Errata

Title & Document Type: 8671B Synthesized CW Generator Operating Manual

Manual Part Number: 08671-90019

Revision Date: December 1985

HP References in this Manual

This manual may contain references to HP or Hewlett-Packard. Please note that Hewlett-Packard's former test and measurement, semiconductor products and chemical analysis businesses are now part of Agilent Technologies. We have made no changes to this manual copy. The HP XXXX referred to in this document is now the Agilent XXXX. For example, model number HP8648A is now model number Agilent 8648A.

About this Manual

We've added this manual to the Agilent website in an effort to help you support your product. This manual provides the best information we could find. It may be incomplete or contain dated information, and the scan quality may not be ideal. If we find a better copy in the future, we will add it to the Agilent website.

Support for Your Product

Agilent no longer sells or supports this product. You will find any other available product information on the Agilent Test & Measurement website:

www.tm.agilent.com

Search for the model number of this product, and the resulting product page will guide you to any available information. Our service centers may be able to perform calibration if no repair parts are needed, but no other support from Agilent is available.

HP 867

Contents

HP 8671B

CONTENTS

Page

Section I GENERAL INFORMATION

| t traduction 1- | 1 |

|---|---|

| Introduction 1- | 1 |

| Specifications | ī |

| Safety Considerations 1- | 1 |

| Instruments Covered by This Manual 1- | 1 |

| 111Strantons Supplement | 1 |

| Manual Changes Supplement | 9 |

| Description | م |

| Options 1- | 2 |

| Mechanical Options 1- | 2 |

| A suggering Supplied | 2 |

| Accessories Supplied | ว |

| Accessories Available 1- |

ပ

ဂ |

| Electrical Equipment Available 1- | З |

| Becommonded Test Equipment | 3 |

| Recommended 1000 Dearphone to the test |

Section II

| Introduction | 2-1 |

|---|---|

| Initial Inspection | 2-1 |

| Preparation For Use | 2-1 |

| Power Requirements | 2-1 |

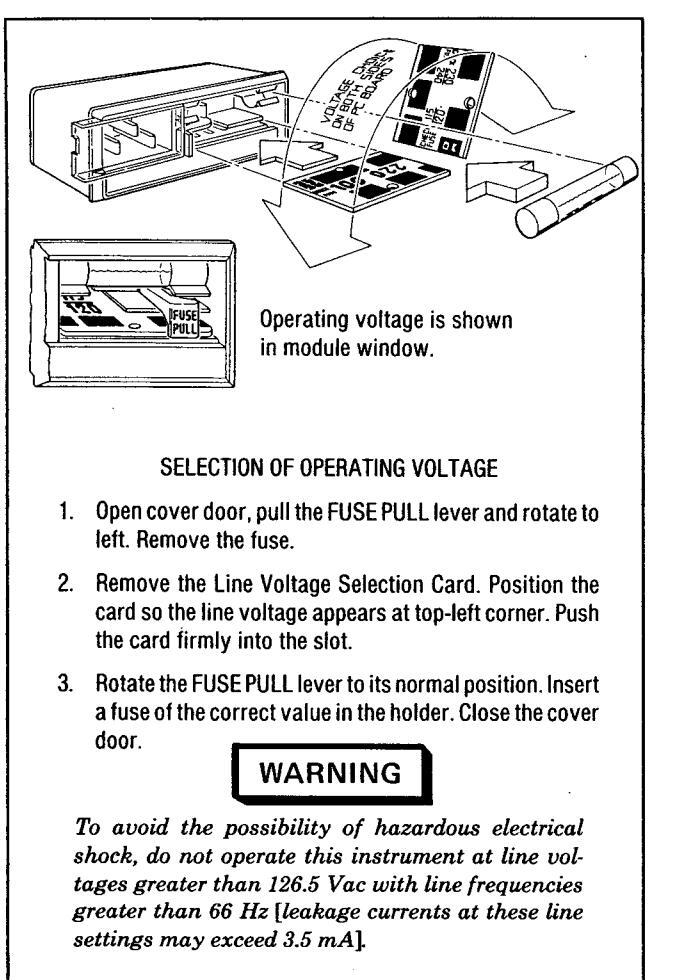

| Line Voltage and Fuse Selection | 2-1 |

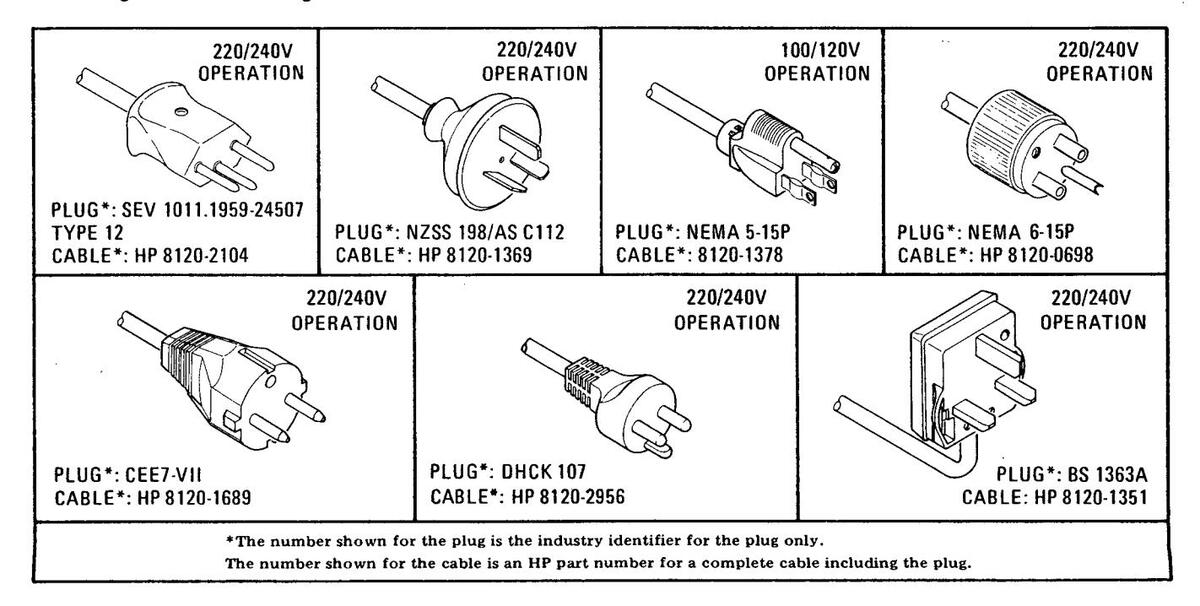

| ∧ Power Cables | 2-1 |

| HP-IB Address Selection | 2-2 |

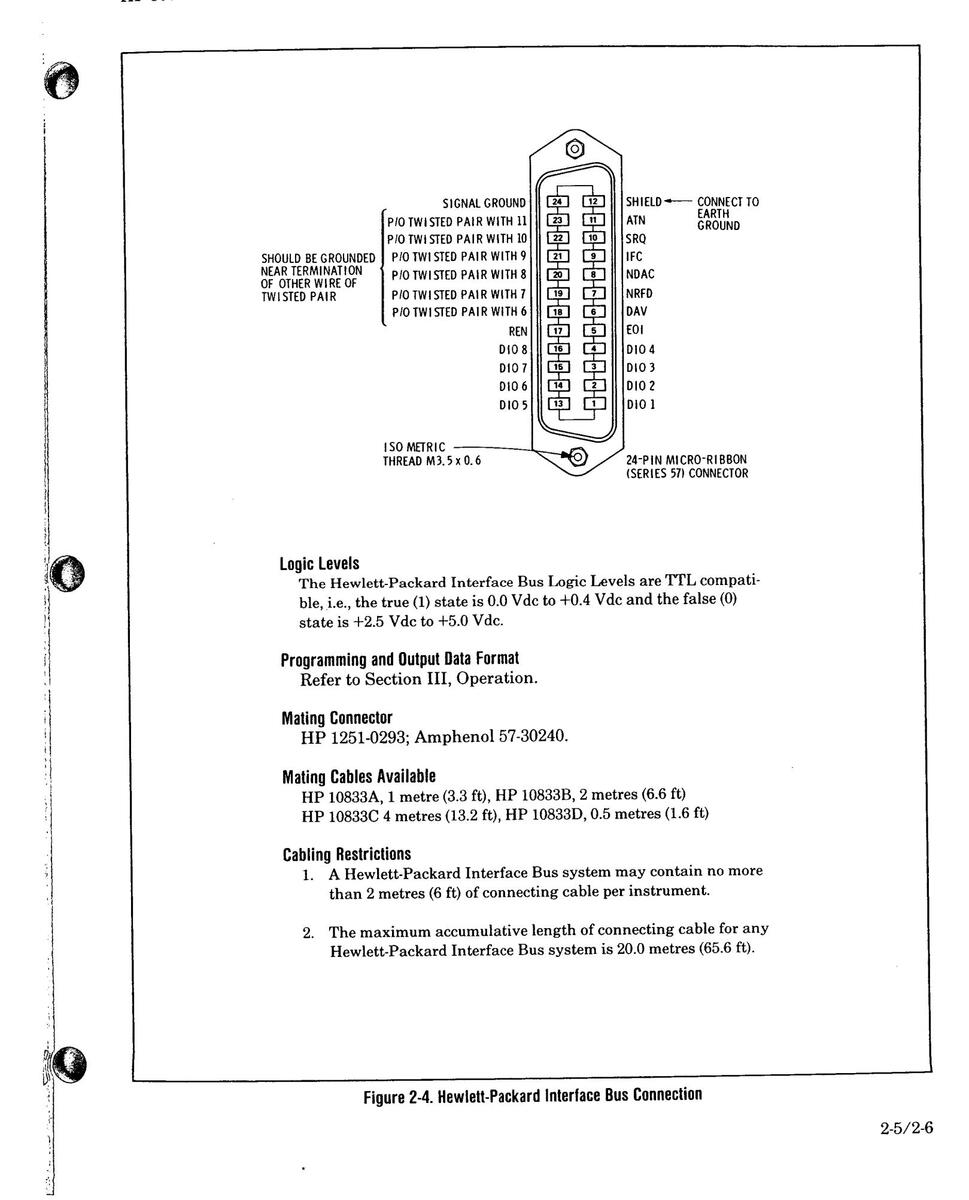

| Interconnections | 2-3 |

| Mating Connectors | 2-3 |

| Operating Environment | 2-3 |

| Bench Operation | 2-4 |

| Rack Mounting | 2-4 |

| Storage and Shipment | 2-4 |

| Environment | 2-4 |

| Packaging | 2-4 |

Section III OPERATION

| Introduction | 3-1 |

|---|---|

| Panel Features | 3-1 |

| Operating Characteristics | 3-1 |

| Local Operation | 3-1 |

| Remote (HP-IB) Operation | 3-1 |

| Operator's Checks | 3-1 |

| Operator's Maintenance | 3-1 |

| Turn-On Instructions | 3-1 |

| Turn-On | 3-1 |

| Frequency Standard Selection | 3-1 |

| Simplified Operation | 3-3 |

| Frequency | 3-3 |

| Output Level | 3-3 |

| ALC | 3-3 |

| Page | |

|---|---|

| ALC Control | . 3-4 |

| Frequency Control | . 3-8 |

| Level Control | 3-12 |

| Peak-Norm Adjustment | 3-15 |

| RF ON/OFF Switch | 3-16 |

| Remote (HP-IB) Operation | 3-17 |

| HP-IB Compatibility | 3-17 |

| Remote Mode | 3-17 |

| Local Mode | 3-17 |

| Addressing | 3-17 |

| Data Messages | 3-17 |

| Receiving Data Messages | 3-19 |

| The Complete Data Message | 3-19 |

| The Abbreviated Data Message | 3-19 |

| Receiving the Clear Message | 3-19 |

| Receiving the Trigger Message | 3-20 |

| Receiving the Remote Message | 3-20 |

| Receiving the Local Message | 3-20 |

| Receiving the Local Lockout Message | 3-20 |

| Receiving the Clear Lockout/Set Local | |

| Message | 3-20 |

| Receiving the Pass Control Message | 3-20 |

| Sending the Require Service Message | 3-20 |

| Sending the Status Byte Message | 3-20 |

| Sending the Status Bit Message | 3-20 |

| Receiving the Abort Message | 3-20 |

| Operator's Checks | , 3-22 |

| Basic Functional Checks | . 3-22 |

| HP-IB Checks | . 3-26 |

Section IV PERFORMANCE TESTS

| Introduction 4-1 |

|---|

| Abbreviated Performance Test 4-1 |

| Calibration Cycle 4-1 |

| Performance Test Record 4-1 |

| Equipment Required 4-1 |

| Test Procedures 4-1 |

| Frequency Range and Resolution Test 4-2 |

| Frequency Switching Time Test 4-5 |

| Output Level, High Level Accuracy |

| and Flatness Test 4-11 |

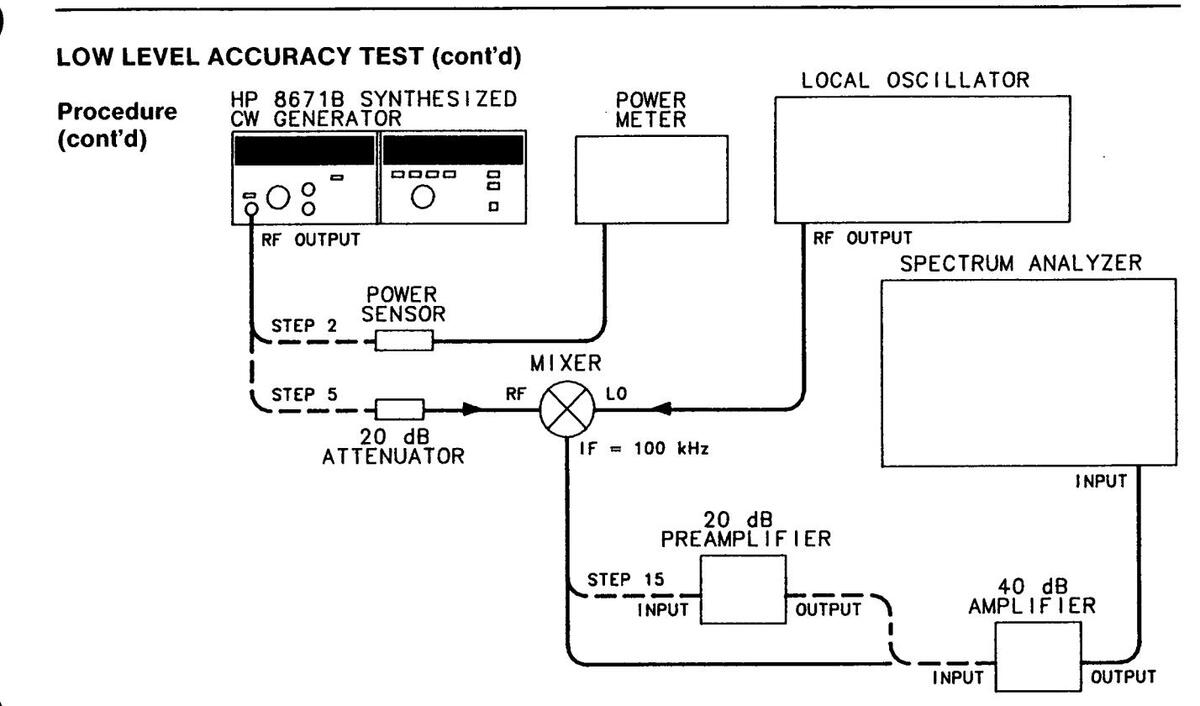

| Low Level Accuracy Test 4-16 |

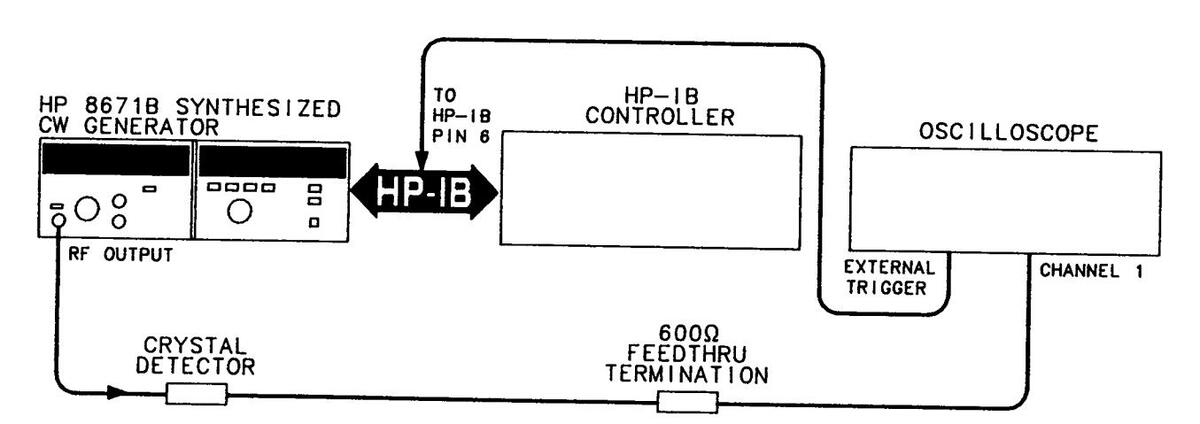

| Output Level Switching Time Test 4-20 |

| Harmonics, Subharmonics & Multiples Test 4-23 |

| Non-Harmonically Related Spurious |

| Signals Test 4-26 |

| Power Line Related Spurious Signals Test 4-28 |

| Single-Sideband Phase Noise Test 4-31 |

| Internal Time Base Aging Rate 4-36 |

L

Contents

ILLUSTRATIONS

| Figu | re Page |

|---|---|

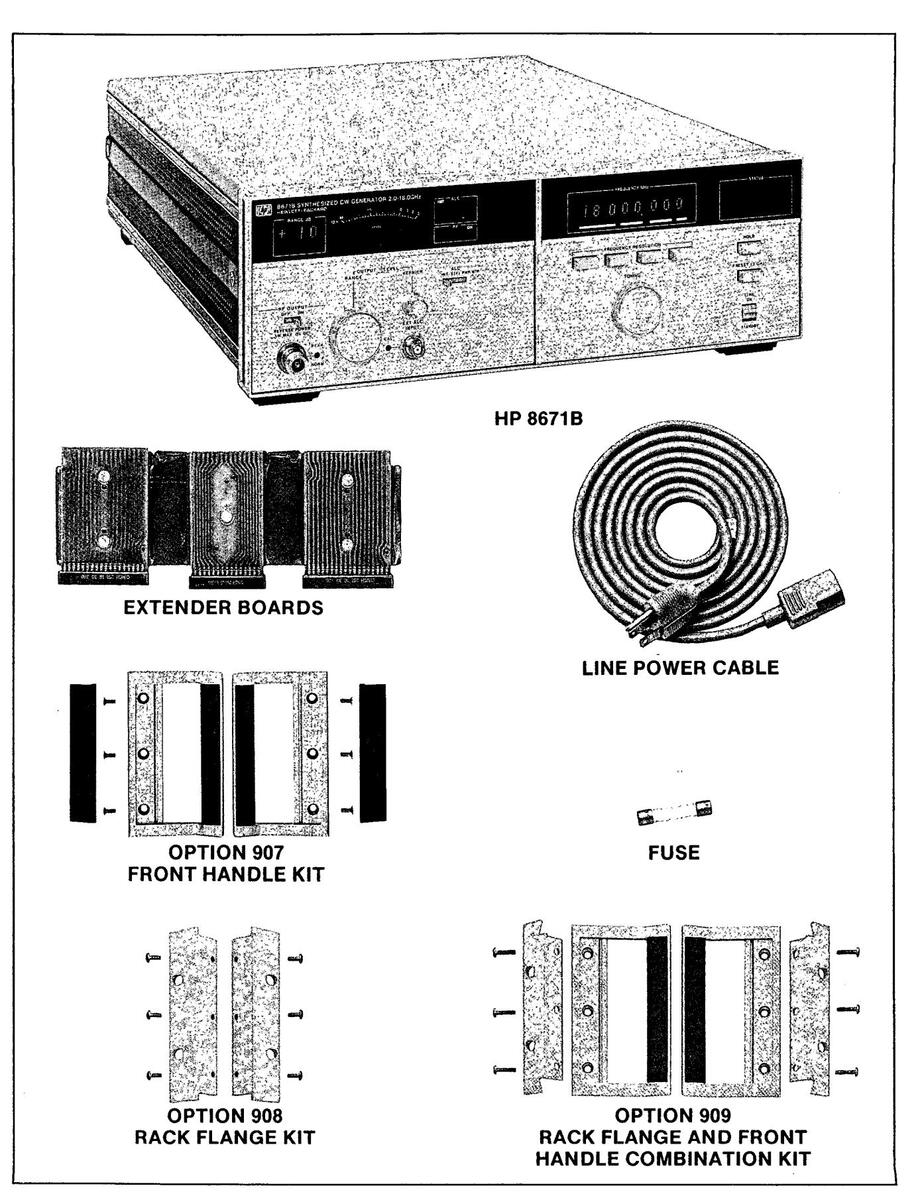

| 1-1. |

HP Model 8671B Accessories Supplied, and

Options 907, 908, and 909 1-0 |

| 2-1. | Line Voltage and Fuse Selection |

| 2-2. | Power Cable and Mains Plug Part |

| Numbers 2-2 | |

| 2-3. | HP-IB Address Switches Shown as Set by |

| the Factory 2-3 | |

| 2-4. | Hewlett-Packard Interface Bus |

| Connection 2-5 | |

| ∆ 3-1. | Front Panel Features |

| 3-2. | Rear Panel Features |

| 3-3. | External Leveling with a Crystal Detector 3-4 |

| 3-4. | External Leveling with a Power Meter 3-5 |

| 3-5. |

Frequency Programming Codes and

Arguments |

| 3-6. |

Frequency Switching Time Showing

Worst Case 3-11 |

| 3-7. | Frequency Checks Test Setup 3-23 |

| Figu | re Page |

|---|---|

| 4-1. | Frequency Range and Resolution |

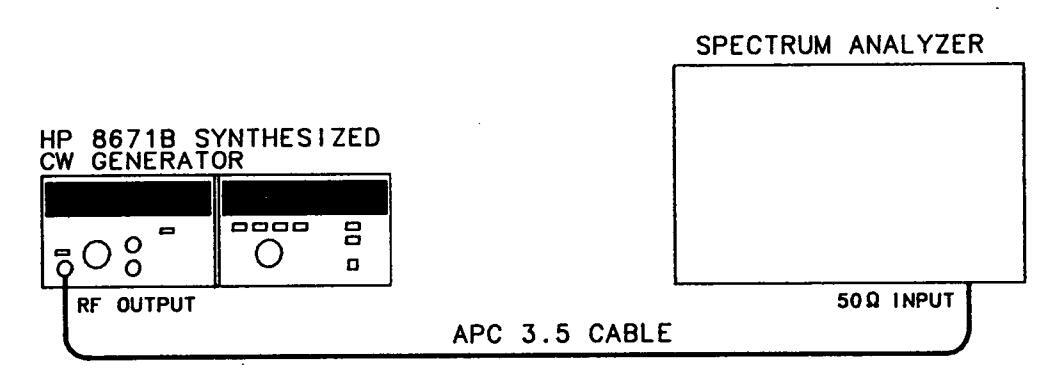

| Test Setup 4-2 | |

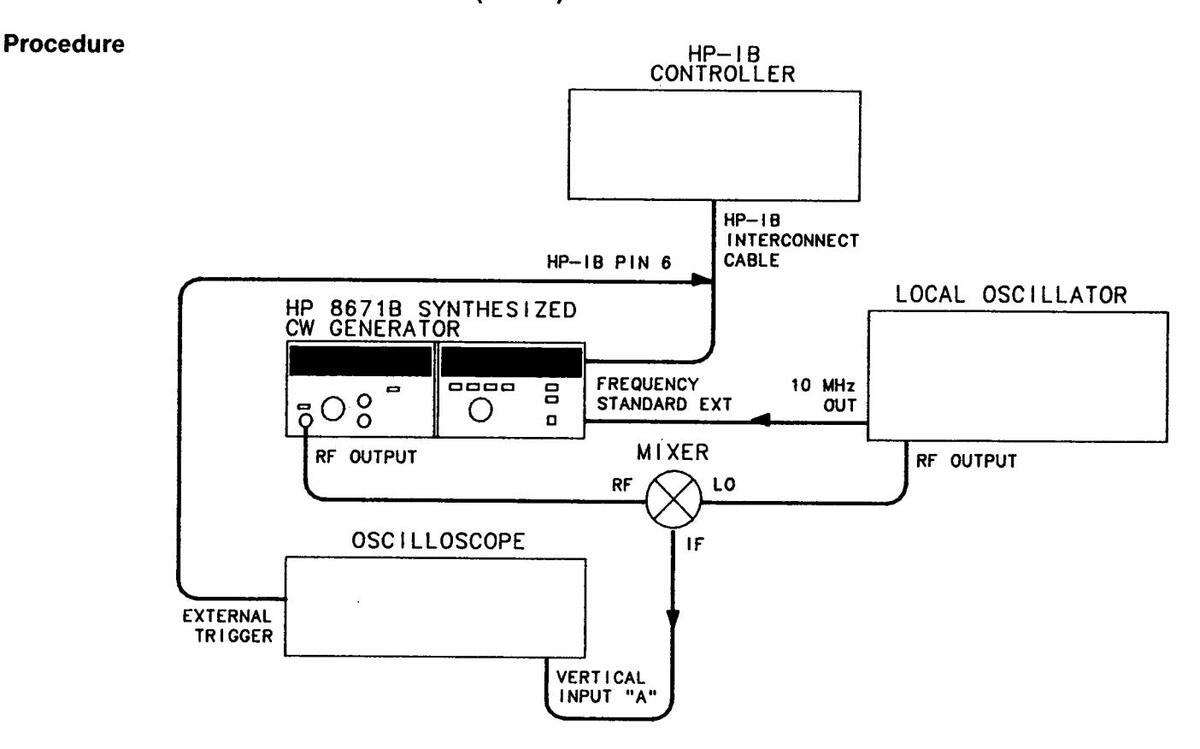

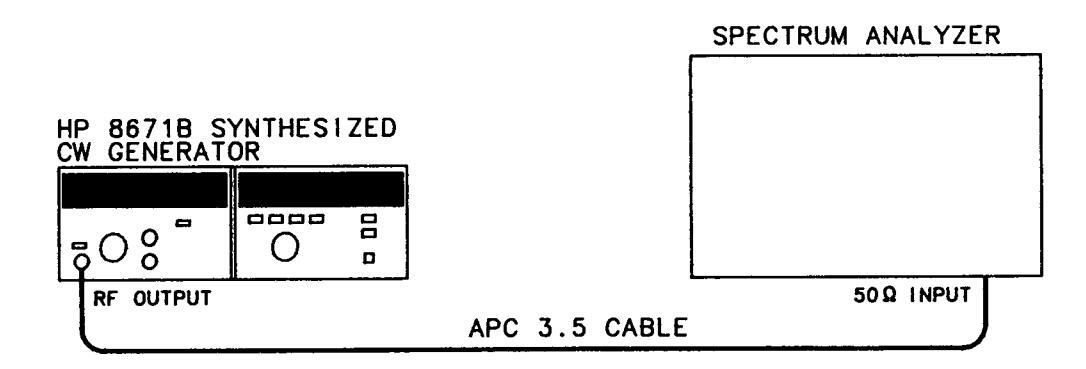

| 4-2. | Frequency Switching Time Test Setup 4-6 |

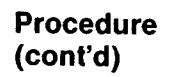

| 4-3. | Frequency Switching Time Measurement |

| Waveform 4-8 | |

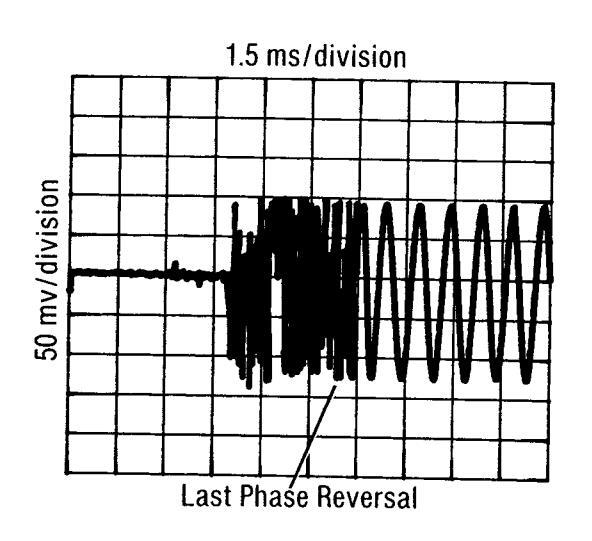

| 4-4. | Amplitude Recover Measurement |

| Waveform 4-10 | |

| 4-5. | Output Level, High Level Accuracy |

| and Flatness Test Setup 4-12 | |

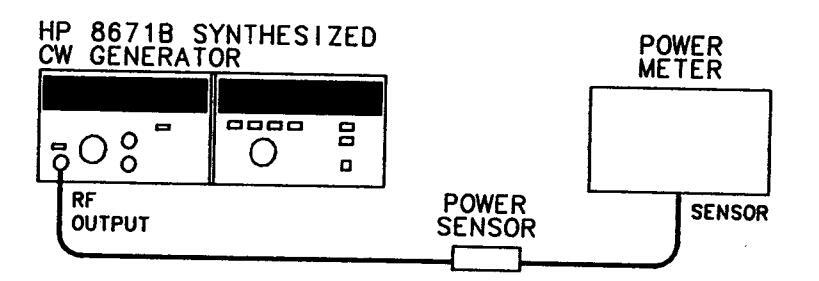

| 4-6. | Low Level Accuracy Test Setup 4-17 |

| 4-7. | Output Level Switching Time Test Setup 4-20 |

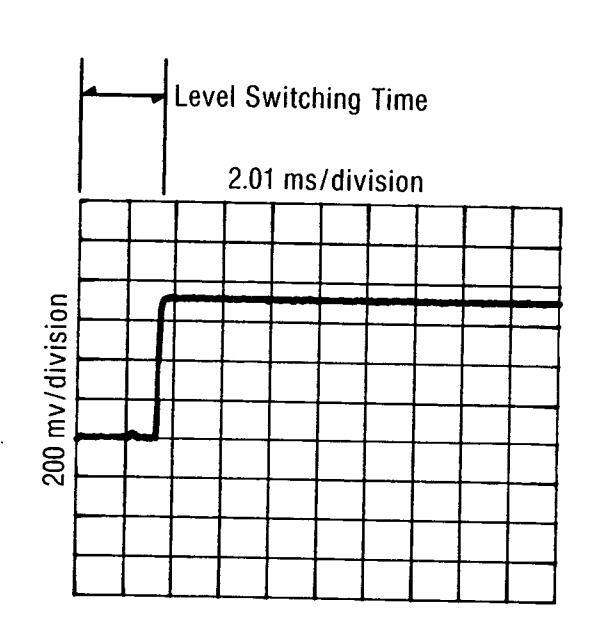

| 4-8 | Output Level Switching Time |

| Measurement Waveform 4-22 | |

| 4-9. | Harmonics, Subharmonics, and Multiples |

| Test Setup 4-23 | |

| 4-10. | Non-Harmonically Related Spurious |

| Test Setup 4-26 | |

| 4-11. | Power Line Related Spurious Signals |

| Test Setup 4-29 | |

