Page 1

Service Guide

8590 Series Analyzers

Assembly-Level Repair

Manufacturing Part Number: 08590-90316

Supersedes: 08590-90300

Printed in USA

April 2001

© Copyright 1992-1998, 2001 Agilent Technologies, Inc.

Page 2

The information contained in this document is subject to change without

notice.

Agilent Technologies makes no warranty of any kind with regard to this

material, including but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Agilent Technologies

shall not be liable for errors contained herein or for incidental or consequential

damages in connection with the furnishing, performance, or use of this

material.

2

Page 3

Certification

Agilent Technologiescertifiesthat this product met its published specifications

at the time of shipment from the factory.Agilent Technologies further certifies

that its calibration measurements are traceable to the United States National

Institute of Standards and Technology, to the extent allowed by the Institute's

calibration facility, and to the calibration facilities of other International

Standards Organization members.

Regulatory Information

The specifications and characteristics chapter in this manual contain

regulatory information.

Warranty

This Agilent Technologies instrument product is warranted against defects in

material and workmanship for a period of one year from date of shipment.

During the warranty period, Agilent Technologies will, at its option, either

repair or replace products which prove to be defective.

For warranty service or repair, this product must be returned to a service

facility designated by Agilent Technologies. Buyer shall prepay shipping

charges to Agilent Technologies and Agilent Technologies shall pay shipping

charges to return the product to Buyer. However, Buyer shall pay all shipping

charges, duties, and taxes for products returned to Agilent Technologies from

another country.

Agilent Technologies warrants that its software and firmware designated by

Agilent Technologies for use with an instrument will execute its programming

instructions when properly installed on that instrument. Agilent Technologies

does not warrant that the operation of the instrument, or software,orfirmware

will be uninterrupted or error-free.

3

Page 4

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from improper or

inadequate maintenance by Buyer, Buyer-supplied software or interfacing,

unauthorized modification or misuse, operation outside of the environmental

specifications for the product, or improper site preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. AGILENT

TECHNOLOGIES SPECIFICALLY DISCLAIMS THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

Exclusive Remedies

THE REMEDIES PROVIDED HEREIN ARE BUYER'S SOLE AND

EXCLUSIVE REMEDIES. AGILENT TECHNOLOGIES SHALL NOT BE

LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT,

OR ANY OTHER LEGAL THEORY.

Assistance

Product maintenance agreements and other customer assistance agreements

are available for Agilent Technologies products.

For any assistance, contact your nearest Agilent Technologies Sales and

Service Office.

4

Page 5

8590 E-Series and L-Series Spectrum

Analyzer Documentation Description

The following guides are shipped with your 8590 E-Series or L-Series

spectrum analyzer.

8590 E-Series Spectrum Analyzers and 8591C Cable TV Analyzer

Calibration Guide

• Tells you how to test your analyzer to determine if the analyzer meets

its specifications.

8590 E-Series and L-Series Spectrum Analyzers User’s Guide

• Tells you how to make measurements with your analyzer.

• Describes the analyzer features.

• Tells you what to do in case of a failure.

8590 E-Series and L-Series Spectrum Analyzers Quick Reference Guide

• Describes how to make a simple measurement with your analyzer.

• Briefly describes the analyzer functions.

• Lists all the programming commands.

5

Page 6

8591C Cable TV Analyzer Documentation

Description

The following guides are shipped with your cable TV analyzer.

8590 E-Series Spectrum Analyzers and 8591C Cable TV Analyzer

Calibration Guide

• Tells you how to test your analyzer to determine if the analyzer meets

its specifications.

8591C Cable TV Analyzer User’s Guides

Cable TV Measurements

• Tells you how to make cable TV measurements with your analyzer.

• Describes the cable TV analyzer mode features.

Spectrum Analyzer Reference

• Tells you how to make measurements using the spectrum analyzer

mode.

• Describes the spectrum analyzer mode features.

• Tells you what to do in case of a failure.

8591C Cable TV Analyzer Getting Started and Quick Reference Guide

• Describes how to make a simple measurement with your analyzer.

• Briefly describes the cable TV and spectrum analyzer functions.

• Provides a quick reference for cable TV and spectrum analyzer

softkeys.

8590 E-Series and L-Series Spectrum Analyzers, and 8591C Cable TV

Analyzer Programmer’s Guide

• Describes analyzer operation via a remote controller (computer) for

Parallel/RS-232 or Parallel/GPIB interface. This manual is provided

when ordering either Option 041, Option 043, or 8591C.

6

Page 7

8594Q QAM Analyzer Documentation

Description

The following guides are shipped with your QAM analyzer.

8590 Series Analyzers Calibration Guide

• Tells you how to test your analyzer to determine if the analyzer meets

its specifications.

8594Q QAM Analyzer User's Guides

Option 190/195 DVB-C/Data Measurements

• Tells you how to make QAM measurements with your analyzer.

• Describes the QAM analyzer mode features.

Spectrum Analyzer Reference

• Tells you how to make measurements using the spectrum analyzer

mode.

• Describes the spectrum analyzer mode features.

• Tells you what to do in case of a failure.

8594Q Option 190/195 DVB-C/Data Measurement QAM Analyzer Getting

Started and Quick Reference Guide

• Provides a quick reference for QAM and spectrum analyzer softkeys.

7

Page 8

Documentation Options

Option 041 or 043: Programmer's Guide

8590 E-Series and L-Series Spectrum Analyzers, and 8591C Cable TV

Analyzer Programmer's Guide

• Describes analyzer operation via a remote controller (computer) for

Parallel/RS-232 or Parallel/GPIB interface.

Option 910: Additional User's Documentation

Provides an additional copy of the user's guides, the calibration guide,

and the quick reference guide.

Option 915: Service Guide and Component-Level Information

Describes troubleshooting and repair of the analyzer.

Option 915 consists of two manuals:

8590 Series Analyzers Assembly-Level Repair Service Guide

• Describes adjustment and assembly level repair of the analyzer.

8590 Series Analyzers Component-Level Repair Service Guide

• Provides information for component-level repair of the analyzer.

How to Order Guides

Each of the guides listed above can be ordered individually. To order, contact

your local Sales and Service Office.

How to Use This Guide

This guide uses the following conventions.

Front-Panel Key This represents a key physically located on the instrument

front panel.

Softkey This indicates a “softkey,” a key whose label is determined by

the instrument's firmware. Softkeys are located on the

display bezel.

Screen Text This indicates text displayed on the instrument screen.

8

Page 9

Contents

1. Introduction

The 8590 Series Analyzers Assembly-Level Repair Service Guide. . . . . . . . . . . . . . . . . . . . . 14

Service Guide Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Analyzer Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Firmware Revision Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Firmware Upgrade Kit Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Reliability Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Adjustment Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Test Equipment You Will Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

When A 3335A Source Is Not Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

If There Are Abnormal Indications During Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Periodically Verifying Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Standard-Value Replacement Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

If You Replace or Repair an Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2. Making Adjustments

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1a. Display (with four access holes in top of shield) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

1b. Display (with eight access holes in top of shield) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2. Sampler Match . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3. 10 MHz Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4. 10 MHz Precision Frequency Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5. Crystal and LC Bandwidth Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6. Cal Attenuator Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7. Log and Linear Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

8. CAL FREQ Adjustment Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9. CAL AMPTD Adjustment Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10. CAL YTF Adjustment Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

11. CAL MXR Adjustment Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

12. Second Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

13. Third Converter and Second IF Bandpass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

14. Comb Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

15. Frequency Response of the 8590L, 8591C, and 8591E . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

16. Frequency Response of the 8592L/94L, 8593E/94E/95E/96E, and 8594Q . . . . . . . . . . . 106

17. Time and Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

18. Modulator Offset and Gain for Option 010 or 011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

19. Entering External ALC Correction Constants for Option 010 or 011 . . . . . . . . . . . . . . 129

20. Checking the External ALC for Option 010 or 011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

21. Correcting for External ALC Error for Option 010 or 011 . . . . . . . . . . . . . . . . . . . . . . . 135

22. First LO Distribution Amplifier for Option 009 or 010 . . . . . . . . . . . . . . . . . . . . . . . . . . 139

23. BITG Power Level for Option 010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

24. Tracking Oscillator for Option 010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

25. Checking the Absolute Amplitude Accuracy for Option 050 . . . . . . . . . . . . . . . . . . . . . . 151

26. Correcting for Absolute Amplitude Accuracy for Option 050 . . . . . . . . . . . . . . . . . . . . . 157

27. Checking the Absolute Amplitude Accuracy for Option 051 . . . . . . . . . . . . . . . . . . . . . . 160

28. Correcting for Absolute Amplitude Accuracy for Option 051 . . . . . . . . . . . . . . . . . . . . . 171

9

Page 10

Contents

2a. Making Adjustments: If 3335A Source Not Available

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .178

6a. Cal Attenuator Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .179

7a. Log and Linear Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

15a. Frequency Response of the 8590L, 8591C, and 8591E . . . . . . . . . . . . . . . . . . . . . . . . . .191

