Page 1

HP Designjet 10000s Printer series

User's Guide

Page 2

Legal notices

The information contained in this document

is subject to change without notice.

Hewlett-Packard makes no warranty of any

kind with regard to this material, including,

but not limited to, the implied warranties of

merchantability and fitness for a particular

purpose.

Hewlett-Packard shall not be liable for errors

contained herein or for incidental or

consequential damages in connection with

the furnishing, performance, or use of this

material.

No part of this document may be photocopied

or translated to another language without the

prior written consent of Hewlett-Packard

Company.

Page 3

Table of contents

1 Introduction

Using this guide .................................................................................................................................. 2

Introduction ................................................................................................................. 2

How do I … ................................................................................................................. 2

The problem is … ....................................................................................................... 2

Tell me about … ......................................................................................................... 2

Index ........................................................................................................................... 2

The printer's main components .......................................................................................................... 2

Front view ................................................................................................................... 3

Rear view .................................................................................................................... 4

The heaters ................................................................................................................ 5

The printer's front panel ..................................................................................................................... 5

Front panel controls and indicators ............................................................................ 6

Using the front panel .................................................................................................. 7

Main scroller controls ......................................................................................................................... 9

Media feed side control panel ..................................................................................... 9

Take-up side control panel ......................................................................................... 9

Foot switches ............................................................................................................ 10

The printer's heaters ........................................................................................................................ 12

The heater's front panel ............................................................................................ 12

Defining heater parameters ...................................................................................... 12

Connect to a computer ..................................................................................................................... 13

Choose the system configuration ............................................................................. 13

Connection procedure .............................................................................................. 13

Turn the power on/off ....................................................................................................................... 14

Turn on the printer .................................................................................................... 15

Turn on the heater .................................................................................................... 16

Turn the power off .................................................................................................... 17

Turn off the printer ............................................................................ 17

Turn off the heaters ........................................................................... 18

Replace an ink cartridge .................................................................................................................. 18

Print Modes ...................................................................................................................................... 21

Safety precautions ........................................................................................................................... 22

General warnings ..................................................................................................... 22

General cautions ...................................................................................................... 23

Handling precautions ....................................................................................................................... 25

Power supply ............................................................................................................ 25

Printer ....................................................................................................................... 25

Regular inspection and maintenance ....................................................................... 25

Consumables ............................................................................................................ 25

ENWW iii

Page 4

2 How do I perform basic media operations?

Install a media roll in the printer using the main scroller .................................................................. 28

Install a media roll in the printer using the sub-scroller .................................................................... 42

Use the take-up reel ......................................................................................................................... 49

Use the media edge guards ............................................................................................................. 57

Tension bars .................................................................................................................................... 58

Feed side tension bar assembly ............................................................................... 59

Take-up side assembly method ................................................................................ 59

Use media tube flanges ................................................................................................................... 60

Install the media tube flanges ................................................................................... 61

Change the printhead height ............................................................................................................ 64

Remove a media roll from the printer ............................................................................................... 66

Load cut sheet .................................................................................................................................. 68

Perform a manual media feed .......................................................................................................... 71

Use manual nesting ......................................................................................................................... 72

Increase/reduce pressure on media ................................................................................................. 76

Pause or cancel print jobs ................................................................................................................ 77

Offset media loading using the main scroller ................................................................................... 78

3 How do I use dual media rolls?

Install dual media rolls on separate scrollers ................................................................................... 95

Install dual media rolls on the main scroller ................................................................................... 108

Use the take-up reel (dual media rolls) .......................................................................................... 116

Dual media rolls take-up method 1 ......................................................................... 116

Dual media rolls take-up method 2 ......................................................................... 119

Dual media rolls take-up method 3 ......................................................................... 122

Dual media rolls take-up method 4 ......................................................................... 125

Adjust the back tension of the sub-scroller .................................................................................... 125

Remove dual rolls media edge guards for full width media printing ............................................... 127

4 How do I perform double-sided printing

Printing on the back of the media after rewinding .......................................................................... 131

Printing on the back of the media from the feed side (after relocating from take-up side) ............. 138

Printing on the back of the media from the take-up reel (without relocating from take-up

side) ............................................................................................................................................... 145

5 How do I print with a liner

Double sided printing with a liner ................................................................................................... 154

Print on mesh tarpaulin (without dedicated liner) ........................................................................... 167

Use the special edge guards for use with a liner ........................................................................... 178

Use the liner separator bar ............................................................................................................. 183

Install the separator bar support assembly ............................................................. 184

Install the separator bar .......................................................................................... 186

6 How do I maintain the printer?

Regular maintenance guide ........................................................................................................... 189

Daily printhead maintenance .......................................................................................................... 190

Wiper blade and sponge cleaning .......................................................................... 191

Capping unit cleaning ............................................................................................. 196

iv ENWW

Page 5

Prepare for extended power down (two to four weeks) .................................................................. 198

Ink system storage ................................................................................................. 199

When returning to the printer after being switched off for an extended period (less than two

weeks) ............................................................................................................................................ 202

Clean ink system .................................................................................................... 202

Charge the ink system ................................................................................................................... 206

Clean the exterior of the printer ...................................................................................................... 206

Clean the rear cover and media feed ............................................................................................. 206

Clean the platen ............................................................................................................................. 207

Carriage cleaning ........................................................................................................................... 209

Replace the waste ink bottle .......................................................................................................... 210

Normal printhead recovery ............................................................................................................. 213

IQ print ........................................................................................................................................... 213

7 How do I get the best image quality?

Print the Image Quality print ........................................................................................................... 216

Interpret the image quality print ...................................................................................................... 218

Manage media types ...................................................................................................................... 219

Copy a media type to create a new one ................................................................. 219

Create a new media type ........................................................................................ 220

Modify media type settings ..................................................................................... 221

Delete a media type ................................................................................................ 222

Calibrate the printer ........................................................................................................................ 223

Calibrate media advance ........................................................................................ 223

Perform printhead position adjustment ................................................................... 225

Back feed adjustment print ..................................................................................... 227

Back feed adjustment while printing ............................................................................................... 228

Adjust heater and print mode settings ............................................................................................ 229

8 The problem is… (troubleshooting topics)

The problem is… (checklist) ........................................................................................................... 234

A printhead crash ........................................................................................................................... 235

Ink cartridge is not installed ............................................................................................................ 238

Ink cartridge is not detected ........................................................................................................... 238

Ink cartridge is near expiry date ..................................................................................................... 238

Ink cartridge has passed its expiry date ......................................................................................... 239

An error message ........................................................................................................................... 239

Service errors ......................................................................................................... 239

POC error messages ...................................................................... 240

Engine error messages ................................................................... 240

System error messages .................................................................. 240

Operator error messages ....................................................................................... 240

Ink cartridge .................................................................................... 240

Waste ink bottle is not installed ....................................................... 242

Waste ink bottle is full ..................................................................... 242

Media crash .................................................................................... 242

Media .............................................................................................. 242

Other messages .............................................................................. 243

The ink LED flashes ................................................ 242

Error LED is flashing ............................................... 243

ENWW v

Page 6

An abnormal sound ........................................................................................................................ 244

9 The problem is print quality

10 Tell me about… (basic knowledge topics)

Operating conditions ...................................................................................................................... 248

Installation space .................................................................................................... 248

Environmental conditions ....................................................................................... 248

Operating temperature and humidity levels .................................... 248

Places where the printer must not be installed ............................... 249

