Page 1

TM 11-6625-3014-14

TECHNICAL MANUAL

OPERATOR’S,ORGANIZATIONAL,

DIRECT SUPPORT, AND GENERAL SUPPORT

MAINTENANCE MANUAL

FOR

MICROWAVE FREQUENCY COUNTER

TD-1225A(V)1/U

(NSN 625-01-103-2958)

HEADQUARTERS, DEPARTMENT OF THE ARMY

SEPTEMBER 1981

Page 2

SAFETY STEPS

TO FOLLOW IF

SOMEONE

IS THE VICTIM

OF ELECTRICAL

SHOCK

DO NOT TRY TO PULL OR GRAB THE INDIVIDUAL

IF POSSIBLE , TURN OFF THE ELECTRICAL POWER

IF YOU CANNOT TURN OFF THE ELECTRICAL

POWER, PULL, PUSH, OR LIFT THE PERSON TO

SAFETY USING A WOODEN POLE OR A ROPE OR

SOME OTHER INSULATING MATERIAL

SEND FOR HELP AS SOON AS POSSIBLE

AFTER THE INJURED PERSON IS FREE OF

CONTACT WITH THE SOURCE OF ELECTRICAL

SHOCK, MOVE THE PERSON A SHORT DISTANCE

AWAY AND IMMEDIATELY START ARTIFICIAL

RESUSCITATION

SAFETY

This product has been designed and tested according to International Safety Requirements. To ensure

safe operation and to keep the product safe, the information, cautions, and warnings in this manual

must be heeded. Refer to Section I for general safety considerations applicable to this product.

Page 3

This manual includes copyright material reproduced by permission of the HEWLETT-PACKARD Company.

TM 11-6625-3014-14

TECHNICAL MANUAL

NO. 11-6625-3014-14

DIRECT SUPPORT, AND GENERAL SUPPORT

DEPARTMENT OF THE ARMY

Washington, D.C.

OPERATOR’S,ORGANIZATIONAL,

MAINTENANCE MANUAL

MICROWAVE FREQUENCY COUNTER

TD-1225A(V)1/U

(NSN 6625-01-103-2958)

HEADQUARTERS

10 September 1981

REPORTING OF ERRORS

You can improve this manual by recommending improvements using DA Form 2028-2 located

in the back of the manual. Simply tear out the self-addressed form, fill it out as shown on the sample, fold it where shown, and drop it in the mail.

If there are no blank DA Forms 2028-2 in the back of your manual, use the standard DA Form

2028 (Recommended Changes to Publications and Blank Forms) and forward to Commander, US

Army Communications and Electronics Materiel Readiness Command, ATTN: DRSEL-ME-MQ,

Fort Monmouth, NJ 07703.

In either case a reply will be forwarded direct to you.

Section

0

TABLE OF CONTENTS

Title

Page

INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . .0-1

0-1

0-2

0-3

0-4

Scope . . . . . . . . . . . . . . . . . . . ...0-1

Indexes of publications . . . . . . . . . . . . . . 0-1

Forms and records . . . . . . . . . . . . . . . .. 0-1

Reporting of equipment improvement

recommendations (EIR) . . . . . . . . . . . . 0-1

Administrative storage . . . . . . . . . . . . . . 0-1

0-5

0-6

Destruction of army electronics materiel . . . . . 0-1

SERIAL PREFIX: 1840A

This manual applies to Serial Prefix 1840A, unless

accompanied by a Manual Change Sheet indicating

otherwise.

This manual is an authentiation of the manufacturer’s commercial literature which,through usage, has been found to cover the

data required to operate and maintain this equipment. Since the manual was not prepared in accordance with military specifications

and AR 310-3, the format has not been structured to consider levels of maintenance.

i

Page 4

Model 5342A

Table of Contents

TABLE OF CONTENTS (Continued)

Section

I

II

Title

GENERAL INFORMATION

1-1.

1-3. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5. Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7. Instrument Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-9.

1-11. Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-13. Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-15. Service Equipment Available

1-17. Recommended Test Equipment

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1.

2-3.

2-5.

2-9.

2-11.

2-15. Storage and Shipment

2-16.

2-19.

2-22. Field Installation of Options

2-24.

2-26.

2-28.

