Page 1

8550 Printer

Copy Module

Automatic Document Feeder

High-Capacity Input

Service Manual

English

Page 2

Page 3

HP Copy Module, ADF, and side

HCI for HP Color LaserJet 8550

series printers

_____________ Service Manual

Page 4

Copyright Information

Copyright © 2000 HewlettPackard Company

All Rights Reserved.

Reproduction, adaptations, or

translation without prior written

permission is prohibited except

as allowed under copyright

laws.

Part number C7834-90902

First edition, April 2000

Printed in USA

Warranty

The information contained in

this document is subject to

change without notice.

Hewlett-Packard makes no

warranty of any kind with

respect to this information.

HEWLETT-PACKARD

SPECIFICALLY DISCLAIMS

THE IMPLIED WARRAN TY OF

MERCHANTABILITY AND

FITNESS FOR A PARTICULAR

PURPOSE.

Hewlett-Packard shall not be

liable for any direct, indirect,

incidental, consequential, or

other damage alleged in

connection with the furnishing or

use of this information.

NOTICE TO U.S.

GOVERNMENT USERS:

RESTRICTED RIGHTS

COMMERCIAL COMPUTER

SOFTWARE: “Use, duplication,

or disclosure by the

Government is subject to

restrictions as set forth in

subparagraph (c) (1)(ii) of the

Rights in Technical Data Clause

at DFARS 52.227-7013.

Trademark Credits

CompuServe™ is a U.S.

trademark of CompuServe, Inc.

MS-DOS

®

is a U.S. registered

trademark of Microsoft

Corporation.

Photoshop™ and PostScript

®

are registered trademarks of

Adobe Systems Incorporated.

TrueType™ is a U.S. trademark

of Apple Computer, Inc.

®

UNIX

is a registered trademark

in the United States and other

countries, licensed exclusively

through X/Open Company

Limited.

Safety Information

WARNING

Electrical Shock Hazard

To avoid electrical shock, use

only supplied power cords and

connect only to properly

grounded (3-hole) wall outlets.

Hewlett-Packard Company

11311 Chinden Boulevard

Boise, Idaho 83714 U.S.A.

Page 5

Contents

1 Product information

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Copy module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Automatic document feeder (ADF) . . . . . . . . . . . . . . . . . . . . . . . .28

Side high-capacity input (side HCI) . . . . . . . . . . . . . . . . . . . . . . .32

Model and serial numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Safety and regulatory information . . . . . . . . . . . . . . . . . . . . . . . .35

2 Service approach

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Service approach overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Parts and supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Ordering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Technical assistance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

3 Operational overview

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Copy module functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Self-diagnostic messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Service mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

4 Adjustments and maintenance

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

MFP print engine adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . .119

Copy module adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

ADF adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .140

Side HCI adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

Periodically replaced parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . .163

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .164

Lubricating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .174

EN Contents 3

Page 6

5 Theory of operation

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .177

Notes on the power switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . .177

Copy module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .178

ADF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .244

Side HCI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .304

6 Removal and replacement

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .327

Required tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .331

Repair notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .332

Copy module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .333

Automatic document feeder (ADF) . . . . . . . . . . . . . . . . . . . . . . .377

Side HCI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .434

7 Troubleshooting

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .455

System-to-device troubleshooting. . . . . . . . . . . . . . . . . . . . . . . .457

Copy module troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . .460

ADF troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .528

Side HCI troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .535

8 Parts and diagrams

Chapter contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .547

How to use this chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .551

Printer parts unique to the HP Color LaserJet 8550MFP . . . . . .552

Stand. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .555

Copy module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .558

ADF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .600

Side HCI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .649

Numerical parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .672

Alphabetical parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .680

Index

4 Contents EN

Page 7

Figures

Figure 1. Copy module front left . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 2. Copy module front right . . . . . . . . . . . . . . . . . . . . . .26

Figure 3. Copy module cross-section . . . . . . . . . . . . . . . . . . .27

Figure 4. Automatic document feeder . . . . . . . . . . . . . . . . . . . 30

Figure 5. Automatic document feeder cross-section . . . . . . . 31

Figure 6. Front of side HCI . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 7. Rear of side HCI . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 8. Cross-section of side HCI . . . . . . . . . . . . . . . . . . . . 34

Figure 9. Copy module control panel . . . . . . . . . . . . . . . . . . . 49

Figure 10. Service mode initial screen . . . . . . . . . . . . . . . . . . .61

Figure 11. Service label (inside the lower front cover of

the copy module) . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 12. Example of a Level 1/Level 2 item screen . . . . . . . . 63

Figure 13. Example of a Level 3 screen . . . . . . . . . . . . . . . . . . 64

Figure 14. Copier, display mode Level 1/Level 2 screen . . . . .65

Figure 15. JAM screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Figure 16. ERR screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 17. Copier, I/O mode Level 1/Level 2 screen . . . . . . . . 77

Figure 18. Copier, I/O mode Level 3 screen example . . . . . . .78

Figure 19. Copier, adjust mode Level 1/Level 2 screen . . . . . . 83

Figure 20. BLANK margins . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Figure 21. Copier, run/check mode Level 1/Level 2 screen . . .93

Figure 22. Copier, machine settings mode

Level 1/Level 2 screen . . . . . . . . . . . . . . . . . . . . . . . 98

Figure 23. Copier, test print mode Level 1/Level 2 screen . . .108

Figure 24. Counter mode, Level 1/Level 2 screen . . . . . . . . .111

Figure 25. Feeder screen, example of a Level 3 item . . . . . .114

Figure 26. Image and non-image width of the leading edge . .122

Figure 27. Image and non-image width of the left or

right margin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Figure 28. BLANK margins . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Figure 29. Adjusting horizontal registration . . . . . . . . . . . . . . 124

Figure 30. Service label . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Figure 31. Standard white plate barcode . . . . . . . . . . . . . . . .134

Figure 32. Adjusting the ADF height . . . . . . . . . . . . . . . . . . . .141

Figure 33. DADF controller PCB cover . . . . . . . . . . . . . . . . . . 142

Figure 34. DSW1 on the DADF controller PCB . . . . . . . . . . . 142

Figure 35. SW3 DADF controller PCB . . . . . . . . . . . . . . . . . . 143

EN Figures 5

Page 8

Figure 36. Testing the ADF adjustment . . . . . . . . . . . . . . . . .143

Figure 37. Rear view of the ADF . . . . . . . . . . . . . . . . . . . . . . 144

Figure 38. Adjusting screw . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Figure 39. DSW1 on the DADF controller PCB . . . . . . . . . . . 145

Figure 40. Testing adjustment . . . . . . . . . . . . . . . . . . . . . . . .146

Figure 41. Adjusting ADF document tray . . . . . . . . . . . . . . . .146

Figure 42. DSW1 on DADF controller PCB . . . . . . . . . . . . . . 147

Figure 43. Measuring the copy paper stop position . . . . . . . . 148

Figure 44. DSW1 on DADF controller PCB . . . . . . . . . . . . . . 149

Figure 45. Positioning paper . . . . . . . . . . . . . . . . . . . . . . . . . .150

Figure 46. Retaining plate adjustment . . . . . . . . . . . . . . . . . .151

Figure 47. Measu rin g th e dis tance from

the copyboard glass to the ADF . . . . . . . . . . . . . .151

Figure 48. Preparing test strips for measuring feeding power. 152

Figure 49. DADF controller cover . . . . . . . . . . . . . . . . . . . . . . 152

Figure 50. DSW1 on DADF controller PCB . . . . . . . . . . . . . . 153

Figure 51. Measuring feeding power . . . . . . . . . . . . . . . . . . . 153

Figure 52. Lock nut glued in place . . . . . . . . . . . . . . . . . . . . .154

Figure 53. ADF sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

Figure 54. LED 1 and 2 on DADF controller PCB . . . . . . . . . . 156

Figure 55. DADF controller PCB . . . . . . . . . . . . . . . . . . . . . . .157

Figure 56. Wing nuts on the adjustment screws . . . . . . . . . . .159

Figure 57. Base plate securing screws . . . . . . . . . . . . . . . . . .160

Figure 58. Paper guide fixing screws . . . . . . . . . . . . . . . . . . .161

Figure 59. Paper guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Figure 60. Paper size card . . . . . . . . . . . . . . . . . . . . . . . . . . .162

Figure 61. Copyboard glass . . . . . . . . . . . . . . . . . . . . . . . . . .165

Figure 62. Copyboard cover . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Figure 63. Belt assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Figure 64. Document tray . . . . . . . . . . . . . . . . . . . . . . . . . . . .168

Figure 65. Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Figure 66. Sensor S1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .169

Figure 67. Reflecting face sensor . . . . . . . . . . . . . . . . . . . . . .170

Figure 68. Registration sensor . . . . . . . . . . . . . . . . . . . . . . . .170

Figure 69. Guide plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .171

Figure 70. Registration sensor . . . . . . . . . . . . . . . . . . . . . . . .171

Figure 71. Registration sensor LED3 cover . . . . . . . . . . . . . .172

Figure 72. Light-emitting face . . . . . . . . . . . . . . . . . . . . . . . . . 172

Figure 73. Separation guide . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Figure 74. Control panel power soft switch, copy module

rear power switch, and power plug . . . . . . . . . . . .177

Figure 75. Copy module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Figure 76. Electrical circuitry . . . . . . . . . . . . . . . . . . . . . . . . . .179

