Page 1

HP Latex 115 Printer

User Guide

Page 2

Edition 2

Legal notices

Trademarks

© Copyright 2017, 2018 HP Development

Company, L.P.

The information contained herein is subject to

change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products and

services. Nothing herein should be construed as

constituting an additional warranty. HP shall not

be liable for technical or editorial errors or

omissions contained herein.

Microsoft® and Windows® are U.S. registered

trademarks of Microsoft Corporation.

Page 3

Table of contents

1 Introduction ............................................................................................................................................................................................... 1

Welcome to your printer .......................................................................................................................................................... 2

Supplementary parts ............................................................................................................................................................... 2

Documentation ......................................................................................................................................................................... 2

Safety precautions ................................................................................................................................................................... 3

The printer’s main components ............................................................................................................................................. 7

The front panel ....................................................................................................................................................................... 10

The Embedded Web Server .................................................................................................................................................. 18

Connectivity and software instructions .............................................................................................................................. 24

Advanced network conguration ........................................................................................................................................ 26

Turn the printer on and o ................................................................................................................................................... 32

Restart the printer .................................................................................................................................................................. 33

2 Useful links .............................................................................................................................................................................................. 34

When you need help .............................................................................................................................................................. 34

3 Handle the substrate and troubleshoot substrate issues ................................................................................................................ 36

Overview .................................................................................................................................................................................. 37

Porous substrates .................................................................................................................................................................. 41

Load a roll onto the spindle .................................................................................................................................................. 42

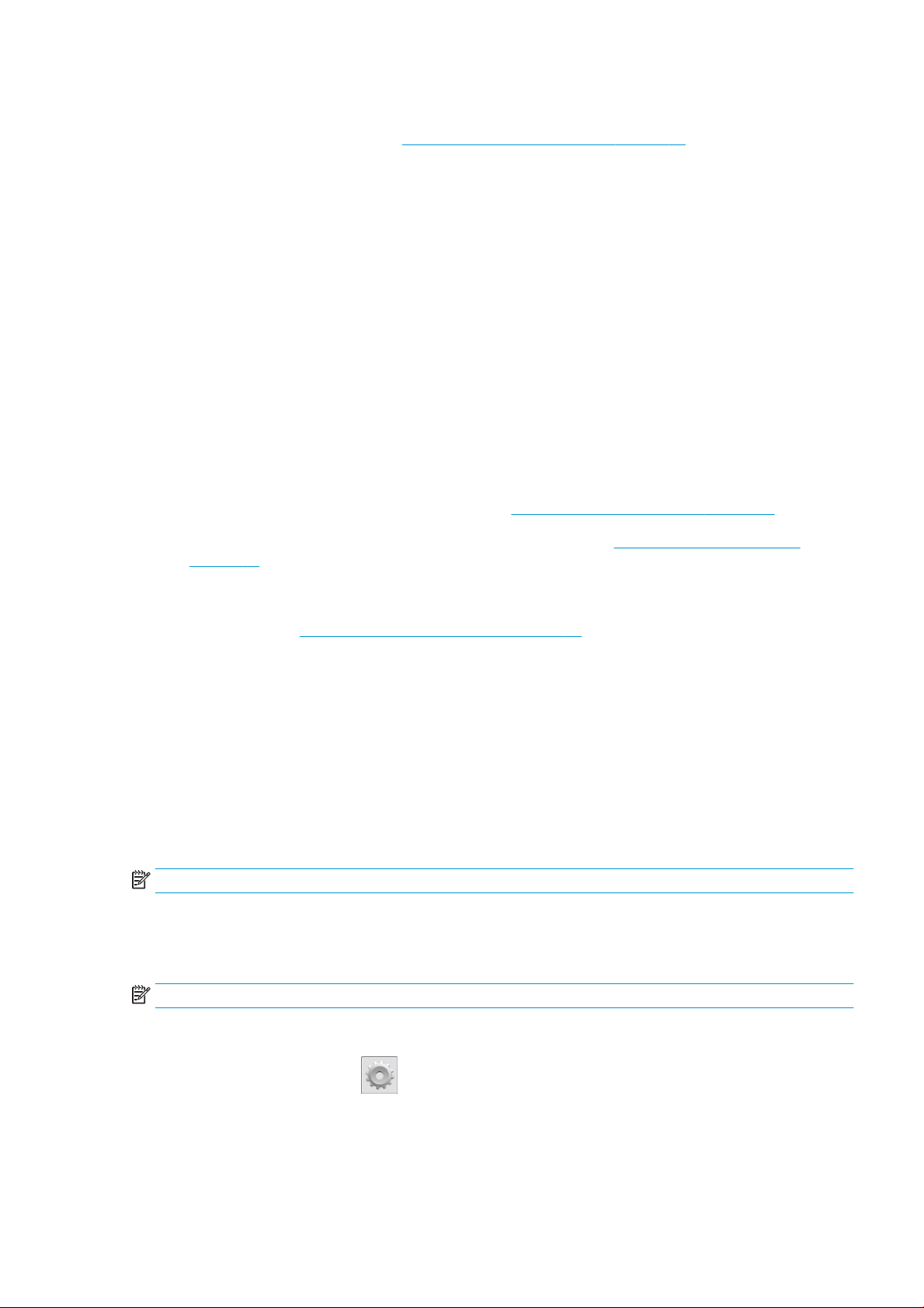

Load a roll into the printer .................................................................................................................................................... 46

Assisted manual load ............................................................................................................................................................ 49

The edge holders ................................................................................................................................................................... 51

Load a cut sheet into the printer ......................................................................................................................................... 53

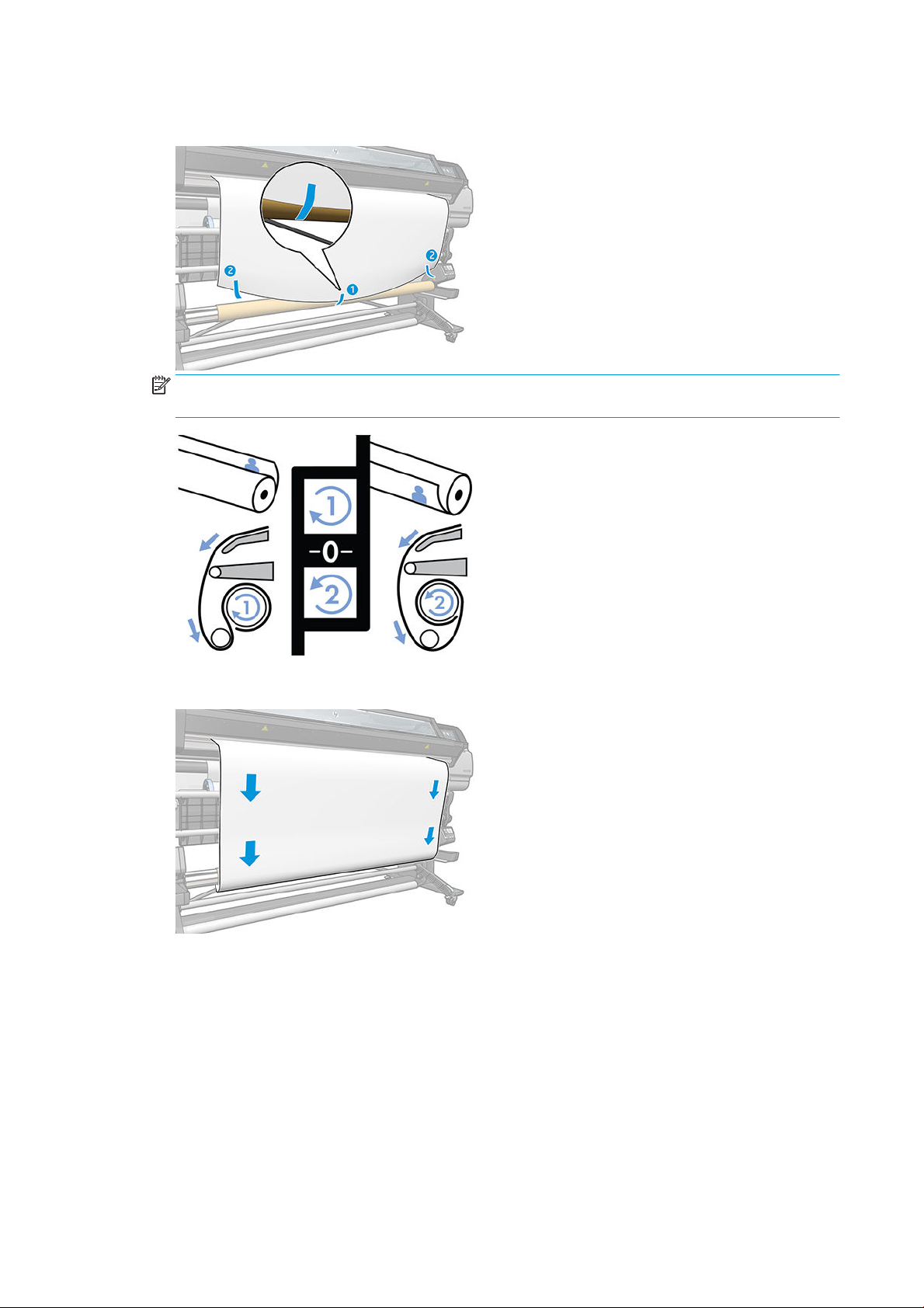

Unload a roll from the printer .............................................................................................................................................. 53

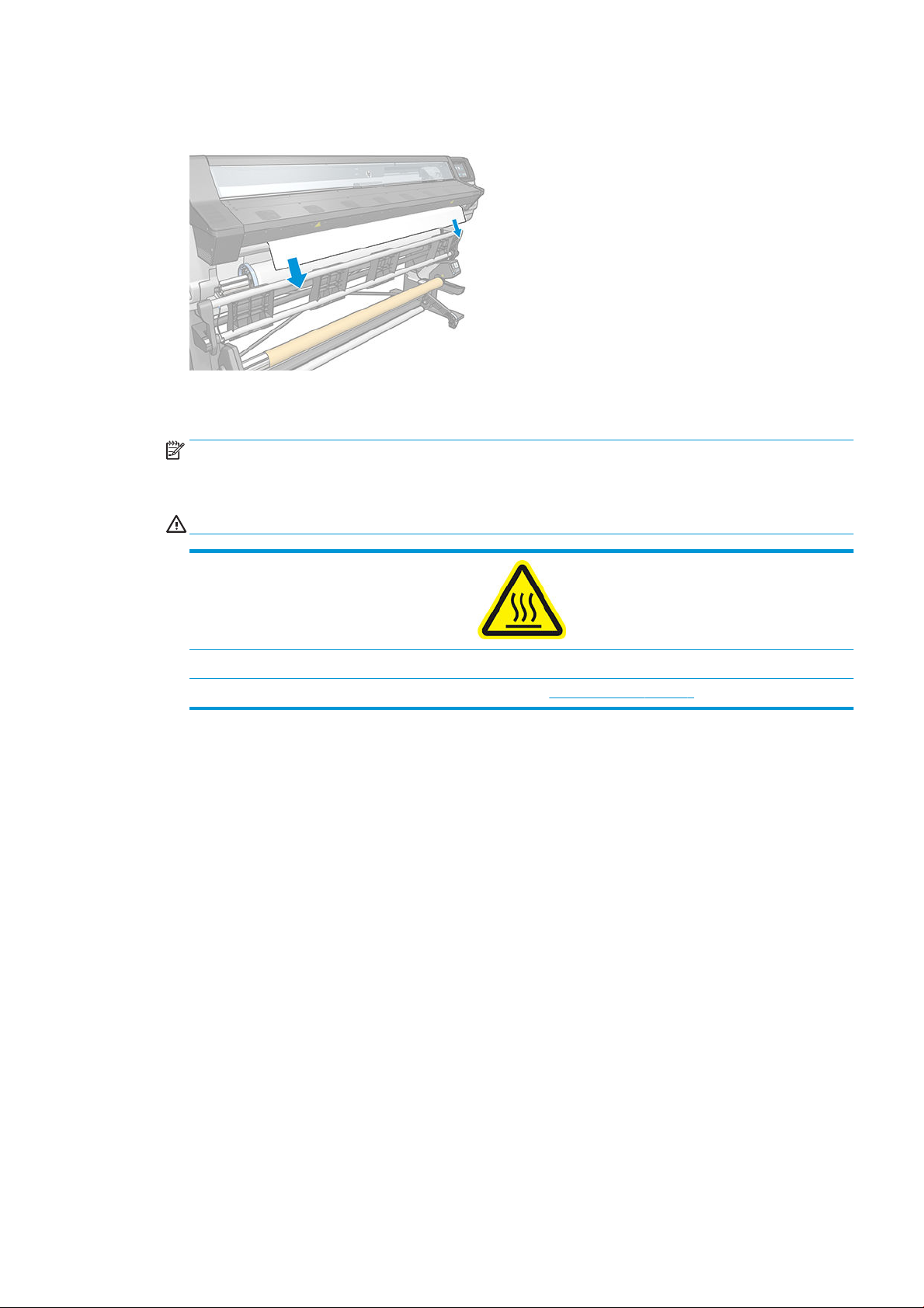

The take-up reel (accessory) ................................................................................................................................................ 54

View information about the substrate ................................................................................................................................ 62

Change substrate width and right edge position .............................................................................................................. 62

Substrate length tracking ..................................................................................................................................................... 62

Cut substrate .......................................................................................................................................................................... 62

Bypass job start safety .......................................................................................................................................................... 63

Store the substrate ................................................................................................................................................................ 63

The substrate cannot be loaded successfully ................................................................................................................... 63

The substrate is mispositioned ............................................................................................................................................ 64

ENWW iii

Page 4

The substrate has jammed ................................................................................................................................................... 64

The substrate is deformed or wrinkled .............................................................................................................................. 67

The substrate has shrunk or expanded .............................................................................................................................. 67

The substrate has bow deformation .................................................................................................................................. 68

Automatic cutter does not work .......................................................................................................................................... 69

Take-up reel substrate jam ................................................................................................................................................... 69

Take-up reel does not wind (if purchased as accessory) ................................................................................................. 69

4 Substrate settings .................................................................................................................................................................................. 71

Substrate presets ................................................................................................................................................................... 72

Online search .......................................................................................................................................................................... 72

HP Media Locator ................................................................................................................................................................... 74

Generic presets ....................................................................................................................................................................... 74

