Page 1

H

Broadband Service Analyzer

Setting Up the

25.6 Mb/s Interface Pod

Page 2

The information contained in this document is subject to change without notice.

TO THE EXTENT ALLOWED BY LOCAL LAW, HEWLETT-PACKARD MAKES NO WARRANTY OF ANY KIND

WITH REGARD TO THIS MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

To the extent allowed by local law, Hewlett-Packard shall not be liable for errors contained herein or for

incidental or consequential damages in connection with the furnishing, performance, or use of this

material.

A copy of the specific warranty terms applicable to your product and replacement parts can be obtained

from your local Sales and Service Office.

New editions of this guide are issued to reflect extensive changes made to the application. Revisions may

be issued between application versions to correct errors in the manual. There may not be a new edition

issued in conjunction with every application version release. The application version at the date of

printing is noted in the following table.

NoticeW

arranty

Printi

ng history

We want to hear from you. If you have any

comments, questions, or suggestions about our

documentation or support, send them to:

Email: cmd-a_support@aus.hp.com

Fax: +61 3 9210 5570

Phone: +61 3 9272 8633

Hewlett-Packard Australia Ltd

Communications Measurements Division Australia

PO Box 221

Blackburn, 3130

Victoria, Australia

Product support

Printed in Australia

© Hewlett-Packard Australia Ltd 1997

All rights reserved.

C

opyright

Manual Name: Setting Up the 25.6 Mb/s Interface Pod

Manual Part Number: E5129-90001

Product Model Number: HP E5129A

Visit the Broadband Service Analyzer web site at http://www.hp.com/go/atmanalyzer

Edition Printing Date Application Version

1 October 1997 A.02.0

Page 3

iii

Contents

Guide to the Broadband Service Analyzer Documentation..........................iv

About the 25.6 Mb/s Interface Pod ................................................................1

Online Help ..................................................................................................... 2

To Access User Online Help...................................................................... 2

Front Panel at a Glance ................................................................................. 3

Cable and Line Connector Details ................................................................. 4

Connector Cable Configurations ............................................................... 5

To Set Up the Interface Pod...........................................................................6

To Insert the Interface Pod ....................................................................... 7

To Remove the Interface Pod................................................................... 8

To Connect to the System Under Test ..................................................... 8

Automatic Configuration Parameters ..................................................... 10

To Manually Configure the Interface Pod .............................................. 11

What to Do Next ...........................................................................................12

Standards and Specifications........................................................................ 13

Communications Standards .................................................................... 13

Physical Specifications ............................................................................ 13

Environmental Specifications................................................................. 14

Page 4

Guide to the HP E5200A Broadband Service Analyzer Documentation

iv

Guide to the HP E5200A Broadband Service

Analyzer Documentation

The HP E5200A Broadband Service Analyzer comes with a comprehensive set

of paper and online documentation. Use the following table to determine

which documents you should use.

What is it? What does it do? Who is it for?

User’s Guide • contains instructions on how to set

up and install the analyzer

• provides an outline of the most

common functions

• provides an outline of the most

common system administration

functions

• lists electrical, mechanical, and

environmental specifications

all users

Application

Guide

contains information on installing and

starting the application, along with an

overview of the application.

all users

Online Help four volumes–User, Macro, UPE

Compatibility, and Test help–contain

information about, and instructions

for using, the analyzer

all users

Quick Reference provides a quick overview of the

analyzer's main features and functions

all users

Setting Up the

Interface Pod

guides

a series of guides that provide

descriptions of, and instructions for

installing, individual interface pods

all users will refer

to at least one of

these guides

Worldwide

Support card

provides information about support,

service, and warranty

all users

Release Notice provides information not available

when this guide was printed

all users

Page 5

1

About the 25.6 Mb/s Interface Pod

About the 25.6 Mb/s Interface Pod

Overview The HP E5129A 25.6 Mb/s Interface Pod is a self-contained, plug-in

module. You use it in conjunction with the HP E5200A Broadband Service

Analyzer to test and analyze a system under test (SUT).

The interface pod generates and analyzes ATM cell streams in a 25.6 Mb/s

4B5B format, in accordance with A TM Forum ATM 25.6 Mb/s over Twisted

Pair Cable, af-phy-004.000.

