Page 1

HP 8517B

S-Parameter Test Set

Operating and

Service Manual

PrintedinUSA

12 August 1998

HP part number 08517-90054

Page 2

Notice

The information contained in this document is subject to change without

notice.

Hewlett-Packard makes no warranty of any kind with regard to this material,

including, but not limited to, the implied warranties of merchantability and

fitnessfor a particular purpose. Hewlett-Packard shall not be liable for errors

contained herein or for incidental or consequential damages in connection

with the furnishing, performance, or use of this material.

Hewlett-Packard assumes no responsibility for the use or reliability of its

software on equipment that is not furnished by Hewlett-Packard.

This document contains proprietary information which is protected by

copyright. All rights are reserved. No part of this document may be

photocopied, reproduced, or translated to another language without prior

written consent of Hewlett-Packard Company.

Restricted Rights Legend

Use, duplication, or disclosure by the U.S. Government is subject to

restrictions as set forth in subparagraph (c)(1)(ii) of the Rights in Technical

Data and Computer Software clause at DFARS 252.227-7013 for DOD

agencies, and subparagraphs (c)(1) and (c)(2) of the Commercial Computer

Software Restricted Rights clause at FAR 52.227-19 for other agencies.

Hewlett-Packard Company

Santa Rosa Systems Division

1400 Fountaingrove Parkway

Santa Rosa, CA 95403-1799, U.S.A.

© Copyright Hewlett-Packard Company 1997, 1998

ii

HP 8517B S-Parameter Test Set Manual

Page 3

What You’ll Find in This Manual…

HP 8517B S-Parameter Test Set

Chapters 1 and 2 • Test set description and installation information

Chapters 3 and 4 • Principles of operation and specifications

Chapters 5, 6, and 7 • Troubleshooting, replacement procedures, and replaceable parts

information

HP 8517B S-Parameter Test Set Manual

iii

Page 4

Warranty

Certification Hewlett-Packard Company certifies that this product met its published

specifications at the time of shipment from the factory. Hewlett-Packard

further certifies that its calibration measurements are traceable to the

United States National Institute of Standards and Technology (NIST,

formerly NBS), to the extent allowed by the Institute’s calibration facility,

and to the calibration facilities of other International Standards

Organization members.

Warranty This Hewlett-Packard system product is warranted against defects in

materials and workmanship for a period corresponding to the individual

warranty periods of its component products. Instruments are warranted for a

period of one year. During the warranty period, Hewlett-Packard Company

will, at its option, either repair or replace products that prove to be defective.

Warranty service for products installed by HP and certain other products

designated by HP will be performed at Buyer’s facility at no charge within

HP service travel areas. Outside HP service travel areas, warranty service

will be performed at Buyer’s facility only upon HP’s prior agreement and

Buyer shall pay HP’s round trip travel expenses. In all other areas, products

must be returned to a service facility designated by HP.

For products returned to HP for warranty service, Buyer shall prepay

shipping charges to HP and HP shall pay shipping charges t o return the

product to Buyer.However,Buyer shall pay all shipping charges, duties, and

taxes for products returned to HP from another country.

HP warrants that its software and firmware designated by HP for use with an

instrument will execute its programming instructions when properly

installed on that instrument. HP does not warrant that the operation of the

instrument, or software, or firmware will be uninterrupted or error free.

LIMITATION OF WARRANTY. The foregoing warranty shall not apply

to defects resulting from improper or inadequate maintenance by Buyer,

Buyer-supplied software or interfacing, unauthorized modification or

misuse, operation outside of the environmental specifications for the

product, or improper site preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. HP

SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OR

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES. THE REMEDIES PROVIDED HEREIN ARE

BUYER’S SOLE AND EXCLUSIVE REMEDIES. HP SHALL NOT BE

LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR

iv

HP 8517B S-Parameter Test Set Manual

Page 5

CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT,

TORT, OR ANY OTHER LEGAL THEORY.

Assistance Product maintenance agreements and other customer assistance agreements

are available for Hewlett-Packard products.

For assistance, call your local Hewlett-Packard Sales and Service Office

(refer to “Service and Support”).

HP 8517B S-Parameter Test Set Manual

v

Page 6

Service and Support

Any adjustment, maintenance, or repair of this product must be performed

by qualified personnel. Contact your customer engineer through your local

HP Service Center. You can find a list of HP Service Centers on the web at

http://www.hp.com/go/tmdir.

If you do not have access to the Internet, one of these HP centers can direct

you to your nearest HP r epresentative:

United States: Hewlett-Packard Company

Test and Measurement Call Center

PO Box 4026

Englewood, CO 80155-4026

(800) 452 4844 (toll-free in US)

Canada: Hewlett-Packard Canada Ltd.

5150 Spectrum Way

Mississauga, Ontario L4W 5G1

(905) 206 4725

Europe: Hewlett-Packard European Marketing Centre

Postbox 999

1180 AZ Amstelveen

The Netherlands

(31 20) 547 9900

Japan: Hewlett-Packard Ltd.

Measurement Assistance Center

9-1, Takakura-Cho, Hachioji-Shi

Tokyo 192, Japan

(81) 426 56 7832

(81) 426 56 7840 (FAX)

Latin America: Hewlett-Packard Latin American Region Headquarters

5200 Blue Lagoon Drive, 9th Floor

Miami, Florida 33126, U.S.A.

(305) 267 4245, (305) 267-4220

(305) 267 4288 (FAX)

Australia/New Zealand: Hewlett-Packard Australia Ltd.

31-41 Joseph Street

Blackburn, Victoria 3130

Australia

1 800 629 485 (Australia)

0800 738 378 (New Zealand)

(61 3) 9210 5489 (FAX)

Asia-Pacific: Hewlett-Packard Asia Pacific Ltd.

17-21/F Shell Tower, Times Square

1 Matheson Street, Causeway Bay

Hong Kong

(852) 2599 7777

(852) 2506 9285 (FAX)

vi

HP 8517B S-Parameter Test Set Manual

Page 7

Safety and Regulatory Information

Review this product and related documentation to familiarize yourself with

safety markings and instructions before you operate the instrument. This

product has been designed and tested in accordance with international

standards.

WARNING

CAUTION

Instrument Markings

The WARNING notice denotes a hazard. It calls attention to a procedure,

practice, or the like, that, if not correctly performed or adh ered to, could result

in personal injury. Do not proceed beyond a WARNING notice until the

indicated conditions are fully understood and met.

The CAUTION notice denotes a hazard. It calls attention to an operating

procedure, practice, or the like, which, if not correctly performed or adhered

to, could result in damage to the product or loss of important data. Do not

proceed beyond a CAUTION notice until the indicated conditions are fully

understood and met.

When you see this symbol on your instrument, you should refer to the instrument’s

!

instruction manual for important information.

This symbol indicates hazardous voltages.

The laser radiation symbol is marked on products that have a laser output.

This symbol indicates that the instrument requires alternating current (ac) input.

The CE mark is a registered trademark of the European Community. If it is

accompanied by a year, it indicates the year the design was proven.

The CSA mark is a registered trademark of the Canadian Standards Association.

1SM1-A This text indicates that the instrument is an Industrial Scientific and Medical Group 1

Class A product (CISPER 11, Clause 4).

This symbol indicates that the power line switch is ON.

This symbol indicates that the power line switch is OFF or in STANDBY position.

HP 8517B S-Parameter Test Set Manual

vii

Page 8

Safety Earth Ground

This is a Safety Class I product (provided with a protectiveearthing

terminal). An uninterruptible safety earth ground must be provided from the

main power source to the product input wiring terminals, power cord, or

supplied power cord set. Whenever it is likely that the protection has been

impaired, the product must be made inoperative and secured against any

unintended operation.

Before Applying Power Verify that the product is configured to match the available main power

source as described in the input power configuration instructions in this

manual. If this product is to be powered by auto-transformer, make sure the

common terminal is connected to the neutral (grounded) side of the ac power

supply.

viii

HP 8517B S-Parameter Test Set Manual

Page 9

Typeface Conventions

Not all of the following conventions may appear within this manual,

however, refer to this listing whenever you encounter on of the special font

characters.

Italics

• Used to emphasize important information:

Use this software only with the HP 8517B Test Set.

• Used for the title of a publication:

Refer to the HP 8517B S-Parameter Test Set Manual

• Used to indicate a variable:

LOAD BIN filename.

Type

Instrument Display • Used to show on-screen prompts and messages that you will see on the

display of an instrument:

The HP 8517B will display the message

Keycap

Softkey

User Entry • Used to indicate text that you will enter using the computer keyboard;

• Used for labeled keys on the front panel of an instrument or on a

computer keyboard:

[Return]

Press

.

• Used for simulated keys that appear on an instrument display:

{Prior Menu}

Press

text shown in this typeface must be typed exactly as printed:

LOAD PARMFILE

Type

.

CAL1 SAVED.

Path Name

Computer Display

• Used for examples of programming code:

#endif // ifndef NO_CLASS

• Used for a subdirectory name or file path:

Edit the file

usr/local/bin/sample.txt

• Used to show messages, prompts, and window labels that appear on a

computer monitor:

Edit Parameters

The

window will appear on the screen.

