Page 1

HP iLO Chassis Management IPMI User Guide

Abstract

This document provides customers with information on the implementation of the Intelligent Platform Management Interface in

HP Moonshot iLO Chassis Management Firmware, including the available commands.

HP Part Number: 742544-003

Published: November 2014

Edition: 1

Page 2

© Copyright 2014

Notices

Confidential computer software. Valid license from HP required for possession, use, or copying. Consistent with FAR 12.211 and 12.212, Commercial

Computer Software, Computer Software Documentation, and Technical Data for Commercial Items are licensed to the U.S. Government under

vendor's standard commercial license.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or omissions contained herein.

Page 3

Contents

1 Introduction and key concepts......................................................................7

Overview................................................................................................................................7

Sensor Data Model...................................................................................................................7

Sensor owner identification...................................................................................................7

Sensor type code.................................................................................................................8

System event log and event messages.....................................................................................8

SDR repository..................................................................................................................10

SDR formats.................................................................................................................10

Reading the SDR repository and device SDR repositories....................................................11

FRU......................................................................................................................................11

FRU inventory device..........................................................................................................12

Standardized timers................................................................................................................12

Watchdog timer................................................................................................................12

POH counter.....................................................................................................................12

Timestamp format...............................................................................................................12

2 The virtual topology of the Moonshot 1500 CM module................................14

3 Discovering managed entities using IPMITool................................................17

4 IPMItool..................................................................................................18

Moonshot IPMItool support — out of band.................................................................................18

Interfaces...............................................................................................................................19

System Interface.................................................................................................................19

LANPlus Interface...............................................................................................................19

Features................................................................................................................................20

Events...................................................................................................................................21

Inventory...............................................................................................................................22

Chassis management..............................................................................................................22

Synopsis................................................................................................................................22

IPMItool Raw command syntax and example..............................................................................24

5 Command specification.............................................................................25

Standard command specification..............................................................................................29

Global commands.............................................................................................................29

Get device ID command................................................................................................29

Cold reset command ....................................................................................................32

Warm reset command...................................................................................................33

Get self test results command .........................................................................................33

Get ACPI power state command .....................................................................................34

Broadcast get device ID command .................................................................................35

IPMI messaging support commands......................................................................................36

Set BMC global enables command .................................................................................36

Get BMC global enables command ................................................................................37

Clear message flags command ......................................................................................37

Get message flags command .........................................................................................38

Enable message channel receive command .....................................................................38

Get message command ................................................................................................39

Send message command...............................................................................................42

Get system GUID command ...........................................................................................44

Set system info parameters command ..............................................................................45

Get system info parameters command..............................................................................46

Master write-read command...........................................................................................49

Contents 3

Page 4

Get channel authentication capabilities command.............................................................50

Get Channel Cipher Suites Command.............................................................................52

Cipher suite records..................................................................................................54

Cipher suite ID numbers............................................................................................55

Set session privilege level command ...............................................................................56

Close session command.................................................................................................57

Get session info command ............................................................................................57

Get AuthCode command ..............................................................................................59

Set channel access command ........................................................................................60

Get channel access command .......................................................................................62

Get channel info command ...........................................................................................63

Set user access command..............................................................................................65

Get user access command..............................................................................................66

Set user name command ...............................................................................................68

Get user name command...............................................................................................68

Set user password command..........................................................................................69

RMCP+ support and payload commands..............................................................................70

Activate payload command............................................................................................71

Deactivate payload command........................................................................................73

Suspend/resume payload encryption command................................................................74

Set channel security keys command.................................................................................75

Get system interface capabilities command.......................................................................77

Get payload activation status command...........................................................................78

Get payload instance info command...............................................................................79

Set user payload access command..................................................................................79

Get user payload access command.................................................................................80

Get channel payload support command...........................................................................81

Get channel payload version command...........................................................................82

IPMI LAN Device Commands...............................................................................................83

Set LAN configuration parameters command....................................................................83

Get LAN configuration parameters command...................................................................83

SOL commands.................................................................................................................92

Set SOL configuration parameters command.....................................................................92

Get SOL configuration parameters command....................................................................93

MC watchdog timer commands...........................................................................................96

Watchdog timer actions.................................................................................................96

Watchdog timer use field and expiration flags..................................................................97

Using the timer use field and expiration flags...............................................................97

Watchdog timer event logging........................................................................................97

Pre-timeout interrupt.......................................................................................................98

Pre-timeout interrupt support detection.........................................................................98

BIOS support for watchdog timer................................................................................98

Reset watchdog timer command .....................................................................................98

Set watchdog timer command ........................................................................................98

Get watchdog timer command .....................................................................................100

Chassis commands..........................................................................................................102

Get chassis capabilities command ................................................................................102

Get chassis status command ........................................................................................103

Chassis control command ............................................................................................104

Chassis identify command ...........................................................................................105

Set power restore policy command ...............................................................................106

Set system boot options command ................................................................................107

Get system boot options command................................................................................107

Get POH counter command .........................................................................................111

Event commands..............................................................................................................112

4 Contents

Page 5

Set event receiver command.........................................................................................112

Get event receiver command........................................................................................113

Platform event message command.................................................................................113

SEL commands................................................................................................................114

SEL device commands..................................................................................................114

Get SEL info command............................................................................................114

Reserve SEL command............................................................................................115

Get SEL entry command..........................................................................................116

Add SEL entry command.........................................................................................116

Clear SEL...................................................................................................................117

SEL record type ranges................................................................................................117

Get SEL time command................................................................................................118

Set SEL time command.................................................................................................118

SDR repository device commands......................................................................................118

SDR record IDs...........................................................................................................118

Get SDR repository info command.................................................................................119

Get SDR repository allocation info command..................................................................120

Reserve SDR repository command.................................................................................120

Reservation restricted commands..............................................................................121

Reservation cancellation..........................................................................................121

Get SDR command......................................................................................................121

Add SDR command.....................................................................................................122

Delete SDR command..................................................................................................123

Clear SDR repository command....................................................................................123

Run initialization agent command..................................................................................124

FRU inventory device commands........................................................................................124

Get FRU inventory area info command...........................................................................125

Read FRU data command........................................................................................125

Write FRU data command.......................................................................................126

Sensor Device Commands.................................................................................................126

Get device SDR info command.....................................................................................126

Get device SDR command............................................................................................127

Reserve device SDR repository command.......................................................................128

Get sensor thresholds command....................................................................................128

Get sensor reading command.......................................................................................129

DCMI specific commands.................................................................................................130

Get DCMI capability info command..............................................................................131

Get asset tag command...............................................................................................133

Get DCMI sensor info command...................................................................................134

Set asset tag command................................................................................................135

Management controller ID string...................................................................................135

Get controller ID string command..................................................................................136

Set controller ID string command...................................................................................136

PICMG specific commands...............................................................................................137

Get PICMG properties command..................................................................................137

Get address info command..........................................................................................137

FRU inventory device lock control command....................................................................138

6 IPMI Messaging and Interfaces.................................................................140

System Interfaces..................................................................................................................140

Message interface description...........................................................................................141

IPMI Messaging Interfaces.................................................................................................141

Network function codes.........................................................................................................141

Completion codes.................................................................................................................142

Channel Model, Authentication, Sessions, and Users.................................................................144

Contents 5

Page 6

Channel numbers.............................................................................................................145

Logical channels..............................................................................................................145

Channel Privilege Levels....................................................................................................145

Users & Password support.................................................................................................146

IPMI sessions...................................................................................................................146

Session-less connections....................................................................................................147

Session inactivity timeouts.................................................................................................147

System interface messaging...................................................................................................147

Bridging..............................................................................................................................148

MC LUN 10b..................................................................................................................148

Send Message command with response tracking..................................................................149

Bridged Request Example..................................................................................................149

IPMB access via master write-read command.......................................................................151

MC IPMB LUNs................................................................................................................151

Sending Messages to IPMB from system software.................................................................152

Keyboard Controller Style Interface.........................................................................................153

KCS Interface/MC LUNs...................................................................................................153

KCS Interface-MC Request message format..........................................................................153

MC-KCS Interface Response Message format.......................................................................153

LAN Interface.......................................................................................................................154

Remote Management Control Protocol (RMCP).....................................................................154

RMCP port numbers....................................................................................................154

RMCP Message Format................................................................................................155

Serial Over LAN (SOL)..........................................................................................................156

7 Support and other resources....................................................................157

Information to collect before contacting HP...............................................................................157

How to contact HP................................................................................................................157

HP authorized resellers..........................................................................................................157

Related information...............................................................................................................157

A Command Assignments...........................................................................159

B Verbose output examples.........................................................................164

Glossary..................................................................................................186

Index.......................................................................................................188

6 Contents

Page 7

1 Introduction and key concepts

Overview

The term Intelligent Platform Management (IPMI), refers to autonomous monitoring and recovery

features implemented directly in platform management hardware and firmware. The key

characteristic of Intelligent Platform Management is that inventory, monitoring, logging, and recovery

control functions are available independently of the main processors, BIOS, and operating system.

Platform management functions are available even when the system is in a powered down state.

IPMI capabilities are a key component in providing enterprise-class management for HA systems.

Platform status information is obtained and recovery actions initiated under situations where system

management software and normal “in-band” management mechanisms are unavailable.

The independent monitoring, logging, and access functions available through IPMI provide a level

of manageability built-in to the platform hardware. This supports systems with no system management

software available for the particular operating system, or the end-user who elects not to load or

enable the system management software.

NOTE: The HP Moonshot-45G Switch Module does not support IPMI. Only the HP Moonshot iLO

Chassis Management Firmware supports IPMI.

Sensor Data Model

The IPMI Sensor Model provides access to monitored information including temperatures, voltages,

and fan status. Instead of providing direct access to the monitoring hardware, IPMI provides access

by abstracted sensor commands, such as the Get Sensor Reading command, implemented

via a management controller. This approach isolates software from changes in the platform

management hardware implementation. Sensors return analog or discrete readings and events

are either discrete or threshold-based. Sensors are classified according to:

• Type of readings

• Type of events

Event types, sensor types, and monitored entities are represented using numeric codes defined in

the IPMI specification. IPMI avoids reliance on strings for management information and using

numeric codes facilitates internationalization, automated handling by higher level software, and

reduces management controller code and data space requirements.

Sensor owner identification

The definition for the Request/Response identifier, Requester’s ID, and Responder’s ID are specific

to the particular messaging interface used. However, the SDR and SEL must contain information

to identify the owner of the sensor. For management controllers, a slave address and LUN identify

the owner of a sensor on the IPMB. For system software, a software ID identifies the sensor owner.

These fields are used in event messages, where events from management controllers or the IPMB

are identified by an eight-bit field where the upper 7 bits represent the slave address or the system

software ID. The least significant bit is 0 if the value represents a slave address and 1 if the value

represents a system software ID.

Sensor number is not part of the sensor owner ID, but is a separate field used to identify a particular

sensor associated with the sensor owner. This combination of sensor owner ID and sensor number

uniquely identify a sensor in the system.

