Page 1

HP Modular Cooling System 200

HP assumes you are

Part Number: 749805-002

User Guide

Abstract

This document is for the person who installs racks and rack products. This procedure is performed only by trained personnel.

qualified in performing installations and trained in recognizing hazards in rack products.

February 2014

Edition: 2

Page 2

© Copyright 2013, 2014 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or omissions contained herein.

Microsoft© and Windows© are U.S. registered trademarks of Microsoft Corporation.

Restricted rights legend

Use, duplication or disclosure by the U.S. Government is subject to restrictions as set forth in subparagraph (c) (1) (ii) of the Rights in Technical Data

and Computer Software clause at DFARS 252.227-70 1 3 for DOD agencies, and subparagraphs (c) (1) and (c) (2) of the Commercial Computer

Software Restricted Rights clause at FAR 52.227-1 9 for other agencies.

HEWLETT-PACKARD COMPANY, Palo Alto, CA 94304-1185, USA

HEWLETT-PACKARD COMPANY, HQ-TRE, 71004 Boeblingen, Germany

Page 3

Contents

Overview ..................................................................................................................................... 5

Introduction .............................................................................................................................................. 5

Configuration factors ..................................................................................................................... 7

Optimum environment and site preparation .................................................................................................. 7

Safety information ..................................................................................................................................... 7

Installation ................................................................................................................................... 8

MCS-200 kit contents................................................................................................................................. 8

Hardware kit contents ................................................................................................................................ 9

Required tools ........................................................................................................................................... 9

Installing the MCS-200 ............................................................................................................................ 10

Powering up and configuring the unit ......................................................................................................... 13

Configuring the IP address through the web interface ......................................................................... 22

Connecting water to the facility ................................................................................................................. 25

Automatic Door Release Kit .......................................................................................................... 30

Automatic Door Release Kit Overview ........................................................................................................ 30

Automatic Door Release Kit ...................................................................................................................... 30

Management module .................................................................................................................. 32

Management module overview ................................................................................................................. 32

Management module components ............................................................................................................. 33

Accessing the management module through a terminal emulation program ..................................................... 34

Logging in through the terminal emulation program............................................................................ 34

Accessing the management module through the web interface ...................................................................... 34

Web interface requirements ............................................................................................................ 35

Logging in through the web interface ............................................................................................... 35

Connecting an alarm device to the management module alarm relay ............................................................. 37

Serial interface ........................................................................................................................... 38

HP Modular Cooling System Utility overview ............................................................................................... 38

Main menu ................................................................................................................................... 38

Configuring HyperTerminal ....................................................................................................................... 43

Configuring Minicom ............................................................................................................................... 44

Operator display ........................................................................................................................ 45

Operator display overview ....................................................................................................................... 45

Operator display components ......................................................................................................... 45

Warning and alarm messages ........................................................................................................ 45

Frequently asked questions .......................................................................................................... 54

MCS-200 frequently asked questions ......................................................................................................... 54

Troubleshooting .......................................................................................................................... 56

MCS-200 troubleshooting......................................................................................................................... 56

Specifications ............................................................................................................................. 57

MCS-200 specifications ........................................................................................................................... 57

Thermal and air flow performance ................................................................................................... 58

Contents 3

Page 4

Environmental specifications ........................................................................................................... 58

HP 642 1200mm Rack specifications ........................................................................................................ 58

Replaceable parts and maintenance and service information ........................................................... 59

Obtaining replaceable parts ..................................................................................................................... 59

Maintenance and service ......................................................................................................................... 59

Air and water heat exchanger maintenance ...................................................................................... 59

Water quality and leveling requirements, and condensation management ......................................... 60

Water quality requirements and specifications ............................................................................................ 60

Acceptable water quality specifications ............................................................................................ 60

Frost damage ................................................................................................................................ 61

Water precautions ......................................................................................................................... 61

Plumbing materials to avoid ............................................................................................................ 61

Leveling requirements ............................................................................................................................... 62

Condensation management ...................................................................................................................... 62

Support and other resources ........................................................................................................ 63

Before you contact HP .............................................................................................................................. 63

HP contact information ............................................................................................................................. 63

Customer Self Repair ............................................................................................................................... 63

Regulatory compliance notices ..................................................................................................... 71

Safety and regulatory compliance ............................................................................................................. 71

Acronyms and abbreviations ........................................................................................................ 72

Documentation feedback ............................................................................................................. 73

Index ......................................................................................................................................... 74

Contents 4

Page 5

Overview

Introduction

The HP Modular Cooling System 200 is an air and water heat exchanger that removes high levels of excess

heat generated by equipment installed in HP racks. The installed equipment takes in cold air through the front

of the closed MCS-200 and uses the air for internal cooling. After the air has been warmed, the MCS-200

expels the air through the rear vents.

HP provides several components to complement or complete your MCS-200. For more information, see the

HP Modular Cooling System 200/100 Options Installation Guide.

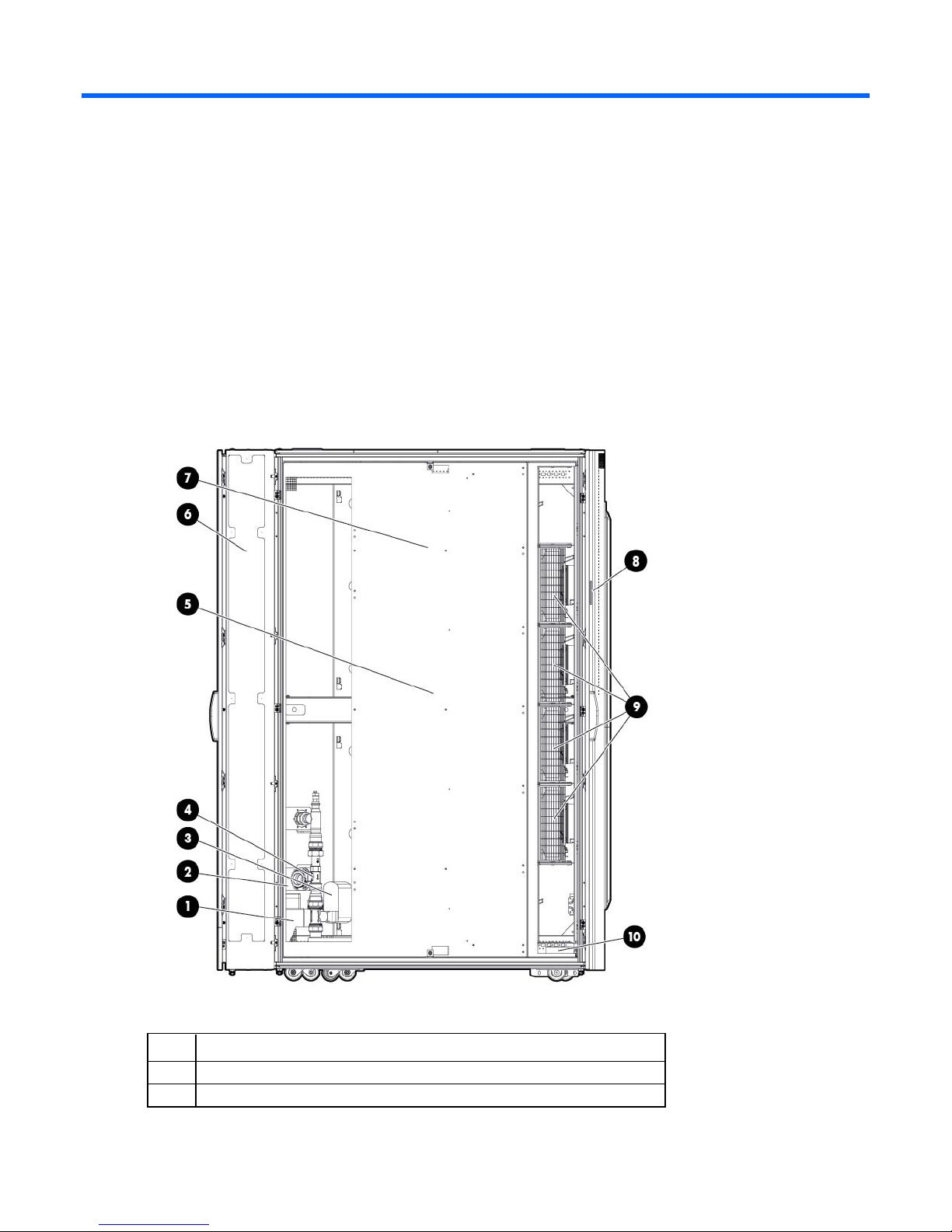

The following illustrations include optional components.

Unit side view

Item Reference

1

2

Condensation pump

Condensation pump controller

Overview 5

Page 6

Item Reference

Management module

3

4

5

6

7

8

9

10

Control valve

Flow meter

Humidity sensor

Rear extension

Heat exchanger unit

TFT touchscreen display

Fan units (4 fans by default, 6 fans maximum)

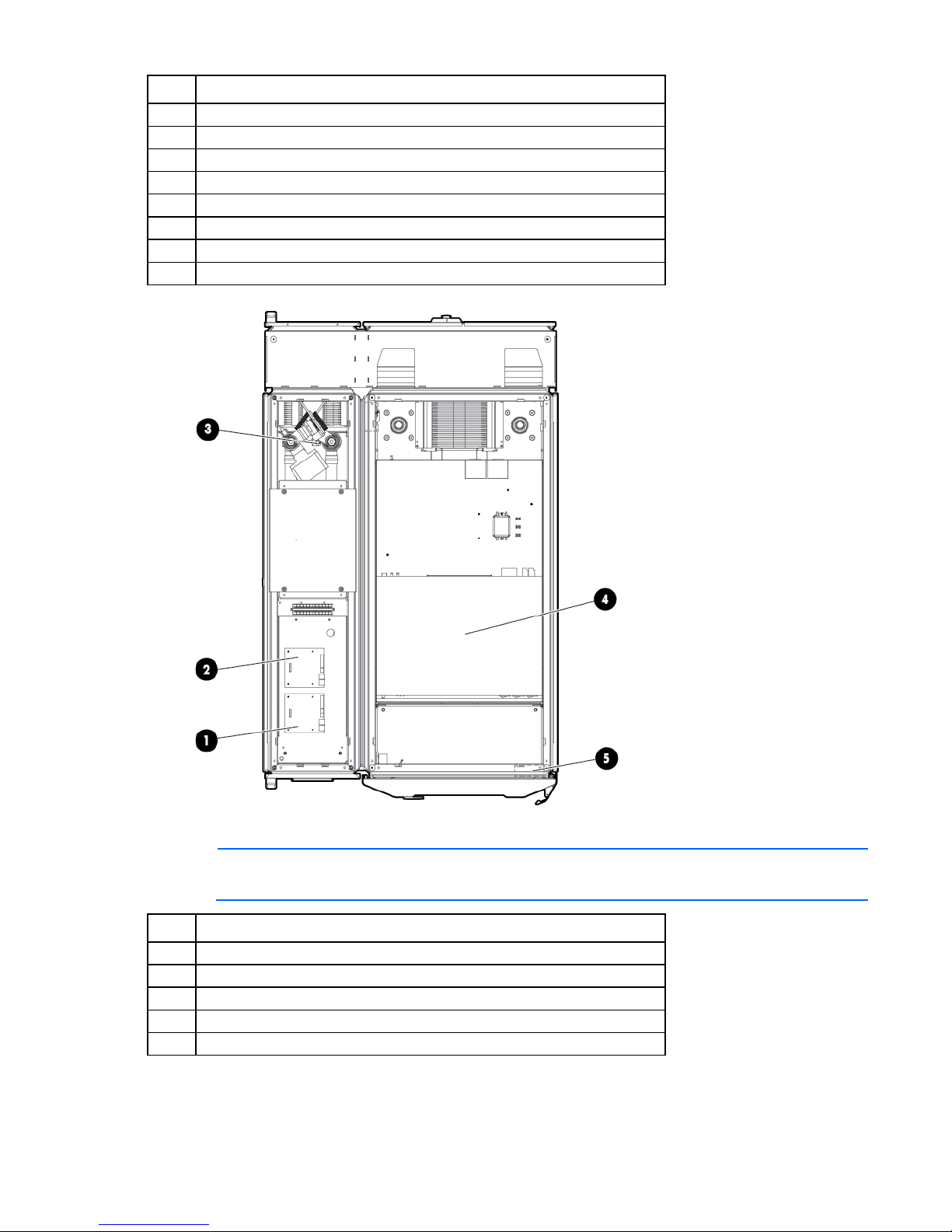

Unit top view

NOTE: For easier viewing, the canopies were removed in the previous illustration.

Item Reference

1

2

3

4

5

Water module

Fan module

Condensation pump transformer 277v (optional)

AC transfer switch

Emergency door opening

Overview 6

Page 7

Configuration factors

Optimum environment and site preparation

CAUTION: Contaminated water might cause decreased cooling capacity or disruption in

service. The water flowing into the MCS-200 unit must meet the guidelines stated in the HP

Modular Cooling System 200/100 Site Preparation Guide. The MCS-200 warranty does not

To provide optimum performance with minimum maintenance, your unit must meet environmental

requirements.

The HP Modular Cooling System 200/100 Site Preparation Guide provides information about planning your

unit configuration efficiently and organizing your site location before delivery of your MCS-200 unit.

To route water lines to your MCS-200 unit, use one of the following methods:

• Through an opening in the raised floor

• Lying on top of the floor

• Through the top of the MCS-200 unit

For more information on routing the water lines, see the Hook Up Kit installation instructions in the HP

Modular Cooling System 200/100 Options Installation Guide.

cover damage caused by contaminated water.

