Page 1

Advanced Test Equipment Rentals

www.atecorp.com 800-404-ATEC (2832)

®

E

s

t

a

b

l

i

s

h

e

d

1

9

8

1

About this Manual

We’ve added this manual to the Agilent website in an effort to help you support

your product. This manual is the best copy we could find; it may be incomplete

or contain dated information. If we find a more recent copy in the future, we will

add it to the Agilent website.

Support for Your Product

Agilent no longer sells or supports this product. Our service centers may be able

to perform calibration if no repair parts are needed, but no other support from

Agilent is available. You will find any other available product information on the

Agilent Test & Measurement website,

www.tm.agilent.com.

HP References in this Manual

This manual may contain references to HP or Hewlett-Packard. Please note that

Hewlett-Packard's former test and measurement, semiconductor products and

chemical analysis businesses are now part of Agilent Technologies. We have

made no changes to this manual copy. In other documentation, to reduce

potential confusion, the only change to product numbers and names has been in

the company name prefix: where a product number/name was HP XXXX the

current name/number is now Agilent XXXX. For example, model number

HP8648A is now model number Agilent 8648A.

Page 2

User and Service Guide

Publication Number 54620-97011

October 1995 (pdf version Dec 1998)

For Safety Information, Warranties, and Regulatory information,

see the pages behind the Index.

© Copyright Hewlett-Packard Company 1994, 1995

All Rights Reserved

HP 54620A/C Logic Analyzer

Page 3

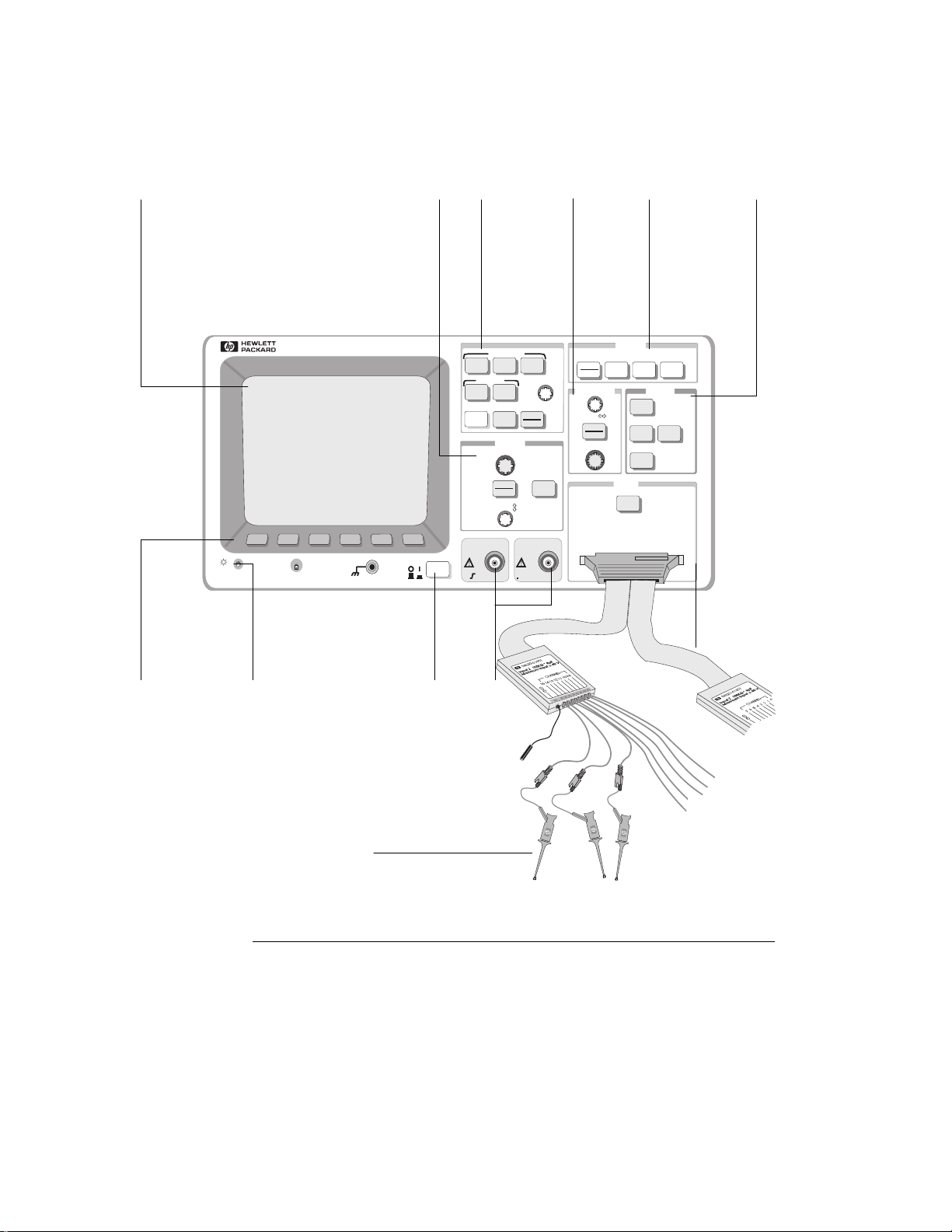

The HP 54620A/C at a Glance

Display sh ows the current input s ignals

and much more

Up to sixteen (16) channels in normal

•

or delayed m ode

Indicators f or gl i tch or normal

•

acquisition, time base, channel

activity, trigger and acquisition status

Softkey labels

•

Measureme nt results

•

Color Palettes

•

Channel Cont rols select, position, and

label in puts

Turn channels on or off individuall y

•

or in groups of 8

Rearrange order of channels to

•

group relat ed signals

Create and dis pl ay labels to ident i fy

•

channels, and set channel col ors

General Controls measure, sav e and

restore res ult s, and configure the

analyzer

Measureme nt k eys provide

•

automatic si ngle or dual-chann el

time and fre quency measurement s,

or use cursors to make manual

measurements

Save or reca l l m easurement

•

configurati ons or previous results

Autoscale performs simple

•

one-button s etup of the analyzer

Horizontal Controls select sweep speed

and delay parameters

Sweep speeds from 5 ns/div to 1 s/div

•

Delay control moves waveform

•

display to point of interest

Delayed mo de and delay allow

•

zooming in t o show a portion of

waveform in detail (split screen)

Storage Keys begin and end data

acquisition

Run/Stop start s and stops continu ous

•

acquisitions

Single perform s one acquisition

•

Autostore accum ulates and displays

•

the results of multiple acquisit i ons

(like persistence on an oscilloscope)

Erase clears the current acquisi tion

•

and all accum ul ated data

Trigger Keys define what data will be

captured by th e analyzer

Edge mode all ow s triggering on a

•

positive or negative edge (or both) of

any single channel

Pattern mode a l l ow s triggering on a

•

pattern of cha nnel s either high, lo w ,

or don’t care , w i th a single edge

qualifier

Advanced mode allows sequential

•

triggers, c om bi ned patterns, patte rns

and edges, p att ern durations, and

edge occurre nce counts

Softkeys extend the functionality of

command keys

Select measurement types, operating

modes, trigger specifications, l abel data,

and more

Trigger Input/Output

Trigger the HP 54620A/C from other

instruments or use the HP54620A/C to

trigger other i nstruments

Channel Inputs through a flexible

probing system

Sixteen chan nel s through a dual

•

8-channel c abl e w i th micro-grabbers

Set logiclevel s as TTL, CMOS , EC L, or

•

to a user-def i nabl e voltage

2

Page 4

Display Channel

Controls

General

Controls

Horizontal

Controls

Storage

Keys

Trigger

Keys

Softkeys

54620A

16 CHANNEL 500 MSa/s

Brightness

Control (for

HP 54620A

only)

LOGIC ANALYZER

Line

Power

Single

channel

Trace

Auto

scale

Trigger out

~5V

ov

Trigger

Input /

Output

Measure time

Save/Recall

Dual

channel

Setup

Display

CHANNEL

Select

On

Off

Position

Cursors

Print

Utility

150

Ext trigger in

1 MQ

+

40 V Max

STORAGE

Run

Single

Auto-

Erase

Stop

Entry

HORIZONTAL

Delay

Main

Delayed

Time/Div

Label

store

TRIGGER

Edge

Mode

Pattern

Adv

5 ns1 s

INPUTS

Logic

levels

Channel

Inputs

Micro-grabbe rs

3

Page 5

In This Book

The

HP 54620A/C User and Service Guide

features of the Logic Analyzer in the design and troubleshooting of digital

system circuitry.

Chapter 1

basic measurements. It also gives an overview of basic analyzer operational

concepts including use and interpretation of the front panel and display.

Chapter 2

instrument configuration features, measure waveform data, control data

acquisition, examine captured data in more detail, set up analyzer trigger

conditions, and shows how to use the analyzer with other instruments.

Chapter 3

kinds of problems that might occur when you begin operating the analyzer.

Chapter 4

between the analyzer time base and other time-dependent functions,

discusses the effect of probes on measurement accuracy, and explains the

glitch detection system. After you have made a few measurements with the

HP 54620A/C, it is a good idea to read this chapter.

Chapter 5

explains how to test the HP 54620A/C to ensure that it operates correctly.

The chapter also shows how adjust and troubleshoot the analyzer.

Chapter 6

various assemblies in the analyzer. The chapter also lists the replaceable

parts for the analyzer and gives ordering information.

Chapter 7

performance standards to which the instrument is tested.

Chapter 8

displayed by the analyzer, explains their causes, and tells what to do to

correct the problem.

If you want to automate HP 54620A/C measurements using a programmable

controller such as an IBM-compatible PC or an HP 9000 Series 700 controller,

see the

Programmer’s Reference

help file on a 3.5" diskette. The diskette includes a help file viewer for

Microsoft Windows 3.1, and Microsoft Write editor versions of the files. ASCII

files are also supplied.

