Page 1

3

P

!

OPERATING

AND

SERVICE

MANUAL

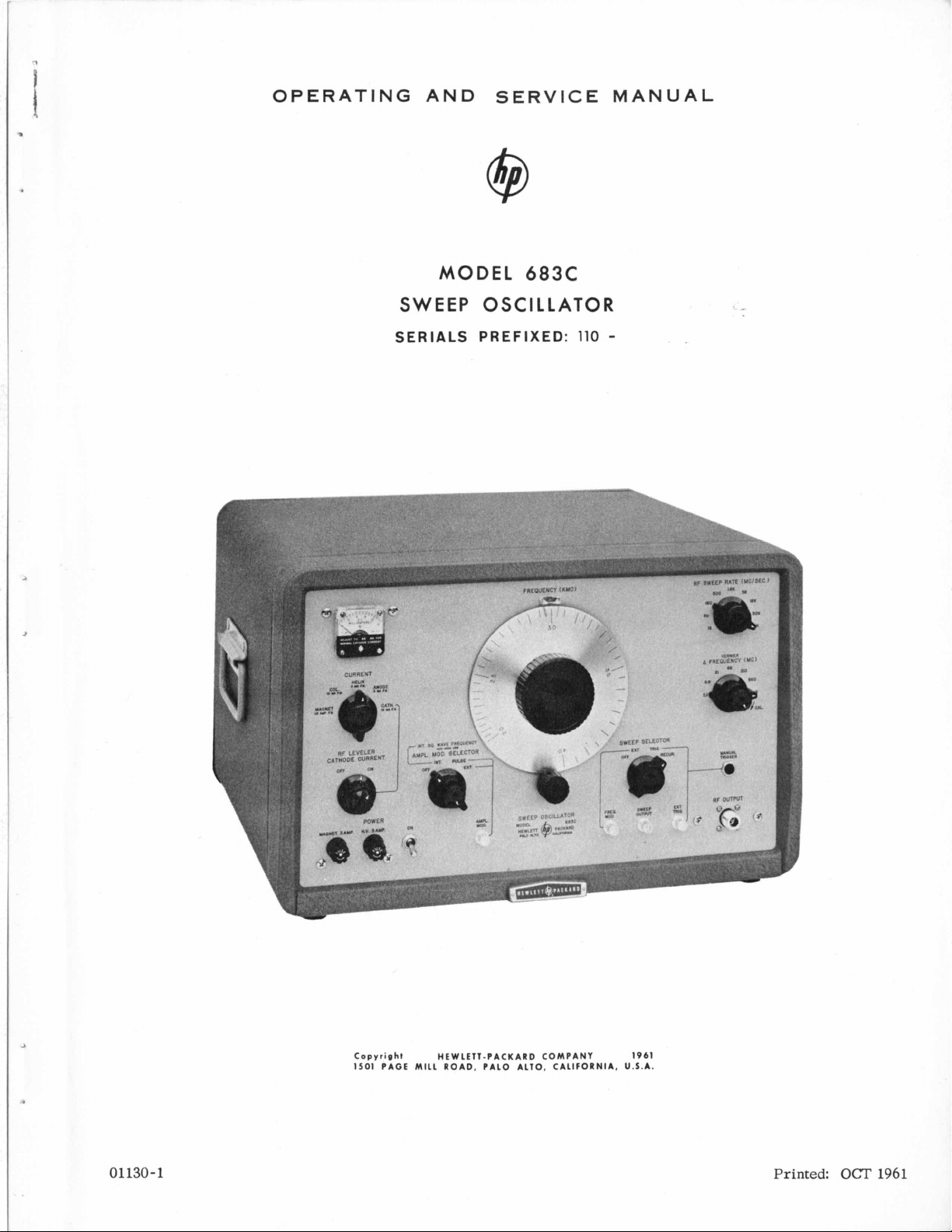

MODEL

6a3c

SWEEP OSCILLATOR

SERIALS PREFIXED:

J

110

-

01130-1

Copyright HEWLETT-PACKARD COMPANY

1501

PAGE

MILL

ROAD, PAL0

ALTO,

CALIFORNIA, U.S.A.

1961

Printed:

Om

1961

Page 2

Model 683C Specifications’

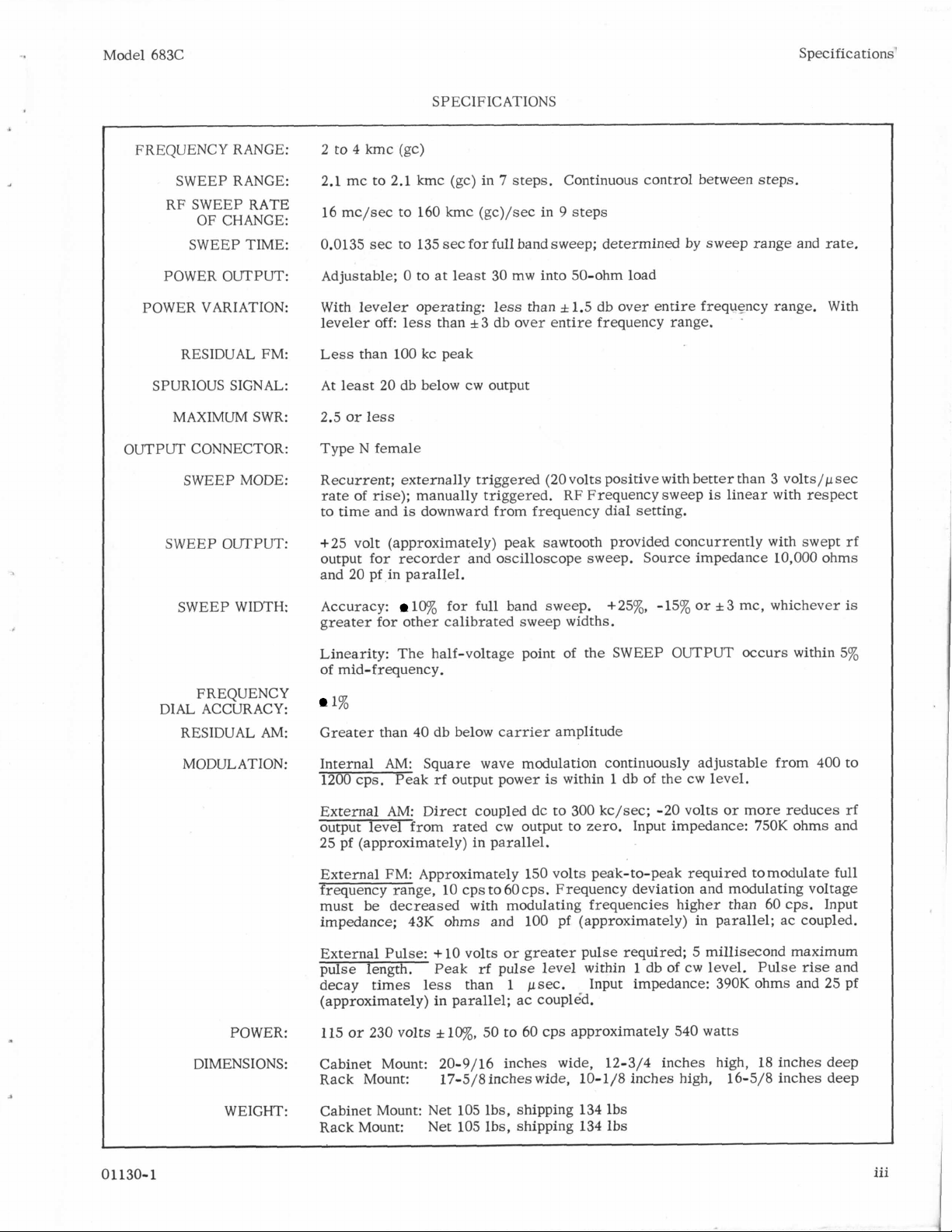

SPECIFICATIONS

FREQUENCY RANGE:

SWEEP RANGE:

RF SWEEP RATE

OF CHANGE:

SWEEP TIME:

POWER OUTPUT:

POWER

SPURIOUS SIGNAL:

OUTPUT CONNECTOR:

VARIATION:

RESIDUAL FM:

MAXIMUM SWR:

SWEEP MODE:

SWEEP OUTPUT:

2 to 4 kmc (gc)

2.1 mc to 2.1 kmc (gc) in

16 mc/sec to 160 kmc (gc)/sec in 9 steps

0.0135

Adjustable;

With leveler operating:

leveler

Less than 100

At least 20 db below

2.5 or

Type N female

Recurrent; externally triggered (20 volts positive with better than 3 volts/psec

rate

to time and

+25 volt (approximately) peak sawtooth provided concurrently with swept

output for recorder and oscilloscope sweep. Source impedance 10,000 ohms

and 20 pf in parallel.

sec

to 135

sec

0

to

at least 30 mw into 50-ohm load

off:

less

than & 3 db over entire frequency range.

kc

peak

less

of

rise); manually triggered. RF Frequency sweep

is

downward from frequency dial setting.

7

steps. Continuous control between steps.

for full band sweep; determined by sweep range and rate.

less

cw

than f 1.5 db over

output

entire

frequency range.

is

.

linear with respect

With

rf

SWEEP WIDTH:

FREQUENCY

DIAL ACCURACY:

RESIDUAL AM:

MODULATION:

POWER:

Accuracy:

greater for other calibrated sweep widths.

Linearity: The half-voltage point of the SWEEP OUTPUT occurs within

of mid-frequency.

1%

Greater than 40 db below carrier amplitude

Internal

1200 cps. Peak

External AM: Direct coupled dc to 300 kc/sec; -20 volts or more reduces

output

25 pf (approximately) in parallel.

External FM: Approximately 150 volts peak-to-peak required to modulate full

frequency range, 10 cps to 60 cps, Frequency deviation and modulating voltage

be decreased with modulating frequencies higher than 60 cps. Input

must

impedance; 43K ohms and 100 pf (approximately) in parallel; ac coupled.

External Pulse:

pulse length.

decay times

(approximately) in parallel; ac coupl6d.

115 or 230 volts

AM:

level

10%

for full band sweep.

Square wave modulation continuously adjustable from 400 to

rf

output power

from rated

+

10 volts or greater pulse required: 5 millisecond maximum

Peak

less

f

lvo,

cw

rf

than 1 psec. Input impedance: 390K ohms and 25 pf

50

is

output to zero. Input impedance: 750K ohms and

pulse level within 1 db of

to 60 cps approximately 540 watts

+25%, -15% or

within 1 db of the

&

3

mc, whichever

cw

level.

cw

level. Pulse

rise

is

5%

rf

and

0

1130-

1

DIMENSIONS:

WEIGHT:

Cabinet Mount: 20-9/16 inches wide, 12-3/4 inches high, 18 inches deep

Rack Mount: 17-5/8inches wide,

Cabinet Mount: Net 105 lbs, shipping 134 lbs

Rack Mount:

Net

105 lbs, shipping 134 lbs

10-1/8

inches high, 16-5/8 inches deep

iii

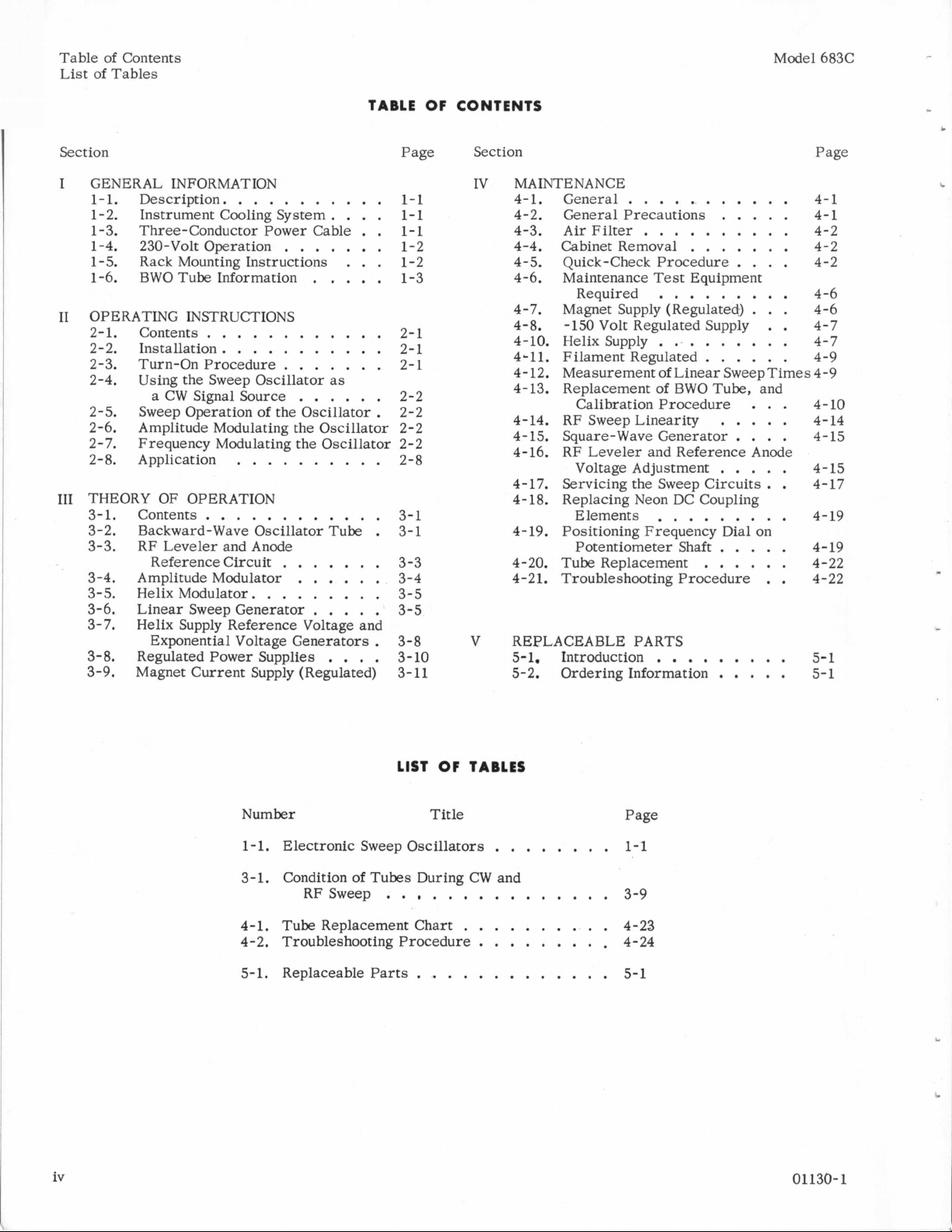

Page 3

Table of Contents

List of Tables

Model 683C

TABLE

Section Page

I

GENERAL INFORMATION

1.1

.

Description

1.2

.

Instrument Cooling System.

1.3

.

Three-Conductor Power Cable

1.4

.

1.5

1.6

I1

OPERATING INSTRUCTIONS

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

111

THEORY OF OPERATION

3-

3.2

3.3

3.4

3.5

3.6

3.7 . Helix Supply Reference Voltage and

3.8

3.9

230-Volt

.

Rack Mounting Instructions

.

BWOTube Information

.

Contents

.

Installation

.

Turn-On Procedure

Using the Sweep Oscillator

.

a CW Signal Source

.

Sweep Operation of the Oscillator

.

Amplitude Modulating the Oscillator

Frequency Modulating the Oscillator

.

.

Application

1

.

Contents

.

Backward-Wave Oscillator Tube

.

RF Leveler and Anode

Reference Circuit

.

Amplitude Modulator

.

Helix Modulator

.

Linear Sweep Generator

Exponential Voltage Generators

.

Regulated Power Supplies

.

Magnet Current Supply (Regulated)

...........

...

. .

Operation

.......

...

.....

............

...........

.......

as

......

.

..........

............

.

.......

......

.........

.....

.

....

1-1

1-1

1-1

1-2

1-2

1-3

2-

1

2-1

2-

1

2-2

2-2

2-2

2-2

2-8

3-

1

3-1

3-3

3-4

3-5

3-5

3-8

3-10

3-11

OF

CONTENTS

Section

IV

MAINTENANCE

4.1

.

General

4.2

.

General Precautions

4.3

4.4

4.5

4.6

4.7

4.8

4.10

4.11

4.12

4.13

4.14

4.15

4.16

4.17

4.18

4.19

4.20

4.21

V REPLACEABLE PARTS

5.1

5.2

Air Filter

.

.

Cabinet Removal

Quick-Check Procedure

.

.

Maintenance

Required

.

Magnet Supply (Regulated)

-150

.

.

Helix Supply

Filament Regulated

.

Measurement of Linear SweepTimes 4-9

.

Replacement

.

Calibration Procedure

RF Sweep Linearity

.

.

Square-Wave Generator

RF

.

Voltage Adjustment

.

Servicing the Sweep Circuits

Replacing Neon DC Coupling

.

Elements

Positioning Frequency Dial on

.

Potentiometer Shaft

.

Tube Replacement

.

Troubleshooting Procedure

.

Introduction

.

Ordering Information

...........

.....

..........

.......

....

Test

Equipment

.........

...

Volt Regulated Supply

.

..........

......

of

BWO Tube. and

...

.....

....

Leveler and Reference Anode

.....

. .

.........

.....

......

.

.........

.....

.

.

Page

c

4-1

4-1

4-2

4-2

4-2

4-6

4-6

4-7

4-7

4-9

4-10

4-14

4-15

4-15

4-17

4-19

4-19

4-22

4-22

5-1

5-1

iv

Number

1.1

.

Electronic Sweep Oscillators

3.1

.

Condition of

RF Sweep

4

.

1

.

Tube Replacement

4.2

.

Troubleshooting Procedure

5.1

.

Replaceable

Tubes

..

Parts

LIST

OF

TABLES

Title

........

During CW and

............

Chart

..........

.........

.............

