Page 1

TM 11-6625-2781-14&P-5

TECHNICAL MANUAL

OPERATOR'S, ORGANIZATIONAL,

DIRECT SUPPORT, AND GENERAL SUPPORT

MAINTENANCE MANUAL

(INCLUDING REPAIR PARTS AND SPECIAL TOOLS LIST)

FOR

PLUG-IN, LOW FREQUENCY

(SPECTRUM ANALYZER)

PL-1387/U

(HP-8556A)

(NSN 6625-00-167-5267)

HEADQUARTERS, DEPARTMENT OF THE ARMY

27 APRIL 1983

Page 2

5

1

234

5

SAFETY STEPS TO FOLLOWING SOMEONE IS THE VICTIM OF ELECTRICAL SHOCK

DO NOT TRY TO PULL OR GRAB THE INDIVIDUAL

IF POSSIBLE, TURN OFF THE ELECTRICAL POWER

IF YOU CANNOT TURN OFF THE ELECTRICAL POWER, PULL, PUSH OR LIFT THE PERSON

TO SAFETY USING A DRY WOODEN POLE OR A DRY ROPE OR SOME OTHER INSULATING

MATERIAL

SEND FOR HELP AS SOON AS POSSIBLE

AFTER THE INJURED PERSON IS FREE OF CONTACT WITH THE SOURCE OF ELECTRICAL

SHOCK, MOVE THE PERSON A SHORT DISTANCE AWAY AND IMMEDIATELY START

ARTIFICIAL RESUSCITATION

Page 3

WARNINGS

Removing the top cover from the Display Section exposes the operator to

dangerous potentials (up to 7000 volts).

INPUT connector ground is isolated from cabinet ground. Any voltage present on

cable shield will be present on connector shell (± 100 VDC maximum). If

contacted, this voltage may cause personal injury.

A

Page 4

SPECTRUM ANALYZER LF SECTION

8556A

Serials Prefixed: 1104A

This manual applies directly to LF Sections with the serial number prefixes listed above.

Serial Prefixes Not Listed

For LF Sections with serial prefixes not listed, a "Manual Changes" insert is included with

this manual.

Copyright HEWLETT-PACKARD COMPANY 1971

1501 PAGE MILL ROAD, PALO ALTO, CALIFORNIA, U.S.A.

Manual Part No. 08556-90004

Microfiche Part No. 08556-90006 Printed JULY 1971

B

Page 5

CERTIFICATION

Hewlett-Packard Company certifies that this instrument met its published specifications at

the time of shipment from the factory. Hewlett-Packard Company further certifies that its

calibration measurements are traceable to the United States National Bureau of

Standards, to the extent allowed by the Bureau's calibration facility, and to the calibration

facilities of other International Standards Organization members.

WARRANTY AND ASSISTANCE

This Hewlett-Packard product is warranted against defects in materials and workmanship

for a period of one year from the date of shipment. Hewlett-Packard will, at its option,

repair or replace products which prove to be defective during the warranty period

provided they are returned to Hewlett-Packard, and provided the preventive maintenance

procedures in this manual are followed. Repairs necessitated by misuse of the product

are not covered by this warranty. NO OTHER WARRANTIES ARE EXPRESSED OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. HEWLETTPACKARD IS NOT LIABLE FOR CONSEQUENTIAL DAMAGES.

If this product is sold as part of a Hewlett-Packard integrated instrument system, the

above warranty shall not be applicable, and this product shall be covered only by the

system warranty.

C/(D blank)

Page 6

This manual contains copyrighted material reproduced by permission of the Hewlett-Packard Company. All rights

reserved.

TM 11-6625-2781-14&P-5

TECHNICAL MANUAL HEADQUARTERS

DEPARTMENT OF THE ARM Y

No. 11-6625-2781-14 & P-5 Washington, DC, 27 April 1983

OPERATOR'S, ORGANIZATIONAL, DIRECT SUPPORT,

AND GENERAL SUPPORT MAINTENANCE MANUAL,

INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS

FOR

PLUG-IN, LOW FREQUENCY

(SPECTRUM ANALYZER)

PL-13871U

(HP-8556A)

(NSN 6625-00-167-5267)

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS

You can improve this manual. If you find any mistakes, or if you know of a way to

improve the procedures, please let us know. Mail your letter or DA Form 2028

(Recommended Changes to Publications and Blank Forms) directly to:

Commander, US Army Communications-Electronics Command and Fort

Monmouth, ATTN: DRSEL-ME-MP, Fort Monmouth, NJ 07703. In either case a

reply will be furnished directly to you.

TABLE OF CONTENTS

SECTION O INTRODUCTION Page

O-1 Scope .............................................................................................................................O-1

O-2 Index of Publications .............................................................................................O-1

O-3 Maintenance Forms, Records, and Reports ..........................................................O-1

O-4 Reporting Equipment Improvement Recommendations (EIR) ...........................O-1

O-5 Administrative Storage .............................................................................................O-1

O-6 Destruction of Army Electronic Materiel .................................................................O-1

i

Page 7

TABLE OF CONTENTS

Section Page

I GENERAL INFORMATION..............................................1-1

1-1. Introduction............................................................1-1

1-5. Instruments Covered by Manual.........................1-1

1-7. Description.............................................................1-1

1-15. Accessories Suppl ied...........................................1-2

1-18. Equipment Required but not Supplied...............1-2

1-20. IF Sections .........................................................1-2

1-22. Display Sections................................................1-2

1-24. Compatibility...........................................................1-2

1-27. Operating Accessories .........................................1-2

1-29. Test Equipment Required....................................1-2

1-31. Warranty..................................................................1-2

II INSTALLATION .................................................................2-1

2-1. Initial Inspection.....................................................2-1

2-2. Mechanical Check.............................................2-1

2-4. Electrical Check.................................................2-1

2-6. DELETED...........................................................2-1

2-9. Preparation for Use ..............................................2-1

2-10. Shipping Configuration ....................................2-1

2-12. Power Requirements ........................................2-1

2-15. Power Cable......................................................2-1

2-17. Operating Environment....................................2-1

2-19. Interconnections................................................2-1

2-22. Storage and Shipment .........................................2-2

2-23. Original Packaging............................................2-2

2-27. Other Packaging Materials .............................2-2

III OPERATION ......................................................................3-1

3-1. Introduction............................................................3-1

3-3. Panel Features ......................................................3-1

3-5. Operator's Checks ................................................3-1

3-7. Operating Considerations ....................................3-1

3-9. RF Input..............................................................3-1

3-12. Amplitude Ranges.............................................3-1

3-16. First Mixer Balance ..........................................3-1

3-23. Operating Instructions .........................................3-2

3-26. Setting the Frequency Scan............................3-2

3-31. Adjusting the Amplitude Scale........................3-2

3-37. Using the Tracking Generator.........................3-8

3-52. Variable Persistence and Storage

Functions.........................................................3-10

3-57. Photographic Techniques ...............................3-10

IV PERFORMANCE TESTS

4-1. Introduction............................................................4-1

4-4. Equipment Required.............................................4-1

4-6. Operational Adjustments......................................4-1

4-8. Front Panel Checks .............................................4-1

4-10. Test Sequence......................................................4-1

4-14. Tracking Generator Amplitude............................4-3

4-15. Marker Accuracy ...................................................4-4

4-16. Scan Width Accuracy............................................4-6

4-17. Center Frequency Accuracy................................4-7

4-18. Frequency Response...........................................4-8

4-19. Average Noise Level ............................................4-10

4-20. Residual Responses ............................................4-12

4-21. Spurious Responses ...........................................4-14

4-22. Residual FM...........................................................4-17

4-23. Noise Sidebands ..................................................4-19

4-24. Input Level Control and Gain Compression......4-21

4-25. Tracking Generator Spectral Purity ...................4-23

ii

Section Page

V ADJUSTMENTS................................................................5-1

5-1. Introduction............................................................5-1

5-4. Test Equipment Required ...................................5-1

5-7. Posidriv Screwdrivers .......................................5-1

5-9. Blade Tuning Tools ..........................................5-1

5-11. HP 11592A Service Kit ....................................5-1

5-14. Extender Cable Installation..............................5-1

5-18. Factory Selected Components............................5-1

5-20. Related Adjustments ............................................5-1

5-23. Voltage Checks .....................................................5-2

5-24. Pre-Attenuator Adjustments:

COMP and C IN.................................................5-4

5-25. 50.150 MHz Local Oscillator

Adjustment: A6T1 .............................................5-6

5-26. Mixer Balance Adjustments: C, R and Z............5-7

5-27. Tracking Generator Adjustments:

AMPL ADJ and FLATNESS ADJ ....................5-8

5-28. Frequency Calibration Adjustment:

OFFSET ADJ, 300 kHz ADJ, and

ZERO ADJ .........................................................5-10

5-30. 8552A 47 MHz LO Adjustment ..........................5-13

VI REPLACEABLE PARTS...................................................6-1

6-1. Introduction............................................................6-1

6-5. DELETED...............................................................6-1

VII MANUAL CHANGES

DELETED

VIII SERVICE ...........................................................................8-1

8-1. Introduction............................................................8-1

8-3. Theory of Operation..........................................8-1

8-5. Recommended Test Equipment ....................8-1

8-8. Troubleshooting ................................................8-1

8-13. General Service Information................................8-1

8-14. Part Location Aids.............................................8-1

8-16. Factory Selected Components........................8-1

8-18. Diagram Notes...................................................8-1

8-20. Servicing Aids on Printed Circuit

Boards .............................................................8-2

8-22. Circuit Board Extender ....................................8-2

8-24. General Service Hints ..........................................8-2

8-25. Etched Circuits ..................................................8-2

8-27. Etched Conductor Repair ...............................8-2

8-29. Component Replacement ...............................8-2

8-36. Logic Circuits and Symbols .................................8-5

8-40. Basic AND Gate (Positive Logic)....................8-6

8-42. Basic OR Gate (Positive Logic) .....................8-6

8-45. Truth Tables.......................................................8-6

8-47. Logic Inversion..................................................8-6

8-49. Binary Circuits and Symbols ..............................8-6

8-51. Reset-Set (RS) Flip-Flop..................................8-6

8-53. The RST Flip-Flop.............................................8-8

8-55. Clocked JK Flip-Flop........................................8-8

8-57. JK Master/Slav e Flip-Flop ...............................8-9

8-60. Preset and Clear ..............................................8-10

8-62. Operational Amplifiers ..........................................8-10

8-63. Circuits and Symbols........................................8-10

8-66. Troubleshooting ................................................8-12

8-70. Dial Calibration Procedure...................................8-12

Page 8

LIST OF ILLUSTRATIONS

Figure Page

1-1 Model 8556A Spectrum A nalyzer LF Section with

8552B IF Section and 141T Display Section ...1-0

1-2 Instrument Identification ..............................................1-1

1-3 Typical Spectrum Analyzer Resolution......................1-6

1-4 Typical Spectrum Analyzer Distortion Products.......1-6

1-5 HP 11592A Service Kit ................................................1-12

2-1 LF Section and IF Section Interconnections ............2-3

3-1 Front Panel Features....................................................3-3

3-2 Operational Adjustments..............................................3-6

3-3 Typical Frequency Response Measurement

(in 50 Ohms) .........................................................3-9

3-4 Typical Amplifier Frequency Response Meas-

urement (in 600 Ohms) using a

Frequency Counter...............................................3-9

4-1 Tracking Generator Test Setup..................................4-3

4-2 Marker Accuracy Test Setup .......................................4-4

4-3 Scan Width Accuracy Display.....................................4-6

4-4 Frequency Response Test Setup ..............................4-8

4-5 Average Noise Level Display ......................................4-11

4-6 Residual Responses Display .......................................4-13

4-7 Spurious Responses Test Setup ................................4-14

4-8 Intermodulation Distortion Products Display.............4-16

4-9 Residual FM Test Setup...............................................4-17

4-10 Residual FM Display.....................................................4-18