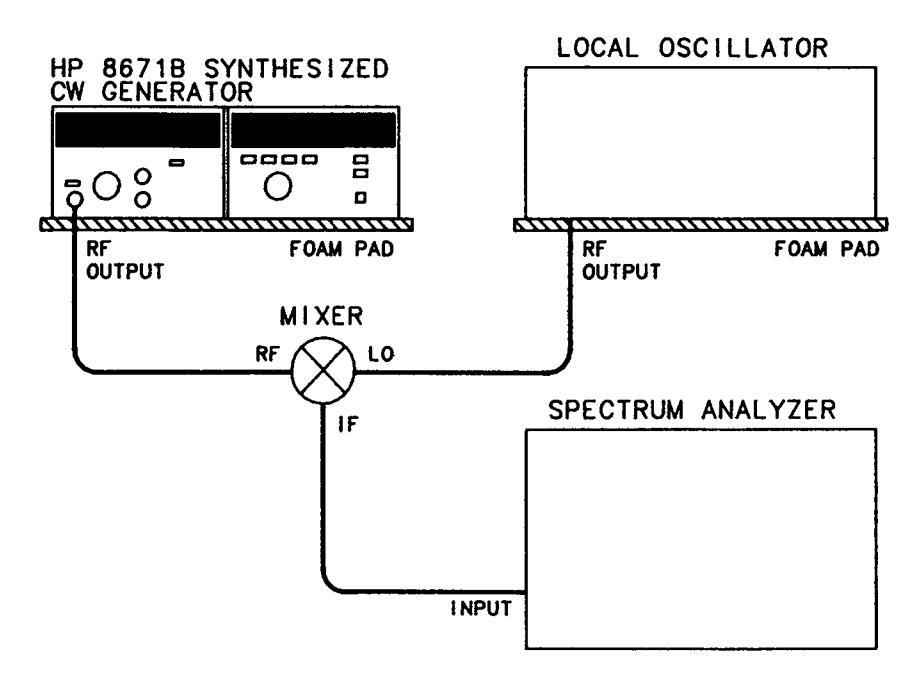

| 4-12. | Single-Sideband Phase Noise Test Setup 4-32 |

| 4-13. | Internal Time Base Aging Rate |

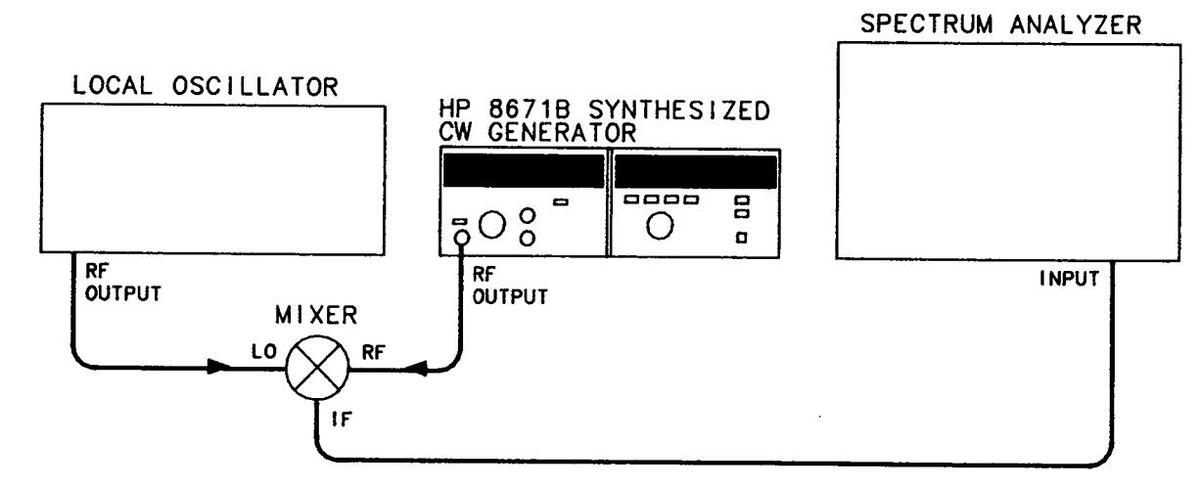

| Test Setup |

TABLES

| Tabl | e Page |

|---|---|

| 1-1. | Specifications 1-4 |

| 1-2. | Supplemental Characteristics 1-7 |

| 1-3. | Recommended Test Equipment 1-8 |

| 2-1. | Allowable HP-IB Address Codes 2-3 |

| 3-1. | Operating Characteristics 3-1 |

| 3-2. | Index of Detailed Operating Instructions 3-1 |

| 3-3. | Message Reference Table 3-18 |

| Tab | le Page |

|---|---|

| 3-4. | Programming Quick Reference Guide 3-21 |

| 4-1. | Output Level, High Level Accuracy |

| and Flatness Test Record 4-14 | |

| 4-2. | Low Level Accuracy Test Record 4-19 |

| 4-3. | Harmonics, Subharmonics & Multiples |

| Test Record 4-25 | |

| 4-4. | Performance Test Record 4-38 |

SAFETY CONSIDERATIONS

GENERAL

This product and related documentation must be reviewed for familiarization with safety markings and instructions before operation.

This product is a Safety Class I instrument (provided with a protective earth terminal).

BEFORE APPLYING POWER

Verify that the product is set to match the available line voltage and the correct fuse is installed.

SAFETY EARTH GROUND

An uninterruptible safety earth ground must be provided from the main power source to the product input wiring terminals, power cord, or supplied power cord set.

WARNINGS

Any interruption of the protective (grounding) conductor (inside or outside the instrument) or disconnecting the protective earth terminal will cause a potential shock hazard that could result in personal injury. (Grounding one conductor of a two conductor outlet is not sufficient protection.) In addition, verify that a common ground exists between the unit under test and this instrument prior to energizing either unit.

Whenever it is likely that the protection has been impaired, the instrument must be made inoperative and be secured against any unintended operation.

If this instrument is to be energized via an autotransformer (for voltage reduction) make sure the common terminal is connected to neutral (that is, the grounded side of the mains supply).

Servicing instructions are for use by servicetrained personnel only. To avoid dangerous electric shock, do not perform any servicing unless qualified to do so.

Adjustments described in the manual are performed with power supplied to the instrument

while protective covers are removed. Energy available at many points may, if contacted, result in personal injury.

Capacitors inside the instrument may still be charged even if the instrument has been disconnected from its source of supply.

For continued protection against fire hazard, replace the line fuse(s) only with 250V fuse(s) of the same current rating and type (for example, normal blow, time delay, etc.). Do not use repaired fuses or short circuited fuseholders.

SAFETY SYMBOLS

Instruction manual symbol: the product will be marked with this symbol when it is necessary for the user to refer to the instruction manual (see Table of Contents for page references).

Indicates hazardous voltages.

Indicates earth (ground) terminal.

WARNING

The WARNING sign denotes a hazard. It calls attention to a procedure, practice, or the like, which, if not correctly performed or adhered to, could result in personal injury. Do not proceed beyond a WARNING sign until the indicated conditions are fully understood and met.

CAUTION

The CAUTION sign denotes a hazard. It calls attention to an operating procedure, practice, or the like, which, if not correctly performed or adhered to, could result in damage to or destruction of part or all of the product. Do not proceed beyond a CAU-TION sign until the indicated conditions are fully understood and met.

General Information

Figure 1-1. HP Model 8671B Accessories Supplied, and Options 907, 908, and 909

SECTION I GENERAL INFORMATION

1-1. INTRODUCTION

This manual contains information required to install, operate, test, adjust and service the Hewlett-Packard 8671B Synthesized CW Generator. Figure 1-1 shows the CW Generator with all of its externally supplied accessories.

The 8671B Operating and Service manual has eight sections. The subjects addressed are:

Section I, General Information Section II, Installation Section III, Operation Section IV, Performance Tests Section V, Adjustments Section VI, Replaceable Parts Section VII, Manual Changes Section VIII, Service

Two copies of the operating information are supplied with the CW Generator. One copy is in the form of an Operating Manual. The Operating Manual is a copy of the first four sections of the Operating and Service Manual. The Operating Manual should stay with the instrument for use by the operator. Additional copies of the Operating Manual can be ordered separately through your nearest Hewlett-Packard office. The part number is listed on the title page of this manual.

Also listed on the title page of this manual, below the manual part number, is a microfiche part number. This number may be used to order 100 x 150 millimetre (4 x 6 inch) microfilm transparencies of this manual. Each microfiche contains up to 96 photo-duplicates of the manual pages. The microfiche package also includes the latest Manual Changes supplement, as well as all pertinent Service Notes.

1-2. SPECIFICATIONS

Instrument specifications are listed in Table 1-1. These specifications are the performance standards or limits against which the instrument may be tested. Supplemental characteristics are listed in Table 1-2. Supplemental characteristics are not warranted specifications, but are typical characteristics included as additional information for the user.

1-3. SAFETY CONSIDERATIONS

This product is a Safety Class I instrument, that is, one provided with a protective earth terminal. The CW Generator and all related documentation should be reviewed for familiarization with safety markings and instructions before operation. Refer to the Safety Considerations page found at the beginning of this manual for a summary of the safety information. Safety information for installation, operation, performance testing, adjustment, or service is found in appropriate places throughout this manual.

1-4. INSTRUMENTS COVERED BY THIS MANUAL

