Page 1

Operation and Service

Guide

HP

8648A/B/C/D

Signal Generator

SERIAL NUMBERS

This manual applies directly to the following HP 8648 model/serial

prefix combinations and below:

HP

8648A

3847A 3847U 3847A 3847U 3847A 3847U 3847A 3847U

HP

8648B BP 8648C

HP

8648D

HP Part No. 08648-90048

Printed in USA April 1999

Supersedes: November 1998

Page 2

Notice. The information contained in this document is subject to

change without notice.

Hewlett-Packard makes no warranty of any kind with regard to this

material, including but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Hewlett-Packard

shall not be liable for errors contained herein or for incidental

or consequential damages in connection with the furnishing,

performance, or use of this material.

@

Copyright Hewlett-Packard Company 1996, 1998

All Rights Reserved. Reproduction, adaptation, or translation without

prior written permission is prohibited, except as allowed under the

copyright laws.

1400 Fountaingrove Parkway, Santa Rosa, CA 95403-1799, USA

FLEX and Motorola are trademarks of Motorola, Inc.

Windows@ and MS Windows@ are U.S. registered trademarks of

Microsoft Corporation.

Windows NT@ is a U.S. registered trademark of Microsoft

Corporation.

Page 3

Certification

Hewlett-Packard Company certifies that this product met its published

specifications at the time of shipment from the factory.

Packard further certifies that its calibration measurements are

traceable to the United States National Institute of Standards and

Technology, to the extent allowed by the Institute’s calibration facility,

and to the calibration facilities of other International Standards

Organization members.

Hewlett-

Information

Warranty

Regulatory

The regulatory information is in Chapter 4, “Specifications.”

This Hewlett-Packard instrument product is warranted against defects

in material and workmanship for a period of one year from date of

shipment. During the warranty period, Hewlett-Packard Company

will, at its option, either repair or replace products which prove to be

defective.

For warranty service or repair, this product must be returned to a

service facility designated by Hewlett-Packard. Buyer shall prepay

shipping charges to Hewlett-Packard and Hewlett-Packard shall pay

shipping charges to return the product to Buyer. However, Buyer shall

pay all shipping charges, duties, and taxes for products returned to

Hewlett-Packard from another country.

Hewlett-Packard warrants that its software and firmware designated

by Hewlett-Packard for use with an instrument will execute its

programming instructions when properly installed on that instrument.

Hewlett- Packard does not warrant that the operation of the

instrument, or software, or firmware will be uninterrupted or

error-free.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from

improper or inadequate maintenance by Buyer, Buyer-supplied

software or interfacing, unauthorized modification or misuse,

operation outside of the environmental specifications for the

product, or improper site preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED.

HEWLETT-PACKARD SPECIFICALLY DISCLAIMS THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND

EXCLUSIVE REMEDIES. HEWLETT-PACKARD SHALL NOT BE

LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT,

TORT, OR ANY OTHER LEGAL THEORY.

. . .

III

Page 4

Assistance

Product

agreements

assistance, contact

Ome.

wm.

maintenance

are available for

Refer to

the

agreements

gour

list of

and

other

customer

Hewlett-Rzckard products.

nearest Hewlett-Rxckard Sales

Sales

and

Service Omes on the

assistance

$br

any

and

Service

following

Page 5

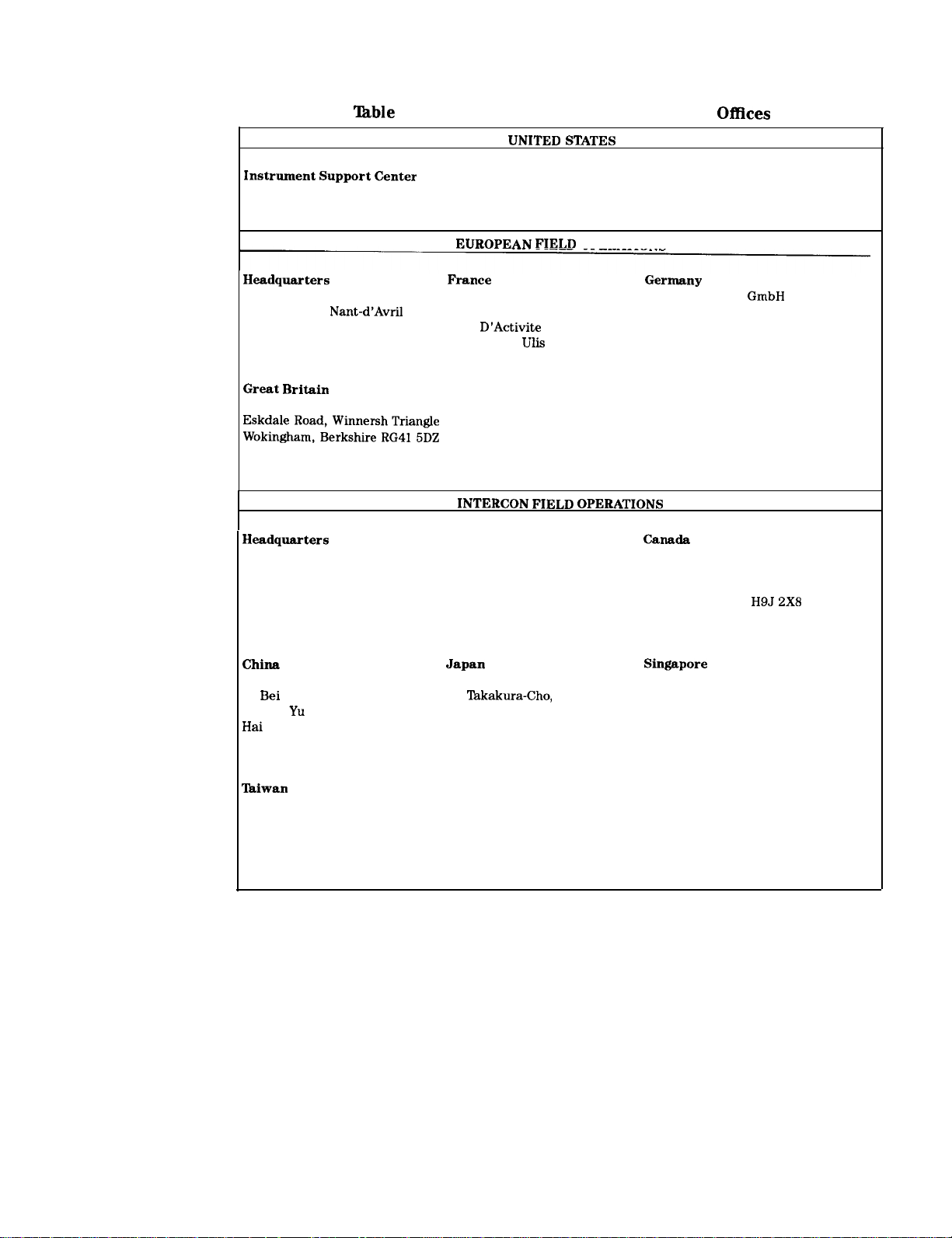

‘able

O-l. Hewlett-Packard Sales and Service

Offices

UNITED

Instrument

Hewlett-Packard Company

(800) 403-0801

Headquarters

Hewlett-Packard S.A. Hewlett-Packard France

150, Route du Nant-d’Avril 1 Avenue Du Canada

12 17 Meyrin O/Geneva

Switzerland F-91947 Les

(41 22) 780.8111 France

Great Britain

Hewlett-Packard Ltd.

