Page 1

Page 2

Page 3

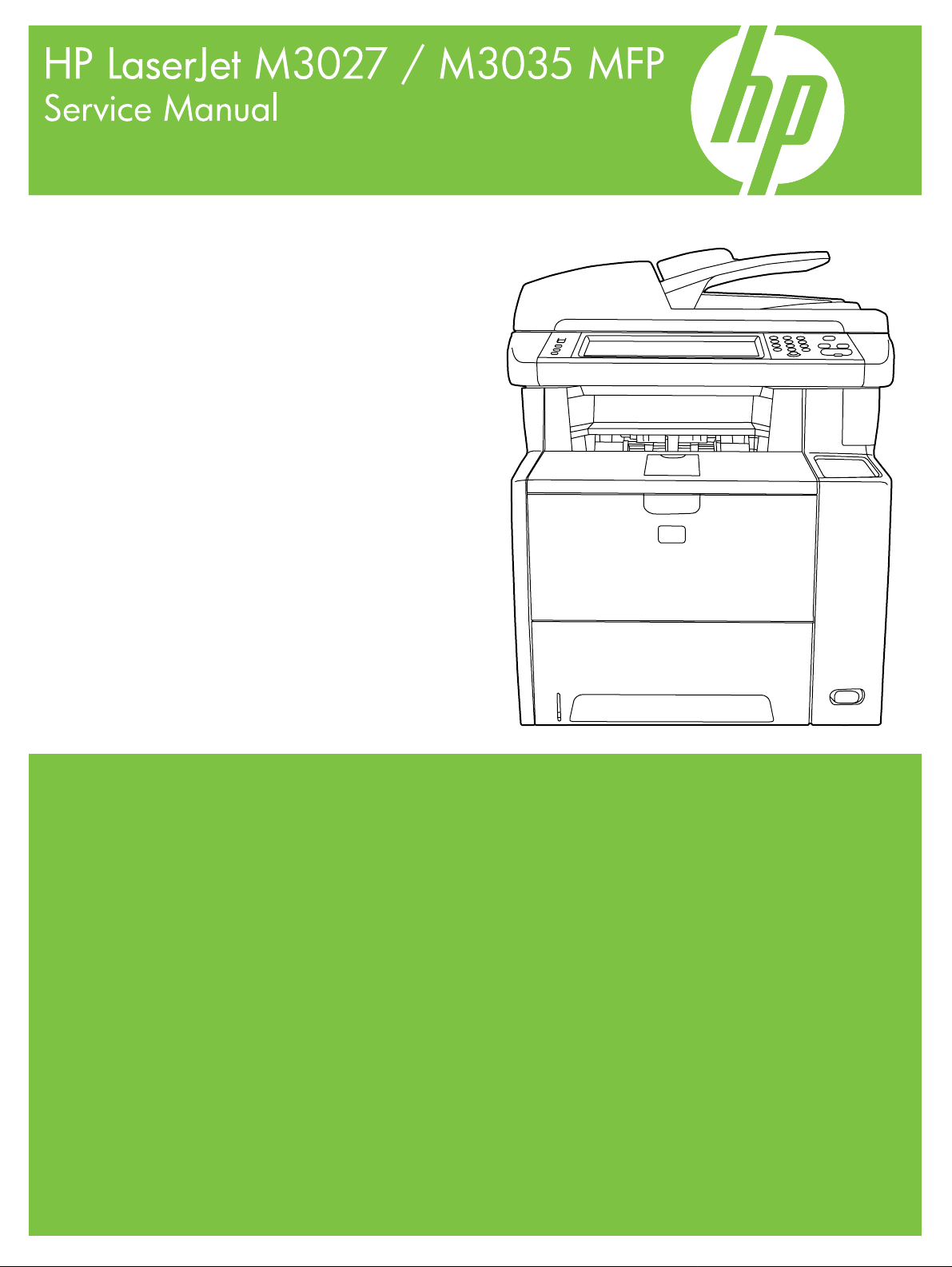

HP LaserJet M3027/M3035 Multifunction

Service Manual

Page 4

Copyright and License

© 2006 Copyright Hewlett-Packard

Development Company, L.P.

Reproduction, adaptation, or translation

without prior written permission is prohibited,

except as allowed under the copyright laws.

The information contained herein is subject

to change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products

and services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Part number: CB414-90940

Edition 1, 10/2006

Trademark Credits

®

Adobe

, Acrobat®, and PostScript® are

trademarks of Adobe Systems Incorporated.

®

Intel

and Pentium® are trademarks or

registered trademarks of Intel Corporation or

its subsidiaries in the United States and other

countries.

Linux is a U.S. registered trademark of Linus

Torvalds.

Microsoft

®

, Windows®, and Windows NT

®

are U.S. registered trademarks of Microsoft

Corporation.

®

UNIX

is a registered trademark of The Open

Group.

ENERGY STAR

®

logo

are U.S. registered marks of the United

®

and the ENERGY STAR

States Environmental Protection Agency.

Page 5

Table of contents

1 Product Information

Chapter contents .................................................................................................................................. 1

Device configurations ........................................................................................................................... 2

Features ............................................................................................................................................... 3

Walkaround .......................................................................................................................................... 5

Device parts ......................................................................................................................... 5

Interface ports ...................................................................................................................... 6

Device software .................................................................................................................................... 7

Supported operating systems .............................................................................................. 7

Minimum system requirements ............................................................................................ 7

Supported printer drivers ..................................................................................................... 8

Select the correct printer driver ............................................................................................ 9

Universal printer drivers ...................................................................................... 9

Driver Autoconfiguration ...................................................................................... 9

Update Now ........................................................................................................ 9

HP Driver Preconfiguration ................................................................................. 9

Priority for print settings ..................................................................................................... 10

Open the printer drivers ..................................................................................................... 11

Software for Macintosh computers .................................................................................... 12

Remove software from Macintosh operating systems ...................................... 12

Utilities ............................................................................................................................... 13

HP Web Jetadmin ............................................................................................. 13

Embedded Web server ..................................................................................... 13

HP Easy Printer Care software ......................................................................... 14

Supported operating systems ........................................................... 14

Supported browsers ......................................................................... 14

Other components and utilities .......................................................................... 14

Media specifications ........................................................................................................................... 15

General guidelines for media ............................................................................................. 15

Paper to avoid ................................................................................................... 16

Paper that can damage the device ................................................................... 16

General media specifications ............................................................................ 17

Select print media .............................................................................................................. 17

Supported media sizes ...................................................................................... 18

Supported media types ..................................................................................... 19

2 Installation and configuration

Chapter contents ................................................................................................................................ 21

Site preparation .................................................................................................................................. 22

ENWW iii

Page 6

Install trays ......................................................................................................................................... 23

Install supplies .................................................................................................................................... 27

Install accessories .............................................................................................................................. 30

3 Maintenance

Chapter contents ................................................................................................................................ 37

Manage supplies ................................................................................................................................ 38

Clean the device ................................................................................................................................. 40

Management tools .............................................................................................................................. 45

Location specifications ....................................................................................................... 22

Operating environment ..................................................................................................... 22

Load tray 1 (multipurpose tray) .......................................................................................... 23

Load tray 2 and optional tray 3 ......................................................................................... 25

Configure trays .................................................................................................................. 26

Supply replacement guidelines .......................................................................................... 27

Change the print cartridge ................................................................................................. 27

Install memory ................................................................................................................... 30

Install device memory ....................................................................................... 30

Check DIMM installation .................................................................................................... 34

Enable memory for Windows ............................................................................................. 34

Use HP Jetdirect print server cards ................................................................................... 35

Install an HP Jetdirect print server card ............................................................ 35

Remove an HP Jetdirect print server card ........................................................ 36

Supplies life ....................................................................................................................... 38

Approximate print-cartridge replacement intervals ............................................................ 38

Manage the print cartridge ................................................................................................. 39

Print-cartridge storage ....................................................................................... 39

Use genuine HP print cartridges ....................................................................... 39

HP policy on non-HP print cartridges ................................................................ 39

Print-cartridge authentication ............................................................................ 39

HP fraud hotline and Web site .......................................................................... 39

Clean the exterior .............................................................................................................. 40

Clean the ADF ................................................................................................................... 40

Clean the scanner lid backing ............................................................................................ 42

Clean the scanner glass .................................................................................................... 43

Clean the fuser .................................................................................................................. 44

Clean spilled toner ............................................................................................................. 44

Use information pages ....................................................................................................... 45

