Page 1

Service Manual

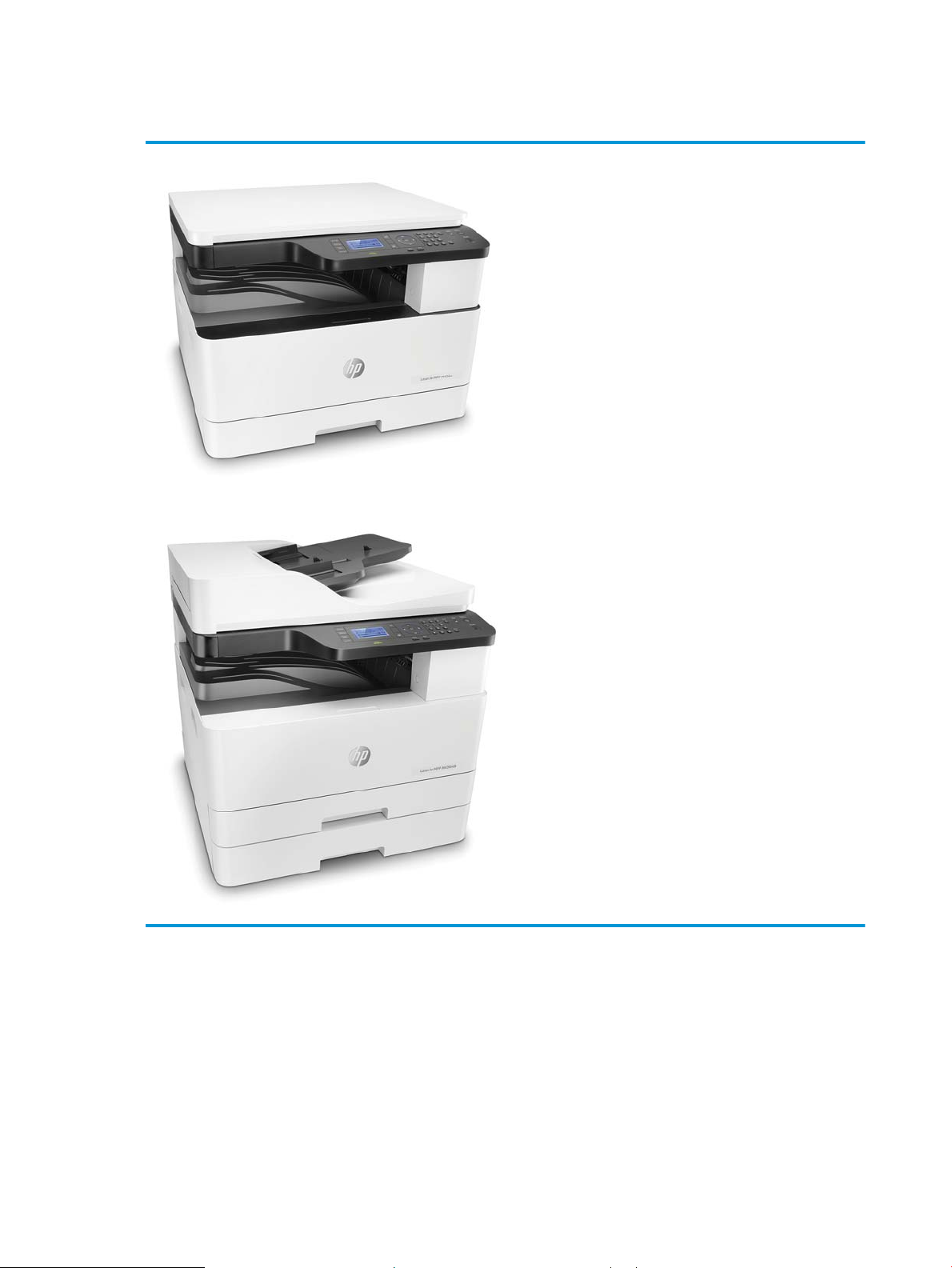

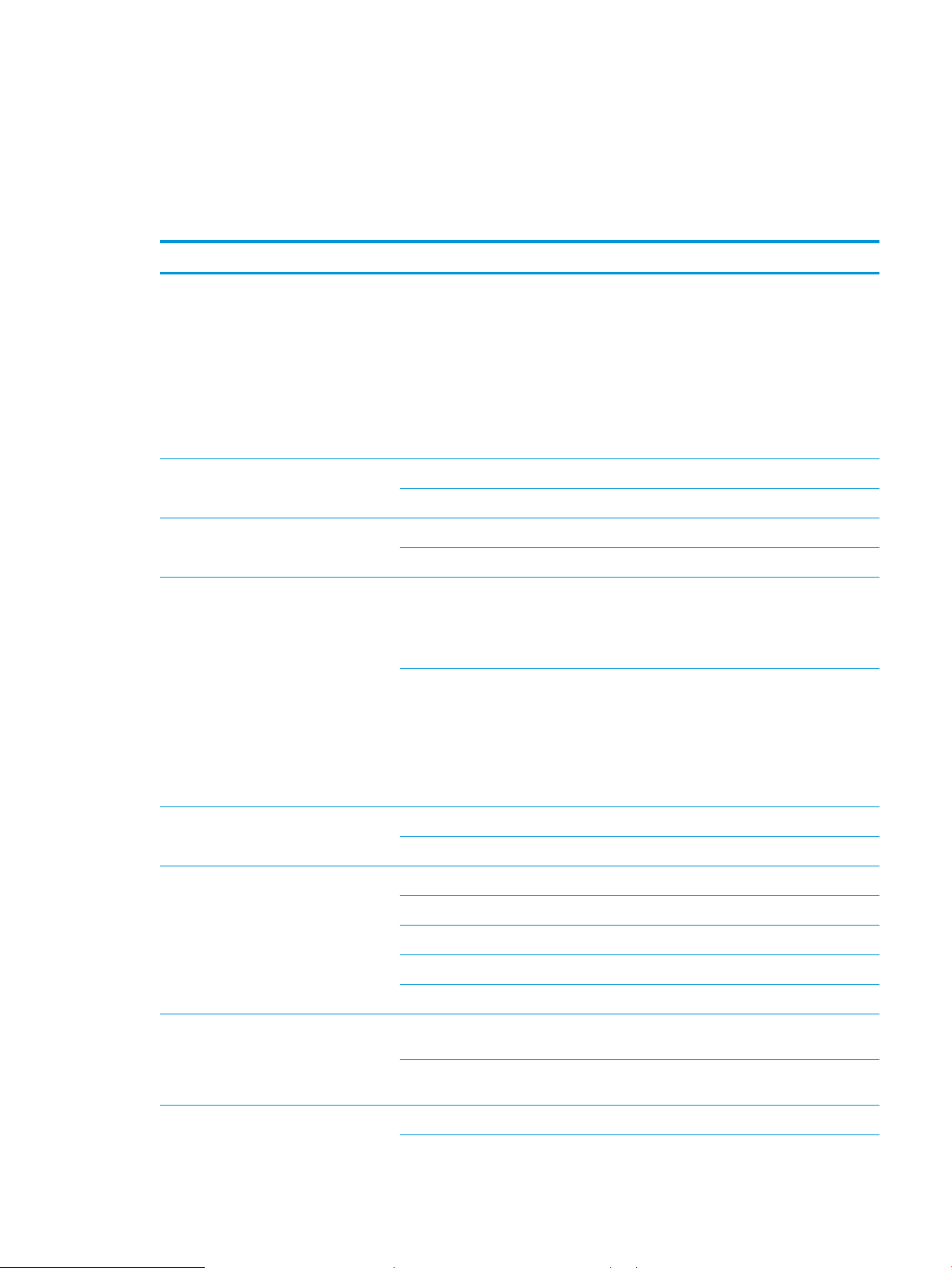

M433a/M436n/M436dn M436nda

LaserJet MFP M433a, M436n, M436dn, M436nda

www.hp.com/support/ljM436MFP

www.hp.com/support/ljM433MFP

Page 2

Page 3

HP LaserJet MFP M433a, M436n, M436dn,

M436nda

Service Manual

Page 4

Copyright and License

Trademark Credits

© Copyright 2018 HP Development Company,

L.P.

Reproduction, adaptation, or translation without

prior written permission is prohibited, except as

allowed under the copyright laws.

The information contained herein is subject to

change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products and

services. Nothing herein should be construed as

constituting an additional warranty. HP shall not

be liable for technical or editorial errors or

omissions contained herein.

Edition 4, 4/2018

Adobe®, Acrobat®, and PostScript® are

tr

ademarks of Adobe Systems Incorporated.

Microsoft®, Windows®, Windows® XP, and

Windows Vista® are U.S. registered trademarks

of Microsoft Corporation.

Page 5

Conventions used in this guide

TIP: Tips provide helpful hints or shortcuts.

NOTE: Notes provide important information to explain a concept or to complete a task.

CAUTION: Cautions indicate procedures that you should follow to avoid losing data or damaging the product.

WARNING! Warnings alert you to specic procedures that you should follow to avoid personal injury,

catastrophic loss of data, or extensive damage to the product.

