Page 1

hp LaserJet 3300mfp

series

service

Page 2

Page 3

hp LaserJet 3300mfp series

Service

Page 4

Copyright Information

©

2002 Hewlett-Packard

Company

All Rights Reserved.

Reproduction, adaptations, or

translation without prior written

permission is prohibited except

as allowed under copyright

laws.

Part number C9124-90948

Second edition, February 2002

Warranty

The information contained in

this document is subject to

change without notice.

Hewlett-Packard makes no

warranty of any kind with

respect to thi s informati o n .

HEWLETT-PACKARD

SPECIFICALLY DISCLAIMS

THE IMPLIED WARRANTY OF

MERCHANTABILITY AND

FITNESS FOR A PARTICULAR

PURPOSE.

Hewlett-Packard shall not be

liable for any direct, indirect,

incidental, consequential, or

other damage alleged in

connection with the furnishing or

use of this information.

NOTICE TO U.S.

GOVERNMENT USERS:

RESTRICTED RIGHTS

COMMERCIAL COMPUTER

SOFTWARE: “Use, duplication,

or disclosure by the

Government is subject to

restrictions as set forth in

subparagraph (c) (1)(ii) of the

Rights in Technical Data Clause

at DFARS 52.227-7013.”

Trademark Credits

Microsoft, Windows, and MSDOS are U.S. registered

trademarks of Microsoft

Corporation.

TrueType is a U.S. trademark of

Apple Computer, Inc.

All other products mentioned

herein may be trademarks of

their respective companies.

Safety Information

WARNING!

Potential Shock Hazard

Always follow basic safety

precautions when using this

product to reduce risk of injury

from fire or electric shock.

1 Read and understand all

instructions in the user

guide.

2 Observe all warnings and

instructions marked on the

product.

3 Use only a grounded

electrical outlet when

connecting the

HP LaserJet 3300mfp

product to a power source.

If you don’t know whether

the outlet is grounded,

check with a qualified

electrician.

4 Do not touch the contacts

on the end of any of the

sockets on the

HP LaserJet 3300mfp.

Replace damaged cords

immediately.

5 Unplug this product from

wall outlets before

cleaning.

6 Do not install or use this

product near water or

when you are wet.

7 Install the product securely

on a stable surface.

8 Install the product in a

protected location where

no one can step on or trip

over the power cord and

the power cord will not be

damaged.

9 If the product does not

operate normally, see the

online user guide.

10 Refer all servicing

questions to qualified

personnel.

Information regarding FCC

Class B, Parts 15 and 68

requirements can be found in

the user guide.:

Hewlett-Packard Company

11311 Chinden Boulevard

Boise, Idaho 83714 U.S.A.

Page 5

Contents

1 Product information

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Overview of product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Front and side view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Back and side view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Firmware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Product Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Model and serial numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Warranty statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Extended warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Print cartridge information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Refilled print cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Recycling print cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

FCC Part 68 Requirements (US). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Telephone Consumer Protection Act (US) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

IC CS-03 requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Regulatory information for EU countries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2 Operation

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Operating environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Identifying the control panel components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Fax controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

To send a fax to one recipient . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

To receive faxes when you hear fax tones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Alphanumeric buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Menu and cancel controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Copy, scan, and start controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Control panel menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

To print the control panel menu structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

To use the control panel keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Control panel error messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Product media specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Supported media sizes (printer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Guidelines for using media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Paper and Transparencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Common media problems table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

EN Contents 3

Page 6

Envelopes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Card stock and heavy media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Loading media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Loading media to print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Selecting originals for the ADF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Media information for the flatbed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Loading originals to copy or scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

To load originals onto the flatbed scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

To load originals into the ADF input tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Printer output paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3 Maintenance

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Life expectancies of parts that wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Scanner calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Cleaning the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Cleaning the exterior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Cleaning the glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Cleaning the lid backing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Cleaning the print path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Cleaning the print cartridge area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Cleaning the printer pickup roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Cleaning the printer separation pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

User-replaceable parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Replacing the printer pickup roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Replacing the printer separation pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Installing a new ADF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

To install a new or replacement ADF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Changing an ADF pick roller assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Removing and replacing the control panel bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4 Operational overview

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Basic functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Formatter system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Central processing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Line Interface Unit (LIU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Scanner formatter PCA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Flash memory or ROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Standard Boot Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

RAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Parallel interface or Universal Serial Bus interface. . . . . . . . . . . . . . . . . . . . . . . 78

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Draft mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

MEt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Enhanced I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4 Contents EN

Page 7

PJL overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Scanner and ADF functions and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Scanner Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Scanner Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

ADF Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

ADF paper path and ADF sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

ADF Jam Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Printer functions and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Engine control unit/power system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Image formation system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Printer paper-feed system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Jam detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Basic sequence of operation (formatter-to-printer). . . . . . . . . . . . . . . . . . . . . . . 98

LIU (fax) functions and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

PSTN operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

The fax subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Formatter in the fax subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

LIU in the fax subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Fax page storage in flash memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

5 Removal and replacement

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Removal and replacement strategy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Required tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Before performing service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Print cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Parts removal order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Separation of scanner from printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Right side cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Scanner side covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Scanner assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Flat lid or ADF assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

The ADF pick roller assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

ADF document feed guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

ADF separation pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Control panel bezel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Control panel chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Scanner formatter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

ADF scanner glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Printer covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Left side door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Back cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Printer top cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Front cover assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Printer assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

EN Contents 5

Page 8

Transfer roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Line Interface Unit (LIU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Formatter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Fuser assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Output rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Fan assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Pickup assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Paper lift-plate assembly and pickup roller shaft . . . . . . . . . . . . . . . . . . . . . . . 157

Right plate assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Left plate assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Bottom assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Left bottom frame support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

ECU fuses and ECU pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Paper-feed assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

6 Troubleshooting

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Basic troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Control panel messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Critical error messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Checking the print cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Solving image-quality problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Solving paper-feed problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Solving print paper-feed problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Solving scanner (copier) paper-feed problems . . . . . . . . . . . . . . . . . . . . . . . . 199

Functional checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Engine test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Half self-test functional check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Drum rotation functional check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Heating element check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

High-voltage power supply check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Paper path check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Updating or recovering the firmware code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Firmware update via flash executable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Firmware recovery DIMM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Troubleshooting tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Internal reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Printing all fax reports at once . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

T.30 protocol trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Service mode functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Secondary service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Developer’s menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

NVRAM init . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

6 Contents EN

Page 9

PJL software commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Repetitive image defect ruler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Main wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Locations of connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Locations of connectors and switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

7 Parts and diagrams

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Ordering parts and supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Related documentation and software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Parts that wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Common hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

How to use the parts lists and diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Scanner assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Scanner and ADF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

