Page 1

W.J.

SERVICE MANUAL

fiORD

l

2111lRkET

P.O.

Box

TELEPHONE(813)

SUIiIPbUS

DIVISION

ST.

606.

SMITHS

Of3125611

N.

(comer

~~

ENTERPRIS

CANlDllNC.

1IalUt'

FALLS,

S5

ONT.

FAX

(613)

ES

W11ti1!!lJ

K7Am

.~

mg

HEWLETT

PACKARD

Page 2

r/l;'

~~PACKARD

HEWLETT

W.J.

SERVICE MANUAL

TELEPHONE

HP 54201A/D

FORD

A

DIVISIONOF3125651

21

MARKET

P.O.

Box

SURPLUS

ST.N.(corner

60S,

SMITHS

(613)

FALLS,

283-5195

ENTERPRISE'

CANADA

MarketIrWillilm)

FAX

ONT.

(613)

INC.

K7A

4T1

283-06

DIGITIZING

SERIAL

This manual applies directly to

instruments

For additional

INSTRUMENTS COVERED BY

important

with

HP 54201A; 2602A

Hp

OSCILLOSCOPE

NUMBERS

serial

number

54201 D; 2602A

information

MANUAL

prefixes:

about

serial

in Section I.

numbers,

see

@ COPYRIGHT HEWLETT·PACKARD COMPANY/COLORADO SPRINGS DIVISION 1986

1900 GARDEN OF THE GODS ROAD,COLORADO SPRINGS, COLORADO U.S.A

Manual Part No. 54201-90902

Microfiche

Part No. 54201-90802

ALL RIGHTS RESERVED

PRINTED:

JANUARY

1986

Page 3

SAFETY

This product has been designed and tested according to international Safety Requirements. To ensure

safe operation and to

must be heeded. Refer to Section i and the Safety Summary for general safety considerations

applicable to this product.

keep {he product safe, the information, cautions, and warnings in this manual,

This apparatus has been designed and tested in accordance with IEC publication

requirements for electronic measuring apparatus, and has been supptiea in

manuai contains some information and warnings which have to be tottowea by the user to ensure safe

operation and to retain the apparatus in safe condition.

CERTIFICATION

Hewtett-Peckert: Company certifies that this product met its published specifications at the time of

silipment from tile factory. Hewlett-Packard further certifies that its calibration measurements are

traceable to the United States National Bureau of Standards, to the extent euowea by the Bureau's

caiibration facility, and to the calibration facilities of other Internationat Standards Organization

members.

a safe condition. This

348, safety

WARRANTY

This Hewlett-Packard product is warranted against defects in material and workmanship

period of one year from date of shipment. During the warranty period, Hewlett-Packard Company

will, at its option, either repair or replace products which prove to be defective.

For warranty service or repair, this product must be returned to a service facility designated by HP.

However, warranty service for products installed by HP and certain other products designated by

HP will be performed at Buyer's facility at no charge within the HP service travel area. Outside HP

service travel areas, warranty service will be performed at Buyer's facility

agreement and Buyer shall pay HP's round trip travel expenses.

For products returned to HP for warranty service, Buyer shall prepay shipping charges to HP and

HP shall pay shipping charges to return the product to Buyer. However, Buyer shall pay all

shipping charges, duties, and taxes for products returned to HP from another country.

only

upon HP's prior

for

a

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from

maintenance by Buyer, Buyer-supplied software or interfacing, unauthortzed modification

misuse, operation outside of the environmental specifications for the product, or Improper site

preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. HP SPECIFICALLY DISCLAIMS THE

IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYER'S SOLE AND EXCLUSIVE REMEDIES. HP

SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL

THEORY.

imp~oper

or .inadequate

or

ASSISTANCE

Product maintenance agreements and other customer assistance agreements are avaiiabie for

Hewlett-Packard products.

For any assistance, contact your nearest Hewiett-Packard Sales and Service Office. Addresses are

provided at the

back of this

manuai.

SCWA984

Page 4

UP

54201A/D SERVICE MANUAL

Your

Your comments assist us in improving the usefulness of our publications. Please complete this questionnaire

and return it to us. Feel free toadd any additionalcomments that you might have. All comments and suggestions

become the property

I.

2. Did the organization of the manual and the index make specific topics easy to fmd?

3. How would you rate:

Comments Please

of

HP.

Did you have any difficulty in understanding or applying the material in this manual?

o None

a. If so, please identify the

b. What can we do to clarify these areas? _

DEasy

The

depth of coverage

Examples

and

o Minimal Difficulty

areas.

0 Fairly Easy 0 Difficult 0 Quite Difficult

Excellent

o

figures

o

o Difficulty

Good

o

o

o Quite Difficult

Adequate

o

o

Poor

o

o

Please explain _

4. What did you find to be most helpful in this manual? _

5. What did you find to be least helpful? _

6. What was your level of knowledge about oscilloscopes before you began using this manual?

o None 0 Beginner 0 Intermediate 0 Expert

Name

Address _

THANK

YOU

FOR

YOUR HELP.

NO POSTAGE NECESSARY

IF

MAILED

IN

U.S.A.

Page 5

FOLD HERE

Flin-

~e..

HEWLETT

PACKARD

FIRST CLASS PERMITNO. 1303 COLORADOSPRINGS,COLORADO

~------~.--------._-------~--------

BUSINESS REPLY CARD

POSTAGE

HEWLETT-PACKARD

COLORADO SPRINGS DIVISION

ATTN: PUBLICATIONS

P.O.

COLORADO SPRINGS, COLORADO 80901·2197

..

_-------_.._-----

WILL BE PAID BY ADDRESSEE

DEPT.

BOX 2197

----------------------._._-------._._------------------------------------------------------------------------.-----------------

FOLD HERE

111111

NO POSTAGE

NECESSARY

IF MAILED

IN THE

UNITED

STATES

Your

cooperationincompleting

will

be

greatly

and

appreciated.

returning

Than you.

this

form

Page 6

SAFETY CONSIDERATIONS

GENERAL • This is a

with terminal for protective earthing).

OPERATION

power

voltage,

are taken (see the following warnings). In addition, note the

instrument's

"Safety

o

Ser

....

personnel. To avoid dangerous electric shock, do not

perform any servicing unless qualified to do so.

~

BEFORE

transformer

the

correct

external markings which are described

Symbols."

lclng

Instructions

Safety

Class I Instrument (provided

APPLYING

primary is matched to the available line

fuse

Is Installed,

I

WARNING

are

for

POWER

and

I

use

verify

Safety

by

servlce-trarned

that

the

Precautions

under

o BEFORE SWITCHING ON THE INSTRUMENT, the

protective earth terminal of the Instrument

connected to the protective conductor of the (mains)

powercord. The mains plug shall only be inserted In a

socket outlet provided

protective action must not be negated by the use of an

extension

conductor

conductor

cord

(grounding). Grounding one

outlet Is not sufficient protection.

with

a protective earth contact. The

(power cable) without a protecttve

conductor

must

of a

be

two-

o Do not Install substitute

modification to the Instrument.

o Adjustments described In the manual are

power supplied to the

are removed. Energy available at

contacted, result In personal

a Any adjustment, maintenance, and repair of the opened

instrument

possible, and when Inevitable, should be carried

a skilled person

o Capacitors Inside the

If the Instrument has been disconnected

under

who

partsorperform

Instrument

Injury

voltage should be avoided as

Is aware of the

Instrument

may

while

.

hazard

many

still be

from

any

unauthorIzed

performed

protective

points

Involved.

charged

Its

much

out

source

with

covers

may, If

only by

even

supply.

SAFETY

;';\

Instruction manual symbol.

ill

to protect against damage to the

marked

the user to refer to the

with

SYMBOLS

The

product

this symbol when It Is necessary

Instruction

product.

manual in

wllf be

order

as

of

for

this

a If

auto-transformer

common terminal Is connected to the

power source.

Any

o

(Inside or outside

protective

hazard

o Whenever it Is likely

the Instrument

against any unintended operation.

o Only fuses With the required rated current, voltage, and

specified

used. Do not use repaired fuses or

fuseholders. To do so could cause a

o Do

gasses or fumes. Operation of any electrical instrument In

such

Instrument is to be energized via an

(for voltage reduction) make

earth

interruption of the protective (grounding)

the

Instrument) or dlsconnecttng the

earth

terminal will cause a potential

that

could result in personal Injury.

that

the protection has been impaired,

must

be made Inoperative and be secured

type

(normal blow, time delay, etc.) should be

shock

not

operate the

an environment constitutes a definite safety

instrumentinthe

presence of flammable

sure

terminal of the

conductor

shock

short

clrculted

or fire hazard.

hazard.

the

Indicates

-L

Earth terminal (sometimes used in manual to

indicate

chassis).

I

WARNING

performed or adhered to, could result In personal Injury. Do

not proceed beyond a

conditions are

~

~

correctly performed or adhered to, could result in

or destruction of

beyond a CAUTION sign until the Indicated conditlons are

fully understood or met.

hazardous

circuit

The WARNING sign denotes a

voltages.

common connected to

grounded

hazard.

I calls attenlion to a procedure, practice,

or the like, which, if not

WARNING

fully understood and met.

The CAUTION sign

calls attention to an operating procedure,

practice, or the like, which, if

part

or all of the

sign until the Indicated

denotesahazard.

product.

Do

correctly

damage

not

proceed

not

S010984

It

It

to

Page 7

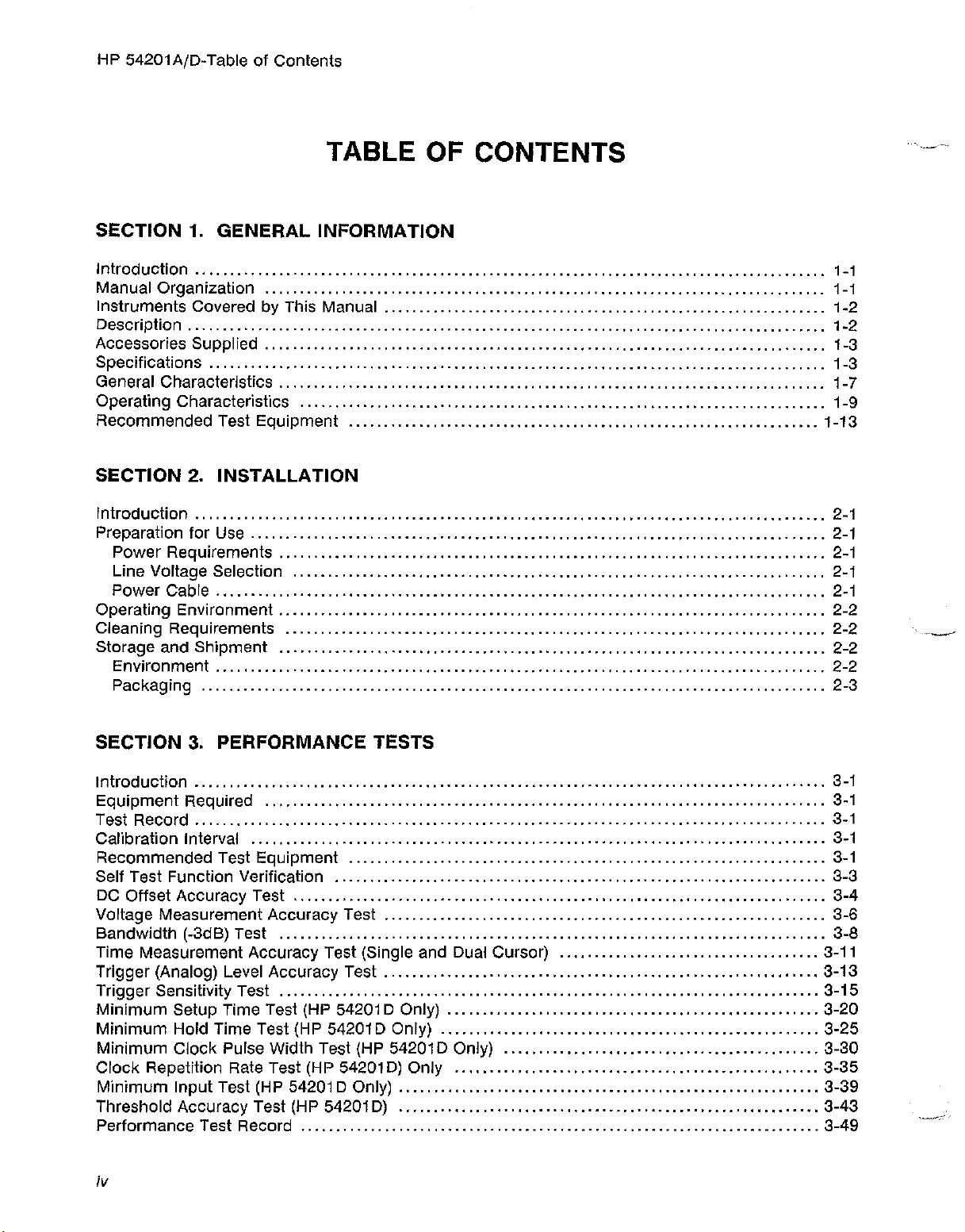

HP 54201A/D-Table of Contents

TABLE OF CONTENTS

SECTION 1. GENERAL INFORMATION

Introduction 1-1

Manual Organization 1-1

Instruments Covered by This Manual 1-2

Description '" , " .. , 1-2

Accessories Supplied 1-3

Specifications , " ,

General Characteristics 1-7

Operating Characteristics 1-9

Recommended Test Equipment 1-13

SECTION 2. INSTALLATION

Introduction , '" ., 2-1

Preparation for Use , , 2-1

Power Requirements 2-1

Line Voltage Selection 2-1

Power Cable ,.. " .. ,

Operating Environment 2-2

Cieaning Requirements 2-2 .

Storage and Shipment 2-2

Environment , ,. '" 2-2

Packaging 2-3

1-3

2-1

~~

SECTION 3. PERFORMANCE TESTS

Introduction , , , 3-1

Equipment Required 3-1

Test Record , , , 3-1

Calibration Interval

Recommended Test Equipment 3-1

Self Test Function Verification 3-3

DC Offset Accuracy Test 3-4

Voltage Measurement Accuracy Test

Bandwidth (-3dB) Test 3-8

Time Measurement Accuracy Test (Single and Dual Cursor) 3-11

Trigger (Analog) Level Accuracy Test 3-13

Trigger Sensitivity Test 3-15

Minimum Setup Time Test (HP 54201D Only) 3-20

Minimum Hold Time Test (HP 54201D Only) 3-25

Minimum Ciock Pulse Width Test (HP 54201D Only) 3-30

Clock Repetition Rate Test (HP 54201D) Only 3-35

Minimum Input Test (HP 54201D Only) 3-39

Threshold Accuracy Test (HP 54201D)

Performance Test Record 3-49

iv

3-1

3-6

3-43

Page 8

HP 54201

AjD

- Table of Contents

SECTION 4. ADJUSTMENT PROCEDURES

Introduction " ,.. , '" , ,.. , 4-1

Calibration Interval 4-1

Front-Panel Calibration 4-2

SYSTEM Calibration Menu 4-2

SYSTEM Test

Equipment Required for Adjustments 4-5

Power Supply Adjustment , , 4-6

Display System Adjustment 4-8

Yoke Adjustment Procedure 4-8

Display Driver

Analog Board Adjustments 4-14

Offset Adjustment Procedures 4-14

Input Compensation and Gain Adjustments 4-16

State Trigger Board Adjustment (54201D Only) 4-20

& Service Menu Calibration , , , 4-3

Adjustment

Procedure 4-11

SECTION 5. REPLACEABLE PARTS

Introduction " ., , '" , , '" '" .. , 5-1

Abbreviations 5-1

Replaceable Parts List 5-1

Ordering Information 5-2

Direct Maii Order

System

5-2

SECTION 6. SERVICE

Introduction , , , , , , , 6-1

Safety Considerations 6-1

logic

ECl

Removal and Installation of Mainframe Components 6-2

Convention , '" ., , , 6-1

Attributes ·· .. ·· · ·· .. · · 6-1

State Trigger Board Removal (HP 54201D only) 6-3

CPU Board Removal 6-3

Power Supply Board Removal ·· ..