Hot swap and

automatic

configuration

Use the “hot swap” feature to insert and remove the interface pod while

the analyzer’s power is switched on. The analyzer automatically detects

the insertion of the interface pod and configures itself accordingly.

Immediately after you connect the interface pod to the SUT, the analyzer

automatically configures the receive and transmit parameters according to

the signal it receives.

Operating modes The interface pod has three operating modes: full duplex, internal

transmit loopback, and receive loopback.

Components The interface pod is shipped with

• a Calibration Certificate

• a set of three connecting cables

• this Set Up guide

Application The HP E5129A 25.6 Mb/s Interface Pod requires an E5200A base unit

with Application Version number A.02.0 or greater.

Passive monitoring The 25.6 Mb/s Interface Pod has one connector only. To use the interface

pod to perform passive monitoring or bi-directional monitoring, you need

to obtain a special four-port junction box. See the application notes that

come with the interface pod for more details, or visit our web site:

www.hp.com/go/atmanalyzer

Page 6

Online Help

2

Online Help

The Online Help provides all the information you need to use the analyzer.

Refer to the HP Broadband Service Analyzer User’s Guide for information

on the Monitor/Simulate help. Refer to theApplication Guide for the B-ISDN

UNI Signaling Tests for information on the B-ISDN UNI Signaling Test help.

The Online Help contains a Reference section. Use the Reference section to

find information about framing formats, alarms, errors, and measurements.

To Access User Online Help

There are four ways to access information in the User Online Help.

• Click the Help button that appears on most screens and windows to

display information about that screen or window.

• From the main screen Help menu, select User to display the User Contents

screen.

• Press F1. If the cursor is in an input field, you see help for that field;

otherwise you see the User Help Contents screen.