Clone a substrate preset ....................................................................................................................................................... 75

Modify a substrate preset ..................................................................................................................................................... 75

Add a new substrate .............................................................................................................................................................. 76

Delete a substrate preset ..................................................................................................................................................... 80

Faster printing ......................................................................................................................................................................... 80

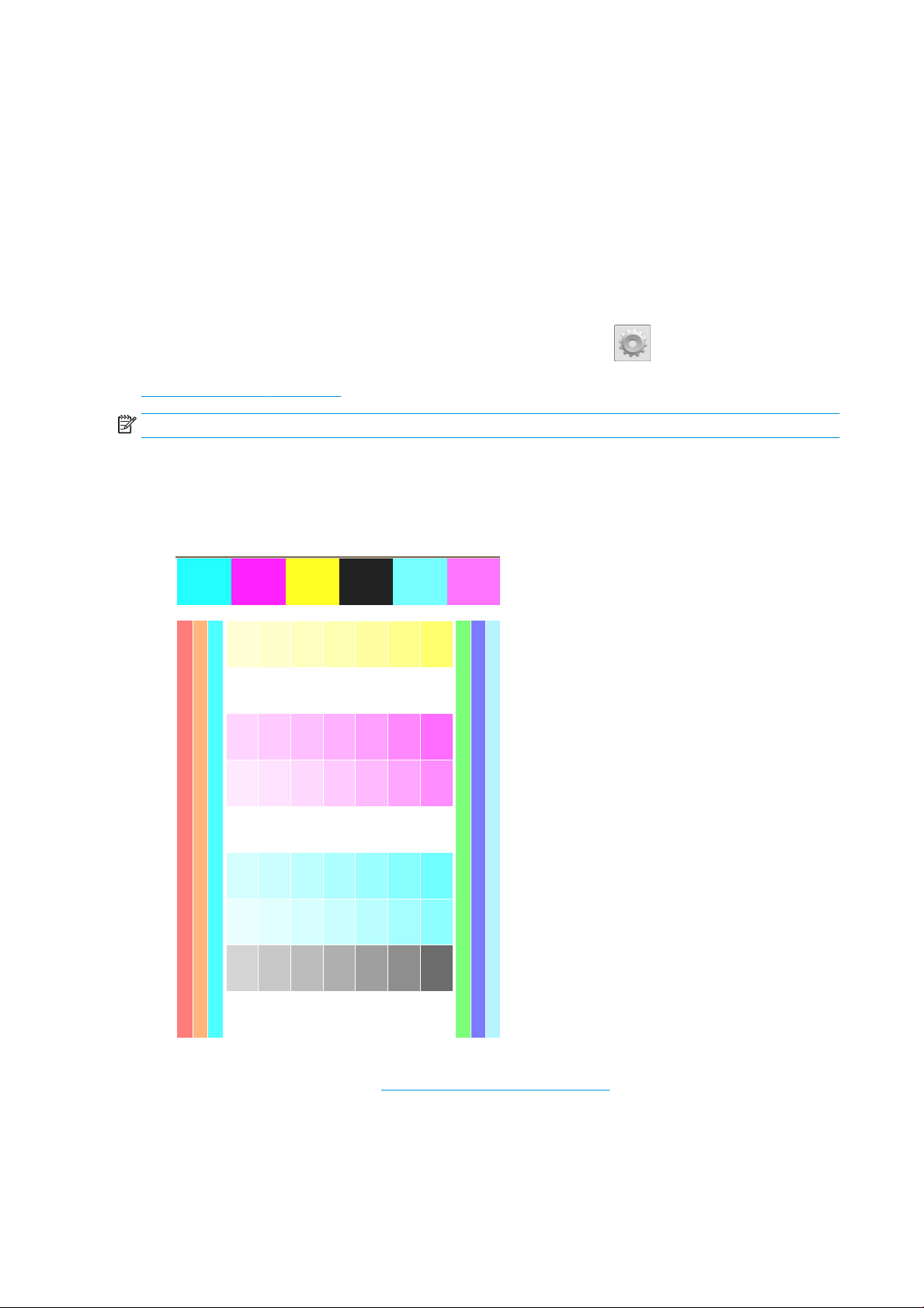

Color calibration ...................................................................................................................................................................... 81

ICC proles ............................................................................................................................................................................... 83

Improve color consistency when tiling ............................................................................................................................... 83

5 Troubleshoot print-quality issues ........................................................................................................................................................ 86

General printing advice ......................................................................................................................................................... 87

Improve print quality ............................................................................................................................................................. 87

Most-common print-quality problems ............................................................................................................................... 93

6 The ink system ..................................................................................................................................................................................... 103

Ink cartridges ........................................................................................................................................................................ 103

Printheads ............................................................................................................................................................................. 103

Maintenance cartridge ........................................................................................................................................................ 104

Safe mode ............................................................................................................................................................................. 105

7 Hardware maintenance ....................................................................................................................................................................... 106

Ink system tips ..................................................................................................................................................................... 107

Maintain the ink cartridges ................................................................................................................................................. 107

Replace an ink cartridge ..................................................................................................................................................... 107

Cannot insert an ink cartridge ........................................................................................................................................... 111

Clean (recover) the printheads ........................................................................................................................................... 111

Align the printheads ............................................................................................................................................................ 112

Front panel recommends reseating or replacing a printhead ...................................................................................... 114

Replace a printhead ............................................................................................................................................................. 114

Cannot insert a printhead ................................................................................................................................................... 120

iv ENWW

Page 5

Clean the electrical connections on a printhead ............................................................................................................. 121

Replace the maintenance cartridge .................................................................................................................................. 125

Cannot insert the maintenance cartridge ........................................................................................................................ 128

Clean and lubricate the carriage rod ................................................................................................................................. 128

Clean the encoder strip ....................................................................................................................................................... 130

Clean the platen ................................................................................................................................................................... 131

Clean the exterior of the printer ........................................................................................................................................ 133

Move or store the printer .................................................................................................................................................... 133

Service maintenance ........................................................................................................................................................... 134

8 Firmware update .................................................................................................................................................................................. 135

Firmware update using a USB ash drive ........................................................................................................................ 135

Firmware update using the Embedded Web Server ...................................................................................................... 136

Automatic rmware updates ............................................................................................................................................. 136

9 Accessories ............................................................................................................................................................................................ 137

Order ink supplies ................................................................................................................................................................ 137

Order accessories ................................................................................................................................................................ 138

10 Troubleshoot other issues ............................................................................................................................................................... 139

The printer cannot get an IP address ............................................................................................................................... 140

Cannot access the Embedded Web Server ...................................................................................................................... 140

The printer is not printing ................................................................................................................................................... 140

The software program slows down or stalls while generating the print job ............................................................. 141

The printer seems slow ...................................................................................................................................................... 141

Communication failures between computer and printer .............................................................................................. 141

Cannot connect to services such as rmware update, online search, or the Printer Data Sharing Agreement ... 142

Front-panel error codes ...................................................................................................................................................... 143

11 Printer specications ......................................................................................................................................................................... 149

Functional specications .................................................................................................................................................... 149

Physical specications ........................................................................................................................................................ 150

Memory specications ........................................................................................................................................................ 150

Power specications ........................................................................................................................................................... 150

Ecological specications ..................................................................................................................................................... 151

Environmental specications ............................................................................................................................................. 151

Acoustic specications ........................................................................................................................................................ 151

Appendix A Summary of common printing problems ....................................................................................................................... 152

Glossary ..................................................................................................................................................................................................... 155

Index ........................................................................................................................................................................................................... 158

ENWW v

Page 6

vi ENWW

Page 7

1 Introduction

●

Welcome to your printer

●

Supplementary parts

●

Documentation

●

Safety precautions

●

The printer’s main components

●

The front panel

●

The Embedded Web Server

●

Connectivity and software instructions

●

Advanced network conguration

●

Turn the printer on and o

●

Restart the printer

ENWW 1

Page 8

Welcome to your printer

Your printer is a color inkjet printer designed for printing high-quality images on exible substrates. Some major

features of the printer are shown below:

● Environmentally friendly, odorless, aqueous latex inks in six colors plus optimizer

● 400 ml ink cartridges

● Sharpest print quality, smooth transitions, and ne details with 1200 real dpi

●

Consistent and repeatable print quality at every print speed

● Prints are completely dry and ready for nishing and delivery

● Print on a wide range of substrates—including most low-cost, uncoated, solvent-compatible substrates

● A range of HP recyclable substrates is available

● Consider un-laminated use with scratch resistance comparable to hard solvent inks on SAV and PVC

banners

● Durable prints with outdoor display permanence up to three years unlaminated, ve years laminated

● Hundreds of ready-made substrate presets easily available

To send print jobs to your printer, you will need Raster Image Processor (RIP) software, which should be run on a

separate computer. RIP software is available from various dierent companies.

Supplementary parts

Supplied with the printer HP Latex Edge Holders

Optional accessories HP Latex 54-in Take-Up Reel (including 2-in reel with 3-in adaptor and Variable Front Tension Kit)

Consumables HP 831 Latex Printheads (1 set included in box)

Documentation

The following documents can be downloaded from http://www.hp.com/go/latex115/manuals/:

● Introductory information

HP Latex 54-in Printer 2-in Spindle (including 2- to 3-in spindle adaptor)

HP Latex User Maintenance Kit

FlexiPRINT HP Basic 100 Series Edition

HP Latex 54-in Printer 2-in Spindle (including 2- to 3-in spindle adaptor)

HP Latex 100/300/500 User Maintenance Kit

HP 821 Latex Ink Cartridges

HP 831 Latex Maintenance Cartridge (1 included in box)

● User guide

● Legal information

● Limited warranty

2 Chapter 1 Introduction ENWW

Page 9

The Quick Response (QR) code images found in some parts of this user guide provide links to additional video

explanations of particular topics. For an example of such an image, see The printer’s main components

on page 7.

Safety precautions

Before using your printer, read the following safety precautions to make sure you use the equipment safely.

You are expected to have the appropriate technical training and experience necessary to be aware of hazards to

which you may be exposed in performing a task, and take appropriate measures to minimize the risks to yourself

and to other people.

General safety guidelines

● There are no operator-serviceable parts inside the printer except those covered by HP's Customer Self

Repair program (see http://www.hp.com/go/selfrepair/). Refer servicing of other parts to qualied service

personnel.

● Turn o the printer and call your service representative in any of the following cases:

– The power cord or plug is damaged.

– The curing enclosures are damaged.

– The printer has been damaged by an impact.

– There is any mechanical or enclosure damage.

– Liquid has entered the printer.

– There is smoke or an unusual smell coming from the printer.

– The printer has been dropped or the curing module has been damaged.

– The printer is not operating normally.

● Turn o the printer in either of the following cases:

– During a thunderstorm

– During a power failure

● Take special care with zones marked with warning labels.

Electrical shock hazard

WARNING! The internal circuits of curing zones, output drier, print-zone heaters, and built-in power supplies

operate at hazardous voltages capable of causing death or serious personal injury.

The printer uses two power cords. Unplug both power cords before servicing the printer.

To avoid the risk of electric shock:

● The printer must be connected to earthed mains outlets only.

● Do not attempt to dismantle the curing modules.

● Do not remove or open any other closed system covers or plugs.

● Do not insert objects through slots in the printer.

ENWW Safety precautions 3

Page 10

Heat hazard

The curing subsystems of the printer operate at high temperatures and can cause burns if touched. To avoid

personal injury, take the following precautions.

● Do not touch the internal enclosures of the printer's curing zones.

● Let the printer cool down when accessing the internal curing zone and output platen in case of a substrate

● Let the printer cool down before performing some maintenance operations.

Fire hazard

The curing subsystems of the printer operate at high temperatures.

To avoid the risk of re, take the following precautions.

● The customer is responsible for meeting the printer's requirements and the Electrical Code requirements

● Connect the power cords to dedicated lines, each protected by a branch circuit breaker according to the

● Use only the power cords supplied by HP with the printer. Do not use a damaged power cord. Do not use

jam.

according to the local jurisdiction of the country where the equipment is installed. Use the power supply

voltage specied on the nameplate.

information detailed in the site preparation guide. Do not use a power strip (relocatable power tap) to

connect both power cords.

the power cords with other products.

● Do not insert objects through slots in the printer.

● Take care not to spill liquid on the printer. After cleaning, make sure all components are dry before using

the printer again.

● Do not use aerosol products that contain ammable gases inside or around the printer. Do not operate the

printer in an explosive atmosphere.

● Do not block or cover the openings of the printer.

● Do not attempt to dismantle or modify the curing modules.

● Ensure that the operating temperature of the substrate recommended by the manufacturer is not

exceeded. If this information is not available, ask the manufacturer. Do not load substrates that cannot be

used at an operating temperature above 125°C (257°F).

● Do not load substrates with auto-ignition temperatures below 250°C (482°F). If this information is not

available, printing must be supervised at all times. See note below.

NOTE: Test method based on EN ISO 6942:2002; Evaluation of materials and material assemblies when

exposed to a source of radiant heat, method B. The test conditions, to determine the temperature when the

substrate starts ignition (either ame or glow), were: Heat ux density 30 kW/m², copper calorimeter, K type

thermocouple.

Mechanical hazard

The printer has moving parts that could cause injury. To avoid personal injury, take the following precautions

when working close to the printer.

● Keep your clothing and all parts of your body away from the printer's moving parts.

● Avoid wearing necklaces, bracelets, and other hanging objects.

● If your hair is long, try to secure it so that it will not fall into the printer.

4 Chapter 1 Introduction ENWW

Page 11

● Take care that sleeves or gloves do not get caught in the printer's moving parts.

● Avoid standing close to the fans, which could cause injury and could also aect print quality (by obstructing

the air ow).

● Do not touch gears or moving rolls during printing.

● Do not operate the printer with covers bypassed.

Light radiation hazard

Light radiation is emitted from the illumination of the print zone. This illumination is in compliance with the

requirements of the exempt group of IEC 62471:2006,

However, you are recommended not to look directly at the LEDs while they are on. Do not modify the module.

Heavy substrate hazard

Special care must be taken to avoid personal injury when handling heavy substrates.

● Handling heavy substrate rolls may require more than one person. Care must be taken to avoid back strain

and/or injury.

● Consider using a forklift, pallet truck, or other handling equipment.

● When handling heavy substrate rolls, wear personal protective equipment including boots and gloves.

Photobiological safety of lamps and lamp systems.

