Page 1

Service Manual

HP 8560A Spectrum Analyzer

SERIAL NUMBERS

Prefix

3207A

and Above

HEWLETT

Eiia

HP Part No. 08560-90081

Printed in USA

PACKARD

August 1992

Page 2

@Copyright Hewlett-Packard Company 1990, 1992

All Rights Reserved. Reproduction, adaptation, or translation without prior written

permission is prohibited, except as allowed under the copyright laws.

1212 Valley House Drive, Rohnert Park, CA 94928-4999, USA

Page 3

Certification

Hewlett-Packard Company certifies that this product met its published specifications at the

time of shipment from the factory. Hewlett-Packard further certifies that its calibration

measurements are traceable to the United States National Institute of Standards and

Technology, to the extent allowed by the Institute’s calibration facility, and to the calibration

facilities of other International Standards Organization members.

Warranty

This Hewlett-Packard instrument product is warranted against defects in material and

workmanship for a period of one year from date of shipment. During the warranty period,

Hewlett-Packard Company will, at its option, either repair or replace products which prove to

be defective.

For warranty service or repair, this product must be returned to a service facility designated

by HP. Buyer shall prepay shipping charges to HP and HP shall pay shipping charges to

return the product to Buyer. However, Buyer shall pay all shipping charges, duties, and taxes

for products returned to HP from another country.

HP warrants that its software and firmware designated by HP for use with an instrument

will execute its programming instructions when properly installed on that instrument. HP

does not warrant that the operation of the instrument, or software, or firmware will be

uninterrupted or error-free.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from improper or inadequate

maintenance by Buyer, Buyer-supplied software or interfacing, unauthorized modification or

misuse, operation outside of the environmental specifications for the product, or improper

site preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. HP SPECIFICALLY

DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE.

Exclusive Remedies

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE

REMEDIES. HP SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER BASED ON

CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

Assistance

Product maintenance agreements and other customer assistance agreements are available for

Hewlett-Packard products.

For any assistance, contact your nearest Hewlett-Packard Sales and Service

Ofice.

. . .

III

Page 4

Safety Symbols

The following safety symbols are used throughout this manual. Familiarize yourself with each

of the symbols and its meaning before operating this instrument.

Caution

Warning

The caution sign denotes a hazard. It calls attention to a procedure which,

if not correctly performed or adhered to, could result in damage to or

destruction of the instrument. Do not proceed beyond a caution sign until the

indicated conditions are fully understood and met.

The

warning

if not correctly performed or adhered to, could result in injury or loss of life.

Do not proceed beyond a

understood and met.

sign denotes a hazard. It calls attention to a procedure which,

warning

General Safety Considerations

Warning

Before this instrument is switched on,

through the protective conductor of the ac power cable to a socket outlet

provided with protective earth contact.

Any interruption of the protective (grounding) conductor, inside or outside

the instrument, or disconnection of the protective earth terminal can result in

personal injury.

sign until the indicated conditions are fully

make sure it has been properly grounded

Warning

Caution

There are many points in the instrument which can, if contacted, cause personal.

injury. Be extremely careful.

Any adjustments or service procedures that require operation of the instrument

with protective covers removed should be performed only by trained service

personnel.

Before this instrument is switched on, make sure its primary power circuitry

has been adapted to the voltage of the ac power source.

Failure to set the ac power input to the correct voltage could cause damage to

the instrument when the ac power cable is plugged in.

iv

Page 5

HP 8560A Spectrum Analyzer Documentation Outline

For ordering information, contact a Hewlett-Packard Sales and Service Office.

Manuals Shipped with Your Instrument

HP 8560A Installation and Verification Manual

n Tells you how to install the spectrum analyzer.

n Tells you what your analyzer’s specifications are.

0

HP

856OA/8561 B/8563A

w

Tells you how to make measurements with your spectrum analyzer.

w

Tells you how to program your spectrum analyzer.

perating

and Programming Manual

HP 8560A Quick Reference Guide

8

Is an abbreviated version of the HP

856OA/8561B/8563A

Operating and Programming

iWanua1

n Provides you with a listing of all remote programming commands.

Options

S

Option 915:

HP 8560A

ervice

Component Level Information

w

The service manual provides information to service your analyzer to the assembly-level (not

always immediately available for new products).

n The component-level information binder provides component-level information for

component-level repair of the analyzer or analyzer family (not always immediately available

for new products).

Manual and HP 8560A/6lB/63A Spectrum Analyzer

Option 910: Extra Manual Set

w

Doubles all documentation shipped with a standard instrument.

Option 916: HP 8560A Quick Reference Guide

1

Adds an extra HP 8560A Quick Reference Guide to the document package.

V

Page 6

Contents

1. General Information

Manual Organization

Manual Text Conventions

Serial Numbers Covered by This Manual

Instrument Variations

HP 85629B Test and Adjustment Module

Service Kit

Recommended Test Equipment

Electrostatic Discharge

Reducing Potential for ESD Damage

Static-Safe Accessories

Returning Instruments for Service

Service Tag

Original Packaging

Other Packaging

Sales and Service Offices

2. Adjustment Procedures

Introduction

Safety Considerations

Which Adjustments Should Be Performed?

Test Equipment

Adjustable and Factory-Selected Components

Adjustment Tools

Instrument Service Position

Using the TAM

Test Equipment

Adjustment Indicator

1. High-Voltage Power Supply Adjustment

2. Display Adjustment

3. IF

4. IF Amplitude Adjustments

5. DC Log Amplifier Adjustments

6. Sampling Oscillator Adjustment

7. YTO Adjustment

8. First LO Distribution Amplifier Adjustment

9. Tracking Generator Power Level Adjustments

10. Frequency Response Adjustment

11. Calibrator Amplitude Adjustment

12. 10 MHz Reference Adjustment (Non-Option 003 only)

13. Demodulator Adjustment

14. External Mixer Bias Adjustment

..............................

.............................

Bandpass

.........................

.......................

.................

.........................

................

.....................

........................

.................

........................

....................

............................

.........................

..........................

........................

........................

...............

...........................

..............

..........................

.....................

............................

...........................

........................

..............

......................

Adjustment

.......................

.....................

...................

.................

.................

............

...........

................

................

.......

....................

................

l-l

l-2

l-2

l-3

l-6

l-6

1-6

l-7

l-7

1-8

1-8

l-8

l-8

1-8

1-11

2-l

2-2

2-2

2-2

2-2

2-3

2-3

2-9

2-9

2-9

2-12

2-14

2-20

2-25

2-29

2-33

2-37

2-40

2-42

2-45

2-48

2-50

2-52

2-55

Contents-l

Page 7

15. External Mixer Amplitude Adjustment

16. Second IF Gain Adjustment

17. Signal ID Oscillator Adjustment

18. 600 MHz Amplitude Adjustment

19. 10 MHz Reference Adjustment (Option 003)

20. Tracking Oscillator Adjustment (Option 002)

3. Assembly Replacement

Access to Internal Assemblies

Cable Color Code

Procedure 1. Analyzer Cover

Procedure 2. Al Front Frame/Al8 CRT

Procedure 3.

Procedure 4.

Procedure 5. A2, A3, A4, and A5 Assemblies

Procedure 6. A6 Power Supply Assembly

Procedure 7.

Procedure 8. A7 through Al3 Assemblies

A7 1st LO Distribution Amplifier

A8 Low Band Mixer

A9 Input Attenuator

A10 Tracking Generator (Option 002)

AllYTO

Al3 Second Converter

Procedure 9. Al4 and Al5 Assemblies

Procedure 10. Al7 CRT Driver

Procedure 11. Bl Fan

Procedure 12.

Procedure 13. Rear Frame/Rear Dress Panel

Procedure 14. W3 Line Switch Cable

Procedure 15. EEROM (A2U501)

Procedure 16. A21 OCXO (Option 003)

...........................

AlAl

Keyboard/Front Panel Keys

AlA

RPG

A6Al

High Voltage Assembly

.........................

.............................

BTl

Battery

......................

.....................

......................

........................

........................

........................

.....................

..............

..................

.................

................

...........

...........

................

............

.............

...............

..............

...............

...................

.................

................

....................

..............

.................

..................

................

2-57

2-60

2-63

2-66

2-68

2-71

3-2

3-2

3-3

3-4

3-11

3-12

3-13

3-19

3-22

3-25

3-28

3-29

3-30

3-31

3-32

3-33

3-34

3-37

3-38

3-39

3-40

3-44

3-50

3-51

4. Replaceable Parts

Ordering Information

Direct Mail-Order System

Direct Phone-Order System

Parts List Format

Firmware-Dependent Part Numbers

5. Major Assembly and Cable Locations

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-l

Contents-2

.........................

...........................

......................

.....................

...................

4-l

4-l

4-2

4-2

4-2

Page 8

6. General Troubleshooting

Introduction .............................

Assembly Level Text

Block Diagrams

...........................

Assembly Test Points

........................

........................

Pad.. .............................

Test Jack

Ribbon Cables

WR PROT/WR ENA

Troubleshooting to a Functional Section

Using the TAM

Diagnostic Functions

TAM Requirements

Test Connectors

Revision Connectors

Inconsistent Results

Erroneous Results

............................

...........................

Softkey

Menus

.................

.................

............................

........................

.........................

..........................

........................

.........................

..........................

Blank Display ...........................

Automatic Fault Isolation

Display/Power Supply

Controller Check

ADC/Interface

IF/LOG Check

.........................

Check

..........................

LO Control Check

......................

.......................

.......................

........................

RF Check ............................

Manual Probe Troubleshooting

Cal Osc. Troubleshooting Mode

Error Messages

............................