IMPORTANT: Before you begin the installation process, review the HP Modular Cooling System

200/100 Site Preparation Guide.

Safety information

The HP Modular Cooling System is tested to the maximum pressure (PS) of 8 bar (116 PSI) without fluid

trapped inside by closed, external valves.

If valves are installed on the external pipe work that could potentially trap fluid inside the MCS-200 unit,

special precautions must be taken. To prevent severe plumbing failure due to extreme pressure, use an

expansion tank with a preinstalled safety valve in the plumbing circuit connected to the unit.

Configuration factors 7

Page 8

Installation

MCS-200 kit contents

• MCS-200 unit installed on an HP Rack (1)

• Automatic Door Release kit (1)

• Rear plate cover (1)

• Condensation hose (blue) (1)

• Condensation hose (clear)* (1)

• Power cord, 4 m (13.1 ft), L6-20 to Walther Procon series A5 connector (2)

• Power cord, 4 m (13.1 ft), IEC-309 to Walther Procon series A5 connector (2)

• CAT5e cable, 7.62 m (25 ft) (1)

• USB program cable* (1)

• Access panel (1)

• Bracket (2)

• M6 trilobe flathead screw (2)

• M6 flathead screw (2)

*This item might ship preinstalled on the MCS-200 unit rather than in the standard kit contents package.

Installation 8

Page 9

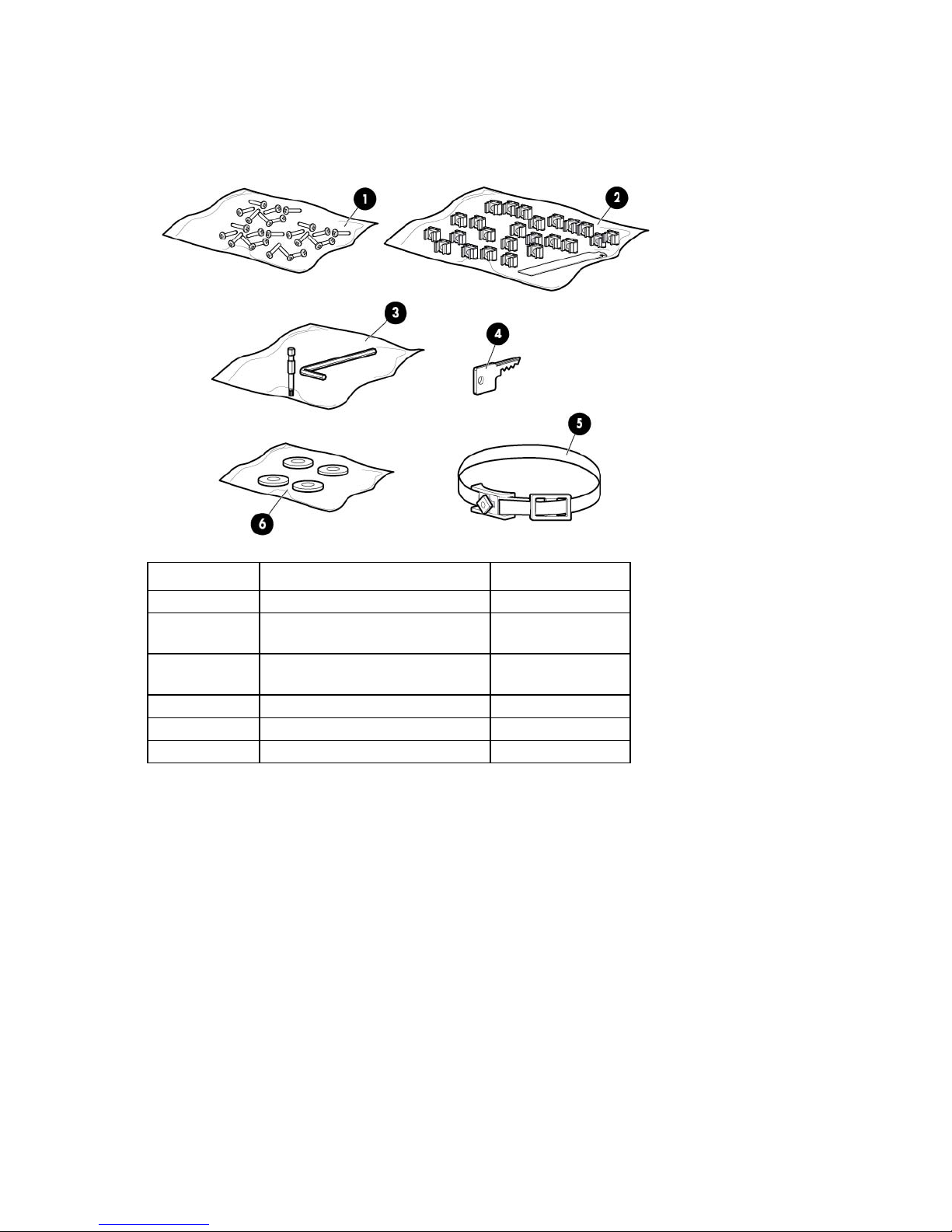

Hardware kit contents

T-25 bit socket

1

If any of the following items are missing or damaged, contact your HP authorized reseller.

Item Description Quantity

1

2

3

4

5

6

Extra hardware might be included for your convenience.

M6 screws 24

M6 cage nuts

Cage nut tool

Allen key

Door/side panel key 2

Quarter turn hook and loop strap 10

Leveling pads 4

Required tools

The following tools are required for installation:

• Flat blade screwdriver

• #2 Phillips screwdriver

• Adjustable wrench

24

1

1

• T-25 Torx screwdriver

• T-30 Torx screwdriver

• Bubble level

• Hose wrenches (2)

Installation 9

Page 10

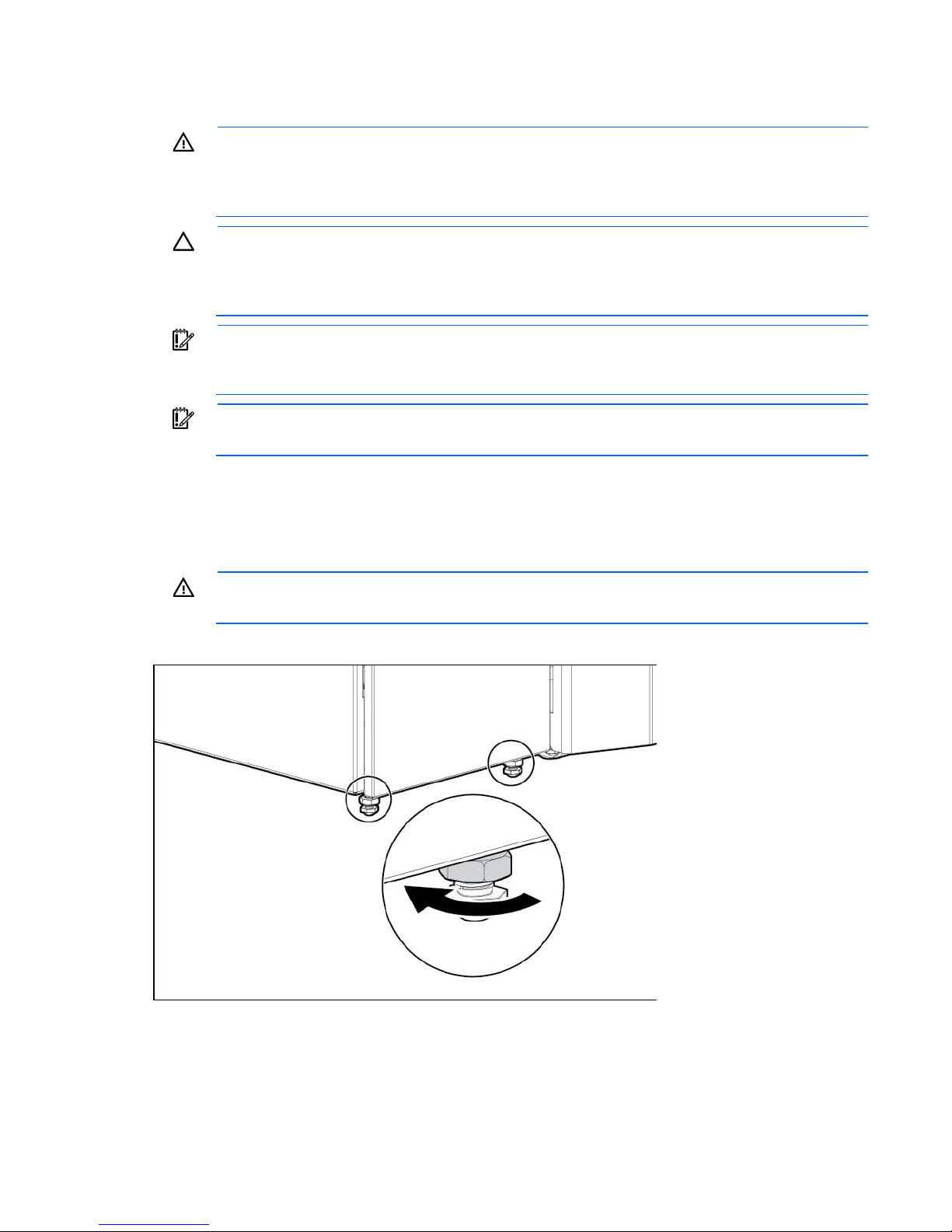

Installing the MCS-200

WARNING: The MCS-200 unit and rack are shipped together on a heavy duty shock pallet

weighing approximately 1600 kg (3600 lb). HP recommends hiring professional movers to move

the heavy duty shock pallet, remove the MCS-200 unit and rack from the pallet, and move the

1. Install the HP Modular Cooling System Hook Up Kit.

2. Read the unpacking instructions on the MCS-200 packaging material.

3. Using four or more people, remove the MCS-200 unit and rack from the pallet.

4. Roll the MCS-200 unit and rack to the final location.

5. To adjust the leveling feet and level the MCS-200 unit, use a bubble level.

MCS-200 unit and rack to the final location.

CAUTION: Contaminated water might cause decreased cooling capacity or disruption in

service. The water flowing into the MCS-200 unit must meet the guidelines stated in the HP

Modular Cooling System 200/100 Site Preparation Guide. The MCS-200 warranty does not

cover damage caused by contaminated water.

IMPORTANT: Because the MCS-200 unit consumes a large quantity of water, do not operate the

MCS-200 unit from a public water system such as one that supplies drinking water. For water

conservation purposes, to cool the MCS-200 unit, use only recycled water systems.

IMPORTANT: Before you begin the installation process, review the HP Modular Cooling System

200/100 Site Preparation Guide.

WARNING: To avoid tipping the MCS-200 unit over, make sure the leveling feet are lowered

when the MCS-200 is equipped, serviced, and operated.

Installation 10

Page 11

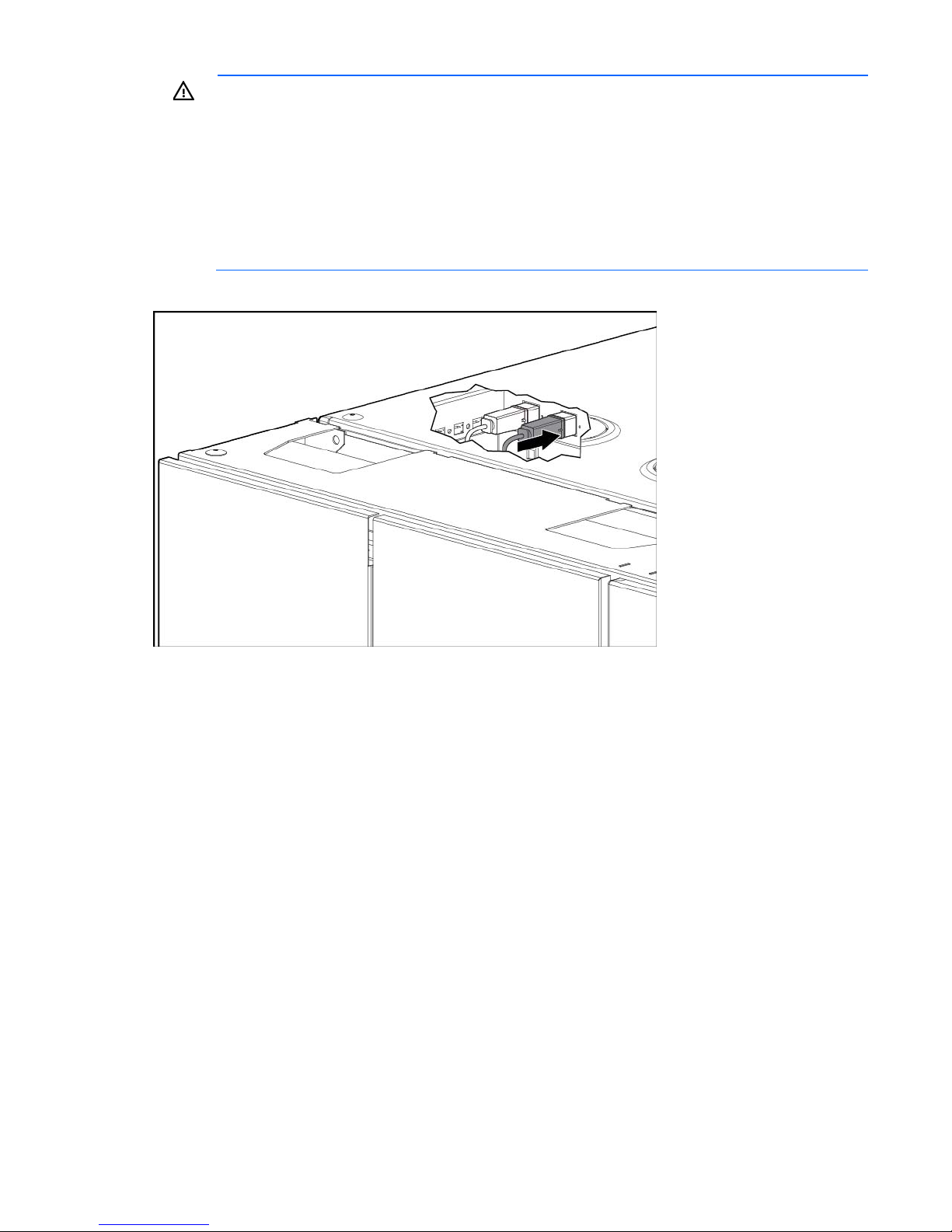

6.

