Page 1

HP 6400/8400 Enterprise Virtual Array User Guide

Abstract

This document describes the components and operation of the HP 6400/8400 Enterprise Virtual Array.

HP Part Number: 5697-2479

Published: September 2013

Edition: 9

Page 2

© Copyright 2009, 2013 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or omissions contained herein.

Warranty

WARRANTY STATEMENT: To obtain a copy of the warranty for this product, see the warranty information website:

http://www.hp.com/go/storagewarranty

Acknowledgements

Microsoft® and Windows® are U.S. registered trademarks of Microsoft Corporation.

Java® and Oracle® are registered U.S. trademark of Oracle Corporation or its affiliates.

UNIX® is a registered trademark of The Open Group.

Page 3

Contents

1 EVA6400/8400 hardware..........................................................................9

M6412A disk enclosures............................................................................................................9

Enclosure layout...................................................................................................................9

I/O modules.....................................................................................................................10

I/O module status indicators..........................................................................................10

Fiber optic Fibre Channel cables..........................................................................................11

Copper Fibre Channel cables..............................................................................................12

Fibre Channel disk drives....................................................................................................12

Disk drive status indicators..............................................................................................12

Disk drive blank............................................................................................................13

Controller enclosures...............................................................................................................13

Operator control panel.......................................................................................................14

Status indicators............................................................................................................15

Navigation buttons........................................................................................................16

Alphanumeric display....................................................................................................16

Power supplies.......................................................................................................................16

Blower module.......................................................................................................................17

Battery module.......................................................................................................................17

HSV controller cabling............................................................................................................18

Storage system racks...............................................................................................................19

Rack configurations............................................................................................................19

Power distribution–Modular PDUs.............................................................................................20

PDUs................................................................................................................................21

PDU A.........................................................................................................................22

PDU B.........................................................................................................................22

PDMs...............................................................................................................................22

Rack AC power distribution.................................................................................................23

Rack System/E power distribution components.......................................................................24

Rack AC power distribution............................................................................................24

Moving and stabilizing a rack..................................................................................................25

2 Enterprise Virtual Array startup ..................................................................27

EVA8400 storage system connections........................................................................................27

EVA6400 storage system connections.......................................................................................28

Direct connect........................................................................................................................28

iSCSI connection configurations................................................................................................29

Fabric connect iSCSI..........................................................................................................29

Direct connect iSCSI...........................................................................................................29

Procedures for getting started...................................................................................................30

Gathering information........................................................................................................30

Host information...........................................................................................................30

Setting up a controller pair using the OCP............................................................................30

Entering the WWN.......................................................................................................31

Entering the WWN checksum.........................................................................................32

Entering the storage system password..............................................................................32

Installing HP P6000 Command View....................................................................................32

Installing optional EVA software licenses...............................................................................33

3 EVA6400/8400 operation........................................................................34

Best practices.........................................................................................................................34

Operating tips and information................................................................................................34

Reserving adequate free space............................................................................................34

Contents 3

Page 4

Using FATA disk drives........................................................................................................34

Using solid state disk drives.................................................................................................34

QLogic HBA speed setting..................................................................................................34

EVA6400/8400 host port negotiates to incorrect speed.........................................................34

Creating 16 TB or greater virtual disks in Windows 2008.......................................................35

Importing Windows dynamic disk volumes............................................................................35

Losing a path to a dynamic disk..........................................................................................35

Microsoft Windows 2003 MSCS cluster installation................................................................35

Managing unused ports......................................................................................................35

Changing the host port connectivity......................................................................................35

Failback preference setting for HSV controllers............................................................................37

Changing virtual disk failover/failback setting.......................................................................39

Implicit LUN transition.........................................................................................................39

Storage system shutdown and startup........................................................................................39

Shutting down the storage system.........................................................................................40

Starting the storage system..................................................................................................40

Saving storage system configuration data...................................................................................40

Adding disk drives to the storage system....................................................................................42

Creating disk groups..........................................................................................................42

Handling fiber optic cables......................................................................................................43

Using the OCP.......................................................................................................................43

Displaying the OCP menu tree.............................................................................................43

Displaying system information..............................................................................................44

Displaying versions system information..................................................................................45

Shutting down the system....................................................................................................45

Shutting the controller down................................................................................................46

Restarting the system..........................................................................................................46

Uninitializing the system......................................................................................................46

Password options...............................................................................................................47

Changing a password........................................................................................................47

Clearing a password..........................................................................................................47

4 Configuring application servers..................................................................48

Overview..............................................................................................................................48

Clustering..............................................................................................................................48

Multipathing..........................................................................................................................48

Installing Fibre Channel adapters..............................................................................................48

Testing connections to the EVA.................................................................................................49

Adding hosts..........................................................................................................................49

Creating and presenting virtual disks.........................................................................................49

Verifying virtual disk access from the host...................................................................................50

Configuring virtual disks from the host.......................................................................................50

HP-UX...................................................................................................................................50

Scanning the bus...............................................................................................................50

Creating volume groups on a virtual disk using vgcreate.........................................................51

IBM AIX................................................................................................................................51

Accessing IBM AIX utilities..................................................................................................51

Adding hosts.....................................................................................................................52

Creating and presenting virtual disks....................................................................................52

Verifying virtual disks from the host.......................................................................................52

Linux.....................................................................................................................................52

HBA drivers.......................................................................................................................52

Verifying virtual disks from the host.......................................................................................53

OpenVMS.............................................................................................................................53

4 Contents

Page 5

Updating the AlphaServer console code, Integrity Server console code, and Fibre Channel FCA

firmware...........................................................................................................................53

Verifying the Fibre Channel adapter software installation........................................................53

Console LUN ID and OS unit ID...........................................................................................53

Adding OpenVMS hosts.....................................................................................................54

Scanning the bus...............................................................................................................55

Configuring virtual disks from the OpenVMS host...................................................................56

Setting preferred paths.......................................................................................................56

Oracle Solaris........................................................................................................................56

Loading the operating system and software...........................................................................56

Configuring FCAs with the Oracle SAN driver stack...............................................................56

Configuring Emulex FCAs with the lpfc driver....................................................................57

Configuring QLogic FCAs with the qla2300 driver.............................................................58

Fabric setup and zoning.....................................................................................................60

Oracle StorEdge Traffic Manager (MPxIO)/Oracle Storage Multipathing..................................60

Configuring with Veritas Volume Manager............................................................................60

Configuring virtual disks from the host...................................................................................61

Verifying virtual disks from the host..................................................................................63

Labeling and partitioning the devices...............................................................................63

VMware................................................................................................................................64

Configuring the EVA6400/8400 with VMware host servers....................................................64

Configuring an ESX server ..................................................................................................64

Loading the FCA NVRAM..............................................................................................64

Setting the multipathing policy........................................................................................65

Specifying DiskMaxLUN.................................................................................................66

Verifying connectivity.....................................................................................................66

Verifying virtual disks from the host.......................................................................................66

Verifying virtual disks from the host.......................................................................................66

HP EVA P6000 Software Plug-in for VMware VAAI.................................................................67

System prerequisites......................................................................................................67

Enabling vSphere Storage API for Array Integration (VAAI).................................................67

Installing the VAAI Plug-in...............................................................................................68

Installation overview.................................................................................................68

Installing the HP EVA VAAI Plug-in using ESX host console utilities...................................69

Installing the HP VAAI Plug-in using vCLI/vMA.............................................................70

Installing the VAAI Plug-in using VUM.........................................................................72

Uninstalling the VAAI Plug-in...........................................................................................74

Uninstalling VAAI Plug-in using the automated script (hpeva.pl).......................................74

Uninstalling VAAI Plug-in using vCLI/vMA (vihostupdate)...............................................74

Uninstalling VAAI Plug-in using VMware native tools (esxupdate)....................................74

Windows..............................................................................................................................75

Verifying virtual disk access from the host..............................................................................75

Setting the Pending Timeout value for large cluster configurations.............................................75

5 Customer replaceable units........................................................................76

Customer self repair (CSR).......................................................................................................76

Parts only warranty service..................................................................................................76

Best practices for replacing hardware components......................................................................76

Component replacement videos...........................................................................................76

Verifying component failure.................................................................................................76

Identifying the spare part....................................................................................................76

Replaceable parts...................................................................................................................77

Replacing the failed component................................................................................................79

Replacement instructions..........................................................................................................79

Contents 5

Page 6

6 Support and other resources......................................................................80

Contacting HP........................................................................................................................80

Subscription service............................................................................................................80

Documentation feedback....................................................................................................80

Related information.................................................................................................................80

Documents........................................................................................................................80

HP websites......................................................................................................................80

Typographic conventions.........................................................................................................81

Rack stability..........................................................................................................................82

Customer self repair................................................................................................................82

A Regulatory compliance notices...................................................................83

Regulatory compliance identification numbers............................................................................83

Federal Communications Commission notice..............................................................................83

FCC rating label................................................................................................................83

Class A equipment........................................................................................................83

Class B equipment........................................................................................................83

Declaration of Conformity for products marked with the FCC logo, United States only.................84

Modification.....................................................................................................................84

Cables.............................................................................................................................84

Canadian notice (Avis Canadien).............................................................................................84

Class A equipment.............................................................................................................84

Class B equipment.............................................................................................................84

European Union notice............................................................................................................84

Japanese notices....................................................................................................................85

Japanese VCCI-A notice......................................................................................................85

Japanese VCCI-B notice......................................................................................................85

Japanese VCCI marking.....................................................................................................85

Japanese power cord statement...........................................................................................85

Korean notices.......................................................................................................................85

Class A equipment.............................................................................................................85

Class B equipment.............................................................................................................86

Taiwanese notices...................................................................................................................86

BSMI Class A notice...........................................................................................................86

Taiwan battery recycle statement..........................................................................................86

Turkish recycling notice............................................................................................................86

Vietnamese Information Technology and Communications compliance marking...............................86

Laser compliance notices.........................................................................................................87

English laser notice............................................................................................................87

Dutch laser notice..............................................................................................................87

French laser notice.............................................................................................................87

German laser notice...........................................................................................................88

Italian laser notice..............................................................................................................88

Japanese laser notice.........................................................................................................88

Spanish laser notice...........................................................................................................89

Recycling notices....................................................................................................................89

English recycling notice......................................................................................................89

Bulgarian recycling notice...................................................................................................90

Czech recycling notice........................................................................................................90

Danish recycling notice.......................................................................................................90

Dutch recycling notice.........................................................................................................90

Estonian recycling notice.....................................................................................................91

Finnish recycling notice.......................................................................................................91

French recycling notice.......................................................................................................91

German recycling notice.....................................................................................................91

6 Contents

Page 7

Greek recycling notice........................................................................................................92

Hungarian recycling notice.................................................................................................92

Italian recycling notice........................................................................................................92

Latvian recycling notice.......................................................................................................92

Lithuanian recycling notice..................................................................................................93

Polish recycling notice.........................................................................................................93

Portuguese recycling notice.................................................................................................93

Romanian recycling notice..................................................................................................93

Slovak recycling notice.......................................................................................................94

Spanish recycling notice.....................................................................................................94

Swedish recycling notice.....................................................................................................94

Battery replacement notices.....................................................................................................94

Dutch battery notice...........................................................................................................94

French battery notice..........................................................................................................95

German battery notice........................................................................................................95

Italian battery notice..........................................................................................................96

Japanese battery notice......................................................................................................96

Spanish battery notice........................................................................................................97

B Error messages.........................................................................................98

C Controller fault management....................................................................107

Using HP P6000 Command View...........................................................................................107

GUI termination event display................................................................................................107

GUI event display............................................................................................................107

Fault management displays...............................................................................................108

Displaying Last Fault Information...................................................................................108

Displaying Detailed Information....................................................................................108

Interpreting fault management information......................................................................109

D Non-standard rack specifications..............................................................110

Rack specifications................................................................................................................110

Internal component envelope.............................................................................................110