4-11 Noise Sidebands Test Setup.......................................4-19

4-12 Noise Sidebands Display.............................................4-20

4-13 Input Level Control and Gain Compression

Test Setup..............................................................4-21

4-14 Tracking Generator Spectral Purity Test Setup .......4-23

5-1 Voltage Checks Test Setup.........................................5-2

5-2 Pre-Attenuator Adjustment Test Setup......................5-4

5-3 50.150 MHz Local Oscillator Adjustment

Test Setup..............................................................5-6

5-4 Mixer Balance Adjustments Test Setup....................5-7

5-5 Tracking Generator Adjustment Test Setup ............5-9

5-6 Frequency Calibration Adjustment Test Setup ........5-10

5-7 47 MHz LO Adjustment Display .................................5-14

6-1 Front Panel Parts, Exploded View..............................6-11

8-1 8556A LF Section with Circuit Board Extended ......8-3

8-2 Examples of Diode and Transistor Marking

Methods..................................................................8-4

8-3 Integrated Circuit Packaging ......................................8-5

8-4 Basic AND and OR Gates ..........................................8-5

8-5 Basic NAND and NOR Gates......................................8-6

8-6 Logic Comparison Diagrams ......................................8-7

8-7 RS Flip-Flop...................................................................8-7

8-8 RST Flip-Flop ................................................................8-8

8-9 The Clocked JK Flip-Flop ...........................................8-9

8-10 JK Master/Slave Flip-Flop ...........................................8-10

8-11 Operational Amplifier Equivalent Circuit ....................8-11

8-12 Dial Restringing Procedure..........................................8-13

8-13 Overall Troubleshooting Tree .....................................8-15

8-14 Top and Bottom Internal Views...................................8-19

8-15 Troubleshooting Block Diagram..................................8-23

8-16 Simplified Analyzer Block Diagram ...........................8-27

Figure Page

8-17 LF Section Block Diagram ...........................................8-27

8-18

8-19 Reserved for Optional Inputs (will not appear in

8-20 this printing).

8-21 Master Board Assembly A11 Component

Locations ...............................................................8-31

8-22 Pre-Attenuator and Preamplifier Assembly A5

Component Locations .........................................8-31

8-23 Pre-Attenuator and Preamplifier: A3, A5 and

All Schematic.........................................................8-31

8-24 Input Level Switch Assembly A3 Component

Locations ...............................................................8-35

8-25 Frequency Converter Assembly A6

Component Locations .........................................8-35

8-26 Post-Attenuator and Frequency Converter:

A3 and A6 Schematic...........................................8-35

8-27 Tracking Generator Frequency Converter

Assembly A9 Component Locations ..................8-39

8-28 Tracking Generator Frequency Converter:

A9 Schematic.........................................................8-39

8-29 Tracking Generator Output Assembly A8

Component Locations .........................................8-43

8-30 3 MHz Oscillator Assembly A8A1

Component Locations .........................................8-43

8-31 Input Level Switch Assembly A3

Component Locations .........................................8-43

8-32 Tracking Generator Output: A3 and A8

Schematic...............................................................8-43

8-33 Integrated Circuit Logic Diagrams .............................8-47

8-34 Frequency Control and Marker Generator

Assembly A7 Component Locations ..................8-47

8-35 20 kHz Marker Circuits: A7 Schematic......................8-47

8-36 Scan Width Switch Assembly A2 Component

Locations ...............................................................8-51

8-37 Frequency Control and Marker Generator

Assembly A7 Component Locations..................8-51

8-38 Frequency Control Circuits:

A1, A2 and A7 Schematic ...................................8-51

8-39 Simplified Analogic Diagram ......................................8-53

8-40 Bandwidth Switch Assembly A1 Component

Locations ...............................................................8-55

8-41 Scan Width Switch Assembly A2 Component

Locations ................................................................8-55

8-42 Analogic Circuits: A1 and A2 Schematic ..................8-55

8-43 Bandwidth Switch Assembly A1

Component Locations .........................................8-59

8-44 Input Level Switch Assembly A3 Component

Locations ...............................................................8-59

8-45 IF Section Control Circuits: A1 and A3

Schematic...............................................................8-59

8-46 Power Supply Assembly A10 Component

Locations ...............................................................8-63

8-47 Master Board Assembly A11 Component

Locations ...............................................................8-63

8-48 Power Supply and Voltage Distribution:

A10 and All Schematic.........................................8-63

iii

Page 9

LIST OF TABLES

Table Page

1-1 Specifications.................................................................1-3

1-2 Supplemental Performance Character istics .............1-6

1-3 Operating Accessories .................................................1-9

1-4 Test Equipment ............................................................1-9

1-5 Test Equipment Accessories.......................................1-11

4-1 Front Panel Checks .....................................................4-2

4-2 Performance Test Record............................................4-25

5-1 Analogic Display Calibration Check...........................5-12

5-2 Check and Adjustment Test Record..........................5-15

Table Page

6-1 Designators and Abbreviations used in

Parts List .................................................................6-1

6-2 Manufacturers Code List..............................................6-2

6-3 Replaceable Parts.........................................................6-3

8-1 Factory Selected Components....................................8-2

8-2 Etched Circuit Soldering Equipment..........................8-4

8-3 Schematic Diagram Notes ..........................................8-14

8-4 Assembly and Component Locations ........................8-19

8-5 Connector P2 Pin Identification .................................8-21

8-6 Connector P3 Pin Identification .................................8-21

8-7 Connector XA11 Pin Identification.............................8-21

APPENDIXES

APPENDIX A. REFERENCES ......................................................................................................A-1

APPENDIX B. MAINTENANCE ALLOCATION

Section I. Introduction ...........................................................................................................B-1

II. Maintenance Allocation Chart .................................................................................B-3

III. Tool and Test Equipment Requirements ..................................................................B-4

APPENDIX C. COMPONENTS OF END ITEM LIST (Not applicable)

Page

APPENDIX D. ADDITIONAL AUTHORIZATION LIST (Not applicable)

APPENDIX E. EXPENDABLE SUPPLIES AND MATERIA LS (Not applicable)

APPENDIX F. PART NUMBER-NATIONAL STOCK NUMBER INDEX ............................................F-1

APPENDIX G. MANUFACTURER'S ERRATA AND MANUAL CHANGES .......................................G-1

iv

Page 10

SECTION O

INTRODUCTION

O-1. Scope

This manual provides technical data, and installation,

operation, and maintenance instructions for the

spectrum analyzer low-frequency plug-in PL1387/U,

Hewlett-Packard model 8556A. The PL1387/U is

referred to throughout this manual as the 8556A.

Appendix A lists pertinent publications. Appendix B

contains the Maintenance Allocation Chart (MAC), which

defines the levels and scope of maintenance functions

for the equipment in the Army system, and a list of the

tools and test equipment required. Appendix F provides

a cross reference between commercial part numbers

and National Stock Numbers (NSN). Appendix G

provides a listing of errors in this manual, and changes

which are to be made to the manual, depending on the

serial number of the 8556A with which the manual is to

be used. As indicated, for plug-ins having serial

numbers from 1124A00121, to 1124A00130, only

change 1 is to be applied to the manual. For plug-ins

with serial numbers 1404A2236 and later models, all

nine changes to the manual are required. The list of

appendices is located on page iv, following LIST OF

TABLES in TABLE OF CONTENTS.

O-2. Consolidated Index of Army Publications and

Blank Forms

Refer to the latest issue of DA PAM 310-1 to determine

whether there are new editions, changes or additional

publications pertaining to the equipment.

O-3. Maintenance Forms, Records, and Reports

a. Reports of Maintenance and Unsatisfactory

Equipment. Department of the Army forms and

procedures used for equipment maintenance will be

those prescribed by TM 38-750, The Army Maintenance

Management system.

b. Report of Packaging and Handling Deficiencies.

Fill out and forward SF 364 (Report of Discrepancy

(ROD)) as prescribed in AR 735-11-2/ DLAR

4140.55/NAVMATINST 4355.73/AFR 400-54/MCO

4430.3E.

c. Discrepancy in Shipment Report (DISREP) (SF

361). Fill out and forward Discrepancy in Shipment

Report (DISREP) (SF 361) as prescribed in AR 55-38

NAVSUPINST 4610.33B AFR 75-18./MCO P

4610.19C/DLAR 4500.15.

O-4. Reporting Equipment Improvement

Recommendations (EIR)

If your plug in 8556A needs improvement, let us know.

Send us an EIR. You, the user, are the only one who

can tell us what you don't like about your equipment. Let

us know why you don't like the design. Put it on an SF

368 (Quality Deficiency Report). Mail it to: Commander,

US Army Communications-Electronics Command and

Fort Monmouth, ATTN; DRSEL-ME-MP, Fort Monmouth,

NJ 07703. We'll send you a reply.

O-5. Administrative Storage

The 8556A plug-in can be stored in stockrooms,

warehouses, or other protected facilities. The equipment

should be protected from excessive humidity, sand, dust,

and chemical contaminants. Before putting the 8556A in

administrative storage, make the following preparations:

a. Complete the operational adjustments

procedure given in figure 3-2 to assure that the plug-in is

operable.

b. If the original packing material is not available, at

least protect the unit with protective plastic or paper

wrapping. Place the unit in a carton or box with

makeshift protective packing material around it.

c. Store the equipment indoors, protected from the

elements. Maintain the equipment at moderate

temperature and humidity.

O-6. Destruction of Army Electronic Materiel

Destruction of Army electronic materiel to prevent enemy

use shall be in accordance with TM 750-244-2.