Page

1-1

3-9

4 . 23

4-24

5-1

01130-1

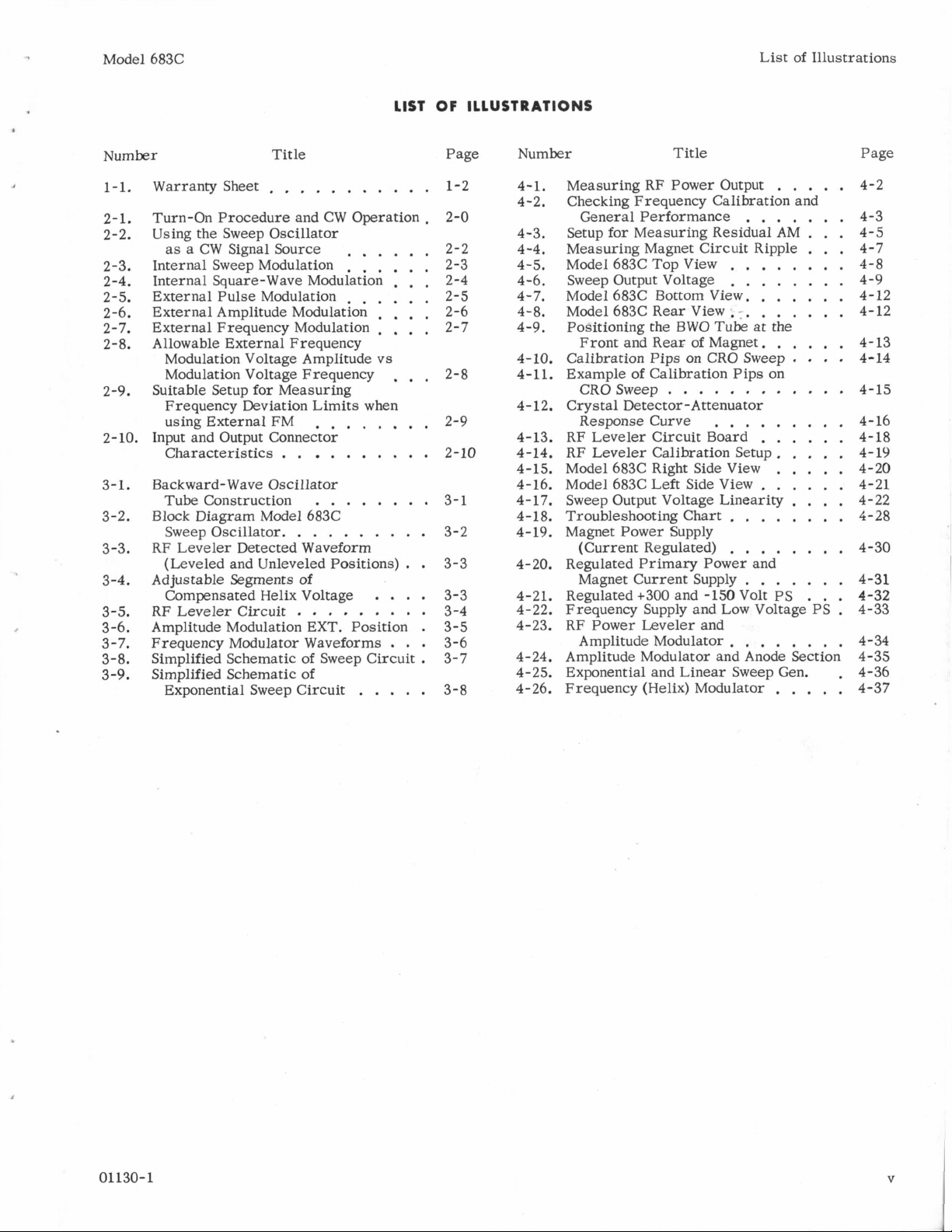

Page 4

Model 683C

LIST

OF

ILLUSTRATIONS

List of Illustrations

Number Title Page

1.1

.

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

2.10

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

Warranty Sheet

Turn-On Procedure and CW Operation

.

Using the Sweep Oscillator

.

as

a

Internal Sweep Modulation

.

Internal Square-Wave Modulation

.

External Pulse Modulation

.

External Amplitude Modulation

.

External Frequency Modulation

.

Allowable External Frequency

.

Suitable Setup for Measuring

.

Input and Output Connector

.

Backward- Wave Oscillator

.

Block Diagram Model 683C

.

RF

.

Adjustable Segments of

.

RF Leveler Circuit

.

Amplitude Modulation EXT

.

Frequency Modulator Waveforms

.

Simplified Schematic

.

Simplified Schematic of

.

CW Signal Source

Modulation Voltage Amplitude vs

Modulation Voltage Frequency

Frequency Deviation Limits when

using External FM

Characteristics

Tube Construction

Sweep Oscillator

Leveler Detected Waveform

(Leveled and Unleveled Positions)

Compensated Helix Voltage

Exponential Sweepcircuit

...........

.

.

.

.

.

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

3-1

3-2

3-3

3-3

3-4

3-5

3-6

3-7

3-8

......

......

...

......

....

....

...

........

..........

........

..........

....

.........

.

Position

...

of

Sweep Circuit

.....

1-2

2-0

Number

.

4.1

4.2

.

4.3

.

4.4

.

4.5

.

4.6

.

4.7

.

4.8

.

4.9

.

4.10

.

4.11

.

4.12

.

4.13

.

4.14

.

4.15

.

4.16

.

4.17

.

4.18

.

4.19

.

4.20

.

4.21

.

4.22

.

4.23

.

4.24

.

4.25

.

4.26

.

Title

Measuring RF Power Output

Checking Frequency Calibration and

General Performance

Setup for Measuring Residual AM

Measuring Magnet Circuit Ripple

Model 683C Top View

Sweep Output Voltage

Model 683C Bottom View

Model 683C Rear View

Positioning the BWO Tube at the

Front and Rear of Magnet

Calibration Pips on CRO Sweep

Example of Calibration Pips on

CRO Sweep

Crystal Detector-Attenuator

Response Curve

RF

Leveler Circuit Board

RF Leveler Calibration Setup

Model 683C Right Side View

Model 683C

Sweep Output Voltage Linearity

Troubleshooting Chart

Magnet Power Supply

(Current Regulated)

Regulated Primary Power and

Magnet Current Supply

Regulated +300 and -150 Volt PS

Frequency Supply and Low Voltage PS

RF Power Leveler and

Amplitude Modulator

Amplitude Modulator and Anode Section

Exponential and Linear Sweep Gen

Frequency (Helix) Modulator

............

Left

........

........

.........

.........

Side View

........

........

........

.....

.......

...

...

.......

......

....

......

.....

.....

......

....

.......

...

. .

.....

.

Page

4-2

4-3

4-5

4-7

4-8

4-9

4-12

4-12

4-13

4-14

4-15

4-16

4-18

4-19

4-20

4-21

4-22

4-28

4-30

4-31

4-32

4-33

4-34

4-35

4-36

4-37

01130-1

V

Page 5

MODEL 683C

ELECTRONIC SWEEP OSCILLATOR

Model 683C

*

This manual specifically describes Model 683C of the

683C sweep oscillators. If, however, the serial number of your instrument

TllO

series, and

in

general describes all

is

prefixed by TO24

or T044, there are parts of themanual which do not apply to your instrument. If your instrument

carries one of these serial numbers, information specific to your instrument

is

furnished with

this manual. This supplementary material includes schematics, parts list, and replacement

paragraphs and illustrations for those items in the manual that do not describe your instrument.

The supplementary data

is

indexed; paragraph and figure numbers are the same as those used

in the manual for the corresponding information.

If

it

is

necessary to order replacement parts, consult the supplementary

the component

always

use

the part number in your supplementary parts list.

is

not listed,

use

the part number given in section V of the manual; otherwise,

parts

list first.

If

vi

01

130-

1

Page 6

Model 683C

Paragraphs

Section

1-1

to

T

1-3

SECTION

GENERAL INFORMATION

1-1.

DESCRIPTION.

The @ Model 683C Sweep Oscillator

($3

Electronic Sweep Oscillators which

microwave bands as shown in table

Table 1-1. Electronic Sweep Oscillators

($9

Model

682C

683C

684C

H01

686C

686C

687C

Sweep oscillators are used as signal

wide variety of laboratory and production tests. They

provide a high-level relatively constant-amplitude

signal that can be rapidly changed in frequency. Thus

they permit the characteristics of microwave systems

or components to be quickly checked over an entire

band of frequencies.

The

@

Model 683C Sweep Oscillator covers the com-

plete

S

wave oscillator (bwo) tube to generate the

The bwo tube has several advantages over previously

used klystron type microwave oscillator tubes when

used in sweep sources.

The bwo tube output frequency and power level are

determined by the values of applied voltage only.

There are no cavity or reflector voltages to adjust or

track. There

lation. Since frequency and power-level adjustments

are electronic, all mechanical problems associated

with tunable-cavity Hystron-type oscillators are

inated. Control of frequency and power level are

simple, positive, and straightforward. By

rf

put from the bwo input, power variations of i1.5 db

are realized,

power from the bwo

full power from the bwo tube

output power

which

The Model 683C Sweep Oscillator

output can be either

internal square-wave source provides square-wave

modulation at any frequency between 400and 12OOcps.

The instrument can be externally pulse modulated or

band from 2 to 4 kmc (gc) and

is

no tendency to switch modes of oscil-

leveler circuit, which programs the

With

the

is

is

adjustable from 0 to a maximum

is

not

less

than 30 milliwatts.

cw

Frequency Range

1.0 to 2.0 kmc (gc)

2.0 to 4.0 kmc (gc)

4.0 to 8.1 kmc (gc)

7.0 to 11.0 kmc (gc)

8.2 to 12.4 kmc (gc)

12.4 to 18.0 kmc (gc)

rf

leveler inoperative, output

kept constant within 6 db, but

or amplitude modulated. An

is

one of several

cover

1-1.

sources

uses

a backward

rf

rf

power out-

is

obtained. The

is

versatile. The

signal.

use

major

for a

elim-

of

an

rf

I

amplitude modulated by

at any percentage from

oscillator can be externally frequency modulated or

swept

in

frequency over any portion or all

4-kmc (gc) range, or

taneously amplitude and frequency modulated.

When used for

lator, the internal circuitry provides an extremely

wide choice of sweeping rates and bandwidth swept.

The rate

and adjustable in calibrated steps from 16 mc/sec to

160 kmc(gc)/sec. The frequency range swept can be

small as 2.1 mc or as wide as 2.1 kmc (gc), as

as

selected by the calibrated seven position

QUENCY switch. In addition, there

control associated with the

which gives continuous adjustment between the fixed

positions

The minimum sweep time of the Model 683C

milliseconds. The sweep time

combined settings of the RF SWEEP RATE and the

A

FREQUENCY switches. These switches are inter-

locked by a differential gear drive which automatically

prevents any combination which would produce a sweep

time

less

The swept

linear with time and, by adjustment of

SELECTOR switch, can be made recurrent or

single sweeps. Single sweeps are started either by

the front-panel pushbutton or by an external positive

pulse (rise time greater than

In addition, a sawtooth voltage of approximately

25 volts

to supply a linear time base for an oscilloscope or

X-Y

recorder.

1-2.

INSTRUMENT COOLING SYSTEM.

The instrument

fan system. The incoming air

excessive dust. This filter must be inspected

quently to insure that it

dirty

filter

excessive heating of the instrument which can cause

early component failure (see figure 4-3).

1-3.

THREE-CONDUCTOR POWER CABLE.

To protect operating personnel, the National Electrical

Manufacturers’ Association (NEMA) recommends that

the instrument panel and cabinet be grounded. All

Hewlett-Packard instruments are equipped with a

three-conductor power cable which,

an appropriate receptacle, grounds the instrument.

The

offset pin

nector

is

its

primary purpose as a sweep oscil-

of

change of frequency

.

than 13.2 milliseconds.

rf

output frequency from the oscillator

is

provided concurrent with each

is

forced-air cooled by a high velocity

may restrict air flow sufficiently to cause

on

the power cable three-prongcon-

the ground pin.

sine

or complex waveforms

0

to

lOC%.

if

desired the 683C can be simul-

A

FREQUENCY switch

3

volts per microsecond).

is

is

not clogged with dirt.

In addition the

of

the 2- to

is

linear with time

A

is

a VERNIER

is

is

determined by the

the

SWEEP

set

rf

sweep

filtered to remove

when

plugged into

FRE-

13.2

is

for

fre-

A

0

1

130-

1

1-1

Page 7

Section

Paragraphs

I

1-4

to 1-5

To preserve the protection feature when operating

the instrument from a two-contact outlet,

use

a threeprong to two-prong adapter and connect the green

pigtail on the adapter to ground.

1-4.

230-VOLT

The @ Model 683C

operation, but

OPERATION.

is

usually shipped wired for 115 vac

is

quickly and easily converted to

operation from a nominal 230-volt 50/60 cps source.

To convert, remove two jumpers between terminals

A2 and A3.

In

addition, remove the jumper

wire

(connecting the two rear terminals of the MAGNET

AMP and

3

minal of the

minal of

a pink lead attached to

either the MAGNET

the

H.

V.

3

AMP.

fuses)

from the rear

H.V.

fuse and reconnect to the side

H.V.

fuse.

This side terminal also has

it.

Do

not change the size of

fuse

or the

H.V.fuse.

ter-

ter-

When

operating from a 230-volt source, T101, the magnet

supply and the fan operate on 115 volts supplied by

T1

primary windings which act as a 2:l autotransformer. This additional load

load carried by the

sets

the expected reduction in current due to 230-volt

H.V.

is

added to the normal

fuse

and approximately off-

operation.

Model 683C

1-5.

RACK MOUNTING INSTRUCTIONS.

When mounting a rack model instrument, leave at

least three inches clearance behind the air intake to

insure

that the air intake

ment which

proper

is

air

circulation. In addition, be certain

is

not near another piece of equip-

discharging hot air

in

the

vicinity of

the Model 6836 air intake.

The following instructions should be followed for easy

installation of a rack model instrument (683CR)

in

an

equipment rack.

Remove the four

1)

screws

from

the

rear of the

in-

strument cabinet and slide the instrument forward

from the cabinet.

the

2) Mount

empty cabinet

four oval head machine

side

of

1-3/4

the cabinet

inches from the top and bottom edges of the

in

the

in

the equipment rack with

screws:

two

screws

on each

mounting holes approximately

mounting flanges.

3) Raise the instrument chassis and slide it gently

into the cabinet. Be certain the power cable passes

freely through the hole in the rear of the cabinet.

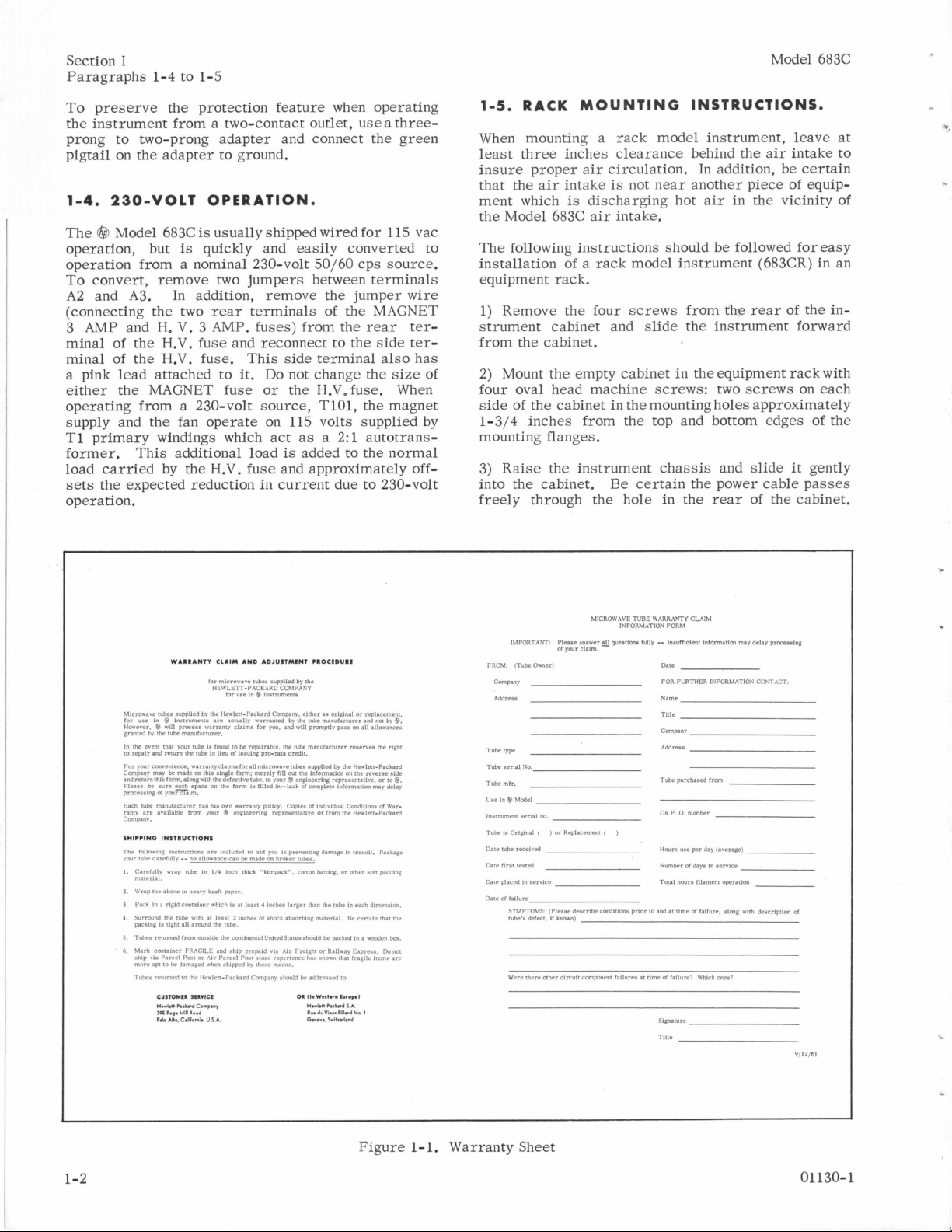

WARRANTY

CLAIM

AND

ADJUSIMINT PROCIDURI

MICROWAVE

INFORMATION

TUBE

WARRANTY CLAIM

Slp.t"re

Title

FORM

9/12/61

Figure

1-1.

Warranty Sheet

1-2 01130-1

Page 8

Model 683C

4)

Fasten the instrument panel securely to the rack.

5)

Replace the four

(if

desired).

This instrument weighs over

If the rack installation

tion or rough handling, additional means of

support should be provided at the rear of

the instrument.

screws

Note

at the rear of the cabinet

100

pounds.

is

subject

to

vibra-

Section

Paragraph 1-6

1-6.

