Page 1

HP ProLiant BL p-Class System

Setup and Installation Guide

January 2003 (Second Edition)

Part Number 230852-002

Page 2

Hewlett-Packard Company shall not be liable for technical or editorial errors or omissions

contained herein. The information in this document is provided “as is” without warranty of

any kind and is subject to change without notice. The warranties for HP products are set forth

in the express limited warranty statements accompanying such products. Nothing herein

should be construed as constituting an additional warranty.

HP ProLiant BL p-Class System Setup and Installation Guide

January 2003 (Second Edition)

Part Number 230852-002

Page 3

Contents

About This Guide

Audience Assumptions..................................................................................................... vii

Important Safety Information ........................................................................................... vii

Symbols on Equipment .................................................................................................... vii

Rack Stability .................................................................................................................... ix

Symbols in Text.................................................................................................................ix

Related Documents..............................................................................................................x

Getting Help ........................................................................................................................x

Technical Support .........................................................................................................x

HP Website ................................................................................................................. xi

Authorized Reseller .................................................................................................... xi

Optional Installation Service ............................................................................................. xi

Reader’s Comments ......................................................................................................... xii

Chapter 1

System Features

Minimum Hardware Requirements ................................................................................. 1-1

Power Components ................................................................................................... 1-5

LEDs ......................................................................................................................... 1-5

Configuration and Management Features ....................................................................... 1-6

Diagnostic Features ......................................................................................................... 1-7

Chapter 2

Planning the Installation

Optimum Environment.................................................................................................... 2-2

Rack Requirements ................................................................................................... 2-2

Space and Airflow Requirements ............................................................................. 2-2

HP ProLiant BL p-Class System Setup and Installation Guide iii

Page 4

Contents

Temperature Requirements .......................................................................................2-3

Power Requirements..................................................................................................2-4

Grounding Requirements ..........................................................................................2-4

Rack Warnings................................................................................................................. 2-5

System Warnings and Cautions .......................................................................................2-6

Chapter 3

Installing System Hardware

Installing System Enclosures ........................................................................................... 3-1

Measuring with the Rack Template...........................................................................3-2

Installing the Rack Rails and Cage Nuts ...................................................................3-2

Installing Enclosures into the Rack ........................................................................... 3-6

Hot-Plug Power Supplies.................................................................................................3-8

Identifying Power Supply Bays................................................................................. 3-9

Installation Guidelines.............................................................................................3-10

Installing a Hot-Plug Power Supply........................................................................3-11

Installing a Power Supply Blank ............................................................................. 3-12

Interconnects..................................................................................................................3-13

Power Distribution Components.................................................................................... 3-16

Installation Guidelines.............................................................................................3-16

Installing a Bus Bar .................................................................................................3-16

Additional System Hardware.........................................................................................3-19

Chapter 4

Cabling and Powering Up the System

Identifying System Components......................................................................................4-1

Enclosures and Management Modules......................................................................4-2

Scalable and Mini Bus Bar Components................................................................... 4-4

Power Bus Box Components.....................................................................................4-6

Cabling the System ..........................................................................................................4-7

Overview ...................................................................................................................4-7

Cabling Configuration Diagrams ..............................................................................4-8

Management Modules ............................................................................................. 4-14

Grounding Cable in Facility DC Power Environments...........................................4-17

Bus Bars ..................................................................................................................4-18

Load-Balancing Signal Cable.................................................................................. 4-23

Cable Bracket ..........................................................................................................4-24

Powering Up the System................................................................................................4-26

iv HP ProLiant BL p-Class System Setup and Installation Guide

Page 5

Appendix A

Regulatory Compliance Notices

Regulatory Compliance Identification Numbers............................................................ A-1

Federal Communications Commission Notice............................................................... A-1

Class A Equipment .................................................................................................. A-2

Modifications ........................................................................................................... A-2

Cables....................................................................................................................... A-2

Canadian Notice (Avis Canadien) .................................................................................. A-2

European Union Notice .................................................................................................. A-3

Japanese Notice .............................................................................................................. A-3

Taiwanese Notice ........................................................................................................... A-3

Battery Replacement Notice........................................................................................... A-4

Appendix B

Electrostatic Discharge

Preventing Electrostatic Damage ....................................................................................B-1

Grounding Methods.........................................................................................................B-2

Appendix C

Troubleshooting

When the System Does Not Power Up............................................................................C-1

System Power Diagnostic Steps................................................................................C-2

Contents

Appendix D

LEDs and Switches

LEDs............................................................................................................................... D-1

Server Blade Enclosure............................................................................................ D-2

Server Blade Management Module ......................................................................... D-3

Power Management Module .................................................................................... D-4

Power Enclosure ...................................................................................................... D-6

Hot-Plug Power Supply ........................................................................................... D-7

Bus Bar .................................................................................................................... D-8

Diagnostic Station.................................................................................................... D-9

Buttons and Switches ................................................................................................... D-10

Power Configuration Switches .............................................................................. D-10

HP ProLiant BL p-Class System Setup and Installation Guide v

Page 6

Contents

Appendix E

Specifications

Server Blade Enclosure................................................................................................... E-1

Power Enclosures............................................................................................................ E-3

North America/Japan................................................................................................ E-3

International ............................................................................................................. E-5

Hot-Plug Power Supply .................................................................................................. E-7

Power Distribution Devices ............................................................................................ E-9

Facility DC.................................................................................................................... E-11

Index

vi HP ProLiant BL p-Class System Setup and Installation Guide

Page 7

This guide provides step-by-step instructions for installation and reference

information for operation, troubleshooting, and future upgrades of the HP ProLiant

BL p-Class System.

Audience Assumptions

This guide is for the person who installs, administers, and troubleshoots servers.

HP assumes you are qualified in the servicing of computer equipment and trained in

recognizing hazards in products with hazardous energy levels.

About This Guide

Important Safety Information

Before installing this product, read the Important Safety Information document

included with the server blade.

Symbols on Equipment

The following symbols may be placed on equipment to indicate the presence of

potentially hazardous conditions:

WARNING: This symbol, in conjunction with any of the following symbols,

indicates the presence of a potential hazard. The potential for injury exists if

warnings are not observed. Consult the documentation for specific details.

HP ProLiant BL p-Class System Setup and Installation Guide vii

Page 8

About This Guide

Weight in kg

Weight in lb

This symbol indicates the presence of hazardous energy circuits or electric

shock hazards. Refer all servicing to qualified personnel.

WARNING: To reduce the risk of injury from electric shock hazards, do not

open this enclosure. Refer all maintenance, upgrades, and servicing to

qualified personnel.

This symbol indicates the presence of electric shock hazards. The area

contains no user or field serviceable parts. Do not open for any reason.

WARNING: To reduce the risk of injury from electric shock hazards, do not

open this enclosure.

This symbol on an RJ-45 receptacle indicates a network interface connection.

WARNING: To reduce the risk of electric shock, fire, or damage to the

equipment, do not plug telephone or telecommunications connectors into this

receptacle.

This symbol indicates the presence of a hot surface or hot component. If this

surface is contacted, the potential for injury exists.

WARNING: To reduce the risk of injury from a hot component, allow the

surface to cool before touching.

These symbols, on power supplies or systems, indicate that the

equipment is supplied by multiple sources of power.

WARNING: To reduce the risk of injury from electric shock,

remove all power cords to completely disconnect power from the

system.

This symbol indicates that the component exceeds the recommended

weight for one individual to handle safely.

WARNING: To reduce the risk of personal injury or damage to the

equipment, observe local occupational health and safety requirements

and guidelines for manual material handling.

viii HP ProLiant BL p-Class System Setup and Installation Guide

Page 9

Rack Stability

WARNING: To reduce the risk of personal injury or damage to the equipment,

be sure that:

• The leveling jacks are extended to the floor.

• The full weight of the rack rests on the leveling jacks.

• The stabilizing feet are attached to the rack if it is a single-rack installation.

• The racks are coupled together in multiple-rack installations.

Symbols in Text

These symbols may be found in the text of this guide. They have the following

meanings:

WARNING: Text set off in this manner indicates that failure to follow directions

in the warning could result in bodily harm or loss of life.

CAUTION: Text set off in this manner indicates that failure to follow directions could

result in damage to equipment or loss of information.

About This Guide

IMPORTANT: Text set off in this manner presents essential information to explain a concept

or complete a task.

NOTE: Text set off in this manner presents additional information to emphasize or supplement

important points of the main text.