The power supply ........................................................................................................................... 249

Power .................................................................................................................... 249

Dryer ....................................................................................................................... 250

Exhaust attachment ................................................................................................ 250

Front panel messages and printer state ......................................................................................... 250

Messages on the front panel .................................................................................. 250

Initialization display ......................................................................... 250

Online state (idle mode) display ...................................................... 251

Online state (print mode) display .................................................... 251

Online state (print pause mode) display ......................................... 251

Online state (print information mode) display ................................. 252

Offline (menu mode) display ........................................................... 252

Shutdown state display ................................................................... 253

11 Tell me about media

Storing media ................................................................................................................................. 255

Disposing of media ......................................................................................................................... 255

Using media ................................................................................................................................... 256

Handling prints ............................................................................................................................... 256

Other precautions ........................................................................................................................... 256

12 Tell me about the ink system

Ink cartridges .................................................................................................................................. 257

Replacing an ink cartridge .............................................................................................................. 259

Ink cartridge storage and disposal ................................................................................................. 260

HP 790 Waste Ink Bottle ................................................................................................................ 261

Precautions for handling the waste ink bottle ......................................................... 261

HP 790 Cap Cleaning Kit ............................................................................................................... 261

HP 790 Wiper Cleaning Liquid Kit .................................................................................................. 262

HP 790 Ink System Storage Kit ...................................................................................................... 262

HP 790 Ink System Cleaning Kit .................................................................................................... 262

Print stop and resume ............................................. 251

Print cancel (end) .................................................... 251

13 Tell me about waste management

General recommendations ............................................................................................................. 266

14 Tell me about front panel menus

vi ENWW

Page 7

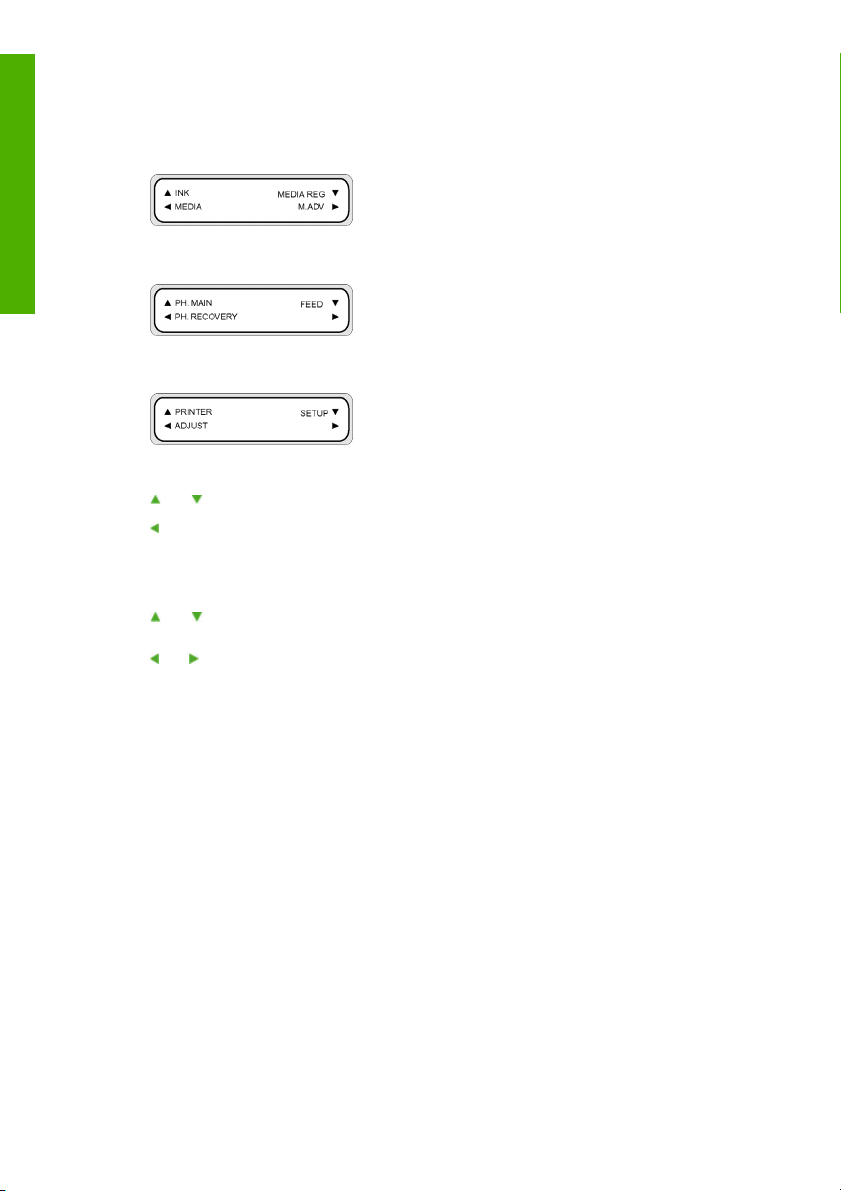

Menu operations ............................................................................................................................ 270

Menu structure ........................................................................................................ 270

Making front panel selections and settings ..................................... 270

To define a setting ................................................... 270

To define a value ..................................................... 271

Character list ........................................................... 272

The INK menu & messages ........................................................................................................... 273

Replacing an empty ink cartridge ........................................................................... 273

Replacing ink cartridges during printing ................................................................. 273

The ink cover is open ...................................................................... 273

The ink cartridge is empty ............................................................... 274

The MEDIA menu ........................................................................................................................... 274

The MEDIA REG menu .................................................................................................................. 275

Selecting a media type number (SELECT MEDIA) ................................................ 276

Setting a media type name (RENAME MEDIA) ...................................................... 276

Media advance value (MEDIA ADV VALUE) .......................................................... 276

Manufacturing default media advance value (MFNG VAL) .................................... 276

Dry time value (DRY TIME VALUE) ....................................................................... 277

Print mode setting (PRINT MODE) ......................................................................... 277

Print direction setting (PRINT DIRECTION) ........................................................... 277

Use media edge guard (USE EDGE GUARD) ....................................................... 278

Media advance mode (MEDIA ADV MODE) .......................................................... 278

Leading edge mode (LEADING EDGE) ................................................................. 278

Vacuum level setting (VACUUM LEVEL) ............................................................... 279

Initial temperature setting for the front heater (FRONT HEATER T) ...................... 279

Initial temperature setting for the print heater (PRINT HEATER T) ........................ 280

Initial temperature setting for the rear heater (REAR HEATER T) ......................... 280

Color stripe setting (COLOR STRIPE) ................................................................... 281

Printhead firing mode setting (IMAGE GRADIENT) ............................................... 281

Printhead height setting (PH HEIGHT VAL) ........................................................... 282

Bidirectional print position (Left) adjustment (YY BIDIR DEF(L)) ........................... 282

Bidirectional print position (Right) adjustment (YY BIDIR DEF(R)) ........................ 282

Bidirectional print position (Left) adjustment (YY BIDIR F.D (L)) ............................ 282

Bidirectional print position (Right) adjustment (YY BIDIR F.D (R)) ......................... 283

Printhead cleaning mode (PH CLEANING) ............................................................ 283

Media back feed adjustment (BACK ADJUST VAL) ............................................... 284

Media advance preference (ADVANCE PREF) ...................................................... 284

Print mode preference (PRINT MODE PREF) ....................................................... 284

Heater preference (HEATER PREF) ...................................................................... 285