BWO

The bwo tube used in this instrument

and has a shorter guaranteed

tional tubes. See the Tube Warranty sheet, figure

for

details. A sheet for your

appendix of this manual. To

useful

suggested that the instrument be turned off when not in

use.

Wave Oscillator Tube Claims and Adjustment Pro-

cedure sheet in this manual should be read and the

instructions followed carefully.

hours of

When replacing the bwo tube, the Backward-

TUBE

service

INFORMATION.

is

very expensive

life

than that of conven-

use

is

increase

obtained from each tube, it

included in the

the number

1-1,

of

is

I

01130-1

Page 9

Section I1

Figure 2-1

Model 6836

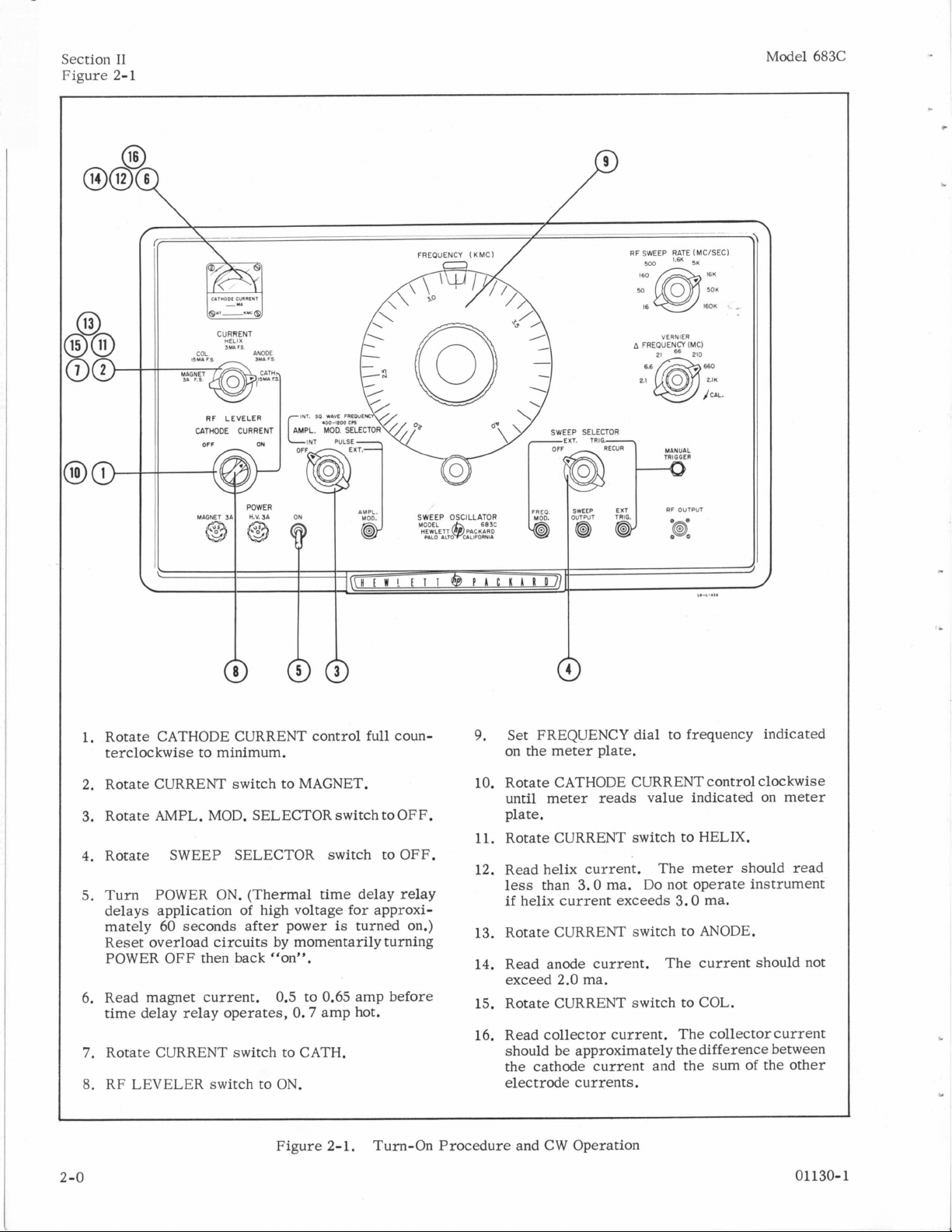

9.

1.

Rotate CATHODE CURRENT control

terclockwise to minimum.

2. Rotate CURRENT switch to MAGNET.

3. Rotate AMPL. MOD. SELECTOR switch toOFF.

4. Rotate SWEEP SELECTOR switch to

5. Turn POWER ON. (Thermal time delay relay

delays application of high voltage for approxi-

mately 60 seconds after power

Reset overload circuits by momentarily turning

POWER

6.

Read magnet current.

time delay relay operates,

7.

Rotate CURRENT switch to CATH.

8.

RF LEVELER switch to

2-0 01130-1

OFF

then back “on”.

0.5

to 0.65 amp before

0.7

amp hot.

ON.

Figure 2-1.

full

coun-

OFF.

is

turned on.)

Turn-On Procedure and CW Operation

Set FREQUENCY dial to frequency indicated

on the meter plate.

10. Rotate CATHODE CURRENT control clockwise

until meter reads value indicated on meter

plate.

11.

Rotate CURRENT switch to HELIX.

12. Read helix current. The meter should read

less

than

3.0

ma. Do not operate instrument

if

helix current exceeds

13.

Rotate CURRENT switch to ANODE.

14. Read anode current. The current should not

exceed 2.0 ma.

15.

Rotate CURRENT switch to COL.

16. Read collector current. The collector current

should be approximately the difference between

the cathode current and the sum of the other

electrode currents.

3.0

ma.

Page 10

Model 683C

Paragraphs 2-1 to 2-3

Section I1

SECTION

OPERATING INSTRUCTIONS

2-1.

CONTENTS.

Section

operating the sweep oscillator, instructions for modulating the

cations of the instrument.

2-2.

The Model 683C Sweep Oscillator should be placed on

a work bench or table with at least 3 inches of clearance at

the filter. To avoid seriously restricted air flow,

be careful not to let loose pieces of paper, etc.

main in the rear area since they can be pulled against

the air filter.

The power cable should be used in a NEMA approved

standard three-prong grounding receptacle (paragraph 1-3).

Complete installation instruction for rack model

struments are given in paragraph 1-5.

2-3.

Good operating practice dictates that you follow ,a

given step-by-step procedure when turning on the

Model 683C, to protect the bwo tube. This routine

will

critical circuits to insure normal operation.

Under normal operation no damage can be done by

improper setting of front panel controls since builtin

high-voltage transformer

in

by momentarily turning off power to the instrument.

In addition to the overload protection, internal

driver-adjust controls preset limits on front panel

controls to safe values. BWO tube currents aremonitored with built-in metering circuits, which provide

a positive check that the bwo tube

in

To place the instrument in operation, the steps outlined

in

Additional data on some of the steps are given below

under STEPS; before performing the turn-on procedure

for the first time, read this supplemental information.

Figure 2-1 shows the front panel controls as

briefly describing the steps of the turn-on procedure.

The unnumbered controls and terminals can be oper-

ated in any order desired, depending on the type of

operation selected. Characteristics of the input and

output connectors are given

With the completion of the turn-on procedure the instrument

set

I1

contains instructions for setting up and

rf

output, and a discussion of some appli-

INSTALLATION.

the

rear to insure adequate air flow through

re-

in-

TURN-ON PROCEDURE.

systematically check out proper operation of all

overload protection cuts off primary power to the

if

excessive current flows

the helix circuit. The overload circuits are reset

screw-

is

being operated

a safe manner.

figure 2-1 should be followed in the order given.

well

as

in

figure 2-10.

is

set

up for

on the FREQUENCY dial. Once

cw

operation at the frequency

cw

operation has

II

been established, the oscillator may be adjusted for

frequency and for amplitude modulation (paragraphs

2-4 through 2-7).

Until thoroughly familiar with instrument operation,

it

is

recommended that you

information which follows.

STEPS:

The number associated with each paragraph

the turn-on procedure step under discussion. See

figure 2-1 for

5. Set POWER to ON. The plastic graticule at the

top of the FREQUENCY dial

fan

will

delays application of high voltage to the main

cuits approximately 60 seconds after

ment

are partly energized when the POWER switch

turned on, but do not regulate until the time-delay

switch has operated and the filaments

lator circuits are energized.

6. Read magnet current on the monitor meter. The

current should be 0.5 to 0.65 ampere when

turned on and

after a

ATE INSTRUMENT IF AFTER WARMUP THE

MAGNET CURRENT

AND

8.

With RF LEVELER switch to

have a power output variation across the band of

i1.5 db or

tion the power variation across the band will not

exceed

9.

It

is

cathode current at the frequency indicated on the

meter plate. The reasons are: a) Only with the

rated cathode current at the frequency specified

will

conditions are not met, the RF LEVELER

give the desired leveling action

10.Rotate CATHODE CURRENT control in a clock-

wise

Normal (at least 30 milliwatts) output

tained with the value of cathode current stamped

on the panel meter. (The maximum

limited by internal adjustments.)

12.Read helix current. The current should be

than 3 ma. DO NOT OPERATE THE INSTRUMENT IF THE HELIX CURRENT EXCEEDS 3MA.

An

overload relay prevents excessive helix

rent. To

POWER off, then back to ON. Excessive helix

current may indicate misalignment of the bwo tube

in

the magnetic field

the

steps not discussed below.

operate.

is

energized. The magnet supply

will

few

minutes operation. DO NOT OPER-

0.725

AMPERE.

less.

3

db.

important that the meter reads the exact

adequate power be produced. b) If the latter

direction and observe the current reading.

reset

refer

to the supplemental

refers

will

glow. The cooling

A

thermal time-delay switch

cir-

the

instru-

circuits

in

the regu-

first

gradually settle to 0.70 ampere

IS

NOT BETWEEN 0.675

ON

the 683C

In the RF LEVELER OFF posi-

(+

1.5 db).

will

current

will

be ob-

less

will

not

is

cur-

the relay, momentarily turn

(see

section IV, Maintenance).

to

is

01130-1

2-

1

Page 11

I

Section

I1

Paragraphs 2-4 to 2-7

Verify proper operation of the helix power supply

by rotating the FREQUENCY dial from 2 to 4 kmc

(gc) and noting that there

current. (BWO

in

helix voltage.

helix

Thus

as the FREQUENCY dial

range

is

a check that helix voltage

16. The collector

ference

current

between cathode current and

the helix and anode current readings.

is

a variation

in

helix

current varies with a change

a variation

in

helix

is

turned through

is

current

its

changing.)

reading should be the dif-

the

sum of

If

there

is

a large difference between this value of collector

current and that shown by the meter,

ment

is

not functioning properly

The instrument

ting a 30 milliwatt or more

is

now operating normally and genera-

cw

signal at the frequency

(see

the

instru-

section

IV).

indicated by the FREQUENCY dial.

2-4.

ment is

the AMPL. MOD. SELECTOR switch

LEVELER to ON.

is

of better than

The output power level

USING THE SWEEP OSCILLATOR AS

A CW SIGNAL SOURCE.

Upon completion of the turn-on procedure, the

set

up for cw operation. However, check that

is

OFF; RF

In

cw operation, output frequency

indicated by the FREQUENCY dial to an accuracy

-+

1%.

is

adjustable from at least

instru-

30 milliwatts down to zero by theCATHODE CURRENT

control. Monitor

the power level near rated value to

ratings are not being exceeded.

higher than 7 ma

helix

current

to 7 ma and check that helix current

This

is

a

check

the bwo

is

discussed in paragraph 4-13B.)

the

cathode current when adjusting

insure

If

cathode current

is

required to get rated power, and

is

higher than 3 ma, set cathode

is

less

that tube

focus

is

correct.

that tube

current

than 3 ma.

(Focusing

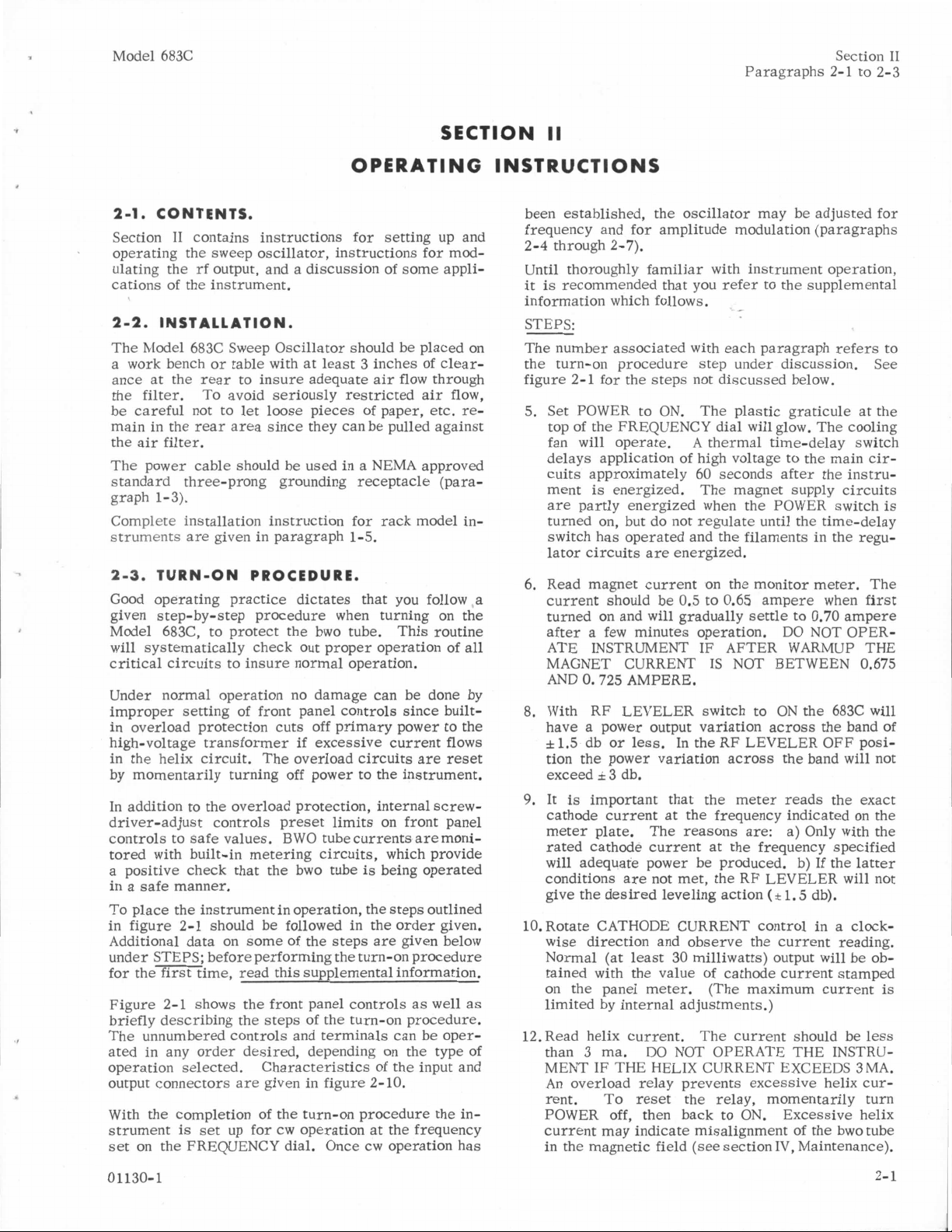

By the addition of a precision attenuator, the 683C can

be used as a signal generator. Figure 2-2 indicates

connection of equipment for such a setup.

fraction of the power

SWEEP OSCILLATOR

POWER METER

lpw TO lOmw

2-4gc

in

@gyL

the line

THERMISTOR

MOUNT

Ipw

TO

2-

4gc

is

IOmw

A

20-db

coupled to the

DIRECTIONAL

COUPLER

I

-4gc

cdb .5db

Figure 2-2. Using the Sweep Oscillator

as a CW Signal Source

Model 683C

auxiliary arm of

The power-monitoring branch

iliary arm. Thus the

on the 431A Power Meter plus 20 db, and the

at the load

is

the

761D Dual Directional Coupler.

is

taken from this aux-

rf

power in the

line

is

the reading

rf

power

the monitored rfpower minus the setting

of the attenuator. The accuracy with which the power

reaching the load can be monitored in this way

is

limited by the accuracy of theattenuator. Rated accuracies of the other components are shown

2-5.

SWEEP OPERATION

OF

THE OSCILLATOR.

After the oscillator has been set up for

the

rf

output should

be

set

to the desired power level

in

figure 2-2.

cw

operation

and the FREQUENCY dial set to the proper setting.

Refer

to figure 2-3, for instructions on how to obtain

sweep operation.

2-6.

AMPLITUDE MODULATING

THE OSCILLATOR.

The 683C provides facilities for modulation with internally-generated square waves, externally-supplied

pulses (683C input, ac coupled), or externally supplied

voltages (683C input, dc coupled). Operation at various

positions of the switch are described

in

figures 2-5,

2-6, and 2-7.

2-7.

FREQUENCY MODULATING

THE OSCILLATOR.

The oscillator can be frequency-modulated from an

external source by placing the SWEEP SELECTOR

switch

in

the

EXT. position and applying a modulating

voltage to the FREQ. MOD. jack (figure 2-7). The

jack

is

ac coupled to an impedance of 43K shunted by

approximately 100 pf.

The bwo

rf

output frequency varies with respect to the

voltage at the input to the FREQ. MOD. jack from

approximately 8.2 mc/volt at 4 kmc (gc) to 23.8 mc/

volt at 2 kmc (gc). The full frequency band (2.1 kmc

[gcJ) may be swept (at a rate of between

10

to 60 cps)

by applying a voltage of 150 volts peak-to-peak to

the FREQ.

MOD.

jack. When sweeping full band,

the FREQUENCY dial should be set at approximately

3.2 kmc (gc). Frequency modulation

is

up and down

from the frequency indicated on the FREQUENCY dial.

Positive-going voltage applied to the FREQ. MOD.

iack increases the freauencv.

is

When the full band

swept, the frequency of the

modulation voltage should be within 10 and 60 cps.

