Page 1

HP A4800A PCI FWD SCSI Host Bus

Adapter

Service and User Guide

Edition 6

Customer Order Number: A3725-90007

Manufacturing Part Number: A3725-96031

E0201

U.S.A.

© Copyright 2001, Hewlett-Packard Company.

Page 2

Legal Notices

The information in this document is subject to change without notice.

Hewlett-Packard makes no warranty of any kind with regard to this

manual, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Hewlett-Packard

shall not be held liable for errors contained herein or direct, indirect,

special, incidental or consequential damages in connection with the

furnishing, performance, or use of this material.

Warranty. A copy of the specific warranty terms applicable to your

Hewlett-Packard product and replacement parts can be obtained from

your local Sales and Service Office.

Restricted Rights Legend. Use, duplication or disclosure by the U.S.

Government is subject to restrictions as set forth insubparagraph (c) (1)

(ii) of the Rights in Technical Data and Computer Software clause at

DFARS 252.227-7013 for DOD agencies, and subparagraphs (c) (1) and

(c) (2) of the Commercial Computer Software Restricted Rights clause at

FAR 52.227-19 for other agencies.

HEWLETT-PACKARD COMPANY

3000 Hanover Street

Palo Alto, California 94304

U.S.A.

Use of this manual and flexible disk(s) or tape cartridge(s) supplied for

this pack is restricted to this product only. Additional copies of the

programs may be made for security and back-up purposes only. Resale of

the programs in their present form or with alterations, is expressly

prohibited.

Copyright Notices. ©copyright 1983-2001 Hewlett-Packard Company,

all rights reserved.

Reproduction, adaptation, or translation of this document without prior

written permission is prohibited, except as allowed under the copyright

laws.

©copyright 1979, 1980, 1983, 1985-93 Regents of the University of

California

2

Page 3

This software is based in part on the Fourth Berkeley Software

Distribution under license from the Regents of the University of

California.

©copyright 1980, 1984, 1986 Novell, Inc.

©copyright 1986-1992 Sun Microsystems, Inc.

©copyright 1985-86, 1988 Massachusetts Institute of Technology.

©copyright 1989-93 The Open Software Foundation, Inc.

©copyright 1986 Digital Equipment Corporation.

©copyright 1990 Motorola, Inc.

©copyright 1990, 1991, 1992 Cornell University

©copyright 1989-1991 The University of Maryland

©copyright 1988 Carnegie Mellon University

Trademark Notices UNIX is a registered trademark of The Open

Group.

X Window System is a trademark of the Massachusetts Institute of

Technology.

MS-DOS and Microsoft are U.S. registered trademarks of Microsoft

Corporation.

OSF/Motif is a trademark of the Open Software Foundation, Inc. in the

U.S. and other countries.

3

Page 4

4

Page 5

1 HP A4800A Adapter Overview

This chapter contains the following sections that describe the

HP A4800A PCI FWD SCSI host bus adapter (HBA):

• “About the A4800A Adapter” on page 7.

Chapter 1 5

Page 6

HPA4800A Adapter Overview

• “Features” on page 9.

• “Supported HP 9000 Servers” on page 10.

• “Cable Specifications” on page 11.

Chapter 16

Page 7

HPA4800A Adapter Overview

About the A4800A Adapter

About the A4800A Adapter

The HP A4800A PCI Fast/Wide/Differential (FWD) SCSI Host Bus

Adapter is an intelligent, high-performance, direct memory access

(DMA) bus master SCSI host bus adapter for HP 9000 and HP e3000

servers. The adapter combines a SCSI executive processor and a PCI

Local Bus interface in a single chip. This adapter supports bootable

devices and can be used with hard drives, tape drives, and other

differential SCSI devices. The adapter is High Voltage Differential

(HVD) SCSI only.

Consult with your Hewlett-Packard representative for more information

on specific system configurations.

Chapter 1 7

Page 8

HPA4800A Adapter Overview

About the A4800A Adapter

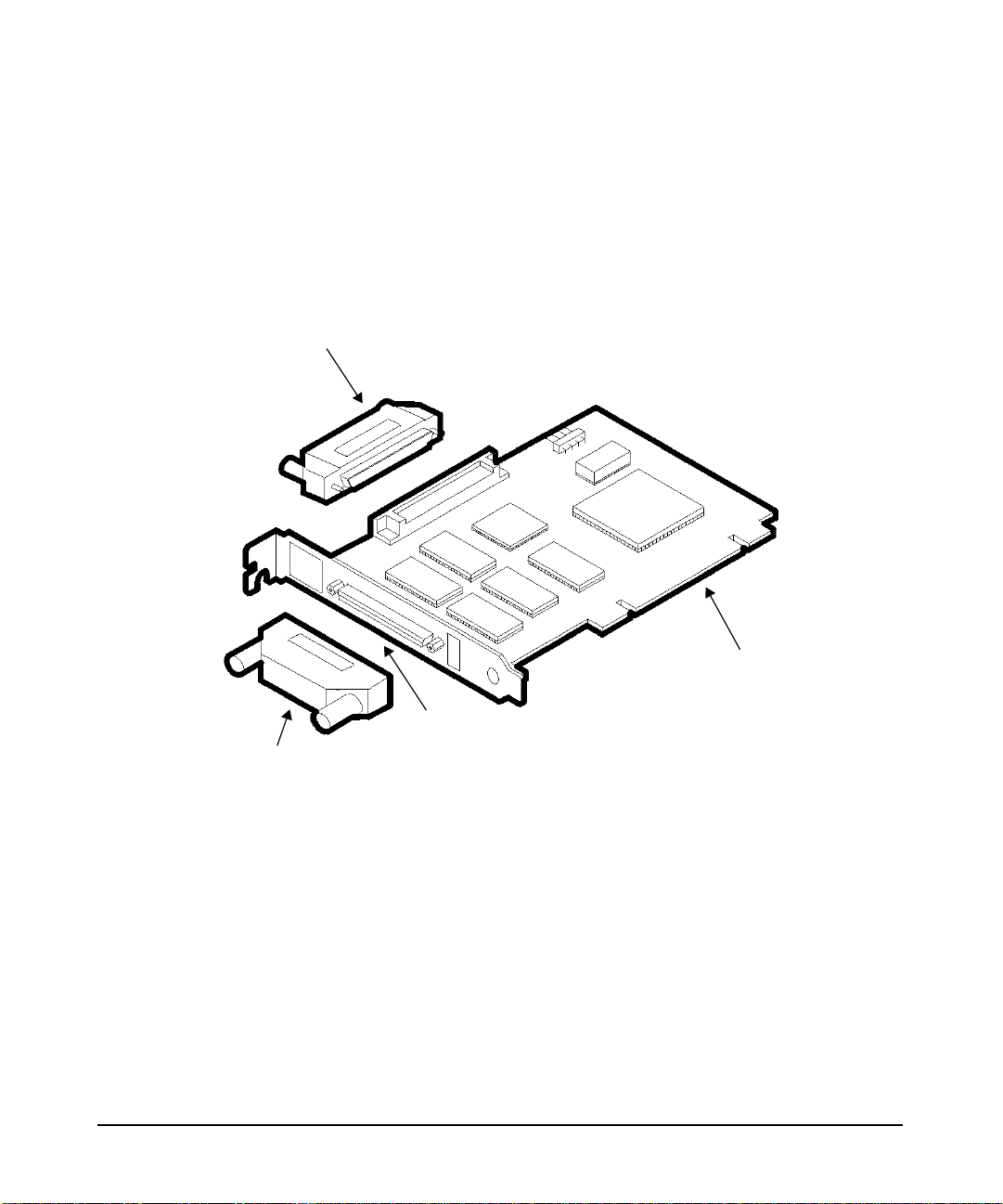

Figure 1-1 below is a drawing of the A4800A adapter.

Figure 1-1 The A4800A PCI Ultra HVD SCSI Host Bus Adapter

Internal terminator

External

Terminator

J1 to PCI

Bus connector

J3

68-pin External SCSI interface

Chapter 18

Page 9

HPA4800A Adapter Overview

Features

The A4800A adapter has the following features:

• Compliance with Intel PCI Local Bus Rev. 2.1 specification.

• Compliance with ANSI X3.131-1994 SCSI-2 standard.

• Support for asynchronous and synchronous transfer modes.

• Synchronous SCSI data transfer rates:

— Wide and Ultra SCSI (40 Mbytes/sec).

— Ultra SCSI (20 Mbytes/sec).

— Wide and Fast SCSI (20 Mbytes/sec) differential.

— Fast SCSI (10 Mbytes/sec) differential.

— Narrow (5 Mbytes/sec) differential.

• Support for differential mode.

Features

• Support for up to 15 SCSI, SCSI-2, or Ultra devices.

• Support for logical unit numbers (LUNs) 0-7.

• Support for bus master DMA.

• 68-pin, High-Density (HD) SCSI external connector.

• Supports HVD SCSI, SCSI-2, or Ultra devices only.