,

~~~~~~~e~;~~~;~i~g

England

(44 734) 696622

Headquarters

Hewlett-Packard Company

3495 Deer Creek Road

Palo Alto, California, USA

94304-1316

(415) 857-5027

Support

Center

EUROPEAN FIELD

France

Zone D’Activite De Courtaboeuf 61352 Bad Homburg v.d.H

(33 1) 69 82 60 60

INTERCON FIELD

Australia

Hewlett-Packard Australia Ltd.

31-41 Joseph Street

Blackburn, Victoria 3130

(61 3) 895-2895 Kirkland, Quebec

Ulis

STATES

Cedex

OPERATIONS

Germany

Hewlett-Packard

Hewlett-Packard Strasse

Germany

(49 6172) 16-O

OPERATIONS

Canada

Hewlett-Packard (Canada) Ltd.

17500 South Service Road

Trans-Canada Highway

Canada

(514) 697-4232

GmbH

H9J

2X8

China

China Hewlett-Packard Company Hewlett-Packard Japan, Ltd.

38

Bei

San Huan Xl Road

Shuang Vu Shu Tokyo 192, Japan

Hai

Dian District (81 426) 60-2111

Beijing, China

(86 1) 256-6888

lbiwan

Hewlett-Packard Taiwan

8th Floor, H-P Building

337 Fu Hsing North Road

Taipei, Taiwan

(886 2) 712-0404

Japan

9-l

‘lakakura-Cho,

Hachioji

Singapore

Hewlett-Packard Singapore (Pte.) Ltd.

150 Beach Road

#29-00 Gateway West

Singapore 0718

(65) 291-9088

V

Page 6

Safety Notes

The following safety notes are used throughout this manual.

Familiarize yourself with each of the notes and its meaning before

operating this instrument.

Caution

Warning

Instrument Markings

Caution denotes a hazard. It calls attention to a procedure that, if

not correctly performed or adhered to, would result in damage to or

destruction of the instrument. Do not proceed beyond a caution sign

until the indicated conditions are fully understood and met.

Warning denotes a hazard. It calls attention to a procedure

which, if not correctly performed or adhered to, could result in

injury or loss of life. Do not proceed beyond a warning note until

the indicated conditions are fully understood and met.

The following markings and caution and warning labels are used on

the instrument. Be sure to observe all cautions and warnings.

The instruction documentation symbol. The product is

marked with this symbol when it is necessary for the user

to refer to the instructions in the manual.

The CE93 mark shows compliance with the European

Community 1993 standards.

A

CE

!

Warning

Warning

Warning

Caution

The CSA mark is the Canadian Standards Association

safety mark.

“ISMl-A” This is a symbol of an Industrial Scientific and Medical

Group 1 Class A product.

Hazardous voltage always present in this area with instrument

power cord connected to ac line.

Do not remove this screw when removing cover from instrument.

Hazardous Voltage

Hazardous electrical shock. Heat sink is live. Disconnect power

supply before servicing.

vi

Page 7

General Safety Considerations

Warning

Warning

Warning

Caution

No operator serviceable parts inside. Refer servicing to qualified

personnel. lb prevent electrical shock, do not remove covers.

If this instrument is used in a manner not specified by

Hewlett-Packard Co., the protection provided by the instrument

may be impaired.

For continued protection against fire hazard replace line fuse

only with same type and rating (3 A 250 V type F). The use of

other fuses or material is prohibited.

Always use the three-prong ac power cord supplied with this

instrument. Failure to ensure adequate earth grounding by not using

this cord may cause instrument damage.

vii

Page 8

How to Use This Guide

This guide uses the

following convention:

Documentation

Description

CFRONT-PANEL

KEY] This represents a key physically located on

the instrument.

Display

This font is used to represent text which

appears on the instrument display.

This guide contains the information required to operate, calibrate, and

repair the signal generator to the assembly level. Included are the

following:

n a quick overview of the signal generator

n examples of typical operation

n a reference section that describes all operation features

n explanations of error messages displayed on the signal generator

n installation instructions

w

tables of specifications

n tables of post-repair information and recommended equipment

required

n theory of operation of the signal generator

n troubleshooting procedures to identify failed assemblies

n disassembly procedures for removal and replacement of assemblies

n replaceable part numbers

n adjustments required after repair or performance test failure

n performance tests to test the instrument to specifications

n supplemental verification tests to test some unspecified parameters

of the instrument

VIII

. . .

Page 9

Contents

1. Operation

Quick Overview ...................

1. Power Key ...................

2. Display .....................

3. Function and Data Keys

4. Increment Set Keys

5. Knobs. .....................

6. MEMORY

7.

Modulation Source

la. Operation Examples

Getting Started ....................

Operation Examples

Setting the RF Output Signal

Setting the Frequency

Setting the Amplitude

Turn on the RF Output

Setting the Modulation

Incrementing or Decrementing the RF Output Signal

Preliminary Steps ..................

Using the Knob ...................

Using the Increment keys

Using the Memory Registers

Saving Instrument Settings in Register Sequences

Selecting the Sequence

Saving Settings in Registers

Checking the Sequence

Checking a Different Sequence

Deleting a Register from the Sequence

Selecting the Sequence

Deleting a Register

Renumbering the Registers in a Sequence

Decreasing the Register Number

Checking the Sequence

Inserting a Register in a Sequence

Saving a New Register

Offsetting the RF Output from a Reference

Setting the Reference Value

Offsetting the RF Output

Turning the Reference Mode Off or On

Setting a New Reference Value

Holding the Output Attenuator Range

Set the Amplitude Level

Holding the Attenuator

Adjusting the Amplitude

....................

................

................

................

.............

...............

.............

...............

...............

...............

...............

..............

..............

..............

............

..............

..........

........

..............

......

..........

..............

..........

..............

.......

.............

..............

.......

..........

.........

..............

...............

..............

. .

...

l-2

l-2

l-2

l-3

l-4

l-4

l-4

l-5

la-l

la-2

la-3

la-3

la-3

la-4

la-4

la-5

la-5

la-5

la-6

la-7

la-8

la-8

la-8

la-10

la-10

la-12

la-12

la-12

la-14

la-14

la-15

la-16

la-17

la-18

la-18

la-19

la-19

la-20

la-21

la-21

la-21

la-22

Contents-l

Page 10

Setting a User Selectable Modulated Frequency and

Waveform (Option

lE2

or

1EP

Only) ........

Setting the Modulation Level ............

Setting the Modulated Waveform ..........

Setting the Modulated Frequency ..........

Signaling a Numeric-Type FLEX Pager (Option

Setting Up Pager Encoding .............

Entering Pager Encoding Settings ..........

Selecting the Format Settings ............

Selecting the Data Rate and Pager Type Settings ...

Selecting the Message Settings ............

Selecting Transmission Repetitions and amplitude . .

Selecting the Pager

Capcode

(Address) ........

Selecting the Protocol Settings ...........

Selecting the Roaming Mode Settings ........

Encoding ......................

lb. Operation Reference

Frequency and Amplitude ...............

1. Knob ......................

2. Digit-Select Arrow Keys .............

3. REFSET ....................

Units

4. REF

OkCFF’

: : : : : : : : : : : : : : : : : :

Function .......................

1. FREQUENCY ..................

2. AMPLITUDE ..................

3.FMAM4M

...................

Setting Up the Pager Encoder .............

1. ENCODER. ...................

Setting the Format .................

FLEX/FLEX-TD

..................

Setting the Data Rate and Pager Type .......

Setting the Message ................

Setting the Encoding Mode ............

Entering the Pager

Capcode

(Address) .......

Setting the Protocol ...............

Setting the Roaming Mode ............

Message During Encoding .............

Signaling Examples ................

SSID/NID

POCSAG

Roaming Example ............

......................

Setting the Data Rate and Pager Type .......

Setting the Message ................

Setting the Encoding Mode ............