3. Backing Up and Reloading Correction Constants

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200

Backing Up Analyzer Correction Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .201

Analyzer Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .204

Reloading the Correction Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .207

Instrument Calibration after Reloading the Correction Constants . . . . . . . . . . . . . . . . . . . .209

4. Troubleshooting the Analyzer

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .216

Problems at Instrument Power-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .219

Troubleshooting an Inoperative Analyzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .221

Troubleshooting the A2 Display Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .227

Isolating an RF, LO, IF, or Video Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .232

Using the Internal Service-Diagnostic Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .238

Troubleshooting the A16 Processor/Video Board Assembly . . . . . . . . . . . . . . . . . . . . . . . . . .249

5. Troubleshooting the IF Section

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .254

Service Equipment You Will Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .254

After an Analyzer Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .255

IF Section Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .255

IF Power-Level Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .256

Troubleshooting the A15 Motherboard Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .266

6. Troubleshooting the RF Section

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .282

Service Equipment You Will Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .283

After an Analyzer Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .283

6a. 8590L, 8591C, and 8591E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .284

6b. 8592L/94L, 8594Q, and 8593E/94E/95E/96E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .287

7. Replacing Major Assemblies

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .294

Service Equipment You Will Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .294

After an Analyzer Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .295

Removal and Replacement Procedures in this Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . .295

Instrument Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .296

A1 Front-Frame Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .298

A1A1 Keyboard/Front-Panel Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .302

A2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .303

RF Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .308

A3 Front-End Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .311

10

Page 11

Contents

A7 Analog Interface Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

A8 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

A15 Motherboard and IF Extrusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

A16 Processor/Video Board and A16A1 Memory Board Assembly . . . . . . . . . . . . . . . . . . . . 330

A16 Processor/Video Board Firmware ROMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

A16A1BT1 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

A17 Memory Card Reader Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

A25 Counter-Lock Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

B1 Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

Rear-Frame Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

8. If You Have A Problem

Contacting Agilent Technologies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

Check the Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

Calling Agilent Technologies Sales and Service Offices . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352

Returning Your Analyzer for Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 355

9. Assembly Descriptions and Block Diagrams

Assembly Descriptions and Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

RF and LO Section for 8590L, 8591E, and 8591C Spectrum Analyzers . . . . . . . . . . . . . . . 359

RF and LO Section for 8592L, 8593E, 8594E, 8594L, 8594Q,

8595E, and 8596E Analyzers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 365

IF Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373

10. Analyzer Options and Block Diagrams

Analyzer Options and Block Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 394

Option Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 397

Troubleshooting Analyzer Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 408

Tracking Generator 8593E, 8594E, 8595E, 8596E Option 010 . . . . . . . . . . . . . . . . . . . . . . 410

First LO Distribution Amplifier (LODA) 8593E, 8594E, 8594Q, 8595E, 8596E

Option 009 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 419

Option 190 DVB-C Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 433

Option 190 DVB-C Service Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 434

11. Major Assembly and Cable Locations

Major Assembly and Cable Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 454

12. Replaceable Parts

Replaceable Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 486

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 487

Standard-Value Replacement Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 497

Component-Level Information Packets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 521

13. Softkey Descriptions

Softkey Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 554

11

Page 12

Contents

14. Analyzer Messages

Interpreting Analyzer Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .614

15. Service Equipment and Tools

Service Equipment and Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .660

16. Safety and Regulatory Information

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .668

Safety Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .668

Instrument Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .669

General Safety Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .670

Protection from Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .672

12

Page 13

1 Introduction

The 8590 Series Analyzers Assembly-Level Repair Service Guide

provides the information needed to adjust and repair the 8590 E-Series

and L-Series spectrum analyzers, the 8591C cable TV analyzer

and 8594Q QAM analyzer to the assembly level.

13

Page 14

Introduction

The 8590 Series Analyzers Assembly-Level Repair Service Guide

The 8590 Series Analyzers Assembly-Level

Repair Service Guide

The 8590 Series Analyzers Component-Level Repair Service Guide

provides component-level information for the repair of individual

analyzer assemblies. The binder contains Component-Level

Information Packets (CLIPs) for selected assemblies. Each CLIP

contains component-level schematics, a component parts list, and

illustrations for component location by reference designator.Each CLIP

has its own part number which is changed whenever the part number

for its related analyzer assembly is changed. A list of all CLIP part

numbers for the 8590 E-Series and L-Series spectrum analyzers, 8591C

cable TV analyzers, and 8594Q QAM analyzers is provided in Chapter

12 of this service guide.

Figure 1-1 8590 E-Series and L-Series Spectrum Analyzers, 8591C Cable TV

Analyzers, and 8594Q QAM Analyzer

14 Chapter1

Page 15

Introduction

Service Guide Organization

Service Guide Organization

The guide is divided into the following chapters.

• Chapter 1, “Introduction,” contains information on the analyzer

identification, firmware revisions and upgrades, and safety and

reliability considerations.

• Chapter 2, “Making Adjustments,” contains the adjustment

procedures needed to adjust the analyzer to meet its specifications.

• Chapter 2a, “Making Adjustments: 3335A Source Not Available,”

contains the adjustment procedures needed to adjust the analyzer to

meet its specifications when a 3335A source is not available.

• Chapter 3, “Backing Up and Reloading Correction Constants,”

contains information for safe-guarding the correction data stored in

the analyzer and restoring the analyzer memory.

• Chapter 4, “Troubleshooting the Analyzer,”contains information for

starting to troubleshoot a analyzer failure.

• Chapter 5, “Troubleshooting the IF Section,” contains specific

troubleshooting information for selected assemblies in the IF section

and the A15 Motherland assembly.

• Chapter 6, “Troubleshooting the RF Section,” contains

troubleshooting information for the RF and LO sections of

the 8590 E-Series and L-Series spectrum analyzer and 8591C cable

TV analyzer. The information is separated by the following tabs.

• Chapter 6a, “8590L, 8591C and 8591E,” contains specific

troubleshooting information for selected assemblies within the RF

and LO sections of the 8590L, 8591E spectrum analyzers, and 8591C

cable TV analyzers.

• Chapter 6b, “8592L/94L, 8594Q, and 8593E/94E/95E/96E,”

contains specific troubleshooting information for selected assemblies

within the RF and LO sections of the 8592L, 8594L, 8593E, 8594E,

8595E, 8596E spectrum analyzers, and the 8594Q QAM analyzer.

• Chapter 7, “Replacing Major Assemblies,” contains instructions for

the removal and replacement of most major assemblies.

• Chapter 8, “Contacting Agilent Technologies,” contains information

on how to contact Agilent Technologies and return the analyzer for

repair.

• Chapter 9, “Assembly Descriptions and Block Diagrams,” contains

information and block diagrams describing analyzer operation and

individual assemblies.

Chapter 1 15

Page 16

Introduction

Analyzer Description

• Chapter 10, “Analyzer Options and Block Diagrams,” contains

information on the available analyzer options.

• Chapter 11, “Major Assembly and Cable Locations,” contains

figures identifying all major assemblies and cables.

• Chapter 12, “Replaceable Parts,” contains information needed to

order assemblies and component-level information for the analyzer.

• Chapter 13, “Softkey Descriptions,” contains a description of the

calibration, service, and diagnostic softkeys.

• Chapter 14, “Analyzer Messages,” contains a description of the

analyzer messages that are displayed when there is a problem with

the analyzer.

• Chapter 15, “Service Equipment and Tools,” contains information

about equipment and tools used to service the analyzer.

Analyzer Description

The 8590 E-Series and L-Series spectrum analyzers, 8591C cable TV

analyzers, and 8594Q QAM analyzers provide measurement

capabilities over the RF and Microwave frequency ranges.

The frequency ranges of 8590 E-Series and L-Series spectrum

analyzers, 8591C cable TV analyzers, and 8594Q QAM analyzers are

described below.

All 8590 E-Series spectrum analyzers, 8591C cable TV analyzers

and 8594Q QAM analyzers are equipped with a memory card reader.

The memory card reader allows the analyzer to use downloadable

software programs. The functional “personality” of the analyzer can

also be altered using the memory card reader. This feature provides the

user with one analyzer that can perform the function of other types of

microwave test equipment.

Further information about the 8590 E-Series and L-Series spectrum

analyzers, and the available options, is provided in Chapter 10,

“Analyzer Options and Block Diagrams,” of this service guide and

the 8590 E-Series and L-Series Spectrum Analyzers User's Guide.

Further information about the 8591C cable TV analyzer and 8594Q

QAM analyzer is provided in the spectrum analyzer reference for your

instrument. Further information about the 8594Q QAM analyzer is

provided in 8594Q QAM Analyzer Spectrum Analyzer Reference User's

Guide.