Chapter 1 9

Page 10

HPA4800A Adapter Overview

Supported HP 9000 Servers

Supported HP 9000 Servers

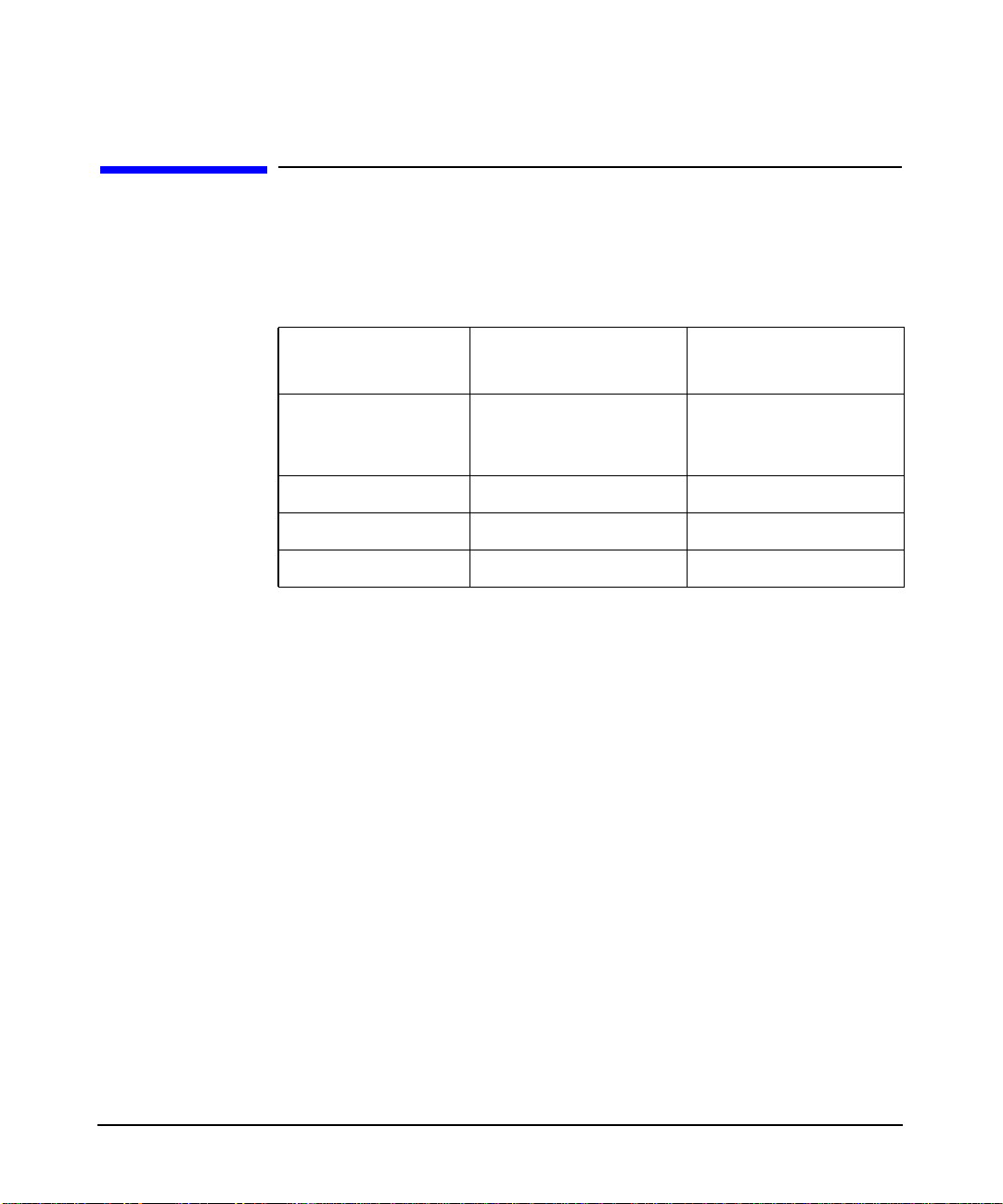

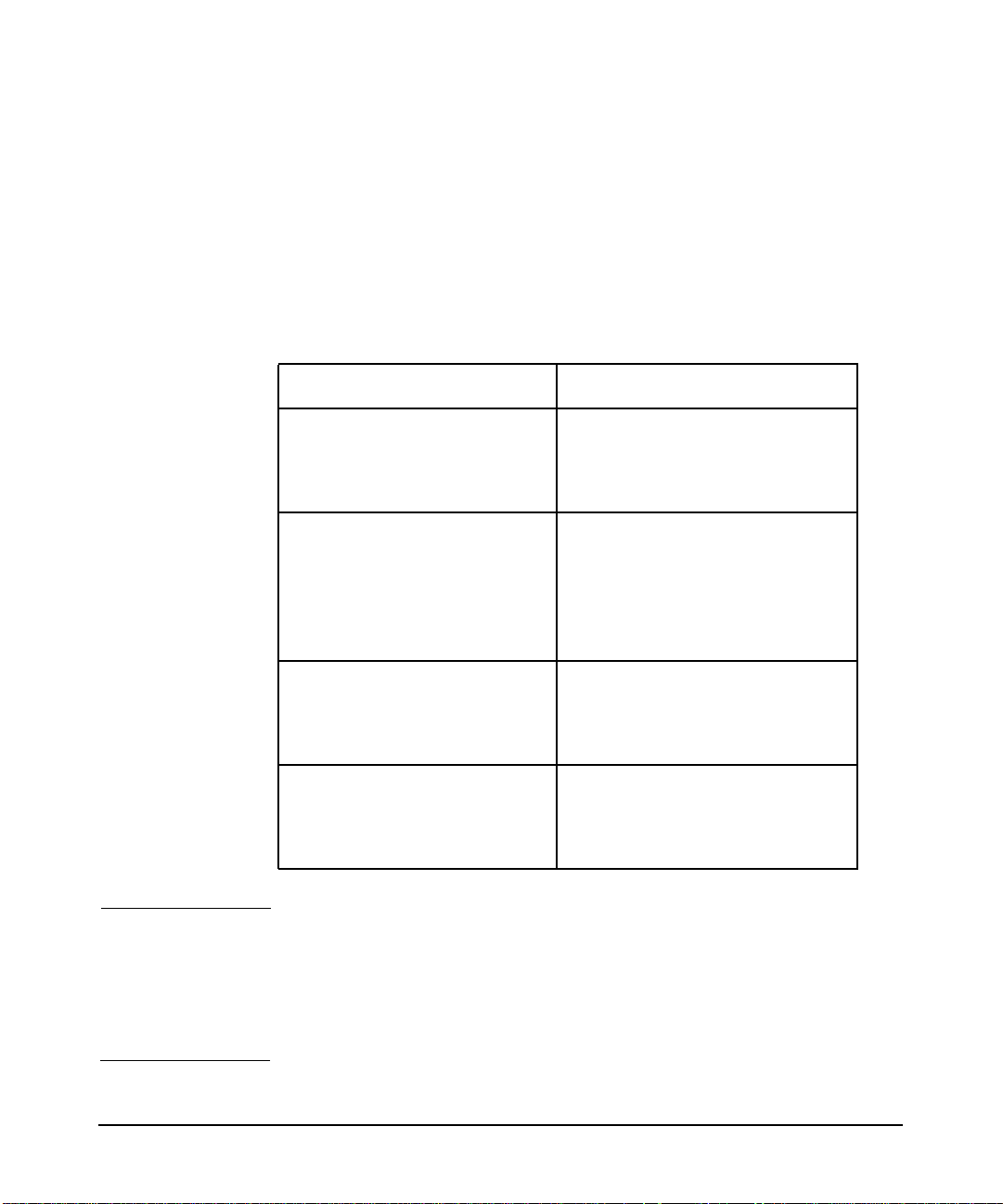

Table 1-1 below shows which HP 9000 servers support the A4800A

adapter.

Table 1-1 A4800A Supported HP 9000 Servers

HP 9000 Server

A-Class 10.20 (for the A180

L-Class 11.0 or 11i

N-Class 11.0 or 11i MPE/iX 7.0 or later

V-Class 11.0 or 11i

Note that the maximum number of SCSI HBAs you can install in any

HP 9000 or HP e3000 server is equal to the maximum number of

corresponding card slots in the server. For example, if you are installing

SCSI PCI HBAs and the server has four PCI card slots, you can install

four SCSI PCI HBAs in that server.

HP-UX Operating

System

and A180C servers

only) & 11.0 or 11i

HP e3000 Operating

System

MPE/iX 7.0 or later

Chapter 110

Page 11

Cable Specifications

The A4800A adapter supports High Voltage Differential (HVD) SCSI

connections only. Internal cables for interconnection with the embedded

CD-ROM drive and DAT tape drive are provided in the system.