Use the HP Easy Printer Care software ............................................................................ 47

Open the HP Easy Printer Care software ......................................................... 47

HP Easy Printer Care software sections ........................................................... 48

Use the embedded Web server ......................................................................................... 49

Open the embedded Web server by using a network connection ..................... 49

Embedded Web server sections ....................................................................... 50

Use HP Web Jetadmin software ........................................................................................ 52

Use the HP Printer Utility for Macintosh ............................................................................ 52

Open the HP Printer Utility ................................................................................ 52

HP Printer Utility features .................................................................................. 53

4 Theory of operation

iv ENWW

Page 7

Chapter contents ................................................................................................................................ 55

Basic operation ................................................................................................................................... 56

ADF/scanner system ......................................................................................................... 57

ADF ................................................................................................................... 57

Sensors in the ADF .......................................................................... 57

ADF paper path ................................................................................ 57

Scanner ............................................................................................................. 58

Formatter ........................................................................................................................... 59

Engine control unit (ECU) .................................................................................................. 60

Pickup/feed/delivery system .............................................................................................. 62

Laser/scanner system ........................................................................................................ 63

Image-formation system .................................................................................................... 64

Step 1: Primary charging ................................................................................... 65

Step 2: Laser beam exposure ........................................................................... 65

Step 3: Developing ............................................................................................ 65

Step 4: Transfer ................................................................................................ 66

Step 5: Separation ............................................................................................ 66

Step 6: Fusing ................................................................................................... 67

Step 7: Drum cleaning ....................................................................................... 67

Internal components ........................................................................................................................... 68

Timing ................................................................................................................................................. 69

Print cartridge memory system ........................................................................................................... 73

5 Removal and replacement

Chapter contents ................................................................................................................................ 75

Introduction ......................................................................................................................................... 77

Removal and replacement strategy .................................................................................. 77

Electrostatic discharge ....................................................................................................... 77

User-replaceable parts ...................................................................................................... 77

Required tools .................................................................................................................... 78

Before performing service .................................................................................................. 78

Parts removal order ........................................................................................................... 79

Automatic document feeder (ADF) and scanner assemblies ............................................................. 80

ADF assembly ................................................................................................................... 80

Scanner assembly ............................................................................................................. 90

Covers ................................................................................................................................................ 94

Right-side cover ................................................................................................................. 94

Formatter shield ................................................................................................................. 95

Fax cover ........................................................................................................................... 96

Left-side cover ................................................................................................................... 97

Legal cover (dust cover) .................................................................................................. 100

Back cover ....................................................................................................................... 101

I/O cover .......................................................................................................................... 103

Fax rail ............................................................................................................................. 104

Top cover ......................................................................................................................... 105

Front, right cover .............................................................................................................. 109

ADF cover ......................................................................................................... 80

ADF input tray ................................................................................................... 82

Control panel ..................................................................................................... 84

ADF ................................................................................................................... 87

ENWW v

Page 8

Fax accessory .................................................................................................................................. 111

Disk drive .......................................................................................................................................... 113

Formatter .......................................................................................................................................... 116

Stapler .............................................................................................................................................. 117

Stapler power-supply ........................................................................................................................ 123

Right-side fan ................................................................................................................................... 128

Engine control unit (ECU) ................................................................................................................. 131

Left-side riser .................................................................................................................................... 138

Fuser ................................................................................................................................................ 139

Laser/scanner ................................................................................................................................... 142

Access plate ..................................................................................................................................... 144

Oblique-roller assembly .................................................................................................................... 146

Left-side fan ...................................................................................................................................... 148

High-voltage power supply (HVPS) .................................................................................................. 149

Feed-guide assembly ....................................................................................................................... 156

Main motor ....................................................................................................................................... 159

Gear assembly ................................................................................................................................. 162

Reinstallation notes for the gear assembly ...................................................................................... 165

Tray 1 solenoid ................................................................................................................................. 166

Tray 2 solenoid ................................................................................................................................. 167

Pickup assembly .............................................................................................................................. 168

Tray 1 media-present sensor and top-of-page sensor ..................................................................... 173

E-label reader (memory tag) ............................................................................................................ 175

Face-down-roller shaft ...................................................................................................................... 177

Cartridge door .................................................................................................................................. 179

Transfer roller ................................................................................................................................... 182

Registration assembly ...................................................................................................................... 183

Tray 1 pickup roller ........................................................................................................................... 186

Tray 2 pickup roller ........................................................................................................................... 187

Separation pad ................................................................................................................................. 189

6 Troubleshooting

Chapter contents .............................................................................................................................. 191

Troubleshooting process .................................................................................................................. 192

Troubleshooting tree ........................................................................................................ 192

Troubleshooting flowchart ................................................................................................ 193

1. Does the control-panel display show READY? ........................................... 193

2. Can you print a configuration page? .......................................................... 194

3. Does the device copy? ................................................................................ 195

4. Does the device send a fax? ....................................................................... 196

5. Does the device receive a fax? ................................................................... 197

6. Can you print from a program? ................................................................... 198

7. Does the job print as expected? .................................................................. 199

8. Does the device select the correct trays? ................................................... 200

Control-panel messages .................................................................................................................. 201

Control-panel message types .......................................................................................... 201

Resolve control-panel messages ..................................................................................... 201

Clear jams ........................................................................................................................................ 214

Common causes of jams ................................................................................................. 214

Jam locations ................................................................................................................... 215

vi ENWW

Page 9

Jam detection .................................................................................................................. 216

Clear jams from the ADF ................................................................................................. 217

Clear jams from the print-cartridge area .......................................................................... 219

Clear jams from the input-tray areas ............................................................................... 220

Clear jams from the duplexer ........................................................................................... 222

Clear jams from the output-bin areas .............................................................................. 223

Interface troubleshooting ................................................................................................................. 225

Communications checks .................................................................................................. 225

LAN hardware test ........................................................................................................... 225

Service mode functions .................................................................................................................... 226

Boot-up key sequences ................................................................................................... 226

Low-level boot-up key sequence for selecting a language, performing a cold

reset, and enabling and disabling embedded LAN ......................................... 227

Medium-level boot-up key sequence for initializing disks ............................... 227

High-level boot-up key sequence for NVRAM initialization, manufacturing,

and skipping disk-load and calibration ............................................................ 227

Service menu ................................................................................................................... 228

Service ID ........................................................................................................................ 228

Restore the service ID ..................................................................................... 229

Convert the service ID to an actual date ......................................................... 229

Troubleshooting tools ....................................................................................................................... 230

Control-panel menus ....................................................................................................... 230

Print Quality menu ........................................................................................... 230

Troubleshooting menu .................................................................................... 231

Early-boot diagnostic test ................................................................................................ 233

Test pages ....................................................................................................................... 234

Engine-test page ............................................................................................. 234

Formatter test page ......................................................................................... 235

Embedded Web server ................................................................................................... 235

Gaining access to the embedded Web server ................................................ 235

Information tab ................................................................................ 235

Settings tab ..................................................................................... 236

Networking tab ............................................................................... 236

Other links ...................................................................................... 236

Image defect ruler ............................................................................................................ 238

Firmware updates and recovery ....................................................................................................... 239

Determine the current level of firmware ........................................................................... 239

Download the new firmware from the HP Web site ......................................................... 239

Transfer the new firmware to the device .......................................................................... 240

Use FTP to upgrade the firmware on a network connection ........................... 240

Use HP Web Jetadmin to upgrade the firmware ............................................. 241

Use MS-DOS commands to upgrade the firmware ......................................... 242

Upgrade the HP Jetdirect firmware .................................................................................. 242

Troubleshoot general printing problems ........................................................................................... 243

Troubleshoot media-handling problems ........................................................................................... 246

Multiple pages feed .......................................................................................................... 246

Pages are wrinkled or folded ........................................................................................... 246

Pages are skewed ........................................................................................................... 247

Troubleshoot print-quality problems ................................................................................................ 248

Print-quality checklist ....................................................................................................... 248

ENWW vii

Page 10

Image-defect examples ................................................................................................... 249

Light print (partial page) .................................................................................................. 250

Light print (entire page) ................................................................................................... 251

Specks ............................................................................................................................. 251

Dropouts .......................................................................................................................... 252

Lines ................................................................................................................................ 252

Gray background ............................................................................................................ 253

Toner smear ................................................................................................................... 253

Loose toner ..................................................................................................................... 254

Repeating defects ........................................................................................................... 254

Repeating image ............................................................................................................. 255