, “Getting Started,” explains how to set up the analyzer and make

, “Making Analyzer Measurements,” shows you how to use the

, “Solving Problems,” shows you how to fix the most common

, “Ensuring Accurate Measurements,” explains the relationships

, “Testing, Adjusting, and Troubleshooting the Logic Analyzer,”

, “Replaceable Parts,” explains how to remove and replace the

, “Performance Characteristics,” lists the measurement

, “Messages,” lists the status and error messages that may be

HP 54620A/C Programmer’s Guide

. The

Programmer’s Reference

is your guide to using the

and the

HP 54620A/C

is supplied as a

4

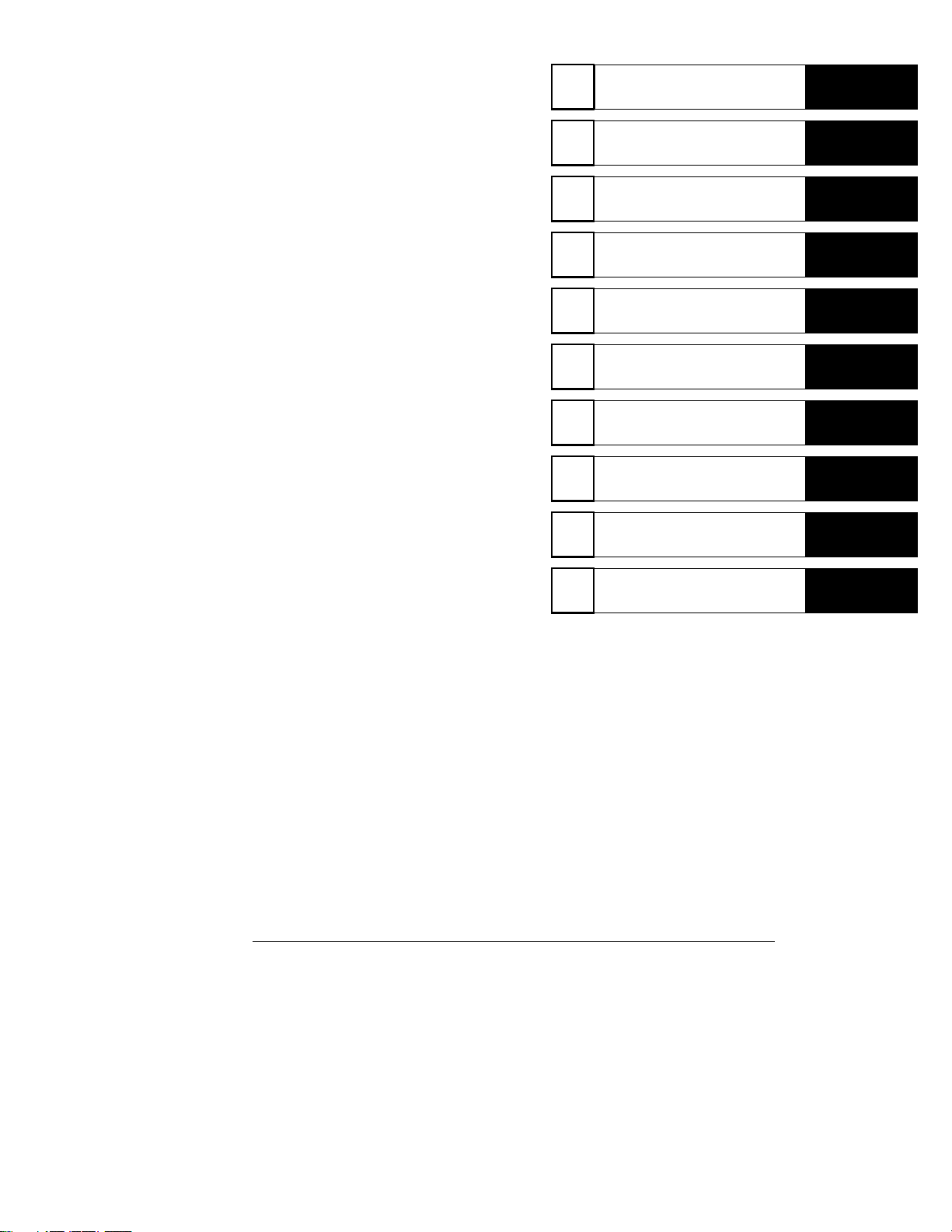

Page 6

Getting Started

1

Making Analyzer

2

Measurem ents

Solv ing Proble ms

3

Ensuring A ccurate

4

Measurem ents

Testing, A djusting, and

5

Troubleshooting the Analyzer

Replaceab le Parts

6

Performance Characteristics

7

Messages

8

Glossary

Index

5

Page 7

6

Page 8

Contents

1 Getting Started

Preparing the Analyzer 21

To check package contents 22

To check optional accessories 24

To power-on the logic analyzer 27

To adjust the handle 28

To adjust display brightness 29

Using Color 30

To select the color palettes and observe colors 31

To assign colors to channels 33

To print in color 34

Making Measurements 35

Learn the front panel 35

To probe a circuit 42

To set up an acquisition using Autoscale 44

To start and stop an acquisition 46

To define a simple edge trigger 47

To adjust the time base (sweep speed) 48

To turn channels on and off 49

To rearrange the channels 50

2 Making Analyzer Measurements

Setting Logic Levels 53

To change the logic threshold for input signals 54

Controlling Data Acquisition 55

To take a single acquisition 56

To use Auto Glitch Detect 57

To accumulate the results of every acquisition 58

To erase the waveform display 58

7

Page 9

Contents

Using Labels 59

To turn the label display on or off 59

To assign a label to a channel 60

To define a new label 62

To initialize the label list 64

Triggering the Analyzer 65

Trigger types 65

To define the trigger mode 70

To define an edge trigger 72

To define a pattern trigger 73

To define an advanced trigger 74

Examining the Captured Data 80

Viewing acquired data with delayed sweep 80

To show both main and delayed sweep displays 82

To change the time reference position 83

To pan the display 86

To modify the graticule 87

To print the display 88

Measuring Waveform Data 89

Ways to measure data 89

To use the cursors 94

To measure waveform parameters on a single channel 96

To measure channel-to-channel delay 98

To measure setup time 100

To measure hold time 102

Using the Analyzer with Other Instruments 104

Extending trigger capabilities 104

To use the external trigger input 108

To use the trigger output 110

8

Page 10

Saving and Recalling the Configuration 111

Using memories to save and recall configurations 111

To save a trace waveform 114

To recall a trace waveform 115

To clear a previously saved trace 116

To save the instrument setup 117

To recall the instrument setup 118

To reset the instrument setup 119

3 Solving Problems

If there is no trace display 123

If the trace display is unusual or unexpected 124

If you can’t see a channel 125

Contents

4 Ensuring Accurate Measurements

Time base and Acquisition 129

Probing the Circuit Under Test 139

Glitch Detection 143

5 Testing, Adjusting, and Troubleshooting the Analyzer

Testing the Analyzer 151

To perform self-tests 152

To test the keyboard 153

To test the display 154

To test the acquisition system 154

Building Test Accessories 155

To make the test connectors 156

To make the dummy load 158

9

Page 11

Contents

Adjusting the Logic Analyzer 159

To adjust the power supply 160

To adjust the display (HP 54620A only) 162

Troubleshooting the Logic Analyzer 164

To troubleshoot the logic analyzer 165

To check the LVPS 168

Testing Threshold Accuracy 169

Step 1. To set up the equipment 170

Step 2. To connect the logic analyzer 171

Step 3. To test the thresholds 172

Testing Time Interval Accuracy 173

Step 1. To connect the logic analyzer 174

Step 2. To set up the equipment 175

Step 3. To set up the logic analyzer 176

Step 4. To make the measurement 177

6 Replaceable Parts

Removing and Replacing Assemblies 181

To remove the cabinet 182

To remove the fan 183

To remove the front panel 184

To remove the display 185

To remove the system board 186

To remove the power supply 187

To remove the keyboard 188

To remove the handle 189

Replaceable Parts 190

To order a replacement part 191

10

Page 12

7 Performance Characteristics

8 Messages

Messages 209

Contents

Glossary

Index

217

225

HP 54620 Documentation

239

11

Page 13

12

Page 14

Figures

Figure 1. Using the Logic Analyzer 19

Figure 1A. Refining the Trigger Specification 20

Figure 2. Items Supplied with the HP 54620A/C Logic Analyzer 23

Figure 3. Optional Accessories for the HP 54620A/C Logic Analyzer 25

Figure 4. HP 54620A Brightness Control 29

Figure 5. HP 54620C with Label Menu Selected and Single Channel

Highlighted 34

