Page 1

HP 85325A R/Q/U/V/W Millimeter Subsystem HP 85326A Millimeter-Wave Interface Kit

Operating and Service Manual

Page 2

Page 3

HP 85325A R/Q/U/V/W Millimeter

Subsystem

HP 85326A Millimeter-Wave Interface Kit

Operating and Service

Manual

HP part number: 85325-90061

Printed in USA

08 December 1998

Edition 2.0

Page 4

Notice

The information contained in this document is subject to change without

notice.

Hewlett-Packard makes no warranty of any kind with regard to this material,

including, but not limited to, the implied warranties of merchantability and

fitness for a particular purpose. Hewlett-Packard shall not be liable for errors

contained herein or for incidental or consequential damages in connection

with the furnishing, performance, or use of this material.

Hewlett-Packard assumes no responsibility for the use or reliability of its

software on equipment that is not furnished by Hewlett-Packard.

This document contains proprietary information which is protected by

copyright. All rights are reserved. No part of this document may be

photocopied, reproduced, or translated to another language without prior

written consent of Hewlett-Packard Company.

Restricted Rights Legend

Use, duplication, or disclosure by the U.S. Government is subject to

restrictions as set forth in subparagraph (c)(1)(ii) of the Rights in Technical

Data and Computer Software clause at DFARS 252.227-7013 for DOD

agencies, and subparagraphs (c)(1) and (c)(2) of the Commercial Computer

Software Restricted Rights clause at FAR 52.227-19 for other agencies.

Hewlett-Packard Company

Santa Rosa Systems Division

1400 Fountaingrove Parkway

Santa Rosa, CA 95403-1799, U.S.A.

© Copyright Hewlett-Packard Company 1998

iv

HP 85325A Operating and Service Manual

Page 5

What You’ll Find in This Manual…

Chapter 1 • Installation

Chapter 2 • Operation

Chapter 3 • General Information

Chapter 4 • Performance Verification

Chapter 5 • Timebase Check and Adjustment

Chapter 6 • Service

Appendix A • Using the HP 8340/41 in Your System

Appendix B • Connecting the Waveguide Properly

HP 85325A Operating and Service Manual

v

Page 6

Warranty

Certification Hewlett-Packard Company certifies that this product met its published

specifications at the time of shipment from the factory. Hewlett-Packard

further certifies that its calibration measurements are traceable to the

United States National Institute of Standards and Technology (NIST,

formerly NBS), to the extent allowed by the Institute’s calibration facility,

and to the calibration facilities of other International Standards

Organization members.

Warranty This Hewlett-Packard system product is warranted against defects in

materials and workmanship for a period corresponding to the individual

warranty periods of its component products. Instruments are warranted for a

period of one year. During the warranty period, Hewlett-Packard Company

will, at its option, either repair or replace products that prove to be defective.

Warranty service for products installed by HP and certain other products

designated by HP will be performed at Buyer’s facility at no charge within

HP service travel areas. Outside HP service travel areas, warranty service

will be performed at Buyer’s facility only upon HP’s prior agreement and

Buyer shall pay HP’s round trip travel expenses. In all other areas, products

must be returned to a service facility designated by HP.

For products returned to HP for warranty service, Buyer shall prepay

shipping charges to HP and HP shall pay shipping charges to return the

product to Buyer.However,Buyer shall pay all shipping charges, duties, and

taxes for products returned to HP from another country.

HP warrants that its software and firmware designated by HP for use with an

instrument will execute its programming instructions when properly

installed on that instrument. HP does not warrant that the operation of the

instrument, or software, or firmware will be uninterrupted or error free.

LIMITATION OF WARRANTY. The foregoing warranty shall not apply

to defects resulting from improper or inadequate maintenance by Buyer,

Buyer-supplied software or interfacing, unauthorized modification or

misuse, operation outside of the environmental specifications for the

product, or improper site preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. HP

SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OR

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES. THE REMEDIES PROVIDED HEREIN ARE

BUYER’S SOLE AND EXCLUSIVE REMEDIES. HP SHALL NOT BE

LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR

vi

HP 85325A Operating and Service Manual

Page 7

CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT,

TORT, OR ANY OTHER LEGAL THEORY.

Assistance Product maintenance agreements and other customer assistance agreements

are available for Hewlett-Packard products.

For assistance, call your local Hewlett-Packard Sales and Service Office

(refer to “Service and Support” on page viii).

HP 85325A Operating and Service Manual

vii

Page 8

Service and Support

Any adjustment, maintenance, or repair of this product must be performed

by qualified personnel. Contact your customer engineer through your local

HP Service Center. You can find a list of HP Service Centers on the web at

http://www.hp.com/go/tmdir.

If you do not have access to the Internet, one of these HP centers can direct

you to your nearest HP representative:

United States: Hewlett-Packard Company

Test and Measurement Call Center

PO Box 4026

Englewood, CO 80155-4026

(800) 452 4844 (toll-free in US)

Canada: Hewlett-Packard Canada Ltd.

5150 Spectrum Way

Mississauga, Ontario L4W 5G1

(905) 206 4725

Europe: Hewlett-Packard European Marketing Centre

Postbox 999

1180 AZ Amstelveen

The Netherlands

(31 20) 547 9900

Japan: Hewlett-Packard Ltd.

Measurement Assistance Center

9-1, Takakura-Cho, Hachioji-Shi

Tokyo 192, Japan

(81) 426 56 7832

(81) 426 56 7840 (FAX)

Latin America: Hewlett-Packard Latin American Region Headquarters

5200 Blue Lagoon Drive, 9th Floor

Miami, Florida 33126, U.S.A.

(305) 267 4245, (305) 267-4220

(305) 267 4288 (FAX)

Australia/New Zealand: Hewlett-Packard Australia Ltd.

31-41 Joseph Street

Blackburn, Victoria 3130

Australia

1 800 629 485 (Australia)

0800 738 378 (New Zealand)

(61 3) 9210 5489 (FAX)

Asia-Pacific: Hewlett-Packard Asia Pacific Ltd.

17-21/F Shell Tower, Times Square

1 Matheson Street, Causeway Bay

Hong Kong

(852) 2599 7777

(852) 2506 9285 (FAX)

viii

HP 85325A Operating and Service Manual

Page 9

Safety and Regulatory Information

Review this product and related documentation to familiarize yourself with

safety markings and instructions before you operate the instrument. This

product has been designed and tested in accordance with international

standards.

WARNING The WARNING notice denotes a hazard. It calls attention to a procedure,

practice, or the like, that, if not correctly performed or adhered to, could result

in personal injury. Do not proceed beyond a WARNING notice until the

indicated conditions are fully understood and met.

CAUTION

Instrument Markings

The CAUTION notice denotes a hazard. It calls attention to an operating

procedure, practice, or the like, which, if not correctly performed or adhered

to, could result in damage to the product or loss of important data. Do not

proceed beyond a CAUTION notice until the indicated conditions are fully

understood and met.

When you see this symbol on your instrument, you should refer to the instrument’s

!

instruction manual for important information.

This symbol indicates hazardous voltages.

The laser radiation symbol is marked on products that have a laser output.

This symbol indicates that the instrument requires alternating current (ac) input.

The CE mark is a registered trademark of the European Community. If it is

accompanied by a year, it indicates the year the design was proven.

The CSA mark is a registered trademark of the Canadian Standards Association.

1SM1-A This text indicates that the instrument is an Industrial Scientific and Medical Group 1

Class A product (CISPER 11, Clause 4).

This symbol indicates that the power line switch is ON.

This symbol indicates that the power line switch is OFF or in STANDBY position.

HP 85325A Operating and Service Manual

ix

Page 10

Safety Earth Ground

This is a Safety Class I product (provided with a protective earthing

terminal). An uninterruptible safety earth ground must be provided from the

main power source to the product input wiring terminals, power cord, or

supplied power cord set. Whenever it is likely that the protection has been

impaired, the product must be made inoperative and secured against any

unintended operation.

BeforeApplying Power Verify that the product is configured to match the available main power

source as described in the input power configuration instructions in this

manual. If this product is to be powered by autotransformer, make sure the

common terminal is connected to the neutral (grounded) side of the ac power

supply.

x

HP 85325A Operating and Service Manual

Page 11

Declaration of Conformity

This is to certify that this product meets the radio frequency interference

requirements of Directive FTZ 1046/1984. The German Bundespost has

been notified that this equipment was put into circulation and has been

granted the right to check the product type for compliance with these

requirements.

If test and measurement equipment is operated with unshielded cables

and/or used for measurements on open set-ups, the user must insure that

under these operating conditions, the radio frequency interference limits are

met at the border of his premises.

Model HP 85325A and Model HP 85326A

Hiermit wird bescheinigt, dass dieses Gert/System in bereinstimmung mit

den Bestimmungen von Postverfgung 1046/84 funkentst"rt ist.

Der Deutschen Bundespost wurde das Inverkehrbringen dieses

Gertes/Systems angezeight und die Berechtigung zur berprfung der Serie auf

Einhaltung der Bestimmungen eingerumt.

Zustzinformation fr Mess-und Testgerte:

Werden Mess- und Testgerte mit ungeschirmten Kabeln und/oder in offenen

Messaufbauten verwendet, so ist vom Betreiber sicherzustellen, dass die

Funk-Entst"rbestimmungen unter Betriebsbedingungen an seiner Grundstcksgrenze eingehalten werden.

HP 85325A Operating and Service Manual

xi

Page 12

Typeface Conventions

Italics • Used to emphasize important information:

Use this software only with the HP xxxxxX system.

• Used for the title of a publication:

Refer to the HP xxxxxX System-Level User’s Guide.

• Used to indicate a variable:

Type

LOAD BIN filename.

Instrument Display • Used to show on-screen prompts and messages that you will see on the

display of an instrument:

The HP xxxxxX will display the message

CAL1 SAVED.

[Keycap]

{Softkey}

User Entry • Used to indicate text that you will enter using the computer keyboard;

• Used for labeled keys on the front panel of an instrument or on a

computer keyboard:

Press

[Return]

.

• Used for simulated keys that appear on an instrument display:

Press

{Prior Menu}

text shown in this typeface must be typed exactly as printed:

Type

LOAD PARMFILE

.

• Used for examples of programming code:

#endif // ifndef NO_CLASS

Path Name

Computer Display

• Used for a subdirectory name or file path:

Edit the file

usr/local/bin/sample.txt

• Used to show messages, prompts, and window labels that appear on a

computer monitor:

The

Edit Parameters

window will appear on the screen.