Plug the network cable into the RJ-45 connector on the transfer switch in the top of MCS-200 unit.

7. Plug the other end of the network cable into your network connection outlet.

WARNING: Before you connect the power cords to a power source, be sure that the unit is

properly grounded for potential equalization caused by high leakage current.

IMPORTANT: Do not connect the power cords into a power supply.

8. Plug the primary power cord into the power connector on the left at the power distribution inside the

MCS-200 unit.

Installation 11

Page 12

WARNING: To reduce the risk of electric shock or damage to the equipment:

Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at all

• Do not disable the power cord grounding plug. The grounding plug is an important safety

feature.

•

times.

• Unplug the power cord from the power supply to disconnect power to the equipment.

• Do not route the power cord where it can be walked on or pinched by items placed against it.

Pay particular attention to the plug, electrical outlet, and the point where the cord extends from

9. If you are using a secondary power cord, plug it into the power connector on the right.

the storage system.

10. Guide the other ends of the power cords through the MCS-200, and then plug them into an appropriate

power source.

11. Install the Automatic Door Release kit hardware. For more information, see the HP Modular Cooling

System 200/100 Rack Options Installation Guide.

Installation 12

Page 13

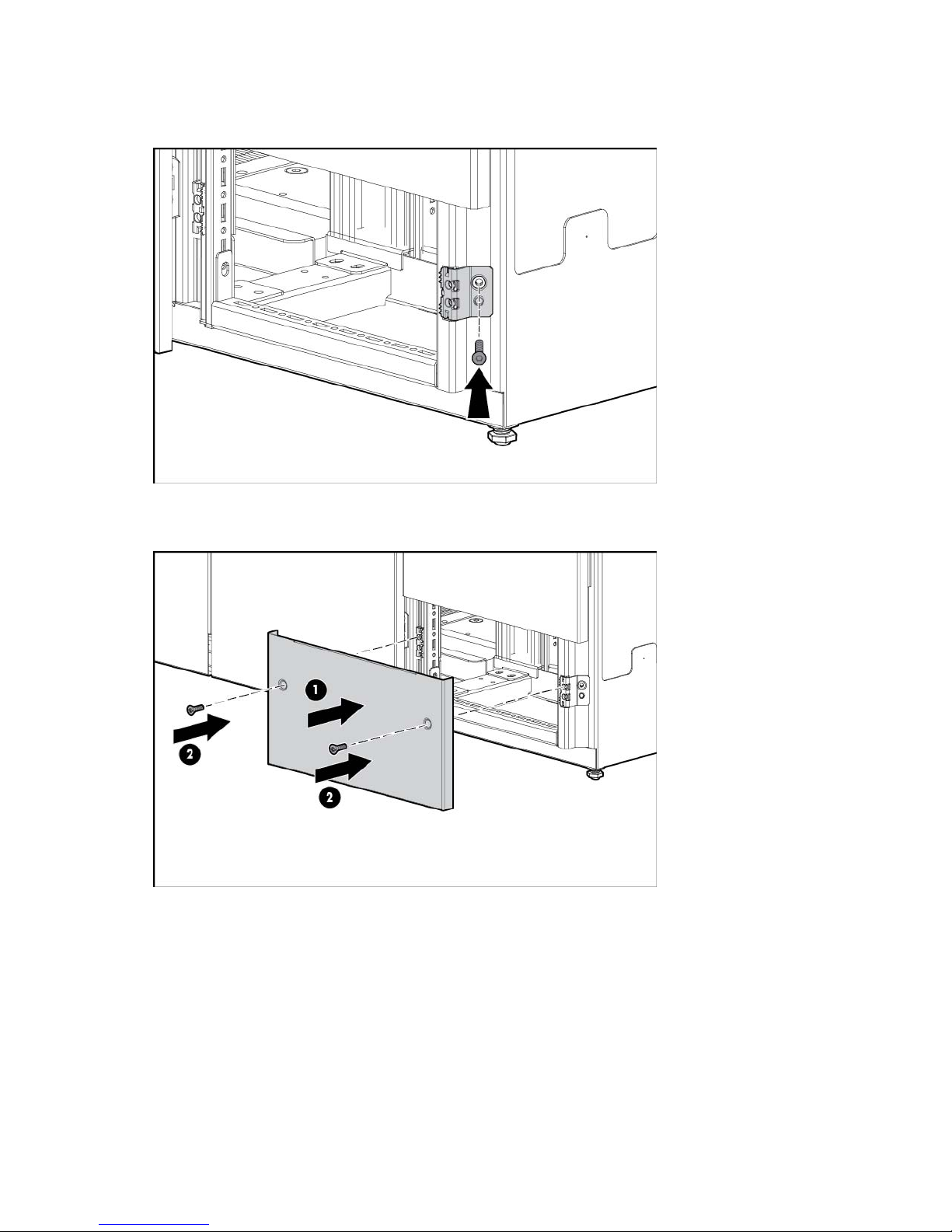

12.

If the rear extension is installed, this step is optional. Using two M6 trilobe flathead screws, secure the

two brackets to the MCS-200 unit frame. For more details on how to install the brackets, see the HP

Modular Cooling System 200/100 Options Installation Guide.

13. Align the access panel with the two brackets.

14. Using two M6 flathead screws, secure the access panel to the brackets on the MCS-200 unit frame.

Powering up and configuring the unit

Installation 13

Page 14

WARNING: To reduce the risk of electric shock or damage to the equipment:

• Do not disable the power cord grounding plug. The grounding plug is an important safety

feature.

• Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at all

times.

• Unplug the power cord from the power supply to disconnect power to the equipment.

• Do not route the power cord where it can be walked on or pinched by items placed against it.

Pay particular attention to the plug, electrical outlet, and the point where the cord extends from

1. Plug the power cord into an appropriate power source in accordance with your local electrical

the storage system.

connection standards.

2. Connect the network cable to your network infrastructure.

NOTE: If you have a DHCP server, you can change the IP address through the web interface

instead of through the virtual serial port. For more information, see "Configuring the IP address

3. If you are connecting through the virtual serial port with the provided USB cable, then you must

through the web interface."

download and install the USB driver, available from the HP website (http://www.hp.com).

4. Using the USB cable provided, connect a PC to the USB port on the management module.

5. If your Windows operating system does not prompt you to install a driver, you must install it manually

through the device manager and locate the downloaded driver.

6. Access the management module through a terminal emulation program, such as Minicom or

HyperTerminal ("Configuring HyperTerminal" on page 43).

7. Confirm that you have set the following parameters to access a terminal emulation program:

o Bits per second: 9600

o Data bits: 8

o Parity: none

o Stop bits: 1

o Flow control: none

8. Log in to the HP Modular Cooling System Configuration Utility:

a. In the login field, enter the user name. The default user name is Admin.

Installation 14

Page 15

b.

In the password field, enter the password. The default password is Admin. The Main Menu screen

appears.

9. Enter the product ID and serial number on the 1 Network Configuration line. The product ID and

10-digit serial number are located on a label inside the rear MCS-200 unit door.

Installation 15

Page 16

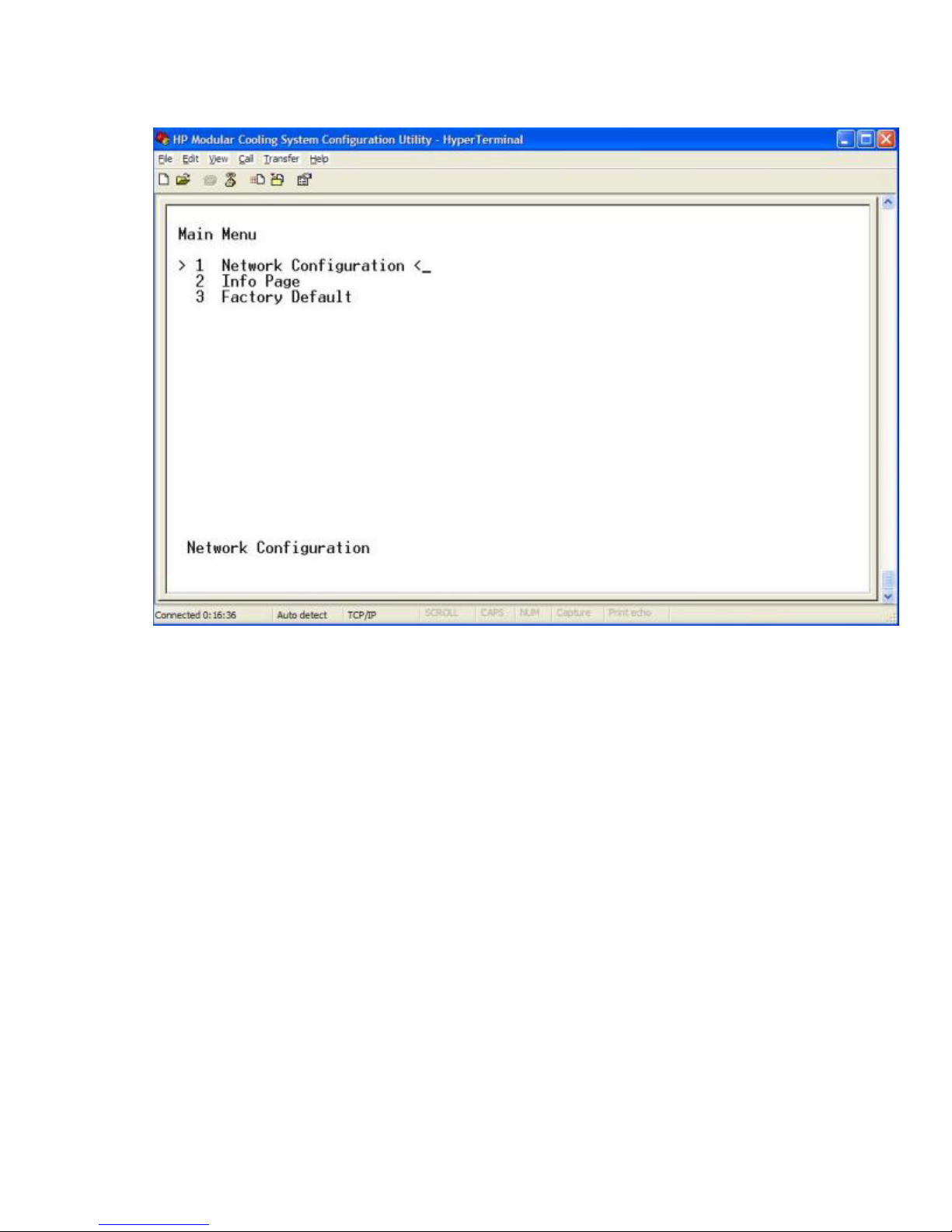

From the Main Menu screen, select 3 Factory Default. and press Enter. The Default Product

a.

Identification screen appears.

b. To set the product ID, select 2 Product ID MCS and press Enter.

c. To set the serial number, select 3 Serial Number MCS and press Enter.

d. To return to the Main Menu screen, press Esc.

