Page 1

Errata

Silicon Investigations

Repair Information - Contact Us

920-955-3693

www.siliconinvestigations.com

Title & Document Type:

Manual Part Number:

Revision Date:

HP References in this Manual

This manual may contain references to HP or Hewlett-Packard. Please note that HewlettPackard's former test and measurement, semiconductor products and chemical analysis

businesses are now part of Agilent Technologies. We have made no changes to this

manual copy. The HP XXXX referred to in this document is now the Agilent XXXX.

For example, model number HP8648A is now model number Agilent 8648A.

About this Manual

We’ve added this manual to the Agilent website in an effort to help you support your

product. This manual provides the best information we could find. It may be incomplete

or contain dated information, and the scan quality may not be idea l. If we find a better

copy in the future, we will add it to the Agilent website.

Support for Your Product

Agilent no longer sells or supports this product. You will find any other available

product information on the Agilent Test & Measurement website:

www.tm.agilent.com

Search for the model number of this product, and the resulting product page will guide

you to any available information. Our service centers may be able to perform calibration

if no repair parts are needed, but no other support from Agilent is available.

Page 2

HP 8511A

Frequency Converter

Test Set

Operating and Service

Manual

HP part number: 08511-90072

Printed in USA

23 September 1999

Revision 1.0

Page 3

Notice

The information contained in this document is subject to c hange w ithout

notice.

Hewlett-Packard makes no wa rranty of a ny kin d with regard to thismate rial,

including, but no t limited to, the implied wa rranties of mercha ntability and

fitness for a par ticular purpose. Hewlett-Packard s hall not be liable for errors

contained herein or for incidental or consequential damage s in c onnection

with the furnishing, performance, or use of this ma terial.

Hewlett-Packard assumes no r esponsibi lity f or the use or r eliabi lity of its

software on equipment t hat is not furnished by Hewlett-Packard.

This document contains proprietary information which is protected by

copyright. All rights a re r eserved. No par t of this document may be

photocopied, reproduced, or trans lated to another language without prior

written consent of Hewlett-Packard C ompa ny.

Restricted Rights Legend

Use, duplication, or disclosure by the U.S. Government is subject to

restrictions as set forth in s ubparagraph ( c)(1)(ii) oft he Ri ghts in Technical

Data and Computer S oftware clause at DFARS 252. 227-7013 for DOD

agencies, and subparagraphs (c)( 1) and (c)(2) of the Commercial Computer

Software Restricted Rights c lause at FAR 52.227-19 f or other agenci es.

Hewlett-Packard Company

Santa Rosa Systems Division

1400 Fountaingrove Parkway

Santa Rosa, CA 95403-1799, U. S.A.

© Copyright Hewlett-Packard Company 1999

iv

HP 8511A Test Set Operating and Service Ma nual

Page 4

What You’ll Find in This Manual…

Chapter 1 • Descriptions, optionsand accessory information.

Chapter 2 • Specifications and definitions.

Chapter 3 • Installation, environmental and preparation information.

Chapter 4 • Information on the operation of this test set.

Chapter 5 • How to do performance tests and otherperformance information.

Chapter 6 • Servicing and replaceable parts information.

HP 8511A Test Set Operating and Service Manual

v

Page 5

Wa rrant y

Certification Hewlett-PackardC ompany c ertifies thatthi s product me t its published

specifications at the tim e o f shipment from the factory. Hewlett-Pa ckard

further ce rti fies that its calibration measurements are traceable to the

United States National Institute of Standards and Technology ( NIST,

formerly N BS), to the extent allowed by the Institute’s c alibration facility,

and to the calibration facilities of other Internati onal Standards

Organization m embers.

Warranty This Hewlett-Packard system product is warranted against defects i n

materials and workmanship for a period corresponding to the individual

warranty periods of its compone nt product s. Instruments are warranted for a

period of one yea r. During the wa rranty period, Hewlett-Packard Company

will, at its option, either repair or replace products tha t pr ove to be defective.

Wa rranty service f or pr oducts insta lled by HP and certain other products

designated by HP will be performed at Buyer’s facility at no charge within

HP s e rv ice travel areas. Outsid e HP serv ice travel areas, warranty servic e

will be performed at Buyer’s facility onl y uponHP ’s prior agreem ent a nd

Buyer shall pay H P’s round trip tr avel expenses. In all othe r areas, products

must be returned to a service facility designated by HP.

For products returned to HP for warranty service, B uyer shall pr epay

shipping charges to H P and HP s hall pay s hipping charges to r eturn the

product to Buyer. However, Buyersha ll pay all shipping charges, duties, and

taxes for products r eturned to HP f rom another country.

HP warrants that its software and firmware designa ted by H P f or use w ith a n

instrument will execute its progr amming instructions whe n pr operly

installed on that instrument. HPdoes not warrant that the operation of the

instrument, or software, or firmware will be uninterr upted or error free.

LIMITATION OF WARRANTY. The f oregoing warranty s hall not apply

to defects resulting from improper or inadequate ma inten anc e by Buyer,

Buyer-supplied s oftware or interfacing, unauthorized modification or

misuse, operation outside of the environmental specifications for the

product, or improper site prepa ration or ma intenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. HP

SPE CIFIC ALLY DIS CLAIMS THE IMPLIED WARRA NTIES OR

MERCHANTABILITYAND F ITNESS FOR A PARTICULAR

PURPOSE.

EXCLUSIVE REMEDIES. THE REMEDIES P ROVID ED HEREIN ARE

BUYER’S SOLE AND EXCLUSIVE R EMEDIES. HP SHALL NOT BE

vi

HP 8511A Test Set Operating and Service Ma nual

Page 6

LIABLE F OR ANY DIRECT, I NDIRECT, SP ECIAL, INCIDENTAL, OR

CONSEQUE NTIAL DAMAGES, WHETHER BASED ON CONTRACT,

TORT, OR ANY OTHER LEGAL THEORY.

Assistance Product maintenance agreements and other customer assistance agreements

are available for Hewlett-Packard products.

Forassistance, call your localHewlett-Packard Sales and Service Office

(refer to “Service a nd Support” on page viii).

HP 8511A Test Set Operating and Service M anual

vii

Page 7

Service and Support

Any adjustment, maintenance, or repair of this product m ust be performed

by qualified personnel. Contact your customer engineer through your local

HP ServiceCenter. You can finda list of HP ServiceCenterson the web at

http://www.hp.com/go/tmdir.

If you do nothave access to the Internet, one of these HP centers candi rect

you to your nearest HP representative:

United States : Hewlett-Packard Company

Test and Measurement Call Center

PO Box 4026

Englewood, CO 80155-4026

(800) 452 4844 (toll-free in US)

Canada: Hewlett-Packard Canada Ltd.

5150 Spectrum Way

Miss iss auga, Ontar io L4W 5G1

(905) 206 4725

Europe: Hewlett-Packard European Marketing Centre

Postbox 999

1180 AZ Amstelveen

The Netherlands

(31 20) 547 9900

Japan: Hewlett-Packard Ltd.

Measurement Assistance Center

9-1, Takakura-Cho, Hachioji-Shi

Tokyo 192, Japan

(81) 426 56 7832

(81) 426 56 7840 (FAX)

Latin America: Hewlett-Packard Latin American Region Headquarters

5200 Blue Lagoon Drive, 9th Floor

Miami, Florida 33126, U.S.A.

(305) 267 4245, (305) 267-4220

(305) 267 4288 (FAX)

Australia/New Zealand: Hewlett-Packard Australia Ltd.

31-41 Joseph Street

Blackburn, Victoria 3130

Australia

1 800 629 485 (Australia)

0800 738 378 (New Zealand)

(61 3) 9210 5489 (FAX)

Asia-Pacific: Hewlett-Packard Asia Pacific Ltd.

17-21/F Shell Tower, Times Square

1 Matheson Street, Causeway Bay

Hong Kong

(852) 2599 7777

(852) 2506 9285 (FAX)

