Page 1

Cut Sheet Printers

Maintenance Manual

Model C40D

E1195

HP Part No. C4672-90005

Page 2

Notice

Hewlett-Packard makes no warranty of any kind with regard to this material, including,

but not limit ed to, the implied warranties of merchantabil ity and fitness for a particular

purpose. Hewlett-Packard shall not be liable for errors contained herein or for incidental

or consequential damages in connection with the furnishing, performance, or use of this

material.

Hewlett-Packard assumes no responsibility for the use or reliability of its software on

equipment that is not furnished by Hewlett-Packard.

This document contains proprietary information which is protected by copyright. All

rights are reserved. No part of this document may be photocopied, reproduced, or translated to another language without the prior written consent of Hewlett-Packard Company.

The information contained in this document is subject to change without notice.

Hewlett-Packard Company

System Peripherals Operation

MS 44MC

19111 Pruneridge Avenue

Cupertino, CA 95014

Printing History

New editions are complete revisions of the manual. Update pages, which are issued

between editions, contain additional and replacement pages to be merged into the manual

by the customer. The date on the title page changes only when a new edition or a new

update is published. No in for mat ion is incorporated into a r eprinting unless it ap pears as a

prior update; the edition does not change when an update is incorporated.

The software code printed alongside the date indicates the version level of the software

product at the time the manual or update was issued. Many product updates and fixes do

not require manual changes and, conversely, manual corrections may be done without

accompanying product changes. Therefore, do not expect a one-to-one correspondence

between product updates and manual updates.

Edition 1 . . . . . . . . . . . . . . . . . . . . . . . . . . .November 1995

Edition 2. . . . . . . . . . . . . . . . . . . . . . . . . . .June 1999

ii June 1999

Page 3

Preface

The C40D Maintenance Manual contains all the information needed to maintain and service Hewlett Packard C40D printers. The C40D printer series are high-speed, non-impact

printers utilizing electrophotographic imaging technology.

The informati on in this manua l is for authorized field repre sentatives wh o are familiar

with basic printer operations. It serves as a supplement to training classes and provides a

basis for discussi on with regional field se rvice engineers and c ust omer s uppor t representatives.

Using This Manual

This manual is organized into the following sections:

Section 1, Troubleshooting

Reviews the organization of the manual, the way the printer works, and how to troubleshoot the printer, including some standard procedures to follow when troubleshooting.

This chapter also inclu des a char t d etail ing ex actly what each c auses e ach error code, i llus trations of all senso rs in the print er, and a list of abbre viati ons use d th roughou t the manual.

Section 2, TAG Cross- Reference Tables

Provides cross-refe re nce tables; look up specific printer problem descrip ti on (in either the

mechanical malfunction, error code, or print quality description tables), then turn to the

TAG indicated on the chart to troubleshoot the problem.

Section 3, Troubleshooting Analysis Guides

Detailed step-by-s tep p rocedu res t o hel p you i solat e and reso lve s peci fic pr inter probl ems.

If you are not sure which TAG to start with, begin with the overview, TAG 001.

Section 4, Print Quality Samples

Shows print test patte rns in dicat ing spec ific proble ms, and refer encin g the TAG that treats

each problem.

Section 5, Diagnostic Tests

Reviews each printer software diagnostic.

Section 6, Wiring Diagrams and Electrical Data

Shows printer schematics and locations of individual components.

Section 7, Removal/Replacement Procedures

Outlines procedures to follow when removing and replacing printer parts, also called

FRUs (Field-Replaceable Units).

June 1999 iii

Page 4

Section 8, Options

Provides information about the optional High Capacity Input and High Capacity Output

bins.

Section 9, General Printer Maintenance

Reviews printer maintenance procedures to complete during service calls.

Index

Provides a list of references to topics mentioned in this manual.

Other Manuals

The C-Series Illustrated Parts Catalog shows every FRU and CRU (customer-replaceable

unit) in the printer, including part number information. This information is frequently

updated.

The C40D Installation Manual, C4672-90007, guides you through unpacking, setup, test-

ing, and network configuration of your C40D printer.

The C40D Operator’s Manual, C4672-90006, contains all the informat ion nee ded to oper-

ate Hewlett Packard C40D printers.

The C40D Technical Reference Manual, C4672-60012, is a complete guide to using fonts

and the PJL and PostScript emulations on the C40D. It also documents aspects of printer

usage in detail.

The Cut Sheet Printers Paper Specifications Guide, C4672-90002, explains the various

kinds of papers usable in the printer, how to care for them, and how to minimize paperrelated problems with the C40D.

Copyright ©1999 Hewlett Packard, Inc. All rights reserved.

November 1995

Please address any comments or questions with respect to this document to:

Publications Manager

System Peripherals Operation

MS 44MC

Hewlett-Packard Company

19111 Pruneridge Avenue

Cupertino, CA 95014

iv June 1999

Page 5

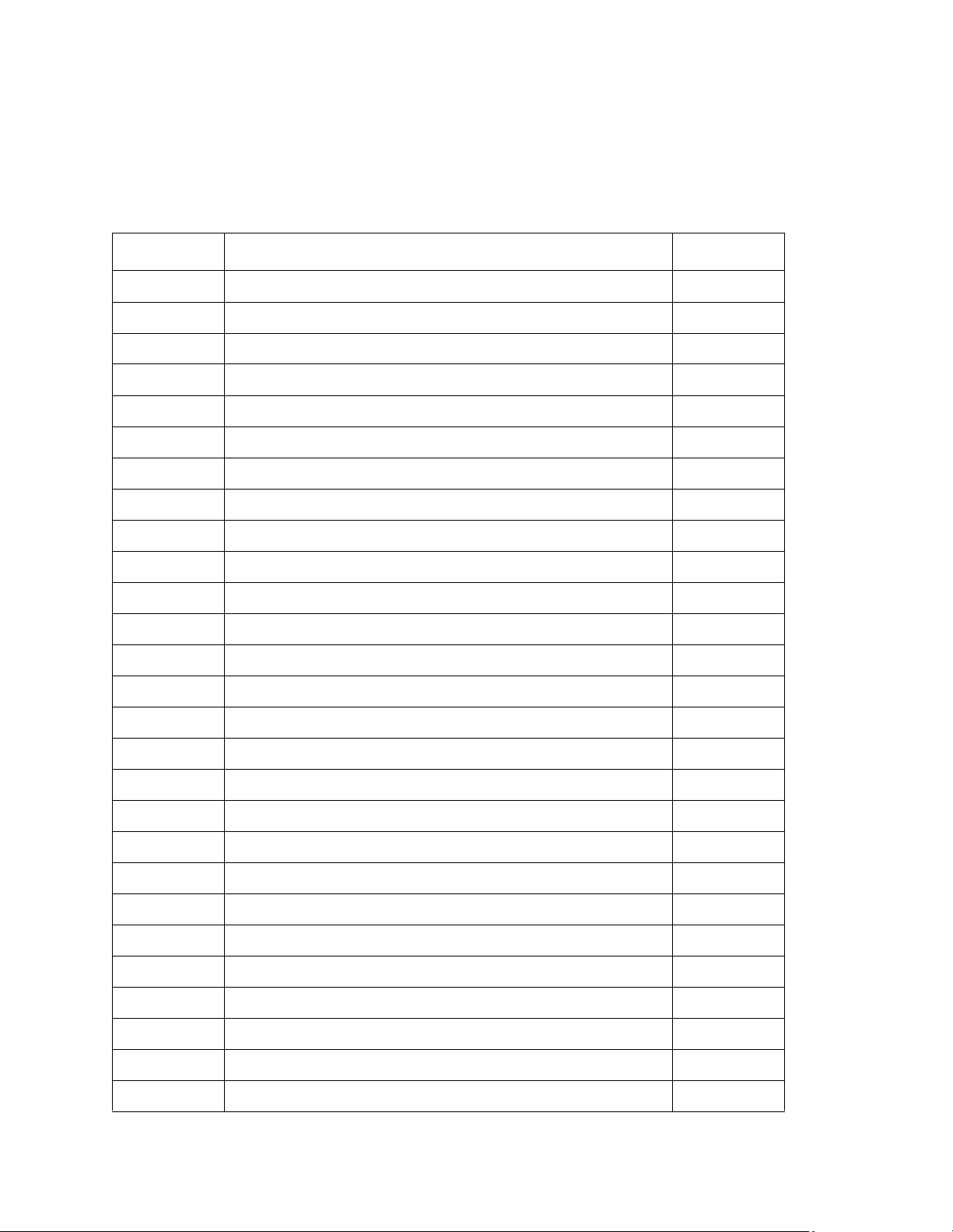

Troubleshooting

Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

The Printing Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Paper Path and Cycle Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Simplex Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Duplex Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Sensors and Switches Illustrations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Sensor and Switch Listing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