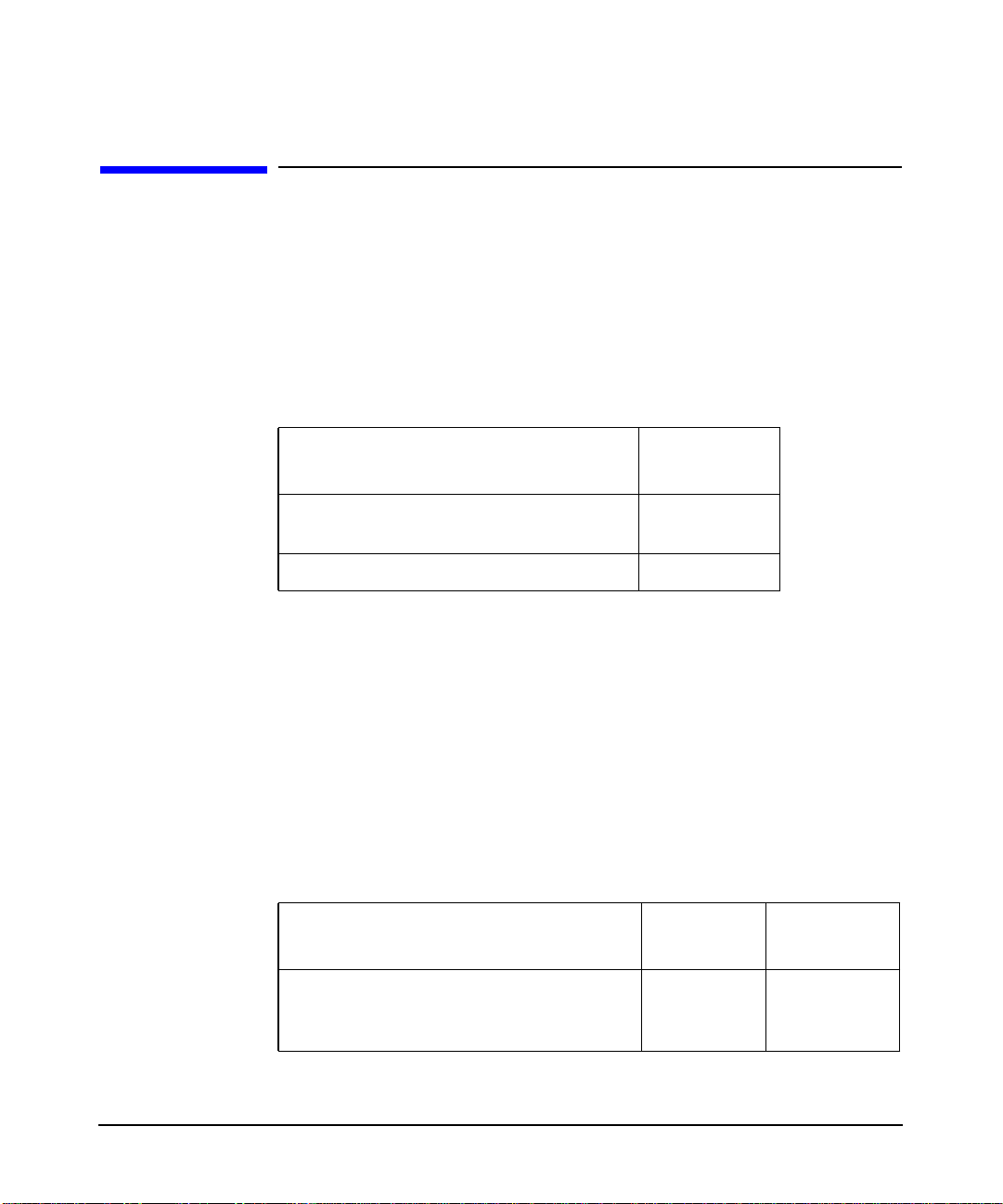

The A5068A SCSI cable kit is required when connecting the A4800A

adapter to internal, non-embedded SCSI devices. Table 1-2 below shows

the parts that make up the A5068A kit.

Table 1-2 A5068A SCSI Cable Kit

HPA4800A Adapter Overview

Cable Specifications

Description

10-inch SCSI shielded cable with back

shell

68-pin HD SCSI terminator A4700-67098

For more information on connecting the adapter to internal disk and

tape devices, refer to the appropriate disk drive or tape drive product

manual.

Part

Number

A4700-67086

For V-Class Systems

If you are connecting external SCSI devices to an A4800A adapter

installed in a V-Class system, you must use one of the cables shown in

Table 1-3 below. Note that cables are normally supplied with the

peripheral device.

Table 1-3 Cables for Connecting External SCSI Devices to the A4800A

Adapter in V-Class Systems

Description

5-meter 68-pin HD/68-pin HD Male

inline terminator SCSI cable for

V-Class

Product

Number

A3401A 875

Option

Chapter 1 11

Page 12

HPA4800A Adapter Overview

Cable Specifications

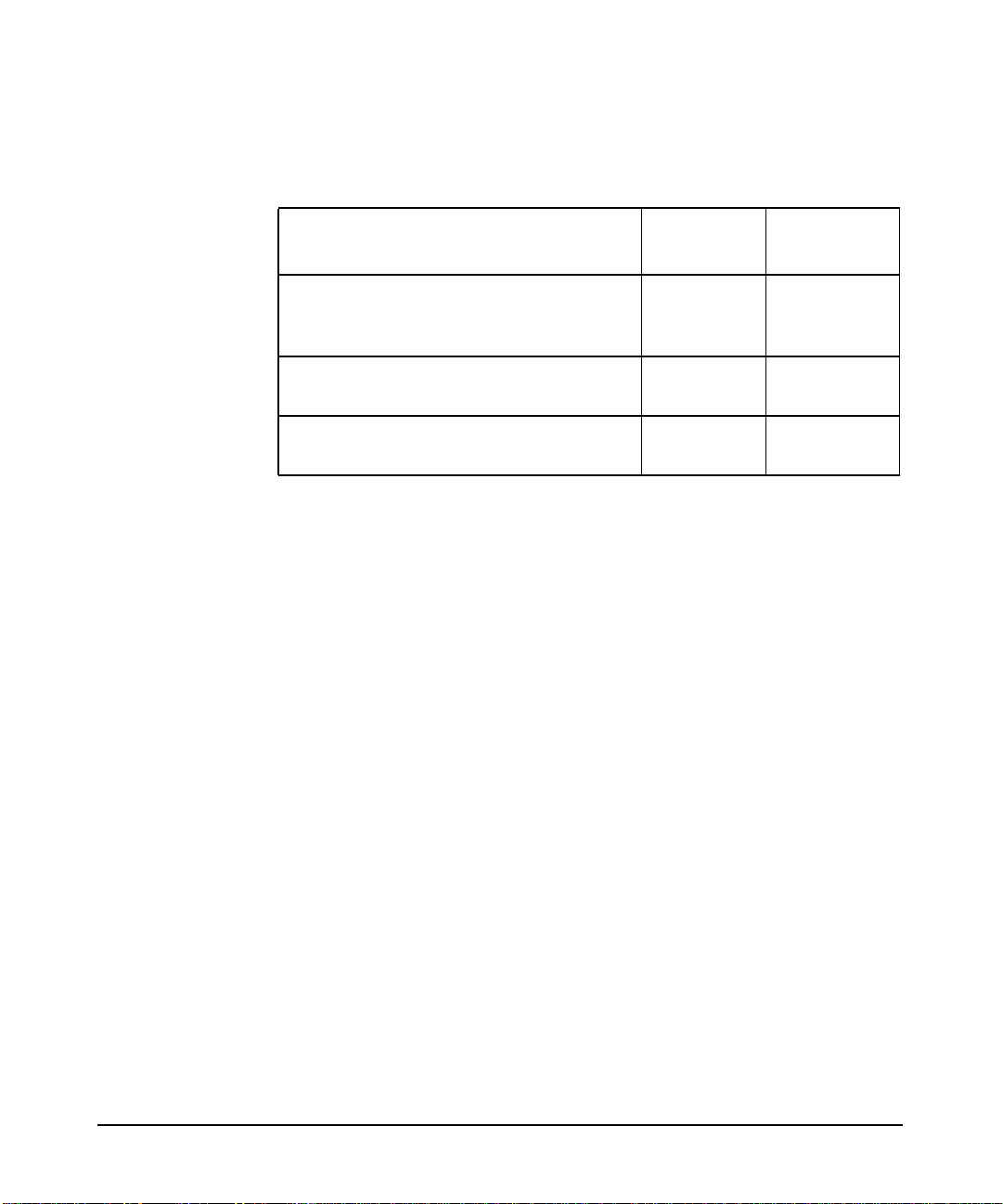

Table 1-3 Cables for Connecting External SCSI Devices to the A4800A

Adapter in V-Class Systems (Continued) (Continued)

Description

10-meter 68-pin HD/68-pin HD Male

inline terminator SCSI cable for

V-Class

2/5-meter 68-pin HD Male inline

terminator SCSI cable for V-Class

2/3-meter 68-pin HD Male inline

terminator SCSI cable for V-Class

Product

Number

A3401A 851

A3401A 871

A3401A 873

Option

Chapter 112

Page 13

2 Installing the A4800A Adapter

This chapter contains the following sections that describe how to install

the A4800A adapter:

• “Preparing for Installation” on page 15.

Chapter 2 13

Page 14

Installing the A4800A Adapter

• “Connecting to External SCSI Devices” on page 16.

• “Handling the A4800A Adapter” on page 17.

• “Looking at Adapter Installation” on page 18.

• “Connecting SCSI Peripheral Devices” on page 25.

• “Terminating the A4800A Adapter” on page 28

• “Setting SCSI IDs” on page 29

• “Verifying Installation” on page 31.

Chapter 214

Page 15

Installing the A4800A Adapter

Preparing for Installation

Preparing for Installation

Installing the host bus adapter requires disassembly of some server

components. Before beginning installation, see the HP 9000 system

manual for detailed instructions about how to install host bus adapters

in the PCI slots.

You will need the following things:

✓ One HP A4800A SCSI adapter.

✓ One grounding (ESD) wrist strap.

✓ Any other tools needed for installing components in the HP 9000 or

HP e3000 system (for example, screwdrivers); see the system’s

documentation.

Chapter 2 15

Page 16

Installing the A4800A Adapter

Connecting to External SCSI Devices

Connecting to External SCSI Devices

If you intend to connect the PCI Ultra SCSI adapter to an external SCSI

device, you need to supply a differential SCSI cable that is long enough

to reach the device. Part numbers for several different cable lengths are

listed in the section titled “Cable Specifications” on page 11.

Chapter 216

Page 17

Installing the A4800A Adapter

Handling the A4800A Adapter

Handling the A4800A Adapter

The host bus adapter is packaged with an ESD kit, which contains

materials to prevent damage from static electricity during installation.

CAUTION The adapter is highly susceptible to damage by electrostatic discharge

during installation and routine maintenance procedures. Do not handle

circuit boards without wearing a wrist strap fastened to a good earth

ground or to the system chassis.

While you are installing the A4800A adapter, please follow these

precautions:

✓ Keep the adapter in its shielded antistatic bag until you are ready to

install it.

✓ Use a wrist strap or other ESD protection. Wrap the strap around

your wrist and attach the copper end to a metal portion of the

computer frame.

✓ Avoid working in carpeted areas.