viii

HP 8511A Test Set Operating and Service Manual

Page 8

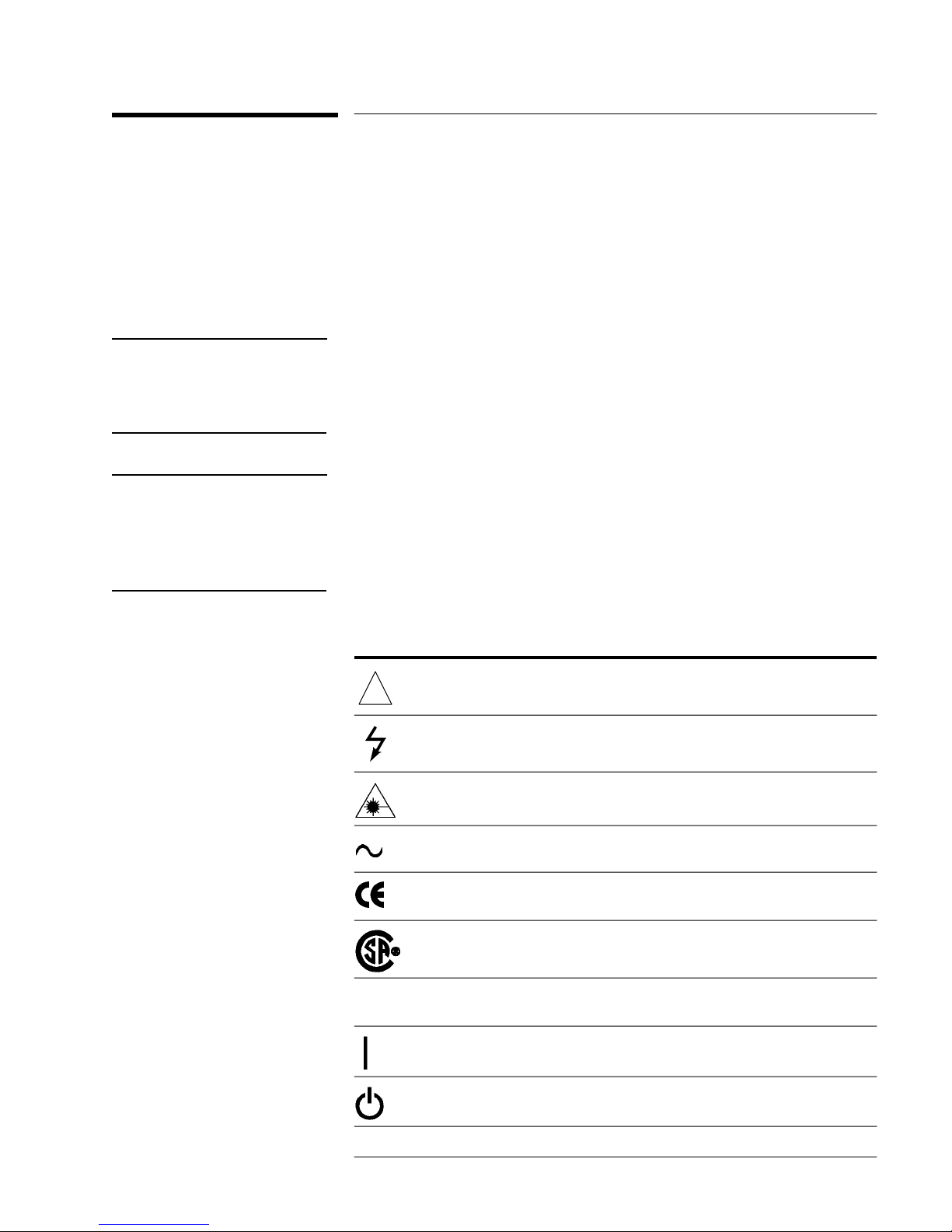

Safety and Regulatory Information

Reviewthis product and related documentation to familiarize yourself with

safety markings and instructions before you operate the instrument. This

product has been designed and tested in accordance with internatio n al

standards.

WARNING

CAUTION

Instrument Markings

The WARNING notice denotes a hazard. It calls attention to a procedure,

practice, or the like, that, if not correctly performed or adhered to, could result

in personal injury. Do not proceed beyond a WARNING notice until the

indicated conditions are fully understood and met.

The CAUTION notice denotes a ha zard. It calls attention to an operating

procedure, practice, or the like, which, if not correctly performed or adhered

to, could result in damage to the product or loss of important data. Do not

proceed beyond a CAUTION notice until the indicated conditions are fully

understood and met.

When you see this symbol on your instrument, you should refer to the instrument’s

!

instruction manual for important information.

This symbol indicates hazardous voltages.

The laser radiation symbol is marked on products that have a laser output.

This symbol indicates that the instrument requires alternating current (ac) input.

The CE mark is a registered trademark of the European Community. If it is

accompanied by a year, it indicates the year the design was proven.

The CSA mark is a registered trademark of the Canadian Standards Association.

1SM1-A This text indicates that the instrument is an Industrial Scientific and Medical Group 1

Class A product (CISPER 11, Clause 4).

This symbol indicates that the power line switch is ON.

This symbol indicates that the power line switch is OFF or in STANDBY position.

HP 8511A Test Set Operating and Service Manual

ix

Page 9

Saf et y Earth

Ground

This is a Safety C lass I product (provided with a pr otective earthing

terminal). An uninterruptible safety ea rth groundmust be provided from the

main power source to the product input wiring te rminals, power cor d, or

supplied power cord set. Wheneve r i t is li kely that the pr otection ha s be en

impaired, the product must be ma de i noperative and secured against any

unintended operation.

Bef ore Applyi ng

Power

Verify that the product is configured to match the available main power

source as described in the input power configuration instructions in this

manual. If this product i s to be powered by a utotransformer, make sure the

commont erminal is connected to the neutral (grounded) si de of the ac power

supply.

x

HP 8511A Test Set Operating and Service Manual

Page 10

HP 8511A Test Set Operating and Service Manual

xi

Page 11

Typeface Con ventions

Italics • Used to emphasize important information:

Use this software only with the HP 8511A.

• Used for the title of a publication:

Refer to the HP8511A System-Level User’s Guide.

• Usedt o indicate a variable:

LOAD BIN filename.

Type

Instrument Display • Used to show on-screen prompts and messages that you will see on the

display of an instrument:

The HP8511A will displaythe message

CAL1 SAVED.

[Keycap]

{Softkey}

User Entry • Used to indicate text that you will enter using the computer keyboard;

• Used for labe led keys on the front panel of an instrument or on a

computer keyboard:

[Return]

Press

.

• Used for simulated keys that appear on an instrumentdisplay:

{Prior Menu}

Press

text shown in this typeface must be typed exactly as printed:

LOAD PARMFILE

Type

.

• Used for examples of programming code:

#endif // ifndef NO_CLASS

Path Name

Computer Display

• Used for a subdirectory name or file path:

Edit the file

usr/local/bin/sample.txt

• Usedt o s how messages, prompts, and window labels that appear on a

computer monitor:

Edit Parameters

The

window will appear on the screen.

• Used for menus, lists, dialog boxes, and button boxes on a computer

monitor from which you make selections using the mouse or keyboard:

EXIT

Double-click

to quit the program.