HP ProLiant BL p-Class System Setup and Installation Guide ix

Page 10

About This Guide

Related Documents

For additional information on the topics covered in this guide, refer to the following

documentation:

• HP ProLiant BL p-Class System Maintenance and Service Guide

• HP ProLiant BL p-Class Server Blade Setup and Installation Guide

• HP ProLiant BL p-Class System Hardware Installation and Configuration Poster

• Servers Troubleshooting Guide

• Integrated Lights-Out User Guide

• ROM-Based Setup Utility User Guide

• White paper: ProLiant BL p-Class System Overview and Planning

• White paper: Configuring a Preboot Execution Environment (PXE) using Red

Hat Linux 7.2 on ProLiant Servers

• ProLiant BL p-Class QuickSpecs

Getting Help

If you have a problem and have exhausted the information in this guide, you can get

further information and other help in the following locations.

Technical Support

In North America, call the HP Technical Support Phone Center at 1-800-652-6672.

This service is available 24 hours a day, 7 days a week. For continuous quality

improvement, calls may be recorded or monitored. Outside North America, call the

nearest HP Technical Support Phone Center. Telephone numbers for worldwide

Technical Support Centers are listed on the HP website,

Be sure to have the following information available before you call HP:

• Technical support registration number (if applicable)

x HP ProLiant BL p-Class System Setup and Installation Guide

www.hp.com.

Page 11

• Product serial number

• Product model name and number

• Applicable error messages

• Add-on boards or hardware

• Third-party hardware or software

• Operating system type and revision level

HP Website

The HP website has information on this product as well as the latest drivers and flash

ROM images. You can access the HP website at

Authorized Reseller

For the name of the nearest authorized reseller:

• In the United States, call 1-800-345-1518.

About This Guide

www.hp.com.

• In Canada, call 1-800-263-5868.

• Elsewhere, see the HP website for locations and telephone numbers.

Optional Installation Service

You may choose to have HP install the system. The installation service, as well as

other services, can be purchased as a CarePaq packaged service or as a customized

service agreement to meet your specific requirements.

The optional installation services are available in all countries where HP has a direct

or indirect service presence. In these countries, service may be ordered from and

directly provided by an HP authorized service reseller, or they may be ordered

directly from HP services.

In the U.S. only, customized or CarePaq services may be ordered by calling

1-800-652-6672.

HP ProLiant BL p-Class System Setup and Installation Guide xi

Page 12

About This Guide

For ordering information, refer to

www.hp.com

Reader’s Comments

HP welcomes your comments on this guide. Please send your comments and

suggestions by e-mail to

ServerDocumentation@hp.com.

xii HP ProLiant BL p-Class System Setup and Installation Guide

Page 13

The HP ProLiant BL p-Class system offers a range of power and performance for

large-volume rollouts in space-constrained environments. The ProLiant BL p-Class

system architecture is a revolutionary step in server modularity that stresses rapid

deployment and remote management.

Minimum Hardware Requirements

To set up the system, you must choose and install several of the modular

components. The following hardware components are required to operate a

ProLiant BL p-Class system. For specific features and supported configurations, refer

to the system QuickSpecs or the ProLiant BL p-Class System Overview and Planning

white paper.

1

System Features

• One ProLiant BL p-Class server blade

• One ProLiant BL p-Class server blade enclosure

• One pair of interconnects

• One single-phase or three-phase ProLiant BL p-Class power enclosure with hot-

plug power supplies, if using AC power—or—one facility DC cable kit, if using

your own DC power

• One pair of power distribution devices (bus bars or power bus box)

• One Compaq branded, telco, or third-party rack cabinet

NOTE: For third-party rack cabinet requirements, refer to the “Rack Requirements” section in

Chapter 2, “Planning the Installation.”