ENWW iii

Page 6

iv Conventions used in this guide ENWW

Page 7

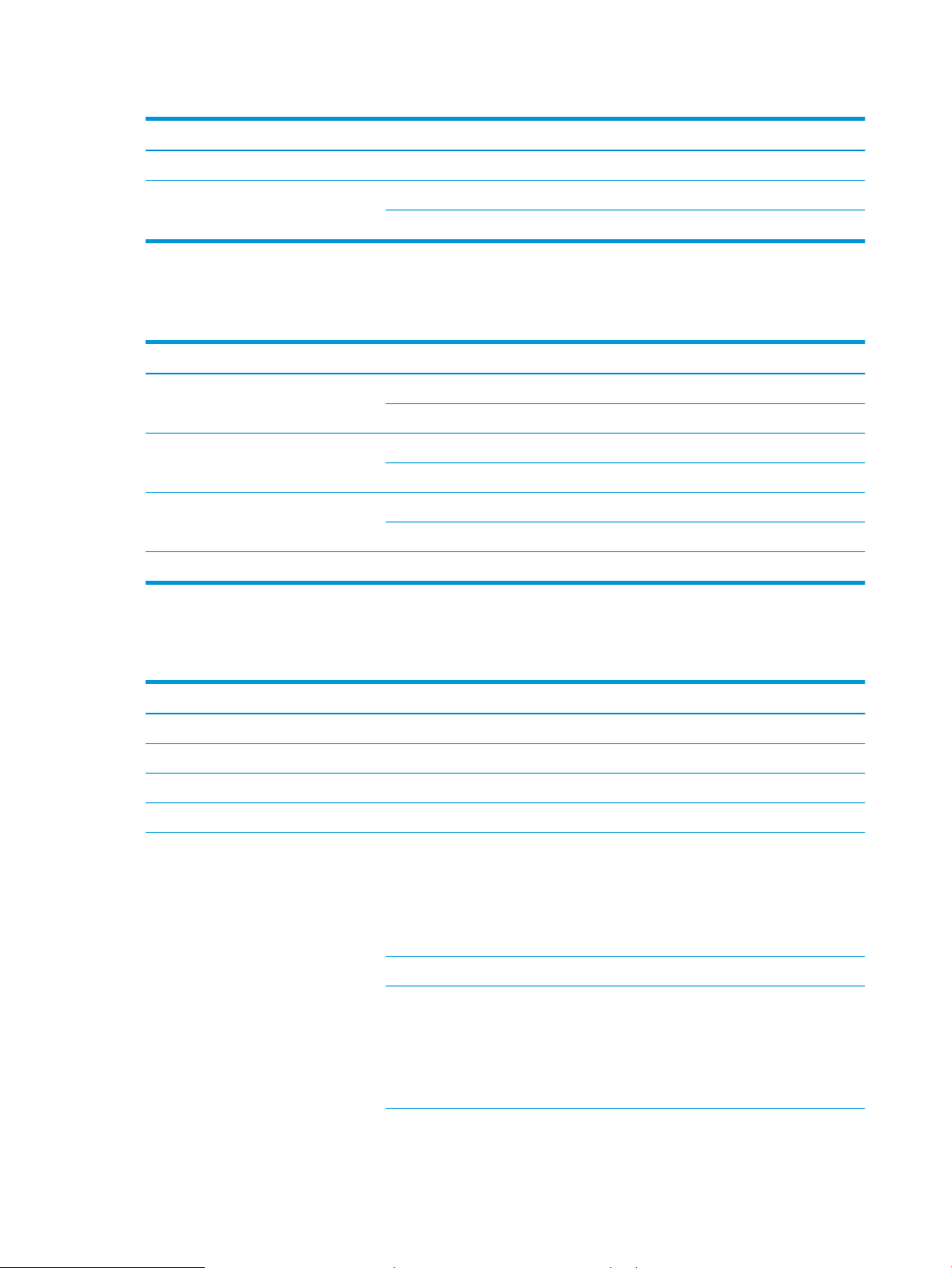

Table of contents

1 Product specs and features .................................................................................................................................................................... 1

Product Overview ..................................................................................................................................................................... 2

Specications ............................................................................................................................................................................ 3

General Specications ......................................................................................................................................... 3

Print specications ............................................................................................................................................... 4

Controller and software specication ............................................................................................................... 4

Scan specication ................................................................................................................................................ 5

Copy specication ................................................................................................................................................ 7

Paper handling specication .............................................................................................................................. 7

Supplies ................................................................................................................................................................. 9

Maintenance parts ............................................................................................................................................... 9

Optional accessories ......................................................................................................................................... 10

System conguration ............................................................................................................................................................ 11

Feeding system ...................................................................................................................................................................... 14

Feeding system overview ................................................................................................................................ 14

Main components and functions ..................................................................................................................... 15

Cassette .............................................................................................................................................................. 17

Pickup roller and friction pad ........................................................................................................................... 18

Registration roller .............................................................................................................................................. 18

MPF(Multi-Purpose Feeder) unit ..................................................................................................................... 19

Image Creation ....................................................................................................................................................................... 21

Printing process overview ................................................................................................................................ 21

Imaging unit ........................................................................................................................................................ 21

Imaging unit overview .................................................................................................................. 21

Drum drive ..................................................................................................................................... 22

Developer unit ............................................................................................................................... 22

Fuser unit ................................................................................................................................................................................. 25

Fuser unit overview ........................................................................................................................................... 25

Fuser duplex exit drive ..................................................................................................................................... 26

Fuser unit temperature control ....................................................................................................................... 26

Laser Scanning unit (LSU) ..................................................................................................................................................... 28

LSU overview ...................................................................................................................................................... 28

ENWW v

Page 8

Laser scanning optical path ............................................................................................................................. 29

Laser synchronizing detectors ........................................................................................................................ 29

Drive system ........................................................................................................................................................................... 31

Drive motors ....................................................................................................................................................... 31

Main drive unit (OPC_DEVE_REGI_MP_pickup) ............................................................................................. 32

Fuser duplex exit drive ..................................................................................................................................... 34

Toner cartridge drive ......................................................................................................................................... 35

Scanner System ..................................................................................................................................................................... 36

Scanner system overview ................................................................................................................................ 36

Scanning system components ........................................................................................................................ 36

Document feeder ................................................................................................................................................................... 38

Document feeder overview ............................................................................................................................. 38

Electrical parts location .................................................................................................................................... 39

Document feeder drive system ....................................................................................................................... 39

Overview ......................................................................................................................................... 39

Document feeder original drive assembly ................................................................................ 40

Document feeder registration drive assembly ........................................................................ 41

Document feeder feed drive assembly ..................................................................................... 42

Document feeder exit drive assembly ...................................................................................... 42

Original return drive ...................................................................................................................... 43

Hardware conguration ........................................................................................................................................................ 44

Overview ............................................................................................................................................................. 44

Circuit Board Locations ..................................................................................................................................... 45

Formatter (Main) board .................................................................................................................................... 45

Formatter (Main) board .................................................................................................................................... 46