Ink handling

HP recommends that you wear gloves when handling ink system components.

Chemical hazard

See the safety data sheets available at http://www.hp.com/go/msds to identify the chemical ingredients of your

consumables. Suicient ventilation should be provided to ensure that potential airborne exposure to these

substances is adequately controlled. Consult your usual air-conditioning or EHS specialist for advice on the

appropriate measures for your location. For more detailed information, see the “Ventilation” and “Air

conditioning” sections of the site preparation guide, available from http://www.hp.com/go/latex115/manuals/.

Ventilation

Ensure that the room in which the system is installed meets local environmental, health, and safety (EHS)

guidelines and regulations.

Adequate ventilation needs to be provided to ensure that potential exposure is adequately controlled. Consult

the Safety Data Sheets available at http://www.hp.com/go/msds to identify chemical ingredients of your ink

consumables. Levels of certain substances in your environment are dependent on workspace variables you

control, such as room size, ventilation performance, and duration of equipment use. Consult your EHS specialist

for advice on the appropriate measures for your location.

Air conditioning

In addition to fresh air ventilation, to avoid health hazards, consider maintaining workplace ambient levels by

ensuring the climatic operating conditions specied in this document (see Environmental specications

on page 151) to avoid operator discomfort and equipment malfunction. Air conditioning in the work area should

take into account that the equipment produces heat. Typically, the printer's power dissipation is 2.2 kW (7.5

kBTU/h).

Air conditioning should meet local environmental, health, and safety (EHS) guidelines and regulations.

ENWW Safety precautions 5

Page 12

CAUTION: The air conditioning units should not blow air directly onto the printer.

Warnings and cautions

The following symbols are used in this manual to ensure the proper use of the printer and to prevent the printer

from being damaged. Follow the instructions marked with these symbols.

WARNING! Failure to follow the guidelines marked with this symbol could result in serious personal injury or

death.

CAUTION: Failure to follow the guidelines marked with this symbol could result in minor personal injury or

damage to the printer.

Warning labels

Label Explanation

Printer label. To identify the printer’s power cord.

Curing label. To identify the curing power cord.

Electric shock hazard. Heating modules operate at hazardous

voltages. Disconnect power source before servicing.

CAUTION: Double pole. Neutral fusing.

Equipment to be connected to earthed mains outlet only. Refer

servicing to qualied service personnel. Disconnect all power cords

before servicing. No operator serviceable parts inside the printer.

Before starting, read and follow the operating and safety

instructions. Ensure that the input voltage is within the printer's

rated voltage range. The printer requires up to two dedicated lines.

This label is located on the e-box.

Risk of burns. Do not touch the curing zone or the output platen of

the printer: they could be hot.

This label is located on the front of the curing module.

Risk of trapped ngers. Do not touch moving gears.

These labels are located at the rear of the printer, on the substrate

input gear.

6 Chapter 1 Introduction ENWW

Page 13

Label Explanation

Moving part. Keep away from the moving printhead carriage. When

printing, the printhead carriage travels back and forth across the

substrate.

This label is located on the rear of the scan axis window, behind the

plastic.

You are recommended to wear gloves when handling the

maintenance cartridge or the platen.

This label is located on the maintenance cartridge.

Electric shock hazard. Heating modules operate at hazardous

voltages. Disconnect all power sources before servicing.

This label is located on the curing control PCA enclosure. For service

personnel only.

NOTE: The nal label position and its size on the printer may vary slightly, but should always be visible and

close to the potential risk area.

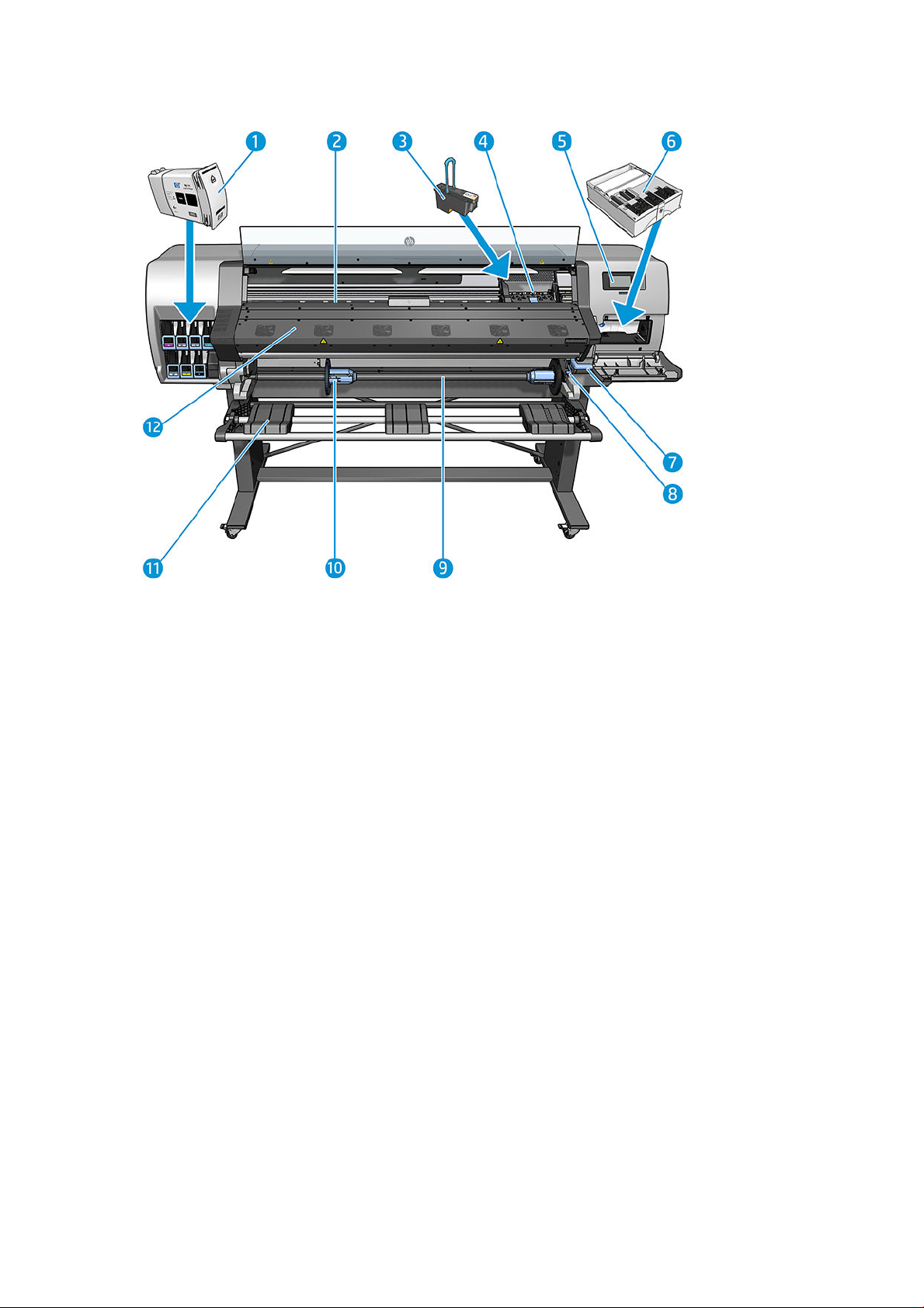

The printer’s main components

The above image is a QR code containing a link to a video; see Documentation on page 2.

The following views of the printer illustrate its main components.

ENWW The printer’s main components 7

Page 14

Front view

1. Ink cartridge

2. Platen

3. Printhead

4. Printhead carriage

5. Front panel

6. Maintenance cartridge

7. Substrate pinch lever

8. Spindle lock lever

9. Spindle

10. Spindle stop with 2-in to 3-in adaptor

11. Loading table

12. Curing module

8 Chapter 1 Introduction ENWW

Page 15

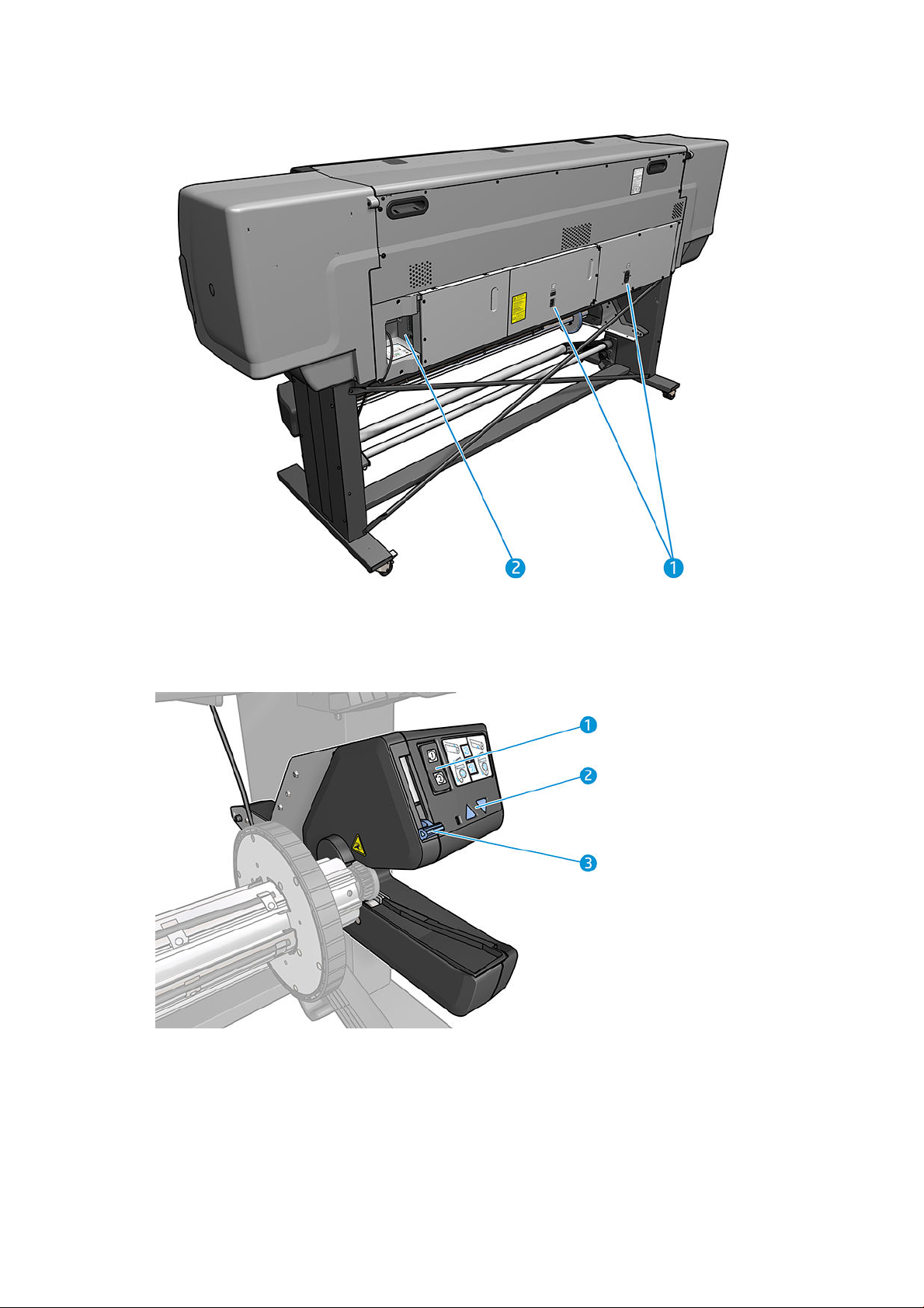

Rear view

1. Power switch and power socket

2. Sockets for communication cables and optional accessories

Take-up reel motor (accessory)

1. Winding-direction switch

2. Manual winding buttons

3. Take-up reel lever

ENWW The printer’s main components 9

Page 16

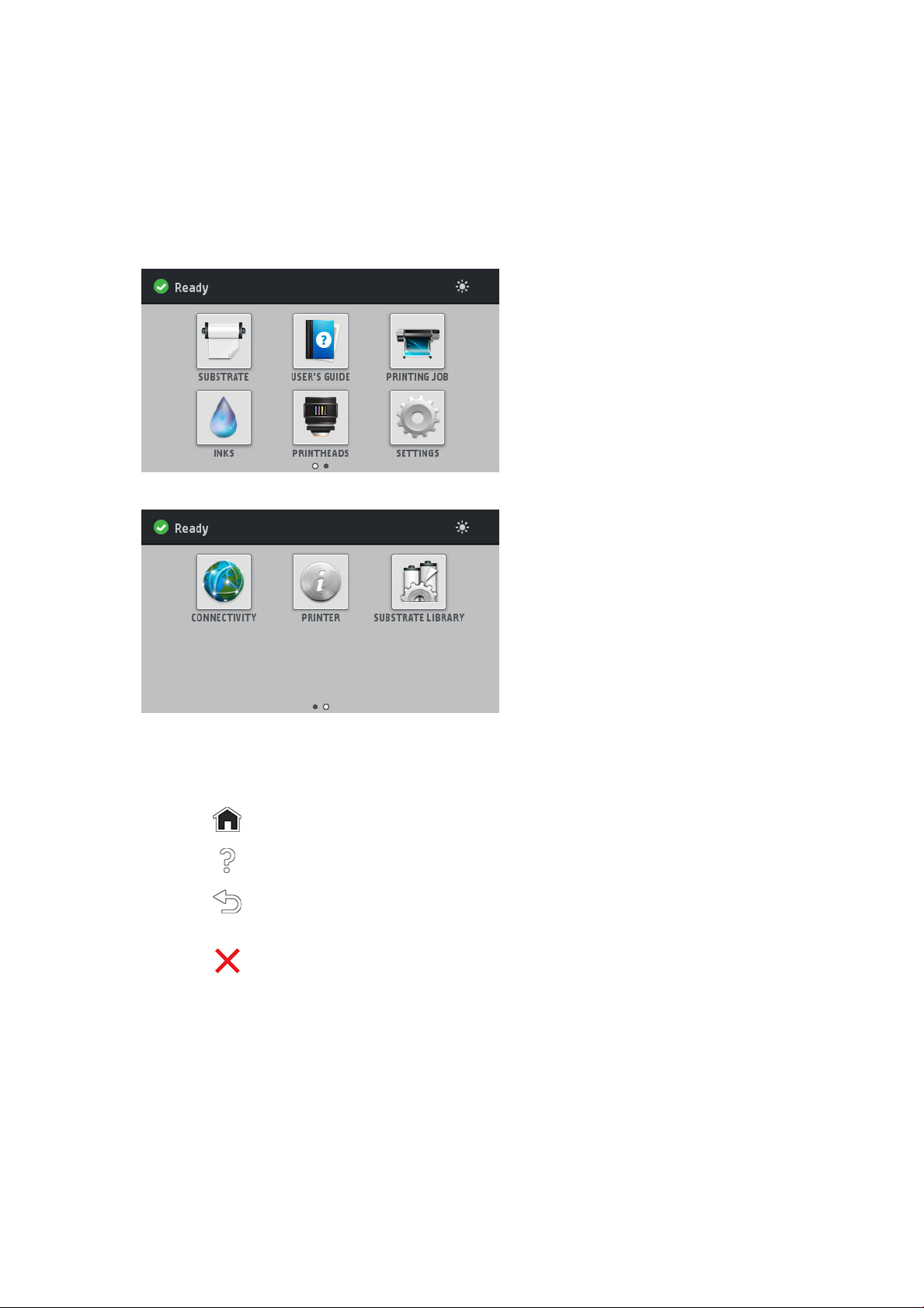

The front panel

Introduction to the front panel

The front panel is a touch-sensitive screen with a graphical user interface; it is located on the front right of the

printer. It gives you complete control of your printer: from the front panel, you can view information about the

printer, change printer settings, perform calibrations and tests, and so on. The front panel also displays alerts

(warning and error messages) when necessary.