• Used for menus, lists, dialog boxes, and button boxes on a computer

monitor from which you make selections using the mouse or keyboard:

Double-click

EXIT

to quit the program.

xii

HP 85325A Operating and Service Manual

Page 13

Contents

1. Installation

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Table 1-1. Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Figure 1-1. Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Using an HP 8340/41 RF Source . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Connecting the Waveguide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Optional 10 MHz Reference Connection . . . . . . . . . . . . . . . . . . . . . 1-4

Checking the Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Receiver Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Setting Up the Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Table 1-2. DENOM Value Table . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Table 1-3. Multiplier DENOM Table . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Mixer LO Power Level Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Initial Fixed Attenuator Value Selections . . . . . . . . . . . . . . . . . . . . . 1-8

Table 1-4. Selecting HP 85326A Reference and Test Attenuation . . 1-9

How to Use the Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Changing Attenuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

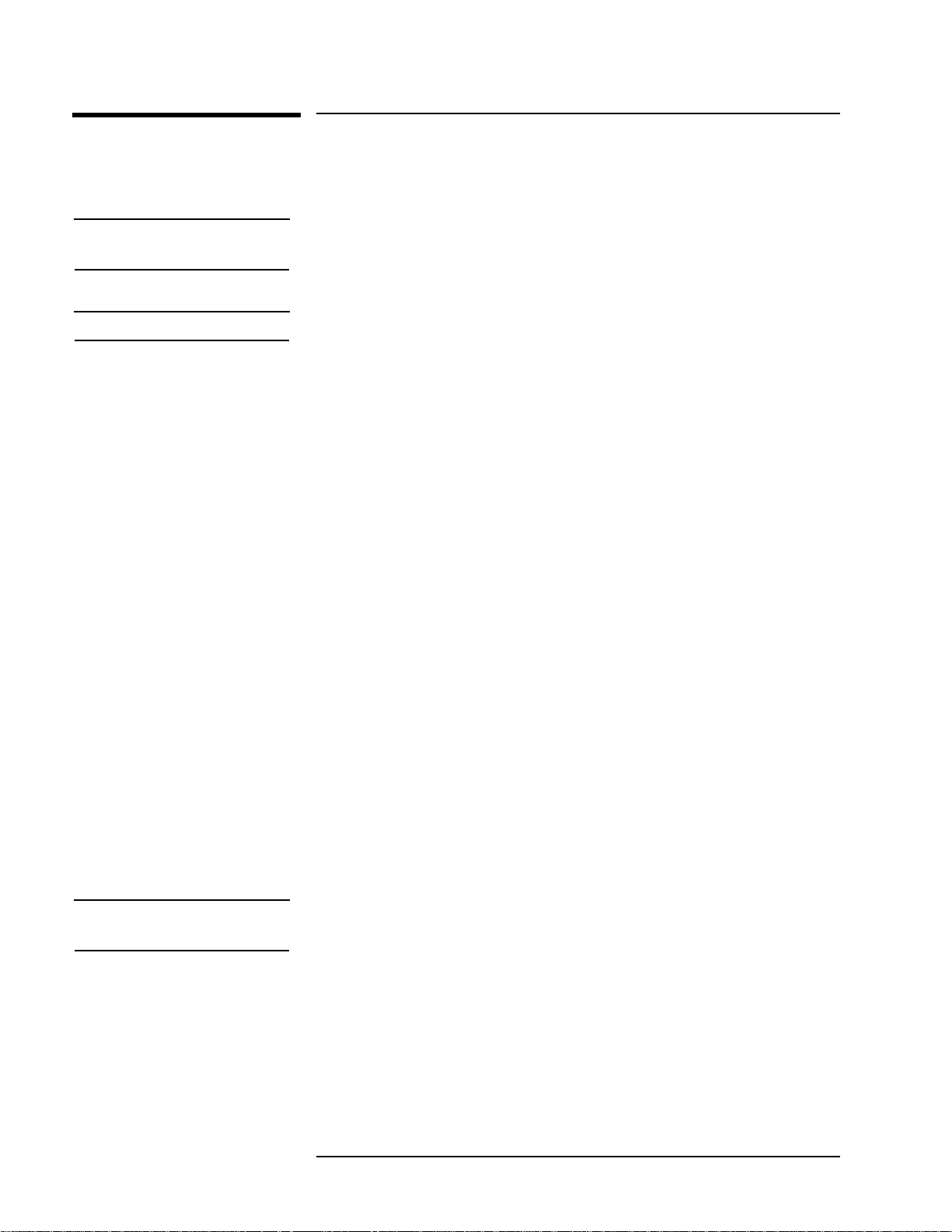

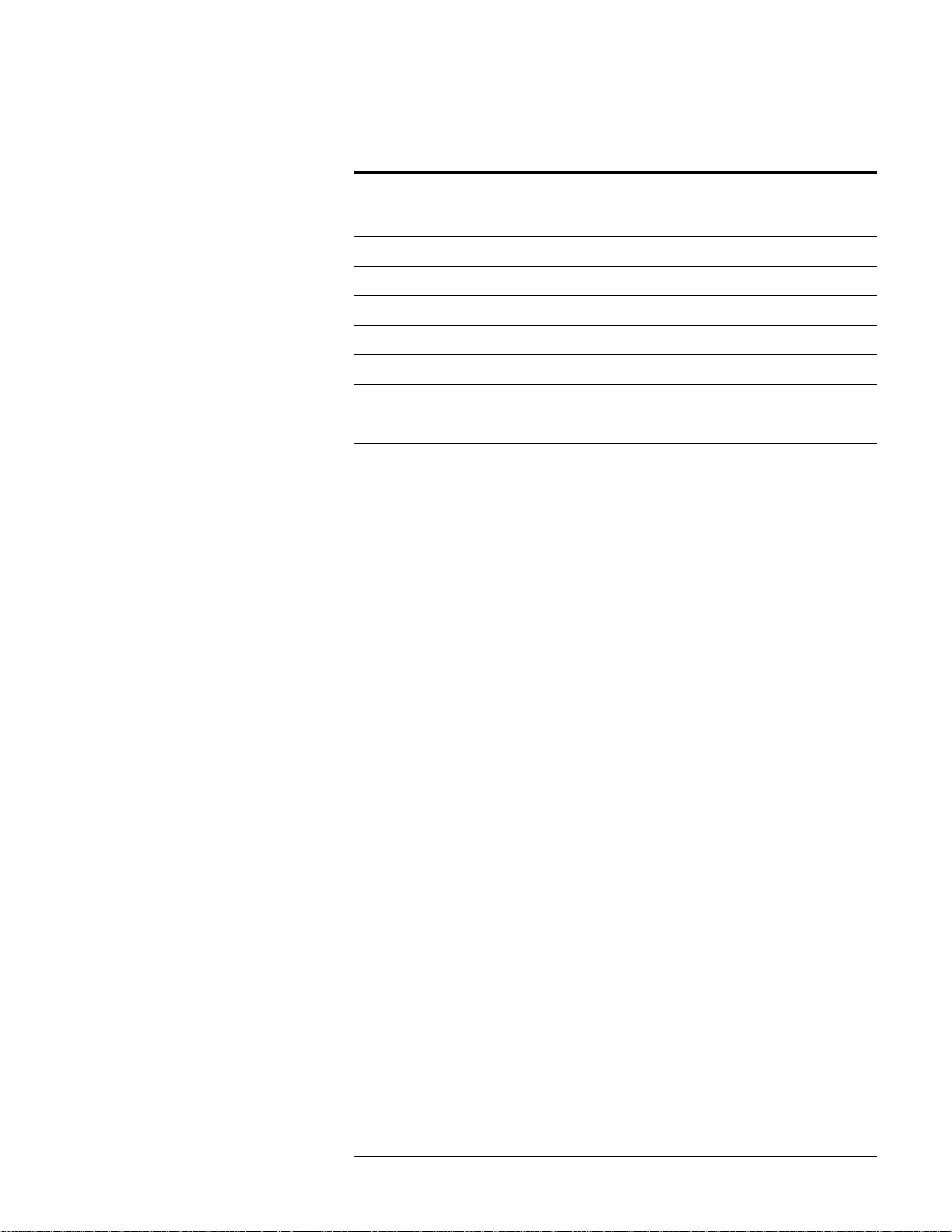

Figure 1-2. Reference Attenuator Installation . . . . . . . . . . . . . . . . 1-10

Figure 1-3. Test Attenuator Installation . . . . . . . . . . . . . . . . . . . . 1-10

Adjustment Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Procedure 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

