Page 1

Product End-of-Life Disassembly Instructions

Product Category: Notebooks and Tablet PCs

Marketing Name / Model

[List multiple models if applicable.]

Name / Model #1 Compaq 510 Notebook

Name / Model #2 Compaq 511 Notebook

Name / Model #3 Compaq 610 Notebook

Name / Model #4

Name / Model #5

Purpose: The document is intended for use by end-of-life recyclers or treatment facilities. It provides the basic instructions

for the disassembly of HP products to remove components and materials requiring selective treatment, as defined by EU

directive 2002/96/EC, Waste Electrical and Electronic Equipment (WEEE).

1.0 Items Requiring Selective Treatment

1.1 Items listed below are classified as requiring selective treatment.

1.2 Enter the quantity of items contained within the product which require selective treatment in the right column, as

applicable.

Quantity

Item Description Notes

Printed Circuit Boards (PCB) or Printed Circuit

Assemblies (PCA)

Batteries All types including standard alkaline and lithium coin

Mercury-containing components For example, mercury in lamps, display backlights,

Liquid Crystal Displays (LCD) with a surface greater

than 100 sq cm

Cathode Ray Tubes (CRT) 0

Capacitors / condensers (Containing PCB/PCT) 0

Electrolytic Capacitors / Condensers measuring

greater than 2.5 cm in diameter or height

External electrical cables and cords 0

Gas Discharge Lamps 0

Plastics containing Brominated Flame Retardants 0

Components and parts containing toner and ink,

including liquids, semi-liquids (gel/paste) and toner

Components and waste containing asbestos 0

Components, parts and materials containing

refractory ceramic fibers

Components, parts and materials containing

radioactive substances

EL-MF877-00 Page 1

Template Revision A

With a surface greater than 10 sq cm 3

or button style batteries

scanner lamps, switches, batteries

Includes background illuminated displays with gas

discharge lamps

Include the cartridges, print heads, tubes, vent

chambers, and service stations.

of items

included

in product

2

0

0

0

0

0

0

Page 2

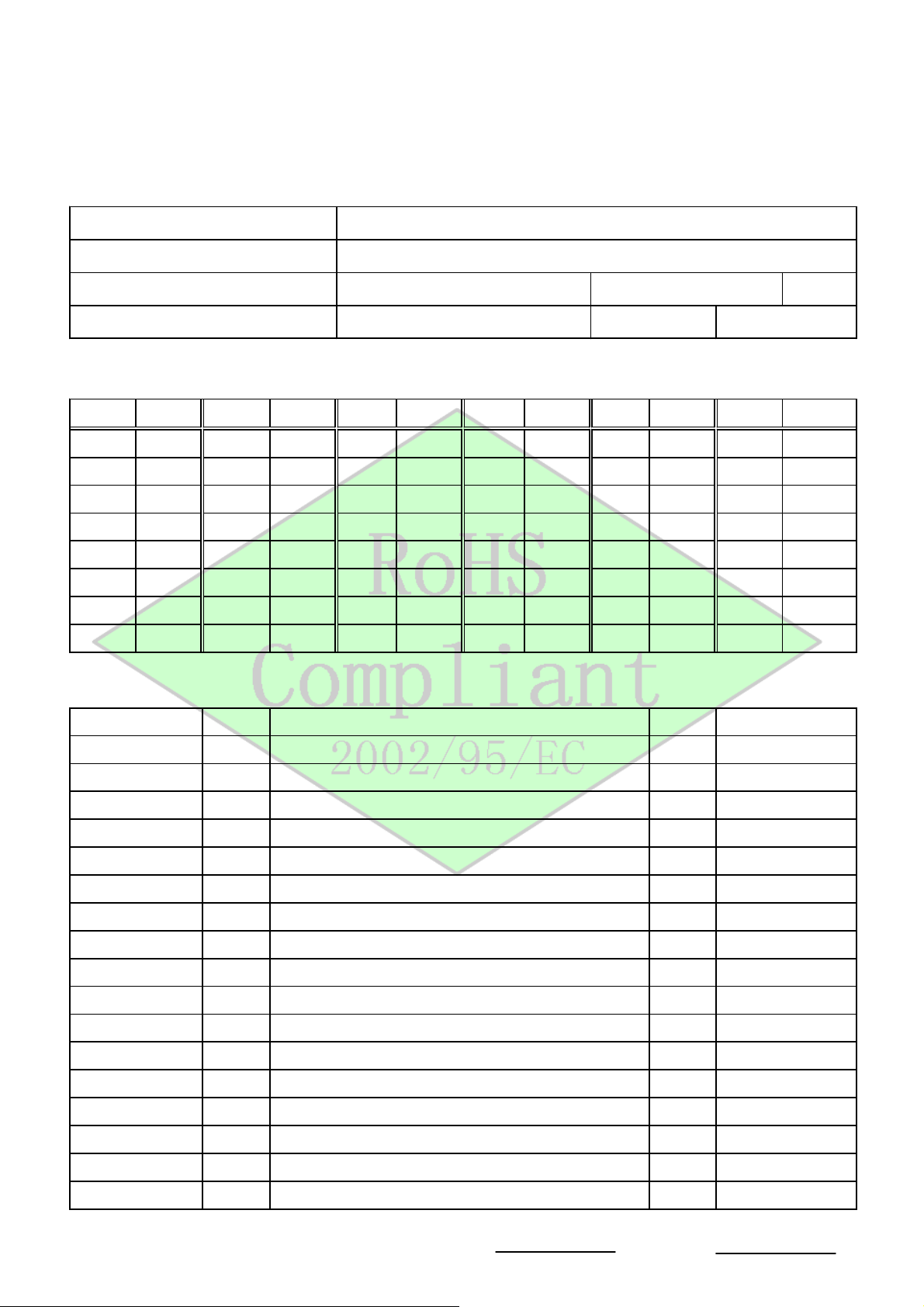

2.0 Tools Required

List the type and size of the tools that would typically be used to disassemble the product to a point where components

and materials requiring selective treatment can be removed.

Tool Description Tool Size (if

applicable)

Description #1 Motor-screw-driver “+”

Description #2 Motor-screw-driver “*”

Description #3 Motor-screw-driver “-”

3.0 Product Disassembly Process

3.1 List the basic steps that should typically be followed to remove components and materials requiring selective treatment:

1. Follow steps described in Disassembly instruction (file attached).

2. If parts can be removed without using a tool, remove it first.

3. Use correct screwdriver and torque value before unlock the screw.

4.

5. .

6.

7.

8.