2-30. Installation of Extended Dynamic Range Option 003 . . . . . . . . 2-7

2-32.

2-34.

2-36.

2-39. 5342A Listen Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2-41.

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

Unpacking and Inspection

Installation Requirements

Power Cable

Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environment

Packaging

Part Numbers for Ordering Option Kits

Installation of 10 MHz Oscillator Option 001 . . . . . . . . . . . . . . . 2-4

Installation of Amplitude Measurement Option 002

Installation of Digital-to-Analog Conversion

Installation of HP-IB Option 011

HP-IB Interconnections

HP-IB Descriptions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(DAC) Option 004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . ...

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Page

1-1

1-1

1-1

1-3

1-3

1-3

1-4

1-4

1-4

2-1

2-1

2-1

2-1

2-2

2-3

2-3

2-4

2-4. . . . . . . .

2-8

III

ii

OPERATION

3-1.

3-3.

3-5.

3-7.

3-10. CHECK, DAC, and ENTER Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-12.

3-14.

3-16.

3-18.

3-20.

3-22.

3-24. SET, RESET, RECALL, and CHS Keys 3-2. . . . . . . . . . . . . . . . . . . . . . .

3-25. SAMPLE RATE, GATE, and REMOTE . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-30.

3-32.

3-34.

3-36. Maximum Input Signal Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-39. Input Cable Considerations

Introduction

Operating Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resolution Keys

FREQ Keys

Automatic Mode

Manual Mode

Offset Frequencies

Amplitude and Offset Measurements

Digital-to-Analog Converter (DAC) Operation

AM Tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

FM Tolerance

Automatic Amplitude Discrimination . . . . . . . . . . . . . . . . . . . . . . 3-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

. . . . . . . . . . . . . . . . . . . . . 3-2

. . . . . . . . . . . . . 3-2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

. . . ...... . . . . . . . . . . . .... ... . 3-4

3-1

3-1

3-1

3-1

3-1

3-2

Page 5

TABLE OF CONTENTS (Continued)

Model 5342A

Table of Contents

Section

Title

III OPERATION (Continued)

3-41. Controls, Indicators, and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-43. Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-45. Operator Key board Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3-47. Error Code Displays

Instrument Error Displays . .

Operator Error Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Limit Errors and Sequence Errors

Amplitude Option 002

Extended Dynamic Range Option 003

HP-IB Interface Option 011

Digital-to-Analog Converter (DAC) Option 004 . . . . . . . . 3-19

(Option 002,011 Only)

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operational Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Complete Performance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required

Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operational Verification Procedures . . . . . . . . . . . . . . . . . . . . . . . . . .

Self-Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Hz—500 MHz Input Sensitivity Test,

(Standard and Option 003 1nstruments Only) . . . . . . . . . . . 4-2

10 Hz—500 MHz Input Minimum Level and

Amplitude Accuracy Test (Option 002) . . . . . . . . . . . . . . . .

10 Hz—500 MHz Input Maximum

Input Test (Option 002)

500 MHz-18 GHz Input Sensitivity Test (Standard and

Option 003 Instruments Only) . . . . . . . . . . . . . . . . . . . . . . . .

500 MHz—18 GHz Input Minimum Level and Amplitude

Accuracy Test (Option 002)

500 MHz-18 GHz High Level Test . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Option 011 HP-IB Verification Program . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Digital-to-Analog Converter (DAC) Output Test (Option 004) . . . 4-16

Performance Test Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Hz—500 MHz Input Sensitivity Test,

(Standard and Option 003 Instruments Only) . . . . . . . . . . . 4-17

10 Hz—500 MHz Input Sensitivity Test, 1

500 MHz—18 GHz Input Sensitivity Test (Standard and

Option 003 Instruments Only)

500 MHz-18 GHz lnput SWR Test . . . . . . . . . . . . . . . . . . . . . . 4-20

500 MHz-18 GHz Maximum Input Test . . . . . . . . . . . . . . . . . . . 4-22

FM Tolerance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatic Amplitude Discrimination Test . . . . . . . . . . . . . . . . .

IV

3-49.

3-51.

3-53.

3-57. Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-59. Time Base Option 001

3-61.

3-63.

3-65.

3-67.

