Page 1

hp LaserJet 9000mfp series printer

service ____________________

This manual is used in conjunction with the HP LaserJet 9000 series

printer service manual.

Page 2

© Copyright Hewlett-Packard

Company, 2002

All Rights Reserved.

Reproduction, adaptation, or

translation without prior written

permission is prohibited, except

as allowed under the copyright

laws.

Part number: C8523-90921

First Edition, March 2002

Warranty

The information contained in this

document is subject to change

without notice.

Hewlett-Packard makes no

warranty of any kind with respect

to this information. HEWLETTPACKARD SPECIFICALLY

DISCLAIMS THE IMPLIED

WARRANTY OF

MERCHANTABILITY AND

FITNESS FOR A PARTICULAR

PURPOSE.

Hewlett-Packard shall not be

liable for any direct, indirect,

incidental, consequential, or

other damage alleged in

connection with the furnishing or

use of this information.

Trademark Credits

Adobe® and PostScript® are

trademarks of Adobe Systems

Incorporated.

Microsoft

Windows

trademarks of Microsoft

Corporation.

TrueType

of Apple Computer, Inc.

UNIX® is a registered trademark

of The Open Group.

®

, MS-DOS®, and

®

are U.S. registered

TM

is a U.S. trademark

Hewlett-Packard Company

11311 Chinden Boulevard

Boise, Idaho 83714 U.S.A.

Page 3

Contents

List of tables

List of figures

1 Product information

Product features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Product specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Product overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Assembly identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

External assembly locations . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Interface connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Regulatory information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Service approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Parts and supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Limited warranty for the print cartridge . . . . . . . . . . . . . . . . . . . 23

Service and support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Worldwide service and support offices . . . . . . . . . . . . . . . . . . 25

2 Product requirements

Space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Initial setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Unpacking the MFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Removing the MFP from the shipping pallet. . . . . . . . . . . . . . . 32

Initial hardware setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Installing the finishing device . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Testing MFP printing and copying functions. . . . . . . . . . . . . . . 36

3 Product configuration

Control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Control panel layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Touch-screen graphical display layout . . . . . . . . . . . . . . . . . . . 39

Settings and defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Setting the display language. . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Setting tray registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Print driver information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Factory default settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Control panel menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Menu map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Using a menu map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Retrieve job menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Information menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Paper handling menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Configure device menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Diagnostics menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Contents 3

Page 4

Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Remote firmware upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Downloading the new firmware to the MFP . . . . . . . . . . . . . . . .52

Using HP Web JetAdmin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

4 Product maintenance

Cleaning the MFP and accessories . . . . . . . . . . . . . . . . . . . . . . . . .56

General cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

ADF cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Glass cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

5 Theory of operation

Differences in print engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Mechanical structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Motors and fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Basic block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Basic system configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Scanner unit systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Scan mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Power supply assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Low-voltage power supply circuit . . . . . . . . . . . . . . . . . . . . . . .78

Scanner controller circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Flatbed operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Flatbed document exposure control . . . . . . . . . . . . . . . . . . . . .81

Flatbed optical drive control . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Flatbed optical unit operation. . . . . . . . . . . . . . . . . . . . . . . . . . .83

Flatbed document size detection . . . . . . . . . . . . . . . . . . . . . . . .84

ADF operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

ADF document exposure control . . . . . . . . . . . . . . . . . . . . . . . .87

ADF document feed control . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

ADF document size detection . . . . . . . . . . . . . . . . . . . . . . . . . .90

ADF feeder sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

ADF document skew detection . . . . . . . . . . . . . . . . . . . . . . . . .92

Scanned data flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Copy processor board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

CPB terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Scanning process control signals. . . . . . . . . . . . . . . . . . . . . . . .95

Typical scanning process flow . . . . . . . . . . . . . . . . . . . . . . . . . .95

Copy processor board LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . .96

6 Removal and replacement

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Removal and replacement strategy . . . . . . . . . . . . . . . . . . . .101

Electrostatic discharge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Required tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

External covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

ADF feeder cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

ADF feeder cover handle . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

ADF back cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

ADF front cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Lower delivery roller cover . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

White board cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Copy processor board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Flatbed rail cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Flatbed back cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Flatbed right cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

4 C8523-90921

Page 5

Flatbed left cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Flatbed upper front cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Flatbed lower front cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

ADF base cover assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Glass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Internal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

ADF optical unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

ADF scanning lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

ADF shading filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Flatbed optical unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Flatbed scanning lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Flatbed shading filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Switch and solenoids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

ADF feeder cover detection switch . . . . . . . . . . . . . . . . . . . . . 141

Weight solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Shutter solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Motors and fans. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Pickup motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Delivery motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Flatbed motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Power supply assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

ADF fan assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Flatbed fan assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

PCB assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

ADF analog processor PCB . . . . . . . . . . . . . . . . . . . . . . . . . . 155

ADF inverter PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

ADF intermediate PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

ADF width detection sensor assembly . . . . . . . . . . . . . . . . . . 158

Flatbed inverter PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Flatbed intermediate PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Scanner controller board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Intermediate PCB assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Power supply assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Rollers and belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Pickup roller (D-roller). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Pickup roller assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Feed roller assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Lower registration roller assembly . . . . . . . . . . . . . . . . . . . . . 171

Lower delivery roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Upper delivery roller assembly . . . . . . . . . . . . . . . . . . . . . . . . 179

Separation belt assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Separation belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Scan engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

7 Troubleshooting

Troubleshooting process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Preliminary operating checks . . . . . . . . . . . . . . . . . . . . . . . . 191

Power on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Power-on defects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Malfunction troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Troubleshooting with control panel messages . . . . . . . . . . . . . . . 194

Control panel display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Event log page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Control panel messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

MFP message tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Alphabetic error messages . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Numeric error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Troubleshooting with the copy processor board . . . . . . . . . . . . . . 203

C8523-90921 5

Page 6

User- and service-level diagnostics . . . . . . . . . . . . . . . . . . . . . . . .205

Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .205

ADF paper-path test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .205

Service test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .206

Service-level diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

ADF and glass calibrations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .209

ADF calibrations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .209

Glass calibrations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .217

Jam troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .220

Jams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .220

Evaluating the information pages . . . . . . . . . . . . . . . . . . . . . . . . . .222

Configuration page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .222

Jetdirect page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .224

Supplies status page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .225

Usage page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .226

File directory page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .227

Image-formation troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . .228

Image defects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .229

Measurement and adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . .232

ADF unit height adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . .232

ADF skew adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .234

ADF width sensor volume adjustment . . . . . . . . . . . . . . . . . . .236

Weight solenoid stroke adjustment . . . . . . . . . . . . . . . . . . . . .237

Scanner controller PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .238

Connector locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .239

Electrical structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .240

Wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .241

8 Parts and diagrams

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .244

Ordering parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .244

Consumables, supplies, accessories,

FRUs, and documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . .245

Common hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .247

Illustrations and parts lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .248

MFP system assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .249

Image scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .251

External panels and covers . . . . . . . . . . . . . . . . . . . . . . . . . . .253

Flatbed scanner assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .255

Flatbed optical assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . .259

ADF scanner assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .260

Paper pickup assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .262

ADF main assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .266

ADF optical assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .268

PCB assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .269

Alphabetical parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .270

Numerical parts list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .274

Index

6 C8523-90921

Page 7

List of tables

Table 1. Features of the HP LaserJet 9000mfp . . . . . . . . . . . . . . . 16

Table 2. Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 3. Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 4. Environmental specifications . . . . . . . . . . . . . . . . . . . . 18

Table 5. Noise level specifications . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 6. Control panel features, and key functions . . . . . . . . . . . . 39

Table 7. Touch-screen graphical display features and functions . . 40

Table 8. Factory default settings . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 9. Retrieve job menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 10. Information menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 11. Paper handling menu default settings . . . . . . . . . . . . . . 47

Table 12. Configure device menu . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 13. Diagnostics menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 14. Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 15. Differences between the HP LaserJet 9000 series

and the HP LaserJet 9000mfp . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 16. Mechanical structure . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 17. Mechanical structure . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Table 18. Motors and fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Table 19. Electrical specifications for the MFP . . . . . . . . . . . . . . . 75

Table 20. Copy processor board LEDs . . . . . . . . . . . . . . . . . . . . . 96

Table 21. Primary steps for troubleshooting . . . . . . . . . . . . . . . . . 190

Table 22. Power-on defects or blank display . . . . . . . . . . . . . . . . 192

Table 23. Malfunction troubleshooting . . . . . . . . . . . . . . . . . . . . . 193

Table 24. Alphabetic error messages . . . . . . . . . . . . . . . . . . . . . . 198

Table 25. Numeric error messages . . . . . . . . . . . . . . . . . . . . . . . 200

Table 26. Troubleshooting copy processor bo ard LEDs . . . . . . . 204

Table 27. Replaced components and required calibrations . . . . . 208

Table 28. General jam troubleshooting . . . . . . . . . . . . . . . . . . . . 220

Table 29. General jam troubleshooting . . . . . . . . . . . . . . . . . . . . 221

Table 30. Image quality checks . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Table 31. Image defects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Table 32. Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Table 33. Consumables, supplies, accessor ies ,

FRUs, and documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Table 34. Hardware table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Table 35. Common torque values . . . . . . . . . . . . . . . . . . . . . . . . 247

Table 36. MFP system assembly . . . . . . . . . . . . . . . . . . . . . . . . . 249

Table 37. Image scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Table 38. Image scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Table 39. External panels and covers (1 of 2) . . . . . . . . . . . . . . . 253

Table 40. External panels and covers (2 of 2) . . . . . . . . . . . . . . . 254

Table 41. Flatbed scanner assembly (1 of 3) . . . . . . . . . . . . . . . . 255

Table 42. Flatbed scanner assembly (2 of 3) . . . . . . . . . . . . . . . . 256

Table 43. Flatbed scanner assembly (3 of 3) . . . . . . . . . . . . . . . . 258

Table 44. Flatbed optical assembly . . . . . . . . . . . . . . . . . . . . . . . 259

Table 45. ADF scanner assembly . . . . . . . . . . . . . . . . . . . . . . . . 261

Table 46. Paper pickup assembly (1 of 2) . . . . . . . . . . . . . . . . . . 263

Table 47. Paper pickup assembly (2 of 2) . . . . . . . . . . . . . . . . . . 265

C8523-90921 7

Page 8

Table 48. ADF main assembly . . . . . . . . . . . . . . . . . . . . . . . . . . .267

Table 49. ADF optical assembly . . . . . . . . . . . . . . . . . . . . . . . . . .268

Table 50. PCB assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .269

Table 51. Alphabetical parts list . . . . . . . . . . . . . . . . . . . . . . . . . . .270

Table 52. Numerical parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . .274

8 List of tables C8523-90921

Page 9

List of figures

Figure 1. Sample identification label . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 2. Assembly identification. . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 3. External assembly locations (front view) . . . . . . . . . . . . . 20

Figure 4. External assembly locations (back view) . . . . . . . . . . . . . 20

Figure 5. Interface connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 6. Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 7. MFP space requirements with a finishing device

(3,000-sheet stapler/stacker shown) (top view) . . . . . . . . . . . . 28

Figure 8. MFP space requirements with a finishing device

(3,000-sheet stapler/stacker shown) (front view) . . . . . . . . . . . 29

Figure 9. Unpacking the MFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 10. Removing the MFP from the shipping pa llet (1 of 2) . . . 32