There is an alternative home screen that you can see by sliding your nger across the screen to the left.

The front panel has a large central area to display dynamic information and icons. On the left and right sides you

can see up to four xed icons at dierent times. Normally they are not all displayed at the same time.

Left and right xed icons

● Press to return to the home screen.

● Press to view help about the current screen.

● Press to go back to the last-visited screen. This does not discard any changes made in the current

screen.

● Press to cancel the current process.

10 Chapter 1 Introduction ENWW

Page 17

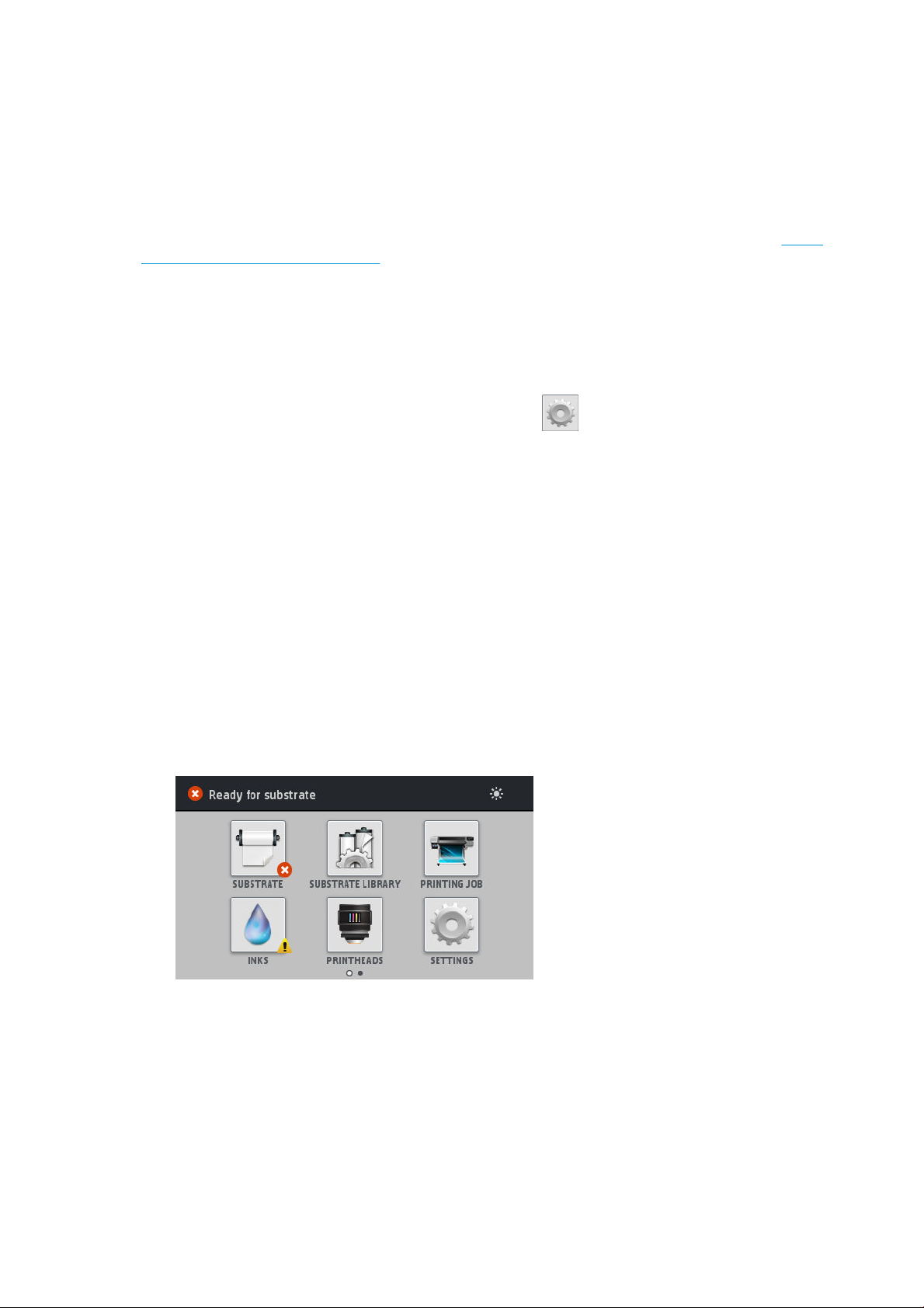

Home screen dynamic icons

The following items are displayed only on the home screen.

● At the top left of the screen is a message showing the printer status or the most important current alert.

Press this message to see a list of all current alerts, with an icon indicating the severity of each alert. You

can press an alert to get help in solving the problem.

● At the top right, press to turn on or o the print-zone illumination light.

● Press to view substrate status and perform substrate-handling operations.

● Press to open the Substrate Library and access the extensive online library of substrate presets.

● Press to view information about the job that is currently printing.

● Press to view ink-cartridge status and perform operations.

● Press to view printhead status and perform operations.

● Press to view and change printer settings in general.

● Press to view network and Internet status and change related settings.

● Press to view information about the printer.

● Press for help.

If the printer is left idle for some time, it goes into sleep mode and switches o the front-panel display. To

change the time that elapses before sleep mode, press , then Setup > Front panel options > Sleep mode

wait time. You can set a time between 5 and 240 minutes; the default is 25 minutes.

The printer wakes from sleep mode and switches on the front-panel display whenever there is some external

interaction with it.

Information about specic uses of the front panel can be found throughout this guide.

ENWW The front panel 11

Page 18

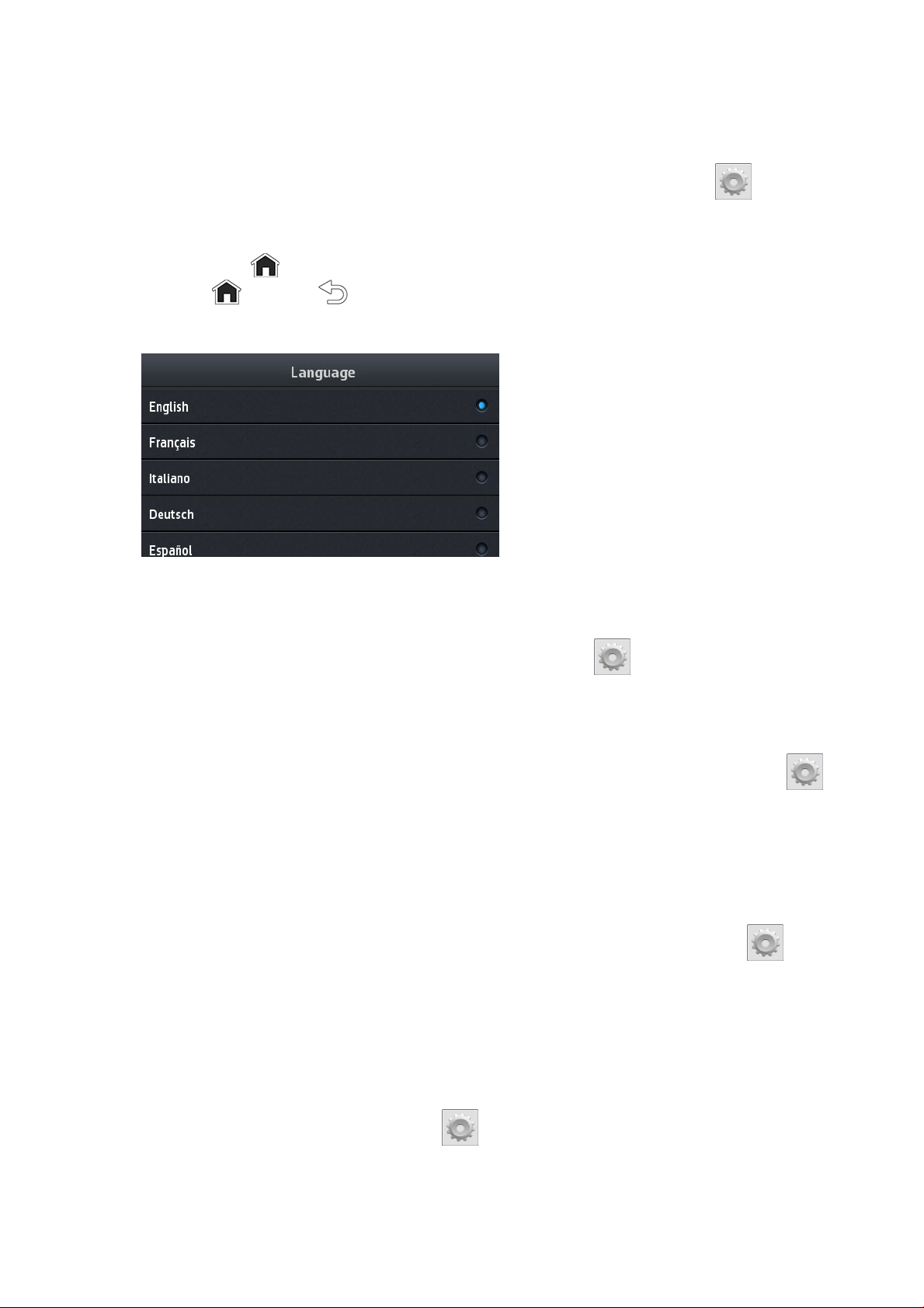

Change the language of the front panel

Two methods are available to change the language that is used for the front-panel menus and messages:

● If you can understand the current front panel language, go to the front panel and press , then Setup >

Front panel options > Language.

● If you cannot understand the current front panel language, start with the printer turned o. Turn it on. As

soon as the icon appears, press it for a few seconds. When all icons have appeared on the front panel,

press followed by . The front panel blinks briey.

Whichever method you used, the language selection menu should now appear on the front panel.

Press the name of your preferred language.

View or set the date and time

To view or set the printer's date and time, go to the front panel and press , then Setup > Front panel

options > Date and time options.

Set altitude

If your printer is operating at more than 500 m (1640 ft) above sea level, go to the front panel and press ,

then Setup > Select altitude, to tell the printer its operating altitude.

Set time before standby

When there are no more jobs to print, or you want to pre-warm the printer (Prepare printing option in the RIP),

the printer´s curing heaters remain on for the specied time and temperature in case another job arrives or in

case you need to avoid any print-quality problem that could be caused by an incorrect temperature in the print

zone. To choose how long the heaters will stay on in this situation, go to the front panel and press then

Substrate > Substrate handling options > Curing standby duration. You can select from 5 to 120 minutes.

The curing temperature during this standby period is set automatically by the printer.

Change the sleep mode setting

If the printer is left turned on but unused for a certain period of time, it automatically goes into sleep mode to

save power. The default period of time it waits is 25 minutes. To change the time the printer waits before it goes

into sleep mode, go to the front panel and press

time. Enter in minutes the wait time that you want, then press OK.

12 Chapter 1 Introduction ENWW

, then Setup > Front panel options > Sleep mode wait

Page 19

Change the loudspeaker volume

To change the volume of the printer's loudspeaker, go to the front panel and press , then Setup > Front

panel options > Speaker volume, and select O, Low, or High.

Turn audio alerts on or o

To turn the printer's audio alerts on or o, go to the front panel and press , then Setup > Front panel

options > Enable audio alert or Disable audio alert. By default, audio alerts are enabled.

Change the front panel display brightness

To change the brightness of the front-panel display, press , then Setup > Front panel options > Display

brightness

, then select a value by moving the scroll bar. Press OK to save the value.

Change the units of measurement

To change the units of measurement that appear on the front panel, press , then Setup > Front panel

options > Unit selection, then English or Metric.

The units of measurement can also be changed in the Embedded Web Server. See Access the Embedded Web

Server on page 20.

Restore factory settings

To restore the printer settings to their original values as set in the factory, go to the front panel and press ,

then Setup > Resets > Restore factory settings. This option restores all of the printer settings except the Gigabit

Ethernet settings and substrate presets.

Check printer status

The front panel and the Embedded Web Server both display the status of the printer, the loaded substrate, and

the ink system.

