Page 1

HP Linear Barcode Scanner II

User Guide

Page 2

© Copyright 2016 HP Development Company,

L.P.

The information contained herein is subject to

change without notice. The only warranties for

HP products and services are set forth in the

express warranty statements accompanying

such products and services. Nothing herein

should be construed as constituting an

additional warranty. HP shall not be liable for

technical or editorial errors or omissions

contained herein.

First Edition: December 2016

Document Part Number: 915238-001

Page 3

About This Guide

This guide provides information on setting up and using the HP Linear Barcode Scanner II.

WARNING! Indicates a hazardous situation that, if not avoided, could result in death or serious injury.

CAUTION: Indicates a hazardous situation that, if not avoided, could result in minor or moderate injury.

IMPORTANT: Indicates information considered important but not hazard-related (for example, messages

related to property damage). A notice alerts the user that failure to follow a procedure exactly as described

could result in loss of data or in damage to hardware or software. Also contains essential information to

explain a concept or to complete a task.

NOTE: Contains additional information to emphasize or supplement important points of the main text.

TIP: Provides helpful hints for completing a task.

iii

Page 4

iv About This Guide

Page 5

Table of contents

1 Setting up the scanner ................................................................................................................................... 1

Connecting the cable ............................................................................................................................................. 1

2 Using the scanner .......................................................................................................................................... 2

Reading barcodes ................................................................................................................................................... 2

3 Safety and maintenance ................................................................................................................................ 3

Ergonomic recommendations ............................................................................................................................... 3

Cleaning .................................................................................................................................................................. 4

4 Programming the scanner .............................................................................................................................. 5

Using programming barcodes ............................................................................................................................... 5

Conguring other setting ...................................................................................................................................... 5

Resetting the defaults ........................................................................................................................................... 5

5 Selecting the interface type ........................................................................................................................... 6

Conguring the interface ....................................................................................................................................... 6

Keyboard interface ................................................................................................................................................. 7

Scancode tables ..................................................................................................................................................... 7

Country mode ........................................................................................................................................................ 8

Caps lock state ..................................................................................................................................................... 11

6 Reading parameters ..................................................................................................................................... 12

Good read green spot duration ............................................................................................................................ 12

7 Scan modes ................................................................................................................................................. 13

Appendix A Technical specications ................................................................................................................. 15

Appendix B LED and beeper indications ............................................................................................................ 17

Error codes ........................................................................................................................................................... 18

Appendix C Technical support .......................................................................................................................... 19

Contacting support .............................................................................................................................................. 19

Preparing to call technical support ..................................................................................................................... 19