When

the frequency of the modulation voltage

is

higher

than 60 cps, the band swept must be reduced to avoid

overload of the helix power supply.

The

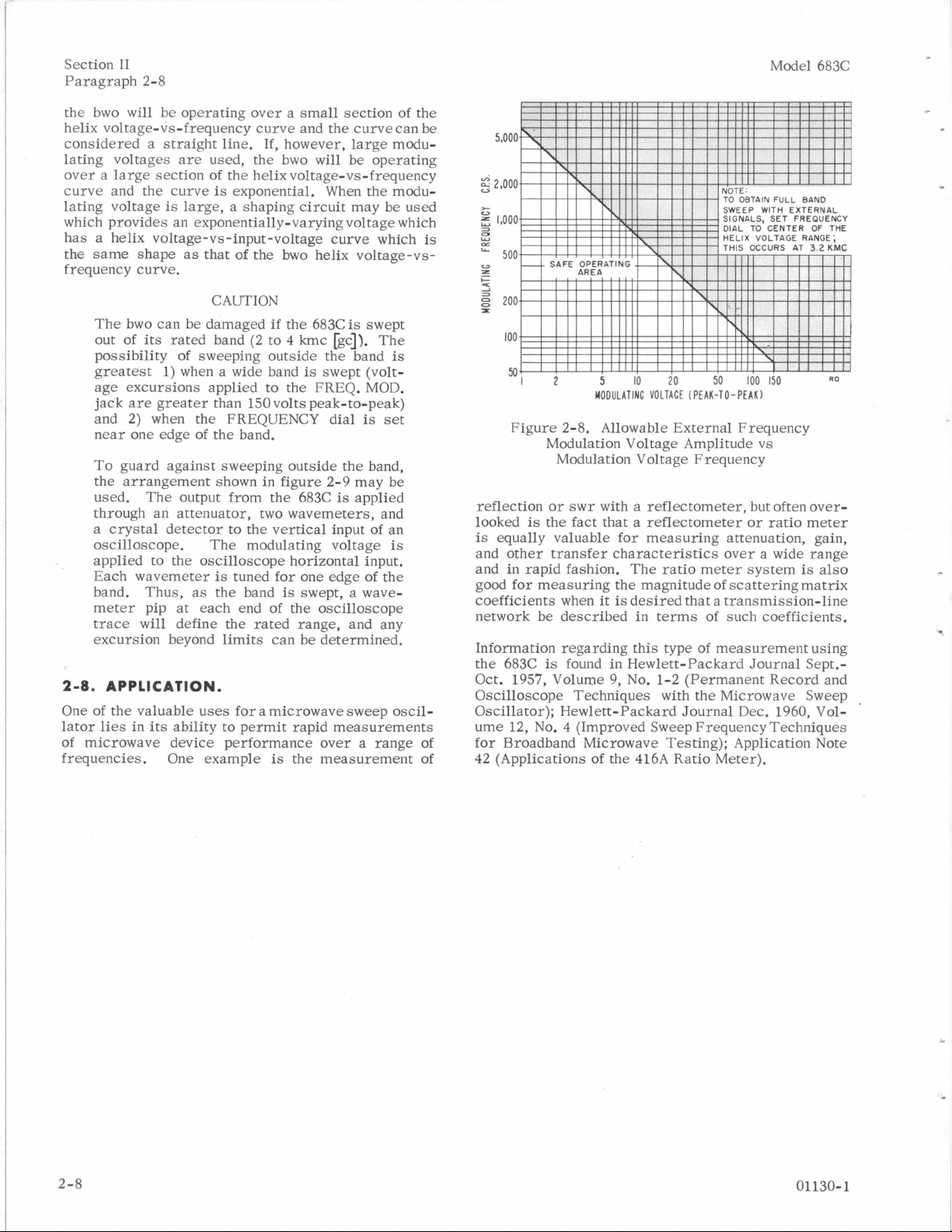

chart shown

as figure 2-8 shows the maximum voltages which

should be applied to the FREQ. MOD. jack

when

mod-

ulating frequencies above 60 cps are used.

For external frequency modulation of the 683C, consideration must be given to the modulation character-

istics

voltage produces an exponential change

of the

of the bwo.

rf

output.

If

A

linear change

in

modulation

in

the frequency

small modulation voltages are used,

2-2

01130-1

Page 12

Model 683C

COL

CURRENT

HELIX

,wr,

ANODE

RF

SWEEP

RATE

IMC/SECI

Section

Figure 2-3

-0

-0

I1

3A

POWER

H.V.

3A

MAGNET

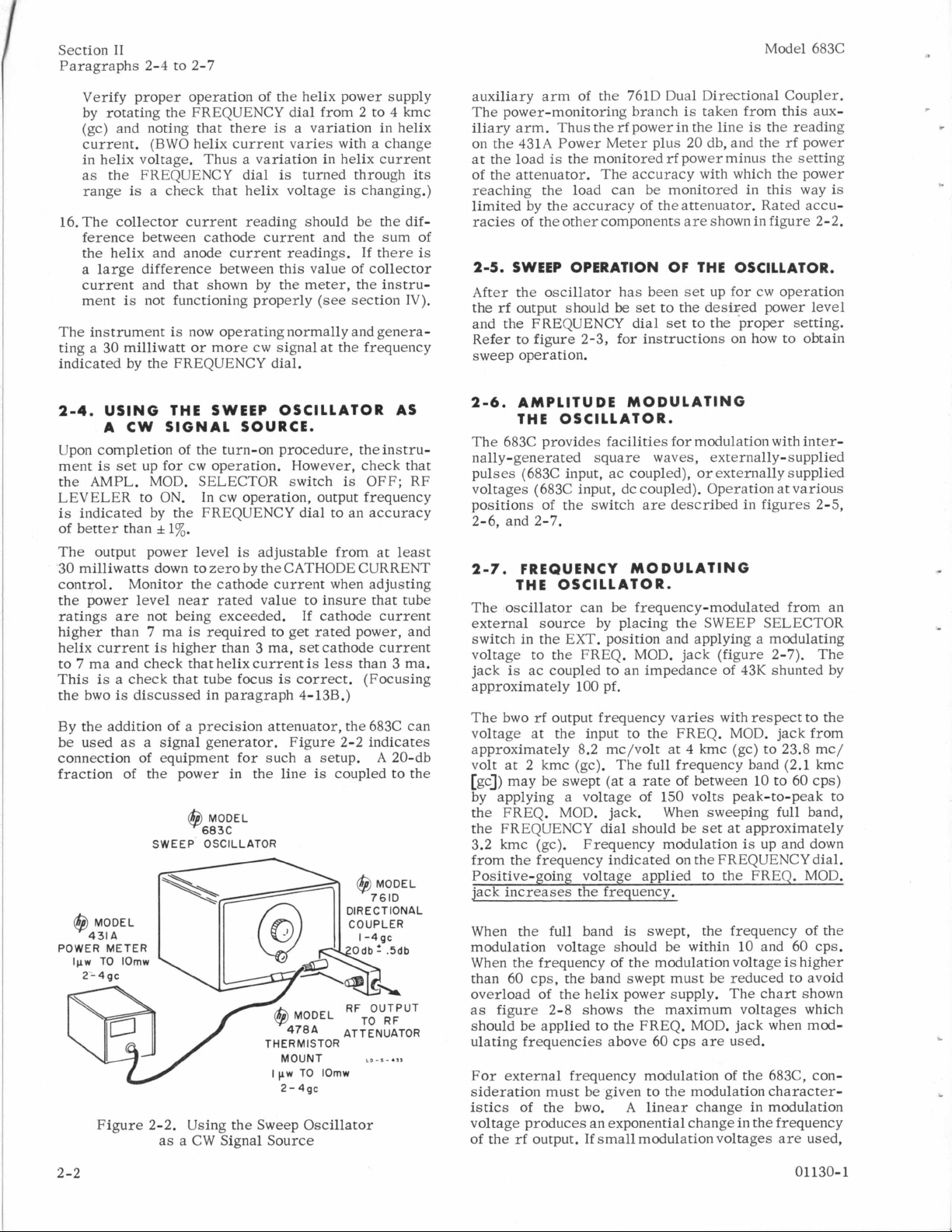

First turn on instrument and adjust for normal out-

put

under

cw

operation as shown in the turn-on

procedure (figure 2-1).

1.

Rotate the AMPL.

OFF,

or other desired mode.

2. Set FREQUENCY (KMC) dial to

(sweep

is

downward from FREQUENCY dial

MOD.

SELECTOR switch to

4

kmc (gc)

setting).

3.

Rotate A FREQUENCY switch to position cor-

responding to number of megacycles to be

swept. Set VERNIER to CAL. For variable

segments

4.

Rotate the RF SWEEP RATE switch totheposi-

of A FREQUENCY, rotate out of CAL.

tion corresponding to the rate of sweep desired

in mc/sec.

The

A

FREQUENCY switch and the RF SWEEP

RATE switch are mechanically interlocked to

prevent a combination

result in a sweep time of

of

settings that would

less

than 0.0137

second.

5.

Rotate SWEEP SELECTOR switch to RECUR

if

automatically recurring sweeps are desired.

6.

Rotate SWEEP SELECTOR switch to

TRIG.

single sweeps are desired. Sweeps may be

started by momentarily pressing MANUAL

TRIGGER button, or by supplying a positive

20-volt pulse to Em. TRIG. jack.

CHARACTERISTICS

-

Direction:

RF sweeps are downward, starting at the

quency indicated on the FREQUENCY (KMC)

dial.

SWEEP OUTPUT voltage

is

a positive going

20-25 volt sawtooth voltage.

Accuracy:

Frequency band swept

sweep. +25%, -15% or

greater, for sweep widths

is

within

i3

mc, whichever

less

f

10%

than full band.

for

if

fre-

full

is

O

1130-

~~

Figure 2-3. Internal Sweep Operation

1

2-3

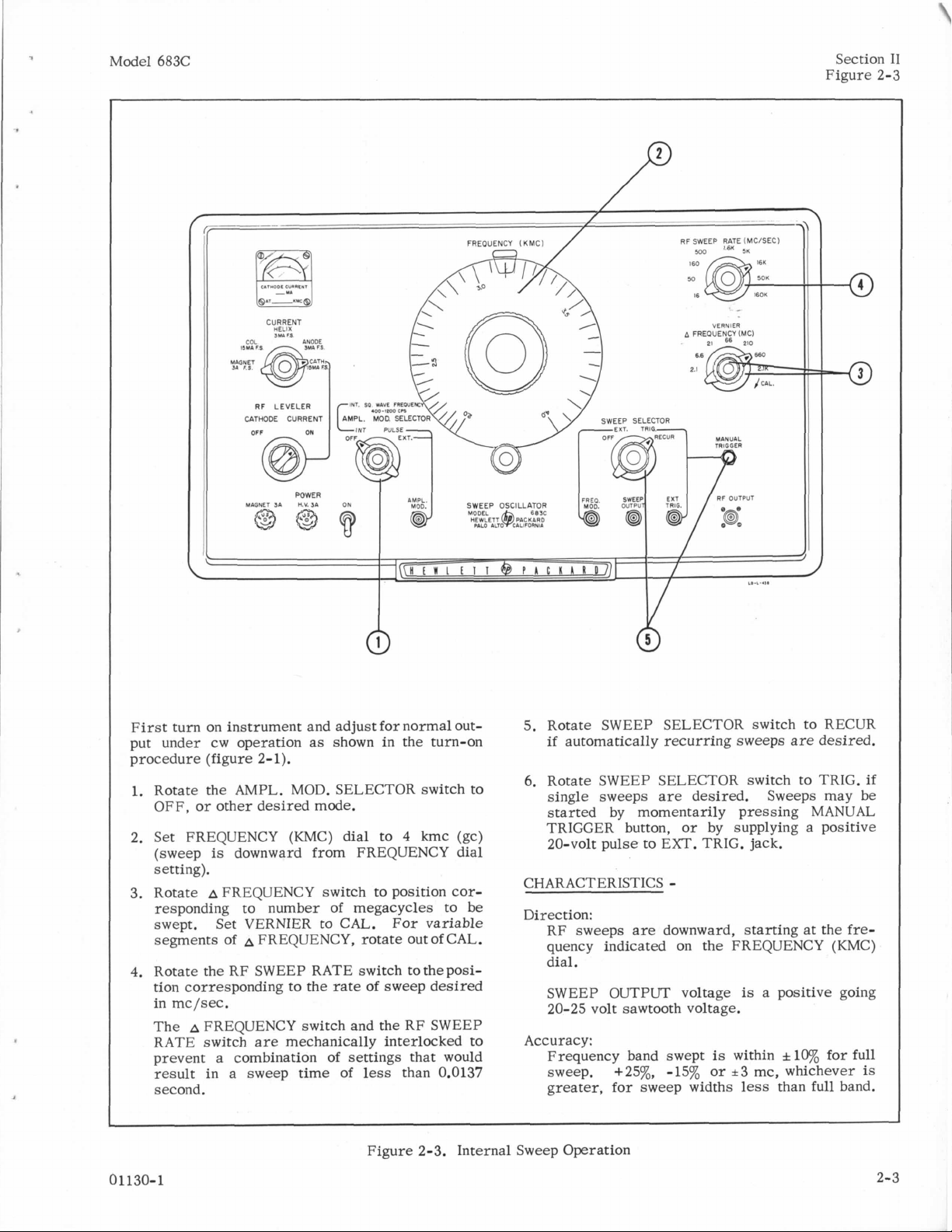

Page 13

Section

I1

Figure 2-4

Model 683C

RF

LEVELER

CATHODE CURRENT

FREQUENCY

(KMC)

RF SWEEP RATE (MCISECI

SW

5%

VERNIER

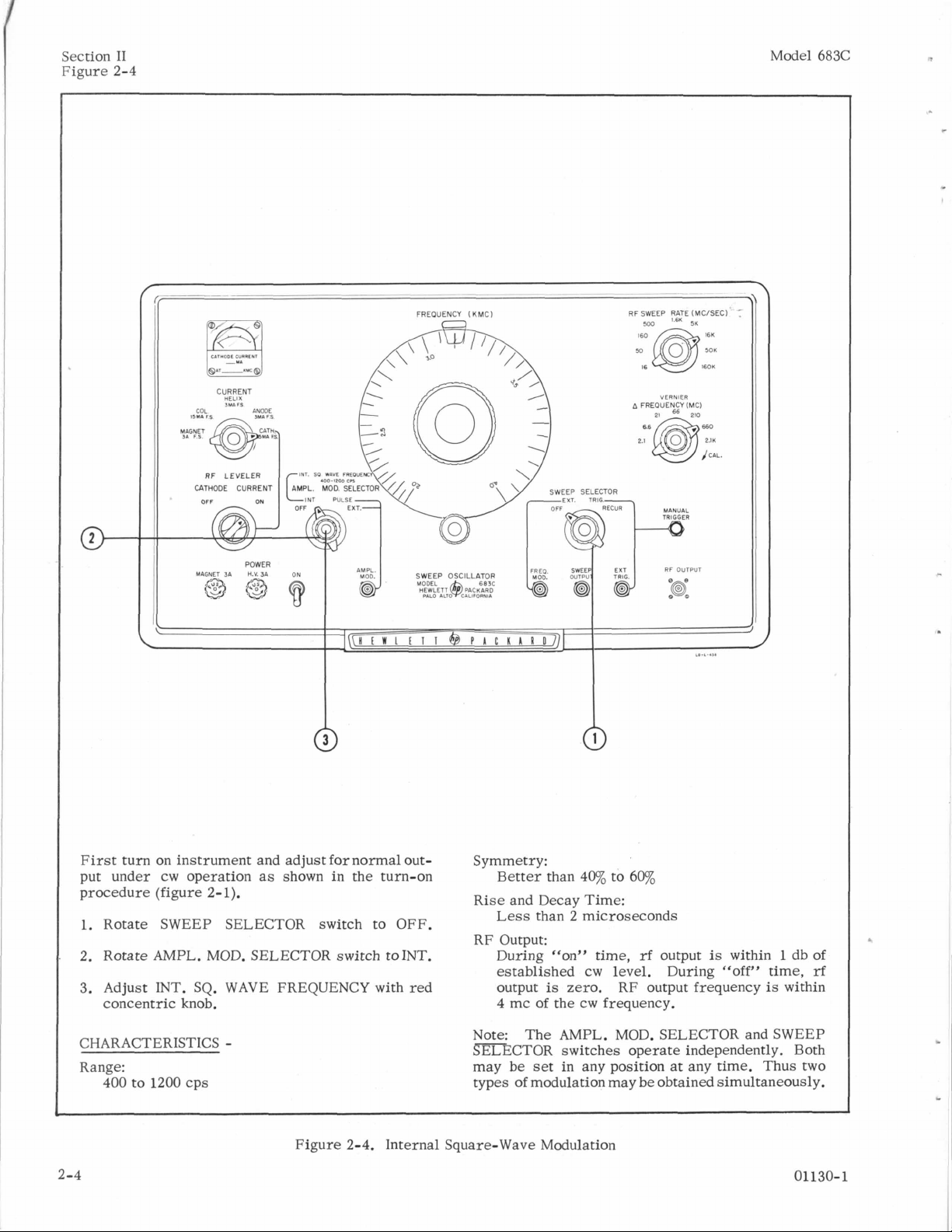

First turn on instrument and adjust

for

normal output under cw operation as shown in the turn-on

procedure (figure 2-1).

1.

Rotate SWEEP SELECTOR switch to OFF.

2. Rotate AMPL. MOD. SELECTOR switch toINT.

3.

Adjust

INT.

SQ. WAVE FREQUENCY with red

concentric knob.

CHARACTERISTICS

-

Range:

400 to 1200 cps

Figure

2-4.

2-4

Symmetry:

Better than 4v0

Rise and Decay

Time:

Less than 2 microseconds

RF Output:

During "onyy time,

established

output

4

mc

of

cw

is

zero. RF output frequency

the

cw

frequency.

Note: The AMPL. MOD. SELECTOR and SWEEP

SELECTOR switches operate independently. Both

may be

types

set

in any position at any time. Thus two

of

modulation may be obtained simultaneously.