✓ Gently place the adapter, printed circuit board (PCB) side down, on

an antistatic work surface pad.

✓ Hold the adapter only by its sides or cover plate. Do not touch any

components on the printed circuit board assembly (PCBA).

✓ Do not use any test equipment to check the components on the PCB.

✓ Do not bump, jar, or drop the adapter. Do not place other objects on

top of the adapter.

✓ Transport the adapter in its shielded bag in an appropriate shipping

container. Do not put other materials in the bag with the adapter.

Chapter 2 17

Page 18

Installing the A4800A Adapter

Looking at Adapter Installation

Looking at Adapter Installation

NOTE The host bus adapter card is supported on the HP N4000 N-class system.

Refer to the Hewlett-Packard eproducts web site

(http://www.eproducts.hp.com) to disassemble the system, install the

adapter in an available PCI slot, and reassemble the system.

Installation can be performed in one of two ways:

• Use the OLAR (On Line Add/Replace) capability (HP-UX 11i)

• Power down the system and then add or replace the HBA

The method you choose will depend on your situation and requirements.

Install Using OLAR (HP-UX 11i)

The letters O, L, A and R stand for On Line Addition [and] Replacement.

This refers to the ability of a PCI I/O card to be installed (replaced or

added) in an HP-UX computer system designed to support this feature

without the need for completely shutting down, then re-booting the

system or adversely affecting other system components. The system

hardware uses the per-slot power control combined with operating

system support in HP-UX 11i to enable this feature.

IMPORTANT Certain “Classes” of hardware are not intended for access by users. At

this time this includes V-Class and SuperDome systems. HP

recommends that these systems only be opened by a qualified HP

Engineer. Failureto observe this requirement can invalidate any support

agreement or warranty to which the owner might otherwise be entitled.

Important Terms and Concepts

The addition or replacement of an OLAR-compatible card may be done in

either one of two ways:

1. Using the SAM utility.

Chapter 218

Page 19

2. Issuing command-line commands using rad.

For detailed information about the use of either of these two procedures,

please refer to the following document:

Configuring HP-UX For Peripherals, HP Part Number B2355-90698

This document may be ordered from HP, or you may view, download and

print it from the following website: www.docs.hp.com

Table 2-1 Important Terms

Term Meaning

OLAR All aspects of the OLAR feature

Power Domain A grouping of 1 or more

Installing the A4800A Adapter

Looking at Adapter Installation

including On-line Addition

(OLA) and On-line Replacement

(OLR).

interface card slots that can be

powered on or off as a unit.

(NOTE: Multi-slot power

domains are not currently

supported)

target card / target card slot The interface card which will be

added or replaced using OLAR,

and the card slot in which it

resides.

affected card / affected card

slot

IMPORTANT In many cases, other interface cards and slots within the system are

dependent upon the target card. For example:

If the target card is a multiple-port card, suspending or deleting drivers

for the target card slot also suspends individual drivers for the multiple

hardware paths on that card).

Chapter 2 19

Interface cards and the card

slots in which they reside, and

which are in the same power

domain as the target slot.

Page 20

Installing the A4800A Adapter

Looking at Adapter Installation

During a card replacement operation, SAM performs a Critical Resource

Analysis, which checks all ports on the target card for critical resources

that would be temporarily unavailable while the card is shut down.

Planning and Preparation

SAM will, generally, prevent you from performing OLAR procedures that

would adversely affect other areas of the server. Refer to Configuring

HP-UX For Peripherals, HP Part Number B2355-90698 for detailed

information.

Critical Resources Because power to the slot must be off when the old

card is removed and the new card is inserted, the effects of shutting

down the card’s functions must be carefully considered.

This is particularly important if there is no on-line failover or backup

card to pick up those functions. For example:

• Which mass storage devices will be temporarily disconnected when

the card is shut down?

• Will a critical networking connection be lost?

A critical resource is one that would cause a system crash or prevent the

operation from successfully completing if the resource were temporarily

suspended or disconnected. For example, if the SCSI adapter to be

replaced connects to the unmirrored root disk or swap space, the system

will crash when the card is shut down.

During an OLAR procedure, it is essential to check the targeted card for

critical resources, as well as the effects of existing disk mirrors and other

situations where a card’s functions can be taken over by another card

that will not be affected.

Fortunately SAM performs a thorough critical resource analysis

automatically, and presents options to you based on its findings. If you

determine that critical resources will be affected by the procedure, you

should replace the card when the server is off-line.

If you must take action immediately, you can use rad to attempt an

on-line addition of a backup card and deletion of the target card.

Chapter 220

Page 21

Installing the A4800A Adapter

Looking at Adapter Installation

Card Compatibility

On-Line Addition (OLA). When on-line adding an interface card, the

first issue that must be resolved is whether the new card is compatible

with the system. Each PCI slot provides a set amount of power. The

replacement card cannot require more power than is available.

The card must also operate at the slot’s bus frequency. A PCI card must

run at any frequency lower than its maximum capability; however, a

card that operated at a maximum of 33 MHz would not work on a bus

running at 66 MHz. rad provides information about the bus frequency

and power available at a slot, as well as other slot-related data.

On-Line Replacement (OLR) When on-line replacing an interface

card, the replacement card must be identical to the card being replaced

or at least be able to operate using the same driver as the replaced card.

This is referred to as like-for-like replacement and should be adhered to

because using a similar but not identical card may cause unpredictable

results. For example, a newer version of the target card which is

identical in terms of hardware may contain an updated firmware version

that could potentially conflict with the current driver.

The PCI specification allows a single physical card to contain more than

one port. A single-port SCSI bus adapter can not be replaced by a

dual-port adapter, even if the additional port(s) on the card are identical

to the original SCSI bus adapter.

When the replacement card is added to the system, the appropriate

driver for that card must be configured in the kernel before beginning

the operation. SAM ensures the correct driver is present. (In most cases,

the replacement card will be the same type as a card already in the

system, and this requirement will be automatically met.) If you have any

question about the driver’s presence, or if you are not certain that the

replacement card is identical to the existing card, you can use ioscan

together with rad to investigate.

• If the necessary driver is not present and the driver is a dynamically

loadable kernel module (DLKM), you can load it manually. Refer to

the section “Dynamically Loadable Kernel Modules” in Chapter 2 of

the document: Configuring HP-UX ForPeripherals,HP Part Number

B2355-90698 for more information.

• If the driver is static and not configured in the kernel, then the card

cannot be On-line Added. The card could be physically inserted

on-line, but no driver would claim it.

Chapter 2 21

Page 22

Installing the A4800A Adapter

Looking at Adapter Installation

OLA/R Restrictions for the A4800A

The HBA has some restrictions in the OLA/R procedure. These

restrictions are explained below.

The restrictions are necessary because the SCSI attributes of initiator

ID, and speed cannot be changed online for this HBA.

OLA of A4800-60001 The HBA can be online added only if the SCSI

attribute values of initiator ID and speed are usable in your

configuration. These values will be set to the current PDC (Processor

Dependent Code) values (if any) or default to the new HBA’s values (see

Table 2-2).

Table 2-2 A4800-60001 - Default SCSI Attribute Values

Attribute Default Value

Initiator ID 7

Speed Fast

If these attributes are not acceptable, you must reboot the system to

access the Boot Console Handler (BCH) prompt and then change the

values in the PDC.

OLR of A4800-60001 the A4800-60001 can be Online Replaced without

special considerations. See the Configuring HP-UX Peripherals manual

for the steps that are necessary to OLR this HBA.

Install/Replace With System Powered Down

Check the manual supplied with the server to perform the following

installation:

Step 1. Shut down the operating system.

Step 2. Power off the system and disconnect the power cord and cables.

Step 3. Access the back of the server cabinet following the instructions in the

server documentation. Refer to the server documentation for instructions

on disassembling the server and installing host bus adapters.

Chapter 222

Page 23

Installing the A4800A Adapter

Looking at Adapter Installation

Step 4. Locate the card separator/extractor slot where you intend to install the

adapter.

Step 5. Remove the blank panel aligned with the PCI slot you intend to use. If

the blank panel has a bracket screw, save it for reuse during the

installation.

Step 6. Following the instructions in the server manual, insert the adapter into

an available PCI slot.

The adapter is keyed to be inserted in only one way. The components on

the adapter may face the opposite way from other boards on the system.

NOTE If the internal bus is not connected to any peripherals it MUST be

terminated using the supplied low profile, internal terminator.

Step 7. Verify that the connectors on the adapter and the bus converter are

aligned properly and firmly seated. The card’s bracket should fit where

the blank panel was removed. Secure the bracket with the bracket screw

from the blank panel, if there is one. Note that, for N-Class systems, a

screw is not used to secure the card.

NOTE If the adapter will only be used with internal SCSI devices, install the

A4700-67098 (1252-6520) differential terminator into the external port.

Step 8. Connect peripheral devices and terminate the SCSI bus.

NOTE A cable for connecting the PCI Ultra SCSI Host Bus Adapter to a disk

tray A or B port connector is supplied with the A5068A product. Cables

for connecting external devices are not supplied with the controller and

must be purchased separately.

Step 9. Set the SCSI ID, if needed.

The default SCSI ID is 7. To change this to a different value for

High-Availability (HA) applications, you must use the Boot Console

Handler (BCH). There are no SCSI address switches or jumpers. You

Chapter 2 23

Page 24

Installing the A4800A Adapter

Looking at Adapter Installation

must invoke the appropriate commands in the SCSI section of the BCH

and change the address electronically to whatever is required for the HA

configuration being used. Refer to “Checking SCSI Bus Compatibility” on

page 36.

NOTE Do not change for MPE/iX. You may need to change "rate" setting.

Step 10. Reassemble the server.