EIA310-D standards..........................................................................................................110

EVA cabinet measures and tolerances.................................................................................110

Weights, dimensions and component CG measurements.......................................................110

Airflow and Recirculation..................................................................................................111

Component Airflow Requirements..................................................................................111

Rack Airflow Requirements...........................................................................................111

Configuration Standards...................................................................................................111

Environmental and operating specifications..............................................................................111

UPS Selection..................................................................................................................111

Shock and vibration specifications......................................................................................113

E Single Path Implementation......................................................................115

High-level solution overview...................................................................................................115

Benefits at a glance..............................................................................................................115

Installation requirements........................................................................................................116

Recommended mitigations.....................................................................................................116

Supported configurations.......................................................................................................116

General configuration components.....................................................................................116

Connecting a single path HBA server to a switch in a fabric zone..........................................116

HP-UX configuration.........................................................................................................118

Requirements..............................................................................................................118

HBA configuration.......................................................................................................118

Risks..........................................................................................................................119

Limitations..................................................................................................................119

Contents 7

Page 8

Windows Server (32-bit) configuration................................................................................119

Requirements..............................................................................................................119

HBA configuration.......................................................................................................120

Risks..........................................................................................................................120

Limitations..................................................................................................................120

Windows Server (64-bit) configuration................................................................................121

Requirements..............................................................................................................121

HBA configuration.......................................................................................................121

Risks..........................................................................................................................121

Limitations..................................................................................................................121

Oracle Solaris configuration..............................................................................................122

Requirements..............................................................................................................122

HBA configuration.......................................................................................................122

Risks..........................................................................................................................123

Limitations..................................................................................................................123

Tru64 UNIX configuration.................................................................................................123

Requirements..............................................................................................................123

HBA configuration.......................................................................................................124

Risks..........................................................................................................................124

OpenVMS configuration...................................................................................................125

Requirements..............................................................................................................125

HBA configuration.......................................................................................................125

Risks..........................................................................................................................125

Limitations..................................................................................................................126

Linux (32-bit) configuration................................................................................................126

Requirements..............................................................................................................126

HBA configuration.......................................................................................................126

Risks..........................................................................................................................127

Limitations..................................................................................................................127

Linux (64-bit) configuration................................................................................................127

Requirements..............................................................................................................127

HBA configuration.......................................................................................................128

Risks..........................................................................................................................128

Limitations..................................................................................................................128

IBM AIX configuration......................................................................................................129

Requirements..............................................................................................................129

HBA configuration.......................................................................................................129

Risks..........................................................................................................................129

Limitations..................................................................................................................129

VMware configuration......................................................................................................130

Requirements..............................................................................................................130

HBA configuration.......................................................................................................130

Risks..........................................................................................................................130

Limitations..................................................................................................................131

Failure scenarios...................................................................................................................131

HP-UX.............................................................................................................................131

Windows Server .............................................................................................................132

Oracle Solaris.................................................................................................................132

OpenVMS and Tru64 UNIX..............................................................................................133

Linux..............................................................................................................................133

IBM AIX..........................................................................................................................134

VMware.........................................................................................................................134

Glossary..................................................................................................136

Index.......................................................................................................147

8 Contents

Page 9

1 EVA6400/8400 hardware

The EVA6400/8400 contains the following hardware components:

• HSV controllers—Contains power supplies, cache batteries, fans, and an operator control

panel (OCP)

• Fibre Channel disk enclosure—Contains disk drives, power supplies, fans, midplane, and I/O

modules

• Fibre Channel Arbitrated Loop cables—Provides connectivity to the HSV controllers and the

Fibre Channel disk enclosures

• Rack—Several free standing racks are available

M6412A disk enclosures

The M6412A disk enclosure contains the disk drives used for data storage; a storage system

contains multiple disk enclosures. The major components of the enclosure are:

• 12-bay enclosure

• Dual-loop, Fibre Channel drive enclosure I/O modules

• Copper Fibre Channel cables

• Fibre Channel disk drives and drive blanks

• Power supplies

• Fan modules

Enclosure layout

The disk drives mount in bays in the front of the enclosure. The bays are numbered sequentially

from top to bottom and left to right. A drive is referred to by its bay number (see Figure 1 (page

9)). Enclosure status indicators are located at the right of each disk. Figure 2 (page 9) shows

the front and Figure 3 (page 10) shows the rear view of the disk enclosure.

