Page 1

Notice

The information in this guide is subject to change without notice.

Compaq Computer Corporation shall not be liable for technical or editorial

errors or omissions contained herein; nor for incidental or consequential

damages resulting from the furnishing, performance, or use of this

material.

This guide contains information protected by copyright. No part of this

guide may be photocopied or reproduced in any form without prior written

consent from Compaq Computer Corporation.

Copyright 1994 Compaq Computer Corporation.

All rights reserved. Printed in the USA.

Compaq, Deskpro, LTE, Contura

Registered U.S. Patent and Trademark Office.

Contura Aero is a trademark of Compaq Computer Corporation.

The software described in this guide is furnished under a license agreement

or nondisclosure agreement. The software may be used or copied only in

accordance with the terms of the agreement.

Product names mentioned herein may be trademarks and/or registered

trademarks of their respective companies.

MAINTENANCE AND SERVICE GUIDE

Compaq Contura Aero Family of Personal Computers

First Edition (February 1994)

Part Number 197235-001

Page 2

Preface

This Maintenance and Service Guide is used for reference when servicing the

Compaq Contura Aero Family of Personal Computers. Additional information

is available in the following publications:

o Compaq Contura Aero Documentation:

- QUICK SETUP

- BEYOND SETUP

- Online USER'S GUIDE

o COMPAQ SERVICE QUICK REFERENCE GUIDE

o Service Training Guides

o Compaq Service Advisories and Bulletins

Compaq Computer Corporation reserves the right to make changes to the

Compaq Contura Aero Family of Personal Computers without notice.

Symbols

The following words and symbols mark special messages throughout this

guide:

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> WARNING <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Text set off in this manner indicates that failure to follow directions in

the warning could result in bodily harm or loss of life.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> CAUTION <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Text set off in this manner indicates that failure to follow directions

could result in damage to equipment or loss of data.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

IMPORTANT: Text set off in this manner presents clarifying information or

specific instructions.

NOTE: Text set off in this manner presents commentary, sidelights, or

interesting points of information.

Technician Notes

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> WARNING <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Only authorized technicians trained by Compaq should repair this equipment.

All troubleshooting and repair procedures are detailed to allow only

subassembly/module level repair. Because of the complexity of the

individual boards and subassemblies, no one should attempt to make repairs

at the component level or to make modifications to any printed circuit

board. Improper repairs can create a safety hazard. Any indications of

component replacement or printed circuit board modifications may void any

warranty.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Page 3

Chapter 1. Illustrated Parts Catalog

Chapter 1.0 Introduction

Chapter 1.1 Illustrated Parts Breakdown: Compaq Contura Aero Family Of Personal Computers

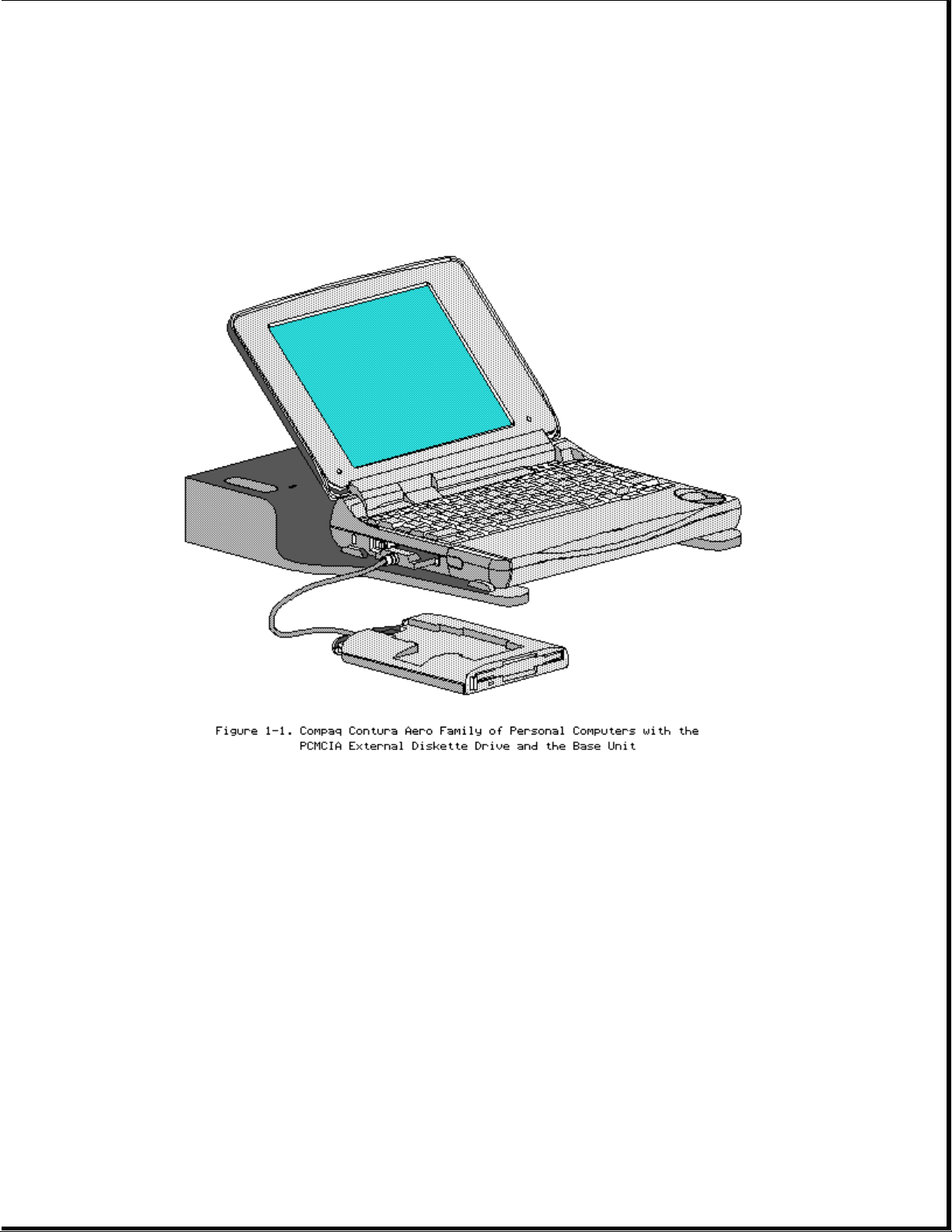

The Compaq Contura Aero Family of Personal Computers joins a display

assembly and system unit together with a clutch secured by screws in the

chassis, display enclosure, and a display pin allowing it to open and

close. The display assembly is secured by screws installed in the front of

the display enclosure. The system unit is secured to the system unit

enclosure by screwlocks in the rear and screws in the bottom of the system

unit enclosure.

SYSTEM UNIT MODULE DESCRIPTION

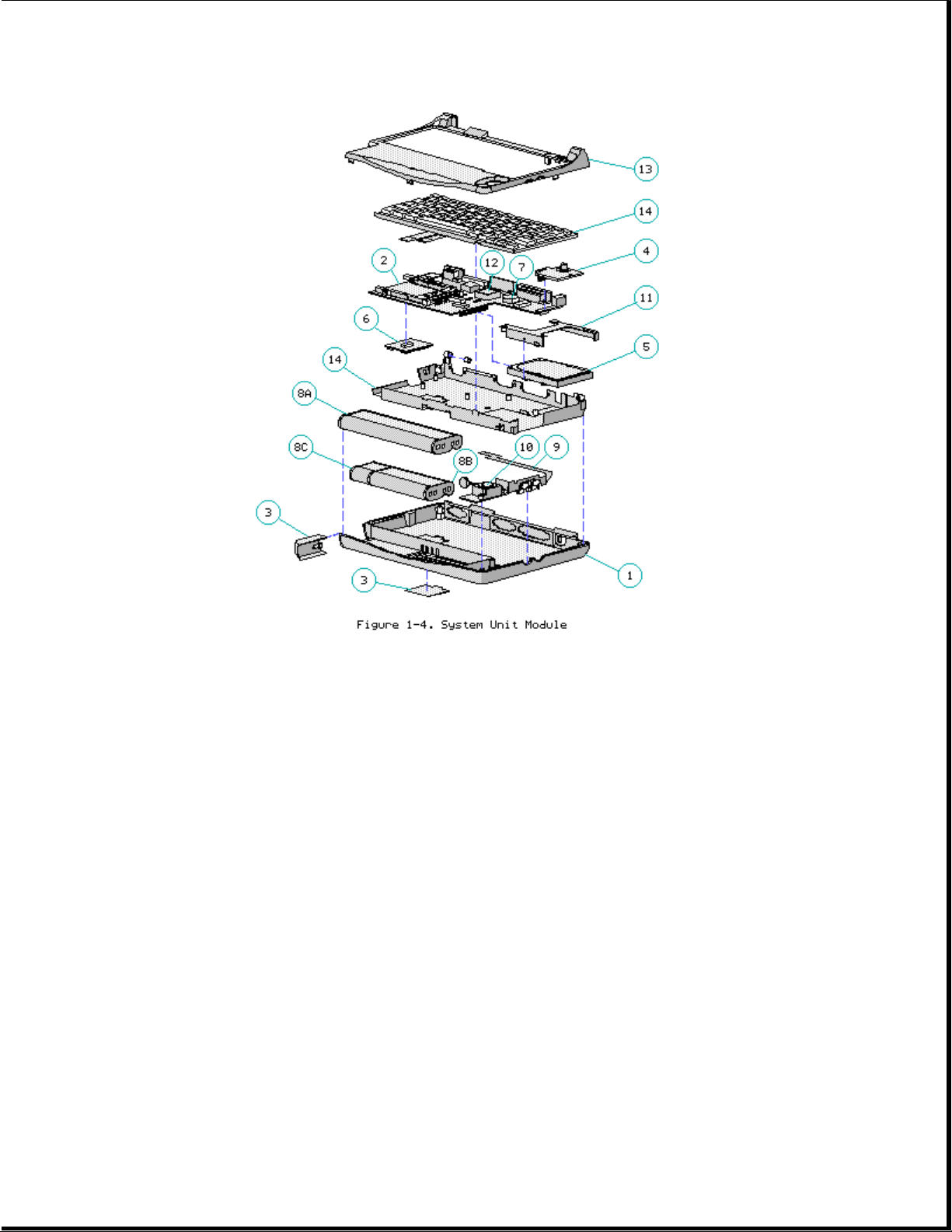

The system unit (Figure 1-4) includes the following replaceable parts:

o Battery and spacer

o Base enclosure

o Keyboard

o Hard drive

o Power supply

Page 4

o PCMCIA ejector rails

o Trackball assembly

o Memory expansion board (optional)

o System board

The keyboard is secured to the system unit with four screws and a hook

latch in the front. Once the screws are removed, the keyboard must be

rotated from the rear forward to disengage it from the hook latch. The

keyboard must be removed to allow access to any of the system board

components. The keyboard is connected to the system board with two ribbon

cables and zero insertion force (ZIF) connectors. The cables do not

necessarily have to be disconnected to service the system board. The

keyboard may be laid on top of the battery compartment to access the system

board.