General Troubleshooting Tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

The Problem: Printer or Host?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Running Test Prints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Protocol Converters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Reading the Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Confirming Line Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Using the Troubleshooting Analysis Guide (TAG) . . . . . . . . . . . . . . . . . . . . 1-15

Sample TAG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Contents

Contents

Standard Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Power-on-reset (POR). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Checking Continuity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Installing the Interlock By-pass Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Producing a Developed Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Producing a Toner Patch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Completing a Service Call. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Clearing the Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Error Message and Code Technical Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

TAG Cross-Reference Tables

Error Code/TAG Cross-Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Print Quality/TAG Cross-Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Mechanical Malfunction/TAG Cross-Reference. . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Troubleshooting Analysis Guides

TAG 001: Troubleshooting a Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

TAG 002: Check Problem Resolution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

TAG 010: Upper Cassette Malfunction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

June 1999 v

Page 6

Contents

TAG 011: Lower Cassette Malfunction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

TAG 012: Upper Cassette Not Latched . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

TAG 013: Lower Cassette Not Latched. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

TAG 020: Paper Jam/Misfeed in Upper Cassette Area . . . . . . . . . . . . . . . . . . . . .3-19

TAG 021: Paper Jam/Misfeed in Lower Cassette Area . . . . . . . . . . . . . . . . . . . . .3-22

TAG 022: Paper Jam in the Transfer or Fuser Area. . . . . . . . . . . . . . . . . . . . . . . .3-26

TAG 023: Paper Jam in the Output Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-30

TAG 025: Paper in Input Area Before Printing . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

TAG 026: Paper in Output Area Before Printing. . . . . . . . . . . . . . . . . . . . . . . . . .3-34

TAG 030: Developer Bias Short/Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-36

TAG 031: Toner Patch Reference Level Incorrect. . . . . . . . . . . . . . . . . . . . . . . . .3-39

TAG 032: Toner Patch Too Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-41

TAG 035: Out of Toner or ADD TONER Indication . . . . . . . . . . . . . . . . . . . . . .3-43

TAG 036: Developer Not Installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-45

TAG 040: Photoconductor Seam Sensor Malfunction. . . . . . . . . . . . . . . . . . . . . .3-46

TAG 044: Charge Corona/Transfer Corona Circuit Open. . . . . . . . . . . . . . . . . . .3-49

TAG 045: Charge Corona Circuit Shorted. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-52

TAG 047: PC Life Data Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-54

TAG 048: Developer Life Error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-55

TAG 050: Transfer Corona Circuit Shorted. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-56

TAG 055: Erase Lamp Malfunction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-58

TAG 070: Fuser Malfunction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-60

TAG 071: Open Fuser/Thermistor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-65

TAG 072: Fuser Temperature Too High . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-66

TAG 097: +12 Vdc Power Shorted or Sensing Problem . . . . . . . . . . . . . . . . . . . . 3-68

TAG 098: -12 Vdc Power Shorted. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-78

TAG 099: +24 Vdc Power Shorted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-80

TAG 100: VPCL Board Interface Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . .3-89

TAG 130: Disk Drive Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-90

TAG 200: RIGS Internal Communication Malfunction. . . . . . . . . . . . . . . . . . . . .3-95

TAG 201: RIGS-VPCL Interface Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . .3-97

TAG 405: RIGS Bit-Map RAM Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-99

TAG 500: +5 Vdc Power Malfunction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-100

TAG 600: Vac Power Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-105

TAG 610: Operator Panel Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-112

vi June 1999

Page 7

Contents

TAG 700: Output Tray Circuit Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-115

TAG 702: Paper Size Detection Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-117

Wiring for the Upper Paper Size Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-119

Wiring for the Lower Paper Size Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-119

TAG 703: Upper Cassette Malfunction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-120

TAG 704: Lower Cassette Malfunction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -121

TAG 705: Multiple Paper Feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-122

TAG 706: Paper Damaged or Wrinkled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-123

TAG 707: Upper Paper Guide Assembly Not Closing . . . . . . . . . . . . . . . . . . . . 3-124

TAG 750: Counter Malfunction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-125

TAG 751: Main Drive Motor Runs Continuously. . . . . . . . . . . . . . . . . . . . . . . . 3-127

TAG 753: Async IO Communications Malfunction . . . . . . . . . . . . . . . . . . . . . . 3-128

TAG 754: Smart I/O Card Malfunction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-131

TAG 800: Prints Blank or With Dark Horizontal Bands. . . . . . . . . . . . . . . . . . . 3-133

TAG 801: Prints Light or Light With Carrier Particles. . . . . . . . . . . . . . . . . . . . 3-137

TAG 802: Prints With Voids or White Spots . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-142

TAG 803: Prints With Light or White Vertical Streaks . . . . . . . . . . . . . . . . . . . 3-144

TAG 804: Prints With Light Horizontal Bands. . . . . . . . . . . . . . . . . . . . . . . . . . 3-145

TAG 805: Black Prints. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-146

TAG 806: Prints with Dark Spots or Scratches. . . . . . . . . . . . . . . . . . . . . . . . . . 3-148

TAG 807: Misregistered/Skewed Prints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-150

TAG 808: Prints Overtoned/Dark Vertical Streaks. . . . . . . . . . . . . . . . . . . . . . . 3-153

TAG 809: Blurred or Smeared Vertical Streaks on Prints. . . . . . . . . . . . . . . . . . 3 -157

TAG 810: Uneven Density or Dark Areas on Prints . . . . . . . . . . . . . . . . . . . . . . 3-161

TAG 811: Background/Residual Images/Dark Prints . . . . . . . . . . . . . . . . . . . . . 3-162

TAG 812: Uneven or No Fusing on Prints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-166

TAG 813: Residual Images on Prints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-168

TAG 815: Prints Resulting From Printhead Malfunctions . . . . . . . . . . . . . . . . . 3-170

TAG 900: Top Cover Interlock Malfunction, Duplex. . . . . . . . . . . . . . . . . . . . . 3-171

TAG 901: Misregistration/Skewed Prints (Duplex) . . . . . . . . . . . . . . . . . . . . . . 3-173

TAG 902: Paper Jam in Duplex Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-177

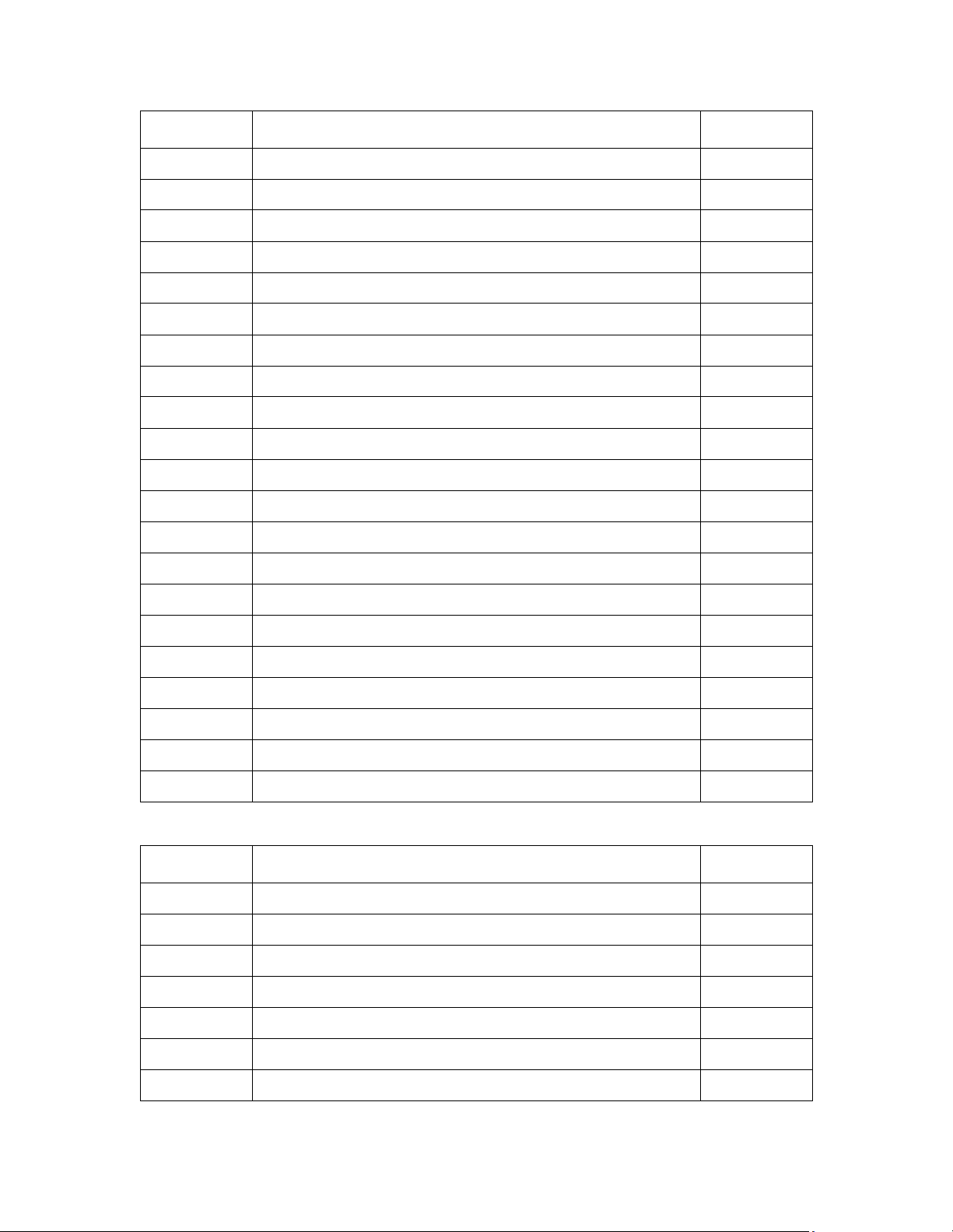

Print Quality Samples

Sample 1: Good Quality Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Sample 2: Washout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Sample 3: Blank Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Sample 4: Light Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