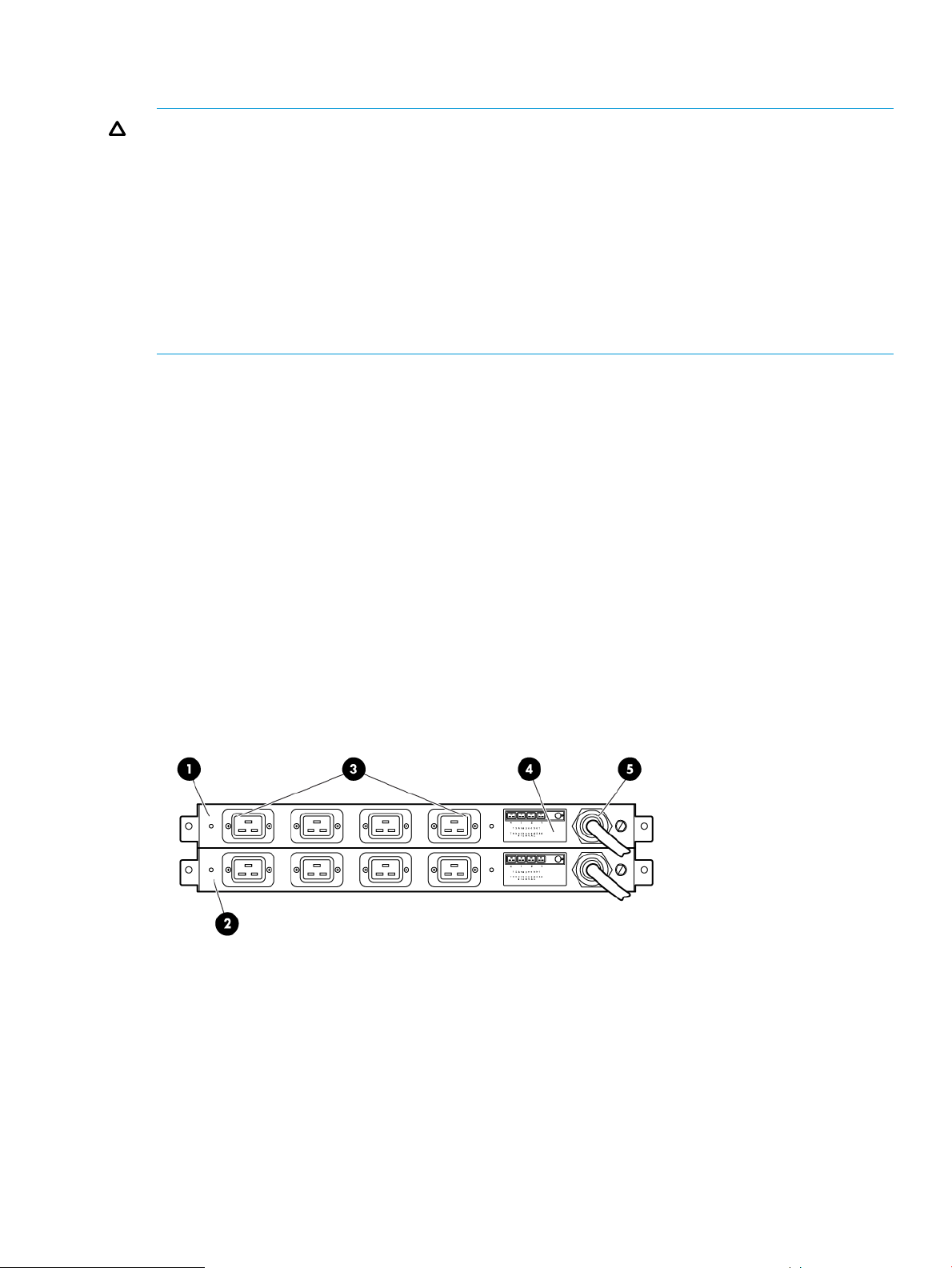

Figure 1 Disk drive bay numbering

Figure 2 Disk enclosure front view without bezel ears

3. Drive LEDs

4. UID push button1. Rack-mounting thumbscrew

5. Enclosure status LEDs2. Disk drive release

M6412A disk enclosures 9

Page 10

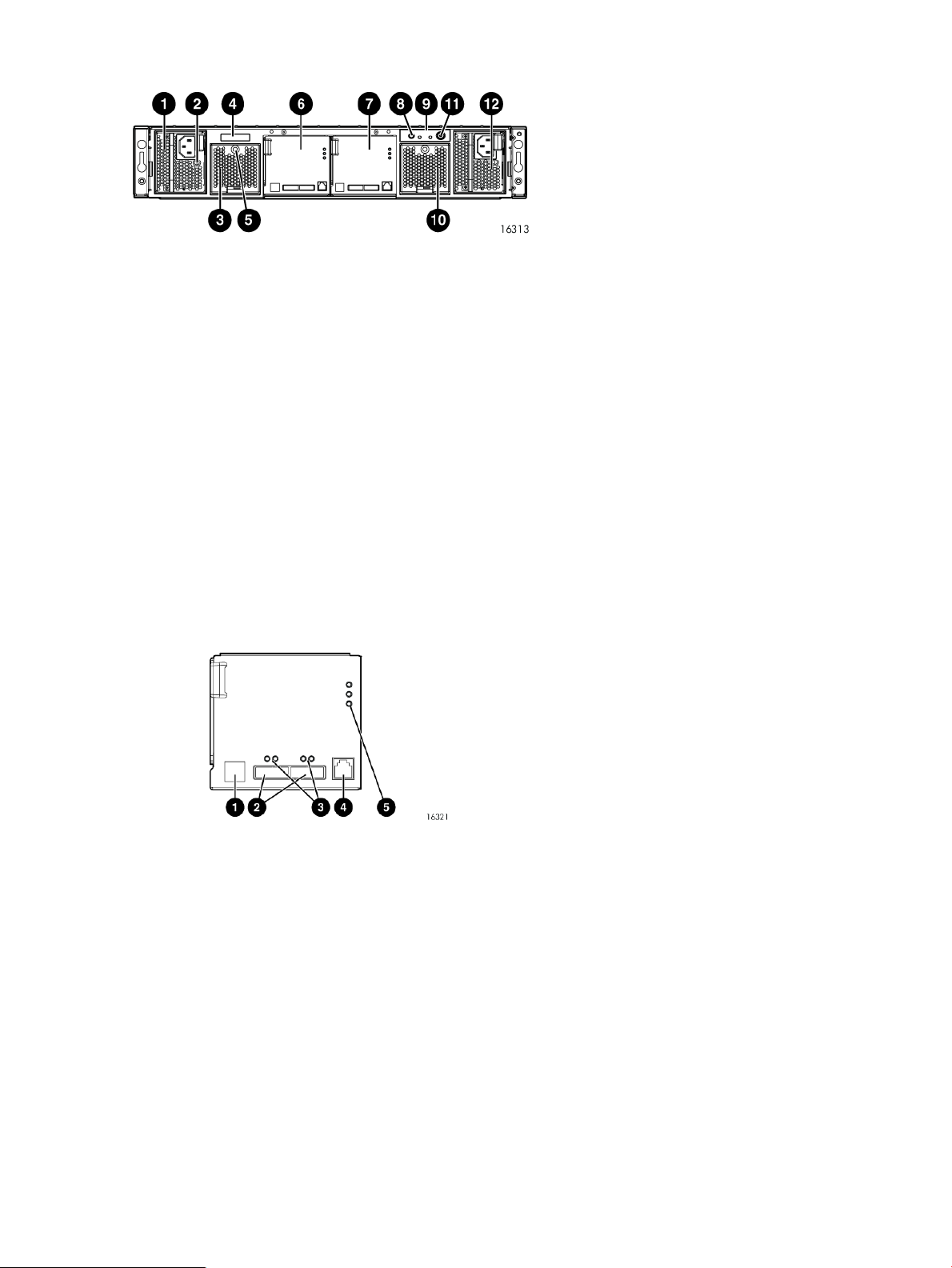

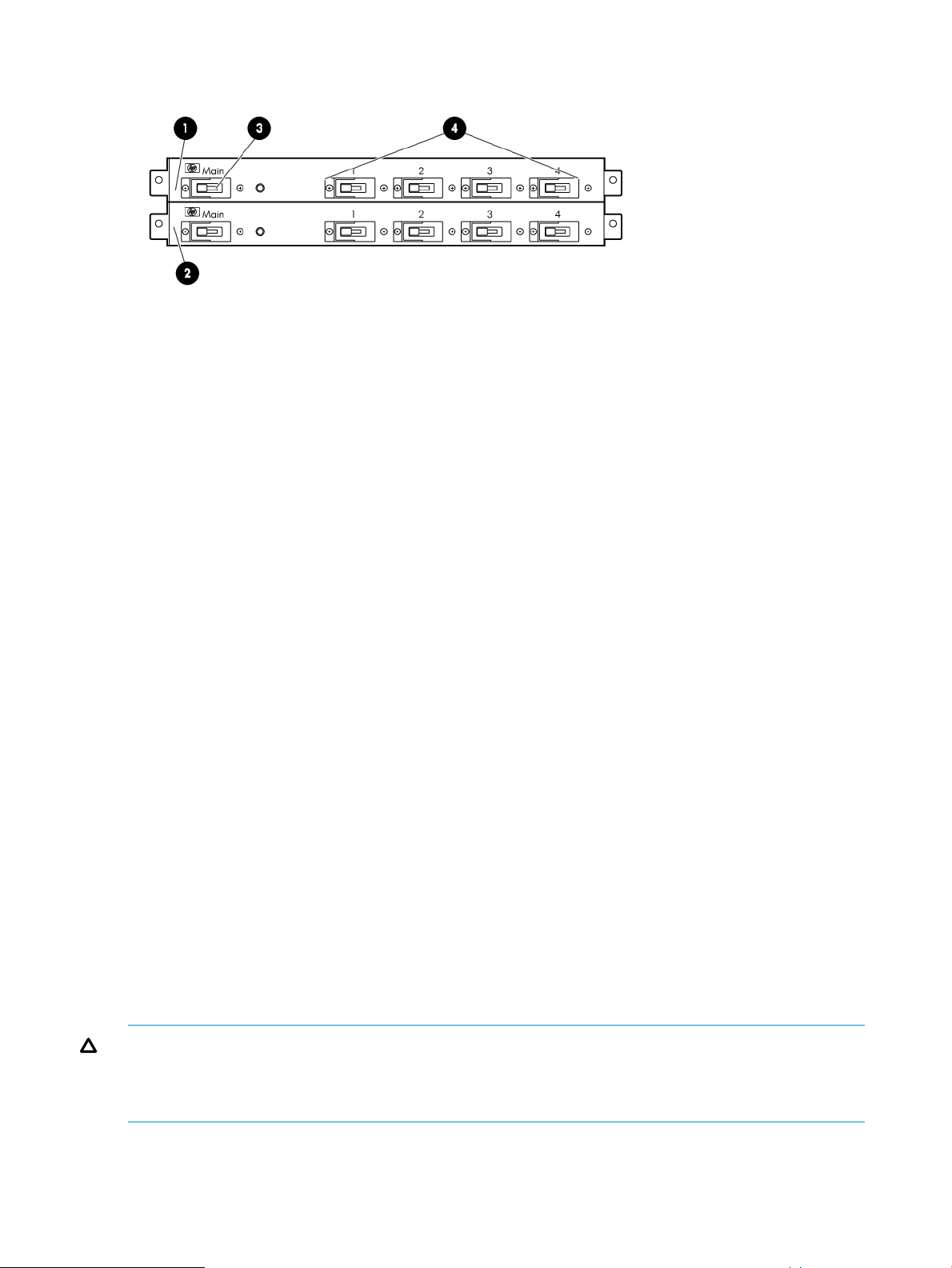

Figure 3 Disk enclosure rear view

I/O modules

Two I/O modules provide the interface between the disk enclosure and the host controllers,

(Figure 4 (page 10)). For redundancy, only dual-controller, dual-loop operation is supported. Each

controller is connected to both I/O modules in the disk enclosure.

Each I/O module has two ports that can transmit and receive data for bidirectional operation.

Activating a port requires connecting a Fibre Channel cable to the port. The port function depends

upon the loop.

7. I/O module B1. Power supply 1

8. Rear UID push button2. Power supply 1 status LED

9. Enclosure status LEDs3. Fan 1

10. Fan 24. Enclosure product number and serial number

11. Power push button5. Fan 1 status LED

12. Power supply 26. I/O module A

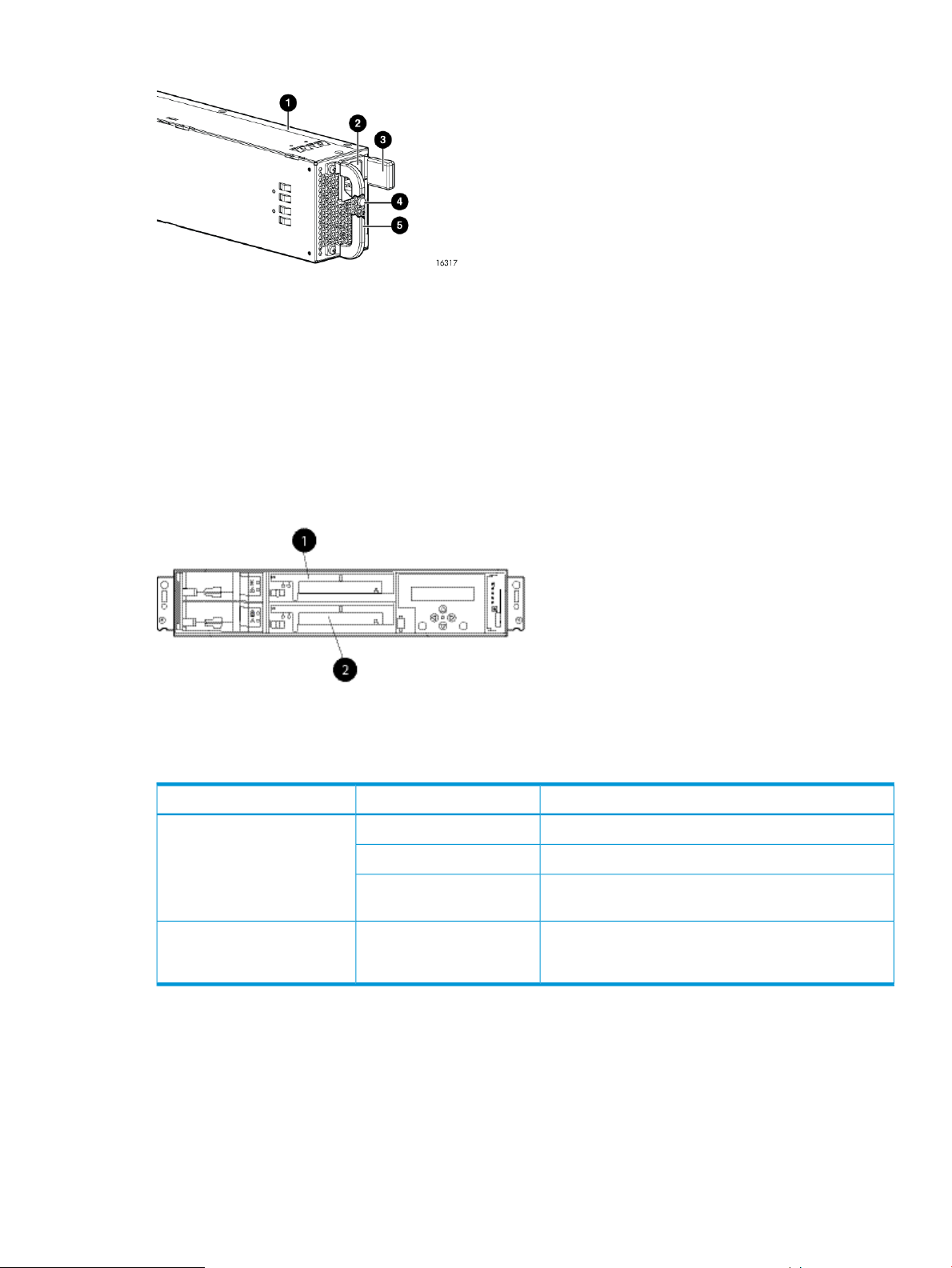

Figure 4 I/O module detail

3. Port 1 (P1), Port 2 (P2) status LEDs

I/O module status indicators

There are five status indicators on the I/O module. See Figure 4 (page 10). The status indicator

states for an operational I/O module are shown in Table 1 (page 11). Table 2 (page 11) shows

the status indicator states for a non-operational I/O module.

