Page 1

User’s Guide

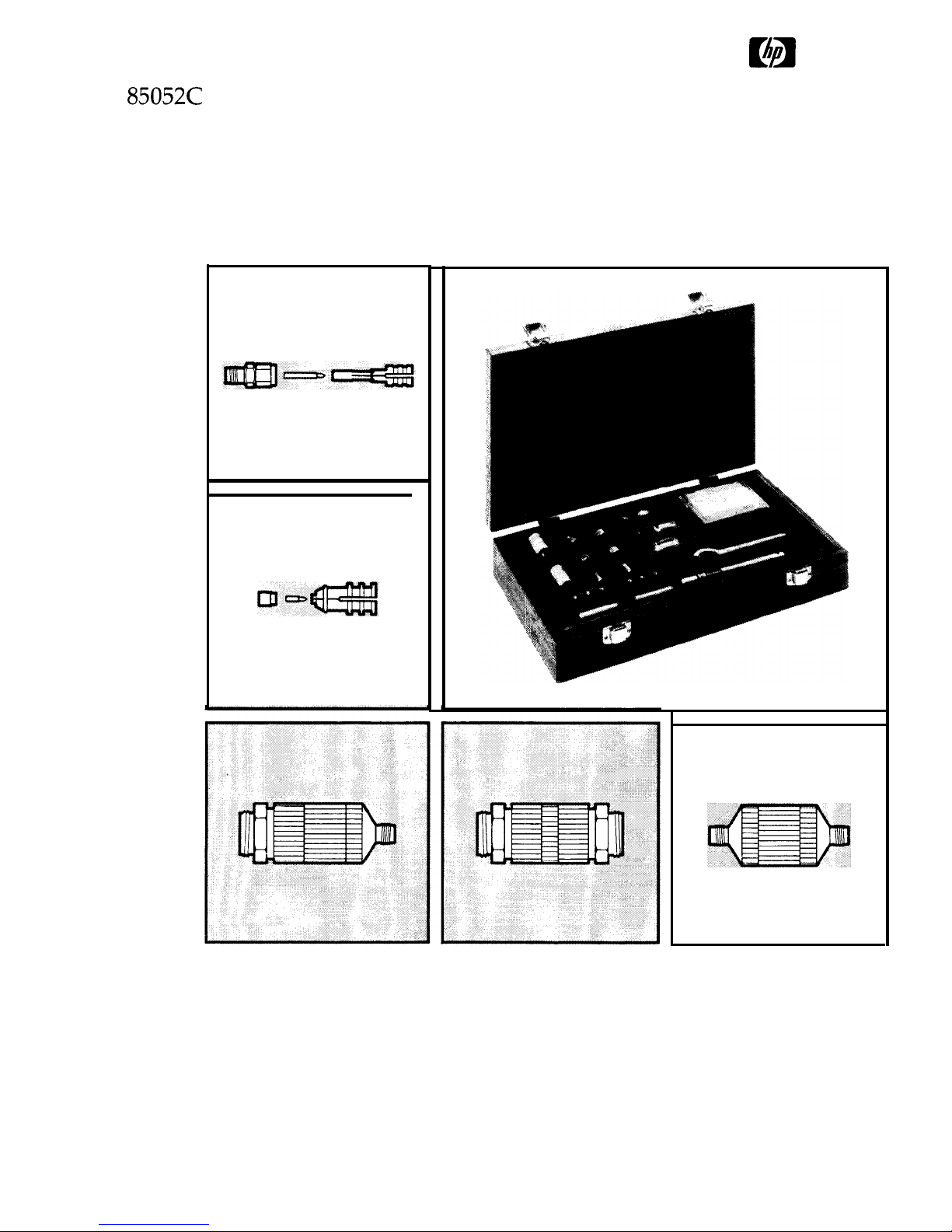

HP 85052C Precision Calibration Kit

HEWLETT

PACKARD

Page 2

TRAINING

VIDEOTAPE

USER’S

PRODUCT NOTE

PRODUCT NOTE

CONNECTOR

SERVICE

GUIDE

a510-5A

851 O-8A

CARE CARD

MANUAL

Using the

HP

85052C

HP

85052c

Operating and

Precision

Service Manual

Calibration Kit

HP

85052C

Precision Calibration Kit Operating and Service Package

Page 3

TABLE OF

CONTENTS

Chapter

1

Introduction to the Calibration Kit

Calibration Kit Components

Air Lines

O-2

GHz

Loads

Reflect Standards

Isolation Standards

Precision Adapters

Tools

5

Chapter 2

Performing a TRL 2-Port Measurement Calibration

Electrostatic Discharge

Clean and Inspect

Cleaning

Using Connector Gages

Configure Port 1 and Port 2

Install Test Port Return Cables

Install Precision Adapters

Air Line Frequency Coverage

Load Calibration Kit Definition

Measure Standards

When Stop Frequency is Greater than 7

GHz

When Start Frequency is Less than 7

GHz

When Start Frequency is Less than 2

GHz

Check the Calibration

11

Chapter 3

Noninsertable Calibrations

General Theory

Noninsertable Device Configurations

Adapter Removal Calibration Procedure

Chapter 4

Other Calibrations

Changing Air Line Frequency Range

Lowband

Reflection Instead of

0 to 2 Loads or 2 to 7 Line

Lowband

Reflection Procedure

26

28

3

Page 4

I

N

T

R

0

D

U

C

T

I

0 N

What’s in this Guide

Th*

IS

guide describes how to use the HP 85052C calibration

Chapter 1

Chapter 2

Chapter 3

Chapter 4

User’s Video

Application Note

Service Manual

Before Proceeding.

.

.

kit

with

the HP 8510 vector network analyzer to perform

the TRL 2-Port measurement calibration technique, and

how to evaluate the results of the calibration.

This chapter introduces the components of the kit, and

describes important connection techniques.

In this chapter, detailed sequences describe how to set up

the network analyzer system, and use the kit to perform

the 3.5 mm TRL

~-POX?

Calibration procedure.

Since many applications require measurement of devices

that are not insertable, this chapter describes the theory of

and how to use the kit to perform the Adapter Removal

procedure for measurement of noninsertable devices.

This chapter, entitled “Other Calibrations,” describes use

of the network analyzer Modify Cal Kit function to redefine

the calibration kit and how to use the Lowband Reflection

option.

This guide is supplemented by a video presentation that

shows how an experienced operator uses the calibration kit

parts. If you have access to this tape, view it along with this

manual first.

Another supplement,

Application Note 326, Microwave

Connector Care, gives

general principles of microwave

connector care. With the exception of changing the

recommended connector cleaning fluid from the previously

recommended liquid freon (a CFC) to isopropyl alcohol, this

connector care manual will serve as an excellent starting

point to become familiar with general requirements for

achieving optimum results using this calibration kit.

Refer to the Service Manual for specifications, replaceable

parts, and other pertinent information. Inside the

calibration kit box a quick reference card illustrates

procedures for connecting and disconnecting the air line.

This memory aid is helpful to the operator who is familiar

with the kit and TRL 2-Port calibration theory.

The parts in this kit are delicate and must be handled with

care to avoid damage that would affect the accuracy of the

calibration. Check all test device connectors carefully

before connecting to the TRL adapters.

Page 5

HP

85052C

Precision Calibration Kit

CHAPTER ON

E

Introduction to the Calibration Kit

The HP 85052C 3.5 mm Precision Calibration Kit is

designed to be used in TRL 2-Port measurement calibration as implemented in vector network analyzers. TRL

stands for Thru-Reflect-Line, naming the main standards

used in the accuracy enhancement procedure.

TRL represents a family of calibration techniques that

measure various combinations of transmission lines and

reflection standards to determine the 2-Port 12-term error

coefficients. The specific calibration technique described

here uses measurements of the zero-length thru connection, identical reflection standards at each port, and one or

more transmission lines of appropriate impedance and

length for the frequency range. Both the TRL 2-PORT and

the Full 2-Port calibration types use the same accuracy

enhancement mathematics to correct the measured data.

TRL, as implemented with this calibration kit, brings convenience, accuracy, and repeatability to the error

correction process because the typical TRL calibration

requires fewer parts that are simpler to connect and

-

disconnect.

The 3.5 mm geometry connector is the most frequently

used connector when frequency coverage up to 26.5

GHz,

reasonable commonality, and durability is desired.

Well constructed connectors and transmission lines can

work up to 34

GHz.

Metrology grade versions of this connector are used for high performance test ports and for

calibration standards. Whether the device uses SMA,

SMA-compatible, or 3.5 mm, the HP 3.5 mm connectors

used on the HP test ports, adapters, cables, and calibration

standards provide the most accurate and repeatable

-

solution.

All male connectors in this kit are HP precision with care-

fully controlled dimensions. All female connectors are of

the HP precision slotless (PSC-3.5) type. These connectors

are designed for long repeatability when used with appropriate technique. This means careful inspection of the kit

parts, familiarity with their use, and careful inspection of

the Device Under Test (DUT) connectors. Refer to the

“Specifications” chapter in the HP

85052C

Service Manual, and the Technical Note included with this manual for

specific information about precision slotless connectors.

5

Page 6

Calibration

Kit Components

Air Lines

The HP

85052C

3.5 mm Precision Calibration Kit contains

components useful for several different calibration techniques. The parts used for the TRL 2-Port calibration are:

l

Longer precision air line for 2 to 7 GHz

l

Shorter precision air line for 7 to 32 GHz

l

Male and female short circuits

l

Male and female fixed loads

Other parts included are:

l

Three precision TRL adapters

. Two adapter anti-rotation clamps

l

Calibration kit definition tape

l

Male and female open circuits

l

Tools

Note the reference card in the box and the material list on

the bottom of the box.