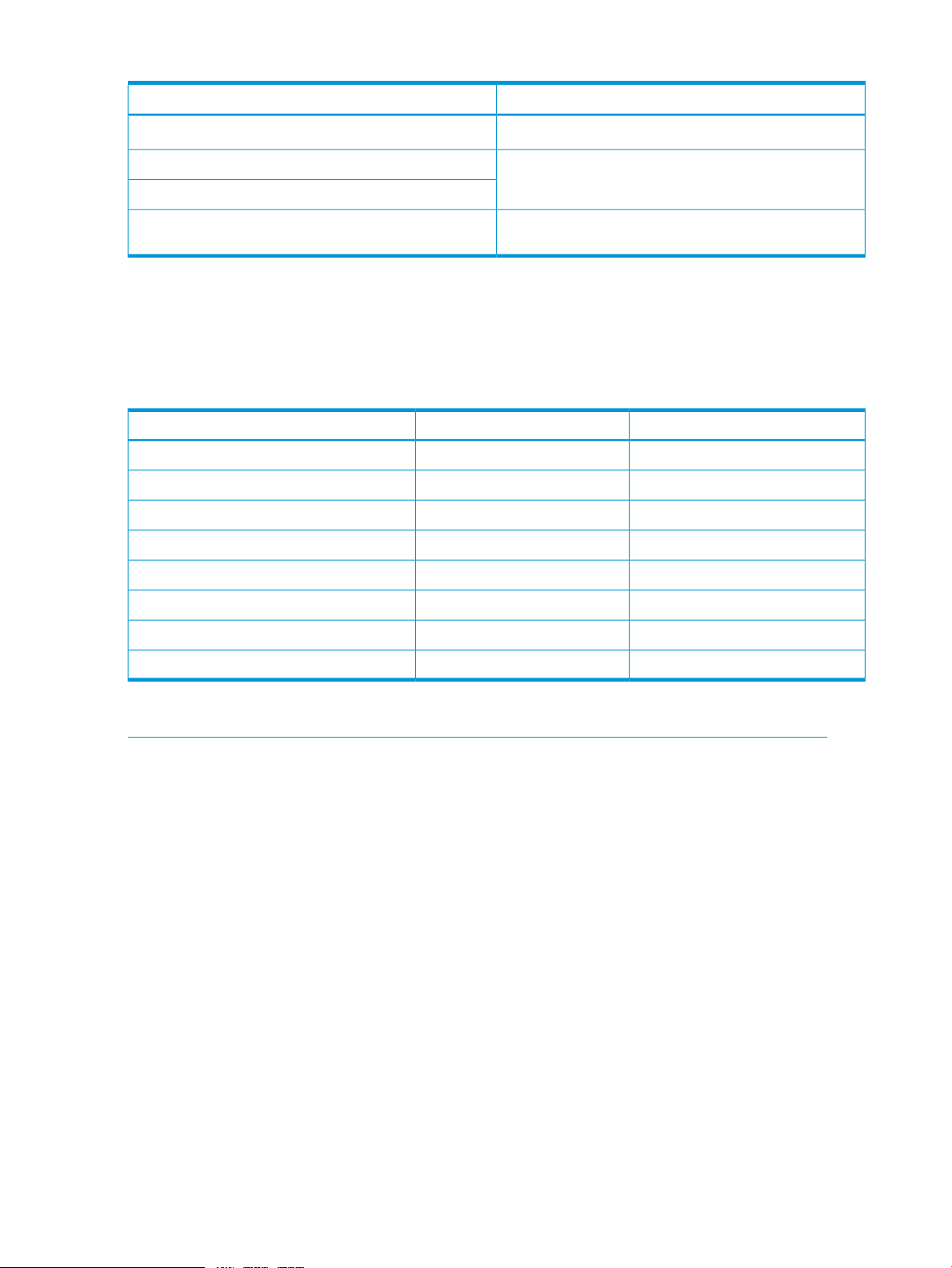

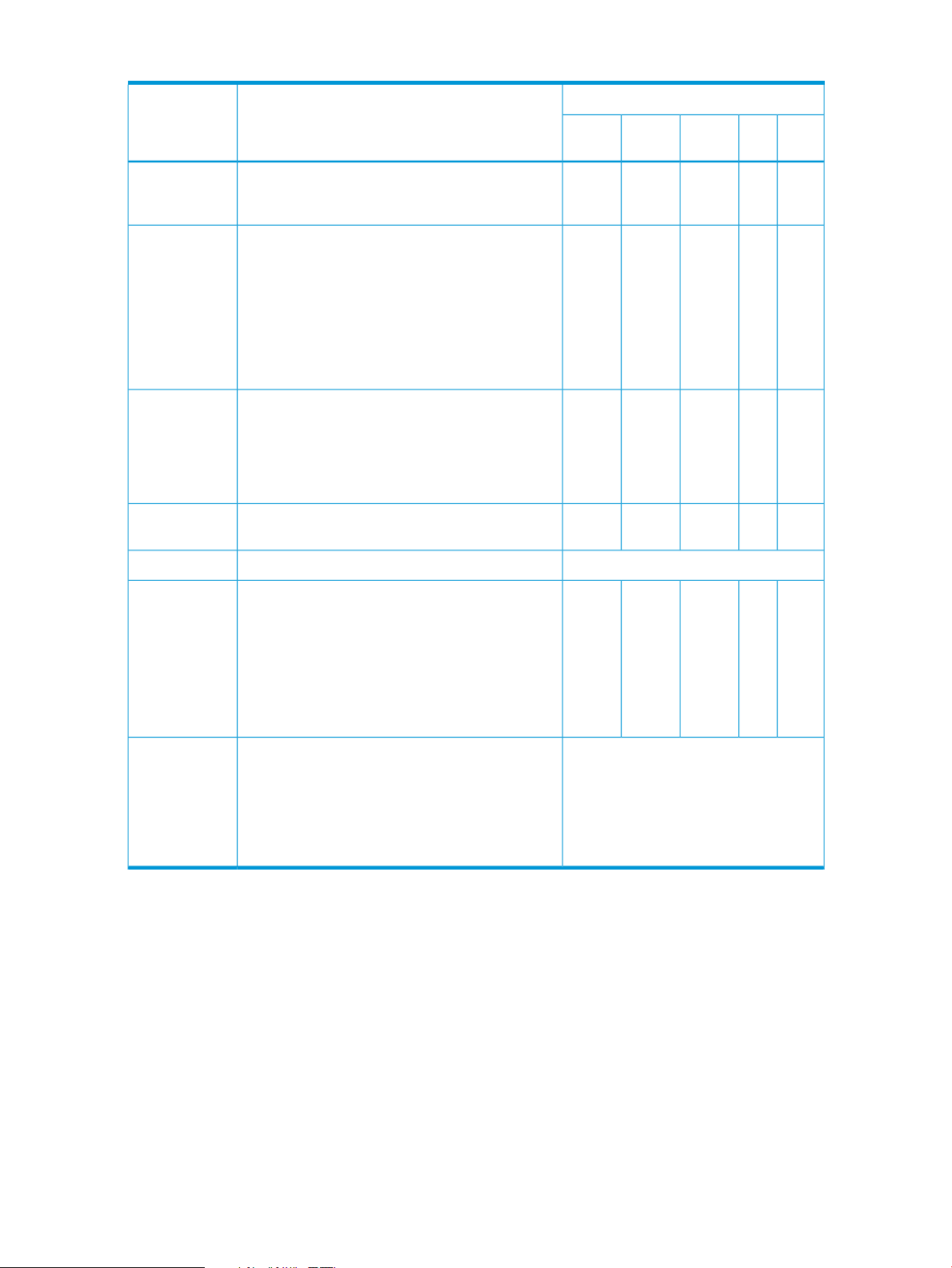

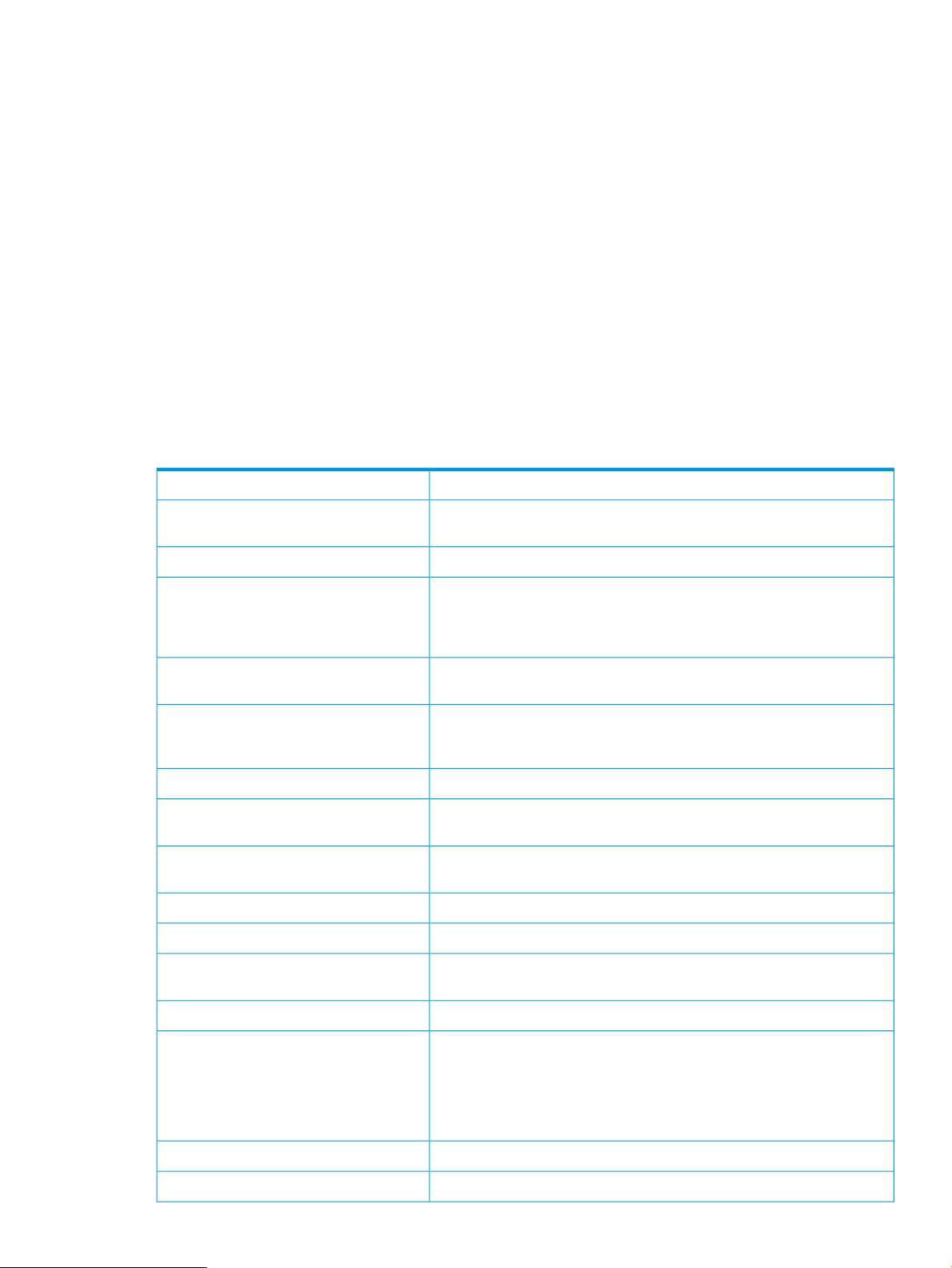

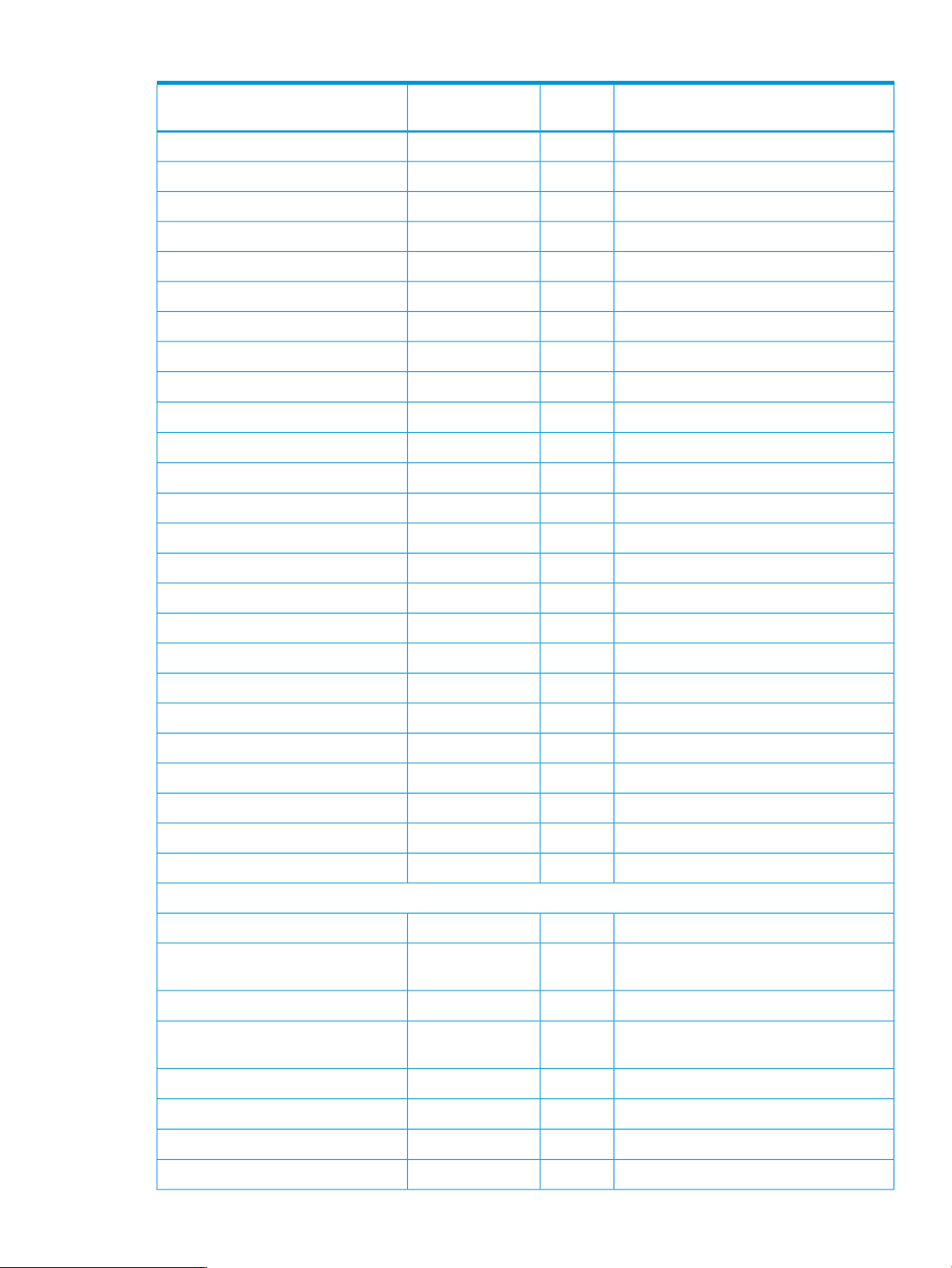

Table 1 Sensor owner ID and sensor number field definition

System Sensor Owner IDIPMB Sensor Owner ID

system software ID (7 bits)7:1 slave address (7 bits)

Overview 7

Page 8

Table 1 Sensor owner ID and sensor number field definition (continued)

System Sensor Owner IDIPMB Sensor Owner ID

0 1b (ID is a software ID)0 0b (ID is a slave address)

sensor number (8 bits, FFh = reserved)LUN (2 bits)

sensor number (1 bit, FFh = reserved)

In Moonshot: 0x82 IPMB address

Sensor type code

Each sensor has a sensor type code and are defined in “Some Moonshot sensor type codes”

(page 8). Sensor type codes are used both in SDRs and event messages. An example of a sensor

type code is code 0x1, which indicates a temperature sensor.