16 Chapter1

Page 17

Introduction

Analyzer Description

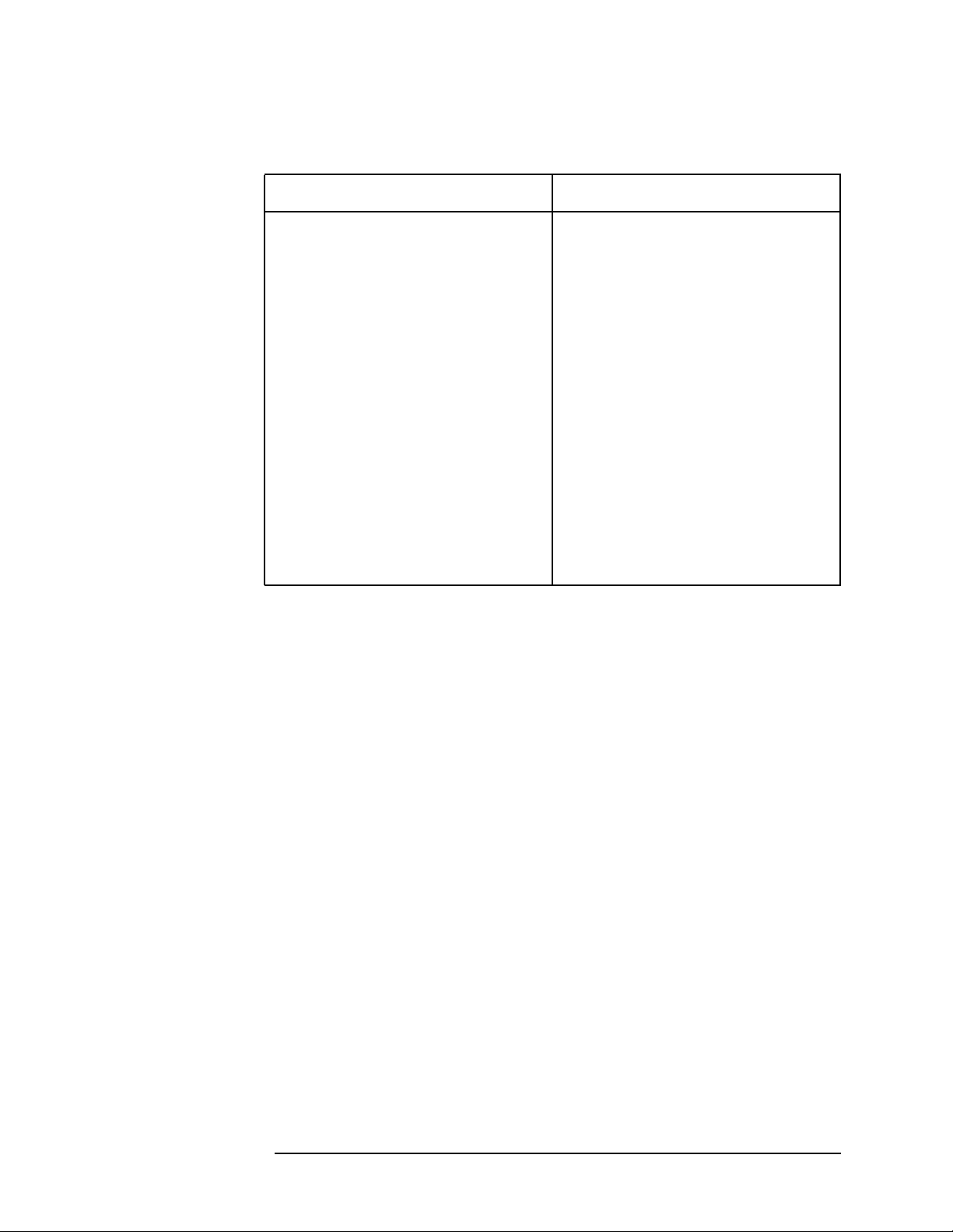

Table 1-1 8590 E-Series and L-Series Spectrum Analyzer, 8591C Cable TV

Analyzer and 8594Q QAM Analyzer Frequency Ranges

Analyzer Model Frequency Range

8590L 9 kHz to 1.8 GHz

8591E 9 kHz to 1.8 GHz

8591C 1 MHz to 1.8 GHz

8592L 9 kHz to 22.0 GHz

8592L (Option 026) 9 kHz to 26.5 GHz

8593E 9 kHz to 22.0 GHz

8593E (Option 026) 9 kHz to 26.5 GHz

8594E 9 kHz to 2.9 GHz

8594L 9 kHz to 2.9 GHz

8594Q 9 kHz to 2.9 GHz

8595E 9 kHz to 6.5 GHz

8596E 9 kHz to 12.8 GHz

Chapter 1 17

Page 18

Introduction

Firmware Revision Date

Firmware Revision Date

When the analyzer is first turned on, a display appears that contains

the copyright date and firmware revision date. (If the analyzer has

either Option 041, IB and parallel I/O, or Option 043, RS-232 and

parallel I/O, the display will also contain the entries shown on the first

line of the example below.)

The version of firmware installed in the analyzer is identified by the

year, month, and day in the following format.

(IB: nn) or (RS232: nnnn)

COPYRIGHT 1986

rev yy.mm.dd

Whenever you contact Agilent Technologies about your analyzer, be

sure to provide the firmware date along with the complete serial

number and option designation. This will ensure that you obtain

accurate service information.

Firmware Upgrade Kit Ordering Information

There are occasions when the factory revises the analyzer firmware to

correct defects or make performance improvements. When a firmware

revision is needed, a service note is distributed by the factory to all

Agilent Technologies service centers. The service note identifies, by

serial-number prefix, the analyzers that require the latest firmware

upgrade kit.

If your analyzer requires a firmware upgrade kit, it can be obtained by

ordering as described in Chapter 12, “Replaceable Parts.”Instructions

for the replacement of the firmware ROMs is located under “A16

Processor/Video Board Firmware ROM” in Chapter 7, “Replacing Major

Assemblies,” of this guide.

18 Chapter1

Page 19

Introduction

Reliability Considerations

Reliability Considerations

Analyzer Input Protection

The analyzer input circuitry can be damaged by power levels that

exceed the maximum safe input-level specifications. Table 1-2 through

Table 1-5 provides the input specifications. To prevent input damage,

these specified levels for your analyzer must not be exceeded.

The analyzer input can also be damaged by large transients. If it is

likely that your analyzer will be exposed to potentially damaging

transients, take whatever precautions are necessary to protect its input

circuitry.

The analyzer input can easily be protected by disconnecting it from the

signal source whenever it is likely that large transients will be present.

When it is impractical to disconnect the analyzer, a transient-limiting

device should be used.

The 11947A Transient Limiter is an analyzer accessory that protects

the input circuitry from transients and accidental overloads. Contact

your local Agilent Technologies sales or service office for more

information about the 11947A.

CAUTION Transients are often produced during electromagnetic interference

(EMI) conducted emissions testing. One type of device, the line

impedance stabilization network (LISN), can produce large transients

when its switch position or voltage input is changed.

Chapter 1 19

Page 20

Introduction

Reliability Considerations

Table 1-2 8590L and 8591E Spectrum Analyzer and 8591C Cable TV

Analyzer &Maximum Safe Input Level

INPUT 50Ω (Input

Attenuation ≥10 dB)

Average Continuous Power

Peak Pulse Power

dc 25 Vdc 100 Vdc

+30 dBm (1 W)

+30 dBm (1 W)

INPUT 75Ω (Input

Attenuation ≥10 dB)

+75 dBmV (0.4 W)

+75 dBmV (0.4 W)

Table 1-3 8592L and 8593E Spectrum Analyzer Maximum Safe Input

Level

INPUT 50Ω (Input Attenuation

≥10 dB bands 1 through 4)

Average Continuous Power

Peak Pulse Power

dc 0 Vdc

+30 dBm (1 W, 7.1 V rms), input attenuation

≥10 dB

+50 dBm (100 W) for <10 µs pulse width and

<1% duty cycle, ssfs input attenuation ≥30 dB

Table 1-4 8594E and 8594L Spectrum Analyzer and 8594Q Analyzer

Maximum Safe Input Level

INPUT 50Ω (Input Attenuation ≥10 dB)

Average Continuous Power

Peak Pulse Power

dc 0 V (dc coupled)

+30 dBm (1 W, 7.1 V rms)

+50 dBm (100 W) for <10 µs pulse width and

<1% duty cycle, input attenuation ≥30 dB

50 V (ac coupled)

Table 1-5 8595E and 8596E Spectrum Analyzer Maximum Safe Input

Level

INPUT 50Ω (Input Attenuation ≥10 dB

above 2.75 GHz)

Average Continuous Power

Peak Pulse Power

dc 0 V (dc coupled)

+30 dBm (1 W, 7.1 V rms)