Cross head

of screwdriver

TORX T8

(2.31mm)

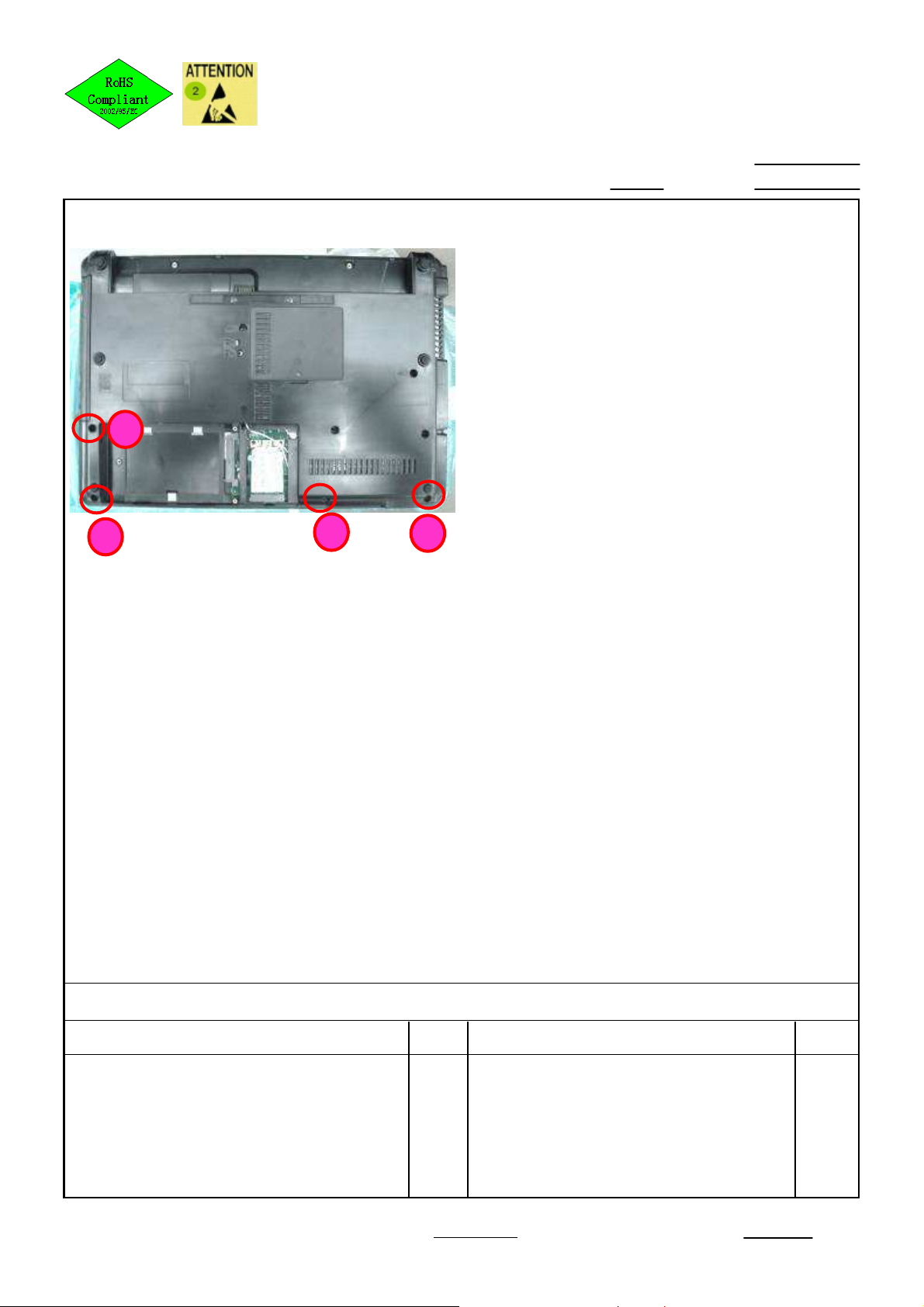

3.2 Optional Graphic. If the disassembly process is complex, insert a graphic illustration below to identify the items

contained in the product that require selective treatment (with descriptions and arrows identifying locations).

EL-MF877-00 Page 2

Template Revision A

Page 3

MANUFACTURING PROCESS INSTRUCTIONS

MECHANICAL ASSEMBLY

Sub-assembly name:

Sub-assembly name:

Sub-assembly name:Sub-assembly name:

Document No.:

Document No.:

Document No.:Document No.:

MODEL : VV09

VV0 9 FA DIS-ASS’Y

VV0 9 FA DIS-ASS’Y

VV0 9 FA DIS-ASS’YVV0 9 FA DIS-ASS’Y

SOP VV09 FA D IS-ASS’Y

SOP VV09 FA D IS-ASS’Y

SOP VV09 FA D IS-ASS’YSOP VV09 FA D IS-ASS’Y

Written by:

Written by:

Written by:Written by:

Date:

Date: 2009/5/18

Date:Date:

A.Cu rrent statio n v ers ion list:

A.Cu rrent statio n v ers ion list:

A.Cu rrent statio n v ers ion list:A.Cu rrent statio n v ers ion list:

Station Version Station Version Station Version Station Version Station Version Station Version

1

2 1.00 10 1.00 18 1.00

3 1.00 11 1.00 19 1.00

4 1.00 12 1.00 20 1.00

5 1.00 13 1.00 21 1.00

6 1.00 14 1.00 22 1.00

7 1.00 15 1.00 23 1.00

8 1.00 16 1.00 24 1.00

B.Ve rsio n Mo dify list:

B.Ve rsio n Mo dify list:

B.Ve rsio n Mo dify list:B.Ve rsio n Mo dify list:

2009/5/18 First SOP for mass production

1.00

Date

Date Con ten t

DateDate

9

Sta tion

Sta tion Ver.

Sta tionSta tion

ALL 1.**

1.00

Zhan g,Yin g

Zhan g,Yin g

Zhan g,Yin gZhan g,Yin g

2009/5/18 Page:

2009/5/182009/5/18

17

1.00

Con ten t Des ig n

Con ten tCon ten t

25 1.00

Revision:

Revision:

Revision:Revision:

Page: 1 of 29

Page:Page:

Ver.

Ver.Ver.