Table 2 Some Moonshot sensor type codes

This only appears in the system node SEL, where the it is

logged by the host system

Reading type codeSensor type codeSensor type

0x10x1Temperature

0xA0x4Fan

0xB0x4Fan redundancy

0x6F0xF1PICMG IPMB0 Physical Link

0x710xC0Health LED

0x700xC0UID LED

0x6F0x8Power supply

0xB0x8Power supply redundancy

For a complete listing of sensor type codes, see the IPMI specification available at:

http://www.intel.com/content/www/us/en/servers/ipmi/second-gen-interface-spec-v2.html

System event log and event messages

The MC provides a centralized, non-volatile SEL. Having the SEL and logging functions managed

by the MC helps ensure that post-mortem logging information is available should a failure occur

that disables the systems processor(s).

A set of IPMI commands allows the SEL to be read and cleared, and for events to be added to the

SEL. The common request message used for adding events to the SEL is an event message. Event

messages are sent to the MC via the IPMB providing the mechanism for satellite controllers to detect

events and log them into the SEL. The controller that generates an event message to another

controller via IPMB is the IPMB Event Generator. The controller receiving event messages is the

IPMB Event Receiver.

In Moonshot, event messages are sent to the zone manager by each cartridge and chassis controller.

There are two event logs, the SEL and the IML. There are OEM specific commands for obtaining

and displaying these logs. For more information, see the related commands in “Command

specification” (page 25).

8 Introduction and key concepts

Page 9

Event messages are special messages sent by management controllers when they detect significant

or critical system management events. This includes messages for events such as:

• temperature threshold exceeded

• voltage threshold exceeded

• power fault

The event message generator notifies the system by sending an Event Request Message to

the event receiver device.

When the event receiver gets a valid event message, it sends a response message to the event

message generator which is typically transferred to the SEL. The event receiver does not interpret

event messages so that new event message types can be added into the system without impacting

event receiver implementation.

SEL commands — The SEL is a non-volatile repository for system events and some system

configuration information. The SEL device access the commands sent by the SEL. Event messages

when received by the event receiver device are written to the SEL.

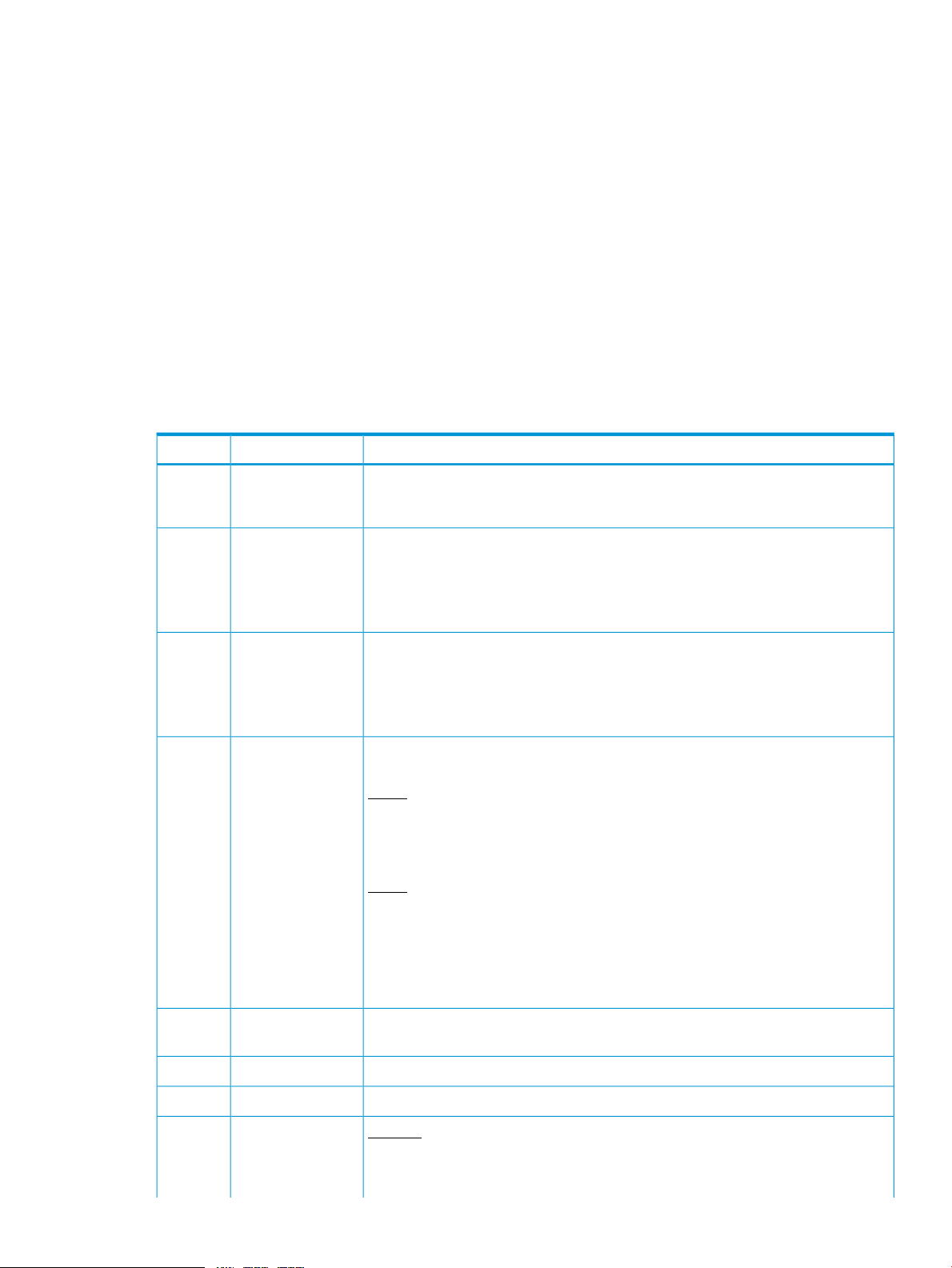

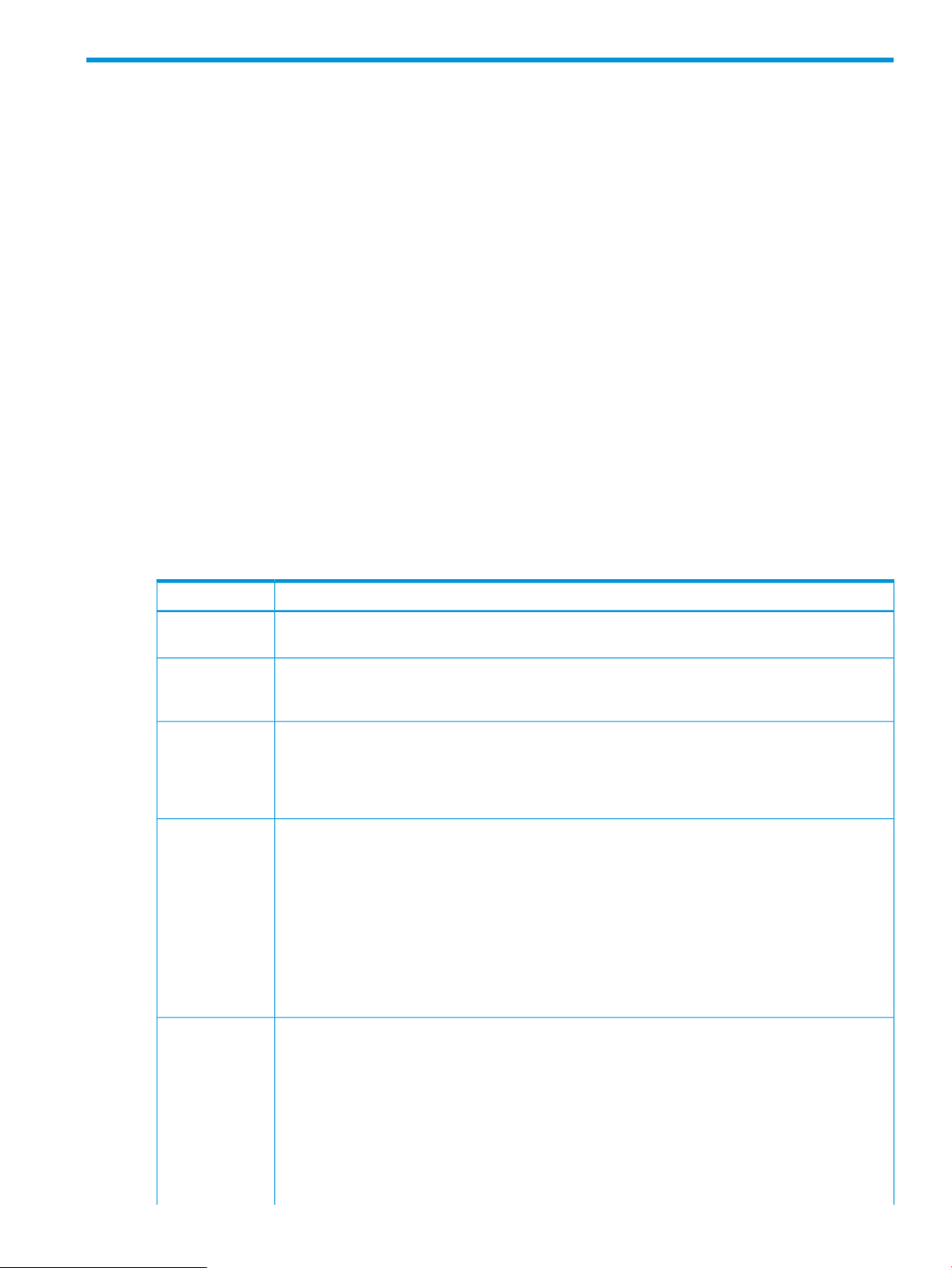

Table 3 SEL event records

DescriptionFieldByte

Record ID1

2

5

6

7

Generator ID8

9

ID used for SEL record access. The Record ID values 0000h and FFFFh have special

meaning in the Even Access commands and must not be used as Record ID values

for stored SEL event records.

[7:0] — Record typeRecord type3

02h = system event record

C0h-DFh = OEM timestamped, bytes 8–16 OEM defined

E0h-FFh = OEM non-timestamped, bytes 4–16 OEM defined

Time when event was logged. LS byte first.Timestamp4

RqSA & LUN if event was generated from IPMB. Software ID if event was generated

from system software.

Byte 1

[7:1] — 7–bit I2C. Slave address, or 7–bit system software ID

[0] 0b = ID is IPMB slave address

1b = System software ID

Byte 2

[7:4] — Channel number. Channel that received the event message 0h if the event

message was received via the system interface, primary IPMB, or internally generated

by the MC.

[3.2] — Reserved. Write as 00b.

[1.0] — IPMB device LUN if byte 1 holds slave address, otherwise 00b.

EvM Rev10

Event message format version (=04h for events in this specification, 03h for IPMI

v1.0 event messages).

Sensor type code for sensor that generated the event.Sensor type11

Number of sensor that generated the event.Sensor #12

Event dirEvent dir 113

[7] — 0b = Assertion event.Event type

1b = Deassertion event.

1

Sensor Data Model 9

Page 10

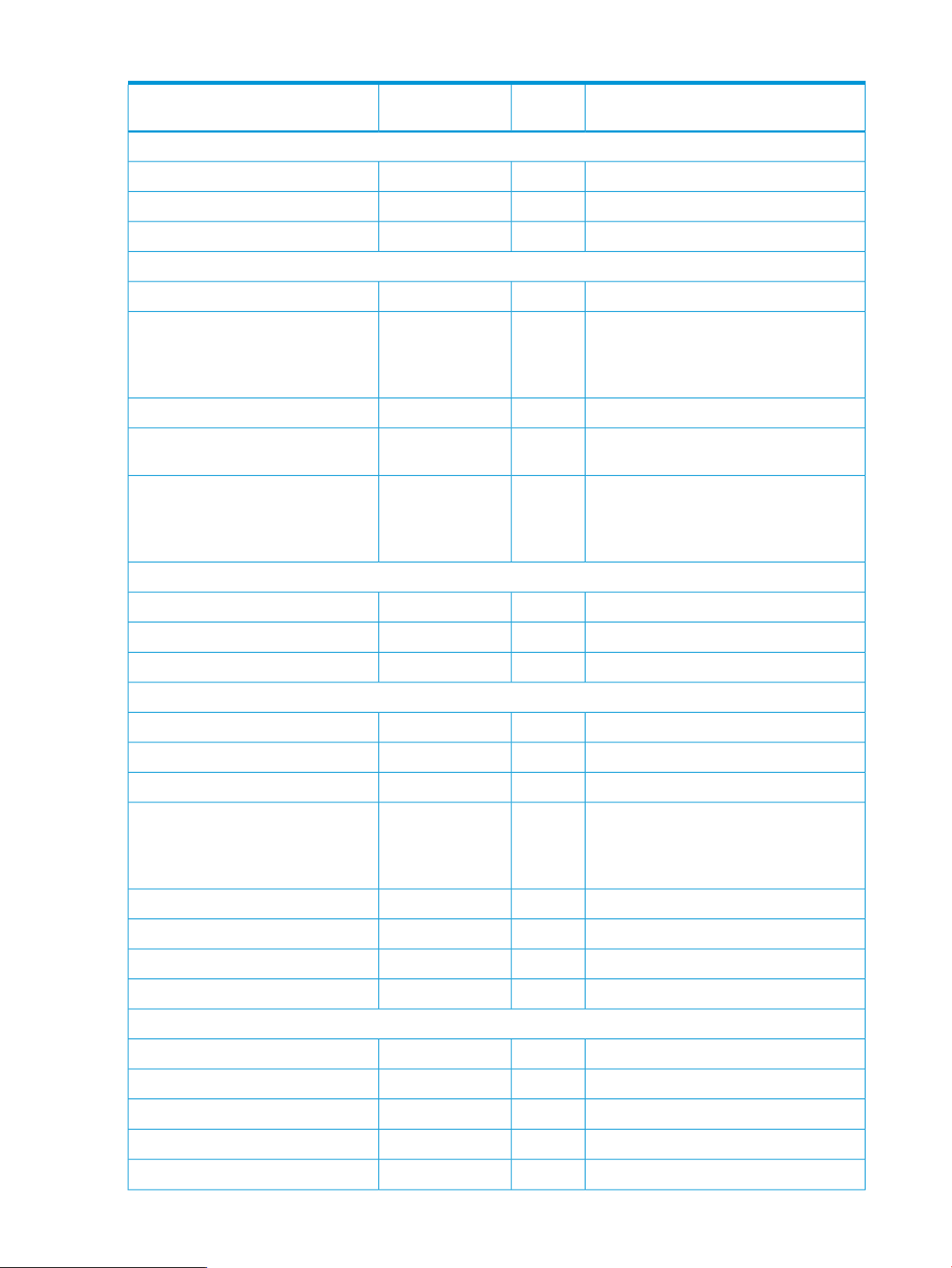

Table 3 SEL event records (continued)

1

The MC must accept Platform Event request messages that are in IPMI v1.0 format (EvM Rev=03h) and log them as IPMI

v1.5/v2.0 records by setting the EVMRev field to 04h and setting the channel number in the generator ID field

appropriately for the channel that received the event.

