Page 1

HP Blade Server bh7800

Site Preparation Guide

June 2002

Manufacturing Part Number:

Version: Third Edition

USA

© Copyright 2002

Page 2

Legal Notices

The information in this document is subject to change without notice.

Hewlett-Packard makes no warranty of any kind with regard to this manual, including, but not limited to, the

implied warranties of merchantability and fitness for a particular purpose. Hewlett-Packard shall not be held

liable for errors contained herein or direct, indirect, special, incidental or consequential damages in

connection with the furnishing, performance, or use of this material.

Restricted Rights Legend. Use, duplication or disclosure by the U.S. Government is subject to restrictions as set forth in subparagraph (c) (1) (ii) of the Rights in Technical Data and Computer Software clause at DFARS 252.227-7013 for DOD agencies, and subparagraphs (c) (1) and (c) (2) of the Commercial Computer Software Restricted Rights clause at FAR 52.227-19 for other agencies.

HEWLETT-PACKARD COMPANY 3000 Hanover Street Palo Alto, California 94304 U.S.A.

Copyright Notices. ©copyright 1983-2002 Hewlett-Packard Company, all rights reserved.

Reproduction, adaptation, or translation of this document without prior written permission is prohibited,

except as allowed under the copyright laws.

ii

Page 3

1. HP Blade Server bh7800 Overview

Display Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

System Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

HP Server bc1100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Network Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Management LAN Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Management Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Fan Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Slot Blocker Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cable Management Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Air Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Shipping Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2. General System and Facility Guidelines

Electrical Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Electrical Load Requirements (Circuit Breaker Sizing) LAHJ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Power Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Distribution Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Grounding Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

System Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Environmental Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Computer Room Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Floor Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Cooling Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Air Conditioning Ducts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Humidity Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Dust and Pollution Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Metallic Particulate Contamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Electrostatic Discharge (ESD) Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Acoustics (noise reduction). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Contents

3. HP Blade Server bh7800 Power

HP Blade Server Initial Power-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Power Cords Supplied. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Chassis Power-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Blade Server Power-Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Connecting AC Power using a PDU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

A. System Specifications and Requirements

System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

B. Power Plug Configuration

iii

Page 4

Contents

Cord Set Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

C. Conversion Factors and Formulas

Conversion Factors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

iv

Page 5

Figures

Figure 1-1. LCD Display Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 1-2. bh7800 Backplane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 1-3. bh7800 Power Supplies (Chassis Rear View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 1-4. HP Server bc1100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 1-5. Network Blade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 1-6. Management LAN Blade (shown with carrier) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 1-7. Management Blade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 1-8. bh7800 Fan Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 1-9. bh7800 Caution Label shown with Slot Blocker Assembly . . . . . . . . . . . . . . . . . . . . . . 21

Figure 1-10. bh7800 Racking for HP Rack System/E Cabinet Showing Cable Tray . . . . . . . . . . . . 22

Figure 1-11. bh7800 Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 1-12. bh7800 Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 1-13. bh7800 Cooling Airflow (Chassis Rear View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 1-14. bh7800 Cooling Airflow (Chassis Side View). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 2-1. Raised Floor Metal Strip Ground System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure A-1. Power Supply Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure B-1. Cord Sets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure B-2. Male Receptacle to Female Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure B-3. Male Plug Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

v

Page 6

Figures

vi

Page 7

Tab les

Table 1. Publication History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 1-1. bh7800 Server Weights and Dimensions as Shipped on a Pallet . . . . . . . . . . . . . . . . . . . 27

Table 2-1. Floor Loading Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 3-1. Server Chassis Power Cords. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 3-2. PDU and UPS Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table A-1. bh7800 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table A-2. Environmental Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table A-3. Weight and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table A-4. Power Dissipation (Theoretical Maximum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table A-5. Power Dissipation and Air Conditioning Requirement Summary . . . . . . . . . . . . . . . . . 53

Table A-6. Power Dissipation and Air Conditioning Requirement Example . . . . . . . . . . . . . . . . . . 54

vii

Page 8

Tables

viii

Page 9

Preface

Before preparing your site for the HP Blade Server bh7800, familiarize yourself with the components that

comprise the bh7800. Use the following reference to determine where to start.

Page 10

Book Layout

• Chapter 1 – provides an overview of the bh7800 components, cooling air flow, shipping dimensions and

weight and CFM value.

• Chapter 2 – provides specific information ensuring the site is ready when the bh7800 arrives. Voltage

fluctuations, grounding and floor loading are some of the topics covered.

• Chapter 3 – covers how to power up the bh7800 and how to power down the bh7800. Power distribution

information and power cords required are specified.

• Appendix A – provides specifications and requirements necessary to ensure the bh7800 environment

provided is suitable for operating the bh7800.

• Appendix B – provides power plug configuration information for the male and female end of the cord set.

• Appendix C – provides conversion factors and formulas used for determining site environment

requirements.

• Glossary – provides a list of terms most commonly used in this manual.

• Index - a quick look up table for common terms and components used in this guide.

Publication History

The Site Preparation guide was never assigned a manufacturing part number. The method for tracking

revisions will be this table.

Table 1 Publication History

Edition Comments

First December 2001 release. CD-ROM, EPSS Web site, and http://docs.hp.com delivery mechanisms.

Second April 2002 release. CD-ROM, EPSS Web site, and http://docs.hp.com delivery mechanisms.

Power dissipation values in appendices were revised.

Third June 2002 release. CD-ROM, EPSS Web site, and http://docs.hp.com delivery mechanisms.

Conversion from MS Word to Framemaker 6.0 to meet Section 508 compliance. Enhanced

graphics and illustrations added.

10

Page 11

1 HP Blade Server bh7800 Overview

The HP Blade Server bh7800 provides customers with a single chassis that can house up to 16 functionally

separate servers, controlled by one management blade. The form factor for all the blades uses the

CompactPCI standard. The chassis mounts in a standard 19-inch EIA rack, in either a two column or four

Chapter 1

11

Page 12

HP Blade Server bh7800 Overview

column style rack. Hewlett-Packard Company offers kits for either type rack. The chassis provides slots in the

front and rear for installation of server blades, and network blades. Each side accommodates 18 blades and

can house up to eight server blades per side.

This chapter provides a high level overview of the various components that comprise the blade server. It is not

the intention of this chapter to cover how to operate the blade server.

12

Chapter 1

Page 13

HP Blade Server bh7800 Overview

Display Panel

Display Panel

The bh7800 display panel provides the controls and indicators commonly used when operating the bh7800.

There are two LCD display assemblies on the bh7800. Remote control over a network is another method used

to operate the bh7800. One display is in the front, just above the card cage. The other is in the rear, just above

the card cage. Both show identical data and are visible regardless of which side of the product you are on. The

rear display assembly is hinged so that it can be lifted up out of the way for access to the hot swap fan

modules. The LCD display panels allow most initialization and system monitoring functions to be performed

without connecting via Telnet or directly connecting to the management blade’s serial port. The display panel

is shown in Figure 1-1.

Figure 1-1 LCD Display Panel

Chapter 1

13

Page 14

HP Blade Server bh7800 Overview

System Backplane

System Backplane

The passive system backplane is centrally located in the bh7800 to accommodate front and rear card cages. 18

CompactPCI slots are available on each side with up to five connectors per slot. For the CompactPCI

standard, the lower two connectors are used for CompactPCI standard connections, and the upper three

connectors are for custom user applications. Additionally, the rear of the backplane has four power

connections (two for each power supply). The front of the backplane also contains the fan harness connector

and two LCD display cable connections. All connectors used on the backplane are press-fit. No special tool is

needed to insert or remove the connectors.

Figure 1-2 bh7800 Backplane

14

Chapter 1

Page 15

HP Blade Server bh7800 Overview

Power Supplies

Power Supplies

Each power supply uses two DC connectors that plug into the backplane, and an AC connector brings line

power into the unit. Two power supplies and two power cords ship with the system.

Each supply contains an internal fan for cooling. In the rear of each supply are two insertion/extraction

handles and latch assemblies for ease of inserting or removing each power supply. Two captive screws secure

each power supply to the system chassis.