6 Figures EN

Page 9

Figure 77. Inputs to and outputs from

the reader controller PCB (1 of 3) . . . . . . . . . . . . .180

Figure 78. Inputs and outputs from the

reader controller PCB (2 of 3) . . . . . . . . . . . . . . . . 181

Figure 79. Inputs and outputs from the

reader controller PCB (3 of 3) . . . . . . . . . . . . . . . . 182

Figure 80. Basic sequence of operations at power-on . . . . . . 183

Figure 81. A4- and letter-size, 2 copies, 4-color, Direct, and

cassette 1 sequence of operations (1 of 2) . . . . . .185

Figure 82. A4- and letter-size, 2 copies, 4-color, Direct, and

cassette 1 sequence of operations (2 of 2) . . . . . .186

Figure 83. Cross-section of exposure system . . . . . . . . . . . .188

Figure 84. Exposure system mechanics . . . . . . . . . . . . . . . . .188

Figure 85. A4- and letter-size, 2 copies, 4-color, Direct,

cassette 1 sequence of operations . . . . . . . . . . . .189

Figure 86. Scanner movement . . . . . . . . . . . . . . . . . . . . . . . . 190

Figure 87. Scanner motor circuit . . . . . . . . . . . . . . . . . . . . . . .191

Figure 88. Changing the reproduction ratio . . . . . . . . . . . . . .192

Figure 89. Controlling the scanning lamp . . . . . . . . . . . . . . . .193

Figure 90. Paper selection sensors . . . . . . . . . . . . . . . . . . . . 197

Figure 91. Sensor operation . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Figure 92. Image processing unit . . . . . . . . . . . . . . . . . . . . . 200

Figure 93. CCD lines and filters . . . . . . . . . . . . . . . . . . . . . . . 201

Figure 94. CCD circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Figure 95. Analog circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203

Figure 96. G image signal . . . . . . . . . . . . . . . . . . . . . . . . . . . .205

Figure 97. Digital image processing . . . . . . . . . . . . . . . . . . . 207

Figure 98. Scanning lamp and lens . . . . . . . . . . . . . . . . . . . . 208

Figure 99. Shading correction measurement . . . . . . . . . . . . .209

Figure 100. CCD position matching . . . . . . . . . . . . . . . . . . . . . 210

Figure 101. Text identification . . . . . . . . . . . . . . . . . . . . . . . . . 211

Figure 102. Sensor color correction measurement . . . . . . . . .212

Figure 103. Background pixel measurement . . . . . . . . . . . . . .213

Figure 104. Input level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .215

Figure 105. Weak and strong sharpness . . . . . . . . . . . . . . . . . 215

Figure 106. Original density compared to CCD output . . . . . .216

Figure 107. Density level conversion . . . . . . . . . . . . . . . . . . . . 216

Figure 108. BGR and YMC levels . . . . . . . . . . . . . . . . . . . . . .217

Figure 109. BGR to YMC conversion . . . . . . . . . . . . . . . . . . . . 218

Figure 110. Gray components . . . . . . . . . . . . . . . . . . . . . . . . .219

Figure 111. Bk signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Figure 112. UCR amount . . . . . . . . . . . . . . . . . . . . . . . . . . . . .220

Figure 113. Chromatic absorption characteristics . . . . . . . . . . 221

Figure 114. Enlargement/correction . . . . . . . . . . . . . . . . . . . . 223

EN Figures 7

Page 10

Figure 115. Image shifts . . . . . . . . . . . . . . . . . . . . . . . . . . . . .224

Figure 116. Shift in main and sub-scanning directions . . . . . .224

Figure 117. Center Shift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Figure 118. Mirror image . . . . . . . . . . . . . . . . . . . . . . . . . . . . .226

Figure 119. Mirror image principle . . . . . . . . . . . . . . . . . . . . . . 226

Figure 120. Image repeat . . . . . . . . . . . . . . . . . . . . . . . . . . . .227

Figure 121. Image repeat principle . . . . . . . . . . . . . . . . . . . . . 227

Figure 122. Slant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .228

Figure 123. Slant principle . . . . . . . . . . . . . . . . . . . . . . . . . . . .228

Figure 124. Curve for items A through D . . . . . . . . . . . . . . . . .229

Figure 125. Curve for black-and-white text mode . . . . . . . . . .229

Figure 126. Framing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .230

Figure 127. Blanking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .230

Figure 128. Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . .233

Figure 129. Copy module fan . . . . . . . . . . . . . . . . . . . . . . . . .234

Figure 130. Cooling fan engaged . . . . . . . . . . . . . . . . . . . . . .234

Figure 131. Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .236

Figure 132. Copy module power distribution . . . . . . . . . . . . . .237

Figure 133. Copy module general circuit diagram (1 of 2) . . . . 240

Figure 134. Copy module general circuit diagram (2 of 2) . . . . 242

Figure 135. ADF electrical circuitry . . . . . . . . . . . . . . . . . . . . . .244

Figure 136. Operation mode communication . . . . . . . . . . . . . .245

Figure 137. Inputs to the DADF controller PCB (1 of 2) . . . . . . 246

Figure 138. Inputs to the DADF controller PCB (2 of 2) . . . . . . 247

Figure 139. Outputs to the DADF controller PCB . . . . . . . . . . .248

Figure 140. ADF motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Figure 141. Top pick-up path . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Figure 142. Face-up (left) output tray . . . . . . . . . . . . . . . . . . . .253

Figure 143. Face-down (top) output tray . . . . . . . . . . . . . . . . .254

Figure 144. Page composition copy sequences . . . . . . . . . . . .255

Figure 145. Picking up originals . . . . . . . . . . . . . . . . . . . . . . . . 256

Figure 146. Pick-up path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Figure 147. Feeding sequence . . . . . . . . . . . . . . . . . . . . . . . .258

Figure 148. Feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Figure 149. Second original pick-up . . . . . . . . . . . . . . . . . . . . .259

Figure 150. Sequence of operations (A4, 2 originals,

top pick-up mode) . . . . . . . . . . . . . . . . . . . . . . . . . 260

Figure 151. Picking up for the first side . . . . . . . . . . . . . . . . . . 261

Figure 152. Reversing from the first side to the second side . . 261

Figure 153. Sequence of operations (reversal) . . . . . . . . . . . . 262

Figure 154. Placement of first original . . . . . . . . . . . . . . . . . . .263

Figure 155. Positioning the first original and pick-up of

second original . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Figure 156. Movement of first and second originals . . . . . . . . .264

8 Figures EN

Page 11

Figure 157. Delivery of originals . . . . . . . . . . . . . . . . . . . . . . . .264

Figure 158. Sequence of operations (reduced page composition; top

pick-up) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .265

Figure 159. Delivery path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Figure 160. Feeding the first original . . . . . . . . . . . . . . . . . . . .266

Figure 161. Delivering the first original and picking up the

second original . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Figure 162. Sequence of operations (small size, pick-up and

delivery) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Figure 163. Detecting an original . . . . . . . . . . . . . . . . . . . . . . . 269

Figure 164. Document tray . . . . . . . . . . . . . . . . . . . . . . . . . . . .270

Figure 165. Registration rollers . . . . . . . . . . . . . . . . . . . . . . . . . 271

Figure 166. Horizontal detection . . . . . . . . . . . . . . . . . . . . . . . . 272

Figure 167. Placement of original . . . . . . . . . . . . . . . . . . . . . . .274

Figure 168. Control of pick-up motor . . . . . . . . . . . . . . . . . . . .275

Figure 169. Control of belt motor . . . . . . . . . . . . . . . . . . . . . . . 277

Figure 170. ADF jam sensors . . . . . . . . . . . . . . . . . . . . . . . . .279

Figure 171. Improper placement of originals . . . . . . . . . . . . . .282

Figure 172. Jam flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . .284

Figure 173. Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . .285

Figure 174. Motors, solenoids, and sensors . . . . . . . . . . . . . . . 286

Figure 175. PCB locations . . . . . . . . . . . . . . . . . . . . . . . . . . . .287

Figure 176. Indicator PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Figure 177. ADF general circuit diagram . . . . . . . . . . . . . . . . .290

Figure 178. ADF controller circui t diagram (1 of 7) . . . . . . . . .292

Figure 179. ADF controller circui t diagram (2 of 7) . . . . . . . . . .294

Figure 180. ADF controller circui t diagram (3 of 7) . . . . . . . . . .296

Figure 181. ADF controller circui t diagram (4 of 7) . . . . . . . . . .298

Figure 182. ADF controller circui t diagram (5 of 7) . . . . . . . . . .300

Figure 183. ADF controller circui t diagram (6 of 7) . . . . . . . . . .301

Figure 184. ADF controller circui t diagram (7 of 7) . . . . . . . . . .301

Figure 185. ADF display board . . . . . . . . . . . . . . . . . . . . . . . . .302

Figure 186. ADF general timing chart (top pick-up mode, A4, and 2

originals—single-sided original to single copy) . . . 303

Figure 187. Deck block diagram . . . . . . . . . . . . . . . . . . . . . . . .304

Figure 188. Deck controller PCB . . . . . . . . . . . . . . . . . . . . . . .305

Figure 189. Deck controller PCB output . . . . . . . . . . . . . . . . . . 306

Figure 190. Pick-up feed rollers . . . . . . . . . . . . . . . . . . . . . . . . 307

