Page 1

TM 11-6625-2965-14&P

TECHNICAL MANUAL

OPERATOR’S ORGANIZATIONAL

DIRECT SUPPORT AND GENERAL SUPPORT

MAINTENANCE MANUAL

[INCLUDING REPAIR PARTS

AND SPECIAL TOOLS LISTS]

POWER SUPPLY PP-7548/U

(HEWLETT-PACKARD MODEL 6205B]

[NSN 6625-00-437-4861]

HEADQUARTERS, DEPARTMENT OF THE ARMY

25 FEBRUARY 1980

Page 2

WARNING

HIGH VOLTAGE is used during the performance of maintenance as

instructed in this manual. DEATH ON CONTACT may result if personnel

fail to observe safety precautions.

DO NOT ATTEMPT to make internal connections or perform adjustments

unless another person, capable of performing first aid, is present.

For electric shock protection, use only extension cord and power receptacles

with a safety-ground connector, or otherwise connect the chassis to a safety

ground.

CERTIFICATION

The Hewlett-Packard Company certifies that this instrument was thoroughly

tested and inspected and found to meet its published specifications when it

shipped from the factory. The Hewlett-Packard Company further certifies that

its calibration measurements are traceable to the U.S. National Bureau of

Standards to the extent allowed by the Bureau’s calibration facility.

Was

WARRANTY AND ASSISTANCE

All Hewlett-Packard products are warranted against defects in materials and

workmanship. This warranty applies for one year from the date of delivery, or,

in the case of certain major components listed in the operating manual, for the

specified period. We will repair or replace products which prove to be

defective during the warranty period. No other warranty is expressed or

implied. We are not liable for consequential damages.

Page 3

TM 11-6625-2965-14&P

This manual contains copyright material reproduced by permission of Hewlett-Packard Company

TECHNICAL MANUAL

HEADQUARTERS

DEPARTMENT OF THE ARMY

W

No. 11-6625-2965-14&P

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT AND

GENERAL SUPPORT MAINTENANCE MANUAL

(INCLUDING REPAIR PARTS AND SPECIAL TOOLS LISTS)

ASHINGTON, DC, 25 February 1980

POWER SUPPLY PP-7548/U (HEWLETT-PACKARD MODEL)

(NSN 6625-00-437-4861)

REPORTING OF ERRORS

Y

OU can improve this manual by recommending improvements using DA Form 2028-2

located in the back of the manual. Simply tear out the self-addressed form, fill it out as shown on

the sample, fold it where shown, and drop it in the mail.

If there are no blank DA Forms 2028-2 in the back of your manual, use the standard DA

Form 2028 (Recommended Changes to Publications and Blank Forms) and forward to the

Commander, US Army Communications and Electronics Materiel Readiness Command, ATTN:

DRSEL-ME-MQ, Fort Monmouth, NJ 07703.

In either case a reply will be furnished direct to you.

This manual is an authentication of the manufacturer’s commercial literature which, through usage, has been

found to cover the data required to operate and maintain this equipment. Since the manual was not prepared

in accordance with military specifications, the format has not been structured to consider levels of

maintenance.

Page 4

TABLE OF CONTENTS

TM 11-6625-2965-14&P

Section Page No.

O INSTRUCTIONS . . . . . . . . . . . . . . . . 0-1

0-l Scope

0-1

0-2 Indexes of Publications 0-1

0-3 Maintenance Forms,

Records and Reports

0-1

0-4 Reporting Equipment

Section

3-38

Special Operating Con-

siderations

Pulse Loading

3-39

3-41

Output Capacitance

3-43

Reverse Voltage Loading

3-45

Reverse Current Loading

Improvement Recommen-

dations (EIR)

0-5 Administrative Storage 0-1

0-6 Destruction of Army

Electronics Materiel 0-1

I

GENERAL INFORMATION . . . . . . . . . . . 1-1

1-1 Description

1-6 Specifications

1-8 Options

1-10 Accessories

1-12 Instrument and Service Man-

ual Identification

1-15 Ordering Additional Manuals 1-2

II INSTALLATION

2-1

Initia1 Inspection

Mechanical Check

2-3

Electrical Check

2-5

Installation Data

2-7

Location

2-9

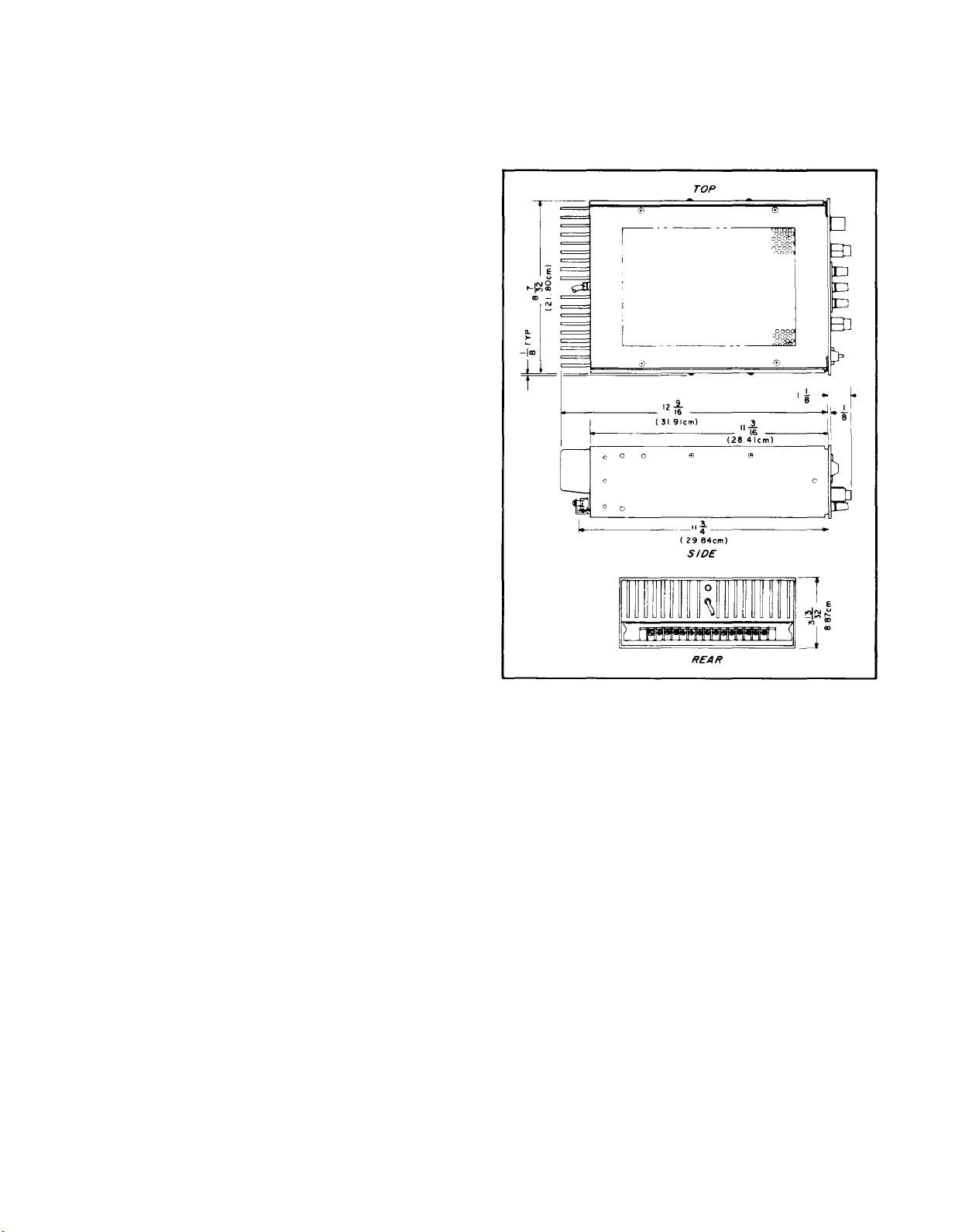

Outline Diagram

2-11

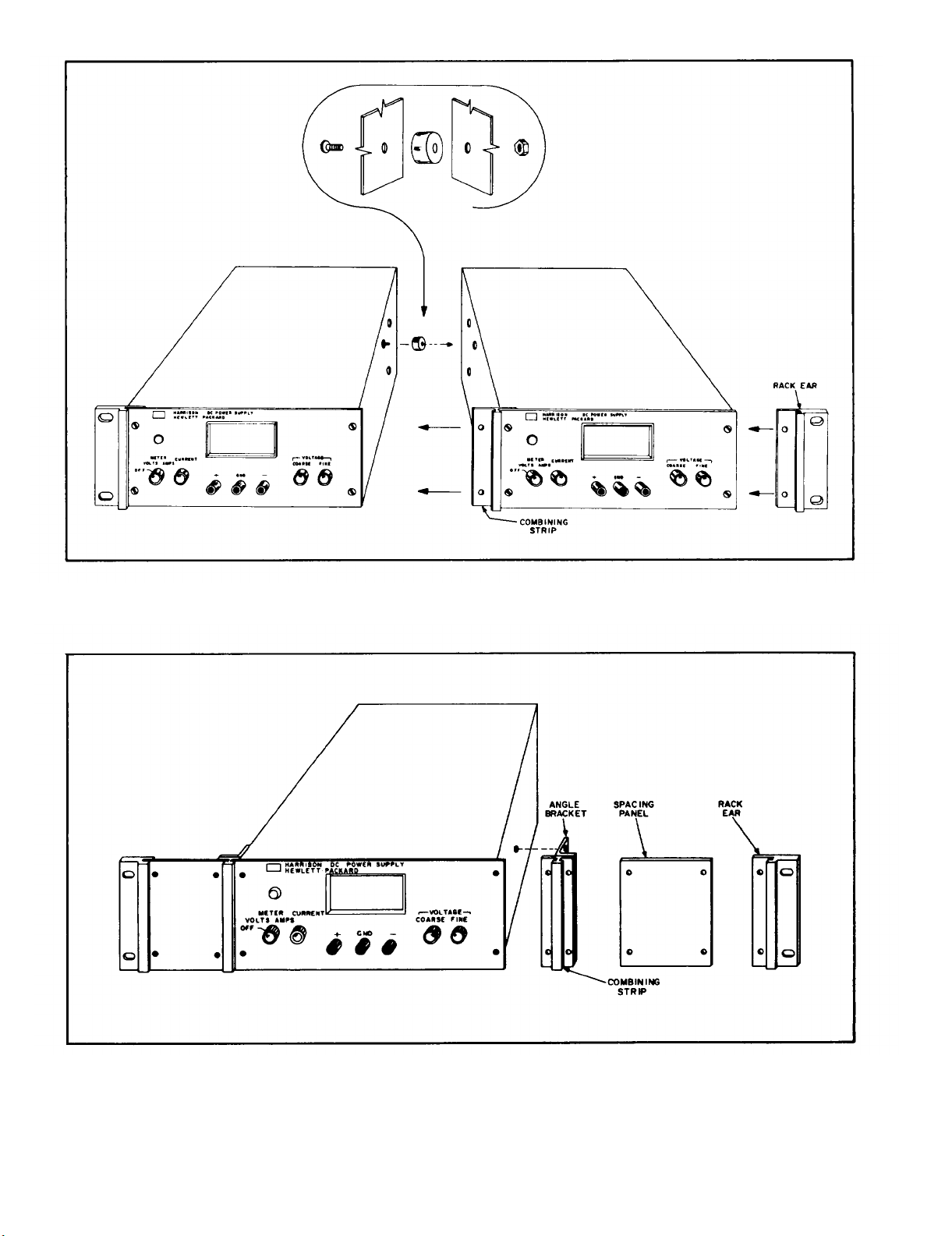

Rack Mounting

2-13

2-17

Input Power Requirements

2-19

Connections for 230 Volt

Operation

Power Cable

2-21

2-24

Repackaging for Shipment

I I I OPERATING INSTRUCTIONS . . . . . . . . 3-1

3-1

Turn-on Checkout Procedure

3-3

Operating Modes

3-5

Norma1 Operating Mode

3-7

Constant Voltage

3-9

Changing Current Limit

3-11

Connecting Load

3-14

Operation Beyond Norma 1

Rated Output

3-16

Optional Operating Modes

3-17

Remote Programming, Con-

stant Voltage

3-25

Remote Sensing

3-30

Series Operation

3-35

Auto-Tracking Operation

. . . . . . . . . . . . . . . . . . .

0-1

1-1

1-1

1-1

1-2

1-2

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-3

2-3

2-3

2-3

3-1

3-1

3-1

3-1

3-2

3-2

3-2

3-2

3-2

3-3

3-4

3-5

IV PRINCIPLES OF OPERATION . . . . . . . . 4-1

4-1

Overall Description

4-8 Detailed Circuit Analysis

4-9 Feedback Loop

4-13 Series Regulator

4-15 Constant Voltage Comparator 4-2

4-19 Error Amplifier and Driver

4-22 Current Limit Circuit

4-26 Reference Circuit

4-29 Meter Circuit

V MAINTENANCE

5-1

Introduction

5-3

General Measurement

Techniques

5-8

Test Equipment Required

Performance Test

5-10

5-12

Constant Voltage Tests

5-38

Output Impedance

Troubleshooting

5-48

5-53

Overa11 Troubleshooting

Procedure

5-58

Repair and Replacement

5-60

Adjustment and Calibration

Meter Zero

5-62

5-64

Ammeter Tracking

5-66

Constant Voltage Programming

Current

5-69

Reference Circuit Adjustments

5-71

Constant Voltage Transient

Recovery Time

5-73

Current Limit Adjustment

VI REPLACEABLE PARTS . . . . . . . . . . .

6-1 Introduction 6-1

6-4 Ordering Information

APPENDIX A

B

C

D

VII CIRCUIT

Page No.

. . . . . . . . . . . . . . . . . . .

