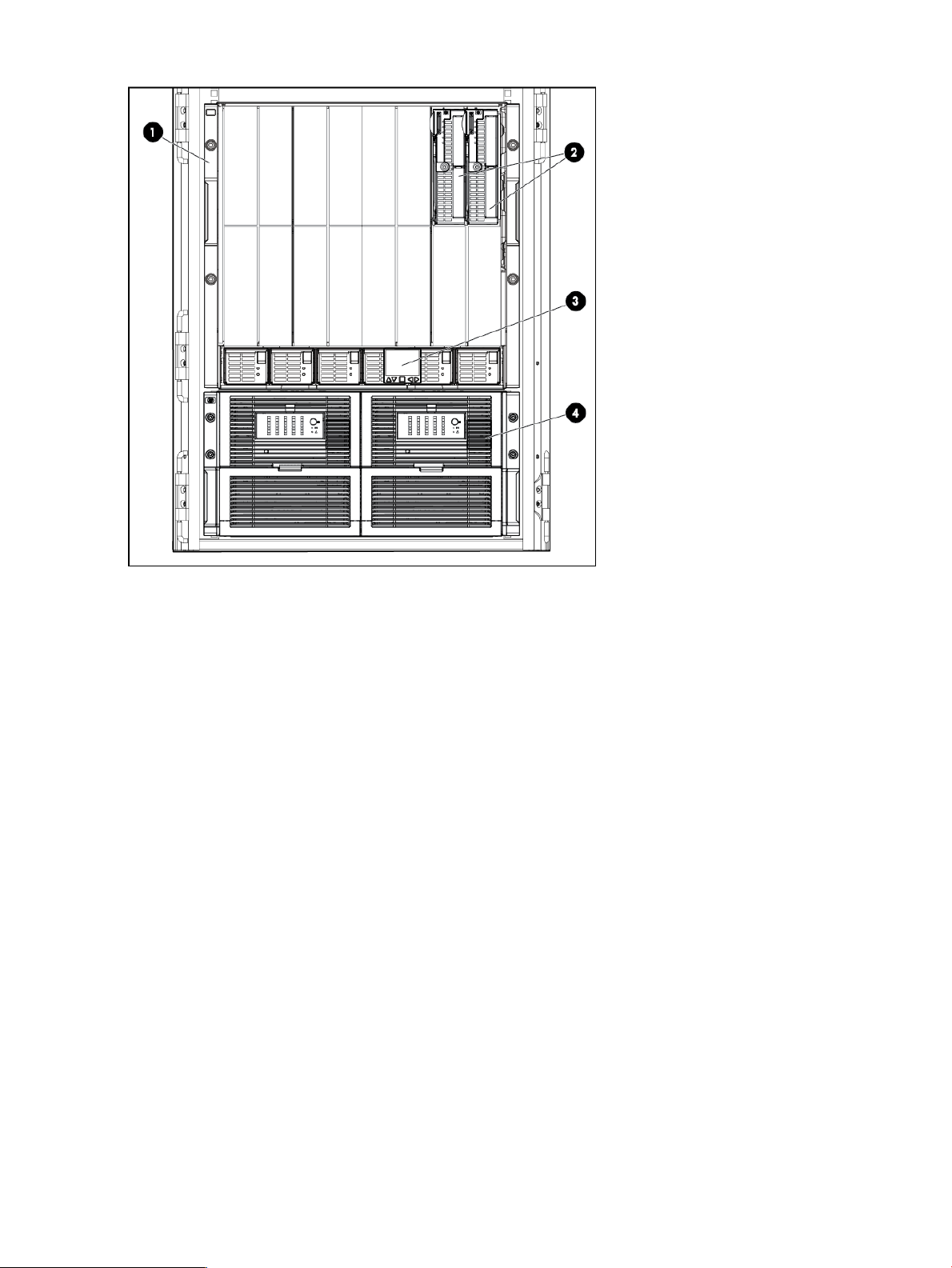

Hardware configuration

Figure 1 (page 6) shows the base configuration of the HP P4800 G2 solution. Figure 2 (page 7)

through Figure 4 (page 9) show additional configurations of the HP P4800 G2 solution.