Media width detection (WIDTH DETECTION) ........................................................ 285

Media width (MEDIA WIDTH) ................................................................................. 285

Liner width (LINER WIDTH) ................................................................................... 285

Unstick mode (UNSTICK MODE) ........................................................................... 286

Printhead rest period (PH REST PERIOD) ............................................................ 286

Printhead rest time (PH REST TIME) ..................................................................... 286

Printhead temperature rest (PH TEMP REST) ....................................................... 286

Deleting a media type (DELETE MEDIA) ............................................................... 287

Copying a media type (COPY MEDIA) ................................................................... 287

Pasting a media type (PASTE MEDIA) .................................................................. 287

Default values for media types ............................................................................... 288

ENWW vii

Page 8

Media advance calibration ............................................................................................................. 289

Media advance calibration print .............................................................................. 289

Media advance adjustment print ............................................................................. 290

Back feed adjustment print ..................................................................................... 290

Media back feed adjustment value ......................................................................... 290

The PH. MAIN menu ...................................................................................................................... 291

Ink system optimization (INK SYS OPT) ................................................................ 291

Cap cleaning (CAP CLEANING) ............................................................................ 292

Wiper cleaning (WIPER CLEANING) ..................................................................... 292

Washing with printheads (WASH PRINTHEADS) .................................................. 292

Printhead height (PH HEIGHT ADJ) ....................................................................... 292

Ink (INK WASTE) .................................................................................................... 293

The PH RECOVERY menu ............................................................................................................ 293

The FEED menu ............................................................................................................................ 293

The PRINTER menu ...................................................................................................................... 294

Configuration print (CONFIG PRINT) ..................................................................... 294

Error log information print (ERROR LOG PRINT) .................................................. 294

History print (HISTORY PRINT) ............................................................................. 294

The ADJUST menu ........................................................................................................................ 295

Adjustment pattern print (TEST PRINTS) ............................................................... 295

Printhead nozzle position adjustment (#YY PH ROW VAL) ................................... 295

Printhead position adjustment (#YY PH TO PH VAL) ............................................ 295

Bidirectional print position (Left) adjustment (YY BIDIR DEF(L)) ........................... 296

Bidirectional print position (Right) adjustment (YY BIDIR DEF(R)) ........................ 296

Bidirectional print position (Left) adjustment (YY BIDIR F.D (L)) ............................ 296

Bidirectional print position (Right) adjustment (YY BIDIR F.D (R)) ......................... 297

The SETUP menu .......................................................................................................................... 297

Language for front panel (LANGUAGE) ................................................................. 297

Acoustic warning (BEEP) ....................................................................................... 297

End of ink acoustic warning (END OF INK BEEP) ................................................. 297

BOOT version display (BOOT VERSION) .............................................................. 298

F/W version display (F/W VERSION) ..................................................................... 298

Main PCA version display (MAIN PCA VER) ......................................................... 298

ICB board version display (CARRIAGE PCA) ........................................................ 298

ASIC version display (ASIC VER) .......................................................................... 298

Heater H/W version display (HEATER HW VER) ................................................... 299

Heater F/W version display (HEATER FW VER) ................................................... 299

HEB board H/W version (HEB Version) ................................................................. 299

USB address (USB ADDRESS) ............................................................................. 299

USB speed (USB SPEED) ..................................................................................... 299

Factory default setting (FACTORY DEFAULT) ...................................................... 300

15 Tell me about the heaters

The heaters .................................................................................................................................... 301

Heater temperature settings ........................................................................................................... 302

Heater preset temperature by medium ................................................................... 303

Flow of heater temperature setting ......................................................................... 304

Temperature control ............................................................................................... 304

Maintaining the preset temperature ................................................ 304

Maintaining the standby temperature .............................................. 305

viii ENWW

Page 9

The heater front panel ............................................................................................ 305

Turning off the heaters .................................................................... 305

Display in normal mode .................................................................. 305

Display — heater on ....................................................................... 306

Display — heater off ....................................................................... 306

Display — heater AC power is turned off ........................................ 306

Heater parameter setup mode ................................................................................ 306

Setup items and parameters ........................................................... 306

Heater error messages .................................................................................................................. 307

16 Tell me about printer specifications

Specifications ................................................................................................................................. 310

Ecological specifications ................................................................................................................ 311

17 Tell me about ordering supplies and accessories

Ordering supplies ........................................................................................................................... 314

Ordering media .............................................................................................................................. 314

Ordering accessories ..................................................................................................................... 315

18 Tell me about getting help

HP Customer Care ......................................................................................................................... 317

HP Designjet Online ....................................................................................................................... 318

Index ...................................................................................................................................................................... 319

ENWW ix

Page 10

x ENWW

Page 11

1 Introduction

Using this guide

●

The printer's main components

●

The printer's front panel

●

Main scroller controls

●

The printer's heaters

●

Connect to a computer

●

Turn the power on/off

●

Replace an ink cartridge

●

Print Modes

●

Safety precautions

●

Handling precautions

●

Introduction

ENWW 1

Page 12

Using this guide

Introduction

Using your printer is organized into the following chapters.

Introduction

This chapter provides a brief introduction to the printer and its documentation for new users.

How do I …

These chapters help you to carry out various procedures such as loading media or changing an ink

cartridge. Many of these procedures are illustrated with drawings.

The problem is …

These chapters help you to solve problems that may occur while printing.

Tell me about …

These chapters contain reference information, including the specifications of the printer, and the part

numbers of media types, ink supplies, and other accessories.

Index

In addition to the table of contents, there is an alphabetical index to help you to find topics quickly.

The printer's main components

The following front and rear views of the printer show the main components.

2 Chapter 1 Introduction ENWW

Page 13

Front view

1. Media Load Lever

2. Printer front panel

3. Right ink supply station

4. Foot switch connection

5. Media winding direction switch

6. Media rewind switch (white)

7. Media advance switch (black)

8. Main scroller

9. Tension bar

10. Tension bar guide

11. Caster wheel

12. Left ink supply station

13. Heater front panel

14. Media pressure lever

15. Sub-scroller

Introduction

ENWW The printer's main components 3

Page 14

Introduction

Rear view

1. Rear cover

2. Media outlet

3. Wiper cover

4. Printer Online — Cancel keys

5. Heater on/off switch

6. Heater power socket

7. Main scroller (take-up reel)

8. USB port

9. Foot switch connector

10. Media winding direction switch

11. Media rewind switch (white)

12. Media advance switch (black)

13. Waste ink bottle

14. Cap cover

15. Carriage Shield

16. Brush

4 Chapter 1 Introduction ENWW

Page 15

17. Printhead height lever

18. Printer power socket

19. Printer power on/off switch

The heaters

The printer includes three heaters for fixing and stabilizing the printed image on the media. Each heater is

controlled separately.

1. Printhead

2. Rear heater (dries the ink and stabilizes the printed image)

3. Print heater (fixes the ink on to the media)

4. Front heater (preheats the media)

5. Tension bar

6. Main scroller

7. Media

Introduction

WARNING! Do not touch heater surfaces in the paper path. This may cause burns.

The printer's front panel

This section describes the various controls and indicators provided on the printer's front panel and how to

use them to control basic printer functions.

ENWW The printer's front panel 5

Page 16

Introduction

Front panel controls and indicators

Your printer's front panel is located on the front of the printer, on the right-hand side. It has the following

important functions:

It must be used to perform certain operations, such as loading and unloading media.