ADF rollers and separation pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Control panel assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Printer assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Printer covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Paper tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Internal assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Internal components (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Internal components (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Electrical components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Paper pickup assembly (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Paper pickup assembly (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Fuser assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Alphabetical parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Numerical parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Index

EN Contents 7

Page 10

8 Contents EN

Page 11

Figures

Figure 1. Front and side view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 2. Back and side view. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

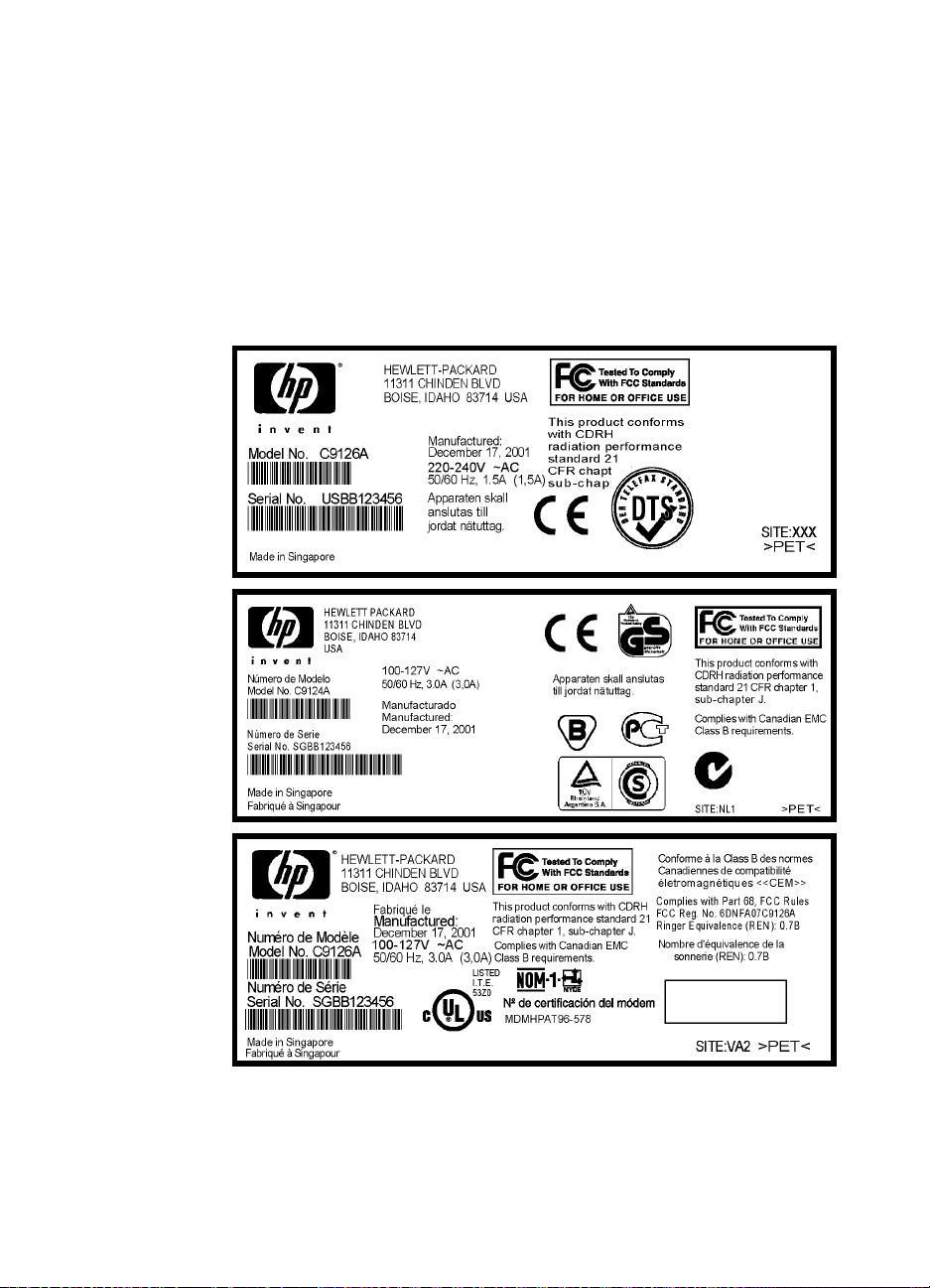

Figure 3. Model and serial number labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 4. Dimensions of product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 5. Fax controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 6. Alphanumeric controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 7. Menu and cancel buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 8. Copy, scan, and start controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 9. Output bin and straight-through output path. . . . . . . . . . . . . . . . . . . . . 54

Figure 10. Product configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 11. Optical diagram of scanner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Figure 12. Document scanner path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Figure 13. Printer unit functional block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Figure 14. ECU loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Figure 15. Overview of laser/scanner operation . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Figure 16. High-voltage power supply circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure 17. Image formation block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Figure 18. Printer paper path. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Figure 19. Solenoid, photosensors, and switches . . . . . . . . . . . . . . . . . . . . . . . . . 97

Figure 20. Printer timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Figure 21. Removing the print cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Figure 22. Removing the right side cover (1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . 113

Figure 23. Removing the right side cover (2 of 3) . . . . . . . . . . . . . . . . . . . . . . . . 114

Figure 24. Removing the right side cover (3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . 115

Figure 25. Removing the right scanner cover . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Figure 26. Removing the left scanner cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Figure 27. Separating the scanner from the printer (1 of 4). . . . . . . . . . . . . . . . . 116

Figure 28. Separating the scanner from the printer (2 of 4). . . . . . . . . . . . . . . . . 117

Figure 29. Separating the scanner from the printer (3 of 4). . . . . . . . . . . . . . . . . 117

Figure 30. Separating the scanner from the printer (4 of 4). . . . . . . . . . . . . . . . . 118

Figure 31. Removing the ADF assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Figure 32. Removing the document feed guide (1 of 2) . . . . . . . . . . . . . . . . . . . 122

Figure 33. Removing the document feed guide (2 of 2) . . . . . . . . . . . . . . . . . . . 122

Figure 34. Removing the ADF separation pad . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Figure 35. Removing the control panel bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Figure 36. Reinstalling the control panel bezel (1 of 2) . . . . . . . . . . . . . . . . . . . . 124

Figure 37. Reinstalling the control panel bezel (2 of 2) . . . . . . . . . . . . . . . . . . . . 124

Figure 38. Removing the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Figure 39. Removing the control panel chassis (1 of 2) . . . . . . . . . . . . . . . . . . . 126

Figure 40. Removing the control panel chassis (2 of 2) . . . . . . . . . . . . . . . . . . . 126

Figure 41. Removing the scanner formatter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

EN Figures 9

Page 12

Figure 42. Removing the ADF scanner glass . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Figure 43. Installing the ADF scanner glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Figure 44. Removing the left side door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Figure 45. Removing the back cover (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Figure 46. Removing the back cover (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Figure 47. Removing the printer top cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Figure 48. Removing the print cartridge door (1 of 2) . . . . . . . . . . . . . . . . . . . . . 133