Hardware components 5

Page 6

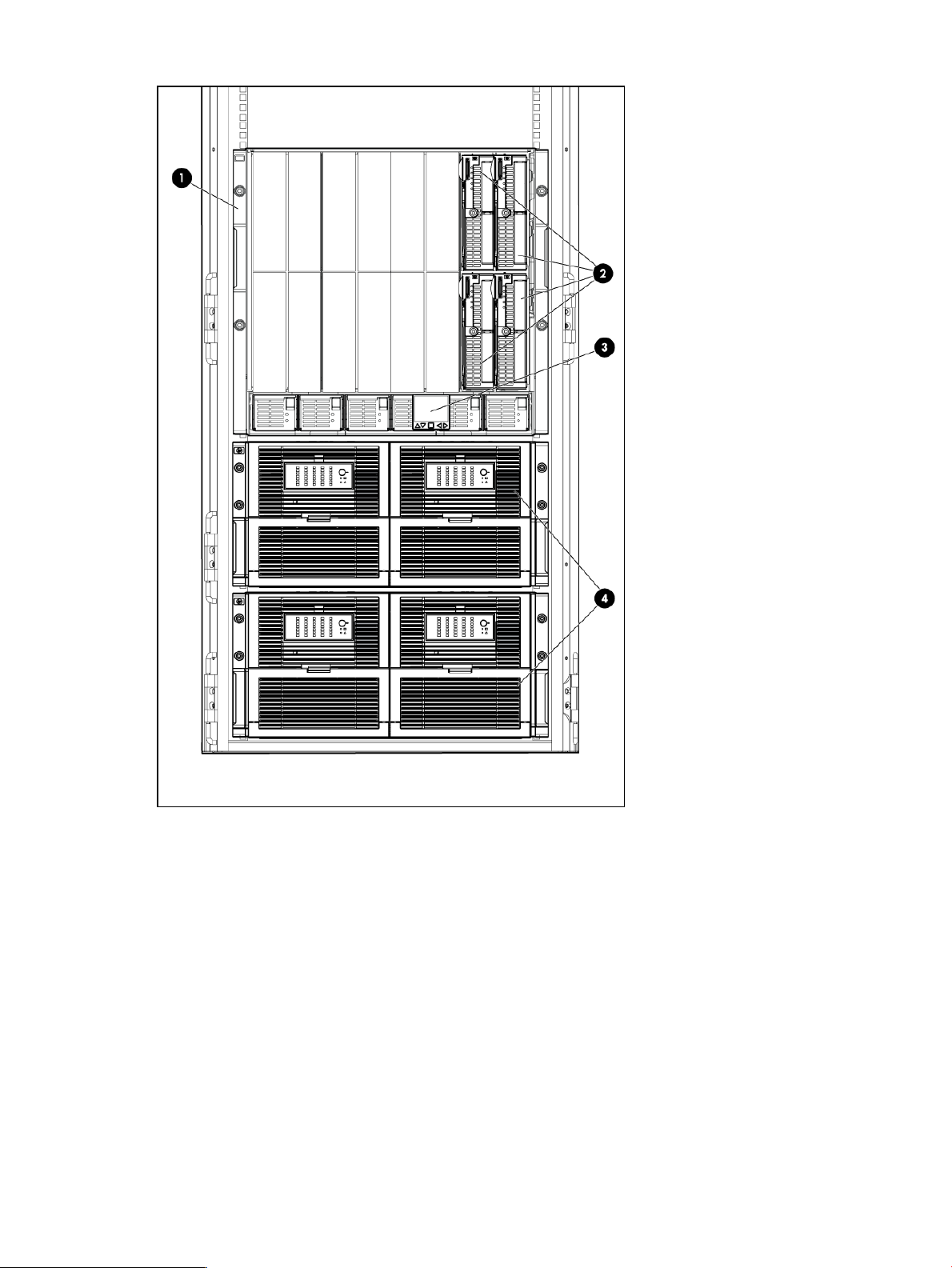

Figure 1 Front view: HP P4800 G2 solution 2 node

1. Blade enclosure (1)

2. Server blades (2)

3. HP BladeSystem Insight Display (1)

4. Disk enclosure (1)

6 Overview

Page 7

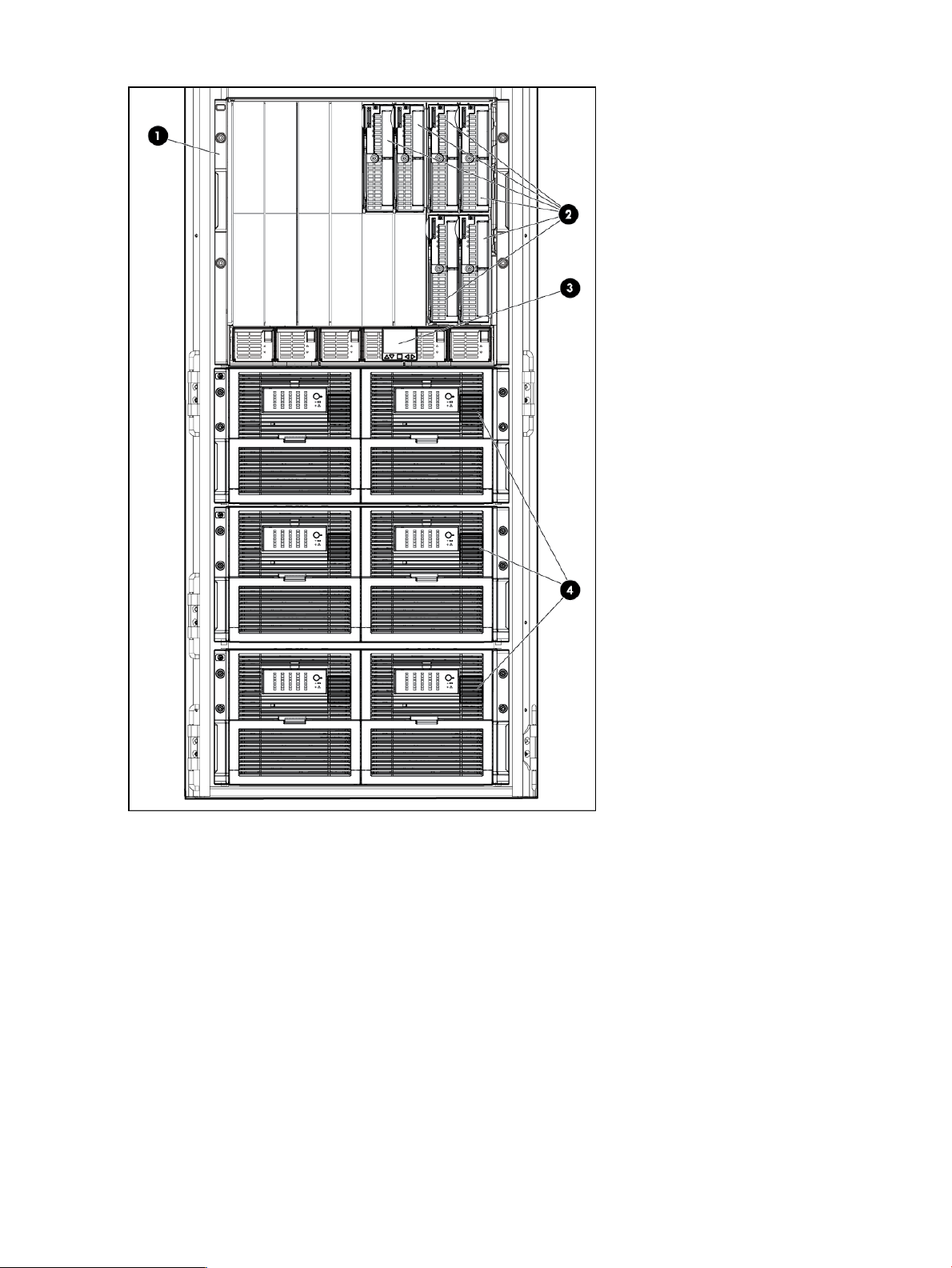

Figure 2 Front view: HP P4800 G2 solution 4 node

1. Blade enclosure (1)

2. Sever blades (4)

3. HP BladeSystem Insight Display (1)

4. Disk enclosures (2)

Hardware configuration 7

Page 8

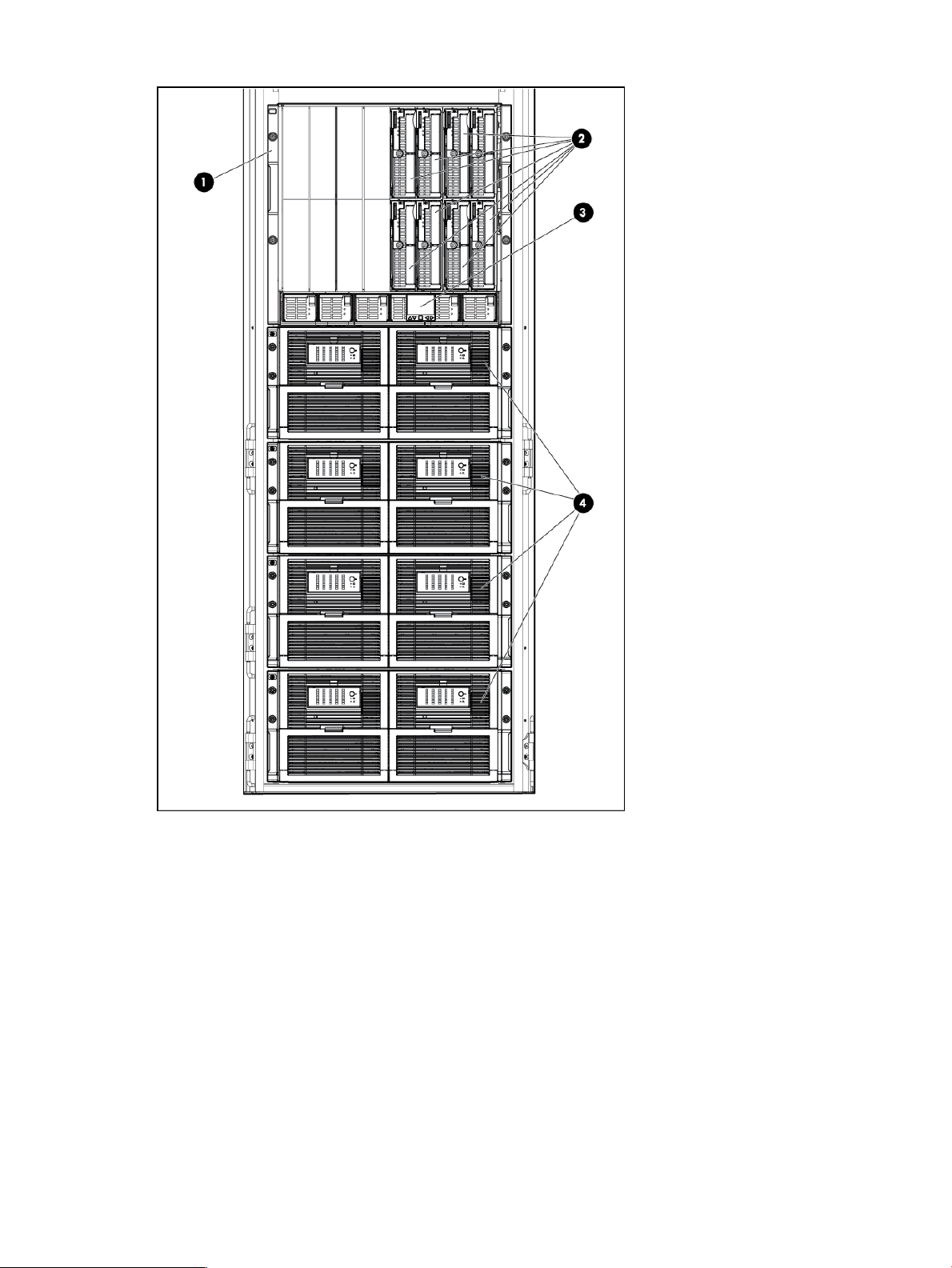

Figure 3 Front view: HP P4800 G2 solution 6 node

1. Blade enclosure (1)

2. Server blades (6)

3. HP BladeSystem Insight Display (1)

4. Disk enclosures (3)

8 Overview

Page 9

Figure 4 Front view: HP P4800 G2 solution 8 node

1. Blade enclosure (1)

2. Server blades (8)

3. HP BladeSystem Insight Display (1)

4. Disk enclosures (4)

Documentation available

For quick installation and setup, see the HP P4800 G2 SAN Solution for BladeSystem Quick Start

Guide.

For links to the latest manuals for HP BladeSystem and other components, see the HP P4800 G2

SAN Solution for BladeSystem Documentation CD.

For detailed instructions about using the HP P4800 G2 SAN Solution for BladeSystem, see the

following resources:

Documentation available 9

Page 10

• Online Help in the Centralized Management Console

Click Help→Help Topics from the menu bar to open the Online Help. Context-sensitive help is

available by clicking the question mark on any window.

• HP P4000 SAN Solution User Guide

Find complete instructions for configuring and managing storage systems and clustered storage

volumes in the User Guide. The User Guide is available in PDF format, installed in the same

directory as the Centralized Management Console program files.

• HP P4000 VSA Installation and Configuration Guide

Find detailed instructions for planning and installing the VSA and getting started with the

Centralized Management Console.

• HP P4000 Remote Copy User Guide

Find information about configuring and using asynchronous replication of storage volumes

and snapshots across geographic distances.

• HP P4000 Multi-Site HA/DR Solution Pack User Guide

Find detailed instructions for designing and implementing the Multi-Site SAN features to

synchronously and automatically mirror data between geographic sites.

• HP P4000 Software Release Notes

Review the Release Notes for the latest information about the product.

The latest versions of these documents, including localized versions, can be found by browsing to

http://www.hp.com/support/manuals. In the Storage section, click Disk Storage Systems and

then select HP P4000 G2 SAN Solutions.

For detailed conguration information related to the HP P4800 G2 solution in Virtual Desktop

Infrastructure (VDI) configurations, see the HP Converged Infrastructure Reference Architecture for

VMware View at http://www.hp.com/go/vdi.

10 Overview

Page 11

2 Backing up HP P4800 G2 solution configurations

HP recommends that you back up all HP P4800 G2 solution components for safekeeping after

initially powering on the HP P4800 G2 solution, and immediately after making changes to an

existing configuration or replacing a component. You must back up each component (for example,

the VC Flex-10 module) separately.

