Page 1

OPERATING AND

SERVICE MANUAL

Relay Accessories

Agilent Models 59510A, 59511A

Agilent Part No. 5957-6382

Serial Numbers:

Agilent Model 59510A, Serials US29080101 and Above

Agilent Model 59511A, Serials US29060101 and Above

* This manual also applies to instruments with the older serial number format described on page 7.

Microfiche Part No. 5957-6383 Printed in USA: April, 1988

Page 2

SAFETY SUMMARY

The following general safety precautions must be observed during all phases of operation, service, and repair of this

instrument. Failure to comply with these precautions or with specific warnings elsewhere in this manual violates safety

standards of design, manufacture, and intended use of the instrument. Agilent Technologies Company assumes no liability

for the customer’s failure to comply with these requirements.

BEFORE APPLYING POWER.

Verify that the product is set to match the available line voltage and the correct fuse is installed.

GROUND THE INSTRUMENT.

This product is a Safety Class 1 instrument (provided with a protective earth terminal). To minimize shock hazard, the instrument chassis

and cabinet must be connected to an electrical ground. The instrument must be connected to the ac power supply mains through a threeconductor power cable, with the third wire firmly connected to an electrical ground (safety ground) at the power outlet. For instruments

designed to be hard-wired to the ac power lines (supply mains), connect the protective earth terminal to a protective conductor before any

other connection is made. Any interruption of the protective (grounding) conductor or disconnection of the protective earth terminal will

cause a potential shock hazard that could result in personal injury. If the instrument is to be energized via an external autotransformer for

voltage reduction, be certain that the autotransformer common terminal is connected to the neutral (earthed pole) of the ac power lines

(supply mains).

FUSES.

Only fuses with the required rated current, voltage, and specified type (normal blow, time delay, etc.) should be used. Do not use repaired

fuses or short circuited fuseholders. To do so could cause a shock or fire hazard.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE.

Do not operate the instrument in the presence of flammable gases or fumes.

KEEP AWAY FROM LIVE CIRCUITS.

Operating personnel must not remove instrument covers. Component replacement and internal adjustments must be made by qualified

service personnel. Do not replace components with power cable connected. Under certain conditions, dangerous voltages may exist even

with the power cable removed. To avoid injuries, always disconnect power, discharge circuits and remove external voltage sources before

touching components.

DO NOT SERVICE OR ADJUST ALONE.

Do not attempt internal service or adjustment unless another person, capable of rendering first aid and resuscitation, is present.

DO NOT EXCEED INPUT RATINGS.

This instrument may be equipped with a line filter to reduce electromagnetic interference and must be connected to a properly grounded

receptacle to minimize electric shock hazard. Operation at line voltages or frequencies in excess of those stated on the data plate may

cause leakage currents in excess of 5.0 mA peak.

SAFETY SYMBOLS.

Instruction manual symbol: the product will be marked with this symbol when it is necessary for the user to refer to the

instruction manual (refer to Table of Contents) .

Indicates hazardous voltages.

Indicate earth (ground) terminal.

The WARNING sign denotes a hazard. It calls attention to a procedure, practice, or the like, which, if not correctly

performed or adhered to, could result in personal injury. Do not proceed beyond a WARNING sign until the

indicated conditions are fully understood and met.

The CAUTION sign denotes a hazard. It calls attention to an operating procedure, or the like, which, if not correctly

performed or adhered to, could result in damage to or destruction of part or all of the product. Do not proceed

beyond a CAUTION sign until the indicated conditions are fully understood and met.

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT.

Because of the danger of introducing additional hazards, do not install substitute parts or perform any unauthorized modification to the

instrument. Return the instrument to an Agilent Technologies Sales and Service Office for service and repair to ensure that safety features

are maintained.

Instruments which appear damaged or defective should be made inoperative and secured against unintended operation until they can be

repaired by qualified service personnel.

2

Page 3

Table of Contents

General Information...............................................................................................................................................................5

Introduction .......................................................................................................................................................................... 5

Description (Figure 1-1) .......................................................................................................................................................5

Specifications........................................................................................................................................................................7

Safety Considerations........................................................................................................................................................... 7

Instrument and Manual Identification...................................................................................................................................7

Options ................................................................................................................................................................................. 7

Installation.............................................................................................................................................................................10

Introduction ........................................................................................................................................................................ 10

Initial Inspection.................................................................................................................................................................10

Mounting ............................................................................................................................................................................ 10

Surface Mounting ...........................................................................................................................................................10

Option 850 Mounting ..................................................................................................................................................... 11

Input Power Requirements..................................................................................................................................................12

Power Cord.........................................................................................................................................................................13

Connections and Operating Information............................................................................................................................15

Introduction ........................................................................................................................................................................ 15

Agilent 595lXA Front Panel...............................................................................................................................................15

DC Power Connections.......................................................................................................................................................17

Sense Lead Connections.....................................................................................................................................................18

Remote Sensing.............................................................................................................................................................. 18

Local Sensing (Figure 3-3).............................................................................................................................................19

Agilent 603XA Configuration ............................................................................................................................................19

Switch Settings...............................................................................................................................................................20

CONFIG Switches......................................................................................................................................................20

RLY LINK or INH/ FLT Switch ................................................................................................................................22

Agilent 603XA/5951XA Serial Data Connection...........................................................................................................22

Agilent 603XA/5951XA Configuration Wake-Up State ................................................................................................22

Remote Inhibit (INH) and Fault (FLT) Lines .................................................................................................................23

INH Input Line ........................................................................................................................................................... 24

FLT Output Line......................................................................................................................................................... 24

Using INH and FLT with Multiple Agilent 603XA/5951XA’s................................................................................... 24

Agilent 603XA Status PoII.............................................................................................................................................24

Agilent 603XA/5951XA Turn-On Sequence.................................................................................................................. 25

General Purpose Configuration........................................................................................................................................... 26

Switch Settings...............................................................................................................................................................27

Agilent 603X LINK or LOGIC CONTROL Switch................................................................................................... 27

Listen Enable Switch.................................................................................................................................................. 27

TTL Input Connections...................................................................................................................................................27

LISTEN ENABLE Input............................................................................................................................................ 28

OPEN/CLOSE Signal.................................................................................................................................................28

NORM/REVInput (Applies only to Agilent Model 59511A)..................................................................................... 28

Remote Inhibit (INH) and Fault (FLT) Lines ................................................................................................................. 28

3

Page 4

Agilent 603XA Programming Commands.......................................................................................................................... 31

Introduction ........................................................................................................................................................................ 31

Changed Command............................................................................................................................................................. 32

Output On/Off................................................................................................................................................................. 32

Added Commands............................................................................................................................................................... 34

DC On/Off...................................................................................................................................................................... 34

Relay On/Off .................................................................................................................................................................. 35

Polarity Normal/Reverse (Model 59511A only).............................................................................................................35

Maintenance..........................................................................................................................................................................37

Introduction ........................................................................................................................................................................ 37

Circuit Operation................................................................................................................................................................ 37

Main Circuit Board.........................................................................................................................................................37

Control Circuits .......................................................................................................................................................... 37

Bias Supply................................................................................................................................................................. 38

Power-on Circuit......................................................................................................................................................... 38

Relays............................................................................................................................................................................. 39

Verification.........................................................................................................................................................................40

Relay Control Verification (TTL Mode) ........................................................................................................................ 40

DC Power Relay Verification.........................................................................................................................................41

Removal and Replacement Procedures............................................................................................................................... 42

Cover .............................................................................................................................................................................. 42

Assembly Removal......................................................................................................................................................... 43

Main Circuit Board Removal.......................................................................................................................................... 43

Troubleshooting Procedures ............................................................................................................................................... 43

Test Setup....................................................................................................................................................................... 43

Bias Supply and Power-On Circuit................................................................................................................................. 44

Microprocessor U101 ..................................................................................................................................................... 44

Relay Circuits.................................................................................................................................................................45

Agilent Model 59510A............................................................................................................................................... 45

Agilent Model 59511A............................................................................................................................................... 45

FLT and INH Circuits..................................................................................................................................................... 46

Parts List.............................................................................................................................................................................47

Agilent Sales and Support offices........................................................................................................................................56

4

Page 5

1

General Information

Introduction

This manual contains instructions for installing, operating and troubleshooting the Agilent Model 59510A and 59511A

Relay Accessories. Each of these models is designed for use with the Agilent 6030A, 6032A, 6033A, and 6038A models in

the Agilent 603XA series of system power supplies. The Agilent 59510A and Agilent 59511A Relay Accessories can be

used with Agilent 603XA supplies that have the following serial numbers:

Agilent Model Serial Numbers *

6030A 2811A-00815 and above

6031A** 2817A-00983 and above

6032A 2818A-03121 and above

6033A 2817A-03452 and above

6038A 2817A-05426 and above

* Models with lower serial numbers can be modified to operate with the Agilent 595XA Relay Accessory. Consult Agilent

regarding a retrofit kit for these models.

**When the Agilent 5951XA Relay Accessory is to be used with the Agilent 6031A System DC Power Supply, care must be

taken to set the Agilent 6031A’s current limit to 60 A or less. The Agilent 6031A power supply is capable of delivering

an output current in excess of Agilent 5951XA’s rating of 60 A, which could cause damage to the Relay Accessory.

Wherever applicable, the instructions given in this manual refer to pertinent information provided in the Operating and

Service Manual for the appropriate Agilent 603XA power supply as follows:

Agilent Model Manual Agilent P/N

6030A 06030-90003

6031A 06031-90003

6032A 06032-90005

6033A 06033-90010

6038A 06038-90003

The Relay Link Supplement, Appendix F (Agilent Part No. 5957-6388) to the above manuals, describes circuit changes to

the Agilent 603X supplies which allow use of the supplies with the Agilent 59510A/59511A. The Agilent 59510A/59511A

Relay Accessory has a logic control input (TTL levels) that allows it to be used with power supplies or devices other than

the supplies specified above. Instructions for using the logic control input in a general purpose configuration are given in

Section 3 of this manual.

Description (Figure 1-1)

The Agilent 59510A and 59511A Relay Accessories are intended for use in power supply applications where either or both

load isolation (connect/disconnect) and polarity reversal are required.

The Agilent 59510A Relay Accessory provides for load connect/disconnect for both the power output and sense leads of the

power supply. The Agilent 59511A Relay Accessory provides for polarity reversal as well as for load connect/disconnect

for both power output and sense leads. In addition, each model includes a fault (FLT) output line and a remote inhibit (INH)

input line. The FLT output line provides a fault reporting capability that is independent of the GPIB service request (SRQ)

General Information

5

Page 6

function. The INH input line provides a way to remotely disconnect (also independent of GPIB computer control) the power

supply output.