Viewing Multiple Messages

Error Message Elimination

System Analyzer Programming Errors (100 to 150)

ADC Errors (200 to 299)

.......................

LO and RF Hardware/Firmware Failures (300 to 399)

YTO Loop Errors (300 to 301)

Roller PLL Errors (302 to 316)

YTO Loop Errors (317 to 318)

Roller Oscillator Errors (321 to 329)

YTO Loop Errors (331)

600 MHz Reference Loop (333)

YTO Leveling Loop (334)

Sampling Oscillator (335)

Automatic IF Errors (400 to 599)

System Errors (600 to 651)

Digital and Checksum Errors (700 to 799)

EEROM Checksum Errors (700 to 704)

Program ROM Check-sum Errors (705 to 710)

RAM Check Errors (711 to 719)

Microprocessor Error (717)

Battery Problem (718)

........................

Model Number Error (719)

System Errors (750 to 757)

....................

...................

......................

......................

...........

..........

...................

...................

...................

.................

......................

...................

.....................

.....................

...................

......................

...............

...............

............

..................

.....................

......................

......................

6-1

6-l

6-l

6-2

6-2

6-2

6-2

6-6

6-8

6-10

6-10

6-11

6-11

6-11

6-12

6-12

6-12

6-12

6-12

6-12

6-13

6-13

6-13

6-13

6-13

6-14

6-15

6-15

6-16

6-16

6-17

6-18

6-18

6-18

6-20

6-20

6-21

6-21

6-22

6-22

6-22

6-31

6-31

6-31

6-32

6-33

6-33

6-33

6-34

6-34

Contents-3

Page 9

Option Module Errors (800 to 899)

User-Generated Errors (902 to 904)

Block Diagram Description

RF Section .............................

A7 LODA ............................

A8 Low Band Mixer ........................

A9 Input Attenuator

All YTO

Al3 Second Converter

A15Al

Third Converter (P/O A15)

Flatness Compensation Amplifiers (P/O A15)

Synthesizer Section

Sweeping the First LO

Reference PLL (P/O A15)

YTO PLL (A7, All, P/O A14, P/O A15)

Offset Lock Loop (P/O A15)

Roller Oscillator PLL (P/O A14)

IF Section .............................

A4 LOG Amplifier/Cal Oscillator assembly

A5 IF Assembly

ADC/Interface

ADC ..............................

Log Expand/Video Functions (P/O A3)

Triggering ............................

Controller Section

EEROM

Firmware

Display ASM

Display/Power Supply Section

A6 Power Supply

Al7 CRT Display Driver

............................

Second IF Distribution Amplifier (P/O A15)

Section

..........................

.............................

............................

...........................

.......................

.......................

.......................

.........................

.......................

.....................

.........................

.......................

.........................

......................

..................

..................

..........

....................

............

..............

....................

..................

..............

...............

....................

6-34

6-34

6-35

6-36

6-36

6-36

6-36

6-36

6-37

6-37

6-37

6-37

6-37

6-37

6-38

6-38

6-38

6-39

6-39

6-40

6-40

6-41

6-42

6-42

6-42

6-42

6-43

6-43

6-43

6-43

6-43

6-43

7. ADC/Interface Section

Troubleshooting Using the TAM

Automatic Fault Isolation

Keyboard/RPG Problems

Keyboard Interface

RPG Interface

Triggering Problems

Flatness Control (RF Gain DACs)

A3 Assembly’s Video Circuits

Log Offset/Log Expand

Video MUX

Video Filter

Video Filter Buffer Amplifier

Positive/Negative Peak Detectors

Peak Detector Reset

Rosenfell Detector

ADCMUX

Variable Gain Amplifier (VGA)

Contents-4

.............................

....................

......................

.......................

.........................

...........................

..........................

...................

.....................

.......................

............................

............................

.....................

...................

.........................

.........................

....................

7-4

7-4

7-7

7-7

7-8

7-9

7-11

7-12

7-

14

7-15

7-15

7-16

7-17

7-18

7-18

7-19

7-21

Page 10

Track and Hold

A3 Assembly’s ADC Circuits

ADC Control Signals

ADC Start/Stop Control

ADC ASM

ADC ...............................

Ramp Counter

A3 Assembly’s Control Circuits

Analog Bus Drivers

Analog Bus Timing

Interface Strobe Select

8. IF Section

Troubleshooting Using the TAM

Troubleshooting A4 Log Amplifier with the TAM

Troubleshooting A5 with the TAM

Troubleshooting A4 Cal Oscillator with the TAM

Automatic IF Adjustment

Parameters Adjusted

Requirements

Performance Test Failures

IF Gain Uncertainty Performance Test

Scale Fidelity Performance Test

Resolution Bandwidths Performance Tests

A4 Assembly’s Log Amplifier Circuits

Log Amplifier

Linear Amplifiers

Video Offset

Video Output

Frequency Counter

AM/FM Demodulator

4.8 kHz IF Filters

4.8 kHz and 10.7 MHz IF Filters

10.6952 MHz VCXO

Input Switch

LO Switch

Synchronous Detector

Limiter

Isolation Amplifier

Detector/Mixer

Log Offset/Gain Compensation

Log Offset Compensation

Log Gain Compensation

Video Mux

A5 IF Section

IF Signature

Common IF Signature Problems

1 MHz Resolution Bandwidth Problems

30 kHz Resolution Bandwidth Problems

3 kHz and 10 kHz Resolution Bandwidth Problems

Step Gains

...........................

........................

.............................

...........................

.........................

.........................

........................

........................

............................

...........................

..........................

............................

...........................

Prescaler/Conditioner

.........................

..........................

.........................

............................

.............................

........................

.............................

........................

..........................

.............................

............................

............................

.............................

......................

.......................

.....................

....................

............

..................

............

.......................

.......................

.................

....................

...............

..................

...............

...................

....................

.....................

......................

...................

................

................

...........

7-21

7-22

7-22

7-23

7-24

7-24

7-25

7-26

7-26

7-27

7-28

8-3

8-4

8-4

8-8

8-9

8-10

8-11

8-12

8-12

8-13

8-13

8-14

8-14

8-15

8-16

8-16

8-17

8-17

8-17

8-18

8-19

8-19

8-19

8-20

8-20

8-20

8-20

8-21

8-21

8-21

8-21

8-22

8-23

8-28

8-30

8-32

8-32

8-33

Contents-5

Page 11

A4 Assembly’s Cal Oscillator Circuit

Cal Oscillator Unlock at Beginning of IF Adjust

Inadequate CAL OSC AMPTD Range

300 Hz to 3 kHz Resolution Bandwidth Out of Specification

Low-Pass Filter

Sweep Generator

AM/FM Demodulation, Audio Amplifier, and Speaker

9. Controller Section

Troubleshooting Using the TAM

Blank Display ...........................

Digital Signature Analysis (DSA)

Display Problems

Line Generators

Blanking

Display Jumbled or Trace Off Screen

Intensity ..............................

Bad Characters or Graticule

Long Lines Dimmer Than Short Lines

Analog Zero-Span Problems

Frequency-Count Marker Problems

Frequency Counter

State- and Trace-Storage Problems

Keyboard Problems

..............................

...........................

..........................

...........................

..........................

.....................

......................

..........................

..........................

..................

............

.................

.......

..........

....................

...............

.................

.................

...................

...................

....

:

8-34

8-35

8-35

8-36

8-40

8-40

8-40

9-l

9-2

9-4

9-4

9-4

9-5

9-7

9-10

9-10

9-11

9-12

9-13

9-14

9-15

9-16

10. Synthesizer Section

Confirming a Faulty Synthesizer Section

Troubleshooting Test Setup

Troubleshooting Using the TAM

General PLL Troubleshooting

PLL Locked at Wrong Frequency

Unlocked PLL

Frequency Span Accuracy Problems

Determining the First LO Span

Confirming Span Problems

YTO Main Coil Span Problems (LO Spans

YTO FM Coil Span Problems (LO Spans 1.01 MHz to 20 MHz)

Roller Oscillator Span Problems (LO Spans 51 MHz)

First LO Span Problems (All Spans)

Unlocked YTO PLL

Operation

Troubleshooting an Unlocked YTO PLL

Unlocked Roller Oscillator PLL

Operation

Confirming an Unlocked Condition

Offset Oscillator PLL

Transfer Oscillator PLL

Main Oscillator PLL

Unlocked Offset Lock Loop (Sampling Oscillator)

Operation

Troubleshooting

...........................

..........................

.............................

.............................

.............................

..........................

......................

....................

.....................

....................

......................

.....................

........................

.......................

........................

.................

...................

...................

>20

MHz)

.................

................

..................

.............

..........

.....

..........

10-2

10-7

10-8

10-13

10-13

10-13

10-15

10-15

lo-16

lo-16

10-17

lo-18

10-21

lo-23

lo-23

lo-25

lo-32

lo-32

lo-32

10-33

10-35

10-37

10-39

10-39

10-39

Contents-6

Page 12

Unlocked Reference PLL

Operation

Troubleshooting

Third LO Driver Amplifier

Sampler and Sampler IF

Sweep Generator Circuit

A21 OCXO (Option 003 only)

11. RF Section

Troubleshooting Using the TAM

Low Band Problems (50 Hz to 2.9 GHz)

Low Band Problems

A7 LODA (LO Distribution Amplifier)

A9 Input Attenuator

Al3 Second Converter

Al4 Frequency Control Assembly ....................

