Page 1

OPERATING AND SERVICE MANUAL

VOLUME 1

HP 8673C

HP 86730

SYNTHESIZED SIGNAL GENERATORS

(Including Options 001,002,003,

004,005,006,908 and 913)

SERIAL NUMBERS

This manual applies directly to instruments with

serial numbers prefixed 2332A.

For additional important information about serial

numbers, see INSTRUMENTS COVERED BY

MANUAL in Section I.

@ Copyright HEWLE’IT-PACKARD COMPANY lgS4

,601 PAGE MILL ROAD, PALO ALTO, CALIFORNIA, U.S.A.

VOLUME 1 PART NUMBER 08673-w1021

Mlcrollche lor cornplato Operating and Service Manual Part No. 08673-80025

PrInted: MARCH lgS4

Page 2

COPYRIGHT AND DISCLAIMER NOTICE

Copyright - Agilent Technologies, Inc. Reproduced with the permission of Agilent

Technologies Inc. Agilent Technologies, Inc. makes no warranty of any kind with regard

to this material including, but not limited to, the implied warranties of merchantability

and fitness for a particular purpose. Agilent Technologies, Inc. is not liable for errors

contained herein or for incidental or consequential damages in connection with the

furnishing, performance, or use of this material or data.

Page 3

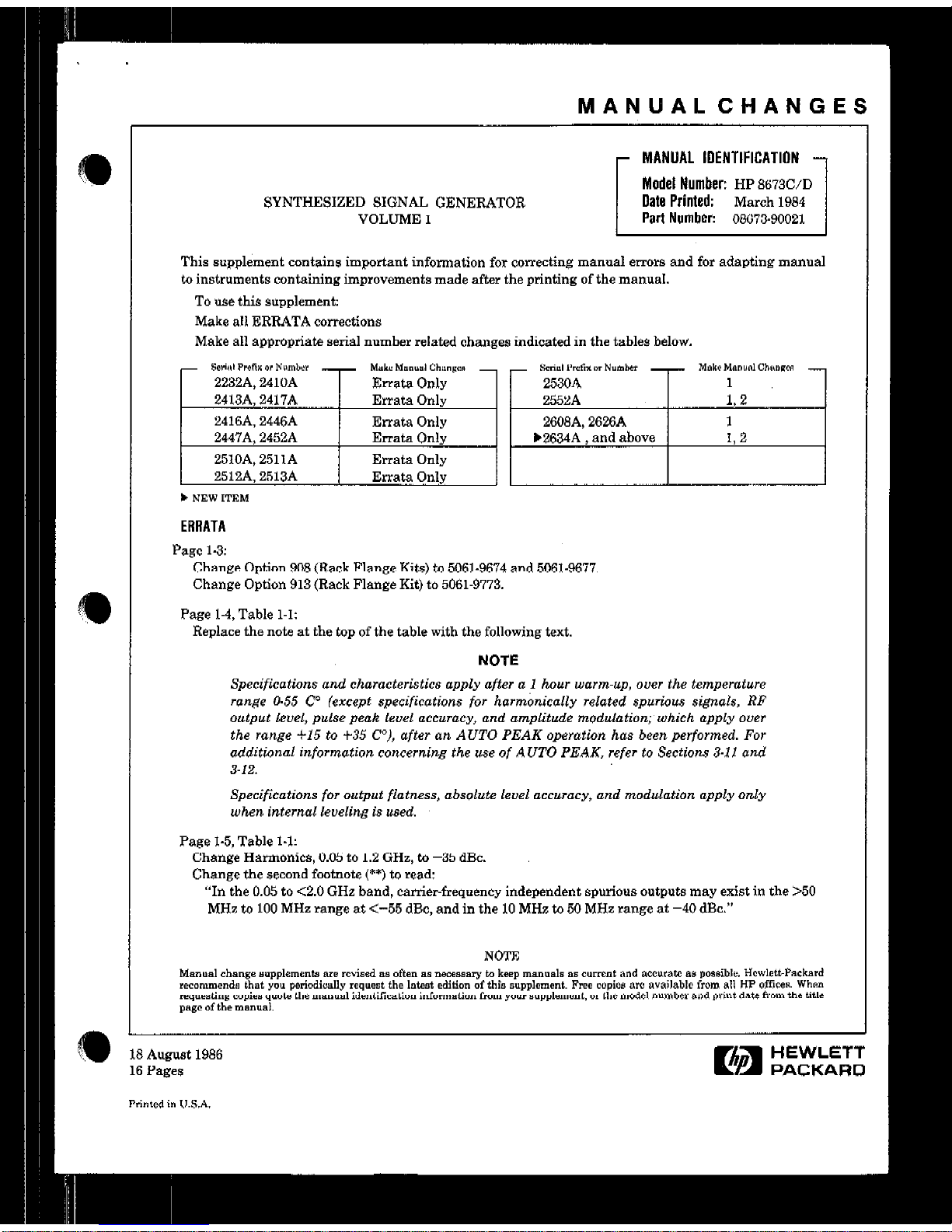

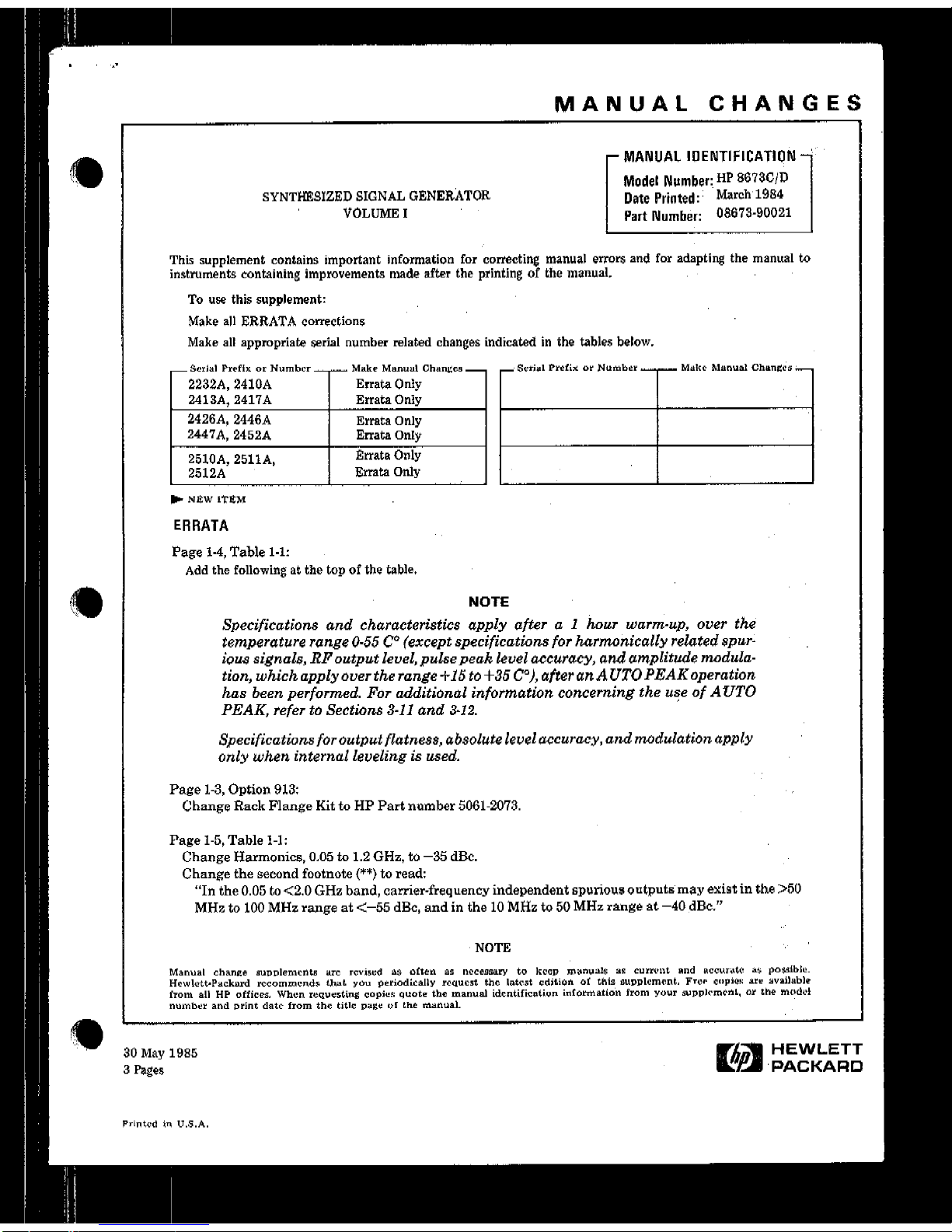

MANUALCHANGES

SYNTHESIZED SIGNAL GENERATOR

VOLUME 1

MANUAL IDENTIFICATION

Model Number:

HP 867X/D

Date Printed:

March 1984

Part Number:

08673-90021

1

This supplement contains important information for correcting manual error8 and for adapting manual

to

instruments

containing improvements made after the printing of the manual.

To use this supplement:

Make all ERRATA corrections

Make all appropriate serial number related changes indicated in the tables below.

- Somd ProfiX “” Nwnk - Make Munu.l Chmcl” - - Srnul ,‘.A* 0. Nvmllcr - Muke Mununl Chll”llCR 2232A, 2410A