Attached to the rear panel of the instrument is a serial number plate. The serial number is in the form: 0000A00000. The first four digits and the letter are the serial number prefix. The last five digits are the suffix. The prefix is the same for identical instruments; it changes only when a configuration change is made to the instrument. The suffix however, is assigned sequentially and is different for each instrument. The contents of this manual apply directly to instruments having the serial number prefix(es) listed under SERIAL NUMBERS on the title page.

1-5. MANUAL CHANGES SUPPLEMENT

An instrument manufactured after the printing of this manual may have a serial number prefix that is not listed on the title page. This unlisted serial number prefix indicates that the instrument is different from those documented in this manual. The manual for this newer instrument is accompanied by a Manual Changes supplement. The supplement contains "change information" that explains how to adapt this manual to the newer instrument.

In addition to change information, the supplement may contain information for correcting errors in the manual. To keep the manual as current and as accurate as possible, Hewlett-Packard recommends that you periodically request the latest Manual Changes supplement. The supplement is identified with the manual print date and part number, both

MANUAL CHANGES SUPPLEMENT (cont'd)

of which appear on the manual title page. Complimentary copies of the supplement are available from Hewlett-Packard.

For information concerning a serial number prefix that is not listed on the title page or in the Manual Changes supplement, contact your nearest Hewlett-Packard office.

1-6. DESCRIPTION

The HP 8671B Synthesized CW Generator has a frequency range of 2.0 to 18.0 GHz. The output is leveled and calibrated from +8 dBm to -120 dBm. Frequency, output level, and ALC modes can be remotely programmed via HP-IB.

The frequency can be tuned with one of four frequency resolutions. Tuning resolutions of 100 MHz, 1 MHz, 10 kHz or 1 kHz are selected by front panel pushbuttons. The 1 kHz tuning resolution will give tuning resolutions of 1 kHz for frequencies from 2.0 to 6.2 GHz, 2 kHz for frequencies from 6.2 to 12.4 GHz, and 3 kHz for frequencies from 12.4 to 18.599997 GHz.

Long-term frequency stability is dependent on the time base, either an internal or external reference oscillator. The internal crystal reference oscillator operates at 10 MHz while an external oscillator may operate at 5 or 10 MHz.

The output of the CW Generator is exceptionally flat due to the action of the internal automatic leveling control (ALC) loop. External leveling control using a diode detector or a power meter to sense output power can be used to level the output at a remote load.

The output level is set using the OUTPUT LEVEL RANGE switch and the OUTPUT LEVEL VERN-IER. The OUTPUT LEVEL RANGE switch changes the output level in 10 dB increments (+10 to -110 dB). The OUTPUT LEVEL VERNIER is then used to adjust the output level over a continuous 13 dB range (-10 to +3 dBm). The output level is read by adding the vernier setting to the range setting.

The CW Generator is compatible with HP-IB to the extent indicated by the following codes: SH1, AH1, T6, TE0, L4, LE0, SR1, RL2, PP2, DC1, DT0, and C0. An explanation of the compatibility code can be found in IEEE Standard 488 (1978),

"IEEE Standard Digital Interface for Programmable Instrumentation" or the identical ANSI Standard MC1.1. For more detailed information relating to programmable control of the CW Generator, refer to Remote Operation, Hewlett-Packard Interface Bus in Section III of this manual

1-7. OPTIONS

1-8. Mechanical Options

The following options may have been ordered and received with the CW Generator. If they were not ordered with the original shipment and are now desired, they can be ordered from the nearest Hewlett-Packard office using the part numbers included in each of the following paragraphs.

Option 907 (Front Handle Kit). Ease of handling is increased with the front panel handles. The Front Handle Kit part number is 5061-9689.

Option 908 (Rack Flange Kit). The CW Generator can be solidly mounted to the instrument rack using the flange kit. The Rack Flange Kit part number is 5061-9677.

Option 909 (Rack Flange and Front Handle Combination Kit). This is a unique part which combines both functions. It is not simply a front handle kit and a rack flange kit packaged together. The Rack Flange and Front Panel Combination Kit part number is 5061-9683.

1-9. ACCESSORIES SUPPLIED

The accessories supplied with the CW Generator are shown in Figure 1-1.

a. The line power cable is supplied in several configurations, depending on the destination of the original shipment. Refer to Power Cables in Section II of this manual.

b. An additional fuse is shipped only with instruments that are factory configured for 100/120 Vac operation. This fuse has a 1.5A rating and is for reconfiguring the instrument for 220/240 Vac operation.

c. Four extender boards are supplied for performance testing, adjusting, and troubleshooting the instrument.

1. One 30-pin (15 x 2) extender board, HP part number 08672-60117.

ACCESSORIES SUPPLIED (cont'd)

- 2. Two 36-pin (18 x 2) extender boards, HP part number 08672-60020.

- 3. One 3-section, 30-pins (15 x 2) per section, extender board, HP part number 08672-60016 (for use in the A2 Assembly).

1-10. ACCESSORIES AVAILABLE

Chassis Slide Mount Kit. This kit is not available as a factory installed option. However, it is extremely useful when the CW Generator is rack mounted. Access to internal circuits and components or the rear panel is possible without removing the CW Generator from the rack. Order HP part number 1494-0059. If the instrument rack mounting slides are to be mounted in a standard EIA rack, then an adapter (HP Part No. 1494-0061) is needed. The slides without the adapter can be directly mounted in the HP system enclosures.

1-11. ELECTRICAL EQUIPMENT AVAILABLE

The CW Generator has an HP-IB interface and can be used with any HP-IB compatible computing controller or computer for automatic systems applications.

The HP-IB Controller is needed for Flatness and ALC adjustment procedures and for performance testing. Controllers that are supported by this manual include the HP 9826A, 9836A, and HP 85B/82937A.

The HP 11720A Support Kit is available for maintaining and servicing the CW Generator. It includes a special test extender board, cables and adapters.

1-12. RECOMMENDED TEST EQUIPMENT

Table 1-3 lists the test equipment recommended for testing, adjusting and servicing the CW Generator. Essential requirements for each piece of test equipment are described in the Critical Specifications column. Other equipment can be substituted if it meets or exceeds these critical specifications.