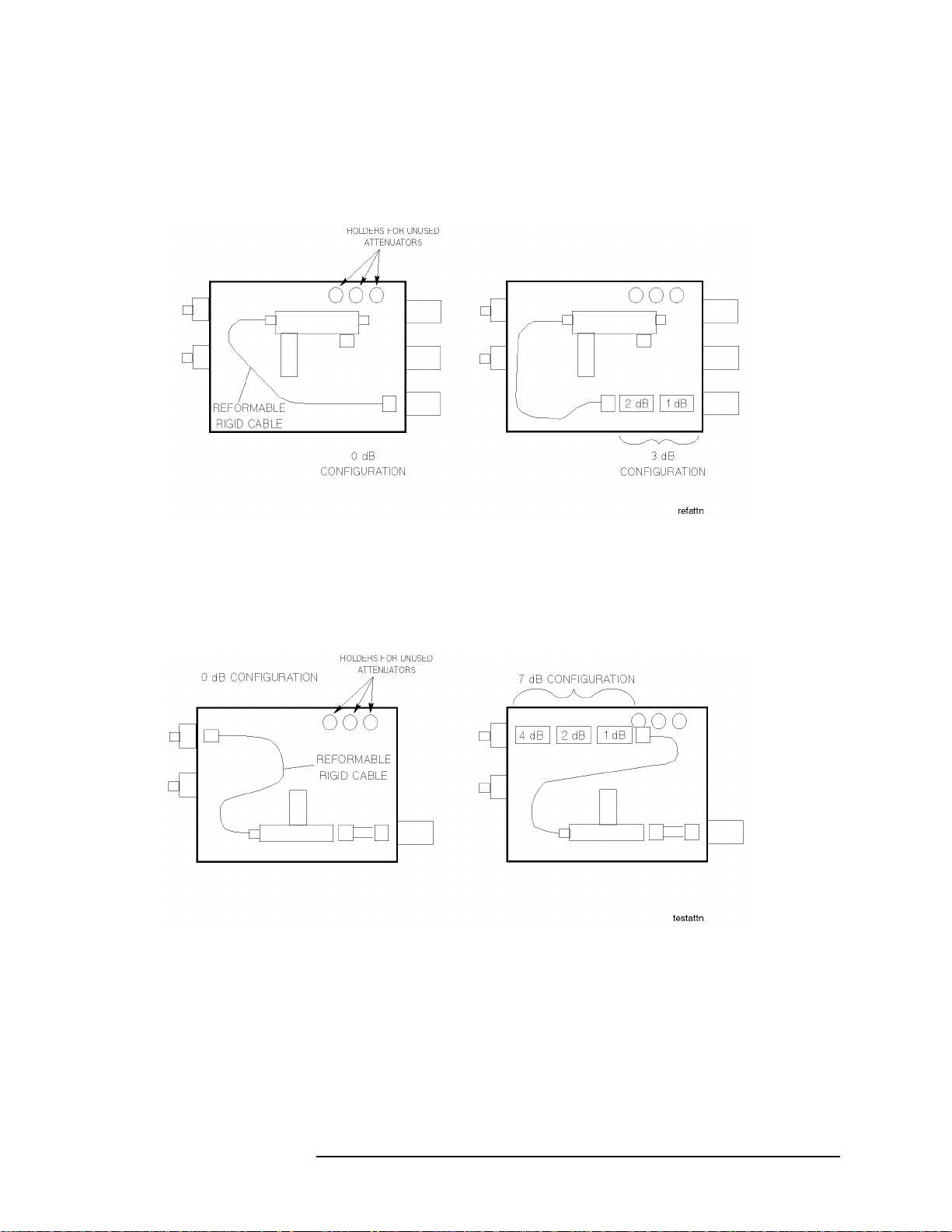

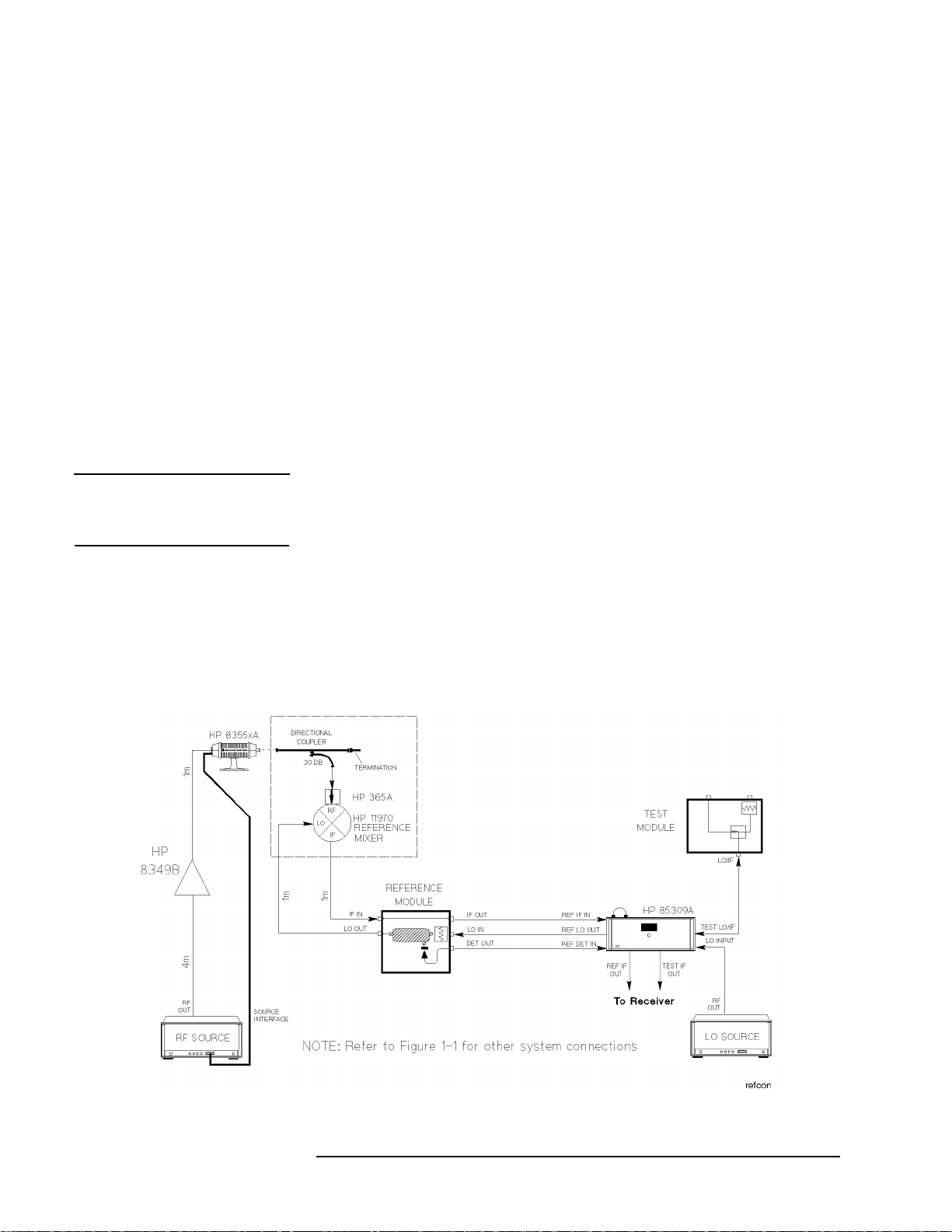

Figure 1-4. Measuring LO Power from the Reference Module . . . 1-11

Figure 1-5. Reference Mixer Connections . . . . . . . . . . . . . . . . . . . 1-12

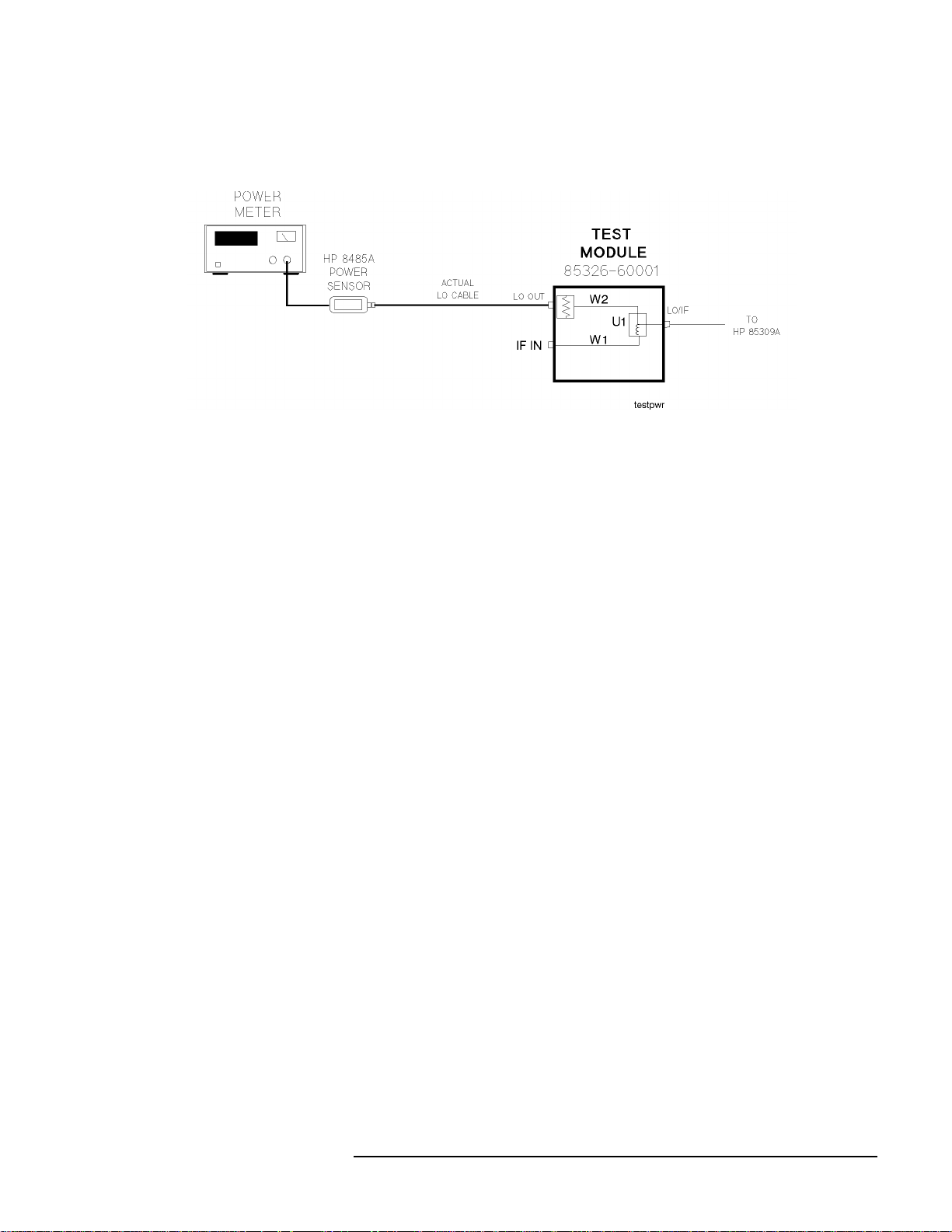

Figure 1-6. LO Power Measurement Point for Test Module . . . . . 1-13

Procedure 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Mixer Operational Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Figure 1-7. Test Mixer Connections . . . . . . . . . . . . . . . . . . . . . . . 1-17

When Using an HP 8350 LO Source . . . . . . . . . . . . . . . . . . . . . . . 1-18

Saving the Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Final Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Figure 1-8. Leveling Control Cables . . . . . . . . . . . . . . . . . . . . . . . 1-20

Figure 1-9. HP 85325A/85326A Installation Block Diagram

(Coupled Reference) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Figure 1-10. HP 85325A/85326A Visual Installation Diagram

(Coupled Reference) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-22

Figure 1-11. HP 85325A/85326A Installation Block Diagram

(Radiated Reference) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

If Using an HP 8340/41 RF Source . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Connecting the Waveguide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

HP 85325A Operating and Service Manual

Contents-i

Page 14

Proper Torque for Coax Connections . . . . . . . . . . . . . . . . . . . . . . . 1-24

Table 1-5. Proper Connector Torque . . . . . . . . . . . . . . . . . . . . . . . 1-24

Turn ON AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

2. Operation

Mixer Operating Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Maximum RF Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Maximum LO Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Required LO Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Connector Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Proper Waveguide Connector Alignment . . . . . . . . . . . . . . . . . . . . . 2-2

3. General Information

Chapter Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

About Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Table 3-1. R, Q, and U Band System Level Specifications . . . . . . . . 3-2

Table 3-2. V and W Band System Level Specifications . . . . . . . . . . . 3-3

MM-Wave Source and Mixer Characteristics . . . . . . . . . . . . . . . . . . . . . 3-4

