Page 1

Latex 300 Printer Series

Service Manual

Publication Date: April 2014

Edition: Edition 1

Page 2

© 2014 Hewlett-Packard Development

Company, L.P.

Legal notices

This document contains proprietary

information that is protected by copyright. All

rights are reserved. No part of this document

may be photocopied, reproduced, or translated

to another language without the prior written

consent of Hewlett-Packard Company.

Warranty

The information contained in this document is

subject to change without notice.

Hewlett-Packard makes no warranty of any

kind with regard to this material, including,

but not limited to, the implied warranties of

merchantability and fitness for a particular

purpose.

Hewlett-Packard shall not be liable for errors

contained herein or for incidental or

consequential damages in connection with the

furnishing, performance, or use of this

material.

Page 3

Safety

The procedures described in this manual are to

be performed by HP-qualified service

personnel only.

Electrical shock hazard

• Ensure that the AC power outlet (mains) has a

protective earth (ground) terminal.

• Disconnect the printer (both power cords)

from the power source performing any

maintenance or servicing operation. The rear

switch is not the disconnecting device, unplug

all power cords before servicing the printer.

• Prevent water or any other liquids from

running onto electrical components or circuits,

or through openings in the enclosure.

Electrostatic discharge

See the beginning of Chapter 4 of this manual

for precautions you should take to prevent

damage to the printer circuits from

electrostatic discharge.

Safety symbols

Serious hazards leading to death, injury, or

damage may result if you do not take the

following precautions:

• The Warning symbol calls attention to a

procedure, practice, or the like, which, if not

correctly performed or adhered to, could result

in personal injury. Do not proceed beyond a

Warning symbol until the indicated conditions

are fully understood and met.

• The Caution symbol calls attention to an

operating procedure, practice, or the like,

which, if not correctly performed or adhered

to, could result in damage to or destruction of

part or all of the printer. Do not proceed

beyond a Caution symbol until the indicated

conditions are fully understood and met.

Page 4

Page 5

Using this manual

Purpose

This service manual contains information necessary to test, calibrate, and service the HP Latex 300 printer

series.

For information about using the printer, see the user’s guide.

Chapters

1 Printer systems

Use this chapter as a reference for technical information about the subsystems, components, and how they

work together.

Of particular importance are the diagrams included for each subsystem of the printer. They can be useful for

both troubleshooting and disassembly.

2 Troubleshooting

Whenever a printer is not functioning correctly due to a fault, use this chapter for step-by-step diagnosis

until you arrive at the solution, which may include replacing a part.

Troubleshooting always begins with a problem; so, when you enter the chapter, navigate to the proper

section and find the troubleshooting steps for your problem.

This chapter does not cover the procedures for the diagnostic tests you must perform while troubleshooting,

nor the replacement procedures you must complete to fix the problem.

3 System error codes

This chapter contains the system error codes which are displayed on the front panel and by the Embedded

Web Server. Each system error code shown in the chapter has a brief description and the steps required to

solve the error.

Most of the troubleshooting steps involve performing a test or a calibration, which can be found in the

following chapter. Before replacing any part that you suspect of causing the system error code, always

perform the test or calibration.

4 Tests, utilities, and calibrations

Use this chapter whenever you need to perform a diagnostic test, service utility, or service calibration. This

chapter is meant to provide procedures and relevant information, not troubleshooting information. For

troubleshooting information, see the Troubleshooting chapter.

These procedures are described in full, so that you know any relevant values for the test, as well as

information about what the printer is actually doing during the test.

The goal of diagnostic tests is to locate the root cause of the problem and the corresponding system error

code or message that will provide you with logical steps to resolution.

Some diagnostic tests or calibrations must be performed after removing a component.

5 Print quality

This chapter describes the print-quality diagnostic procedures. Further troubleshooting advice can be found

in the user’s guide.

6 Ink supplies

This chapter describes and discusses the components of the ink supply system.

ENWW v

Page 6

7 Parts and diagrams

The purpose of this chapter is to detail all of the available service parts of the printer. This information is

presented in tables, organized by subsystem, and includes the following:

●

Official service part names

●

Part numbers

●

Illustrations of the service parts

Use this chapter whenever you need to order a service part.

8 Removal and installation

The purpose of this chapter is to provide procedures for removing and installing service parts. Each service

part has a removal procedure detailed in this chapter, and installation procedures and notes are included as

needed.

Useful information such as access notes and screw types (head sizes) are provided to help you work

efficiently.

9 Preventive maintenance

Maintenance alerts are displayed by the front panel and Embedded Web Server whenever maintenance is

required. While most of these alerts can be resolved by the customer, some require a service engineer.

Use the preventive maintenance chapter whenever you need to perform a preventive maintenance procedure

due to an alert the customer receives from the front panel or Embedded Web Server, or to get reference

information on life counters and maintenance that must be performed by the customer.

10 Move, store, or repack the printer

This chapter gives advice on moving, storing, and repacking the printer.

11 Safety precautions

This is an industrial printer that uses high voltages: service operations can be hazardous. The safety chapter

covers all the guidelines and checks you need to perform in order to service the printer.

You are expected to have appropriate technical training and experience necessary to be aware of hazards to

which you may be exposed in performing a task, and take appropriate measures to minimize the risks to

yourself and to other people.

Readership

The primary readers of this service manual are HP service engineers, although secondary readership may

include resellers. All procedures must be performed by HP service engineers or authorized service-delivery

partners, except for those procedures clearly marked otherwise.

vi Using this manual ENWW

Page 7

Table of contents

1 Printer systems ............................................................................................................................................. 1

Electrical system .................................................................................................................................................... 2

Substrate path ..................................................................................................................................................... 22

Ink Delivery System (IDS) .................................................................................................................................... 29

Scan axis and carriage ......................................................................................................................................... 32

Service station and waste management ............................................................................................................ 36

Heating system .................................................................................................................................................... 39

Front panel ........................................................................................................................................................... 42

2 Troubleshooting .......................................................................................................................................... 43

Troubleshooting the printer ................................................................................................................................ 44

Troubleshooting system error codes .................................................................................................................. 44

Performing a service test on a failed assembly .................................................................................................. 45

Performing the necessary service calibrations .................................................................................................. 45

The printer does not power on ............................................................................................................................ 45

How to read the power switch LEDs .................................................................................................................... 46

How to read the Formatter LEDs ......................................................................................................................... 46

How to read other LEDs ....................................................................................................................................... 48

Voltage check at installation ............................................................................................................................... 50

Troubleshooting substrate jams or printhead crashes ...................................................................................... 50

The printer continuously rejects printheads ...................................................................................................... 51

The cutter does not function (Latex 360 only) ................................................................................................... 52

Troubleshooting the printer heaters .................................................................................................................. 52

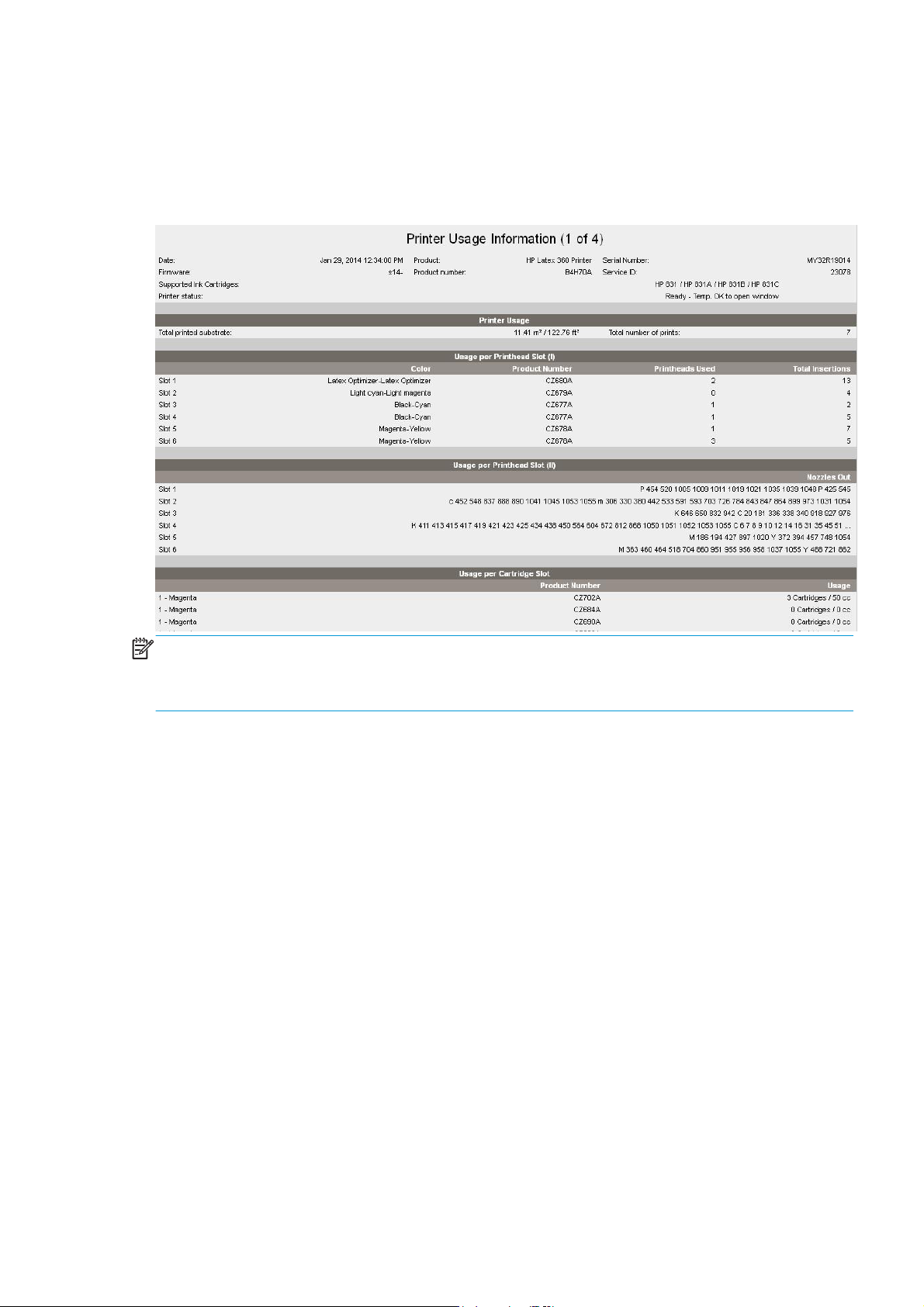

How to interpret the service information pages ................................................................................................. 55

How to obtain the printer log and the diagnostics package ............................................................................... 63

3 System error codes ...................................................................................................................................... 65

Introduction ......................................................................................................................................................... 66

System error codes and warnings—explanation ............................................................................................... 67

Continuable and non-continuable error codes ................................................................................................... 70

4 Service Tests, Utilities, and Calibrations ...................................................................................................... 142

Introduction ....................................................................................................................................................... 143

Initialization Self Test ....................................................................................................................................... 143

ENWW vii

Page 8

Diagnostic Menu ................................................................................................................................................ 143

Service Menu ...................................................................................................................................................... 164

5 Print quality .............................................................................................................................................. 188

Initial print-quality troubleshooting actions .................................................................................................... 189

RIP and front panel settings .............................................................................................................................. 189

How to use the print-quality plots .................................................................................................................... 189

Printhead alignment status plot ....................................................................................................................... 190

Printhead health test plot ................................................................................................................................. 190

Optimizer health test plot ................................................................................................................................. 191

Substrate-advance test plot ............................................................................................................................. 191

Advanced printhead health test plot ................................................................................................................ 193

Advanced alignment diagnostic print ............................................................................................................... 194

Plot for escalation only ..................................................................................................................................... 196

Geometry check ................................................................................................................................................. 196

Scan-axis check ................................................................................................................................................. 197

Misregistration check ........................................................................................................................................ 198

Force drop detection ......................................................................................................................................... 199

Troubleshooting non-uniform curing ............................................................................................................... 199

Substrate advance issues .................................................................................................................................. 201

6 Ink supplies ............................................................................................................................................... 203

What are ink supplies? ...................................................................................................................................... 204

Waste management system ............................................................................................................................. 206

General information about the ink supplies ..................................................................................................... 207

General precautions when handling ink supplies ............................................................................................. 207

Priming the ink system ...................................................................................................................................... 207

When should you replace the ink supplies? ...................................................................................................... 208

Obtaining ink cartridge and printhead information .......................................................................................... 208

Troubleshoot ink cartridge and printhead issues ............................................................................................. 208