Figure 11. Removing the MFP from the shipping pa llet (2 of 2) . . . 32

Figure 12. Initial hardware setup (1 of 4). . . . . . . . . . . . . . . . . . . . . 33

Figure 13. Initial hardware setup (2 of 4). . . . . . . . . . . . . . . . . . . . . 33

Figure 14. Initial hardware setup (3 of 4). . . . . . . . . . . . . . . . . . . . . 34

Figure 15. Initial hardware setup (4 of 4). . . . . . . . . . . . . . . . . . . . . 34

Figure 16. Installing the finishing device (1 of 2). . . . . . . . . . . . . . . 35

Figure 17. Installing the finishing device (2 of 2). . . . . . . . . . . . . . . 36

Figure 18. Control panel layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 19. Touch-screen graphical display layout. . . . . . . . . . . . . . 39

Figure 20. Registration page (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 21. Registration page (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 22. ADF delivery system (1 of 5) . . . . . . . . . . . . . . . . . . . . . 57

Figure 23. ADF delivery system (2 of 5) . . . . . . . . . . . . . . . . . . . . . 57

Figure 24. ADF delivery system (3 of 5) . . . . . . . . . . . . . . . . . . . . . 58

Figure 25. ADF delivery system (4 of 5) . . . . . . . . . . . . . . . . . . . . . 58

Figure 26. ADF delivery system (5 of 5) . . . . . . . . . . . . . . . . . . . . . 58

Figure 27. Upper ADF glass strip (1 of 4) . . . . . . . . . . . . . . . . . . . . 59

Figure 28. Upper ADF glass strip (2 of 4) . . . . . . . . . . . . . . . . . . . . 59

Figure 29. Upper ADF glass strip (3 of 4) . . . . . . . . . . . . . . . . . . . . 60

Figure 30. Upper ADF glass strip (4 of 4) . . . . . . . . . . . . . . . . . . . . 60

Figure 31. ADF rollers (1 of 6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 32. ADF rollers (2 of 6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 33. ADF rollers (3 of 6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 34. ADF rollers (4 of 6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 35. ADF rollers (5 of 6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 36. ADF rollers (6 of 6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 37. Differences in print engine . . . . . . . . . . . . . . . . . . . . . . . 66

Figure 38. Mechanical structure (1 of 2) . . . . . . . . . . . . . . . . . . . . . 68

Figure 39. Mechanical structure (2 of 2) . . . . . . . . . . . . . . . . . . . . . 69

Figure 40. Motors and fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 41. Basic block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Figure 42. Basic system configuration . . . . . . . . . . . . . . . . . . . . . . 74

Figure 43. Power supply assembly . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 44. PowerSave flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Figure 45. Low-voltage power supply circuit . . . . . . . . . . . . . . . . . . 78

Figure 46. Printer power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 47. Scanner controller circuit . . . . . . . . . . . . . . . . . . . . . . . . 80

C8523-90921 9

Page 10

Figure 48. Flatbed document exposure control . . . . . . . . . . . . . . . .81

Figure 49. Flatbed optical drive control . . . . . . . . . . . . . . . . . . . . . .82

Figure 50. Flatbed optical unit operation . . . . . . . . . . . . . . . . . . . . .83

Figure 51. Flatbed document size detection. . . . . . . . . . . . . . . . . . .84

Figure 52. Functions operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Figure 53. ADF angle detection . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Figure 54. ADF document exposure control. . . . . . . . . . . . . . . . . . .87

Figure 55. ADF document feed control. . . . . . . . . . . . . . . . . . . . . . .88

Figure 56. ADF document size detection . . . . . . . . . . . . . . . . . . . . .90

Figure 57. ADF feeder sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Figure 58. Document skew jam . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Figure 59. Scanned data flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Figure 60. Copy processor board. . . . . . . . . . . . . . . . . . . . . . . . . . .94

Figure 61. Copy processor board LEDs . . . . . . . . . . . . . . . . . . . . . .96

Figure 62. Control panel (1 of 3). . . . . . . . . . . . . . . . . . . . . . . . . . .102

Figure 63. Control panel (2 of 3). . . . . . . . . . . . . . . . . . . . . . . . . . .102

Figure 64. Control panel (3 of 3). . . . . . . . . . . . . . . . . . . . . . . . . . .103

Figure 65. ADF feeder cover (1 of 3) . . . . . . . . . . . . . . . . . . . . . . .104

Figure 66. ADF feeder cover (2 of 3) . . . . . . . . . . . . . . . . . . . . . . .104

Figure 67. ADF feeder cover (3 of 3) . . . . . . . . . . . . . . . . . . . . . . .105

Figure 68. ADF feeder cover handle (1 of 2) . . . . . . . . . . . . . . . . .106

Figure 69. ADF feeder cover handle (2 of 2) . . . . . . . . . . . . . . . . .106

Figure 70. ADF back cover (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . .107

Figure 71. ADF back cover (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . .107

Figure 72. ADF front cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

Figure 73. Delivery roller cover. . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Figure 74. White board cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Figure 75. Copy processor board. . . . . . . . . . . . . . . . . . . . . . . . . .111

Figure 76. Flatbed rail cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

Figure 77. Flatbed back cover (1 of 2) . . . . . . . . . . . . . . . . . . . . . .113

Figure 78. Flatbed back cover (2 of 2) . . . . . . . . . . . . . . . . . . . . . .113

Figure 79. Flatbed right cover (1 of 2) . . . . . . . . . . . . . . . . . . . . . .114

Figure 80. Flatbed right cover (2 of 2) . . . . . . . . . . . . . . . . . . . . . .114

Figure 81. Flatbed left cover (1 of 2) . . . . . . . . . . . . . . . . . . . . . . .115

Figure 82. Flatbed left cover (2 of 2) . . . . . . . . . . . . . . . . . . . . . . .115

Figure 83. Flatbed upper front cover . . . . . . . . . . . . . . . . . . . . . . .116

Figure 84. Flatbed lower front cover. . . . . . . . . . . . . . . . . . . . . . . .117

Figure 85. ADF base cover assembly (1 of 9) . . . . . . . . . . . . . . . .118

Figure 86. ADF base cover assembly (2 of 9) . . . . . . . . . . . . . . . .118

Figure 87. ADF base cover assembly (3 of 9) . . . . . . . . . . . . . . . .119

Figure 88. ADF base cover assembly (4 of 9) . . . . . . . . . . . . . . . .119

Figure 89. ADF base cover assembly (5 of 9) . . . . . . . . . . . . . . . .120

Figure 90. ADF base cover assembly (6 of 9) . . . . . . . . . . . . . . . .120

Figure 91. ADF base cover assembly (7 of 9) . . . . . . . . . . . . . . . .121

Figure 92. ADF base cover assembly (8 of 9) . . . . . . . . . . . . . . . .121

Figure 93. ADF base cover assembly (9 of 9) . . . . . . . . . . . . . . . .122

Figure 94. Glass (1 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Figure 95. Glass (2 of 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Figure 96. ADF optical unit (1 of 8). . . . . . . . . . . . . . . . . . . . . . . . .125

Figure 97. ADF optical unit (2 of 8). . . . . . . . . . . . . . . . . . . . . . . . .126

Figure 98. ADF optical unit (3 of 8). . . . . . . . . . . . . . . . . . . . . . . . .126

Figure 99. ADF optical unit (4 of 8). . . . . . . . . . . . . . . . . . . . . . . . .127

Figure 100. ADF optical unit (5 of 8). . . . . . . . . . . . . . . . . . . . . . . .127

Figure 101. ADF optical unit (6 of 8). . . . . . . . . . . . . . . . . . . . . . . .128

Figure 102. ADF optical unit (7 of 8). . . . . . . . . . . . . . . . . . . . . . . .128

Figure 103. ADF optical unit (8 of 8). . . . . . . . . . . . . . . . . . . . . . . .129

Figure 104. ADF scanning lamp (1 of 5). . . . . . . . . . . . . . . . . . . . .130

Figure 105. ADF scanning lamp (2 of 5). . . . . . . . . . . . . . . . . . . . .130

Figure 106. ADF scanning lamp (3 of 5). . . . . . . . . . . . . . . . . . . . .131

10 List of figures C8523-90921

Page 11

Figure 107. ADF scanning lamp (4 of 5) . . . . . . . . . . . . . . . . . . . . 131

Figure 108. ADF scanning lamp (5 of 5) . . . . . . . . . . . . . . . . . . . . 132

Figure 109. ADF shading filter (1 of 2) . . . . . . . . . . . . . . . . . . . . . 133

Figure 110. ADF shading filter (2 of 2) . . . . . . . . . . . . . . . . . . . . . 133

Figure 111. Flatbed optical unit (1 of 6). . . . . . . . . . . . . . . . . . . . . 134

Figure 112. Flatbed optical unit (2 of 6). . . . . . . . . . . . . . . . . . . . . 134

Figure 113. Flatbed optical unit (3 of 6). . . . . . . . . . . . . . . . . . . . . 135

Figure 114. Flatbed optical unit (4 of 6). . . . . . . . . . . . . . . . . . . . . 135

Figure 115. Flatbed optical unit (5 of 6). . . . . . . . . . . . . . . . . . . . . 136

Figure 116. Flatbed optical unit (6 of 6). . . . . . . . . . . . . . . . . . . . . 136

Figure 117. Flatbed scanning lamp (1 of 3). . . . . . . . . . . . . . . . . . 137

Figure 118. Flatbed scanning lamp (2 of 3). . . . . . . . . . . . . . . . . . 137

Figure 119. Flatbed scanning lamp (3 of 3). . . . . . . . . . . . . . . . . . 138

Figure 120. Flatbed shading filter (1 of 3) . . . . . . . . . . . . . . . . . . . 139

Figure 121. Flatbed shading filter (2 of 3) . . . . . . . . . . . . . . . . . . . 139

Figure 122. Flatbed shading filter (3 of 3) . . . . . . . . . . . . . . . . . . . 140

Figure 123. ADF feeder cover detection switch . . . . . . . . . . . . . . 141

Figure 124. Weight solenoid (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . 142

Figure 125. Weight solenoid (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . 142

Figure 126. Shutter solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Figure 127. Pickup motor (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . 144

Figure 128. Pickup motor (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . 144

Figure 129. Delivery motor (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . 146

Figure 130. Delivery motor (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . 146

Figure 131. Flatbed motor (1 of 3). . . . . . . . . . . . . . . . . . . . . . . . . 148

Figure 132. Flatbed motor (2 of 3). . . . . . . . . . . . . . . . . . . . . . . . . 148

Figure 133. Flatbed motor (3 of 3). . . . . . . . . . . . . . . . . . . . . . . . . 149

Figure 134. Power supply assembly (1 of 6). . . . . . . . . . . . . . . . . 150

Figure 135. Power supply assembly (2 of 6). . . . . . . . . . . . . . . . . 150

Figure 136. Power supply assembly (3 of 6). . . . . . . . . . . . . . . . . 151

Figure 137. Power supply assembly (4 of 6). . . . . . . . . . . . . . . . . 151

Figure 138. Power supply assembly (5 of 6). . . . . . . . . . . . . . . . . 152

Figure 139. Power supply assembly (6 of 6). . . . . . . . . . . . . . . . . 152

Figure 140. ADF fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Figure 141. Flatbed fan assembly. . . . . . . . . . . . . . . . . . . . . . . . . 154