Errata Only 2530A

1

2413A, 2417A Errata Only 2552A

L2

2416A. 2446A

Erratn Only

2603A, 2626A 1

2447A, 2452A Errata Only

)2634A , and above 1,2

2510A, 2511A Errata Only

2512A. 2513A

Errata Only

b NEW ITEM

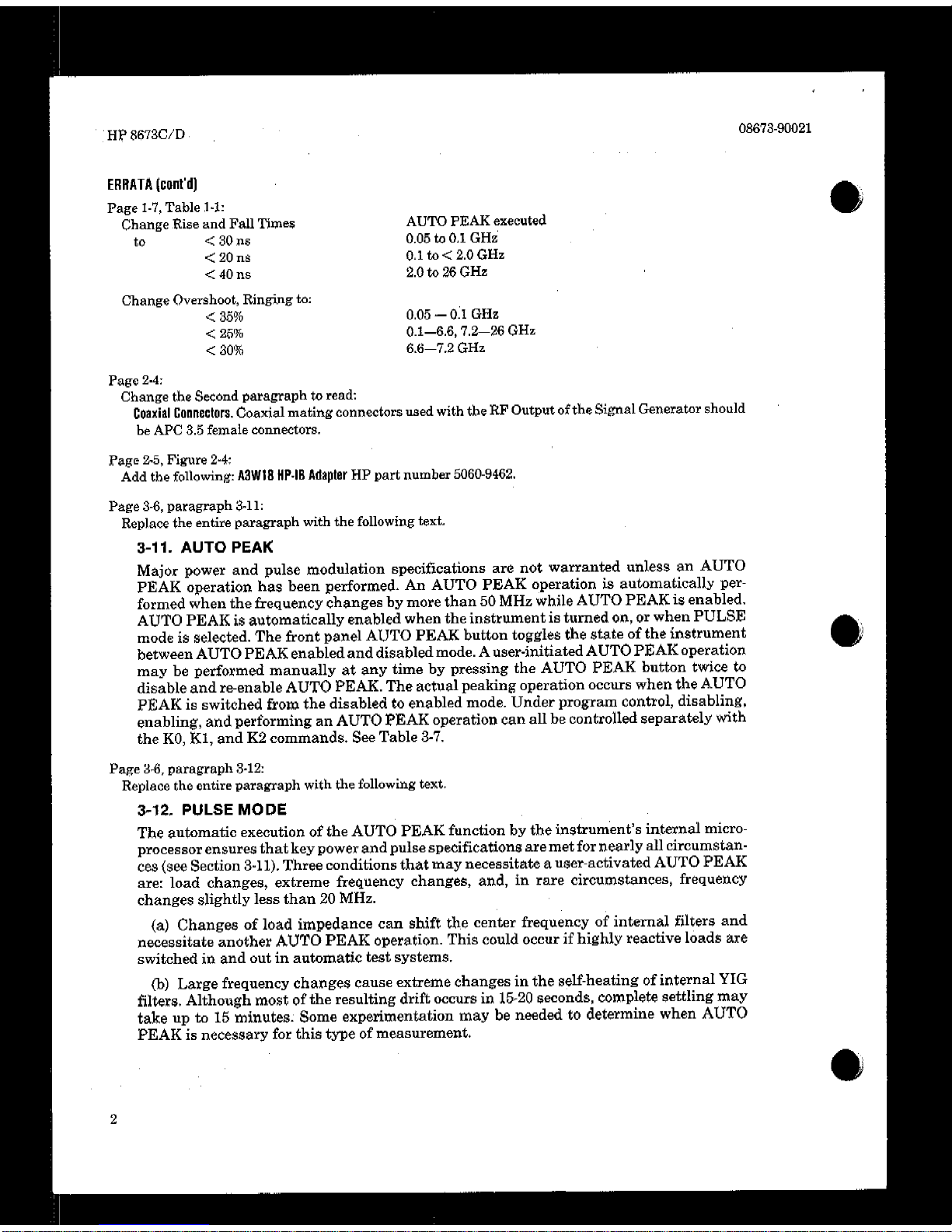

ERRATA

Pago 1-3:

Change Option 908 (Hack Flangs Kits) to

5061-9674 and 5061-9677.

Change Option 913 (Rack Flange Kit) to 5061-9773.

Page 1-4, Table 1-l:

Replace the note at the top of the table with the following text.

NOTE

Specifications and characteristics apply after a 1 hour warm-up, over the temperature

range 0.55 ‘2 (except specifications for harmonically related spurious signals, RP

output lcuel, puke peak level accuracy, and amplitude modulatimqwhich apply ouer

the range 415 to f35 CO)), after an AUTO PEAK operation has been performed. For

additional information concerning the use of AUTO PEAK, refer to Sections 3.11 and

3-12.

Specifications for output flatness, absolute level accuracy, and modulation apply only

when internal leveling is used.

Page 1-5, Table 1-l:

Change Harmonics, 0.05 to 1.2 GHz, to -35 dBc.

Change the second footnote (**) to read:

“In the 0.05 to <2.0 GHz band, carrier-frequency independent spurious outputs may exist in the >50

MHz to 100 MHz range at <-55 dBc, and in the 10 MHz to 50 MHz range

at

-40 dBc.”

; August

Pages

MCd in I,.

1986

Ea

HEWLETT

PACKARD

Page 4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

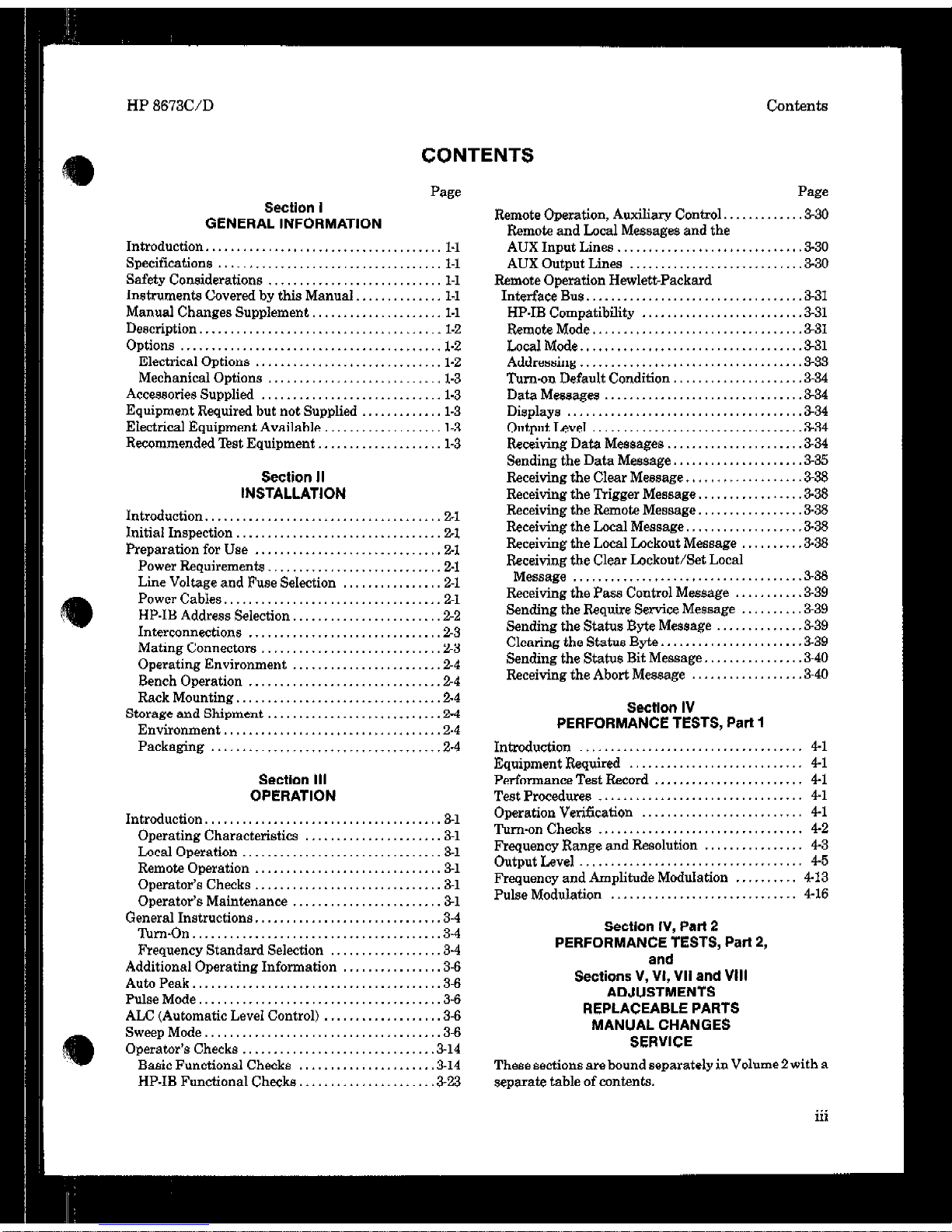

HP 8673C/D COntents

CONTENTS

Sectlon

I

GENERAL INFORMATION

Page

Introduction ...................................... 1-l

Specifications .................................... 1-l

Safety Considerations ............................ 1-1

Instrumenta Covered by this Manual .............. 1-I

Manual Changes Supplement ..................... 1-I

Deecxiption.......................................1.2

Options .......................................... 1.2

Electrical Options ..............................