Figure 49. Removing the print cartridge door (2 of 2) . . . . . . . . . . . . . . . . . . . . . 134

Figure 50. Removing the front cover (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Figure 51. Front cover removed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Figure 52. Removing the front cover (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Figure 53. Removing the front guide assembly (1 of 3). . . . . . . . . . . . . . . . . . . . 137

Figure 54. Removing the front guide assembly (2 of 3). . . . . . . . . . . . . . . . . . . . 138

Figure 55. Removing the front guide assembly (3 of 3). . . . . . . . . . . . . . . . . . . . 138

Figure 56. Removing the left and right support covers . . . . . . . . . . . . . . . . . . . . 139

Figure 57. Removing the transfer roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Figure 58. Removing the LIU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Figure 59. Removing the formatter (1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Figure 60. Removing the formatter (2 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Figure 61. Removing the formatter (3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Figure 62. Removing the fuser assembly (1 of 4) . . . . . . . . . . . . . . . . . . . . . . . . 144

Figure 63. Removing the fuser assembly (2 of 4) . . . . . . . . . . . . . . . . . . . . . . . . 145

Figure 64. Removing the fuser assembly (3 of 4) . . . . . . . . . . . . . . . . . . . . . . . . 146

Figure 65. Removing the fuser assembly (4 of 4) . . . . . . . . . . . . . . . . . . . . . . . . 147

Figure 66. Removing the output rollers (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Figure 67. Removing the output rollers (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Figure 68. Removing the motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Figure 69. Removing the solenoid (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Figure 70. Removing the solenoid (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Figure 71. Removing the fan (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Figure 72. Removing the fan (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Figure 73. Removing the pickup assembly plate (1 of 3). . . . . . . . . . . . . . . . . . . 155

Figure 74. Removing the pickup assembly plate (2 of 3). . . . . . . . . . . . . . . . . . . 156

Figure 75. Removing the pickup assembly plate (3 of 3). . . . . . . . . . . . . . . . . . . 156

Figure 76. Removing the paper lift-plate assembly (1 of 3). . . . . . . . . . . . . . . . . 157

Figure 77. Removing the paper lift-plate assembly (2 of 3). . . . . . . . . . . . . . . . . 158

Figure 78. Removing the paper lift-plate assembly (3 of 3). . . . . . . . . . . . . . . . . 158

Figure 79. Paper lift-plate springs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Figure 80. Removing the pickup roller shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Figure 81. Removing the right plate assembly (1 of 2) . . . . . . . . . . . . . . . . . . . . 160

Figure 82. Removing the right plate assembly (2 of 2) . . . . . . . . . . . . . . . . . . . . 161

Figure 83. Removing the left plate assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Figure 84. Removing the left bottom frame support . . . . . . . . . . . . . . . . . . . . . . 163

Figure 85. Removing the ECU pan (1 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Figure 86. Removing the ECU pan (2 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Figure 87. Removing the ECU pan (3 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Figure 88. Removing the ECU pan (4 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

10 Figures EN

Page 13

Figure 89. Removing the ECU pan (5 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Figure 90. Removing the paper-feed assembly (1 of 4) . . . . . . . . . . . . . . . . . . . 168

Figure 91. Removing the paper-feed assembly (2 of 4) . . . . . . . . . . . . . . . . . . . 169

Figure 92. Removing the paper-feed mechanism (3 of 4) . . . . . . . . . . . . . . . . . . 170

Figure 93. Removing the paper-feed mechanism (4 of 4) . . . . . . . . . . . . . . . . . . 171

Figure 94. Engine test switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Figure 95. Locating connectors for the heating element check. . . . . . . . . . . . . . 203

Figure 96. Print cartridge high-voltage connection points (right side) . . . . . . . . . 204

Figure 97. Print cartridge high-voltage connection points (left side) . . . . . . . . . . 204

Figure 98. High-voltage connector assembly (right side) . . . . . . . . . . . . . . . . . . 205

Figure 99. High-voltage connector assembly (left side). . . . . . . . . . . . . . . . . . . . 205

Figure 100. Overriding SW301 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Figure 101. Using the firmware recovery DIMM . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Figure 102. Example of a T.30 trace of a successfully sent fax . . . . . . . . . . . . . . 227

Figure 103. Example of a T.30 trace of a successfully received fax . . . . . . . . . . . 228

Figure 104. NVRAM PJL factory variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Figure 105. Repetitive image defect ruler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Figure 106. Main wiring (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Figure 107. Main wiring (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Figure 108. Locations of printer connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Figure 109. Locations of connectors and switches . . . . . . . . . . . . . . . . . . . . . . . . 240

Figure 110. Scanner covers and ADF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Figure 111. ADF rollers and separation pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Figure 112. Control panel assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Figure 113. Printer covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Figure 114. Paper tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Figure 115. Internal components (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Figure 116. Internal components (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Figure 117. Electrical components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Figure 118. Paper pickup assembly (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Figure 119. Paper pickup assembly (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Figure 120. Fuser assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

EN Figures 11

Page 14

12 Figures EN

Page 15

Tables

Table 1. Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 2. Environmental specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 3. Performance of HP LaserJet 3300mfp series. . . . . . . . . . . . . . . . . . . . 19

Table 4. Performance of ADF for copying/scanning. . . . . . . . . . . . . . . . . . . . . . 20

Table 5. Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 6. Acoustic emissions (HP LaserJet 3300mfp series) . . . . . . . . . . . . . . . 20

Table 7. Skew specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 8. HP LaserJet 3330 fax specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 9. Control panel menu structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 10. Control panel error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 11. Media types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 12. Life expectancies of parts that wear. . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 13. Product startup messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Table 14. Basic sequence of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Table 15. Basic troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Table 16. Alert and warning messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Table 17. Critical error messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Table 18. Solving print image-quality problems . . . . . . . . . . . . . . . . . . . . . . . . . 188

Table 19. Solving scanning (copying) image-quality problems . . . . . . . . . . . . . 194

Table 20. Solving print paper-feed problems . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Table 21. Solving scanner paper-feed problems . . . . . . . . . . . . . . . . . . . . . . . . 199

Table 22. Fax receive error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Table 23. Fax send error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Table 24. Fax phase sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Table 25. Appropriate responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Table 26. Fax abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Table 27. Country/region codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Table 28. Switch functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Table 29. Technical support websites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Table 30. Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Table 31. Common fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Table 32. Scanner and ADF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Table 33. ADF rollers and separation pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Table 34. Control panel assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Table 35. Printer covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Table 36. Paper tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Table 37. Internal components (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Table 38. Internal components (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Table 39. Electrical components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Table 40. Paper pickup assembly (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Table 41. Paper pickup assembly (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

EN Tables 13

Page 16

Table 42. Fuser assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Table 43. Alphabetical parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Table 44. Numerical parts list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

14 Chapter - Tables EN

Page 17

1Product information

Chapter contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Overview of product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Front and side view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Back and side view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Hardware description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Firmware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Model and serial numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Warranty statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Extended warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Print cartridge information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Refilled print cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Recycling print cartridges . . . . . . . . . . . . . . . . . . . . . . . . . 26

FCC Part 68 Requirements (US) . . . . . . . . . . . . . . . . . . . . . . . 26

Telephone Consumer Protection Act (US) . . . . . . . . . . . . 27

IC CS-03 requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Regulatory information for EU countries . . . . . . . . . . . . . . 28

EN Chapter contents 15

Page 18

Introduction

The HP LaserJet 3300mfp series is designed to:

Print: Print documents easily with the laser-quality you have

come to expect from an HP LaserJet product.

