Page 1

,...,..,.

HP DOC

Back to Welcome

.

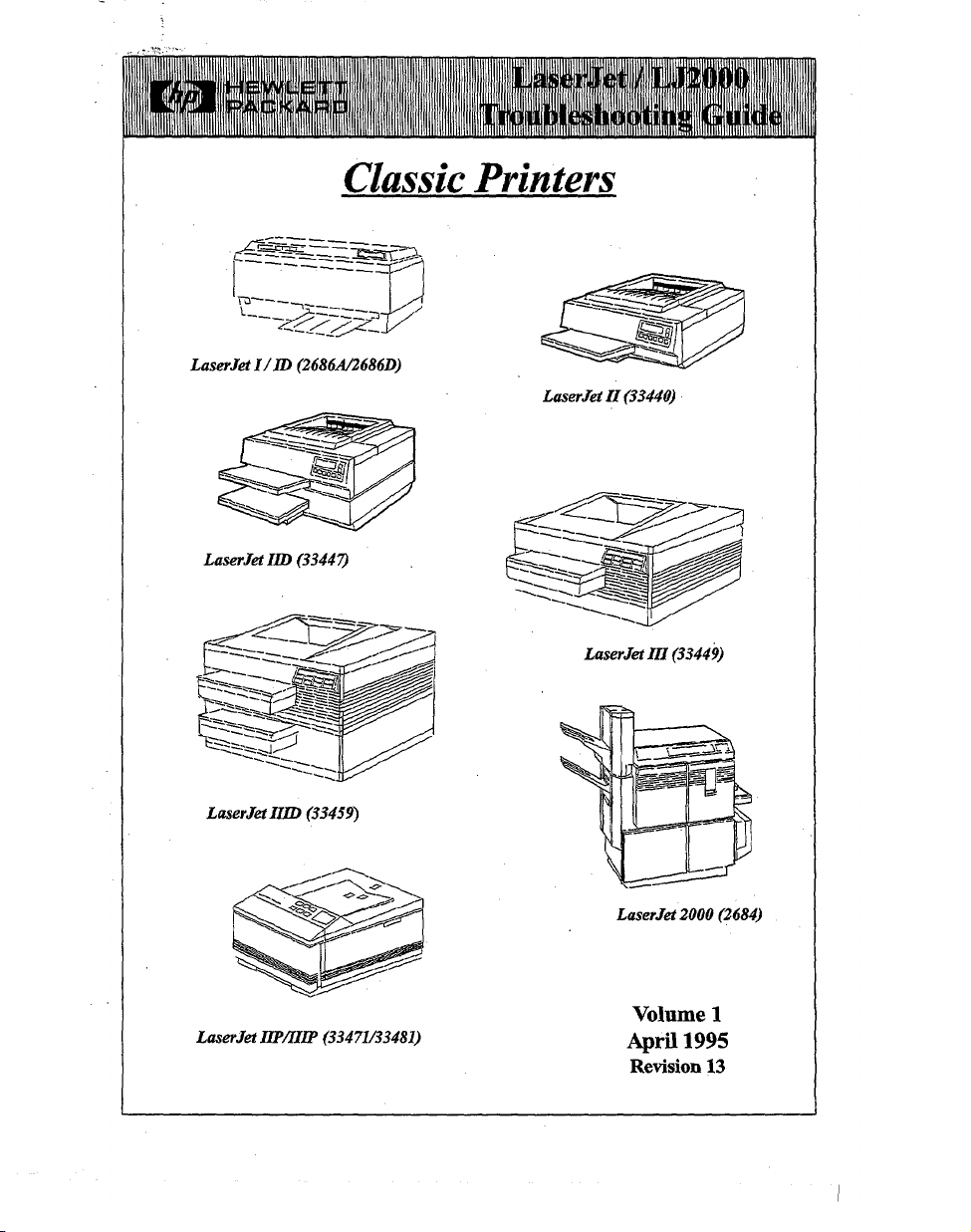

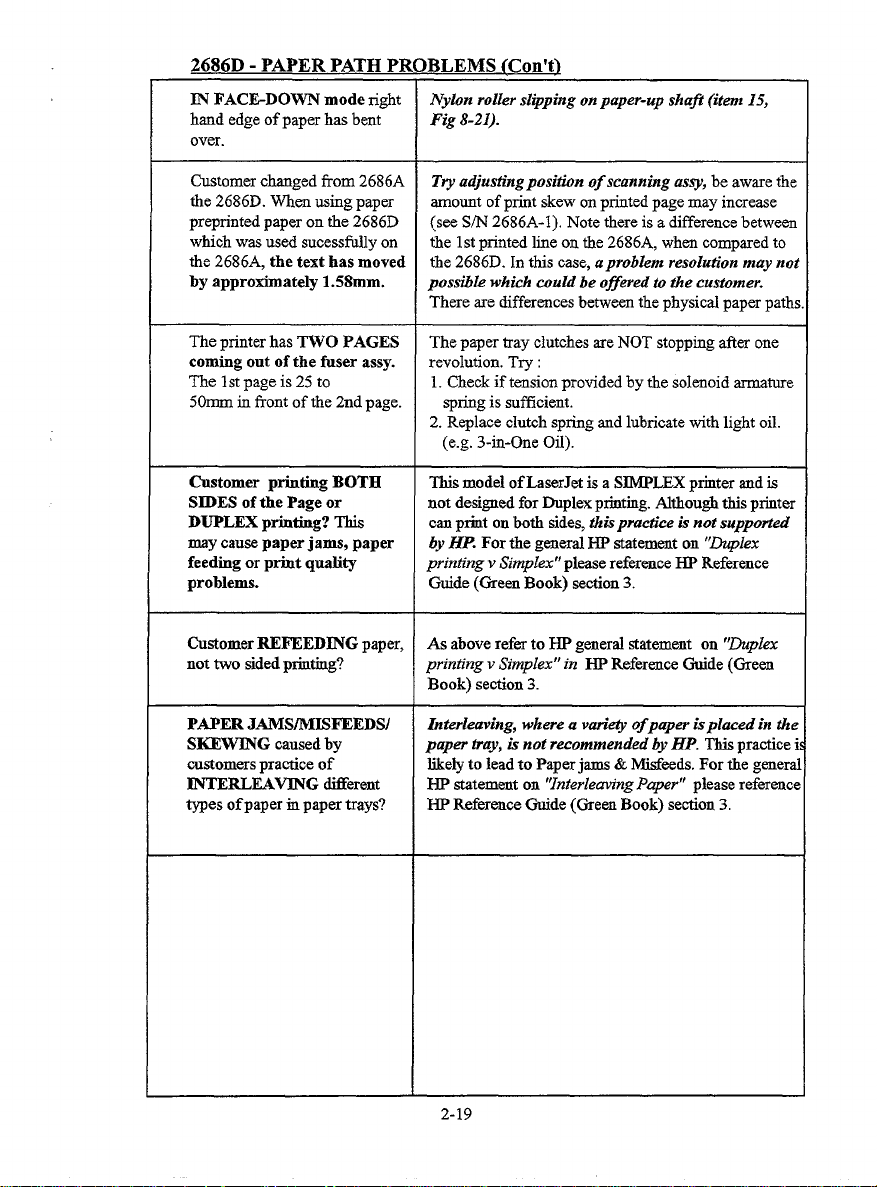

Classic Printers

La.er.kt II (33440)

LaserJet ILD(3344~

LaserJ@ IIID (33459)

La.wrJetIIMUIP (33471/33481)

LaserJd III (33449)

LaserJ& 2000 (2684)

Volume 1

April 1995

Revision 13

Page 2

Notice

Tbisdoeument SmIercedes allmeviousrevisions of the LaserJet/JumboJet

‘fkoubleshoothw Guide.

The information contained in this documentis subject to change without any

notice.

Nopsrtofthisdocumentmay bephotocopied,reproduced,ortramdatedtithout

the prior written consent of Hewlett-PackardCompany.

Editor

Bob Edwards, UK Response Centre

iipti 1995

Revision 13

Page 3

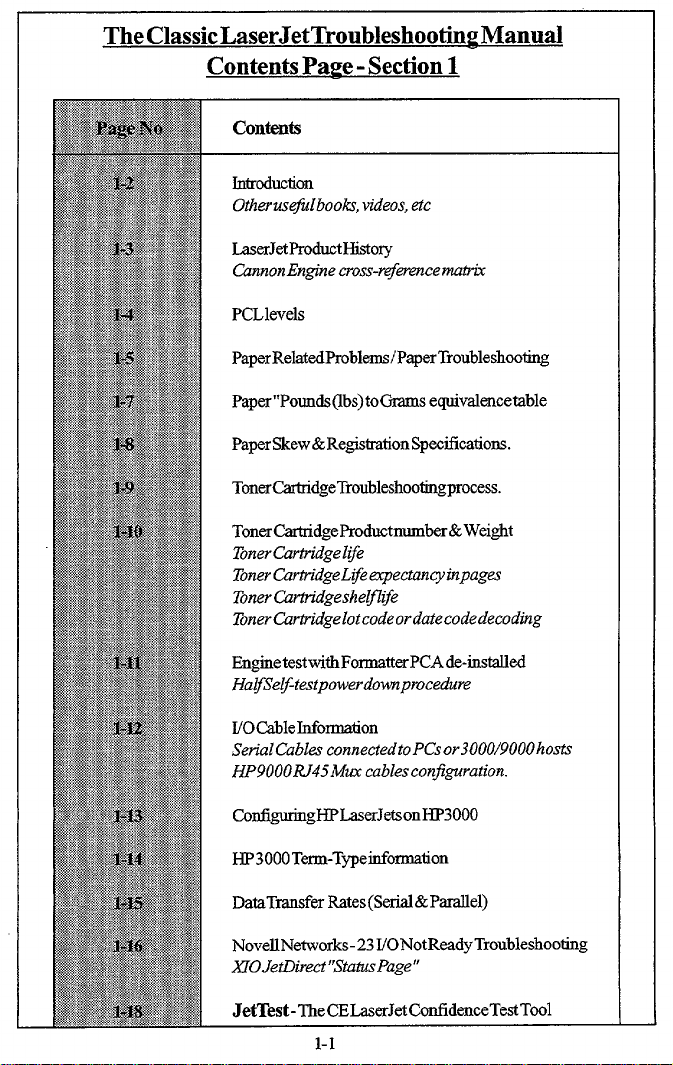

TheClassicLaserJetTroubleshootin~ Manual

Contents Pa~e-Section 1

Contents

Introduction

Othemsejidbooti, videos,etc

LaserJetProductHistory

Gmnom%sg”necross-r@rencemabix

PCLlevels

PaperRelatedPmblems/PaperTroubleshooting

Paper’’Pounds(lbs)toOrams equivalencetable

PaperSkew&Registration Specifications.

TonerCartridgeTroubleshootingProcess.

TonerCarhidgeProdnctnumber& Weight

TonerCurtridgelije

TonerCbrti”dgeLijeeqectamyinpages

Toner(lmtridgeshelfife

TonerCar&idgelotcodeordatecodedecoding

EnginetestwithFormatterPCA de-installed

Ha&e&testpowerdompmcedure

I/OCableMonnation

SerialCables connectedtoPCsor3000/9000hosfi

HP9000RJ45114Kxcablescon@wation.

Cor@qningHPLaserJetson HP3000

HP3000Tenn-T~e information

DataTfansfer Rates(Serial&Parallel)

NovellNetworks- 23I/ONotReadyTroubleshootig

XOJetDirect’’StatusPage”

Jet’Iest-TheCELaserJetConfidemceTestTool

1-1

—

Page 4

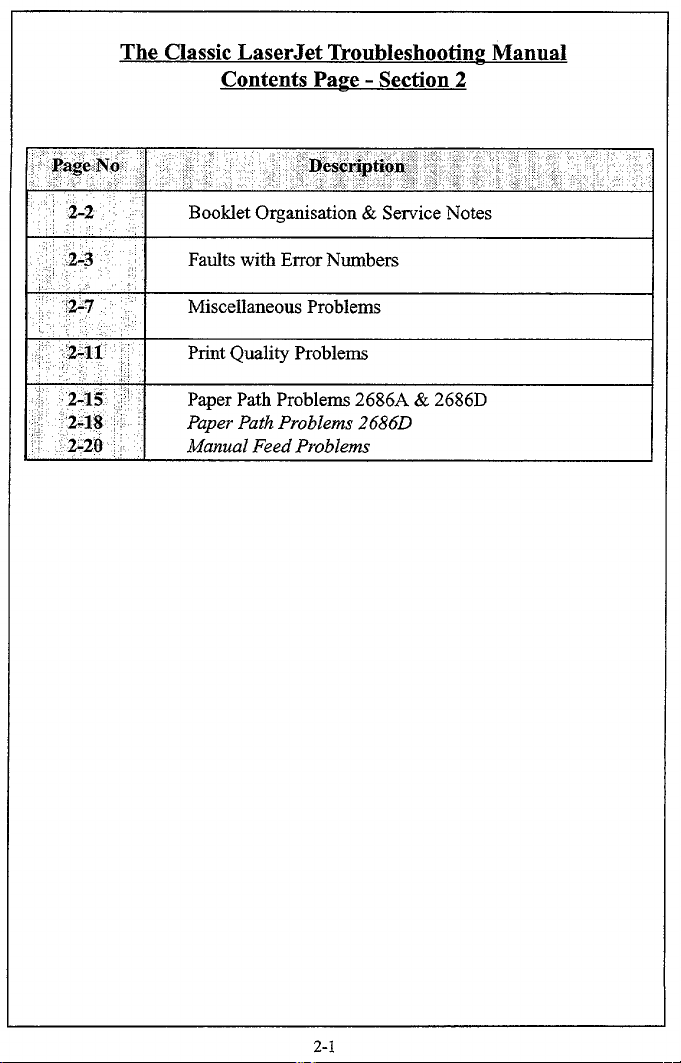

The Classic LaserJet TroubIeshootinp Manual

Contents Pave - Section 2

2-1

Page 5

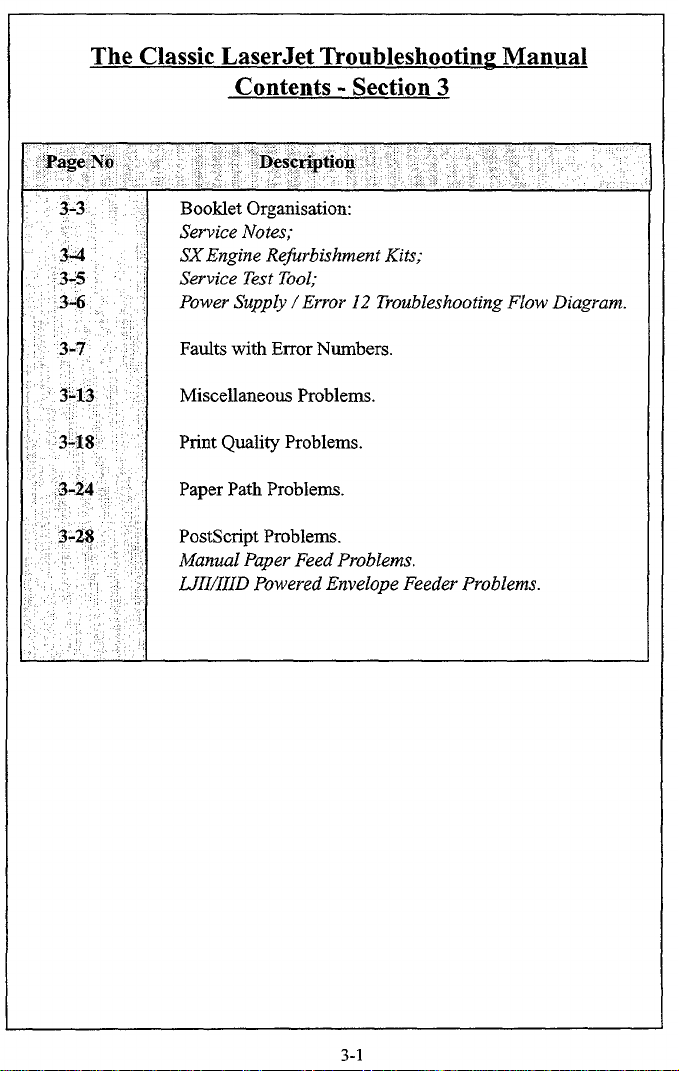

The Classic LaserJet Troubleshooting Manual

Contents - Section 3

Booklet Organisation

Service Notes;

SXEngine Re~rbishment Kits;

Service Test Tool;

Power Supply /Error 12 Troubleshooting Flow Diagram.

Faults with Error Nnmbers.

Miscellaneous Problems.

Print Quality Problems.

Paper Path Problem.

PostScript Problems.

Manual Paper Feed Problems.

LJIIIIIID Powered Envelope Feeder Problems.

3-1

!

Page 6

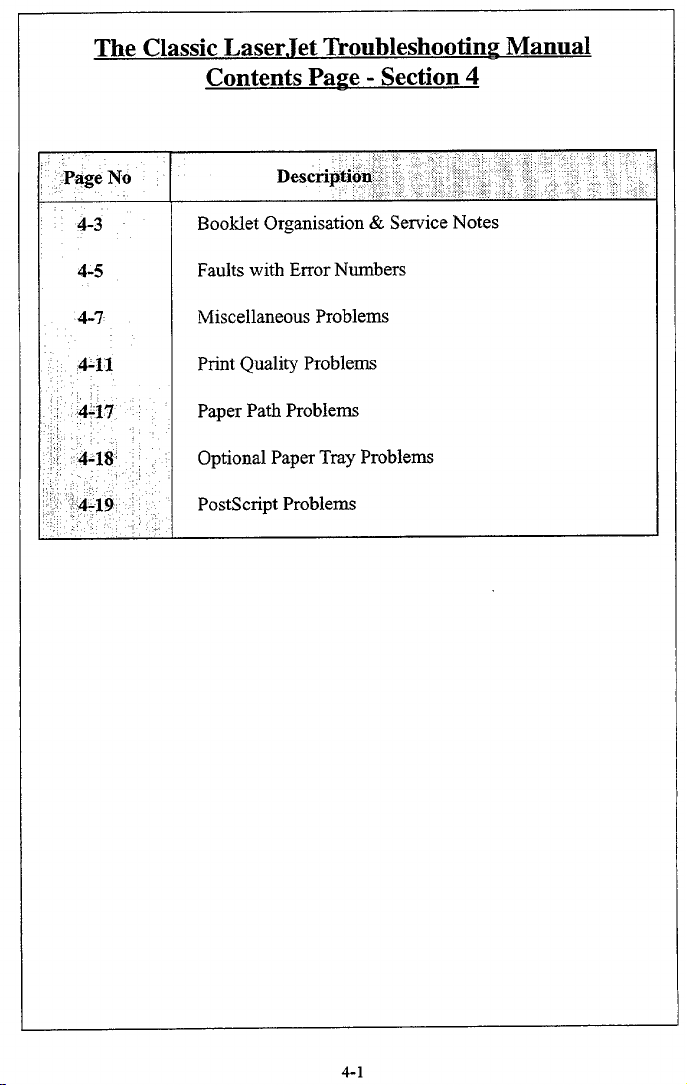

The Classic Laser.Tet Troubleshooting Manual

Contents Page - Section 4

4-3

4-5

4-7

4-11 Print Quality Problems

: 4-17 Paper Path Problems

,,

,,,

,: 4-18 Optional Paper Tray Problems

“ :’4-19

Booklet Organisation & Service Notes

Faults with Error Numbers

Miscellaneous Problems

PostScript Problems

4-1

Page 7

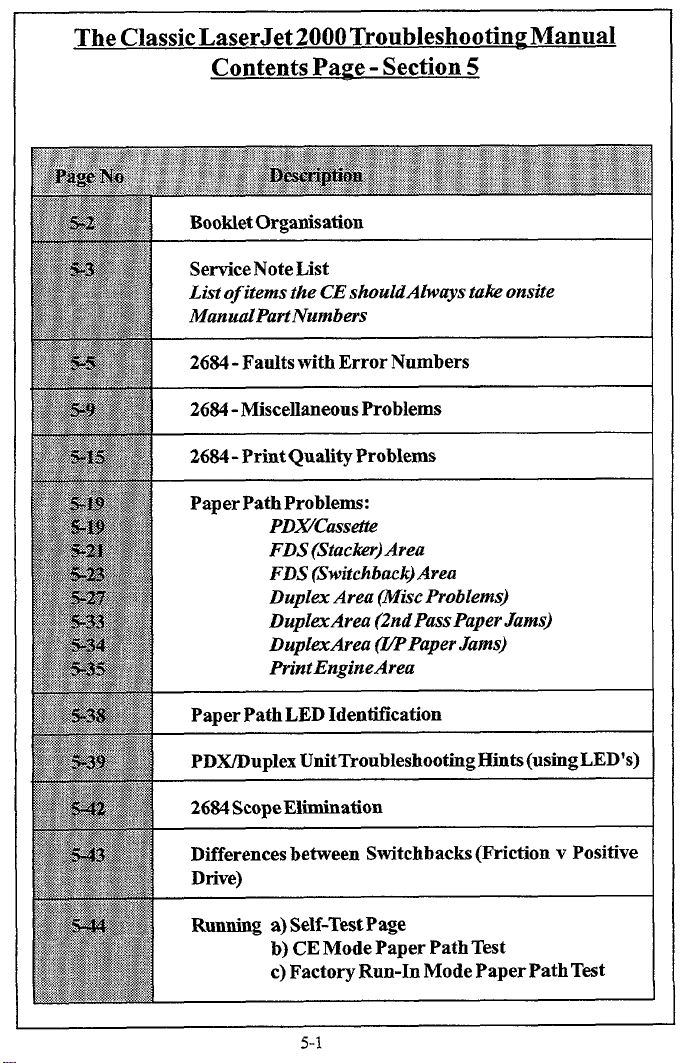

5-1

Page 8

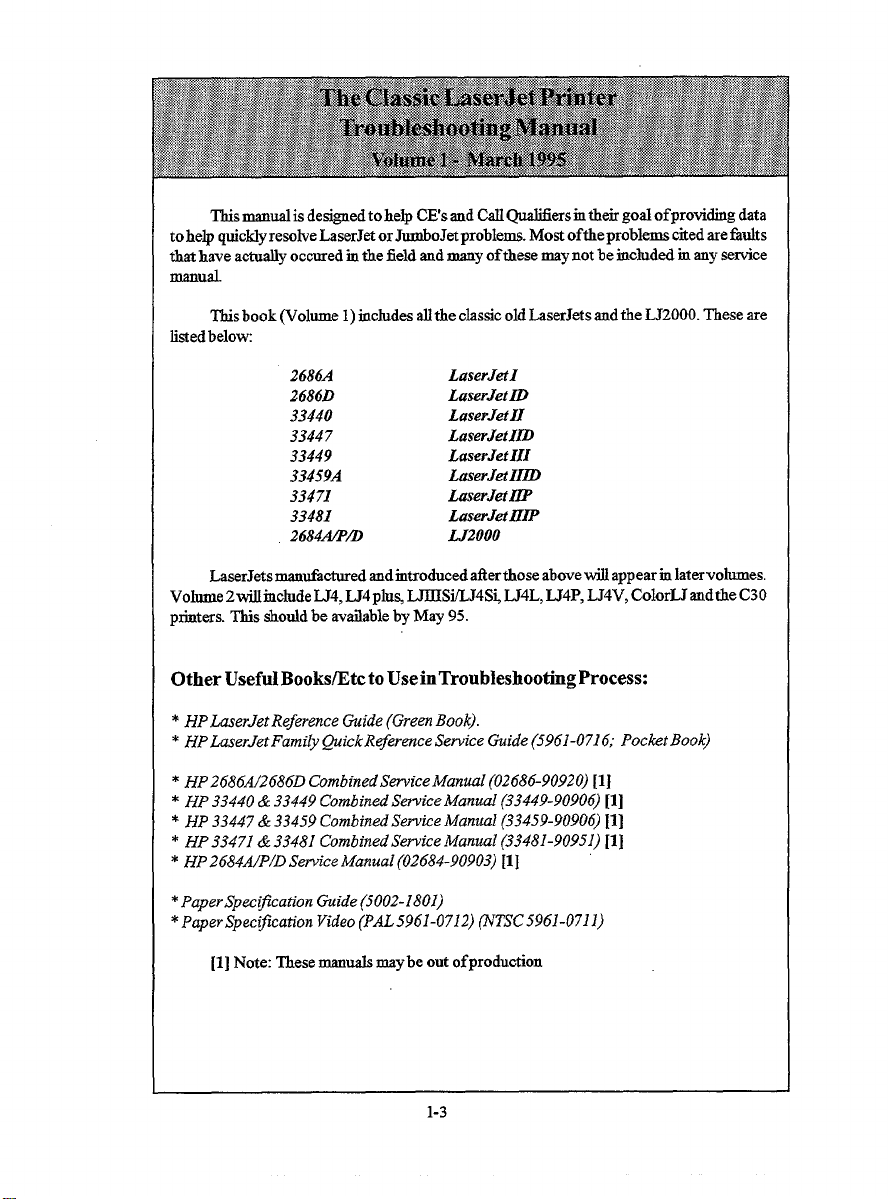

W mauurd is designed to help CE’Sand Cd @ersrntbeir gosl ofproviding data

to help quic~resolve LaserJet or JuruboJetproblems. Most oftheproblems cfied are tidts

that have actually occured in the field and many ofthese may not be included m any service

Lusnusl.