A solid green LED indicates normal operation for either power supply. A solid yellow LED indicates a power

supply failure. Power supplies are hot swappable.

Figure 1-3 bh7800 Power Supplies (Chassis Rear View)

Chapter 1

15

Page 16

HP Blade Server bh7800 Overview

HP Server bc1100

HP Server bc1100

Up to 16 1 slot IA-32 server blades can be inserted in the bh7800 chassis. The 1 slot, 1way IA-32 blade server

is a self-contained system. It includes all memory, processor, firmware, I/O adapters, and core I/O required to

install the operating system. The board is CompactPCI and hot plug compliant and operates as a

CompactPCI master in the host slot. It is also Network Equipment Building Standards (NEBS) compliant.

Some I/O connections will be driven through the backplane and some local connections will be available from

the front panel.

A daughter board known as the Remote Management Card (RMC) provides LAN-based system console access

as well as remote system management functions. LAN-based access to the system console via Telnet is

provided to initially configure parameters stored in firmware on the blade. Remote system management

functions include power, reboot and inventory control.

Figure 1-4 HP Server bc1100

16

Chapter 1

Page 17

HP Blade Server bh7800 Overview

Network Blade

Network Blade

The network blade is a 24-port 10/100 switch with a gigabit uplink connection. The blade provides 16 of the

24 ports to the backplane, and 8 remaining ports out to the bulkhead. In addition, the network blade comes in

three uplink options: Tx (copper), Sx (short-wave optical), or Lx (long-wave optical).

The bh7800 system must contain one network blade, but can optionally contain two. The backplane actually

contains two separate LANs, LAN-A and LAN-B, so that a second blade provides backup protection for the

LAN segment.

The uplink connection aggregates all communications in the bh7800. This gigabit connection aggregates the

traffic from all 16 ports.

The blade may be hot swapped without taking down a live system. Of course, if only one switch is in the

cabinet, all external communications cease while the blade is being swapped. With a second switch in the

chassis, external communications are only interrupted on the LAN connected to the corresponding switch

being hot swapped. The switch in front slot 12 corresponds to LAN-A and the switch in rear slot 13

corresponds to LAN-B.

Figure 1-5 Network Blade

Chapter 1

17

Page 18

HP Blade Server bh7800 Overview

Management LAN Blade

Management LAN Blade

The two Rear Transition Modules (RTMs) are unique in the bh7800 product. The RTM is a pseudo standard

CompactPCI solution. Each RTM is a 3U blade rather than a 6U blade. CompactPCI card format and the

bulkhead is not a CompactPCI standard. A custom carrier holds each PCA in the bh7800 backplane. The

custom card guide is inserted in a dedicated location in the rear card cage. The RTM is more commonly

referred to as the management LAN blade.

Figure 1-6 Management LAN Blade (shown with carrier)

18

Chapter 1

Page 19

HP Blade Server bh7800 Overview

Management Blade

Management Blade

The bh7800 includes a management blade that allows remote and local management of the individual server

and network blades. The blade monitors the chassis environment such as power, temperature, and overall

server blade health. The blade can be accessed via a serial connection on the chassis or it can be accessed via

the control and management LAN.

The blade provides management support for the console LAN management signals. Provision for control of

the console LAN management signals for the sixteen IA-32 server blades or two LAN switches is in the 38 slot

chassis.

Figure 1-7 Management Blade

Chapter 1

19

Page 20

HP Blade Server bh7800 Overview

Fan Modules

Fan Modules

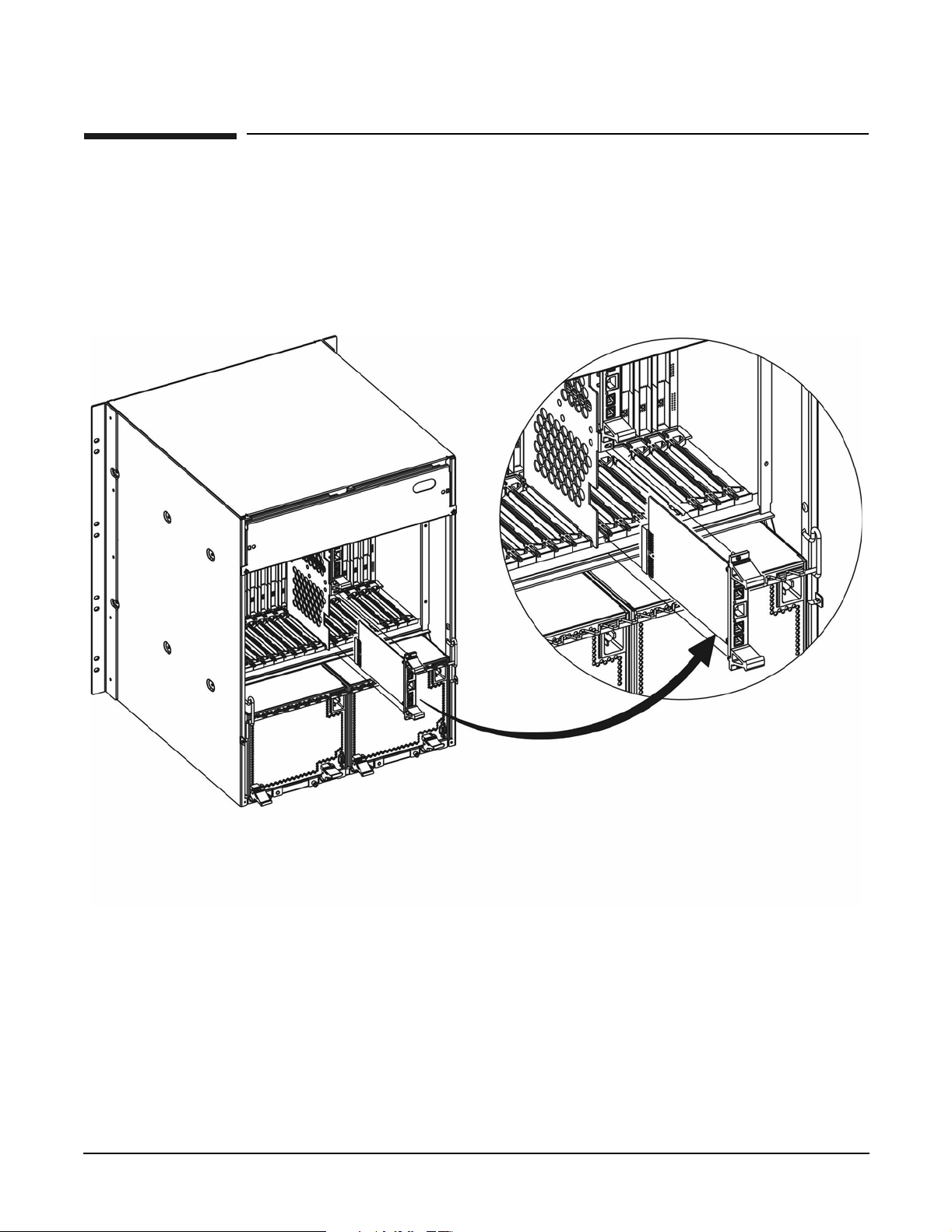

There are two fan module assemblies in the bh7800. They are hot swap modules. Each fan module has an

LED to indicate fan failure. Also, each fan can go into the fan module only one way due to the length and

location of the fan cable with its blind mate connector. Once each fan module is securely seated in the chassis,

two screws are tightened to secure each fan and prevent it from backing out of the chassis due to vibration.

Figure 1-8 bh7800 Fan Assemblies

20

Chapter 1

Page 21

HP Blade Server bh7800 Overview

Slot Blocker Assembly

Slot Blocker Assembly

The bh7800 uses a closed, pressurized cooling system. Fans draw air in the bottom at the front of the chassis,

direct it upwards across the front blades, over the top of the backplane, downwards over the rear blades and

into the power supplies where it exits out the back of the bh7800.

Any slot that isn’t occupied by a blade must contain a slot blocker to channel cool air in the proper direction to

maintain the cooling system pressure. A caution label on the chassis (bottom figure) indicates how serious

this requirement is.