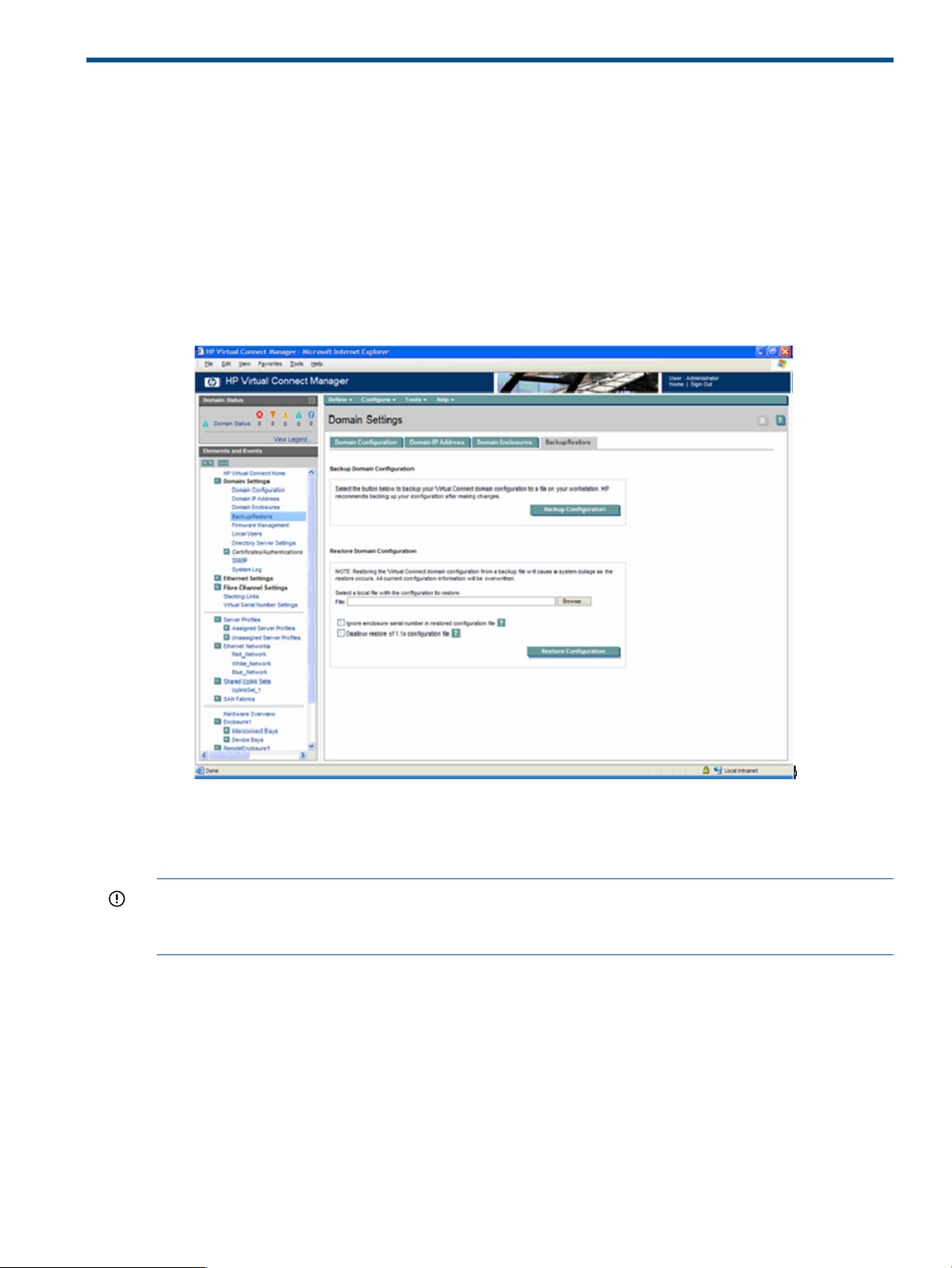

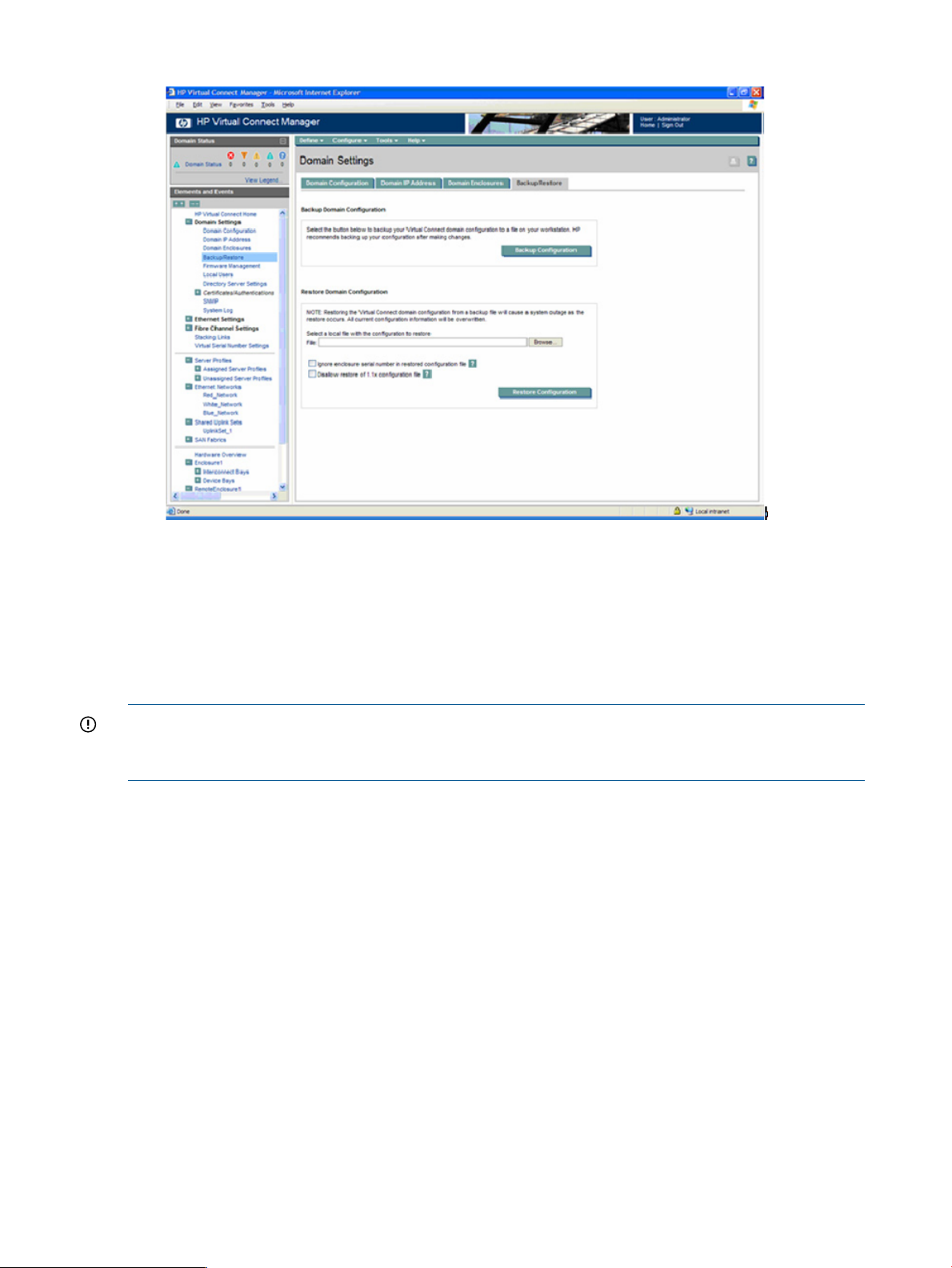

Backing up or restoring the Virtual Connect domain configuration

Use the Virtual Connect Manager to back up the VC Flex-10 module configuration.

1. From Onboard Administrator, go to the Virtual Connect Manager, Domain Settings

Backup/Restore pane.

2. Click Backup Configuration.

3. Navigate to the hard drive location for the backup file.

4. Name the file (usually the domain name), and then click Save.

IMPORTANT: Virtual Connect Manager cannot use backup configurations created with previous

versions of Virtual Connect Manager. For example, if you are currently using 2.01, you cannot

use a backup configuration that was created using 1.20.

To restore a domain configuration:

1. Browse to the backup file.

2. Select the file.

3. Select Ignore enclosure serial number in restored configuration file to restore a configuration

that was generated on another enclosure. If this item is not selected, a configuration generated

on another enclosure is rejected.

4. Select Disallow restore of 1.1x configuration file to restore the firmware to a revision other

than what is stored in the configuration file.

5. Click Restore Configuration.

6. Confirm the domain configuration to be restored, and then click OK.

Backing up or restoring the Virtual Connect domain configuration 11

Page 12

Figure 5 Virtual Connect Manager Domain Settings

Backing up the SAS switch

The SAS switch configuration cannot be backed up using the CMC. If you are replacing one SAS

switch, duplicate the configuration from the other switch. If you are replacing both SAS switches,

you must restore the configuration from a backup captured using the VSM CLI. For information

about backing up and restoring the SAS configuration using the CLI, see the HP Virtual SAS

Manager User Guide.

IMPORTANT: HP recommends that you not change the SAS zoning on the SAS switches or the

cabling between the SAS switches and the disk enclosures. See “HP P4800 G2 solution cabling”

(page 31) for the recommended cabling.

Backing up remaining HP P4800 G2 solution configurations

The following methods may be used to back up the remaining HP P4800 G2 solution configurations:

• Use your own system backup utility to back up data.

• Back up the configuration to an FTP server.

12 Backing up HP P4800 G2 solution configurations

Page 13

3 Maintaining the HP P4800 G2 solution

This chapter provides information to troubleshoot, upgrade, and recover the HP P4800 G2 solution.

Troubleshooting

For detailed troubleshooting information about the HP P4800 G2 solution components, see the

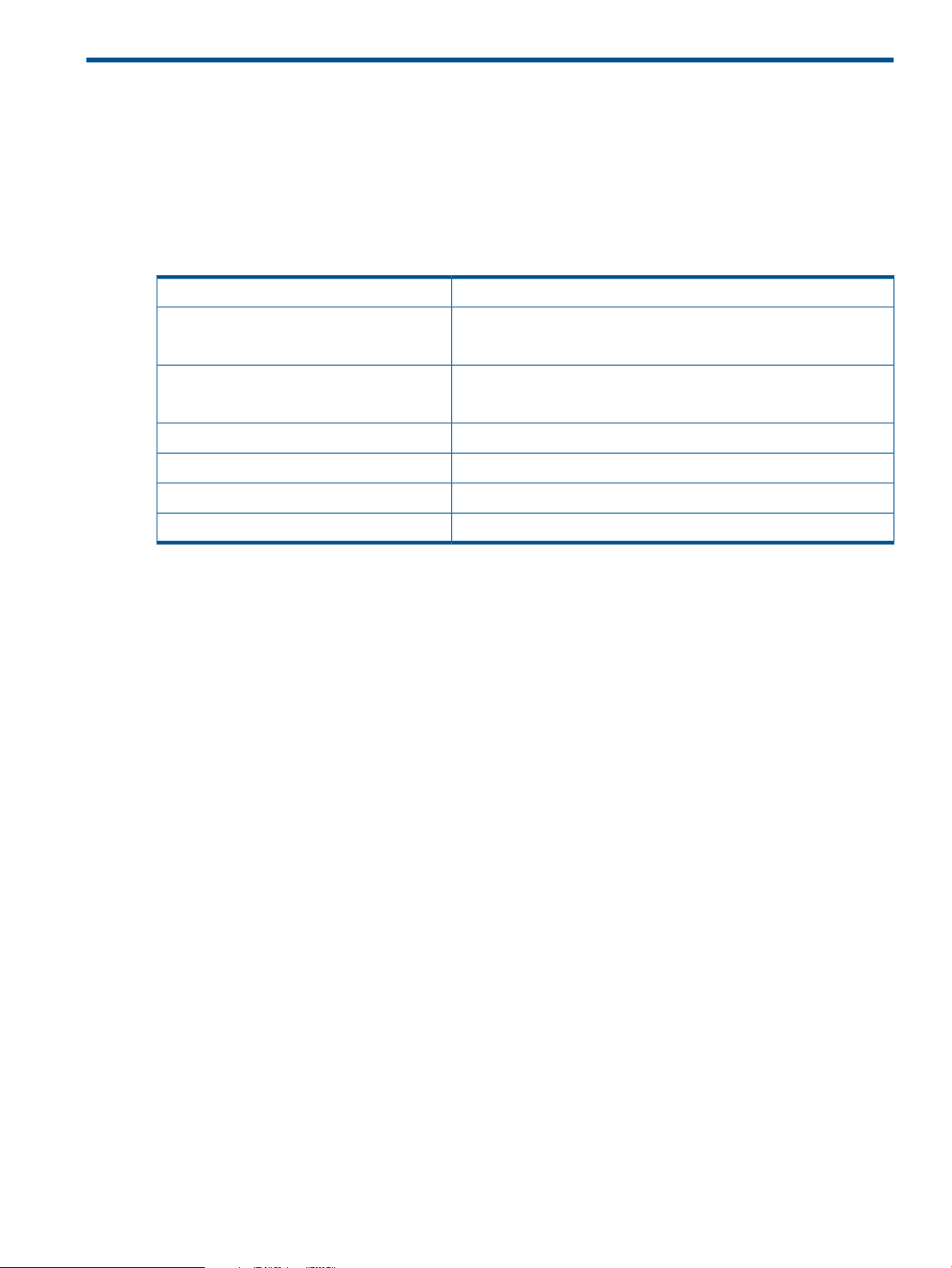

documents listed in Table 1 (page 13).