The hard drive is connected directly to the system board with no

intervening cables. It is mounted to the chassis with a hard drive bracket.

The hard drive bracket is secured to the hard drive with three screws.

The power supply is secured to the system board with one threaded standoff.

There is no cable between the power supply and the system board; the power

supply connects directly to the system board.

The trackball assembly consists of the trackball, buttons, flex cable, and

speaker. The trackball plugs directly into the cable with a low insertion

force (LIF) connector and mounts with two screws in the right front corner

of the base enclosure. The flex cable includes the buttons and speaker. The

buttons fit in a recessed area on the right side of the base enclosure and

control the functions of the trackball. The speaker is connected to the

flex cable with two wires and fits in a narrow area in the right front

corner of the base enclosure. Sound is directed through the enclosure. The

remainder of the flex cable is routed behind and over the hard drive

assembly and plugs with a LIF connector directly into the system board.

The system board is mounted directly to the chassis. All system module

components connected to the system board must be removed prior to removing

the system board.

The PCMCIA rails are secured to the system board header with two screws at

the top. The rails plug directly into the system board connector.

The memory expansion board plugs into the system board in the bottom of the

base enclosure. Remove the door, and the memory expansion board plugs into

a single connector. System memory can be increased to a maximum 12 MB by

adding an 8 MB Memory Expansion Board. A 4 MB Memory Expansion Board is

also available.

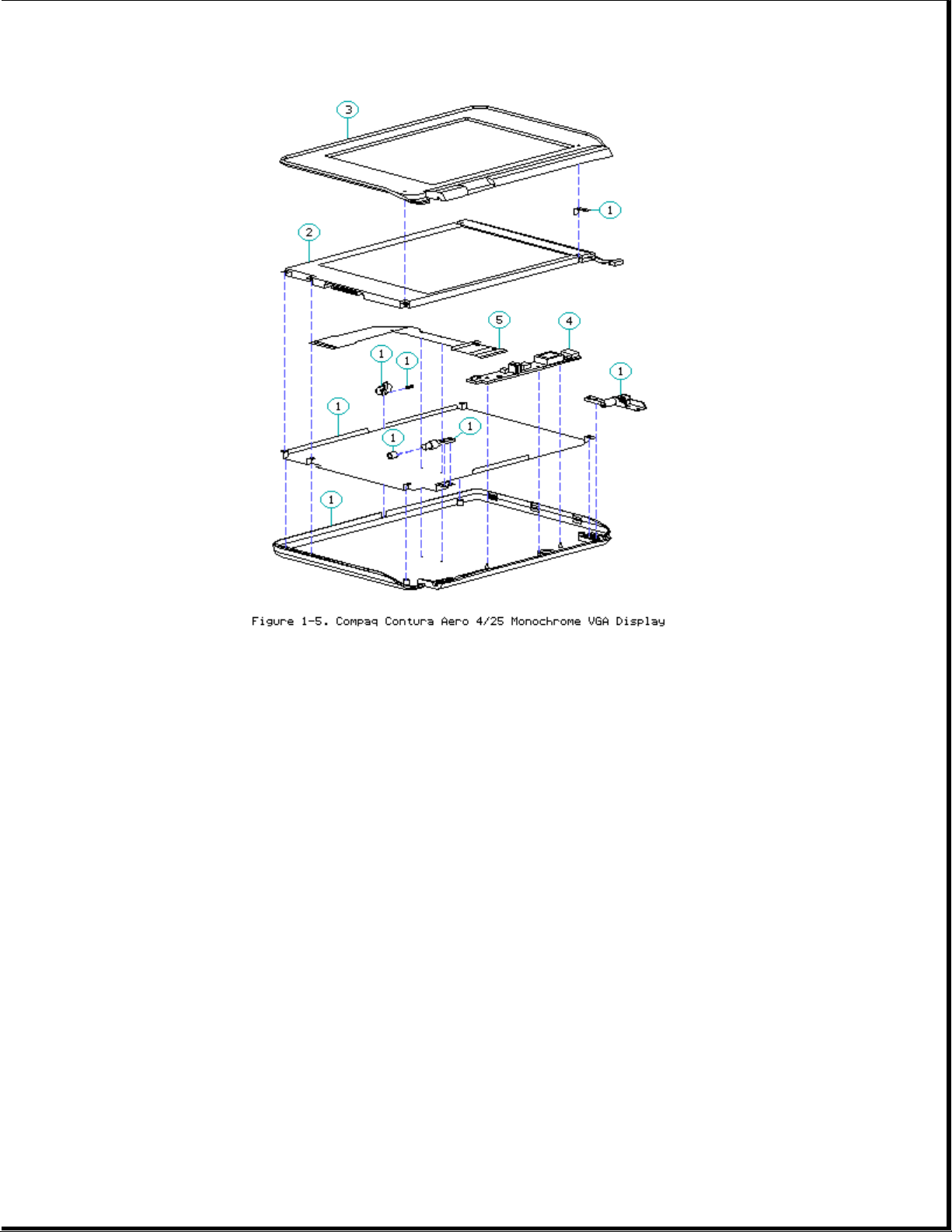

DISPLAY ASSEMBLY MODULE DESCRIPTION

The display assembly (Figures 1-5 and 1-6) includes the following

replaceable parts:

o Display bezel

o Liquid crystal display (LCD) panel

o Display inverter board

o Display cable

o Display shield

o Display enclosure

Page 5

Compaq Contura Aero 4/25

The display assembly is secured with two screws in the bottom corners of

the display bezel and by a screw in a clutch and a pin to the base

enclosure. To remove the display assembly from the base enclosure, the

display bezel must be removed first. Then the CPU cover is removed to allow

access to the system board.

The monochrome LCD is secured to the display enclosure with two screws in

the top left corner and one screw in the top right corner. The bottom

right corner has two small cables attached to a connector for the backlight

and the inverter board.

The display cable is a flex cable plugged into a connector on the left side

of the LCD, folded, and secured to the display shield with a pressure

sensitive adhesive. One end of the display cable is exposed at the bottom

of the display enclosure and is connected to the system board with a zero

insertion force (ZIF) slider. The other end is connected with a low

insertion force (LIF) connector to the display inverter board.

The display inverter board is aligned in the bottom of the display

enclosure with pins. One end connects to the display cable; the other end

plugs into the backlight cable of the LCD panel and is held in place with

pressure sensitive adhesive tape.

The display shield lays in the display enclosure.

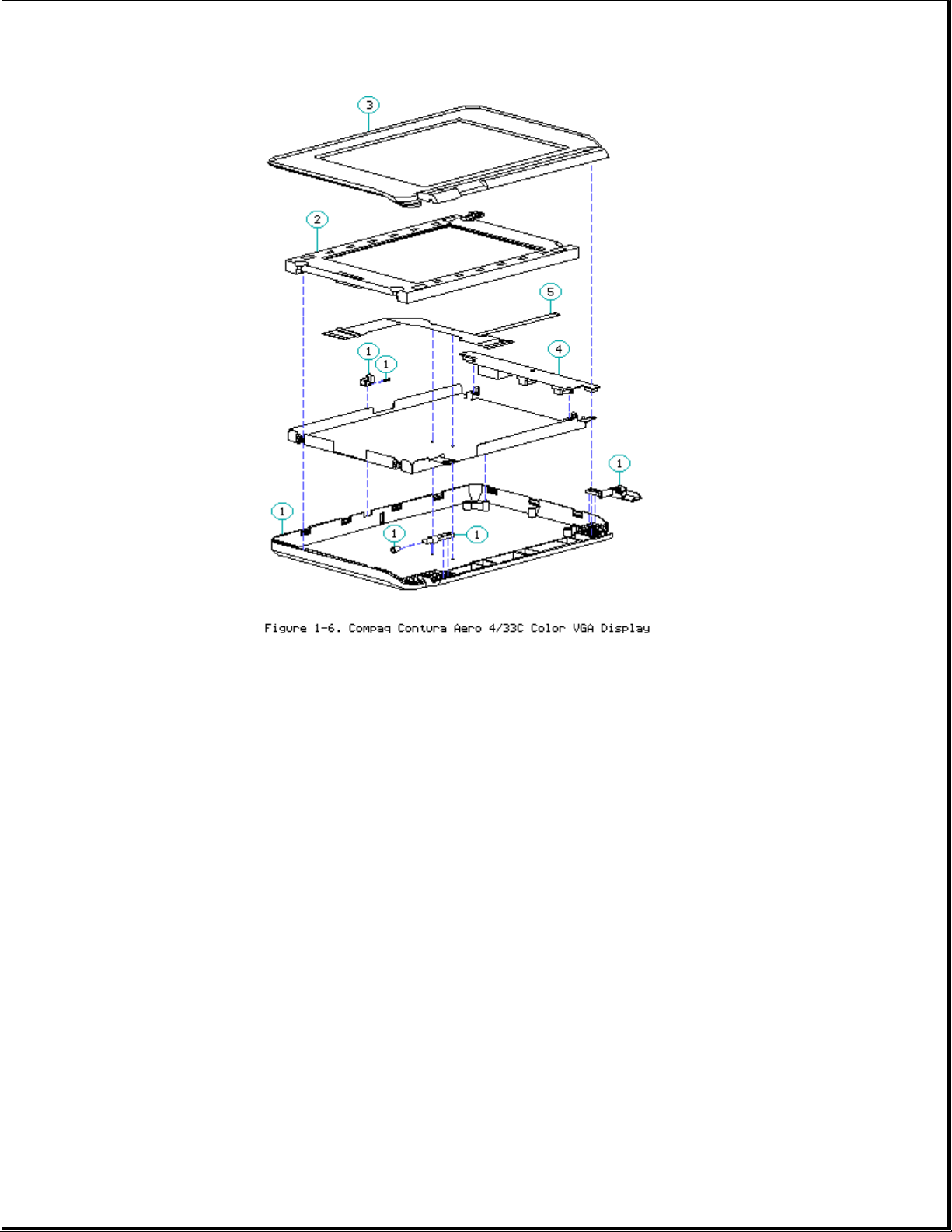

Compaq Contura Aero 4/33C

The display assembly is secured with two screws in the bottom corners of

the display bezel and by a screw in a clutch and a pin to the base

enclosure. To remove the display assembly from the base enclosure, the

display bezel must be removed first. Then the CPU cover is removed to allow

access to the system board.