June 1999 vii

Page 8

Contents

Sample 5: Light Print With Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Sample 6: Voids or White Spots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Sample 7: Light Vertical Streaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Sample 8: Blank Vertical Bands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Sample 9: Light Horizontal Bands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Sample 10: Black or Dark Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

Sample 11: Dark Specks, Lines, or Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Sample 12: Dark Vertical Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Sample 13: Skewed Prints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Sample 14: Misregistration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Sample 15: Overtoned Print. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Sample 16: Blurred Images or Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-19

Sample 17: Varying Print Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

Sample 18: Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Sample 19: Residual Images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

Sample 20: Wrinkles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-23

Sample 21: Fusing Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

Diagnostic Tests

How to Run Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 -3

Operator Panel Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Upper Cassette Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Lower Cassette Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Fuser Thermistor Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Sensor Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Roller Clutch Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Counter Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Jogging Motor Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Photoconductor Seam Sensor Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Toner Supply Motor Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Charge Corona Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Transfer Corona Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Erase Lamp Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Toner Empty Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Negative Developer Bias Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Duplex Motor Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

Duplex Sensor Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

Duplex Clutch Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 -13

Duplex Tray Paper-Guide Motor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

viii June 1999

Page 9

High-Capacity Output (HCO) Sensor Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

High-Capacity Input (HCI) Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

LED Printhead Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

RIGS Board Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Com. Wrap Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Display File Version Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Format Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Clear Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Disk Drive Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Wiring Diagrams and Electrical Data

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Printhead Circuit Board Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Connector (J/P) Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Acronyms and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Connectors Inside the Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Contents

Connectors Inside the Left Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Connectors on the Duplex Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Connectors Inside the Right Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Connectors Inside the Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-16

Connectors on the Back Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Connectors Inside the Back Cover (J/P2-14). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Connectors Inside the Back Cover (Continued) J/P 18-62 . . . . . . . . . . . . . . . . . . 6-19

Connectors Inside the Back Cover (Continued) J/P 64-85 . . . . . . . . . . . . . . . . . . 6-20

Connectors Inside the Back Cover (Continued) J/P 90-800 . . . . . . . . . . . . . . . . . 6-21

Voltage Isolation Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

-12 Vdc Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

+5 Vdc Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 -22

+12 Vdc Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

+24 Vdc Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

Ground System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Host Interface Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

RS-232C Host Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

Standard DCE to DTE RS-232C Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

Special Considerations for RS-232 Host Interface Users. . . . . . . . . . . . . . . . 6-29

DTE Host to Printer (Option 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

DTE Host to Printer (Option 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

IBM PC/XT to Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

IBM PC/AT to Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

Macintosh Communication Port to Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

June 1999 ix

Page 10

Contents

Centronics Parallel Host Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-33

IBM Parallel to Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-34

Removal/Replacement Procedures

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

Power Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

Photoconductor Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

Front Cover Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

Back Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

Left Side Cover Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-7

Right Side Cover Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

Vacuum Transport Unit Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-9

Rear Duplex Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-10

Front Duplex Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-11

Operator Panel Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-12

Counter Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-13

RIGS Board Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-14

VPCL Board Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-15

Printhead Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-16

Printhead Circuit Board (ARIF) Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-18

Hard Disk Drive Housing Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-19

Floppy and Hard Disk Drive Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-20

Cooling Fan Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-21

Toner Motor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-22

This space left blank intentionally. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-23

AC Power Supply Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-24

DC Power Supply Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-26

High Voltage Unit Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 -27

Photoconductor Seam Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-28

Photoconductor Rear Guide Rail Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-30

Power Control Board Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-33

Upper or Lower Paper Size Sensor Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-34

Upper Cassette Mount Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-35

This space left blank intentionally. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-39

Lower Cassette Mount Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-40

This space left blank intentionally. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-44

Upper Paper Guide Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-45

Upper Paper Guide Roller Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-47

x June 1999

Page 11

Contents

ULower Paper Guide Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-48

Paper Timing Guide Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-49

Cleaner Drive Belt Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-51

Cleaner Drive Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-52

Fuser Drive Belt Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-53

Fuser Drive Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-54

Paper Feed Drive Belt Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-55

Paper Timing Roller Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-56

Upper Feed Roller Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-57

Lower Feed Roller Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-58

Upper Pick-Up Roller Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-59

Pick-Up Roller Drive Idler Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-60

Pick-Up Roller Drive Gear Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-61

Lower Pick-Up Roller Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-62

Exit Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-63

Exit Pinch Roller Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-65

Upper Static Brush Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-67

Lower Static Brush Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-68

Exit Roller Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 -69

Exit Cover Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-71

Paper Exit Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-73

Paper Full Sensor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-74

Front Cover Interlock Switch Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-75

Back Cover Interlock Switch Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-76

Top Cover Interlock Switch Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-77

Erase Lamp Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 -78

EP Cover Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-79

Main Motor Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-82

Main Gear Drive Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-85

Duplex Control Board #1 Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-86

Duplex Control Board #2 Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-87

Duplex Tray Registration Motor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-88

Duplex Skew Correction Cable Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-89

Upper Duplex Drive/Clutch Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . . . 7-91

Duplex Route Motor/Solenoid Assembly Removal . . . . . . . . . . . . . . . . . . . . . . . 7-92

“A” Roller Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-93

June 1999 xi

Page 12

Contents

“B” Roller Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-94

“C” Roller Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-96

“C” Roller Solenoid Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-97

Duplex Route Separator Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-98

Duplex Paper Path Sensor Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-99

Options

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

1200-Sheet/2500-Sheet Feeder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-4

Guide to Component Acronyms/Physical Locations. . . . . . . . . . . . . . . . . . . . .8-4

Bench Test Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

Prefeed Adjustment Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-7

1200-Sheet Feeder Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-7

2500-Sheet Feeder Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-7

Connection Diagram for 1200-Sheet/2500-Sheet Feeder. . . . . . . . . . . . . . . . . . . . .8-8

Connection Diagram for 1200-Sheet /2500-Sheet Feeder . . . . . . . . . . . . . . . . . . . .8-8

Input Control Board Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

1400-Sheet Stacker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-10

Guide to Component Abbreviations/Physical Locations. . . . . . . . . . . . . . . . .8-10

Bench Test Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-11

Connector Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-13

Front View (cover removed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-13

Left Side View (left cover removed). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-13

Rear Side View (cover removed). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 -14

Top View (top cover removed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-14

Connection Diagram for the 1400-Sheet Stacker . . . . . . . . . . . . . . . . . . . . . . . . . .8-15

Output Control Board Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 -16

General Printer Maintenance

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 -4

Tool Requirements: Service Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-4

Tools/Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-5

Printer/Maintenance Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-5

Printer Maintenance Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-6

Every-Call Cleaning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-7

Adjusting Paper Feed Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-10

Adjusting Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-11

Lubrication Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-12

xii June 1999

Page 13

Contents

Front View Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

Front View Lubrication Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

Rear View Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

Rear View Lubrication Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

Top View Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

Duplex Holding Tray Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-18

Tune-Up Maintenance Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

June 1999 xiii

Page 14

Contents

xiv June 1999

Page 15

Troubleshooting

Section 1 T roubleshooting

Section 1

June 1999 Troubleshooting 1-1

Page 16

Troubleshooting

Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

The Printing Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Paper Path and Cycle Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Simplex Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Duplex Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Sensors and Switches Illustrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Sensor and Switch Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

General Troubleshooting Tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

The Problem: Printer or Host?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Running Test Prints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Protocol Converters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Reading the Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

Confirming Line Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

Using the Troubleshooting Analysis Guide (TAG). . . . . . . . . . . . . . . . . . . . .1-15

Sample TAG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

Contents

Standard Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

Power-on-reset (POR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

Checking Continuity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

Installing the Interlock By-pass Tool. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

Producing a Developed Image. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-18

Producing a Toner Patch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-18

Completing a Service Call. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-19

Clearing the Error Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-19

Error Message and Code Technical Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . .1-20

1-2 Troubleshooting June 1999

Page 17

Troubleshooting

The information in this Field Service Manual is directe d towa rd aut hor ized field represen-

tatives who are familiar with basic printer operations. It serves as a supplement to training

classes and provides a basis for discussion with regional field service engineers and customer suppor t representatives.