xii

HP 8511A Test Set Operating and Service Manual

Page 12

Contents

1. General Information

Introduction ............................................1-1

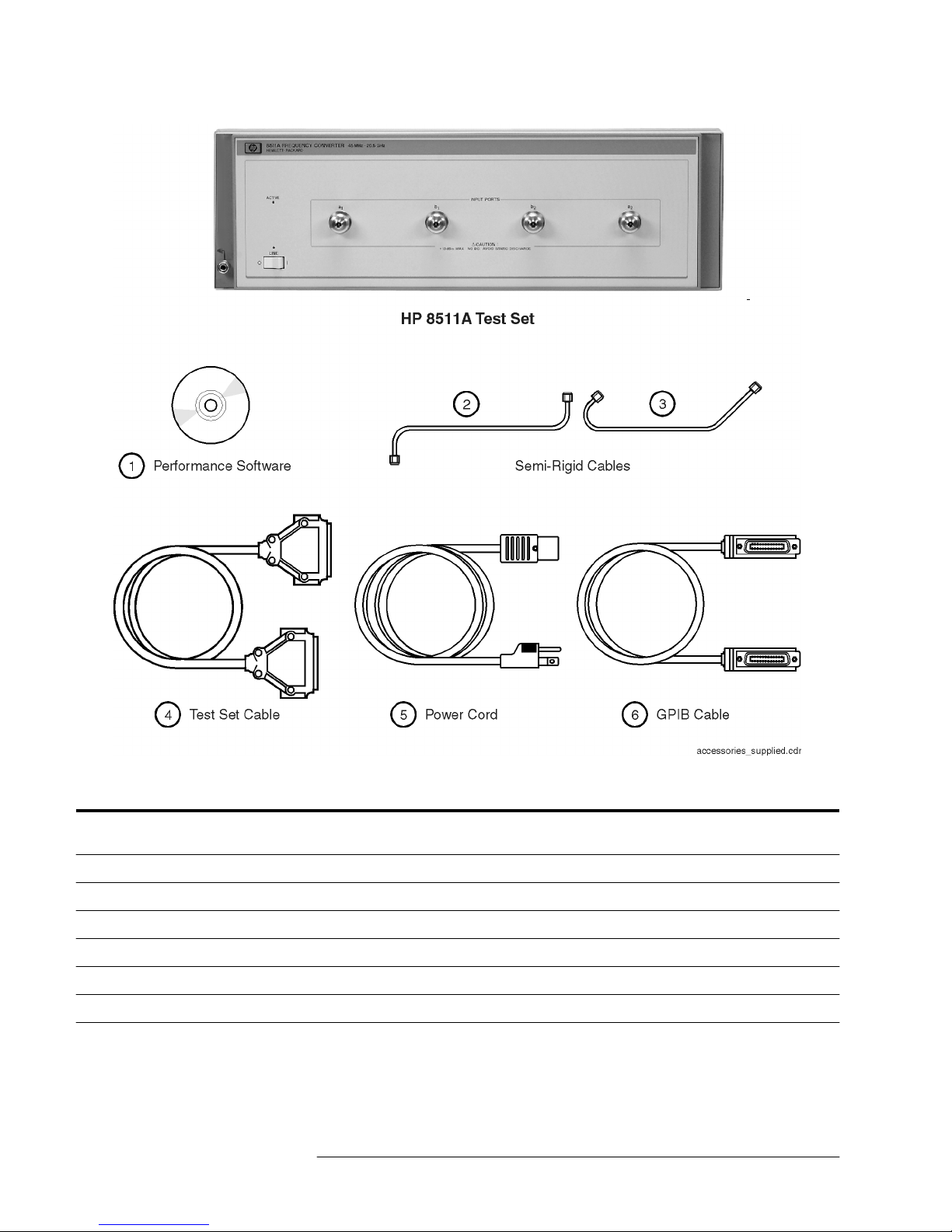

Figure 1-1. HP 8511A Test Se t with A ccessories Supplied ........1-2

Verifying the HP 8511A ......................................1-3

DescriptionandOperatingCharacteristics ........................1-4

Figure 1-2. Example of an HP 8511A Meas urement Set-up .......1-5

SoftwareandHardwareRequirements ...........................1-7

ComputerRequirements...................................1-7

Options ...................................................1-8

Option001 .............................................1-8

Option908 .............................................1-8

Option910 .............................................1-8

Option913 .............................................1-8

Service and Support Opti ons ..................................1-9

OptionW03 ............................................1-9

OptionW30 ............................................1-9

OptionW31 ............................................1-9

Option1BN ............................................1-9

Option1BP.............................................1-9

Accessories ...............................................1-10

Accessories Supplied ....................................1-10

AccessoriesAvailable....................................1-10

Cables................................................1-10

OperatingandSafetyPrecautions..............................1-11

ElectrostaticDischarge(ESD) .............................1-11

Service ...............................................1-11

AdditionalEquipmentRequired............................1-11

Miscellaneous .............................................1-12

Adjustments ...........................................1-12

Replacement Parts ......................................1-12

2. Specifications

Definitions ................................................2-1

Table 2- 1. HP 8510/HP 8511A Performance ..................2-1

Figure 2-1. Conversion Example ............................2-2

Table 2- 2. HP 8510/HP 8511A Characteristics ................2-2

Table 2- 3. HP 8510/HP 8511A Characteristics (part 2) ..........2-3

DynamicAccuracy.......................................2-3

Figure 2-2. Worst Case Dynamic Accuracy (Magnitude) .........2-3

Figure 2-3. Worst Case Dynamic Accuracy (Phase) .............2-3

SourceofSystemDynamicAccuracyErrors...................2-4

HP 8511A Test Set Opera ting and Service Man ual

Contents -i

Page 13

Table 2-4. IF Amplif ier Gain Accuracy ...................... 2-4

Table 2-5. HP 8511A Power Requirements and P hysical

Characteristics ...................................... 2-4

SpecificationAssumptions ................................... 2-5

RecommendedTestEquipment............................. 2-6

Table 2-6. Recommended Test Equipment .................... 2-6

3. Installation

Introduction ............................................ 3-1

Initial Inspection ........................................ 3-1

Table 3-1. Contents of the HP 8511A Shipping Containe r ....... 3-1

EnvironmentalConsiderations ................................ 3-2

OperationandStorage.................................... 3-2

PreparationforUse ...................................... 3-2

Static-freeWorkstation ................................... 3-2

F igur e 3-1. Static Safe Work Area .......................... 3-2

F igur e 3-2. Attaching the R ack Mounting Hardware ............ 3-3

ConnectingtheTestSet...................................... 3-4

MatingConnectors ...................................... 3-4

PowerandControlConnections ............................ 3-4

SignalPathConnections .................................. 3-4

F igur e 3-3. HP 8511A System Connections ................... 3-5

Packaging................................................. 3-6

4. Operation

Introduction ............................................... 4-1

FrontPanelFeatures ..................................... 4-1

F igur e 4-1. FrontPanel Feature s ........................... 4-1

F igur e 4-2. Rear Panel F eatur e s ........................... 4-2

OperatorsCheck ........................................... 4-3

Equipment............................................. 4-3

Table 4-1. Necessary Equipment ........................... 4-3

Procedure ............................................. 4-3

F igur e 4-3. Hardware Configuration for Operator’s Check ...... 4-4

F igur e 4-4. Typi cal Operator’s Chec k CRT Trac e .............. 4-4

Controlling Multiple Test Sets ................................ 4-6

F igur e 4-5. RF and IF Switching with Tw o T es t Sets ............ 4-7

Table 4-2. HP 33311C Coaxial Switch Positions with Two

Test Sets ........................................... 4-7

Installation ................................................ 4-8

Operation ................................................. 4-9

Initialization at Power-up ................................. 4-9

SelectingaTestSet ...................................... 4-9

F igur e 4-6. RF and IF Switching with F our Test Sets .......... 4-10

Table 4-3. HP 33311C Coaxial Switch Positions with Four

Test Sets .......................................... 4-10

Contents-ii

HP 8511A Test Set Operating and Service Manual

Page 14

MeasurementCalibration .................................4-11

OperationalChecks .....................................4-12

PerformanceVerification .................................4-12

5. P erf o rmance Tests

PortReturnLoss ............................................5-2

TestProcedure(optional) ..................................5-2

6. Service and Replaceable Parts

Repl aceable P ar t s ...........................................6-2

Introduction ............................................6-2

ExchangeAssembliesAvailable.............................6-2

Repl aceable P arts List ....................................6-2

ReferenceDesignations ...................................6-2

Table 6-1. HP 8511A Replace able Parts ......................6-3

Repl acem ent P r o ced ures ......................................6-6

Replacingthe(T1)PowerTransformer .......................6-6

Procedure ..............................................6-6

F igur e 6-1. WireConnections to Line ModuleFL1 ..............6-7

Replacingthe(B1)Fan....................................6-8

Procedure ..............................................6-8

ReplacingtheFrequencyConverter ..........................6-9

Procedure ..............................................6-9

F igur e 6-2. HP 8511A Major Assemblies ....................6-10

F igur e 6-3. HP 8511A Miscellaneous Mechanical, Chassis and

Elect rical Parts .....................................6-11

Table 6-2. HP 8511A Option 001 Replaceable P arts ...........6-12

F igur e 6-4. Part s Unique to HP 8511A Option 001 ............6-13

F igur e 6-5. HP 8511A Motherboar d ........................6-14

F igur e 6-6. T est Sets Interconnect Table (1 of 2) ...............6-15

F igur e 6-7. T est Sets Interconnect Table (2 of 2) ...............6-17

HP 8511A Test Set Operating and Service Manual

Contents-iii

Page 15

-iv

HP 8511A Test Set Operating and Service Manual

Page 16

1

General Information

Introduction The HP 8511A four channel frequency converter test set is an integral

component of the HP 8510 measurement system. The HP 8511A

documentation is to be used with the HP 8510 documentation, and may be

inserted into the HP 8510 test accessories binder provided with your

HP 8510 manual set.

The HP 8511A Operating portion consists of:

• General Information

• Installation

• Operation

• Performance Tests

The HP 8511A Service portion consists of:

• Replaceable parts

• Service information

HP 8511A Test Set Opera ting and Service Man ual

1-1

Page 17

General Informat ion

Figu re 1- 1 HP 8511A Test Set with Accessories Supplied

Reference

Designator

1 08511-60024 2 HP 8511 A ,B and A ntenna Meas urement Syst em Per formanc e Verifica tion Softwar e As sembly

2 08510-20006 1 Semi -rigi d cable

3 08510-20005 1 Semi -rigi d cable

4 08510-60102 1 Test set cable assembly

5 8120-1348 1 Power cord (USA only)

6 8120-3445 1 GPIB ca bl e

HP Par t Num b er Qty Descripti o n

1-2

HP 8511A Test Set Opera ting and Service Man ual

Page 18

General Infor mati on

Verifying the HP 8511A

Verifying the HP 8511A

The HP 8511A has been designed to operate specifically with the HP 8510

network analyzer .

• To install the instrument, turn to Chapter 3, “Installation” of this

manual.

• To check the proper operation of the HP 8511A, see “Operators Check”

on page 4-3 of this manual.

• To verify that the instrument meets its published specifications, use the

HP 8511A,B and Antenna Measurement System Performance

Verification Software (HP part number 08511-60024).

• To troubleshoot the HP 8511A, begin with the “Service and Equipment

Overview” chapter of the HP 8510 On-Site Service Manual.

HP 8511A Test Set Opera ting and Service Man ual

1-3

Page 19

General Informat ion

Description and Operating Characteristics

Description and Operating Characteristics

The HP 8511A four channel frequency conve rter test set, has been designed

to operate with the HP 8510 network analyzer a nd other microwave

accessories (like c ouplers and power splitters). The HP 8511A provides a

conv enient means of customizing a test configuration for a variety of

applications within the frequency range of 45 MHz to 26.5 GHz. In addition

to configurations for measuring reflection and transmission parameters of

one-port or two-port devices, youcan build configurations to characterize

antenna parameters, radar c ross sections and fr equenc y translation devices.

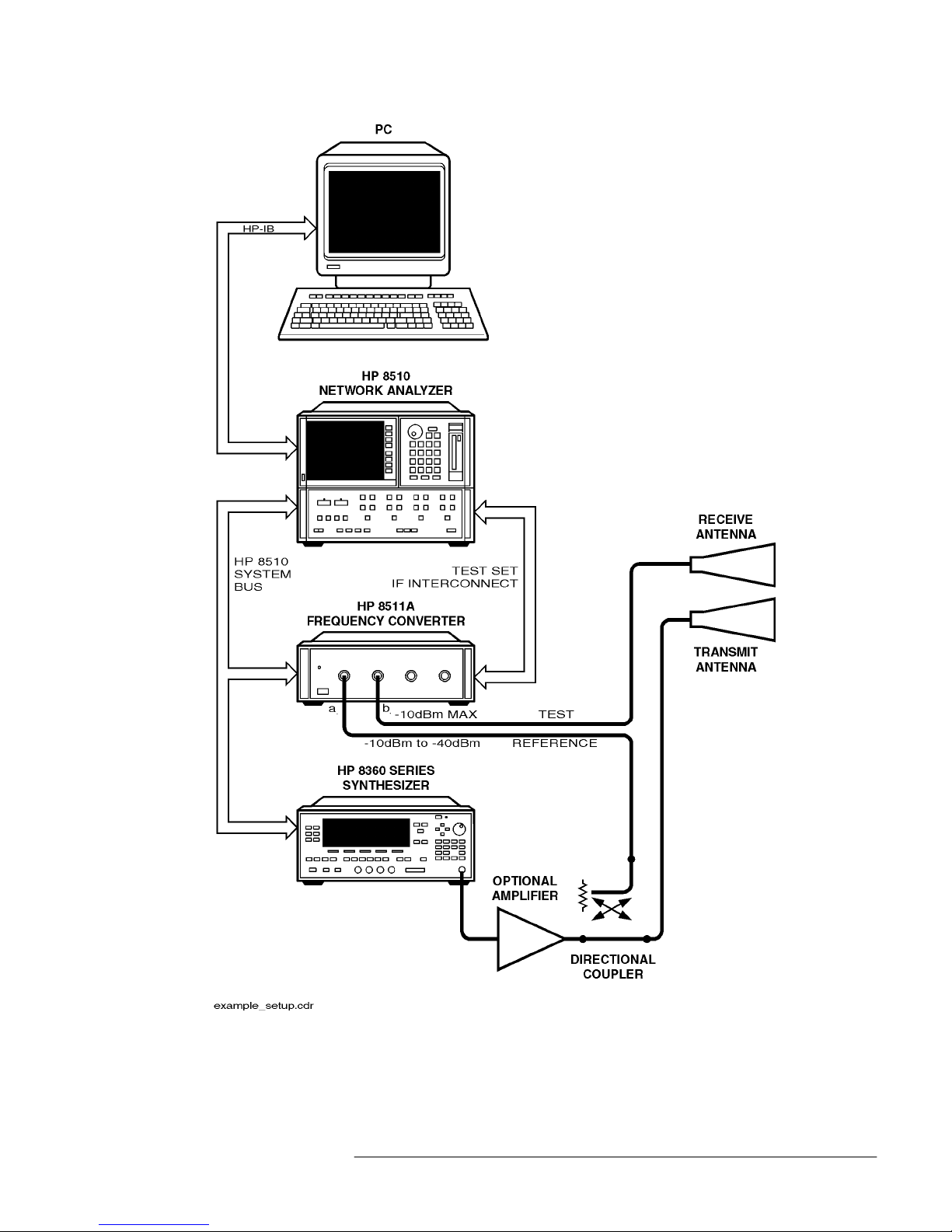

Figure 1-2 on page 1-5 shows one possible measurement set-up.