Figure 6. HP 54620A Logic Analyzer Front Panel 36

Figure 7. HP 54620A/C Display 38

Figure 8. Sample Autoscale Measurement 44

Figure 9. Edge Trigger on Channel 0 47

Figure 10. Logic Threshold Setup 53

Figure 11. Waveform Display with Auto Glitch Detect Enabled 57

Figure 12. HP 54620A/C Label Definition Display 61

Figure 13. Pattern Trigger Setup 67

Figure 14. Advanced Trigger Setup (with Overview On) 68

Figure 15. Advanced Trigger Softkeys for Operators with Two Sources 69

Figure 16. Acquisition Memory 70

Figure 17. Pulse Train with Constant-Duration Pulse 77

Figure 18. Sequential Output from State Machine 77

Figure 19. System Failure on Third Keystroke 78

Figure 20. Delayed Sweep 81

Figure 21. Time Reference at Center, Delay of 15 µs on Main Sweep 84

Figure 22. Delayed Sweep with Delay of 8 µs 85

Figure 23. Measuring the Period of an Irregular Waveform 90

Figure 24. Single-Channel Measurements 91

Figure 25. Channel-to-Channel Delay Measurement 92

Figure 26. Measurement Within the Delayed Sweep Window 93

Figure 27. Setup Time Measurement 101

Figure 28. Hold Time Measurement 103

Figure 29. Connections for External Trigger from an Emulator 105

Figure 30. Connections for External Trigger using an Oscilloscope Probe 106

Figure 31. Connections for Triggering an Oscilloscope 107

Figure 32. Using the External Trigger Input as an Edge Trigger 109

13

Page 15

Contents

Figure 33. Trace Memory Save/Recall 112

Figure 34. Setup Memory 113

Figure 35. Relationship Between Time base and Analyzer Functions 129

Figure 36. Acquisition Memory 131

Figure 37. Memory Bar 132

Figure 38. Single Acquisition, Time Reference Center, Positive

Delay of 75 µs 134

Figure 39. Panning the Display to View the Start of Acquisition 135

Figure 40. Single Acquisition, Time Reference Right, Negative

Delay of 80 µs 136

Figure 41. Panning the Display to View the Trigger Point 137

Figure 42. DC and Low-Frequency Probe Equivalent Circuit 139

Figure 43. High-Frequency Probe Equivalent Circuit 140

Figure 44. Impedance versus Frequency for Both Probe Circuit Models 140

Figure 45. Common Mode Input Voltage Model 141

Figure 46. Glitch Display 144

Figure 47. Aliasing 144

Figure 48. Reconstruction of Waveform with Glitch Capture 145

Figure 49. Waveform Display with Sampling Rate Too Low 146

Figure 50. Waveform Display with Sufficient Sampling Rate 147

Figure 51. Data Output Relative to Clock 148

Figure 52. 8-by-2 Connector Setup 156

Figure 53. 1-by-2 Connector Setup 157

Figure 54. Power Supply Adjustment 161

Figure 55. Display Adjustment 163

Figure 56. Threshold Test Setup 171

Figure 57. Time Interval Accuracy Setup 174

Figure 58. Front Panel Removal 184

Figure 59. Unhooking the Power Switch Shaft 187

Figure 60. Exploded View of Logic Analyzer 192

14

Page 16

Tables

Table 1. Power Cords 26

Table 2. Color Palettes and Mapping of Colors to Display Components 32

Table 3. Threshold Voltage Settings 54

Table 4. Trigger Operators and Sources 75

Table 5. Readout Settings 95

Table 6. HP 54620A/C Factory-Preset Default Configuration Settings 119

Table 7. Sweep Speed and Sampling Interval 130

Table 8. Materials Required (Making Test Connectors) 156

Table 9. Equipment Required (Adjusting Power Supply) 160

Table 10. Equipment Required (Adjusting Display) 162

Table 11. Equipment Required (Troubleshooting Logic Analyzer) 164

Table 12. Display Signals 166

Table 13. Equipment Required (Testing Threshold Accuracy) 169

Table 14. Threshold Test Settings 172

Table 15. Equipment Required (Testing Time Interval Accuracy) 173

Table 16. HP 54620A/C Replaceable Parts 193

Table 17. Input channels 197

Table 18. Horizontal System 198

Table 19. Acquisition System 199

Table 20. Trigger System 200

Table 21. Display System 202

Table 22. Measurement Functions 202

Table 23. Setup Functions 203

Table 24. Power Requirements 203

Table 25. General Characteristics for HP 54620A Only 204

Table 26. General Characteristics for HP 54620A and HP 54620C 205

Table 27. General Characteristics for HP 54620C Only 206

15

Page 17

16

Page 18

1

Getting Started

Page 19

Getting Started

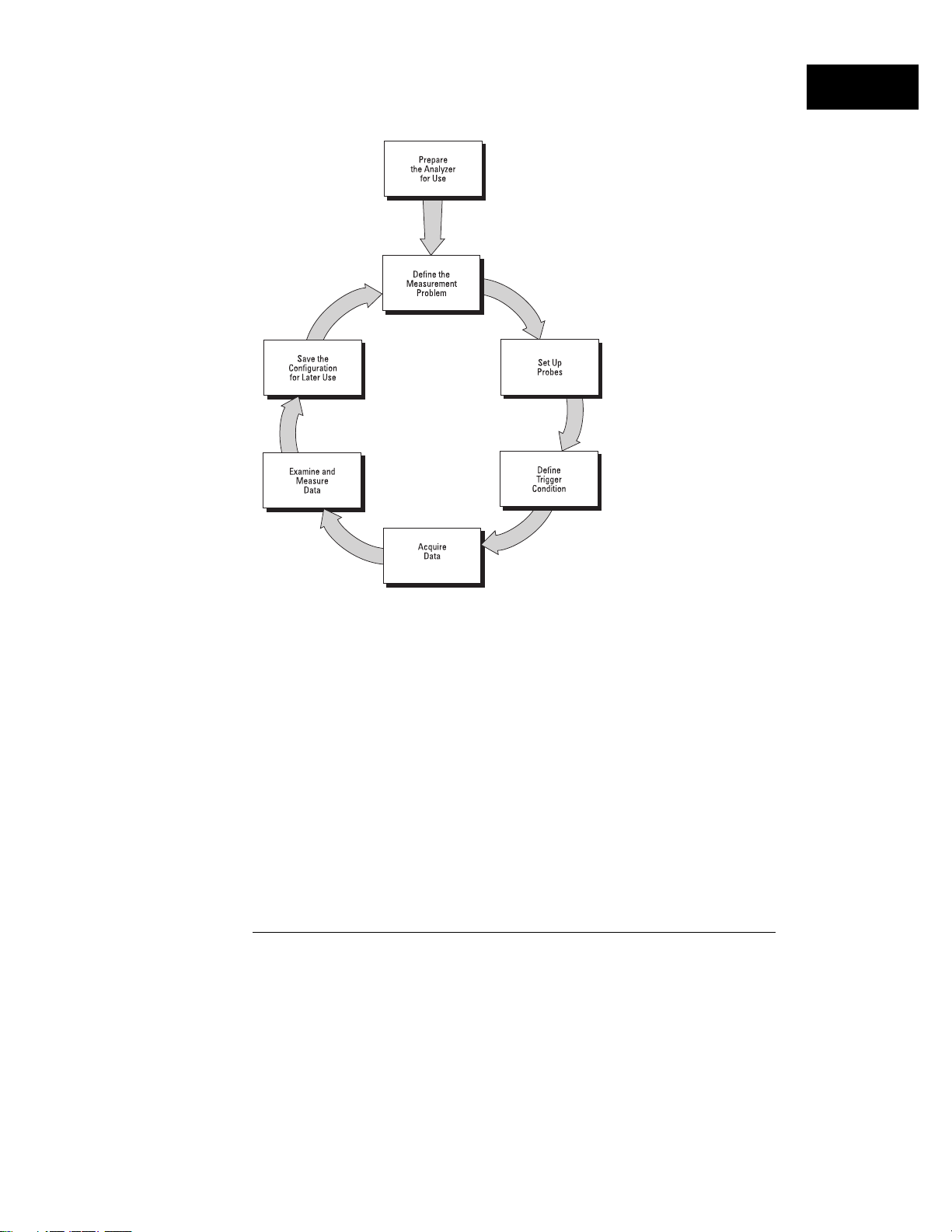

When you use the logic analyzer to help test and troubleshoot your

systems, you will follow the general process shown in figure 1:

• Prepare the analyzer by connecting it to power and setting up the

handle and screen brightness as desired.

• Define the measurement problem by understanding the parameters

of the system you wish to test and the expected system behavior.

• Set up channel inputs by connecting the data probes to the

appropriate signal and ground nodes in the circuit under test.

• Define the trigger condition by setting the analyzer configuration to

capture only the system events you wish to view.

• Use the analyzer to acquire data, either in continuous or single-shot

fashion.

• Examine the data and make measurements on it using various

analyzer features.

• Save the measurement or configuration for later re-use or

comparison with other measurements.

The process is repeated as necessary until you verify correct

operation or find the source of the problem.