Table 1 Component troubleshooting information

ResourceComponent

HP ProLiant BL460c G7 Server Blade User GuideHP 4460sb G2 server blade

HP ProLiant Servers Troubleshooting Guide

HP ProLiant BL460c G6 Server Blade User GuideHP 4000sb server blade

HP ProLiant Servers Troubleshooting Guide

HP Smart Array Controllers for HP ProLiant Servers User Guide.HP Smart Array P700m controller

HP 3Gb SAS BL Switch user guideHP 3Gb SAS BL switch

HP 600 Modular Disk System Maintenance and Service GuideDisk enclosure

HP BladeSystem c-Class Enclosure Troubleshooting GuideBlade enclosure

CMC does not detect drives

Symptom

• The server blade will not boot the CMC, or the CMC does not list the storage drives or OS

boot drives.

Cause

• The BIOS was reset to factory defaults.

Resolution

Reset the BIOS by selecting Onboard P410i as the boot controller.

1. Restart the server blade, upon power on, press F9 to enter BIOS setup menu.

2. Select Boot Controller Order.

3. Select Ctrl:2 PCI Embedded HP Smart Array P410i controller.

4. Select Controller Order 1.

5. To exit the submenu, press Esc.

6. To exit the setup menu, press Esc.

7. To confirm the changes, press F10.

8. Confirm that the PCI Embedded HP Smart Array P410i controller is listed as the Current Boot

Controller.

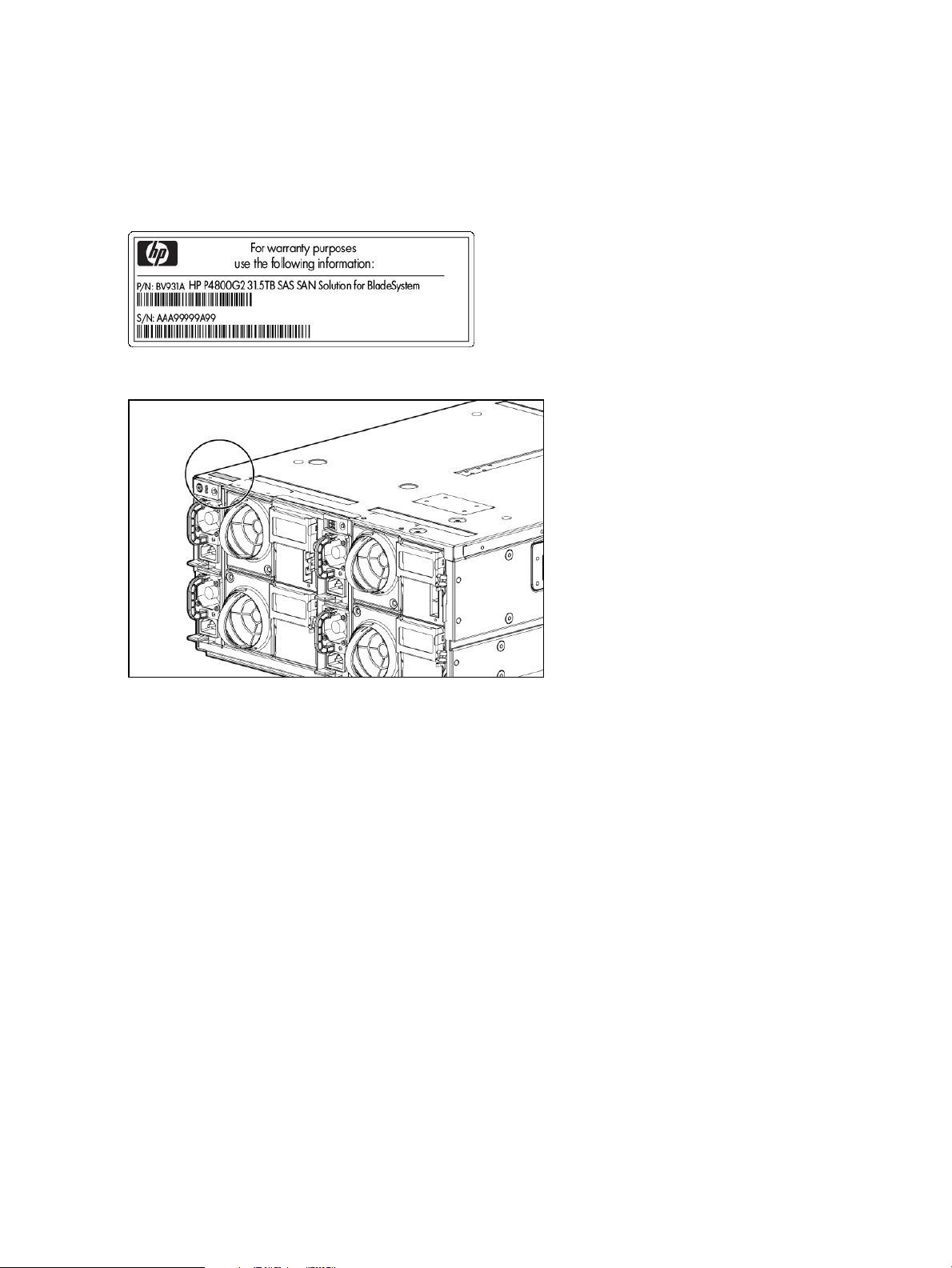

Locating the HP P4800 G2 solution warranty entitlement labels

You must locate and identify the serial number on the HP P4800 G2 solution components to obtain

service under the warranty. A warranty entitlement label (see Figure 6 (page 14)) is placed in each

of the following locations on the HP P4800 G2 solution:

• Top of the disk enclosure drawer. To access the label, pull out a disk enclosure drawer and

look at the top of the drawer near the front.

• Right side of the server blade. To access the label, pull out the affected server blade and look

on the right side of the blade.

Troubleshooting 13

Page 14

• Top of the SAS switch, near the back. To access the label, pull the affected SAS switch out of

the blade enclosure and look at the top of the SAS switch.

• Back of the disk enclosure chassis, left-hand front, top corner of the chassis.

The back of the disk enclosure chassis may be the most accessible label, as shown in Figure 7

(page 14).

Figure 6 Warranty entitlement label

Figure 7 Warranty entitlement label location

Performing field system recovery of the HP P4800 G2 solution

Overview

The field system recovery procedures for the HP P4800 G2 solution includes the following tasks:

• Obtaining the feature registration license key for the HP P4800 G2 solution.

• Running server diagnostics

• Re-imaging the HP P4460sb G2 server blade or the HP P4000sb server blade with the SAN/iQ

software and re-installing the license key.

Before you start

Have the following items ready:

• BIOS version I27, 09/30/2010 installed on the HP P4800 G2 solution

• USB flash drive, formatted with a Windows FAT 32 file system (this is the default for Windows

XP)

• HP P4000 Storage System Quick Restore .iso or CD created from the .iso

• HP SmartStart CD x64

• HP P4000 Management Software DVD

14 Maintaining the HP P4800 G2 solution

Page 15

Obtaining a license key

You must obtain a license key for the server blade before you begin the SAN/iQ software imaging

process. First, you obtain the MAC address of the HP P4800 G2 solution, then request the license

key using the MAC address.

Obtain the MAC address

Complete the following steps:

1. Log into iLO for the server blade.

2. Navigate to the System Information →NIC tab to obtain the eth0/Port 1 MAC address.

3. Copy the MAC address for future use.

Request the license key

The easiest way to enter the license key into the HP P4800 G2 solution is by using a USB flash

drive. You may also enter in the license key if you do not have a USB flash drive.

1. Go to the HP Software Licensing portal at https://webware.hp.com and click Manage licenses.

2. Follow the steps to reprint the original license key.

3. Prepare the key for use in the system recovery process.

Name the file as follows, with no file extension:

featurekey_<MAC address with no colons>

For example:

featurekey_0030482A189B

4. Save this file to the USB flash drive.

5. If you have more than one server blade to image, repeat steps in both sections “Obtain the

MAC address” (page 15) and “Obtaining a license key” (page 15).

6. Re-image the SAN/iQ software.

Re-imaging the server blade with the SAN/iQ software

If you do not have the license key, start with the instructions, “Obtaining a license key” (page 15),

for obtaining the MAC address and license key.

To re-image the server blades, perform the steps in the following sections for each blade.

Verify minimum server requirements

1. Log in to the iLO for the server blade.

2. Mount the HP SmartStart CD x64 using Virtual Mount.

3. Boot the server blade from the CD.

4. Select a language.

5. Accept the HP End User License Agreement.

6. Select Maintenance.

7. Select HP Insight Diagnostics.

8. On the Survey tab, verify that the specified items in the Overview category (default) meet the

minimum requirements listed in Table 2 (page 16).

CAUTION: If any items do not meet the requirements listed in Table 2 (page 16) and Table 3

(page 16), do not continue with this procedure.

Performing field system recovery of the HP P4800 G2 solution 15

Page 16

Table 2 Minimum requirements, overview category

Minimum requirementItem

CPU

NIC

CPU on the server blade: Intel Xeon Processor @ 2.40

Ghz

37 hard drives, which include the following:Type and number of drives

• Slot 2: 35 drives on the HP Smart Array P700m

controller

• Slot 0: 2 drives on the HP Smart Array P410i

controller

24 GBMemory

For the HP P4460sb G2 server blade, the Network

Controller is Emulex OneConnect 10Gb NIC:

v2.102.453.0 or later.

The HP P4000sb server blade has a Broadcom Network

Controller with no minimum requirement.

9. From the Categories list, select Storage.

10. Verify that the specified item meets the minimum requirements listed in Table 3 (page 16).

Table 3 Minimum requirements, storage category

Minimum requirementItem

Array Controller in Slot 0: HP Smart Array P410i

controller

• Model: HP P410i

• Firmware: 3.52 or later

• Installed Memory: 0 MB

• BIOS boot device order: 1

Array Controller in Slot 2: HP Smart Array P700m

controller

Run server diagnostics

1. On the HP Insight Diagnostics Test tab, select Quick Test and specify the number of loops.

2. Click Begin Testing.

The Survey Tab displays the data from the tests.

Wait for the tests to finish, which may take several minutes.

3. When the tests have completed, select the Log tab and check the failure log to see if the Quick

Test reports any failures.

4. If the Quick Test reports any errors, fix all errors before continuing.

If you need more information about an error, run a Complete Test on any component that

reported a failure.

If you want to run only specific tests, use the Custom Test option.

For assistance with the Complete or Custom Test options, see the HP SmartStart CD x64 or

contact HP technical support.

• Model: HP P700m

• Firmware: 7.22 or later

• Installed Memory: 512 MB

• Battery1: OK

• BIOS boot device order: 2

5. Click Exit Diagnostics.

6. Disconnect the HP SmartStart CD x64 from Virtual Media and reboot.

16 Maintaining the HP P4800 G2 solution

Page 17

7. Image the SAN/iQ software.

Image the SAN/iQ software

IMPORTANT: If the server blade accidentally power-cycles during the SAN/iQ software imaging

process, you cannot successfully resume or restart the imaging. You must begin with “Re-imaging

the server blade with the SAN/iQ software” (page 15).