The front panel recommends replacing or reseating a printhead ................................................................... 209

Warranty information for ink supplies .............................................................................................................. 210

7 Parts and Diagrams .................................................................................................................................... 212

Printer Support .................................................................................................................................................. 213

Left Cover .......................................................................................................................................................... 214

Right cover ......................................................................................................................................................... 215

Front Covers ...................................................................................................................................................... 216

Top and Rear Covers .......................................................................................................................................... 217

Left Side Assemblies ......................................................................................................................................... 218

Right Side Assemblies ....................................................................................................................................... 219

Scan Axis Assemblies ........................................................................................................................................ 220

Carriage Assemblies .......................................................................................................................................... 221

viii ENWW

Page 9

Electronics ......................................................................................................................................................... 222

Drive Roller and Substrate Axis motor ............................................................................................................. 223

Substrate path ................................................................................................................................................... 224

Center Guide and Pinchwheels .......................................................................................................................... 225

Substrate Input Assemblies .............................................................................................................................. 226

Curing Assemblies ............................................................................................................................................. 227

Curing Fans Assemblies ..................................................................................................................................... 228

Printzone and Ink Collector ............................................................................................................................... 229

Take-Up Reel ..................................................................................................................................................... 230

Miscellaneous Parts .......................................................................................................................................... 231

8 Removal and installation ........................................................................................................................... 232

Introduction ....................................................................................................................................................... 236

Customer Self Repair parts ............................................................................................................................... 237

Service calibration guide to removal and installation ...................................................................................... 238

Drive roller ......................................................................................................................................................... 240

Front panel ........................................................................................................................................................ 244

Right cover ......................................................................................................................................................... 246

Left cover ........................................................................................................................................................... 249

Left impinging module cover ............................................................................................................................ 251

Right impinging module cover .......................................................................................................................... 252

Rear cover .......................................................................................................................................................... 253

Top cover ........................................................................................................................................................... 254

Right connector cover ....................................................................................................................................... 258

E-box extension ................................................................................................................................................. 260

Window sensor .................................................................................................................................................. 261

Belt assembly .................................................................................................................................................... 262

E-box .................................................................................................................................................................. 262

Impinging pressure sensor ................................................................................................................................ 264

Impinging recirculation cover ........................................................................................................................... 266

Impinging heater module .................................................................................................................................. 268

Impinging air curtain ......................................................................................................................................... 270

Impinging air curtain thermal switch ................................................................................................................ 272

Impinging air curtain resistors .......................................................................................................................... 273

Impinging air curtain fans ................................................................................................................................. 276

Room-temperature sensor ............................................................................................................................... 277

Impinging holding brackets ............................................................................................................................... 280

Impinging heater-controller enclosure ............................................................................................................ 284

Window trims ..................................................................................................................................................... 285

Output platen .................................................................................................................................................... 288

Input roller ......................................................................................................................................................... 290

Maintenance-cartridge door ............................................................................................................................. 291

Maintenance-cartridge door sensor ................................................................................................................. 292

Substrate sensor ............................................................................................................................................... 293

ENWW ix

Page 10

Right rollfeed module assembly ....................................................................................................................... 294

Left rollfeed module assembly ......................................................................................................................... 295

Take-up reel motor ........................................................................................................................................... 296

Take-up reel left module .................................................................................................................................. 298

Take-up reel deflector supports ....................................................................................................................... 299

Tension bar ........................................................................................................................................................ 301

Take-up reel sensors ......................................................................................................................................... 303

Line sensor assembly ........................................................................................................................................ 304

Color sensor assembly ...................................................................................................................................... 307

Color sensor actuator assembly ....................................................................................................................... 310

Cartridge tray ..................................................................................................................................................... 312

Opening the window .......................................................................................................................................... 313

Window .............................................................................................................................................................. 314

Top cover fans ................................................................................................................................................... 316

Rear fans ............................................................................................................................................................ 317

Scan-axis motor ................................................................................................................................................ 319

Oiler assembly ................................................................................................................................................... 322

Lubrication felts ................................................................................................................................................ 325

Floater and PIP assembly .................................................................................................................................. 326

Under-carriage protector assembly ................................................................................................................. 330

Front tube shelf ................................................................................................................................................. 331

Rear tube shelf .................................................................................................................................................. 332

Aerosol fan assembly ........................................................................................................................................ 334

Spit roller motor ................................................................................................................................................ 335

Cleaning roll motor assembly ........................................................................................................................... 336

Rewinder ............................................................................................................................................................ 337

Primer assembly ................................................................................................................................................ 341

Primer valves ..................................................................................................................................................... 343

Primer valves cable ........................................................................................................................................... 346

Service station ................................................................................................................................................... 348

Drop detector .................................................................................................................................................... 352

Cutter assembly ................................................................................................................................................ 354

Ink Supply Station (ISS) ..................................................................................................................................... 355

APS assembly .................................................................................................................................................... 359

Encoder strip and encoder sensor .................................................................................................................... 362

Carriage PCA ...................................................................................................................................................... 365

Carriage flex cables ........................................................................................................................................... 368

Carriage assembly ............................................................................................................................................. 370

Ink supply tubes and trailing cable ................................................................................................................... 375

Static front platens (360) .................................................................................................................................. 380

Static front platens (330) .................................................................................................................................. 381

Static front platens (310) .................................................................................................................................. 382

Substrate-axis motor ........................................................................................................................................ 383

Encoder disc and sensor .................................................................................................................................... 385

x ENWW

Page 11

Substrate lever assembly ................................................................................................................................. 387

Substrate lever sensor ...................................................................................................................................... 390

Ink Collector sensor ........................................................................................................................................... 391

Ink Collector sensor cable ................................................................................................................................. 393

Vacuum rubbers ................................................................................................................................................ 394

Roller gear protector ......................................................................................................................................... 396

Print-zone lockers ............................................................................................................................................. 397

OMAS .................................................................................................................................................................. 399

OMAS cable ........................................................................................................................................................ 401

Pinchwheel assembly ........................................................................................................................................ 403

Individual pinchwheel rollers ............................................................................................................................ 411

Vacuum fan ........................................................................................................................................................ 415

Vacuum fan cable .............................................................................................................................................. 417

Carriage bushings .............................................................................................................................................. 419

Formatter battery .............................................................................................................................................. 419

Solid State Drive (SSD) ...................................................................................................................................... 420

Heater control assembly fan ............................................................................................................................. 422

Heater control assembly ................................................................................................................................... 424

Ink supply station PCAs ..................................................................................................................................... 427

Interconnect PCA ............................................................................................................................................... 429

Formatter PCA ................................................................................................................................................... 430

OMAS controller PCA ......................................................................................................................................... 431

Power Supply Unit (PSU) ................................................................................................................................... 432

PrintMech PCA ................................................................................................................................................... 433

Engine PCA ......................................................................................................................................................... 433

Printer ID PCA ..................................................................................................................................................... 434

Air curtain and print-zone heater control PCA .................................................................................................. 435

Curing Control PCA ............................................................................................................................................. 435

Curing power interconnect PCA ......................................................................................................................... 437

LAN PCA .............................................................................................................................................................. 439

Inner light PCA ................................................................................................................................................... 439

Entry Mylar ........................................................................................................................................................ 441

Heater Control ................................................................................................................................................... 442

9 Preventive maintenance ............................................................................................................................ 444

Moisture on the printer ..................................................................................................................................... 445

Belt swelling ...................................................................................................................................................... 445

Clean the printer ................................................................................................................................................ 445

Clean and lubricate the carriage rail ................................................................................................................. 445

Clean the encoder strip ..................................................................................................................................... 445

Scheduled maintenance .................................................................................................................................... 446

Level of printer usage ....................................................................................................................................... 446

ENWW xi

Page 12

10 Repackaging instructions ......................................................................................................................... 448

Reuse packaging material ................................................................................................................................. 448

Removing consumables .................................................................................................................................... 448

Reinstalling retention parts .............................................................................................................................. 450

Securing with adhesive tape ............................................................................................................................. 452

Covering the printer .......................................................................................................................................... 454

Special checks before turning on the printer .................................................................................................... 459

11 Safety precautions ................................................................................................................................... 460

General safety guidelines .................................................................................................................................. 461

Electrical shock hazard ..................................................................................................................................... 461

Heat hazard ....................................................................................................................................................... 461

Fire hazard ......................................................................................................................................................... 461

Mechanical hazard ............................................................................................................................................. 462

Scan-axis encoder strip hazard ......................................................................................................................... 462

Lifting and handling ........................................................................................................................................... 462

Warning labels ................................................................................................................................................... 462

Index ........................................................................................................................................................... 465

xii ENWW

Page 13

1 Printer systems

●

Electrical system

●

Substrate path

●

Ink Delivery System (IDS)

●

Scan axis and carriage

●

Service station and waste management

●

Heating system

●

Front panel

ENWW 1

Page 14

Electrical system

Description

The electrical system controls all the printing systems and the heating systems inside the printer. Most parts

of the control electronics are placed inside the ’E-box’.

Components

The electronics can be divided into different functional subsystems and will be described accordingly.

●

Front Panel: The Front Panel includes a display, touchscreen, magic frame buttons, a power button, and

a speaker. It is connected to the Formatter PCA.

◦

HP Latex 310/330: The front panel has a 4.3” LCD display.

◦

HP Latex 360: front panel has a 8” LCD display.

●

Substrate Path: Controls the substrate movement; Drive Roller and Rewinder motors, Take-Up Reel,

two Vacuum Fans (controlled by an Eola PCA), Pinch Lever Sensor, Media Sensor.

◦

In the HP Latex 360 it also controls the OMAS sensor and Ink Collector/Platen Sensors.

●

Scan Axis: Printhead firing control and sensors for color and substrate detection (Carriage PCA,

encoder, Tetris and SOL (in HP Latex 360) sensors, and Carriage movement control using the scan

motor).

●

Service Station: Printhead maintenance. It controls the monocassette, web wipe, and spit on roll

motors, a drop detector, the primer system, an aerosol fan and some sensors.

●

Ink Supply: Control of ink through two ISS PCAs.

●

Curing Impinging System: Control of the impinging fans, pressure sensor, ambient temperature sensor

(310/330 only), and heater control that supplies the power to the impinging resistors.

●

Air Curtain and print-zone heaters: Provides the power and control for the air curtain resistors and

fans, and print zone resistors and fans. Also supplies the Air Curtain and Printzone Heaters Control box

cooling fan and ambient temperature sensor (HP360 only).

●

Inner Lights: Composed of three equal boards that illuminate the print zone.