18

Page 20

Figure 1

Getting Started

Using the Logic Analyzer

19

Page 21

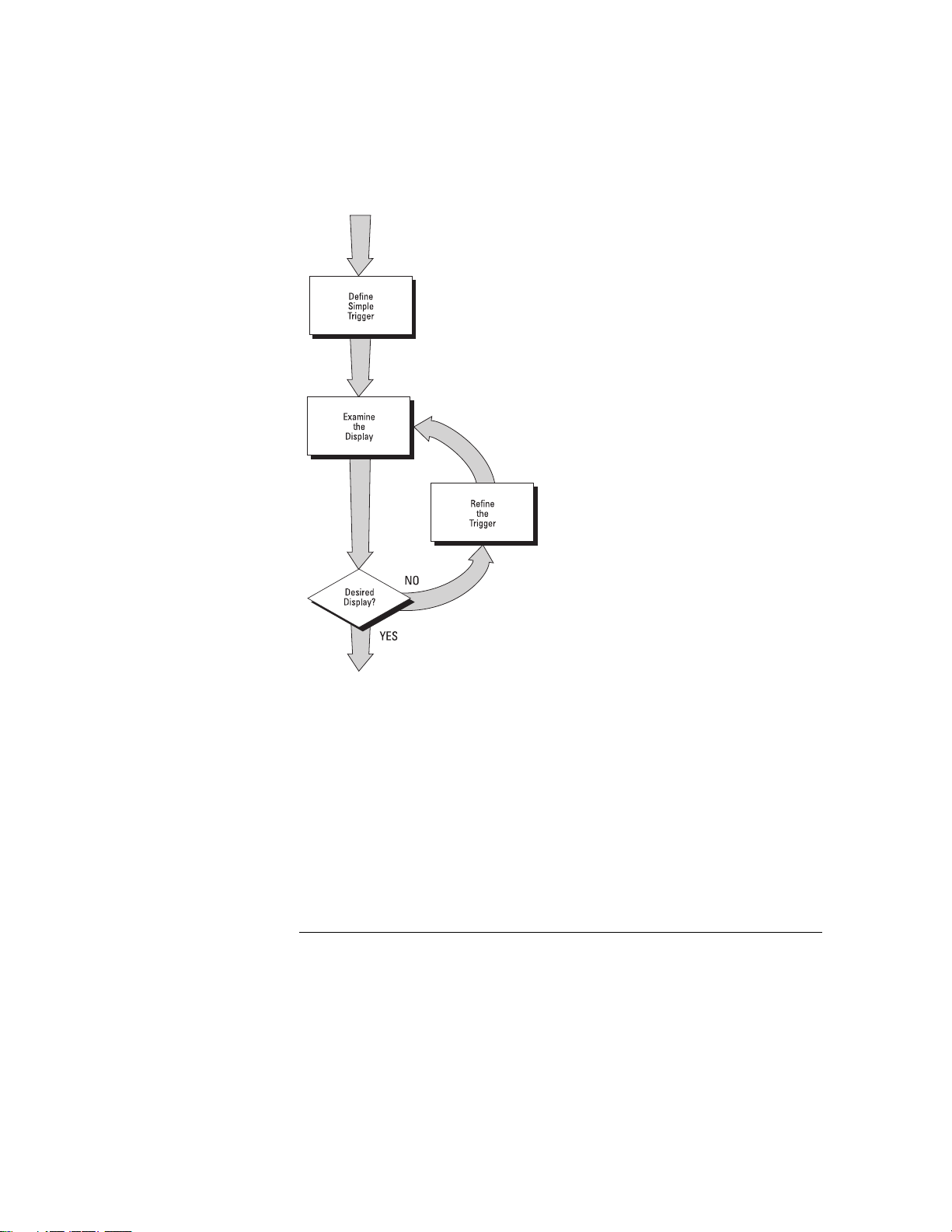

Figure 1A

Getting Start ed

The high-speed display of the HP 54620A/C can be used to isolate

infrequently changing signals. You can then use the characteristics of

these signals to help refine the trigger specification. See the figure

below.

Refining the Tr i gger Specification

This chapter discusses analyzer preparation and probe setup, and

contains a general introduction to trigger definition and data

acquisition. For more information on triggering, data acquisition, data

examination and measurement, and configuration, see chapter 2,

“Making Analyzer Measurements.”

20

Page 22

Preparing the Analyzer

To prepare your logic analyzer for use, you need to do the following:

1

Check to ensure that you received everything that is supplied with

the analyzer.

2

Connect the analyzer to power and switch it on.

3

Connect the probe cable to the analyzer and connect probes to the

circuit of interest. (You can use the front panel calibration test point

as a stimulus while learning to use the analyzer.)

The following pages show you how to do each of these tasks. After you

have completed them, you will be ready to use the analyzer.

21

Page 23

Getting Start ed

To check pack age contents

To check package contents

•

Verify that you received the following items in the HP 54620A/C

packaging.

See figure 2. If anything is missing, contact your nearest Hewlett-Packard

Sales Office. If the shipment was damaged, contact the carrier, then contact

the nearest Hewlett-Packard Sales Office.

HP 54620A/C Logic Analyzer.

Power cord (see table 1).

HP 54620-61801 16-channel probe cable.

HP 5090-4356 grabbers (in resealable plastic bag; quantity 20).

HP 5959-9334 2" ground lead set (quantity 5).

HP 54620A/C User’s Guide.

HP 54620A/C Programmer’s Guide.

HP 54620A/C Programmer’s Reference (3.5" diskette).

22

Page 24

Figure 2

HP 54620A/C

Logic Analyzer

HP 54620-61801

16-Channel Cable

(leads attached; with labels)

Getting Started

To check pac kage contents

!

HP 5959-9334

2" Ground Lead Set (5)

Power Cord

(Varies depending on country)

HP 5090-4356

Grabber (20)

HP 54620A/C User's Guide

HP 54620A/C Programmer's Guide

Items Supplied with the HP 54620A/C Logic A nal yzer

HP 54620A/C

Programmer's Reference

pkg-cnts.cdr

23

Page 25

Getting Start ed

To check optional accessories

To check optional accessories

•

Verify that you received the optional accessories you ordered.

See figure 3. If anything is missing, contact your nearest Hewlett-Packard

Sales Office. If the shipment was damaged, contact the carrier, then contact

the nearest Hewlett-Packard Sales Office.

Option 101—Front panel dust cover and accessory pouch.

Option 103—HP 54654A Operator’s self-paced Training Kit, including

case, manual, and circuit board with battery.

Option 104—HP 5041-9409 Carrying Case (useful for protecting the

instrument in shipment or when checked as airline baggage).

Option 106—HP 34801A BenchLink software for Microsoft Windows

(provides an interface to the instrument from any Windows-compatible

PC, allowing the user to save and restore setups and capture

measurements for further review).

Option 001—RS-03 Magnetic Shielding for CRT (HP 54620A only)

(not shown in figure 3).

Option 1CM—Rackmount kit (allows mounting the HP 54620A/C in an

EIA-standard rack). This kit is not shown in figure 3.

24

Page 26

Figure 3

Getting Started

To check optional accessories

Optional Accessories for the HP 54620A/C Logic Analyzer

25

Page 27

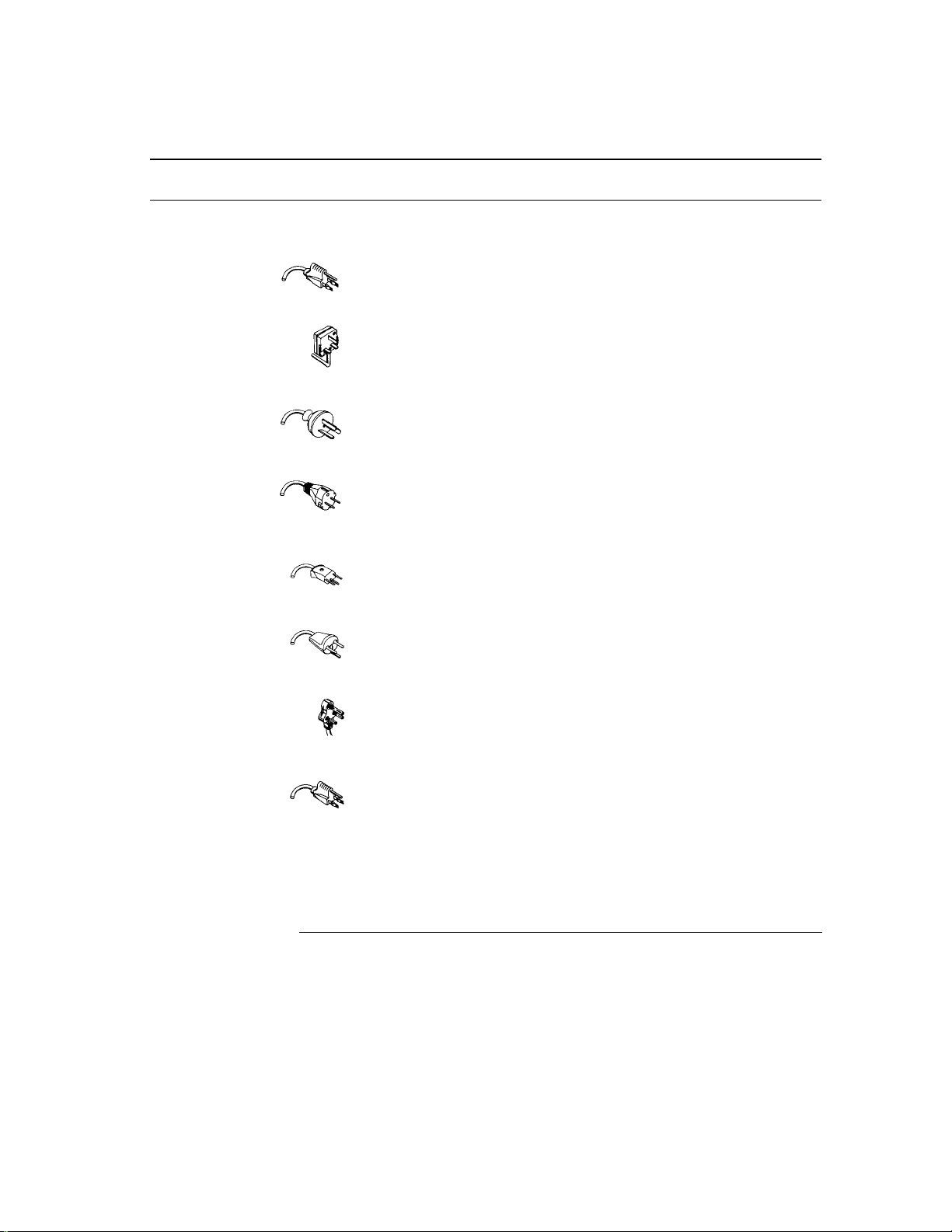

Table 1

Power Cords

Getting Start ed

To check optional accessories

Plug Type Cable Part

No.

Opt 903 (U.S.A.)

124V **

Opt 900 ( U.K.)

250V

Opt 901 (A ustralia)

250V

Opt 902 (Eur ope)

250V

Opt 906 (S w i tz erland)

250V

Opt 912 (D enm ark)

220V

8120-13 78 Straight (NEMA5-15P*) 90/228 Jade Gray

8120-1351 Straight (BS136A*) 90/228 Gray

8120-1369 Straight

8120-1689

8120-2857

8120-2104 Straight (SEV1011*) 79/200 Mint Gray

8120-29 57 Straight (DHCK107*) 79/200 Mint Gray

Plug Description Length

in/cm

(NZSS198/ASC*)

Straight (CEE7-Y11*)

Straight (S hi el ded)

79/200 Gray

79/200

79/200

Color

Mint Gray

Coco Brown

Opt 917 (Africa)

250V

Opt 918 (Japan)

100V

* Part number shown for plug is industry identifier for plug only.

Number shown for cable is HP part numb er for comple te cable including plug.