The color LCD is secured to the display enclosure with four screws in the

corners of the LCD panel. The top right corner has two small cables

attached to a connector for the backlight and the inverter board.

The display cable is a flex cable plugged into a ZIF connector on the left

side of the LCD, folded, and secured to the display shield with a pressure

sensitive adhesive. One end of the display cable is exposed at the bottom

of the display enclosure and is connected to the system board with a ZIF

connector. The other end plugs into a LIF connector on the display inverter

board in the lower right hand corner of the display enclosure.

The display inverter board is aligned on the right side of the display

enclosure and mounted component side down. One end connects to the display

cable; the other end plugs into the backlight cable of the LCD panel.

The display shield lays in the display enclosure and has tabs that bend

over the screw holes of the LCD and secure the display shield to the LCD.

Page 6

Page 7

Chapter 1.2 System Unit Module

Page 8

Table 1-1. System Unit

===========================================================================

Description Spare Part No. Notes

===========================================================================

1 Base enclosure 197253-001 Includes screw covers.

--------------------------------------------------------------------------2 System board, 4 MB Does not include PCMCIA ejector

rails.

Compaq Contura 197241-001 Includes screw covers.

Aero 4/25

Compaq Contura 199222-001

Aero 4/33C

--------------------------------------------------------------------------3 Door assembly 197239-001 Includes battery and memory

expansion board doors.

--------------------------------------------------------------------------4 Power supply, DC-DC 190521-001 Includes screw covers.

--------------------------------------------------------------------------5 Hard drive

- Model 250 199233-001 Does not include hard drive

- Model 170 190661-001 bracket. Includes screw covers.

- Model 84 190660-001

--------------------------------------------------------------------------6 Memory expansion

board

Page 9

- 4 MB 190565-001

y

- 8 MB 190596-001

--------------------------------------------------------------------------7 Real time clock 117099-001

battery

--------------------------------------------------------------------------8 NiMH Battery Pack

- 8A: Extended Life 190626-001 Extended Life battery does not

- 8B: Standard 190697-001 include spacer. Standard battery

- 8C: Spacer 197317-001 includes spacer.

--------------------------------------------------------------------------9 Trackball cable and 197312-001 Includes screw covers.

speaker assembly

---------------------------------------------------------------------------

10 Trackball assembly 197286-001 Includes screw covers.

---------------------------------------------------------------------------

11 Hard drive bracket 197236-001 Includes screws and screw

covers.

---------------------------------------------------------------------------

12 System ROM 197229-001 Includes screw covers.

---------------------------------------------------------------------------

13 CPU cover 197311-001 Includes screw covers.

---------------------------------------------------------------------------

14 CPU chassis 199276-001 Includes clip and screw covers.

===========================================================================

Chapter 1.3 VGA Displa

Page 10

Table 1-2. Compaq Contura Aero 4/25 Monochrome VGA Display

===========================================================================

Description Spare Part No. Notes

===========================================================================

1 Display enclosure 197237-001 Includes enclosure, clutch, pin,

kit latch, spring, screws, display

shield, slotted bushing, ground

clip, screw covers and logo.

---------------------------------------------------------------------------

2 Display panel 190624-001 Includes labels, screw covers.

---------------------------------------------------------------------------

3 Display bezel 197344-001 Includes screw covers.

---------------------------------------------------------------------------

4 Backlight inverter 190522-001 Includes adhesive tape, screw

board covers.

---------------------------------------------------------------------------

5 Display cable 197238-001 Includes ZIF slider and screw

covers.

---------------------------------------------------------------------------

6 Display hardware * 197316-001 Includes screws, ground clip,

and screw covers.

---------------------------------------------------------------------------

* Not Shown

===========================================================================

Page 11

Table 1-3. Compaq Contura Aero 4/33C Color VGA Display

===========================================================================

Description Spare Part No. Notes

===========================================================================

1 Display enclosure 199257-001 Includes enclosure, clutch, pin,

kit latch, spring, screws, display

shield, slotted bushing, screw

covers and logo.

---------------------------------------------------------------------------

2 Display panel 199232-001 Includes labels, screw covers.

---------------------------------------------------------------------------

3 Display bezel 199260-001 Includes screw covers.

---------------------------------------------------------------------------

4 Backlight inverter 199223-001 Includes screw covers.

board

---------------------------------------------------------------------------

5 Display cable 199258-001 Includes ZIF slider and screw

covers.

---------------------------------------------------------------------------

6 Display hardware * 197316-001 Includes screws and screw

covers.

---------------------------------------------------------------------------

* Not Shown

===========================================================================

Page 12

Chapter 1.4 Keyboards

Table 1-4. Notebook Keyboards

===========================================================================

Description Spare Part Number

===========================================================================

1 U.S. 190620-001

2 U.K. 190620-003 *

3 German 190620-004 *

4 French 190620-005 *

5 Italian 190620-006 *

6 Spanish 190620-007 *

7 Danish 190620-008 *

8 Norwegian 190620-009 *

9 Swedish/Finnish 190620-010 *

10 Swiss 190620-011 *

11 French Canadian 190620-012 *

12 Portuguese 190620-013 *

13 Latin American 190620-016 *

14 Belgium 190620-018 *

15 Japanese 190620-019 *

---------------------------------------------------------------------------

* Not Shown

===========================================================================

Table 1-5. Enhanced Keyboards

Page 13

===========================================================================

Description Spare Part Number

===========================================================================

1 Enhanced II Keyboard U.S. 112573-001 (No longer

available)*

2 Enhanced III Keyboard U.K. 140536-103 *

3 Enhanced III Keyboard German 140536-104 *

4 Enhanced III Keyboard French 140536-105 *

5 Enhanced III Keyboard Italian 140536-106 *

6 Enhanced III Keyboard Spanish 140536-107 *

7 Enhanced III Keyboard Danish 140536-108 *

8 Enhanced III Keyboard Norwegian 140536-109 *

9 Enhanced III Keyboard Swedish/Finnish 140536-110 *

10 Enhanced III Keyboard Swiss 140536-111 *

11 Enhanced III Keyboard French Canadian 140536-112 *

12 Enhanced III Keyboard Portuguese 140536-113 *

13 Enhanced III Keyboard Turkish 140536-114 *

14 Enhanced III Keyboard Greek 140536-115 *

15 Enhanced III Keyboard Latin American 140536-116 *

16 Enhanced III Keyboard Arabic 140536-117 *

17 Enhanced III Keyboard Belgian 140536-118 *

18 Enhanced III Keyboard Japanese 140536-119 *

19 Enhanced III Keyboard BHCSY ** 140536-120 *

20 Enhanced III Keyboard Hungarian 140536-121 *

21 Enhanced III Keyboard Polish 140536-122 *

22 Enhanced III Keyboard Slovakian 140536-123 *

23 Enhanced III Keyboard Russian 140536-124 *

24 Enhanced III Keyboard Czech 140536-129 *

25 Enhanced III Keyboard Thai 140536-130 *

--------------------------------------------------------------------------* Not Shown

** Bosnia-Herzegovina, Croatia, Slovenia, and Yugoslavia

===========================================================================

Chapter 1.5 Cables

Page 14

Table 1-6. Cables

===========================================================================

Description Spare Part Number

===========================================================================

1 Display Cable (Compaq Contura Aero 4/25) 197238-001

2 Trackball/Speaker Cable 197312-001

3 Communication Cable 197318-001

4 Display Cable (Compaq Contura Aero 4/33C) 199258-001

===========================================================================

Chapter 1.6 AC Adapter And Power Cord

Page 15

Table 1-7. AC Adapter and Power Cord

===========================================================================

Description Spare Part Number

===========================================================================

1 AC Adapter 190621-001

2 Power Cord (U.S./Canada) 197230-001

3 Power Cord (U.K.) 197232-001 *

4 Power Cord (Europe) 197231-001 *

5 Power Cord (Japan) 197233-001 *

6 Power Cord (Asia Pacific) 197234-001 *

--------------------------------------------------------------------------* Not shown

===========================================================================

Table 1-8. Documentation and Software

===========================================================================

Description Spare Part Number

===========================================================================

MAINTENANCE AND SERVICE GUIDE 197235-001

--------------------------------------------------------------------------QUICK SETUP CARD, BEYOND SETUP

English 197243-001

German 197243-041

French 197243-051

Italian 197243-061

Spanish 197243-071

Page 16

--------------------------------------------------------------------------COMPAQ SERVICE QUICK REFERENCE GUIDE 106854-001

--------------------------------------------------------------------------LOTUS ORGANIZER MANUAL

English 137885-001

German 137885-041

French 137885-051

Italian 137885-061

Spanish 137885-071

--------------------------------------------------------------------------Online USER'S GUIDE

English 190512-001

German 190512-041

French 190512-051

Italian 190512-061

Spanish 190512-071

--------------------------------------------------------------------------WINLINK (diskettes)

English 197330-001

German 197330-041

French 197330-051

Italian 197330-061

Spanish 197330-071

===========================================================================

Table 1-9. Accessories

===========================================================================

Description Spare Part Number

===========================================================================

Automobile adapter 190551-001

Memory expansion board

4 MB 190565-001

8 MB 190596-001

Base unit 190568-001

PCMCIA external diskette drive 190563-001

Mobile port expander 197364-001

Carrying case 121423-001

Briefcase 129930-001

Slipcase cover 197242-001

===========================================================================

Table 1-10. Mounting Hardware

===========================================================================

Description Spare Part Number

===========================================================================

Kit, CPU base screws and screwlocks 197315-001

Kit, display screws 197316-001

Trackball removal tool 194041-001

===========================================================================

Table 1-11a. Fastener List for CPU Base Screws and Screwlocks

Page 17

===========================================================================

Description Type Where Used Part Number Drive Qty

===========================================================================

M2.5 x 7.0 * Hex System board to 139576-004 3/16 2

chassis

--------------------------------------------------------------------------M2.5 x 3.55 * Hex Power supply board to 197257-001 3/16 1

chassis

--------------------------------------------------------------------------#4-40 * Hex I/O connector 106902-004 3/16 4

--------------------------------------------------------------------------M3.0 x 3.0 Pan Hard drive bracket to 139574-001 PH/1 3

hard drive

--------------------------------------------------------------------------M2.0 x 7.0 Pan PCMCIA rails to 144762-002 PH/1 2

chassis

--------------------------------------------------------------------------M2.0 x 2.5 Truss Keyboard to chassis 144863-002 T8/SL 3

--------------------------------------------------------------------------M2.5 x 12.0 Truss Hard drive to keyboard 144864-005 T8/SL 1

to chassis

--------------------------------------------------------------------------M2.5 x 6.0 Truss Clutch, system board 144865-003 T8/SL 7