Figure 1-9 bh7800 Caution Label shown with Slot Blocker Assembly

Chapter 1

21

Page 22

HP Blade Server bh7800 Overview

Cable Management Tr ay

Cable Management Tray

The ½ EIA unit high (1/2U) cable management tray provides a channel for cables and helps prevent the

accidental disconnection of cables from their respective blades. The tray is provided for HP Rack System/E

four post cabinets, Nortel four post cabinets and Chatsworth two post cabinets. The tray allows data cables to

be securely attached to the chassis and to maintain the critical bend radius associated with high speed data

cables.

Figure 1-10 bh7800 Racking for HP Rack System/E Cabinet Showing Cable Tray

22

Cable Management Tray

Chapter 1

Page 23

HP Blade Server bh7800 Overview

Front View

Front View

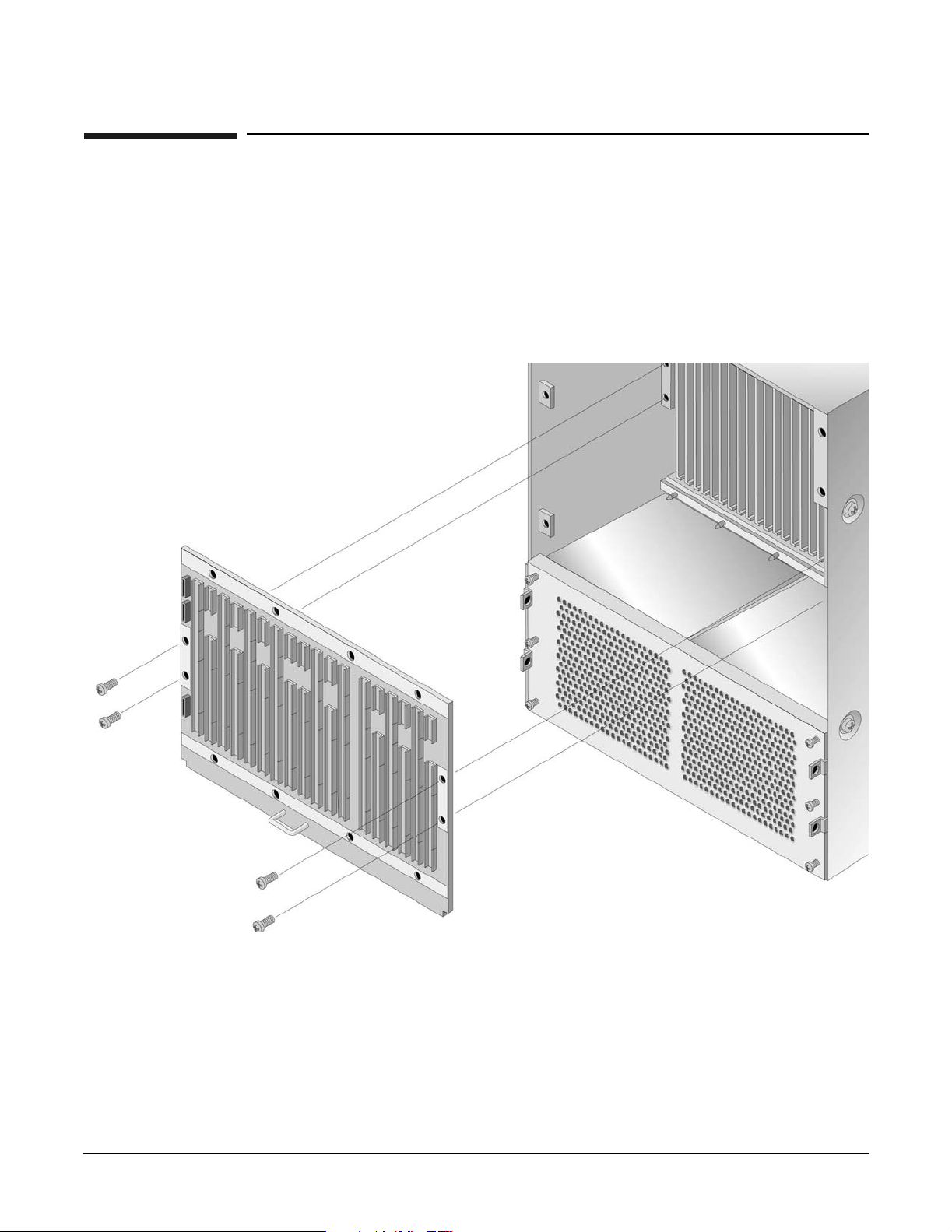

The components available at the front of this 13 EIA unit high (13U) server are

• Eighteen individual CompactPCI slots supporting defined configurations for 1 slot and 2 slot PCA’s

• One front LCD display panel

• The system backplane is removable from the front and is centrally located in the chassis

• Front cable management bracket (not shown)

Figure 1-11 bh7800 Front View

Chapter 1

23

Page 24

HP Blade Server bh7800 Overview

Rear View

Rear View

The components available at the rear of this 13 EIA unit high (13U) server are

• Two hot swap N+1 power supplies

• Two hot swap N+1 fan modules (hidden behind the rear panel display)

• Eighteen individual CompactPCI slots supporting defined configurations for 1 slot and 2 slot PCAs.

• One rear LCD display panel

• Rear cable management bracket (not shown)

Figure 1-12 bh7800 Rear View

24

Chapter 1

Page 25

Air Flow

Figure 1-13 bh7800 Cooling Airflow (Chassis Rear View)

HP Blade Server bh7800 Overview

Air Flow

The bh7800 utilizes a front to back cooling scheme. Four 150mm diameter 48V DC fans cool the system, one

in each power supply and two in independent carriers. Refer to Appendix A for System Specifications. Air

enters the vent along the lower front surface of the chassis and passes through the front sections of the power

Chapter 1

25

Page 26

HP Blade Server bh7800 Overview

Air Flow

supplies and up through the front card cage. Air then passes over the top of the backplane, through the top

rear fans and down through the rear card cage. It travels through the rear sections of the power supplies and

out through the rear power supply fans.

Figure 1-14 bh7800 Cooling Airflow (Chassis Side View)

Air Intake Temperature

The recommended air intake temperature for the bh7800 server is between 68 degrees F and 77 degrees F (25

degrees C and 30 degrees C) at 225 CFM.

26

Chapter 1

Page 27

HP Blade Server bh7800 Overview

Shipping Dimensions and Weights

Shipping Dimensions and Weights

Table 1-1 lists the dimensions and weights of the bh7800 server with the shipping pallet.

Table 1-1 bh7800 Server Weights and Dimensions as Shipped on a Pallet

Equipment Width (cm) Depth/Length (cm) Height (cm) Weight (kg)

bh7800 server

on shipping

ab

pallet

a. Shipping box, pallet and container add approximately 23 lbs to the total system

weight.

b. Specifications given in Table 1-1 are for a fully configured system.

21.25 inches (53.98 cm)

30.50 inches (77.47 cm)

29.38 inches (74.63 cm)

203 lbs (92.08 kg)

Chapter 1

27

Page 28

HP Blade Server bh7800 Overview

Shipping Dimensi ons and We ights

28

Chapter 1

Page 29

2 General System and Facility Guidelines

This chapter provides general computer facility guidelines for planning and preparing the site. Careful site

planning and preparation ensures trouble-free installation and reliable operation of HP servers. Factors that

may contribute to less than optimal equipment operation are also highlighted. Refer to Appendix A for more

information on guidelines specific to the bh7800.

Chapter 2

29

Page 30

General System and Facility Guidelines

Electrical Factor s

Electrical Factors

NOTE Electrical practices and suggestions in this guide are based on North American practices. For

countries and areas outside North America, local electrical codes will take precedence over

North American electrical codes.

An example would be the recommendation that the PE (protective earthing) conductor be green

with yellow stripes. This requirement is a North American directive and does not override the

local code requirements for a country or area outside North America.

Local Authority Has Jurisdiction (LAHJ) and should make the final decision regarding

adherence to country-specific or area-specific electrical codes and guidelines.