Misformed characters ...................................................................................................... 255

Page skew ....................................................................................................................... 256

Curl or wave .................................................................................................................... 256

Wrinkles or creases ......................................................................................................... 257

Vertical white lines ........................................................................................................... 257

Tire tracks ....................................................................................................................... 258

White spots on black ....................................................................................................... 258

Scattered lines ................................................................................................................ 259

Blurred print .................................................................................................................... 259

Random image repetition ................................................................................................. 260

Diagrams .......................................................................................................................................... 261

Device component locations ............................................................................................ 261

Main assemblies ............................................................................................. 261

Main parts ....................................................................................................... 262

Sensors and switches ..................................................................................... 263

Motors, fans, and solenoids ............................................................................ 264

PCAs ............................................................................................................... 265

Wiring diagrams ............................................................................................................... 266

7 Parts and diagrams

Chapter contents .............................................................................................................................. 269

Ordering parts and supplies ............................................................................................................. 270

Parts ................................................................................................................................ 270

Related documentation and software .............................................................................. 270

Supplies ........................................................................................................................... 270

Consumables and accessories ........................................................................................................ 271

Consumables and accessories ........................................................................................ 271

ADF/scanner assembly .................................................................................................................... 272

Covers .............................................................................................................................................. 274

Internal components ......................................................................................................................... 276

Tray 2 pickup assembly .................................................................................................................... 290

Alphabetical parts list ....................................................................................................................... 292

Numerical parts list ........................................................................................................................... 302

Appendix A Supplies and accessories

Order parts, accessories, and supplies ............................................................................................ 314

Order directly from HP ..................................................................................................... 314

Order through service or support providers ..................................................................... 314

viii ENWW

Page 11

Order directly through the embedded Web server (for printers that are connected to a

network) ........................................................................................................................... 314

Order directly through the HP Easy Printer Care software .............................................. 314

Part numbers .................................................................................................................................... 315

Paper-handling accessories ............................................................................................ 315

Print cartridge .................................................................................................................. 315

Memory ............................................................................................................................ 315

Cables and interfaces ...................................................................................................... 315

Stapler accessories ......................................................................................................... 316

Print media ....................................................................................................................... 316

Appendix B Service and support

Hewlett-Packard limited warranty statement .................................................................................... 319

Customer self repair warranty service .............................................................................................. 320

Print cartridge limited warranty statement ........................................................................................ 320

HP Customer Care ........................................................................................................................... 322

Online Services ................................................................................................................ 322

Telephone support ........................................................................................................... 322

Software utilities, drivers, and electronic information ....................................................... 322

HP direct ordering for accessories or supplies ................................................................ 322

HP service information ..................................................................................................... 322

HP service agreements ................................................................................................... 322

HP Easy Printer Care software ........................................................................................ 323

HP support and information for Macintosh computers ..................................................... 323

HP maintenance agreements ........................................................................................................... 324

On-site service agreements ............................................................................................. 324

Next-day on-site service .................................................................................. 324

Weekly (volume) on-site service ..................................................................... 324

Repacking the device ...................................................................................................... 324

Extended warranty ........................................................................................................... 325

Appendix C Specifications

Physical specifications ..................................................................................................................... 328

Electrical specifications .................................................................................................................... 328

Acoustic emissions ........................................................................................................................... 329

Operating environment ..................................................................................................................... 329

Appendix D Regulatory information

FCC regulations ............................................................................................................................... 332

Environmental product stewardship program ................................................................................... 333

Protecting the environment .............................................................................................. 333

Ozone production ............................................................................................................ 333

Power consumption ......................................................................................................... 333

Toner consumption .......................................................................................................... 333

Paper use ........................................................................................................................ 333

Plastics ............................................................................................................................ 333

HP LaserJet print supplies ............................................................................................... 333

HP print supplies returns and recycling program information .......................................... 334

Paper ............................................................................................................................... 334

ENWW ix

Page 12

Material restrictions .......................................................................................................... 33 4

Disposal of waste equipment by users in private households in the European Union .... 335

Material Safety Data Sheet (MSDS) ................................................................................ 335

For more information ....................................................................................................... 335

Telecom statement ........................................................................................................................... 337

Declaration of conformity .................................................................................................................. 338

Safety statements ............................................................................................................................. 339

Laser safety ..................................................................................................................... 339

Canadian DOC regulations .............................................................................................. 339

VCCI statement (Japan) .................................................................................................. 339

Power cord statement (Japan) ......................................................................................... 339

EMI statement (Korea) ..................................................................................................... 339

EMI statement (Taiwan) ................................................................................................... 340

Laser statement for Finland ............................................................................................. 340

Appendix E Working with memory and print server cards

Overview .......................................................................................................................................... 342

Glossary ........................................................................................................................................................... 343

Index ................................................................................................................................................................. 345

x ENWW

Page 13

1 Product Information

Chapter contents

Device configurations

●

Features

●

Walkaround

●

Device software

●

Media specifications

●

ENWW Chapter contents 1

Page 14

Device configurations

HP LaserJet M3027 HP LaserJet M3027x HP LaserJet M3035 HP LaserJet M3035xs

Prints up to 27 pages-per-

●

minute (ppm) on letter-sized

media, and up to 25 ppm on

A4–sized media

256 megabytes (MB) total of

●

random access memory

(RAM), upgradable up to

512 MB

Internal 40 gigabyte (GB) or

●

larger hard disk

100-sheet multipurpose tray

●

(tray 1), 500-sheet input tray

(tray 2), 50-sheet automatic

document feeder (ADF),

and 250-sheet output bin

Hi-Speed universal serial

●

bus (USB) 2.0 port and

enhanced input/output

(EIO) slot

HP Jetdirect embedded

●

print server for Ethernet

10/100Base-T network

One open dual inline

●

memory module (DIMM)

slot

HP LaserJet M3027, plus:

Automatic two-sided

●

printing accessory

33.6 kpbs analog fax

●

Prints up to 35 ppm on

●

letter-sized media, and up to

33 ppm on A4–sized media

256 MB total RAM,

●

upgradable up to 512 MB

Internal 40 GB or larger hard

●

disk

100-sheet tray 1, 500-sheet

●

tray 2, 50-sheet ADF, and

250-sheet output bin

Hi-Speed USB 2.0 port and

●

EIO slot

HP Jetdirect embedded

●

print server for Ethernet

10/100Base-T network

One open DIMM slot

●

Automatic two-sided

●

printing accessory

HP LaserJet M3035, plus:

33.6 kpbs analog fax

●

20-sheet convenience

●

stapler

500-sheet input tray

●

(tray 3)

2 Chapter 1 Product Information ENWW

Page 15

Features

Feature Description

Performance

User interface

Printer drivers

Resolution

Storage features

Fonts

400 MHz processor

●

Control-panel help

●

Windows® and Macintosh printer drivers

●

Embedded Web server to gain access to support and to order supplies (administrator tool for network-connected

●

models only)

HP Easy Printer Care software (a Web-based status and troubleshooting tool)

●

HP PCL 5

●

HP PCL 6

●

HP postscript level 3 emulation

●

FastRes 1200—produces 1200-dots-per-inch (dpi) print quality for fast, high-quality printing of business text and

●

graphics

ProRes 1200—produces 1200-dpi printing for the best quality in line art and graphic images

●

Internal 40 GB or larger hard drive

●

Fonts, forms, and other macros

●

Job retention

●

93 internal fonts available for PCL

●

80 printer-matching screen fonts in TrueType format available with the software solution

●

Accessories

Connectivity

Environmental

features

Supplies

Accessibility

Additional fonts can be added.

●

Optional 500-sheet input tray (tray 3) (standard on the HP LaserJet M3035xs MFP)

●

100-pin 133 MHz dual inline memory modules (DIMMs)

●

Hi-Speed USB 2.0 connection

●

HP Jetdirect full-featured embedded print server

●

HP Web Jetadmin software

●

Enhanced input/output (EIO) slot

●

Foreign interface harness (FIH) port for attaching optional third-party paper-handling devices

●

Sleep mode setting

●

ENERGY STAR® qualified

●

The supplies status page contains information about toner level, page count, and estimated pages remaining.

●

The product checks for an authentic HP print cartridge at cartridge installation.

●

Internet-enabled supply-ordering capabilities (using HP Easy Printer Care software)

●

The online user guide is compatible with text screen-readers.

●

The print cartridge can be installed and removed by using one hand.

●

ENWW Features 3

Page 16

Feature Description

All doors and covers can be opened by using one hand.