** These cords are included in the CSA certi fication approval for the equipment.

8120-4600 Straight (SABS164) 79/200 Jade Gray

8120-4753 Straight Miti 90/230 Dark Gray

26

Page 28

To power-on the logic analyzer

1

Connect the power cord to the rear of the

HP 54620A/C, then to a suitable ac voltage source.

2

Press the power switch.

Getting Started

To power-on the logic analyzer

The HP 54620A/C power supply

automatically adjusts for input line voltages

in the range 100 to 240 VAC. Therefore, you

do not need to adjust the input line voltage

setting. The line cord provided is matched

by HP to the country of origin of order.

Ensure that you have the correct line cord.

See table 1.

The HP 54620A/C performs a self-test, then

shows the display. The instrument is ready

to use.

27

Page 29

Getting Start ed

To adjust the handle

To adjust the handle

1

Grasp the handle pivot points on each side of the

instrument and pull the pivot out until it stops.

2

Without releasing the pivots, swivel the handle to

the desired position. Then release the pivots.

28

Page 30

Figure 4

Getting Started

To adjust d is play brightness

To adjust display brightness

•

To decrease display brightness, rotate the brightness control

counterclockwise.

•

To increase display brightness, rotate the brightness control

clockwise.

The brightness control is at the lower left corner of the display. See figure 4.

HP 54620A Brightness Control

The "A" model includes a brightness control. There is no brightness control

on the HP 54620C.

29

Page 31

Using Color

With the HP 54620C color logic analyzer, you can select any of the

seven available color palettes to assign colors to channels, cursors,

stored waveforms, and text. You can assign each channel one of four

waveform colors.

The seven color palettes allow additional customization, which allows

you to easily distinguish between channel waveforms. In addition,

when making measurements on a channel, wherever the channel

number appears on screen, it is highlighted in the selected color.

The color palettes are individually named, and you can choose the

palette that best suits your needs. You can change from the Default

palette to any of the following:

• Alternate 1 works well for people who are colorblind.

• The colors in Alternate 2 are compatible with those used in

HP 545XX-series oscilloscopes.

• Alternate 3 sets the cursors to yellow.

• Inverse 1 works well for hard copies.

• Inverse 2 works well for overhead transparencies.

• A Monochrome palette is also available.

In each palette, different colors are used for cursors, waveforms,

softkeys, and Autostore. The background is always black, unless you

select the Inverse palettes, which use a white background. Softkeys

and the grid are always in white, except in the Inverse palettes, which

set them to black.

This section shows you how to:

Select the color palettes and observe colors

•

Assign colors to channels

•

Print in color

•

30

Page 32

To select the color palettes and observe colors

To select the color palettes and observe colors

Getting Started

Press

Displa y

The name of the palette appears under the softkey. For example, Default.

Press the

Palette

. Look at the

softkey. Continue to cycle through the palettes

1

2

Palette

softkey.

and observe colors applied to the cursors, waveforms, and softkeys.

Notice that the softkeys are white in all palettes, except the Inverse palettes,

where they are black.

3

Press the

The graticule is always white, except in the Inverse palettes, where it is black.

4

Press

A single color shows cursors in the display area, the active cursor selected,

and the cursor measurement Time and Hex readouts.

5

Press

The current measurement readout is displayed in the cursor color whenever

the Show Meas softkey is On in single-channel measurement Next Menu, or

in the dual-channel measurement menu. You can toggle the Show Meas keys

and see the current measurement change between the cursor color and white.

6

Press

The autostored waveforms are displayed in blue when using the Default and

Alternate color palettes, and in cyan in the Inverse color palettes.

7

Press

Grid

softkey and set the grid to

Cursor s

Single channel

Autost or e

Autost or e

. Press

.

to turn it off. Then press

Active Cursor t2

. Press the

Full

.

Freq

softkey, then

.

Erase

Period

.

.

Press

Edge

The activity indicator for each channel is displayed is in the same color

assigned to the channel. Channel indicators for channels not displayed are

white, except in the Inverse palettes, where they are black. If you define an

edge trigger, the channel and trigger edge are displayed in the channel color

in the upper-right corner of the screen.

. Look at the channel activity indicators.

Rotate the Select knob to cycle through through the channels.

The channel number and corresponding activity indicator are both

highlighted in the color applied to the channel. For a channel not displayed

on the screen, as you rotate the Select knob, that channel number appears in

the upper-left corner in the same color applied to the corresponding selected

activity indicator.

8

9

31

Page 33

Getting Start ed

To select the color palettes and observe colors

The following table shows the color palettes and the palette colors mapped to

the display components.

Table 2

Color Palettes and Mapping of Colors to Display Components

Palette Color Display

Component

Default

Alternat e 1

Alternate 2

green

yellow

magenta

cyan

red

white

white

blue

black

red

cyan

yellow

magenta

green

white

white

blue

black

cyan

yellow

green

magenta

red

white

white

blue

black

cursors

waveform1

waveform2

waveform3

waveform4

softkeys

graticule

autostore

background

cursors

waveform1

waveform2

waveform3

waveform4

softkeys

graticule

autostore

background

cursors

waveform1

waveform2

waveform3

waveform4

softkeys

graticule

autostore

background

Palette Color Display

Component

Alternat e 3

Inverse 1

Inverse 2

yellow

magenta

cyan

green

red

white

white

blue

black

cyan

red

blue

green

magenta

black

black

cyan

white

black

red

blue

magenta

green

black

black

cyan

white

cursors

waveform1

waveform2

waveform3

waveform4

softkeys

graticule

autostore

background

cursors

waveform1

waveform2

waveform3

waveform4

softkeys

graticule

autostore

background

cursors

waveform1

waveform2

waveform3

waveform4

softkeys

graticule

autostore

background

In the monochrome palette, all of the display components are in white, except the background, which is black.

32

Page 34

To assign colors to channels

Getting Started

To assign colors to channels

Press

Label

The single channel softkey is highlighted in color. This softkey is used to

assign one color to a single channel. The softkey just to the left is used to

assign one color to a group of channels. The activity indicator for each

displayed channel has the same color assigned to the channel.

. Look at the

Press the single channel softkey, labeled

1

2

Assig n Ch an ne l Colors

X CHXX

(where X is the

softkeys.

selected channel number). Press it again, and rotate the Select knob

to cycle through the channels and select the one you want.

Pressing this softkey increments the channel number.

Press

Next Color

.

3

The channel highlights in the selected color. Continue to set as many

channels to the colors you want.

4

5

Chan 0-3

Press

it changes to

If all four channels in a group are assigned the same color, the softkey shows

that color when you select it. If the channels in the group vary in color, the

softkey is white.

Next Color

Press

. The softkey highlights. Press it a few more times and

Chan 4-7, Chan 8-11

, and

Chan 12-15

.

. Continue to press this softkey to view the

waveform colors currently available.

The channel group softkey appears in the selected color, and the channels in

the group, if displayed on the screen, also display in the selected color.

Changing the color for a channel group will change the color for all channels

in the group, even if not all of the channels are displayed on the screen.

Colors Coord inate to Display Activity and Selections

When using colors on the HP 54620C color Logic Analyzer, all of the activity for a

specific cha nnel , i ncluding the channel color assignment softkey, chann el

waveform, channel activity in di cator, and trigger condition indicato r (when

defined for the s am e channel) are displayed in the same col or on screen.

The following figure shows the HP 54620C with the Label menu selected and

the Assign Channel Colors softkeys displayed.

33

Page 35

Getting Start ed

To print in color

Figure 5

Channel

labels

Channel

activity

indicator

Softkeys

HP 54620C w ith Label Menu Selected and Single Channel Hi ghl ighted

Trigger condi tion

To print in color

1

Press

Steps 2-4 are valid if you are using the HP 54652B Interface Module. The

HP 54652B is the recommended module for non-HP-IB applications. The

HP 54659B will function as a hardcopy and computer I/O, but none of its

advanced features are active in the logic analyzer. The HP 54652B and

HP 54659B each have dual interfaces (a parallel port and RS-232). If you are

using these modules, you can set the Destination to either Parallel or RS232.

Because there are no color printers with an HP-IB Interface, the HP 54650A

module is not recommended for color printing.

2

Press

This selects the HP DeskJet Color Printer format.

3

Set the Destination to

4

Press

The current display will be sent out the parallel port to the HP DeskJet color

printer attached to your logic analyzer, and printed in color.

34

Print

Hardcopy Menu

Previous Menu

.

. Then press

Parall el

.

. Then press

Format

Print Sc re en

until it displays

HP DJCo lor

.

.

Page 36

Making Measurements

To make measurements using the HP 54620A/C, you set up the

instrument using front-panel controls, then read the display results.

Learn the front panel

The HP 54620A front panel is shown in the following figure. The HP 54620C

differs only in that it does not have intensity control.

Front-Panel Functions

The front panel has several functional groups:

Display

settings, and shows color palettes (HP 54620C).

Channel Controls

add descriptive labels to them, and assign colors (HP 54620C).

General Controls

configuration and measurement result save/recall, printing, and autoscale

functions.

Horizontal Controls

delayed sweep functions.

Storage Keys

acquisition, and screen erasure.

Trigger Keys

Softkeys

dynamically depending on the required function.

Trigger Input / Output

instruments or use the HP 54620A/C to trigger another instrument.

Signal Inputs

probes.

Shows measurement results, some instrument configuration

Move or rearrange channels, turn them on or off,

Includes various measurement functions,

Adjusts the time base, horizontal mode, and

Controls start and stop of acquisition, persistent

Sets up analyzer trigger mode and trigger conditions.

Sets up various options for each major function, varying

Trigger the HP 54620A/C from external

Connects the HP 54620A/C acquisition system to the

35

Page 37

Figure 6

Getting Start ed

Learn the fro nt panel

Display Channel

Controls

General

Controls

Horizontal

Controls

Storage

Keys

Trigger

Keys

HP 54620C

does not have

display

intensity

HP 54620A Logic Analyzer Front Panel

36

Softkeys

Trigger

Input /

Output

Signal

Inputs

Page 38

Getting Started

Learn the fron t panel

Keypad and Softkeys

There are three types of keys on the front panel:

White keys have an immediate action, such as starting or stopping the

•

analyzer. There are no menus associated with white keys.