Table 3-3. MM-Wave Source Information . . . . . . . . . . . . . . . . . . . . 3-4

Table 3-4. MM-Wave Mixer Information . . . . . . . . . . . . . . . . . . . . . 3-4

Supplied Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Table 3-5. Supplied Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Maximum RF Cable Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Figure 3-1. L

, LR, and LT Cables . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

S

Table 3-6. Maximum Cable Lengths (meters) . . . . . . . . . . . . . . . . . 3-6

Formulas for Cable Length Maximums . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure 3-2. L

, LR, LT Cable Lengths, Example . . . . . . . . . . . . . . . . 3-7

S

4. System Performance Verification

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Non-Banded Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Table 4-1. Recommended Test Equipment (non-banded) . . . . . . . . . 4-2

Band-Dependent Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Table 4-2. Recommended Test Equipment (banded) . . . . . . . . . . . . 4-3

Transmitter Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Receiver Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

First Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Second Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Setting Up The Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Table 4-3. Proper Connector Torque . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Figure 4-1. Initial Equipment Configuration . . . . . . . . . . . . . . . . . . 4-8

Table 4-4. Switch Positions for Analyzer Mode . . . . . . . . . . . . . . . . 4-9

Install the Performance Verification Software Onto a Hard Disk . . . . . 4-10

Copy Onto a Hard Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Starting The Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Contents-ii

HP 85325A Operating and Service Manual

Page 15

Softkey Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Loading the Program From a Hard Disk . . . . . . . . . . . . . . . . . . . . 4-11

Running the Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Helpful Hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Detailed Test Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

CW Frequency Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Maximum Leveled Power Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

RF to IF Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

IF Noise Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Channel Crosstalk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Compression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

5. Synthesized LO Source Timebase Check and Adjustment

Description and Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Table 5-1. Suggested Adjustment Interval for LO Sources . . . . . . . 5-1

Figure 5-1. LO Source 10 MHz Timebase Adjustment Setup . . . . . 5-2

Figure 5-2. 10 MHz Standard Adjustment Location . . . . . . . . . . . . 5-3

6. Service

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Figure 6-1. System Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Transmitter Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

The Purpose of Each Device in the Transmitter Section . . . . . . 6-3

Allowable HP-IB Cable Lengths . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Extender Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Receiver Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Purpose of Each Device in the Receiver Section . . . . . . . . . . . . 6-4

Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Non-Banded Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Table 6-1. Recommended Test Equipment (Non-Banded) . . . . . . . . 6-7

Band-Dependent Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Table 6-2. Recommended Test Equipment (Banded) . . . . . . . . . . . . 6-8

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Special 5/16 Inch Wrench . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Replaceable Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

How to Order Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

MM-Wave Module Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Test Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Table 6-3. Test Module (85326-60001)Parts . . . . . . . . . . . . . . . . . 6-11

Figure 6-2. HP 85326A (85326-60001) . . . . . . . . . . . . . . . . . . . . 6-11

When Replacing a Diplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Reference Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Table 6-4. Reference Module (85326-60002)Parts . . . . . . . . . . . . 6-12

Figure 6-3. HP 85356A (85326-60002) . . . . . . . . . . . . . . . . . . . . 6-12

Band-Related Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

HP 85325A Operating and Service Manual

Contents-iii

Page 16

Table 6-5. Parts Supplied in Specific Bands . . . . . . . . . . . . . . . . . . 6-13

Repairing a Mixer or Source Module . . . . . . . . . . . . . . . . . . . . 6-13

Miscellaneous Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Table 6-6. Miscellaneous Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

7. Using the HP 8340/41 in Your System

Figure A-1. HP 8340/41 RF Source . . . . . . . . . . . . . . . . . . . . . . . . . A-1

8. Connecting the Waveguide Properly

Handling and Storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Connecting WR-62 Waveguide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Precision Flanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Figure B-1. Alignment Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Aligning Two Precision Flanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Figure B-2. Inserting Slip Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Figure B-3. Align Flanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Figure B-4. Inspect Flange Connections . . . . . . . . . . . . . . . . . . . . . B-4

Aligning Precision and Non-Precision Flanges . . . . . . . . . . . . . . . . B-5

Figure B-5. Align Pin with Head . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Figure B-6. Tighten Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Contents-iv

HP 85325A Operating and Service Manual

Page 17

Installation

1

Installation

This chapter explains how to:

• set up the equipment

• adjust LO power levels

• check mixer operation

• perform final installation

WARNING This equipment is capable of radiating millimeter-wave energy from the end of

an unterminated waveguide. Do not look directly into the open end of any

waveguide when it is connected to a source of millimeter-wave energy.

Take precautions consistent with ANSI C95.1 - 1982, a study performed by the

American National Standards Institute that sets limits for human exposure to

microwaveand millimeter-wave energy. Copies of this publication are available

from:

CAUTION

American National Standards Institute

11 West 42 Street

New York, New York 10036

Telephone: (212) 642-4900

WEB site: www.ansi.org

Do not connect LO power to the HP 11970 mixers until you adjust the LO

power in “Mixer LO Power Level Adjustment” on page 1-8. If you connect

LO power before adjusting it you could permanently damage the mixers.

HP 85325A Operating and Service Manual

1-1

Page 18

Installation

Required Equipment

Required Equipment

The following equipment is required when performing installation.

Table 1-1 Equipment Required

Item Qty HP Model or Part Number

Power Meter 1 HP 436, 437, or 438

Power Sensor 1 HP 8485A

5/16 inch Wrench 1 08555-20097 (supplied with HP 85326A)

T-10 Torx Driver 1 8710-1623 (supplied with HP 85326A)

1/4 inch Wrench 1 8710-0510 (supplied with HP 85325A)

3/16 inch Wrench 1 8710-0013 (supplied with HP 85325A)

3/32 Hex Ball Driver 1 8710-1539 (supplied with HP 85325A)

Adapter, 3.5 mm (f) to (f) 1 1250-1749

1-2

HP 85325A Operating and Service Manual

Page 19

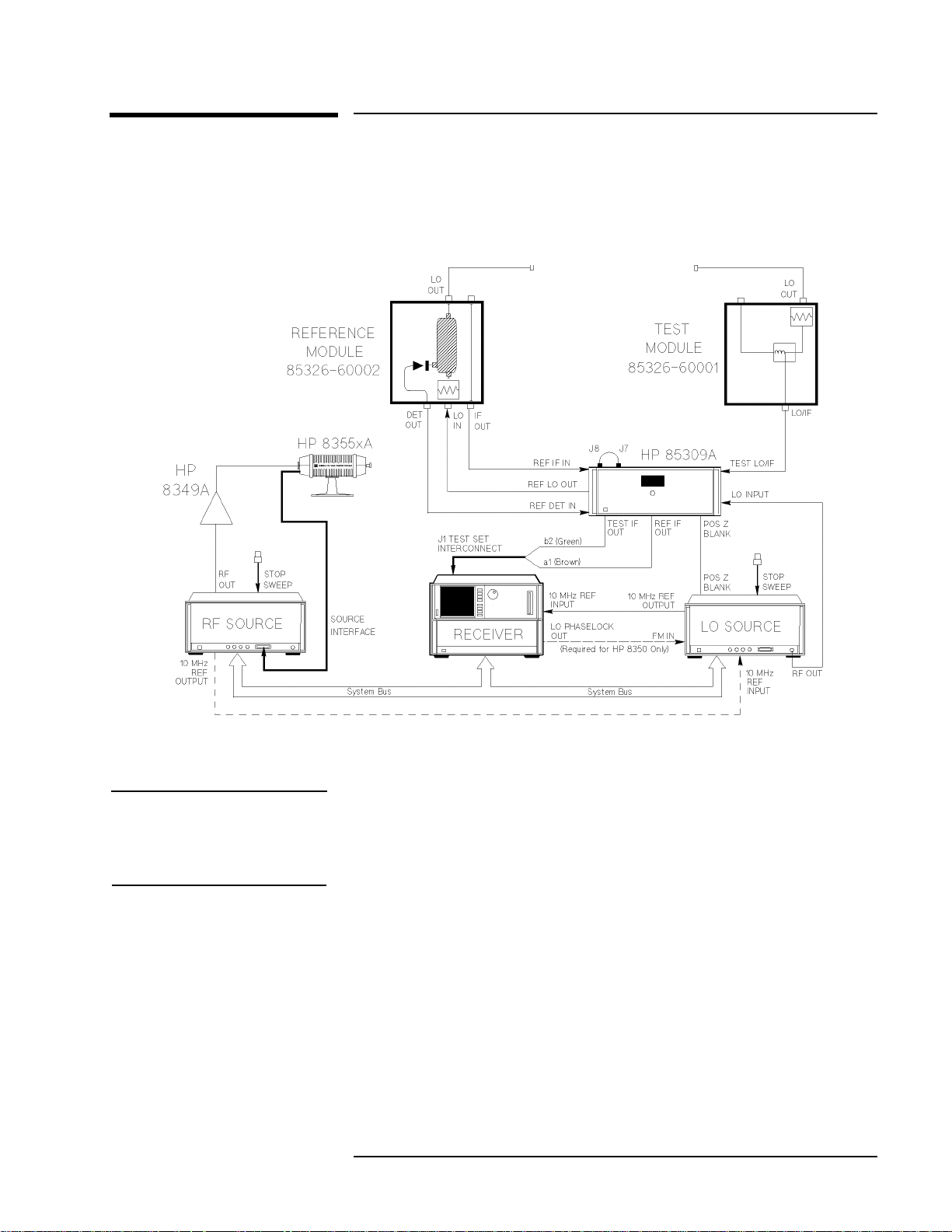

Initial Setup

Connect the equipment as shown in Figure 1-1.

Installation

Initial Setup

Figure 1-1 Initial Setup

NOTE

Using an HP 8340/41 RF Source

Connecting the Waveguide

It is important that you connect the mm-wave head to the RF source (as

shown in Figure 1-1) before using the procedures in this manual. The

mm-wave head configures the RF source so it will accept mm-wave band

start and stop frequency commands from the receiver.

If you are using an HP 8340/41 as an RF source, refer to Appendix A for

setup information.

When connecting the waveguide, refer to Appendix B, “Connecting the

Waveguide Properly.” Use the waveguide accessory hardware kit when

connecting the waveguide components.

HP 85325A Operating and Service Manual

1-3

Page 20

Installation

Initial Setup

Optional 10 MHz Reference Connection

NOTE

Procedure 1. Set up the sources so that they are not under HP 8530 control.

The 10 MHz reference connection (see Figure 1-1 on page 1-3) between the

RF and LO sources locks the signal frequency of the two sources together.