SDR repository

With IPMI’s extensibility and scalability each platform implementation can have a different

population of management controllers and sensors, and different event generation capabilities.

IPMI allows system management software to retrieve information from the platform and automatically

configure itself to the platform’s capabilities, enabling the use of plug and play, platform-independent

instrumentation software.

Information that describes the platform management capabilities is provided via two mechanisms:

DescriptionFieldByte

Event type

Type of trigger for the event, such as, a critical threshold going high or state asserted.

Also indicates class of the event. Example: discrete, threshold, or OEM. The event

type field is encoded using the event/reading type code.

Event request message, event data field contents.Event data 114

Event request message, event data field contents.Event data 215

Event request message, event data field contents.Event data 316

• Capability commands — these are commands within the IPMI command set that return

• SDRs — these contain information about the type and number of sensors in the platform, sensor

The primary purpose of SDRs is to describe the sensor configuration of the platform management

subsystem to system software. SDRs also include records describing the number and type of devices

connected to the system’s IPMB, records that describe the location and type of FRU Devices (devices

that contain field replaceable unit information).

SDRs are kept in a single, centralized, non-volatile storage area managed by the MC. This storage

area is the SDR repository. In Moonshot, the SDRR is kept by the zone manager; the remaining

controllers have device SDRs. Additional device SDRs are kept at the cartridge and system node

level. All SDR repositories provide a mechanism for information to be obtained independently from

the controller by the BIOS system management or remote management.

SDR formats

The general SDR format consists of three major components: the record header, record key fields,

and the record body. To save space, sensors that only generate events do not require SDRs, in

addition, generic system management software does not access sensors unless they are reported

by SDRs.

information on other commands and functions that the controller can handle.

threshold support, event generation capabilities, and sensor type readings.

10 Introduction and key concepts

Page 11

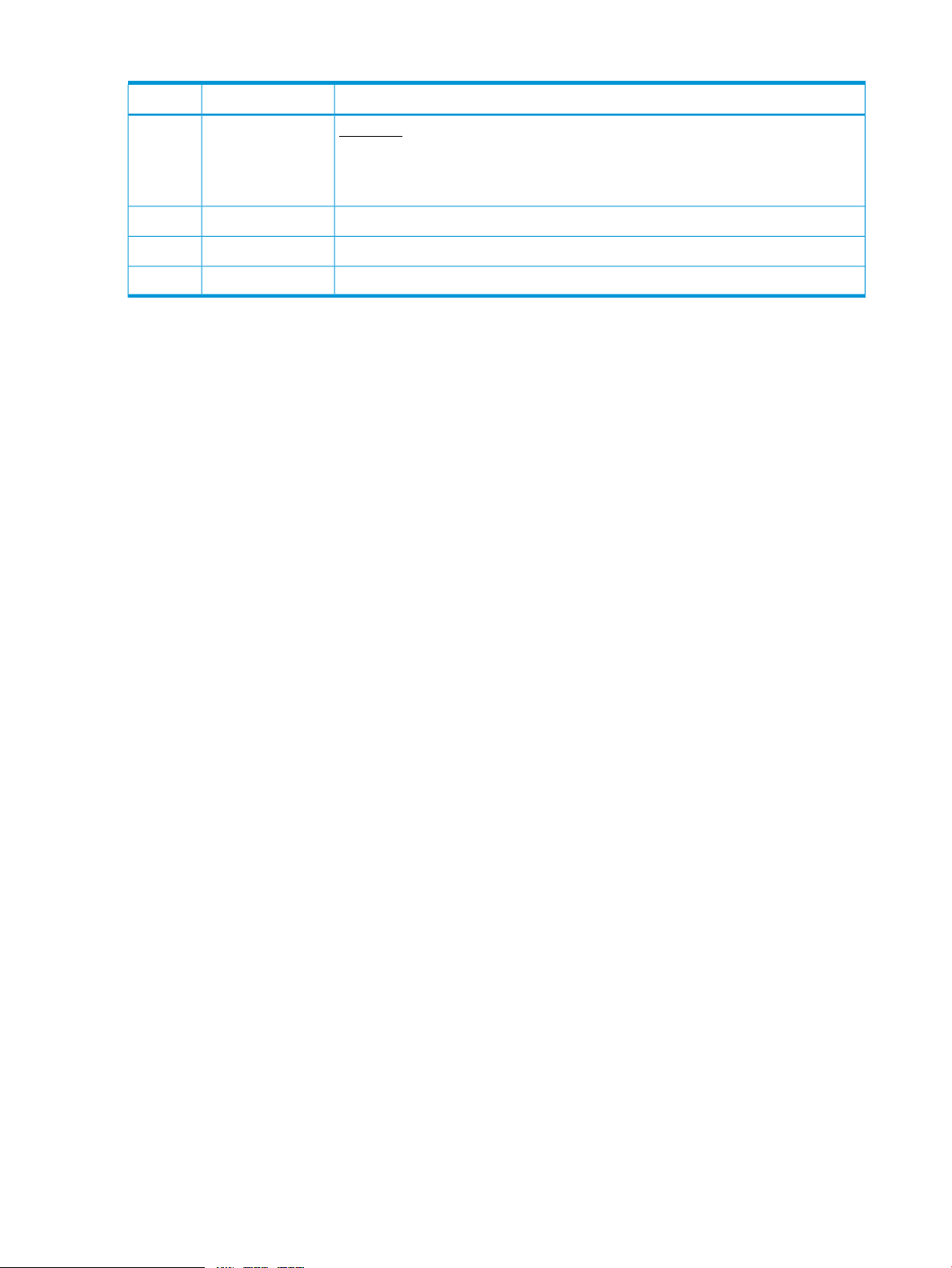

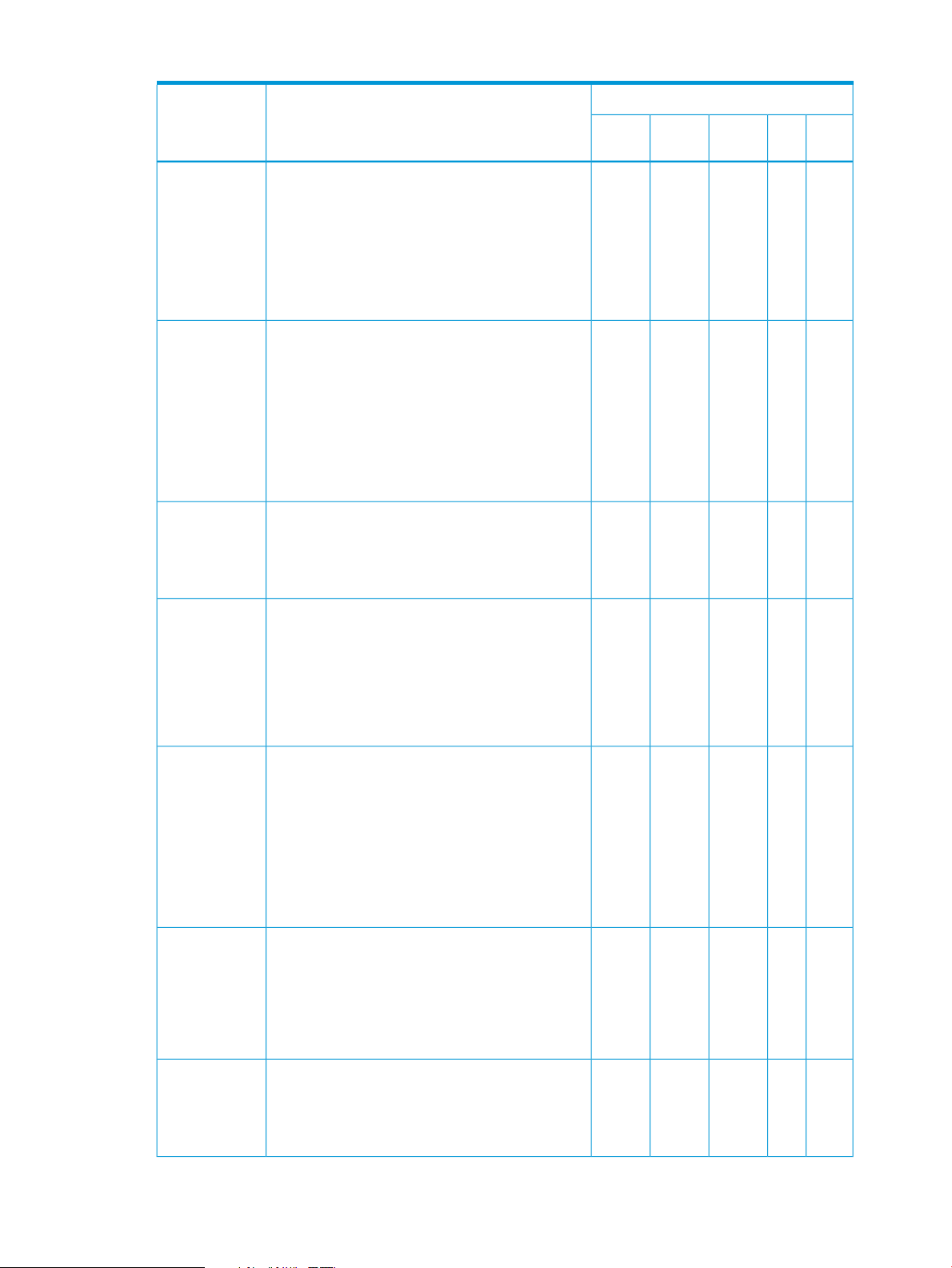

Table 4 Sensor data record formats

Record bodyRecord Key fieldsRecord header

Record ID — a value used for

accessing sensor data records.

SDR version — version number of the

SDR specification.

Record type — a number representing

the type of record. Example, 01h =

8–bit sensor with thresholds.

Record length — the number of bytes

of data following the record length

field.

The record key bytes are the

contiguous bytes following the record

header. The number of bytes vary

according to record type. Together,

they make up a set of unique fields for

a given record specifying location (for

example, slave address, LUN and Bus

ID) and sensor number.

Reading the SDR repository and device SDR repositories

An application that retrieves records from the SDR repository must first read them sequentially using

the Get SDR command. This command returns the requested record and the record ID of the next

SDR in sequence.

NOTE: Record IDs are not required to be sequential or consecutive and applications should not

assume that SDR record IDs follow any particular numeric ordering.

Retrieve succeeding records by issuing the Get SDR or Get device SDR command using the

next record ID returned in the previous response. This is continued until the End of Record ID

is encountered.

Once all the desired records have been read, the application can randomly access the records

according to their Record ID. An application that seeks to access records randomly must save a

data structure that retains the record key information according to the record ID.

Contains specific information to the

sensor data record

FRU

IMPORTANT: Record IDs may change with time, it is important for applications to first verify that

the Record Key information matches the record retrieved.

If the record ID is no longer valid for a record key, then, access the SDR records again as described

above until the record matches the record key.

An application can tell whether records have changed by examining the most recent addition

timestamp using the Get SDR repository info or Get device SDR repository info

command, depending on the zone in which the command is issued.

If the record information has changed, an application does not need to list out the entire contents

of all records. The Get SDR or Get device SDR allows a partial read of the SDR. Thus, an

application can search for a given Record Key by just retrieving that portion of the record.

The IPMI specifications include support for storing and accessing multiple sets of non-volatile FRU

data for different modules in the system. An enterprise-class system typically has FRU information

for each major system board such as the processor board, memory board or I/O board. FRU data

includes serial number, part number, model, and asset tag.

IPMI FRU information is accessible via the IPMB and management controllers. The information can

be retrieved at any time, independent of the main processor, BIOS, system software, or OS, via

out-of-band interfaces, such as the ICMB, a remote management card, or other device connected

to the IPMB. FRU information is still available when the system is powered down.

With these capabilities FRU information is available even under failure conditions when access

mechanisms that rely on the main processor are unavailable. This facilitates the creation of

automated remote inventory and service applications. IPMI does not seek to replace other FRU or

FRU 11

Page 12

inventory data mechanisms such as those provided by SM BIOS, and PCI vital product data. Rather,

IPMI FRU information is typically used to complement that information or provide information access

out-of-ban or under system down conditions.

IPMI provides FRU information in two ways: via a management controller, or via FRU SEEPROMs.

FRU information that is managed by a management controller is accessed using IPMI commands.