v

Page 6

vi

Page 7

1 Setting up the scanner

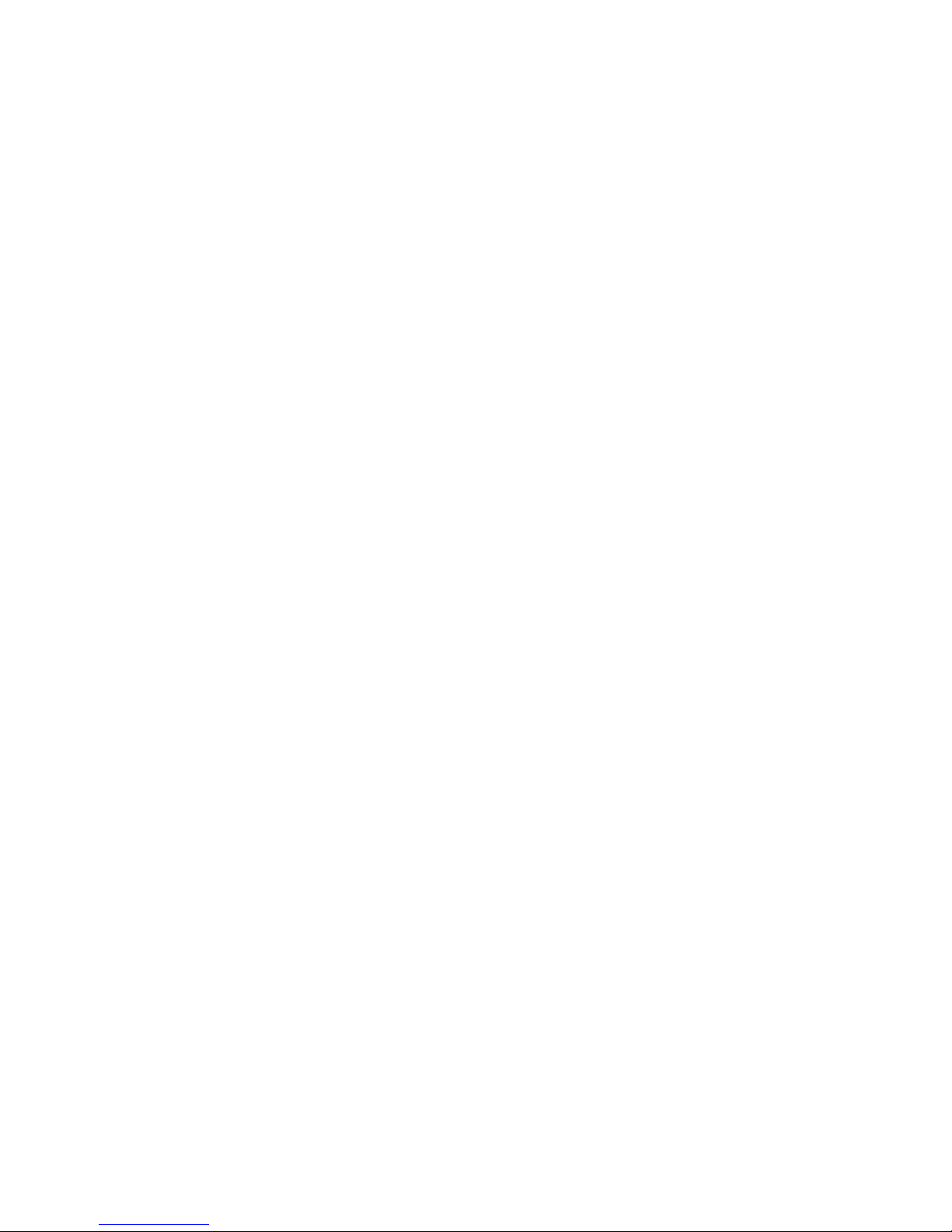

Connecting the cable

1. Connect the interface cable to the bottom of the scanner.

2. Connect the other end of the interface cable to a USB connector on the host device.

To disconnect the cable from the scanner, insert a paper clip into the hole in the front of scanner and remove

the cable from the scanner as shown below.