OPE board ........................................................................................................................................................... 47

SMPS (LVPS) board (HP LaserJet MFP M436n/M436dn Printer only) ....................................................... 49

SMPS (LVPS) board (HP LaserJet MFP M436nda Printer only) ................................................................... 50

HVPS board ......................................................................................................................................................... 52

BLU PBA (back light unit) .................................................................................................................................. 55

Document feeder board ................................................................................................................................... 55

Tray 3 accessory board .................................................................................................................................... 57

Sensor location .................................................................................................................................................. 57

2 Removal and replacement .................................................................................................................................................................... 61

For additional service and support ...................................................................................................................................... 63

Removal and replacement strategy ................................................................................................................................... 64

Electrostatic discharge ..................................................................................................................................... 64

Required tools .................................................................................................................................................... 65

Types of screws ................................................................................................................................................. 65

Service approach .................................................................................................................................................................... 65

vi ENWW

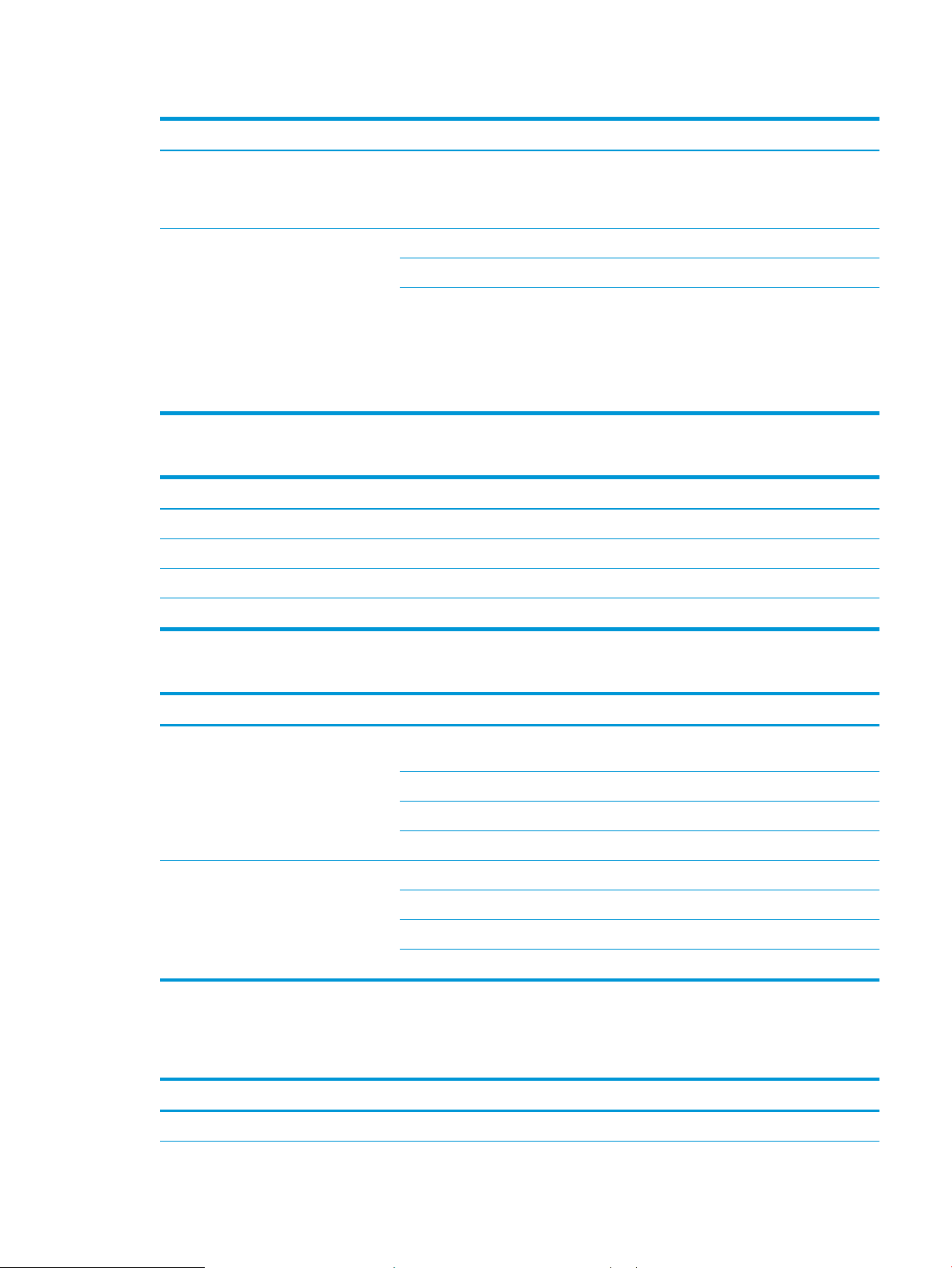

Page 9

Before performing service ............................................................................................................................... 65

Releasing Plastic Latches ................................................................................................................................. 65

After performing service .................................................................................................................................. 65

Post-service test ................................................................................................................................................ 66

Print-quality test ........................................................................................................................... 66

Removal: Toner cartridge ..................................................................................................................................................... 67

Introduction ........................................................................................................................................................ 67

Overview ......................................................................................................................................... 67

Before performing service .......................................................................................................... 67

Required tools ............................................................................................................................... 67

After performing service .............................................................................................................. 67

Post service test ............................................................................................................................ 68