Gray keys bring up softkey menus, allowing you to modify the instrument’s

•

measurement configuration.

Softkeys under the display dynamically change to indicate currently valid

•

menu selections. Softkeys that are blank (that is, for which there is no

corresponding label) have no function in the selected menu.

Some keys, such as

while in the menus that they activate.

Control Knobs

The HP 54620A has six control knobs. The HP 54620C has five control knobs;

it does not have an intensity control knob.

The Time/Div knob changes the current time base setting (sweep speed)

•

of the analyzer in Main or Delayed sweep. The setting of the timebase

affects sample rate and other analyzer functions as well. See chapter 4,

“Ensuring Accurate Measurements,” for more information.

The Delay knob sets the delay time with respect to the time reference in

•

either Main or Delayed sweep.

The Select knob chooses the channel on which the next action will operate.

•

The Position knob moves the selected channel to a new vertical position

•

on the display.

The Entry knob selects from multiple choices in menus. It also

•

occasionally duplicates the function of the Select knob.

The display intensity knob (HP 54620A only—marked only with an

•

intensity symbol) adjusts display brightness.

On/Off

and

Label

, also have special functions

37

Page 39

Figure 7

Getting Start ed

Learn the fro nt panel

Display

This figure shows the HP 54620A/C display.

Status

Indicators

Channel

numbers

Waveform

display area

Memory bar

Measurement

field

Softkeys

HP 54620A/C Display

Channel

labels

interval

Glitch

mode

DelaySampling

Time/Div

Setting

Trigger

Condition

The display is divided into five regions:

Status indicators are along the top of the display.

•

Channel numbers and labels are along the left edge of the display.

•

Waveforms are in the center of the display.

•

Measurement results and messages are just below the waveform display

•

area.

Softkey labels are along the bottom of the display.

•

Acquisition

Indicator

38

Page 40

Getting Started

Learn the fron t panel

Status Indicators

Status indicators include the following:

Channels that are turned off; these are visible only if you select a channel

•

that is off by using the Select knob.

Sampling interval is a function of the Time/Div setting and varies from 2 ns

•

to 8 ms.

Glitch mode is indicated by “GL”, and indicates that glitch detection is

•

enabled. This is automatically enabled for sampling intervals greater than

8 ns. At time base speeds faster than 1 µs/div (sampling intervals of 4 ms

and faster) glitch mode is disabled.

Delay includes the time reference indicator, the offset markers, and the

•

delay measurement. The time reference indicator is a left arrow (←) if the

trigger event is at the beginning of acquisition memory, a right arrow (→)

if the event is at the end of acquisition memory, and a down arrow (↓) if it

is at the center. The offset markers and delay measurement work together

when you adjust the delay knob and Horizontal Mode is set to Main, to

indicate how far you have delayed the trigger event from the initial time

reference position.

Time/Div shows the time base setting. Time per division is variable from

•

5 ns/div to 1 s/div.

Trigger condition shows the current trigger mode. For edge trigger mode,

•

it will also show the trigger condition. If the last acquisition was initiated

by pressing the Single key, the letters “Sngl” appear in this position

(unless the last single acquisition was auto triggered).

Acquisition indicator shows the current acquisition condition, that is,

•

whether the acquisition system is running, stopped, or in autostore mode.

When the analyzer is in Normal trigger mode, the Trigger condition indicators

flash while the analyzer is searching for the trigger condition, which occurs

after the pre-trigger buffer is full. When the analyzer is in Auto trigger mode,

the word “Auto” flashes to the left of the Trigger condition indicator if the

analyzer did not find the trigger and was therefore triggered automatically

after a time-out.

The trigger condition indicators might also flash if the analyzer is stopped.

This indicates that the analyzer is finding a trigger condition and is driving

the trigger out port.

39

Page 41

Getting Start ed

Learn the fro nt panel

Channel Numbers and Labels

The channel numbers are always shown along the left edge of the display.

You can assign channel labels to help you remember the function of each

channel in your circuit, or disable the labels to increase the waveform display

area. See chapter 2, “Making Analyzer Measurements,” for more information

on using labels.

When using the HP 54620C color logic analyzer, you can assign colors to

channels using the Label menu. See “Using Color” in this chapter for more

information about assigning colors to channels.

Waveform Display

The waveform display area shows all acquisition results. You can change the

graticule or turn it off entirely using the Display menu. See chapter 2,

“Making Analyzer Measurements.”

When using the HP 54620C color logic analyzer, the waveform display shows

all activity and selections pertaining to a particular channel in the color

assigned to that channel. See “Using Color” in this chapter for more

information about assigning colors to channels.

40

Page 42

Getting Started

Learn the fron t panel

Memory Bar and Measurement Field

The memory bar is a horizontal line below the waveform display area which

shows what fraction of acquisition memory is displayed and the position of

the display with respect to acquisition memory. When the analyzer is

stopped, you can change the size of the display with respect to acquisition

memory using the Time/Div control, allowing you to zoom in on a specific

portion of memory.

Below the memory bar is the measurement field. This area is used to display

results for single- and dual-channel measurements, activity indicators, trigger

settings, error messages, and status messages.

Softkeys

Softkeys are shown along the bottom of the display. Some softkeys have an

immediate action, such as taking you to another menu or initiating a

measurement.

Other softkeys allow you to scroll through a list of choices, such as channels

or trigger operators. You can scroll through the choices by pressing the

softkey repeatedly. For some softkeys, you can use the Entry knob to scroll

through the choices. For channel lists, you can always use the Select knob or

Entry knob to scroll through the choices.

Occasionally a softkey label is displayed with two choices below it, one of

which is highlighted. The highlighted choice is the one that is currently

active. Pressing the softkey toggles the highlight to the other choice.

When several softkeys are displayed with a labeled bar over them, it means

that either the softkeys are related or that the choices are mutually exclusive.

When using the HP 54620C color logic analyzer color palettes, some

channel-specific softkeys display the color assigned to the particular channel.

See “Using Color” in this chapter for more information about assigning colors

to channels.

41

Page 43

Getting Start ed

To probe a circuit

To probe a circuit

1

Turn off the power supply to the circuit under

test.

Turning off power to the circuit under test

prevents damage that might occur if you

accidentally short two lines together while

connecting probes. You can leave the

HP 54620A/C powered on because no

voltage appears at the probes.

2

Connect the probe cable to the HP 54620A/C.

The cable is indexed so you can connect it only

one way. You do

HP 54620A/C.

4

Connect the grabber to a node in the circuit you

want to test.

not

need to power-off the

3

Connect a grabber to one of the probe leads.

(Other probe leads are omitted from the figure

for clarity.)

5

For high-speed signals, connect a ground lead to

the probe lead, connect a grabber to the ground

lead, and attach the grabber to ground in the

circuit under test.

42

Page 44

Getting Started

To probe a circuit

6

Connect the ground lead on each set of channels,

using a probe grabber. The ground lead improves

signal fidelity to the analyzer, ensuring accurate

measurements.

8

If you need to remove a probe lead from the

cable, insert a paper clip or other small pointed

object into the side of the cable assembly, and

push to release the latch while pulling out the

probe lead.

7

Repeat steps 3 through 6 until you have

connected all test points of interest.

See “Probing the Circuit Under Test” in

chapter 4 for information on how probing

affects measurement accuracy.

43

Page 45

Getting Start ed

To set up an acquisition using Aut oscale

To set up an acquisition using Autoscale

Example

Figure 8

•

To configure the analyzer quickly, press

•

To undo the effects of autoscale, press

Undo Autoscale

•

To set the instrument to the factory-default measurement

configuration, press

softkey in the Setup menu.

Setup

, then press the

Autosc ale

Setup

, then press the

Default Setup

.

softkey in the Setup menu.

Connect the probes for channels 0, 1, 2, and 3 to the calibration output

on the front panel of the logic analyzer. Set the analyzer to the factory

default configuration by pressing

Autosc ale

press

Notice that the default trigger condition is a rising edge trigger on

channel 0.

. You should see a display similar to the following.

Setup

Defaul t Se tu p

, then

. Then

Sample Aut oscale Measureme nt

44

Page 46

Getting Started

To set up an acquisition using Auto scale

How Does Autoscale Work?

If there is at l east one channel with an active signal, t he analyzer turns o ff al l

other channel s having no activity, that is, where no t ransitions through the logic

threshold are occurring, and turns on all channels having activity. TTL, ECL, and

variable thr esholds are used wh i l e testing for signal activity.

Channels not previously displayed will be added below t hose channels already

being displayed with the lowest num bered channel at th e top. Higher numbered

channels will be displayed in order down the di splay. The channels that ar e on

are scaled vertically to best fit the screen.

The analyzer checks for activi ty using a window of 20 ms, allowing it to

recognize signals as slow as 50 Hz for autoscalin g. C hannels that are turned off

will have blank activity indicators in the display. If the analyzer does not find any

channel with an active signal, i t restores the setup to t he pre-autoscale state.

Sweep speed is set to give an opti m al l y scaled display of all the active cha nnel s.

Autoscaling attempts to find a Time/div setting su ch that the slowest si gnal has

between 1 and 3 periods display ed, w i th no more than 125 periods of the fastes t

signal displayed. If these crit eri a cannot be satisifed, then a Time/div setting is

selected that i s as slow as possible, yet shows le ss than 125 periods of the

fastest signal.

Triggering (ex cept for auto/normal m ode) and channel label s are not affected,

unless an ext ernal trigger is found. Delay is set t o z ero. The analyzer is set to

Run mode (cont i nuous acquisition) .

The Undo Auto scale function returns the instrument to the setup that existe d

prior to Autos cal e being activated .

When using th e HP 54620A/C, pressing Autoscale returns t he Auto Glitch Detec t

capability in the Display menu to the enabled status.