1-2

Mechanical Options ............................ 1-3

Accessories Supplied ............................. l-3

Equipment Required but not Supplied ............. 1-3

Electrical Equipment Available ................... 1-3

Recommended ‘I&t Equipment .................... l-3

Section II

INSTALLATION

Introduction ..................................... .2-l

Initial Inspection ................................ .2-l

Preparation for Use ............................. ,2-l

Power Requirements. .......................... .2-l

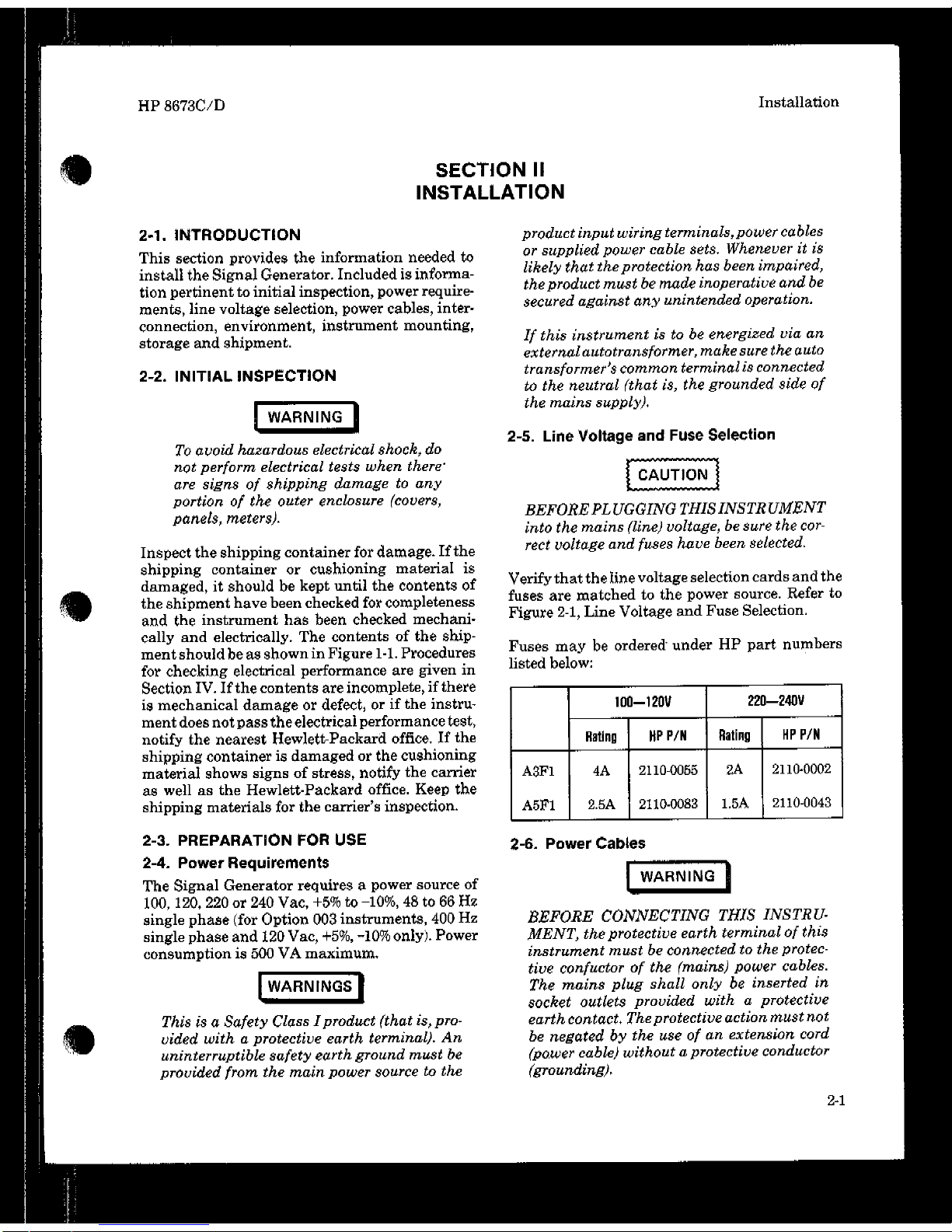

Line Voltage and Fuse Selectmn ................ 2-I

PowerCables................................... -I

HP.IB Address Selection ........................ %2

Interconnections ............................... %3

Mating Connectors ............................. %3

operating Environment ........................ %4

Bench Operation ............................... %4

Rack Mounting ................................ .2-4

Storage and Shipment ........................... .2-4

Environment .................................. .2.4

Packaging ................................... ..2 -4

Section Ill

OPERATION

Introduction......................................a- 1

Operating Characteristics ..................... .3-l

Local Operation ................................ Sl

Remote Operation ............................. .51

Operator’sChecks..............................& 1

Operator’s Maintenance ....................... .51

General Instructions ............................. .3-4

nm-On

....................................... .3-4

Frequency Standard Selection ................. .3-4

Additional Operating Information ............... .3-6

AutoPeak........................................3 -6

Pulse Mode. ..................................... .3-6

ALC (Automatic Level Control) .................. .3-6

SweepMode...................................... -6

Operator’s Checks .............................. ,514

Basic Functional Checks ..................... ,914

HP-IB Functional Checks ..................... ,523

Page

Remote Operation, Auxiliary Control ............. $30

Remote and Local

Messages

and the

AUX Input Lines ............................. ,3-30

AUX Output Lines ........................... .3-30

R&mote Operation HewlettiPackard

Interface Bus .................................. .3-31

HP-IB Compatibility ......................... .3-31

Remote Mode ................................. ,331

Local Mode,, ................................. ,331

Addressing .................................... $33

Turn-on Default Condition .................... .3-34

Data Messages ............................... ,834

D’ 1 wp ays ...................................... 834

Output Level ................................. .3-34

Receiving Data Messages ..................... ,534

Sending the Data

Meeeage .................... .3-35

Receiving

the Clear Message .................. .3-38

Receiving the Trigger Message ................ .3-38

Receiving the Remote Message. ............... .3-38

Receiving the Local Message. ................. .3-38

Receiving the Local Lockout Message ......... .3-38

Receiting the Clear Lockout/Set Local

Message .................................... .3-38

Receiving the Pass Control Message .......... .3-39

Sending the Require Service Message ......... .3-39

Sending the Statue Byte Mesaage ............. .3-39

Clearing the Statue

Byte ...................... .3-39

Sending the Status Bit Message ............... .3-40

Receiving the Abort Message ................. .3-40

Sectlon IV

PERFORMANCE TESTS, Part 1

Introduction .................................... 4-1

Equipment Required ............................ 4-1

Performance Test Record ........................ 4-1

Test Procedures ................................. 4-1

Operation Verification .......................... 4-1

Turn-on Checks ................................. 4-2

Frequency Range and Resolution ................ 4-3

output Level .................................... 4-5

Frequency and Amplitude Modulation .......... 4.13

Pulse Modulation .............................. 4-16

Section IV, Pm-l 2

PERFORMANCE TESTS, Part 2,

and

Sections V, VI, VII and VIII

ADJUSTMENTS

REPLACEABLE PARTS

MANUAL CHANGES

SERVICE

These sections are bound separately in Volume 2 with a

separate table of contents.

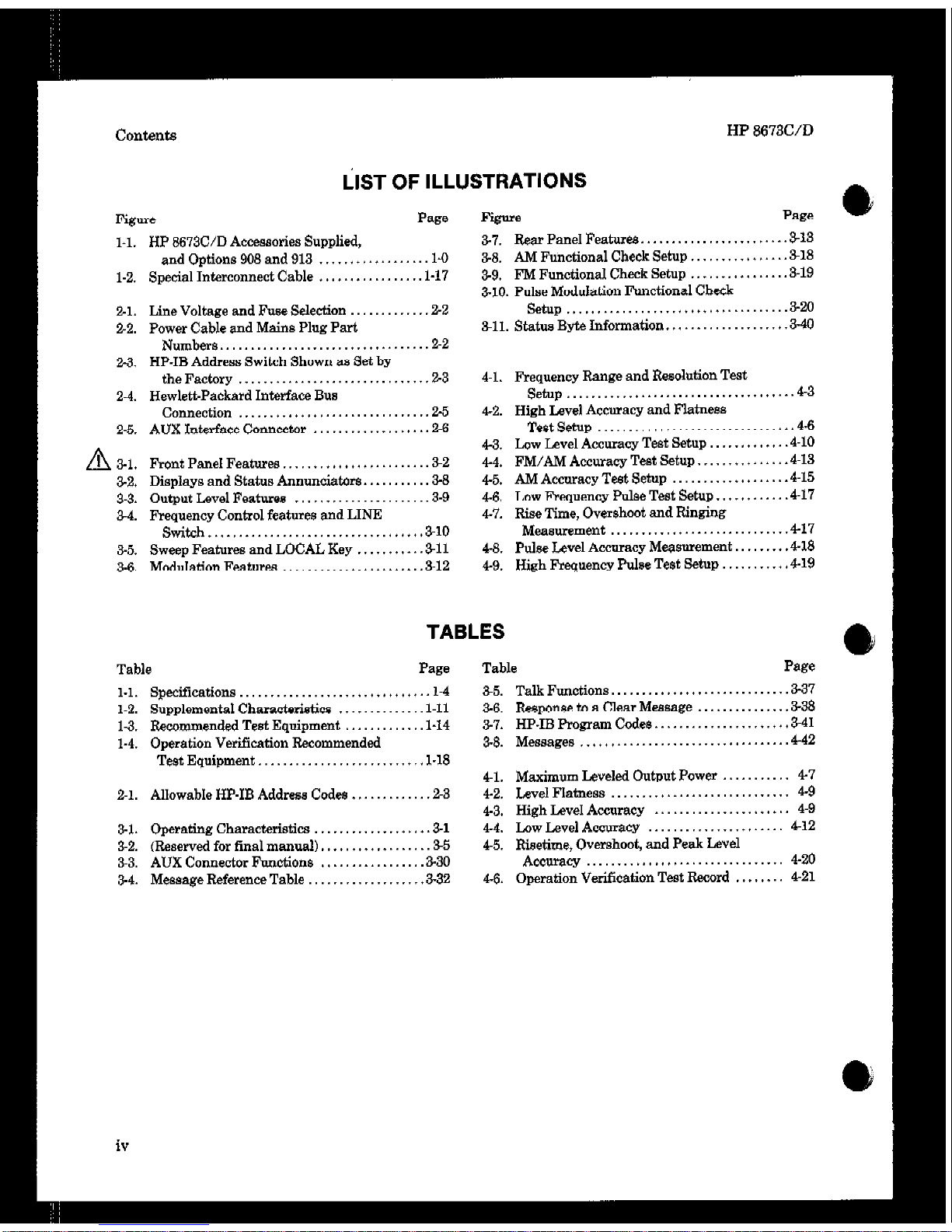

Page 22

Contents

Figure

ilST OF ILLUSTRATIONS

Page

Figure

HP 8673WD

Page

l-l.

1-2.

2-l.

22.

2-3.

2-4.

2-6.

n

1 51.

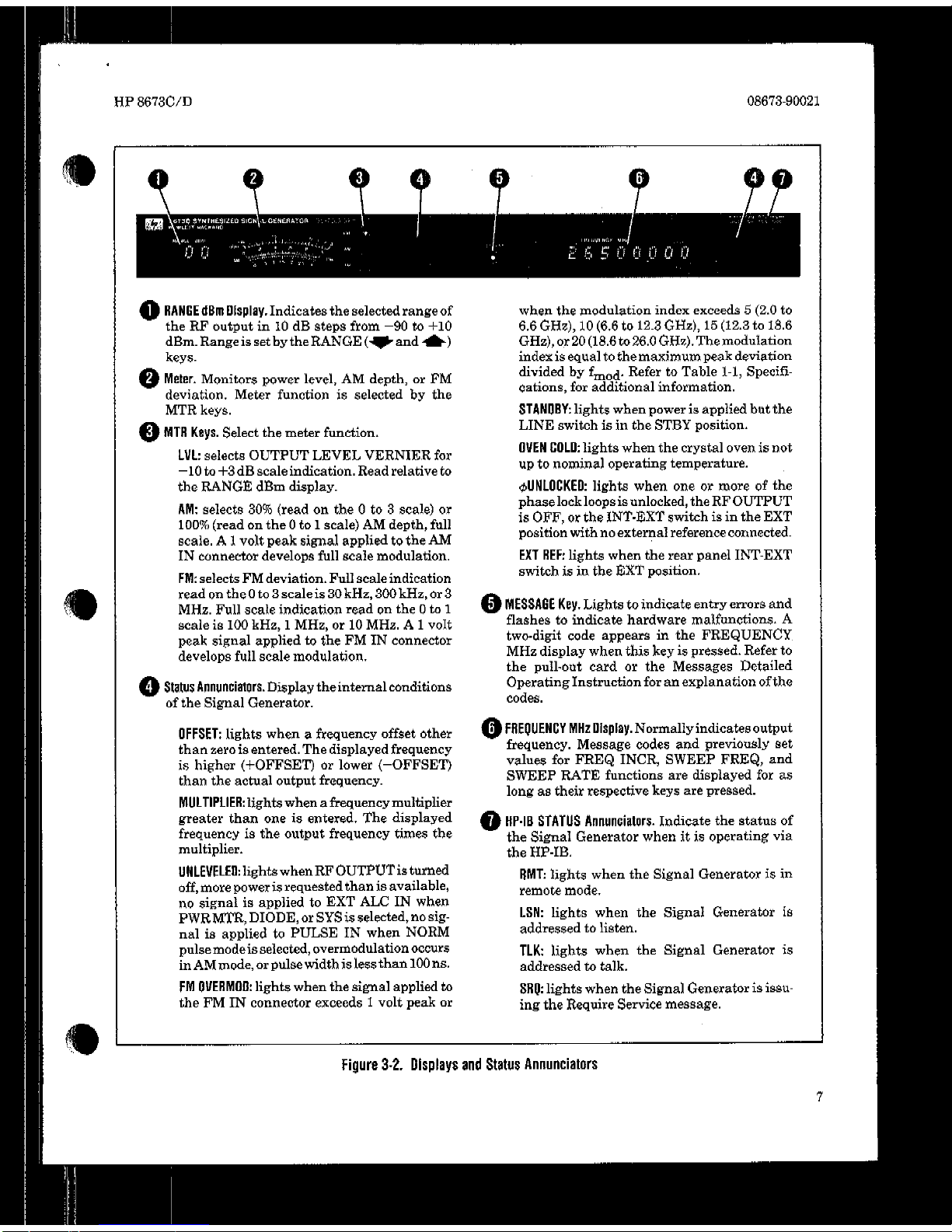

3-2.