References

Components of End

Item

Maintenance

Allocation

Manual

Changes

DIAGRAMS

backdating

........... 7-1

3-6

3-6

3-6

3-6

3-6

4-1

4-2

4-2

4-2

4-2

4-3

4-3

4-3

5-1

5-1

5-1

5-2

5-3

5-3

5-7

5-9

5-9

5-12

5-13

5-13

5-13

5-13

5-15

5-15

5-15

. . . . 6-1

6-1

A-1

B-1

C-1

ii

Page 5

TM 11-6625-2965-14&P

LIST OF ILLUSTRATIONS

Figure

2-1

2-2

2-3

2-4

3-1

3-2

3-3

3-4

3-5

3-6

3-7

3-8

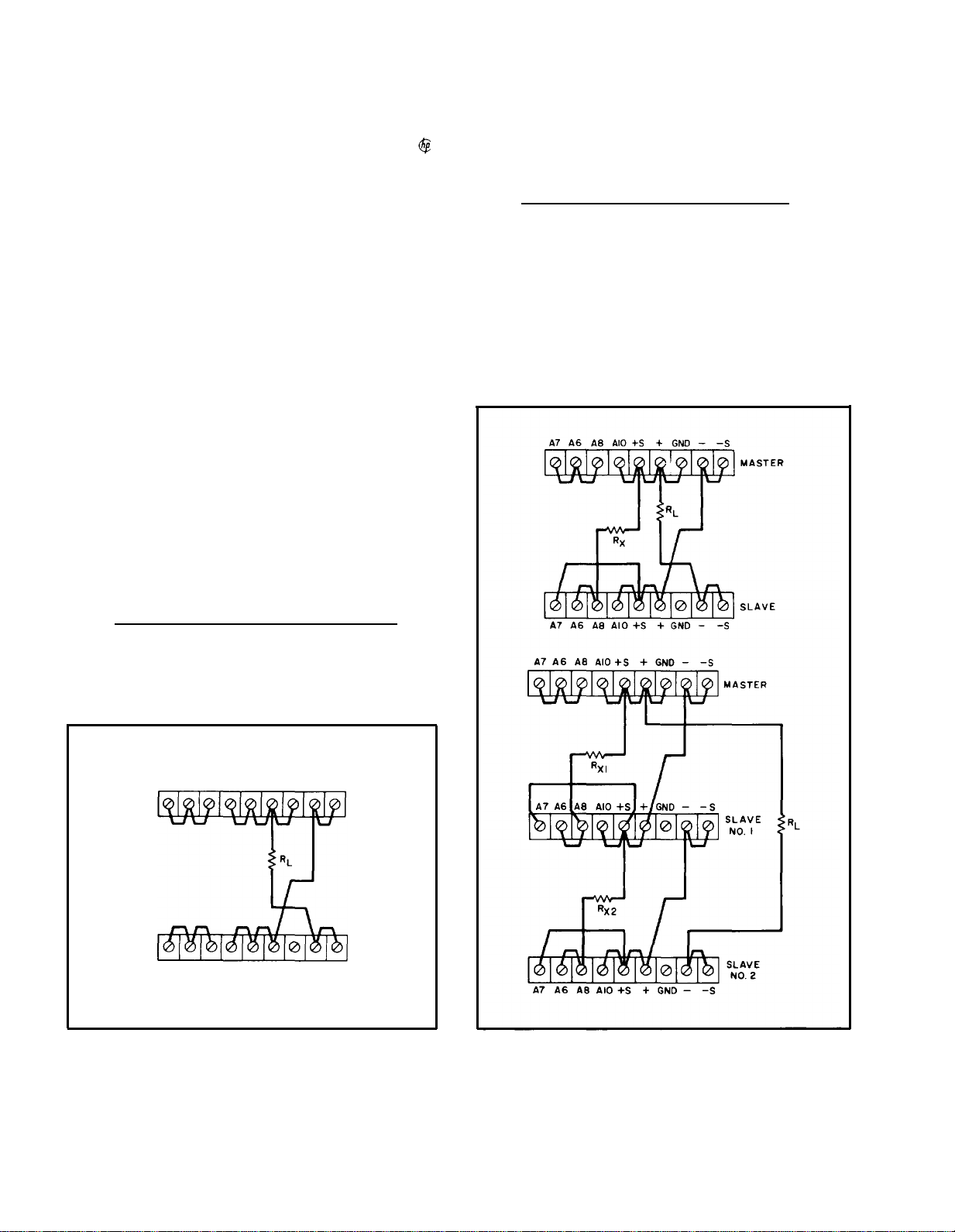

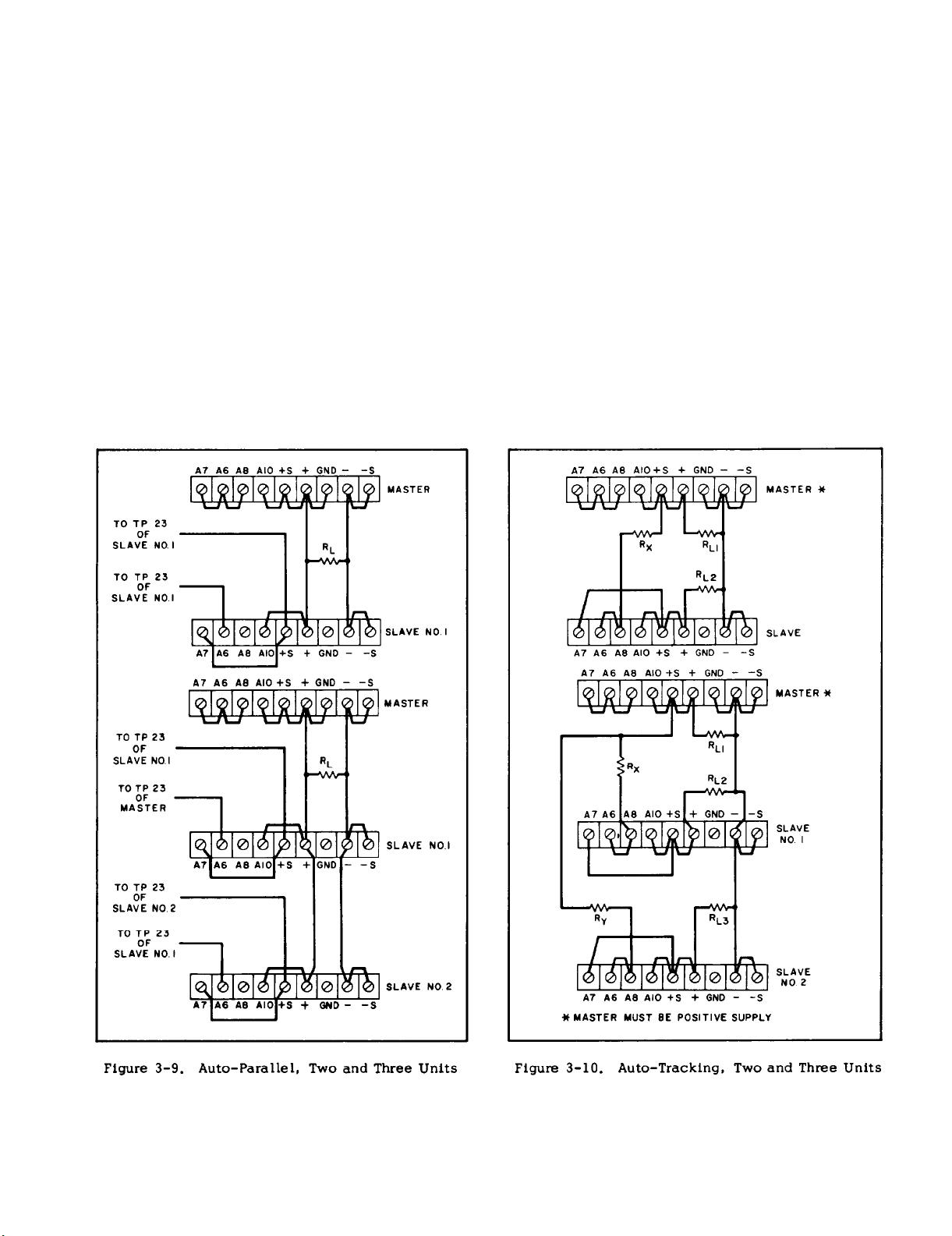

3-9

3-10

4-1

Page No.

Outline Diagram 2-1

Rack Mounting, Two Units 2-2

Rack Mounting, One Unit 2-2

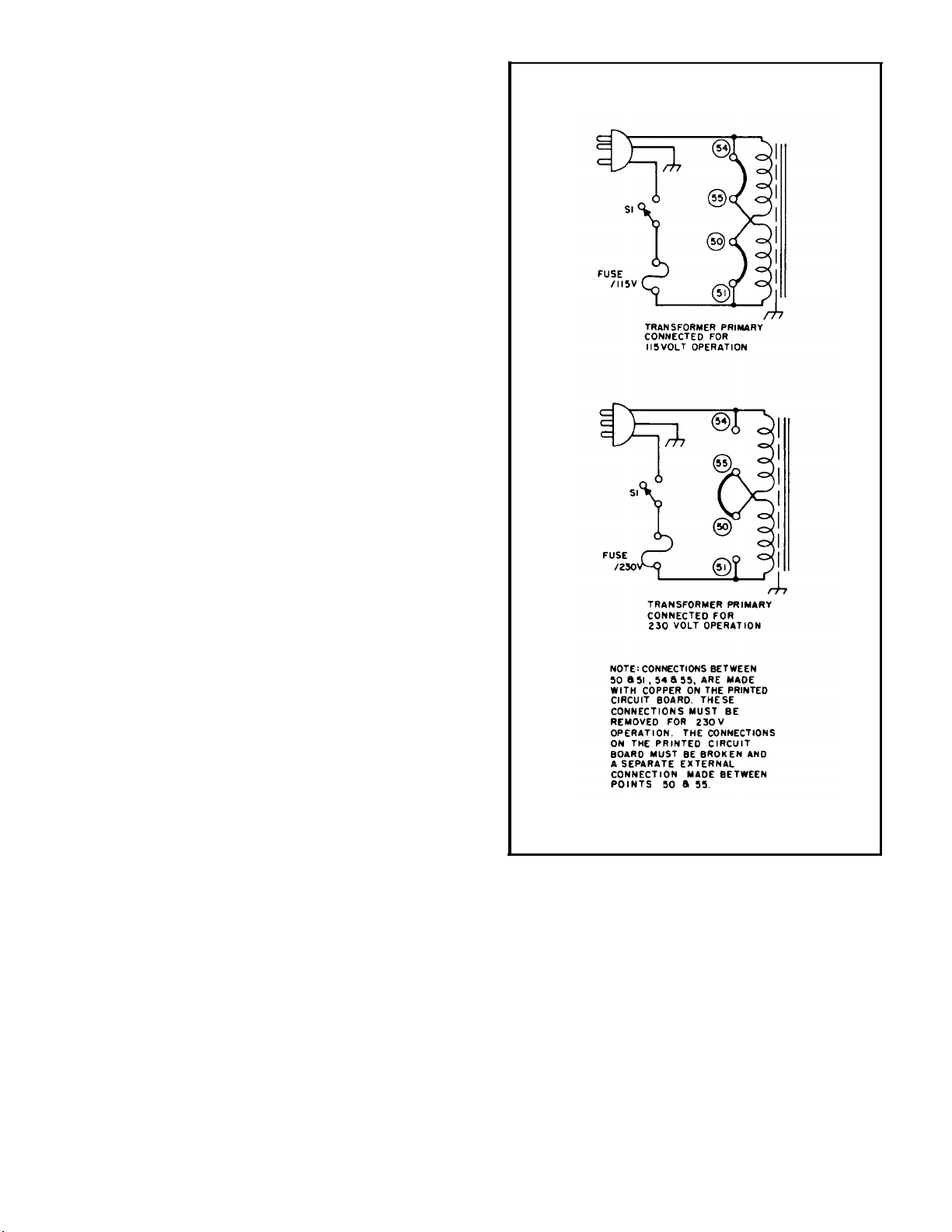

Primary Connections 2-3

Front Panel Controls and Indicators 3-1

Normal Strapping Pattern

Current Limit Alteration

Remote Resistance Programming 3-3

Remote Voltage Programming

Remote Sensing 3-3

Norma I Series Connections 3-4

Auto-Series, Two and Three Units 3-4

Auto-Parallel, Two and Three

Units

Auto-Tracking, Two and Three

Units 3-5

Overa11 Block Diagram 4-1

3-1

3-2

3-3

3-5

LIST OF TABLES

Figure

4-2

5-1

5-2

5-3

5-4

5-5

5-6

5-7

5-8

5-9

5-10

5-11

Page No.