2 Chapter 1 Printer systems ENWW

Page 15

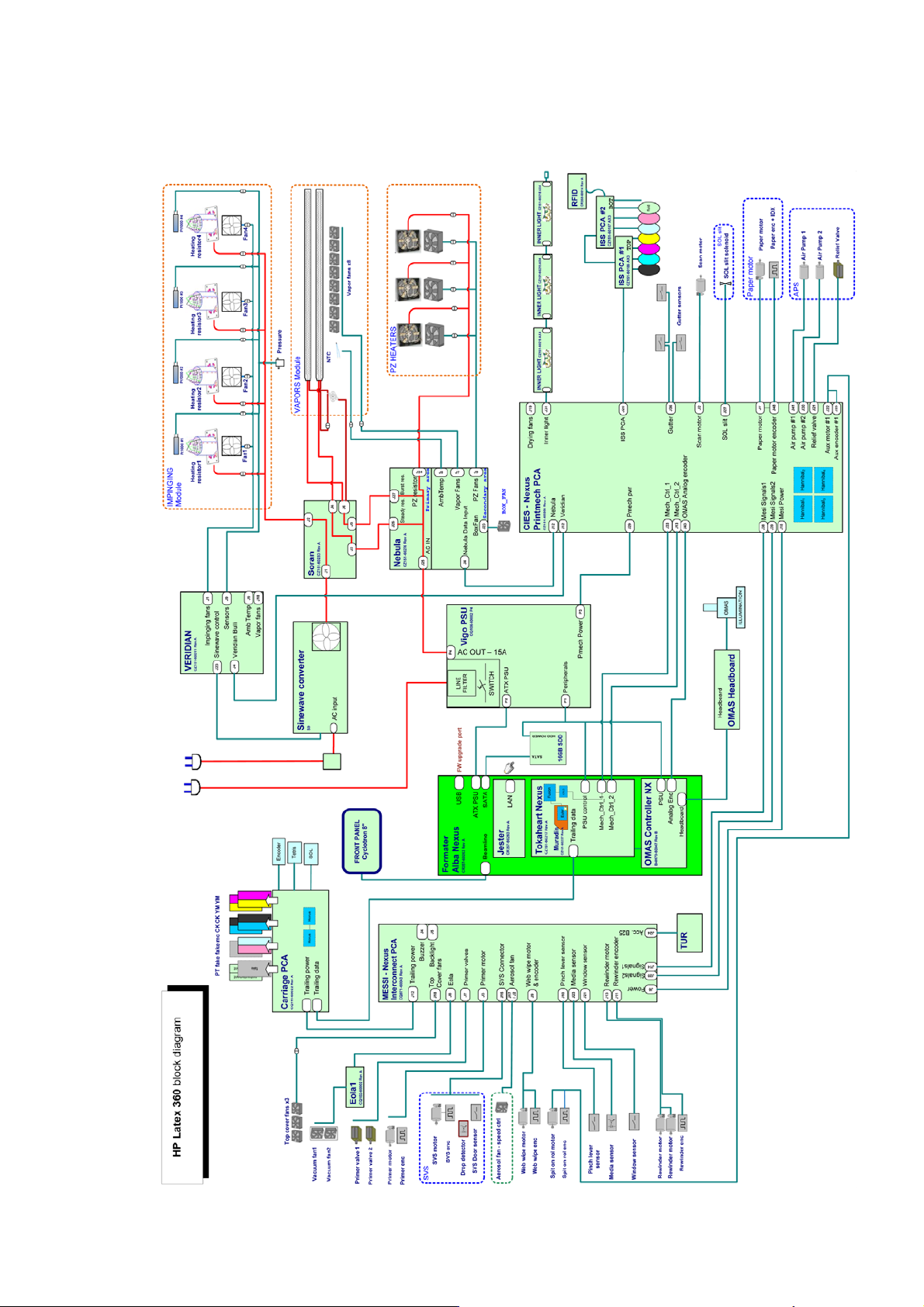

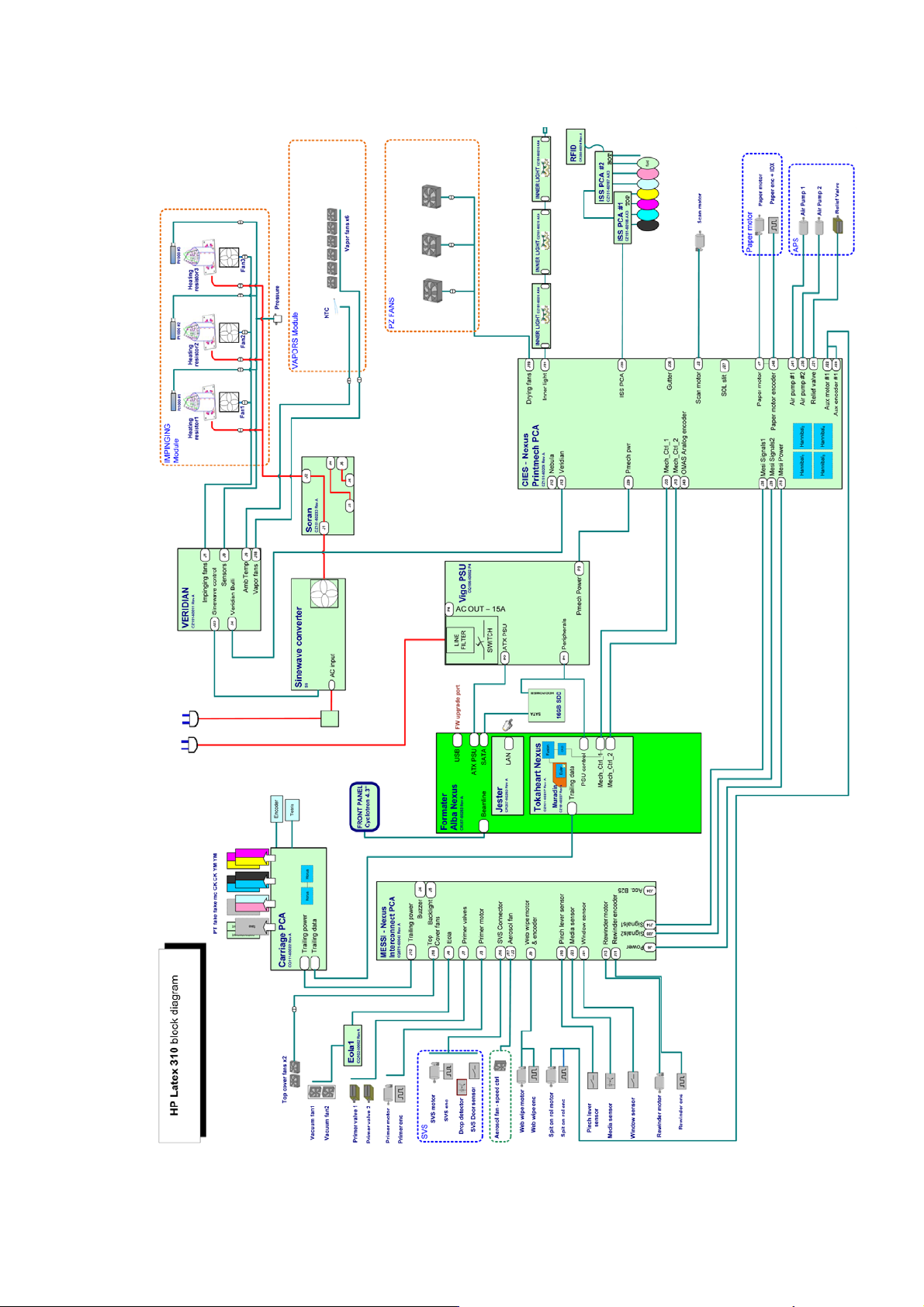

Block diagrams

HP Latex 360

ENWW Electrical system 3

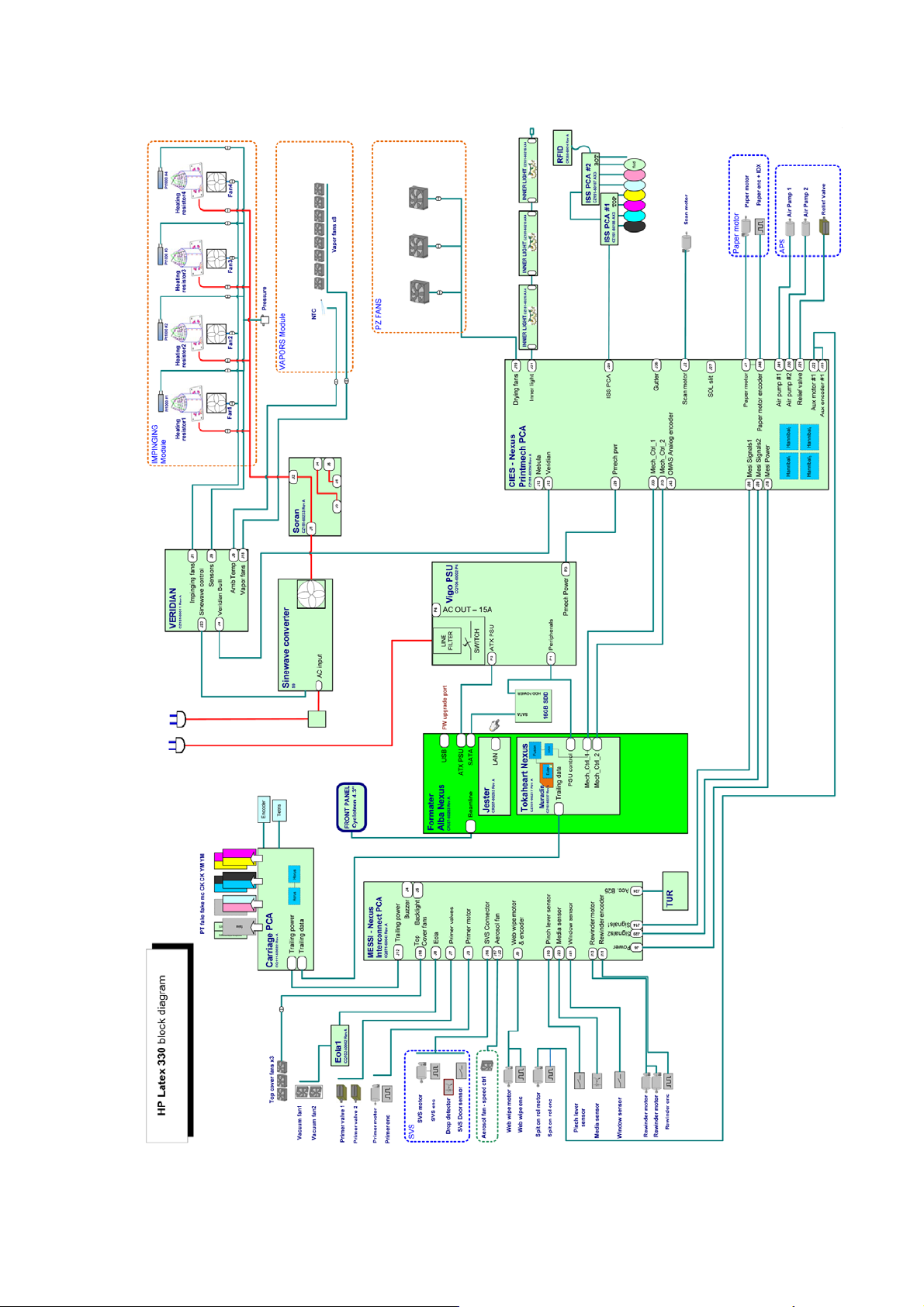

Page 16

HP Latex 330

4 Chapter 1 Printer systems ENWW

Page 17

HP Latex 310

ENWW Electrical system 5

Page 18

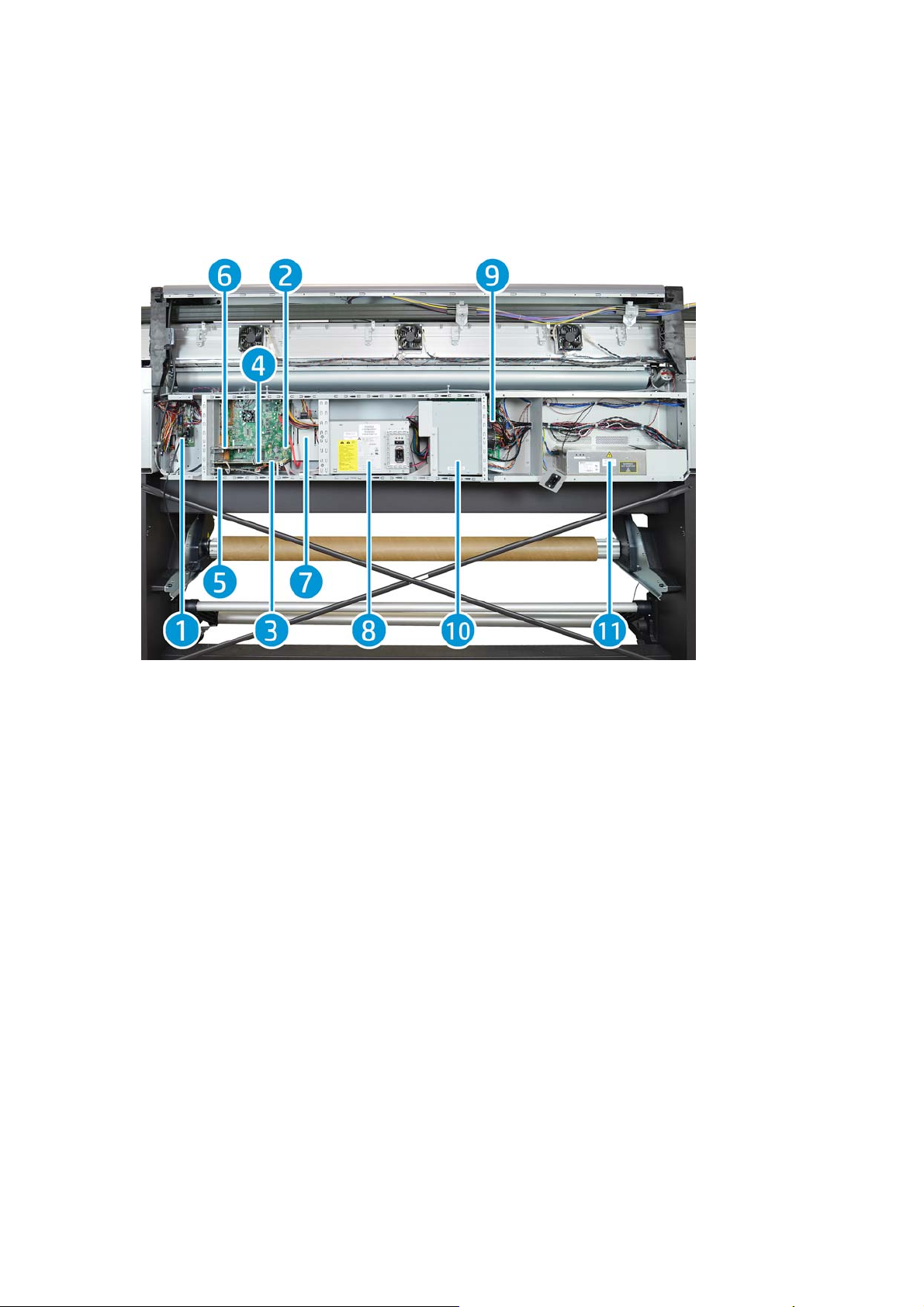

E-Box Components

Description

The E-box contains most of the electronics of the printer.