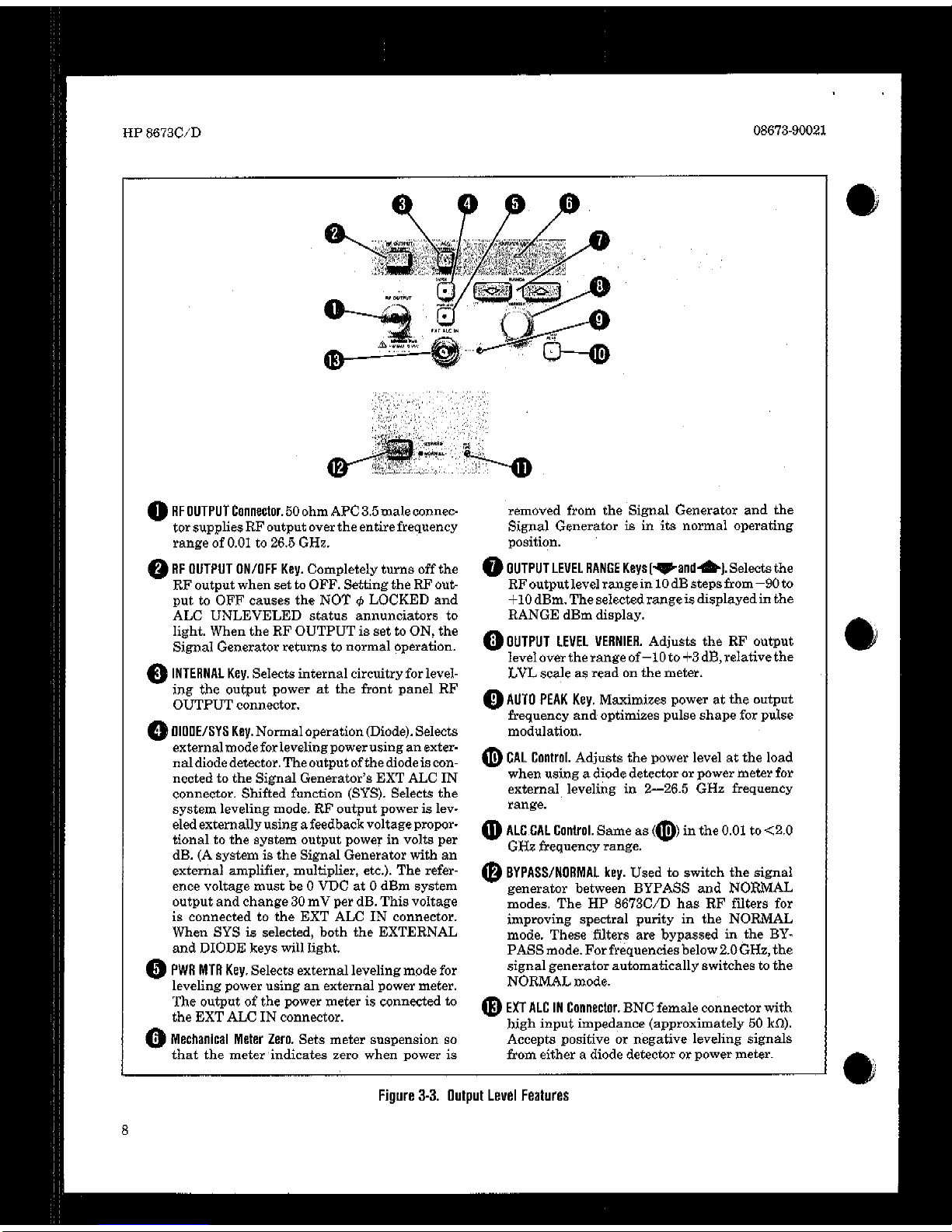

3-3.

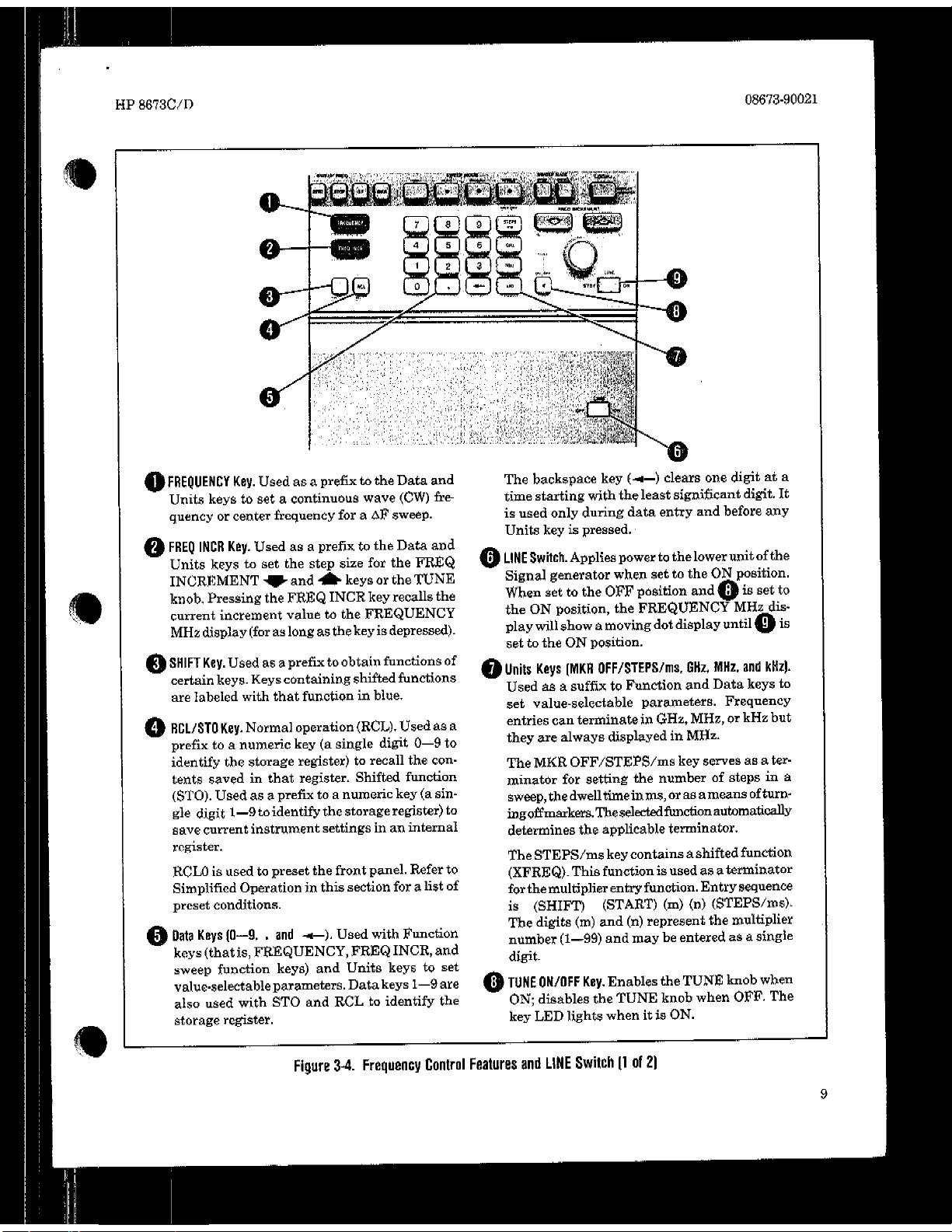

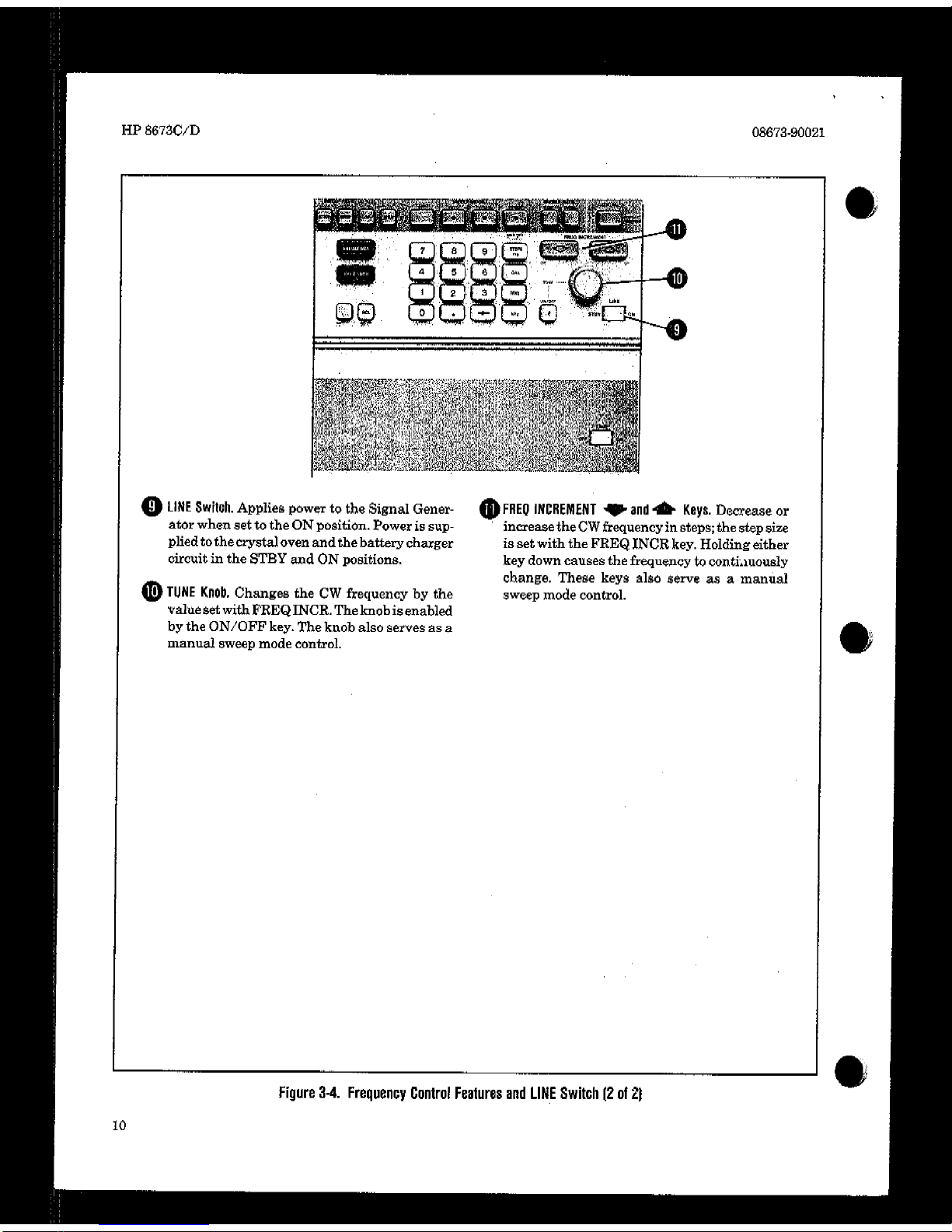

84.