●

Media can be loaded in tray 1 by using one hand.

●

4 Chapter 1 Product Information ENWW

Page 17

Walkaround

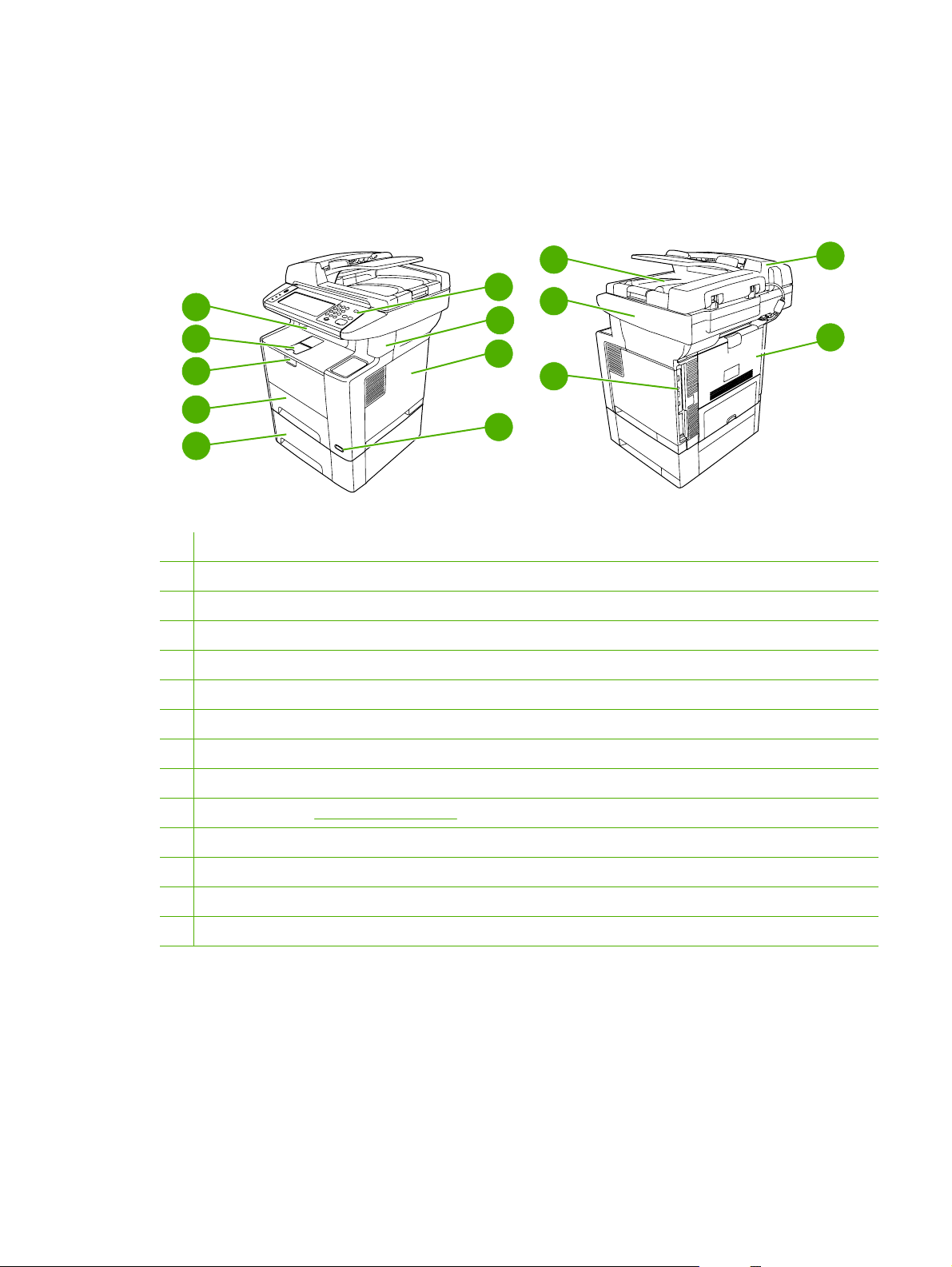

Device parts

Before using the product, familiarize yourself with its components.

12

6

5

11

7

4

8

3

10

2

9

1

1 Optional tray 3

2 Tray 2

3 Tray 1 (pull to open)

4 Latch to open the front door (provides access to the print cartridge)

5 Top output bin

6 Control panel

13

14

7 Convenience stapler

8 Right-side cover (provides access to DIMMs)

9 On/off switch

10 Interface ports (see Interface ports on page 6)

11 Scanner assembly

12 ADF output bin

13 Automatic document feeder (ADF)

14 Rear output bin (pull to open)

ENWW Walkaround 5

Page 18

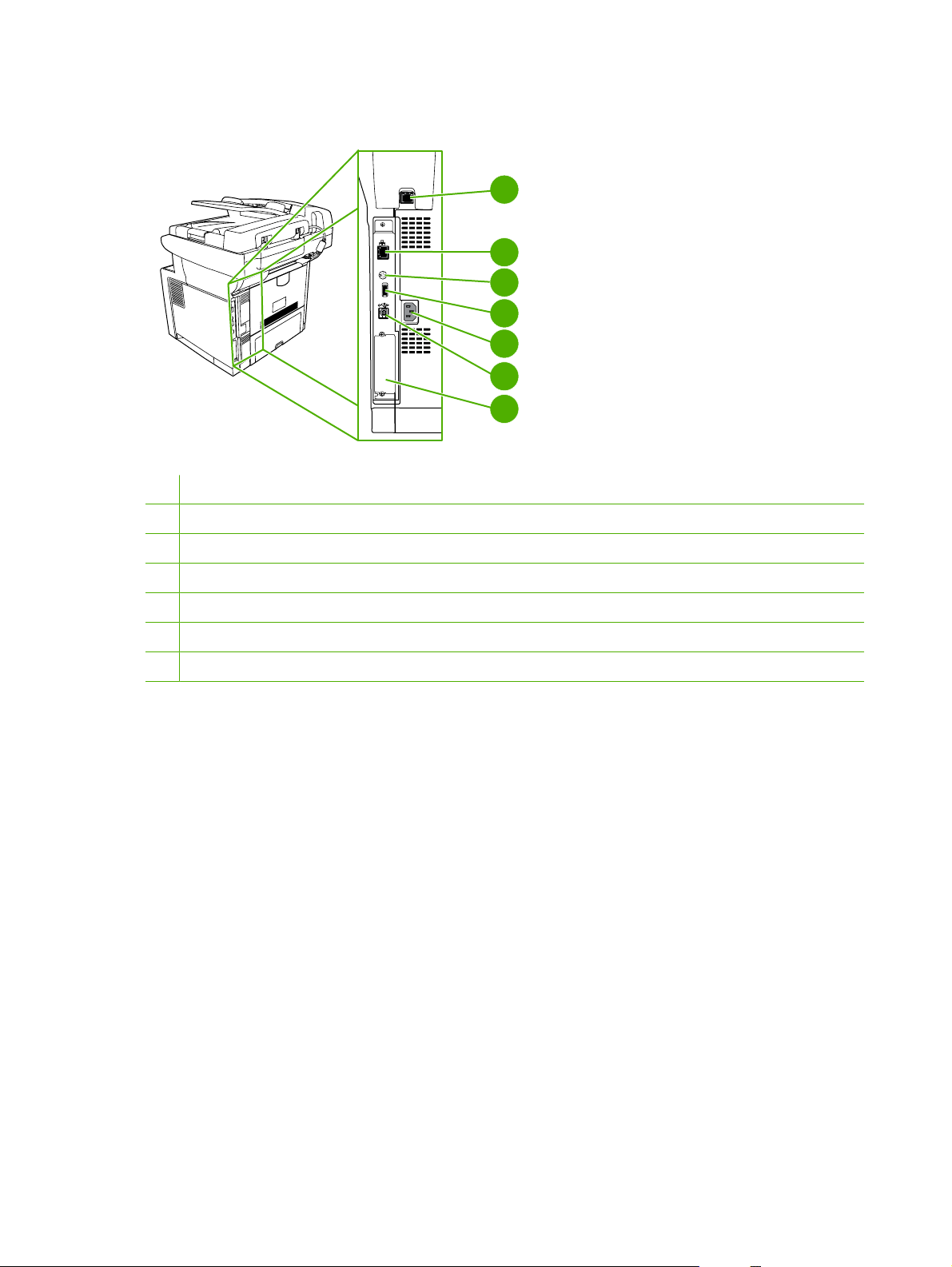

Interface ports

1 Fax port (HP LaserJet M3027x and HP LaserJet M3035xs only)

2 Network connection

3 Foreign interface harness (FIH) port

1

2

3

4

5

6

7

4 Type A Hi-Speed USB 2.0 connection for adding accessories

5 Power connection

6 Type B Hi-Speed USB 2.0 connection for printing

7 EIO slot

6 Chapter 1 Product Information ENWW

Page 19

Device software

The printing-system software is included with the device. See the getting started guide for installation

instructions.

