Page 1

ARMY

NAVY EE010-BJ-MMA-010/E154 DCDUAL

TM 11-6130-416-14

AIR FORCE

TECHNICAL MANUAL

T.O. 35C1-2-847-1

OPERATOR’S, ORGANIZATIONAL,

DIRECT SUPPORT AND GENERAL SUPPORT

MAINTENANCE MANUAL

FOR

POWER SUPPLY, DUAL DC

(H-P MODEL 6255A)

(NSN 6130-00-065-6811)

DEPARTMENTS OF THE ARMY, NAVY, AND AIR FORCE

31 JANUARY 1983

Page 2

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.O.35C1-2-847-1

SAFETY STEPS TO FOLLOW IF SOMEONE

IS THE VICTIM OF ELECTRICAL SHOCK

DO NOT TRY TO PULL OR GRAB THE lNDl-

VIDUAL

IF POSSIBLE, TURN OFF THE ELECTRICAL

POWER

IF YOU CANNOT TURN OFF THE ELECTRICAL

POWER, PULL, PUSH, OR LIFT THE PERSON TO

SAFETY USING A WOODEN POLE OR A ROPE

OR SOME OTHER INSULATING MATERIAL

SEND FOR HELP AS SOON AS POSSIBLE

AFTER THE INJURED PERSON IS FREE OF CONTACT WITH THE SOURCE OF ELECTRICAL

SHOCK, MOVE THE PERSON A SHORT

DISTANCE AWAY AND IMMEDIATELY START

ARTIFICIAL RESUSCITATION

Page 3

TM 11-6130-416-14/EE010-BJ-JMA-010/E154 DCDUAL/T.O. 35C1-2-847-1

INSERT LATEST CHANGED PAGES. DESTROY SUPERSEDED PAGES.

LIST OF EFFECTIVE PAGES

Dates of issue for original and changed pages are:

Original . . 0 . .

TOTAL NUMBER OF PAGES IN THIS PUBLICATION IS

Page

No.

Title. . . . . . . . . .

A. . . . . . . . . . . .

i

- vii. . . . . . . . .

viii Blank. . . . . . . .

1-1 - 1-4. . . . . . . .

2-1 - 2-2. . . . . . . .

3-1 - 3-8

4-1 - 4-6..............

5-1 - 5-23 . . . . . . . .

5-24 - Blank . . . . . . . .

A-1 . . . . . . . . . . .

A-2 Blank. . . . . . . .

B-1

- B-4 . . . . . . . .

C-1

- C-2. . . . . . . .

D-1 . . . . . . . . . . .

D-2 Blank. . . . . . . .

E-1 . . . . . . . . . . .

E-2 Blank.... . . . .

Index-1

Report of Errors. . . . .

FO-l

- Index-10. . . .

- FO-2 . . . . . . .

# Change

No. No.

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Page

83 CONSISTING OF THE FOLLOWING:

# Change

No.

Page

No.

# Change

No.

# Zero in this column indicates an original page.

A

Page 4

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.O.35Cl-2-847-1

WARNING

DANGEROUS VOLTAGE

Is Used in the Operation of this Equipment

DEATH ON CONTACT

may result if personnel fail to observe safety precautions

Never work on electronic equipment unless there is another person

nearby who is familiar with the operation and hazards of the equipment

and who is competent in administering first aid.

is aided by operators, he must warn them about dangerous areas.

When the technician

Whenever possible, the power supply to the equipment must be shut off

before beginning work on the equipment. Take particular care to

ground every capacitor likely to hold a dangerous potential. When

working inside the equipment, after the power has been turned off,

always ground every part before touching it.

Be careful not to contact high-voltage connections when installing or

operating this equipment.

Whenever the nature of the operation permits, keep one hand away from

the equipment to reduce the hazard of current flowing through vital

organs of the body.

Do not be misled by the term “low voltage.” Potentials as low as 50

volts may cause death under adverse conditions.

B

Page 5

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.0.35Cl-2-847-1

Do not touch heat sinks or power transistors mounted on

heat sinks as they may be very hot after the instrument

has been on and operating.

CAUTION

Do not directly short out any of the large capacitors as

it places too much stress on them. Discharge capacitors

through a load resistor.

C/(D blank)

Page 6

Page 7

This manual contains copyright material reproduced by permission of the

Hewlett-Packard Company.

TM 11-6130-416-14

EE010-BJ-MMA-010/E154 DCDUAL

T.O.35C1-2-847-1

TECHNICAL MANUAL

NO. 11-6130-416-14

TECHNICAL MANUAL

EEO10-BJ-MMA-010/E154 DCDUAL

TECHNICAL ORDER

NO. 35CI-2-847-I

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT, AND GENERAL SUPPORT

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS

DEPARTMENTS OF THE ARMY,

THE NAVY,

AND THE AIR FORCE

Washington, DC, 31 January 1983

MAINTENANCE MANUAL

FOR

POWER SUPPLY, DUAL DC

(H-P Model 6255A)

(NSN 6130-00-065-6811)

You can help improve this manual.

If you find any mistakes or

if you know of a way to improve the procedures, please let us

know.

Publications and Blank

of

Communications-Electronics Command and Fort Monmouth,

DRSEL-ME-MP, Fort Monmouth,

Mail your letter, DA Form 2028 (Recommended Changes to

this

manual

Forms),

direct to:

or DA Form 2028-2 located in back

Commander, US

Army

ATTN:

NJ 07703.

For Air Force, submit AFTO Form 22 (Technical Order System

Publication Improvement Report and Reply) in accordance with

paragraph 6-5, Section VI, T.O. 00-5-1. Forward direct to prime

ALC/MST.

For Navy, mail comments to the Commander, Naval Electronics

Systems Command, ATTN:

ELEX 8122, Washington, DC 20360.

In either case, a reply will be furnished direct to you.

This manual is an authentication of the manufacturer’s commercial literature which,

through usage, has been found to cover the data required to operate and maintain

this equipment.

specifications and AR

Since the manual was not prepared in accordance with military

310-3,

the format has not been structured to consider levels

of maintenance.

i

Page 8

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.O35C1-2-847-1

TABLE OF CONTENTS

Section

I

GENERAL INFORMATION . . . . . . . . . . . .1-1

1-A.1

1-A.3

1-A.4

1-A.6

1-A.8

Page No.

Scope

1-1

Index of Publications 1-1

Army

Air Force

Maintenance Forms,

1-1

1-1

1-1

Section

3-3

3-5

3-7

3-9

3-11

3-14

Operating Modes

Normal Operating Mode

Constant Voltage

Constant Current

Connecting Load

Operation of Supply

Records and Reports

1-A.9

Reports of Maintenance

3-16

Optional Operational

and Unsatisfactory

1-A.11

1-A.13

1-A.15

Equipment

1-1

Report of Packaging

and Handling

Deficiencies

1-1

Discrepancy in Shipment

Report (DISREP)

(SF 361)

1-1

Reporting Equipment

3-17

3-24

3-30

3-35

3-39

3-42

Remote Programming,

Remote Programming

Parallel Operation

Auto-Tracking

Improvement

1-1

1-1

1-1

1-2

1-2

1-2

1-3

1-3

1-3

3-45

3-46

3-48

3-51

3-53

3-55

IV PRINCIPLES OF OPERATION . . . . . . . ...4-1

4-1

4-5

4-8

4-9

1-A.18

l-A.20

1-A.22

1-A.24

1-1

1-6

1-8

1-10

1-13

Recommendations (EIR)

Air Force

Navy

Administrative

Storage

Destruction Of Army

Electronics Materiel

Description

Specifications

Options

Instrument Identifica-

tion

Ordering Additional

Manuals

4-14

II

INSTALLATION

2-1

2-3

2-5

2-7

2-9

Initial Inspection

Mechanical Check

Electrical Check

Installation Data

Location

2-11 Rack Mounting

2-13 Input Power Requirements 2-1

2-15 Connections for 230 Volt

Operation

2-17 Power Cable

2-20 Repackaging for Shipment 2-2

. . . . . . . . . . . . . . . . . . .2-1

4-16

2-1

2-1

4-20

2-1

2-1

2-1

4-25

4-28

2-1

4-31

4-34

2-1

2-2

V MAINTENANCE . . . . . . . . . . . . . . . . . . . . .5-1

5-1

5-3

III OPERATING INSTRUCTIONS . . . . . . . . . . .3-1

3-1

Operating Controls and

Indicators

3-1

5-8

Page No.

3-1

3-1

3-1

3-2

3-2

Beyond Rated Output

Modes

Constant Voltage

Constant Current

Remote Sensing

Series Operation

3-2

3-2

3-2

3-3

3-4

3-4

3-5

Operation

3-6

Special Operating Considerations

Pulse Loading

Output Capacitance

Reverse Voltage Loading

Reverse Current Loading

3-6

3-6

3-6

3-7

3-7

Overvoltage Protection

Crowbar

3-7

Overall Block Diagram

Discussion 4-1

Simplified Schematic

4-2

Detailed Circuit Analysis 4-3

Feedback Loop

Series Regulator

4-3

4-3

Constant Voltage Input

Circuit

4-3

Constant Current Input

Circuit 4-4

Voltage Clamp Circuit

4-4

Mixer and Error

Amplifiers

Reference Circuit

Meter Circuit

Introduction

4-4

4-5

4-5

5-1

General Measurement

Techniques

5-1

Test Equipment

Required

5-2

ii

Page 9

TM 11-6130-416-14/EE010-BJ-NMA-010/E154 DCDUAL/T.O.35Cl-2-847-1

TABLE OF CONTENTS (CONTINUED)

Section

5-10

5-12

5-34

5-39

5-41

5-46

5-47A.1

5-47A.3

5-47A.5

5-47A.7

5-47A.9

5-47A.11

5-47A.13

5-47A.15

5-47A.17

5-47A.19

5-47A.21

5-47A.23

5-47A.25

5-47A.27

Page No.

Performance Test

Constant Voltage

Tests

Constant Current

(CC) Tests

Troubleshooting

Trouble Analysis

Repair and Replace-

ment

Fuse Replacement

Cover Removal

Power Cable

Replacement

Switch S1

Replacement

Transformer T1

Replacement

Overvoltage

Protection Crowbar

P.C. Board Replace-

ment

Main Left P.C.

Board Replacement

(Viewed from Front

of Power Supply)

Main Right P.C.

Board Replacement

(Viewed from Front

of Power Supply)

Capacitator C14

Replacement

Capacitors C5, C6

Replacement

Power Transistor Q4,

Q6, Replacement

Power Transistor Q7,

Replacement

Transistor Q3

Replacement

Voltage/Current

Programming Control

Replacement

5-2

5-2

5-8

5-9

5-9

5-14

5-15

5-15

5-17

5-17

5-17

5-18

5-18

5-18

5-19

5-19

5-19

5-20

5-20

5-20

Section

Page No.

5-47A.29 Silicon Rectifier

CR19 Replacement

5-47A.31

Meter Switch S2

Replacement

5-47A.33 Meter Replacement

5-20

5-21

5-21

5-47A.35 Shunt Resistor

(R81, R82, or R83)

Replacement

5-21

5-47A.37 Fuse Holder Assembly

Replacement

5-21

5-47A.39 Neon Lamp DS1

Replacement

5-21

5-47A.41 Crowbar Adjust

Potentiometer R5

Replacement

5-22

5-48 Adjustment and

Calibration

5-50 Meter Zero.

5-52 Voltmeter Tracking

5-54 Ammeter Tracking

5-22

5-22

5-22

5-22

5-56 Constant Voltage

Programming Current

5-22

5-59 Constant Current

Programming Current

5-23

5-62 Reference Circuit

Adjustments

5-23

5-64 Constant Voltage

Transient Response

5-23

VI REPLACEABLE PARTS . . . . . . . . . . . . . . .6-1

6-1

6-4

Introduction

Ordering Information

6-1

6-1

APPENDIX A . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

APPENDIX B . . . . . . . . . . . . . . . . . . . . . . . . B-1

APPENDIX C . . . . . . . . . . . . . . . . . . . . . . . . C-1

APPENDIX D . . . . . . . . . . . . . . . . . . . . . . . D-1

APPENDIX E . . . . . . . . . . . . . . . . . . . . . . . E-1

INDEX

Index 1

iii

Page 10

Figure

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.O.35C1-2-847-1

LIST OF ILLUSTRATIONS

Page No.

Figure

Page No.