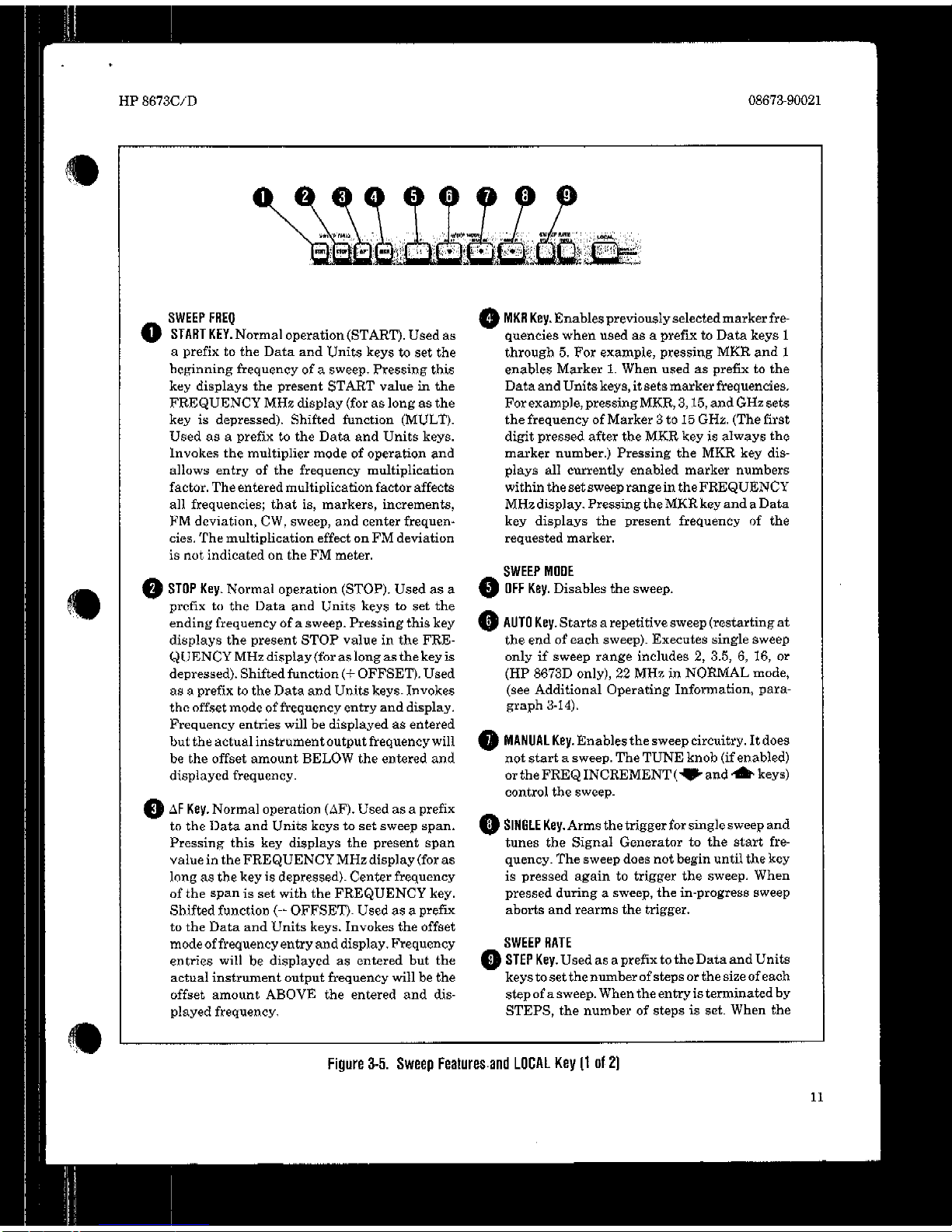

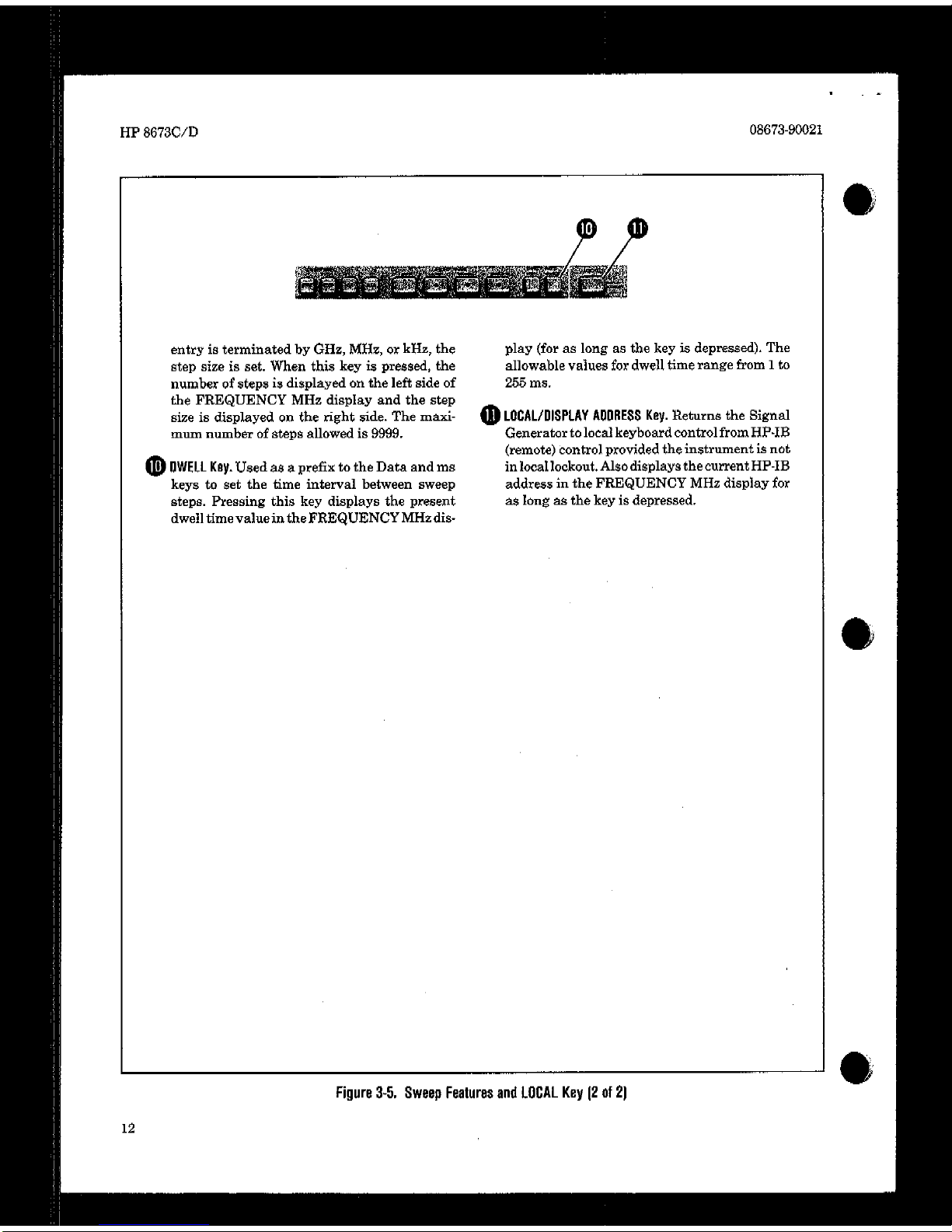

3-5.

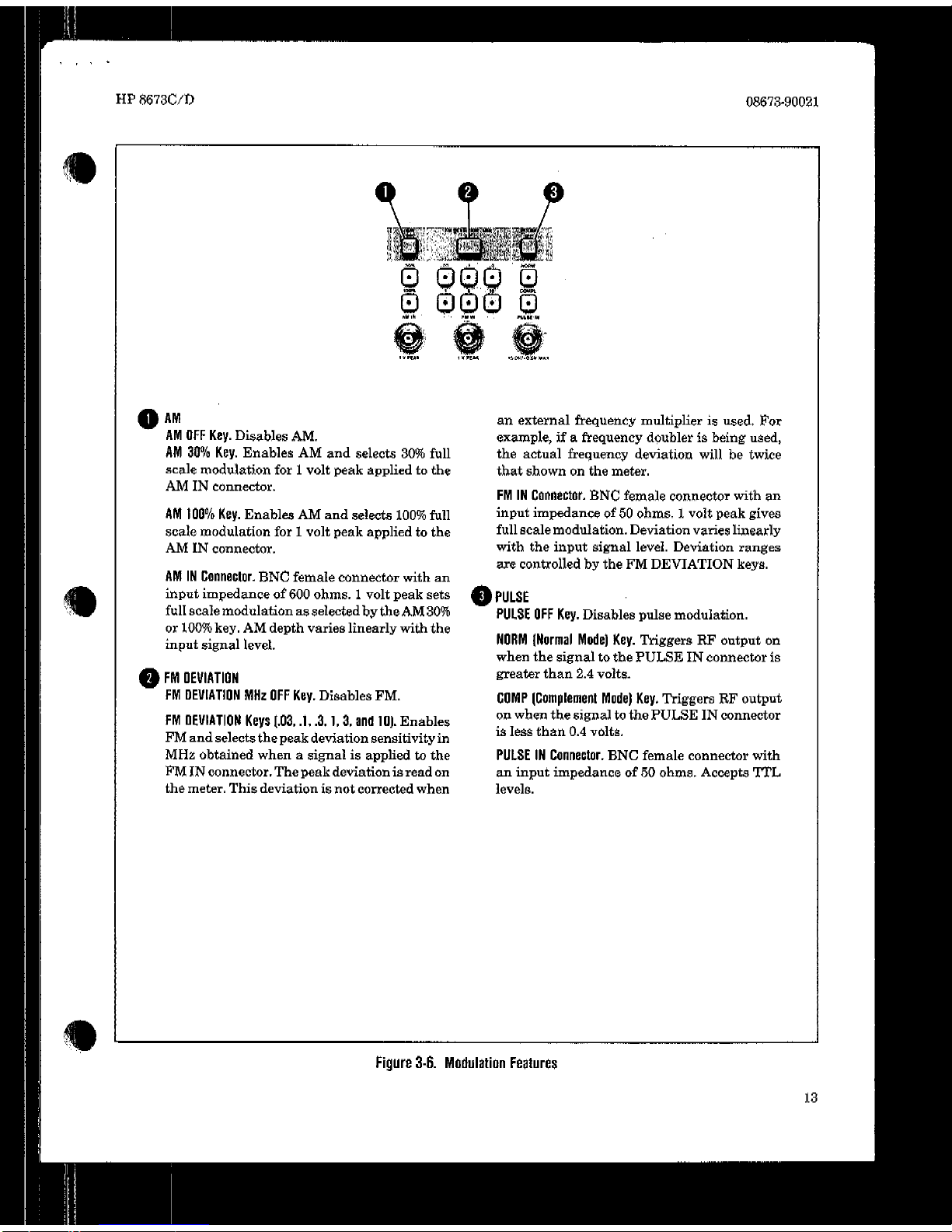

3-6.