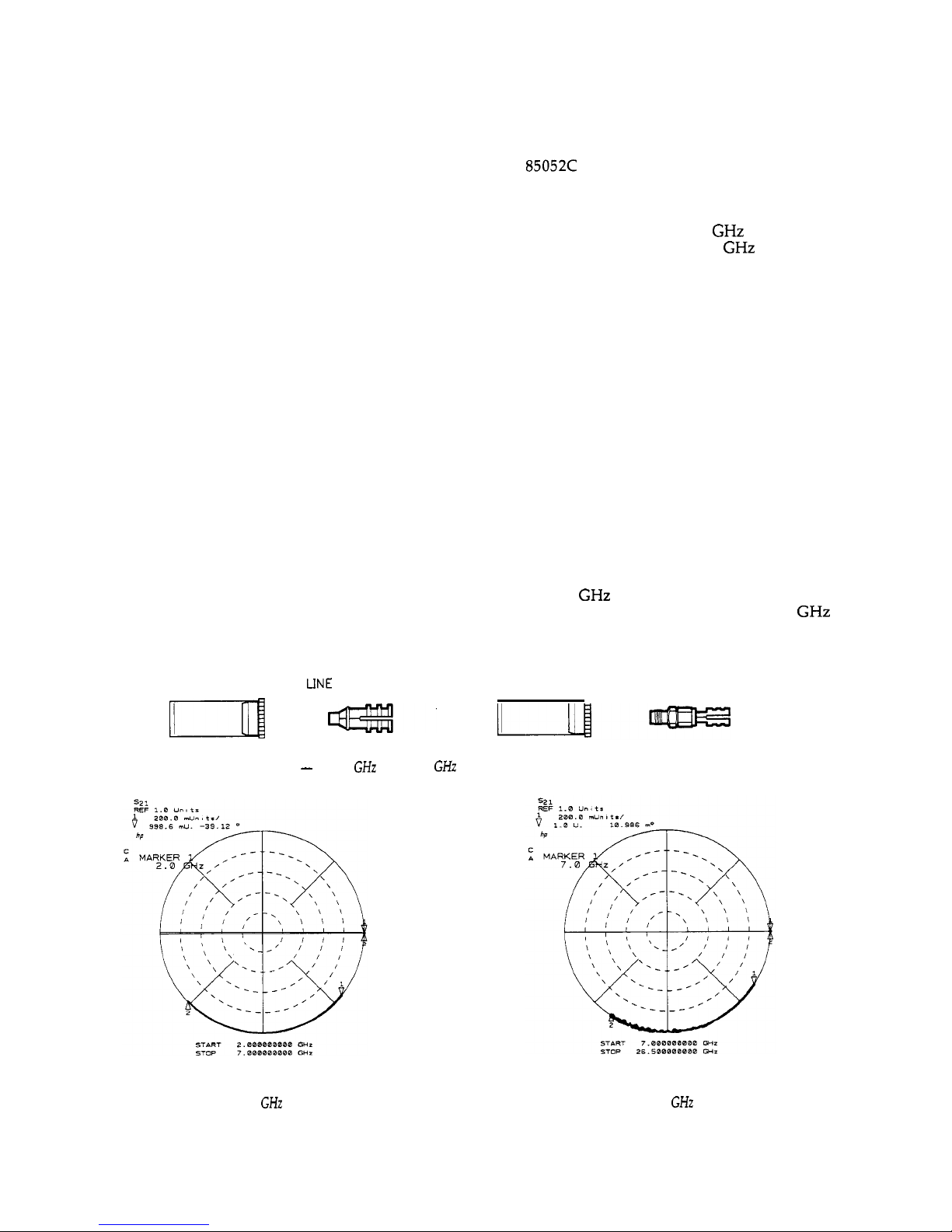

These are precision air lines. Each one is always stored in

its installation tool to help prevent damage and preserve

cleanliness.

The shorter air line is used for measurement calibration

over the 7 to 32 GHz frequency range. The longer air line is

used for measurement calibration over the 2 to 7

GHz

range. Each air line is fully specified at all frequencies

within its stated range.

7-32

LINE

II

a’

2-7 LINE

Line Standards - 7 to 32

GHz

and 2 to 7

GHz

Air

Lines Installed in Tools with Storage Bottles

Polar Display Showing Phase Response

of

Longer

Air Line Over 2

to

7

GHz

Frequency Range

Polar Display Showing Phase Response of Shorter

Air Line over 7 to 26.5

GHz

Frequency Range

Page 7

Air Lines Removed From

installation

Tools

Each air line consists of a separate outer conductor and

center conductor and includes its own tool used for

installing and removing the parts from the test port. Both

are insertable. Each has a male end and a female end. The

male end of the air line fits into the installation tool.

The parts may be removed for inspection, if necessary, but

the tool is always used to install the parts for calibration.

Use extreme care in handling these parts. Use static dissipative finger sheaths, or “finger cots” to prevent contamination. Liquid or solid residue on the connector parts will

degrade performance. In particular, the inner conductors

can be easily deformed by squeezing. Do not use

metallic

tweezers or other devices to pick up or hold the parts.

installing

the

Air

Lines in

installation

Tools

0 to 2

GHz

Loads

Th’

IS

implementation of the TRL 2-Port calibration allows

measurement of the loads to determine the error coefficients up to 2

GHz.

Technically, the measurement is

treated as an infinite-length transmission line whose input

reflection is the reference impedance, Z,.

Note:

The male and female broadband loads are

manufactured to tolerances that assure equivalent responses,

at least below 2

GHz.

If one is damaged or otherwise

becomes defective, calibration

erroriwill

result.

0

to 2

GHz

Loads -Male and Female Fixed Broadband Loads

Page 8

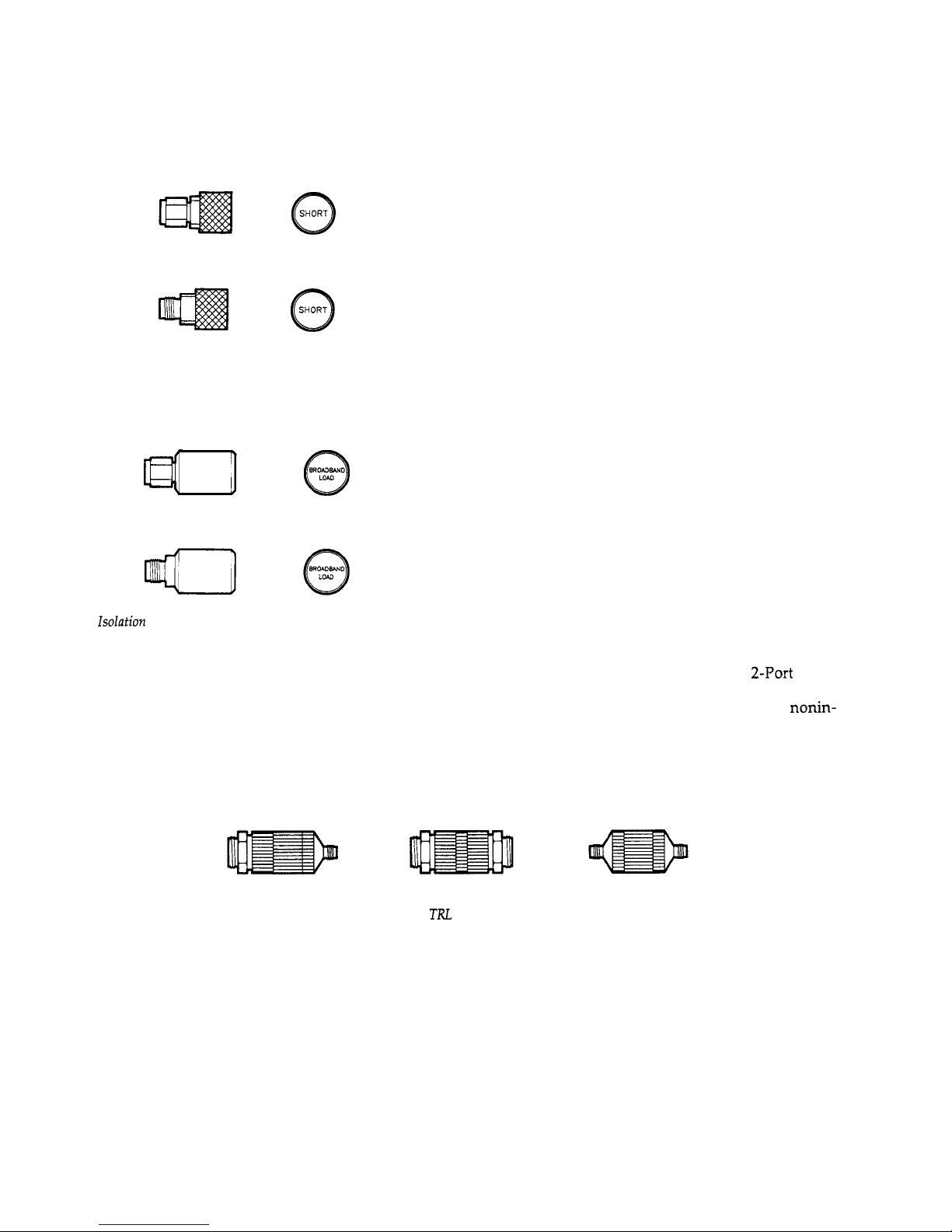

Reflect Standards

Reflect Standards -Male and Female Short Circuits

Isolation Standards

isolation

Standards -Male and Female Broadband Loads

Precision Adapters

In this TRL 2-Port calibration, the reflect standards are

identical short circuits with one connected to Port 1 and

one to Port 2.

The male short circuit and the female short circuit are

manufactured to tolerances that assure equivalent

responses. If one is damaged or otherwise becomes

defective, calibration errors will result. Errors will also

result if the open circuits are used in the procedure instead

of the short circuits (unless the calibration kit standard

assignment definition is changed).

The fixed loads used for the isolation part of the calibration

are the same broadband loads as used for the O-2 loads

measurement. Exact equivalent responses are not required

for this step.