Analog Board Removal , 6-5

Motherboard Removal 6-5

Keyboard and CRT Removal , , , , ,.. , , '" 6-5

Display Driver Board Removal 6-7

Troubleshooting 6-8

Self Test Failures 6-9

Board Replacement · ·

Product Support Kit 6-13

Key-Down Power-Up Reset 6-16

Troubleshooting Flowchart 6-18

Power Supply Voltage Check 6-23

Interface Stimulus Test , '" , , 6-24

Display Driver Signals 6-26

Keyboard Test 6-27

····················

···

6-3

6-11

v

Page 9

HP 54201A/D - Table of Contents

SERVICE GROUP

Introduction 6A-1

Safety Considerations 6A-1

Specifications 6A-2

Power Supply Block Diagram 6A-2

Power Suppiy Theory Of Operation , , " ., .. .. 6A-5

Primary Section 6A-5

Control Section 6A-6

Control Power Supply 6A-?

PWM Failure Modes 6A-?

Secondary Section 6A-1O

LED Failure Indications 6A-1O

Mnemonics 6A-13

GA.

POWER SUPPLY

APPENDIX A. SELF-TEST DOCUMENTATION

Introduction A-1

Self Test 0 - CPU/Memory A-1

Self Test 1 - Acquisition/Trigger A-2

Analog Board Self Tests A-3

State Board Self Tests A-4

Self Test 2 - Input A-8

vi

Page 10

HP 54201A/D - General Information

SECTION 1

GENERAL INFORMATION

I

WARNING

Service information tnctuaeo in this manuai is for use of trained service

oersonnet. To avoid etectrtcet shock, do not perform any service

procedures in the manual or do any servicing to the HP 54201AID

unless you are qualified.

1-1. INTRODUCTION

This manual contains technical information concerning the installation, performance testing,

adjustments, and servicing of the HP 54201A and HP 54201D Digitizing Oscilloscopes. When

information concerns both models the system will be referred to as the HP

I

54201AfD.

1-2. MANUAL ORGANIZATION

Section 1, General Information. This section contains a description of this manual and the

Instrument. This section also gives the specifications, general characteristics, operating

characteristics and recommended test equipment for the HP

Section 2, Installation. This section explains how to prepare the HP 54201AID for use.

Section 3, Performance Tests. This section describes both the self test capabilities of the HP

54201AID as well as the procedures for the full Performance Test.

Section 4, Adjustments. The HP 54201

performance after some major repairs have been made. This section provides the necessary

adjustment procedures.

Section 5, Replaceable Parts. This section contains ordering information and a list of all

replaceable parts in the HP

Section 6, Service. This section contains disassembly and assembly procedures and

documentation and procedures for isolation and replacement of faulty circuit boards.

Service Group 6A, Power Supply. This section contains block diagrams and component level

theory, troubleshooting and schematic information necessary to service the HP 54201

supply.

54201A/D system.

AID requires several adjustments to restore specified

54201A/D.

AID power

Appendix A, Self Test Documentation. This section contains an overview of how the HP

self tests werk and what portions of the HP 54201AID circuitry they check.

54201A/D

1-1

Page 11

HP 54201AID - General Information

1-3. INSTRUMENTS COVERED BY THIS MANUAL

Attached to the instrument is a serial number sticker. The serial number is in the form

OOOOAOOOOO.

five digits are the suffix. The prefix is the same for all identical HP 54201A or HP 54201D

instruments; the prefix only changes when a change is made to the instrument. The suffix,

however, is assigned sequentially and is different for each instrument. The contents of this manual

applies to instruments with serial number prefix(es) listed under SERIAL NUMBERS on the title

page. The serial number is also displayed on the HP 54201

Peripherals menu is selected.

An instrument manufactured after the printing of this manual may have a serial number prefix not

listed on the title page. This unlisted serial prefix indicates the instrument is different from those

described in this manual. The manual for this newer instrument is accompanied by a

Manual Changes supplement. The supplement contains "change information" that explains

adapt the manual to the newer instrument.

In addition to change information, the supplement may contain information for correcting errors in

the manual. To keep this manual as current and accurate as possible, Hewlett-Packard

recommends that you periodically request the latest Manual Changes supplement. The

supplement is identified by the manual print date and part number, both of which appear on the

manual title page. Complimentary copies of this supplement are available on request.

It is in two parts; the first four digits and the ietter are the serial prefix and the last

AID screen when the SYSTEM

yellow

how

to

Shown on the title page is a microfiche part number. This number can be used to order 4

microfilm transparencies of this manual. Each microfiche contains up to

manual pages.

96 photoduplicates of the

X 6 inch

1-4. DESCRIPTION

The HP 54201A and HP 54201D Digitizing Oscilloscopes are dedicated, two-channel,

simultaneous, waveform acquiring digital storage oscilloscopes with full HP-IB programmability,

digitized waveform data output, and resident parametric waveform measurements.

The HP

and a single-shot digital storage bandwidth of 50 MHz (200 rneqesamptes/secono) With Infinite

store time and waveform data output. It also provides parametric information about the analog

characteristics of waveforms.

The HP 54201D has all the features of the HP 54201A with the addition of parallel and serial logic

trigger qualification capabilities. The HP 54201D includes 3 pods, each containing

bit

54201A/D is a generai purpose digitizing oscilioscope with 300 MHz repetitive

+ clock organization.

?andV1dd.th

8 bit + 1 parity

1-2

Page 12

HP 54201AjD - General Information

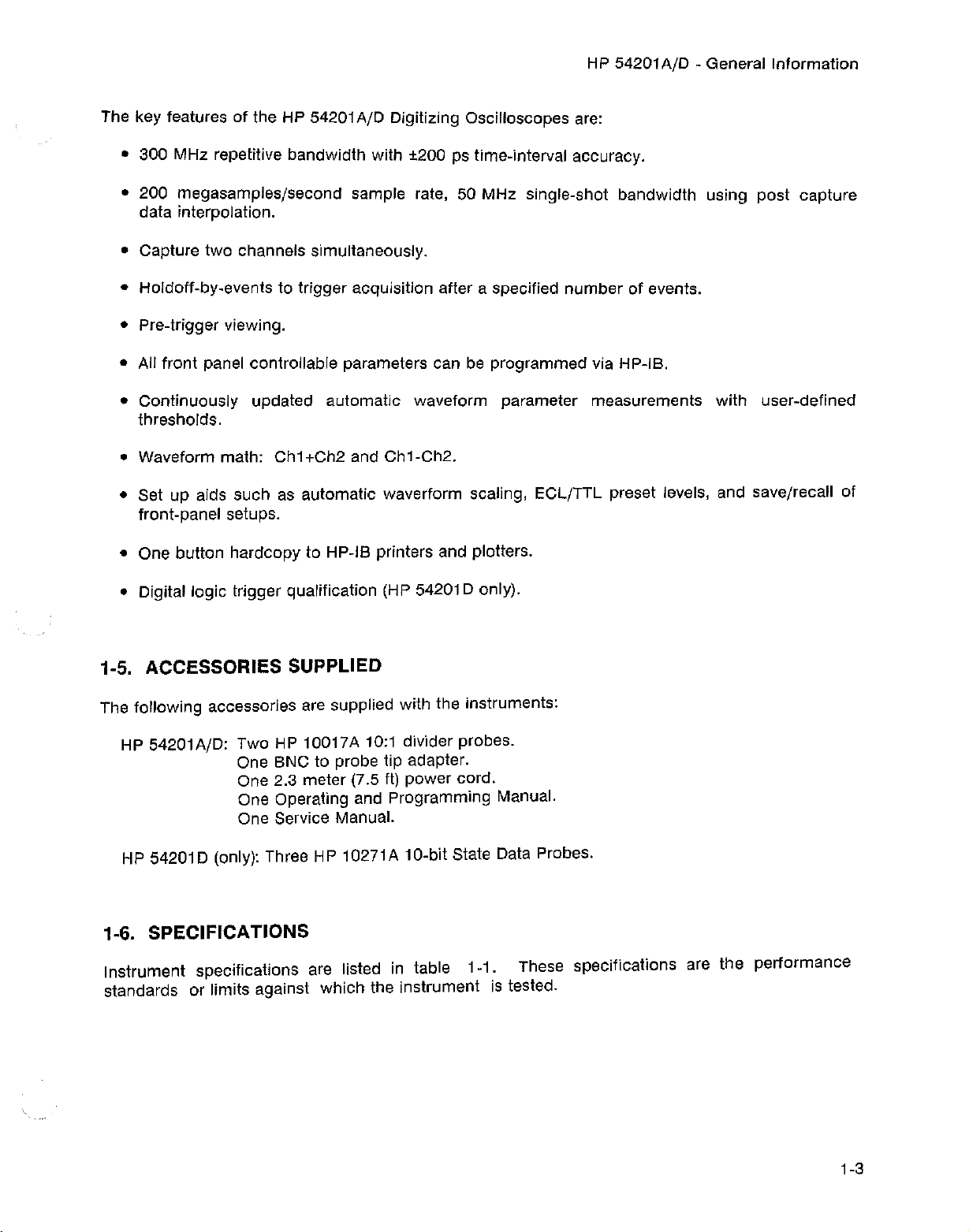

The key features of the HP 54201AjD Digitizing Oscilloscopes are:

• 300 MHz repetitive bandwidth with ±200 ps lime-interval accuracy.

• 200 megasamplesjsecond sample rate, 50 MHz single-shot bandwidth using post capture

data interpolation.

• Capture two channels simultaneously.

•

Holdoff-by-events

• Pre-trigger viewing.

• All front panel controllabie parameters can be programmed via HP-IB.

• Continuously updated automatic waveform parameter measurements with user-defined

thresholds.

• Waveform math: Ch1+Ch2 and Ch1-Ch2.

to trigger acquisition alter a specified number of events.

• Set up aids such as automatic waverform scaling,

front-panel setups.

• One button hardcopy to HP-IB printers and plotters.

• Digital logic trigger qualification (HP 54201D only).

ECl/TTl

1-5. ACCESSORIES SUPPLIED

The following accessories are supplied with the instruments:

HP 54201AjD: Two HP 10017A 10:1 divider probes.

One BNC to probe tip adapter.

One 2.3 meter (7.5

One Operating and Programming Manual.

One Service Manual.

HP 542010 (only): Three HP 10271A 10-bit State Data Probes.

It) power cord.

1-6. SPECIFICATIONS

preset levels, and save/recall of

Instrument specifications are listed in table 1-1. These specifications are the performance

standards or limits against which the instrument is tested.

1-3

Page 13

HP 54201A/D - General Information

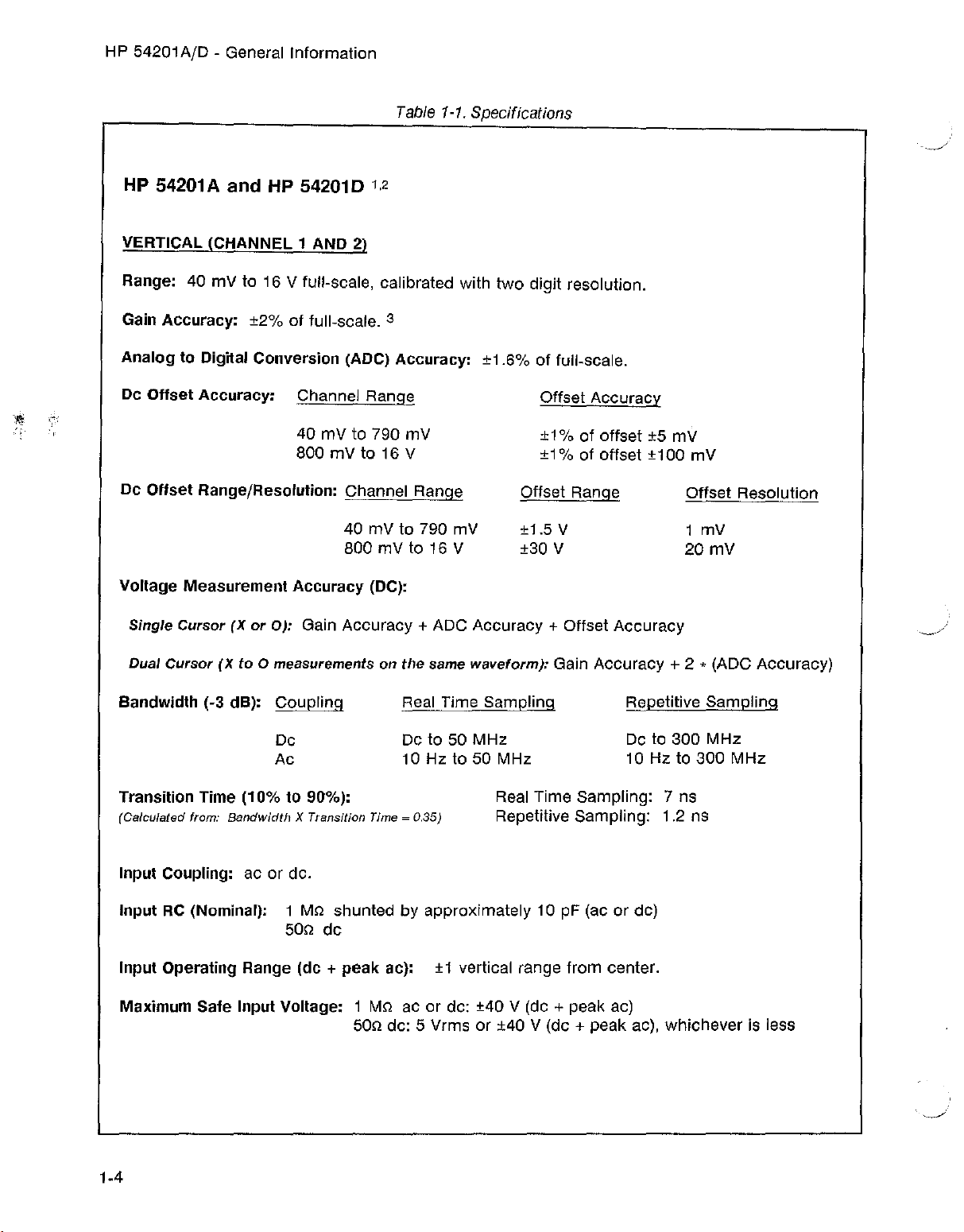

HP

54201Aand

HP 542010 1,2

VERTICAL (CHANNEL 1 AND 2)

Table 1-1. Specifications

Range: 40 mV to 16 V full-scale, calibrated with

Gain

Analog

Dc

Offset

Accuracy:

to Digital Conversion (ADC) Accuracy: ±1.6% of full-scale.