This book (Volume 1)ticludes allthe classic old LaserJets andthe LJ2000. These are

Iistedbelow

2686A

2686D

33440

33447

33449

33459A

33471

33481

2684~D

LaserJets manufactured and introduced afierthose above will appear m latervolumes.

Volume 2willrnclude LJ4, LJ4plu~ LJ131S~4S~ LJ4L, LJ4P, LJ4V, ColorLJ andthe C30

printers. This shodd be availableby May 95.

LaserJetI

LaserJetLV

LaserJetII

LaserJetILD

LaserJetIII

LaserJetIID

LaserJetIIP

LaserJetflLP

LJ2000

Other UsefulBooks/Etcto Usein~oubIeshooting Process:

* HP herJet Reference Guide (Green Book).

* HP LurerJetFamily Quick R#erence Service Guide (5961-071 6; Pocket Book)

* HP 2686A/2686D Combined Service Manwl (02686-90920) [1]

* HP 33440& 33449 Combined Service Manual (33449-90906) fl]

* HP 33447&33459 Combined Service Manual (33459-90906) 11]

* HP 33471&33481 Combined Service Manual (33481-90951) Ill

* HP 2684A/P/D Sewice Manual (02684-90903) II j

* Paper Specl~cation Guide (5002-1801)

*Paper Specification Video (PAL 5961-0712) @TSC 5961-071 1)

[1] Note: ~ese mti maybe out ofproduction

1-3

Page 9

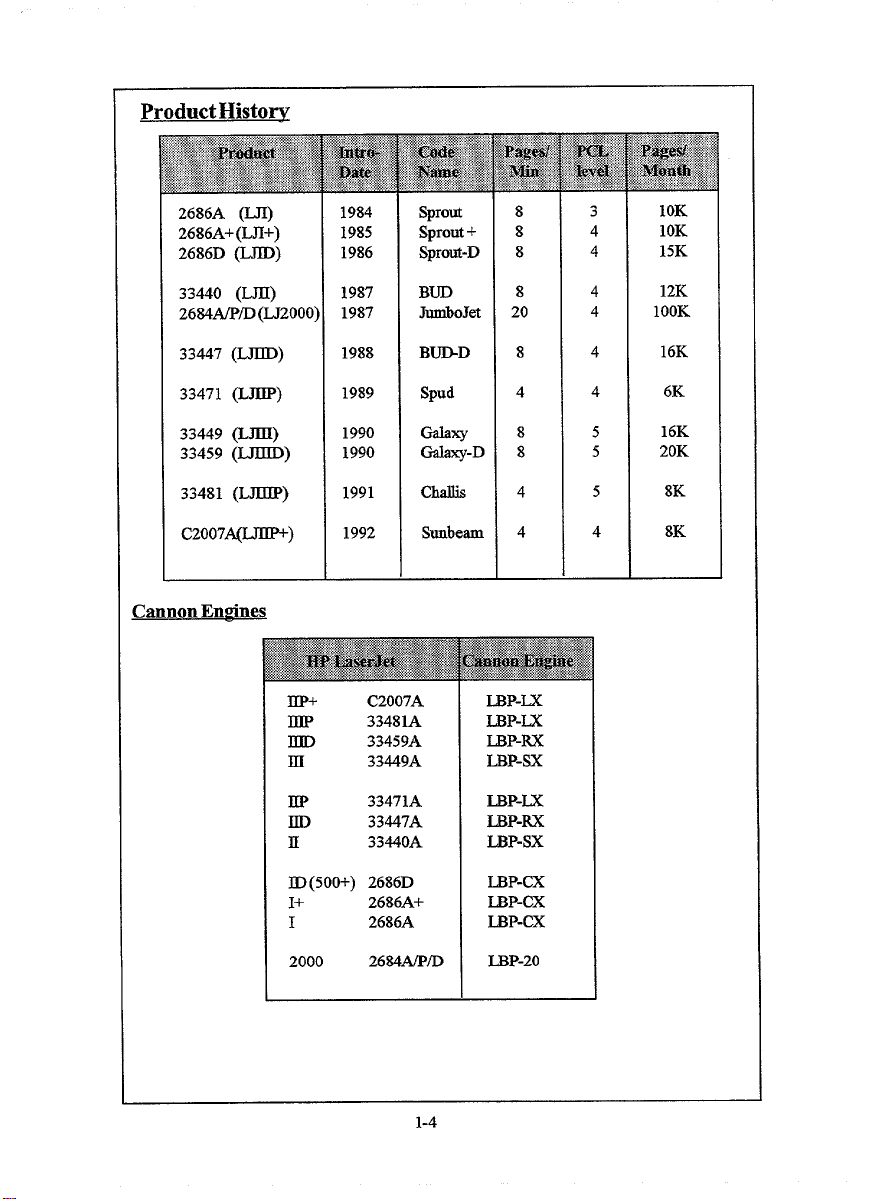

Product Histom

p

‘~

~;~,~...;::;;.,

~@y+:@::$w&&,,....,*,,,:,?,9::f,>

r. ,,,,.,LI

~%%&i:. EB*<“vi’%is~:wik:

2686A (LJI) 1984

2686A+ (LJI+) 1985

2686D ~)

1986 Sprout-D

Sprout

Sprout +

,y:$-<t;fi,f~,,;

) ?2<.t y:.?~i+$j?

%*y:

...........! ,,,,,,,,.!+,,,,, ,,.!

:$*&k %i!iil%:$w;

8

8

8

*

3

4

4

IOK

10K

15K

33440 (m) 1987 BUD

2684A/P/D (LJ2000)

33447 (LJllD)

33471 (LJIIP)

33449 (LJ131)

33459 (L.nllD) 1990

33481 (LJB3P)

C2007A(LJIIP+)

Cannon

En@nes

1987 JumboJet

1988

1989 Spud

m+

m 33481A

IaD 33459A

m 33449A

m 33471A LBP-LX

IID 33447A

E 33440A

BUD-D 8 4

1990 Galaxy

1991

1992

@w-D

Challis 4

Suabearn

C2007A mP-M

8

20

4

8

8

4

LBP-LX

LBP-RX

LBP-SX

DP-RX

mP-sx

4 12K

4

4

5 16K

5 20K

5

4 8K

lOOK

16K

6K

8K

ID(500+) 2686D LBP-CX

1+

I 2686A

2000 26 S4AtPfD

2686A+ LBP-CX

mP-cx

LBP-20

1-4

Page 10

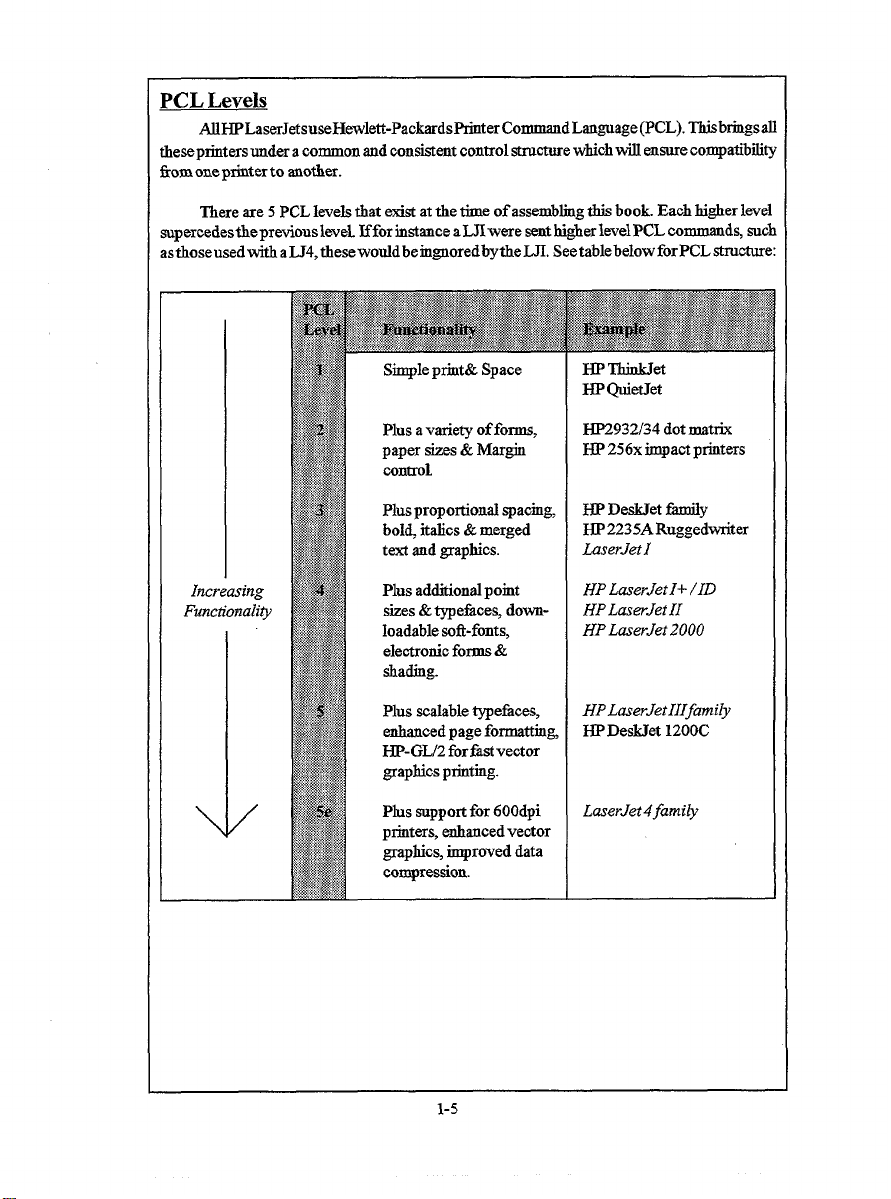

PCL Levels

AllHPLaserJetsuseHewlett-PacdcardsPrinterCommandLanguage(PCL). Wbringsall

tkeseprintersuuder a common and consiient control Stru-e whichti ensure compatibtity

tiomonepriuterto snother.

mere are 5 PCL levels that exi~ at the time of assembling this book. Each higher level

supercedesthe previous leveLIffor instance aLJI were sentkigherlevel PCL commands, such

astkoseused with a LJ4, tiese wotidbe ingnoredbytke LJI. Seetablebelow forPCL strutie:

I

HP

Simple print& Space

wet

HP@etJet

Plus avari~ of fore,

paper sizes &Margin

controL

Plus proportional spacing,

bolt italics &merged

text and ~apkics.

Plus additional pornt

sizes & ~efice~ downIoadable sofi-fonts,

electronic forma &

~ading.

Plus scalable typetices,

enhanced page formatting,

~-GL/2 forfkstvector

grapkics printing.

\

I

I

Plus support for 600dpi

ptiters, enhanced vector

graphics improved data

compression.

HP2932/34 dot matrix

HP 256x impact printers

HP DeWet fkmily

HP2235ARuggedwriter

hserJetI

HP LaserJetI+ /ID

HPLaserJetII

HP LaserJet 2000

HPLaserJetIIIfami~

HP DeskJet 1200C

LaserJet 4family

1-5

Page 11

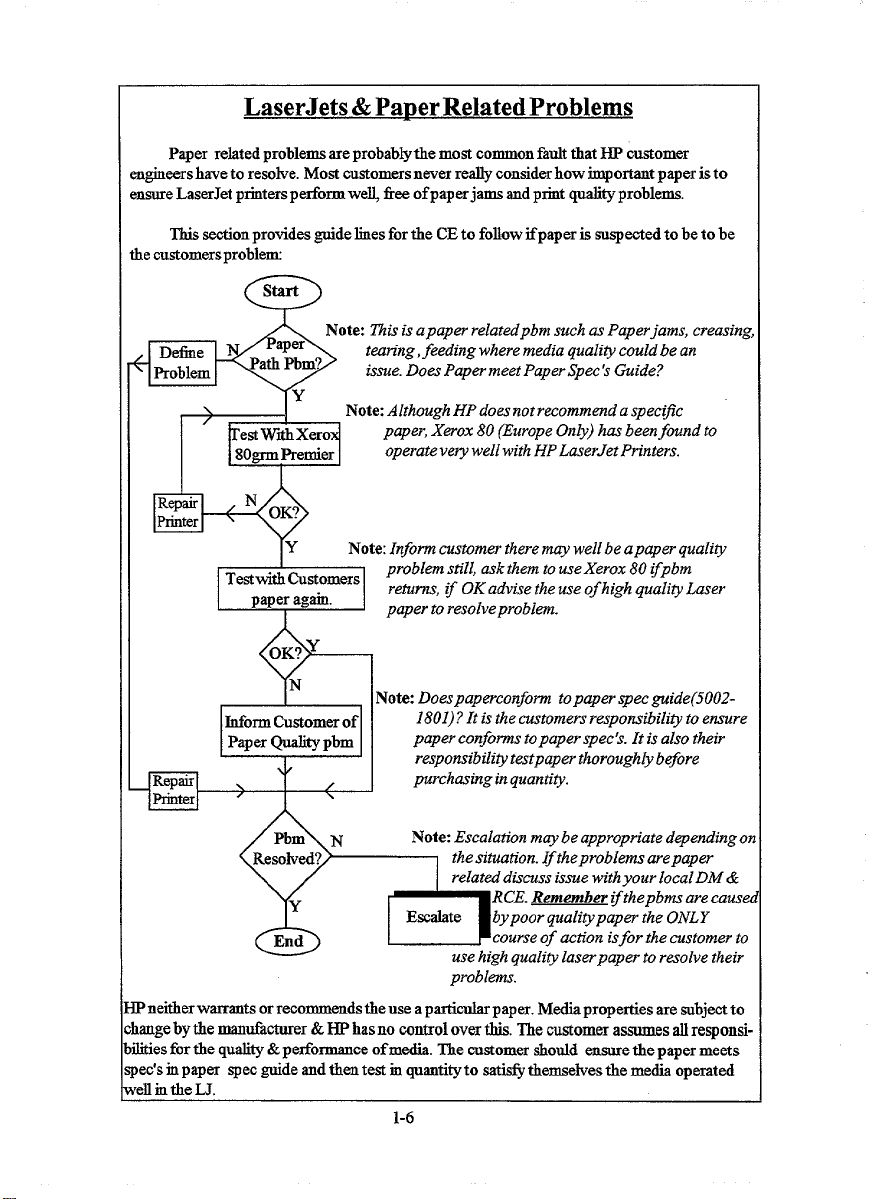

LaserJets & Paper Related Problems

Paper related problems are probably the most common fault that HP cuwomer

n@-s hiweto resolve. Most customers never really consider how important paper is to

nsureLaserJet printers perform we~ free of paper jams and print quality problems.

This section provides guide lines for the CE to follow ifpaper is suspected to be to be

le customers problem

-

Note This is apaper relatedpbm such as Paperjams, creasing,

, Define

‘ Problem

%

r

aper

ath Pbm?

Y

eti WhhXero

80grm Premier

t~n”ng, feeding where media quality could be an

issue. Does Paper meet Paper Spec ’sGuide?

Note: Although HP does not recommend a specl~c

paper, Xerox 80 (Europe Only) has beenfound to

operate very well with HP LaserJet Printers.

TY

OK? y

+

Pneither warrants or recommends the use a particular paper. Media properties are subject to

snge by tie msnticturer & HP has no control over this. me customer assumes allresponsities for the quality &performance of media. me customer should ensure the paper meets

cc’sin paper spec guide and then test m quantity to satisfy themsehes the media operated

>11m the LJ.

Note: Inform customer there w well be a p~er quality

p~oblem still, ask them to ~seXerox 80 ~pbrn -

returns, z~OK advise the use of high qualiy Laser

paper to resolveproblem.

N

~otc Doespaperconform topaper spec guide(5002-

1801)?It is the customers responsibili~ to ensure

paper confoms topaper spec’s. It is also their

responsibility testpaper thoroughly b~ore

purchasing inquanti~.

Note Escalation may be appropriate depending oz

the situation. If theproblems arepaper

related dismss isme with your local DM &

Etite

1-6

RCE. Remember z~thepbms are causel

bypoor quali~paper the ONLY

course of action isfor the customer to

use high quali~ laserpaper to resolve their

problems.

Page 12

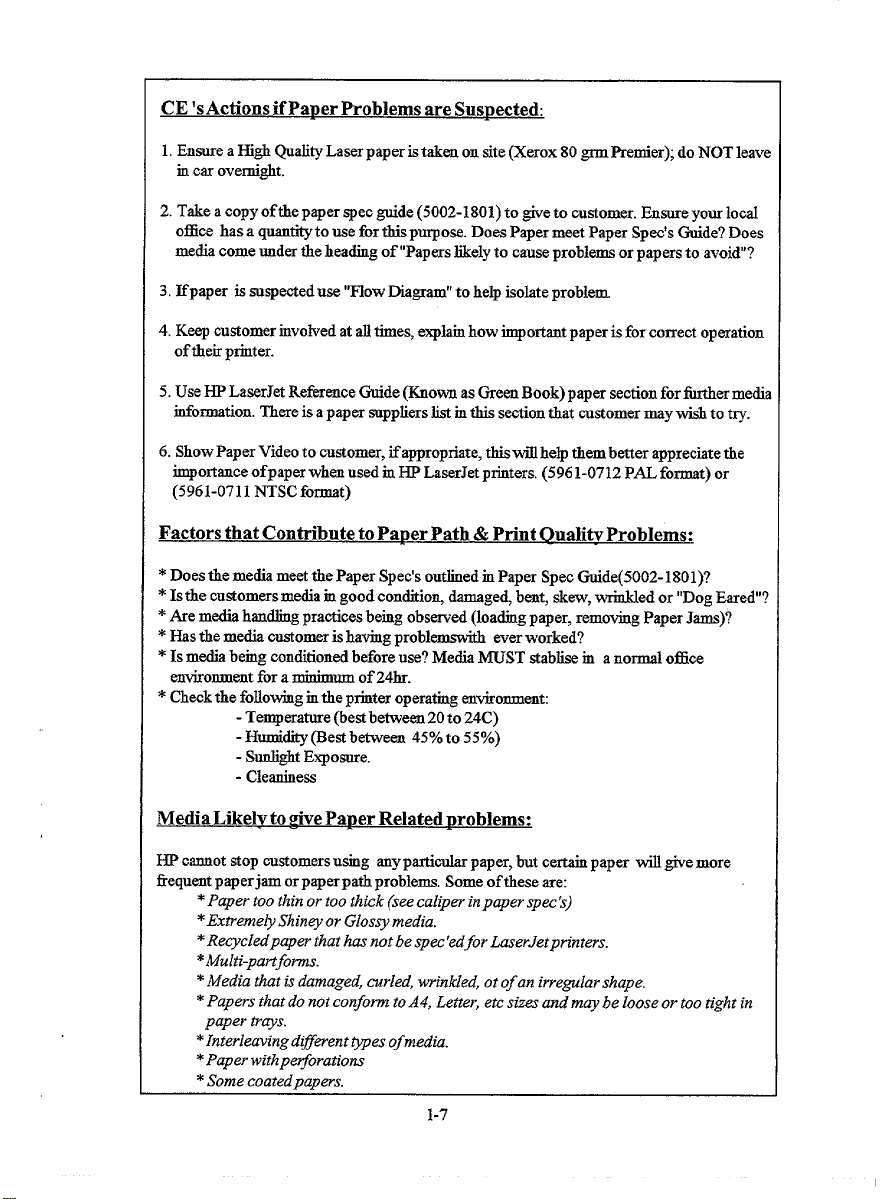

CE ‘sActions if Paper Problems are Suspected:

1.Ensure aHigh QualityLaser paper istaken on site (Xerox 80 grm Premier); do NOT leave

m car ovemi@t.

2. Take a copy of the paper spec guide (5002-1801) to @e to customer. Ensure your local

office has a quan~ to use for this purpose. Does Paper meet Paper Spec’s Guide? Does

media come under the heading of “Papers likely to cause problems or papers to avoid”?

3, Ifpaper ia suspected use “HOWDiagram”to help isolate problem,

4. Keep customer involved at all times, explarnhow important paper is for correct operation

of their printer.

5. Use HP LaserJW Reference Ouide (Knowu as Oreen Book) paper section for fiuther media

information. There is a paper suppliers list in this section that customer maywisb to try.

6. Show Paper Video to customer, inappropriate, this will help them better appreciate the

importance of paper when used in ~ LaserJet printers. (596 1-0712 PAL formst) or

(5961-071 1NTSCformat)

Factors that Contribute to paDerPath & Print C)ualitvProbIems:

*Does the media meet the Paper Spec’s outlined m Paper Spec Gnide(5002- 1801)?

*Is the customers media m good contilon, damage~ bent, skew, wriukled or “Dog Eared”?

*Are media haadling practices beiag observed (loading paper, removing Paper Jams)?

*Has the media customer is having problem ever worked?

* Is media berng conditioned before use? Media WST stabliae m a normal office

enviroammt for a minimum of 24hr.

* Check the follotig mthe printer operating entionment

- Temperature (best between 20to 24C)

- Humi@ (Beat between 45% to 55%)

- SunJightExposure.

- Clearriness

Media Likelv to tive Paner Related Drob]ems:

HP cannot stop customers using anypartiti paper, but certain paper will give more

frequent paper jam or paper path problems. Some of these are:

*Paper too thin or too thick (see caliper inpaper spec ‘s)

*Extremely Shiney or Glossy media.

* Recycledpaper that has not be spec ‘edfor LaserJetpn”nters.

*Multi-patifom.

*Media tkat is damaged, curled, wrinkled, ot of an irregrdar shape.

*Papers that do not conform toA4, Letter, etc sues md may be loose or too tight in

paper trays.

*Interleaving dl~ment types of

*Paper withpevorations

*Some coatedpapers.

media.

1-7

Page 13

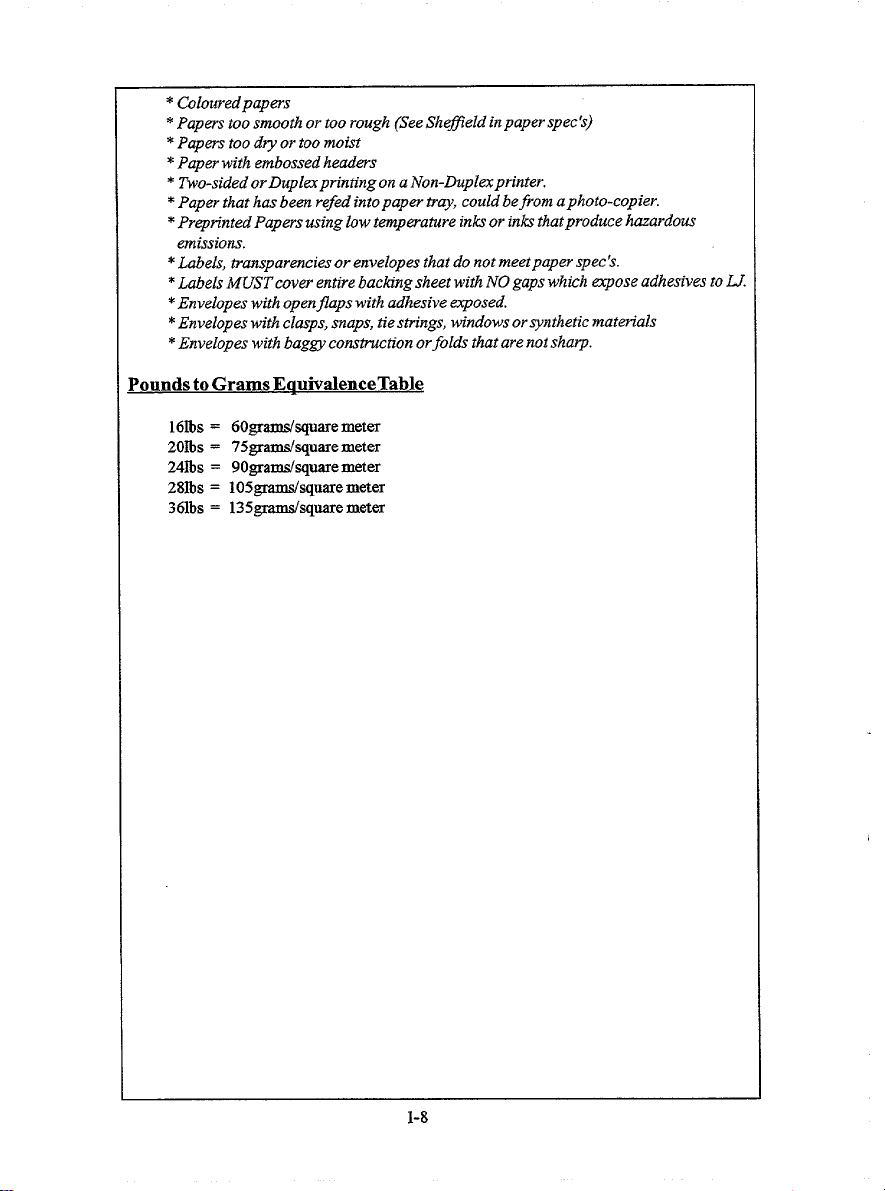

*Colouredpapers

*Papers too smooth or too rough (See She@eld inpaper spec ‘s)

*Papers too dry or too moist

*Paper with embossed headers

* Two-sided or Duplex printing on a Non-Duplexpn”nter.