HP 8673C/D Accessories Supplied,

and Options 908 and 913

................. .1-O

Special Interconned Cable ................

. l-17

Line Voltage and Fuee Selection ............

.%2

Power Cable and Mains Plug Part

Numbers .................................

.2-2

HP-IB Address Switch Shown a8 Set by

theFactory.. ...........................

..2 3

Hewlett-Packard Interface Bus

Connection.. .............................

25

AWX Interface Connector ..................

.%6

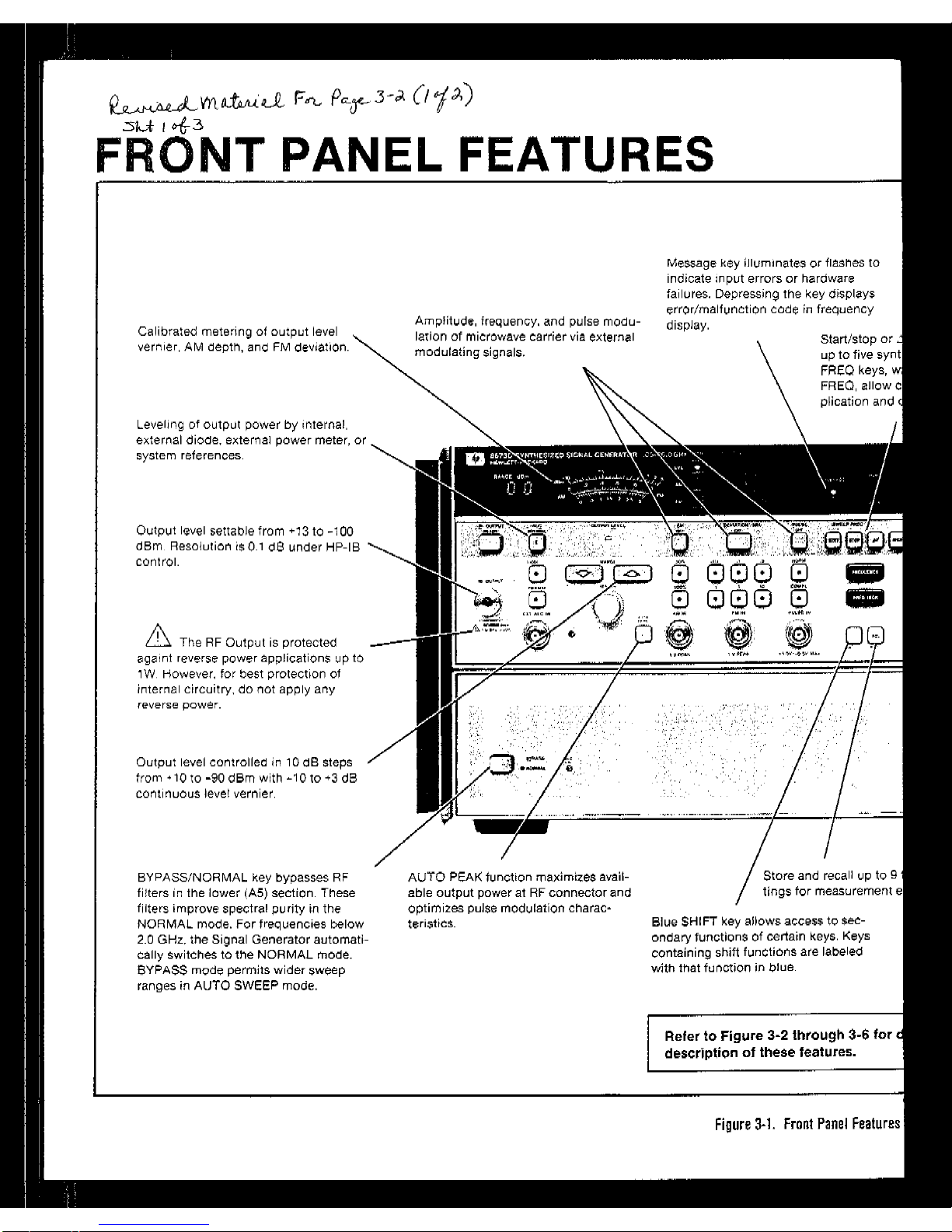

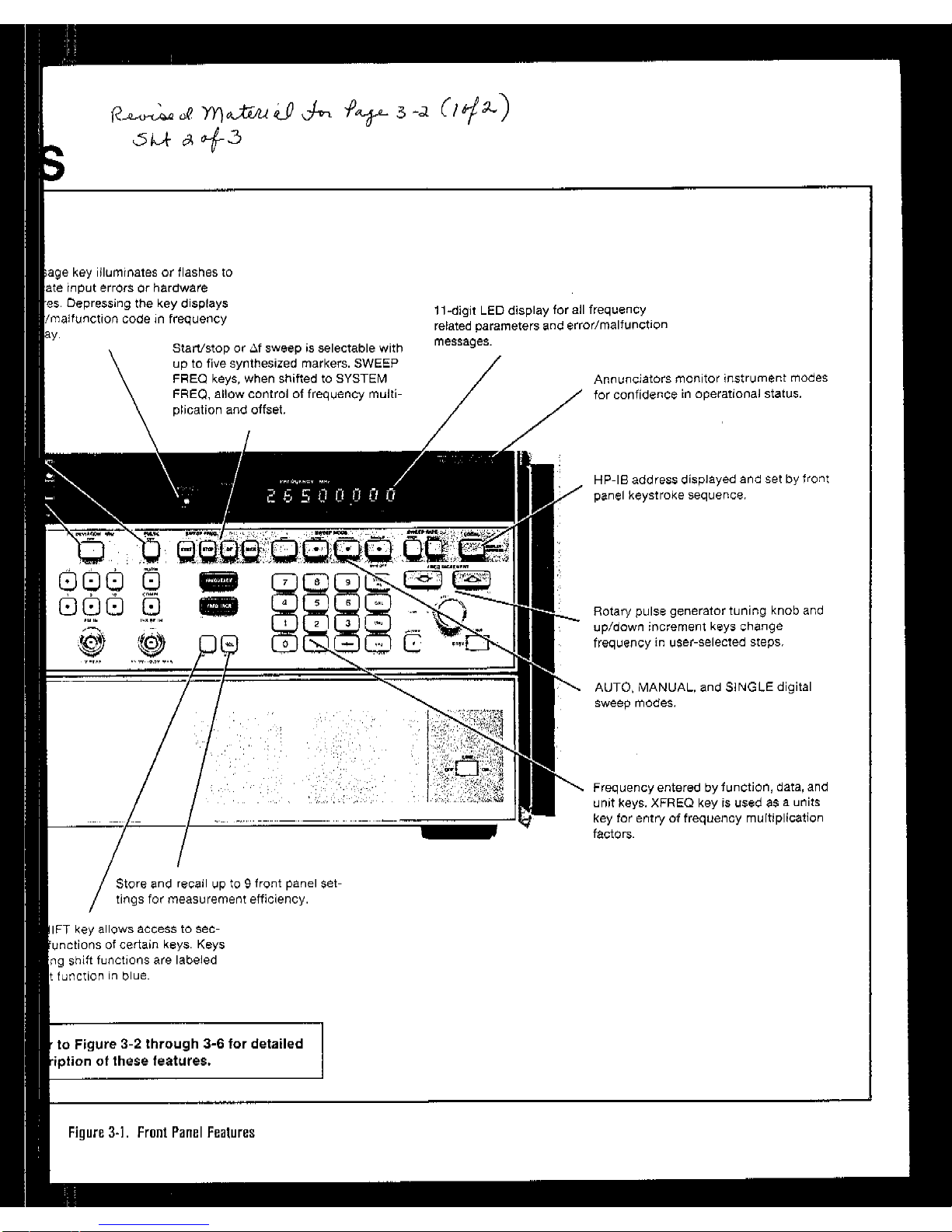

Front Panel Features .......................

.32

Displays and Statue Annunciators ..........

.58

output Level Features .....................

.3-9

Frequency Control features and LINE

switch .................................

..510

Sweep Features and LOCAL Key ..........

,911

Modulation Features ......................

.S-12

57.

3-a.

s-9,

S-10.

Sll.

4-l.

4-2.

4-3.

4-4.

4-5.

4-6.

4.7.

4-8.

49.

Rear Panel Features

.......................

.913

AM Fuixtional Check Setup

...............

,318

FM Functional Check Setup

................

S-19

Pulse Modulation Functional Check

setup ....................................

Z-20

Statue Byte Information.,

.................

,340

Frequency Range and Resolution Test

setup . . . , , . . .k3

High Level Accuracy and Flatness

Test Setup *. , . . . . , . .4-6

Low Level Accuracy Test Setup . *,. , . , .4-10

FM/AM Accuracy Test Setup. . . , . .4-13

AM Accuracy Test Setup . , , . .4-15

Low Frequency Pulse Test Setup.. , . , , . .4-17

Rise Time, Overshoot and Ringing

Measurement . . t t . . . .4-17

Pulse Level Accuracy Measurement.. . . . .4-18

High Frequency Pulse Test Setup . . . t 4-19

TABLES

Table Page Table Page

1.1.

1-2.

13.

1-4.

2-l.

3-L

3-2.

3-3.

3-4.

Specitications ...............................

l-4

Supplemental Characteristics ..............

l-11

Recommended Test Equipment

............ . l-14

Operation Verification Recommended

Test Equipment ...........................

l-18

Allowable HP-IB Address Codes

............. %3

Operating Characteristics ..................

.3-l

(Reserved for final manual),

................ .55

AWX Connector Functions ................

,530

Message Reference Table ...................

3-32

as.

56.

37.

34.

4-l.

4.2.

4.3.

4.4.

4.5.