Copy: Make superior laser-quality copies. With the software, you

can make up to 99 copies of a 50-page original. You can also

enlarge, reduce, adjust contrast, and collate.

Scan: Scan documents to create electronic text or graphics files.

Fax: On the HP 3330, send and receive documents via standard

fax communications.

Overview of product

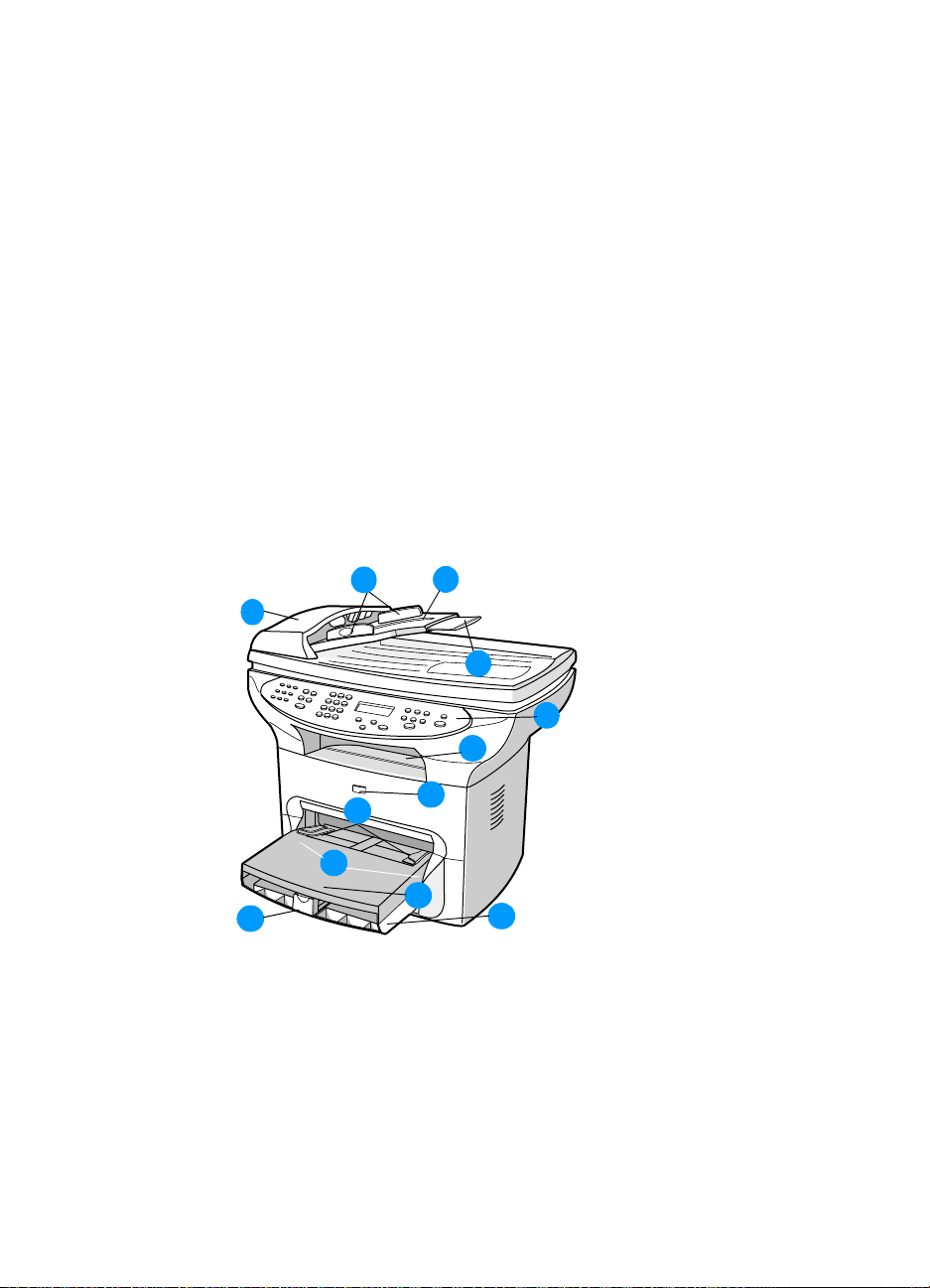

Front and side view

3

1

9

12

10

Figure 1. Front and side view

1

Automatic document feeder (ADF)

2 ADF media input tray

3 Side media guides for the ADF

4 Long media extension for the ADF

5 Control panel

2

4

5

6

7

8

11

6 Output bin

16 Chapter 1 - Product information EN

Page 19

Print cartridge door

7

8 Priority input tray

9 Side media guides for the priority input tray

10 Media support for the main input tray

11 Main input tray

12 Side media guides for the main input tray (inside cover, not

shown)