• Used for menus, lists, dialog boxes, and button boxes on a computer

monitor from which you make selections using the mouse or keyboard:

EXIT

Double-click

to quit the program.

HP 8517B S-Parameter Test Set Manual

ix

Page 10

x

HP 8517B S-Parameter Test Set Manual

Page 11

Contents

Notice ..................................................... ii

RestrictedRightsLegend................................ ii

WhatYou’llFindinThisManual…..............................iii

HP8517BS-ParameterTestSet ..........................iii

Warranty ...................................................iv

Certification .............................................iv

Warranty ................................................iv

Assistance............................................... v

Service and Support . .........................................vi

SafetyandRegulatoryInformation.............................. vii

Safety Earth Ground . . . ...................................viii

BeforeApplyingPower ...................................viii

Typeface Conventions ........................................ix

1. Getting Started

HowtoUseThisManual .....................................1-1

TestSetDescription .........................................1-2

Figure 1-1. Standard HP 8517B Test Set Block Diagram .........1-2

Figure 1-2. Option 004, HP 8517B Test Set Block Diagram .......1-3

Figure 1-3. Option 007, HP 8517B Test Set Block Diagram .......1-3

HP8517BTestSetOptions ...................................1-4

Table 1-1. HP 8517B Options and Descriptions ................1-4

VerifyingTestSetOperation ..................................1-5

Table 1-2. Test Set Operation Verification .....................1-5

CheckingSystemOperation.............................1-5

CheckingSpecifications................................1-5

Troubleshooting the Test Set . . ..........................1-5

MaintainingMeasurementAccuracy ............................1-6

InstrumentsSupportedbyThisManual ..........................1-7

Figure 1-4. Instrument Serial-Number Label Example ...........1-7

InstrumentFirmwareCompatibility .............................1-8

Table 1-3. Source Firmware Revision Compatibility Matrix .......1-8

Service and Support Options Available ..........................1-9

Table 1-4. Service and Support Options ......................1-9

Accessories ...............................................1-10

RecommendedTestEquipment ...............................1-12

Table 1-6. Recommended Test Equipment ....................1-12

OperatingandSafetyPrecautions..............................1-13

Table 1-7. Maximum Input Power Levels ....................1-13

SafetyPrecautions ......................................1-13

HP 8517B S-Parameter Test Set Manual

Contents-1

Page 12

2. Installation

InitialInspection ........................................... 2-2

OperatingEnvironment................................... 2-2

StoringtheTestSet ...................................... 2-2

AccessoriesSupplied .................................... 2-2

Figure 2-1. Accessories Supplied with the HP 8517B Test Set .... 2-3

Table 2-1. Accessories in Figure 2-1 ........................ 2-3

InstallingtheTestSetIntoaSystemRack ....................... 2-4

InstallingtheTestSetonaBench........................... 2-4

Figure 2-2. Recommended Static-Free Workstation Configuration .2-4

ConfiguringtheTestSetinaSystem ........................... 2-5

Figure 2-3. Configuring an HP 8517B Test Set in a System ...... 2-5

ConnectingtheSystemCables ............................. 2-6

Table 2-2. Connection Instructions and Connector Descriptions .. 2-6

ConnectSystemPower................................ 2-6

andControlCables ................................... 2-6

Signal Path Connections . .............................. 2-6

TestPortConnectors.................................. 2-6

Anti-RotationClamp.................................. 2-6

ReplacingO-RingsinAnti-RotationClamps .................. 2-6

PackagingtheTestSet....................................... 2-7

3. Operating the HP 8517B Test Set

Front-PanelFeatures ........................................ 3-1

Figure 3-1. Front-Panel Features of the HP 8517B Test Set ...... 3-1

Table 3-1. Front-Panel Description ......................... 3-1

Rear-PanelFeatures......................................... 3-2

Figure 3-2. Rear-Panel Features of the HP 8517B Test Set ....... 3-2

Table 3-2. Rear-Panel Descriptions ......................... 3-2

ControllingMultipleTestSets ................................ 3-3

Figure 3-3. RF and IF Switching with Two Test Sets ............ 3-4

Table 3-3. RF and IF Switch Settings in Figure 3-3, Above ....... 3-4

Multiple Test-Set Connections . . .............................. 3-5

InitializationatPower-Up................................. 3-5

SelectingaTestSet ...................................... 3-5

Table 3-4. Selecting a Test Set When Multiple Units are Configured 3-6

TestSetIFSwitching ................................. 3-6

TestSetAddressing................................... 3-6

RFSwitchDriverControl.............................. 3-6

Figure3-4. RFandIFSwitchingwithFourTestSets........ 3-7

Table 3-5. Coaxial Switch Settings for Figure 3-4, Above ........ 3-7

MeasurementCalibration .................................... 3-8

MeasuringHigh-PowerDeviceswithOption004 ................. 3-9

ChangingSignalPathStatesAfterSystemCalibration............. 3-10

ChangingtheTestPortAttenuators ........................ 3-10

StoringTraceMemories ................................. 3-11

ViewingNormalizedParameters........................... 3-11

Contents-2

HP 8517B S-Parameter Test Set Manual

Page 13

MakingOperationalChecks ..................................3-13

PerformanceVerification ....................................3-14

UsingAnti-RotationClamps .................................3-15

Attachthefirstclamp.................................3-15

Figure 3-5. Using a Torque Wrench Correctly ................3-16

Positioningthethumb-screw ...........................3-16

Figure 3-6. Visually Aligning Clamp and Nut Flats ............3-17

Positioning the connector .............................3-17

Figure 3-7. Mating the Clamp and Nut Flats .................3-17

Aligningthethumb-screw .............................3-18

Figure 3-8. Aligning the Thumbscrew With the Counter-SinkHole 3-18

Attachingthesecondclamp............................3-18

4. Specifications

MechanicalSpecifications ....................................4-1

SupplementalCharacteristics ..................................4-1

Table 4-1. HP 8510/HP 8517B Mechanical Specifications .......4-1

Table 4-2. HP 8510/HP 8517B Supplemental Characteristics .....4-1

5. Troubleshooting the Test Set

TheoryofOperation .........................................5-2

Figure 5-1. Standard HP 8517B RF Block Diagram ............5-2

TheRFSourcePower.....................................5-2

TheReferenceSignalPath.................................5-3

TheTestSignalPath......................................5-3

The S

and S21Measurements .............................5-3

11

TheSamplerControlSwitching.............................5-3

TheLOSignalControl....................................5-4

Troubleshooting Sequence . ...................................5-5

Figure 5-2. Troubleshooting Flowchart ......................5-5

Equipment Needed But Not Supplied . . ......................5-6

Table 5-1. Equipment Required, But Not Supplied ..............5-6

Troubleshooting Procedures ...................................5-7

Table 5-2. Power Supply Voltages to A15 .....................5-7

Table 5-3. Power Supply Voltages to A27 .....................5-7

Figure 5-3. Power Supply Fuses and Test Points ...............5-8

HP-IBAddressSwitch ....................................5-8

Figure 5-4. Instrument HP-IB Switch Setting ..................5-9

FuseLocation ...........................................5-9

Figure 5-5. Fuse and Voltage Cam Location ...................5-9

Figure 5-6. The ACTIVE LED Location .....................5-10

IftheSelf-TestFailstoRunProperly ....................5-10

Figure 5-7. HP 8518B Test Set, A4 Board Assembly LEDs .......5-11

Table 5-4. Instrument Self-Test Indicator State Definitions ......5-11