Components

1. Interconnect PCA

2. Formatter PCA

3. Engine PCA

4. Printer ID PCA

5. OMAS PCA

6. LAN PCA

7. Solid State Disk Drive (SSD)

8. Power Supply Unit (Main PSU)

9. Printmech PCA

10. Air Curtain and Printzone Heaters control PCA

11. Heater Control

Functionality

Interconnect PCA

The Interconnect PCA is an interconnect board with connectors that helps distribute power, and control

signals from the Printmech board, to all the elements connected to the right side of the machine, including

the following:

6 Chapter 1 Printer systems ENWW

Page 19

●

Take-Up Reel

●

Vacuum Fans (passes through; the actual control is inside Eola)

●

Valves and Motors for Primer, Rack Engage, SVS, and Aerosol Fan

●

Top Cover Fans

●

Rewinder Motor

●

Pinch Lever, Media and Window Sensors

Formatter PCA

The motherboard of the printer. It is the same type of board as found in a standard computer.

Engine PCA

The main controller of the printer. It is responsible for all the processes performed in real-time, and is the

ultimate controller of all electromechanical systems. The Engine PCA controls all substrate path components

(Drive Roller, Spindle Motors, OMAS, etc.), and all non-substrate path components (Carriage, Scan Axis Motor,

Print Head Cleaning Assembly, Service Station, etc). Attached to this board, is the Printer ID PCA.

Printer ID PCA

Contains printer identification. When replacing the Engine PCA, take care not to lose it.

OMAS PCA (360 only)

Controls the Optical Media Advance Sensor, used to measure substrate advance.

LAN Communication Card

Provides LAN communication.

Solid State Disk Drive (SSD)

Contains:

●

The printer firmware

●

The operating system

●

All calibration values, product number, serial number, and so on. In order to avoid loss in the case of

SSD failure, a backup is made in the ISS top board.

IMPORTANT: In order to prevent any loss of calibration values, do not replace the following at the same

time:

●

The Hard Disk Drive and the ISS Top Board.

Power Supply Unit (Main PSU)

This PSU delivers power to all the parts of the printer except heater elements. The internal rails are: 5V_sb;

3V3, 5V, 12V, 24V, and 42V.

PrintMech PCA

The PrintMech PCA is mainly used to control the mechatronics of the printer. For routing reasons, only the

parts connected to the left side of the printer are connected to this board:

●

Scan-Axis Motor

●

Substrate-Axis Motor

●

Ink Pressurizing Pumps and Valve

ENWW Electrical system 7

Page 20

●

Ink Collector Sensors

●

Ink Supply PCAs Connection

●

Inner Light PCAs Connection

●

Spit-on-Roll Motor (routed to the right side of the printer)

The remaining functionality implemented in the PrintMech PCA is sent to the right side of the printer through

the Mini Interconnect PCA and its three cables (power + data).

Heater Control

Converts the input voltage from the mains to a voltage in the output that is controlled by the Curing Control

PCA, and depends on the quantity of power required for impinging.

The converter has three cables: one power cable for the input, one for output, and finally the control cable.

The control part of the converter that interfaces with the Curing Control PCA is powered at 24 V.

There are three LEDs: Status (off or fault), PWM (if power is being delivered to the output), and ACOK (if Vin is

in range).

Air Curtain and Printzone Heaters control PCA

Controls the Air curtain and Printzone Heaters. For further details refer to:

on page 11.

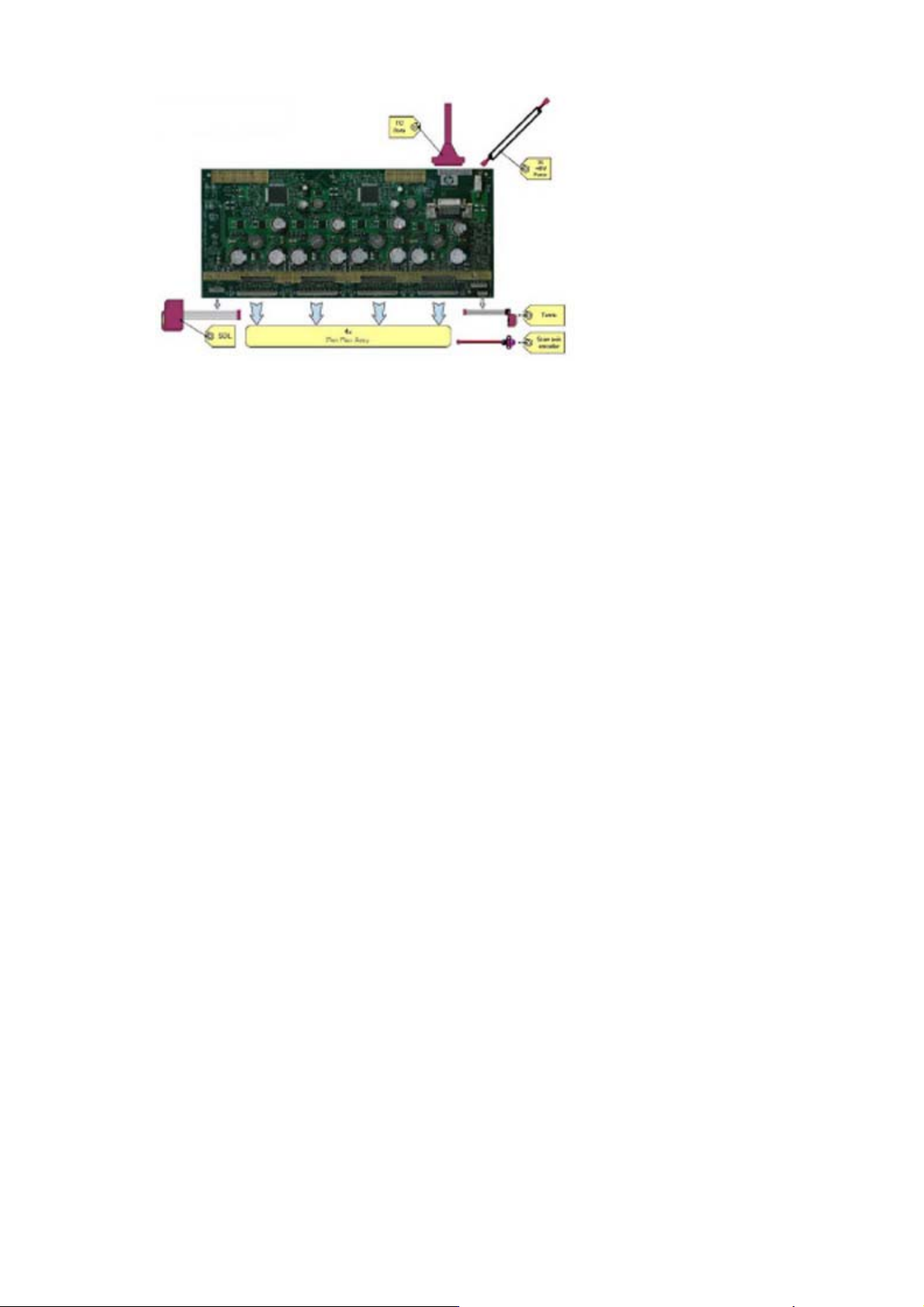

Carriage Electronics

Description

The carriage contains electronics for controlling and firing printheads. It also contains electronics for

controlling the external sensors (SOL and Tetris) and the scan-axis encoder.

Heating-System Electronics

The electronics of the carriage receive power and data from the trailing cables, which include both power

(+42V) and data (LVDS) cables. The power cable connects the carriage with the Mini interconnect board, and

the data cable connects the carriage with the engine PCA.

Components

Carriage PCA

The carriage PCA contains electronics that control how and when the ink is dropped from each printhead. It

receives information from the sensors.

8 Chapter 1 Printer systems ENWW

Page 21

SOL Spectrophotometer (HP Latex 360)

The SOL is a color sensor located on the left side of the carriage. The main function of the SOL is to measure

color samples printed on the loaded substrate, and then placed in the print platen zone.

Before taking any color measurement, the SOL must be initialized. The SOL initialization process takes

approximately 7 minutes. This process consists of three steps:

●

Sensor switch on

●

Sensor warm up

●

Sensor calibration

When the initialization process has finished, the shutter opens automatically and the carriage is moved along

the scan axis to place the SOL on top of each sample and take a color measurement. After the

measurements, the shutter is closed, and the sensor is switched off.

Tetris

The Tetris is used to align the printheads, and to locate the edges of the substrate and measure its size. The

alignment procedure consists of a series of patterns first printed, then scanned using the Tetris, and finally

an internal process is used to correct the timing of when and where the nozzles of the printheads fire, and

detect any possible nozzle-out issues.

Scan-axis encoder

The line encoder is located on the carriage; it measures and counts the movements of the scan axis. An

optical, infrared wavelength encoder is used: the same type of encoder used in most of the HP large-format

printers. The encoder signal is converted to LVDS logic levels, and directly routed through the data TC.

Printhead flex

To connect the carriage to the printheads, a delicate flexible circuit with small golden dimples is used.

Printheads are inserted into unique slots and a spring-loaded mechanism pushes the electrical contacts of

the printheads into the printhead flex, which subsequently connects the printhead to the carriage electronics.

Printhead flexes are the most delicate and sensitive part of the carriage. If the printheads are inserted with

too much force, or they are misaligned, they can easily be damaged.

Ink Supply Station (ISS) Electronics

Description

There are two ISS PCAs (as in the DJ L25500/L26500 printers).

ENWW Electrical system 9

Page 22

Components

Top and bottom ISS PCAs

The ISS electronics are powered from a +12 V line coming from the PrintMech, and a linear regulator on the

ISS PCAs generates the +5 V used to power all the devices on the board.