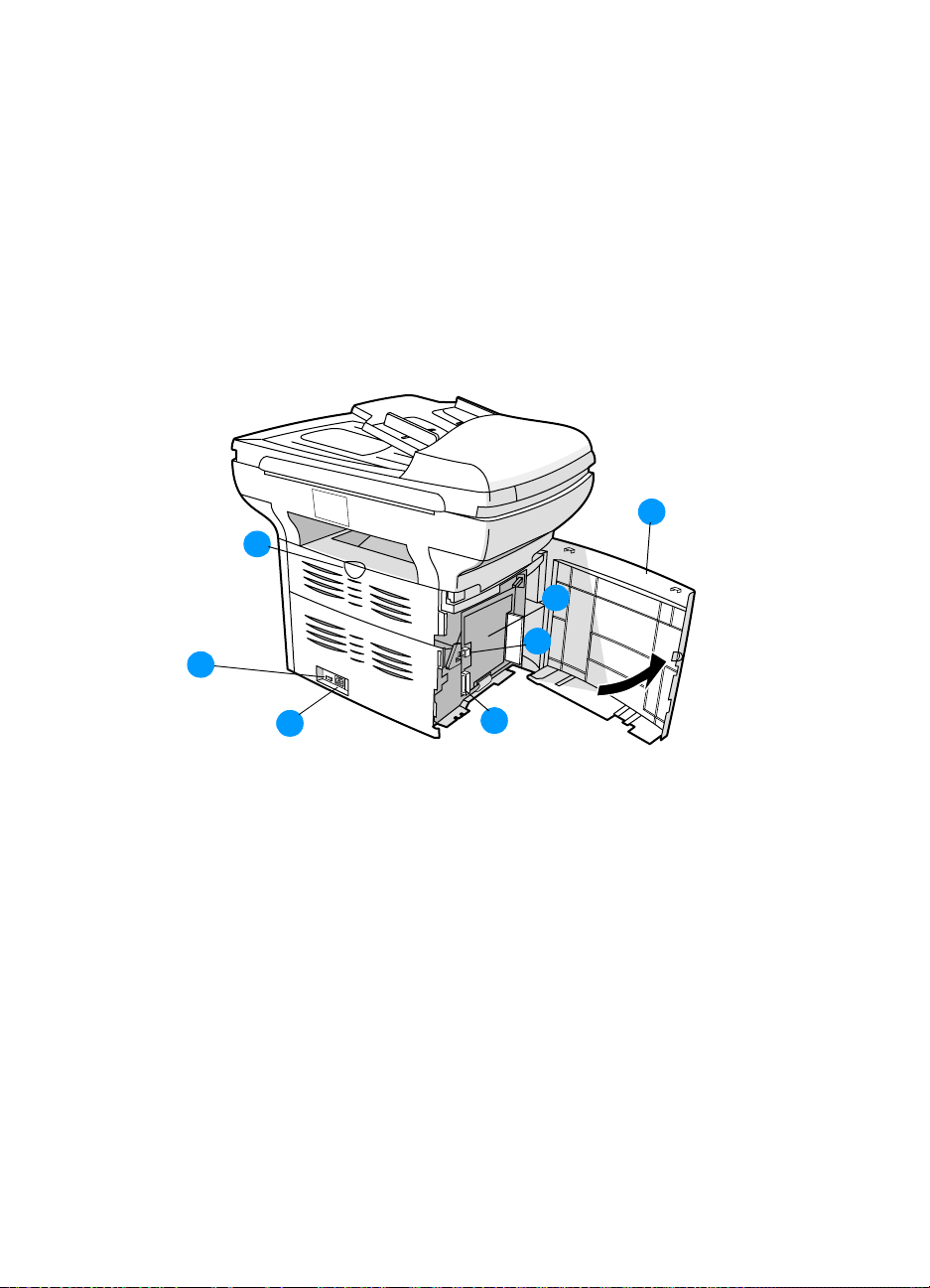

Back and side view

1

2

7

3

6

5

Figure 2. Back and side view

1

Left side panel

2 Straight-through output door

3 USB port

4 Parall el port

5 Power receptacle

6 Power switch (220-240 volt units)

7 LIU (hp LaserJet 3330mfp only...not shown in graphic)

EN Overview of product 17

4

Page 20

Hardware description

The product provides 1200 dot-per-inch (dpi) printing. The flatbed

scanner scans at 600 pixels-per-inch (ppi) with 24-bits per pixel (bpp)

and most models contain an automatic document feeder (ADF) that

holds up to 50 pages. On the HP LaserJet 3330mfp, the formatter

and LIU provide Group-3-compatible faxing capabilities.

The product prints 15 pages per minute (ppm) on letter-size paper or

14 ppm on A4. With 1200 dpi printing resolution, the product has

exceptional text and graphics print quality. The simple control panel

and improved paper handling make this product very easy to use.

The main input tray has a 250-sheet capacity for continuous, multiplepage printing. The priority input tray allows for manual feed of up to

ten sheets. Both trays are center-justified for all supported paper

sizes. The output bin holds up to 125 sheets.

The product has a very fast first-page-out, at less than ten seconds.

The formatter board contains 4 MB of ROM, 32 MB of RAM, and an

embedded 32-bit Coldfire V3 processor. There is one DIMM slot

available for font or memory expansion (supporting an 8 MB, 16 MB,

32 MB, or 64 MB DIMM).

The print engine has a 1,000 average (10,000 peak) page-per-month

duty cycle. The standard toner life is 2,500 pages, and the highcapacity toner life is 3,500 pages with 5% toner coverage.

18 Chapter 1 - Product information EN

Page 21

Firmware description

The firmware in the product includes:

Enhanced PCL 6 with status readback

80 PCL and 80 Postscript™ fonts

Pixel placement, mosaic characters

Memory Enhancement technology (MEt) with hardware

compression and decompression

The firmware also has REt and EconoMode functionality.

Product Specifications

Table 1. Physical specifications

Category Specification

Height 496 mm (19.5 inches)

Depth 520.7 mm (20.5 inches)

Width 546.1 mm (21.5 inches)

Weight (cartridge

installed)

15.9 kg (35.0 lbs) (models with ADF)

14.1 kg (31.1 lbs) (models without ADF)

Table 2. Environmental specifications

Category Specification

Operating

environment (unit

plugged into an AC

outlet)

Storage environment

(unit not plugged

into an AC outlet)

Temperature: 15° to 32.5° C (59° to 90.5° F)

Humidity: 10% to 80% relative humidity

(no condensation)

Temperature: -20° to 40° C (-4° to 104° F)

Humidity: Less than 95% relative humidity

(no condensation)

Table 3. Performance of HP LaserJet 3300mfp series

Category Specification

Print resolution 1200 dpi

Print speed 15 ppm (Letter)

14 ppm (A4)

EN Product Specifications 19

Page 22

Table 4. Performance of ADF for copying/scanning

Category Specification

Scan resolution 600 PPI (24-bit pixels per inch) optical, with 256

levels of gray and 24-bit color

Copy speed Up to 15 ppm

Table 5. Electrical specifications

110-V Models 220-V Models

Power requirements

Note: Power sources are not

interchangeable.

Minimum recommended

circuit capacity

Power consumption Copying (maximum): 330 W

Values subject to change. See http://www.hp.com/support/lj3300 for current information

110 to 127 volts +/-10%

50 to 60 Hz +/-2 Hz

4.5 A at 115 V 2.3 A at 230 V

Printing (maximum): 300 W

Standby: 14 Watts

Power save: 14 Watts

Table 6. Acoustic emissions (HP LaserJet 3300mfp series)

220 to 240V +/-10%,

50 to 60 Hz +/-2 Hz

Copying (maximum): 330 W

Printing (maximum): 300 W

Standby: 14 Watts

Power save: 14 Watts

Off: 0 Watts

Sound Power Level Declared per ISO 9296

Printing (maximum)

Copying (maximum)

Standby/PowerSave

L

= 6.1 Bels (A)

WAd

= 6.6 Bels (A)

L

WAd

Essentially inaudible

SPL Bystander Position Declared per ISO 9296

Printing (maximum)

Copying (maximum)

Standby/PowerSave

Values subject to change. See http://www.hp.com/support/lj3300 for current information. During

other operations, acoustic emissions may vary.