--------------------------------------------------------------------------M2.5 x 16.0 Truss Base 144865-005 T8/SL 4

--------------------------------------------------------------------------* Screwlocks

===========================================================================

Table 1-11b. Fastener List for the Compaq Contura Aero 4/25 Display

===========================================================================

Description Type Where Used Part Number Drive Qty

===========================================================================

M2.0 x 4.0 Truss Pin 144863-001 T8/SL 2

M2.5 x 4.5 Truss Clutch 144864-001 T8/SL 2

M2.0 x 6.0 Pan Bezel 197341-002 PH/1 2

M2.0 x 2.5 Truss Panel to enclosure 144863-002 T8/SL 3

===========================================================================

Table 1-11c. Fastener List for the Compaq Contura Aero 4/33C Display

===========================================================================

Description Type Where Used Part Number Drive Qty

===========================================================================

M2.0 x 4.0 Truss Pin and inverter board 144863-001 T8/SL 2

M2.5 x 4.5 Truss Clutch 144864-001 T8/SL 2

M2.0 x 6.0 Pan Bezel 197341-002 PH/1 2

M3.0 x 6.0 Truss Panel to enclosure 198889-001 T8/SL 4

===========================================================================

Table 1-12. Miscellaneous Kits

===========================================================================

Description Spare Part Number

===========================================================================

Base unit tilt feet 197346-001

Page 18

CPU enclosure feet 197345-001

Battery and memory doors 197239-001

PCMCIA eject rails 197314-001

Carton, quantity 5 137863-001

Carton and buns, quantity 1 137864-001

Display connector slider 140071-001

Plate logo 197251-001

Battery spacer 197317-001

===========================================================================

Page 19

Chapter 2. Service Preliminaries

Chapter 2.0 Introduction

This chapter provides general service information for the computer and the

base unit.

Adherence to the procedures and precautions described in this chapter is

essential for proper service.

Chapter 2.1 Electrostatic Discharge (International)

A sudden discharge of static electricity from a finger or other conductor

can destroy static sensitive devices or micro circuitry. Often the spark is

neither felt or heard, but damage occurs. An electronic device exposed to

electrostatic discharge (ESD) may not be affected at all and will work

perfectly throughout a normal cycle. Or it may function normally for a

while, then degrade in the internal layers, reducing its life expectancy.

Networks built into many integrated circuits provide some protection, but

in many cases, the discharge contains enough power to alter device

parameters or melt silicon junctions.

Generating Static

Table 2-1 shows how different activities generate static electricity and at

different electrostatic voltage levels.

Table 2-1. Typical Electrostatic Voltages

===========================================================================

Event 10% 40% 55%

===========================================================================

Walking across carpet 35,000V 15,000V 7,500V

Relative Humidity

Walking across vinyl floor 12,000V 5,000V 3,000V

Motions of bench worker 6,000V 800V 400V

Removing DIPS from plastic tubes 2,000V 700V 400V

Removing DIPS from vinyl trays 11,500V 4,000V 2,000V

Removing DIPS from styrofoam 14,500V 5,000V 3,500V

Removing bubble pack from PCBs 26,000V 20,000V 7,000V

Packing PCBs in foam lined box 21,000V 11,000V 5,000V

--------------------------------------------------------------------------NOTE: 700 volts can degrade a product.

===========================================================================

Preventing Electrostatic Damage To Equipment

Many electronic components are sensitive to ESD. Circuitry design and

Page 20

structure determine the degree of sensitivity. The following proper

packaging and grounding precautions are necessary to prevent damage:

o Protect all electrostatic parts and assemblies with conductive or

approved containers or packaging.

o Keep electrostatic sensitive parts in their containers until they arrive

at static free stations.

o Place items on a grounded surface before removing them from their

container.

o Always be properly grounded when touching a sensitive component or

assembly.

o Place reusable electronic sensitive parts from assemblies in protective

packaging or conductive foam.

Use transporters and conveyors made of antistatic belts and metal roller

bushings. Mechanized equipment used for moving materials must be wired to

ground and proper materials selected to avoid static charging. When

grounding is not possible, use an ionizer to dissipate electric charges.

Preventing Damage to Drives

To prevent static damage to hard drives, use the following precautions:

o Handle drives gently, using static guarding techniques.

o Store drives in the original shipping containers.

o Avoid dropping drives from any height onto any surface.

o Handle drives on surfaces that have at least one inch of shock proof

foam.

o Always place drives PCB assembly side down on the foam.

Grounding Methods

The method for grounding must include a wrist strap or a foot strap at a

grounded workstation. When seated, wear a wrist strap connected to a

grounded system. When standing, use footstraps and a grounded floor mat.

Table 2-2. Static Shielding Protection Levels

===========================================================================

Method Voltages

===========================================================================

Antistatic Plastic 1,500

Carbon Loaded Plastic 7,500

Metallized Laminate 15,000

===========================================================================

Grounding Workstations

Page 21

To prevent static damage at the workstation, use the following precautions:

o Cover the workstation with approved static dissipative material. Provide

a wrist strap connected to the work surface and properly grounded tools

and equipment.

o Use static dissipative mats, heel straps, or air ionizers to give added

protection.

o Handle electrostatic sensitive components, parts, and assemblies by the

case or PCB laminate. Handle them only at static free workstations.

o Avoid contact with pins, leads, or circuitry.

o Turn off power and input signals before inserting and removing connectors

or test equipment.

o Use fixtures made of static safe materials when fixtures must directly

contact dissipative surfaces.

o Keep work area free of nonconductive materials such as ordinary plastic

assembly aids and Styrofoam.

o Use field service tools, such as cutters, screwdrivers, vacuums, that are

conductive.

o Use a portable field service kit with a static dissipative vinyl pouch

that folds out of a work mat. Also use a wrist strap and a ground cord

for the work surface. Ground the cord to the chassis of the equipment

undergoing test or repair.

Grounding Equipment

Use the following equipment to prevent static electricity damage to the

equipment:

Wrist Straps are flexible straps with a minimum of 1 megohm +/- 10%

resistance to the ground cords. To provide proper ground, a strap must be

worn snug against the skin. On grounded mats without banana plug

connectors, connect a wrist strap with alligator clips.

Heelstraps/Toestraps/Bootstraps can be used at standing workstations and

are compatible with most types of boots and shoes. On conductive floors or

dissipative floor mats, use them on both feet with a minimum of 1 megohm

resistance between operator and ground. To be effective, the conductive

strips must be worn in contact with the skin.

Recommended Materials and Equipment

Other materials and equipment that are recommended for use in preventing

static electricity include:

o Antistatic tape

o Antistatic smocks, aprons, or sleeve protectors

Page 22

o Conductive bins, and other assembly or soldering aids

o Conductive foam

o Conductive table top workstations with ground cord of 1 megohm of

resistance

o Static dissipative table or floor mats with hard tie to ground

o Field service kits

o Static awareness labels

o Wrist straps and footwear straps providing 1 megohm +/- 10% resistance

o Material handling packages

o Conductive plastic bags

o Conductive plastic tubes

o Conductive tote boxes

o Metal tote boxes

o Opaque shielding bags

o Transparent metallized shielding bags

o Transparent shielding tubes

SERVICE CONSIDERATIONS

Listed below are some of the considerations that should be kept in mind

during the disassembly and assembly of the computer.

Tool Requirements:

o Flat bladed screwdriver

o Torx T8 screwdriver (included in 130619-001)

o Hex socket driver (3/16)

o 25 Pin printer loopback plug (included in 100767-001)

o 9 Pin serial loopback plug (included in 100767-001)

o Cross recess (Phillips) screwdriver (included in 130619-001)

o Trackball tool (spare part number 194041-001)

o Case utility tool (spare part number 119070-001 and included in

10076-001)

o PCMCIA external diskette drive (part number 190533-001)

o Preloaded application diskettes

Page 23

Screws

The screws used in these products are not interchangeable. If an incorrect

screw is used during the reassembly process, it could cause damage to the

unit. Compaq strongly recommends that all screws removed during the

disassembly process be kept with the part that was removed, then returned

to their proper locations.

IMPORTANT: As each subassembly is removed from the computer, it should be

placed away from the work area to prevent damage.