3-69. HP-lB Programming (Option 011) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-79. 9825A Program Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

3-81. HP-lB Programming Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-83. Remote Programming of Diagnostic Mode 6

PERFORMANCE TESTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-1.

4-3.

4-5.

4-7.

4-9.

4-11.

4-12.

4-13.

4-14.

4-15.

4-16.

4-17.

4-18.

4-19.

4-27.

4-28.

4-29.

4-30.

4-31.

4-32.

4-33.

4-34.

4-35.

Page

3-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 3-18

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

3-18

3-18

3-18

3-18

3-19

3-28

3-30

4-1

4-1

4-1

4-1

4-1

4-2

4-2

4-3

4-4

4-5

4-6

4-17

4-18

4-19

4-24

4-26

iii

Page 6

Model 5342A

Table of Contents

TABLE OF CONTENTS (Continued)

Section

IV

V

Title

PERFORMANCE TESTS (Continued)

4-36.

4-37.

4-38.

4-39.

4-40.

ADJUSTMENTS

5-1.

5-4.

5-6.

5-8.

5-10. Safety Considerations

5-12. Adjustment Procedures

5-13.

5-17.

5-19.

5-21.

5-28.

5-30. Oscillator Adjustments

5-31.

5-32.

5-33. Option 002 Amplitude Measurement Adjustments

5-34.

5-38.

5-39. Option 002/003 Adjustments

5-40.

5-41. Option 004 Digital-to-Analog (DAC) Adjustments . . . . . . . . . . . . . . 5-13

500 MHz—18 GHz Input Minimum Level and Amplitude

Accuracy Test (Option 002)

10 Hz—500 MHz Input Minimum Level and

Amplitude Accuracy Test (Option 002)

10 Hz—500 MHz Input Maximum

Input Test (Option 002)

10 Hz—500 MHz Input SWR Test (Option 002)

Digital-to-Analog Converter (DAC) Output

Test (Option 004)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

Equipment Required

Factory Selected Components

Adjustment Locations

Power Supply Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Synthesizer Adjustment

Offset Synthesizer Adjustments

IF Adjustment

Direct Count Adjustment

A24 Standard Oscillator

Option 001 Oven Oscillator (10544A) . . . . . . . . . . . . . . . . . . . . . . 5-9

A16 Adjustments

A27 Adjustments (Resistors A27R9,A27R10) . . . . . . . . . . . . . . . . 5-11

A11, A25 Adjustments (Resistors A11R14, A25R31)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

Page

4-28

4-29

4-30

4-31

5-10

5-10

5-12

5-12

5-1

5-1

5-1

5-1

5-1

5-1

5-3

5-3

5-4

5-5

5-8

5-8

5-8

iv

VI

VII

Vlll

REPLACEABLE PARTS

6-1.

6-3.

6-5.

6-7.

6-11. Ordering Information

6-14. Direct Mail Order System

6-17. Option Retrofit Kits

MANUAL CHANGES

7-1.

7-3.

7-6.

SERVICE

8-1.

8-3.

8-5.

Introduction

Exchange Assemblies

Abbreviations and Reference Designations

Replaceable Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

Manual Changes

Older Instruments

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

Schematic Diagram Symbols and Reference Designators . . . . . . . 8-1

Reference Designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1

6-1

6-1

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1

6-4

6-4

6-4

6-4

7-1

7-1

7-1

7-7

8-1

8-1

8-1

Page 7

TABLE OF CONTENTS (Continued)

Model 5342A

Table of Contents

Section

Vlll

Title

SERVICE

8-7.

Identification Markings on Printed-Circuit Boards

8-11.

8-13.

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-18.

8-20.

8-22.

Signal Names

Disassembly and Reassembly

8-24.

8-26.

8-28.

Front Frame Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-30.

8-32.

8-34.

8-36.

Factory Selected Components

8-38.

8-40.

8-42.

8-44.

8-46.

Service Accessory Kit 10842A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

8-48.

8-50.

8-52.

8-58.

Logic Symbols

8-60.

8-62.

8-64.

8-73.

8-75.

8-77.

8-79.

8-81.

8-83.

8-94.

8-99.

8-101.

8-105.

8-110.

8-112.

8-114.

8-116.

8-120.

8-124.

8-126.

8-128.

8-130.