The printing system includes software for end users and network administrators, and printer drivers for

access to the device features and communication with the computer.

NOTE For a list of printer drivers and updated HP printer software, go to www.hp.com/go/

LJM3027mfp_software or www.hp.com/go/LJM3035mfp_software.

Supported operating systems

The device supports the following operating systems:

Full software installation

Windows XP (32-bit and 64-bit)

●

Windows Server 2003 (32-bit and 64-bit)

●

Windows 2000

●

Mac OS X V10.2.8, V10.3, V10.4 and later

●

NOTE For Mac OS V10.4 and later, PPC and Intel Core Processor Macs are supported.

Minimum system requirements

In order to install and use the device software, your computer must meet the following minimum

requirements:

Windows requirements

Pentium II (233 MHz) processor

●

64 MB of RAM

●

35 MB of disk space

●

Printer driver only

Linux (Web only)

●

UNIX model scripts (Web only)

●

SVGA 800x600 16-bit color monitor

●

Macintosh requirements

G3, G4, or G5 PowerPC processor

●

128 MB of RAM

●

30 to 50 MB of disk space

●

ENWW Device software 7

Page 20

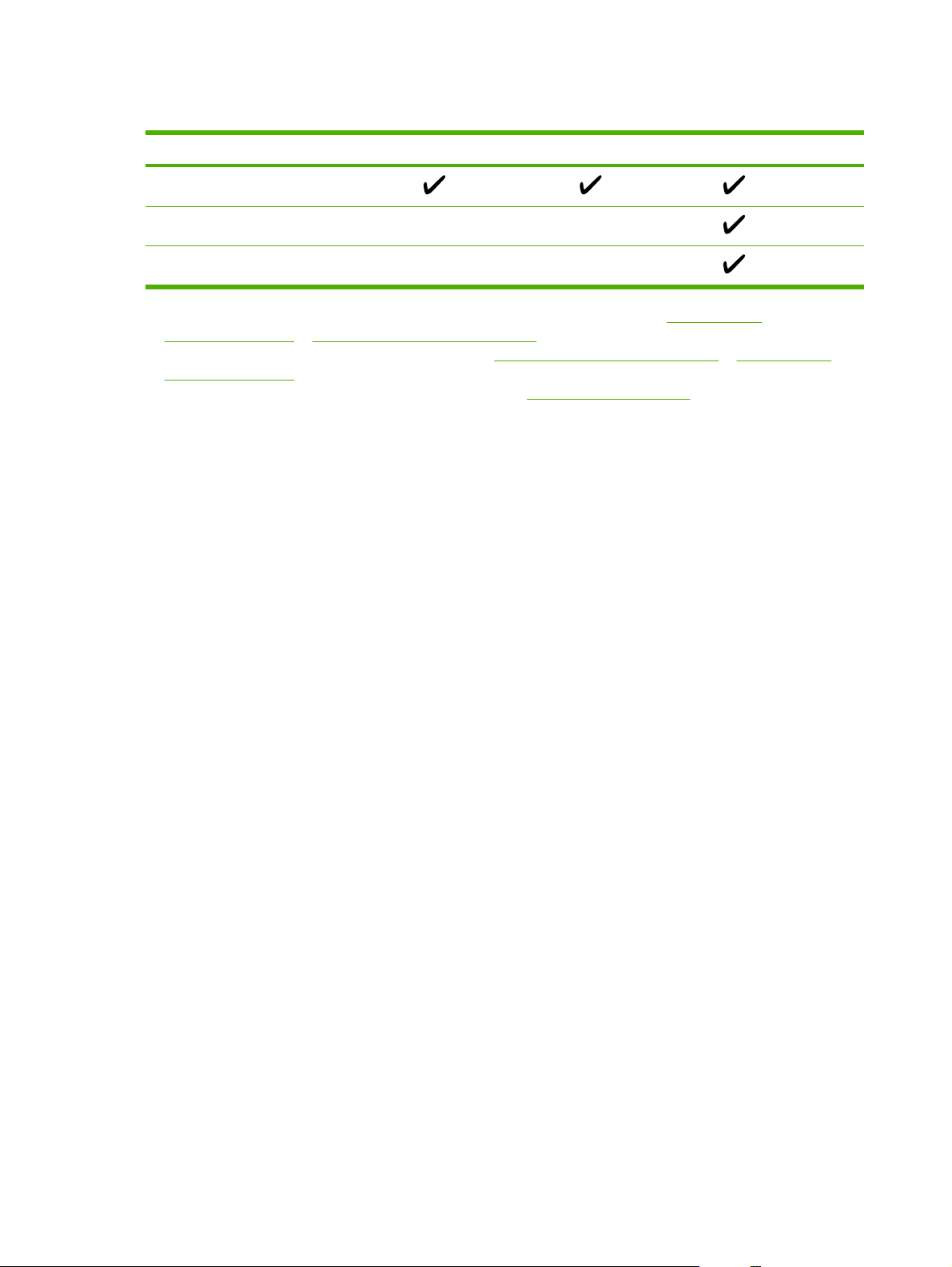

Supported printer drivers

Operating system

Windows

2,3

1

PCL 5 PCL 6 PS level 3 emulation

Mac OS X V10.2 and later

4

Linux

1

Not all device features are available from all drivers or operating systems.

2

For Windows 2000 and Windows XP (32-bit and 64-bit), download the PCL 5 driver from www.hp.com/go/

LJM3027mfp_software or www.hp.com/go/LJM3035mfp_software.

3

For Windows XP (64-bit), download the PCL 6 driver from www.hp.com/go/LJM3027mfp_software or www.hp.com/go/

LJM3035mfp_software.

4

For Linux, download the postscript level 3 emulation driver from www.hp.com/go/linuxprinting.

The printer drivers include online Help that has instructions for common printing tasks and also describes

the buttons, checkboxes, and drop-down lists that are in the printer driver.

8 Chapter 1 Product Information ENWW

Page 21

Select the correct printer driver

Printer drivers allow you to gain access to the device features and allow the computer to communicate

with the device (using a printer language). Check the installation notes and readme files on the device

CD for additional software and languages.

The device uses the PCL 5, PCL 6, and HP postscript level 3 emulation printer description language

(PDL) drivers.

Use the PCL 6 printer driver for the best overall performance.

●

Use the PCL 5 printer driver for general office printing.

●

Use the HP postscript level 3 emulation driver for printing from postscript level 3 emulation needs,

●

or for postscript flash font support.

Universal printer drivers

The HP Universal Print Driver Series for Windows includes separate HP postscript level 3 emulation

and HP PCL 5 versions of a single driver that provides access to almost any HP device while providing

system administrator with tools to manage devices more effectively. The Universal Print Driver is

included on the device CD, under the Optional Software section. For more information, go to

www.hp.com/go/universalprintdriver.

Driver Autoconfiguration

The HP LaserJet PCL 5, PCL 6, and PS level 3 emulation drivers for Windows 2000 and Windows XP

feature automatic discovery and driver configuration for device accessories at the time of installation.

Some accessories that the Driver Autoconfiguration supports are the duplexing unit, optional paper

trays, and dual inline memory modules (DIMMs).

Update Now

If you have modified the device configuration since installation, the driver can be automatically updated

with the new configuration. In the Properties dialog box (see

on the Device Settings tab, click the Update Now button to update the driver.

HP Driver Preconfiguration

HP Driver Preconfiguration is a software architecture and set of tools that you can use to customize and

distribute HP software in managed corporate printing environments. Using HP Driver Preconfiguration,

information technology (IT) administrators can preconfigure the printing and default settings for

HP printer drivers before installing the drivers in the network environment. For more information, see

the HP Driver Preconfiguration Support Guide, which is available at

Open the printer drivers on page 11),

www.hp.com/go/hpdpc_sw.

ENWW Device software 9

Page 22

Priority for print settings

Changes to print settings are prioritized depending on where the changes are made:

NOTE The names of commands and dialog boxes might vary depending on your software

program.