4-6.

Talk Functions ............................

.3-37

Response to a Clear Message

...............

Z-38

HP-IB Program Codes

.....................

.3-41

Messages..

.............................. ..4-4 2

Maximum Leveled Output Power ...........

4-7

Level Flatness

.............................

4-9

High Level Accuracy ......................

4-9

Low Level Accuracy ......................

4-12

Risetime, Overshoot, and Peak Level

Accuracy ................................

4-20

Operation Verification Test Record ........ 4-21

iv

Page 23

HP 8673C/D Safety Considerations

SAFETY CONSIDERATIONS

GENERAL

This product and related documentation must be

reviewed for familiarization with safety markings

and instructions before operation.

This product is a Safety Class I instrument (pro-

vided with a protective earth terminal).

BEFORE APPLYING POWER

Verify that the product is set to match the available line voltage and the correct fuse is installed.

SAFETY EARTH GROUND

An uninterruptible safety earth ground must be

provided from the main power source to the product input wiring terminals, power cord, or sup

plied power cord set.

Any interruption of the protective (grounding)

conductor (inside or outside the instrument) or

disconnecting the protective earth terminal will

cause a potential shock hazard that could result in

personal injury. (Grounding one conductor of a

two conductor outlet is not sufficient protection.)

In addition, verify that a common ground exists

between the unit under test and this instrument

prior to energizing either unit.

Whenever it is likely that the protection has been

impaired, the instrument must be made inoperative

and be secured against any unintended operation.

If this instrument is to be energized via an auto-

transformer (for voltage reduction) make sure the

common terminal is connected to neutral (that is,

the grounded side of the mains supply).

Servicing instructions are for use by servicetrained personnel only. To avoid dangerous electric shock, do not perform any servicing unless

qualified to do so.

Adjustments described in the manual are performed with power supplied to the instrument

while protective covers are removed. Energy available at many points may, if contacted, result in

personal injury.

Capacitors inside the instrument may still be

charged even if the instrument has been discon-

nected from its source of supply.

For continued protection against fire hazard, re-

place the line fuse(s) only with 250V fuse(s) of the

same current rating and type (for example, normal

blow, time delay, etc.). Do not use repaired fuses or

short circuited fuseholders.

SAFETY SYMBOLS

Instruction manual symbol: the product

will be marked with this symbol when it is

necessary for the user to refer to the instruction manual (see Table of Contents for

page references).

Indicates hazardous voltages.

Indicates earth (ground) terminal.

The WARNING sign denotes a

hazard. It calls attention to a

procedure, practice, or the like,

which, if not correctly performed

or adhered to, could result in personal injury. Do not proceed beyond a WARNING sign until the

indicated conditions are fully

understood and met.

The CAUTION sign denotes a

hazard. It calls attention to an

operating procedure, practice, or

the like, which, if not correctly

performed or adhered to, could

result in damage to or destruction of part or all of the product.

Do not proceed beyond a CAUTION sign until the indicated

conditions are fully understood

and met.

Page 24

General Information

BP 8673C/D

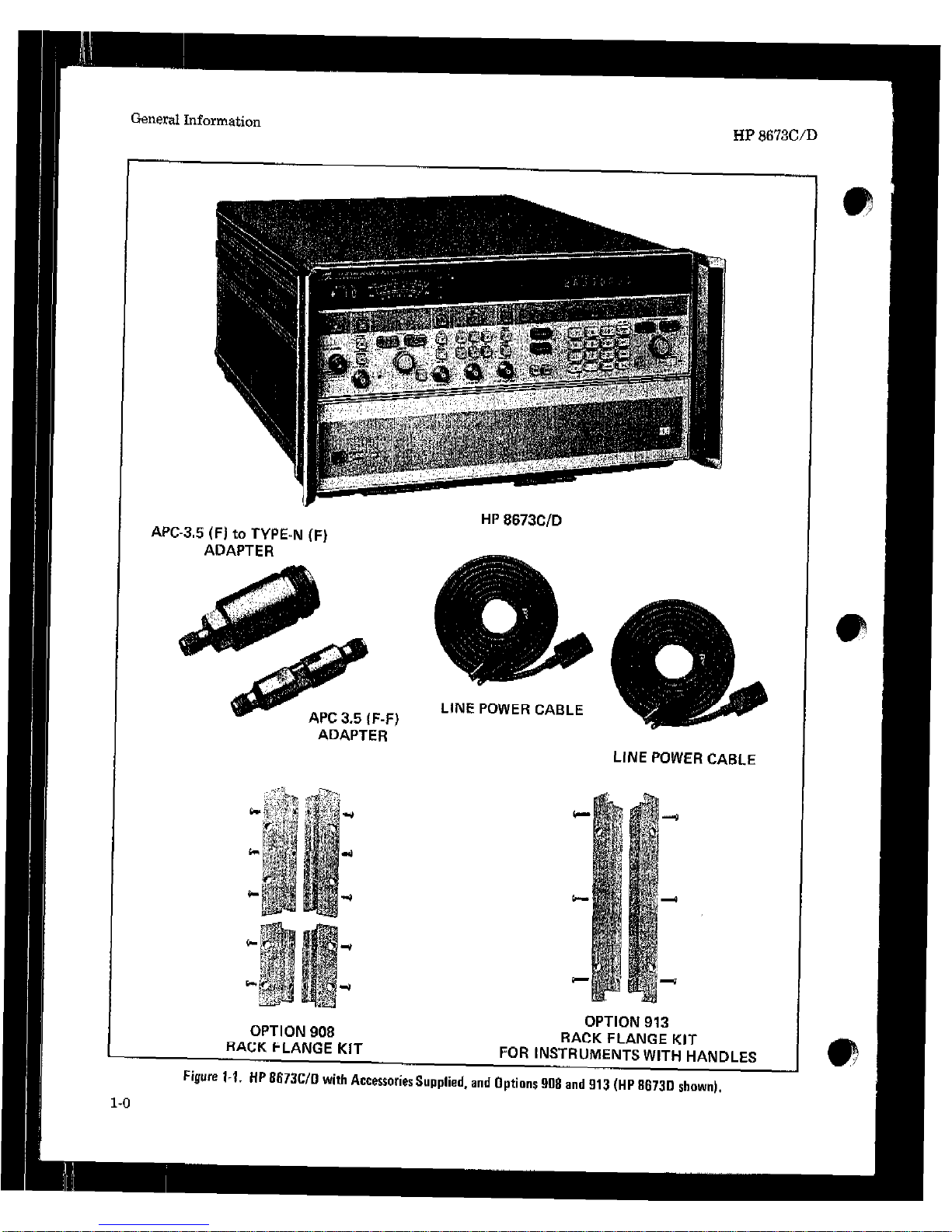

MC-3.5 (F) to TYPE-N (F)

ADAPTER

HP 6673ClD

LINE POWER CABLE

ADAPTER

LINE POWER

CABLE

OPTION 908

RACK FLANGE KIT

OPTION 913

RACK FLANGE KIT

FOR INSTRUMENTS WITH HANDLES

Fkwe 1-l. HP 867X/D with AccessoriesSupplied. and Options 908 and 913 (HP 86730 shown).

Page 25

HP 8673WD

General Information

SECTION I

GENERAL INFORMATION

l-l. INTRODUCTlON

This manual contains information required to

install, operate, test, adjust and service the HP

8673C/D Synthesized Signal Generators. Figure

1-I shows an 8673D Signal Generator with all of

its externally supplied accessories.

The 8673C/D Operating and Service manual is

divided into two volumes and eight sections as

follows:

Volume 1 (Operating Information):

Section I, General Information

Section II, Installation

Section III, Operation

Section IV, Part 1

Operation Verification

Volume 2 (Service Information)

Section IV, Part 2

Performance Tests

Section

V,

Adjustments

Section VI, Replaceable Parts

Section VII, Manual Changes

Section VIII, Service

The 8673C/D 10 MHz Reference Oscillator A3A8,

is a field repairable component. A separate operat-

ing and service manual, HP Part No. 10811-90002,

is provided for this assembly and should be retained with the 8673C/D manual.

In addition, the following manuals are supplied

with the Signal Generator:

Volume 1 (two copies)

Volume 2 (one copy)

One copy of Volume 1 (Operating Information)

should remain with the instrument for use by the

operator. Additional copies of either volume can

be ordered separately through your nearest

Hewlett-Packard office. The part number is listed

on the title page of each volume.

Also listed on the title page of this volume, below

the manual part number, is a microfiche part

number. This number may be used to order 100 x

150 millimetre (4 x 6 inch) microfilm transparencies of the complete operating and service manual

(Volumes 1 and 2). Each microfiche contains up to

96 photo-duplicates of the manual pages, The

microfiche package also includes the latest Man-

ual Changes supplement, as well as all pertinent

Service Notes.