Figure 142. ADF analog processor PCB. . . . . . . . . . . . . . . . . . . . 155

Figure 143. ADF inverter PCB (1 of 2) . . . . . . . . . . . . . . . . . . . . . 156

Figure 144. ADF inverter PCB (2 of 2) . . . . . . . . . . . . . . . . . . . . . 156

Figure 145. ADF intermediate PCB. . . . . . . . . . . . . . . . . . . . . . . . 157

Figure 146. ADF width detection sensor assembly. . . . . . . . . . . . 158

Figure 147. Flatbed inverter PCB (1 of 2) . . . . . . . . . . . . . . . . . . . 159

Figure 148. Flatbed intermediate PCB (1 of 2) . . . . . . . . . . . . . . . 160

Figure 149. Flatbed intermediate PCB (2 of 2) . . . . . . . . . . . . . . . 161

Figure 150. Scanner controller board (1 of 4) . . . . . . . . . . . . . . . . 162

Figure 151. Scanner controller board (2 of 4) . . . . . . . . . . . . . . . . 162

Figure 152. Scanner controller board (3 of 4) . . . . . . . . . . . . . . . . 163

Figure 153. Scanner controller board (4 of 4) . . . . . . . . . . . . . . . . 163

Figure 154. Intermediate PCB assembly. . . . . . . . . . . . . . . . . . . . 164

Figure 155. Power supply assembly (1 of 6). . . . . . . . . . . . . . . . . 165

Figure 156. Power supply assembly (2 of 6). . . . . . . . . . . . . . . . . 165

Figure 157. Power supply assembly (3 of 6). . . . . . . . . . . . . . . . . 166

Figure 158. Power supply assembly (4 of 6). . . . . . . . . . . . . . . . . 166

Figure 159. Power supply assembly (5 of 6). . . . . . . . . . . . . . . . . 167

Figure 160. Power supply assembly (6 of 6). . . . . . . . . . . . . . . . . 167

Figure 161. Pickup roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Figure 162. Pickup roller assembly . . . . . . . . . . . . . . . . . . . . . . . . 169

Figure 163. Feed roller assembly . . . . . . . . . . . . . . . . . . . . . . . . . 170

Figure 164. Lower registration roller assembly (1 of 10). . . . . . . . 171

Figure 165. Lower registration roller assembly (2 of 10). . . . . . . . 172

C8523-90921 11

Page 12

Figure 166. Lower registration roller assembly (3 of 10) . . . . . . . .173

Figure 167. Lower registration roller assembly (4 of 10) . . . . . . . .173

Figure 168. Lower registration roller assembly (5 of 10) . . . . . . . .174

Figure 169. Lower registration roller assembly (6 of 10) . . . . . . . .174

Figure 170. Lower registration roller assembly (7 of 10) . . . . . . . .175

Figure 171. Lower registration roller assembly (8 of 10) . . . . . . . .175

Figure 172. Lower registration roller assembly (9 of 10) . . . . . . . .176

Figure 173. Lower registration roller assembly (10 of 10) . . . . . . .176

Figure 174. Lower delivery roller (1 of 2) . . . . . . . . . . . . . . . . . . . .177

Figure 175. Lower delivery roller (2 of 2) . . . . . . . . . . . . . . . . . . . .177

Figure 176. Upper delivery roller . . . . . . . . . . . . . . . . . . . . . . . . . .179

Figure 177. Separation belt assembly (1 of 6) . . . . . . . . . . . . . . . .180

Figure 178. Separation belt assembly (2 of 6) . . . . . . . . . . . . . . . .180

Figure 179. Separation belt assembly (3 of 6) . . . . . . . . . . . . . . . .181

Figure 180. Separation belt assembly (4 of 6) . . . . . . . . . . . . . . . .181

Figure 181. Separation belt assembly (5 of 6) . . . . . . . . . . . . . . . .182

Figure 182. Separation belt assembly (6 of 6) . . . . . . . . . . . . . . . .182

Figure 183. Separation belts (1 of 3) . . . . . . . . . . . . . . . . . . . . . . .183

Figure 184. Separation belts (2 of 3) . . . . . . . . . . . . . . . . . . . . . . .183

Figure 185. Separation belts (3 of 3) . . . . . . . . . . . . . . . . . . . . . . .184

Figure 186. Scan engine (1 of 7) . . . . . . . . . . . . . . . . . . . . . . . . . .185

Figure 187. Scan engine (2 of 7) . . . . . . . . . . . . . . . . . . . . . . . . . .185

Figure 188. Scan engine (3 of 7) . . . . . . . . . . . . . . . . . . . . . . . . . .186

Figure 189. Scan engine (4 of 7) . . . . . . . . . . . . . . . . . . . . . . . . . .186

Figure 190. Scan engine (5 of 7) . . . . . . . . . . . . . . . . . . . . . . . . . .187

Figure 191. Scan engine (6 of 7) . . . . . . . . . . . . . . . . . . . . . . . . . .187

Figure 192. Scan engine (7 of 7) . . . . . . . . . . . . . . . . . . . . . . . . . .188

Figure 193. Sample event log page . . . . . . . . . . . . . . . . . . . . . . . .195

Figure 194. Example of events on the event log . . . . . . . . . . . . . .196

Figure 195. Copy processor board LEDs . . . . . . . . . . . . . . . . . . . .203

Figure 196. Left side front calibration (1 of 4). . . . . . . . . . . . . . . . .209

Figure 197. Left side front calibration (2 of 4). . . . . . . . . . . . . . . . .210

Figure 198. Left side front calibration (3 of 4). . . . . . . . . . . . . . . . .210

Figure 199. Left side front calibration (4 of 4). . . . . . . . . . . . . . . . .211

Figure 200. Sample configuration page . . . . . . . . . . . . . . . . . . . . .223

Figure 201. Sample Jetdirect page. . . . . . . . . . . . . . . . . . . . . . . . .224

Figure 202. Sample supplies status page . . . . . . . . . . . . . . . . . . .225

Figure 203. Sample usage page . . . . . . . . . . . . . . . . . . . . . . . . . .226

Figure 204. Sample file directory page. . . . . . . . . . . . . . . . . . . . . .227

Figure 205. ADF unit height adjustment (1 of 2). . . . . . . . . . . . . . .232

Figure 206. ADF unit height adjustment (2 of 2). . . . . . . . . . . . . . .233

Figure 207. ADF skew adjustment (1 of 3). . . . . . . . . . . . . . . . . . .234

Figure 208. ADF skew adjustment (2 of 3). . . . . . . . . . . . . . . . . . .235

Figure 209. ADF skew adjustment (3 of 3). . . . . . . . . . . . . . . . . . .235

Figure 210. ADF width sensor volume adjustment. . . . . . . . . . . . .236

Figure 211. Weight solenoid stroke adjustment . . . . . . . . . . . . . . .237

Figure 212. Scanner controller PCB. . . . . . . . . . . . . . . . . . . . . . . .238

Figure 213. Connector locations. . . . . . . . . . . . . . . . . . . . . . . . . . .239

Figure 214. Circuit diagram (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . .241

Figure 215. Circuit diagram (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . .242

Figure 216. MFP system assembly . . . . . . . . . . . . . . . . . . . . . . . .249

Figure 217. Image scanner (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . .251

Figure 218. Image scanner (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . .252

Figure 219. External panels and covers (1 of 2). . . . . . . . . . . . . . .253

Figure 220. External panels and covers (2 of 2). . . . . . . . . . . . . . .254

Figure 221. Flatbed scanner assembly (1 of 3) . . . . . . . . . . . . . . .255

Figure 222. Flatbed scanner assembly (2 of 3) . . . . . . . . . . . . . . .256

Figure 223. Flatbed scanner assembly (3 of 3) . . . . . . . . . . . . . . .257

Figure 224. Flatbed optical assembly. . . . . . . . . . . . . . . . . . . . . . .259

12 List of figures C8523-90921

Page 13

Figure 225. ADF scanner assembly . . . . . . . . . . . . . . . . . . . . . . . 260

Figure 226. Paper pickup assembly (1 of 2) . . . . . . . . . . . . . . . . . 262

Figure 227. Paper pickup assembly (2 of 2) . . . . . . . . . . . . . . . . . 264

Figure 228. ADF main assembly. . . . . . . . . . . . . . . . . . . . . . . . . . 266

Figure 229. ADF optical assembly . . . . . . . . . . . . . . . . . . . . . . . . 268

Figure 230. PCB assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

C8523-90921 13

Page 14

14 List of figures C8523-90921

Page 15

1 Product information

Chapter contents

Product features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Product specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Product overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Assembly identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

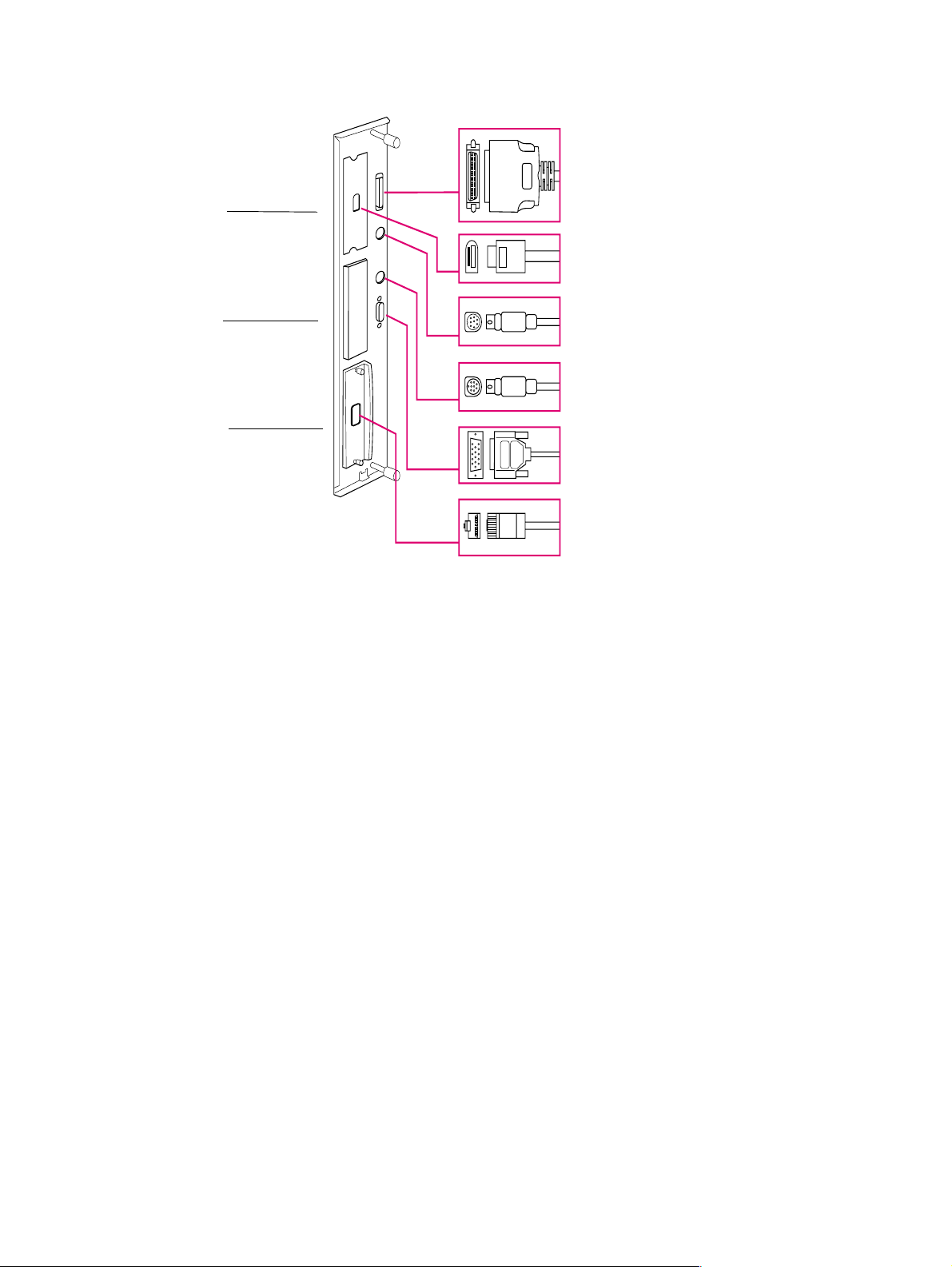

Interface connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Regulatory information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Service approach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Parts and supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Limited warranty for the print cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Service and support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Worldwide service and support offices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

C8523-90921 Chapter contents 15

Page 16

Product features

Table 1. Features of the HP LaserJet 9000mfp

HP LaserJet 9000mfp (C8523A) (Q2458A)

This section lists the major product features of the HP LaserJet 9000mfp.