Page Setup dialog box: Click Page Setup or a similar command on the File menu of the program

●

you are working in to open this dialog box. Settings changed here override settings changed

anywhere else.

Print dialog box: Click Print, Print Setup, or a similar command on the File menu of the program

●

you are working in to open this dialog box. Settings changed in the Print dialog box have a lower

priority and do not override changes made in the Page Setup dialog box.

Printer Properties dialog box (printer driver): Click Properties in the Print dialog box to open

●

the printer driver. Settings changed in the Printer Properties dialog box do not override settings

anywhere else in the printing software.

Default printer driver settings: The default printer driver settings determine the settings used in

●

all print jobs, unless settings are changed in the Page Setup, Print, or Printer Properties dialog

boxes.

Printer control panel settings: Settings changed at the printer control panel have a lower priority

●

than changes made anywhere else.

10 Chapter 1 Product Information ENWW

Page 23

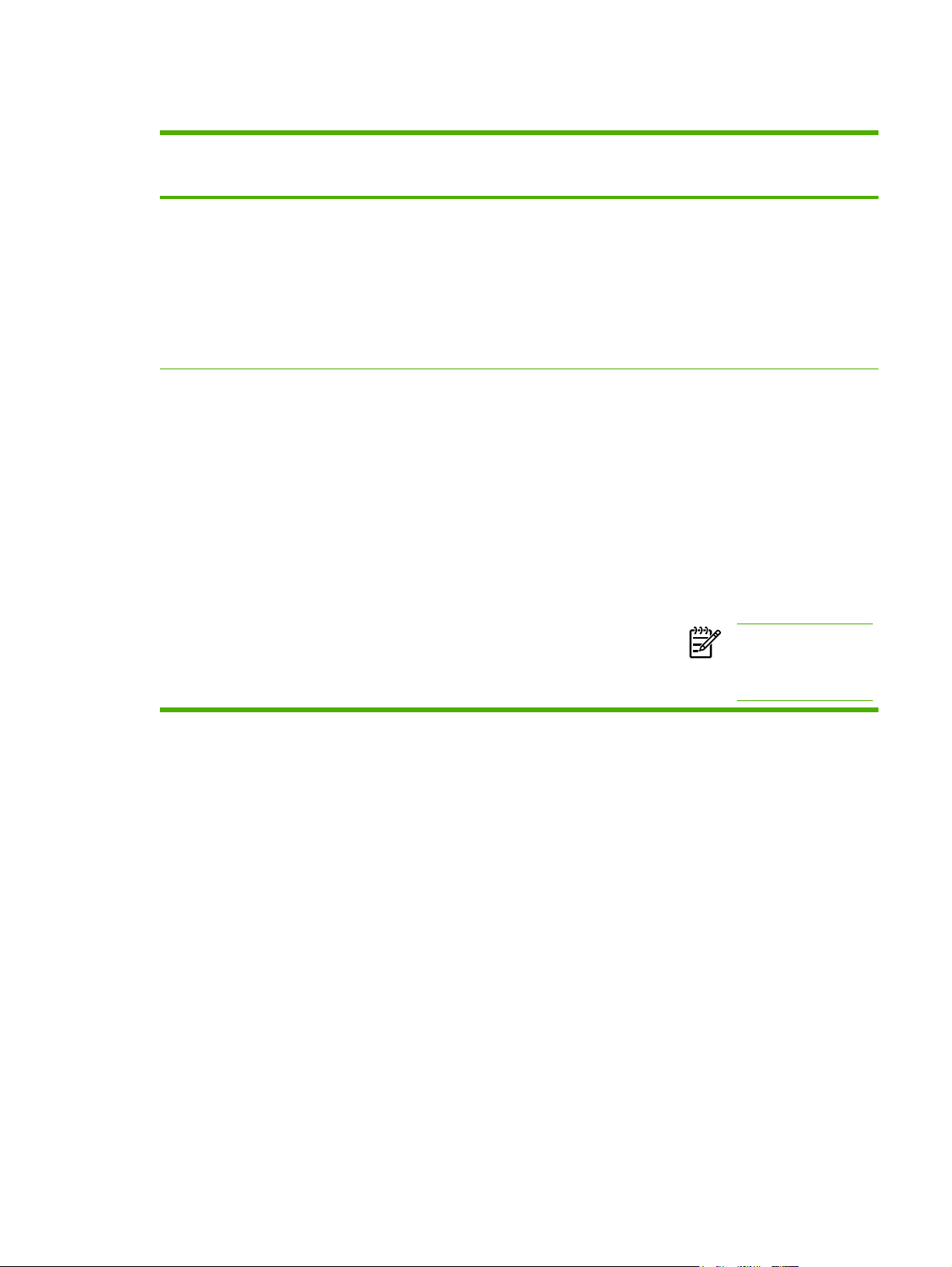

Open the printer drivers

Operating System To change the settings for all

print jobs until the software

program is closed

Windows 2000, XP,

and Server 2003

Mac OS X V10.2.8,

V10.3, V10.4 and

later

1. On the File menu in the

software program, click

Print.

2. Select the driver, and then

click Properties or

Preferences.

The steps can vary; this

procedure is most common.

1. On the File menu, click

Print.

2. Change the settings that

you want on the various

pop-up menus.

To change the default settings

for all print jobs

1. Click Start, click Settings,

and then click Printers or

Printers and Faxes.

2. Right-click the driver icon,

and then select Printing

Preferences.

1. On the File menu, click

Print.

2. Change the settings that

you want on the various

pop-up menus.

3. On the Presets pop-up

menu, click Save as and

type a name for the preset.

These settings are saved in the

Presets menu. To use the new

settings, you must select the

saved preset option every time

you open a program and print.

To change the device

configuration settings

1. Click Start, click Settings,

and then click Printers or

Printers and Faxes.

2. Right-click the driver icon,

and then select

Properties.

3. Click the Device Settings

tab.

1. In the Finder, on the Go

menu, click Applications.

2. Open Utilities, and then

open Print Center (OS X

V10.2.8) or Printer Setup

Utility.

3. Click on the print queue.

4. On the Printers menu,

click Show Info.

5. Click the Installable

Options menu.

NOTE Configuration

settings might not be

available in Classic

mode.

ENWW Device software 11

Page 24

Software for Macintosh computers

The HP installer provides PostScript® Printer Description (PPD) files, Printer Dialog Extensions (PDEs),

and the HP Printer Utility for use with Macintosh computers.

For network connections, use the embedded Web server (EWS) to configure the device. See

Web server on page 13.

The printing system software includes the following components:

PostScript Printer Description (PPD) files

●

The PPDs, in combination with the Apple PostScript printer drivers, provide access to device

features. Use the Apple PostScript printer driver that comes with the computer.

HP Printer Utility

●

Use the HP Printer Utility to set up device features that are not available in the printer driver:

Name the device.

●

Assign the device to a zone on the network.

●

Assign an internet protocol (IP) address to the device.

●

Download files and fonts.

●

Configure the device for IP or AppleTalk printing.

●

You can use the HP Printer Utility when your device uses a universal serial bus (USB) cable or is

connected to a TCP/IP-based network. For more information, see

Macintosh on page 52.

Use the HP Printer Utility for

Embedded

Remove software from Macintosh operating systems

To remove the software from a Macintosh computer, drag the PPD files to the trash can.

12 Chapter 1 Product Information ENWW

Page 25

Utilities

The device is equipped with several utilities that make it easy to monitor and manage the device on a

network.

HP Web Jetadmin

HP Web Jetadmin is a browser-based management tool for HP Jetdirect-connected printers within your

intranet, and it should be be installed only on the network administrator’s computer.

To download a current version of HP Web Jetadmin and for the latest list of supported host systems,

www.hp.com/go/webjetadmin.

visit

When installed on a host server, any client can gain access to HP Web Jetadmin by using a supported

Web browser (such as Microsoft® Internet Explorer 4.x or Netscape Navigator 4.x or later) by navigating

to the HP Web Jetadmin host.

Embedded Web server

The device is equipped with an embedded Web server, which provides access to information about

device and network activities. This information appears in a Web browser, such as Microsoft Internet

Explorer or Netscape Navigator.

The embedded Web server resides on the device. It is not loaded on a network server.

The embedded Web server provides an interface to the device that anyone who has a networkconnected computer and a standard Web browser can use. No special software is installed or

configured, but you must have a supported Web browser on your computer. To gain access to the

embedded Web server, type the IP address for the device in the address line of the browser. (To find

the IP address, print a configuration page. For more information about printing a configuration page,

Use information pages on page 45.)

see

For a complete explanation of the features and functionality of the embedded Web server, see

embedded Web server on page 49.