O-1

Page 11

General Information Model 8556A

MODEL 8556A

1-0

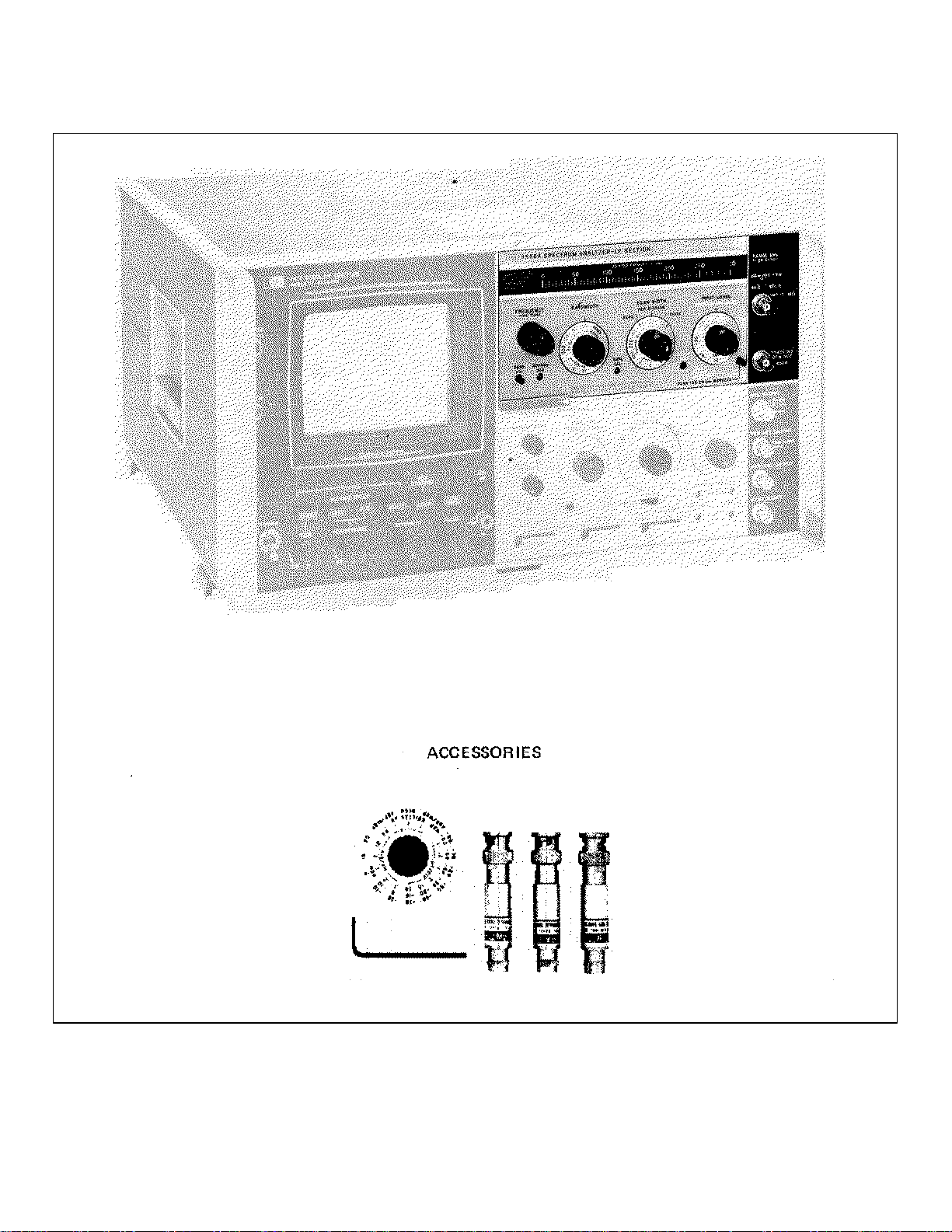

Figure 1-1. Model 8556A Spectrum Analyzer LF Section with 8552B IF Section and 141T Display Section

Page 12

Model 8556A General Information

SECTION I

GENERAL INFORMATION

1-1. INTRODUCTION

1-2. This manual contains all information required to

install, operate, test, adjust and service the HewlettPackard Model 8556A Spectrum Analyzer LF Section.

This section covers instrument identification, description,

options, accessories, specifications and other basic

information.

1-3. Figure 1-1 shows the Hewlett-Packard Model

8556A Spectrum Analyzer LF Section with the Model

8552B Spectrum Analyzer IF Section and the Model

141T Display Section. Also shown are the accessories

supplied with the 8556A (see paragraph 1-15).

1-4. The various sections in this manual provide

information as follows:

SECTION II, INSTALLATION, provides

information relative to incoming inspection,

power requirements, mounting, packing,

shipping, etc.

SECTION III, OPERATION, provides information

relative to operating the instrument.

SECTION IV, PERFORMANCE TESTS,

provides information required to ascertain that

the instrument is performing in accordance with

published specifications.

SECTION V, ADJUSTMENTS, provides

information required to properly adjust and align

the instrument after repairs are made.

SECTION VI, REPLACEABLE PARTS, provides

ordering information for all replaceable parts and

assemblies.

SECTION VII, MANUAL CHANGES, normally

will contain no relevant information in the original

issue of a manual. This section is reserved to

provide back-dating and up-dating information in

manual revisions or reprints.

SECTION VIII, SERVICE, includes all

information required to repair the instrument.

1-5. INSTRUMENTS COVERED BY MANUAL

1-6. Hewlett-Packard instruments carry a serial number

(see Figure 1-2) on the back panel. When the serial

number prefix on the instrument serial number plate of

your instrument is the same as one of the prefix

numbers on the inside title page of this manual, the

manual applies directly to the instrument. When the

instrument serial number prefix is not listed on the inside

title page of this manual, manual change sheets and

manual updating information is provided. Later editions

or revisions to the manual will contain the required

change information in Section VII.

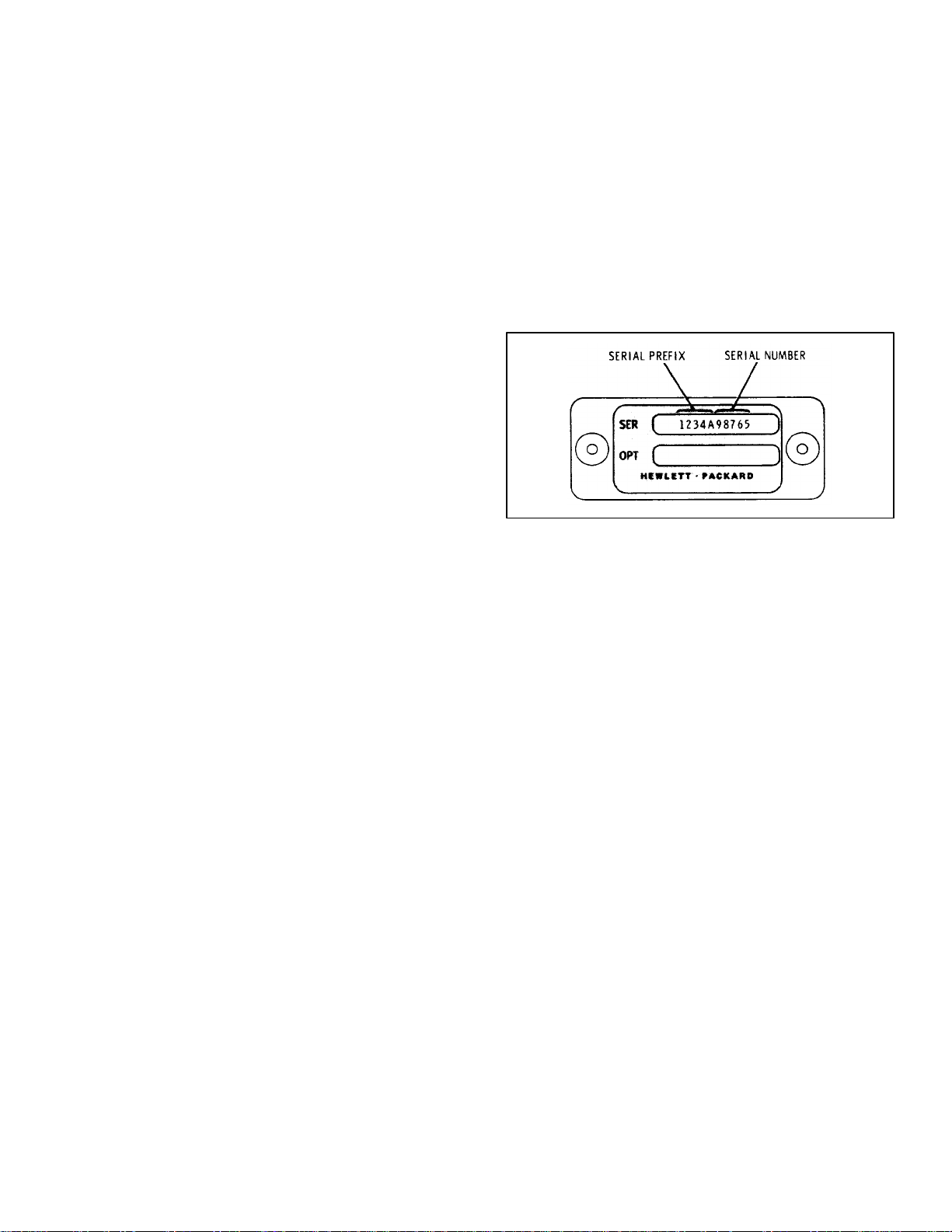

Figure 1-2. Instrument Identification

1-7. DESCRIPTION

1-8. The Hewlett-Packard Model 8556A Spectrum

Analyzer LF Section covers the frequency range from 20

Hz to 300 kHz. When it is combined with an IF Section

and a Display Section it functions as the tuning section

of a low frequency spectrum analyzer.

1-9. The analyzer electronically scans input signals and

displays their frequency and amplitude on a CRT. The

horizontal, x-axis, is calibrated in units of frequency and

the vertical, y-axis, is calibrated in absolute units of

voltage (pV, mV, dBV) or power (dBm). Therefore,

absolute and relative measurements of both amplitude

and frequency can be made.

1-10. The horizontal (frequency) axis can be swept

three different ways:

a. The center of the CRT is set to a frequency

determined by the dial and the analyzer is swept

symmetrically about that frequency.

b. The analyzer is not swept but is used as a fixed

frequency receiver. Signal amplitude can be read on the

CRT and signal modulation can be viewed as with an

oscilloscope.

1-1

Page 13

General Information Model 8556A

c. The analyzer is swept from 0 Hz to a higher

frequency selectable from 200 Hz to 200 kHz.

1-11. The vertical (amplitude) axis provides relative and

absolute measurement capability in volts, dBV, dBm into

600 ohms unbalanced, and dBm into 50 ohms.

1-12. The LF Section's input is isolated from the

instrument chassis so that the CRT display is free of line

frequency spurious responses due to ground loops.

1-13. Accurate frequency calibration is provided by

selecting 20 kHz markers.

1-14. The LF Section also contains a tracking generator

that produces a calibrated signal that precisely tracks the

analyzer tuning frequency. This signal can be used to

test the frequency response of a device; it can also be

used, with a frequency counter, for making frequency

measurements that are accurate to 1 Hz (see Section

III).