Connecting the cable 1

Page 8

2 Using the scanner

Reading barcodes

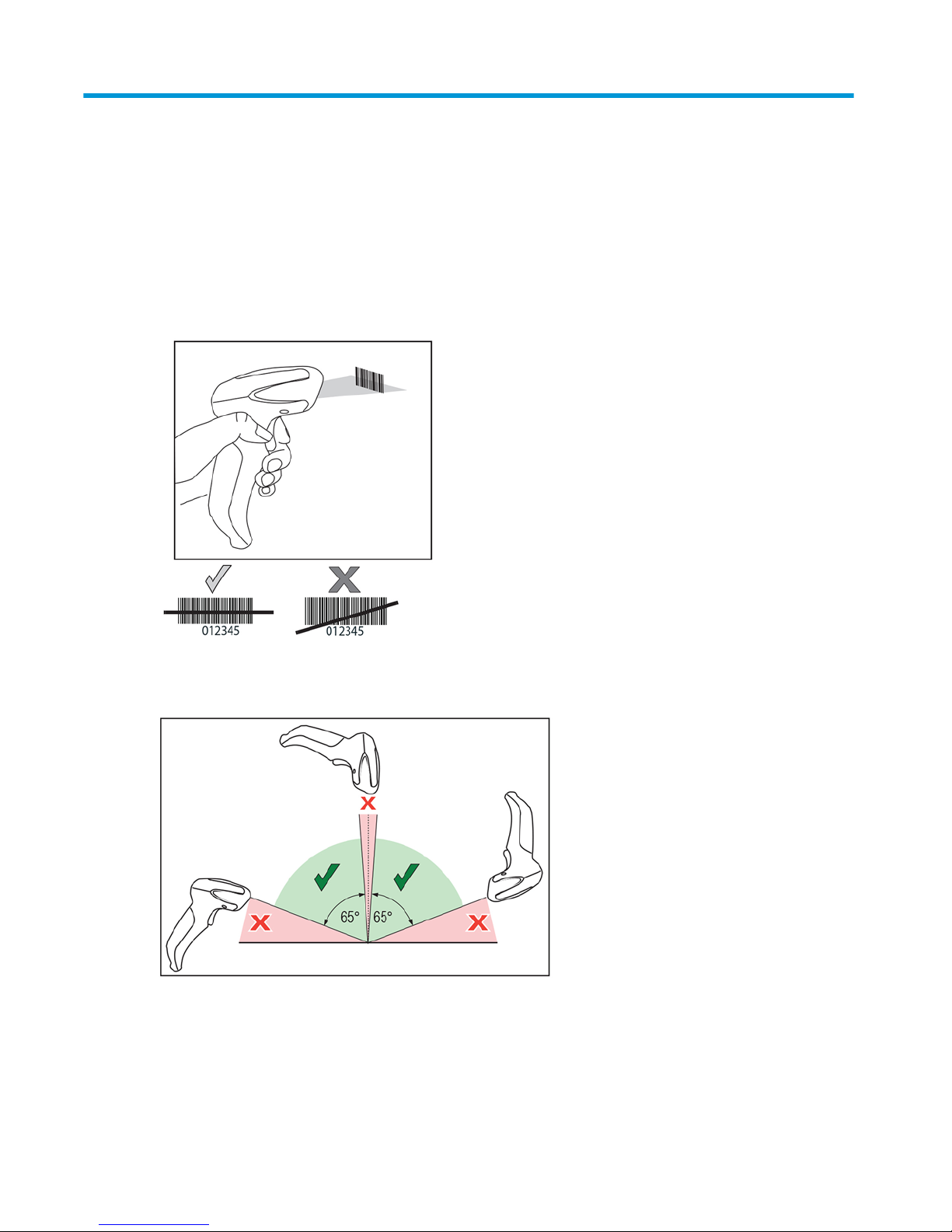

Point the scanner at the target and pull the trigger to enable the illuminator (red beam) to decode the barcode

label. The illuminator will remain on until the trigger is released, or a label is read, or the "maximum scan on

time" is reached. When scanning a barcode label, you can adjust the distance or angle to the label to help

facilitate reading. Make sure that the scan line crosses every bar and space of the barcode.

Do not hold the scanner directly over the barcode. Light reecting directly back into the scanner from the

barcode is known as specular reection. This specular reection can make decoding diicult. You can tilt the

scanner up to 65° forward or back and achieve a successful decode.

2 Chapter 2 Using the scanner

Page 9

3 Safety and maintenance

Ergonomic recommendations

WARNING! In order to avoid or minimize the potential risk of ergonomic injury, follow the recommendations

below. Consult with your local Health & Safety Manager to ensure that you are adhering to your company’s

safety programs to prevent employee injury.

●

Reduce or eliminate repetitive motion

●

Maintain a natural position

●

Reduce or eliminate excessive force

●

Keep objects that are used frequently within easy reach

●

Perform tasks at correct heights

●

Reduce or eliminate vibration

●

Reduce or eliminate direct pressure

●

Provide adjustable workstations

●

Provide adequate clearance

●

Provide a suitable working environment

●

Improve work procedures

Ergonomic recommendations 3

Page 10

Cleaning

Exterior surfaces and scan windows exposed to spills, smudges, or debris require periodic cleaning to ensure

best performance during scanning.

Use a soft, dry cloth to clean the product. If the product is very soiled, clean it with a soft cloth moistened with

a diluted non-aggressive cleaning solution or diluted ethyl alcohol.

IMPORTANT: Do not use abrasive or aggressive cleansing agents or abrasive pads to clean scan windows or

plastics.

Do not spray or pour liquids directly onto the unit.

4 Chapter 3 Safety and maintenance

Page 11

4 Programming the scanner

The scanner is factory-congured with a set of standard default features. After scanning the interface

barcode from the “Interfaces” section, select other options and customize your scanner using the

programming barcodes available in the HP Retail Linear Barcode Scanner Programming Reference Guide (PRG).

Check the corresponding features section for your interface, and the Data Editing and Symbologies chapters

of the PRG.

Using programming barcodes

This guide contains barcodes that allow you to recongure your scanner. Some programming barcode labels,

like the Reset Default Settings barcode, require only the scan of that single label to enact the change.

Other barcodes require the scanner to be placed in Programming Mode prior to scanning them. Scan an

ENTER/EXIT barcode once to enter Programming Mode, scan the desired parameter settings, and then scan

the ENTER/EXIT barcode again to accept your changes. The scanner exits Programming Mode and returns to

normal operation.

Conguring other setting

Additional programming barcodes are available in the PRG that allow you to customize programming

features. If your installation requires dierent programming than the standard factory default settings, refer

to the PRG.