+50 dBm (100 W) for <10 µs pulse width and

<1% duty cycle, input attenuation ≥30 dB

50 V (ac coupled)

20 Chapter1

Page 21

Introduction

Adjustment Procedures

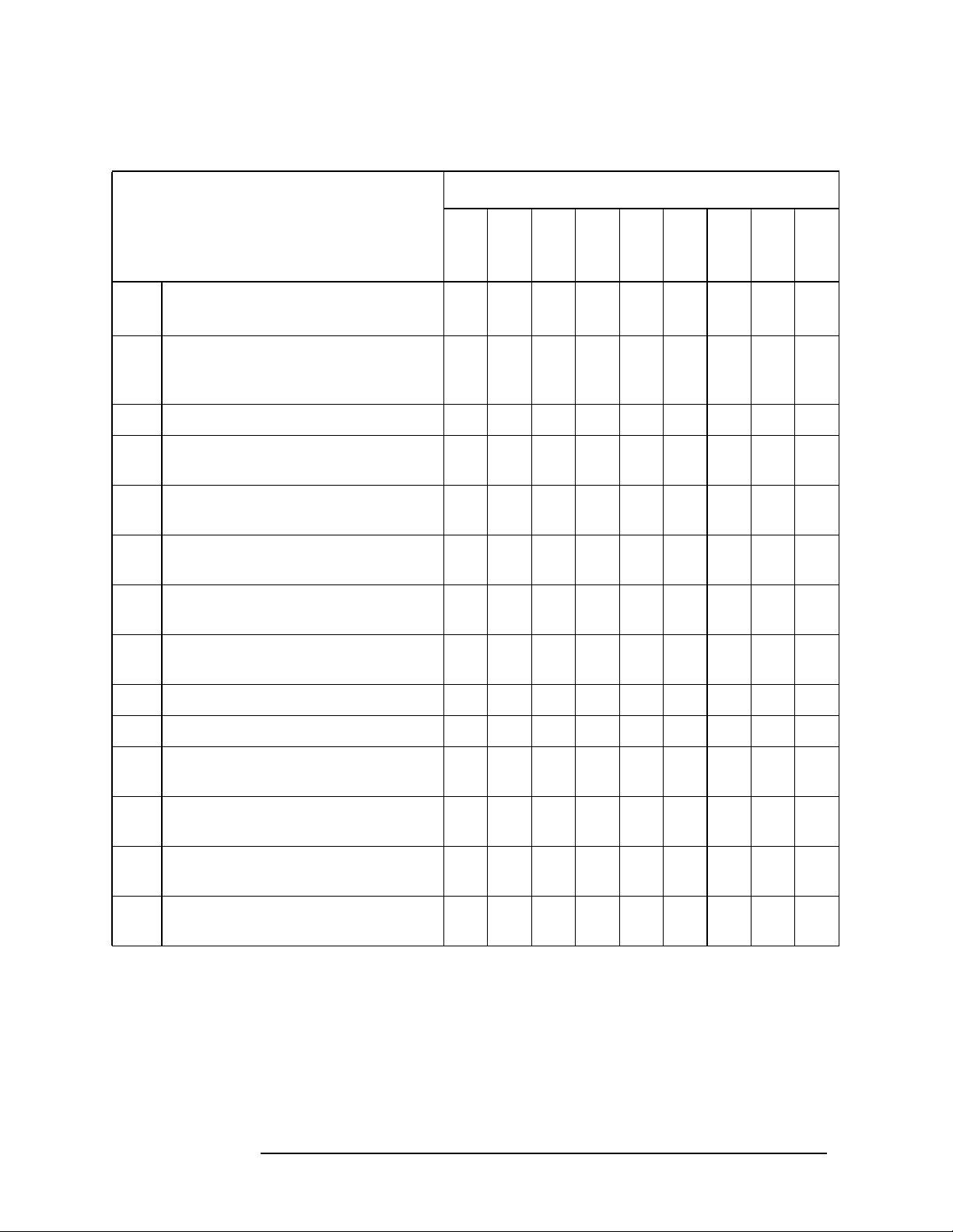

Adjustment Procedures

The following table lists the analyzer adjustments in Chapter 2 and

Chapter 2a and the models that they apply to. Select the model of the

analyzer being adjusted and note the adjustments marked in the

analyzer model column to determine which adjustments should be

performed.

Table 1-6 8590 E-Series and L-Series Spectrum Analyzer, 8591C Cable TV

and 8594Q QAM Analyzer Adjustment Procedures

Adjustment for Spectrum Analyzer Model:

Adjustment Procedure Name

8590L

8591C

1. Display •••••••••

2. Sampler Match •••••••••

3. 10 MHz Reference •••••••••

4. 10 MHz Precision Frequency

Reference

5. Crystal and LC Bandwidth Filter •••••••••

6.

6a.

7.

7a.

8. CAL FREQ Adjustment Routine •••••••••

9. CAL AMPTD Adjustment Routine •••••••••

10. CAL YTF Adjustment Routine • • •

11. CAL MXR Adjustment Routine • • •

Cal Attenuator Error

Cal Attenuator Error

Log and Linear Amplifier

Log and Linear Amplifier

a

b

a

b

•• •• ••

•••••••••

•••••••••

•••••••••

•••••••••

8591E

8592L

8593E

8596E

8594E

8594L

8594Q

8595E

12. Second Converter • • •

13. Third Converter and Second IF

Bandpass

14. Comb Generator • •

15. Frequency Response of the 8590L,

8591C, and 8591E

a

Chapter 1 21

•••••••••

•••

Page 22

Introduction

Adjustment Procedures

Table 1-6 8590 E-Series and L-Series Spectrum Analyzer, 8591C Cable TV

and 8594Q QAM Analyzer Adjustment Procedures

Adjustment for Spectrum Analyzer Model:

Adjustment Procedure Name

8590L

8591C

15a. Frequency Response of the 8590L,

8591C, and 8591E

16. Frequency Response of the 8592L,

8593E,8594E, 8594L, 8594Q,8595E,

8596E

17. Time and Date •••••••••

18. Modulator Offset and Gain for

Option 010 or 011

19. Entering External ALC Correction

Constants for Option 010 or 011

20. Checking the External ALC for

Option 010 or 011

21. Correcting the External ALC Error

for Option 010 or 011

22. First LO Distribution Amplifier for

Option 009 or 010

23. BITG Power Level for Option 010 • • •

b

•••

•••

•••

•••

•••

8592L

8591E

••••••

8593E

8596E

•• •

8594E

8594L

8594Q

8595E

24. Tracking Oscillator for Option 010 • • •

25. Checking the Absolute Amplitude

Accuracy for Option 050

26. Correcting for Absolute Amplitude

Accuracy for Option 050

27. Checking the Absolute Amplitude

Accuracy for Option 051

28. Correcting for Absolute Amplitude

Accuracy for Option 051

••• •

••• •

••• •

••• `•

a. If a 3335A source is not available, use the alternative adjustment with the same

number found in Chapter 2a , “Making Adjustments: If 3335A Source Not Avail-

able.”

b. If a 3335A source is not available, substitute this adjustment for the one with the

same number found in Chapter 2 , “Making Adjustments.”

22 Chapter1

Page 23

Introduction

Safety

Safety

Familiarize yourself with the safety symbols marked on the analyzer,

and read the general safety instructions and the symbol definitions

given in Chapter 16 , “Safety and Regulatory Information,” before you

begin the procedures in this chapter.

Test Equipment You Will Need

Refer to Chapter 1 of the calibration guide for your instrument for a list

of recommended equipment for the analyzer adjustments. Any

equipment that meets the critical specifications given in the table can

be substituted for the recommended model.

If a 3335A Synthesizer/Level Generator is not available, see Chapter 1

of the calibration guide for your instrument for alternative

recommended test equipment, accessories, and adapters.

When A 3335A Source Is Not Available

The 3335A Synthesizer Level Generator signal source has become

obsolete because parts used in the manufacture of this instrument are

no longer available from suppliers. To meet the need of our customers,

this service guide has been revised to add new adjustments that do not

use the 3335A Synthesizer Level Generator. This revision includes the

addition of signal sources required to replace the 3335A, changes i to

the test equipment setup illustrations, and changes in the steps

required to execute the adjustments.

Since all of our customers will not need to replace their 3335A

Synthesizer Level Generators immediately, the original adjustments

which use the 3335A signal generator have been retained. The

revisions have been incorporated in this service guide as Chapter 2a ,

“Making Adjustments: If 3335A Source Not Available.”

Chapter 1 23

Page 24

Introduction

If There Are Abnormal Indications During Adjustment

If There Are Abnormal Indications During

Adjustment

If the indications received during an adjustment do not agree with the

normal conditions given in the adjustment procedures, a fault exists in

your analyzer. The fault should be repaired before proceeding with any

further adjustments. Refer to the troubleshooting and repair

information in Chapter 4, “Troubleshooting the Analyzer,” of this guide.

Periodically Verifying Calibration

The analyzer requires periodic verification of operation. Under most

conditions of use, you should test the analyzer at least once a year with

either operation verification or the complete set of performance

verification tests located in the calibration guide for your instrument.

When test results show proper operation and calibration, no

adjustments are necessary. However, if test results indicate that the

instrument does not meet specifications, the cause should be

determined and rectified. Refer to the troubleshooting information in

Chapter 4, “Troubleshooting the Analyzer,” before attempting

recalibration.