Figure 5-8. Service Adapter Connections ....................5-12

UsingtheServiceAdapter.............................5-12

ServiceAdapterConclusions...........................5-13

Table 5-5. Results Observations ...........................5-13

HP 8517B S-Parameter Test Set Manual

Contents-3

Page 14

UnratioedPowerTest................................ 5-14

Figure 5-9. Diagram of IF Signal Path ..................... 5-14

IsolatingSignalPathProblems............................ 5-14

TestingSignalPaths1-4.............................. 5-14

TestingPaths5and6 ................................ 5-16

Figure 5-10. RF Path 1 and Path 2, HP 8517B Standard Test Set .5-17

Figure 5-11. RF Path 3 and Path 4, HP 8517B Standard Test Set .5-18

Figure 5-12. RF Path 5 and Path 6, HP 8517B Standard Test Set .5-19

Figure 5-13. RF Path 1 through Path 4,

HP 8517B Option 007 Test Set ......................... 5-20

Figure 5-14. RF Signal for Path 1 through Path 4,

HP 8517B Option 007 ............................... 5-21

Figure 5-15. RF Path 5 and Path 6, HP 8517B Option 007 ...... 5-22

Table 5-6. Test Results for Path 1 through Path 6 ............. 5-23

SampleDiagnostics..................................... 5-23

Table 5-7. Most Probable Failures

(B indicates Bad; — indicates Good) .................... 5-23

6. HP 8517B Test Set Replacement Procedures

Figure 6-1. ESD-Safe Workstation Configuration .............. 6-2

PerformanceTests .......................................... 6-2

Adjustments............................................... 6-2

Equipment Needed But Not Supplied . .......................... 6-3

Table 6-1. Replacement-Procedure Tools Needed .............. 6-3

Figure 6-2. HP 8517B Major Assembly Location Diagram ...... 6-4

AssemblyReplacementProcedures............................. 6-5

InitialPrecautions ....................................... 6-5

Switch/SplitterReplacement............................... 6-5

A18Switch/SplitterAssembly .......................... 6-5

FrequencyConverterReplacement.......................... 6-5

A14,A10toA13FrequencyConverterAssembly .......... 6-5

RegulatorBoardReplacement ............................. 6-6

A15RegulatorBoardAssembly......................... 6-6

FilterCapacitorReplacement .............................. 6-6

C1toC4FilterCapacitors ............................. 6-6

TestPortConnectorReplacement........................... 6-7

2.4mmTestPortConnectors........................... 6-7

Figure 6-3. Diagram of 2.4 mm Test Port Connector ............ 6-7

FanAssemblyReplacement ............................... 6-8

B1FanAssembly .................................... 6-8

PowerTransformerReplacement ........................... 6-8

T1PowerTransformer ................................ 6-8

Figure 6-4. Wire Connections to FL1 Line Module ............. 6-9

O-RingReplacement.................................... 6-10

Figure 6-5. Positioning the O-Ring Within the Clamp .......... 6-10

FrontPanelandInterfaceBoardReplacement ................ 6-10

A1FrontPanelandInterfaceBoardAssembly ............ 6-10

Contents-4

HP 8517B S-Parameter Test Set Manual

Page 15

BiasTeesReplacement...................................6-11

A7andA9BiasTees .................................6-11

TestPortCouplerReplacement ............................6-11

A6andA8TestPortCouplers..........................6-11

TestPortAttenuatorReplacement ..........................6-11

A16orA17PortAttenuators...........................6-11

Input Amplifier Replacement ..............................6-12

A22InputAmplifierAssembly .........................6-12

BufferAmplifierReplacement.............................6-12

A23toA26BufferAmplifiers..........................6-12

PostRegulatorBoardReplacement .........................6-13

A27PostRegulatorBoardAssembly ....................6-13

7. HP 8517B Replaceable Parts

Introduction................................................7-1

Rebuilt-ExchangeAssemblies ..............................7-1

ReplaceablePartsList ....................................7-1

OrderingInformation..................................7-2

ToOrderParts....Fast!...............................7-2

Table 7-1. Reference Designation Abbreviations ..............7-2

Table 7-2. Manufacturer Names and Addresses ................7-3

Table 7-3. Standard Abbreviations ..........................7-4

Table 7-4. Multipliers, Abbreviation and Description ...........7-10

Figure 7-1. Power Cable and Plug Part Numbers ..............7-11

Table 7-5. Instrument Fuses ..............................7-12

Figure 7-2. The Low Cost Rebuilt-Exchange Procedure .........7-13

Table 7-6. Major AssemblyReference Designator and PartsInformation

7-14

Figure 7-3. Major Assembly Locations in the Standard

HP 8517B Test Set ...................................7-15

Table 7-7. Semi-Rigid Cable Assemblies in the Standard

HP 8517B Test Set ...................................7-16

Table 7-8. Flexible Cable Assemblies in the Standard

HP 8517B Test Set ...................................7-17

Table 7-9. Miscellaneous Parts, Front Panel HP 8517B Test Set ..7-19

Table 7-10. Test Port Connector Assembly Components .........7-20

Table 7-11. Miscellaneous Parts, Rear Panel HP 8517B Test Set ..7-21

Figure 7-4. Detailed Views of Hardware Stack-Ups ............7-23

Table 7-12. Miscellaneous Parts, Top Internal View ............7-24

Table 7-13. Miscellaneous Parts, Motherboard ...............7-25

Table 7-14. Parts Unique to HP 8517B Option 001 Test Set ......7-27

Table 7-15. Parts Unique to HP 8417B Option 002 Test Set ......7-29

Table 7-16. Parts Unique to HP 8517B Option 004 Test Set ......7-30

Table 7-17. Parts Unique to HP 8517B Option 007 Test Set ......7-31

Table 7-18. Parts Unique to Option 002 “plus” Option 007 .....7-33

Table 7-19. Parts Unique to Option 004 “plus” Option 007 .....7-34

Table 7-20. Instrument Chassis Replaceable Parts .............7-35

HP 8517B S-Parameter Test Set Manual

Contents-5

Page 16

Contents-6

HP 8517B S-Parameter Test Set Manual

Page 17

1

Getting Started

This is the operating and service manual for the HP 8517B S-parameter test

set. It is to be used in conjunction with the HP 8510C Network Analyzer

Operating and Service Manual. Together, these manuals provide

information needed to configure the system and make measurements.

How to Use This Manual

Step 1. Review Chapter 1, “Getting Started” and Chapter 2, “Installation” of this manual to

learn about:

• Using this test set

• Using options of the test set

• Preparing the site for operation

• Understanding safety considerations

• Unpacking the instrument and checking it for shipment damages

• Configuring the HP 8517B test set with the HP 8510C Network Analyzer

Step 2. Insert the contents of this manual into the HP 8510C Test Sets and Accessories

binder behind the tab labeled “Test Sets.”

Step 3. Review the

supplied with the HP 8510C manuals set.

Refer to the calibration kit documentation for complete information about care,

cleaning, gaging, and connecting precision devices. Knowledge and application of

proper connector care is essential to achieving good connections and maintaining

maximum performance quality with your precision calibration devices.

Step 4. Read Chapter 3, “Operation,” to learn about test set front- and rear-panel features.

This chapter also has information about controlling multiple test sets, measuring

high power devices, using the anti-rotation clamps on the cables, and connecting

devices to the test set.

Step 5. Refer to Chapters 4 through 7 for reference information about specifications,

troubleshooting, replacement procedures, and replacement parts information.

Connector Care Quick Reference Card

(HP part number 08510-90360)

HP 8517B S-Parameter Test Set Manual

1-1

Page 18

Getting Started

Test Set Description

Test Set Description

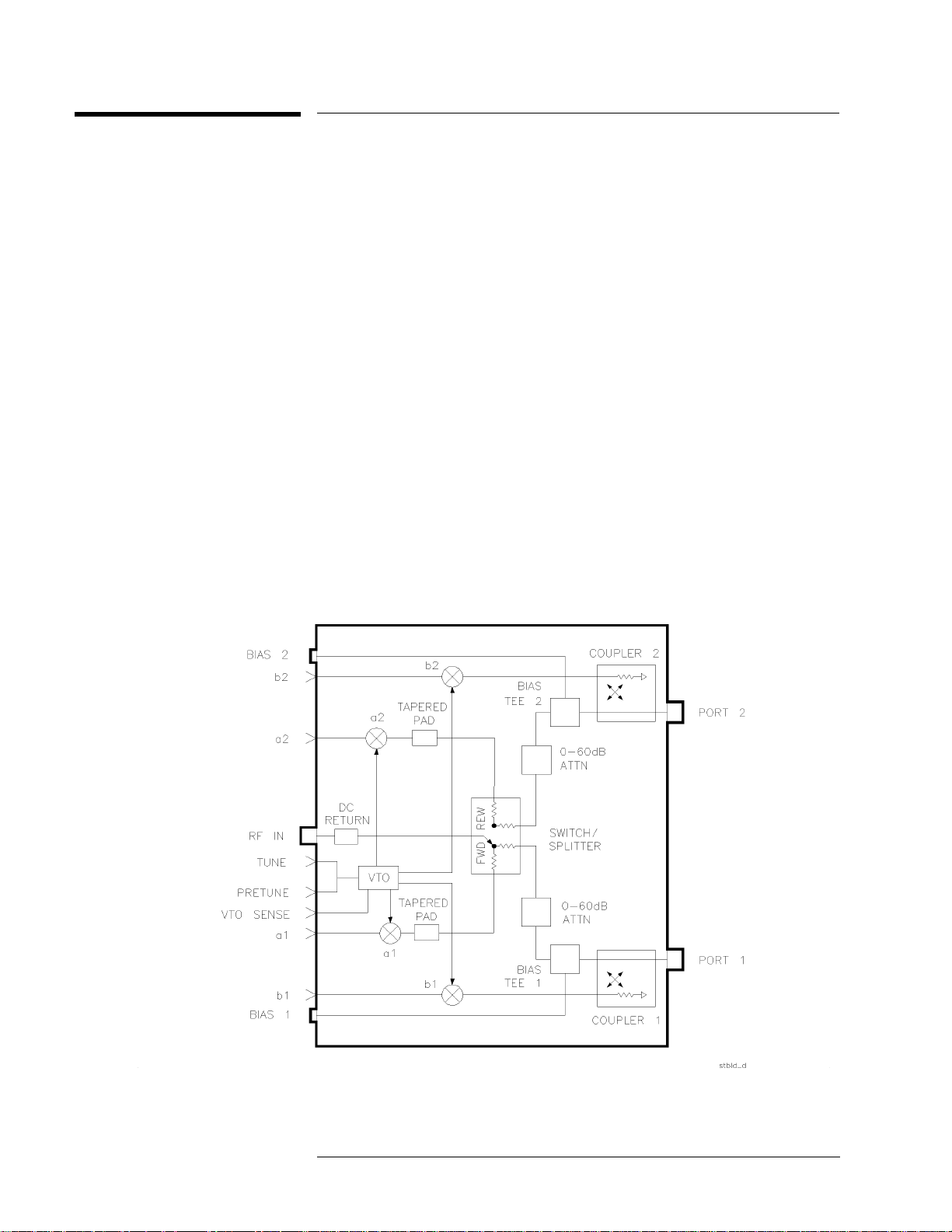

The HP 8517B test set configured with an HP 8510B/C network analyzer

and an HP 8360 series source, creates a system capable of making

S-parameter measurements from 45 MHz to 50 GHz. The system is

particularly suited for making two-port device measurements. You can

measure all four S-parameters without physically reversing the DUT (device

under test).