When the sources are separated by a long distance, make sure the 10 MHz

signal is at least -17 dBm or greater at the 10 MHz REF INPUT. The

10 MHz REF OUTPUT produces 0 dBm.

Checking the Signal

You can check to see if a 10 MHz signal is reaching the destination source as

follows:

This procedure assumes at least one source has a front panel.

2. Connect the 10 MHz cable between the LO and RF source 10 MHz REF

jacks. Make sure you use the 10 MHz REF IN on the source with a front

panel. (This will be called the receiving unit.)

3. Preset the sources.

4. If

EXT REF is displayed on the bottom-left of the receiving units display,

the signal is satisfactory.

1-4

HP 85325A Operating and Service Manual

Page 21

Receiver Settings

Installation

Receiver Settings

NOTE [[Brackets]

Setting Up the Receiver

{Braces}

1. Turn ON the RF source. Make sure it is set to HP-IB address 19.

2. Turn ON the LO source. Make sure it is set to HP-IB address 18.

indicate a display softkey selection.

3. Turn ON the following components in the order shown: a. RF power amplifier (if used) b. HP 85309A c. Receiver

NOTE

If your LO source is an HP 8350, it is normal for

to appear on the screen at this time. The message will go away later, when

you connect the reference mixer.

4. Press:

indicate a front-panel key or on a computer key board.

CAUTION, NO IF FOUND or

CAUTION: SOURCE 1 FAILURE RF UNLOCKED

[USER PRESET]

[SYSTEM]

{HPIB ADDRESSES}

{SOURCE #2}

[1][8] [x1]

5. If using an HP 8510, press:

6. If using an HP 8530, press:

(sets address of the LO source)

{TEST SET}

{CONVERTER} {SET ADDRESS}

Press:

[RECALL]

{MORE} {FACTORY PRESET}

Press:

[SYSTEM]

{MORE} {SYSTEM PHASELOCK}

a. If using a synthesized LO, select

b. If using an HP 8350 source, select

[3][1] [x1]

[3][1] [x1]

{LOCK TYPE: NONE}

{LOCK TYPE: EXTERNAL}

.

.

HP 85325A Operating and Service Manual

1-5

Page 22

Installation

Receiver Settings

7. Press:

NOTE

I In some setups,

{SOURCE 1: INTERNAL}

[PRIOR MENU]

{POWER LEVELING}

{SOURCE 1: MM MODULE LEVELING}

{SOURCE 1: MM MODULE LEVELING}

is not appropriate. Select

if:

❍ Using an HP 8510B

❍ Using an HP 8510C with firmware Revision 6.1 or lower.

❍ The source interface cable is not connected to the HP 836xx.

❍ Using an HP 8340/41, and it is not connected as shown in

Appendix A.

8. Press:

{SOURCE 2: INTERNAL}

[PRIOR MENU]

{EDIT MULT. SRC.}

9. Press:

{DEFINE: SOURCE #1}

{MULTIPLIER NUMER.}

10. Press

{MULTIPLIER DENOM.}

a. If source 1 (the RF source) is an HP 836xx, and the source interface

cable is connected: press

b. If source 1 is an HP 836xx and the source interface cable is not

connected, enter the DENOM. value for your band (shown in

Table 1-2), remember to terminate with

Table 1-2 DENOM Value Table

Band DENOM Value Start Freq (GHz) Stop Freq (GHz)

[1] [x1]

and do one of the following:

[1] [x1]

[x1]:

R 2 26.5 40

Q 3 33 50

U 3 40 60

V 4 50 75

W 6 75 110

1-6

HP 85325A Operating and Service Manual

Page 23

Receiver Settings

c. If source 1 is an HP 8340/41, enter the DENOM value (in Table 1-2

on page 1-6) for your band. Terminate with

[x1]

.

11. Press:

Installation

{OFFSET FREQUENCY}

{DONE}

[0] [x1]

12. Press:

{DEFINE: SOURCE #2}

{MULTIPLIER NUMER.}

13. Press

{MULTIPLIER DENOM.}

[1] [x1]

remember to terminate with

Table 1-3 Multiplier DENOM Table

Band DENOM Value Start Freq (GHz) Stop Freq (GHz)

R 8 26.5 40

Q103350

U104060

V145075

W1875110

, and enter the value (shown in Table 1-3),

[x1]:

14. Press:

{OFFSET FREQUENCY}

{DONE}

15. Press:

16. Press:

{RECEIVER}{CONSTANT FREQUENCY}

{DONE} {MULT. SRC: ON / SAVE}

17. Press STIMULUS

{POWER SOURCE 1}

{POWER SOURCE 2}

[PRIOR MENU]

{STEP}

18. Enter the start and stop frequencies using the

[2][0] [MHz]

[MENU]

[0] [x1]

[1][0] [x1]

[2][0] [MHz]

{POWER MENU}

[START]

and

[STOP]

the start/stop frequencies shown in Table 1-2 for your specific mixer.

keys. Use

HP 85325A Operating and Service Manual

1-7

Page 24

Installation

Mixer LO Power Level Adjustment

Mixer LO Power Level Adjustment

NOTE [Brackets]

{Braces}

CAUTION

It is critical that you set LO power before connecting the HP 11970 mixers.

indicate a front-panel key or a computer key board.

indicate a display softkey selection.

Initial Setup 1. If using an HP 8530A, press:

Initial Fixed Attenuator Value Selections

[DOMAIN]

2. Place the receiver in the single point (CW) mode by pressing: STIMULUS

3. Press

millimeter band.

The internal fixed attenuator value in the reference module is set so the

mixer LO input port is not damaged by excessive power (maximum power

for an HP 11970x is +20 dB). The maximum unleveled power is possible if

the ALC loop of the HP 85309A and reference module is broken.

{FREQUENCY}

[MENU]

[CENTER]

and enter the lowest frequency available in your

,

{SINGLE POINT}

.

NOTE

To check what the maximum unleveled power level is:

1. Disconnect the detector voltage feedback cable at the reference module

while monitoring the power level as shown in Figure 1-4 on page 1-11.

Perform the test within the frequency range of operation.

2. Install an attenuator in the reference module which has a value that

keeps the power level below your mixers damage level. (See Figure 1-2

on page 1-10)

The attenuator values shown in Table 1-4 on page 1-9 can be used if

HP 85381A RF cable assemblies are used.

3. Determine the minimum attenuator value for the 85326-60001 (test

module), and the 85326-60002 (reference module) using Table 1-4 on

page 1-9.

1-8

HP 85325A Operating and Service Manual

Page 25

Mixer LO Power Level Adjustment

Table 1-4 Selecting HP 85326A Reference and Test Attenuation

Installation

Length of LO Cable from

HP 85309A

(LV Cable)

9 meters 0 dB 0 dB

8 meters 1 dB 0 dB

7 meters 1 dB 1 dB

6 meters 2 dB 1 dB

5 meters 2 dB 2 dB

4 meters 3 dB 2 dB

1.5 to 3 meters 3 dB 3 dB

1. Assumes use of HP 85381A cable type.

2. A standard HP 85325A system uses 8, 6, or 4 meter cables.

1

to Reference Module

Reference Module

2

Attenuation Required

Test Module Attenuation

Required

How to Use the Chart

Determine the length of the LO cable that goes from the HP 85309A REF

LO OUT connector to the reference module's LO IN connector.

Look the length up in Table 1-4 to find the appropriate amount of attenuation

for the test and reference modules.

Procedure

HP cables have label sleeves marked C04, C06, or C08. The number

represents the length of the cable in meters. Standard systems use LO cables

that are 4, 6, or 8 meters in length. Other lengths are not standard but might

apply to special systems.

Changing Attenuation

1. Use the supplied #10 TORX driver to remove the screws securing the module covers.

2. Observe the attenuator that is connected to the reformable cable. Hold

the body of this attenuator in place with one of the supplied 5/16 inch

wrenches.

3. Use the other 5/16 inch wrench to disconnect the reformable cable.

4. Remove other attenuators, as required, using this method.

5. Place unused attenuators in the holders (see Figure 1-2 and Figure 1-3

on page 1-10.)

6. Replace the reformable cable.

HP 85325A Operating and Service Manual

1-9

Page 26

Installation

Mixer LO Power Level Adjustment

7. Make sure the connections inside the module are secure before replacing

the module covers (8 to 10 in-lbs of torque is recommended).

8. Replace the module covers and screws. Tighten the screws until they are

snug. Do not over-tighten.

Figure 1-2 Reference Attenuator Installation

Figure 1-3 Test Attenuator Installation

1-10

HP 85325A Operating and Service Manual

Page 27

Adjustment Procedures

Installation

Adjustment Procedures

NOTE [Brackets]

{Braces}

LO power must be adjusted before connecting the HP 85325A mixers to

avoid damaging them. Use Procedure 1 or 2, as appropriate:

indicate a front-panel key on a computer keyboard.

indicate a display softkey selection.

• Procedure 1

Use this procedure if you are only going to use the HP 85325A/HP

85325A mixer configuration.

• Procedure 2

Use this procedure if you are going to reconfigure your system between

HP 85325A/HP 85326A mixers and other mixer types. Procedure 2

eliminates the need to readjust LO power when switching between the

HP 85325A and other mixers.

Procedure 1 This procedure applies to systems that only use HP 85325A mixers.

Initial Setup 1. Zero and calibrate the power meter (refer to your power meter manual).

2. Determine the power sensor calibration factor at 4 GHz, and set the power meter accordingly.

3. Connect the power meter as shown in Figure 1-4.

Figure 1-4 Measuring LO Power from the Reference Module

4. Measure the power output of the reference module as shown in

Figure 1-4. Be sure to measure power at the end of the LO cable.

HP 85325A Operating and Service Manual

1-11

Page 28

Installation

Adjustment Procedures

Adjust the LO Power to

the Reference Mixer

NOTE

1. Adjust the HP 85309A front panel LO POWER ADJUST control until

the power meter reads between 17 and 17.8 dBm. The “LO POWER

OUT OF RANGE” light should be off.

2. Note the reading of the HP 85309A display and write it down here:

HP 85326A DETECTOR VOLTAGE SETTING:______________ millivolts

If the LO power adjust setting is ever changed, you can return to the

appropriate power level for the millimeter system by referring to this setting.

To return to the original power level, Turn the LO POWER ADJUST knob

until the voltage reading matches the value written above.

To find the maximum unleveled power, disconnect the detector voltage

feedback cable at the reference module while monitoring the power level as

shown in Figure 1-4 on page 1-11. Remember to perform the test within the

frequency range of operation.