Standard-Value Replacement Components

Part numbers for standard-value replacement components used in the

adjustment procedures are located in Chapter 12, “Replaceable Parts,”

of this service guide.

24 Chapter1

Page 25

Introduction

If You Replace or Repair an Assembly

If You Replace or Repair an Assembly

If one or more analyzer assemblies has been replaced or repaired,

related adjustment procedures should be done prior to verifying

operation. Refer to Table 1-7 to determine which adjustment to perform

after replacing or repairing an assembly. Find the assembly that has

been repaired or replaced in the left-hand column. Then perform the

adjustments marked across the adjustment column for that assembly.

It is important that adjustments are performed in the order indicated to

ensure that the instrument meets all of its specifications.

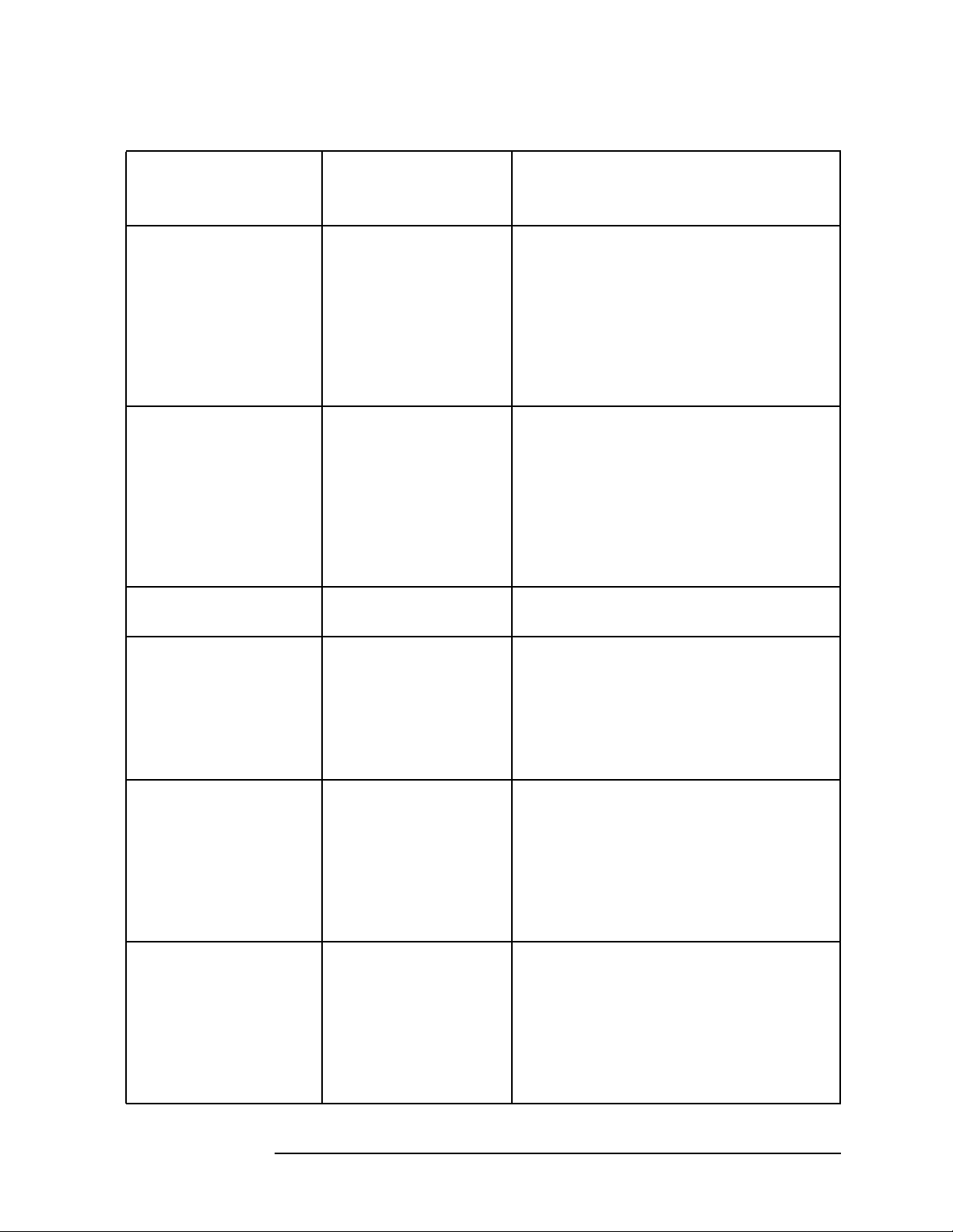

Table 1-7 Adjustments and Tests for Replaced or Repaired Assemblies

Replaced or Repaired

Assembly

A1 Front Frame CAL AMPTD Frequency Response

A2 Display Display

A3A1 Comb Generator Comb Generator

A3A2 Microwave

Switch

A3A3 Low-Pass Filter CAL FREQ

A3A4 Second

Converter

Related Adjustments

and Adjustment

Routines

CAL AMPTD

CAL YTF

CAL FREQ

CAL AMPTD

CAL YTF

CAL AMPTD

CAL YTF

CAL FREQ

CAL AMPTD

CAL YTF

Related PerformanceVerificationTests

Residual Responses

Frequency Response

Residual Responses

Comb Generator Frequency Accuracy

Frequency Response

Residual Responses

Frequency Response

Residual Responses

Frequency Response

Residual Responses

Noise Sidebands

System Related Sidebands

Frequency Response

Other Input Related Spurious Responses

Spurious Response

Gain Compression

Displayed Average Noise

Residual Responses

A3A5 Input Attenuator CAL FREQ

CAL AMPTD

CAL YTF

Frequency Response

Chapter 1 25

Frequency Response

Residual Responses

Page 26

Introduction

If You Replace or Repair an Assembly

Table 1-7 Adjustments and Tests for Replaced or Repaired Assemblies

Replaced or Repaired

Assembly

A3A6 Dual Mixer or

Low Band Mixer

A3A7 YIG-Tuned

Oscillator

A3A8 YIG-Tuned Filter

or A3A8 Switched

YIG-Tuned Filter

Related Adjustments

and Adjustment

Routines

CAL FREQ

CAL AMPTD

CAL YTF

CAL MXR

Frequency Response

First LO

Distribution Amplifier

for Option 009 or 010

CAL FREQ

CAL AMPTD

CAL YTF

CAL FREQ

CAL AMPTD

CAL YTF

CAL MXR

Frequency Response

Related PerformanceVerificationTests

Noise Sidebands

System Related Sidebands

Frequency Response

Other Input Related Spurious Responses

Spurious Response

Gain Compression

Displayed Average Noise

Residual Responses

Frequency Readout & Marker Count Accy

Noise Sidebands

System Related Sidebands

Residual FM Frequency Span Readout Accy

Frequency Response

Other Input Related Spurious Responses

Spurious Response

Residual Responses

Noise Sidebands System Related Sidebands

Frequency Response

Other Input Related Spurious Responses

Spurious Response

Displayed Average Noise

Residual Responses

A3A9 Bandpass Filter CAL FREQ

CAL AMPTD

A3A10 Directional

Coupler

A3A11 Step-Recovery

Diode

A3A12 3 dB Attenuator CAL FREQ

A3A13 Isolator CAL FREQ

CAL FREQ

CAL AMPTD

CAL YTF

CAL FREQ

CAL AMPTD

CAL AMPTD

CAL AMPTD

CAL YTF

None

System Related Sidebands

Frequency Response

Other Input Related Spurious Responses

Spurious Responses

Residual Responses

Comb Generator Frequency Accuracy

None

System Related Sidebands

Frequency Response

Other Input Related Spurious Responses

Spurious Responses

Residual Responses

26 Chapter1

Page 27

Introduction

If You Replace or Repair an Assembly

Table 1-7 Adjustments and Tests for Replaced or Repaired Assemblies

Replaced or Repaired

Assembly

A3A14 LO Distribution

Amplifier (LODA)

A3A15 Tracking

Generator

A3 Input Attenuator CAL FREQ

Related Adjustments

and Adjustment

Routines

First LO

Distribution Amplifier

for Option 009 or 010

only

CAL FREQ

CAL AMPTD

CAL YTF

First LO

Distribution Amplifier

for Option 009 or 010

CAL FREQ

CAL AMPTD

CAL YTF

BITG Power Level for

Option 010

CAL AMPTD

Related PerformanceVerificationTests

Frequency Readout and Marker Count Accy

Noise Sidebands

System Related Sidebands

Residual FM

Frequency Span Readout Accuracy

Frequency Response

Other Input Related Spurious Responses

Spurious Response

Residual Responses

Frequency Readout and Marker Count Accy

Noise Sidebands

System Related Sidebands

Residual FM

Frequency Span Readout Accuracy

Frequency Response

Other Input Related Spurious Responses

Spurious Response

Residual Responses

Frequency Response

A4 First Converter Frequency Response

CAL FREQ

CAL AMPTD

A5 Second Converter Second Converter

CAL FREQ

CAL AMPTD

A6 YIG-Tuned

Oscillator

CAL FREQ

CAL AMPTD

Noise Sidebands

System Related Sidebands

Frequency Response

Spurious Response

Gain Compression

Displayed Average Noise

Residual Responses

Noise Sidebands

Residual FM

System Related Sidebands

Frequency Response

Spurious Response

Gain Compression

Displayed Average Noise

Residual Responses

Noise Sidebands

Residual FM

System Related Sidebands

Frequency Span Readout Accuracy

Frequency Response

Spurious Response

Displayed Average Noise

Residual Responses

Chapter 1 27

Page 28

Introduction

If You Replace or Repair an Assembly

Table 1-7 Adjustments and Tests for Replaced or Repaired Assemblies

Replaced or Repaired

Assembly

A7 Analog Interface CAL FREQ

A7A1 Tracking

Generator Control

Related Adjustments

and Adjustment

Routines

CAL AMPTD

CAL YTF (8592L,

8593E, 8595E, 8596E

only)