Entering the Pager

Capcode

(Address) .......

Message During Encoding .............

RESYNC.. ....................

Setting the Encoding Mode ............

Message During

PN15

.......................

Resynchronizing

..........

Setting the Data Rate ...............

Message During Encoding .............

SERVICE

......................

Setting the Data Rate . . . . . . . . . . . . . . . lb-35

1EP

Only)

la-23

la-23

la-24

la-24

la-25

la-26

la-27

la-27

la-28

la-29

la-29

la-30

la-31

1 a-32

la-32

lb-2

lb-2

lb-2

lb-3

lb-3

lb-3

lb-4

lb-4

lb-5

lb-5

lb-6

lb-7

lb-8

lb-9

lb-9

lb-12

lb-14

lb-16

lb-18

lb-19

lb-22

lb-23

lb-25

lb-27

lb-27

lb-29

lb-31

lb-32

lb-32

lb-33

lb-33

lb-33

lb-34

lb-34

lb-34

lb-35

Contents2

Page 11

Message During Servicing

.............

Pulse Modulation ...................

1. PULSE .....................

Increment Set ....................

1.

INCRSET

START/STOP Encoding

PREV and NEXT

....................

..............

.................

Data .........................

1. MHz/dBm kHz/mV

Units Conversion

ENTER

SHIFT

.....................

......................

%/pV rad/dBpV

.................

........

2. Backspace ....................

3. emf .......................

4.f ........................

Instrument Preset ..................

pGim)@

.....................

p?Fmg(DEL)

.....................

HP-IB

........................

1. ADRS ......................

2. LOCAL .....................

Memory .......................

l.SAV .......................

2. REG ......................

3. Register Recall Arrows

4.SEQ..

.....................

..............

5. DEL ......................

Renumbering the Registers

............

Modulation Source ..................

1. MOD ON/OFF ..................

2.

INT400HzINTl

kHz

3. (FREQUENCY) 4. (FREQUENCY/ WAVEFORM)

5. EXTACEXTDC

.................

6.1kHz+EXTDC

Setting the Modulation Level

7. MOD INPUT/OUTPUT

..............

...

................

...........

..............

RF Output ......................

1. RF ON/OFF ...................

2.A’I”l’NHOLD ...................

Vernier Ranges ..................

3. RF OUTPUT ...................

Rear Panel ......................

1. 10 MHz REF INPUT and OUTPUT

2. DISPLAY CONTRAST

3. AUXILIARY INTERFACE

4. Line Voltage Connector

5. HP-IB Connector

6.

TIMEBASE

ADJ and Language Switches

7. External Pulse Input

Remote Interface (Accessory)

...............

.............

.............

.................

...............

.............

.........

......

1. MOD ON/OFF ..................

2. RF ON/OFF ...................

3. Sequence Selection Arrows

4. Register Recall Arrows

Memory Interface (Accessory)

............

..............

.............

lb-35

lb-36

lb-36

lb-38

lb-38

lb-38

lb-38

lb-39

lb-39

lb-39

lb-39

lb-39

lb-40

lb-40

lb-40

lb-41

lb-41

lb-41

lb-45

1 b-45

lb-45

lb-46

lb-47

lb-47

lb-48

lb-48

lb-49

lb-49

lb-50

lb-51

lb-51

lb-51

lb-52

lb-52

lb-53

lb-53

lb-54

lb-54

lb-54

lb-54

lb-55

lb-56

lb-56

lb-56

lb-56

lb-57

lb-57

lb-57

lb-57

lb-58

lb-58

lb-58

lb-58

lb-59

1 b-60

Contents-3

Page 12

1. POWER

2. Copy Arrow Keys

.....................

................

Making a Copy ..................

3.

BUSY

......................

lc. Operation Messages

Front Panel Operation Messages ............

HP-IB

. Command Errors ...............

HP-IB Execution Errors ................

HP-IB Device-Specific Errors .............

HP-IB Query Errors ..................

Service Messages ...................

2. HP-IB Programming

Background .....................

Programming Guidelines ...............

HP-IB Definition ..................

What is Programmable ...............

HP-IB Address ...................

Error Messages ...................

Programming Language ...............

Query .......................

Advanced Programming ...............

Programming Examples ................

Programming RF Frequency .............

Programming RF Frequency and FM Modulation ...

Querying RF Frequency ...............

Programming RF Amplitude .............

Programming Pulse Modulation (Option

Programming Pager Encoder (Option

lE6)

1EP)

......

HP-IB Status Reporting ................

External Modulation Input Level Status .......

Example: Check the Condition of Modulation Input

(High or Low) .................

Example: Generate a Service Request for External

Modulation ..................

Reverse Power Protection Status

Example: Check the condition of’the

RPP : : : : :

Unspecified Power (Amplitude) Entry Status .....

Example: Check the Condition of Unspecified Power

Entry .....................

Pager Encoding Status (Option

1EP

Only) ......

Example: Check the end of message encoding ...

Example: Check the start of each frame ......

SCPI Command Reference ...............

ABORt

Subsystem (Option

1EP

Only) ........

AM Subsystem ...................

CAL Subsystem ...................

DM Subsystem (Option 1EP Only) ..........

FM Subsystem ...................

FREQuency Subsystem ...............

INITiate Subsystem (Option

1EP

Only) ........

OUTPut Subsystem .................

PAGing

Subsystem (Option

1EP

Only) ........

PM Subsystem . . . . . . . . . . . . . . . . . . .

.....

lb-60

lb-60

lb-60

lb-61

lc-1

lc-5

lc-7

lc-7

lc-7

lc-8

2-l

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-2

2-3

2-3

2-3

2-4

2-4

2-4

2-5

2-12

2-14

2-14

2-15

2-16

2-16

2-17

2-17

2-18

2-18

2-19

2-20

2-21

2-21

2-22

2-22

2-23

2-24

2-24

2-24

2-25

2-37

Contents-4

Page 13

POWer

Subsystem

PULM Subsystem

STATUS

SYSTem

Subsystem

Subsystem

TRIGger Subsystem (Option

Changing Parameters While Encoding (Option

.................

..................

.................

.................

1EP

Only)

........

1EP

Using the Buffer Memory for the Arbitrary Messages . .

HP-IB Capabilities

HP-IB Connector Information

HP 8656/57 Compatible Language

Program Code Implementation

Receiving the Clear Message

Additional Programming Information

..................

.............

...........

...........

.............

........

3. Installation

Unpacking Your Signal Generator

Connecting AC Power

Power Requirements

Replacing the Fuse

.................

................

.................

Turning On the Signal Generator

Connecting to Other Instruments

Storing the Signal Generator

Shipping the Signal Generator

...........

...........

...........

.............

.............

4. Specifications

Options

Frequency Specifications

Internal Reference Oscillator

output

Spectral Purity

Frequency Modulation

Phase Modulation

Amplitude Modulation

Modulation Source

Remote Programming

Environmental

General

Modulation Generator Option 1 E2

Pulse Modulation Option

Pager Encoder/Signaling Option 1 EP

Frequency

Frequency Modulation

Pager Signaling

Modulation Source

General

Regulatory Information

IS0 9002 Compliant

Statement of Compliance

Noise Declaration

.......................

...............

.............

........................

....................

................

...................

................

..................

.................

....................

.......................

...........

.............

lE6

..........

.....................

...............

...................

.................

......................

................

.................

..............

..................

only)

2-38

2-38

2-39

2-40

2-40

2-41

2-41

2-43

2-44

2-45

2-46

2-48

2-48

3-l

3-2

3-2

3-3

3-5

3-5

3-5

3-6

4-1

4-2

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-8

4-9

4-9

4-10

4-11

4-11

4-11

4-12

4-12

4-12

4-12

4-13

4-13

4-13

4-13

Contents-5

Page 14

5. Service

Shipping Your Instrument Back to Hewlett-Packard . . .

Recommended Test Equipment . . . . . . . . . . . .

Post-Repair . . . . . . . . . . . . . . . . . . . . . .

Safety Notes . . . . . . . . . . . . . . . . . . . . .

5a. Theory of Operation

Introduction

Overview

Al Front Panel

A2 Power Supply

A3 Motherboard

A4 Reference

A5 Sig Gen Synth

A6 Output (HP 8648A)

A6 Output (HP

A7 Attenuator (HP 8648A)

A10 Frequency Extension (HP

Al 1 Attenuator (HP

Al2 Reverse Power Protection (HP

Al3 Pulse Modulator (HP

Al4 Modulation Generator (Option

A30 Pager Encoder (HP 8648A Option