Throughout this chapter, the LAHJ acronym will be used to indicate Local Authority Has Jurisdiction.

Proper design and installation of a power distribution system for a HP server requires specialized skills.

Those responsible for this task must have a thorough knowledge and understanding of appropriate electrical

codes and the limitations of the power systems for computer and data processing equipment.

In general, a well-designed power distribution system exceeds the requirements of most electrical codes. A

good design, when coupled with proper installation practices, produces the most trouble-free operation.

A detailed discussion of power distribution system design and installation is beyond the scope of this

document. However, electrical factors relating to power distribution system design and installation must be

considered during the site preparation process.

The electrical factors discussed in this section are:

• Electrical load requirements (circuit breaker sizing)

• Power quality

• Distribution hardware

• Grounding Systems

• System installation guidelines

Electrical Load Requirements (Circuit Breaker Sizing) LAHJ

Appendix A summarizes electrical power load (KVA input) requirements for this server but additional

capacity should be added for equipment upgrading or expansion.

It is a good practice to derate power distribution systems for one or more of the following reasons:

• Circuit protection devices should be rated at 20% above the systems root-mean-square (RMS) current

ratings to avoid nuisance tripping from load shifts or power transients.

• Safety agencies derate most power connectors to 80% of their RMS current ratings.

Power Quality

HP equipment is designed to operate over a wide range of voltages and frequencies. However, damage can

occur if these ranges are exceeded. Severe electrical disturbances can exceed the design specifications of the

equipment.

30

Chapter 2

Page 31

General System and Facility Guidelines

Electrical Factors

Sources of Volt age Fluc tuations

Voltage fluctuations, sometimes called glitches, affect the quality of electrical power. Common sources of these

fluctuations are:

• Fluctuations occurring within the facility’s distribution system

• Utility service low-voltage conditions (such as sags or brownouts)

• Wide and rapid variations in input voltage levels

• Wide and rapid variations in input power frequency

• Electrical storms

• Large inductive sources (such as motors and welders)

• Faults in the distribution system wiring (such as loose connections)

• Microwave, radar, radio, or cell phone transmissions

Power System Protection

Computer systems can be protected from the sources of many of these electrical disturbances by using:

• A dedicated power distribution system

• Power conditioning equipment

• Over- and under-voltage detection and protection circuits

• Screening to cancel out the effects of undesirable transmissions

• Lightning arresters on power cables to protect equipment against electrical storms

Precautions have been taken during power distribution system design to provide immunity to power outages

of less than one cycle. However, testing cannot conclusively rule out loss of service. Therefore, adherence to

the following guidelines provides the best possible performance of power distribution systems for HP server

equipment:

• Dedicated power source—Isolates server power distribution system from other circuits in the facility.

• Missing-phase and low-voltage detectors—Shuts equipment down automatically when a severe power

disruption occurs. For peripheral equipment, these devices are recommended but optional.

• Online Uninterruptible Power Supply (UPS)—Keeps input voltage to devices constant and should be

considered if outages of one-half cycle or more are common.

Refer to qualified contractors or consultants for each situation.

Distribution Hardware

This section describes wire selection and the types of raceways (electrical conduits) used in the distribution

system.

Wire Selection

Use copper conductors instead of aluminum, as aluminum’s coefficient of expansion differs significantly from

that of other metals used in power hardware. Because of this difference, aluminum conductors can cause

connector hardware to work loose, overheat, and fail.

Chapter 2

31

Page 32

General System and Facility Guidelines

Electrical Factor s

Raceway Systems (Electrical Conduits) LAHJ

Raceways (electrical conduits) form part of the protective ground path for personnel and equipment.

Raceways protect the wiring from accidental damage and also provide a heatsink for the wires.

Any of the following types may be used:

• Electrical Metallic Tubing (EMT) thin-wall tubing

• Rigid (metal) conduit

• Liquidtight with RFI shield grounded (most commonly used under raised floors)

Building Distribution

All building feeders and branch circuitry should be in rigid metallic conduit with proper connectors (to

provide ground continuity). Conduit that is exposed and subject to damage should be constructed of rigid

galvanized steel.

Grounding Systems

Power Distribution Safety Grounding LAHJ

The power distribution safety grounding system consists of connecting various points in the power

distribution system to earth ground using green (green/yellow) wire ground conductors. Having these ground

connections tied to metal chassis parts that may be touched by computer room personnel protects them

against shock hazard from current leakage and fault conditions.

Power distribution systems consist of several parts. Hewlett-Packard recommends that these parts be solidly

interconnected to provide an equipotential ground to all points.

Main Building Electrical Ground

The main electrical service entrance equipment should have an earth ground connection, as required by

applicable codes. Connections such as a grounding rod, building steel, or a conductive type service pipe

provide an earth ground.

Electrical Conduit Ground

All electrical conduits should be made of rigid metallic conduit that is securely connected together or bonded

to panels and electrical boxes, so as to provide a continuous grounding system.

Power Panel Ground

Each power panel should be grounded to the electrical service entrance with green (green/yellow) wire ground

conductors. The green (green/yellow) wire ground conductors should be sized per applicable codes (based on

circuit over current device ratings).

NOTE The green wire ground conductor mentioned above might be a black wire marked with green

tape. LAHJ

Computer S afe ty G round

Ground all computer equipment with the green (green/yellow) wire included in the branch circuitry. The

green (green/yellow) wire ground conductors should be connected to the appropriate power panel and should

be sized per applicable codes (based on circuit over current device ratings).

32

Chapter 2

Page 33

General System and Facility Guidelines

Electrical Factors

Dual Power Source Grounding

When dual power sources are utilized, strong consideration should be given to measure voltage potentials.

The use of dual power might create an electrical potential that can be hazardous to personnel and might

cause performance issues for the equipment.

Dual power sources might originate from two different transformers or two different UPS devices. Voltage

potentials from ground pin to ground pin of these sources should be measured and verified to be at or near 0.0

volts. Voltage levels that deviate or are measured above 3.0 volts should be further investigated. Increased

voltages might be hazardous to personnel, and should be further investigated.

Cabinet Perform anc e Grounding (Hig h Frequency Groun d)

Signal interconnects between system cabinets require high frequency ground return paths. Connect all

cabinets to site ground.

NOTE In some cases power distribution system green (green/yellow) wire ground conductors are too

long and inductive to provide adequate high frequency ground return paths. Therefore, a

ground strap (customer-supplied) should be used for connecting the system cabinet to the

site-grounding grid (customer-supplied). When connecting this ground, ensure that the raised

floor is properly grounded for high frequency.

Power panels located in close proximity to the computer equipment should also be connected to site grounding

grid. Methods of providing a sufficiently high frequency ground grid are described in the next sections.

Raised Floo r “Hi gh Frequency Noise” Grounding

If a raised floor system is used, install a complete signal-grounding grid for maintaining equal potential over

a broad band of frequencies. The grounding grid should be connected to the equipment cabinet and electrical

2

service entrance ground at multiple connection points using a minimum #6 AWG (16mm

) wire ground

conductor. Figure 2-1 illustrates a metallic strip grounding system.

NOTE Regardless of the grounding connection method used, the raised floor should be grounded as an

absolute safety minimum.

Hewlett-Packard recommends the following approaches:

• Excellent - Add a grounding grid to the subfloor. The grounding grid should be made of copper strips

mounted to the subfloor. The strips should be 0.032 in. (0.08 cm) thick and a minimum of 3.0 in. (8.0 cm)

wide. Connect each pedestal to four strips using 1/4 in. (6.0 mm) bolts tightened to the manufacturer’s

torque recommendation.

• Better - A grounded #6 AWG minimum copper wire grid mechanically clamped to floor pedestals and

properly bonded to the building/site ground.

• Good - Use the raised floor structure as a ground grid. In this case, the floor must be designed as a ground

grid with bolted down stringers and corrosion resistive plating (to provide low resistance and attachment

points for connection to service entrance ground and HP server equipment). The use of conductive floor

tiles with this style of grid further enhances ground performance. The structure needs to be mechanically

bonded to a known good ground point.