Step 11. Power on the system and reboot the operating system.

Step 12. The A4800A adapter runs an automatic self test. Error messages, if any

are generated, appear on the system console.

Chapter 224

Page 25

Connecting SCSI Peripheral Devices

Connect multiple SCSI devices by chaining them together with shielded,

68-pin, High-Density (HD) cables. The connectors on these cables are

keyed to ensure proper pin-1 to pin-1 registration. Refer to the

peripheral manual for instructions on attaching SCSI cables. Peripheral

storage devices are normally shipped with the required SCSI cables.

Table 2-3 below shows the SCSI bus widths and speeds that have been

established by the SCSI Trade Association (STA).

Table 2-3 SCSI Bus Widths and Speeds

(1)

Type

SCSI-1 8 5

SCSI Bus

Width (in Bits)

Installing the A4800A Adapter

Connecting SCSI Peripheral Devices

SCSI Bus Speed

Maximum Data

Rate (in

MBytes/Second)

Fast SCSI 8 10

Fast Wide SCSI 16 20

Ultra SCSI 8 20

Wide Ultra SCSI 16 40

Ultra2 SCSI 8 40

Wide Ultra2

SCSI

(1)

Absence of the word “Wide” means an 8-bit bus width;

using the term “Narrow” to avoid ambiguity is acceptable,

too.

You can connect up to eight SCSI, Fast SCSI, and Ultra SCSI devices on

a single-ended Ultra SCSI bus if they are evenly spaced on a 1.5 m Ultra

2 SCSI cable (0.19 m between devices).

Chapter 2 25

16 80

Page 26

Installing the A4800A Adapter

Connecting SCSI Peripheral Devices

You can connect up to four devices if they are evenly spaced on a 3 m

Ultra SCSI cable (0.75 m between devices). The single-ended SCSI bus

must not exceed 3 m (total internal and external cable lengths) even with

fewer than four devices.

Table 2-4 below shows the maximum bus length for each of the SCSI

types.

Table 2-4 Maximum SCSI Bus Lengths

(1)

High

Voltage

l (HVD)

Maximum

Devices

Type

Maximum Bus Length (in Meters)

Low

Single-ende

d (SE)

Voltage

Differentia

Differentia

l (LVD)

SCSI-1 6 12.5 25 8

Fast SCSI 3 12.5 25 8

Fast Wide

3 12.5 25 16

SCSI

Ultra SCSI 1.5 12.5 25 8

Ultra SCSI 3 - - 4

Wide Ultra

- 12.5 25 16

SCSI

Wide Ultra

1.5 - - 8

SCSI

Wide Ultra

3--4

SCSI

Ultra2 SCSI

WideUltra2

SCSI

(2)

(2)

12.5

12.5

(2)

(2)

8

16

Chapter 226

Page 27

Installing the A4800A Adapter

Connecting SCSI Peripheral Devices

Table 2-4 Maximum SCSI Bus Lengths (Continued) (Continued)

Maximum Bus Length (in Meters)

Type

Single-ende

d (SE)

Low

Voltage

Differentia

Differentia

l (LVD)

(1)

This parameter can be exceeded in point-to-point and engineered

(1)

High

Voltage

l (HVD)

Maximum

Devices

applications.

(2)

Single-ended and High Voltage Differential are not defined at Ultra2

speeds.

Chapter 2 27

Page 28

Installing the A4800A Adapter

Terminating the A4800A Adapter

Terminating the A4800A Adapter

The A4800A has no auto-termination setting. Termination must be

provided by a physical terminator. When the HBA is at the end of the

SCSI bus, the terminator should be installed and secured at either the

internal or external connector (whichever does not have a cable attached)

as shown in Figure 1-1 on page 8.

When the adapter is used in High-Availability (HA) applications (such as

MC/ServiceGuard) and it is required to be in the middle of the bus, the

adapter’s terminator must be removed.

The SCSI bus must be properly terminated. Terminatorsmay be ordered

separately if needed (When ordered with the HBA, the part number is

A4800A option 2. When ordered separately, the part number is C2905A).

The first and last physical SCSI devices connected on the ends of the

SCSI bus must have terminators attached. All other SCSI devices on the

SCSI bus must have their terminators removed or disabled. Note that

the host bus adapter is also on the bus.

IMPORTANT The A4800A does not provide automatic termination.

NOTE When the adapter is used in HA applications that use two SCSI host bus

adapters (such as MC/ServiceGuard) and it is required to be in the

middle of the bus, the adapter’s SCSI ID will need to be changed (for

example, from 7 to 6). Each device on the bus must have a unique ID.

Refer to “The SCSI Command” on page 37.

To disable the adapter’s termination, you need to physically remove the

terminator from the HBA connector. Termination for this bus must now

be provided by some other SCSI device (e.g. disk, disk array, or other

HBA, as required).

Chapter 228

Page 29

Installing the A4800A Adapter

Setting SCSI IDs

Setting SCSI IDs

You must assign a separate SCSI ID (0 through 15 for a 16-bit SCSI bus)

to the SCSI host bus adapter and each SCSI device. The priority of the

device on the SCSI bus is determined by the SCSI ID of the device. The

order of SCSI ID priorities (from highest to lowest) is 7, 6, 5, 4, 3, 2, 1, 0,

15, 14, 13, 12, 11, 10, 9, and 8. A device with SCSI ID 7 has the highest

priority, and one with SCSI ID 8 has the lowest.

When you are assigning SCSI IDs, we recommend you to give the SCSI

host bus adapter higher priority than the other SCSI devices on the bus.

SCSI ID 7 is the preset SCSI ID for the A4800A SCSI host bus adapter

(giving it the highest priority on the SCSI bus). Set each of the other

SCSI devices on the bus to one of the remaining SCSI IDs.

For a multi-initiator (High Availability [HA]) configuration, where

multiple SCSI host bus adapters are connected to the same SCSI bus,the

SCSI host bus adapter that carries most of the traffic must be assigned a

SCSI ID of 7 (giving it the highest priority). Later, you must change the

SCSI ID of each of the remaining SCSI host bus adapters on the bus from

the preset setting (7) to the next highest priority remaining SCSI IDs (for

example, 6, 5, 4, and so on).

If you plan to boot your system from a hard disk drive on the SCSI bus,

you must assign that drive the next highest priority unassigned SCSI ID.

If there is only one SCSI host bus adapter (SCSI ID = 7), the hard disk

drive would be assigned a SCSI ID of 6. If there are multiple SCSI host

bus adapters, the hard disk drive would be assigned the next highest

priority SCSI ID available after all of the SCSI host bus adapters have

been assigned higher priority SCSI IDs.

To change the SCSI ID of the A4800A host bus adapter, refer to

“Checking SCSI Bus Compatibility” on page 36.

The peripheral device SCSI IDs are usually set with jumpers or a switch

on the peripheral. Refer to the peripheral manufacturer’s instructions to

determine the ID of each device and how to change it.

IMPORTANT You must not have duplicate SCSI IDs on a SCSI bus; the system will

hang or crash if you have duplicate SCSI IDs on the bus.

Chapter 2 29

Page 30

Installing the A4800A Adapter

Setting SCSI IDs

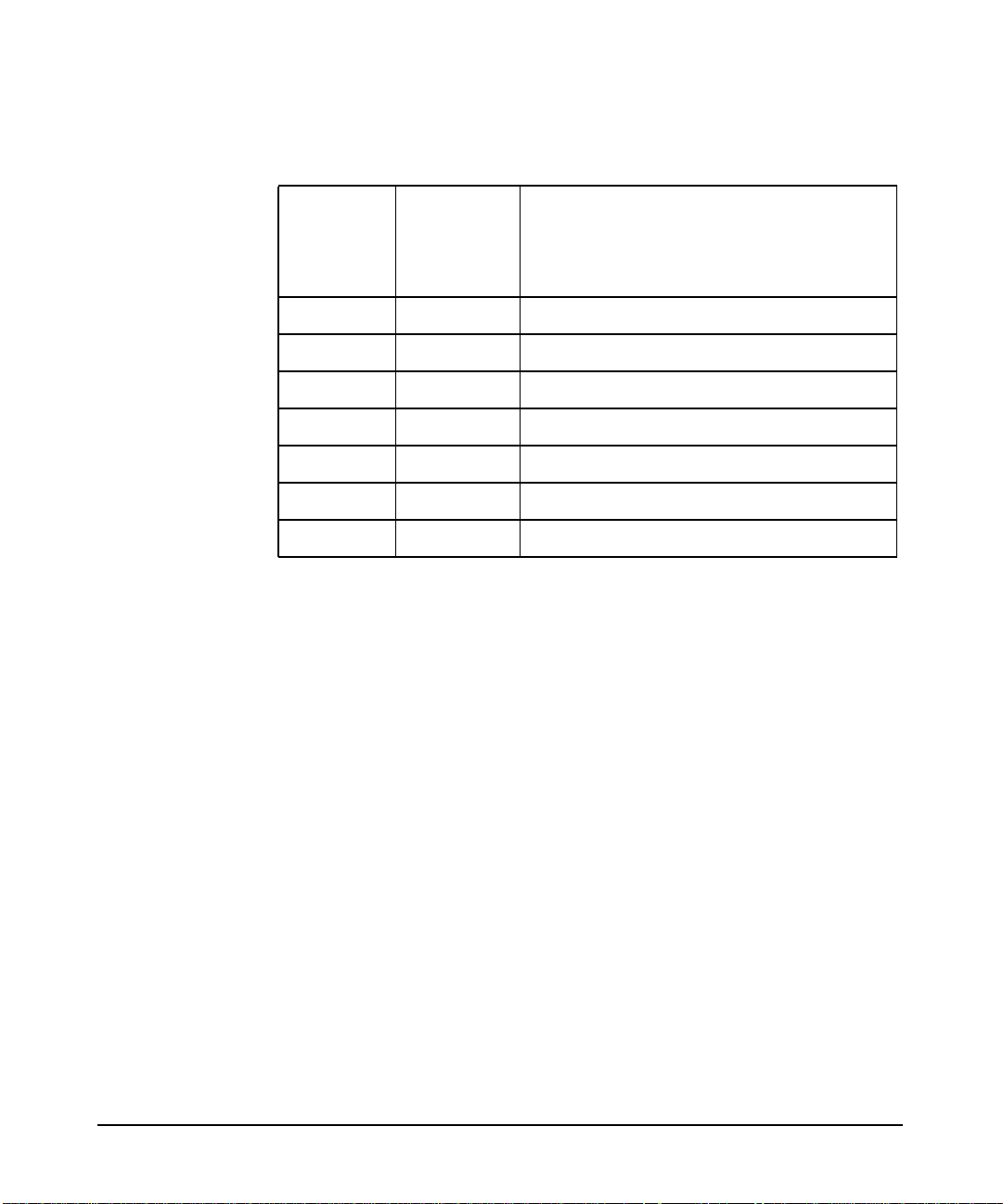

Make necessary changes, if any, to the SCSI IDs and record the IDs for

future reference. To keep a record of the IDs, you can use Table 2-5.