Theory of Operation

Section 1

Theory of Operation

The printer uses an electrophotographic imaging system, which is based on LED array

technology. Two key components of the printer are the image generation system (RIGS)

controller and the pr inte r contr ol lo gic (AVPCL) boar d. A brie f descr ipti on o f the func tion

of each of these components follows.

Risc Image Generation System (RIGS) controller: Each printer is equipped with an

RIGS controller, which provides the interface between the host computer, the AVPCL

board, the interface cards, and the disk drives.

Video Printer Control Logic (AVPCL) board: The AVPCL board directs the mechanical functions of the printer and print cycle timing, and controls the LED printhead. The

AVPCL board also receives initial machine information, such as empty paper cassettes,

paper jams, and fuser problems.

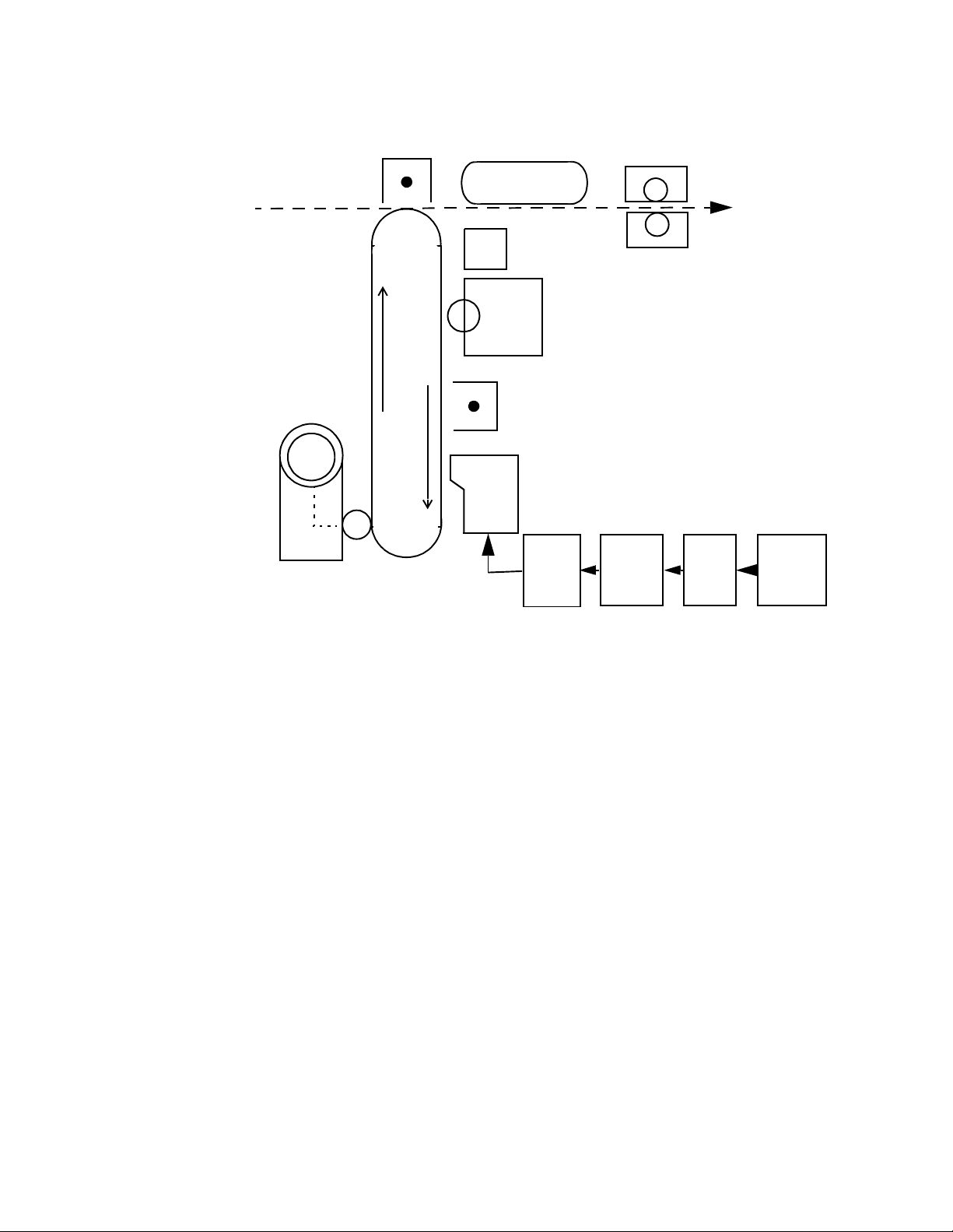

The Printing Process

The illustration on the following page details the printing process. The numbers represent

the sequence of events from the time that the RIGS controller receives data, through the

production of a print image, to the preparation for another print.

1 Receiving data

Host data is receive d t hro ugh the Signal Interf ace PCA and passed to the RISC Imag e

Generating System (RIGS) PCA, which temporar ily st ores the dat a in RAM. The data

may consist of information generated on the host computer and sent over the host

communication interface or it may consist of information generated by printer software, such as a request for test prints or to print the directory of the hard disk.

June 1999 Troubleshooting 1-3

Page 18

Theory of Operation

2Bit Image

The RIGS transforms the host file into a bit map image of 1s and 0s and stores them in

bitmap RAM.

3 Charging the photoconductor belt

When the IGS controller receives data, it causes the AVPCL board to turn on the main

motor, which rotates the photoconductor belt. As the photoconductor belt rotates, the

charge corona applies a high negative charge to it, which repels toner from the photoconductor belt.

4 Exposing the image

The negatively charged belt then passes the LED printhead, where the AVPCL drives

the LEDs on and of f to dischar g e th e are as of the be lt at a den sity of 300 d ots pe r inch .

The 1s in the memory turn the LEDs on; 0s turn the LEDs off. The discharged areas

create a latent mirror image of the print on th e photoconductor belt.

5 Developing the image

As the photoconductor belt continues to rotate, it brings the latent image to the developer. A negative developer bias is applied to toner and the toner is transferred to the

surface of the photoconductor belt. The negatively charged toner (which clings to

small metal carrier beads) is attracted to the discharged areas of the belt; the carrier

beads do not transfer. The belt, with the developed image on its surface, t hen rotates

out of the developer. At this time you can remove the photoconductor belt and read

what is printed on it, which you may need to do when troubleshooting print problems.

6 Activating paper

As the image is be ing de velope d, a she et of paper is t ransp orted to t he phot oconduct or

belt. The AVPCL board controls thi s act i v it y. A series of paper pick-up, feed , an d ti m ing rollers guide the pa per so th e develo ped ima ge is pr operly reg ister ed with t he lead ing edge of the sheet.

7 Transferring the image to the paper

Next, the paper contacts the surface of the photoconductor belt. Above the paper and

the belt is the transfe r cor ona , whic h has a high positive charge, and attracts the devel oped image from the bel t to th e surf ace of t he pape r. At this point, you can remove the

printed image to verify print quality, but the toner is not yet fused.

8 Fusing the image to the paper

The vacuum transport advances the paper with the image to the fuser where heat and

pressure bond the toner to the paper. The print then arrives at the paper output tray.

9 Cleaning routine

After a print is made, the photoconductor belt must be cleaned for the next print. The

belt first passes the erase lamp where any remaining latent image is erased. The belt

continues to the cleaner where a charged brush rotates against th e surface to remove

any residual toner. This toner is recycled to the developer for reuse.

1-4 Troubleshooting June 1999

Page 19

Paper Path and Cycle Sequence

Paper Path and Cycle Sequence

6

Paper Input

Toner

5

Developer

Transfer Corona

7

Photoconductor

Vac uu m Transport

Erase Lamp

9

Cleaner

3

Charge Corona

4

LED Printhead

AVPCL

Fuser

8

Paper

Output

RIGS

Interface

21

HOST

The RIGS board signals t he AVPCL boar d that a page of dat a is r eady t o be pri nted. When

this happens the following sequence takes place.

Simplex Printing

1 AVPCL software downloaded to the AVPCL board from the disk drive system turns

on the main motor.

2 The AVPCL board engages the paper pick clutch which causes the roller to feed a

sheet of paper.

3 The paper is passed to the feed roller where the AVPCL board has engaged the feed

roller clutch.

4 The feed roller passes the p aper to the pap er timing roller. Prior to rea ching the paper

timing roller, the paper passes over the paper timing s ens or. If the paper does not energize this sensor in a specified amount of time, a jam error (020/021) will occur. The

leading edge of the paper is registered against the paper timing roller. The paper timing clutch is engaged and the paper is passed over the photoconductor for transfer.

This registers the paper to the printer and the image to the paper. The paper timing

sensor also signals the AVCPL to begin sending data.