The system is also designed for making measurements on non-reciprocal

devices or components like transistors, amplifiers or isolators where S

measurements are required.

Two directional couplers are used for signal separation. The configuration is

illustrated in the following figures:

12

• Figure 1-1, “Standard HP 8517B Test Set Block Diagram"

• Figure 1-2, “Option 004, HP 8517B Test Set Block Diagram"

• Figure 1-3, “Option 007, HP 8517B Test Set Block Diagram"

For active-device measurements, two bias tees apply external DC bias to

both test port center conductors.

Figure 1-1 Standard HP 8517B Test Set Block Diagram

1-2

HP 8517B S-Parameter Test Set Manual

Page 19

Getting Started

Test Set Description

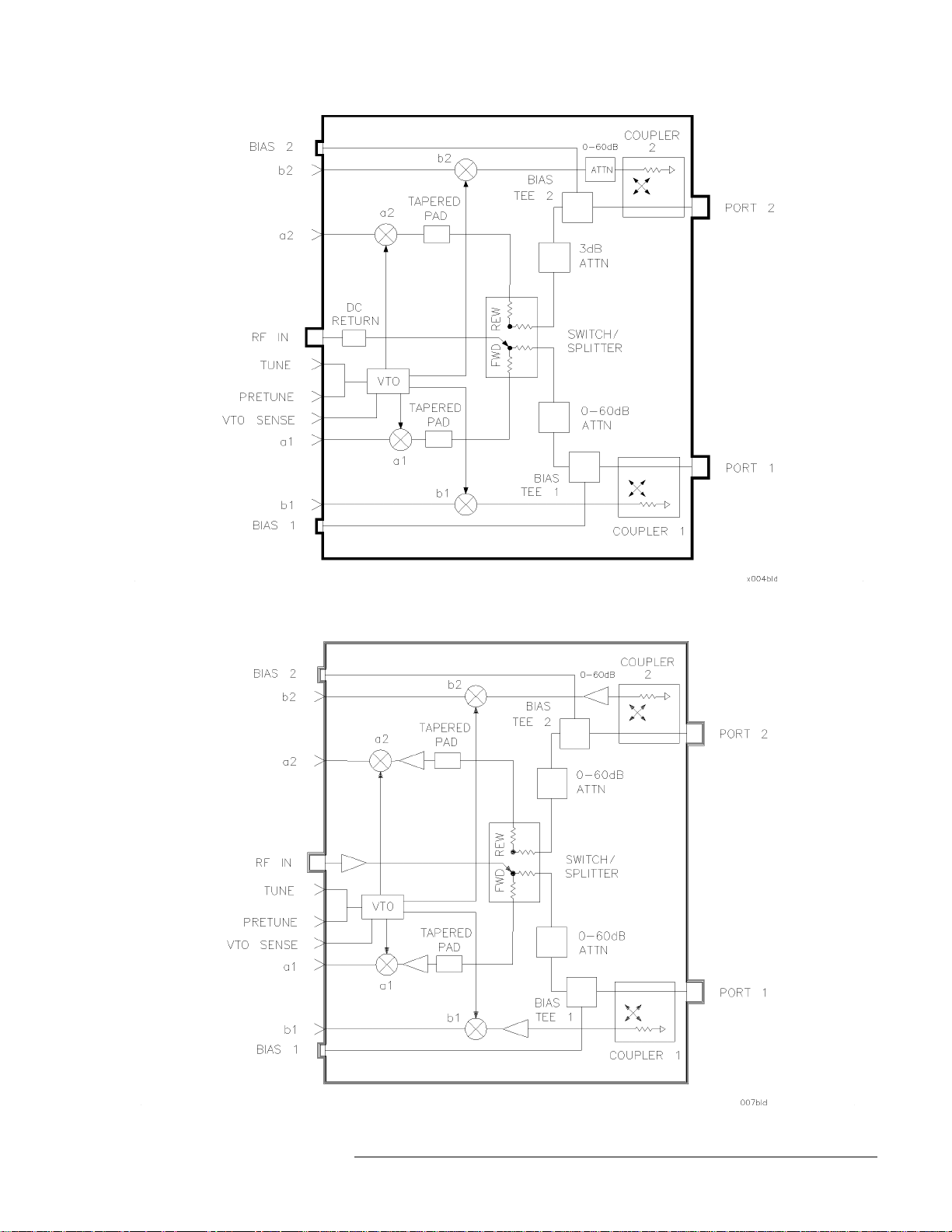

Figure 1-2 Option 004, HP 8517B Test Set Block Diagram

Figure 1-3 Option 007, HP 8517B Test Set Block Diagram

HP 8517B S-Parameter Test Set Manual

1-3

Page 20

Getting Started

HP 8517B Test Set Options

HP 8517B Test Set Options

Options for the HP 8517B test set are described in Table 1-1, below.

Table 1-1 HP 8517B Options and Descriptions

Options HP 8517B Test Set Option Description

Option 001 Adds IF switching capability for up to four test set connections to the HP 8510C Network

Analyzer.

The test set used is selected from the network analyzer. Refer to “Controlling Multiple Test

Sets” in Chapter 3, “Operation” of this manual for more information.

Option 002 Deletes the programmable attenuators and bias tees.

Note:

If bias is required but attenuation is not, the bias can be applied externally by using an

HP 11612B bias tee.

Option 004 Moves P ort 2 attenuator in front of the b2 sampler, allowing devices with output power up to 30

dBm (1 W) to be measured. Adds a 3 dB attenuator which protects the switch splitter from high

power into Port 2.

Option 007 Adds five amplifiers, two 10 dB attenuators, two 6 dB attenuators, and two tapered attenuators.

These components increase the available power and dynamic range of the test set.

Option 908 Supplies the hardware required for rack mounting the test set when its handles are removed.

Refer to Chapter 2, “Installation” for more information.

Option 910 Adds a duplicate copy of this manual to the shipment.

Option 913 Supplies the hardware required for rack mounting the test set with its handles attached. Refer

to Chapter 2, “Installation” for more information.

Option 002 “plus” 007 Removes the bias tee, and retains the high dynamic range capability in the test set.

Option 004 “plus” 007 Adds high-dynamic range and high power measurement capability to Port 2.

1-4

HP 8517B S-Parameter Test Set Manual

Page 21

Verifying Test Set Operation

The test set is designed to operate with an HP 8510C network analyzer. You

canverifyitsoperationby:

Table 1-2 Test Set Operation Verification

Getting Started

Verifying Test Set Operation

Checking System Operation Perform a system calibration as described in the

Programming Manual

therefore the test set, are operating properly.

Checking Specifications Specifications for the test set, and the system, can be determined by running

the specification and performance verification software described in the

8510C On-Site Service Manual

Verification”. Additional mechanical specifications and supplemental

characteristics are in Chapter 4, “Specifications” of this manual.

Troubleshooting the Test Set To troubleshoot the test set, refer to the

Use the information in that manual to determine if the test set is at fault. If the

test set is at fault, refer to Chapter 5, “Troubleshooting the Test Set” in this

manual to isolate the trouble.

. A successful calibration indica tes that the system, and

, Chapter 8, “Specification and Performance

HP 8510C Operating and

HP

HP 8510C On-Site Service Manual

.

HP 8517B S-Parameter Test Set Manual

1-5

Page 22

Getting Started

Maintaining Measurement Accuracy

Maintaining Measurement Accuracy

Precision measurements rely on a precision calibration of the network

analyzer. As a general rule, the shorter the time lapse between a calibration

and a device measurement, the more precise the measurement results will be

(within the limitations of your system).

Hewlett-Packard recommends calibrating your system every few hours, or at

least re-verifying your system’s calibration this frequently. Doing so helps

retain measurement precision.

The frequency of calibrations is determined by both the location of the

system and the ambient temperature stability in its operating area.

1-6

HP 8517B S-Parameter Test Set Manual

Page 23

Getting Started

Instruments Supported by This Manual

Instruments Supported by This Manual

A serial number label is attached to the rear panel of the test set. There are

two parts to the serial number: a prefix, and a suffix. See Figure 1-4, and

read the following descriptions:

• The prefix includes the first four digits of the serial number, plus the

letter. The contents of this manual apply directly to test sets with the

same serial number prefix as the one(s) on the title page.

• The suffix includes the last five digits of the serial number, which is

sequential and unique to each test set. You will need this part of the

number to report test-set problems to an HP sales and service engineer.