1 of 29

1 of 291 of 29

Sun,Amos

1.00

Des ig n

Des ig nDesig n

Auditor:

Tabulator:

Zhang, Ying

Page 4

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

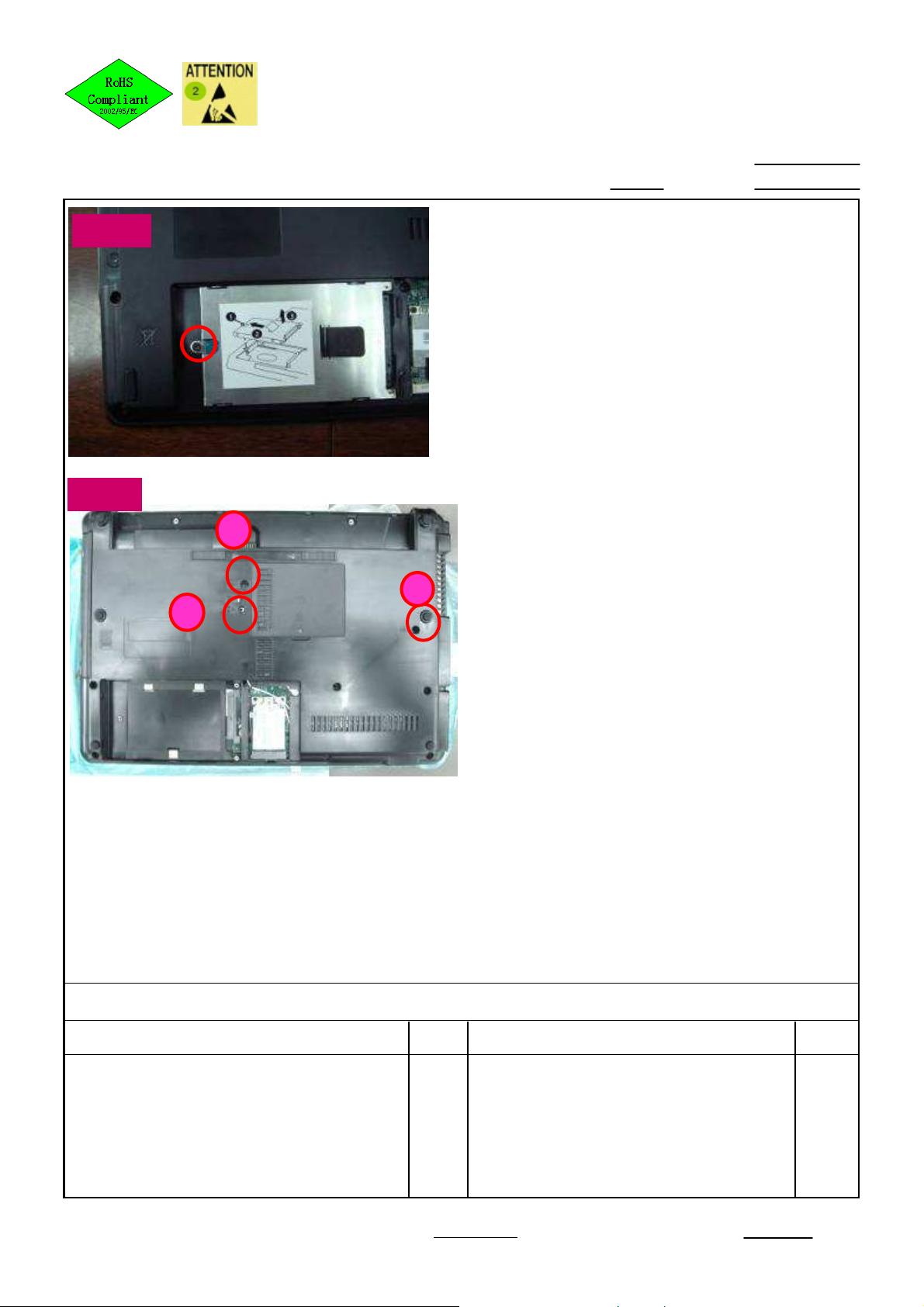

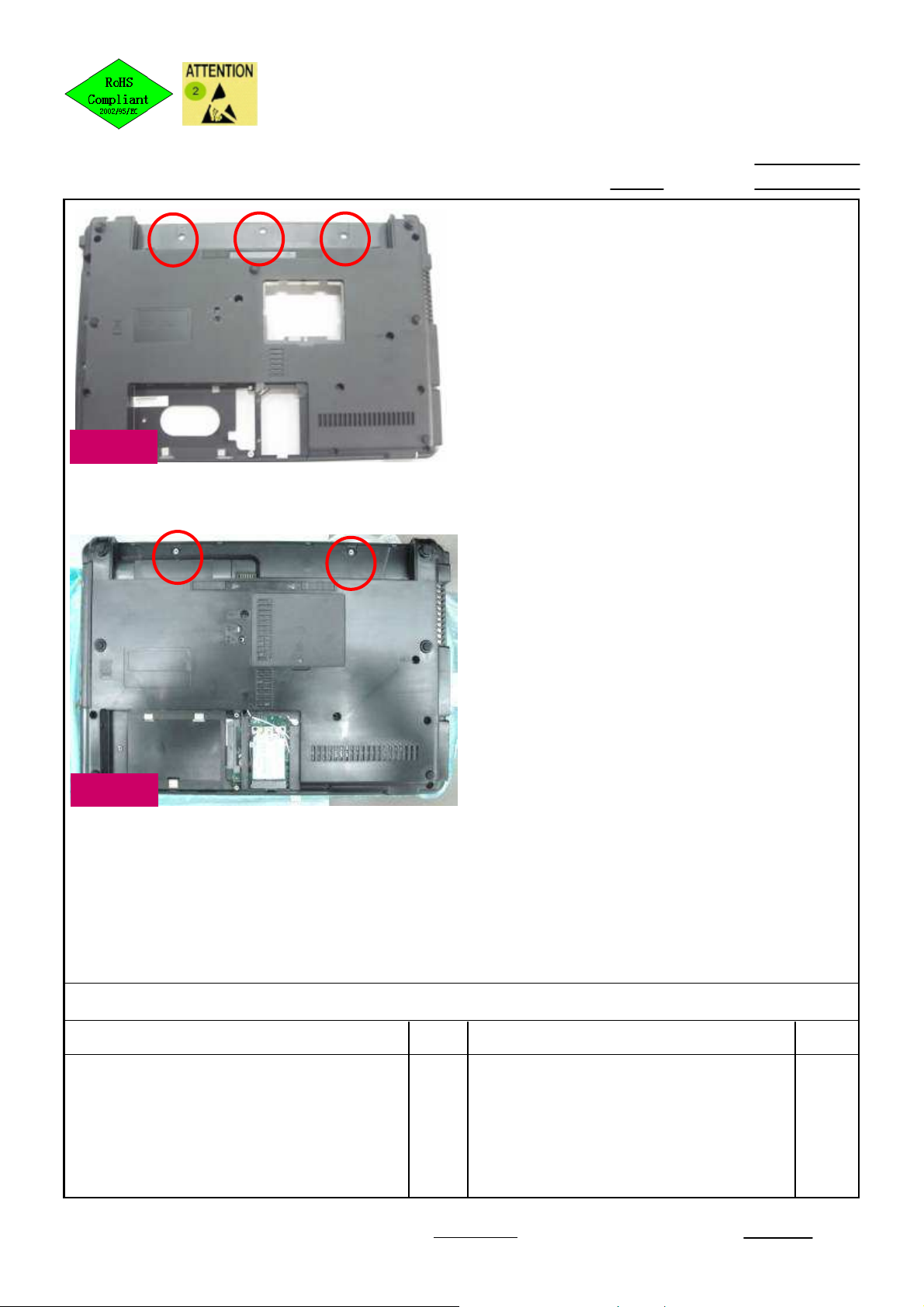

Fig.1

Fig.2

Disassemble Battery & COVER

1.Pull latch, slip battery, and take it out.

Battery must be paralleled with machine

when pushing out. (Fig.1)

2.Loosen screws of HDD Cover*2 and

DDR Cover*1.(Fig.2)

Torsion:2.0 ± 0.2 kgf.cm。

Screws can't be stripped.

3. Disassemble DDR Cover ,HDD Cover and

WLAN Cover.

1.00

1(1/1)

2009/05/18

WLAN

Cover

Point for attention:

Fixture list(Fixture standard)

Automatic crossing screw driver

If finding some defects, notice the gaffer and assistant

:

::

Qty

1

Tabulator:_________

Zhang Ying

Fixture list(Fixture standard)