Remove: Toner cartridge .................................................................................................................................. 68

Removal: Transfer roller ....................................................................................................................................................... 71

Introduction ........................................................................................................................................................ 71

Overview ......................................................................................................................................... 71

Before performing service .......................................................................................................... 71

Required tools ............................................................................................................................... 71

After performing service .............................................................................................................. 71

Post service test ............................................................................................................................ 71

Remove: Transfer roller .................................................................................................................................... 71

Removal: Fuser unit ............................................................................................................................................................... 74

Introduction ........................................................................................................................................................ 74

Overview ......................................................................................................................................... 74

Before performing service .......................................................................................................... 74

Required tools ............................................................................................................................... 74

After performing service .............................................................................................................. 74

Post service test ............................................................................................................................ 74

Remove: Fuser unit ........................................................................................................................................... 74

Removal: Imaging unit (drum unit and developer) ........................................................................................................... 77

Introduction ........................................................................................................................................................ 77

Overview ......................................................................................................................................... 77

Before performing service .......................................................................................................... 77

Required tools ............................................................................................................................... 77

After performing service .............................................................................................................. 77

Post service test ............................................................................................................................ 77

Remove: Imaging unit (drum unit and developer) ....................................................................................... 77

Removal: Pickup roller and friction pad .............................................................................................................................. 88

Introduction ........................................................................................................................................................ 88

Overview ......................................................................................................................................... 88

Before performing service .......................................................................................................... 88

ENWW vii

Page 10

Required tools ............................................................................................................................... 88

After performing service .............................................................................................................. 88

Post service test ............................................................................................................................ 88

Remove: Pickup roller and friction pad .......................................................................................................... 88

Removal: MP pickup roller and friction pad ....................................................................................................................... 91

Introduction ........................................................................................................................................................ 91

Overview ......................................................................................................................................... 91

Before performing service .......................................................................................................... 91

Required tools ............................................................................................................................... 91

After performing service .............................................................................................................. 91

Post service test ............................................................................................................................ 91

Remove: MP pickup roller and friction pad .................................................................................................... 91

Removal: Document feeder pickup roller assembly ........................................................................................................ 96

Introduction ........................................................................................................................................................ 96

Overview ......................................................................................................................................... 96

Before performing service .......................................................................................................... 96

Required tools ............................................................................................................................... 96

After performing service .............................................................................................................. 96

Post service test ............................................................................................................................ 96

Remove: Document feeder pickup roller assembly ..................................................................................... 96

Removal: Document feeder friction pad ............................................................................................................................ 98

Introduction ........................................................................................................................................................ 98

Overview ......................................................................................................................................... 98

Before performing service .......................................................................................................... 98

Required tools ............................................................................................................................... 98

After performing service .............................................................................................................. 98

Post service test ............................................................................................................................ 98

Remove: Document feeder friction pad ......................................................................................................... 98

Removal: Rear cover ........................................................................................................................................................... 100

Introduction ...................................................................................................................................................... 100

Overview ...................................................................................................................................... 100

Before performing service ........................................................................................................ 100

Required tools ............................................................................................................................. 100

After performing service ........................................................................................................... 100

Post service test ......................................................................................................................... 100

Remove: Rear cover ........................................................................................................................................ 100

Removal: Front cover .......................................................................................................................................................... 102

Introduction ...................................................................................................................................................... 102

Overview ...................................................................................................................................... 102

Before performing service ........................................................................................................ 102

Required tools ............................................................................................................................. 102

viii ENWW

Page 11

After performing service ........................................................................................................... 102

Post service test ......................................................................................................................... 102

Remove: Front cover ...................................................................................................................................... 102

Removal: Left cover ............................................................................................................................................................ 104

Introduction ...................................................................................................................................................... 104

Overview ...................................................................................................................................... 104

Before performing service ........................................................................................................ 104

Required tools ............................................................................................................................. 104

After performing service ........................................................................................................... 104

Post service test ......................................................................................................................... 104

Remove: Left cover ......................................................................................................................................... 104

Removal: Formatter board ................................................................................................................................................. 106

Introduction ...................................................................................................................................................... 106

Overview ...................................................................................................................................... 106

Before performing service ........................................................................................................ 106

Required tools ............................................................................................................................. 106

After performing service ........................................................................................................... 106

Post service test ......................................................................................................................... 106

Remove: Formatter board ............................................................................................................................. 106

Removal: LVPS board .......................................................................................................................................................... 108

Introduction ...................................................................................................................................................... 108

Overview ...................................................................................................................................... 108

Before performing service ........................................................................................................ 108

Required tools ............................................................................................................................. 108

After performing service ........................................................................................................... 108

Post service test ......................................................................................................................... 108

Remove: LVPS board ...................................................................................................................................... 108

Removal: Front cover open sensor ................................................................................................................................... 110

Introduction ...................................................................................................................................................... 110

Overview ...................................................................................................................................... 110

Before performing service ........................................................................................................ 110

Required tools ............................................................................................................................. 110

After performing service ........................................................................................................... 110

Post service test ......................................................................................................................... 110

Remove: Front cover open sensor ............................................................................................................... 110

Removal: Side unit ............................................................................................................................................................... 112

Introduction ...................................................................................................................................................... 112

Overview ...................................................................................................................................... 112

Before performing service ........................................................................................................ 112

Required tools ............................................................................................................................. 112

After performing service ........................................................................................................... 112

ENWW ix

Page 12

Post service test ......................................................................................................................... 112

