Page 1

Installing the Flame Ionization Detector

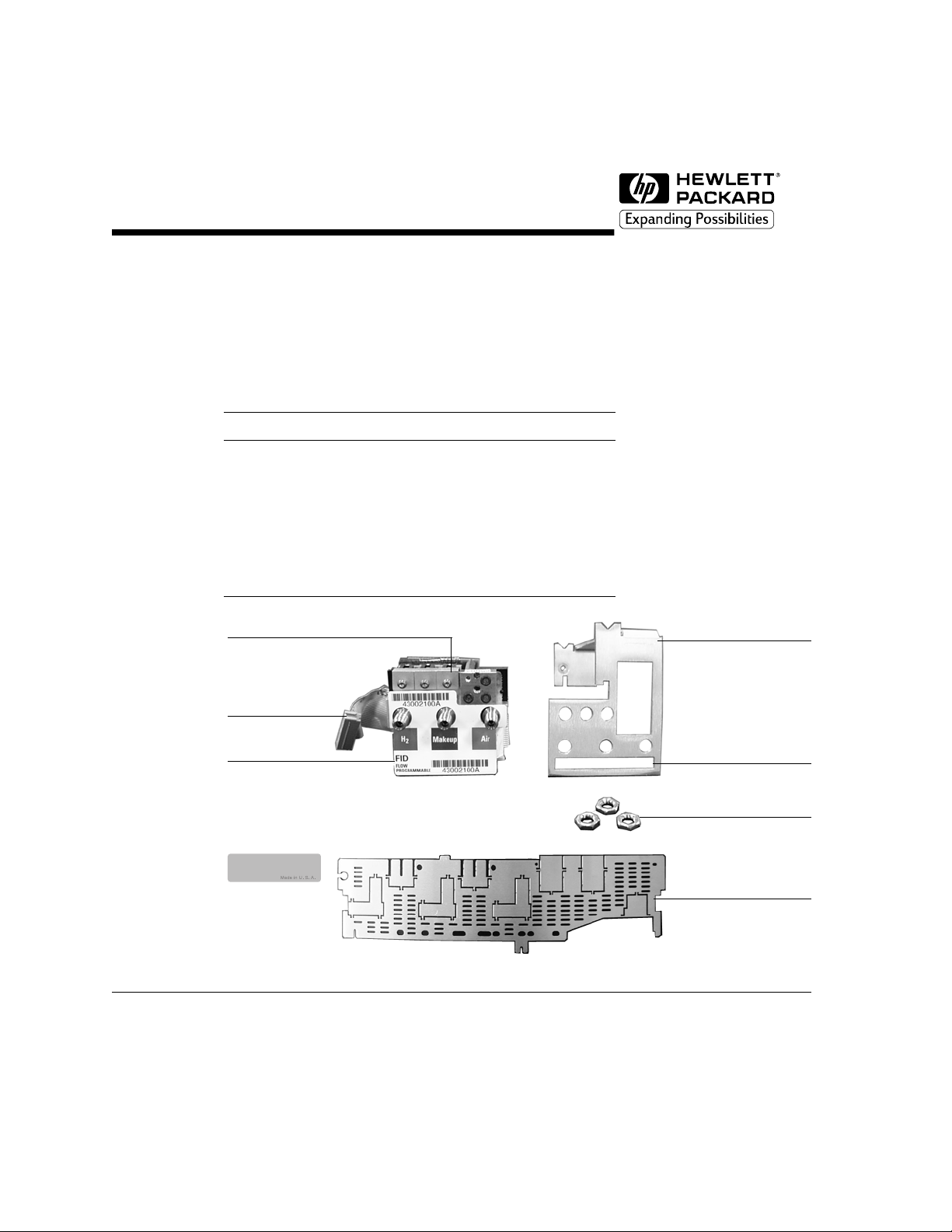

EPC Flow Control Manifold

The FID EPC Flow Control Manifold kit can be used to replace any HP 6890

Series FID EPC flow control manifold.

This kit contains:

Kit G1531-60720 Qty.