Multiple Range Meter Circuit,

Simplified Schematic

Front Panel Terminal Connections 5-1

Output Current Measurement

Technique

Differential Voltmeter Substitute,

Test Setup

Output Current, Test Setup 5-4

Load Regulation, Test Setup

CV Ripple and Noise, Test Setup 5-5

CV Noise Spike, Test Setup

Transient Recovery Time,

Test Setup

Transient Recovery Time,

Waveforms

Output Impedance, Test Setup

Servicing Printed Wiring Boards

4-4

5-1

5-2

5-4

5-6

5-7

5-7

5-8

5-14

Table

1-1 Specifications

5-1 Test Equipment Required

5-2 Reference Circuit Troubleshooting

5-3 Overall Trouble shooting 5-9

5-4 High Output Voltage Troubleshooting

5-5 Low Output Voltage Troubleshooting

5-6 Selected Semiconductor Characteristics

5-7 Checks and Adjustments After Replacement of Semiconductor Devices 5-12

6-1 Reference Designators

6-2 Description Abbreviations

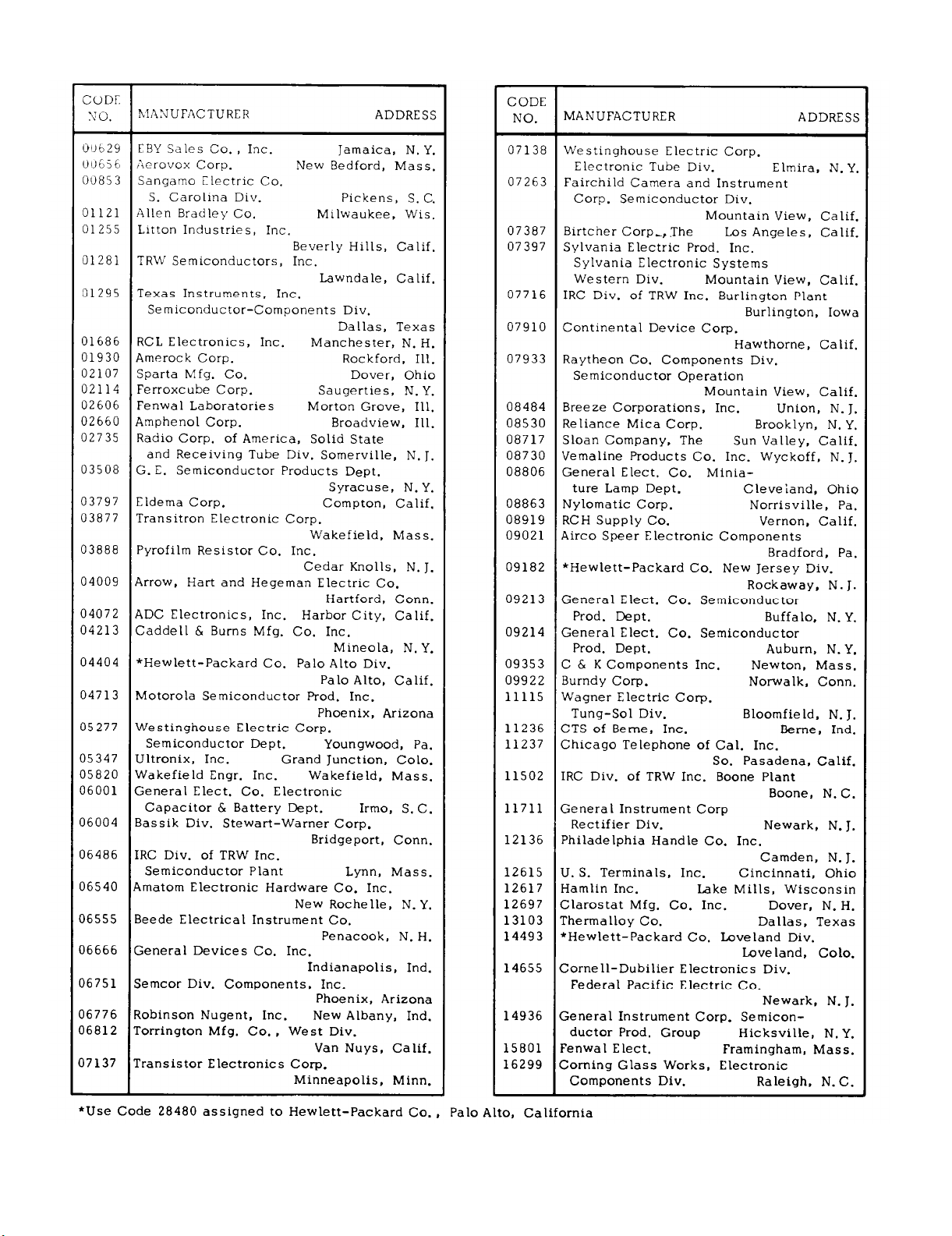

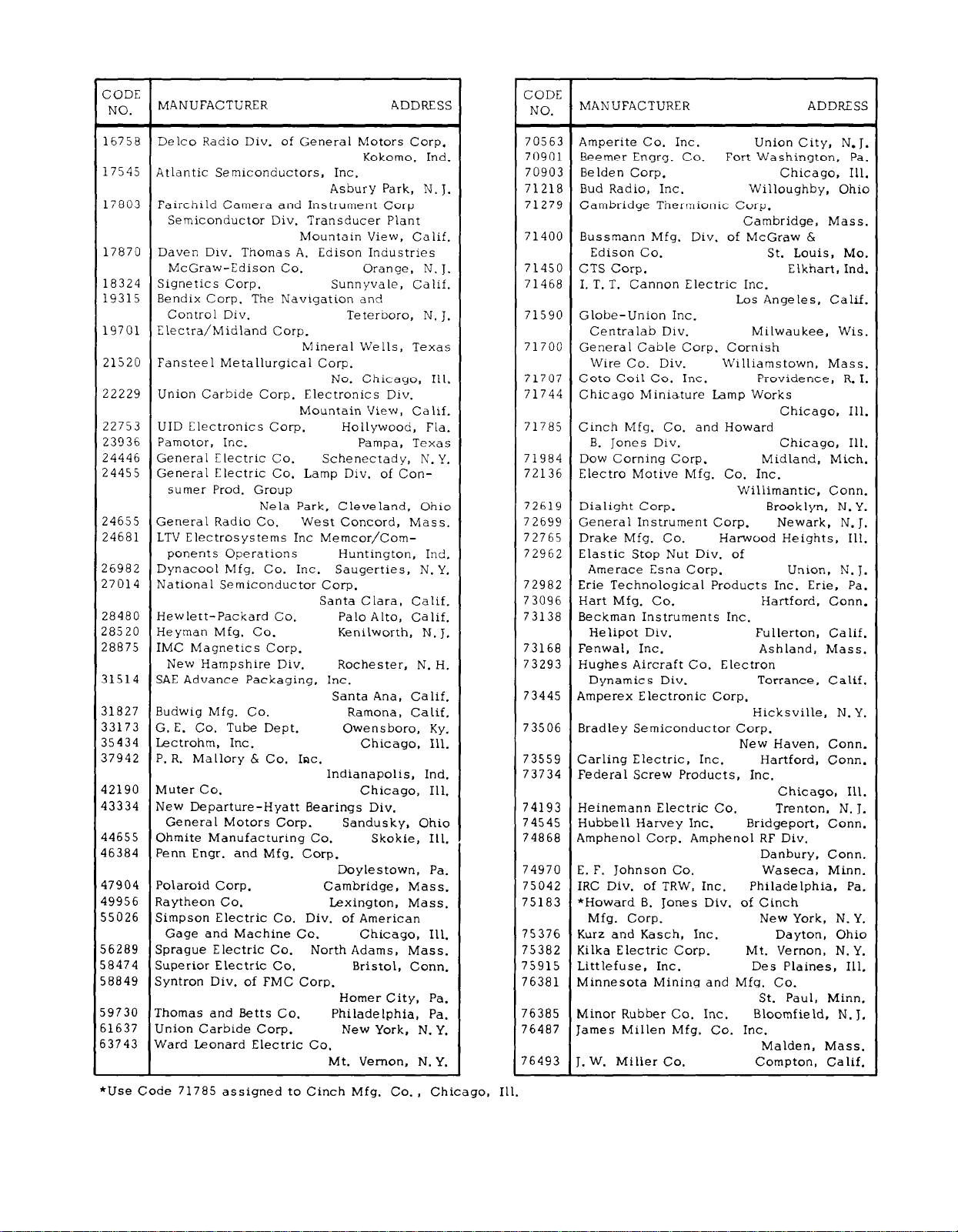

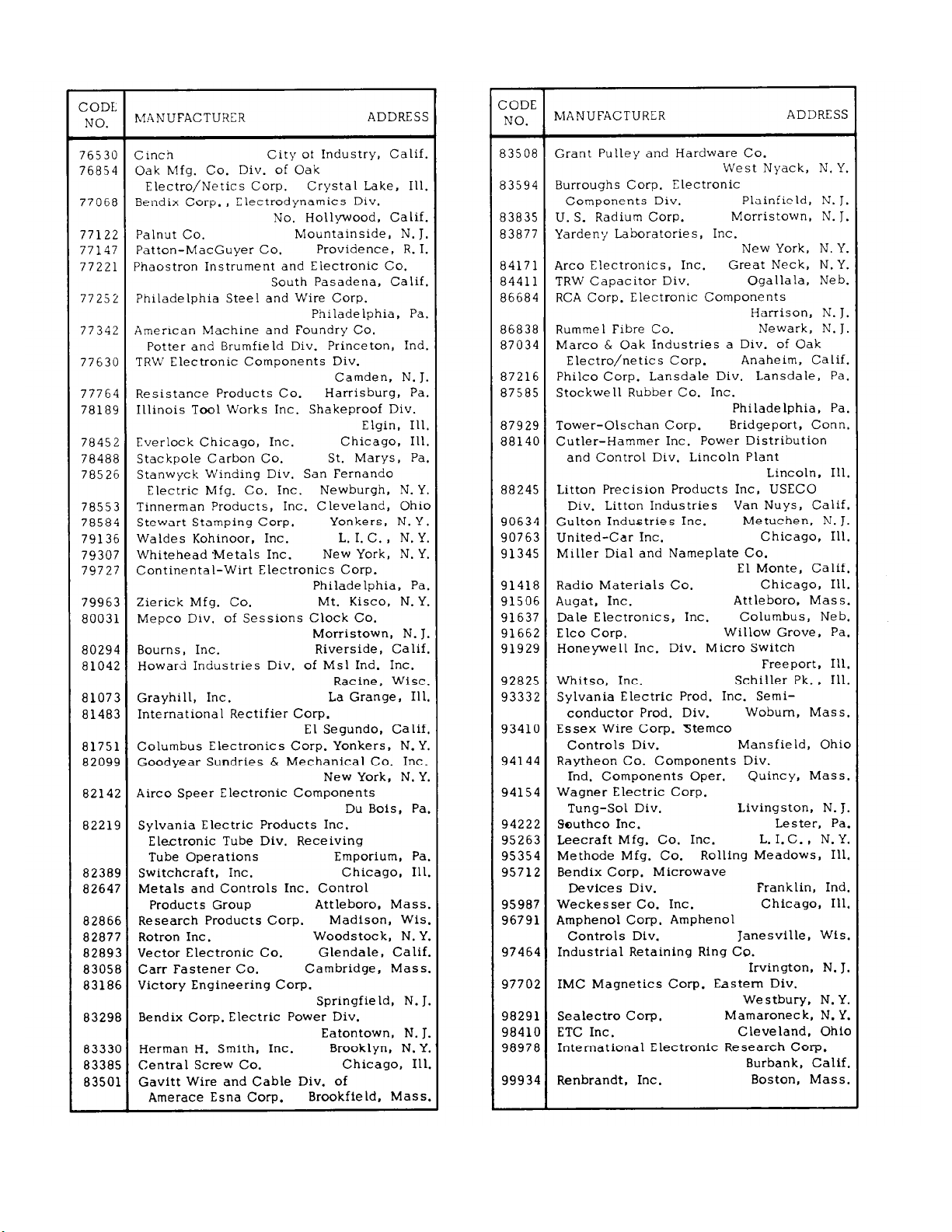

6-3 Code List of Manufacturers

6-4 Replaceable Parts

Page No.

1-3

5-2

5-9

5-11

5-11

5-12

6-1

6-1

6-2

6-5

iii

Page 6

SECTION O

INSTRUCTIONS

TM 11-6625-2965-14&P

0-1.

Model 6205) having serial prefix number 7L2301 and up. For serial prefixes

below 7L2301 refer to Appendix E.

inclusion of change page.

0-2.

whether there are new editions , changes, or additional publications pertain-

ing to the equipment.

modification work orders (MWO

0-3.

the Army forms and procedures used for equipment maintenance will be those

described by TM 38-750, The Army Maintenance Management System,

DD Form 6 (Packaging Improvement Report) as prescribed in AR 700-58/

NAVSUPINST 4030.29/AFR 71-12/MCO P4030.29A, and DLAR 4145.8.

SCOPE

This manual applies directly to Power Supply PP-7548/U (Hewlett-Packard

For serials above 7L4450 check for

INDEXES OF PUBLICATIONS

DA Pam 310-4.

a.

b.

DA Pam 310-7.

MAINTENANCE FORMS, RECORDS AND REPORTS

a.

Reports of Maintenance and Unsatisfactory Equipment.

b.

Report of Packaging and Handling Deficiencies.

Refer to the latest issue of DA Pam 310-4 to determine

Refer to DA Pam 310-7 to determine whether there are

S

) pertaining to the equipment.

Department of

Fill out and forward

c.

Discrepancy in Shipment Report (DISREP) (SF 361). Fill out and

forward Discrepancy in Shipment Report (DISREP) (SF 361) as prescribed in

AR 55-38/NAVSUPINST 4610.33B/AFR 75-18/MCO P461O.19C and DLAR 4500.15.

0-4.

Send us an EIR.

don’t like about your equipment.

Tell us why a procedure is hard to perform.

Deficiency Report).

Electronics Materiel Readiness Command and Fort Monmouth, ATTN: DRSEL-ME-

MQ, Fort Monmouth, New Jersey 07703. We'll send yOu a reply.

0-5.

shall be in accordance with paragraph 2-5.

0-6.

accordance with TM 750-244-2.

REPORTING EQUIPMENT IMPROVEMENT RECOMMENDATIONS(EIR)

If your Power Supply PP-7548/U (HP-6205) needs improvement, let us know.

You, the user,

Mail it to Commander, US Army Communications and

ADMINISTRATIVE STORAGE

Administrative storage of equipment issued to and used by Army activities

DESTRUCTION OF ARMY ELECTRONICS MATERIEL

Destruction of Army electronics materiel to prevent enemy use shall be in

are the only one who can tell us what you

Let us know why you don’t like the design.

Put it on an SF 368 (Quality

0-1

Page 7

TM 11-6625-2965-14&P

1-1 DESCRIPTION

1-2

This power supply, Figure 1-1, is completely

transistorized and suitable for either bench or relay rack operations, The dual supply consists of

two independently controlled dual range sections;

both identical to the other. Each section can fur-

nish either a 0-40 Volt output at 300mA or a 0-20

Volt output at 600mA. Each section has its own

front panel meter and operating controls, The oper-

ating modes (40V or 20V) are selected by means of

the front panel RANGE switches, The VOLTAGE controls permit each output voltage to be continuously

adjusted throughout either output range.

may be programmed from a remote location by

means of an external voltage source or resistance.

b. Remote Sensing. The degradation in

regulation which would occur at the load because

of the voltage drop which takes place in the load

leads can be reduced by using the power supply in

the remote sensing mode of operation.

c. Series and Auto-Series Operation, Power

supplies may be used in series when a higher output voltage is required in the voltage mode of operation or when greater voltage compliance is required in the constant current mode of operation,

Auto-Series operation permits one knob control of

the total output voltage from a “master” supply.

d. Parallel and Auto-Parallel Operation, The

power supply may be operated in parallel with a

similar unit when greater output current capability

is required.

knob control of the total output current from a

“master” supply.

e. Auto-Tracking.

used as a “master” supply, having control over one

(or more) “slave”

ages for a system.

1-6 SPECIFICATIONS

Auto-Parallel operation permits one

The power supply may be

supplies that furnish various volt-

Figure 1-1. DC Power Supply, Model 6205B

1-3 Both sections of the supply are of the regulated, Constant Voltage/Current Limiting, type.

Each section is fully protected from overloads by

the fixed current limit which is set by means of an

internal adjustment.

1-4 Both front and rear terminals are available

for each section. Either the positive or negative

terminals may be grounded or the supply can be

operated at up to a maximum of 300 Volts off ground.

Each meter can be used to measure either output

voltage or output current in one of two ranges. The

voltage or current ranges are selected by the ap-

plicable METER switch on the front panel.

1-5 Two sets of programming terminals, located

at the rear of the unit, allow ease in adapting to

the many operational capabilities of the supply. A

brief description of these capabilities is given

below:

a, Remote Programming,

The power supply

1-7 Detailed specifications for the power supply

are given in Table 1-1.

1-8 OPTIONS

1-9 Options are factory modifications of a standard instrument that are requested by the customer.

The following options are available for the instru-

ment covered by this manual, Where necessary, de-

tailed coverage of the options is included through-

out the manual.

Option No.

07

11

Voltage 10-Turn Pot: A single control

that replaces both coarse and fine

voltage controls and improves output

nettability.

Overvoltage_Protection_“Crowbar”:

A completely separate circuit for protecting delicate loads against power

supply failure or operator error. This

independent device monitors the output voltage and within 10µsec imposes

a virtual short-circuit (crowbar) across

the power supply output if the preset

Description

11

Page 8

TM 11-6625-2965-14P

trip voltage is exceeded. When Option 11 is requested by the customer

the device is connected at the factory.

Trip Voltage Range: 2.5 to 44 Volts,

screwdriver adjustable.

Detailed coverage of Option 11 is included in Appendix A at the rear of

manuals that support power supplies

containing Option 11.

13

28

1-10 ACCESSORIES

1-11 The accessories listed in the following chart

may be ordered with the power supply or separately

from your local Hewlett-Packard field sales office

(refer to list at rear of manual for addresses).

Three Digit Graduated Decadial

Voltage Control: Control that replaces

coarse and fine voltage controls permitting accurate resettability.

230Vac Input:

shipped is wired for l15Vac input.