Three precision adapters are included in this kit. Two are

always recommended for the 3.5 mm TRL 2-Port

measurement calibration. All three can be used in the

adapter removal calibration for measurement of nonin-

sertable devices. Complete performance verification

assumes use of the precision adapters in this kit as the test

ports.

MALE to FEMALE

MALE to MALE

FEMALE to FEMALE

Precision

TRL

test port adapters

Page 9

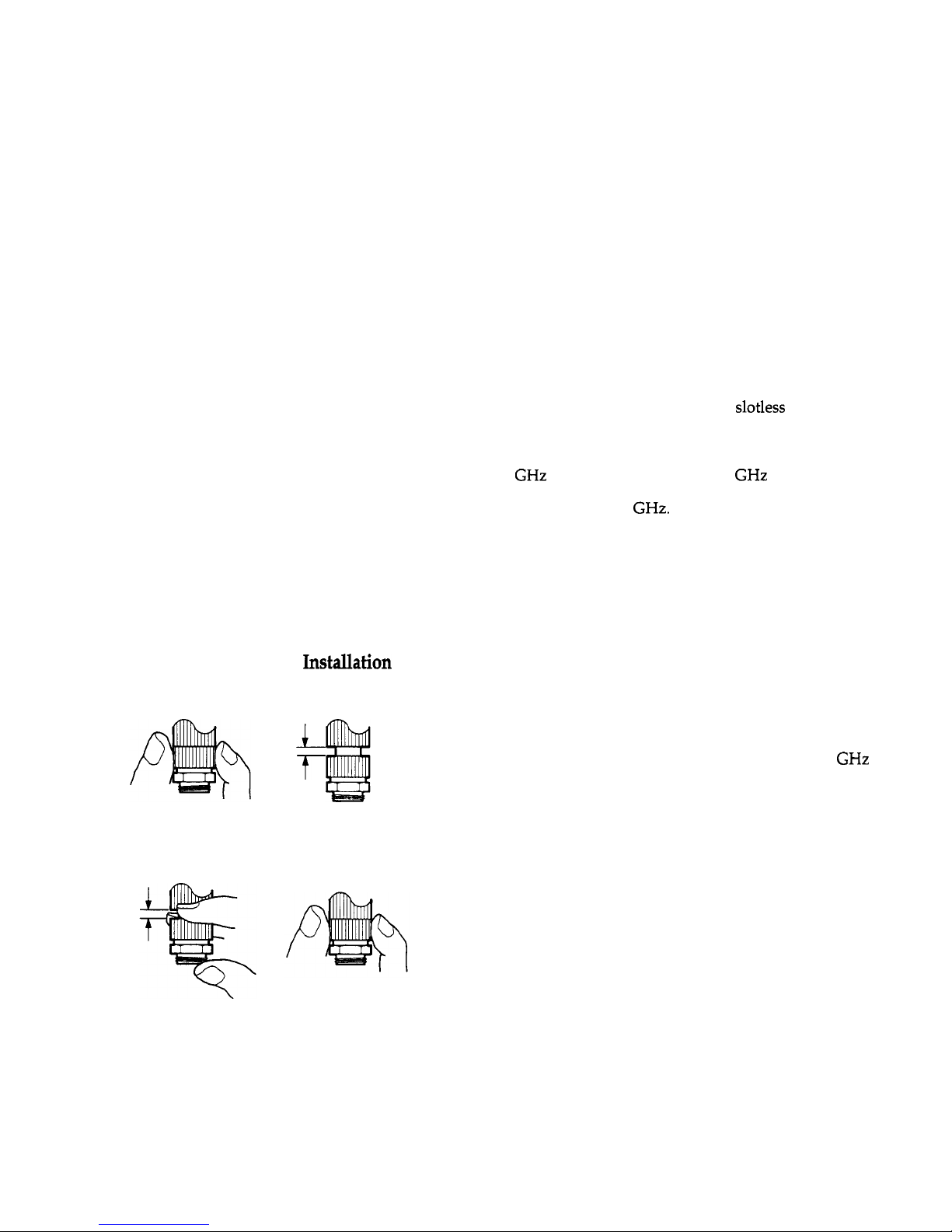

Recession Limits

The female receptacle recession and the male pin

recession, along with other mechanical specifications of

Port 1 and Port 2, must be within limits to meet complete

measurement specifications. The precision adapters

supplied in this kit are manufactured to metrology

standards in order to obtain the best measurement

accuracy specifications. If other connectors than these

precision adapters are used as the test ports, they must be

fully inspected. Using other than the highest quality

connectors as the test ports will reduce accuracy and

repeatability as well as possibly damaging the calibration

standards.

Precision Connectors

For general use, any 3.5 mm precision

slotless

female connector can be used for the female test port. The 3.5 mm

precision male connector used on the male end of these

adapters is always required for measurements between

7-32 GHz in order to connect the 7-32 GHz air line in this

kit. Any 3.5 mm precision male connector can be used at

frequencies less than 7

GHz.

hstdation

Feature

The precision adapter male connector has a special feature

to allow installation of the 7-32 air line.

GAP

_L

t

l

Grasp the knurled sleeve and move the nut to its

extended position by pulling on it.

This is the position used for measurement of the 7-32 GHz

air line.

Extended Position

GAP

. Now move the sleeve forward and push the nut back

into its standard position.

This position is used to install the short air line, for

connecting the other calibration standards, and for

connecting the device under test.

Standard Position

9

Page 10

/o

I

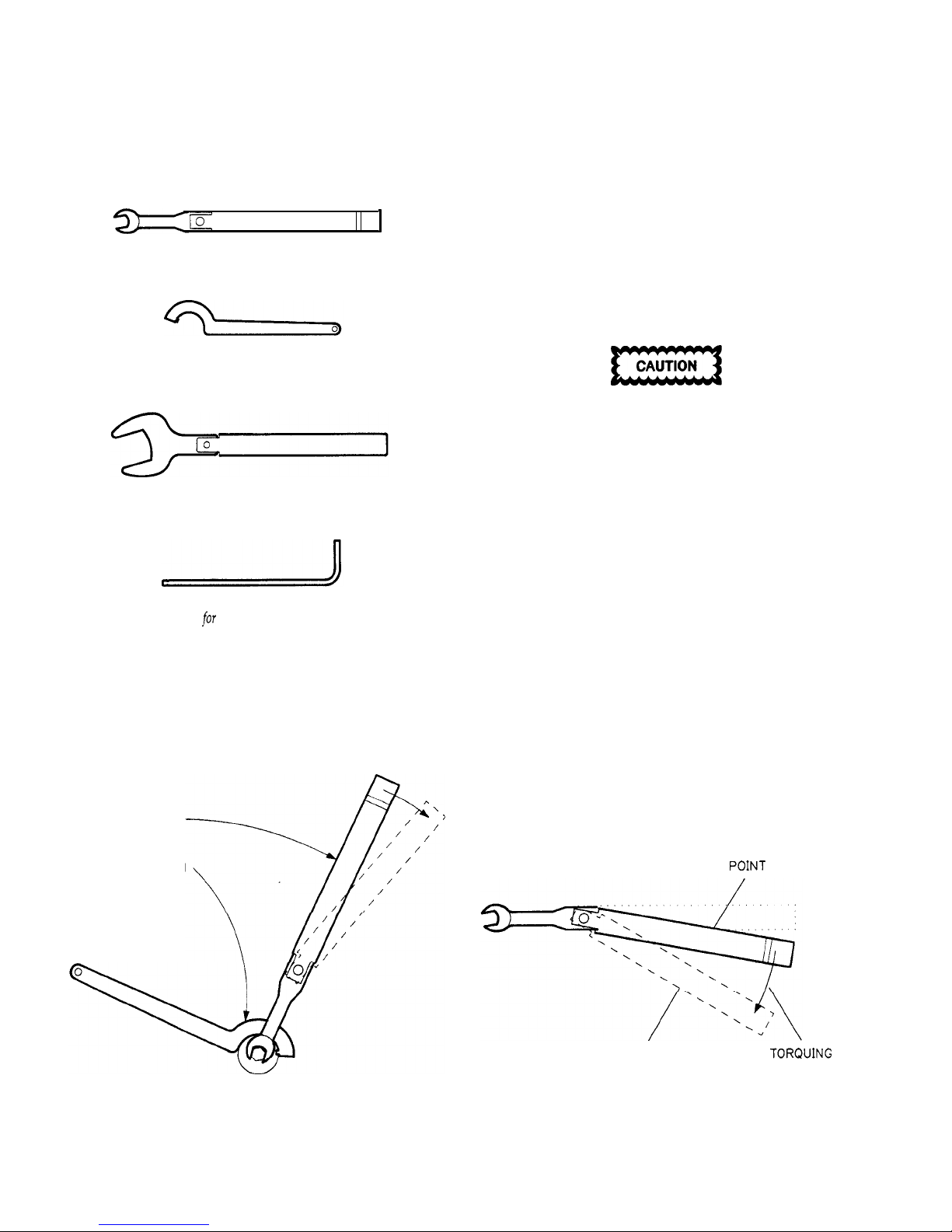

Torque Wrench

Tools

At q

or

ue wrench and spanner wrench are included in the

kit to loosen and tighten the connectors. The small torque

wrench is used for the 3.5 mm nuts. The large torque

wrench is used for the 20 mm nuts on the precision

adapters. It is included with the test set. The spanner

wrench is used to hold the precision adapter while using

the appropriate torque wrench to tighten the connection.

Also included is the hex wrench for tightening and

loosening the adapter anti-rotation clamp securing screws.

Spanner Wrench

When making connections, turn the nut on the device,

never turn the device itself. Turning the device will cause

excessive wear of both connector mating surfaces and

cause debris to collect in the female receptacle.

Torque Wrench (not included)

When making a connection:

Hex Wrench

for

AdapterAnti-Rotation Clamp

1.

Carefully engage the male and female contacts, and

then tighten the nut by hand.

2.

If necessary, use the spanner to hold one device

stationary against the direction of torque.

3.