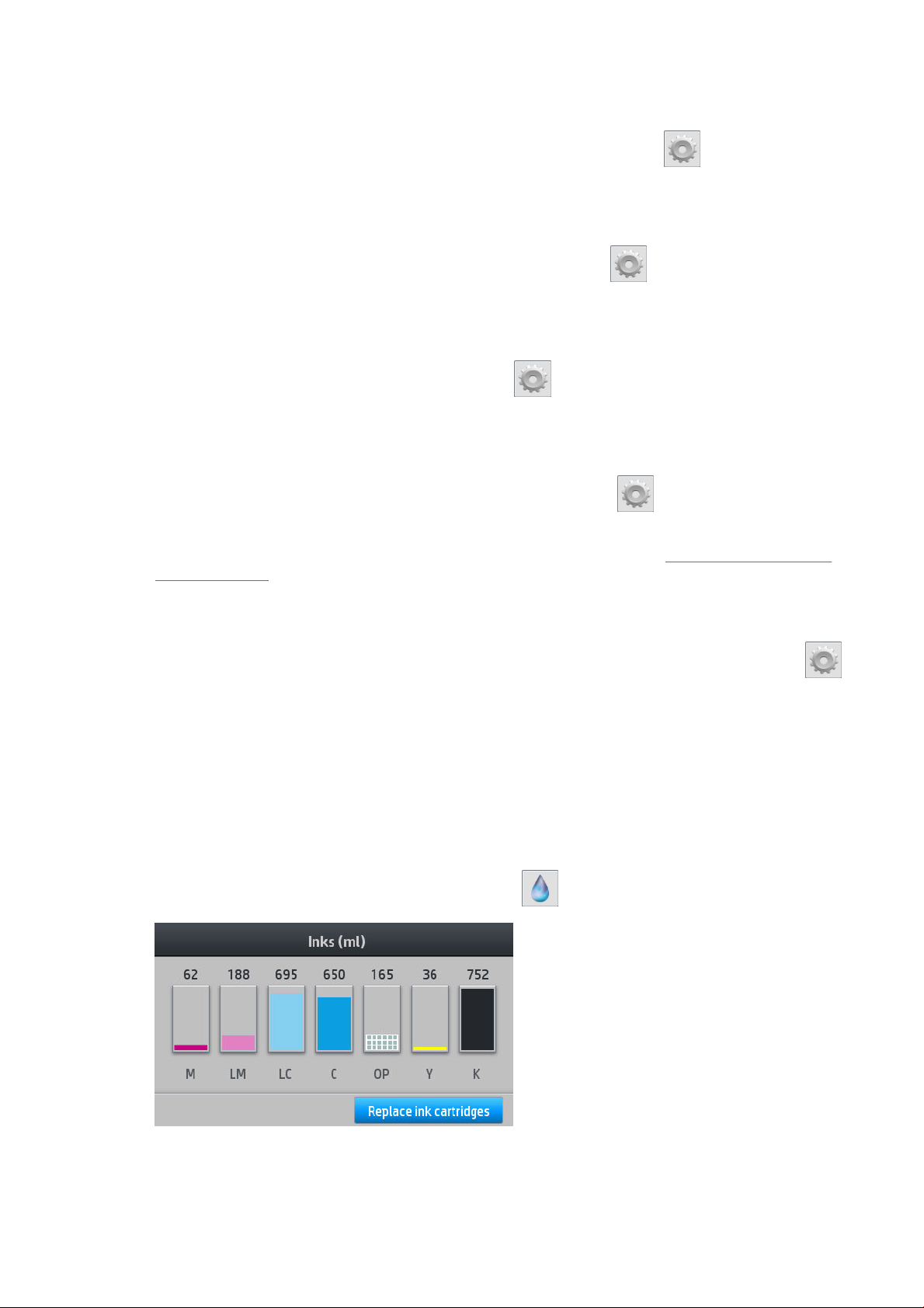

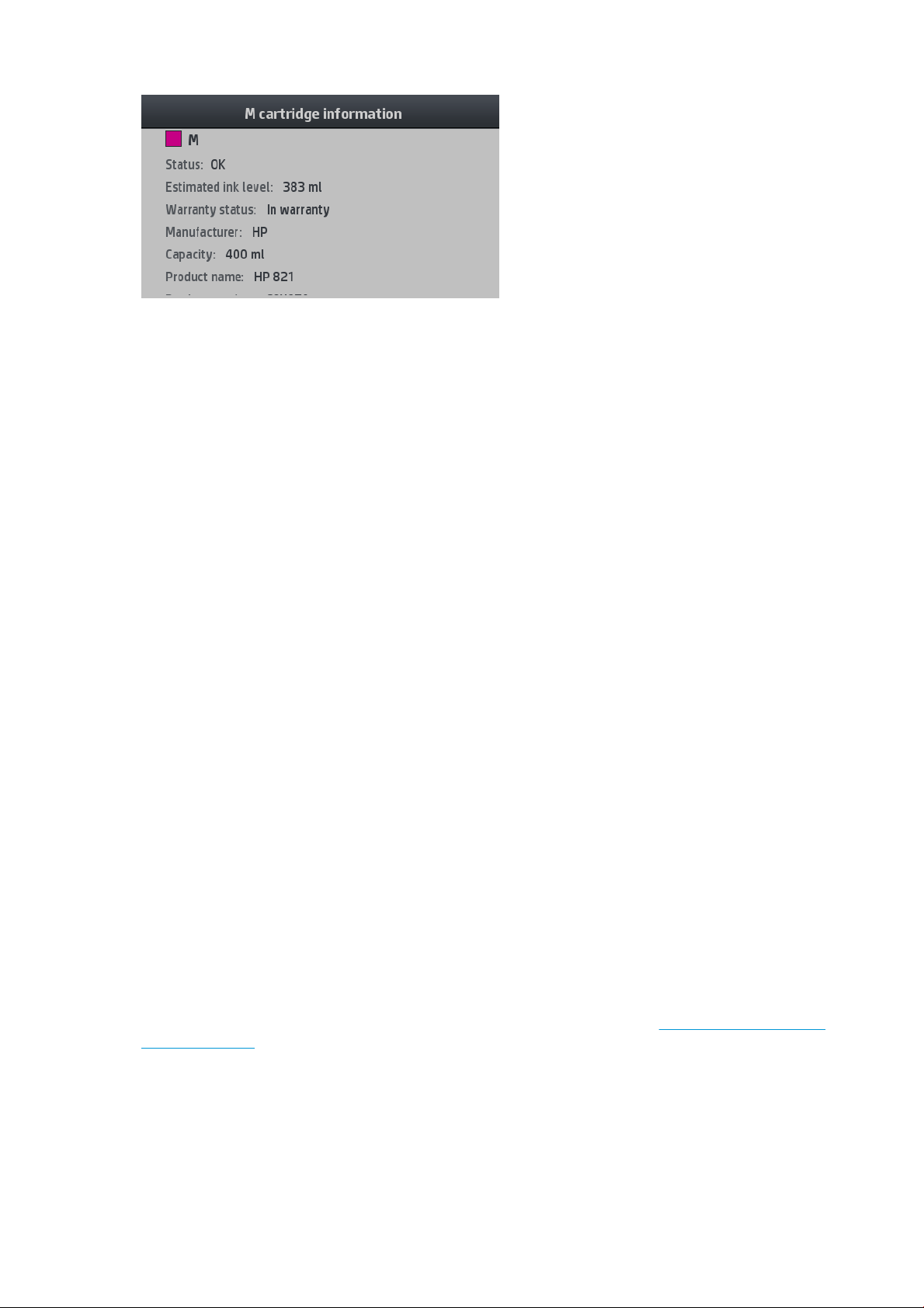

Check the status of the ink cartridges

You can see the ink levels in your ink cartridges by pressing on the front panel's home screen.

For more details about any particular ink cartridge, press the rectangle representing that cartridge. The following

information is shown.

ENWW The front panel 13

Page 20

● Status

● Estimated ink level

● Warranty status

● Manufacturer

● Capacity

● Product name

● Product number

● Serial number

● Expiration date

● Supported ink cartridges

These are the possible ink cartridge status messages that you can see on the front panel:

● OK: The cartridge is working normally, with no known problems.

● Missing: There is no cartridge present, or it is not correctly connected to the printer.

● Low: The ink level is low.

● Very low: The ink level is very low.

● Empty: The cartridge is empty.

● Reseat: You are recommended to remove the cartridge and then reinsert it.

● Replace: You are recommended to replace the cartridge with a new cartridge.

● Expired: The cartridge’s expiration date has passed.

● Incorrect: The cartridge is not compatible with this printer. The message includes a list of compatible

cartridges.

● Non-HP: The cartridge is used, relled, or counterfeit.

You can also view the status of the ink cartridges in the Embedded Web Server. See Access the Embedded Web

Server on page 20.

14 Chapter 1 Introduction ENWW

Page 21

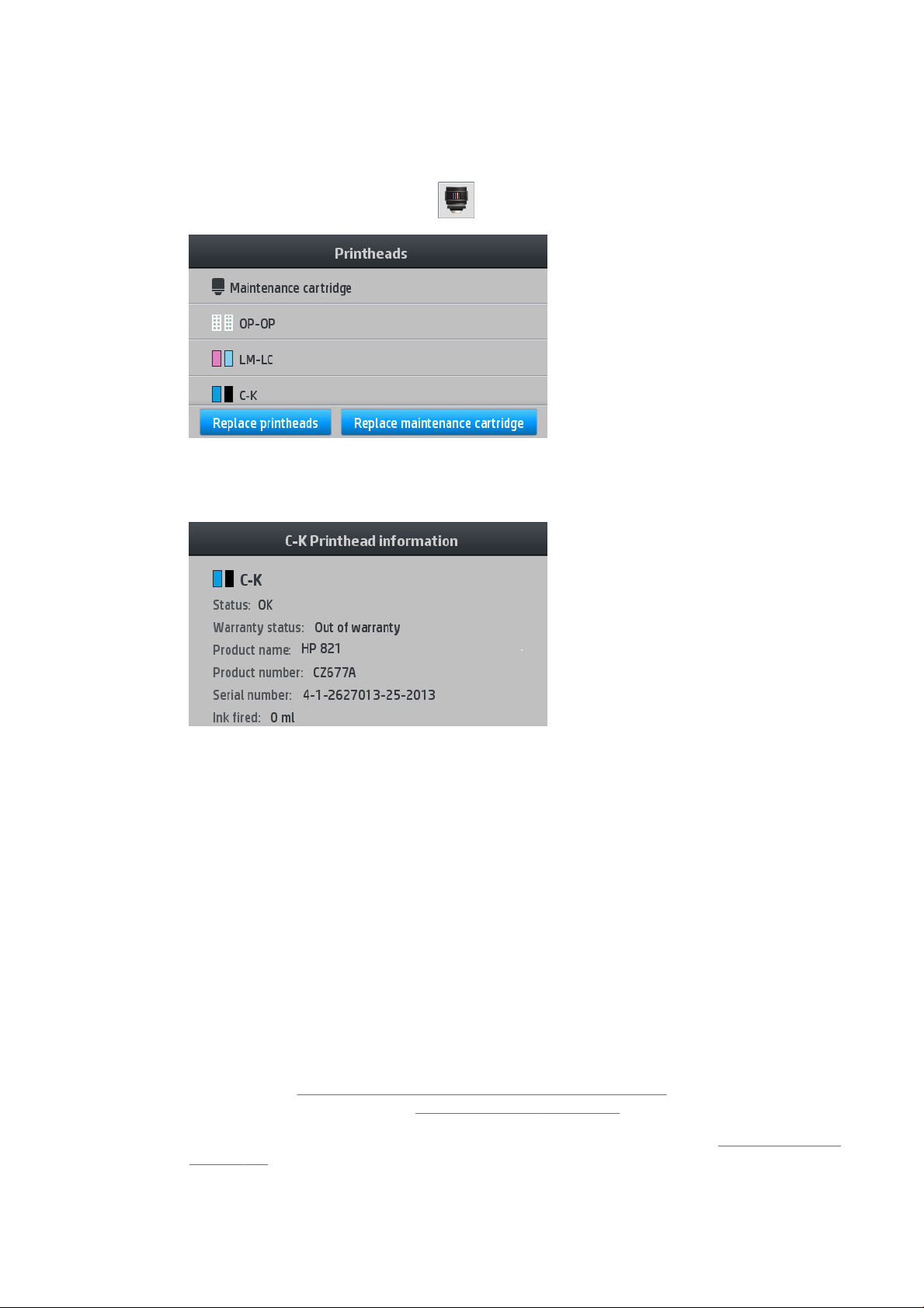

Check the status of a printhead

The printer automatically checks and services the printheads after each print. Follow these steps to get more

information on your printheads:

1. On the front panel's home screen, press .

2. Select the printhead for which you want to see information.

3. The front panel shows the following information.

● Status

● Warranty status

● Product name

● Product number

● Serial number

● Ink red

● Install date

These are the possible printhead status messages that you can see on the front panel:

● OK: The printhead is working normally, with no known problems.

● Missing: There is no printhead present, or it is not correctly installed in the printer.

● Reseat: You are recommended to remove the printhead and then reinsert it. If that fails, clean the electrical

connections (see Clean the electrical connections on a printhead on page 121). If that fails, replace the

printhead with a new printhead (see Replace a printhead on page 114).

● Replace: The printhead is failing. Replace the printhead with a working printhead (see Replace a printhead

on page 114).

ENWW The front panel 15

Page 22

● Replacement incomplete: The printhead replacement process has not completed successfully; restart the

replacement process and let it nish completely.

● Remove: The printhead is not a suitable type for use with your printer.

● Non-HP ink: Ink from a used, relled, or counterfeit ink cartridge has passed through the printhead. See the

limited warranty document provided with your printer for details of the warranty implications.

You can also use the Embedded Web Server to check the printhead status and the warranty status. See Access

the Embedded Web Server on page 20.

Check the le system

It is possible to check the integrity of the le system on the printer's hard disk, and automatically correct any

errors. You are recommended to do this about once every six months, or if you notice any trouble in accessing

les on the hard disk.

To execute the le system check, go to the front panel and press , then Preventive maint. tasks > File

system check

If the printer is aware of damage to the le system, for instance after a severe software problem, it may start a

le system check automatically. This can take about ten minutes.