1-4

HP 8511A Test Set Opera ting and Service Man ual

Page 20

General Infor mati on

Description and Operating Characteristics

F igure 1-2 Example of an HP 8511A Measurement Set-up

HP 8511A Test Set Opera ting and Service Man ual

1-5

Page 21

General Informat ion

Description and Operating Characteristics

Table 2-1 on pa ge 2-1 lists the operating specificationsand characteristics of

the HP 8511A. N ote that the performance of theHP 8511A is v eri fiable only

as part of an HP 8510 system. Verification is performed at the ports of the

HP 8511A.

1-6

HP 8511A Test Set Opera ting and Service Man ual

Page 22

Software and Hardware Requirements

Software and Hardware Requirements

General Infor mati on

Computer

Requirements

The computer requirements to successfully install and operate the software

are as follows:

• 100% IBM-PC compatible computer.

• Pentium 133 or better.

• Windows 95

, Windows 98or Windows NT 4.0 installed.

• GPIBinterfacecard and cable, or Hewlett-Packard GPIBcard and cable.

• HP BASIC for Windows, version 6.32 or later installed.

• ACD-ROMdrive.

• HP 8511A,B and Antenna Measurement System Performance

Verification Software.

• Internet Explorer

43.0 or higher or Netscape4.0 or higher.

HP 8511A Test Set Opera ting and Service Man ual

1-7

Page 23

General Informat ion

Options

Options

Option 001 Option 001 adds IF switching capability to allow u p t o four test s et s to be

connected to the HP 8510 at the same time. The tes t se t in use is selected

from the HP 8510 f ront panel. The 20 M Hz IF s ignal is transmitted from the

standard test sets thr ough the option 001 test set to the HP 8510. IF

switching is performed automatically by the option 001 test set, without

reconnections.

Option 908 Option 908 supplies the test set with the parts required to rack mount it with

the handles removed. Refer to Chapter 3, “Installation” of this manual for

additional information.

Option 910 Provides a duplicate tes t set manual a t the time of purchase.

Option 913 Option 913 supplies the test set with the parts required to rack mount it with

handles. Refer to Chapter 3, “Installation” of t his manual for a dditional

informati o n .

1-8

HP 8511A Test Set Opera ting and Service Man ual

Page 24

Servic e and Support Options

Option W03 Warranty Conversion

Option W03 converts the standard one year retur n to Hewlett-Packard

warranty to a 90 day on-site warra nty. W03 can only be order ed at the time

of instrument purchase. Instruments ordered with option WOS are identified

on the serial number la be l, or on a special iden tifica tion la be l s u pplie d w ith

the instrume nt.

Option W30 Extended Service (R eturn)

Option W30 adds two additional years of r eturn-to-HP service, to follow the

first year of warranty. Option W30 can be ordered only atthetimeofsale.

Instruments ordered with option W30 are identified on the serial number

label, or on a special identification label supplied witht he instrument.

General Infor mati on

Service and Support Options

Option W31 Extended Service(On-Site)

Option W30 adds two a dditi onal ye ars of on-site repair coverage, to follow

the first year of warranty. Option W31 can be ordered only at the time of

sale.

Option 1BN Certificate of C alibration

Option 1BN adds MIL-STD 45662A C ertificate of Calibration to t he

instrument. This option must be ordered when the i nstrument is ordered.

Option 1BP Certificate of C alibration (Wi th Data)

Option 1BP adds a MIL-STD 45662A certificate of C alibration and the

corresponding calibration data to the instrument. This option must be

ordered when the instrument is or dere d.

NOTE

Additional system warranty inf ormation is included inthe

HP 8510 manual set.

HP 8511A Test Set Opera ting and Service Man ual

1-9

Page 25

General Informat ion

Accessor ies

Accessor ies

Accessories Supplied Figure 1-1 on page 1-2 refers to the HP 8511A with the accessories and part

numbers supplied.

Accessories Available The HP 8511A c an s upport a multitude of m easureme nt systems . The

calibration, verification and adapt er kits listed below may or may not be

applicable for any given system. Please consult with your local HP Field

Engineer for specific recommendations. Additional information is included

in the H P 8510 manual set and the HP 8510 data sheet.

Connector Type Calibration Kit Verification Kit Adapter Kit

3.5 mm HP 85052B,E HP 85053B

7 mm HP 85050B,C,D HP 85051B

Type-N 50

3.5 to 7 mm HP 85130A,B

Ω

HP 85054B HP 85055A

Cables The choice of cables depends on t he type ofsignal separation device(s) used

and the syst em configuration. A twe nty foot long IF interconnect cable can

be ordered using HP pa rt number 08510-60103.

1-10

HP 8511A Test Set Operating and Service Ma nual

Page 26

Electro s ta tic

Discha rge (ES D)

General Infor mati on

Operating and Safety Precautions

Operating and Safet y Precauti on s

CAUTION

Ground yourself (with a wrist strap) and the instrument, especially when

making or breaking conne ctions at the input ports. Do not exceed the

instrument’s maximum inputpower level of + 13 dB m as +13 dBm is the

damage level.

Other than the above ESD precautions, you ne ed obser ve only normal

precautions in handling and opera ting the HP 8511A.

Serv ice The voltages in this test set warrant normal caution for operator safety.

Service should be per formed onl y by qua lified personnel. Form ore

information on service s trategy, troubleshooting procedures, replaceable

parts an d s imila r information refe r to the H P 8510 On-Site Service Manual.

Additi onal Equ ipment

Required

Table 2-6 on page 2-6 lists additional equipment andaccessories required

for use w ith the HP 8511A f reque ncy converter. The table also note s which

items are required toverif y the pe r formance of the test set and whic h i tems

are required for operation. Other equipment may be substituted if its

specificat ions meet or exceed the specifications listed in the critical

specificat ions column.

HP 8511A Test Set Operating and Service Manual

1-11

Page 27

General Informat ion

Miscella neous

Miscellaneous

Adjust men ts The HP 8511A ha s no a djustments. Specifically, no attempt should be made

to adjus t the samplers.

Replacement Parts The r eplaceable parts are listed in Chapter 6, “Service and Replaceable

Parts” of t h is manual.

1-12

HP 8511A Test Set Operating and Service Ma nual

Page 28

2

Specifications

Definitions

Specifications and characteristics differas defined in Table 2-1. Both are

based on certain operating conditions. Those conditions are defined in

“Specification Assumptions” on page 2-5.

Table 2-1 HP 8510/HP 8511A Performance

Parameter 0.045 to 8 GHz 8 to 20 GHz 20 to 26.5 GHz

1

Frequency Response Tracking

Magnitude (ripple)

Phase (ri pple)

Magnitude slope

4

Crosstalk

High Level Noise

Magnitude (ratio)

Phase (ratio)

Low Level Noise

Conver si on Gain

1. These performance parameters are field verifiable using the supplied software and the performance tests documented in the

Antenna Measurement System Performance Verification Software Installation and Getting Started Guide

2. Deviation from a least-squares-straight-line fit, excluding noise and slope. Ratio measurement of any two ports. (Note: b2 to b1 trac king is n ot field verified

with the performance test software.)

3. Slope of least-squares-straight-line fit over full frequency range.

4. Uncorrected port to port crosstalk with averaging factor of 1024.

5. Trace noise, sweep to sweep variation.

6. Low level noise measured with 50 ohm load at port, and calculated as the mean value of a 101 point trace with IF averaging set at one. Low level

noise varies with averaging factor 10 log (averaging factor).

7. See Figure 2-1 on page 2-2.

2

3

5

6

7

±

0.5 dB

±

5 degrees

±

0.08 dB/G Hz

−

80 dB

0.012 dB r m s

0.1 degrees rms

−

95 dBm

±

0.5 dB

±

5 degrees

±

0.08 dB/G Hz

−

80 dB

0.02 dB rms

0.15 degrees rms

−

90 dBm

+

2 dB to −12 dB

±

0.5 dB

±

5 degrees

±

0.08 dB/G Hz

−

80 dB

0.04 dB rms

0.25 degrees rms

−

85 dBm

HP 8511A,B and

(HP part number 5962-0493).

HP 8511A Test Set Opera ting and Service Man ual

2-1

Page 29

Specificat io ns

Figu re 2- 1 Conversion Example

Table 2- 2 HP 8510/HP 8511A Characteristics

Parameter 0.045 to 8 GHz 8 to 20 GHz 20 to 26.5 GHz

2

Dynamic Range

all inputs

Accuracy Enhanced Crosstalk

−

115 dB

1. The performance parameters listed are characteristic of the HP 8511A/HP 8510. They are typical or nominal figures and are not f ield verifi able.

2. Determined by 0.1 dB compression level and system low level noise. Low level noise measured with 50 ohm load at port and 1024 averaging factor.

Noise floor varies with averaging factor:10 log (averaging factor).

3. Effective crosstalk with isolation calibration, excludes noise.

3

105 dB

(

−

10 to −115 dBm)

−

115 dB

1

105 dB

(−10 to −115 dBm)

−

113 dB

98 dB

(−15 to −113 dBm)

2-2

HP 8511A Test Set Opera ting and Service Man ual

Page 30

Table 2-3 HP 8510/HP 8511A Characteristics1(part 2)

Tracking Drift (typical) Magnitude 0.001 x V °C, Linear

Input Ports

Connector type:

Impedance:

Damage level:

Phase (0.1

female 3.5 mm

50 ohms nominal

+

13 dBm (20 mW) CW RF input2

+

f(GHz)) x V °C, degrees

Specificat ion s

Port input power for phase lock:

1. The performance parameters listed are characteristic of the HP 8511A/HP 8510. They are typical or nominal figures and are not f ield verifi able.