A7 LODA Drive

Al5 RF Assembly

Confirming a Faulty Third Converter

Confirming Third Converter Output

Third Converter

Flatness Compensation Control

Control Latches

SIG ID Oscillator

10 MHz Reference

A10 Tracking Generator (Option 002)

Block Diagram Description

Tracking Oscillator ........................

Upconverter ...........................

Pentupler ............................

Modulator ............................

Coupler .............................

Output Mixer

Output Amplifier .........................

Bias Board ............................

Output Goes Unleveled (ERR 900 or ERR 901)

Excessive Residual FM

Flatness Out-of-Tolerance

Vernier Accuracy Out-of-Tolerance

Harmonic/Spurious Outputs Too High

Power Sweep Not Functioning Properly

No Power Output

.............................

...........................

...........................

........................

..........................

......................

........................

........................

.....................

....................

.................

..........................

.................

.........................

.........................

..........................

.................

..................

..........................

....................

..........................

..........................

..................

......................

..........................

.............

.......................

......................

..................

.................

................

..........................

lo-42

lo-42

lo-42

10-44

10-45

10-47

lo-52

11-2

11-4

11-5

11-6

11-7

11-8

11-9

11-9

11-10

11-10

11-11

11-11

11-13

11-13

11-13

11-14

11-18

11-18

11-18

11-18

11-18

11-18

11-18

11-18

11-19

11-19

11-19

11-20

11-21

11-21

1 l-22

11-23

11-23

Contents-7

Page 13

12. Display/Power Supply Section

Troubleshooting Using the TAM

Blank Display

Blank Display

Display Distortion

Focus Problems

Intensity Problems

A6 Power Supply Assembly

Dead Power Supply

Line Fuse Blowing

Supply Restarting Every 1.5 Seconds (Kick Start)

Low Voltage Supplies

High Voltage Supplies

CRT Supply Dropping Out

Blanking Signal

Buck Regulator Control

DC-DC Converter Control

Power Up

A. Component-Level Information Packets

Index

...........................

............................

..........................

............................

..........................

.........................

.........................

........................

........................

...........................

.......................

.............................

....................

......................

......................

......................

............

12-4

12-5

12-6

12-7

12-8

12-9

12-11

12-11

12-13

12-13

12-13

12-14

12-15

12-15

12-16

12-16

12-17

Contents-8

Page 14

Figures

l-1. Serial Number Label Example

l-2. Example of a Static-Safe Workstation

1-3. HP 8560A Shipping Container and Cushioning Materials

2-1. High-Voltage Power Supply Adjustment Setup

2-2. Display Adjustment Setup

2-3. CRT Adjust Pattern

2-4. A2 Display Adjustment Locations

2-5. IF

2-6. IF Amplitude Adjustment Setup

2-7. IF Amplitude Adjustment Locations

2-8. Sampler Adjustment Setup

2-9. Coarse-Tune Adjustment Setup

2-10. YTO Adjustment Setup

2-11. First LO Distribution Amplifier Adjustment Setup

2-12. Tracking Generator Power Level Adjustments Setup and Adjustment

2-13. Frequency Response Adjustment Setup

2-14. Calibrator Amplitude Adjustment Setup

2-15. 10 MHz Frequency Reference Adjustment Setup

2-16. Demodulator Adjustment Setup

2-17. External Mixer Bias Adjustment Setup

2-18. External Mixer Amplitude Adjustment Setup

2-19. Location of

2-20. Signal ID Oscillator Adjustment Setup

2-21. 600 MHz Amplitude Adjustment Setup

2-22. 10 MHz Reference Adjustment (Option

2-23. Tracking Oscillator Adjustment Setup

3- 1.

3-2. Discharging the Post-Accelerator Cable

3-3. A9, A18, and Line-Switch Assembly Mounting Screws

3-4. Front-Frame Mounting Screws

3-5. Installing the CRT and Front-Frame Assemblies

3-6. Placing the CRT into the Front Frame

3-7. A2, A3, A4, and A5 Assembly Removal

3-8. Assembly Cables (1 of 2)

3-8. Assembly Cables (2 of 2)

3-9. Coaxial Cable Clip

3-10. HP-IB and

3-11. A6 Power Supply Connections

3-12. Power Supply Cover

3-13. Al7 CRT Driver Mounting Screws

3-14. Assembly Locations

Bandpass

Locations

Hinged Assemblies

Adjustment Setup

............................

A15Al

AlAl Wl

........................

.......................

.........................

.........................

.......................

.......................

.........................

Cable Placement

.........................

.........................

....................

.................

.........

.............

......................

...................

....................

...................

.................

......................

....................

...........

................

................

............

...................

................

..............

.................

................

003)/Setup

.................

................

....................

.................

................

................

....................

..................

and Adjustment Location

..........

............

l-2

1-7

l-10

2-12

2-14

2-17

2-18

2-20

2-25

2-26

2-33

2-35

2-37

2-40

2-43

2-45

2-48

2-50

2-52

2-55

2-57

2-61

2-63

2-66

2-69

2-72

3-3

3-5

3-6

3-7

3-8

3-9

3-14

3-15

3-16

3-17

3-18

3-20

3-21

3-23

3-26

Contents-9

Page 15

3-15. RF Section Bias Connections . . . . . . . . . . . . . . . . . . . . .

3-16. A9 Mounting Screws at Right Frame

3-17. A10 Tracking Generator Mounting Screws

3-18. All Mounting Screws

........................

3-19. Al4 and Al5 Assembly Removal

3-20. Al4 and Al5 Assembly Cables

3-21. Al7 Mounting Screws

3-22. Main Deck Screws

3-23. A6 Power-Supply Cover

........................

.........................

.......................

....................

3-24. W3 Dress and Connection to A6 Power Supply

3-25. Line Switch Mounting Screw and Cable Dress

3-26. W3 Cable Connector

3-27. Side Frame Mounting Screws

3-28. A21 OCXO Mounting Screws

........................

.....................

.....................

4-l. Parts Identification, Assembly Mounting

4-2. Parts Identification, Cover Assembly

4-3. Parts Identification, Main Chassis

4-4. Parts Identification, RF Section

....................

4-5. Parts Identification, Front Frame

4-6. Parts Identification, Rear Frame

5-

1. Hinged Assemblies

5-2. Top View (A2 Unfolded)

.........................

.......................

5-3. Top View (A2 and A3 Unfolded)

5-4. Top View (A2, A3, A4, and A5 Unfolded)

5-5. Bottom View (Al5 Unfolded)

.....................

5-6. Bottom View (Al5 and Al4 Unfolded)

5-7. Front End

5-8. Rear View

6-l. Assembly Test Points

.............................

.............................

........................

6-2. Ribbon Cable Connections (1 of 2)

6-3. WR ENA Softkey Menu

6-4. Functional Sections

6-5. Phase Lock Loops

..........................

6-6. Simplified Block Diagram

.......................

.........................

......................

6-7. HP 8560A Overall Block Diagram (Sheet 1 of 3)

6-7. HP 8560A Overall Block Diagram (Sheet 2 of 3)

6-7. HP 8560A Overall Block Diagram (Sheet 3 of 3)

7-l. A3 Test Connectors

.........................

7-2. A3 Interface Assembly Block Diagram

8-1. A4 and A5 Test Connectors

.....................

8-2. IF Section Troubleshooting with TAM

8-3. IF Adjust Signature

.........................

8-4. Detailed IF Adjust Signature (1)

8-5. Detailed IF Adjust Signature (2)

8-6. Detailed IF Adjust Signature (3)

8-7. Detailed IF Adjust Signature (4)

8-8. Detailed IF Adjust Signature (5)

8-9. Noisy Signature

8-10. Noise with Correct Shape

8-11. Region B Amplitude Variation

8-12. Region B Amplitude Offset

...........................

......................

....................

......................

.................

...............

...................

.............

.............

................

.................

...................

...................

...................

...................

...............

................

..................

............

............

............

.................

.................

...................

...................

...................

...................

...................

3-27

3-30

3-31

3-32

3-34

3-36

3-37

3-41

3-43

3-45

3-46

3-47

3-49

3-51

4-21

4-33

4-35

4-37

4-39

4-41

5-4

5-4

5-5

5-6

5-7

5-8

5-9

5-10

6-3

6-4

6-7

6-35

6-39

6-45

6-47

6-49

6-51

7-4

7-29

8-3

8-7

8-25

8-25

8-26

8-26

8-27

8-27

8-28

8-29

8-29

8-30

Contents-10

Page 16

8-13. Faulty Crystal Short

8-14. Faulty LC Pole

...........................

8-15. Faulty Crystal Symmetry

........................

......................

8-16. Output Waveform, 10 kHz Resolution Bandwidth

8-17. Output Waveform, 3 kHz Resolution Bandwidth

8-18. Output Waveform, 1 kHz Resolution Bandwidth

8-19. Output Waveform, 300 Hz Resolution Bandwidth

8-20. Failed Crystal Set Symptoms

8-21. A4 Log Amplifier Block Diagram

8-22. A5 IF Assembly Block Diagram

8-23. Cal Oscillator Block Diagram

9-l. A2 Test Connectors

.........................

9-2. Line Generator Output Waveforms

9-3. Blanking Waveforms

........................

9-4. Expanded Blanking Waveforms

9-5. Switch Driver Waveform LCHAR

9-6. Distorted X/Y Line Generator Waveforms

9-7. Expanded X/Y Line Generator Waveforms

9-8. Normal X/Y Line Generator Waveforms

9-9. Delta X Waveform

9-10.

Delta Y Waveform

9-

11.

DEFl

Synchronization

.........................

.........................

........................

9-12. A2 Controller Block Diagram

10-l. YTO Loop Test Setup

........................