Speed

Resolution

Consumables

Throughput

Language

and fonts

Enhanced memory

and memory expansion

l 50 pages per minute (ppm), automatic document feeder (ADF) scanning

of and printing on letter-size or ISO A4-size paper

l 8-second standby to first page print

l 2.4 seconds or less for the first scan from the ADF

l 3.7 seconds or less for the first scan from the scanner glass

l 600 dots per inch (dpi) with Resolution Enhancement technology (REt)

l HP FastRes 1200 (1200-dpi-like quality at up to 50 ppm for letter and A4)

l Up to 256 levels of gray

l No-shake, no pull-tab print cartridge

l 3,000-sheet stapler/stacker staple cartridge

l Multifunction finisher staple cartr idge

l 100-page capacity ADF

l 25 percent to 400 percent scalability using the scanner glass

l 25 percent to 200 percent scalability using the ADF

l Transmit Once, Raster Image Processing (RIP) Once technology

l PostScript

l HP Printer Command Language (PCL) 6 driver

l HP PCL 5e driver for compatibility with previous products

l Printer job language (PJL)

l Printer management language

l 80 scalable TrueType

l Memory Enhancement technology (MEt) automatically compresses data

®

(PS) Level 3 emulation with 35 built-in PS language fonts

TM

typefaces

to use RAM more efficiently

l 128 megabytes (MB) of RAM, expandable to 384 MB using industry-

standard 100-pin dual inline memory modules (DIMMs)

Functions

Finishing

l Two-sided copying (duplex printing)

l Image modification

l Color digital sending

l Wide-format printing

l Document finishing

l 3,000-sheet stapler/stacker

l 3,000-sheet stacker

l Multifunction finisher

16 Chapter 1 Product information C8523-90921

Page 17

Product specifications

Identification

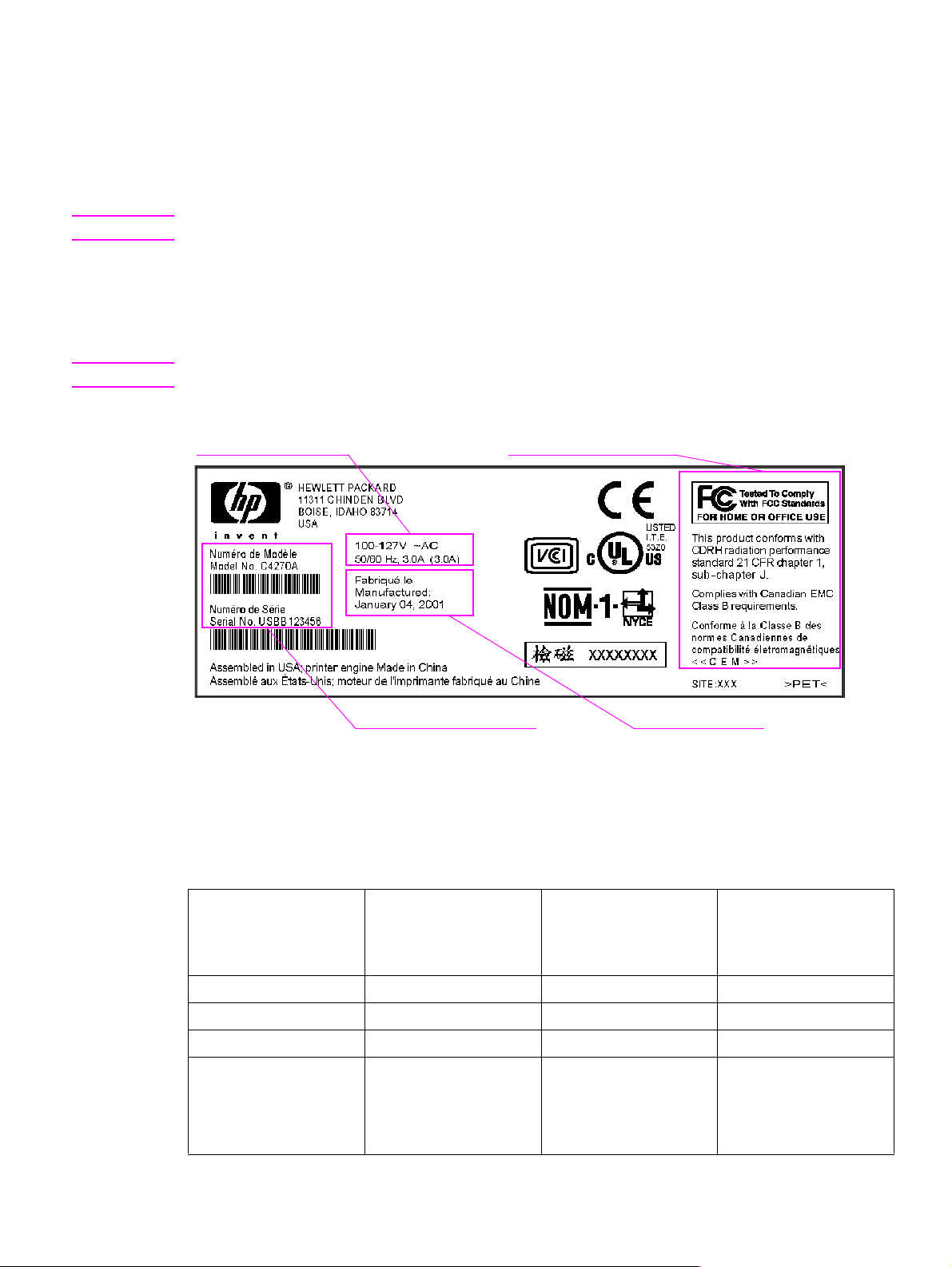

The model number and serial number are listed on an identification label located on the back cover.

The model number is alphanumeric, such as C4270A.

Note There is a user-accessible label inside the right door of the print engine.

The serial number contains information about the country/region of origin and the revision level,

production code, and production number of the MFP. An example of a serial number is

USBB123456.

The identification label also contains electrical information and regulatory information (see figure 1).

Note The electrical information and regulatory information vary by country/region.

Electrical information Regulatory information

Model and serial number

Figure 1. Sample identification label

Specifications

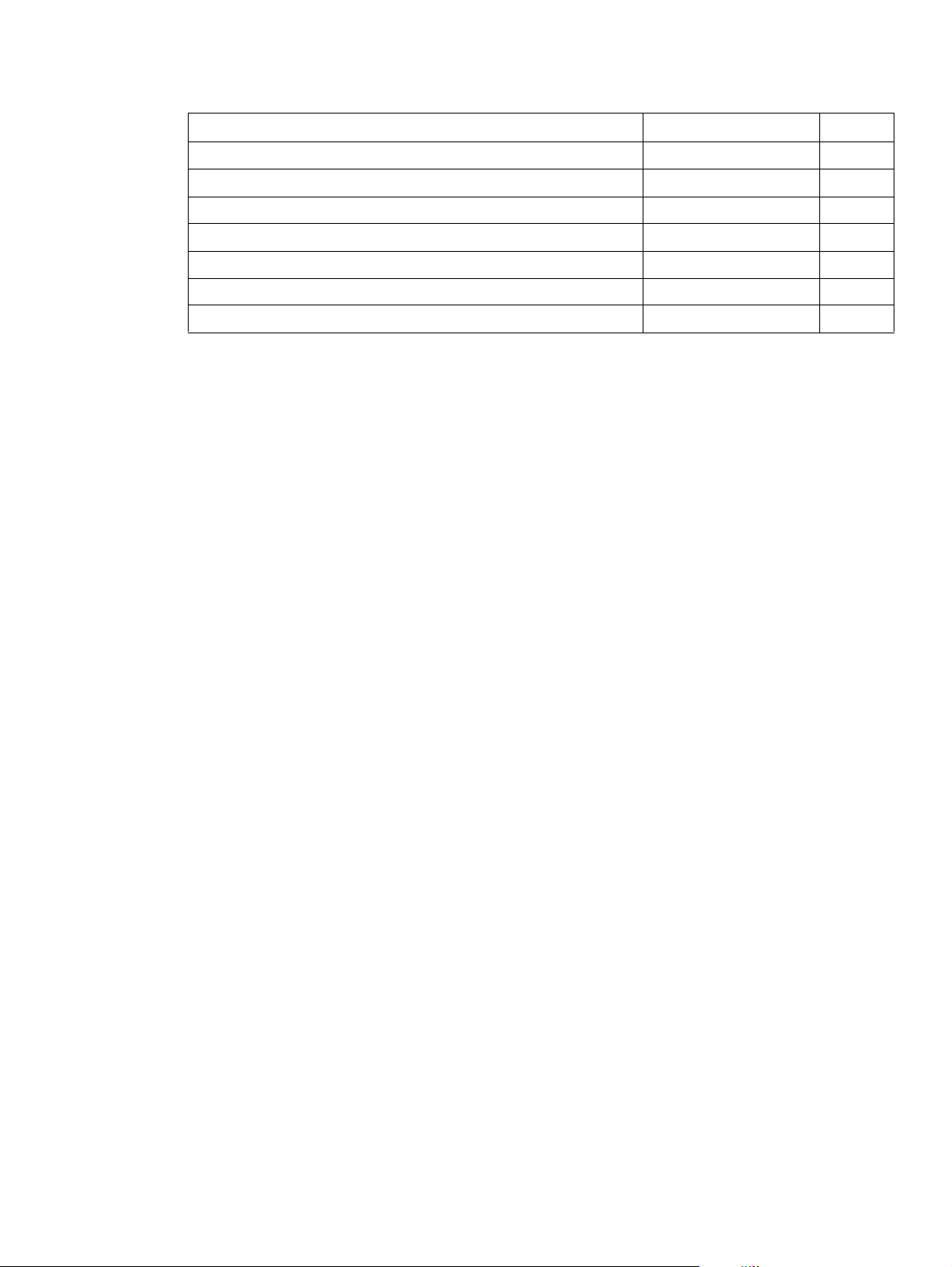

Table 2. Physical specifications

Specification HP LaserJet 9000mfp HP LaserJet 9000mfp

Height 1,219.2 mm (48 in) 1,219.2 mm (48 in) 1,219.2 mm (48 in)