1-1

2-1

3-1

3-2

3-3

3-4

3-5

3-6

3-7

3-8

3-9

3-10

3-11

3-12

3-13

4-1

4-2

DC Power Supply

Primary Connections

Front Panel Control and

Indicators

Normal Strapping Pattern

Remote Resistance

Programming(Constant

Voltage)

Remote Voltage

Programming (Constant

Voltage)

Remote Resistance

Programming (Constant

Current)

Remote Voltage

Programming (Constant

Current)

Remote Sensing

Normal Series Connections

Auto-Series, Two and

Three Units

Normal Parallel ,

Connections

Auto-Parallel, Two and

Three Units

Auto-Tracking, Two and

Three Units

Model 6255A and 6289A

Overvoltage Protection

Crowbar

Overall Block

Diagram

Simplified Schematic

v

2-1

3-1

3-1

3-2

3-3

3-3

3-3

3-4

3-4

3-5

3-5

3-5

3-6

3-8

4-1

4-2

4-3

4-4

5-1

5-2

5-3

5-4

5-5

5-6

5-7

5-8

5-9

5-10

5-11

5-12

5-13

5-14

FO-1

FO-2

Voltmeter Connections,

Simplified Schematic

Ammeter Connections,

Simplified Schematic

Front Panel Terminal

Connections

Output Current

Measurement Technique

Differential Voltmeter

Substitute Test Setup

Output Current, Test

Setup

Load Regulation, Constant

Voltage Test Setup

CV Ripple and Noise Test

Setup

CV Noise Spike Test Setup 5-6

Transient Response

Test Setup

Transient Response,

Waveforms

CV Programming, Speed,

Test Setup

Output Impedance,

Test Setup

CC Ripple and Noise Test

Setup

Servicing Printed Wiring

Boards

Model 6255A Modular

Cabinet

6255A Schematic

Parts Location/Intercon-

nection Diagram

4-5

4-5

5-1

5-1

5-2

5-2

5-4

5-4

5-6

5-6

5-7

5-7

5-8

5-13

5-16

Table

5-1

5-2

5-4

5-5

iv

1-1

5-3

LIST OF TABLES

Page No.

Specifications

Test Equipment Required 5-3

Common Troubles

Reference, Bias, and

Filtered DC

Troubleshooting

Low Output Voltage

Troubleshooting

High Output Voltage

Troubleshooting

1-4

5-9

5-11

5-11

5-12

Table

5-6

5-7

5-8

Selected Semiconductor

Characteristics

Checks and Adjustments

After Replacement of

Semiconductor Devices

Calibration and

Adjustment Summary

Page No.

5-14

5-14

5-15

Page 11

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.0.35C1-2-847-1

Figure 1-1.

Typical DPR Series DC Power Supply

v/(vi blank)

Page 12

Page 13

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.0.35C1-2-847-1

SECTION I

GENERAL INFORMATION

1-A.1

1-A.2

6255A Dual DC Power Supply with Option

11 Overvoltage Protection Crowbar Circuit (power supply serial numbers

2012A-4996 and up). Responsibilities

for all levels of maintenance are specified by the Maintenance Allocation

Chart (MAC) contained in

1-A.3

1-A.4

1-A.5

PAM 310-1 to determine whether there

are new editions, changes or additional

publications pertaining to the equip-

ment.

1-A.6

1-A.7

cal Index and Requirements Table

(NIRT).

1-A.8

REPORTS

1-A.9

UNSATISFACTORY EQUIPMENT

1-A.10

and procedures used for equipment main-

tenance will be those prescribed by

38-750,

System (Army).

will use AFM 66-1 for maintenance re-

porting and T.O. 00-35D54 for unsatis-

factory equipment reporting. Navy personnel will report maintenance performed utilizing the Maintenance Data

Collection Subsystem (MDCS) IAW

OPNAVINST 4790.2, Vol 3, and unsatis-

factory material/conditions (UR

submissions) IAW OPNAVINST 4790.2, Vol

2,

chapter 17.

SCOPE

This manual describes the Model

Appendix B.

INDEX OF PUBLICATIONS

ARMY

Refer to the latest issue of DA

AIR

FORCE

Use T.O. 0.1-31 Series Numeri-

MAINTENANCE FORMS, RECORDS AND

REPORTS

Department of the Army forms

The Army Maintenance Management

OF

MAINTENANCE AND

Air

Force personnel

TM

1-A.12

(Report of Discrepancy (ROD) as pre-

scribed in AR 735-11-2/DLAR 4140.55/

NAVMATINST 4355.73/AFR 400-54/MCO

4430.3E.

1-A.13

(DISREP) (SF

1-A.14

ancy in Shipment Report (DISREP) (SF

361) as prescribed in AR 55-38/

NAVSUPINST 4610.33B/AFR 75-18/MCO

P4610.19C/DLAR 4500.15.1-4.

1-A.15

IMPROVEMENT RECOMMENDATIONS) (EIR)

1-A.16

1-A.17

needs improvement, let us know.

us an EIR.

only one who can tell us what is not

liked about your equipment. Let us

know why you do not like the design.

Tell us why a procedure is hard to per-

form.

Deficiency Report).

der, US Army Communications-Electronics

Command and Fort Monmouth, ATTN:

DRSEL-ME-MP, Fort Monmouth,

We will send you a

1-A.18

1-A.19

encouraged to submit EIRs in accordance

with AFM 900-4.

1-A.20

1-A.21

to submit EIRs through their local

Beneficial Suggestion Program.

1-A.22

Fill out and forward SD 364

DISCREPANCY IN SHIPMENT REPORT

361)

Fill out and forward Discrep-

REPORTING EQUIPMENT

ARMY

If the Power Supply, Dual DC

Send

You, the user, are the

Put it on an SF 368 (Quality

Mail it to Comman-

NJ

07003.

reply

AIR FORCE

Air Force personnel are

NAVY

Navy personnel are encouraged

ADMINISTRATIVE STORAGE

1-A.11

HANDLING

REPORT OF PACKAGING AND

DEFICIENCIES

1-1

1-A.23

Refer to

TM 11-5805-683-12

or

Page 14

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.O.35C1-2-847-1

TM 11-5805-681-12,

Administrative storage of equip-

age.

ment issued to and used by Army activi-

ties will have preventive maintenance

performed in accordance with the Pre-

ventive Maintenance Checks and Services

(PMCS) procedure listed before storing.

When removing the equipment from administrative storage,the PMCS should be

performed to assure operational readi-

ness.

equipment for shipment or limited stor-

age are also covered.

90-1 if

charts.

1-A.24

ELETRONICS

1-A.25

ics materiel to prevent enemy use shall

be in accordance with

Disassembly and repacking of

there are no published PM

DESTRUCTION OF ARMY

MATERIEL

Destruction of Army electron-

Administrative Stor-

Refer to

TM 750-244-2.

TM 749-

1-3

Each supply has both

Either the positive or negative output terminal may

be grounded or the power supply can be operated

floating

at up to a

1-4

and operating controls.

tiple range type and can measure output voltage or

current. The voltage or current

by the applicable METER switch

1-5 TWO

the rear of the unit allow ease in adapting to the

many operational capabilities of the power supply.

A

below:

from a remote location by means of an external

voltage source or resistance.

Each section has its own front panel meter

sets of programming terminals located at

brief description

a.

Remote

The power supply maybe programmed

b. Remote Sensing

front

maximum

Programming

and rear

of

300 volts off

The meters are of the mul-

ranges

on

of these capabilities

terminals.

are selected

the front panel.

ground.

is

given

1-1

DESCRIPTION

1-2

completely transistorized and suitable

for either rack or bench operation. It

is a dual supply consisting of two independently controlled sections; both

identical to each other.

will be referred to as the left and

right side power supplies as viewed from

front of unit.

regulated,Constant Voltage/Constant

Current source that will furnish full

rated output

rated output current or can be continuously adjusted throughout either output

range.

can be used to establish the output cur-

rent limit

when the supply is used as a constant

voltage source and the VOLTAGE control(s)

voltage limit

is used as a constant current source.

Each section will automatically crossover from constant voltage to constant

current operation and vice versa if the

output current or voltage exceeds these

preset limits.

This power supply,

Each section is a well-

voltage at

The front panel CURRENT controls

(overload or

can be

used to establish the

(ceiling) when

Figure 1-1,

These sections

the maximum

short circuit)

the supply

is

The degradation in regulation which

would occur

in

the

supply in the remote sensing mode of operation.

c.

when a higher output voltage is required in the

voltage mode of operation or

compliance

of operation. Auto-Series operation permits one

knob control of the total output voltage

“master"

parallel

rent capability

permits one knob control

from

“master” supply, having control

“slave” supplies that furnish various voltages for

a system.

1-6

1-7

supply.

d. Parallel and Auto-Parallel Operation

a

e.

SPECIFICATIONS

Detailed specifications

at the

load leads can be reduced by using the power

Series and Auto-Series Operation

Power supplies maybe used in series

is

required in

The power supply may be operated

with a

is

required. Auto-Parallel

“master” supply.

Auto-Tracking

The power supply maybe used

load because of the voltage drop

when

the

similar unit when greater output cur-

of

the total output current

for

greater voltage

constant current mode

from a

in

operation

as

over

one (or more)

the power supply

a

1-2

Page 15

TM 11-6130-416-14/EE010-BJ-MM-010/E154 DCDUAL/T.O.35C1-2-847-1

are given in

1-8

1-9

ard instrument that are requested by the customer.

The following options are available for the instru-

ment covered by this manual. Where necessary,

detailed coverage of the options is included through-

out the manual.

Option No.

Table 1-1.

NOTE

Since both sections of this supply

are identical, only one section will

be discussed throughout the remain-

ing portions of this manual. All

descriptions, illustrations,

and adjustments apply equally to

both sections of the supply.

OPTIONS

Options are factory modifications

Description

07

Voltage 10-Turn Pot: A single control that replaces both coarse and fine

voltage controls and improves output

settability.

6258A power supplies.

Standard item on Model

tests,

of a

stand-

Trip Voltage Margin: The minimum

crowbar trip setting above the desired

operating output voltage to

false crowbar tripping is 4% of the

output voltage setting +2V.

Refer to

of operation and

schematic diagram.

13

14 Three Digit Graduated Decadial Cur-

28

Paragraph 3-55

Figure 3-13

Three Digit Graduated Decadial Volt-

age Control: Control that replaces

coarse and fine voltage controls permitting accurate resettability.

rent Control: Control that replaces

coarse and fine current controls permitting accurate resettability.

Rewire for 230V AC Input: Supply as

normally shipped is wired for 115VAC

input. Option 28 consists of reconnecting the input transformer for 230V

AC operation.

prevent

for details

for the

08

09

10

11

Current 10-Turn Pot: A single control that replaces both coarse and fine

current controls and improves out put

settability.

Voltage and Current 10-Turn Pot:

Consists of Options 07 and 08 on the

same instrument.

Chassis Slides: Enables convenient

access to power supply interior for

maintenance purposes.

Internal Overvoltage Protection

“Crowbars”: This option includes

two crowbar circuits, one for each

power supply within the 6253A or

or 6255A. Each crowbar protects

delicate loads by monitoring the output voltage and firing an SCR that

shorts the output when the preset

trip voltage is exceeded. The circuit

boards are factory installed within

the supply. The “Crowbar Adjust”

controls are mounted on the front

panel to permit convenient adjust-

ment.

Trip Voltage Range:

6253A

2.5 to 23V 2.5 to 44V

6255A

1-10

1-11

by a three-part serial number tag. The first part is

the power supply model number. The second part is

the serial number prefix, which consists of a number-letter combination that denotes the date of a

significant design change. The number designates

the year, and the letter A through L designates the

month, January through December, respective y. The

third part is the power supply serial number.

1-12 If

ply does not agree with the prefix on the title page

of this manual, change sheets are included to up-

date the manual.

information is given in an appendix at the rear of

the manual.

power supply.

INSTRUMENT IDENTIFICATION

Hewlett-Packard power supplies are identified

the serial number prefix on your power sup-

Where applicable, backdating

1-13

be obtained from regular publication

distribution channels.

ORDERING ADDITIONAL MANUALS

1-14

One manual is shipped with each

Additional manuals may

1-3

Page 16

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.0035C1-2-847-1

Table 1-1. Specifications

INPUT:

105-125/210-250

50-400

OUTPUT:

Two independent outputs each of which can

be set at 0-40 volts @ 0-1.5 amps.

LOAD REGULATION:

Constant Voltage

2mv for a full load to no load change in output

current.

Constant Current

250µa for a zero to maximum change in output

voltage.

LINE REGULATION:

Constant Voltage

2mv for any line voltage change within the input

rating.

Constant Current -250µa for any line voltage change within the input rating.

RIPPLE AND NOISE:

Constant Voltage

Constant Current --

cps.

VAC, single phase,

-- Less than 0.01% plus

-- Less than 0.01% plus

-- Less than 0.01% plus

Less than 0.01% plus

-- Less than 200µv rms.

Less than 500µa rms.

OVERLOAD PROTECTION:

A continuously acting constant current circuit

protects the power supply for all overloads including a direct short placed across the terminals in constant voltage operation. The constant

voltage circuit limits the output voltage in the

constant current mode of operation.

METERS:

Each front panel meter can be used as either a

0-50V or 0-5 volt voltmeter or as a 0-1.8A or

0-0.18 amp ammeter.

OUTPUT CONTROLS:

Coarse and fine voltage controls and coarse

and fine current controls set desired output voltage or current.

OUTPUT TERMINALS:

Six output posts (three per section)

are provided on the front panel and output terminal

strips are located on the rear of the chassis. All

power supply output terminals are isolated from

the chassis and either the positive or negative

terminals may be connected to the chassis

through a separate ground terminal located on the

output terminal strip.