Page 7

3

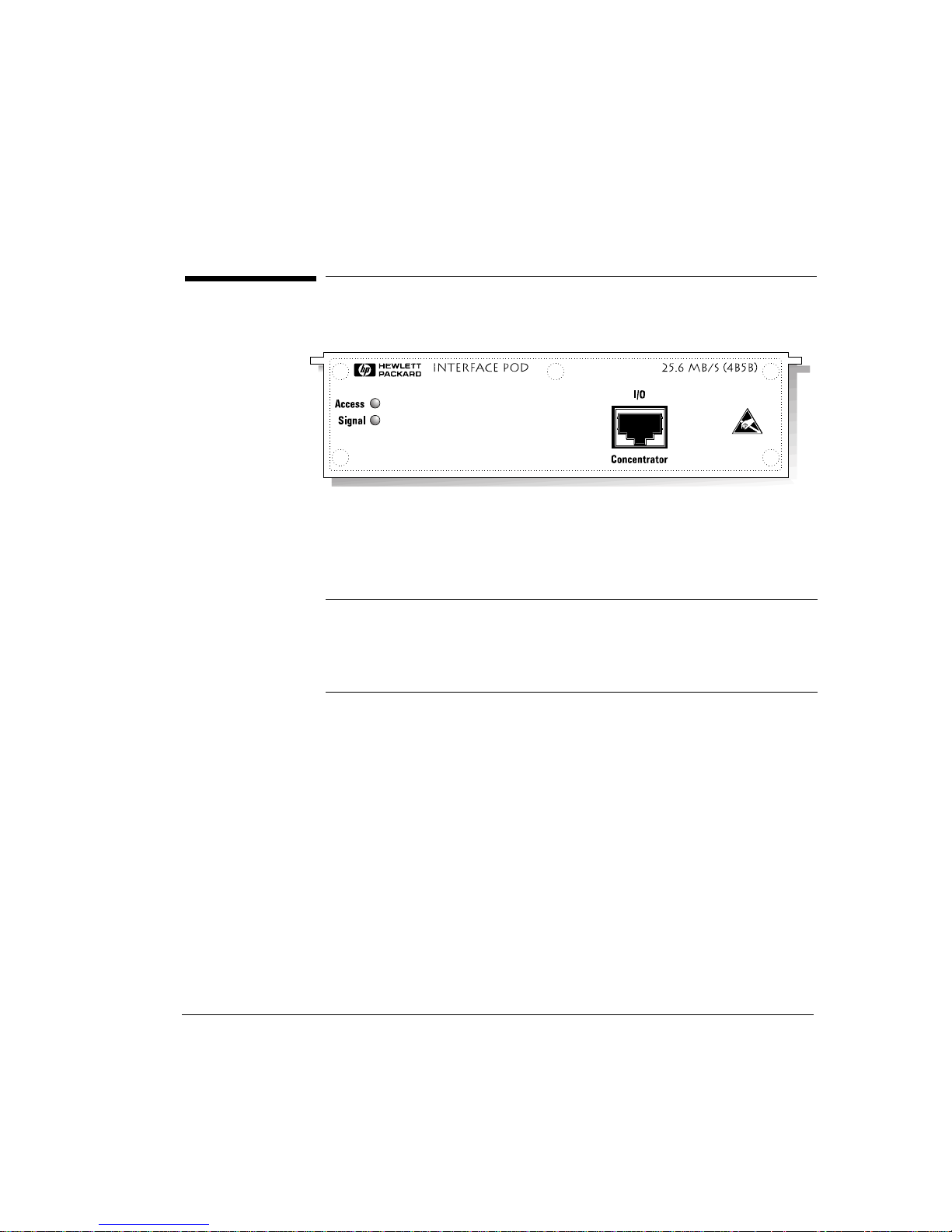

Front Panel at a Glance

Front Panel at a Glance

Access

(green LED) Lights each time the interface pod is accessed by the

network.

Signal

(yellow LED) Lights when a valid signal is present at the input connector.

I/O Concentrator

(UTP) Accepts an electrical signal from and provides a signal to the SUT.

Page 8

Cable and Line Connector Details

4

Cable and Line Connector Details

The HP E5129A 25.6 Mb/s Interface Pod’s connector pin configuration

adheres to the specification defined in the IBM Corporation’s ATM 25.6

Mb/s PHY Compatibility Specification, Version 2.0, 15 October, 1993.

Note In order to comply with EMC regulations, you must use one of the three connection

cables that are supplied with the interface pod to connect to the system under test. See

Connector Cable Configurations on the next page for details.

Page 9

5

Cable and Line Connector Details

Connector Cable Configurations

The interface pod comes with three cables:

• part number E1619-64300 connects a user device to the network (2 to

3 in the table below)

• part number E1619-64301 connects the interface pod to a user device

(1 to 2 in the table below)

• part number E1619-64302 connects the interface pod to the network

equipment (1 to 3 in the table below)

The following table sets out the pin configurations for the three connector

types:

1. Interface Pod

Connector

2. User Device

Connector

3. Network Equipment

Connector

Pin Signal Pin Signal Pin Signal

1 1 TxA 1 RxA

2 2 TxB 2 RxB

3 RxA 3 3

4 TxA 4 4

5 TxB 5 5

6 RxB 6 6

7 7 RxA 7 TxA

8 8 RxB 8 TxB

Pin 1

Pin 8

Page 10

To Set Up the Interface Pod

6

To Set Up the Interface Pod

Caution Handle the interface pod with care to avoid electrostatic discharge (ESD)

damage during unpacking, installation, and operation. The connectors on

the front and rear of the interface pod are susceptible to ESD.

1 Insert the interface pod into the analyzer.

See “T o Insert the Interface Pod” on page7. The procedure is the same for

all interface pods.

2 Connect the interface pod to the system under test.

See “To Connect to the System Under Test” on page 8. The analyzer

automatically recognizes and configures the interface pod.

3 If you want to change any of the configuration parameters, see “To

Manually Configure the Interface Pod” on page 11.

Page 11

7

To Set Up the Interface Pod

To Insert the Interface Pod

You can insert and remove interface pods at any time, even when the

analyzer is powered on. Initially, you insert an interface pod when you set

up the analyzer. Subsequently, you insert an interface pod when you

change the physical layer interface that you want to monitor.

1 Hold the interface pod with the front panel connectors facing you and

the Hewlett-Packard logo facing upwards.