HP ProLiant BL p-Class System Setup and Installation Guide 1-1

Page 14

System Features

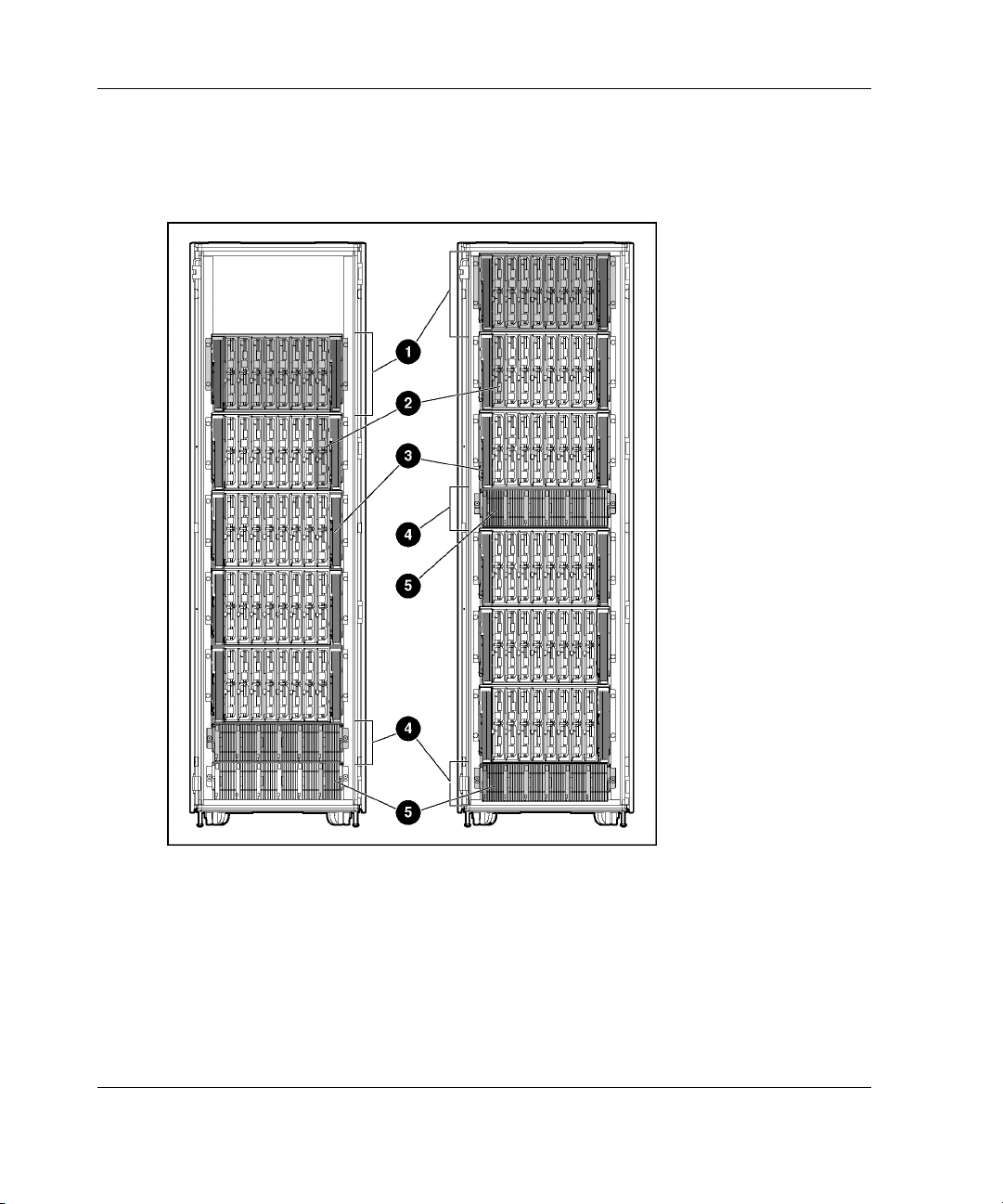

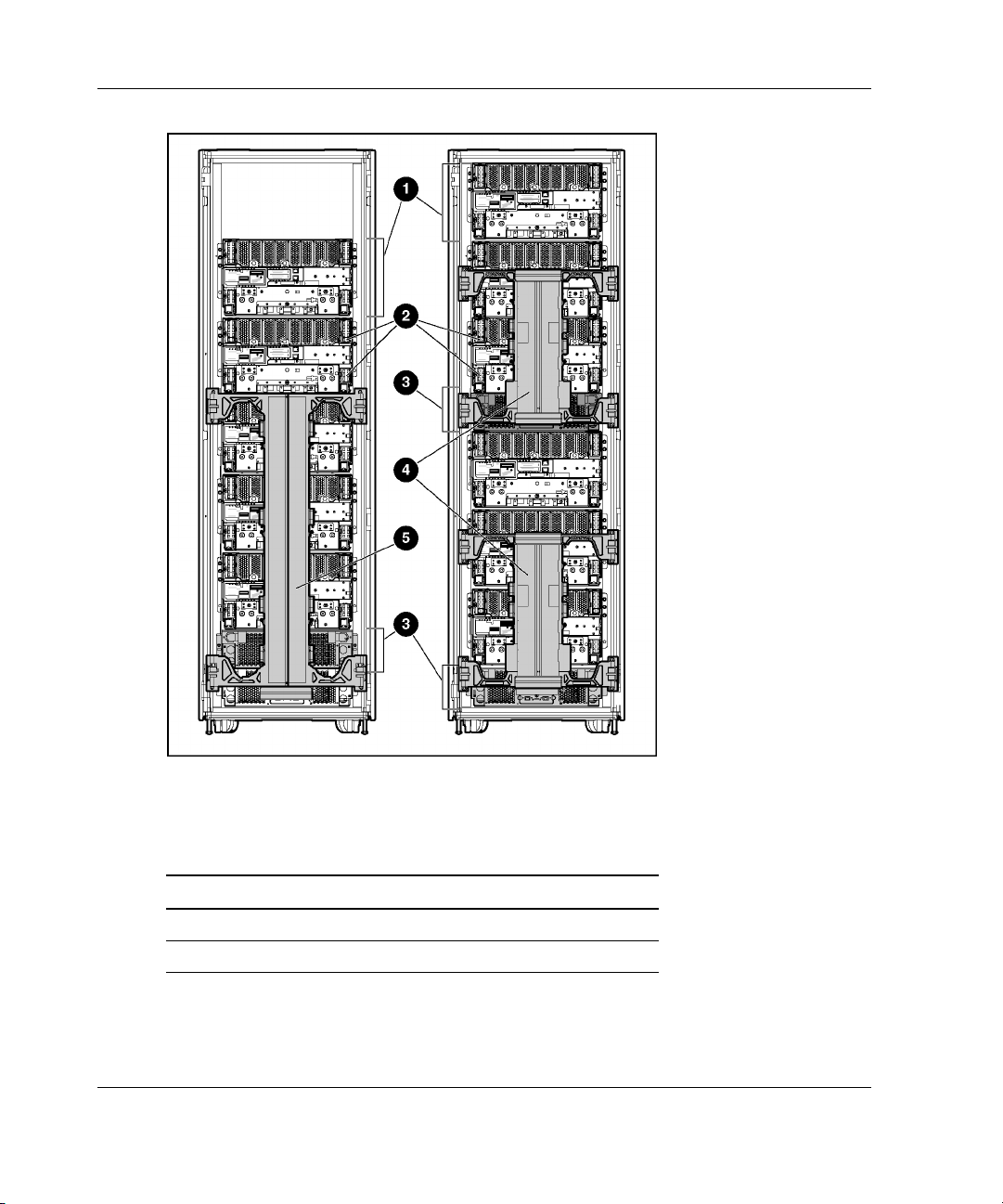

Figures 1-1 and 1-2 and Tables 1-1 and 1-2 identify system components. The scalable

configuration is shown on the left, and the full-rack 42U configuration (two pairs of

mini bus bars) is shown on the right.

Figure 1-1: System components in a 42U rack (front)

1-2 HP ProLiant BL p-Class System Setup and Installation Guide

Page 15

System Features

Table 1-1: System Components (Front)

Item Description

1 Server blade enclosures

2 Server blades

3 Interconnects

4 Power enclosures

5 Hot-plug power supplies

HP ProLiant BL p-Class System Setup and Installation Guide 1-3

Page 16

System Features

Figure 1-2: System components in a 42U rack (rear,

cables removed for clarity)

Table 1-2: System Components (Rear)

Item Description

1 Server blade enclosures

2 Interconnect modules

continued

1-4 HP ProLiant BL p-Class System Setup and Installation Guide

Page 17

Table 1-2: System Components (Rear) continued

Item Description

3 Power enclosures

4 Mini bus bars* (pair)

5 Scalable bus bars (pair)

* Two mini bus bar pairs support a full-rack (42U)

configuration.

Power Components

The system requires bus bars or power bus boxes to distribute power to the server

blade enclosures. Table 1-3 identifies enclosure capabilities for each device.

Table 1-3: Power Distribution Schemes

System Features

LEDs

Power

Components

Scalable bus bars Up to 2 Up to 5

Mini bus bars 1 Up to 3

Mini bus bars × 2 2 Up to 6

Power bus boxes 1 1

Power Enclosures or

Facility DC Feeds

Server Blade Enclosures

Supported

The system contains several sets of LEDs that indicate the status of hardware

components and settings. For a detailed explanation of LEDs, refer to Appendix D,

“LEDs and Switches.”

HP ProLiant BL p-Class System Setup and Installation Guide 1-5

Page 18

System Features

Configuration and Management Features

HP offers an extensive set of features and optional tools to support effective server

blade configuration and management:

• ProLiant Essentials Rapid Deployment Pack

• ROM-Based Setup Utility (RBSU)

• Option ROM Configuration for Arrays (ORCA) Utility

• Redundant ROM Support

• Remote ROM flash

• ROMPaq Utility

• Insight Manager 7

• Diagnostics Utility

• Automatic Server Recovery-2 (ASR-2)

• Integrated Management Log (IML)

For more detailed information about these tools and utilities, refer to the

documentation that ships with the system.

1-6 HP ProLiant BL p-Class System Setup and Installation Guide

Page 19

Diagnostic Features

Hardware, software, and firmware diagnostic tools available for your use include:

• System LEDs

• Diagnostic station

• Diagnostic cable

• Diagnostic port

• Insight Manager 7

• Power-On Self Test (POST)

• Server Diagnostics

For more information about diagnostic tools, refer to the software documentation that

ships with the system.

System Features

HP ProLiant BL p-Class System Setup and Installation Guide 1-7

Page 20

2

Planning the Installation

For maximum performance and availability from the server blade, be sure that the

operating environment meets the required specifications for the following:

• Rack compatibility

• Space and airflow

• Temperature

• Power

• Electrical grounding

• Floor strength

Refer to the “Optimum Environment” section in this chapter and the ProLiant

BL p-Class System Overview and Planning white paper that is available on the

Documentation CD or at

www.hp.com

HP ProLiant BL p-Class System Setup and Installation Guide 2-1

Page 21

Planning the Installation

Optimum Environment

When installing the ProLiant BL p-Class system in a rack, select a location that meets

the environmental standards described in the following paragraphs.

Rack Requirements

The ProLiant BL p-Class system is compatible with the following racks:

• 42U, 36U, and 22U Compaq branded racks

— Compaq branded 10000 and 9000 Series racks (42U, 36U, and 22U) are

compatible. (The system is optimized for 10000 Series racks.)

— Compaq branded 7000 Series 42U racks require an extension kit (P/N

154392-B21) to increase rack depth from 83.82 cm (33 inches) to 93.98 cm

(37 inches). The 7000 Series 36U and 22U racks are not compatible.

• Telco racks

• Third-party rack cabinets that meet the following requirements:

— Standard 48.26-cm (19-inch) width

— Depth of 73.66 cm (29 inches) between front and rear RETMA rails

— Minimum 7.62 cm (3 inches) clearance between rear RETMA rails and rear

rack door to accommodate system cabling

— Front and rear doors must have a minimum of 65 percent open area to

provide adequate airflow

Space and Airflow Requirements

To enable servicing and adequate airflow, observe the following spatial requirements

when deciding where to install a Compaq branded, telco, or third-party rack:

• Leave a minimum clearance of 63.5 cm (25 inches) in front of the rack.

• Leave a minimum clearance of 76.2 cm (30 inches) in back of the rack.

• Leave a minimum clearance of 121.9 cm (48 inches) from the back of the rack to

the rear of another rack or row of racks.

2-2 HP ProLiant BL p-Class System Setup and Installation Guide

Page 22

Planning the Installation

ProLiant servers draw in cool air through the front door and expel warm air through

the rear door. Therefore, the front and rear rack doors must be adequately ventilated

to enable ambient room air to enter the cabinet, and the rear door must be adequately

ventilated to enable the warm air to escape from the cabinet.

IMPORTANT: Do not block the ventilation openings.

When any vertical space in the rack is not filled by servers or rack components, the

gaps between the components cause changes in airflow through the rack and across

the servers. Cover all gaps with server blanks to maintain proper airflow.

Compaq branded 9000 Series racks provide proper server cooling from flow-through

perforations in the front and rear doors that provide 65 percent open area for

ventilation.

CAUTION: When using a Compaq branded 7000 Series rack, you must install the

high airflow rack door insert [P/N 327281-B21 (42U)] to provide proper front-to-back

airflow and cooling.

CAUTION: Always use server blanks to fill empty vertical spaces in the rack. This

arrangement ensures proper airflow. Using a rack without server blanks results in

improper cooling that can lead to thermal damage.

Temperature Requirements

To ensure continued safe and reliable equipment operation, install or locate the

system in a well-ventilated, climate-controlled environment.

The maximum recommended ambient operating temperature (TMRA) for most

server products is 35°C (95°F). The temperature in the room where the rack is

located must not exceed 35°C

HP ProLiant BL p-Class System Setup and Installation Guide 2-3

(95°F).