10-2. Sampler and Sampling Oscillator Test Setup

10-3. Al4 and Al5 Test Connectors

10-4. PLL Locked at Wrong Frequency

10-5. Unlocked PLL

...........................

10-6. Input to YTO FM Coil Driver

10-7. Input to

Main/FM/VCO

10-8. Troubleshooting an Unlocked YTO PLL

10-9.

Simplified Sweep Generator

10-10. Simplified Sweep Generator during Retrace

10-11. Simplified Synthesizer Section

10-12. Simplified Al4 Assembly Block Diagram

10-13. Simplified Al5 Assembly Block Diagram

10-14. Frequency Control Block Diagram

10-15. RF Assembly Block Diagram

11-l. Al4 and Al5 Test Connectors

11-2. A7 LODA Drive

..........................

11-3. 10 MHz Reference at A15J302

11-4. 10 MHz TTL-Reference at

.....................

...................

....................

.....................

..................

....................

...................

...............

...............

................

.....................

..............

....................

...................

....................

Sweep Switch

................

................

.....................

...............

....................

................

................

...................

.....................

....................

....................

U303

Pin 5

.................

11-5. HP 8560A RF Section Troubleshooting Block Diagram

12-l. Simplified Section Block Diagram

12-2. Al7 Test Connector

12-3. Probe Power Socket

12-4. Buck Regulator Waveform

.........................

.........................

......................

12-5. A6 Power Supply Block Diagram

12-6. Al7 CRT Driver Block Diagram

A-l. Interconnect Diagram

........................

...................

...................

...................

............

............

............

............

.........

8-31

8-31

8-33

8-37

8-38

8-38

8-39

8-39

8-43

8-45

8-47

9-3

9-5

9-6

9-7

9-8

9-9

9-9

9-10

9-11

9-12

9-13

9-17

10-5

10-6

10-8

10-13

10-14

lo-18

10-19

lo-26

10-47

lo-48

10-49

10-50

10-51

10-53

10-54

11-2

11-10

11-15

11-16

11-25

12-2

12-5

12-7

12-12

12-19

12-21

A-7

Contents-l 1

Page 17

Tables

l-l. Service Kit Contents

l-2. Static-Safe Accessories

l-3. Hewlett-Packard Sales and Service Offices

1-4. Recommended Test Equipment

2-l. Related Adjustments (1 of 2)

2-l. Related Adjustments (2 of 2)

2-2. Adjustable Components (1 of 3)

2-2. Adjustable Components (2 of 3)

2-2. Adjustable Components (3 of 3)

2-3. Factory Selected Components

2-4. TAM Adjustments

2-5. Required Test Equipment for TAM

2-6. Factory-Selected LC Filter Capacitors

2-7. LC Factory-Selected Capacitor Selection

2-8. Factory-Selected XTAL Filter Capacitors

2-9. XTAL Factory-Selected Capacitor Selection

2-10. Capacitor Part Numbers

2-11. Sampling Adjustments

2-12. Conversion Loss Data

2-13. A15U802 Values

2-14. Tracking Oscillator Range Centering

3-l. Required Tools ...........................

4-2. Reference Designations, Abbreviations and Multipliers (1 of 4)

4-2. Reference Designations, Abbreviations, and Multipliers (2 of 4)

4-2. Reference Designations, Abbreviations, and Multipliers (3 of 4)

4-2. Reference Designations, Abbreviations, and Multipliers (4 of 4)

4-3. Manufacturers Code List (1 of 3)

4-4. Replaceable Parts

6-l. Location of Assembly Troubleshooting Text

7-l. W2 Control Cable Connections (1 of 2)

7-2. Automatic Fault Isolation References

7-3. TAM Tests Versus A3 Test Connectors

7-4. Keyboard Matrix

7-5. Counter Frequencies

7-6. Trigger MUX Truth Table

7-7. A3U102 Latch Outputs

7-8.

HMUX-SELO/l

7-9. Logic Levels at A3U108

7-10. Demultiplexer A3U410 Truth Table

7-11. Demultiplexer A3U500 Truth Table

8-l. Automatic Fault Isolation References

8-2. TAM Tests Versus Test Connectors (1 of 2)

8-3. Sweep Width Settings

Versus Detector Mode

........................

........................

...............

....................

.....................

.....................

...................

...................

...’................

.....................

.........................

..................

.................

................

...............

..............

.......................

........................

........................

..........................

.................

......

......

......

......

...................

..........................

..............

.................

.................

................

..........................

.........................

......................

.......................

................

.......................

..................

..................

.................

..............

........................

l-6

l-8

1-12

1-13

2-4

2-5

2-6

2-7

2-8

2-8

2-10

2-10

2-22

2-22

2-23

2-23

2-24

2-36

2-59

2-62

2-73

3-2

4-3

4-4

4-5

4-6

4-7

4-10

6-9

7-2

7-5

7-6

7-7

7-9

7-9

7-16

7-18

7-20

7-28

7-28

8-4

8-5

8-9

Contents-12

Page 18

8-4. Available Reference Level Range

8-5. Signal Level for Reference Level Display

9-l. TAM Tests Versus Test Connectors

9-2. Gate Times

10-l. Center Frequency Tuning Values

10-2. Sampling Oscillator Test Frequencies

10-3. YTO Frequency in TEST Position

10-4. Automatic Fault Isolation References (1 of 2)

10-4. Automatic Fault Isolation References (2 of 2)

10-5. TAM Tests versus Test Connectors (1 of 2)

10-5. TAM Tests versus Test Connectors (2 of 2)

10-6. Sweep Signal Destination versus Span

10-7. Harmonic Mixing Number versus Center Frequency

10-8. Settings of Sweep Switches

10-9.

Settings of Sweep Switches

10-10. Settings for Switches and Comparators

lo-

11. Amplifier Polarities

10-12. YTO Frequency Errors with A14J23 on Pins 2 and 3

10-13. Voltages in FM Coil and Main Loop Drivers

10-14. Main Coil Coarse and Fine DACs Voltages

10-15. Sampling Oscillator PLL Divide Ratios

11-1. Automatic Fault Isolation References

11-2. TAM Tests versus Test Connectors

11-3. Attenuator Pin Values

11-4. RF Section Mnemonic Table

12-1. Wl Power-Cable Connections (1 of 2)

12-1. Wl Power-Cable Connections (2 of 2)

12-2. Automatic Fault Isolation References

12-3. TAM Tests versus Test Connectors

A-l. HP 8560A Spectrum Analyzer Documented Assemblies

A-2. A4 and Al6 Assemblies Shipped with HP 8560As Serial Prefixed below 3207A

A-3. Al5 RF Assemblies Shipped with HP 8560As Serial Prefixed below 3029A .

............................

......................

......................

.........................

........................

...................

................

..................

...................

.................

..................

..............

..............

...............

...............

.................

...........

................

..........

..............

...............

................

.................

..................

.....................

.................

.................

.................

....,.............

.........

8-12

8-12

9-2

9-

14

10-3

10-7

10-8

10-9

10-10

10-11

10-12

10-15

10-15

10-17

10-19

10-22

lo-25

lo-28

10-30

10-31

10-40

11-3

11-4

11-7

11-17

12-3

12-4

12-4

12-5

A-2

A-4

A-5

Contents-13

Page 19

General Information

This HP 8560A Spectrum Analyzer Service Manual contains information required to adjust

and service the HP 8560A Spectrum Analyzer to the assembly level.

For component-level information, refer to the HP

Component Level Information.

856OA/61B/63A

Spectrum Analyzer

Manual Organization

Chapter 1, General Information, contains information about service kit contents,

recommended test equipment, returning an instrument for service, and sales and service

offices.

Chapter 2, Adjustment Procedures, contains the necessary adjustment procedures to adjust

the instrument properly after repair.

Chapter 3, Assembly Replacement, contains instructions for removal and replacement of all

major assemblies.

Chapter 4, Replaceable Parts, contains the information necessary to order parts or assemblies

for the instrument.

Chapter 5, Major Assembly and Cable Locations, contains figures identifying all major

assemblies and cables.

Chapter 6, General Troubleshooting, contains instrument-level troubleshooting information,

block diagrams, and troubleshooting information covering the instrument’s six functional

areas.

Chapters 7 through 12 contain troubleshooting information covering the instrument’s six

functional areas.

Appendix contains the component-level documented assemblies matrix and the HP 8560A

Interconnect Diagram.

General Information

1-l

Page 20

Manual Text Conventions

The following text conventions are used throughout this manual:

m

Softkeys

Display

Text

Serial

This service manual applies directly to HP 8560A spectrum analyzers with serial numbers

prefixed 3207A and above. For HP 8560A spectrum analyzers with serial numbers prefixed

below

Hewlett-Packard makes frequent improvements to its products to enhance their performance,

usability, or reliability. HP service personnel have access to complete records of design changes

to each type of equipment, based on the equipment’s serial number. Whenever you contact

HP about your analyzer, have the complete serial number available to ensure obtaining the

most complete and accurate information possible.

3207A, order HP Part Number 08560-90038.

Boxed text in this typeface represents a mechanical key physically located on the

instrument.

Shaded text indicates a

activated by pressing corresponding keys surrounding the display. The labels

displayed are determined by the mechanical front-panel key depressed and the

instrument’s firmware.

Text printed in this typeface indicates text appearing on the screen.