Figure 1-lA shows the Agilent 59510A/59511A Relay Accessory configured with an Agilent 603XA power supply. A GPIB

interface in the Agilent 603XA power supply recognizes relay commands from the computer and provides serial data to the

Agilent 59510A/59511A via a special connection labeled RLY LINK. The Agilent 5951XA converts the serial data into

relay control signals.

The computer can control the connect/disconnect and polarity reversal (Agilent 59511A only) functions via the Agilent

603XA supply’s serial data link to the Agilent 59510A/59511A. The closing and opening of the relays in the Agilent

59510A/59511A can be coordinated with the enabling and disabling of the power supply output to allow switching the

relays when the power supply output is disabled in order to prolong relay life. The microprocessor within the Agilent

59510A/59511A Relay Accessory properly sequences the power and sense relays to minimize overshoots at the power

supply output.

Figure 1-lB shows the Agilent 59510A/59511A Relay Accessory configured in a general purpose application. This

configuration allows the Agilent 59510A/59511A to be used with power supplies or devices other than Agilent 603XA

power supplies. Logic control inputs are provided that allow TTL logic levels to control the connect/disconnect and polarity

reversal (Agilent 59511A) functions. The logic control inputs have pull-up resistors which allow them to accept signals from

relays or open-collector devices.

The Agilent 59510A/59511A Relay Accessory is designed to fit in a rack height of 5¼ inches and is approximately 7¼

inches wide and 8 inches deep. All necessary connections are made at the front panel.

6

General Information

Figure 1-1. Agilent 59510A/59511A Configurations

Page 7

Specifications

Table 1-1 lists the specifications for the Agilent 59510A/59511A Relay Accessories. The 603XA power supply

specifications are listed in the applicable manual (see page 1).

Safety Considerations

This product is a Safety Class 1 instrument, which means that it is provided with a protective earth terminal. The instrument

and this manual should be reviewed for safety markings and instructions before operation. Refer to the Safety Summary

page at the beginning of this manual for a summary of general safety information. Safety information for specific procedures

is located at appropriate places in the manual.

The Agilent 5951XA Relay Accessory contains mercury displacement relays. Because mercury is a hazardous material,

defective relays must be disposed of properly (refer to page 38).

Agilent Technologies power supplies are designed to comply will the following regulatory standards: IEC 348, VDE 0411,

CSA 556B, VDE 0871/6.78 level B (FTZ 1046/84), UL1244.

Instrument and Manual Identification

Agilent Technologies instruments are identified by a 10-digit serial number. The first two letters indicate the country of

manufacture. The next four digits are a code that identify either the date of manufacture or of a significant design change.

The last four digits are a sequential number assigned to each instrument.

Older serial number formats used with these instruments had a two-part serial number, i.e. 2701A-00101. This manual also

applies to instruments with these older serial number formats.

If the serial number prefix on your Relay Accessory differs from that shown on the title page of this manual, a yellow

Manual Change sheet that is supplied with the manual defines the differences between your unit and the unit described in

this manual. The yellow change sheet may also contain information for correcting errors in the manual.

Options

850: One rack mount kit.

910: One extra operating and service manual shipped with each Relay Accessory.

W30: 2 year additional Return-to-Agilent Service.

General Information

7

Page 8

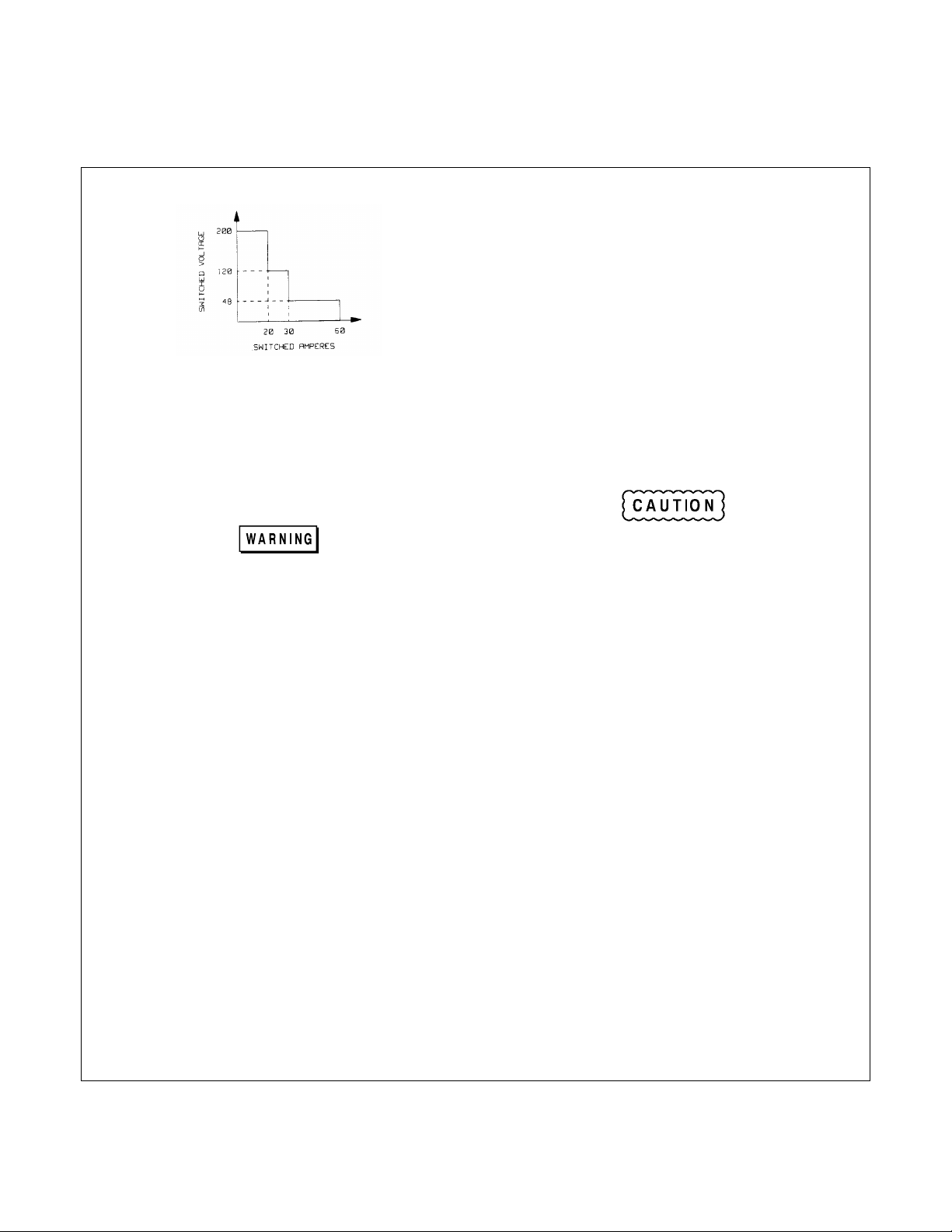

Table 1-1. Agilent Model 59510A and 59511A Specifications

Operating Range: (Both Models)

Inductive Load: 10mH maximum

Note that switching of inductive loads places stresses on the

Agilent 5951XA power relay contacts which can

significantly degrade relay life. It is advisable to switch

these loads under low or zero output conditions, e.g. with

the power supply output disabled. In general, switching any

load under zero output conditions maximizes relay life.

For applications with > 10 mH inductance, consult

Agilent Technologies for applicability and safety.

Using the Agilent 5951XA relays to interrupt high

currents through highly inductive loads will cause

high levels of energy to discharge across the relay

contacts. The resulting rise in temperature and

pressure may cause a breach in the hermeticity of

the seals in the mercury-filled cylinders of the

power relays. Since mercury is a toxic substance,

this is a potentially hazardous condition.

Care should be taken in all applications not to

exceed the operating range specifications in order

to avoid compromising the reliability or the

physical integrity of the mercury-displacement

relays in the Agilent 5951XA.

FOR THESE REASONS, THE AGILENT

5951XA SHOULD NOT BE USED WITH THE

AGILENT 603XA HIGH INDUCTANCE

OPTIONS J01, J02. AND J07.

Agilent Model PARD (mVp-p max).

6032A 20

6033A 20

6038A 20

Isolation:

A IN/B IN to A OUT/B OUT: 200Vdc max.

A IN/B IN/A OUT/B OUT to Ground: ± 500Vdc max.

Agilent 603X LINK to Ground: ± 42Vdc max.

*LOGIC CONTROL/INH to Ground: ± 240Vdc max.

*FLT to Ground: ± 240Vdc max.

FLT to LOGIC CONTROL/INH ±42Vdc max.

The Agilent 603X LINK, LOGIC CONTROL, and

INH signals on the control connector J101 are

referenced to the same common. This means that if

the Agilent 5951XA relay accessory is being used in

the Agilent 603XA configuration (see page 16), these

signals on the control connector J101 must be

restricted to ± 42Vdc from ground, in accordance

with the restrictions of the Agilent 603XA FLT/INH

port float voltage specification (refer to appropriate

Agilent 603XA Operating and Service Manual). The

FLT signal on J101 has its own common which may

float ± 42Vdc from the other; signal common on J101

and up to ± 240Vdc from ground. The LOGIC

CONTROL, INH, and FLT signals may be floated up

to ± 240Vdc from ground ONLY if they are not

driven by or driving signals of the FLT/INH port of

an Agilent Technologies instrument AND the Agilent

603X LINK signals are left disconnected.

As a general rule, if a connection is made from any

point on control connector J101 to any point or the

FLT/INH port of an Agilent Technologies instrument,

all signals on J101 must be restricted to no greaser

than ± 42Vdc from ground.

AC Input: A line select switch on the front panel permits

either 100/120Vac or 220/240Vac operation ( - 13%, +

6% 48-63 Hz).

8

General Information

Settling Time (TTL Control):

Connect: 440 mS

Disconnect: 160 mS

Polarity Reversal: 600 mS

Page 9

Table 1-1. Agilent Model 59510A and 59511A Specifications (continued)

Maximum Input power: 60VA

PARD: The Agilent 5951XA Relay Accessory incorporates

a filter which, when used with certain models of the

Agilent 603XA power supply family, yields improved

output noise performance at the AOUT/BOUT

terminals of the Agilent 5951XA.

Control Signals Timing:

INH input signal hold time:

1.5 ms minimum

LOGIC CONTROL inputs (TTL levels) hold time:

1.5 ms minimum

to FLT propagation: 1.5 ms maximum

INH

Temperature:

Operating: 0 to +55 degrees Celsius

Storage: -40 to +75 degrees Celsius

DC Voltage Drop (at 60A): DC voltage drop of 0.5V

maximum between A IN and A OUT and 0.5V

maximum between B IN and B OUT.