This isolates software from direct access to the non-volatile storage device, allowing the hardware

implementor to utilize whatever type of non-volatile storage required.

FRU inventory device

The FRU inventory device contains information such as the serial number, part number, asset tag,

and short descriptive string for the FRU. The contents of a FRU inventory record are specified in

the platform management FRU information storage definition.

The FRU inventory device is a logical device and is not necessarily implemented as a separate

physical device. This device contains the SDR repository device and typically holds FRU inventory

Information for the main system board and chassis. In addition, there may be a separate FRU

inventory device that provides access to the FRU information for a replaceable module such as a

memory module.

FRU devices can be located either behind a management controller or directly on the IPMB. The

sensor data records include a FRU device locator record that tells software where the device is

located and the type of commands required to access the FRU device. FRU devices can be located

in three types of location:

• Behind a management controller and accessed using Read/Write FRU data commands.

Multiple FRU devices can be behind a management controller.

• SEEPROM on a private bus behind a management controller. These devices are accessed

using Master Write-Read commands.

• SEEPROM on the IPMB. These devices are typically accessed using a Master Write-Read

command to the IPMB via the MC.

Standardized timers

Watchdog timer

IPMI provides a standardized interface for a system watchdog timer that can also be used for

BIOS, OS, and OEM applications. The timer can be configured to automatically generate selected

actions when it expires; including power off, power cycle, reset, and interrupt. The timer function

automatically logs the expiration event. Setting 0 for the timeout interval result causes the timeout

action to be initiated immediately. This provides a means for devices on the IPMB, such as remote

management cards, to use the watchdog timer to initiate emergency reset and other recovery

actions dependent on the capability of the timer.

In Moonshot, watchdog timers are implemented by the system node controllers.

POH counter

The standardized power-on hours (POH) counter is optional. It returns a counter value proportional

to the system operating power-on hours.

In Moonshot, the POH counter is implemented at the system node controller.

Timestamp format

A timestamp is a key component of event logging and tracking changes to the SDRs and the SDR

repository.

Time is an unsigned, 32–bit value representing the local time as the number of seconds from

00:00:00,January 1, 1970.

12 Introduction and key concepts

Page 13

The timestamps used for SDR and SEL records are specified in relative local time (that is, the

difference between the timestamp does not include the GMT offset). Converting the timestamp to

a GMT-based time requires adding the GMT offset for the system and is obtained from system

software level interfaces. IPMI commands do not store or return GMT offset for the system.

Applications may use ANSI C time standard library routines for converting the SEL timestamp into

other time formats.

Special timestamp values

0xFFFFFFFF indicates an invalid or unspecified time value.

0x00000000 through 0x20000000 indicate events that occur after initialization of the SEL device

up to when the timestamp is set with the system time value. These timestamp values are relative to

the completion of the SEL devices initialization, and not January 1, 1970.

Standardized timers 13

Page 14

2 The virtual topology of the Moonshot 1500 CM module

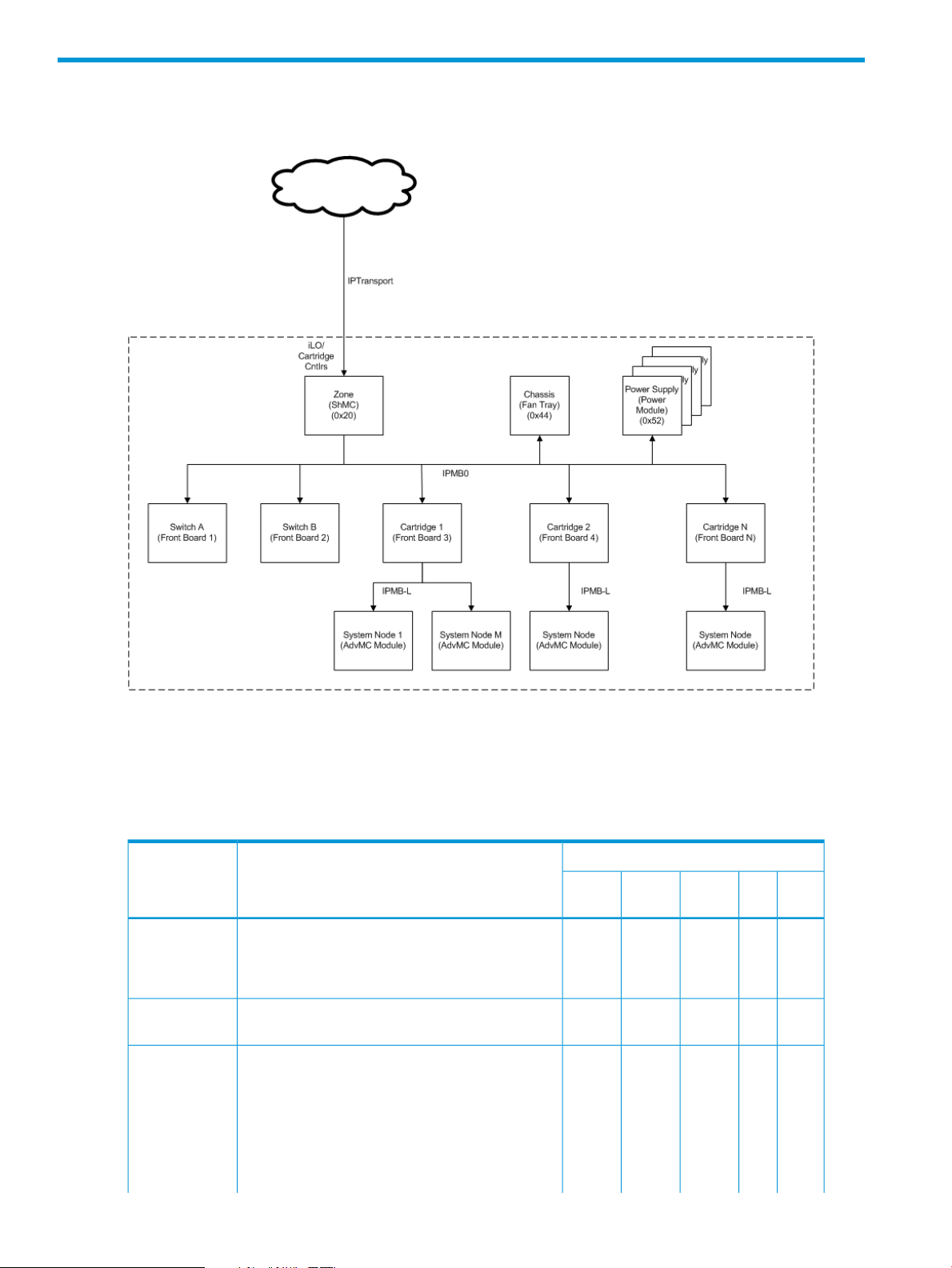

Figure 1 Moonshot virtual IPMI topology

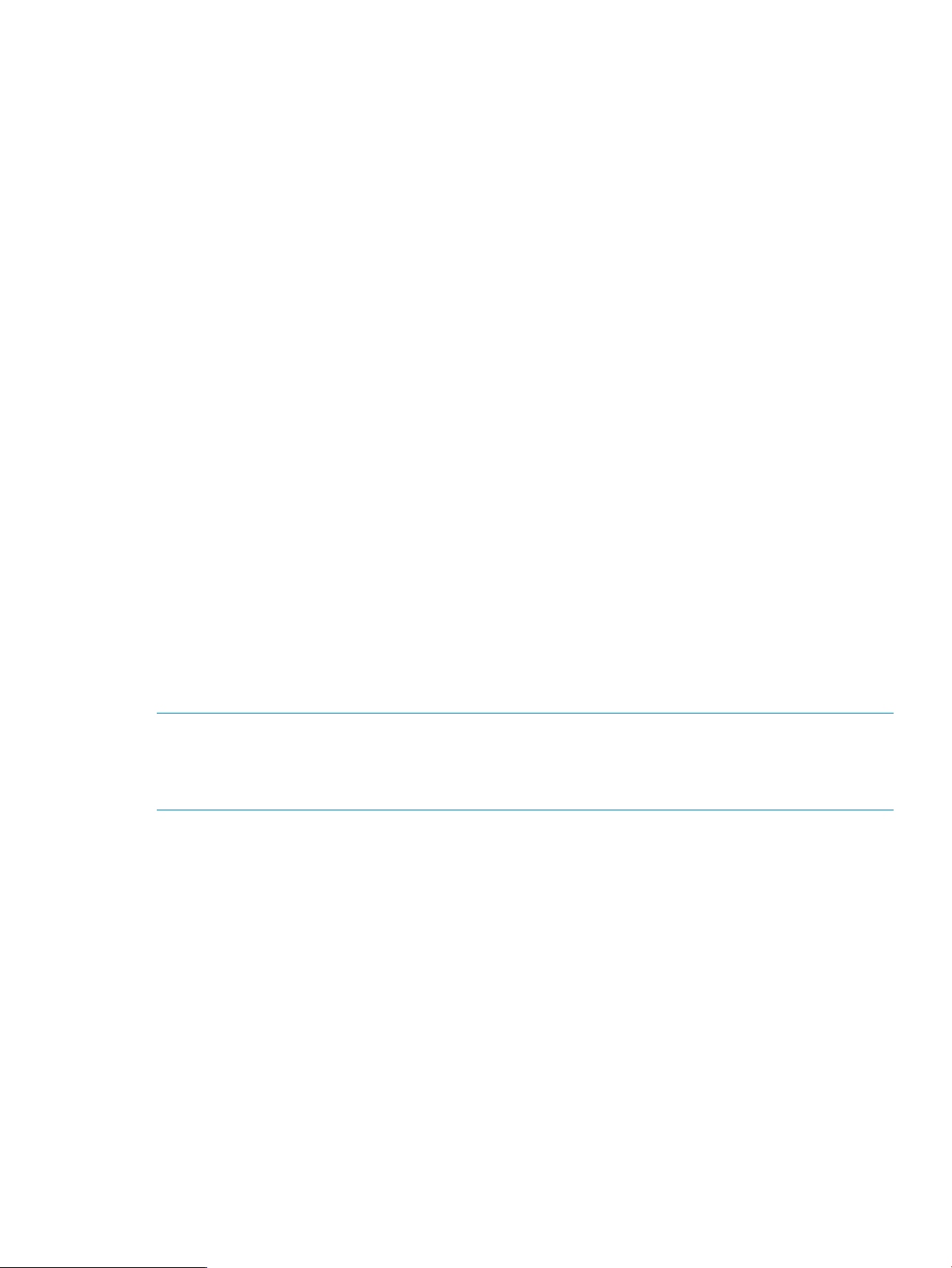

There are five virtual management controller (MC) entity types represented within the HP Moonshot

1500 Chassis Management module.

Table 5 (page 14) summarizes the various functions available in Moonshot and the virtual

management controllers to which they apply.

Table 5 Moonshot virtual management controller functions

Applicable Virtual Management ControllerDescriptionFunction

NodeCartPower

xxxxxThe MC must implement the mandatory IPM Device

xThe implementation must provide MC access via

IPM Device

System Interface

SDR Repository

ChassisZone

Supply

commands. If an IPMB is provided, the mandatory

commands must be accessible from the IPMB unless

otherwise noted.

one of the specified IPMI system interfaces.

xThe MC must provide a SDR Repository to hold

Sensor, Device Locator, and Entity Association

records for all sensors in the platform management

subsystem. This does not need to include SDRs for

sensors that only generate events. If the SDR

Repository is writable, it is recommended that at

least 20% additional space is provided for add-in

platform management extensions.

14 The virtual topology of the Moonshot 1500 CM module

Page 15

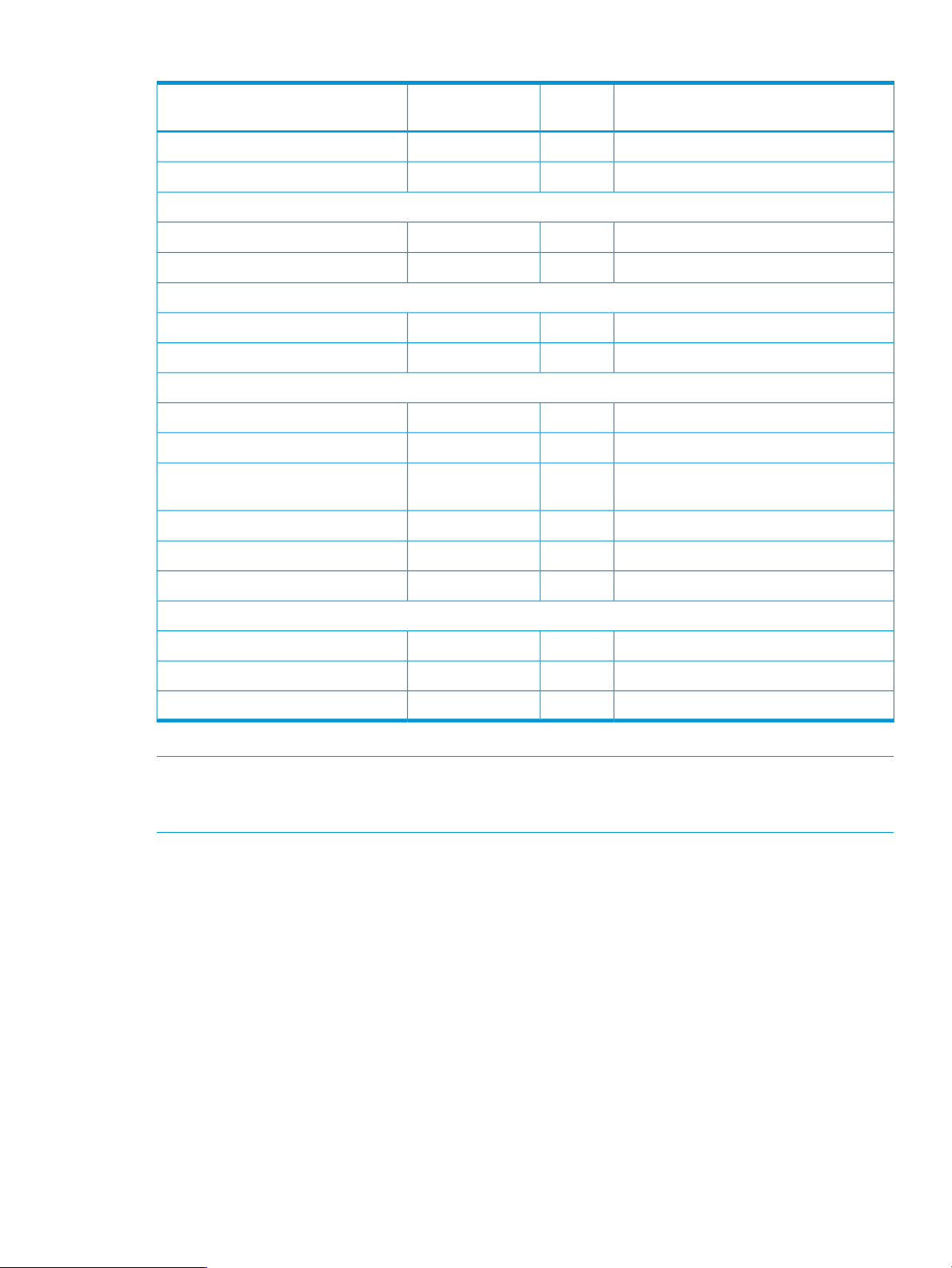

Table 5 Moonshot virtual management controller functions (continued)

Applicable Virtual Management ControllerDescriptionFunction

IPMB Interface

Watchdog

Timer

The SDR Repository must be accessible via the

system interface. If an IPMB is provided, the SDR

Repository must be readable via that interface as

well. SDR update via the IPMB interface is optional.