When performing the following step, connect the LO, IF, and detector

voltage cables to the reference MODULE first, then connect cables to the

mixer. This lowers the risk of electrostatic damage to the mixers.

3. Connect the reference mixer to the reference module and directional coupler, refer to Figure 1-5.

The warning beeper should now stop.

4. Press

[ENTRY OFF]

to remove the error message from the receiver display.

Figure 1-5 Reference Mixer Connections

1-12

HP 85325A Operating and Service Manual

Page 29

Installation

Adjustment Procedures

Adjust the LO Power to

the Test Mixer

Figure 1-6 LO Power Measurement Point for Test Module

1. Zero the power meter.

2. Measure the LO power output of the test module as shown in Figure 1-6.

3. The LO power should be between +16 and +17 dBm. If the LO power is

outside this range, you must change the amount of attenuation inside the

test module. This is accomplished by adding or removing attenuators

inside the module.

Use various combinations of the 1, 2, and 4 dB attenuators to adjust the

LO power to the required range.

4. If you have more than one test module, repeat power measurement for

each test channel module as explained above.

HP 85325A Operating and Service Manual

1-13

Page 30

Installation

Adjustment Procedures

Procedure 2 This procedure applies to systems that use HP 85320A/B mixers, in addition

to the HP 85325A.

Initial Setup 1. Refer to the detector voltage label on the HP 85320B reference mixer.

Set the HP 85309A “LO POWER ADJUST” control to match this value.

You do not need to connect the HP 85320B mixer to the system.

2. Zero and calibrate the power meter.

3. Determine the power sensor calibration factor at 4 GHz, and set the power meter accordingly.

4. Connect the power sensor to the LO output of the HP 85326A reference

module (refer to Figure 1-4 on page 1-11). Be sure to connect the power

sensor to the end of the LO cable.

Checking the Reference

LO Power

1. Measure the power output of the reference module. a. If measured power is between 15 and 17.5 dBm, no adjustment is

necessary. Go directly to the Adjusting LO Power to the Test Mixer

section on page 1-15.

b. If the measured level is outside of the above range, you will have to

change the LO power whenever you switch between HP 85320A/B

and HP 85325A mixer systems. For HP 85320A/B mixers, refer to

the HP 85320A/B Mixer Modules User's Guide

Since you must set the LO power separately for each type of mixer,

adjust the LO power for the millimeter-wave mixers at this time. To do

this, perform Procedure 1, starting at “Adjusting LO Power to the

Reference Mixer.” on page 1-12.

2. Adjust the HP 85309A front panel LO POWER ADJUST control until

the power meter reads between 17 and 17.8 dBm. The “LO POWER

OUT OF RANGE” light should be off.

3. Note the reading of the HP 85309A display and write it down here:

HP 85326/85320 DETECTOR VOLTAGE SETTING: ________ millivolts.

If the LO POWER ADJUST setting is ever changed, you can return to the

appropriate power level for the millimeter system by referring to this setting.

To return to the original power level, Turn the LO POWER ADJUST knob

until the voltage reading matches the value written above.

NOTE

When performing the following step, connect the LO, IF, and detector

voltage cables to the reference module first, then connect cables to the mixer.

This lowers the risk of electrostatic damage to the mixers.

1-14

HP 85325A Operating and Service Manual

Page 31

Installation

Adjustment Procedures

4. Connect the reference mixer to the reference module and directional

coupler, refer to Figure 1-5 on page 1-12. The warning beeper on the

receiver should stop.

Adjust the LO Power to

the Test Mixer

NOTE

5. Press

[ENTRY OFF]

to remove the error message from the receiver display.

1. Measure the LO power output of the test module as shown in Figure 1-6

on page 1-13.

2. Look up the power level (see below) and perform the corresponding action.

If power is:

❍ Less than 14.75 dBm: Reduce the amount of attenuation in the test

module until power is between 14.75 and 16.25 dBm.

If you have removed all attenuators from the test module, and power is still

less than 14.75 dBm, this means that you cannot switch between the

HP 85325A mixers and your other mixers without readjusting LO power

each time. Perform “Procedure 1" on page 1-11 to adjust LO power for the

HP 85325A mixers. To adjust LO power for the other mixers, refer to the

operating manual for those mixers.

❍ 14.75 to 16.25 dBm: Proper LO power, no further adjustment is

needed.

❍ Greater than 16.25 dBm: Add attenuation inside the test module

until power is between 15 and 16.25 dBm.

3. If you have more than one test module, repeat the power measurement

(the previous two steps) for each test module.

HP 85325A Operating and Service Manual

1-15

Page 32

Installation

Mixer Operational Check

Mixer Operational Check

NOTE [Brackets]

{Braces}

NOTE

When installing the mixers, connect the 3.5 mm cables to the test/reference

modules before connecting them to the mixers. This will minimize the

danger of an electrostatic discharge damaging the mixers.

1. Make sure the equipment is connected as shown in Figure 1-5 on

page 1-12.

2. Press: STIMULUS

3. Enter the start and stop frequencies of your millimeter band.

4. Make sure averaging is OFF by pressing: RESPONSE

5. Measure the a1 input as follows:

If using an HP 8510, press:

indicate a front-panel key or computer keyboard.

indicate a display softkey selection.

[MENU]

{STEP}

[MENU]

{AVERAGING OFF}

PARAMETER

[MENU]

{USER 1 a1}

If using an HP 8530, press:

PARAMETER

{SERVICE PARAMETERS}

{SERVICE 1 a1}

[MENU]

The signal you are measuring is from the coupled arm of the directional

coupler.

6. Set the display reference value so the trace is centered vertically: Press

[REF VALUE]

and turn the rotary knob.

7. Write down the reference value, you will need it later in this procedure: REF VALUE = ____________________________

8. Set display scale to 1 dB/division, press:

[SCALE] [1] [x1]

1-16

HP 85325A Operating and Service Manual

Page 33

Installation

Mixer Operational Check

9. Make sure the signal is at anticipated levels. The coupled arm attenuates

the output of the HP 8355xA by 30 dB (this can vary depending on the

type of coupler used). Power flatness should be approximately +/-3 dB

across the band.

10. Press:

[DISPLAY]

{DATA -> MEMORY}

11. Disconnect the reference mixer from the coupled arm of the directional

coupler. Put the test mixer in its place, as shown in Figure 1-7.

NOTE

If your system has more than one test channel, connect the coupled arm to

the first test channel (TEST 1).

12. Connect the Test LO and Test IF cables to the test module first, then to

the test mixer.

NOTE

Figure 1-7 Test Mixer Connections

Perform steps 13 through 18 ONLY if using a synthesized LO source.

Proceed to “When Using an HP 8350 LO Source” on page 1-18 if you have

an HP 8350 LO source.

HP 85325A Operating and Service Manual

1-17

Page 34

Installation

Mixer Operational Check

13. Determine which receiver input has the test signal connected to it (b1, b2, or a2).

14. Measure that input using the USER softkeys (on HP 8510) or SERVICE

PARAMETER softkeys (on HP 8530).

15. Press:

[DISPLAY]

{SELECT DEFAULTS}

{DEFAULT to MEMORY: 1}

{DATA and MEMORY}

Adjust the display reference so the two traces are centered vertically.

Refer to the value you wrote down in Step 7.

16. Set display scale to 1 dB/division.

17. Make sure the two signals are within 3 dB of each other.

When Using an HP 8350 LO Source

18. If your system has more than one test channel, check each one in the same way.

Perform the following steps ONLY if using an HP 8350 LO source:

1. Press

{DATA and MEMORY}

2. On the rear panel of the HP 85309A: a. Disconnect the green (b2) wire from the TEST IF OUT connector. b. Move the brown (a1) cable from the REFERENCE IF OUT

connector to the TEST IF OUT connector.

3. Make sure the two displayed traces are within 3 dB of each other. (This

step is required so the receiver can phase lock.)

4. If your system has a second test channel: a. Move the red (b1) wire to the TEST IF OUT connector. b. Make sure the two displayed traces are within 3 dB of each other.

5. If your system has a third test channel: a. Move the yellow (a2) wire to the TEST IF OUT connector. b. Make sure the two displayed traces are within 3 dB of each other.

6. Move the a1 and b2 (and possibly b1 and a2) input lines back to their

original configuration.

1-18

HP 85325A Operating and Service Manual

Page 35

Saving the Setup

Installation

Saving the Setup

NOTE [Brackets]

{Braces}

Press

[SAVE]

you press

system will be recalled.

indicate a front-panel key or a computer keyboard.

indicate a display softkey selection.

{USER PRESET 8}

[USER PRESET]

to save the current instrument setup. Whenever

or turn the receiver on, the proper settings for this

HP 85325A Operating and Service Manual

1-19

Page 36

Installation

Final Installation

Final Installation

This procedure assumes that the other components of the antenna

measurement system are already connected. Refer to the installation

instructions for the receiver or HP 85310A if necessary.

CAUTION

Figure 1-8 Leveling Control Cables

If you disconnect the detector voltage cable (while the LO source is on), LO

power will go to maximum. This will damage the millimeter-wave mixers as

soon as they are connected.

If you disconnect the LO signal cable, the LO power will go to maximum

while the HP 85309A tries to send the appropriate amount of power to the

mixers. If you then reconnect the LO cable, the LO power to any connected

mixer will initially be at damage levels. The HP 85309A will detect the high

LO power and reduce it, but the mixers could be damaged before power is

reduced.

Remember that the HP 85309A sends the same LO power to both mixers. If

high LO power occurs then both millimeter-wave mixers may be destroyed.

Do not connect LO power to the HP 11970 mixers until you adjust the LO

power.Refer to the “Mixer LO Power Level Adjustment” on page 1-8 If you

connect LO power before adjusting it you could permanently damage the

mixers.

1-20

HP 85325A Operating and Service Manual

Page 37

Procedure 1. Move all system components to their final location.

2. Connect the system using one of these methods: a. If you are using a coupled reference channel, connect the system as

shown in Figure 1-9 and Figure 1-10 on page 1-22.

b. If you are using a radiated reference, connect as shown in

Figure 1-11 on page 1-23.

Refer to Figure 1-1 on page 1-3 for system-level connections.

Installation

Final Installation

Figure 1-9 HP 85325A/85326A Installation Block Diagram (Coupled Reference)

HP 85325A Operating and Service Manual

1-21

Page 38

Installation

Final Installation

Figure 1-10 HP 85325A/85326A Visual Installation Diagram (Coupled Reference)

1-22

HP 85325A Operating and Service Manual

Page 39

Installation

Final Installation

Figure 1-11 HP 85325A/85326A Installation Block Diagram (Radiated Reference)

If Usingan HP 8340/41 RF Source

Connecting the Waveguide

If you are using an HP 8340/41 as an RF source, refer to Appendix A for

setup information.