Accuracy:

±2%

of full-scale. 3

Channel Range

40 mV to 790 mV

800mVt016V

Dc

Offset

Voltage

Single

Dual

Bandwidth (-3 dB):

Range/Resolution: Channel Range

40 mV to 790

800mVt016V

Measurement

Cursor(Xor

Cursor(Xto

Accuracy

0):

Gain

0 measurements on

(DC):

Accuracy

Coupling

Dc

Ac

mV

+ ADC Accuracy + Offset

the

same

Real Time Sampling

Dc to 50

10 Hz to 50 MHz

two

digit resolution.

Offset Range

±1.5 V

±30 V

waveform):

MHz

Offset

±1%ofoffset

±1% of offset ±100

Accuracy

±5 mv

mV

Offset Resolution

1 mV

mV

20

Accuracy

Gain Accuracy + 2 * (ADC Accuracy)

300

Sampling

MHz

300

MHz

Repetitive

Dc to

10 Hz to

Transition Time

(Calculated from: Bandwidth X Transition Time = 0.35)

(10%to90%):

Real Time Sampling: 7 ns

Repetitive Sampling: 1.2 ns

Input Coupling: ac or de.

Input RC (Nominal): 1 MQ shunted by approximately 10 pF (ae or de)

50Q de

Input Operating Range (dc

Maximum Safe Input Voltage: 1 MQ ae or de: ±40 V (de

+

peak

ae): ±1 vertical range

50Q de: 5 Vrms or ±40

from

+ peak ae)

V (de + peak ac),

1-4

center.

whichever

is less

Page 14

HP 54201AID - General Information

Table 1-1. Specifications (continued)

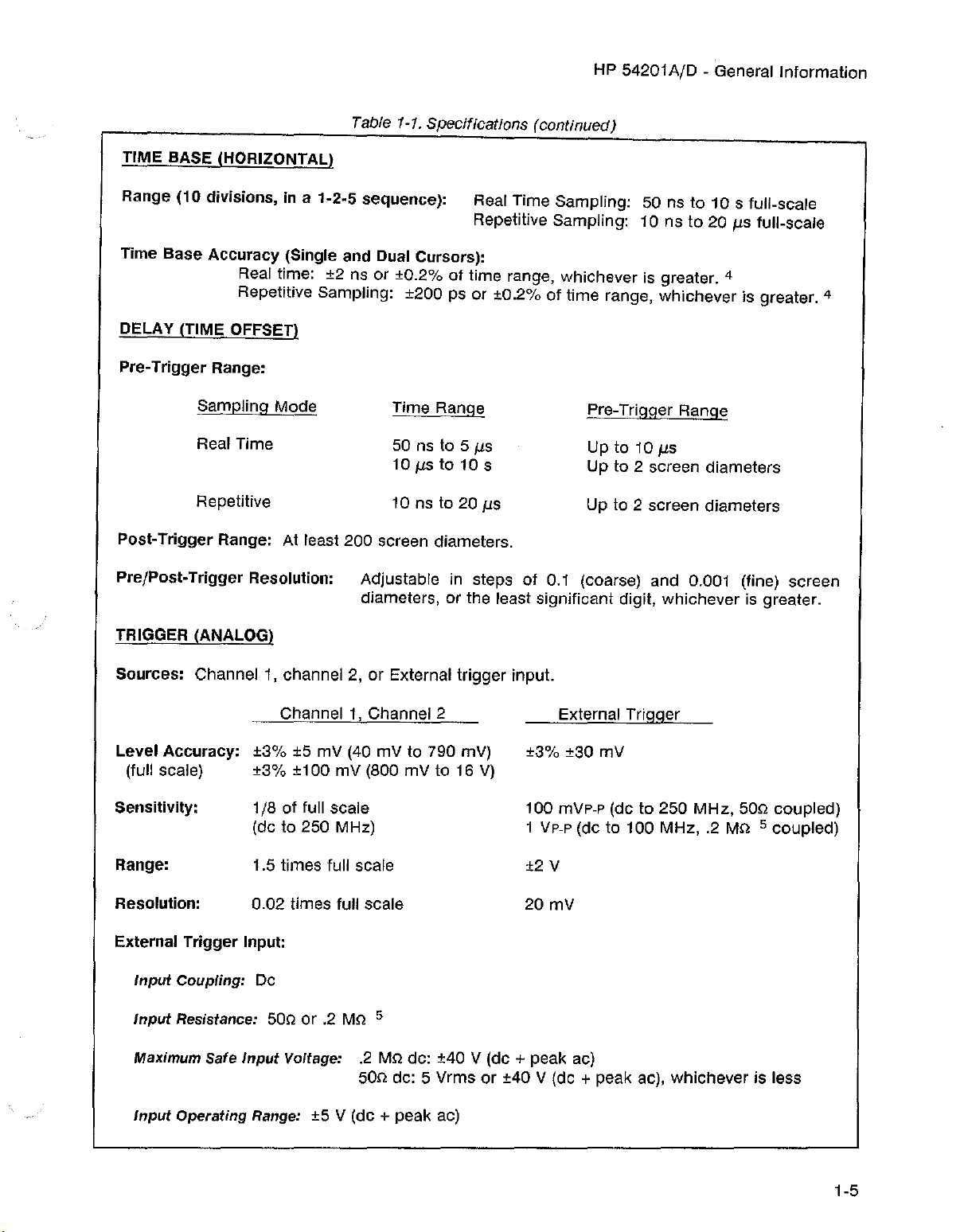

TIME BASE (HORIZONTAL)

Range (10 divisions, in a 1-2-5 sequence): Real Time Sampling: 50 ns to 10 s full-scale

Repetitive Sampling: 10 ns to 20

/.Is

full-scale

Time Base Accuracy (Single and Dual Cursors):

Real time: ±2 ns or ±0.2% of time range, whichever is greater. 4

Repetitive Sampling: ±200 ps or ±0.2% of time range, whichever is greater. 4

DELAY (TIME OFFSET)

Pre-Trigger Range:

Sampling Mode

Real Time

Repetitive

Time Range

50 ns to 5

10

/.Is

to 10 s

10 ns to 20

/.IS

/.IS

Pre-Trigger Range

Up to 10

/.IS

Up to 2 screen diameters

Up to 2 screen diameters

Post-Trigger Range: At least 200 screen diameters.

Pre/Post.Trigger Resolution: Adjustable in steps of 0.1 (coarse) and 0.001 (fine)

diameters, or the least significant digit, whichever is greater.

TRIGGER (ANALOG)

Sources: Channel 1, channel 2,orExternal trigger input.

Level Accuracy:

Channel 1, Channel 2

±3%

±5 mV (40 mV to 790 mv)

External Trigger

±3% ±30 mV

(full scale) ±3% ±100 mV (800 mV to 16 V)

Sensitivity:

Range:

1/8 of full scale

(de to 250 MHz)

1.5 times full scale

100 mVp-p (de to 250

MHz,

500 coupled)

1 Vp-p (de to 100 MHz, .2 MO 5 coupled)

±2 V

screen

Resolution:

0.02 times full scale

External Trigger Input:

Input

Coupling: Dc

Input

Resistance: 500 or .2 Mo 5

Maximum Safe

Input

Operating Range: ±5 V (de + peak ae)

Input

20 mV

Voltage: .2 MQde: ±40 V (de + peak ac)

50Q de: 5 Vrms or ±40 V (de + peak ac), whichever is less

1-5

Page 15

HP 54201

AID

- General Information

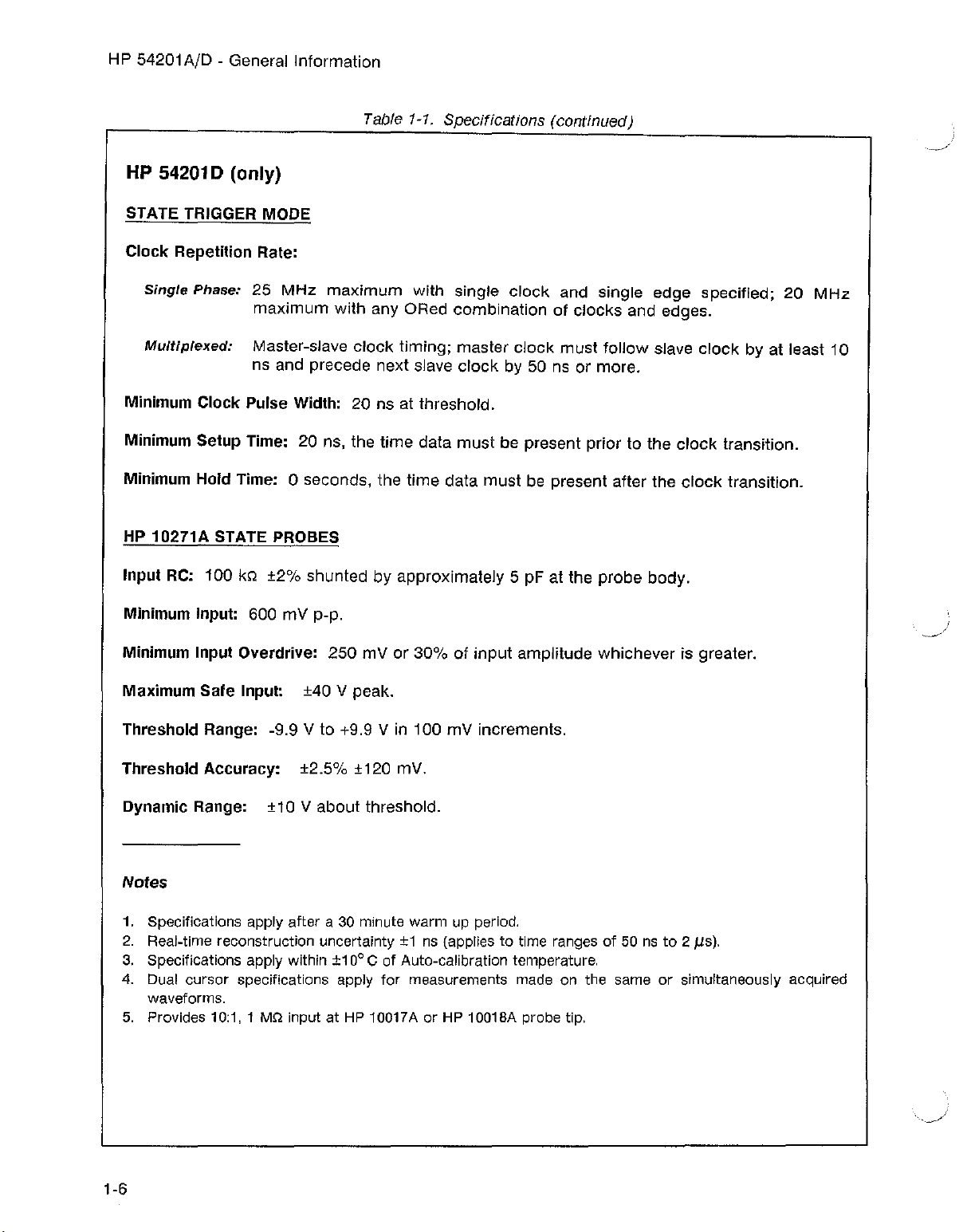

HP 542010 (only)

STATE TRIGGER MODE

Table 1-1. Specifications (continued)

Clock

Repetition Rate:

Single

Multiplexed:

Phase:

25 MHz

maximum

Master-slave

maximum

with

clock

with single

any ORed combination of

timing; master

ns and precede next slave

clock

Minimum Clock Pulse Width: 20 ns at threshold.

Minimum Setup Time: 20

ns, the

Minimum Hold Time: 0 seconds, the

time

data

time

must

data

HP 10271A STATE PROBES

Input RC: 100

Minimum Input: 600 mV

Minimum Input Overdrive:

Maximum

kQ

±2%

Sale

Input: ±40 V peak.

shunted by approximately 5 pF at the

p-p,

250

mV or 30% of

input

clock

and single edge specified; 20

clock

clocks

must

and edges.

follow

slave

by 50 ns or more.

be present prior to the

must

be present after the

probe

body.

amplitude whichever is greater.

clock

clock

clock

MHz

by at least 10

transition.

transition.

Threshold Range:

-9.9 V to +9.9 V in 100 mV increments.

Threshold Accuracy: ±2.5% ±120 mY.

Dynamic Range: ±10 V

about

threshold.

Notes

1. Specifications apply after a 30

2.

Real-time

3. Specifications apply within ±10°C of Auto-calibration temperature.

4. Duai cursor specifications apply for

waveforms.

5.

Provides

reconstruction uncertainty±1ns

10:1,1 MQ inputat HP

minute

10017A

warm up

period.

(applies

measurements

or HP

10018A

to time

made

probetip.

1-6

ranges

on the

of 50 ns to 2I1s).

same

or simultaneously acquired

Page 16

HP 54201A/D - General Information

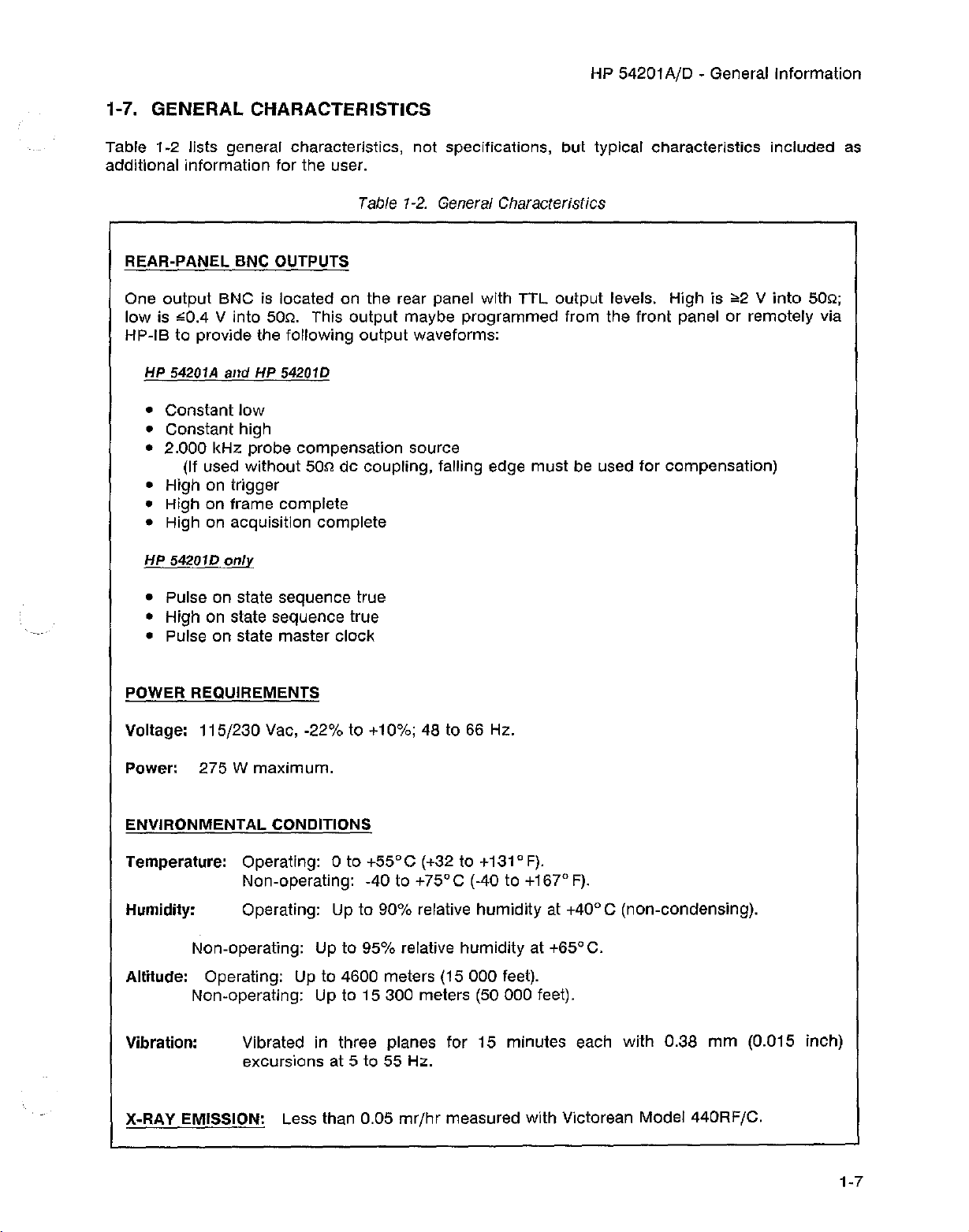

1-7. GENERAL CHARACTERISTICS

Table 1-2 lists general characteristics, not specifications, but typical characteristics included as

additional information for the user.