The ISS PCAs are two electronic PCAs located at the rear of the Ink Supply Station. The ISS PCAs provide the

following:

●

●

●

●

●

●

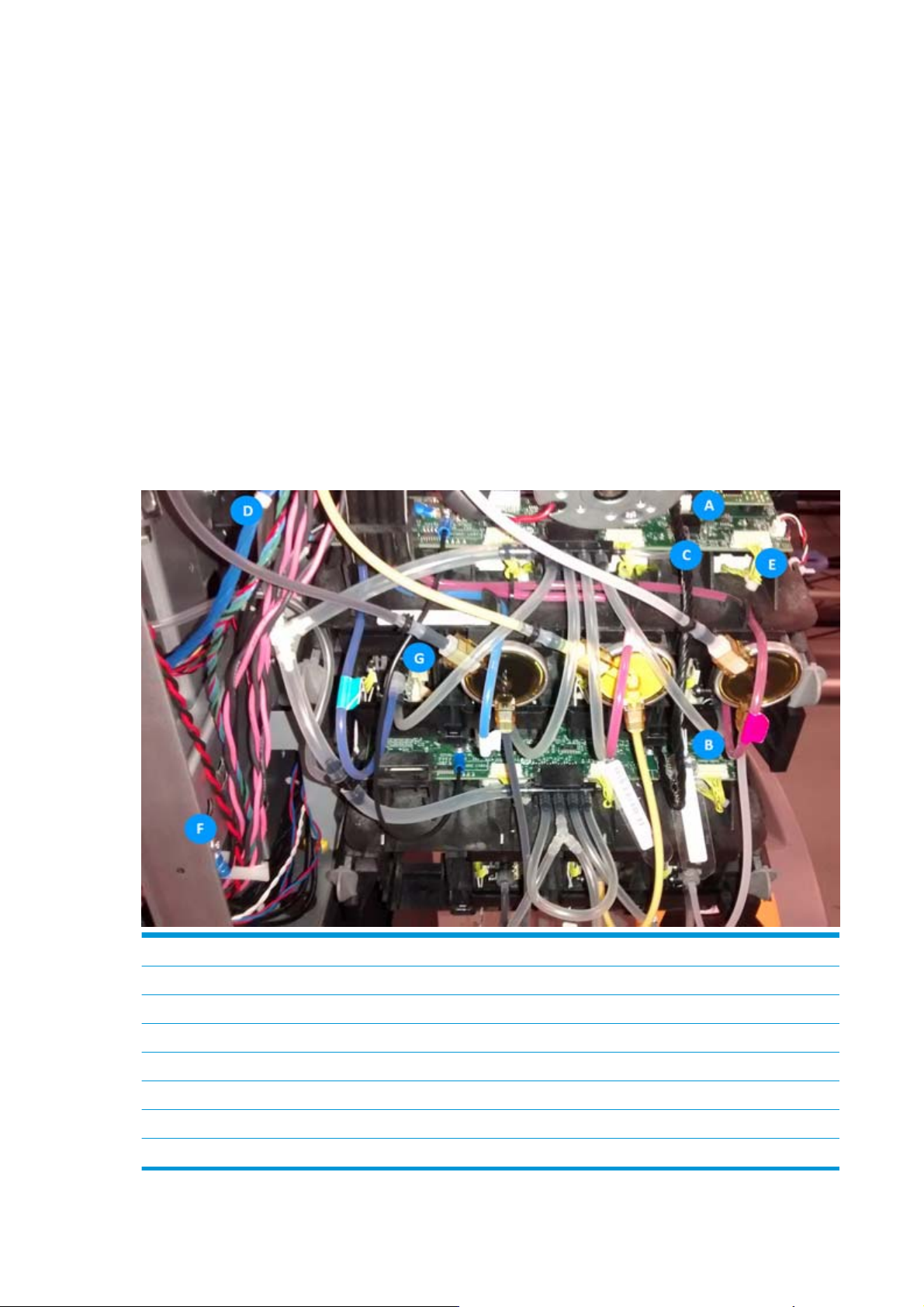

Below is a picture showing the connections and components located at the rear of the ISS.

Ink-Supply presence detection

Ink-Cartridge broken-bag detection

Ink-Supply smart-chip interface

Air-Pressure measurement and air-pump shutdown

Humidity and temperature measurements

System back-up EEPROM

Marking Description

AISS Top PCA

BISS Lower PCA

C Cable: ISS Top PCA to ISS Lower PCA

D Cable: ISS Top PCA to PrintMech PCA (blue)

E Cables (6): ISS PCAs (Top and Lower) to Ink Cartridge and PIP

F ISS grounding cable

GPIP sensor (6)

10 Chapter 1 Printer systems ENWW

Page 23

Both top and bottom ISS PCAs share the same PCB; the only difference between them is that the bottom PCA

is a simplification of the top PCA. The top PCA contains these additional parts:

●

EEPROM

●

Connection from the PrintMech PCA

●

Air pressure sensor

●

Temperature and humidity sensors

Both PCAs are connected through an 8-pin connector. The second ISS connector is connected to the

PrintMech PCA in a daisy-chained connection, the first ISS board by means of this 8-pin connector.

Vacuum-Fan Electronics

Description

There is one EOLA PCA to control two different brushless blowers generating the required vacuum to hold the

substrate. This PCA is connected to the Mini interconnect PCA (right side).

Heating-System Electronics

Description

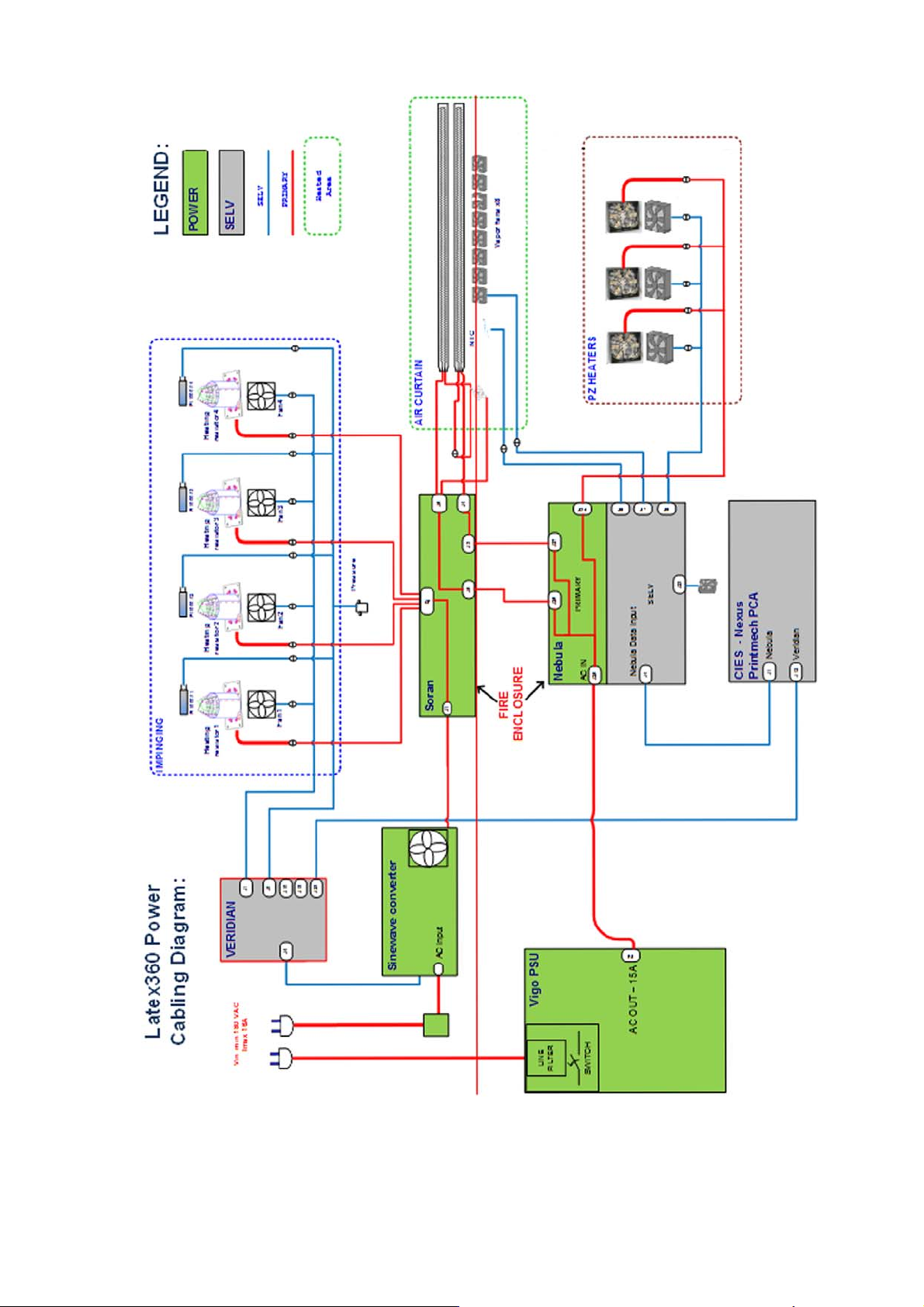

In the Latex 360 Power, power is delivered to 3 subsystems:

●

Impinging (Drying and curing): Controlled through Curing Control PCA

●

Air curtain: Controlled through Air Curtain and Printzone Heaters Control PCA

●

Print zone heating: Controlled through Air Curtain and Printzone Heaters Control PCA

WARNING! The PRI (POWER) area is not isolated, and there is an electrical shock hazard. The PCA is

connected directly to the AC mains input. The power cords should be disconnected before manipulating the

power elements.

The following diagrams show configuration, the Primary area, and its connection:

ENWW Electrical system 11

Page 24

Components

Air Curtain and Printzone Heaters Control PCA:

12 Chapter 1 Printer systems ENWW

Page 25

The Air Curtain and Printzone Heaters Control PCA is only present in Latex 360 printers, and is placed inside

the EEbox. The Air Curtain and Printzone Heaters Control is the PCA that controls the power delivered to the

air curtain resistors and the printzone heaters. The AC power input comes from the Main PSU, but there is a

pass through from the input power plug to the PCA AC input. The PCA has a primary non-isolated area, and a

SELV isolated area. The power available is balanced between both subsystems based on burst control, the

control is provided from the same PCA. The Air Curtain and Printzone Heaters Control also controls both

subsystems' fans; the ambient temperature sensor, and the box fan installed for cooling the PCA.

Curing Control PCA:

The Curing Control PCA is placed at the impinging bracket on its left side and executes the servo that applies

the power to the impinging module. The Curing Control PCA is present in all three SKUs; In the Latex 360

printer it controls the impinging sensors (Temperature and pressure) and the Heater Control, and in the Latex

330 & Latex 310 printers, it controls the air curtain fans, and reads the ambient temperature sensor. The

Curing Control PCA has no power (PRI) lines.

Curing Power Interconnect:

The Curing Power Interconnect PCA is placed just above the Curing Control PCA. Both PCAs are housed in the

same fire proof box. The Curing Power Interconnect PCA is connected to power lines and provides the

interconnection interface for the curing module, and for the air curtain resistors (Latex 360 only). The Curing

Power Interconnect PCA is present in all three SKUs.

Table 1-1 Connection differences between SKUs in the Heating System:

Ambient temp. sensor Air Curtain and Printzone

Printzone fans Air Curtain and Printzone

Air curtain fans Air Curtain and Printzone

Air curtain resistors Air Curtain and Printzone

Printzone resistors Air Curtain and Printzone

Electrical configuration

NOTE: An electrician is required for the setup and configuration of the electrical system used to power the

printer. Make sure that your electrician is appropriately certified according to local regulations, and supplied

with all the information regarding the electrical configuration.

HP Latex 360 HP Latex 330 HP Latex 310

Curing Control Curing Control

Heaters Control

Printmech Printmech

Heaters Control

Curing Control Curing Control

Heaters Control

xx

Heaters Control/Curing Power

Interconnect

xx

Heaters Control

ENWW Electrical system 13

Page 26

Your printer requires the following electrical components to be supplied and installed by the customer,

according to the Electrical Code requirements of the local jurisdiction of the country where the equipment is

installed.

Single-phase power

Table 1-2 Single-phase line specifications:

HP Latex 360 HP Latex 330 HP Latex 310

Printer Curing Printer Curing Printer Curing

Number of

power cords

Input voltage ~200-240 V +-10% (two wires and protective earth)

Input frequency 50 / 60 Hz

Maximum load

current (per

power cord)

Power

consumption per

power cord in

printing mode

Power

consumption in

ready mode

Circuit breakers

NOTE: The circuit breakers must meet the requirements of the printer and be in accordance with the

Electrical Code requirements of the local jurisdiction of the country where the equipment is installed.

The printer requires two power cords that meet the following requirements.