●

It can display up-to-date information about the status of the printer, the ink cartridges, the media, etc.

●

It can provide guidance when using the printer.

●

It displays warning and error messages when appropriate.

●

It can be used to change the values of printer settings, consequently changing the operation of the

●

printer.

The front panel has the following components:

1. Audio warning beeper.

2. The keys to set printer functions.

The Online key switches the printer online or offline and provides access to the front panel menu

●

groups.

The Shift key is used to switch between the menu groups.

●

The Cancel key cancels an input parameter.

●

The OK key selects a menu or confirms a parameter.

●

The four arrow keys select a menu or select menu options (selection, number up/down).

●

3. The LEDs light, flash, or turn off to indicate the status of the printer.

A. The green Data LED shows the data reception state.

Flashing: print commands are being received from the computer

●

Off: nothing is being received from the computer

●

6 Chapter 1 Introduction ENWW

Page 17

B. The orange Error LED indicates whether an error has occurred.

On: an error has occurred

●

Flashing: warning state (take-up reel time-out error)

●

Off: normal (no error has occurred)

●

C. The green Ink LED shows the status of the ink cartridges.

On: all ink cartridges are present

●

Flashing: ink is running out in at least one cartridge

●

Off: no ink (ink has run out in at least one cartridge)

●

D. The green Media LED shows whether media is loaded.

On: media is loaded (roll or cut sheet)

●

Off: no media is loaded

●

4. The power key turns the printer on and off.

5. The LCD displays information and menus.

6. The green Online LED indicates whether the printer is online.

On: online

●

Flashing: online pause mode

●

Off: offline

●

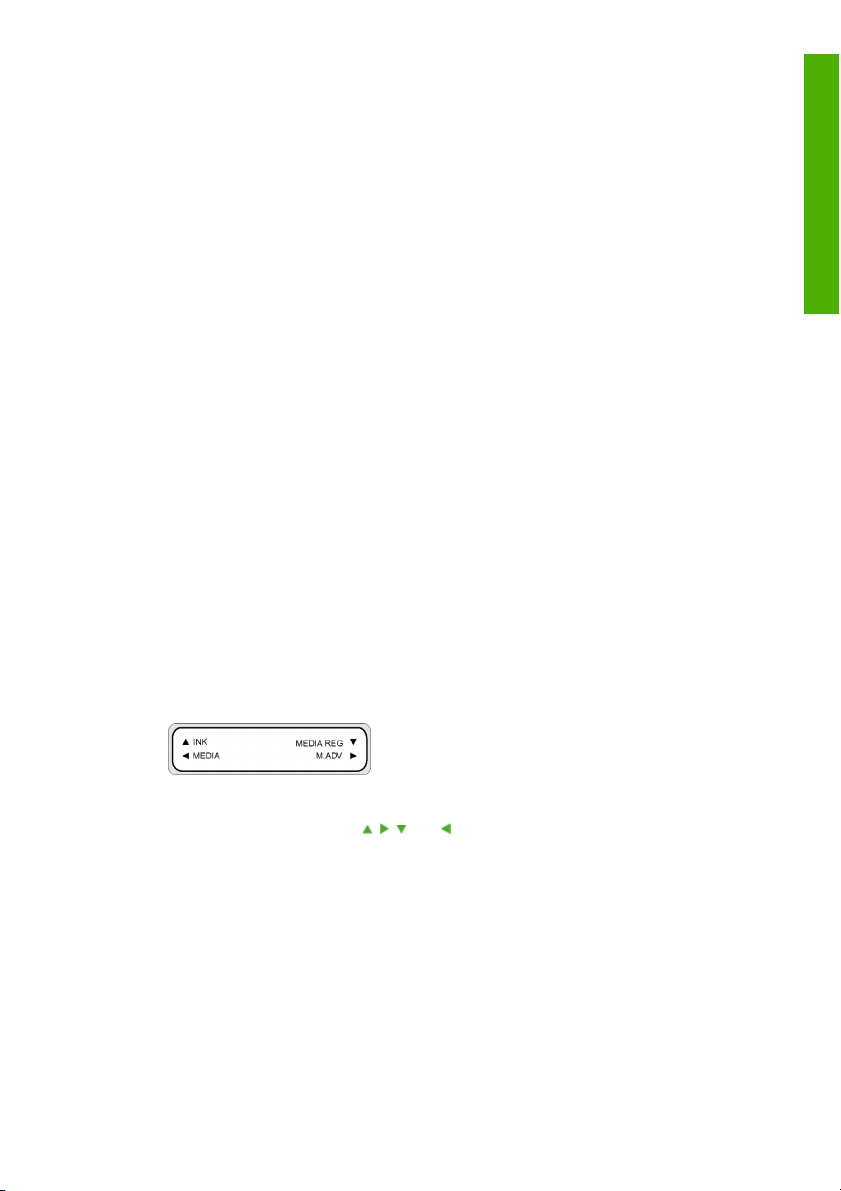

Using the front panel

To enable menu operations:

1. Enter the offline mode by pressing the Online key.

2. When the printer enters the offline mode, a menu group screen is displayed.

Introduction

Menu group selection:

Select a menu group using the

●

ENWW The printer's front panel 7

, , , and keys.

Page 18

Introduction

Switch between menu group screens with the Shift key.

●

To access a menu, use the arrow key that corresponds to the menu group you want to access.

To switch to the next menu group, press Shift.

To switch to the next menu group, press Shift.

If you select a menu in the menu groups, you will then be able to select an option or submenu:

and keys: change between menus at the same level.

●

key: return to menu group selection.

●

OK key: select a submenu or option so that parameters can be changed.

●

Setting or changing parameters:

and keys: switch between parameters, or increase or decrease a selected value.

●

and keys: change the digit you need to modify when entering a value.

●

Setting a parameter or canceling:

OK key: sets a parameter.

●

Cancel key: cancels an input parameter value and returns to the submenu/option selection.

●

8 Chapter 1 Introduction ENWW

Page 19

Main scroller controls

This section describes the controls provided for the feed and take-up side scroller drive units and the

associated remote foot switches.

Media feed side control panel

NOTE Media advance and rewind always refers to the media travel through the media path

from the feed side to the take-up side of the printer and NOT to the media advance or rewind on

the actual main scrollers.

The media feed controls are located on the control panel next to the main scroller drive unit at the feed side

of the printer. This control panel provides the necessary switches to control the manual advance or rewind

of media through the media path (from the feed side to take-up side of the printer). It also provides and

method of selecting which side of the main scroller to wind the media (inside or outside).

Main scroller drive controls:

1. The white two-position media winding direction switch (1) which is used to select which side of the

main scroller to wind the media on (inside or outside).

2. The black media advance push switch (2), which is used to feed media from the main scroller through

the print path (from the feed side to take-up side of the printer) in the direction set with the winding

direction switch (1). The same operation can also be controlled using the black button on the foot

switch connected at the feed side of the printer.

3. The white media rewind push switch (3), which is used to rewind media to the main scroller through

the print path (from the feed side to take-up side of the printer) back onto the main scroller. The same

operation can also be controlled using the black button on the foot switch connected to the feed side

of the printer.

Introduction

Take-up side control panel

NOTE Media advance and rewind always refers to the media travel through the media path

from the feed side to the take-up side of the printer and NOT to the media advance or rewind on

the actual main scrollers.