Table 1-2. General Characteristics

REAR-PANEL BNC OUTPUTS

One output BNC is located on the rear panel with TTL output levels. High is

low is

~0.4

V into

50Q.

This output maybe programmed from the front panel or remotely via

HP-IB to provide the following output waveforms:

HP 54201A

• Constant

and

HP 54201D

low

• Constant high

• 2.000 kHz probe compensation source

(If used without

50Qde coupling, falling edge must be used for compensation)

• High on trigger

• High on frame complete

• High on acquisition complete

HP 54201D

only

• Pulse on state sequence true

• High on state sequence true

• Pulse on state master clock

POWER REQUIREMENTS

Voltage: 115/230

Vac, -22% to +10%; 48 to 66 Hz.

,,2 V

into

50Q;

Power: 275

W maximum.

ENVIRONMENTAL CONDITIONS

Temperature: Operating: 0 to

+55°C

(+32 to +131° F).

Non-operating: -40 to +75°C (-40 to +167° F).

Humidity: Operating: Up to 90% relative humidity at +40

Non-operating: Up to 95% relative humidity at +650C.

Altitude: Operating: Up to 4600 meters (15 000 feet).

Non-operating: Up to 15 300 meters (50 000 feet).

Vibration:

Vibrated in three planes for 15 minutes each with 0.38

excursions at 5 to 55 Hz.

mr/hr

X-RAY EMISSION: Less than 0.05

measured with Victorean Model 440RF/C.

0

C (non-condensing).

mm

(0.015 inch)

1-7

Page 17

HP 54201AID - General Information

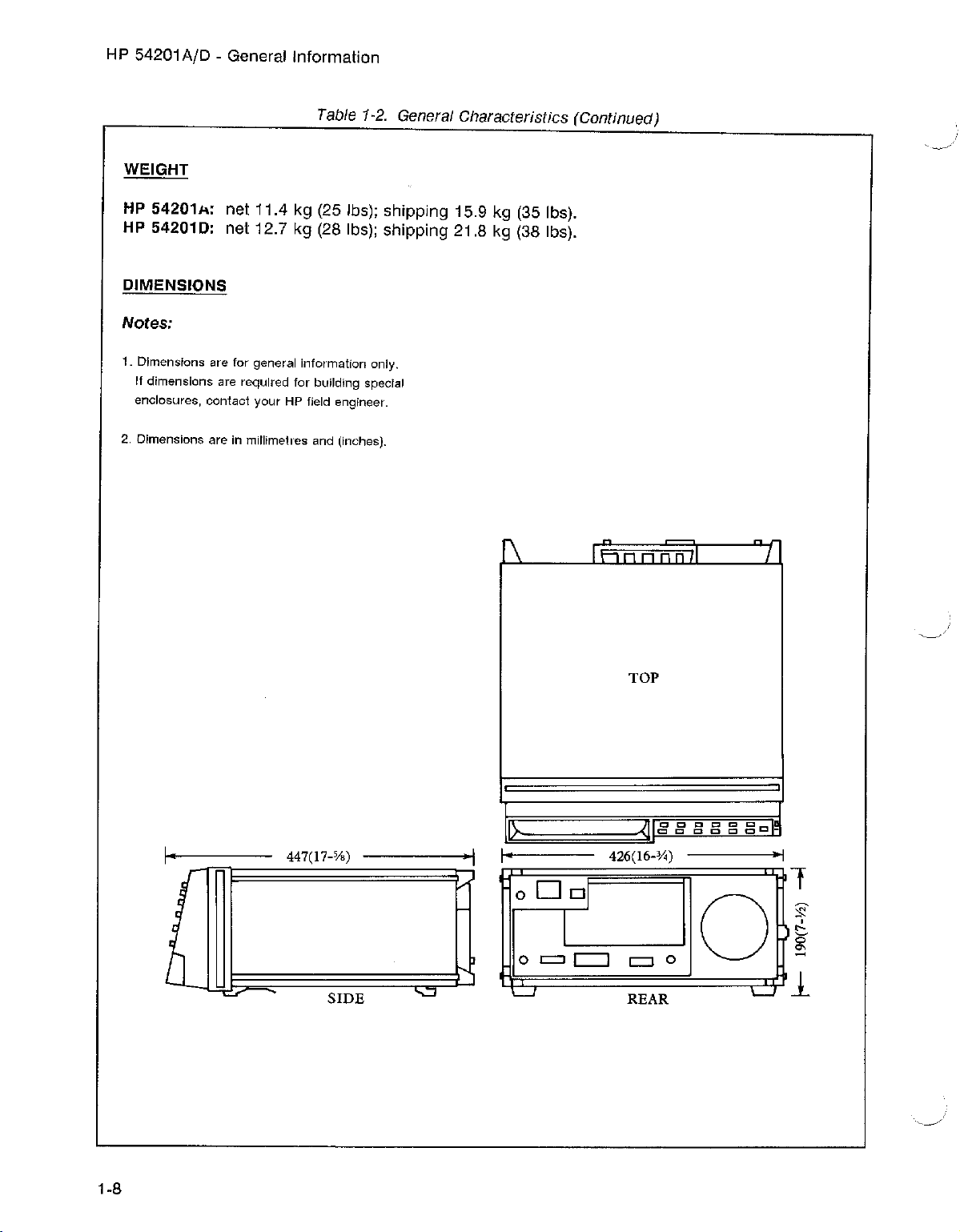

Table 1-2. General Characteristics (Continued)

WEIGHT

HP

54201A: net 11.4 kg (25 Ibs); shipping 15.9 kg (35 Ibs).

HP 542010: net 12.7 kg (28 Ibs); shipping 21.8 kg (38 Ibs).

DIMENSIONS

Notes:

1. Dimensions are for general information only.

If dimensions are required for building special

enclosures, contact your HP field engineer.

2. Dimensions are In mltltrnetres and (Inches).

I-

I

A

447(17-%)

SIDE

1 I

f\

1>-

I-

°

0

L...J

DOl

I

= c::::J

fF

TOP

?lr.CCl:lIccccl!

ClCCDCC

426(16-%) -I

=0

REAR

0

I

I

1

'--

1-8

Page 18

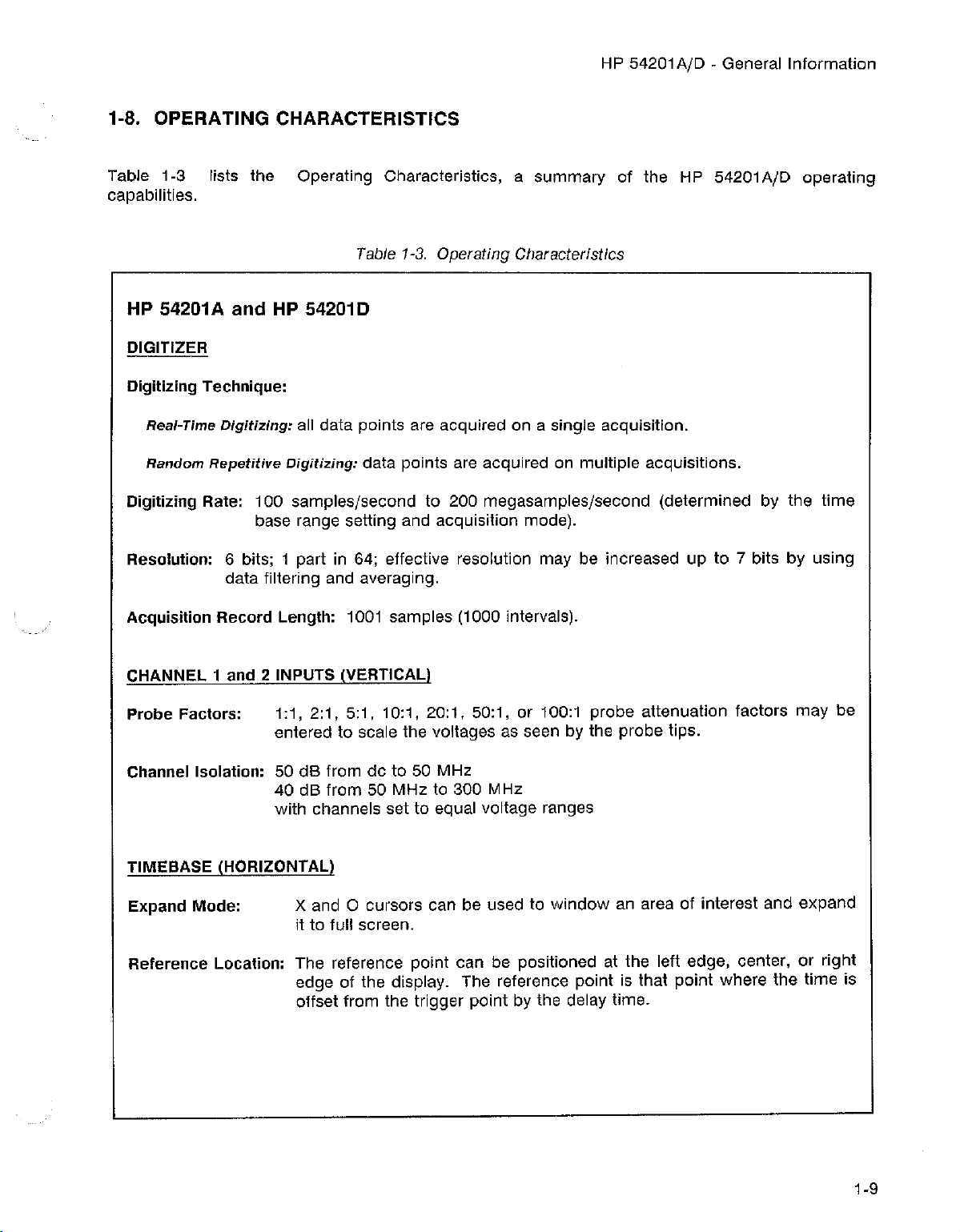

HP 54201A/D - General Information

1-8. OPERATING CHARACTERISTICS

Table 1-3 lists the Operating Characteristics, a summary of the HP 54201AID operating

capabilities.

Table 1-3. Operating Characteristics

HP 54201A

and

HP 54201D

DIGITIZER

Digitizing Technique:

Real-Time

Random

Digitizing Rate: 100 samples/second to 200

Digitizing:

Repetitive

all data points are acquired on a single acquisition.

Digitizing:

data points are acquired on multiple acquisitions.

rneqasamples/second (determined by the time

base range setting and acquisition mode).

Resolution: 6 bits; 1 part in 64; effective resolution may be increased up to 7 bits by using

data filtering and averaging.

Acquisition Record Length: 1001 samples (1000 intervals).

CHANNEL 1 and 2 INPUTS (VERTICAL)

Probe Factors:

1:1,2:1,5:1,10:1,20:1,50:1,

or 100:1 probe attenuation factors

may

be

entered to scale the voltages as seen by the probe tips.

Channel Isolation: 50 dB from de to 50 MHz

40 dB from 50 MHz to 300 MHz

with channels set to equal voltage ranges

TIMEBASE (HORIZONTAL)

Expand Mode: X and

0 cursors can be used to

window

an area of interest and expand

it to full screen.

Reference Location: The reference point can be positioned at the left edge, center, or right

edge of the display. The reference point is that point where the time is

offset from the trigger point by the delay time.

1-9

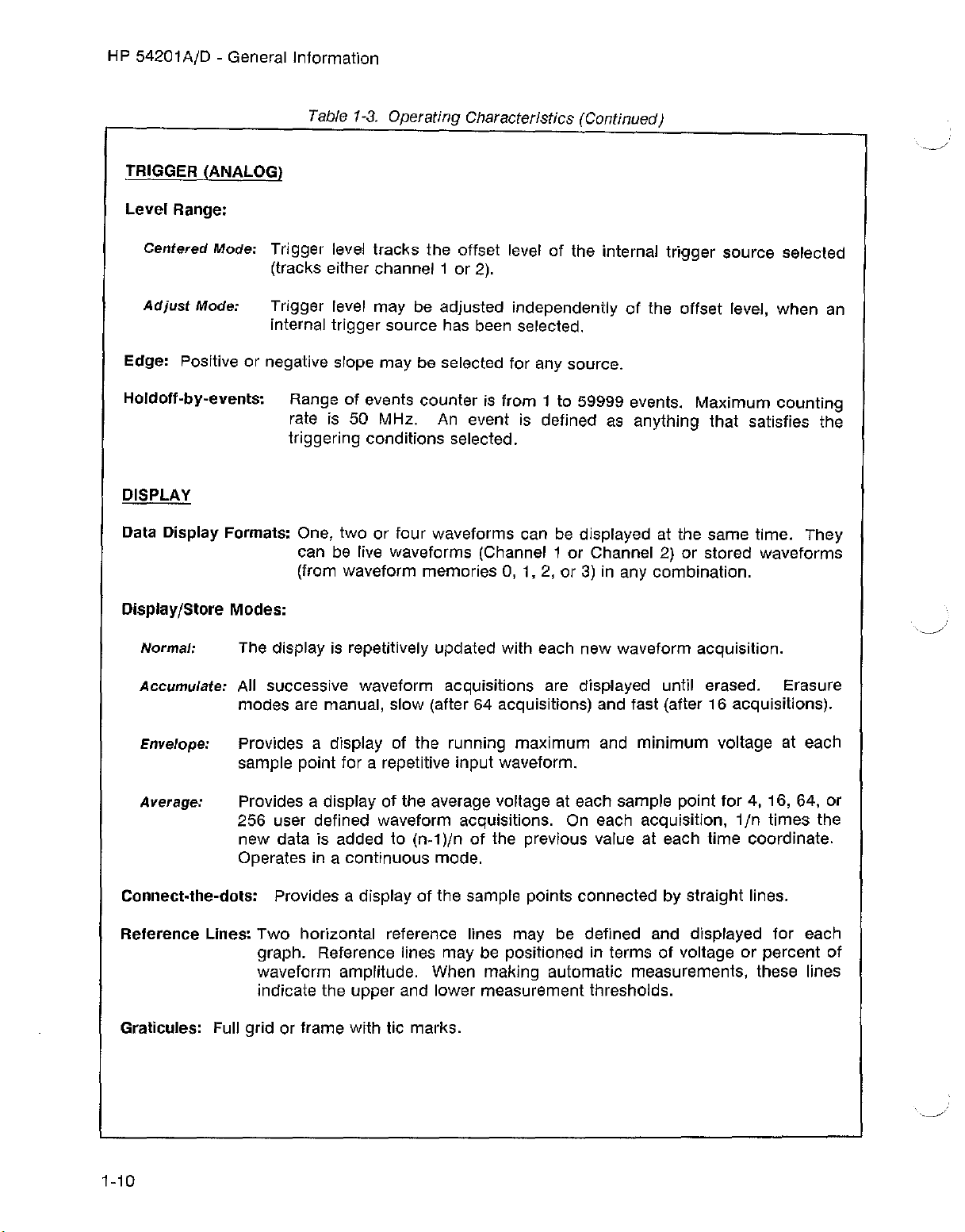

Page 19

HP 54201A/D - General Information

Table 1-3. Operating Characteristics (Continued)

TRIGGER (ANALOG)

Level Range:

Centered

Mode: Trigger level tracks the offset level of the internal trigger source selected

(tracks either channel 1 or 2).