Dimensions: (Both Models)

Width Height Depth

7.35 in. 5.14 in. 7.82 in.

186.8 mm 130.6 mm 198.6 mm

Weight (lbs): 59510A 59511A

Net Weight: 5 8

Shipping Weight: 8 11

Shipping Weight 9 12

with Option 850:

Mounting Orientation: ± 10° from vertical

General Information

9

Page 10

2

Installation

Introduction

This section contains instructions for inspecting and mounting the Relay Accessory, and connecting it to ac power.

Initial Inspection

This accessory was thoroughly inspected and tested before it left the factory. As soon as you receive it, remove it from its

packing case and check to make sure that it has not been damaged in shipment. Check that there are no broken connectors,

etc., and that the unit is free from dents and scratches.

If any damage is found, you should file a claim with the carrier immediately and notify the Agilent Technologies Sales and

Service office nearest you. Keep the original packing materials for the carrier’s inspection or in the event the unit has to be

returned to Agilent Technologies. Warranty information is printed on the inside cover of this manual. Your Agilent

Technologies Sales and Service office will furnish the address of the nearest service office to which the unit can be shipped.

Mounting

The Relay Accessory units utilize mercury displacement relays. Consequently, the units must be

vertically mounted (or oriented) to ensure proper operation and avoid damage to equipment (See Table

1-1 Specifications).

The Relay Accessory unit is convection cooled and can operate without loss of performance within the temperature range of

0 to 55 degrees C. If the unit is to be used on a bench or any flat surface, attach the four adhesive backed rubber feet to the

bottom of the Agilent 5951XA unit. The feet are shipped in a plastic bag along with two quick disconnect plugs and spare

fuses.

The unit can also be mounted in a standard 19 inch rack panel or enclosure. It can be rack mounted in either of two ways:

1. Drilling two holes in the mounting surface and using screws to engage the threaded inserts in the bottom of the Agilent

5951XA.

2. Using the Option 850 Rack Mounting Kit.

Ventilation holes are located on both sides of the Agilent 5951XA as well as in the back. Make sure that

the back and at least one side is left unobstructed. Failure to do so could cause overheating and damage.

10 Installation

Page 11

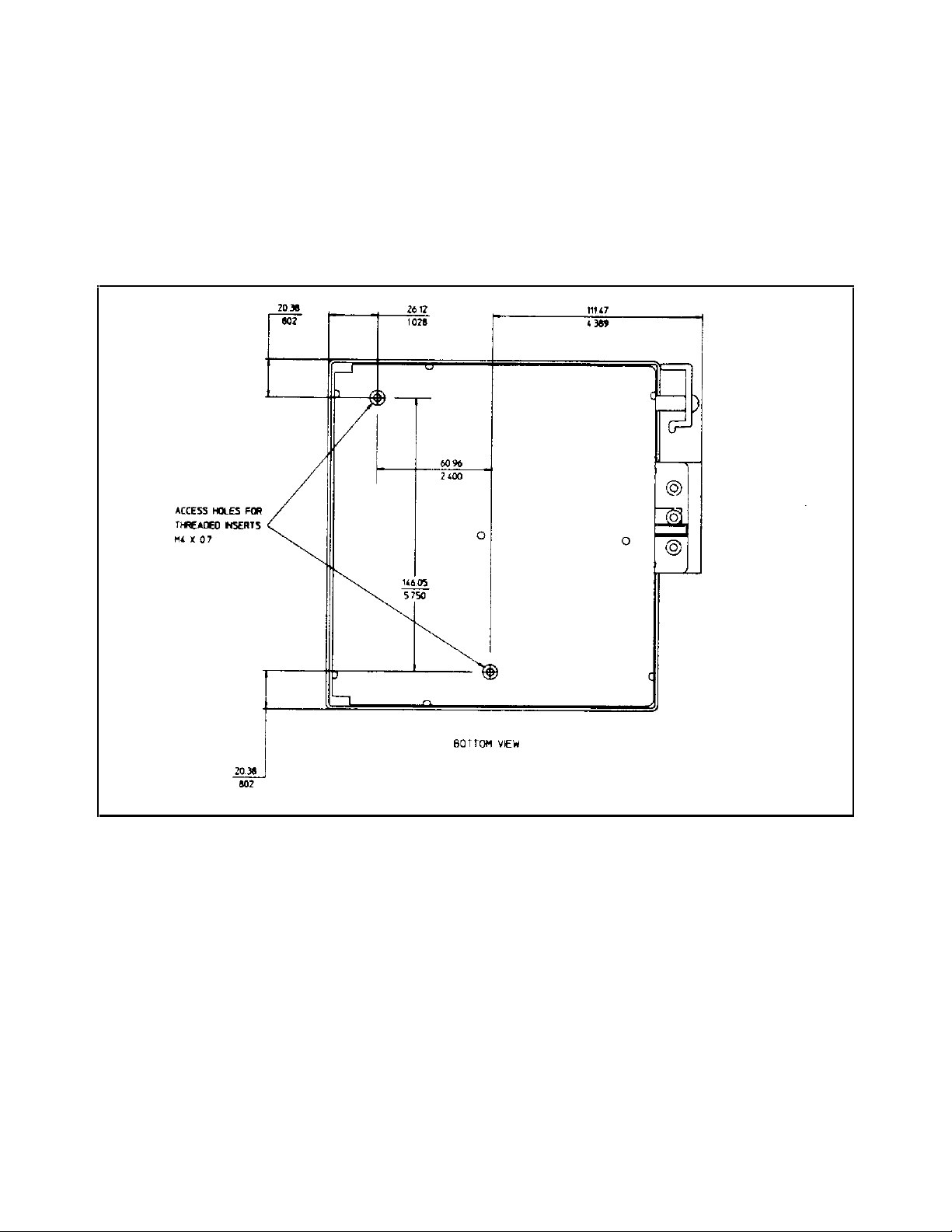

Surface Mounting

The Agilent 5951XA can be mounted against surfaces by means of machine screws. There are two threaded inserts on the

bottom of the Agilent 5951XA (see Figure 2-1). The user must drill two holes in the surface against which the Agilent

5951XA is to be mounted and pass M4 screws (10 mm long) through these holes to engage the threaded inserts within the

Agilent 5951XA. Remember to keep the Agilent 5951XA oriented vertically (see Mounting Orientation in Table 1-1) for

proper operation.

Figure 2-1. Threaded Insert Locations for Surface Mounting

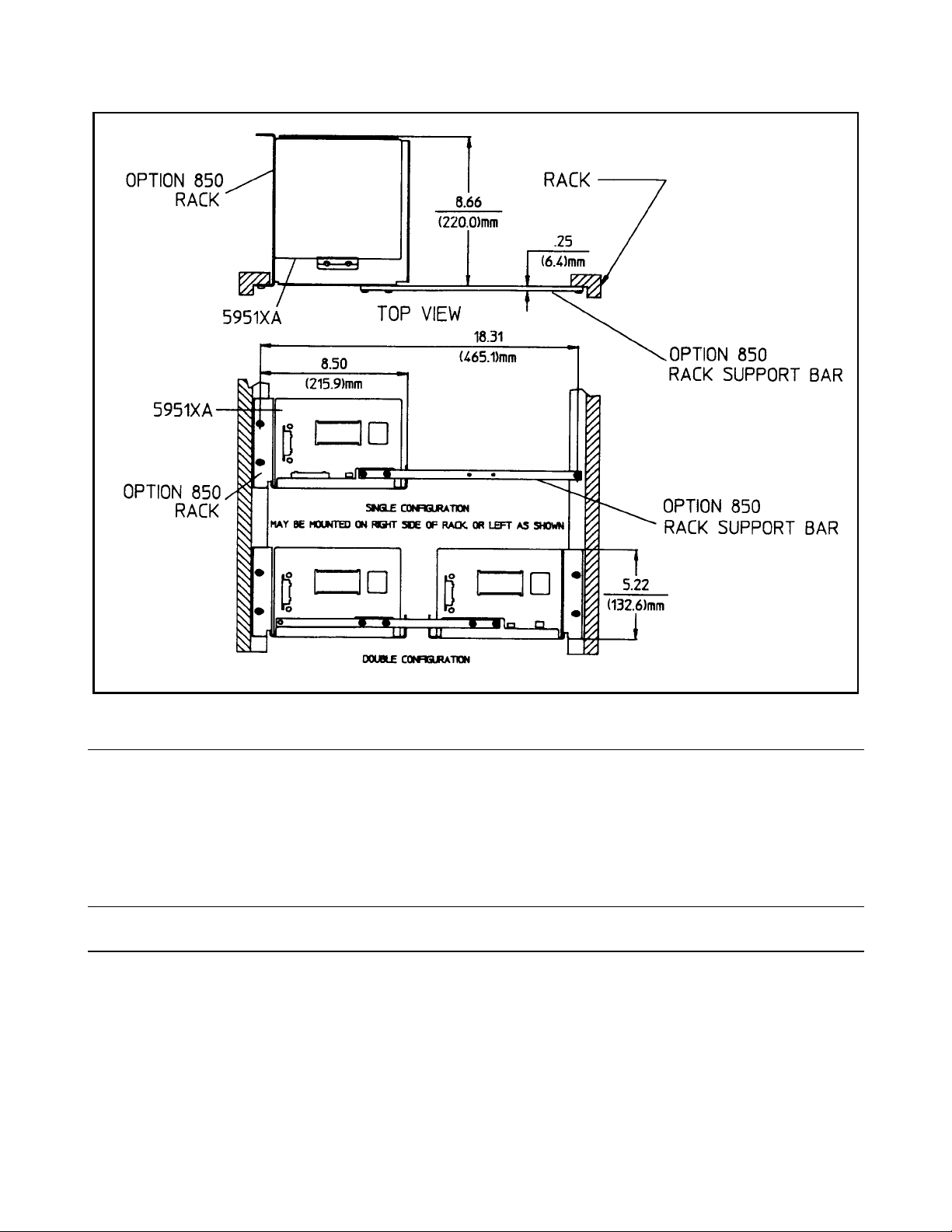

Option 850 Mounting

Rack mount kit Option 850 can be used to mount a single Agilent 5951XA unit on the left or right side of the rack as shown

in Figure 2-2. Two units can be mounted side by side in the rack using two Option 850 kits.

The Agilent 5951XA unit rests on the Option 850 rack as shown in Figure 2-2. Two threaded inserts, located on the bottom

of the Agilent 5951XA, line up with holes in the rack. Use two flat head M4 screws (10 mm long) to secure the unit in the

rack.