5 The AVPCL board engages the paper timing roller clutch and, at the same time, turns

on the transfer corona to pr ovi de a hi gh positive voltage. The devel oped image on the

photoconductor comes in contact with the paper and the high positive voltage causes

the image to transfer to the p aper.

June 1999 Troubleshooting 1-5

Page 20

Paper Path and Cycle Sequence

6 Because the toner is not yet fixed to the paper, a vacuum transport assembly, gripping

the paper from the back side, moves the paper to the fuser, where heat and pressure

bond the toner to the paper.

7 Upon leaving the fuser, the paper comes in contact with the paper exit sensor. (If the

paper does not energize this sensor in a given amount of time after leaving the paper

timing sensor [step 4], a jam error (022) will occur.)

8 The exit roller moves the paper to the exit tray. (If the exit sensor is not cleared in a

specified amount of time, a jam error (023) will occur.)

Duplex Printing

When duplex is selected, the AVPCL board controls the paper motion with page scheduling assistance from the RIGS board. The duplex page router is engaged. When in duplex

mode, it is important to note that the printer runs multiple pages through the paper path at

the same time to increase speed.

1 In a duplex job, the duplex r outer so lenoid be hind the fuser is engaged and mecha nical

fingers route the paper to the duplex area. Also, the “A” roller clutch engages to turn

the “A” and “B” rollers (connected via a belt).

2 The paper upon passing through the “B” roller comes in contact with the duplex sen-

sor. (If the paper does not energize this sensor in a given amount of time, a jam error

(060) will occur.)

3 The “C” roller bidirectional motor turns on and passes the paper into the turnaround

tray. The paper sensor in the turnaround tray is activated and the paper is center registered. (If the paper does not energize this sensor in a given amount of time after leaving the duplex sensor, a jam error (061) will occur.)

1-6 Troubleshooting June 1999

Page 21

Paper Path and Cycle Sequence

4 At this time the s ole noid for the router at the turnaround t ra y engages so the paper can

be routed to be printed on the duplex side.

5 In a given amount of time after t h e pa per energizes the paper sensor in the turnaround

tray, the bidirectional motor reverses and passes the paper to the paper timing roller.

(If the paper do es not energize the paper timing sensor in a given am ount o f time after

leaving the turnaround sensor, a jam error (062) will occur.)