Adjust

Mode:

Trigger level may be adjusted independently of the offset level, when an

internal trigger source has been selected.

Edge: Positive or negative slope may be selected for any source.

Holdoff-by-events: Range of events counter is from 1 to 59999 events. Maximum counting

rate is 50 MHz. An event is defined as anything that satisfies the

triggering conditions selected.

DISPLAY

Data Display Formats: One, two or four waveforms can be displayed at the same time. They

can be live waveforms (Channel 1 or Channel 2) or stored waveforms

(from waveform memories

O.

1,2,

or 3) in any combination.

Display/Store Modes:

Normal:

Accumulate:

The display is repetitively updated with each new waveform acquisition.

All successive waveform acqulsitlcns are displayed until erased. Erasure

modes are manual. slow (after 64 acquisitions) and fast (after 16 acquisitions).

Envelope: Provides a display of fhe running maximum and minimum voltage at each

sample point for a repetitive input waveform.

Average: Provides a display of the average voltage at each sample point for 4, 16, 64, or

256 user defined waveform acquisitions. On each acquisition, 1/n times the

new data is added to (n-t)/n of the previous value at each time coordinate.

Operates in a continuous mode.

connect-the-dots. Provides a display of the sample points connected by straight lines.

Reference Lines: Two horizontal reference lines may be defined and displayed for each

graph. Reference lines may be positioned in terms of voltage or percent of

waveform amplitude. When making automatic measurements, these lines

indicate the upper and lower measurement thresholds.

Gralicules: Full grid or frame with lie marks.

1-10

Page 20

HP 54201

AID

- General Information

Table 1-3.

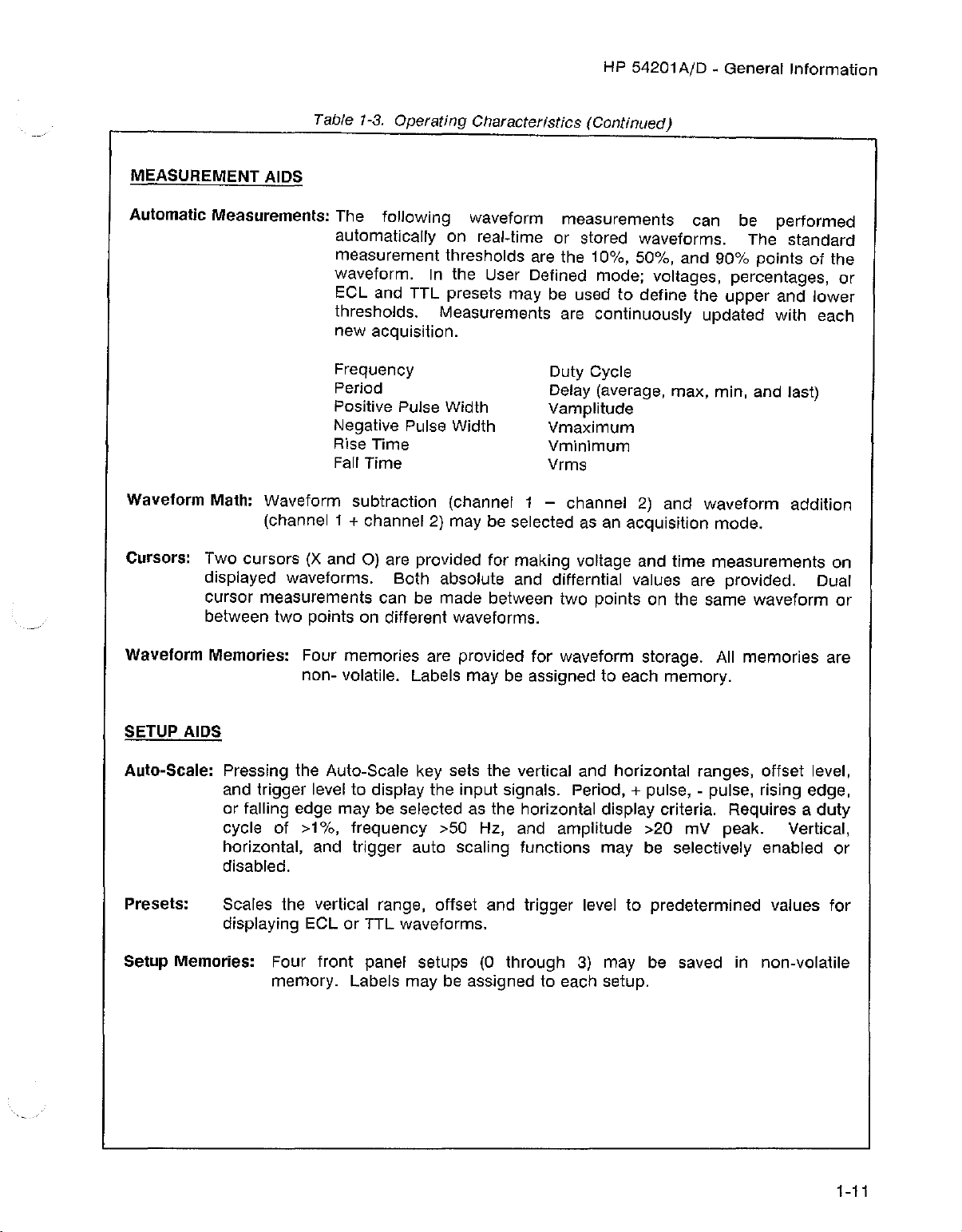

MEASUREMENT AIDS

Automatic Measurements:

The following waveform measurements can be performed

Operating

Characteristics

(Continued)

automatically on real-time or stored waveforms. The standard

measurement thresholds are the 10%, 50%, and 90% points of the

waveform. In the User Defined mode; voltages, percentages, or

ECl

and

TTL

presets may be used to define the upper and lower

thresholds. Measurements are continuously updated with each

new acquisition.

Frequency

Period

Positive Pulse Width

Negative Pulse Width

Rise Time

Fall Time

Waveform Math: Waveform subtraction (channel 1 - channel 2) and waveform addition

(channel 1

Cursors: Two cursors (X and

+ channel 2) may be selected as an acquisition mode.

0)

are provided for making voltage and time measurements on

Duty Cycle

Delay (average, max, min, and last)

Vamplitude

Vmaximum

Vminimum

Vrms

displayed waveforms. Both absolute and differntial vaiues are provided. Dual

cursor measurements can be made between two points on the same waveform or

between two points on different waveforms.

Waveform Memories: Four memories are provided for waveform storage. All memories are

SETUP AIDS

Auto-Scale:

non- volatile.

Pressing the Auto-Scale key sets the vertical and horizontal ranges, offset level,

and trigger level to display the input signals. Period,

labels

may be assigned to each memory.

+ pulse, - pulse, rising edge,

or falling edge may be selected as the horizontai display criteria. Requires a duty

cycle of >1%, frequency >50 Hz, and amplitude >20 mV peak. Vertical,

horizontal, and trigger auto scaling functions may be selectively enabled or

disabled.

Presets: Scales the vertical range, offset and trigger level to predetermined values for

displaying

Setup Memories: Four front panel setups

ECl

or TTL waveforms.

(O

through 3) may be saved in non-volatile

memory. Labels may be assigned to each setup.

1-11

Page 21

HP 54201AjD - General Information

Table 1-3. Operating Characteristics (Continued)

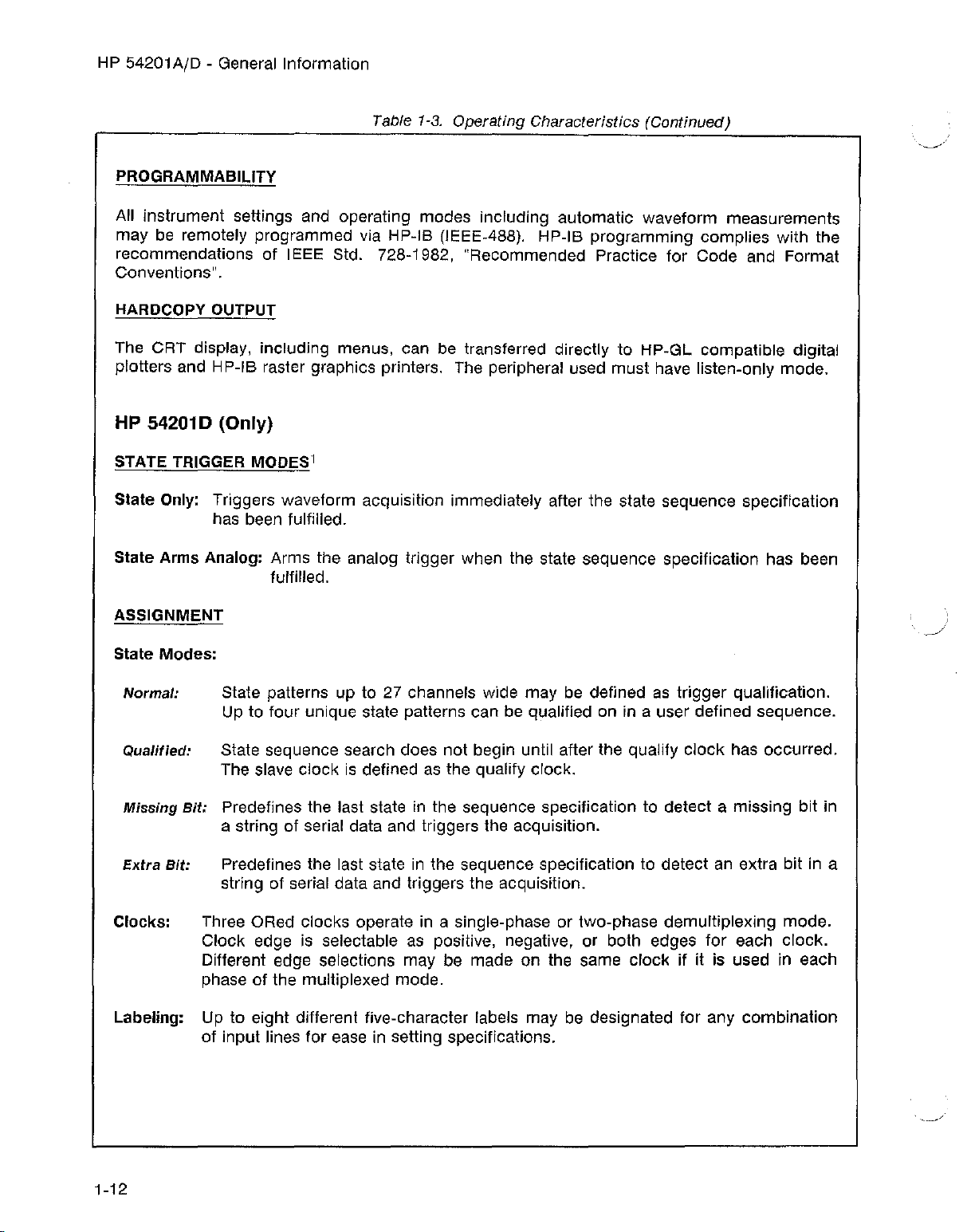

PROGRAMMABILITY

All instrument settings and operating modes including automatic waveform measurements

may be remotely programmed via HP-IB (IEEE-488). HP-IB programming complies with the

recommendations of IEEE Std. 728-1982, "Recommended Practice for Code and Format

Conventions".

HARDCOPY

OUTPUT

The CRT display, including menus, can be transferred directly to HP-GL compatible digital

plotters and HP-IB raster graphics printers. The peripheral used must have listen-only mode.

HP

542010

STATE TRIGGER

(Only)

MODES1

Slale Only: Triggers waveform acquisition immediately after the state sequence specification

has been fulfilled.

State Arms Analog: Arms the analog trigger when the state sequence specification has been

fulfilled.

ASSIGNMENT

Stale Modes:

Normal:

Qualified:

State patterns up to 27 channels wide may be defined as trigger qualification.

Up to four unique state patterns

can

be qualified on in a user defined sequence.

State sequence search does not begin until after the qualify clock has occurred.

The slave clock is defined as the qualify clock.

Bil:

Missing

Predefines the last state in the sequence specification to detect a missing bit in

a string of serial data and triggers the acquisition.

Extra

Bit:

Predefines the last state in the sequence specification to detect an extra bit in a

string of serial data and triggers the acquisition.

Clocks: Three ORed clocks operate in a single-phase or two-phase demultiplexing mode.

Clock edge is selectable as positive, negative, or both edges for each clock.

Different edge selections may be made on the same clock if it is used in each

phase of the multiplexed mode.

Labeling: Up to eight different five-character labels may be designated for any combination

of input lines for ease in setting specifications.