L

= 48 dB (A)

pAm

L

= 50 dB (A)

pAm

Essentially inaudible

20 Chapter 1 - Product information EN

Page 23

Table 7. Skew specifications

Category Specification

Print skew 0.87% (1.65 mm over 190 mm in width) for

cut-sheet media (leading edge)

0.80% (2.0 mm over 250 mm in length) for

cut-sheet media except A5 size

1.50% (3.3 mm over 220 mm in length) for

envelopes, postcards, and A5-size media

The media registration defines how a sheet of media is positioned relative to the

electrophotographic image on the drum. The specified tolerances do not include variation in the

media dimensions from nominal. All vertical lines will be parallel to the reference, or left edge of the

media, within the specifications.

Table 8. HP LaserJet 3330 fax specifications

Category Specification

Fax transmission speed 3 seconds/page (ITU-T Test Image #1 )

Right/left margins for printed

pages

Top/bottom margins for printed

pages

Fax compatibility ITU Group 3; ECM

Fax coding schemes MH, MR, and MMR

Modem speed Up to 33,600 bits per second (bps)

Speed dialing Yes

Distinctive ring detect Yes

Fax resolution (standard) 203 by 98 dots per inch (dpi)

Fax resolution (fine) 203 by 196 dpi

Fax resolution (superfine) 300 by 300 dpi (no halftone)

Fax resolution (photo) 300 by 300 dpi (halftone enabled)

6.3 mm (0.25 inch)

5.08 mm (0.2 inch)

EN Product Specifications 21

Page 24

Model and serial numbers

The model number and serial number are listed on an identification

label located on the inside of the print cartridge door.

The serial number contains information about the country/region of

origin, revision level, production code, and production number of

the product.

The label also contains power rating and regulatory information.

Figure 3. Model and serial number labels

22 Chapter 1 - Product information EN

Page 25

Warranty statement

DURATION OF WARRANTY: One year from date of purchase.

1 HP warrants to you, the end-user customer, that HP hardware, accessories, and

supplies, will be free from defects in materials and workmanship after the date of

purchase, for the period specified above. If HP receives notice of such defects

during the warranty period, HP will, at its option, either repair or replace products

which prove to be defective. Replacement products may be either new or like

new.

2 HP warrants to you that HP software will not fail to execute its programming

instructions after the date of purchase, for the period specified above, due to

defects in material and workmanship when properly installed and used. If

HP receives notice of such defects during the warranty period, HP will replace

software media which does not execute its programming instructions due to such

defects.

3 HP does not warrant that the operation of HP products will be uninterrupted or

error-free. If HP is unable, within a reasonable time, to repair or replace any

product to a condition as warranted, you will be entitled to a refund of the

purchase price upon prompt return of the product.

4 HP products may contain remanufactured parts equivalent to new in performance

or may have been subject to incidental use.

5 Warranty does not apply to defects resulting from (a) improper or inadequate

maintenance or calibration, (b) software, interfacing, parts, or supplies not

supplied by HP, (c) unauthorized modification or misuse, (d) operation outside of

the published environmental specifications for the product, or (d) improper site

preparation or maintenance.

6 HP MAKES NO OTHER EXPRESS WARRANTY OR CONDITION WHETHER

WRITTEN OR ORAL. TO THE EXTENT ALLOWED BY LOCAL LAW, ANY

IMPLIED WARRANTY OR CONDITION OF MERCHANTABILITY,

SATISFACTORY QUALITY, OR FITNESS FOR A PARTICULAR PURPOSE IS

LIMITED TO THE DURATION OF THE EXPRESS WARRANTY SET FORTH

ABOVE. Some countries, states, or provinces do not allow limitations on the

duration of an implied warranty, so the above limitation or exclusion might not

apply to you. This warranty gives you specific legal rights and you might also have

other rights that vary from country to country, state to state, or province to

province.

EN Warranty statement 23

Page 26

7 TO THE EXTENT ALLOWED BY LOCAL LAW, THE REMEDIES IN THIS

WARRANTY STATEMENT ARE YOUR SOLE AND EXCLUSIVE REMEDIES.

EXCEPT AS INDICATED ABOVE, IN NO EVENT WILL HP OR ITS SUPPLIERS

BE LIABLE FOR LOSS OF DATA OR FOR DIRECT, SPECIAL, INCIDENTAL,

CONSEQUENTIAL (INCLUDING LOST PROFIT OR DATA), OR OTHER

DAMAGE, WHETHER BASED IN CONTRACT, TORT, OR OTHERWISE. Some

countries, states, or provinces do not allow the exclusion or limitation of incidental

or consequential damages, so the above limitation or exclusion may not apply to

you.

FOR CONSUMER TRANSACTIONS IN AUSTRALIA AND NEW ZEALAND, THE

WARRANTY TERMS CONTAINED IN THIS STATEMENT, EXCEPT TO THE

EXTENT LAWFULLY PERMITTED, DO NOT EXCLUDE, RESTRICT OR

MODIFY AND ARE IN ADDITION TO THE MANDATORY STATUTORY RIGHTS

APPLICABLE TO THE SALE OF THIS PRODUCT TO YOU.

Extended warranty

HP SupportPack provides coverage for the HP hardware product and

all HP-supplied internal components. The hardware maintenance

warranty covers a three-year period from the date of the HP product

purchase. The customer must purchase the HP SupportPack within

90 days of the HP product purchase. Customers can contact the

nearest HP-authorized dealer about this service.

24 Chapter 1 - Product information EN

Page 27

Print cartridge information

The print cartridge is designed to simplify replacement of the major

consumable parts. The print cartridge contains the printing

mechanism and a supply of toner.

At five percent page coverage, a standard print cartridge will print

approximately 2,500 pages. However, a cartridge should print more

pages if it regularly prints pages with less coverage, such as short

memos. The cartridge might print fewer pages if heavy or bold print is

used.

For best results, always use a print cartridge before the expiration

date stamped on the cartridge box.

Refilled print cartridges

While Hewlett-Packard does not prohibit the use of refilled print

cartridges during the warranty period or while the product is under a

maintenance contract, it is not recommended for the following

reasons:

Repairs resulting from the use of refilled cartridges are not

covered under Hewlett-Packard warranty or maintenance

contracts.

Hewlett-Packard has no control or process to ensure that a

refilled cartridge functions at the high level of reliability of a new

HP LaserJet toner cartridge. Hewlett-Packard also cannot predict

the long-term reliability effect on the product from using different

toner formulations found in refilled cartridges.

The print quality of HP LaserJet print cartridges influences the

customer’s perception of the product. Hewlett-Packard has no

control over the actual print quality of a refilled cartridge.

Parts that are critical to print quality may not be replaced when

the cartridge is refilled with toner.

Recycling print cartridges

In order to reduce waste, Hewlett-Packard offers a recycling program.

Cartridge components that do not wear out are recycled. Plastics and

other materials are recycled. Hewlett-Packard pays the shipping

EN Print cartridge information 25

Page 28

costs from the user to the recycling plant (within the United States).