Resetting the defaults

If you aren’t sure what programming options are in your scanner, or you’ve changed some options and want

your custom factory settings restored, scan the barcode below to reset the scanner to its initial conguration.

Refer to the PRG for other options and a listing of standard factory settings.

NOTE: Factory defaults are based on the interface type. Be sure your scanner is congured for the correct

interface before scanning this label. See Selecting the interface type on page 6 for more information.

Reset Default Settings

Using programming barcodes 5

Page 12

5 Selecting the interface type

Upon completing the physical connection between the scanner and its host, scan the appropriate barcode to

select your system’s correct interface type. Information and programming options for each interface type are

provided in this chapter. For defaults and additional information, refer to the PRG.

Conguring the interface

Scan the appropriate programming barcode to select the interface type for your system.

NOTE: Unlike some other programming features and options, interface selections require that you scan only

one programming barcode label. DO NOT scan an ENTER/EXIT barcode prior to scanning an interface selection

barcode.

Some interfaces require the scanner to start in the disabled state when powered up. If additional scanner

conguration is desired while in this state, pull the trigger and hold for ve seconds. The scanner will change

to a state that allows programming with barcodes.

USB-COM

USB COM to simulate RS-232 standard interface

Select USB-COM-STD

Download the correct USB Com driver from http://www.hp.com/support.

USB-OEM

USB-OEM

(can be used for OPOS/UPOS/JavaPOS)

Select USB-OEM

6 Chapter 5 Selecting the interface type

Page 13

Keyboard interface

Use the programming barcodes below to select options for a USB keyboard.

Keyboard

USB keyboard with alternate key encoding

Select USB Alternate Keyboard

USB keyboard with standard key encoding

Select USB Keyboard

Scancode tables

Refer to the PRG for information about control character emulation for keyboard interfaces.

Keyboard interface 7

Page 14

Country mode

This feature species the country/language supported by the keyboard. Only USB Keyboard (without alternate

key encoding) supports all country modes.

All other interfaces support ONLY the following country modes: U.S., Belgium, Britain, France, Germany, Italy,

Spain, and Sweden.

Country mode

ENTER/EXIT PROGRAMMING MODE

Country Mode = U.S.

Country Mode = Belgium

Country Mode = Britain

Country Mode = Croatia*

Country Mode = Czech Republic*

Country Mode = Denmark*

8 Chapter 5 Selecting the interface type

Page 15

Country mode

Country Mode = France

Country Mode = French Canadian

Country Mode = Germany

Country Mode = Hungarian

Country Mode = Italy

Country Mode = Japanese 106-key*

Country Mode = Lithuanian

Country Mode = Norway*

Country mode 9

Page 16

Country mode

Country Mode = Poland*

Country Mode = Portugal*

Country Mode = Romania*

Country Mode = Slovakia*

Country Mode = Spain

Country Mode = Sweden

Country Mode = Switzerland*

*Supports only the interfaces listed in the Country Mode feature

description.

10 Chapter 5 Selecting the interface type

Page 17

Caps lock state

This option species the format in which the reader sends character data. This is used by USB keyboard

interfaces.

00 = Caps lock o, send character data in normal format.

01 = Caps lock on, send character data in reverse case.

02 = Auto Caps lock.

Caps lock state

ENTER/EXIT PROGRAMMING MODE

Caps Lock State = Caps Lock OFF

Caps Lock State = Caps Lock ON

Caps Lock State = AUTO Caps Lock Enable

Caps lock state 11

Page 18

6 Reading parameters

Move the scanner toward the target and center the aiming pattern and illumination system to capture and

decode the image. See Using the scanner on page 2 for more information.

The aiming system will briey switch o after the acquisition time, and if no code is decoded will switch on

again before the next acquisition. The illuminator will remain on until the symbol is decoded.

As you read code symbols, adjust the distance at which you are holding the scanner.

Good read green spot duration

Successful reading can be signaled by a good read green spot. Use the barcodes that follow to specify the

duration of the good read pointer beam after a good read.

Good read green spot duration

ENTER/EXIT PROGRAMMING MODE

Green Spot Duration = Disable (Green Spot is O)

Green Spot Duration = Short (300 msec)

Green Spot Duration = Medium (500 msec)

Green Spot Duration = Long (800 msec)

12 Chapter 6 Reading parameters

Page 19

7 Scan modes

The scanner can operate in one of several scanning modes.