1

Table 1-1. Specifications (1 of 3)

Note: Specifications apply after 1-hour warm-up, over the temperature range 0 to 55°C (except specifications for RF output level which apply over the range 15 to 35° C). Specifications for output flatness and absolute level accuracy apply only when internal leveling is used.

| Electrical Characteristics | Performance Limits | Conditions |

|---|---|---|

|

FREQUENCY

Range |

2.0—18.0 GHz

(Overrange to 18.599997 GHz) |

' |

| Resolution |

1 kHz

2 kHz 3 kHz |

2.0 to 6.2 GHz

6.2 to 12.4 GHz 12.4 to 18.0 GHz |

| Accuracy and Stability |

Same as reference

oscillator |

|

|

Switching Time

Frequency (to be within the specified resolution -1 kHz in 2.0 to 6.2 GHz range, etc.) |

<15 ms | |

|

Amplitude (after switching

frequency) to be within ±3 dB of final level |

<15 ms | When switching within the same range |

|

Reference Oscillator

Frequency |

10 MHz | |

| Aging Rate | <5 x 10 -10 /day |

After a 10 day warmup (typically

24 hours in a normal operating environment) |

| SPECTRAL PURITY | · | |

|

Single-sideband Phase Noise

2.0—6.2 GHz |

<58 dBc

<-70 dBc <-78 dBc <-86 dBc <-110 dBc |

1 Hz bandwidth

10 Hz offset from carrier 100 Hz offset from carrier 1 kHz offset from carrier 10 kHz offset from carrier 100 kHz offset from carrier |

| 6.2—12.4 GHz |

<-52 dBc

<-64 dBc <-72 dBc <-80 dBc <-104 dBc |

10 Hz offset from carrier

100 Hz offset from carrier 1 kHz offset from carrier 10 kHz offset from carrier 100 kHz offset from carrier |

| 12.4—18.0 GHz |

<-48 dBc

<-60 dBc <-68 dBc <-76 dBc <-100 dBc |

10 Hz offset from carrier

100 Hz offset from carrier 1 kHz offset from carrier 10 kHz offset from carrier 100 kHz offset from carrier |

| Harmonics | <−25 dBc | At +8 dBm |

HP 8671B

General Information

Table 1-1. Specifications (2 of 3)

| Electrical Characteristics | Performance Limits | Conditions |

|---|---|---|

| SPECTRAL PURITY (cont'd) | ||

| Subharmonics and multiples thereof | <-25 dBc | At +8 dBm |

| Spurious Signals, non-harmon- | <-70 dBc | 2.0—6.2 GHz |

| ically related, except power line | <-64 dBc | 6.2—12.4 GHz |

| and fan rotation related | <-60 dBc | 12.4—18.0 GHz |

|

Power line related and fan

rotation related within 5 Hz below line frequencies and |

||

| multiples thereof | <-50 dBc | <300 Hz offset from carrier |

| 2.0—6.2 GHZ | <-60 dBc | 300 Hz to 1 kHz offset from carrier |

| · | <-65 dBc | >1 kHz offset from carrier |

| 6 2_12 4 CHz | <-44 dBc | <300 Hz offset from carrier |

| 0.2-12.1 0112 | <-54 dBc | 300 Hz to 1 kHz offset from carrier |

| <-59 dBc | >1 kHz offset from carrier | |

| 12.4—18.0 GHz | <-40 dBc | <300 Hz offset from carrier |

| <-50 dBc | 300 Hz to 1 kHz offset from carrier | |

| <-55 dBc | >1 kHz offset from carrier | |

|

RF OUTPUT

Output Power |

+8 dBm to120 dBm | +15 to +35°C |

| Remote Programming Absolute | ||

| Level Accuracy | +10 dB output level range | |

| 2.0—6.2 GHz | 0 dB output level range | |

| ±1.00 dB | -10 dB output level range | |

| +1 70 dB | -20 dB output level range | |

| ±1.90 dB | -30 dB output level range | |

| ±1.90 dB & ±0.3 dB per 10 dB step | <-30 dB output level range | |

| 6 2—12 4 GHz | ±1.25 dB | +10 dB output level range |

| ±1.25 dB | 0 dB output level range | |

| ±1.75 dB | -10 dB output level range | |

| ±1.95 dB | -20 dB output level range | |

| ±2.15 dB | -30 dB output level range | |

| Con an oraling to to the Bo | ||

| 12.4—18.0 GHz | ±1.50 dB | +10 dB output level range |

| ±1.50 dB | 0 dB output level range | |

| ±2.10 dB | -10 dB output level range | |

| ±2.30 dB | -30 dB output level range | |

| +2.40 dB & ±0.4 dB per 10 dB step | <-30 dB output level range | |

1-5

1

1

| Electrical Characteristics | Performance Limits | Conditions |

|---|---|---|

|

RF OUTPUT (cont')

Manual Absolute Level Accuracy |

Add ±0.75 dB to remote

programming absolute level accuracy |

Absolute level accuracy specifica-

tions include allowances for detec- tor linearity, temperature, flatness, attenuator accuracy, and |

|

Remote Programming Output

Level Resolution |

1 dB | measurement uncertainty. |

| Flatness (total variation) | 0 dBm Range, +15°C to +35°C | |

|

1.50 dB

2.00 dB 2.50 dB |

2.0 to 6.2 GHz

2.0 to 12.4 GHz 2.0 to 18.0 GHz |

|

|

Output Leveling Switching

Time (to be within ±1 dB of final level) |

<20 ms | |

|

REMOTE OPERATION

Frequency |

Programmable over the full range v

mode. |

with the same resolution as manual |

|

Output Level

RF Output ALC |

Programmable in 1 dB steps, +8 to

Programmable to either ON or OFF Programmable for internal, crystal |

–120 dBm, plus 5 dB of overrange

F. diode, or power meter leveling. |

| Interface Function Codes | SH1, AH1, T6, TE0, L4, LE0, SR1, I | RL2, PP2, DC1, DT0, and C0. |

|

GENERAL

Operating Temperature |

0 to +55°C (see note at the beginning | ng of this table). |

| Power | 100, 120, 220, or 240V, +5%, -10%, 4 | 48—66 Hz, 300 VA maximum. |

| E.M.I. |

Conducted and radiated interference

MIL-I-6181D. |

ce is within the requirements of |

| Net Weight | 27.2 kg (60 lbs) | |

|

Dimensions: Height

Width Depth |

146 mm (5.7 in.)

425 mm (16.8 in.) 620 mm (24.4 in.) For ordering cabinet accessories, m System II |

odule sizes are 5-1/4H, 1 MW, 23D, |

| Accessories | Power Cord, Operating and Service extender boards. | Manual, and four |

Table 1-1. Specifications (3 of 3)

HP 8671B

Table 1-2. Supplemental Characteristics

Supplemental characteristics are intended to provide information useful in applying the instrument by giving typical, but non-warranted, performance parameters.

FREQUENCY

Internal Reference: The internal reference oscillator accuracy is a function of time base calibration ± aging rate, ± temperature effects, and ± line voltage effects. Typical temperature and line voltage effects are <1 x 10-7/°C and <5 x 10-10/+5% to -10% line voltage change. Reference oscillator is kept at operating temperature in STANDBY mode with the instrument connected to mains power. The aging rate is <1.5 x 10-9/day after a 24 hour warmup.

External Reference Input: 5 or 10 MHz at a level of 0.1 to 1 Vrms into 50Ω. Stability and spectral purity of the microwave output will be partially determined by characteristics of the external reference frequency.

Reference Outputs: 10 MHz at a level of 0.2 Vrms into 50Ω. 100 MHz at a level of 0.2 Vrms into 50Ω.

SPECTRAL PURITY

Residual FM : 80 Hz rms in a 50 Hz—15 kHz Post-detection bandwidth from 2—6.2 GHz. Residual FM doubles in the 6.2—12.4 GHz range and triples in the 12.4—18.0 GHz range.

RF OUTPUT

For power settings >+3 dBm, changes in frequency from <10 GHz to >16 GHz may require a settling period for the power to stabilize at the set level. Spurious output oscillations may occur for settings above +8 dBm.

External leveling device characteristics will determine output flatness, absolute level accuracy, and switching time in external leveling modes.

Maximum Reverse Power: 1W RF input; 1 MHz—20 GHz, 0 Vdc.

Impedance: 50Ω.

Source SWR: .

General Information

1

| ahla 1.9 | Recommended | Test Fauinme | nt (1 of 3) |

|---|---|---|---|

| 4006 1-0. | ncoummenucu | I COL LUUIDING |

| lnstrument | Critical Specifications |

Recommended

Model |

Use* |

|---|---|---|---|

| AC Voltmeter |

Range: 1 mV to 10V

Accuracy: ±1.5% of full scale ±1.5% of reading Frequency Response: 3 kHz to 3 MHz |

HP 400E | А |

|

Attenuator,

Fixed 3 dB |

Range: dc to 1 GHz

Accuracy: ±0.5 dB SWR: < 1.3 |

HP 8491A

Option 003 |

А |

|

Attenuator,

Fixed 20 dB |

Range: dc to 18 GHz

Accuracy: ±1.0 dB SWR: <1.6 |

HP 8491B

Option 020 |

C, P |

|

Cable, Special

Interconnect |

See YTO Loop Phase Detector Adjustments in

Section V |

Locally Fabricated | А |

| Controller, HP-IB |

HP-IB compatibility as defined by IEEE

Standard 488-1978 and the identical ANSI Standard MC1.1: SH1, AH1, T2, TE0, L2, LE0, SR0, RL0, PP0, DC0, DT0, and C1, 2, 3, 4, 5. |

HP 85B/82937A

or 9826A Option 011 or 9836A with BASIC 2.0 Operating System |

C, A,

T, P |

| Crystal Detector |

Frequency Range: 2 to 18 GHz

Frequency Response: ±1.5 dB |

HP 8470B

Option 012 |

P, A |

| Current Probe | Frequency Range: 2 to 35 MHz | HP 1110B | А |

|

Digital Voltmeter

(DVM) |

Range: -60V to +40V dc

Resolution: 100 µV on 1V dc range |

HP 3456A

or HP 3455A |

А, Т |

|

Foam Pads

(2 required) |

43 × 58 cm (17 × 23 in.), 5 cm (2 in.) thick | Р | |

| Frequency Counter |

Range: 2 to 18 GHz

Resolution: 1 kHz 10 MHz Frequency Standard Output: ≥0.1 Vrms |

HP 5343A | P, A, T |

| Frequency Standard | Long Term Stability: Better than 10 -10 /day | HP 5065A | P, A |

| High Impedance Probe |

Frequency: 400 MHz

Output Impedance: 50Ω (compatible with Spectrum Analyzer). |

HP 1121A | Т |

| Local Oscillator |

Range: 2 to 18 GHz

Level: +7 dBm Single Sideband Phase Noise and Spurious Signals: Same as HP 8340A |

HP 8340A | P, A |

| Logic State Analyzer | 8 Bit Display, Triggerable | HP 1630A | Т |

1-8

HP 8671B

| Table 1-3. | Recommended | Test Equipment | t (2 of 3 ) |

|---|

| Instrument | Critical Specifications |

Recommended

Model |

Use* |

|---|---|---|---|

| Logic Pulser | TTL compatible | HP 546A | Т |

| Mixer |

Response: 2 to 18 GHz

VSWR, LO: ≤ 2.5:1 VSWR, RF: ≤ 4.0:1 |

RHG DMS1–18 1 | P, A |

| Oscilloscope |

Bandwidth: 50 MHz

Vertical Sensitivity: 50 mV/div Vertical Input: 50Ω ac or dc coupled External Trigger Capability |

HP 1980B | P, A, T |

| Power Meter |

Frequency: 2 to 18 GHz

Range: +17 to -25 dBm |

HP 436A | Р, А, Т |

| Power Sensor |

r Sensor

Frequency: 2 to 18 GHz Input Impedance: 50Ω SWR: < 1.28 Range: +17 to -25 dBm Must be compatible with power meter |

Р, А, Т | |

|

Power Source,

Variable Frequency AC |

Range: 110 to 120 Vac

Frequency: 52 to 58 Hz Accuracy ± 2 Hz |

California Instruments

501TC/800T 2 |

Р |

| Power Supply | 0 to 40 Vdc | HP 6200B | A, T |

| Amplifier, Frequency: 100 kHz 20 dB Gain: 20 ± 5 dB' Output Power: > -10 dBm Noise Figure: < 5 dBm | Impedance: 50ΩHP 8447A | Р | |

|

Amplifier,

40 dB |

plifier, Frequency: 100 kHz H

Gain: 45 ± 5 dB Output Power: > -10 dBm Impedance: 50Ω |

Р | |

| Probe, 10:1 | Must be compatible with the oscilloscope. | HP 10017A | A |

| Signal Generator | Output Level: -5 to -20 dBm at 240 MHz | HP 8640B or HP 8340A | A |

|

Spectrum Analyzer

(with Tracking Generator) |

Frequency Range: 20 Hz to 300 kHz

Frequency Span/Division: 20 Hz minimum Noise Sidebands: > 90 dB below CW signal, 3 kHz offset, 100 Hz IF bandwidth Input Level Range: -10 to -60 dBm Log Reference Control: 70 dB dynamic range in 10 dB steps Accuracy: ± 0.2 dB |

HP 8556A/8552B/141T | А |

| Instrument | Critical Specifications |

Recommended

Model |

Use* |

|---|---|---|---|

| Spectrum Analyzer |

Frequency Range: 5 Hz to 50 kHz

Resolution Bandwidth: 1 Hz minimum Frequency Span/Division: 5 Hz to 500 Hz Amplitude Range: 0 to -70 dB |

HP 3580A | P, T |

| Spectrum Analyzer |

Frequency Range: 100 kHz to 22 GHz

Frequency Span/Division: 2 kHz minimum Amplitude Range: +10 to -90 dBm Noise Sideband: > 75 dB down 30 kHz from signal at 1 kHz resolution bandwidth Resolution Bandwidth: 30 Hz to 300 kHz |

HP 8566B | P, A |

| Sweep Oscillator |

Center Frequency: 150 to 200 MHz

Center Frequency Resolution: 0.1 MHz Sweep Range: 10 and 200 MHz |

HP 86222B/8620C

or HP 8340A |

A |

| Termination | 50Ω BNC | HP 11593A | Α |

| Termination | 600Ω BNC Feedthrough | HP 11095A | P, A |

| Test Coupler Adapter | See YTM Adjustments in Section V | Locally fabricated | A |

| Test Oscillator |

Level: 0 to 3V into 50Ω or 300Ω

Range: 60 Hz to 10 kHz |

HP 3335A | A, T |

| [ahie | 1.3 | Recommended | Toet | Fauinment | 13 of | 2) |

|---|---|---|---|---|---|---|

| םועם ו | 1-0. | ກຮວບແມ່ນເຮັບບໍ່ເ | 1621 | ะบบเมณะณ | 15 10 | പ |

* C = Operator's Check, P = Performance Tests, A = Adjustments, T = Troubleshooting

1 RHG Electronics Laboratory, Inc., 161 East Industry Court, Deer Park, NY 11729, Tel. (516) 242-1100, TWX 510-227-6083.

2 California Instruments, 5150 Convoy Street, San Diego, CA 92111, Tel. (714) 279-8620.

HP 8671B

SECTION II

2-1 INTRODUCTION

This section provides the information needed to install the CW Generator. Included is information pertinent to initial inspection, power requirements, line voltage selection, power cables, interconnection, environment, instrument mounting, storage and shipment.

2-2. INITIAL INSPECTION

WARNING

To avoid hazardous electrical shock, do not perform electrical tests when there are signs of shipping damage to any portion of the outer enclosure (covers, panels, meters).

Inspect the shinping container for damage. If the shipping container or cushioning material is damaged, it should be kept until the contents of the shinment have been checked for completeness and the instrument has been checked mechanically and electrically. The contents of the shinment should be as shown in Figure 1-1 Procedures for checking electrical performance are given in Section IV. If the contents are incomplete, if there is mechanical damage or defect. or if the instrument does not pass the electrical performance test. notify the nearest Hewlett-Packard office. If the shipping container is damaged or the cushioning material shows signs of stress. notify the carrier as well as the Hewlett-Packard office. Keep the shipping materials for the carrier's inspection.

2-3. PREPARATION FOR USE

2-4. Power Requirements

The CW Generator requires a power source of 100, 120, 220 or 240 Vac, +5% to -10%, 48 to 66 Hz single phase. Power consumption is 300 VA maximum.

This is a Safety Class I product (that is, provided with a protective earth terminal). An uninterruptible safety earth ground must be provided from the main

power source to the product input wiring terminals, power cord or supplied power cord set. Whenever it is likely that the protection has been impaired, the product must be made inoperative and be secured against any unintended operation.