Installation 11

Page 12

Figure 2-2. Option 850 Rack Mounting

Input Power Requirements

You can operate the unit from a nominal 100V, 120V, 220V, or 240V single phase power source at 48 to 63Hz. You can

check the line voltage setting of the unit by examining the LINE SELECT switch S101 setting (see Figure 2-3). You can

change the unit to accept 100, 120, 220, or 240Vac by setting S101 to the 100/120V or 220/240V position. The same rating

fuse (0.5A) is used for a 110,120, 220, or 240Vac input. The fuse, designated F1, is located inside the unit near the LINE

SELECT switch.

Note The Agilent 5951XA has no on/off switch. To turn the unit on/off, you must connect/disconnect the power

cord.

12 Installation

Page 13

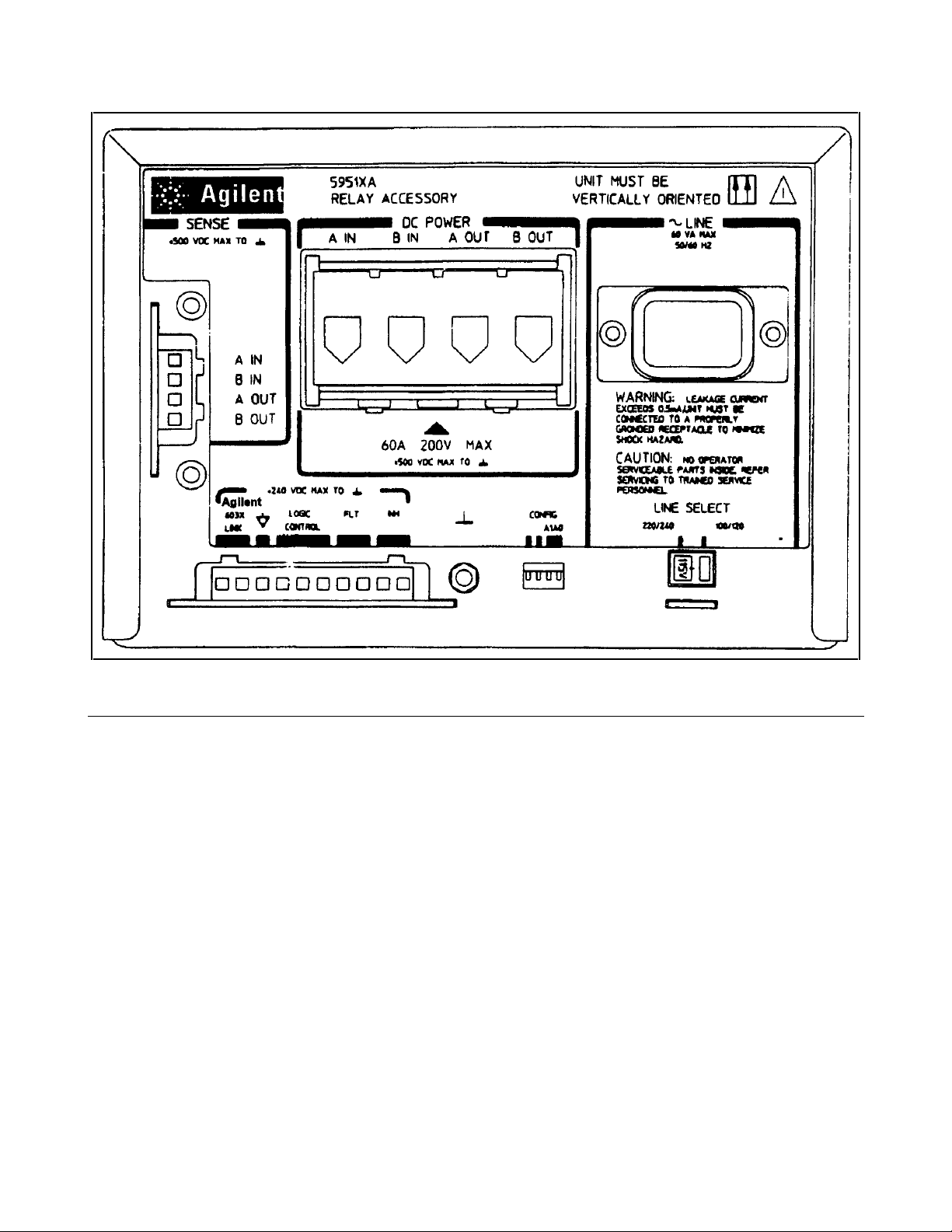

Figure 2-3. Relay Accessory Front Panel

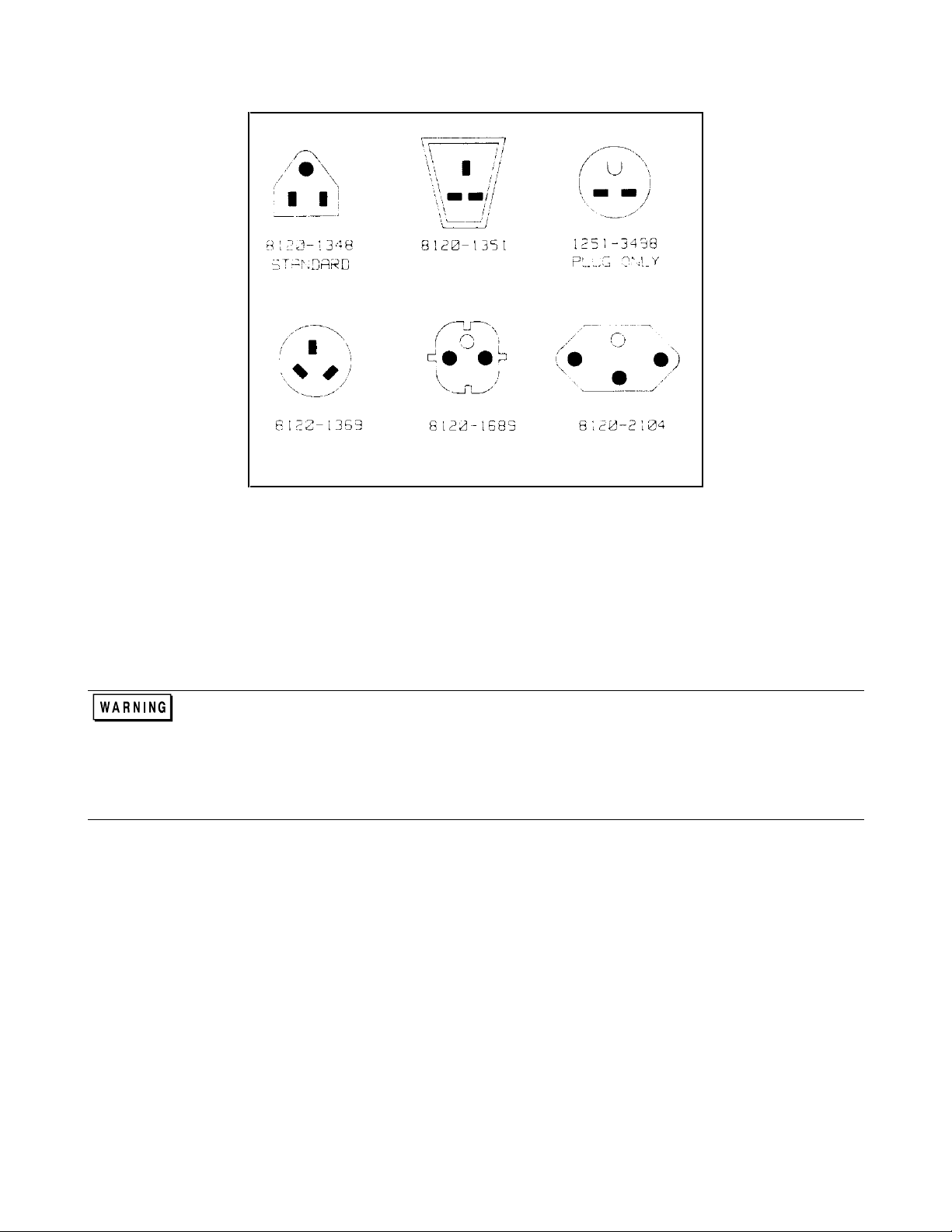

Power Cord

The unit is shipped from the factory with a power cord that has a plug appropriate for your location. Figure 2-4 shows the

standard configuration of plugs used by Agilent Technologies. Below each drawing is the Agilent part number for the

replacement power cord equipped with a plug of that configuration. If a different power cord is required, contact the nearest

Agilent Technologies Sales and Service office.

Installation 13

Page 14

Figure 2-4. Available Power Cords

For your protection, the National Electrical Manufacturer’s Association (NEMA) recommends that the unit’s panel and

cabinet be grounded. This unit is equipped with a three-conductor power cord; the third conductor being ground. The unit is

grounded only when the power cord is plugged into the appropriate receptacle. Do not operate this unit without an adequate

cabinet ground connection.

SHOCK HAZARD Connect the power cord to a grounded receptacle before you connect any external

floating voltages to the Relay Accessory.

The offset pin on the standard three-prong power cord connector is the ground connection. If a two-contact

receptacle is encountered, it must be replaced with a properly grounded three-contact receptacle in

accordance with the National Electrical Code, local codes and ordinances. The work should be done by a

qualified electrician.

14 Installation

Page 15

3

Connections and Operating Information

Introduction

HAZARDOUS MATERIAL The DC power relay(s) in the Agilent 5951XA have a maximum current

rating of 60 amps. The relays contain mercury which is sealed in a steel tube. The tubes may rupture if the

current rating is exceeded. Do not connect the Agilent 5951XA to a power supply capable of delivering more than 60 amps.

This section explains how to make connections and set switches in order to operate the Agilent 5951XA Relay Accessory in

an Agilent 603XA configuration and in a general purpose configuration. The following main discussions are provided:

•

Agilent 5951XA Front Panel

•

DC Power Connections

•

Sense Lead Connections

•

Agilent 603XA Configuration

•

General Purpose Configuration

Agilent 595lXA Front Panel

Figure 3-1 illustrates the front panel of the Agilent 5951XA where connections and switch selections are made.

Figure 3-1. Agilent 59510A/59511A Front Panel Connections

Connections and Operating Information 15

Page 16

DC POWER Connections --

A barrier block (TB1) with four screw-down type terminals connects the input and output

dc power wires. The A IN and B IN terminals are used to connect the Relay Accessory to

the power supply’s + and output terminals, respectively. The A OUT and B OUT

terminals are used to connect the Relay Accessory to the load. See page 3.

SENSE Connections --

Control Connections --

A four pin connector J201 (quick disconnect mating plug P201 supplied) connects the

input and output sense leads. The A IN and B IN pins (1 and 2) are used to connect the

Relay Accessory to the power supply’s + S and - S terminals, respectively. The A OUT

and B OUT pins (3 and 4) are used to connect the Relay Accessory to the load’s + and sense leads, respectively. See pages 14 and 15.