Option 28 consists of reconnecting

the input transformer for 230Vac operation.

Supply as normally

14523A

1-12 INSTRUMENT AND SERVICE MANUAL

IDENTIFICATION

1-13 Hewlett-Packard power supplies are identified by a three-part serial number tag. The first

part is the power supply model number. The second part is the serial number prefix, which consists of a number-letter combination that denotes

the date of a significant design change. The number designates the year, and the letter A through

L designates the month, January through December

respectively, with “I” omitted. The third part is

the power supply serial number.

1-14 If the serial number prefix on your power

supply does not agree with the prefix on the title

page of this manual, change sheets are included

to update the manual. Where applicable, backdating information is given in an appendix at the

rear of the manual.

ORDERING ADDITIONAL MANUALS

1-15

Rack Kit for mounting two 3½” high

supplies. (Refer to Section II for de-

tails.)

C05

14513A

Description

8” Black Handle that can be attach-

ed to side of supply.

Rack Kit for mounting one 3½” high

supply. (Refer to Section II for details.)

1-16

One manual is shipped with each power supply, Additional manuals may be purchased from

your local Hewlett-Packard field office (see list

at rear of this manual for addresses). Specify the

model number, serial number prefix, and Part

number provided on the title page.

1-2

Page 9

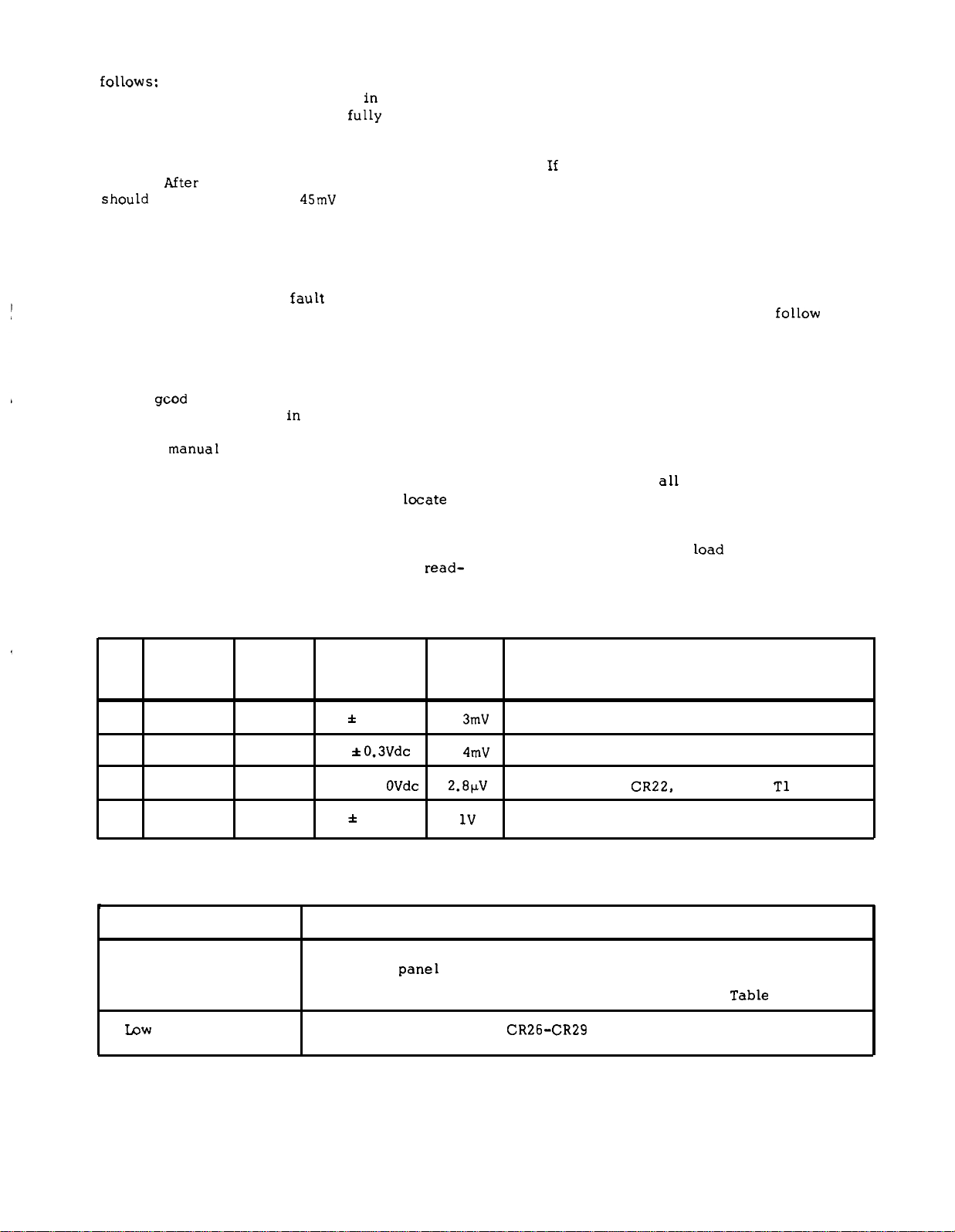

Table 1-1.

Specifications

TM 11-6625-2965-14&P

INPUT:

l15Vac ±10%, single phase, 48-440 Hz.

OUTPUT:

Two independent outputs, each of which can

be set at either 0-40 Volts @ 0.3 Amp or 0-20

Volts @ 0.6 Amp.

LOAD REGULATION:

Less than 0,01% plus 4mV for a full load to no

load change in output current.

LINE REGULATION:

Less than 0.01% plus 4mV for any line voltage

change within the input rating.

RIPPLE AND NOISE:

Less than 200µVrms 1mV p-p,

TEMPERATURE RANGES:

operating: 0 to 50°C. Storage: -40 to + 750C.

TEMPERATURE COEFFICIENT:

Less than 0.02% plus lmV per degree Centi-

grade.

STABILITY.

Less than 0.10% plus 5mV total drift for 8

hours after an initial warm-up time of 30 minutes at constant ambient, constant line voltage,

and constant load.

INTERNAL IMPEDANCE AS A CONSTANT VOLT-

AGE SOURCE:

Less than 0.02 ohms from dc to lkHz.

Less than 0.5 ohms from lkHz to 1OOkHz.

Less than 3.0 ohms from 1OOkHz to lMHz.

TRANSIENT RECOVERY TIME:

Less than 50µsec for output recovery to with-

in 10mV following a full load current change in

the output.

OVERLOAD PROTECTION:

A fixed current limiting circuit protects the

power supply for all overloads including a

direct short placed across the terminals in con-

stant voltage operation.

METERS:

Each front panel meter can be used as either a

0-50 or 0-5 Volt voltmeter or as a 0-0.75 or

0.075 Amp ammeter.

OUTPUT CONTROLS:

RANGE switches select desired operating mode

for each section and coarse and fine VOLTAGE

controls set desired output voltages.

OUTPUT TERMINALS:

Six “five-way” output posts (three for each

section of supply) are provided on the front

panel and two output terminal strips (one per

section) are located on the rear of the chassis.

A1l power supply output terminals are isolated

from the chassis and either the positive or negative terminals may be connected to the chassis

through separate ground terminals located on

the output termina1 strips.

ERROR SENSING:

Error sensing is normally accomplished at the

front terminals if the load is attached to the

front or at the rear terminals if the load is at-

tached to the rear terminals. Also, provisions

are included on the rear termina1 strips for remote sensing.

REMOTE RESISTANCE PROGRAMMING:

200 ohms per Volt.

REMOTE VOLTAGE PROGRAM MING:

1 Volt per Volt.

COOLING:

Convection cooling is employed. The supply

has no moving parts.

SIZE:

3~½" H x 12-5/8" D x 8½" W. Two of the units

can be mounted side by side in a standard 19”

relay rack.

WEIGHT:

10 lbs, net, 13 lbs. shipping.

FINISH:

Light gray front panel with dark gray case.

POWER CORD:

A three-wire, five-foot power cord is provided

with each unit.

1-3

Page 10

TM 11-6625-2965-14&P

SECTION II

INSTALLATION

2-1 INITIAL INSPECTION

2-2 Before shipment, this instrument was in-

spected and found to be free of mechanical and

electrical defects. As soon as the instrument is

unpacked,

occurred in transit. Save all packing materials

until the inspection is completed. If damage is

found, a claim should be filed with the carrier.

Hewlett-Packard Sales and Service office should

be notified.

2-3 MECHANICAL CHECK

2-4 This check should confirm that there are no

broken knobs or connectors, that the cabinet and

panel surfaces are free of dents and scratches,

and that the meter is not scratched or cracked.

2-5

inspect for any damage that may have

ELECTRICAL CHECK

2-6 The instrument should be checked against its

electrical specifications. Section V includes an

“ in-cabinet” performance check to verify proper

instrument operation,

2-7 INSTALLATION DATA

2-8 The instrument is shipped ready for bench

operation. It is necessary only to connect the instrument to a source of power and it is ready for

operation.

2-9 LOCATION

2-10 This instrument is air cooled. Sufficient

space should be allotted so that a free flow of

cooling air can reach the sides and rear of the in-

strument when it is in operation. It should be used

in an area where the ambient temperature does not

exceed 50°C.

2-11 OUTLINE DIAGRAM

2-12 Figure 2-1 is an outline diagram showing the

dimensions of the instrument.

2-13 RACK MOUNTING

2-14 This instrument may be rack mounted in a

standard 19 inch rack panel either alongside a

similar unit or by itself. Figures 2-2 and 2-3 show

Figure 2-1. Outline Diagram

how both types of installations are accomplished.

2-15 To mount two units side-by-side, proceed

as follows:

a. Remove the four screws from the front

panels of both units.

b. Slide rack mounting ears between the

front panel and case of each unit.

c. Slide combining strip between the front

panels and cases of the two units.

d. After fastening rear portions of units together using the bolt, nut, and spacer, replace

panel screws.

2-16 To mount a single unit in the rack panel,

proceed as follows:

a. Bolt rack mounting ears, combining

straps, and angle brackets to each side of center

2-1

Page 11

TM 11-6625-2965-14&P

Figure 2-2. Rack Mounting, Two Units

Figure 2-3.

Rack Mounting, One Unit

Page 12

TM 11-6625-2965-14&P

spacing panels. Angle brackets are placed behind

combining straps as shown in Figure 2-3.

b. Remove four screws from front panel of

unit.

Slide combining strips between front

c.

panel and case of unit.

d. Bolt angle brackets to front sides of case

and replace front panel screws.

2-17 INPUT POWER REQUIREMENTS

2-18 This power supply may be operated from

either a nominal 115 Volt or 230 Volt 48-440 Hertz

power source. The unit, as shipped from the factory, is wired for 115 Volt operation. The input

power required when operated from a 115 Volt 60

Hertz power source at full load is 31 Watts and

0.35 Amperes.

2-19 CONNECTIONS FOR 230 VOLT OPERATION

2-20 Normally, the two primary windings of the

input transformer are connected in parallel for operation from 115 Volt source. To convert the power

supply to operation from a 230 Volt source, the

power transformer windings are connected in series

as follows:

a.

Unplug the line cord and remove the unit

from case.

b. Break the copper between 54 and 55 and

also between 50 and 51 on the printed circuit

board. The se are shown in Figure 2-4, and are

labeled on copper side of printed circuit board.

Add strap between 50 and 55.

c.

d. Replace existing fuse with 1 Ampere,

230 Volt fuse.

normally.

Return unit to case and operate

2-21 POWER CABLE

2-22 To protect operating personnel, the National

Electrical Manufacturers Association (NEMA) recommends that the instrument panel and cabinet be

grounded. This instrument is equipped with a

three conductor power cable. The third conductor

is the ground conductor and when the cable is

plugged into an appropriate receptacle, the instrument is grounded. The offset pin on the power

cable three-prong connector is the ground connection.

2-23 To preserve the protection feature when operating the instrument from a two-contact outlet,

use a three-prong to two-prong adapter and connect the green lead on the adapter to ground.

2-24 REPACKAGING FOR SHIPMENT

2-25 To insure safe shipment of the instrument, it

is recommended that the package designed for the

Figure 2-4.

instrument be used. The original packaging material is reusable. If it is not available, contact

your local Hewlett-Packard field office to obtain

the materials. This office will also furnish the

address of the nearest service office to which the

instrument can be shipped. Be sure to attach a

tag to the instrument which specifies the owner,

model number, full serial number, and service re-

quired, or a brief description of the trouble,

2-3

Primary Connections

Page 13

SECTION Ill

OPERATING INSTRUCTIONS

TM 11-6625-2965-14&P

3-1 TURN-ON CHECKOUT PROCEDURE

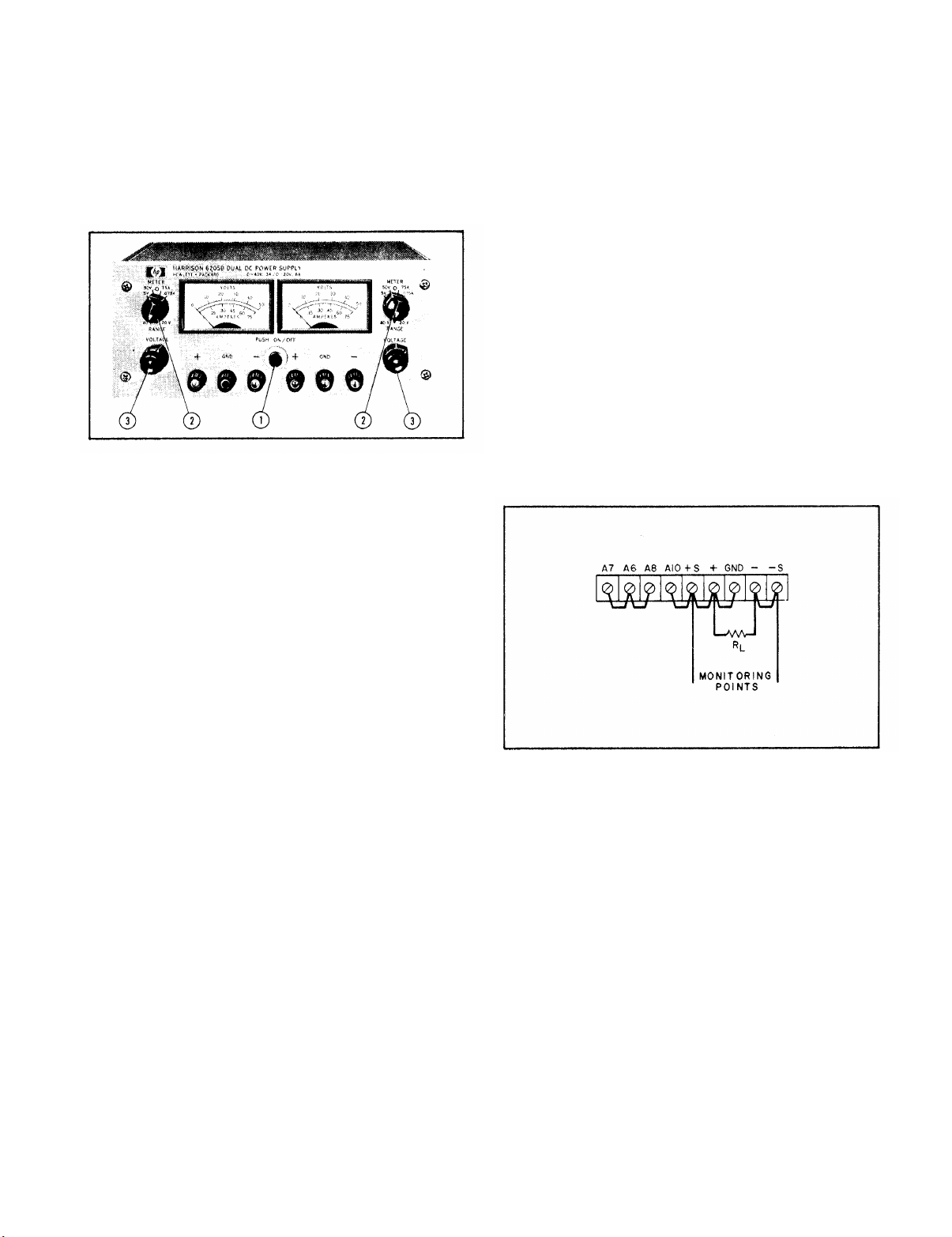

Figure 3-1.