1. Log in to the iLO for the server blades.

2. Mount the HP P4000 Storage System Quick Restore .iso using Virtual Mount.

3. When prompted, insert the USB flash drive containing the license key file.

NOTE: Use the iLO Dongle (delivered with the HP P4800 G2 solution) to convert the USB

flash drive into a USB port so that you can plug in the USB key.

4. When prompted to identify the OS version to install, enter Y.

IMPORTANT: Manually entering the license key

If the installer program cannot find a properly formatted license key on the USB flash drive,

you will be given the chance to enter in the license key.

Enter the license key if prompted. You have three attempts to correctly enter a valid HP license

key. If all three attempts are unsuccessful, restart the process with Step 1.

5. Finish the SAN/iQ software imaging.

Finish the SAN/iQ software imaging

The imaging process starts and displays the Auto Imaging Done message when complete.

1. Disconnect the Virtual Media using iLO.

2. Remove the USB flash drive from the Dongle.

3. Reboot the server blades.

4. Enter start to log into the server blade.

5. Navigate to Network TCP/IP Settings.

6. Assign an IP address to the server blade.

The server blade is now ready for use.

Next steps

Install the CMC from the HP P4000 Management Software DVD. Open the CMC, and use the

wizards on the Getting Started Launch Pad to begin using the HP P4800 G2 solution.

Repairing a storage system

For instructions on repairing a storage system, see the “Repairing a Storage System” and the

“Powering Off the Storage System” sections in the HP P4000 SAN Solution User Guide.

RAID 10 disk replacement and rebuild behavior

The RAID 10 configuration includes a single hot spare in bay 35.

When a disk is removed or fails in a RAID 10 configuration, the hot spare automatically begins

rebuilding. When the failed disk is replaced, the replacement disk begins rebuilding rather than

becoming the hot spare. At that time, the disk in bay 35 transitions back to being a hot spare. This

means that a simple disk replacement involves two rebuilds.

If more than one disk fails or is removed, the hot spare begins rebuilding one of the failed or

removed disks. When the multiple failed disks are replaced, the P700 controller attempts to restore

the disk in bay 35 as a hot spare, but it can only rebuild a single disk at a time. Any disks that

Repairing a storage system 17

Page 18

are queued for rebuilding will be reported as "OK" by the RAID controller (via the hpacucli). The

Disk Status tab in the CMC shows all disks as unsafe to remove, except the disk that is currently

rebuilding.

Upgrading SAN/iQ software

For instructions on upgrading the SAN/iQ software, see the P4000 SAN Solution Software Release

Notes.

Adding capacity to an existing P4800 G2 SAN

The P4800 G2 SAN can be expanded in 2-node increments, up to a total of eight server blades

and four disk enclosures. Adding additional nodes to an existing SAN requires field installation.

Because of the recommendation to power off the SAS switches and corresponding disk enclosures

if installing the new equipment into the same rack, the customer must first safely take the SAN

offline.

Before adding nodes to an existing SAN, upgrade to the latest SAN/iQ software. Otherwise, the

new nodes will operate at the older software version.

Customer requirements

Before beginning the equipment installation, the customer must perform the following actions:

• Disconnect iSCSI sessions from the SAN volumes and snapshots

• Use the Shut Down Management Group feature in the CMC

After the field installation, the customer can finish adding the configured storage to the existing

SAN as follows:

• Manually power on the server blades for the existing SAN and wait for the management

group to come up in the CMC

• Discover the new server blades in the CMC using the Find feature

• Add the newly discovered systems to the existing management group and cluster, or create

a new cluster if desired

If adding the new storage to the existing cluster, the volume and snapshot data restripes on

all the storage systems.

Upgrading firmware

Follow the procedures for upgrading the firmware of each component located in the individual

component product user guides. For more information, see the component guides listed in

“Additional component removal and replacement instructions” (page 20).

The following operations will take a volume offline:

• Upgrading the controller firmware

All controllers must run the same firmware version. (For instructions, see the component guides

listed in “Component removal and replacement instructions” (page 20).)

Since zero-downtime firmware flash is not supported for the controllers in the HP P4800 G2

solution, you must run the flash utility on both of the server blades. After running flash utility,

reboot both server blades so the update occurs.

• Upgrading the disk enclosure firmware

• Upgrading the disk enclosure drive firmware

IMPORTANT: Be sure to first power down the disk enclosures before upgrading the disk

enclosure drive firmware.

18 Maintaining the HP P4800 G2 solution

Page 19

• Upgrading the SAS switch firmware

• Upgrading the VC Flex-10 firmware

• Upgrading the server blade firmware

If a volume is not replicated, upgrades to the server blade firmware and OA firmware (BIOS) will

take the volume offline.

Upgrading firmware 19

Page 20

4 Removing and replacing the HP P4800 G2 solution

components

This section contains information and procedures specific to replacing the HP P4800 G2 solution

components.

Additional component removal and replacement instructions

For detailed information about the removal and replacement of HP P4800 G2 solution components,

see the resources listed in Table 4 (page 20). These documents are located on the HP P4800 G2

SAN Solution for BladeSystem documentation CD that accompanies the HP P4800 G2 solution.

Table 4 Component removal and replacement instructions

ResourceComponent

HP ProLiant BL460c G7 Server Blade Maintenance and Service GuideHP P4460sb G2 server blade

HP ProLiant BL460c G6 Server Blade Maintenance and Service GuideHP P4000sb server blade

HP 3Gb SAS BL Switch Replacement InstructionsHP SAS switch (pass-through modules)

HP Smart Array Controllers for HP ProLiant Servers User GuideHP Smart Array P700m controller

HP 600 Modular Disk System Maintenance and Service GuideHP disk enclosures

HP BladeSystem c7000 Enclosure Maintenance and Service GuideHP c-Class blade enclosure

HP Smart Array Controllers for HP ProLiant Servers User GuideHP Smart Array P410i controller (BIOS boot

controller)

Identifying hot pluggable and non-hot pluggable components

IMPORTANT: Hot add and hot removal of the disk enclosures are not supported by HP P4800

G2 SAS BladeSystem SAN Solution.

The following HP P4800 G2 solution components are hot-pluggable; therefore, you do not need

to power down the device before replacing a part:

• Drives

• External fans

• Power supplies

• Blade disk drives

All other HP P4800 G2 solution components are not hot-pluggable. You must first power down

the device before replacing a part.

CAUTION: To prevent losing access to data during any maintenance operation on components

of the SAS fabric, including the SAS switches, SAS cables, and I/O modules on the disk enclosure,

first power down the server blades using the procedures to shut down the management group in

the CMC Online Help or HP P4000 SAN Solution User Guide.

Replacing the server blade and server blade components

For more detailed instructions on replacing the server blade or server blade components, see

Table 4 (page 20) for resources.

20 Removing and replacing the HP P4800 G2 solution components

Page 21

Replacing a server blade

This section describes the implications for the HP P4800 G2 solution software and not the

mechanical aspects of replacing the server blade.

WARNING! Administrators should verify the firmware version of a replacement server blade

before inserting it in the blade enclosure.

WARNING! Be sure to only replace a server blade in the bay from which it was removed. Do

not swap or move server blades in a blade enclosure or disk enclosure in HP P4800 G2 solution

systems. If you do, nodes will lose failover ability and you may lose connectivity to the disks and

network.

WARNING! For cooling practices, do not leave a server bay open for an extended period of

time. When removing an active component, immediately replace it with a blank.

IMPORTANT: If the boot disk(s) from the blade being replaced are available, placing them in

the new blade allows it to boot to its original configuration. Do not reset the network settings if

you are using the original boot disk(s) on the blade being replaced.

IMPORTANT: If the original boot disk(s) are not available or are damaged, the blade must be

re-imaged using a recovery CD. Doing so requires that the administrator access the console of the

blade through the iLO (or blade KVM dongle) to set the server name and IP address. If you are

not using the original boot disk(s), be sure to reset the network settings.

IMPORTANT: The HP P4800 G2 solution should handle a single blade failure for an extended

period of time without loss of data or lost access to the data. The cluster, however, will remain in

a degraded state until the replacement blade is functioning.

To prepare the server blade for replacement:

1. Confirm the RAID and customer data.

Ensure that RAID is configured on the old blade and that the customer data exists on the disk

enclosures.

2. Confirm the IP address.

Ensure that the existing server blade is configured with a static or reserved IP address and not

DHCP. If necessary, convert the server blade to a static or reserved IP address. Record this IP

address for verification after the process is complete.

3. Record the MAC address.

Record the MAC address of the old blade for later use. Also record the server blade hostname

for later verification.

4. Delete the NIC bond.

Delete any NIC bond previously established on the old blade by using the console or the

CMC. The NIC bond must be deleted because it retains the MAC address of the old blade.

If you are unable to delete the NIC bond at this time, make sure to delete it on the power

cycle following the blade swap.

To replace the server blade or its system board:

1. Power down the server blade.

To power down the server blade from the CMC, see the “Powering off the storage system”

instructions in the HP P4000 SAN Solution User Guide.

2. Note the server blade bay number, and then remove the server blade from the blade enclosure.

NOTE: For instructions on removing and replacing server blade components, see Table 4

(page 20) for the applicable server blade maintenance and service guide.

Replacing the server blade and server blade components 21

Page 22

3. Ensure that all components of the original blade are in place in the replacement blade. In

particular, ensure that:

• The original system disks are in place. This task is essential.

• The memory size of the replacement blade is a minimum of 24 GB or larger.

• The HP Smart Array P700m controller card is in place.

4. Insert the blade in its original bay in the blade chassis.

5. Connect to the iLO, create a user, and assign the password (make sure the password is the

same password that is assigned to the other blades). The IP address is configured automatically

to be the same IP address as the original blade.

For more information, see “HP P4800 G2 solution cabling” (page 31).

6. Boot the server blade.

7. Verify that the server blade can access the disk storage by using the CMC.

Replacing a server blade disk drive

The system disk on a server blade comprises a logical RAID 0 disk that is mirrored over two physical

SFF disk drives in the server blade. As long as one drive continues to operate, the server blade

can operate.

You do not need to power down the server blade; instead, you can hot-swap disk drives. However,

you must replace the removed drive with a drive of the same size or larger.

To replace a disk drive in the server blade:

1. Check the state of the internal logical disk drive.

For more information, see Table 1 (page 13) for the applicable server blade user guide.

2. If the state is failed, follow the procedure in “Replacing both server blade disk drives”

(page 22).

3. Remove the failed drive.

If you remove the wrong drive, the mirror set will break, and the server blade may crash.

Reinsert the good drive and reboot the server blade.

For instructions on removing the drive, see Table 4 (page 20) for the applicable server blade

maintenance and service guide.