45

Page 47

Getting Start ed

To start and stop an acquisition

To start and stop an acquisition

•

To begin an acquisition, press the

The analyzer begins acquiring data while searching for a trigger condition.

The RUN indicator is shown in the upper-right corner of the display. If a

trigger occurs, the acquired data is shown in the display.

•

To stop an acquisition in process, press the

The analyzer stops acquiring data, and the STOP indicator is shown in the

upper-right corner of the display. If the analyzer was triggered (even by auto

triggering) and the acquisition buffer is full, the results are displayed on the

screen. If the acquisition buffer is not full, the waveform display area will be

blank.

See “To define the trigger mode” in chapter 2 for information on how the

analyzer trigger mode affects the search for the trigger condition.

Run/St op

key.

Run/St op

key.

46

Page 48

To define a simple edge trigger

Getting Started

To define a s imple edge trigger

Example

Figure 9

Press

Edge

.

Do one of the following:

Press the

•

input as the trigger source.

Trg In

softkey under

Source

to choose the External Trigger

1

2

or

Select a channel as the trigger source using either the Select knob, the

•

Entry knob, or the softkey.

You can choose a channel that is turned off as the source for the edge

trigger.

3

Press one of the

Edge

softkeys to choose whether the trigger will

occur on the rising edge, falling edge, or either edge of the input

signal.

Connect the probe for channel 0 to the front-panel calibration test point.

Then set up a falling edge trigger on channel 0. You should see a stable

display of the channel, as shown below.

Edge Trigger on Channel 0

47

Page 49

Getting Start ed

To adjust the ti m e base (sweep speed)

To adjust the time base (sweep speed)

•

To increase the sweep speed (decrease the amount of time per

division on the display), turn the Time/Div knob clockwise.

•

To decrease the sweep speed (increase the amount of time per

division on the display), turn the Time/Div knob counterclockwise.

The sweep speed is adjustable from 5 ns/div to 1 s/div in 1, 2, 5 increments.

Turning on

When using the HP 54620A/C, and Auto Glitch Detect is disabled, you can

adjust the sweep speed to 2 s/div and 5 s/div. "GL" is not displayed if the logic

analyzer Auto Glitch Detect is disabled.

The current sweep speed setting affects other instrument operating

parameters. For example:

The sampling period is a function of the Time/div setting, but changes only

•

when a new acquisition begins.

To avoid missing fast events or short pulses, the analyzer automatically

•

switches to glitch mode at all time base settings slower than 1 µs/div. The

glitch mode indicator “GL” will appear in the status line.

Vernier

in the Main/Delayed menu gives finer increments.

In advanced triggering, the minimum limit for a pattern duration trigger is

•

two sample periods. Because the sampling rate depends on the Time/Div

setting and Auto Glitch Detect setting, the minimum duration and

resolution of the duration will change as the Time/Div setting changes, or

as the Auto Glitch Detect setting changes.

See chapter 4, “Ensuring Accurate Measurements,” for more information.

48

Page 50

To turn channels on and off

Getting Started

To turn channels on and off

•

To turn off a specific channel, press

using the Select knob, then press the leftmost softkey until

On/Off

, select a channel

Off

highlighted.

•

To turn on a specific channel, press

using the Select knob, then press the leftmost softkey until

On/Off

, select a channel

On

is

highlighted.

If you are already in the

key to toggle a particular channel on or off. The list of channels that are

off is in the upper-left corner of the display. You can also use the first

softkey to select a channel when the On/Off softkey menu is present.

•

To turn channels 0 through 7 on, press

On

softkey under “Chan 0 - 7.”

•

To turn channels 0 through 7 off, press

Off

softkey under “Chan 0 - 7.”

A corresponding set of On and Off softkeys is available for channels 8 through

15.

The analyzer does not disable input for channels that are off. It simply does

not display those channels. So, you can assign labels to channels that are off

or use them in a trigger specification. Also, if you turn a channel on after an

acquisition, the data acquired for that channel will be displayed. A channel

must be on, though, if you wish to make measurements using the single- or

dual-channel measurement features.

On/Off

menu, you can press the

On/Off

On/Off

On/Off

, then press the

, then press the

is

49

Page 51

Getting Start ed

To rearrange the channels

To rearrange the channels

1

Turn the Select knob to choose the channel you want to move.

Only channels that are currently on may be moved.

2

Turn the Position knob to choose a new location for the selected

channel.

Turning the Position knob counterclockwise moves the channel down;

turning the knob clockwise moves the channel up.

The combination of the Select and Move knobs gives you a feature similar to

that of a waveform position control on an oscilloscope, except that you can

only move the waveform to certain discrete locations.

You can also change the general order in which channels are displayed. Press

On/Off or Display, then press Order to toggle between 0-15 and 15-0

orderings.

50

Page 52

2

Making Analyzer Measurements

Page 53

Making Analyzer Measurements

The HP 54620A/C provides a full set of features to help automate your

measurement tasks. You can:

• Set up the analyzer for different logic thresholds, allowing

simultaneous timing measurements on sets of signals from different

logic families.

• Modify the way the analyzer acquires data.

• Label input signals to make it easier to relate the display to the

circuit under test.

• Set up simple or complex trigger conditions, as needed, to capture

only the sequence of events you want to examine.

• Use delayed sweep to examine the waveforms of interest.

• Make measurements on a single waveform or on one waveform with

respect to another.

• Trigger the analyzer from other instruments or use the analyzer to

trigger other instruments.

• Save the measurement for comparison with others or save the

analyzer configuration for later use in making the same

measurement.

This chapter explains how to do all these things and more. If you are

not familiar with basic analyzer operations, see chapter 1, “Getting

Started.”

52

Page 54

Figure 10

When threshold is set

correctly, the activity

indicators s how

double-heade d arr ow s

for rapidly-changing

signals, or high or low

for static or very

low-frequency signals

Setting Logic Levels

You can adjust the logic threshold levels used by the analyzer for

three independent groups of input signals: channels 0-7, channels

8-15, and the external trigger. Because of this, you can make

simultaneous measurements on signals from different logic families.

For example, you could connect channels 0-7 to TTL signals, channels

8-15 to ECL signals, and the external trigger to an analog signal. Then,

you can set the threshold voltages to the appropriate value for each

group.

Selects the gro up of

channels for which

threshold will be set

Choose from preset TTL,

CMOS, or ECL thresholds, or

set a user- defined threshold

Logic Thresh old Setup

Shows the thr eshold

for the selected

family, or sets a

user-defined

threshol d usi ng the

Entry knob

53

Page 55

Making Anal yzer Measurement s

To change the logic threshold for in put signals

To change the logic threshold for input signals

Table 3

1

Press

2

Press the

Logic Le ve ls

Set

softkey to highlight the range of channels for which

.

you want to set the logic threshold.

User

.

Chan 0-7

, or

(channels 0 through 7),

TRIG IN

User

(the external trigger input).

to select the threshold.

, set the threshold voltage using the Entry knob.

Ranges available are

(channels 8 through 15), and

3

4

5

TTL, CMOS, ECL

Press

If you selected

Turning the Entry knob while in this menu automatically sets the Threshold

option to

User

Repeat steps 2 through 4 for each group of channels for which you

Chan 8-15

want to set the threshold.

You can exit the threshold setting menu by pressing any other front-panel

key.

The threshold voltage setting is used by the input comparators to determine

whether an input signal is a logic low or logic high. The settings for each

option are shown in table 2.

Threshold Voltage Settings

Option Voltage

TTL 1.50 V

CMOS 2.50 V

ECL -1.30 V

User Continuous ly variable from –6.00 V to +6.00 V

54

Page 56

Controlling Data Acquisition

During an acquisition, the logic analyzer examines the input voltage

at each input probe at a sampling rate defined by the time base setting

(Time/Div knob). At each sample, it compares the input voltage to the

logic threshold. If the voltage is above the threshold, the analyzer

stores a “1” in sample memory; otherwise, it stores a “0.” When sample

memory is full, the display logic reconstructs the input waveform from

the pattern of bits stored in sample memory. To control the

HP 54620A/C acquisition process, you can

• perform continuous acquisitions by pressing the Run/Stop key, and

stop them by pressing it again,

• make one acquisition, then stop, by pressing the Single key,

• store the results of several acquisitions by pressing Autostore, or

• erase the results of all acquisitions by pressing Erase.

Chapter 1, “Getting Started,” explains how to use the Run and Stop

functions. The others are explained in this section.

Auto Glitch Detect

The HP 54620A/C automatically enables Auto Glitch Detect upon

powerup. When the Auto Glitch Detect feature is enabled, it puts the

instrument in glitch detect mode at all sweep speeds of 1 µs/div and

slower where the sampling speed must be reduced, thereby

preventing aliases from being displayed.

When Auto Glitch Detect is disabled, the HP 54620A/C acquisition

system has a record length of 8K samples at all sweep speeds. In

addition, you can extend the sweep speed to 2 s/div and 5 s/div in the

Main display mode. See “Glitch Detection” in chapter 4.

When Auto Glitch Detect is enabled, a waveform display that contains

glitches, separated by the sampling intervals, is an indication that the

waveform is being undersampled. A faster Time/Div setting is needed

to obtain a correct display of the waveform. This easy indication of

undersampling is not available when Auto Glitch Detect is disabled.

55

Page 57

Making Anal yzer Measurement s

To take a sing le acquisition

You can detect the presence of aliases in the analyzer’s display simply

by selecting a faster sweep speed. If the waveform display changes

more than expected, it is an alias being caused by undersampling.

Whenever a waveform is being displayed as a solid bar, it is highly

likely that when you expand the waveform the display will contain

aliases.

Aliasing Produces Misleading Inf orm ation

Aliasing produces misleading i nformation. The gl i tch detect circuitry helps

prevent alia sing by identifyin g additional transitions that occur between

samples.