3-2 The front panel controls and indicators are

shown in Figure 3-1.

is described below:

A. Push ON/OFF button

that button lights,

B. Set range switch

mode and meter switch to desired voltage range.

C. Adjust coarse and fine voltage controls

Front Panel Controls and Indicators

The normal turn-on sequence,

① and observe

② to desired operating

③ until desired output voltage is indicated on

meter.

Set meter switch to highest current range

D.

and short

meter.

terminals

be used for both sections of supply.

circuit output terminals.

E.

Observe short circuit output current on

Remove short and connect load to output

F.

(front or rear),

For Model 6205B, this procedure should

G.

erational capabilities of the supply. A more theoretical description concerning these operational

features is contained in Application Note 90 and

in various Tech Letters. Copies of these can be

obtained from your local Hewlett-Packard field

office,

3-5 NORMAL OPERATING MODE

3-6 The power supply is normally shipped with

its rear terminal strapping connections arranged

for Constant Voltage/Current Limiting, local sensing, local programming, single unit mode of operation. This strapping pattern is illustrated in Figure 3-2. The operator selects a constant voltage

output using the front panel controls (local programming, no strapping changes are necessary).

Figure 3-2.

Norma 1 Strapping Pattern

3-3 OPERATING MODES

3-4 The power supply is designed so that its

mode of operation can be selected by making

strapping connections between particular terminals

on the terminal strip at the rear of the power supply.

The terminal designations are stenciled in

white on the power supply above their respective

terminals. Although the strapping patterns illustrated in this section show the positive terminal

grounded, the operator can ground either termina1

or operate the power supply up to 300Vdc off

ground (floating). The following paragraphs describe the procedures for utilizing the various op-

3-7 CONSTANT VOLTAGE

3-8 To select a constant voltage output turn on

the supply and, with no load connected, adjust

the VOLTAGE controls for the desired output volt-

age. To check the current limit, connect an ex-

ternal ammeter across the output of the

turn the VOLTAGE controls fully clockwise, and

observe the reading.

adjusted to approximately 100mA above the current

rating of the supply.

is not compatible with the anticipated load requirements, the limit can be changed as outlined

in the following paragraphs.

3-1

The current limit is factory

If the existing current limit

supply,

Page 14

TM 11-6625-2965-14&P

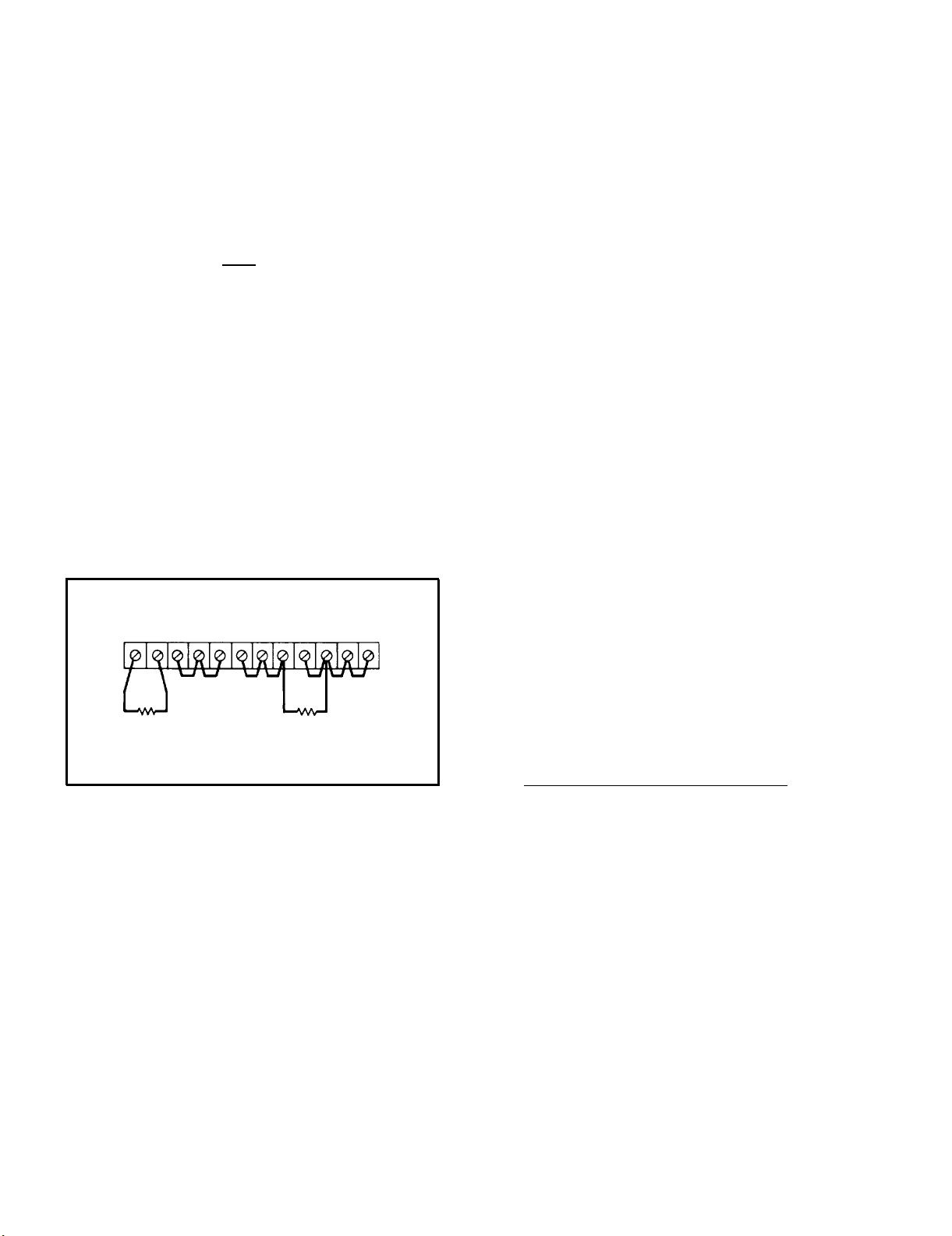

3-9 CHANGING CURRENT LIMIT

3-10 The current limit can be varied by adjusting

resistor R81, located on the printed wiring board.

This adjustment procedure is described in Paragraph 5-74. In Models 6204B and 6206B, the current limit may be reduced to a value lower than

that attainable by adjusting R81, by adding an external resistor as shown in Figure 3-3. The approximate value of the external resistance (Rx) can

be determined by using the following equation

=1.75

R

X

I

E

where: I = the output current

E

R = the internal current sampling resist-

I

ance for the particular operating mode

to be used.

1.75 . the approximate voltage drop across

the internal sampling resistance at

the current limit crossover point.

NOTE

The power supply’s performance will

be somewhat degraded if it is operated

too close to (within 10OmA) the current

limit crossover point.

3-13 If load considerations require that the output

power distribution terminals be remotely located

from the power supply, then the power supply output terminals should be connected to the remote

distribution terminals via a pair of twisted or

shielded wires and each load separately connected

to the remote distribution termina1s. For this case,

remote sensing should be used (Paragraph 3-25).

3-14 OPERATION BEYOND NORMAL RATED OUTPUT

3-15 Although the supply can deliver greater than

the rated output on both the lower and higher voltage ranges without being damaged, it can not be

guaranteed to meet all of its performance specifications.

Generally when operating the supply in

this manner, the output is unstable when connected to a load.

When greater than the lower rated

voltage is required, the higher voltage range

should be used.

This range will deliver half as

much output current and all specifications will

apply as listed in Table 1-1. However, if the line

voltage is maintained above its nomina1 value, the

supply will probably operate within specifications

above its rated output.

3-16 OPTIONAL OPERATING MODES

3-17 REMOTE PROGRAMMING, CONSTANT VOLTAGE

A1 A2 A6 A7 A8 A9 -S – GND + +S A10

Rx

Figure 3-3.

Current Limit Alteration

R

L

3-11 CONNECTING LOAD

3-12 Each load should be connected to the power

supply output terminals using separate pairs of

connecting wires.

This will minimize mutual cou-

pling effects between loads and will retain full

advantage of the low output impedance of the power

supply.

Each pair of connecting wires should be

as short as possible and twisted or shielded to reduce noise pickup. (If shield is used, connect one

end to power supply ground terminal and leave the

other end unconnected. )

3-18 The constant voltage output of the power

supply can be programmed (controlled) from a remote location if required. Either a resistance or

voltage source can be used for the programming

device.

The wires connecting the programming

terminals of the supply to the remote programming

device should be twisted or shielded to reduce

noise pickup. The VOLTAGE controls on the front

panel are disabled according to the following pro-

cedures.

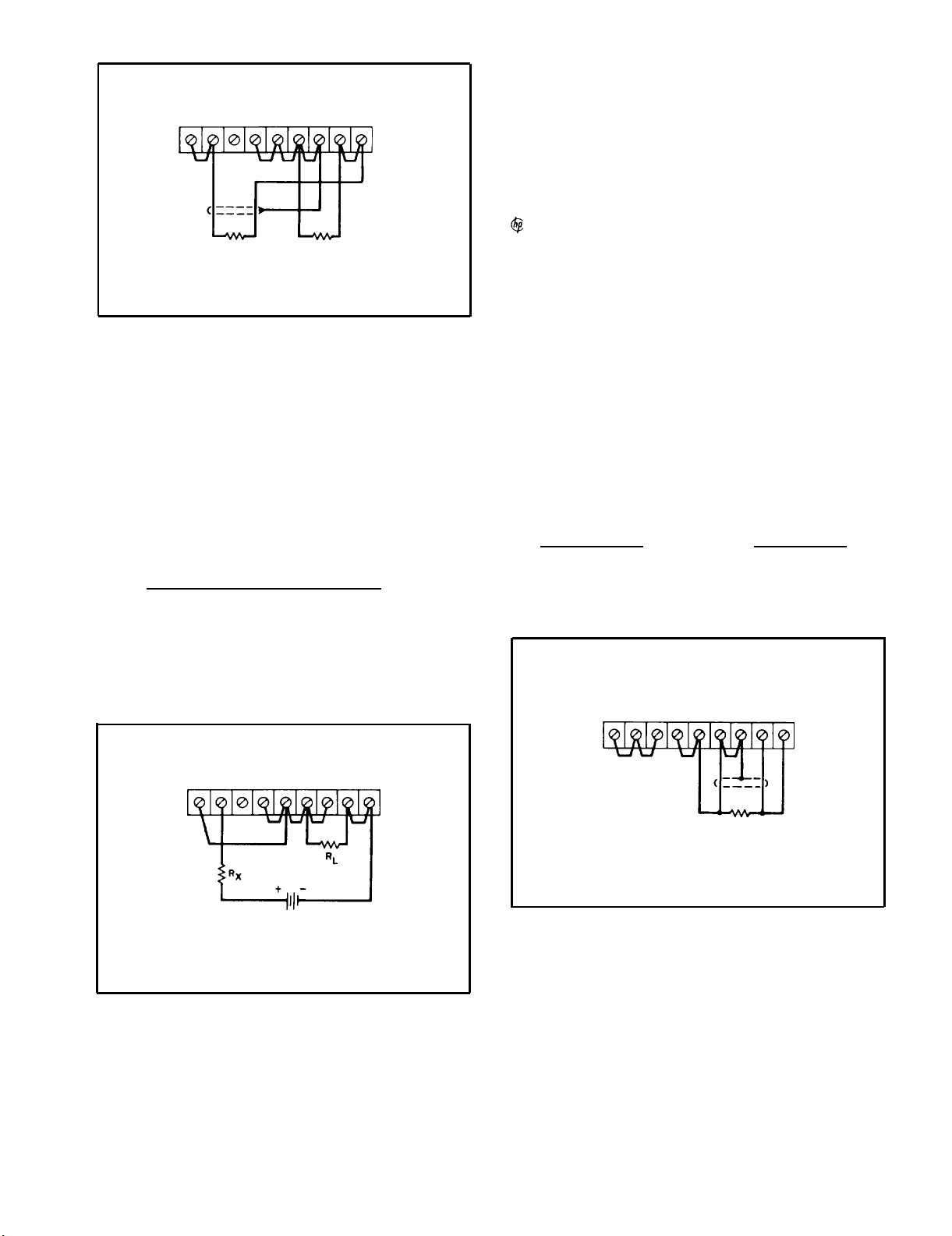

3-19 Resistance Programming (Figure 3-4). In

this mode, the output voltage will vary at a rate

determined by the programming coefficient (200

ohms per Volt for Model 6204B and 6205B or 300

ohms per Volt for Model 6206 B). The output voltage will increase by 1 Volt for each 200 ohms (or

300 ohms) added in series with the programming

terminals. The programming accuracy is 1% of the

programmed voltage. If greater programming ac-

curacy is required, it may be achieved by chang-

ing resistor R13 as outlined in Section V.

3-20 The output voltage of the power supply

should be zero Volts ± 20 millivolts when zero

ohms is connected across the programming terminals. If a zero ohm voltage closer than this is required, it may be achieved by changing resistor

R6 or R8 as described in Section V.

3-2

Page 15

A7 A6 A8 A10+S + GND - –S

Figure 3-4.

PROGRAMMING

RESISTOR

Remote Resistance Programming

R

L

3-21 To maintain the stability and temperature

coefficient of the power supply, u se programming

resistors that have stable, low noise, and low

temperature (less than 30ppm per degree Centigrade) characteristics. A switch can be used in

conjunction with various resistance values in

order to obtain discrete output voltages.

The

switch should have make-before-break contacts

to avoid momentarily opening the programming

terminals during the switching interval.