Issuing department:

Qty

IE

Page 5

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

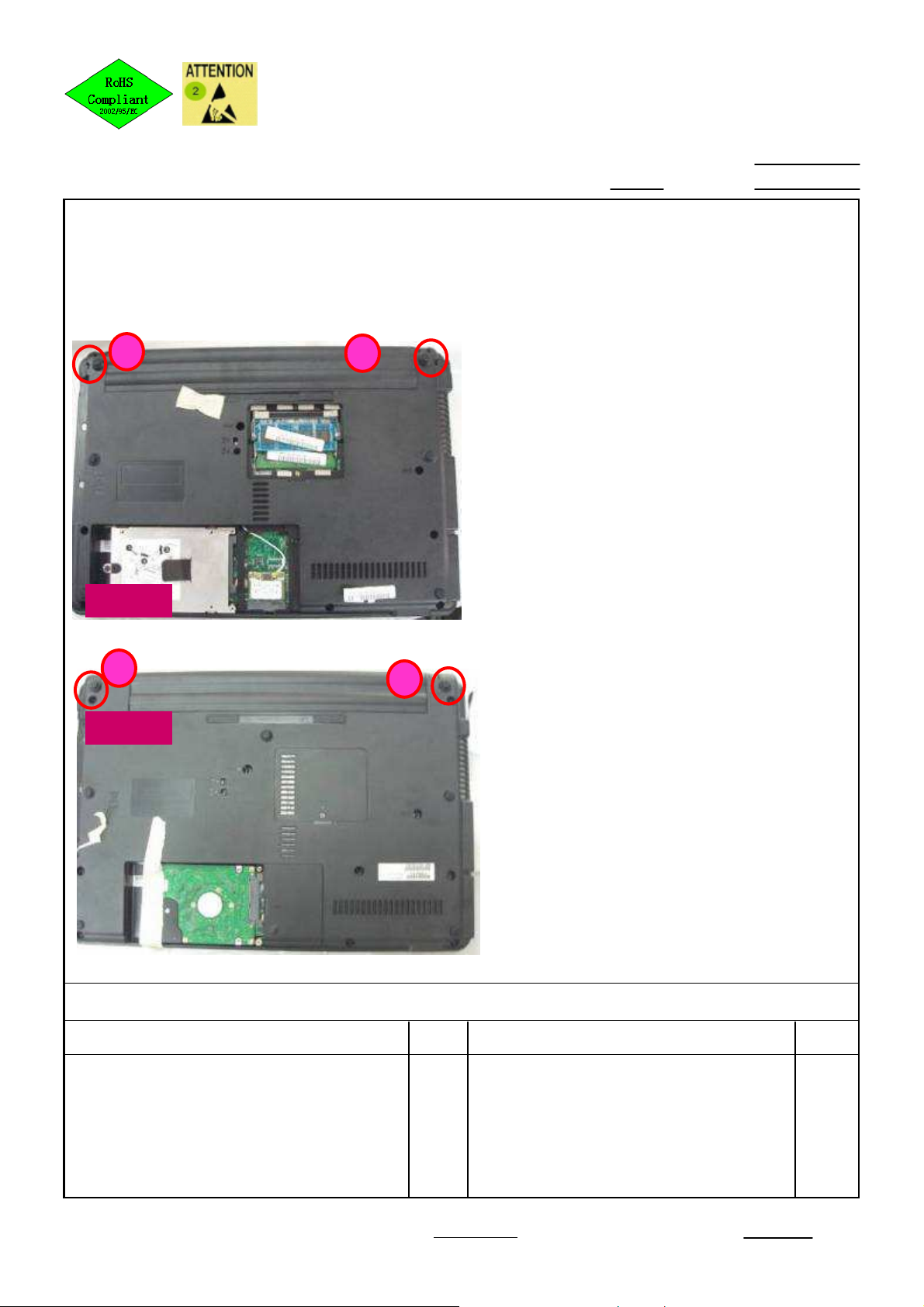

Fig.1

图图图图二二二二

Fig.2

Disassemble HDD& Loosen screws

1. Loosen screws of HDD*1.(Fig.1)

Torsion:2.0 ± 0.2 kgf.cm;

Screws can't be stripped.

2. Loosen screws of ODD & K/B * 3 (Fig.2)

Torsion:2.0 ± 0.2 kgf.cm;

Screws can't be stripped.

3. Pull the puller and to Disassemble HDD.

(Fig.1)

1

3

2

1.00

2(1/1)

2009/05/18

Point for attention:

Fixture list(Fixture standard)

Automatic crossing screw driver

If finding some defects, notice the gaffer and assistant

:

::

Qty

1

Tabulator:_________

Zhang Ying

Fixture list(Fixture standard)

Issuing department:

Qty

IE

Page 6

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

15”

Loosen screws

1. Loosen screws (6052B0096201) of SW

cover .