1-12

Page 22

HP 54201A/D - General Information

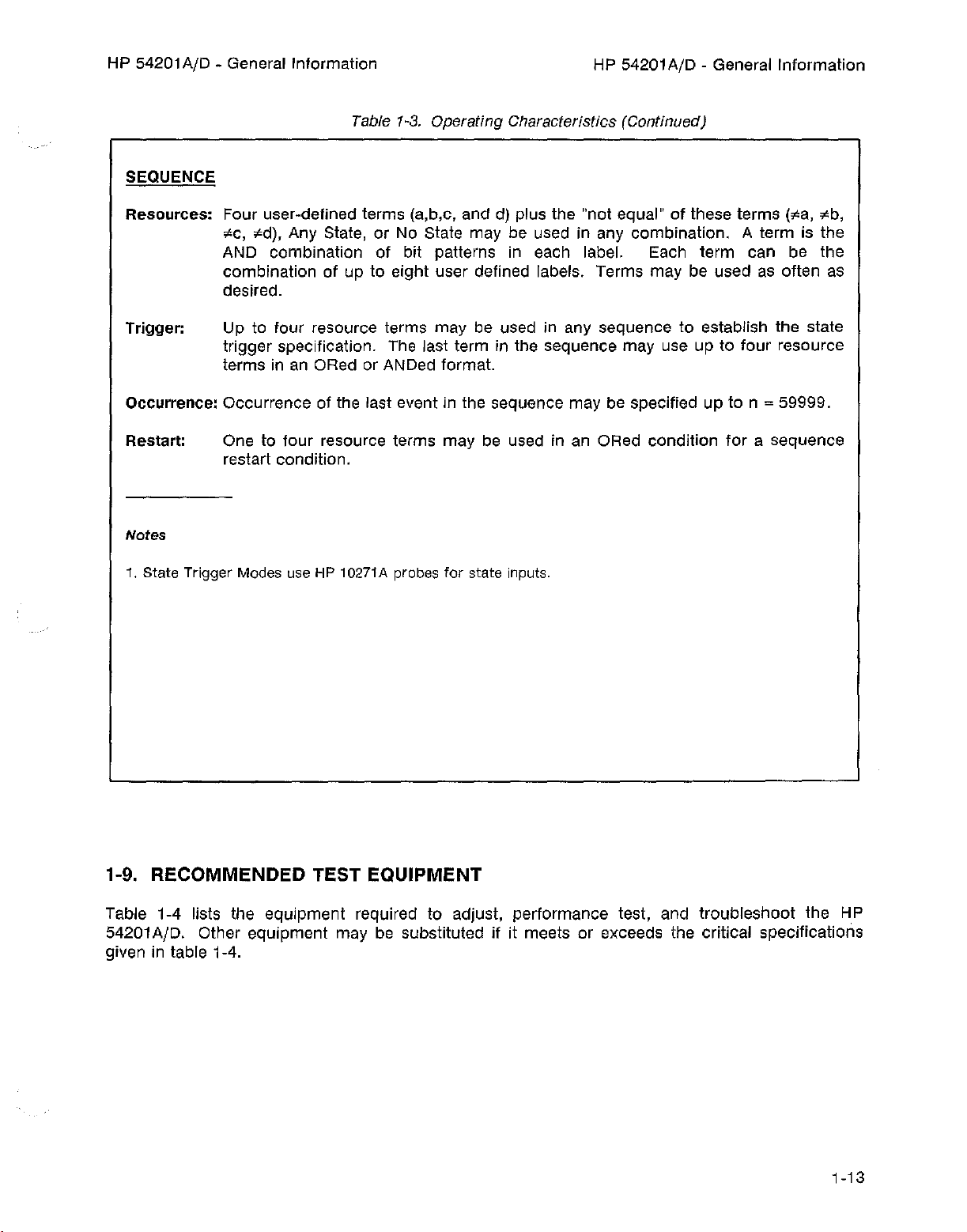

Table 1-3. Operating Ctierecteristtcs (Continued)

SEQUENCE

HP 54201A/D - General Information

Resources: Four user-defined terms (a.b,c, and d) plus the "not equal" of these terms

"c,

"d), Any State, or No State may be used in any combination. A term is the

("a,

seb,

AND combination of bit patterns in each label. Each term can be the

combination of up to eight user defined labels. Terms may be used as often as

desired.

Trigger: Up to four resource terms may be used in any sequence to establish the state

trigger specification. The last term in the sequence may use up to four resource

terms in an ORed or ANDed format.

Occurrence: Occurrence of the last event in the sequence may be specified up to n

Restart:

One to four resource terms may be used in an ORed condition for a sequence

= 59999.

restart condition.

Nofes

1. State Trigger

Modes

useHP 10271A

probes

for state

inputs.

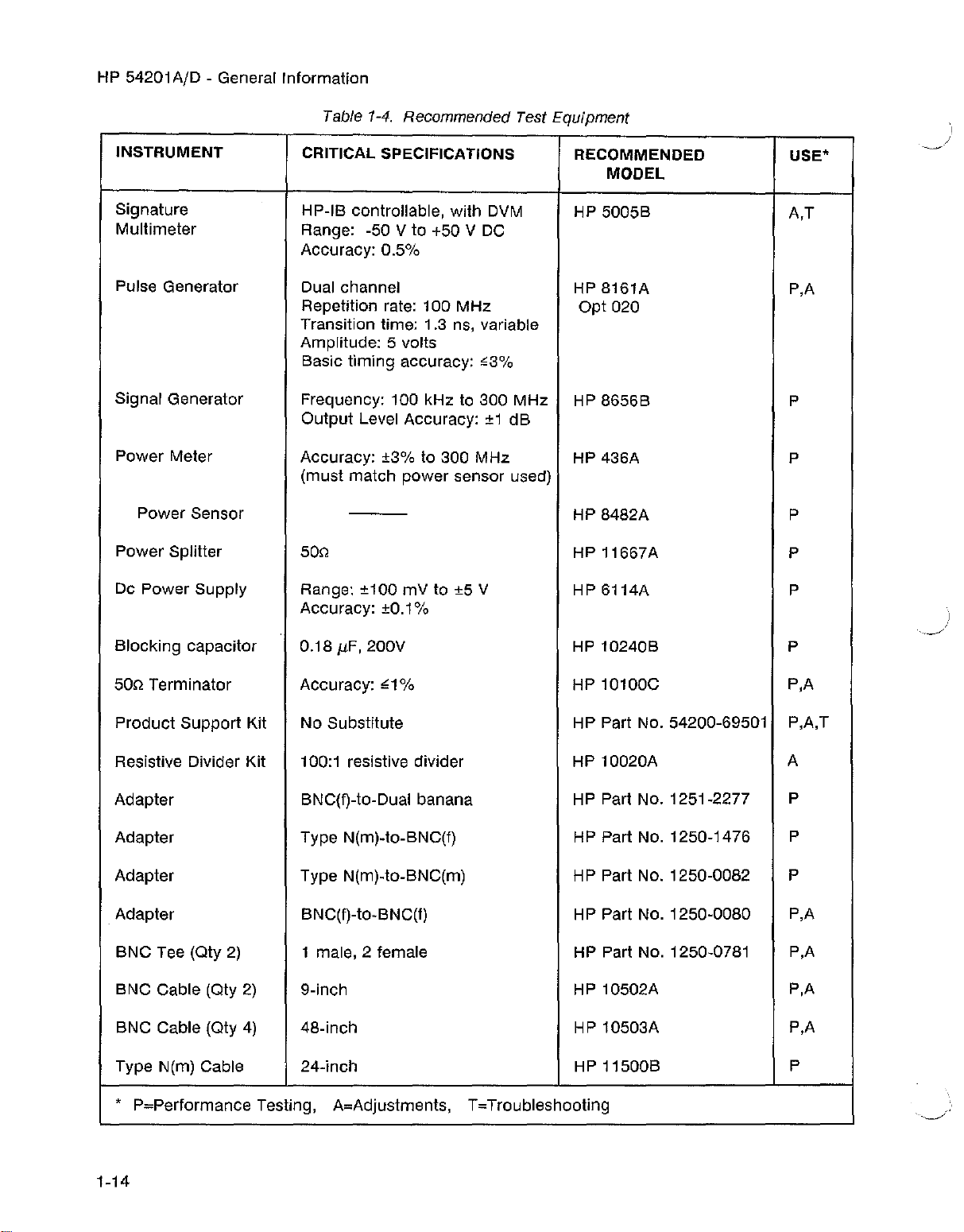

1-9. RECOMMENDED TEST EQUIPMENT

Table 1-4 lists the equipment required to adjust, performance test, and troubleshoot the HP

54201A/D. Other equipment may be substituted if it meets or exceeds the critical specifications

given in table 1-4.

1-13

Page 23

HP 54201 AID - General Information

INSTRUMENT

Signature

Multimeter

Pulse Generator

Signal Generator

Power Meter

Power Sensor

Power Splitter

Table 1-4. Recommended Test Equipment

CRITICAL SPECIFICATIONS

HP-IB controllable, with DVM

Range: -50 V to +50 V DC

Accuracy: 0.5%

Dual channel

Repetition rate: 100

MHz

Transition time: 1.3 ns, variable

Amplitude: 5 volts

Basic timing accuracy:

~3%

Frequency: 100 kHz to 300 MHz

Output Level Accuracy: ±1 dB

Accuracy: ±3% to 300 MHz

(must match power sensor used)

50Q

RECOMMENDED

MODEL

HP 5005B

HP 8161A

opt

020

HP 8656B P

HP 436A

HP 8482A P

HP 11667A

"

~J

USE'

A,T

P,A

P

P

Dc Power Supply

Range: ±100 mV to ±5 V

HP 6114A

Accuracy: ±0.1%

Blocking capacitor 0.18

50Q Terminator Accuracy:

Product Support Kit

Resistive Divider Kit 100:1 resistive divider

Adapter BNC(f)-to-Dual banana

Adapter Type N(m)-to-BNC(f)

jJ.F,

200V

<:1

% HP 10100C P,A

HP 10240B P

No Substitute HP Part No. 54200-69501

HP 10020A

HP Part No. 1251-2277

HP Part No. 1250-1476

Adapter Type N(m)-to-BNC(m) HP Part No. 1250-0082

Adapter BNC(f)-tO-BNC(f) HP Part No. 1250-0080

BNC Tee (Qty 2)

BNC Cable (Qty 2)

BNC Cable (Qty 4)

1 male, 2 female

9-inch

48-inch

HP Part No. 1250-0781

HP 10502A

HP 10503A

P

P,A,T

A

P

P

P

P,A

P,A

P,A

P,A

Type N(m) Cable 24-inch HP 11500B

, P=Performance Testing,

A=Adjustments, T=Troubleshooting

1-14

P

Page 24

HP 54201AID - Installation

SECTION 2

INSTALLATION

2-1. INTRODUCTION

This section contains the initial operation information for the HP 54201AfD. Included are power

and grounding requirements, operating environment requirements, cleaning methods and storage

and shipment requirements.

2-2. PREPARATION FOR USE

2-3. Power Requirements

The HP 54201A/D requires a power source of either 115 or 230 VAC -22% to +10%; single phase,

48 to 66 Hz; 275 watts maximum.

[:~~~~]

The instrument may be damagedifthe Line Voitage Select Switch

is not properly set to match the input voitage.

2-4. Line Voltage Selection

Before turning ON the instrument verify that the Line Voltage Select Switch on the rear panel

matches the input line voltage. The 6 Amp fuse installed satisfies both voltage settings of 115 and

230 VAC.

2-5. Power Cable

This instrument is equipped with a three-wire power cable. When connected to an appropriate AC

power outlet, this cable grounds the instrument cabinet. The type of power cable plug shipped

with the instrument depends on the country of destination. See figure 2-1 for option numbers of

power cables and plug configurations available. Part numbers for each cable option are listed in

the replaceable parts section of this manual.

CPT[OO 992

CAEl£_ toP

~

OPTION

9131

CAEIl..E:i1

Hl'

e12B~16g2

812B-e;96

C(NTltOIT

""""'"

250Y OPERArICN 220\1'

c:fITICH 912

CA9..E)t toP

fl./S1"RAILIA

foEW

Z<flA<D

8120-2951

~

CPTION 904

CAa..E:1t

~

(IF'ERATJCN

I-P 812B-BS98

OPTlQIl

CAELEII

913&

loP 9120-2'296

~

U.S.~

SWITZERLFI\lD

~EIV

CPERATtCN

OF'riOl

(ABL.£11 tF' 8120-1103

(PTIm

CAIl.,E:*

STD.

loP 812a--1521

u.s.~

~

iasv

9.

Cf'ERFITiON

.....IiED K[t«i[k)1

~

250V

OF'ERATIQII

~.

~

2S0V

<l"ERATlON

Figure 2-1. Power Cord Configurations

Q

250V

OF'£RAT

I

ON

2-1

Page 25

HP 54201A/D - Installation

2-6. OPERATING

ENVIRONMENT

The operating environment is noted in table 1-2. Note should be made of the non-condensing

humidity limitation. Condensation within the instrument can cause poor operation or malfunction.

Protection should be provided against internal condensation.

The HP 54201A/D will operate to all specifications, within the temperature and humidity range

given in table 1-2. However, reliability is enhanced by operating the instrument within the following

ranges.

Recommended Temperature: +20 to +35° C (+68 to +95° F)

Recommended Humidity: 20% to 80% non-condensing

High temperature/humidity combinations should be avoided.

2-7. CLEANING REQUIREMENTS

I

<:>

When cleaning the HP 54201A/D, CAUTION must be exercised on which cieaning agents are used.

USE MILD SOAP AND WATER. If a harsh soap or solvent is used, the water-base paint finish

WILL BE damaged.

BE CAREFUL when cleaning the keyboard. Water can damage the

keyboard circuitryifit seeps under the keys.

2-8. STORAGE AND SHIPMENT

2-9. Environment

The instrument may be stored or shipped in environments within the following limits:

Temperature: _40°C to

Humidity: Up to 90% at

Altitude:... Up to 15 300 metres (50 000 Feet)

,-75°C

65°C

The instrument should also be protected from temperature extremes which cause condensation

within the instrument. Condensation within the instrument may cause malfunction if the

instrument is operated under these conditions.

2-2

Page 26

2-10. Packaging

HP 54201A/D - Installation

2-11.

TAGGING FOR SERVICE. If the instrument is to be shipped to a Hewlett-Packard office for

service or repair, attach a tag showing owner (with address), complete instrument serial number,

and a description of the service required.

2·12.

ORIGINAL PACKAGING. If the original packing material is not available or is unserviceable,

material identical to those used in factory packaging are available through Hewlett-Packard offices.

If the instrument is to be shipped to a Hewlett-Packard office for servicing, attach a tag showing

owner (with address), model number, complete instrument serial number, and a description of the

service required. Mark the container FRAGILE to ensure careful handling. In any correspondence,

refer to the instrument by model number and serial number.

2-13.

OTHER PACKAGING. The following general instructions should be used for repacking with

commercially available materials.

a. Wrap instrument in heavy paper or plastic.

b. Use a strong shipping container. A double-wall carton made of 350 lb. test material is

adequate.

c. Use a layer of shock-absorbing material 70 to 100 mm (3 to 4 inch) thick around all sides of

the instrument to provide firm cushioning and prevent movement inside the container.

Protect control panel with cardboard.

d. Seal Shipping container securely.

e. Mark shipping container FRAGILE to ensure careful handling.

f. In any correspondence, refer to instrument by model number and full serial number.

2-3/(2-4 blank)

Page 27

.:»

,

Page 28

HP 54201AID - Performance Tests

SECTION 3

PERFORMANCE TESTS

3-1. INTRODUCTION

This section describes the HP 54201AfD Self Tests and Performance Test Procedures. The Self

Tests, resident in ROM, are a series of tests that confirm proper function of the mainframe

hardware and firmware. While the Self Tests provide the user with a confidence level of greater

than 90%, it does not verify the critical specifications given in table 1-1 of Section 1. The

Performance Tests test for complete instrument compliance to these critical specifications.