Cables and Connectors

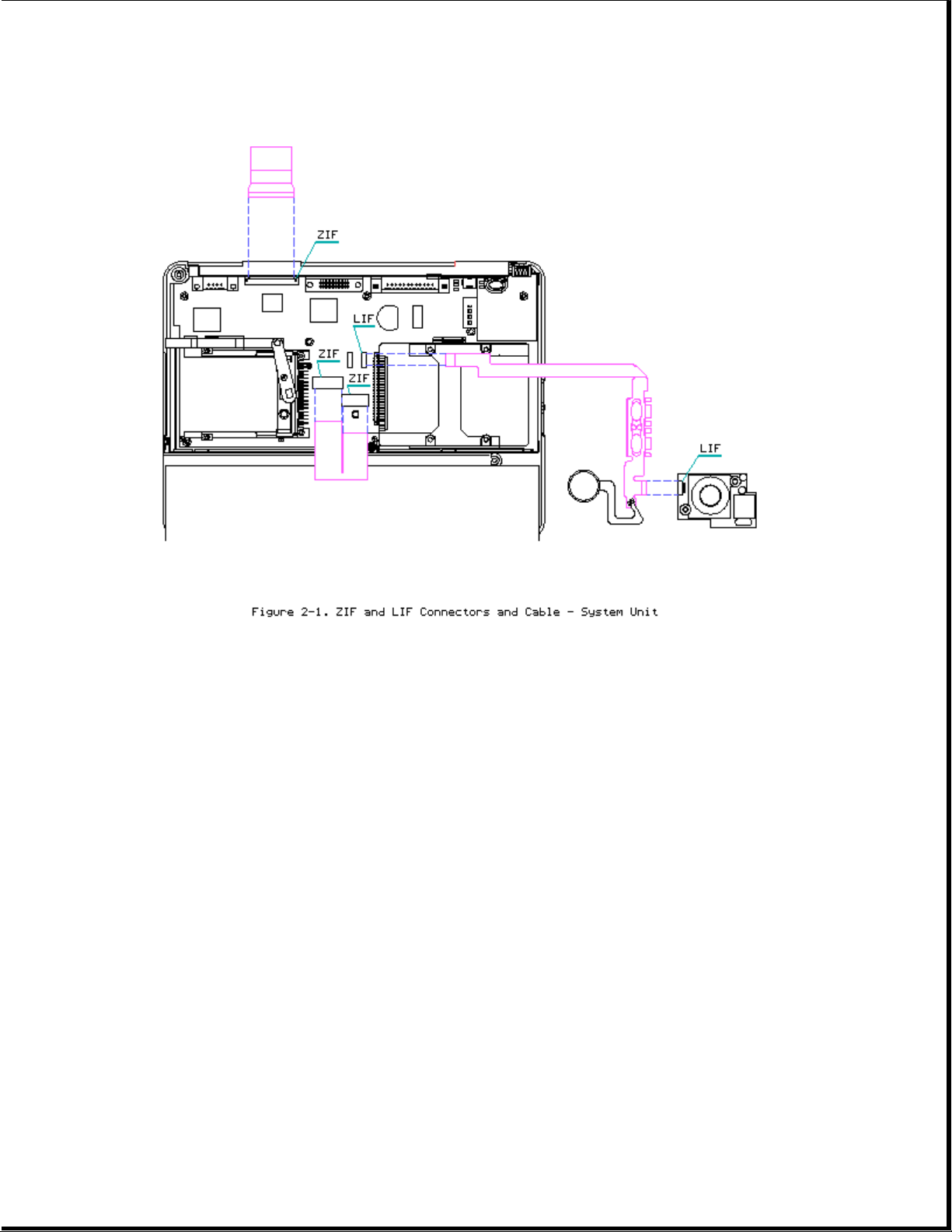

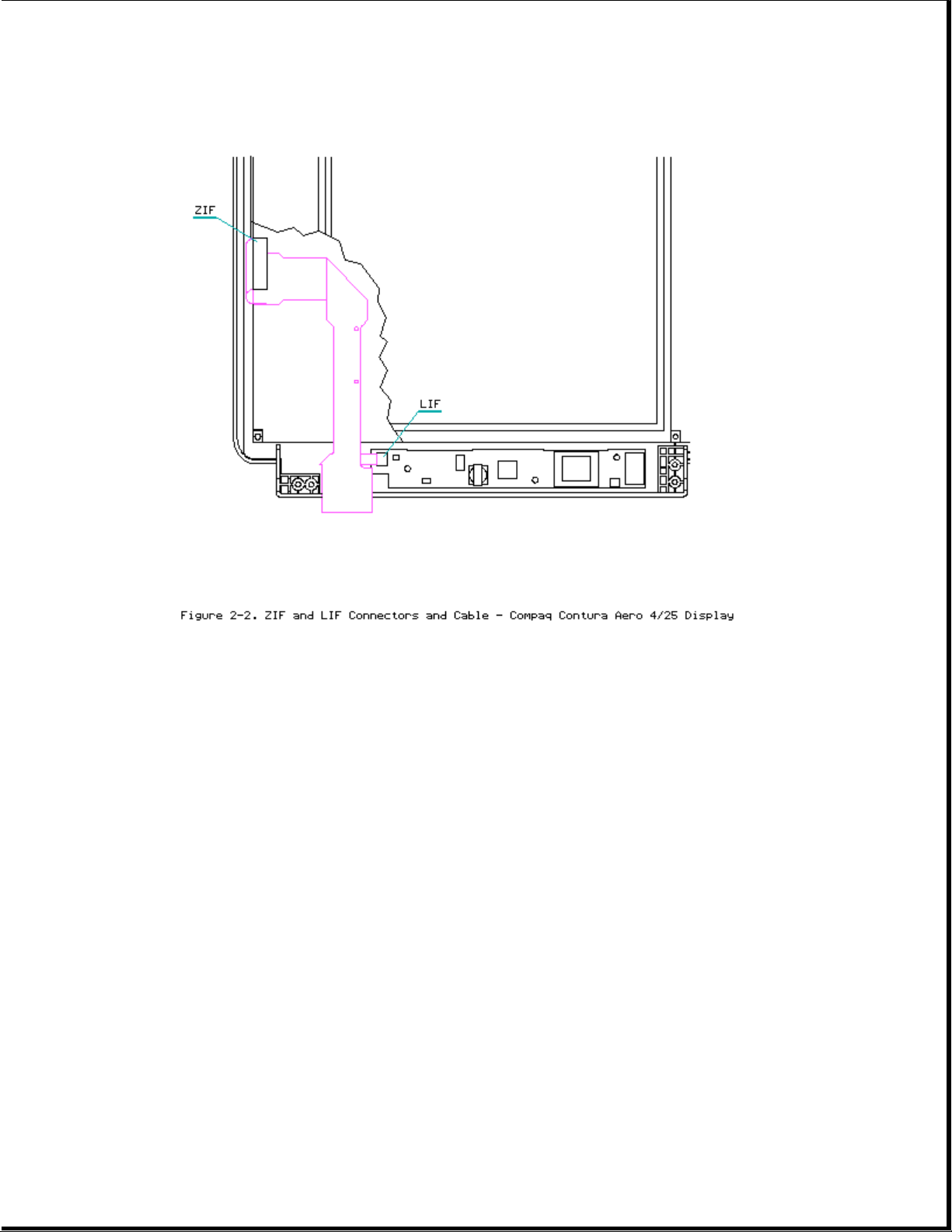

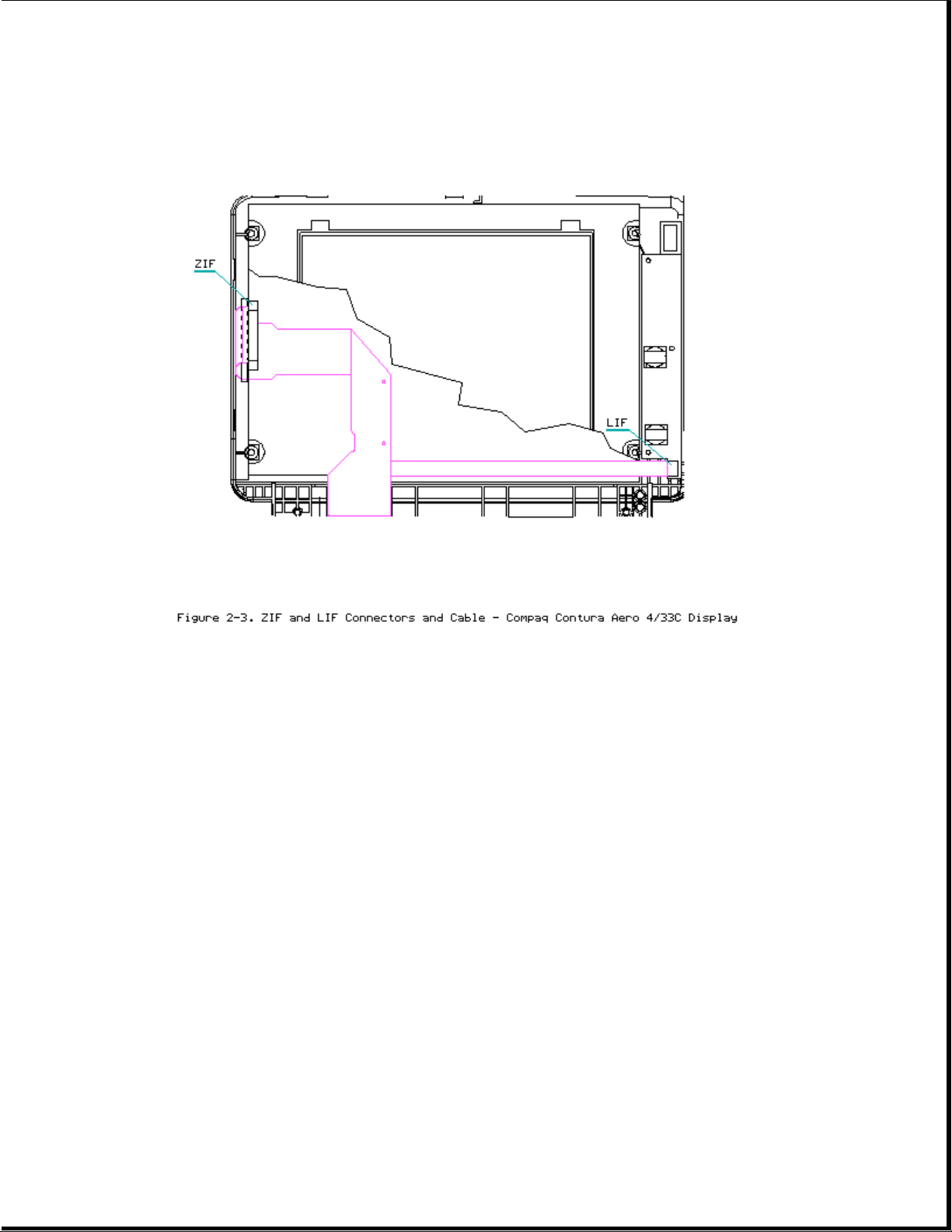

Most cables used throughout the unit are flex cables (Figures 2-1, 2-2,

2-3). These cables must be handled with extreme care to avoid damage. Apply

only the tension required to seat or unseat the cables during insertion or

removal from the connector. Handle cables by the connector or pull tabs

whenever possible. In all cases, avoid bending, twisting, or tearing the

cables, and ensure that cables are placed in such a way that they cannot be

caught or snagged by parts being removed or replaced.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> CAUTION <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

When servicing these units, ensure that cables are placed in their proper

location during the reassembly process. Improper cable placement can cause

severe damage to the unit.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Page 24

Page 25

Page 26

Plastics

)

The plastics used can be damaged by application of excessive force during

disassembly and reassembly. When handling the plastic cases and housing

assemblies, use care. Do not use screwdrivers or similar tools to pry apart

plastics. Where necessary, use the Case utility tool (spare part number

119070-001). Proper handling of this tool is illustrated in the

disassembly and reassembly procedures.

Disposal of a Used Battery

Battery components are considered environmentally harmful. Disposal of a

Nickel Metal Hydride (NiMH) Battery Pack should comply with country, state,

province, or local regulations. Whenever possible, battery components

should be recycled.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> CAUTION <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Never attempt to open or service a battery pack. Opening a battery pack not

only damages the pack and makes it unusable, but also exposes potentially

harmful battery components.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Chapter 2.1 Electrostatic Discharge (U.S. and Canada

Page 27

A sudden discharge of static electricity from a finger or other conductor

can destroy static sensitive devices or micro circuitry. Often the spark is

neither felt or heard, but damage occurs. An electronic device exposed to

electrostatic discharge (ESD) may not be affected at all and will work

perfectly throughout a normal cycle. Or it may function normally for a

while, then degrade in the internal layers, reducing its life expectancy.

Networks built into many integrated circuits provide some protection, but

in many cases, the discharge contains enough power to alter device

parameters or melt silicon junctions.

Generating Static

Table 2-1 shows how different activities generate static electricity and at

different electrostatic voltage levels.