2 Insert the interface pod into Port 1 or Port 2 of the analyzer.

3 Push the interface pod firmly into the analyzer until the connector at

the rear is properly seated. The clip on the base of the interface pod

clicks into place when the interface pod is fully inserted.

Caution You must always have two interface pods inserted in the the HP E5200A

Broadband Service Analyzer while it is operating. If your operations

require only a single interface pod, insert the blank interface pod

(provided with the analyzer) into the other port. The two interface pods

are necessary to maintain a balanced airflow for cooling of internal

components and to comply with EMC standards.

Page 12

To Set Up the Interface Pod

8

To Remove the Interface Pod

When you remove the interface pod, make sure you store it in a dust free

location that meets the environmental requirements listed in

“Environmental Specifications” on page 14. An electrostatic-safe bag has

been supplied for the storage of each interface pod.

To Connect to the System Under Test

Before you connect the interface pod to the system under test (SUT),

ensure that you have

• connected the HP E5200A Broadband Service Analyzer to the

controlling computer (workstation or notebook PC)

• inserted the HP E5129A 25.6 Mb/s Interface Pod

Select the cable you need from the three provided. See “Connector cable

configurations” on page 5. Connect the cable to the UTP connection on the

front of the interface pod and to the network element you want to test.

Gently press on the clip

underneath the

interface pod and pull

the interface pod out of

the analyzer.

Page 13

9

To Set Up the Interface Pod

Some common system and test connections are

• an intrusive system connection—network element

• remote loopback

• in-line test connections

See the HP E5200A Broadband Service Analyzer User’s Guide or the

Online Help for details about these system connections.

The analyzer automatically sets the interface pod transmit and receive

parameters and configures according to the signal it receives from the

interface pod. See “Automatic Configuration Parameters” on page 10 for

more details.

If you remove the interface pod and replace it with another while you are

logged in to the analyzer, the screen displays the message

Auto configuring, please wait...

Automatically configuring physical interfaces and

protocols according to the monitored signal.

Note The UNI Signaling Test Application does not display a message while it performs autoconfiguration.

Receive (Rx)

Page 14

To Set Up the Interface Pod

10

Automatic Configuration Parameters

After you insert the interface pod and connect it to the SUT, the analyzer

automatically configures to the 25.6 Mb/s electrical signal.

The analyzer sets the remaining physical layer receive and transmit

parameters to the following defaults:

• reference (internal) clock

• full duplex, transmit and receive

• fill cell filter DISABLED

• X8 marker generation OFF

See also The Online Help contains information about the ATM and signaling layer

automatic configuration parameters.

Page 15

11

To Set Up the Interface Pod

To Manually Configure the Interface Pod

• Note See the UNI Signaling Test Application’ s Helpfor information

on configuring the 25.6 Mb/s interface pod from the B-ISDN UNI

Signaling Test Application.

When the configuration is complete, the analyzer updates all relevant

screens and windows to reflect the new configuration parameters.

1

From the Configure

menu, select the

appropriate port;

then select Set Up.

Click Auto to set the

parameters to the default

settings. A message

warns you that the

reconfiguration will cause

some measurements and

data to be lost and asks if

you want to continue.

Click OK.

2

Click the ATM25 tab.

3

Select the parameters

you require.

4

Click to set the

configuration

or

Page 16

What to Do Next

12

X8 Timing Marker Source Setting

When you change the X8 timing marker source setting, the traffic

generator settings are cleared. The analyzer does this because it has to recalculate and re-adjust the total allowable transmit bandwidth to

• allow for the X8 marker when you enable X8 marker generation

• allocate all available bandwidth to transmit traffic when you disable X8

marker generation

Fill Cell Filter Setting

This setting allows you to specify that the analyzer generates idle or

unassigned cells to fill unused bandwidth. When this option is disabled,

unused bandwidth is handled at the physical line level by the transmit

drivers.

What to Do Next

The interface pod is now ready for use.

See the Online Help to find out the different tasks you can perform using

the analyzer and interface pod.