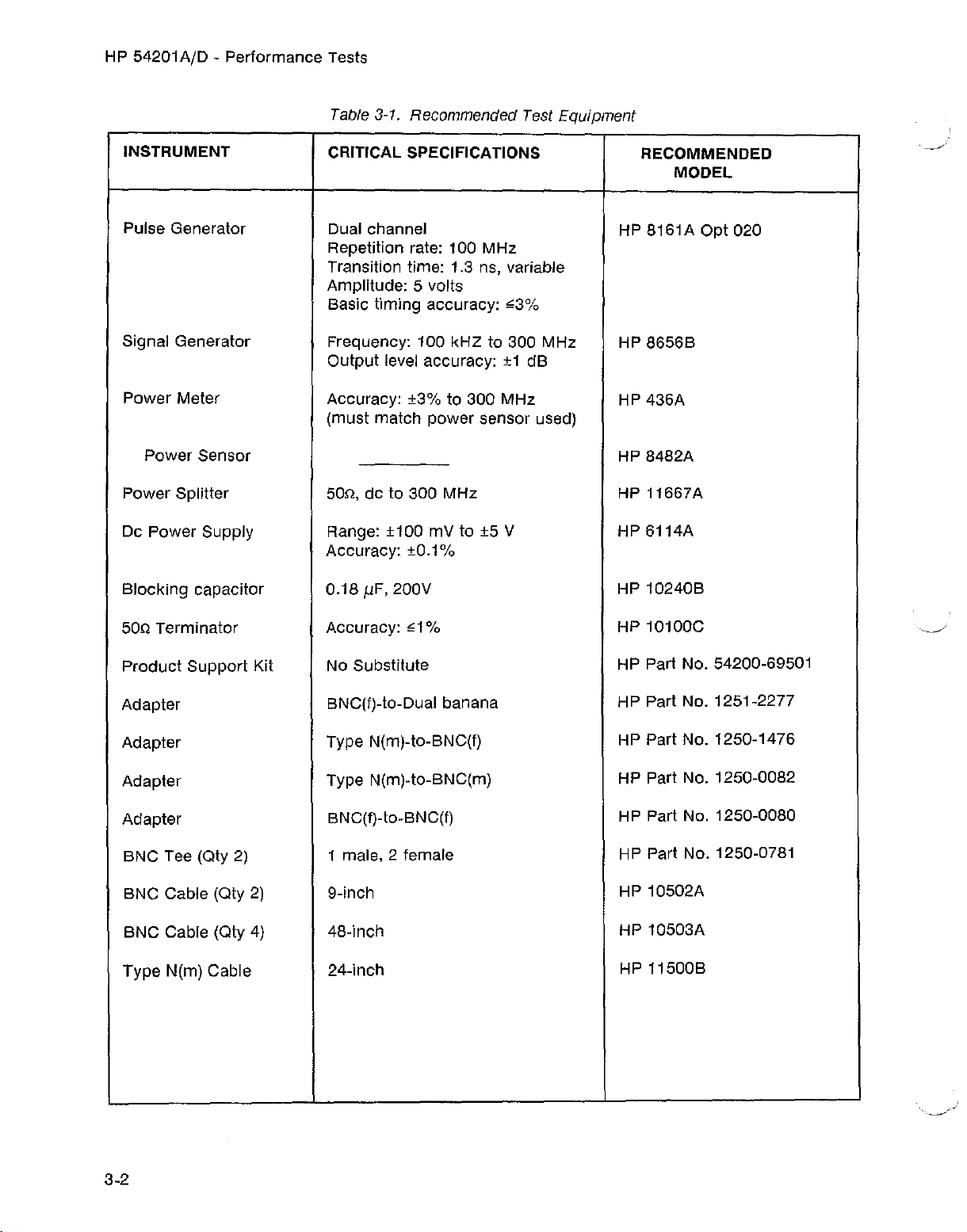

3-2. EQUIPMENT REQUIRED

The only equipment required for the Self Test is a standard

equipment required to perform the Performance Tests is listed in table 3-1. Other equipment may

be substituted if it meets or exceeds the critical specifications listed in table 3-1.

BNC

cable, 1 meter in iength. The

3-3. TEST RECORD

Results of performance tests may be tabulated on the Performance Test Record (table 3-2) at the

end of this section. The Test Record lists all of the tested specifications and their acceptable

limits. The results recorded at incoming inspection can be used for comparison in periodic

maintenance and troubleshooting and after repairs or adjustments.

Note

AI/ow instrument to warm up for at least 30 minutes

performance tests.

prior

to beginning

3-4. RECOMMENDED TEST EQUIPMENT

Table 3-1 lists the equipment required to performance test the HP 54201A/D. Other equipment

may be substituted if it meets or exceeds the critical specifications given in table 3-1.

3-1

Page 29

HP 54201A/D - Performance Tests

Table 3-1. Recommended Test Equipment

INSTRUMENT

Pulse Generator

CRITICAL SPECIFICATIONS

Dual channel

Repetition rate: 100 MHz

Transition time: 1.3 ns, variable

Amplitude: 5 volts

Basic timing accuracy: ;;3%

Signal Generator

Frequency: 100 kHZ to 300 MHz

Output level accuracy: ±1 dB

Power Meter

Accuracy: ±3% to 300 MHz

(must match power sensor used)

Power Sensor

Power Splitter 50n, de to 300 MHz

Dc Power Supply

Range: ±100 mV to ±5 V

Accuracy: ±0.1%

0.18

fJ.F,

Blocking capacitor

200V

RECOMMENDED

MODEL

HP 8161A

opt

HP 8656B

HP 436A

HP 8482A

HP11667A

HP 6114A

HP 10240B

020

50Q Terminator

Product

Support Kit

Adapter

Adapter

Adapter

Adapter

BNC Tee (Qty 2)

BNC Cable (Qty 2)

BNC Cable (Qty 4)

Type N(m) Cable

Accuracy: ;;1%

No Substitute

BNC(f)-to-Dual banana

Type N(m)-to-BNC(f)

Type N(m)-to-BNC(m)

BNC(f)-to-BNC(f)

1 male, 2 female

9-inch

48-inch

24-inch

HP 10100C

HP Part No. 54200-69501

HP Part No. 1251-2277

HP Part No. 1250-1476

HP Part No. 1250-0082

HP Part No. 1250-0080

HP Part No. 1250-0781

HP 10502A

HP 10503A

HP11500B

3-2

Page 30

HP 54201AjD - Performance Tests

3-5. SELF

TEST

FUNCTIONAL VERIFICATION

The Self Tests, resident in ROM, are a series of tests that confirm proper function of the mainframe

hardware and firmware. While the Self Tests provide the user with a confidence level of greater

than 90%, they do

not

verify the critical specifications given in table 1-1 of Section 1. Perform the

Performance Tests for complete instrument compiiance to these critical specifications.

To execute the self tests, press the SYSTEM menu key, then press the NEXTjPREV key until the

Test & Service menu is displayed as shown below. Using the Field arrow keys, move the biinking

cursor

to the Execute Selftest field. Enter either 0, 1, or 2 and follow the instructions displayed on

screen. An audible beep will be heard when each self test has been completed.

A failure of a seif test should be followed by resident SYSTEM

(in this order). The self tests snould then be re-selected to

menu

check

calibration routines 0, 5, and 6

whether the self-calibration

routines corrected the error. Repeated failure of a self-test, or faiiure of a self-caiibration routine

may

dictate the need of a particular hardware adjustment.

System

[

Execute

Test

SpeCification

&

SerVice

Self

test

Status:

]

•

Acquired

Frame

TALk

01181

OI1L

__.

,,'

o

1

'2

Execute

o

1

2

3

CPU/I\1emorl~

AcqUiBiti~n/Trigger

Input

Service.

TirneHull

Ext

Trigger

Ext

Trigger

Hardware

Null

HystereSiS

Service

Figure 3-1. SYSTEM Self Tests Menu

PERFORMANCE TESTS

After the instrument has warmed up at least 30 minutes, perform a key-down power-up reset. This

will preset the HP 54201

front panel key

down

AID

to a predetermined condition and clear the display memory. Hold any

while applying power to the instrument. Hold the key

down

long enough

for

the power-up tune to be completed.

3-3

Page 31

HP 54201A/D - Performance Tests

PERFORMANCE TESTS

3-6. DC OFFSET ACCURACY TEST

Specification:

Channel Range

Offset Accuracy

40 mV to 790 mV

800mVt016V

Equipment Required:

DC Supply HP 6114A

BNC(f)-to-Dual Banana Adapter HP Part No. 1251-2277

Procedure:

1. Configure STATUS Configuration menu as shown in figure 3-2.

2.

Connect

3. Apply +1.00 V from DC Supply to Channel 1 input.

4. Press the DISPLAY menu key and select one graph with Channel 1 displayed.

5. The display should appear similar to figure 3-3.

6. Select the

0.98 V and 1.02 V.

7. Apply -1.00 V from the DC Supply to Channel 1 input.

the

output

Vmin

of the DC Supply to Channel 1 input of the HP 54201A/D.

and

Vmax

measurements for Channel 1 on the HP 54201A/D. The limits are

±1% of offset ±5 mV

±1% of offset ±100 mV

8. Set HP 54201A/D Channel 1 offset to -1.00 V.

9. The limits of

10. Set HP 54201A/D Channel 1 voltage range to 800 mY.

11. The limits of

12. Apply +1.00 V

13. Set HP 54201A/D Channel 1 offset to +1.00 V.

14. Limits of

15. Repeat steps 3 through 14 substitutinq Channel 2 for Channel 1.

3-4

Vmin

Vmin

Vmln

from

and

and

Vmax

for Channel 1 are -0.98 V and -1.02 V.

and

Vmax

for Channel 1 are -0.89 V and -1.11 V.

the DC Supply to Channel 1 input.

Vmax

for

Channel 1 are 0.89 V and 1.11 V.

Page 32

PERFORMANCE TESTS

HP 54201A/D - Performance Tests

[4

Onl

_________

CPR

[ 1: 1 ]

MoJ

[de

J

[Ave]

J

[

]

Confl

Pange

Offset

Probe

Coupl

ing

S'tore

Auto

Labe

Tr'

igger------~----~-----------------~

Analog

tlcce

Scele

1

uratlOn]

40

mV

1.

0 0 V

[ 1: 1

[de

J [1

[Ave

[Enabled

Analo

Son-c

e

Level

Pr-

-~-

[ 1: 1 ]

ob e

Figure 3-2. STATUS Configuration Menu

Status:

Setup

Input

1.

Enabled

,'.1···dW

1. [I II

000

V

J t i rto

[4

~

2

]

Refer

for

Acquired

Label

to

State

Ass

iqnmentand

Auto

On

Even

Coupling

Scale

t

Frame

TALK

Trigger

OIelL'i

[

Auto

1.

00 us

[Real

0.00000

[

Center

[

PerIod

Sequence

00258

TIme

Menus

__

]

S

.,m_

[de

] t i

Mn

________________________________

Gr-eph

1: '

...

..

;F

....

5.00

mV/div

'

Figure

3-3e

DISPLAY Waveform

Status:

1.

0[1 \I

Acquired

II

max

V

min

ns/di'J

1[10

Frame

TALK

D 999

D

~

998

00173

ONLY

mil

mV

100.[1

_

Fie

3-5

Page 33

HP 54201 A/D - Performance Tests

PERFORMANCE TESTS

3-7. VOLTAGE MEASUREMENT ACCURACY TEST

Single

Specification:

Cursor

(X or

0)

Gain Accuracy

= (±2% of

full scale)

Equipment Required:

DC Supply HP 6114A

BNC(f)-to-Dual Banana Adapter HP Part No. 1251-2277

Procedure:

1. Configure STATUS Configuration

2.

Connect

3. Apply +100 mV

4. Press the DISPLAY menu key and select one graph with Channel 1 displayed.

5. The display should appear similar to figure 3-5.

6. Display the cursor values by pressing the VALUES key on the 54201 A/D. The limits of Vx are

84 mV to 116 mY.

the

+ ADC Accuracy

+ (±1.6% of

full scale)

output

of the DC Supply to

from

DC Supply to Channel 1 input.

menu

+ Offset Accuracy

+ (±1% of offset ±5 mY) 40 mV to 790 mV range

(±1% of offset ±100 mY) 800 mV to 16 V range

as shown in figure 3-4.

Channelt

input of the HP 54201AID.

I

-.

.:»

7.

Apply·1

8. Limits of Vx are -84 mV to -116 mY.

9. Apply -5.00 V from DC Supply to Channel 1 input.

10. Set HP 54201A/D Channel 1 voltage range to 16 V.

11. Limits of Vx are -4.32 V to -5.68 V.

12. Apply +5.00 V from DC Supply to Channel 1 input.

13. Limits of Vx are 4.32 V to 5.68 V.

14. Repeat steps 2 through 13 substituting Channel 2 for Channel 1.

3-6

00 mV

from

DC supply to Channel 1 input.

Page 34

PERFORMANCE TESTS

HP 54201A/D - Performance Tests

Stetus

Panqe

Offset

Probe

Loup

St.or

Auto

Label

T~~

i 9£1er

110de

Analog

If.onF1urat

I i nq

e Flode

Sc a I e

---------------------------

[

Rnalo

Sour-ce

Leve

Pr-cb e

Figure 3-4. STATUS Configuration Menu

Ion]

-----------T

Onl~

I."m

1

Q O.lI V

'''#11,,4'4;"

'1..=.

[ 1, 1 ]

_________

1

]

••

,

Status:

Se t up

Input

3 0

mV

*

2

Refer

for

""G'dWi

No

Trigger

Label

i

rnebase----------,

SamplIng

tloce

Range

Ac:qu i

roe

Ire

181.j

Reference

Auto

Scale

to

State

ASSignment

Auto

Scale

On

Event

Co

up1ing

Found

TALI;

@

[

[Real

[

[

Trigger

and

[

Imm.l

[de

O~IL

'r'

200

MH=

uto

1.

0 s

0.00000

enter

erlod

Menus

Sequence

Enable

]

[l

.

]

1me

s

~Il"i

________________________________

x Se l

ec

t.ed

ClW80r~

X

98.0

1130

Cur-eor- 0

98.0

1813

Cur-e cr- 0-><

13.130

13.013

I!l-~-._----------

mV

ns

mV

ns

\I

s

Figure 3-5. DiSPLAY Waveform

Status:

[I.

00 V

Acquired

V

ma)~

D

V min D=

1013

ns/div

Frame

TALK

om,

99.2

96.8

..

~~-.~~--

00490

'(

mV

mV

iaa.[I ru

_

3-7

Page 35

HP 54201AID - Performance Tests

3-8. BANDWIDTH (-3dB) TEST

Specification:

Coupling

PERFORMANCE TESTS

Real Time Sampling

Repetitive Sampling

Dc

Ac

Equipment Required:

Signal Generator HP 8656B

Power Meter HP 436A

Power Sensor HP 8482A

SOn

Power Splitter ,... ... . HP 11667A

Type N(m) Cable. 24-inch HP 11500B

Type N(m)-to-BNC(m) Adapter HP Part No. 1250-0082

Ensure that Power Meter has been zeroed and calibrated to match Power Sensor.

Procedure:

Real Time

1. Configure STATUS configuration menu as shown in figure 3-6.

2. Configure test equipment as shown in figure 3-7.

3. Set Signal Generator sinewave output to 200 kHz, 0.5

Dc to 50 MHz

10 Hz to 50 MHz

Note

V amplitude.

Dc to 300 MHz

10 Hz to 300 MHz

4. Set Power Meter Cal Factor

dB reference.