Table 2-5 Record of SCSI IDs

SCSI ID SCSI Device

15

14

13

12

11

10

9

8

7 Adapter (default)

6

5

4

3

2

1

0

Chapter 230

Page 31

HP 9000

Installing the A4800A Adapter

Verifying Installation

Verifying Installation

After installing the adapter and attaching peripheral devices, verify that

all components are working. Refer to your system documentation for

information on verifying operation.

Step 1. To verify that the adapter is correctly installed, execute the following

command:

ioscan -f

The ioscan output could look like this:

ext_bus 0 0/0/0 c720 CLAIMED INTERFACE Ultra wide SCSI

The third column represents the hardware path of the slot the adapter is

installed in. For information about the ioscan command, refer to your

operating system reference manual or the ioscan man page.

Step 2. Verify that the adapter and driver display.

Step 3. Verify that the devices you attached to the adapter display.

Chapter 2 31

Page 32

Installing the A4800A Adapter

Verifying Installation

HP e3000 Assuming an N-Class system with an I/O card being added to slot #12,

we will expect path 1/0/0/0 to be returned for our card.

Step 1. From BCH menus:

------------------------------------------------------

-Command Description

------- ----------ALL Display all system information

...

IO Display I/O interface information

...

-------------------------------------------------Information Menu: Enter command > io

I/O MODULE INFORMATION

Path Slot IODC

Type (dec) Number HVERSION SVERSION Vers

---- ----- ------ -------- -------- ---System bus adapter 0 0x8030 0xc10 0x0

Local bus adapter 0/0 Built_In 0x7820 0xa00 0x0

Local bus adapter

...

Local bus adapter 1/0 12 0x7820 0xa00 0x0

...

PCI DEVICE INFORMATION

Path Vendor Device Bus Slot

Description (dec) Id Id # #

----------- ----- ---- ---- --- --Ethernet cntlr 0/0/0/0 0x1011 0x19 0 Built_In

SCSI bus cntlr 0/0/1/0 0x1000 0xc 0 Built_In

SCSI bus cntlr 0/0/2/0 0x1000 0xf 0 Built_In

SCSI bus cntlr 0/0/2/1 0x1000 0xf 0 Built_In

Comp. ser cntlr 0/0/4/0 0x103c 0x1048 0 Built_In

Comp. ser cntlr 0/0/5/0 0x103c 0x1048 0 Built_In

SCSI bus cntlr 1/0/0/0 0x1000 0xf 128 12

Information Menu: Enter command >main

Main Menu: Enter command or menu > sea 1/0/0/0

Searching for potential boot device(s) - on Path 1/0/0/0

This may take several minutes.

To discontinue search, press any key (termination may not be immediate).

Path# Device Path (dec) Device Path (mnem) Device Type

----- ----------------- ------------------ ---------- P0 1/0/0/0.6 intscsia.6 Random access media

Main Menu: Enter command or menu >

Chapter 232

Page 33

3 Troubleshooting

This chapter contains the following sections that describe how to

troubleshooting the A4800A adapter:

• “General Procedure” on page 35.

Chapter 3 33

Page 34

Troubleshooting

• “Checking SCSI Bus Compatibility” on page 36.

• “Using Support Tools Manager (STM)” on page 41

• “Contacting Your Hewlett-Packard Representative” on page 42.

Chapter 334

Page 35

General Procedure

The A4800A adapter is a single field-replaceable unit (FRU) and does not

contain any field-serviceable parts. Troubleshooting procedures

described in this section are limited to verifying that the adapter is

operational and a valid connection is established.

In general, follow these steps to troubleshoot the A4800A adapter:

Step 1. Check the connection.

Make sure that the correct cable is used, connected, and operating

properly and that there are no bent pins in any of the connectors.

Step 2. Check SCSI bus compatibility.

Ensure transfer rate compatibility with the attached devices using the

SCSI boot menu command.

Step 3. Check the adapter.

Troubleshooting

General Procedure

Inspect the adapter to make sure it is seated properly in the PCI bus slot.

If necessary, power down the system, reseat the adapter, and restart the

system.

Step 4. Run diagnostics.

If a visual inspection of the adapter and cable(s) does not reveal any

problems, or if an action taken as a result of the inspection does not

produce a working adapter, you may want to run diagnostics to

determine whether the adapter can communicate and respond to PCI

bus instructions. Diagnostics are described in the next section.

If diagnostics determine that the controller is defective, you must replace

it. Contact your local Hewlett-Packard customer representative or call

the HP Response Center.

Chapter 3 35

Page 36

Troubleshooting

Checking SCSI Bus Compatibility

Checking SCSI Bus Compatibility

You can ensure SCSI controller and SCSI device compatibility by using

the SCSI command to display and select SCSI bus parameters.

The SCSI command is available from the boot menu displayed after the

test station has booted (if autoboot is disabled). The boot menu looks like

this (for highlighting reasons, the SCSI command is in bold here):

Command Description

------- ----------AUto [BOot|SEArch ON|OFF] Display or set the specified flag

BOot [PRI|ALT|<path> <args>] Boot from a specified path

BootTimer [time] Display or set boot delay time

CLEARPIM Clear PIM storage

CPUconfig [<proc>] [ON|OFF] Configure/Deconfigure Processor

DEfault Set the sytem to defined values

DIsplay Display this menu

ForthMode Switch to the Forth OBP interface

IO List the I/O devices in the system

LS [<path>|flash] List the boot or flash volume

OS [hpux|sppux] Display/Select Operating System

PASSword Set the Forth password

PAth [PRI|ALT|CON] [<path>] Display or modify a path

PDT [CLEAR|DEBUG] Display/clear Non-Volatile PDT state

PIM_info [cpu#] [HPMC|TOC|LPMC] Display PIM of current or any CPU

RESET [hard|debug] Force a reset of the system

RESTrict [ON|OFF] Display/Select restricted access to Forth

SCSI [INIT|RATE] [bus slot val] List/Set SCSI controller parms

SEArch [<path>] Search for boot devices

SECure [ON|OFF] Display or set secure boot mode

TIme [cn:yr:mo:dy:hr:mn[:ss]] Display or set the real-time clock

VErsion Display the firmware versions

Chapter 336

Page 37

Troubleshooting

Checking SCSI Bus Compatibility

The SCSI Command

As explained above, you can use the SCSI command to check the

compatibility of the SCSI adapter and the SCSI device(s), by displaying

and setting SCSI bus parameters.

NOTE See “HP e3000 Communicator for MPE/iX release 7.0” for MPE/iX

guidelines on rate. http://docs.hp.com/mpeix/pdf/30216-90312.pdf

Displaying Transfer Rates

To use the SCSI command to display the SCSI transfer rate for an

adapter, follow this syntax:

SCSI rate

bus_number slot_number

where

bus_number

Specifies the number of the bus the adapter is installed

on.

slot_number

Specifies the number of the slot the adapter is in.

For example:

• To display the SCSI transfer rate for the adapter installed on bus 5

slot 2, issue this command:

SCSI rate 5 2

The output could look something like this:

PCI device /5.2 = no limit

• To list transfer rates for all bus and slot numbers, issue this

command:

SCSI rate

Chapter 3 37

Page 38

Troubleshooting

Checking SCSI Bus Compatibility

Setting Transfer Rates

To use the SCSI command to set the SCSI transfer rate for an adapter,

follow this syntax:

SCSI rate

bus_number slot_number rate

where

bus_number

Specifies the number of the bus the adapter is installed

on.

slot_number

rate

Specifies the number of the slot the adapter is in.

Specifies the adapter’s transfer rate:

• 0 (no limit)

• 10 (Fast SCSI)

• 20 (Ultra SCSI)

For example, to set the SCSI transfer rate for the adapter installed on

bus 5 slot 2 to Fast SCSI and then display the results, issue these

commands:

SCSI rate 5 2 10

SCSI rate 5 2

The output (of the second command) could look something like this:

PCI device /5.2 = fast SCSI

Chapter 338

Page 39

Troubleshooting

Checking SCSI Bus Compatibility

Displaying SCSI IDs

To use the SCSI command to display the initiator (SCSI) IDs for an

adapter, follow this syntax:

SCSI init

bus_number slot_number

where

bus_number

Specifies the number of the bus the adapter is installed

on.

slot_number

Specifies the number of the slot the adapter is in.