6 At this point, the same steps happen as during a simplex cycle.

June 1999 Troubleshooting 1-7

Page 22

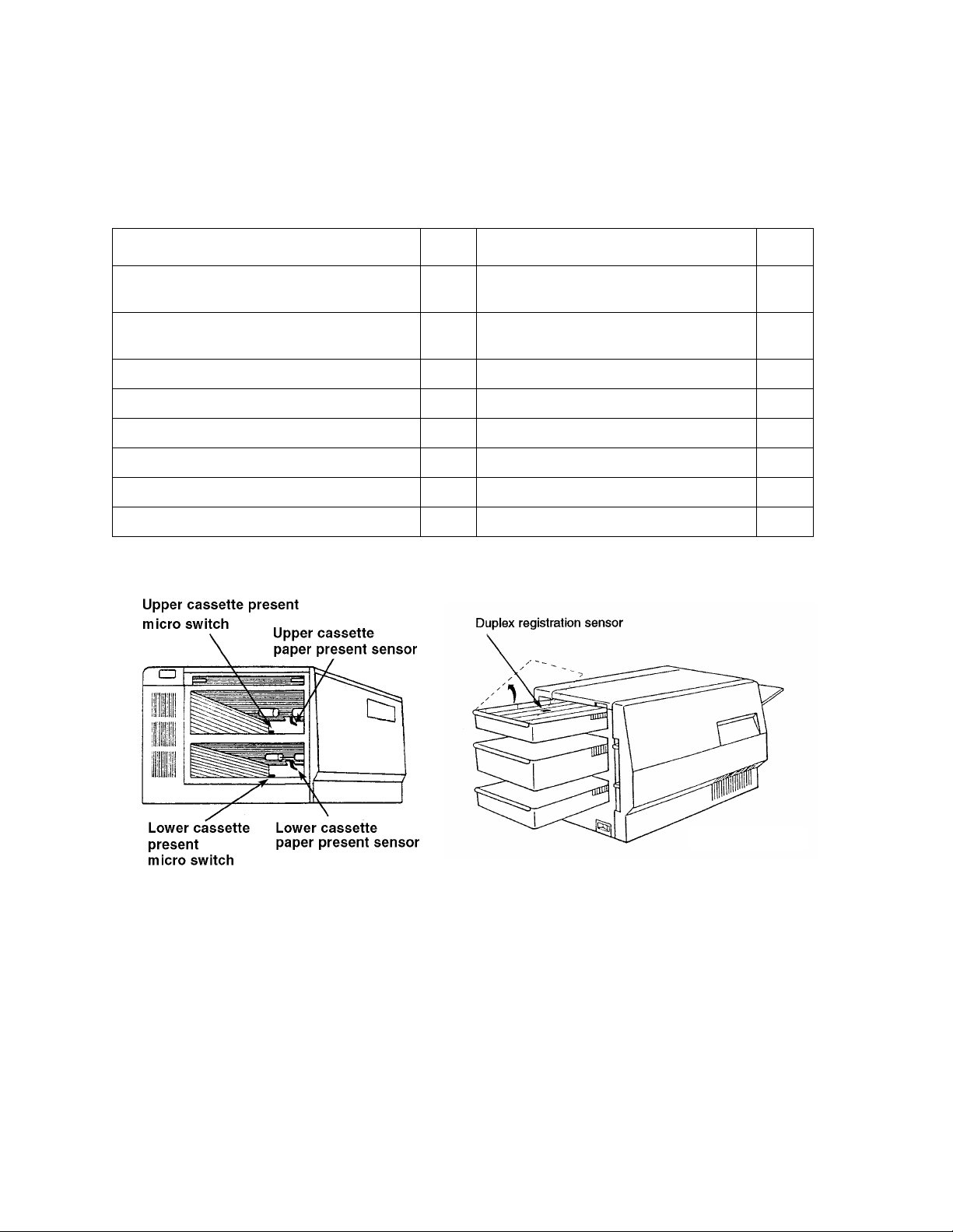

Sensors and Switches Illustrations

Sensors and Switches Illustrations

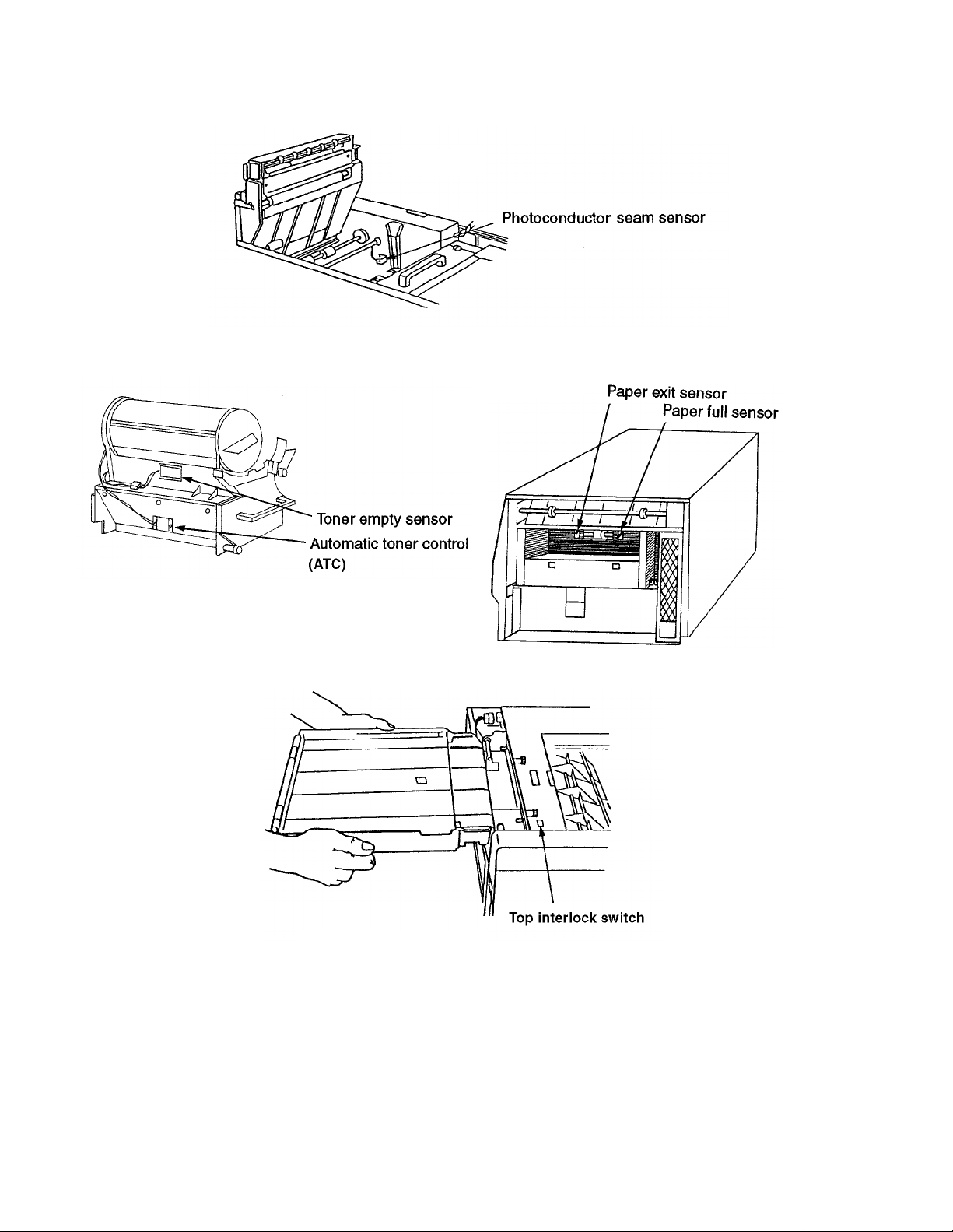

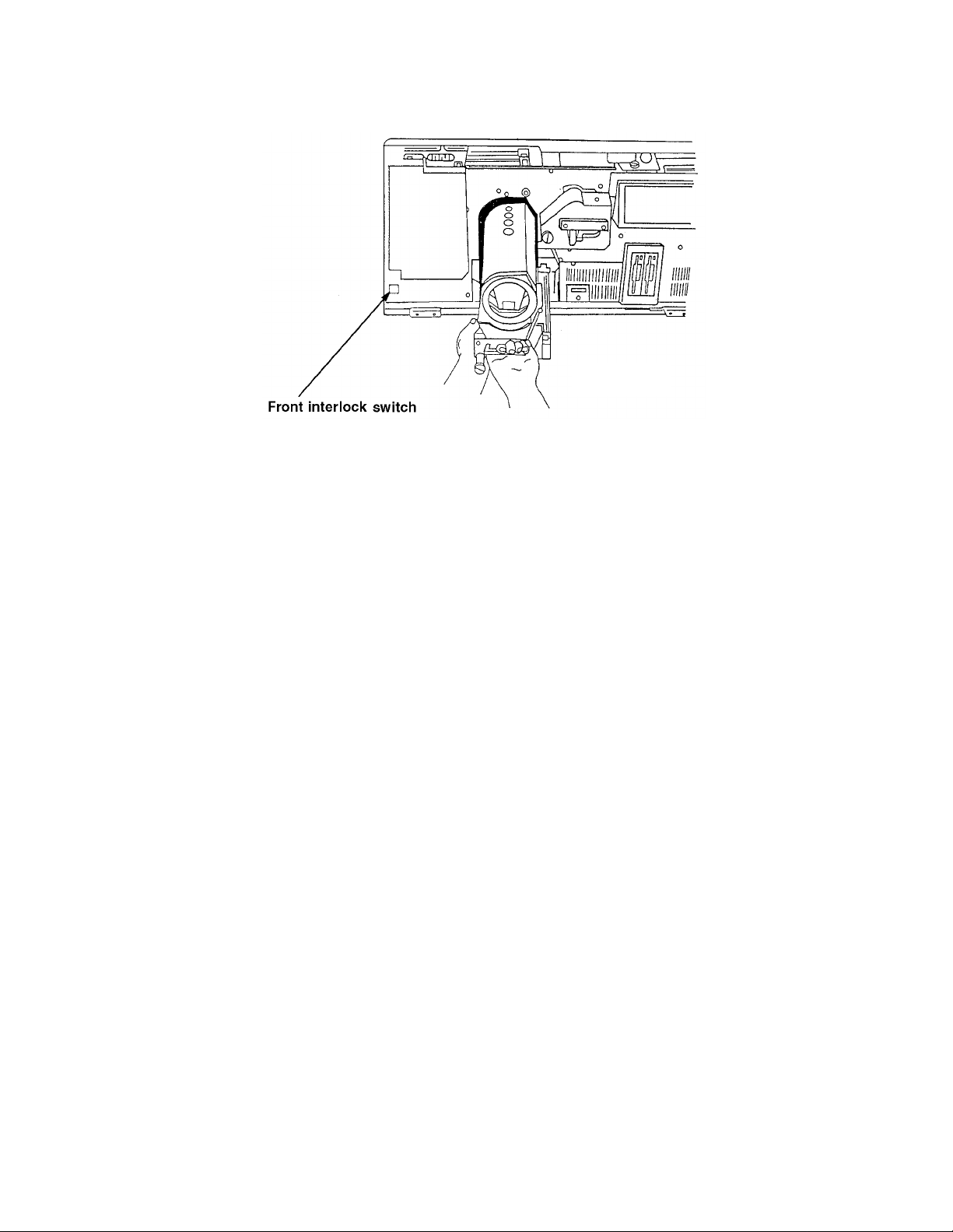

The following pages illustrate the locations of the printer’s sensors and switches.

Sensor and Switch Listing

Sensor/Switch Name Page Sensor/Switch Name Page

Cassette paper present sensors, upper and

lower

Cassette present micro switches, upper and

lower

Duplex registration sensor 1-8 Paper size sensors, upper and lower 1-9

Duplex paper path sensor 1-9 Paper timing se nsor 1-9

Interlock switch, duplex cover 1-9 Photoconductor seam sensor 1-9

Interlock switch, front 1-11 Automatic toner control 1-10

Interlock switch, rear 1-9 Toner empty sensor 1-10

Interlock switch, top 1-10 Toner patch sensor 1-9

.

1-8 Paper exit sensor 1-10

1-8 Paper full sensor 1-10

Front left view

1-8 Troubleshooting June 1999

Page 23

Sensors and Switches Illustrations

Rear view

Left end view

Front view

Top view

Developer right view

June 1999 Troubleshooting 1-9

Page 24

Sensors and Switches Illustrations

To p view

Developer left view

Right side view

Top left, duplex tray view

1-10 Troubleshooting June 1999

Page 25

Troubleshooting

Throughout the printer’s life problems occur, such as when it produces poor quality prints

or malfunctions in another way. Use the tools provided in this manual to diagnose and

resolve printer problems. These tools include:

Troubleshooting

Front view

• The Troubleshooting Analysis Guide, which contains troubleshooting procedures

called TAGs. TAG 001: Troubleshooting a Problem explains how to use TAGs.

• Cross reference tables, which link error messages, print quality problems, and

mechanical malfunctions to specific TAGs.

• Print quality samples, which hel p i dentify a printing probl em and its associated TAGs.

• Diagnostics, which can uncover a range of problems.

The next several pages revie w troublesho oting basi cs and standa rd procedur es followed in

every troubleshooting sessi on, inc lud ing:

• Identifying whether a problem belongs to the printer or host

• Isolating protocol converter problems

• Running test prints

• Reading the error log

• Confirming line power

• Using TAGs

• Power-On Reset

• Installing the interlock by-pass tool

• Checking continuity

• Producing a developed image

• Producing a toner patch

• Completing a service call

• Clearing the error log

June 1999 Troubleshooting 1-11

Page 26

Troubleshooting

General Troubleshooting Tips

When a printer problem arises, swapping out all printer supplies may temporarily mask

the problem. This is an unsat isfacto ry , short-t erm, and ex pensive solution to correcting the

proble m. Dust and other contamination, rather than printer supplies, are more often the

causes of problems. Clean consumable connectors, alignment guides, and areas before

changing consumables.

Many failures add excess toner to the printer’s engine. When you are advised to de-tone

the printer as part of a problem fix, run at least 200 test prints before deciding that the

problem is resolved.

When you replace the photoconductor, run at least 500 prints before checking print quality. This number of prints is required to “synch” the new PC belt to the developer.

The Problem: Printer or Host?

The printer is one comp onent i n a lar ge host sys tem. Befo re y ou star t any tr oubles hooti ng,

make sure that the problem really belongs to the printer rather than to some other component in the host system. Print quality problems and mechanical malfunctions are almost

always associated with the printer. However, host interface and software emulation problems can be caused by some other component of the host system even though, at first

glance, they appea r to be printer probl ems. For ins tance, text print ed in t he wrong lo catio n

on a page, improper page breaks, and missing segments of data strongly indicate a host,

not a printer, problem.

The first step i n trou blesho oting any pr oblem i s to isola te t he pri nter from t he hos t sy stem;

you can then run test prints. Producing test prints exercises the printer as a stand-alone

machine, ensuring that the basic printer software and all mechanical functions of the

printer are working.

Running Test Prints

1 Disconnect the host interface.

2 Make sure “Ready” displays on the panel.

3 Press

4 Press MENU

5 Press h to highlight “Test Print”

6 Press

7 Choose “Simplex” or “Duplex” (Duplex is the default. Press

8 Press

9 To stop printing the test pattern, press

If the test pattern prints suc cessfull y, the problem probably originates with the host syste m

or a protocol converter connected to the host.