Page 17

13

Standards and Specifications

Standards and Specifications

Communications Standards

Physical Specifications

af-phy-004.400 ATM 25.6 Mb/s over Twisted Pair Cable, ATM Forum

ITU-T I.432.5 B-ISDN User Interface for Physical Layer

ATM 25.6 PHY compatibility

specification

IBM Corporation

Weight

1.0 kg ( 2.2 lbs) (nominal)

Dimensions

Height: 44 mm (1.73 inches)

Width: 149 mm (5.87 inches)

Length: 222 mm (8.74 inches)

Page 18

Standards and Specifications

14

Environmental Specifications

Parameter Nominal Min. Max. Notes

Operating Temperature

5oC

(41

o

F)

45

o

C

(113

o

F)

with two interface pods installed

Storage Temperature

–40oC

(–40

o

F)

70

o

C

(158

o

F)

Humidity

15% 90% at 40oC (104oF)

Altitude

4.6 km

(2.86 miles)

Page 19

Certification

Hewlett-Packard Australia Ltd (HP)

certifies that this product met its

published specifications at the time of

shipment from the factory. HP further

certifies that its calibration

measurements are traceable to the

extent allowed by the calibration

facilities of other International

Standards Organization members.

Warranty

The hardware is warranted against defects

in materials and workmanship. If HP

receives notice of such defects during the

warranty period, HP shall, at its option,

either repair or replace hardware products

which prove to be defective.

HP software and firmware products that

are designated by HP for use with a

hardware product, when properly installed

on that hardware product are warranted

not to fail to execute their programming

instructions due to defects in materials and

workmanship. If HP receives notice of such

defects during the warranty period, HP

shall repair or replace software media and

firmware which do not execute their

programming instructions due to such

defects. HP does not warrant that the

operation of the software, firmware, or

hardware shall be uninterrupted or error

free.

If HP is unable, within a reasonable time,

to repair or replace any product to a

condition as warranted, Buyer shall be

entitled to a refund of the purchase price

upon return of the product to HP.

For product warranties requiring return to

HP, this product must be returned to a

service facility designated by HP. Buyer

shall prepay shipping charges to HP (and

shall pay all duties and taxes) for products

returned to HP for warranty service. Except

for products returned to buyer from

another country, HP shall pay for return of

products to Buyer.

Duration and Commencement of the

Warranty

The hardware has a three year, return to

HP Service Centre warranty, commencing

at delivery date (type 7A).

The software and firmware has a 90 day,

replacement warranty commencing at

delivery date (type 3C).

Limitation of Warranty

The foregoing warranty shall not apply to

defects resulting from improper or

inadequate maintenance by Buyer, Buyersupplied products or interfacing,

unauthorized modification or misuse,

operation outside of the environmental

specifications of the products, or improper

site preparation or maintenance.

TO THE EXTENT ALLOWED BY LOCAL

LAW, THE WARRANTY SET FORTH ABOVE

IS EXCLUSIVE AND NO OTHER

WARRANTY, WHETHER WRITTEN OR

ORAL, IS EXPRESSED OR IMPLIED AND HP

SPECIFICALLY DISCLAIMS THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE.

Exclusive Remedies

TO THE EXTENT ALLOWED BY LOCAL

LAW, THE REMEDIES PROVIDED HEREIN

ARE BUYER’S SOLE AND EXCLUSIVE

REMEDIES AND, IN NO EVENT SHALL HP

BE LIABLE FOR DIRECT, INDIRECT,

SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES (INCLUDING

LOSS OF PROFITS) WHETHER BASED ON

CONTRACT, TORT, OR ANY OTHER LEGAL

THEORY.

Restricted Rights Legend

Use, duplication, or disclosure by the

Government is subject to the restrictions as

set forth in subdivision (b)(3)(ii) of the

Rights in Technical Data and Computer

Software clause at 52.227-7-13. HewlettPackard Company, 3000 Hanover Street,

Palo Alto, California 94304.

Additional Information for Test and

Measurement Equipment

If test and measurement equipment is

operated with unscreened cables and/or

used for measurements on open setups,

the user has to ensure that under operating

conditions the Radio Interference Limits are

still met at the border of the user’s

premises.