Internal Square-Wave Modulation

to

60%

rf

output

level. During

is

within 1 db

"off"

time,

is

within

01

of

rf

130-

1

Page 14

Model 683C

Section

Figure 2-5

I1

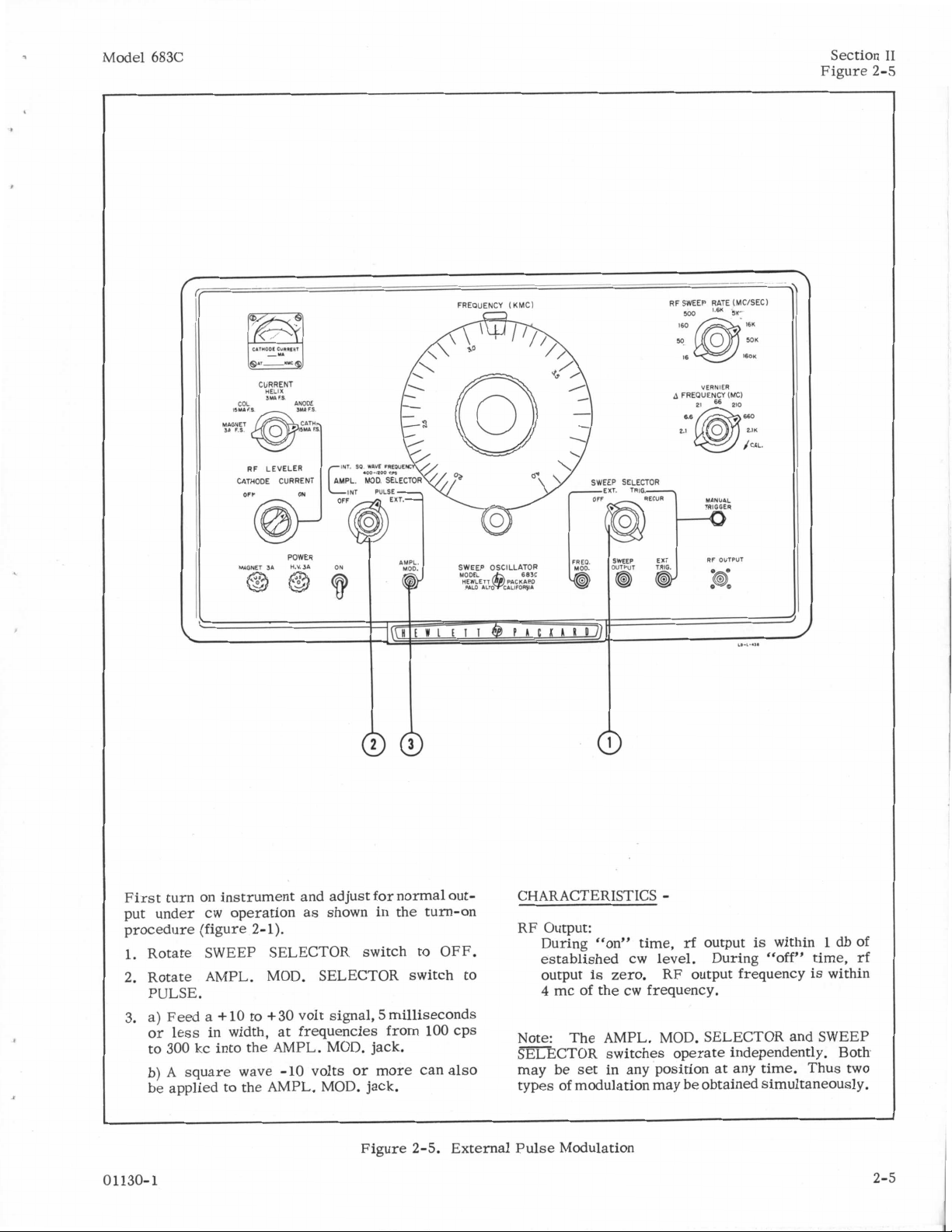

First turn on instrument and adjustfor normal output under

procedure (figure 2-1).

1.

Rotate SWEEP SELECTOR switch to OFF.

2. Rotate AMPL. MOD. SELECTOR switch to

PULSE.

3.

a) Feed

or

to

b)

be applied to the AMPL. MOD. jack.

01130-

1

cw

operation as shown in the turn-on

a

+

10

to

+30

volt signal, 5 milliseconds

less

in width, at frequencies from

300

kc into the AMPL. MOD. jack.

A

square wave

-10

volts

100

or

more can also

Figure 2-5. External Pulse Modulation

cps

CHARACTERISTICS

RF

Output:

During "on" time,

established

output

4

Note: The AMPL. MOD. SELECTOR and SWEEP

-

SELECTOR switches operate independently. Both

may be set in any position

types

is

zero. RF output frequency

mc

of

the cw frequency.

of

modulation may be obtained simultaneously.

-

rf

cw

level. During "off" time,

output

is

within 1 db

at

any time. Thus two

is

of

rf

within

2-5

Page 15

Section

I1

Figure 2-6

RF

SWEEP RATE (MCISEC)

yI0

5x

Model 683C

CURRENT

HELIX

,udrs

COL

RF

CATHODE CURRENT

OFF

LEVELER

ANODE

3YA

@

31

POWER

n.v.m

MAGNET

16

FS

I601

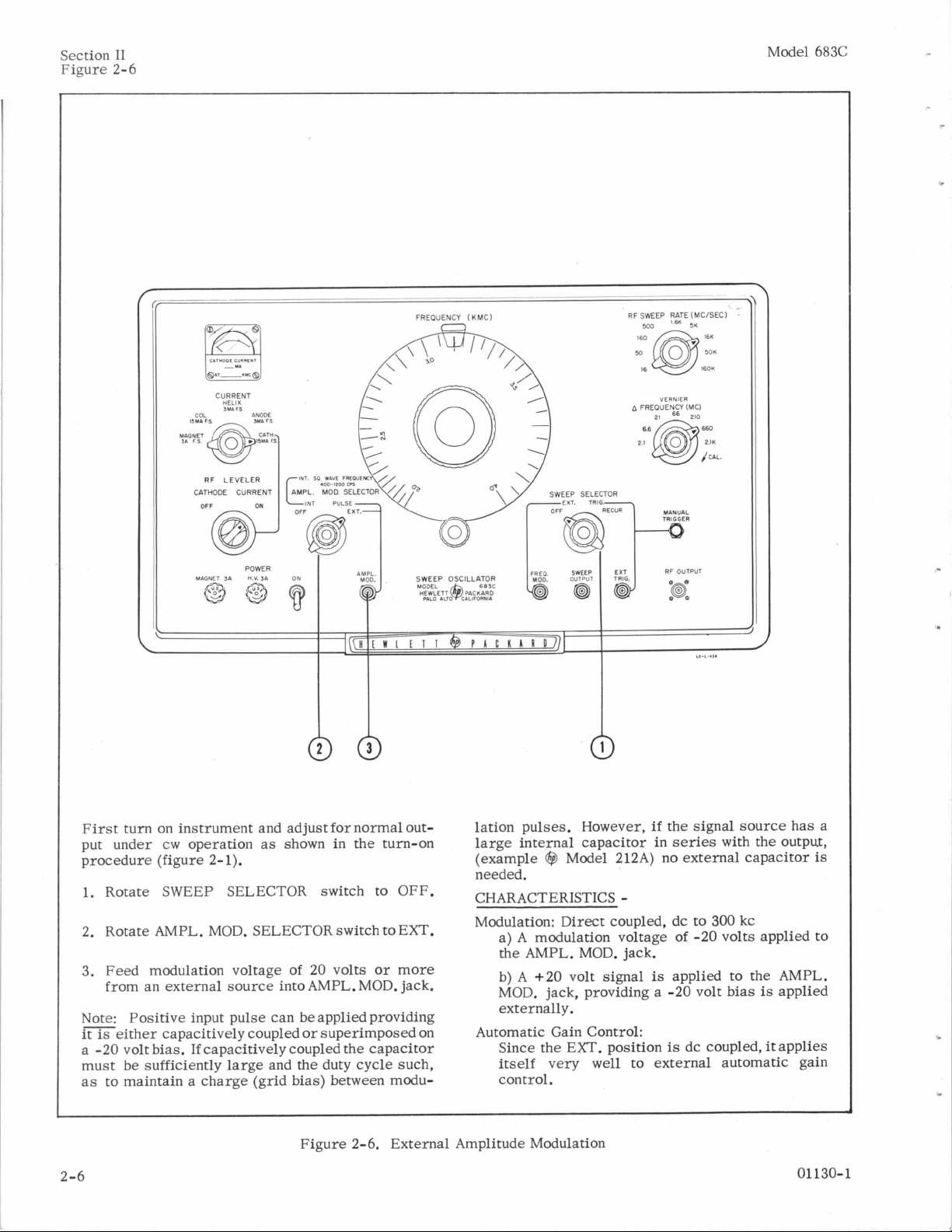

First turn on instrument and adjust for normal output under

procedure (figure 2-

cw

operation as shown

1).

in

the turn-on

lation pulses. However,

large internal capacitor in

(example

($9

Model 212A) no external capacitor

if

the signal source has a

series

with the output,

needed.

1.

Rotate SWEEP SELECTOR switch to OFF.

2. Rotate AMPL. MOD. SELECTOR switch to EXT.

CHARACTERISTICS

-

Modulation: Direct coupled, dc to 300 kc

a)

A

modulation voltage of -20 volts applied to

the AMPL. MOD. jack.

3.

Feed modulation voltage

from an external source into AMPL. MOD. jack.

Note:

-

Positive input pulse can be applied providing

it is either capacitively coupled or superimposed on

a -20 volt bias.

If

capacitively coupled the capacitor

must be sufficiently large and the duty cycle such,

as to maintain a charge (grid bias) between modu-

of

20 volts or more

b)

A

+20 volt signal

is

applied to the AMPL.

MOD. jack, providing a -20 volt bias

externally.

Automatic Gain Control:

Since the EXT. position

itself very

well

is

dc coupled,

to external automatic gain

control.

is

applied

it

applies

Figure 2-6. External Amplitude Modulation

2-6 01

is

130-

1

Page 16

I

Model 683C

RF

LEVELER

CATHODE CURRENT

FREQUENCY (KMCI

RF SWEEP RAT€ IMCISEC)

VERNIER

Section

Figure 2-7

I1

31

POWER

H.V.3A

MAGNET

@@

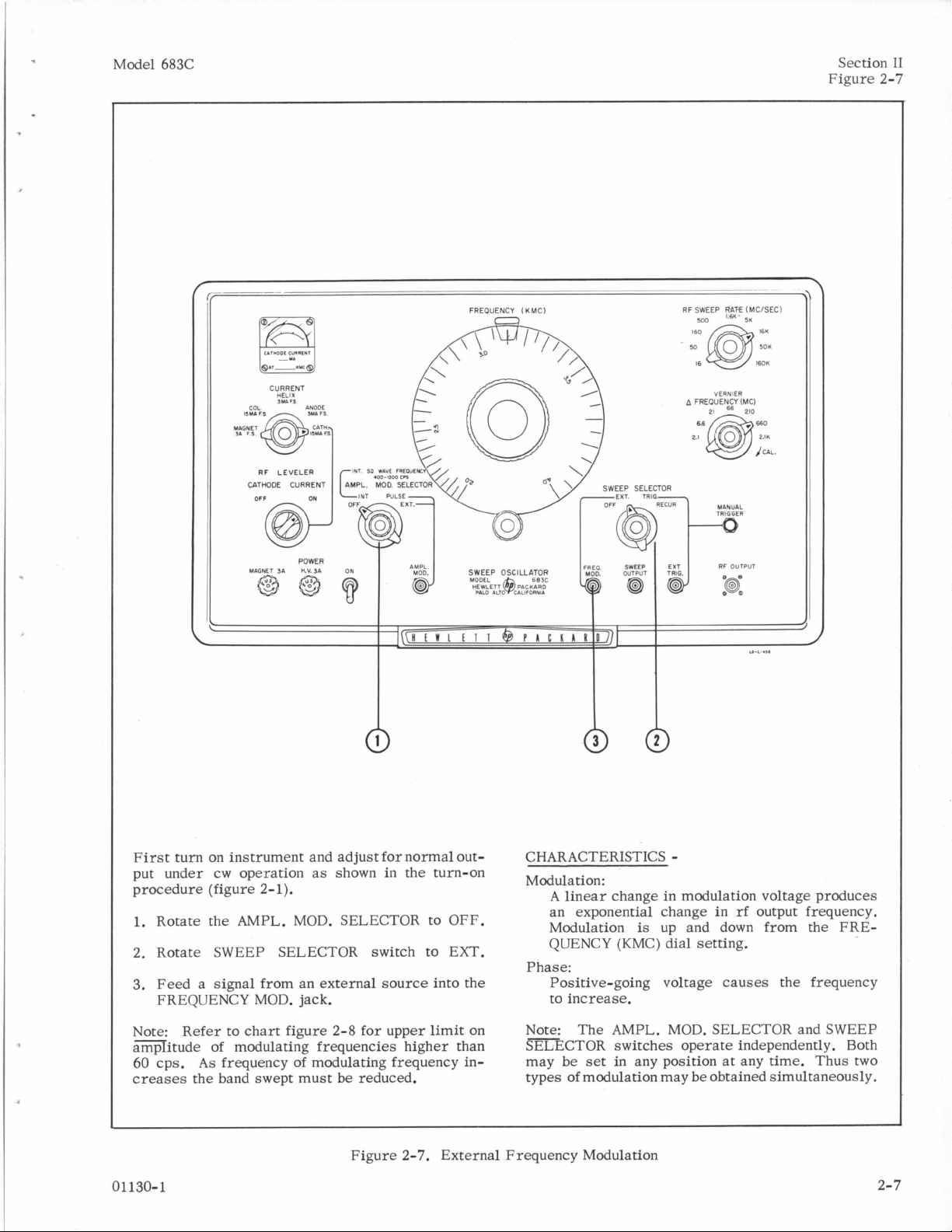

First

turn on instrument and adjust

put under

cw

operation as shown in the turn-on

procedure (figure 2-1).

Rotate the AMPL. MOD. SELECTOR

1.

2. Rotate SWEEP SELECTOR switch to EXT.

3.

Feed a signal from an external source into the

FREQUENCY MOD. jack.

for

normal out-

to

OFF.

CHARACTERISTICS

-

Modulation:

A

linear change in modulation voltage produces

an exponential change in

Modulation

is

up and down from the FRE-

rf

output frequency.

QUENCY (KMC) dial setting.

Phase:

Positive-going voltage causes the frequency

to increase.

Note: Refer to chart figure 2-8 for upper limit on

amplitude of modulating frequencies higher than

60 cps.

As

frequency

of

modulating frequency in-

creases the band swept must be reduced.

Figure

2-7.

01130-1

Note:

The AMPL. MOD. SELECTOR and SWEEP

SELECTOR switches operate independently. Both

may be

set

in any position at any time. Thus two

types of modulation may be obtained simultaneously.

External Frequency Modulation

2-7

Page 17

Section 11

Model 683C

Paragraph 2-8

the

bwo will be operating over a small section of the

helix voltage-vs-frequency

considered a straight

curve

and the

line.

If, however, large modu-

curve

can be

lating voltages are used, the bwo will be operating

over a large section of the helix voltage-vs-frequency

curve and

lating voltage

the

curve

is

large, a shaping

is

exponential. When the modu-

circuit

may be used

which provides an exponentially-varying voltage which

has a helix

the same shape as that

voltage-vs-input-voltage

of

the bwo helix voltage-vs-

curve which

is

frequency curve.

CAUTION

The bwo can be damaged if

out of its rated band (2 to

possibility of sweeping outside

greatest 1) when a wide band

age excursions applied to the FREQ. MOD.

jack are greater than 150 volts peak-to-peak)

and

2)

when the FREQUENCY dial

near one edge of

the

band.

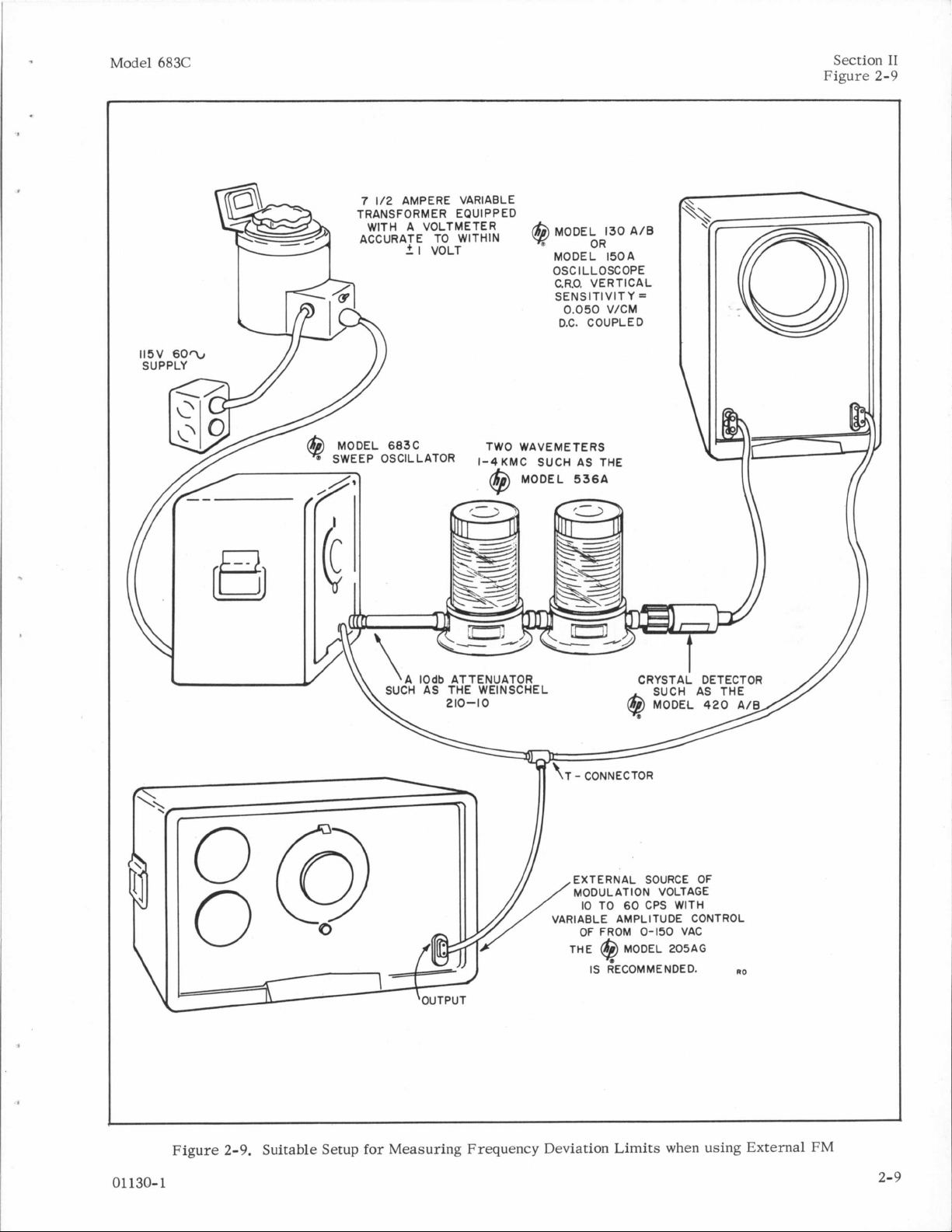

To guard against sweeping outside the band,

the arrangement shown

used. The output from

through an attenuator, two wavemeters, and

a crystal detector to the vertical input of an

oscilloscope. The modulating voltage

applied to the oscilloscope horizontal input.