To join this recycling effort, follow the instructions inside the print

cartridge box.

FCC Part 68 Requirements (US)

This equipment complies with FCC rules, Part 68. On the back of this

equipment is a label that contains, among other information, the FCC

registration number and ringer equivalence number (REN) for this

equipment. If requested, this information must be provided to the

telephone company. The REN is used to determine the quantity of

devices which may be connected to the telephone line. Excessive

RENs on the telephone line may result in the devices not ringing in

response to an incoming call. In most, but not all, areas, the sum of

the RENs should not exceed five (5.0). To be certain of the number of

devices that may be connected to the line, as determined by the total

RENs, contact the telephone company to determine the maximum

REN for the calling area.

This equipment uses the following USOC jacks: RJ11C.

An FCC-compliant telephone cord and modular plug is provided with

this equipment. This equipment is designed to be connected to the

telephone network or premises wiring using a compatible modular

jack which is Part 68-compliant. This equipment cannot be used on

telephone company-provided coin service. Connection to Party Line

Service is subject to state tariffs. If this equipment causes harm to the

telephone network, the telephone company will notify you in advance

that temporary discontinuance of service may be required. If advance

notice isn't practical, the telephone company will notify you as soon

as possible. Also, you will be advised of your right to file a complaint

with the FCC if you believe it is necessary. The telephone company

may make changes in its facilities, equipment, operations, or

procedures that could affect the operation of the equipment. If this

happens, the telephone company will provide advance notice in order

for you to make the necessary modifications in order to maintain

uninterrupted service. If trouble is experienced with this equipment,

please contact HP for repair and (or) warranty information. If the

trouble is causing harm to the telephone network, the telephone

company may request that you remove the equipment from the

network until the problem is resolved. The following repairs can be

done by the customer: replace any original equipment that came with

the product. This includes the print cartridge, the paper trays, the

ADF, the control panel bezel, the ADF pick roller assembly, the power

cord, and the telephone cord. It is recommended that the customer

26 Chapter 1 - Product information EN

Page 29

install an AC surge arrestor in the AC outlet to which this device is

connected. This is to avoid damage to the equipment caused by local

lightning strikes and other ele ctr i c al sur g es.

Telephone Consumer Protection Act (US)

The Telephone Consumer Protection Act of 1991 makes it unlawful

for any person to use a computer or other electronic device, including

fax machines, to send any message unless such message clearly

contains, in a margin at the top or bottom of each transmitted page or

on the first page of the transmission, the date and time it is sent and

an identification of the business, other entity , or individual sending the

message and the telephone number of the sending machine or such

business, other entity, or individual. (The telephone number provided

cannot be a 900 number or any other number for which charges

exceed local or long-distance transmission charges.) In order to

program this information into your facsimile, please see the HP

3300mfp User Guide.

IC CS-03 requirements

NOTICE: The Industry Canada label identifies certified equipment.

This certification means the equipment meets certain

telecommunications network protective, operational, and safety

requirements as prescribed in the appropriate Terminal Equipment

Technical Requirement document(s). The Department does not

guarantee the equipment will operate to the user’s satisfac tion. Bef ore

installing this equipment, users should ensure that it is permissible for

the equipment to be connected to the facilities of the local

telecommunications company. The equipment must also be installed

using an acceptable method of connection. The customer should be

aware that compliance with the above conditions may not prevent

degradation of service in some situations. Repairs to certified

equipment should be coordinated by a representative designated by

the supplier. Any repairs or alterations made by the user to this

equipment, or equipment malfunctions, may give the

telecommunications company cause to request the user to

disconnect the equipment. Users should ensure for their own

protection that the electrical ground connections of the power utility,

telephone lines, and internal metallic water pipe system, if present,

are connected together. This precaution can be particularly important

in rural areas.

Caution: Users should not attempt to make such connections

themselves, but should contact the appropriate electric inspection

authority, or electrician, as appropriate. The Ringer Equivalence

Number (REN) of this device is 0.7.

EN FCC Part 68 Requirements (US) 27

Page 30

Notice: The Ringer Equivalence Number (REN) assigned to each

terminal device provides an indication of the maximum number of

terminals allowed to be connected to a telephone interface. The

termination on an interface may consist of any combination of devices

subject only to the requirement that the sum of the Ringer

Equivalence Number of all the devices does not exceed five (5.0).

The standard connecting arrangement code (telephone jack type) for

equipment with direct connections to the telephone network is

CA11A.

Regulatory information for EU countries

This equipment has been designed to work in all of the countries of

the European Economic Area (Public Switched Telephone Networks)

only . Network compatibility is dependent on internal software settings.

Contact your equipment supplier if it is necessary to use the

equipment on a different telephone network. For further product

support, contact Hewlett-Packard at the phone numbers provided in

the support flyer that came with the product.

28 Chapter 1 - Product information EN

Page 31

2Operation

Chapter contents

Operating environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Identifying the control panel components. . . . . . . . . . . . . . . . . 31

Fax controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

To send a fax to one recipient . . . . . . . . . . . . . . . . . . . . . . 31

To receive faxes when you hear fax tones . . . . . . . . . . . . 32

Alphanumeric buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Menu and cancel controls . . . . . . . . . . . . . . . . . . . . . . . . . 34

Copy, scan, and start controls. . . . . . . . . . . . . . . . . . . . . . 34

Control panel menu structure. . . . . . . . . . . . . . . . . . . . . . . . . . 35

To print the control panel menu structure . . . . . . . . . . . . . 35

To use the control panel keys . . . . . . . . . . . . . . . . . . . . . . 35

Control panel error messages . . . . . . . . . . . . . . . . . . . . . . . . . 38

Product media specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Supported media sizes (printer). . . . . . . . . . . . . . . . . . . . . 45

Guidelines for using media. . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Paper and Transparencies . . . . . . . . . . . . . . . . . . . . . . . . 46

Common media problems table. . . . . . . . . . . . . . . . . . . . . 46

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Envelopes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Card stock and heavy media. . . . . . . . . . . . . . . . . . . . . . . 48

Loading media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Loading media to print. . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Selecting originals for the ADF. . . . . . . . . . . . . . . . . . . . . . . . . 50

Media information for the flatbed . . . . . . . . . . . . . . . . . . . . . . . 51

Loading originals to copy or scan. . . . . . . . . . . . . . . . . . . . . . . 51

To load originals onto the flatbed scanner. . . . . . . . . . . . . 51

To load originals into the ADF input tray . . . . . . . . . . . . . . 52

Printer output paths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

EN Chapter contents 29

Page 32

Operating environment

Place the product on a sturdy, level surface in a well-ventilated area

that meets the following environmental requirements:

temperature: 15° to 32.5° C (59° to 90.5° F)

humidity: 10% to 80% relative humidity (no condensation)

away from direct sunlight, open flames, and ammonia fumes

sufficient space around the product to allow for proper access

and ventilation

74 cm (29 in)

53 cm (21 i n)

81 cm (32 in)

Figure 4. Dimensions of product

30 Chapter 2 - Operation EN

Page 33

Identifying the control panel components

Fax controls

Fax capability is available on the HP LaserJet 3330 product only. Use

the fax controls to send and receive faxes. These controls and the fax

menu or software are used to change commonly used fax settings.