Chapter 2

33

Page 34

General System and Facility Guidelines

Electrical Factor s

Equipment Grounding Implementation Details

Connect all Hewlett-Packard equipment cabinets to the site ground grid as follows:

1. Attach one end of each ground strap to the applicable cabinet ground lug.

2. Attach the other end to the nearest pedestal base (raised floor) or cable trough ground point (nonraised

floor).

3. Check that the braid contact on each end of the ground strap consists of a terminal and connection

hardware (a 1/4-in. (6.0 mm) bolt, nuts, and washers).

4. Check that the braid contact connection points are free of paint or other insulating material and treated

with a contact enhancement compound (similar to Burndy Penetrox).

Figure 2-1 Raised Floor Metal Strip Ground System

34

Chapter 2

Page 35

General System and Facility Guidelines

Electrical Factors

System Installation Guidelines

This section contains information about installation practices. Some common pitfalls are highlighted. Wiring

connections and data communications cable installations are discussed.

NOTE In domestic installations, the proper receptacles should be installed prior to the arrival of

Hewlett-Packard equipment. Refer to the appropriate installation guide for installation

procedures.

Wiring Connections

Expansion and contraction rates vary among different metals. Therefore, the integrity of an electrical

connection depends on the restraining force applied. Connections that are too tight, compress or deform the

hardware and cause it to weaken. This usually leads to high impedance preventing circuit breakers from

tripping when needed or can contribute to a buildup of high frequency noise.

CAUTION Connections that are too loose or too tight can have a high impedance that cause serious

problems, such as erratic equipment operation. A high impedance connection overheats and

sometimes causes fire or high temperatures that can destroy hard-to-replace components such

as distribution panels or system bus bars.

Wiring connections must be properly torqued. Many equipment manufacturers specify the proper connection

torque values for their hardware.

Ground connections must only be made on a conductive, nonpainted surface. When equipment vibration is

present, lock washers must be used on all connections to prevent connection hardware from working loose.

Data Communications Cables

Power transformers create high-energy fields in the form of electromagnetic interference (EMI). Heavy foot

traffic can create electrostatic discharge (ESD) that can damage electronic components. Route data

communications cables away from these areas. Use shielded data communications cables that meet approved

industry standards to reduce the effects of external fields.

Chapter 2

35

Page 36

General System and Facility Guidelines

Environmental Factors

Environmental Factors

The environmental factors discussed in this section are:

• Computer Room Preparation

• Space Requirements

• Floor Loading

• Cooling Requirements

• Air Conditioning Ducts

• Humidity Level

• Dust and Pollution Control

• Metallic Particulate Contamination

• Electrostatic Discharge (ESD) Prevention

• Acoustics (noise reduction)

Computer Room Preparation

The following guidelines are recommended when preparing a computer room for a HP server.

• Locate the computer room away from the exterior walls of the building to avoid the heat gain from

windows and exterior wall surfaces.

• When exterior windows are unavoidable, use windows that are double or triple glazed and shaded to

prevent direct sunlight from entering the computer room.

• Maintain the computer room at a positive pressure relative to surrounding spaces.

• Use a vapor barrier installed around the entire computer room envelope to restrain moisture migration.

• Caulk and vapor seal all pipes and cables that penetrate the envelope.

• Use at least a 12-inch raised floor for minimum favorable room air distribution system (underfloor

distribution).

• Ensure a minimum clearance of 12 inches between the top of the server cabinet and the ceiling to allow

for return airflow and ensure that all ceiling tiles are in place.

• Allow 18 inches (or local code minimum clearance) from the top of the server cabinet to the fire sprinkler

heads.

Space Requirements

This section contains information about space requirements for a HP server. This data should be used as the

basic guideline for space plan developments. Other factors, such as airflow, lighting, and equipment space

requirements must also be considered.

Delivery Space Requirements

There should be enough clearance to move equipment safely from the receiving area to the computer room.

Permanent obstructions, such as pillars or narrow doorways, can cause equipment damage.

36

Chapter 2

Page 37

General System and Facility Guidelines

Environmental Factors

Delivery plans should include the possible removal of walls or doors. The physical dimensions for applicable

computers and peripheral equipment are summarized in Appendix A.

Operational Space Requirements

Other factors must be considered along with the basic equipment dimensions. Reduced airflow around

equipment causes overheating, which can lead to equipment failure. Therefore, the location and orientation of

air conditioning ducts, as well as airflow direction, are important. Obstructions to equipment intake or

exhaust airflow must be eliminated.

The locations of lighting fixtures and utility outlets affect servicing operations. Plan equipment layout to take

advantage of lighting and utility outlets. Do not forget to include clearance for opening and closing equipment

doors.

Clearance around and above the cabinets must be provided for proper cooling airflow through the equipment.

The service area space requirements, outlined in Appendix A, are minimum dimensions. If other equipment is

located so that it exhausts heated air near the cooling air intakes of the computer system cabinets, larger

space requirements are needed to keep ambient air intake to the computer system cabinets within the

specified temperature and humidity ranges.

Space planning should also include the possible addition of equipment or other changes in space

requirements. Equipment layout plans should also include provisions for the following:

• Channels or fixtures used for routing data cables and power cables

• Access to air conditioning ducts, filters, lighting, and electrical power hardware

• Power conditioning equipment

• Cabinets for cleaning materials

• Maintenance area and spare parts

Floor Plan Grid

A floor plan grid is helpful for planning the location of equipment in the computer room. In addition to its use

for planning, a floor plan grid should also be considered when planning the locations of the following items:

• Air conditioning vents

• Lighting fixtures

• Utility outlets

• Doors

• Access areas for power wiring and air conditioning filters

• Equipment cable routing

Chapter 2

37

Page 38

General System and Facility Guidelines

Environmental Factors

Floor Loading

The computer room floor must be able to support the total weight of the installed computer system as well as

the weight of the individual cabinets as they are moved into position.

Floor loading is usually not an issue in nonraised floor installations. The information presented in this section

is directed toward raised floor installations.

NOTE An appropriate floor system consultant should verify any floor system under consideration for a

HP server installation.

Raised Floor Loading

Raised floor loading is a function of the manufacturer’s load specification and the positioning of the

equipment relative to the raised floor grid. While Hewlett-Packard cannot assume responsibility for

determining the suitability of a particular raised floor system, it does provide information and illustrations

for the customer or local agencies to determine installation requirements.

The following guidelines are recommended:

• Because many raised floor systems do not have grid stringers between floor stands, the lateral support for

the floor stands depends on adjacent panels being in place. To avoid compromising this type of floor

system while gaining under floor access, remove only one floor panel at a time.

• Larger floor grids (bigger panels) are generally rated for lighter loads.

CAUTION Do not position or install any equipment cabinets on the raised floor system until you have

carefully examined it to verify that it is adequate to support the appropriate installation.

Floor Loading Terms

Table 2-1 defines floor-loading terms.

Table 2-1 Floor Loading Terminology

Term Definitio n

Dead load The weight of the raised panel floor system, including the under structure.

2

(kg/m2).

2

(kg/m2).

2

(6.45 cm2) area at the panel’s

Live load

Concentrated load

Expressed in lb/ft

The load that the floor system can safely support. Expressed in lb/ft

The load that a floor panel can support on a one-inch

weakest point (typically the center of the panel), without the surface of the panel

deflecting more than a predetermined amount.

Ultimate load The maximum load (per floor panel) that the floor system can support without

failure. Failure expressed by floor panel(s) breaking or bending. Ultimate load is

usually stated as load per floor panel.

Rolling load The load a floor panel can support (without failure) when a wheel of specified

diameter and width is rolled across the panel.

38

Chapter 2

Page 39

Table 2-1 Floor Loading Terminology (Continued)

Term Definitio n

General System and Facility Guidelines

Environmental Factors

Average floor load

Computed by dividing total equipment weight by the area of its footprint. This

2

value is expressed in lb/ft

(kg/m2).

Cooling Requirements

Air conditioning equipment requirements and recommendations are described in the following sections.

Appendix A summarizes air conditioning requirements for this HP server.