Trigger Single: When the trigger is pulled, scanning begins until one of the following occurs:

●

A programmable duration has elapsed

●

A label has been read

●

The trigger is released

●

"Maximum scan on time" is reached

This mode is associated with typical handheld scanner operation.

Trigger Hold Multiple: When the trigger is pulled, scanning begins and the product scans until the trigger is

released, a programmable duration has elapsed, or the "maximum scan on time" is reached. Reading a label

does not disable scanning. "Double read" time-out prevents undesired multiple reads while in this mode.

Trigger Pulse Multiple: Scanning begins when the trigger is pulled and continues after the trigger is released

until the trigger is pulled again or until the "maximum scan on time" is reached or a programmable duration

has elapsed. Reading a label does not disable scanning. "Double read" time-out prevents undesired multiple

reads.

Flashing: The reader ashes on and o regardless of the trigger status. Code reading takes place only during

the ash on time. "Double read" time-out prevents undesired multiple reads.

Always On: The illuminator is always on regardless of the trigger status and the reader is always ready for

code reading. "Double read" time-out prevents undesired multiple reads.

Object Detection: In this mode the scanner looks for scene changes within its eld of view to initiate read

attempts. To help the user nd the position of the reading line, the green spot can be congured to be on.

When an object’s presence is detected in the scene, the illuminator turns on and turns o the green spot.

Scanning continues until the Object Gone Timeout expires after last read. "Double read" time-out prevents

undesired multiple reads while the scanner is in this mode.

Trigger Object Sense: This is similar to Object Detection. A trigger pull is required to activate the decoder.

NOTE: See the Product Reference Guide (PRG) for more information.

Scan mode

Scan Mode = Trigger Single

Scan Mode = Trigger Hold Multiple

13

Page 20

Scan mode

Scan Mode = Trigger Pulse Multiple

Scan Mode = Flashing

Scan Mode = Always On

Scan Mode = Object Detection

Scan Mode = Trigger Object Sense

14 Chapter 7 Scan modes

Page 21

A Technical specications

The following table contains physical and performance characteristics, user environment, and regulatory

information.

Item Description

Physical characteristics

Color Black

Dimensions Height 6.4"/163 mm

Length 3.6"/91 mm

Width 1.6"/41 mm

Weight (without cable) Approximately 5.3 ounces/150 g

Electrical characteristics

Voltage and current

1

Input voltage: 4.5 - 14.0 VDC

Operating (typical): 140 mA

Operating (max): 380 mA

Idle/standby (typical): 50 mA

Performance characteristics

Light source LEDs

Roll (tilt) tolerance

2

Up to ± 45°

Pitch tolerance

2

± 65°

Skew (yaw) tolerance

2

± 70°

Field of view 56 ± 2°

Print contrast minimum 25% minimum reectance

1

Typical input current measured @5V under factory default conguration.

2

Based on ISO 15423 specications.

Depth of eld (guaranteed)

1

Symbology

Code 39 5 mil: 0.8" - 7" (2 cm - 18 cm)

7.5 mil: 0.8"- 12" (2 cm - 30 cm)

10 mil: 0.8" - 17" (2 cm - 44 cm)

20 mil: up to 29.5" (75 cm)

EAN 13 mil: 0.8" - 23" (2 cm - 58 cm)

15

Page 22

Depth of eld (guaranteed)

1

Minimum element width Max Resolution = 4 mil

1

13 mils DOF based on EAN. All other 1D codes are Code 39. All labels grade A, typical environmental

light, 20°C, label inclination 10°

Decode capability

1D barcodes

UPC/EAN/JAN (A, E, 13, 8); UPC/EAN/JAN (including P2 /P5); UPC/EAN/JAN (including ISBN / Bookland &

ISSN); UPC/EAN Coupons; Code 39 (including full ASCII); Code 39 Trioptic; Code39 CIP (French

Pharmaceutical); LOGMARS (Code 39 w/ standard check digit enabled); Code 32 (Italian Pharmacode 39);

Code 128; Code 128 ISBT; Interleaved 2 of 5; Standard 2 of 5; Interleaved 2 of 5 CIP (HR); Industrial 2 of

5; IATA 2 of 5 Air cargo code; Datalogic 2 of 5, Code 4, Code 5, Follet 2 of 5, BC412, Code 11; Codabar;

Codabar (NW7); ABC Codabar; EAN 128; Code 93 ; MSI; PZN; Plessey; Anker Plessey; GS1 DataBar

Omnidirectional; GS1 DataBar Limited; GS1 DataBar Expanded; GS1 DataBar Truncated; DATABAR

Expanded Coupon.