Remove: Side unit ........................................................................................................................................... 112

Removal: Side cover-open sensor .................................................................................................................................... 114

Introduction ...................................................................................................................................................... 114

Overview ...................................................................................................................................... 114

Before performing service ........................................................................................................ 114

Required tools ............................................................................................................................. 114

After performing service ........................................................................................................... 114

Post service test ......................................................................................................................... 114

Remove: Side cover-open sensor ................................................................................................................. 114

Removal: Platen cover (M433a/M436n/M436dn only) ................................................................................................. 117

Introduction ...................................................................................................................................................... 117

Overview ...................................................................................................................................... 117

Before performing service ........................................................................................................ 117

Required tools ............................................................................................................................. 117

After performing service ........................................................................................................... 117

Post service test ......................................................................................................................... 117

Remove: Platen cover (M433a/M436n/M436dn only) ............................................................................. 117

Removal: Document feeder unit (optional) ..................................................................................................................... 119

Introduction ...................................................................................................................................................... 119

Overview ...................................................................................................................................... 119

Before performing service ........................................................................................................ 119

Required tools ............................................................................................................................. 119

After performing service ........................................................................................................... 119

Post service test ......................................................................................................................... 119

Remove: Document feeder unit (optional) ................................................................................................. 119

Removal: Document feeder cover .................................................................................................................................... 122

Introduction ...................................................................................................................................................... 122

Overview ...................................................................................................................................... 122

Before performing service ........................................................................................................ 122

Required tools ............................................................................................................................. 122

After performing service ........................................................................................................... 122

Post service test ......................................................................................................................... 122

Remove: Document feeder cover ................................................................................................................. 122

Removal: Document feeder open cover .......................................................................................................................... 125

Introduction ...................................................................................................................................................... 125

Overview ...................................................................................................................................... 125

Before performing service ........................................................................................................ 125

Required tools ............................................................................................................................. 125

After performing service ........................................................................................................... 125

Post service test ......................................................................................................................... 125

x ENWW

Page 13

Remove: Document feeder open cover ....................................................................................................... 125

Removal: Document feeder stacker ................................................................................................................................. 127

Introduction ...................................................................................................................................................... 127

Overview ...................................................................................................................................... 127

Before performing service ........................................................................................................ 127

Required tools ............................................................................................................................. 127

After performing service ........................................................................................................... 127

Post service test ......................................................................................................................... 127

Remove: Document feeder stacker ............................................................................................................. 127

Removal: Document feeder board ................................................................................................................................... 129

Introduction ...................................................................................................................................................... 129

Overview ...................................................................................................................................... 129

Before performing service ........................................................................................................ 129

Required tools ............................................................................................................................. 129

After performing service ........................................................................................................... 129

Post service test ......................................................................................................................... 129

Remove: Document feeder board ................................................................................................................ 129

Removal: Document feeder registration-cover-detect sensor .................................................................................... 131

Introduction ...................................................................................................................................................... 131

Overview ...................................................................................................................................... 131

Before performing service ........................................................................................................ 131

Required tools ............................................................................................................................. 131

After performing service ........................................................................................................... 131

Post service test ......................................................................................................................... 131

Remove: Document feeder registration-cover-detect sensor ................................................................ 131

Removal: Document feeder motor solenoid clutch ....................................................................................................... 133

Introduction ...................................................................................................................................................... 133

Overview ...................................................................................................................................... 133

Before performing service ........................................................................................................ 133

Required tools ............................................................................................................................. 133

After performing service ........................................................................................................... 133

Post service test ......................................................................................................................... 133

Remove: Document feeder motor solenoid clutch ................................................................................... 133

Removal: Document feeder exit idle sensor ................................................................................................................... 138

Introduction ...................................................................................................................................................... 138

Overview ...................................................................................................................................... 138

Before performing service ........................................................................................................ 138

Required tools ............................................................................................................................. 138

After performing service ........................................................................................................... 138

Post service test ......................................................................................................................... 138

Remove: Document feeder exit idle sensor ............................................................................................... 138

ENWW xi

Page 14

Removal: Document feeder exit sensor .......................................................................................................................... 140

Introduction ...................................................................................................................................................... 140

Overview ...................................................................................................................................... 140

Before performing service ........................................................................................................ 140

Required tools ............................................................................................................................. 140

After performing service ........................................................................................................... 140

Post service test ......................................................................................................................... 140

Remove: Document feeder exit sensor ....................................................................................................... 140

Removal: Document feeder length-width sensor .......................................................................................................... 142

Introduction ...................................................................................................................................................... 142

Overview ...................................................................................................................................... 142

Before performing service ........................................................................................................ 142

Required tools ............................................................................................................................. 142

After performing service ........................................................................................................... 142

Post service test ......................................................................................................................... 142

Remove: Document feeder length-width sensor ...................................................................................... 142

Removal: OPE unit ............................................................................................................................................................... 144

Introduction ...................................................................................................................................................... 144

Overview ...................................................................................................................................... 144

Before performing service ........................................................................................................ 144

Required tools ............................................................................................................................. 144

After performing service ........................................................................................................... 144

Post service test ......................................................................................................................... 144

Remove: OPE unit ........................................................................................................................................... 144

Removal: Platen unit ........................................................................................................................................................... 147

Introduction ...................................................................................................................................................... 147

Overview ...................................................................................................................................... 147

Before performing service ........................................................................................................ 147

Required tools ............................................................................................................................. 147