.....................

.....................

...................

..................

..................

...................

..................

...............

8648B/C/D)

.............

.............

8648B/C/D)

8648B/C/D)

...........

8648B/C/D)

8648B/C/D

Option

lE2)

.......

1EP)

5b. Troubleshooting Information

Introduction

Troubleshooting Checklist

.....................

...............

AC Mains (line) Fuse Removal .............

lb

Remove the Fuse

................

Modulation Test Points and Power Supply LEDs

Power Supply Distribution ..............

Block Diagrams

....................

......

....

lE6)

...

.....

.....

5-l

5-2

5-5

5-8

5a-1

5a-3

5a-3

5a-5

5a-5

5a-6

5a-6

5a-7

5a-7

5a-7

5a-8

5a-8

5a-8

5a-9

5a-9

5a-9

5b-1

5b-2

5b-3

5b-3

5b-4

5b-5

5b-7

Contents-6

5~.

Service Error Messages

6. Replaceable Parts

Introduction . . . . . . . . . . . . . . . . . . . . .

Assembly Replacements . . . . . . . . . . . . . . .

7. Adjustments

Test Equipment ....................

Equipment Setup for Automated Tests

Test Point Extender

.................

........ 7-l

Manual Adjustments .................

Internal Reference Oscillator Adjustment

.......

Pager Encoder Timebase Frequency Adjustment

Automated Adjustments ................

AM Level and Distortion

..............

AM Level .....................

Detector Offset

Output Level

AM Level: FE

Predistortion and Detector Offset

Prelevel

......................

...................

....................

...................

..........

Output Level: Frequency Extension Calibration

...

...

6-l

6-l

7-l

7-2

7-3

7-4

7-6

7-8

7-9

7-11

7-13

7-14

7-15

7-17

7-18

7-19

Page 15

AM Modulator

Time Base DAC

Motherboard Audio Path

DCFM

.......................

Audio Generator

HF Power Level Accuracy

LF Output Level

LF Power Level Accuracy

FSK Deviation

Filter Path

Service Support Software

Required Test Equipment

Installing the Software

Running the Service Support Software

Starting the Software

Identifying the DUT

...................

...................

..............

..................

..............

..................

..............

...................

.....................

...............

..............

...............

........

...............

...............

Selecting the Performance Test or Adjustments and

the Test. ...................

Defining the Location where the Test Results are

Saved ....................

Running the Tests and Adjustments

........

Reviewing the Test and Adjustment Results

Printing the Test and Adjustment Results

Exiting the Software

Support Software Administration

Software Configuration

The User Configuration

The Administration Configuration

Adding Test Equipment

Removing Test Equipment

Editing Test Equipment

Adding Device Drivers

Removing Device Drivers

Adding Test Drivers

Removing Test Drivers

Adding Datapacks

Removing Datapacks

Motherboard Repair Utility

...............

..........

..............

.............

........

..............

.............

..............

..............

.............

................

..............

................

...............

.............

Reading Information from the A3 Motherboard

Storing Information in the A3 Motherboard

....

......

...

....

7-20

7-22

7-23

7-25

7-26

7-27

7-30

7-31

7-33

7-34

7-35

7-35

7-36

7-42

7-42

7-43

7-44

7-46

7-47

7-47

7-49

7-49

7-50

7-50

7-50

7-50

7-51

7-54

7-55

7-56

7-59

7-60

7-62

7-63

7-65

7-66

7-68

7-70

8. Performance Tests

Calibration Cycle

Required Test Equipment

Performance Test Descriptions

FM Accuracy Performance Test

...................

...............

.............

...........

FM Accuracy Performance Test (Option

FM Distortion Performance Test

AM Accuracy Performance Test

...........

...........

AM Accuracy Performance Test (Option lE2 only)

AM Distortion Performance Test

...........

Phase Modulation Distortion Performance Test

Residual FM Performance Test

Harmonics Performance Test

Spurious Performance Test

............

............

.............

lE2

Only)

. .

. .

....

Contents-7

8-l

8-2

8-5

8-6

8-8

8-10

8-12

8-13

8-14

8-15

8-17

8-19

8-20

Page 16

DC FM Frequency Error Performance Test . . . . . .

RF Level Accuracy Performance Test . . . . . . . . .

Pulse Modulation On/Off Ratio Performance Test

(Option

lE6

Only) . . . . . . . . . . . . . . . .

Pulse Modulation Rise Time Performance Test (Option

lE6

Only) . . . . . . . . . . . . . . . . . . . .

Pager Encoder Timebase Accuracy Performance Test

(Option 1EP Only) . . . . . . . . . . . . . . . .

FSK Deviation Accuracy Performance Test (Option

Only) . . . . . . . . . . . . . . . . . . . . . .

Internal Timebase: Aging Rate Performance Test

(Option

lE5

Only) . . . . . . . . . . . . . . . .

Power Level Accuracy Performance Test (Automated) .

HP 8648A Test Record . . . . . . . . . . . . . . .

HP

8648B

Test Record . . . . . . . . . . . . . . .

HP 8648C Test Record . . . . . . . . . . . . . . .

HP 8648D Test Record . . . . . . . . . . . . . . .

9. Supplemental Verification Tests

Required Test Equipment List . . . . . . . . . . . . .

CW Frequency Accuracy Supplemental Verification Test

9 kHz RF Level Accuracy Supplemental Verification Test

Index

8-21

8-22

8-26

8-27

8-29

1EP

8-30

8-35

8-38

8-41

8-61

8-85

8-109

9-2

9-3

9-8

Contents-l

Page 17

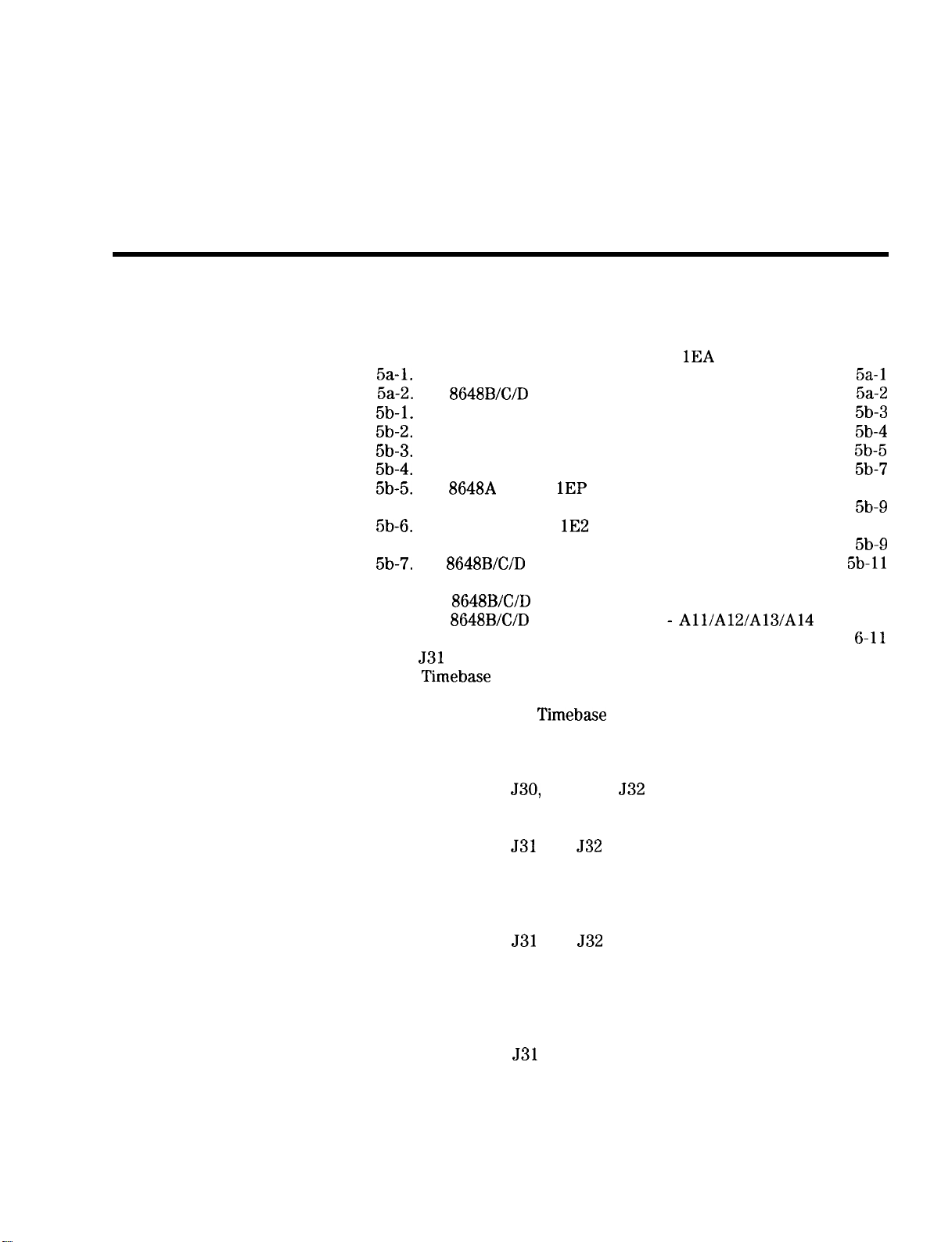

Figures

2-l. HP 8648 Status Register Model

2-2. Paging Encoding Status

3-l. Replacing the Fuse

...............

.................

3-2. Power Cable and Mains Plug

4-l. Typical Output Power with Option

5a-1.

HP 8648A Simplified Block Diagram

5a-2.

HP

8648B/C/D

5b-1.

Fuse Removal

5b-2.

Location Diagram

5b-3.

Bottom View of Motherboard with Cover Removed . .

5b-4.

HP 8648A Block Diagram

5b-5.

HP

8648A

Simplified Block Diagram

...................

..................

..............

Option

1EP

A30 Pager Encoder Block

...........

............

1EA

.......

.........

.......

Diagram ....................

5b-6.

HP 8648A Option

lE2

Al4 Modulation Generator Block

Diagram ....................

5b-7.

HP

8648B/C/D

Block Diagram (1 of 2)

6-l. HP 8648A Replaceable Parts

6-2. HP

6-3. HP

8648B/C/D

8648B/C/D

Replaceable Parts

Replaceable Parts -

.............

...........

........

All/A12/A13/A14

Detailed View ..................

7-l.

531

Test Point Extender

7-2. Timebase Adjust Switch Location

7-3. Internal Reference Oscillator Adjustment Setup

...............

..........

....

7-4. Pager Encoder Timebase Frequency Adjustment Setup

7-5. Variable Capacitor Location

7-6. AM Level and Distortion Test Setup 1

7-7. AM Level and Distortion Test Setup 2

7-8. Location of

530,

531, and

7-9. AM Level Test Setup 1

7-10. AM Level Test Setup 2

7-11. Location of

531

and

532

7-12. Detector Offset Test Setup

7-13. Output Level Test Setup

7-14. AM Level: FE Test Setup 1

7-15. AM Level: FE Test Setup 2

7-16. Location of

531

and

532

7-17. Predistortion and Detector Offset Test Setup

7-18. Prelevel Test Setup

.................

.............

........

........

532

on the Motherboard

...............

...............

on the Motherboard

.....

..............

..............

.............

.............

on the Motherboard

.....

.....

7-19. Output Level: Frequency Extension Calibration Test

Setup ......................

7-20. AM Modulator Test Setup

7-21. Location of

531

on the Motherboard

7-22. Time Base DAC Test Setup

7-23. Motherboard Audio Path Test Setup

7-24. DCFM Test Setup

..................

7-25. Audio Generator Test Setup

..............

.........

.............

.........

.............

. .

2-13

2-18

3-3

3-4

4-3

5a-1

5a-2

5b-3

5b-4

5b-5

5b-7

5b-9

5b-9

5b-11

6-3

6-9

B-11

7-3

7-4

7-4

7-6

7-7

7-9

7-9

7-10

7-11

7-11

7-12

7-13

7-14

7-15

7-15

7-16

7-17

7-18

7-19

7-20

7-21

7-22

7-24

7-25

7-26

Contents-9

Page 18

7-26. HF Power Level Accuracy Test Setup for Power Levels

>-10dBm

...................

7-27. HF Power Level Accuracy Test Setup for Power Levels

of-lOto-70dBm

...............

7-28. HF Power Level Accuracy Test Setup for Power Levels

< -70 dBm and < 1300 MHz ...........

7-29. HF Power Level Accuracy Test Setup for Power Levels

< -70 dBm and > 1300 MHz ...........