Disclaimer

Except where otherwise stated, the

parameters described are warranted

performance specifications. Parameters

described as “typical” or “nominal” are

supplemental characteristics that provide a

useful indication of typical, but nonwarranted, performance.

FOR CONSUMERS IN AUSTRALIA, NEW ZEALAND AND THE UNITED KINGDOM:

THE WARRANTY TERMS CONTAINED IN THIS STATEMENT, EXCEPT TO THE EXTENT

LAWFULLY PERMITTED, DO NOT INCLUDE, RESTRICT OR MODIFY AND ARE IN ADDITION TO THE IMPLIED MANDATORY

STATUTORY RIGHTS APPLICABLE TO THE SALE OF THIS PRODUCT TO YOU.

Page 20

Warnings

The following general safety

precautions must be observed during

all phases of operation, service, and

repair of this product. Failure to

comply with these precautions or

with specific warnings elsewhere in

this manual violates safety

standards of design, manufacture,

and intended use of the product.

Hewlett-Packard Australia Limited

assumes no liability for the

customer’s failure to comply with

these requirements.

Ground the equipment For safety

Class 1 equipment (equipment having a

protective ground terminal), an

uninterruptible safety ground must be

provided from the mains power source to

the product input wiring terminals or

supplied power cable.

DO NOT operate the product in an

explosive atmosphere or in the

presence of flammable gases or

fumes. For continued protection against

fire, replace the line fuse(s) only with

fuse(s) of the same voltage and current

rating and type. DO NOT use repaired fuses

or short-circuited fuse holders.

Keep away from live circuits

Operating personnel must not remove

equipment covers or shields. Procedures

involving the removal of covers and shields

are for use by service-trained personnel

only. Under certain conditions, dangerous

voltages may exist even with the

equipment switched off. To avoid electrical

shock, DO NOT perform procedures

involving cover or shield removal unless you

are qualified to do so.

DO NOT operate damaged

equipment Whenever it is possible that

the safety protection features built into this

product have been impaired, either through

physical damage, excessive moisture, or

any other reason, REMOVE POWER and do

not use the product until safe operation can

be verified by service-trained personnel. If

necessary, return the product to a HewlettPackard Sales and Service Office for service

and repair to ensure the safety features are

maintained.

DO NOT substitute parts or modify

equipment Because of the danger of

introducing additional hazards, do not

install substitute parts or perform any

unauthorized modification to the product.

Return the product to a Hewlett-Packard

Sales and Service Office for service and

repair to ensure features are maintained.

DO NOT clean with fluids

Doing so may make the equipment unsafe

for use.

Safety Symbols

Instruction manual symbol affixed to

product. Indicates that the user must refer

to the manual for specific Warning or

Caution information to avoid personal

injury, or damage to the product.

Protective conductor terminal indicates the

field wiring terminal that must be

connected to ground before operating the

equipment—protects against electrical

shock in case of fault.

Frame or chassis ground terminal—typically

connects to the equipment’s metal frame.

Earth (ground) terminal.

Alternating current (ac).

Direct current (dc).

Indicates hazardous voltages.

WARNING

Calls attention to a procedure, practice, or

condition that could cause bodily injury or

death.

CAUTION

Calls attention to a procedure, practice, or

condition that could possibly cause damage

to equipment or permanent loss of data.

Indicates that antistatic precautions should

be taken.

Page 21

Avertissement

Cet appareil répond aux normes de la

“Classe de sécurité 1” et est muni d’un fil

de mise à la terre pour votre protection.

Pour prévenir les risques de choc

électrique, la broche de mise à la terre du

cordon d’alimentation ne doit pas être

désactivée.

Restrictions d’utilisation

L’utilisateur se doit d’observer les mesures

de précaution énumérerais-dessous pour

toutes les phases d’utilisation, de service et

de réparation de cet appareil. Le fait de ne

pas s’y conformer équivaut à ne pas

respecter les mises en gardes spécifiques

contenues dans ce manuel et constitue une

violation des normes de sécurité relatives à

la conception, la fabrication et l’utilisation

prévue de cet appareil. La société HewlettPackard n’assume aucune responsabilité

envers un client qui manquerait de se

conformer à ces exigences.