Figure 5. Fax controls

The HP 3330 has extensive faxing capabilities. This manual

describes only sending a fax to one recipient and receiving a fax. For

a full description of the fax capabilities, see “Faxing” in the User

Guide on the product CD.

To send a fax to one recipient

1 Dial the fax number using one of the following methods:

• Use the alphanumeric buttons on the product’s control panel.

• If the fax number you are calling has been assigned to a one-

touch key, press that key.

• If the fax number you are calling has a speed-dial code, press

speed dial, enter the speed-dial code using the alphanumeric

buttons, and press

Note When dialing with the alphanumeric buttons, include any pauses

or other needed numbers, such as an area code, an access code

for numbers outside a PBX system (usually a 9 or 0), or a longdistance prefix. For more information, see “Using dialing

characters” in the User Guide on the product CD.

EN Identifying the control panel components 31

menu/enter.

Page 34

2 Load the document into the ADF input tray.

3 Press fax/send.

When the last page of the fax has exited the product, you can start

sending another fax, copying, or scanning.

To fax to numbers you use regularly, you can assign a one-touch key

or speed-dial code as described in the User Guide on the product CD.

If you have electronic phone books available, you may be able to use

them for selecting recipients. Electronic phone books are generated

with third-party applications.

Note If y ou want to improve the quality of a paper document before faxing

it, scan the document, straighten or clean the image, and send it

as a fax from the software. For more information, see the product

software Help.

To receive faxes when you hear fax tones

In general, incoming faxes to the product are automatically received.

However, if other devices are connected to the same phone line, the

product may not be set to answer automatically.

If the product is connected to a phone line that receives both fax and

phone calls, and you hear fax tones when you answer the extension

phone, receive the fax in one of two ways:

If you are near the product, press fax/send on the control panel.

Press 1-2-3 in sequence on the extension phone keypad, listen

for fax transmission sounds, then hang up.

Note F or the 1-2-3 sequence to work, the extension phone setting must

be set to Yes in the fax menu.

32 Chapter 2 - Operation EN

Page 35

Alphanumeric buttons

On the HP 3330, use the alphanumeric buttons to enter fax data into

the product’s display screen and dial phone numbers for faxing. For a

full description on using alphanumeric key characters, see “Using

Dialing Characters” in the User Guide on the product CD.

Figure 6. Alphanumeric controls

Note K eypad buttons are numeric on non-fax models and alphanumeric

on the HP LaserJet 3330mfp.

EN Identifying the control panel components 33

Page 36

Menu and cancel controls

Use these controls to choose menu options, determine the product’s

status, and cancel the current job.

Figure 7. Menu and cancel buttons

Copy, scan, and start controls

Use these controls to change commonly used default settings, to start

scanning, and to start copying. For instructions on copying, see

“Copying” in the User Guide. For instructions on scanning, see

“Scanning” in the User Guide. The User Guide is located on the

product CD.

Figure 8. Copy, scan, and start controls

34 Chapter 2 - Operation EN

Page 37

Control panel menu structure

A hierarchical diagram of the control panel menu structure follows.

Refer to this menu structure to make changes to settings and

features.

To print the control panel menu structure

1 Press menu/enter.

2 Use the < or > key to select Reports and then press menu/

enter

.

3 Use the < or > key to select Menu Structure and then press

menu/enter. The product exits the Menu settings and prints the

report.

To see which settings are currently selected, print a configuration

report.

To use the control panel keys

1 Press menu/enter to begin.

2 Use the < or > key to select one of the choices from the main

Menu, and then press

menu/enter.

3 Use the < or > key to select one of the choices from the submenu

and press

4 If applicable, use the < or > key to select one of the choices from

the second submenu and press

EN Control panel menu structure 35

menu/enter.

menu/enter.

Page 38

Table 9. Control panel menu structure

Main Menu Submenu Submenu

Fax Job Status

Fax Functions.............. Send Fax Later

Time/Date, Header...... Time/Date

Copy Setup..... ............. Default Qual i ty

Reports........................ Demo Page

Stop Recv To PC

Reprint Last

Polling Receive

Clear Saved Faxes

Fax Header

Def. Light/Dark

Def. Collation

Def. # Of Copies

Def. Redu/Enlrg

Fax Activity Log....................

Fax Call Report....................

PhoneBook Report

Menu Structure

Config Report

Block Fax List

PCL Font List

PS Font List

All Fax Reports

Print Log Now

Auto Log Print

Print Report Now

Print Report

Include 1st Page

36 Chapter 2 - Operation EN

Page 39

Table 9. Control panel menu structure

Main Menu Submenu Submenu

Fax Setup.................... Phone Book .........................

Fax Send Setup ...................

Fax Recv. Setup..................

All Faxes..............................

Common Settings........ Language

Def. Paper Size

Print Density

Volume Settings................... Alarm Volume

Service......... ................ Print T.30 Trace

Restore Defaults

Cleaning Mode

Power Save T ime

Less Paper Curl

Individual Setup

Add

Delete

Group Setup

Add Group

Delete Group

Del. # In Group

Delete All

Def. Resolution

Def. Light/Dark

Dialing Mode

Redial On Busy

Redial-No Answer

Dial Prefix

Detect Dial Tone

Billing Codes

Answer Mode

Rings To Answer

Answer Ring Type

Extension Phone

Silence Detection

Fit To Page

Stamp Faxes

Forward Fax

Block Faxes

Add Entry

Delete Entry

Clear All

Error Correction

V. 34

Ring Volume

Key Press Volume

EN Control panel menu structure 37

Page 40

Control panel error messages

These control panel error messages are listed alphabetically.

Messages are accompanied by the cau se of the messa ge and us erlevel steps to resolve the problem.

Table 10. Control panel error messages

Message Cause Solution

Cleaning Mode.

Wait 1-3 Min.

Fax Busy.

Canceled Send

### Is Empty

[Enter] To Add

###: [Group Name]

Phbook/SpeedDial

50 Fuser Error

The product is running an internal

cleaning cycle.

The fax line to which you were

sending a fax was busy. The

product has cancelled sending

the fax.

The one-touch key or speed-dial

code has not been programmed

and therefore cannot be added to

a group.

The product is waiting for you to

press a programmed one-touch

key or enter a speed-dial code to

a group-dial code.

The product has experienced an

internal hardware error.

Wait for the product to finish the

cleaning cycle. The message will

clear when the cycle is finished.

Call the recipient to ensure that

the fax machine is on and ready.

Check that you are dialing the

correct fax number.

Check that the redial on busy

option is enabled.

Unplug the product telephone

cord from the wall, plug in a

telephone, and try making a call.