TEMPERATURE RANGES:

Operating:

TEMPERATURE COEFFICIENT:

Constant Voltage

500µv per degree Centigrade.

Constant Current

0.8ma per degree Centigrade.

STABILITY:

Constant Voltage

2.5mv total drift for 8 hours after an initial warmup time of 30 minutes at constant ambient, constant line voltage, and constant load.

Constant Current -4ma total drift for 8 hours after an initial warm-up

time of 30 minutes at constant ambient, constant

line voltage, and constant load.

OUTPUT

Approximated by a

resistance in series with a

microhenry inductance.

TRANSIENT RECOVERY TIME:

Less than 50µsec

15 mv following a full load current change in the

output.

0 to

50°C.

Storage: -20 to +85°C.

-- Less than 0.02% plus

-- Less than 0.02% plus

-- Less than 0.10% plus

Less than 0.10% plus

IMPEDANCE

for output recovery to within

10

(TYPICAL):

milliohm

1

ERROR SENSING:

Error sensing is normally accomplished at the

front terminals if the load is attached to the front

or at the rear terminals if the load is attached to

the rear terminals.

on the rear terminal strip for remote sensing.

REMOTE PROGRAMMING:

Remote programming of the supply output at ap-

proximately 200 ohms per volt

is made available at the rear terminals. In con-

stant current mode of operation, the current can

be remotely programmed at approximately 500 ohms

per ampere.

COOLING:

Convection cooling is employed. The supply

has no moving parts.

SIZE:

3- 1/2" H x 14- 1/2"

mounted in a standard 19” relay rack.

WEIGHT:

28 lbs. net, 35 lbs. shipping.

FINISH:

Light gray front panel with dark gray case.

POWER CORD:

A three-wire, five-foot power cord is provided

with each unit.

Also, provision is included

in

constant voltage

D x

19” W. Easily rack

1-4

Page 17

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.O.35C1-2-847-1

SECTION II

INSTALLATION

2-1

INITIAL INSPECTION

2-2

Before shipment, this instrument was inspected and found to be free of mechanical and electrical defects. As soon as the instrument is un-

packed, inspect for any damage that may have oc-

curred in transit. Save all packing materials until

the inspection is completed.

2-3

MECHANICAL CHECK

2-4

This check should confirm that there are no

broken knobs or connectors, that the cabinet and

panel surfaces are free of dents and scratches,

and that the meter is not scratched or cracked.

either

power

tory, is wired for 115 volt operation. The input

power required when operated from a 115 volt 60

cycle power source at full load is 235 watts and

2.6 amperes.

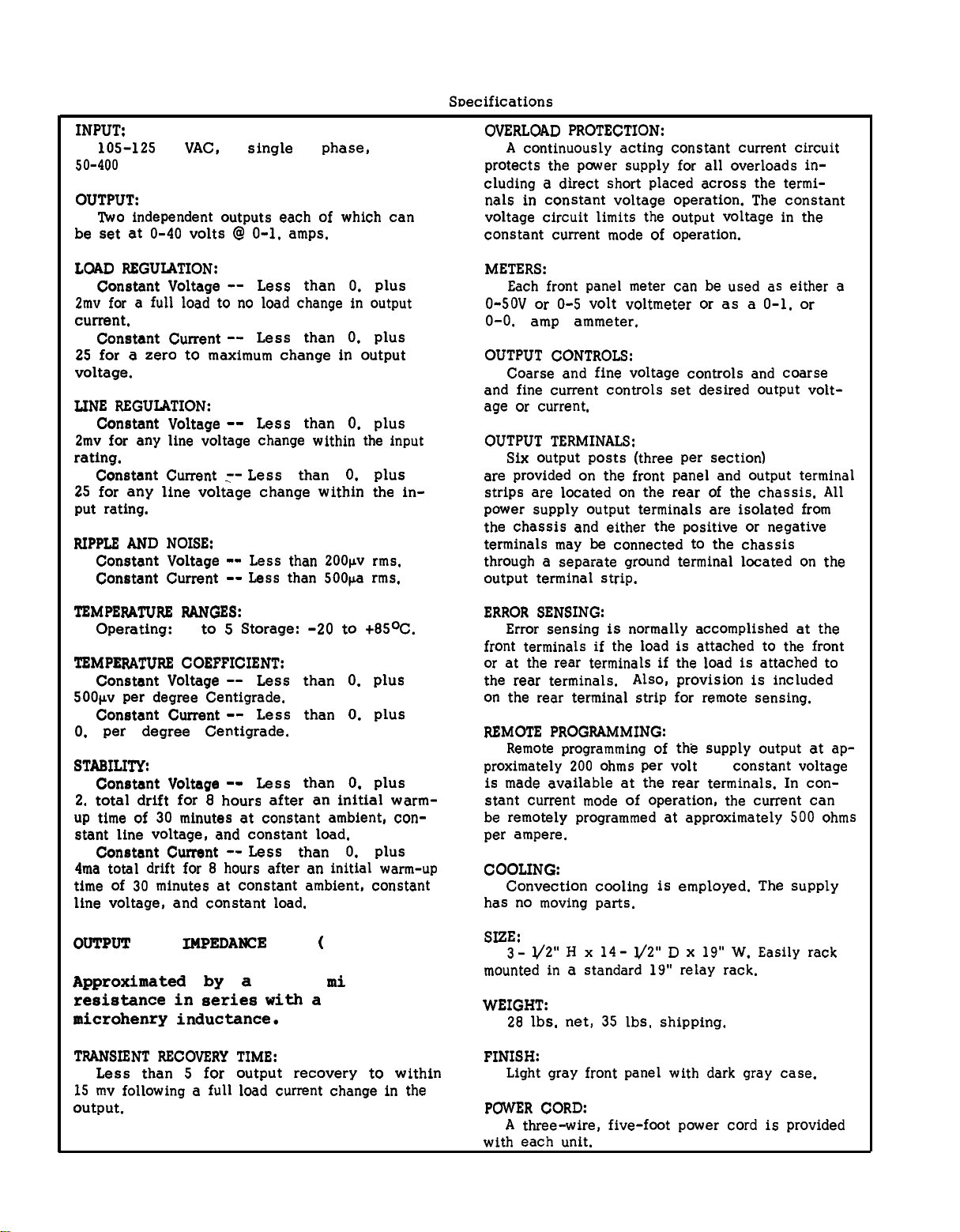

2-15

a nominal 115 volt or 230 volt 50-400 cycle

source. The unit, as shipped from the fac-

CONNECTIONS FOR 230 VOLT OPERATION

(Figure 2-1)

2-5

ELECTRICAL CHECK

2-6

The instrument should be

electrical

“in-cabinet” performance check to verify proper

instrument operation.

2-7

2-8

operation. It is necessary only to connect the

instrument to a source of power and it is ready for

operation.

2-9

2-10

space should be allotted so that a free flow of

cooling air can reach the sides and rear of the

instrument when it is in operation. It should be

used in an area where the ambient temperature does

not exceed 50°C.

2-11

2-12

easily rack mounted in a conventional 19 inch rack

panel using standard mounting screws.

2-13

2-14

specifications.

INSTALLATION DATA

The instrument is shipped ready for bench

LOCATION

This instrument is air cooled. Sufficient

RACK MOUNTING

This instrument is full rack size and can be

INPUT POWER REQUIREMENTS

This power supply may be operated from

checked

Section V includes an

against its

Figure 2-1.

2-16

put transformer are connected in parallel for operation from 115 volt source. To convert the power

power transformer windings are connected in series

as follows:

Normally, the two primary windings of the in-

supply to operation from a 230 volt source, the

Primary Connections

2-1

Page 18

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.O.35C1-2-847-1

a.

Unplug the line cord and remove the

unit covers.

b.

Break the copper between 54 and 55 and

also between 50 and 51 on the printed circuit

board. These are shown in

Figure 2-1,

and are

labeled on copper side of printed circuit board.

c.

Add strap between 50 and 55.

d.

Replace existing fuse with 2 ampere,

230 volt fuse. Return unit to case and operate

cable three-prong connector is the ground connection.

2-19 To

operating the instrument from a two-contact outlet,

use a three-prong to two-prong adapter and connect the green lead on the adapter to ground.

2-20

REPACKAGING FOR SHIPMENT

normally.

2-21 To

2-17

POWER CABLE

it is recommended that the package designed for

the instrument be used. The original packaging

2-18 To

protect

operating

personnel,the

National

material is reusable.

Electrical Manufacturers Association(NEMA)recommends that the instrument panel and cabinet be

grounded.

This instrument is equipped with a

three conductor power cable. The third conductor

is the ground conductor and when the cable is

plugged into an appropriate receptacle, the instrument is grounded. The offset pin on the power

preserve the protection feature when

insure safe shipment of the instrument,

2-2

Page 19

TM ll-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.O.35C1-2-847-1

OPERATING INSTRUCTIONS

3-1

OPERATING CONTROLS

3-2

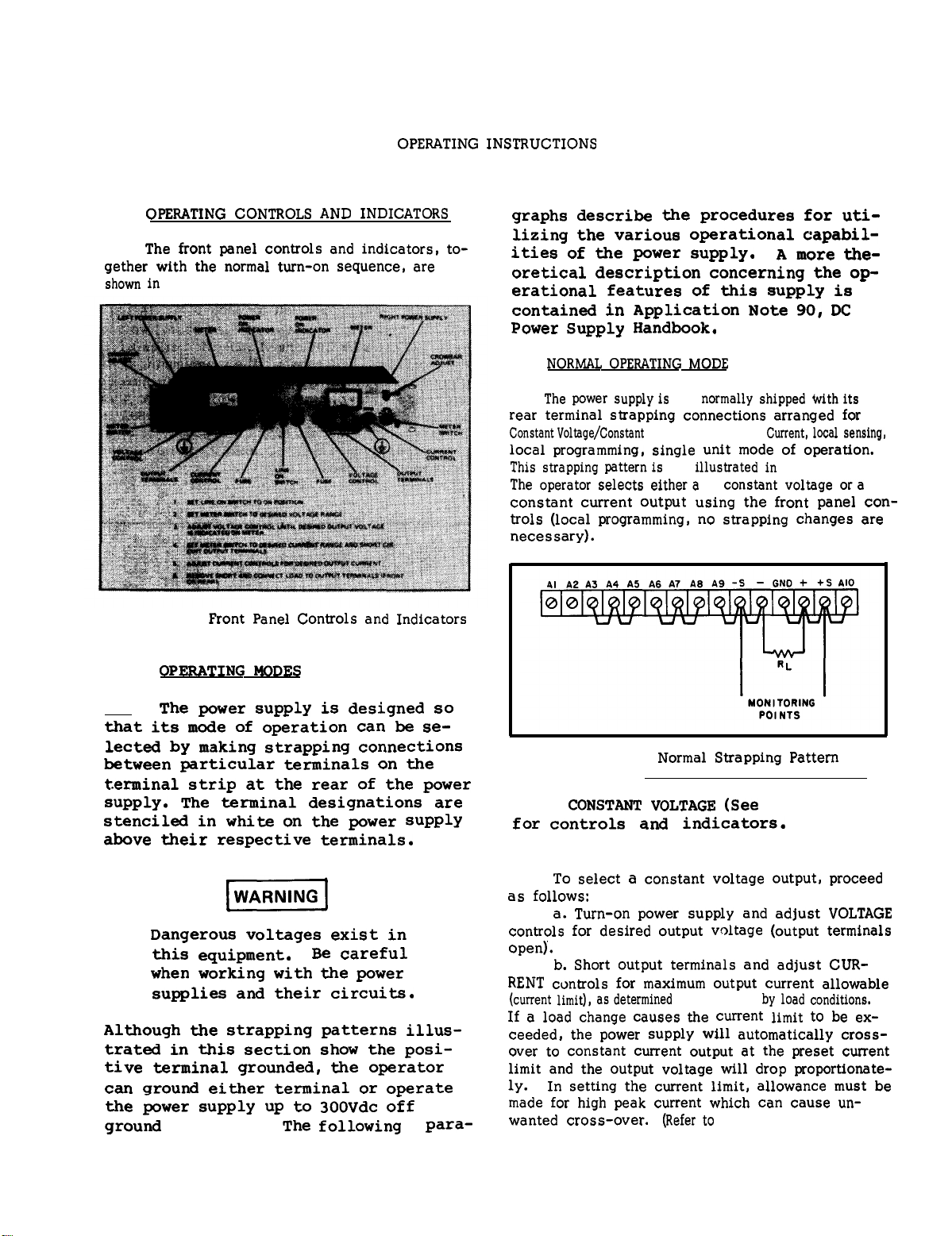

The front panel controls and indicators, together with the normal turn-on sequence, are

shown in

Figure 3-1.

AND

INDICATORS

SECTION III

graphs describe the procedures for uti-

lizing the various operational capabilities of the power supply.

oretical description concerning the operational features of this supply is

contained in Application Note 90, DC

Power Supply Handbook.