7-30. LF Output Level Test Setup .............

7-31. LF Power Level Accuracy Test Setup for Power Levels

of?-40dBm

.................

7-32. LF Power Level Accuracy Test Setup for Power Levels

of<-40dBm .................

7-33. FSK Deviation Test Setup ..............

7-34. Filter Path Test Setup ................

7-35. Welcome Screen ..................

7-36. Important Information Screen ............

7-37. Choose Destination Location Screen .........

7-38. Select Program Folder Screen ............

7-39. Start Copying Files Screen .............

7-40. Installation Status Gauge ..............

7-41. Setup Complete Screen ...............

7-42. Setup Complete Screen ...............

7-43. HP Service Support Program Group .........

7-44. HP Service Software for PC’s Selections .......

7-45. User Information Dialog Box ............

7-46. DUT Selection Dialog Box ..............

7-47. Select Test Equipment and Tests Window .......

7-48. Save As Dialog Box .................

7-49. HP Service Support Software Window ........

7-50. HP Service Support Software Window Displaying Test

Results .....................

7-51. Print the Log File? Dialog Box ...........

7-52. The User Information Window ............

7-53. Test Equipment Drivers in the File Drop-Down Menu .

7-54. Adding Test Equipment Using the Test Equipment Menu

7-55. Adding the Equipment Information Using the New Test

Equipment Window ...............

7-56. Removing and Editing Test Equipment Using the Test

Equipment Window ...............

7-57. The Select Test Equipment and Tests Window ....

7-58. Test Equipment Drivers in the File Drop-Down Menu .

7-59. Adding a Device Driver Using the Test Equipment

Drivers Window .................

7-60. Using the Open Dialog box to Search for a Device

Driver File to Add ................

7-61. Removing a Device Driver Using the Test Equipment

Drivers Window .................

7-62. Test Drivers in the File Drop-Down Menu ......

7-63. Adding a Test Driver Using the Test Drivers Window

7-64. Using the Open Dialog Box to Search for a Test Driver

File to Add ...................

7-65. Removing a Test Driver Using the Test Drivers Window

7-66. Datapacks in the File Drop-Down Menu .......

7-67. Adding a

Datapack

Using the Datapacks Window . . .

7-27

7-28

7-28

7-29

7-30

7-31

7-32

7-33

7-34

7-36

7-37

7-38

7-38

7-39

7-39

7-40

7-40

7-42

7-42

7-43

7-43

7-44

7-46

7-47

7-47

7-49

7-50

7-51

7-52

7-53

7-54

7-56

7-57

7-57

7-58

7-59

7-60

7-61

.

7-61

7-62

7-63

7-64

Contents-l

0

Page 19

7-68. Using the Open Dialog Box to Search for a

File to Add

7-69. Removing a

7-70. 110 Port Error Message

...................

Datapack

Using the Datapacks Window

...............

7-71. HP Service Support Program Group

Datapack

.........

7-72. HP Service Software for PC’s Selections .......

7-73. Password Requested by User Information Dialog Box .

7-74. HP8648 Motherboard Repair Utility Window .....

7-75. HP Service Support Program Group

.........

7-76. HP Service Software for PC’s Selections .......

7-77. Password Requested by User Information Dialog Box .

7-78. HP8648 Motherboard Repair Utility Window .....

8-l. FM Accuracy Equipment Setup

8-2. FM Accuracy Equipment Setup for HP

8-3. FM Accuracy Equipment Setup for Option

8-4. FM Accuracy Equipment Setup for HP

Option

lE2

...................

8-5. FM Distortion Equipment Setup

8-6. FM Distortion Equipment Setup for HP

8-7. AM Accuracy Equipment Setup

8-8. AM Accuracy Equipment Setup for Option

8-9. AM Distortion Equipment Setup

...........

8648B/C/D

lE2

. .

....

8648B/C/D

...........

8648B/C/D

. .

...........

lE2

....

...........

8-10. Phase Modulation Distortion Equipment Setup ....

8-11. Phase Modulation Distortion Equipment Setup for HP

8648B/C/D

8-12. Residual FM Equipment Setup

8-13. Harmonics Equipment Setup

8-14. Spurious Equipment Setup

...................

............

............

.............

8-15. DC FM Frequency Error Equipment Setup ......

8-16. Equipment Setup for the HP 8648A and HP

5 1300MHz.

8-17. Equipment Setup for the HP

..................

8648B/C/D

8648B/C/D

> 1300 MHz .

8-18. Pulse Modulation On/Off Ratio Equipment Setup. ...

8-19. Pulse Modulation On/Off

Risetime

Equipment Setup.

.

8-20. Pager Encoder Timebase Accuracy Equipment Setup .

8-21. FSK Deviation Accuracy Equipment Setup ......

8-22. Internal Timebase: Aging Rate Test Setup ......

8-23. HF Power Level Accuracy Test Setup Setup for Power

Levels > -10 dBm

...............

8-24. HF Power Level Accuracy Test Setup for Power Levels

of-lOto-70dBm

...............

8-25. HF Power Level Accuracy Test Setup for Power Levels

< -70 dBm and 5 1300 MHz

...........

8-26. HF Power Level Accuracy Test Setup for Power Levels

< -70 dBm and > 1300 MHz

9-

1. Frequency Accuracy Equipment Setup

...........

........

9-2. 9 kHz RF Level Accuracy Equipment Setup .....

.

7-64

7-65

7-67

7-68

7-68

7-69

7-69

7-70

7-70

7-71

7-72

8-6

8-7

8-8

8-9

8-10

8-11

8-12

8-13

8-14

8-15

8-16

8-17

8-19

8-20

8-21

8-22

8-23

8-26

8-27

8-29

8-30

8-36

8-38

8-39

8-39

8-40

9-3

9-8

Contents-l 1

Page 20

Ihbles

O-l. Hewlett-Packard Sales and Service Offices ......

2-1. Programming Command Statements and Descriptions .

2-2. Dictionary of Terms .................

2-3. IEEE 488.2 Capabilities ...............

5

1. Recommended Test Equipment ...........

5-2. Adjustments and Performance Tests Required after

Repair or Replacement of an HP 8648A Assembly .

5-3. Adjustments and Performance Tests Required after

Repair or Replacement of an HP

Assembly ....................

5a-1.

Al Front Panel (Keyboard) .............

6-l. HP 8648A Replaceable Parts .............

6-2. HP

7-l.

7-2. An Example of Calibration Data for Power Sensors . .

8-l. High Power Level Accuracy Work Table .......

8-2. FSK Deviation Accuracy Work

8-3. HP 8648A Test Record ...............

8-4. HP 8648A Test Record ...............

8-5. FM Accuracy Performance Test ...........

8-6. FM Accuracy Performance Test Option

8-7. FM Distortion Performance Test ...........

8-8. AM Accuracy Performance Test ...........

8-9. AM Accuracy Performance Test Option

8-10. AM Distortion Performance Test ...........

8-l 1. Phase Modulation Distortion Performance Test ....

8-12. Residual FM Performance Test ............

8-13. Harmonics Performance Test .............

8-14. Spurious Performance Test .............

8-15. DC FM Frequency Error Performance Test ......

8-16. RF Level Accuracy Performance Test .........

8-17. Pager Encoder Timebase Accuracy Performance Test

8-18. FSK Deviation Accuracy Performance Test (Option

8-19. Internal Timebase: Aging Rate Performance Test

8-20. HP 8648B Test Record ...............

8-21. HP 8648B Test Record ...............

8-22. FM Accuracy Performance Test - Part 1 .......

8-23. FM Accuracy Performance Test - Part 2 .......

8-24. FM Accuracy Performance Test Option

8-25. FM Accuracy Performance Test Option

8-26. FM Distortion Performance Test - Part 1 .......

8-27. FM Distortion Performance Test - Part 2 .......

8-28. AM Accuracy Performance Test ...........

8648B/C/D

531

Test Point Extender Parts List ..........

(Option

Only) ......................

(Option

Replaceable Parts ...........

1EP

Only) ................

lE5

Only) ................

Table

8648B/C/D

.........

lE2

......

lE2

lE2 -

lE2 -

.....

1EP

Part 1 . .

Part 2 . .

2-i

2-20

2-43

5-2

5-5

5-6

5a-4

6-5

6-13

7-2

7-53

8-25

8-33

8-41

8-42

8-43

8-44

8-45

8-46

8-48

8-50

8-51

8-51

8-52

8-53

8-54

8-55

8-60

8-60

8-60

8-61

8-62

8-63

8-63

8-64

8-64

8-65

8-65

8-66

Contents-l 2

Page 21

8-29. AM Accuracy Performance Test Option

8-30. AM Distortion Performance Test . . . . . . . . . . .

8-31. Phase Modulation Distortion Performance Test - Part 1

8-32. Phase Modulation Distortion Performance Test - Part 2

8-33. Residual FM Performance Test . . . . . . . . . . . .

8-34. Harmonics Performance Test . . . . . . . . . . . .

8-35. Spurious Performance Test . . . . . . . . . . . . .

8-36. DC FM Frequency Error Performance Test . . . . . .

8-37. RF Level Accuracy Performance Test - Part 1 . . . . .

8-38. RF Level Accuracy Performance Test - Part 2 . . . . .

8-39. RF Level Accuracy Performance Test - Part 3 . . . . .

8-40. RF Level Accuracy Performance Test with Options