SDR Repository access when the system is powered

up or in ACPI ‘S1’ sleep is mandatory, but access

when the system is powered -down or in a >S1

sleep state is optional.

MC must provide the system interface to the IPMB.

If an IPMB is imp lemented, at least one of the

specified IPMB connectors must be provided. Refer

to the IPMB Protocol specification for connector

definition. In addition the MC must implement a

message channel that allows messages to be sent

from the IPMB to the system interface, and

vice-versa, and any other mandatory IPMB support

functions and commands.

Timer interface, with support for system reset action.

Certain functions within the Watchdog Timer are

optional. Refer to the sections on the Watchdog

Timer for information.

ChassisZone

Supply

NodeCartPower

xxxxxThe IPMB is highly recommended, but optional. The

xThe MC must provide the standardized Watchdog

Event Receiver

SEL Interface

FRU Inventory

Initialization

Agent

xxThe MC must implement an Event Receiver function

and accept Event Messages via the system interface.

If an IPMB is provided, the Event Receiver function

must also accept Event Messages from the IPMB.

Event Receiver operation while the system is

powered up or in ACPI ‘S1’ sleep is mandatory,

but operation when the system is powered down or

in a >S1 sleep state is optional.

xxThe MC must provide a System Event Log interface.

The event log must hold at least 16 entries. SEL

access must be provided via the system interface.

The SEL must be fully accessible via all mandatory

SEL commands through all supported interfaces to

the MC whenever the system is powered up or in

ACPI 'S1' sleep state. SEL read access is always

mandatory whenever the MC is accessible, and

through any interface that is operational, regardless

of system power state.

xxxxxThe MC must provide a logical Primary FRU

inventory device , accessible via the Write- and

Read FRU Data commands. The FRU

Inventory Device Info command must also

be supported. It is highly recommended that all other

management controllers also provide a Primary FRU

inventory device. (This was optional in IPMI v1.0.)

xxxxxThe initialization agent function is one where the

MC initializes event generation and sensors both

internally and on other management controllers

according to initialization settings stored in the SDR

for the sensor.

15

Page 16

Table 5 Moonshot virtual management controller functions (continued)

Applicable Virtual Management ControllerDescriptionFunction

Sensors

Internal Event

Generation

External Event

Generation

LAN Messaging

would provide sensors for baseboard temperature,

voltage, and chassis intrusion monitoring.

Watchdog Timer. It is highly recommended that

sensors generate events to eliminate the need for

system management software to poll sensors, and

to provide “post -mortem” failure information in the

SEL. Internal event generation for sensors is optional,

but highly recommended - particularly for

‘environmental’ (e.g. temperature and voltage)

sensors.

Receiver command to allow it to be set as an IPMB

Event Generator and send its event messages to

another management controller. This would

primarily be used for development and test

purposes.

Messaging over LAN

ChassisZone

Supply

xAbility for the MC to send and receive IPMI

Not implemented yet.Ability to send an Alert over the LANLAN Alerting

NodeCartPower

xxxxxThe MC can provide sensors. A typical server MC

xxxxxThe MC must generate internal events for the

xxxThe MC could be designed to accept the Set Event

Bridging

Support

Platform Event

Filtering (PEF)

Policies optional. Refer to the sections on PEF for

messages between two interfaces connected to the

MC.

The following support is required if the

corresponding interfaces are supported:

• LAN <–> IPMB

• LAN <–> System Interface

n event. This capability is mandatory if paging or

alerting is supported. Certain actions within PEF areand Alert

information. The Alert action and Alert Policies are

mandatory if serial/modem or LAN alerting is

supported.

xxxxxThe ability to transfer IPMI request and response

Not implemented yet.Ability for MC to perform a selectable action on a

16 The virtual topology of the Moonshot 1500 CM module

Page 17

3 Discovering managed entities using IPMITool

Enter the IPMItool sdr list all command to show all management controller records, whether

you are querying an SDRR from the Virtual Zone MC or you are querying a device SDR for Virtual

Cartridge MC records. For example:

# ipmitool —l lanplus —H iloatx-gem-2c -U admin —P admin123 sdr list all

ZoMC | Static MC @ 20h | ok

254 | Log FRU @FEh f0.60 | ok

IPMB0 Phys Link | 0x00 | ok

ChasMgmtCtlr1 | Static MC @ 44h | ok

PsMgmtCtlr1 | Dynamic MC @ 52h | ok

PsMgmtCtlr2 | Dynamic MC @ 54h | ok

PsMgmtCtlr3 | Dynamic MC @ 56h | ok

PsMgmtCtlr4 | Dynamic MC @ 58h | ok

CaMC | Dynamic MC @ 82h | ok

CaMC | Dynamic MC @ A0h | ok

CaMC | Dynamic MC @ A6h | ok

CaMC | Dynamic MC @ DAh | ok

CaMC | Dynamic MC @ A4h | ok

Querying an SDRR from the Zone Management Controller

• Enter the sdr list all command to show all management controller records.

• Management controller records

Chassis controller – statically assigned, always should be present. Even though always

◦

assigned address 0x44, record should be parsed to learn address and channel number

(IPMB=0).

◦ Power supply controllers --- full complement of records always present. Dynamic indication

in record indicates to application that controller may or may not be present. When not

present, the controller will “nak”. Even though always assigned address 0x52-0x58,

records should be parsed to learn address and channel number (IPMB=0).

◦ Cartridge controllers are dynamically added/deleted to the SDRR upon cartridge

insertion/deletion. Possibility of “nak” condition during deletion transitions. Records

should be parsed to learn addresses and channel number (IPMB=0).

Querying a device SDR for a Cartridge Management Controller

• Management controller records

◦ System node controllers – statically assigned, always should be present. Number of system

node controllers is dependent on cartridge type. Some cartridges may not contain host

systems such as switches. Other cartridges may contain 1 or 4 system nodes. Records

should be parsed for addressing and channel number routing. System nodes routed on

channel 7 (IPMB-L).

You can learn the phsical locations of managed entities by entering the PICMG get address

info command. Use the IPMB address of the cartridge to get the physical address (slot number).

You can also learn the chassis topology through chassis FRU serial number for Zones with the same

chassis.

17

Page 18

4 IPMItool

IPMI tool is a simple command-line interface to systems that support the IPMI v1.5 specification. It

provides the ability to read the sensor data repository and print sensor values, display the contents

of the system event log, print field replaceable unit information, read and set LAN configuration

parameters, and perform remote chassis power control. It was originally written to take advantage

of IPMI-over-LAN interfaces but is also capable of using the system interface as provided by a

kernal device driver such as Open IPMI. IPMItool is available under a BSD-compatible license.

System Management Software is generally complex and makes platform management only part

of a much larger management picture. However, many system administrators and developers rely

on command-line tools that can be scripted and systems that can be micro-managed. IPMItool takes

a different approach to SMS and provides a completely command-line oriented tool. Therefore, it

is not designed to replace the Open IPMI library. Where possible, it supports printing

comma-separated values for output to facilitate parsing by other scripts or programs. It is designed

to run quick command response functions that can be as simple as turning the system on or off or

as complex as reading in the sensor data records and extracting and printing detailed sensor

information for each record.

Moonshot IPMItool support — out of band

Single-bridging out of band command

You must single-bridge out of band commands to reach specific chassis management controller or

cartridge management controller to discover management controller addresses.

Enter the sdr list all command at the zone management controller to discover chassis and

cartridge management controller addresses. For example,

• Chassis Controller

-b 0 -t 0x44

• Cartridge Controller Slot 1

-b 0 –t 0x82

• Cartridge Controller Slot 2

-b 0 –t 0x84

where:

• -b <ipmi channel number>

• -t <target slave address>

Double-bridging out of band commands

You must double-bridge out of band commands to reach specific system node management

controllers to discover system node management controller addresses.

Enter the sdr list all at the cartridge management controller to discover system node

management controller addresses. For example,

• –System Node Controller 2 (0x74) on Cartridge Controller Slot 1 (0x82)

-T 0x82 -B 0 –b 7 -t 0x74

• –System Node Controller 1 (0x72) on Cartridge Controller Slot 2 (0x84)

18 IPMItool

-T 0x84 -B 0 –b 7 -t 0x72

Page 19

where:

• –B <transit channel for bridged request (dual bridge)>

• –T <transit address for bridge request (dual bridge)>

• -b <ipmi channel number>

• -t <target slave address>

Interfaces

IPMItool supports dynamic loading of interfaces that correspond to low-level communication methods

for accessing IPMI systems. The most common of these are the System Interface provided by the

OpenIPMI Linux kernal driver and IPMI over LAN interfaces.

System Interface

There are multiple types of system interfaces, and they are all similar enough to enable a single

driver like OpenIPMI to support them all. They can be connected to any system bus such as ISA

or X-bus that allows the main processor to access I/O mapped locations and meet the timing

specifications. The varieties of system interfaces include KCS and SSIF. All of these are supported

in recent versions of the OpenIPMI driver for the Linux kernal. IPMItool uses this driver to access

the system interface through a character device node at /dev/ipmi0. To use this interface with

IPMItool provide the -l open parameter on the command line.

LANPlus Interface

The LANPlus interface communicates with the MC over an ethernet LAN connection using UDP

under IPv4. The LANPlus interface uses the RMCP+ protocol. RMCP+ facilitates improved

authentication and data integrity checks as well as encryption and the ability to carry multiple

types of payloads. Generic Serial Over LAN support requires RMCP+, so the IPMItool sol

activate command requires the use of LANPlus.

RMCP+ session establishment uses a symmetric challenge-response protocol called RAKP (Remote

Authenticated Key-Exchange Protocol) which allows the negotiation of many options.

NOTE: IPMItool does not allow the user to specify the value of every option, defaulting to the

most obvious settings marked as required in the v2.0 specification. Authentication and integrity

HMACS are produced with SHA1, and encryption is performed with AES-CBC-128. Role-level

logins are not yet supported.

IPMItool must be linked with the OpenSSL library in order to perform the encryption functions and

support the LANPlus interface. If the required packages are not found it will not be compiled and

supported.

ipmitool -I lanplus -H <hostname>[-U <username>][-P <password>]<command>

A hostname must be given on the command line in order to use the LAN interface with IPMItool.

The —C option allows the authentication integrity and encryption algorithms to be used for LANPlus

sessions based on the cipher suite ID found in IPMI v2.0. The default cipher suite is 3 which specifies

RAKP-HMAC-SHA1 authentication, HMAC-SHA1–96 integrity, and AES-CBC-128 encryption

algorithms.

Interfaces 19

Page 20

Example 1 Raw Get Device ID to chassis satellite controller over LAN

# ipmitool -I lanplus -H 16.85.178.125 -U admin -P admin123 -L Administrator -b 0 -t 0x44 raw 6 1

15 01 02 01 02 29 0b 00 00 00 85 00 00 00 00

Example 2 Powering on C2N1 over LAN

# ipmitool -I lanplus -H 16.85.178.125 -U admin -P admin123 -L Administrator -B 0 –T 0x84 –b 7 –t 0x72 chassis

power on

Chassis Power Control: Up/On

Example 3 Activating SOL on C2N1 over LAN

# ipmitool -I lanplus -H 16.85.178.125 -U admin -P admin123 -L Administrator -B 0 –T 0x84 –b 7 –t 0x72 sol

activate

Activates SOL session for C2N1

Features

Instead of directly accessing the monitoring hardware for device entry, IPMI provides access to

sensor data through abstracted messaging commands. Some common types of sensors that can

be found in the system include baseboard and processor temperature sensors, processor and DIMM

presence sensors, fan speed and failure monitoring, and baseboard, processor and SCSI terminating

voltage sensors. The amount of data available for each sensor can be overwhelming, so by default

IPMItool only displays the sensor name, reading and status. Considerably more output can be seen

by enabling the verbose output option.