Width 1,276.4 mm (50.3 in) 2,299.6 mm (90.6 in) 2,501.13 mm (98.47 in)

Depth 1,084.6 mm (42.7 in) 1,084.6 mm (42.7 in) 1,084.6 mm (42.7 in)

Weight

(without print cartridge)

76.2 kg (167.64 lb) 3,000-sheet stacker

Manufacture date

with 3,000-sheet

stacker or 3,000-shee t

stapler/stacker

103.7 kg (228.62 lb)

3,000-sheet stapler/

stacker

106.7 kg (235.23 lb)

HP LaserJet 9000mfp

with multifunction

finisher

1,16.9 kg (257.72 lb)

C8523-90921 Product specifications 17

Page 18

Table 3. Electrical specifications

Volts Frequency Amperes (amps) Watts (W) (typical) Thermal units per hour

(Btu/hr)

100-127 Vac

± 10 percent

220-240 Vac

± 10 percent

50/60 Hz

± 2 Hz

50/60 Hz

± 2 Hz

Minimum

recommended current

capacity =

15-amp dedicated

circuit

Minimum

recommended current

capacity =

6.5 amp

printing = 1,075 W

standby = 440 W

PowerSave 1 = 70 W

low power = 230 W

off = .5 W

ADF printing = 1,130 W

printing = 1,070 W

standby = 415 W

PowerSave 1 = 70 W

low power = 230 W

off = 1.3 W

ADF printing = 1,075 W

printing = 3,670 Btu/hr

standby = 1,500 Btu/hr

PowerSave 1 = 240 Btu/hr

low power = 785 BTu/hr

off = 1.7 Btu/hr

ADF printing = 3,860

printing = 3,650 Btu/hr

standby = 1,420 Btu/hr

PowerSave 1 = 240 Btu/hr

low power= 785 Btu/hr

off = 4.5 Btu/hr

ADF printing = 3,670

WARNING! Po wer requirements are based on the region where the MFP is sold. Do not conv ert operating voltages.

This can damage the MFP and void the product warranty.

The electrical and environmental specifications must be maintained to ensur e the proper operation of

the MFP. Consider the following points before installing the MFP:

l Install the MFP in a well-ventilated, dust-free area.

l Install the MFP on a level, flat surface that can support its size and weight. Do not install on

carpet or on other soft surfaces. Make sure all four MFP feet are level.

l Make sure the power supp ly circui try is adequate. (See “Product specifications” on page 17.)

l Install the MFP where temperature and humidity are st able, with no abrupt changes (away from

water sources, humidifiers, air conditioners, refrigerators, or other major appliances). (See

“Product specifications” on page 17.)

l Install away from direct sunlight, areas that experience vibration, open flames, ammonia fumes,

ultrasonic heaters, and devices that emit a magnetic field. If the MFP is placed near a window,

make sure the window has a curtain or blind to block direct sunlight.

l Maintain enough space around the MFP for proper access and ventilation. (See “Space

requirements” on page 28.)

Table 4. Environmental specifications

Operating/printing Storage/standby

Temperature

(MFP and print cartridge)

Relative humidity 20 percent to 80 percent 15 percent to 90 percent

10 degrees to 32.5 degrees C

(50 degrees to 90.5 degr e e s F)

-20 degrees to 40 degrees C

(-4 degrees to 104 degrees F)

Table 5. Noise level specifications

Operator position Bystander (1m) Sound power

Copying at 50 ppm L

Idle L

PowerSave inaudible inaudible inaudible

57 db(A) L

Pam

40 db(A) L

Pam

60 db(A) L

Pam

40 db(A) L

Pam

7.4 bels(A)

WAd

5.7 bels(A)

WAd

Note Testing per International Standards Organization (ISO) 9296.

18 Chapter 1 Product information C8523-90921

Page 19

Product overview

Assembly identification

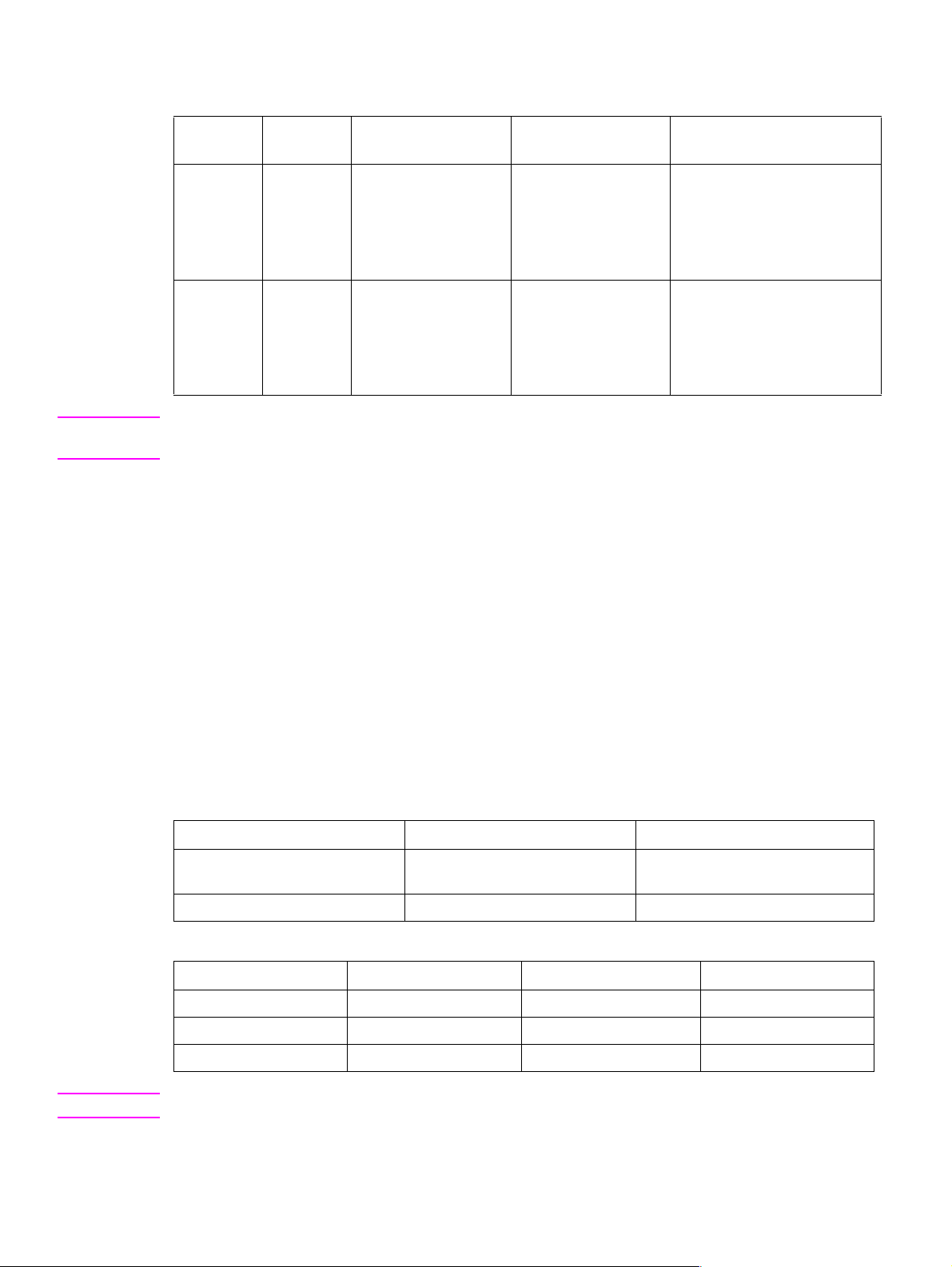

For service issues and section identification, the MFP has been separated into three sections.

l copy/scan engine

l print engine

l finishing device

Copy/scan engine

Finishing device

Figure 2. Assembly identification

Note A finishing device is required with the HP LaserJet 9000mfp.

Print engine

C8523-90921 Product over view 19

Page 20

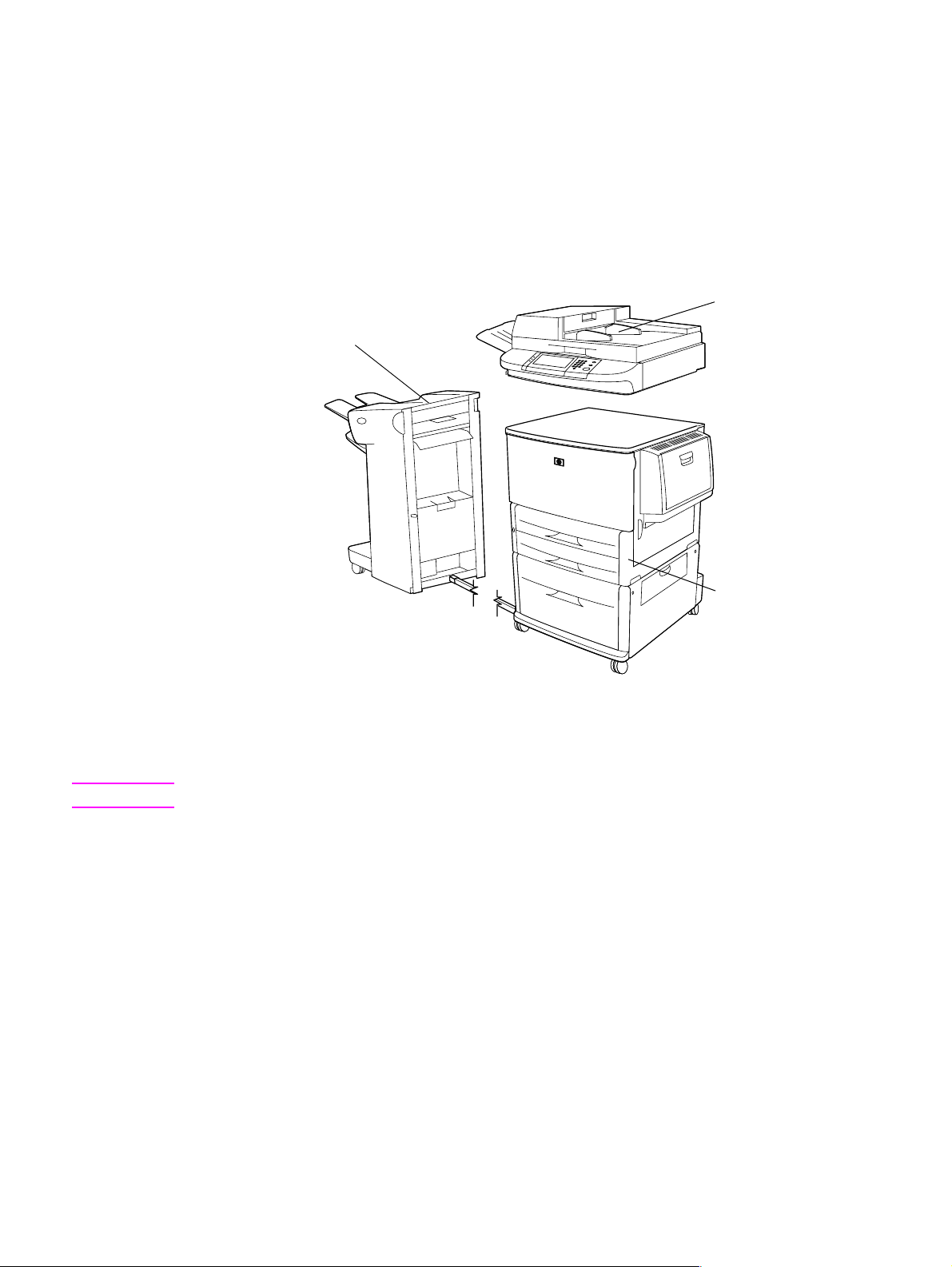

External assembly locations

ADF output bin

Control panel

Bin 1

Bin 2

Front door

Power button

Finishing device

(3000-sheet

stacker shown)