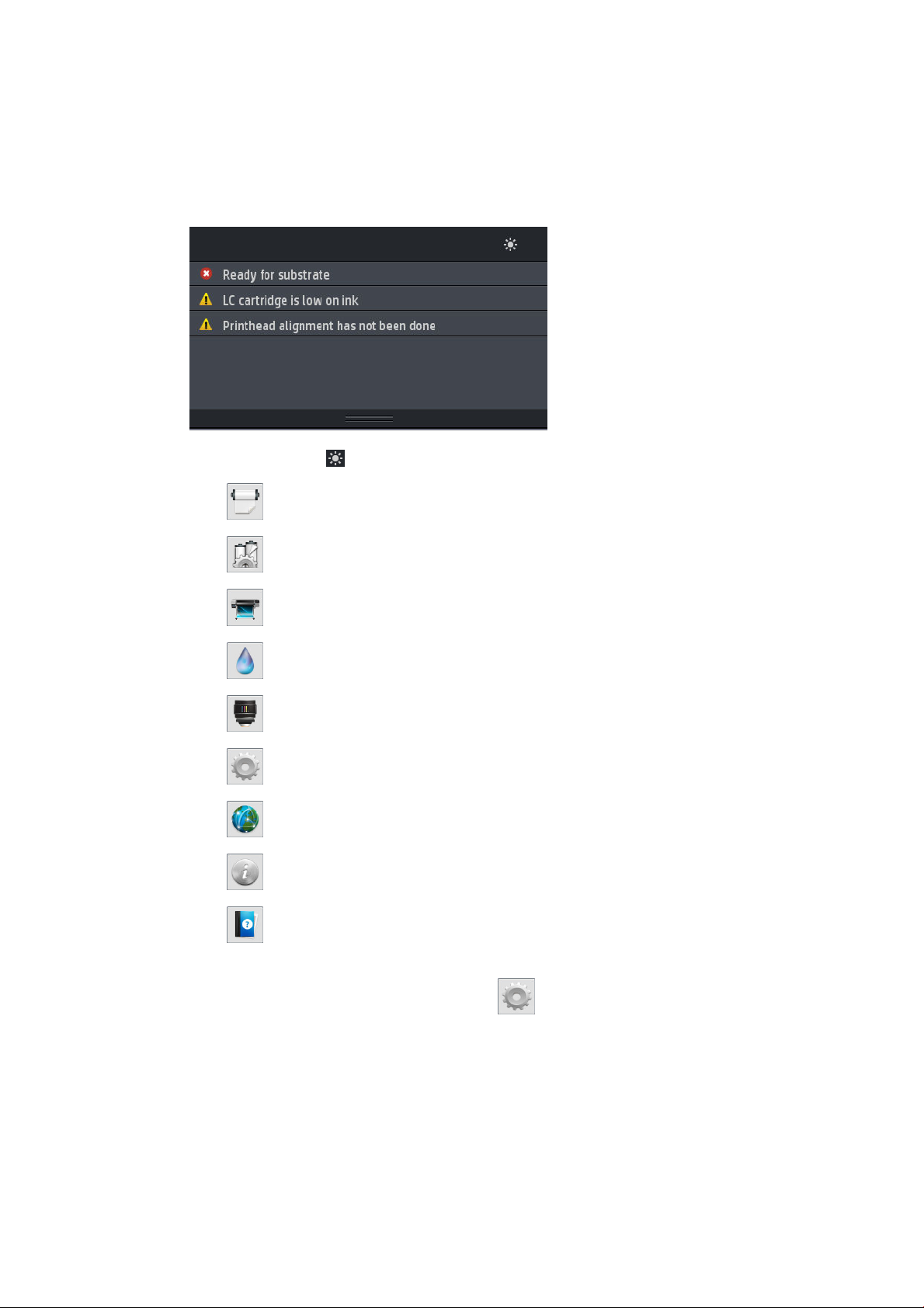

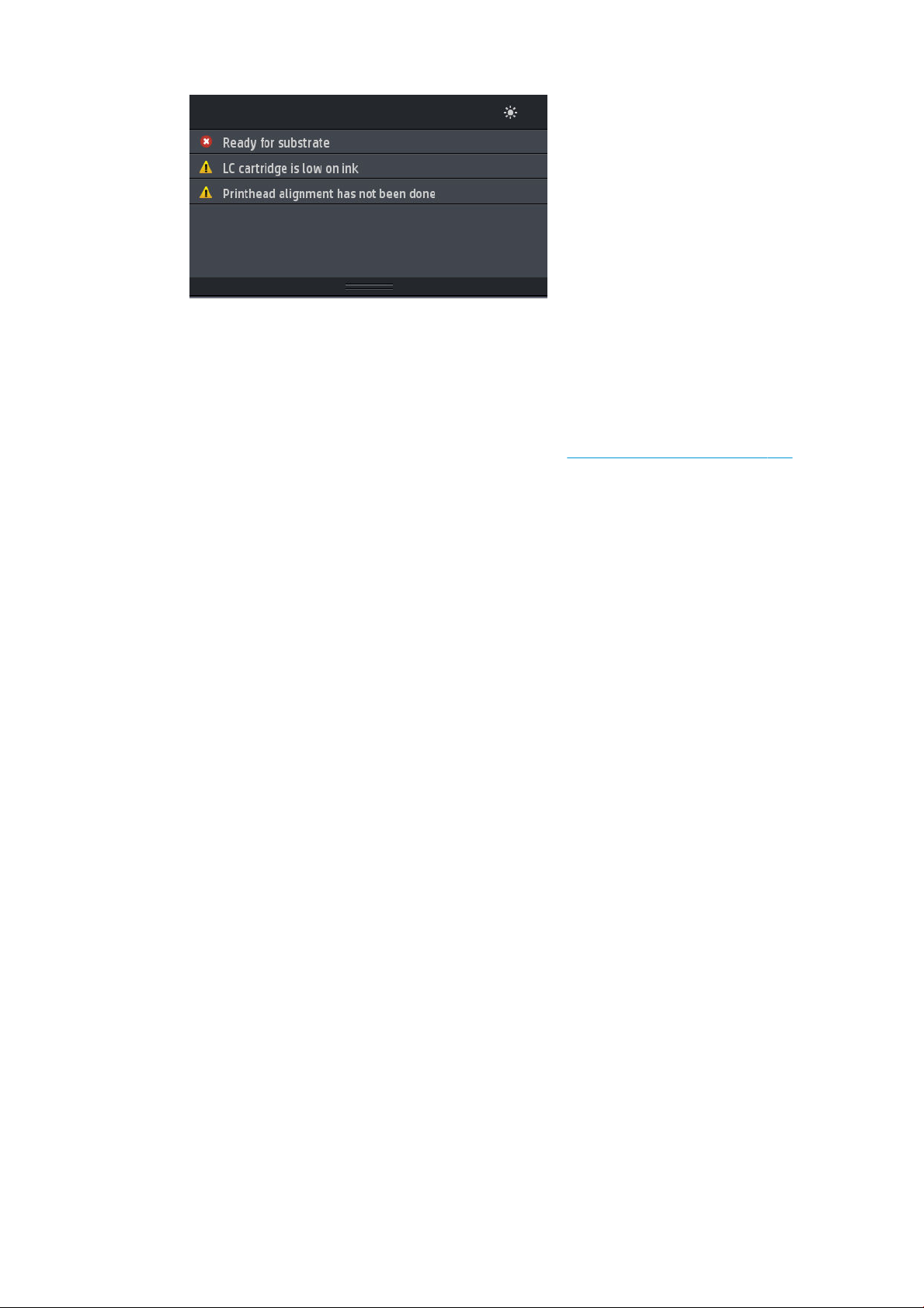

Printer alerts

The printer can communicate two types of alerts:

● Errors: When the printer is unable to print.

● Warnings: When the printer needs attention for an adjustment, such as a calibration, preventive

● Advice: When a rmware update is available or the downloaded rmware is ready to be installed.

Printer alerts appear in the front panel and in the Embedded Web Server.

● Front-panel display: The front panel shows the alerts in the upper left part of the screen (notication bar).

.

maintenance, or ink cartridge replacement.

Only one alert is shown at a time. If you press the notication bar, all the current printer alerts are shown.

The list of alerts can be folded back by pressing or sliding up the bottom row of the list.

16 Chapter 1 Introduction ENWW

Page 23

● Embedded Web Server: The Embedded Web Server shows only one alert at a time, which is judged to be

An alert may require you to perform a maintenance operation; see Hardware maintenance on page 106.

The following alerts require a service engineer:

● Service Maintenance Kit 1

● Service Maintenance Kit 2

● Service Maintenance Kit 3

Printer states

The printer may be in any one of the following states; some of them require waiting:

● Ready (cold): The printer is powered on but has not printed yet, and the heaters are not turned on.

● Preparing to print: The printer is warming up the heaters and preparing the printheads to print. This takes 1

Clicking an alert opens the application that could help to resolve it. Firmware update advice is dismissed

when entering the Printer application. Once dismissed, there won’t be any reminder later on about the

same advice (in the case of rmware updates, a new notication appears when there a new rmware

release becomes available).

the most important.

to 6 min.

● Ready for substrate

● Ready for side A/B

● Printing

● Printing side A/B

● Drying: This takes 1.5 to 5 min.

● Finishing: The printer is cooling down and preparing for stand-by. This takes 0.5 to 5 min.

If jobs of the same print mode as the already-printed le are sent while the printer is Drying or Finishing, the

printer goes to Preparing to print.

To save time between prints, you are recommended to use nesting to print several jobs in the same workow.

Change margins

The printer margins determine the area between the edges of your image and the edges of the substrate.

The side margins for a particular print job are selected in the RIP software; if the job exceeds the substrate width,

it will be clipped.

ENWW The front panel 17

Page 24

The front panel oers additional settings for the top and bottom margins: see Table 11-4 Margins on page 150.

These settings apply only to single prints when the automatic cutter is not in use.

To set the top margin at the front panel, press , then Substrate > Substrate handling options > Extra top

margin.

To set the bottom margin at the front panel, press , then Substrate > Substrate handling options > Extra

bottom margin.

NOTE: The extra top/bottom margin set in the front panel is applied in addition to the top/bottom margin

selected in the RIP.

NOTE: The side margins can be adjusted in the RIP.

Request the printer’s internal prints

The internal prints provide various kinds of information about your printer. Request these prints from the front

panel, without using a computer.

Before requesting any internal print, make sure that substrate is loaded and that the Ready message appears on

the front-panel display.

To print an internal print, press , then Setup > Internal prints, then select the type of internal print that you

want.

The following internal prints are available:

● Usage report: Shows estimates of the total number of prints, number of prints by substrate family, number

of prints by print-quality option, and total amount of ink used per color. The accuracy of these estimates is

not guaranteed.

● Service information: Provides information that service engineers require.

Check lifetime usage statistics

There are two ways of checking your printer's usage statistics.

NOTE: The accuracy of the usage statistics is not guaranteed.

● From the Embedded Web Server, go to the Main tab and select History > Usage. See The Embedded Web

Server on page 18.

● From the front panel, press , then Setup > Internal prints > User information prints > Print usage

report.

The Embedded Web Server

18 Chapter 1 Introduction ENWW

Page 25

Introduction to the Embedded Web Server

The Embedded Web Server is a Web server running inside the printer. You can use it to obtain printer

information, manage settings and presets, align printheads, upload new rmware and troubleshoot problems.

Service engineers can use it to retrieve internal information that helps to diagnose printer problems.

You can access the Embedded Web Server remotely by using an ordinary Web browser running on any computer.

See Access the Embedded Web Server on page 20.

The Embedded Web Server window displays three separate tabs. Buttons near the top of each page provide

access to online help and supplies reordering.

Main tab

The Main tab provides information about the following items.

● Substrate, ink, printhead and maintenance status

● Temperature of the curing module

● Substrate and ink usage and accounting

Setup tab

The Setup tab enables you to complete these tasks.

● Specify printer settings such as units of measurement and refresh date

● Specify network and security settings

● Set the date and time

● Update rmware

● Align printheads

● Upload substrate presets

● Congure e-mail notications

Support tab

The Support tab oers various kinds of help with your printer.

● Browse helpful information from a variety of sources

● Troubleshoot problems

ENWW The Embedded Web Server 19

Page 26

● Access HP links for technical support with your printer and accessories

● Access service support pages that show current and historical data on the usage of your printer

Networking tab

The Networking tab enables you to change the printer’s networking conguration.

Printer Data Sharing Agreement tab

The Printer Data Sharing Agreement tab enables you to sign the Printer Sharing Data Agreement and congure

your participation.

Access the Embedded Web Server

Use the Embedded Web Server to view printer information remotely through an ordinary Web browser running

on any computer.

The following browsers are known to be compatible with the Embedded Web Server:

● Internet Explorer 7 and later for Windows

● Safari 3 and later for Mac OS X

● Mozilla Firefox 3.6 and later

● Google Chrome 7 and later

To use the Embedded Web Server on any computer, open your Web browser and type the printer's IP address in

the browser's address bar. The printer's IP address appears on the printer’s front panel, after pressing .

If you follow these instructions but fail to open the Embedded Web Server, see Cannot access the Embedded

Web Server on page 140.

Change the language of the Embedded Web Server

The Embedded Web Server functions in the following languages: English, Portuguese, Spanish, Catalan, French,

Italian, German, Simplied Chinese, Traditional Chinese, Korean, and Japanese. It uses the language that you

specied in your Web browser options. If you specify a language that it cannot support, it functions in English.

To change the language, change your Web browser's language setting. For example, in Chrome, Settings,

Language (in the advanced settings view), make sure that the language you want is at the top of the list in the

dialog box; or, in Internet Explorer version 8, go to the Tools menu and select Internet Options > Languages. Make

sure that the language you want is at the top of the list in the dialog box.

To complete the change, close and reopen your Web browser.

Restrict access to the printer

From the Embedded Web Server, you can select Setup > Security to set an administrator password. Once set, this

password must be given in order to perform the following printer functions:

● Clear accounting information.

● Update the printer’s rmware.

● Change security settings.

● View protected printer information.

● Change Internet connection settings.

20 Chapter 1 Introduction ENWW

Page 27

● Change some networking settings.

● Congure the Printer Data Sharing Agreement.

● Run connectivity troubleshooting tests.

For more information, see the Embedded Web Server's online help.

If you forget the administrator password, you can delete the current password from the front panel: press ,

then Setup > Connectivity > Advanced > Embedded Web Server > Reset EWS password.