FID EPC flow control manifold 1

Mounting bracket, HP 6890 1

Top rear panel 1

Installation sheet (this document) 1

Blank label 1

Hex nut, 7/16 inch 3

Copyright© 1998

Hewlett-Packard Company

Printed in USA 9/98

HP Part No. G1531-90320

Gang fitting

installs here

Ribbon cable

ID tag

FID EPC flow control manifold

Blank label

HP 6890 mounting bracket

Figure 1 FID EPC flow control manifold replacement kit

Slot for label tag

7/16 inch hex nuts

Top rear panel

1

Page 2

Tools required

7/16 inch open-ended wrench

T-20 Torx driver

Needle-nosed pliers

Safety information

Before continuing, read the safety information in your GC Operating Manual.

Removing the existing manifold

WA R NI N G Hydrogen gas is flammable and potentially explosive. Before replacing the

manifold, turn off the hydrogen gas at the source.

WA R NI N G Before proceeding, turn off the oven and any heated zones and let them cool

down. Turn off all detector gases at their supply, then turn off the main power

switch and unplug the power cord.

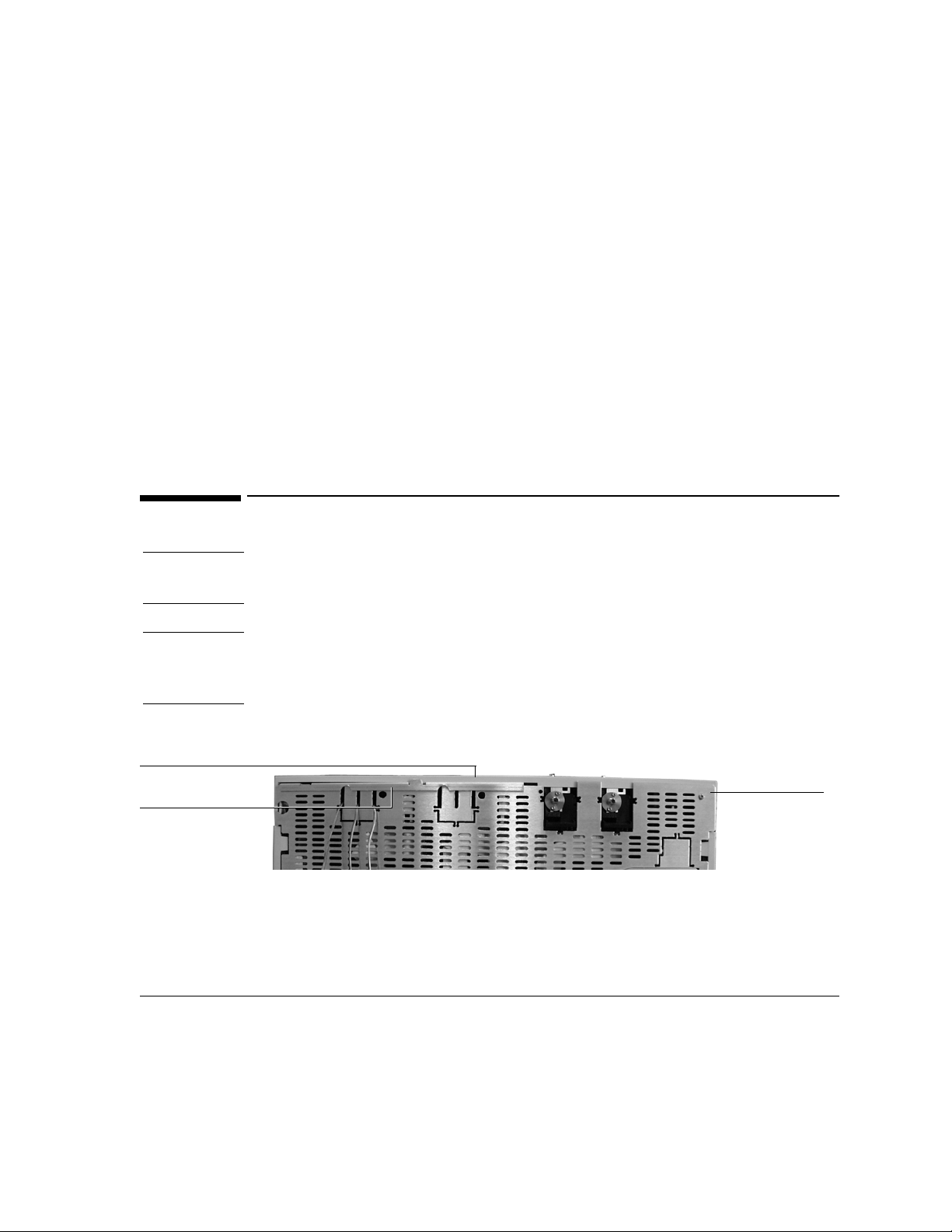

1. Remove the pneumatics cover and the RFI shield under it. See Figure 2.

Pneumatics cover

RFI shield

Figure 2 Back view of HP 6890

2

Top rear panel

Page 3

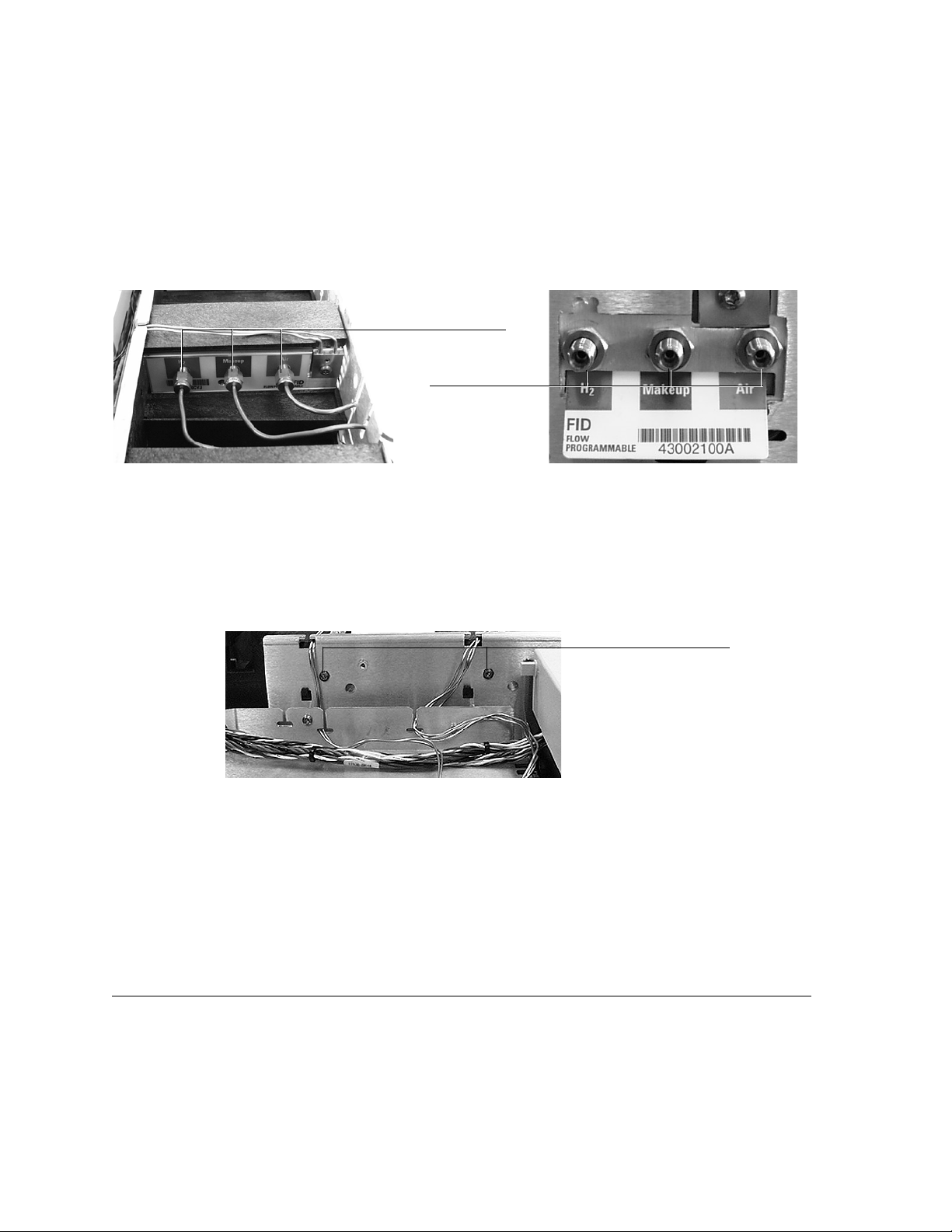

2. Remove the gas supply tubing from the present manifold. See Figure 3.

Disconnect gas lines

OR

Disconnect gas lines

Manifold, installed before May 1998

Figure 3 Remove the gas connections

3. Remove the detector cover and the top rear panel.

4. Remove the Torx T-20 mounting screw from the front of the manifold. See

Figure 4.