Each wavemeter

band. Thus, as

is

tuned for one edge of the

the

meter pip at each end of the oscilloscope

trace will define the rated range. and any

excursion beyond limits can be ietermined.

2-8.

APPLICATION.

the

683Cis swept

4

kmc [gc]). The

is

swept (volt-

in

figure 2-9 may be

the

683C

band

is

swept, a wave-

the

is

band

is

set

applied

is

is

5

10

20

50

100

150

MODULATING VOLTAGE (PEAK-TO-PEAK)

RO

Figure 2-8. Allowable External Frequency

Modulation Voltage Amplitude

vs

Modulation Voltage Frequency

reflection or

looked

is

equally valuable for measuring attenuation, gain,

swr

with a reflectometer, but often over-

is

the fact that a reflectometer or ratio meter

and other transfer characteristics over a wide range

and

in

rapid fashion. The ratio meter system

is

also

good for measuring the magnitude of scattering matrix

coefficients when it

is

desired that a transmission-line

network be described in terms of such coefficients.

Information regarding this type of measurement using

the 683C

is

found in Hewlett-Packard Journal Sept.Oct. 1957, Volume 9, No. 1-2 (Permanent Record and

Oscilloscope Techniques with the Microwave Sweep

One of the valuable uses for a microwave sweep oscil- Oscillator); Hewlett-Packard Journal Dec. 1960, Vollator lies in its ability to permit rapid measurements ume 12, No.

4

(Improved Sweep Frequency Techniques

of microwave device performance over a range of for Broadband Microwave Testing); Application Note

frequencies.

One example

is

the measurement of 42 (Applications of

the

416A Ratio

Meter).

,

2-8

01130-1

Page 18

Model

683C

7

1/2

AMPERE VARIABLE

TRANSFORMER €QUI PP ED

WITH A VOLTMETER

ACCURATE TO WITHIN

+I

VOLT

@

MODEL 150A

OSCILLOSCOPE

C.R.O. VERTICAL

SENSITIVITY

0.050

D.C. COUPLED

V/CM

A/B

=

Section

Figure 2-9

I1

SWEEP I-4-KMC

TWO WAVEMETERS

SUCH

AS THE

EXTERNAL SOURCE OF

MODULATION VOLTAGE

IO

TO

60

VARIABLE AMPLITUDE CONTROL

OF

IS

CPS WITH

FROM

0-150

MODEL 205AG

RECOMMENDED.

VAC

RO

11130-1

Figure

2-9.

Suitable Setup

for

Measuring Frequency Deviation Limits when using External FM

2-9

Page 19

Section

Figure 2-10

I1

Model 683C

.

RF

OUTPUT

s

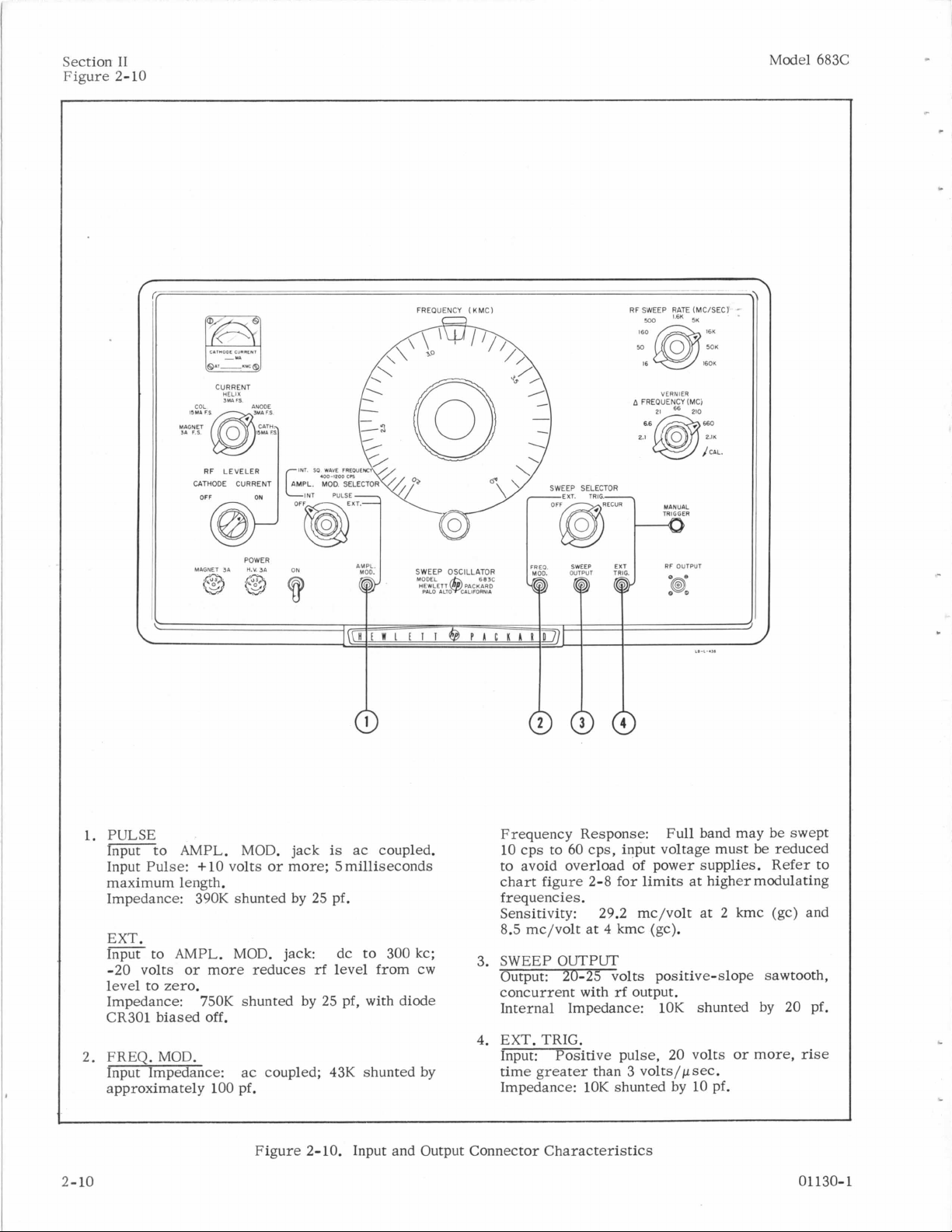

1.

PULSE

Ixto AMPL. MOD. jack

Input Pulse:

maximum length.

Impedance: 390K shunted by 25 pf.

EXT.

Input

to AMPL. MOD. jack dc

-20 volts

level to zero.

Impedance: 750K shunted by 25 pf, with diode

CR301

2. FREQ. MOD. Input: Positive pulse, 20 volts

Input Impedance:

approximately

+

10

or

more reduces

biased off.

100

volts or more; 5 milliseconds

ac coupled; 43K shunted by

pf.

is

ac coupled.

to

300

rf

level from cw

kc;

Frequency Response: Full band may be swept

10

cps

to

to avoid overload

chart figure 2-8 for limits at higher modulating

frequencies.

Sensitivity: 29.2 mc/volt at 2 kmc (gc) and

8.5 mc/volt at

3.

SWEEPOUTPUT

Output: 20-25 volts positive-slope sawtooth,

concurrent with

Internal Impedance:

4. EXT.TRIG.

time greater than

Impedance: 10K shunted by

60 cps, input voltage must be reduced

of

4

kmc (gc).

rf

output.

3

volts/psec.

power supplies. Refer to

10K

shunted by 20 pf.

10

pf.

or

more,

rise

2-10

Figure 2-

10.

Input and Output Connector Characteristics

01

130-

1

Page 20

Model 683C

Paragraphs 3-1 to 3-2

Section

Ill

SECTION

THEORY

3-1.

CONTENTS.

This section explains how the circuits of the sweep

oscillator operate. First, the overall operation of

the backward-wave osCillator tube

the bwo tube

characteristics of the tube are understood, an overall

picture of the purpose of the various circuits

easily understood.

3-2.

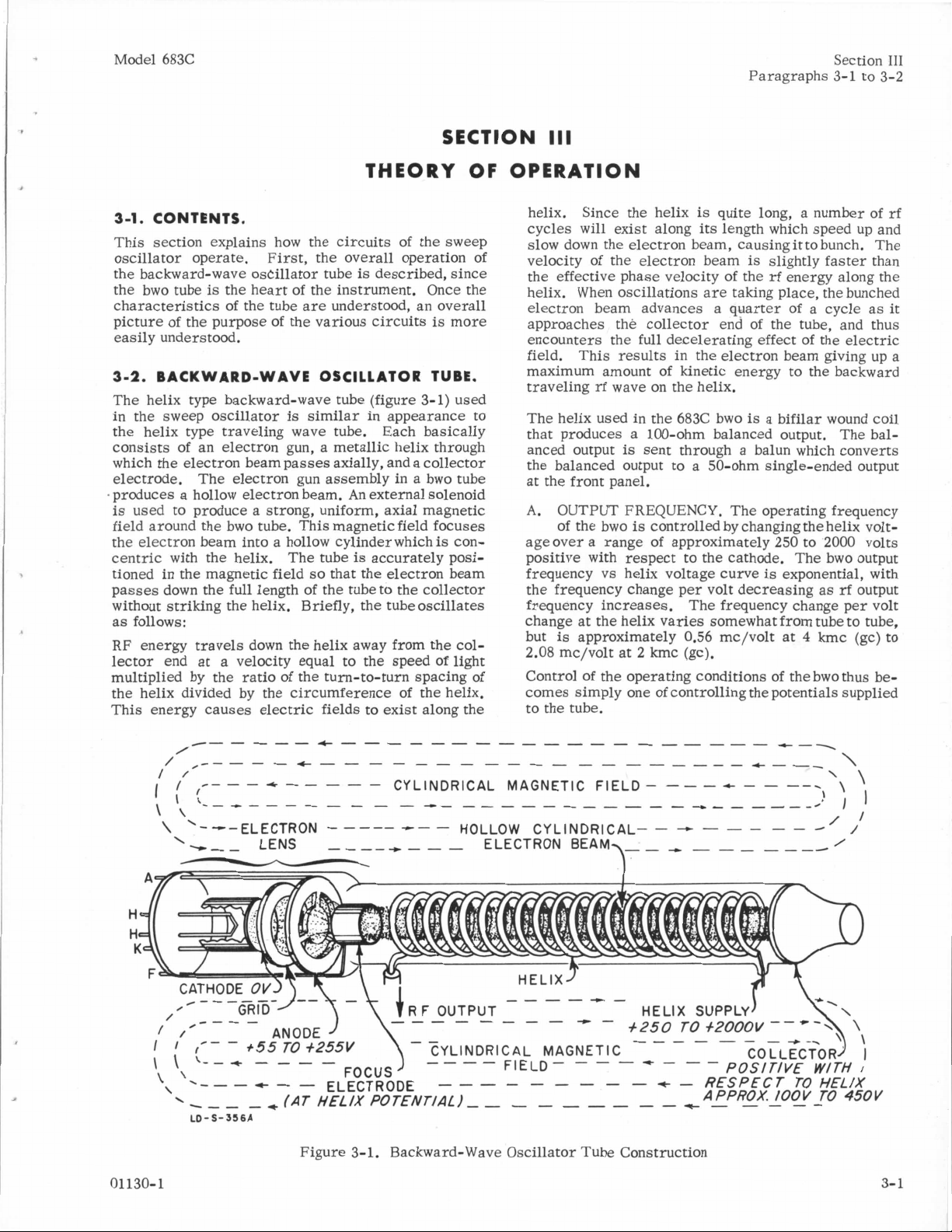

BACKWARD-WAVE OSCILLATOR TUBE.

The helix type backward-wave tube (figure 3in

the sweep oscillator

the helix type traveling wave tube, Each basically

consists of an electron gun, a metallic helix through

which the electron beam passes axially, and a collector

electrode. The electron gun assembly

.produces a hollow electron beam.

is

used to produce a strong, uniform, axial magnetic

field around the bwo tube. This magnetic field focuses

the electron beam into a hollow cylinder which

centric with the helix. The tube

tioned

passes down the full length of the tube to the collector

without striking the helix. Briefly, the tube oscillates

as follows:

RF energy travels down the helix away from the

lector end at a velocity equal to the speed of light

multiplied by the ratio of the turn-to-turn spacing of

the helix divided by the circumference of the helix.

This energy causes electric fields to exist along the

is

the heart of the instrument. Once

in

the magnetic field

is

similar

so

is

described, since

the

is

more

1)

used

in

appearance to

in

a bwo tube

An

external solenoid

is

con-

is

accurately posi-

that the electron beam

col-

111

OF

OPERATION

helix. Since the helix

cycles will exist along its length which speed up and

slow down the electron beam, causingit

velocity of the electron beam

the effective phase velocity of the

helix. When oscillations are taking place, the bunched

electron beam advances a quarter of a cycle as it

approaches

encounters the full decelerating effect of the electric

field. This results

maximum amount of kinetic energy to the backward

traveling

The helix used

that produces a 100-ohm balanced output.

anced output

the balanced output to a 50-ohm single-ended output

at the front panel.

A.

OUTPUT FREQUENCY. The operating frequency

of the bwo

ageover a range of approximately 250 to 2000 volts

positive with respect to the cathode.

frequency

the frequency change per volt decreasing as

frequency increases. The frequency change per volt

change at the helix varies somewhat from tube to tube,

but

is

2.08 mc/volt at

Control of the operating conditions of the bwo thus be-

comes simply one of controlling the potentials supplied

to the tube.

is

quite long, a number of

to

is

slightly faster than

rf

the

collector end of the tube, and thus

in

the electron beam giving up a

rf

wave on the helix.

in

the 683C bwo

is

sent through a balun which converts

is

controlled by changing the helix volt-

vs

helix voltage curve

approximately 0.56 mc/volt at 4 kmc (gc) to

2

kmc (gc).

is

a bifilar wound coil

is

bunch. The

energy along the

The bal-

The bwo output

exponential, with

rf

rf

output

01 130-

Figure 3-1. Backward-Wave Oscillator Tube Construction

3-

1

1

Page 21

Section 111

Paragraph 3-2 cont’d

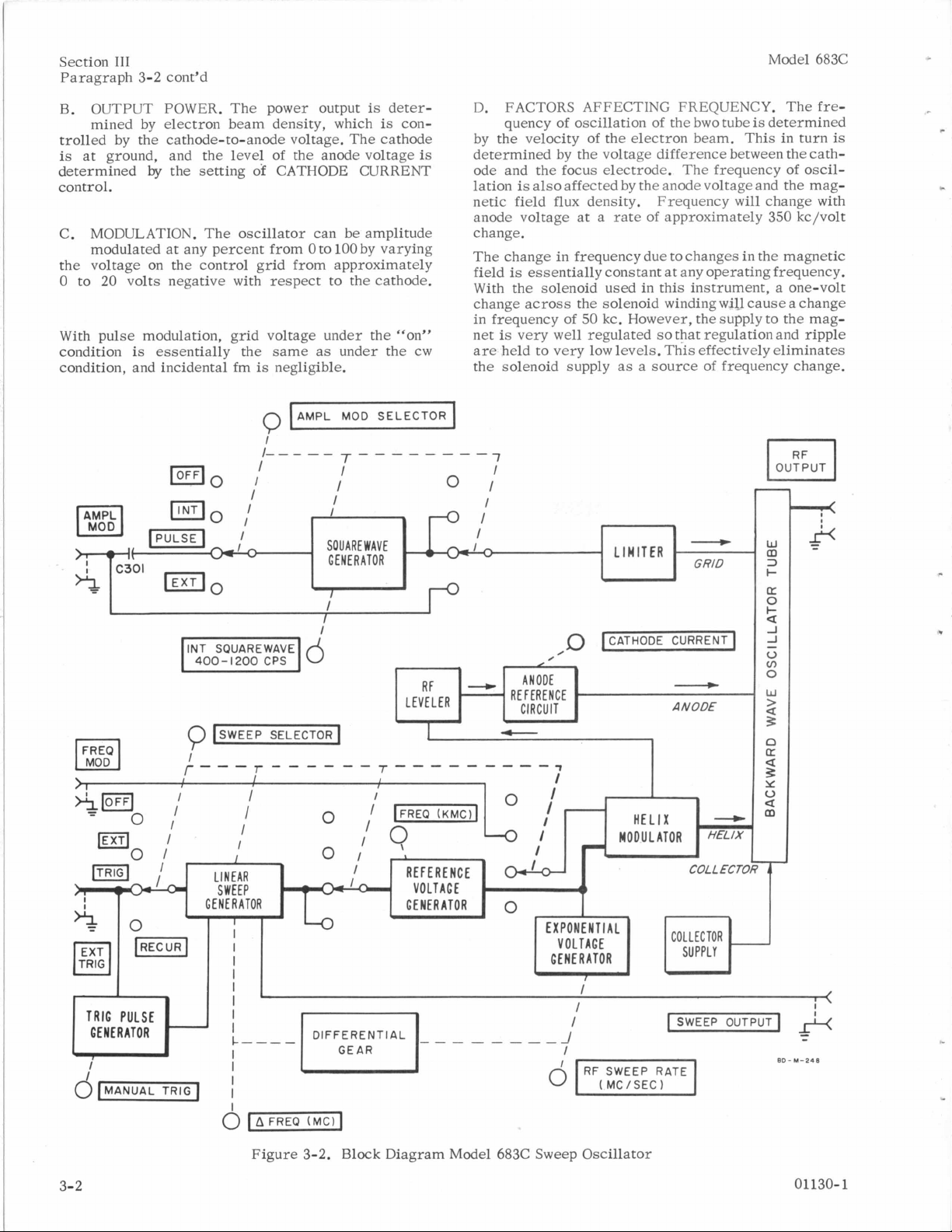

B.