ENWW Main scroller controls 9

Page 20

Introduction

The media take-up controls are located on the control panel next to the main scroller (take-up reel) drive

unit at the take-up side of the printer. This control panel provides the necessary switches to control the

manual advance or rewind of media through the media path (from the feed side to take-up side of the

printer). It also provides the method of selecting which side of the main scroller (for take-up) to wind the

media (inside or outside).

Scroller drive controls:

1. The white media rewind push switch (1), which is used to rewind media from the main scroller (take-

up reel) through the print path (from the feed side to take-up side of the printer) in the direction set

with the winding direction switch (3). The same operation can also be controlled using the black button

on the foot switch connected to the feed side of the printer

2. The black media advance push switch (2), which is used to feed media to the main scroller (take-up

reel) through the print path (from the feed side to take-up side of the printer). The same operation can

also be controlled using the black button on the foot switch connected at the feed side of the printer.

3. Three position media winding direction switch (3) which is used to disable the drive and to select which

side of the scroller to wind the media on (inside or outside).

Foot switches

The printer is equipped with two remote foot switches, one to control main scroller drive functions on the

feed side and the other to control the main scroller drive functions on the take-up side. Both foot switches

are identical and contain a black push switch (2) and a white push switch (1). These switches each have

exactly the same functions as their equivalent push switches on the control panels for the main feed and

take-up reel units.

10 Chapter 1 Introduction ENWW

Page 21

Introduction

ENWW Main scroller controls 11

Page 22

The printer's heaters

Introduction

This section describes how to control the printer's heaters used for drying the printed media.

The heater's front panel

The heater's front panel is located on the front of the printer, on the left-hand side. The heater front panel

displays the settings for the Front, Print, and Rear heaters. It can also be used to control the temperature

settings.

1. The display screen, at the top of the panel, shows the target temperature and the current temperature

of each heater.

2. The three On/Off switches turn the three heaters on or off. The three pairs of

to raise or lower the target temperatures of the respective heaters.

Defining heater parameters

1. On the heater front panel press the On/Off key, and the and keys at the same time to enter the

parameter setup mode.

or keys can be used

2. Select a setup parameter using the and keys on the heater front panel and press the On/Off key

on the heater front panel to modify the setup item displayed.

3. Use the

12 Chapter 1 Introduction ENWW

and keys to select the value and press the On/Off key to confirm.

NOTE If you have selected an incorrect setup value, you can press the On/Off key again

to cancel the setting and repeat from step 2.

Page 23

4. To exit the parameter setup mode, scroll to the EXIT option and press the On/Off key to select YES.

5. Press the On/Off key on the heater front panel to confirm.

Connect to a computer

This section describes system configuration and cable connection procedures.

NOTE Before connecting or disconnecting the USB cable, turn the printer OFF.

Choose the system configuration

The following connections are possible.

1. Printer

2. USB interface

3. Printer server (RIP)

Connection procedure

CAUTION Make sure the USB cable is correctly routed to avoid contact with the media.

NOTE Before you connect the USB cable, you should ensure that the RIP is installed so that

the printer can be detected by your operating system. Refer to the instructions that came with

your RIP for installation instructions.

Introduction

ENWW Connect to a computer 13

Page 24

Introduction

Connect a USB cable as follows:

1. Disconnect the USB cable (2) from the rear of your printer if it is already connected.

2. Turn the printer off at the front panel.

3. Power off the printer using the power switch at the rear.

4. Connect a USB cable (2) to the USB connector (1) at the rear of the printer.

5. Use the cable clamps (4) provided, to secure the USB cable (2) to either side, according to the location

of the computer relative to the printer.

6. Connect a USB cable to the USB connector on your computer (3).

7. Power on the printer using the power switch at the rear.

8. Turn the printer on at the front panel.

9. On your computer, select the printer.

Turn the power on/off

WARNING! Only use a 200-240 V AC power supply voltage.

Be sure the printer is well-grounded. Failure to ground the printer may result in electrical shock,

fire, and susceptibility to electromagnetic interference.

CAUTION Always hold the power cord by the plug when connecting and disconnecting from

the power outlet. Never pull on the cord because this may damage it and create risk of fire and

electric shock.

14 Chapter 1 Introduction ENWW

Page 25

Turn on the printer

1. Turn off (position 0) the printer switch (1) on the rear of the printer, and plug one end of the supplied

power cable into the power socket (2) of the printer. Insert the other power plug of the cable into a

suitable electrical outlet.

WARNING! Avoid overloading the printer’s electrical outlet with multiple devices. Use only

the electrical cord supplied by HP with the printer. Do not damage, cut, or repair the power

cord. A damaged power cord causes a risk of fire and electric shock. Replace a damaged

power cord with an HP-approved power cord.

2. Turn on (position 1) the printer switch (1) on the rear of the printer (left hand side viewed from the rear

of the printer).

3. Press the POWER ON/OFF key (1) on the front panel.

Introduction

ENWW Turn the power on/off 15

Page 26

Introduction

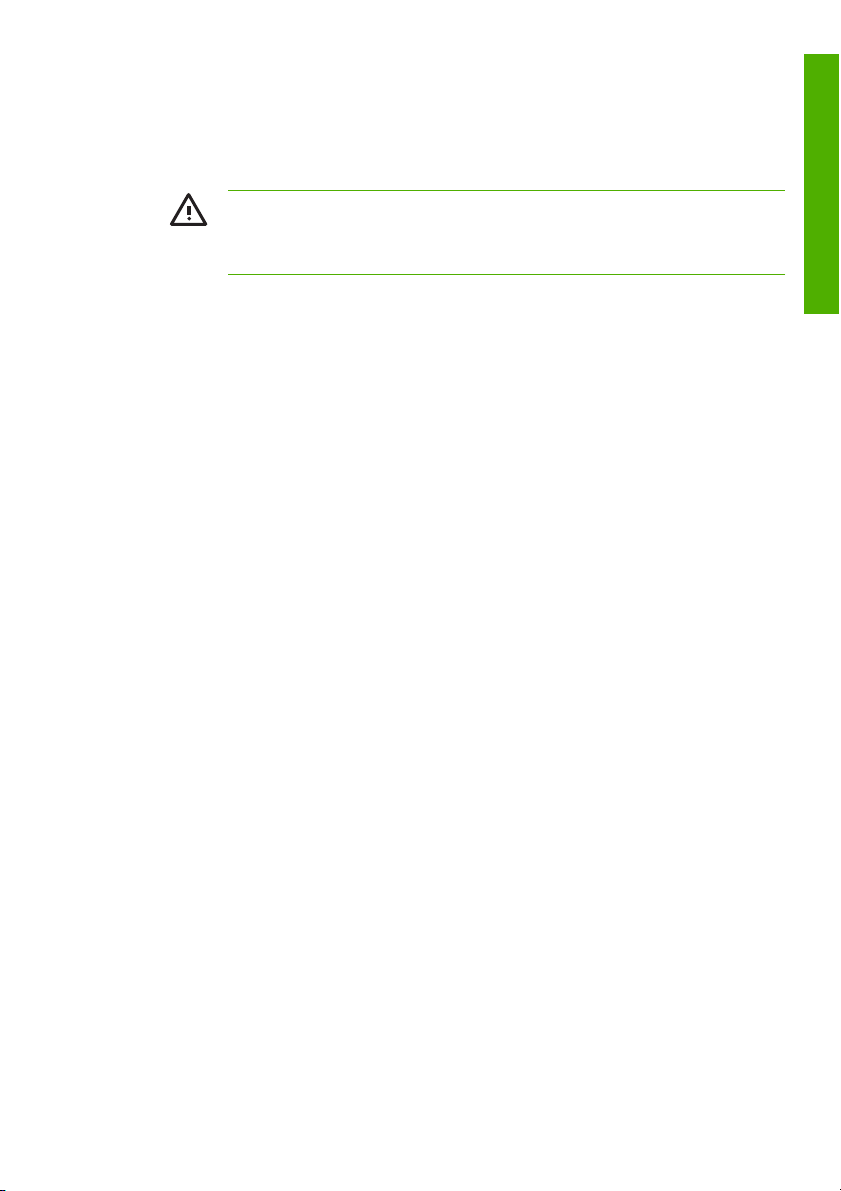

4. When you press power on, the printer performs a power-on self-diagnostic test and the following

messages are displayed on the front panel.