Table 2-1. Typical Electrostatic Voltages

===========================================================================

Relative Humidity

Event 10% 40% 55%

===========================================================================

Walking across carpet 35,000V 15,000V 7,500V

Walking across vinyl floor 12,000V 5,000V 3,000V

Motions of bench worker 6,000V 800V 400V

Removing DIPS from plastic tubes 2,000V 700V 400V

Removing DIPS from vinyl trays 11,500V 4,000V 2,000V

Removing DIPS from styrofoam 14,500V 5,000V 3,500V

Removing bubble pack from PCBs 26,000V 20,000V 7,000V

Packing PCBs in foam lined box 21,000V 11,000V 5,000V

--------------------------------------------------------------------------NOTE: 700 volts can degrade a product.

===========================================================================

Preventing Electrostatic Damage To Equipment

Many electronic components are sensitive to ESD. Circuitry design and

structure determine the degree of sensitivity. The following proper

packaging and grounding precautions are necessary to prevent damage:

o Protect all electrostatic parts and assemblies with conductive or

approved containers or packaging.

o Keep electrostatic sensitive parts in their containers until they arrive

at static free stations.

o Place items on a grounded surface before removing them from their

container.

o Always be properly grounded when touching a sensitive component or

assembly.

Page 28

o Place reusable electronic sensitive parts from assemblies in protective

packaging or conductive foam.

Use transporters and conveyors made of antistatic belts and metal roller

bushings. Mechanized equipment used for moving materials must be wired to

ground and proper materials selected to avoid static charging. When

grounding is not possible, use an ionizer to dissipate electric charges.

Preventing Damage to Drives

To prevent static damage to hard drives, use the following precautions:

o Handle drives gently, using static guarding techniques.

o Store drives in the original shipping containers.

o Avoid dropping drives from any height onto any surface.

o Handle drives on surfaces that have at least one inch of shock proof

foam.

o Always place drives PCB assembly side down on the foam.

Grounding Methods

The method for grounding must include a wrist strap or a foot strap at a

grounded workstation. When seated, wear a wrist strap connected to a

grounded system. When standing, use footstraps and a grounded floor mat.

Table 2-2. Static Shielding Protection Levels

===========================================================================

Method Voltages

===========================================================================

Antistatic Plastic 1,500

Carbon Loaded Plastic 7,500

Metallized Laminate 15,000

===========================================================================

Grounding Workstations

To prevent static damage at the workstation, use the following precautions:

o Cover the workstation with approved static dissipative material. Provide

a wrist strap connected to the work surface and properly grounded tools

and equipment.

o Use static dissipative mats, heel straps, or air ionizers to give added

protection.

o Handle electrostatic sensitive components, parts, and assemblies by the

case or PCB laminate. Handle them only at static free workstations.

o Avoid contact with pins, leads, or circuitry.

Page 29

o Turn off power and input signals before inserting and removing connectors

or test equipment.

o Use fixtures made of static safe materials when fixtures must directly

contact dissipative surfaces.

o Keep work area free of nonconductive materials such as ordinary plastic

assembly aids and Styrofoam.

o Use field service tools, such as cutters, screwdrivers, vacuums, that are

conductive.

o Use a portable field service kit with a static dissipative vinyl pouch

that folds out of a work mat. Also use a wrist strap and a ground cord

for the work surface. Ground the cord to the chassis of the equipment

undergoing test or repair.

Grounding Equipment

Use the following equipment to prevent static electricity damage to the

equipment:

Wrist Straps are flexible straps with a minimum of 1 megohm +/- 10%

resistance to the ground cords. To provide proper ground, a strap must be

worn snug against the skin. On grounded mats without banana plug

connectors, connect a wrist strap with alligator clips.

Heelstraps/Toestraps/Bootstraps can be used at standing workstations and

are compatible with most types of boots and shoes. On conductive floors or

dissipative floor mats, use them on both feet with a minimum of 1 megohm

resistance between operator and ground. To be effective, the conductive

strips must be worn in contact with the skin.

Recommended Materials and Equipment

Other materials and equipment that are recommended for use in preventing

static electricity include:

o Antistatic tape

o Antistatic smocks, aprons, or sleeve protectors

o Conductive bins, and other assembly or soldering aids

o Conductive foam

o Conductive table top workstations with ground cord of 1 megohm of

resistance

o Static dissipative table or floor mats with hard tie to ground

o Field service kits

o Static awareness labels

o Wrist straps and footwear straps providing 1 megohm +/- 10% resistance

Page 30

o Material handling packages

o Conductive plastic bags

o Conductive plastic tubes

o Conductive tote boxes

o Metal tote boxes

o Opaque shielding bags

o Transparent metallized shielding bags

o Transparent shielding tubes

SERVICE CONSIDERATIONS

Listed below are some of the considerations that should be kept in mind

during the disassembly and assembly of the computer.

Tool Requirements:

o Flat bladed screwdriver

o Torx T8 screwdriver (included in 130619-001)

o Hex socket driver (3/16)

o 25 Pin printer loopback plug (included in 100767-001)

o 9 Pin serial loopback plug (included in 100767-001)

o Cross recess (Phillips) screwdriver (included in 130619-001)

o Trackball tool (spare part number 194041-001)

o Case utility tool (spare part number 119070-001 and included in

10076-001)

o PCMCIA external diskette drive (part number 190533-001)

o Preloaded application diskettes (Compaq Order Center, 1-800-952-7689)

Screws

The screws used in these products are not interchangeable. If an incorrect

screw is used during the reassembly process, it could cause damage to the

unit. Compaq strongly recommends that all screws removed during the

disassembly process be kept with the part that was removed, then returned

to their proper locations.

IMPORTANT: As each subassembly is removed from the computer, it should be

placed away from the work area to prevent damage.

Page 31

Cables and Connectors

Most cables used throughout the unit are flex cables (Figures 2-1, 2-2,

2-3). These cables must be handled with extreme care to avoid damage. Apply

only the tension required to seat or unseat the cables during insertion or

removal from the connector. Handle cables by the connector or pull tabs

whenever possible. In all cases, avoid bending, twisting, or tearing the

cables, and ensure that cables are placed in such a way that they cannot be

caught or snagged by parts being removed or replaced.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> CAUTION <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

When servicing these units, ensure that cables are placed in their proper

location during the reassembly process. Improper cable placement can cause

severe damage to the unit.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Page 32

Page 33

Plastics

The plastics used can be damaged by application of excessive force during

disassembly and reassembly. When handling the plastic cases and housing

assemblies, use care. Do not use screwdrivers or similar tools to pry apart

plastics. Where necessary, use the Case utility tool (spare part number

119070-001). Proper handling of this tool is illustrated in the

disassembly and reassembly procedures.

Disposal of a Used Battery

Battery components are considered environmentally harmful. Disposal of a

Nickel Metal Hydride (NiMH) Battery Pack should comply with country, state,

province, or local regulations. Whenever possible, battery components

should be recycled.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> CAUTION <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Never attempt to open or service a battery pack. Opening a battery pack not

only damages the pack and makes it unusable, but also exposes potentially

harmful battery components.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Compaq offers its portable product customers an environmentally sound

method for disposing of depleted Compaq rechargeable battery packs used in

Compaq laptop and subnotebook personal computers.

Page 34

In the interest of our customers and the protection of our environment,

Compaq has initiated a disposal/recycling program for these battery packs.

Further, because Compaq is funding all costs associated with the program,

it is offered at no cost to the Compaq laptop and notebook customer.

IMPORTANT: Toll Free Number (U.S) 1-800-524-9859, (Canada) 1-800-263-5868

Customers in North America can take advantage of this program immediately.

If you want to safely dispose of a depleted Compaq rechargeable battery

pack, call the Compaq toll free telephone number. A recorded message asks

you to provide your name, mailing address, and information about the

battery pack. Within approximately two to three weeks, Compaq will send a

postage paid "battery mailer" envelope preaddressed to the reclamation

facility. Place the Compaq rechargeable battery pack into the battery

mailer and mail it to the Compaq address shown on the mailer. Do not return

Compaq rechargeable battery packs to Authorized Compaq Service Providers

(except in the case of service or warranty exchanges) nor to any Compaq

address other than the address on the preaddressed battery mailer envelope.

Page 35

Chapter 3. Removal and Replacement Procedures

Chapter 3.0 Introduction

This chapter provides subassembly/module level removal and replacement

procedures for the Compaq Contura Aero Family of Personal Computers.

After completing all necessary removal and replacement procedures, run the

diagnostics program to verify that all components operate properly.

Chapter 3.1 Replacement Procedures

For replacement procedures, follow the removal procedures in this chapter

in reverse order.

Chapter 3.2 Disassembly/Assembly Sequence Chart

This section provides instructions for removing and replacing these

components:

|

3.4 |---BATTERY PACK

|

3.5 |---CPU COVER

|

3.6 |---KEYBOARD

|

3.7 |---VGA BACKLIT DISPLAY

| |--Compaq Contura Aero 4/25

| |----Bezel

| |----Inverter Board

| |----LCD Panel

| |--Compaq Contura Aero 4/33C

| |----Bezel

| |----Inverter Board

| |----LCD Panel

|

3.8 |---POWER SUPPLY

|

3.9 |---TRACKBALL

|

3.10 |---HARD DRIVE

|

3.11 |---SYSTEM BOARD

| |---Real time Clock Battery

|

3.12 |---CHASSIS

Chapter 3.3 Preparation Procedures

Before beginning the removal and replacement procedures, follow these

steps (Figure 3-1):

Page 36

1. Turn off the power switch on the computer.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> CAUTION <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Turn off the computer before any cables are connected or disconnected.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

2. Disconnect all external devices (diskette drive, base unit, printer, and

other devices) from the computer.

3. Disconnect the power cord from the electrical outlet.

4. Disconnect the AC adapter cable from the computer.

Chapter 3.4 Removing The Battery Pack

To remove an installed battery pack, follow these steps (Figure 3-2):

1. Press the battery release latch on the cover of the battery compartment

2. Slide the door forward. The battery will spring out slightly

Page 37

3. Remove the battery pack by gently pulling it out of the battery

compartment

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> CAUTION <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Metal objects will damage the battery pack as well as the connectors in the

compartment. To prevent damage, do not let metal objects touch any of the

connectors. Do not place any objects other than the battery pack in the

battery compartment.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

NOTE: Be careful not to misplace the battery door or battery spacer (if

applicable).

To replace the battery pack, follow these steps:

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> CAUTION <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

To prevent damage to the battery contacts, do not force the battery pack

into the battery compartment.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Page 38

1. Align the slot in the battery pack with the rib inside the computer.

2. Insert the battery pack, with the battery contacts facing to the inside

of the battery compartment.