Hold the torque wrench with your thumb and index

finger near the end of the handle.

4.

Tighten the connection until the ball in the handle

crests on the cam (as the handle begins to “break”,

releasing tension).

TIGHTEN WITH

TORQUE WRENCH

HOLD WITH

SPANNER WRENCH

It is not recommended or necessary to fully “break” the

handle of the torque wrench to reach the fully-specified

torque. As soon as the handle moves out of alignment, the

connection is properly torqued.

Reverse the above procedure to disconnect the connectors.

HANDLE BEGINS TO BREAK

(

CORRECT

POINT

TO STOP

)

HANDLE FULLY BROKEN

TORQUING

(NOT RECOMMENDED)

DIRECTION

Using the Spanner and Torque Wrench

Correct Torque Value

10

Page 11

C

H

A

I?

T

E R

T

W

0

Performing a TRL Z-Port

Measurement Calibration

This example describes use of the HP 3.5 mm precision

calibration kit to measure an insertable device. When the

test device is insertable, the test ports can be connected

together to establish the Thru connection during

calibration.

The procedure used for performing any measurement

calibration is as follows:

.

1.

Clean and inspect all connectors.

2.

Initiate measurement calibration procedure and

measure standards.

3.

Verify the calibration.

4. Connect the device under test.

The rest of this section explains the above steps.

Electrostatic Discharge

wheny

ou make connections to the network analyzer,

either directly to the test set port or indirectly through a

cable that is connected to the test set port, protect the

instrument against electrostatic discharge (ESD). Always

wear a grounding wrist strap connected to a conductive

bench mat when working near sensitive equipment.

The human body almost always has some static charge.

You are not usually aware of this charge because the

human threshold for the perception of a static discharge

shock is about 30

kV.

ESD as low as 60 volts can damage

sensitive microcircuits.

Clean and Inspect

The accuracy of error-corrected measurements using the

network analyzer depends upon the quality of the

measurement calibration. In turn, the quality of the

calibration depends on the condition and cleanliness of the

test ports and calibration standards, and the operator’s skill

in making connections. Repeatability and accuracy are

improved by removing contaminants from mating surfaces

during cleaning.

Carefully inspect the following for cleanliness and

damage. Look for deformation of the male pin or the

female receptacle, and for metallic and organic residue on

the mating surfaces.

l

Test set test ports

l

Test port cables

l

Precision adapters

l

Calibration standards

l

DUT Connectors

11

Page 12

A low power magnifier, less than 6x, is adequate to inspect

the parts. Do not be concerned with minor defects such as

scratches visible only with the magnifier; these will

probably not affect performance. If inspection shows

moisture, oil, or other residue, clean the parts.

When examining the female connector, look at the inner

contact to see that the gripping fingers are not bent.

The greatest variable in the accuracy and repeatability for

these demanding measurements is the experience and

attention to detail of the person actually making the

connections. Before going on, examine all parts carefully.

SPRING FORCES INNER

INSERTED MALE PIN

Detail of Precision

Slotless

Female Connector

Cleaning

The parts must be clean in order to achieve best results.

Use isopropyl alcohol, dry air or nitrogen, and lint-free

swabs to remove contaminants.

In general, do not force cleaning materials into connector

parts and do not immerse the part in cleaning fluids. Just

moisten the swab and wipe the surface lightly. To dry the

part, use a dry swab or light pressure from a dry air or

nitrogen source.

Do not leave lint or particles of the swab in the connector.

If there is doubt about the condition of the connector, use

the connector gages to check the connector dimensions.

The same care should be used for all connectors, especially

the device under test.

12

Page 13

Using Connector Gages

Before Connecting

Gaging is optional for the precision connectors in this

calibration kit if the male and female center conductors are

concentric and do not show physical damage.

However, due to the large range of dimensions found on

most DUT connectors, the DUT connectors must always be

inspected and gaged before connecting them to the

precision adapters. This is not usually a problem for the

DUT female connectors, but may be a problem for DUT

male connectors, especially the economical SMA and

SMA-compatible types.

BLACK

%G

(

RECESSION

)

RED PLUS SIGN

(NOT

USED)

LIMIT POINTER

DIAL

INDICATOR

FEMALE 3.5 mm

CONNECTOR

GAGE

BLACK PLUS

SIGN

(

PROTRUSION

)

RED MINUS

SIGN

(

NOT USED

)

GAGE INCREMENT

0.0001 INCH

,r

’

ZERO SET KNOB

Connector

Gage

13

Page 14

Measurement Errors

The gage measures the pin depth (recession) of the

connectors. If the pin depth to too far negative, errors will

result from excessive air gap in the connection.

Connector Damage

If the pin depth is positive (protrusion), both mating

connectors will almost certainly be damaged.

Also, if the male pin diameter is greater than the maximum

3.5 mm specification, it will cause permanent damage to

the female receptacle. If you try to measure the pin depth

and the gage will not fit over the pin, it is an immediate

indication that the pin is too large and must not be

connected to the precision adapters. The male pin of the

DUT connector may fit into the gage and give a correct

measurement, but still be slightly too large for the

precision adapter female receptacle.

Repair and Replacement

In general, bent or deformed parts cannot be repaired in

the field. It is necessary to return the part to an HP service

center for repair or replacement. The air line center and

outer conductors must be replaced as a set. Refer to the

replaceable parts chapter in the service manual supplied

with the calibration kit for replacement part numbers and

ordering information.

--A-

RECESSION

Cross Section

of

Female Connector Showing Recession limits

RECESSION

_)

j_

Cross Section

of

Male Connector Showing Recession Limits

14

Page 15

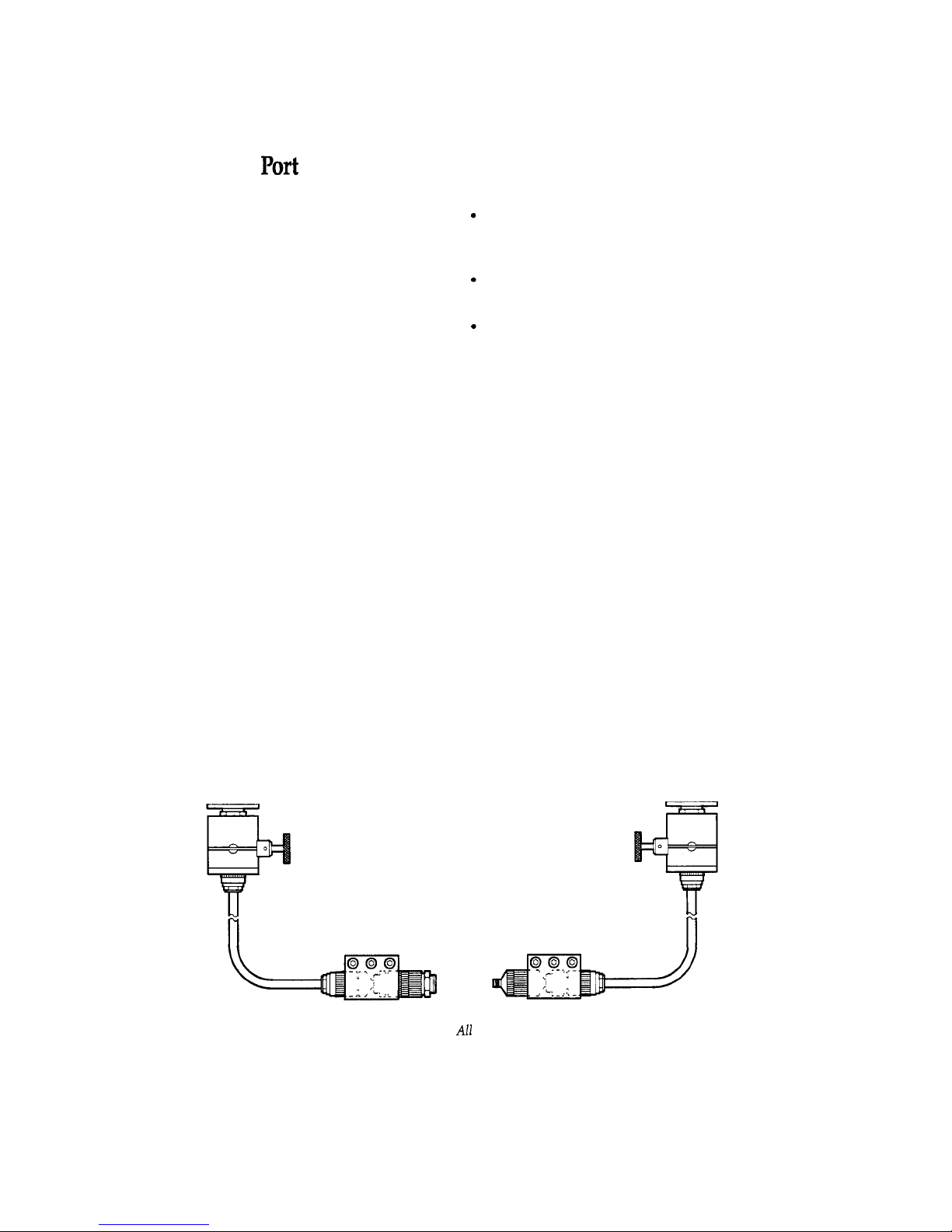

Configure Port 1 and Port 2

s

everal

configurations are possible, depending upon the

frequency range, available cables, operator convenience,

and DUT requirements. Following is an example hookup

using the two-cable set and two examples using a single

cable. The appropriate precision adapters are installed on

the ends of the cables and become Port 1 and Port 2.

TEST SET

PORT 1

TEST PORT

ANTI-ROTATION

TEST SET

PORT 2

I

81

!~,

!il

ADAPTER

ANTI-ROTATION

PORT 1

PORT 1

PORT

PORT

1

2

Dual Cable Setup

PORT 2

Single Cable,

Port 1

Female

PORT 2

Single Cable, Port 1 Male

15

Page 16

Install Test

Port

Return Cables

When all parts are ready for use, connect the test port

extension cables. To connect a cable to the test set:

Loosen the test port anti-rotation clamp securing screw

and slide the clamp over the cable far enough to provide

access to the cable connector.