*Paper that ha been refed into paper tray, could befrom aphoto-copier.

* Prepn”ntedPapers using low temperature inks or inti thatproduce hazardous

emissions.

*Labels, transparencies or envelopes that do not meet paper spec ‘s.

* tiels MUST cover entire backing sheet with NO gaps which expose adhesives to M.

*Envelopes with openjlaps with adhesive exposed.

*Envelopes with clasps, snaps, tie strings, windows or~nthetic maten”als

*Envelopes with baggy construction orfolds that are not sha~.

Pounds to Grams EauivalenceTable

161bs= 60grtisquare meter

201bs = 75gmma/squsre meter

241bs = 90gratisquare meter

281bs = 105grams/square meter

361bs = 135@square meter

1-8

Page 14

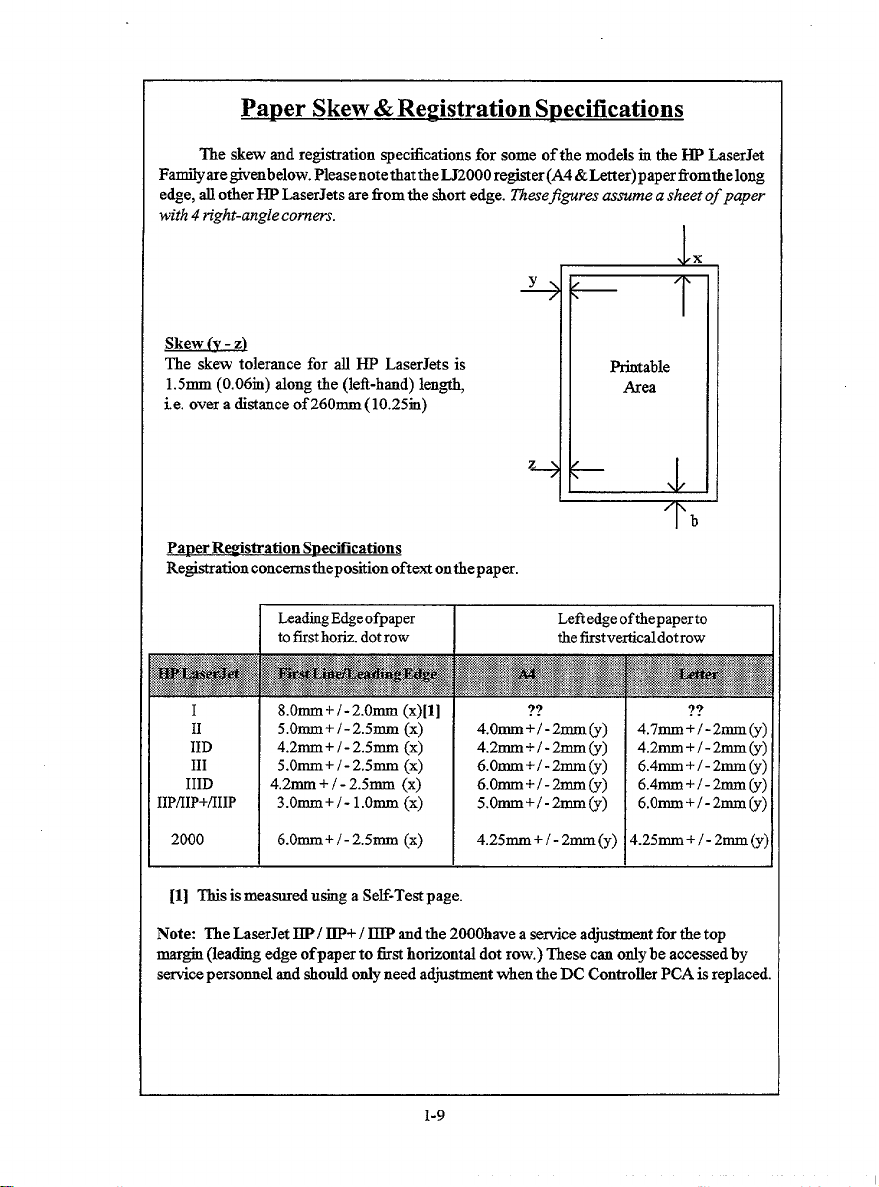

Paper Skew &Registration Specifications

The skew and registration specifications for some of the models in the HP LaserJet

Familyare@enbelow. Pleasenotethatthe LJ2000 regiater(A4 &Letter) paperfiomthelong

edge, all other W LaserJets are from the short edge. ~esefi~res assume a sheet of paper

with 4 right-angle corners.

J

Y

Skew (v- z)

The skew tolerance for all HP LaserJets is

1.5mm (0.06m) along the (lefi-hand) len@,

~e. over a distance of 260mm (10.25rn)

4

Printable

I

Area

2

PaDer RWstration Suetilcations

Re@strationconcemsthepostilon oftext ontiepaper.

LeadingEdgeofpaper

tofirst horiz. dot row thefirstverticaldot row

I

I 8.Omm+/- 2.Omm (x)[l]

II

IID

III 5.Omm+/-2.5mm

IIID

IIPflIP+/IIIP

2000 6.0mm+ /- 2.5mm

[1] This is measured using a Self-Test page.

Note: The LaserJet ItP / IIP+ / IIIP and the 2000have a setice adjustment for the top

-gin (leafig edge of paper to fiat hotiontal dot row.) These can only be accessed by

service personnel and ahotid only need adjustmmt when the DC Controller PCA is replaced.

5.0mm+/-2.5mm

4.2mm+ /- 2.5mm

4.2mm + / - 2.5mm

3.omm+/- l.omm (x) 5.Omm+/-2mm@)

I

(X)

(X)

(X)

(X) 6.Omm+/-2mm(y)

(X)

4.Omm+/-2mm(y)

4.2mm+/-2mm~)

6.Omm+/-2mm(y)

4.25rnm+ /- 2mm(y)

Lefiedgeofthepaperto

??

/~

lb

??

4.7mm+/-2mm(y)

4.2mm+/-2nnn(y)

6.4rmn+l - 2rmn(y)

6.4mm+/- 2mm (y)

6.Omm+/- 2mm (y)

4.25mm+ /- 2mm(y)

1-9

Page 15

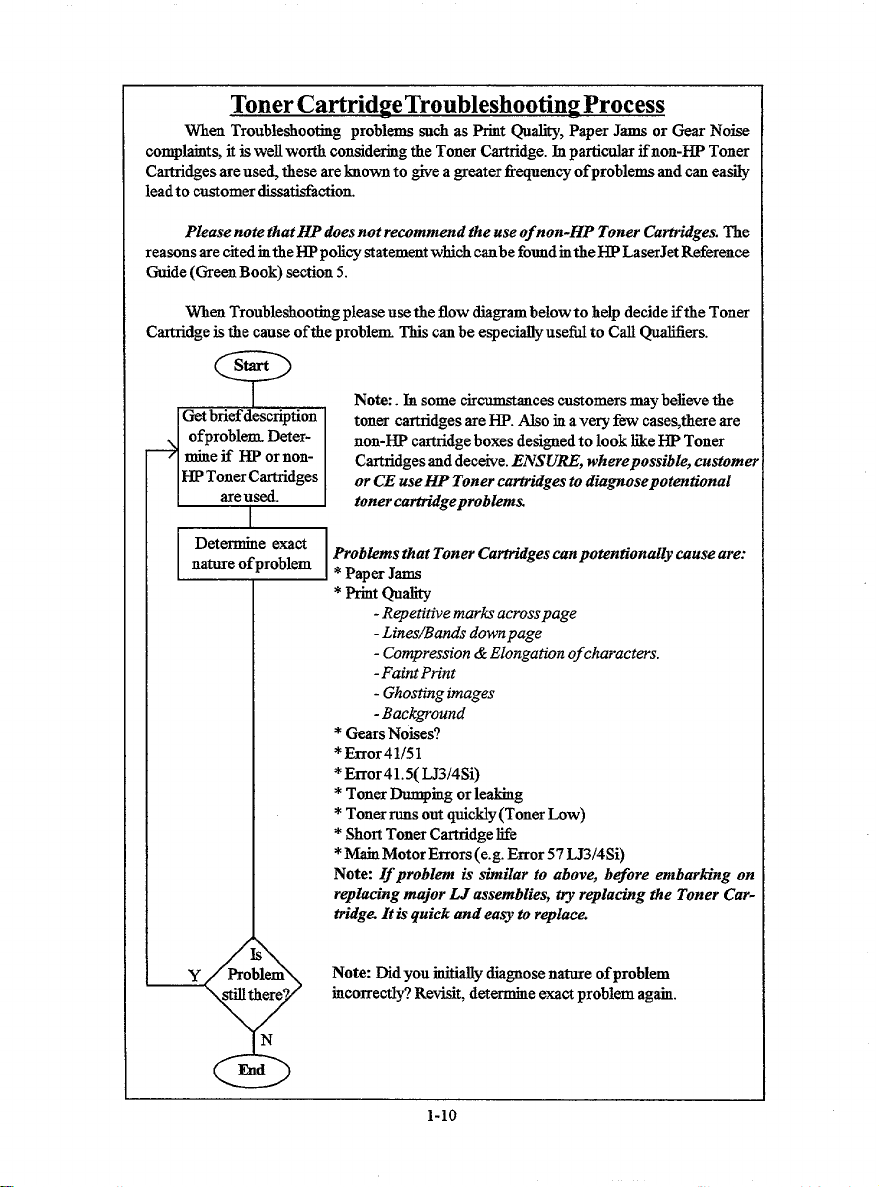

Toner Cartridge TroubIeshootin~ Process

When Troubleshooting problema such as Print Qu~, Paper Jams or Gear Noise

complaints, it is well worth considering the Toner Cartridge. In partidar ifnon-HP Toner

Cartridges are use~ tkese are kuown to give a greater frequency of problems and can easily

lead to c~omer dissatisfaction.

Please note thatHP does not recommend the use of

reasons are cited rnthe HP policy statement wkich canbe found in the HP LaserJet Reference

Guide (Green Book) section 5.

Wken Troubleakooting please use the flow diagram below to help decide ifthe Toner

Cartridge is the cause of the problem This can be especiallyuse~ to Call Qualifiers.

Get briefdescription

ofproblem. Deter-

mine if HP or non-

HPToner Cartridges

are used.

Determine exact

nature of problem

No*. In some circmnatauces customers may believe the

toner cartridges are HP. Also in a very fw case~there are

non-HP cartridge boxes designed to look like HP Toner

Cartridges and deceive. ENSU~, wherepossible, customer

or CE useHP Toner cartridges to diagnosepoten~”onal

toner cartridgeproblems.

Probkrms fiat Toner Cartn”dgescanpotentionally cause are:

*Paper Jams

*Print Quality

-Repetitive marks acrosspage

-LineslBmds downpage

- Compression &Elongation ofcharacters.

-FaintPnnt

- Ghosting images

-Background

* Gears Noises?

*Error4 1/5 1

*Error 41.5( LJ3/4Si)

* Toner Dumping or leaking

* Toner runs out quickly (Toner Low)

* Short Toner Cartridge life

*Main Motor Errors (e.g. Error 57LJ3/4Si)

Note: If problem is sbnilar to above, before embarking on

replaa”ngmajor LJ assemblies, try replacing tie Toner Cartridge. It is quick and ea~ to replace.

non-HP Toner Cartridges. The

Y

Note Did you itdtkdly dia~ose natnre of problem

incorrectly? Revisit, determine exact problem again.

1-1o

Page 16

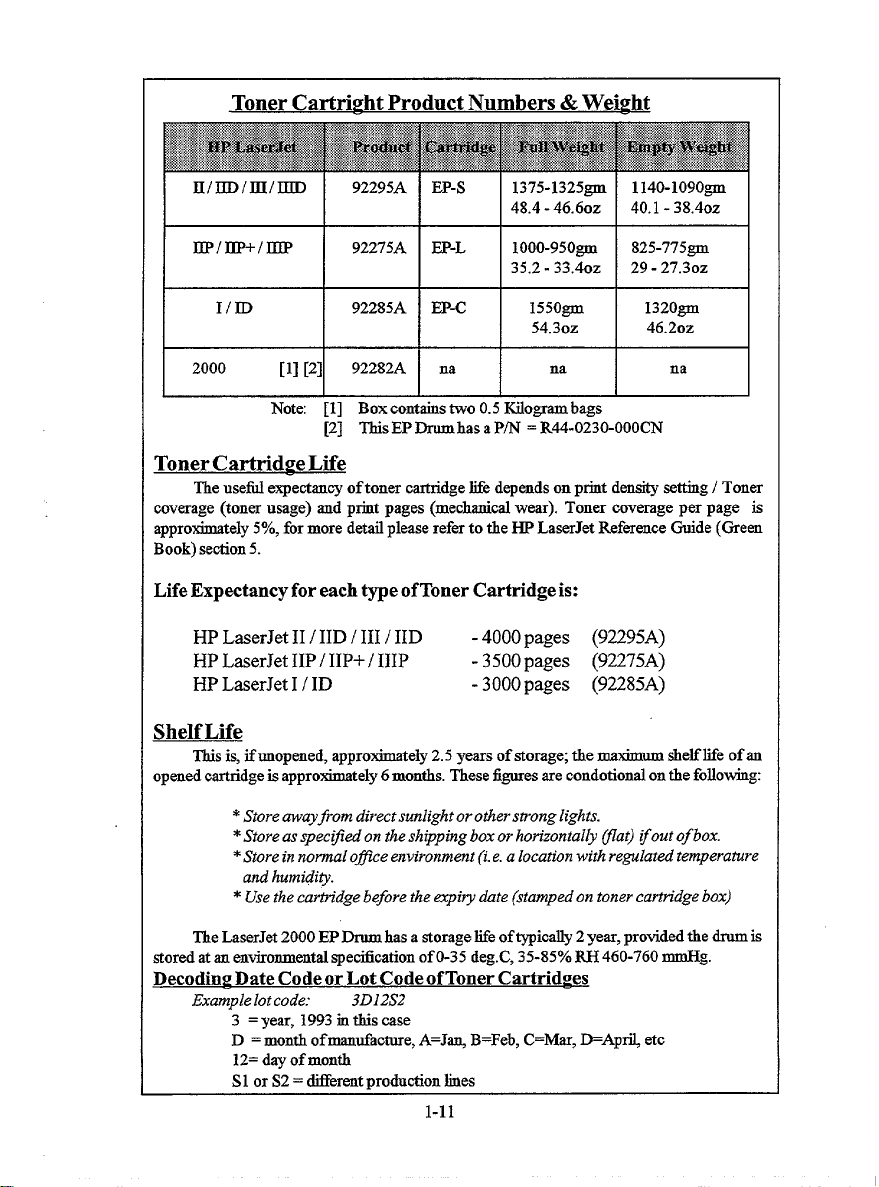

Toner Cartright Product Numbers& Weiyht

11/m) /m/lJJD

W/m+/m 92275A EP-L

I/lD 92285A EP-c

2000 [1] [2]

Note [1] Box contains WO 0.5 Kilogram bags

92295A EP-S

92282A na

[2] ThisEP Drnmhas a P/N = R44-0230-OOOCN

1375-1325gm l140-lo90gm

48.4- 46.60z 40.1- 38.40z

looo-950gm

35.2- 33.40z

1550gm 1320grn

54.30Z 46.20z

na na

825-775gro

29- 27.30z

TonerCartridge Life

Tke useti expectan~ of toner cartridge Me depends on print den~ setting / Toner

coverage (toner usage) imd print pages (mechanical wear). Toner coverage per page is

approximately

Book) section 5.

570, for more detail please refm to the HP LaserJet Refwence Guide (Green

Life Expectancy for each type ofToner Cartridge is:

HP LaserJet II / IID / III / IID

-4000 pages (92295A)

HP LaserJet 11P/ IIP+/ 111P -3500 pages (92275A)

HP LaserJet I / ID -3000 pages (92285A)

SheIfLife

Thisis,

if unopened, approximately 2.5 years of storage; tie maximum skelfMe of an

opened cartridge is approximately 6 montks. T’kesefigures are condotiond on tke following

*Store awayfrom direct surdight or other strong lights.

*Store as specl~d on the shipping box or horizontally fla~ l~out of box.

*Store in normal ofice environment (i.e. a location with regulated temperature

and humidi~.

* Use the carti”dge before the expiry date (stamped on toner cartn”dgebox)

The LaserJet 2000 EP Drum has a storage Me of typically 2 year, provided the dnun is

stored at an enviromnentd speci.tication of O-35deg.C, 35-85% RH 460-760 mrnHg.

Decodintr Date Code or Lot Code of Toner Cartrid~es

Example lot code: 3D12S2

3 =year, 1993 in this case

D = montk ofmantiacture, A=J~ B=Feb, C=Mar, D=Apfi etc

12= day of montk

S1 or S2 = different production lines

1-11

Page 17

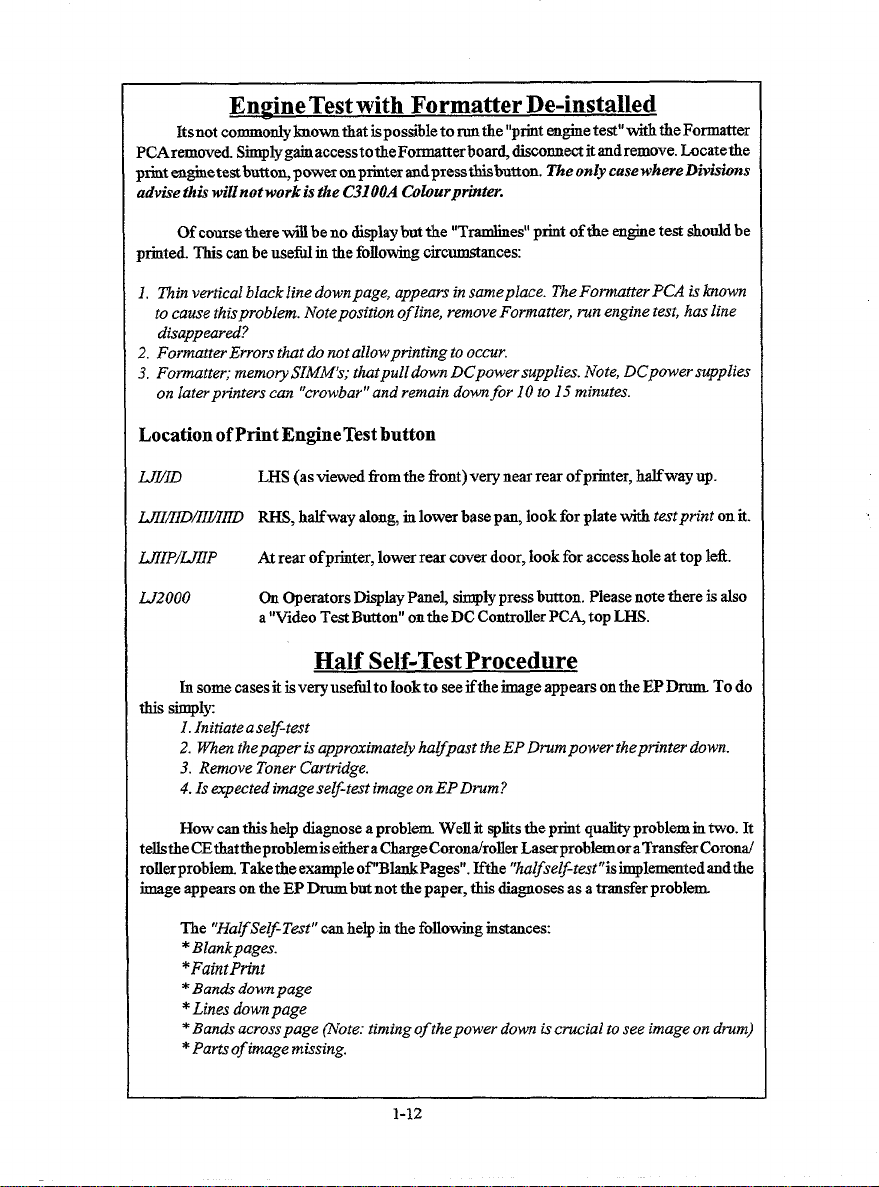

I

PCAremoved. S@lygain accesstothe Formatterboar~ disconnect it and remove. Locatethe

print enginetestbutton, power onprinter audpress~button. Tke only case whereDiviskms

advise this wiMnot work is the C3100A Coburprinter.

ptited. This can be usefi in the following circumstances

1, Thin vertical black line downpage, appurs in sameplace. The FormatterPCA is known

to cause thisproblem. Noteposition of line, remove Formatter, run engine test, has line

disappear?

Formatter Errors that do not allowprinting to occur.

2,

3, Formatter; memo~SIMWs; titpulldown DCpowersupplies. Note, DCpowersupplies

on later pn”nterscan “crowbar”and remain downfor 10 to 15 minutes.

Engine Test with Formatter De-installed

Itsnot commonly known tkat impossibleto ruu the “print engine test” with the Formatter

Of course there will be no displaybut the “Trsrrdines”print of the engine test shodd be

Location of Print Engine Test button

I

UYID

UIPID/IIIMIID RHS, halfway along, in lower base pan, look for plate witk testprint on it.

~IPIDIIP

LJ2000

LHS (as viewed fiomthe front) very near rear ofprinter, halfway up.

At rear ofprinter, lower rear cover door, look for access hole at top lefi.

Operators ~lay Panel @ly press button. Please note there is also

on

a“Video Test Button” onthe DC Controller PC~ top LHS.

Half Self-Test Procedure

In some casesit isveryuseflto Iookto see ifthe image appears on the EPDrum To do

this simply

I. Initiate ase~-test

2. ~en thepaper is approximately ka~past the EP Drum power thepn”ntw down.

3. Remove Toner Cmtndge.

4. Is expected image se~-test image on EPDrum?

How cantbishelp dis~ose a problem WeE it splits the ptit quality problem in two. It

tellsthe CEthattheproblemis eithera ChsrgeCorons/roller LaserproblemoraTrder tirona/

rollerproblem Tskethe example of “BlankPages”. Ifthe “kalfself-test”is implemented andtke

image aPPears on the EP Drum but not the paper, this diagoses as a transfer problem

The “HalfSelf Test” caa help m the following instances

*Blankpages.

*Fain tPtit

*Bands down page

*Lines down page

*Bands across page (Note: timing of the power down iscrucial lo see image on drum)

*Pam of image missing.