Figure 1-4 Instrument Serial-Number Label Example

serial.tif

HP 8517B S-Parameter Test Set Manual

1-7

Page 24

Getting Started

Instrument Firmware Compatibility

Instrument Firmware Compatibility

To use the HP 8517B test set at f requencies up to 50 GHz, use an

HP 83650B or HP 83651B source.

If your network analyzer or source do not meet the required frequency

ranges for your measurement needs, you need to upgrade your system.

Please contact an HP Sales and Service representativeforinformation.These

offices are listed in “Service and Support” on page vi at the front of this

manual

Table 1-3 Source Firmware Revision Compatibility Matrix

Instrument Model

Number and Name

HP 8517B Test Set HP 8510B Network Analyzer

HP 8517B,

Option 007 Test Set

Compatible With Model: Firmware Revision

HP 8510C Network Analyzer

HP 8510C Network Analyzer 7.0 or higher, only Yes, up to the higher

B.06.00 and higher

C.06.00 and higher

Compatible With HP

8340 Series

Sources?

Yes, up to the higher

frequency limits.

frequency limits.

Compatible With

HP 8350 Series

Sources?

Yes, up to the higher

frequency limits.

No, not compatible

1-8

HP 8517B S-Parameter Test Set Manual

Page 25

Getting Started

Service and Support Options Available

Service and Support Options Available

A variety of service and support products are available for coverage of

repair, calibration, and verificationissues. Contact your HP sales and service

engineer for details. Their office addresses and phone numbers are listed in

the front of this document.

The purchase of an HP 8517B includes a one year on-site service warranty.

In the event of failure, Hewlett-Packard provides service for the system.

NOTE

System installation is not included.

Table 1-4 Service and Support Options

Option Number Option Description

Option W30 Adds a three year customer return-repair coverage warranty to the instrument.

Customers may return the instrument to HP within that three year period for repair.

Option W31 Adds a three year on-site repair coverage warranty for next-day on-site repair of the

instrument. Customers may return the instrument to HP within that three year period for

repair and get next-day service on their instrument.

Option 1BN Adds to the instrument a MIL-STD 45662A Certificate of Calibration.

ordered when the instrument order is placed

Option 1BP Adds to the instrument a MIL-STD 45662A Certificate of Calibration and the

corresponding calibration data.

placed

.

Option UK6 Adds a certificate of calibration (rather than the MIL-STD certificate) and the

corresponding calibration data to the instrument.

instrument order is placed.

This option must be ordered when the instrument order is

.

This option must be ordered when the

This option must be

HP 8517B S-Parameter Test Set Manual

1-9

Page 26

Getting Started

Accessories

Accessories

The accessories supplied with the test set, including part numbers, are listed

in “Accessories Supplied” in this section and in the “Replaceable Parts List”

of this manual.

Accessories Available Table 1-5 describes accessories available for the HP 8517B test set. For

additional HP 8510C system accessories information,refer to the HP 8510C

manual set.

Table 1-5 HP 8517B Test Set Accessories Available

Accessory Type Accessory Model Number Contents or Description

Calibration Kit

Verification Kit

1

1

HP 85056A 2.4 mm Calibration Kit Contains open and short circuits

Fixed and sliding loads (2)

2.4 mm to 2.4 mm adapters

2.4 mm connector tools and gauges

HP 85057S 2.4 mm Verification Kit Contains precision airline, mismatched airline,

20 dB and 40 dB attenuators

Cables HP 85133C 2.4 mm Test Port Return

Cable

HP 85133D 2.4 mm Test Port Return

Cable Set

HP 85133E 2.4 mm Flexible Test Port

Return Cable

HP 85133F 2.4 mm Flexible Test Port

Return Cable Set

HP 85134D 3.5 mm Test Port Return

Cable Set

HP 85134E 3.5 mm Flexible Test Port

Return Cable

HP 85134F 3.5 mm Flexible Test Port

Return Cable Set

HP 85135C 7 mm Test Port Return

Cable

Used when measuring a 2.4 mm-ported device connected directly to

Port 1 of the test set. The test port return cable is connected

between the device under test and Port 2.

Used when measuring a 2.4 mm-ported device connected between

the cable ends.

Used when measuring a 2.4 mm-ported device connected directly to

Port 1 of the test set. The test port return cable is connected

between the device under test and Port 2.

Used when measuring a 2.4 mm-ported device connected between

the cable ends.

Used when measuring a 3.5 mm device under test connected

between the cable ends.

Used when measuring one end of a 3.5 mm device connected

directly to an HP 85130F adapter at Port 1. The test-port return

cable is connected between the device and Port 2.

Used when measuring a 3.5 mm device connected between the

cable ends.

Used when measuring one end of a 7 mm device connected

directly to an HP 85130E adapter at Port 1. The test port return

cable is connected between the device and Port 2.

Cables (Continued) HP 85135D 7 mm Test Port Return

Cable Set

1-10

HP 8517B S-Parameter Test Set Manual

Used when measuring a 7 mm device connected between the cable

ends.

Page 27

Table 1-5 HP 8517B Test Set Accessories Available (Continued)

Accessory Type Accessory Model Number Contents or Description

Getting Started

Accessories

HP 85135E 7 mm Flexible Test Port

Return Cable

HP 85135F 7 mm Flexible Test Port

Return Cable Set

Adapters HP 85130E Special 2.4 mm to 7 mm

Adapter Set

HP 85130F Special 2.4 mm to 3.5 mm

Adapter Set

HP 85130G Special 2.4 mm to 2.4 mm

Adapter Set

HP 11904S 2.4 mm to K-2.9 mm

Adapter Kit

Test Fixture Kit HP 85041A Transistor Test Fixture Kit

(TTF)

2

Used when measuring one end of a 7 mm device connected directly

to an HP 85130E adapter at Port 1. The test port return cable is

connected between the device and Port 2.

Used when measuring a 7 mm device connected between the cable

ends.

Used to convert special 2.4 mm test set ports into a 7 mm connector

interface (m or f).

Used to convert special 2.4 mm ports of the test set into a 3.5 mm

connector interface (m or f).

Used to convert special 2.4 mm ports of the test set into a standard

2.4 mm connector interface (m or f). These adapters function as

“test port savers.”

Used to calibrate the test set using 2.4 mm devices, then to change

the test ports to 2.92 mm and perform fully error corrected

measurements. The kit contains (2) 2.4 mm to 2.92 mm (m)

adapters and (2) 2.4 mm to 2.92 (f) adapters.

A comprehensive measurement system for testing and

characterizing stripline packaged microwave transistors. Although

the fixture contains 7 mm connectors and its frequency limit is

18 GHz, the kit may be adapted for use with the test set. Use

HP 85135C or HP 85135E cables with the HP 85130E adapter set.

Please consult your HP Sales and Service representative for

recommendations.

NOTE

1. NIST traceable data and uncertainties are available.

2. The K-connector is developed and manufactured by the Wiltron Company (Morgan Hill, California).

For more information about other 2.4 mm adapters, refer to the “2.4 mm

Adapters and Calibration Accessories,” Operating Note, (HP part number

11900-90003).

HP 8517B S-Parameter Test Set Manual

1-11

Page 28

Getting Started

Recommended Test Equipment

Recommended Test Equipment

Additional equipment and accessories required for use with the test set are

listed in Table 1-6. The table lists which items are required to verify the

performance of the test set and which are required to operate it. O ther

equipment may be substituted if their specifications meet or exceed those

listed in the critical specifications column

Table 1-6 Recommended Test Equipment

Item

Network Analyzer no substitute HP 8510B or HP 8510C O, P, T

Source no substitute HP 83651B O, P, T

Controller no substitute HP 9000 Series 200 or 300 with 3 Mbyte RAM and

Disk Drive is compatible with the

Multimeter range: 0 to 50 V HP 3456A T

Oscilloscope 50 MHz bandwidth HP 1740A T

O = Operation; P = Performance Test; T = Troubleshooting

Critical

Specifications

controller

Recommended Model Use

N/A

HP BASIC 3.0 or higher or PCC-305 or PC-308

HP BASIC Controller with 3 Mbyte Basic Language

Processor RAM

is compatible with the controller P

1-12

HP 8517B S-Parameter Test Set Manual

Page 29

Operating and Safety Precautions

Operating and Safety Precautions

Getting Started

CAUTION

ESD Sensitive Assemblies

Test set assemblies are very sensitivetodamage from electrostatic discharge.

They may or may not continue to function if subjected to electrostatic

discharge. Their reliability, however, will be impaired. Handle the

instrument devices at static-safe work stations, only.

Operating Precautions Observe the following normal precautions when handling and operating the

test set:

• Do not exceed the input power levels listed below:

Table 1-7 Maximum Input Power Levels

Power Level Test Port

+17 dBm Port 1

+17 dBm Port 2

1

+30 dBm

1. This is the maximum input power allowed with HP 8517B Option 004, or

Option 004 “plus” Option 007, when the attenuator is set to

attenuation, the maximum input power allowed is +17 dBm.

Port 2 (Option 004, or Option 004 “plus” 007)

≤

20 dB. Without

• Do not exceed +15 dBm into the test set with the source RF input.