When connecting a waveguide, refer to Appendix B, “Connecting the

Waveguide Properly.” Use the Waveguide Accessory Hardware Kit when

connecting the waveguide components.

HP 85325A Operating and Service Manual

1-23

Page 40

Installation

Final Installation

Proper Torque for Coax Connections

The coax RF connectors in the setup must be properly torqued or the system

will not provide its best performance. Proper connection torque also keeps

moisture out the connectors, and eliminates radio frequency interference

(RFI) from the connector interface. The amount of torque required depends

on the type of connector. Table 1-5 lists the proper torque values. Do not

over-tighten connectors.

Table 1-5 Proper Connector Torque

Connector Torque / cm-kg Torque / N-cm Torque / in-lbs

Type-N 52 508 45 8710-1935

3.5 mm 9.2 90 8 8720-1765

SMA 5.7 56 5 8710-1582

2.4 mm 9.2 90 8 8720-1765

Wrench Part

Number

Turn ON AC Power Turn ON the AC power for all of the components in the following order:

1. RF and LO sources, RF power amplifier

2. HP 85309A LO/IF unit

3. Receiver

1-24

HP 85325A Operating and Service Manual

Page 41

Operation

2

CAUTION

NOTE

Operation

Leveling Feedback Loop

Never interrupt the LO leveling feedback from the reference module leveling

coupler, detector, or leveling cables. Doing so can cause the LO power to

exceed the damage level of the HP 11970 mixers.

Electrostatic Discharge

When installing the mixers, connect the SMA cables to the test/reference

modules before connecting them to the mixers. This will minimize the

danger of an electrostatic discharge damaging the mixers.

The HP 85325 millimeter wave system is designed to be used with a

HP 85310A or HP 85301B. Refer to these instrument manuals for system

level operating information.

HP 85325A Operating and Service Manual

2-1

Page 42

Operation

Mixer Operating Parameters

Mixer Operating Parameters

Operate the HP 11970A mixers within the following operating parameters:

Maximum RF Input Power

Maximum LO Input

CW: No greater than +20 dBm

Pulse: No greater than +24 dBm at

Average: No greater than +20 dBm

No greater than +20 dBm

< 1 µs

Power

Required LO Power The HP 11970 mixers require +14 to +18 dBm at the LO input.

Connector Care Leave the plastic waveguide flange cap on whenever the system waveguide

connectors are not connected together.This protects the mating surface from

scratches, which can degrade performance.

Proper Waveguide Connector Alignment

If you are using Q, U, V, or W bands, waveguide flanges must be aligned

properly or measurement errors may result. Refer to Appendix B.

2-2

HP 85325A Operating and Service Manual

Page 43

General Information

3

General Information

Chapter Contents

Product Description

•

• Specifications

• MM-Wave Source and Mixer Characteristics

• Supplied Equipment

• Maximum Cable Lengths

Product Description

The HP 85325A millimeter subsystem is designed for use with the

HP 85309A distributed frequency converter. The subsystem (in conjunction

with the transmit RF source, source amplifier, and HP 85309A)

downconverts mm-wave frequencies to a 20 MHz IF signal. This IF signal is

required by the HP 8510 or HP 8530 receiver.

The frequency range of your millimeter-wave system depends on whether

you are using an R, Q, U, V, or W band source module.

HP 85325A Operating and Service Manual

3-1

Page 44

General Information

Specifications

Specifications

About Specifications • All millimeter bands are specified with HP 11970 harmonic mixers.

• Sensitivity is defined as signal equals noise. Averaging will improve

sensitivity by 10 log x (averaging factor).

• Channel isolation is the coherent RF leakage from the reference mixer to

the test mixer with inputs terminated.

• To insure best system performance, take care in connecting all

waveguide flanges by securing all four screw points. Appendix B

explains how to connect waveguide connectors properly.

• For specified performance of the mm-wave source, refer to

documentation for the RF source module used.

Table 3-1 R, Q, and U Band System Level Specifications

HP R85325A

R Band

Frequency Range (GHz) 26.5 to 40 GHz 33 to 40 GHz 40 to 50 GHz 40 to 48 GHz 48 to 60 GHz

mm Wave Source Module HP 83554A HP 83555A HP 83556A

Max. Output Power (dBm)

Sensitivity (dBm)

(S/N = 1, with 0 averages

Sensitivity (dBm)

(S/N = 1, with 128 averages)

Dynamic Range (dB)

(0 averages)

Compression Lvl (dBm)

(at 0.1 dB)

Channel Isolation (dB)

(reference to test)

Typical Match

1. the input of test and reference isolators.

1

1

1

(dB) 15.5 15.5 15.5 15.5 15.5

+7 +3 +3 +3 +3

-88 -85 -85 -86 -86

-109 -106 -106 -107 -107

-79 -71 -77 -72 -78

-19 -24 -21 -24 -21

-100 -100 -100 -100 -100

HP Q85325A

Q Band

HP U85325A

U Band

3-2

HP 85325A Operating and Service Manual

Page 45

Table 3-2 V and W Band System Level Specifications

HP V85325A HP W85325A

Frequency Range (GHz) 50 - 75 GHz - V Band 75 - 110 GHz - W Band

mm Wave Source Module HP 83557A HP 83558A

General Information

Specifications

Sensitivity (dBm)

(S/N = 1, with 0 averages

Sensitivity (dBm)

(S/N = 1, with 128 averages)

Dynamic Range (dB)

(0 averages)

Compression Lvl (dBm)

(at 0.1 dB)

Channel Isolation (dB)

(reference to test)

Typical Match

1. At the input of test and reference isolators.

1

(dB)

-78

(-82 typical)

-99

(-103 typical)

60

(68 typical)

-18 -15

-100 -100

9.5 9.5

-71

(-74 typical)

-92

(-95 typical)

56

(62 typical)

HP 85325A Operating and Service Manual

3-3

Page 46

General Information

MM-Wave Source and Mixer Characteristics

MM-Wave Source and Mixer Characteristics

The following tables identify the INPUT and OUTPUT characteristics of the

HP 8355xA series millimeter-wave sources and HP 11970x mixers.

Table 3-3 MM-Wave Source Information

MM Source Model # Output Frequency MM-Wave Output1Harmonic Number RF Input Level

HP 83554A 26.5 - 40 GHz 7 dBm 2 +17 dBm

HP 83555A 33 - 50 GHz 3 dBm 3 +17 dBm

H P83556A 40 - 60 GHz 3 dBm 3 +17 dBm

HP 83557A 50 - 75 GHz 3 dBm 4 +17 dBm

HP 83558A 75 - 110 GHz 0 dBm 6 +17 dBm

1. At 25

°C± 5°

C

Table 3-4 MM-Wave Mixer Information

Mixer Model # RF Frequency

HP 11970A 26.5 - 40 GHz 8 +16

HP 11970Q 33 - 50 GHz 10 +16

HP 11970U 40 - 60 GHz 10 +16

HP 11970V 50 - 75 GHz 14 +16

HP 11970W 75 - 110 GHz 18 +16

Range

Harmonic Number LO Power Level

±

2 dBm

±

2 dBm

±

2 dBm

±

2 dBm

±

2 dBm

3-4

HP 85325A Operating and Service Manual

Page 47

Supplied Equipment

The following items are supplied with the HP x85325A and the HP 85326A.

Table 3-5 Supplied Parts

General Information

Supplied Equipment

Description Standard

Quantity

With the HP x85325A:

MM-Wave Source

Module

Directional Coupler 1 1 1 HP 752D

Mixers 2 3 4 HP 11970 C01

Isolators 2 3 4 HP 365A

1/4 inch Wrench 1 1 1 8710-0510

3/16 inch Wrench 1 1 1 8710-0013

3/32 Hex Ball Drive 1 1 1 8710-1539

4-40,0.4inch Screws 50 50 50 3030-0221

4-40, 0.5 inch Screws 50 50 50 3030-0209

4-40 Hex Nuts 50 50 50 2260-0002

4-40 Captive Screws 50 50 50 1390-0765

With the HP 85326A:

T-10 TORX Driver 1 1 1 8710-1623

1 1 1 HP 8355xA

Option 001

Quantity

Option 002

Quantity

Model or Part

Number

5/16 inch Wrench 1 1 1 8720-0015

4 dB Attenuator

1 dB Attenuator

1 dB Attenuator

With both:

Operating and Service

Manual

1. This attenuator is shipped inside the test module.

2. These attenuators are shipped inside the test and reference modules.

1

2

2

1 2 3 0955-0208

2 3 4 0955-0301

2 3 4 0955-0321

1 1 1 85325-90061

HP 85325A Operating and Service Manual

3-5

Page 48

General Information

Maximum RF Cable Lengths

Maximum RF Cable Lengths

In millimeter-wave systems, there is a length limit on the HP 85381A LO

cable that goes from the LO source to the LO INPUT of the HP 85309A (L

and the L

HP 85309A and the LO IN on the reference module).

L

= source module cable

S

L

= reference module cable

R

L

= test module cable

T

cable (the cable that goes between the REF LO OUT of the

R

)

S

Figure 3-1 L

Refer to Figure 3-1 and Table 3-6 to determine the maximum L

, LR, and LT Cables

S

length.

S

Table 3-6 Maximum Cable Lengths (meters)

Cable Type LO Frequency (max)

GHz

HP 85381A 6 17 6

MaCom FA29RX 6 18 11

3-6

HP 85325A Operating and Service Manual

LO Source to

HP 85309A (L

S

HP 85309A to

)

HP 85325A/B (LR, LT)

Page 49

General Information

Maximum RF Cable Lengths

Formulas for Cable Length Maximums

The maximum LO source frequency required when driving the HP 11970x

waveguide mixers is 6.11 GHz. The two cable lengths (L

and LT) are

R

affected by this maximum frequency. Refer to the diagram below.

NOTE

Figure 3-2 L

, LR, LT Cable Lengths, Example

S

The maximum length of the LO cables (L

or LT) is a function of:

R

a. the LO power required by the mixers

b. the LO output power available from the HP 85309A across the LO

frequency range (3 to 6 GHz)

c. the loss through other microwave components in the LO path.

Test and reference cables must be the same length.

The output LO power of the HP 85309A is normally greater than +20.8 dBm

between 3 and 6 GHz. The mixers require a nominal +16 dBm (+14 dBm

minimum). The difference between these two LO power levels (+ 20.8 dBm

and +16 dBm) determines the maximum loss of the test and reference path.