Figure 191. Pick-up feed signals . . . . . . . . . . . . . . . . . . . . . . . 308

Figure 192. Signal transfer points . . . . . . . . . . . . . . . . . . . . . . 309

Figure 193. Pick-up signal levels . . . . . . . . . . . . . . . . . . . . . . .309

Figure 194. Lifter operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Figure 195. Remaining paper detection . . . . . . . . . . . . . . . . . .311

EN Figures 9

Page 12

Figure 196. Paper-size-detection switch and

detection plate (A4) . . . . . . . . . . . . . . . . . . . . . . . .312

Figure 197. Paper-size-detection switch and

detection plate (LTR) . . . . . . . . . . . . . . . . . . . . . . . 312

Figure 198. Jam detection levels . . . . . . . . . . . . . . . . . . . . . . .313

Figure 199. Stationary jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Figure 200. Side HCI power supply . . . . . . . . . . . . . . . . . . . . .314

Figure 201. Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .315

Figure 202. Solenoids and motors . . . . . . . . . . . . . . . . . . . . . . 316

Figure 203. PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

Figure 204. Deck controller PCB . . . . . . . . . . . . . . . . . . . . . . .319

Figure 205. User LED PCB . . . . . . . . . . . . . . . . . . . . . . . . . . .320

Figure 206. Remaining-paper-detection PCB . . . . . . . . . . . . .320

Figure 207. Deck controller PCB general circuit diagram . . . . . 324

Figure 208. Front view of copy module . . . . . . . . . . . . . . . . . . .333

Figure 209. Rear view of copy module . . . . . . . . . . . . . . . . . . .333

Figure 210. Removing the copy module lower front cover . . . .334

Figure 211. Removing the copy module upp er right cover . . . .334

Figure 212. Removing the copy module upper rear cover . . . . 335

Figure 213. Removing the copy module upper left cover . . . . .335

Figure 214. Removing the copy module rear cover . . . . . . . . .336

Figure 215. Removing the copy module upper front cover . . . .337

Figure 216. Removing the copy module scanner motor . . . . . .338

Figure 217. Removing the copy module th e

scanner motor driver PCB . . . . . . . . . . . . . . . . . . .339

Figure 218. Preparing to remove the ROM DIMM . . . . . . . . . .340

Figure 219. Opening the claws . . . . . . . . . . . . . . . . . . . . . . . . .341

Figure 220. Lifting the ROM DIMM to detach . . . . . . . . . . . . . .341

Figure 221. Inserting the ROM DIMM . . . . . . . . . . . . . . . . . . . . 342

Figure 222. Engaging the ROM DIMM . . . . . . . . . . . . . . . . . . . 342

Figure 223. Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . .344

Figure 224. Detaching the control panel . . . . . . . . . . . . . . . . . . 345

Figure 225. Detaching the metal plat e on the LCD assembly .346

Figure 226. Detaching the LCD assembly . . . . . . . . . . . . . . . .346

Figure 227. Copyboard glass . . . . . . . . . . . . . . . . . . . . . . . . . . 347

Figure 228. Scanner drive cable . . . . . . . . . . . . . . . . . . . . . . . . 348

Figure 229. Securing the metal cable clamp (front view) . . . . . 349

Figure 230. Securing the metal cabl e clamp (rear view) . . . . .349

Figure 231. Mirror tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .350

Figure 232. Detaching and reattaching the

mirror positioning tool (front view) . . . . . . . . . . . . .350

Figure 233. Detaching and reattaching the

mirror positioning tool (rear view) . . . . . . . . . . . . .351

10 Figures EN

Page 13

Figure 234. Securing the metal cable clamp to the

mirror 1 mount (front view) . . . . . . . . . . . . . . . . . .351

Figure 235. Securing the metal cable clamp to the

mirror 1 mount (rear view) . . . . . . . . . . . . . . . . . .351

Figure 236. Cable positioning . . . . . . . . . . . . . . . . . . . . . . . . . .352

Figure 237. Copyboard glass . . . . . . . . . . . . . . . . . . . . . . . . . . 353

Figure 238. Flexible cable warning label . . . . . . . . . . . . . . . . . 353

Figure 239. Releasing the connector to the flexible cable . . . . 354

Figure 240. Disconnecting the flexible cable . . . . . . . . . . . . . . 355

Figure 241. Connecting the flexible cable . . . . . . . . . . . . . . . .356

Figure 242. Scanning lamp cover . . . . . . . . . . . . . . . . . . . . . . .357

Figure 243. Scanning lamp inside cover . . . . . . . . . . . . . . . . . .357

Figure 244. Anti-reflecting plate . . . . . . . . . . . . . . . . . . . . . . . 358

Figure 245. Detaching the scanning lamp . . . . . . . . . . . . . . . .359

Figure 246. Removing the scanning lamp . . . . . . . . . . . . . . . .360

Figure 247. Scanning lamp heater . . . . . . . . . . . . . . . . . . . . . .360

Figure 248. Replacing the scanning lamp . . . . . . . . . . . . . . . .361

Figure 249. Scanning lamp adjustment . . . . . . . . . . . . . . . . . .362

Figure 250. White plate cover removal . . . . . . . . . . . . . . . . . . .363

Figure 251. Replacing the white plate cover . . . . . . . . . . . . . . .363

Figure 252. Detaching the claws . . . . . . . . . . . . . . . . . . . . . . . 364

Figure 253. Detaching the intensity-detection PCB . . . . . . . . .364

Figure 254. Lens mount cover . . . . . . . . . . . . . . . . . . . . . . . . . 365

Figure 255. Detaching the CCD unit . . . . . . . . . . . . . . . . . . . . . 365

Figure 256. CCD unit connectors . . . . . . . . . . . . . . . . . . . . . . . 366

Figure 257. Electrical unit screws and connectors . . . . . . . . . . 367

Figure 258. Reader controller PCB connectors . . . . . . . . . . . .367

Figure 259. Removing the reader controller PCB cover (1 of 2) 368

Figure 260. Removing the reader controller PCB cover (2 of 2) 368

Figure 261. Removing the electrical unit . . . . . . . . . . . . . . . . .369

Figure 262. Holding the electrical unit . . . . . . . . . . . . . . . . . . . 369

Figure 263. Detaching the electrical unit cover . . . . . . . . . . . . .370

Figure 264. Electrical unit connectors . . . . . . . . . . . . . . . . . . . . 370

Figure 265. ECO PCB replacement . . . . . . . . . . . . . . . . . . . . .371

Figure 266. AP-IP PCB removal . . . . . . . . . . . . . . . . . . . . . . . .372

Figure 267. Removing the copy module main power

supply PCB (DCP1) . . . . . . . . . . . . . . . . . . . . . . . . 373

Figure 268. Accessory power supply . . . . . . . . . . . . . . . . . . . . 374

Figure 269. Power supply cooling fan . . . . . . . . . . . . . . . . . . . . 375

Figure 270. Inverter PCB unit . . . . . . . . . . . . . . . . . . . . . . . . . .376

Figure 271. ADF external covers . . . . . . . . . . . . . . . . . . . . . . .377

Figure 272. Opening the ADF . . . . . . . . . . . . . . . . . . . . . . . . . .378

Figure 273. Removing the ADF . . . . . . . . . . . . . . . . . . . . . . . .379

Figure 274. Mounting screws . . . . . . . . . . . . . . . . . . . . . . . . . . 380

EN Figures 11

Page 14

Figure 275. Body cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 380

Figure 276. Mounting screws . . . . . . . . . . . . . . . . . . . . . . . . . . 380

Figure 277. Document tray . . . . . . . . . . . . . . . . . . . . . . . . . . . .381

Figure 278. Side guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 382

Figure 279. Side guide and screws . . . . . . . . . . . . . . . . . . . . . 383

Figure 280. Opened side guide . . . . . . . . . . . . . . . . . . . . . . . . 383

Figure 281. Mounting the gear . . . . . . . . . . . . . . . . . . . . . . . . . 384

Figure 282. Setting the width detection volume . . . . . . . . . . . .384

Figure 283. Setting the screws and mounting lock . . . . . . . . . .385

Figure 284. Connector J12 on pick-up motor . . . . . . . . . . . . . . 385

Figure 285. Pick-up motor cable guide . . . . . . . . . . . . . . . . . . .386

Figure 286. Detaching the pick-up motor unit . . . . . . . . . . . . . .386

Figure 287. Feeder motor unit . . . . . . . . . . . . . . . . . . . . . . . . .387

Figure 288. Feeder motor color sensor . . . . . . . . . . . . . . . . . . 387

Figure 289. Feeder motor drive belts . . . . . . . . . . . . . . . . . . . .388

Figure 290. Belt motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .389

Figure 291. Belt motor clock sensor . . . . . . . . . . . . . . . . . . . . .389

Figure 292. Belt motor count position . . . . . . . . . . . . . . . . . . . .390

Figure 293. Feeding the belt drive roller . . . . . . . . . . . . . . . . . .390

Figure 294. Replacing the belt motor . . . . . . . . . . . . . . . . . . . . 391

Figure 295. Adjusting belt tension . . . . . . . . . . . . . . . . . . . . . . 391

Figure 296. Clutch unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 392

Figure 297. E-ring and bushing . . . . . . . . . . . . . . . . . . . . . . . . 392