3-5

NORMAL

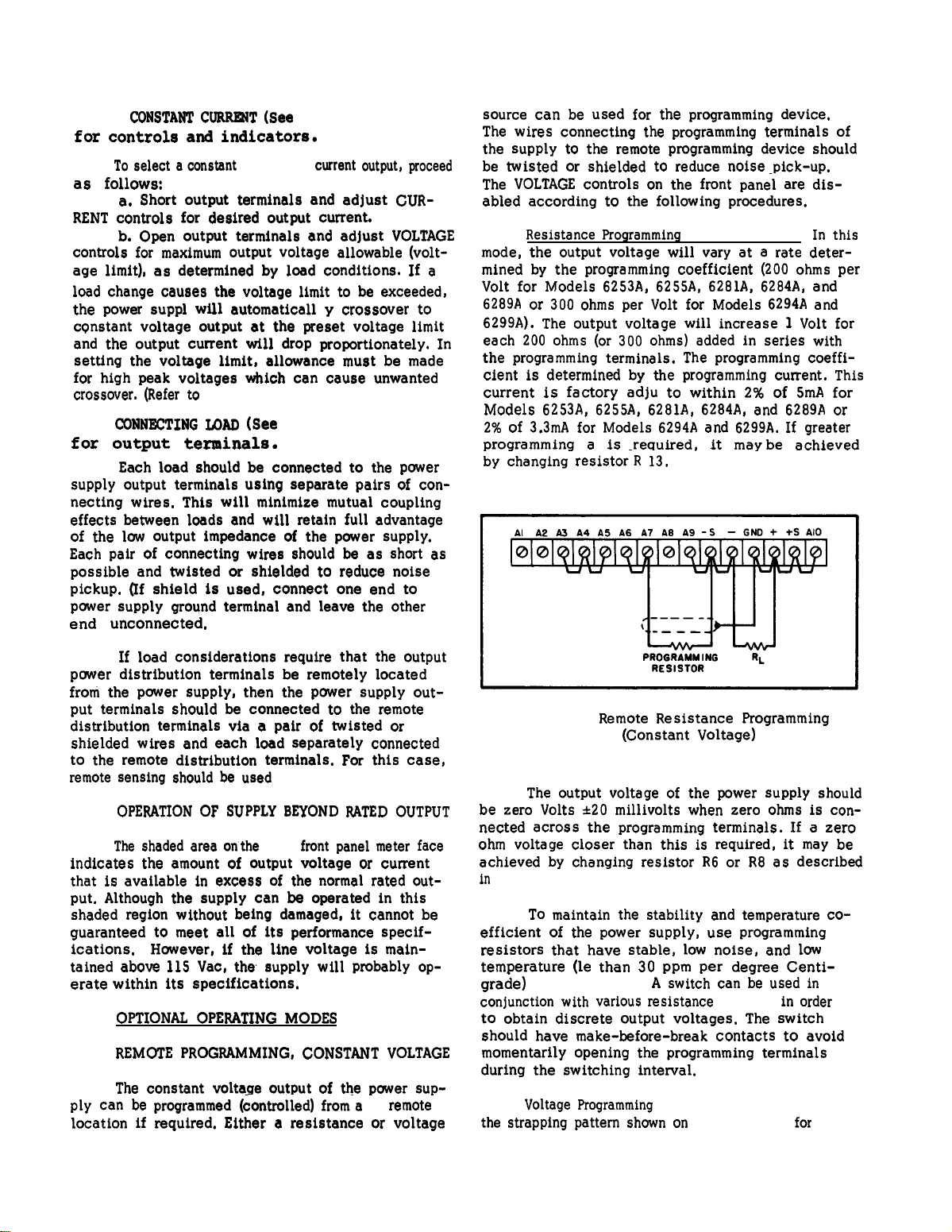

3-6

The power supply

rear terminal strapping connections arranged for

Constant

local programming, single unit mode of operation.

This strapping pattern

The operator selects either

constant current output using the front panel controls (local programming, no strapping changes are

necessary).

OPERATING MODE

is

normally shipped with

Voltage/Constant

is

illustrated

a

constant voltage or

A more the-

its

Current,

local sensing,

in Figure 3-2.

a

Figure 3-1.

3-3

3-4

that its mode of operation can be se-

lected by making strapping connections

between particular terminals on the

terminal strip at the rear of the power

supply. The terminal designations are

stenciled in white on the power supply

above their respective terminals.

Although the strapping patterns illus-

trated in this section show the positive terminal grounded, the operator

can ground either terminal or operate

the power supply up to 300vdc off

ground(floating).

OPERATING MODES

The power supply is designed so

Dangerous voltages exist in

this equipment.

when working with the power

supplies and their circuits.

Front Panel Controls and Indicators

Be careful

The following

para-

Figure 3-2.

3-7

for

3-8

as follows:

controls for desired output voltage (output terminals

open).

RENT controls for maximum output current allowable

(current

If a load change causes the current limit to be exceeded, the power supply will automatically crossover to constant current output at the preset current

limit and the output voltage will drop proportionately.

made for high peak current which can cause un-

wanted cross-over.

CONSTANT VOLTAGE (See

controls and indicators.)

To select a constant voltage output, proceed

a. Turn-on power supply and adjust VOLTAGE

b. Short output terminals and adjust CUR-

limit),

as

In setting the current limit, allowance must be

Normal Strapping Pattern

Figure 3-1

determined by

(Refer to

Paragraph 3-46.)

load conditions.

3-1

Page 20

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.O.351-2-847-1

3-9

for controls and indicators.)

3-10

as follows:

RENT controls for desired output current.

controls for maximum output voltage allowable (volt-

age limit), as determined by load conditions. If a

load change causes the voltage limit to be exceeded,

the power supply will automatically

constant voltage output at the preset voltage limit

and the output current will drop proportionately.

setting the voltage limit, allowance must be made

for high peak voltages which can cause unwanted

crossover.

3-11

for output terminals.)

3-12

supply output terminals using separate pairs of connecting wires. This will minimize mutual coupling

effects between loads and will retain full advantage

of the low output impedance of the power supply.

Each pair of connecting wires should be as short as

possible and twisted or shielded to reduce noise

pickup. (If shield is used, connect one end to

power supply ground terminal and leave the other

end unconnected.)

CONSTANT CURRENT (See

To select a

a. Short output terminals and adjust CUR-

b. Open output terminals and adjust VOLTAGE

(Refer to

CONNECTING LOAD (See

Each load should be connected to the power

constant

Paragraph 3-46.)

Figure 3-1

current output, proceed

y

crossover to

Figure 3-1

In

source can be used for the programming device.

The wires connecting the programming terminals of

the supply to the remote programming device should

be twisted or shielded to reduce noise pick-up.

The VOLTAGE controls on the front panel are disabled according to the following procedures.

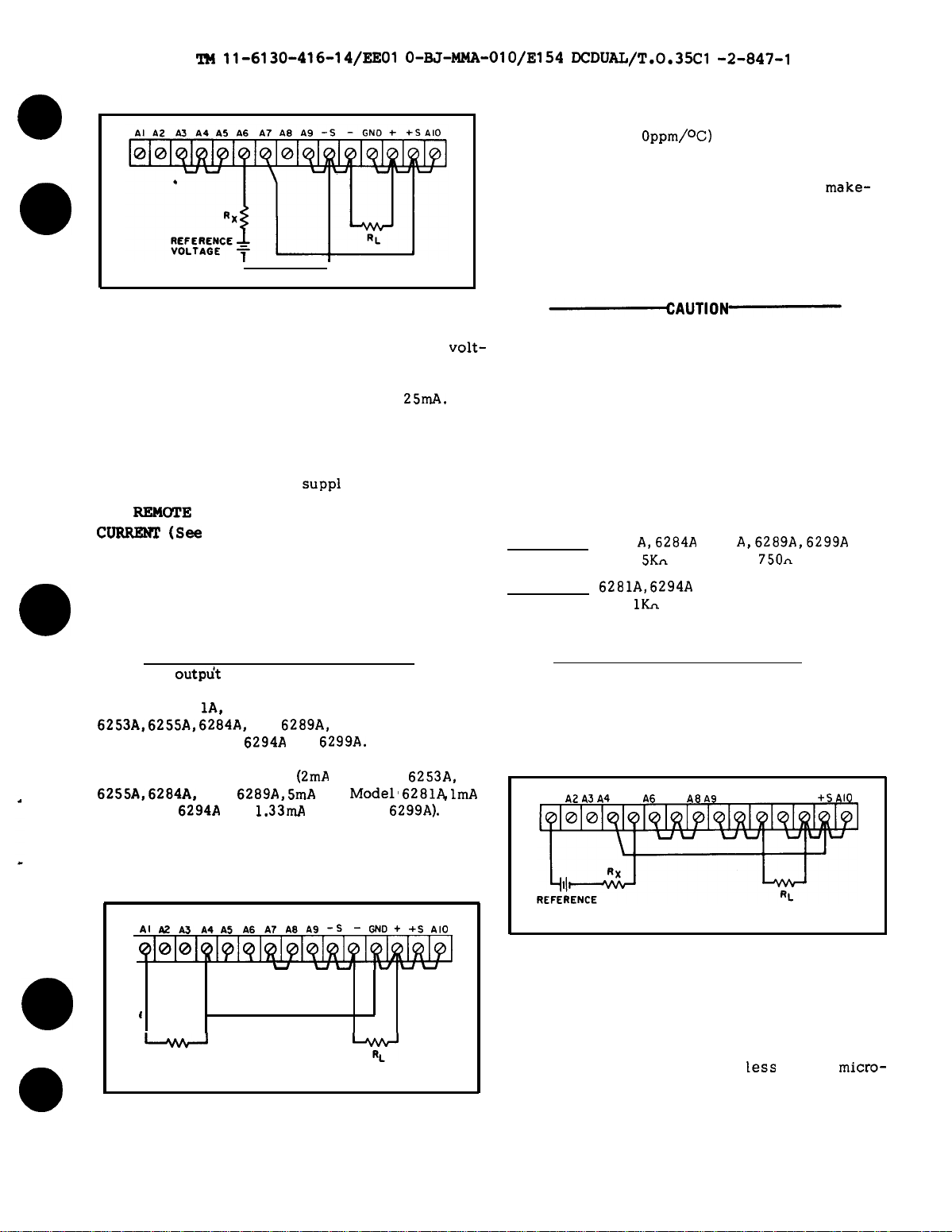

3-19

Resistance Programming

mode, the output voltage will vary at a rate determined by the programming coefficient (200 ohms per

Volt for Models 6253A, 6255A, 6281A, 6284A, and

6289A or 300 ohms per Volt for Models 6294A and

6299A). The output voltage will increase 1 Volt for

each 200 ohms (or 300 ohms) added in series with

the programming terminals. The programming coefficient is determined by the programming current. This

current is factory adjusted

Models 6253A, 6255A, 6281A, 6284A, and 6289A or

2% of 3.3mA for Models 6294A and 6299A. If greater

programming accuracy

by changing resistor-R 13.

is

(Figure 3-3). In

to

within 2% of 5mA for

required, it maybe achieved

this

3-13 If

power distribution

from the power supply, then the power supply out-

put terminals should be connected to the remote

distribution

shielded wires and each load separately connected

to the remote distribution

remote sensing should be used

3-14

3-15

indicates the amount of output voltage or current

that is available in excess of the normal rated output. Although the supply can be operated in this

shaded region without being damaged, it cannot be

guaranteed to meet all of its performance specifications.

tained above 115 Vac, the supply will probably operate

3-16

3-17

3-18

ply can be programmed (controlled)

location if required. Either a resistance or voltage

load considerations

terminals be remotely located

terminals via a pair of twisted or

OPERATION OF SUPPLY BEYOND RATED OUTPUT

The shaded area on

However, if the line voltage is main-

within its specifications.

OPTIONAL OPERATING

REMOTE PROGRAMMING, CONSTANT VOLTAGE

The constant voltage output of the power sup-

require that the output

terminals. For this case,

(Paragraph 3-20).

the

front panel meter face

MODES

from

a

remote

Figure 3-3.

3-20

The output voltage of the power supply should

be zero Volts ±2O millivolts when zero ohms is connetted acress the programming terminals. If a zero

ohm voltage closer than this is required, it may be

achieved by changing resistor R6 or R8 as described

in

Paragraph 5-59.

3-21 To

efficient of the power supply, use programming

resistors that have stable, low noise, and low

temperature (less than 30 ppm per degree Centigrade)characteristics.

conjunction

to obtain discrete output voltages. The switch

should have make-before-break

momentarily opening the programming terminals

during the switching interval.

3-22

Voltage Programming

the strapping pattern shown on

Remote Resistance Programming

(Constant Voltage)

maintain the stability and temperature co-

A switch can be used in

with various resistance

(Figure 3-4). Employ

values in

contacts to avoid

Figure 3-4

for

order

3-2

Page 21

‘m 11-6130-416-14/EEOI O-BJ-M.MA-0113/E154 DCDUAL/T.0.35Cl -2-847-l

3-27 Use stable, low noise, low temperature coefficient (less than 3

to maintain the power supply temperature coefficient

and stability specifications. A switch may be used

to set discrete values of output current.

before-break type of switch should be used since

the output current will exceed the maximum rating

of the power supply if the switch contacts open

during the switching interval.