A ten pin connector J101 (quick disconnect mating plug P101 supplied) is provided for

making the following connections:

Agilent 603X LINK(pins 1-2): These two pins provide the serial data link with the

Agilent 603XA supply to control the Relay Accessory (see page 18).

common (pin 3): provides the common connection for the serial data link or the logic

control input.

LOGIC CONTROL (pins 4-6): These three pins are used for connecting TTL compatible

signals to control the Relay Accessory when it is used in a general purpose configuration

(see page 22).

FLT (pins 7 and 8): These two pins are used to connect the fault output line. See page 19

(Agilent 603X configuration) or page 24 (general purpose configuration). Pin 7 is the FLT

output signal, pin 8 is its common.

INH (pins 9 and 10): These two pins are used to connect the inhibit input line. See page

19 (Agilent 603X configuration) or page 23 (general purpose configuration). Pin 9 is the

INH input signal; pin 10 is its common.

CONFIG Switches --

16 Connections and Operating Information

Four switches (S102-1 to 4), each of which can be set to ’’1" or ’’0", make the following

Listen Enable On/Off (S102-1): This switch is meaningful only in the LOGIC CONTROL

mode. With S102-1 set to "0", the Relay Accessory will always respond to the LOGIC

CONTROL lines. With S102-1 set to ’’1’’, the Relay Accessory will only respond to the

LOGIC CONTROL lines when the LISTEN ENABLE input U101-6) is a TTL low level.

S102-1 is factory set to ’’0’’.

Agilent 603X LINK or LOGIC CONTROL (S102-2): This switch selects either Agilent

603X LINK (serial data) or LOGIC CONTROL (TTL levels) as the controlling input. The

"1" position selects the Agilent 603X LINK and the "0" position selects LOGIC

CONTROL. S102-2 is factory set to ’’1’’.

Page 17

Addresses A1 and A0 (S102-3 and 4): These switches are meaningful only in the Agilent

603X LINK mode to select the address of the Relay Accessory. S102-3 and S102-4 are

both factory set to "0’’. The Agilent 603X power supplies currently will only communicate

with a Relay Accessory at address "0’’. Addresses 1-3 are provided for possible future use.

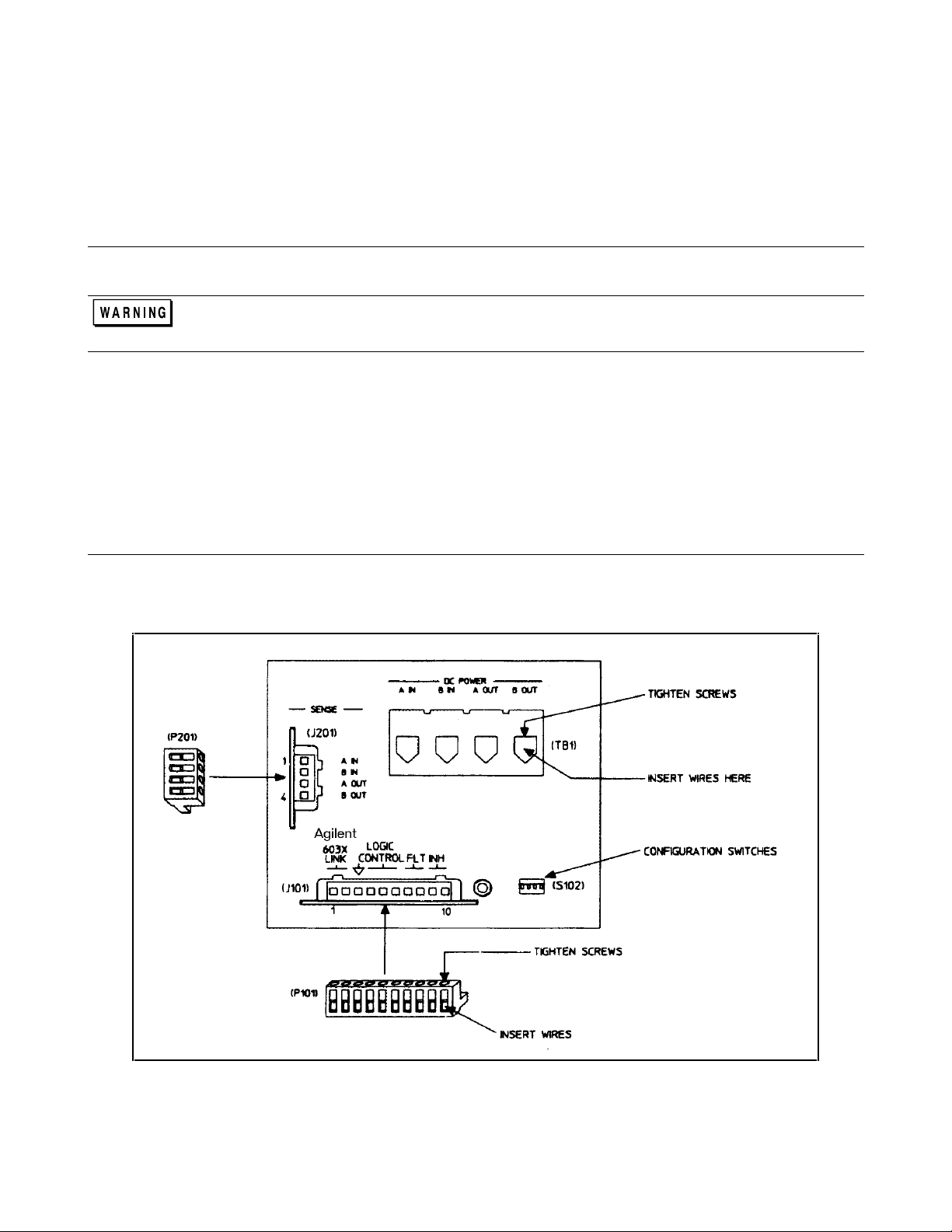

Figure 3-2. DC Power and Sense Lead Connections Remote Sensing

SHOCK HAZARD Turn off input ac power at the power supply and disconnect the Relay Accessory’s line

cord before changing any connections. Make certain that all wires are properly connected, screws are

tightened, and connectors securely installed before reapplying power.

DC Power Connections

The dc power connections between the power supply and the Relay Accessory and between the load and the Relay

Accessory are shown in Figure 3-2. The power supply’s output terminals are connected to the Relay Accessory’s DC

POWER input terminals and the load leads are connected to the Relay Accessory’s DC POWER output terminals as follows:

Relay Accessory

DC POWER Terminal

A IN

B IN

A OUT

B OUT

The dc power wires are connected to the screw-down terminals on the DC POWER barrier block TB1 as specified above.

Each wire is inserted into the appropriate terminal and the corresponding screw is tightened until the wire is securely

fastened (see Figure 3-1).

Connects To

Power Supply +

Power Supply -

Load +

Load -

Connections and Operating Information 17

Page 18

To satisfy safety requirements, the wires that connect the power supply output voltage to the Relay Accessory and to the

load should at least be heavy enough not to overheat while carrying the power supply output current that would flow if the

load were shorted. Stranded AWG # 6 copper wire is rated for 50 amps at 105 degrees C conductor temperature. (The

maximum allowable conductor temperature is based on +60 degrees C ambient temperature plus 45 degrees C temperature

rise because of continuous dc current). This is based on use of a twisted pair to connect the load to the power supply output.

Refer to Section III in the applicable Agilent 603XA Operating and Service Manual (see introduction) to help you select the

proper wire size.

Sense Lead Connections

Note A plastic safety cover for SENSE connector J201 is provided. When the quick disconnect plug P201 is

installed in J201, the plastic safety cover need not be used.

SHOCK HAZARD The safety cover should be installed over J201 to prevent accidentally touching J201

pins when P201 is not installed. Harmful voltages may be present at these pins when power is applied.

Remote Sensing

The sense lead connections shown in Figure 3-2 are for remote sensing. Remote sensing allows the power supply to

automatically increase the output voltage and compensate for the voltage drop in the DC POWER leads. Thus, remote

sensing will help to provide the best possible regulation at the load. This is especially useful for CV operation with loads

that vary and have significant load-lead resistance. For remote sensing, make sure that the straps between the supply’s + and

+ S terminals and between the - and - S terminals are disconnected. The power supply’s sense terminals are then connected

to the Relay Accessory’s input SENSE connector pins and the load sense leads are connected to the Relay Accessory’s

output. SENSE connector pins as follows:

Relay Accessory

SENSE Connector

A IN (J201-1)

B IN (J201-2)

A OUT (J201-3)

B OUT (J201-4)

The sense wires are connected to the pins of the SENSE connector mating plug P201 as specified above. Each wire is

inserted into the appropriate pin and the corresponding screw is tightened until the wire is securely fastened (see Figure 3-l).

The plug is then installed in the SENSE connector (J201).

Connects To

Power Supply + S

Power Supply - S

Load + Sense

Load - Sense

Note When the Agilent 5951XA Relay Accessory is in the power off state, the SENSE A IN and SENSE B IN

terminals are not connected to any points internally. This means that if there is no other path between the

power supply’s + S/ - S Sense terminals and its + /- output terminals, respectively, the supply’s output may

overshoot. All Agilent Technologies power supplies with the remote sense feature have internal resistors

which provide a moderately high impedance path between the output and sense terminals, and therefore

will not overshoot under these conditions. If the power supply being used is not an Agilent supply and

does not have these internal sense resistors, it is recommended that a resistor of approximately 1 KΩ be

connected between the supply’s + and + S terminals and between the - and - S terminals.

Incorrect wiring of the sense leads or failure to remove the power supply’s own sense straps when using

remote sensing may cause internal protection fuses F201 and F202 to blow requiring fuse replacement

(see Section 5). To avoid nuisance blowing, check all connections before applying power. Also, test

the sensing setup with a low value of power supply output voltage before applying full output voltage.

18 Connections and Operating Information

Page 19

Because the sensing leads carry only a few milliamperes, the wires used for sensing can be much lighter than the load leads.

The sense leads should be a shielded, twisted pair to minimize noise pickup of external noise. Any noise picked up on the

sensing leads will appear at the supply’s output, and CV load regulation may be adversely affected. The shield should be

grounded at the power supply end only, and should not be used as one of the conductors. The sensing leads should be

connected as close to the load as possible. The shield around these leads should also be grounded at one end only. Refer to

Section III in the applicable Agilent 603XA Operating and Service Manual (see introduction) for more information

concerning remote sensing.