−

2. Do not exceed

5 dBm input to sampler for proper phase lock operation.

Frequency:

0.045 to 8 GHz

8 to 20 GHz

20 to 26.5 GHz

Minimum:

−

35 dBm

−

40 dBm

−

38 dBm

Maximu m:

−

5 dBm

−

5 dBm

−

5 dBm

Dynamic Accuracy Figure 2-2and Figure 2- 3 ill ustrate worst case ma gnitude and phase

uncertaintydue to IF residual s and detector inaccuracies. This data excludes

uncertainty due to noise, f requency response, dir ectivity, port matches and

connector repeatability.

Figu re 2- 2 Worst Case Dynamic A ccuracy (Magnitude)

Figu re 2- 3 Worst Case Dynamic A ccuracy (Phase)

* Phase detector accuracy is bett er than 0.02 degrees, useful for measurements where only phase changes.

*

HP 8511A Test Set Opera ting and Service Man ual

2-3

Page 31

Specificat io ns

Sou rce of Sys tem

Dynamic Accuracy

Errors

Table 2- 4 IF Amplifier Gain Ac curacy

The factors affecting dynamic accuracy listed below are primarily a function

of the IF detector. C ompr ession through, is primarily a function oft he

sampler/mixer circuitry. In order to mea sure the se values, some of the

system cables must be dis connected to gain access to the individual

instrume nts.

IF Amplifier Power Range

−

10 to −34 dBm 0

−

34 to −46 dB

−

46 to −58 dB

−

58 to −70 dB

≤

70

Detector Circularity Error

IF Residuals

IF Linearity

1

Maximum Gain Error (dB)

±

0.005

±

0.010

±

0.015

±

0.025

±

0.003 dB peak

140 dBm

0.003 dB

1

−

±

±

Incremental Phase Accuracy

(Phase versus Phase)

at Measurement Reference

1. Measured at the IF input to the HP 8510, not at the test set test ports.

0.001 degrees/degree, not to exceed 0.02

degrees peak.

Table 2- 5 HP 8511A Power Requirements and Physical C haracteristics

Operat ing Temperature 0 °C to 55 °C

±

Power 110, 120, 220 or 240

Dimensions 460 mm x 133 mm x 609 mm (18.1 x 5.25 x 24 inches)

Weight 13 kg (29 lb) net; 17 kg (38 lb) shipping

10% Vac; 47 to 66 Hz line frequency

2-4

HP 8511A Test Set Opera ting and Service Man ual

Page 32

Specificat ion s

Spec ificat ion Assum p tion s

Specific ation Assumptions

The specifications of the HP 8511A assume that the f ollowing operating

conditions are met:

• All s ystem instruments have reached stable operatingtemperature.

• RF source: HP 8360 series source. Other sources recommended in the

HP 8511A Performance Test procedures may be used for verification

within the frequency limits of those sources. When used with another

recommended source, the performance specifications may differ from

those for the HP 8510, HP 8511A, HP 8360 series configuration. The

performance test softwarewill display and print the limits for the chosen

configuration.

• Performance verification temperature: 23 ±3 ° C.

• RF source power levels as follows:

Test

Compression, Crosstalk

Conversion Gain, Tracking, High Level Noise

Power at Input Level (dBm)

0.045 to 18 GHz 18 to 26.5 GHz

−

10

−

15

−

15

−

20

HP 8511A Test Set Opera ting and Service Man ual

2-5

Page 33

Recommended T est

Equipment

Table 2-6 RecommendedTe st Eq u ipment

Specificat io ns

Specification Assumptions

Item Critical Specifications

Network analyzer no substitute HP 8510B, C

PC no substitute See “Computer

Disk drive compatible with controller

Multimeter range: 0 to 50V H P 3456A

Oscilloscope 50 MHz bandwidth HP 1740A

Power Meter HP 436 Option 022

Power sensor dc to 26.5 GHz (APC 3.5) HP 8485A

Power splitter dc to 26.5 GHz (APC 3.5) HP 11667B (5086-7408)

Female to female adapter dc to 26.5 GHz (APC 3.5) 1250-1749

Male to male adapter dc to 26.5 GHz (APC 3.5) 1250-1748

Recommended Model

(or Part Number)

Requirements” on

page 1-7 for detailed

information.

HP 437

HP 438

HP E4418

HP E4419

50 ohm load (male connector) dc to 26.5 GHz (APC 3.5) HP 909D option 040

Torque wrench, 8 in-lb, 5/16 in 8710-1765

RF cable, 1 m RF source to splitter 26.5 GH or 50 GHz (as needed)

Use good quality flex or

semirigid cable.

Attenuator, 6 dB (qty 2) dc to 26.5 GHz (APC 3.5) HP 8493C option 006

Attenuator, 10 dB dc to 26.5 GHz (APC 3.5) HP 8493C option 010

RF cable 1 M APC 3.5

RF cable 10 in (qty 2) APC 3.5

2-6

HP 8511A Test Set Opera ting and Service Man ual

Page 34

3

Installation

Introduction This chapter explains how to install the HP 8511A test set. The topics

covered include initial inspection, environmental considerations, positioning

and connecting the test set for use, and packaging the instrument. Refer to

the “Installation” chapter of the HP 8510 On-Site Service manual for more

complete system connection and turn-on instructions.

Initial Inspection Inspect the shipping container (including cushioning material) for damage.

If it is damaged, keep it until you have checked the contents for

completeness. The contents are listed in Table 3-1.

In addition,check the test setmechanicallyand electrically. If thetestset and

shipping container are undamaged, passing the Operator’s Check (in

Chapter 4, “Operation”) should suffice for incoming inspection. If the test

set does not pass the Operator’s Check, refer to the troubleshooting

procedures in the HP 8510 On-Site Service Manual or call your local HP

Customer Engineer.

If the shipping container is damaged or defective, keep the shipping

materials and notify both the carrier and the nearest Hewlett-Packar d office.

The HP office will arrange for repair orreplacement of the test set without

waiting for settlement of the claim. If the components receivedwith the test

set are incomplete, notify your nearest HP office and the deficient parts will

be sent to you.

Table 3-1 Contents of the HP 8511A Shipping Container

Item Part Number

Power Cord 8120-1 348

Tes t set cable assembly 08510- 60102

GPIB cable 8120-3445

Performance test software (CD-ROM) assembly 08511-60024

HP 8511A Operating and Service Manual

Semi-rigid cables (2)

1. For performance testing and operator’s check.

1

08511-90072

08510-20005

08510-20006

HP 8511A Test Set Opera ting and Service Man ual

3-1

Page 35

Installation

Environmental Considerations

Environmental Considerations

Operationand Storage To perform within specifications, the HP 8511A should be operated in

temperatures between 0 °Cand+55°C with relative humidity between 5%

and 95% at 40 °C (maximum dry bulb temperature). It may be operated at

altitudes up to 4,500 metres (15,000 feet).

The HP 8511A may be stored in temperatures from

relative humidity up to 90% at +65 °C (maximum dr y bulb temperature) and

at altitudes up to 15,240 metres (50,000 feet).

Preparation for Use P ositioning the Test Set

Typically the HP 8511A is placed under the HP 8510 network analyzer or

the source whether it is rack-mounted or used on a bench. To install the

flanges to rack mount the instrument (with or without handles) ina standard

19 inch rack, refer to Figure 3-2 on page 3-3.

Static-free

Workstation

When installing the test set for use on a bench, place it on a grounded

anti-static work surface to lessen the chance of ESD damage. The anti-static

surface should extend far enough in front of the test set to provide effective

protection at the test ports and cable ends. If your test set is equipped with a

grounding receptacle, you may use that in place of a static mat.

− 40 °Cto+75°C, with

Figure 3-1 Static Safe Work Area

3-2

HP 8511A Test Set Opera ting and Service Man ual

Page 36

Installation

Environmental Considerations

F igure 3-2 Attach ing the Rack Mounting Hardware

The recommended system rack is the HP 85043C. I nstructions for

rack-mounting the HP 851 1A in a system configuration with the H P 8510

are provided in the “Installation” section of the HP 8510 On-Site Service

Manual and in the HP 85043C System Rack Installation Manual (HP part

number 85043-90022).

HP 8511A Test Set Opera ting and Service Man ual

3-3

Page 37

Installation

Connecting the Test Set

Connecting the Test Set

Mating Connectors IN PUT PORTS al, bl, b2 anda2 are precision 3.5 mmfemale connectors

and mate with precision 3.5 mm male connectors.

The TEST SET INTERCONNECT c onnector is a series D subminiature

female conne ctor with 7 RF cavities. It mates w ith t he corresponding male

connector.

The 8510 SY ST EM BUS connector is a f emale GPIB type c onnector and

mates with the corr esponding male connectors of GPIB cables.

Power and Control

Connections

Signal Path

Connections

The following connections, with the exception of line power, a re il lustrated

in F igure 3- 3 on page 3-5. That figure also shows connections r equired for

the RF source.

1. Connect the line cord between an electrical outlet and the line module to

supply power to the frequency converter.

2. Connect the test set IF interconnect cable from the J11 TEST SET

INTERCONNECT connector on the rear pa nel of the HP 8511A t o the

J1 TESTSET INTERCONNECT connector on t he rear pane l ofthe

HP 85102 IF detector.

3. Connect the system bus cable from the HP 8511A J12 HP 8510

SYSTEM BUS connector to the HP 8510 INTERCONNECT

connector of the HP 85101 display/processor. The test set IF

interconnect cable and the s ystem bus cable transmit control signals

between the test set and the network analyzer.

The IF signa ls fr om the test set ar e transm itted to the HP 85102 1F detector

by the test s et IF interconnect cable supplied. Longer IF interconnect cables

are available (see “Cables” on page 1-10) of this manual.

RF signa ls are typically tran smitted from the s ource to the DU T (device

under test) or s ignal se paration devices by 3. 5 mm flexible or semi-rigid

cables.

3-4

HP 8511A Test Set Opera ting and Service Man ual

Page 38

Installation

Connecting the Test Set

F igure 3-3 HP 8511A System Connections

HP 8511A Test Set Opera ting and Service Man ual

3-5

Page 39

Installation

Packaging

Packaging

If reshipping is r equired,each test set should be repackaged in the original

factory package. Containers and materials identical to those used by the

factory are available through Hewlett-Packard offices.