14” Loosen screws *2,

15” Loosen screws *3

Torsion:2.0 ± 0.2 kgf.cm;

Screws can't be stripped.

1.00

3(1/2)

2009/05/18

14”

Point for attention:

Fixture list(Fixture standard)

Automatic crossing screw driver 1

If finding some defects, notice the gaffer and assistant

:

::

Qty

Tabulator:_________

Fixture list(Fixture standard)

Zhang Ying

Issuing department:

Qty

IE

Page 7

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

1

14”

Loosen screws

1. Loosen screws (6052B0111701 ) *2

Torsion:2.0 ± 0.2 Kgf.cm

Screws can't be stripped or dropped

into machine.

2

1.00

3 (2/2)

2009/05/18

1

15”

Point for attention:

Fixture list(Fixture standard)

Automatic crossing screw driver 1

If finding some defects, notice the gaffer and assistant

:

::

2

Qty

Fixture list(Fixture standard)

Qty

Tabulator:_________

Zhang Ying

Issuing department:

IE

Page 8

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

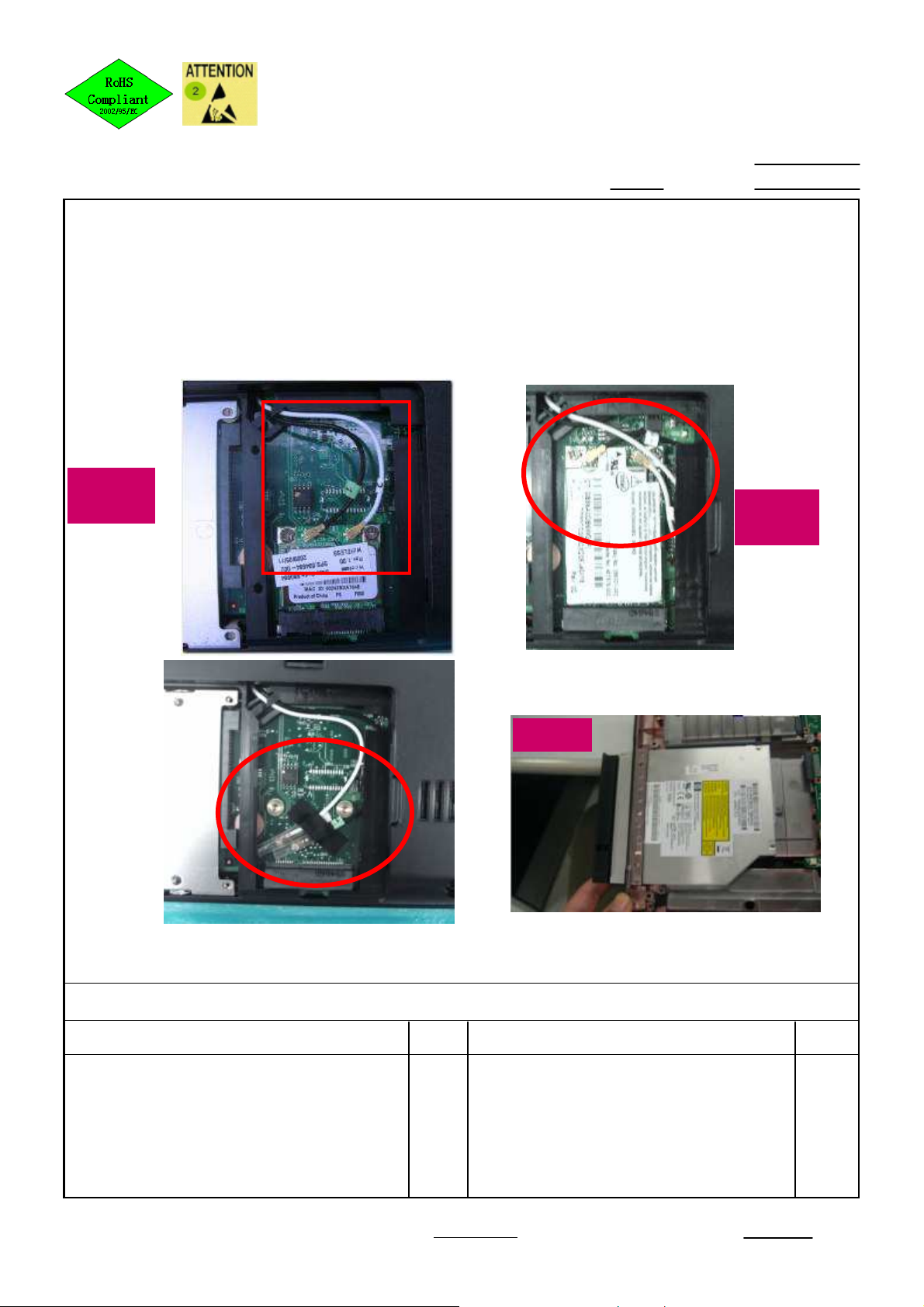

1. Disassemble Antenna cable from WLAN CARD。

2. Take out ODD.(Fig.1)

Half

Card

Disassemble Antenna cable & ODD

1.00

4(1/1)

2009/05/18

Long

card

Without

WLAN

CARD

Point for attention:

Fixture list(Fixture standard)

If finding some defects, notice the gaffer and assistant

:

::

Qty

Fig.1

Fixture list(Fixture standard)

Qty

Tabulator:_________

Zhang Ying

Issuing department:

IE

Page 9

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

14 “

1

2

15 “

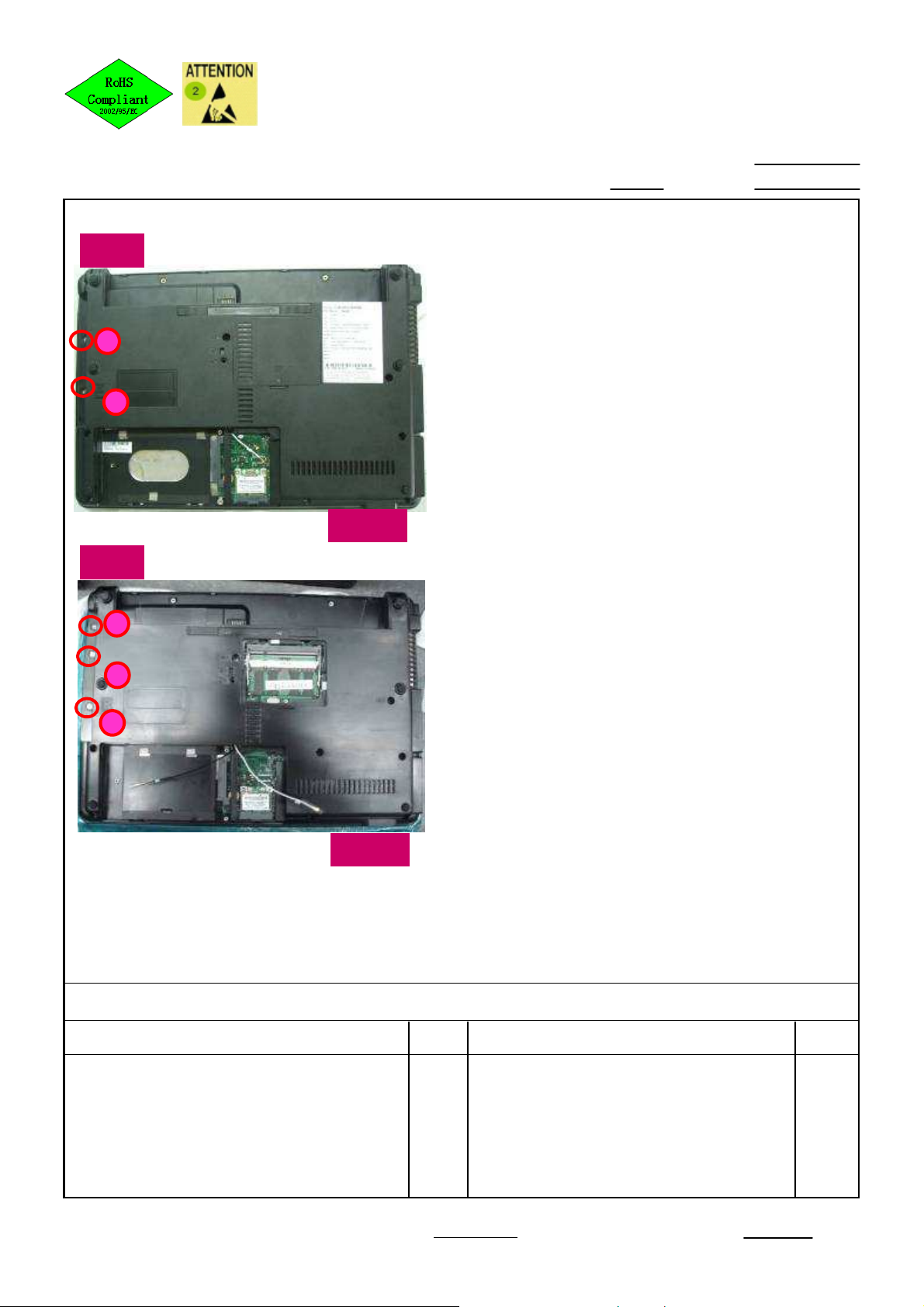

Loosen screws of ODD

2

1. Loosen screws (6052B0097001) of ODD。

14” Loosen screws *2,

15” Loosen screws *3,

Loosen screws with the sequence as figures

showing

Torsion:2.0 ± 0.2 Kgf.cm

Screws can't be stripped or dropped into

machine.

Fig.1

5(1/1)

2009/05/181.00

1

2

3

Fig.2

Point for attention:

Fixture list(Fixture standard)

Automatic crossing screw driver 1

If finding some defects, notice the gaffer and assistant

:

::

Qty

Fixture list(Fixture standard)

Qty

Tabulator:_________

Zhang Ying

Issuing department:

IE

Page 10

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

1

2

Loosen screws of BTCB

3

1. Loosen screws of BTCB

(6052A0021901 ) * 4

Torsion:2.0 ± 0.2 Kgf.cm

Screws can't be stripped or

dropped into machine.

2. Turn over the machine in the

surface .

4

6(1/1)

2009/05/181.00

Point for attention:

Fixture list(Fixture standard)

Automatic hexagonal screw driver 1

If finding some defects, notice the gaffer and assistant

:

::

Qty

Tabulator:_________

Fixture list(Fixture standard)

Zhang Ying

Issuing department:

Qty

IE

Page 11

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

Fig.1

②

②

②②

Disassemble SW/C

①

①

①①

②

②

②②

1. Disassemble SW/C , Fig.1 g.1

14” : 6070B0350501

15” : 6070B0351101

Sequence:123

2. Turn over the K/B , Fig.2

3

7(1/1)

2009/05/181.00

Fig.2

Point for attention:

Fixture list(Fixture standard)

If finding some defects, notice the gaffer and assistant

:

::

Qty

Fixture list(Fixture standard)

Qty

Tabulator:_________

Zhang Ying

Issuing department:

IE

Page 12

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

Fig.1

Disassemble SW/C&K/B FFC

1. Loosen Lock piece, take out K/B FFC from

MB CNTR. Fig.1

2. Disassemble SW/C&K/B .

1.00

8(1/1)

2009/05/18

Point for attention:

Fixture list(Fixture standard)

If finding some defects, notice the gaffer and assistant

:

::

Qty

Tabulator:_________

Zhang Ying

Fixture list(Fixture standard)

Issuing department:

Qty

IE

Page 13

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

14”

Loosen screws ,,,,Disassemble Speaker

1. Disassemble Speaker CNTR.(Fig.4)

2. Loosen screws of Speaker

(6039B0031401) 。

14” : 6052A0004501 * 3, Fig.1

15” : 6052A0004501 * 2, Fig.2

15” : 6052A0003501 * 1, Fig.3

Torsion:2.0 ± 0.2 Kgf.cm

Screws can't be stripped or dropped into

machine.

9(1/1)

2009/05/181.00

Fig.4

1

Fig.1

15”

1

Point for attention:

Fixture list(Fixture standard)

If finding some defects, notice the gaffer and assistant

:

::

2

Fig.2

2

3

Qty

3

Fixture list(Fixture standard)

Fig.3

Qty

Automatic crossing screw driver 1

Tabulator:_________

Zhang Ying

Issuing department:

IE

Page 14

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

Disassemble LCM Cable

1. Disassemble LCM Cable CNTR。

2. Disassemble Camera CNTR。

15’

Fig.1

图一

10(1/1)

2009/05/181.00

Fig.2

图二

14’

Point for attention:

Fixture list(Fixture standard)

If finding some defects, notice the gaffer and assistant

:

::

Qty

Fig.3

图三

Fixture list(Fixture standard)

Qty

Tabulator:_________

Zhang Ying

Issuing department:

IE

Page 15

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

Fig.1

Disassemble Antenna Cable, Camera Cable

1.Pull out Antenna cable along the slot of BTCB. (Fig.1).