Connect the cable to the test port and tighten using the

torque wrench.

Slide the clamp toward the port, aligning it so that the

flats on the clamp mate with flats around the test port.

Tighten the clamp securing screw. This clamp keeps the

cable from becoming loose from the test set connector.

Install Precision Adapters

T

o install the precision adapters and adapter anti-rotation

clamp:

.

Connect the adapter to the cable, tighten finger tight, and

then use the spanner and the torque wrench to achieve

the final torque.

l

Loosen the adapter anti-rotation clamp securing screws

and slide the clamp over the adapter. Align the clamp so

that it can grip both the cable connector body and the

adapter body. Tighten the clamp securing screws. The

screw tightening order is not important.

The adapter anti-rotation clamp assures that the TRL

adapter does not become loose during calibration and

measurement.

l

Connect the second TRL adapter and its anti-rotation

clamp to serve as Port 2.

PORT 1

PORT 2

Two Cable Setup with

AZ1

Components Connected

16

Page 17

Air Line Frequency

COVerage

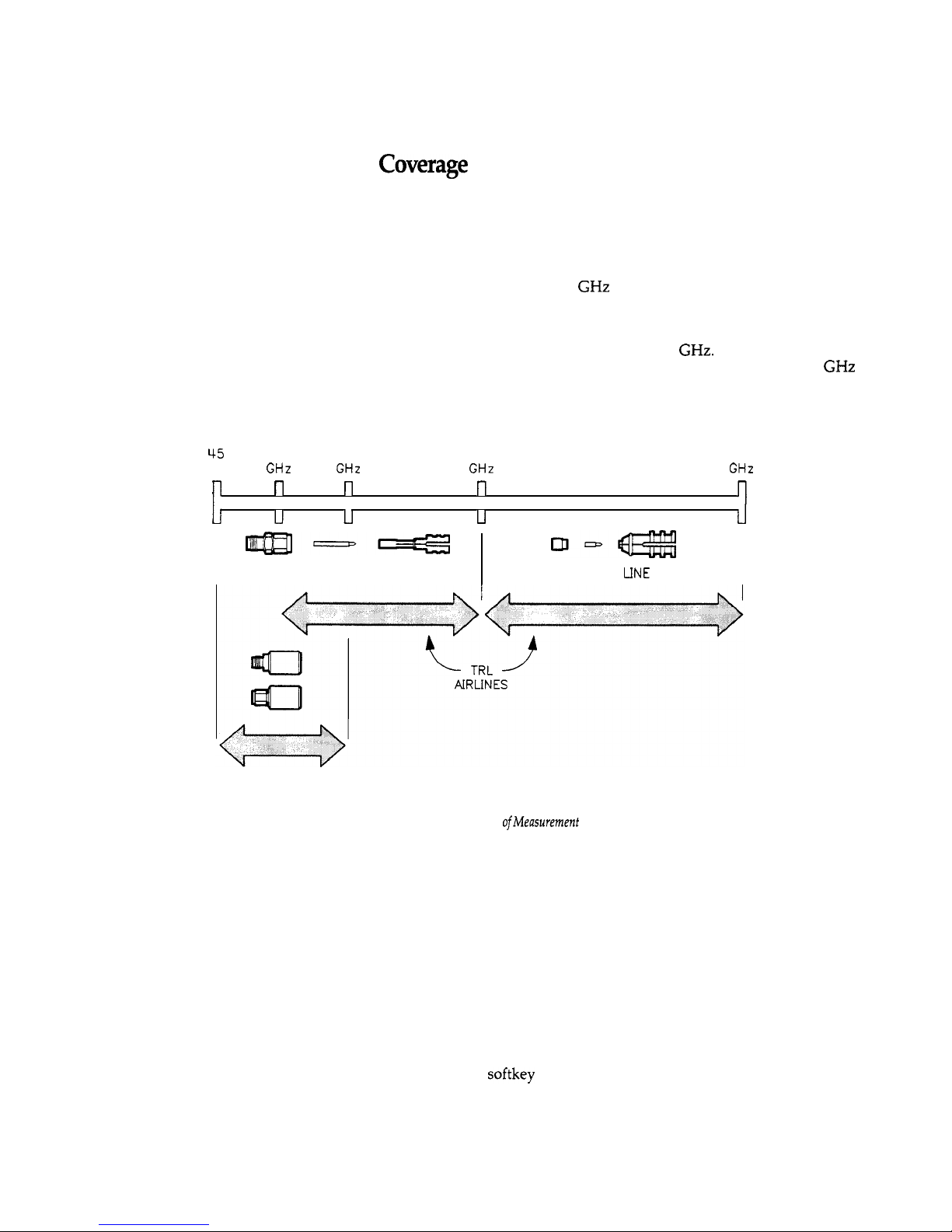

This illustration shows the frequency range covered by the

air line and fixed loads for the Lines part of the TRL 2-Port

calibration procedure. If measuring over the entire

frequency range, measure the 7-32 Line first, then the 2-7

Line, then the O-2 Loads. If measuring over a reduced

frequency range, only those standards for that frequency

range need to be measured. For example, if you are testing

over the 3-22 GHz range, only the 7-32 Line and the 2-7

Line must be measured.

The standard label for the 2-7 Line would indicate that its

data is valid only from 2 to 7

GHz.

However, you may

choose to use data from the 2-7 Line down to the 1 GHz by

simply not measuring the O-2 Loads. If the O-2 Loads are

measured after the 2-7 Line, the O-2 Loads data will replace

data from the 2-7 Line.

45

1

2

7

32

MHZ

GHz

GHz GHz GHz

F1

l-l

i-l

l-l

Ir

Jl

Ll

u

u

II

aEl-I

2-7 LINE

m-m

7-32

LINE

O-2 LOADS

Frequency Coverage for Line Part

ofMeasurement

Calibration

Load Calibration Kit Definition

To begin measurement calibration, first load the calibration

kit definition from tape or disk.

Press:

TAPE/DISC

STORAGE is TAPE

LOAD

CAL KIT 1-2

CAL KIT 1

FILE 1

When the calibration kit definition is loaded, the CAL 1

softkey label will read 3.5 mm C. 1.

17

Page 18

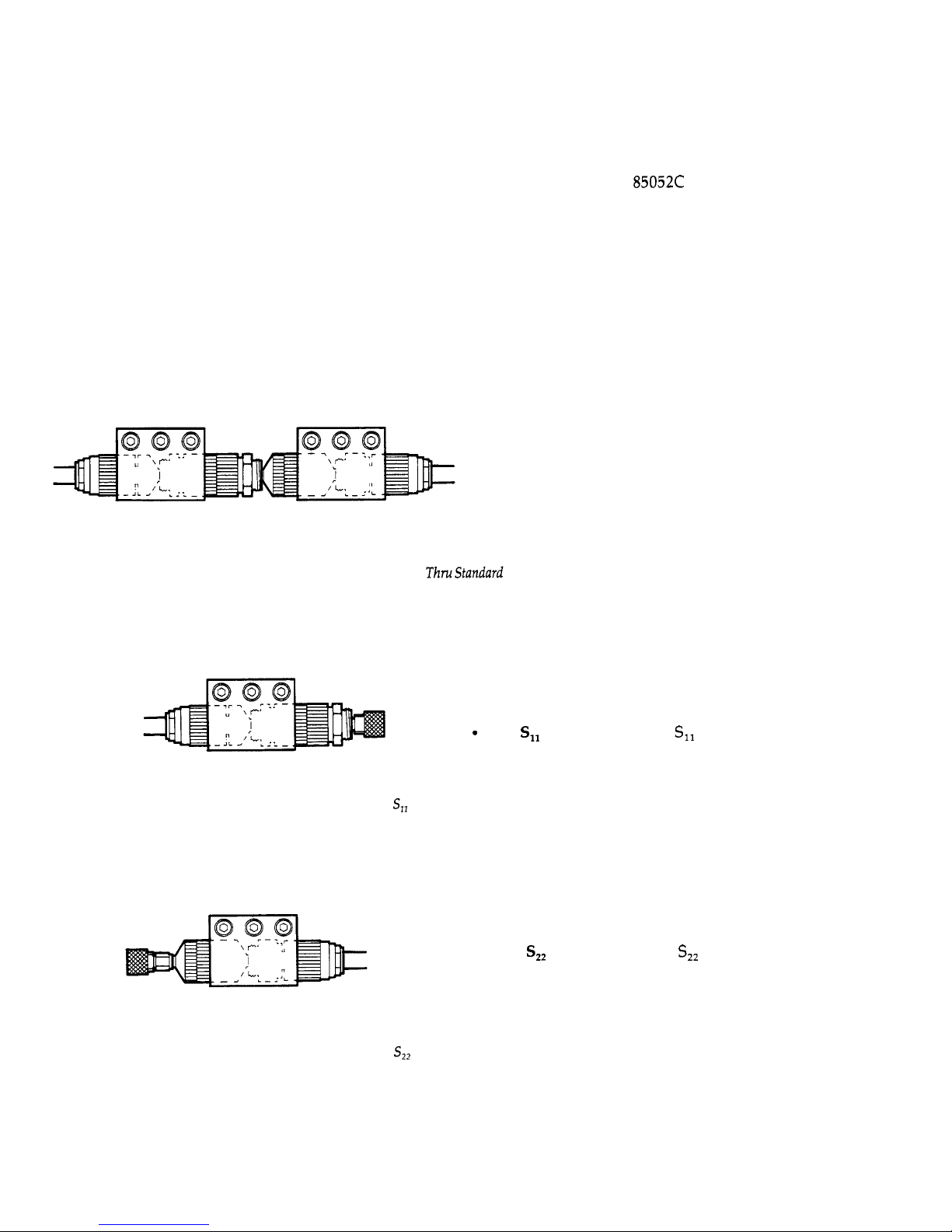

Measure Standards

N

ow

perform the TRL 2-Port measurement calibration

procedure using the HP

85052C

3.5 mm Precision

Calibration Kit.