Inadvertent shorting of sense terminals may cause internal (inside Agilent 5951XA) local sense

protection resistors R205 and R206 to open, necessitating replacement. Again, verify connections and

test the

sensing setup at a low output voltage before applying full output.

Local Sensing (Figure 3-3)

You can use the DC POWER connect/disconnect and reversing (Agilent 59511A only) features of the Relay Accessory

without using remote sensing connections between the Agilent 5951XA and the load. For local sensing, connect jumpers

between the power supply’s + and + S terminals and between the - and - S terminals as shown in Figure 3-3. In this

configuration, SENSE connector J201 on the Agilent 5951XA is not used.

Figure 3-3. DC Power and Sense Lead Connections, Local Sensing

Connections and Operating Information 19

Page 20

Agilent 603XA Configuration

Before you program the Agilent 603XA/5951XA configuration, complete the general steps outlined below. Each step is

described in greater detail in the referenced paragraph(s). Figure 3-4 illustrates the connections and switch settings required

for the Agilent 603XA/5951XA configuration.

1. Connect the DC POWER and SENSE leads (pages 3-13 through 3-15).

2. Ensure that the CONFIG switches on the Agilent 5951XA are selecting Agilent 603X LINK and address 0 (page 16).

3. Ensure that the RLY LINK/ INH FLT switch on the Agilent 603XA is selecting RLY LINK (page 3-18).

4. Make the serial data connection between the Agilent 603XA and the Agilent 5951XA (page 3-18).

5. If desired, you can connect the INH and FLT lines. The remote inhibit (INH) and fault (FLT) lines are described in

detail on pages 19 and 20.

6. Apply AC power to the Agilent 5951XA and the Agilent 603XA (page 21).

7. Verify the wiring and switch settings by checking the configuration with a low power supply output voltage before

applying full output voltage.

Note A switch inside the Agilent 603XA is factory set so that, at power on, the Agilent 603XA/5951XA

configuration ’’wakes-up’’ with the power supply output enabled and disconnected (relay opened) from the

load. See page 18.

Switch Settings

In order to program the Agilent 603XA/5951XA configuration, switches on the Agilent 603XA and the Agilent 5951XA

must be set to the positions shown in Figure 3-4. A small screw driver or ball point pen will be helpful in setting the

switches.

CONFIG Switches

These switches (S102-1 to S102-4) are located on the rear panel of the Agilent 5951XA as shown in Figure 3-1. In order to

program the Agilent 603XA/5951XA configuration, switches S102-3 and S102-4 must select address 0, and switch S102-2

must be set to the Agilent 603X LINK position (’’1").

The address (S102-3, S102-4) must be set to 0 in order for the Agilent 603XA to communicate with the Agilent 5951XA

(addresses 1-3 are provided for possible future use). If S102-2 is not set to the Agilent 603X LINK position, the Agilent

603XA power supply will generate "error 9’’ when it receives a relay command (e.g. RELAY ON) and it will not attempt to

send serial data to the Agilent 5951XA. Also, if the Agilent 603XA expects to send data to the Relay Accessory but does

not receive any response to its communications over the serial data cable, it will also generate "error 9". The switches

S102-2 to S102-4 are read by the Agilent 5951XA only at power-on. Switch S102-1 is only active in the Logic Control

(TTL) mode. For safety considerations, it is recommended that the Agilent 5951XA be unplugged before any of the S102

switches are manipulated.

20 Connections and Operating Information

Page 21

Figure 3-4. Agilent 603X Configuration

Figure 3-5. Relay Link Connector and Selector Switch on Agilent 603XA Rear Panel

Connections and Operating Information 21

Page 22

RLY LINK or INH/ FLT Switch

This switch (A8Sl-l), is one of 7 DIP switches located below the GPIB connector on the rear of the Agilent 603XA supply

as shown in Figure 3-5. In order to program the Agilent 603XA/5951XA configuration, switch A8Sl-l must be set to the

RLY LINK position (see Fig. 3-4). With A8Sl-1 set to RLY LINK, connector A8J8 (RLY LINK or INH/FLT) functions as

a serial data link for relay control instead of as a connector for the remote inhibit (INH) input line and the fault (FLT) output

line. If switch A8Sl-l is not set to the RLY LINK position, the Agilent 603XA will generate error 9 when it receives a relay

command (e.g. RELAY ON) and will not attempt to communicate with the Agilent 5951X Relay Accessory via the serial

data cable. The functions performed by the remaining DIP switches A8SI-2 through A8Sl-7 are described in the Agilent

603XA Operating and Service Manual (see page 1).

Agilent 603XA/5951XA Serial Data Connection

The serial data connection is made between connector A8J8 on the rear of the Agilent 603XA supply and the Agilent 603X

LINK connector pins (J101-1 to 3) on the front of the Agilent 5951XA using a shielded cable as shown in Figure 3-6.

The serial data output (A8J8-1) from the Agilent 603XA is connected to the input (J101-1) of the Agilent 5951XA. The

serial data readback (Jl01-2) from the Agilent 5951XA is connected to the input (A8J8-3) of the Agilent 603XA. Note that

pin A8J8-2 is left unconnected. The common connection is made between A8J8-4 and J101-3. The cable shield should only

be grounded (connected to common) at the power supply end (A8J8-4) as shown in Figure 3-6.

A 4-pin quick disconnect mating plug for A8J8 is supplied with the Agilent 603XA supply and a 10-pin quick disconnect

mating plug (P101) for J101 is supplied with the Agilent 5951XA. Each cable wire is inserted into the appropriate mating

plug pins (see Figures 3-5 and 3-6) and the corresponding screw is tightened until the wire is securely fastened.

Figure 3-6. Serial Data Link Cable Connection

Agilent 603XA/5951XA Configuration Wake-Up State

A switch (inside the Agilent 603XA supply) is factory set so that at power-on, the Agilent 603XA/5951XA configuration

’’wakes-up" with the power supply output enabled and disconnected (relay open) from the load. The switch (A7S1) is

located on the power supply’s interface board and can be set to the alternate position in which the Agilent 603X/5951XA

configuration "wakes-up" with the power supply output enabled but connected (relay closed) to the load. Refer to Figure 7-7

and paragraph 5-77 in the Agilent 603XA Operating and Service Manual if you want to gain access to the power supply

interface board A7 in order to change the setting of switch A7S1.

22 Connections and Operating Information

Page 23

SHOCK HAZARD Changing the setting of switch A7S1-D requires the removal of protective covers. To

avoid the possibility of personal injury, remove the power supply from operation before opening the

cabinet. Turn off ac power and disconnect the line cord, GPIB plug, load, remote sense leads, and INH/FLT

connector before removing protective covers. Refer to the Maintenance section of the appropriate Agilent

603XA Operating and Service Manual for procedures for accessing the A7 PSI Board of the power supply.

Observe all precautions in this section to avoid personal injury or damage to equipment.

As shown in Figure 3-7, A7S1 is comprised of eight separate switches. Switch A7S1-D determines the "wake-up’’ state of

the Relay Accessory. With A7S1-D set to "0", the "wakeup’’ state is relay open. With A7S1-D set to ’’1", the wakeup state is

relay closed. The remaining A7S1 switches are described in the Agilent 603X manual. Note that if you do change switch

A7S1-D, make sure that you do not disturb any of the other A7S1 switch settings. Switches A7S1-E to H are set at the

factory for each particular model and must not be changed.

Figure 3-7. Switch A7S1 (Located inside the Agilent 603X Supply)

Remote Inhibit (INH) and Fault (FLT) Lines

The remote inhibit (

Figure 3-1) are used in place of the

603XA/5951XA configuration. The

register bit, independently of the service request (SRQ) function available through the GPIB. The

remote inhibit (RI) bit in the power supply’s fault register and provides a way to disconnect the power supply output from

the load. The fault registers are described in detail in the applicable Agilent 603XA Operating and Service Manual (see

page 1). Both

commons for the

other. Refer to Table 1-1 for details.

INH

FLT

) input (J101-9 and 10) and the fault (

INH

input and

INH

line provides the user with a means of knowing the status of any unmasked fault

FLT

and

are negative true, i.e., they are active when they are low levels. Pins 8 and 10 are the

FLT

and

signals, respectively. Both

INH

) output J101-7 and 8) on the Relay Accessory (see

FLT

output on the Agilent 603XA power supply in an Agilent

FLT

INH

FLT

and

may be floated relative to ground and to each

INH

Connections and Operating Information 23

line controls the

Page 24

INH Input Line

When

power relay (normal or reverse) disconnecting the load from the Agilent 603XA output. Also, with

Accessory is in the local sense state, that is, the Agilent 603XA’s + S and - S sense terminals are connected to the Agilent

603XA’s + and - output terminals via the LOCAL SENSE relay contacts inside the Relay Accessory.

is Low, the Relay Accessory will execute the equivalent of a RELAY OFF command which opens the DC

INH

Low, the Relay

INH

The Relay Accessory will not respond to the RELAY ON or OUT ON commands while the

goes High, the Relay Accessory will not return to the state previous to the

INH

off state.

While

603XA by setting a bit in its status response to indicate that a remote inhibit condition exists. The Agilent 603XA will

disable its output upon detection of this condition. The Agilent 603XA output can be enabled again by means of the Agilent

603XA standard command RST (see Section III in the Agilent 603XA Operating and Service Manual). The RST command

should be issued only after the Relay Accessory is no longer remote inhibited (after

the Relay Accessory is remote inhibited (

FLT Output Line

The

register is set. For example,

register is unmasked. The RI bit is unmasked using the UNMASK RI command as described in Section III of the Agilent

603XA Operating and Service Manual. If RI was the only fault bit set, the

Agilent 603XA fault register (FAULT?). The other power supply conditions that can turn on the

the Agilent 603XA manual.

Using INH and FLT with Multiple Agilent 603XA/5951XA’s

Figure 3-8 illustrates three Agilent 5951XA’s (A,B, and C) in which the

the next. Also, the RI bit must be unmasked in each of the Agilent 603XA supplies. A fault condition in any one supply will

cause all of the power supply outputs to be disconnected from their respective loads without computer involvement or any

external circuitry.

is Low, the Relay Accessory will respond to the routine status poll request (see page 20) from the Agilent

INH

is Low), the Agilent 603XA and the Agilent 5951XA will remain inhibited.

INH

output line of the Relay Accessory is turned on (Low level) when any unmasked bit in the Agilent 603XA’s fault

FLT

is turned on if the

FLT

input line is turned on and the remote inhibit (RI) bit in the fault

INH

FLT

output of one is connected to the

FLT

Low condition but will remain in the

INH

goes High). If RST is issued when

INH

line will go High (off) upon reading the

line is held Low. When

INH

line are discussed in

FLT

INH

input of

SHOCK HAZARD Float voltage restrictions for the INH and FLT signals must be observed to avoid risk

of personal injury or damage to equipment. Refer to the Isolation Specification listed in Table 1-1.