Tray 3

Figure 3. External assembly locations (front view)

ADF feeder

ADF

Tray 1

Tray 2

Right door

Vertical

transfer door

Tray 4

Left door

Power-cord

connector

Paper-handling

power connector

Tray 4 power-cord

connector

Figure 4. External assembly locations (back view)

Interface

connection

panel

20 Chapter 1 Product information C8523-90921

Page 21

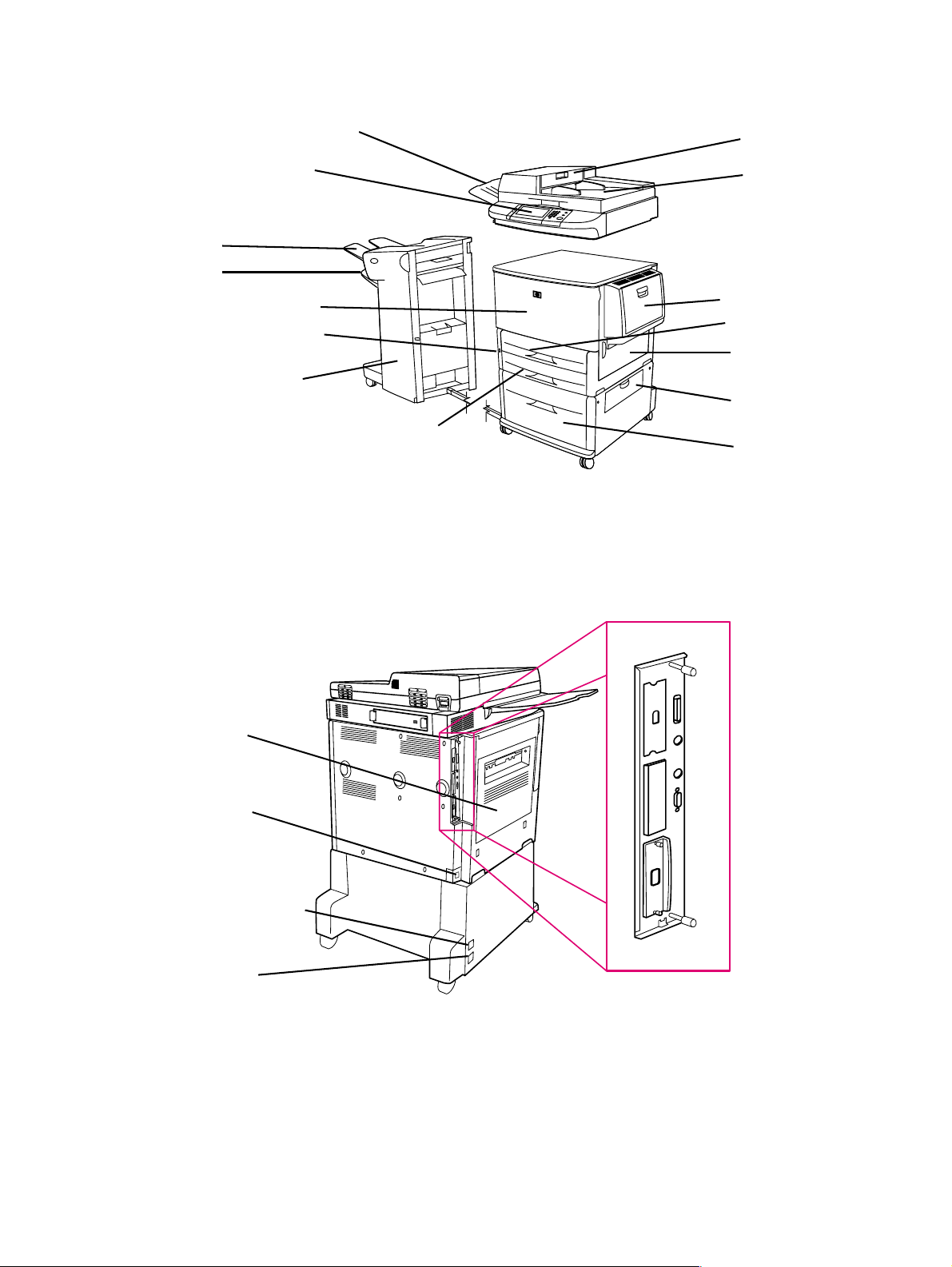

Interface connections

Copy

connect

card

Hard

disk

Jetdirect

card

Figure 5. Interface connections

Parallel connector

High-speed

copy-connect

connector

Foreign interface

connector

HP Fast InfraRed Connect

(optional IR pod)

HP Jet-Link connector

(accessories connector)

HP Jetdirect print

server RJ-45

connector

C8523-90921 Product over view 21

Page 22

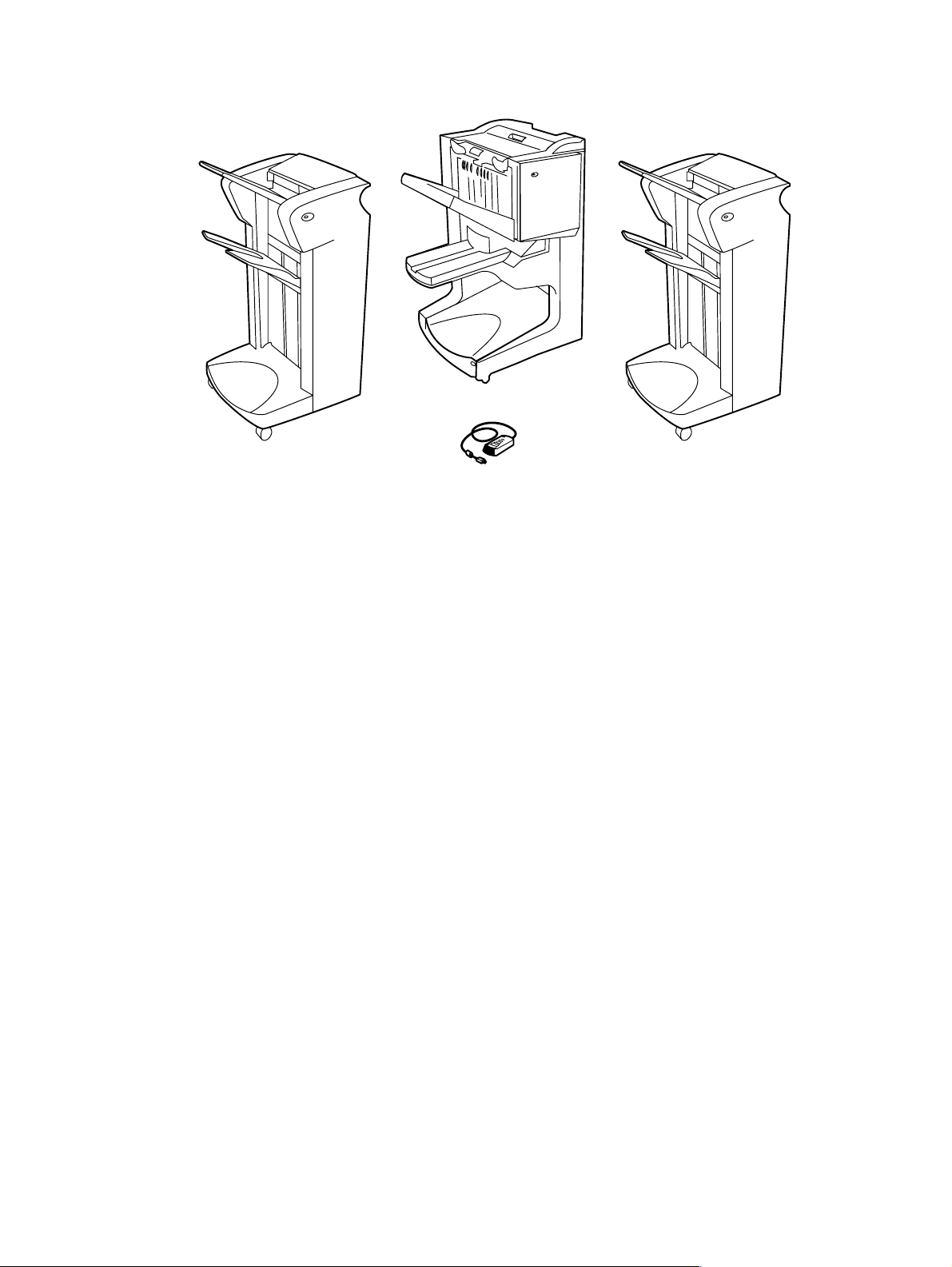

Accessories

Multifunction finisher

3,000-sheet stapler/stacker

Figure 6. Accessories

Optional HP Fast

3,000-sheet stacker

InfraRed Connect pod

22 Chapter 1 Product information C8523-90921

Page 23

Regulatory information

For regulatory information and requirements , FCC regula tio ns, and declaration of confo rmity, please

see the start guide.

For environmental product stewardship program information, please see the use guide.

Service approach

Repair of the MFP normally begins with a three-step process:

1 Isolate the problem to the major system (the host computer, the network and/or server, or the

MFP).

2 Determine whether the problem is located in the print engine, the copy/scan engine, or the

finishing device.

3 Troubleshoot the problem using “Malfunction troubleshooting” in chapter 7.

Once a faulty part is located, repair is usually accomplished by assembly-level replacement of field

replaceable units (FRUs). Some mechanical assemblies can be repaired at the subassembly level.

Hewlett-Packard does not support replacement of components on the printed circuit assemblies.

Parts and supplies

Information about ordering

“Ordering parts” in chapter 8 of this manual contains FRU and replacement part numbers.

Replacement parts can be ordered from the HP Customer Support (HPCS) organization.

“Consumables, supplies, accessories, FRUs, and documentation” in chapter 8 of this manual

contains information about products specifically designed for this MFP. Order accessories from

HPCS.

Note See “W orldwide service and support offices” on page 25 to find information for a local HP office in the

appropriate region.

HPCS phone listings

l HPCS (for U.S.)

(1) (800) 752-0900

l HPCS (for Canada)

(1) (800) 387-3867

l HPCS (for Europe)

(49 7031) 142253

Exchange program

HP might offer remanufactured assemblies for parts. These can be ordered through HPCS.

Warranty

For warr anty information and requirements , see the start guide.

Limited warranty for the print cartridge

For print cartridge warranty information, see the start guide.