andlE6-Part3.

8-41. RF Level Accuracy Performance Test - Part 4 . . . . .

8-42. Pulse Modulation On/Off Ratio Performance Test

(Option

8-43. Pulse Modulation Rise Time Performance Test (Option

lE6

8-44. Internal Timebase: Aging Rate Performance Test

(Option

8-45. HP 8648C Test Record . . . . . . . . . . . . . . .

8-46. HP 8648C Test Record

8-47. FM Accuracy Performance

8-48. FM Accuracy Performance Test - Part 2

8-49. FM Accuracy Performance Test Option

8-50. FM Accuracy Performance Test Option

8-51. FM Distortion Performance Test - Part 1 . . . . . . .

8-52. FM Distortion Performance Test - Part 2 . . . . . . .

8-53. AM Accuracy Performance Test . . . . . . . . . . .

8-54. AM Accuracy Performance Test Option lE2

8-55. AM Distortion Performance Test . . . . . . . . . . .

8-56. Phase Modulation Distortion Performance Test - Part 1

8-57. Phase Modulation Distortion Performance Test - Part 2

8-58. Residual FM Performance Test . . . . . . . . . . . .

8-59. Harmonics Performance Test . . . . . . . . . . . .

8-60. Spurious Performance Test . . . . . . . . . . . . .

8-61. DC FM Frequency Error Performance Test . . . . . .

8-62. RF Level Accuracy Performance Test - Part 1 . . . . .

8-63. RF Level Accuracy Performance Test - Part 2 . . . . .

8-64. RF Level Accuracy Performance Test - Part 3 . . . . .

8-65. RF Level Accuracy Performance Test with Options

andlE6-Part3.

8-66. RF Level Accuracy Performance Test - Part 4 . . . . .

8-67. Pulse Modulation On/Off Ratio Performance Test

(Option

8-68. Pulse Modulation Rise Time Performance Test

(Option

8-69. Internal Timebase: Aging Rate Performance Test

(Option lE5 Only) . . . . . . . . . . . . . . . .

8-70. HP 8648D Test Record . . . . . . . . . . . . . . .

8-71. HP 8648D Test Record . . . . . . . . . . . . . . .

8-72. FM Accuracy Performance Test - Part 1

8-73. FM Accuracy Performance Test - Part 2

8-74. FM Accuracy Performance Test Option

8-75. FM Accuracy Performance Test Option

lE6

Only) . . . . . . . . . . . . . . . . . . . .

lE5

lE6

lE6

. . . . . . . . . . . . . . . .

Only) . . . . . . . . . . . . . . . .

Only) . . . . . . . . . . . . . . . .

Test’- Part

. . . . . . . . . . . . . . . .

Only) . . . . . . . . . . . . . . . .

Only) . . . . . . . . . . . . . . . .

lE2

‘1 ’ : 1 : : : :

lE2 lE2 -

lE2 -

lE2 -

. . . . .

1EA

. . . . . . .

Part 1 . .

Part 2 . .

. . . . .

1EA

. . . . . . .

. . . . . . .

Part 1 . .

Part 2 . .

:

8-68

8-70

8-71

8-71

8-71

8-72

8-73

8-74

8-75

8-81

8-81

8-82

8-82

8-82

8-83

8-83

8-85

8-86

8-87

8-87

8-88

8-88

8-89

8-89

8-90

8-92

8-94

8-95

8-95

8-95

8-96

8-97

8-98

8-99

8-105

8-106

8-106

8-107

8-107

8-108

8-108

8-109

8-110

8-111

8-111

8-112

8-112

Contents-13

Page 22

8-76. FM Distortion Performance Test - Part 1

8-77. FM Distortion Performance Test - Part 2

8-78. AM Accuracy Performance Test

...........

8-79. AM Accuracy Performance Test Option

8-80. AM Distortion Performance Test

...........

.......

.......

lE2

.....

8-81. Phase Modulation Distortion Performance Test - Part 1

8-82. Phase Modulation Distortion Performance Test - Part 2

8-83. Residual FM Performance Test

8-84. Harmonics Performance Test

8-85. Spurious Performance Test

8-86. DC FM Frequency Error Performance Test

8-87. RF Level Accuracy Performance Test - Part 1

8-88. RF Level Accuracy Performance Test - Part 2

8-89. RF Level Accuracy Performance Test - Part 3

8-90. RF Level Accuracy Performance Test with Options

andlE6-Part3.

................

8-91. RF Level Accuracy Performance Test - Part 4

............

............

.............

......

.....

.....

.....

1EA

.....

8-92. Pulse Modulation On/Off Ratio Performance Test

(Option

lE6

Only) ................

8-93. Pulse Modulation Rise Time Performance Test

(Option

lE6

Only) ................

8-94. Internal Timebase: Aging Rate Performance Test

(Option

9-

1. HP 8648A Frequency Accuracy Supplemental

lE5

Only) ................

Verification Test .................

9-2. HP 8648B Frequency Accuracy Supplemental

Verification Test .................

9-3. HP 8648C Frequency Accuracy Supplemental

Verification Test .................

9-4. HP

86481)

Frequency Accuracy Supplemental

Verification Test .................

9-5. HP 8648A Option

Supplemental Verification Test

9-6. HP 8648B Option

Supplemental Verification Test

9-7. HP 8648C Option

Supplemental Verification Test

lE5

Frequency Accuracy

lE5

Frequency Accuracy

lE5

Frequency Accuracy

..........

..........

..........

9-8. HP 8648D Option lE5 Frequency Accuracy

Supplemental Verification Test

..........

9-9. HP 8648B 9 kHz RF Level Accuracy Supplemental

Verification Test .................

9-10.

HP 8648C 9 kHz RF Level Accuracy Supplemental

Verification Test .................

9-l 1. HP 8648D 9 kHz RF Level Accuracy Supplemental

Verification Test .................

8-113

8-114

8-115

8-116

8-117

8-117

8-118

8-118

8-119

8-120

8-121

8-122

8-128

8-129

8-129

8-130

8-131

8-131

8-131

9-4

9-4

9-5

9-5

9-6

9-6

9-7

9-7

9-9

9-9

9-10

Contents-14

Page 23

Operation

“Operation” contains the following information:

1 Operation Provides a quick overview of the instrument’s

operation.

la Operation

Examples

lb Operation

Reference the instrument’s functions.

lc Operation

Messages HP-IB remote operation messages.

Provides examples to help you learn how to

operate the instrument.

Provides quick access to information about each of

Provides information about both front-panel and

1

Note

For information about service messages numbered 500 and above,

refer to Chapter

5c,

“Service Error Messages.”

Operation l-l

Page 24

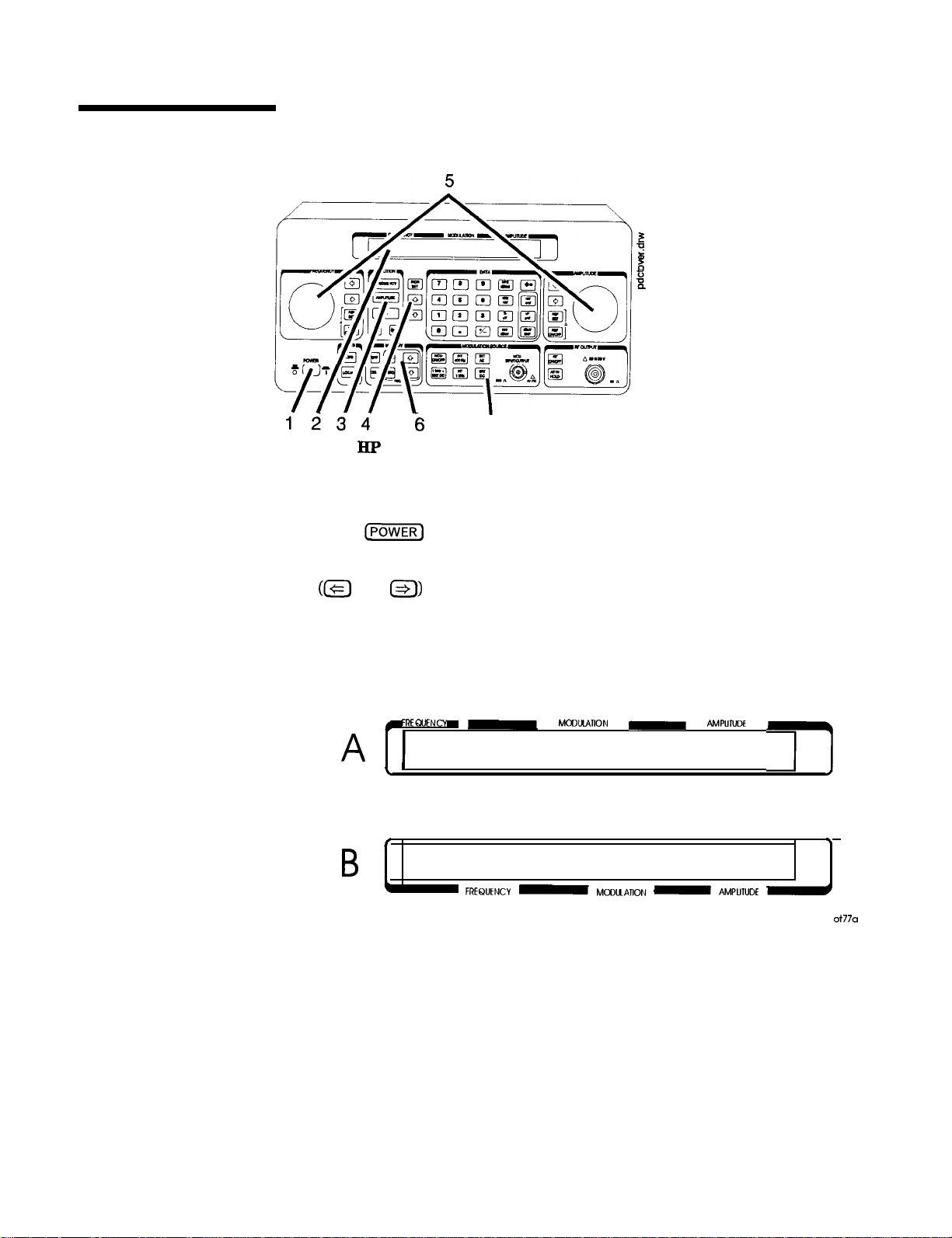

Quick Overview

1. Power Key

2. Display

234

Press

s

HP

8648 Signal Generator

(i%iK)

to power up the instrument. The instrument powers up

7

to the same state it was in when power was turned off, except that

the RF output will be turned off and the digit-select arrow keys

(@

and

a)

will be reset to the least significant digit.

The display can be one of two displays depending on the serial

number prefix of your instrument as illustrated below.

4

,\FRfgUENCY -

MCOUAIION -

AMPUI~E

I

A

/

B

4

FREQUENCY -

MCOUATION -

AMPUIUDE -

/

,

1-2 Operation

ot77a

Page 25

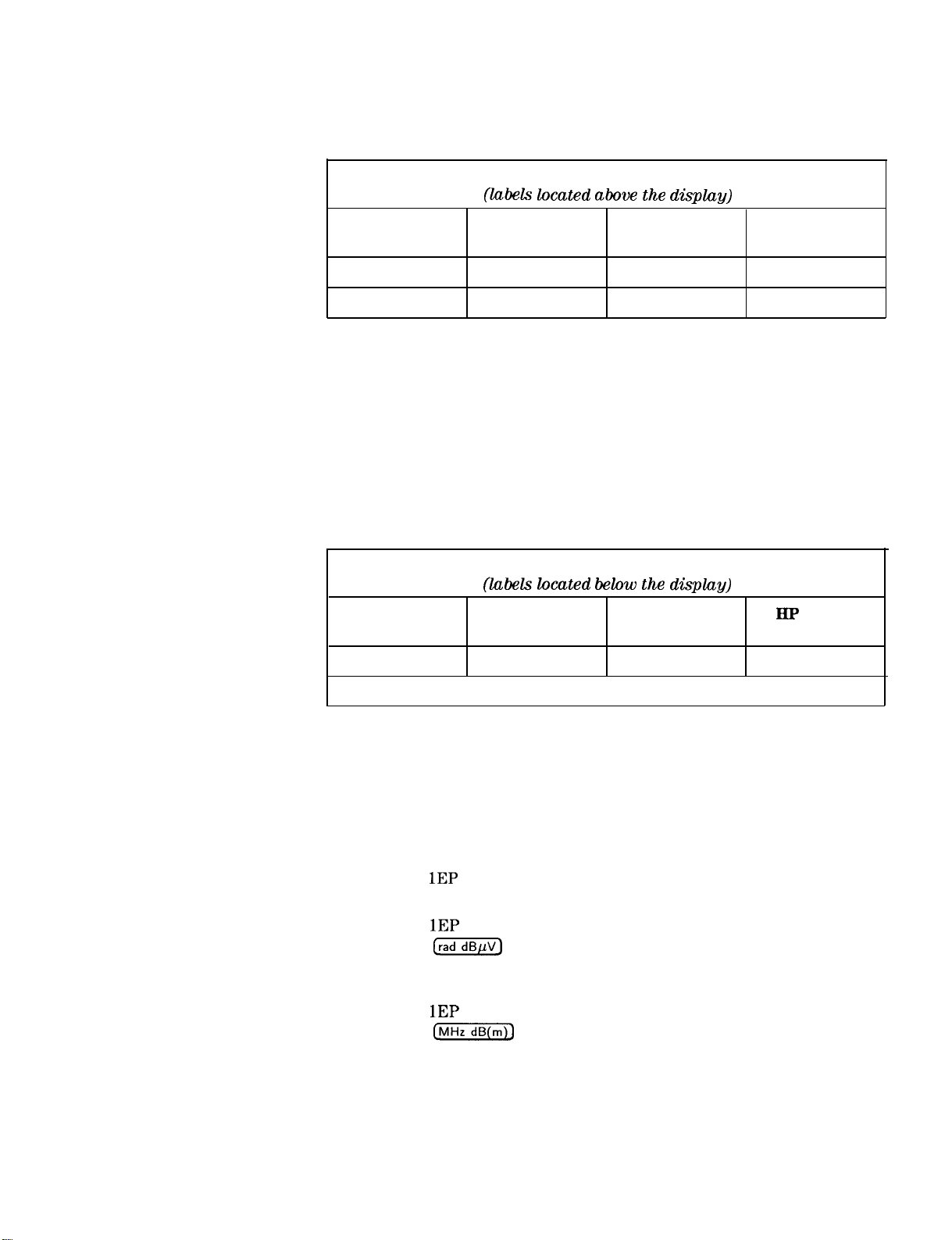

The following table describes the prefixes that apply to the various HP

8648 models equipped with an LCD.

A. Liquid Crystal Display (LCD)

(labels located above the

display)

BP 8648A BP 8648B

Prefix Preflx

3636A and below 3623A and below 3623A and below 3613A and below

3643U and below 3642U and below 3642U and below 3642U and below

The display contrast of the LCD can be achieved using the adjustment

that is located on the rear panel of these instruments. Note that this

adjustment is only available for instruments equipped with an LCD.

It allows you to adjust the contrast of the LCD. Turn the adjustment

to optimize the display for viewing from most angles. If the display is

blank, first attempt to adjust the display contrast before returning the

instrument for service.

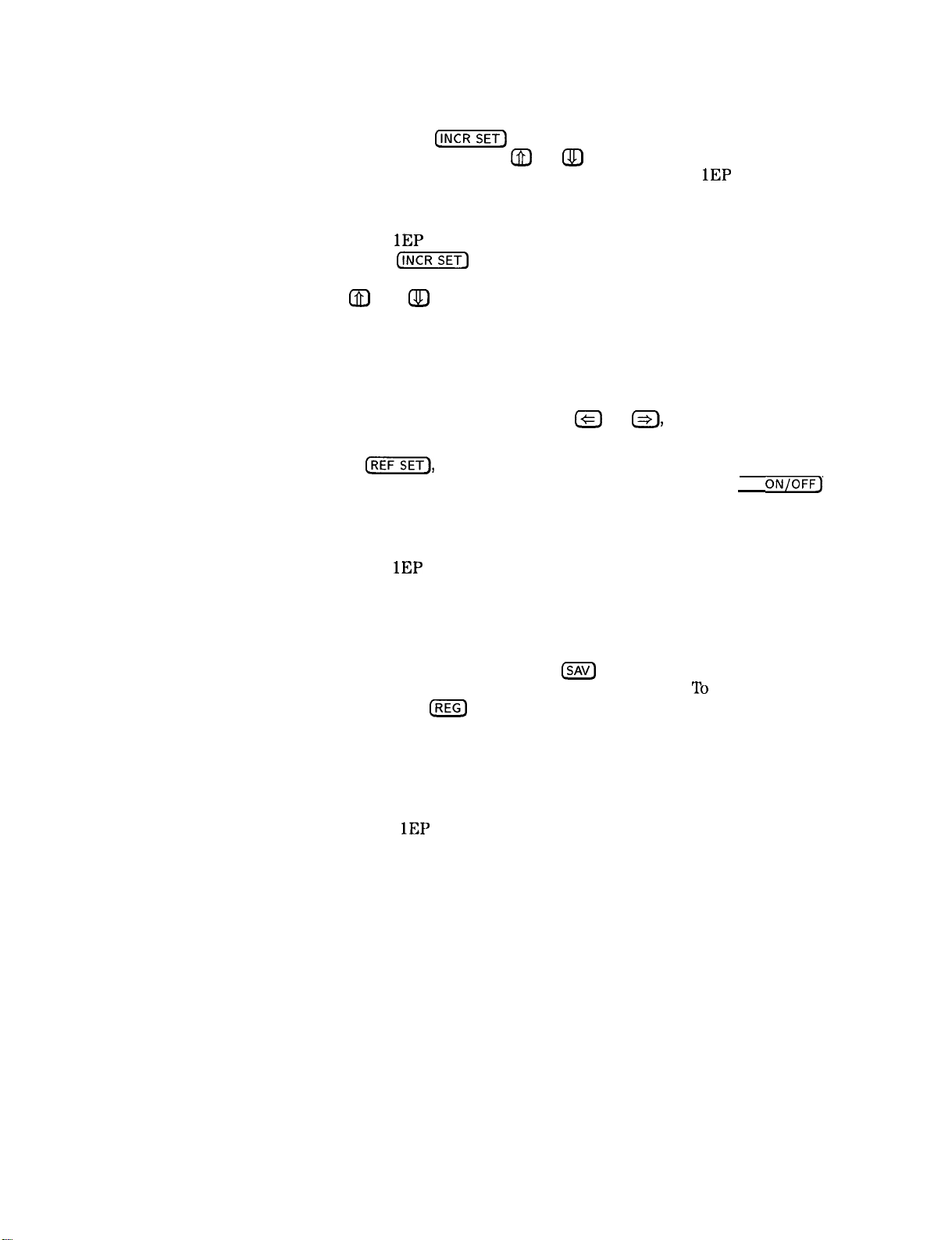

The following table describes the prefixes that apply to the various HP

8648 models equipped with a VFD.

B. Vacuum Fluorescent Display (VFD)

(labels located below the

BP 8648A BP 8648B BP 8648C

Prefix Prefix Prefix Prefix

3836A and above 3836A and above 3836A and above 3836A and above

BP 8648C

Prefix

display)

BP 8648D

Prefix

ElP

8648D

3. Function and Data Keys

3836U and above 3836U and above 3836U and above 3836U and above

The VFD is a 2x40 display. The intensity of the this display is at 100

% and cannot be adjusted.

The keys in the FUNCTION and DATA blocks allow you to enter

values for setting the frequency, amplitude, and modulation level of

the RF output signal.

If Option

pager encoder (ENCODER) mode and FM mode.

If Option

mode, the

input alphabetical characters using the DATA and MODULATION

SOURCE blocks when you are in pager encoder mode.

If Option

mode, the

key must be used to store any numeric or alphabetic characters

entered by way of the DATA and MODULATION source blocks.

I

1EP

is present, the [FM) (ENCODER) key will toggle between

1EP

is present and the signal generator is in the ENCODER

L-j

1EP

(jjdB(ml)