Table 1-3 Dedicated lines per SKU:

222

16 A 16 A 3 A 16 A 3 A 13 A

2.5 kW 2.1 kW 200 W 2.4 kW 200 W 2.0 kW

85 W 72 W 70 W

HP Latex 360 HP Latex 330 HP Latex 310

Printer Curing Printer Curing Printer Curing

Dedicated line Yes Yes Not required. Do

Branch circuit

breaker

Residual current

circuit breaker

(1)

2 poles, 16 A/20 A according to local laws and printer maximum load current

Required Recommended Recommended

not overload

lines. See Table

2-3

2 poles, 30 mA residual, at least 20 A capacity

Yes Not required. Do

not overload

lines. See Table

2-3

Not required. Do

not overload

lines. See Table

2-3

(1) Also known as Ground Fault Circuit Interrupter (GFCI)

14 Chapter 1 Printer systems ENWW

Page 27

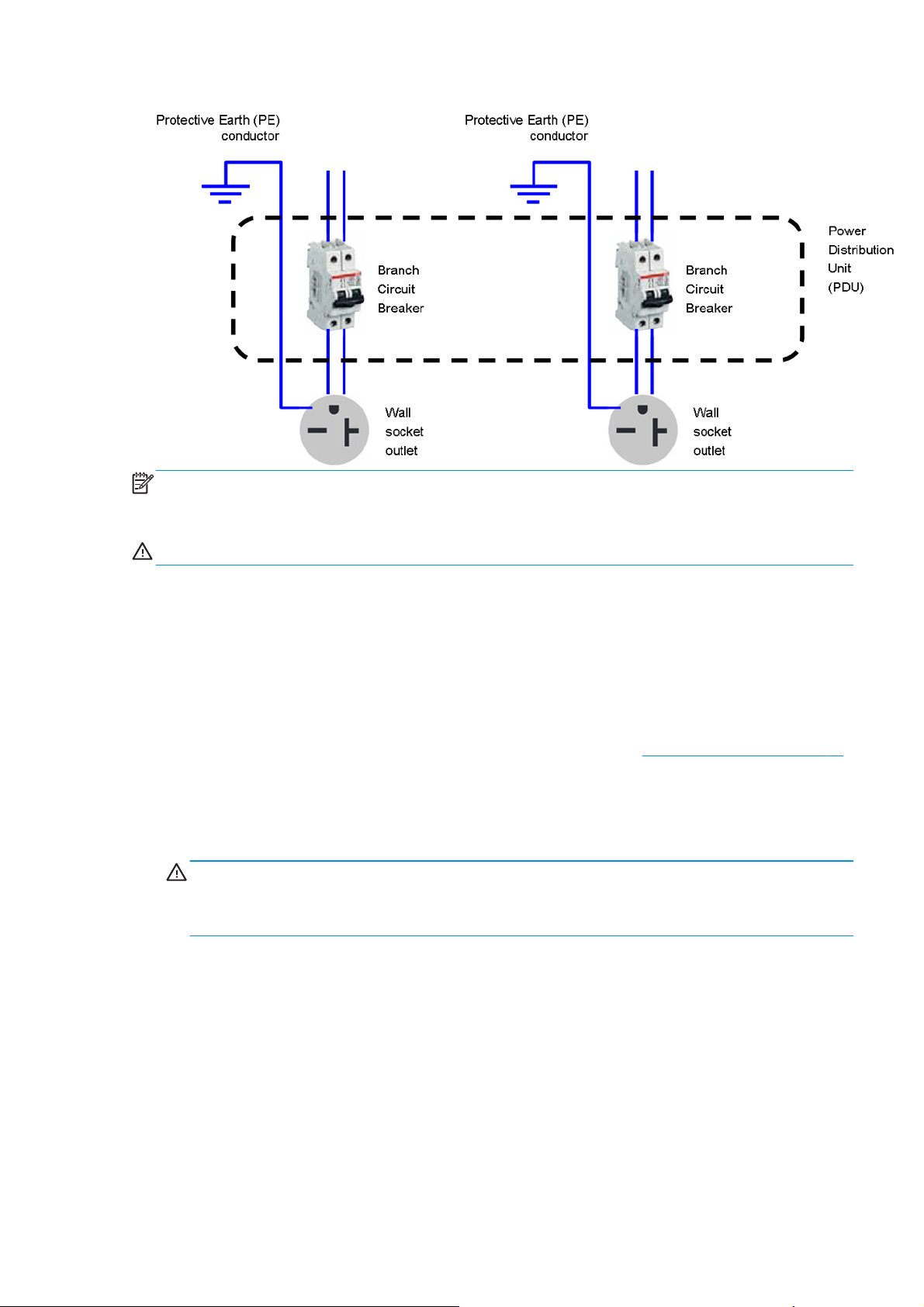

Figure 1-1 Electrical configuration diagram (for reference only)

NOTE: The Power Distribution Unit (PDU) must be rated to meet the power requirements of the printer, and

be in accordance with the Electrical Code requirements of the local jurisdiction of the country where the

equipment is installed.

WARNING! Do not use a power strip (relocatable power tap) to connect both power cords.

Wall receptacles and power cords

Two power cords are provided with your printer, according to the printer's electrical specifications. If those

cords do not reach your PDU and/or UPS, a certified electrician must install suitable extension cables on the

day of installation.

To make sure you have the right wall socket outlets (wall receptacles) ready for installation, check the

following:

1. The wall socket outlets must be suitable for printer input ratings. See

2. The wall socket outlets must be suitable for the power cord plug type used in the country of

installation. The list shows examples of the power cords and the plugs provided with the printer

according to the country. To make sure you have the right wall receptacle, find your country in the

appropriate table and check the plug type.

WARNING! Only use the power cord supplied by HP with the printer. Do not use a power strip

(relocatable power tap) to connect both power cords. Do not damage, cut, or repair the power cord. With

a damaged power cord, there is risk of fire and electric shock. Always replace a damaged power cord

with an HP-approved power cord.

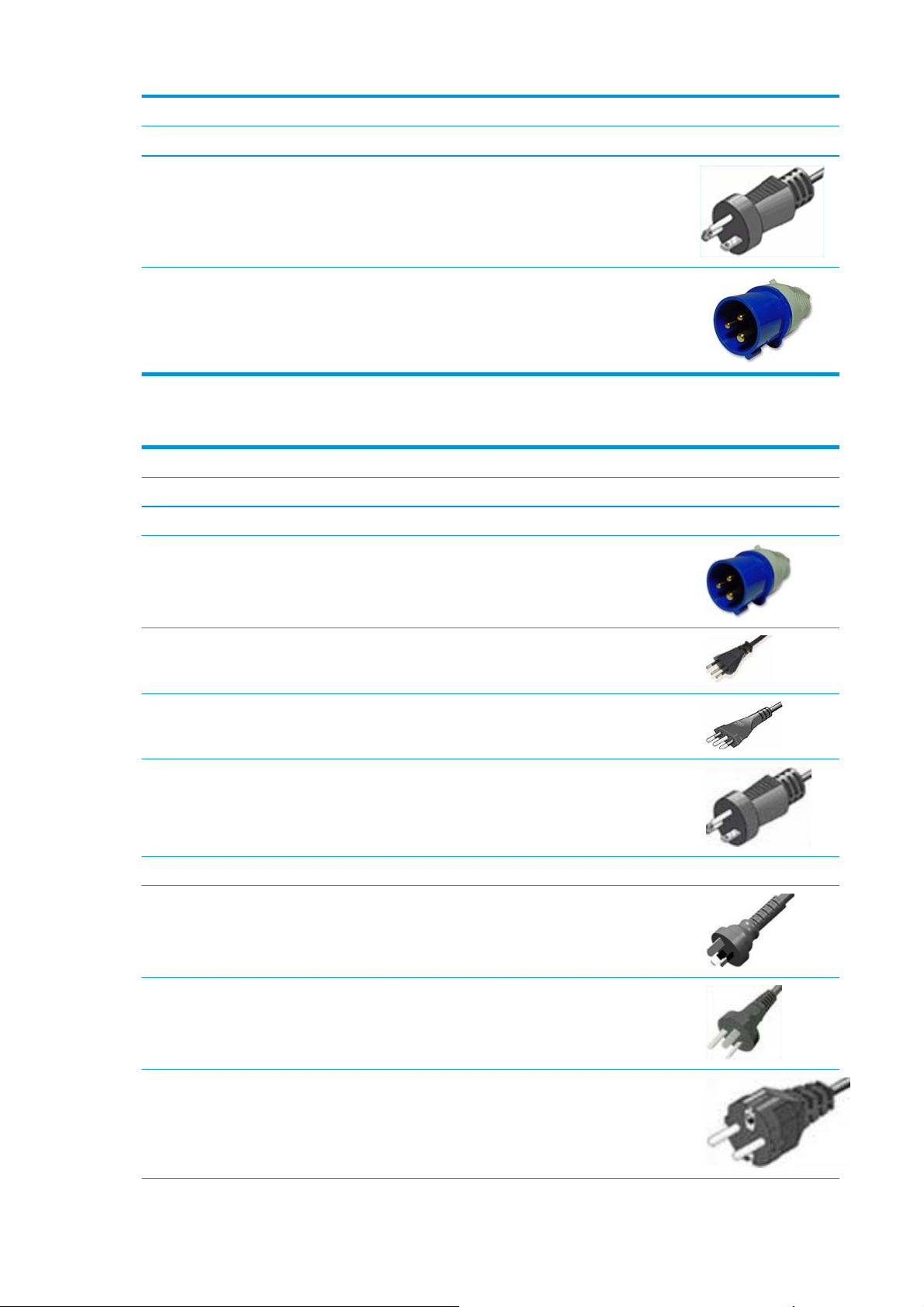

Table 1-4 HP Latex 330/360 Printers— Printer power cord specifications:

Single-phase power on page 14.

ENWW Electrical system 15

Page 28

NOTE: For HP Latex 330/360 Printers— Use two power cords from below

Country HP Part Number * Length Plug type Plug

USA, Canada, Mexico,

Japan, Philippines, Thailand

International 8120-6897 4.5 m IEC 60309, 240 V, 16 A, 2L

8120-6893 4.5 m NEMA 6-20P, 240 V, 20 A,

non-locking

+PE

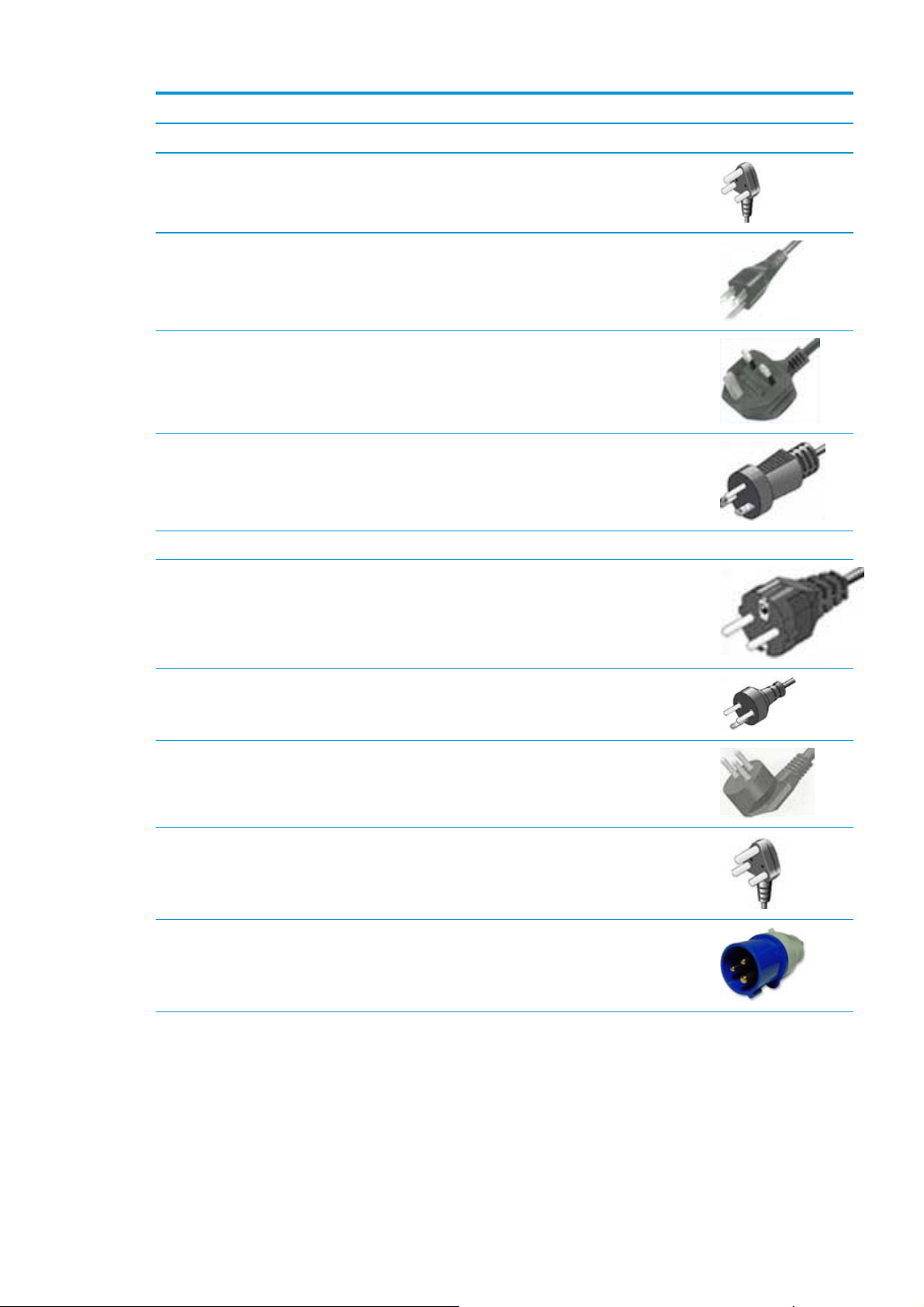

Table 1-5 HP Latex 310 Pinter — Power cord specifications per region:

NOTE: For HP Latex 310 Printers — Use two power cords from below

Country HP Part Number * Length Plug type Plug

America Region

Argentina 8120-6897 4.5 m IEC 60309, 240V, 16A,

2L+PE

Brazil 8121-110 2.5 m NBR 14136

Chile, Uruguay 8121-0923 2.5 m CEI 23-50

USA, Canada, Mexico 8120-6360 2.5 m NEMA 6-20P, 240 V, 20

A, non-locking

Asia Pacific and Japan Region

Australia/New Zealand 8120-6351 2.5 m AS/NZS 3112-3 (15A)

China 8121-0924 2.5 m GB 1002 (16A)

Korea, Indonesia 8120-6352 2.5 m CEE 7-VII

16 Chapter 1 Printer systems ENWW

Page 29

NOTE: For HP Latex 310 Printers — Use two power cords from below

Country HP Part Number * Length Plug type Plug

India 8121-1074 2.5 m IS 1293

Taiwan 8121-1033 4.5 m CNS 690

Hong Kong, Singapore 8120-6898 4.5 m BS 1363/A (13A fused)

Japan, Philippines,

Thailand

Europe, Middle East and Africa Region

Europe Russia 8120-6352 2.5 m CEE 7-VII

Denmark 8121-1077 2.5 m DK 2-5A

Israel 8121-1010 2.5 m SI 32

South Africa 8121-0915 2.5 m SABS 164

8120-6360 2.5 m NEMA 6-20P, 240 V, 20

A, non-locking

Switzerland,

Liechtenstein

8120-6897 4.5 m IEC 60309, 240 V, 16 A,

2L+PE

ENWW Electrical system 17

Page 30

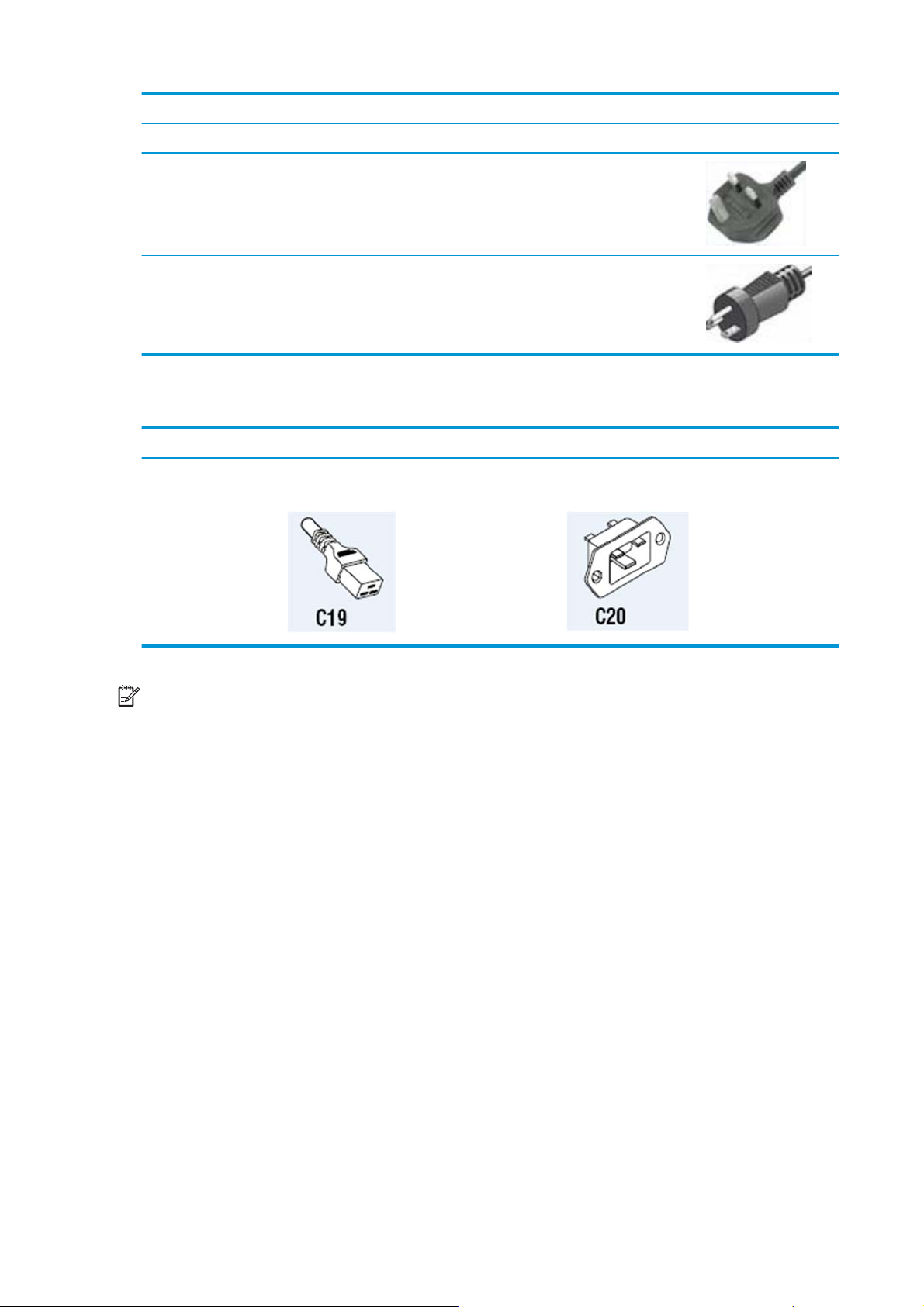

NOTE: For HP Latex 310 Printers — Use two power cords from below

Country HP Part Number * Length Plug type Plug

U.K. 8120-6898 4.5 m BS 1363/A (13A fused)

Middle East 8120-6360 2.5 m NEMA 6-20P, 240 V, 20

A, non-locking

Table 1-6 Appliance coupler (printer connection):

Country Appliance coupler (power cable) Appliance coupler inlet (printer)

All Detachable terminal as per IEC60320-1 C19

(squared type)

NOTE: Place the wall receptacle close enough to the printer so the plug can be plugged and unplugged

easily.

Electronic Cables Routing

This section can be used as a reference section, to check the original routing of the cables

Detachable inlet as per IEC60320-1 C20 (squared

type)

18 Chapter 1 Printer systems ENWW

Page 31

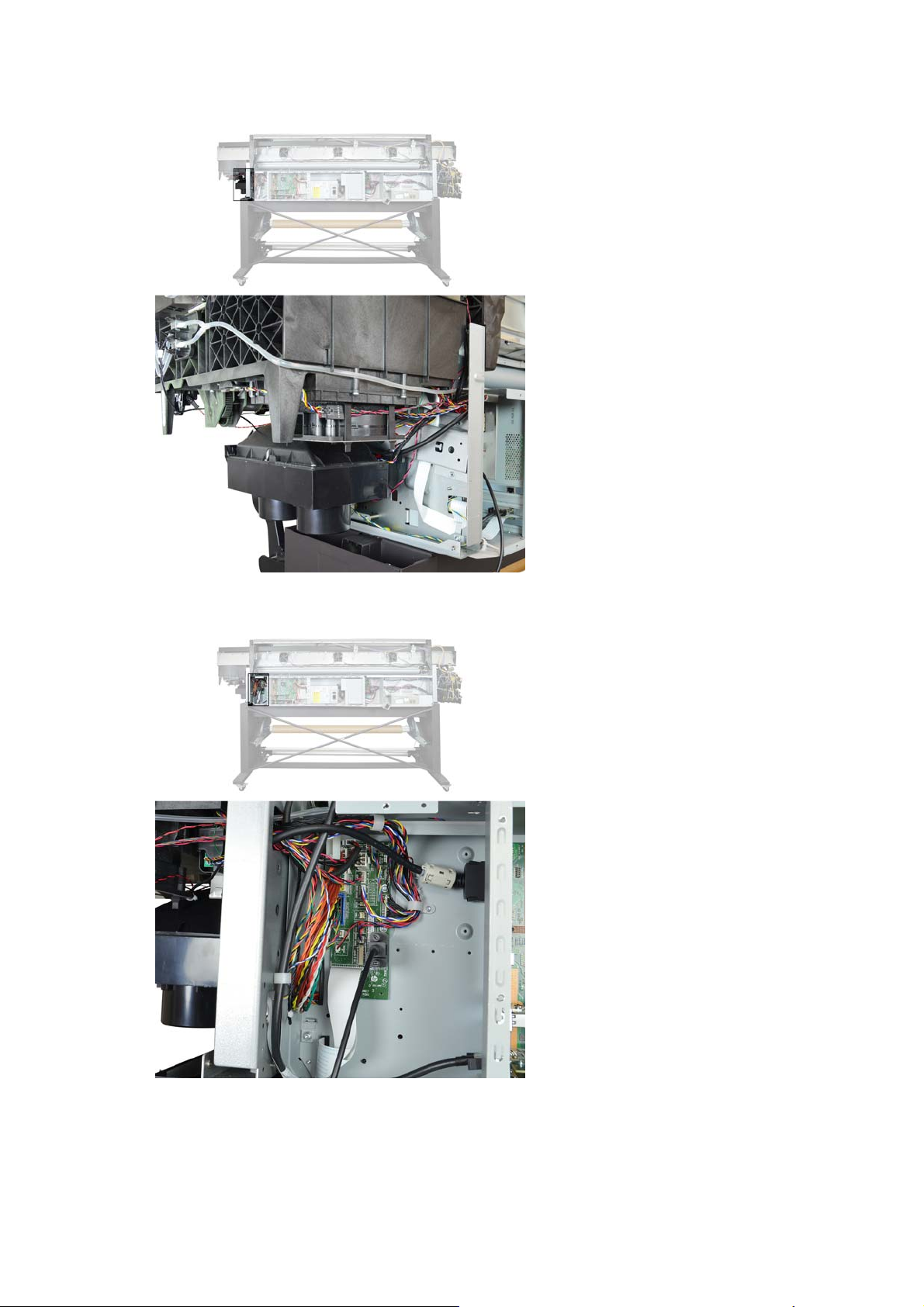

Rear Service Station Cables Routing

Interconnect PCA Cables Routing

ENWW Electrical system 19

Page 32

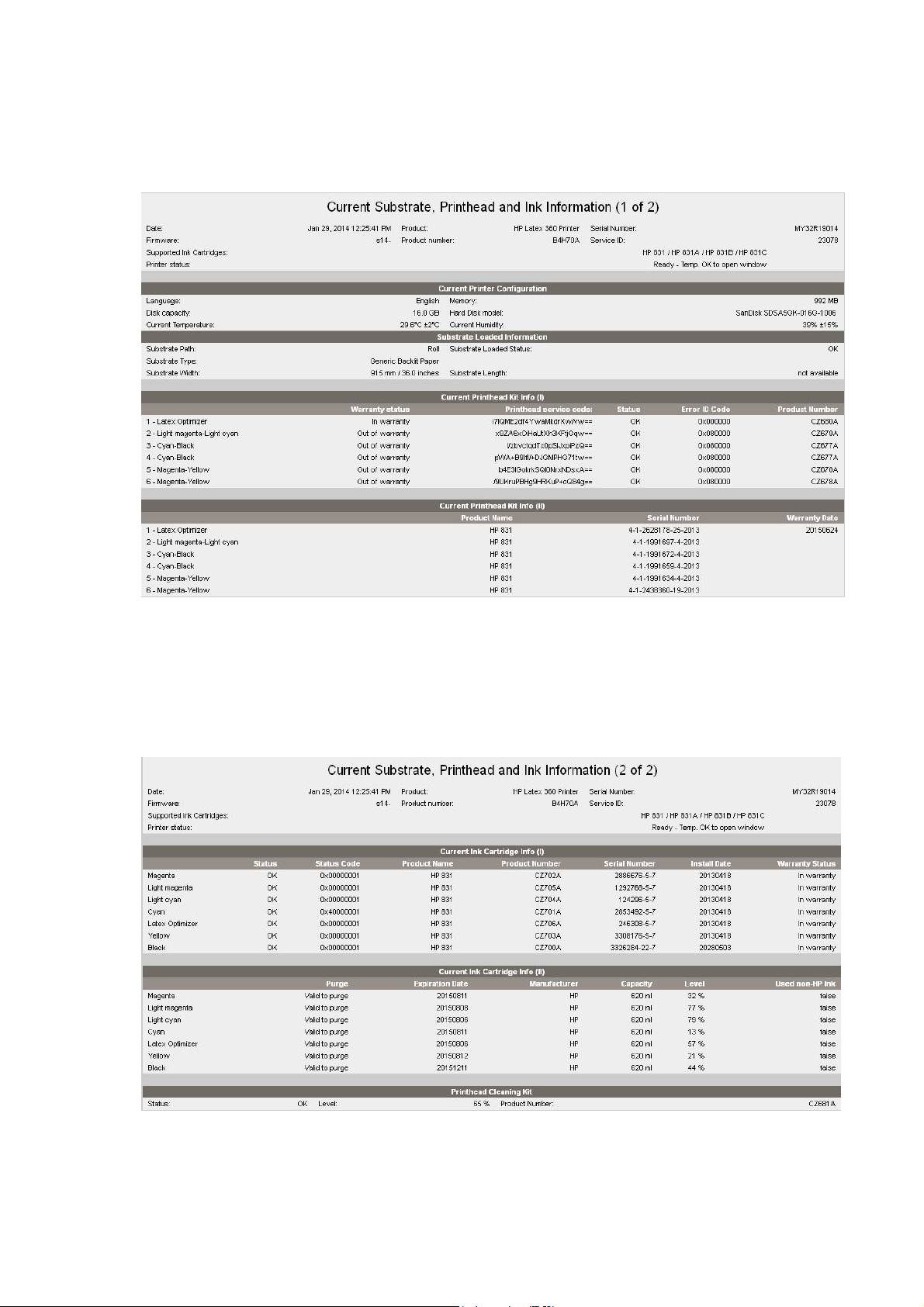

Electronics Main PCA Cavity Cables Routing

Printmech PCA Cables Routing (behind Heaters Control Assembly)