Page 23

Planning the Installation

Power Requirements

WARNING: Risk of fire or damage to the equipment.

Each AC power cord for the power enclosure has an electrical rating based on

the model and power supply configuration. The rating is marked on the side of

the enclosure. It is important that the system be configured and loaded

according to the guidelines in the ProLiant BL p-Class System Overview and

Planning white paper. Failure to follow these guidelines may result in an

overload of the electrical circuits feeding the power enclosure.

Also, when performing system upgrades, you must refer back to the ProLiant

BL p-Class System Overview and Planning white paper to be sure that the new

configuration does not overload the existing power enclosure scheme.

WARNING: To reduce the risk of personal injury, fire, or damage to the

equipment, do not overload the AC supply branch circuit that provides power

to the rack. Consult the electrical authority having jurisdiction over your

facility’s wiring and installation requirements.

The installation of this equipment shall be in accordance with local/regional electrical

regulations governing the installation of information technology equipment by

licensed electricians. This equipment is designed to operate in installations covered

by NFPA 70, 1999 Edition (National Electric Code) and NFPA 75, 1992 Edition

(code for Protection of Electronic Computer/Data Processing Equipment).

Grounding Requirements

For proper operation and safety, the server must be properly grounded. In the

United States, you must install the equipment in accordance with NFPA 70, 1999

Edition (National Electric Code) Article 250 as well as any local and regional

building codes. In Canada, the equipment must be installed in accordance with

Canadian Standards Association, CSA C22.1, Canadian Electrical Code.

In all other countries, the installation must follow any regional or national electrical

wiring codes, such as the International Electrotechnical Commission (IEC) 364, parts

1 through 7. Furthermore, you must be sure that all power distribution devices used

in the installation—such as branch wiring and receptacles—are listed or certified

grounding-type devices.

2-4 HP ProLiant BL p-Class System Setup and Installation Guide

Page 24

Rack Warnings

Before installing the rack, observe the following warnings:

WARNING: To reduce the risk of personal injury or equipment damage, always

be sure that the rack is adequately stabilized before installing or removing a

component.

WARNING: To reduce the risk of personal injury or equipment damage, be

sure that:

• The leveling jacks are extended to the floor.

• The full weight of the rack rests on the leveling jacks.

• The stabilizers are attached to the rack for single-rack installation.

• The racks are installed together in multiple-rack installations.

WARNING: To reduce the risk of personal injury or equipment damage, at

least two people are needed to safely unload the rack from the pallet. An empty

42U rack can weigh as much as 115 kg (253 lb), can stand more than 2.1 m

(7 ft) tall, and may become unstable when being moved on its casters.

Never stand in front of the rack when it is rolling down the ramp from the

pallet; always handle the rack from both sides.

WARNING: When installing enclosures in a telco rack, be sure that the rack

frame is adequately secured to the top and bottom of the building structure.

Planning the Installation

HP ProLiant BL p-Class System Setup and Installation Guide 2-5

Page 25

Planning the Installation

System Warnings and Cautions

Before installing the system, carefully review the following warnings and cautions:

WARNING: To reduce the risk of personal injury or damage to equipment,

heed all warnings and cautions throughout the installation instructions.

WARNING: To reduce the risk of electric shock or damage to the equipment,

only enter or perform service on specific parts of the system as instructed in

the user documentation.

WARNING: A risk of electric shock from high leakage current exists. Before

connecting the AC supply to the power enclosures, be sure that the electrical

outlets are properly earth grounded.

WARNING: A risk of injury from electric shock and hazardous energy levels

exists.

Each power enclosure has two separate power supply cords. A single

rack/cabinet may contain up to two power enclosures. In all cases, power is

supplied in a redundant fashion and removing any single source of power

does not necessarily shut down any portion of the system. When performing

any service other than hot-plug module replacement, you must completely

disconnect all power to that portion of the system.

In the case of the server blade enclosures, shut off the circuit breakers to both

A and B power feeds and then disconnect both power feed cables before

servicing.

In the case of the power enclosures, shut off the circuit breakers to both A and

B power feeds and then disconnect both power cords from the wall outlet

before servicing.

WARNING: To reduce the risk of personal injury from hot surfaces, allow the

internal system components to cool before touching them.

2-6 HP ProLiant BL p-Class System Setup and Installation Guide

Page 26

Planning the Installation

WARNING: The power enclosure and the server blade enclosure are very

heavy. To reduce the risk of personal injury or damage to the equipment:

• Observe local occupational health and safety requirements and guidelines

for manual material handling.

• Remove hot-plug power supplies and server blades from their enclosures

before installing or removing the enclosures.

• Use caution and get help to lift and stabilize enclosures during installation

or removal, especially when the enclosure is not fastened to the rack.

WARNING: To reduce the risk of personal injury or damage to the equipment,

you must adequately support the power enclosure and the server blade

enclosure during installation and removal. These enclosures are not secured

to the rack frame.

WARNING: Always use at least two people to lift an enclosure into the rack. If

the enclosure is being loaded into the rack above chest level, a third person

must assist with aligning the enclosure with the rails while the other two

people support the weight of the enclosure.

CAUTION: When performing non-hot-plug operations, you must power down the

server blade and/or the system. However, it may be necessary to leave the server

blade powered up when performing other operations, such as hot-plug installations

or troubleshooting.

CAUTION: Protect the equipment from AC power fluctuations and temporary

interruptions with a regulating facility UPS device. This device protects the hardware

from damage caused by power surges and voltage spikes and keeps the system in

operation during a power failure.

CAUTION: Always be sure that equipment is properly grounded before beginning

any installation procedure. Electrostatic discharge resulting from improper grounding

can damage electronic components. For more information, refer to Appendix B,

“Electrostatic Discharge.”

HP ProLiant BL p-Class System Setup and Installation Guide 2-7

Page 27

3

Installing System Hardware

This chapter provides installation procedures for the following system infrastructure

components:

• Power enclosures

• Server blade enclosures

• Hot-plug power supplies

• Interconnects and their respective modules

• Bus bars

You can also refer to the installation procedures on the HP ProLiant BL p-Class

System Hardware Installation and Configuration poster.

Installing System Enclosures

To install a power enclosure or server blade enclosure, use the sections in this chapter

to complete the following steps:

1. Measure with the rack template.

2. Install the rack rails and cage nuts.

3. Load the enclosures into the rack.

HP ProLiant BL p-Class System Setup and Installation Guide 3-1

Page 28

Installing System Hardware

Measuring with the Rack Template

Telco Rack Configurations

If you are installing components in a telco rack, refer to the telco rack template and

documentation that ship with the telco enclosure option kits.

Power Bus Box Configurations

If you are installing a power bus box configuration, refer to the power bus box rack

template and documentation that ship with the power bus box option kit.

Scalable and Mini Bus Bar Configurations

If you are installing a scalable or mini bus bar configuration, refer to the template and

documentation that ship with either option kit.

Installing the Rack Rails and Cage Nuts

You must install two rack rails to support each enclosure. Rack rails have the

following features:

• Adjustable depth of 60.96 cm to 91.44 cm (24 inches to 36 inches)

IMPORTANT: For proper bus bar installation and clearance, the rack rail depth must be

set from 73.66 cm to 76.20 cm (29 inches to 30 inches).

• Depth indicator, visible in the middle of the rail

• “L” and “R” markings to identify left and right rack rails (from the front of the

rack)

WARNING: To reduce the risk of personal injury and damage to the

equipment, always begin by mounting the heaviest item on the bottom of the

rack. Continue to populate the rack from the bottom to the top. Failure to do so

may make the rack unstable.