3. Push firmly on the battery pack until it slides into place.

4. Slide the battery door on until the lock snaps into place.

Chapter 3.5 Removing The Cpu Cover

To remove the CPU cover, follow these steps:

1. Remove the battery pack (Figure 3-2).

2. Turn the computer upside down.

3. Remove the four screws from the bottom of the computer (Figure 3-3).

4. Remove the screw from the clutch on the display enclosure in the rear of

the computer (Figure 3-3).

5. Turn the computer right side up.

Page 39

6. Slide the latch on the front of the computer to the right and open the

display (Figure 3-4).

7. Remove the screw covers from the bottom right and left corners of the

display panel assembly. Using a Phillips screwdriver, remove the two

screws (Figure 3-5).

Page 40

8. Remove the bezel from the display assembly by gently pulling the

bezel frame and working from the bottom up (Figure 3-6).

Page 41

9. Unsnap the CPU cover with the Case utility tool and lift it off of the

computer (Figure 3-7).

Page 42

To replace the CPU cover, reverse the previous steps.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> CAUTION <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

When replacing the CPU cover, be sure not to pinch the trackball cables on

the right side of the cover (see Figure 3-41).

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Chapter 3.6 Removing The Keyboard

To remove the keyboard, follow these steps:

1. Remove the battery pack (Section 3.4).

2. Remove the display bezel and the CPU cover (Section 3-5).

3. Remove the four screws that secure the keyboard (Figure 3-8).

Page 43

4. Gently lift up on the rear of the keyboard and unhook it from the hook

latches in the front (Figure 3-9).

Page 44

5. Rotate the rear of the keyboard toward you until the two ZIF connectors

are exposed and lay the keyboard upside down on top of the battery

compartment (Figure 3-10).

NOTE: You may not have to disconnect the cables from the keyboard to have

access to the component you want to remove and/or replace.

Page 45

6. Using the Case utility tool, carefully lift up on the two ZIF sliders

one at a time to release the keyboard cables (Figure 3-10).

7. Carefully lift the keyboard out of the computer.

To replace the keyboard, reverse the previous steps.

NOTE: When replacing the keyboard, position the clip on the rear of the

keyboard [1] on top of the display cable ZIF slider [2]

(Figure 3-10).

Chapter 3.7 Removing The VGA Backlit Display

Compaq Contura Aero 4/25 Display

To remove the monochrome VGA backlit display from the Compaq Contura

Aero 4/25 Personal Computer, follow these steps:

1. Remove the battery pack (Section 3.4).

2. Remove the display bezel and the CPU cover (Section 3.5).

Page 46

3. Remove the keyboard (Section 3.6).

4. Release the ZIF slider attaching the display cable to the system board.

NOTE: It may not be necessary to remove the display assembly from the base

enclosure to service the system board. The display will support

itself in an open position without falling over.

5. Remove the remaining screw on the back of the display assembly to

release the clutch from the base enclosure (Figure 3-12).

Page 47

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> CAUTION <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Do not bend the support loop.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

6. Lift the display assembly out of the computer by sliding it to the right

to pull the display pin out of the support loop. (Figure 3-13).

Page 48

To replace the display assembly, follow these steps:

1. Position the display assembly by aligning the display clutch and pin

with the support loop and keyed bushing (Figure 3-14).

Page 49

2. Reattach the screw to the base enclosure and clutch.

To reconnect the display cable to the system board, follow these steps

(Figure 3-15):

1. Insert the display cable into the ZIF connector and lightly press the

slider down to lock the connector.

2. Push the curved portion of the display cable inward with your finger,

remove your finger, close the computer, and immediately reopen.

The display cable should pop into place around the hinge forming an "S"

shape.

Page 50

Display Inverter Board

To remove the display inverter board, follow these steps:

1. Remove the display bezel (Figures 3-5 and 3-6).

2. Remove the display cable and the backlight cable from the display

inverter board in the bottom of the display enclosure by gently pulling

the cables toward you, then unplugging from the inverter board LIF

connector (Figure 3-16).

Page 51

3. Lift the inverter board out of the display enclosure (Figure 3-17).

Page 52

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> CAUTION <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

When servicing these units, ensure that cables are placed in their proper

location to avoid pinching during the reassembly process. Improper cable

placement can cause severe damage to the unit.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

To replace the inverter board, follow these steps:

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> CAUTION <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

These steps must be followed whenever replacing any component in the

display assembly because of high susceptibility to electrostatic discharge,

which will damage the LCD panel.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

1. Attach the inverter board LIF connector to the display cable.

2. Attach the backlight cable to the inverter board.

3. Align the inverter board with the three mounting posts.

Liquid Crystal Display Panel

Page 53

To remove the backlit liquid crystal display (LCD) panel, follow these

steps:

1. Remove the display bezel (Figures 3-5 and 3-6).

2. Remove the remaining two top left screws and the one top right screw

that secure the LCD panel to the display enclosure (Figure 3-18).

3. Remove the top clutch screw and ground clip bracket in the bottom right

corner of the display enclosure (Figure 3-18).

4. Carefully rotate the LCD panel to the left and out of the display

enclosure (Figure 3-19).

Page 54

5. Remove the display cable from the rear of the LCD panel by gently

pulling the cable toward you (Figure 3-20).

6. Carefully lift up on the ZIF connector to release the display cable from

the side of the LCD panel (Figure 3-20).

Page 55

To replace the LCD panel, follow these steps:

1. Remove the pressure sensitive adhesive backing from the back of the

display cable. Align the holes in the cable with the mounting pins on

the display enclosure.

2. Connect the display cable to the LCD panel with the ZIF connector.

3. Lay the LCD panel into the display enclosure with the bottom of the

display cable exposed.

4. Secure the LCD panel with three screws to the display enclosure.

5. Secure the support bracket with one screw in the bottom right corner of

the display enclosure.

Latch, Clutch, Pin, and Display Shield

To remove and replace the latch from the middle of the display enclosure,

the clutch, pin, and the display shield, follow these steps (Figure 3-21):

1. Remove the display bezel (Section 3.5).

2. Using a small flat bladed screwdriver, remove the spring from the latch.

Page 56

Pry the latch away from the display enclosure.

3. Using a Phillips screwdriver, remove the remaining screw from the clutch

and then remove the clutch out of the display enclosure.

4. Remove the two screws from the pin and remove the pin from the display

enclosure.

5. Remove the display shield by lifting it out of the display enclosure

(Figure 3-22).

Page 57

To replace the display shield, lay it inside of the display enclosure.

To replace the latch, attach the spring to the latch and snap them into the

display enclosure.

To replace the clutch and pin, reverse the previous steps.

Compaq Contura Aero 4/33C Display

To remove the color VGA backlit display assembly from the Compaq Contura

Aero 4/33C Personal Computer, follow these steps:

1. Remove the battery pack (Section 3.4).

2. Remove the display bezel (Figures 3-5 and 3-6).

3. Remove the CPU cover (Section 3.5).

4. Remove the keyboard (Section 3.6).

5. Release the ZIF connector attaching the display cable to the system

board (Figure 3-23).

Page 58

6. Release the clutch from the display enclosure by removing the remaining

screw on the back of the base enclosure (Figure 3-24).

Page 59

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> CAUTION <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Do not bend the support loop.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

7. Lift the display panel assembly out of the computer by sliding it to

the right to pull the display pin out of the support loop

(Figure 3-25).

Page 60

To replace the display panel assembly, follow these steps:

1. Position the display assembly by aligning the display clutch and pin

with the support loop and keyed bushing (Figure 3-26).

Page 61

2. Reattach the screw to the base enclosure and clutch.

To reconnect the display cable to the system board, follow these steps

(Figure 3-27):

1. Insert the display cable into the ZIF connector and lightly press the

slider down to lock the connector.

2. Push the curved portion of the display cable inward with your finger,

remove your finger, close the computer, and immediately reopen.

The display cable should pop into place around the hinge forming an "S"

shape.

Page 62

Display Inverter Board

To remove the display inverter board, follow these steps:

1. Remove the display bezel (Figures 3-5 and 3-6).

2. With a Phillips screwdriver, remove the three screws that secure the

inverter board to the display enclosure (Figure 3-28).

Page 63

3. Gently lift the inverter board out of the display enclosure and unplug

the display cable and the backlight cable (Figure 3-29).

Page 64

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> CAUTION <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

When servicing these subassemblies, ensure that cables are placed in their

proper location to avoid pinching during the reassembly process. Improper

cable placement can cause severe damage to the computer.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

To replace the inverter board, follow these steps:

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> CAUTION <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Because of high susceptibility to electrostatic discharge that will damage

the LCD panel, these steps must be followed whenever replacing any

component in the display assembly.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

1. Connect the inverter board connector to the display cable.

2. Connect the backlight cable to the inverter board.

3. Place the inverter board with the component side down on the right side

of the display enclosure and secure with three screws.

Page 65

Liquid Crystal Display Panel

To remove the backlit liquid crystal display (LCD) panel, follow these

steps:

1. Remove the display bezel (Section 3.5).

2. Remove the remaining four screws that secure the LCD panel to the

display enclosure and carefully bend back the tabs that secure the

display shield to the LCD panel (Figure 3-30).

3. Carefully rotate the LCD panel to the left and out of the display

enclosure (Figure 3-31).

Page 66

4. Remove the display cable from the rear of the LCD panel by gently

pulling the cable toward you (Figure 3-32).

5. Carefully lift up on the ZIF connector to release the display cable from

the side of the LCD panel (Figure 3-32).

Page 67

To replace the LCD panel, follow these steps:

1. Remove the pressure sensitive adhesive backing from the back of the

display cable. Align the holes in the cable with the mounting pins on

the display enclosure.

2. Connect the display cable to the LCD panel by inserting it into the ZIF

connector.

3. Lay the LCD panel into the display enclosure with the bottom of the

display cable exposed.

IMPORTANT: Ensure that the ferrite [1] on the display cable is not pinched

between the display enclosure and the ZIF connector [2]

(Figure 3-33).

Page 68

4. Carefully press down the tabs of the display shield back into place.

5. Secure the LCD panel with four screws to the display enclosure.

Latch, Clutch, Pin, and Display Shield

To remove and replace the latch, the clutch, and display shield from the

display assembly, follow these steps:

1. Remove the remaining four screws that secure the LCD panel to the

display enclosure and carefully bend back the tabs that secure the

display shield to the LCD panel and remove the LCD panel (Figures 3-30,

3-31).

2. Using a Phillips screwdriver, remove the screws from the clutch and the

pin (Figure 3-34).

3. Lift the display shield out of the display enclosure (Figure 3-34).

Page 69

4. Using a small flat bladed screwdriver, remove the spring from the latch.

Pry the latch away from the display enclosure [1] (Figure 3-35).