Figure 298. Clutch unit slip stop . . . . . . . . . . . . . . . . . . . . . . . . 393

Figure 299. Delivery motor connectors . . . . . . . . . . . . . . . . . . . 394

Figure 300. Delivery motor cable retainer . . . . . . . . . . . . . . . . .394

Figure 301. Detaching the delivery motor . . . . . . . . . . . . . . . . . 395

Figure 302. Document tray mount . . . . . . . . . . . . . . . . . . . . . .396

Figure 303. Paper-retaining solenoid . . . . . . . . . . . . . . . . . . . . 396

Figure 304. Inlet guide plate . . . . . . . . . . . . . . . . . . . . . . . . . . .397

Figure 305. Pick-up roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 397

Figure 306. Reversing roller drive belt . . . . . . . . . . . . . . . . . . . 398

Figure 307. Separation belt unit . . . . . . . . . . . . . . . . . . . . . . . . 398

Figure 308. Separation guide plate . . . . . . . . . . . . . . . . . . . . . . 399

Figure 309. Inside guide plate . . . . . . . . . . . . . . . . . . . . . . . . . 399

Figure 310. Roller unit stopper . . . . . . . . . . . . . . . . . . . . . . . . . 400

Figure 311. Roller unit E-ring, gear, and timing belt . . . . . . . . .400

Figure 312. Removing the E-ring, arm, and gear . . . . . . . . . . . 401

Figure 313. Removing the feeding roller unit . . . . . . . . . . . . . .401

Figure 314. Right hinge unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 402

Figure 315. E-ring and bushing . . . . . . . . . . . . . . . . . . . . . . . . 402

Figure 316. Solenoid mount . . . . . . . . . . . . . . . . . . . . . . . . . . . 403

Figure 317. Detaching the spring, screw, and arm . . . . . . . . . .403

12 Figures EN

Page 15

Figure 318. Link arm shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . 404

Figure 319. Sensor mount . . . . . . . . . . . . . . . . . . . . . . . . . . . .404

Figure 320. Tension spring . . . . . . . . . . . . . . . . . . . . . . . . . . . .405

Figure 321. Grip ring, clock plate, sensor mount, and spring . .405

Figure 322. Registration roller . . . . . . . . . . . . . . . . . . . . . . . . .406

Figure 323. Timing belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .407

Figure 324. Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 408

Figure 325. Unlocking and removing the gear . . . . . . . . . . . . .408

Figure 326. Grip ring and bushing . . . . . . . . . . . . . . . . . . . . . .409

Figure 327. Detaching the lower guide stopper . . . . . . . . . . . .409

Figure 328. Removing the spring . . . . . . . . . . . . . . . . . . . . . . . 410

Figure 329. Registration sensor cover . . . . . . . . . . . . . . . . . . . 410

Figure 330. Disconnecting the sensor connector . . . . . . . . . . .411

Figure 331. Paper guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .411

Figure 332. Reversing plate (front view) . . . . . . . . . . . . . . . . . 412

Figure 333. Detaching the reversing plate (rear view) . . . . . . . 412

Figure 334. Front plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .413

Figure 335. Delivery/reversing roller . . . . . . . . . . . . . . . . . . . . . 413

Figure 336. Body cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 414

Figure 337. E-ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 414

Figure 338. Delivery roller unit . . . . . . . . . . . . . . . . . . . . . . . . . 415

Figure 339. Removing the screw and spring . . . . . . . . . . . . . .416

Figure 340. Disengaging the connector . . . . . . . . . . . . . . . . . . 416

Figure 341. Detaching the timing belt and motor unit . . . . . . . .417

Figure 342. Detaching the delivery roller unit . . . . . . . . . . . . . . 418

Figure 343. Gear and timing belt . . . . . . . . . . . . . . . . . . . . . . .419

Figure 344. Unlocking and removing the gear . . . . . . . . . . . . .419

Figure 345. Reversing guide spring, front . . . . . . . . . . . . . . . . .420

Figure 346. Reversing guide spring, rear . . . . . . . . . . . . . . . . . 420

Figure 347. Detaching the solenoid unit . . . . . . . . . . . . . . . . . .420

Figure 348. Reversing the sensor jack and grounding cord . . .421

Figure 349. Detaching the reversing guide . . . . . . . . . . . . . . . .421

Figure 350. Document tray mounting plate . . . . . . . . . . . . . . . .422

Figure 351. Stopper plate solenoid . . . . . . . . . . . . . . . . . . . . . . 422

Figure 352. Solenoid positioning . . . . . . . . . . . . . . . . . . . . . . . 423

Figure 353. Test strips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 424

Figure 354. Delivery roller and pick-up roll . . . . . . . . . . . . . . . .424

Figure 355. Inserting the test strip . . . . . . . . . . . . . . . . . . . . . .425

Figure 356. Paper-deflecting solenoid . . . . . . . . . . . . . . . . . . .426

Figure 357. Flapper plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

Figure 358. E-ring and bushing . . . . . . . . . . . . . . . . . . . . . . . . 427

Figure 359. Delivery roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 428

Figure 360. Paper-guide plate . . . . . . . . . . . . . . . . . . . . . . . . .428

EN Figures 13

Page 16

Figure 361. Sensor flag and connector . . . . . . . . . . . . . . . . . . . 429

Figure 362. Delivery roller mount . . . . . . . . . . . . . . . . . . . . . . . 429

Figure 363. Delivery roller and stamp solenoid mount . . . . . . .429

Figure 364. Stamp solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . 430

Figure 365. Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .431

Figure 366. Placing the spring in the temporary position on the

retaining hook . . . . . . . . . . . . . . . . . . . . . . . . . . . . 431

Figure 367. Detaching the solenoid . . . . . . . . . . . . . . . . . . . . .432

Figure 368. Detaching the side plate . . . . . . . . . . . . . . . . . . . .432

Figure 369. Delivery unit linking plate . . . . . . . . . . . . . . . . . . . . 433

Figure 370. Removing the feeding belt . . . . . . . . . . . . . . . . . . . 433

Figure 371. External covers . . . . . . . . . . . . . . . . . . . . . . . . . . .434

Figure 372. Rear cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 434

Figure 373. Upper left cover and screws . . . . . . . . . . . . . . . . .435

Figure 374. Front cover and screws . . . . . . . . . . . . . . . . . . . . .435

Figure 375. Rear cover and screws . . . . . . . . . . . . . . . . . . . . . 436

Figure 376. Upper right cover and screws . . . . . . . . . . . . . . . . 436

Figure 377. Paper-size limit panel . . . . . . . . . . . . . . . . . . . . . .437

Figure 378. Fixing plate and limit panel . . . . . . . . . . . . . . . . . .438

Figure 379. Connectors and cable clamps . . . . . . . . . . . . . . . .439

Figure 380. Pick-up unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .439

Figure 381. Pick-up roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 440

Figure 382. Feed roller and separation roller . . . . . . . . . . . . . .441

Figure 383. Preparing to remove the lifter wire . . . . . . . . . . . . .442

Figure 384. E-ring and pulley cover . . . . . . . . . . . . . . . . . . . . . 442

Figure 385. Pulley cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .443

Figure 386. Screw and lifter wire . . . . . . . . . . . . . . . . . . . . . . .444

Figure 387. Parts removal behind the lifter wire . . . . . . . . . . . .445

Figure 388. Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .446

Figure 389. Paper-detection unit . . . . . . . . . . . . . . . . . . . . . . . 446

Figure 390. Lifter drive unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 447

Figure 391. Rear panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 447

Figure 392. E-ring and gear . . . . . . . . . . . . . . . . . . . . . . . . . . . 448

Figure 393. E-ring and pulley cover . . . . . . . . . . . . . . . . . . . . . 448

Figure 394. Bracket removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 449

Figure 395. Lifter wire removal . . . . . . . . . . . . . . . . . . . . . . . . .450

Figure 396. Tightening the lifter wire . . . . . . . . . . . . . . . . . . . . 451

Figure 397. Lifter motor (M1) . . . . . . . . . . . . . . . . . . . . . . . . . . 452

Figure 398. Feeder motor (M2) . . . . . . . . . . . . . . . . . . . . . . . . . 452

Figure 399. Pick-up motor (M3) . . . . . . . . . . . . . . . . . . . . . . . . 453

Figure 400. Deck controller PCB . . . . . . . . . . . . . . . . . . . . . . .453

Figure 401. Power supply PCB . . . . . . . . . . . . . . . . . . . . . . . . .454

Figure 402. Standard image sample . . . . . . . . . . . . . . . . . . . . .464

14 Figures EN

Page 17

Figure 403. Horizontal stripe test print . . . . . . . . . . . . . . . . . . . 466

Figure 404. 256-color test print . . . . . . . . . . . . . . . . . . . . . . . . . 467

Figure 405. 256-gradation test print . . . . . . . . . . . . . . . . . . . . . 468

Figure 406. 16-gradation test print . . . . . . . . . . . . . . . . . . . . . . 469

Figure 407. Halftone test print . . . . . . . . . . . . . . . . . . . . . . . . . 470

Figure 408. Grid test print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 471