I

1-12

I

Page 18

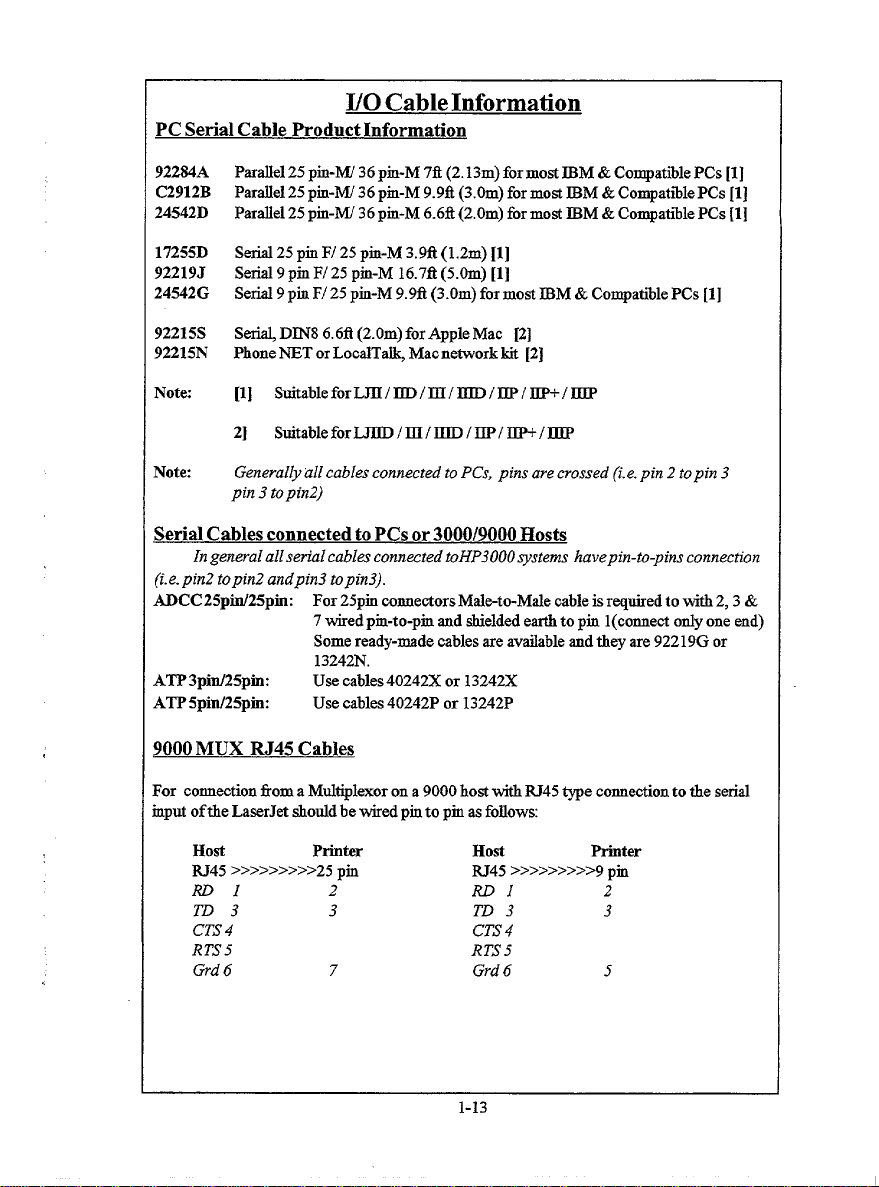

I/O Cable Information

PC Sefial Cable Product Information

922S4A Parallel 25 pin-~ 36pm-M 78 (2.13m) for moat IBM & Compatible PCs [1]

C2912B Parallel 25 piu-~ 36 pm-M 9.9fi (3.Om) for most IBM & Compatible PCs [1]

24542D ParMel 25 pin-M/ 36pin-M 6.6R (2.Om) for moat IBM & Compatible PCs [1]

17255D Serial 25 pin F/ 25 pin-M 3.9fi(l.2m) [1]

92219J

24W2G Serial 9 pin F/25 pin-M 9.9fi (3.Om)for most D3M& Compatible PCs [1]

Serial 9pm F/25 pin-M 16.7R(5.Om) [1]

92215S

92215N Phone NET or LocalTa~ Macnetwork kit [2]

Note:

Note Generally all cables connected to PCs, pins are crossed (i.e. pin 2 to pin 3

S@ DINS 6.6fi (2.Om)for Apple Mac [2]

[1] SuitableforLJH/~ /131/~ /~/ ILP+/llIP

2]

Suitable forLJIID/lll/~ /lIP/lTP+/133P

pin 3 topin2)

~

In general allserialcables connected toHP3000~stems havepin-to-pins connection

(i.e.pin2 topin2 andpin3 topin3).

ADCC25pird25pin:

ATP3pid25pin: Use cables 40242X or 13242X

ATP5pin/25pin: Use cables 40242P or 13242P

For 25pm connectors Male-to-Male cable is required to with 2,3&

7 wired prn-to-piu and shielded earth to pin l(connect only one end)

Some ready-made cables are available and they are 92219G or

13242N.

9000 MUX RJ45 Cables

For connection from a Mukiplexor on a 9000 host with RJ45 me connection to the serial

rnput of tie LaserJet shotid be wired pin to pm as follows

Hoat Printer

~45 >~>>~>>>Y25 piO RJ45 >>>>>>>>>9 pm

ml 2 RDl 2

TD 3 3

CTS 4 CTS 4

RTS5 RTS5

Grd 6 7 Grd 6 5

Host Printer

TD 3

3

1-13

Page 19

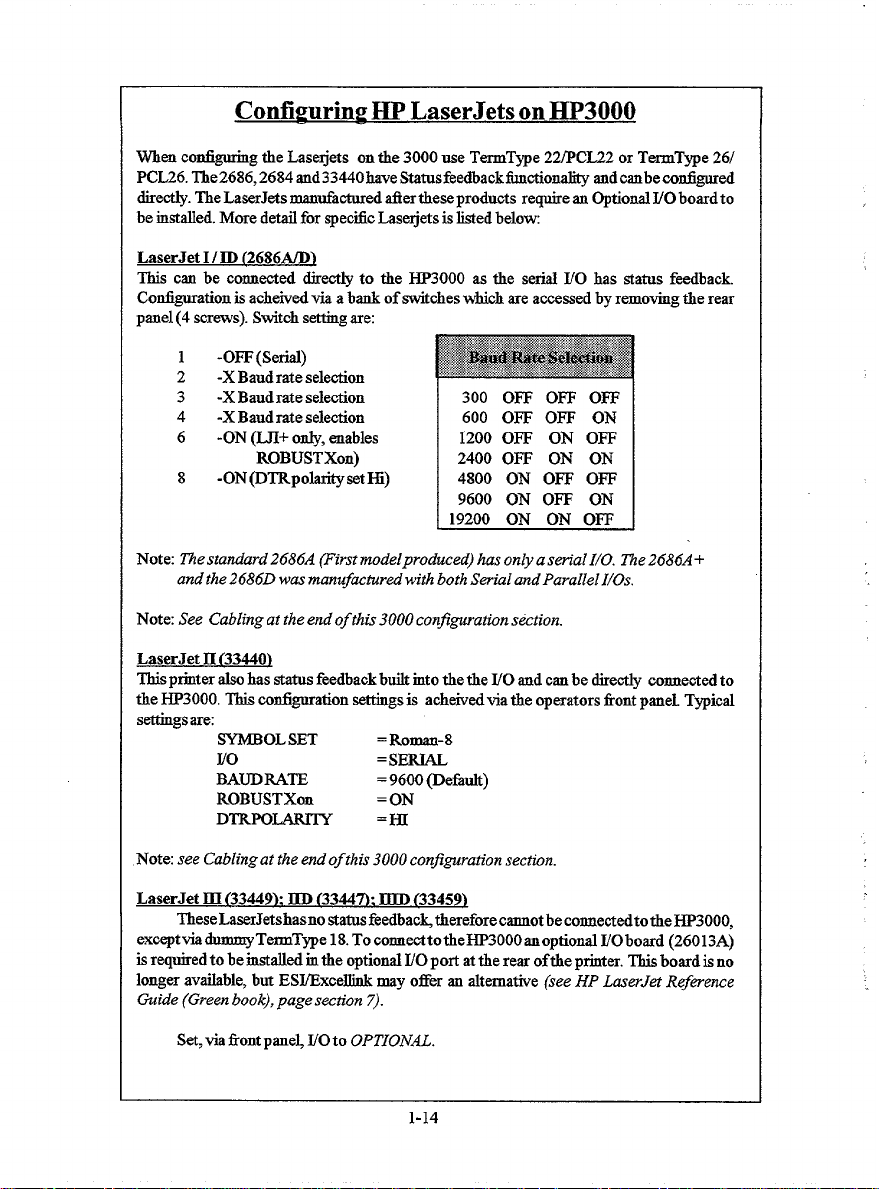

ConfigurinpHP LaserJets on HP3000

configuring the Laserjets on the 3000 use TerrnType 22@CL22 or TermType 26/

When

PCL26. The2686, 2684 and33440have Statusfeedbackfb.uction@ andcanbecotdigared

dire~. TheLaserJets mantiactured fiertkeseproducts require an Optional J/O bosrdto

be inst~ed. More dti for spectic Laserjets is listed below

LaserJet I/ID (26860)

This can be connected directly to the HP3000 as the serial I/O has status feedback.

Configuration is acheived via a bank of switches which are accessed by removing the rear

panel (4 scrws). Switch setting are:

1

-OFF(Serial)

2

-X Baud rate selection

3

-X Baud rate selection

4

-X Baud rate selection

6

-ON (L3i+ ordy, enables

ROBUSTXon)

8

-ON(DTRpolarityset Hi)

Note: Thestandard2686A First modelproduce~ has on@a sm”alI/O. ~e 2686A+

and the 2686D was ntanuf~tired with both Serial and Parallel I/Os.

Note: See Cabling at the end of this 3000 con$~ation section.

LaserJet II (33440\

Thisptiter ~ has status feedback built into the the I/O and can be directly connected to

the HP3000. This configuration settings is acheivedtia the operators front psneL Typical

settings are

SYMBOL SET = Roman-8

J/o

BAUDRA~ =9600 (Defati)

ROBUSTXon

DTRPO~ ‘m

=s=

= ON

~$,*.

,!$.>-,.*,>.?:~,f,*;:*<;:,,

,,.,,, ,.:;

,*$ ;y. x$ :V$#$~ .>

*# ,:

?~

,“$/j,,,,,

300 Om OFF OFF

600 OFF OFF ON

1200 OFF ON OFF

2400 OFF ON ON

4800 ON OFF OFF

9600 ON OFF ON

19200 ON ON OW

❑.

&

,~;, ~~~<:*@$~$j,;; 7:;~

.,.*,. ,.,

,?

Note see Cabling at the end of this 3000 con~guration section.

LaserJet III (33449): IID (3344n: DID {33459)

These LaserJetshasno statnsfeedbac~therefore cannot beconnectedtothe HP3000,

exceptvia dummyTenuT~e 18. To connecttotheHP3000 anoptional I/Oboard (260 13A)

is required to be installed iu the optional I/O port at the rear of the priuter. This board is no

longer available, but ESJ/ExcelJink may ofir an alternative (see HP tierJet Ref@ence

Guide (Green book), page section 7).

Set, via front pane~ I/Oto OPTIONAL.

1-14

Page 20

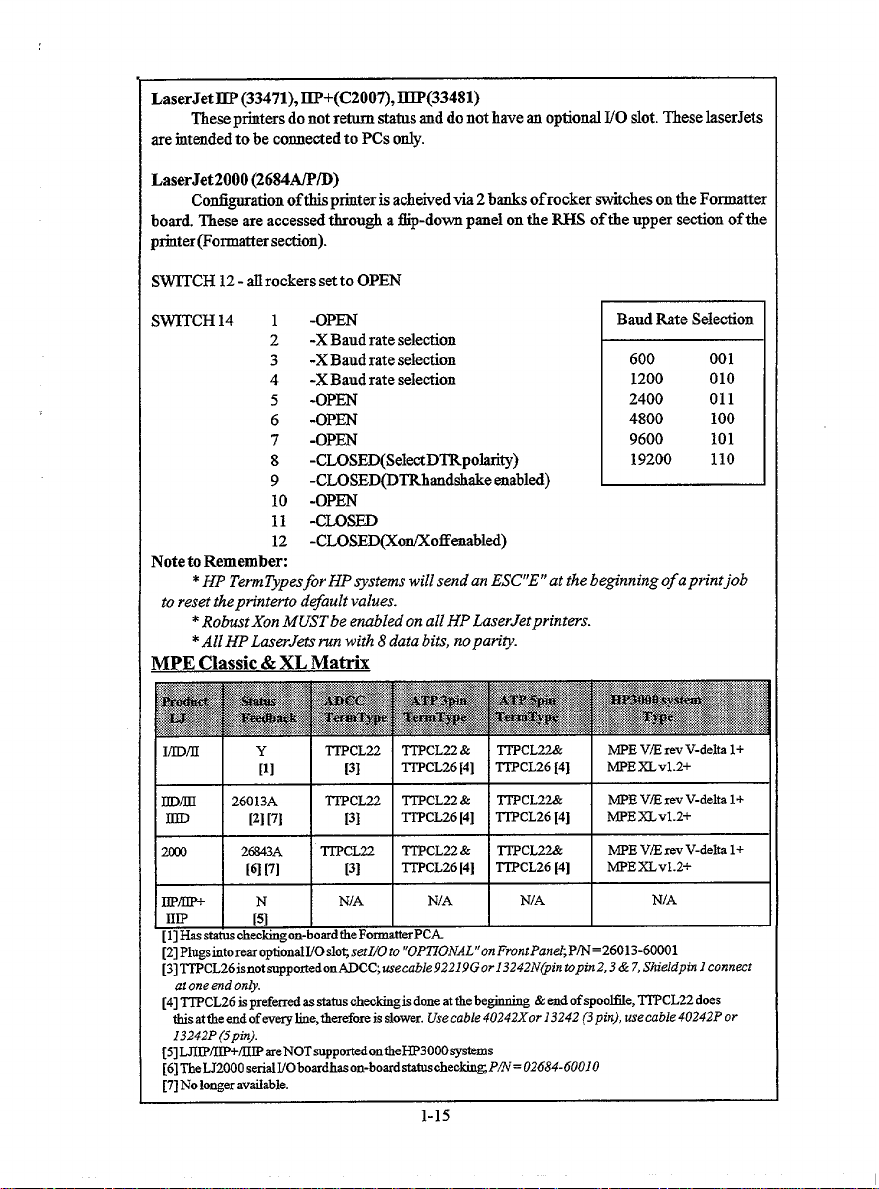

aserJetILP (33471), ~+(C2007), IIIP(33481)

These ptiters do not return status and do not have an optional I/O slot. ~ese laserJet,

rerntendedto be cotmected to PCs ordy.

,aserJet2000 (2684A/P/D)

Contignration ofthia printer is acheivedvia 2 banks of rocker *ches on the Formattf

~srd. ~ese are accessed throu~ a fip-down panel on the RHS of the upper section of th

rinter@omttersetion).

WITCH 12- all rockers set to OPEN

WITCH 14 1

-OPEN

Baud Rate Selection

2 -X Baud rate seletion

3 -X Baud rate selection

4 -X Baud rate selecdon

5 -OPEN

6 -OPEN

7 -OPEN

8 -CLOSED(SelectDTRpolarity)

-CLOSED(DTRhandahake enabled)

9

600

1200

2400 011

4800 100

9600 101

19200 110

10 -OPEN

-CLOSED

11

-CLOSED(Xotioffenabled)

12

‘oteto Remember:

*HP TerrnTypesfor HP ~stems will send an ESC”E” at the be~”nningof sprint job

to reset theprinterto defardt values.

*Robust Xon MUST be enabled on all HP LaserJetprinters.

*AllHP LaserJets run with 8 data bits, no pan”@.

IPE Classic&XL Matrix

001

010

[2] PhgsintoresrqrtionslVOslotsetI/Oto“OP170NAL’’onFrontPanzPJN=26013-60001

[3]~CL26isnot~potied .n~CC;wecable92219G orl3242N@inBpti2.3&7,Shieldpin 1 connct

atone end on@.

[4] TTPCL26

thissttheendofeveryIirre,therefareisslower.Use

13242P (5pin).

[5]LJItP/IR+/IIIPareNOTsuppartedontheHP3000~stems

ispreferredssstatuscheckingisdoneatthebeginning&endofspoofie,TI’PCL22does

cable 40242Xor 13242 (3pin), use cable 40242P or

[6]TheLJ2OOOserislVOboardheeon-bosrdsts@oheckiugPfi=02684-60010

[7]NoIonge.ravaiiable.

1-15

Page 21

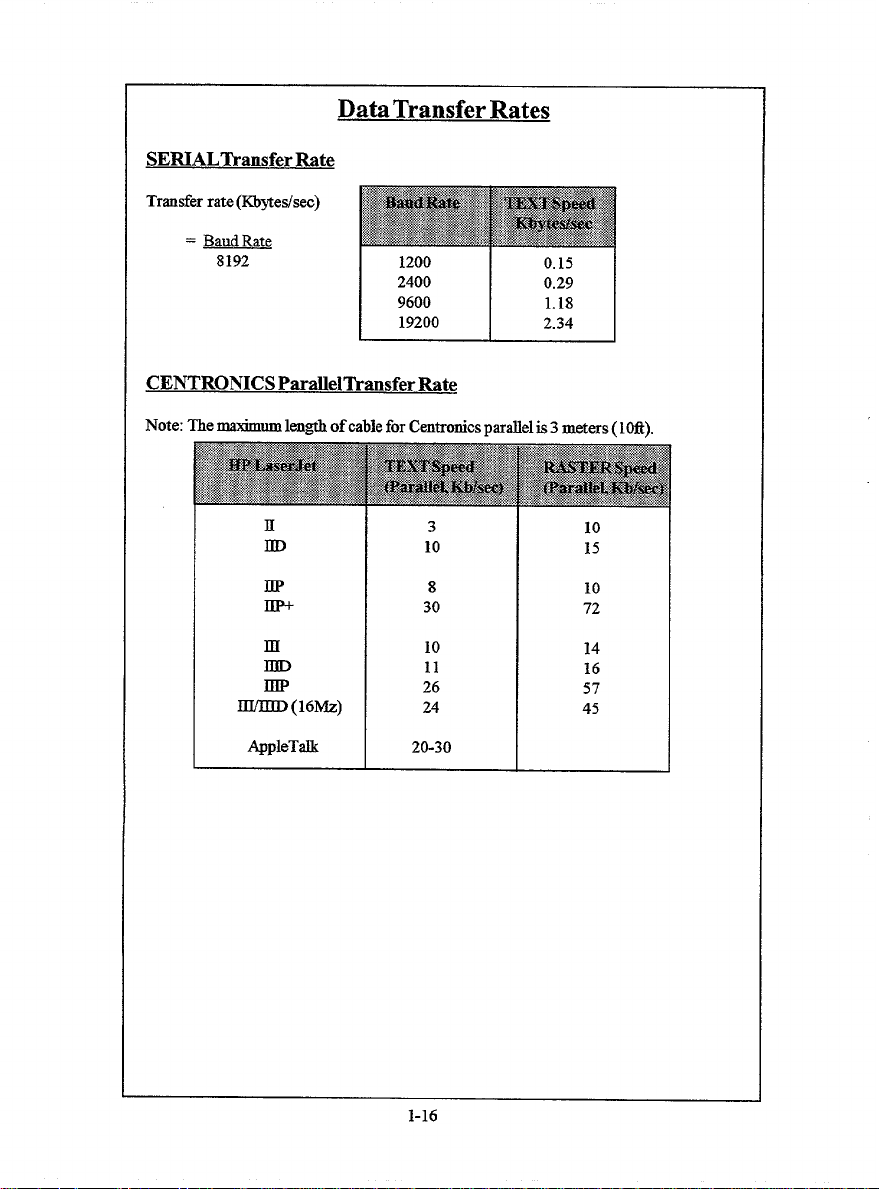

Data Transfer Rates

SERIALTransfer Rate

Transfer rate (Kbytes/see)

= Bad Rate

8192

CENTRONICS Parallel~ansfer Rate

Note: The matium length of cable for Centronics nardel is 3 meters ( lM).

1(

m

IIF

IIP+

m

IDD

m

~(16Mz)

AppleTalk

3

10

8

30

10

11

26

24

20-30

10

15

10

72

14

16

57

45

1-16

Page 22

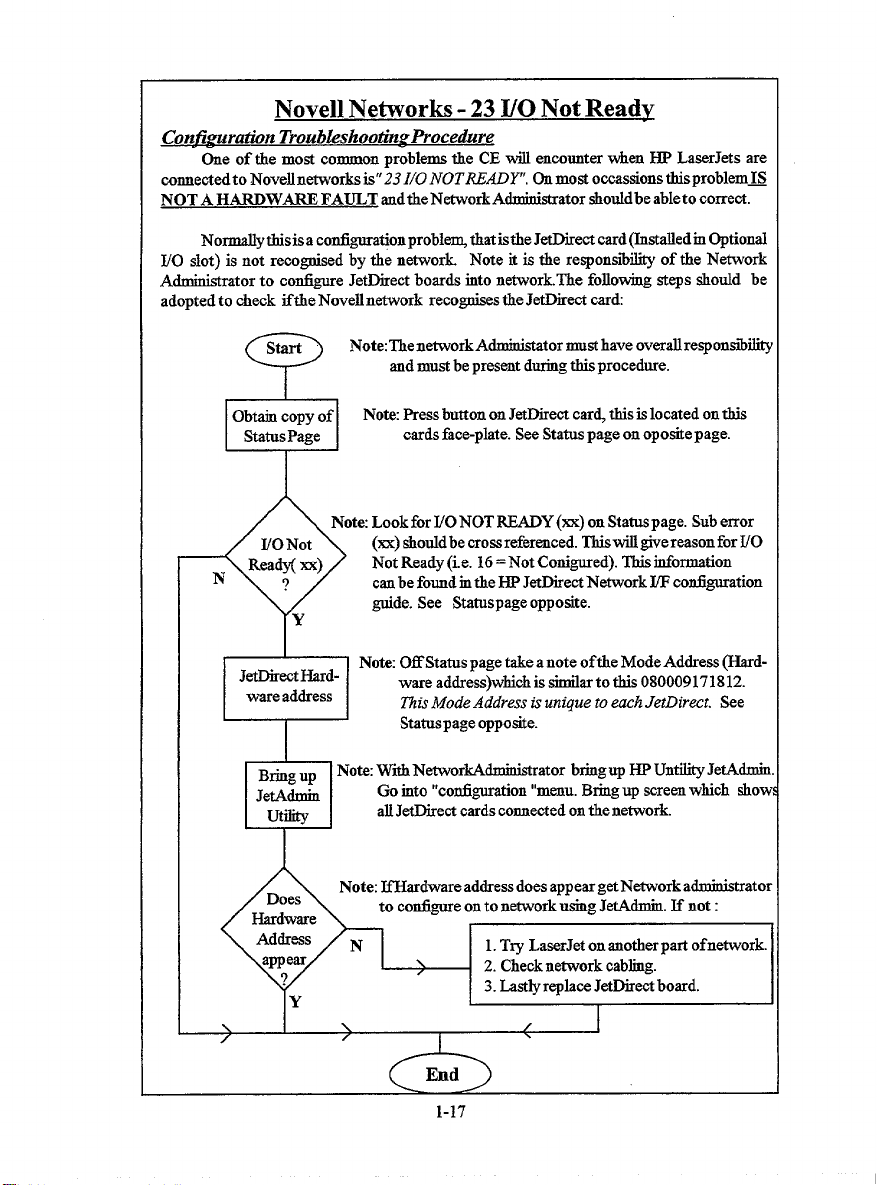

Novell Networks -23 I/O Not Readv

Coniiguratin TroubLeshootin~Pi’ocedure

of tie most common problems the CE will encounter when ~ LaserJets are

One

mnnected to Novell n-orks is” 23 1/0 NOTREADY”. On

NOT A H~WARE FAULT andthe NetworkA~ator shotidbe able to correct.

Notiythisisa co-ationprobl~ thatistheJe~ect card(Installedrn Optional

I/O slot) is not reco~ed by the network. Note it is tie responsii~ of the N*ork

Administrator to configure JetDirect boards into network. The foJlowing steps should be

adopted to check ifthe Novell n~ork reco@es the JetDirect card

Note: Then~orkA_ator nmst have overall responsibii

and must be present dtig this procedure.

most occasions tiproblem~

COPY Of

Obtain

Status Page

N

Jet13ir-Hard-

ware address

B~g up Note With NetworkAdministrator bring up HP Untility JetAdmir

JetAdmin

utility

No@ Press button on JetDirect car~ this is located on this

cards face-plate. See Status page on oposite page.

Note Look for I/O NOT READY(xx) on Status page. Sub error

(x) shotidbe crosreferenced. ThiswillgivereasonforUO

Not Ready (i.e. 16= Not Configured).Tkis information

canbe found m tke HP JetJ)irect Network ~ con.figuration

guide. See Statuspage opposite.

Note Off Status page take a note oftke Mode Address (Hard-

ware address)wkich is sirnilarto this 080009171812.

~is Mode Address is unique to emh JetDirmt. See

Statuspage opposite.

Go into “con6guration “menu. Bring up screen which shov

alIJetDirect cards connected en the network.

Note: JfHardware address does appear get Network a~atol

to contignre on to network using JetAdmin. If not:

1.Try LaserJet on another part ofnetwork.