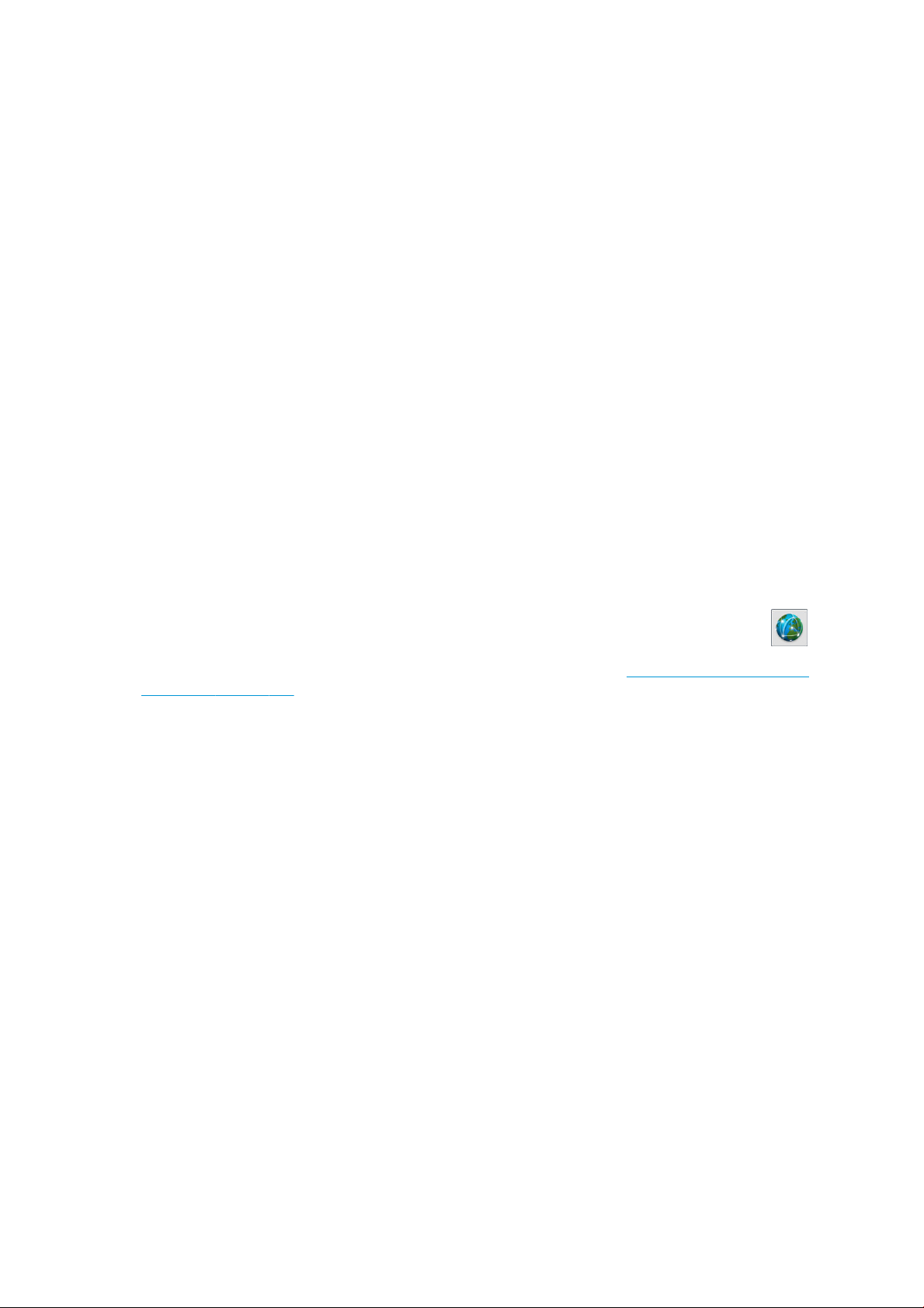

Join the Printer Data Sharing Agreement

You can activate or deactivate the Printer Data Sharing Agreement from the Embedded Web Server or from the

printer's front panel.

NOTE: From the front panel, press , then Setup > Printer Data Sharing Agreement.

The Printer Data Sharing Agreement is a statistical printer-usage tracking system. It may also be used to

determine eligibility for certain usage-based reward programs, or to monitor the device in connection with

optional services such as proactive cartridge replacement, pay-per-use contracts, or support agreements

(availability varies by product, region, and country). See the Printer Data Sharing Agreement tab of the

Embedded Web Server for details on the data collected and HP’s use of the data. Once the Printer Data Sharing

Agreement is enabled, your printer will automatically send 'usage snapshots' to HP through the Internet

approximately once a week, for as long as the Printer Data Sharing Agreement remains enabled. The snapshot

les are collected on a repository server, then automatically processed to extract the relevant data, which are

stored in a usage database. Sending the data does not interfere with the normal operation of your printer, and

does not require attention of any kind. You can stop participating at any time, in which case data transmissions

stop immediately.

The PDSA conguration page of the Printer Data Sharing Agreement tab is where you can start, stop, or change

your participation in the Printer Data Sharing Agreement. By default, only anonymous usage data are sent to HP,

but you have the option to include the printer’s serial number. This may be necessary for certain programs or

services, and may allow us to provide you with better product service and support. Once you have made any

changes to the settings, click the Apply button to apply them.

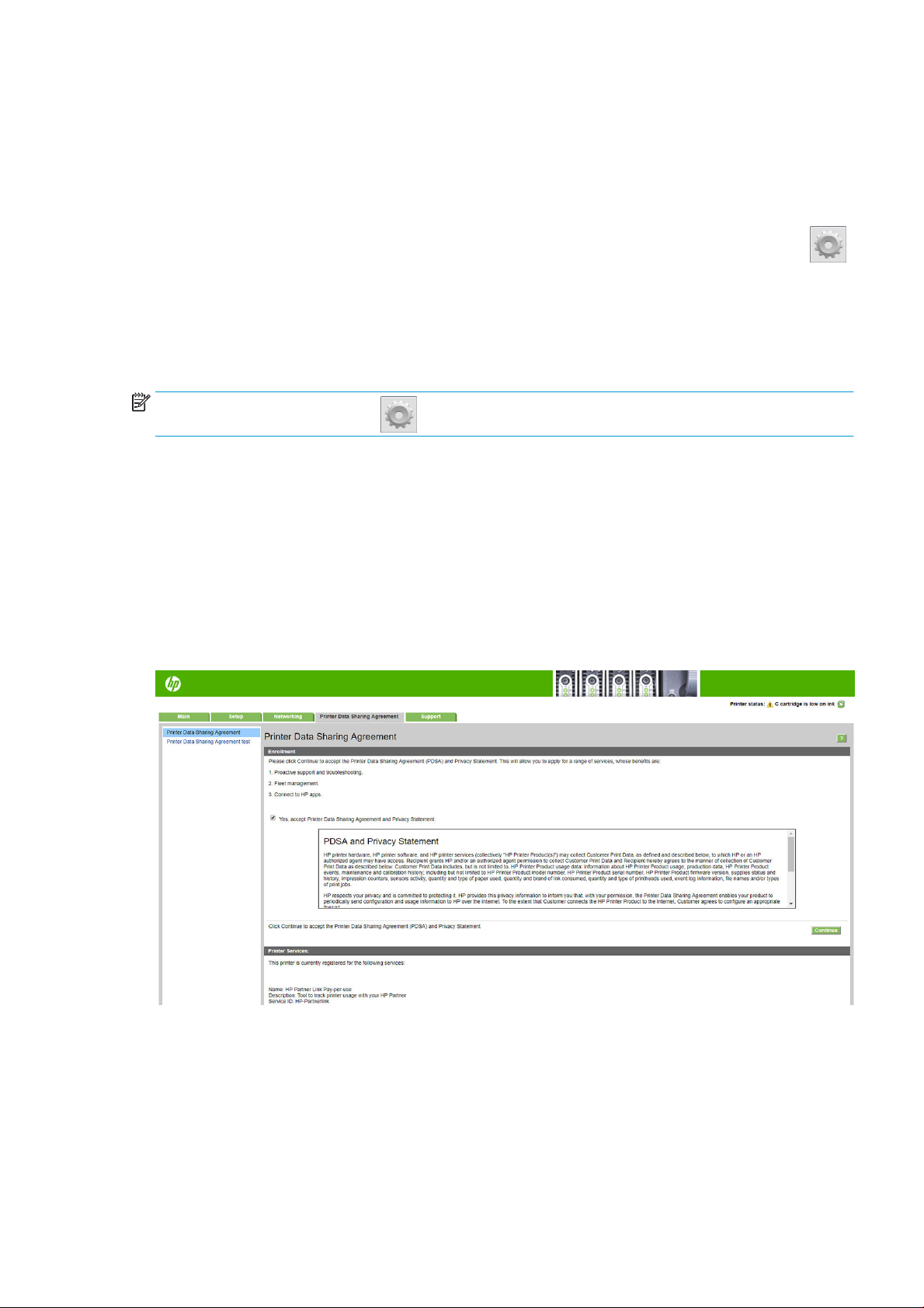

If the Printer Data Sharing Agreement was enabled before clicking the Apply button, a connectivity test is

automatically made to determine whether Printer Data Sharing Agreement data can be successfully delivered to

HP.

ENWW The Embedded Web Server 21

Page 28

If the test completes successfully, conguration is complete and you can proceed to any other Embedded Web

Server page, or close the browser window. If the test fails, follow the instructions to try to identify and x the

problem.

The PDSA status and test page of the Printer Data Sharing Agreement tab can be used to check the current

status (enabled or not, anonymous data or not), and to run a connectivity test to check that Printer Data Sharing

Agreement data can be successfully delivered to HP.

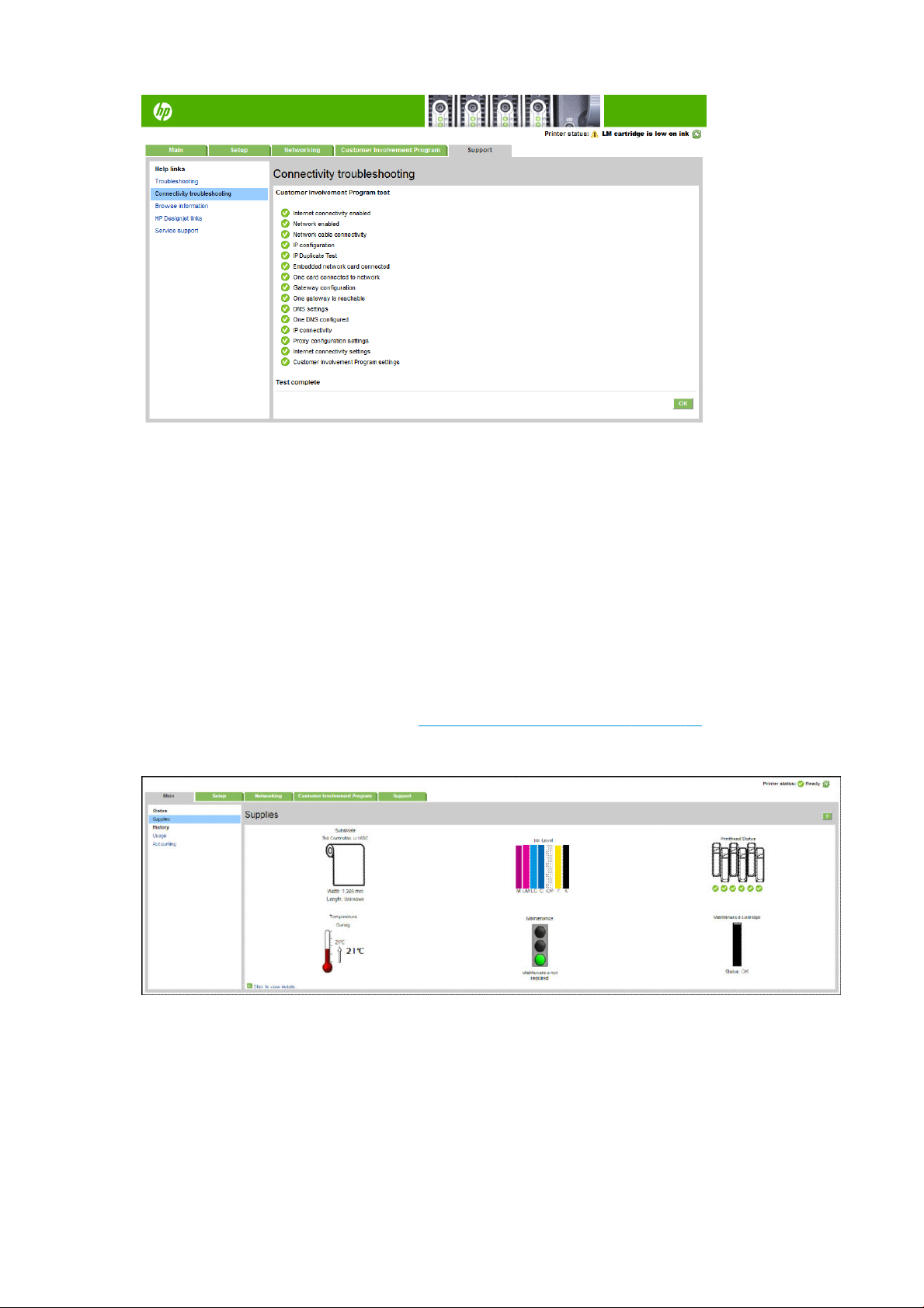

Check printer status

The front panel and the Embedded Web Server both display the status of the printer, the loaded substrate, and

the ink system.

Check the status of the ink system

1. Access the Embedded Web Server (see Access the Embedded Web Server on page 20).

2. Go to the Supplies page on the Main tab.

The Supplies page shows you the status of the loaded substrate, the ink cartridges, the printheads, the heater,

and the maintenance cartridge.

The traic light shows whether maintenance is required.

For further information, click Click to view details.

22 Chapter 1 Introduction ENWW

Page 29

Request email notication of specic error conditions

1. In the Embedded Web Server (see Access the Embedded Web Server on page 20), go to the Email Server

page on the Setup tab and ensure that the following elds are correctly lled in:

● SMTP server. This is the IP address of the outgoing mail server (Simple Mail Transfer Protocol [SMTP])

that processes all email messages from the printer. If the mail server requires authentication, email

notications will not work.

● Printer email address. Each email message that the printer sends must include a return address. This

address does not need to be a real, functional email address, but it should be unique, so that

recipients of the message can identify the printer that sent it

2. Go to the Notication page, which is also on the Setup tab.

3. Click the New icon to request new notications, or click the Edit icon to edit notications that have already

been set up. Then specify the email addresses to which notications are sent, and select the incidents that

result in notication messages.

Get accounting information

There are various dierent ways of getting accounting information from your printer:

● View printer usage statistics for a particular job, see Check usage statistics for a job on page 23.

● View printer usage statistics for the whole lifetime of the printer, see Check lifetime usage statistics

on page 23.

● Request accounting data by email. The printer sends data in XML at regular intervals to a specied email

address; the data may be interpreted and summarized by a third-party application, or displayed as an Excel

spreadsheet. See Request accounting data by email on page 24.

● Use a third-party application to request printer status, printer usage or job accounting data from the printer

through the Internet. The printer provides data in XML to the application whenever requested. HP provides

a Software Development Kit to facilitate the development of such applications.