20 Chapter 1 Printer systems ENWW

Page 33

Left Interconnect Cables Routing

Left End Rear Chassis Cables Routing

ENWW Electrical system 21

Page 34

Rear ISS Cables Routing

Substrate path

Description

The substrate path moves the substrate from the input spindle to the take-up reel, through the print path,

while the carriage prints on the substrate. The objectives of the substrate path while advancing the substrate

are:

●

Maintain an accurate advance

●

Maintain a constant advance

●

Keep the substrate flat

●

Advance the substrate straight along the substrate axis

Substrate path workflow overview

The following steps describe the substrate path workflow.

22 Chapter 1 Printer systems ENWW

Page 35

1. The substrate is loaded onto the input spindle (1), which is driven by the rewinder mechanism to

provide back tension to the substrate. The substrate is fed through the input platen where an optical

sensor detects substrate presence, around the drive roller (2), under the pinchwheels (3), over the

print zone (4) and the overdrive platen (5), and finally it is either left free or looped through the

diverter (6) through the tension bar (7) to be collected on the take-up reel (8).

2. The rewinder has a motor that primarily acts as a brake to maintain tension on the substrate. The

rewinder may turn in either direction, depending on which is the printable side of the input substrate roll

and its winding direction.

3. The drive roller also has a motor, and is the primary component that advances the substrate. The

substrate is pressed to the drive roller by the pinchwheels, ensuring a smooth substrate advance. The

motor receives feedback from an encoder located at the left side of the roller, inside a protected

enclosure on the left of the left sideplate.

4. The surface of the substrate path where the substrate is printed is called the print platen. The print

platen is designed to give minimal resistance to the substrate advance, and includes suction holes that

apply vacuum to the substrate.

5. The printer detects and controls the substrate advance. The OMAS sensor, located on a special cut-out

section of the print platen, is a sensor that is able to detect very small errors in the advance of the

substrate. These errors are communicated to the motors on the drive roller, and small correctional

adjustments are applied to the movement of the substrate.

NOTE: The OMAS sensor cannot see the fibers on some substrates, such as transparent substrate or

very dark or very reflective substrates. In these cases, the OMAS sensor can be disabled. To disable the

OMAS sensor, see

1.3.3 Enable/Disable OMAS on page 167.

6. The vacuum pressure is adjusted depending on the substrate type and print options used. It draws the

substrate to the print platen, making sure that the substrate is flat.

7. After the platen, the substrate goes through the curing zone and finally leaves the printer, either to be

collected on the take-up reel or to be cut.

8. When the take-up reel is in use, the substrate must be threaded, first passing in front of the loading

table used as a diverter, then under the tension bar and rerouted to the output roll loaded in the takeup reel. This system creates tension on the outgoing substrate for proper winding. The take-up reel can

operate in both directions with the rewinder, winding with the printed face outside or inside.

Startup, substrate load, substrate selection

During startup, the printer checks that the substrate path components are functioning correctly. When

shutting down, if a substrate is loaded, the printer remembers the substrate definition. This may be modified

through the front panel with the option ’Change loaded substrate’ from the substrate menu list.

ENWW Substrate path 23

Page 36

During substrate loading the printer may ask the user two interactions:

1. To rewind manually the substrate: The printer automatically checks the direction of the loaded

2. To align the substrate in order to avoid skew: the printer measures skew. If the skew is too large the

Components

Spindle

substrate (printed face outwards or printed face inwards). If the ’curve’ of substrate is too large the

printer cannot detect it and the printer asks the user to rewind manually. Once the substrate is rewound

the printer can detect automatically

printer will ask the user to lift the pinchwheels (big blue lever on right hand side), and align the

substrate. The substrate must be aligned against itself (substrate edge must be aligned with input roll

edge).

The aluminum spindle of the 360 printer can load 3-inch core rolls. The 2-inch spindle of the 310 and 330

printers has an adaptor for 3-inch cores.

The spindle holds the core of the roll when its rubber bands are nipped between the core of the roll and the

aluminum extrusion.

On the 3-inch spindle, the hub on the left side has two possible fixed positions: the end position allows

loading maximum width rolls, but there is a second position at 2.6 inches (65 mm) from the end that can be

selected.

The right hub can be set along any length of the spindle so any length of roll can be loaded.

The right end of the spindle contains a gear which is used to transmit the movement from the rewinder to the

roll.

24 Chapter 1 Printer systems ENWW

Page 37

Spindle latch

The spindle latch prevents the substrate roll from slipping from its position when printing. It is not necessary

to close it when inserting the spindle, it closes automatically. But the user must lift the small blue lever in

order to release the spindle and extract the roll of substrate.

Rewinder

The rewinder motor keeps constant tension on the input substrate to prevent skew problems. There is a

motor and a transmission that gives torque to the spindle in order to provide the necessary back tension.

Substrate sensor

The Input Platen has an optical sensor that detects substrate presence. When the substrate is inserted into

the entry area, the sensor is activated and the drive roller starts turning to help the loading process. The

substrate load process has been triggered and the printer will provide instructions through the front panel.

When the substrate roll is exhausted and the bottom edge clears the substrate sensor, printing is

interrupted.

ENWW Substrate path 25

Page 38

OMAS sensor (substrate advance sensor)

OMAS is located under the third front platen slab from the right only the top window can be seen:

OMAS is composed of two parts: the sensor and its optics located under the platen and a PCI control board on

the main electronics box. Both are connected through a ribbon cable that runs through the vacuum beam, by

the right sideplate, and into the electronics box.

The optical sensor detects the surface of the back of the substrate as it moves across the platen. The sensor

is able to evaluate the exact movement of the substrate, and communicate any small adjustments required

by the system to move the substrate accurately.

The window of the OMAS sensor must be cleaned of dust and ink to work correctly. The cleaning procedure is

described in the user’s guide, in the section ‘Clean the substrate-advance sensor window’.

During the substrate load, the printer detects that the substrate has reached the print platen when the OMAS

captures its image.

NOTE: The OMAS sensor cannot detect the surface of some substrates, such as plastic or very dark ones. In

these cases, the OMAS sensor must be disabled, and instead the printer uses feedback from the Driver Roller

encoder to calculate the substrate advance. To disable the OMAS sensor, locate the OMAS Sensor selector

from the print options menu of the RIP and set it to OFF. This can also be done from the Service menu

Enable/Disable OMAS on page 167.

Drive roller and motor

1.3.3

The drive roller and motor advance the substrate through the substrate path. The motor requires 42 V, and is

controlled by the Printmech PCA.

The drive roller receives the torque from the motor through a worm as in the Z6100 and other Designjets.

Drive roller encoder disc and encoder PCA

The Drive Roller Encoder Disc and Encoder PCA provide the feedback system for the Drive Roller.

26 Chapter 1 Printer systems ENWW

Page 39

●

The Encoder disc is a round disc mounted to the left end of the Drive Roller.

●

The Encoder PCA is mounted with a sensor that reads the encoder movements of the disc (the disc turns

with the drive roller).

Pinchwheels

The pinchwheels press the substrate against the Drive Roller to make sure that the Drive Roller can advance

the substrate correctly.

●

The pinchwheels are activated with the blue lever at the right side of the substrate roll and usually do

not have to be lifted unless to correct skew during substrate load or to clear jams.

●

The pinchwheel system has a sensor that detects if the system is up or down.

Vacuum pump, vacuum tube assembly, vacuum beam

The print zone is the area of the substrate path where the transmission of ink to the substrate occurs. The

main function of the system can be defined as providing the surface where the substrate is printed, keeping it

controlled during the process, playing a main roll on the final IQ of the plots and on the operational reliability

of the printer. The subsystem is composed of the print platen assembly, which is the physical interface with

the substrate, and the vacuum system which is the mechanical system where the vacuum pressure used to

control the substrate is generated and conduced.

The platen gives a convenient shape to the wet substrate, avoiding uncontrolled expansion of the substrate.

The main components are:

●

Platen assembly

◦

Front platens, rear platens, OMAS platen

◦

Linear blade 64-inch + springs (same as DJ Z6100 or L26500)

◦

Foams, foam fillings, and foam wall

●

Right vacuum fan assembly with EOLA control board (as with the HP Designjet Z6200 or T7100)

Related tests, utilities, and calibrations

●

Rewinder test

●

Drive Roller test

●

Substrate Path sensor test

●

Vacuum Test

●

OMAS Test

●

Rewinder Motor polarity test

●

Substrate path menu

2.1 Rewinder System on page 147

2.2 Drive Roller on page 147

2.3 Substrate Path Sensors on page 148

2.4 OMAS Module on page 148

1.3 Substrate Path Menu on page 166

●

Substrate advance adjustment

2.3 Substrate Advance Menu on page 175

Service parts

●

Drive Roller

●

Substrate Path Assemblies

●

Center guide Pinchwheels Assemblies

ENWW Substrate path 27

Page 40

●

Substrate Entry Assemblies

●

Take-up reel Assemblies

Removal and installation

●

Rewinder

●

Vacuum Fan

●

OMAS

●

Output Platen

●

Print Platen

●

Input Roller

●

Output Roller

●

Substrate Sensor

●

Pinchwheel Assembly

●

Center Guide

●

Driver Roller

●

Rollfeed Modules

●

Take-up reel

28 Chapter 1 Printer systems ENWW

Page 41

Ink Delivery System (IDS)

Ink Delivery System

The ink deliver system (IDS) is located in the left enclosure of the printer (inside the left covers) and delivers a

continuous supply of ink to the printheads. It can detect an ink leakage anywhere in the system, including

inside an Ink Cartridge. It also tracks and determines when an Ink cartridge needs replacing.

Rear of the Ink Supply Station

ENWW Ink Delivery System (IDS) 29

Page 42

Ink tubes

There are 6 ink tubes that deliver the inks to the printheads in the carriage and two additional tubes which

are used as a support structure. They are bundled together in a carrier and held on a shelf on the inside of the

top cover with clips.

Insulation sleeve

The ink tubes are protected from the high temperatures of the Dryer Assembly by a heat resistant insulation

sleeve, which protects the main body of the tubes that are static.

Upper and lower Ink Supply Station (ISS)

The Ink Supply Station (ISS) is divided into the upper and lower sections. They have six slots for holding the

ink cartridges. Each slot has a unique shape (or lock out) which matches with an equal shape at the end of the

applicable ink cartridge. this arrangement avoids the incorrect insertion of an ink cartridge, which would

cause major damage to the ink system.

There are two places for additional slots but these are covered over.

The upper and lower ISS both contain PCAs, although the top PCA contains more functionality, such as the

pressure sensor, see

Ink Supply Station (ISS) Electronics on page 9.

Non-return valves

The two non-return valves are only for the inks on the lower IDS. This is to ensure that when the pump stops

and the cartridges are nearly empty, that the ink does not flow back to the cartridge.

Ink seals