10. Change the DHCP configuration, and then enter the IP address, IP subnet mask, and gateway:

Installation 16

Page 17

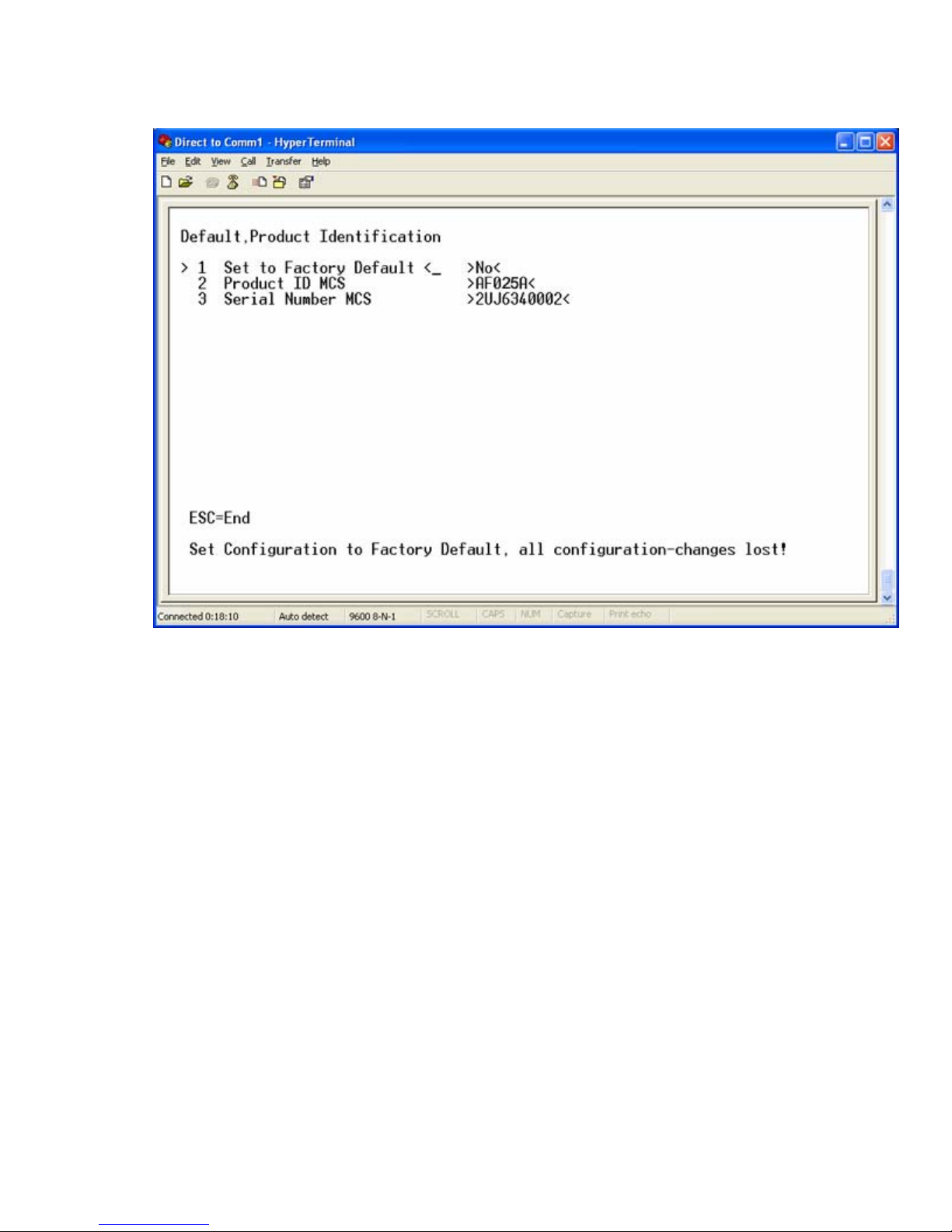

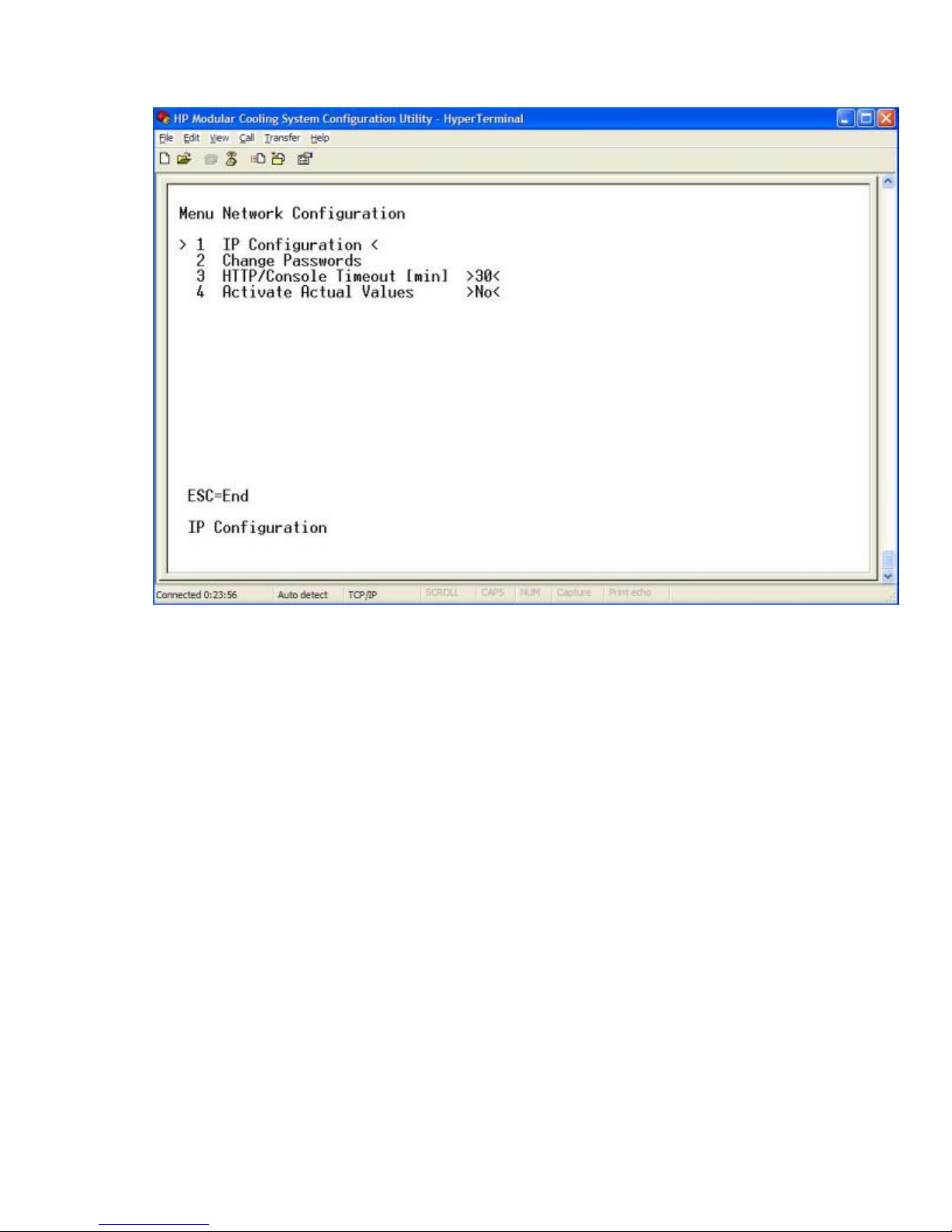

From the Main Menu screen, select 1 Network Configuration and press Enter. The Menu

a.

Network Configuration screen appears.

Installation 17

Page 18

Select 1 IP Configuration and press Enter. The IP Configuration screen appears.

b.

c. To disable DHCP, select 4 Enable/Disable DHCP and press Enter.

d. Select 1 IP Address, and then enter the new IP address.

e. Select 2 IP Subnet mask, and then enter the IP subnet mask.

f. Select 3 IP Def. Router, and then enter the gateway.

11. Activate the values:

Installation 18

Page 19

a.

Return to the Main Menu Network Configuration screen.

b. Select 4 Activate Actual Values and press Enter.

c. To reboot, at the prompt, enter y. You must reboot to activate the IP settings, product ID, and serial

number values.

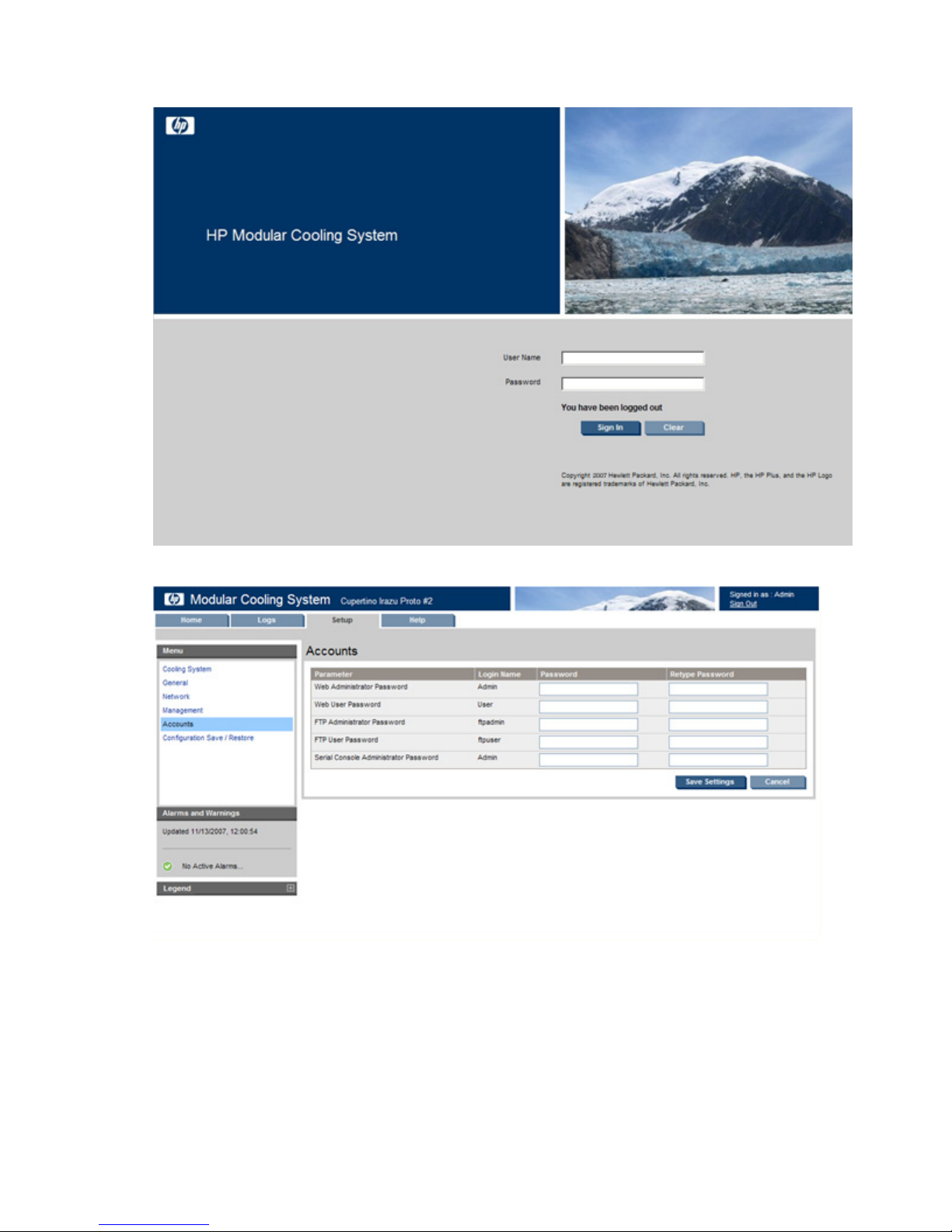

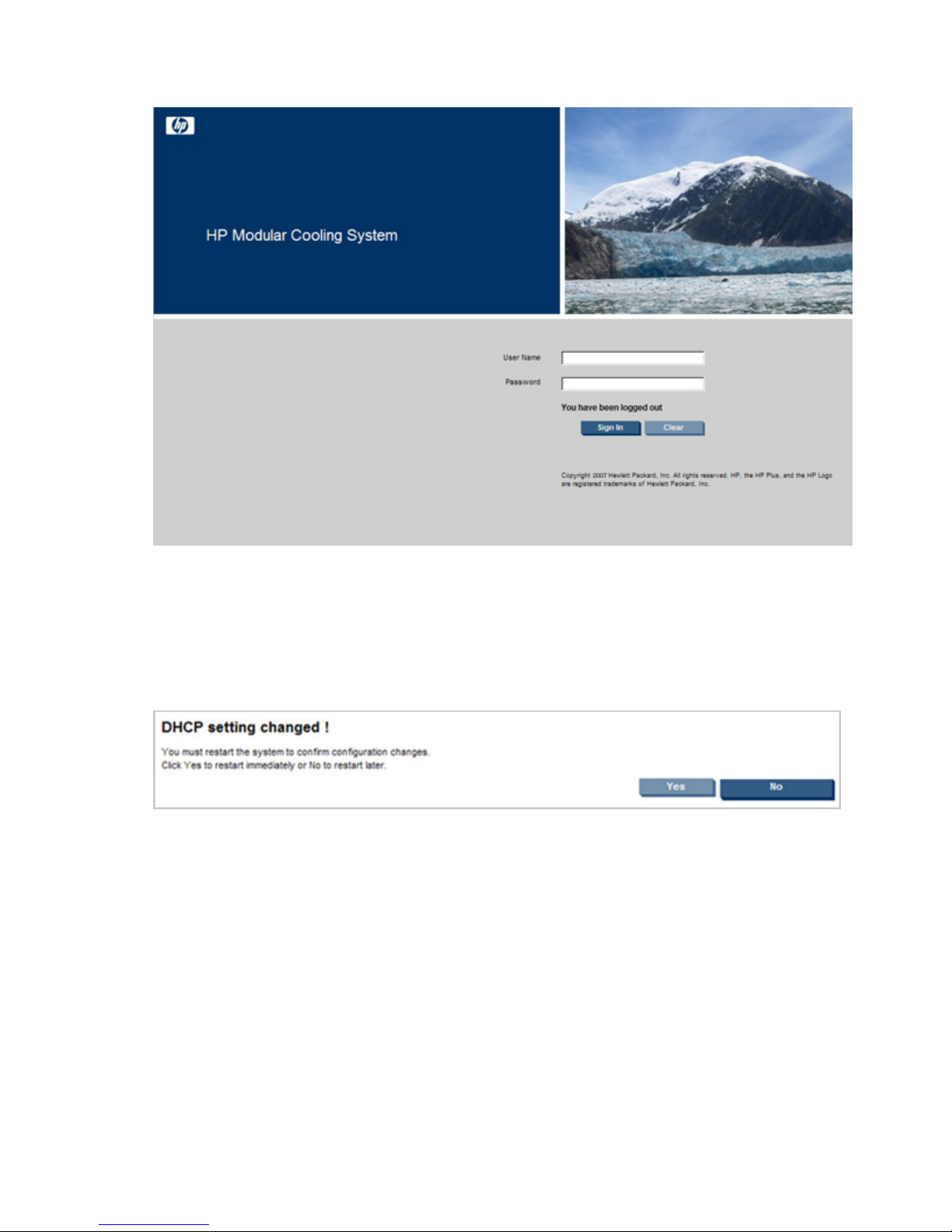

12. Access the Management module through the web interface:

a. Launch a supported browser. The browser window appears.

b. In the Address field (Microsoft® Internet Explorer) or the Location field (Firefox Mozilla), enter

http://ipaddress (where ipaddress is the IP address of the management module).