Basic Air Conditioning Equipment Requirement

The cooling capacity of the installed air conditioning equipment for the computer room should be sufficient to

offset the computer equipment dissipation loads, as well as any space envelope heat gain. This equipment

should include:

• Air filtration

• Cooling or dehumidification

• Humidification

• Reheating

•Air distribution

• System controls adequate to maintain the computer room within the specified operating ranges of this HP

Server.

Lighting and personnel must also be included. For example, a person dissipates about 450 BTUs per hour

while performing a typical computer room task.

Air Conditioning System Guidelines

The following guidelines are recommended when designing an air conditioning system and selecting the

necessary equipment:

• The air conditioning system that serves the computer room should be capable of operating 24 hours a day,

365 days a year. It should also be independent of other systems in the building.

• Consider the long-term value of computer system availability, redundant air conditioning equipment or

capacity.

• The system should be capable of handling any future computer system expansion.

• Air conditioning equipment air filters should have a minimum rating of 45% (based on “ASHRAE

Standard 52-76, Dust Spot Efficiency Test”).

• Introduce only enough outside air into the system to meet building code requirements (for human

occupancy) and to maintain a positive air pressure in the computer room.

Air Conditioning System Types

The following three air conditioning system types are listed in order of preference:

• Complete self-contained package unit(s) with remote condenser(s). These systems are available with up or

down discharge and are usually located in the computer room.

Chapter 2

39

Page 40

General System and Facility Guidelines

Environmental Factors

• Chilled water package unit with remote chilled water plant. These systems are available with up or down

discharge and are usually located in the computer room.

• Central station air handling units with remote refrigeration equipment. These systems are usually

located outside the computer room.

40

Chapter 2

Page 41

General System and Facility Guidelines

Environmental Factors

Basic Air Distribution Systems

A basic air distribution system includes supply air and return air.

An air distribution system should be zoned to deliver an adequate amount of supply air to the cooling air

intake vents of the computer system equipment cabinets. Supply air temperature should be maintained

within the following parameters:

• Ceiling supply system—From 55 °F (12.8 °C) to 60 °F (15.6°C)

• Floor supply system—At least 60 °F (15.6 °C)

If a ceiling plenum return air system or a ducted ceiling return air system is used, the return air grill(s) in the

ceiling should be above the exhaust area or the exhaust row.

The following three types of air distribution system are listed in order of recommendation:

• Underfloor air distribution system—Downflow air conditioning equipment located on the raised floor of

the computer room uses the cavity beneath the raised floor as plenum for the supply air.

Return air from an underfloor air distribution system can be ducted return air (DRA) above the ceiling.

Perforated floor panels (available from the raised floor manufacturer) should be located around the front

of the system cabinets. Supply air emitted though the perforated floor panels is then available near the

cooling air intake vents of the computer system cabinets.

• Ceiling plenum air distribution system—Supply air is ducted into the ceiling plenum from upflow air

conditioning equipment located in the computer room or from an air-handling unit (remote).

The ceiling construction should resist air leakage. Place perforated ceiling panels (with down discharge

air flow characteristics) around the front of the system cabinets. The supply air emitted downward from

the perforated ceiling panels is then available near the cooling air intake vents of the computer system

cabinets.

Return air should be ducted back to the air-conditioning equipment though the return air duct above the

ceiling.

• Above ceiling ducted air distribution system—Supply air is ducted into a ceiling diffuser system from

upflow air conditioning equipment located in the computer room or from an air-handling unit (remote).

Return air from an above ceiling ducted air distribution system may be ducted return air (DRA) above the

ceiling, or ceiling plenum return air (CPRA).

Adjust the supply air diffuser system grilles to direct the cooling air downward around the front of the

computer system cabinets. The supply air is then available near the cooling air intake vents of the

computer system cabinets.

Air Conditioning System Installation

All air conditioning equipment, materials, and installation must comply with any applicable construction

codes. Installation of the various components of the air conditioning system must also conform to the air

conditioning equipment manufacturer’s recommendations.

Chapter 2

41

Page 42

General System and Facility Guidelines

Environmental Factors

Air Conditioning Ducts

Use separate computer room air conditioning ductwork. If it is not separate from the rest of the building, it

might be difficult to control cooling and air pressure levels. Ductwork seals are important for maintaining a

balanced air conditioning system and high static air pressure. Adequate cooling capacity means little if the

direction and rate of air flow cannot be controlled because of poor duct sealing. Also, the ducts should not be

exposed to warm air, or humidity levels may increase.

Humidity Level

Maintain recommended humidity level at 40 to 60% RH. High humidity causes galvanic actions to occur

between some dissimilar metals. This eventually causes a high resistance between connections, leading to

equipment failures. High humidity can also have an adverse affect on some magnetic tapes and paper media.

CAUTION Low humidity contributes to undesirably high levels of electrostatic charges. This increases the

electrostatic discharge (ESD) voltage potential. ESD can cause component damage during

servicing operations. Paper feed problems on high-speed printers are usually encountered in

low-humidity environments.

Low humidity levels are often the result of the facility heating system and occur during the cold season. Most

heating systems cause air to have a low humidity level, unless the system has a built-in humidifier.

Dust and Pollution Control

Computer equipment can be adversely affected by dust and microscopic particles in the site environment.

Specifically, disk drives, tape drives, and some other mechanical devices can have bearing failures resulting

from airborne abrasive particles. Dust may also blanket electronic components like printed circuit boards

causing premature failure due to excess heat and/or humidity build up on the boards. Other failures to power

supplies and other electronic components can be caused by metallically conductive particles, including zinc

whiskers. These metallic particles are conductive and can short circuit electronic components. Use every

effort to ensure that the environment is as dust and particulate free as possible. See following heading titled

“Metallic Particulate Contamination” for additional details.

Smaller particles can pass though some filters and over a period of time, cause problems in mechanical parts.

Small dust particles can be prevented from entering the computer room by maintaining the air conditioning

system at a high static air pressure level.

Other sources of dust, metallic, conductive, abrasive, and/or microscopic particles can be present. Some

sources of these particulates are:

• Subfloor shedding

• Raised floor shedding

• Ceiling tile shedding

These particulates are not always visible to the naked eye. A good check to determine their possible presence

is to check the underside of the tiles. The tile should be shiny, galvanized, and free from rust.

The computer room should be kept clean. The following guidelines are recommended:

• Smoking—Establish a no-smoking policy. Cigarette smoke particles are eight times larger than the

clearance between disk drive read/write heads and the disk surface.

• Printer—Locate printers and paper products in a separate room to eliminate paper particulate problems.

42

Chapter 2

Page 43

General System and Facility Guidelines

Environmental Factors

• Eating or drinking—Establish a no eating or drinking policy. Spilled liquids can cause short circuits in

equipment such as keyboards.

• Tile floors—Use a dust-absorbent cloth mop rather than a dry mop to clean tile floors.

Special precautions are necessary if the computer room is near a source of air pollution. Some air pollutants,

especially hydrogen sulfide (H

wiring and delicate sound equipment. The use of activated charcoal filters reduces this form of air pollution.

S), are not only unpleasant but corrosive as well. Hydrogen sulfide damages

2

Metallic Particulate Contamination

Metallic particulates can be especially harmful around electronic equipment. This type of contamination may

enter the data center environment from a variety of sources, including but not limited to raised floor tiles,

worn air conditioning parts, heating ducts, rotor brushes in vacuum cleaners or printer component wear.

Because metallic particulates conduct electricity, they have an increased potential for creating short circuits

in electronic equipment. This problem is exaggerated by the increasingly dense circuitry of electronic

equipment.

Over time, very fine whiskers of pure metal can form on electroplated zinc, cadmium, or tin surfaces. If these

whiskers are disturbed, they may break off and become airborne, possibly causing failures or operational

interruptions. For over 50 years, the electronics industry has been aware of the relatively rare but possible

threat posed by metallic particulate contamination. During recent years, a growing concern has developed in

computer rooms where these conductive contaminants are formed on the bottom of some raised floor tiles.