Oppm/oC) programming resistors

A

make-

Figure 3-4.

Remote Voltage Programming

(Constant Voltage)

voltage programming. In this mode, the output

volt-

age will vary in a 1 to 1 ratio with the programming

voltage (reference voltage) and the load on the programming voltage source will not exceed

25mA.

3-23 The impedance matching resistor (Rx) for the

programming voltage source should be approximately

500 ohms to maintain the temperature and stability

SUPP1

specifications of the power

REMOl’E

3-24

CURRENl! (Ses

PROGRAMMING, CONSTANT

Figure 3-1 for controls and

y.

indicators. )

3-25 Either a resistance or a voltage source can be

used to control the constant current output of the

supply. The CURRENT controls on the front panel

are disabled according to the following procedures.

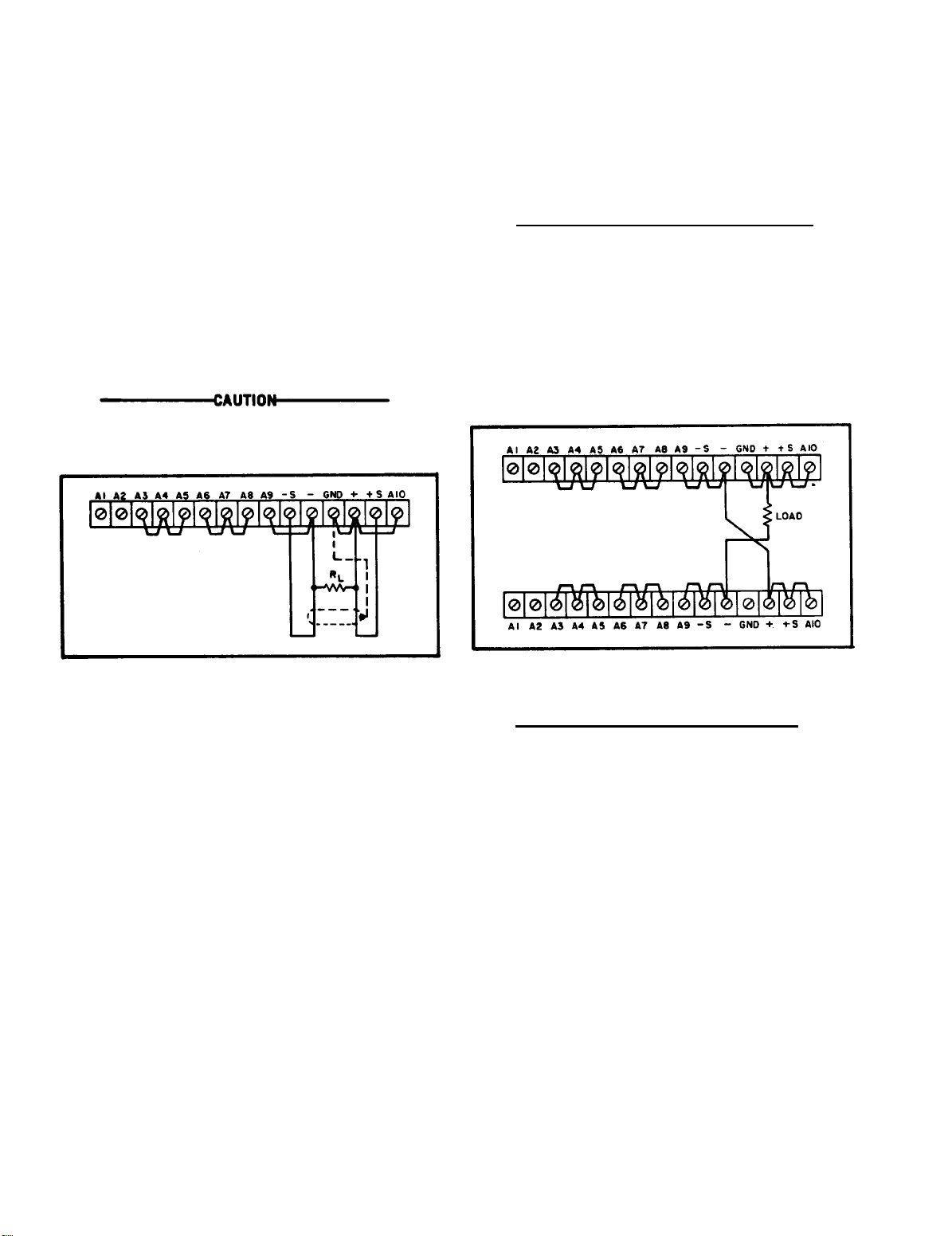

3-26 Resistance Programming (Figure 3-5). In this

outpdt

mode, the

by the programming coefficient — 200 ohms per Amp

for Model 628

6253A, 6255A, 6284A,

Ampere for Models

ming coefficient is determined by the Constant Cur-

rent programming current

6255A, 6284A,

for Model

current is adjusted to within 10% at the factory. If

greater programming accuracy is required, it maybe

a thieved by changing resistor R 19 as outlined in

Section V.

current varies at a rate determined

1A,

500 ohms per Ampere for Models

and

6289A,

and 1000 ohms per

6294A

and

6299A.

The program-

(2mA

for Models

and

6294A

6289A, 5mA

and

1.33mA

for Model’

for Model

6253A,

6281A lmA

6299A).

This

If the programming terminals

should open at any time during this

mode, the output current will rise to a

value that may damage the power supply and/or the load. To avoid this

possibility, connect a resistor across

the programming terminals having the

value listed below. Like the programming resistor, this resistor should be

of the low noise, low temperature coefficient type.

Model

Resistance

Model

Resistance

3-28 Voltage Programming (Figure 3-6). In this

mode, the output current will vary linearly with

changes in the programming voltage. The programming voltage should not exceed 1.2 Volts. Voltage in

excess of 1.2 Volts will result in excessive power

dissipation in the instrument and possible damage.

Al A2 A3 A4 AS A6 A? A8 A9 -S – GNO + +S

6253

A,6284A 6255

1.

5Kn

6281A, 6294A

lKA

(Al and AS)

A,6289A,6299A

750n

AIO

AI A2A3A4A5A6A7A8A9

OlOlOIQ1~lQ1

u

-----

1

-----

PROGRAMMING

RESISTOR

Figure 3-5.

b

Remote Resistance Programming

(Constant Current)

VOLTAGE

-S-

GM++ SAIO

u

1%’lddq@..j&l

y

3-3

Figure 3-6.

3-29 The output current will be the programming

voltage divided by 1 ohm. The current required

from the voltage source will be

ampere. The impedance matching resistor (Rx)

should be approximately 500 ohms if the temperature

coefficient and stability specifications of the power

supply are to be maintained.

Remote Volta ge Programming

(Constant Current)

less

than 25

micro-

Page 22

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.O.35C1-2-847-1

3-30 REMOTE SENSING (See Figure 3-7)

3-31 Remote sensing is used to maintain good regu-

lation at the load and reduce the degradation of regulation which would occur due to the voltage drop

in the leads between the power supply and the load.

Remote sensing is accomplished by utilizing the

strapping pattern shown in Figure 3-7. The pwer

supply should be turned off before changing strap-

ping patterns. The leads from the +S terminals to

the load will carry less than 10mA of current, and

it is not required that these leads be as heavy as

the load leads. However, they must be twisted or

shielded to minimize noise pick-up.

Observe polarity when connecting the

sensing leads to the load.

that it is possible to operate a power supply simultaneously in the remote sensing and Constant Voltage/Constant Current remote programming modes.

3-35 SERIES OPERATION

3-36 Normal Series Connections (Figure 3-8). Two

or more power supplies can be operated in series to

obtain a higher voltage than that available from a

single supply. When this connection is used, the

output voltage is the sum of the voltages of the individual supplies. Each of the individual supplies

must be adjusted in order to obtain the total output

voltage. The power supply contains a protective

diode connected internally across the output which

protects the supply if one power supply is turned off

while its series partner(s) is on.

Figure 3-7.

Remote Sensing

3-32 Note that it is desirable to minimize the drop

in the load leads and it is recommended that the

drop not exceed 1 Volt per lead if the power supply

is to meet its dc specifications. If a larger drop

must be tolerated, please consult a Hewlett-Packard

field representative.

NOTE

Due to the voltage drop in the load

leads, it may be necessary to readjust

the current limit in the remote sensing

mode.

3-33 The procedure just described will result in a

low dc output impedance at the load. If a low ac

impedance is required, it is recommended that the

following precautions be taken:

a. Disconnect output capacitor C20 by dis-

connecting the strap between A9 and -S.

b. Connect a capacitor having similar char-

acteristics (approximately same capacitance, same

voltage rating or greater, and having good high frequency characteristics) across the load using short

leads.

3-34 Although the strapping patterns shown in Figures 3-3 through 3-6 employ local sensing, note

Figure 3-8.

Normal Series Connections

3-37 Auto-Series Connections (Figure 3-9). The

Auto-Series configuration is used when it is desir-

able to have the output voltage of each of the series

connected supplies vary in accordance with the

setting of a control unit. The control unit is called

the master; the controlled units are called slaves.

At maximum output voltage, the voltage of the

slaves is determined by the setting of the front

panel VOLTAGE control on the master. The master

supply must be the most positive supply of the

series. The output CURRENT controls of all series

units are operative and the current limit i

S equal to

the lowest control setting. If any output CURRENT

controls are set too low, automatic crossover to

constant current operation will occur and the out-

put voltage will drop. Remote sensing and pro-

gramming can be used; however, the strapping ar-

rangements shown in the applicable figures show

local sensing and programming.

3-38 In order to maintain the temperature coefficient and stability specifications of the power supply,

the external resistors (Rx) shown in Figure 3-9

should be stable, low noise, low temperature coefficient (less than 30 ppm per degree Centigrade)

resistors. The value of each resistor is dependant

3-4

Page 23

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.O.35Cl-2-847-1

on the maximum voltage rating of the “master” sup-

ply. The value of Rx is this voltage divided by the

voltage programming current of the slave supply

(1/Kp where K

P is the voltage programming coef-

ficient). The voltage contribution of the slave is

determined by its voltage control setting.

controls of each power supply can be separately

set. The output voltage controls of one power supply should be set to the desired output voltage;

the other power supply should be set for a slightly

larger output volts ge.

The supply set to the lower

output voltage will act as a constant voltage

source; the supply set to the higher output will act

as a constant current source, dropping its output

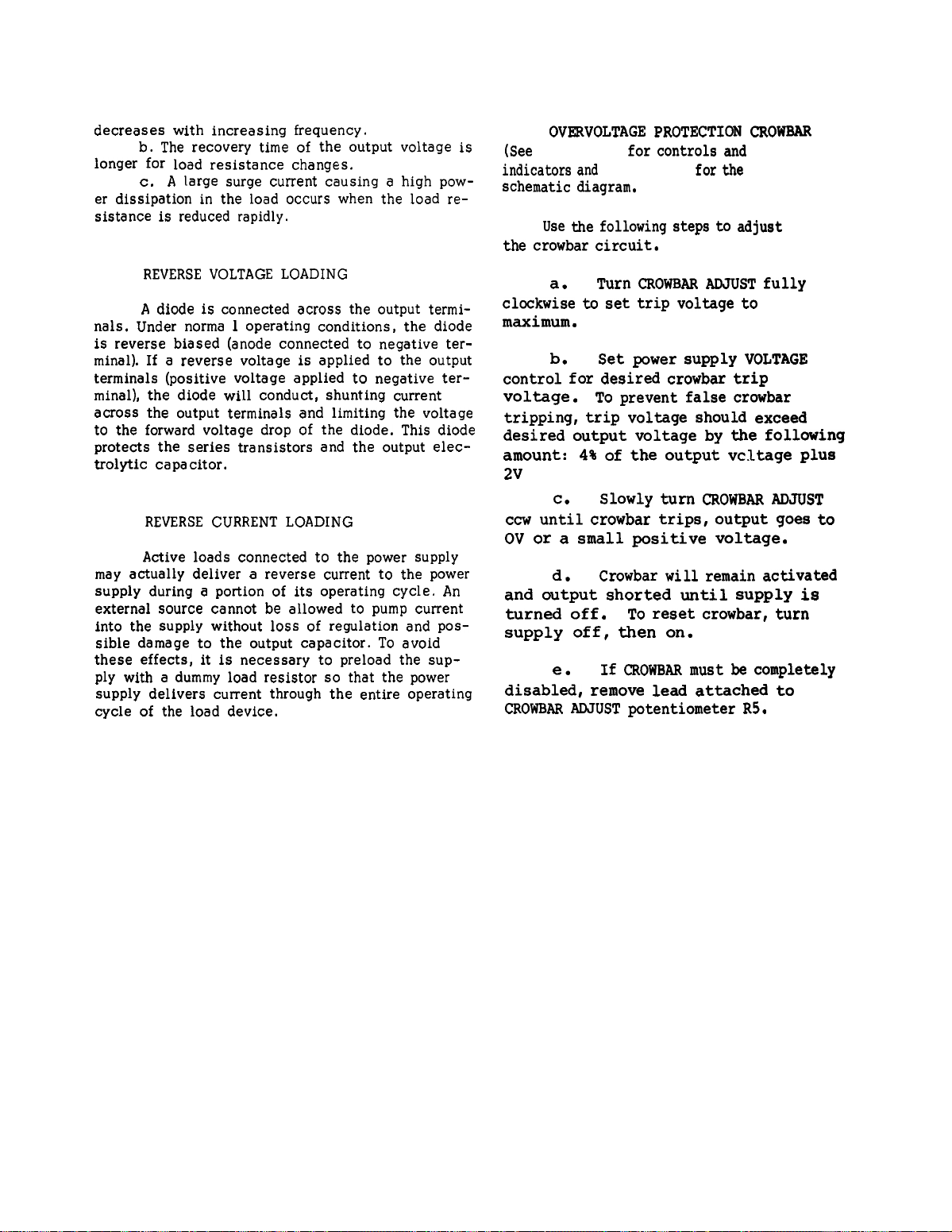

Figure 3-10.