1-15. ACCESSORIES SUPPLIED

1-16. The 8556A LF Section requires a special knob on

the IF Section in place of the standard LOG REF LEVEL

control. The special knob has three scales: one is used

for the LF Section log calibration (red scale), one for log

calibration with the RF Sections (black scale), and one

for linear calibration with all units (blue scale). This knob

and an allen wrench to install it are supplied with each

8556A. Extra knobs (HP 08556-00013) are available.

1-17. The 8556A is supplied with the following

accessories: HP 11095A 600 ohm Feed Thru

Termination

HP 11048C 50 ohm Feed Thru Termination

HP 11660A Tracking Generator Shunt (50

ohm output)

1-18. EQUIPMENT REQUIRED BUT NOT SUPPLIED

1-19. The 8556A LF Section must be mated with an IF

Section, such as the 8552A or the 8552B, and a Display

Section, such as the 140T or the 141T, before the units

can perform as a spectrum analyzer.

1-20. IF Sections

greater frequency stability, narrower bandwidths and an

expanded log scale (2 dB per division).

1-22. Display Sections

1-23. The 140T Display Section is equipped with a fixed

persistence, non-storage CRT; the 141T Display Section

is equipped with a variable persistence, storage CRT.

The 143S Display Section has a large screen (8x10

inch) CRT.

1-24. COMPATIBILITY

1-25. The 8556A LF Section is fully compatible with all

current 8552A/B IF Sections; 8552A's with serial prefix

991 and below, and 8552B's with serial prefix 977 and

below must be modified. The modification consists of

adding a white-blue-grey (24 AWG) wire between

8552A/B connectors XA8 pin 8 and J3 pin 40. (See

appropriate 8552 manual for location of connectors.)

NOTE

The 8556A requires a special knob on

the IF Section in place of the

standard LOG REF LEVEL control

(see EQUIPMENT SUPPLIED).

1-26. The 8556A LF Section is fully compatible with all

HP 140S/T, HP 141S/T, and HP 143S Display Sections.

The 8556A can be used with HP 140A/B and 141A/B

Oscilloscope Mainframes but some performance

specifications will be slightly degraded. (For more

information, contact your nearest Hewlett-Packard

office.)

1-27. OPERATING ACCESSORIES

1-28. Operating accessories for use with the

8556A]8552/140 Spectrum Analyzer are listed in Table

1-3. They include a frequency counter, an oscilloscope

camera, and various attenuators and probes.

1-29. TEST EQUIPMENT REQUIRED

1-30. Tables 1-4 and 1-5 list the test equipment and test

equipment accessories required to check, adjust and

repair the 8556A LF Section.

1-21. The 8552A IF Section features calibrated

bandwidths, log and linear amplitude calibration, and

calibrated scan times. The 8552B IF Section has all of

the features of the 8552A and, in addition, manual scan,

1-2

1-31. WARRANTY

1-32. The 8556A LF Section is warranted and certified

as indicated on page C.

Page 14

Model 8556A General Information

Table 1-1. Specifications

8556A/8552B/8552A

FREQUENCY

Range:

20 Hz to 300 kHz - 8552B IF Sec tion

100 Hz to 300 kHz - 8552A IF Section

Tuning Dial Ranges of 0-30 kHz and 0-300 kHz.

Scan Width: (On a 10 div. CRT horizontal axis.)

Per Division: 10 calibrated scan widths from 20 Hz/div

to 20 kHz/div in a 1,2, 5 sequence.

0-10f: 10 calibrated preset scans, from 200 Hz to 200

kHz in a 1, 2, 5 sequence. Analyzer scans from zero

frequency to ten times the scan width per division

setting.

Zero: Analyzer is a fixed tuned receiver.

Accuracy:

Center Frequency: After 1 hour warmup, zero and 300

kHz adjustments, and with the Fine Tune centered,

the dial indicates the display center frequency within

the following specifications:

With 8552B IF Section:

0-30 kHz Range: ±500 Hz

0-300 kHz Range: ±3 kHz

Stability:

Residual FM:

With 8552B IF Section:

Sidebands >60 dB down 50 Hz or more from CW

signal, scan time ≥1 sec/div, 10 Hz band width.

With 8552A IF Section:

Less than 20 Hz peak-to-peak.

Noise Sidebands: More than 90 dB below CW signal,

3 kHz away from signal, with a 100 Hz IF bandwidth.

Frequency Drift: (After 1 hour warmup.)

With 8552B IF Section: Less than 200 Hz/10 min.

With 8552A IF Section: Less than 1 kHz /10 min.

Resolution:

Bandwidth Ranges: IF bandwidths of 10 Hz (50 Hz for

8552A) to 10 kHz are provided in a 1, 3, 10

sequence.

With 8552A IF Section:

0-30 kHz Range: ±1 kHz

0-300 kHz Range: ±5 kHz

Marker: RF markers every 20 kHz accurate to within

±0.01%. Markers controlled by front panel on/off

switch.

Scan Width:

With 8552B IF Section:

Frequency error between any two points on the

display is less than ±3% of the indicated frequency

separation.

With 8552A IF Section:

Frequency error between any two points on the

display is less than ±5% of the indicated frequency

separation.

Bandwidth Accuracy: Individual IF bandwidth 3 dB

points calibrated to ±20% (10 kHz band width ±5%).

Bandwidth Selectivity: 60 dB/3 dB IF bandwidth ratios.

With 8552B IF Section: <11:1 for IF bandwidths from

30 Hz to 3 kHz; <20:1 for 10 kHz IF bandwidth. For

10 Hz bandwidth, 60 dB points are separated by

less than 100 Hz.

With 8552A IF Section: <25:1 for IF bandwidths from

50 Hz to 300 Hz; <20:1 for IF bandwidths from 1 kHz

to 10 kHz.

1-3

Page 15

General Information Model 8556A

Table 1-1. Specifications (cont'd)

AMPLITUDE

Absolute Amplitude Calibration Range:

Log Modes:

dBV 0 dBV = 1 V rms

dBm-600Ω 0 dBm = 1 mW - 600Ω

dBm-502Ω 0 dBm = 1 mW - 502Ω

Input impedance is 1 MΩ. dBm ranges are referenced

with input properly terminated externally.

Log Range: From -150 dBm/dBV to +10 dBm/dBV in

10 dB steps. Log reference level vernier, 0 to -12

dB continuously.

Log Display Range: 10 dB/div on a 70 dB display, or 2

dB/div on a 16 dB display (with 8552B only).

Linear Sensitivity: From 0.1 µV/div to 1V/div in a 1, 2,

10 sequence. Linear sensitivity vernier X1 to X0.25

continuously.

Dynamic Range :

Average Noise Level: Specified with a 600Ω or less

source impedance and INPUT LEVEL at -60

dBm/dBV.

1 kHz IF 10 Hz IF

Mode Bandwidth Bandwidth

dBm-50 Ω <-122 dBm (180 nV) <-142 dBm (18 nV)

dBm-600Ω <-130 dBm (250 nV) <-150 dBm (25 nV)

dBV <-132 dBV (250 nV) <-152 dBV (25 nV)

Linear <400 nV <40 nV

Spurious Responses: Input signal level ≤ INPUT LEVEL

Setting: out of band mixing responses,

TRACKING GENERATOR

harmonic and intermodulation distortion products are

all more than 70 dB below the input signal level 5

kHz to 300 kHz; 60 dB 20 Hz to 5 kHz. Third order

intermodulation products are more than 70 dB below

the input signal level, 5 kHz to 300 kHz with signal

separation >300 Hz.

Residual Reponses: (no signal present at input): with

the INPUT LEVEL at -60 dBm/dBV and the input

terminated with 600Ω or less, all line related residual

responses from 0-500 Hz are below -120 dBm/dBV.

All other residual responses are below -130

dBm/dBV.

Gain Compression: For input signal level 20 dB above

INPUT LEVEL setting gain compression is less than

1 dB.

INPUT LEVEL Control: -10 to -60 dBm/dBV in 10 dB

steps. Accuracy ±0.2 dB. Marking indicates

maximum input levels for 70 dB spurious-free

dynamic range.

Accuracy:

Log Linear

Frequency Response: ±0.2 dB ±2.3%

Switching Between

Bandwidths (at 20°C),

100 Hz to 10 kHz: ±0.5 dB ±5.8%

30 Hz to 10 kHz: ±1.0 dB +12%

10 Hz to 10 kHz: ±1.5 dB ±20%

Display: ±.25 dB/dB ±2.8% of full

but not more 8 div display

than ±1.5 dB

over 70 dB

display range

Frequency Range: Tracks the analyzer tuning, 20 Hz to

300 kHz.

Amplitude Range: Continuously variable from 100 mV

rms to greater than 3V rms into an open circuit.

Amplitude Accuracy: With TRACKING GEN LEVEL in

CAL position, output level at 100 kHz is 100 mV ±0.3

dB into an open circuit.

Frequency Response: ±0.25 dB 50 Hz to 300 kHz.

1-4

Output Impedance: 600Ω.

Spectral Purity:

Residual FM:

With 8552B IF Section: <1 Hz peak-to-peak.

With 8552A IF Section: <20 Hz peak-to-peak.

Harmonic Signals: >40 dB down.

Spurious Outputs: >50 dB down.

Page 16

Model 8556A General Information

Table 1-1. Specifications (cont'd)

INPUT

Input Impedance : 1 MΩ shunted by ≈ 32 pF.

Maximum Input Level: 10V rms, ±200 Vdc.

Ground terminals of BNC input connectors are isolated

from the analyzer chassis ground to minimize ground

loop pickup at low frequencies.

Scan Time: 16 internal scan rates from 0.1 ms/div to 10

sec/div in a 1, 2,5 sequence.

Scan Time Accuracy:

0.1 ms/div to 20 ms/div: ±10%

50 ms/div to 10 sec/div: ±20%.

Power Requirements: 115 or 230 volts ±10%, 50 to 60

Hz, less than 225 watts.

Dimensions:

Model 140T or 141T Display Section: 9-1/5" high

(including height of feet) x 16-3/4" wide x 18-3/8"

deep (229 x 425 x 467 mm).

Model 143S Display Section: 21" high (including height

of feet) x 16-3/4" wide x 18-3/8" deep (533 x 425 x

467 mm).

Maximum Voltage. Isolated Ground to Chassis Ground:

±100 Vdc.

Isolated Ground to Chassis Ground Impedance: 100 kΩ

shunted by approximately 0.3 µf.

GENERAL

Weight:

Model 8556A LF Section: Net. 8 lb (3,7 kg).

Model 8552B IF Section: Net. 9 lb (4,1 kg).

Model 8552A IF Section: Net. 9 lb (4,1 kg).

Model 140T Normal Persistence Display Section: Net

37 lb (16,8 kg).

Model 141T Variable Persistence Display Section:

Net, 40 lb (18 kg).

Model 143S Large Screen Display Section: Net 62 lb

(28,1 kg).