Whenever the w aveform display is not as expected, it mi ght be an alias—t he

result of undersampling. Alway s try to use a sweep speed that produces a

sampling interval that is at least 1/2 of the shortest time interval to be acquired.

To take a single acquisition

•

Press

The analyzer starts the acquisition system and begins searching for the

trigger condition.

When the analyzer is in Autostore mode (see “To accumulate the results of

every acquisition”) pressing Single adds the results of the new acquisition to

the current display contents.

See “To define the trigger mode” in this chapter for more information on how

the analyzer’s trigger mode affects handling of the trigger condition.

56

Single

.

Page 58

To use Auto Glitch Detect

Making Anal yzer Measurement s

To use Auto Glitch Detect

Figure 11

1

Press

Make sure the

Auto Glitch Detect feature is enabled upon powerup, and puts the logic

analyzer in glitch detect mode for all time base speeds slower than 1 µs/div.

When Auto Glitch Detect is disabled, aliasing can occur, which produces

misleading information for data reconstruction. See “Glitch Detection” in

chapter 4.

The following display shows no aliasing with Auto Glitch Detect enabled; the

waveform appears as expected when expanded.

Displa y

Preferred Mo de of Operation

The preferred m ode of HP 54620A /C operation is Auto Glitch Detect enabled.

However, there might be a situat i on that requires the us e of the instrument’s full

8K memory to capture the waveform of interest. This can be accomplished by

selecting Auto Glitch Detect Disable mode. In this mode you will have no

indication that the waveform mig ht be undersampled.

.

Auto Glitch Detect Enable

softkey is highlighted. The

Waveform D i splay with Aut o Glitch Detect Enab le d

57

Page 59

Making Anal yzer Measurement s

To accumulate the results of ever y acquisition

To accumulate the results of every acquisition

•

Press

When Autostore is on, the analyzer updates pixel memory (display memory)

with new acquisitions, but does not erase the results of previous acquisitions.

Instead, for each pixel memory location turned on by a previous acquisition,

the analyzer changes the display brightness to half-bright (or to the

Autostore color for HP 54620C). Thus, the results of each new acquisition are

displayed at full brightness (or to the Autostore color for HP 54620C), and

the results of all previous acquisitions are displayed at half brightness.

The indicator “STORE” is displayed at the right end of the status line when

Autostore is selected.

When the analyzer is in Autostore mode, pressing

result of the new acquisition to the current display contents.

To turn off Autostore while in Run mode, press

Autost or e

.

Single

Autost or e

adds the

again.

To erase the waveform display

•

Press

Acquisition memory and the current display are immediately erased. If the

instrument is in Run or Autostore mode, however, and the analyzer finds a

trigger condition, the display will be quickly updated after the erasure.

Erase

.

58

Page 60

Using Labels

The HP 54620A/C allows you to define and assign labels to each input

channel. Or, you can turn labels off to increase the waveform display

area.

In addition, the HP 54620C allows you to assign colors to channels.

This makes it easy to associate input channels with their functions in

the system under test.

To turn the label display on or off

•

To display channel labels, press

Label

, then press the

Labels

softkey until On is highlighted.

•

To turn off channel labels display, press

Labels

•

To toggle the channel labels display, press

softkey until

Off

is highlighted.

Label

Label

, then press the

repeatedly

until the labels are on or off as desired.

The following figure shows the HP 54620C color logic analyzer label menu.

You can highlight an individual channel or a set of channels.

59

Page 61

Making Anal yzer Measurement s

To assign a label to a channel

To assign a label to a channel

1

Press

2

Press the

The following figure shows the label maker. A label definition menu is shown

on the right-hand side of the display.

3

Select the channel for which you want to assign a label using the

Label

.

Define Labels

softkey.

Select knob.

You can assign labels to channels that are off and to channels that are on.

4

Use the Entry knob to choose the label you want to assign from the

list of labels.

The Entry knob moves the cursor through the label list, then through the

character list. You can also define custom labels. The label list includes all

predefined labels, and custom labels you have defined, unless it is

re-initialized. See “To define a new label.”

5

Press the

The selected label is transferred to the entry field.

6

Press the

The label is assigned to the selected channel.

Label display is automatically enabled when you enter the Define Labels

menu. Thus, if the labels were off, they are turned on while you define labels.

If you exit the Define Labels menu, and the labels were off before you

entered the menu, they are turned off when you exit.

Copy

softkey.

Assign Label

softkey.

60

Page 62

Figure 12

Making Anal yzer Measurement s

To assign a label to a channel

If you defined a new label, it is added to the label list and will be saved with

the analyzer configuration.

Shows what

will be put in

the entry

field when

you press

Copy

Press to delete

the character at

the cursor in th e

entry field

Scroll through the label

and character lists

using the Entry knob

Press to i nsert

a space in the

entry field at

the cursor

Press to copy

the selected

label/character

to the entry f ield

The entry field

shows you w hat

will be assigned to

the channel

Press to move the

cursor through the

entry field

Select

the

channel

with the

Select

knob

Pres s t o assign

the label to the

channel

HP 54620A/C Label Definition Display

61

Page 63

Making Anal yzer Measurement s

To define a new label

To define a new label

1

Press

2

Press the

A label definition menu is shown on the right-hand side of the display.

3

To use an existing label as the basis for the new label, use the Entry

knob to choose a label from the list of labels. Then press the

Label

.

Define Labels

softkey.

Copy

softkey.

The Entry knob moves the cursor through the label list, then through the

character list. The label list includes all predefined labels, and custom labels

you have defined, unless it is re-initialized. When you press the Copy softkey,

the selected label is transferred to the entry field.

4

To enter characters into the new label:

a

Press the

corresponds to the point where you want to replace a character.

b

Enter or delete a character.

To enter a character, use the Entry Knob to choose a character from

•

the character list. Then press the

To insert a space, press the

•

To delete the current character, press the

•

Delet e Character

moves successive characters forward by one position.

5

Press the

The label is assigned to the selected channel.

Label display is automatically enabled when you enter the Define Labels

menu. Thus, if the labels were off, they are turned on while you define labels.

If you exit the Define Labels menu, and the labels were off before you

entered the menu, they are turned off when you exit.

Position

Assign Label

softkey until the cursor position in the entry field

softkey.

Copy

Insert Space

deletes the character under the cursor and

softkey.

Delet e Ch ar ac ter

softkey.

softkey.

62

Page 64

Making Anal yzer Measurement s

To define a new label

Label Assig nm ent Auto-Increment Features

When you assign a label ending in a digit, such as A DDR0 or DATA0, the

analyzer aut om atically increment s the digit and disp l ays the modified label in the

entry field. Then, the analyzer changes the selected channel to the next c hannel

down on the dis pl ay that is on. This m akes it easier to as sign successive l abel s

to numbered co ntrol lines and data bus lines.

Label List M anagement

The label lis t contains 75 of the most recently used l abel s. The list does not save

duplicate label s, nor does it save multiple labels that differ by, at m ost, two

trailing num eri c characters.

The label lis t is non-volatile. Thus, after you us e the label list for awhi l e, your

labels will predominate, mak i ng it easier to customize the analyzer display for

your needs.

When you first begin using the an al yzer, there are seven blank entries a t t he

beginning of the label lis t. A s you define custom labels, these spaces are filled.

One blank space is always retai ned to allow entry of a new label. When you

initialize the label list, all of your custom labels will be cleared, and the label lis t

will be returned to its factory configuration.

63

Page 65

Making Anal yzer Measurement s

To initialize t he label list

To initialize the label list

1

Press

2

Press the

A message appears, warning you that this operation will overwrite the

current label list.

•

•

When you first begin using the analyzer, there are seven blank entries at the

beginning of the label list. As you define custom labels, these spaces are

filled. One blank space is always retained to allow entry of a new label. When

you initialize the label list, all of your custom labels will be cleared.

Label

To confirm the operation, press the

press Yes again to initiate the operation.

To cancel the operation, press the No softkey.

.

Initialize Label List

softkey.

softkey. You will be prompted to

Yes

64

Page 66

Triggering the Analyzer

The HP 54620A/C allows you to synchronize the analyzer display to

the actions of the circuit under test by defining a trigger condition.

The analyzer offers three types of triggering, allowing you to match

the complexity of the trigger to that of the data you want to capture.

Trigger types

These trigger types are as follows:

Edge trigger

•

Pattern trigger

•

Advanced trigger

•

Changes to the current trigger specification are handled in real-time. If

the analyzer is stopped when you change a trigger specification, it uses

the new specification as soon as you press

Autost ore

or

triggering specification, it immediately begins a new acquisition using the

new trigger definition.

. If the analyzer is in Run mode when you change a

Run/St op , Single

,

Edge Trigger

In edge trigger, you define a single rising or falling edge (or either) that must

be recognized on an input channel to satisfy the trigger condition.

Edge trigger is best when there is a unique waveform edge that defines the

events you wish to capture. For example, a gate signal that defines the

beginning of a pulse train on another channel will often make a good edge

trigger. Edge trigger is less useful when the set of events that occur after the

edge change dramatically after every edge, or when the edges occur very

frequently in relation to other signals.

65

Page 67

Making Anal yzer Measurement s

Trigger type s

Pattern Trigger

In pattern trigger, you define a pattern of highs, lows, and don’t care inputs

that must be recognized across the input channels during any given input

sample. The pattern may be combined with one edge on any input channel to

form the complete trigger specification.

Pattern trigger is best when there is a unique pattern that occurs across a

group of signals, and the pattern defines the events you want to capture. For

example, suppose you have a state machine that outputs a series of hex

digits, and only outputs the digit ‘A’ once in every sequence. You can use a

pattern trigger to capture this event.

Pattern trigger is less useful when the same pattern occurs many times, and

most of those occurrences have little to do with the events you wish to

capture. For example, suppose that this same state machine generates

hundreds of states, and the state “C” occurs several times in the sequence,

with a different sequence of states after each occurrence. A pattern trigger

will not provide a stable waveform display.

The pattern trigger occurs when the pattern is entered; that is, the trigger