C8523-90921 Regulatory information 23

Page 24

Service and support

World Wide Web

Print drivers, updated HP MFP firmware, and product and support information can be obtained from

the following URLs:

l U.S., http://www.hp.com/support/lj9000

l Europe, http://www.hp .com/support/lj9000

l China, ftp://www.hp.com.cn/support/lj9000

l Japan, ftp://www.jpn.hp.com/support/lj9000

l Korea, http://www.hp.co.kr/support/lj9000

l Taiwan, http://www.hp.com.tw/support/lj9000, or the local driver we bsite, http://www.dds.com.tw

HP support assistant CD-ROM

This support tool offers a comprehensive online information system designed to provide technical

and product information about He wlett-Packard products. To subscribe to this quarterly service in the

U.S. or Canada, call (1 ) (800) 457-1762 . In Hong Kong SAR, Indonesia, Malaysia, or Singapore, call

Mentor Media at (65) 740-4477.

HP-authorized resellers and support

To locate HP-authorized resellers and support, call (1) (800) 243-9816 in the U.S. or

(1) (800) 387-3867 in Canada. See “Worldwide service and support offices” on page 25 for areas

outside of North America.

HP service agreements

Call (1) (800) 743-8305 in the U.S. or (1) (800) 268-1221 in Canada.

HP PartnerCare

You can use the following information to contact HP PartnerCare:

l PartnerShip Web. http://www.partner.americas.hp.com

e-mail at websupport@mnl.com

l Connect Online. http://www.connect-online.hp.com

e-mail at PTS, INFOLINE (HP-Germany, exgen1)

l Asia Pacific countries/regions. http://partnercare.asiapac.hp.com/

l Canada Partner. http://www.canada.hp.com

l Latin America. http://www.conecta.latinamerica.hp.com

e-mail at SUPPORT-TEAM,LAR (HP-Miami, exgen1)

24 Chapter 1 Product information C8523-90921

Page 25

Worldwide service and support offices

l For the U.S., call (1) (208) 323-2551 Mon day through F riday from 6 A.M. to 6 P.M., Mountain time.

l For Canada, call (1) (90 5) 206- 4663 o r (1) (800) 38 7-386 7 Mond ay through Friday from 8 A.M. to

8

P.M., Mountain time.

l For customers outside of North America, use the follo wing list and call the appropriate telep hone

number for the country or region.

Europe

l Austria: 43 (0)810 00 6080

l Belgium

Dutch: 32 (0)2 626-8806

French: 32 (0)2 626-8806

l Czech Republic: 42 (0)2 6130 7310

l Denmark: +45 39 29 4099

l International English: +44 (0)207 512 52 02

l Finland: 358 (0)203 47 288

l France: 33 (0)1 43 62 34 34

l Germany: 49 (0)180 52 58 143

l Greece: +30 (0)1 619 64 11

l Hungary: +36 (0)1 382-1111

l Ireland: +353 (0)1 662 5525

l Italy: 39 02 264 10350

Africa and Middle East

l Egypt: +202 7956222

l International English: +44 (0)207 512 52 02

l Israel: +972 (0)9 9524848

l South Africa

Inside RSA: 086 000 1030

Outside RSA: +27-11 258 9301

l Netherlands: 31 (0)20 606 8751

l Norway: 47 22 11 6299

l Poland: +48 22 865 98 00

l Portugal: 351 21 3176333

l Romania: +40 1 315 44 42 (or 01 3154442)

l Russian Federation

Moscow: +7 095 797 3520

St. Petersburg: +7 812 346 7997

l Spain: +34 902 321 123

l Sweden: +46 (0)8 619 2170

l Switzerland: +41 (0)848 80 11 11

l Tu rkey: +90 212 221 69 69

l Ukraine: +7 (380-44) 490-3520

l U.K.: +44 (0)207 512 52 02

l United Arab Emirates, Bahrain, Jordan, Kuwait,

Lebanon, Oman, Palestine, Qatar, Saudi Arabia,

and Yemen: 971 4 883 8454

Asia-Pacific countries/regions

l Australia: (03) 8877 8000

l China: +86 (0)10 6564 5959

l Hong Kong SAR: +85 (2) 2802 4098

l India: +91 11 682 6035

l Indonesia: +62 (21) 350-3408

l Japan: +81 3 3335-8333

l Republic of Korea

Seoul: +82 (2) 3270-0700

Outside Seoul: 080 999-0700

Latin America

l Argentina: 0810-555-5520

l Brazil

Greater Sao Paulo: (11) 3747-7799

Outside Greater São Paulo: 0800-157751

l Chile: 800-22-5547

l Guatemala: 800-999-5305

l Malaysia: +60 (3) 295 2566

l New Zealand: +64 (9) 356 6640

l Philippines: +63 (2) 867 3551

l Singapore: +65 272 5300

l Taiwan: +886 (2) 2717 0055

l Thailand: +66 (2) 661 4000

l Vietnam: +84 (0) 8 823 4530

l Mexico

Mexico City: 52-58-9922

Outside Mexico City: 01-800-472-6684

l Peru: 0-0800-10111

l Puerto Rico: 1-877-2320-589

l Venezuela

Caracas: 207 8488

Outside Caracas: 800 47 777

C8523-90921 Service approach 25

Page 26

26 Chapter 1 Product information C8523-90921

Page 27

2 Product requirements

Chapter contents

Space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Initial setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Unpacking the MFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Removing the MFP from the shipping pallet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Initial hardware setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 3

Installing the finishing device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Testing MFP printing and copying functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

C8523-90921 Chapter contents 27

Page 28

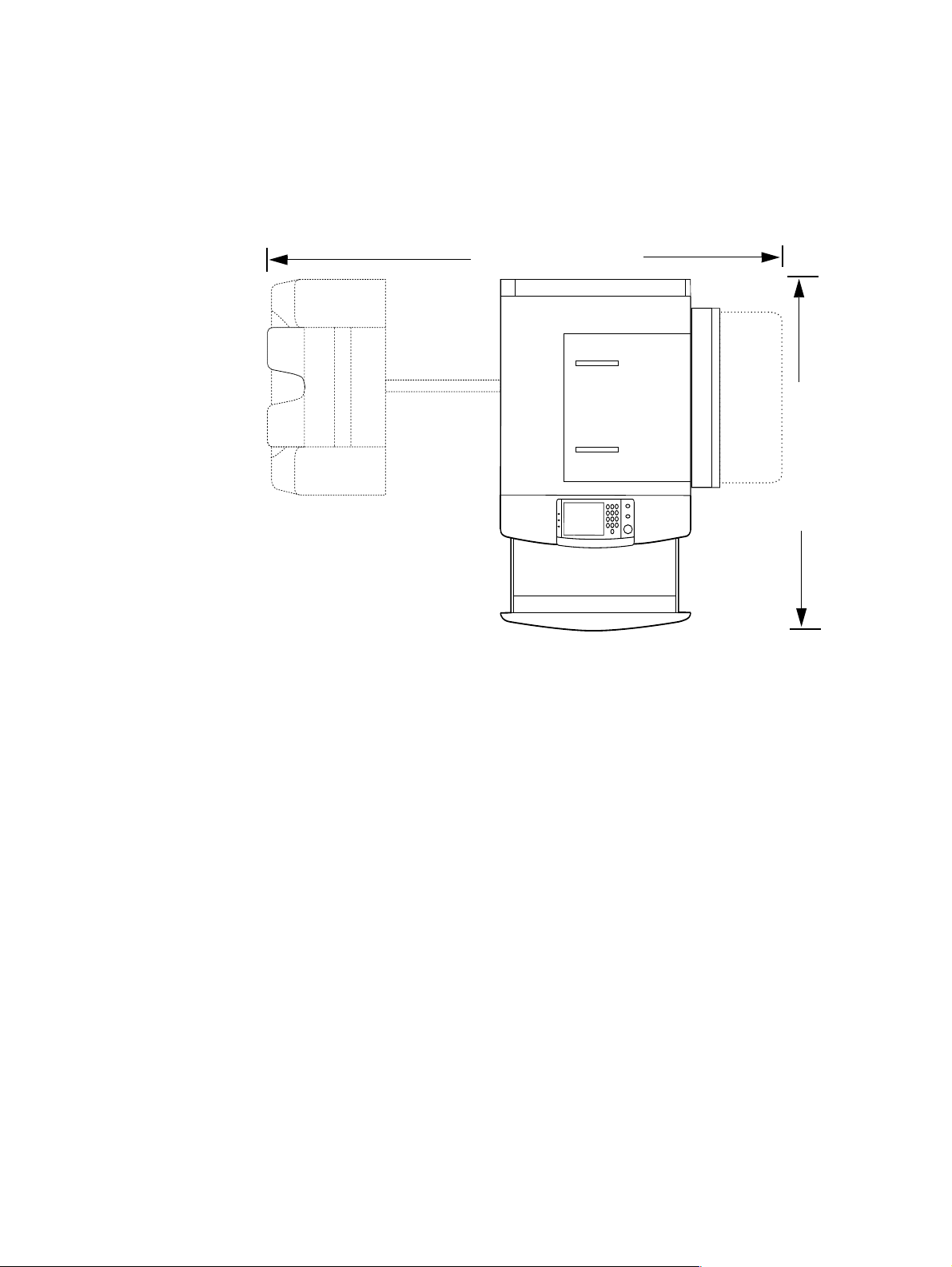

Space requirements

The dimensions of the shipping box that contains the HP LaserJet 9000mfp are 40 inches wide, 36

inches deep, and 57 inches hi gh. The customer m ust locate a do or or receiving area lar ge enough to

accept delivery of the shipping box.

MFP physical dimensions

2501.1 mm (98.5 in)

1084.6 mm (42.7 in)

Figure 7. MFP space requirements with a finishing device (3,000-sheet stapler/st acker shown) (top

view)