To facilitate discovery of features, IPMI includes a set of records called SDRs kept in a single

centralized non-volatile storage area. These records include software information such as how

many sensors are present, what type they are, their events, threshold info and more. This allows

software to interpret and present sensor data without any prior knowledge about the platform.

20 IPMItool

Page 21

Example 4 Output from sdr list all command

ZoMC | Static MC @ 20h | ok

254 | Log FRU @FEh f0.60 | ok

IPMB0 Phys Link | 0x00 | ok

ChasMgmtCtlr1 | Static MC @ 44h | ok

PsMgmtCtlr1 | Dynamic MC @ 52h | ok

PsMgmtCtlr2 | Dynamic MC @ 54h | ok

PsMgmtCtlr3 | Dynamic MC @ 56h | ok

PsMgmtCtlr4 | Dynamic MC @ 58h | ok

CaMC | Dynamic MC @ A6h | ok

CaMC | Dynamic MC @ A8h | ok

CaMC | Dynamic MC @ AAh | ok

CaMC | Dynamic MC @ ACh | ok

CaMC | Dynamic MC @ AEh | ok.

.

.

.

CaMC | Dynamic MC @ A4h | ok

Example 5 Output from sdr list all command at cartridge

01-Front Ambient | 21 degrees C | ok

02-CPU | 40 degrees C | ok

03-DIMM | 25 degrees C | ok

04-Cart Ctrlr | 24 degrees C | ok

05-CPU Zone | 29 degrees C | ok

06-LOM Zone | 36 degrees C | ok

CaMC | Dynamic MC @ A4h | ok

SnMC | Dynamic MC @ 72h | ok

SnMC 1 | Log FRU @01h c1.62 | ok

Events

See “Verbose output examples” (page 164) for an example of verbose output from the sdr list

all command.

Events are special messages sent by the management controller when they detect system

management events. Some examples of events are temperature threshold exceeded, voltage

threshold exceed, correctable ECC memory error, etc. These events are processed and usually

logged in the SEL. This is similar to the SDR in that it provides a centralized non-volatile storage

area for platform events that are logged autonomously by the MC or directly with event messages

sent from the host.

There is an abundance of information available from an event log entry. By default IPMItool displays

only the basic data for the event and the sensor that triggered it. Detailed information is available

with the verbose option.

Example 6 Output from sel list command

0 | 04/16/2013 | 20:22:01 | Power Supply #0x04 | Failure detected | Asserted

1 | 06/28/2013 | 20:36:17 | Power Supply #0x02 | Presence detected | Deasserted

2 | 07/28/2013 | 00:20:52 | Power Supply #0x02 | Failure detected | Asserted

3 | 08/04/2013 | 00:23:10 | Power Supply #0x02 | Presence detected | Deasserted

4 | 08/09/2013 | 14:34:48 | Fan #0x07 | Transition to Off Line | Asserted

5 | 08/09/2013 | 14:34:49 | Fan #0x07 | Transition to Running | Deasserted

See “Verbose output examples” (page 164) for an example of verbose output from the sel list

command.

Events 21

Page 22

Inventory

IPMI supports multiple sets of non-volatile FRU information for different parts in the system. This

provides access to data such as serial number, part number, asset tag, and other information for

major modules in the system including the baseboard, chassis, processors, memory, power supplies,

and even the management controller itself. This information is even available when the system is

powered down or non-operational, facilitating the creation of automated remote inventory and

service applications. IPMItool can read and display full FRU information for the system as well as

detailed descriptions of power supplies and full DIMM SPD data.

Example 7 Output from the fru print command

FRU Device Description : ChasMgmtCtlr1

Chassis Type : Rack Mount Chassis

Chassis Part Number : 700349-B21

Chassis Serial : 600012J0SD

Chassis Extra : d09701640003000000

Chassis Extra : d1110102000000

Board Mfg Date : Fri Dec 7 19:54:00 2012

Board Mfg : HP

Board Product : HP Moonshot 1500 Chassis Management Module

Board Serial : 1G24900006J0SE

Board Part Number : 712678-001

Board Extra : d25835

Board Extra : 700369-001

Product Manufacturer : HP

Product Name : HP Moonshot 1500 Chassis

Product Part Number : 700451-001

Chassis management

This feature provides standardized chassis status and control functions that allow a remote system

to be turned on/off or rebooted without manual intervention. It also provides commands for causing

the chassis to physically identify itself with an implementation dependant mechanism such as turning

on visible lights, displaying messages on an LCD, emitting beeps through a speaker, etc. IPMItool

fully supports the available chassis management commands and can eliminate trips to the data

center or server room to reset a frozen machine or help identify the single system in a rack that

must be removed.

Example 8 Sample chassis power commands

root@JSMITH-LX:/# ipmitool -I lanplus -H ILOH101GEMINI -U Administrator -P password sdr list all

(output)

root@JSMITH-LX:/# ipmitool -I lanplus -H ILOH101GEMINI -U Administrator -P password -t 0xa4 power status

Chassis Power is on

In all of the above examples only a portion of the available output is shown, the full output is much

richer and tells a full story about the system health and status; in addition verbose output options

are available which increase the output information. See “Verbose output examples” (page 164)

for examples of verbose output.

Synopsis

ipmitool [-chvV] [-Iopen <command>]

ipmitool [-chvV] -Ilan -H<hostname>

[-p<port>]

[-U<username>]

[-A<authtype>]

[-L<privlvl>]

[-aEPf<password>]

[-o<oemtype>]

22 IPMItool

Page 23

<command>

ipmitool [-chvV] -Ilanplus -H<hostname>

[-p<port>]

[-U<username>]

[-L<privlvl>]

[-aEPf<password>]

[-o<oemtype>]

[-C<ciphersuite>]

<command>

Description

This program allows management of IPMI functions of either the local system via a kernal device

driver or a remote system using IPMI v1.5 and IPMI v2.0. These functions include printing FRU

information, LAN configuration, sensor readings and remove chassis power control.

IPMI management of a local system interface requires a compatible IPMI kernel driver to be installed

and configured. On Linux this driver is called OpenIPMI and it is included in standard distributions.

Options

Prompt for the remote server password.—a

—A <authtype>

—C<ciphersuite>

—E

—f<password_file>

—H <address>

— I <interface>

—o<oemtype>

Specify the authentication type to use during IPMI v1.5 LAN session

activation. Supported types are NONE, PASSWORD, MD5 or OEM.

Present output in CSV format. Not available with all commands.—c

The remote server authentication, integrity, and encryption algoritms to

use for IPMI v2 lanplus connections. Default = 3 and specifies

RAKP-HMAC-SHA1 authentication, HMAC-SHA1–96 integrity, and

AES-CBC-128 encryption algorithms.

The remote server password is specified by the environment variable

ipmi_password.

Specifies a file containing the remote server password. If this option is

absent or if the <password_file> is empty the password defaults to

NULL.

Get basic usage help from the command line.—h

Remote server address can be IP address or hostname. This option

is required for LAN and LANPLUS interfaces.

Selects the IPMI interface. Supported interfaces display in the usage help

output.

Force session privilege level, defaults to admin.—L<privlvl>

Set the local IPMB address. Default = 0x20.—m<local address>

Select OEM type. Use —o list to see a list of currently supported OEM

types.

-P<password>

Remote server UDP port. Default = 623.-p<port>

Remote server password specified on the command line. It is not

recommended to specify a password on the command line.

NOTE: If no password method is specified, the IPMI tool prompts the

user for a password, if no password is entered, the remote server password

is set to NULL.

Bridge IPMI requests to the remote target address.—t<target address>

Remote server username. Default = NULL—U<username>

Synopsis 23

Page 24

—v

Increase verbose output level. May be specified multiple times to increase

levels of debug output, for example, specifying three times results in

hexdumps of all incoming and outgoing packets.

Display version information.—V

IPMItool Raw command syntax and example

1. Syntax — Target command towards specific virtual controller

• —b <ipmi channelnumber>

• —t <target slave address>

• -m <source slave address>

• Chassis controller —b 0 —t 0x44 —m 0x20

• Power supply A controller -b 0 -t 0x52 -m 0x20

• Power supply B controller -b 0 -t 0x54 -m 0x20

• Power supply C controller -b 0 -t 0x56 -m 0x20

• Power supply D controller -b 0 -t 0x58 -m 0x20

2. Examples:

• Raw Get Device ID to chassis satellite controller over LAN:

ipmitool -I lanplus -H 16.85.178.125 -U admin -P admin123 -L

Administrator -b 0 -t 0x44 -m 0x20 raw 6 1

• Power on to C2N1 over LAN:

ipmitool -I lanplus -H 16.85.178.125 -U admin -P admin123 -L

Administrator -B 0 –T 0x84 –b 7 –t 0x72 -m 0x20 chassis power on

• SOL to C2N1 over LAN

ipmitool -I lanplus -H 16.85.178.125 -U admin -P admin123 -L

Administrator -B 0 –T 0x84 –b 7 –t 0x72 -m 0x20 sol activate

24 IPMItool

Page 25

5 Command specification

IPMI provides standardized interfaces and commands for configuring the platform managemenet

subsystem. This enables cross-platform software to SDRs are an example of the interface for

configuring sensor population and behavior on a system. There are also commands for configuring

capabilities such as LAN and serial/modem remote protocols, user passwords and privilege levels,

platform event filtering, alert destinations, and others.

This section provides specifications for elements that apply to all requests and responses.

See “Completion codes” (page 142).

Unless otherwise noted, reserved bits and fields in commands (request messages) and responses

are written as 0. Applications must ignore the state of reserved bits when they are read.

Unless otherwise specified, commands that are listed as mandatory must be accessed via LUN

00b. An implementation may elect to make any command available on any LUN or channel as

long as it does not conflict with other requirements in this specification.

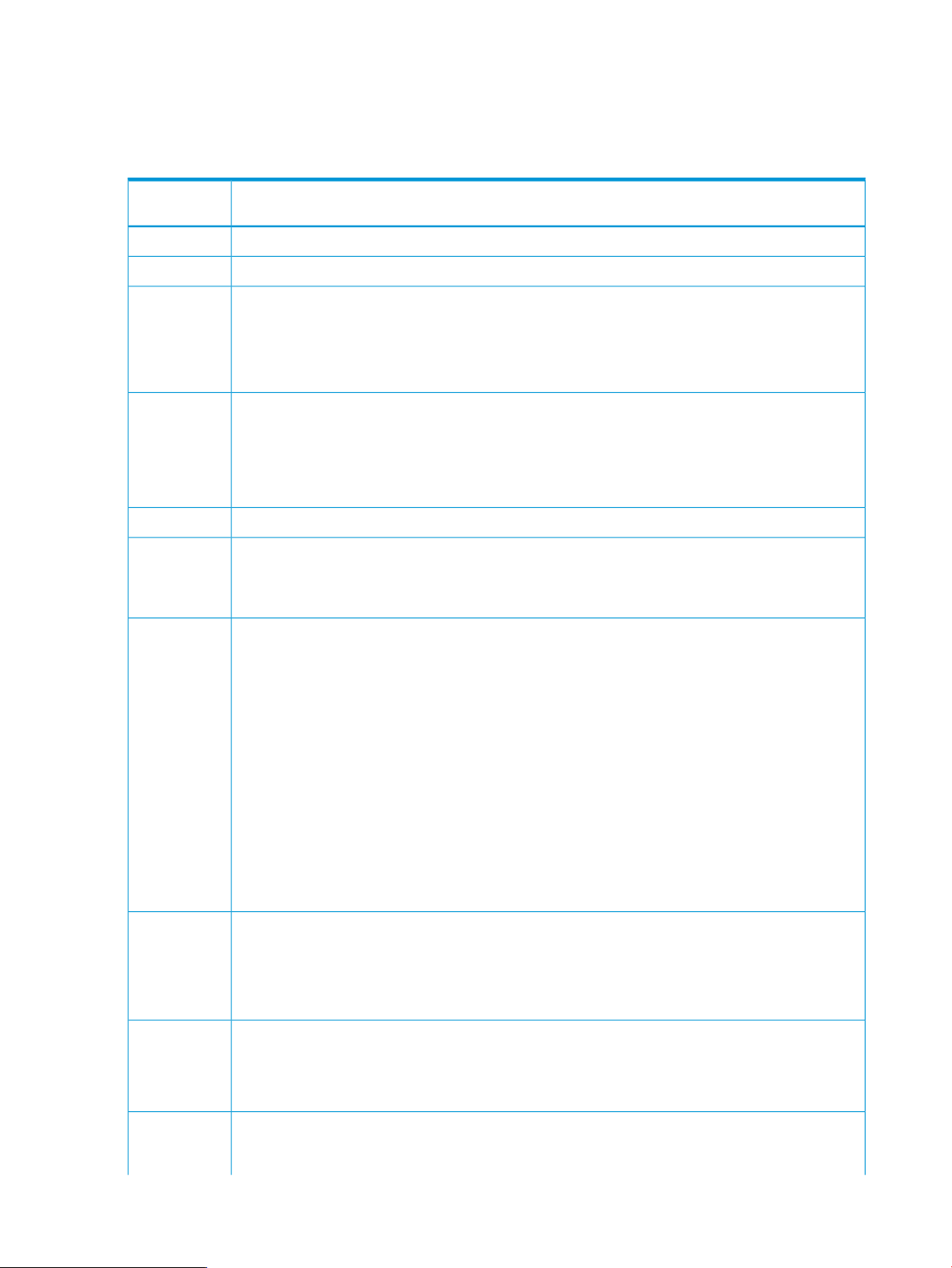

Command table notation

The following section includes command tables that list the data that is included in a request or a

response for each command. The completion code for a response is included as the first byte of

the response data field for each command. The NetFn and command byte values for each command

are specified in separate tables.