(If a 64" paper roll is loaded).

NOTE Unless there is an emergency, only turn off the printer while PRINTER READY is

displayed on the front panel. Do not turn off the printer while INITIALIZING or PH

RECOVERY is displayed on the front panel to avoid ink drops and damage to the printhead.

5. When you turn the printer power on, the heater front panel display turns on. Turn on the heater power

on/off switch at the rear of the printer to use the heater.

When the heater power is off, the following message is displayed on the front panel.

Turn on the heater

Press the power switch (1) at the rear of the printer (right hand side viewed from the rear of the printer).

NOTE Use the heater switch at the rear of the printer only when turning the printer off completely

for removal, installation, or servicing.

16 Chapter 1 Introduction ENWW

Page 27

Turn the power off

Turn off the printer

WARNING! The printer has an internal clock which allows it to wash the printheads

automatically, flushing some ink through the printhead, which keeps the printheads in good

condition. This is done after the first 20 hours without printing and every 3 days. If the printer is

switched off for a long period, this process does not happen. If the ink does not flow through the

printheads from time to time, the ink will dry inside the nozzles, reaching a point where it is

impossible to recover them and the printhead will fail. This will mean an expensive printhead

replacement.

The printer power switch on the rear of the printer should be used only when the printer is turned

off to move it, to connect it to a computer, or to install or maintain printer parts.

CAUTION If you need to leave the printer unattended for any reason, ensure that the printer

is on, the ink cartridges are full, and the waste ink bottle is empty, so that automatic

maintenance (performed after the first 20 hours without printing and every 3 days) can be

completed successfully for the time you are not present. If needed, install new ink cartridges. The

ink cartridges that you replace can be reused when you return them to your printer, if they still

contain ink.

WARNING! Turn the printer off and unplug the power cable from the power outlet in any of the

following cases; when placing your hands inside the printer, if there is smoke or an unusual smell

coming from the printer, if the printer is making an unusual noise not heard during normal

operation, a piece of metal or a liquid (not part of cleaning and maintenance routines) touches

internal parts of the printer, during an electrical (thunder/lightning) storm, during a power failure.

CAUTION Always hold the power cord by the plug when connecting and disconnecting it from

the power outlet. Never pull on the cord because this may damage it and create risk of fire and

electric shock.

Introduction

Turn off the power by pressing the power on/off key on the front panel for a couple of seconds.

The front panel displays the message above to indicate that a shutdown process is in progress. After the

process ends, the power is turned off.

If you intend to turn the printer off for a short time, you can avoid the printhead wash operation by pressing

the power on/off key while pressing the Cancel key.

The printhead wash operation is always recommended.

ENWW Turn the power on/off 17

Page 28

Introduction

CAUTION The printer power switch at the rear of the printer should only be used when the

printer is turned off to move it, connect it to a computer, or to install or maintain printer parts.

Turn off the power on/off switch, wait for at least ten seconds, then turn it on again.

The printer washes the printheads 20 hours after the last printing process and every 3 days. We

recommend that the printer power is always left on.

Turn off the heaters

Turn off the heaters by pressing the On/Off keys on the heater front panel.

Under normal conditions of use, you do not need to turn off the heaters using the heater power switch

(1) on the rear of the printer.

NOTE Use the heater switch at the rear of the printer only when turning the printer off completely

for removal, installation, or servicing.

Replace an ink cartridge

CAUTION Always use genuine HP ink cartridges. These have been designed for high-quality

imaging performance and reliable printer operation. Using non-HP inks may cause poor print

quality, printer malfunction, or printer failure. The hazard characteristics of different solvent inks

can vary widely. HP has not conducted product safety testing for non-HP inks with this printer

and is not responsible for any loss or damage that may result if non-HP inks are used.

HP ink cartridges must be installed before the “Install By” date printed on the cartridge. Use of

the ink cartridge 3 months beyond the “Install By” date may cause deterioration in print quality or

a printer malfunction.

NOTE

If an ink cartridge cannot be inserted, check that the color matches the slot. A mechanical key

prevents an ink cartridge from being inserted into the wrong slot.

Do not shake ink cartridges before inserting into the printer.

18 Chapter 1 Introduction ENWW

Page 29

The front panel will advise you when you need to change an ink cartridge.

XX: Ink name (K: Black, Lm: Light magenta, Lc: Light cyan)

XX: Ink name (C: Cyan M: Magenta Y: Yellow)

NOTE The printer will continue to print while you are replacing an ink cartridge.

To replace an empty ink cartridge:

1. Press the clip (1) to open the ink cover (2).

Introduction

ENWW Replace an ink cartridge 19

Page 30

Introduction

2. Remove an ink cartridge (1) from the printer.

3. Insert a new ink cartridge (1) into the printer.

4. Close the ink cover (1).

20 Chapter 1 Introduction ENWW

Page 31

Print Modes

This printer provides 14 different print modes. Choose the print mode to use based on the type of media,

the productivity , and the image quality.

NOTE The recommended print mode for this printer is the “NORMAL” mode. Use the other

modes if productivity and image quality are important.

The FAST print modes should be used when the PC processing the print job has a slow CPU or

has low memory or a small capacity HDD. With these modes the emphasis is on the PC

processing speed and therefor the RIP time is decreased, but the input resolution is 360 x 360

dpi. Consequently, the printed image quality could be degraded compared to the normal modes.

The media width and nest origin settings cannot be saved.

1. “NORMAL” (Productivity + Image quality oriented — 4–pass) This is the standard print mode for this

printer and is the mode you should normally use. It provides a print resolution of 720 x 720 dpi at a

print speed of 16 m2/h. The image quality is processed at high resolution.

2. “H-QUALITY” (Image quality oriented — 8–pass) This mode is used for media that has poor drying

performance or shows noticeable uneven printing in NORMAL mode. The print resolution is the same

as NORMAL mode, 720 x 720 dpi, and the print speed is half the speed of the NORMAL mode.

3. “H-DENSITY” (High density printing — 8–pass) This mode is designed for printing on transparent

media such as FF, transparent vinyl chloride, and other such media, where high density is required.

If media that has poor drying performance is used, unidirectional printing is effective. A solid image

of 100% density is printed at 200% density. The print speed is the same as H-QUALITY.

4. “3 TIMES” (High density printing — 12–pass) This mode is designed for printing on transparent media

such as FF, transparent vinyl chloride, and other such media, where high density is required. A solid

image of 100% density is printed at 300% density. The print speed is three times slower than NORMAL

mode.