2. Checknetwork cabling.

3. Lastly replace JetDirect board.

\

/

1-17

/

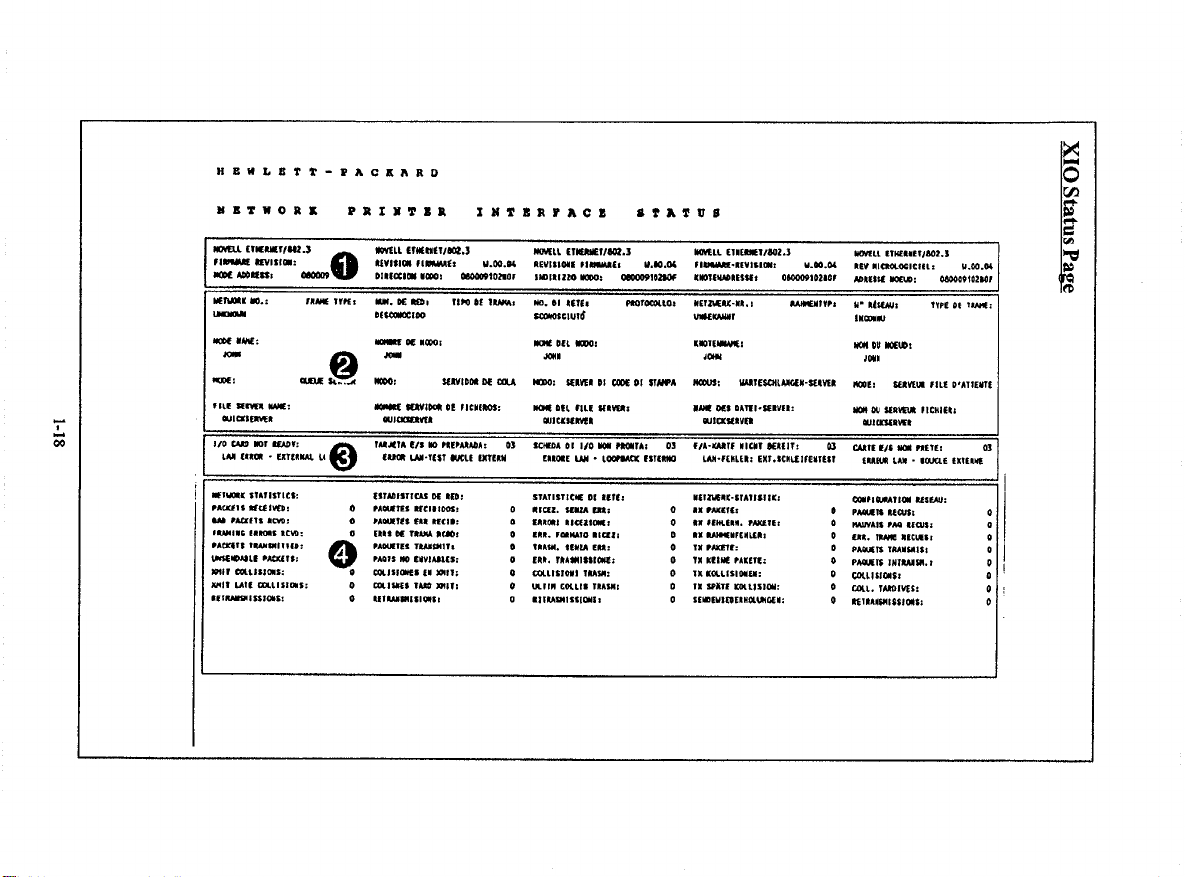

Page 23

1-18

XIO Status Pape

Page 24

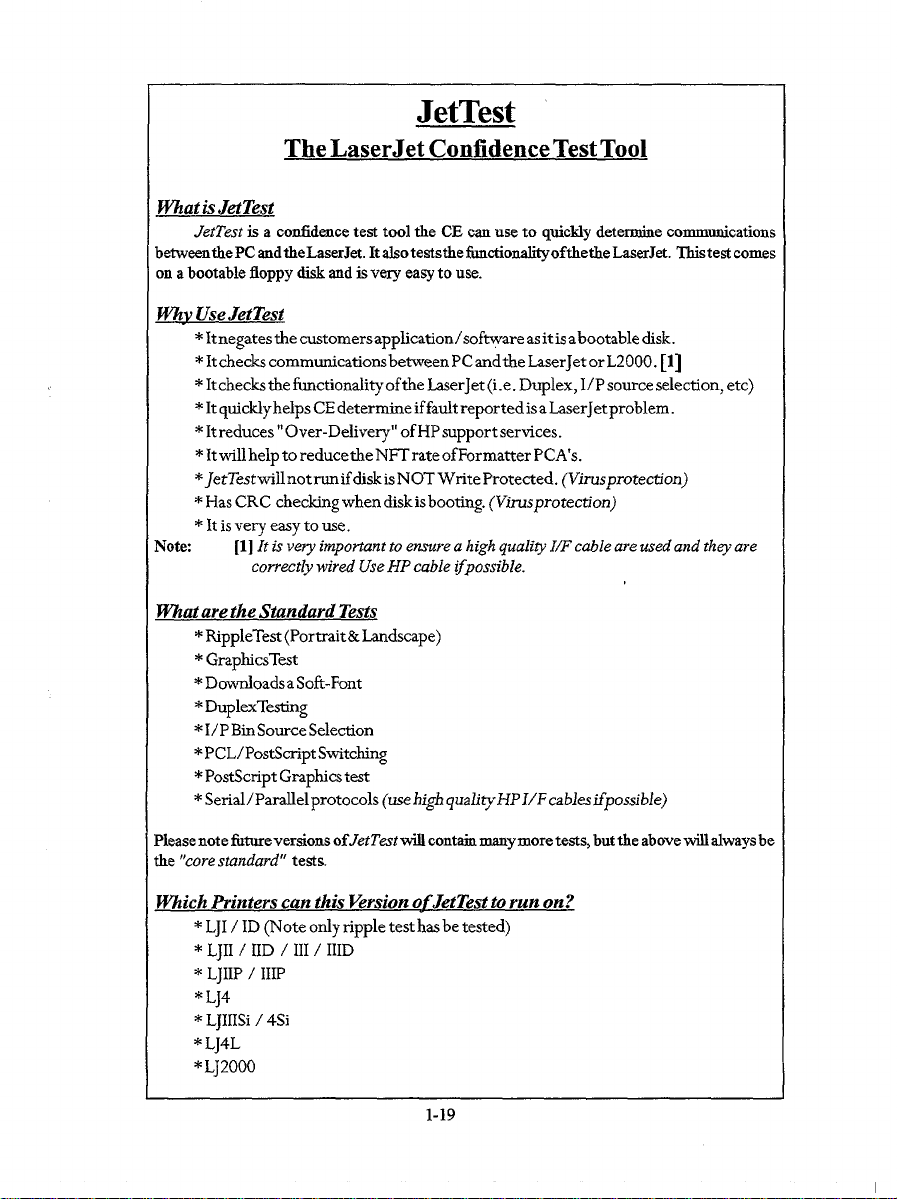

JetTest

The LaserJet Confidence Test Tool

WhatisJetTest

JetTest is a confidence test tool tie CE can use to quickly detetie communications

betweenthe PC andtheLaserJet. It alsoteststhe fimctionalityofthethe LaserJet. ~stest comes

on a bootable floppy disk and is very easy to use.

WhvUseJetTest

negates the customers application/sof~are asit isabootable disk.

*It

*It checks communications between PC andthe LaserJet or L2000. [1]

checks tie functionality of the LaserJet (i.e. Duplex, I/P source selection, etc)

*It

*It quickly helps CE determine if fault reported is a LaserJetproblem.

*It reduces” Over-Delivery” of HP support services.

*It will help to reduce the NFT rate of Formatter PCA’S.

*JetTestwill not run if disk is NOT Write Protected.

Has CRC checking when disk is booting. (Virusprotection)

*

It is very easy to use.

*

Itis ve.y important to ensure a high qualiy I/F cable are used and thq are

Note

[1]

correctly wired Use HP cable lfpossible.

Matarethe Standard Tests

RippleTest (Portrait& Landscape)

*

* GraphicsTest

* Dotioads a Soft-Font

* DuplexTesting

*1/ P Bin Source Selection

* PCL/PostScript Switching

*PostScript Graphics t=t

* Serial/ Parallel protocols (use high

quality HP I/F cables impossible)

(Virusprotection)

Please note fiturevertions ofJetZ’estwill contain manymore tests, but tie aboveti alwaysbe

tie “corestandard” testa.

Which Printers can this Version ofJetTest to run on?

LJI / ID (Note only ripple test has be tested)

*

* LJII / IID / III / IIID

* LJIIP / 111P

* LJ4

L IIISi / 4Si

*

J

* LJ4L

*LJ2000

1-19

Page 25

How to RUNJtiTest

1.Install the Bootable disk inA: Drive of PCA

2. Power off fie PC, then on again or CTrl, Shift &DEL Keys together

3 .Takeapprox 1 minute to BOOT-up.

4.The J~EST screen will appear,then simpIy follow to menu driven screens and

choose test you wish to run, number of copies, etc.

Note: The mouse will ody work ifthe PC has serial mouse, ifnot use TAB and/or arrow keys.

I

How to Obtaina Covv ofJetTmt

JetTestwasproduced by Steve Oakes(UJSMauchester) and Bob Edwards (UKRC) and

has been widely diatriiuted tioughout the UK and also to mmry countries worldwide. Ifyou

need a copy please send a 3 1/2 inch HD floppy disk to Bob Edwards in the UK Birmingham

office (ext 59369) with return address and I wilIbe ~d to -d you a copy.

mat oftheFuture ofJ&Test

At this time (March 95)we arerntheprocess ofupdatingJetTestto includenewLaserJet

products. We alsorntendtorevampJetTestto allowittobe ea~updatedandto rncludeatider

choice of tests. This will probably be available by the Autumn (Fall) of this year. We will of

course update the field of prowess m this area.

I

1-20

Page 26

Classic Printers

LaserJetI / LaserJetID

I

2686A /2686D

Page 27

BooMet Or~anisation - Please Read

This 2686fl section has been divided into 4 parts, which areas follows:

1) Faults with Error Numbers

2) Miscellaneous Problems

3) Print Quality Problems

4) Paper Path Problems

Service Notes UD to SCDt 86

2686A-I

2686A-2

2686A-3

2686A-4

2686A-5

2686A-6

2686A-7A

2686A-8

2686A-9

2686A-10

2686ABIAU-1

2686BIAU-2

2686ABIAU-3

2686ABIAU-4

2686ABIAU-5

Print Skew.

Replacement of Lasers (DC Controller Compatibility)

Di;fictity Clearing Error 50.

Service Mannal changes since publication.

Change to Level 840606 Firmware.

LaserJet Plus (Options 200 & 220)

Vertical Smear.

LaserJet I/F PCA Failures.

Correcting Errors 20,21, 22& 40.

Correct Value for R117 on Connector J107

Voltage Configuration (220/240v, 50Hz).

Print Skew.

Replacement of Lasers (DC Controller Compatibility)

Difficulty Clearing Error 50.

Service Manual changes since publication.

2686ABIAU-6

2686~lAU-7

LaserJet Plus (Options 200 & 220)

2686AB/AU-8A V@ical Smear. 2686AJ3/AU-9 LaserJetW PCA Failures.

2686AB/AU-10 Correcting Errors20, 21,22& 40.

2686AB/AU-l 1 CorrectValue for RI17 on ConnectorJI07.

2-2

Page 28

~q86wD -FAULTS*H.EtiOfiWMBERS,

Please note that all Paper Jams or Error 13 problems, refer to the Paper Path part

of this section of this manual.

1. Check Laser Power level (45mw).

PERMANENT “02”

(Long waiting) 3. Faulty Scanner unti

2. Faulty Solid State Laser.

4. Check fuses on DC PS~ain Motor PCA.

5. Replace DC PS/Main Motor PCA.

6. Replace W PCA.

PERMANENT “05”

(Self-Test)

ERROR 11

ERROR 11, When Manual In this case the 2686A Plus was mistaken for a 2686A

Mode is Selected. Std, atsome time in the past the W had replacedfor (

“LC 11” Lower cassette Faulty Lower Paper Stie Switch. Replace this assy.

Permanently “OUT OF

PAPER” (2686D)

PERMANENT

“ERROR 12”

2686D ERROR 12

Intermittently

(Updated)

(Andy Cassels - Aberdeen)

1. Faulty ~ PCA.

1. Caused by bad Paper cusette micro-switch

(item 36, Fig-8-17).

69004 instead of a 69005. At some time later the

customer began to use Manual Mode md this fault

appeared.

I. Faul~ DC Controller.

2. When lid closes not ati”vating switch in ~ Power

Interlock assy.

3. Print engine transformer.

4. Misskrg DC Voltage, replace DC Power

Supply~otor Driver PCA.

The latch (FA2-5678-OOOCN)which holds down the

uppermain body on the LHS had a small crackin it.

It was difficult to see the crackand printer appearsto

function correctly. On applying power it would

intermittently give E~OR 12 or the printer would

not power up at all. This was caused by the motor

starting up and causing upper chassis to flex. Due to

this movement (1 to 2mm), this was enough to trigger

the interlock. When the interlock had operated, power

is cut, motors stpped, frame returns to its correct posi

tion, then power is reapplied. This scenario can thus

repeat. Replace latck FA2-5678-OOOCN.

2-3

Page 29

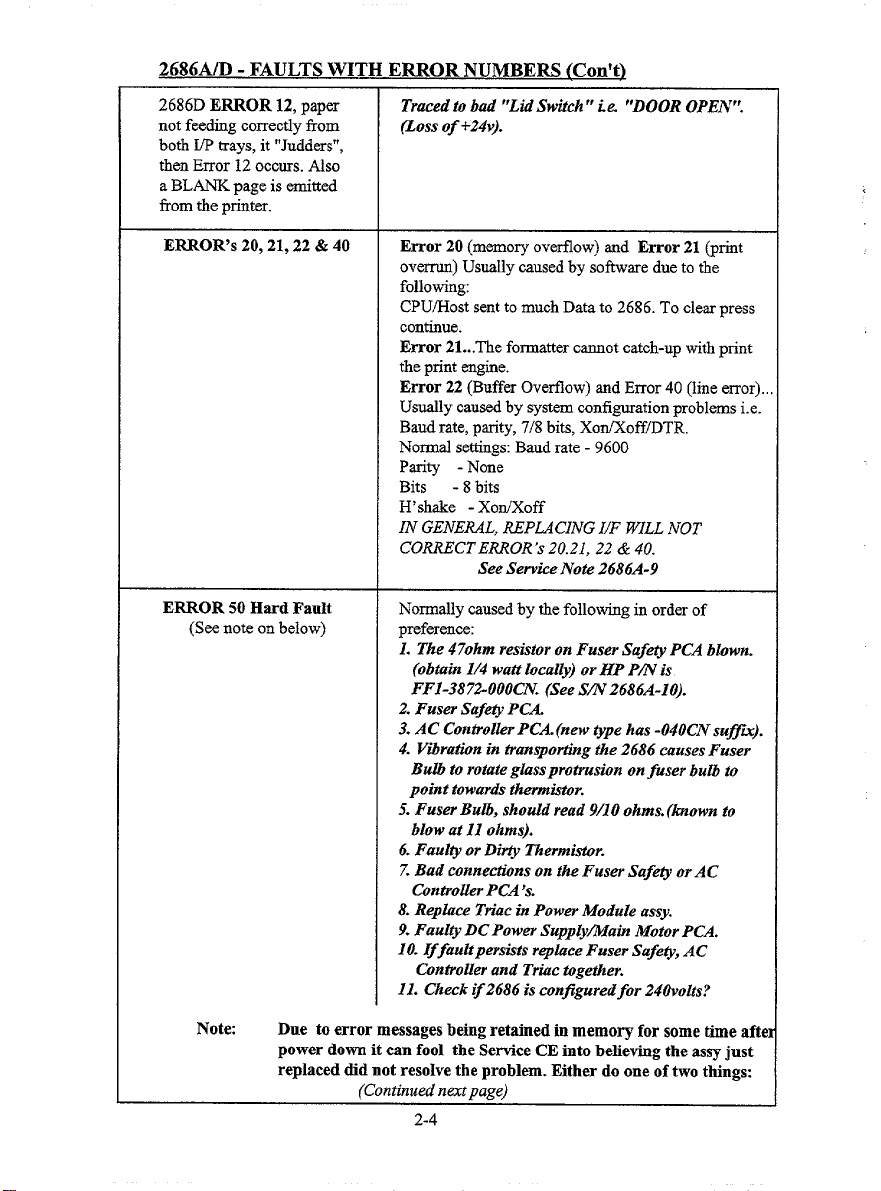

2686A/D - FAULTS WITH ERROR NUMBERS (Con’t)

2686D ERROR 12, paper

not feeding correctlyfrom

both I/P trays, it “Judders”,

then Error12 occurs. Also

a BLANK page is emitted

from the printer.

ERROR’s 20,21, 22& 40

ERROR 50 Hard Fault

(S= note on below)

Traced to bad “Lid Switch” ie “DOOR OPEN”.

(Loss of +24v).

Error 20 (memory overflow) and Error 21 (print

ovemm) Usually caused by software due to the

following

CPU~ost sent to much Data to 2686. To clear press

continue.

Error 21...The formatter cannot catch-up with print

the print engine.

Error 22 (Buffer Overflow) and Error 40 (line error).,

Usually caused by system configuration problems i.e.

Baud rate, parity, 7[8 bits, Xofioff/DTR,

Normal settings: Baud rate -9600

Parity - None

Bits

-8 bits

H’stie - XotiXoff

IN GENERAL, REPLACING IIF WILL NOT

CORJU?CTERROR

‘S 20.21, 22& 40.

See Servke Note 2686A-9

Normally caused by the following in order of

preference:

L The 470hm resistor on Fuser Safe@ PCA blown.

(obtain 1/4 watt local~) or HP PIN is

FF1-3872-OOOCN.(See Sfl 2686A-10).

2. Fuser Saf@ PCA.

3. AC Controller PCA.(new @pe has -040CN suffm).

4. Vibration in @anspo&g the 2686 causes Fuser

Bulb to rotate glass protrusion on fuser bulb to

point towards thermistor.

5. Fuser Bulb, should read 9/10 ohms. (known to

blow at 11 ohms).

6. Faulty or Dirty Thermistor.

Z Bad connections on the Fuser Saf@ or AC

Controller PCA ‘s.

8. Repbce The in Power Module assy.

9. Faul@ DC Power SuppfyMain Motor PCA.

10. Iffaultpersists replace Fuser Safety, AC

ControUer and Trtic together.

11. Check z~2686 is conjiguredfor 240volts?

N’otc Due to error messages being retained in memory for some time afte

power down it can fool the Service CE into believing the assy just

replaced did not resolve the problem. Either do one of two things:

(Continued nextpage)

2-4

Page 30

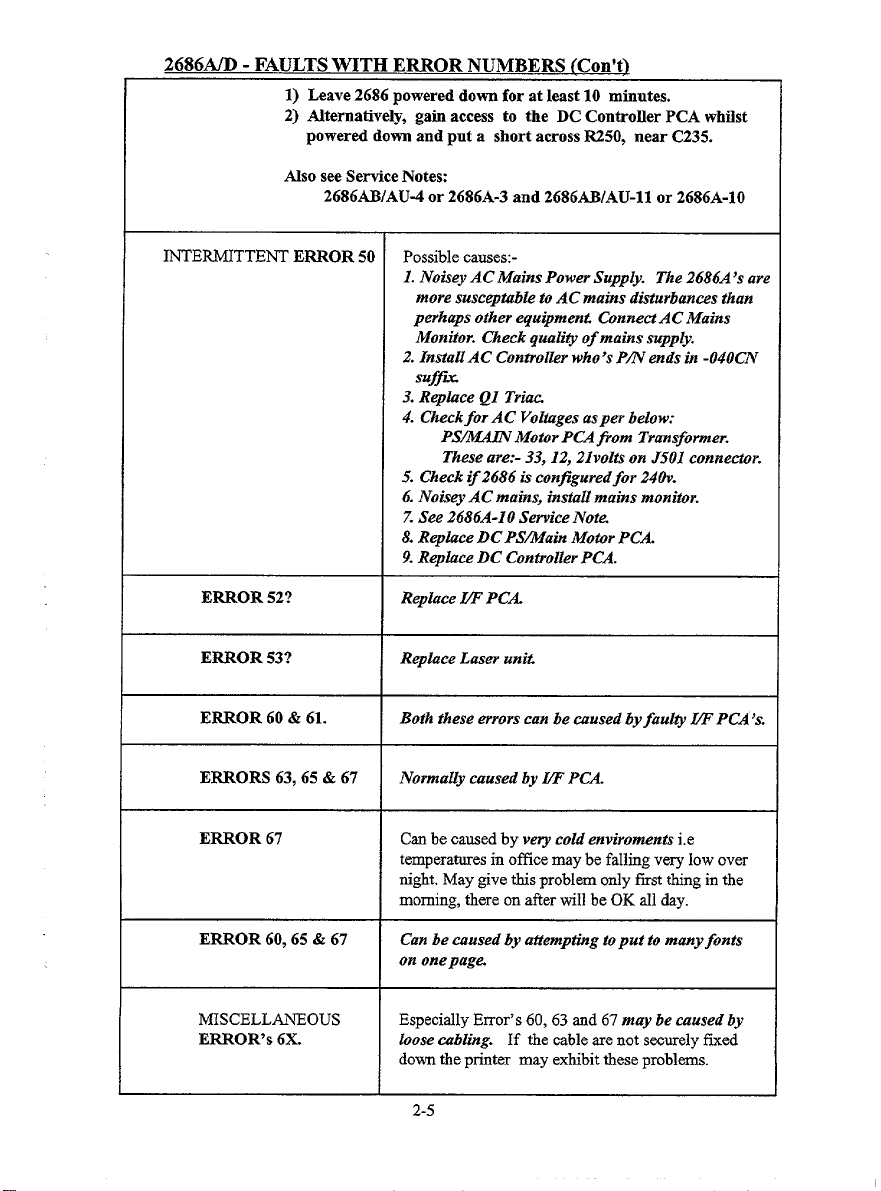

26~6AM - FAIJ1 ,TS WITH F.RROR NITMRW,RS (Pnn$tl

-. --.-— ------- .----- -. =.- -.. .w...__=.- ,_w-.

1) Leave 2686 powered down for at least 10 minutes.

2) Alternatively, gain access to the DC Controller PCA whilst

powered down and put a short across R250, near C235.

Also see Service Note~

2686N/AU-4 or 2686A-3 and 2686~/AU-11 or 2686A-10

INTERMITTENT ERROR 50

ERROR 52?

ERROR 53?

E~OR 60 & 61.

ERRORS 63, 65& 67

Possible causes-

1. Nohey AC Mains Power Supply. The 2686A’s are

more susceptabfe to AC mains disturbances than

perhaps other equipment ConnectAC Mains

Monitor. Check quality of mains supply.

2. InstallAC Controller who’s Pm ends in -040CN

Suffa

3. Replace QI Triac.

4. Checkfor AC Voltages asper below:

PS/W Motor PCA @om Transformer.

These are:- 33, 12, 21volts on J501 connetir.

5, Check z~2686 is conjiguredfor 240v.

6. Noisv AC mains, instaU mains monitor.

Z See 2686A-10 Service Note.

8. Replace DC PS~ain Motir PCA.

9. Replace DC Controller PCA.

Replace ~ PCA

Replace Laser unit

Both these errors can be wused byfaulty W PCA ‘s.

Normally caused by LT PCA.

ERROR 67

ERROR 60, 65& 67

MISCELLANEOUS

ERROR’s 6X.

Cm be caused by very cold environmentsi.e

temperatures in office maybe falling very low over

night. May give this problem only first thing in the

morning, there on after will be OK all day.

Can be caused by atteinptkag to put to many fonts

on one page

Especially Error’s 60,63 and 67 may be caused by

loose ubfing. If the cable are not securely fixed

down the printer may exhibit these problems.

2-5

Page 31

2686A/D-,MISCELL~EOtiS’PROBLEMS ~~

ARC~G? Check all earthing assoicated with Transfer Corona,

ensure all earth connection and all wires associated

with Varistor PCA have good continuity, check 16Mej

ohm(R9) by Transfer Corona is OK.

No FRONT PANEL 1. Probably the I/F power supply that lies at the botton

DISPLAY?

of the 2686A. Check the 5 volts coming from this

PCA.

2. Faulty W PCA.

3. Check wires under VF Power Supply have not been

punctured, especially after reassembly. If are has

not been taken to route lower cables carefuUy, this

cause unit to Smoke and hmage L!FPCA.

VERY LONG “WAITING

FOR DATA” 02 on Display

FrontPanel.