For example:

• To display the SCSI ID for the adapter on bus 5 slot 2, issue this

command:

SCSI init 5 2

The output could look something like this:

PCI device /5.2 = 7

• To list the SCSI IDs for all bus and slot numbers, issue this

command:

SCSI init

Chapter 3 39

Page 40

Troubleshooting

Checking SCSI Bus Compatibility

Setting SCSI IDs

To use the SCSI command to set the initiator (SCSI) ID for an adapter,

follow this syntax:

SCSI init

bus_number slot_number ID_number

where

bus_number

Specifies the number of the bus the adapter is installed

on.

slot_number

ID_num

Specifies the number of the slot the adapter is in.

Specifies the adapter’s SCSI ID number.

For example, to set the SCSI ID for the adapter installed on bus 5 slot 2

to 6 and then display the results, issue these commands:

SCSI init 5 2 6

SCSI init 5 2

The output (of the second command) could look something like this:

PCI device /5.2 = 6

Chapter 340

Page 41

Troubleshooting

Using Support Tools Manager (STM)

Using Support Tools Manager (STM)

STM is a software application that can be run from the console to obtain

status and descriptive information about the A4800A adapter, diagnose

problems, and update firmware. See the Support Tools Manager User’s

Guide for more details about STM.

Chapter 3 41

Page 42

Troubleshooting

Contacting Your Hewlett-Packard Representative

Contacting Your Hewlett-Packard

Representative

If the equipment is covered by an HP service contract, document the

problem as a service request and forward it to your HP representative.

Include the following information where applicable:

• Describe the problem, including the events and symptoms leading up

to the problem. Attempt to describe the source of the problem.

Include HP-UX or MPE/iX commands, communication subsystem

commands, functionality of user programs, result codes and

messages, and data that can reproduce the problem.

• Obtain the version, update, and fix information for all software.

1. To check the version of the kernel, enter this command:

uname -r

To check patches, enter:

what /stand/vmunix | grep scsi

2. To check the version of MPE/iX enter: SHOWME

To check patches, enter: PRINT HPSWINFO.PUB.SYS

This allows HP to determine if the problem is already known and the

correct software is installed at your site.

• Illustrate as clearly as possible the context of any messages. Record

all error messages and numbers that appear at the user terminal

and the system console.

• Prepare the formatted output and a copy of the log file for the HP

representative to analyze.

• Prepare a listing of the HP-UX or MPE/iX I/O configuration being

used for the HP representative to analyze.

• Try to determine the general area within the software where the

problem may exist. Refer to the appropriate reference manual and

follow the guidelines on gathering information for that product.

Chapter 342

Page 43

Troubleshooting

Contacting Your Hewlett-Packard Representative

• Document your interim (workaround) solution. The cause of the

problem can sometimes be found by comparing the circumstances in

which the problem occurs with the circumstances in which the

problem does not occur.

• In the event of a system failure, obtain a full memory dump.

• For HP-UX: If the directory /var/adm/crash exists, the HP-UX

utility /sbin/savecore automatically executes during reboot to save

the memory dump. HP recommends that you create the

/tmp/syscore directory after successfully installing this product.

Send the output of the system failure memory dump to the HP

representative.

• For MPE/iX: If you use AUTORESTART and DUMPTODISK

products follow your normal system recovery steps. Otherwise take a

memory dump and save the resulting tape. Contact HP Support for

analysis of your failure.

If the equipment is not covered by an HP service contract, there may be a

charge for time and materials.

Chapter 3 43

Page 44

Troubleshooting

Contacting Your Hewlett-Packard Representative

Chapter 344

Page 45

A SCSI Sense Codes

This appendix shows the possible codes that appear in SCSI error

messages.

Appendix A 45

Page 46

SCSI Sense Codes

HP 9000 The following example shows a typical SCSI error message:

[+6708 72410001 002a9858 0:7] scsi disk: CHECK CONDITION on disk 0:6:5:0

Read of logical block 509856, count 128

disk sd45a, block 254920, 65536 bytes

Valid = 1, Error code = 0x70

Segment number = 0x00, Filemark = 0, EOM = 0, ILI = 0

Sense key = 0x1, "RECOVERED ERROR"

Information = 0x00 0x07 0xc7 0xe4

[+6709 72410001 002a9a10 0:7] scsi disk: Additional sense length = 0x0a

Command-specific information = 0x00 0x00 0x00 0x00

Additional sense = 0x18, Qualifier = 0x01

Field replaceable unit code = 0xea

SKSV = 1, C/D = 0, BPV = 0, Bit pointer = 0

Field pointer = 0x0003

The status (CHECK CONDITION) and sense key (RECOVERED

ERROR)—shown in bold in the example above—are interpreted for you

in the error message text. Each Additional sense and its corresponding

Qualifier code—shown in bold in the example above—require

interpretation on your part. Use the two codes together to determine the

meaning. In the example above, the Additional sense (0x18) and

Qualifier (0x01) codes together mean “recovered data with error

correction and retries applied.” You can look up the various codes and

keys in the tables on the next pages.

MPE/iX Use the CSTM tool to look at hardware error information. Information

about CSTM can be found in the article “TERMDSM: User Interface

Change undre System Diagnostics” in the “Communicator 3000 MPE/iX

Release 6.5”. http://docs.hp.com/mpeix/pdf/30216-90291.pdf

Appendix A46

Page 47

SCSI Sense Codes

Table A-1 below lists all possible SCSI status codes and their meanings.

Table A-1 SCSI Status Codes

SCSI

Status

Code

0x00 Good

0x02 Check condition

0x04 Condition met

0x08 Busy

0x10 Intermediate

0x14 Intermediate—condition met

0x18 Reservation conflict

0x22 Command terminated

Meaning

0x28 Queue full

Appendix A 47

Page 48

SCSI Sense Codes

Table A-2 below lists all possible SCSI sense keys and their meanings.

Table A-2 SCSI Sense Keys

SCSI

Sense

Key

0 No sense

0x1 Recovered error

0x2 Not ready

0x3 Medium error

0x4 Hardware error

0x5 Illegal request

0x6 Unit attention

0x7 Data protect

Meaning

0x8 Blank check

0x9 Vendor-specific

0xa Copy aborted

0xb Aborted command

0xc Equal

0xd Volume overflow

0xe Miscompare

0xf Reserved

Appendix A48

Page 49

Table A-3 below lists the Additional sense codes and Qualifier codes and

their meanings. Remember that you must use the combined codes—an

Additional sense code/Qualifier code pair—to find the correct meaning.

Table A-3 SCSI Additional Sense Code/Qualifier Code Pairs

SCSI Sense Codes

SCSI

Addition

al Sense

Code

0x00 0x00 No additional sense information

SCSI

Qualifier

Code

0x01 Filemark detected

0x02 End-of-partitions/medium detected

0x03 Setmark detected

0x04 Beginning of partition/medium detected

0x05 End-of-data detected

0x06 I/O process terminated

0x11 Audio play operation in progress

0x12 Audio play operation paused

0x13 Audio play operation successfully

completed

0x14 Audio play operation stopped due to

error

Meaning

0x15 No current audio status to return

0x01 0x00 No index/sector signal

0x02 0x00 No seek complete

0x03 0x00 Peripheral device write fault

0x01 No write current

0x02 Excessive write errors

Appendix A 49

Page 50

SCSI Sense Codes

Table A-3 SCSI Additional Sense Code/Qualifier Code Pairs (Continued)

SCSI

Addition

al Sense

Code

0x04 0x00 Logical unit not ready, cause not

0x05 0x00 Logical unit does not respond to selection

0x06 0x00 Reference position found

0x07 0x00 Multiple peripheral devices selected

0x08 0x00 Logical unit communication failure

SCSI

Qualifier

Code

reportable

0x01 Logical unit in process of becoming ready

0x02 Logical unit not ready, initializing

command required

0x03 Logical unit not ready, manual

intervention required

0x04 Logical unit not ready, format in progress

0x01 Logical unit communication time-out

Meaning

0x02 Logical unit communication parity error

0x09 0x00 Track following error

0x01 Tracking servo failure

0x02 Focus servo failure

0x03 Spindle servo failure

0x0a 0x00 Error log overflow

0x0c 0x00 Write error

0x01 Write error recovered with auto

reallocation

0x02 Write error—auto reallocation failed

Appendix A50

Page 51

SCSI Sense Codes

Table A-3 SCSI Additional Sense Code/Qualifier Code Pairs (Continued)

SCSI

Addition

al Sense

Code

0x10 0x00 ID crc or ecc error

0x11 0x00 Unrecovered read error

SCSI

Qualifier

Code

0x01 Read retries exhausted

0x02 Error too long to correct

0x03 Multiple read errors

0x04 Unrecovered read error—auto reallocate

failed

0x05 l-ec uncorrectable error

0x06 circ unrecovered error

0x07 Data resynchronization error

0x08 Incomplete block read

0x09 No gap found

0x0a Miscorrected error

Meaning

0x0b Unrecovered read error—recommend

reassignment

0x0c Unrecovered read error—recommend

rewrite the data

0x12 0x00 Address mark not found for ID field

0x13 0x00 Address mark not found for data field

Appendix A 51

Page 52

SCSI Sense Codes

Table A-3 SCSI Additional Sense Code/Qualifier Code Pairs (Continued)

SCSI

Addition

al Sense

Code

0x14 0x00 Recorded entity not found

0x15 0x00 Random positioning error

0x16 0x00 Data synchronization mark error

0x17 0x00 Recovered data with no error correction

SCSI

Qualifier

Code

0x01 Record not found

0x02 Filemark or setmark not found

0x03 End-of-data not found

0x04 Block sequence error

0x01 Mechanical positioning error

0x02 Positioning error detected by read of

medium

applied

0x01 Recovered data with retries

Meaning

0x02 Recovered data with positive head offset

0x03 Recovered data with negative head offset

0x04 Recovered data with retries and/or circ

applied

0x05 Recovered data using previous sector ID

0x06 Recovered data without ecc—data

auto-reallocated

0x07 Recovered data without ecc—recommend

reassignment

0x08 Recovered data without ecc—recommend

rewrite

Appendix A52

Page 53

SCSI Sense Codes

Table A-3 SCSI Additional Sense Code/Qualifier Code Pairs (Continued)