5. “H-QUALITY2” (Image quality oriented — 16–pass) This mode is used for media that has poor drying

performance or shows noticeable uneven printing in H-QUALITY mode. The print resolution is the

same as NORMAL mode, 720 x 720 dpi, and the print speed is half the speed of the H-QUALITY

mode.

6. “H-DENSITY2” (High density printing — 16–pass) This mode is designed for printing on transparent

media such as FF, transparent vinyl chloride, and other such media, where high density is required.

Use this mode for media that has poor drying performance or shows noticeable uneven printing in HDENSITY mode. A solid image of 100% density is printed at 200% density. The print speed is half the

speed of the H-DENSITY mode.

7. “DRAFT” (Productivity oriented — 2–pass) This mode provides a print resolution of 360 x 720 dpi at

a print speed of 30 m2/h but with a much lower density than the NORMAL mode. Consequently,

depending on the type of media used, uneven printing may be noticeable. A solid image of 100%

density is printed at 50% density of the NORMAL mode. This mode is very useful for checking layout.

8. “FAST” (Reduced PC processing time— 4–pass) This mode has an equivalent density and the same

print speed as the NORMAL mode.

9. “F-H-QUALITY” (Reduced PC processing time — 8–pass) This mode is used for media that has poor

drying performance or shows noticeable uneven printing in FAST mode but at half the speed of the

FAST mode.

Introduction

ENWW Print Modes 21

Page 32

10. “F-H-DENSITY” (Reduced PC processing time + High density printing — 8–pass) This mode provides

Introduction

equivalent density and print speed to the H-DENSITY mode.

11. “F-3 TIMES” (Reduced PC processing time + High density printing — 12–pass) This mode provides

equivalent density and print speed to the 3–TIMES mode.

12. “F-H-QUAL2” (Reduced PC processing time — 16–pass) This mode is used for media that has poor

drying performance or shows noticeable uneven printing in F-H-QUALITY mode. The print speed is

half the speed of the F-H-QUALITY mode.

13. “F-H-DENS2” (Reduced PC processing time + High density printing — 16–pass) This mode provides

equivalent density to the H-DENSITY mode but at half the speed.

14. “FINE DRAFT” (Productivity + Image quality oriented — 4–pass) This mode provides a print resolution

of 540 x 720 dpi at a print speed of 20 m2/h which is 20% faster than the NORMAL mode. The image

quality for photographs is almost equivalent to that of the NORMAL mode, but a solid image of 100%

density is printed at 75% density of the NORMAL mode. Consequently, if the darkness of the colors

is important, you should use the NORMAL mode.

Safety precautions

The following symbols are used in this manual to ensure the proper use of the printer and to prevent the

printer from being damaged. Follow the instructions marked with these symbols.

WARNING! Failure to follow the guidelines marked with this symbol could result in serious

personal injury or death.

CAUTION Failure to follow the guidelines marked with this symbol could result in minor personal

injury or damage to the product.

General warnings

Only use a 200-240 V AC power supply voltage. Avoid overloading the printer’s electrical outlet with

●

multiple devices.

Be sure the printer is well-grounded. Failure to ground the printer may result in electrical shock, fire,

●

and susceptibility to electromagnetic interference.

Do not disassemble or repair the printer yourself. Do not reinstall the printer in a new location. Call

●

your local HP Service Representative for service.

Use only the electrical cord supplied by HP with the printer. Do not damage, cut, or repair the power

●

cord. A damaged power cord has risk of fire and electric shock. Replace a damaged power cord with

an HP-approved power cord.

Do not allow metal or liquids (except those used in HP Cleaning Kits) to touch the internal parts of the

●

printer. Doing so may cause fire, electric shock, or other serious hazards.

Power OFF the printer and unplug the power cable from the power outlet in any of the following cases:

●

●

●

When placing your hands inside the printer.

If there is smoke or an unusual smell coming from the printer.

22 Chapter 1 Introduction ENWW

Page 33

If the printer is making an unusual noise not heard during normal operation.

●

A piece of metal or a liquid (not part of cleaning and maintenance routines) touches internal parts

●

of the printer.

During an electrical (thunder/lightning) storm.

●

During a power failure.

●

Inks used in the printer and liquids in the HP Cleaning kits contain an organic solvent (ethylene glycol

●

monobutyl ether acetate, CAS No. 112-07-2). Observe all local, state, and federal regulations related

to the handling, use, storage, and disposal of organic solvents.

Ink and fluids used in the Cleaning Kits are combustible. Do not use or store within 8 meters (25 feet)

●

of open flames, sparks, or other sources of ignition.

Do not operate printer within 8 meters (25 feet) of open flames, sparks, or other sources of ignition.

●

Do not smoke within 8 meters (25 feet) of the printer.

Install and operate the printer in a well-ventilated area.

●

The printer installation must meet local, state, and federal regulations on the emissions of volatile

●

organic compounds in the workplace. It is the responsibility of the user to comply with these

regulations. HP recommends that installations use an ink vapor extraction and exhaust system or an

HP Air Purification System. Before installing a system exhausting ink vapors to the outside

atmosphere, consult with your local air quality control authorities. It is your responsibility to comply

with all local, state, and federal air pollution control regulations and building codes.

Avoid contact between ink and skin, eyes, and clothing.

●

Immediately wash skin with soapy water.

●

Remove clothing soaked with ink from contact with skin.

●

Use an approved eye wash station if ink is splashed into eyes and consult a doctor if necessary.

●

If an approved eye wash station is unavailable, flush eyes with cold water and consult a doctor

if necessary.

Do not swallow ink. If swallowed, do not induce vomiting, but seek immediate medical attention.

●

Keep ink cartridges, cleaning kits, and waste ink bottles out of the reach of children.

●

Be sure all operators are trained in the use of emergency equipment such as eye wash stations and

●

fire extinguishers and know where they are located.

Introduction

General cautions

Handle media rolls with care. They can be heavy and difficult to move in confined spaces. In some

●

cases, two people should move and install media rolls. Dropping a media roll could cause personal

injury or damage to the printer.

Allow and maintain adequate space around printer for immediate access to safety equipment such

●

as eye wash stations, fire extinguishers, glove and safety glass dispensers, and fireproof waste

storage containers.

Treat any media, used cleaning and maintenance supplies, and wipes soaked with ink as combustible

●

materials. Handle and dispose of properly.

ENWW Safety precautions 23

Page 34

Introduction

If an Air Purification System is installed, allow adequate space for exhaust hoses from the printer.

●

Locate these hoses and the Air Purification System so that they do not pose a trip hazard or interfere

with the operation of the printer such as loading and unloading media, replacing ink cartridges,

inspecting and replacing the waste ink bottle.

Always hold the power cord by the plug when connecting and disconnecting from the power outlet.

●

Never pull on the cord because this may damage it and create risk of fire and electric shock.

Do not touch heater surfaces in the paper path. This may cause burns.

●

In order to ensure the safe operation of the printer, heed all of the cautions and warnings contained

throughout this manual.

24 Chapter 1 Introduction ENWW

Page 35

Handling precautions

These precautions are recommended to avoid damage to your printer and its components.

Power supply

Only use a 200-240 V AC power supply voltage.

●

Check the printer electrical outlet for proper polarity and grounding before connecting printer. Failure

●

to do so may result in fire and electric shock hazards.

Be sure the printer is well-grounded. Failure to ground the printer may result in electrical shock, fire,

●

and susceptibility to electromagnetic interference.

Avoid overloading the printer’s electrical outlet with multiple devices.