28 Chapter 2 Product requirements C8523-90921

Page 29

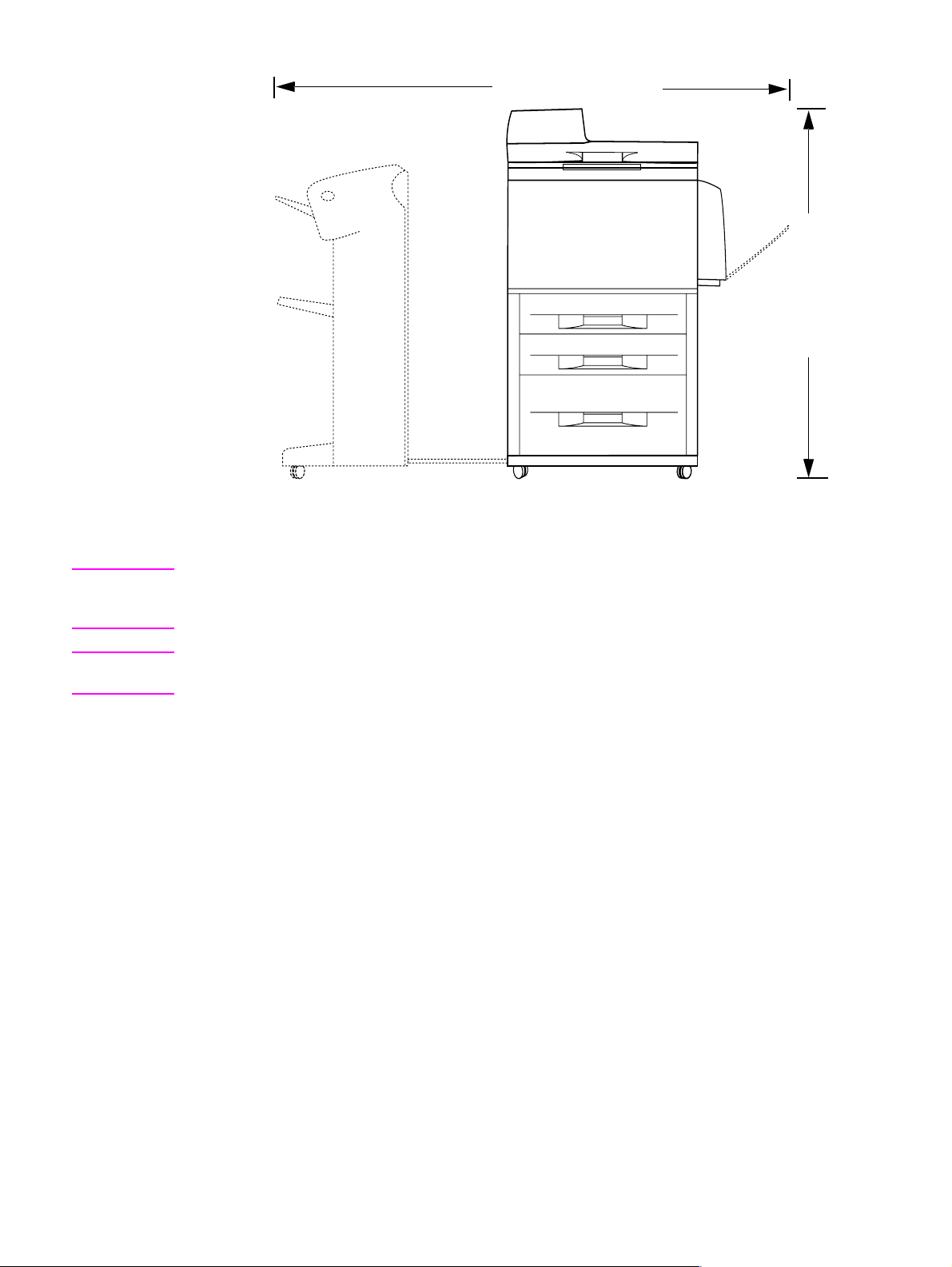

2501.1 mm (98.5 in)

1219.2 mm (48 in)

Figure 8.

MFP space requirements with a finishing device (3,000-sheet stapler/st acker shown) (front

view)

Note Before remo ving th e p lastic wr a pp ing ar ound t he box, make sure t hat ade qua te spa ce is availab le to

unpack the MFP and to roll the produ ct off of the shipping p allet. At least 1 0 f e et of clear ance arou nd

the box is required to remove all the shipping materials.

Note The front of the shipping bo x contains a slot that, when op ened, rev eals the softw are, the manual, and

power cords.

C8523-90921 Space requirements 29

Page 30

Setup

Initial setup

The initial MFP setup includes the following steps:

l Remove the MFP from the box.

l Set up and install the MFP.

l Set up and install the finishing device.

l Verify installation.

l Familiarize yourself with the MFP.

Note The initial setup package does not include any software or network setup. Do not load any printer

software or connect the MFP to the netw ork, ev en if the customer has an e xistin g network connection

in use. If an administrator does not, problems can occur to the network connection.

The shipping box contains the following items:

l HP LaserJet 9000mfp

l One or two power cords

Note The 110-volt MFP has two power cords, and the 220-volt MFP has one y-power cord.

l ADF output bin

l High-speed copy connect cable

l Control panel overlay

l Print cartridge

l Printer software on CD-ROM (includes the user introduce guide)

l Start guide

l Finishing device

Note The finishing device is delivered in a separate box.

Note The MFP is delivered with the duplexer, tray 1, and tray 4 installed.

30 Chapter 2 Product requirements C8523-90921

Page 31

Unpacking the MFP

1 Remove the plastic wrap from the shipping box.

2 Remove the two white, plastic shipping locks, and then remove the top of the box. Pull the locks

straight out to remove them from the box.

3 Remove the six remaining shipping locks that hold the sides in place.

4 Remove the reinforcing ribbon from the top of the box.

5 Carefully remove the sides of the box.

Note Four corner supports in the box can fall out when the sides are removed.

6 Remove and set aside the bag that co ntains the print cartridge (located on the top of t he printer).

Also remove the manual, cables, and software from the front piece of Styrofoam.

7 Remove the ramps (callout 1) by gently lifting them up. The ramps are located near the back

piece of Styrofoam.

2

1

Figure 9. Unpacking the MFP

8 Lift the two Styrofoam pieces away from the MFP.

9 Remove the plastic wrap from the MFP, and set aside the ADF output bin.

2

C8523-90921 Setup 31

Page 32

Removing the MFP from the shipping pallet

1 Break apart the ramps and push them into the slots on the front of the shipping pallet (callout 1).

2

2

1

Figure 10. Removing the MFP from the shipping pallet (1 of 2)

2 Unlock the wheels on tray 4 and point them forward so that they line up with the ramps.

3 Hold the MFP behind the wheels on tray 4 (callout 2) and ease it off of t he wood supports.

WARNING! Do not remove the MFP b y holding ot her parts of the MFP. This can result in damage to the MFP and

injury to the people lifting the MFP.

2

2

2

Figure 11. Removing the MFP from the shipping pallet (2 of 2)

4 Carefully move the MFP off the supports and onto the ramps. Support the front of t he MFP while

rolling it off of the shipping pallet.

32 Chapter 2 Product requirements C8523-90921

Page 33

Initial hardware setup

1 Press the shipping lock (callout 1), located on the left side of the scan engine , to war d the fr ont of

the MFP to unlock it.

Note Show the user where the shipping lock is located. Before the MFP can be moved, the flatbed optical

unit must be “parked” and locked. To lock the carriage, touch MENUS, then CONFIGURE DEVICE, touch

RESETS, touch LOCK CARRIAGE, and then engage the mechanical lock.

2

2

1

Figure 12. Initial hardware setup (1 of 4)

2 Open the left door.

3 Pull the shipping tape straight ba ck to remove the two fuser shipping locks. Make sure the fuser

levers ar e in the “down” position before printing.

4 Remove the remainder of the orange shipping tape inside th e left door.

5 Open trays 2, 3, and 4, and remove the shipping tape and the tray locks (tw o per tray).

6 Make sure that the custom/standard switch is in the “standard” position. Show the user where to

locate this switch and explain its purpose.

7 Open the top of the ADF and pull out the packing material (callout 2).

2

2

2

Figure 13. Initial hardware setup (2 of 4)

C8523-90921 Setup 33

Page 34

8 Install the high-speed copy connect cable (callou t 3). Show the user t he shape of the connectors ,

and how the connectors match up.

CAUTION Make sure that the high-speed co py conn ect cable is install ed correctly. The cable can be be installed

incorrectly if it is forced.

Figure 14. Initial hardware setup (3 of 4)

9 Install the two copy processor board (CPB) protectors (callout 4) on the back of the MFP.

2

2

2

2

3

4

Figure 15. Initial hardware setup (4 of 4)

10 Install the ADF output bin.

11 Open the front door and install the print cartridge.

Note The print cartridge does not have a pull tab.

Note The toner seal automatically rolls up when a new print cartridge is installed in the printer. The motor

used to drive the OPC (imaging drum) is initializ ed in the r everse direction, which rolls t he to ner se al

onto a spindle inside the print cartridge. The noise the printer makes when this occurs is normal.

34 Chapter 2 Product requirements C8523-90921

Page 35

Installing the finishing device

The MFP is delivered with a finishing de vice . The f inishing de vice co mes in its own bo x, and m ust be

set up and installed with the MFP. The following are finishing devices:

l 3,000-sheet stacker

l 3,000-sheet stapler/stacker

l Multifunction finisher

Note Make sure that the printer and finishing device are installed on a level surface so that they function

correctly.

1 Position the printer in its permanent location, allowing room to install the finishing device.

2 Lock the front wheels on the printer.

3 Open the box that contains the finishing de vice and remove the packing material. The box

includes two bins: a face-up bin (callout 1), and a stacker bin or a stapler bin (callout 2).

Note The multifunction finisher is delivered with the bins installed.

1

2

2

2

Figure 16. Installing the finishing device (1 of 2)

4 Place the finishing device in upright position.

5 Remove all of the orange packing materials and tape from the finishing device and the cables.

6 Position the finishing device on the left side of the printer.

7 Lower the connecting rod to a horizontal position.

8 Place the end of the connecting rod into the U-shaped metal slot on tray 4 and align the

connecting rod with the gray alignment label.

9 Slide the blue plastic bracket into the metal slot until it locks into place.

10 Connect the Jet-Link cable to the printer by attaching it to the connector labeled “Finishing

Device”.

Note Make sure that the Jet-Link cable is connected securely to the printer. The finishing device will not

operate unless the Jet-Link cable is connected.

11 Install the power cord(s).

12 Connect the power cord on the finishing device to the upper connection on tray 4.

13 Connect the printer power cord to the printer.

C8523-90921 Setup 35

Page 36

14 Connect the tray 4 power cord to tray 4.

15 Slide the finishing device toward the MFP and lock it in place.

Note Adjust the blue lev elers on the finishing device to mak e sure no gap exists betwe en the finishing device

and the MFP.

16 To attach the stacker bin, align the slots on the stacker bin with the metal bar on the finishing

device. Push in the stacker bin firmly.

Note Locate the paper stop clips and mak e sure the y cradle t he connecting rod. Th e graphic be low (callout

3) indicates the incorrect installation of the paper stop clips.

2

2

Figure 17. Installing the finishing device (2 of 2)

17 Attach the face-up bin.

18 Press the power button to turn on the MFP. The READY message appears on the control panel

when the MFP has warmed up.

19 Make sure the LEDs on the front of the finishing device, tray 4, and the MFP are green. This

indicates that the finishing device and the MFP are functional.

3

Testing MFP printing and copying functions

1 Adjust the paper guides in the trays for letter- or A4-size paper. Load paper in each tray.

2 Print a configuration page from the MFP control panel.

3 Make a copy of the configuration page by placing it on the glass.

4 Make a copy of the configuration page using the ADF.

36 Chapter 2 Product requirements C8523-90921

Page 37

3 Product configuration

Chapter contents

Control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Control panel layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Settings and defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Setting the display language. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Setting tray registration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Print driver information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Factory default settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 3

Control panel menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Using a menu map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Retrieve job menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Information menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Paper handling menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Configure device menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Remote firmware upgrade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Downloading the new firmware to the MFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Using HP Web JetAdmin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

C8523-90921 Chapter contents 37

Page 38

Control panel

Control panel layout

The control panel includes a touch-screen graphical display, three job-control buttons, a numeric

keypad, and three light-emitting diode (LED) indicator lights.

Touch-screen graphical display

Ready light

Data light

Attention

light

Figure 18. Control panel layout

Numeric keypad

Reset

Stop

Start

38 Chapter 3 Product configuration C8523-90921

Page 39

Control panel features

Table 6. Control panel features, and key functions

Feature or key Function

T ouch-screen graphical

display

Ready light

Data light

Attention light

RESET

STOP

START

Numeric keypad

l Provides access to settings, help screens, copy functions, and shows device

status.

l Off—the product is offline or has an error.

l On—the product is ready.

l Blinking—the product is going offline.

l Off—the product has no data to print.

l On—the product has data to print but is offline.

l Blinking—the product is processing the data.

l Off—the product has no error.

l On—the product has a critical error; turn power off and then on.

l Blinking—action is required; see the graphical display.

Resets the job settings to factory or user-defined default values.

l

Cancels the active job.

l

Begins a copy job, starts digital sending, or continues a job that has been

l

interrupted.