If this instrument is to be energized via an external autotransformer, make sure the autotransformer's common terminal is connected to the neutral (that is, the grounded side of the mains supply).

2-5. Line Voltage and Fuse Selection

CAUTION

BEFORE PLUGGING THIS INSTRUMENT into the mains (line) voltage, be sure the correct voltage and fuses have been selected.

Verify that the line voltage selection cards and the fuses are matched to the power source. Refer to Figure 2-1, Line Voltage and Fuse Selection.

Fuses may be ordered under HP part numbers 2110-0003, 3.0A (250V) for 100/120 Vac operation and 2110-0043, 1.5A (250V) for 220/240 Vac operation.

2-6. Power Cables

BEFORE CONNECTING THIS IN-STRUMENT, the protective earth terminal of this instrument must be connected to the protective conductor of the (mains) power cables. The mains plug shall only be inserted in socket outlets provided with a protective earth contact. The protective action must not be negated by the use of an extension cord (power cable) without a protective conductor (grounding).

This instrument is equipped with a three-wire power cable. When connected to an appropriate ac power receptacle, this cable grounds the instrument

Figure 2-1. Line Voltage and Fuse Selection

Power Cables (cont'd)

cabinet. The power cable plug shipped with each instrument depends on the country of destination. Refer to Figure 2-2 for the part numbers of power cables available.

2-7. HP-IB Address Selection A

In the CW Generator, the HP-IB talk and listen addresses and the parallel poll sense and response line can be selected by internal switches. Refer to Table 2-1 for a listing of talk and listen addresses. The address is factory set for a Talk address of "S" and a Listen address of "3". (In octal this is 23; in decimal this is 19.)

To change the HP-IB address or to select a different parallel poll response, proceed as follows:

WARNINGS

Internal switch settings should be changed only by service trained persons who are aware of the potential shock hazard of working on an instrument with protective covers removed.

To avoid hazardous electrical shock, the line (mains) power cable should be disconnected before attempting to change any internal switch settings.

Figure 2-2. Power Cable and Mains Plug Part Numbers

Table 2-1 Allowable HP-18 Address Codes

| Address Swit | ches (Octal) |

Talk

Address Char- |

Listen

Address Char- |

Decimal

Equiva- Ient |

|---|---|---|---|---|

| 51 | 52 | duiti | CD | |

| 0 | 0 |

س

۸ |

1 | |

| 0 | - A | ! | ||

| 0 | 2 | 0 | # | 2 |

| 0 | 3 |

т

с |

||

| 0 | 4 |

۵/ |

||

| 0 | 5 | 70 | 6 | |

| 0 | b | ~~ , | 7 | |

| 0 | 1 | |||

| 1 | 0 | Н | ( | 8 |

| 1 | 1 | ) |

y

to |

|

| 1 | 2 | J | 10 | |

| 1 | 3 | K | + | 11 |

| 1 | 4 | 12 | ||

| 1 | 5 | M | _ | 13 |

| 1 | 6 | N | • | 14 |

| 1 | 7 | 0 | 1 | 15 |

| 2 | 0 | Р | 0 | 16 |

| 2 | 1 | Q | 1 | 17 |

| 2 | 2 | R | 2 | 18 |

| 2 | 3 | S. | 3 | 19 |

| 2 | 4 | Т | 4 | 20 |

| 2 | 5 | U | 5 | 21 |

| 2 | 6 | V | 6 | 22 |

| 2 | 7 | W | 7 | 23 |

| 3 | 0 | Х | 8 | 24 |

| 3 | 1 | Y | 9 | 25 |

| 3 | 2 | Z | : | 26 |

| 3 | 3 | [ | ; | 27 |

| 3 | 4 | < | 28 | |

| 3 | 5 | = | 29 | |

| 3 | 6 | 0 | > | 30 |

HP-IB Address Selection (cont'd)

a. Set the LINE switch to STANDBY. Disconnect the line power cable.

b. Remove the CW Generator's top cover by removing the two plastic standoffs from the rear of the top cover and loosening the screw at the middle of the rear edge of the top cover. Then remove the A2 Assembly's protective cover. Refer to the Disassembly Procedures in Section VIII, Service Sheet A.

c. Select the new address as shown in Table 2-1. The switches are shown in Figure 2-3. The HP-IB ADDRESS SELECT switch settings (for S1 and S2) are in the octal code. For example, the factory selected addresses are set to 23 (decimal 19). Therefore, the listen address is '3' and the talk address is 'S'.

d. If the parallel poll sense or response switches are to be changed, remove any HP-IB cables or connectors from the HP-IB connector, and remove the HP-IB connector. Then remove the A2A9 Board Assembly.

e. The PARALLEL POLL SENSE switch (S4) is set to either the OFF, 0 (zero) or 1 (one) position. The zero position provides a false (+2.5 to 5 volts) output on the asserted HP-IB data line; the one position provides a true (0 to +0.4V) output on the asserted HP-IB data line.

f. The PPR (Parallel Poll Response) switch (S3) is set to select one of eight lines (one of 1 through 8 of the HP-IB data bus). The selected line passes the CW Generator's parallel poll response to the HP-IB controller.

g. Re-install the A2A9 Assembly and HP-IB connector.

h. Replace the A2 Assembly's internal cover, the instrument's top cover, and rear standoffs.

| Part Land | 1. Languel | the hast a second | A 14 . A . A . |

|---|---|---|---|

| 11 11 | 4 1 / 1 | 1. (1.1.) | 1 |

| S1 |

\

$2 |

||

| S1 | Š2 |

Figure 2-3. HP-IB Address Switches Shown as Set by the Factory

2-8. Interconnections

Interconnection data for the Hewlett-Packard Interface Bus is provided in Figure 2-4.

2-9. Mating Connectors

HP-IB Interface Connector. The HP-IB mating connector is shown in Figure 2-4. Note that the two securing screws are metric.

Coaxial Connectors. Coaxial mating connectors used with the CW Generator RF output should be 500 Type N male connectors.

2-10. Operating Environment

The operating environment should be within the following limitations:

0

Operating Environment (cont'd)

| Temperature | 0 to +55°C |

|---|---|

| Humidity | |

| Altitude | <4570 metres (15,000 feet) |

NOTE

Specifications for RF Output apply only between +15 and +35°C.

2-11. Bench Operation

The instrument cabinet has plastic feet and foldaway tilt stands for convenience in bench operation. (The plastic feet are shaped to ensure selfaligning of the instruments when stacked.) The tilt stands raise the front of the instrument for easier viewing of the front panel.

2-12. Rack Mounting

WARNING

The CW Generator weighs 27.2 kg (60 lbs), therefore extreme care must be exercised when lifting to avoid personal injury. Use equipment slides when rack mounting the instrument.

Rack mounting information is provided with the rack mounting kits. If the kits were not ordered with the instrument as options, they may be ordered through the nearest Hewlett-Packard office. Refer to the paragraph entitled Mechanical Options in Section I.

2-13. STORAGE AND SHIPMENT

2-14. Environment

The instrument should be stored in a clean, dry environment. The following environmental limitations apply to both storage and shipment:

| Temperature | 55 to +75°C |

|---|---|

| Humidity | |

| Altitude | 15,300 metres (50,000 feet) |

2-15. Packaging

Preparation for Packaging. Remove handles and/or rack mount flanges before packaging instrument for shipping.

Tagging for Service. If the instrument is being returned to Hewlett-Packard for service, please complete one of the blue repair tags located at the back of this manual and attach it to the instrument.

Original Packaging. Containers and materials identical to those used in factory packaging are available through Hewlett-Packard offices. Mark the container "FRAGILE" to assure careful handling. In any correspondence refer to the instrument by model number and full serial number.

Other Packaging. The following general instructions should be used for re-packaging with commercially available materials:

a. Wrap the instrument in heavy paper or plastic. (If shipping to a Hewlett-Packard office or service center, complete one of the blue tags mentioned above and attach it to the instrument.)

b. Use a strong shipping container. A doublewall carton made of 2.4 MPa (350 psi) test material is adequate.

c. Use enough shock-absorbing material (75 to 100 mm layer; 3 to 4 inches) around all sides of the instrument to provide firm cushion and prevent movement in the container. Protect the front panel with cardboard.

d. Seal the shipping container securely.

e. Mark the shipping container "FRAGILE" to assure careful handling.

SECTION III OPERATION

3-1. INTRODUCTION

This section provides complete operating information for the CW Generator. Included are both simplified and detailed operating instructions, detailed descriptions of the front and rear panel, local and remote operator's checks, and operator's maintenance.

3-2. Panel Features

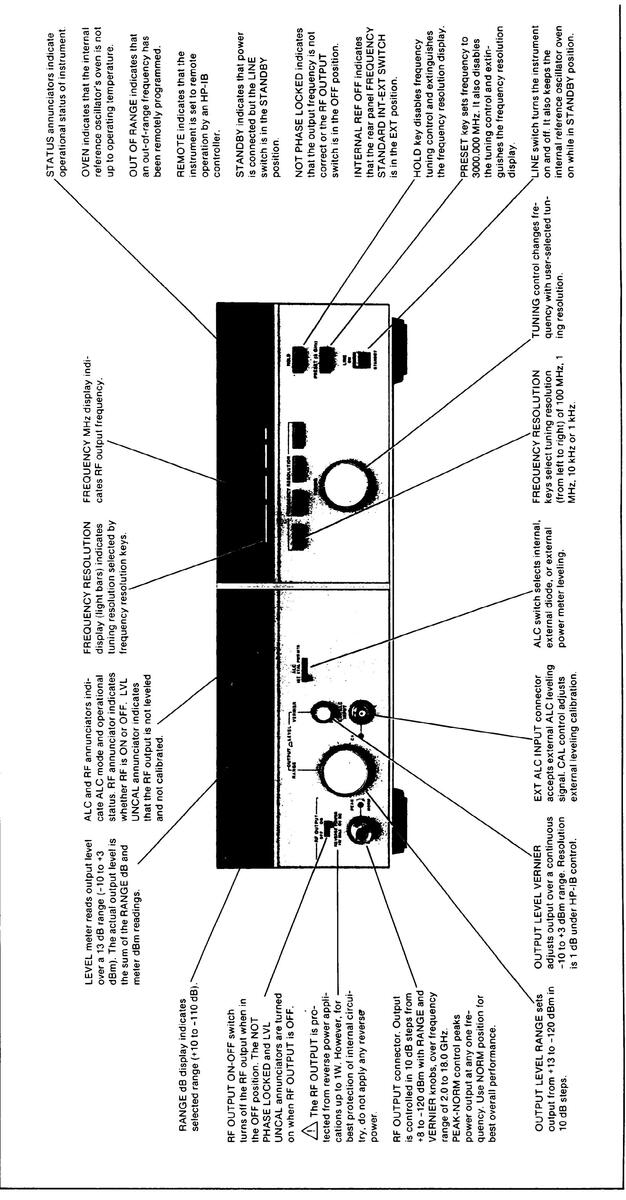

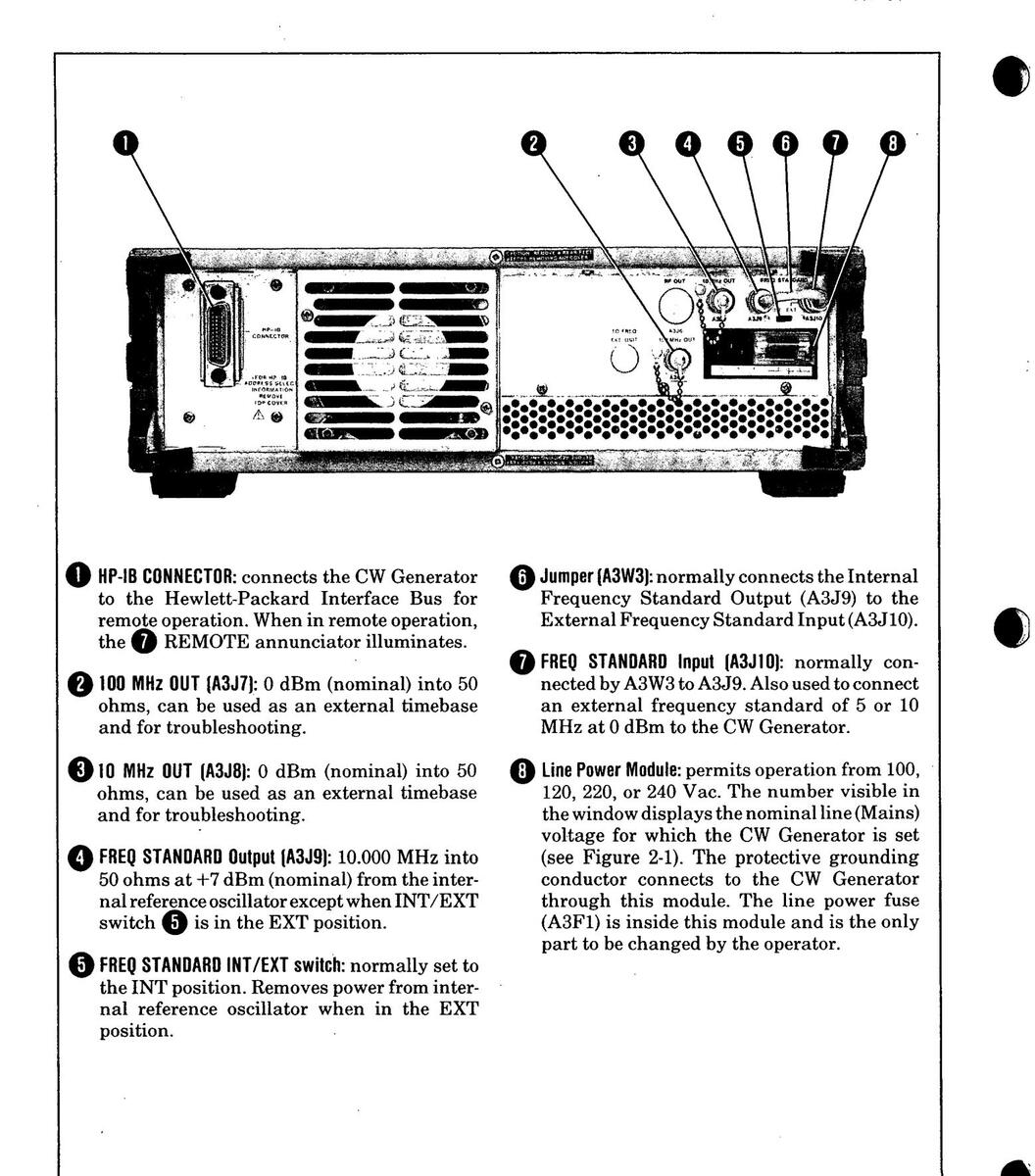

Front and rear panel features are described in detail in Figures 3-1 and 3-2.

3-3. Operating Characteristics

Table 3-1 briefly summarizes the major operating characteristics of the CW Generator. This table is not intended to be a complete listing of all operations and ranges, but gives a general idea of the instrument's capabilities. For more information on the CW Generator's capabilities, refer to Table 1-1, Specifications, and Table 1-2, Supplemental Characteristics. For information on HP-IB capabilities, refer to Table 3-3, Message Reference Table.

3-4. Local Operation

Information covering front panel operation of the CW Generator is given in the sections described below. To quickly learn the operation of the instrument, begin with Operating Characteristics and Simplified Operation. (Operator's Checks can also be used to gain familiarity with the instrument.) Once familiar with the general operation of the instrument, use the Detailed Operating Instructions as a reference for more complete operating information.

Turn-On Information. Instructions relating to the CW Generator turn-on procedure and frequency standard selection are presented to acquaint the user with the general operation of the instrument.

Simplified Operation. The instructions located on the inside of the fold provide a quick introduction to the operation of the CW Generator. In addition, an index to the Detailed Operating Instructions

is provided to direct the user to the more complete discussion of the topic of interest.

Detailed Operating Instructions. The Detailed Operating Instructions provide the complete operating reference for the CW Generator user. The instructions are organized alphabetically by subject. They are indexed by function in Table 3-2.