3-2 HP ProLiant BL p-Class System Setup and Installation Guide

Page 29

Installing System Hardware

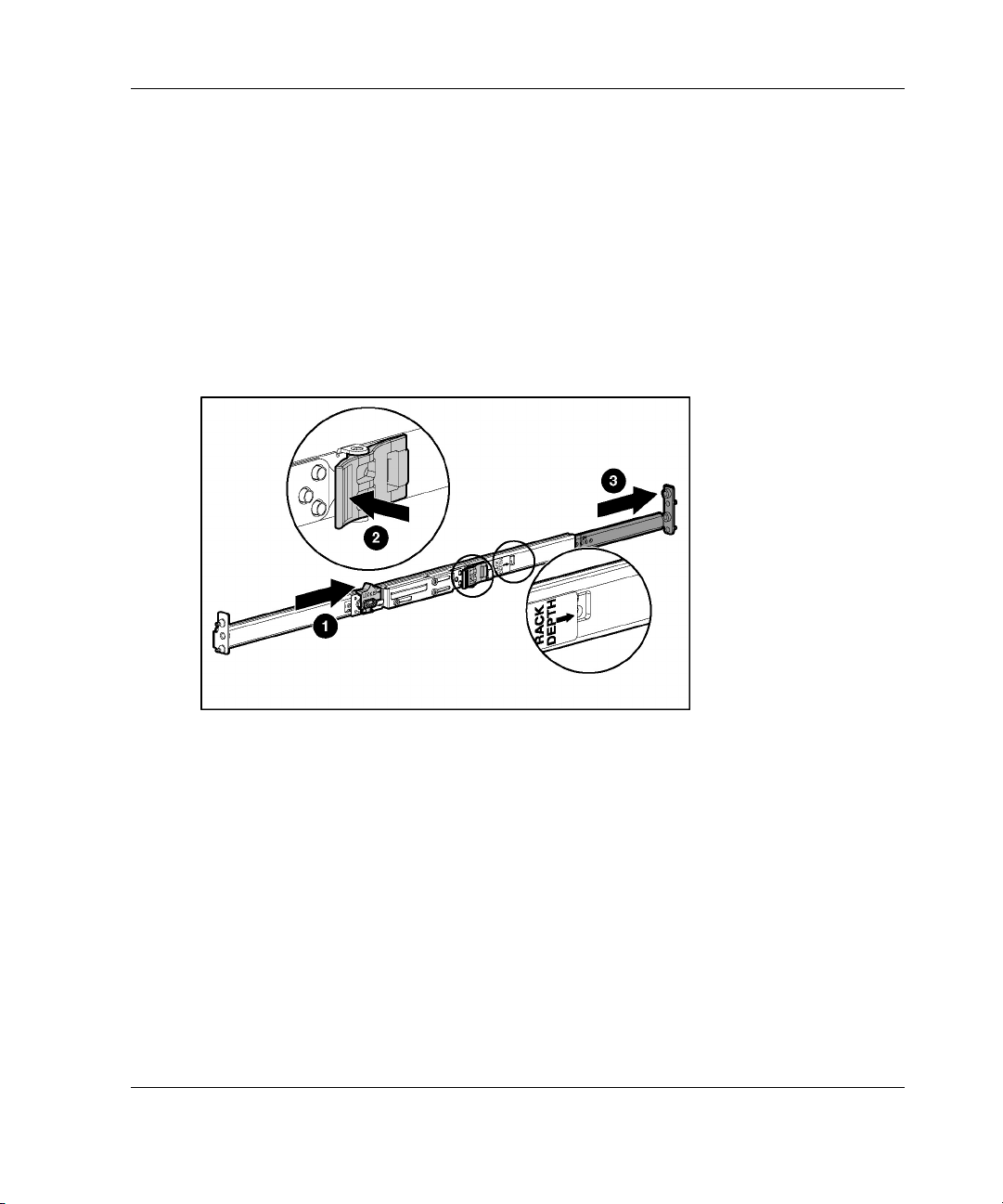

To install the rack rails and cage nuts:

1. Position yourself at the front of the rack.

2. Measure the depth of the rack.

3. Be sure that the rail locking gear is in the unlocked position (1).

4. Press the rail locking tab to unlock the rack rail (2).

5. Adjust the rack rail to the depth of the rack using the numbers on the rack rail as

a guide (3). The depth of a Compaq branded rack (29 inches) is clearly indicated

on the rack rails.

Figure 3-1: Unlocking and adjusting a rack rail

IMPORTANT: Numbers on the rack rail provide a gross adjustment of the depth of the

rack rail. You may need to adjust the rack rail depth again to ensure a proper fit.

6. Insert the rear of the right rack rail into the rack at the marks you made when

measuring with the template.

NOTE: The rack rails feature “L” and “R” markings to identify the left and right rack rails

(from the front of the rack).

HP ProLiant BL p-Class System Setup and Installation Guide 3-3

Page 30

Installing System Hardware

Figure 3-2: Inserting the rear of the rack rail

7. Compress the spring-loaded rack rail toward the rear of the rack (1).

8. Using the marks you made when measuring with the template, align the front of

the right rail with the holes and release the rail, allowing it to lock into

position (2).

9. Engage the locking gear (3).

Figure 3-3: Inserting the front of the rack rail and

engaging the locking gear

3-4 HP ProLiant BL p-Class System Setup and Installation Guide

Page 31

Installing System Hardware

CAUTION: Rack rails must be installed as tightly as possible. Failure to obtain a

proper fit may result in damage to equipment.

10. Repeat steps 1 through 9 for the left rack rail.

IMPORTANT: To ease installation, install all cage nuts for enclosures, bus bar hinges,

and cable brackets at this time.

11. Using the marks you made when measuring with the template, install the cage

nuts for enclosures, bus bar hinges, and the cable bracket.

IMPORTANT: In AC power configurations, the bottom hinges for each bus bar are

installed into cage nuts and the ends of power enclosure rack rails. In these locations, the

rails have extrusions to align the hinges and holes to accept screws. In facility DC power

configurations, you must install cage nuts to support the bottom hinges. Refer to the

template for hinge locations.

Figure 3-4: Installing Cage Nuts

HP ProLiant BL p-Class System Setup and Installation Guide 3-5

Page 32

Installing System Hardware

Installing Enclosures into the Rack

WARNING: Be sure that the power enclosure AC power cords are not

connected to a power source.

WARNING: To reduce the risk of personal injury and damage to the

equipment, always begin by mounting the heaviest item on the bottom of the

rack. Continue to populate the rack from the bottom to the top. Failure to do so

may make the rack unstable.

WARNING: Remove all hot-plug power supplies before loading a power

enclosure into the rack. Blanks can be left in the enclosure for installation.

WARNING: Remove all server blades before loading a server blade enclosure

into the rack. Blanks can be left in the enclosure for installation.

WARNING: At least two people must lift an enclosure into the rack together. If

the enclosure is loaded into the rack above chest level, a third person MUST

assist with aligning the enclosure with the rails while the other two people

support the weight of the enclosure.

WARNING: To reduce the risk of personal injury or damage to the equipment,

you must adequately support the power enclosure and the server blade

enclosure during installation and removal. They are not secured to the rack

frame.

To load a power enclosure or server blade enclosure into the rack:

1. Install the rack rails and cage nuts. Refer to the “Installing the Rack Rails and

Cage Nuts” section in this chapter.

IMPORTANT: You must install rack rails and cage nuts for each enclosure.

2. Position yourself at the front of the rack.

NOTE: Blanks can remain in the enclosures during installation because they do not add

significant weight to the component.

3-6 HP ProLiant BL p-Class System Setup and Installation Guide

Page 33

Installing System Hardware

3. Align the enclosure guiding fins with the guiding groove in the rack rails.

4. Slide the enclosure fully into the rack (1).

IMPORTANT: Be sure power cords and cables are accessible at the back of the rack.

5. Tighten the thumbscrews to secure the enclosure in the rack (2).

IMPORTANT: Be sure that the guiding fins on the enclosure seat properly in the guiding

groove on the rack rail.

Figure 3-5: Loading a power enclosure into the rack

HP ProLiant BL p-Class System Setup and Installation Guide 3-7

Page 34

Installing System Hardware

Figure 3-6: Loading a server blade enclosure, with

blanks, into the rack

6. Repeat steps 1 through 5 for subsequent enclosures.

After installing enclosures, you can install hot-plug power supplies and interconnects.

Refer to the “Hot-Plug Power Supplies” and “Interconnects” sections in this chapter.

You can also perform some cabling procedures. Refer to Chapter 4, “Cabling and

Powering Up the System.”

Hot-Plug Power Supplies

Hot-plug power supplies convert AC input power to -48 VDC output power for use

by the server blade enclosure. All power enclosure models use the standard hot-plug

power supply.

3-8 HP ProLiant BL p-Class System Setup and Installation Guide

Page 35

Identifying Power Supply Bays

Use Figure 3-7 and Table 3-1 to identify power supply bays.

Figure 3-7: Power supply bays

Installing System Hardware

Table 3-1: Power Supply Bays

Item Component Configuration

1 Power supply bay 1 (populated)

2 Power supply bay 2

3 Power supply bay 3

4 Power supply bay 4 (populated)

5 Power supply bay 5

6 Power supply bay 6

HP ProLiant BL p-Class System Setup and Installation Guide 3-9

Bus A

Bus B

Page 36

Installing System Hardware

Installation Guidelines

Observe the following requirements when installing a hot-plug power supply into the

power enclosure:

• Always install hot-plug power supplies in the bottom power enclosure first, if

more than one power supply enclosure is installed.

• HP recommends installing hot-plug power supplies in a redundant configuration,

as described in Table 3-2.

Table 3-2: Hot-Plug Power Supply Redundant

Configurations

Model Power Supplies Bays Populated

Single phase 2 Bays 1 and 4

4 Bays 1, 2, 4, and 5

Three phase 6 All six bays

Or

Bays 2 and 5

Note: Single-phase models of the power enclosure only require

four bays for a maximum configuration.