Although this problem is relatively rare, it may be an issue within your computer room. Since metallic

contamination can cause permanent or intermittent failures on your electronic equipment, Hewlett-Packard

strongly recommends that your site be evaluated for metallic particulate contamination before installation of

electronic equipment.

Electrostatic Discharge (ESD) Prevention

Static charges (voltage levels) occur when objects are separated or rubbed together. The voltage level of a

static charge is determined by the following factors:

• Types of materials

•Relative humidity

• Rate of change or separation

Static Protection Measures

Follow these precautions to minimize possible ESD-induced failures in the computer room.

• Maintain recommended humidity level and airflow rates in the computer room.

• Install conductive flooring (conductive adhesive must be used when laying tiles).

• Use conductive wax if waxed floors are necessary.

• Ensure that all equipment and flooring are properly grounded and are at the same ground potential.

• Use conductive tables and chairs.

• Use a grounded wrist strap (or other grounding method) when handling circuit boards.

• Store spare electronic modules in antistatic containers.

Chapter 2

43

Page 44

General System and Facility Guidelines

Environmental Factors

Acoustics (noise reduction)

Computer equipment and air conditioning blowers cause computer rooms to be noisy. Ambient noise level in a

computer room can be reduced as follows:

• Dropped ceiling—Cover with a commercial grade of fire-resistant, acoustic rated, fiberglass ceiling tile.

• Sound deadening—Cover the walls with curtains or other sound deadening material.

• Removable partitions—Use foam rubber models for most effectiveness

44

Chapter 2

Page 45

3 HP Blade Server bh7800 Power

This chapter provides part numbers for all the cord sets (power cords) available for the bh7800 server. Basic

power up and power down is covered. The power distribution unit information and cord set part numbers

complete the chapter.

Chapter 3

45

Page 46

HP Blade Server bh7800 Power

HP Blade Server Initial Power- Up

HP Blade Server Initial Power-Up

Before applying power to the bh7800, verify that the terminal (a PC with a terminal emulator installed will

suffice) is connected to the management blade and turned on.

Power Cords Supplied

Each bh7800 power supply uses a C19 type receptacle. There are multiple power cord options available for the

bh7800. Table 3-1 contains a list of the power cords approved to ship with the bh7800. The geographic

location typically determines which power cords ship with the server.

Table 3-1 Server Chassis Power Cords

Part

Number

8120-6894 C19 100-120 V North

8120-6895 C19 Unterminated

8120-6897 C19 IEC-309 4.5 m

8120-6899 C19 CEE 7-7 4.5 m

8120-6903 C19 L6-20 4.5 m

8121-0070 C19 GB 1002 4.5 m

8121-0161 C19 ISI-32 2.5 m

Powering up the bh7800 consists of powering up the chassis and powering up the server blades. These two

power on operations occur nearly simultaneously.

NOTE To ensure a successful power-up, make sure that all slots are covered so that air flow integrity

Plug Type at

Power Supply

is maintained.

Cord Description

America 5-20P

International/Europe

Cord

Length

4.5 m

4.5 m

Chassis Power-Up

CAUTION Before applying power to the bh7800, the power receptacle must be verified by a qualified HP

representative or a qualified electrician to ensure proper grounding and line voltage level is

present.

Step 1. Plug in the power cords between the bh7800 power supplies and the power outlets. The bh7800

chassis will immediately begin to power-up and the monitor will display power-up self test data.

The green LED on each power supply should be ON.

Step 2. Look for the status LED on the management blade slot for the front LCD panel (slot F9). When

chassis power-up has been successfully accomplished, the management blade status LED will be

green. You can now log on to the management blade to perform chassis and blade configuration.

46

Chapter 3

Page 47

HP Blade Server bh7800 Power

HP Blade Server Initial Power- Up

HP Server Power-Up

Step 1. Locate the server blade in slot F1 (server front, slot 1) and plug in a VGA monitor to the monitor

port.

Step 2. Plug in a keyboard to one of the two USB ports on the same server blade in slot F1. Without further

interaction, the VGA monitor will begin to display boot/self test data and, upon successful

completion of boot and self test procedures, the login prompt will be displayed. When server blade

power-up has been successfully completed, the status LED for slot F1 will be green.

All server blades power up simultaneously and, when the Green LED above each server blade slot is

illuminated, they are ready for configuration.

Blade Server Power-Down

NOTE Power-down procedures primarily apply to server blades. The chassis is powered down only

after all server blades are shut down.

Shut Down A Selected HP Server

This procedure is focused on an individual blade.

Step 1. At the login prompt on the slot F1 VGA monitor, enter the appropriate command to halt the OS and

observe the screen messages. When the “power down” message appears, the blue “hot-swap” LED

will illuminate. Power-down is now complete.

Step 2. The server blade can now be safely removed from the server.

NOTE If a server blade is being removed, a maximum of three minutes is allowed to cover the opening,

either with a server blade or a slot cover. After three minutes, the server chassis will begin a

power-down sequence to prevent the other server blades from overheating.

Emergency Chassis Power-Down

The bh7800 is designed to run continuously. Under normal conditions, only the server blades, all of which are

hot pluggable, will be powered-off and on.

Step 1. If there is time, to ensure that no data is lost, perform an orderly shutdown of the server blades

then pull the plug out of each power supply.

Step 2. If there is no time, however, simply pull the plug out of each power supply

CAUTION If an orderly shutdown of the server blades isn’t performed prior to power removal, all unsaved

data located on the server blades at that time will be lost.

Chapter 3

47

Page 48

HP Blade Server bh7800 Power

Connecting AC Power using a PDU

Connecting AC Power using a PDU

The bh7800 temporarily draws a large inrush current, when first connected to an AC power source. The

inrush current is much greater than the bh7800’s normal operating current and generally, the AC power

source can handle the normal inrush current.

Power Distribution Unit (PDU)

A PDU may be used at customer sites to reduce the number of circuit breaker slots needed.

This PDU may be referred to as a Relocatable Power Tap outside Hewlett-Packard.

CAUTION The bh7800 requires a theoretical maximum of 16.0 amps at 100V AC, 13.9 amps at 115V AC,

8.0 amps at 200V AC and 6.7 amps at 240V AC. Follow local electrical codes for installing the

proper sized wiring and circuit breaker for your installation.

When the bh7800 is installed in a HP Rack System/E rack, it can be used with several PDU styles. The

following PDUs will work with the bh7800:

• 16 amp 100-240VAC

• 30 amp 200-240VAC

• 60 amp 200-240VAC

The 60 amp PDU takes up 3-EIA units in a Rack System/E rack. Therefore, a maximum of two bh7800

chassis can be mounted in a 2.0m cabinet when using this PDU. Up to three bh7800 chassis can be mounted

in the 2.0m Rack System/E rack when using the 30 amp or 16 amp PDU, or an external cabinet PDU/power

solution.

Documentation for installation will accompany the PDU. Documentation may also be found at the Rack

Solutions Web site at http://www.hp.com/racksolutions.

Table 3-2 contains a list of the power cords approved for the bh7800 for connection to a PDU or UPS as noted

in the cord description column.

Table 3-2 PDU and UPS Power Cords

Part Number

8120-6884 C19 C19/C20 Jumper

8120-6961 C19 C19/C20 Jumper

Plug Type at

Power Supply

Cord Description Cord Length

2.5 m Cord from PDU to Server

4.5 m Cord from PDU to Server

8120-8494 C19 240V NA UPS

C19/L6-30P

48

4.5 m

Chapter 3

Page 49

A System Specifications and Requirements

This appendix contains specific parameters applicable to the bh7800 server. Temperature, power

requirements, and power dissipation figures are provided.

Appendix A

49

Page 50

System Specifications and Requirements

System Specifications

System Specifications

NOTE The Marked Electrical for the bh7800 server is 16 A. The recommended circuit breaker size is

20 amps for North America. For countries or areas outside North America, consult your local

electrical authority having jurisdiction for the recommended circuit breaker size.