Accessories Included:

Model 11660A Tracking Generator Shunt

Model 11048B 50Ω Feed Thru Termination

Model 11095A 600Ω Feed Thru Termination

1-5

Page 17

General Information Model 8556A

Table 1-2. Supplemental Performance Characteristics

FREQUENCY CHARACTERISTICS

Range: With 300 kHz Center Frequency and 20 kHz/div

Scan Width, analyzer will scan linearly to 400 kHz.

Center Frequency Control: Approximately 10 turns to

cover full dial indicator in both 0-30 kHz and 0-300 kHz

ranges.

Fine Tune: Single turn control, ±50 Hz on 0-30 kHz

range, ±500 Hz on 0-300 kHz range.

Zero Adjust: ±40 kHz range with 8552A, ±12 kHz range

with 8552B.

0-10f Scan Mode: With zero properly adjusted in PER

DIVISION scan, 0 to 10f scan mode will scan from 0

(±500 Hz or 0.2 div, whichever is greater) to ten times

the scan width per division setting. Offset may be

reduced to 0 readjusting frequency zero. Scan

accuracy ±5%.

AMPLITUDE CHARACTERISTICS

Dynamic Range : For operation from 5 kHz to 300 kHz

with signal levels greater than INPUT LEVEL setting,

see Figure 1-4 for typical distortion.

Accuracy:

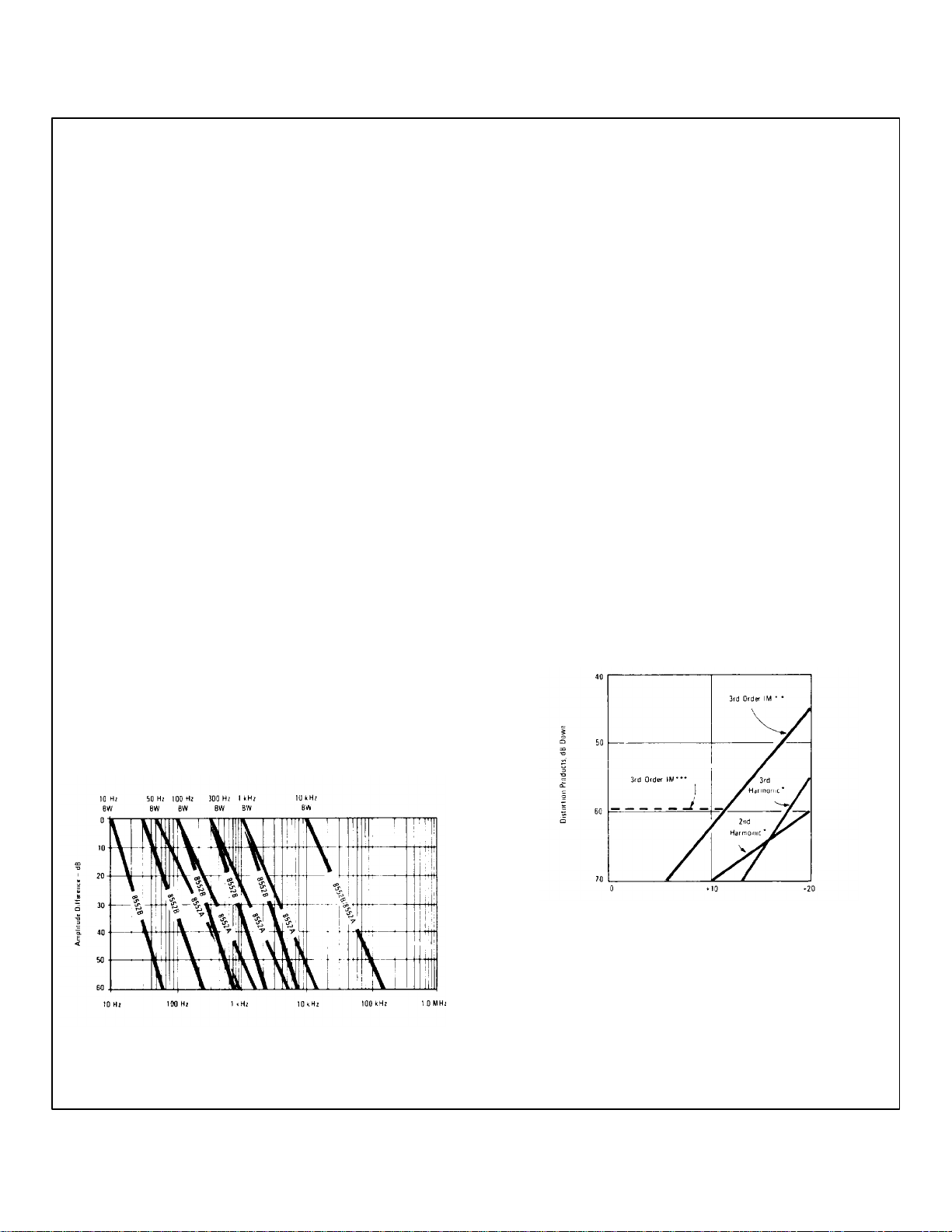

Resolution: See Figure 1-3 for curves of typical

8556A/8552B/8552A Spectrum Analyzer resolution

using different IF bandwidths. free dynamic range.

Warmup Drift: (Typical - first hour's operation.)

With 8552B: 500 Hz

With 8552A: 15 kHz

Long Term Drift: (Typical - at fixed center frequency

after one hour warmup.)

With 8552B: 70 Hz/10 min

With 8552A: 400 Hz/10 min

Temperature Drift: (Typical.)

With 8552B: 200 Hz/°C

With 8552A: 2 kHz/°C

Input Level: Provides 50 dB control of input

preamplification and attenuation to prevent input

overload. INPUT LEVEL markings of -60 dBm/dBV to 10 dBm/dBV indicate maximum input level for a

minimum of 70 dB spurious

Log Reference Level: INPUT LEVEL and LOG REF

LEVEL controls provide continuous log reference levels

from +10 dBm/dBV to -80 dBm/dBV (may be decreased

to -92 dBm/dBV by using 12 dB Log Reference Level

Vernier).

Figure 1-3. Typical Spectrum Analyzer

1-6

Signal Level dB Above INPUT LEVEL Setting

* Single input signal, 300 Hz to 300 kHz. Second

and third harmonic distortion products typically 10

dB higher below 30 Hz.

** Two input signals, 5 kHz to 300 kHz with > 300 Hz

signal separation.

*** Two input signals, frequency below 5 kHz with

<300 Hz signal separation.

Figure 1-4. Typical Spectrum Analyzer Distortion

Products

Page 18

Model 8556A General Information

Table 1-2. Supplemental Performance Characteristics (cont'd)

AMPLITUDE CHARACTERISTICS (cont'd)

Accuracy ±0.2 dB (2.3%). Input may be overloaded

up to 20 dB with the analyzer still providing useful

measurement capability. See Figure 1-4.

Log Reference Level Control: Provides 90 dB of IF

gain control in 10 dB steps to cover log and linear

ranges. Accurate to ±0.2 dB (±2.3%).

Log Reference Level Vernier: Provides continuous 12

dB range. Accurate to ±0.1 dB (±1.2%) in 0, -6, -12

dB positions: otherwise ±0.25 dB (±2.8%).

Log Reference Level, switching between 10 dB/div

and 2 dB/div log scales (8552B only):

DISPLAY CHARACTERISTICS

Variable Persistence/Storage (Model 141T):

Plug-ins: Accepts Model 8550 series Spectrum

Analyzer plug-ins and Model 1400 series time

domain plug-ins.

Cathode-ray Tube:

Type: Post-accelerator storage tube, 9000 volt

accelerating potential; aluminized P31 phosphor:

etched safety glass faceplate reduces glare.

Graticule: 8 x 10 division (approximately 7,1 x 8.9 cm)

parallax-free internal graticule: five subdivisions per

major division on horizontal and vertical axes.

Persistence:

Normal: Natural persistence of P31 phosphor

(approximately 0.1 second).

Variable:

Normal Writing Rate Mode: Continuously variable

from less than 0.2 second to more than one

minute (typically to two or three minutes).

Maximum Writing Rate Mode: Typically from 0.2

second to 15 seconds.

Erase: Manual: erasure takes approximately 350 ms;

CRT ready to record immediately after erasure.

Storage Time: Normal writing rate; more than 2 hours at

reduced brightness (typically 4 hours). More than one

minute at maximum brightness.

Accuracy: ±0.6 dB

Temperature Stability: ±0.07 dB/°C.

Amplitude Stability: ±0.07 dB/°C in log. ±0.6 %°C in

linear.

Display Uncalibrated Light: Warns if a combination of

control settings (IF or video bandwidth, scan time or

scan width) degrades absolute calibration for CW

signals. Typically accurate to ±1 position in scan width

or scan time setting.

Video Filter: Averages displayed noise: bandwidth of 10

kHz, 100 Hz and (8552B only) 10 Hz. Bandwidth

accuracy ±20%.

Fast Writing Speed: More than 15 minutes (typically 30

minutes) at reduced brightness or more than 15

seconds at maximum brightness.

Functions Used with Time Domain Plug-ins Only:

Intensity modulation, calibrator, beam finder.

Normal Persistence (Model 140T):

Plug-ins: Same as 141T.

Cathode-ray Tube:

Type: Post-accelerator. 7300 volt potential medium-

short persistence (P7) phosphor, tinted and etched

safety glass face-plate reduces glare. (Normal

persistence of P7 phosphor approximately 3 sec.)

Graticule: 8 x 10 division (approximately 7,6 x 9,5

cm) parallax-free internal graticule: five

subdivisions per major division on horizontal and

vertical axes.

Functions Used with Time Domain Plug-ins Only:

Same as 141T.

Normal Persistence Large Screen Display (Model

143S):

Plug-ins: Same as 141T.

Cathode Ray Tube:

Type: Post-accelerator. 20 kV accelerating

potential aluminized P31 phosphor. (Persistence

approximately 0.1 sec).

Graticule: 8 x 10 divisions (approximately 8 x 10inch) parallax-free internal graticule. five

subdivisions per major division on horizontal and

vertical axes.

Functions Used with Time Domain Plug-ins Only:

Same as 141T.

1-7

Page 19

General Information Model 8556A

Table 1-2. Supplemental Performance Characteristics (cont'd)

GENERAL CHARACTERISTICS

Scan Mode:

Int: Analyzer repetitively scanned by internally

generated ramp; synchronization selected by scan

trigger.

Single: Single scan with reset actuated by front panel

pushbutton.

Ext: Scan determined by 0 to +8 volt external signal;

scan input impedance more than 10 kΩ.

Blanking: -1.5V external blanking signal required.

Manual: Scan determined by front panel control;

continuously variable across CRT in either direction

(8552B only).

Scan Trigger: For Internal Scan Mode, select between:

Auto: Scan free runs.

Line: Scan synchronized with power line frequency.

Ext: Scan synchronized with more than 2 volt (20 volt

max.) trigger signal (polarity selected by internally

located switch in Model 8552 IF Section).