5. Remove the clutch [2] and the pin [3] out of the display enclosure

(Figure 3-35).

Page 70

To replace the display shield, lay it inside of the display enclosure.

To replace the latch, attach the spring to the latch and snap them into the

display enclosure.

Chapter 3.8 Removing The DC-DC Power Supply

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> CAUTION <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Before removing the CPU cover, be sure the AC Adapter is unplugged and the

battery pack is removed from the battery compartment. If the battery pack

remains in the battery compartment, it will damage the power supply.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

To remove the power supply, follow these steps:

1. Remove the battery pack (Section 3.4).

2. Remove the display bezel (Figures 3-5 and 3-7).

3. Remove the CPU cover (Section 3.5).

4. Remove the keyboard (Section 3.6).

Page 71

5. Remove the threaded standoff that secures the power supply

(Figure 3-36).

6. Gently grasp the power supply and pull up to unplug (Figure 3-36).

To replace the power supply, reverse the previous steps.

Chapter 3.9 Removing The Trackball/Buttons/Speaker Assembly

To remove the trackball, follow these steps:

1. Remove the battery pack (Section 3.4).

2. Remove the display bezel (Figures 3-5 and 3-6).

3. Remove the CPU cover (Section 3.5).

4. Remove the keyboard (Section 3.6).

5. Using a small screwdriver, remove the two screws that secure the

trackball to the base (Figure 3-37).

Page 72

6. With the Case utility tool, disconnect the trackball cable from the

system board connector. (Figure 3-38).

Page 73

7. Remove the trackball, speaker, and cable assembly. Unplug the trackball

from the cable/buttons/speaker assembly (Figure 3-39).

Page 74

To replace the trackball/cable assembly, follow these steps:

1. Connect the trackball to the small tab on the cable assembly

(Figure 3-40).

Page 75

2. Fold up the trackball and fold back the button section of the cable

(Figure 3-41).

3. Place the speaker in the recessed area in the right front corner of the

base enclosure and the buttons in the recessed area on the right and

secure with two screws (Figure 3-41).

Page 76

4. Route the speaker wires over the trackball and around the base enclosure

screw hole (Figure 3-42).

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> CAUTION <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

The trackball cable and speaker wires must be routed carefully to prevent

them from being pinched when the CPU cover is replaced.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Page 77

5. Route the folded portion of the trackball cable behind and over the hard

drive. Plug the cable into the system board LIF connector (Figure 3-43).

Page 78

Chapter 3.10 Removing The Hard Drive

To remove the hard drive, follow these steps:

1. Remove the battery pack (Section 3.4).

2. Remove the display bezel (Figures 3-5 and 3-7).

3. Remove the CPU cover (Section 3.5).

4. Remove the keyboard (Section 3.6).

5. Disconnect the trackball cable from the system board, but do not remove

the trackball cable assembly completely (Section 3.9).

6. Remove the hard drive and bracket assembly from the system chassis by

gently sliding the hard drive bracket horizontally off the system board

connector (Figure 3-44).

IMPORTANT: Do not pull up on the hard drive before the system board

connector and drive connector are disengaged.

7. After the connectors separate, lift the hard drive and the bracket

straight up and out of the computer (Figure 3-44).

Page 79

8. To remove the hard drive bracket from the hard drive, with a P1

screwdriver, remove the three screws from the sides of the bracket and

slip the hard drive out of the bracket. (Figure 3-45).

IMPORTANT: Ensure that the screwdriver tip fits the recess properly or

damage may occur to the screw head.

Page 80

To replace the hard drive, follow these steps:

1. Place the hard drive inside the hard drive bracket and align the holes

on the side.

2. Align the hard drive inside the bracket by inserting the screws into the

holes, then tightening the screws.

3. Slide the hard drive bracket into the system chassis.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>> CAUTION <<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

To prevent damage to the system board connectors ensure that the hard drive

is aligned correctly.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<<

Chapter 3.11 Removing The System Board

Before you can remove the system board, you must remove the optional memory

expansion board, optional base unit, and the optional PCMCIA external

drive, if applicable.

To remove the system board, follow these steps:

Page 81

1. Remove the battery pack (Section 3.4).

2. Remove the display bezel (Figures 3-5 and 3-6)

3. Remove the CPU cover (Section 3.5).

4. Remove the keyboard (Section 3.6).

5. Remove the power supply (Section 3.8).

6. Remove the trackball (Section 3.9).

7. Remove the hard drive (Section 3.10).

8. Using a hex socket driver, remove the six screw locks from the rear of

the computer that secure the connectors to the chassis (Figure 3-46).

9. Open the computer and remove the two remaining standoffs from the system

board with a hex socket driver (Figure 3-47).

Page 82

10. Remove the two Phillips screws from the PCMCIA rails (Figure 3-48).

Page 83

11. Remove the three remaining screws from the system board (Figure 3-49).

NOTE: An insulator must be present under the center screw. If the insulator

is not present, order a new system board.

Page 84

12. Rotate the system board out of the system chassis (Figure 3-50).

Page 85

13. Slide the PCMCIA rails out of the system board (Figure 3-51).

Page 86

To replace the system board, reverse the previous steps.

Real Time Clock Battery

To remove the real time clock battery, follow these steps:

1. Remove the display bezel (Figures 3-5 and 3-6).

2. Remove the CPU cover (Section 3.5).

3. Remove the keyboard (Section 3.6).

4. Remove the real time clock battery from the system board by inserting a

nonconductive probe into the battery holder and pushing back on the

battery to release it (Figure 3-52).

Page 87

To replace the real time clock battery, reverse the previous steps.

Chapter 3.12 Removing The Chassis

To remove the system chassis, follow these steps:

1. Remove the battery pack (Section 3.4).

2. Remove the display bezel (Figures 3-5 and 3-6).

3. Remove the CPU cover (Section 3.5).

4. Remove the keyboard (Section 3.6).

5. Remove the VGA backlit display.

6. Remove the power supply (Section 3.8).

7. Remove the trackball (Section 3.9).

8. Remove the hard drive (Section 3.10).

9. Remove the system board (Section 3.10).

10. Remove the system chassis by gently separating it from the computer

Page 88

base and lifting it out (Figure 3-53).

To replace the system chassis, reverse the previous steps.

Page 89

Chapter 4. Power On Self Test (POST)

Chapter 4.0 Introduction

This section lists the assemblies checked by the Power On Self Test (POST).

The section also includes procedures for clearing the power on password.

Chapter 4.1 POST

POST is a series of diagnostic tests that run automatically when the system

is turned on. POST checks the following assemblies to ensure that the

computer system is functioning properly:

o Keyboard

o Power supply

o System board

o System memory

o Memory expansion board

o Controller circuitry

o VGA display

o Hard drive

POST also detects the type of mass storage device installed in the

computer. If POST finds an error in the system, an error condition is

indicated by an audible and/or visual message. Refer to Chapter 5, "Error

Messages and Codes," for more information about the error codes and a

recommended course of action.

Chapter 4.2 Preliminary Steps

If you encounter an error condition, complete the following steps before

starting troubleshooting procedures:

1. Turn off the computer by holding down the FN key and pressing the power

button. Do not remove the battery pack.

2. Remove the computer from the base unit, if applicable. Connect the AC

Adapter. Connect the printer if you want to test it or use it to log

error messages.

3. Install all appropriate loopback plugs and terminating plugs for

complete testing.

4. Turn on the computer by pressing the power button.

5. Clear the power on password, if preset by the user.

You will know that the power on password is set when a key icon (o--m)

appears on the screen when POST completes. If this occurs, you must

enter the password to continue. If you enter the password incorrectly,

a broken key icon (o-x-m) is displayed. Try again. After three

unsuccessful tries, you must turn off the computer, then on again before

Page 90

you can continue. To delete the password, type the current password

immediately followed by a backslash (\) and press the Enter key.

NOTE: If you don't have access to the power on password, you must

disable the power on password by removing the real time clock

battery. Refer to section 3.11, "Real Time Clock Battery," for

removal procedures. Once the real time clock battery is removed,

short the real time clock battery terminals in the processor board

by touching the battery terminals with two ends of a wire. Replace

all components, and resume POST.

Page 91

Chapter 5. Error Messages and Codes

Chapter 5.0 Introduction

This chapter contains Power On Self Test (POST) messages, Diagnostic error

codes, and memory error codes.

The messages and codes appear in tables that include a description of the

error, the probable cause, and the recommended action that should be taken

to resolve the error condition.

Chapter 5.1 Power On Self Test Messages

An error message results if a problem is encountered from the Power On Self

Test utility. This utility runs automatically when the system is turned

on.

Table 5-1 lists the messages for POST, the audible (beep) message, probable

cause, and recommended action.

Table 5-1. Power On Self Test Messages

===========================================================================

Message: 101 ROM Error

Beeps: 1 Long, 1 Short (Beeps can be disabled by the user from

the Computer Setup utility.

Probable Cause: ROM checksum option

Recommended Action: 1. Verify the correct ROM.

2. Replace the system board.

---------------------------------------------------------------------------

Message: 101 ROM Error

Beeps: 1 Long, 1 Short (Beeps can be disabled by the user from

the Computer Setup utility.

Probable Cause: System ROM

Recommended Action: 1. Verify the correct ROM.

2. Replace the system board.

---------------------------------------------------------------------------

Message: 101 ROM Error

Beeps: 1 Long, 1 Short (Beeps can be disabled by the user from

the Computer Setup utility.

Probable Cause: VDU ROM checksum error

Recommended Action: 1. Verify the correct ROM.

2. Replace the system board.

---------------------------------------------------------------------------

Message: 101 ROM Error

Beeps: 1 Long, 1 Short (Beeps can be disabled by the user from

the Computer Setup utility.

Page 92

Probable Cause: System, ROM checksum error

Recommended Action: 1. Verify the correct ROM.

2. Replace the system board.

---------------------------------------------------------------------------

Message: 101 ROM Error

Beeps: 1 Long, 1 Short (Beeps can be disabled by the user from

the Computer Setup utility.

Probable Cause: Second system ROM does not pass the checksum

Recommended Action: 1. Verify the correct ROM.

2. Replace the system board.

---------------------------------------------------------------------------

Message: 101 ROM Error

Beeps: 1 Long, 1 Short (Beeps can be disabled by the user from

the Computer Setup utility.

Probable Cause: Option ROM does not pass the checksum

Recommended Action: 1. Verify the correct ROM.

2. Remove PCMCIA card and retest.

3. Replace the system board.

---------------------------------------------------------------------------

Message: 102 System Board Failure

Beeps: None (Beeps can be disabled by the user from the

Computer Setup utility.

Probable Cause: System Board