4. Manufacturing diagnostic port1. Double 7–segment display: enclosure ID

5. I/O module status LEDs2. 4 Gb I/O ports

10 EVA6400/8400 hardware

Page 11

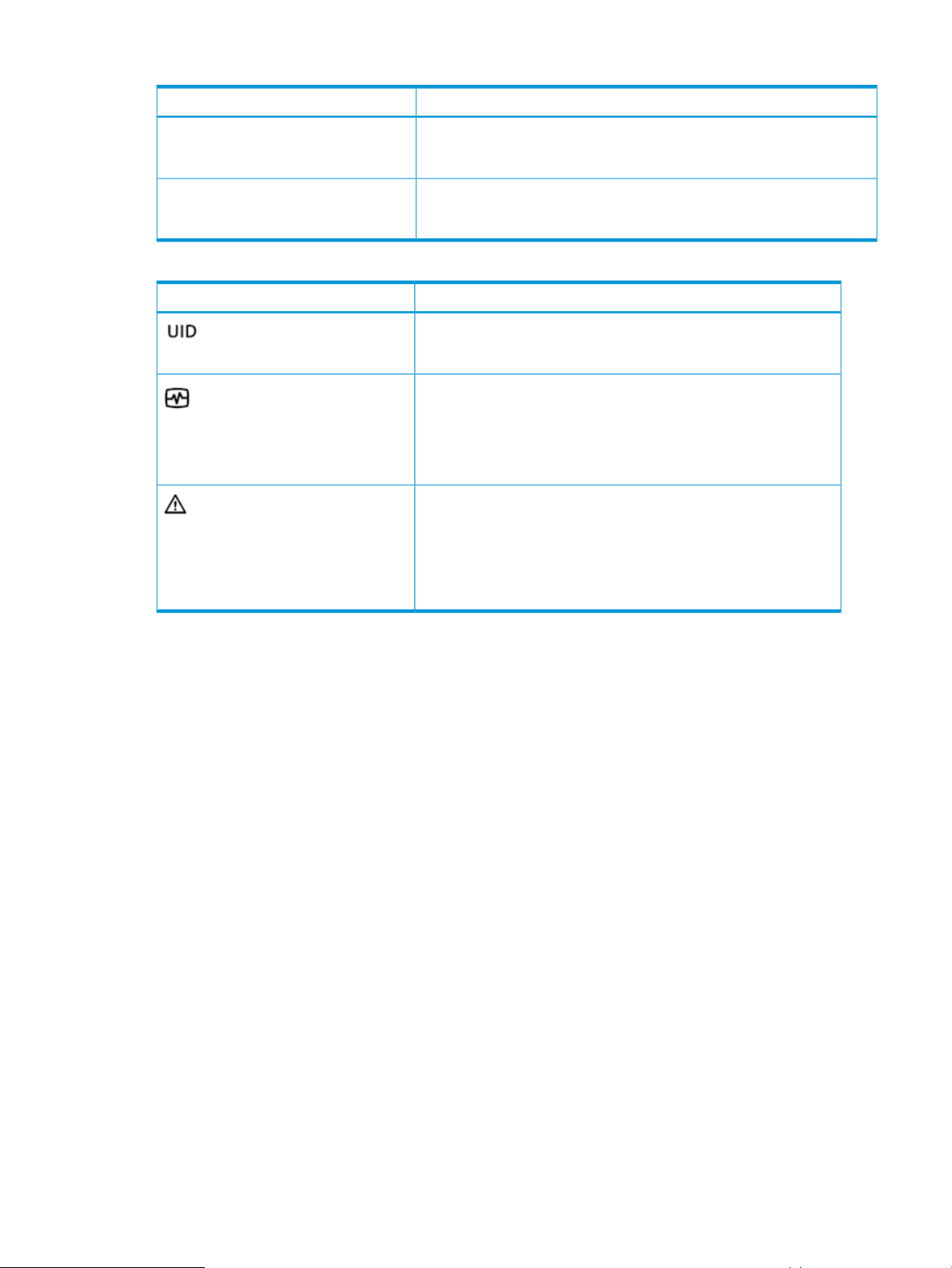

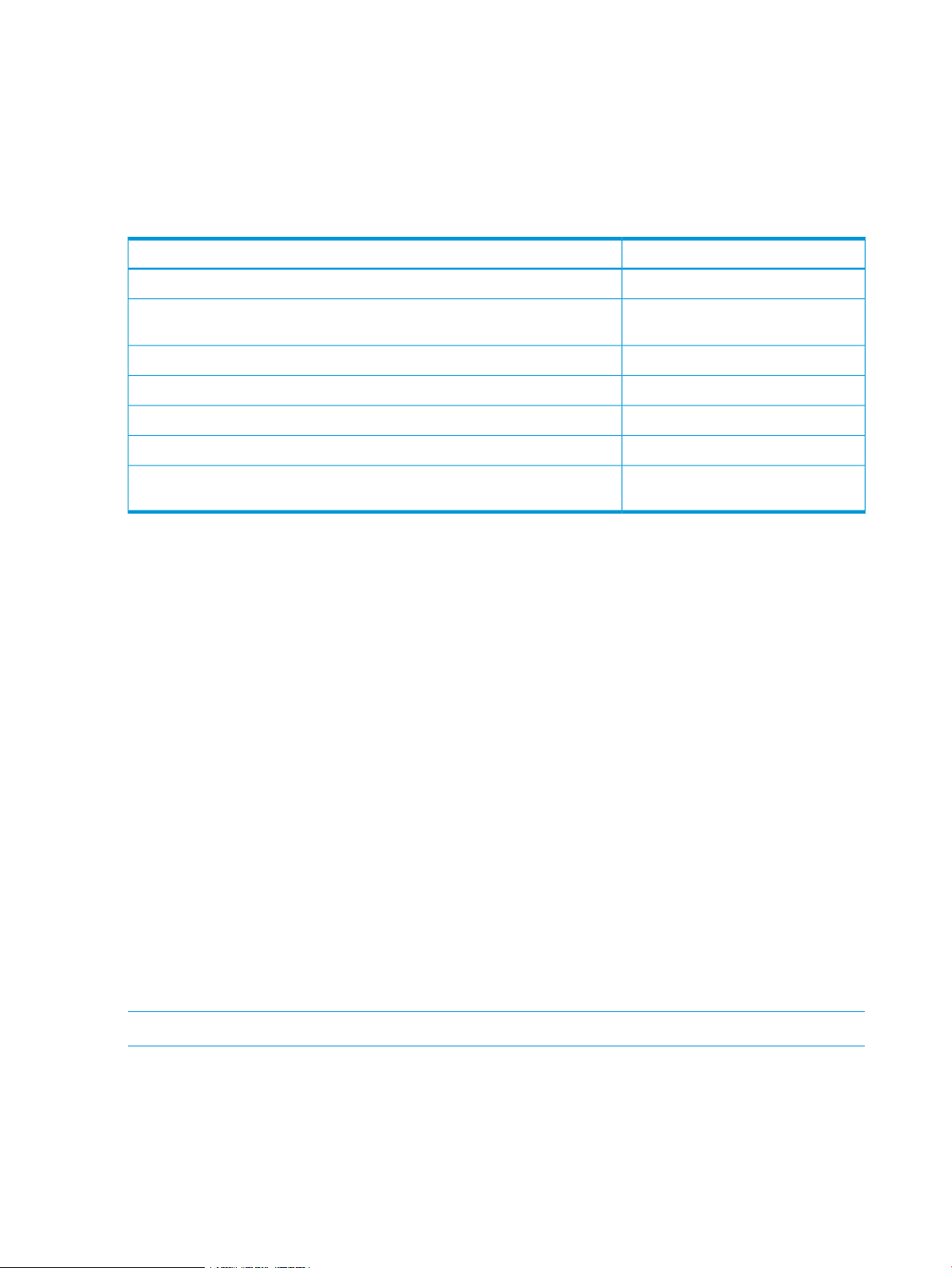

Table 1 Port status LEDs

DescriptionStatus LED

Green (left)

Amber (right)

Table 2 I/O module status LEDs

• Solid green— Active link

• Flashing green—Locate, remotely asserted by application client

• Solid amber—Module fault, no synchronization

• Flashing amber—Module fault

DescriptionStatus LED

• Locate

• Flashing blue—Remotely asserted by application client

• Module health indicator

• Flashing green—I/O module powering up.

• Solid green—Normal operation

• Green off—Firmware malfunction

• Fault indicator

• Flashing amber—Warning condition (not visible when solid

amber showing)

• Solid amber—Replace FRU

• Amber off—Normal operation

Fiber optic Fibre Channel cables

The Enterprise Virtual Array uses orange, 50-µm, multi-mode, fiber optic cables for connection to

the SAN or the host, where there is a direct connection to the host. The fiber optic cable assembly

consists of two 2-m fiber optic strands and small form-factor connectors on each end. See

Figure 5 (page 12).

To ensure optimum operation, the fiber optic cable components require protection from

contamination and mechanical hazards. Failure to provide this protection can cause degraded

operation. Observe the following precautions when using fiber optic cables.

• To avoid breaking the fiber within the cable:

Do not kink the cable◦

◦ Do not use a cable bend-radius of less than 30 mm (1.18 inch)

• To avoid deforming, or possibly breaking the fiber within the cable, do not place heavy objects

on the cable.

• To avoid contaminating the optical connectors:

Do not touch the connectors◦

◦ Never leave the connectors exposed to the air

◦ Install a dust cover on each transceiver and fiber cable connector when they are

disconnected

If an open connector is exposed to dust, or if there is any doubt about the cleanliness of the

connector, clean the connector as described in “Handling fiber optic cables” (page 43).

M6412A disk enclosures 11

Page 12

Figure 5 Fiber Optic Fibre Channel cable

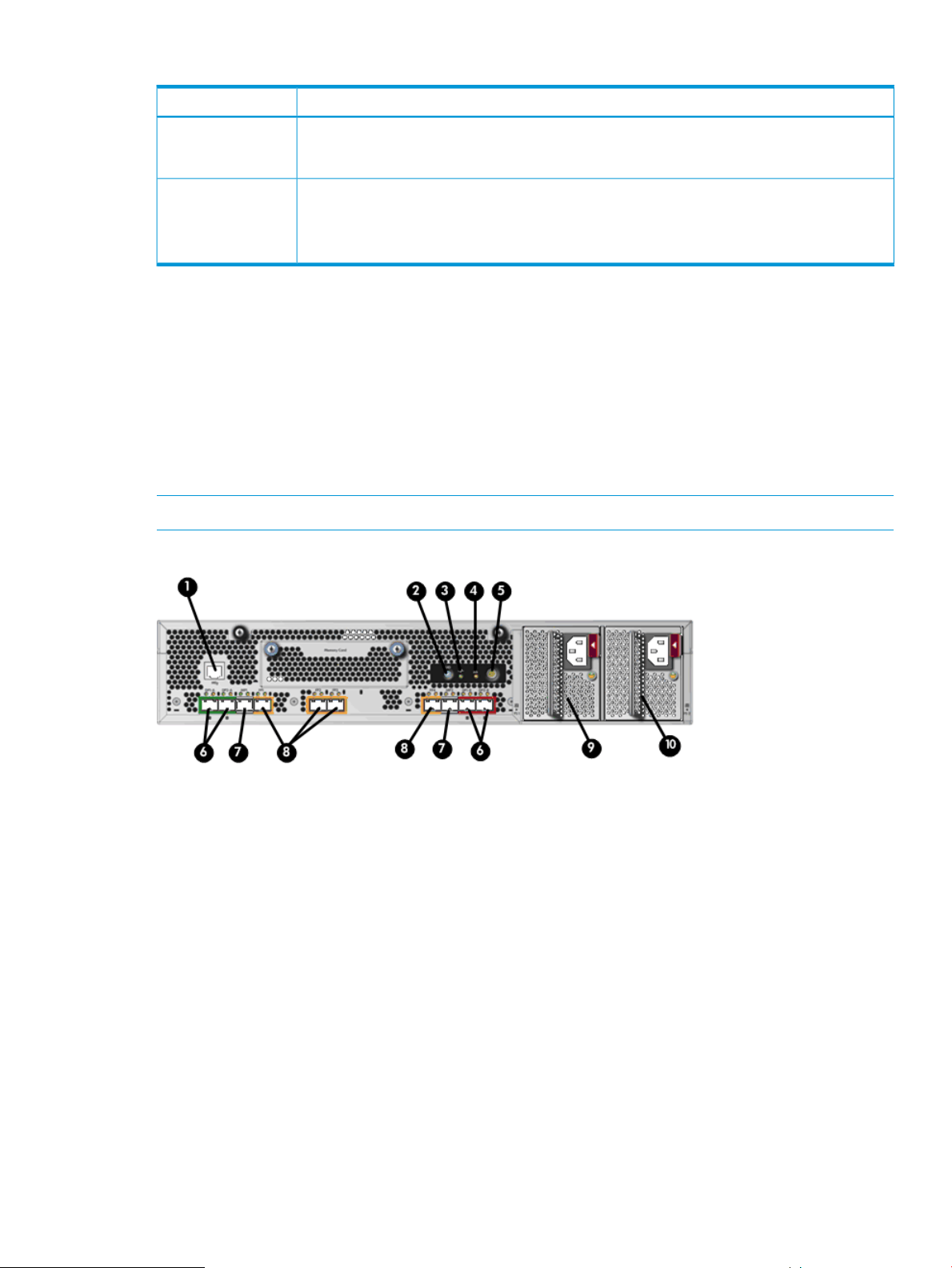

Copper Fibre Channel cables

The Enterprise Virtual Array uses copper Fibre Channel cables to interconnect disk shelves. The

cables are available in 0.6-meter (1.97 ft.) and 2.0-meter (6.56 ft.) lengths. Copper cables provide

performance comparable to fiber optic cables. Copper cable connectors differ from fiber optic

small form-factor connectors (see Figure 6 (page 12)).

Figure 6 Copper Fibre Channel cable

Fibre Channel disk drives

The Fibre Channel disk drives are hot-pluggable and include the following features:

• Dual-ported 4 Gbps Fibre Channel controller interface that allows up to 96 disk drives to be

supported per array controller enclosure

• Compact, direct-connect design for maximum storage density and increased reliability and

signal integrity

• Both online high-performance disk drives and FATA disk drives supported in a variety of

capacities and spindle speeds

• Better vibration damping for improved performance

Up to 12 disk drives can be installed in a drive enclosure.