Mise à la terre

Afin de minimiser les risques de choc

électrique, le châssis et le cabinet de

l’appareil doivent être mis à la terre.

L’appareil est équipé d’un cordon

d’alimentation muni d’une fiche

homologuée à trois lames, compatible c.a.

La prise murale et la prise femelle de la

rallonge électrique doivent respecter les

normes de sécurité de la “Commission

Électrotechnique Internationale” (IEC).

Environnement

Ne faites pas fonctionner cet appareil en

présence de gaz inflammables ou de

vapeurs dangereuses. L’utilisation de

n’importe quel appareil électrique dans ces

conditions constitue un risque élevé pour

votre sécurité.

Service et ajustement

Des “tensions dangereuses” résident dans

cet appareil. Par conséquent, le service et

l’ajustement doivent être effectué

uniquement par une personne qualifiée.

Ne remplacez pas de composantes lorsque

le cordon d’alimentation est sous tension. Il

pourrait y avoir présence de “tension

dangereuses” même lorsque l’appareil est

déconnecté.

Manipulation du tube cathodique

Une manipulation brusque, ou le fait de

secouer l’appareil, peut provoquer le bris du

tube cathodique. L’implosion qui s’en

suivrait entraînerait la dispersion à grande

vélocité d’éclats de verre. Le retrait ou

l’installation du tube cathodique ne doit

être exécuté que par un technicien qualifié,

portant un masque et des gants de sécurité

homologués.

Service non autorisé

L’installation de pièces étrangères, ou tous

modification apportée à l’appareil sans le

consentement de Hewlett-Packard est

formellement interdit. Le fait de procéder à

de tels modifications sans autorisation

pourrait entraîner l’annulation de la

garantie de l’appareil ou de tout contrat de

service.

Pour un service et des réparations

autorisées, retournez l’appareil à un point

de vente et service Hewlett-Packard.

Symboles des sécurité

Attention (voir documents

d’accompagnement)

Le conducteur protectif indique que la prise

de terre doit être connectèe avant d’utiliser

l’equipment—protège contre le choc

electrique en cas de faute.

Borne de terre

Borne de masse, châssis

Courant alternatif

Courant continu

Risque de choc electriques

WARNING

Attire l’attention sur une procédure, une

pratique, ou des conditions qui peuvent

entraîner des blessures corporelles ou la

mort.

CAUTION

Attire l’attention sur une procédure, une

pratique, ou des conditions qui peuvent

endommager l’équipement.

Signale que des précautions antistatique

doivent étre prises.

ou

Page 22

page inner margin

hanging column right margin

body text left margin

body text bottom margin

footer rulling line

footer text base line

outer margin for text and artwork

Right

body text drop

top margin for modules

DECLARATION OF CONFORMITY

According to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name Hewlett-Packard Australia Ltd

Manufacturer’s Address Communications Measurements Division Australia

347 Burwood Highway

Burwood East 3151

Victoria, Australia

declares that the product:

Product Name 25.6 Mb/s Interface Pod

Model Numbers HP E5129A

Product Options This declaration covers all options of the above product.

conforms to the following product specifications:

Safety EN 61010-1: 1993/IEC 1010-1: 1990 + A1

EMC EN 55011:1991/CISPR 11:1990 (Group 1, Class A

1

)

EN 50082-1:1992

IEC 801-2:1991

2

4 kV CD, 8 kV AD

IEC 801-3:1984 3 V/m

IEC 801-4:1988 0.5 kV Signal Lines, 1 kV Power Lines

Supplementary Information This product herewith complies with the requirements of the Low Voltage

Directive 73/23/EEC and the EMC Directive 89/336/EEC.

1

The product meets the listed specifications when installed in an HP

E5200A with interface pods installed in both ports.

2

Bit error performance will be reduced under these conditions.

Melbourne, Australia, July 1996 Issue 1

Graeme Cobb - Quality Manager

European Contact: Your local Hewlett-Packard Sales and Service Office or Hewlett-Packard GmbH, Department ZQ/

Standards Europe, Herrenberger Straße 130, D-71034 Böblingen, Germany (FAX +49-7031-14-3143).

Loading...

Loading...