3-5. Remote (HP-IB) Operation

The CW Generator is capable of remote operation via the Hewlett-Packard Interface Bus (HP-IB).

HP-IB is Hewlett-Packard's implementation of the IEEE Standard 488, "IEEE Standard Digital Interface for Programmable Instrumentation", also described by the identical ANSI Standard MC1.1. For a more detailed information relating to programmable control of the CW Generator, refer to Remote (HP-IB) Operation in this section.

This section includes discussions on capabilities, addressing, input and output formats, the status byte and service request. In Table 3-4 is a complete summary of programming codes. In addition, programming examples are given in HP-IB Checks and in the Detailed Operating Instruction.

3-6. Operator's Checks

Operator's Checks are procedures designed to verify proper operation of the CW Generator's main functions. Two procedures are provided as described below.

Basic Functional Checks. This procedure requires only a 50 ohm load or attentuator to perform. For greater assurance, a microwave counter and a power meter can be used. This procedure assures that most front panel controlled functions are being properly executed by the CW Generator.

HP-IB Checks. This procedure assumes that front panel operation has been verified with the Basic Functional Checks. The procedure checks all of the applicable bus messages summarized in Table 3-3.

3-1

| Frequency |

Range: 2.0 to 18.0 GHz

(Overrange to 18.599997 GHz) |

|||

|---|---|---|---|---|

| Resolution: 1 kHz 2.0 to 6.2 GHz | ||||

| 2 kHz 6.2 to 12.4 GHz | ||||

| 3 kHz 12.4 to 18.0 GHz | ||||

| Output Level | Range: -120 to +8 dB in 10 dB steps | |||

| Vernier: -10 to +3 dBm continuously variable | ||||

| ALC | Internal, external crystal detector, or external power meter leveling. | |||

Table 3-1. Operating Characteristics

Table 3-2. Index of Detailed Operating Instructions

| 3-14 | ALC CONTROL | |

| Local Procedure | 3-4 | |

| Internal Leveling | 3-4 | |

| External Crystal Detector Leveling | 3-4 | |

| External Power Meter Leveling | 3-4 | |

| Remote Procedure | 3-5 | |

| Comments | 3-7 | |

| 3-15 | FREQUENCY CONTROL | 3-8 |

| Local Procedure | 3-8 | |

| Remote Procedure | 3-8 | |

| Comments | 3-10 | |

| 3-16 | LEVEL CONTROL | 3-12 |

| Local Procedure | 3-12 | |

| Remote Procedure | 3-12 | |

| Comments | 3-13 | |

| 3-17 | PEAK-NORM ADJUSTMENT | 3-15 |

| Local Procedure | 3-15 | |

| Comments | 3-15 | |

| 3-18 | RF ON-OFF SWITCH | 3-16 |

| 0 10 | Local Procedure | 3.16 |

| Remote Procedure | 3.16 | |

| Comments | 3-16 | |

3-7. Operator's Maintenance

WARNING

For continued protection against fire hazard, replace the line fuse with a 250V fuse of the same rating only. Do not use repaired fuses or short-circuited fuseholders.

Operator's maintenance consists of replacing defective primary fuses. This fuse is located in the line module assembly. Refer to Figure 2-1 for instructions on changing the fuse.

3-8. TURN-ON INSTRUCTIONS

efore the instrument is switched on, all protective earth termi-1als, extension cords, autotransformers and devices connected to it should be connected to a protective earth grounded socket. Any interruption of the protective earth Brounding will cause a potential shock hazard that could result in personal injury.

Only 250V normal blow fuses with the required rated current should be used. Do not use repaired fuses or short circuit fuseholders. To do so could cause a shock or fire hazard.

Before the instrument is switched on, it must be set to the voltage of the power source or damage to the instrument may result.

A The CW Generator's RF OUTPUT is protected against reverse power applications up to 1W. However, for greatest protection of expensive internal components, be careful not to apply any reverse power to the RF OUTPUT.

3-9. Turn-On

Turn-On Procedure. The CW Generator has a STANDBY state and an ON state. Whenever the power cable is plugged in, an oven is energized to keep the reference oscillator at a stable operating temperature. If the CW Gener-ator is already plugged in, set the LINE switch to ON.

If the power cable is not plugged in, follow these instructions.

On the rear panel:

- Check the line voltage switch for correct voltage selection.

- 2. Check that the fuse rating is appropriate for the line voltage used (see Figure 2-1).

- Plug in the power cable.

On the front panel, set the LINE switch to ON.

NOTE

The OVEN status annunciator should light to indicate that the CW Generator requires warming up. The annunciator should turn off within fifteen minutes and the CW Generator should be ready for general use.

Furn-On Configuration . The CW Generator turns on at the same frequency as before it was switched to STANDBY or even completely off (that is, if line

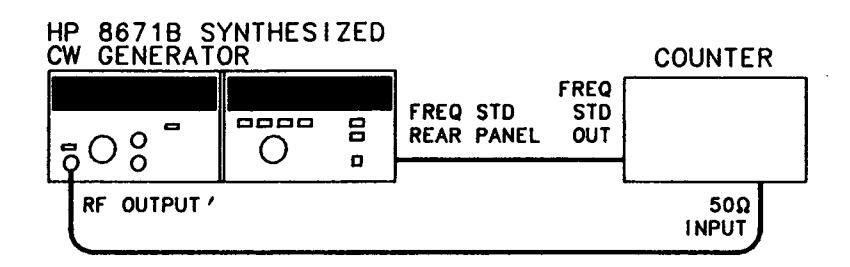

3-10. Frequency Standard Selection

A FREQ STANDARD INT/EXT switch and two connectors are located on the rear panel. A jumper normally connects the FREQ STANDARD INT connector (A3J9) to the FREQ STANDARD EXT connector (A3J10). The

requency Standard Selection (cont'd)

FREQ STANDARD EXT connector can accept a reference signal to be used instead of the CW Generator's internal reference oscillator.

When the FREQ STANDARD INT/EXT switch is in the INT position and the jumper is connected between A3J9 and A3J10, the internal reference scillator is enabled.

When the FREQ STANDARD INT/EXT switch is in the EXT position and the jumper is disconnected from the FREQ STANDARD EXT connector, a requency standard of 5 or 10 MHz at 0 dBm (nominal) can be connected.

the INTERNAL REF OFF status annunciator on the front panel will light when an external reference is being used. Also, the NOT PHASE LOCKED status annunciator may light if the external reference is not of sufficient accuracy in frequency or has an insufficient power level. The external reference must be within -200 Hz of 10 MHz or ±100 Hz of 5 MHz for reliable locking to occur. If the external reference level is not within the specified limits (0.1 to 1 Vrms into 50 ohms), its level may be sufficient to urn off the NOT PHASE LOCKED status annunciator. However. he phase noise of the CW Generator may be degraded.

Operation FRONT PANEL FEATURES

Ô

3-11. SIMPLIFIED OPERATION

3-12. Frequency

Frequency is set using the FREQUENCY RESO-LUTION keys and the TUNING knob. For example, to set the frequency to 15345.678 MHz:

Press PRESET (3 GHz). This is not always necessary, but it will set the right-hand six digits to 0, and may provide a convenient starting point.

Select the 100 MHz FREQUENCY RESOLUTION key and adjust the TUNING knob for a frequency of 15300.000 MHz.

Select the 1 MHz FREQUENCY RESOLUTION key and adjust the TUNING knob for a frequency of 15345.000 MHz. Select the 10 kHz FREQUENCY RESOLUTION key and adjust the TUNING knob for a frequency of 15345.670 MHz.

Select the 1 kHz FREQUENCY RESOLUTION key and adjust the TUNING knob for a frequency of 15345.678 MHz.

Press HOLD to disable the TUNING knob.

3-13. Output Level

The output level is set with the OUTPUT LEVEL RANGE and VERNIER controls.

First, adjust RANGE to step the output level up or down by increments of 10 dB. The selected range is shown in the RANGE dB display.

Adjust VERNIER between -10 and +3 dBm, as read on the meter, for the desired output level.

The output level is determined by adding the RANGE dB display to the LEVEL dBm meter reading.

3-14. ALC

ALC (automatic level control) has three modes of operation. They are:

INT (Internal leveling)

- XTAL (External leveling using a crystal diode detector)

- PWR MTR (External leveling using a power meter)

Internal leveling is selected for most applications. In this mode, an internal detector senses the level at the input of the 10 dB step attenuator, and the internal leveling circuitry keeps the output level constant. Loss of leveling is indicated by the LVL UNCAL annunciator.

For external leveling a crystal diode detector or power meter can be used. Operation is described further in the Detailed Operating Instructions.

3-15. ALC CONTROL

Description

Local

Procedure

tion The Synthesized CW Generator has three modes of Automatic Level Control (ALC):

INT (Internal leveling) XTAL (External leveling using a crystal diode detector) PWR MTR (External leveling using a power meter)

For most applications internal ALC (INT) will be used. With internal ALC the output power remains flat over the entire 2 to 18 GHz frequency range.

External ALC is used when the power level at a remote point must be kept constant. External ALC reduces power variations due to external cables and connectors.

The ALC switch selects the leveling mode. Positive or negative detectors can be used to supply the external ALC input voltage. A calibration adjustment allows the externally leveled power to be adjusted to match the VERNIER setting over a limited output power range. The calibration adjustment does not affect internal leveling

ALC mode and status are indicated by the ALC display. The display indicates which leveling source is selected and when the output is unleveled. The status of the ALC, whether leveled or unleveled, can also be determined remotely by reading the status byte.

To use Internal Leveling:

Set the ALC selector to INT. The output level will be the sum of the range and VERNIER settings.

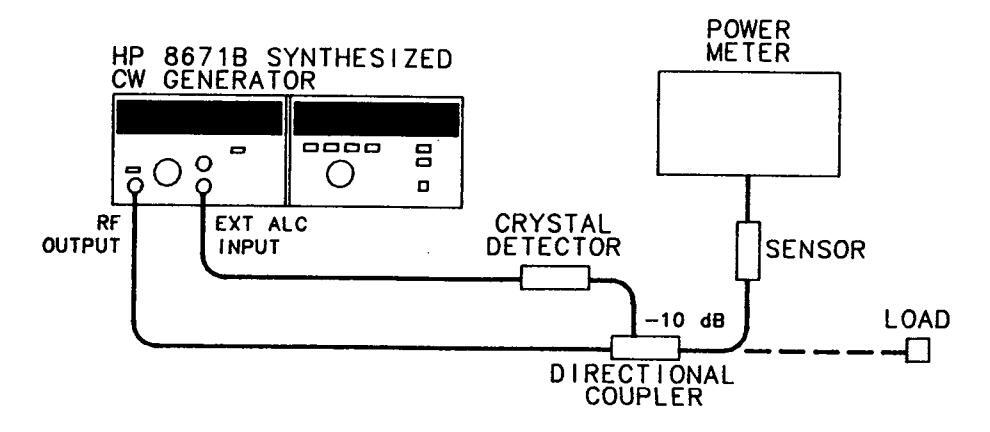

To use XTAL (External Crystal) Leveling:

- 1. Connect the crystal detector and the 10 dB coupler as shown in Figure 3-3.

- 2. Set the ALC selector to INT and adjust the VERNIER to read 0 dBm on the meter. This allows calibration of the meter to the leveled point.

- 3. Set the output level range to 0 dB and the ALC selector to XTAL.

- 4. Adjust the ALC CAL control to set the level read on the power meter to the nearest 10 dBm. If the ALC control does not have enough range for a low power level adjustment, step the RANGE down until the adjustment can be made.

This level should be within -3 dB and +10 dB of the desired level. This calibrates the meter to agree with the leveled power. If the detector is operating in the square law

Figure 3-3. External Leveling with a Crystal Detector

ALC CONTROL (cont'd)

Local Procedure (cont'd)

region, the VERNIER will now control the level over a continuous 13 dB range, and the CW Generator's meter reading will track with the power meter reading as the VERNIER control is varied through the -10 to +3 dBm range.

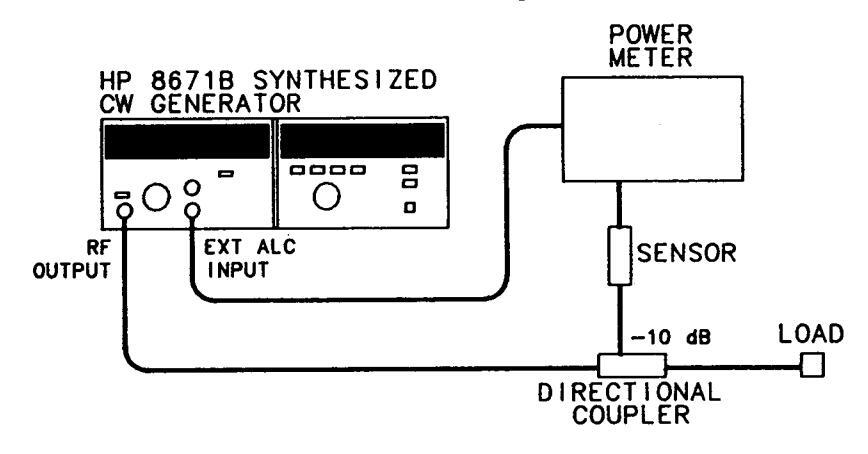

To use external power meter leveling:

- 1. Set the ALC selector to INT and adjust the VERNIER to read 0 dBm on the meter. This allows calibration of the CW Generator's meter to the leveled point.

- 2. Connect power meter to the point where leveling is to be used as shown in Figure 3-4. A directional coupler can be used to sample the power at the desired point. Set the output level to the desired power and select the range hold function on the power meter. This disables range changes and keeps the leveled power from oscillating.

- 3. Connect the recorder output of the power meter to the external ALC input connector. The recorder output is a voltage that is proportional to the measured power in watts. This voltage varies from 0 to 2 volts for each power meter range. Leveling as low as -60 dBm can be accomplished with a sensitive power sensor using this method.

- 4. Set the output level range to 0 dB and the ALC selector to PWR MTR.

- 5. Adjust the ALC CAL controls to set the level read on the power meter to the nearest 10 dBm. This level should be within -3 dB and +10 dB of the desired level (minus the coupling factor of the directional coupler). This calibrates the CW Generator's meter to agree with the leveled power. This power leveling method has a slow settling time but has the advantage of high sensitivity and temperature compensation.

If the ALC CAL control does not have enough range for a low power level adjustment, step the RANGE down until the adjustment can be made.

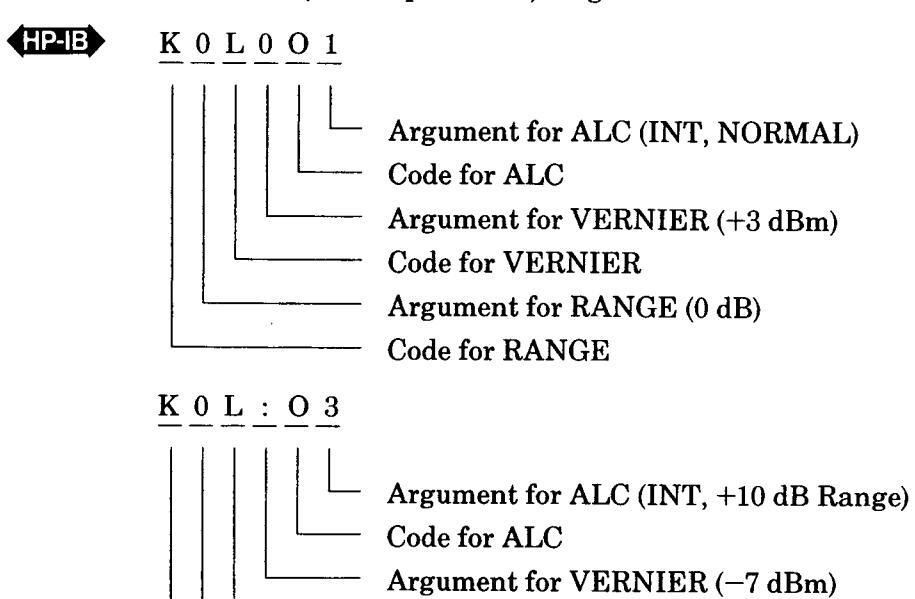

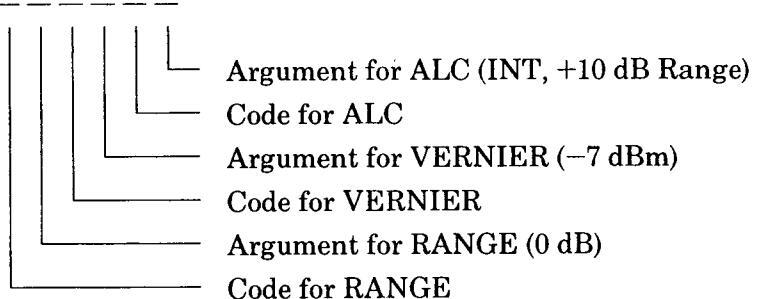

Remote Procedure

The ALC program code controls the function of the RF output ON/OFF switch, the ALC selector and the +10 dB range of output power. The program string consists of the letter O followed by a single argument representing the desired combination of the control positions.