The login screen appears.

13. Log in through the web interface:

a. Enter the user name in the User Name field. The default user name is Admin.

b. Enter the password in the Password field. The default password is Admin.

Installation 19

Page 20

c.

Click Sign In.

14. Click Setup>Accounts, and then change the default Web Admin and Web User passwords.

15. Click Save Settings.

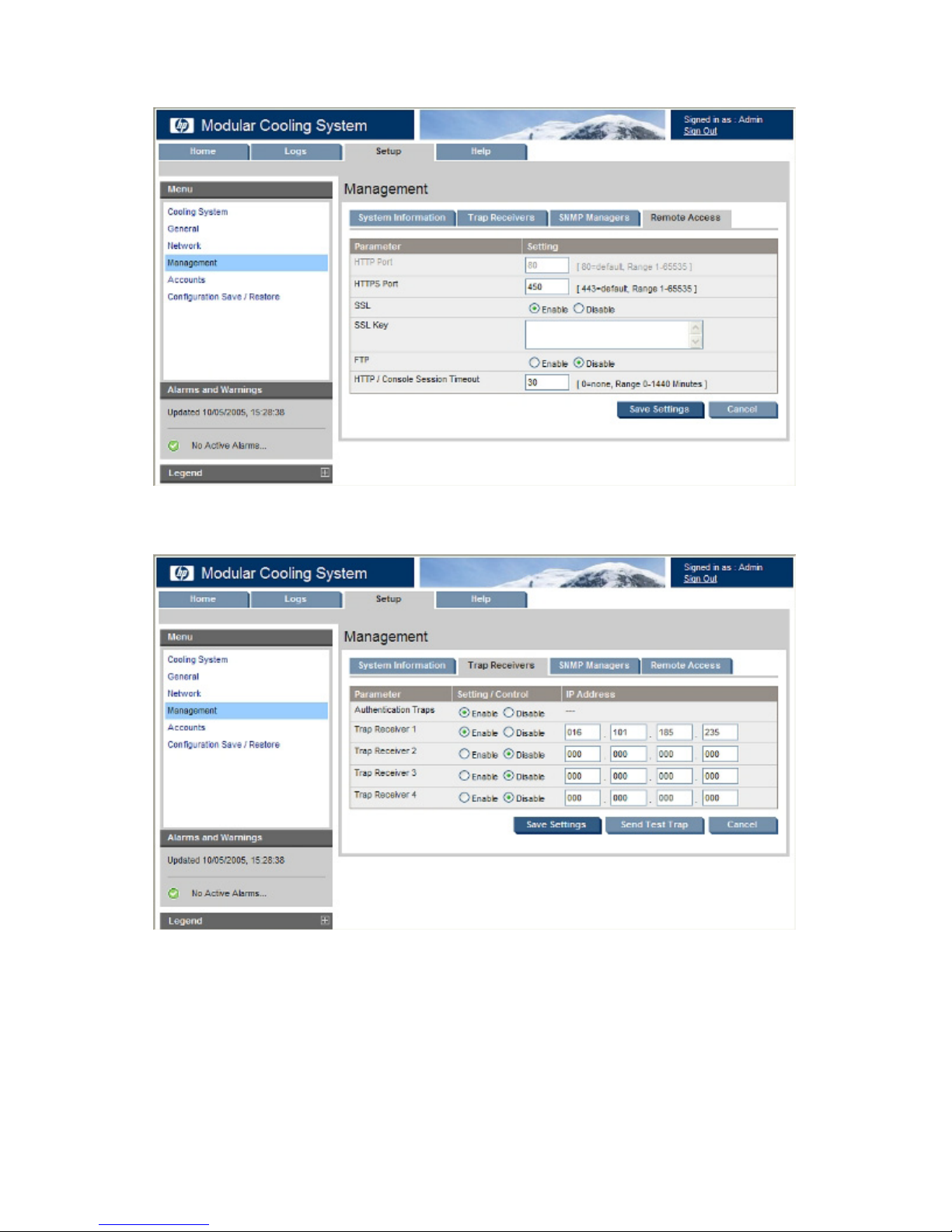

16. Optional, but HP-recommended: Click Setup>Management>Remote Access, and then select SSL

Enable.

Installation 20

Page 21

17.

Optional: Enter an SSL key.

18. Click Save Settings.

19. To set up your trap receivers, click Setup>Management>Trap Receivers.

20. Click Save Settings.

Installation 21

Page 22

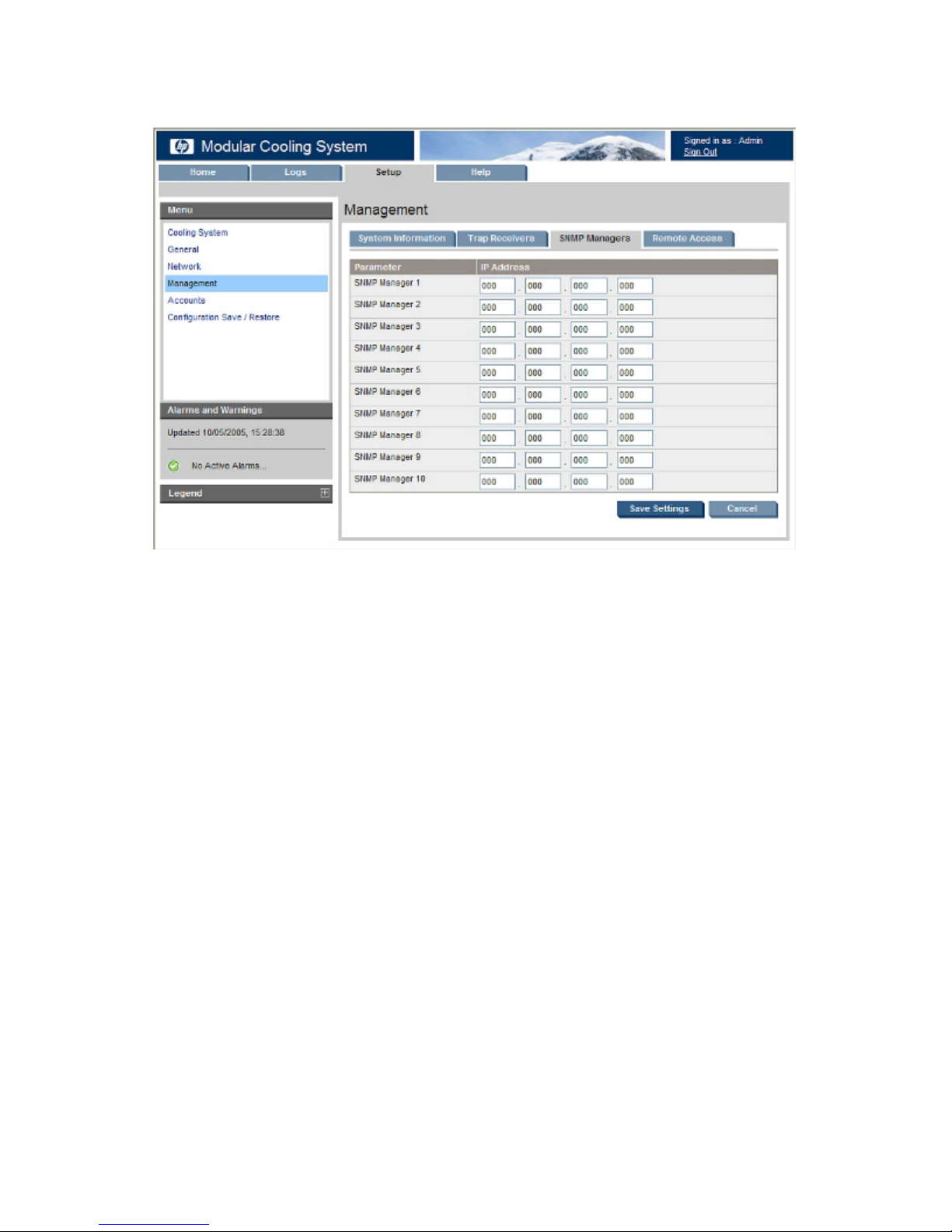

21.

Optional, but HP-recommended: To set up your SNMP managers, click Setup>Management>SNMP

Managers.

22. Click Save Settings.

Configuring the IP address through the web interface

1. View the IP address received from DHCP on the operator display.

2. Access the Management module through the web interface:

a. Launch a supported browser. The browser window appears.

b. In the Address field (Microsoft® Internet Explorer) or the Location field (Mozilla Firefox), enter

http://ipaddress (where ipaddress is the IP address of the management module).

The login screen appears.

3. Log in through the web interface:

a. Enter the user name in the User Name field. The default user name is Admin.

b. Enter the password in the Password field. The default password is Admin.

Installation 22

Page 23

c.

Click Sign In.

4. Click Setup>Network.

a. To disable DHCP, click the radio button. The default setting is enabled. Whenever you make a

change regarding DHCP, you must restart the server. A new screen will appear prompting you to

restart.

— To restart the server immediately, select Yes.

— To return to the Network screen, select No.

b. Click Save Settings.

c. In the IP Address field of the management module, change the IP address.

d. Change the network mask of the management module.

e. Change the default gateway of the management module.

f. Click Save Settings. A new screen appears, indicating that the server must be restarted for the

changes to take effect. If any new settings are saved, the server restarts automatically.

Installation 23

Page 24

g.

Log in to the new IP address.

5. Click Setup>Accounts, and then change the default Web Admin and Web User passwords.

6. Click Save Settings.

7. (Optional, but HP-recommended) Click Setup>Management>Remote Access, select SSL Enable.

8. (Optional) Enter an SSL key.

9. Click Save Settings.

Installation 24

Page 25

10.

To set up your trap receivers, click Setup>Management>Trap Receivers.

11. Click Save Settings.

12. (Optional, but HP-recommended) To set up your SNMP managers, click Setup>Management>SNMP

Managers.

13. Click Save Settings.

For more information on adjusting the management module settings through the web interface, see the HP

Modular Cooling System 200/100 Web Interface User Guide.

Connecting water to the facility

CAUTION: Before attaching the hoses to the MCS-200 unit, verify that the water supply and

return are closed. Water that leaks into the unit can cause significant damage.

CAUTION: Do not over tighten the connection. Tightening the connection too much might

damage the gaskets.

NOTE: The MCS-200 unit is equipped with a failed-open control valve. For water to flow through

the unit without restrictions during the initial water hook up, HP recommends that the control valve

is set manually to Open through the web interface.

Installation 25

Page 26

1.

Route the water hoses from the HP Modular Cooling System Hook Up Kit through the floor cut-out, and

then use a hose wrench to install each main hose to the MCS-200 unit. For information on floor cut out

dimensions, see the HP Modular Cooling System 200/100 Site Preparation Guide.

2. Route the two drain hoses to the drain collection system catch basin:

a. Install and route the blue drain hose into either the water return line or the gravity drain collection

system catch basin.

b. Route the preinstalled clear drain hose into the gravity drain collection system catch basin.

c. Position the gravity drain collection system below the water collection pan, enabling gravity to draw

the water out of the water collection pan and into the gravity drain collection system basin.

3. Log in to the web interface:

a. Enter the user name in the User Name field. The default user name is Admin.

Installation 26

Page 27

b.

Enter the password in the Password field. The default password is Admin.

c. Click Sign In.

4. Click Setup>Advanced.

5. In the Temperature Control field, select Manual, and then click Save Settings.

You can now set the Fan Speed Target and Water Valve fields manually.

6. In the Water Valve field, to open the valve completely, enter 100, and then click Save Settings.

Installation 27

Page 28

7.

Turn on the water by opening the ball valves at the facility water line connections.

8. In the web interface, click the Home tab.

9. To verify that the water source is available and turned on, select the Overview menu, and then verify the

Water Flow status.

Installation 28

Page 29

10.

If necessary, remove trapped air from the heat exchanger by opening the bleeder valve on the top rear

side of the cooling unit. To verify that the heat exchanger is bleeding correctly, verify that a few drops

of condensation pass through the clear tube.

11. After you have verified the flow and removed the air, in the web interface, click Setup>Advanced.

12. In the Temperature Control field, select Automatic, and then click Save Settings.

The installation is complete.

Installation 29

Page 30

Automatic Door Release Kit

Automatic Door Release Kit Overview

The Automatic Door Release Kit is designed as a safety mechanism in the event that the MCS-200 unit shuts

off unexpectedly. If the MCS-200 unit shuts off unexpectedly, the electromagnetic locks on the front door, the

rear master door, and the rear slave door are immediately deactivated. This deactivation of the

electromagnetic locks will cause the release springs on each door to spring the rack doors open and allow

air flow and cooling to the servers in the rack.

The Automatic Door Release Kit is included with your MCS-200 unit. For specific installation instructions, see

Automatic Door Release Kit

the HP Modular Cooling System Automatic Door Release Kit Installation Instructions included with the kit.

To view the HP Automatic Door Release hardware installation instructions, see the HP Modular Cooling

System Rack Options Installation Guide.