Figure 409. CMYK 64-gradation test print . . . . . . . . . . . . . . . . 472

Figure 410. RGB 64-gradation test print . . . . . . . . . . . . . . . . . . 473

Figure 411. Full-color 16-gradation test print . . . . . . . . . . . . . .474

Figure 412. Full-color light area 16-gradation test print . . . . . .475

Figure 413. Leakage breaker . . . . . . . . . . . . . . . . . . . . . . . . . . 520

Figure 414. DIP switch on the DADF controller PCB . . . . . . . .534

Figure 415. Figure 5-101 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .535

Figure 416. Figure 5-102 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .536

Figure 417. Interface assembly location . . . . . . . . . . . . . . . . . .552

Figure 418. ECO-2 PCB Assembly . . . . . . . . . . . . . . . . . . . . . .553

Figure 419. Interface assembly . . . . . . . . . . . . . . . . . . . . . . . .554

Figure 420. Stand assembly . . . . . . . . . . . . . . . . . . . . . . . . . . .556

Figure 421. Assembly location diagram . . . . . . . . . . . . . . . . . .561

Figure 422. External covers and panels . . . . . . . . . . . . . . . . . .562

Figure 423. Internal components (1 of 3) . . . . . . . . . . . . . . . . . 564

Figure 424. Internal components (2 of 3) . . . . . . . . . . . . . . . . . 566

Figure 425. Internal components (3 of 3) . . . . . . . . . . . . . . . . . 568

Figure 426. Power cord terminal assembly . . . . . . . . . . . . . . . 570

Figure 427. Control panel assembly . . . . . . . . . . . . . . . . . . . . .572

Figure 428. Copyboard cover assembly . . . . . . . . . . . . . . . . . .574

Figure 429. Mirror assembly 1 . . . . . . . . . . . . . . . . . . . . . . . . . 576

Figure 430. Electrical tray assembly . . . . . . . . . . . . . . . . . . . . . 578

Figure 431. Dc power supply PCA . . . . . . . . . . . . . . . . . . . . . .580

Figure 432. APC power supply PCA . . . . . . . . . . . . . . . . . . . . .582

Figure 433. Noise filter PCA . . . . . . . . . . . . . . . . . . . . . . . . . . .583

Figure 434. Control panel PCA . . . . . . . . . . . . . . . . . . . . . . . . .584

Figure 435. Control panel CPU PCA . . . . . . . . . . . . . . . . . . . . 585

Figure 436. Control panel inverter PCA . . . . . . . . . . . . . . . . . . 586

Figure 437. Reader controller PCA . . . . . . . . . . . . . . . . . . . . . .587

Figure 438. Analog image processor PCA . . . . . . . . . . . . . . . . 588

Figure 439. Motor driver PCA . . . . . . . . . . . . . . . . . . . . . . . . . .589

Figure 440. Inverter PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . .590

Figure 441. Connectors (1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . 591

Figure 442. Connectors (2 of 3) . . . . . . . . . . . . . . . . . . . . . . . . 597

Figure 443. Connectors (3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . 598

Figure 444. Assembly locations . . . . . . . . . . . . . . . . . . . . . . . .605

Figure 445. Mounting hardware . . . . . . . . . . . . . . . . . . . . . . . . 606

EN Figures 15

Page 18

Figure 446. External covers and panels . . . . . . . . . . . . . . . . . .607

Figure 447. DF assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 608

Figure 448. Document tray assembly . . . . . . . . . . . . . . . . . . . .612

Figure 449. Upper cover assembly . . . . . . . . . . . . . . . . . . . . . . 614

Figure 450. RF assembly (1 of 4) . . . . . . . . . . . . . . . . . . . . . . .616

Figure 451. RF assembly (2 of 4) . . . . . . . . . . . . . . . . . . . . . . .620

Figure 452. RF assembly (3 of 4) . . . . . . . . . . . . . . . . . . . . . . .624

Figure 453. RF assembly (4 of 4) . . . . . . . . . . . . . . . . . . . . . . .628

Figure 454. Right paper delivery assembly . . . . . . . . . . . . . . . 630

Figure 455. Paper feed motor assembly . . . . . . . . . . . . . . . . . .632

Figure 456. Belt drive motor assembly . . . . . . . . . . . . . . . . . . .634

Figure 457. Upper paper guide assembly . . . . . . . . . . . . . . . . . 636

Figure 458. Lower paper guide assembly . . . . . . . . . . . . . . . . . 638

Figure 459. Separation roller assembly . . . . . . . . . . . . . . . . . .640

Figure 460. Paper separation assembly . . . . . . . . . . . . . . . . . .642

Figure 461. RDF controller PCA . . . . . . . . . . . . . . . . . . . . . . . .644

Figure 462. Connectors (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . 645

Figure 463. Connectors (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . 648

Figure 464. Assembly locations . . . . . . . . . . . . . . . . . . . . . . . .652

Figure 465. Mounting hardware . . . . . . . . . . . . . . . . . . . . . . . . 653

Figure 466. External covers and panels . . . . . . . . . . . . . . . . . .654

Figure 467. Internal components (1 of 3) . . . . . . . . . . . . . . . . . 656

Figure 468. Internal components (2 of 3) . . . . . . . . . . . . . . . . . 658

Figure 469. Internal components (3 of 3) . . . . . . . . . . . . . . . . . 660

Figure 470. Lifter drive assembly . . . . . . . . . . . . . . . . . . . . . . . 663

Figure 471. Paper pick-up assembly (1 of 2) . . . . . . . . . . . . . .664

Figure 472. Paper pick-up assembly (2 of 2) . . . . . . . . . . . . . .666

Figure 473. Deck controller PCA . . . . . . . . . . . . . . . . . . . . . . .668

Figure 474. Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .669

16 Figures EN

Page 19

Tables

Table 1. First copy time (in seconds*). . . . . . . . . . . . . . . . . . . . 24

Table 2. Copying speed (pages per minute). . . . . . . . . . . . . . . 24

Table 3. Operating conditions—copy/print . . . . . . . . . . . . . . . .25

Table 4. Electrical specifications—copy/print . . . . . . . . . . . . . . 25

Table 5. Physical specifications—copy/print. . . . . . . . . . . . . . . 25

Table 6. Electrical specifications—ADF . . . . . . . . . . . . . . . . . . 29

Table 7. Physical specifications—ADF . . . . . . . . . . . . . . . . . . .29

Table 8. Supported media—ADF . . . . . . . . . . . . . . . . . . . . . . .29

Table 9. Operating conditions—side HCI . . . . . . . . . . . . . . . . . 32

Table 10. Electrical specifications—side HCI . . . . . . . . . . . . . . . 32

Table 11. Physical specifications—side HCI. . . . . . . . . . . . . . . . 32

Table 12. Ordering parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 13. Technical support websites. . . . . . . . . . . . . . . . . . . . . 40

Table 14. Asia Pacific region Customer Care Centers . . . . . . . . 46

Table 15. Copy module functionality. . . . . . . . . . . . . . . . . . . . . . 51

Table 16. Common settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 17. Copy module settings . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 18. Timer settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Table 19. Adjustment/cleaning . . . . . . . . . . . . . . . . . . . . . . . . . .56

Table 20. Self-diagnostic (error) messages . . . . . . . . . . . . . . . . 59

Table 21. Service mode sub-items . . . . . . . . . . . . . . . . . . . . . . . 60

Table 22. Copier, display mode menu . . . . . . . . . . . . . . . . . . . .65

Table 23. Copier, display mode Level 2 and Level 3 menus . . . 66

Table 24. Country code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Table 25. Language code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Table 26. Series code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 27. JAM screen legend . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Table 28. Types of jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Table 29. First 2 digits of FFFF (type of jam) . . . . . . . . . . . . . . .72

Table 30. Last 2 digits of FFFF (jam sensor) . . . . . . . . . . . . . . . 73

Table 31. G (pick-up position) . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 32. Pick-up jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Table 33. Detecting jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Table 34. ERR screen legend . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Table 35. Copier, I/O mode descriptions. . . . . . . . . . . . . . . . . . . 77

Table 36. Copier, I/O mode Level 2 and Level 3 menus. . . . . . . 79

Table 37. Copier, adjust menu descriptions . . . . . . . . . . . . . . . . 83

Table 38. Copier, adjust mode Level 2 and Level 3 menus . . . .84

EN Tables 17

Page 20

Table 39. Copier, run/check mode menu descriptions . . . . . . . . 93

Table 40. Copier, run/check mode Level 2 and Level 3 menus . 94

Table 41. Control panel key descriptions . . . . . . . . . . . . . . . . . . 96

Table 42. Copier, machine settings menu descriptions . . . . . . .98

Table 43. Copier, machine settings mode Level 2 and

Level 3 menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Table 44. Copier, machine settings mode,

soft counter specifications. . . . . . . . . . . . . . . . . . . . . 103

Table 45. Soft counter defaults by voltage and country . . . . . .107

Table 46. Copier, test print mode Level 2 and Level 3 menus . 109

Table 47. Test print options . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Table 48. Copier counter menu descriptions . . . . . . . . . . . . . .111

Table 49. Copier, counter mode Level 2 and Level 3 menus . .112

Table 50. Feeder options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Table 51. Serviceable printer parts . . . . . . . . . . . . . . . . . . . . . 119

Table 52. Feeding power measurements . . . . . . . . . . . . . . . . . 154

Table 53. Periodically replaced parts . . . . . . . . . . . . . . . . . . . . 163