• Never apply a dc voltage to the source RF input of the test set.

• Do not torque any connection at the test port connectors to more than

90 N-cm (8 in-lb). The wrench supplied with your accessory kit is

calibrated for 90 N-cm (8 in-lb) torque.

• Do not torque any connection to more than 90 N-cm (8 in-lb) at the

source RF input or on the back of your test set.

Safety Precautions The voltages inside this test set warrant normal caution for operator safety.

Nevertheless, service should be performed by qualified personnel, only.

Service strategy, troubleshooting procedures, replaceable parts, and other

information about the test set are provided in this manual or the HP 8510C

On-Site Service Manual.

HP 8517B S-Parameter Test Set Manual

1-13

Page 30

Getting Started

Operating and Safety Precautions

1-14

HP 8517B S-Parameter Test Set Manual

Page 31

2

Installation

This chapter contains installation information. Topics include initial

inspection,environmental considerations,testset location when using it with

the HP 8510C network analyzer, and making connections to the test set.

Refer to “Installation” in the HP 8510C On-Site Service Manual for

complete system connection and turn-on instructions.

Refer to “Packaging the Test Set” for information about shipping the

instrument.

HP 8517B S-Parameter Test Set Manual

2-1

Page 32

Installation

Initial Inspection

Initial Inspection

Inspect the shipping container and cushioning materials for damage. If there

is damage, keep the container until you have checked the contents for

completeness.

If shipping materials are damaged, complete the performance tests outlined

in the HP 8510C On-Site Service Manual. If the test set fails the

performance tests, or is damaged or defective, keep the shipping materials.

Notify both the carrier and the nearest Hewlett-Packard Sales and Service

Office (listed in “Service and Support” at the front of this manual).

The office can arrange for repair or replacement of the test set without

waiting for the claim settlement.

Operating Environment

For the HP 8517B to operate within specifications, the ambient temperature

must remain between 0

95% (at 40

operated at altitudes up to 4,500 meters (15,000 feet).

° C dry bulb temperature, maximum). The instrument can be

° Cand+55° C. Keep relative humidity to less than

Storing the Test Set Acceptable storage temperatures range from –40° Cto+75° C, with relative

humidity

up to 15,240 meters (50,000 feet).

≤90% at +65° C (maximum dry bulb temperature) and at altitudes

Accessories Supplied Figure 2-1 illustrates accessories supplied with the test set. If you did not

receive one of these accessories with the test set, notify your nearest HP

Sales and Service Office so that the m issing parts can be sent to you.

2-2

HP 8517B S-Parameter Test Set Manual

Page 33

Installation

Initial Inspection

Figure 2-1 Accessories Supplied with the HP 8517B Te st Set

Table 2-1 Accessories in Figure 2-1

(1) Power Cord U.S.A. only (6) Female 2.4 mm to Female 2.4 mm Adapter

(2) Test Set Interconnect Cable (7) 20 mm, 98 N-cm (8 in-lb) Torque Wrench

(3) HP-IB Cable (8) 1/2” x 9/16” Open End Wrench

(4) Specification and Performance Verification Software (9) RF Source Cable, Bench-top Configuration

(5) Anti-rotation Clamps (10) RF Source Cable, Rack Configuration

CAUTION

Assemblies in the test set are extremely sensitive to damage by static

electricity. They may or may not continue to function if subjected to an

electrostatic discharge. Their reliability, however, will be impaired.

CAUTION

Always use an anti-static wrist strap when calibrating or verifying the test set

or while using the test set to measure devices. Never touch test port center

conductors. Use a wrist strap when connecting the extended center

conductor of a sliding load termination.

HP 8517B S-Parameter Test Set Manual

2-3

Page 34

Installation

Installing the Test Set Into a System Rack

Installing the Test Set Into a System Rack

The HP 85043C system rack is the recommended model to use. To

rack-mount the test set into a system configured with the H P 8510C, refer to

the “Installation” chapter of the HP 8510C On-Site Service Manual and to

the HP 85043C System Rack Manual.

Installing the Test Set on a Bench

When installing the test set for use on a bench, place it on a grounded

anti-static work surface to reduce the chance of ESD damage. The antistatic

surface should extend far enough in front of the test set to provide effective

protection for the test ports and cable ends. See Figure 2-2.

A grounding receptacle is provided on the test set as an alternate grounding

point for your anti-static wrist-strap.

Figure 2-2 Recommended Static-Free Workstation Configuration

2-4

HP 8517B S-Parameter Test Set Manual

Page 35

Installation

Configuring the Test Set in a System

Configuring the Test Set in a System

Figure 2-3 illustrates the cable connections for installing an HP 8517B in a

system. Refer to the information that follows to install the test set.

Figure 2-3 Configuring an HP 8517B Test Set in a System

HP 8517B S-Parameter Test Set Manual

2-5

Page 36

ConnectingtheSystem Cables

Table 2-2 Connection Instructions and Connector Descriptions

Installation

Configuring the Test Set in a System

Connect System Power

and Control Cables

Signal Path Connections The IF interconnect cable transmits IF signals from the test set to the HP 85102 IF detector.

Test Port Connectors Port 1 and Port 2 are male, NMD-2.4 mm connectors, and mate to female 2.4 mm connectors.

Anti-Rotation Clamps Use the anti-rotation clamps (item 5, Figure 2-1) to stabilize the test port or RF cable at the

Check the test-set line module (see item (1) in Chapter 3, Figure 3-2 of this manual). It must be set for

the correct voltage in your region. Refer to Chapter 5, “Troubleshooting” of this manual for information

about changing the voltage selection or replacing the line fuse.

• After setting or confirming the line-voltage module, connect the test set power cord to an electrical

outlet.

• Attach the HP 8517B IF-interconnect cable from J11 TEST SET INTERCONNECT (on the test set’s

rear panel) to J1 TEST SET INTERCONNECT on the rear panel of the HP 85102 IF detector.

• Attach the system bus cable from HP 8517B J12 HP 8510 SYSTEM BUS connector to HP 8510C

INTERCONNECT on the HP 85101 display/processor.

The test set IF interconnect cable and the system bus cable transmit control signals between the test

set and the network analyzer.

• Attach one end of the 2.4 mm RF cable (item 9 or 10, Figure 2-1) to the RF output on the rear panel

of the HP 83651 Synthesized Sweeper.

• Attach the other end of the RF cable to the RF input on the HP 8517B Test Set.

connection, or to stabilize an adapter at the connection.

• Connect test port cables or adapters to the test ports.

• Torque the connections to 90 N-cm (8 in lb).

• Loosen the anti-rotation clamp thumb screw enough to slip the clamp over the cable and up to the

front panel. The clamp end with the flats should come to rest on the flats of the test port shoulder.

• Finger-tighten the thumb screws to prevent further loosening or tightening of the test port/RF cable

connection. Refer to Chapter 3, “Operation” of this manual for additional information.

Replacing O-Rings in Anti-Rotation Clamps

The anti-rotationclamp’s internal O-ring is a field-replaceable part. There is

no need to disassemble the anti-rotation clamp.

When the O-ring no longer holds the RF cable securely, replace it by

following the instructions in Chapter 6, “ Replacement Procedures.”

2-6

HP 8517B S-Parameter Test Set Manual

Page 37

Installation

Packaging the Test Set

Packaging the Test Set

To repackage the test set, use its original factory packaging.

Refer to the test set using its complete model and serial numbers in any

correspondence to an HP Sales and Service Office.

Containers and materials identical to those used in the original shipment by

the factory are available through Hewlett-PackardSales and Service Offices.

However, commercially available, comparable packaging materials may be

used, also.

1. Wrap the test set in heavy paper or anti-static plastic.

2. If you are shipping the test set to an HP Sales or Service office, complete

and attach a service tag (located in the HP 8510C manual set).

3. Use sufficient shock absorbing material on all sides of the test set to

provide a thick, firm cushion and prevent movement.

4. Seal the shipping container securely and mark it “FRAGILE.”

HP 8517B S-Parameter Test Set Manual

2-7

Page 38

Installation

Packaging the Test Set

2-8

HP 8517B S-Parameter Test Set Manual

Page 39

3

Operating the HP 8517B Test Set

This chapter contains illustrations and descriptions of the HP 8517B frontand rear-panel features. Information about operating multiple test sets

(Option 001) is also provided.

Front-Panel Features

Figure 3-1 Front-Panel Features of the HP 8517B Test Set

Table 3-1 Front-Panel Description

(1) Line Switch This switch turns the test set on or off. When the side of the switch labeled “0” is depressed, the

test set is OFF; when the side labeled “1” is depressed, the test set is ON.

(2) Line LED This LED is lit when the test set line switch is ON and not lit when the test set line switch is OFF.

(3) Active LED This LED lights about two seconds after power is turned on, following the successful conclusion of

the self-test. If the test set is used with other test sets (Option 001) and is not addressed by the HP

8510C, then this light remains off.

(4) Port 1 This test port transmits RF energy from the source to the DUT and receives reflected or transmitted

RF energy from the DUT. The reflected RF energy is coupled to a sampler within the instrument.

Connections made to this input must be torqued to 90 N-cm (8 in-lb), and no more.