Will not recognise NEW

CHARACTER FONTS

92286J, 92286G & 92286H.

Laserjet 2686 plus outputs at

50% of expected rate with

some applications when using Note Throughput OK when using internal default font.

operational fast font cartridge.

TONER CARTRIDGE 1. Customer not shaking ca~”dge.

problem’s

Customer changes horn the

2686A to 2686D LJ. When unit, be aware you may increase the amount print

using PREP~ED paper

that was previously used on the difference between the first printed line on 2686A

2686A it was found the text hat’

displaced by approximately

1.58mm in relationship to the therefore a resolution may NOT be available The

preprinted lines or boxes. customer may need to compensate by either changing

See “PERMANENT 02” in 2686WD “Fatits with

ErrorNumbers”at the beginning on this section of

manual.

Reference Servtie Note 2686A-5.

Reference Service Note 2686A-6.

2. End stopsfallen out (see Video). Problem only sea

in the early introduction phase of this pm”nter.

3. Drum Shutter damage (L @ Rfade).

4. TONER Cartridge in red zone

5. DFS Cartridge

6. See “LASER PRINTER PRINT QUALITT”

book (UK only)

Try adjusting thephysicalpositin of the scanning

skews on page (See S/N 2686A-1). Note there is a

when compared to a 2686D. The aetualphysicalpape,

path length between the printers is slightly dz~eren~

the position of the preprinted images of repositioning

laser printer images.

2-7

Page 32

““”.. = -

. . -------- . . --- .,- . ----------

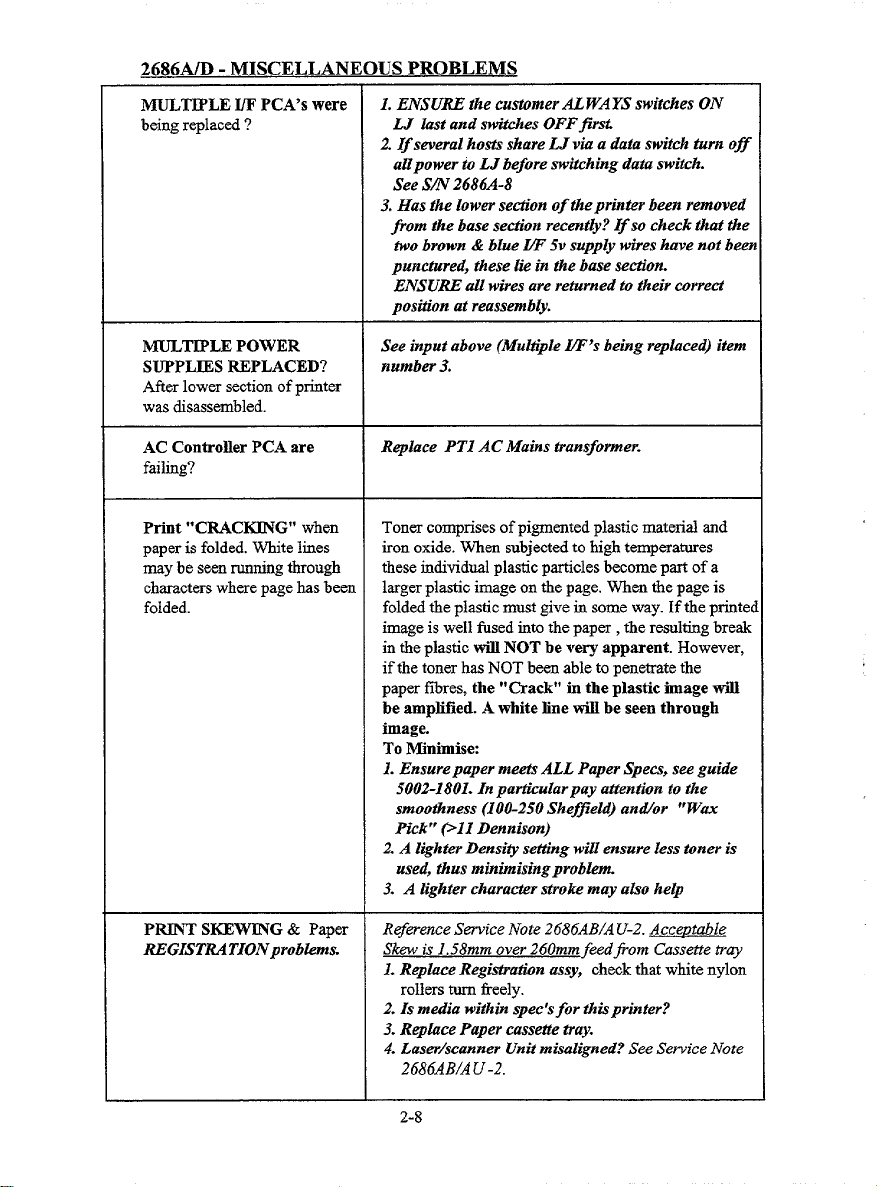

MULTDLE ~ PCA’S were

being replaced ?

MULTIPLE POWER

SUPPLIES REPLACED?

After lower section of printer

was disassembled.

AC Controller PCA are

failing?

Print “CRACKING” when

paper is folded. White lines

may be seen rnnning tbrougb

ch-cters where page has been

folded.

1. ENSU~ the customer AL WAYS switches ON

LJ lmt and switches OFFfirst

2. If several hosts share LJ via a data switch turn off

aZZpowerto LJ before switching data switch.

See S/N 2686A-8

3. Has the lower section of theprinter been removed

from the base seti”on recent~? ~so check that tie

two brown & blue ~ 5V supply m“reshave not been

punctured, these lie in tie base seti”on.

ENSURE all wires are returned to their correct

position at reassemb~.

See input above (Mutiple W’s being replaced) item

number 3.

Replace PT1 AC Mains transformer.

Toner comprises of pigmented plastic material and

iron oxide. WIIcn subjected to high temperatures

these individual plastic particles become part of a

larger plastic image on the page. When the page is

folded the plastic must give in some way. If the printed

image is well fused into the paper , the resulting break

in the plastic will NOT be very apparent. However,

if the toner has NOT been able to penetrate the

paperfibres, the “Crack” in the plastic image will

be amp~led. A white line will be seen through

image.

To Minimise:

1. Ensure paper meets ALL Paper Specs, see guide

5002-180L In patiularpay attention to the

smoothness (100-250 Sheffield) andor “W&

Pick” ~11 Dennison)

2. A lighter Density seti”ng WD

ensure lesstiner is

used, thus minbnisingproblem.

3. A lighter character stroke may ako he~

Pm S~W~G & Paper R@wence Service Note 2686AB/A U-2. AcceDtab~e

REGISTRATIONprobiems.

Skew is 1.58mm over 260mm feedfiom Cassette tray

L Replace Registration assy, check that white nylon

rollers turn freely.

2. Is media within spec’sfor this printer?

3. RepCacePaper cassette tray

4. Laser/scanner Unit misaligned? See Service Note

2686AB1AU-2.

2-8

Page 33

-“””mu - ,T.l”uuuum, ,Uu ““ . ..WJDMML.1” ,G”M .L

~~G EDGES OF

ENVELOPES “Wrinkled”

Adjust springtension on FuserPressurerollers, Mis

may help. Note, envelopes areproblematr”c due to

as it passes throughfuser tha-r construction. Contact RCE for further informs

assy. tion

Customer printing BOTH Thismodel of bserJet is a SIMPLEXprinterandis

SIDES of tke Page or

DUPLEX printing?

~S can print on both sides, thisprti”ce is not supported

WY cause paper jams, paper

not designedfor Duplex printing.Although this printer

byHP. For the generalHP statementon “Duplex

feeding or print quality printing v Simplex” please referenceHP Reference

problems. Guide (Green Book) section 3.

Customer RE~ED~G paper, As above ref= to HP general statement on “Duplex

not two sided printing? printing v Simplex” in HP Reference Guide (Green

Book) seetion 3.

PAPER JAMS/MISFEEDS/ Interleaving, where a variety ofpaper is placed in the

SKEWING caused by

paper tray, is not recommended by HP. ~ practice k

customers practice of likely to lead to Paper jams& Misfeeds. For the general

~ERLEAVING ~ermt HP statement on ‘interleaving Paper” please reference

types ofpaper m paper trays? HP Reference Guide (Green Book) section 3.

2-9

Page 34

2686A/D-PR~

T QUfiITY PROBLEMS

MARKS

REGULAR INTERVALS

Prints in only a sma~ portion

of the page with “Print Test”

and only a small portion of

“Self Test”. See below:

ELONGATION OF PRINT 1. Replace DC PS,ain Motor Pa

in the direction of paper

movement.

BACKGROUND

ON PAPER AT

If marks repeat at re~ar intervals, measure distance

between marks to determine where tie problem lies:-

Marks %375” apart - Drum Related

8.0” apart - Drum gear Related

2.5”

apart - Fusm Roller Related

Paper tray size microswitck problem. Check

operation of these switches, alternatively paper size

switch cables may be defective. There are 3 micro-

switches to the left of the paper tray, which sense type

of paper tray (A4, 1lx 8.5, etc) installed.

2. Check drive mechanism, gear train& motor

3. Replace main motir

4. Is the use of Non-HP Toner Cart’s causing this

pbm?

] 1. AdjustPriittDensi@ dial

2. Ground Spring in centre of drum dn”vegear, is it

damaged or missing?

3. Check Laser Power adjustment

4. Replace HVPS.

5. Replace DC Controller PCA

6. Replace DC Power Supp& ~ain Motor Dvr PCA.

VERTICAL SMEAR problem.

Thin grey band in approx

middle of paper. Band in the

direction of paper movement.

This band is Approx 6 to 12m

wide. This problem is also

known as “VERTICAL

FOGGED STRIPES”.

WAW PRINT

Reference Service Note 2686A-7.

L Pay special attention to the quality of media used

2. Supply customer with 2686A Paper Spec’s Guidfi

3. Replace Feed Guide Assy (RGI-1039-OOOCN)

4. Dirty Primary Corona.

5. Tiy replacing Toner Cartridge.

6. Clean interior ofprinter.

1. Repbce Scanner unit

2. Rplace DC Controller PCA.

2-11

Page 35

2686A/D - PRINT OUALITY PRO.BLEMS (Con’t)

MARK ON PAPER in line 1. Separation belt installed upside down.

with SEPWTION BELT. 2. Dirty Separation Belt

3. Dirty Separatin RoUer.

4. Replace Toner Cartridge.

GHOST CHARACTER on the

Ov@lling t?tepaper tray can thepick-up rollers to

43rd line? drag on the paper, causing motor to slow down,

causing EP Cartridge to stall slightly. Causing inprope

transfer of printed data born drum to paper.

LIGHT WGES?

1. Adust Print Densiq Dial

2. Try Laser QuaZi@Paper.

3. Replace Transfm Corona.

4. Check Laser Power. (Laser Checker Too~

5. Replace HWS.

6. Replace DC Controller PCA.

Z Check Drum Sensitivity switches.

RANDOM LIGHT

Clean centre of large brass drum drive gear.

PATCHES over the page BEWARE, do not darnageorlose spring in the

orGRADIENT from left to

centreof this brassgear.

right?

LIGHT PRINT ON RHS

side of paperin the diection of

paper movement.

1. Due to a missing or loose earth conneti”on on

2686A situated nmr the RHS hinge as viewed

@om the front of theprinter.

2. Missing Doctor bladepin in EP Ca~”dge, replace

EP tirtridge. Have not seen this problem for a ion,

time

3. Replace Varistor PCA, there maybe dz~ferences of

outpub ie narrow bands of darkprint at the far

RHS, whereas a missing doctor blade pin wdl not

LIGHT AREA bottom RHS

Replace Feeder Guide Assy andpossibly the

md irre@ar. Transfer Corona.

LIGHT PRINT in same

position down page? Always

in dirmtion of paper movement.

Image very light in in this area.

BLANK PAGES?

BLACK PAGES?

Clean Optics Exit mirror to Drum.

L Empty toner cartridge?

2. Has seal been removed in toner ca~”dge?

3. Replace Trmsfer corona, wire broken?

4. Replace HWS.

5. Replace DC Controller.PCA.

1. Replace EP Toner cartn”dge

2. Replace HVPS.

2-12

Page 36

2686A/D - PRINT C)UALITY PROBLEMS_(_Conlt)

Sharp THIN LINES

Horizontal Lines across

Page

1. Replace Scanning Assy

2. Replace Laser Unit, check laser power.

3. Replace DC POwer Supply~ain Motor Dvr PCA.

RANDOM GAPS between

connective lines across page?

THIN VERTICAL “BLACK”

LINES/STWES down page?

THIN VERTICAL “~ITE”

L~S/STRIPES down page?

BANDS Down page ? Fuser

Rollers scored. on thefuser separation pawls (page 8-58

PRINT SKEWING & Paper

REGIST~TIONproblems.

Faulty brass dram drive gear, the centre collar was

protruding wtich prevented the silver pin locking in th

end of the EP cartridge.~is resulted in the b

stopping intermittently.

1. Is Fuser Cleaning Pad dirty? Replace if necessary..

2. Scotig onfuser roller? replace z~necessary.

3. Scoring on EP Ca~”dge, try another cartridge

1. Replace Totier Cartn”dg&

2. Dirty Fuser Cleaning Pao!

3. Dirty Transfer Corona wire.

4. Ckeckfor obstacles or OP mirror contamination

in laser beam path. Laser Shutter?

5. Reptice stunning assy.

Scoring is normally caused by a build up of dust, etc

This problem is accentuated by the use of non-sup

ported media i.e paper with a high cotton content or

with talc/clay content. See 2686 Paper Spec Guides.

The use teflon coated darnage resistant fuser rollers

have been found to be more reliable. Use Higk Quali@

Laser medti asperpaper spec’s.

Reference Service Note 2686AB/A U-2. Acceptable

Skew is 1.58mm over 260mm feedfrom Cassette tray

1. Replace Registration assy, check that white nylon

rollers turn freely.

2. 1smedia witkin spec’sfor this printer?

3. Replace Paper cassette tray.

4. Laser/scanner Unit misaligned? See Service Note

2686AB/A U -2.

item34).

STAINS on REAR of PAPER

EP Cartridges DEGRADING

extremely quickly of found to

be D.F.S on arrival.

I. Clean interinr ofprinter.

2. Dirty Fuser Cleaning Pad.

3. Replace Fusing assy.

Check the EP Cartridges are HP and are not refilled

EP Cartridges. BEWARE, although the cartridges

may be in a HP or look alike boxes, it still could be of

the refilled variety.

2-13

Page 37

2686ti26i6D-P~ER:PATH PROBLEMS

ERROR 13’s Paper Jams

(Summary)

FJRST PRJNTED PAGE

JAM’s, but operates OK thereon

afterwardsuntil the printerhas

been turnedoff orunused for

some time. @RROR 13)

1. Using ~SUPPORTED PAPER, 79 grrns max,

use high quality laser bond paper to test.

2. Paper Jams/Smears - caused by broken or

missing separadon belt or incorrectly instalIed

3. Paper Jams caused by EP Toner Cartridge shutter

not opening. The plastic strut in the base(~S)

base (US) whti opens this shutter was broken.

4. Paper Jam caused by Paper Cassette clutch collet

(item-4,Fig 8-IV hose. This also applies to

2686D’s.

5. Paper jams at rear access door - due to a resti”ctin

in the guidefiom the rear aaess up to the

registration assy. Use slightly stiff cardstock md

push up from the rearaccess doorareainto this guide

to clearobstruction.

6. PaperJamat Regishation area- Registration

solenoid binding or shutter not moving correctly.

Replaced regis~tion assy.

7. Paper Jam at Registration Assy - due to cover hinges

incorrectly set causing a lack offriction between the

registration rollers.

8. Paper Jam at Fuser Assy - caused byfuser exit

sensor.

See page 8-49 in Service Manual, item 9 Registration

Shutterassy. On this assy thereis arubbergrommet

which when the printeris unused for aperiod of time

sticks, This causes the Registration assy not to operate

correctly, thus Paper Jam3einove this grommet as a

temporary measure, replace registration assy at a later

time z~not immediately available.

FAJSE PAPER JAMS, no

paperfed at all.

(ERROR 13)

FALSE PAPER JAMS, i.e

paperfeeds thru OK, but with

no printing, then a false paper

jam occurs. (ERROR 13)

Onpower up, beforepower

up initialisation has completed,

main motor energises ERROR

13 occurs.

Springs on Registration Shutter assy not positioned

correctly,fooling the LJinto belieting paper has

stuck in this assy. i.e. sensor activated at all times.

Reposition these springs into its correct location or

replace registration assy.

Ref page 8-37 item 4/25, the allen screw may come

loose or it may slip on its shaft. This results in the “D

cassette pick roller incorrectly positioned.

1. F&t edge of ‘D’ rolJer should face paper tray, or

2. Too much paper in paper tray may cause the same

problem.

Registration Sensor arm binding. A misalignment of

the Registration Shutter Spring (page 8-49, item 15)

Realign to wrrectproblem.

2-15

Page 38

A“””-. ””” U - .-. U.. .-. .1 . I.VHUU,..” ,G”I. *Z

PAPER JAMM3NG at rear

of printer,in areabetween

Fromrear of 2686A, ptil back Lower Castie guide

(page 8-3’7,item 7), push somefair~ rigidpaper

rear access door and Reg Assy. up awards registration area @ clear any blockage.

Alternatively the guide plates in this area are too C1OS,

and W-llhave to be stripped down to correct this

problem.

ERROR 13- 1st page leaves Replace Exit fuser Sensor.

1“protruding fiorn fuser assy.

ERROR 13-

OCCurS when

leading edge of paper is about

Replace EP Catige, either shutter not opening or it

is restricting paper movement.

to enter separation belt roller.

ERROR 13- Occurs after Repkace back door springs (RS1-2011-OOOCN).

paper is picked up, dl movement stops then jam message.

ERROR 13 when warming up.

1.Registration pbte bent or misaligned, also cheek

Does not get to “00 READY “ springs on this assy.

condition before paper jam 2. Replace Registradon assy.

occurs.

PERMANENT ERROR 13 The 24v was being pulled down by faulty AC Cent

on switching-on.

PCA. Replaee AC Controller PCA.

ERROR 13, 6mm of Paper Replace Fuser Exit Sensor.

protruding out of the Fuser

Rollers.

2686A Paper Jams when user Paper Feed clutch found to be heavily congeled in

begins operating printer for

firsttime in the morning. resolvedprobkm.

the

grease/paper dust. ~roughly cleaning clutd

No problems after first initial

nasage.

LOSING TOF when using 1. Check quali~ of Labels.(Use Ave~)

label paper horn the manual 2. Repkrm Manual Feed Assy(FG1-2354-OOOC~.

feed I/P tray. 3. Check alignment of manual idler poller on Reg

assy in relationship to rotir on the manual feed

assy.

2686D -in FACE-DOWN

MODE RH edge of paper

rollers sl@ping on paperpick-up shafi (item I.

Nylon

Fig 8-21).

BENT over.

2-16

Page 39

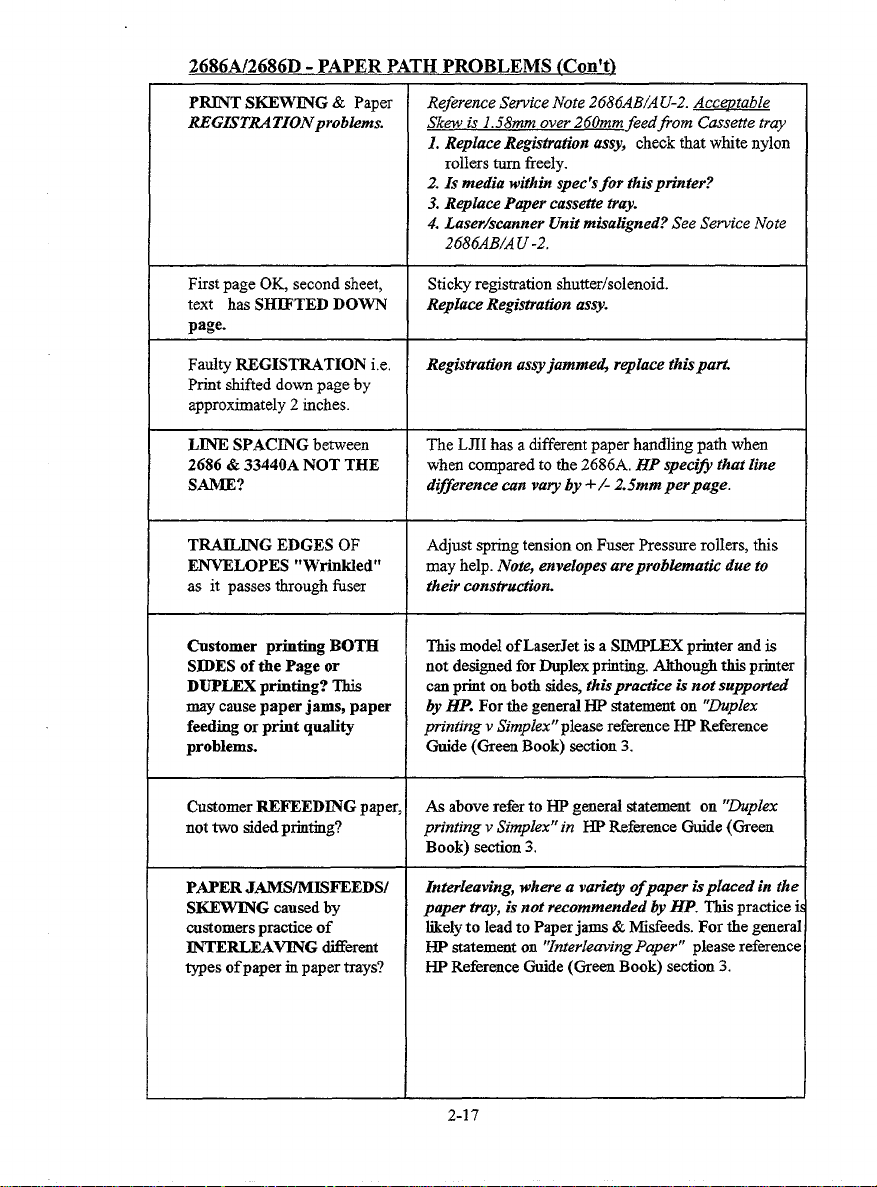

2686A/2686D - PAPER PATHPROBLEMS (Con’t)

PRINT SKEW~G & Paper Reference Service Note 2686AB/A U-2. Accqtable

REGISTUTIONproblems. Skew is 1.58inm over 260mm feedfiom Cassette tray

1. Replace Registiatio@ assy, check that white nylon

rollers turn freely.

2. Is media withti spec’sfor this printer?

3. Replace Paper cassette tray.

4. Laser/scanner Unit misaligned? See Service Note

2686AB/A U -2.

First page OK, second sheet,

text has SHETED DOWN

Sticky registration shutierisolenoid.

Replace Registration as~.

page.

Faulty REGISTRATION i.e.

Print shifted down page by

approximately 2 inches.

LINE SPACING between The LJII has a different paper handling path when

2686 & 33440A NOT THE when compared to the 2686A, HP specifi that Iine

Registration assyjammed replace thispati

SAME? d~foence uir vary by +/- 2.5mm perpage.

T~G EDGES OF

ENVELOPES “Wrinkled” may help. Note, envelopes areprob&matti due to

as it passes through fuser their instruction.

@stomer printig BOTH

SIDES of the Page or

DUPLEX printing? Tbia

may cause paper jams, paper

feeding orprint quality

problems. Guide (Green Book) section 3.

Customer REFEEDING paper,

not two aidedprinting?

Adjust spring tension on FuserPressurerollers, this

This model of LaserJetis a SIMPLEX printerand is

not designed forDuplex printing.Although this printer

canprint on botb tide$ thisprad”ce is not suppotied

byHP. Forthe generalHP statementon “Duplex

printing v Simplex” please reference HP Rderence

Aa above refer to HP general statement on “~plex

printing v Simplex” in HP Refmence Guide (Green

Book) section 3.

PAPER JAMS/M~FEEDS/

SKEWfNG caused by

customers practice of

INTERLEAVING Merent

~es of paperin paper tiys? HP Reference Guide (Green Book) section 3.

Interleaving, where a variety ofpaper isplaced in the

paper tray, is not recommended by HP. Tbia practice i

likely to lead to Paper jams& Mifeeds. For the general

HP statement on ‘!IrUerlem”ngPaper” please refwence

2-17

Page 40

2686D - PAPER PATH PROBLEMS

2686D - ERROR 13, feeds OK Replace registration asv and CHECK quality of the

from upper tray, jams from

lower tray. ALWAYS prints Ist

page, 2nd page is just leaving

the fuser assy, 3rd page is half

way up the rear acc=s door,

paper jam occurs

2686D - When paper is fed

from UPPER TRAY, one sheet

is fed incorrectly from the

LOWER TRAY?