Table 54. Items to be cleaned . . . . . . . . . . . . . . . . . . . . . . . . . 166

Table 55. Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Table 56. Warm-up and standby phases . . . . . . . . . . . . . . . . . 184

Table 57. Sequence functions . . . . . . . . . . . . . . . . . . . . . . . . . 187

Table 58. Scanning lamp/scanning lamp heater errors. . . . . . . 196

Table 59. Identifying original size, metric . . . . . . . . . . . . . . . . . 199

Table 60. Identifying original-size, inches . . . . . . . . . . . . . . . . .199

Table 61. PCB functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .206

Table 62. BGR->YMC conversion. . . . . . . . . . . . . . . . . . . . . . .217

Table 63. Enlargement/reduction and image processing . . . . . 222

Table 64. Copy module fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Table 65. Power saving function. . . . . . . . . . . . . . . . . . . . . . . . 235

Table 66. Copy module main power supply . . . . . . . . . . . . . . . 239

Table 67. Accessories power supply (secondary side). . . . . . .239

Table 68. Page composition sizes . . . . . . . . . . . . . . . . . . . . . .255

Table 69. Europe/Asia (A4). . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Table 70. U.S. (Letter). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .273

Table 71. Relationship betwee n pic k-up motor signals and

the pick-up roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Table 72. Relationship betwee n be lt mo to r dr ive signa l an d

the feeding belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Table 73. Jam detection sensors . . . . . . . . . . . . . . . . . . . . . . . 279

Table 74. Jam detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .280

Table 75. Improper placement of originals sensors . . . . . . . . .282

Table 76. Improper placement detection. . . . . . . . . . . . . . . . . . 283

Table 77. Motors, solenoids, and sensors . . . . . . . . . . . . . . . .286

Table 78. PCB functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .287

18 Tables EN

Page 21

Table 79. LEDs on the indicator PCB . . . . . . . . . . . . . . . . . . . .288

Table 80. Names and abbreviations of signals . . . . . . . . . . . . .289

Table 81. Remaining paper detection switches . . . . . . . . . . . .311

Table 82. Sensor functions . . . . . . . . . . . . . . . . . . . . . . . . . . . .315

Table 83. Solenoid and motor functions . . . . . . . . . . . . . . . . . .316

Table 84. PCB functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .317

Table 85. Deck controller switches and LEDs. . . . . . . . . . . . . . 319

Table 86. User LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .320

Table 87. Signal names and codes. . . . . . . . . . . . . . . . . . . . . . 321

Table 88. Service tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

Table 89. Test pattern types . . . . . . . . . . . . . . . . . . . . . . . . . . .465

Table 90. Common image faults . . . . . . . . . . . . . . . . . . . . . . . . 476

Table 91. Repetitive image defects. . . . . . . . . . . . . . . . . . . . . . 482

Table 92. Errors based on LED lighting cycle. . . . . . . . . . . . . . 537

Table 93. Interface assembly location. . . . . . . . . . . . . . . . . . . . 552

Table 94. ECO-2 PCB Assembly . . . . . . . . . . . . . . . . . . . . . . .553

Table 95. Interface assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 554

Table 96. Stand screw/ring kit. . . . . . . . . . . . . . . . . . . . . . . . . . 555

Table 97. Stand assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .557

Table 98. Screw/ring kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 558

Table 99. Belt kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .559

Table 100. Gear/pulley kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .560

Table 101. Spring kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .560

Table 102. External covers and panels. . . . . . . . . . . . . . . . . . . . 563

Table 103. Internal components (1 of 3) . . . . . . . . . . . . . . . . . . .565

Table 104. Internal components (2 of 3) . . . . . . . . . . . . . . . . . . .566

Table 105. Internal components (3 of 3) . . . . . . . . . . . . . . . . . . .569

Table 106. Power cord terminal assembly . . . . . . . . . . . . . . . . .571

Table 107. Control panel assembly. . . . . . . . . . . . . . . . . . . . . . . 573

Table 108. Copyboard cover assembly. . . . . . . . . . . . . . . . . . . . 575

Table 109. Mirror assembly 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . 577

Table 110. Electrical tray assembly . . . . . . . . . . . . . . . . . . . . . .579

Table 111. Dc power supply PCA . . . . . . . . . . . . . . . . . . . . . . . .581

Table 112. APC power supply PCA . . . . . . . . . . . . . . . . . . . . . .582

Table 113. Noise filter PCA. . . . . . . . . . . . . . . . . . . . . . . . . . . . .583

Table 114. Control panel PCA . . . . . . . . . . . . . . . . . . . . . . . . . .584

Table 115. Control panel CPU PCA . . . . . . . . . . . . . . . . . . . . . . 585

Table 116. Control panel inverter PCA . . . . . . . . . . . . . . . . . . . .586

Table 117. Reader controller PCA . . . . . . . . . . . . . . . . . . . . . . .587

Table 118. Analog image processor PCA. . . . . . . . . . . . . . . . . . 588

Table 119. Motor driver PCA. . . . . . . . . . . . . . . . . . . . . . . . . . . . 589

Table 120. Inverter PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 590

Table 121. Connectors (1 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . .591

EN Tables 19

Page 22

Table 122. Connectors (2 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . .597

Table 123. Connectors (3 of 3) . . . . . . . . . . . . . . . . . . . . . . . . . .598

Table 124. Belt kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .600

Table 125. Bushing kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 601

Table 126. Gear/pulley kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .601

Table 127. Pin kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .602

Table 128. Screw/ring kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 602

Table 129. Spring kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .604

Table 130. Mounting hardware . . . . . . . . . . . . . . . . . . . . . . . . . .606

Table 131. External covers and panels. . . . . . . . . . . . . . . . . . . . 607

Table 132. DF assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .609

Table 133. Document tray assembly. . . . . . . . . . . . . . . . . . . . . . 613

Table 134. Upper cover assembly . . . . . . . . . . . . . . . . . . . . . . .615

Table 135. RF assembly (1 of 4). . . . . . . . . . . . . . . . . . . . . . . . . 617

Table 136. RF assembly (2 of 4). . . . . . . . . . . . . . . . . . . . . . . . . 621

Table 137. RF assembly (3 of 4). . . . . . . . . . . . . . . . . . . . . . . . . 625

Table 138. RF assembly (4 of 4). . . . . . . . . . . . . . . . . . . . . . . . . 629

Table 139. Right paper delivery assembly . . . . . . . . . . . . . . . . .631

Table 140. Paper feed motor assembly . . . . . . . . . . . . . . . . . . .633

Table 141. Belt drive motor assembly. . . . . . . . . . . . . . . . . . . . . 635

Table 142. Upper paper guide assembly . . . . . . . . . . . . . . . . . .637

Table 143. Lower paper guide assembly . . . . . . . . . . . . . . . . . .639

Table 144. Separation roller assembly . . . . . . . . . . . . . . . . . . . . 641

Table 145. Paper separation assembly. . . . . . . . . . . . . . . . . . . . 643

Table 146. RDF controller PCA. . . . . . . . . . . . . . . . . . . . . . . . . . 644

Table 147. Connectors (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . .645

Table 148. Connectors (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . .648

Table 149. Bushing kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 649

Table 150. Gear/pulley kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .649

Table 151. Screw/ring kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 650

Table 152. Spring kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .651

Table 153. Mounting hardware . . . . . . . . . . . . . . . . . . . . . . . . . .653

Table 154. External covers and panels . . . . . . . . . . . . . . . . . . . 655

Table 155. Internal components (1 of 3) . . . . . . . . . . . . . . . . . . .657

Table 156. Internal components (2 of 3) . . . . . . . . . . . . . . . . . . .659

Table 157. Internal components (3 of 3) . . . . . . . . . . . . . . . . . . .661

Table 158. Lifter drive assembly . . . . . . . . . . . . . . . . . . . . . . . . .663

Table 159. Paper pick-up assembly (1 of 2) . . . . . . . . . . . . . . . .665

Table 160. Paper pick-up assembly (2 of 2) . . . . . . . . . . . . . . . .667

Table 161. Deck controller PCA . . . . . . . . . . . . . . . . . . . . . . . . . 668

Table 162. Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 669

Table 163. Numerical parts list . . . . . . . . . . . . . . . . . . . . . . . . . . 672

Table 164. Alphabetical parts list . . . . . . . . . . . . . . . . . . . . . . . .680

20 Tables EN

Page 23

1

Product information

Chapter contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Copy module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Automatic document feeder (ADF) . . . . . . . . . . . . . . . . . . . . 28

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Side high-capacity input (side HCI). . . . . . . . . . . . . . . . . . . . 32

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Model and serial numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Safety and regulatory information . . . . . . . . . . . . . . . . . . . . . 35

Declaration of conformity. . . . . . . . . . . . . . . . . . . . . . . 35

FCC regulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

EN Chapter contents 21

Page 24

22 Chapter 1 - Product information EN

Page 25

Introduction

The HP Color LaserJet 8550 Multi-Function Printer (MFP) system

consists of the following:

l Copy module

l Stand

l Print engine

l Optional automatic document feeder (ADF)

l Optional side high-capacity input (side HCI)

Copy module

Features

Control panel l 320-by-230 dot LCD touch screen

Copy speed (letter/A4)

Copy speed (ledger/A3)