OUTPUT POWER. The power output

mined by electron beam density, which

trolled by the cathode-to-anode voltage. The cathode

is

at

ground, and the level of the anode voltage

determined

control.

C. MODULATION. The oscillator can be amplitude

modulated at any percent from

the voltage on the control grid from approximately

0

to

With pulse modulation, grid voltage under the “on”

condition

condition, and incidental fm

by

the setting of CATHODE CURRENT

0

20 volts negative with respect

is

essentially the same

is

negligible.

AMPL

I

/-----

I

to

as

is

deter-

is

con-

100

by varying

to

the cathode.

under the cw

MOD

SELECTOR

r-------

I

I

is

Model 6836

D.

FACTORS AFFECTING FREQUENCY. The

quency

by the velocity

determined by the voltage difference between the cathode and the focus electrode. The frequency

lation

netic field flux density. Frequency will change with

anode voltage

change.

The change in frequency due

field

With the solenoid used in this instrument,

change

in frequency of

net

is

are

held

the solenoid supply

-7

I

01

of

oscillation

of

the electron beam. This in turn

is

alsoaffected by the anode voltageand the mag-

at

a

is

essentially constant

across

very well regulated

the solenoid winding will cause a change

50

kc. However, the supply

to

very low levels. This effectively eliminates

rate

as

of

the bwo tube

of

approximately

to

changes in the magnetic

at

any operating frequency.

is

to

so

that regulation and ripple

a

source

of frequency change.

determined

350

a

fre-

is

of

oscil-

kc/volt

one-volt

the mag-

.

>I

%

-

w

C301

I\

e.

.,

IEXTIO

Q

ISWEEP

LINEAR

SWEEP

GENE R ATOR GENERATOR

I

I

t

I

SELECTOR

SOUARE WAVE

GENERATOR

i

I

I

I--------

I

LEVELER

VOLTAGE

RF

I

I

“

---c

-

0

LIMITER

0

CATHODE

/

.

ANODE

REFERENCE

CIRCUIT

-1

I

41

EXPONENTIAL COLLECTOR

CURRENT

-

ANODE

I-

I

-W

GRID

1

m

~

3

IY

0

I-

U

-I

J

-

V

v)

0

W

>

4

0

U

a

s

Y

TRIG PULSE

It

GENERATOR

I

3-2

I

I

I

I

Figure 3-2. Block Diagram Model 683C Sweep Oscillator

SWEEP OUTPUT

ED-H-248

01130-1

Page 22

Model 683C

15OWW

(2I.Td b)

w

=

(20db)

0

@-

IWW

(Odb)

Figure 3-3.

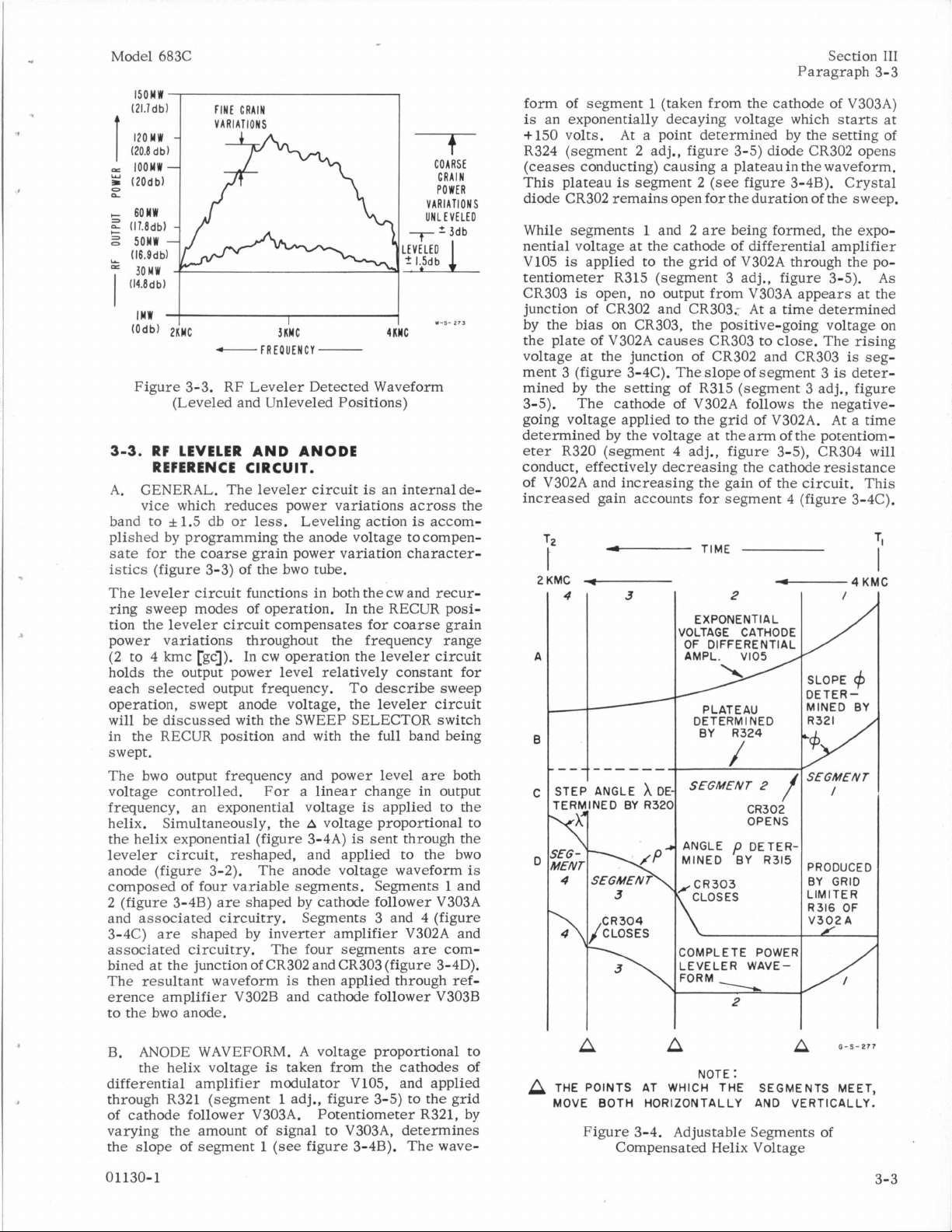

3-3.

RF LEVELER

REFERENCE CIRCUIT.

A.

GENERAL. The leveler circuit

vice which reduces power variations across the

band to 1.5 db or

plished by programming the anode voltage to compensate for the coarse grain power variation characteristics (figure 3-3) of the bwo tube.

The leveler circuit functions

ring sweep modes of operation.

tion the leveler circuit compensates for coarse grain

power variations throughout the frequency range

(2 to 4 kmc [gc]).

holds the output power level relatively constant for

each selected output frequency. To describe sweep

operation, swept anode voltage, the

will be discussed with the SWEEP SELECTOR switch

in

the RECUR position and with the

swept.

The bwo output frequency and power level are both

voltage controlled. For a linear change in output

frequency, an exponential voltage

helix. Simultaneously, the

the

helix exponential (figure 3-4A)

leveler circuit, reshaped, and applied to the bwo

anode (figure 3-2). The anode voltage waveform

composed of four variable segments. Segments 1 and

2 (figure 3-4B) are shaped by cathode follower V303A

and associated circuitry. Segments 3 and 4 (figure

3-4C) are shaped by inverter amplifier V302A and

associated circuitry. The four segments are combined at the junction of CR302 and CR303 (figure 3-4D).

The resultant waveform

erence

to the bwo anode.

B. ANODE WAVEFORM.

differential amplifier modulator V105, and applied

through R321 (segment

of cathode follower V303A. Potentiometer R321, by

varying the amount of signal to V303A. determines

the slope of segment

amplifier V302B and cathode follower V303B

the helix voltage

FINE

GRAIN

-+-

Lx

2

1.5db

2KYC 3KWC 4KWC

-FREOUENCY

RF Leveler Detected Waveform

(Leveled and Unleveled Positions)

I

-

AND

ANODE

is

an internal de-

less.

Leveling action

in

both the

In the RECUR posi-

In

cw

operation the

A

voltage proportional to

is

then applied through

A

is

1

voltage proportional to

taken from the cathodes of

1

adj., figure 3-5) to the grid

(see

figure 3-4B). The wave-

leveler

leveler

full

is

is

sent through the

is

cw

and

band being

applied to the

COARSE

GRAIN

POWER

VARIATIONS

UNLEVELED

2

3db

*-I-

273

accom-

recur-

circuit

circuit

is

ref-

Section

Paragraph 3-3

form of segment

is

an exponentially decaying voltage which starts at

+I50 volts.

R324 (segment 2 adj., figure 3-5) diode CR302 opens

(ceases conducting) causing a plateau

This plateau

diode CR302 remains open for the duration of the sweep.

While segments

nential voltage at the cathode of differential amplifier

VI05

is

applied to the grid of V302A through the potentiometer R315 (segment 3 adj., figure 3-5).

CR303

junction of CR302 and CR303.r At a time determined

by the bias on CR303, the positive-going voltage on

the plate of V302A causes CR303 to close. The rising

voltage at the junction of CR302 and CR303

ment

mined by the setting of R315 (segment

3-5). The cathode of V302A follows the negativegoing voltage applied to the grid of V302A. At a time

determined by the voltage at thearm of the potentiom-

eter

conduct, effectively decreasing the cathode resistance

of V302A and increasing the gain of the circuit. This

increased gain accounts for segment

is

open, no output from V303A appears at the

3

(figure 3-4C). The slope of segment

R320 (segment 4 adj., figure 3-5), CR304

i'

2KMC

41

STEP ANGLE

EG-h

VENT

4

SEGMEN

1

(taken from the cathode of V303A)

At

a point determined by

is

segment 2

-

3

/p

1

and 2 are being formed, the expo-

(see

TIME

I

EXPONENTIAL

VOLTAGE CATHODE

OF DIFFERENTIAL

P LATE AU

DETERMINED

BY A324

1

MINED ANGLE

COMPLETE POWER

in

figure 3-4B).

4

-

2

CR302

OPENS

p

BY

DETER- R315

2

the

setting of

the waveform.

3

is

3

adj., figure

(figure 3-4C).

i

SLOPE

DETERMINED BY

SEGMENT

/

PRODUCED

BY GRID

LIMITER

R316 OF

V302A

111

Crystal

As

is

seg-

deter-

will

4

KMC

4

I

A

A

A

THE POINTS AT WHICH THE

MOVE BOTH HORIZONTALLY AND VERTICALLY.

Figure 3-4. Adjustable Segments of

Compensated Helix Voltage

a

NOTE

SEGMENTS MEET,

6-5-217

01130-1

3-3

Page 23

Section 111

Paragraph 3-4

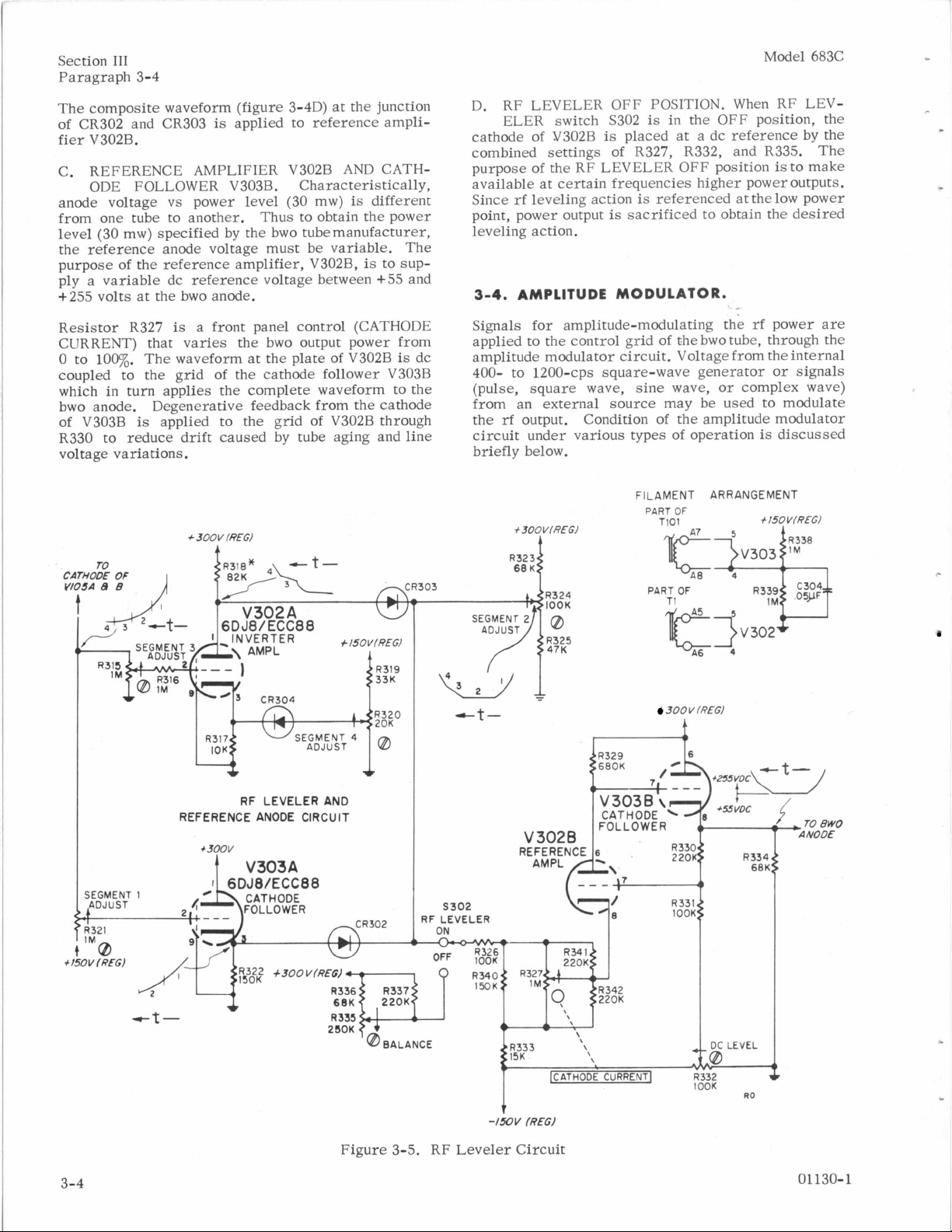

The composite waveform (figure 3-4D) at the junction

of CR302 and CR303 is applied to

fier

V302B.

reference

ampli-

C. REFERENCE AMPLIFIER V302B AND CATH-

ODE FOLLOWER V303B. Characteristically,

anode voltage

vs

power

level

(30 mw)

is

different

from one tube to another. Thus to obtain the power

level (30 mw) specified by

reference

the

purpose of

ply a variable dc

anode voltage must be variable. The

the

reference amplifier, V302B,

reference

the

bwo tubemanufacturer,

is

voltage between

to sup-

+55

and

+255 volts at the bwo anode.

Model 683C

D.

RF LEVELER OFF POSITION. When RF LEVELER switch S302 is in the

cathode of Y302B

is

placed at a dc reference by the

OFF

position, the

combined settings of R327, R332, and R335. The

purpose of the RF LEVELER OFF position

is

to make

available at certain frequencies higher power outputs.

Since

rf

leveling action

point, power output is sacrificed to obtain

is

referenced atthelow power

the

desired

leveling action.

3-4.

AMPLITUDE MODULATOR.

Resistor R327

is

a front panel control (CATHODE

CURRENT) that varies the bwo output power from

0

to 100%. The waveform at the plate of V302B

coupled to

which

the

grid of

in

turn applies the complete waveform to the

the

cathode follower V303B

is

dc

bwo anode. Degenerative feedback from the cathode

of V303B

is

applied to the grid of V302B through

R330 to reduce drift caused by tube aging andline

voltage variations.

i3OOV

(REG)

A

TO

CATHODE

VIOSA

OF

a

B

V302A

R320

20K

Y

RF LEVELER AND

REFERENCE ANODE CIRCUIT

1

Signals for amplitude-modulating the

applied to

the

control grid of the bwo tube, through the

rf

power are

amplitude modulator circuit. Voltage from the internal

400- to 1200-cps square-wave generator or signals

(pulse, square wave,

sine

wave, or complex wave)

from an external source may be used to modulate

the

rf

output. Condition of the amplitude modulator

circuit under various types of operation

is

discussed

briefly below.

FILAMENT ARRANGEMENT

PART

OF

et-

i

300

I33231

68

K

!&a24

V/REG)

IOOK

TI01

300

V

c

A0

(REG1

tl5OVIREG)

t-/

3-4

JEGMENT

JEGMENT

ADJUST

ADJUST

pam

R321

1

IM@

\e/

3V

(REG1

3V

(REG1

1

1

CATHODE

FOLLOW

E R

S302

?F

-CR302

vu

BALANCE

Figure 3-5. RF Leveler Circuit

Figure 3-5. RF Leveler Circuit

LEVEL.ER

ON

R333

15K

-fx)V

-fx)V

(REG)

(REG)

"?"

\

\

\

\

ICATHODE

ICATHODE

CURRENT]

CURRENT]

R331

IOOK

R332

R332

IOOK

IOOK

..