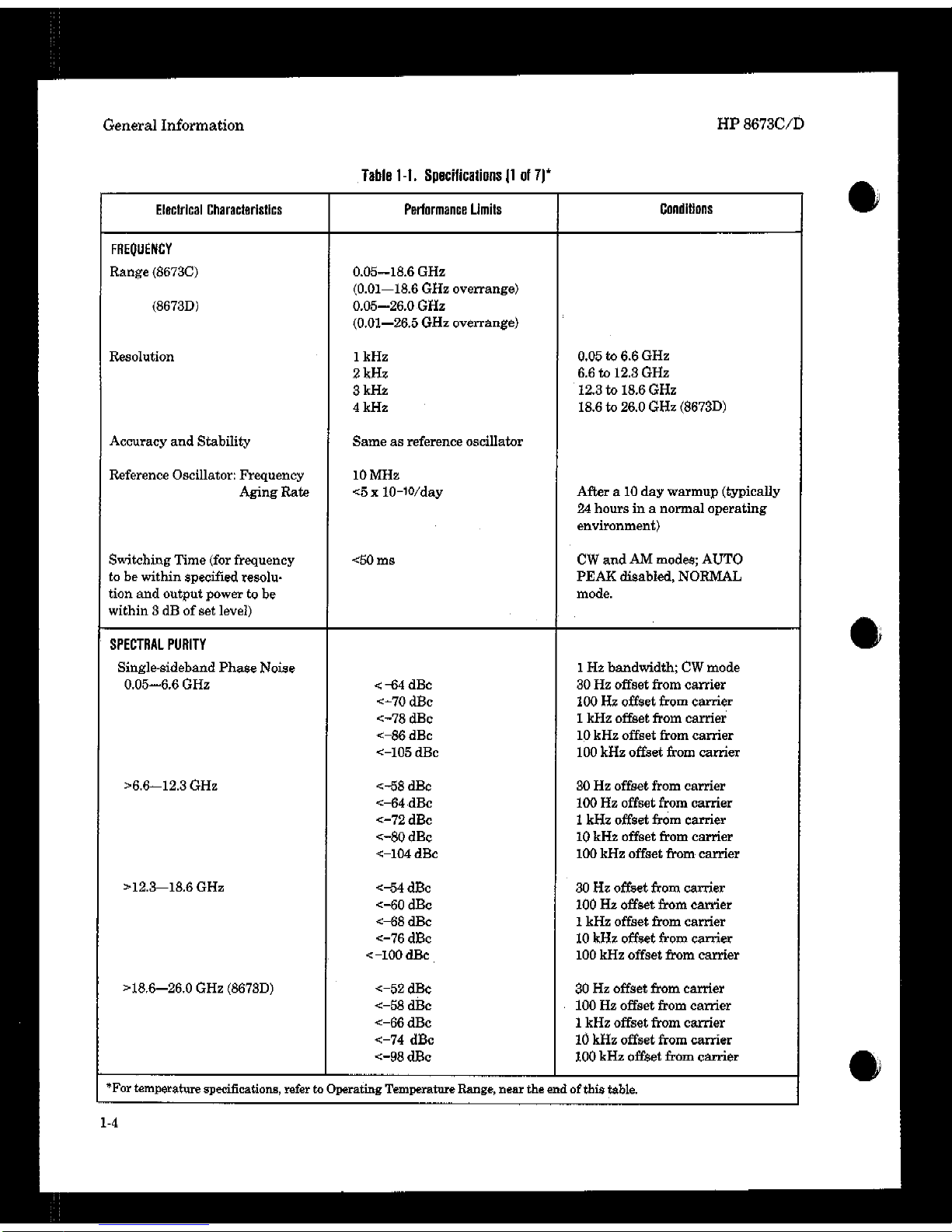

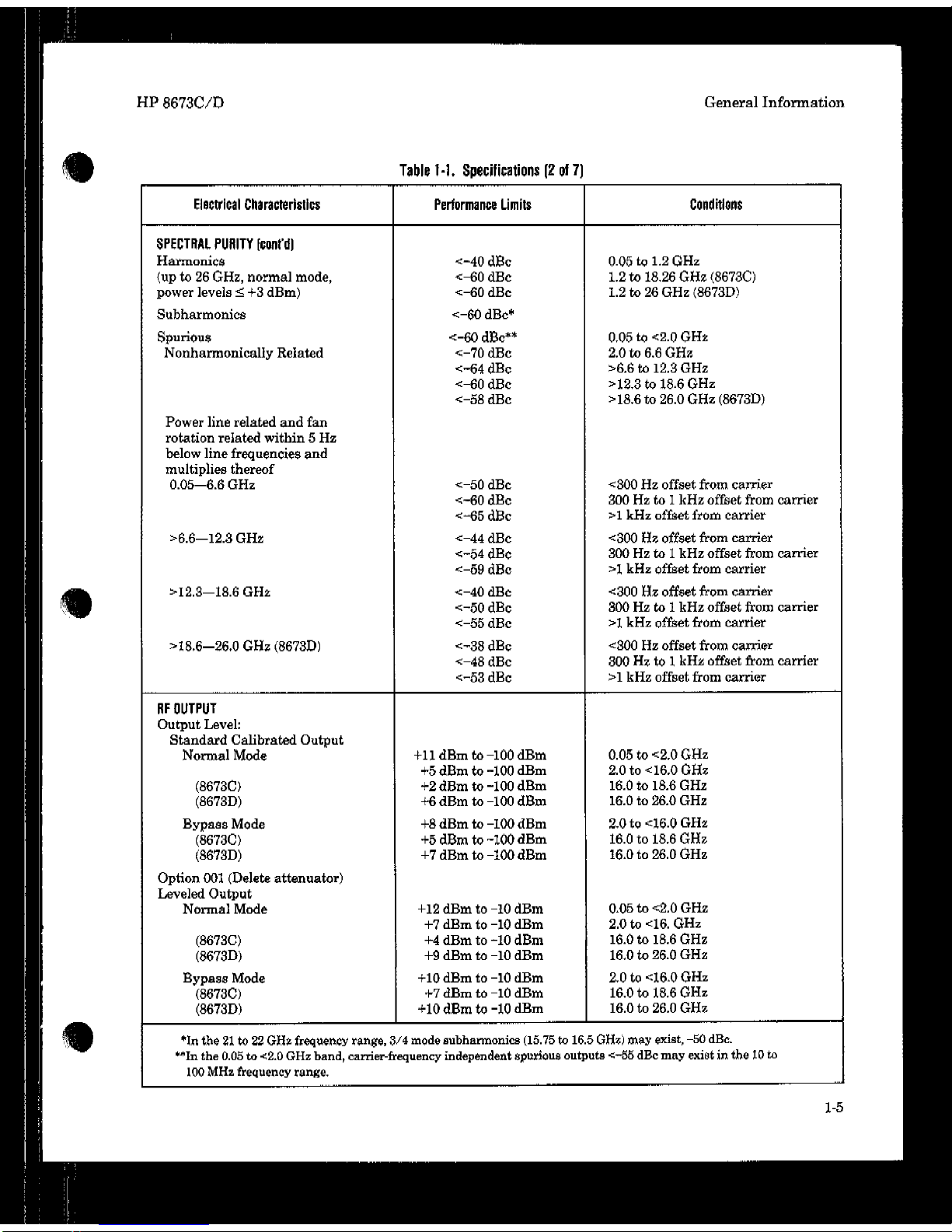

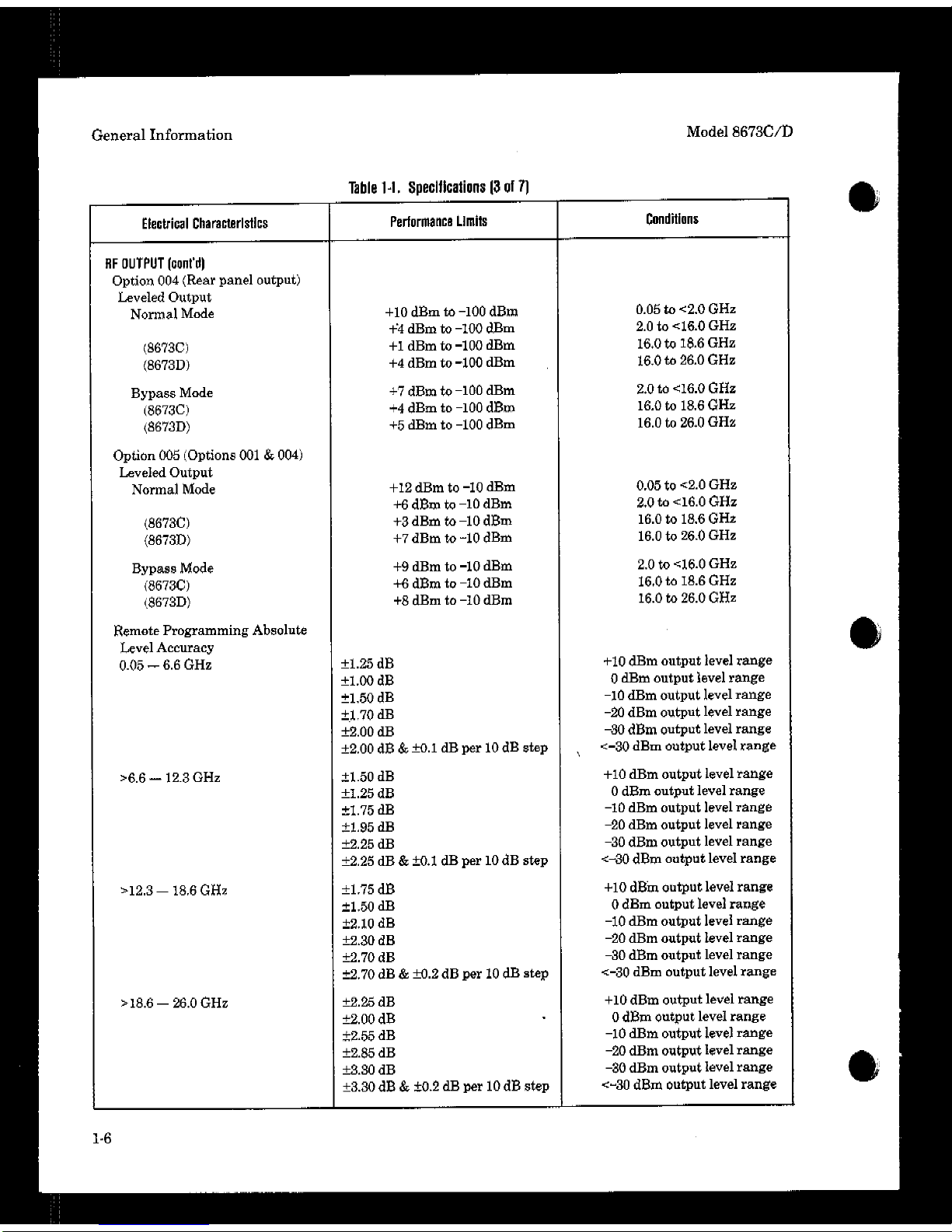

l-2. SPEClFlCATlONS

Instrument specifications are listed in Table l-l.

These specifications are the performance standards or limits against which the instrument may

be tested, Supplemental characteristics are listed

in Table 1-2. Supplemental charactsristics are not

warranted specifications, but are typical characteristics included as additional information for

the user.

1-3. SAFETY CONSIDERATIONS

This product is a Safety Class I instrument, that

is, one provided with a protective earth terminal.

The Signal Generator and all related documentation should be reviewed for familiarization with

safety markings and instructions before operation. Refer to the Safety Considerations page

found at the beginning of this manual for a summary of the safety information. Safety information for installation, operation, performance testing, adjustment, or service is found in appropriate

places throughout this manual.

1-4. INSTRUMENTS COVERED BY THIS

MANUAL

Attached to the rear panel of the instrument is a

serial number plate. The serial number is in the

form: OOOOAOOOOO. The first four digits and the

letter are the serial number prefix. The last five

digits are the suffix. The prefix is the same for

identical instruments; it changes only when a configuration change is made to the instrument. The

suffix, however is assigned sequentially and is

different for each instrument. The contents of this

manual apply directly to instruments having the

serial number prefix(es) listed under SERIAL

NUMBERS on the title page.

1-5. MANUAL CHANGES SUPPLEMENT

An instrument manufactured after the printing of

this manual may have a serial number prefix that

is not listed on the title page. This unlisted serial

number prehx indicates that the instrument is different from those documented in this manual. The

1-I

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

Page 63

Page 64

Page 65

Page 66

Page 67

Page 68

Page 69

Page 70

Page 71

Page 72

Page 73

Page 74

Page 75

Page 76

Page 77

Page 78

Page 79

Page 80

Page 81

Page 82

Page 83

Page 84

Page 85

Page 86

Page 87

Page 88

Page 89

Page 90

Page 91

Page 92

Page 93

Page 94

Page 95

Page 96

Page 97

Page 98

Page 99

Page 100

Loading...

Loading...