Video: Scan internally synchronized to envelope of RF

input signal (signal amplitude of 1.5 major divisions

peak-to-peak required on display section CRT).

Auxiliary Outputs:

Vertical Output: Approximately 0 to -0.8V for 8 division

deflection on CRT display; approximately 100Ω

output impedance.

Scan Output: Approximately -5 to +5V for 10 div CRT

deflection, 5k Ω output impedance.

Pen Lift Output: 0 to 14V (0V, pen down). Output

available in Int and Single Scan modes and Auto,

Line, and Video Scan Trigger.

CRT Baseline Clipper: Front panel control adjusts

blanking of CRT trace baseline to allow more detailed

analysis of low repetition rate signals and improved

photographic records to be made.

EMI: Conducted and radiated interference is within

requirements of MIL-I-16910C and MIL-I-6181D and

methods CE03 and RE02 of MIL-STD-461 (except 35

to 40 kHz) when 8556A and 8552B are combined in a

140T or 141T Display Section.

1-8

Temperature Range: Operating, 0°C to +55°C,

storage, -40 °C to +75°C.

Page 20

Model 8556A General Information

Table 1-3. Operating Accessories

Model Number Description

HP 10004A 10:1 Divider Probe (oscilloscope type)

HP 1001A Probe to BNC Adapter

HP 1110A Current Probe: Sensitivity: 1 mV/mA

Bandwidth: 1700 Hz (3 dB down)

30 MHz(3 dB down)

Electronic Counter

HP 5381A Frequency Range: 10 Hz to 80 MHz

Sensitivity: 25 mV Input Impedance: 1 Megohm

Gate Time: 0.1, 1 and 10 sec.

Resolution: 1 Hz

Readout: 7 digits

HP 4437A 600 ohm Unbalanced Attenuator

Range: 0-119.9 dB in 0.1 dB increments

Accuracy: ± 0.2 dB to 90 dB

± 0.5 dB to 110 dB

± 1.0 dB to 119.9 dB

Input Power: 1 watt max

HP 197A Oscilloscope Camera

Table 1-4. Test Equipment

Item Minimum Specifications Suggested Use*

Model

AC Voltmeter Voltage Range: 1 mV to 10V full scale (-10 to +2 dB HP 400EL P,A,T

on dB scale)

Frequency Range: 20 Hz to 400 kHz

Accuracy: ± (2.5% of full scale +2.5% of reading)

AC to DC Converter Output: 1V dc for full scale

meter deflection

AC to DC Converter Accuracy: ± (1% of full scale

+1% of reading)

Input Impedance: 10 MΩ shunted by ≈ 25 pF

Oscilloscope Frequency Range: dc to 50 MHz HP 180A/ A, T

AC or DC Coupling 1801A/

Sensitivity: 0.005 V/DIV 1820B

Voltage Accuracy: ±3%

X10 Oscilloscope Probe (2) Division Accuracy: 3%

Resistance: 10 MΩ shunted by 10 pF

*Use: Performance = P: Adjustment = A; Troubleshooting = T

HP 10004A A, T

1-9

Page 21

General Information Model 8556A

Table 1-4. Test Equipment (cont'd)

Item Minimum Specifications Suggested Use*

Model

Frequency Range: 0-60 MHz HP 5327C P, A, T

Counter Sensitivity: 0.1V rms sine wave

Display: 7 digits

Accuracy: ±0.001%

Digital Display: 4 digits HP 3480B, P, A, T

Voltmeter Range: 0 to 100.0 V full scale 3484A

(2 required) 0 to 1000.0 K ohms full scale Opt. 042

for perfor- Accuracy: ± (0.02%7 of reading + 0.05% of range)

mance tests) Polarity: automatic indication

L-C Meter Range: 10 to 40 pF Tektronix A

Accuracy: within 3% of full scale Type 130

Test Oscillator Frequency Range: 20 Hz to 300 kHz HP 651B P, A, T

Dial Accuracy: ±3%

Max Output: > 3.0V into 50 or 600 ohms

Flatness: ± 3%

Distortion: < 1%

Output Monitor: voltmeter monitors output level at

input of attenuator in volts or dB; accurate to ±2%C,

of full scale

Attenuator: range, 90 dB in 10 dB steps

accuracy, ± 0.075 dB, -60 dBm to

+20 dBm

Oscillator Frequency Range: 30 Hz to 100 Hz HP 204D P

Dial Accuracy:± 3%

Max Output: 2.5 V into 600 ohms

Distortion: 0.1% ( 60 dB)

Hum and Noise: <0.01% of output

Filter Set Selectable 500 Hz and 50 kHz Bandpass Filters: White P

> 30 dB of attenuation to second harmonic: Model 2640

> 40 dB of attenuation to third and higher

harmonics

Spectrum HP 8556A/ P

Analyzer 8552B/141T

Only

1-10

*Use: Performance = P: Adjustment A. Troubleshooting = T

Page 22

General Information Model 8556A

Table 1-5. Test Equipment Accessories

Item Minimum Specifications Suggested Use*

Model

BNC Tee One BNC male, two BNC female connectors HP 1250-0781 P

Adapter Selectro Plug to BNC Jack HP 1250-1236 A, T

Adapter Selectro Jack to BNC Jack HP 1250-1237 A, T

Adapter UHF Plug to BNC Jack (UG-273/U) HP 1250-0071 A

Cable Assy Male BNC to Dual Banana Plug, 45 inches long HP 11001A P

Cable Assy Male BNC Connectors, 24 inches long HP 11086A A

Cable Assy Dual Banana Plugs, 44 inches long HP 11000A P

Cable Assy(2) Male BNC Connectors, 48 inches long HP 10503A P, A, T

Cable Assy Dual Banana Plug to Alligator Clips, 5 feet long HP 11002A A, T

Extender 10 Pins, 20 Conductors, for plug-in circuit boards HP 5060-0256 A, T

Board

Screwdrivers Phillips No. 1 A, T

Phillips No. 2 A, T

Pozidriv No. 1 (Stanley No. 5531) HP 8710-0899 A, T

Pozidriv No. 2 (Stanley No. 5332) HP 8710-0900 A, T

Tuning Tool Non-Metallic Shaft (J.F.D. Model No. 5284) HP 8710-1010 A

50-Ohm Supplied with 8556A HP 11048B P, A, T

Feed Thru

Termination

600-Ohm Supplied with 8556A HP 11095A P, A, T

Feed Thru

Termination

Tracking Supplied with 8556A HP 11660A P

Gen Shunt

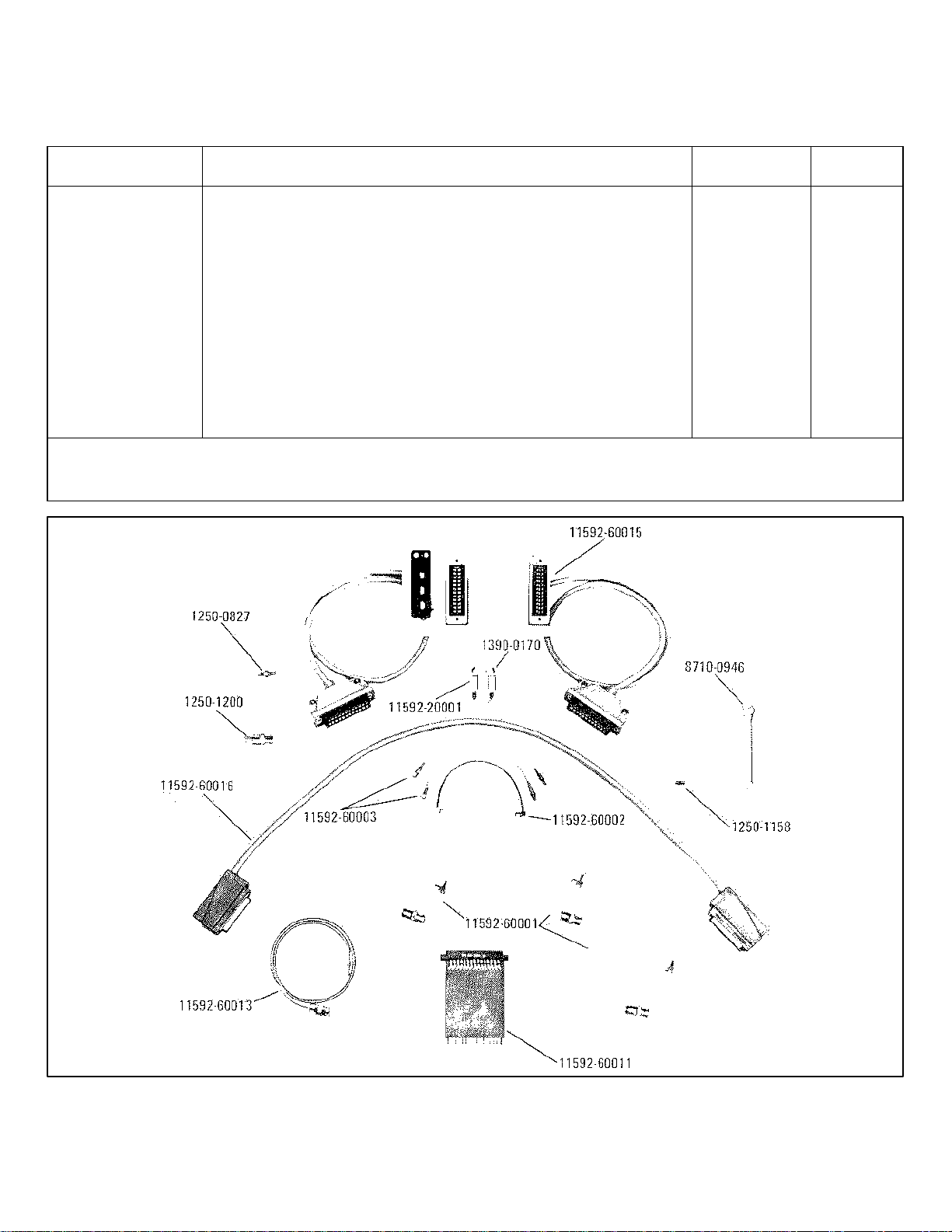

Service Kit Contents: HP 11592A A, T

Display Section to Spectrum Analyzer Extender

Cable Assembly (HP 11592-60015)

Tuning Section to IF Section Interconnection

Cable Assembly (HP 11592-60016)

Selectro Female to BNC Male Test Cable ,3 each,

36 inches long (HP 11592-60001)

Selectro Male to Selectro Female Test Cable,

2 each, 8 inches long (HP 11592-60003)

*Use: Performance = P: Adjustment =A: Troubleshooting = T

1-11

Page 23

General Information Model 8556A

Table 1-5. Test Equipment Accessories (cont'd)

Item Minimum Specifications Suggested Use*

Model

Service Kit Selectro Female to Selectro Female Test Cable, HP 11592A A, T

(cont'd) 2 each, 8 inches long (HP 11592-60002)

Extender Board Assembly, 15 pins, 30 conductors,

for plug-in circuit boards (HP 11592-60011)

Fastener Assembly (2 each: HP 11592-2001 and

HP 1390-0170)

Selectro Jack-to-Jack Adapter (HP 1250-0827)

Wrench, open end, 15/16 inch (HP 8710-0946)

BNC Jack-to-OSM Plug Adapter (HP 1250-1200)

OSM Plug-to-Plug Adapter (HP 1250-1158)

Cable Assembly R and P Connector

(HP 11592-60013)

* Use: Performance = P: Adjustment = A: Troubleshooting = T.