If comparable packagingmaterialsare used, wrap the test setin heavy paper

or anti -static material. If shipping to an HP Office or Service Ce nter,

complet e and attach a service tag ( refer to the “I nstallation”chapter in the

HP 8510 On-Site Service Manual). Us e s ufficient shock absorbing m aterial

on all sides of the HP 85llA to provide a thick, firm cus hion and t o prevent

movement. Seat the shipping container securely and mark it FRAGILE.

In any correspondence with HP, refer to the HP 8511A by full model and

serial number (located on the rear panel).

3-6

HP 8511A Test Set Opera ting and Service Man ual

Page 40

4

Operation

Introduction

Thischapterillustratesthefeatures and functions of the front and rear panels

of the HP 8511A (see Figure 4-1 and Figure 4-2 on page 4-2).

CAUTION

Front Panel Features

Static Sensitive. Handle only at a static safe w ork station. Damage level of

input ports: > +13 dBm (20 mW) or > 1.0 Vdc.

Figure 4-1 Front Panel Features

1. Line Switch. This switch turns the test set on and off. When the side of

the switch labeled O is depressed, the test set is off; l is on.

2. Line LED. This LED goes on and off with the test set.

3. Active LED. This LED lights about two seconds after power is turned

on, following the successful conclusion of self-test.

4. Input Ports a1, b1, b2, a2. These input ports transmit RF energy to the

samplers within the instrument.

HP 8511A Test Set Opera ting and Service Man ual

4-1

Page 41

Operation

NOTE

The a1 or a2 input port must be used for system phaselock.

Figu re 4- 2 Rear Panel Fe atures

5. Li ne module. This assembly house s the line cor d c onnector, line fuse

and line voltage selector. Pull out the ri ght side of t he line module c over

to replace or change the fuse, or to c hange the voltage selection. Note

that the voltage selector drum must be removed to rotate itt o a different

setting. Recommended fuse va lues a re pri nted on the rear panel.

6. J10 Test Set Interconnect. This connector is used only in test sets with

Option 001. It allows connecting a second tes t set toan HP 8510 s ys tem

and automatically selecting the IF output from either t est set f or

processing by the HP8510.

7. J11 Test Set Interconnect. This connector transmits the IF signal from

the test set tothe HP 85102 IF Detector. I t a lso transmits control signals

bidirectionally.

8. HP 8510 Sys tem Bus Address Switch. Thi s five-gang bi nary-weighted

switch selects the system bus address of the test set. T he binaryweight

of each pole is indi cated on the rear panel as are the on and off positions.

Decimal twenty (off-off-on-off-on, from left to right) is the default

setting.

9. J12 HP 8510 System Bus Connector. This c onnector is used for GPIB

communications with the HP 85101 display/processor.

4-2

HP 8511A Test Set Opera ting and Service Man ual

Page 42

Equipment

Operators Check

The purpose of this check is to confirm that the H P 8511A f requency

conve rter functions properly as part ofan HP 8510 system. See Chapter 5,

“Performance Tests” for m ore inf ormation.

Table 4-1 Ne cessary Equipment

Description Model or HP Part Number

Network analyzer system HP 8510B,C

Semi-rigid cables (2) 08510-20005

Power splitter HP 11667B (5086-7408)

Operation

Operators Check

08510-20006

1

20 dB pad (attenuator) HP 8493C option 020

1. Supplied with the HP 8510 service kit.

NOTE

This procedure must be pe rformed with a properly configured and

operational HP 8510 s ystem. See Figure 3-3 on page 3- 5 or the

“Installation” chapter of the HP 8510 On-Sit e Se rvice Manual for more

informati o n .

Procedure Plug in and tur n on the frequency converter. The line LED should light

immediately and the active LED should light in about two s econds. Those

indications mean that the instrument has passed its self-test. In case of

difficulty, refer to the ‘Main Troubleshooting Procedure” chapter in the n the

HP 8510 On-Site Service Manual or c ontact your local HP Service Office.

Turn on t he source and then the HP 8510.

1. Press

[PRESET]

HP 8360 series s ystems:

Press STIMULUS

sweep time to 200 ms. In narrow band systems, the power level in

the frequency band generated should match the level shown in

Figure 4-4 on page 4-4 for a given frequency.

on the HP85102 to preset the HP 8510.

[MENU] [ST EP]

and then use the entry keys to set the

HP 8511A Test Set Opera ting and Service Man ual

4-3

Page 43

Operation

Operators Check

NOTE

All of the observed tracesshould de crease from −15 ±5dBat45MHzto−35

±5 dB at 26.5 MHz, similar to Figure 4-4.

a1 and b1 Test

2. Loosely connect the 20 dB pad to the power splitter and the RF source

cable to the pad as shown in Figure 4-3 on page 4-4. Connect the other

end of the RF source cable to the output of the source. Rotate the

semi-rigid cables to the required position for connection to ports a1 and

b1. Tighten all connections.

Figure 4-3 Hardware Configuration for Operator’s Check

3. Press PARAMETER

[MENU] [User 1 a1]

to observe the a1 powerlevel trace.

Figure 4-4 Typical Operator’s Check CRT Trace

4. Press

[User 4 b1]

to observe the b1 power level trace.

4-4

HP 8511A Test Set Opera ting and Service Man ual

Page 44

Operators Check

a2 and b2 Test

5. Reconnect the s emi-rigid ca bles (as in step 2) to ports a2 and b2.

Disregard the running error messa ge

Caution: “NO IF FOUND”

.

Operation

6. Press

[Us er 3 a2] [REDEFINE PARAMETER] [PHAS E L OCK] [a2] [REDEFINE DONE]

observe the a2 power level trace.

7. Press

[Us er 2 b2] [REDEFINE PARAMETER] [PHASE LOCK] [a2] [REDEFINE DONE]

see the b2 trace.

8. If any of the tracesare not within the li mits notedin this procedure,

check all of the connections and repeat the procedure. If symptoms

persist, refer to the “Service and Equipment Overview” chapter in the

HP 8510 On-Site Se rvice Manual.

to

to

HP 8511A Test Set Opera ting and Service Man ual

4-5

Page 45

Operation

Controlling Multiple Test Sets

Controlling Multiple Test Sets

Option 001 for the HP 851X-series test sets allows an HP 8510 to alternately

control up to four test sets. While a measurement is proceeding on test set

number 1, which is equipped with option 001, test device hookup can be

accomplished on Test Set number 2,which does not need to be equipped

with option 001, unless another test set is to be connected. When the

measurement on test set number 1 is complete, then the HP 8510 can control

test set number 2.

In a s tandard test set, the 20 MHz IF and control signals are applied directly

to J11 TEST SET INTERCONNECT, which connects to the HP 8510.

Option 001 adds a set of IF switches, control swit ches, and the JIO TEST

SET INTERCONNECT connector. This allows the selectionof 20 MHz test

set IF signals. As shown in Figure 4-5 on page 4-7, test set number l can

apply its IF to the HP 8510 or it can switch to pass the IF from test set

number 2 through the J10 TEST SET INTERCONNECT to the HP 8510.

4-6

HP 8511A Test Set Opera ting and Service Man ual

Page 46

Operation

Controlling Multiple Test Sets

F igure 4-5 RF and IF Switching with Two Test Sets

Table 4-2 HP 33311C Coaxial Switch Positions with Two Test Sets

New ADDRESS of Test Set Test Set Selected HP 33311C Coaxial Switch Port Selected

20 1 Port 1

21 2 Port 2

HP 8511A Test Set Opera ting and Service Man ual

4-7

Page 47

Operation

Installation

Inst al l a tio n

Set each test set rear panel address switch to the address li sted i n Tabl e 4-2

on page 4-7 i f using a two te st set configuration, and Table 4-3 on page 4- 10

if configurin g mor e than two t est s ets. Use the s upplie d te s t s et inte r connec t

cable to connect test s et number 1, J11 to the H P 8510. Use the s upplied test

set interconnect cable to connect test set number 2,J11, t o test set number 1,

J10. You ma y continue this test set “ daisy chain” to include up to four test

sets if the t otal le ngth of all test set interconnect cables does not e xceed 13

meters (about 40 feet). T he last test set in the chain does not requir e option

001.

If the R F coaxial switch (s) is not incorpor a ted into the sys tem, then the RF

input to the tes t s et must be manually switched to the active test set.

4-8

HP 8511A Test Set Opera ting and Service Man ual

Page 48

Operation

Operation

Oper ation

Initialization at

Power-up

Upon power-up, the IF switches must be configured so t hat only one system

test set is active. The following procedure shows how to make one te st s et

active.

1. Check th e active lights of all syst em te st sets.

2. Check the HP 8510’s expected test set address by pres sing

SET]

. This should match the address of the desired tes tset. If not, change

the address.

3. If unselected test setsare active, (active light ON), deactivate the test set

by temporarily addressing it. Then return to the desired address.

[LOCAL] [TEST

Selecting a Test Set TestSet IF Switching. The activetest set is selectedby the built-in

capability of the HP 8510 to generate an addressed command to the test set.

Each time the HP 8510 ADDRESS of TEST SET function is changed (see

HP 8510 LOCAL Menu), the HP 8510 switches the pr eviously addressed

test set IF to external and the newly addressed test set IF to internal. The test

set front panel ACTIVE indicatorshows the test set status. When the test set

is activethe IF signals from the test set are applied directly to J11 TEST SET

INTER CONNE CT. When the test set is inactive the IF signals appearing at

J10 are passed through to J 11and on to the next test set or the HP 8510.

The address of the test set can be changed manually from the HP8510 front

panel by selecting the ADDRESS of TEST SET function then e nt ering the

[XI],

address of the test set and pressing

control using the HP 8510 GPIB ADDRESS; command. The GPIB address

of a particular test s etis set by a ddre ss switches on the test set rear panel.