3-10 HP ProLiant BL p-Class System Setup and Installation Guide

Page 37

Installing a Hot-Plug Power Supply

To install a hot-plug power supply:

CAUTION: Always install either a hot-plug power supply or a power supply blank to

maintain proper airflow and cooling in the power enclosure. Improper airflow can lead

to thermal damage.

1. Press the release button (1).

2. Open the release lever (2).

3. Slide the hot-plug power supply fully into the bay (3).

4. Close the release lever (4).

Installing System Hardware

Figure 3-8: Installing a hot-plug power supply

5. If you are performing a hot-plug installation, be sure that the hot-plug power

supply power LED illuminates green. Refer to the “Hot-Plug Power Supply”

section in Appendix D, “LEDs and Switches.”

HP ProLiant BL p-Class System Setup and Installation Guide 3-11

Page 38

Installing System Hardware

Installing a Power Supply Blank

To install a power supply blank:

CAUTION: Always install either a hot-plug power supply or a power supply blank to

maintain proper airflow and cooling in the power enclosure. Improper airflow can lead

to thermal damage.

1. Slide the power supply blank into the power supply bay until the blank is fully

seated.

Figure 3-9: Installing a power supply blank

2. Repeat step 1 to fill all empty power supply bays.

3-12 HP ProLiant BL p-Class System Setup and Installation Guide

Page 39

Interconnects

Each server blade enclosure requires a pair of interconnects to provide network

access for data transfer or remote management. The leftmost and rightmost bays of

each server blade enclosure are interconnect bays for these devices.

IMPORTANT: Interconnect options vary. A server blade enclosure requires a pair of

interconnects of the same type. Do not mix two types of interconnects in the same enclosure.

(Figures 3-10 through 3-12 show the RJ-45 patch panel.) Refer to the documentation that

ships with the interconnect option you have selected.

First install the appropriate connectors at the rear of the rack, then move to the front

of the rack to install the interconnect.

To install the interconnect modules (rear of rack):

1. Remove the protective covers on the end of each interconnect module.

2. Install the appropriate interconnect modules into the enclosure at the back of the

rack.

Installing System Hardware

Figure 3-10: Installing interconnect modules (RJ-45

patch panel modules shown)

HP ProLiant BL p-Class System Setup and Installation Guide 3-13

Page 40

Installing System Hardware

To install the interconnect (front of rack):

1. Press the release button (1).

2. Open the ejector lever (2).

Figure 3-11: Unlocking an interconnect (RJ-45 patch

panel shown)

3-14 HP ProLiant BL p-Class System Setup and Installation Guide

Page 41

Installing System Hardware

3. Slide the interconnect into the server blade enclosure interconnect bay (1).

4. Close the ejector levers (2).

5. Repeat steps 1 through 4 for the second interconnect.

Figure 3-12: Installing an interconnect (RJ-45 patch

panel shown)

If you installed interconnect switches, you must configure them with the appropriate

software utilities. For more information, refer to the documentation that ships with

the interconnect switch.

HP ProLiant BL p-Class System Setup and Installation Guide 3-15

Page 42

Installing System Hardware

Power Distribution Components

The system requires components to distribute -48 VDC power from the power

enclosure or facility -48 VDC source to the server blade enclosures.

Installation Guidelines

Observe the following guidelines:

• Always be sure to set the rack rail depth for enclosures between 73.66 cm and

76.20 cm (29 inches and 30 inches) for proper bus bar clearance in a rack with a

rear rack door.

• Always be sure that power components are disconnected and that all circuit

breakers on bus bars and power enclosures are locked in the off position before

installing the bus bars. For circuit breaker locations, refer to Chapter 4, “Cabling

and Powering Up the System.”

Installing a Bus Bar

1. Using the marks you made when measuring with the template, install the cage

nuts for hinges and the cable bracket, if you have not already done so.

IMPORTANT: In AC power configurations, the bottom hinges for each bus bar are

installed into cage nuts and the ends of power enclosure rack rails. In these locations, the

rails have extrusions to align the hinges and holes to accept screws. In facility DC power

configurations, you must install cage nuts to support the bottom hinges.

3-16 HP ProLiant BL p-Class System Setup and Installation Guide

Page 43

Installing System Hardware

Figure 3-13: Installing cage nuts

NOTE: Enclosures and cables have been removed from the following figures for clarity.

2. Align a bus bar hinge with the rack (1).

3. Slide the hinge toward the outside edge of the rack (2).

4. Install the screws to secure the hinge (3).

Figure 3-14: Installing hinges

HP ProLiant BL p-Class System Setup and Installation Guide 3-17

Page 44

Installing System Hardware

5. Repeat steps 1 through 3 for the other three hinges.

6. Hang the bus bars on the hinges.

Figure 3-15: Hanging the bus bars on the hinges

7. Insert the hinge nut into the bottom of the top hinge (1).

8. Insert the hinge bolt and use a 4 mm (5/32 inch) Allen wrench to tighten the bolt

into the nut (2).

Figure 3-16: Securing the bus bars to the hinges

3-18 HP ProLiant BL p-Class System Setup and Installation Guide

Page 45

9. Repeat steps 7 and 8 for each hinge.

The bus bars ship with locking latches for securing the bus bars and a cable bracket

for routing network cables. These components are installed after cabling is complete.

For cabling procedures, refer to Chapter 4, “Cabling and Powering Up the System.”

Additional System Hardware

The system requires different types of hardware depending on your power

configuration or server blade configuration needs, including:

• Power bus boxes

• Facility DC power cables

• Diagnostic station

For installation procedures of these components, refer to the Documentation CD or

the documentation that ships with the option.

Installing System Hardware

HP ProLiant BL p-Class System Setup and Installation Guide 3-19

Page 46

Cabling and Powering Up the System

Identifying System Components

Figures 4-1 through 4-3 and Tables 4-1 through 4-3 identify connector and cable

locations on system components:

• Power enclosure and power management module

• Server blade enclosure and server blade management module

• Interconnects

4

• Bus bars and power bus boxes

The diagnostic station has multiple cabling configurations for configuration and

diagnostic purposes. For cabling procedures, refer to the documentation that ships

with the diagnostic station.

HP ProLiant BL p-Class System Setup and Installation Guide 4-1

Page 47

Cabling and Powering Up the System

Enclosures and Management Modules

Figure 4-1: Enclosures and management module

components (rear)

Table 4-1: Enclosure and Management Module Components

Item Description

1 Server blade enclosure

2 Server blade management module

3 Server blade management module service port*

4

* The service port is for advanced diagnostics performed by qualified service

personnel only. Refer to the ProLiant BL p-Class System Maintenance and

Service Guide.

4-2 HP ProLiant BL p-Class System Setup and Installation Guide

Server blade management link connectors (top to enclosure

above, bottom to enclosure below)

continued

Page 48

Cabling and Powering Up the System

Table 4-1: Enclosure and Management Module Components continued

Item Description

5 DC power input connector for bus A

6 DC output power cable pairs (-48V and return) for bus A

7 Grounding cable screw

8 Power management link connector to enclosure above

9

10 Power management module service port*

11 Power management link connector to enclosure below

12 Power management module

13 DC output power cable pairs (-48V and return) for bus B

14 Load-balancing signal cable connector

15 Power enclosure

16 DC power input connector for bus B

* The service port is for advanced diagnostics performed by qualified service

personnel only. Refer to the ProLiant BL p-Class System Maintenance and

Service Guide.

Power enclosure AC circuit breakers (to hot-plug power

supplies) for bus B (left) and bus A (right)

HP ProLiant BL p-Class System Setup and Installation Guide 4-3

Page 49

Cabling and Powering Up the System

Scalable and Mini Bus Bar Components

Figure 4-2: Scalable (shown on left) and mini (shown on

right) bus bar components

4-4 HP ProLiant BL p-Class System Setup and Installation Guide

Page 50

Cabling and Powering Up the System

Table 4-2: Mini and Scalable Bus Bar Components

Item Description

1 DC power output cables with couplers

2 DC circuit breakers

3 DC power input connector access

4 DC power input connector access cover

HP ProLiant BL p-Class System Setup and Installation Guide 4-5

Page 51

Cabling and Powering Up the System

Power Bus Box Components

Figure 4-3: Power bus box components (some internal

pieces removed for clarity)

Table 4-3: Power Bus Box Components

Item Description

1 DC power input connectors

2 Access cover

3 DC power output cables with coupler (installed)

Not shown Circuit breaker (on opposite side)

4-6 HP ProLiant BL p-Class System Setup and Installation Guide

Page 52

Cabling the System

Overview

After all system hardware is installed, you can cable the components. Examples of

system cabling for different configurations are available in the “Cabling

Configuration Diagrams” section in this chapter.