1-12

Figure 1-5. HP 11592A Service Kit

Page 24

Model 8556A Installation

SECTION II

INSTALLATION

2-1. INITIAL INSPECTION

2-2. Mechanical Check

2-3. Check the shipping carton for evidence of damage

immediately after receipt. If there is any visible damage

to the carton, request the carrier's agent be present

when the instrument is unpacked. Inspect the

instrument for physical damage such as bent or broken

parts and dents or scratches. If damage is found refer to

paragraph 2-6 for recommended claim procedures. If

the instrument appears to be undamaged, perform the

electrical check (see paragraph 2-4). The packaging

material should be retained for possible future use.

2-4. Electrical Check

2-5. The electrical check consists of following the

performance test procedures listed in Section IV. These

procedures allow the operator to determine that the

instrument is, or is not, operating within the

specifications listed in Table 1-1. The initial performance

and accuracy of the instrument are certified as stated on

the inside front cover of this manual. If the instrument

does not operate as specified, refer to paragraph 2-6 for

the recommended claim procedure.

2-6.

2-7. DELETED

WARNING

INPUT connector ground is isolated from cabinet

ground. Any voltage present on cable shield will be

present on connector shell (± 100 VDC maximum). If

contacted, this voltage may cause personal injury.

together, electrically connected and inserted in a display

section or oscilloscope mainframe of the 140-series. For

mechanical and electrical connections, refer to Figure

2-1 and paragraph 2-20.

2-12. Power Requirements

2-13. The Spectrum Analyzer can be operated from a

50 to 60 hertz input line that supplies either a 115 volt or

230 volt (±10% in each case) power. Consumed power

varies with the plug-ins used but is normally less than

225 watts. Line power enters the Display Section or

Mainframe, where it is converted to dc voltages, and

then is distributed to the LF and IF Sections via internal

connectors.

2-14. The 115/230 power selector switch at the rear of

the Display Section must be set to agree with the

available line voltage. If the line voltage is 115 volts, the

slide switch must be positioned so that 115 is clearly

visible. The instrument is internally fused for 115 volt

operation, when shipped. If 230 volt source is to be

used, refer to fuse replacement procedures in the

Display Section manual.

2-8.

2-9. PREPARATION FOR USE

CAUTION

Before applying power, check the

rear panel slide switch on the Display

Section for proper position (115 or

230 volts).

2-10. Shipping Configuration

2-11. Because of individual customer requirements,

shipping configurations are flexible. Preparation for use

is based on the premise that the LF and IF Sections are

installed in a Display Section; thus, the Spectrum

Analyzer is physically and functionally complete for use.

Since the LF and IF Sections are usually received

separately, the plug-ins must be mechanically fitted

2-15. Power Cable

2-16. To protect operating personnel, the National

Electrical Manufacturers Association (NEMA) and the

International Electrotechnical Commission (IEC)

recommends that the instrument panel and cabinet be

grounded. The Spectrum Analyzer is equipped with a

three-conductor power cable: the third conductor is the

ground conductor, and when the cable is plugged into an

appropriate receptacle, the instrument is grounded. To

preserve the protection feature when operating the

instrument from a two-contact outlet, use a three-prong

to two-prong adapter and connect the green lead on the

adapter to ground.

2-17. Operating Environment

2-18. The Spectrum Analyzer uses a forced-air cooling

system to maintain required operating temperatures

within the instrument. The air intake and filter are

located on the rear of the Display Section; air is

exhausted through the side panel perforations.

2-1

Page 25

Installation Model 8556A

When operating the instrument, choose a location

which provides at least three inches of clearance around

the rear and both sides. Refer to the Display Section

manual for maintenance instructions for the cooling

system.

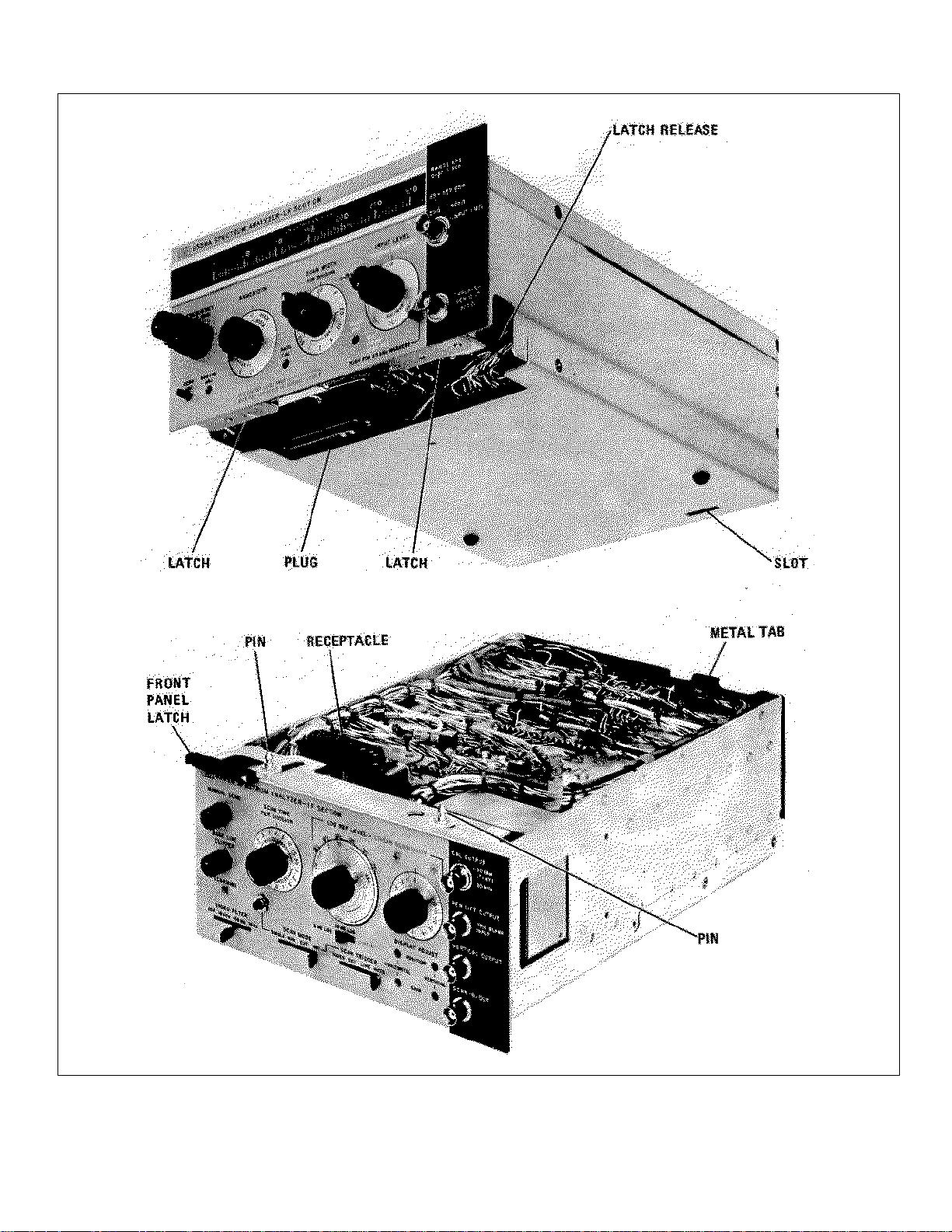

2-19. Interconnections

2-20. The LF and IF Sections are normally shipped

separately; the plug-ins must be mechanically fitted

together, electrically connected, and then inserted in the

Display Section or mainframe. To make these

connections, refer to Figure 2-1 and proceed as follows:

a. Set the IF Section on a level bench. Locate slot

near right rear corner of LF Section: also, locate metal

tab on IF Section that engages with this slot.

b. Grasp the 8556A LF Section near middle of

chassis and raise until it is a few inches above the IF

Section.

c. Tilt LF Section until front of assembly is about 2

inches higher than the rear.

d. Engage assemblies in such a way that metal tab

on the rear of the IF Section slips through the slot on LF

Section.

e. With the preceding mechanical interface

completed, gently lower LF Section until electrical plug

and receptacle meet.

a. Push front panel latch in direction of arrow until it

releases.

b. Firmly grasp the middle of latch flange and pull

LF/RF Sections straight out.

c. Locate black press-to-release level near right

front side of LF Section. Press this lever and

simultaneously exert an upward pulling force on front

edge of LF Section.

d. When the two sections separate at the front,

raise LF Section two or three inches and slide metal tab

at rear of IF Section out of the slot in which it is engaged.

2-22. STORAGE AND SHIPMENT

2-23. Original Packaging

2-24. The same containers and materials used in

factory packaging may be used.

2-25. If the instrument is being returned to HewlettPackard for servicing, attach a tag indicating service

required, return address, instrument model number and

full serial number. Mark the container FRAGILE to

assure careful handling.

2-26. In any correspondence refer to the instrument by

model number and full serial number.

2-27. Other Packaging Materials

f. Position LF Section as required to mate the plug

and receptacle. When plug and receptacle are properly

aligned, only a small downward pressure is required to

obtain a snug fit.

g. After the LF and IF Sections are joined

mechanically and electrically, the complete assembly is

ready to insert in the Display Section.

h. Pick up the LF/IF Sections and center in

opening of Display Section. Push forward until assembly

fits snugly into Display Section.

i. Push in front panel latch to securely fasten

assembly in place.

2-21. To separate the LF/IF Sections from Display

Section and to separate the LF Section from the IF

Section, proceed as follows:

2-2

2-28. The following general instructions should be

followed when repackaging with commercially available

materials:

a. Wrap the instrument in heavy paper or plastic.

If shipping to a Hewlett-Packard Service Office or Center

attach a tag indicating the type of service required,

return address, model number and full serial number.)

b. Use a strong shipping container. A double wall

carton made of 350 pound test material is adequate.

c.Use enough shock-absorbing material (three to fourinch layer) around all sides of the instrument to provide

firm cushion and prevent movement inside the container.

Protect the control panel with cardboard.

d. Seal the shipping container securely.

e. Mark the shipping container FRAGILE to assure

careful handling.

Page 26

Model 8556A Installation

Figure 2-1. LF Section and IF Section Interconnections

2-3/2-4

Page 27

Model 8556A Operation

SECTION III

OPERATION

3-1. INTRODUCTION

3-2. This section provides complete operating

instructions for the HP 8556A Spectrum Analyzer LF

Section as used with an 8552 series IF Section and a

140 series Display Section.