To enable the automatic door release:

1. Click Setup>Advanced.

2. In the Emergency Door Opening field, select Enable.

When the function has been enabled, an indicator appears on the Home tab showing the current status of the

rack doors. Also, a new button appears on the Advanced tab, enabling you to test the feature.

Automatic Door Release Kit 30

Page 31

To test the Automatic Door Release feature:

1. At the bottom of the screen, click the Door Opening Test button. A new screen appears.

2. Choose one of the following:

o To begin the test and open the rack doors, click OK.

o To return to the Advanced screen, click Quit.

NOTE: To avoid an increase in relative humidity, after completing the Door Opening test, be

sure the doors are closed. To verify that the doors are closed, go to the Home screen.

NOTE: You can also perform this test from the Operator Display.

Automatic Door Release Kit 31

Page 32

Management module

Management module overview

The HP Modular Cooling System has a management module, which can be accessed remotely through the

web interface. The management module analyzes, queries, and manages various measurements and

warning and alarm messages from the unit.

The management module (on page 32) analyzes measurements provided by each sensor or module,

generates any necessary warning or alarm messages, and then sends them to the web interface. When a

new warning or alarm occurs, the warning and alarm messages (on page 45) appear on the operator

display as well as on the web interface Alarms menu and Alarm History menu. An alarm relay is also

activated (if installed on the unit and enabled in the appropriate web interface menu), and an audible alarm

is signaled by the internal beeper (if enabled in the appropriate web interface menu).

The management module performs regulation operations such as:

• Retrieving all measurements from the fan units and the water units in cycles, approximately once per

second (temperature, fan speed, and chilled water flow rate)

• Analyzing all measurements and generated alarm and warning messages

• Calculating heat removed from the water flow rate and temperature of the water supply and return

• Measuring water flow rate

• Regulating the server air inlet temperature by controlling the water flow

• Sending control settings for fan speeds back to the MCS-200 unit

• Sending various system values to the web interface

The web interface displays various measurements and warning and alarm messages (on page 45) from the

management module. Also, various system values can be set through the web interface and sent to the

management module. For more information about the web interface, see the HP Modular Cooling System

Web Interface User Guide.

The following values can be set through the web interface and sent to the management module:

• Server Intake Temperature Set Point—Target value used by the management module for server intake

regulation

• High Temperature Threshold—Temperature difference above Server Intake Temperature Set Point for

temperature-critical alarm message

• Warning Temperature Threshold—Temperature difference above Server Intake Temperature Set Point

for temperature warning message

• Low Temperature Threshold—Temperature difference below Server Intake Temperature Set Point for

temperature warning message

The following values are displayed in the web interface for information only:

• Fan Speed—Displays the fan speed percentage

• Water Valve—Displays the water valve state

Management module 32

Page 33

• Fan Module—Displays the Server Intake and Server Exhaust Temperature as well as the RPM of each

•

•

•

•

•

•

fan

• Water Inlet Temperature—Displays the temperature of the water coming into the MCS-200 unit to be

used to cool the servers

• Water Outlet Temperature—Displays the temperature of the water after removing the server heat

• Water Flow—Displays the value of the water flow in liters/gallons per minute

Management module components

The management module is located on the lower front of the MCS-200 unit, behind the front door.

Item Reference Description

C key Used to confirm warnings, critical alarms, and

1

Power/alarm LED Used to indicate the internal status of the management

2

configuration setting changes, as well as to turn off the

audible alarm. To confirm these situations, press and

hold the C key for five seconds, or click the Clear Alarms

button on the Setup tab>General menu on the web

interface.

module, and to signal warnings and critical alarms.

If the LED is green, the management module has

power, and conditions are normal.

If the LED is green and blinking, communication is

taking place.

If the LED is yellow, a warning has been issued.

If the LED is red, a critical alarm has been issued.

If the LED is blinking green, yellow and red, then a

configuration setting change has been made. To save

the new configuration settings to the internal memory

Mini USB

3

connection

of the management module, press and hold the C key

for five seconds.

If the LED is off, the management module has no

power.

Used for USB connections for initial setup.

Management module 33

Page 34

Accessing the management module through a

terminal emulation program

1. Verify that a serial cable is connected between the management module and a host computer.

2. Launch a terminal emulation program such as HyperTerminal ("Configuring HyperTerminal" on page

43) or Minicom.

For information about configuring the management module, see the HP Modular Cooling System Web

Interface User Guide.

3. Log in through the terminal emulation program ("Logging in through the terminal emulation program"

Logging in through the terminal emulation program

on page 34).

1. Enter the user name in the login field. The default user name is Admin.

2. Enter the password in the password field. The default password is Admin. The Main Menu screen

appears.

Accessing the management module through the web

interface

1. Launch a supported browser. The browser window appears.

Management module 34

Page 35

2.

•

•

•

•

In the Address field (Microsoft® Internet Explorer) or the Location field (Mozilla), enter one of the

following:

http://hostname[:port number]

-orhttps://hostname[:port number] (if SSL is enabled)

where hostname is the IP address of the management module and port number is the port number if

using a port other than the default 80 for http and 443 for https. The login screen appears.

3. Log in through the web browser ("Logging in through the web interface" on page 35).

Web interface requirements

The following table lists the minimum requirements necessary to operate the web interface.

Component Requirement

Web browser on a client

Monitor resolution

Desktop resolution

Microsoft® Internet Explorer 8.0

Red Hat Linux operating system (32-bit only)

SUSE Linux operating system (32-bit only)

Mozilla Firefox 4.0

Minimum supported resolution of 1024 x 768, 16-bit

high color. (Maximize the browser window for optimal

display.)

SLES 11 Mozilla Firefox 3.6.17

To configure the desktop resolution:

1 Right-click the mouse, and select Configure

Desktop.

2 Select 1152 x 864.

3 Select 75 Hz.

Logging in through the web interface

1. Enter the user name in the User Name field. The default user name is Admin.

NOTE: Passwords are case-sensitive.

2. Enter the password in the Password field. The default password is Admin.

3. Choose one of the following options:

o Click Sign In. The HP Modular Cooling System web interface appears.

o To clear the credentials, click Clear.

Management module 35

Page 36

For instructions on changing the password, see the HP Modular Cooling System Web Interface User

Guide.

Only one Admin session and one User session are supported at a time. If a second session is initiated (after

successful login) or a console session timeout occurs, sessions can be terminated. In both situations, the

existing session is terminated and the login screen appears. Admin session logins, logouts, and terminations

are recorded in the Event Log menu. The console session timeout length can be enabled, disabled, or

modified in the Remote Access tab. The default is 30 minutes.

Management module 36

Page 37

Connecting an alarm device to the management

The connection to the alarm relays is hard wired. For more information, see connection

module alarm relay

An alarm device can be connected to the management module alarm relay through the RJ-12 connector. You

can enable or disable the alarm relay for specific alarms and warnings through the web interface. 24 V DC

up to 100 mA is available directly from the management module or the alarm relay can switch up to 30 V at

1 A. For more information, see the HP Modular Cooling System 200/100 Web Interface User Guide.

NOTE:

description on the management module.

Alarm relay item Specification

Type of alarm relay

Maximum current

consumption

Maximum voltage

Potential-free change-over contact

100 mA with internal

or

1 A with external power connection

DC, 24 V internal

or

DC, 30 V with external power connection

Management module 37

Page 38

Serial interface

HP Modular Cooling System Utility overview

The HP Modular Cooling System Configuration Utility is used for entering network settings, accessing

controls, reviewing the details on the info page, and resetting to factory defaults.

First, log in to a terminal emulation program. ("Logging in through the terminal emulation program" on page

34) After you have successfully initiated a terminal emulation session, the HP Modular Cooling System

Configuration Utility appears.

• Open a submenu by entering the corresponding option number at the prompt.

• Enter or change configuration information by following the onscreen prompts.

• Press Esc or enter 0 at the submenu prompt to go to the previous menu.

-orPress Esc or enter 0 at the main menu prompt to exit the utility.

• The management module must be reset before configuration changes can take effect.

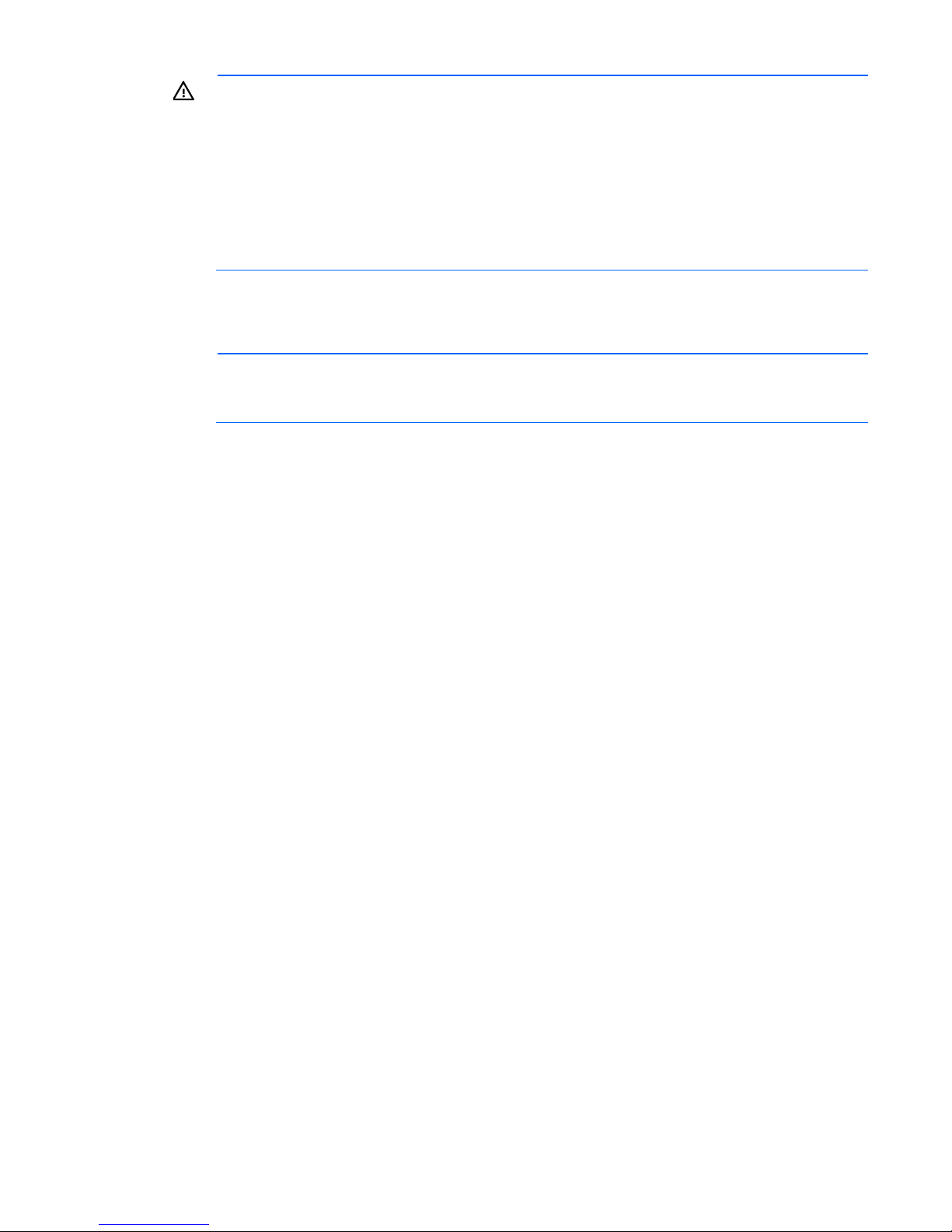

Main menu

Serial interface 38

Page 39

Option number Submenu Description

1

2

3

Network Configuration Enter or change network properties for the

Info Page View parameters for the management module.

Factory Default Change parameters back to default settings.

Menu Network Configuration submenu

management module.

Option number Submenu Description

1

2

3

4

IP Configuration Enter or change the IP configuration for the

management module.

Change Passwords Enter or change the passwords for the

management module.

HTTP/Console Timeout [min] Enter or change the minimum HTTP/console

timeout for the management module.

Activate Actual Values Select to accept changes and restart the unit.

Serial interface 39

Page 40

IP Configuration submenu

Option number Submenu Description

1

2

3

4

IP Address Enter or change the IP address for the

management module.

IP Subnet mask Enter or change the subnet mask for the

management module.

IP Def. Router Enter or change the default router for the

management module.

Enable/Disable DHCP Select to enable or disable DHCP.

Serial interface 40

Page 41

Change Passwords submenu

Option number Submenu Description

1

2

3

4

5

Console Password 'Admin' Change the Admin password.

FTP Password 'ftpuser' Change the FTP user password.

FTP Password 'ftpadmin' Change the FTP Admin password.

HTTP Password 'User' Change the HTTP user password.

HTTP Password 'Admin' Change the HTTP Admin password.

Serial interface 41

Page 42

Info page

The Info page displays the following parameters:

• IP Address

• Subnetmask

• Router/Gateway

• MAC Address

• SysName

• SysContact

• SysLocation

• Software Version

• Hardware Version

• Firmware

• Serial Number

• Manufacture Date

• CMC-Info

Serial interface 42

Page 43

Factory Default submenu

Option number Submenu Description

1

2

3

Set to Factory Default Set the management module to factory default.

Product ID MCS Set the MCS unit product ID.

Serial Number MCS Set the MCS unit serial number.

Configuring HyperTerminal

1. From the Microsoft® Windows® desktop menu, click Start>All

Programs>Accessories>Communication>HyperTerminal. The Connection Description window

appears.