N.umbers

Covered by This Manual

softkey. Softkey labels appear on the display and can be

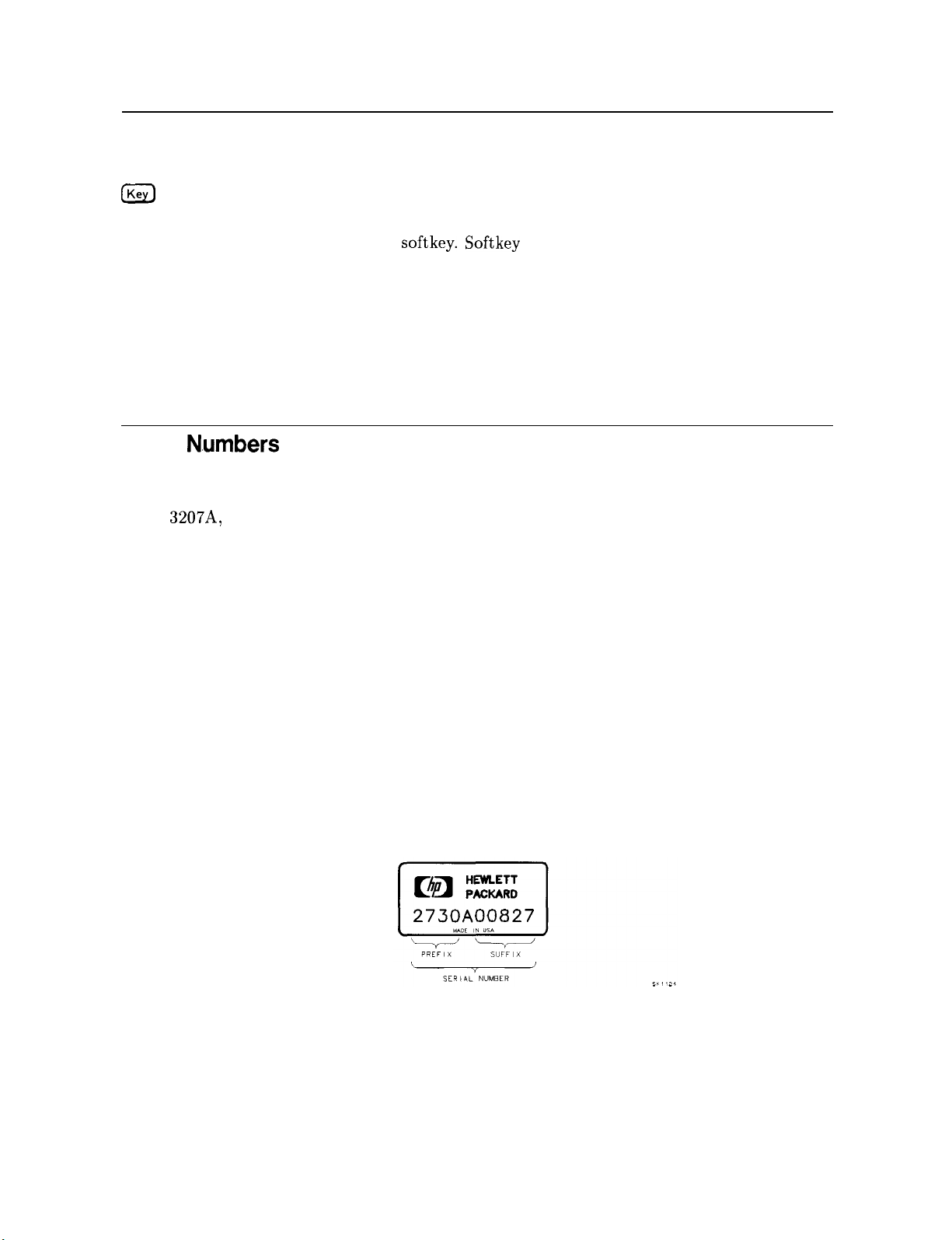

The serial number label is attached to the rear of the analyzer. The serial number has two

parts: the prefix (the first four numbers and a letter), and the suffix (the last five numbers).

See Figure l-l.

The first four numbers of the prefix are a code identifying the date of the last major design

change incorporated in your analyzer. The letter identifies the country in which the unit

was manufactured. The five-digit suffix is a sequential number and is different for each

unit. Whenever you list the serial number or refer to it in obtaining information about your

analyzer, be sure to use the complete number, including the full prefix and the suffix.

Figure l-l. Serial Number Label Example

l-2 General Information

Page 21

Instrument Variations

The following text lists the unique assemblies contained in the HP 8560A Options 001, 002,

003, and all combinations.

HP 8560A Option 001 (Rear-Panel 2nd IF Output)

Al5 RF Assembly

w19

Rear-panel JlO

HP 8560A Option 002 (Tracking Generator)

A10 Tracking Generator

Al5 RF Assembly

Front dress-panel

w14

W16

W36

W42

w43

W46

w47

W48

unique part number

added

added

added

unique part number

unique part number

added

added

deleted

deleted

added

added

added

added

Rear-panel J 11

Front-panel

Front-panel J6

HP 8560A Option 012 (001 + 002)

Al5 RF Assembly unique part number

w19

Rear-panel JlO

A10 Tracking Generator

Front dress-panel

w14 added

W16

W36

W42 deleted

w43

53

added

deleted

added

added

added

added

unique part number

added

deleted

added

General Information 1-3

Page 22

W46

added

w47

W48

Rear-panel J 11

Front-panel

Front-panel J6

HP 8560A Option 003 (Precision Frequency Reference)

Al5 RF Assembly

A21 OCXO

w49

w50

HP 8560A Option 013 (001 + 003)

Al5 RF Assembly

w19

Rear-panel JlO

53

added

added

added

deleted

added

unique part number

added

added

added

unique part number

added

added

A21 OCXO

w49

w50

HP 8560A Option 023 (002 + 003)

Al5 RF Assembly

A10 Tracking Generator

Front dress-panel

w14

W16

W36

W42

w43

W46

w47

W48

added

added

added

unique part number

added

unique part number

added

added

deleted

deleted

added

added

added

added

Rear-panel

Front-panel

1-4 General Information

Jll

53

added

deleted

Page 23

Front-panel J6

added

A21 OCXO

w49 added

w50

HP 8560A Option 123 (001 + 002 + 003)

Al5 RF Assembly

w19

Rear-panel JlO

A10 Tracking Generator

Front dress-panel

w14

W16

W36

W42

w43

W46

added

added

unique part number

added

added

added

unique part number

added

added

deleted

deleted

added

added

w47

W48

Rear-panel

Front-panel J3

Front-panel J6

A21 OCXO

w49

w50

Jll

added

added

added

deleted

added

added

added

added

General Information l-5

Page 24

HP 85629B Test and Adjustment Module

When attached to the spectrum analyzer’s rear panel, the HP 85629B Test and Adjustment

p

Module (TAM)

rovides diagnostic functions for the HP 8560A. Because the TAM connects

directly to the analyzer’s internal data and address bus, it controls the analyzer’s hardware

directly. It would be impossible to control the hardware to the same extent either from the

analyzer’s front panel or over the HP-IB.

The TAM measures voltages at key points in the circuitry and flags a failure whenever the

voltage falls outside the limits. The TAM locates the failure to a small functional area which

can be examined manually.

Service Kit

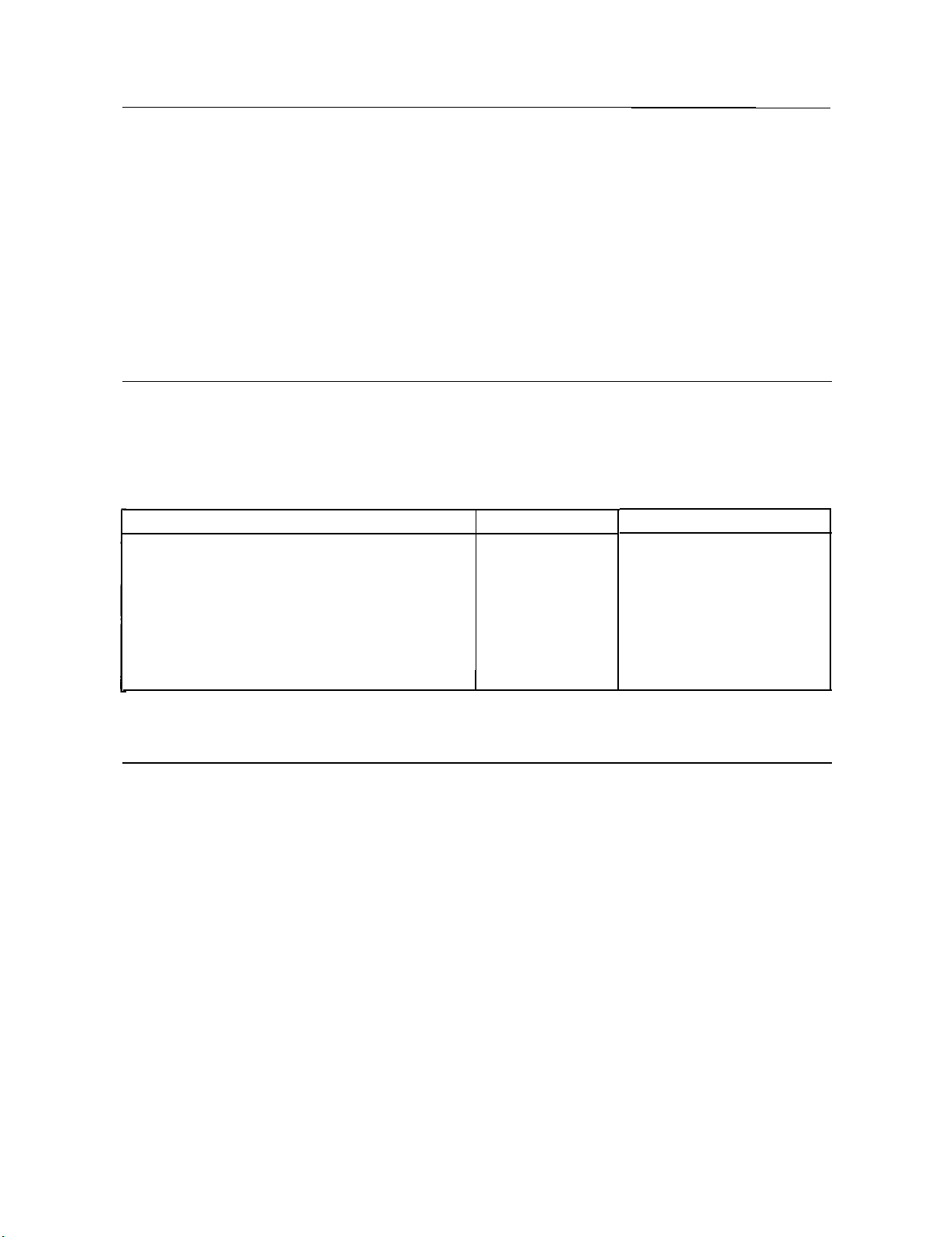

The HP 8560A Service Kit (HP part number 08562-60021)

contains service tools required to

repair the instrument. Refer to Table l-l for a list of items in the service kit.