●

Use only the electrical cord supplied by HP with the printer.

●

Printer

Wipe the printer clean with a soft cloth. A cloth moistened with a neutral detergent may be used. Do

●

not allow liquid to enter the printer. This may create risk of fire and electrical shock and cause a

malfunction. Do not clean the printer with benzene or paint thinner. This may damage the paint.

Never touch the printhead nozzles. They can be easily damaged or clogged.

●

Regular inspection and maintenance

Clean the capping unit and wiper blade every day.

●

Check the moisture of the wiper sponge every day.

●

Store the ink system when leaving the printer for a long time (two weeks or more with the power off).

●

Clean and charge the ink system before printing when leaving the printer for a long time.

●

Consumables

Ink inside the ink cartridge is combustible. Do not expose or store near open flames, sparks, or other

●

sources of ignition.

HP ink cartridges must be installed before the “Install By” date printed on the cartridge. Use of the ink

●

cartridge 3 months beyond the “Install By” date may cause deterioration in print quality or a printer

malfunction.

Do not disassemble the ink cartridges. Ink cartridges are intended for single use only.

●

Avoid contact between ink and skin, eyes, and clothing.

●

Immediately wash skin with soapy water.

●

Remove clothing soaked with ink from contact with skin.

●

Use an approved eye wash station if ink is splashed into eyes and consult a doctor if necessary.

●

If an approved eye wash station is unavailable, flush eyes with cold water and consult a doctor

if necessary.

Introduction

ENWW Handling precautions 25

Page 36

Introduction

Use only an HP waste ink bottle. The bottle must be installed according to instructions or waste ink

●

may overflow. An HP waste ink bottle must always be installed before turning the printer ON. Automatic

and manual service cycles produce waste ink that must be contained in an HP waste ink bottle. Do

not remove the cap from its tether to the HP waste ink bottle. The cap is needed to properly seal the

HP waste ink bottle for disposal. Keep the HP waste ink bottle upright. Do not place on tables or

shelves where it could fall. Waste ink is combustible. Keep an HP waste ink bottle containing waste

ink away from open flames, sparks, or other sources of ignition. The level in the HP waste ink bottle

must be checked by visual inspection to prevent overflow. If the waste ink level is above the indication

line, the bottle must be replaced with an empty HP waste ink bottle.

Place a sheet of paper under the HP waste ink bottle on the floor when removing a bottle containing

●

waste ink. This will help clean up any ink spills. If soaked with ink, treat the paper as a combustible

material and dispose of properly.

Do not store HP ink cartridges in direct sunlight. Store HP ink cartridges in a cool, dry place. This

●

prevents deterioration of the ink during storage.

26 Chapter 1 Introduction ENWW

Page 37

2 How do I perform basic media

p

operations?

This chapter explains how to perform basic media operations and guides you through the normal sequence

of tasks required to load roll or sheet media in the printer. It also provides details of any other tasks

associated with manipulation of the media.

The following different tasks are described:

Install a media roll in the printer using the main scroller

●

Install a media roll in the printer using the sub-scroller

●

Use the take-up reel

●

Use the media edge guards

●

Tension bars

●

Use media tube flanges

●

Change the printhead height

●

Remove a media roll from the printer

●

Load cut sheet

●

Perform a manual media feed

●

Use manual nesting

●

Increase/reduce pressure on media

●

Pause or cancel print jobs

●

Offset media loading using the main scroller

●

erations?

o

How do I perform basic media

ENWW 27

Page 38

Install a media roll in the printer using the main scroller

p

CAUTION Do not touch heater surfaces in the paper path. This may cause burns.

Handle media rolls with care. They can be heavy and difficult to move in confined spaces. In some

cases, two people should move and install media rolls. Dropping a media roll could cause

personal injury or damage to the printer.

The printer's front panel messages will guide you through the process of loading media. To install a media

roll:

How do I perform basic media

o

erations?

1. Place the media roll (1) on a suitable table or handling cart (2).

2. Adjust the media roll spacer on the main scroller to a position equivalent to the middle (half the width)

of the media roll you are going to load.

NOTE The media roll spacer stops the weight of the media from causing the roll to sag at

the center.

a. Remove the two locking screws (1) of the media roll spacer.

b. Slide the spacer (3) to the required position on the main scroller (2). There are three positions

available, each of which corresponds to the middle position of different width media rolls.

c. Replace and tighten the two locking screws (1).

28 Chapter 2 How do I perform basic media operations? ENWW

Page 39

3. Install the media roll on the main scroller.

p

a. Verify the media winding direction for the side of the media you are going to print onto, either the

inside of the media (1) or the outside of the media (2).

b. Carefully slide the media tube (2) onto the main scroller (1).

erations?

o

How do I perform basic media

ENWW Install a media roll in the printer using the main scroller 29

Page 40

How do I perform basic media

p

o

erations?

c. Use the media positioning tool (2) to set the correct distance between the media (3) edge and

the main scroller flange (1).

d. Turn the hand-wheel (1) of the main scroller clockwise until it reaches the stop to lock the media

roll to the main scroller.

30 Chapter 2 How do I perform basic media operations? ENWW

Page 41

e. Slide the toothed flange spacer (1) over the main scroller (2) until it is fully engaged with the

p

media tube.

f. Slide the flange stopper (2) over the main scroller until you can align and fully engage it with the

keyway in the flange spacer (1).

g. Fully tighten the locking knob (3) on the flange stopper (2) to lock it to the flange spacer (1) and

the main scroller.

erations?

o

How do I perform basic media

4. Install the main scroller in the printer.

If you are working alone you will need a transport cart (2) to install the main scroller (1).

ENWW Install a media roll in the printer using the main scroller 31

Page 42

How do I perform basic media

p

o

erations?

If there are two people available to load the main scroller (1) by hand, one person will need to use the

scroller handling grip (2) to support the main scroller (1).

a. Carefully position the drive end (1) of the main scroller into the drive slot (2).

32 Chapter 2 How do I perform basic media operations? ENWW

Page 43

b. Carefully lower the opposite end (4) of the main scroller into the scroller retainer (3).

p

5. Adjust the tension bar guide.

a. Loosen the locking knob (2).

b. Move the tension bar guide (1) so that it is aligned with its position label (3).

c. Fully tighten the tension bar guide locking knob (2) to lock the tension bar guide (1).

erations?

o

How do I perform basic media

ENWW Install a media roll in the printer using the main scroller 33

Page 44

6. Open the rear cover (1).

p

How do I perform basic media

o

erations?

7. Move the media edge guards (1) to each end of the platen so they will not be hidden under the media.

8. Lift the media load lever (1).

9. Set the feed direction switch (1) to select the way the media is going to be printed, either on the inside

or the outside of the media.

34 Chapter 2 How do I perform basic media operations? ENWW

Page 45

10. At the front of the printer, use the black media advance switch (2), or the black media advance switch

p

on the foot switch, to feed enough media to insert it into the media feeder.

11. Load the media into the media feeder.

CAUTION Inserting the media obliquely or inserting media with wrinkles could cause a

media jam or skewed feed.

a. Insert the top edge of the media (1) into media feeder (2) while stretching it outwards to prevent

any wrinkling.

b. If the media curls up (1) or down (2), making it hard to insert into the media feeder, place a

backing sheet (3) on or under the curled media to make loading easier.

erations?

o

How do I perform basic media

ENWW Install a media roll in the printer using the main scroller 35

Page 46

How do I perform basic media

p