To set the CW Generator to the +10 dB range, you must first set it to 0 dB with the range command (code and argument) K0. Then you can set the +10 dB range with the appropriate ALC command.

The codes are summarized in the table under Program Codes.

Figure 3-4. External Leveling with a Power Meter

ALC CONTROL (cont'd)

Example

To set internal ALC with an output level of +3 dBm:

Local

Set ALC selector to INT, RF output to ON, range to 0 dB and VERNIER for +3 dBm.

Set ALC selector to INT, RF output to ON, range to +10 dB and VERNIER to -7 dBm.

— Code for VERNIER

— Argument for RANGE (0 dB)

- Code for RANGE

| Deseure Onde | ALC Mode | |||

|---|---|---|---|---|

| rrogram Gode | RF | RANGE | ALC | Argument |

| OFF | NORM |

INT

XTAL PWR MTR |

0

4 < |

|

| OFF | +10 |

INT

XTAL PWR MTR |

2

6 > |

|

| (letter O, not zero) | NORM |

INT

XTAL PWR MTR |

1

5 = |

|

| ON | +10 |

INT

XTAL PWR MTR |

3

7 ? |

|

| _ | ||

|---|---|---|

| Program | Codes | HP-IB |

ALC CONTROL (cont'd)

Comments

Output level flatness is dependent on the ALC circuitry and the maximum available power. In order to have a leveled output it is necessary for the ALC circuitry to continuously control the output level. This can only occur if the selected output power is below the maximum power level available at each frequency. For leveled output power in the +10 dB range, it is necessary that the LVL UNCAL annunciator remain off.

External ALC leveling also requires that the CW Generator can produce enough power to overcome losses in the intervening circuitry. The LVL UNCAL annunciator must remain off to achieve leveling. The 0 dB range should be used when using external leveling. If any of the lower ranges are used, the CW Generator must produce a higher level to overcome the attenuation introduced by the range selected.

For output level settings above +8 dBm, spurious oscillations can occur, resulting in sidebands on the carrier at a level of 30 to 50 dBc. These oscillations occur only over small portions of the frequency range. They can usually be eliminated by performing a PEAK-NORM adjustment or by reducing the output level VERNIER setting 1 or 2 dB.

Typical output level switching times are detailed under Level Control. Enabling the RF output requires less than 30 milliseconds. Disabling the RF output can be accomplished in less than 5 milliseconds.

The state of the RF output (on or off) and the status of the +10 dB range (selected or not selected) can be obtained by reading the status byte. The status of the ALC circuitry (leveled or not leveled) can also be monitored by reading the status byte. Once the status byte indicates that the output is leveled, an application can continue without waiting the specified time for the output level to settle.

Related Sections

Level Control PEAK-NORM Adjustment

3.16 FREQUENCY CONTROL

Description The CW Generator uses a simple, convenient frequency tuning system.

All frequencies can be remotely programmed or entered manually by a tuning knob. The knob can be turned in either direction without encountering a mechanical stop. Also, the faster it is turned the greater the frequency change per revolution.

In addition, four degrees of coarse to fine tuning can be selected. Frequency resolution keys located above the tuning knob select 100 MHz, 1 MHz, 10 kHz or 1 kHz tuning increments. Due to frequency multiplication to generate frequencies above 6.2 GHz, the minimum tuning increment (resolution) is 2 kHz above 6.2 GHz and 3 kHz above 12.4 GHz.

Once a desired frequency has been set, pressing the HOLD key will disable the tuning control and prevent unintentional changes in the frequency. The preset key sets the output frequency to 3000.000 MHz for conveniently setting the least significant digits to zeroes.

When the CW Generator is turned off or the power cable is removed, the last frequency setting is stored in battery-powered memory. When the instrument is powered up, the frequency returns to the stored value. This feature maintains the frequency setting even after power failures or extended periods without power.

Local Procedure

To set the output frequency to any desired frequency:

- 1. Press PRESET (3 GHz). This is not always necessary, but it will set the right-hand six digits to 0, and may provide a convenient starting point.

- 2. Select the desired tuning increment (100 MHz, 1 MHz, 10 kHz, or 1 kHz) by pressing the appropriate FREQUENCY RESOLUTION key, and use the TUNING knob to set the frequency digits above the rightmost lighted segment in the frequency resolution display.

- 3. Once the desired frequency is set, press the HOLD key to disable the TUNING knob.

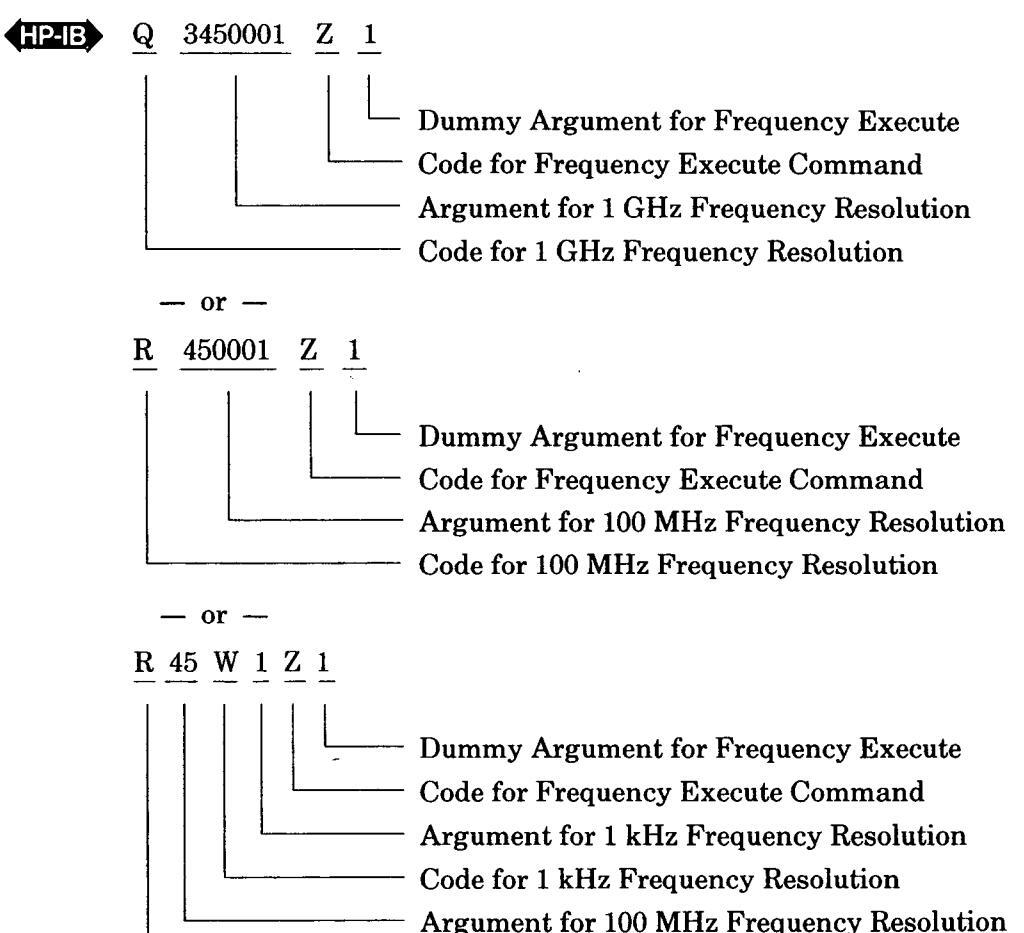

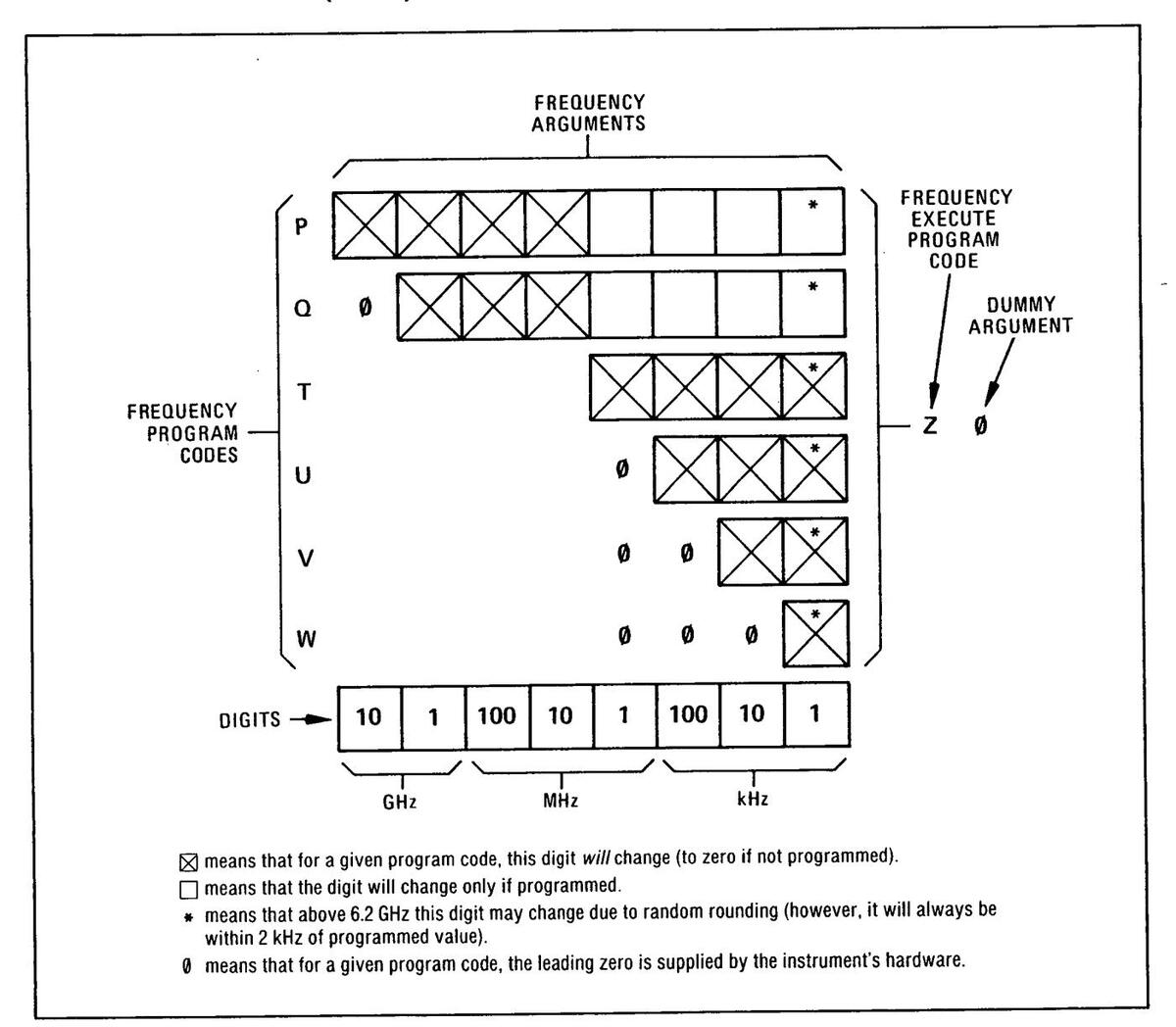

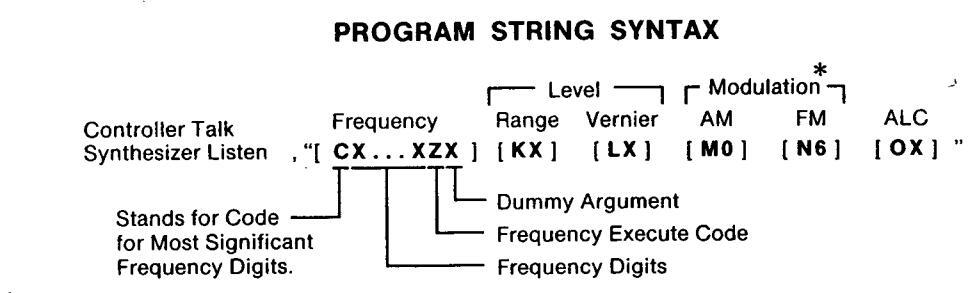

RemoteThe CW Generator accepts any frequency within its range (2000.000 to 18599.997 MHz)Procedureto 8 significant digits. Above 6.2 GHz the frequency is randomly rounded up or down to<br/>be compatible with the 2 kHz or 3 kHz resolution at the programmed frequency.

The CW Generator ignores spaces, commas, decimal points, carriage returns and line feeds.

Within the CW Generator, frequency information is stored in two separate blocks of four digits each. The effects of programming codes on the two internal frequency data blocks are shown in Figure 3-5. One block contains the 10 GHz through 10 MHz frequency digits and the other contains the 1 MHz through 1 kHz digits. Programming within one block does not change the other blocks unless it is necessary to round off a frequency above 6.2 GHz. The programming codes indicate the most significant digit being programmed.

The output frequency does not change until the frequency execute command (Z1) is received by the CW Generator. This command must be sent sometime after the frequency data has been sent.

Frample

To change frequency from 3000.231 MHz to 3450.001 MHz:

Local

- Press the 100 MHz (leftmost) FREQUENCY RESOLUTION key. Adjust TUNING for a frequency of 3400.000 MHz.

- 2. Press the 1 MHz (next) FREQUENCY RESOLUTION key. Adjust TUNING for a frequency of 3450.000 MHz.

- 3. Press the 1 kHz (rightmost) FREQUENCY RESOLUTION key. Adjust TUNING for a frequency of 3450.001 MHz.

————————————————————————————————————

| PROGRAM ( | CODES | ARGUMENTS | |

|---|---|---|---|

| FREQUENCY |

10 GHz

1 GHz 100 MHz 10 MHz 1 MHz 100 kHz 100 kHz 1 kHz EXECUTE |

@ or P

A or Q B or R C or S D or T E or U F or V G or W J or Z |

0 THROUGH 9 |

Program Codes

FREQUENCY CONTROL (cont'd)

Figure 3-5. Frequency Programming Codes and Arguments

Comments Due to the use of frequency multiplication to generate frequencies above 6.2 GHz, the frequency sometimes cannot be set precisely to a desired value. Frequencies between 2 and 6.2 GHz can be set to the nearest 1 kHz. All frequencies between 6.2 and 12.4 GHz can be set within 1 kHz of the desired value. All frequencies between 12.4 and 18 GHz can be set within 2 kHz of the desired frequency.

When the CW Generator is programmed to a frequency that is not evenly divisible, a random roundoff occurs. To prevent this, remote programming one should perform a calculation to determine whether the frequency can be set exactly.