Interfaces supported Keyboard Wedge, USB Com Std., USB Keyboard, USB OEM

User environment

Operating temperature 0°C to 50°C (32°F to 122°F)

Storage temperature -40°C to 70°C (-40°F to 158°F)

Humidity Operating: 0% to 95% relative humidity, non-condensing

Drop specications Scanner withstands 18 drops from 1.5 meters (5.0 feet) to

concrete

Ambient light immunity Up to 120,000 Lux

Contaminants spray/rain/dust/particulates IEC 529-IP42

16 Appendix A Technical specications

Page 23

B LED and beeper indications

The scanner’s beeper sounds and its top multi-color LED illuminates to indicate various functions or errors. An

optional “green spot” also performs useful functions. The following tables list these indications. One

exception to the behaviors listed in the tables is that the scanner’s functions are programmable, and so may

or may not be turned on. For example, certain indications such as the power-up beep can be disabled using

programming barcode labels.

Indicator Description LED Beeper

Power-up beep The scanner is in the process of

powering up.

N/A Scanner beeps four times at

highest frequency and volume

upon power up.

Good read beep A label has been successfully

scanned.

LED behavior for this indication

is congurable via the feature

“Good Read: When to Indicate”

(see the PRG for information).

The scanner will beep once at

current frequency, volume,

mono/bitonal setting and

duration upon a successful

label scan.

ROM failure There is an error in the

scanner’s software/

programming.

Flashes. Scanner sounds one error beep

at highest volume.

Limited scanning label read Indicates that a host

connection is not established.

N/A Scanner “chirps” six times at

the highest frequency and

current volume.

Scanner active mode The scanner is active and ready

to scan.

The LED is steadily lit1.

N/A

Scanner disabled The scanner has been disabled

by the host.

The LED blinks continuously. N/A

Green spot1 ashes

momentarily

Upon successful read of a label,

the software turns the green

spot on for the time specied

by the congured value.

N/A N/A

1

Except when in sleep mode or when a Good Read LED Duration other than 00 is selected.

Programming mode - The following indications ONLY occur when the scanner is in programming mode.

Indication Description LED Beeper

Label programming mode entry A valid programming label has

been scanned.

LED blinks continuously. Scanner sounds four low-

frequency beeps.

Label programming mode

rejection of label

A label has been rejected. N/A Scanner sounds three times at

lowest frequency and current

volume.

Label programming mode

acceptance of partial label

In cases where multiple labels

must be scanned to program

one feature, this indication

acknowledges each portion as

it is successfully scanned.

N/A Scanner sounds one short beep

at highest frequency and

current volume.

17

Page 24

Indication Description LED Beeper

Label programming mode

acceptance of programming

Conguration option(s) have

been successfully programmed

via labels and the scanner has

exited programming mode.

N/A Scanner sounds one high-

frequency beep and four lowfrequency beeps followed by

reset beeps.

Label programming mode

cancel item entry

Cancel label has been scanned. N/A Scanner sounds two times at

low frequency and current

volume.

Error codes

Upon startup, if the scanner sounds a long tone, this means the scanner has not passed its automatic Selftest

and has entered FRU (Field Replaceable Unit) isolation mode. If the scanner is reset, the sequence will be

repeated. Press and release the trigger to hear the FRU indication code.

The following table describes the LED ashes/beep codes associated with an error found.

Number of LED ashes/beeps Error Corrective action

1 Conguration Contact Helpdesk for assistance.

2 Interface PCB Contact Helpdesk for assistance.

6 Digital PCB Contact Helpdesk for assistance.

11 Imager Contact Helpdesk for assistance.

18 Appendix B LED and beeper indications

Page 25

C Technical support

Contacting support

To resolve a hardware or software problem, go to http://www.hp.com/support. Use this site to get more

information about your product, including links to discussion forums and instructions on troubleshooting. You

can also

nd information on how to contact HP and open a support case.

Preparing to call technical support

If you can not solve a problem, you may need to call technical support. Have the following information

available when you call:

●

If the product is connected to an HP POS computer, provide the serial number of the POS computer

●

Purchase date on invoice

●

The spares part number located on the product

●

Condition under which the problem occurred

●

Error messages received

●

Hardware conguration

●

Name and version of the hardware and software you are using

Contacting support 19

Loading...

Loading...