Modulator Offset and

Gain for Option 010 or

011

Entering External ALC

Correction

Constants for Option

010 or 011 Checking the

External ALC for Option

010 or 011

Correcting the External

ALC Error for Option

010 or 011

Related PerformanceVerificationTests

Frequency Readout and Marker Count Accy

Noise Sidebands

Residual FM

System Related Sidebands

Frequency Span Readout Accuracy

Sweeptime Accuracy

Scale Fidelity

Reference Level Accuracy

Absolute Amplitude Calibration and

Resolution Bandwidth Switching

Uncertainties

Frequency Response

Absolute Amplitude, Vernier, and Power

Sweep Accuracy

Tracking Generator Level Flatness

Harmonic Spurious Outputs

Non-Harmonic Spurious Outputs

Tracking Generator Feedthrough

A8 Power Supply None System Related Sidebands

Spurious Responses

Residual Responses

A9 Third Converter Third Converter

&Second IF Bandpass

CAL FREQ

CAL AMPTD

BITG Power Level for

Option 010 only

A10 LODA Control

(Opt. 009) or Tracking

Generator Control

(Opt. 010)

First LO

Distribution Amplifier

for Option 009 or 010

only

CAL FREQ

CAL AMPTD

CAL YTF

Noise Sidebands

System Related Sidebands

Absolute Amplitude Calibration and

Resolution Bandwidth Switching

Uncertainties

Other Input Related Spurious

Spurious Responses

Displayed Average Noise

Residual Responses

Frequency Response

Absolute Amplitude, Vernier and Power

Sweep Accuracy

Tracking Generator Level Flatness

28 Chapter1

Page 29

Introduction

If You Replace or Repair an Assembly

Table 1-7 Adjustments and Tests for Replaced or Repaired Assemblies

Replaced or Repaired

Assembly

A11 Bandwidth Crystal and IC

A12Amplitude Control CAL FREQ

A13 Bandwidth Crystal and IC

A14 Log Amplifier Log and Linear

A15 Motherboard CAL FREQ

A16 Processor/Video

A16A1 Memory

Related Adjustments

and Adjustment

Routines

Bandwidth Filter CAL

FREQ

CAL AMPTD

CAL AMPTD

Bandwidth Filter CAL

FREQ

CAL AMPTD

Amplifier

CAL FREQ

CAL AMPTD

CAL AMPTD

10 MHz Reference

CAL FREQ

CAL AMPTD

CAL YTF (8592L,

8593E, 8595E, 8596E

only)

CAL MXR † (8592L,

8593E, 8595E, 8596E

only)

Cal Attenuator Error †

Frequency Response †

Time and Date

Related PerformanceVerificationTests

Resolution Bandwidth Accuracy

Absolute Amplitude Calibration and

Bandwidth Switching Uncertainties

Scale Fidelity

Displayed Average Noise

Resolution Bandwidth Accuracy

Absolute Amplitude Calibration and

Bandwidth Switching Uncertainties

Scale Fidelity

Reference Level Accuracy

Complete Operation Verification

Reference Level Accuracy

Frequency Response

† These adjustments are not necessary if valid correction constants are recovered from the

defective A16 processor/video assembly. See the A16 processor/video board assembly replacement

procedure in this service guide.

Chapter 1 29

Page 30

Introduction

If You Replace or Repair an Assembly

30 Chapter1

Page 31

2 Making Adjustments

The procedures in this chapter adjust the analyzer electrical

performance to the specifications described in Chapter 2 of the

calibration guide for your instrument.

Most adjustments require access to the interior of the analyzer.

If a 3335A source is not available, use the alternative adjustments with

the same number found in Chapter 2a.

31

Page 32

Making Adjustments

Before You Start

Before You Start

There are three things you should do before starting an adjustment

procedure.

• Check that you are familiar with the safety symbols marked on the

analyzer, and read the general safety considerations and the symbol

definitions given in the front of this service guide.

• Check that the analyzer has been turned on and allowed to warm up

for at least 30 minutes at room temperature before making any

adjustments. The analyzer must be allowed to stand at room

temperature at least 2 hours prior to the 30 minute warmup.

• Read the rest of this section.

32 Chapter2

Page 33

Making Adjustments

1a. Display (with four access holes in top of shield)

1a. Display

(with four access holes in top of shield)

This adjustment applies to:

All 8590 E-Series and L-Series spectrum analyzers

8591C cable TV analyzers

8594Q QAM analyzers

There are two different types of displays. If your display has four holes

in the top of the shield, continue with this procedure. If it has eight

holes, go to the next procedure.

The horizontal and vertical display positions are adjusted using

front-panel softkeys. These positions are then stored in nonvolatile

memory.

There are two focus adjustments, fine and coarse. The fine adjustment

is located on the left side of the display assembly and can be accessed

with the instrument cover on or off.The coarse adjustment is located on

the rear of the display assembly and can only be adjusted with the

instrument cover off.

Procedure

Display Position

1. Press the following analyzer keys to adjust the horizontal position.

PRESET

CAL, More 1 of 4

CRT HORZ POSITION

2. Rotate the knob until the display is centered horizontally.

3. Press the following analyzer softkey to adjust the vertical position.

CRT VERT POSITION

4. Rotate the knob until the display is centered vertically.

5. Press the following analyzer keys to store the horizontal and vertical

position values into nonvolatile memory.

CAL

CAL STORE

Chapter 2 33

Page 34

Making Adjustments

1a. Display (with four access holes in top of shield)

Fine Focus

1. Adjust the front panel INTENSITY control for a comfortable viewing

intensity.

2. Use an adjustment tool to access the fine focus adjustment. See

Figure 2-1. Adjust as necessary for a focused display. If one of the

end-stops of the fine focus adjustment is reached, proceed with the

“Coarse Focus Adjustment” section.

Figure 2-1 Fine Focus Adjustment Location

34 Chapter2

Page 35

Making Adjustments

1a. Display (with four access holes in top of shield)

Coarse Focus

The Coarse Focus adjustment point is located at the rear of the display

assembly, therefore, it is required to place the display in a service

position to perform this procedure.

1. Turn the analyzer

LINE switch to OFF. Remove the instrument cover

assembly.

2. Place the display in a service position.

WARNING The analyzer contains potentially hazardous voltages. Refer to

the safety symbols provided on the analyzer, and in the general

safety instructions in this guide, before operating the unit with

the cover removed. Ensure that safety instructions are strictly

followed. Failure to do so can result in severe or fatal injury.

3. Turn the analyzer

LINE switch to ON.

4. Center the fine focus adjustment. Refer to Figure 2-1 for the

adjustment location.

5. Adjust the coarse focus adjustment for the best possible focus. See

Figure 2-2.

Figure 2-2 Coarse Focus Adjustment Location

(rear view of display assembly)

Chapter 2 35

Page 36

Making Adjustments

1b. Display (with eight access holes in top of shield)

1b. Display

(with eight access holes in top of shield)

This adjustment applies to:

All 8590 E-Series and L-Series spectrum analyzers

8591C cable TV analyzers

8594Q QAM analyzers

CAUTION All display adjustments are described in this adjustment procedure.

However, the FOCUS adjustment is the only adjustment that can be

performed without removing the instrument cover.

For all other adjustments, it is strongly recommended that you return

the instrument to your local sales and service office.

There are two different types of displays. If your display has eight holes

in the top of the shield, continue with this procedure. If it has four

holes, go to the preceding procedure.

If you are going to make adjustments to your display, only make the

adjustments that would correct the problem that the display is

experiencing.

The following is a list of adjustments described in this procedure:

• Focus • Centering

• Horizontal Hold • Vertical Hold

• Vertical Size • Vertical Linearity

• Brightness • Contrast

The horizontal and vertical display positions should first be adjusted

using front-panel softkeys. These positions are then stored in

nonvolatile memory.

The Focus adjustment is located on the left side of the instrument and

can be accessed with the instrument cover on or off. All other

adjustments must be made with the instrument cover removed.