By default, user names are not included in accounting information. If you would like to include them, check the

box Show user name in job accounting in the Security menu.

Check usage statistics for a job

You can use the Embedded Web Server to check usage statistics for a particular job: go to the Main tab and select

History > Accounting.

NOTE: The accuracy of the usage statistics is not guaranteed.

Check lifetime usage statistics

There are two ways of checking your printer's usage statistics.

NOTE: The accuracy of the usage statistics is not guaranteed.

● From the Embedded Web Server, go to the Main tab and select History > Usage.

● From the front panel, press , then Setup > Internal prints > User information prints > Print usage

report.

ENWW The Embedded Web Server 23

Page 30

Request accounting data by email

1. Obtain the IP address of the outgoing mail server (SMTP) from your IT department; this is required in order

to send email messages.

2. Ensure that the outgoing email server is congured to enable relaying of email messages that the printer

will send.

3. Open your Web browser and connect to the printer’s Embedded Web Server.

4. Select the Setup tab.

5. From the Conguration menu in the left-hand column, select Date & Time.

6. Ensure that the printer's date and time have been set correctly.

7. From the Conguration menu, select Email server.

8. Enter the IP address of the outgoing mail server (SMTP).

9. Specify an email address for the printer. The latter does not need to be a valid email address, because the

printer will not receive messages; but it should have the form of an email address. It serves to identify the

printer when it sends email messages.

10. From the Conguration menu, select Printer settings.

11. Set Send accounting les to Enabled.

12. Set Send accounting les to to the email address (or addresses) to which you want the accounting

information sent. This may be an address that you have created specically to receive automatically

generated messages from the printer.

13. Set Send accounting les every to the frequency with which you want the information sent, choosing a

specic number of days or prints.

14. You may want to set Exclude personal information from accounting email to On, so that the accounting

messages will not contain personal information. If this option is O, information such as user name, job

name, and account ID will be included.

When you have completed the above steps, the printer will send accounting data by email with the frequency

that you specied. The data are provided in XML and can easily be interpreted by a third-party program. The data

provided on each print job include when the job was submitted, when the job was printed, the printing time, the

type of image, the number of pages, the number of copies, the paper type and size, the amount of each color of

ink used and various other attributes of the job. Accounting data are also provided on scan and copy jobs.

You can download an Excel template from HP's Web site (http://www.hp.com/go/designjet/accounting/) that will

enable you to display the XML data more readably in the form of a spreadsheet.

Analysis of the accounting data will enable you to bill customers precisely and exibly for the use of your printer.

You can, for instance:

● Bill each customer for the total amount of ink and paper used by that customer over a particular period.

● Bill each customer separately per job.

● Bill each customer separately for each project, broken down by job.

Connectivity and software instructions

Connection method

Your printer can be connected in the following way.

24 Chapter 1 Introduction ENWW

Page 31

Connection type Speed Maximum cable length Other factors

Gigabit Ethernet Fast; varies according to

network traic

NOTE: The speed of any network connection depends on all the components that are used in the network,

which can include network interface cards, hubs, routers, switches, and cables. If any one of these components

cannot operate at high speed, you will have a low-speed connection. To get the expected performance from your

printer, you should use equipment that supports 1000TX Full Gigabit. The speed of your network connection can

also be aected by the total amount of traic from other devices on the network.

Connect the printer to your network

The printer is able to congure itself automatically for most networks, in a similar way to any computer in the

same network. The rst time you connect it to a network, this process may take a few minutes. If necessary, see

Advanced network conguration on page 26.

Once the printer has a working network conguration, you can check its network address from the front panel:

press .

Network conguration

For more details about the current network conguration, go to the front panel and press , then

Long (100 m=328 ft) Requires extra equipment

(switches)

Using IPv6

Connectivity > Network connectivity > Gigabit Ethernet > Modify conguration. From here it is possible, though

not normally necessary, to change the settings manually; this can also be done remotely using the Embedded

Web Server.

TIP: You may nd it helpful to print out the full printer network conguration on paper. This can be done from

the front panel: press , then Internal prints > Service information prints > Print connectivity conguration. If

you do not print out the full network conguration, consider making a note of the printer's IP address and

network name.

If you accidentally miscongure the printer’s network settings, you can restore the network settings to their

factory values from the front panel: press , then Connectivity > Network connectivity > Advanced > Restore

factory settings. Then you must restart the printer. This automatically provides a working network conguration

for most networks. The printer’s other settings remain unchanged.

Your printer supports almost all network connectivity features using IPv6, just as it does using IPv4. To make full

use of IPv6, you may need to connect your printer to an IPv6 network in which there are IPv6 routers and

servers.

In most IPv6 networks, the printer will congure itself automatically as follows, and no user conguration is

necessary:

1. The printer assigns itself a link-local IPv6 address (which starts with “fe80::”).

2. The printer assigns itself stateless IPv6 addresses as indicated to it by any IPv6 routers on the network.

3. If no stateless IPv6 addresses can be assigned, the printer will try to obtain IPv6 addresses using DHCPv6.

It will also do so if the routers instruct it to do so.

ENWW Connectivity and software instructions 25

Page 32

The stateless and DHCPv6 IPv6 addresses can be used to access the printer, and in most IPv6 networks this will

be appropriate.

The link-local IPv6 address works only in the local subnet. Although it is possible to access the printer using this

address, it is not recommended.

It is possible to assign a manual IPv6 address to the printer, using the front panel or the Embedded Web Server. It

is also possible to disable IPv6 completely in the printer. However, it is not possible to disable IPv4 in the printer,

and therefore it is not possible to congure the printer as IPv6-only.

NOTE: In typical IPv6 use, your printer will have multiple IPv6 addresses, although it has only one IPv4 address.

TIP: You are recommended to give a name to the printer. You can do this from the front panel or (more easily)

from the Embedded Web Server.

TIP: You will generally nd it easier to use IPv4 unless you have a specic need to use IPv6.

Microsoft Windows Vista, Microsoft Windows Server 2008, later versions of Windows, and the new HP Printing

and Imaging devices have IPv6 enabled by default. For further information on IPv6, see

http://h20000.www2.hp.com/bc/docs/support/SupportManual/c00840100/c00840100.pdf. This document

discusses how name resolution plays a fundamental role in Dual-Stack transition methods. Using the name

resolution algorithm in Windows, the document goes through various network environments and studies how

the introduction of routable IPv6 addresses will aect network applications. It also discusses DHCPv6, SLAAC and

the impact to DNS, and makes some recommendations.

Connect the printer to the Internet

To connect to the Internet, go to the front panel and press , then Connectivity > Connectivity wizard. The

connectivity wizard also checks that the printer’s

only once, when rst setting up the printer.

An Internet connection is needed for various printer functions described in this guide, such as the Embedded

Web Server.

RIP software installation

Install the RIP software by following the instructions provided with the software.

Advanced network conguration

You will probably not need to read this section, but the information is provided as it may be useful in some cases.

The printer provides a single RJ-45 connector port for a network connection. In order to meet Class B limits, the

use of shielded I/O cables is required.

The embedded Jetdirect print server supports connection to IEEE 802.3 10Base-T Ethernet, IEEE 802.3u

100Base-TX Fast Ethernet and 802.3ab 1000Base-T Gigabit Ethernet compliant networks. When connected and

powered on, the printer auto-negotiates with your network to operate with a link speed of 10, 100, or 1000

Mbps, and to communicate using full- or half-duplex mode. However, you can manually congure the link using

the printer's front panel, or through other conguration tools once network communication is established.

rmware is up to date. Normally you need to run the wizard

The printer can support multiple network protocols simultaneously, including TCP/IPv4 and TCP/IPv6. For

security, it includes features to control IP traic to and from the printer.

26 Chapter 1 Introduction ENWW

Page 33

Verify correct operation

1. Print an IO Conguration page to check for status messages.

2. In the upper section of the IO Conguration page, look for the status message I/O Card Ready.

3. If I/O Card Ready appears, the print server is operating properly. Proceed to the next section.

If a message other than I/O Card Ready appears, try the following:

a. Turn the printer o and then on again to re-initialize the print server.

b. Check that the status indicator lights (LEDs) are providing proper status.

NOTE: See Troubleshooting on page 27 for link conguration and troubleshooting information.

See the HP Jetdirect Print Servers Administrator’s Guide for your print server model to interpret and troubleshoot

other messages.

Precongure network settings if required

If your network requires that you congure network settings before you add the printer to your network

systems, you can do so now.

However, in most cases, you can skip this section. Instead, you can proceed directly to the next section to install

the printer on your network computer systems. The network installation software will allow you to congure

basic network settings and add the printer to your system conguration.

Tools for preconguration

The following tools can be used to precongure your network settings:

● The front panel

● The Embedded Web Server

● You can use an advanced conguration method, such as BootP, DHCP, Telnet, or the arp and ping

commands. For instructions, see the HP Jetdirect Print Servers Administrator’s Guide for your print server

model.

After the printer is congured with network settings, the conguration values are saved and maintained even

after it is turned o and on again.

Troubleshooting

IO Conguration page

The IO Conguration page provides comprehensive print server status. It is an important diagnostic tool,

especially if network communications are not available. For a description of messages that may appear on the IO

Conguration page, see the HP Jetdirect Print Servers Administrator’s Guide for your print server model.

LEDs

The printer has status lights (LEDs) that indicate the link status and network activity:

● When the green light is on, the printer has successfully linked to the network.

● When the yellow light is blinking, there is network transmission activity.

ENWW Advanced network conguration 27

Page 34

Link troubleshooting

If the printer does not successfully connect to the network:

● Both LEDs will be o.

● LAN Error - Loss of Carrier will be indicated on the IO Conguration page.

If a link failure is indicated, try the following:

● Check cable connections.

● Print an IO Conguration page and check link settings.

Item Description

Port Cong If the printer is properly linked, this item has one of the following values:

– 10BASE-T HALF: 10 Mbps, half-duplex

– 10BASE-T FULL: 10 Mbps, full-duplex

– 100TX-HALF: 100 Mbps, half-duplex

– 100TX-FULL: 100 Mbps, full-duplex

– 1000TX FULL

If the printer is not properly linked, one of the following messages will appear:

Auto Negotiation Indicates whether auto-negotiation for link conguration is on or o.

Reset network parameters

Network parameters (for example, the IP address) can be reset to factory default values by a cold reset: turning

the printer o and on again. After a cold reset, print an IO Conguration page to conrm that factory-reset values

have been assigned.

CAUTION: A factory-installed HP Jetdirect X.509 certicate will be saved over a cold reset to factory default

values. However, a Certicate Authority (CA) certicate that has been installed by the user to validate a network

authentication server will not be saved.

Menu items

Menu item

Sub-menu item Sub-menu item Values and Description

– UNKNOWN: The printer is in an initialization state.

– DISCONNECTED: A network connection has not been detected. Check network cables. Recongure the

link settings, or restart the printer.

– ON (default): The printer will attempt to automatically congure itself onto the network at the proper

speed and communication mode.

– OFF: You must manually congure the link speed and communication mode using the front panel. Your

settings must match those of the network for proper operation.

TCP/IP Host Name An alphanumeric string, up to 32 characters, used to

identify the device. This name is listed on the HP Jetdirect

conguration page. The default host name is NPIxxxxxx,

where xxxxxx is the last six digits of the LAN hardware

(MAC) address.

28 Chapter 1 Introduction ENWW

Page 35

Menu item Sub-menu item Sub-menu item Values and Description

IPV4 Settings Cong Method Species the method that TCP/IPv4 parameters will be

congured on the HP Jetdirect print server.

Bootp: Use BootP (Bootstrap Protocol) for automatic

conguration from a BootP server.

DHCP (default): Use DHCP (Dynamic Host Conguration

Protocol) for automatic conguration from a DHCPv4

server. If selected and a DHCP lease exists, DHCP Release

and DHCP Renew menus are available to set DHCP lease

options.

Auto IP: Use automatic link-local IPv4 addressing. An

address in the form 169.254.x.x is assigned automatically.

Manual: Use the Manual Settings menu to congure TCP/

IPv4 parameters.

DHCP Release This menu appears if Cong Method was set to DHCP and a

DHCP lease for the print server exists.

No (default): The current DHCP lease is saved.

Yes: The current DHCP lease and the leased IP address are

released.

DHCP Renew This menu appears if Cong Method was set to DHCP and a

DHCP lease for the print server exists.

No (default): The print server does not request to renew the

DHCP lease.

Yes: The print server requests to renew the current DHCP

lease.

Manual Settings (Available only if Cong Method is set to Manual) Congure

parameters directly from the printer control panel:

IP Address: The unique IP address of the printer (n.n.n.n).

Subnet Mask: The subnet mask for the printer (n.n.n.n).

Syslog Server: The IP address of the syslog server (n.n.n.n)

used to receive and log syslog messages.

Default Gateway: The IP address (n.n.n.n) of the gateway or

router used for communications with other networks.

Idle Timeout: The time period, in seconds, after which an

idle TCP print data connection is closed (default is 270

seconds, 0 disables the timeout).

Default IP Specify the IP address to default to when the print server is

unable to obtain an IP address from the network during a

forced TCP/IP reconguration (for example, when manually

congured to use BootP or DHCP).

Auto IP: A link-local IP address 169.254.x.x is set.

Legacy: The address 192.0.0.192 is set, consistent with

older HP Jetdirect devices.

Primary DNS Specify the IP address (n.n.n.n) of a Primary DNS Server.

NOTE: This item appears only if Manual conguration is a

higher priority than DHCP in the Cong. Precedence table,

congured through the embedded Web server.

ENWW Advanced network conguration 29

Page 36

Menu item Sub-menu item Sub-menu item Values and Description

Secondary DNS Specify the IP address (n.n.n.n) of a Secondary Domain

Name System (DNS) Server.

NOTE: This item will appear only if Manual conguration is

a higher priority than DHCP in the Cong. Precedence table,

congured through the embedded Web server.

IPV6 Settings Enable Use this item to enable or disable IPv6 operation on the

print server.

O: IPv6 is disabled.

On (default): IPv6 is enabled.

Address Use this item to manually congure an IPv6 address.

Manual Settings: Use the Manual Settings menu to enable

and manually congure a TCP/ IPv6 address.

Enable: Select this item and choose On to enable manual

conguration, or O to disable manual conguration.

Address: Use this item to type a 32 hexadecimal digit IPv6

node address that uses the colon hexadecimal syntax.