Use the

ENWW Device software 13

Page 26

HP Easy Printer Care software

The HP Easy Printer Care software is a program that you can use for the following tasks:

Discovering printers on the network and checking the status of each device

●

Setting and viewing device and supplies alerts for multiple printers at the same time

●

Shopping online for supplies

●

Using HP online troubleshooting and maintenance tools

●

You can use the HP Easy Printer Care software when the device is directly connected to your computer

or when it is connected to a network. To download the HP Easy Printer Care software, go to

www.hp.com/go/easyprintercare.

Supported operating systems

For information about supported operating systems, go to

Supported browsers

To use the HP Easy Printer Care software, you must have one of the following browsers:

Microsoft Internet Explorer 5.5 or later

●

Netscape Navigator 7.0 or later

●

Opera Software ASA Opera 6.05 or later

●

All pages can be printed from the browser.

Other components and utilities

Windows Macintosh OS

Software installer — automates the printing system

●

installation

Online Web registration

●

www.hp.com/go/easyprintercare.

PostScript Printer Description files (PPDs) — use with the

●

Apple PostScript drivers that come with the Mac OS

The HP Printer Utility — change device settings, view

●

status, and set up printer-event notification from a Mac.

This utility is supported for Mac OS X V10.2.8, V10.3,

V10.4 and later.

14 Chapter 1 Product Information ENWW

Page 27

Media specifications

The device accepts a variety of media, such as cut-sheet paper, including up to 100% recycled fiber

content paper; envelopes; labels; transparencies; and custom-size paper. Properties such as weight,

composition, grain, and moisture content are important factors that affect device performance and output

quality. Media that does not meet the guidelines that are outlined in this manual can cause the following

problems:

Poor print quality

●

Increased jams

●

Premature wear on the device, requiring repair

●

NOTE Some media might meet all of media specifications and still not produce satisfactory

results. Improper handling, unacceptable temperature and humidity levels, and other variables

over which Hewlett-Packard has no control can affect print quality. Before purchasing large

quantities of media, make sure that it meets the requirements that are specified in the user guide

and in theHP LaserJet Printer Family Print Media Guide, which is available for download

http://www.hp.com/support/ljpaperguide. Always test paper before buying large quantities.

at

CAUTION Using media that does not meet HP specifications can cause problems for the

device, requiring repair. This repair is not covered by the HP warranty or service agreements.

General guidelines for media

Before purchasing any paper or specialized forms in quantity, verify that your paper supplier has

obtained and understands the print-media requirements that are specified in the HP LaserJet Printer

Family Print Media Guide.

HP Customer Care on page 322 to order the HP LaserJet Printer Family Print Media Guide. To

See

download a copy of the guide, go to

It is possible that paper could meet all of the guidelines in this chapter or the HP LaserJet Printer Family

Print Media Guide and still not print satisfactorily. This can result from abnormal characteristics of the

printing environment or other variables over which HP has no control (for example, extremes in

temperature and humidity).

Hewlett-Packard Company recommends testing any paper before buying it in large quantities.

CAUTION Using paper that does not conform to the specifications listed here or in the print

media guide can cause problems that require service. This service is not covered by the HewlettPackard warranty or service agreements.

www.hp.com/support/ljpaperguide.

ENWW Media specifications 15

Page 28

Paper to avoid

The product can handle many types of paper. Using paper that does not meet specifications will cause

lower print quality and increase the chance of jams.

Do not use paper that is too rough. Use paper with a tested smoothness rating of 100–250 Sheffield.

●

Do not use paper, other than standard 3-hole punched paper, that contains cutouts or perforations.

●

Do not use multipart forms.

●

Do not use paper that has already been printed on, or that has been fed through a photocopier.

●

Do not use paper that contains a watermark if you are printing solid patterns.

●

Do not use heavily embossed or raised-letterhead papers.

●

Do not use papers that have heavily textured surfaces.

●

Do not use offset powders or other materials that prevent printed forms from sticking together.

●

Do not use paper that has a colored coating that was added after the paper was produced.

●

Paper that can damage the device

In rare circumstances, paper can damage the device. The following paper must be avoided to prevent

possible damage to the device:

Do not use paper with staples attached.

●

Do not use transparencies, labels, or photo or glossy paper designed for Inkjet printers or other

●

low temperature printers. Use only media that is specified for use with HP LaserJet printers.

Do not use any media that produces hazardous emissions, or that melts, offsets, or discolors when

●

exposed to the temperature of the fuser.

Do not use paper that is embossed or coated, or any media that is not designed to withstand the

●

fusing temperature of the device. Do not use letterhead paper or preprinted forms that are made

with dyes or inks that cannot withstand the heat of the fuser.

To order HP LaserJet printing supplies, see

Order parts, accessories, and supplies on page 314.

16 Chapter 1 Product Information ENWW

Page 29

General media specifications

For complete paper specifications for all HP LaserJet devices, see the HP LaserJet Printer Family Print

Media Guide (available at

Category Specifications

Acid content 5.5 pH to 8.0 pH

Caliper 0.094 to 0.18 mm (3.0 to 7.0 mils)

Curl in ream Flat within 5 mm (0.02 in)

Cut edge conditions Cut with sharp blades with no visible fray.

Fusing compatibility Must not scorch, melt, offset, or release hazardous emissions when heated to 200°

Grain Long grain

Moisture content 4% to 6% by weight

Smoothness 100 to 250 Sheffield

Select print media

This device accepts a variety of media, such as cut-sheet paper, including up to 100% recycled fiber

content paper; envelopes; labels; transparencies; and custom-size paper. Properties such as weight,

composition, grain, and moisture content are important factors that affect device performance and output

quality. Paper that does not meet the guidelines that are outlined in this manual can cause the following

problems:

www.hp.com/support/ljpaperguide) .

C (392°F) for 0.1 second.

Poor print quality

●

Increased jams

●

Premature wear on the device, requiring repair

●

NOTE Some paper might meet all of the guidelines in this manual and still not produce

satisfactory results. This might be the result of improper handling, unacceptable temperature and

humidity levels, or other variables over which Hewlett-Packard has no control. Before purchasing

large quantities of media, make sure that it meets the requirements that are specified in this user

guide and in the HP LaserJet Printer Family Print Media Guide, which is available for download

www.hp.com/support/ljpaperguide. Always test paper before buying large quantities.

at

CAUTION Using media that does not meet HP specifications can cause problems for the

device, requiring repair. This repair is not covered by the HP warranty or service agreements.