Original type

Magnification

Resolution

Advanced copying features:

l Up to 100 continuous copies

l Auto clear (two minute standard; variable, can be disabled)

l Auto color select (identifies original to select four-color or mono copy)

l One-touch adjust (vivid colors, tranquil colors, lighten image, darken

l Color adjust (color balance, density range YMCK adjustment)

l Auto power save (30-minute standard; variable, can be disabled)

l Low power (one-hour standard; variable in user mode)

l Original mode (text/photo/map, printed image, photo, black text)

l 6 pages per minute (ppm) full color

l 24 ppm monochrome

l 3 ppm full color

l 12 ppm monochrome

l Sheet, book, three-dimensional

object (2 kilogram maximum)

l N i n e preset reduction and

enlargement percentages

l Zoom: 25% to 400%, by 1%

increments

l 600 dots per inch by 600 lines per

inch

image, highlight reproduction, old-fashioned photo)

EN Introduction 23

Page 26

Advanced copying features (continued):

l Frame erase l Image shift

l Blind margin l Margin

l Auto gradation correction l Color balance

l Auto exposure l Sharpness

l Auto paper select l Single color

l Auto zoom l Image separation

l Two-page separation l Mode memory and recall

l Heavy-sheet original l Framing/blanking

l Image creation l Image combination

Specifications

Speed

Table 1. First copy time (in seconds*)

Type Size 4-color Mono-color

Plain paper A4, Letter 34 18

Thick paper A4, Letter 50 35

Transparency A4, Letter 57 41

*Times shown assume A4-size media, direct copy using cassette 1, face-up delivery,

and no pre-scanning; for face-down delivery, add three seconds for plain paper, six

seconds for thick paper, and seven seconds for transparencies.

Table 2. Copying speed (pages per minute)

Source Size 4-color Mono-color

Plain paper Cassette

Multifeeder

Thick paper Multifeeder A3/11 by 17

Transparency Multifeeder A4/LTR 2.1 ppm 2.8 ppm

A3, B4, A4R,

B5, 11 by 17,

Legal, Letter

A4/LTR 6 ppm 24 ppm

A4/LTR

3 ppm 12 ppm

1.2 ppm

2.4 ppm

1.7 ppm

3.4 ppm

24 Chapter 1 - Product information EN

Page 27

Environmental

Table 3. Operating conditions—copy/print

Temperature 15° to 27.5° C

59° to 81.5° F

Humidity 20% to 80% RH

Atmospheric pressure 786 to 1013 hPa (560 to 760 mmHg)

Acoustic emissions 74 dB copying

Ozone emissions 0.05 ppm or less

62 dB standby

0.02 ppm or less

Electrical

Table 4. Electrical specifications—copy/print

Power source:

110 V units

220 V units

Maximum power consumption 1.5 kW or less

100-127 Vac ± 10% at 50 Hz ± 2 Hz,

60 Hz ± 2 Hz

220-240 Vac ± 10% at 50 Hz ± 2 Hz

Physical

Table 5. Physical specifications—copy/print

Weight 39 kg (348 lb)

Dimensions (mm) Width: 673 mm (26.5 in)

Height: 190 mm (7.5 in)

Depth: 787 mm (31.0 in)