Equipment Required

Display adjustment tool, 0.075 inch hex (part number 8710-1010)

36 Chapter2

Page 37

Making Adjustments

1b. Display (with eight access holes in top of shield)

Procedures

Before Performing any Adjustment

Before performing any display adjustment, press the following analyzer

keys.

CONFIG, More 1 of 3, More 2 of 3

DEFAULT SYNC

CAL, More 1 of 4, More 2 of 4

DEFAULT CAL DATA

Focus

The Focus potentiometer is located on the left side of the instrument

and can be accessed with the instrument cover on or off. Use the

specified adjustment tool to make this adjustment.

1. Adjust the front-panel INTENSITY control for a comfortable viewing

intensity.

2. Adjust as necessary for a focused display. See Figure 2-1.

Figure 2-3 Focus Adjustment Location

Chapter 2 37

Page 38

Making Adjustments

1b. Display (with eight access holes in top of shield)

Centering

Perform this adjustment only if the displayed image is not horizontally

centered on the display.

The Centering potentiometer is accessible through the top of the

display's cover. The instrument cover must be removed for access to the

display's cover. Refer to Figure 2-4 for the location of this adjustment.

Use the specified adjustment tool to make this adjustment.

1. Press

CAL, More 1 of 4, CRT HORZ POSITION.

2. Set the CRT horizontal position setting to 12.

3. Set the Centering potentiometer so the displayed image is positioned

approximately at the center of the display.

Figure 2-4 Display Adjustment Locations

38 Chapter2

Page 39

Making Adjustments

1b. Display (with eight access holes in top of shield)

Horizontal Hold

Perform this adjustment only if the displayed image is rolling

horizontally across the display.

The Horizontal Hold potentiometer is accessible through the top of the

display's cover. The instrument cover must be removed for access to the

display's cover. Refer to Figure 2-4 for the location of this adjustment.

Use the specified adjustment tool to make this adjustment.

1. If the display is unreadable, first adjust the Horizontal Hold

potentiometer for a stable display.

2. Press

CAL, More 1 of 4, CRT HORZ POSITION.

3. Set the CRT horizontal position setting to 12.

4. Find the clockwise position of the Horizontal Hold potentiometer

where the display begins to roll horizontally.

5. Find the counter-clockwise position of the Horizontal Hold

potentiometer where the display begins to roll horizontally.

6. Set the adjustment to a position approximately midway between the

clockwise and counter clockwise position where the display does not

roll horizontally.

Vertical Hold

Perform this adjustment only if the displayed image is rolling vertically

on the display.

The Vertical Hold potentiometer is accessible through the top of the

display's cover. The instrument cover must be removed for access to the

display's cover. Refer to Figure 2-4 for the location of this adjustment.

Use the specified adjustment tool to make this adjustment.

1. If the display is unreadable, first adjust the Vertical Hold

potentiometer for a stable display.

2. Press

3. Press

CONFIG, More 1 of 3, More 2 of 3.

SYNC NRM NTSC (NTSC).

4. Adjust the Vertical Hold potentiometer so that the display image is

not rolling vertically.

Chapter 2 39

Page 40

Making Adjustments

1b. Display (with eight access holes in top of shield)

5. Press SYNC NRM PAL (PAL).

6. Adjust the Vertical Hold potentiometer so that the display image is

not rolling vertically.

7. Repeat step 1 to step 5 until no adjustment is necessary for either

the NTSC or the PAL mode.

8. Press

DEFAULT SYNC.

This is the third softkey from the top.

Vertical Size

Perform this adjustment only if the displayed image is too tall or too

short for the display.

The Vertical Size potentiometer is accessible through the top of the

display's cover. The instrument cover must be removed for access to the

display's cover. Refer to Figure 2-4 for the location of this adjustment.

Use the specified adjustment tool to make this adjustment.

1. Press

CAL, More 1 of 4, CRT VERT POSITION.

2. Set the CRT vertical position setting so that softkey labels are

adjacent to the keys at the right to which they are associated.

3. Adjust the Vertical Size potentiometer so that the uppermost softkey

label is adjacent to the uppermost softkey and the lowermost softkey

label is adjacent to the lowermost softkey.

4. Repeat step 2 and step 3 if necessary.

Vertical Linearity

Perform this adjustment only if the vertical space between the horizontal

graticules are not equal on the display.

The Vertical Linearity potentiometer is accessible through the top of

the display's cover. The instrument cover must be removed for access to

the display's cover. Refer to Figure 2-4 for the location of this

adjustment. Use the specified adjustment tool to make this adjustment.

1. Adjust the Vertical Linearity potentiometer so that the vertical

space between each of horizontal graticules are approximately equal.

40 Chapter2

Page 41

Making Adjustments

1b. Display (with eight access holes in top of shield)

Brightness and Contrast

Perform these adjustments only if the brightness and contrast of the

display is not correct.

The Brightness and Contrast potentiometers are accessible through the

top of the display's cover. The instrument cover must be removed for

access to the display's cover. Refer to Figure 2-4 for the locations of

these adjustments. Use the specified adjustment tool to make these

adjustments.The Brightness and Contrast potentiometers are

interactive adjustments.

1. Adjust the Contrast potentiometer to the full clockwise position (the

image is no longer displayed).

2. Adjust the front-panel INTEN knob to the full clockwise position.

3. Adjust the Bright potentiometer until the background is just barely

extinguished (the background is dark).

4. Adjust the front-panel INTEN knob to the full counter-clockwise

position.

5. Adjust the Contrast potentiometer until the image is just barely

extinguished.

6. Adjust the front-panel INTEN knob to the full clockwise position and

verify there is not background illumination. If necessary, re-adjust

brightness and contrast so that the front-panel INTEN will go from

a dark screen to a bright screen with a dark background.

7. Adjust the front-panel INTEN knob for comfortable brightness and

adjust the display focus.

Chapter 2 41

Page 42

Making Adjustments

2. Sampler Match

2. Sampler Match

This adjustment applies to:

All 8590 E-Series and L-Series spectrum analyzers

8591C cable TV analyzers

8594Q QAM analyzers

The match between the sampling oscillator and the sampler is

optimized by first setting the sampling-oscillator frequency for

midrange, then adjusting the sampler-match adjustment for maximum

dc volts as read on a digital multimeter.

Equipment Required

Digital multimeter

DMM test leads

Procedure

1. Turn the analyzer LINE switch to OFF. Remove the instrument over

assembly.

2. Turn the analyzer LINE switch to ON.

3. Set the center frequency of the analyzer to 194 MHz. If you are

adjusting an 8590L, or 8591E spectrum analyzer, or an 8591C cable

TV analyzer, set the center frequency to 265 MHz.

4. Press the following analyzer keys.

SPAN, 10, MHz

5. Connect the digital multimeter (DMM) from chassis ground to

A25TP1. Refer to Figure 2-5.

6. Adjust A25C107 for maximum voltage as read on the DMM. This

voltage must be −1.5 V ±1.0 V.

7. Measure the voltage at A25TP2. It should be +1.5 V ±1.0 V. If it is

not, readjust A25C107 until a compromise is established between

the two test points, such that the voltage specifications of step 6 and

step 7 are met.

42 Chapter2

Page 43

Figure 2-5 A25 Counter Lock Assembly Test Points

Making Adjustments

2. Sampler Match

Chapter 2 43

Page 44

Making Adjustments

3. 10 MHz Reference

3. 10 MHz Reference

This adjustment applies to:

All 8590 E-Series and L-Series spectrum analyzers

8591C cable TV analyzers with Option 704

8594Q QAM analyzers with Option 704

The internal 10 MHz time base is adjusted for frequency accuracy. This

procedure does not adjust for long-term drift or aging rate. Only

short-term accuracy is adjusted.

A frequency counter is connected to the CAL OUT, which is locked to

the 10 MHz reference. This yields better effective resolution.

The time base is adjusted for a frequency of 300 MHz as read by the

frequency counter.

Equipment Required

Microwave frequency counter

Frequency standard

Cable, 122 cm (48 in) (two required)

Figure 2-6 10 MHz Reference Adjustment Setup

44 Chapter2

Page 45

Making Adjustments

3. 10 MHz Reference

Procedure

Note that to properly adjust the time base, a frequency standard with a

better time base accuracy than that of the analyzer is required.

1. Connect the equipment as shown in Figure 2-6.

2. Set the microwave frequency counter controls as follows:

50 Ω/1 MΩ...........................................50 ΩImpedance

10 Hz–500 MHz/500 MHz–18 GHz ...10 Hz–500 MHz

SAMPLE RATE .......................................... Midrange

FREQUENCY STANDARD ................... EXTERNAL

3. Press the following analyzer keys.

PRESET

FREQUENCY, −2001, Hz

CAL, More 1 of 4, More 2 of 4, More 3 of 4

SERVICE CAL, CAL TIMEBASE

4. A number will be displayed in the active function block of the

analyzer display. This is the setting of the DAC (0 to 255) which

controls the frequency of the internal time base. Use the knob or

keyboard to change the DAC setting until the frequency counter

reads 300 MHz ±75 Hz (±0.25 ppm).