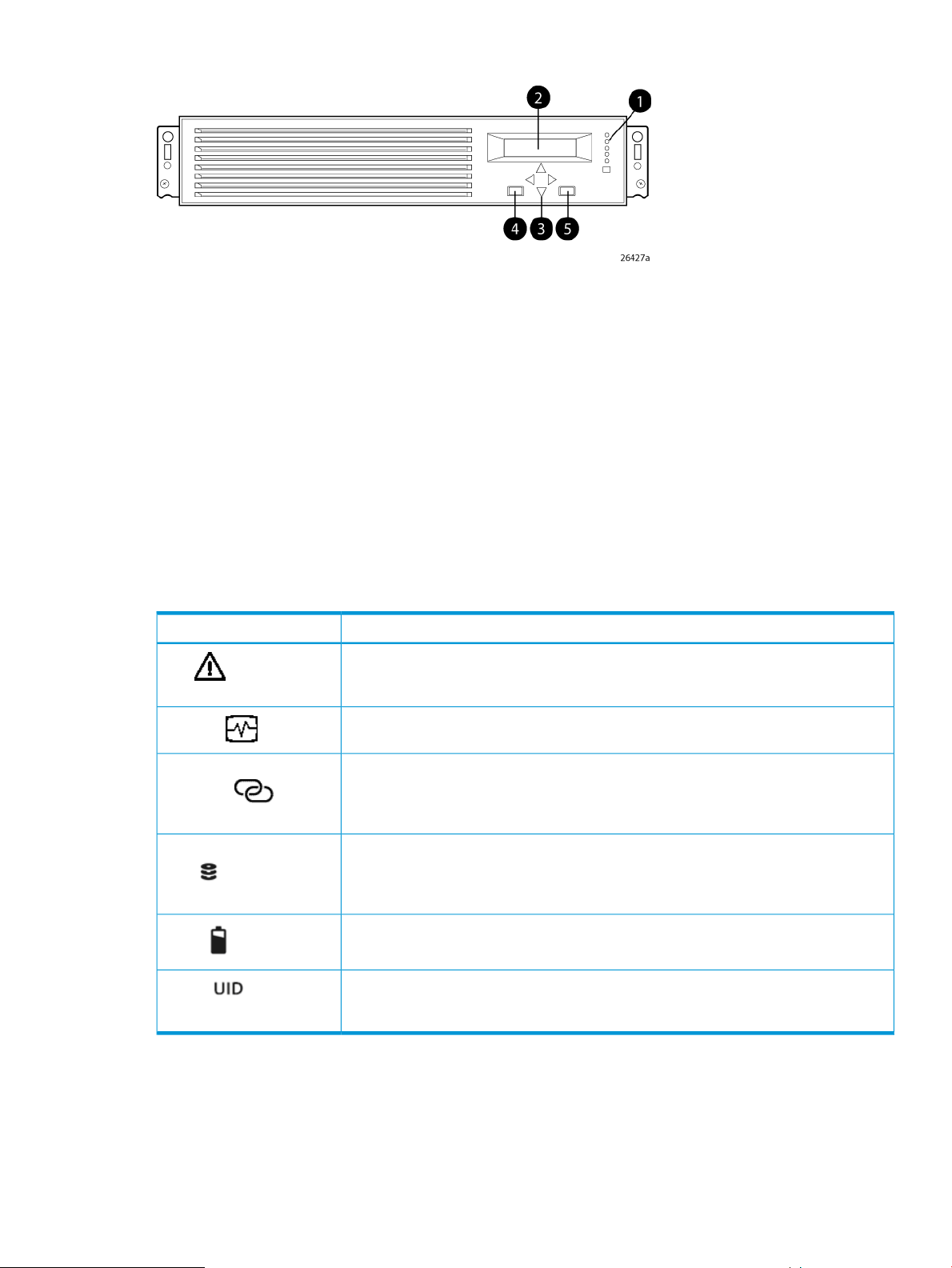

Disk drive status indicators

Two status indicators display drive operational status. Figure 7 (page 12) identifies the disk drive

status indicators. Table 3 (page 13) describes them.

Figure 7 Disk status indicators

12 EVA6400/8400 hardware

2. Green1. Bi-color (amber/blue)

Page 13

Table 3 Disk status indicator LED descriptions

DescriptionDrive LED

Bi-color (top)

Green (bottom)

Disk drive blank

To maintain the proper enclosure air flow, a disk drive or a disk drive blank must be installed in

each drive bay. The disk drive blank maintains proper airflow within the disk enclosure.

Controller enclosures

This section describes the major features, purpose, and function of the HSV400 and HSV450

controllers. Each Enterprise Virtual Array has a pair of these controllers. Figure 8 (page 13) shows

the HSV400 controller rear view and Figure 9 (page 14) shows the HSV450 controller rear view.

The front of the HSV400 and HSV450 is shown in Figure 10 (page 14).

NOTE: Some controller enclosure modules have a cache battery located behind the OCP.

Figure 8 HSV400 controller rear view

• Slow flashing blue (0.5 Hz)—Used to locate drive.

• Solid amber—Drive fault.

• Flashing—Drive is spinning up or down and is not ready.

• Solid—Drive is ready to perform I/O operations.

• Flickering—Indicates drive activity.

6. DPI ports1. Serial port

7. Mirror ports2. Unit ID

8. Fiber ports3. Controller health

9. Power supply 14. Fault indicator

10. Power supply 25. Power

Controller enclosures 13

Page 14

Figure 9 HSV450 controller rear view

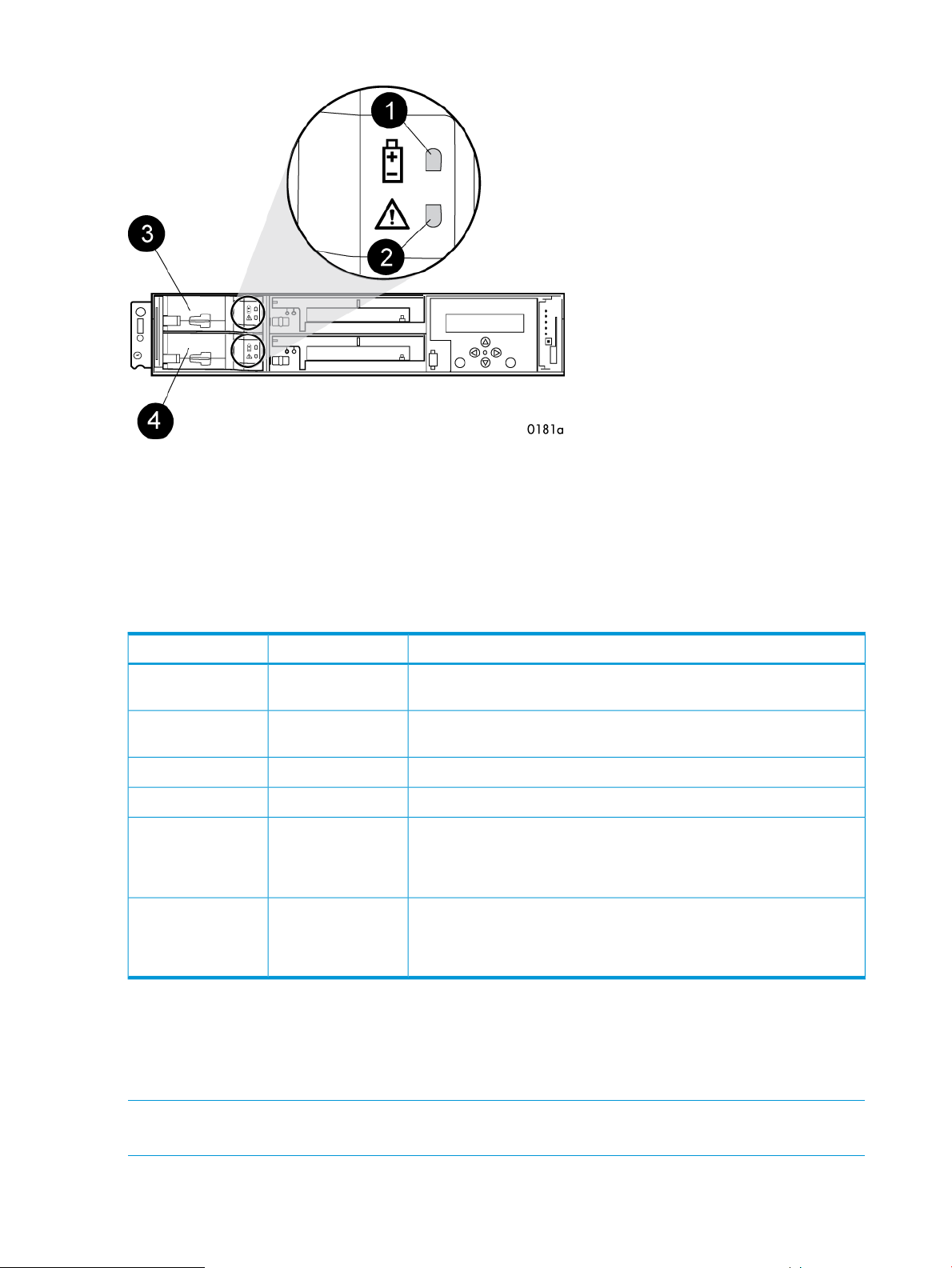

Figure 10 Controller front view

6. DPI ports1. Serial port

7. Mirror ports2. Unit ID

8. Fiber ports3. Controller health

9. Power supply 14. Fault indicator

10. Power supply 25. Power

4. Blower 2

Operator control panel

The operator control panel (OCP) provides a direct interface to each controller. From the OCP you

can display storage system status and configuration information, shut down the storage system,

and manage the password.

The OCP includes a 40-character LCD alphanumeric display, six push-buttons, and five status

indicators. See Figure 11 (page 15).

HP P6000 Command View is the tool you will typically use to display storage system status and

configuration information or perform the tasks available from the OCP. However, if HP P6000

Command View is not available, the OCP can be used to perform these tasks.