TM 11-6625-2965-14&P

programming voltage source should be approximately 1000 ohms if the temperature and stability

specifications of the power supply are to be maintained. The programming accuracy is 1% of the

programmed voltage.

3-24 Methods of voltage programming with gain

are discussed in Application Note 90, Power Supply

Handbook; available at no charge from your local

Sales Office.

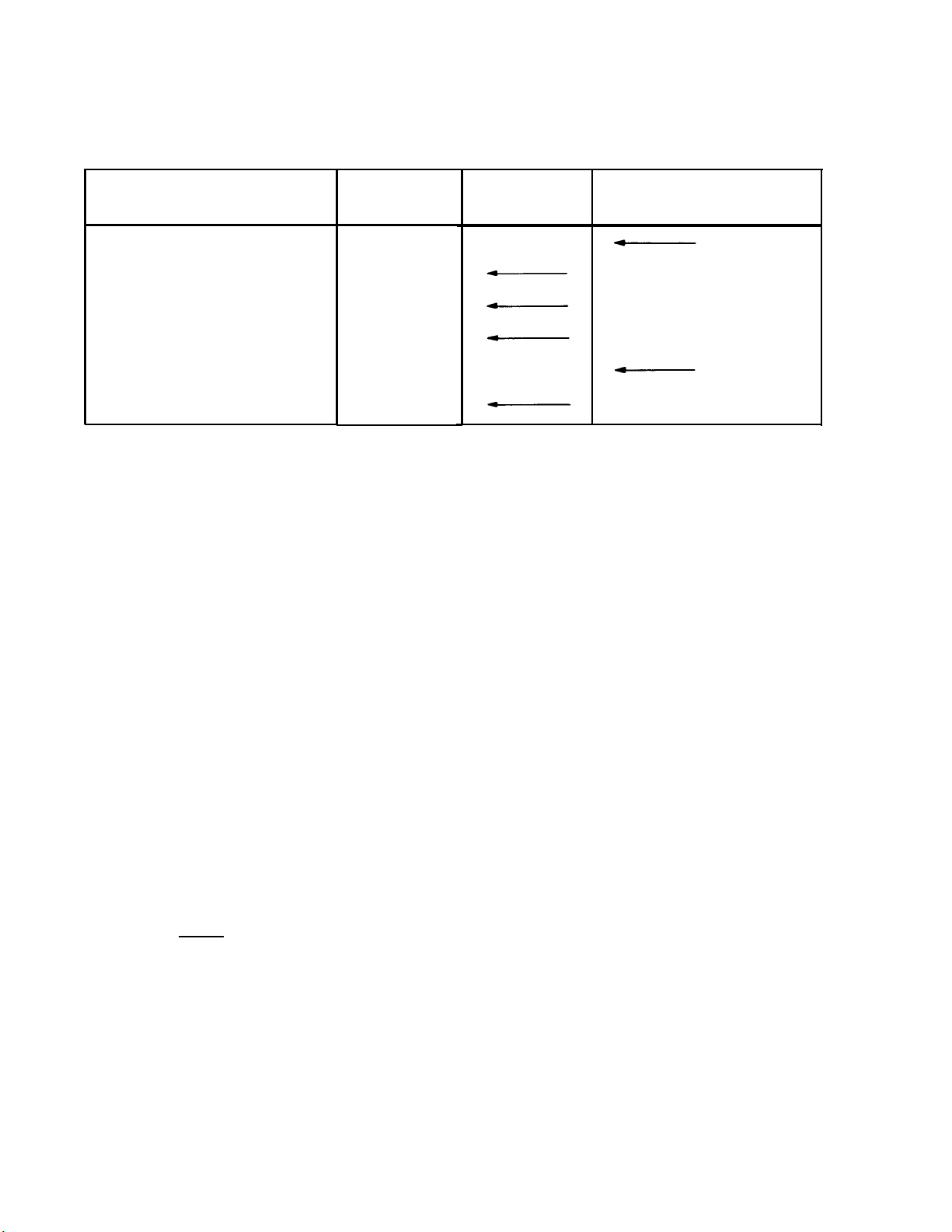

3-25 REMOTE SENSING (See Figure 3-6)

3-26 Remote sensing is used to maintain good

regulation at the load and reduce the degradation

of regulation which would occur due to the voltage

drop in the leads between the power supply and

the load. Remote sensing is accomplished by uti-

lizing the strapping pattern shown in Figure 3-6.

The power supply should be turned off before

changing strapping patterns. The leads from the

+S terminals to the load will carry less than 10

milliamperes of current, and it is not required that

these leads be as heavy as the load leads. However, they must be twisted or shielded to minimize

noise pick-up.

CAUTION

3-22 Voltage Programming (Figure 3-5). Employ

the strapping pattern shown on Figure 3-5 for

voltage programming.

In this mode, the output

voltage will vary in a 1 to 1 ratio with the pro-

gramming voltage (reference voltage) and the load

on the programming voltage source will not exceed

25 microampere.

A7 A6 A8 A10 +S + GND - -S

REFERENCE

VOLTAGE

Figure 3-5. Remote Voltage Programming

3-23 The impedance (Rx) looking into the external

Observe polarity when connecting the

sensing leads to the load.

A7 A6 A8 A10+S + AND– –S

R

L

Figure 3-6. Remote Sensing

3-27 For reasonable load lead lengths, remote

sensing greatly improves the performance of the

supply. However, if the load is located a consid-

erable distance from the supply, added precautions

must be observed to obtain satisfactory operation.

Notice that the voltage drop in the load leads sub-

3-3

Page 16

TM 11-6625-2965-14&P

tracts directly from the available output voltage

and also reduces the amplitude of the feedback error signals that are developed within the unit. Because of these factors it is recommended that the

drop in each load lead not exceed 1 Volt. If a

larger drop must be tolerated, please consuIt a

sales

engineer.

NOTE

Due to the voltage drop in the load

leads, it may be necessary to readjust

the current limit in the remote sensing

mode.

3-28

Another factor that must be considered is

the inductance of long load leads which could affect the stability of the feedback loop and cause

oscillation. In these cases, it is recommended

that the output capacitor (C20) be physically removed from the power supply and placed across

the output terminals.

3-29 Although the strapping patterns shown in

Figures 3-4 and 3-5 employ local sensing, notice

that it is possible to operate a power supply simultaneously in the remote sensing and the remote

programming modes.

ages of the individual supplies. Each of the individual supplies must be adjusted in order to obtain

the total output voltage. The power supply contains a protective diode connected internally

across the output which protects the supply if one

power supply is turned off while its series partner(s) is on.

3-32 Auto-Series Connections (Figure 3-8). The

Auto-Series configuration is used when it is desirable to have the output voltage of each of the

series connected supplies vary in accordance with

the setting of a control unit. The control unit is

called the master; the controlled units are called

slaves. At maximum output voltage, the voltage

of the slaves is determined by the setting of the

front panel VOLTAGE control on the master. The

master supply must be the most positive supply of

the series.

The current limit settings of all series

3-30 SERIES OPERATION

3-31 Normal Series Connections (Figure 3-7).

Two or more power supplies can be operated in

series to obtain a higher voltage than that available from a single supply. When this configuration

is used, the output voltage is the sum of the volt-

A7 A6 A8 A10-S + GND – –S

A7 A6 A8 A10 - S + GND – –S

Figure 3-7. Normal Series Connections

Figure 3-8, Auto-Series, Two and Three Units

3-4

Page 17

units are effective and the current limit for the

entire configuration is equal to the lowest current

limit setting. If any of the settings are too low,

automatic crossover to current limiting operation

will occur and the output voltage will drop. Re-

mote sensing and programming can be used; however, the strapping arrangements shown in the applicable figures show local sensing and programming.

3-33 In order to maintain the temperature coeffi-

cient and stability specifications of the power

supply, the external resistors (Rx) shown in Figure

3-8 should be stable, low noise, low temperature

coefficient (less than 30ppm per degree Centigrade)

resistors. The value of each resistor is dependant

on the maximum voltage rating of the master sup-

ply,

The value of Rx is this voltage divided by the

voltage programming current of the slave supply

(l/Kp where Kp is the voltage programming coeffi-

cient). The voltage contribution of the slave is

determined by its voltage control setting.

TM 11-6625-2965-14&P

3-34 Auto-Parallel. The strapping patterns for

Auto-Parallel operation of two and three

plies are shown in Figure 3-9. Auto-Parallel operation permits equal current sharing under all load

conditions, and allows complete control of the output current from one master power supply. The output current of each slave will be approximately

equal to the master’s regardless of the load conditions. Because the output current controls of each

slave are operative, they should be set to maximum

to avoid having the slave revert to constant current

operation; this would occur if the master output

current setting exceeded the slave’s. In Model

6205B, it is necessary to make internal connections

in order to operate the supply in this mode. The

internal connections, specified in Figure 3-9,

made to the sampling terminals of the current sam-

pling terminals of the current sampling resistor,

R54 (see Figure 5-2).

power sup-

are

3-5

Page 18

TM 11-6625-2965-14&P

3-35 AUTO-TRACKING OPERATION (See Figure 3-10)

3-36 The Auto-Tracking configuration is used

when it is necessary that several different voltages

referred to a common bus, vary in proportion to the

setting of a particular instrument (the control or

master).

A fraction of the master’s output voltage

is fed to the comparison amplifier of the slave supply, thus controlling the slave’s output. The master must have the largest output voltage of any

power supply in the group (must be the most posi-

tive supply in the example shown on Figure 3-10).

3-37 The output voltage of the slave is a percentage of the master’s output voltage, and is determined by the voltage divider consisting of R

Rx and R

supply, R

Y) and the voltage control of the slave

, where:

p

E

M RP

E = Rx+Rp

S

Turn-on and turn-off of the power supplies is controlled by the master.

Remote sensing and programming can be used; although the strapping patterns for these modes show only local sensing and

programming.

In order to maintain the temperature

coefficient and stability specifications of the pow-

er supply, the external resistors should be stable,

low noise, low temperature (less than 30ppm per

O

C) resistors.

3-38

SPECIAL OPERATING CONSIDERATIONS

X (or

not desired, set the preset limit for the peak requirement and not the average.

3-41 OUTPUT CAPACITANCE

3-42 An internal capacitor, acress the output terminals of the power supply, helps to supply highcurrent pulses of short duration during constant

voltage operation.

Any capacitance added exter-

nally will improve the pulse current capability, but

will decrease the safety provided by the current

limiting circuit.

A high-current pulse may damage

load components before the average output current

is large enough to cause the current limiting circuit to operate.

3-43 REVERSE VOLTAGE LOADING

3-44 A diode is connected across the output terminals.

Under normal operating conditions, the

diode is reverse biased (anode connected to negative terminal).

If a reverse voltage is applied to

the output terminals (positive voltage applied to

negative terminal), the diode will conduct, shunting current across the output terminals and limiting the voltage to the forward voltage drop of the

diode.

This diode protects the series transistors

and the output electrolytic capacitors.

3-45 REVERSE CURRENT LOADING

3-39 PULSE LOADING

3-40 The power supply will automatically cross

over from constant voltage to constant current operation in response to an increase (over the preset

limit) in the output current, Although the

preset

limit may be set higher than the average output

current high peak currents (as occur in pulse loading) may exceed the preset current limit and cause

crossover to occur.

If this crossover limiting is

3-46 Active loads connected to the power supply

may actually deliver a reverse current to the power

supply during a portion of its operating cycle. An

external source cannot be allowed to pump current

into the supply without loss of regulation and possible damage to the output capacitor.

To avoid

these effects, it is necessary to preload the supply with a dummy load resistor so that the power

supply delivers current through the entire operating cycle of the load device.

3-6

Page 19

SECTION IV

PRINCIPLES OF OPERATION

REFERENCE

REGULATOR

CIRCUIT

TM 1 I-6625-2965-14&P

t

AC

INPuT TRANSFORMER

POWER

NOTE

— DENOTES VOLTAGE

— DENOTES CURRENT

FEEOBACK PATH VOLTAGE

LIMIT PATH

I

~o

Pm

RANGE

SWITCH

(s2)

BIAS

SUPPLY

RECTIFIER

AND

FILTER

Figure 4-1.

IAS

B

v

VOLTAGES

SERIES

REGULATOR

A

DRIVER

AMPL

Overall Block Diagram

CURRENT

LIMITING

CIRCUIT

+

4

*

CURRENT

sAMPLING

RESISTORS

CONSTANT

INPUT

CIRCUIT

CIRCUIT

P/o

2

4

4

4

4

4

1,

Q

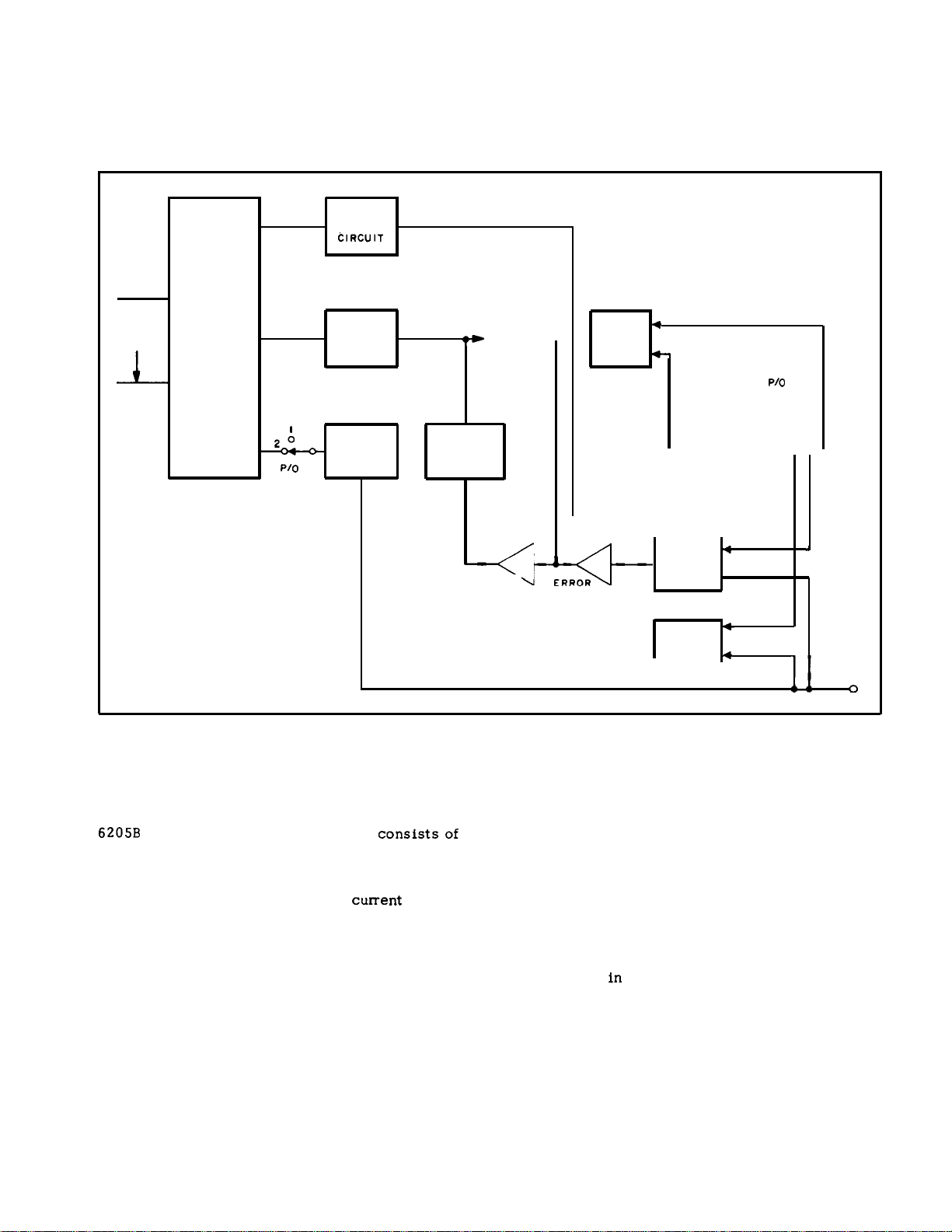

4-1 OVERALL DESCRIPTION

4-2

Figure 4-1 shows one section of the Model

6205B

dual power supply. The supply

consistsof

two dual range sections; each identical to the

other. Each section consists ofa rectifier and fil-

ter, a series regulator, an error amplifier and driver,

a constant voltage input circuit, a

cument limiting

circuit, a reference regulator circuit, a bias supply,

and a metering circuit.