(5) Bias Fuse The fuses that limit bias applied to Port 1 and Port 2 are located in these holders (see the

instrument front panel or the replaceable parts list for the fuse values).

HP 8517B S-Parameter Test Set Manual

3-1

Page 40

Table 3-1 Front-Panel Description (Continued)

(6) a1 LED This LED indicates that the test set is internally switched to the S11 or S21 mode and source power

is switched to Port 1.

(7) a2 LED This LED indicates that the test set is internally switched to the S

is switched to Port 2.

(8) Port 2 This test port transmits RF energy from the source to the DUT and receives reflected or transmitted

RF energy from the DUT.

or S12 mode and source power

22

Rear-Panel Features

Figure3-2 Rear-Panel Features of the HP 8517B Test Set

Table 3-2 Rear-Panel Descriptions

(1) Line Module Houses the line cord connector, line fuse and line voltage selector. Pull out the right side

of the line module cover to replace or change the fuse or to change the voltage selection.

Remove the voltage selector drum to rotate it to a different voltage setting. Recommended

fuse values are printed on the rear panel.

(2) RF Input A 2.4 mm connector that receives RF energy from the source. Connections made to this

input must be torqued no more than 90 N-cm (8 in-lb).

(3) J10 Test Set Interconnect Used only in test sets with Option 001. It allows connecting another test set to the option

001 test set. Up to four test sets can be serially connected to the analyzer. The HP 8510C

system automatically selects the IF output from the chosen test set for processing and

display. Refer to “Controlling Multiple Test Sets” in this chapter for more information.

(4) J11 Test Set Interconnect Transmits the IF signal from the test set to the HP 85102 IF detector. It also transmits

control signals bi-directionally.

(5) HP 8510 System Bus Address Switch A five-pole binary-weighted switch sets the test-set’s system bus address. The binary

weight of each pole is indicated on the rear panel. So are the On and Off positions. The

default setting is decimal twenty (off-off-on-off-on, from left to right).

HP 8517B S-Parameter Test Set Manual

3-2

Page 41

Table 3-2 Rear-Panel Descriptions (Continued)

(6) J12 8510 System Bus Connector Used for HP-IB communications with the HP 85101 display/processor.

(7) Port 2 Bias A female BNC connector used to supply bias through the center conductor of Port 2 to

active devices under test.

(8) Port 1 Bias A female BNC connector used to supply bias through the center conductor of Port 1 to

active devices under test.

Controlling Multiple Test Sets

HP 851X Series, Option 001 test sets allow an HP 8510C to alternately

control up to four test sets connected to it. For example:

• While a measurement is underway on test set number 1 (equipped with

Option 001), a test device can be connected to test set number 2 (which

does not need Option 001).

• When the measurement on test set number 1 is complete, the HP 8510C

can then control test set number 2.

In a standard test set, the 20 MHz IF and control signals are applied directly

to J11 TEST SET INTERCONNECT, which is attached to the HP 8510C.

Option 001 adds a set of IF switches, control switches, and the J10 TEST

SET INTERCONNECT attachment. This configuration allows the selection

of the 20 MHz test set IF signal.

As shown in Figure 3-3 on page 3-4, test set number 1 can:

• apply its IF signal to the HP 8510C, or it can

• switch to pass the IF signal from test set number 2, through J10 TEST

SET INTERCONNECT, and into the HP 8510C.

HP 8517B S-Parameter Test Set Manual

3-3

Page 42

Figure 3-3 RF and IF Switching with Two Test Sets

Table 3-3 RF and IF Switch Settings in Figure 3-3, Above

New ADDRESS of

Test Set

20 Number 1 Port 1

21 Number 2 Port 2

1. Not all system connections are illustrated.

2. In dual source configurations, the second source may be multiplexed in a similar manner. If only one

1, 2

dual source test set is used, the second source may be connected directly to the appropriate test

set.

Test Set Number

Selected

Coaxial Switch Port Selected

HP 8517B S-Parameter Test Set Manual

3-4

Page 43

Multiple Test-Set Connections

For dual test-set configurations, set each rear panel address switch on each

test set to the address shown in Figure 3-3. Refer to Figure 3-4 on page 3-7

for the configuration of two or more test sets.

• Use the supplied test set interconnect cable to attach test set number 1,

J11 to the network analyzer.

• Use the supplied test set interconnect cable to attach test set number 2,

J11 to test set number 1, J10.

You may connect up to four test sets in a series if the total length of all test

set interconnect cables does not exceed 13 meters (about 40 feet). The last

test set connected in the chain does not require Option 001.

If the RF coaxial switch is not incorporated into the system, the RF input to

the test set must be manually switched to the active test set.

Initialization at Power-Up

At power-up, configure the IF switches so that only one system test set is

active. T o verify which test set is active, use the following steps:

1. Verify that all system test set LEDs are lit.

2. View the network analyzer’s test set address by pressing the

INSTRUMENT STATE,

address of the test set is displayed on the screen.

The address displayed must match the address of the test set selected. If

not, enter the correct address using the network analyzer’s key pad.

3. If an unselected test set’s LEDs are lit, deactivate it. Do this by entering

its address, pressing

[x1]

followed by

.

[LOCAL]

[x1]

, t hen entering the address of the test set desired,

key, then press

{TEST SET}

.

The HP-IB

Selecting a Test Set To select another test set, follow the procedure in Table 3-4 on page 3-6 of

this chapter.

HP 8517B S-Parameter Test Set Manual

3-5

Page 44

Table 3-4 Selecting a Test Set When Multiple Units are Configured

Test Set IF Switching A test set is selected via the built-in capability of the analyzer to generate an addressed

command to each test set. Each time you change the

function (refer to LOCAL [MENU] in the

network analyzer does the following:

HP 8510C Operation and Service Manual

• switches the IF signal of the previously addressed test set to external

• switches the IF signal of the newly addressed test set to internal

• sets the test set’s front panel ACTIVE LED to indicate test-set status

• applies the active test set’ s IF signals directly to J11 T EST SET INTERCONNECT

• passes the inactive test set’s IF signals at J10 through to J11 and on to the next

test set or to the network analyzer

Test Set Addressing You can change the test set address via program control, or via the network analyzer front

panel keys. You must also change the mechanical switches on the test-set’s rear panel.

Here’s how:

1. Change the test set address via the network analyzer keys;

a. On the analyzer’s front panel, press the INSTRUMENT STATE [LOCAL] key, then

{TEST SET}

press

b. Using the key pad, enter the desired address for the test set, then press [x1]. The new

HP-IB address appears on the display.

2. Change the test set address via the HP-IB command:

. The test set’s address appears on the display.

From the controller, enter the HP-IB ADDRESS; command, followed by the

address value. Refer to the command reference for programming details.

3. Reset the mechanical switches on the test-set’s rear panel. Set the switches to match the

new HP-IB address displayed on the network analyzer screen.

{HP-IB ADDRESS} {TEST SET}

), the

RF Switch Driver Control When the

generates a code sequence. The code sequence is automatically issued across the

HP 8510C system bus to the device at the ADDRESS of RF SWITCH .

In the recommended configuration, the device is an HP 11713A attenuator/switch driver. The

switch/driver in turn controls one or more coaxial switches. These switches, (shown in a

Figure 3-3, and Figure 3-4) are used to choose which test set receives the RF output from the

network analyzer source.

The exact command issued depends upon the new value of the

{TEST SET}

{HP-IB ADDRESS} {TEST SET}

value, also shown in shown in a Figure 3-3 and Figure 3-4.

function is changed, the network analyzer

{HP-IB ADDRESS}

HP 8517B S-Parameter Test Set Manual

3-6

Page 45

Figure 3-4 RF and IF Switching with Four Test Sets

Table 3-5 Coaxial Switch Settings for Figure 3-4, Above

New ADDRESS

of Test Set

20 1 Port 1 Port 1

21 2 Port 1 Port 2

22 3 Port 2 Port 1

23 4 Port 2 Port 2

1. Not all system connections are shown.

2. In dual source configurations, the second source can be multiplexed in a similar manner.

3. If only one dual source test set is used, the second source can be directly connected to the

1, 2, 3

appropriate test set.

Test Set Selected

1, 2, 3

Coaxial Port Selected

with Switch #1

Coaxial Port Selected

with Switch #2

HP 8517B S-Parameter Test Set Manual

3-7

Page 46

Measurement Calibration

After selecting the active test set, complete the system calibration procedure

as usual. When you select a different test set, make sure that you recall the

cal set that applies to that test set.

NOTE

Since the cal-set limited instrument state does not include the number of the

active test set, a cal set which does not apply to the current test set can be

turned on without displaying the HP 8510C caution messages. However, this

causes errors in the data displayed because incorrect error coefficients are

applied to the measured data.

For convenience, store a hardware-state file and an instrument-state file for

each combination of test set to cal set. You may also store your hardware

state file on a tape or disk for future use.