5. Operator Control Panel (OCP)1. Battery 1

6. Status indicators2. Battery 2

7. Unit ID3. Blower 1

14 EVA6400/8400 hardware

Page 15

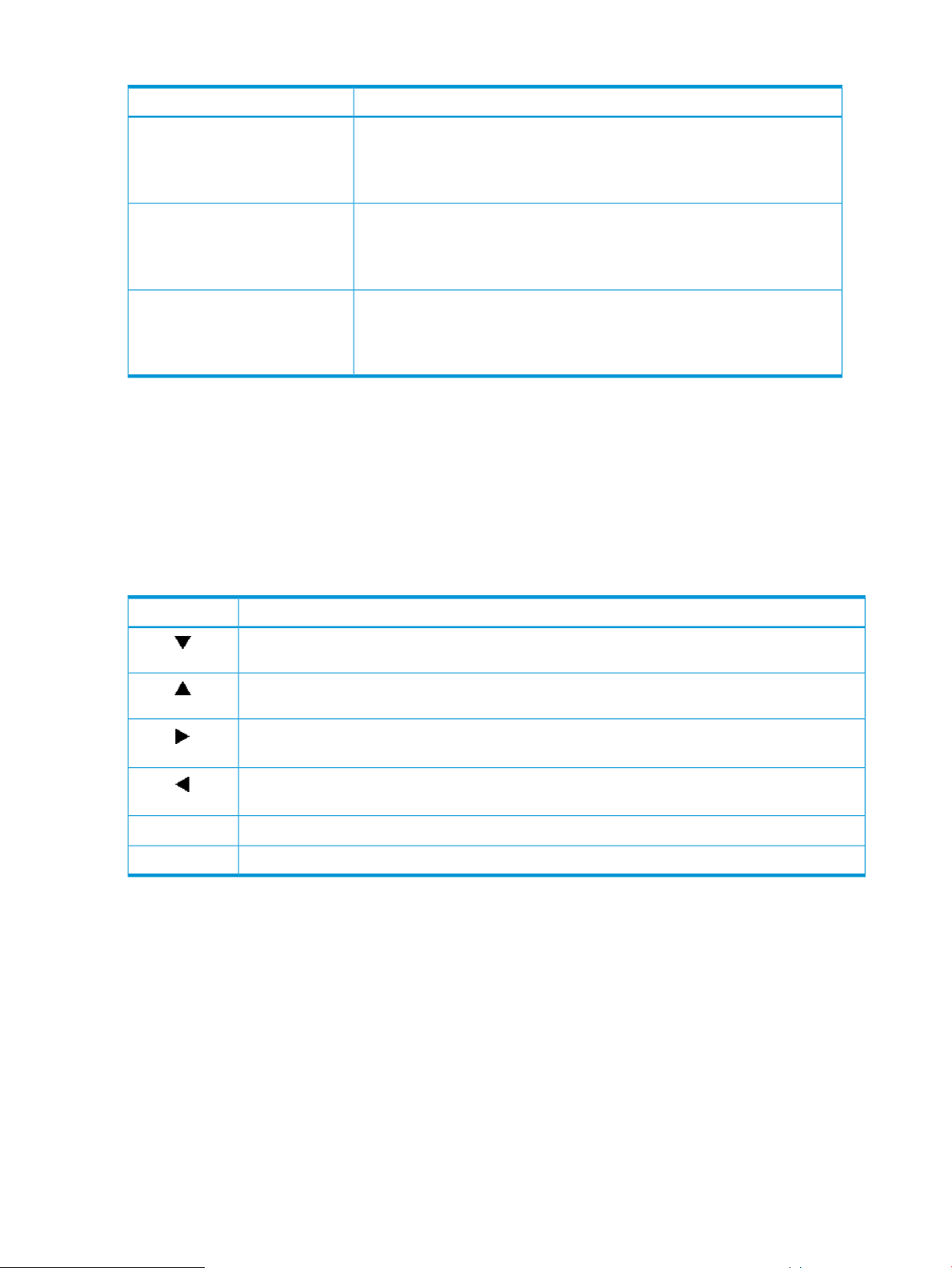

Figure 11 Controller OCP

1. Status indicators (see Table 4 (page 15)) and UID button

2. 40-character alphanumeric display

3. Left, right, top, and bottom push-buttons

4. Esc

5. Enter

Status indicators

The status indicators display the operational status of the controller. The function of each indicator

is described in Table 4 (page 15). During initial setup, the status indicators might not be fully

operational.

The following sections define the alphanumeric display modes, including the possible displays,

the valid status indicator displays, and the pushbutton functions.

Table 4 Controller status indicators

DescriptionIndicator

When the indicator is a solid amber, it means there was a boot failure. When it flashes,

Fault

Controller

Physical link to hosts

established

Virtual disks presented to

hosts

Battery

Unit ID

the controller is inoperative. Check either HP P6000 Command View or the LCD Fault

Management displays for a definition of the problem and recommended corrective action.

When the indicator is flashing green slowly, the controller is booting up. When the

indicator turns to solid green, boot is successful and the controller is operating normally.

When this indicator is green, there is at least one physical link between the storage

system and hosts that is active and functioning normally. When this indicator is amber,

there are no links between the storage system and hosts that are active and functioning

normally.

When this indicator is green, all virtual disks that are presented to hosts are healthy and

functioning normally. When this indicator is amber, at least one virtual disk is not

functioning normally. When this indicator is off, there are no virtual disks presented to

hosts and this indicates a problem with the virtual disk on the array.

When this indicator is green, the battery is working properly. When this indicator is

amber, there is a battery failure.

Press to turn on (solid blue); press again to turn it off. This LED mimics the function of the

UID on the back of the controller.This indicator comes on in response to a Locate command

issued by HP P6000 Command View.

Each port on the rear of the controller has an associated status indicator located directly above it.

Table 5 (page 16) lists the port and its status description.

Controller enclosures 15

Page 16

Table 5 Controller port status indicators

Status indicator descriptionPort

Fibre Channel host ports

Fibre Channel device ports

Fibre Channel cache mirror ports

1

On copper Fibre Channel cables, the SFP is integrated into the cable connector.

Navigation buttons

The operation of the navigation buttons is determined by the current display and location in the

menu structure. Table 6 (page 16) defines the basic push button functions when navigating the

menus and options.

To simplify presentation and to avoid confusion, the pushbutton reference names, regardless of

labels, are left, right, top, and bottom.

Table 6 Navigation button functions

• Green—Normal operation

• Amber—No signal detected

• Off—No SFP1detected or the Direct Connect OCP setting is incorrect

• Green—Normal operation

• Amber—No signal detected or the controller has failed the port

• Off—No SFP1detected

• Green—Normal operation

• Amber—No signal detected or the controller has failed the port

• Off—No SFP1detected

Alphanumeric display

The alphanumeric display uses two LCD rows, each capable of displaying up to 20 alphanumeric

characters. By default, the alphanumeric display alternates between displaying the Storage System

Name and the World Wide Name. An active (flashing) display, an error condition message, or

a user entry (pressing a push-button) overrides the default display. When none of these conditions

exist, the default display returns after approximately 10 seconds.

Power supplies

FunctionButton

Moves down through the available menus and options

Moves up through the available menus and options

Selects the displayed menu or option.

Returns to the previous menu.

Used for “No” selections and to return to the default display.Esc

Used for “Yes” selections and to progress through menu items.Enter

Two power supplies provide the necessary operating voltages to all controller enclosure components.

If one power supply fails, the remaining supply is capable of operating the enclosure.

16 EVA6400/8400 hardware

Page 17

Figure 12 Power supply

1. Power supply

3. Latch

Blower module

Fan modules provide the cooling necessary to maintain the proper operating temperature within

the controller enclosure. If one fan fails, the remaining fan is capable of cooling the enclosure.

Figure 13 Blower module pulled out

Table 7 Fan status indicators

4. Status indicator (solid green on—normal operation; solid

amber—failure or no power)

5. Handle2. AC input connector

2. Blower 21. Blower 1

Battery module

Batteries provide backup power to maintain the contents of the controller cache when AC power

is lost and the storage system has not been shutdown properly. When fully charged the batteries

can sustain the cache contents for to 96 hours. Three batteries are used on the EVA8400 and two

batteries are used on the EVA6400. Figure 14 (page 18) illustrates the location of the cache

batteries and the battery status indicators. See Table 8 (page 18) for additional information on

the status indicators.

Off

OnAmber

DescriptionFault indicatorStatus indicator

Normal operation.Solid greenGreen

Maintenance in progress.Blinking

Amber is on or blinking, or the enclosure is powered

down.

Fan failure. Green will be off. (Green and amber are

not on simultaneously except for a few seconds after

power-up.)

Blower module 17

Page 18

Figure 14 Battery module

3. Battery 01. Status indicator

4. Battery 12. Fault indicator

The table below describes the battery status indicators. When a battery is first installed, the fault

indicator goes on (solid) for approximately 30 seconds while the system discovers the new battery.

Then, the battery status indicators display the battery status as described in the table below.

Table 8 Battery status indicators

DescriptionFault indicatorStatus indicator

OffOn

OffFlashing

Flashing (fast)Flashing (fast)

FlashingFlashing

Normal operation. A maintenance charge process keeps the battery fully

charged.

Battery is undergoing a full charging process. This is the indication you

typically see after installing a new battery.

Battery fault. The battery has failed and should be replaced.OnOff

The battery has experienced an over temperature fault.FlashingOff

Battery code is being updated. When a new battery is installed, it may

be necessary for the controllers to update the code on the battery to the

correct version. Both indicators flash rapidly for approximately 30

seconds.

Battery is undergoing a scheduled battery load test, during which the

battery is discharged and then recharged to ensure it is working properly.

During the discharge cycle, you will see this display. The load test occurs

infrequently and takes several hours.

HSV controller cabling

All data cables and power cables attach to the rear of the controller. Adjacent to each data

connector is a two-colored link status indicator. Table 5 (page 16) identifies the status conditions

presented by these indicators.

NOTE: These indicators do not indicate whether there is communication on the link, only whether

the link can transmit and receive data.

18 EVA6400/8400 hardware

Page 19

The data connections are the interfaces to the disk drive enclosures or loop switches (depending

on your configuration), the other controller, and the fabric. Fiber optic cables link the controllers

to the fabric, and, if an expansion cabinet is part of the configuration, link the expansion cabinet

drive enclosures to the loop is in the main cabinet. Copper cables are used between the controllers

(mirror port) and between the controllers and the drive enclosures or loop switches.

Storage system racks

All storage system components are mounted in a rack. Each configuration includes one enclosure

holding both controllers (the controller pair), FC cables the controller and the disk enclosures. Each

controller pair and all the associated drive enclosures form a single storage system.

The rack provides the capability for mounting 483 mm (19 inch) wide controller and drive

enclosures.

NOTE: Racks and rack-mountable components are typically described using “U” measurements.

“U” measurements are used to designate panel or enclosure heights. The “U” measurement is a

standard of 41 mm (1.6 inch).

The racks provide the following:

• Unique frame and rail design—Allows fast assembly, easy mounting, and outstanding structural

integrity.

• Thermal integrity—Front-to-back natural convection cooling is greatly enhanced by the innovative

multi-angled design of the front door.

• Security provisions—The front and rear door are lockable, which prevents unauthorized entry.

• Flexibility—Provides easy access to hardware components for operation monitoring.

• Custom expandability—Several options allow for quick and easy expansion of the racks to

create a custom solution.

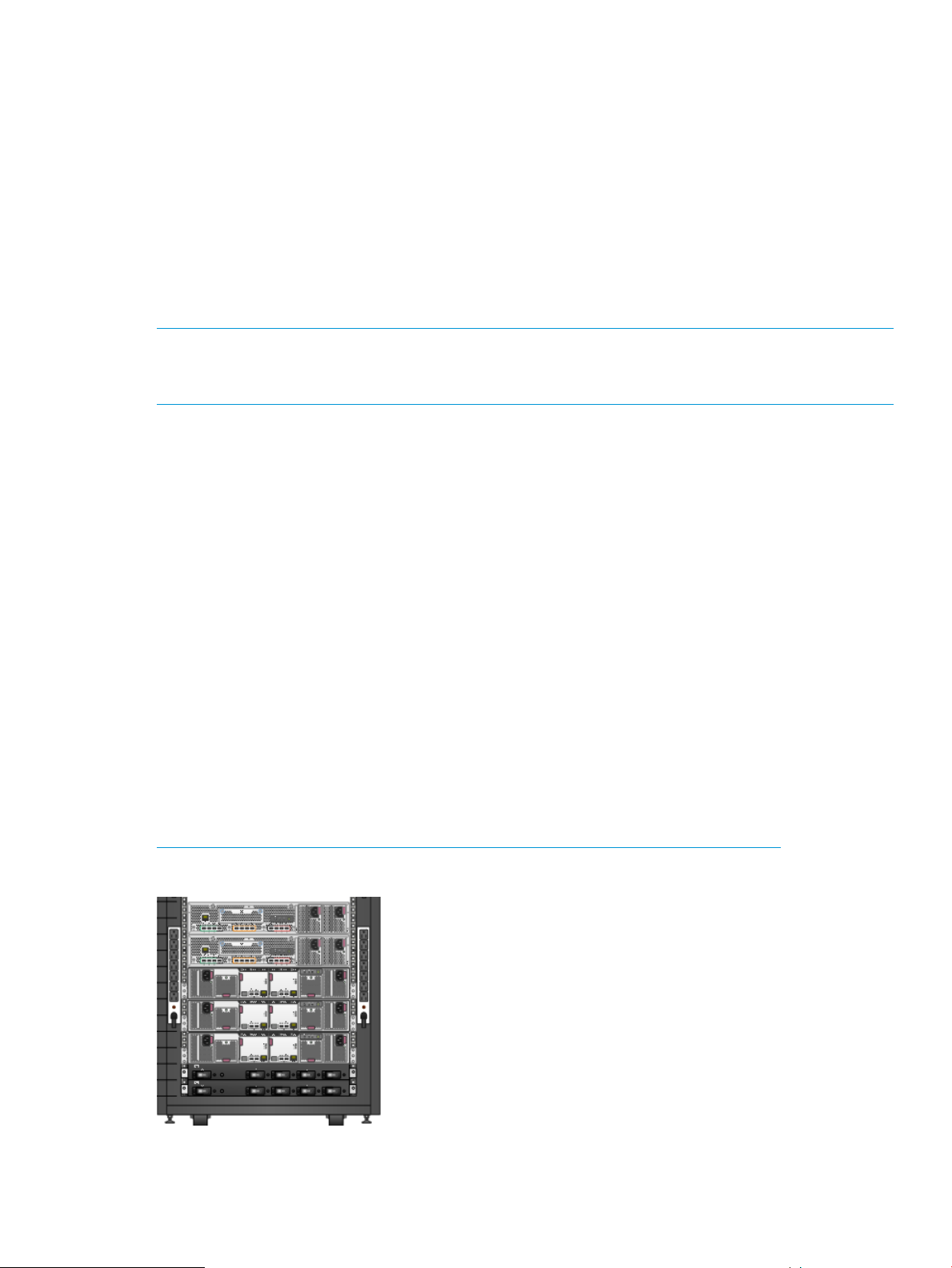

Rack configurations

Each system configuration contains several disk enclosures included in the storage system. See

Figure 15 (page 19) for a typical EVA6400/8400 rack configuration. The standard rack is the

42U HP 10000 Intelligent Series rack. The EVA6400/8400 is also supported with 22U, 36U,

42U 5642, and 47U racks. The 42U 5643 is a field-installed option and the 47U rack must be

assembled onsite because the cabinet height creates shipping difficulties.