HP 85325A Operating and Service Manual

3-7

Page 50

General Information

Maximum RF Cable Lengths

The loss through the HP 85326A and the associated 1 meter cable is about

1.6 dB. The loss associated with either the L

or LTcables cannot exceed 3.2

R

dB.

If using an HP 85381A type cable, the length should not exceed 5 meters.

CAUTION

The damage level for the HP 11970x mixer is +20 dBm. This can occur if

the ALC loop is broken and the proper setup procedure was not used for the

HP 85325A internal attenuator values.

3-8

HP 85325A Operating and Service Manual

Page 51

System Performance Verification

4

System Performance Verification

Introduction

This performance verification should be performed at least once a year.

This procedure verifies that the millimeter subsystem meets or exceeds its

published specifications. Specifications are listed in Chapter 3. If traceability

to a local standards organization is required, then it can be done with this

procedure. One such standards organization is the United States National

Institute of Standards and Technology.

The performance verification is composed of two parts:

• transmitter verification

• receiver verification

The transmitter verification should be performed first. This allows the

receiver verification to be run with a transmitter that is known to be within

specifications.

Recommended Test Equipment

The following tables list major instruments required for performing the

millimeter wave measurement system verification. Substitute test

instruments can be used if they meet or exceed the critical specification

shown in the Table 4-1 on page 4-2 and Table 4-2 on page 4-3. “No

substitute” means you must use the listed device. Miscellaneous adapters

and cables are also required, and may not be listed in the tables.

To determine the recommended equipment for testing each of the millimeter

wave system instruments, refer to the manual for that instrument.

HP 85325A Operating and Service Manual

4-1

Page 52

System Performance Verification

Non-Banded Equipment

Item Critical Specification Recommended Model (or Part Number)

The following equipment is part of the antenna measurement system

Receiver No substitute See Compatible Instruments

LO Source No substitute See Compatible Instruments

LO/IF Unit No substitute HP 85309A

RF Source No substitute See Compatible Instruments

Amplifier

Additional Equipment Needed

Controller No substitute HP 9000 series 300

Floppy Disk Drive

Hard Disk Drive

Printer HP-IB Interface HP 2225A or 2227B

Verification Software No substitute HP 85325-10001

Frequency Counter

Power Meter

Power Sensor

Oscilloscope

Connector Adapters Type-N and 3.5 mm Various

Table 4-1 shows equipment that is not millimeter wave band dependent. The

equipment can be used with any millimeter system.

Table 4-1 Recommended Test Equipment (non-banded)

2

4

4

678

6

6

9

Frequency band of test No recommended model

Double sided high density HP 9122C

HFS formatted

No substitute HP 5343A opt. 001 or opt 002

HP 5351B opt. 001 or opt.002,

HP 5350B opt. 001 or opt. 002 with HP-IB

No substitute HP 436A,437B,438A

No substitute HP 8485A or 8481A

50MHz bandwidth

1

1

1

3

5

10

3/32 Hex Ball Driver No substitute 8710-1539 (supplied with HP 85325A)

5 in-lb Torque Wrench No substitute 8710-1582 (supplied with HP 85301B)

11

1. Located in the HP 85310A manual.

2. Not all antenna test systems will use an amplifier.

3. Requires HP BASIC revision 6.0 or higher with 3 Mbytes of RAM memory.

4. A hard disk with one 3.5inch floppy disk may be used.

5. Consists of three disks

6. For traceability verification the Power Meter/Sensor and Frequency Counter should be traceable. No other traceableinstruments are

required.

7. Requires a 20 dB attenuator on the RF input.

8. Optional if using synthesized sources.

9. Needed for Chapter 5 only. This adjustment is only required if the LO and RF synthesizer's timebases are not connected together.

10. Type-N(m) to 3.5 (f), type-N (f) to 3.5 (f), 3.5 (f) to 3.5 (f).

11. Use this wrench for all SMA/3.5 mm connections in this procedure.

4-2

HP 85325A Operating and Service Manual

Page 53

System Performance Verification

Band-Dependent Equipment

Table 4-2 shows equipment that is millimeter wave band dependent. Fixed

terminations, variable attenuators, and directional couplers are only usable

in one band. Therefore, if your system has more than one millimeter wave

band, you must have a termination, variable attenuator, and directional

coupler for each band.

Table 4-2 Recommended Test Equipment (banded)

Item Critical Specification Recommended Model or Part Number

Power Meter No substitute Anritsu ML83A (for V or U bands only)

Power Sensor No substitute R band: HP R8486A

Fixed Termination

1

Return loss >30 dB R band: HR R910A

Q band: HP Q8486A

U band: Anritsu ML715A

V band: Anritsu ML716A

W band: HP W8486A

Q band: HP Q910A

U band: HP U910A

V band: HP V910C

W band: HP W910C

Variable Vane Attenuator 0 to 40 dB attenuation R band: HP R382A

Q band: HP Q382A

U band: HPU382A

V band: Millitech DRA-15 (v-band)

W band: Millitech DRA-10 (w-band)

Directional Coupler Coupling factor 10 dB R band: HP R752C

Q band: HP Q752C

U band: HP U752C

V band: HP V752C

W band: HP W752C

1. You must have a fixed termination for each test channel of your system

HP 85325A Operating and Service Manual

4-3

Page 54

System Performance Verification

Transmitter Performance Verification

Transmitter Performance Verification

The transmitter performance verification checks the transmitter section of

the antenna measurement system. The following tests are performed:

System Configuration Sets up the millimeter wave system for verification. It is also used to input

the system hardware's model and serial numbers.

CW Frequency Accuracy Checks the frequency accuracy of the transmitter source. The Self Test

performs the HP 8360 series full self test.

Maximum Leveled Power Ensures that the RF source and the optional amplifier produce the specified

leveled power.

RF Source Calibration Calibrates the transmitter for use as the test source for the receiver portion of

the verification.

See “Detailed Test Description” on page 4-15 for additional information.

4-4

HP 85325A Operating and Service Manual

Page 55

System Performance Verification

Receiver Performance Verification

Receiver Performance Verification

The receiver performance verification checks the receiver section of the

antenna measurement system. The tests are divided into two sections.

First Section The first section tests the various parameters of the receiver system. The

results of these tests are used to calculate the specified parameters in the

section below. It is possible to have one of these tests fail but still be within

the specified parameters of the millimeter subsystem. These tests consist of:

RF to IF Conversion Measures the power loss of the mixers when the RF signal is converted to

the IF signal. This is not a specified system performance parameter.

IF Noise Measures sensitivity (the RMS noise level of the trace data when the test or

reference channels are terminated with a 50 ohm load). This is not a

specified system performance parameter.

Crosstalk Measures signal leakage between the antenna reference and the test

channels. This is a specified system performance parameter.

Compression Measures input power at which the mixers exhibit 0.1 dB compression. This

is a specified system performance parameter.

Second Section The second section takes the results of the above section and calculates the

specified parameters of the millimeter subsystem. These tests consist of:

Tracking Results Calculates the conversion gain tracking between channels using RF to IF

conversion measurements from the first section.This is not a specified

system performance parameter.

Sensitivity Results Calculates the actual sensitivity of the receiver in RMS power using IF

Noise and RF to IF Conversionmeasurements from the first section.This is a

specified system performance parameter.

Crosstalk Results Calculates the actual crosstalk between all channels using Crosstalk and RF

to IF Conversion measurements from the first section. This is a specified

system performance parameter.

HP 85325A Operating and Service Manual

4-5

Page 56

System Performance Verification

Receiver Performance Verification

Dynamic Range Results Calculates the dynamic range of the system using Compression, IF Noise,

and RF to IF Conversion measurements from the first section. This is a

specified system performance parameter.

See “Detailed Test Description” on page 4-15 for additional information.

4-6

HP 85325A Operating and Service Manual

Page 57

System Performance Verification

Setting Up The Equipment

Setting Up The Equipment

Procedure 1. Be sure that the correct HP BASIC operating system, drivers, and

language extensions are loaded into the computer controller.

2. The receiver, LO/IF unit, mixers, LO source, and cables should be in the

same configuration in which they are normally used. Make sure that all

cables are connected properly, and that the receiver is in the same

multiple source mode as is used in your system. All connectors should

be properly torqued, refer to Table 4-3 for proper torque specifications.

Table 4-3 Proper Connector Torque

CAUTION

CAUTION

Connector

Type-N 52 508 45 8710-1935

3.5 mm 9.2 90 8 8720-1765

SMA 5.7 56 5 8710-1582

2.4 9.2 90 8 8720-1765

Torque

cm-kg

Torque

N-cm

Torque

in-lbs

Wrench

Part Number

Never exceed the recommended torque when attaching cables.

3. Connect test equipment to the system components as shown in

Figure 4-1 on page 4-8. The mixers must be placed near the verification

system during the performance verification.

Do not connect the LO cables to the mm-wave mixers until the LO power

level has been checked.

HP 85325A Operating and Service Manual

4-7

Page 58

System Performance Verification

Setting Up The Equipment

NOTE

Figure 4-1 Initial Equipment Configuration

This procedure assumes you will be using some of the cables from your

actual range, specifically, the cables between the LO/IF unit and the mixers.

This requires that the cables be pulled from their installation location so that

the mixers can be placed near the verification system. If the cables cannot be

pulled, they must be tested separately. In this case the mixers should be

connected to the verification system with a backup set of HP 85381 cables of

the same type and length as the cables normally used in the system.

4. Turn on all equipment and allow it to warm up for one hour. If you cannot bring the mixer down from the antenna tower, consider taking

the RF source and power meter up to the mixers. In this case, two additional

HP-IB extenders will be required: One to connect the power meter to the

general HP-IB bus, and one to connect the RF source to the receiver system

bus.

4-8

HP 85325A Operating and Service Manual

Page 59

5. Make sure the HP 8360's languageswitches are set to the Analyzer Mode

shown in Table 4-4. The HP 8360A will not work with your antenna

measurement system while set to the TMSL mode.

Table 4-4 Switch Positions for Analyzer Mode

L3 L2 L1 A5 A4 A3 A2 A1

001XXXXX

0 =switch down. 1 = switch up

X = leave as is

Turn the HP 8360A OFF, then ON to implement the switch change.

System Performance Verification

Setting Up The Equipment

HP 85325A Operating and Service Manual

4-9

Page 60

System Performance Verification

Install the Performance Verification Software Onto a Hard Disk

Install the Performance Verification Software

Onto a Hard Disk

The Performance Verification Software (p/n 85325-60001) is not shipped

with the HP 85325A or the HP 85326A; however, this software can be

ordered through your local sales and service office. See the Service and