2686D, When labels are fed

mannaJly, the image loses

TOF and also manual I/p seems

to snatch at label when feeding . 000CW to wrreti

ERROR 13- 2686D after pape r Delivery sensor PS6 faul~, though it seemed OK

exits delivery exit area in face

in face up mode orin face down

mode. This erroroccurs when

paperis aboutto enterthe

holding trayarea.

ERROR 13- 2686D, PAPER

JAMS IN HOLDING TRAY

AREA. Paper entering holding

Tray from fuser assy collides

with paper about to exit the

the holding tray.

media being used If paper is NOT checked the

problem will most likely recur again.

NOTE: Media is known to cause this problem, use

paper that meets 2686A/D Paper Spec’s guide.

Stic@ lower cJutch,possibly caused by using

incorrect lubrkant. Dismantle clutch, clean and use

light oil to lubricate. (3-in-One)

Replace clutch spring and other parts if necessary.

DO NOT use grease.

Ensure Idler roller on the Manual feed assy are

aligned with the lower Manual feed roller. Bend

metalwork on idler as~ (Page 8-48 Pm FGl-2354-

when measured with a DVM.

1. Adjust pot on Paper Control PCA, this controls ti{

speed ofpaper exiting the holding tray.

NOTE:- these pots are initiaJly factory set

2. Replm% Paper Control PCA.

2686D ERROR 12

Intermittently

(Up&te@

(Andy Cassels - Aberdeen)

The latch (FA2-5678-OOOCN)which holds down the

upper main body on the LHS had a small crack in it.

It was difficnJt to see the crack and printer appears to

function correctly. On applying power it wodd

intermittently give ERROR 12 or the printer would

not power up at dl. This was caused by the motor

starting up and causing upper chassis to flex. Due to

this movement (1 to 2mm), this was enough to trigger

the interlock. When the interlock had operated, power

is cut, motors stpped, frame returns to its correet posi

tion, then power is reapplied. This smario crarthus

repeat. Replace latch FA2-5678-OOOCN.

2-18

Page 41

. . ..-

. ... . .. . . . . .. .

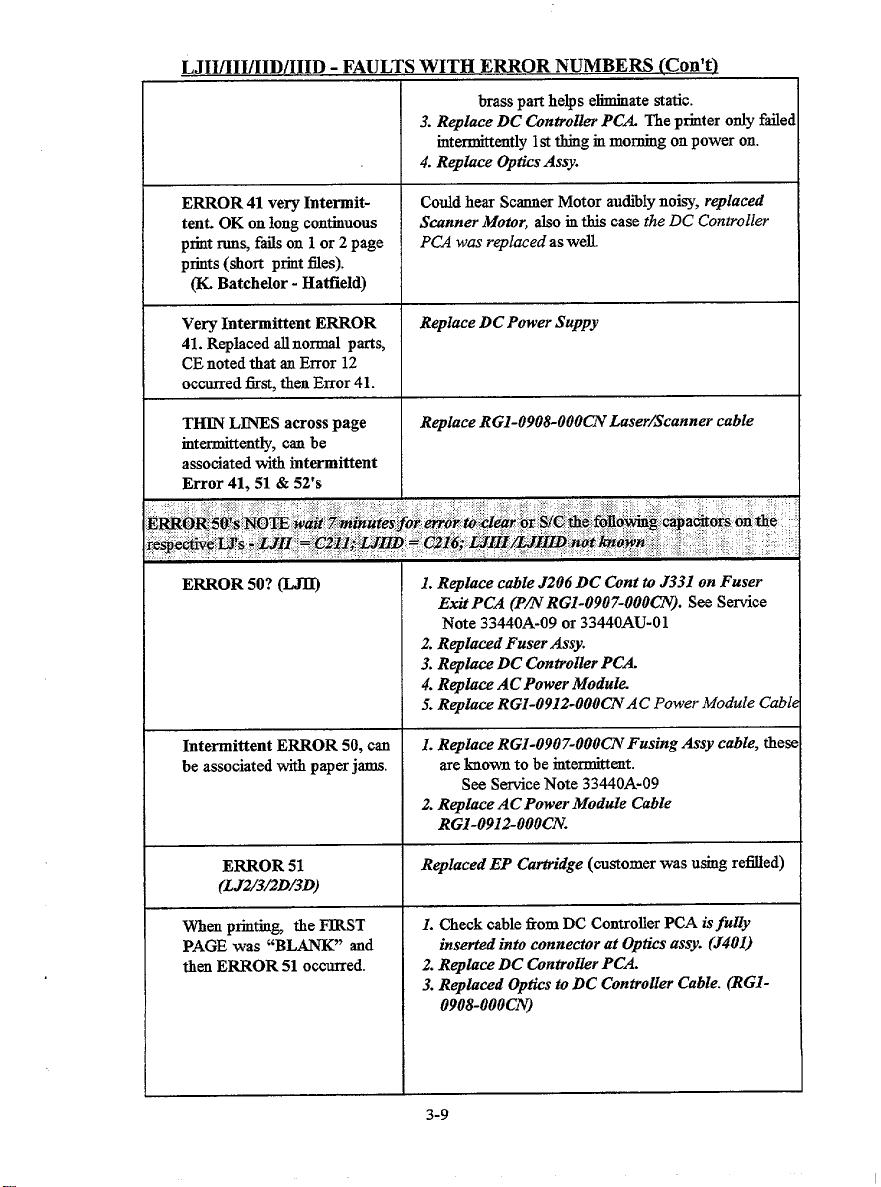

~ FACEDOWN mode right

1.----.,. ” ,-” - .2

Nylon roller slipping onpaper-up sha@ (item 15,

hand edge of paper has bent Fig 8-21).

over.

~stomer changed from 2686A TW adjusting position of scanning assyj be aware the

the 2686D. When using paper amount of print skew on printed page may increase

preprinted paper on the 2686D (see S/N 2686A-1). Note there is a difference between

which was used successfullyon

the 2686A, the

text has moved the 2686D. In this case, a problem resolution may not

the 1st printed line on the 2686A, when compared to

by approximately 1.58mm. possible which wuld be offered to the customer.

There are differences between the physical paper paths

The printer has TWO PAGES The paper tray clutches are NOT stopping after one

coming out of the fuser assy. revolution. Try:

The 1st page is 25 to 1. Check if tension provided by the solenoid armature

5Gmrnin front of the 2nd page. spring is sufficient.

2. Replace clutch spring and lubricate with light oil.

(e.g. 3-in-One Oil).

Customer printing BOTH This model of LaserJet is a SfMPLEX printer and is

SIDES of the Page or not designed for Duplex pfiting. Athougb this ptiter

DUPLEX printing? This can priot on both sides, this practice is not suppotied

WY cause paper jams, paper

byHP. Forthe generalHP statementon “@lex

feeding or print quality printing v Simplex” please referenceHP Reference

problems. Guide (GreenBook) section 3.

CustomerHEFEEDING paper, As above refer to HP general statement on “DrAplex

not two sidedpriutiug? printing v Simplex” in HP ReferenceGuide (Green

Book) section 3.

PAPER JAMS/MISFEEDS/ Interleaving, where a vm”ety ofpaper is placed in the

SKF~G caused by

paper tray, is not recommended by HP. This practicei

customerspractice of likely to leadto Paperjams& Weeds. Forthe gened

INTERLM~G ~erent HP atatemimton ‘Interleaving Paperf’ please refaence

types of paperin papertrays? ~ Refmence Guide (Green Book) section 3,

2-19

Page 42

2686A/D - MANUAL FEED PROBLEMS

2686D, When labels are fed

manually, the image loses

TOF and also manual I/P seems mtilwork on idler assy (Page 8-48 Pm FGZ-2354-

to snatch at label when feeding.

LOSING TOF when using 1. Ckeck quali~ of Labels. (Use Avery)

label paper fed from manual 2. Replace Manual Feed Assy(FG1-2354-OOOCN).

feed input tray. 3. Ckeck alignment of manual idfer roller on.

NO MANUAL FEED, Ensure correct intirfacepca is instaffed, shotid be

ERROR 11 OCCURS when 69005 not 69004.

MANUAL FEED is 02686-69005 for 2686A+ & 2686D(senal & Parallel)

SELECTED. 02686-69004 for Std 2686A (serial I/F only)

MANUAL FEED, Two pages Customer notpressing FOWEED a@ermanually

of data printed on same

page.

Feeds one sheet via manual Replace Inte~ace PCA!

IR, gives permanent status

ERROR 11 (paperout) cleared

temponaly by powering down

printer.

Ensure Idler roller on the Manual feed assy are

aligned with the lower Manual feed roller. Bend

OOOC~ to correti

feedingpaper, resultsin 2 pages of data on one page.

2-20

Page 43

Classic Printers

LaserJet II (33440)

LaserJet III (33449)

LaserJet IID (33447)

LaserJet IIID (33459)

Page 44

,., ,,,

33440#33447&33449M33459A,LaserJet Printers:

,,, .

,.

:,

Booklet Organisation -

This

section has been divided into 4 part% which are as follows

1) Faults with Error Numbers [Error 13b@aperJams) in Paper Path section]

Miscellaneous Problems

2j

Print Quality Problems

3)

Paper Path Problems [All Error 13k {Paperjam] in this section]

4)

5)

PostScript Problems

- / ~ Only Faults

6)

Appendiz

T

Service

33440A- 1

33440A-2

33440A-3

33440A-4

33440A-5

33440A-6

33440A-7

33440A-8

33440A-9

33440AB/AU-9

3344OA-10

33440A-1 1

33440A-12

Notes UD to Feb 95

Parallel UO Incompatib@

Shim Under Laser / Scanner Unit

Rubber Foot

RS-422 Operation

Laser Power

White Pages

Replaceable Ozone Filter & Housing

NTF Rate of the L3 Interface PCA

Error 41, 50, 51 or 52 Error’s and cable PiN’s

Error 12& 55 connectd to Vectrs ES, CS, ES/12 or QS using 220/240v

Lubrication of Fuser Assy Oround Contact.

Upper Cooling Fan

Fuser ~ - Potentional Safety Concern

Please Read

33440A-T-1

33447ABIAU-I

33447ABIAU-2

33447ABIAU-3

33447AB/AU-4

33447ABIAU-5

33447ABIAU-6

33447AB/AU-7

33447AB/AU-8

33447AB/AU-9

33447AB/AU- 10 Light Brown “Oil-Like” Stain on the Front Side of a Duplexed Page.

33449A-O 1A

33449A-02

33449A-03 Opening the Top cover when the Release Button is Inoperative.

33449A-04 DC Contro~er PC~ Interchangeability Notice.

Internal Cable replscemmt

AC Power Modtie (Incorrect P/N)

Lubrication of Fuser Assy Oround Conta~.

Replacement of Duplex Drive Roller Clutch

Packaging the LJD for Shipprng

Printrng Labels m Duplex Mode is NOT supported

Upper Cooling Fan

Duplex Paper Jams

HP26013A Status readback I/O

Fuser Assy - Potentional Safety Concern

LaserJet Ill Update for HP 33440 PersonneL

HP26013AStatns Readback I/O (optional I/O PCA)

3-3

Page 45

33449A-05

Fuser Assy - Potentional Safety Concern

33459A-OIA

33459A-02

33459A-03

33459A-04

33443A-1

33444A- I

33445A- 1

26013A- 1

88141A-1

33439P-01

33439Q-01

LaserJet IIII) Update for the HP33447A Stice Personnel

DC Controller PC~ Interchangeability Notice.

Fuser Assy - Potentional Safety Concern

Light Brown “Oil-Like” Stain on the Front Side of a Duplexed Page.

1 Mb Memory Card Accesso~

2 Mb Memory Card Accessow

3 Mb Memory Card Accessov

HP26013A Status readback I/O

JetScript, Warranty Processing& Quality Trackiug

HP 33439P/Q PostScript Camidges

~ 33439P/Q PostScript Cartridges

LJ2/2D/3/3D SX Entine Refurbishment Kit

Both the 240v & the 115v SX engines now have a Stice Msintenence Kt available.

This kit is msde available for long term wear and the priuter still has NO PM Schedtie provision. The Pm for fiese kits are:

This kit includes the fo~owing parts for the LJII and L3LU:

It does not include the Ozone Filter (92295@ which shotid be revlaced at 50K napes.

Printers not equipped with replaceable Ozone Housing Shodd be updated by the CE usrng

P/N RGI-1753-OOOCN

* 33449-69008 240v kit

*33449-69007 I15v kit

- 240v or I15v Rebuilt FuserAsw.

- Paper Pick-up Roller

- Separation Pad

- Transfw Corona ASV

- New ‘Yxiai” exhaustfan.

If the pfiters are LJHD or L~’s the additional parts shotid be ordered

- RG1-2499-OOOCN Upper Feed RollerAs~

- RG1-2500-OOOCN Lower Feed Roller ASW

- RF1-2548-OOOCN Lower Separation Pad

- RGI-1356-OOOCN Duplex Paper Alignment ~ObIique’~ Roller

- RG1-2498-OOOCN tiplex %ide ASW

3-4

Page 46

Service Test Tool Boards

LaserJet IMII

a vmy useti too~ for the mm LaserJets, which is installed rnto the DC

Thisis

Controller PCA at J210. An access plate can be found and this is located on the RHS of the

printer on the bottom cover pan. Its Part Number k

~ test board allows the CE to check the following visually (LED)

* +5Vdc & -5Vdc Power Supply

* +24A VdcPower Supply

*DBAC @resence of the Developer ACBias enable line)

*DBDC @resence of the Developer DC Bias enable line)

*PRLM@Y @resence of the Primary Corona endle line)

* TRANSFER @resence of the Transfm Corona endie line)

33440-67905 Service Test Tool

This tool additionally allows user to print the follotig print samples

It also has a READY INHJBIT switch which allows

AU

* Whife Page This is use~ for detecting ~t leaks, toner spills, defective EP

Drums, primary corona fkilure~ etc

* Veti-cal Lines USM for measming skew, deteeting scanner motor speed

problems (lines will be wavy).

*Horiz Lines Usefol for measuring horizontal skew, detecting paper motion

problems (lines will be wavy).

*Black Pages UseM for detecting white spots, drop outs, drum defects,

transfm system probelms, etc.

* No paper in the paper trays

* Non Paper tray

* No EP Caxt installed

* Beam Deteet igpored

* Paper Jams are ignored.

inall a very good diagnostic Tool

LJIIDAJIIID

Part Number 33447-67906

tool does all the above fimction~ but additionally provides visoal indication

This

the following solenoids enabled and Photo-Sensors operating

*SL301 (Upper Paper Feed Clut&)

*SLI (Lower Paper Feed Clutch)

*SL302 (Registration Ctit&)

*SL 7 (Switchback De@ecto~

*SL5 (Switchback Drive Contro~

*SL6 Switcirbaek Directional

*SL3 (Vert Reg Guide Roller)

*SL2 (Duplex Drive Rolle~

*SL4 (Vert Reg Guide Assy)

*PS2 (Lower Motor Clock)

*PS4 (Switchback Paper sensor-Paper Jarn

*PS5 pert Reg Assy “Home” Posiiion)

*PS301 (Upper Tray-Paper Ou+

*PS302 (Upper Tray- manual Feed)

*PSI (Lower Tray - Paper Ou#

*PS6 (Lower Tray - Manual Feed)

*PS3 (Dup Roller Sensor - Jam Dete&”on)

*PS331 (Em-tSensor- Jam Detection)

3-5

Page 47

LJII/111DC Power SUDDIV/ Error 12

Troubleshooting

With Error 12, No Display, Dead & Power Supply problems on the LJII, ~ ~ &

~ printers use the flow diagram below to help isolate the problem Do NOT jump to

cause, use a Iogicd troubleahootig for the more difEdt types of this problem Error 12

means the Top Lid is open or the +24v is missing. Use this process to ascertain why the

+24v is not present.

Error 12 or

no Disphy

u

Mea~e DC

Voltages

I

Any tig?

I

YEs

I

W PCA (Display *be lost)

Do Missing Vloltages reappear?

Do Missing Voltages reappear?

Disconnect DC Con’t PCA (Grd PIN 7 on

the DC PS/MTR DW Module, this will

Disconnect

I

Jo

DisconnectDC Contt

bring up the DC Voltages)

Do Missing Voltages reappear?