RF Switch Driver Commands. A related feature of the HP 8510 is that

when the HP 8510 ADDRESS of TEST SET function is changed, a code

sequence is automatically issued over the HP 8510 system bus to the de vice

at the ADDRESS of RF SWITCH. In the recommended configuration, this

device is an HP 11713A attenuator/switch driver which in turn controls one

or more HP 33311C coaxial switch. As shown in Figure 4-5 on page 4-7 and

Figure 4-6 on page 4-10, these switches are used to select which of the test

sets receive the RF Output of the network analyzer s ource. The exact

command issued depends upon the new value of the ADDRESS of TEST

SET function, also shown in Figur e 4-5 on page 4-7 and Figure 4-6 on

page 4-10.

or it can be changed under program

HP 8511A Test Set Opera ting and Service Man ual

4-9

Page 49

Operation

Operation

Figu re 4 - 6 RF and IF Switching with Four Test Sets

Table 4- 3 HP 33311C Coaxial Switch Positions with Four Te st Sets

Ne w ADDRESS of Test Set Test Set Selected

20 1 Port 1 Port 1

21 2 Port 1 Port 2

22 3 Port 2 Port 1

23 4 Port 2 Port 2

4-10

HP 33311C Coaxial Switch Port Selected

Switch #1 Switch #2

HP 8511A Test Set Operating and Service Ma nual

Page 50

Operation

Operation

Measurement

Calib r ation

After selecting the active test set, perform the system calibration procedure

as usual.When you select a dif f erent test set , make sure that you recallthe

cal set thatapplies to that tes t set .

Since the cal set limited instrument s tate does not include the number of the

act i vetest set, a cal set which does not applyto the current tes t set can be

turned on without any HP 8510 caution messages appearing. This w ill cause

errors inthe displayed data because incorrect errorcoefficients are applied to

the measured data.

It may be conve nient to store a hardwa re state file and an instrument state

file for each combination of test set and cal set. Y ou may also store your

hardware sate file on a disk for future us e. T o change the configuration,

simply recall the appropriate hard ware stat efile, which sets the address of

test set and issues the RF switch command, then the appropriate instrument

stat e f ile, whi ch recalls th e cal set.

HP 8511A Test Set Operating and Service Manual

4-11

Page 51

Operation

Operation

Operational Checks To check operation of a multi ple te st set configuration:

1. Connect a device with a known response at tes t s et number 1.

Perfor m ance

Verification

2. Press HP 8510

[LOCAL] [TEST SET], [ADDRESS of T EST SET].

3. Enter the address of test set number 1(this would be 20).

4. Press

5. Press

[xl].

The test set number 1 measurement should appear.

[DISPLAY] (D ATA-MEMORY] [DISPLA Y: DATA and MEMORY]

to store the trace

for latercomparison.

6. Use ADDRESSof TEST SET to select test set number 2.

7. Switch back to test set number 1.

8. Observe any difference in the response between the stored trace and the

result after switching back and forth between the test sets. Repeat for

each of the test sets. Any difference in the data believed due to the

option 001 IF s witch or RF switching must be investigated.

Standard system performance verification procedures are used to verify the

operation of the option 001 test set as test set number 1. To ve rifythe

performance of another test set in the chain, select it as the active test set and

proceed as usual.

4-12

HP 8511A Test Set Operating and Service Ma nual

Page 52

5

Performance Tests

The HP 8511A ships with the HP 8511A/B and Antenna Measurement

System Performance Verification Software assembly (HP part number

08511-60024). This assembly includes performance verification software

with on-line help and an installation and getting started manual (HP part

number 5962-0493).

Follow the HP 8511A/B and Antenna Measurement System Performance

Verification Software assembly documentation to install the software and to

verify the performance of your test set.

HP 8511A Test Set Opera ting and Service Man ual

5-1

Page 53

Test Pr ocedu re

(optional)

Performance Tests

Port Return Loss

Port Return Loss

NOTE

An HP 8515A tes t set is required to perform this test.

1. Disconnect the HP 8511A from the GPI B, the test set IF interconnect

and the RF source signal. Leave it connected to the line power.

2. Place the HP 8515 test set on top of the HP 8511A. C onnect the

HP 8515 test set in the system by connecting the GPIB, the tes t set IF

interconnect, the RF source power , and the line power to it.

3. Turn on the HP 8511A and tr eat it like a devi ce under test. You will use

the HP 8515 test set to make S11 measurements of each port on the

HP 8511A.

4. Perform the calibration at the end of the cable and take care to avoid

overly sharp cable bends (defined in the cable manual). Then measure

the return loss of each port on the HP 8511A.

5-2

HP 8511A Test Set Opera ting and Service Man ual

Page 54

6

Service and Replaceable Parts

This chapter of the HP 8511A manual contains service information

and replaceable parts lists. Topics covered in this chapter include

checks of the major assemblies and assembly removal procedures.

Other service information is also located in the MAIN

TROUBLESHOOT ING section of theHP 8510 On-Site

Service Manual.

HP 8511A Test Set Opera ting and Service Man ual

6-1

Page 55

Service and Replaceabl e Pa rts

Replaceable Part s

Replaceable Parts

Introduction This chapter contains information for ordering parts. “Exchange Assemblies

Available” des cribes how to order assemblies which are available on an

exchange basis. Figure 1-1 on page 1-2 and Figure 1-2 on page 1-5 identify

the parts of a standard HP 8511A. Figure 3- 2 on page 3-3 identifies the parts

unique to O ption 001 and Figure 3-3 on page 3-5 is a component location

diagram of the mot herboard.

Exchange A ssemblies

Available

The assemblies below arereplaceable on a rebuilt exchange basis at a cost

saving. T hey are notfield-repairable. Defective assemblies must be r eturned

for credit to realize the cost savings. Thus, assemblies requi red for s pare

parts stock should be order ed by the new assembly part number which is

included in the replaceable part s list of this section. See the parts list for the

orderable part numbers.

• A2 = IF multiplexer board assembly (option 001 only)

• A3 = VTO summing amplifier board assembly

• A4 = GPIB board assembly

• A10, A11, A12, 13 = sampler assembly (inputs bl, b2, a1, a2)

• A14 = VTO driver

• A15 = regulator board assembly

Replaceable Parts List Accompanying each replaceable parts illustration is a replaceable parts list.

Each list is arranged in alpha-numerical order by reference designator. The

reference designator keys the part listed to the illustration. Quantity refers to

the total number of the part in the instrument. The description is a brief

written description of the part and may be used for ordering purposes.

Reference

Designations

• A=assembly

• B=fan

• C = capacitor

• W = cable, wire

• T=transformer

6-2

HP 8511A Test Set Opera ting and Service Man ual

Page 56

Table 6- 1 HP 8511A Replaceable Parts

Reference Designation HP Part Number Qty Description

A1 08511-60009 1 Assembly, front panel

0180-2671 4 C AL 12000U 30V

08511-60024 1 HP 8511A/B and Antenna Measurement System Performance Verification Software

Assembly

08510-20005 1 Cable (semi-rigid)

08510-20006 1 Cable (semi-rigid)

08510-60102 1 Cable Assembly, Test Set

08510-90360 1 Quick Reference Connector Care Card

W31 08511-20001 1 Cable RF A12J1-A1

W32 08511-20002 1 Cable RF A1011-B1B2

Service and Replaceabl e Pa rts

Replaceable Part s

W34 08511-20004 1 Cable RF A13J1-A2

W13 08511-60021 1 Cable SMA/SMB 150C

W15 08511-60022 1 Cable SMA/SMB 150C

W16 08513-60136 1 Cable SMB/MSC 483W

W18 08513-60138 1 Cable SMB/MSC 457W

W20 08513-60140 1 Cable SMB/SMB 305W

W13 08513-60133 1 Cable assembly A3J1-A14J1

W14 08513-60134 1 Cable assembly A3J2-J11A7

C22, 23, 26 08513-60144 1 Cable SMB/MSC 457W

W25 08513-60145 1 Cable SMB/MSC 610W

W26 08513-60146 1 Cable SMB/MSC 610W

W27 08513-60147 1 Cable SMB/MSC 762W

08511-90072 1 HP 8511A Operating and Service Manual

08512-20005 1 RFI gasket

08513-00001 1 Deck

08513-00005 1 Mounting bracket LH

08513-00006 1 Mounting bracket RH

08513-00015 1 Plate, support cap

08513-00017 1 Bracket CONV AY

08513-00018 1 Insulator brace

08513-00037 1 Bracket enclosure

08513-00040 1 Cover (test set top)

HP 8511A Test Set Opera ting and Service Man ual

6-3

Page 57

Service and Replaceabl e Pa rts

Replaceable Part s

Table 6- 1 HP 8511A Replaceable Parts (Continued)

Reference Designation HP Part Number Qty Description

08513-00041 1 Cover (side PERF)

08513-20013 1 Brace (deck)

08513-20015 1 Mounting bar

A19 08513-60001 1 Mother board assembly

A15 08513-60007 1 Regulator board assembly

A15 08513-69007 1 Regulator board assembly (rebuilt)

A3 08513-60008 1 Board assembly VTO summing amp

A3 08513-69008 1 Board assembly VTO summing amp (rebuilt)

A10, A11, A12, A13, A14 5087-7041 1 Sampler assembly + VTO driver

A10, A11, A12, A13, A14 5087-6041 1 Sampler assembly + VTO driver (rebuilt)

A20 08513-60006 1 GPIB interface board assembly

08513-6 0156 2 EN C assembly double r

08513-65002 1 INTMD board assembly

08514-60010 1 Rear panel

08515-80003 1 PROM program

0955-0207 1 Attenuator 5 dB 2 W SMA

1250-1251 1 Adapter F SMA F SMA

1252-4694 1 CAP PROT 50PIN F

1252-4695 1 CAP PROT 50PIN M

1252-5007 1 CAP PROT 24PIN F

1400-0054 1 CLP CA .07D .37W

1400-0650 2 CLP CA .25D .75W

1400-0757 1 CLP CA .25D 1.00W

1400-1209 1 CLP CA .69D 1.00W

1401-0050 3 CAP PROT .125lD

1401-0245 5 CAP COND .240lD

B1 08513-20031 1 Fan Assembly

C1, C2, C3, C4 0180-2671 4 CAP FXD 30 Vdc AL

5001-0539 2 Trim side 132.6H

T1 9100-4616 1 Tansformer power

5021-5804 1 Frame FM rear

5021-5837 4 Corner strut

6-4

HP 8511A Test Set Opera ting and Service Man ual

Page 58

Table 6- 1 HP 8511A Replaceable Parts (Continued)

Reference Designation HP Part Number Qty Description

5021-8403 1 FR front 132.6H

5040-6988 1 Cover (front frame)

5041-8801 4 Foot FM .5 M

5041-8802 1 Trim strip

5041-8821 2 Standoff RR panel

5062-3747 1 Cover (bottom)

5062-3757 1 Cover (side)

5062-3989 1 Front handle kit

5062-6618 4 3.5 mm bulkhead female connector

5087-7041 1 Frequency converter, sampler assembly

6990-0028 5 Hole-plug .438 DNY

Service and Replaceabl e Pa rts

Replaceable Part s

6990-0086 5 Hole-plug .375 DNY

8120-1348 1 Cable, BNC 1 foot

8120-3445 1 Cable GPIB, 1 meter

85102-00041 2 Cover blank

9220-4962 1 End cap Corr Flt

08510-10035 1 Test Set Performance Software

HP 8511A Test Set Opera ting and Service Man ual

6-5

Page 59

Replacing the (T1)

Power Transformer

Service and Replaceabl e Pa rts

Replacement Procedures

Replacement Procedures

WARNING

Turn the test set OFF and disconnect the power cord from the mains.