Since both sections of the

supply are identical, only one section is described

below.

4-3 The ac line voltage is first applied to the

power transformer, The tap for the appropriate

voltage range is selected by S2. The input is then

rectified and filtered. This raw dc is then fed to

the series regulator which alters its conduction to

obtain the proper regulated dc output voltage.

4-4 Any changes in output voltage are felt by

constant voltage comparator which compares a

portion of the output with a fixed reference volts ge.

If a difference exists, the comparator circuit sends

a n error signal to the series regulator via the error

amplifier and driver stages. This error signal

changes the conduction of the series regulator so

that a constant output voltage is maintained.

4-5 Changes

in output current are reflected in the

voltage drop across the current sampling resistor

network. If this voltage drop exceeds a preset

limit, the current limit transistor conducts, sending

a turn-down signal to the series regulator via the

driver. This signal changes the conduction of the

4-1

the

Page 20

TM 11-6625-2965-14&P

series regulator so that the output current is limited

to the proper value.

4-6 The reference circuit provides stable reference voltages used in the constant voltage comparator and current limit circuits. The bias circuit

provides the less critical bias voltages used in the

supply.

4-7 The meter circuit provides a continuous indi-

cation of output voltage or current in both ranges.

4-8 DETAILED CIRCUIT ANALYSIS

4-9 FEEDBACK LOOP

4-10 The feedback loop functions continuously to

keep the output voltage constant during normal op-

eration of the supply. For purposes of this discussion, assume that the output voltage instantane-

ously rises (goes positive) due to a variation in the

external load circuit. Note that the change may be

in the form of a slow rise in the output voltage or a

positive going ac signal. An ac signal is coupled

to summing point A6 through capacitor Cl and a dc

voltage is coupled to A6 through R 10.

4-11 The rise in output voltage causes the voltage

at A6 and thus the base of Q1A to decrease (go negative). Q1A now decreases its conduction and its

collector voltage rises. The positive going error

voltage is amplified and inverted by Q3 and fed to

the base of the series transistor(s) via emitter fol-

lower Q4. The negative going input causes the

series transistor(s) to decrease its conduction so

that it drops more of the line voltage, reducing the

output voltage to its original level.

4-12 If the external load resistance decreases to

a certain crossover point, the supply will operate

in the current limiting mode. In the current limit

mode, Q1O conducts sending a negative going,

turn-down signal to the series regulator via driver

Q4 .

4-13 SERIES REGULATOR

4-14 The series regulator consists of transistor

stage Q7 (and Q6 on Model 6206 B). The regulator

serves as a series control element by altering its

conduction so that the output voltage is kept constant and the current limit is never exceeded, The

conduction of the transistor(s) is controlled by the

feedback voltage obtained from driver Q4. Diode

CR11, connected across the regulator circuit, protects the series transistor(s) against reverse voltages that could develop across it during parallel or

auto-parallel operation if one supply is turned on

before the other.

4-15 CONSTANT VOLTAGE COMPARATOR

4-16 The circuit consists of the coarse and fine

programming resistors (Rl0A and R 10 B), and a differential amplifier stage (Ql and associated com-

ponents). Transistor Q1 consists of two transistors

housed in a single package. The transistors have

matched characteristics minimizing differential

voltages due to mismatched stages. Moreover,

drift due to thermal differentials is minimized,

since both transistors operate at essentially the

same temperature.

4-17 The constant voltage comparator continuously compares a fixed reference voltage with a portion of the output voltage and, if a difference ex-

ists, produces an error voltage whose amplitude

and phase is proportional to the difference.

error output is fed back to the series regulator,

through the (mixer) error and driver amplifiers. The

error voltage changes the conduction of the series

regulator which, in turn, alters the output voltage

so that the difference between the two input voltages applied to the differential amplifier is reduced

to zero.

voltage constant.

4-18 Stage Q1B of the differential amplifier is

connected to a common (+S) potential through impedance equalizing resistor R5. Resistors R6 and

R8 are used to zero bias the input stage, offsetting minor base-to-emitter voltage differences in

Q1. The base of Q1A is connected to a summing

point at the junction of the programming resistors

and the current pullout resistors, R12 and R13.

Instantaneous changes in output voltage result in

an increase or decrease in the summing point potential. Q1A is made to conduct more or less, in

accordance with summing point voltage change.

The resultant output error voltage is fed back to

the series regulator via the remaining components

of the feedback loop.

the base Q1A, limits the current through the pro-

gramming resistors during rapid voltage turn-down.

Diodes CR1 and CR2 form a limiting network which

prevent excessive voltage excursions from over

driving stage Q1A.

programming resistors, increases the high frequency gain of the input amplifier. Resistor R1 3, shunt-

ing pullout resistor R12, is factory selected so

that all of the + 6.2 Volt reference is dropped across

R12 and R13. Linear constant voltage programming

is assured with a constant current flowing through

R1O.

removed to avoid current surges and increase the

programming speed.

4-19 ERROR AMPLIFIER AND DRIVER

4-20 The error and driver amplifiers amplify the

error signal from the constant voltage comparator

circuit to a leve1 sufficient to drive the series

regulator transistor(s).

current limiting input if Q10, the current limiting

transistor, conducts.

The above action maintains the output

Resistor Rl, in series with

Capacitor Cl, shunting the

C20 stabilizes the feedback loop and may be

Driver Q4 also receives a

The

4-2

Page 21

4-21 Stage Q3 contains a feedback equalizer network, C5 and R30, which provides for high frequency roll off in the loop gain in order to stabilize

the feedback loop. Q17 establishes a stable emitter bias potential for error amplifier Q3. Emitter

follower transistor(s) Q4 (and Q5) serves as the

driver (and predriver) element for the series regula-

tor.

4-22 CURRENT LIMIT CIRCUIT

4-23 The current limit circuit limits the output

current to a preset value determined by the setting

of R81. Switch S2B selects the proper sampling

resistance to maintain an equal voltage drop acress

the current sampling network in both ranges.

TM 11-6625-2965-14&P

4-28 The reference circuit consists of series regulating transistor Q9 and error amplifier Q8. Output voltage changes are detected by Q8 whose base

is connected to the junction of a voltage divider

(R41, R42) connected directly across the supply.

Any error signals are amplified and inverted by Q8

and applied to the base of series transistor Q9.

The series element then alters its conduction in the

direction, and by the amount, necessary to maintain the voltage across VR1 and VR2 constant. Resistor R46, the emitter resistor for Q8, is connected

in a manner which minimizes changes in the refer-

ence voltage caused by variations in the input line.

Output capacitor C9 stabilizes the regulator loop.

4-29 METER CIRCUIT (Figure 4-2)

4-24 When S2 is set to the 20 Volt position, R54

and R55 are connected in parallel. When S2 is set

to the 40 Volt position, the current sampling network consists solely of R54. Note that in the

twenty Volt range, twice as much current can be

delivered as in the forty Volt range. Since the

twenty Volt range has a sampling resistance equal

to half the value of that for the forty Volt range, an

equal sampling resistor voltage drop is obtained in

both ranges. This also applies to S2 in the 6206B.

4-25 R81 sets the bias of Q10, and thus, the

threshold point at which Q10 conducts and current

limiting begins. If this threshold is exceeded, Q10

begins to conduct, forward biasing CR16 and send-

ing a turn-down signal to the series regulater via

the driver. If the current through the current sampling network decreases below the threshold point,

Q10 turns off and no longer affects the operation of

the supply.

4-26 REFERENCE CIRCUIT

4-27 The reference circuit (see schematic) is a

feedback power supply similar to the main supply.

It provides stable reference voltages which are

used throughout the unit. The reference voltages

are a 11 derived from smoothed dc obtained from the

full wave rectifier (CR22 and CR23) and filter capacitor C10. The +6.2 and -6.2 voltages, which are

used in the constant voltage input circuit for comparison purposes, are developed across temperature

compensated Zener diodes VR1 and VR2. Resistor

R43 limits the current through the Zener diodes to

establish an optimum bias level.

4-30 The meter circuit provides continuous indications of output voltage or current on a single

multiple range meter.

The meter can be used either

as a voltmeter or an ammeter depending upon the

position of the METER section of switch S2 on the

front panel of the supply. This switch also selects

one of two meter ranges on each scale. The meter

circuit consists

of METER-RANGE switch S2, vari-

ous multiplying resistors and the meter movement.

4-31 When measuring voltage, the meter is placed

directly across the output of the supply between

the +S and -S terminals. With the METER section

of S2A in the higher voltage position (terminals A2

and A10) multiplying resistors R60, R61, R72, and

the parallel combination of R73 and R87, are in

series with the meter. For low output voltages, the

METER switch S2A can be set to the first position

(terminals 1 and 9) which removes R61 from its

series position allowing a larger percentage of the

output voltage to be felt acress the meter.

4-32 When measuring current; the meter circuit is

connected across the current sampling resistor

network as shown on Figure 4-2 and indicates the

output current that flows through the network. The

RANGE section S2B connects the appropriate re-

sistance in series with the meter so that its maxi-

mum deflection range is full-scale in the high current (low voltage) operating mode and half-scale in

the low current (high voltage) operating mode. This

circuit obviates the need for a dual current scale

which would be necessary since the voltages drop-

ped across the current sampling network in both

operating modes are equal for proportional currents.

4-3

Page 22

TM 11-6625-2965-14&P

Figure 4-2.

Multiple Range Meter Circuit, Simplified Schematic

4-4

Page 23

SECTION V

MAINTENANCE

5-1 INTRODUCTION

5-2 Upon receipt of the power supply, the per-

formance check (Paragraph 5-10) should be made.

This check is suitable for incoming inspection. If

a fault is detected in the power supply while making the performance check or during normal operation, proceed to the troubleshooting procedures

(Paragraph 5-48). After troubleshooting and repair

(Paragraph 5-58), perform any necessary adjustments and calibrations (Paragraph 5-60). Before

returning the power supply to normal operation,

repeat the performance check to ensure that the

fault has been properly corrected and that no other

faults exist. Before doing any maintenance checks,

turn-on power supply, allow a ha if-hour warm-up,

and read the general information regarding meas-

urement techniques (Paragraph 5-3).

5-3

GENERAL MEASUREMENT TECHNIQUES

Figure 5-1.

TM 11-6625-2965-14&P

Front Pane1 Terminal Connections

5-4

The measuring device must be connected

across the sensing leads of the supply or as close

to the output terminals as possible when measur-

ing the output impedance, transient response, regulation, or ripple of the power supply in order to

achieve valid measurements. A measurement made

acress the load includes the impedance of the

leads to the load and such lead lengths can easily

have an impedance several orders of magnitude

greater than the supply impedance, thus invalidating the measurement.

5-5 The monitoring device should be connected

to the +S and -S terminals (see Figure 3-2) or as

shown in Figure 5-1. The performance characteristics should never be measured on the front termi-

nals if the load is connected across the rear termi-

nals. Note that when measurements are made at

the front terminals, the monitoring leads are con-

nected at A, not B, as shown in Figure 5-1. Fail-

ure to connect the measuring device at A will re-

sult in a measurement that includes the resistance

of the leads between the output terminals and the

point of connection.

Figure 5-2. Output Current Measurement Technique

5-6 For output current measurements, the current

sampling resistor should be a four-terminal resis-

tor. The four terminals are connected as shown in

Figure 5-2. In addition, the resistor should be of

the low noise, low temperature coefficient (less

than 30ppm/°C) type and should be used at no

more than 5% of its rated power so that its temperature rise will be minimized.

When using an oscilloscope, ground one ter-

5-7

minal of the power supply and then ground the case

of the oscilloscope to this same point. Make cer-

tain that the case is not also grounded by some

other means (power line). Connect both oscillo-

scope input leads to the power supply ground terminal and check that the oscilloscope is not exhibiting a ripple or transient due to ground loops,

pick-up, or other means.

5-1

Page 24

TM 11-6625-2965-14&P

5-8 TEST EQUIPMENT REQUIRED

5-9 Table 5-1 lists the test equipment required

to perform the various procedures described in this

Section.

NOTE

A satisfactory substitute for a differential voltmeter is to arrange a reference voltage source and null detector

as shown in Figure 5-3. The reference voltage source is adjusted so

that the voltage difference between

the supply being measured and the

reference voltage will have the re-

quired resolution for the measurement

being made. The voltage difference

will be a function of the null detector

that is used. Examples of satisfactory null detectors are: 419A null

detector, a dc coupled oscilloscope

utilizing differential input, or a 50mV

meter movement with a 100 division

scale. For the latter, a 2mV change in

voltage will result in a meter deflection of four divisions.

Figure 5-3. Differential Voltmeter Substitute,

Test Setup

CAUTION

Care must be exercised when using an

electronic null detector in which one

input terminal is grounded to avoid

ground loops and circulating currents.