WARNING: To reduce the risk of electric shock or injury due to high current

electrical energy, be sure that all power is completely disconnected at the

source before beginning any power connections to the power bus bars or

power bus box.

To cable the system:

1. Cable the management modules. Refer to the “Management Modules” section in

this chapter.

If you are configuring a full-rack 42U solution with two pairs of mini bus bars,

you must also do the following:

a. Set the power configuration switches to establish the two power zones. Refer

to the “Power Configuration Switches” section in Appendix D, “LEDs and

Switches.”

Cabling and Powering Up the System

b. Cable the power management module in zone 2 (upper pair of mini bus bars)

to both adjacent server blade management modules, above and below. This

connection enables system management to establish a full-rack topology.

Refer to the “Management Modules” section in this chapter.

WARNING: Be sure that all circuit breakers are locked in the off position

before connecting any power components.

2. Connect the bus bars or power bus boxes to the enclosures. Refer to the “Bus

Bars” section in this chapter.

IMPORTANT: When connecting power devices, be sure to connect both buses.

HP ProLiant BL p-Class System Setup and Installation Guide 4-7

Page 53

Cabling and Powering Up the System

3. Connect the grounding cable to the server blade enclosures, if you are using a

facility DC power source. Refer to the “Grounding Cable in Facility DC Power

Environments” section in this chapter.

IMPORTANT: If the configuration does not include power enclosures, omit step 4.

4. Connect the load-balancing signal cable between power enclosures (scalable bus

bar configuration only). Refer to the “Load-Balancing Signal Cable” section in

this chapter.

5. If you have facility DC power, install the facility DC cables. Refer to the

documentation that ships with the facility DC cable kit.

6. Install the cable bracket and connect the network cables to the interconnects.

Refer to the “Cable Bracket” section in this chapter.

7. Connect to your AC or facility DC power source and power up the system. Refer

to the “Powering Up the System” section in this chapter.

Cabling Configuration Diagrams

Scalable Bus Bar

Figure 4-4 identifies scalable bus bar cabling for two power enclosures and five

server blade enclosures.

4-8 HP ProLiant BL p-Class System Setup and Installation Guide

Page 54

Cabling and Powering Up the System

Figure 4-4: Scalable bus bar cabling configuration

HP ProLiant BL p-Class System Setup and Installation Guide 4-9

Page 55

Cabling and Powering Up the System

Table 4-4: Scalable Bus Bar Configuration

Item Description

1 Network cables (number of cables depends on interconnect

option or solution)

2 Bus bar DC output power cables with couplers

3 Management module cables

4 Power enclosure DC output power cables

5 Power enclosure load-balancing signal cable

6 Power enclosure AC input power cords

Mini Bus Bar

Figure 4-5 identifies mini bus bar cabling for one power enclosure and three server

blade enclosures.

4-10 HP ProLiant BL p-Class System Setup and Installation Guide

Page 56

Cabling and Powering Up the System

Figure 4-5: Mini bus bar cabling configuration

Table 4-5: Mini Bus Bar Configuration

Item Description

1 Network cables (number of cables depends on

interconnect option or solution)

2 Bus bar DC output power cables with couplers

3 Management module cables*

4 Power enclosure DC output power cables

5 Power enclosure AC input power cords

* In a full-rack 42U solution, an additional management module

cable connects modules between the two pairs of mini bus

bars.

HP ProLiant BL p-Class System Setup and Installation Guide 4-11

Page 57

Cabling and Powering Up the System

Power Bus Box

Figure 4-6 identifies power bus box cabling for one power enclosure and one server

blade enclosure.

Figure 4-6: Power bus box cabling configuration

Table 4-6: Power Bus Box Configuration

Item Description

1 Network cables (number of cables depends on

interconnect option or solution)

2 Power bus box DC power output cables with couplers

3 Management module cables

4 Power enclosure DC output power cables

5 Power enclosure AC input power cords

Facility DC

The facility DC configuration can be used with any type of bus bar or power bus box

configuration. Figure 4-7 identifies facility DC cabling with a mini bus bar

configuration containing one power enclosure and three server blade enclosures.

4-12 HP ProLiant BL p-Class System Setup and Installation Guide

Page 58

Cabling and Powering Up the System

Figure 4-7: Facility DC cabling configuration (with mini

bus bars)

Table 4-7: Facility DC Configuration with

Mini Bus Bars

Item Description

1 Network cables (number of cables depends on

interconnect option or solution)

2 Bus bar DC output power cables

3 Management module cables

4 Grounding cable

5 Facility DC input power cables

HP ProLiant BL p-Class System Setup and Installation Guide 4-13

Page 59

Cabling and Powering Up the System

Management Modules

The server blade management modules and power management modules are cabled

together in daisy-chain fashion to provide the management link. Each management

module has two management link connectors: one to connect to enclosures above and

one to connect to enclosures below. Cabling the management modules enables the

system to identify rack topology for power and data management.

CAUTION: Do not install NIC cabling or telephone cabling into the management link

connectors; these devices are not supported.

Management Cabling Guidelines

Observe the following guidelines for cabling the management modules.

On the server blade management module:

• The upper management link connector connects to enclosures above the module.

• The lower management link connector connects to enclosures below the module.

On the power management module:

• The right management link connector connects to enclosures above the module.

• The left management link connector connects to enclosures below the module.

Additional Guidelines for 42U Solution

Observe the following additional guidelines for configuring a full-rack 42U solution

with two pairs of mini bus bars:

• You must set the power configuration switches to establish the two power zones.

Refer to the “Power Configuration Switches” section in Appendix D, “LEDs and

Switches.”

• You must cable the power management module in zone 2 (upper pair of mini bus

bars) to both adjacent server blade management modules, above and below. This

connection enables system management to establish a full-rack topology.

4-14 HP ProLiant BL p-Class System Setup and Installation Guide

Page 60

Cabling and Powering Up the System

Figure 4-8: Cabling the power management module in

zone 2 (two mini bus bar configuration)

To cable management modules:

1. Connect one end of the management cable into the management link connector

on a management module (1).

2. Connect the other end of the management cable into the management link

connector on the next management module (2).

NOTE: Management modules are used only for information management (asset tracking, for

example). Disconnecting the management module cabling does not affect system operation.

HP ProLiant BL p-Class System Setup and Installation Guide 4-15

Page 61

Cabling and Powering Up the System

Figure 4-9: Cabling management modules (power

cabling removed for clarity)

3. Repeat steps 1 and 2 to cable all the modules in the rack.

IMPORTANT: After you power up the infrastructure, you can identify improper

management module cabling. Improper cabling causes all the management link connector

LEDs on the management modules to flash.

4. Be sure the power configuration switches are set properly if you have a full-rack

solution with two pairs of mini bus bars. Refer to the “Power Configuration

Switches” section in Appendix D, “LEDs and Switches.”

4-16 HP ProLiant BL p-Class System Setup and Installation Guide

Page 62

Cabling and Powering Up the System

Grounding Cable in Facility DC Power Environments

The grounding cable satisfies an enclosure-to-enclosure grounding requirement in

facility DC power environments. Each type of bus bar supports a different number of

enclosures; therefore, each facility DC cable option kit contains a grounding cable to

support the appropriate number of enclosures.

WARNING: If using facility DC power, cables must be installed by a licensed

electrician or trained service personnel familiar with high-power circuitry.

To connect the grounding cable:

1. Insert the mounting screw through the grounding cable lead and into the

enclosure (1).

2. Tighten the mounting screw to secure the grounding cable to the enclosure (2).

Figure 4-10: Connecting a grounding cable (power and

management cabling removed for clarity)

3. Repeat steps 1 and 2 as needed for the configuration until all enclosures in the

rack are connected by the grounding cable.

4. Connect the lower end of the grounding cable to the facility grounding

connection.

HP ProLiant BL p-Class System Setup and Installation Guide 4-17

Page 63

Cabling and Powering Up the System

Bus Bars

This section provides first-time installation procedures. If you are installing a bus bar

after initial installation, be sure that the system is powered down and power supplies

are removed.

WARNING: Be sure that all power enclosure and bus bar circuit breakers are

locked in the off position before connecting any power components. Refer to

the “Scalable and Mini Bus Bar Components” section in this chapter.

NOTE: To simplify cabling for multiple server blade enclosures, begin cabling the enclosures

sequentially from bottom to top. The couplers are labeled by bus and by number.

To connect couplers to server blade enclosure:

1. Unfasten the hook-and-latch strap securing the power cable and coupler.

2. Connect the bus A coupler to the DC input connectors for bus A on the server

blade enclosure.