ONLINE.

e to select “Test Print”

h to choose simplex.)

e to start. A directory of the boot device and multiple listings of fonts prints. A

continuous flow of the test pattern then prints.

f. The printer will print a ll test prints stored in

the printer’s buffer, then stop.

1-12 Troubleshooting June 1999

Page 27

Troubleshooting

Protocol Converters

Many protocol converters have a self-test function or configuration mode that enables the

user to check the proper functioning of the control. You can reconnect the host interface

and ask the customer to exercise this function of the converter. If the printer receives data

and prints it (even if the output is garbled) the problem may belong to the host or the protocol converter.

Reading the Error Log

The formatted error log is mainta ined by the printer in a file named “Error.log.” You have

the option to print this log when you are at the same panel used to print test prints. See

“Running Test Prints” on page 1-12.

• The first section lists the numbers and text of the last 15 errors.

• The second section of the formatted log lists paper jams. A 3-digit error code (or

codes) is followed by the error text and a 4-digit number indicating how many times

the error has occurred since the error log was last cleared. (Clearing the error log is

described on page 1-19.)

• The third section provides a complete er ror hist ory since the error log was last c leared.

Errors are listed in numeric order in the first column, with the number of times each

error occurred listed in the second column.

• The fourth section indicates the last error that required a power-on-reset (POR).

The error log is two pag es long. This partial ill ustration shows the main co mponents of t he

log.

June 1999 Troubleshooting 1-13

Page 28

Troubleshooting

Confirming Line Power

Erratic printer problems can be caused by improper line power. As a rule, the voltage of

the outlet should be checked at installation. However, if you are unable to isolate an inter-

mittent problem, the power shoul d be chec ked agai n. Consul t your co untry’s national electric code for the proper procedures to check for acceptable voltages, as outlined on the

following chart.

Probe connections 120v printer 230v printer

red to AC hot

black to AC neutral

red to AC neutral

black to ground

red to AC hot

black to ground

120v +/- 10% 230v +/- 10%

3 vac or less 3 vac or less

120v +/- 10% 230 +/- 10%

Please see Section 5, Diagnostic Tests, for additional information about troubleshooting

specific print er pro b le ms.

Please see Section 6, Wiring Diagrams and Electrical Data, for additional information

about the printer’s electrical systems.

1-14 Troubleshooting June 1999

Page 29

Troubleshooting

Using the Troubleshooting Analysis Guide (T AG)

The Troubleshooting Analysis Guide provides problem-solving sequences to help you

identify and resolve printer problems. Each TAG addresses a particular symptom or error

message of the printer. The TAG number often matches an error message code displayed

on the printer’s operator panel.

TAG Number

Starting

actions

Yes/ No

Question

To Do

TA G Name

TAG 001: Troubleshooting a Problem

Error Message: All related error messages are listed here.

Possible Causes: All possible causes are listed here.

Possible Defects: All possible defective parts are listed here. (In no particular order.)

1

To start:

• Disconnect all peripheral cables

• Power-on-reset the printer.

Is an error message displayed?

No: Run test prints, following the procedure outlined in Secti on 1, then repeat this step. If the

answer is still no, refer to the mechanical malfunctions cross-reference chart in Section 2 to

determine which TAG to follow. Then turn to that TAG.

Yes: Note the error message and continue.

2

Power-on-reset the printer.

Did the power-on-reset end with an error message?

No:

Continue.

Yes: Refer to the error message cross-reference table in Section 2, using either the code that dis-

played after steps 1 and 2, or if multiple error messages continue to appear, the first error message that displays. Turn to the TAG associated with the message.

Sample TAG

Each TAG walks through a comprehensive procedure specifi c to a si ngle pr oblem. As y ou

progress through a TAG and eliminate possible causes, you may be directed to another

step out of sequence in the same TAG or to another TAG altogether.

The TAG number and its title may be followed by a listing of possible error messages,

possible causes, or possible defective parts related to the TAG.

The TAG then directs you to perform cert ai n t as ks. Based on the resul ts of t hes e tasks, the

TA G poses questions that can be answered by either yes or no. For yes answers, you follow one path; for no answers, follow another path. Some of the paths may lead you to

other TAGs, so that you can methodically diagnose and re solve problems . When you ha ve

corrected a problem, you will be directed to TAG 002 to confirm that the problem has been

completely resolved and standard cleanup procedures observed.

June 1999 Troubleshooting 1-15

Page 30

Troubleshooting

If it’s not clear how t o diagnose a problem y ou’r e work ing on, follow the ste ps outlined in

TA G 001, which includes references to the cross reference tables contained in Section 2,

TAG Cross- Reference Tables. Or, you may turn directly to the tables to get started.

As you use TAGs, you will sometimes refer to othe r s ect i ons of this manual for addi ti onal

information:

• Section 4, Print Quality Sample s, contai ns print qual ity samples you’l l use to compare

• Section 5, Diagnostic Tests, outlines how to conduct printer diagnostic tests.

• Section 6, Wiring Diagrams and Electrical Data, provides all wiring and connector

• Section 7, Removal/Replacement Procedures, provides step-by-step procedures for

• Section 8, Options, reviews printer options (HCI, HCO) information.

• Section 9, General Printer Maintenance, presents general printer maintenance proce-

the customer’s test prints with flawed and good print samples.

diagrams.

removing and replacing all field-replaceable parts on the printer.

dures.

1-16 Troubleshooting June 1999

Page 31

Standard Procedures

While using the TAGs, you may be asked to perform some of the following procedures.

Specific instructions for completing these procedures are included here, rather than

repeated in the body of each TAG. Please read this information before following any TAG.

Power-on-reset (POR)

When directed to power-on-reset the printer:

1 Turn off the printer.

2 Wait at least 5 seconds.

3 Turn the power back on.

Checking Continuity

Make sure the printer is turned off and the power disconnecte d. Failure to do s o may

result in personal injury, equipment damage, or both.

To perform a continuity check:

Standard Procedures

1 Turn off the printer and disconnect the power cord.

2 Set your meter to the lowest ohm setting.

3 Interpret the results as follows:

• An infinite reading indicates an open circuit.

• A zero or specific reading indicates continuity.

4 To check an open or short circuit to ground:

• Turn off the printer and disconnect the power cord.

• Locate the circuit in question. (Refer to Section 6, Wiring Diagrams and Electri cal

Data, for circuit locations.)

• Check all connectors and wiring on each side for corrosion, foreign objects, bent

pins, loose socket housings, and/or loose wires.

Installing the Interlock By-pass Tool

The interlock by-pass tool overrides the cover interlock switches, allowing you to operate

the printer with the covers open. The interlock by-pass tool is a white plastic, V-shaped

tool with two finger pads. To use the tool, open the cover and locate the interlock switch

(for locations, see illustrations in “Sensors and Switches Illustrations” on page 1-8).

Squeeze the tool between thumb and forefinger and insert it into the interlock switch.

The printer ships with two spare interlock by-pass tools concealed behind the right cover.

Replace them when you are finished using them.

Do not attempt to close the printer cover while the interlock by-pass too l is in place.

June 1999 Troubleshooting 1-17

Page 32

Standard Proced ures

Producing a Developed Image

Producing a developed image helps determine where exactly in the print cycle a problem

may be occurring. To produce a developed image:

1 Open the top cover and install an interlock by-pass tool.

2 Power-on-reset the printer.

3 Run a series of test prints. See “Running Test Prints” on page 1-12.

4 As test patterns print, observe paper moving from the upper paper tray to the paper

timing roller w here it pauses briefly.

5 As soon as a sheet of paper begins to move from the paper timing roller, remove the

interlock by-pass tool.

6 Remove the photoconductor.

7 Examine the photoconductor belt to verify that a developed image was produced.

Caution: Do not touch the surface of the photoconductor belt; this damages the belt

and results in poor print quality.

Producing a Toner Patch

To produce a toner patch:

1 Turn off the printer.

2 Open the top cover and install an interlock by-pass tool.

3 Turn on the printer.

4 Start running test prints. When the leading edge of the first print enters the fuser, wait

one second then remove the interlock by-pass tool.

5 Remove the photoconductor.

Producing a toner patch on the photoconductor.

1-18 Troubleshooting June 1999

Page 33

Standard Procedures

6 Examine the photoconductor to verify that a toner patch has been produced. You may

have to rotate the belt slightly to observe the patch.

Caution: Do not touch the surface of the photoconductor belt; this damages the belt

and results in poor print quality.

Completing a Service Call

After resolving any printer problem, complete the service call as follows:

1 Reassemble the printer.

2 Perform the every-call cleaning procedure, described in Section 9, General Printer

Maintenance.

3 Power-on-reset the printer.

4 Clear the error log. (See the procedure described next.)

5 Run test prints in both the simplex and duplex mode from both the upper and lower

paper cassettes.