Table l-l. Service Kit Contents

Description

Cable Puller

PC Board Prop

Line Filter Assembly

Line Switch Cable

Extender Cable

BNC to SMB (snap-on) Cable

Connector Extractor Tool Kit

Quantity

1

1

1

1

1

2

1

HP Part Number

5021-6773

5021-7459

5061-9032

5062-0728

5062-0737

85680-60093

8710-1791

Recommended Test Equipment

Equipment required for operation verification, performance tests, adjustments,

troubleshooting, and the Test and Adjustment Module is listed in Table l-4. Other equipment

may be substituted if it meets or exceeds the critical specifications listed in the table. Refer to

the HP 856OA Installation and Verification Manual for the performance tests.

1-6 General Information

Page 25

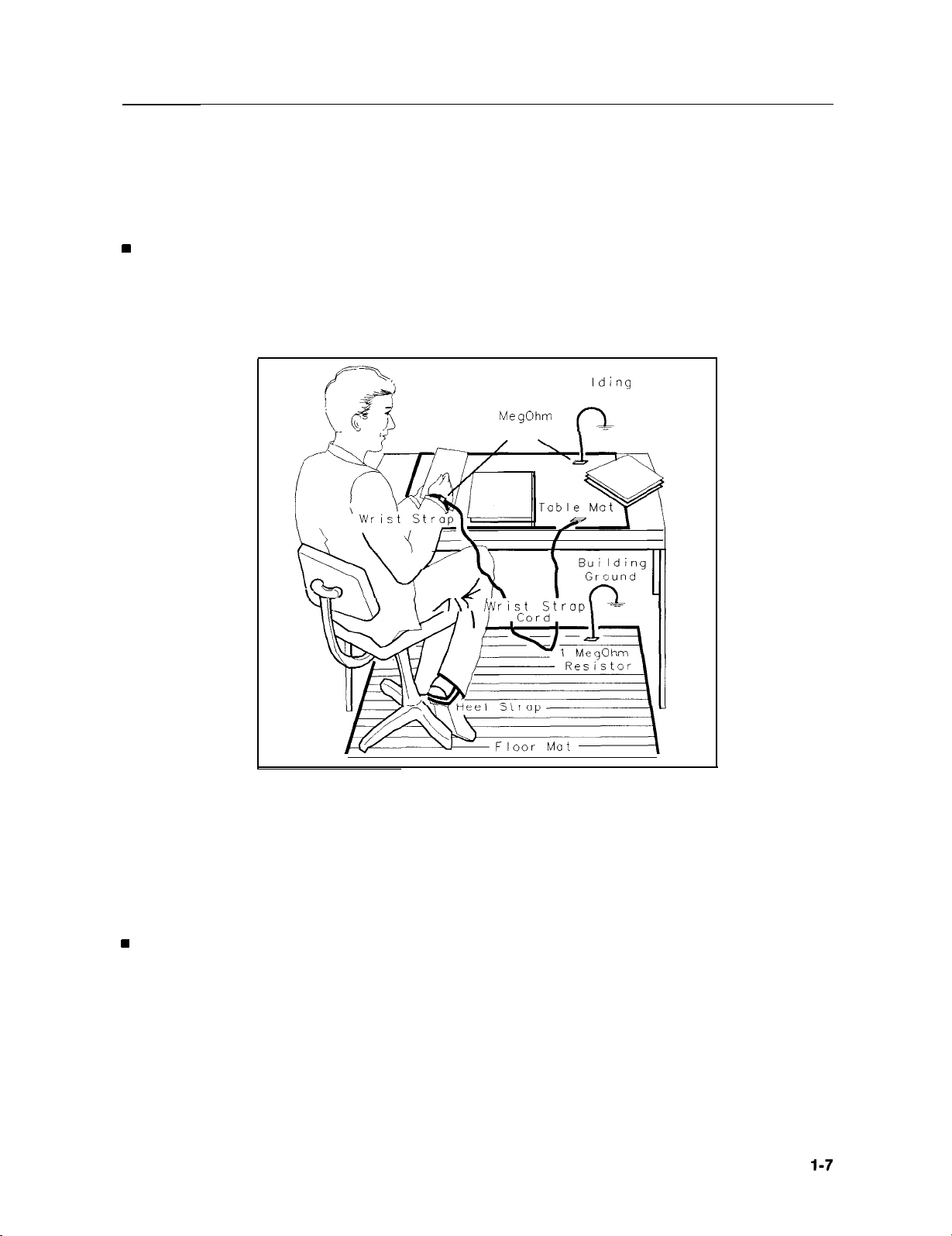

Electrostatic Discharge

Electrostatic discharge (ESD)

can damage or destroy electronic components. Therefore,

all work performed on assemblies consisting of electronic components should be done at a

static-free workstation. Figure l-2 is an example of a static-safe work station using two kinds

of ESD protection:

w

Conductive table mat and wrist-strap combination.

n Conductive floor mat and heel-strap combination.

These methods may be used together or separately.

Bui

lding

Ground

1

MegOhm

Resistor

I /TV

hhirist

StroD\

*

5111125

Figure 1-2. Example of a Static-Safe Workstation

Reducing Potential for ESD Damage

The suggestions that follow may help reduce ESD damage that occurs during

testing and servicing.

w

Before connecting any coaxial cable to an analyzer connector for the first time each day,

momentarily ground the center and outer connectors of the cable.

n Personnel should be grounded with a resistor-isolated wrist strap before touching the center

in of any connector and before removing any assembly from the unit.

n Be sure all instruments are properly earth-grounded to prevent build-up of static discharge.

General Information

nstrument

l-7

Page 26

Static-Safe Accessories

Table 1-2. Static-Safe Accessories

HP Part

Number

9300-0797

9300-0980

9300-1383

9300-l169

ESD heel-strap (reusable 6 to 12 months).

Set includes: 3M static control mat 0.6 m x 1.2 m (2 ft x 4 ft) and 4.6 cm (15 ft)

ground wire. (The wrist-strap and wrist-strap cord are not included. They must

be ordered separately.)

Wrist-strap cord 1.5 m (5 ft)

Wrist-strap, color black, stainless steel, without cord, has four adjustable links

and a 7 mm post-type connection.

Description

Returning Instruments for Service

Service Tag

If you are returning the instrument to Hewlett-Packard for servicing, fill in and attach a blue

service tag. Service tags are supplied in the back of this chapter.

Please be as specific as possible about the nature of the problem. If you have recorded any

error messages that appeared on the screen, or have completed a performance test record, or

have any other specific data on the performance of the analyzer, please send a copy of this

information with the unit.

Original Packaging

Before shipping, pack the unit in the original factory packaging materials if they are available.

If the original materials are unavailable, identical packaging materials may be acquired

through’any Hewlett-Packard Sales and Service Office. Descriptions of the packaging materials

are listed in Figure l-3.

Other Packaging

Caution

Repackage the analyzer in the original packaging materials or with commercially available

materials described in steps 4 and 5, below.

1. Attach a completed service tag to the instrument.

1-8 General Information

Analyzer damage can result from using packaging materials other than those

specified. Never use styrene pellets in any shape as packaging materials. They

do not adequately cushion the equipment or prevent it from shifting in the

carton. They cause equipment damage by generating static electricity and by

lodging in the analyzer fan.

Page 27

2. Install the front-panel cover on the instrument.

3. Wrap the instrument in antistatic plastic to reduce the possibility of damage caused by

electrostatic discharge.

4. Use the original materials or a strong shipping container that is double-walled, corrugated

cardboard carton with 159 kg (350 lb)

ursting strength. The carton must be both large

b

enough and strong enough to accommodate the analyzer and allows at least 3 to 4 inches

on all sides of the analyzer for packing material.

5. Surround the equipment with at least 3 to 4 inches of packing material, or enough to

prevent the equipment from moving in the carton. If packing foam is unavailable, the best

TM

alternative is SD-240 Air Cap

Air Cap looks like a plastic sheet covered with

from Sealed Air Corporation (Commerce, CA 90001).

l-1/4

inch air-filled bubbles. Use the

pink-colored Air Cap to reduce static electricity. Wrap the equipment several times in this

material to both protect the equipment and prevent it from moving in the carton.