Figure 4-11: Connecting bus A coupler to the server

blade enclosure (mini bus bar shown)

3. Repeat step 2 for the bus B coupler.

4-18 HP ProLiant BL p-Class System Setup and Installation Guide

Page 64

Cabling and Powering Up the System

To connect power cables to the bus bars:

IMPORTANT: You need a Torx T25 driver to connect DC power cables to a scalable or

mini bus bar.

IMPORTANT: Install the power cabling for bus bar connections on bus A first.

IMPORTANT: If the configuration does not include power enclosures, omit steps

1 through 10, below. Refer to the documentation that ships with the facility DC cables

option installation kit.

1. Remove the screws securing the access cover to the bus bar (1).

2. Remove the access cover from the bus bar (2).

IMPORTANT: When you remove the cable guide, the protective caps for the P2 power

cable connections are freed. Save these caps to reinstall them later.

3. Remove the screw securing the cable guide (3).

4. Remove the cable guide (4).

Figure 4-12: Removing the access cover and cable

guide (scalable bus bar shown)

HP ProLiant BL p-Class System Setup and Installation Guide 4-19

Page 65

Cabling and Powering Up the System

5. Install the power enclosure cables on the bus bar. The bus bar connectors are

color-coded to match the cables and keyed to fit the proper pin.

IMPORTANT: Always install the first pair of power cables on the bus bar connectors

marked P1 to prevent cable tangling.

Figure 4-13: Connecting power enclosure cables

(scalable bus bar shown)

4-20 HP ProLiant BL p-Class System Setup and Installation Guide

Page 66

Cabling and Powering Up the System

6. Install the cable guide (1).

7. Install the screw to secure the cable guide (2).

NOTE: You may need a magnetic driver to install this screw.

8. Install the access cover (3).

9. Install the screws to secure the access cover (4).

IMPORTANT: If you are installing power cables for one power enclosure only, be sure to

reinstall the protective caps into the unfilled locations of the cable guide.

Figure 4-14: Installing the cable guide and access cover

(cables removed for clarity)

10. Repeat steps 1 through 9 for bus bar B.

HP ProLiant BL p-Class System Setup and Installation Guide 4-21

Page 67

Cabling and Powering Up the System

11. Install the bus bar locking latches on the top and bottom of the bus bars:

a. Set the locking latch on the bus bar (1).

b. Rotate the locking latch to lock it into place (2). To install the lower locking

latch, invert the directions of the arrows in Figure 4-15.

Figure 4-15: Installing bus bar locking latches

4-22 HP ProLiant BL p-Class System Setup and Installation Guide

Page 68

Load-Balancing Signal Cable

The load-balancing signal cable enables two power enclosures in a scalable bus bar

configuration to balance their power output for the system’s power load demand.

IMPORTANT: If the load-balancing signal cable is not installed, the management software

issues alerts.

To connect the load-balancing signal cable:

1. Connect one end of the load-balancing signal cable into the connector on a power

enclosure.

2. Connect the other end of the load-balancing signal cable into the connector on

the second power enclosure.

Cabling and Powering Up the System

Figure 4-16: Connecting the load-balancing signal cable

HP ProLiant BL p-Class System Setup and Installation Guide 4-23

Page 69

Cabling and Powering Up the System

Cable Bracket

The bus bars and power bus boxes ship with a cable bracket. When routing network

cables, you can use the bracket and cable clamps to secure cables and clear the path

for opening and closing the bus bars.

When installing power bus boxes, you can use the bracket and tie-wraps to secure the

bus boxes to the rack. For cable bracket installation with power bus boxes, refer to

the documentation that ships with the power bus boxes.

To install the cable bracket for scalable and mini bus bars:

1. Using the marks you made when measuring with the template, install the cage

nuts, if you have not done so already.

2. Align the cable bracket with the cage nuts.

3. Install the cable bracket on the rack (1).

4. Tighten the thumbscrews (2). Cage nuts for these locations should have been

installed during the “Installing the Rack Rails and Cage Nuts” procedure in

Chapter 3, “Installing System Hardware.”

Figure 4-17: Installing the cable bracket

4-24 HP ProLiant BL p-Class System Setup and Installation Guide

Page 70

Cabling and Powering Up the System

5. Connect the network cables to the appropriate interconnects and their respective

modules. For connector locations, refer to the documentation that ships with the

interconnect option kit or to the server blade setup and installation guide.

6. Gather the network cables for the left and right sides of the rack.

7. Insert the ends of the cable retaining brackets into the cable bracket (1).

8. Tighten the thumbscrews to secure the cable retaining brackets over the

cables (2).

Figure 4-18: Installing the cable retaining brackets

HP ProLiant BL p-Class System Setup and Installation Guide 4-25

Page 71

Cabling and Powering Up the System

Powering Up the System

After cabling the system, connect to the power source and apply power to the system.

To power up the system:

WARNING: Be sure that all power enclosure, bus bar, and power bus box

circuit breakers are locked in the off position before connecting any power

components.

1. Connect to the power source:

— If the facility has an AC source, connect the power enclosure AC power

cords to an AC outlet.

— If the facility has a DC source, install the Facility DC cables kit. Refer to the

documentation that ships with that kit.

2. Apply power to the facility power connection, if needed.

IMPORTANT: If the power configuration does not include power enclosures, omit steps 3

through 5.

3. Unlock the circuit breakers on the power enclosure (1).

4. Set the switches to on (2). This action applies AC power to the hot-plug power

supplies.

5. Lock the switch in the on position (3).

4-26 HP ProLiant BL p-Class System Setup and Installation Guide

Page 72

Cabling and Powering Up the System

Figure 4-19: Unlocking and setting the circuit breaker

to on

6. Be sure that the hot-plug power supply LEDs, power enclosure DC power LEDs,

and bus bar power LEDs are green. Refer to Appendix D, “LEDs and Switches.”

IMPORTANT: Only unlock circuit breakers for couplers that are attached to a server

blade enclosure.

7. Unlock the circuit breaker switches on the bus bars or power bus boxes and set

the switches to on. This action applies DC power to the server blade enclosures.

8. Be sure that the server blade enclosure DC power LEDs are green. Refer to

Appendix D, “LEDs and Switches.”

9. Be sure to lock all the circuit breaker switches in the on position. This action

prevents anyone from accidentally powering down the system.

NOTE: Circuit breakers continue to function in the event of an overload condition even if

they are locked.

Power is now applied to all system hardware.

HP ProLiant BL p-Class System Setup and Installation Guide 4-27

Page 73

Regulatory Compliance Notices

Regulatory Compliance Identification Numbers

For the purpose of regulatory compliance certifications and identification, your

product has been assigned a unique series number. The series number can be found

on the product nameplate label, along with all required approval markings and

information. When requesting compliance information for this product, always refer

to this series number. The series number should not be confused with the marketing

name or model number of the product.

A

Federal Communications Commission Notice

Part 15 of the Federal Communications Commission (FCC) Rules and Regulations

has established Radio Frequency (RF) emission limits to provide an interference-free

radio frequency spectrum. Many electronic devices, including computers, generate

RF energy incidental to their intended function and are, therefore, covered by these

rules. These rules place computers and related peripheral devices into two classes, A

and B, depending upon their intended installation. Class A devices are those that may

reasonably be expected to be installed in a business or commercial environment.

Class B devices are those that may reasonably be expected to be installed in a

residential environment (i.e., personal computers). The FCC requires devices in both

classes to bear a label indicating the interference potential of the device as well as

additional operating instructions for the user.

HP ProLiant BL p-Class System Setup and Installation Guide A-1

Page 74

Regulatory Compliance Notices

The rating label on the device shows which class (A or B) the equipment falls into.

Class B devices have an FCC logo or FCC ID on the label. Class A devices do not

have an FCC logo or FCC ID on the label. Once the class of the device is determined,

refer to the following corresponding statement.

Class A Equipment

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. Operation of

this equipment in a residential area is likely to cause harmful interference, in which

case the user will be required to correct the interference at personal expense.

Modifications

The FCC requires the user to be notified that any changes or modifications made to

this device that are not expressly approved by Hewlett-Packard Company may void

the user's authority to operate the equipment.

Cables

Connections to this device must be made with shielded cables with metallic RFI/EMI

connector hoods in order to maintain compliance with FCC Rules and Regulations.

Canadian Notice (Avis Canadien)

This Class A digital apparatus meets all requirements of the Canadian InterferenceCausing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur

le matériel brouilleur du Canada.

A-2 HP ProLiant BL p-Class System Setup and Installation Guide

Page 75

European Union Notice

Products bearing the CE marking comply with the EMC Directive (89/336/EEC) and

the Low Voltage Directive (73/23/EEC) issued by the Commission of the European

Community and if this product has telecommunication functionality, the R&TTE

Directive (1999/5/EC).