Agilent 603XA Status PoII

The Agilent 603XA queries the status of the Relay Accessory at regular intervals. The state of the RI (remote inhibit) mask

is encoded within the status query. When it receives the status query, the Relay Accessory will be updated according to the

information encoded within the status query. The Relay Accessory will then respond by echoing the status query command

back to the Agilent 603XA with the INH input line state encoded within this echo. The Agilent 603XA may then disable its

output depending upon the remote inhibit information received.

24 Connections and Operating Information

Page 25

Figure 3-8. FLT/INH Connections

Agilent 603XA/5951XA Turn-On Sequence

The Agilent 603XA queries the status of the Agilent 5951XA at regular intervals as described above. If communications are

broken (e.g., serial data link cable is disconnected) between the Agilent 603XA and the Agilent 5951XA, the Agilent

5951XA will assume a safe state (relay opened), the Agilent 603XA will generate ’’error code 9’’, and the ERROR indicator

on the Agilent 603XA front panel will light. The Agilent 5951XA will resume normal operation when communications are

re-established. The Agilent 603XA ERROR indicator will remain on until the error query (ERR?) is received.

Connections and Operating Information 25

Page 26

It is recommended that you apply AC power to the Agilent 5951XA first and then turn on the Agilent 603XA power supply.

If the Agilent 603XA is turned on before the 5051XA, "error 9" will be generated. Normal communication between the

Agilent 603X and the Agilent 5951XA will be established after the Agilent 5951XA is turned on. The "error 9" generated

by the Agilent 603X is cleared by sending the error query ’’ERR?". If both the Agilent 603XA and the Agilent 5951XA are

powered up simultaneously, e.g. via the same rack power switch, no error will be generated.

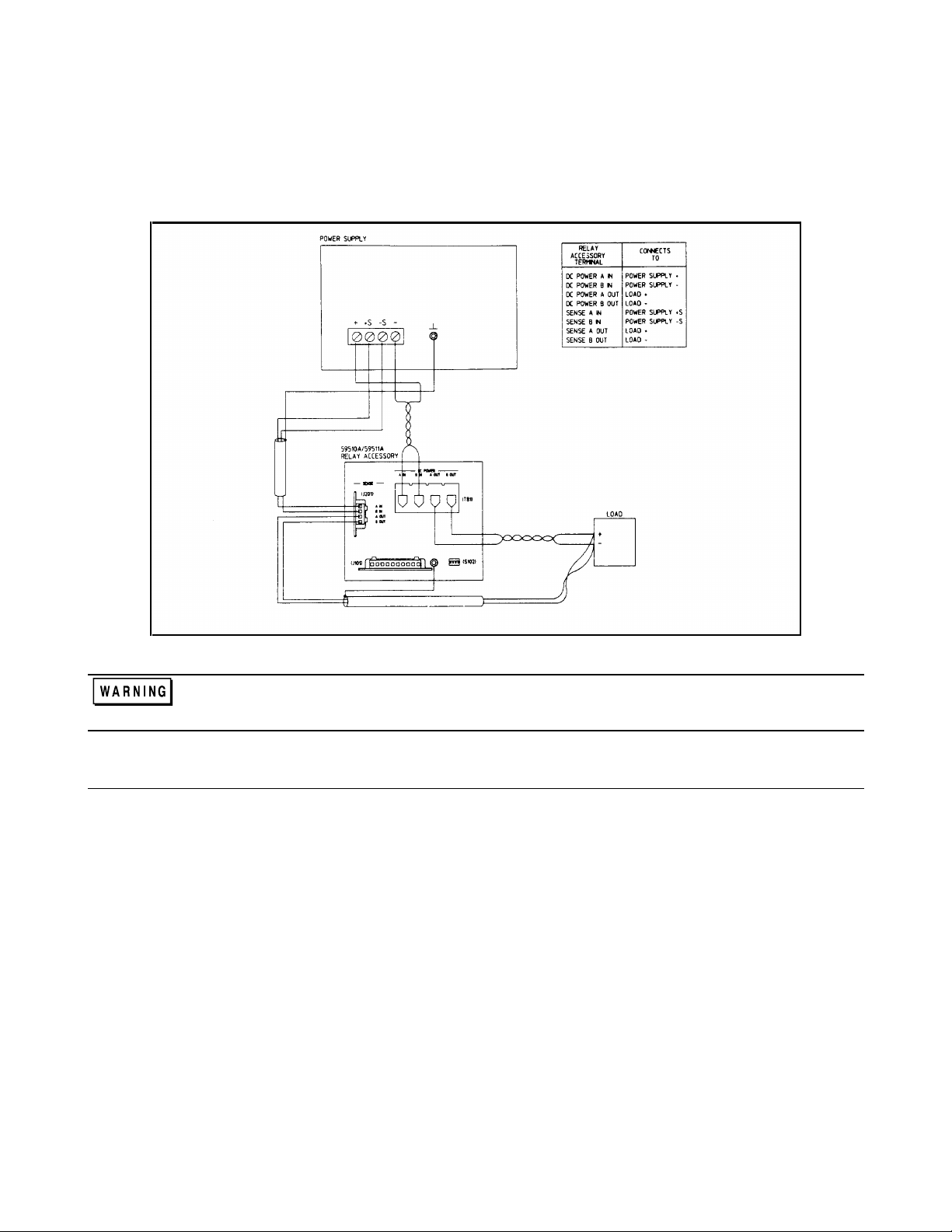

General Purpose Configuration

Figure 3-9 illustrates a general purpose configuration that consists of a power supply, a TTL level control device, the Relay

Accessory, and the load. In order to control the Relay Accessory in this configuration, follow the general steps outlined

below. Each step is described in greater detail in the referenced paragraph(s).

Figure 3-9. General Purpose Configuration

26 Connections and Operating Information

Page 27

1. Connect the DC POWER and SENSE leads (pages 13 through 15 ).

2. Ensure that the CONFIG switches (S102) on the Agilent 5951XA are selecting LOGIC CONTROL (TTL input) and

the desired LISTEN ENABLE position (see page 23).

3. Make the LOGIC CONTROL (TTL levels) connections (see page 23).

4. If desired, you can connect the INH and FLT lines (see page 24).

5. Apply AC power to the Agilent 5951XA unit, the power supply, and the TTL control device.

6. Verify the wiring and switch settings by checking the configuration with a low power supply output voltage before

applying full output voltage.

Note At power on, the Relay Accessory ’’wakes-up’’ with its DC power and remote sense relays open, the local

sense relay closed, and with the normal polarity mode in effect. After power is on, the Relay Accessory

goes to the state specified by the LOGIC CONTROL (TTL levels) inputs. If no inputs are connected, the

Agilent 5951XA will remain with the ’’wake-up" conditions in effect.

Switch Settings

In order to control the general purpose configuration, set the CONFIG switches (S102) on the Agilent 5951XA as follows:

Agilent 603X LINK or LOGIC CONTROL Switch

Set switch S102-2 to the LOGIC CONTROL position as shown in Figure 3-9. In this position, the Agilent 5951XA will

respond to the ITL inputs (see pages 23 and 24) and ignore any commands sent via the Agilent 603XA LINK input.

Listen Enable Switch

With S102-1 set to the "0’’ position, the Relay Accessory will continuously respond to signals on the LOGIC CONTROL

input lines. With S102-1 set to "1", the

respond to signals on the LOGIC CONTROL lines (see LISTEN ENABLE input).

LISTEN ENABLE input (J101-6) determines when the Relay Accessory will

TTL Input Connections

The TTL control inputs are connected to the LOGIC CONTROL pins J101-3 through J101-6 as shown in Figure 3-9. The

TTL input signals are: OPEN/

common connection is made to J101-3.

The LOGIC CONTROL, INH, and FLT signals must be restricted to no greater than ± 42Vdc from ground

unless specific requirements are fulfilled. Refer to the Isolation Specifications in Table 1-1 for details.

Failure to observe these requirements may result in damage to equip1nent and/or personal injury.

CLOSE (J101-4), NORMAL/REVERSE (J101-5), and LISTEN ENABLE (J101-6). The TTL

Connections and Operating Information 27

Page 28

LISTEN ENABLE Input.

This input determines if the microprocessor in the Relay Accessory will respond to changes on the TTL input lines. If

LISTEN ENABLE is false (High level), the Relay Accessory will remain in its current state regardless of the state of the

OPEN/

CLOSE

and NORM/ REV inputs. When LISTEN ENABLE is held true (Low level), the Relay Accessory will

respond to these inputs.

Switch S102-1 on the rear of the Agilent 5951XA allows the

(false). The Relay Accessory is shipped from the factory with S102-1 set to "0" so that

LISTEN ENABLE input to be held Low (true) or to float High

LISTEN ENABLE is held Low.

If you want the Relay Accessory to continuously ’’listen’’ for commands on the TTL input lines, leave S102-1 set to the ’’0"

position. If you want to use the

lines, set S102-1 to "1". With S102-1 set to ’’1" the Relay Accessory will listen only when

LISTEN ENABLE input to select when the Relay Accessory will "listen" to the TTL input

LISTEN ENABLE

(Jl01-6) is true

(Low). This line can be used to control any one of a number of Relay Accessories. Figure 3-10 illustrates the connections

required to control three units. The TTL control device selects the unit by setting the applicable

LE1 , LE2 , or LE3 ) Low.

LISTEN ENABLE

line (

OPEN/CLOSE Signal

As long as the OPEN/

CLOSE input is held Low, the DC power and remote sense relays will be closed. Releasing the line

(floats High) will open these relays and return the Relay Accessory to the local sense state. (This is assuming that

LISTEN ENABLE is low. If LISTEN ENABLE is high, the Agilent 5951XA will not respond to changes on the

OPEN/CLOSE input, but will remain in its original state.)

NORM/REV Input (Applies only to Agilent Model 59511A).

If the normal polarity power relay K1 and remote sense normal relay K202 are closed, a Low level at this input causes the

relays to go through the open state before they end up in the reverse polarity state (reverse polarity power relay K2 and

remote sense reverse relay K203 both closed). Remember that the NORM/

REV input is level sensitive and must be held

Low in order to keep Relay Accessory in the reverse polarity state. Releasing the line will return the Relay Accessory to the

normal polarity state. (This is assuming

respond to changes on the NORM/

REV

LISTEN ENABLE

is low. If

LISTEN ENABLE

input, but will remain in its original state.)

is high, the Agilent 59511A will not

Note Agilent 662X series of GPIB Multiple Output DC Power Supplies equipped with Option 750 provide four

open collector outputs which can provide Low true TTL compatible levels to control the Agilent 5951XA.