2. Enter a description and select an icon for the connection. The Connect To window appears.

3. Select the Com port through which to connect. The Com Properties window appears.

4. Select the following parameter values.

Parameter Value

Transmission rate

Data bits

Parity

Stop bits

Flow control

9600 Bps

8

None

1

None

Serial interface 43

Page 44

Minicom is a utility that is loaded during the installation of Linux. However, if you

5.

When a connection is established, press Enter and then log in. The Main menu for the management

module appears. Follow the onscreen options to configure the management module.

Configuring Minicom

NOTE: The following example uses Red Hat Linux 3.0. For more information, refer to your Linux

1. Log in to a Linux console, or open a terminal and enter minicom-s at the command prompt. The

2. Select Serial Port Setup. The Change which setting? menu appears.

3. Select Option A (Serial Device). Manually change the device type from "dev/modem" to "/dev/ttyS0"

4. Select Option E (Bps/Par/Bits). The Comm Parameters menu appears.

5. Select E (Speed 9600 Bps), and press Enter. The designation 9600 8 N1 appears next to Option E.

6. Select Option F (Hardware Flow Control).

7. Be sure that the Change which setting? menu is configured as follows:

operating system Help or documentation.

IMPORTANT:

do not select the option to install the Linux Utilities during the operating system installation, you

cannot use Minicom without downloading the Minicom X.X.i386.rpm file from the Red Hat

website. (Refer to the procedure for installing RPMs on the Red Hat website.)

Configuration menu appears.

and press Enter.

o A—Serial Device: /dev/ttyS0

o B—Lockfile Location: /var/lock

o C—Callin Program:

o D—Callout Program:

o E—Bps/Par/Bits: 9600 8 N1

o F—Hardware Flow Control: No

o G—Software Flow Control: No

8. Press Enter to return to the Configuration menu. Scroll down to the Save setup as default option, and

press Enter. Scroll down the Configuration menu to the Exit from the Minicom option, and press Enter.

9. From the command prompt, enter Minicom. As soon as a connection is established, press Enter and

log in. The Main menu for the management module appears. Follow the onscreen options to configure

the management module.

Serial interface 44

Page 45

Operator display

Operator display overview

The operator display provides information on the system operation, viewable on the outside of the MCS-200

front door. When the management module issues an alarm or warning, the warning and alarm messages

display ("Warning and alarm messages" on page 45) on the operator display, as well as on the web

Operator display components

interface Alarms menu and Alarm History menu.

The operator display on the front door of the MCS-200 unit has a digital touch-screen.

To scroll through the menu options, press the appropriate button on the bottom of the screen.

Warning and alarm messages

The following tables describe the possible warning and alarm messages that the MCS-200 unit sends to the

management module. These messages appear on the operator display and on the web interface Alarms

menu and Alarm History menu.

Fan unit failed or not installed

Indicators Meaning

Operator display alarm message

Web interface alarm message

Condition

Sensors

SNMP notification

Fan 1, 2, 3, 4, 5, or 6 Failed

Fan 1, 2, 3, 4, 5, or 6 Failed or Not Installed

Fan 1, 2, 3, 4, 5, or 6 is running at less than the minimum RPM

Fan 1, 2, 3, 4, 5, or 6

Warning

Operator display 45

Page 46

Indicators Meaning

Water flow Low

Type of message

Warning

Solution:

1. Remove the fan unit.

2. Reinstall the same fan unit.

If the warning message does not clear after the module is reseated, replace the fan unit with a CSR part. For

more information on CSR parts, see "Replaceable parts and maintenance and service information (on page

59)."

HEX (heat exchanger unit) temperature in failed (Server Intake Temperature failed)

Indicators Meaning

Operator display alarm message

Web interface alarm message

Condition

Sensors

SNMP notification

Type of message

HEX1, HEX2, or HEX3 Temp. In Failed

Top Heat Exchanger Intake Air Temperature Sensor to Server Failed

Temperature reading is beyond limit (possible open circuit)

HEX1, HEX2, or HEX3 sensors (This value is the water to air heat exchanger

unit temperature of the intake to the servers.)

Warning

Warning

Solution:

Contact HP, or see the HP website (http://www.hp.com).

HEX temperature out failed (Server Exhaust Temperature failed)

Indicators Meaning

Operator display alarm message

Web interface alarm message

Condition

Sensors

SNMP notification

Type of message

HEX1, HEX2, or HEX3 Temp. Out Failed

Top Heat Exchanger Exhaust Air Temperature Sensor from Server Failed

The temperature reading is beyond limit (possible open circuit)

Fan 1, 2, 3, 4, 5 or 6 sensors (This value is the fan unit temperature of the

exhaust from the servers.)

Warning

Warning

Solution:

Contact HP, or see the HP website (http://www.hp.com).

Low water flow

Indicators Meaning

Operator display alarm message

Web interface alarm message

Condition

Modules

SNMP notification

Type of message

Water flow Low

No or low water flow

Water group

Warning

Warning

Operator display 46

Page 47

Solution:

Warning

Verify the water supply.

Water temperature input is out of range

Indicators Meaning

Operator display alarm message

Web interface alarm message

Condition

Sensors

SNMP notification

Type of message

Water Temp. In Failed

Water Unit Temperature Input Out of Range

Water temperature sensor is not working properly (possible open circuit).

Water group sensor

Warning

Warning

Solution:

1. Verify the water supply.

2. Verify whether the water temperature is below or above the water temperature expected range.

3. Contact your building supervisor.

4. Contact HP, or see the HP website (http://www.hp.com).

Water temperature output is out of range

Indicators Meaning

Operator display alarm message

Web interface alarm message

Condition

Sensors

SNMP notification

Type of message

Water Temp. Out Failed

Water Unit Temperature Output Out of Range

Water temperature sensor is not working properly (possible open circuit).

Water group sensor

Warning

Solution:

1. Verify the water supply.

2. Verify whether the water temperature is below or above the water temperature expected range.

3. Contact your building supervisor.

4. Contact HP, or see the HP website (http://www.hp.com).

Water flow sensor is not working properly

Indicators Meaning

Operator display alarm message

Web interface alarm message

Condition

Sensor

SNMP notification

Type of message

Water flow Sensor?

Water flow Sensor Value Out of Range

Water flow sensor is not working properly.

Water group

Warning

Warning

Solution:

Operator display 47

Page 48

1.

Verify the water supply.

2. Contact HP, or see the HP website (http://www.hp.com).

Water flow valve is closed

Indicators Meaning

Operator display alarm message

Web interface alarm message

Condition

Modules

SNMP notification

Type of message

Water Valve?

Water Valve Failed

Water flow valve is closed, and water flow is detected.

Water group

Warning

Warning

Solution:

1. Verify the water valve is closed.

2. Contact HP, or see the HP website (http://www.hp.com).

Leak detector sensor is not working properly

Indicators Meaning

Operator display alarm message

Web interface alarm message

Condition

Sensors

SNMP notification

Type of message

Leak detector?

Leak detector Failed

Leak detector sensor is not working properly.

Leak detector sensor

Warning

Warning

Solution:

Contact HP, or see the HP website (http://www.hp.com).

Uneven heat load

Indicators Meaning

Operator display alarm message

Web interface alarm message

Condition

Sensors

SNMP notification

Type of message

Heat Load?

Heat Load Warning

Measured air temperature values are dramatically different from top to

bottom.

Air temperature sensors

Warning

Warning

Solution:

1. Verify that nothing is blocking the heat path.

2. Verify that the server is loading.

3. Adjust the Temperature Difference for Heat Load Warning in the Advanced tab.

Heat overload condition (High Temperature Threshold field)

Operator display 48

Page 49

Temperature too high

Indicators Meaning

Operator display alarm message

Web interface alarm message

Condition

Modules or sensors

Temperature too high

Heat overload condition

The average server air temperature is above the temperature assigned in the

web interface Intake Temp tab High Temperature Threshold field.

SNMP notification

Type of message

Critical

Alarm

Solution:

1. Verify the water inlet temperature.

2. Verify that the flow matches the specifications required for heat load.

3. Adjust the temperature assigned in the web interface Intake Temp tab High Temperature Threshold field.

Leakage detected

Indicators Meaning

Operator display alarm message

Web interface alarm message

Condition

Modules or sensors

SNMP notification

Type of message

Leakage Detected

Leakage Detected

Leak is detected

Leakage detector actuated

Critical

Alarm

Solution:

1. Open the rack doors.

2. Power down the rack-mounted components.

3. Turn off the water to the MCS-200 unit.

4. Locate and correct the leak.

Communication failure

Indicators Meaning

Operator display alarm message

Web interface alarm message

Condition

Modules or sensors

SNMP notification

Type of message

Comm. Failure I²C

Comm. Failure I²C

The management module cannot communicate with the MCS-200 unit

sensors.

Any module or sensor

Critical

Alarm

Solution:

Power cycle the management module. If the alarm message continues to appear, replace the management

module with a CSR part. For more information on CSR parts, see "Replaceable parts and maintenance and

service information (on page 59)."

Operator display 49

Page 50

Temperature below threshold (Low Temperature Threshold field)

The water flow loss emergency door opening temperature threshold has

Indicators Meaning

Operator display alarm message

Web interface alarm message

Condition

Temperature too low

Temperature too low

The average server air temperature is lower than the temperature assigned

in the web interface Intake Temp tab Low Temperature Threshold field.

Sensors

SNMP notification

Type of message

Air temperature sensor

Warning

Warning

Solution:

1. Verify water flow matches specifications required for heat load.

2. Verify whether the water temperature is below the expected range.

3. Adjust the temperature assigned in the web interface Intake Temp tab Low Temperature Threshold field.

4. Contact your building supervisor.

Temperature above threshold (Warning Temperature Threshold field)

Indicators Meaning

Operator display alarm message

Web interface alarm message

Condition

Modules or sensors

SNMP notification

Type of message

Temperature Warning

Temperature Warning

Average server air temperature is above the temperature assigned in the

web interface Intake Temp tab Warning Temperature Threshold field

Air temperature sensor

Warning

Warning

Solution:

1. Verify water flow matches specifications required for heat load.

2. Verify whether the water temperature is above the expected range.

3. Adjust the temperature assigned in the web interface Intake Temp tab Warning Temperature Threshold

field.

4. Contact your building supervisor.

Emergency Door Opening due to Water Flow Loss (0 l/min; 36/34/35°C) (0 gal/min; 97/93/95°F)

Indicators Meaning

Operator display alarm message

Web interface alarm message

Condition

Modules or sensors

Emergency Door, Flow

Emergency Door Opening due to Water Flow Loss (0 l/min; 36/34/35°C)

(0 gal/min; 97/93/95°F)

The interface alarm message displays the temperatures of the fans so that

you can see which temperature has been exceeded and caused the alarm.

been exceeded or the water flow is less than 2 l/min (.5283 gal/min).

Server Intake Temperature, Water Flow Meter

Operator display 50

Page 51

Indicators Meaning

SNMP notification

Type of message

Critical

Alarm

Solution:

1. Verify the water supply and that the MCS-200 unit is receiving water.

2. Verify that the water pressure delta is accurate.

3. Verify that the water flow loss emergency door opening temperature threshold is not less than 5°C

(41°F) above or more than 20°C (68°F) above the Server Intake Temperature Set Point.

4. Adjust the temperature in the Server Intake Temperature Set Point or the Water Flow Loss Emergency

Door Opening Temperature Threshold fields to prevent false alarms.

IMPORTANT: Use caution when entering temperatures in the Emergency Door Opening fields.

Setting the temperature thresholds too low might cause the MCS unit to shut down.

Emergency Door Opening due to High Temperature (35/36/38°C) (95/97/100°F)

Indicators Meaning

Operator display alarm message

Web interface alarm message

Condition

Modules or sensors

SNMP notification

Type of message

Emergency Door, Heat

Emergency Door Opening due to High Temperature (35/36/38°C)

(95/97/100°F)

The interface alarm message displays the temperatures of the fans so that

you can see which temperature has been exceeded and had caused the

alarm.

The High Temperature Emergency Door Opening Threshold has been

exceeded.

Server Intake Temperature

Critical

Alarm

Solution:

1. Verify the water supply and that the MCS-200 unit is receiving water.

2. Verify that the High Temperature Emergency Door Opening Threshold is not less than 5°C (41°F) above

or more than 20°C (68°F) above the Server Intake Temperature Set Point, or that it is not below the

Water Flow Loss Emergency Door Opening Temperature Threshold.

3. Adjust the temperature in the Server Intake Temperature Set Point or the Water Flow Loss Emergency

Door Opening Temperature Threshold fields to prevent false alarms.

IMPORTANT: Use caution when entering temperatures in the Emergency Door Opening fields.

Setting the temperature thresholds too low might cause the MCS unit to shut down.

The condensation pump has exceeded x cycles

Indicators Meaning

Operator display alarm message

Web interface alarm message

Excessive moisture

The condensation pump has exceeded x cycles

Operator display 51

Page 52

Indicators Meaning

hour window. The clock stops and the counters are reset to zero for warning purposes if the

Condition

The water level has exceeded the permissible level of the condensation

pump sensor.

Modules or sensors

SNMP notification

Type of message

Condensation pump sensor

Warning

Warning

Solution:

1. To determine the cause, look for leaks or condensation.

2. If no leaks are found, adjust the temperature in the Excessive Moisture: Condensation Pump Cycles

Warning Threshold field.

IMPORTANT: Use caution when entering temperatures in the Condensation Pump Threshold

fields. Be sure to determine the proper default settings to prevent false alarms, without masking

problems with the MCS.