The following notation is used in the command tables.

Request data

Response data

4

5:7

(3)

DescriptionNotation

Identifies the portion of the table that lists the fields that are included in the data portion of a request

message for the given command.

Identifies the portion of the table that lists the fields that are included in the data portion of a response

message for the given command. The completion code is always listed as the first byte in the

response data field.

Single byte field. A single value in the byte column of a command table is used to identify a single

byte field. The value represents the offset to the field within the data portion of the message. In some

cases a single byte field follows a variable length field in which case the single byte offset is

represented with an alphabetic variable and number representing the single byte field’s location

relative to the end of the variable length field. For example: N+1.

Multi-byte field. The byte column indicates the byte offset(s) for a given field. For a multi-byte field,

the first value indicates the starting offset, the second value (following the colon) indicates the offset

for the last byte in the field. For example, 5:7 indicates a three-byte field spanning byte offsets 5,

6, and 7.

In some cases, multi-byte fields may be variable length, in which case an alphabetic variable is

used to represent the ending offset, for example: 5:N. Similarly, a field may follow a variable length

field. In this case the starting value is shown as an offset relative to the notation used for the previous

field, for example, if the previous field were 5:N, the next field would be shown starting at N+1.

A variable length field may follow a variable length field, in which case a relative starting offset is

shown with an alphabetic value indicating a relative ending offset, for example, N+1:M.

Optional Fields. When used in the byte column of the command tables, parentheses are used to

indicate optional data byte fields. These can be absent or present at the choice of the party

generating the request or response message. Devices receiving the message are required to accept

any legal combination of optional data byte fields.

Unless otherwise indicated, if an optional byte field is present, all prior specified byte fields must

also be present. Similarly, if an optional byte field is absent all following byte fields must also be

absent. For example, suppose a request accepts 4 data bytes. If data byte 3 was shown in

parentheses as (3), it would indicate that byte 3 and following were optional. A legal request could

consist of just bytes [1 and 2], bytes [1, 2, and 3,] or bytes [1, 2, 3 and 4]. A request which

eliminates byte 3, but includes byte 4. (a request with data bytes [1, 2, and 4]), is illegal.

25

Page 26

DescriptionNotation

Multi-byte fields that are shown as optional cannot be split. Either all bytes for the field are present

or absent. For example, if a four byte multi-byte field is listed as optional, it is illegal to include the

first two bytes, but not the second two bytes.

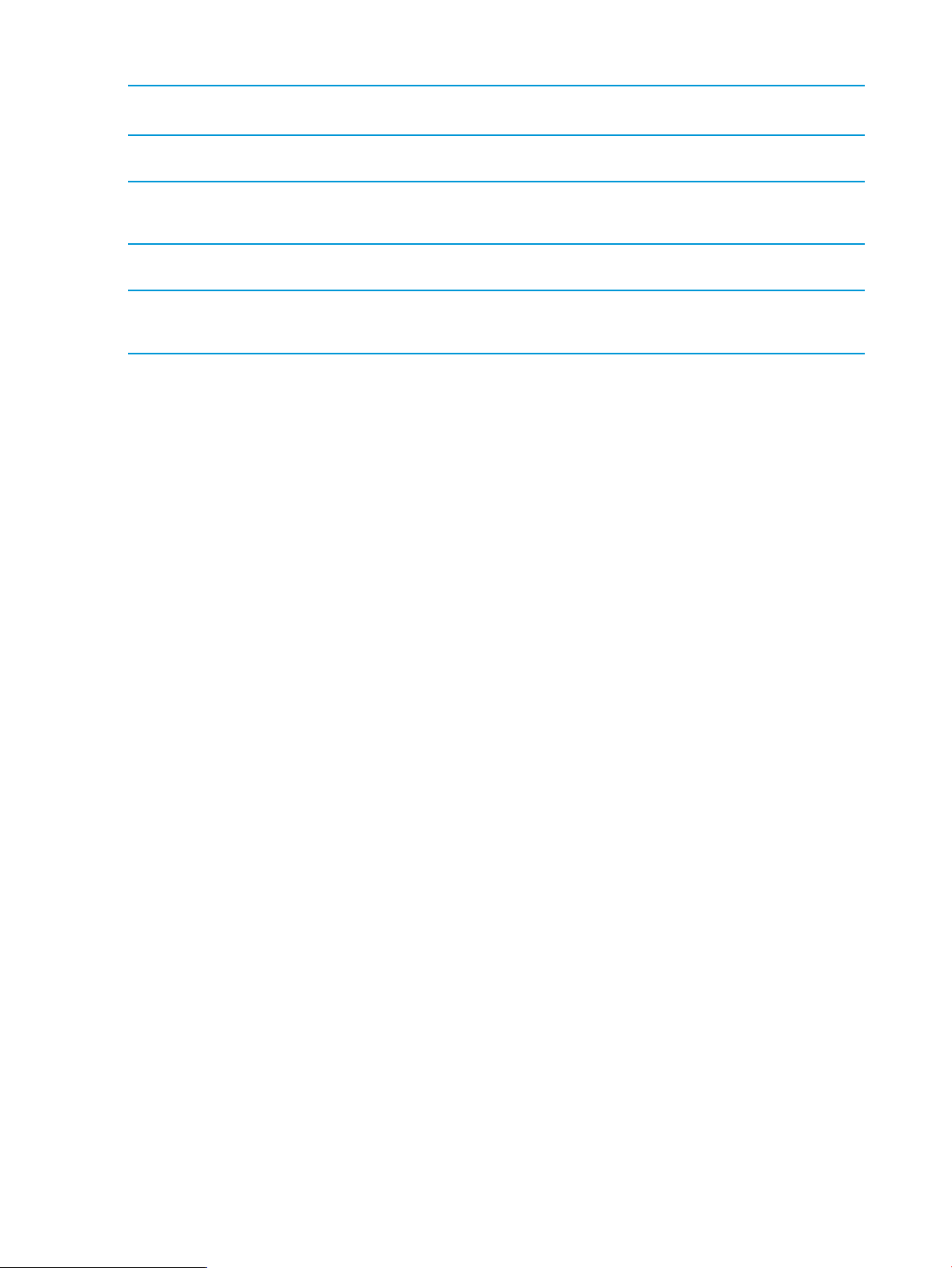

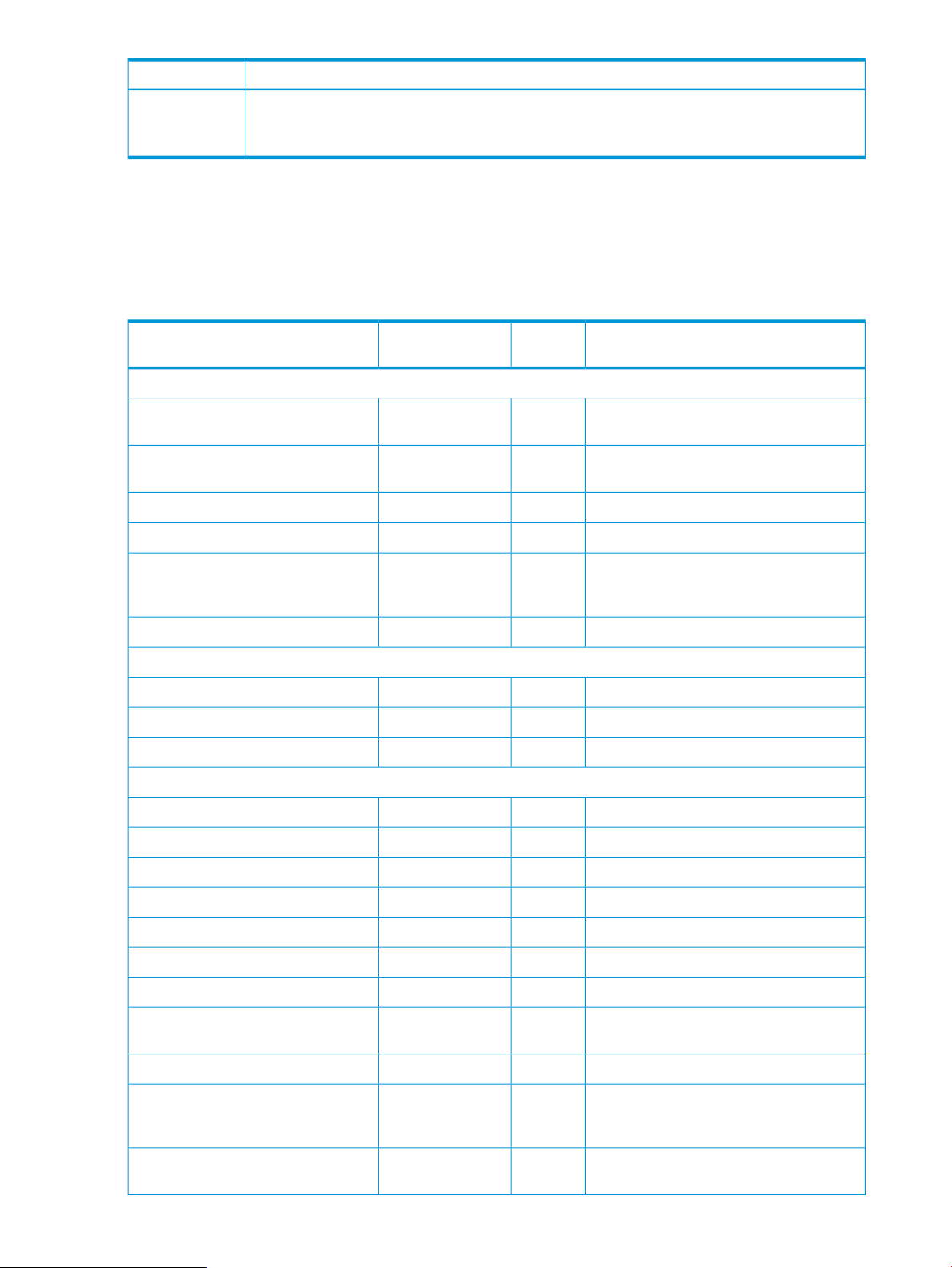

Table 6 (page 26) lists the available Moonshot IPMI commands and, where available, the equivalent

iLO Chassis Management CLI command. The IPMI commands and capabilities available for

Moonshot are not completely analogous to the commands available at the iLO Chassis Management

CLI, and so not every IPMI command has a CLI equivalent. Additionally, where there are analogous

commands, the responses offered by the two commands may not be equivalent.

Table 6 Moonshot IPMI commands and their iLO CM CLI equivalents

IPMI Device Global Commands

1

MC Watchdog Timer Commands

IPMI Messaging Support Commands

NetFnMoonshot IPMI Command

Code

0x01App (0x06)Get Device ID

0x01App (0x06)Broadcast ‘Get Device ID’

0x04App (0x06)Get Self Test Results

Moonshot iLO CM CLI command equivalentCommand

Show chassis info provides a partially

equivalent response.

Show chassis info provides a partially

equivalent response.

Reset CM0x02App (0x06)Cold Reset

Reset CM0x03App (0x06)Warm Reset

Show log IML provides a partially

equivalent response (specifically, failures

that were written to the iML)

show node power CxNy0x07App (0x06)Get ACPI Power State

IPMI specific0x22App (0x06)Reset Watchdog Timer

IPMI specific0x24App (0x06)Set Watchdog Timer

IPMI specific0x25App (0x06)Get Watchdog Timer

Capabilities

26 Command specification

IPMI specific0x2EApp (0x06)Set BMC Global Enables

IPMI specific0x2FApp (0x06)Get BMC Global Enables

IPMI specific0x30App (0x06)Clear Message Flags

IPMI specific0x31App (0x06)Get Message Flags

IPMI specific0x32App (0x06)Enable Message Channel Receive

IPMI specific0x33App (0x06)Get Message

IPMI specific0x34App (0x06)Send Message

0x37App (0x06)Get System GUID

0x59App (0x06)Get System Info Parameters

The physical node UUID is not shown in the

CLI.

Not supported in CLI.0x58App (0x06)Set System Info Parameters

Show node info returns the MAC

address; other parameters returned by the

IPMI command are IPMI specific.

IPMI specific0x38App (0x06)Get Channel Authentication

Page 27

Table 6 Moonshot IPMI commands and their iLO CM CLI equivalents (continued)

NetFnMoonshot IPMI Command

Code

Moonshot iLO CM CLI command equivalentCommand

IPMI specific0x3BApp (0x06)Set Session Privilege Level

IPMI specific0x3CApp (0x06)Close Session

IPMI specific0x3DApp (0x06)Get Session Info

IPMI specific0x3FApp (0x06)Get AuthCode

IPMI specific0x40App (0x06)Set Channel Access

IPMI specific0x41App (0x06)Get Channel Access

IPMI specific0x42App (0x06)Get Channel Info

Set user privilege0x43App (0x06)Set User Access

show user0x44App (0x06)Get User Access

add user0x45App (0x06)Set User Name

show user0x46App (0x06)Get User Name

set user password0x47App (0x06)Set User Password

IPMI specific0x48App (0x06)Activate Payload

IPMI specific0x49App (0x06)Deactivate Payload

Chassis Device Commands

IPMI specific0x4AApp (0x06)Get Payload Activation Status

IPMI specific0x4BApp (0x06)Get Payload Instance Info

IPMI specific0x4CApp (0x06)Set User Payload Access

IPMI specific0x4DApp (0x06)Get User Payload Access

IPMI specific0x4EApp (0x06)Get Channel Payload Support