ENWW Media specifications 17

Page 30

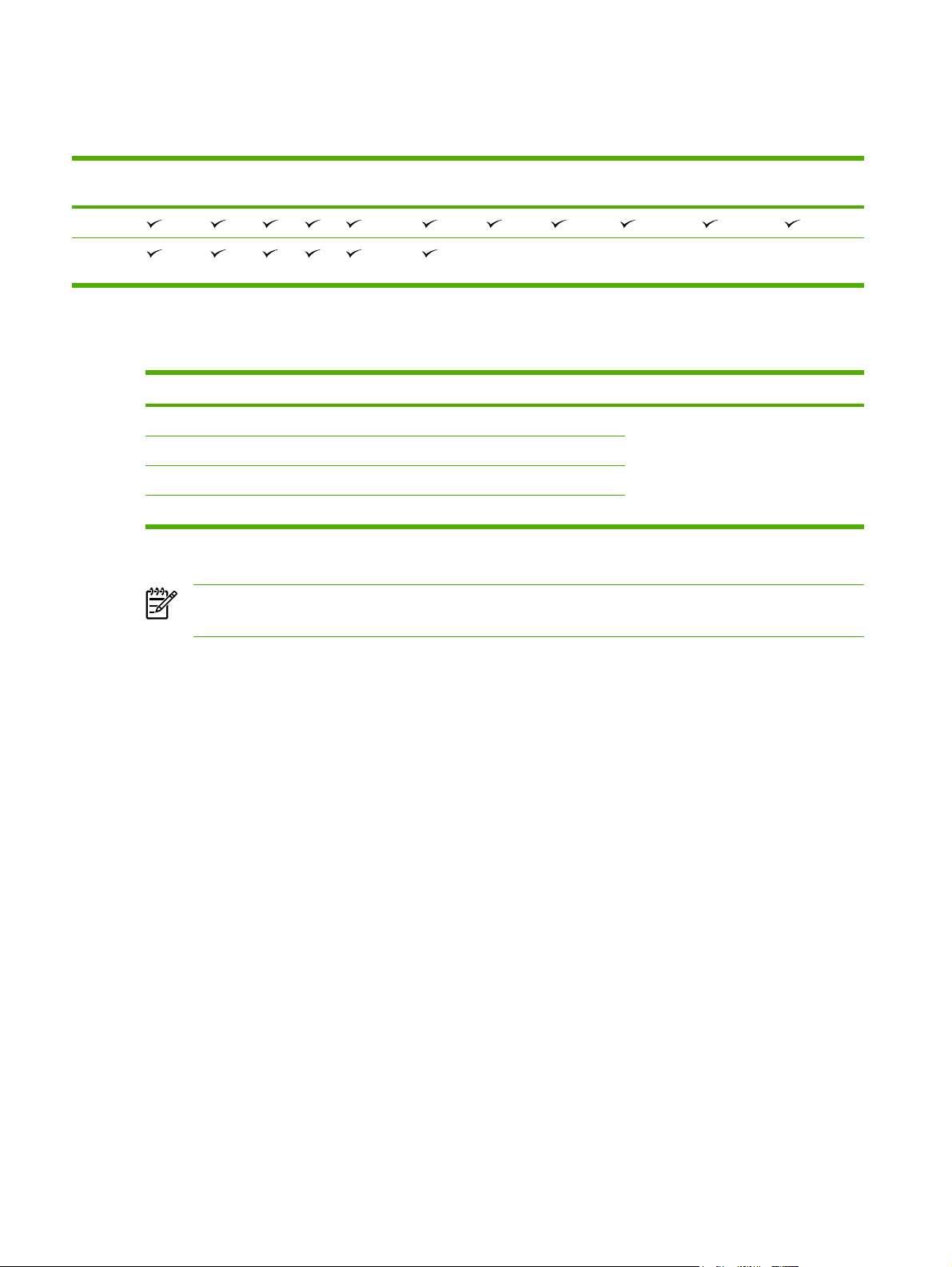

Supported media sizes

Table 1-1 Supported media sizes

Input

tray

Tray 1

Tray 2,

tray 3

Letter Legal A4 A5 Executive

(JIS)

1

Supported envelope sizes are #10, Monarch, C5, DL, and B5.

Table 1-2 Automatic 2-sided printing

Media size Dimensions Weight and thickness

Letter 216 x 279 mm (8.5 x 11 in)

Legal

A4 211 x 297 mm (8.3 x 11.7 in)

JIS 216 x 330 mm (8.5 x 13 in)

1

Automatic 2-sided printing on weights heavier than those shown can produce unexpected results.

B5 (JIS) 16K Custom Statement S Postcard

(JIS)

1

60 to 120 g/m2 (16 to 32 lb bond)

216 x 356 mm (8.5 x 14 in)

NOTE Automatic 2-sided (duplex) printing is available with the HP LaserJet M3027x, HP

LaserJet M3035, and HP LaserJet M3035xs models.

Envelope

1

Manual 2-sided printing. Most of the supported media sizes and types listed for printing from tray 1

can be manually duplexed. See the user guide for more information.

18 Chapter 1 Product Information ENWW

Page 31

Supported media types

Table 1-3 Tray 1 media types

Type Dimensions Weight or thickness Capacity

Plain Minimum: 76 x 127 mm (3 x 5 in)

Preprinted

Maximum: 216 x 356 mm

60 to 199 g/m

60 to 120 g/m2 (16 to 32 lb)

2

(16 to 53 lb)

100 sheets

100 sheets

1

(8.5 x 14 in)

Letterhead

Prepunched

Bond

Recycled

Colored paper

Rough

Light

Custom

Transparencies

Envelopes

60 to 120 g/m2 (16 to 32 lb)

60 to 120 g/m2 (16 to 32 lb)

60 to 120 g/m2 (16 to 32 lb bond)

60 to 120 g/m2 (16 to 32 lb)

60 to 120 g/m2 (16 to 32 lb)

60 to 199 g/m2 (16 to 53 lb)

60 to 75 g/m2 (16 to 20 lb)

60 to 199 g/m2 (16 to 53 lb)

2

0.10 to 0.14 mm thick (4.7 to 5 mils thick) Up to 60 sheets

75 to 90 g/m2 (20 to 24 lb)

100 sheets

100 sheets

100 sheets

100 sheets

100 sheets

Up to 100 sheets

100 sheets

Up to 100 sheets

10 envelopes

Labels 0.10 to 0.14 mm thick (4.7 to 5 mils thick) Up to 60 sheets

Cardstock

1

Capacity can vary depending on media weight and thickness and environmental conditions. Smoothness should be 100 to

250 (Sheffield). For ordering information, see

2

Use only transparencies that are designed for use with HP LaserJet printers. This printer can detect transparencies that were

Supplies and accessories on page 313.

Greater than 163 g/m

2

(greater than 43 lb)

Up to 100 sheets

not designed for use with HP LaserJet printers. For more information, see the user guide.

Table 1-4 Tray 2 and tray 3 media types

Type Dimensions Weight or thickness Capacity

Plain Minimum: 140 x 216 mm (5.5 x 8.5 in)

Preprinted

Maximum: 216 x 356 mm (8.5 x 14 in)

Letterhead

Prepunched

Bond

Recycled

Colored paper

60 to 120 g/m

60 to 120 g/m2 (16 to 32 lb)

60 to 120 g/m2 (16 to 32 lb)

60 to 120 g/m2 (16 to 32 lb bond)

60 to 120 g/m2 (16 to 32 lb)

60 to 120 g/m2 (16 to 32 lb)

60 to 120 g/m

2

(16 to 32 lb)

2

(16 to 32 lb)

Up to 500 sheets

Up to 500 sheets

Up to 500 sheets

Up to 500 sheets

Up to 500 sheets

Up to 500 sheets

Up to 500 sheets

ENWW Media specifications 19

Page 32

20 Chapter 1 Product Information ENWW

Page 33

2 Installation and configuration

Chapter contents

Site preparation

●

Install trays

●

Install supplies

●

Install accessories

●

ENWW Chapter contents 21

Page 34

Site preparation

Location specifications

Place the device on a sturdy, level surface in a well-ventilated area that meets the following

environmental requirements:

Temperature: 15° to 32°C (59° to 89°F)

●

Humidity: 10% to 80% relative humidity (no condensation)

●

Away from direct sunlight, open flames, and ammonia fumes

●

Allow sufficient space around the device for access and ventilation. (See

●

dimensions with all doors and trays fully opened on page 328 for the minimum space

requirements.)

Operating environment

Table C-2 Printer

Environmental condition Recommended Allowed

Temperature (device and print cartridge) 17° to 25°C (63° to 77°F) 15° to 32°C (59° to 89°F)

Relative humidity 30% to 70% (no condensation) 10% to 80% (no condensation)

NOTE Optimum performance of the device is assured under the recommended temperature

and humidity specifications. Print quality might deteriorate and occurrences of paper jams might

increase when the device is operated within the allowed temperature and humidity specifications.

22 Chapter 2 Installation and configuration ENWW

Page 35

Install trays

Load tray 1 (multipurpose tray)

Tray 1 holds up to 100 sheets of paper, up to 75 transparencies, up to 50 sheets of labels, or up to 10

envelopes. For information about loading special media, see the user guide.

1. Open tray 1 by pulling the front cover down.

2. Slide out the plastic tray extender. If the media that is being loaded is longer than 229 mm (9 in),

also flip open the additional tray extender.

3. Slide the media-width guides slightly wider than the media.

ENWW Install trays 23

Page 36

4. Place media into the tray (short-edge in, print-side up). The media should be centered between

the media-width guides and under the tabs on the media-width guides.

5. Slide the media-width guides inward until they lightly touch the media stack on both sides without

bending it. Make sure that the media fits under the tabs on the media-width guides.

NOTE Do not add media to tray 1 while the device is printing. This could cause a jam. Do not

close the front door when the device is printing.

24 Chapter 2 Installation and configuration ENWW

Page 37

Load tray 2 and optional tray 3

Trays 2 and 3 support only paper. For supported paper sizes, see Media specifications on page 15.

1. Pull the tray out of the device and remove any paper.

2. On the rear paper-length guide, press the tab and slide it so that the pointer matches the paper

size that you are loading. Make sure that the guide clicks into place.