Electrocution can result if power is not removed from the test set prior to this

procedure.

Procedure 1. Turn the test set on its right side.

2. Unplug the transformer connector at J2 on the A15 regulator board.

3. Using a large pozidriv screwdriver, remove the four screws and washers

that hold the transformer onto the rear panel.

4. Using a large pozidriv screwdriver, remove the screw that holds the

transf ormer angle bracket tothe main deck. The transformer wires

soldered to the line module are short, so do not pull the transformer out

too far.

5. Carefully remove the transformer from the test set and put it on the

bench close to the test set.

6. Strip the heat shrink tubing off the transformer wires soldered to the line

module, and unsolder the wires.

7. Unsolder the transformer ground wire connected to the chassis side rail.

8. Remove the transformer.

9. When you replace the transformer,refer to Figure 6-1 for the location of

6-6

the wires connected to the line module.

HP 8511A Test Set Opera ting and Service Man ual

Page 60

Service and Replaceabl e Pa rts

Replaceme n t Procedur es

Figu re 6- 1 Wire Connections t o Line M odule FL1

HP 8511A Test Set Opera ting and Service Man ual

6-7

Page 61

Replacing the (B1) F an

Service and Replaceabl e Pa rts

Replacement Procedures

WARNING

Turn the test set OFF and disconnect the power cord from the mains.

Electrocution can result if power is not removed from the test set prior to this

procedure.

To replace the fan (B1), you must remove the transformer (T1) so that the

ends of the fan wires can be unsoldered from the line module FL1. Refer to

the Table 6-1 on page 6-3 for the part numbers used.

Procedure 1. Turn the test set on its right side.

2. Unplug the transformer connector at J2 on the A15 regulator board.

3. Using a large pozidriv screwdriver, remove the four screws and washers

that hold the transformer onto the rear panel.

4. Using a large pozidriv screwdriver, remove the screw that holds the

transf ormer angle bracket tothe main deck. The transformer wires

soldered to the line module are short, so do not pull the transformer out

too far.

5. Carefully remove the transformer from the test set and put it on the

bench close to the test set.

6. Strip the heat shrink tubing off the two fan wires and unsolder the wires

for the line module. Cut any cable ties holding the fan wires to nearby

cables.

7. Using a small pozidriv screwdriver, remove the screwand lock washer

that secure the green/yellow fan ground wire to the top of the rear panel

frame.

8. Using a small pozidriv screwdriver, remove the four screws that hold the

fan to the rear panel and remove the fan.

6-8

HP 8511A Test Set Opera ting and Service Man ual

Page 62

Replacing t he

Freq uenc y Convert er

Service and Replaceabl e Pa rts

Replaceme n t Procedur es

WARNING

Turn the test set OFF and disconnect the power cord from the mains.

Electrocution can result if power is not removed from the test set prior to this

procedure.

The frequency converter consists of a voltage-tuned oscillator (VTO)

assembly and foursamplers.

Procedure 1. Remove the semi-rigid cable attached to each of the four samplers.

2. Remove the two in-line attenuators from the samplers.

3. Remove the six flexible cables from the frequency converter by gently

pulling on the gold connector.

4. Remove the four frequency converter mounting plate screws and the

bracket screw that fastens the frequency converter to the chassis.

5. Unplug the ribbon cable near the front panel.

6. Unplug the four harnessed (multi-colored) wire and socket assemblies.

7. Lift the frequency converter out of the test set.

8. Remove the frequency converter bracket by removing the two pozidriv

screws.

HP 8511A Test Set Opera ting and Service Man ual

6-9

Page 63

Service and Replaceabl e Pa rts

Replacement Procedures

F igure 6-2 HP 8511A Major A ssemblies

6-10

HP 8511A Test Set Operating and Service Ma nual

Page 64

Service and Replaceabl e Pa rts

Replaceme n t Procedur es

Figu re 6- 3 HP 8511A Misce llaneous Mechanical, Chassis and Electrical Parts

HP 8511A Test Set Operating and Service Manual

6-11

Page 65

Service and Replaceabl e Pa rts

Replacement Procedures

Table 6-2 HP 8511A Option 001 Replaceable Parts

Reference

Designator

A2 08513-60004 1 IF multiplexor board assembly

A2 08513-69004 1 IF multiplexor board assembly (rebuilt)

W1 08513-60121 1 Cable assembly A12J3-A2J1

W2 08513-60122 1 Cable assembly A13J3-A2J7

W3 08513-60123 1 Cable assembly A10J3-A2J4

W4 08513-60124 1 Cable assembly A11J3-A2J10

W5 08513-60125 1 Cable SMB/MSC 635W

W6 08513-60126 1 Cable SMB/MSC 533W

W7 08513-60127 1 Cable SMB/MSC 737W

W8 08513-60128 1 Cable assembly A2J11-J11A3

W9 08513-60129 1 Cable SMB/MSC 711W

W10 08513-60130 1 Cable SMB/MSC 546W

HP Part

Number

08510-60102 1 Cable assembly, test set

08510-60106 1 Cable, test set IF interconnect

Qty Description

W11 08513-60131 1 Cable SMB/MSC 762W

W12 08513-60132 1 Cable SMB/MSC 457W

W15 08513-60135 1 Cable SMB/MSC 610W

W17 08513-60137 1 Cable SMB/MSC 483W

W19 08513-60139 1 Cable SMB/MSC 457W

W24 08513-60144 1 Cable SMB/MSC 457W

W25 08513-60145 1 Cable SMB/MSC 610W

W26 08513-60146 1 Cable SMB/MSC 610W

W27 08513-60147 1 Cable SMB/MSC 762W

85102-00041 1 Cover blank

6-12

HP 8511A Test Set Operating and Service Ma nual

Page 66

Service and Replaceabl e Pa rts

Replaceme n t Procedur es

Figu re 6- 4 Parts Unique to HP 8511A Option 001

HP 8511A Test Set Operating and Service Manual

6-13

Page 67

Service and Replaceabl e Pa rts

Replacement Procedures

F igure 6-5 HP 8511A Motherboard

6-14

HP 8511A Test Set Operating and Service Ma nual

Page 68

HP 8511A Test Set Operating and Service Manual

Table6-6 Test Sets Interconnect Table (1 of 2)

Signal Enters

(Assembly)

→

A1 Front

Panel

A2 IF

Multiplexer

A3 VTO

Summing

Amp

A4 GPIBA5Attenuator/

Switch

A10

Sampler

A11

Sampler

A12

Sampler

A13

Sampler

A14 VTO/

Driver

A15

Regulator

A16 Step

Attenuator 1

A17 Step

Attenuator 2

A20 Rear

Panel

Mnemonic Description

Signal Enters

Motherboard

(Connector/Pin)

Signal Exits

Motherboard

(Connector)

→

J1 XA2 XA3 XA4 XA5 J2 J4 J5 J 6 J3 XA15 J8 J9 J7

Active

AB0

AB1

AB2

Active LED Indicator

Address Bus Bit 0

Address Bus Bit 1

Address Bus Bit 2

XA4-3

XA4-29

XA4-8

XA4-30

Motherboard Pin Numbers

4

29

8

30

29

8

30

29

8

30

AB3

AB4

A1S11

A1S10

Address Bus Bit 3

Address Bus Bit 4

Attenuator 1 Section 1 In

Attenuator 1 Section 1 Out

XA4-9

XA4-31

XA5-4

XA5-26

9

31

2

13

A1S21

A1S20

A1S31

A1S30

Attenuator 1 Section 2 In

Attenuator 1 Section 2 Out

Attenuator 1 Section 3 In

Attenuator 1 Section 3 Out

XA5-24

XA5-3

XA5-23

XA5-2

9

3

5

11

A1S41

A1S40

A1S11

A1S10

Attenuator 1 Section 4 In

Attenuator 1 Section 4 Out

Attenuator 2 Section 1 In

Attenuator 2 Section 1 Out

XA5-25

XA5-1

XA5-44

XA5-22

10

4

2

13

A2S21

A2S20

A2S31

A2S30

Attenuator 2 Section 2 In

Attenuator 2 Section 2 Out

Attenuator 2 Section 3 In

Attenuator 2 Section 3 Out

XA5-18

XA5-42

XA5-40

XA5-20

9

3

5

11

A2S41

A2S40

BNMINT

BSRQ

Attenuator 2 Section 4 In

Attenuator 2 Section 4 Out

Buffered Non-Maskable Interrupt

Buffered Service Request

XA5-19

XA5-41

XA4-28

XA4-2

28

4

28

2

28

10

4

DB0

DB1

DB2

DB3

Data Bus Bit 0

Data Bus Bit 1

Data Bus Bit 2

Data Bus Bit 3

XA4-15

XA4-37

XA4-16

XA4-38

15

37

16

38

15

37

16

38

15

37

16

38