RO

RO

01130-1

Page 24

Model 683C

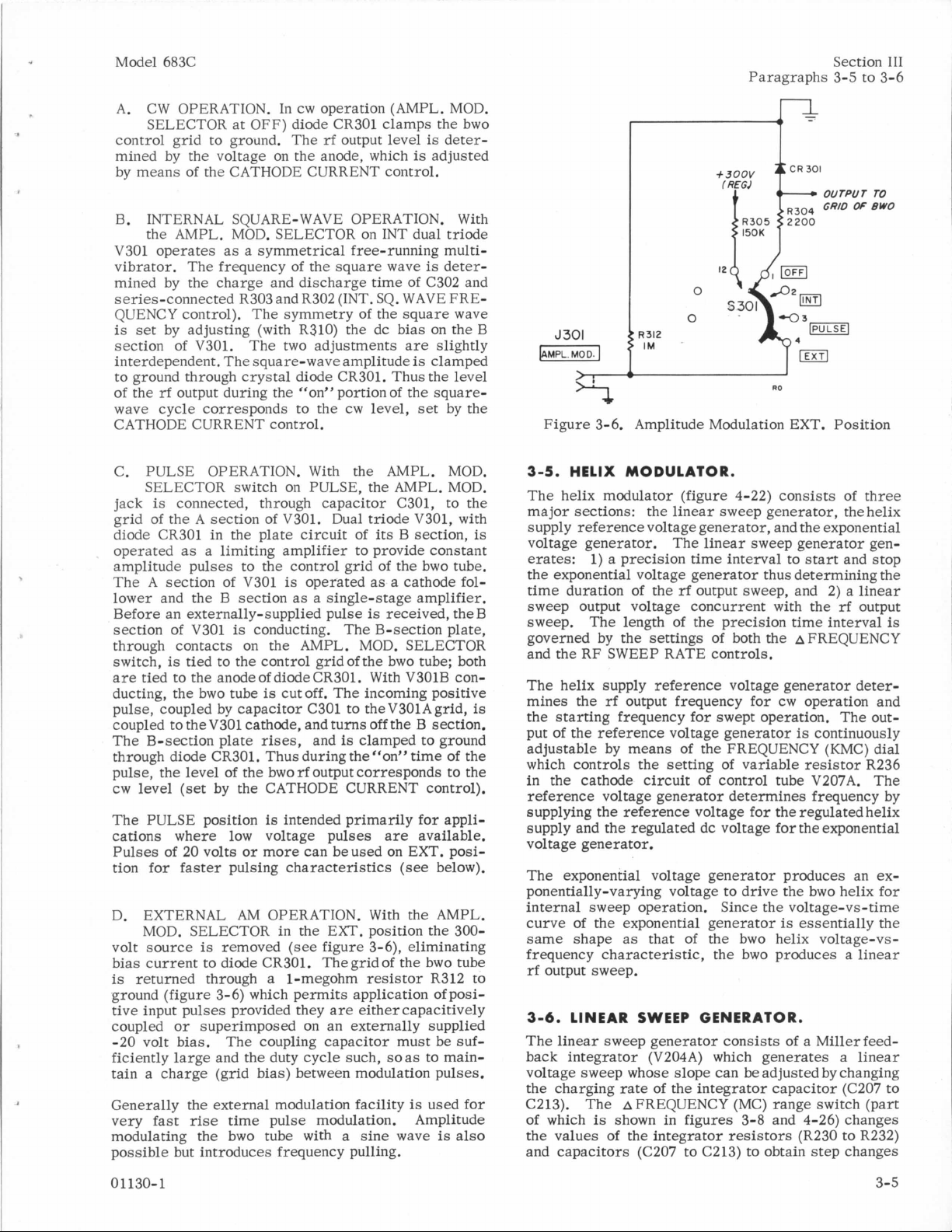

A.

CW

OPERATION.

In

cw operation (AMPL.

MOD.

SELECTOR at OFF) diode CR301 clamps the bwo

control grid to ground. The

mined by the voltage on

rf

output level

the

anode, which

is

is

adjusted

deter-

by means of the CATHODE CURRENT control.

B.

INTERNAL SQUARE-WAVE OPERATION. With

the AMPL.

MOD.

SELECTOR on INT dual triode

V301 operates as a symmetrical free-running multivibrator. The frequency

mined

by

the charge and discharge time of C302 and

of

the

square wave

is

deter-

series-connected R303 and R302 (INT. SQ. WAVE FREQUENCY control). The symmetry of

is

set by adjusting (with

R3lO)

the

square wave

the dc bias on the

B

section of V301. The two adjustments are slightly

interdependent. The square-wave amplitude

is

clamped

to ground through crystal diode CR301. Thus the level

of the

rf

output during the “on”portionof the squarewave cycle corresponds to the cw level, set by the

CATHODE CURRENT control.

Paragraphs 3-5 to 3-6

Section

OUTPU

r

OF

TO

BWO

’5

R304

GRID

-

RO

Figure 3-6. Amplitude Modulation EXT. Position

Ill

C. PULSE OPERATION. With the AMPL.

SELECTOR switch on PULSE, the AMPL.

jack

is

connected, through capacitor C301, to the

grid of the

diode CR301

A

section of V301. Dual triode V301,

in

the plate circuit of

its

B

MOD.

MOD.

with

section,

is

operated as a limiting amplifier to provide constant

amplitude pulses to the control grid of the bwo tube.

The

A

section of V301

lower and the

B

Before an externally-supplied pulse

section of V301

is

through contacts on the AMPL.

switch,

is

tied to the control grid of the bwo tube; both

is

operated as a cathode fol-

section as a single-stage amplifier.

is

received,

the

conducting. The B-section plate,

MOD.

SELECTOR

are tied to the anode of diode CR301. With V301B conducting, the bwo tube

pulse, coupled by capacitor C301 to theV301Agrid,

is

cut off. The incoming positive

is

coupled to theV301 cathode, and turns off the B section.

The B-section plate rises, and

is

clamped

to

ground

through diode CR301. Thus during the “on” time of the

pulse, the level of the bwo

rf

output corresponds to the

cw level (set by the CATHODE CURRENT control).

The PULSE position

is

intended primarily

for

applications where low voltage pulses are available.

Pulses of

tion for faster pulsing characteristics

D.

volt source

20

volts or more can beused on EXT. posi-

EXTERNAL

MOD.

SELECTOR

is

(see

below).

AM

OPERATION. With the AMPL.

in

the Em. position the 300-

removed (see figure 3-6), eliminating

bias current to diode CR301. Thegridof the bwo tube

is

returned through a 1-megohm resistor R312 to

ground (figure 3-6) which permits application of posi-

tive input pulses provided

they

are either capacitively

coupled or superimposed on an externally supplied

-20

volt bias. The coupling capacitor must be

sufficiently large and the duty cycle such, soas to maintain a charge (grid bias) between modulation pulses.

Generally

very fast

modulating the bwo tube with a sine wave

the

external modulation facility

rise

time pulse modulation. Amplitude

is

used for

is

also

possible but introduces frequency pulling.

B

3-5.

HELIX MODULATOR.

The helix modulator (figure 4-22) consists of three

major sections:

the

linear sweep generator, the helix

supply reference voltage generator, and the exponential

voltage generator. The linear sweep generator generates:

1)

a precision time interval to start and stop

the exponential voltage generator thus determining the

time duration of the

sweep output voltage concurrent with the

sweep. The length of the precision time interval

rf

output sweep, and

2)

a linear

rf

output

is

governed by the settings of both the AFREQUENCY

and the RF SWEEP RATE controls.

The helix supply reference voltage generator determines the

rf

output frequency for cw operation and

the starting frequency for swept operation. The output of the reference voltage generator

adjustable by means of the FREQUENCY

which controls the setting

in

the cathode circuit of control tube V207A. The

of

variable resistor R236

is

continuously

(KMC)

dial

reference voltage generator determines frequency by

supplying the reference voltage for the regulated helix

supply and the regulated dc voltage for the exponential

voltage generator.

The exponential voltage generator produces an exponentially-varying voltage to drive the bwo helix for

internal sweep operation. Since the voltage-vs-time

curve

of the exponential generator

is

essentially

the

same shape as that of the bwo helix voltage-vsfrequency characteristic, the bwo produces a linear

rf

output sweep.

3-6.

LINEAR SWEEP GENERATOR.

The linear sweep generator consists of a Miller feed-

back integrator (V204A) which generates a linear

voltage sweep whose slope can be adjusted by changing

the charging rate

of

the integrator capacitor ((2207 to

C213). The AFREQUENCY (MC) range switch (part

of which

is

shown in figures 3-8 and 4-26) changes

the values of the integrator resistors (R230 to R232)

and capacitors (C207 to (2213) to obtain step changes

01130-1

3-5

Page 25

Section

Figure

111

3-7

Model

683C

:N

I I !

v201

PIN

7

(0)

I

:

-1I5V

v201

PIN

1

(C)

I

;

-I14V,

'J

I

I

V208

PIN

9

(

rn)

s2-40v

V208

v202

I

PIN

7

DIODE

I

I

-25V.

-1ov'

,-23V

V204

PIN

(e)

3-6

8

;

I

t3T0

tt

fpTO

A

.-2.0

14

=

SWEEP TIME

lz1

15

RECOVERY AN0 HOLD-OFF TIME

FREOUENCY

,

NOTES

2.

I

KMC

-

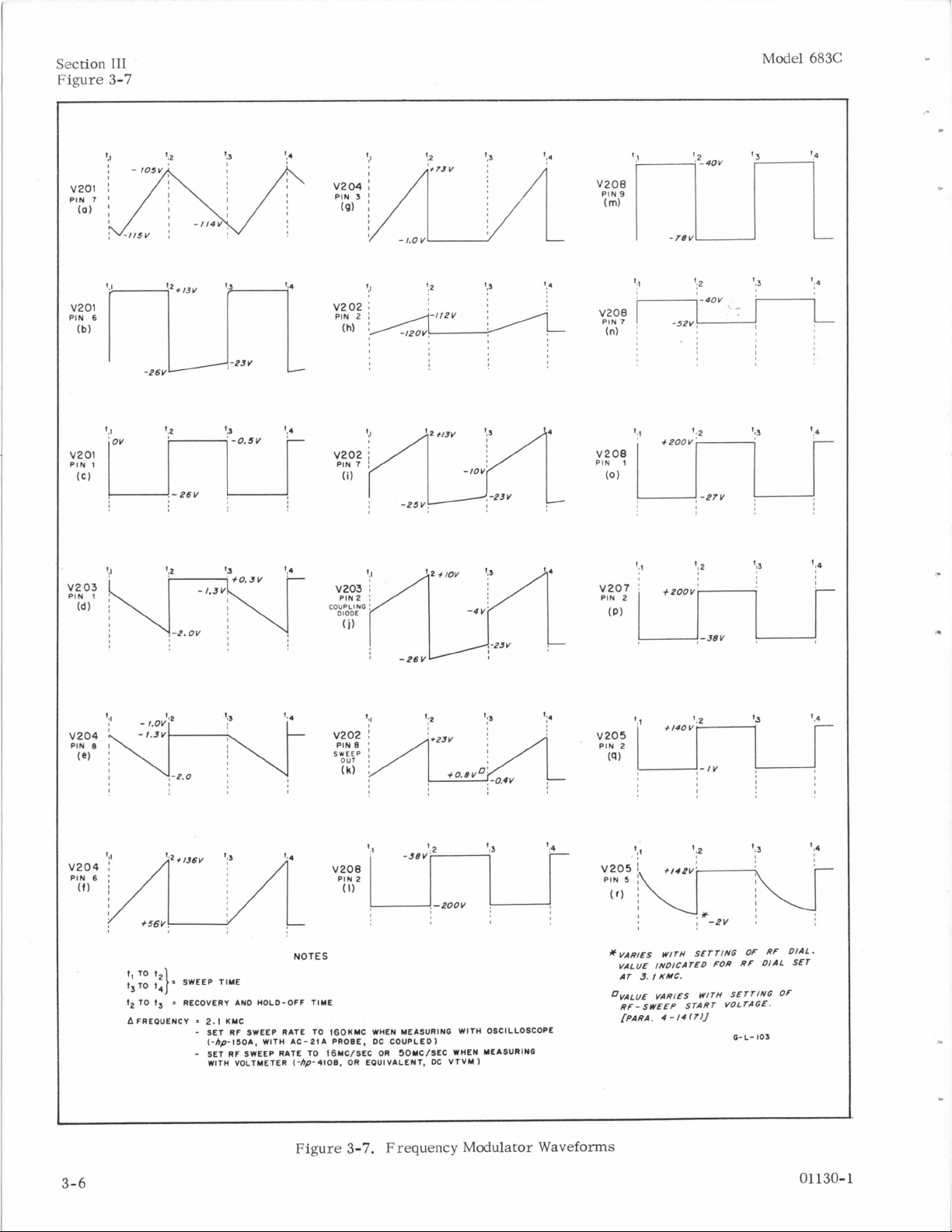

SET RF SWEEP RATE

(-bp150A, WITH AC-2tA PROBE, DC COUPLED)

-

SET RF SWEEP RATE

WITH

VOLTMETER

TO

t6OKMC WHEN YEASURING WITH OSCILLOSCOPE

TO

16YC/SEC

(-hp-4lOB,

Figure

OR

OR

3-7.

SOMC/SEC WHEN MEASURlNO

EQUIVALENT, OC

Frequency Modulator

VTVM)

Waveforms

*VARIES

a~~~~~

WITH

f

KMC.

VARIES

4 - I4

SETTING

FOR

WITH

171J

RF

SETTING OF

G- L-

VALUE INDICATED

Ar

3.

RF-SWEEP START VOLTAGE.

[PARA.

OF

RF

DIAL

103

DIAL.

SET

01

130-

1

Page 26

Model 683C

Paragraph 3-6 cont’d

Section

I11

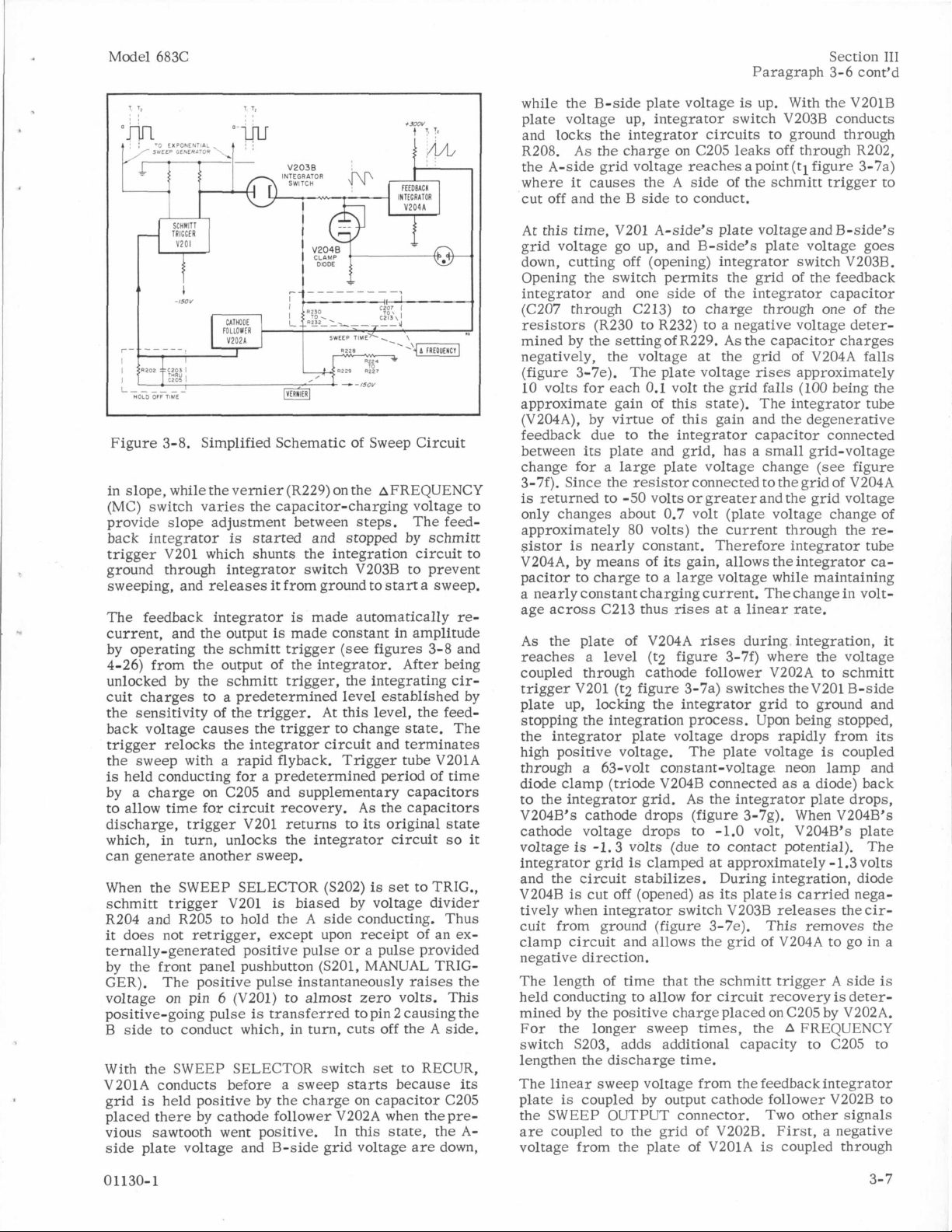

Figure 3-8. Simplified Schematic of Sweep Circuit

in slope, while the

(MC) switch varies the capacitor-charging voltage to

provide slope adjustment between steps. The feedback integrator

trigger V201 which shunts the integration circuit to

ground through integrator switch V203B to prevent

sweeping, and releases

The feedback integrator

current, and the output

by operating the schmitt trigger

4-26) from the output of the integrator. After being

unlocked by the schmitt trigger, the integrating

cuit charges to a predetermined level established by

the sensitivity of the trigger.

back voltage causes the trigger to change state. The

trigger relocks the integrator circuit and terminates

the sweep with a rapid flyback. Trigger tube V201A

is

held conducting for a predetermined period of time

by a charge on C205 and supplementary capacitors

to allow time for circuit recovery.

discharge, trigger V201 returns to

which, in turn, unlocks the integrator circuit

can generate another sweep,

When the SWEEP SELECTOR (S202)

schmitt trigger V201

R204 and R205 to hold the

it does not retrigger, except upon receipt of an externally-generated positive pulse or a pulse provided

by the front panel pushbutton (S201, MANUAL TRIGGER). The positive pulse instantaneously raises the

voltage

positive-going pulse