2.Disassemble Antenna Cable ,Camera Cable.(Fig.2)

11(1/1)

2009/05/181.00

Point for attention:

Fixture list(Fixture standard)

If finding some defects, notice the gaffer and assistant

:

::

Fig.2

Qty

Fixture list(Fixture standard)

Qty

Tabulator:_________

Zhang Ying

Issuing department:

IE

Page 16

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

1

Loosen screws of LCM ( For 14”)

1. Loosen screws of LCM

(6052B0098201 ) * 4。

Torsion:3.5 ± 0.2 Kgf.cm

Screws can't be stripped or dropped into

machine.

2

12(1/2)

2009/05/181.00

14’

Point for attention:

Fixture list(Fixture standard)

Automatic hexagonal screw driver 1

If finding some defects, notice the gaffer and assistant

:

::

Qty

3

4

Fixture list(Fixture standard)

Qty

Tabulator:_________

Zhang Ying

Issuing department:

IE

Page 17

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

1

Loosen screws of LCM( For 15”)

1. Loosen screws of LCM

(6052B0098201 ) * 4。

Torsion:3.5 ± 0.2 Kgf.cm

Screws can't be stripped or dropped into

machine.

2

3

12(2/2)

2009/05/181.00

15’

Point for attention:

Fixture list(Fixture standard)

Automatic hexagonal screw driver 1

If finding some defects, notice the gaffer and assistant

:

::

Qty

4

Fixture list(Fixture standard)

Qty

Tabulator:_________

Zhang Ying

Issuing department:

IE

Page 18

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

15”

14”

1

Loosen screws

1

2

1. Loosen screws of TPCB.

(6052B0098201) * 2 (for 14”);

(6052B0098201) * 2 (for 15”)

Torsion:2.0 ± 0.2 Kgf.cm

Screws can't be stripped or dropped into

machine.

2. Turn over the machine in the surface .

3. Loosen screws of BTCB(6052A0021901 ) *2。

Torsion:2.0 ± 0.2 Kgf.cm

Screws can't be stripped or dropped into

machine.

13(1/1)

2009/05/181.00

2

Point for attention:

Fixture list(Fixture standard)

Automatic hexagonal screw driver 1

If finding some defects, notice the gaffer and assistant

:

::

Qty

4

Fixture list(Fixture standard)

3

Qty

Tabulator:_________

Zhang Ying

Issuing department:

IE

Page 19

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

Fig.1

Fig.2

Disassemble TPCB

1. Disassemble TPCB (Fig.1)。

2. Disassemble TPCB TOUCH PAD FFC

from M/B(Fig.2)。

14(1/1)

2009/05/181.00

Point for attention:

Fixture list(Fixture standard)

If finding some defects, notice the gaffer and assistant

:

::

Qty

Tabulator:_________

Zhang Ying

Fixture list(Fixture standard)

Issuing department:

Qty

IE

Page 20

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

Fig.1

Fig.2

Disassemble Bluetooth

1

2

1. Loosen screws of Bluetooth

(6052A0004501) *2

2. Disassemble Bluetooth Cable from MB CNTR

(Fig.2)

3. Disassemble Cable and Bluetooth

Torsion:1.0 ± 0.2 Kgf.cm

Screws can't be stripped or dropped into

machine.

1.00

15(1/1)

2009/05/18

Point for attention:

Fixture list(Fixture standard)

Automatic crossing screw driver 1

If finding some defects, notice the gaffer and assistant

:

::

Qty

Tabulator:_________

Fixture list(Fixture standard)

Zhang Ying

Issuing department:

Qty

IE

Page 21

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

Loosen screws of M/B and ODD extension board

14”

Fig.1

15”

1. Loosen screws of M/B

(6052A0034902) * 1 (Fig.1)。

Torsion:2.0 ± 0.2 Kgf.cm

Screws can't be stripped or dropped into

machine.

2. Disassemble RJ11 Cable (Fig.1).

The machine have not Modem, which

disassemble the False shell

(6051B0409801) . (Fig.3).

FOR 15” ONLY

3. Loosen screws of ODD extension board

(6052A0034902) *2。

Torsion:2.0 ± 0.2 Kgf.cm

Screws can't be stripped or dropped into

machine.

16(1/1)

2009/05/181.00

Point for attention:

Fixture list(Fixture standard)

If finding some defects, notice the gaffer and assistant

:

::

ODD/B

screws

M/B

screws

Fig.2

Qty

False

shell

Fixture list(Fixture standard)

Fig.3

Qty

Automatic crossing screw driver 1

Tabulator:_________

Zhang Ying

Issuing department:

IE

Page 22

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

Fig.1

Disassemble FAN Cable and M/B

1. Disassemble FAN Cable CNTR , Fig.2,

Fig.3。

2. Take out M/B 。

Disassemble above the M/B first by right

hand;

Please don't touch LED light part while

taking and fetching M/B.

17(1/1)

2009/05/181.00

Fig.2

Point for attention:

Fixture list(Fixture standard)

Automatic crossing screw driver 1

If finding some defects, notice the gaffer and assistant

:

::

Qty

Tabulator:_________

Fixture list(Fixture standard)

Zhang Ying

Fig.3

Issuing department:

Qty

IE

Page 23

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

Fig.1

Disassemble FAN

1. Loosen screws of FAN (6052A0003501) * 2。

Torsion:2.0 ± 0.2 Kgf.cm

Screws can't be stripped .

2. Take down FAN (6033B0019801).

18(1/1)

2009/05/181.00

Point for attention:

Fixture list(Fixture standard)

Automatic crossing screw driver 1

If finding some defects, notice the gaffer and assistant

:

::

Qty

Tabulator:_________

Fixture list(Fixture standard)

Zhang Ying

Issuing department:

Qty

IE

Page 24

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

Disassemble WLAN and Loosen screws

Intel discrete

4

2

3

1

For platform without WLAN, needn’t to

disassemble WLAN

1. Put MB on supporting fixture.

2. Loosen two screws (6052A0034902) and take

down WLAN. (Fig.1)

3. Loosen screws of thermal elastic*2

Torsion:1.5 ± 0.2 Kgf.cm

Screws can't be stripped .