4. Insert the replacement drive.

Replacing both server blade disk drives

As long as one disk drive in the server blade continues to operate, the server blade can operate.

However if both disk drives fail, the system disk is lost and you must restore the server blade.

To reinstall a server blade:

1. Remove both disk drives.

2. Insert two replacement drives.

3. Reinstall the server blade by following the quick restore instructions, see “Performing field

system recovery of the HP P4800 G2 solution” (page 14).

Replacing the controller and controller components

This section describes how to replace the controller and its components (see Figure 8 (page 23)).

22 Removing and replacing the HP P4800 G2 solution components

Page 23

Figure 8 HP Smart Array P700m controller

1. Status LEDs (runtime LEDs)

2. Connector

3. Cache

4. Connector for the cable to the cache

5. Mezzanine connector to system board

Replacing the controller

The following steps refer to “HP Smart Array P700m controller” (page 23).

1. Verify component failure by checking LED and error messages.

To interpret the illumination pattern of these LEDs, see “Runtime LEDs for P700m model” in the

HP Smart Array Controllers for HP ProLiant Servers User Guide.

2. Back up all data.

3. Close all applications.

4. Power down the server blade using the CMC.

Wait at least 1 minute for the blade to power down. This procedure flushes all data from the

cache.

To power down the server blade from the CMC, see the “Powering off the storage system”

instructions in the HP P4000 SAN Solution User Guide.

CAUTION: Since the HP P4800 G2 solution uses external data storage, make sure that the

server blade is the first unit to be powered down and the last to be powered up. This precaution

ensures that the system does not mark the drives as failed when the server blade is powered

up.

5. Remove the server blade from the blade enclosure.

6. Remove the access panel from the server blade.

7. Remove the cache, keeping it connected to the battery.

NOTE: When removing the cache to transfer data, the battery must remain connected so

that the data is preserved.

8. Remove the existing controller.

9. Install the replacement controller.

Replacing the controller and controller components 23

Page 24

10. Plug the cache into the connector on the controller, routing the battery cable so that the cache

and battery can be removed together if necessary.

NOTE: Keep the battery connected to the cache so that the data is preserved.

11. Reinstall the access panel.

12. Reinstall the server blade in the blade enclosure.

After reinstalling the server blade, reset the BIOS. For instructions, see “CMC does not detect

drives” (page 13).

13. Verify component status.

14. Confirm that both server blades are running the same firmware version.

NOTE: Use the CMC Hardware Report to view the controller firmware version.

If the server blades are not running the same firmware version, update the controller firmware

with the Smart Update Firmware DVD located at hp.com/support and drivers.

For detailed instructions, see “Installing a mezzanine controller in a previously configured server

blade” in the HP Smart Array Controllers for HP ProLiant Servers User Guide.

For instructions on replacing the battery and cache, see “Upgrading or replacing controller options”

in the HP Smart Array Controllers for HP ProLiant Servers User Guide.

Replacing the VC Flex-10 module

CAUTION: Be sure to update the firmware on the new VC Flex-10 module. This operation will

take the volumes offline.

IMPORTANT: Clients will lose connectivity during this procedure unless using a bonded network.

If not using a bonded network, clients should be disconnected before starting the procedure. In

addition, both externally facing uplinks must be connected to your external network. If uplinks are

not connected to the external network, connectivity will be lost when one of the Flex-10 switches

goes offline during a firmware update.

To replace a VC Flex-10 module:

1. Disconnect the network connections into the VC Flex-10 module (bay 1 or 2).

2. Remove the VC Flex-10 module.

3. Replace the VC Flex-10 module.

4. Reconnect the cables that were disconnected in Step 1 to their original ports.

5. Restore the configuration settings.

For more information, see “Backing up HP P4800 G2 solution configurations” (page 11).

Replacing the SAS switch

This section provides instructions for removing and replacing the SAS switch in the HP P4800 G2

solution.

CAUTION: Before replacing the SAS switch, be sure to power down the server blades using the

procedures to shut down the management group in the CMC Online Help or HP P4000 SAN

Solution User Guide.

24 Removing and replacing the HP P4800 G2 solution components

Page 25

IMPORTANT: Replace the SAS switches one at a time. When you remove a switch, I/O continues

on the remaining switch. Before resetting a switch, verify that all storage is accessible by the

remaining data path. Replacing both SAS switches at one time disconnects the storage and could

compromise data integrity.

If a SAS switch fails, storage access continues through the remaining SAS switch. This causes

storage access to set a preference to all LUNs in the remaining data path. This preference remains

in place until the controllers in the blade enclosure are power cycled, or the remaining path becomes

unavailable.

CAUTION: Power down the disk enclosure before disconnecting a SAS cable. Failing to do so

may damage the I/O module.

To replace the SAS switch:

1. Remove the power cable.

2. Disconnect the SAS cables, noting which cable goes to which port.

3. Remove the switch.

4. Install the replacement switch.

5. Attach the power cable.

6. Update the switch firmware.

a. Open the HP Virtual SAS Manager.

b. Select Force VSM Active.

This selection copies the zone and firmware information from the active switch to the passive,

replacement switch. The replacement switch then becomes the active switch.

7. Reconnect the SAS cables to their original locations, see “HP P4800 G2 solution cabling”

(page 31).

NOTE: Do not attach the SAS cables to the replacement switch until the firmware update is

complete.

Wait at least 60 seconds before removing another SAS switch.

The SAS switch should now provide a redundant access path to storage. Storage controllers will

distribute I/O evenly over the switches upon restart.

Replacing a SAS cable

CAUTION: Failing to follow these steps in this order may damage the I/O module.

1. Before disconnecting a SAS cable, power down the server blades using the procedures to

shut down the management group in the CMC Online Help or HP P4000 SAN Solution User

Guide.

2. Manually power off the disk enclosure.

3. Replace the SAS cable.

See “HP P4800 G2 solution cabling” (page 31) for an illustration of HP P4800 G2 solution

connectivity.

Replacing a SAS cable 25

Page 26

Replacing the disk enclosure I/O module

This section describes how to remove and replace the disk enclosure I/O module on the HP P4800

G2 solution.

CAUTION: Before replacing the I/O module, be sure to power down the server blades using the

procedures to shut down the management group in the CMC Online Help or HP P4000 SAN

Solution User Guide. In addition, be sure the hard drive drawer is closed completely before

removing or replacing the disk enclosure I/O module.

CAUTION: Power down the disk enclosure before disconnecting a SAS cable.

To remove the component:

1. Disconnect the SAS cables, and release the I/O handle.

2. Push the I/O handle down to unlatch the I/O module.

3. Remove the I/O module.

Figure 9 Removal of the I/O module

CAUTION: For best cooling practices, do not operate the enclosure for extended periods with

more than one component or blank removed. When removing an active component, replace it

with a blank.

To replace the I/O module, reverse the removal procedure.

Replacing the disk enclosure power supply

There are four power supplies in each disk enclosure chassis—two on the left and two on the right.

The system can operate with a single power supply on the left and a single power supply on the

right.

1. Remove a power cable.

2. Remove the power supply unit.

3. Insert a new power supply unit.

4. Reattach the power cable.

Replacing the disk enclosure fan

There are four fans in each disk enclosure chassis. The system can operate for a short period with

one fan removed.

NOTE: The disk enclosure drawer must be closed while you replace the fan module.

26 Removing and replacing the HP P4800 G2 solution components

Page 27

1. Remove fan unit.

2. Insert the new fan unit.

Replacing the disk enclosure hard drive

CAUTION: Before replacing the disk enclosure hard drive, be sure to power down the server

blades using the procedures to shut down the management group in the CMC Online Help or HP

P4000 SAN Solution User Guide.

IMPORTANT: Before pulling a drive out of the disk enclosure, HP recommends that you use the

CMC to turn on the drive LED so that you can physically identify the correct drive to replace.

For detailed instructions on how to physically remove and replace a hard drive, see the “Removal

and replacement procedures” chapter in the HP 600 Modular Disk System Maintenance and

Service Guide.

For general instructions on replacing disk drives and ensuring data availability, see the HP P4000

SAN Solution User Guide.

Replacing the disk enclosure hard drive 27

Page 28

5 Support and other resources

Contacting HP

For worldwide technical support information, see the HP support website:

http://www.hp.com/support

Before contacting HP, collect the following information:

• Product model names and numbers

• Technical support registration number (if applicable)

• Product serial numbers

• Error messages

• Operating system type and revision level

• Detailed questions

Subscription service

HP recommends that you register your product at the Subscriber's Choice for Business website:

http://www.hp.com/go/e-updates

After registering, you will receive e-mail notification of product enhancements, new driver versions,

firmware updates, and other product resources.

HP Insight Remote Support software

HP strongly recommends that you install HP Insight Remote Support software to complete the

installation or upgrade of your product and to enable enhanced delivery of your HP Warranty,

HP Care Pack Service or HP contractual support agreement. HP Insight Remote Support supplements

your monitoring, 24x7 to ensure maximum system availability by providing intelligent event

diagnosis, and automatic, secure submission of hardware event notifications to HP, which will

initiate a fast and accurate resolution, based on your product’s service level. Notifications may be

sent to your authorized HP Channel Partner for on-site service, if configured and available in your

country. The software is available in two variants:

• HP Insight Remote Support Standard: This software supports server and storage devices and

is optimized for environments with 1 to 50 servers. Ideal for customers who can benefit from

proactive notification, but do not need proactive service delivery and integration with a

management platform.

• HP Insight Remote Support Advanced: This software provides comprehensive remote monitoring

and proactive service support for nearly all HP servers, storage, network, and SAN

environments, plus selected non-HP servers that have a support obligation with HP. It is

integrated with HP Systems Insight Manager. A dedicated server is recommended to host both

HP Systems Insight Manager and HP Insight Remote Support Advanced.

Details for both versions are available at:

http://www.hp.com/go/insightremotesupport

To download the software, go to Software Depot:

http://www.software.hp.com

Select Insight Remote Support from the menu on the right.

28 Support and other resources

Page 29

Related information

The following documents provide related information:

• HP Converged Infrastructure Reference Architecture for VMware View

• HP BladeSystem c-Class Enclosure Troubleshooting Guide

• HP BladeSystem c7000 Enclosure Maintenance and Service Guide

This document should only be used by persons qualified to service computer equipment.