6. Seal the shipping container securely with strong nylon adhesive tape.

7. Mark the shipping container

“FRAGILE, HANDLE WITH CARE” to assure careful

handling.

8. Retain copies of all shipping papers.

General Information

l-9

Page 28

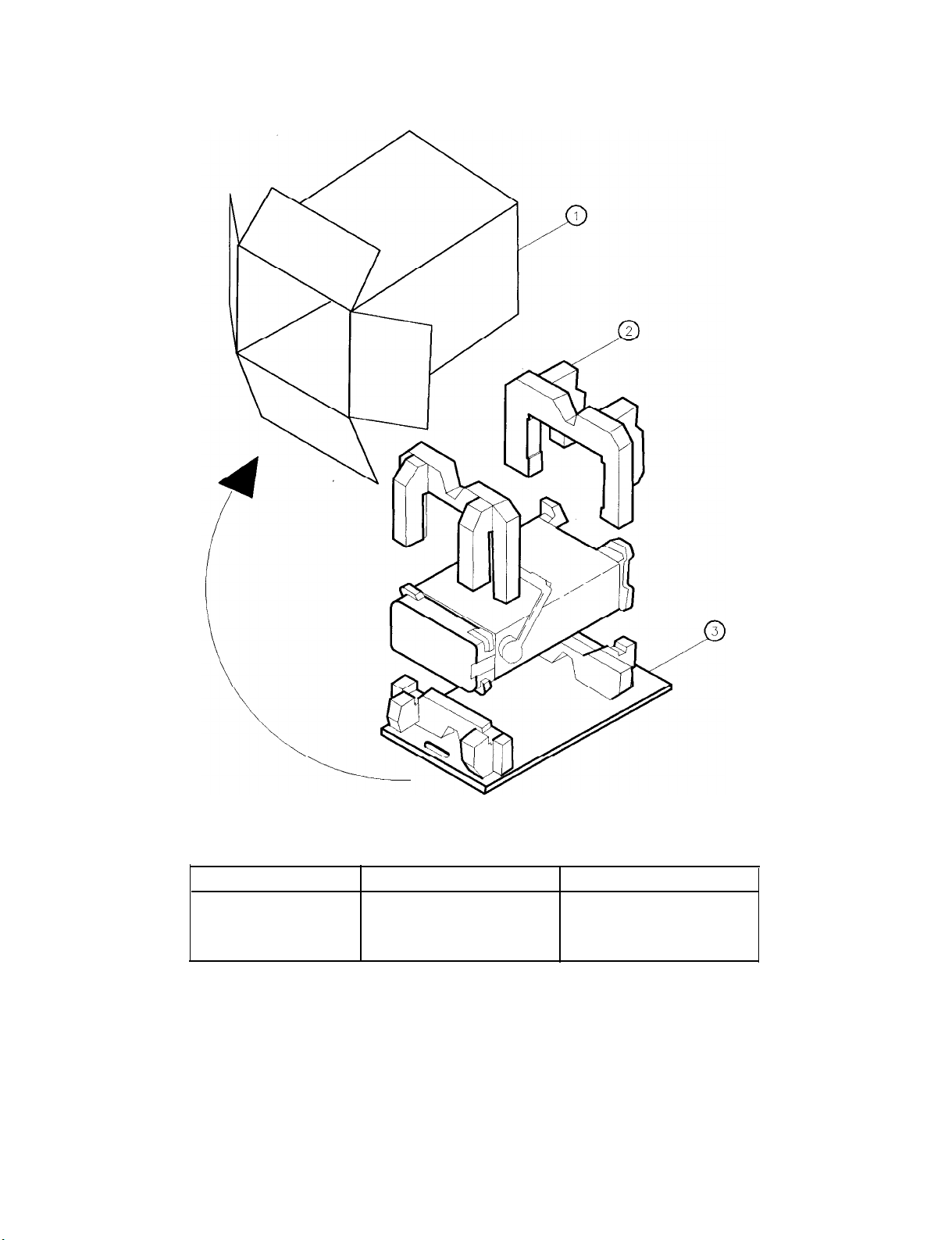

SK1126

Item

1

2

3

Figure 1-3. HP 8560A Shipping Container and Cushioning Materials

l-1 0 General Information

Description

9211-5636

08590-80013

08590-80014

HP Part Number

Outer Carton

Pads (2)

Bottom Tray

Page 29

Sales and Service Offices

Hewlett-Packard has sales and service offices around the world providing complete support for

Hewlett-Packard products. To obtain servicing information, or to order replacement parts,

contact the nearest Hewlett-Packard Sales and Service Office listed in Table l-3.

In any correspondence, be sure to include the pertinent information about model numbers,

serial numbers, and assembly part numbers.

Note

Within the USA, a toll-free phone number is available for ordering

replacement parts. Refer to the “Ordering Information” section in Chapter 4,

“Replaceable Parts,” for the phone number and more information.

General Information l-l 1

Page 30

Table 1-3. Hewlett-Packard Sales and Service Offices

US FIELD OPERATIONS EUROPEAN OPERATIONS

HEADQUARTERS

HEADQUARTERS

Hewlett-Packard Company Hewlett-Packard S.A.

19320 Pruneridge Avenue

Cupertino, CA 95014, USA 1217 Meyrin

(800) 752-0900

150, Route du Nant-d’Avri1

2/Geneva

Switzerland

(41 22) 780.8111

California

Hewlett-Packard Co.

France

1421 South Manhattan Ave. Hewlett-Packard France

Fullerton, CA 92631

(714) 999-6700

1 Avenue Du Canada Blackburn, Victoria 3130

Zone

D’Activite

De Courtaboeuf (61 3) 895-2895

F-91947 Les Ulis Cedex

Hewlett-Packard Co.

301 E. Evelyn

France

(33 1) 69 82 60 60

Mountain View, CA 94041

(415) 694-2000

Colorado

Hewlett-Packard Co.

24 Inverness Place, East

Englewood, CO 80112

Germany

Hewlett-Packard

GmbH

Berner Strasse 117 Canada

6000 Frankfurt 56

West Germany

(49 69) 500006-O

(303) 649-5000

Great Britain

Georgia

Hewlett-Packard Co.

2000 South Park Place

Atlanta, GA 30339

(404) 955-1500

IlklOiS

Hewlett-Packard Ltd.

Eskdale Road, Winnersh Triangle Kanagawa 229, Japan

Wokingham, Berkshire

RGll

England

(44 734) 696622

Hewlett-Packard Co.

5201 Tollview Drive

Rolling Meadows, IL 60008

(708) 255-9800

New Jersey

Hewlett-Packard Co.

120 W. Century Road

Paramus, NJ 07653

(201) 599-5000

Texas

Hewlett-Packard Co.

930 E. Campbell Rd.

Richardson, TX 75081

(214) 231-6101

INTERCON OPERATIONS

HEADQUARTERS

Hewlett-Packard Company

3495 Deer Creek Rd.

Palo Alto, California 94304-1316

(415) 857-5027

Australia

Hewlett-Packard Australia Ltd.

31-41 Joseph Street

Canada

Hewlett-Packard (Canada) Ltd.

17500 South Service Road

Trans-Canada Highway

Kirkland, Quebec H9J 2X8

(514) 697-4232

Japan

Yokogawa-Hewlett-Packard Ltd.

1-27-15 Yabe, Sagamihara

5DZ (81 427) 59-1311

China

China Hewlett-Packard, Co.

38

Bei

San Huan Xl Road

Shuang Yu Shu

Hai Dian District

Beijing, China

(86 1) 256-6888

Singapore

Hewlett-Packard Singapore

Pte. Ltd.

1150 Depot Road

Singapore 0410

(65) 273 7388

Taiwan

Hewlett-Packard Taiwan

8th Floor, H-P Building

337 Fu Hsing North Road

Taipei, Taiwan

(886 2) 712-0404

1-12 General Information

Page 31

Table 1-4. Recommended Test Equipment

Instrument

Synthesized

Sweeper

(two required)

Synthesizer/

Level Generator

Synthesized

Signal Generator Residual SSB Phase Noise at 10 kHz offset

Pulse/Function Frequency Range: 10 kHz to 50 MHz HP 8116A

Generator

AM/FM

Signal Generator

Microwave Frequency Range: 9 MHz to 6.9 GHz

Frequency Counter Time base Accuracy (Aging): <5 x

Universal

Counter

Oscilloscope

Spectrum Analyzer

* Part of Microwave Workstation

P

=

Performance Tests; A = Adjustments; M = Test & Adjustment Module; T = Troubleshooting;

V = Operation Verification

Frequency Range: 10 MHz to 7

Frequency Accuracy (CW): 1 x

Leveling Modes: Internal & External

Modulation Modes: AM & Pulse

Power Level Range: -80 to

Frequency Range: 200 Hz to 80 MHz

Frequency Accuracy: 1 x

Flatness: f0.15 dB

Attenuator Accuracy: <&0.09 dB

Frequency Range: 5 MHz to 2.5

(320 MHz <fc <640 MHz): <-131 dBc/Hz

Pulse Width: 200 ns;

Output Amplitude: 5 V peak-to-peak

Functions: Pulse

TTL Sync Output

Frequency Range: 1 MHz to 200 MHz HP 8640B

Frequency Modulation Mode

Modulation Oscillator Frequency: 1

FM Peak Deviation: 5 kHz

External Frequency Reference Input

Modes: TI

Time Interval Measurement Range: 20 ms to 75 s

Frequency Measurement Range: 17

Frequency Resolution: 1 MHz at 10 MHz

External Frequency Reference Input

Time base accuracy (Aging):