Note:

The standards are measured in the order: Thru,

Reflect, Line, Isolation in order to connect the load

standards just once.

Press:

CAL

CAL 1

TRL 2-PORT

l

Connect the TRL male adapter (Port 1) to the TRL female

adapter (Port 2).

l

Press THRU. The HP 8510 makes six measurements; they

are S,,, S,,, S,,, S,,, and two specially redefined user

parameters.

l

Connect the Short circuit to Port 1.

.

Press

S,,

REFLECT SHORT.

S,,

is measured.

S,,

Reflect Short Standard

l

Connect the Short circuit to Port 2.

l

Press

S,,

REFLECT SHORT.

S,,

is measured.

l

Press LINES.

S,, Reflect Short Standard

18

Page 19

When Stop Frequency is Greater than 7

GHz

If the stop frequency is greater than 7 GHz, install the 7-32

GHz

air line as follows:

l

Move the Port 1 nut to its standard position and carefully

insert the air line into the male connector using the

installation tool.

Insert Air Line

l

Squeeze the installation tool (closing the slot) to release

the center conductor. Then pull the tool away from the

connector, leaving the outer and the center conductors in

place.

Sqeeze

Tool to Release, then Pull

GOOD

BAD

-IL-

GAP

l

Examine the outer and center conductors to see that they

are in place and concentric. If the center conductor is not

centered, use the installation tool to align it.

Check Concentricity

l

Move the adapter nut to its extended position.

Extended Position with Air Line Installed

19

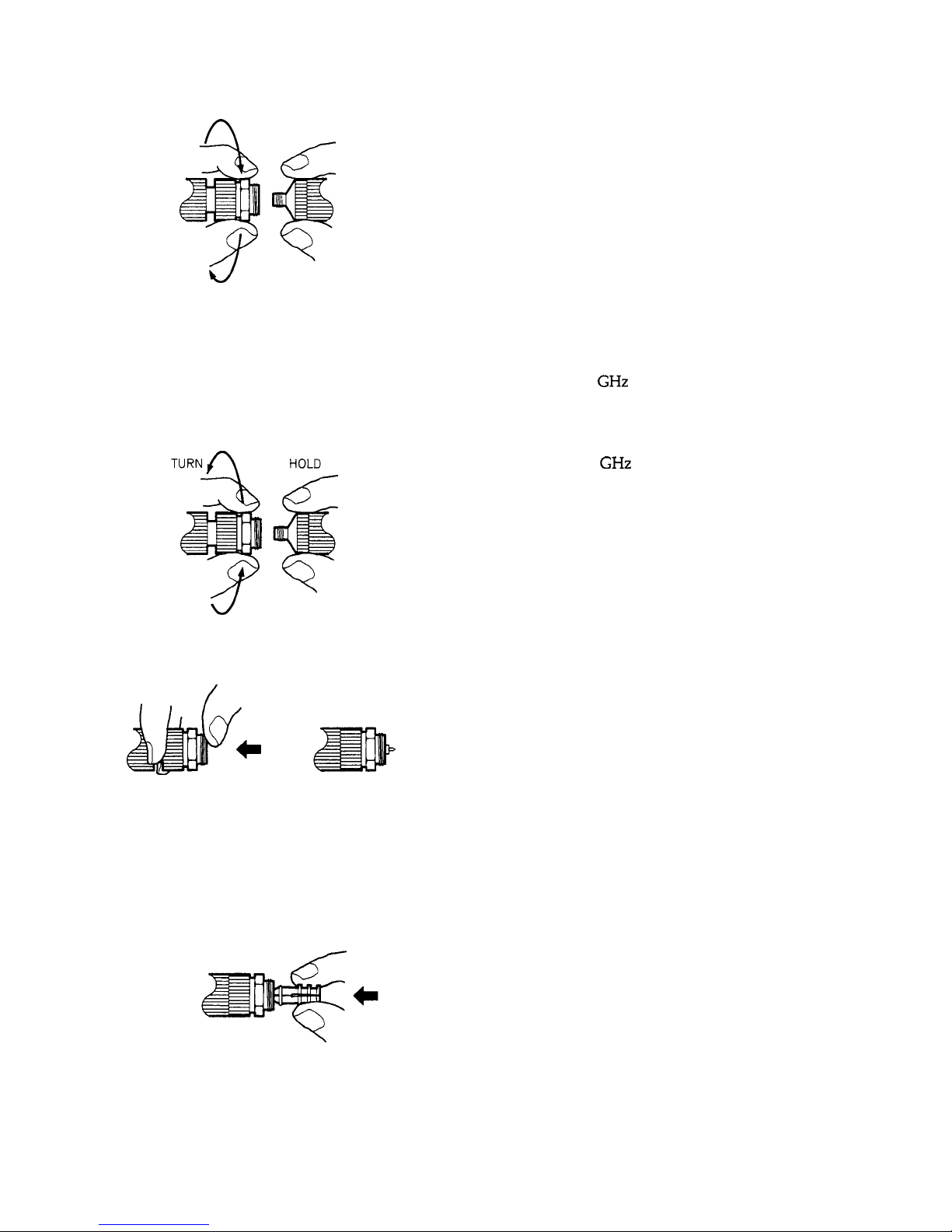

Page 20

TURN

n

HOLD

.

Carefully align and engage the Port 2 female contact

with the Port 1 male contact.

l

Tighten finger tight, then use the spanner and torque

wrenches to achieve the final torque.

Connect Port

2

l

Press 7-32 LINE. The HP 8510 makes six measurements.

All frequencies of the current range are measured, but only

data from 7 to 32

GHz

is used to compute error coefficients.

To remove the 7-32

GHz

air line:

l

Loosen the Port 1 nut, and then carefully move the Port 2

adapter away.

Disconnect Port 2

l

Move the adapter nut to its standard position.

Standard Position with Air Line Installed

l

Examine the outer and center conductors to see that they

are in place.

l

Carefully press the insertion tool onto the connector.

Connect the Insertion Tool

20

Page 21

Hold the tool close to the connector without squeezing

the tool. Carefully pull the assembly away from the

connector.

Remove the 7-32 Line

. Check to see that both the inner and the outer conductors

have been removed and are secure in the installation

tool.

If any part of the air line remains attached to the male port,

first press the tool back onto the connector. Then, try to

withdraw the tool and the air line parts again without

closing the slot.

If the air line center conductor remains with the female

port, use the installation tool to remove it as follows:

Squeeze the tool and push it to engage the center

conductor.

Hold the tool close to the connector, squeeze the tool

without closing the slot, and pull the assembly away.

Use your fingers to remove the center conductor from the

tool.

Remove Center

Conductorfrom

Port 2

(if

necessary)

l

Carefully insert the center conductor back into the

installation tool, male end first.

21

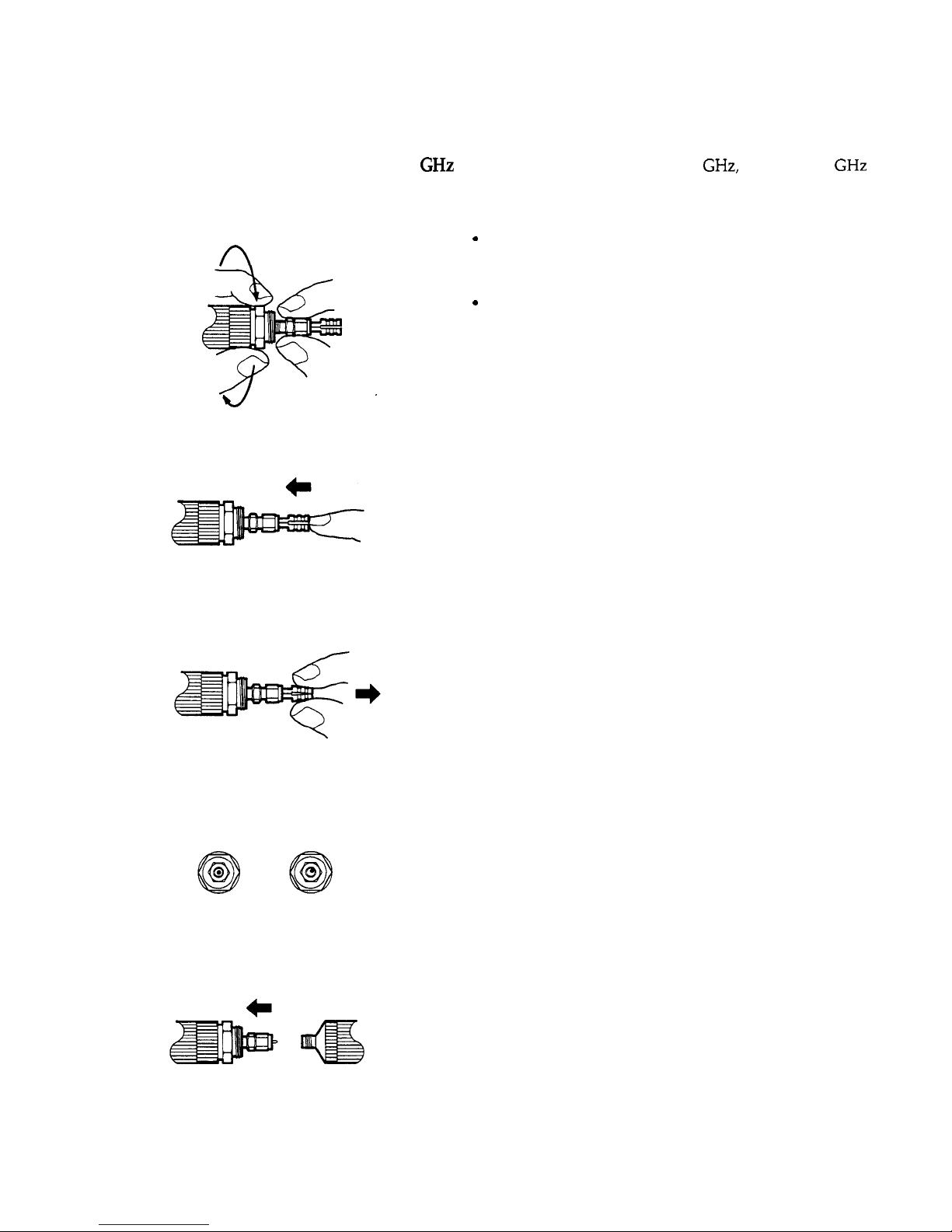

Page 22

When Start Frequency is Less Than 7

GHz

If the start frequency is less than 7 GHz, install the 2-7 GHz

air line as follows:

TURN

f\

HOLD

.