• HP BladeSystem c7000 Enclosure Quick Setup Instructions

• HP BladeSystem Onboard Administrator User Guide

• HP Integrated Lights-Out 2 User Guide

• Virtual Connect for c-Class BladeSystem User Guide

• HP P4000 SAN Solution User Guide

• HP ProLiant BL460c G7 Server Blade Maintenance and Service Guide

• HP ProLiant BL460c G7 Server Blade Installation Instructions

• HP ProLiant BL460c G7 Server Blade User Guide

• HP ProLiant BL460c G6 Server Blade Maintenance and Service Guide

• HP ProLiant BL460c G6 Server Blade Installation Instructions

• HP ProLiant BL460c G6 Server Blade User Guide

• HP 3Gb SAS BL Switch replacement instructions

• HP 3Gb SAS BL Switch installation instructions

• HP 3Gb SAS BL Switch user guide

• HP Smart Array Controllers for HP ProLiant Servers User Guide

• HP Virtual SAS Manager User Guide

• HP Direct-Connect External SAS storage for HP BladeSystem Solutions Deployment Guide

• HP ProLiant Servers Troubleshooting Guide

• HP 600 Modular Disk System User Guide

• HP 600 Modular Disk System Maintenance and Service Guide

This document describes removal and replacement procedures for the disk enclosure (also

known as the HP 600 Modular Disk System). It should only be used by persons qualified to

service computer equipment.

You can find these documents on the Manuals page of the HP Business Support Center website:

http://www.hp.com/support/manuals

To locate a HP P4800 G2 solution document, see “Documentation available” (page 9).

HP websites

For additional information, see the following HP websites:

• http://www.hp.com

• http://www.hp.com/go/storage

• http://www.hp.com/service_locator

• http://www.hp.com/support/manuals

• http://www.hp.com/support/downloads

Related information 29

Page 30

Rack stability

Rack stability protects personnel and equipment.

WARNING! To reduce the risk of personal injury or damage to equipment:

• Extend leveling jacks to the floor.

• Ensure that the full weight of the rack rests on the leveling jacks.

• Install stabilizing feet on the rack.

• In multiple-rack installations, fasten racks together securely.

• Extend only one rack component at a time. Racks can become unstable if more than one

component is extended.

Customer self repair

HP customer self repair (CSR) programs allow you to repair your HP product. If a CSR part needs

replacing, HP ships the part directly to you so that you can install it at your convenience. Some

parts do not qualify for CSR. Your HP-authorized service provider will determine whether a repair

can be accomplished by CSR.

For more information about CSR, contact your local service provider, or see the CSR website:

http://www.hp.com/go/selfrepair

Replaceable parts

This product contains replaceable parts. To identify the replaceable parts, see the individual

component guides listed in “Component removal and replacement instructions” (page 20).

Parts that are available for customer self repair (CSR) are indicated as follows:

✓ Mandatory CSR. You order the part directly from HP and repair the product yourself. On-site or

return-to-depot repair is not provided under warranty.

• Optional CSR. You can order the part directly from HP and repair the product yourself, or you

can request that HP repair the product. If you request repair from HP, you may be charged for the

repair depending on the product warranty.

-- No CSR. The replaceable part is not available for self repair. For assistance, contact an

HP-authorized service provider.

For more information about CSR, contact your local service provider. For North America, see the

CSR website:

http://www.hp.com/go/selfrepair

To determine the warranty service provided for this product, see the warranty information website:

http://www.hp.com/go/storagewarranty

To order a replacement part, contact an HP-authorized service provider or see the HP Parts Store

online:

http://www.hp.com/buy/parts

30 Support and other resources

Page 31

A HP P4800 G2 solution cabling

The HP P4800 G2 solution SAS cabling is shown in Figure 10 (page 31) through Figure 13

(page 34).

Figure 10 HP P4800 G2 solution 2-node cabling

1. HP VC Flex-10 modules (2)

2. HP 3Gb SAS BL switches (2)

3. HP ProLiant Onboard Administrator

4. Disk enclosure power on button

31

Page 32

Figure 11 HP P4800 G2 solution 4-node cabling

1. HP VC Flex-10 modules (2)

2. HP 3Gb SAS BL switches (2)

3. HP ProLiant Onboard Administrator

4. Disk enclosure power on buttons (2)

32 HP P4800 G2 solution cabling

Page 33

Figure 12 HP P4800 G2 solution 6-node cabling

1. HP VC Flex-10 modules (2)

2. HP 3Gb SAS BL switches (2)

3. HP ProLiant Onboard Administrator

4. Disk enclosure power on buttons (3)

33

Page 34

Figure 13 HP P4800 G2 solution 8-node cabling

1. HP VC Flex-10 modules (2)

2. HP 3Gb SAS BL switches (2)

3. HP ProLiant Onboard Administrator

4. Disk enclosure power on buttons (4)

34 HP P4800 G2 solution cabling

Page 35

B Regulatory compliance notices

This section contains regulatory notices for the HP P4800 G2 SAN Solution for BladeSystem.

Regulatory compliance identification numbers

For the purpose of regulatory compliance certifications and identification, this product has been

assigned a unique regulatory model number. The regulatory model number can be found on the

product nameplate label, along with all required approval markings and information. When

requesting compliance information for this product, always refer to this regulatory model number.

The regulatory model number is not the marketing name or model number of the product.

Product specific information:

HP P4000sb server blade

HP 4460sb G2 server blade

Regulatory model number: HSTNS-BC38-S

FCC and CISPR classification: Class A, 22:2005

These products contain laser components. See Class 1 laser statement in the “Laser compliance

notices” (page 39) section.

Federal Communications Commission notice

Part 15 of the Federal Communications Commission (FCC) Rules and Regulations has established

Radio Frequency (RF) emission limits to provide an interference-free radio frequency spectrum.

Many electronic devices, including computers, generate RF energy incidental to their intended

function and are, therefore, covered by these rules. These rules place computers and related

peripheral devices into two classes, A and B, depending upon their intended installation. Class A

devices are those that may reasonably be expected to be installed in a business or commercial

environment. Class B devices are those that may reasonably be expected to be installed in a

residential environment (for example, personal computers). The FCC requires devices in both classes

to bear a label indicating the interference potential of the device as well as additional operating

instructions for the user.

FCC rating label

The FCC rating label on the device shows the classification (A or B) of the equipment. Class B

devices have an FCC logo or ID on the label. Class A devices do not have an FCC logo or ID on

the label. After you determine the class of the device, refer to the corresponding statement.

Class A equipment

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instructions, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which

case the user will be required to correct the interference at personal expense.

Class B equipment

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment

Regulatory compliance identification numbers 35

Page 36

off and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit that is different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio or television technician for help.

Declaration of Conformity for products marked with the FCC logo, United States only

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

For questions regarding this FCC declaration, contact us by mail or telephone:

• Hewlett-Packard Company P.O. Box 692000, Mail Stop 510101 Houston, Texas 77269-2000

• Or call 1-281-514-3333

Modification

The FCC requires the user to be notified that any changes or modifications made to this device

that are not expressly approved by Hewlett-Packard Company may void the user's authority to

operate the equipment.

Cables

When provided, connections to this device must be made with shielded cables with metallic RFI/EMI

connector hoods in order to maintain compliance with FCC Rules and Regulations.

Canadian notice (Avis Canadien)

Class A equipment

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de la class A respecte toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

Class B equipment

This Class B digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de la class B respecte toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

European Union notice

This product complies with the following EU directives:

• Low Voltage Directive 2006/95/EC

• EMC Directive 2004/108/EC

Compliance with these directives implies conformity to applicable harmonized European standards

(European Norms) which are listed on the EU Declaration of Conformity issued by Hewlett-Packard

for this product or product family.

36 Regulatory compliance notices

Page 37

This compliance is indicated by the following conformity marking placed on the product:

Certificates can be obtained from http://www.hp.com/go/certificates.

Hewlett-Packard GmbH, HQ-TRE, Herrenberger Strasse 140, 71034 Boeblingen, Germany

Japanese notices

Japanese VCCI-A notice

Japanese VCCI-B notice

This marking is valid for non-Telecom products and EU

harmonized Telecom products (e.g., Bluetooth).

Japanese VCCI marking

Japanese power cord statement

Korean notices

Class A equipment

Japanese notices 37

Page 38

Class B equipment

Taiwanese notices

BSMI Class A notice

Taiwan battery recycle statement

Turkish recycling notice

Türkiye Cumhuriyeti: EEE Yönetmeliğine Uygundur

38 Regulatory compliance notices

Page 39

Laser compliance notices

English laser notice

This device may contain a laser that is classified as a Class 1 Laser Product in accordance with

U.S. FDA regulations and the IEC 60825-1. The product does not emit hazardous laser radiation.

WARNING! Use of controls or adjustments or performance of procedures other than those

specified herein or in the laser product's installation guide may result in hazardous radiation

exposure. To reduce the risk of exposure to hazardous radiation:

• Do not try to open the module enclosure. There are no user-serviceable components inside.

• Do not operate controls, make adjustments, or perform procedures to the laser device other

than those specified herein.

• Allow only HP Authorized Service technicians to repair the unit.

The Center for Devices and Radiological Health (CDRH) of the U.S. Food and Drug Administration

implemented regulations for laser products on August 2, 1976. These regulations apply to laser

products manufactured from August 1, 1976. Compliance is mandatory for products marketed in

the United States.

Dutch laser notice

French laser notice

Laser compliance notices 39

Page 40

German laser notice

Italian laser notice

Japanese laser notice

40 Regulatory compliance notices

Page 41

Spanish laser notice

Recycling notices

English recycling notice

Disposal of waste equipment by users in private household in the European Union

This symbol means do not dispose of your product with your other household waste. Instead, you should

protect human health and the environment by handing over your waste equipment to a designated

collection point for the recycling of waste electrical and electronic equipment. For more information,

please contact your household waste disposal service

Recycling notices 41

Page 42

Bulgarian recycling notice

Изхвърляне на отпадъчно оборудване от потребители в частни домакинства в Европейския

съюз

Този символ върху продукта или опаковката му показва, че продуктът не трябва да се изхвърля заедно

с другите битови отпадъци. Вместо това, трябва да предпазите човешкото здраве и околната среда,

като предадете отпадъчното оборудване в предназначен за събирането му пункт за рециклиране на

неизползваемо електрическо и електронно борудване. За допълнителна информация се свържете с

фирмата по чистота, чиито услуги използвате.

Czech recycling notice

Likvidace zařízení v domácnostech v Evropské unii

Tento symbol znamená, že nesmíte tento produkt likvidovat spolu s jiným domovním odpadem. Místo

toho byste měli chránit lidské zdraví a životní prostředí tím, že jej předáte na k tomu určené sběrné

pracoviště, kde se zabývají recyklací elektrického a elektronického vybavení. Pro více informací kontaktujte

společnost zabývající se sběrem a svozem domovního odpadu.

Danish recycling notice

Bortskaffelse af brugt udstyr hos brugere i private hjem i EU

Dette symbol betyder, at produktet ikke må bortskaffes sammen med andet husholdningsaffald. Du skal

i stedet den menneskelige sundhed og miljøet ved at afl evere dit brugte udstyr på et dertil beregnet

indsamlingssted for af brugt, elektrisk og elektronisk udstyr. Kontakt nærmeste renovationsafdeling for

yderligere oplysninger.