Figure 4 Removing the detector flow manifold

5. Disengage the detector tubing from the slots in the chassis so that the gang

fitting on the manifold can be removed easily. See Figure 4.

Manifold, installed after May 1998

Torx T-20 screws

holding detector manifolds

3

Page 4

Caution Make sure you are properly grounded with an ESD strap before continuing.

6. Unlock the detector manifold’s ribbon cable from the pneumatics control

board and detach the connector. The adjacent ribbon cable may have to be

removed as well.

7. If you are removing a manifold that was installed before May 1998, slide it

a few centimeters out of its slot in the pneumatics carrier. See Figure 5.

8. Remove the one Torx T-20 screw holding the gang fitting on the manifold.

See Figure 5.

Caution Do not lose the O-rings under the gang fitting.

Remove screw

and gang fitting

OR

Manifold, installed before May 1998 Manifold, installed after May 1998

Figure 5 Removing the gang fitting

4

Page 5

Installing the new manifold

Caution Always hold the manifold by its support bracket to avoid damaging board

components.

1. Slip the ID tag on the new manifold through the slot in the mounting bracket,

then align the bracket holes over the gas fittings. Secure the bracket with

three 7/16 inch hex nuts. See Figure 6.

Mounting bracket

Gang fitting

installs here

7/16 inch hex nuts

ID tag

through slot in bracket

Ribbon cable

Figure 6 Bracket mounted onto the manifold

2. Peel the blank label from its backing and paste it on the mounting bracket

over the screw heads. See Figure 7.

3. If the tubing from the gang fitting bends to the left, reshape it so that it bends

up and back from the block as shown in Figure 8.

5

Page 6

4. Insert the gang fitting through the cutout in the manifold bracket and install

it onto the new manifold assembly so that the tubing runs back and away

from the fitting.

• Be sure the left tube clears the inner edge of the bracket. See Figure 8.

• Be sure that the O-rings are in place.

Tighten the gang fitting screw firmly to compress the O-rings.

5. Route the ribbon cable behind the manifold assembly as shown in Figure 7.

Then, slide the manifold and bracket assembly into the slot until the bracket

seats flush against the end of the rails. See Figure 8.

Back view of manifold Manifold installed with cable routed to left

Figure 7 Routing the ribbon cable

6

Page 7

Route tubing along

this path

Check for interference

Bracket is flush with

carrier rails

Attach gang fitting

Figure 8 Manifold, after installation

6. Route the gas tubing behind the manifold, over the top of the chassis, and

through the slots as shown in Figure 4 and Figure 8.

7. Connect the ribbon cable to the mating connector on the pneumatics board.

Arrange the cable to keep it away from the valves and keep it from being

pinched against the manifold.

For the back detector, you may want to loosen the manifold and slide it out

of the carrier a few centimeters to connect the cable to the pneumatics

board. Then, reinstall the manifold.

8. Secure the manifold in place using the Torx T-20 screw. See Figure 4.

9. Using a pair of needle-nosed pliers, remove the appropriate top rear panel

detector cutout for the FID. Also remove any cutouts needed to access other

manifolds or accessories installed in the GC. See Figure 9.

7

Page 8

Insert tip of

pliers here

Back inlet

Front detector

Auxiliary

Left most screw slot

Back detector

Front inlet

Figure 9 Top rear panel cutouts

10. Place the new top rear panel on its left-most mounting screw. Use the screw

as a hinge and angle the panel while sliding each manifold ID tag through

its cutout in the panel, working from left to right. When all the tags are

through the panel, finish installing the panel on the GC.

11. Install the RFI shield, the pneumatics cover, and the detector top cover.

12. Connect the source gas lines to the manifold. See Figure 10.

Copyright© 1998

Hewlett-Packard Company

Printed in USA 9/98

HP Part No. G1531-90320

Figure 10 Gas line connections

13. Restore gas pressures and check all fittings for leaks.

8

Loading...

Loading...