.

Move the Port 1 nut to its standard position. Carefully

insert the air line outer conductor and center pin into the

male connector using the installation tool.

Hold the air line outer conductor and tighten the Port 1

nut finger tight. Use the torque wrench to achieve the

final torque.

Connect the 2-7 Line

l

Press the tool lightly to engage the center conductor.

Engage the Center Conductor

l

Squeeze the tool to close the slot, then pull the tool away

from the connector, leaving the center conductor.

Remove the Tool

l

Examine the outer and center conductors to see that they

are in place and concentric. If the center conductor is not

centered, use the tip of the installation tool to align it.

GOOD BAD

Check the Concentricity

l

Move the air line nut back to expose the center

conductor. Carefully engage the Port 2 female contact

with the Port 1 male contact. Be patient making this

connection because it is easy to move the center

conductor off center.

Move the Nut Back

22

Page 23

l

Move the nut forward to engage the threads, tighten

finger tight, then use the spanner and the torque wrench

to achieve the final torque.

Connect Port 2

.

Press 2-7 LINE. The HP 8510 makes six measurements.

All frequencies of the current range are measured, but only

data from 1

GHz

to 7

GHz

is used to compute error

coefficients.

To remove the 2-7

GHz

air line:

l

Loosen the air line nut and carefully move Port 2 away

from Port 1.

Disconnect Port 2

Engage

the Tool

TURN

f\

HOLD

l

Insert the tool and lightly press it to engage the center

conductor.

l

Loosen the adapter nut and then disconnect the outer

conductor from the adapter. The center conductor will be

removed with the outer conductor.

Remove 2-7

Line

Note: It is important to be very careful to move Port 2 away

in a straight motion because the center conductor may stay in

Port 2. If the center conductor remains with the female port,

use the installation tool to remove it. Carefully insert the

center conductor back into the insertion tool, male end first.

Remove the Center Conductorfrom Port 2

(if

necessary)

23

Page 24

When Start Frequency is Less than 2

GHz

If the start frequency is less than 2 GHz, measure the O-2

Loads as follows:

-

,r .- -..- -

l

Connect a fixed load to Port 1 and a fixed load to Port 2.

’ ..

l

Press O-2 LOADS. The HP 8510 makes six measurements.

All frequencies are measured, but only data up to 2

GHz

are used. These measurements replace error coefficients

obtained from measurement of the 2-7

GHz

air line below

2

GHz.

Leave the loads connected for the Isolation step.

Connect the

O-2

Loads

l

Press LINES DONE.

l

Press ISOLATION.

If maximum transmission dynamic range is not required, skip

the isolation part of the calibration by pressing OMIT

ISOLATION and then ISOLATION DONE.

Or, to obtain maximum transmission dynamic range,

perform the isolation part of the calibration as follows:

.

Connect a fixed load to Port 1 and a fixed load to Port 2.

.

Increase the AVERAGING FACTOR for the isolation

measurement to at least 128. Then press FWD. ISOL’N

ISOL’N STD.

S,,

is measured.

.

.

.

Press REV. ISOL’N ISOL’N STD.

S,,

is measured.

Press ISOLATION DONE. You may wish to reduce the

averaging factor for measurement of the device under test.

Press SAVE TRL

2-PORT.

Fomard

and Reverse isolation Standards

When the computation of error coefficients is complete, press

CAL SET 1 (or any other cal set). Error coefficients derived

from measurement of the TRL standards are computed and

saved, and then 2-Port correction is turned on.

Carefully

inspect

the

connectors

on the device under test

and measure their center conductor pin depth before

connecting the device under test to the system.

Device-

under-test connectors with incorrect pin size, pin depth,

or pin alignment can damage the test port adapters.

24

Page 25

Check the Calibration

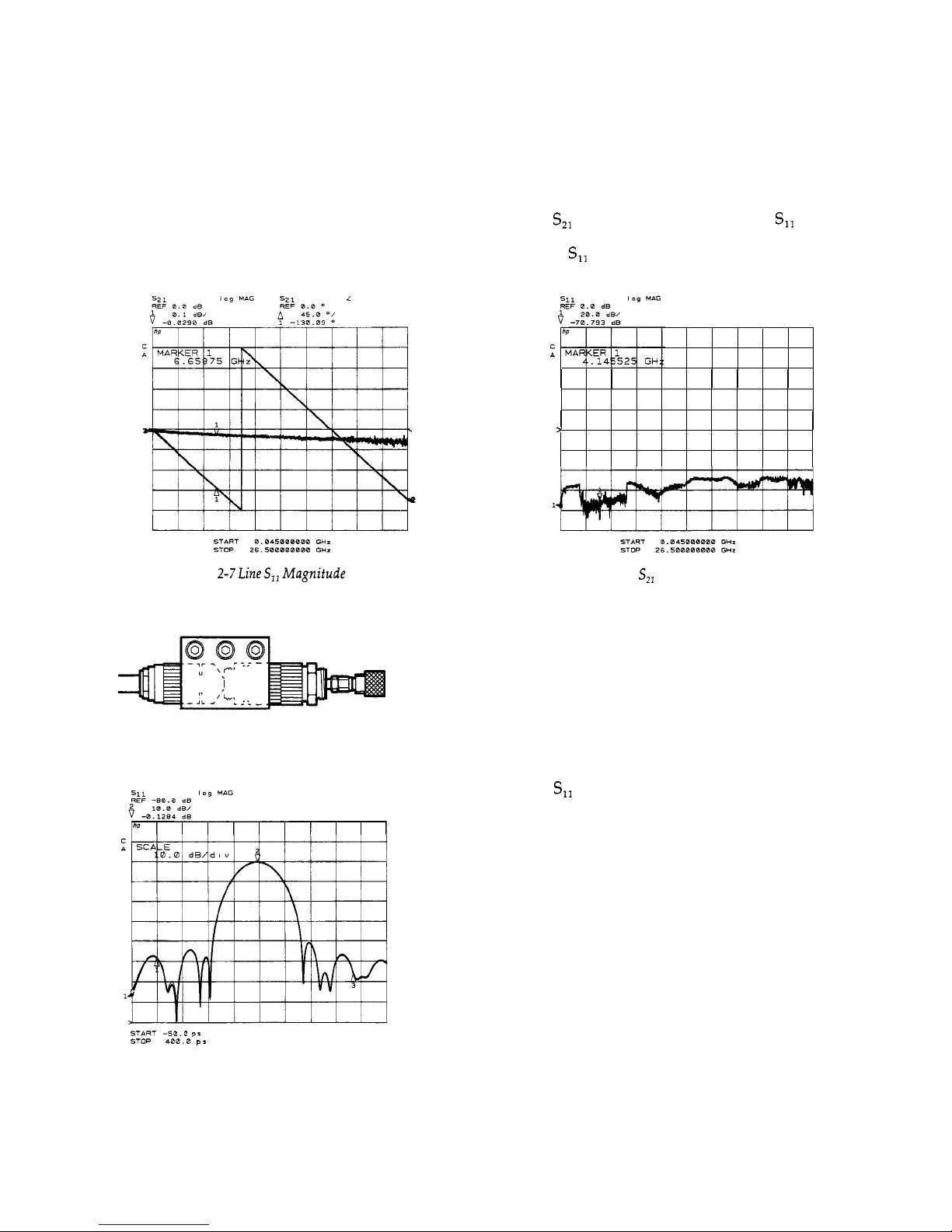

A good first check of the calibration is to measure the

transmission and reflection characteristics of the longer air

line. Connect the air line between Port 1 and Port 2 and

view the

Szl

magnitude and phase and the S,, magnitude.

The air line should exhibit low insertion loss and linear

phase. The S,, should be constant over the entire

frequency range.

2-7 Line with Short Circuit

>

2-7 Line

S,,

Magnitude and Phase

For a second check, connect the 2-7 Line to Port 1, then

connect the Short circuit to the end of the air line, and view

the reflection response.

Select:

S

D

OMAIN

TIME BAND PASS

View the

S,,

response. Use the marker to measure the

responses at 0 seconds (a rough measure of effective

directivity) and the mismatch at twice the length of the air

line (a rough measure of effective source match). The trace

should appear as shown below. If not, the calibration has

not been performed correctly or the calibration devices are

defective.

START -50.0

PI

*TOP

400.0

PI

Plot of Time Band Pass with Shorted Air Line

25

Page 26

CHAPTER

T H R E E

Noninsertable Devices

Noninsertable Device Configurations

General Theory

Th

e o owing sequence describes the adapter removal

f 11

method of calibration for measurement of a noninsertable

device. This procedure is the most complete and effective

calibration procedure for measurement of noninsertable

devices. Although this technique does require two separate

2-Port calibrations, it remains the only traceable method

for minimizing the uncertainty in this measurement. The

three precision adapters in this calibration kit provide the

parts required to make the process relatively easy.

Detailed information about the adapter removal

calibration is contained in HP Product Note 8510-13,

available from your local HP Sales Office.

The previous calibration sequence assumed that the device

under test is insertable; it has a male connector on one port

and a female connector on the other port. Thus, the

measurement system can be calibrated and then the test

device inserted without changing the system test port

connectors.