For more information on HP rack offerings for the EVA6400/8400, see:

http://h18004.www1.hp.com/products/servers/proliantstorage/racks/index.html

Figure 15 Storage system hardware components – back view

Storage system racks 19

Page 20

Power distribution–Modular PDUs

NOTE: This section describes the most common power distribution system for EVA6400/8400s.

For information about other options, see the HP power distribution units website:

http://h18004.www1.hp.com/products/servers/proliantstorage/power-protection/pdu.html

AC power is distributed to the rack through a dual Power Distribution Unit (PDU) assembly mounted

at the bottom rear of the rack. The characteristics of the fully-redundant rack power configuration

are as follows:

• Each PDU is connected to a separate circuit breaker-protected, 30-A AC site power source

(100–127 VAC or 220–240 VAC ±10%, 50 or 60-Hz, ±5%). The following figures illustrate

the most common compatible 60-Hz and 50-Hz wall receptacles.

NEMA L6-30R receptacle, 3-wire, 30-A, 60-Hz

NEMA L5-30R receptacle, 3-wire, 30-A, 60-Hz

IEC 309 receptacle, 3-wire, 30-A, 50-Hz

• The standard power configuration for any Enterprise Virtual Array rack is the fully redundant

configuration. Implementing this configuration requires:

◦ Two separate circuit breaker-protected, 30-A site power sources with a compatible wall

receptacle.

◦ One dual PDU assembly. Each PDU connects to a different wall receptacle.

◦ Four to eight (depending on the rack) Power Distribution Modules (PDM) per rack. PDMs

are split evenly on both sides of the rack. Each set of PDMs connects to a different PDU.

– Eight PDMs for 42U, 47U, and 42U 5642 racks

– Six PDMs for 36U racks

– Four PDMs for 22U racks

◦ The drive enclosure power supplies on the left (PS 1) connect to the PDMs on the left with

a gray, 66 cm (26 inch) power cord.

◦ The drive enclosure power supplies on the right (PS 2) connect to the PDMs on the right

with a black, 66 cm (26 inch) power cord.

◦ Each controller has a left and right power supply. The left power supplies of each should

be connected to the left PDMs and the right power supplies should be connected to the

right PDMs.

NOTE: Drive enclosures, when purchased separately, include one 50 cm black cable and one

50 cm gray cable.

20 EVA6400/8400 hardware

Page 21

PDUs

The configuration provides complete power redundancy and eliminates all single points of failure

for both the AC and DC power distribution.

CAUTION: Operating the array with a single PDU will result in the following conditions:

• No redundancy

• Louder controllers and disk enclosures due to increased fan speed

• HP P6000 Command View will continuously display a warning condition, making issue

monitoring a labor-intensive task

Although the array is capable of doing so, HP strongly recommends that an array operating with

a single PDU should not:

• Be put into production

• Remain in this state for more than 24 hours

Each Enterprise Virtual Array rack has either a 50- or 60-Hz, dual PDU mounted at the bottom rear

of the rack. The PDU placement is back-to-back, plugs facing toward the front (Figure 16 (page

21)), with circuit breaker switches facing the back (Figure 17 (page 22)).

• The standard 50-Hz PDU cable has an IEC 309, 3-wire, 30-A, 50-Hz connector.

• The standard 60-Hz PDU cable has a NEMA L6-30P, 3-wire, 30-A, 60-Hz connector.

If these connectors are not compatible with the site power distribution, you must replace the PDU

power cord cable connector. One option is the NEMA L5-30R receptacle, 3-wire, 30-A, 60-Hz

connector.

Each of the two PDU power cables has an AC power source specific connector. The circuit

breaker-controlled PDU outputs are routed to a group of four AC receptacles. The voltages are

then routed to PDMs, sometimes called AC power strips, mounted on the two vertical rails in the

rear of the rack.

Figure 16 Dual PDU—front view

4. Power receptacle schematic1. PDU B

5. Power cord2. PDU A

3. AC receptacles

Power distribution–Modular PDUs 21

Page 22

PDU A

Figure 17 Dual PDU—rear view

3. Main circuit breaker1. PDU B

4. Circuit breakers2. PDU A

PDU A connects to AC PDM A1–A4.

A PDU A failure:

• Disables the power distribution circuit

PDU B

PDMs

• Removes power from from the left side of the rack

• Disables disk enclosure PS 1

• Disables the left power supplies in the controllers

PDU B connects to AC PDM B1–B4.

A PDU B failure:

• Disables the power distribution circuit

• Removes power from the right side of the rack

• Disables disk enclosure PS 2

• Disables the right power supplies in the controllers

Depending on the rack, there can be up to eight PDMs mounted in the rear of the rack:

• The PDMs on the left vertical rail connect to PDU A

• The PDMs on the right vertical rail connect to PDU B

Each PDM has seven AC receptacles. The PDMs distribute the AC power from the PDUs to the

enclosures. Two power sources exist for each controller pair and disk enclosure. If a PDU fails, the

system will remain operational.

CAUTION: The AC power distribution within a rack ensures a balanced load to each PDU and

reduces the possibility of an overload condition. Changing the cabling to or from a PDM could

cause an overload condition. HP supports only the AC power distributions defined in this user

guide.

22 EVA6400/8400 hardware

Page 23

Figure 18 Rack PDM

1. Power receptacles

2. AC power connector

Rack AC power distribution

The power distribution in an Enterprise Virtual Array rack is the same for all variants. The site AC

input voltage is routed to the dual PDU assembly mounted in the rack lower rear. Each PDU

distributes AC to a maximum of four PDMs mounted on the left and right vertical rails (see

Figure 19 (page 24)).

• PDMs A1 through A4 connect to receptacles A through D on PDU A. Power cords connect

these PDMs to the left power supplies on the disk enclosures and to the left power supplies on

the controllers.

• PDMs B1 through B4 connect to receptacles A through D on PDU B. Power cords connect

these PDMs to the right power supplies on the disk enclosures and to the right power supplies

on the controllers.

NOTE: The locations of the PDUs and the PDMs are the same in all racks.

Power distribution–Modular PDUs 23

Page 24

Figure 19 Rack AC power distribution

Rack System/E power distribution components

AC power is distributed to the Rack System/E rack through Power Distribution Units (PDU) mounted

on the two vertical rails in the rear of the rack. Up to four PDUs can be mounted in the rack—two

mounted on the right side of the cabinet and two mounted on the left side.

Each of the PDU power cables has an AC power source specific connector. The circuit

breaker-controlled PDU outputs are routed to a group of ten AC receptacles. The storage system

components plug directly into the PDUs.

Rack AC power distribution

The power distribution configuration in a Rack System/E rack depends on the number of storage

systems installed in the rack. If one storage system is installed, only two PDUs are required. If

multiple storage systems are installed, four PDUs are required.

6. PDM 51. PDM 1

7. PDM 62. PDM 2

8. PDM 73. PDM 3

9. PDM 84. PDM 4

10. PDU 25. PDU 1

24 EVA6400/8400 hardware

Page 25

The site AC input voltage is routed to each PDU mounted in the rack. Each PDU distributes AC

through ten receptacles directly to the storage system components.

• PDUs 1 and 3 (optional) are mounted on the left side of the cabinet. Power cords connect

these PDUs to the number 1 disk enclosure power supplies and to the controllers.

• PDUs 2 and 4 (optional) are mounted on the right side of the cabinet. Power cords connect

these PDUs to the number 2 disk enclosure power supplies and to the controllers.

For additional information on power distribution support, see the following website:

http://h18004.www1.hp.com/products/servers/proliantstorage/power-protection/pdu.html

Moving and stabilizing a rack

WARNING! The physical size and weight of the rack requires a minimum of two people to move.

If one person tries to move the rack, injury may occur.

To ensure stability of the rack, always push on the lower half of the rack. Be especially careful

when moving the rack over any bump (such as door sills, ramp edges, carpet edges, or elevator

openings). When the rack is moved over a bump, there is a potential for it to tip over.

Moving the rack requires a clear, uncarpeted pathway that is at least 80 cm (31.5 inch) wide for

the 60.3 cm (23.7 inch) wide, 42U rack. A vertical clearance of 203.2 cm (80 inch) should ensure

sufficient clearance for the 200 cm (78.7 inch) high, 42U rack.

CAUTION: Ensure that no vertical or horizontal restrictions exist that would prevent rack movement

without damaging the rack.

Make sure that all four leveler feet are in the fully raised position. This process will ensure that the

casters support the rack weight and the feet do not impede movement.