After performing service ........................................................................................................... 147

Post service test ......................................................................................................................... 147

Remove: Platen unit ....................................................................................................................................... 147

Removal: Upper platen ....................................................................................................................................................... 151

Introduction ...................................................................................................................................................... 151

Overview ...................................................................................................................................... 151

Before performing service ........................................................................................................ 151

Required tools ............................................................................................................................. 151

After performing service ........................................................................................................... 151

Post service test ......................................................................................................................... 151

Remove: Upper platen ................................................................................................................................... 151

Removal: CIS unit ................................................................................................................................................................. 154

xii ENWW

Page 15

Introduction ...................................................................................................................................................... 154

Overview ...................................................................................................................................... 154

Before performing service ........................................................................................................ 154

Required tools ............................................................................................................................. 154

After performing service ........................................................................................................... 154

Post service test ......................................................................................................................... 154

Remove: CIS unit ............................................................................................................................................. 154

Removal: Scan drive unit .................................................................................................................................................... 156

Introduction ...................................................................................................................................................... 156

Overview ...................................................................................................................................... 156

Before performing service ........................................................................................................ 156

Required tools ............................................................................................................................. 156

After performing service ........................................................................................................... 156

Post service test ......................................................................................................................... 156

Remove: Scan drive unit ................................................................................................................................ 156

Removal: Scan home-position sensor and cover-open sensor ................................................................................... 158

Introduction ...................................................................................................................................................... 158

Overview ...................................................................................................................................... 158

Before performing service ........................................................................................................ 158

Required tools ............................................................................................................................. 158

After performing service ........................................................................................................... 158

Post service test ......................................................................................................................... 158

Remove: Scan home-position sensor and cover-open sensor ............................................................... 158

Removal: Laser/scanner unit (LSU) ................................................................................................................................... 160

Introduction ...................................................................................................................................................... 160

Overview ...................................................................................................................................... 160

Before performing service ........................................................................................................ 160

Required tools ............................................................................................................................. 160

After performing service ........................................................................................................... 160

Post service test ......................................................................................................................... 160

Remove: Laser/scanner unit (LSU) ............................................................................................................... 160

Removal: Main drive motor ................................................................................................................................................ 162

Introduction ...................................................................................................................................................... 162

Overview ...................................................................................................................................... 162

Before performing service ........................................................................................................ 162

Required tools ............................................................................................................................. 162

After performing service ........................................................................................................... 162

Post service test ......................................................................................................................... 162

Remove: Main drive motor ............................................................................................................................ 162

Removal: Exit motor (MFP M436nda only) ...................................................................................................................... 164

Introduction ...................................................................................................................................................... 164

ENWW xiii

Page 16

Overview ...................................................................................................................................... 164

Before performing service ........................................................................................................ 164

Required tools ............................................................................................................................. 164

After performing service ........................................................................................................... 164

Post service test ......................................................................................................................... 164

Remove: Exit motor (MFP M436nda only) .................................................................................................. 164

Removal: Fuser motor ........................................................................................................................................................ 166

Introduction ...................................................................................................................................................... 166

Overview ...................................................................................................................................... 166

Before performing service ........................................................................................................ 166

Required tools ............................................................................................................................. 166

After performing service ........................................................................................................... 166

Post service test ......................................................................................................................... 166

Remove: Fuser motor ..................................................................................................................................... 166

Removal: Paper empty registration MP sensor .............................................................................................................. 168

Introduction ...................................................................................................................................................... 168

Overview ...................................................................................................................................... 168

Before performing service ........................................................................................................ 168

Required tools ............................................................................................................................. 168

After performing service ........................................................................................................... 168

Post service test ......................................................................................................................... 168

Remove: Paper empty registration MP sensor .......................................................................................... 168

Removal: MP clutch ............................................................................................................................................................. 172

Introduction ...................................................................................................................................................... 172

Overview ...................................................................................................................................... 172

Before performing service ........................................................................................................ 172

Required tools ............................................................................................................................. 172

After performing service ........................................................................................................... 172

Post service test ......................................................................................................................... 172

Remove: MP clutch ......................................................................................................................................... 172

Removal: Registration clutch ............................................................................................................................................. 174

Introduction ...................................................................................................................................................... 174

Overview ...................................................................................................................................... 174

Before performing service ........................................................................................................ 174

Required tools ............................................................................................................................. 174

After performing service ........................................................................................................... 174

Post service test ......................................................................................................................... 174

Remove: Registration clutch ......................................................................................................................... 174

Removal: Fuser fan .............................................................................................................................................................. 177

Introduction ...................................................................................................................................................... 177

Overview ...................................................................................................................................... 177

xiv ENWW

Page 17

Before performing service ........................................................................................................ 177

Required tools ............................................................................................................................. 177

After performing service ........................................................................................................... 177

Post service test ......................................................................................................................... 177

Remove: Fuser fan .......................................................................................................................................... 177

Removal: HVPS board ......................................................................................................................................................... 179

Introduction ...................................................................................................................................................... 179

Overview ...................................................................................................................................... 179

Before performing service ........................................................................................................ 179

Required tools ............................................................................................................................. 179

After performing service ........................................................................................................... 179

Post service test ......................................................................................................................... 179

Remove: HVPS board ..................................................................................................................................... 179

Removal: Temperature humidity sensor ......................................................................................................................... 181

Introduction ...................................................................................................................................................... 181

Overview ...................................................................................................................................... 181