key functions as a SHIFT key. This key lets you

is present and the signal generator is in the ENCODER

key functions as an ENTER key. The ENTER

I

I

Operation 1-3

Page 26

4. Increment Set Keys

When you press a FUNCTION key, that function becomes the active

function. Press

the active function. Press @) or @J at any time to change the active

function setting by the increment value. (If Option

and the signal generator is in the ENCODER mode, these keys have

alternate functions.)

(‘NCR]

to view or change the increment value for

1EP

is present

5. Knobs

6. MEMORY

If Option

mode, the

starts or stops any pager encoding activity. In addition, in this mode,

the

move the blinking cursor between each parameter when you are

entering the pager encoding settings.

The knobs are always active when the instrument is in local (front

panel) control. Turn them to increase or decrease the frequency or

amplitude of the RF output. Press a or

adjust the knob’s resolution.

Press

reference value and turn on the reference mode. Press (REF ON/OFF) to

turn on and off the reference mode without changing the reference

value. When the reference mode is on, the displayed value indicates

the offset between the reference value and the RF output signal.

If Option 1EP is present and the signal generator is in the ENCODER

mode, the AMPLITUDE/ENCODER knob is used to enter a setting for

a pager encoding parameter.

Memory registers allow you to save instrument set-ups and recall

them whenever you wish. Press

number to save the instrument’s current settings.

settings, press

allow you to recall registers in numerical sequence. You can arrange

your registers in up to ten different sequences.

(jjj

and

@GZQ,

1EP

is present and the signal generator is in the ENCODER

(jj]

(7J-J

key functions as a START/STOP key. This key

function as PREV and NEXT keys. These keys let you

(ZJ

next to each knob, to

next to each knob, to set the displayed value as the

a

and enter a two-digit register

‘Ib

recall the

(REG)

and enter the register number. The arrow keys

1-4 Operation

The number of the currently selected sequence and the last register

selected are always displayed in the lower-left corner of the display to

help you keep track of where you are in your testing process.

(If Option

on any pager encoding menu.) The memory register examples

provided in Chapter la, “Operation Examples,” show you how

to create a sequence and how to delete or add registers in your

sequence.

1EP

is present, the sequence and register are not displayed

Page 27

7. Modulation Source

Press

CMOD

ON/OFF) to turn on or off the modulation source. Press

@KiZiG@

or

@i7iiKJ

to select one of the internal source tones

for modulating the RF output signal. These tones are also available

as an output signal at the MOD INPUT/OUTPUT port when they are

selected. Press

C-1

or

[EXTDC)

to ac- or dc-couple an external

audio source via the MOD INPUT/OUTPUT port.

Press

(1kt-b

+ EXT

DC)

to frequency modulate the RF signal with

the internal 1 kHz tone and an external source at the same time.

(Additional internal plus external modulation capabilities are available

for HP-IB operation.)

ClkHz

+ EXT

DC)

will also amplitude or phase

modulate the RF signal with the internal 1 kHz tone but it will not be

dc-coupled.

If Option 1EP is present, the

Option

lE2

is present, the

[@7iiK]

(NTIkHz)

(FREQUENCY) key, or if

(FREQUENCY/WAVEFORM)

key scrolls between five states: a fixed 1 kHz internal source and a

variable-frequency internal source with four different waveform

selections. The four modulation waveforms are sine, triangle, square,

and sawtooth (or ramp).

Operation

l-5

Page 28

Operation Examples

This section contains operating examples to help you learn how to

operate the signal generator. These examples can be performed

without any additional equipment. The pager testing example can

only be performed if Option 1EP is present.

la

Getting Started

If this is the first time you have operated this instrument, perform

each of the following examples for a quick introduction to general

operation. After you have completed the examples, try operating the

instrument’s remaining functions on your own. If you have trouble

or want additional information on a function, refer to Chapter lb,

“Operation Reference.” If a message is displayed that you do not

understand, refer to Chapter lc, “Operation Messages.”

Operation Examples la-l

Page 29

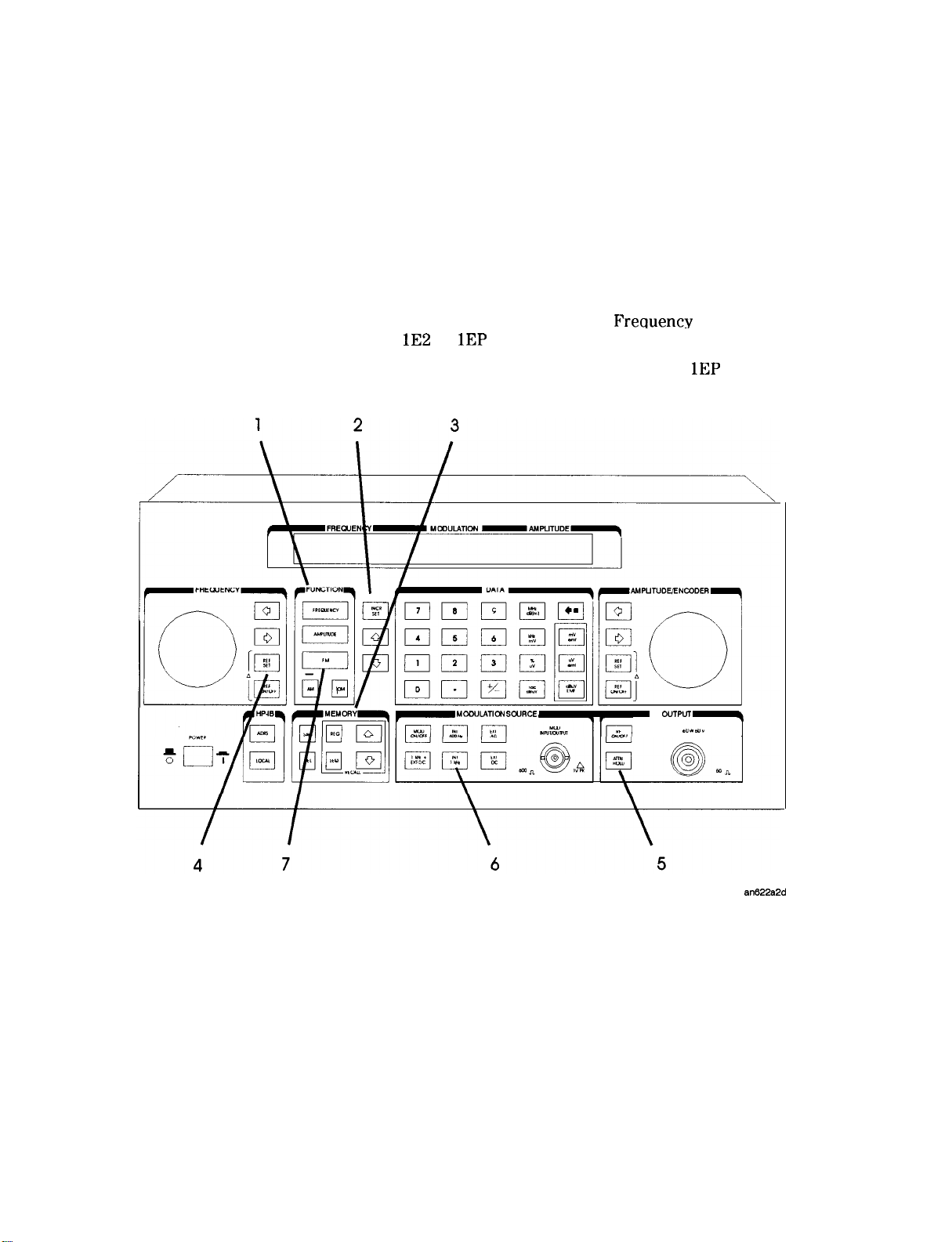

Operation Examples

This section provides the following examples of signal generator

operation. The item numbers of the operation examples correspond to

the numbers called out on drawing of the instrument front panel.

1. Setting the RF Output Signal

2. Incrementing or Decrementing the RF Output Signal

3. Using the Memory Registers

4. Offsetting the RF Output from a Reference

5. Holding the Output Attenuator Range

6. Setting a User Selectable Modulated

(Option

lE2

or

1EP

Only)

Freauency

7. Signaling a Numeric-Type FLEX Pager (Option

YcnnJLATIoN

SOURCE

RF

OUTPUT

A

and Waveform

1EP

Only)

“*Lu”

\

la-2 Operation Examples

an622a2d

Page 30

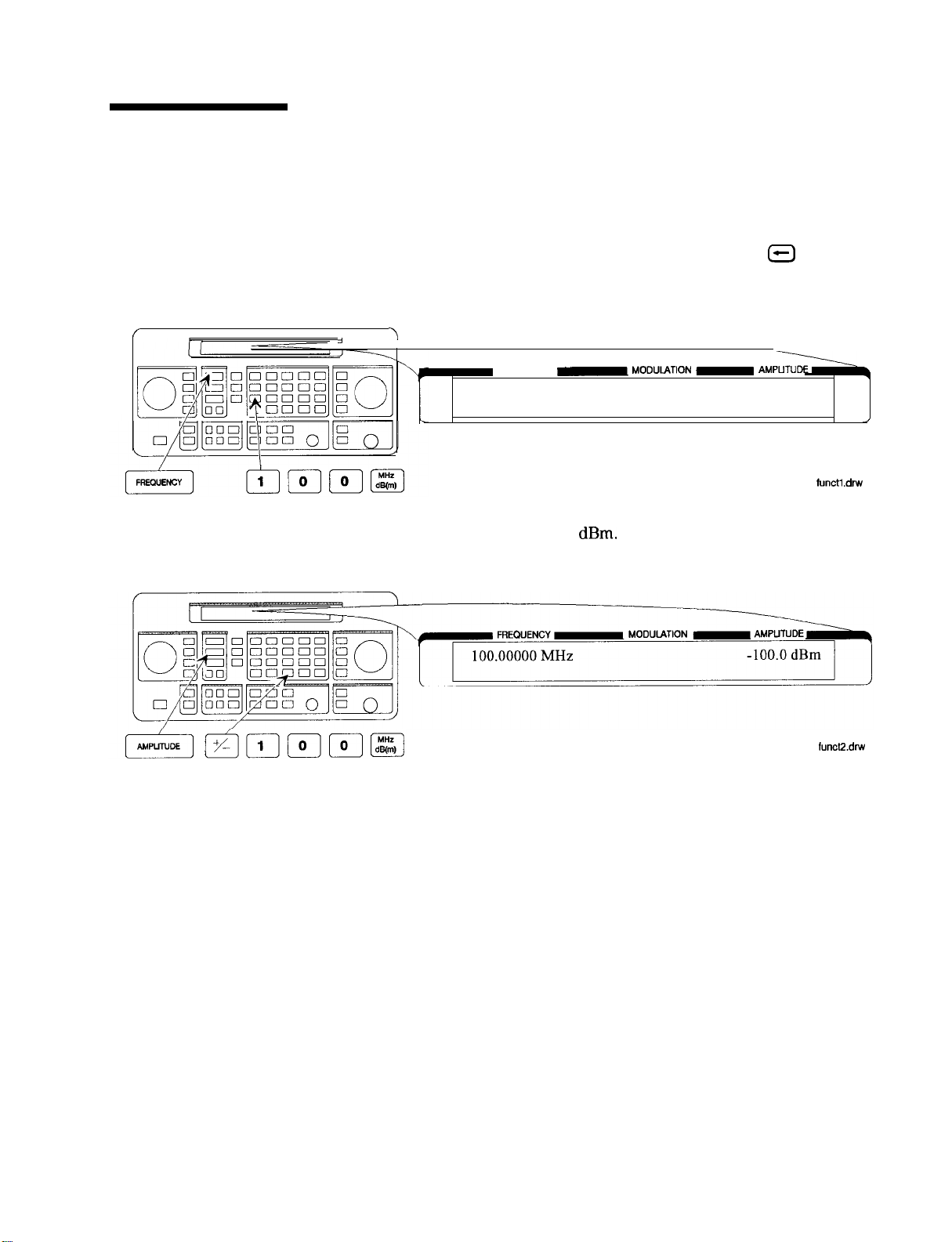

Setting the RF Output Signal

In this example, you will set the frequency, amplitude, and modulation

level of the RF output signal.

Setting the Frequency

/

Setting the Amplitude

1. Set the frequency to 100 MHz using the keys shown below the

instrument diagram.

If you make a mistake while entering a value, press a to correct

it.

J

\

FREQUENCY

100.00000 MHz

2. Set the amplitude to -100 dBm.

-

MODUfATlON -

AMP-

fund1

.drw

4

J

funcfZ.dw

Operation Examples la-3

Page 31

Turn on the RF Output

3. Press

C-1

to turn on the RF output.

RF OFF is displayed below the amplitude setting when the RF

output is turned off.

Setting the

Modulation

II ” ~“““’ ;I

4. Set the FM deviation to 3 kHz.

The modulation rate is displayed below the deviation setting. Use

the MODULATION SOURCE keys to select a modulation source and

turn modulation on or off.

3

FREQUENCY

100.00000 MHz

\

-

MODULATION

FM 3.00

kHz

1kHz

-

AMPLITUDE

-100.0 dBm

funct4.drw

,

/

la-4 Operation Examples

Page 32

Incrementing or Decrementing the RF Output Signal

In this example, you will increment the amplitude and frequency of

the RF output signal.

Preliminary Steps

[ FwJ,‘,,

]

[+] [o] 10 [z]

Using the Knob

1. If they are not already set, set the frequency to 100 MHz, and the

amplitude to -100 dBm.

FREQUENCY

100.00000 MHz

2. Increment the amplitude using the knob.

Press @ or

(TJ

-

when you wish to adjust the increment resolution.

MODULATION

MODUl.ATlON

-

AMPLITUDE

-100.0

dBm

lncrl

.dnv

incr2.dw

Operation Examples la-5

Page 33

Using the Increment

keys

3. Enter a frequency increment of 25 kHz.

The $ symbol is displayed when you press

that the displayed value is the increment set value.

2500000:kHz

L

4. Increment the RF output frequency in 25 kHz steps.

The increment keys affect the last FUNCTION selected

(FREQUENCY, AMPLITUDE, FM, AM or

@iiZWi]

-101.0

dM).

to indicate

dBm

/

000

OOn

0

o--

0 00

q c

0 not

0

0 q OCI

OrI

II

$

FREQUENCY

100.02500 MHz

-

MODULATION

,-

AMP”>

-101 .O dBm

h

fncr4.dw

la-6 Operation Examples

Page 34

Using the Memory Registers

The memory register examples show you how to create a sequence of

registers, delete a register from that sequence, renumber the registers

in the sequence, and insert a new register in the sequence.

Up to 10 register sequences can be defined (0 through 9). A sequence

can contain up to 100 registers (00 through 99). There are a total of

300 registers available in the instrument. The registers can be used

in the sequences in any combination (such as 10 sequences of 30

registers each, or 3 sequences of 100 registers each) as long as the

total does not exceed 300 registers. It is not possible to have all 10

sequences each contain 100 registers as that would be 1000 registers.

(If Option

1oo.ooOOoMHz

1EP

is present, there are a total of 70 registers available.)

FREWENCY

B

EGOI

\

MODuATlON

FM

3.OOKz

1lcHzoFF

m .uw”nmE

-I

36.0dBm

RFOFF

z

SEQ 0

SEQ

9

REG 00

REG

99

Operation Examples la-7

Page 35

Saving Instrument

Settings in Register

Sequences

SE0

0

b3

In this ten step example, you will use the memory keys to create