Replace DC PS / Mtr

I

PCA Loads

I

I

I

NO

Driver Amy

NO

Refer to

Troubleshooting

“Error 12Printer

open

YEs

Replace Formatter

PCA

Replace Fa@

Load

YEs

Replace DC

Controller PCA

3-6

Page 48

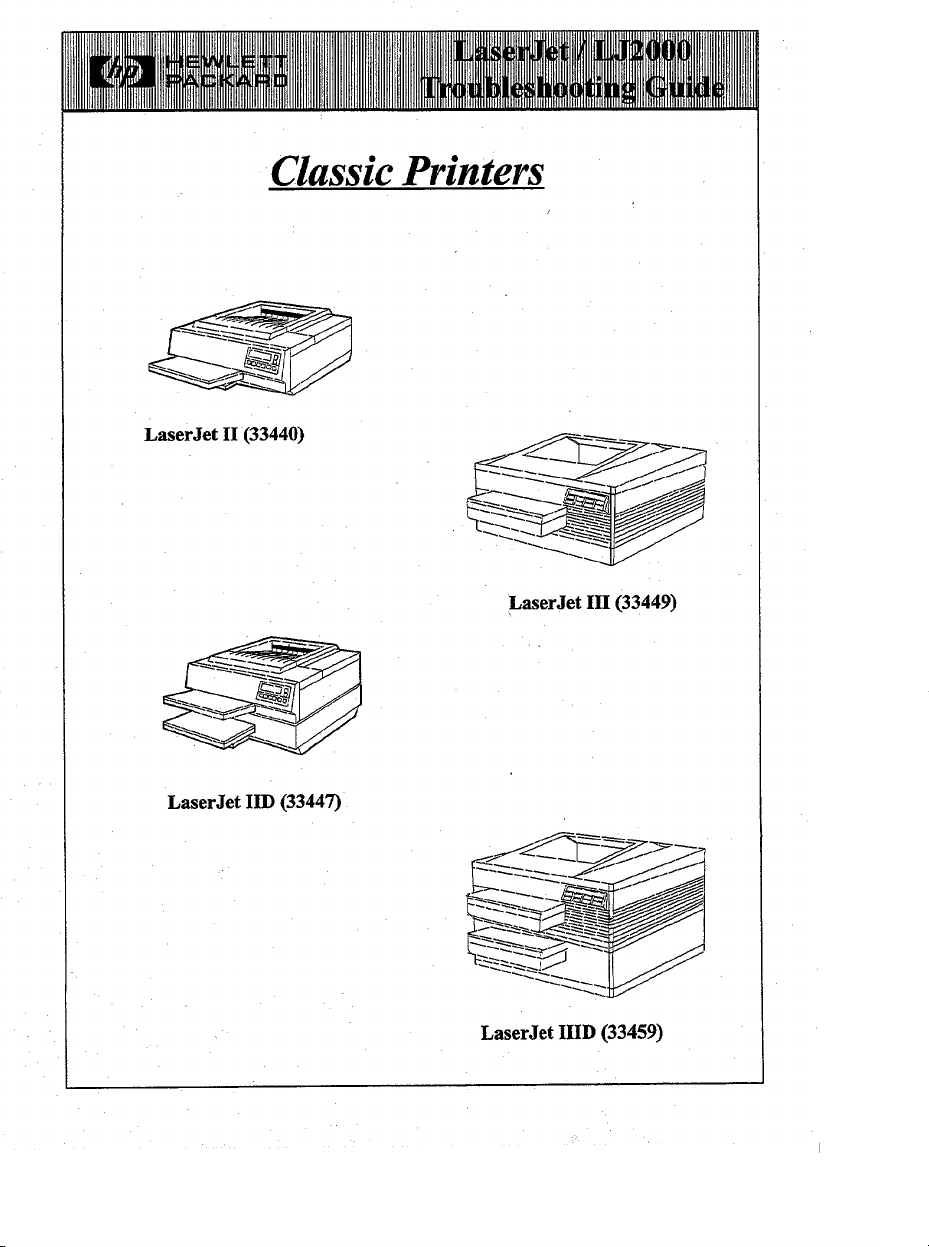

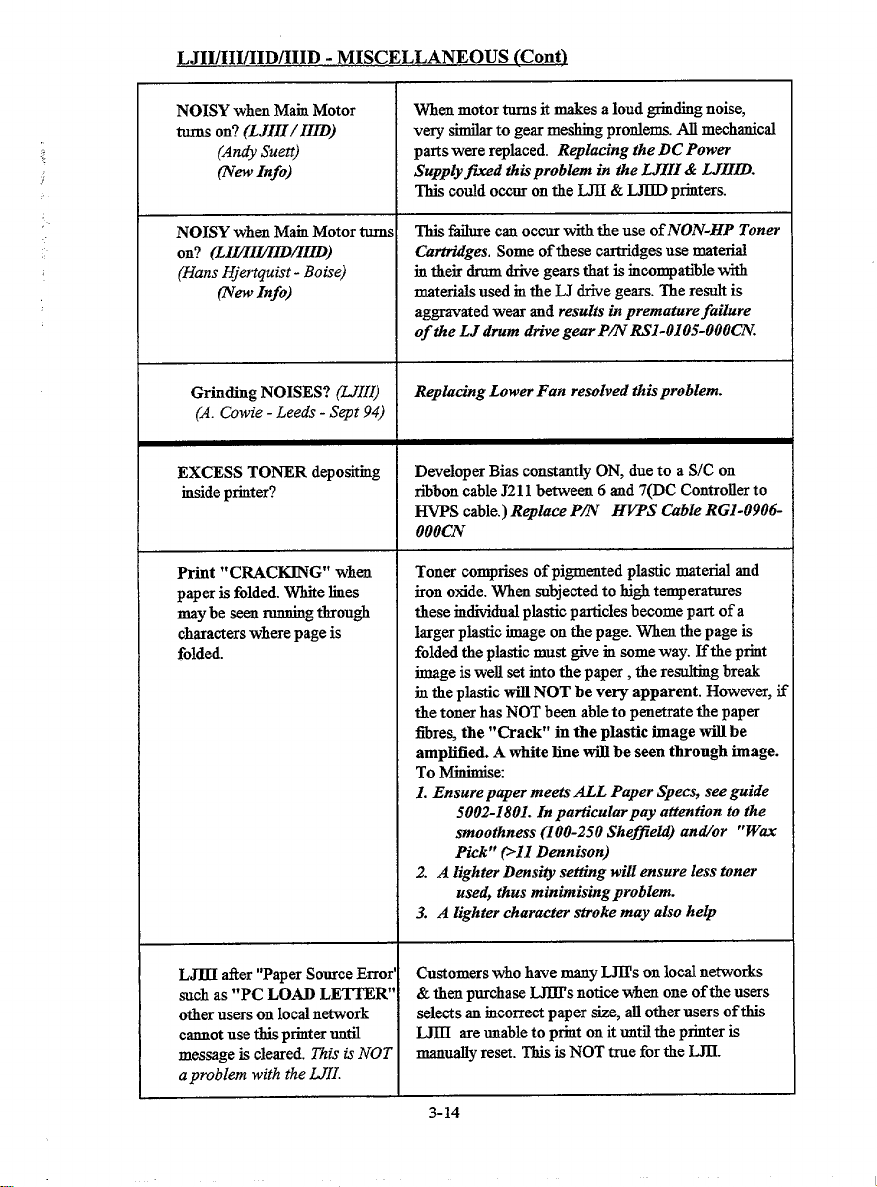

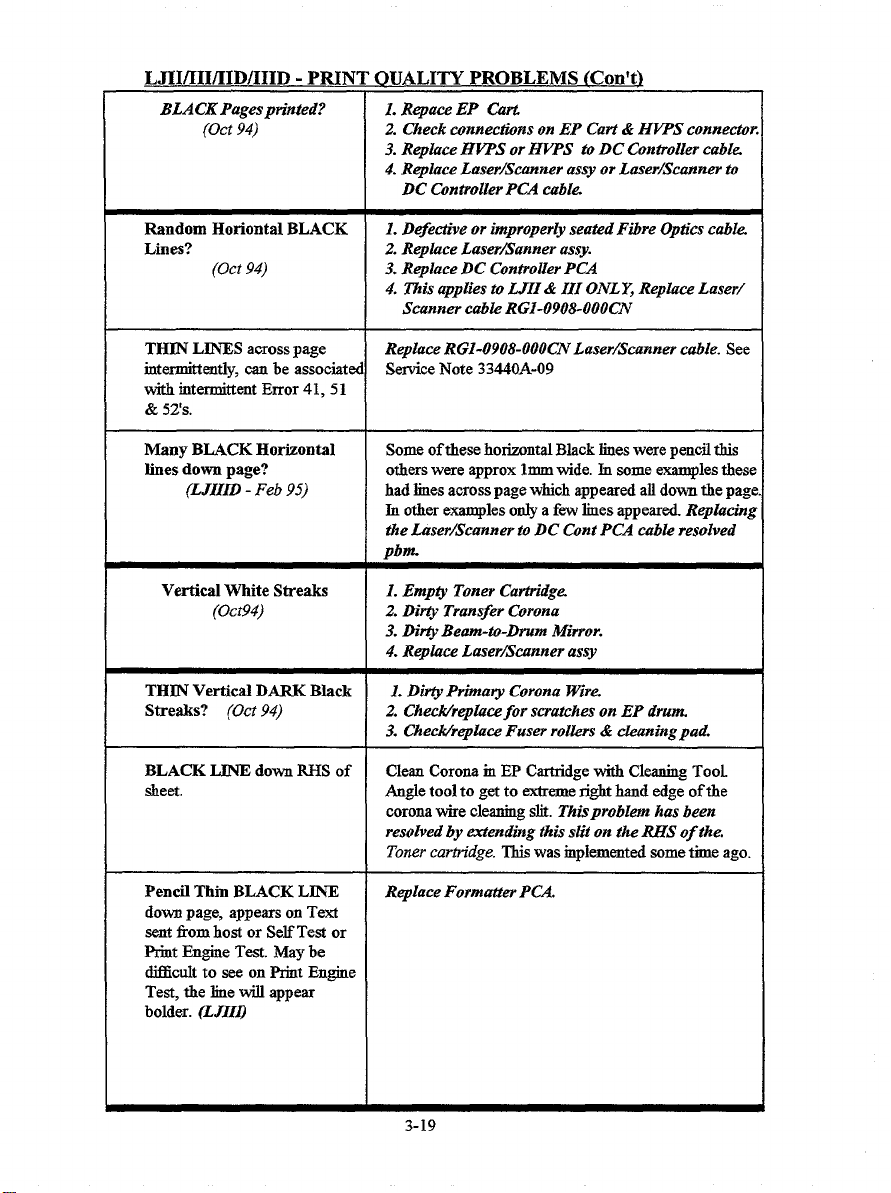

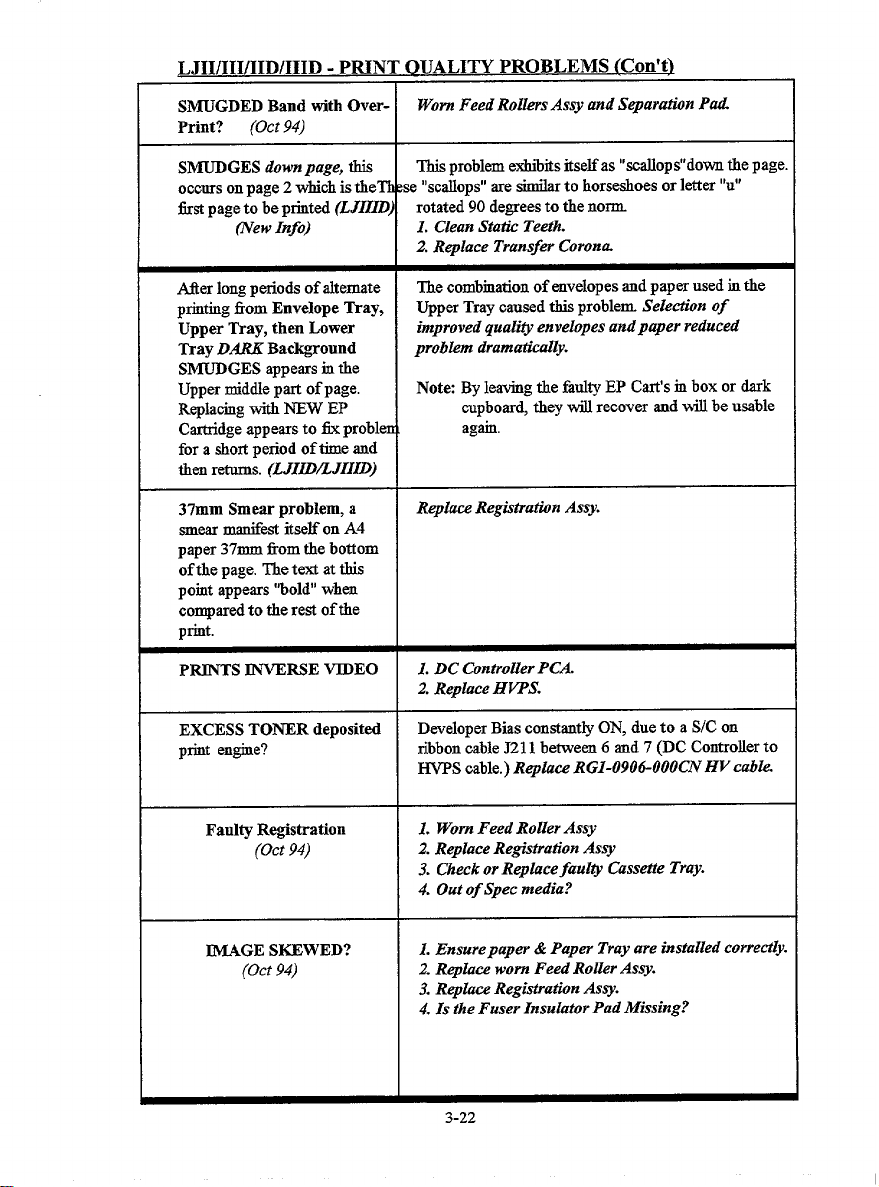

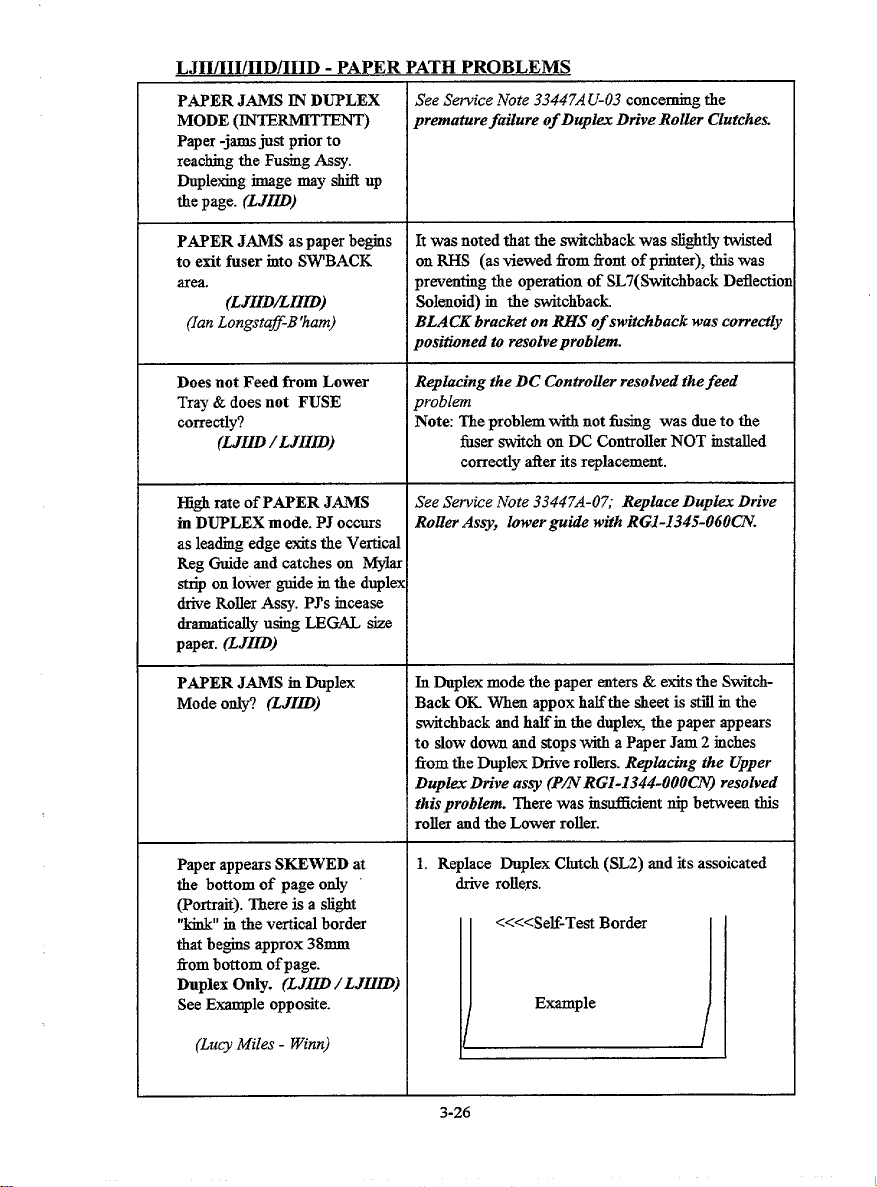

LJImm@mID - FAmTS wI~@ EWOR WMBERS

Please note for all Paper Jams or ERROR 13 problems, refer to Par)erPath part

of this section of this manual.

LJIII ~er “Paper Source Error’ Customers who have many LJI1’son local networks

such as “PC LOAD LETTER” & then purchase ~’s notice when one of the users

otier users on local network selects au incorrect paper size, all otier users of this

cannot use this printer untfl LJIII are unable to print on it until the printer is

message is cleared. This is NOT manually reset. l?zis is NOT truefor the LJII.

aproblem with the LJII.

“PC LOAD A4° , continuous Replace Formatter PCA.

tier power is applied to printer.

(Ger O’Mathony - Dublin)

(New Info) (LJII~

“UC TRAY EMPTY” all the L Replace Paper ControlPCA

LJIID /LJIIID)

tie? (

2. Replaced DC Controller.

3. Replace size sensor PCB (RG9-0605-OOOCN).

“UC LOAD A4° message

continuously? Also, if tie have equally occurred on the ~ or L.JIM).

“CONT~ buttom was Two blocks on the LHS & the RHS had broken OR

pressed the printed image was This allowed the cassette tray to be rnsetied too far,

smaller than it shotid be? causing rncorrect tray@ info to be smt to the DC

(New Info) (MIID) Controller PCA. These Blocks do NOT show up in

WAITING FOR “02” 1. Disconnect f/F cable, is fauk still apparent. Badly

Forever? wired W cables Isave causedproblems and

“05 SELF TEST” message

appears rntermittentiy either

whilst printer is idle or when the DC Power snpplies voltages to gro~d,

printing?

(LJIID - Feb 95) resolved this problem.

Intermittent ERROR 12

ERROR 12,55, 64& 67 L Replace HVPS.

This problem occurred on the Upper tray, but cotid

Sefice Manual on Page 8-45, item 1. It akows main

body assy ordy, not these blocks. These blocks have

the following Pm

1. Replace these blocks.

normally shows up on Centronics cabies. Typically

pm 36 is grounded causing the problem,

2. Replace L2?

This problem was caused by the cable running by

lower h rubbing and wearin~ then shorting one of

Simp~ insulatig the bared cable and re-routing

I. Replace AC Power assy

(RA1-3917-OOOCN) LHS

(R.A1-3913-OOOCN) RHs

3-7

Page 49

LJII/HI/IID/IIID - FAULTS WITH ERROR NUMBERS(Con’t\

ERROR 12 or 55’s

ERROR 12, 11OVprinter

Usedwith step dow

transformer. Printer would

power up, as LJZH began to

take load a “Clickiug” noise

was heard and pxinter exkibite~

Emor 12.

ERROR 12 or no Display

(LJIfl

PERMANENT ERROR

16 “Toner Low”.

1. Check Jumper J209 is wnnected on DC Cent PCA

2. See Service Note 33440AB/A U-09 wken

connected to a Vectra.

Customer was using a - variable transformer that

obviously codd not supply the current the printer

required. Customer to ensure the transformer can

supply the necessary current to the LaserJd

1. Repkce the DC Controller PCA. (See S/N

33440AB/AU-09 if used w“th Vectra)

2. Rephce Formatter PCA.

3. Replace DC Power Supply.

4. Reptice Scanner Motor.

5. AC Power Module.

See Error 12 flow diagram at end of this section

Appendix Al.

L Grey wirefiom ~S sub-block to HVPS was

connected to lowerposition instead of upper

positin.

2. Replace HWS

3. Replace HVPS to DC Con@oUercable @~RGI0906-OOOC~

4. Replace DC Controller PCA.

ERROR 20 Memory

Overflow

When continuous SeE-Test

’04’is used on PLC 5 printers

ERROR 20 my

OCCUI’.

(LJIII/IIID)

ERROR 41 (Intermittent)

(LJIQ

Downloading too many sofi-fonts/graphti Initiate

a ‘fit Font” and work out how much memoxy this

takes mmpared to the memory actmdly available.

Referenw ‘~ogr

armning =ts m Tech Ref Man.

Standard User Memory is 395Kb.(LJII)

This is normal for PCL5pvinter, NOT PCL4. Due to

HPGL2 vwor commands used on SeIt-Teat and the

additional memory it requires. The number of pages

of Self-test which are printed before this error may

occur depends on the av~ble RAM. Ifprinter is

powered bwn more RAM maybe available, tierefore

ERROR 20 may take longer to appear. No remedial

actions is required to correct this problem

Z. See Service Note 33440A-09 concerning

Error’s 41,50,51 & 52. Replace Laser/Scauner

cab~ RG1-0908-OOOW

2. Check grounding bushing on LHS of Reg assy.

Especially when replacrng Reg Asay, ensure

this brass buaking is orientated correctly. This(Con~

3-8

Page 50

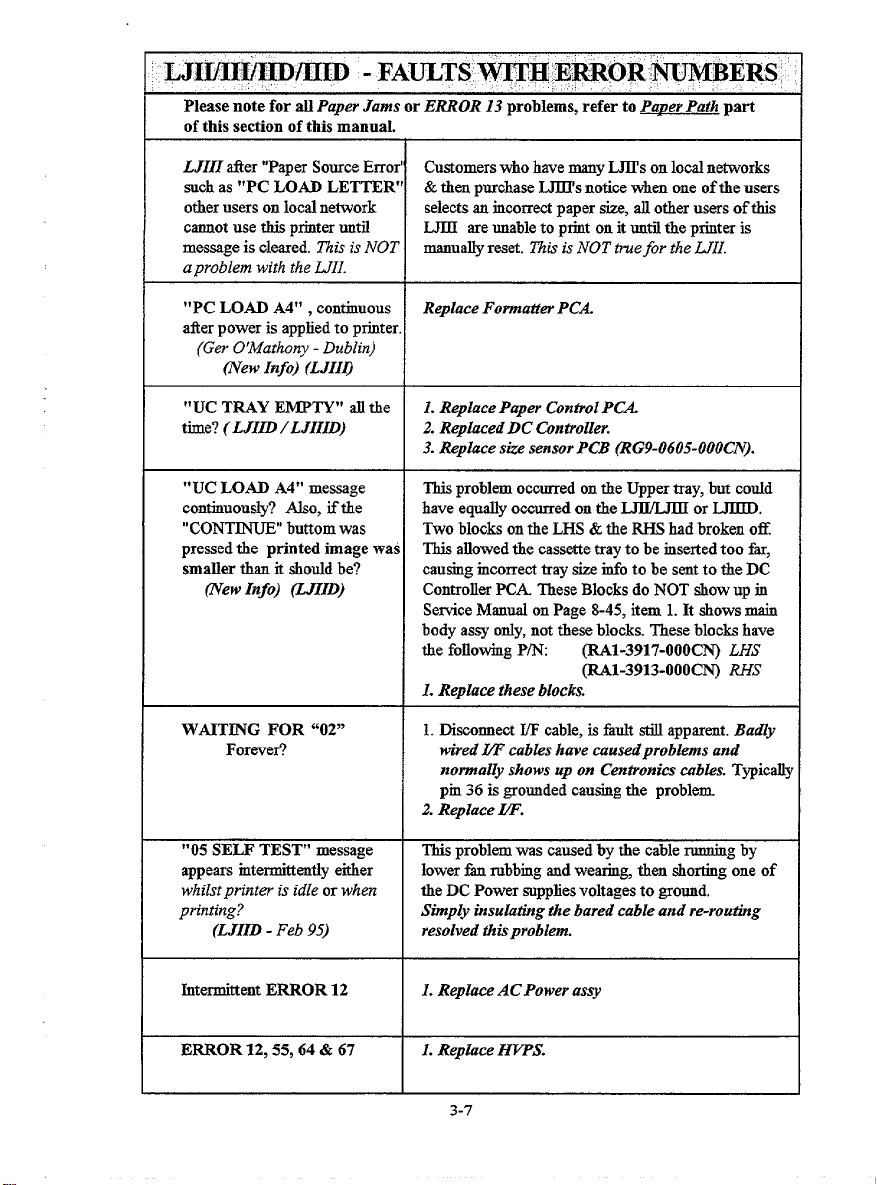

LJII/111/IID/IIID - FAUL

;WITH EKKUK NUMBEKS lCon’tl

3. Replace DC Controller PCA. The printer ordy faile

4. Repkce Optics Assy.

—————

brass part helps eliminate static.

intermittently 1st tking in morning on power on.

----- -———-.- ...

ERROR 41 very Intermittent. OK on long continuous

print runs, fails on 1or 2 page

prints (short print tiles).

(K Batchelor - Hatield)

Very Intermittent ERROR

41. Replaced d normal parts,

CE noted that an Error 12

occurred fist, then Error 41.

THIN LINES across page

rntermittently, can be

associated with intermittent

Error 41,51 & 52’s

ERROR 50? ~

Intermittent ERROR 50, can

be associated with paper jams.

Codd hear Scanner Motor audiily noisy, replaced

Sunner Motor, ho in this case

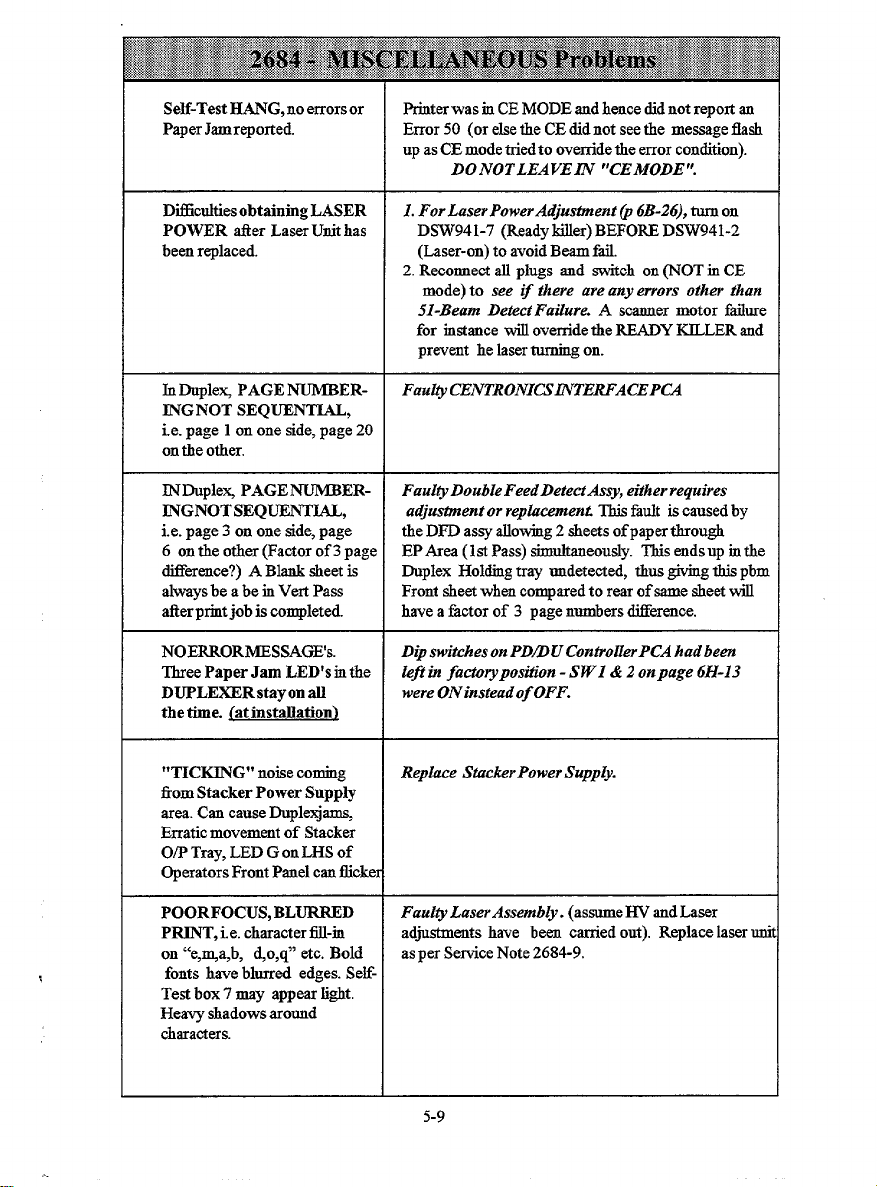

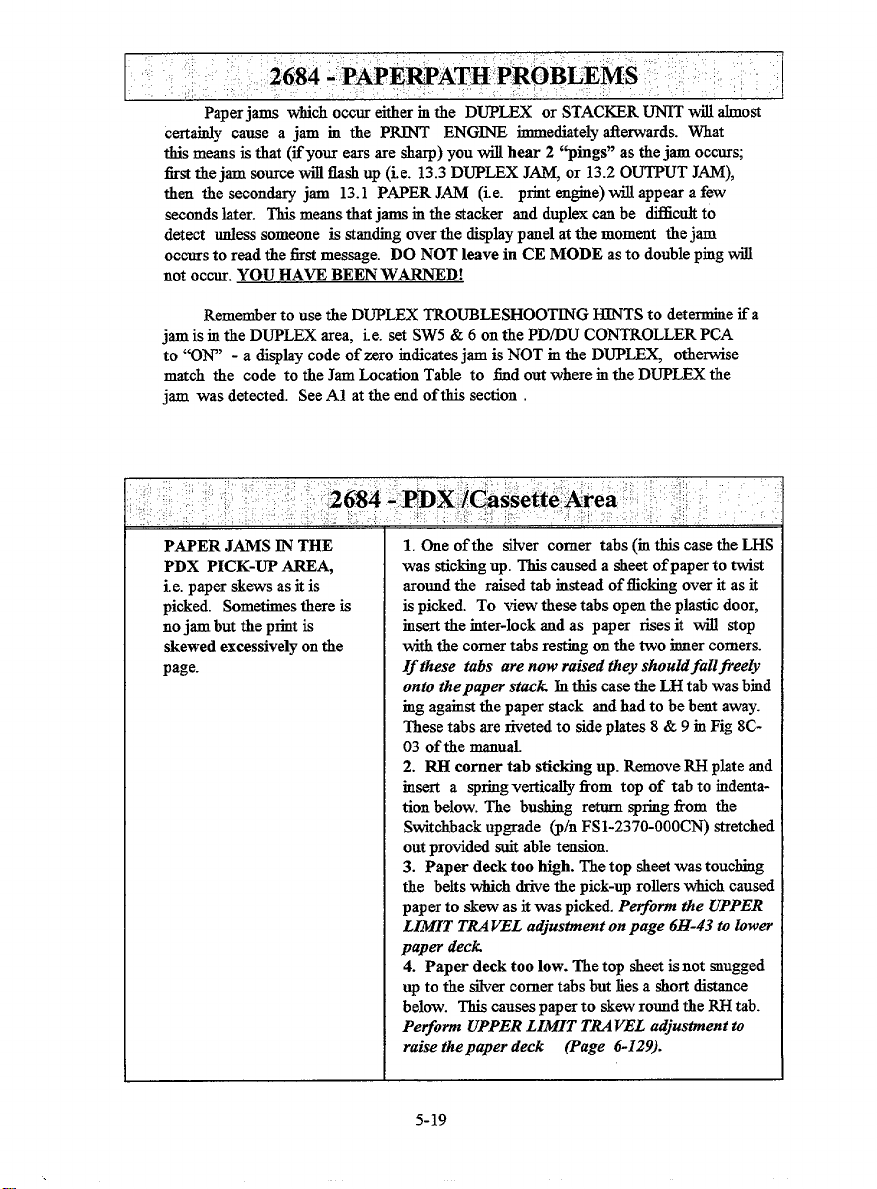

PCA was i-~laced as well.