Up to four Agilent 59510A’s can be controlled by connecting to the OPEN/

59510A. Up to two Agilent 59511A’s can be controlled by connecting to the OPEN/

NORM/

REV inputs on each Agilent 59511A. Refer to the Operating Instructions for the 662XA Option

CLOSE input on each Agilent

CLOSE and

750 (APPENDIX E, Agilent Part No. 5957-6372).

Remote Inhibit (INH) and Fault (FLT) Lines

In the LOGIC CONTROL (TTL input) mode, a Low level INH signal will always disconnect the power supply output from

the load and cause the

A Low level on the

Accessory will again respond to the OPEN/

28 Connections and Operating Information

FLT line to go true (Low). FLT will go false (High) when INH goes false (High).

INH line will also override the OPEN/ CLOSE line. When the INH line is released (High), the Relay

CLOSE

input provided that the

LISTEN ENABLE line is true.! Consequently, it

Page 29

is recommended that the INH input be driven by a latching type circuit. Activity on the NORM/

REV line while INH is true

(Low) will not affect the Relay Accessory since polarity has no meaning when the DC power relay is opened.

Figure 3-10. Logic Control of Multiple Relay Accessories

Connections and Operating Information 29

Page 30

Page 31

Agilent 603XA Programming Commands

Introduction

This section describes the commands that have been changed or added to the Agilent 603XA standard commands to permit

programming the Agilent 5951XA/603XA configuration from a GPIB controller. The programming syntax for all of the

commands is described in Section III of the Agilent 603XA Operating and Service Manual (see page 1).

Note The current Agilent 603XA Option 700 CIIL (control interface intermediate language) programming

capability does not include relay (Agilent 59510A/59511A) control. Control of the Agilent

59510A/5951lA is presently available only in the standard programming language as described in this

section.

The commands are received by the Agilent 5951XA from the Agilent 603XA via the serial data link described in

603XA/5951XA serial data connection. Table 4-1 lists and briefly describes each of the changed and added commands.

Each command is described in greater detail in subsequent paragraphs.

Figure 4-1 illustrates how the power supply’s output and sense leads are connected or disconnected from the load and how

polarity reversal is accomplished. A tabulation is included on Figure 4-1 that specifies how the Agilent 603XA LINK

commands and the LOGIC CONTROL inputs control the DC POWER and SENSE relays in the Relay Accessory.

Table 4-1. Additional and Changed Commands

4

Command Type Description

OUT < on/off > Standard (changed) Programs both the power supply output and the relay. For on/off = 1 or ON,

the power supply output is disabled, the relay is closed, and then the output

is enabled. For on/off = 0 or OFF, the output is disabled and then the relay

is opened. Having the output off (disabled) when the relay changes state

extends the life of the relay.

OUT? Standard (changed) Queries the power supply output setting independent of the actual power

supply output state or the state of the relay. The response is either OUT 1

(setting = output enabled) or OUT 0 (settling = output disabled).

POL < norm/rev > Standard (added) Instructs the Relay Accessory (Agilent 59511A only) to provide either

normal polarity (norm/rev = NORM or 1) or reverse polarity (norm/rev =

REV or 0) at the load.

POL? Standard (added) Queries the relay polarity setting (Agilent 59511A only). The response is

either POL 0 (setting = polarity reversed) or POL 1 (setting = polarity

normal).

DC < on/off > Standard (added) On/off = 0 or OFF turns off the power supply output (disables the power

mesh). On/off = 1 or ON turns on the power supply output (enables the

power mesh). The DC <on/off> command does not affect the state of the

relay.

DC? Standard (added) Queries the power supply output setting. The response is either DC 0

(setting = output disabled) or DC 1 (setting = output enabled).

Agilent 603XA Programming Commands 31

Page 32

Table 4-1. Additional and Changed Commands (continued)

Command Type Description

RELAY < on/off > Standard (added) Opens (on/off = OFF or 0) or closes (on/off = ON or 1) the relay. The

RELAY <on/off> does not affect (turn on/off) the power supply output.

RELAY? Standard (added) Queries the relay setting. The response is either RELAY 0 (setting =

opened) or RELAY I (setting = closed).

Changed Command

The actions performed by the Output on/off command (see Table 3-7 in the Agilent 603X Operating and Service Manual)

have changed. The Output on/off and the added commands (e.g., Relay on/off) described later can be used to control the

Relay Accessory provided that the RLY LINK-INH/FLT switch A8S1-1 is in the RLY LINK position. Using the output

command is the preferred method because it disables the power supply’s output while the relays are switched, thus

prolonging relay life.

Note When the RLY LINK-INH/FLT switch A8S1-1 on the Agilent 603X power supply is in the INH/FLT

position, the functions of the Output command and the other standard commands are same as described in

Table 3-7 of the Agilent 603X Operating and Service Manual. The added commands (DC on/off, Relay

on/off, and Polarity norm/rev) will generate error 9 if sent with A8S1 in the INH/FLT position.

Output On/Off

The power supply output is enabled/disabled and the relay closed/opened using the OUT command:

OUT ON or OUT 1

This command first disables the power supply output, delays to permit the output to downprogram sufficiently, then closes

the power relay, and finally, after a delay to guarantee relay settling, enables the power supply output. The

downprogramming delay depends upon the model as specified below. The OUT ON (or OUT 1) command also places the

Agilent 603XA/5951XA configuration in the remote sense state. In the remote sense state, the power supply’s sense

terminals are connected to the load’s sense leads via the remote sense relay contacts in the Agilent 5951XA.

Agilent Model Delay

6030 600 mS

6031 500 mS

6032 400 mS

6033 200 mS

6038 400 mS

OUT OFF or OUT 0

This command first disables the power supply output and then opens the relay after the specified delay. The OUT OFF (or

OUT 0) command also places the Agilent 603XA/5951XA configuration in the local sense state. In the local sense state, the

power supply’s sense terminals are connected to the supply’s output terminals via local sense relay contacts in the 5951XA.

32 Agilent 603XA Programming Commands

Page 33

Figure 4-1. Relay Accessory/Power Supply Output Control

Agilent 603XA Programming Commands 33

Page 34

Note The delays between disabling the output of the power supply and the closure or opening of the relay

contacts do not guarantee that the current is zero during relay closure or opening. The delays were chosen

to provide reasonable reduction in output before relay contact activity in order to prolong relay life. In

applications where it is necessary to guarantee zero output conditions, e.g. when using highly inductive

loads, it is advisable to use the DC On/Off and RELAY On/Off commands with a suitable WAIT between

them. In general, to extend relay life, it is advisable to switch the relays under low or zero output

conditions.

The state of the Output on/off setting may be read by sending:

OUT?

and addressing the power supply to talk. The response from the power supply is in the format:

OUT 0 or OUT1

in which 0 indicates the power supply output setting is disabled; and 1 indicates that the supply output setting is enabled.

Note that the actual output state may not be reflected. For example, if the setting is output enabled, but an overvoltage

condition has caused the output to be disabled, an OUT? query will return OUT 1.

Added Commands

Relay on/off, DC on/off, and Polarity on/off commands have been added to the Agilent 603XA standard programming

commands in order to control the Agilent 5951XA/603XA configuration. The DC on/off and Relay on/off commands allow

independent control of the power supply output and the relays. An Output command, issued after a Relay and/or DC

command(s), will supersede these command(s) and restore both the power supply output and the relays to the same state

(e.g. power supply output enabled and relay closed).

At power-on, the default states are power supply output enabled (DC ON) and relay opened (RELAY OFF). These default

states can be reconfigured on Agilent 603XA supplies by changing one of the A7S1 identification switches on the power

supply interface board (see 603XA/5951XA configuration wake-up state). The alternate power-on default setting is power

supply output enabled (DC ON) and the relay closed (RELAY ON).

The power-on default state for the Polarity on/off command is normal polarity (POL NORM). The POL command only

applies to Agilent Model 59511A. If it is used to program an Agilent 603XA/59510A configuration, programming error 9

will be generated by the Agilent 603XA supply when it attempts to execute the POL command.

DC On/Off

The power supply output is enabled/disabled without affecting the state of the Relay Accessory using the DC command:

DC ON or DC 1

The DC ON command enables the power supply output.

DC OFF or DC 0

The DC OFF command disables the power supply output. When disabled the output is approximately zero volts.

The state of the DC on/off setting may be read by sending:

34 Agilent 603XA Programming Commands

Page 35

DC?

and addressing the power supply to talk. The response from the power supply is in the format:

DC 0 or DC 1

in which 0 indicates that the power supply output setting is disabled, and 1 indicates that the power supply output setting is

enabled. Note that the DC ? command returns the state of the power supply output setting as controlled by the DC or OUT

commands.

Relay On/Off

The relay is closed/opened using the RELAY command:

RELAY ON or RELAY 1

The RELAY ON command closes the relay connecting the power supply’s output to the load. It also places the supply in the

remote sense state.

RELAY OFF or RELAY 0

The RELAY OFF command opens the relay disconnecting the power supply’s output from the load. It also places the supply

in the local sense state.

The state of the Relay on/off setting may be read by sending:

RELAY?

and addressing the power supply to talk. The response from the power supply is in the format:

RELAY 0 or RELAY 1

in which 0 indicates that the relay setting is opened, and 1 indicates that the setting is closed. Note that the RELAY?

command returns the setting of the relay as controlled by the RELAY and/or OUT commands. A relay opened due to the

remote inhibit (INH) signal will not affect the response to RELAY?. A low level inhibit (INH) signal will always cause the

relay to open. For example, if a RELAY ON command has been sent to close the relay and then an INH signal opens the

relay, a subsequent RELAY? command will result in a response of RELAY 1 indicating that the relay is programmed to be

closed, although it is actually open.

Polarity Normal/Reverse (Model 59511A only)

The polarity of the power supply output voltage at the load is changed using the POL command:

POL NORM or POL 1

POL NORM disables the power supply output, changes the output polarity setting to normal (opens the reverse polarity

relays and closes the normal polarity relays), and then enables the power supply output.

POL REV or POL 0

POL REV disables the power supply output, changes the output polarity setting to reverse (opens the normal polarity relays

and closes the reverse polarity relays), and then enables the power supply output.

Agilent 603XA Programming Commands 35

Page 36

Note If the polarity is already that which is called for by the POL command, there will be no change in the

power supply output or the state of the relay.

The power-on default is normal polarity. If the 603XA power supply’s output is enabled and one of the relays (normal or

reverse) is closed when the 603XA receives a POL command to reverse polarity, the 603XA will do the following:

1. Disable its output.