a sequence containing three registers. Each register will contain a

different frequency setting.

Selecting the Sequence

1. Select sequence 0.

If there are registers saved in sequence 0, the message shown

in the display below will not appear. Note that the steps in this

example will cause the settings in registers 00, 01, and 02 of

sequence 0 to be changed.

regseql

Saving Settings in Registers

.dnv

2. Set the frequency to 10 MHz.

3. Save the instrument settings in register 00.

J

FREQUENCY

10.00000 MHz

SEQ 0 REG 00

-

MODUIATION

-

AMPUTLIDE

regseqZ.dnv

1

,

I

la-8 Operation Examples

Page 36

4. Set the frequency setting to 11 MHz.

FFIEQUENCY ,-

MODULATION

-

5. Save the instrument settings in register 01.

6. Set the frequency to 12 MHz.

AMPLITU

regseqldrw

regseq&drw

Operation Examples la-9

Page 37

7. Save the instrument settings in register 02.

regseq9.dw

FREQUENCY

-

MODULATION

-

AMPLITUDE

12.00000 MHz

SEQ 0 REG 02

Checking the Sequence

8. Recall the registers in sequence 0.

The @) and @J keys recall registers or sequences depending on

which key was pressed last

FREQUENCY

SEQ 0 REG 01

-

12.00000 MHz

SEQ 0 REG 02

10.00000 MHz

SEQ 0 REG 00

(m

or

(SEQ).

MODULATION

-

AMPLITUDE

regseq7.drw

la-l 0

Operation Examples

Checking a

Different

9. Select sequence 1.

16

\

SEQ

Sequence

FREQUENCY

1

-

MODULATION

--,

AMPUTUDE

/

rea9.dw

Page 38

10. Step through the registers in sequence 1 if there are registers

saved in it.

Note

Sequence 1 does not contain the settings you saved in sequence

0. The instrument enables you to save different settings in each

sequence to create up to ten different sequences for your testing.

Remember when you save or recall a register, be sure that the correct

sequence is also selected.

reqO.dw

Operation Examples

la-l 1

Page 39

Deleting a Register

from the Sequence

In this example, you will delete a register from the sequence you

created in the preceding example.

Selecting the Sequence

1. Select sequence 0.

I

1.i..

SE0

flc5

0

Note

FREQUENCY

\

SEQ 0

-

MODULATION

-

AMPLITUDE

delregO.drw

Deleting a Register

2. Delete register 01 from sequence 0.

The contents of the register are recalled when it is deleted. This

allows you to resave the contents if you need to.

4

FREQUENCY

11 .OOOOO MHz

SEQ 0 REG --

-

MODULATION

-,

AMPLITUDE

,

la-12 Operation Examples

delregl

.drw

Page 40

Step through the remaining registers in sequence 0.

3.

The deleted register number has been removed from the sequence.

Note that the instrument does not renumber the registers when

one is deleted.

FREOUENCY -

12.00000 MHz

SEQ 0 REG 02

10.00000 MHz

SEO

0 REG 00

MODULATION

-

AMPUTUDE

delreg2.drw

Operation Examples la-13

Page 41

Renumbering the

Registers in a

Sequence

In this example, you will eliminate the skip from register 00 to register

02 in sequence 0 caused when you deleted register 01 in the previous

example.

Decreasing the Register Number

1. Delete register 02.

The settings saved in register 02 are recalled when it is deleted.

2. Save the settings from register 02 into register 01.

12.00000 MHz

\

SEQ 0 REG 01

nemwta2.dnv

/

la-14 Operation Examples

Page 42

Checking the Sequence

3. Step through the register sequence.

I

I

12.00000

LSEQOREGO~

I

10.00000MHz

SEOOREGOO

MHz

I

r

numseq3.drw

Note

In this example, you renumbered one register. When you need to

renumber two or more registers, use

each register until you get to the last register in the sequence, then

use (DEL).

[REG)

instead of (DEL) to recall

Operation Examples la-15

Page 43

Inserting a Register in

a Sequence

In this example, you will insert a register into the sequence you

created in the previous example. The process involves incrementing

each register number that comes after the point in the sequence

where you wish to insert a register.

1. Recall the last register in sequence 0.

mu

L

i ‘I””

000

Em

0 00

00 0

0 or

0

PJ

!a GCEI

4

I \

-J

FREQUENCY

12.00000 MHz

\

SEQ 0 REG 01

-

MODULATION

2. Save the recalled settings into register 02.

-

AMPUTUDE

/

insseql .dw

insseq2.dnv

Operation Examples

la-l 6

3. Recall register 00.

Register 01 can now be used to save the settings that are saved in

register 00.

FREQUENCY

-

MODULATION

-

AMP>

Insseq3.dw

,

Page 44

4. Save the recalled settings into register 01.

Register 00 can now be used to save the new settings.

9

FREQUENCY

-

10.00000 MHz

SEQ 0 REG 01

Saving a New Register

5. Set the frequency to 8 MHz.

FREQUENCY

8.00000 MHz

I

6. Save the settings in register 00.

-

MODULATION

MODULATION

-

AMPUT-

,

/

inswq4.drw

-

AMPUTUDE

I

insseq5.drw

Press

0-J

to check the new sequence.

8.00000 MHz

insseq6.drw

Operation Examples

la-l 7

Page 45

Offsetting the RF Output from a Reference

In this example, you will enter an RF output frequency, set it as the

reference value, and then offset the RF output frequency 10 MHz

below the reference value.

Setting the

Reference

Value

1. Set the frequency to 500 MHz.

500.00000 MHz

2. Set 500 MHz as the reference frequency.

The A symbol appears in the display to indicate that the reference

mode is selected. The output frequency is still 500 MHz.

refl

.drw

la-l 6

refZ.dn%

Operation Examples

Page 46

Offsetting the RF

output

3. Offset the output frequency 10 MHz below the reference

frequency.

You can enter in the offset value directly, or use the knob or

and

(IJ

keys.

@J

i

i ‘I’

EE

00

00

n

000

000

r--l

[pfjry

Attention!

[o] [Z]

FREQUENCY

-10.00000

-

nMHz

MODULATION

-

AMPLITUDE

L

ref3,drw

In the reference mode, the output frequency equals the reference

/

frequency f the displayed offset frequency.

Turning

the Reference Mode Off or On

4. Turn off the reference mode to display the actual output

frequency.

FREQUENCY

490.00000

-

MHz

MODULATION

-

AMPLITUDE

5. Turn on the reference mode without changing the reference

frequency.

.

----=A

-

011

\I

y-1(1.00000~MH~

i-----~

;

I

i

/I

11 “I

-

-------

11

110 ij$!~jE&i~~~~~

‘h?fEEk3~iA

1 0 ~J~Kqp+i

FIEF

ON/OFF

i-

0

JI;; 0 Jj

r^L^. ._..^.,

riit""eNLT

p.

L

..^ -... __.^..

M"U"lAl I"N -

rel4.dnv

-TIITl,n~~

AM, Y YYL

1

ref5.dw

Operation Examples la-19

Page 47

6. Change the displayed units to

kHz.

Note that for amplitude, reference settings are displayed in

dB

units only.

FREQUENCY

-

MODULATION

-

AMPUTUDE

-1OOOO.OOakHz

Setting a New Reference Value

7. Set the current output frequency as the new reference frequency

at any time.

ref7.dr-a

la-20 Operation Examples

Page 48

Holding the Output Attenuator Range

In this example, you will hold the output attenuator so it does not

change ranges when you change the amplitude setting. This will

prevent attenuator range changes from affecting the output signal.

Set the Amplitude

Level

[=I

I+/-]

[s]

[T--y

Holding the

Attenuator

a&7?2iJjm:I,I’

1. Set the amplitude level to -82 dBm.

[Z]

2. Hold the attenuator at this setting.

I

\

J ,

FREGUENCY -

MODULATION

-82.0

dBm

-

AMPLITUDE

-82.0

dBm

HOLD

/

Operation Examples la-21

Page 49

Adjusting the

Amplitude

3. Adjust the amplitude setting.

Now amplitude changes do not cause the attenuator to change its

range setting. Consequently, amplitude changes are limited to the

range provided by the instrument’s vernier. For information about

the instrument’s vernier ranges, refer to Chapter lb, “Operation

Reference.

”

la-22 Operation Examples

Page 50

Setting a User

Selectable

Modulated

Frequency and

Waveform

(Option lE2 or

Only)

1EP

Note

Setting the

Modulation Level

This modulation example can only be performed if Option

is present.

In this example, you will select the modulation level and the

modulated frequency and waveform of the RF signal output.

1. Select FM modulation with a deviation of 25 kHz.

Either LAM) or

The modulation type (FM, AM, or

(deviation or depth) is displayed on the top line of the front-panel

display as shown.

(jKJ

modulation may be used instead of (FM.

4M)

and the modulation level

pRE9uENCY

-

MOD”LATlON

FM25.0kHz

-

AMPUTUDE

lE2

or

1EP

c

Operation Examples la-23

Page 51

Setting the Modulated

Waveform

(Frequency/

Waveform)

2. Press the

@KiiZ’

(FREQUENCY/WAVEFORM) key until

selected.

Repetitively pressing the

(INT’