3-3. PANEL FEATURES

3-4. Front panel controls, indicators and connectors are

shown and briefly described in Figure 3-1. Rear panel

controls and connectors are shown and described

in Figure 3-2. For a detailed description of IF Section

and Display Section controls and indicators, refer to their

manuals.

3-5. OPERATOR'S CHECKS

3-6. Upon receipt of the analyzer, or when any plug-in is

changed, perform the operational adjustments listed

in Figure 3-2. This procedure corrects for minor

differences between units and ensures that the LF

Section, IF Section and Display Section are properly

matched.

3-7. OPERATING CONSIDERATIONS

3-8. Front panel controls, indicators and connectors are

shown and briefly described in Figure 3-1. The following

information covers general operating considerations.

3-9. RF Input

3-10. The 8556A has an input impedance of 1 Megohm,

shunted by approximately 32 pF, so compensated

oscilloscope probes (see Table 1-3) can be connected

directly to INPUT and used for in-circuit testing. To

compensate an oscilloscope probe for use with the

8556A, use the probe's BNC adaptor to connect the

probe tip to TRACKING GEN OUT. Adjust the probe for

optimum signal flatness on the CRT display.

3-11. Use the feedthrough terminations, 50 ohm and

600 ohm, when the device to be tested must be

terminated in its characteristic impedance (for example,

when measuring dBm). To make a feedthrough

termination for some other impedance, simply connect a

resistor across the analyzer INPUT (connect the resistor

to INPUT ground, not chassis ground). The value of the

resistor should be equal to the characteristic impedance

of the device.

CAUTION

Do not apply more than 10 V rms and

±200 Vdc to INPUT.

3-12. Amplitude Ranges

3-13. The LOG/LINEAR switch on the IF Section works

in conjunction with the dBm/dBV switch on the LF

Section. With LINEAR selected, the analyzer measures

voltage. With LOG selected (either 2 dB or 10 dB on the

8552B), the analyzer measures voltage in dBV (that is,

dB referenced to 1 volt) or power in dBm. The LF

Section is calibrated to measure dBm in 50 or 600 ohms.

3-14. To use 2 dB LOG, first find the signal using 10 dB

LOG; display the desired portion of the signal on the top

16 dB of the CRT display, then switch to 2 dB LOG. The

top of the display, the LOG REF graticule, remains the

same. The -70 dB graticule line becomes -14 dB (each

major division becomes 2 dB).

NOTE

Do not make any VERTICAL GAIN or

POSITION adjustments in 2 dB LOG

as the front panel calibration will

become invalid.

3-15. The LOG REF LEVEL control on the IF Section

has three scales (see EQUIPMENT SUPPLIED in

Section I): the red scale is used for LF Section log

calibration, the black scale is used for RF Section log

calibration, and the blue scale is used for linear

calibration on all units. If the IF Section being used does

not have the red scale, subtract 20 dB from the black

scale to obtain the LOG REF level on the CRT.

3-16. First Mixer Balance

3-17. The first mixer in the 8556A is balanced to insure

a low level of first local oscillator feedthrough appearing

on the display. Excessive LO feedthrough may result in

inaccurate amplitude calibration and excessive

intermodulation distortion. With the dBm/dBV switch set

to 50Ω dBm and INPUT LEVEL set to -60 dBm/dBV, the

first LO feedthrough (zero frequency marker) should be

below -80 dBm. If it is above this level, perform the first

mixer balance adjustment specified below.

3-1

Page 28

Operation Model 8556A

3-18. Remove the top cover from the Display Section

(with power off).

WARNING

Removing the top cover from the

Display Section exposes the operator

to dangerous potentials (up to 7000

volts).

3-19. Set the analyzer controls as follows:

FREQUENCY......................................................0 kHz

BANDWIDTH.......................................................3 kHz

SCAN WIDTH ....................................... PER DIVISION

PER DIVISION.................................................. 10 kHz

INPUT LEVEL ..........................................-60 dBm/dBV

dBm/dBV ....................................................50 Q2 dBm

BASE LINE CLIPPER ............................................ ccw

VIDEO FILTER .................................................. 10 kHz

SCAN TIME PER DIVISION .............5 MILLISECONDS

LOG/LINEAR ..............................................10 dB LOG

LOG REF LEVEL ............................................ -40 dBm

SCAN MODE ..........................................................INT

SCAN TRIGGER ................................................AUTO

POWER ................................................................. ON

NOTE

This procedure assumes that the

analyzer is calibrated as specified in

Figure 3-2 and has been allowed to

warm up at least one-half hour.

3-20. Center the LO feedthrough signal on the display

with the FREQUENCY control.

3-21. Using a non-metallic adjustment tool, alternately

adjust C and R MIXER BALANCE ADJUSTMENTS

(available on the LF Section top cover) to null the LO

feedthrough.

3-22. When the signal is below -80 dBm, turn power off

and replace the top cover.

3-23. OPERATING INSTRUCTIONS

3-24. The following instructions should enable an

operator to make fast, accurate measurements with the

low frequency analyzer. To define each instrument

application is beyond the scope of this manual. For

further details, there is a complete discussion of 8556A

applications in Application Note 134. This application

note is available from your local HP Sales and Service

Office.

3-25. In general, operation of the Spectrum Analyzer

may be accomplished through the following steps:

a. Set the analyzer to scan the appropriate

frequency range with the proper resolution.

b. Adjust the amplitude scale as necessary for the

measurement.

c. Complete the measurement, and interpret the

results.

3-26. Setting the Frequency Scan

3-27. There are three ways to set the frequency scan on

the 8556A. The first is the 0-10f mode of operation.

When this mode is selected, the spectrum analyzer

scans from "zero" frequency to a preset upper limit

selected by the PER DIVISION control. For example, if

the PER DIVISION control is set to 10 kHz, and the 010f mode is selected, the spectrum analyzer will scan

from 0 to 100 kHz, 10 kHz per division. Scans may be

selected from 20 Hz per division to 20 kHz per division in

a 1, 2, 5 sequence.

3-28. The second way to set the frequency scan is the

PER DIVISION mode. In this mode, the frequency scan

is symmetrical about the CENTER FREQUENCY tuned

by the FREQUENCY control. The CENTER

FREQUENCY dial indicates this frequency in two

ranges, 0-30 kHz or 0-300 kHz. The horizontal scale is

then selected by the PER DIVISION setting.

3-29. The third way is the ZERO scan mode. The

spectrum analyzer becomes a fixed-tuned receiver at the

frequency indicated by the CENTER FREQUENCY dial.

In this mode, amplitude variations are displayed versus

time on the CRT.

3-30. Once the proper frequency scan is chosen, the

resolution needed for the particular measurement should

be determined. Resolution is mainly a function of the IF

bandwidth selected. As narrower IF bandwidths are

used, the resolution increases. At the same time, the

spectrum analyzer must be swept at a slower rate. The

bandwidth used should be only as narrow as is

necessary for the particular application. The best

procedure is to select the bandwidth necessary for the

desired resolution, and then slow the scan rate (SCAN

TIME PER DIVISION) until the DISPLAY UNCAL light is

unlit.

3-31. Adjusting the Amplitude Scale 3-32. Once the

desired signals are displayed on the CRT the amplitude

is set to give an optimum display. The first consideration

is how the amplitude is to be measured. The 8556A can

measure power in dBm (for 50 ohm or 600 ohm

systems), and it can measure voltage on a linear scale

or in dB referred to one volt (dBV) on a log scale.

3-33. If power is the desired parameter, set the

dBm/dBV switch to dBm for the appropriate

3-2

Page 29

Model 8556A Operation

FRONT PANEL FEATURES

(1) DISPLAY UNCAL: warning light indicates that the

CRT display has become uncalibrated due to

incompatible settings of SCAN WIDTH, SCAN

TIME PER DIVISION, BANDWIDTH, and VIDEO

FILTER controls.

(2) FREQUENCY: tunes the CENTER FREQUENCY

in SCAN WIDTH PER DIVISION and ZERO scan

modes. FINE TUNE allows high resolution

adjustments in narrow scans.

(3) ZERO ADJ: calibrates CENTER FREQUENCY

dial for "zero" frequency.

(4) 300 kHz ADJ: calibrates CENTER FREQUENCY

dial for 300 kHz.

(5) BANDWIDTH: selects resolution bandwidth of the

spectrum analyzer from 10 Hz to 10 kHz in a 1, 3

sequence. (8552A, 50 Hz and 100 Hz to 300 kHz

in a 1, 3 sequence.)

(6) AMPL CAL: calibrates display amplitude for

absolute voltage and power measurements.

(7) CENTER FREQUENCY: dial indicates the

CENTER FREQUENCY for SCAN WIDTH PER

DIVISION and ZERO scan modes. Calibrated in 5

kHz increments for 0-300 kHz range and 500 Hz

increments for 0-30 kHz range.

(8) SCAN WIDTH: selects spectrum analyzer

frequency scanning mode. 0-10f repetitively tunes

the spectrum analyzer from "zero" frequency to ten

times the setting of the PER DIVISION control.

(e.g., with PER DIVISION control set at 1 kHz,

scan would be from 0-10 kHz, or 1 kHz per

division.) PER DIVISION mode scans the

spectrum analyzer symmetrically about the

CENTER FREQUENCY with a scan width set by

the PER DIVISION control. In the ZERO scan

mode, the analyzer becomes a fixed frequency

receiver at the CENTER FREQUENCY.

(9) PER DIVISION: selects the CRT horizontal

calibration (frequency scale) in the PER DIVISION

and 0-10f frequency scan modes.

(10) TRACKING ADJ: tunes the TRACKING GEN

OUT frequency to precisely track the tuning

frequency of the spectrum analyzer.

(11) INPUT LEVEL: adjusts the input signal level to

the input mixer and input preamplifier to maximize

dynamic range. This control should be set to

agree with the signal level read on the CRT.

(12) TRACKING GEN LEVEL: adjusts the output level

of the tracking signal present at the TRACKING

GEN OUT. When the CAL position is selected, it

gives an output of 100 mV for calibrating the

spectrum analyzer display. The output can be

increased to 3V.

(13) RANGE kHz : selects CENTER FREQUENCY dial

range of 0-30 kHz or 0-300 kHz.

(14) INPUT: one megohm unbalanced input for signals

to be measured.

(15) dBm/dBV: selects log display absolute calibration

for dB1V or dBm referred to 50 ohms or 600

ohms. For correct dBm measurements, an

external termination of the proper impedance must

be provided for the input signals.

(16) TRACKING GEN OUT: output signal tracks the

spectrum analyzer tuning frequency. The signal

may be used for swept frequency response

measurements or to drive a frequency counter for

accurate frequency measurements. The signal

output also serves to accurately calibrate the

display for absolute amplitude.

(17) kHz MARKERS: places crystal controlled

markers with 20 kHz spacing on CRT. These

markers are accurate to 0.01',, and are useful for

calibrating the frequency axis.