TYPE

Differential

Voltmeter

Variable

Voltage

AC Voltmeter

Oscilloscope

Oscillator

DC Voltmeter

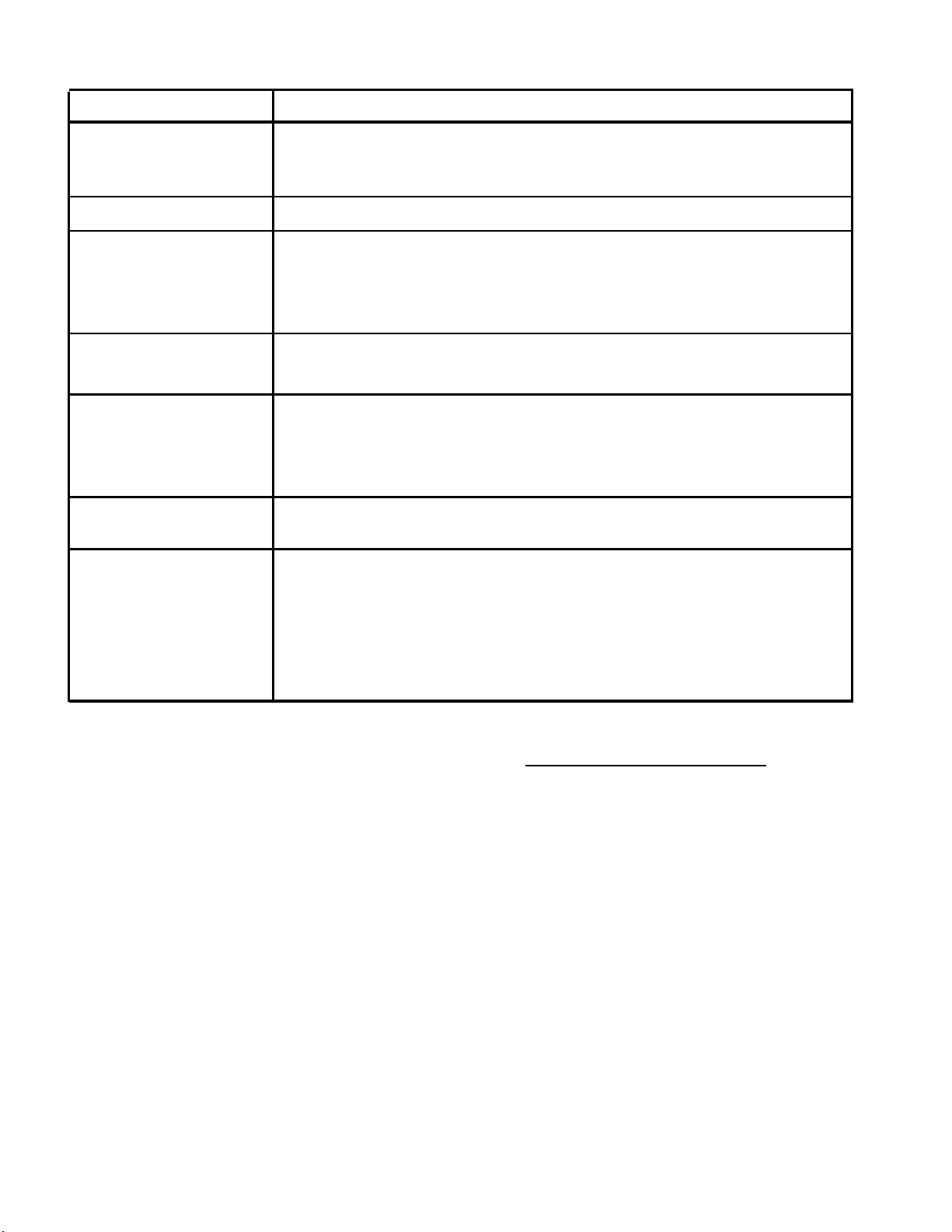

Table 5-1.

REQUIRED

CHARACTERISTICS

Sensitivity: lmV full scale

(min.). Input impedance:

10 megohms (min.).

Range: 90-130 Volts

Equipped with voltmeter accurate within 1 Volt.

Accuracy: 2%. Sensitivity:

lmV full scale deflection

(min.).

Sensitivity: 10µV/cm. Differential input.

Range: 5Hz to 600kHz

Accuracy: 2%

Accuracy: 1%. Input resistance: 20,000 ohms/Volt (min.).

Test Equipment Required

USE

Measure dc voltages;

calibration procedures

Vary ac input

Measure ac voltage and

ripple

Display transient response

waveforms

Impedance Checks

Measure dc voltages

RECOMMENDED

MODEL

3420 (See Note)

403 B

140 A plus

1402A plug in.

200 CD

412A

Repetitive

Load Switch

Rate: 60-400 Hz, 2µsec rise

and fall time.

Measure transient response

5-2

See Figure 5-6

Page 25

Table 5-1.

TM 11-6625-2965-14&P

Test Equipment Required (Continued)

TYPE

Resistor

Resistor Value: 5 , 0.5%, 4.5 Watts,

Resistor Value: 6204B and 6205B, 28 ,

Resister

Resistor

Resistor Value: See Paragraph 5-67.

Capacitor

Decade

Resistance

Box

6204B, 6205B; 133 , ± 10% 15W

6206B; 120 , ±1O% 15W

20ppm, 4-Terminal.

2W (min.).

6206B, 27 , 10W (min.).

1Κ ± 1%, 2 Watt non-induc- Measure impedance

tive

100 ohms, ±5%, 10 Watt Measure impedance

± 0.1%, 5 Watt

500µf, 50WVdc

Range: 0-150K (min.). Measure programming

Accuracy: 0.1% plus 1 ohm

Make-before-break contacts.

REQUIRED

CHARACTERISTICS

USE

Load Resistor, HIGH range

Current sampling

Load resistor, low range

Calibrate programming current

Measure impedance

coefficients

RECOMMENDED

MODEL

----

R54 or R55,

Section VI

----

----

----

----

----

----

5-10 PERFORMANCE TEST

5-11 The following test can be used as an incoming inspection check and appropriate portions of

the test can be repeated either to check the oper-

ation of the instrument after repairs or for periodic

maintenance tests. The tests are performed using

a 115Vac 60 Hz, single phase input power source.

If the correct result is not obtained for a particular check, do not adjust any controls; proceed to

troubleshooting (Paragraph 5-48).

NOTE

For Model 6205B supplies, the following performance checks should be

performed twice in order to check both

independent sections of the supply.

5-12 CONSTANT VOLTAGE TESTS

5-13 For Constant Voltage measurements, the

measuring device must be connected acress the

rear sensing terminals of the supply in order to

achieve valid indications. A measurement made

acress the load includes the impedance of the

leads to the load and such lead lengths can easily

have an impedance several orders of magnitude

greater than the supply impedance (1 milliohm at

dc), thus invalidating the measurement.

5-14 To avoid mutual coupling effects, each

monitoring device must be-connected directly to

the sensing terminals by separate pairs of leads.

The load resistor is connected acress the output

terminals and must be selected according to the

output voltage and current of the supply. When

measuring the constant voltage performance spec-

ifications, the CURRENT controls should be set

well above the maximum output current which the

supply will draw, since the onset of constant cur-

rent action will cause a drop in output voltage,

increased ripple, and other performance changes

not properly ascribed to the constant voltage operation of the supply.

5-15 Voltage Output and Voltmeter Accuracy. To

check the output voltage, proceed as follows:

a. Connect 133 ohm load resistor (120 ohms

for Model 6206B) across rear output terminals of

supply.

b. Connect differential voltmeter acress +S

and -S terminals of supply observing correct polarity.

5-3

Page 26

TM 11-6625-2965-14&P

Set METER switch to highest voltage

c.

range and RANGE switch to highest voltage mode

and turn on supply.

d. Adjust VOLTAGE controls until front panel

meter indicates exactly the maximum rated output

voltage.

e. Differential voltmeter should indicate

maximum rated output voltage within 3%.

5-16 Output Current and Ammeter Accuracy. To

check the output current, proceed as follows:

a.

Connect test setup shown in Figure 5-4.

b.

Set METER switch to lowest current

range and RANGE switch to high voltage mode.

c.

Turn on supply and adjust VOLTAGE controls until front panel meter indicates exactly 300

mA (0.5 Ampere for Model 6206B supplies).

d. Differential voltmeter should read 1.5 ±

0.045Vdc.

ferential voltmeter.

e. Disconnect load resistors.

f.

Reading on differential voltmeter should

not vary from reading recorded in Step d by more

than 8mVdc for Models 6204B and 6205B or 10mVdc

for Model 6206B supply.

Figure 5-4.

Load Regulation.

5-17

Definition: The change

static value of dc output voltage resulting from a change in load resistance from open circuit to a value

which yields maximum rated output

current (or vice versa).

To check the constant voltage load regula-

5-18

proceed as follows:

tion,

a.

Connect test setup as shown in Figure

5-5.

b. Turn CURRENT controls fully clockwise.

c. Turn-on supply and adjust VOLTAGE con-

trols until front panel voltmeter indicates exactly

the maximum rated output voltage.

d. Read and record voltage indicated on dif-

Output Current, Test Setup

∆Ε in the

OUT

Figure 5-5.

5-19 Line Regulation.

Definition: The change,

static value of dc output voltage resulting from a change in ac input voltage over the specified range from low

line 10% less than nominal to high

line 10% more than nominal or from

high line to low line.

5-20 To test the constant voltage line regulation,

proceed as follows:

a. Connect variable auto transformer between input power source and power supply power

input.

b. Turn CURRENT controls fuIly clockwise.

c. Connect test setup shown in Figure 5-5.

d. Adjust variable auto transformer for low

line (104Vac).

e. Set METER switch to highest current

range and turn on supply.

f. Adjust VOLTAGE controls until front

panel voltmeter indicates exactly the maximum

rated output voltage.

Read and record voltage indicated on

9.

differential voltmeter.

h. Adjust variable auto transformer for high

line (126Vac).

Load Regulation, Test Setup

∆Ε in the

OUT

I

5-4

Page 27

Reading on differential voltmeter should

i.

not vary from reading recorded in Step g by more

than 8mVdc for Models 6204B and 6205B or 10mVdc

for Model 6206B.

Ripple and Noise.

5-21

Definition: The residual ac voltage

which is superimposed on the dc

output of a regulated power supply.

Ripple and noise may be specified

and measured in terms of its RMS

or (preferably) peak-to-peak value.

Ripple and noise measurement can be made at any

input ac line voltage combined with any dc output

voltage and load current within rating.

5-22 The amount of ripple and noise that is pres-

ent on the power supply output is measured either

in terms of the RMS or (preferably) peak-to-peak

value. The peak-to-peak measurement is particu-

larly important for applications where noise spikes

could be detrimental to a sensitive load, such as

logic circuitry.

The RMS measurement is not an

ideal representation of the noise, since fairly

high output noise spikes of short duration could

be present in the ripple and not appreciably increase the RMS value.

TM 11-6625-2965-14&P

5-23 The technique used to measure high frequency noise or “ spikes”

on the output of a power supply is more critical than the low frequency ripple

and noise measurement technique; therefore the

former is discussed separately in Paragraph 5-31,

5-24 Ripple and Noise Measurements. Figure

5-6A shows an incorrect method of measuring p-p

ripple. Note that a continuous ground loop exists

from the third wire of the input power cord of the

supply to the third wire of the input power cord of

the oscilloscope via the grounded power supply

case, the wire between the negative output terminal of the power supply and the vertical input of

the scope, and the grounded scope case. Any

ground current circulating in this loop as a result

of the difference in potential E

between the two

G

ground points causes an IR drop which is in series

with the scope input. This IR drop, normally hav-

ing a 60

HZ line frequency fundamental, plus any

pickup on the unshielded leads interconnecting

the power supply and scope, appears on the face

of the CRT. The magnitude of this resulting noise

signal can easily be much greater than the true

ripple developed between the plus and minus out-

put terminals of the power supply, and can com-

pletely invalidate the measurement.

5-25 The same ground current and pickup problems

Figure 5-6. CV Ripple and Noise, Test Setup

can exist if an RMS voltmeter is substituted in

place of the oscilloscope in Figure 5-6. However,

the oscilloscope display, unlike the true RMS

meter reading, tells the observer immediately

whether the fundamental period of the signal displayed is 8.3 milliseconds (1/120 Hz) or 16.7 milliseconds (1/60Hz). Since the fundamental ripple

frequency present on the output of an supply is

120Hz (due to full-wave rectification), an oscillo-

scope display showing a 120Hz fundamental component is indicative of a “clean” measurement setup, while the presence of a 60

HZ fundamental usu-

ally means that an improved setup will result in a

more accurate (and lower) value of measured ripple.

5-26 Although the method shown in Figure 5-6A is

not recommended for ripple measurements, it may

prove satisfactory in some instances provided certain precautionary measures are taken. One meth-

od of minimizing the effects of ground current flow

(IG) is to ensure that both the supply and the test

instrument are plugged into the same ac power

buss.

5-5

Page 28

TM 11-6625-2965-14&P

5-27 To minimize pick up, a twisted pair or (preferably) a shielded two-wire cable should be used

to connect the output terminals of the power supply

to the vertical input terminals of the scope. When

using a twisted pair, care must be taken that one

of the two wires is connected both to the grounded

terminal of the power supply and the grounded input terminal of the oscilloscope. When using

shielded two-wire cable, it is essential for the

shield to be connected to ground at one end only to

prevent any ground current flowing through this

shield from inducing a signal in the shielded leads.

5-28 To verify that the oscilloscope is not displaying ripple that is induced in the leads or pick-

ed up from the grounds, the (+) scope lead should

be shorted to the (-) scope lead at the power sup-

ply terminals. The ripple value obtained when the

leads are shorted should be subtracted from the

actual ripple measurement.

5-29 If the foregoing measures are used, the

single-ended scope of Figure 5-6A may be adequate

to eliminate non-real components of ripple so that

a satisfactory measurement can be obtained.

ever, in stubborn cases or in measurement situations where it is essential that both the power supply case and the oscilloscope case be connected

to ground (e. g. if both are rack-mounted), it may

be necessary to use a differential scope with floating input as shown in Figure 5-6B. If desired, two

single-conductor shielded cables may be substituted in place of the shielded two-wire cable with

equal success.

jection, a differential oscilloscope displays only

the difference in signal between its two vertical

input terminals, thus ignoring the effects of any

common mode signal introduced because of the difference in the ac potential between the power supply case and scope case. Before using a differential input scope in this manner, however, it is imperative that the common mode rejection capability

of the scope be verified by shorting together its

two input leads at the power supply and observing

the trace on the CRT.

line, the scope is properly ignoring any common

mode signal present.

line, then the scope is not rejecting the ground

signal and must be realigned in accordance with the

manufacturer’s instructions until proper common

mode rejection is attained.

Because of its common mode re-

If this trace is a straight

If this trace is not a straight

How-

5-31 Noise Spike Measurement. When a high frequency spike measurement is being made, an in-

strument of sufficient bandwidth must be used; an

oscilloscope with a bandwidth of 20 MHz or more

is adequate. Measuring noise with an instrument

that has insufficient bandwidth may conceal high

frequency spikes detrimental to the load.

5-32 The test setup illustrated in Figure 5-6A is

generally not acceptable for measuring spikes; a

differential oscilloscope is necessary. Furthermore, the measurement concept of Figure 5-6B

must be modified if accurate spike measurement

to be achieved:

1. As shown in Figure 5-7, two coax cables, must be substituted for the shielded twowire cable.

2. Impedance matching resistors must be

included to eliminate standing waves and cable

ringing, and the capacitors must be connected to

block the dc current path.

3. The length of the test leads outside the