5. Put the HP 54201

minimum peak of displayed waveform. Record this vo-x voltage number.

6. Change frequency of Signal Generator to 50 MHz and change Cal Factor

the 50 MHz value from cal chart.

7. Change Timebase Range of HP 54201AID to 200 ns Real Time.

8. Put

a cursor on maximum peak of waveform and X cursor on minimum peak of waveform.

AID a cursor on maximum peak of displayed waveform and put X cursor on

% to 200 kHz value from cal chart, then press dB[REF] to set a 0

% on Power Meter to

9. Adjust amplitude of Signal Generator so that vo-x has same reading as the number recorded in

step 5. Step 8 may need to be repeated to keep the cursors at the waveform peaks. The

Power Meter reading must be

10. Repeat steps 1 through

3-8

63 dB.

9 for Channel 2, specifying Channel 2 as the trigger source.

Page 36

PERFORMANCE TESTS

HP

54201

AID - Performance Tests

Status

Char.ne

Offset

Aut

T~-·

Analog

[Confl

I

UI.l!iI!ElImlO_III':---;-----::-----:--Tiroebase-------

Ranfl8

Probe

Coup1ing

St.ore

Lebe

i

Mode [

ilcce

oSca

1

gger-----------------------------,

ur-atrcn

Input

•

U

1e

Anala

Source

Lave

Probe

_".i.~dSl

I

[ 1: 1 ]

Figure 3-6. STATUS Configuration Menu

_________Starus..

I

Setup

1

- Hoce

*

Onl

]

0. [1 Ii

2

Refer

for

Labe

Assignment

IJaitinfl

1

Sampling

Rance

Hcqu

2:}:~ence

But.c SC;9.le

to

Auto

On

Coup

Ir

St'at,e

Scale

Event

I

in'j

e

for'

TAL~

@

[

[Rea

[

[

Tr

igger

and

[

~

[dc]

Ir

ic

qer- _

onC

,;,

100

rlHz

Tr

t c ' ]

10.0

",S

1 T Hoe

0.00000

Cente!r

Per-f

Plenus

Sequence

Ena

led

[SO n

s

ad

HP

436A

POWER

METER

HP

8482A

POWER

SENSOR

i

I

I

Power Sensor Cable

r

Figure

3-7.

HP

8656B

SIGNAL

GENERATOR

-Type

N(m)

Cable

(

in)

HP

HP

1I667A

POWER

SPLITTER

--I

(Channel

-

j

N(m)-BNC(m)

Adapter

Bandwidth Test Connections.

54201A/D

Input)

3-9

Page 37

HP 54201AID - Performance Tests

PERFORMANCE TESTS

Repetitive

11. Change frequency of Signal Generator to 200 kHz, 0.5 V amplitude.

12. Change Timebase Range of HP 54201A/D to 10

13. Set Power Meter Cal Factor

dB reference.

14. Put the HP 54201AjD

minimum peak of displayed waveform. Record this

15. Change frequency of Signal Generator to 300 MHz and change Cal Factor % on Power Meter

to the 300 MHz value from cal chart.

16. Change Timebase Range of HP 54201AjD to 10 ns.

17. Put

18. Adjust amplitude of Signal Generator so that Vo-x has same reading as the number recorded

19. Repeat steps 11 through 18 for Channel 1, specifying Channel 1 as the trigger source.

0 cursor on maximum peak of waveform and X cursor on minimum peak of waveform.

in step 14. Step 17 may need to be repeated to keep the cursors at the waveform peaks. The

Power Meter reading must be

0 cursor on maximum peak of displayed waveform and put X cursor on

% to 200 kHz value from cal chart, then press dB[REF] to set a 0

,;3 dB.

us Repetitive mode.

Vo-x voltage number.

3-10

Page 38

HP 54201A/D - Performance Tests

PERFORMANCE TESTS

3-9. TIME MEASUREMENT ACCURACY TEST (DUAL CURSORS)

Specification: Real Time Sampling: ±2 ns or ±0.2% of time range, whichever is greater.

Repetitive Sampling: ±200 ps or ±0.2% of time range, whichever is greater.

Equipment Required:

Signal Generator HP 8656B

Type N(m)-to-BNC(f) Adapter HP Part No. 1250-1476

Procedure:

1. Set the output of Signal Generator to 2.5 MHz, 500 mV amplitude.

2. Configure STATUS Configuration menu as shown in figure 3-8.

3. Connect a BNC cable from the RF output of the Signal Generator to Channel 1 input of the HP

54201A/D.

4. Press the VALUES key to display cursor

5. Position the X cursor approximately halfway up the first rising slope, and position the 0 cursor

on the second rising slope such that Vo-x is as small a value as possible. The display should

appear similar to figure 3-9.

6. Read the Cursor O-X time value on the display. The limits of Cursor O-X time are 398 ns and

402 ns.

7. Change the frequency of the Signal Generator to 250 MHz.

8. Change the 54201AfD time range to 10 ns, and set Data Filter in DISPLAY menu to OFF.

9. Position the X cursor approximately halfway up the first rising slope, and position the

on the second rising slope such that Vo-x is as small a value as possible.

10. Read the Cursor O-X time value on the display. The limits of Cursor O-X time are 3.8 ns and

4.2 ns.

values.

0 cursor

3-11

Page 39

HP 54201A/D - Performance Tests

Stat

U:;::

[Confl

1I!1!I!I

ur-a

..

1t:~-------=-----=---T

Range

Offset

Pr-obs

Coupling

Stnr

a lqods

AutC:1

Scale

Label

TI"igge,----------------------------,

Flode

Analog

[

Ana

Scur-c

Leva

loOn

a

I

Pr-obe

PERFORMANCE TESTS

t i on I

I.';"••'

'..4";;;;;11

_________

I ]

[ 1: 1 ]

Status:

Setup

*

Refer

for

''''lima

~1I;!!~1mI.

0.0

Ii

No

Trigger

Label

i meb

8.8

e--------,

Samp

1i ng @

110de

F'ange

Acquire

Delat.!

Refe;'ence

Auto

ScaLe

to

State

Assignment

Auto

Scale

On

Event

Coup

ling

Found

TAU~

[Auto

[Real

[

[

Trigger

and

[

~

[de

OI'lL

\'

280

r'1Hz

1.0

US

TIme

0.00000

Center

PerIod

Menus

Sequence

Enabled

]

[50

.

]

s

n

Graph

o

Selected

Cur-eor- x

0.00

-412

Cur-cor- 0

0.00

-12

Cur-sor-

D.OD

40D

_

o-x

Figure 3-8. STATUS Configuration Menu

[

Off

[Dlsa

On

200

1:

r-=-=-~-=...:..=-----=-=...:..=------=-:=------"---I

V

ns

Ii

ns

rnV/dl"o"

0.0D

II

-500.0

]

led]

rt:

V

n:

3-12

Figure 3-9. DISPLAY Waveform

Page 40

PERFORMANCE TESTS

3-10. TRIGGER (ANALOG) LEVEL ACCURACY TEST

HP 54201AjD - Performance Tests

Specification:

±3% of channel range ±5 mV (40 mV to 790 mV channel range)

±3% of channel range ±100 mV (800 mV to 16 V channel range)

Equipment Required::

Pulse Generator

BNC Tee HP Part No. 1250-0781

BNC Cable, 9-inch

BNC Cable, 48-inch HP 10503A

BNC(f)-to-BNC(f)

Equipment Setup: HP 8161A

Procedure:

(my

Adapter HP Part No. 1250-0080

Channel 1, Channel 2 Trigger

__

2) HP 10502A

Period (PER):

Width (WID):

Leading Edge (LEE):

Trailing Edge (TRE):

High Level (HILl: +1.5 V +1.5 V

Low

Level (LOL):

Delay (DEL):

Output mode:

10

f.lS

A Output B Output

fJ.s

5

2.49

f.ls

f.ls

2.49

-1.5 V -1.5 V

0.00 ns

Enable Disable

5 us

2.49 us

2.49 us

0.00 ns

HP 8161A

1. Configure

2. Connect a BNC cable from the A output of Pulse Generator to Channel 1 input of HP

54201AjD.

3. Press DISPLAY menu key and select one graph with Channel 1 displayed. The waveform

should appear similar to figure 3-11.

4. Move the

5. Limits ofVXare 283 mV and 317 mV.

6. Change HP 54201AjD Channel 1 offset to -300 mV and trigger slope to negative.

7. With the

8. Change HP 54201AfD Channel 1 voltage range to 800 mV.

9. With the X cursor at the position where Tx is equal to 0, the limits of Vx are -176 mV and

-424 mV.

10. Change HP 5420"IAjD Channel 1 offset to 300 mV and trigger slope to positive.

11. With the

12. Repeat steps 2 through 11 for Channel 2, specifying Channel 2 as the trigger source.

STATUS Configuration menu as shown in figure 3-10.

X cursor to the position where Tx is equal to

O.

X cursor at the position where Tx = 0, the limits of Vx are -283 mV and -317 mV.

X cursor at the position where Tx =0, the limits of Vx are 176 mV and 424 mV.

3-13

Page 41

HP 54201A/D - Performance Tests

Status

Pange

Offoet

Prob

Coupling

Store

Auto

Label

Noce

Analog

[Confl

e

Mode

Scale

[

[Enabled

Analo

Sour'c.e

Leve

Pr-obe

PERFORMANCE

uratlonJ

,-,cil··'

'1111

'13;;;;;14.

I Q

[ 1 : 1 ]

_________

1

]

Onl ]

TESTS

Status:

Setup

Input

.'llliiM

_IIIIID.

P."'"

IDDIIC

[Enabled

,'.,nda

IIJ~ID~III

11

300

*

mV

2

Refer

for

Acquired

Lab

e I

I

]

to

State

Assignment

Put.o

On

Event

Coupling

Sea

Frame

TALK

[

[Real

[

Trigger

and

[

1e

l!Imll

[de

00017

ONL

\'

200

11Hz

Trl

'd

200

ns

TIme

0,00oOO s

Center

Menus

Sequence

Enabled

] [1

_

]

Mn

Graph

X

~3e

lee

Cur-ecr-

Cur-eor- 0

Cur-ssor-

294

0,00

100

-100,0

-194

-100,0

Figure 3-10, STATUS Configuration Menu

UlOID

ted

~<

mV

s

mV

ns

0->:',

mV

ns

1:

50.0

mV/div

1

-

.>

----

----

3DO

-----

.--

»<

-------

mV

.>

20.0

x---

-

-----

ns/div

---

.>:

-----

-100,0

n

-----~------

3-14

Figure 3-11, DISPLAY Waveform

Page 42

PERFORMANCE TESTS

3-11. TRIGGER SENSITIVITY TEST

HP 54201

AID

- Performance Tests

Specification: Internal:

External:

Equipment Required:

Pulse Generator

Signal Generator , ,

Power Meter HP 436A

Power Sensor HP 8482A

Power Splitter

50n Terminator HP 10100C

BNC Cable, 9-inch HP 10502A

BNC Cable, 48-inch

Type N(m)-to-BNC(f) Adapter HP Part No. 1250-1476

Type N(m)-to-BNC(m) Adapter HP Part No. 1250-0082

Type N(m) Cable, 24-inch HP 11500B

Equipment Setup:

1/8 of full scale.

100

mVp.p (de to 250 MHz, 50n coupled)

VP.p (de to 100 MHz, .2 Mn coupled)

1

HP 8161A

Period (PER):

Width (WID):

Leading Edge (LEE):

Trailing Edge (TRE):

Hiqh Level (HIL):

Low

Level (LOL):

Delay (DEL):

Output mode:

1 ms

A Output

500

f.ls

249

us

249

J.1.s

+2.5 V

-2.5 V

0.00 ns

Enable

B Output

500

J.1.s

1 ns

1 ns

+2.5 V

-2.5 V

0.00 ns

Disable

HP 8161A

HP 8656B

HP 11667A

HP 10503A

Procedure:

Internal Trigger

1. Configure STATUS Configuration menu as shown in figure 3-12.

2. Connect 48-inch BNC cable from the A output of Pulse Generator to Channel 1

54201A/D.

3. Display Channel 1. The triggered waveform should appear similar to figure 3-13.

4. Move the

5. Note the value of Vx.

6. Change the trigger slope to

X cursor to the Tx = 0.0 s position.

[-SlOpe]

and note the value of vx.

input

of the HP

3-15

Page 43

HP 54201 AID - Performance Tests

PERFORMANCE TESTS

Status

[[onfl

uratlon]

II!Il!I!D.;--~;_--~--___;:~-T

Range

OfFce-.

Pr-

0 be

Coup

ling

St.or-e

Auto

Labe

Tr-

i

tloce [

Ana 1og

Mode

Scal

a

I

gger-----------------------------,

Analo

Sour-ce

Leve

Pr-obe

1.";;

[Centered]

I

[ 1 : 1

Figure 3-12. STATUS Configuration Menu

Onl

_________

]

••

'".'.Iaw

[1.0 Ii

Status:

Setup

*

Refer

for

Waiting

Label

i

rneb

8.S

e--------~

Sampling

I'loce

e

Ran£1

Acquire

De

I,,~

Refer-ence

Auto

Scale

to

State

Assignment

Auto

Scale

On

Event

Cuup

l t nq

for

Trigger

TRU~

CW,L

@

10.0

[

Tr-t

100

[Peal

0.08000

[

Center

[

PerIod

Triqqer

and~§equence

Y'

MHz

'd

~s

Time

Menus

_

]

s

Rdm-

[de ]

[5[1

n

3-16

x

5e

le c t ed

Cur-s

or-

226

[1.0[1

Cur-s or- I)

-645

-5[1.0

Cu-eor-

-871

-5[1.[I 1'8

:<

0-><

mV

8

mV

1;.-------------'

>'3

m\i

Figure 3-13. DISPLAY Waveform

-------_.

_-_'7""-

----+:--...,...---..,....,....---

-50.00

--------

11'

Page 44

HP

54201AjD

- Performance Tests

PERFORMANCE TESTS

7. The difference in the Vx value (Vx[+slope) minus Vx[-slope) } should be no more than 2V.

8. Repeat steps 1 through 7 for Channel 2, specifying Channel 2 as the trigger source.

9. Disconnect Pulse Generator from HP

54201AjD.

External Trigger

10. Configure STATUS Configuration menu as shown in figure 3-14.

Nole

Ensure that Power Meter has been zeroed and calibrated to match Power Sensor.

11. Connect test equipment as shown in figure 3-15, except without the 50Qterminator.

mV

12. Set Signal Generator sinewave output to 250 MHz, 70

13. Set Power Meter Cal Factor

% to 250 MHz value from cal chart.

14. Adjust Signal Generator outpul for a reading of 25

amplitude.

fJ.W

on Power Meter (25

fJ.W

into 50Q

provides 100 mVp-p).

15. Disconnect Power Sensor from Power Splitter and connect that port of Power Splitter to

Channell

input of HP 54201A/D using the Type N(m)-to-BNC(f) adapter and the 9-inch BNC

cable.

16. Display Channel 1 and verify that a stable sine wave is displayed.

17. Configure STATUS Configuration menu as shown in figure 3-16.

18. Connect test equipment as shown in figure 3-15.

19. Set Signal Generator output to 100 MHz, 700 mV amplitude.

20. Set Power Meter Cal Factor