SCSI

Addition

al Sense

Code

0x18 0x00 Recovered data with error correction

0x19 0x00 Defect list error

SCSI

Qualifier

Code

applied

0x01 Recovered data with error correction and

retries applied

0x02 Recovered data—data auto-reallocated

0x03 Recovered data with circ

0x04 Recovered data with lec

0x05 Recovered data—recommend

reassignment

0x06 Recovered data—recommend rewrite

0x01 Defect list not available

0x02 Defect list error in primary list

Meaning

0x03 Defect list error in grown list

0x1a 0x00 Parameter list length error

0x1b 0x00 Synchronous data transfer error

0x1c 0x00 Defect list not found

0x01 Primary defect list not found

0x02 Grown defect list not found

0x1d 0x00 Miscompare during verify operation

0x1e 0x00 Recovered ID with ecc

0x20 0x00 Invalid command operation code

Appendix A 53

Page 54

SCSI Sense Codes

Table A-3 SCSI Additional Sense Code/Qualifier Code Pairs (Continued)

SCSI

Addition

al Sense

Code

0x21 0x00 Logical block address out of range

0x22 0x00 Illegal function

0x24 0x00 Invalid field in cdb

0x25 0x00 Logical unit not supported

0x26 0x00 Invalid field in parameter list

0x27 0x00 Write protected

0x28 0x00 Not ready to ready transition (medium

SCSI

Qualifier

Code

0x01 Invalid element address

0x01 Parameter not supported

0x02 Parameter value invalid

0x03 Threshold parameters not supported

may have changed)

0x01 Import or export element assessed

Meaning

0x29 0x00 Power on, reset, or bus device reset

occurred

0x2a 0x00 Parameters changed

0x01 Mode parameters changed

0x02 Log parameters changed

0x2b 0x00 Copy cannot execute since host cannot

disconnect

0x2c 0x00 Command sequence error

0x01 Too many windows specified

Appendix A54

Page 55

SCSI Sense Codes

Table A-3 SCSI Additional Sense Code/Qualifier Code Pairs (Continued)

SCSI

Addition

al Sense

Code

0x2f 0x00 Commands cleared by another initiator

0x30 0x00 Incompatible medium installed

0x31 0x00 Medium format corrupted

0x32 0x00 No defect spare location available

0x33 0x00 Tape length error

0x36 0x00 Ribbon, ink, or tower failure

0x37 0x00 Rounded parameter

0x39 0x00 Saving parameters not supported

SCSI

Qualifier

Code

0x01 Cannot read medium—unknown format

0x02 Cannot read medium—incompatible

format

0x03 Cleaning cartridge installed

0x01 Defect list update failure

Meaning

0x3a 0x00 Medium not present

Appendix A 55

Page 56

SCSI Sense Codes

Table A-3 SCSI Additional Sense Code/Qualifier Code Pairs (Continued)

SCSI

Addition

al Sense

Code

0x3b 0x00 Sequential positioning error

SCSI

Qualifier

Code

0x01 Tape position error at

beginning-of-medium

0x02 Tape position error at end-of-medium

0x03 Tape or electronic vertical forms unit not

ready

0x04 Slew failure

0x05 Paper jam

0x06 Failed to sense top-of-form

0x07 Failed to sense bottom-of-form

0x08 Reposition error

0x09 Read past end of medium

0x0a Read past beginning of medium

Meaning

0x0b Position past end of medium

0x0c Position past beginning of medium

0x0d Medium destination element full

0x0e Medium source element empty

0x3d 0x00 Invalid bits in identify message

0x3e 0x00 Logical unit has not self-configured yet

Appendix A56

Page 57

SCSI Sense Codes

Table A-3 SCSI Additional Sense Code/Qualifier Code Pairs (Continued)

SCSI

Addition

al Sense

Code

0x3f 0x00 Target operation conditions have

0x40 0x00 RAM failure

0x41 0x00 Data path failure

0x42 0x00 Power-on or self-test failure

0x43 0x00 Message error

0x44 0x00 Internal target failure

0x45 0x00 Select or reselect failure

0x46 0x00 Unsuccessful soft reset

SCSI

Qualifier

Code

changed

0x01 Microcode has been changed

0x02 Changed operating definition

0x03 Inquiry data has changed

nn

Diagnostic failure on component

Meaning

nn

0x47 0x00 SCSI parity error

0x48 0x00 Initiator detected error message received

0x49 0x00 Invalid message error

0x4a 0x00 Command phase error

0x4b 0x00 Data phase error

0x4c 0x00 Logical unit failed self-configuration

0x4e 0x00 Overlapped commands attempted

Appendix A 57

Page 58

SCSI Sense Codes

Table A-3 SCSI Additional Sense Code/Qualifier Code Pairs (Continued)

SCSI

Addition

al Sense

Code

0x50 0x00 Write append error

0x51 0x00 Erase failure

0x52 0x00 Cartridge fault

0x53 0x00 Media load or eject failed

0x54 0x00 SCSI to host system interface failure

0x55 0x00 System resource failure

0x56 0x00 Reserved

0x57 0x00 Unable to recover table of contents

SCSI

Qualifier

Code

0x01 Write append position error

0x02 Position error related to timing

0x01 Unload tape failure

0x02 Medium removal prevented

Meaning

0x58 0x00 Generation does not exist

0x59 0x00 Updated block read

0x5A 0x00 Operator request or state change input

(unspecified)

0x01 Operator medium removal request

0x02 Operator selected write protect

0x02 Operator selected write permit

Appendix A58

Page 59

SCSI Sense Codes

Table A-3 SCSI Additional Sense Code/Qualifier Code Pairs (Continued)

SCSI

Addition

al Sense

Code

0x5B 0x00 Log exception

0x5C 0x00 RPL status change

0x5D 0x00 Reserved

0x5E 0x00 Reserved

0x5F 0x00 Reserved

0x60 0x00 Lamp failure

0x61 0x00 Video acquisition error

SCSI

Qualifier

Code

0x01 Threshold condition met

0x02 Log counter at maximum

0x03 Log list codes exhausted

0x01 Spindles synchronized

0x02 Spindles not synchronized

Meaning

0x01 Unable to acquire video

0x02 Out of focus

0x62 0x00 Scan head positioning error

0x63 0x00 End of user area encountered on this

track

0x64 0x00 Illegal mode for this track

0x65 0x00 Reserved

0x66 0x00 Reserved

0x67 0x00 Reserved

0x68 0x00 Reserved

Appendix A 59

Page 60

SCSI Sense Codes

Table A-3 SCSI Additional Sense Code/Qualifier Code Pairs (Continued)

SCSI

Addition

al Sense

Code

0x69 0x00 Reserved

0x6A 0x00 Reserved

0x6B 0x00 Reserved

0x6C 0x00 Reserved

0x6D 0x00 Reserved

0x6E 0x00 Reserved

0x6F 0x00 Reserved

SCSI

Qualifier

Code

Meaning

Appendix A60

Page 61

B Regulatory Information

This appendix contains all of the regulatory-related information for the

A4800A adapter.

Appendix B 61

Page 62

Regulatory Information

Regulatory Statements

Regulatory Statements

This section contains all of the regulatory statements for the A4800A

adapter.

FCC Statement (For U.S.A. Only)

The Federal Communications Commission (in 47 CFR 15.105) has

specified that the following notice be brought to the attention of the users

of this product.

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense. The end user of

this product should be aware that any changes or modifications made to

this equipment without the approval of Hewlett-Packard could result in

the product not meeting the Class A limits, in which case the FCC could

void the user's authority to operate the equipment.

IEC Statement (Worldwide)

This is a Class A product. In a domestic environment this product may

cause radio interference in which case the user may be required to take

adequate measures.

DOC Statement (Canada)

This Class A digital apparatus meets all requirements of the Canadian

interference-Causing Equipment Regulations.

Cet appareil numerique do la classe A respecte toutes les exigences du

Reglement sur le materiel brouilleur du Canada.

Appendix B62

Page 63

Regulatory Information

Regulatory Statements

Spécification ATI Classe A (France

DECLARATION D’INSTALLATION ET DE MISE EN EXPLOITATION

d’un matériel de traitement de l’information (ATI), classé A en fonction

des niveaux de perturbations radioélectriques émis, définis dans la

norme européenne EN 55022 concernant la Compatibilité

Electromagnétique.

Cher Client,

Conformément à la Réglementation Française en vigueur l’installation

ou le transfert d’installation, et l’exploitation de cet appareil de classe A,

doivent faire l’objet d’une déclaration (en deux exemplaires)

simultanément auprès des services suivants:

• Comité de Coordination des Télécommunications 20, avenue de

Ségur - 75700 PARIS

• Préfecture du département du lieu d’exploitation

Le formulaire à utiliser est disponible auprès des préfectures.

La déclaration doit être faite dans les 30 jours suivant la mise en

exploitation.

Le non respect de cette obligation peut être sanctionné par les peines

prévues au code des Postes et Télécommunications et celles indiquées

dans la loi du 31 mai 1993 susvisée.

Arrêté du 27 Mars 1993, publié au J.O. du 28 Mars - ATI

VCCI Statement (Japan)

Appendix B 63

Page 64

Regulatory Information

Regulatory Statements

Declaration of Conformity

Appendix B64

Loading...

Loading...