6 Fill in the Repair/Maintenance record taped inside the front cover. Make sure the

problem description and steps taken to resolve the problem are clearly documented.

Clearing the Error Log

1 Enter the diagnostic mod e of the printer:

• Turn off the printer and wait 5 seconds.

• Hold down the MENU and STATUS keys simult aneously as you t urn the printer back

on. Wait for all three LEDs to come on. This takes approximately 30 seconds.

2 Press

3 Once a test name is di splayed, use the

4 Press the

5 Press

6 Press

7 Press

8 Press

9 Confirm that the error log has been cleared.

10 Exit diagnostic mode (power-on reset)

h to display the first available test.

h key to move through the available tests.

h key until “Clear Error Log” shows on the display.

e

to activate the procedure.

h to advance to the drive where the error log is maintained. This is usually the

boot drive.

h to clear the error log on the selected drive.

f to exit the procedure.

11 Print the error log. All errors in all sections should be reset to zero.

June 1999 Troubleshooting 1-19

Page 34

Error Message and Code Technical Definitions

Error Message and Code Technical Definitions

Error messages/codes are listed here alphanumerically. Sensor and switch locations

referred to throughout these descriptions are illustrated on page 1-8.

Type Message Description

MACHINE CHECK

Unknown Error

PAPER JAM

020 Upper Cassette

PAPER JAM

021 Lower Cassette

PAPER JAM

022 Transfer/Fuser

PAPER JAM

023 At/Near Exit

PAPER JAM

024 At/Near HCO Exit

PAPER JAM

Paper Jams

025 At/Near Input

1. There is no text associated with the error.

2. The error is not included in the error look-up tables.

A VPCL board detected that the paper being fed from the upper

cassette did not reach the timing paper sensor within the allotted time.

A VPCL board detected that the paper being fed from the lower

cassette did not reach the timing paper sensor within the allotted time.

AVPCL board detected that the timing paper sensor was activated immediately after one of the covers were closed or the

leading edge of the paper did not activate the exit paper sensor within the allotted time.

A VPCL board detected that the exit paper sensor in the printer

(or in the HCO if installed) did not deactivate within the allotted

time.

AVPCL board detected that the paper did not reach the HCO

exit paper sensor within the allotted time.

A VPCL board detected that either the exit paper sensor (within

the printer) or the paper exit sensor (within the HCO) were activated immediately after one of the covers was closed.

PAPER JAM

026 At/Near Output

PAPER JAM

027 In Duplex Area

PAPER JAM

060 Duplex Roller

PAPER JAM

061 Duplex Path

PAPER JAM

062 Duplex Tray

1-20 Troubleshooting June 1999

(HCO only). The paper exit sensor (within the HCO) did not

become activated or deactivated within the allotted time.

The AVPCL board detected paper in the duplex area after

clearing a jam.

AVPCL board detected that the leading edge of the paper did

not activate the BC sensor within the allotted time.

AVPCL board detected that the trailing edge of the paper did

not deactivate the BC sensor within the allotted time.

Paper picked from the registration tray did not reach the timing

roller sensor within the allotted time.

Page 35

Error Message and Code Technical Definitions

Type Message Description

MACHINE CHECK

TPS Too Low

Error #031

MACHINE CHECK

TPS Too Light

Error #032

MACHINE CHECK

TPS Signal Overload

Error #033

MACHINE CHECK

Toner Control Errors

No Developer

Error #036

MACHINE CHECK

TPS Too High

Error #037

AVPCL board detected a signal from the toner patch sensor

board indicating that the reference voltage level on the photoconductor was too low.

AVPCL board detected a signal from the toner patch sensor

board indicating that the toner patch on the photoconductor

was too light.

AVPCL board detected too many successive signals from the

toner patch sensor board for a toner feed.

AVPCL board detected no developer electrical interlock signal

from the J25 connector.

AVPCL board detected a signal from the toner patch sensor

board indicating that the reference voltage level on the photoconductor was too high.

June 1999 Troubleshooting 1-21

Page 36

Error Message and Code Technical Definitions

Type Message Description

MACHINE CHECK

No Signal from PSS

Error #040

MACHINE CHECK

PSS Sensor Shorted

Error #041

MACHINE CHECK

PSS Sensor Open

Error #042

MACHINE CHECK

AVPCL NVRAM

Error #043

MACHINE CHECK

Charge Corona Open

Error #044

MACHINE CHECK

OPC Rotation Errors

Charge Corona Short

Error #045

MACHINE CHECK

PC Life Data Error

Error #047

AVPCL board sensed that the signal from the photoconductor

seam sensor either was not of sufficient amplitude or did not

show the proper timing.

AVPCL board detected an abnormally high amount of current

needed to drive the photoconductor seam sensor LED (within

the photoconductor).

AVPCL board detected an open connection to the photoconductor seam sensor LED (within the photoconductor).

AVPCL board non-volatile RAM error.

AVPCL board dete cted a sign al f rom the hig h-vo ltage power

supply indicatin g th at eith er the ch ar g e coro na or tra nsf e r

corona circuits have an open connecti on.

AVPCL board detected a signal from the high-voltage power

supply indicating an abnormally high load on the bias voltage

to the charge corona.

AVPCL board received invalid life data from the photoconductor serializer board.

MACHINE CHECK

Developer Life Error

Error #048

MACHINE CHECK

CRU Series Mismatch

Error #049

MACHINE CHECK

Transfer Corona Short

Error #050

MACHINE CHECK

Transfer Corona Open

Error #051

HVPS Errors

MACHINE CHECK

Eraser Lamp Error

Error #055

MACHINE CHECK

Duplex not installed

Error #069

AVPCL board received invalid life data received from the

developer serializer board.

AVPCL board detected invalid data from either the photoconductor or developer units. Verify that the CRUs are correct for

this printer.

AVPCL board detected a signal from the high-voltage power

supply indicating an abnormally high load on the bias voltage

to the transfer corona.

AVPCL board detected a signal from the high-voltage power

supply indicating an open connection in the transfer corona circuit. (Diagnostic test only.)

AVPCL board detected that the current needed to drive the

erase lamp assembly was either higher or lower than the specified limits. (Diagnostic test only.)

Duplex turnaround tray is not electrically connected to the

printer. (Diagnostic test only.)

1-22 Troubleshooting June 1999

Page 37

Error Message and Code Technical Definitions

Type Message Description

MACHINE CHECK

Fuser/Thermal Fuse

Error #070

MACHINE CHECK

No Fuser/Thermistor

Error #071

MACHINE CHECK

F user Temp Too High

Error #072

Fuser Control Errors

MACHINE CHECK

F user Temp Too Low

Error #073

MACHINE CHECK

Duplex Registration

Error #086

Errors

Jogger

MACHINE CHECK

Bad PC Type

Error #091

A VPCL board sensed, via the fuser thermistor, that the temperature of the fuser did not change within the allotted time.

A VPCL board sensed an open connection in the fuser thermistor circuit.

AVPCL board sensed that the resistance of the fuser thermistor was too low indicating that the temperature of the fuser

was higher than the specified limit.

AVPCL board sensed that the resistance of the fuser thermistor was too high indicating that the temperature of the fuser

was lower than the specified limit.

AVPCL board detected a signal from the duplex control board

#2 indicating that either the registration side sensor was activated and would not deactivate or was deactivated and would

not activate after a command was sent to the duplex control

board #2 to turn on the resist motor.

AVPCL board detected that the photoconductor is installed

improperly, or is of the wrong type. Verify that the photoconductor is the correct type for the printer.

MACHINE CHECK

Bad Dev Type

Error #092

MACHINE CHECK

+12 DC Power Failure

LVPS Errors

Error #097

MACHINE CHECK

+24 DC Power Failure

Error #099

MACHINE CHECK

IML Error

Error #130

MACHINE CHECK

Bad AVPCL ROM Checksum

Error #140

MACHINE CHECK

AVPCL PIA1 Reset Fail

AVPCL Error

Error #160

MACHINE CHECK

AVPCL PIA1 R/W at POR

Error #161

AVPCL board detected that the developer is installed improperly, or is of the wrong type. Verify that the developer is the correct type for the printer.

AVPCL board detected a signal from the RIGS board indicating the absence of +12 Vdc.

AVPCL board detected a signal from the RIGS board indicating the absence of +24 Vdc.

RIGS board detected an error when attempting to download

information to the AVPCL flash EPROM.

RIGS board detected an error from the AVPCL board during

initial AVPCL diagnostic.

RIGS board detected an error from the AVPCL board during

initial AVPCL diagnostic.

RIGS board detected an error from the AVPCL board during

initial AVPCL diagnostic.

June 1999 Troubleshooting 1-23

Page 38

Error Message and Code Technical Definitions

Type Message Description

MACHINE CHECK

AVPCL PIA1 Reset Fail

Error #170