5. Once the time base has been adjusted for minimum deviation from

300 MHz, press

CAL, CAL STORE. The new DAC number is now

stored in nonvolatile memory.

Chapter 2 45

Page 46

Making Adjustments

4. 10 MHz Precision Frequency Reference

4. 10 MHz Precision Frequency Reference

This adjustment applies to:

All 8590 E-Series spectrum analyzers, Option 004

8591C cable TV analyzers

8594Q QAM analyzers

Replacement oscillators are factory adjusted after a complete warmup

and after the specified aging rate has been achieved. Readjustment

should not be necessary after oscillator replacement, and is not

recommended.

Note that the analyzer must be ON continuously for at least 24 hours

immediately prior to adjusting the oscillator to allow both the

temperature and frequency of the oscillator to stabilize. Failure to allow

sufficient stabilization time could result in the misadjustment of the

oscillator.

The frequency of the internal 10 MHz frequency reference is compared

to a known frequency standard and adjusted for minimum frequency

error. This procedure does not adjust the short-term stability or

long-term stability of the 10 MHz Ovenized Crystal Oscillator (OCXO),

which are determined by characteristics of the particular oscillator and

the environmental and warmupconditions to which it has been recently

exposed. The analyzer must be ON continuously for at least 24 hours

immediately prior to oscillator adjustment to allow both the

temperature and frequency of the oscillator to stabilize.

Equipment Required

Frequency standard

Frequency counter

Cable, BNC, 122 cm (48 in) (two required)

Figure 2-7 Precision Frequency Reference Setup

46 Chapter2

Page 47

Making Adjustments

4. 10 MHz Precision Frequency Reference

Procedure

1. Place the analyzer on its side as shown in Figure 2-7 and set the

LINE switch of the analyzer to ON.

2. Allow the analyzer to remain powered ON and undisturbed for at

least 24 hours, so that both the temperature and frequency of the

OCXO can stabilize.

3. Connect the frequency standard to the frequency counter rear-panel

TIMEBASE IN/OUT connector. Refer to Figure 2-7.

4. Disconnect the jumper between the 10 MHz REF OUTPUT and EXT

REF IN jacks on the analyzer rear panel. Connect a BNC cable

between the 10 MHz REF OUTPUT jack and INPUT A on the

frequency counter.

5. Set the frequency counter controls as follows:

FUNCTION/DATA ....................................... FREQA

INPUT A:

x10 ATTN ........................................................ OFF

AC ............................................. OFF (DC coupled)

50 Ω Z .................... OFF (1 MΩ input impedance)

AUTO TRIG ........................................................... ON

100 kHz FILTER A .............................................. OFF

INT/EXT switch (rear panel) .............................. EXT

6. On the frequency counter select a 1 second gate time and a 10 MHz

offset of the displayed frequency by pressing the following frequency

counter keys.

GATE TIME, 1, GATE TIME

MATH, SELECT/ENTER

CHS/EEX, 10, CHS/EEX, 6, SELECT/ENTER

SELECT/ENTER

The frequency counter should now display the difference between

the frequency of the INPUT A signal and 10.0 MHz with a displayed

resolution of 10 MHz (0.010 Hz).

7. Locate the FREQ ADJ control on the OCXO. See Figure 2-8. Remove

the dust cap screw.

8. Use a nonconductive adjustment tool to adjust the FREQ ADJ

control on the OCXO for a frequency counter indication of 0.00 Hz.

Chapter 2 47

Page 48

Making Adjustments

4. 10 MHz Precision Frequency Reference

9. Select a 10 second gate time by pressing the following frequency

counter keys.

GATE TIME, 10, GATE TIME

The frequency counter should now display the difference between

the frequency of the INPUT A signal and 10.0 MHz with a resolution

of 0.001 Hz (1 MHz).

10.Wait at least 2 gate periods for the frequency counter to settle, and

then adjust the FREQ ADJ control on the OCXO for a stable

frequency counter indication of 0.000 ±0.010 Hz.

11.Replace the dust cap screw on the OCXO.

Figure 2-8 Oven Reference Adjustment Location

48 Chapter2

Page 49

Making Adjustments

5. Crystal and LC Bandwidth Filter

5. Crystal and LC Bandwidth Filter

This adjustment applies to:

All 8590 E-Series and L-Series spectrum analyzers

8591C cable TV analyzers

8594Q QAM analyzers

The crystal and LC bandwidth filter circuits are adjusted for symmetry,

center frequency, and peak amplitude.

First, correction constants are turned off. This allows for uncorrected 3

dB resolution bandwidth centering and amplitude adjustments.

New corrections are then generated by performing the CAL FREQ and

CAL AMPTD adjustment routines.

Equipment Required

Crystal shorts (set of three)

Cable, BNC, 23 cm (9 in)

Additional Equipment for 75 Ω Input

Cable, BNC, 75 Ω, 30 cm (12 in)

Procedure

1. Turn the analyzer LINE switch to OFF. Remove the instrument cover

assembly.

2. Turn the analyzer LINE switch to ON, then press the following

analyzer keys.

PRESET

CAL, More 1 of 4

CORRECT ON OFF (OFF)

Chapter 2 49

Page 50

Making Adjustments

5. Crystal and LC Bandwidth Filter

Crystal Alignment

3. Connect the CAL OUT to the INPUT 50 Ω with the BNC cable.

75 Ω input: Connect the CAL OUT to the INPUT 75 Ω with the 75 Ω

BNC cable.

Figure 2-9 Crystal Symmetry and Centering

CAUTION Use only 75 Ω cables, connectors, or adapters on instruments equipped

with 75 Ω inputs or damage to the input connectors will occur.

4. Press the following analyzer keys.

FREQUENCY, 300, MHz

SPAN, 10, MHz

PEAK SEARCH

MKR FCTN, MK TRACK ON OFF (ON)

75 Ω input:

SPAN, 200, kHz

AMPLITUDE, 20, −dBm

SCALE LOG LIN (LIN)

More 1 of 2, AMPTD UNITS, dBm

BW, 3, kHz

AMPLITUDE, More 1 of 2, AMPTD UNITS, dBm

50 Chapter2

Page 51

Making Adjustments

5. Crystal and LC Bandwidth Filter

5. Press AMPLITUDE, then use the knob to place the signal at the sixth

graticule line from the bottom.

6. Press BW, 30, kHz on the analyzer.

CAUTION Shorting the crystal test points to ground may permanently damage the

bandwidth board assembly. If you make your own shorts, it is advisable

to insulate the bare wires and connectors.

7. Connect the crystal shorts (through the access holes on the assembly

cover) across the following pairs of test points.

A13TP1 and A13TP2

A11TP1 and A11TP2

A11TP4 and A11TP5

8. Adjust A13C54 CTR for minimum signal amplitude. Then adjust

A13C38 SYM and A13C54 CTR for a centered and symmetrical

bandpass response as shown in Figure 2-9.

9. Remove the crystal short from A13TP1 and A13TP2 and connect it

across A13TP4 and A13TP5.

10.Adjust A13C25 CTR for minimum signal amplitude. Then adjust

A13C15 SYM and A13C25 CTR for a centered and symmetrical

bandpass response.

11.Remove the crystal short from A11TP4 and A11TP5. Connect the

short across A13TP1 and A13TP2.

12.Adjust A11C54 CTR for minimum signal amplitude. Then adjust

A11C38 SYM and A11C54 CTR for a centered and symmetrical

bandpass response.

13.Remove the crystal short from A11TP1 and A11TP2. Connect the

short across A11TP4 and A11TP5.

14.Adjust A11C25 CTR for minimum signal amplitude. Then adjust

A11C15 SYM and A11C25 CTR for a centered and symmetrical

bandpass response.

Chapter 2 51

Page 52

Making Adjustments

5. Crystal and LC Bandwidth Filter

15.Remove the crystal shorts and press the following analyzer keys.

PEAK SEARCH

MKR FCTN, MK TRACK ON OFF (ON)

SPAN, 50, kHz

MKR FCTN, MK TRACK ON OFF (OFF)

BW, 3, kHz

PEAK SEARCH, MARKER DELTA

BW, 30, kHz

PEAK SEARCH

16.Verify that the MARKER ∆ frequency does not exceed 3 kHz.

If the signal shift is out of tolerance, repeat step 3 to step 16.

17.Press the following analyzer keys.

MKR

MARKER 1 ON OFF (OFF)

52 Chapter2

Page 53

Making Adjustments

5. Crystal and LC Bandwidth Filter

LC Alignment

18.Press the following analyzer keys.

BW, 100, kHz

SPAN, 5, MHz

19.Widen all but one of the LC filter poles by shorting A11TP10 and

A11TP11, A11TP12 and A11TP13, and A13TP10 and A13TP11

using the crystal shorts.

CAUTION Use a tool with a nonmetallic body to make the LC dip adjustment.