Dutch recycling notice

Inzameling van afgedankte apparatuur van particuliere huishoudens in de Europese Unie

Dit symbool betekent dat het product niet mag worden gedeponeerd bij het overige huishoudelijke afval.

Bescherm de gezondheid en het milieu door afgedankte apparatuur in te leveren bij een hiervoor bestemd

inzamelpunt voor recycling van afgedankte elektrische en elektronische apparatuur. Neem voor meer

informatie contact op met uw gemeentereinigingsdienst.

42 Regulatory compliance notices

Page 43

Estonian recycling notice

Äravisatavate seadmete likvideerimine Euroopa Liidu eramajapidamistes

See märk näitab, et seadet ei tohi visata olmeprügi hulka. Inimeste tervise ja keskkonna säästmise nimel

tuleb äravisatav toode tuua elektriliste ja elektrooniliste seadmete käitlemisega egelevasse kogumispunkti.

Küsimuste korral pöörduge kohaliku prügikäitlusettevõtte poole.

Finnish recycling notice

Kotitalousjätteiden hävittäminen Euroopan unionin alueella

Tämä symboli merkitsee, että laitetta ei saa hävittää muiden kotitalousjätteiden mukana. Sen sijaan sinun

on suojattava ihmisten terveyttä ja ympäristöä toimittamalla käytöstä poistettu laite sähkö- tai

elektroniikkajätteen kierrätyspisteeseen. Lisätietoja saat jätehuoltoyhtiöltä.

French recycling notice

Mise au rebut d'équipement par les utilisateurs privés dans l'Union Européenne

Ce symbole indique que vous ne devez pas jeter votre produit avec les ordures ménagères. Il est de

votre responsabilité de protéger la santé et l'environnement et de vous débarrasser de votre équipement

en le remettant à une déchetterie effectuant le recyclage des équipements électriques et électroniques.

Pour de plus amples informations, prenez contact avec votre service d'élimination des ordures ménagères.

German recycling notice

Entsorgung von Altgeräten von Benutzern in privaten Haushalten in der EU

Dieses Symbol besagt, dass dieses Produkt nicht mit dem Haushaltsmüll entsorgt werden darf. Zum

Schutze der Gesundheit und der Umwelt sollten Sie stattdessen Ihre Altgeräte zur Entsorgung einer dafür

vorgesehenen Recyclingstelle für elektrische und elektronische Geräte übergeben. Weitere Informationen

erhalten Sie von Ihrem Entsorgungsunternehmen für Hausmüll.

Recycling notices 43

Page 44

Greek recycling notice

Απόρριψη άχρηοτου εξοπλισμού από ιδιώτες χρήστες στην Ευρωπαϊκή Ένωση

Αυτό το σύμβολο σημαίνει ότι δεν πρέπει να απορρίψετε το προϊόν με τα λοιπά οικιακά απορρίμματα.

Αντίθετα, πρέπει να προστατέψετε την ανθρώπινη υγεία και το περιβάλλον παραδίδοντας τον άχρηστο

εξοπλισμό σας σε εξουσιοδοτημένο σημείο συλλογής για την ανακύκλωση άχρηστου ηλεκτρικού και

ηλεκτρονικού εξοπλισμού. Για περισσότερες πληροφορίες, επικοινωνήστε με την υπηρεσία απόρριψης

απορριμμάτων της περιοχής σας.

Hungarian recycling notice

A hulladék anyagok megsemmisítése az Európai Unió háztartásaiban

Ez a szimbólum azt jelzi, hogy a készüléket nem szabad a háztartási hulladékkal együtt kidobni. Ehelyett

a leselejtezett berendezéseknek az elektromos vagy elektronikus hulladék átvételére kijelölt helyen történő

beszolgáltatásával megóvja az emberi egészséget és a környezetet.További információt a helyi

köztisztasági vállalattól kaphat.

Italian recycling notice

Smaltimento di apparecchiature usate da parte di utenti privati nell'Unione Europea

Questo simbolo avvisa di non smaltire il prodotto con i normali rifi uti domestici. Rispettare la salute

umana e l'ambiente conferendo l'apparecchiatura dismessa a un centro di raccolta designato per il

riciclo di apparecchiature elettroniche ed elettriche. Per ulteriori informazioni, rivolgersi al servizio per

lo smaltimento dei rifi uti domestici.

Latvian recycling notice

Europos Sąjungos namų ūkio vartotojų įrangos atliekų šalinimas

Šis simbolis nurodo, kad gaminio negalima išmesti kartu su kitomis buitinėmis atliekomis. Kad

apsaugotumėte žmonių sveikatą ir aplinką, pasenusią nenaudojamą įrangą turite nuvežti į elektrinių ir

elektroninių atliekų surinkimo punktą. Daugiau informacijos teiraukitės buitinių atliekų surinkimo tarnybos.

44 Regulatory compliance notices

Page 45

Lithuanian recycling notice

Nolietotu iekārtu iznīcināšanas noteikumi lietotājiem Eiropas Savienības privātajās mājsaimniecībās

Šis simbols norāda, ka ierīci nedrīkst utilizēt kopā ar citiem mājsaimniecības atkritumiem. Jums jārūpējas

par cilvēku veselības un vides aizsardzību, nododot lietoto aprīkojumu otrreizējai pārstrādei īpašā lietotu

elektrisko un elektronisko ierīču savākšanas punktā. Lai iegūtu plašāku informāciju, lūdzu, sazinieties ar

savu mājsaimniecības atkritumu likvidēšanas dienestu.

Polish recycling notice

Utylizacja zużytego sprzętu przez użytkowników w prywatnych gospodarstwach domowych w

krajach Unii Europejskiej

Ten symbol oznacza, że nie wolno wyrzucać produktu wraz z innymi domowymi odpadkami.

Obowiązkiem użytkownika jest ochrona zdrowa ludzkiego i środowiska przez przekazanie zużytego

sprzętu do wyznaczonego punktu zajmującego się recyklingiem odpadów powstałych ze sprzętu

elektrycznego i elektronicznego. Więcej informacji można uzyskać od lokalnej firmy zajmującej wywozem

nieczystości.

Portuguese recycling notice

Descarte de equipamentos usados por utilizadores domésticos na União Europeia

Este símbolo indica que não deve descartar o seu produto juntamente com os outros lixos domiciliares.

Ao invés disso, deve proteger a saúde humana e o meio ambiente levando o seu equipamento para

descarte em um ponto de recolha destinado à reciclagem de resíduos de equipamentos eléctricos e

electrónicos. Para obter mais informações, contacte o seu serviço de tratamento de resíduos domésticos.

Romanian recycling notice

Casarea echipamentului uzat de către utilizatorii casnici din Uniunea Europeană

Acest simbol înseamnă să nu se arunce produsul cu alte deşeuri menajere. În schimb, trebuie să protejaţi

sănătatea umană şi mediul predând echipamentul uzat la un punct de colectare desemnat pentru reciclarea

echipamentelor electrice şi electronice uzate. Pentru informaţii suplimentare, vă rugăm să contactaţi

serviciul de eliminare a deşeurilor menajere local.

Recycling notices 45

Page 46

Slovak recycling notice

Likvidácia vyradených zariadení používateľmi v domácnostiach v Európskej únii

Tento symbol znamená, že tento produkt sa nemá likvidovať s ostatným domovým odpadom. Namiesto

toho by ste mali chrániť ľudské zdravie a životné prostredie odovzdaním odpadového zariadenia na

zbernom mieste, ktoré je určené na recykláciu odpadových elektrických a elektronických zariadení.

Ďalšie informácie získate od spoločnosti zaoberajúcej sa likvidáciou domového odpadu.

Spanish recycling notice

Eliminación de los equipos que ya no se utilizan en entornos domésticos de la Unión Europea

Este símbolo indica que este producto no debe eliminarse con los residuos domésticos. En lugar de ello,

debe evitar causar daños a la salud de las personas y al medio ambiente llevando los equipos que no

utilice a un punto de recogida designado para el reciclaje de equipos eléctricos y electrónicos que ya

no se utilizan. Para obtener más información, póngase en contacto con el servicio de recogida de

residuos domésticos.

Swedish recycling notice

Hantering av elektroniskt avfall för hemanvändare inom EU

Den här symbolen innebär att du inte ska kasta din produkt i hushållsavfallet. Värna i stället om natur

och miljö genom att lämna in uttjänt utrustning på anvisad insamlingsplats. Allt elektriskt och elektroniskt

avfall går sedan vidare till återvinning. Kontakta ditt återvinningsföretag för mer information.

Battery replacement notices

Dutch battery notice

46 Regulatory compliance notices

Page 47

French battery notice

German battery notice

Battery replacement notices 47

Page 48

Italian battery notice

Japanese battery notice

48 Regulatory compliance notices

Page 49

Spanish battery notice

Battery replacement notices 49

Page 50

Glossary

Acronyms and Abbreviations

CMC Central Management Console

CSR Customer Self Repair

DHCP Dynamic Host Configuration Protocol

EBIPA Enclosure bay IP addressing

ESX VMware's enterprise-class virtualization platform

FBWC Flash-backed write cache

FCC Federal Communications Commission

FOM Failover Manager

iLO 2 HP Integrated Lights-Out 2

iSCSI Internet SCSI)

KVM Keyboard, video, mouse switch

LUN Logical unit number

NIC Network interface card

OA Onboard Administrator

POST Power-on self test

RBSU ROM-based setup utility

RF Radio frequency

SAN Storage Area Network

SAS Serial-Attached SCSI

SFF Small Form Factor

SSH Secure Shell

UPS Uninterruptible power supply

VIP Virtual IP address

50 Glossary

Page 51

Index

A

available documents, 9

B

backing up

configurations, 11

backup configuration, 12

battery replacement notices, 46

C

cabling

diagram, 31

HP P4800 G2 solution, 31

Canadian notice, 36

component

replacement instructions, 20

components

hardware, 5

hot-pluggable, 20

non-hot-pluggable, 20

configuration

back view, 5

backing up, 11, 12

factory settings, 11

front view, 5

configuration backup

methods, 12

secure copy tool, 12

contacting HP, 28

controller

replacing, 22

customer self repair, 30

parts list, 30

D

Declaration of Conformity, 36

disk drive

server blade, 22

disk enclosure

fan, 26

hard drive, 27

power supply, 26

disk enclosure fan

replacing, 26

disk enclosure hard drive

replacing, 27

disk enclosure I/O module

replacing, 26

disk enclosure power supply

replacing, 26

Disposal of waste equipment, European Union, 41

document

related information, 29

documentation

HP website, 29

documentation available, 9

E

European Union notice, 36

F

Federal Communications Commission notice, 35

firmware

upgrades, 18

firmware upgrade, 20

Flex-10 module

replacing, 24

Flex-10 module, replacing, 24

H

hard drive

disk enclosure, 27

help

obtaining, 28

HP

technical support, 28

I

I/O module

replacing, 26

Insight Remote Support software, 28

J