AMD discrete

4

19(1/2)

2009/05/181.00

2

1

3

Point for attention:

Fixture list(Fixture standard)

Automatic crossing screw driver 1

If finding some defects, notice the gaffer and assistant

:

::

Qty

Fixture list(Fixture standard)

Qty

VV09 M/B B side supporting fixture 1

Tabulator:_________

Zhang Ying

Issuing department:

IE

Page 25

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

Fig.1

GOOD

Assemble Wireless Card

1. Pick and place 1PCS Wireless Card every time, only

hold the two sides of RAM with figures(Fig.1)

Wear the gloves, pay attention to ESD.

Forbid pressing one side of Wireless Card and picking

it on the other side(Fig.2 and Fig.3)

Forbid holding the two surfaces of Wireless Card(Fig.4)

Forbid fetching more than two Wireless Card at the

same time(Fig.5)

Several Wireless Card can’t touch each other,

especially the Golden figures(Fig.6)

1.00

Fig.2

press one side

of Wireless

Card and

picking it on

the other side

Fetch more

than two

Wireless Card

at the same

time

Fig.5

NG

19(2/2)

2009/5/18

Fig.3

NG

Fig.4

NG

Point for attention:

Fixture list(Fixture standard)

If finding some defects, notice the gaffer and assistant

:

::

hold the two

surfaces of

Wireless Card

Qty

Fig.6

Several Wireless

Card can’t touch

each other,

especially the

Golden figures

Fixture list(Fixture standard)

Qty

Tabulator:_________

Zhang Ying

Issuing department:

IE

Page 26

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

Fig.1

Fig.2

Take down RAM and 15“ ODD extension board

1. Put MB on supporting fixture.

2. Take down DDR 。(IF have two , need

disassemble the two DDR)

3.Tear the tape of acetic acid

(6054A0076201 ) *1 and gasket

(6054B0430101 )*1 from RJ11 Cable .

(Fig.2)

FOR 15” ONLY

tape of acetic acid

4. Take down 15“ ODD extension board

, Fig.3。

20(1/1)

2009/05/181.00

gasket

Fig.3

Point for attention:

Fixture list(Fixture standard)

Automatic crossing screw driver 1

If finding some defects, notice the gaffer and assistant

:

::

Qty

Fixture list(Fixture standard)

Qty

VV09 M/B B side supporting fixture 1

Tabulator:_________

Zhang Ying

Issuing department:

IE

Page 27

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

Loosen screws and take down THERMAL

1. Put MB on supporting fixture.

1

4

2. Loosen four screws of Thermal 。

Torsion:1.5 ± 0.2 Kgf.cm

Screws can't be stripped .

2

3

Don’t hold the Copper Pipe of Thermal.

3. Take down CPU Thermal.

AMD DIS

1

4

THERMAL MODULE,AMD,DISCRETE6043B0065101

THERMAL MODULE,AMD,UMA6043B0065201

THERMAL MODULE,INTEL,UMA6043B0065301

THERMAL MODULE,INTEL,DISCRETE6043B0065401

22(1/2)

2009/05/181.00

3

2

AMD UMA

Point for attention:

Fixture list(Fixture standard)

Automatic crossing screw driver 1

VV09 M/B B side supporting fixture 1

If finding some defects, notice the gaffer and assistant

:

::

Qty

Fixture list(Fixture standard)

Qty

Tabulator:_________

Zhang Ying

Issuing department:

IE

Page 28

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

Loosen screws and take down THERMAL

1. Put MB on supporting fixture.

2. Loosen four screws of Thermal 。

Torsion:1.5 ± 0.2 Kgf.cm

Screws can't be stripped .

2

3

Don’t hold the Copper Pipe of Thermal.

3. Take down CPU Thermal.

1

4

Intel UMA

THERMAL MODULE,AMD,DISCRETE6043B0065101

THERMAL MODULE,AMD,UMA6043B0065201

THERMAL MODULE,INTEL,UMA6043B0065301

22(2/2)

2009/05/181.00

2

4

3

1

Intel DIS

Point for attention:

Fixture list(Fixture standard)

Automatic crossing screw driver 1

If finding some defects, notice the gaffer and assistant

:

::

Qty

THERMAL MODULE,INTEL,DISCRETE6043B0065401

Fixture list(Fixture standard)

Qty

VV09 M/B B side supporting fixture 1

Tabulator:_________

Zhang Ying

Issuing department:

IE

Page 29

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

Fig.1

图一

图一

图一图一

Fig.2

OPEN Status

Take out CPU

1. Put MB on supporting fixture.

2. Take down CPU from CPU SOCKET

with suck pen.

(take down it in counter clockwise)

23(1/1)

2009/05/181.00

CLOSED Status

Point for attention:

Fixture list(Fixture standard)

Flat screw driver 1

suck pen 1

VV09 M/B B side supporting fixture 1

If finding some defects, notice the gaffer and assistant

:

::

Qty

Tabulator:_________

Fixture list(Fixture standard)

Zhang Ying

Issuing department:

Qty

IE

Page 30

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

Fig.1

2

Take down MODEM and RJ11 cable

1

1. Put M/B on supporting fixture

2. Loosen screws (6052A0034902) * 2

and take down MODEM from M/B ,

(Fig1,Fig2)

3. Take down RJ11 CABLE

(6017B0119501 ) from Modem. (Fig.3)

Torsion:1.5 ± 0.2 Kgf.cm

Screws can't be stripped

1.00

24(1/1)

2009/05/18

MODEM

1

2

图图图图二二二二

Fig.2

Point for attention:

Fixture list(Fixture standard)

Automatic crossing screw driver 1

VV09 M/B B side supporting fixture 1

If finding some defects, notice the gaffer and assistant

:

::

Qty

Fig.2

图三

图三

图三图三

Fixture list(Fixture standard)

Qty

Tabulator:_________

Zhang Ying

Issuing department:

IE

Page 31

Working Instruction

Document No. : SOP VV09 FA DIS-ASS’Y Station :

Name : Ver. : Date :

LCM CNTR

LCM CNTR

LCM CNTRLCM CNTR

Visual inspect M/B

Mylar

1. Cosmetic inspecting。

Don’t touch the LED lamp fetching M/B 。

Inspect the cable manager dropped or not 。

Inspect Audio Jack iron part coming off or not。

Inspect LCM CNTR PIN askew and cracked or

not 。

25(1/1)

2009/05/181.00

MIC Jack

MIC Jack

Audio Jack

Audio Jack

Audio JackAudio Jack

Point for attention:

Fixture list(Fixture standard)

MIC JackMIC Jack

If finding some defects, notice the gaffer and assistant

:

::

Qty

Tabulator:_________

Zhang Ying

Fixture list(Fixture standard)

Issuing department:

Qty

IE

Loading...

Loading...