Normal Parallel Connections

Figure 3-9.

Auto-Series, Two and Three Units

3-39 PARALLEL OPERATION (See Figure 3-1

for controls and indicators.)

3-40 Normal Parallel Connections (Figure 3-10).

Two or more power supplies can be connected in

parallel to obtain a total output current greater than

that available from one power supply. The total

output current is the sum of the output currents of

the individual power supplies. The output CURRENT

3-5

Figure 3-11.

Auto-Parallel, Two and Three Units

Page 24

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.O.35C1-2-847-1

voltage until it equals that of the other supply. The

constant voltage source will deliver only that frac-

tion of its total rated output current which is neces-

sary to fulfill the total current demand,

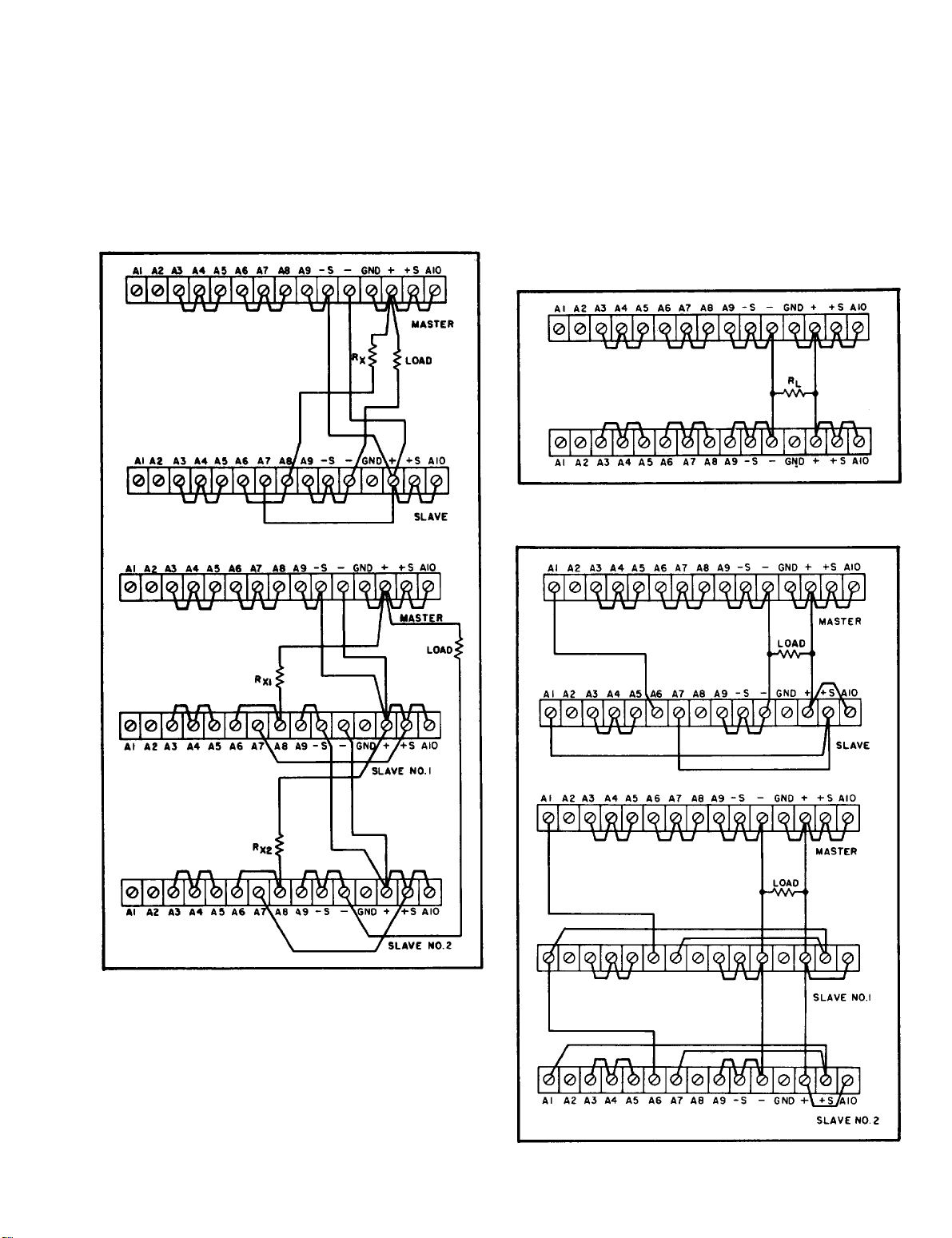

3-41

Auto-Parallel

shown in

permits equal current sharing under all load conditions, and allows complete control of output cur-

rent from one master power supply. The output current of each slave will be approximately equal to

the master’s regardless of the load conditions.

Because the output current controls of each slave

are operative, the y should be set to maximum to

avoid having the slave revert to constant current

operation; this would occur if the master output

Auto-Parallel.

Figure 3-11.

current setting exceeded the slave’s.

The strapping patterns for

operation of two power supplies are

Auto-Parallel

operation

3-42

AUTO-TRACKING OPERATION (See

3-43

it is necessary that several different voltages referred to a common bus, vary in proportion to the

setting of a particular instrument (the control or

master). A fraction of the master’s output voltage

is fed to the comparison amplifier of the slave supply, thus controlling the slave’s output. The master

must have the largest output voltage of any power

supply in the group (must be the most positive supply in the example shown on

3-44

age of the master's

mined by the voltage divider consisting of Rx (or Rx

and Ry)

Rp.

of the power supplies is controlled by the master.

Remote sensing and programming can be used; although the strapping patterns for these modes show

only local sensing and programming. In order to

maintain the temperature coefficient and stability

specifications

sistors should be stable, low noise, low temperature

(less than 30ppm per °C) resistors.

The Auto-Tracking configuration

Figure 3-12).

The output voltage of the slave is a percent-

output voltage, and is deter-

and

where:

the voltage control of the slave supply,

ES=EMRp/Rx+Rp.

Turn-on and turn-off

of

the power supply, the external re-

Figure 3-12)

is

used when

3-45

3-46

3-47

over from constant voltage to constant current operation, or the reverse, in response to an increase

(over the preset limit) in the output current or volt-

age, respective y. Although the preset limit may be

set higher than the average output current or voltage,

high peak currents or voltages (as occur in pulse

loading) may exceed the preset limit and cause

crossever

desired, set the preset limit for the peak requirement and not the average.

3-48

3-49 An

output terminals of the power supply, helps to supply high-current pulses of short duration during

constant voltage operation. Any capacitance added

externally will improve the pulse current capability,

but will decrease the safety provided by the con-

stant current circuit. A high-current pulse may damage load components before the average output current is large enough to cause the constant current

circuit to operate.

SPECIAL OPERATING CONSIDERATIONS

PULSE LOADING

The power supply will automatically

to

occur.

OUTPUT CAPACITANCE

internal capacitor, connected acress the

If this crossover limiting is not

cross-

Figure 3-12.

Auto-Tracking,

Two and Three Units

3-50

constant current operation are as follows:

3-6

The effects of the output capacitor during

The output impedance of the power supply

a.

Page 25

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.O.35C1-2-847-1

decreases with increasing frequency.

b. The recovery time of the output voltage is

longer for load resistance changes.

c.A

large surge current causing a high power dissipation in the load occurs when the load resistance is reduced rapidly.

3-51

3-52

nals. Under norms 1 operating conditions, the diode

is reverse biased (anode connected to negative terminal). If a reverse voltage is applied to the output

terminals (positive voltage applied to negative terminal), the diode will conduct, shunting current

across the output terminals and limiting the voltage

to the forward voltage drop of the diode. This diode

protects the series transistors and the output electrolytic capacitor.

3-53

3-54

may actually deliver a reverse current to the power

supply during a portion of its operating cycle. An

external source cannot be allowed to pump current

into the supply without loss of regulation and pos-

sible damage to the output capacitor. To avoid

these effects, it is necessary to preload the sup-

ply with a dummy load resistor so that the power

supply delivers current through the entire operating

cycle of the load device.

REVERSE VOLTAGE LOADING

A diode is connected across the output termi-

REVERSE CURRENT LOADING

Active loads connected to the power supply

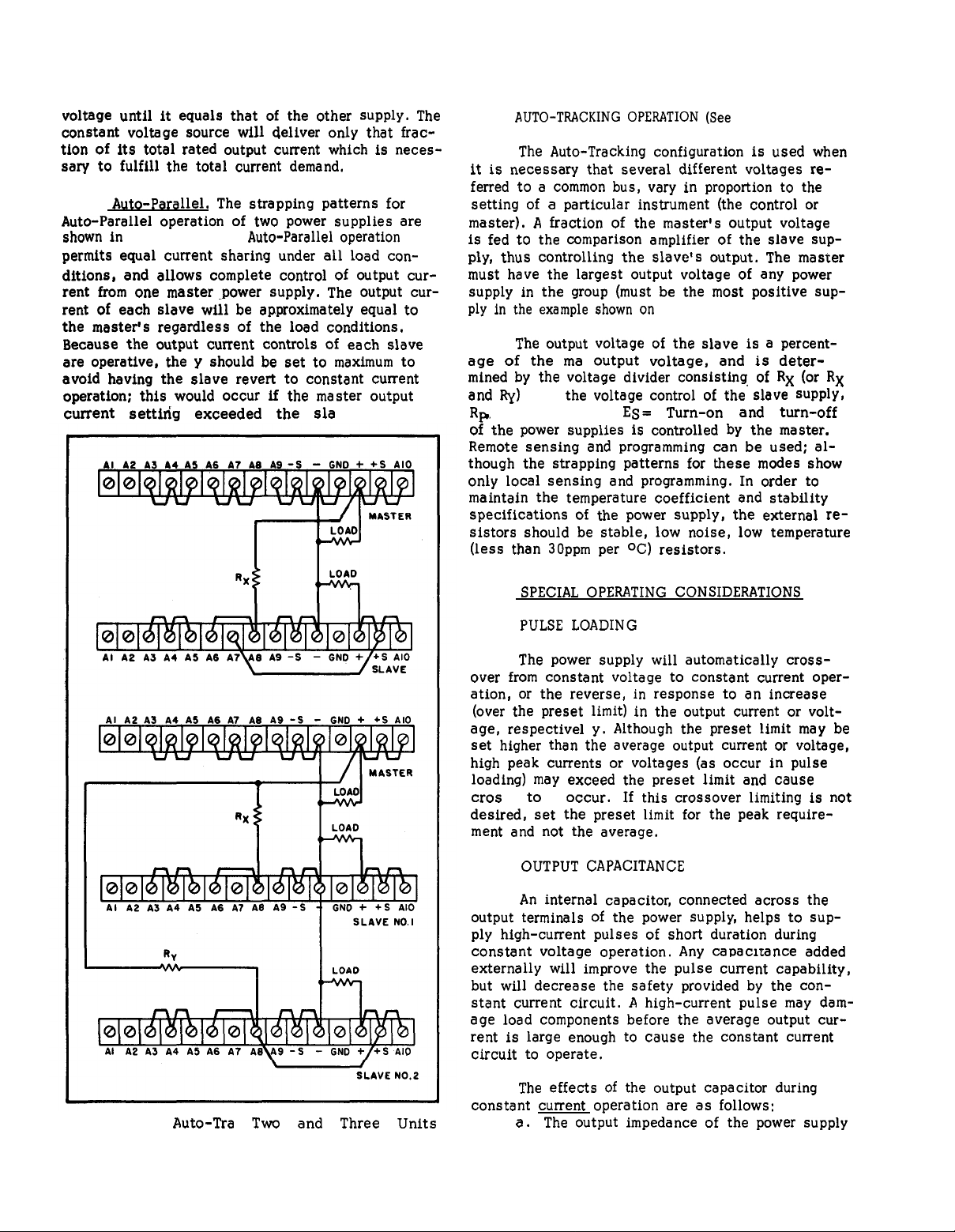

3-55

OVERVOLTAGE PROTECTION CROWBAR

(See

Figure 3-1

indicators and

schematic diagram.)