Table A-1 bh7800 Specifications

Parameter Characteristics

Nominal input voltage range 100 to 240 Volts AC (single wide range)

Operating voltage (min/max) 90 to 264 Volts AC

Frequency range (non-strappable) 50 - 60 Hz 47 to 63 Hz

Number of phases One

Inrush current (maximum peak) 35 Amps

Theoretical Maximum input current

Power cords

Acoustics Not to exceed 70.0 dB at operator level

KVA rating 1.6 @ 100 - 240V AC

Power factor 0.98 @ 100 - 240V AC

Ground leakage current (mA) Less than 1.75 mA per supply

a. With future upgrades.

b. The bh7800 ships with two power supplies and each supply has it's own power cord. The AC

input to the bh7800 is divided into two separate and redundant power supplies. Both power

cords should always be plugged in and supplying power to the bh7800.

b

a

16 Amps

Two for normal operation but can run on one. Systems are always sold with two power supplies.

Not to exceed 7.5 Bels

50

Appendi x A

Page 51

Figure A-1 Power Supply Label

System Specifications and Requirements

System Specifications

Appendix A

51

Page 52

System Specifications and Requirements

System Specifications

Table A-2 Environmental Conditions

Parameters Conditions

Temp erature

Operating 68 °F to 77 °F (20 °C to 25 °C) Recommended

41 °F to 95 °F (5 °C to 35 °C) up to 5000 feet

Non-Operating -40 °F to 158 °F (-40 °C to 70 °C) (Storage)

Shock Immunity 18 °F per hour (10 °C) (Maximum Rate of Change)

Humidity (noncondensing)

Operating 40% to 60% RH at 72(F (22 °C) Recommended

Non-Operating 5% to 90% RH at 149(F (65 °C) (Storage)

Altitude (ASL)

Operating 0 to 3,048 m (10,000 ft)

a

Non-Operating 0 to 4,572 m (15,000 ft)

a. Above 5000 feet, derate 1 °C per 1000 feet altitude to 30 °C at 10,000 feet.

Table A-3 Weight and Dimensions

Maximum Weight Approximately 180 lbs (81.65 kg.), depending on

configuration - excludes keyboard and monitor.

Height 22.5 inches (57.15 cm)

Width 16.73 inches (42.49cm)

Depth 18.0 inches (45.72 cm)

Required front clearance for access 36 inches (91.44 cm)

Required rear clearance for access 36 inches (91.44 cm)

Table A-4 Power Dissipation (Theoretical Maximum)

Component

Chassis 0.0 Watts

HP Server bc1100 23.6 Watts

Watts

a

Network Blade 7.5 Watts

Management Blade 18.6 Watts

Management LAN Blade 0.1 Watts

a. Use these wattage values to perform calculations in Table A-5.

52

Appendi x A

Page 53

System Specifications and Requirements

System Specifications

This table can be copied and used to plan your air conditioning requirements for your server(s). Use the

footnotes at the bottom of this page to assist in calculating the values.

See Table A-6 for an example of how to arrive at a value required for air conditioning based on the system

configuration described for Table A-6.

Table A-5 Power Dissipation and Air Conditioning Requirement Summary

Component Quantity

Multiply Qty.

by Watts value

then divide

total Watts by

a

0.7

Power

Dissipated

(expressed in

kilowatts)

Air

Conditioning

Required

(expressed in

tons)

Chassis 1 Watts = 0 Watts = 0 0.0

HP Server

1 to 16

bc1100

Network

1 or 2

Blade

Management

1

Blade

Management

1 or 2

LAN Blade

Power Supply

2 Accounted for

(see footnote)

Accounted for (see footnote)

Accounted for (see footnote)

c

Totals N/A N/A

a. For example, if you have two bc1100 blades the calculation for this would be:

(2 x 23.6 Watts)/0.7 = 67.43 Watts.

b. Air Conditioning Required = kilowatts/3.517 = tons needed

c. The power supply thermal load is included in the value calculated for the

blades. The power supply efficiency is 0.7 so when you divide by 0.7, the

resulting value represents the thermal load of the blade plus the thermal

load in the supply due to each blade.

b

Appendix A

53

Page 54

System Specifications and Requirements

System Specifications

To illustrate how to use Table A-5, let us assume that we have a single chassis server loaded with 10 HP

server bc1100 blades, one network blade, one management blade, and two management LAN blades.

Table A-6 Power Dissipation and Air Conditioning Requirement Example

Component Quantity

Multiply Qty.

by Watts value

then divide

total Watts by

a

0.7

Power

Dissipated

(expressed in

kilowatts)

Air

Conditioning

Required

(expressed in

b

tons)

Chassis 1 Watts = 0 Watts = 0 0.0

HP Server

10 337.14 0.337 0.096

bc1100

Network Blade 1 21.43 0.021 0.006

Management

2 26.57 0.027 0.008

Blade

Management

2 0.286 0.0003 0.0001

LAN Blade

Power Supply 2 Accounted for Accounted for Accounted for

Totals N/A N/A 0.385 0.11

a. For example, if you have two bc1100 blades the calculation for this would be: (2 x

23.6 Watts)/0.7 = 67.43 Watts

b. Air Conditioning Required = kilowatts/3.517 = tons needed

Table A-6 indicates that 0.167 tons of air conditioning is required for this server example.

54

Appendi x A

Page 55

B Power Plug Configuration

There are several different cord sets (power cables) designed for the bh7800. The country or area destination

will determine which cord set ships with the bh7800. This guide provides the site preparation specialist with

the knowledge of what to expect to receive based on their geographic destination.

Appendix B

57

Page 56

Power Plug Configuration

Cord Set Description

Cord Set Description

The power cables (cord sets) shipping with the bh7800 will be 4.5 meter or 2.5 meter long cables. The cord set

below shows a 5-20P plug on one end and the C19 female plug on the other end.

Figure B-1 Cord Sets

Example of a 5-20P to C19 Cord Set

Female End of Cord Set

The female plug for the bh7800 is a C19 type plug that mates with the C20 receptacle in each power supply

installed in the bh7800.

Figure B-2 Male Receptacle to Female Plug

C20 Male Receptacle

(at power supply)

C19 Female Plug

(on cord set end)

58

Appendi x B

Page 57

Power Plug Configuration

Cord Set Description

Male End of Cord Set

Depending on the country or area the bh7800 is shipped to, the male plug on the other end of the power cable

will vary.

Figure B-3 Male Plug Types

Unterminated Plug

CEE 7-7 Plug

ISI 32 Pl u g

L6-20 Plug

L6-30 Plug

IEC 309 Plug

NEMA 5-20P Plug

GB 1002 Plug

Appendix B

59

Page 58

Power Plug Configuration

Cord Set Description

60

Appendi x B

Page 59

C Conversion Factors and Formulas

Conversion factors and formulas for data calculations for systems not conforming specifically to the

configurations listed in this Site Preparation Guide are provided. Conversion factors used in this document

are provided.

Appendix C

61

Page 60

Conversion Factors and Formulas

Conversion Factors

Conversion Factors

Refrigeration

• 1 watt = kcal/h

• 1 watt = 3.412 Btu/h

-4

• 1 watt = 2.843 x 10

• 1 ton = 200 Btu/min

• 1 ton = 12,000 Btu/h

• 1 ton = 3,517.2 W

Metric Equivalents

tons

• 1 centimeter = 0.3937 in

• 1 meter = 3.28 ft

• 1 meter = 1.09 yds

• 1 in. = 2.54 cm

• 1 ft = 0.305 m

3

• 1 CFM = 1.7m

KVA Conversion

Three Phase

Equation C-1

Single Phase

Equation C-2

/h

KVA V A 3()1000⁄××=

KVA V A 1000⁄×=

Formulas

• KVA = Voltag e x Cur rent (amps)

• Watts = VA x PF

• BTU = Watts x 3.41

62

Appendi x C

Page 61

Glossary

A-B

Apparent power A value of power for AC circuits

that is calculated as the product of RMS current

times RMS voltage, without taking the power factor

into account.

ASHRAE Standard 52-76 Industry standard for air filtration efficiency set forth by the American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Inc.

ASL Above sea level.

Btu/h The abbreviation for British thermal units.