Before performing service ........................................................................................................ 181

Required tools ............................................................................................................................. 181

After performing service ........................................................................................................... 181

Post service test ......................................................................................................................... 181

Remove: Temperature humidity sensor ..................................................................................................... 181

Removal: Developer unit .................................................................................................................................................... 184

Introduction ...................................................................................................................................................... 184

Overview ...................................................................................................................................... 184

Before performing service ........................................................................................................ 184

Required tools ............................................................................................................................. 184

After performing service ........................................................................................................... 184

Post service test ......................................................................................................................... 184

Remove: Developer unit ................................................................................................................................. 184

Removal: SCF (optional Tray 3) ......................................................................................................................................... 194

Introduction ...................................................................................................................................................... 194

Overview ...................................................................................................................................... 194

Before performing service ........................................................................................................ 194

Required tools ............................................................................................................................. 194

After performing service ........................................................................................................... 194

Post service test ......................................................................................................................... 194

Remove: SCF board ......................................................................................................................................... 195

Remove: SCF drive unit .................................................................................................................................. 196

Remove: SCF feed roller ................................................................................................................................. 198

ENWW xv

Page 18

3 Troubleshooting ................................................................................................................................................................................... 199

Control panel ........................................................................................................................................................................ 200

Understanding the status LED ........................................................................................................................................... 201

Clearing jams ........................................................................................................................................................................ 203

Introduction ...................................................................................................................................................... 203

Tray 2 ................................................................................................................................................................ 203

In optional Tray 3 ............................................................................................................................................ 205

In Multi-purpose Tray 1 .................................................................................................................................. 208

Inside the printer ............................................................................................................................................. 209

In the exit area ................................................................................................................................................. 211

In the duplex unit area ................................................................................................................................... 213

Clearing original document jams .................................................................................................................. 215

Original paper jam in front of scanner .................................................................................... 215

Original paper jam inside of scanner ....................................................................................... 217

Original paper jam in exit area of scanner .............................................................................. 220

Original paper jam in scanner duplex path ............................................................................. 222

Firmware upgrades ............................................................................................................................................................. 224

Determine the installed revision of rmware ............................................................................................. 225

Perform a rmware upgrade ........................................................................................................................ 226

HP Embedded Web Server ........................................................................................................ 226

USB Firmware Upgrade ............................................................................................................. 226

Tech Mode ............................................................................................................................................................................. 227

Overview ........................................................................................................................................................... 227

Entering Tech mode ....................................................................................................................................... 227

Tech mode menu ............................................................................................................................................ 227

Tech Mode Menu description ........................................................................................................................ 229

Control Panel Error Messages ........................................................................................................................................... 238

11-2T11, Paper mismatch Tray 2 Load [A4] [Plain] Continue ⊙ Cancel X ............................................ 238

11-2T21, Paper mismatch Tray 3 Load [A4] [Plain] Continue ⊙ Cancel X ............................................ 238

11-2T61, Paper mismatch Tray 1Load [A4] [Plain] Continue ⊙ Cancel X ............................................. 238

A1-1110, Error: #A1-1110 / Motor Failure: #A1-1110. Turn o then on. Call for service if the

problem persists ............................................................................................................................................. 238

A1–5513, Error: #A1–5513 / Motor Failure: #A1-1110. Turn o then on. Call for service if the

problem persists ............................................................................................................................................. 239

A2-1210, Error: #A2-1210 / Fan Failure: #A2-1210. Turn o then on. Call for service if the

problem persists ............................................................................................................................................. 241

A2-2110, Error: #A2-2110 / Fan Failure: #A2-2110. Turn o then on. Call for service if the

problem persists ............................................................................................................................................. 241

A3-3311, A3-3312, A3-3320, A3-3411, A3-3412 Sensor errors .......................................................... 242

C1-1110, C1-111A Toner errors ................................................................................................................... 243

C1-1140, C1-1160, C1-1170 Toner errors ................................................................................................. 244

xvi ENWW

Page 19

C1-1313, C1-1314 Errors .............................................................................................................................. 245

C1-1411 Toner Not Installed / Toner cartridge is not installed. Install it ............................................... 247

C1-1512, Toner Not Compatible / Toner cartridge is not compatible. Check guide ............................. 247

C1-1711, C1-1712 Errors .............................................................................................................................. 248

C3-1110, Prepare IMG. Unit / Prepare new imaging unit ......................................................................... 248

C3-1140, C3-1150, C3-1170 Imaging unit errors ..................................................................................... 249

C3-1312, C3-1411, C3-1414 Imaging unit errors ..................................................................................... 249

C3-1512, IMG. Not compatible / Imaging unit is not compatible. Check guide ..................................... 250

C3-1711, C3-1712 Imaging unit errors ...................................................................................................... 251

C9-2110, C9-2120, Prepare TR. Roller / Prepare with new transfer roller ........................................... 252

C9-2220, Error: #C9-2220 / TR Failure: #C9-2220. Install TR roller again ........................................... 252

H1-1210, Paper jam in tray 2 ....................................................................................................................... 254

H1-1220 Tray 2 door is open. Close it ......................................................................................................... 254

H1-1230, Error: #H1-1230 / Input System Failure: #H1-1230. Check tray 3 connection .................. 255

H1-1252, H1-1254, Paper empty in tray 2 / Paper is empty in tray 3. Load paper ............................ 255

M1-1110, Paper jam in tray 1 ....................................................................................................................... 255