3-56

Use the following steps to adjust

the crowbar circuit.

a. Turn CROWBAR ADJUST fully

clockwise to set trip voltage to

maximum.

b.

control for desired crowbar trip

voltage.

tripping, trip voltage should exceed

desired output voltage by the following

amount:4% of

2V.

c.

ccw until crowbar trips, output goes to

OV or a small positive voltage.

d.

and output shorted until supply is

turned off.

supply off, then on.

e.

disabled, remove lead attached to

CROWBAR ADJUST potentiometer R5.

for controls and

Figure 3-13

Set power supply VOLTAGE

To prevent false crowbar

the output voltage plus

Slowly turn CROWBAR ADJUST

Crowbar will remain activated

To reset crowbar, turn

If CROWBAR must be completely

for the

3-7

Page 26

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.O.35C1-2-847-1

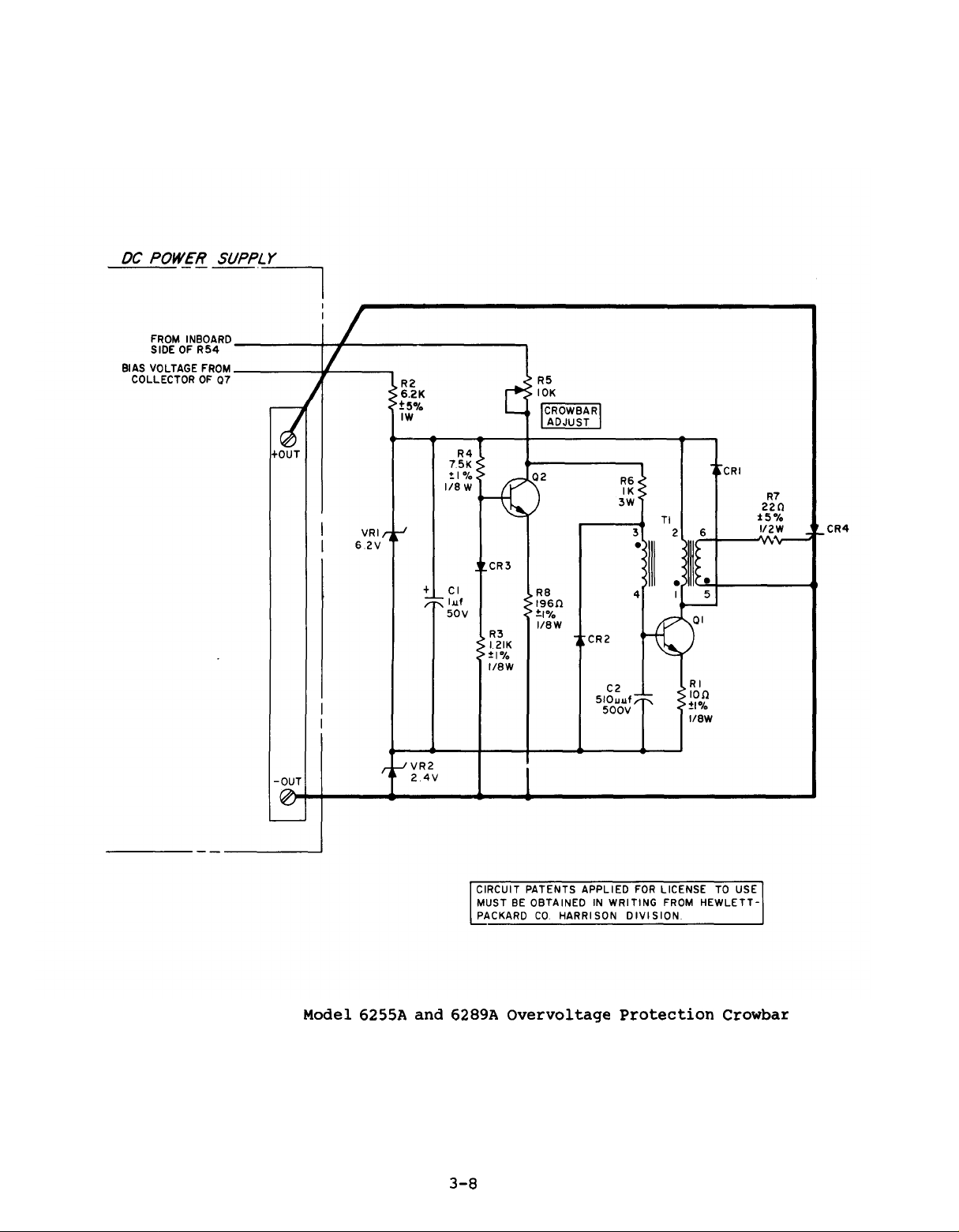

Figure 3-13.

Model 6255A and 6289A Overvoltage Protection Crowbar

3-8

Page 27

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.O.35C1-2-847-1

SECTION IV

PRINCIPLES OF OPERATION

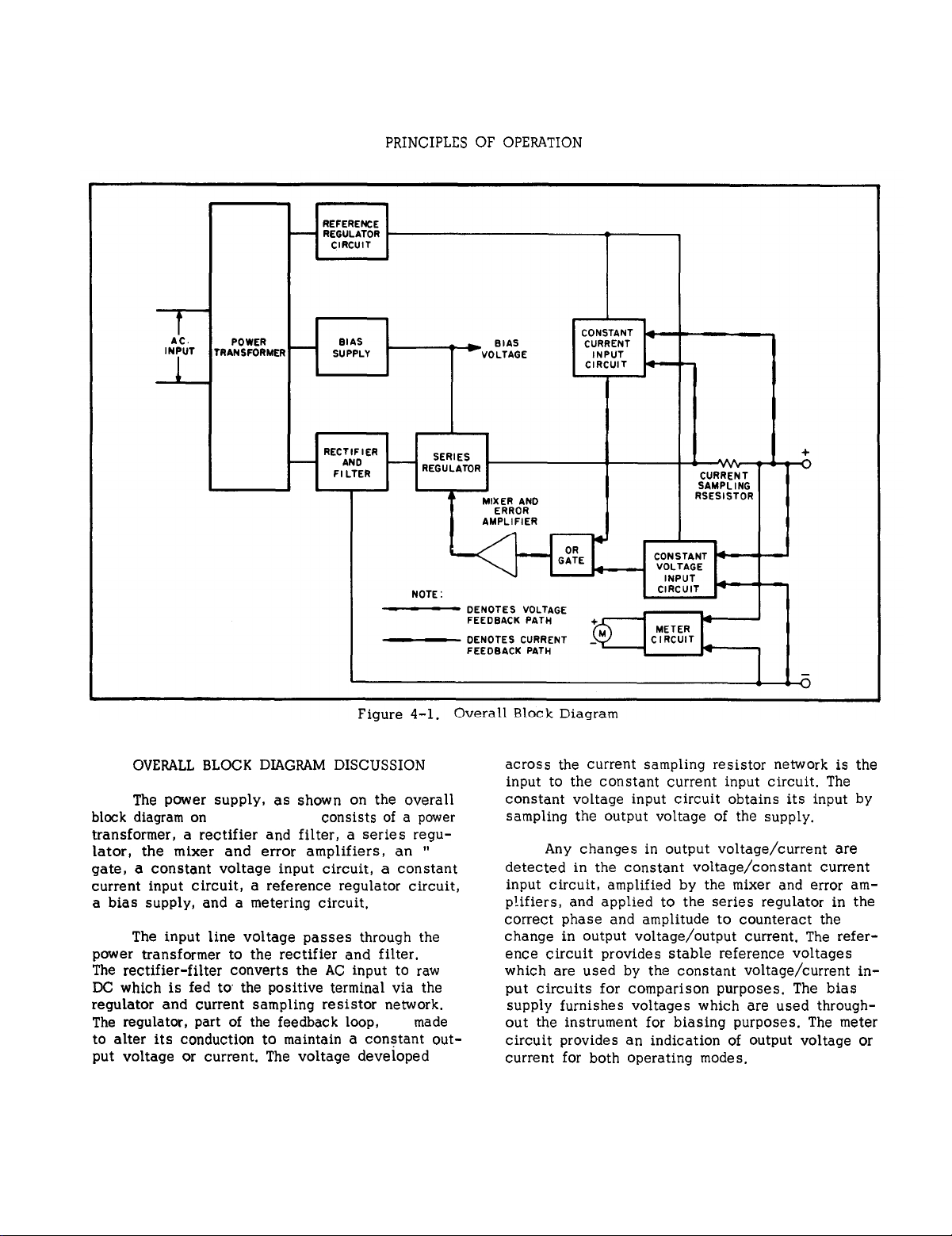

Figure 4-1.

4-1

OVERALL BLOCK DIAGRAM DISCUSSION

4-2

The power supply, as shown on the overall

block diagram on

transformer,

Figure 4-1,

a

rectifier and filter, a series regu-

consists of a power

lator, the mixer and error amplifiers, an “OR”

gate, a constant voltage input circuit, a constant

current input circuit, a reference regulator circuit,

a bias supply, and a metering circuit.

4-3

The input line voltage passes through the

power transformer to the rectifier and filter.

The rectifier-filter

DC

which is fed to the positive terminal via the

converts the AC input to raw

regulator and current sampling resister network.

The regulator, part of the feedback loop,

is

made

to alter its conduction to maintain a constant output voltage or current. The voltage developed

across the current sampling resistor network is the

input to the constant current input circuit. The

constant voltage input circuit obtains its input by

sampling the output voltage of the supply.

4-4

Any changes in output voltage/current

detected in the constant voltage/constant

are

current

input circuit, amplified by the mixer and error amplifiers, and applied to the series regulator in the

correct phase and amplitude to counteract the

change in output voltage/output current. The reference circuit provides stable reference voltages

which are used by the constant voltage/current

in-

put circuits for comparison purposes. The bias

supply furnishes voltages which are used through-

out the instrument for biasing purposes. The meter

circuit provides an indication of output voltage or

current for both operating modes.

4-1

Page 28

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.O.35C1-2-847-1

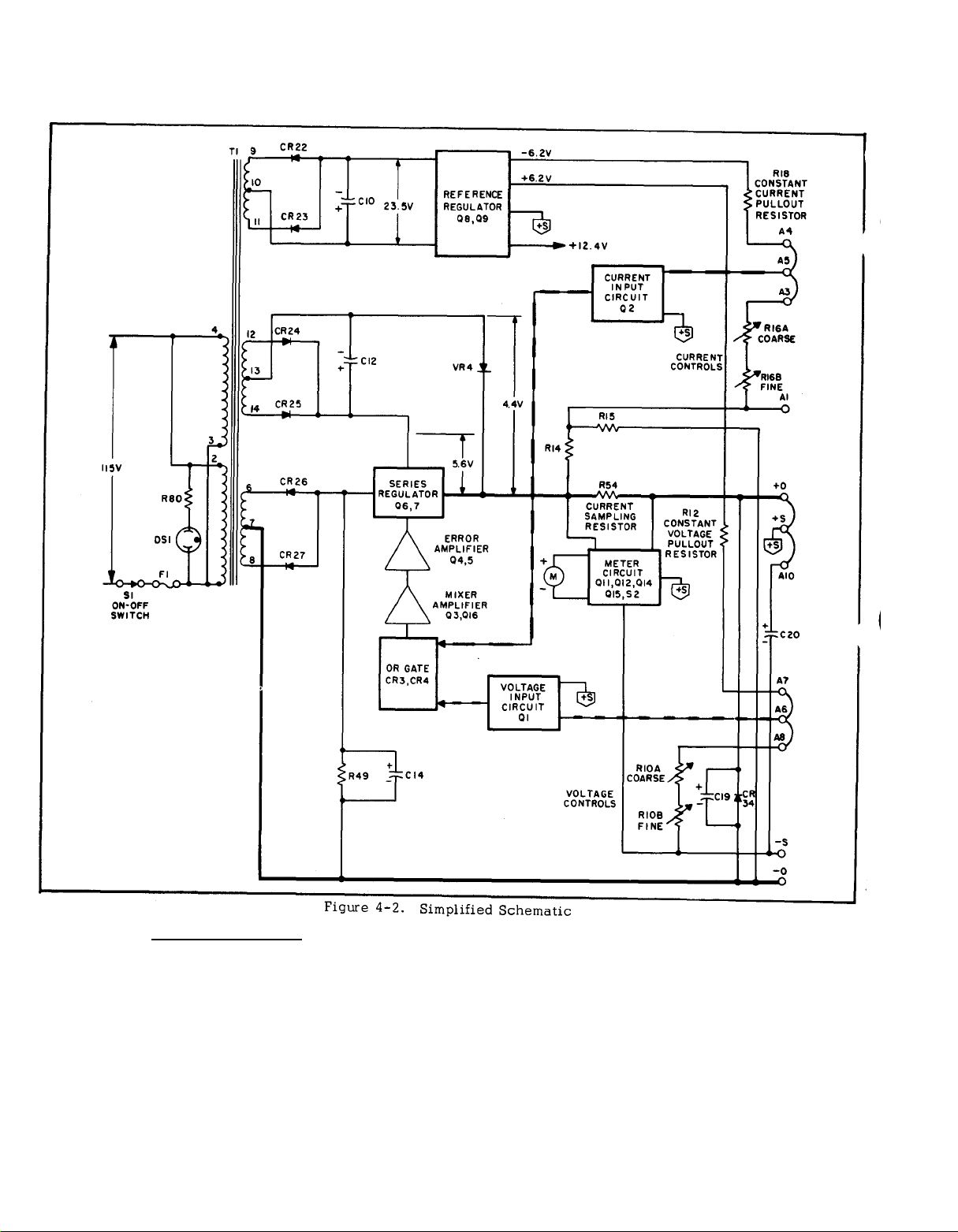

Figure 4-2.