Supported media sizes

l

A3 l B4

l A4R l B5

l A4 l 11-by -17 inches

l legal l letter

EN Copy module 25

Page 28

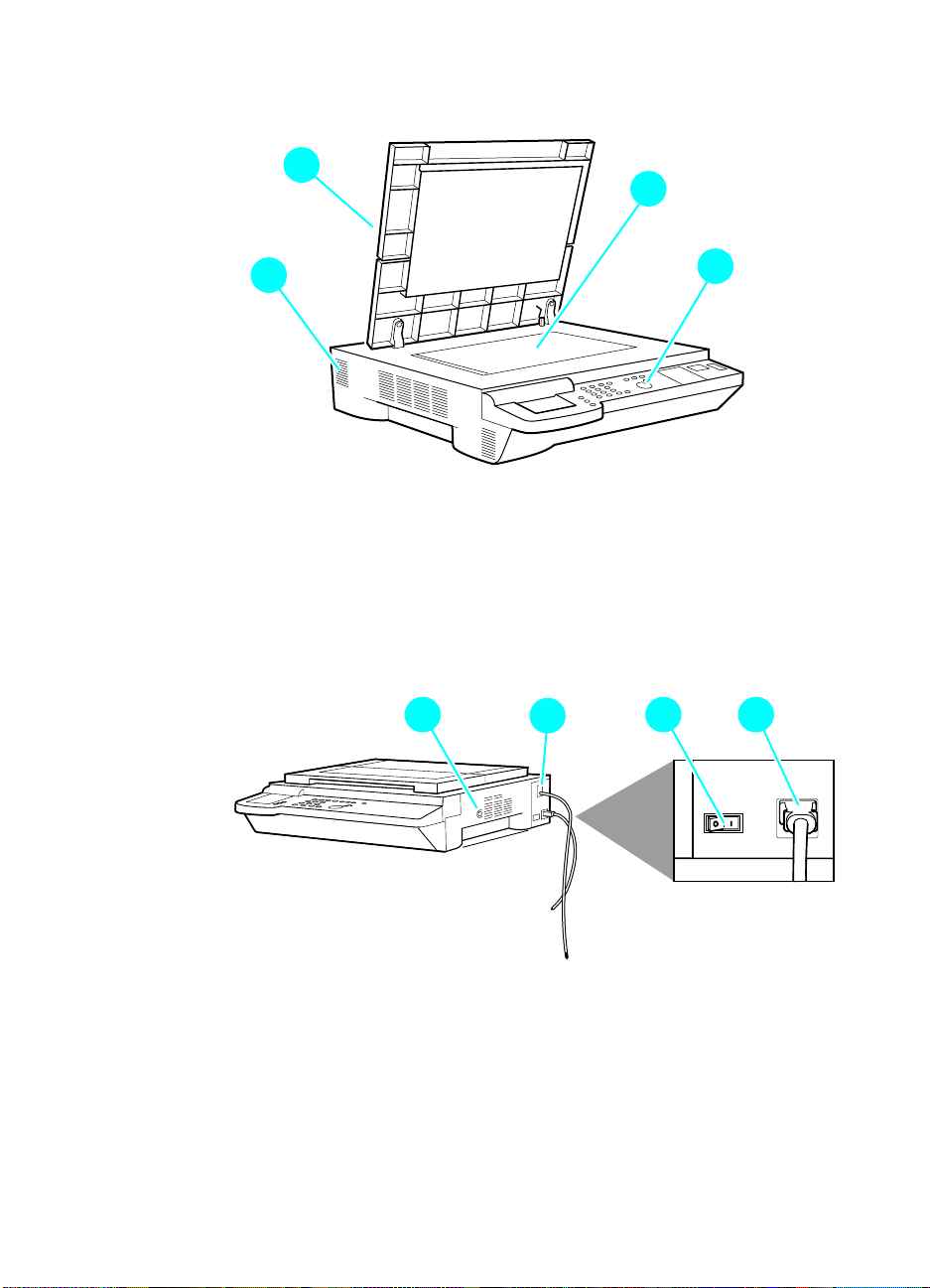

Overview

2

1

2

4

Figure 1. Copy module front left

1 Copyboard cover

2 Copyboard glass

3 Control panel

4 Power supply cooling fan air inlet

2

2

2

3

2

Figure 2. Copy module front right

1 Control key switch

2 Power supply cord connector

3 Rear power switch

4 Printer power cord connector

26 Chapter 1 - Product information EN

2

2

2 2

3 41

Page 29

2

2

2 2

4 5

2

6

2

3

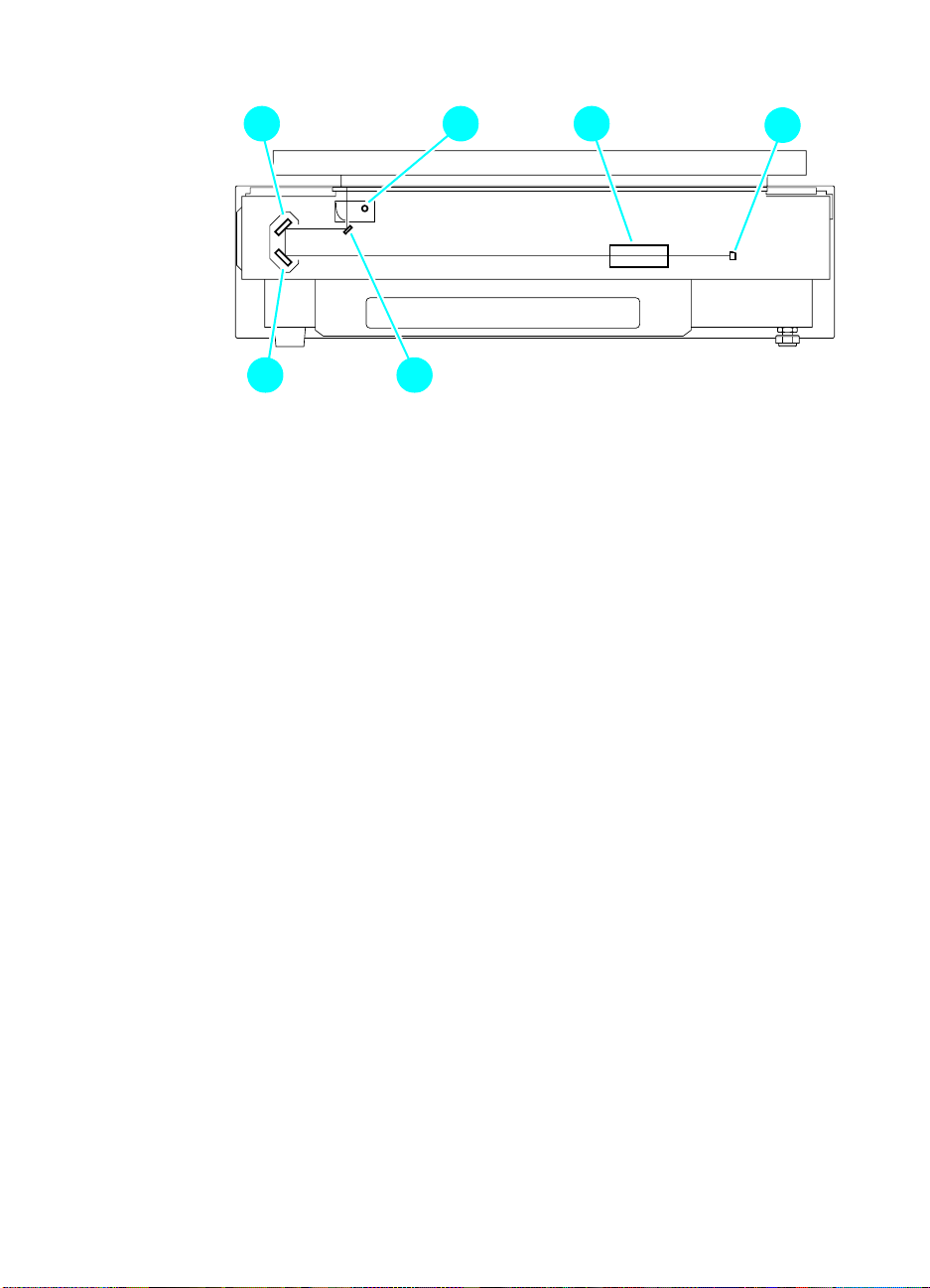

Figure 3. Copy module cross-section

1 Number 1 mirror

2 Number 2 mirror

3 Number 3 mirror

4 Scanning lamp

5 Lens

6 Charge-coupled device (CCD)

2

1

EN Copy module 27

Page 30

Automatic document feeder (ADF)

The ADF is not part of the standard MFP bu ndle. It can be ordered as

an option.

Features

The ADF can identify the size of an original in terms of its length

(feeding direction) and width for communication to its host computer.

Features include:

l 24 copies per minute

l circulating, auto-duplexing pickup me thod

l communication with copier using interprocess communication

(IPC)

28 Chapter 1 - Product information EN

Page 31

Specifications

Electrical

Table 6. Electrical specifications—ADF

Power supply 24 Vdc (from the copy module)

Maximum power consumption Less than 170 W

Physical

Table 7. Physical specifications—ADF

Weight Approximately 14.8 kg (32.6 lb)

Weight does not include the document output

tray.

Dimensions Width: 641 mm (25.2 in)

Height: 152 mm (6.0 in)

Depth: 508 mm (20.0 in)

Dimensions do not include document output

tray.

Supported media

Table 8. Supported media—ADF

Sizes Weights Capacity

A5, B5, A4, Letter, Legal 50 to 105 g/m

B4, A3, 11 by 17, Legal 50 to 105 g/m

2

2

50 sheets

25 sheets

ADF media selection guidelines

Do not use the following as originals in the ADF:

l transparencies, or paper with an opacity of 80% or less

l carbon-backed sheets

l sheets with paste-ups or binding

l sheets with cut-outs, holes, or tears

l sheets with a clips, staples, or glue

l sheets with curling, wrinkling, or creasing

CAUTION Do not feed the same original more than once, to protect against

damage.

EN Automatic document feeder (ADF) 29

Page 32

Overview

2 2

1 2 4

2

5

Figure 4. Automatic document feeder

1 Upper cover

2 Side guide

3 Last-page detector

4 Original-set indicator

2

6

2

2

7 8

2

3

5 Document tray

6 Sub-tray

7 Body cover

8 Document output tray

2

30 Chapter 1 - Product information EN

Page 33

2

1

2

2

2 2 2 2

4 5 6 7

2

3

2

13

2

8

2

9

22

Figure 5. Automatic document feeder cross-section

1 Reversing roller

2 Paper deflecting plate

3 Feeding roller (separation

function)

4 Separation belt (feeding

function)

5 Pre-separation guide

6 Delivery/pick-up roller

7 Paper retaining plate

121415

22

11

8 Pick-up roller

9 Delivery roller

10 Feeding belt link roller

11 Retaining rolls

12 Feeding belt

13 Paper stopper plate

14 Feeding belt drive roller

15 Registration roller

2

10

EN Automatic document feeder (ADF) 31

Page 34

Side high-capacity input (side HCI)

Features

l holds up to 1,000 sheets of 20-pound (lb) media

l supports media weights of 64 g/m

accommodates either letter- or A4-size media

l

Specifications

Environmental

Table 9. Operating conditions—side HCI

Temperature 10° to 32.5° C (50° to 90.5° F)

Humidity 20% to 80% RH

Atmospheric pressure 786 to 1013 hPa (560 to 760 mm Hg)

Electrical

2

to 105 g/m

2

Table 10. Electrical specifications—side HCI

Power supply:

110 V units

220 V units

Power consumption Less than 22 W

100 to 120 Vac (50/60 Hz)

220 to 240 Vac (50 Hz)

Physical

Table 11. Physical specificat ions—side HCI

Weight Approximately 18.5 kg (40.8 lb)

Dimensions (mm) Width: 317 mm (12.5 in)

Height: 280 mm (11.0 in)

Depth: 571 mm (22.5 in)

32 Chapter 1 - Product information EN

Page 35

Overview

2

2

2

3

Figure 6. Front of side HCI

1 Upper right cover

2 Paper-size selection tab

3 User LED

2

1

2

4

2

5

Figure 7. Rear of side HCI

4 Interface connector

5 Power receptacle

EN Side high-capacity input (side HCI) 33

Page 36

2

4

2

1

2

2

2

3

2

5

Figure 8. Cross-section of side HCI

1 Feed roller

2 Pick-up roller

3 Paper-size limit panel

4 Separation roller

5 Lifter

34 Chapter 1 - Product information EN

Page 37

Model and serial numbers

The serial number on the HP Color LaserJet 8550MFP is t he pr imar y

identification number for this MFP bundle. The serial number is

located on the back of the print engine.

Accessories also have their own unique serial numbers, which are

located on the back of each accessory.

Safety and regulatory information

Declaration of conformity

according to ISO/IEC Guide 22 and EN 45014

Manufacturer’s Name:

Manufacturer’s Address:

declares, that the product

Product Name:

Model Number:

Product Options:

conforms to the following Product Specifications:

Safety: IEC 950:1991+A1+A2+A3+A4 / EN 60950:1992+A1+A2+A3+A4+A11

EMC: CISPR 22:1997 / EN 55022:1998 Class A

Supplementary Information:

The product herewith complies with the requirements of the EMC Directive 89/336/EEC and the Low Voltage

Directive 73/23/EEC, and carries the CE-Marking accordingly.

1

The product was tested in a typical configuration with Hewlett-Packard Personal Computer Systems.

2

This Device complies with Part 15 of the FCC Rules. Operation is subject to the following two Conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation

June 17, 1999

For Regulatory Topics ONLY, contact:

Australia Contact: Product Regulations Manager, Hewlett-Packard Australia Ltd., 31-41 Joseph

European Contact: Your Local Hewlett-Packard Sales and Service Office or Hewlett-Packard

USA Contact: Product Regulations Manager, Hewlett-Packard Company, PO Box 15, Mail Stop

IEC 825-1:1993 +A1/EN 60825-1:1994 +A11 Class 1 (Laser/LED)

EN 61000-3-2:1995

EN 61000-3-3:1995

EN 55024:1998

FCC Title 47 CFR, Part 15 Class A

AS / NZS 3548:1995

Street, Blackburn, Victoria 3130, Australia

GmbH, Department HQ-TRE / Standards Europe, Herrenberger Straße 110-140,

D-71034 Böblingen, (Fax: +49-7031-14-3143)

160, Boise, Idaho 83707-0015, (Phone: 208-396-6000)

Hewlett-Packard Company

11311 Chinden Boulevard

Boise, Idaho 83714-1021

USA

Color LaserJet 8550MFP Accessories

C7836A, C7837A, and C7839A

All

1

2

/ ICES-002, Issue 2

EN Model and serial numbers 35

Page 38

FCC regulations

This equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment

generates, uses, and can radiate radio frequency energy. If it is not

installed and used in accordance with the instructions, it may cause

harmful interference to radio communicati ons. However, there is no

guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television

receptions, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

l Reorient or relocate the receiving antenna.

l Increase separation between equipment and receiver.

l Connect equipment to an outlet on a circuit different from that to

which the receiver is located.

l Consult your dealer or an experienc ed radio/TV technician.

Note Any changes or modifications to the printer that are not expressly

approved by HP could void the user’s authority to operate this

equipment.

Use of a shielded interface cable is required to comply with the Class

B limits of Part 15 of FCC rules.

36 Chapter 1 - Product information EN