Default settings will vary, depending on the humidity level of your data center and the heat load

The condensation pump has run more than x seconds

generated by the equipment in the MCS.

Indicators Meaning

Operator display alarm

message

Web interface alarm

message

Condition

Modules or sensors

SNMP notification

Type of message

Excessive moisture

The condensation pump has run more than x seconds

The water level has exceeded the permissible level of the condensation pump sensor.

Condensation pump sensor

Warning

Warning

Solution:

1. To determine the cause, look for leaks or condensation.

2. If no leaks are found, adjust the temperature in the Excessive Moisture: Condensation Pump Running

Time Warning Threshold field.

IMPORTANT: Use caution when entering temperatures in the Condensation Pump Threshold

fields. Be sure to determine the proper default settings to prevent false alarms, without masking

problems with the MCS.

Default settings will vary, depending on the humidity level of your data center and the heat load

generated by the equipment in the MCS.

NOTE: A 24-hour clock starts when the condensation pump runs for the first time in more than 24

hours. A warning is issued if either the cycle threshold or pump running time is exceeded within

the 24thresholds are not exceeded within 24 hours after the last time the condensation pump runs.

Operator display 52

Page 53

NOTE: To clear the condensation pump cycles warning, click Cooling System in the left

Rack door sensor

navigation frame to access the Cooling System screen, and then click the Alarms/Warnings tab.

Under the Warnings section, set Alarm Reset to Manual and click Save Settings. Then, return to

the General menu and click Clear Alarms.

This step only clears the warning when the condensation pump is not running.

Both doors are open

Indicators Meaning

Operator display alarm

Both front and rear rack doors are open.

message

Web interface alarm

Both doors are open.

message

Condition

Both the front and rear rack doors are open. The system shuts down the fans and closes

the water valve.

Modules or sensors

SNMP notification

Type of message

Alarm

Alarm

Solution:

1. Verify that the front and rear doors are closed.

2. Verify that an operating condition has not triggered the automatic door opening feature.

NOTE: Be sure your temperature threshold is not set too low. See Emergency Door Opening

messages.

Water Input Temperature is lower than dew point

Indicators Meaning

Operator display alarm

message

Web interface alarm

message

Condition

Modules or sensors

SNMP notification

Type of message

Dew point warning

Water Input Temperature lower than dew point

Either the front or rear door is open, and the water input temperature is lower than the

calculated dew point. The fans automatically switch to 75% of maximum speed.

Humidity sensor

Warning

Warning

Solution:

1. Verify that both the front and rear doors are closed.

2. Verify that the server load meets the minimum load specified for inlet water temperature in the HP

Modular Cooling System 200/100 Site Preparation Guide.

Operator display 53

Page 54

Frequently asked questions

, up to 10% of the total power supplied to the rack may

Yes, the control system automatically adjusts the water flow and air

MCS-200 frequently asked questions

Question Answer

What cooling capacity ranges are

available in the MCS-200 unit?

Is special IT equipment required for

use with the MCS-200 unit?

Does the additional heat from the

MCS-200 unit increase the room

temperature?

Can the level of heat removal be

regulated in proportion to the waste

heat generated?

How is water connected to the

MCS-200 unit?

Can the MCS-200 unit operate with

the front or rear door open?

Does the MCS-200 unit require

maintenance?

Is a false floor necessary?

Does condensation form?

How does the MCS-200 unit control

humidity?

Does the air flow within the

MCS-200 unit produce static

electricity?

The cooling capacity of the heat exchanger unit depends on the water

supply temperature and the server inlet set point. The MCS-200 unit is

capable of cooling rack-mounted components consuming up to 50 kW

of electrical power.

No, all IT equipment that uses the front-to-back cooling system (99% of

IT equipment) can be used without restriction in conjunction with the v

unit.

In some cases

be lost to the room, depending on the server air setting and the room

temperature.

flow to remove heat generated in the rack.

The water is connected to the unit using a 1.25-inch flexible hose and

quick-disconnect automatic shutoff hose fittings. For more information,

see the HP Modular Cooling System Hook-Up Kit Installation

Instructions.

Yes, due to the air curtain effect, the air will function normally with little

air lost. When the doors are open during operation, room air mixes

with air supplied to the servers.

No, assuming that the water quality is maintained, the MCS-200 unit

is maintenance-free. For more information about water quality, see the

HP Modular Cooling System 200/100 Site Preparation Guide on the

HP website.

No, a false floor is not necessary to operate the MCS-200 unit. For

more information, see the HP Modular Cooling System 200/100 Site

Preparation Guide on the HP website.

During normal operation some condensation may form, but the

MCS-200 unit condensation control system ensures that the

condensation does not reach any rack-mounted components or cause

any damage. In most cases, the condensation evaporates prior to

reaching the MCS-200 unit condensation control system.

There is some room-air interchange, so the moisture content of the air

inside the unit is the same as the room.

Very low humidity levels in the chilled air may produce static

electricity. However, static electricity is not a problem if the MCS-200

unit is operated at the specified settings located in the HP Modular

Cooling System 200/100 Site Preparation Guide and the

Environmental specifications section.

Frequently asked questions 54

Page 55

Question Answer

port x set flow=Xonxof

If you have the Automatic Door Release Kit installed and enabled, an

Why do I get an extra line feed sent

from Microsoft® Windows® when I

access the serial interface using an

HP serial console switch?

Is water prevented from entering the

MCS-200 unit if a pipe breaks?

What will happen if water stops

flowing to the MCS-200 unit?

Can I install an MCS-200 unit to an

existing rack in my data center?

Can I cool two racks with one

MCS-200 unit?

Can I install an existing rack in my

data center to my MCS-200 unit as

my secondary rack?

Will my secondary rack have the

ability to use the Automatic Door

Release Kit?

Enter these commands while logged in as Admin on the HP serial

console switch console port (where port x is the port connected to the

MCS management module):

port x set out lf=strip

Yes, the MCS-200 unit is physically separate from the server

enclosure. Therefore, there is no situation in which water can come

directly in contact with the servers. The base unit of each cooling

module acts as a condensation tray for water. These trays are

connected together, so that any water drains away at once through the

condensation drain. Also, each heat exchanger module has a leak

and condensation tray that transfers water to the bottom of the

MCS-200 unit where it flows to the building condensation return

system. If a leak occurs, the integrated leak sensor detects it and an

alarm would is issued so that action can be quickly taken.

alarm will trigger the doors of the rack to open, allowing the servers to

be cooled by the room ambient temperature.

No, the MCS-200 unit ships with an empty HP rack. However,

Configure to Order (CTO) is available.

Yes, the HP Expansion Rack Kit is available to install to your MCS-200

unit. You can cool a rack on either side of the MCS-200 unit.

No, you must order the HP Expansion Rack Kit to ensure the proper fit

and functionality of the secondary rack.

Yes, you can install the HP Automatic Door Release Kit on your

Expansion Rack. If the Automatic Door Release function is enabled, it

automatically controls the automatic door release functionality of both

racks.

Frequently asked questions 55

Page 56

Troubleshooting

MCS-200 troubleshooting

Issue Resolution

The water flow is low or not flowing.

The fan speed is too low.

The fan speed is too high.

The average server intake

temperature (air going to the servers)

is too high.

The average server intake

temperature (air going to the servers)

is too low.

The average exhaust temperature

(air coming out of the servers) is too

high.

The average exhaust temperature

(air coming out of the servers) is too

low.

The settings that have been modified

through the web interface are not

accepted, and the management

module LED is blinking red, yellow,

or green.

The measurement readings on the

management module display or web

interface seem to be incorrect, and

the management module LED is

blinking red, yellow, or green.

The heat exchanger unit stops

operating correctly.

For more information, see the "Temperature Control settings" section

in the HP Modular Cooling System 200/100 Web Interface User

Guide located on the Documentation CD included with this product.

For more information, see the "Cooling performance parameters"

section in the HP Modular Cooling System 200/100 Web Interface

User Guide located on the Documentation CD included with this

product.

For more information, see the "Cooling performance parameters"

section in the HP Modular Cooling System 200/100 Web Interface

User Guide located on the Documentation CD included with this

product.

For more information, see the "Cooling performance parameters"

section in the HP Modular Cooling System 200/100 Web Interface

User Guide located on the Documentation CD included with this

product.

For more information, see the "Cooling performance parameters"

section in the HP Modular Cooling System 200/100 Web Interface

User Guide located on the Documentation CD included with this

product.

For more information, see the "Cooling performance parameters"

section in the HP Modular Cooling System 200/100 Web Interface

User Guide located on the Documentation CD included with this

product.

For more information, see the "Cooling performance parameters"

section in the HP Modular Cooling System 200/100 Web Interface

User Guide located on the Documentation CD included with this

product.

Press and hold the management module C key for five seconds to

confirm these settings.

Press and hold the management module C key for five seconds to

confirm these settings.

Remove the corresponding fan unit to keep the Automatic Door

Release Kit from holding the rack doors open.

Troubleshooting 56

Page 57

Specifications

478 kg (1,054 lb) Weight includes rear extension, which

MCS-200 specifications

Item Specification

Voltage

Maximum height

(including the rack)

Maximum width

(including the rack)

Maximum depth

(including the rack and

rack handle)

Maximum shipping

height (on skid)

Maximum shipping

width (on skid)

Maximum shipping

depth (on skid)

Net weight (including

the empty rack)

Shipping Weight (gross

with packaging)

Effective cooling

Rated current maximum

Steady state current

with maximum fans

Cooling medium

Prefuse

Minimum

recommended water

inlet temperature

Permissible operating

pressure pmax

Maximum operating

noise level

NOTE: The abbreviation L42W10, L20 is part of the type plate information and stands for hot air

temperature of 42°C (107°F), chilled water temperature of 10°C (50°F), and cold air temperature

of 20°C (68°F).

230 VAC +/- 10%, 50 Hz and 277 VAC +/- 10%, 60 Hz

200.7 cm (79 in)

90.4 cm (35.6 in) maximum

151 cm (59.5 in) (Depth includes rear extension)

228.5 cm (90.0 in)

122.0 cm (48.0 in)

182.9 cm (72.0 in)

weighs 30 kg (67 lb).

732 kg (1,614 lb) Weight includes rear extension, which

weighs 30 kg (67 lb).

50 kW at 124 l/min (32.8 US gal/min)

(L42W10, L20)

230 VAC - 18 Amps

230 VAC - 13.0 Amps

water

20A

7°C (45°F)

8 bar (116 psi)

79 dB(A)

Specifications 57

Page 58

124 l/min (32.8 US gal/min)

124 l/min (32.8 US gal/min)

Thermal and air flow performance

Maximum thermal and air flow

Single rack Dual rack

performance parameters

Air temperature—Inlet to rack-mounted

components

Chilled water temperature

Total rack-mounted component air flow

Chilled water flow rate

Chilled water pressure differential at

flow needed to meet thermal

specifications

Heat lost to room

Server heat load

25ºC (68ºF) 25ºC (68ºF)

7º–18°C (45º–64°F) 7º–18°C (45º–64°F)

4,500 cfm (7,650 m3/h) or less at

0 or more pressure drop across the

rack mounted components

1.0 bar delta pressure 1.0 bar delta pressure

Approximately 10% maximum

depending on the MCS settings

and room temperature

50 kW maximum 25 kW maximum

Environmental specifications

Features Specifications

Operating temperature:

Recommended

Allowable

Non-operating temperature

Transit temperature

Storage temperature

Operating humidity:

Recommended minimum

Recommended maximum

Allowable range

Non-operating humidity

Operating altitude

Non-operating altitude

NOTE: For safety, the MCS-200 unit is equipped with a dew point sensor and control system

which creates an alarm that sounds if the chilled water temperature is lower than the dew point

temperature. This condition might create excessive condensation on the heat exchanger.

Therefore, the unit must be operated in non-condensing operating conditions.

18ºC (64.4ºF) to 27ºC (80.6ºF)

15ºC to 32ºC (59ºF to 90ºF)

0ºC to 60ºC (32ºF to 140ºF)

-30ºC to 60ºC (-22ºF to 140ºF), up to 72 hours

-20ºC to 60ºC (-4ºF to 140ºF)

5.5°C (41.9°F) dew point

60% relative humidity and 15°C (59°F) dew point

20 to 80% relative humidity (non-condensing)

5 to 95% relative humidity (non-condensing)

-76.2 to 3,048 m (-250 to 10,000 ft)

-76.2 to 9,144 m (-250 to 30,000 ft)

(Specification per rack)

2,400 cfm (4,050 m3/h) or less at

0 or more pressure drop across the

rack mounted components

Approximately 10% maximum

depending on the MCS settings

and room temperature

HP 642 1200mm Rack specifications

U height Width Depth Dynamic load (gross) Static load

42U

598 mm

(23.8 in)

1,300 mm

(47.24 in)

1,043 kg

(2,300 lb)

1,361 kg

(3,000 lb)

Specifications 58

Page 59

Replaceable parts and maintenance and service

information

Obtaining replaceable parts

For more information on replaceable parts, see the HP Modular Cooling System Maintenance and Service

Guide.

1. Go to the HP website (http://www.hp.com/support).

2. From the left menu bar, select Support and Troubleshooting Information.

3. In the product field, enter HP Modular Cooling System, and click Enter.

4. From the Resources section, select Manuals.

5. From the Quick jump to manuals section, select Service and maintenance information.

Maintenance and service

Air and water heat exchanger maintenance

For information on maintenance and service, refer to the HP website (http://www.hp.com).