4-5

SIMPLIFIED SCHEMATIC (See Figure

3-1 for controls and indicators.)

4-6 A simplified schematic of the power supply

is shown in Figure 4-2. It shows the operating

controls; the ON-off switch, the voltage and current programming controls R10 and R16. Figure

4-2 also shows the internal sources of bias and

reference voltages and their nominal magnitudes

with an input of 115 VAC.

4-7

Diode CR34, connected across the output

terminals of the power supply, is a protective de-

vice which prevents internal damage that might

occur if a reverse voltage were applied across the

output terminals.

connected across the output terminals when the

normal strapping pattern shown on Figure 4-2 is

employed.

Note that this capacitor can be removed

if an increase in the programming speed is desired.

Under these conditions,

insure loop stability.

4-2

Output capacitor, C20, is also

capacitor C19 serves to

Page 29

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.O.35C1-2-847-1

4-8 DETAILED CIRCUIT ANALYSIS [Refer

to overall schematic diagram (FO-1) at

rear of manual.]

4-9

controls and indicators.)

4-10 The feedback loop functions continuously to

keep the output voltage constant, during constant

voltage operation, and the output current constant,

during constant current operation. For purposes of

this discussion, assume that the unit is in con-

stant voltage operation and that the programming

resistors R10 A and B have been adjusted so that

the supply is yielding the desired output voltage.

Further assume that the output voltage instantaneously rises (goes positive) due to a variation in

the external load circuit.

4-11 Note that the change maybe in the form of a

slow rise in the output voltage or a positive going

AC signal.

point A6 through capacitor C1 and a DC voltage is

coupled to A6 through R10.

4-12 The rise in output voltage causes the voltage

at A6 and thus the base of Q1A to decrease (go

negative). Q1A now decreases its conduction and

its collector voltage rises. The positive going error voltage is amplified and inverted by Q3 and fed

to the bases of series transistors Q6 and Q7 via

emitter followers Q5 and Q4. The negative going

input causes Q6 and Q7 to decrease their conduction so that they drop more of the line voltage, and

reduce the output voltage to its original level.

FEEDBACK LOOP (See Figure 3-1 for

An AC signal is coupled to summing

dissipated in series transistor Q6. The bias voltage

for Q7 is developed across zener diode VR5, The

The conduction of Q7 will decrease as the collector-

to-emitter voltage of Q6 approaches the voltage

developed across the biasing diodes, At low output voltages Q7 is completely cutoff and all of the

load current flows through the shunt resistors. The

voltage that is dropped acress Q7 and the shunt

resistors reduces the voltage dropped across Q6,

thus diminishing its power dissipation. The reliability of the regulator is further increased by

mounting the shunt resistors outside the rear of

the cabinet so that the internal components are

operated under lower temperature conditions.

Diode CR11, connected across Q6, protects it from

reverse voltages that could develop across it dur-

ing parallel or auto-parallel operation if one supply is turned on before the other. Diodes CR18

and CR19 perform a similar function for Q7.

4-16 CONSTANT VOLTAGE INPUT CIRCUIT

(See Figure 3-1 for controls and in-

dicators.)

4-17 The circuit consists of programming resistor

R10A and B, and a differential amplifier stage (Q1

and associated components). Transistor Q1 con-

sists of two transistors housed in a single package.

The transistors have matched characteristics min-

imizing differential voltages due to mismatched

stages.

tials is minimized, since both transistors operate

at essentially the same temperature.

Moreover, drift due to thermal differen-

4-13 If the external load resistance is decreased

to a certain crossover point, the output current in-

creases until transistor Q2A begins to conduct.

During this time, the output voltage has also decreased to a level so that the base of Q1A is at a

high positive potential.

tion, its collector voltage decreases by the amount

necessary to back bias OR gate diode CR3 and the

supply is now in the constant current mode of operation.

current operation commences is determined by the

setting of CURRENT control R16. The operation of

the feedback loop during the constant current operating mode is similar to that occuring during

constant voltage operation except that the input to

the differential amplifier comparison circuit is obtained from the current sampling resistor network.

4-14 SERIES REGULATOR

4-15 The series regulator consists of transistor

stages Q6 and Q7 (see schematic at rear of manual).

Transistor Q6 is the series element, or pass transis-

tor, which controls the output. Transistor Q7, together with shunt resistors R81, R82, and R83, are

connected in a manner which minimizes the power

The crossover point at which constant

With Q1A in full conduc-

4-18 The constant voltage input circuit continuously compares a fixed reference voltage with a

portion of the output voltage and, if a difference

exists, produces an error voltage whose amplitude

and phase is proportional to the difference.

error output is fed back to the series regulator,

through an OR gate and the mixer/error amplifiers.

The error voltage changes the conduction of the

series regulator which, in turn, alters the output

voltage so that the difference between the two input voltages applied to the differential amplifier is

reduced to zero.

output voltage constant.

4-19 Stage Q1B of the differential amplifier is

connected to a common (+S) potential through impedance equalizing resistor R5. Resistors R6 and

R8 are used to zero bias the input stage, offsetting

minor base-to-emitter voltage differences in Q1.

The base of Q1A is connected to a summing point at

the junction of the programming resistor and the

current pullout resistor, R12. Instantaneous

changes in output voltage result in an increase or

decrease in the summing point potential. Q1A is

then made to conduct more or less, in accordance

with the summing point voltage change.

The above action maintains the

The

The re-

4-3

Page 30

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.O.35C1-2-847-1

sultant output error voltage is fed back to the

series regulator via OR-gate diode CR3 and the

remaining components of the feedback loop, Resistor R1, in series with the base of Q1A, limits

the current through the programming resistor during

rapid voltage turn-down.

form a limiting network which prevent excessive

voltage excursions from over driving stage Q1A.

Capacitors C1 and C2, shunting the programming

resistors, increase the high frequency gain of the

input amplifier.

resistor R12, serves as a trimming adjustment for

the programming current.

4-20

CONSTANT CURRENT INPUT CIRCUIT

(See

Figure 3-1

dicators.)

4-21

eration to the constant voltage input circuit. It

consists basically of the current programming resistors R16A and B, and a differential

stage (Q2 and associated components). Like

transistor Q1 in the voltage input circuit, Q2 consists of two transistors,

teristics,

4-22

cuit continuously compares a fixed reference voltage with the voltage drop

across the current sampling resistor

R54.

ferential amplifier produces an error

voltage which is proportional to this

difference.

in the feedback loop (amplifiers and

series regulator) function to maintain

4-23

tential through impedance equalizing resistor R26.

Resistors R25 and R28 are used to zero bias the input stage, offsetting minor base-to-emitter

differences in Q2.

put current on the positive line are felt at the current summing point and, hence, the base of Q2A.

Stage Q2A varies its conduction in accordance

with the polarity of the change at the summing

point. The change in Q2A’s conduction also varies

the conduction of Q2B due to the coupling effects

of the common emitter resister, R22. The error

voltage is taken from the collector of Q2B and fed

back to the series regulator through OR-gate diode

CR4 and the remaining components of the feedback

loop. The error voltage then varies the conduction

of the regulator so that the output current is main-

tained at the proper level.

This circuit is similar in appearance and op-

that are housed in a single package.

The constant current input cir-

If a difference exists, the dif-

the drop across the current sampling

resistors, and consequently the output

current, at a constant value.

Stage Q2B is connected to a common (+S) po-

Resistor R13, shunting pullout

for controls and in-

The remaining components

Instantaneous changes in out-

Diodes CR1 and CR2

amplifier

having matched charac-

voltage

4-24

Resistor R20, in conjunction with R21 and C3

helps stabilize the feedback loop, Diode CR5 limits voltage excursions on the base of Q2A. Resister R19, shunting the pullout resistor, serves as a

trimming adjustment for the programming current

flowing through R16.

4-25

4-26

stant voltage programming resisters are a shunt

load acress the output terminals of the power supply. If the output voltage changed, the current

through these resistors would tend to change re-

sulting in an output current change. The clamp

circuit is a return path for the voltage programming

current, the current that normally flows through the

programming resistors.

current into the constant voltage summing point

(A6) constant, thus eliminating the error due to

shunting effects of the constant voltage programming resistors.

4-27

back biases CR30 and Q1O during constant voltage

operation. When the power supply goes into con-

stant current operation, CR30 becomes forward

biased by the collector voltage of Q1A. This re-

sults in conduction of Q1O and the clamping of the

summing point at a potential only slightly more

negative than the normal constant voltage potential.

Clamping this voltage at approximately the same

potential that exists in constant voltage operation,

results in a constant voltage across, and consequently a constant current through the pullout re-

sistor (R12).

4-28

4-29

error signal from the constant voltage or constant

current input circuit to a level sufficient to drive

the series regulator transistors.

potential for mixer amplifier Q3 is established by

the emitter follower.

error voltage input from either the constant voltage

or constant current circuit via the OR-gate diode

(CR3 or CR4) that is conducting at that time.

Diode CR3 is forward biased, and CR4 reversed

biased, during constant voltage operation. The

reverse is true during constant current operation.

4-30

an equalizing network which provides for high frequency roll off in the loop gain response in order to

stabilize the feedback loop. Emitter follower transistors Q4 and Q5 are the error amplifiers serving

as the driver and predriver elements, respectively,

for the series regulator. Transistor Q4, together

VOLTAGE CLAMP CIRCUIT

During constant current operation the con-

The circuit maintains the

The voltage divider, R51, R52, and VR3,

MIXER AND ERROR AMPLIFIERS

The mixer and error amplifiers amplify the

The emitter bias

Transistor Q3 receives the

The RC network, composed of C5 and R30, is

4-4

Page 31

TM 11-6130-416-14/EE010-BJ-MMA-010/E154 DCDUAL/T.O.35C1-2-847-1

with diode CR17, provides a low resistance dis-

charge path for the output capacitance of the power

supply during rapid down programming.

4-31

4-32

supply similar to the main supply. It provides

stable reference voltages which are used throughout the unit.

rived from smoothed

wave rectifier (CR22 and CR23) and filter capacitor

C10. The +6.2 and -6.2 voltages, which are used

in the constant voltage and current input circuits

for comparison purposes, are developed across

temperature compensated Zener diodes VR1 and

VR2. Resister R43 limits the current through the

Zener diodes to establish an optimum bias level.

4-33

ulating transistor Q9 and error amplifier Q8. Output voltage changes are detected by Q8 whose base

is connected to the junction of a voltage divider

(R41, R42) connected directly across the supply. Any

error signals are amplified and inverted by Q8 and

applied to the base of series transistor Q9. The

series element then alters its conduction in the

direction and by the amount necessary to maintain

the voltage across VR1 and VR2 constant. Resistor

R46, the emitter resistor for Q8, is connected in a

manner which minimizes changes in the reference

voltage caused by variations in the input line.

Output capacitor C9 stabilizes the regulator loop.

4-34

controls and indicators.)

REFERENCE CIRCUIT

The reference circuit is a feedback power

The reference voltages are all de-

DC

obtained from the full

The regulating circuit consists of series reg-

METER CIRCUIT (See

Figure 3-1

for

this divider is connected across the sampling re-

sistor network. The amplified output of the differ-

ential amplifier is used to deflect the meter.

4-38

having a fixed gain of ten, Stage Q11B of the am-

plifier receives a negative voltage from the appli-

cable voltage divider when S2 is in one of the

voltage positions while stage Q11A is connected

to the +S (common) terminal. With S2 in a current

position, stage Q11A receives a positive voltage

from the applicable voltage divider while stage

Q11B is connected to the +S terminal. The differential output of the amplifier is taken from the

collectors of Q12 and Q14. Transistor Q15 is a

constant current source which sets up the proper

bias current for the amplifier. Potentiometer R63

permits zeroing of the meter.

current limiting feature which protects the meter

movement against overloads. For example, if

METER switch S2 is placed in the low current

range when the power supply is actually delivering a higher ampere

fiers are quickly driven into saturation limiting the

current through the meter to a safe value.