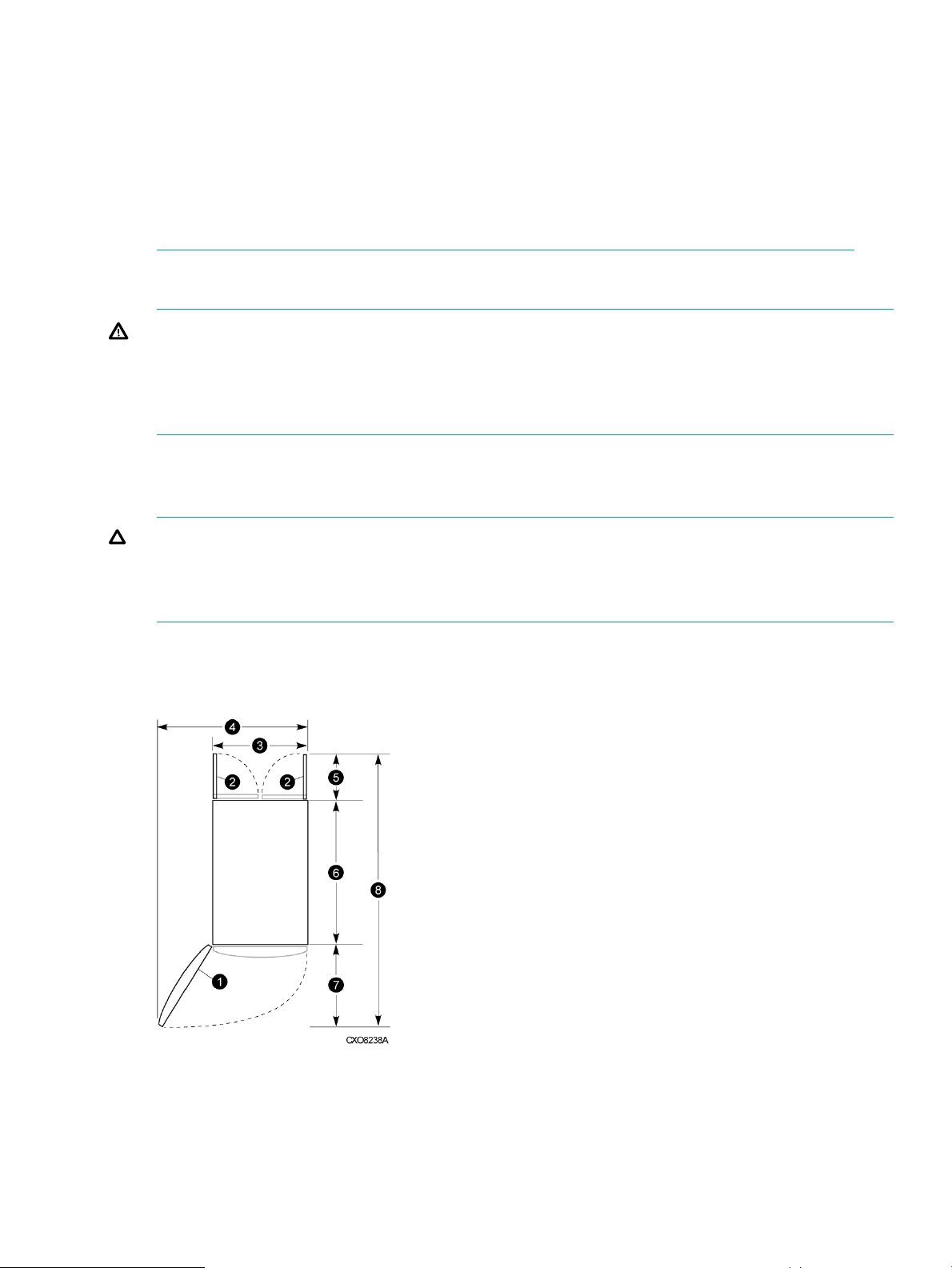

Each rack requires an area 600 mm (23.62 inch) wide and 1000 mm (39.37 inch) deep (see

Figure 20 (page 25)).

Figure 20 Single rack configuration floor space requirements

5. Rear service area depth 300 mm1. Front door

6. Rack depth 1000 mm2. Rear door

7. Front service area depth 406 mm3. Rack width 600 mm

8. Total rack depth 1706 mm4. Service area width 813 mm

Moving and stabilizing a rack 25

Page 26

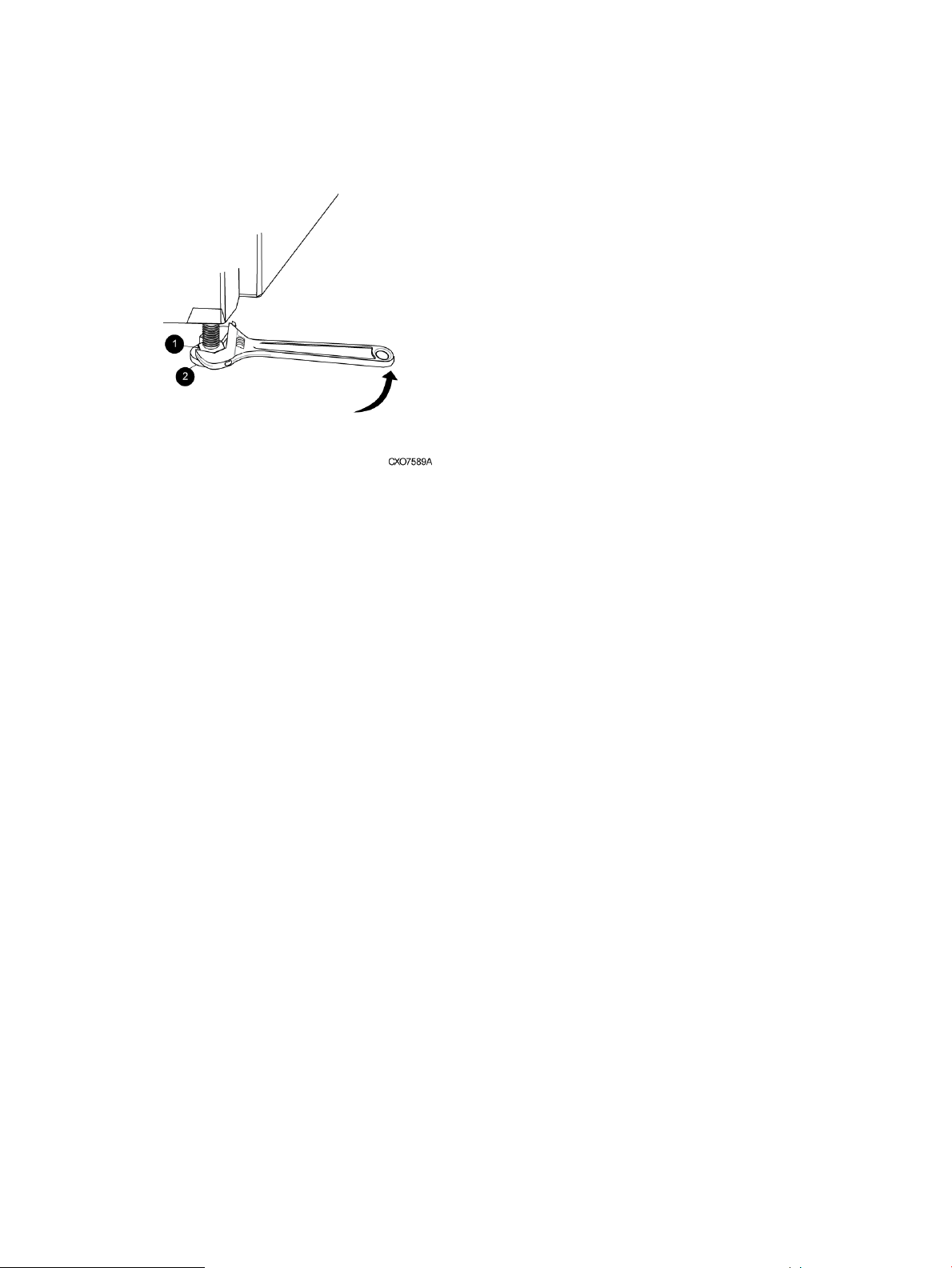

If the feet are not fully raised, complete the following procedure:

1. Raise one foot by turning the leveler foot hex nut counterclockwise until the weight of the rack

is fully on the caster (see Figure 21 (page 26)).

2. Repeat Step 1 for the other feet.

Figure 21 Raising a leveler foot

2. Leveler foot1. Hex nut

3. Carefully move the rack to the installation area and position it to provide the necessary service

areas (see Figure 20 (page 25)).

To stabilize the rack when it is in the final installation location:

1. Use a wrench to lower the foot by turning the leveler foot hex nut clockwise until the caster

does not touch the floor. Repeat for the other feet.

2. After lowering the feet, check the rack to ensure it is stable and level.

3. Adjust the feet as necessary to ensure the rack is stable and level.

26 EVA6400/8400 hardware

Page 27

2 Enterprise Virtual Array startup

This chapter describes the procedures to install and configure the Enterprise Virtual Array. When

these procedures are complete, you can begin using your storage system.

NOTE: Installation of the Enterprise Virtual Array should be done only by an HP authorized

service representative. The information in this chapter provides an overview of the steps involved

in the installation and configuration of the storage system.

EVA8400 storage system connections

Figure 22 (page 27) shows how the storage system is connected to other components of the storage

solution.

• The HSV450 controllers connect via four host ports (FP1, FP2, FP3, and FP4) to the Fibre

Channel fabrics. The hosts that will access the storage system are connected to the same

fabrics.

• The HP P6000 Command View management server also connects to the fabric.

• The controllers connect through two loop pairs to the drive enclosures. Each loop pair consists

of two independent loops, each capable of managing all the disks should one loop fail.

Figure 22 EVA8400 configuration

11. Drive enclosure 16. Fabric 11. Network interconnection

12. Drive enclosure 27. Fabric 22. Management server

13. Drive enclosure 38. Controller A3. Non-host

9. Controller B4. Host A

10. Cache mirror ports5. Host B

EVA8400 storage system connections 27

Page 28

EVA6400 storage system connections

Figure 23 (page 28) shows a typical EVA6400 SAN topology:

• The HSV400 controllers connect via four host ports (FP1, FP2, FP3, and FP4) to the Fibre

Channel fabrics. The hosts that will access the storage system are connected to the same

fabrics.

• The HP P6000 Command View management server also connects to both fabrics.

• The controllers connect through one loop pair to the drive enclosures. The loop pair consists

of two independent loops, each capable of managing all the disks should one loop fail.

Figure 23 EVA6400 configuration

Direct connect

NOTE: Direct connect is supported on Microsoft Windows only.

Direct connect provides a lower cost solution for smaller configurations. When using direct connect,

the storage system controllers are connected directly to the hosts, not to SAN Fibre Channel switches.

Make sure the following requirements are met when configuring your environment for direct connect:

• A management server running HP P6000 Command View must be connected to one port on

each EVA controller. The management host must use dual HBAs for redundancy.

• To provide redundancy, it is recommended that dual HBAs be used for each additional host

connected to the storage system. Using this configuration, up to four hosts (including the

management host) can be connected to an EVA6400/8400.

28 Enterprise Virtual Array startup

9. Controller B5. Host B1. Network interconnection

10. Cache mirror ports6. Fabric 12. Management server

11. Drive enclosure 17. Fabric 23. Non-host

12. Drive enclosure 28. Controller A4. Host A

Page 29

• The Host Port Configuration must be set to Direct Connect using the OCP.

• HP P6000 Continuous Access cannot be used with direct connect configurations.

• The HSV controller firmware cannot differentiate between an empty host port and a failed

host port in a direct connect configuration. As a result, the Connection state dialog box on

the Controller Properties window displays Connection failed for an empty host

port. To fix this problem, insert an optical loop-back connector into the empty host port; the

Connection state will display Connected. For more information about optical loop-back

connectors, contact your HP-authorized service provider.

iSCSI connection configurations

The EVA6400/8400 support iSCSI attach configurations using the HP MPX100. Both fabric connect

and direct connect are supported for iSCSI configurations. For complete information on iSCSI

configurations, go to the following website:

http://h18006.www1.hp.com/products/storageworks/evaiscsiconnect/index.html

NOTE: An iSCSI connection configuration supports mixed direct connect and fabric connect.

Fabric connect iSCSI

Fabric connect provides an iSCSI solution for EVA Fibre Channel configurations that want to

continue to use all EVA ports on FC or if the EVA is also used for HP P6000 Continuous Access.

Make sure the following requirements are met when configuring your MPX100 environment for

fabric connect:

• A maximum of two MPX100s per storage system are supported

• Each storage system port can connect to a maximum of two MPX100 FC ports.

• Each MPX100 FC port can connect to a maximum of one storage system port.

• In a single MPX100 configuration, if both MPX100 FC ports are used, each port must be

connected to one storage system controller.

• In a dual MPX100 configuration, at least one FC port from each MPX100 must be connected

to one storage system controller.

• The Host Port Configuration must be set to Fabric Connect using the OCP.

• HP P6000 Continuous Access is supported on the same storage system connected in MPX100

fabric connect configurations.

Direct connect iSCSI

Direct connect provides a lower cost solution for configurations that want to dedicate controller

ports to iSCSI I/O. When using direct connect, the storage system controllers are connected directly

to the MPX100s, not to SAN Fibre Channel switches.

Make sure the following requirements are met when configuring your MPX100 environment for

direct connect:

• A maximum two MPX100s per storage system are supported.

• In a single MPX100 configuration, if both MPX100 FC ports are used each port must be