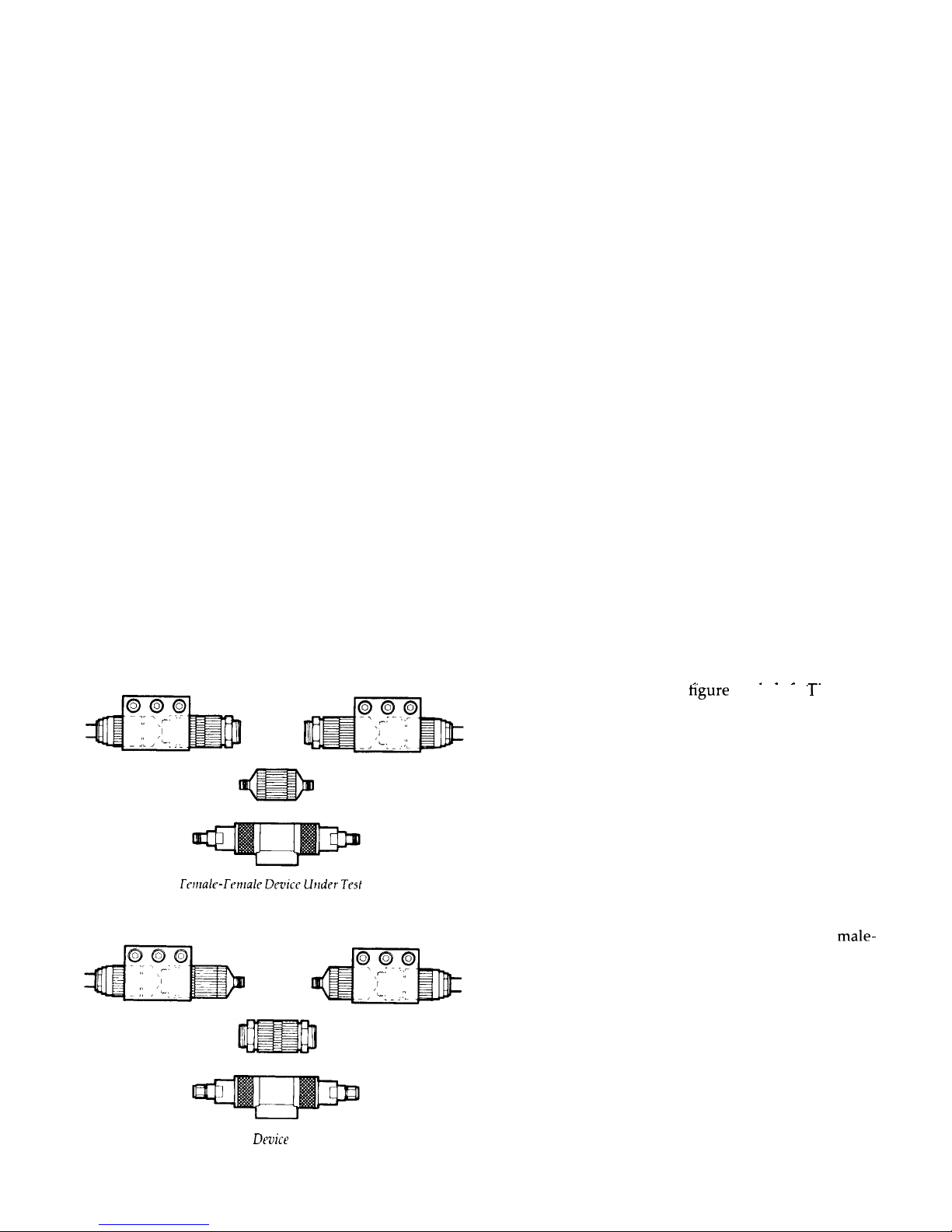

However, the majority of devices used in microwave

systems are noninsertable. Of interest here are devices

having either both male or both female 3.5 mm connectors

on Port 1 and Port 2.

Female to Female

If the device you are measuring has two female connectors,

_.

. . _ -.

your setup would look like the

hgure

on the left. ‘1 he

female-to-female precision adapter is substituted for the

device under test to accomplish this calibration.

Male to Male

If the device you are measuring has two male connectors,

your setup would look like the figure on the left. The

male-

to-male precision adapter is substituted for the device

under test to accomplish this calibration.

Male-Male Dmice Under Test

Page 27

Adapter Removal

Calibration Procedure

Create Cal Set for Port

1

Port

2

Cal

Srt

Create Cal Set for Port 2

Port

2 Cal

Set

Adapter Removal Mathematics

Renmr the

Adapter and

Cormect

the

DUT

First create the Port 1 calibration set by performing the TRL

2-Port calibration between Port 1 and the adapter. Keep

the adapter connected to Port 2 during the entire

procedure. Save the calibration in Cal Set

1.

Next create the Port 2 calibration set by performing the

TRL 2-Port calibration between Port 2 and the adapter.

Keep the adapter connected to Port 1 during the entire

procedure. Save the calibration in Cal Set 2.

The Adapter Removal function mathematically combines

the Port 1 cal set with the Port 2 cal set to produce a third

cal set having the effects of the adapter removed. The

resulting cal set is as if Port 1 and Port 2 could be connected

together.

When the two calibrations have been saved, proceed with

the adapter removal sequence as follows:

Press:

CAL

MORE

MODIFY CAL SET

ADAPTER REMOVAL

Press

CAL SET for PORT 1,

then

CAL SET 1.

Press

CAL SET for PORT 2,

then

CAL SET 2.

Press

ADAPTER 3.5 mm C.l.

This specifies the

calibration kit that includes the length specification for the

precision adapter.

Press

MODIFY & SAVE,

then

CAL SET 3.

The new calibration set is computed and stored. 2-Port

correction is turned on.

Now remove the third adapter and connect the device under

test.

The display should now show an accurate S-parameter

measurement of the device.

27

Page 28

28

C

H

A

P

T

E R

Other Calibrations

F

0

U

R

Changing the Air Line

of

your application requires a frequency range slightly

Frequency Range

beyond the standard frequency range of one of the

precision air lines, you may extend the frequency range of

one of the air lines in order to accomplish the calibration by

connecting only one of the air lines.

The error coefficients are determined with best accuracy

when the Thru and the Line phase response is separated by

t

90 degrees at corresponding frequencies. When the

transmission phase response of a line standard is the same

or gets very close to zero or 180 degrees of the Thru

standard at the same frequency, the result becomes less

certain. The correct result cannot be determined when the

phase response is exactly equal or 180 degrees apart. This

is why a particular length air line covers a specific

frequency range.

To evaluate the phase response, first do a simple transmission frequency response calibration using the Thru

standard (Port 1 connected directly to Port

2),

then

measure the S,, phase of the air line. The standard air line

frequency specifications provide for greater than 20

degrees separation.

Experiment with this by using the Modify Cal Kit function

to change the Minimum Frequency or Maximum

Frequency specification for the air line, and then

performing the TRL 2-Port calibration procedure. With

correction on, trace noise on the error-corrected trace may

increase at the points where the phase of the air line used

for calibration approaches the phase of the thru, often

showing large discontinuities at the point where the phase

of both standards is identical or separated by 180 degrees.

If this error is acceptable in your measurement, change the

standard label for the air line and save the redefined cal kit

on tape for later use. If the error is not acceptable, reload

the standard cal kit definition.

Lowband

Reflection instead Of

The

Lowband

Reflection part of the

TRL

2-Port

procedure

O-2 Loads or 2-7 Line

is optional. If used, error coefficients obtained by this

procedure replaces measurements of the O-2 loads.

For this calibration kit, the

lowband

reflection part of the

calibration is typically not used because measurement of

the O-2 Loads provides better accuracy (given that the

loads are in good condition and repeatable).

If you do not select

LOWBAND

REFLECTION, the error

coefficients obtained from measurement of the TRL

standards are used over the complete current frequency

range. If you do select

LOWBAND

REFLECTION, error

coefficients obtained from these additional calibration steps

will be used up to 2 GHz.

In actual measurement applications, the

Lowband

Reflection

option will not produce greater accuracy than using the O-2

Loads. If you are uncertain, it is relatively simple to compare

measurement results using the different techniques.

Page 29

Lowband

Reflection Procedure

Selecting the Lowband Reflection part of the procedure

guides you through these additional steps to measure an

open circuit, short circuit, and fixed load at Port 1 and an

open circuit, short circuit, and fixed load at Port 2. So, if the

start frequency is less than 2

GHz

and you wish to use the

open/short/load technique for calibration below 2

GHz,

then after measuring the Thru, Reflect, Isolation and

Line

standards and before pressing SAVE TRL 2-PORT, perform

the following lowband reflection sequence.

Measure Thru, Reflect, Isolation, and Line standards. If the

start frequency is less

than 2

GHz,

press

LOWBAND

REFLECTION.

l

Press LOWBAND REFLECT’N

l

Connect the Short circuit to Port 1 and then press

(S,,):

SHORT.

. Connect the Open circuit to Port 1 and then press

(S,,):

OPEN.

l

Connect the Fixed Load to Port 1 and then press

(S,,):

LOAD.

l

Connect the Short circuit to Port 2 and then press

(S,,):

SHORT.

l

Connect the Open circuit to Port 2 and then press

(S,,):

OPEN.

.

Connect the fixed load to Port 2 and then press

(S,,):

LOAD.

l

Press REFLECT’N DONE.

l

Press SAVE TRL

2-PORT,

and then

CAL SET 1,

(or any

other cal set).

When SAVE is pressed, error coefficients from measurement

of the Open, Short, and Load are used for frequencies below 2

GHz;

and coefficients from measurement of the Thru, Reflect

and Line are used for frequencies above 2

GHz.

29

Page 30

u!!

HEWLETT

PACKARD

Customer Order Number

85052-90059

Printed in USA April 1995

Loading...

Loading...