To determine whether a frequency can be set to a given value, divide the desired frequency (in kHz) by two if it is between 6.2 and 12.4 GHz, or by three if it is above 12.4 GHz. IF the result is a whole number (with no remainder) the frequency can be set to the

C

FREQUENCY CONTROL (cont'd)

Comments (cont'd)

desired value. For example, 16 GHz divided by three (it is above 12.4 GHz) is 5333333.33 kHz, so this frequency cannot be set exactly. The nearest frequencies that can be set are 15.999999 GHz (5.333333 × 3) and 16.000002 GHz (5.333334 × 3).

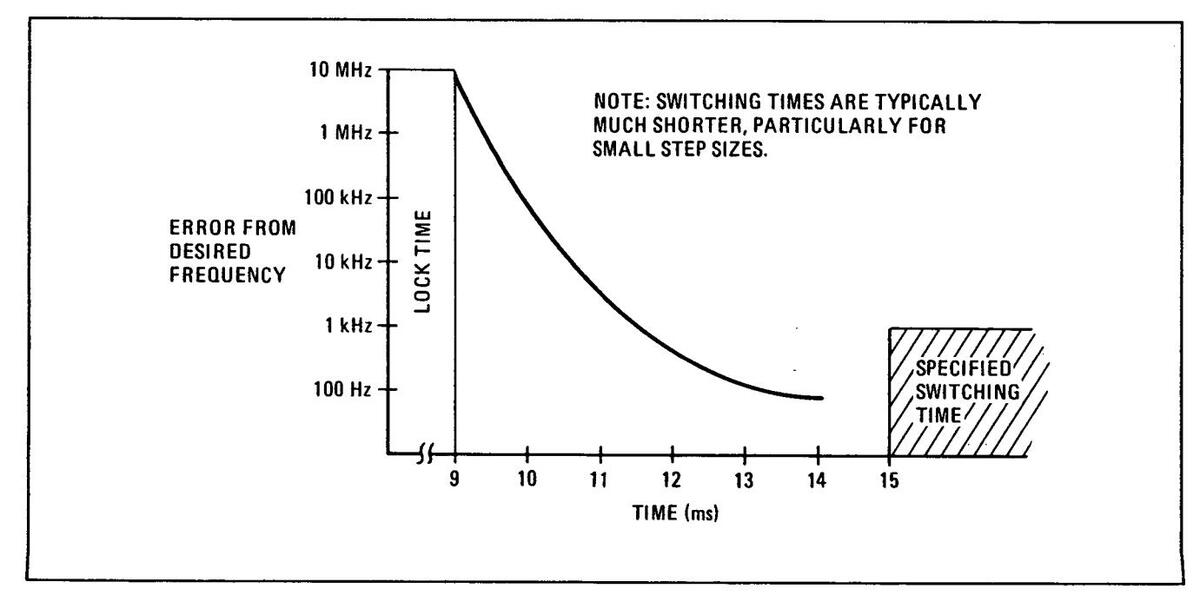

The time it takes to switch from one frequency to the next depends on the largest frequency digit being changed. Generally, the smaller the digit being changed, the shorter the switching time. Typical switching times by largest digit being changed for frequencies between 2 and 6.2 GHz can be summarized as follows:

|

Largest Digit

Changed |

Time to be

Within 1 kHz |

|---|---|

| 100 MHz | 10 ms |

| 10 MHz | 10 ms |

| 1 MHz | 10 ms |

| 100 kHz | 5 ms |

| 10 kHz | 3 ms |

| 1 kHz | 1.5 ms |

For frequencies above 6.2 GHz, actual frequency digits being changed must be determined by dividing the output frequency by two (6.2 to 12.4 GHz) or three (12.4 to 18 GHz). The actual data transfer time is only a small portion of the frequency switching time and can be ignored.

For applications that require fast execution, the status byte can be checked until the frequency is phase locked. Once the status byte indicates that the CW Generator is phase locked, the application may continue with the assurance that the frequency is correct. Figure 3-6 shows the typical worst case lock and settling times.

1

3-17. LEVEL CONTROL

Description The Synthesized CW Generator is calibrated over a wide range of output power levels from +8 dBm to -120 dBm. The output level is set with a RANGE selector and a VERNIER control. The output level is the sum of the settings of these two controls.

The RANGE selector varies the output level in 10 dB steps. The selected range (+10 dB to -110 dB) is digitally displayed in the RANGE display. This display indicates the selected range in both local and remote modes. Output level ranges of 0 dB to -110 dB are programmable with the range program code. The +10 dB range is selected using the ALC program code.

The VERNIER knob continuously varies the output level in the 0 dB range from -10 to +3 dBm. The VERNIER setting is indicated by the front panel meter.

In local mode the VERNIER can be varied continuously over the full 13 dB range. In remote mode the VERNIER can be programmed in fourteen 1 dB steps from -10 dBm to +3 dB. Because the VERNIER can be controlled over greater than 10 dB in both local and remote mode, it is possible to overlap range settings by 3 dB. This is useful in applications where the ability to vary the output power continuously about a given level is critical.

Local To set the output level to any desired value:

Procedure

- 1 Set the CW Generator ALC mode to internal (INT).

- 2. Set the OUTPUT LEVEL RANGE to within -3 to +10 dB of the desired output level. For example, for a -56 dBm output level choose the -50 dB range.

- 3. Adjust the OUTPUT LEVEL VERNIER setting until the sum of the range display and the meter is equal to the desired output level.

Some output levels may be set using either of two adjacent ranges. Either range may be used. For example, +3 dBm may be set with a 0 dB range and +3 dBm VERNIER setting or a +10 dB range and -7 dBm VERNIER setting.

Setting output levels above +8 dBm may cause an ALC unleveled condition due to insufficient power available. The meter will indicate the actual power available when the unleveled condition occurs.

RemoteThe 0 dB to -110 dB ranges and the VERNIER setting are programmed with the output<br/>level program codes. The VERNIER setting is programmed in 1 dB steps from -10 dBm<br/>to +3 dBm. The range is programmed in 10 dB steps from 0 dB to -110 dB. The +10 dB<br/>range is programmed by setting RANGE to 0 dBm and ALC to +10 dB.

When switching from local to remote mode, the VERNIER is reset to -10 dB and the range remains unchanged.

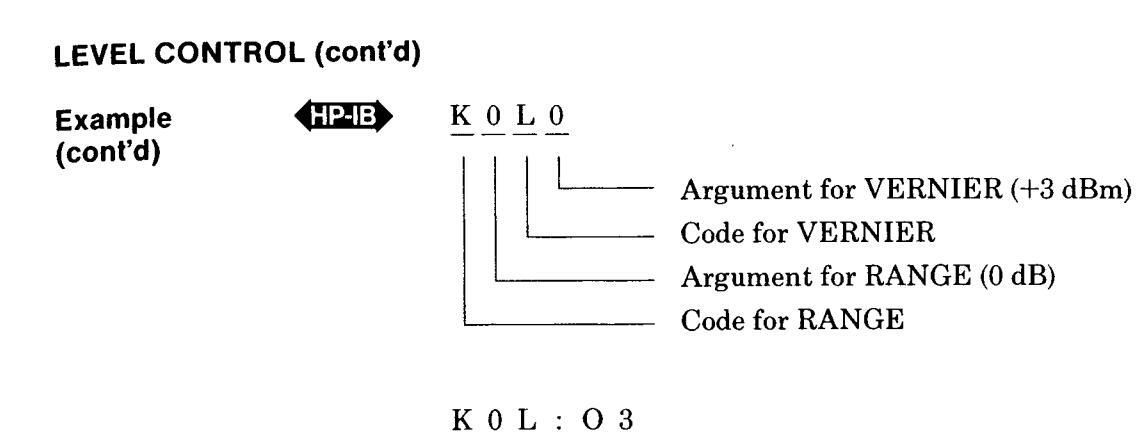

Example To set the output level to +3 dBm:

Local

Set RANGE to 0 dB and VERNIER to +3 dBm.

Or

Set RANGE +10 dB and VERNIER to -7 dBm.

| ſ | Program Codes | Argumen | its | Program Codes | Argumen | its | |

|---|---|---|---|---|---|---|---|

| OUTPUT LEVEL RANGE | К |

0 dBm

-10 -20 -30 -40 -50 -60 -70 -80 -90 -100 -110 |

0

1 2 3 4 5 6 7 8 9 : ; |

OUTPUT LEVEL VERNIER | L |

+3 dB

+2 +1 0 -1 -2 -3 -4 -5 -6 -7 -8 -9 -10 |

0

1 2 3 4 5 6 7 8 9 :; < = |

Comments Output level flatness is dependent on the ALC circuitry and the maximum available power. In order to have a leveled output it is necessary for the ALC circuitry to continuously control the output level. This can only occur if the selected output power is below the maximum power level available at each frequency. For leveled output power in the +10 dB range, it is necessary that the LVL UNCAL annunciator remain off. If it lights, adjust the PEAK-NORM control, or reduce the VERNIER setting.

For output level settings above +8 dBm, spurious oscillations can occur, resulting in sidebands on the carrier at a level of 30 to 50 dBc. These oscillations occur only over small portions of the frequency range.

Program Codes

LEVEL CONTROL (cont'd)

Comments (cont'd) They can usually be eliminated by performing a PEAK-NORM adjustment or by reducing the OUTPUT LEVEL VERNIER setting 1 or 2 dB.

External ALC leveling also requires that the CW Generator can produce enough power to overcome losses in the intervening circuitry. The LVL UNCAL annunciator must remain off to achieve leveling. If it lights adjust the PEAK-NORM control, or decrease the the VERNIER setting.

Typical output level range change execution time for a 10 dB step is less than 20 milliseconds. An output level VERNIER change of 1 dB will take less than 10 milliseconds. These times are typical for remote programming. The actual data transfer time is a very small part of the execution time and may be ignored for most controllers.

The RF output changing from enabled to disabled takes less than 5 milliseconds. To enable the RF output from a disabled state requires less than 30 milliseconds.

The state of the RF output (on or off) and the +10 dB range (selected or not selected) can be obtained by reading the status byte. These two functions are programmed along with the ALC mode. For more information see ALC Control.

RelatedALC ControlSectionsPEAK-NORM Adjustment

3-18. PEAK-NORM ADJUSTMENT

Description The PEAK-NORM control adjusts an internal filter for maximum power output at a single frequency. This filter is adjusted for best over-all performance with the control in the detent position (NORM), but can be adjusted for maximum power (and reduced harmonics and sub-harmonics) at any one frequency. This adjustment will result in lower maximum power at most other frequencies, and therefore should be left in the NORM position except when maximum power is needed. It should only be required at power levels above +8 dBm.

To maximize the output power at a set frequency:

This adjustment cannot be remotely programmed

Adjust the PEAK-NORM adjustment until the LVL UNCAL annunciator turns off, or for maximum meter reading with the VERNIER fully clockwise.

Remote Procedure

Dracedure

Local

Example To peak an output level of +10 dBm at 8 GHz due to a LVL UNCAL indication:

- 1. Adjust the PEAK-NORM adjustment until the LVL UNCAL annunciator turns off, or for maximum meter reading with the VERNIER fully clockwise.

- 2. Return the PEAK-NORM adjustment to NORM (detented) position before resuming normal instrument operation. The +8 dBm output power level is affected by this adjustment and is only specified with the PEAK-NORM adjustment set to NORM.

Comments

For output level settings above +8 dBm, spurious oscillations can occur, resulting in sidebands on the carrier at a level of 30 to 50 dBc. These oscillations occur only over small portions of the frequency range.

They can usually be eliminated by performing a PEAK-NORM adjustment or by reducing the output level VERNIER setting 1 or 2 dB.

The PEAK-NORM adjustment must be in the NORM (detented) position to guarantee the specified +8 dBm level over the entire frequency range.

1

3-19. RF ON/OFF SWITCH

seconds.

| Description |

The RF ON/OFF switch provides a convenient way of turning off the output signal.

This is useful when calibrating detectors, zeroing power meters, or making noise mea- surements with no signal applied. With the switch in the off position the internal 2 to 6.2 GHz oscillator is turned off to prevent any signal leakage to the RF output connector. The RF annunciator indicates the position of the RF ON/OFF switch in local mode and the programmed state when in remote mode. With the internal 2 to 6.2 GHz oscillator turned off, the CW Generator is no longer phase locked or leveled so the LVL UNCAL and NOT PHASE LOCKED annunciators are lighted. |

|---|---|

| Local | To disable the RF output: |

| Procedure | Set the RF ON/OFF switch to OFF. Note that the OFF, LVL UNCAL and NOT PHASE LOCKED annunciators should be lighted. |

| To enable the RF output: | |

| Set the RF ON/OFF switch to ON. The LVL UNCAL and NOT PHASE LOCKED annunciators should extinguish and the ON annunciator should light. | |

|

Remote

Procedure |

See ALC Control for a description of how to program the RFON/OFF switch function. |

|

Program

Codes |

See ALC Control |

| Comments | The status of the RF output (on or off) can be determined by reading the status byte. A service request is not generated for LVL UNCAL or NOT PHASE LOCKED when the RF output is set to OFF. |

| The RF output off-to-on transition typically requires less than 30 milliseconds when remotely programmed. The on-to-off transition typically requires less than 5 milli- |

A

3-20. REMOTE (HP-IB) OPERATION

The CW Generator can be operated through the Hewlett-Packard Interface Bus (HP-IB). HP-IB compatibility, programming and data formats are described in the following paragraphs.

All front panel functions except that of the ALC CAL control, PEAK-NORM control, and LINE switch are programmable via HP-IB.

A quick test of the CW Generator's HP-IB interface is described in this section under HP-IB Checks. These checks verify that the CW Generator can respond to or send each of the applicable bus messages described in Table 3-3.

3-21. HP-IB Compatibility

The CW Generator's programming capability is described by the twelve HP-IB messages listed in Table 3-3. The CW Generator's compatibility with HP-IB is further defined by the following list of interface functions: SH1, AH1, T6, TE0, L4, LE0, SR1, RL2, PP2, DC1, DT0, and C0. A more detailed explanation of these compatibility codes can be found in IEEE Standard 488-1978 and the identical ANSI Standard MC1.1.

3-22. Remote Mode

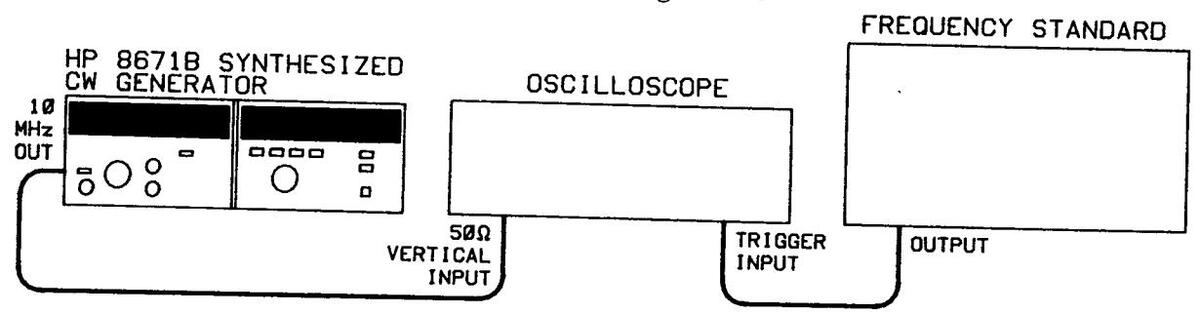

Remote Capability. The CW Generator communicates on the bus in both remote and local modes. In remote, the CW Generator's front panel controls are disabled except for the LINE switch. However, front panel displays remain active and valid. In remote, the CW Generator can be addressed to talk or listen. When addressed to listen, the CW Generator automatically stops talking and responds to the following messages: Data. Clear (SDC). Remote, Local, and Abort. When addressed to talk, the CW Generator automatically stops listening and sends one of the following messages: Data, Require Service, or Status Byte, Whether addressed or not the CW Generator responds to the Clear (DCL), Clear Lockout/Set Local, and Abort messages. In addition, the CW Generator can issue the Require Service message and the Status Bit message.