To change the configuration, recall the appropriate hardware state file. The

hardware state file:

• sets the address of test set

• issues the RF switch c ommand, then

• recalls the appropriate instrument state file which

• recalls the cal set

HP 8517B S-Parameter Test Set Manual

3-8

Page 47

Measuring High-Power Devices with Option 004

The HP 8517B, Option 004 test set enables devices with output power up to

30 dBm (1 watt) to be measured at Port 2, without adding external

attenuators. Reverse dynamic range (S

When measuring devices having greater than +17 dBm output power, you

must use the Port 2 step attenuator to decrease the power to

The step attenuator has to be set during calibration for the value needed

during device measurements. However, this setting may cause inadequate

power level during calibration. Refer to “Changing Signal Path States After

System Calibration” on page 3-10 for additional information.

) degrades by approximately 3 dB.

12

≤+17 dBm.

HP 8517B S-Parameter Test Set Manual

3-9

Page 48

Changing Signal Path States After System Calibration

Changing an internal attenuator or any external equipment after completing

the calibration means the measurement results cannot be specified.You must

use your own estimation of the potential error contribution due to the

change.

For example, when the port attenuation is changed with correction ON, the

message

whether the error is tolerable in the particular application and how to

compensate for the change.

The application question is: “Does increasing the signal level during

calibrationimprovethe calibration enough to risk a possible increase in error

contributions when you change the setup?”

The only reason for changing an internal attenuator or external equipment

between calibrations and measurements is to maximize the signal level

under both conditions, thus minimizing uncertainty due to noise.

CAUTION: CORRECTION MAY BE INVALID displays. You must judge

Changing the Test Port Attenuators

Many factors enter into a setup-change decision, for example:

• is it more accurate to calibrate at a low signal level without changing the

setup, or

• is it more accurate to change the setup to optimize levels for both the

calibration and measurement

Changing attenuators at Port 1 or Port 2 does not change the test set

mismatch, directivity, or isolation characteristics severely. It does change the

frequency response magnitude and phase, however. The difference between

frequencyresponsecalibrationand measurement can be normalized by using

HP 8510C trace memories.

If only the attenuators at Port 1 or Port 2 are changed, use the following

procedure to minimize errors:

1. Connect a short, or a thru, and set Port 1 and Port 2 attenuators for the

best IF signal levels during calibration.

2. Perform the appropriate measurement calibration.

3. Connect the correct calibration standard, set Port 1 and Port 2

attenuators to the value required for operating the test device.

HP 8517B S-Parameter Test Set Manual

3-10

Page 49

If you view the response of a short circuit, notice that:

Storing Trace Memories

• Changing Port 1 attenuator has negligible effect on S

• Changing Port 2 attenuator has negligible effect on S

marker reading

11

marker reading

22

This is due to the way the attenuators are paired. Both the reference and the

test signal are changed by approximately equal amounts.

When viewing S

or S12, however, changing Port 1 or Port 2 attenuators

21

offsets the marker reading by the difference value between Port 1 attenuator

and Port 2 attenuator.

To compensate for the main frequency response effects due to changing

the attenuators, use the HP 8510C trace memories and trace mathematics

function, as explained below:

1. Connect the thru used for calibration and set the port attenuators to the

value used for device measurement.

S

2. Recheck the user parameter levels, then press PARAMETER [

3. Press MENUS

DISPLAY:

Press

[DISPLAY]

{DATA-->MEMORY n}

,then

{DATA AND MEMORIES}

to store the S21trace in default trace

.

].

21

memory 1. This trace represents the frequency response difference

between the S

signal path calibration and the measurement.

21

Viewing Normalized Parameters

[S12]

4. Press PARAMETER

{SELECT DEFAULTS}

{DEFAULT to MEMORY: 2}

{DATA-->MEMORY 2}

, then press the following DISPLAY: menu keys:

The S12trace is now stored in trace memory 2. This trace is the

frequency response difference of the S

signal path between calibration

12

and measurement.

Use the traces stored in memory 1 and memory 2 to normalize the corrected

data to the new levels after the attenuation is changed. The next example

uses normalization for S

1. Press MENUS

[DISPLAY]

2. Press PARAMETER

3. Press PARAMETER

4. Press PARAMETER

{SELECT DEFAULTS}

21

or S

[S11]

[S22]

[S21]

only. To view the corrected parameters:

12,

,then

{DATA AND MEMORIES}

and view the S11measurement.

and view the S22measurement.

, then the following DISPLAY: menu keys:

{DEFAULT to MEMORY: 1}

{MATH ( / ) }

HP 8517B S-Parameter Test Set Manual

3-11

Page 50

5. View the S21measurement. If the thru is connected, the transmission

coefficient should be 1

6. Press PARAMETER

{SELECT DEFAULTS}

{DEFAULT to MEMORY: 2}

∠0°.

[S12]

, then press the following DISPLAY: menu keys:

7. Press PARAMETER

connected, the transmission coefficient should be 1

Normalization is turned OFF for S

[S12]

to view the S12measurement. If the thru is

∠0°.

and S22measurements. Then the

11

appropriate memory is selected and normalization is turned on to view S

and S12.

Since these are accurate, repeatable attenuators, this sequence may be

effective in your application. If other parts of the test must be changed,

especially components connected to the test ports, this procedure may

require additional steps to adequately compensate for the changes.

21

HP 8517B S-Parameter Test Set Manual

3-12

Page 51

Making Operational Checks

To check the operation of multiple test-set configurations, do the following:

1. Connect a device with a known response to test set number 1. Press the

following HP 8510C front-panel keys:

INSTRUMENT STATE

AUXILIARY MENUS

{HP-IB ADDRESSES}

{TEST SET}

2. When the message TEST SET HP-IB ADDRESS appears, enter

address of test set number 1, then press

[LOCAL]

[SYSTEM]

[20]

[x1]

. The measurementtrace from

,the

test-set number 1 should display.

3. Store the trace in memory by pressing the following keys:

MENU

{DATA AND MEMORIES}

{DATA --> MEMORY n}

DISPLAY

4. Next, enter the HP-IB address of test s et number 2, followed by

re-enter the address of test set number 1 followed by

[DISPLAY]

: {DATA and MEMORY]

[x1]

[x1]

,then

.

5. Repeat the above procedure for each of the other test sets in the system.

Observe any difference in the response between the stored trace and the

results trace by switching back and f orth between the test sets.

Any differences in data that you suspect are due to the IF switch (Option

001) or to RF switching, must be checked out. Refer to Chapter 5,

“Troubleshooting the Test Set” in this manual.

HP 8517B S-Parameter Test Set Manual

3-13

Page 52

Performance Verification

Standard system performanceverification procedures verifythe operationof

an Option 001 test set used as test set number 1.

To verify the performance of a different test set in the configuration, enter its

HP-IB address (as explained in “Making Operational Checks” on page 3-13)

to select it, then continue with this procedure.

Refer to the HP 8510C On-Site Service Manual for its performance

verification procedure.

HP 8517B S-Parameter Test Set Manual

3-14

Page 53

Using Anti-Rotation Clamps

During the performance verification procedure, use anti-rotation clamps to

secure RF connections at the test ports of each test set. While installed, each

clamp stabilizes the connector on RF cable to the large nut on the test set’s

RF test port. I f an adapter is used, the clamp stabilizes the adapter to the

front panel RF port connector.

Without these clamps, the test port connections can loosen when a device

under test is moved. As a result, the loosening can invalidate calibrationsand

measurements.

NOTE

NOTE

These instructions refer to an installation using HP RF cables. However, the

anti-rotation clamps may also be used with front panel adapters. Adapter

installations are similar. There are two anti-rotation clamps included in the

test set accessories box.

Attach the first clamp

Remove one anti-rotation clamp from the accessories box. Loosen its

thumb-screw until it is nearly freed from the counter-sink socket in the

clamp body. The clamp is shown as item (5) in Figure 2-1, “Accessories

Supplied with the HP 8517B Test Set.”

1. Gently push the clamp (round-hole end first) over and past the RF cable

connector to be used.

2. Fit the rubber O-ring in the round end of the clamp over the connector.

If the O-ring is not snug or is damaged, refer to the Chapter 6, “Replacement

Procedures” for instructions about replacing the internal O-ring.

3. Wiggle the clamp to ease it over the connector.

NOTE

4. Attach the cable to the test port and tighten it as specified in the cable

manual.

Do not twist the cable as you attach it to the test port.

Use the torque wrench supplied with your calibration kit to tighten the cable

to 90 N-cm (8 in-lb). Do not over-torque the connection. See Figure 3-5.

HP 8517B S-Parameter Test Set Manual

3-15

Page 54

CAUTION

Important! The test set RF connector becomes loosened easily. Hold the RF

cable securely throughout the remainder of this procedure. Do not allow the

cable to rotate.

Figure 3-5 Using a Torque Wrench Correctly

Positioning the thumb-screw

See Figure 3-6. Position the clamp so the thumb-screw is positioned at the

top of the clamp.

• Turn the clamp to visually align the clamp flats with the flats on the test

port connector nut.

• This positioning minimizes rotating the connector in the procedure step.

HP 8517B S-Parameter Test Set Manual

3-16

Page 55

NOTE

The flats may actually be in any orientation, with respect to the front panel.

Figure 3-6 Visually Aligning Clamp and Nut Flats

Positioning the connector

See Figure 3-7. Maneuver the clamp over the RF connector and onto the test

port connector.