Bandwidth (3

Minimum Vertical Deflection Factor: <2 mV/div

Frequency Range: 4

Typical Residual FM: <l Hz Pk-to-Pk in 100 ms

(Fundamental Mixing)

Critical Specifications

for Equipment Substitution

GHz

10eg/day

+16 dBm

10e7/month

GHz

&

Triangle

kHz

lo-“/day

AFB, Frequency Count

kHz to 11 MHz

<3

x

10m7/month

dB): dc to 100 MHz

kHz to 7 GHz

of

Recommended Use

Model

8340A*

HP

HP

3335A*

HP 8663A

HP

5343A*

Option 001

HP

5334A/B

HP

1980A/B* A,T

HP

8566A/B

P,A,M,V

P

PAT,

M,V

PAT,

M,V

p,v

P

A

PAT

General Informationl- 13

Page 32

Table 1-4. Recommended Test Equipment (continued)

Instrument

Measuring

Receiver

Power Sensor

Power Sensor

Power Sensor

4mplifier

Digital Voltmeter Range: -15 V dc to +120 V dc

DVM Test Leads

10 dB Step Attenuation Range: 30 dB

Attenuator Frequency Range: dc to 80 MHz

1 dB Fixed Attenuation Range: 12 dB

Attenuator

’

Part of Microwave Workstation

P = Performance Tests; A = Adjustments; M = Test & Adjustment Module; T = Troubleshooting

V = Operation Verification

Compatible w/Power Sensors

dB Relative Mode

Resolution: 0.01 dB

Reference Accuracy: <&1.2%

Frequency Range: 50 MHz to 6.9 GHz

Maximum SWR:

1.15 (2.0 to 6.5 GHz)

Frequency Range: 250 MHz to 350 MHz

Power Range: 100 nW to 10

Maximum SWR: 1.15 (250 to 350 MHz)

Frequency Range: 100 kHz to 2.9 GHz HP 8482A*

Maximum SWR:

1.1 (1 MHz to 2.0 GHz)

1.30 (2.0 GHz to 2.9 GHz)

Frequency Range: 2.0 to 2.9 GHz HP 11975

Minimum Output Power (Leveled)

2.0 to 8.0 GHz: $16

Output SWR (Leveled):

Accuracy:

Input Impedance: 21

236

Connectors: BNC (f)

Frequency Range: dc to 80 MHz

Connectors: BNC (f)

Critical Specifications

for Equipment Substitution Model

1.15 (50 to 100 MHz)

1.10 (100 MHz to 2 GHz)

1.20 (12.4 to 18 GHz)

PW

dBm

<1.7

<fl

mV on 10 V Range

Ma

inches, alligator clips, probe tips

Recommended Use

HP

8902A*

HP

8485A*

HP 8484A

HP

3456A*

HP 34118A

HP 355D

HP 355C

PAT,

M,V

PAT,

M,V

P,A

PAT,

M,V

P

A

A,T

p,v

P,V,A

1-14 General Information

Page 33

Table 1-4. Recommended Test Equipment (continued)

Instrument

20 dB Fixed

Attenuator

Frequency Range: dc to 6.5 GHz

Attenuation Accuracy:

Critical Specifications

for Equipment Substitution

<fl

dB

Recommended

Model

HP 8491B

Option 020

Use

p,v

Maximum SWR: 1.2 (dc to 6.5 GHz)

10 dB Fixed

Attenuator

Frequency Range: dc to 6.5 GHz

Attenuation Accuracy:

<f0.6

dB

HP 8491B

Option 010

p,v

Maximum SWR: 1.2 (dc to 6.5 GHz)

Signature Multimeter

Reference Attenuator

Termination

Clock Frequency

>lO

MHz

Supplied with HP 8484A

Frequency Range: dc to 22 GHz

Impedance:

Maximum SWR:

5OQ

<1.22

HP

5005A/B

HP 11708A

HP

909D

T

P,A

P,M,V

Connector: APC 3.5

Low-Pass Filter

Cutoff Frequency: 50 MHz

0955-0306

P,M,V

Rejection at 80 MHz: >50 dB

12 MHz Low-Pass-Filter Cutoff Frequency: 12 MHz

0955-0518

P

g-element Tchebychev, 0.1 dB ripple

Rejection at 18 MHz: >45 dB

Directional

Bridge

Frequency Range: 5 MHz to 50 MHz

Coupling: 6.0 dB (nominal)

HP 8721A

P

Directivity: 30 dB minimum

Power Splitter

VSWR:

Frequency Range: 1 kHz to 22 GHz

<1.45

HP 11667B

P,A,M,V

Insertion Loss: 6 dB (nominal)

Output Tracking:

Equivalent Output SWR:

Product Support Kit No Substitute

Adapter

Type N (f) to BNC (m)

Adapter Type N (m) to BNC (f)

(three required)

Adapter

Adapter

Adapter

(two required)

Adapter

Type N (f) to BNC (f)

Type N (f) to APC 3.5 (m)

Type N (m) to APC 3.5 (m)

Type N (m) to APC 3.5 (f)

<0.25

dB

<1.22

08562-60021

1250-1477

1250-1476

1250-

1474

1250-1750 A

1250-1743

P,A,M,V

1250-1744

A,T

A

p,v

p,v

P,A,V

P = Performance Tests; A = Adjustments; M = Test & Adjustment Module; T = Troubleshooting;

V = Operation Verification

General Information 1-15

Page 34

Table 1-4. Recommended Test Equipment (continued)

ment Substitution

Type N (m) to SMA (f)

Length:

Cable,

Cable, HP-IB

5052

Coaxial Connectors: BNC (m)

(five

required)

Length: 2 122 cm (48 in.)

Required w/Performance Test Software

(12 required) Required w/HP 85629B Test

291

cm (36 in.)

&

Adjustment Module

HP 10503A

HP 10833B

P,A,V

PAM

Length: 2 m (6.6 ft.)

Cable Frequency Range: 10 kHz to 6.9 GHz

(three required) Maximum SWR:

<1.4

at 6.9 GHz

8120-4921

P,A,M,V

Maximum Insertion Loss: 2 dB

Connectors: APC 3.5 (m), both ends

Length: 2 91 cm (36 in.)

Photometer/

No Substitute

JlG-TV

A

Tek

Radiometer

Controller

Required to run Operation Verification Software

No substitute.

HP 9816A,

HP

9836A/C,

V

or HP 310

Power Supply

Tuning Tool

Output Voltage:

224

V dc

Output Voltage Accuracy:

N/A

<f0.2

HP 6114A

V

8710-1010

A

A

P = Performance Tests; A = Adjustments; M = Test & Adjustment Module; T = Troubleshooting

V = Operation Verification

1-16 General Information

Page 35

Adjustment Procedures

Introduction

This chapter contains information on automated and manual adjustment procedures for the

HP 8560A spectrum analyzer. Perform the automated procedures using the HP 85629B

Tests and Adjustment Module (TAM). N

Adjustments should be performed after a repair or performance test failure.

Introduction

Safety Considerations

Which Adjustments Should Be Performed? ..........................................

Test Equipment

Adjustable and Factory-Selected Components ........................................

Adjustment Tools

Instrument Service Position

Using the TAM

Test Equipment ....................................................................

Adjustment Indicator ..............................................................

1. High-Voltage Power Supply Adjustment .........................................

2. Display Adjustment

3. IF

4. IF Amplitude Adjustments

5. DC Log Amplifier Adjustments

6. Sampling Oscillator Adjustment ................................................

7. YTO Adjustment

8. First LO Distribution Amplifier Adjustment

9. Tracking Generator Power Level Adjustments

10. Frequency Response Adjustment

11. Calibrator Amplitude Adjustment

12. 10 MHz Reference Adjustment (Non-Option 003 only)

13. Demodulator Adjustment

14. External Mixer Bias Adjustment ..............................................

15. External Mixer Amplitude Adjustment ........................................

16. Second IF Gain Adjustment

17. Signal ID Oscillator Adjustment ...............................................

18. 600 MHz Amplitude Adjustment ..............................................

19. 10 MHz Reference Adjustment (Option 003)

20. Tracking Oscillator Adjustment

.........................................................................

..............................................................

....................................................................

..................................................................

........................................................

.......................................................................

..........................................................

Bandpass

Adjustment .......................................................

.....................................................

.............................................................

....................................................

.................................................

perform adjustments as routine maintenance.

ever

................................................

....................................

..................................

..............................................

.............................................

.........................

.................................. .2-68

...............................................

..2- 2

..2- 3

..2- 9

..2-14

.2-29

..2-3 7

.2-42

.2-45

..2-5 2

.2-55

..2-6 0

.2-71

2

..2-

.2-2

..2- 2

.2-2

..2- 3

.2-9

..2- 9

.2-12

2-20

2-25

2-33

.2-40

2-48

.2-50

.2-57

2-63

.2-66

1

Note

Before performing any adjustments, allow the instrument to warm up for 5

minutes.

Adjustment Procedures

2-l

Page 36

Safety Considerations

Although this instrument has been designed in accordance with international safety standards,

this manual contains information, cautions, and warnings which must be followed to ensure

safe operation and to prevent damage to the instrument. Service and adjustments should be

performed only by qualified service personnel.

Warning

Warning

Warning

Warning

Adjustments in this section are performed with power supplied to the instrument

and protective covers removed. There are voltages at many points in the

instrument which can, if contacted, cause personal injury. Be extremely careful.

Adjustments should be performed only by trained service personnel.

Power is still applied to this instrument with the m switch in the off position.

Before removing or installing any assembly or printed circuit board, remove the

line-power cord.

Capacitors inside the instrument may still be charged, even if the instrument has

been disconnected from its source of supply.