Page

(Continued)

. . . . . . . . . . . . . 8-2

Assembly Identification

Safety Symbols

Top Cover Removal

Bottom Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Removal of A1 Display Assembly and A2 Display

Assembly from Front Panel Frame. . . . . . . . . . . . . . . . . . . . . . . 8-13

Replacement of LED’s in Front Panel Switches

Removal of U1 Sampler, A25 Preamplifier, and

A26 Sampler Driver

Procedure for Selecting Resistor R15 on

Direct Count Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

Procedure for Selecting Resistor R16 for Capacitor C10

on Direct Count Amplifier A3

Procedures for Selecting Resistor R16 on

Main Loop Amplifier A9

Procedure for Selecting Resistor A16R2 on

A16 Assembly (Option 002 or 003) . . . . . . . . . . . . . . . . . . . . . . . 8-17

Equipment Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Parts

Using Extender Board 05342-60036

Logic Concepts

Negation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Implementation and Polarity Indication . . . . . . . . . . . . . . 8-23

Other Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dependency Notation “C” “G” “V” “F” . . . . . . . . . . . . . . . . . . 8-26

Control Blocks

Complex Logic Devices . . . . . . . . . . . . . . . . . . . . . . . . . . .

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Harmonic Heterodyne Technique . . . . . . . . . . . . . . . . . . . . . .

HP 5342A Overall Operation

FM Tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatic Amplitude Discrimination . . . . . . . . . . . . . . . . . . . . . . . . . 8-40

Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HP 5342A Block Diagram Description

Direct Count Section

Synthesizer Section

Main Loop Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Offset Loop Operation

IF Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Time Base/PSR Section

Control Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Detailed Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . 8-42

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . 8-16

8-4

8-4

8-5

8-6

8-12

8-12

8-12

8-13

8-13

8-15

8-16

8-18

8-18

8-20

8-22

8-22

8-22

8-25

8-27

8-28

8-36

8-36

8-39

8-40

8-41

8-42

8-42

8-42

8-43

8-43

8-46

8-46

8-46

v

Page 8

Model 5342A

Table of Contents

TABLE OF CONTENTS (Continued)

Section

vi

Title

VIII

8-132.

8-138.

8-145.

8-152.

8-154.

8-158.

8-166.

8-172.

8-176.

8-181.

8-190.

8-198

8-202.

8-206.

8-215.

8-225.

8-228.

8-240.

8-242.

8-244.

8-247.

8-257.

8-262.

8-266.

8-269.

8-278.

8-280.

8-282.

8-284.

8-290.

8-294.

8-296.

8-297.

8-300.

8-305.

8-306.

8-310.

8-314.

8-331.

8-340.

8-346.

8-347.

8-349.

8-358.

8-366.

8-369.

8-372.

8-374.

8-375.

8-379.

SERVICE (Continued)

A1 Display Assembly and A2 Display Driver Assembly

Keyboard Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A3 Direct Count Amplifier Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 8-48

A4 Offset VCO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-49

A5 RF Multiplexer Assembly

A6 Offset Loop Amp/Search Generator Assembly

A7 Mixer/Search Control Assembly

A8 Main VCO Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-52

A9 Main Loop Amplifier Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-53

A10 Divide-by-N Assembly

Two Modulus Prescaler Technique . . . . . . . . . . . . . . . . . . . . . . . . 8-55

Counter (Divider) Chain Utilizing 9’s Complement

A11 IF Limiter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A12 IF Detector Assembly

A13 Counter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-59

A14 Microprocessor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Microprocessor Operation . .

A15 Option 011 HP-IB Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-65

A16 Option 002 Amplitude Measurements Assembly and

A16 Option 003 Extended Dynamic Range Assembly . . . . . . 8-65

A17 Timing Generator Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-65

Pseudorandom Sequence Generation . . . . . . . . . . . . . . . . . . . . .

Gate Time Generation

Sample Rate Generation . . . . . . .

A18 Time Base Buffer Assembly

A19, A20, A21 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A22 Motherboard

A23 Power Module . . .

A24 Oscillator Assembly

A25 Preamplifier

A26 Sampler Driver Assembly . . . .

Options Theory (Options 002,003,004, and 011) . . . . . . . . . . . . . . 8-72

Option 002 Amplitude Measurements Overall Theory

Introduction

Block Diagram . .

Option 002 Detailed Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

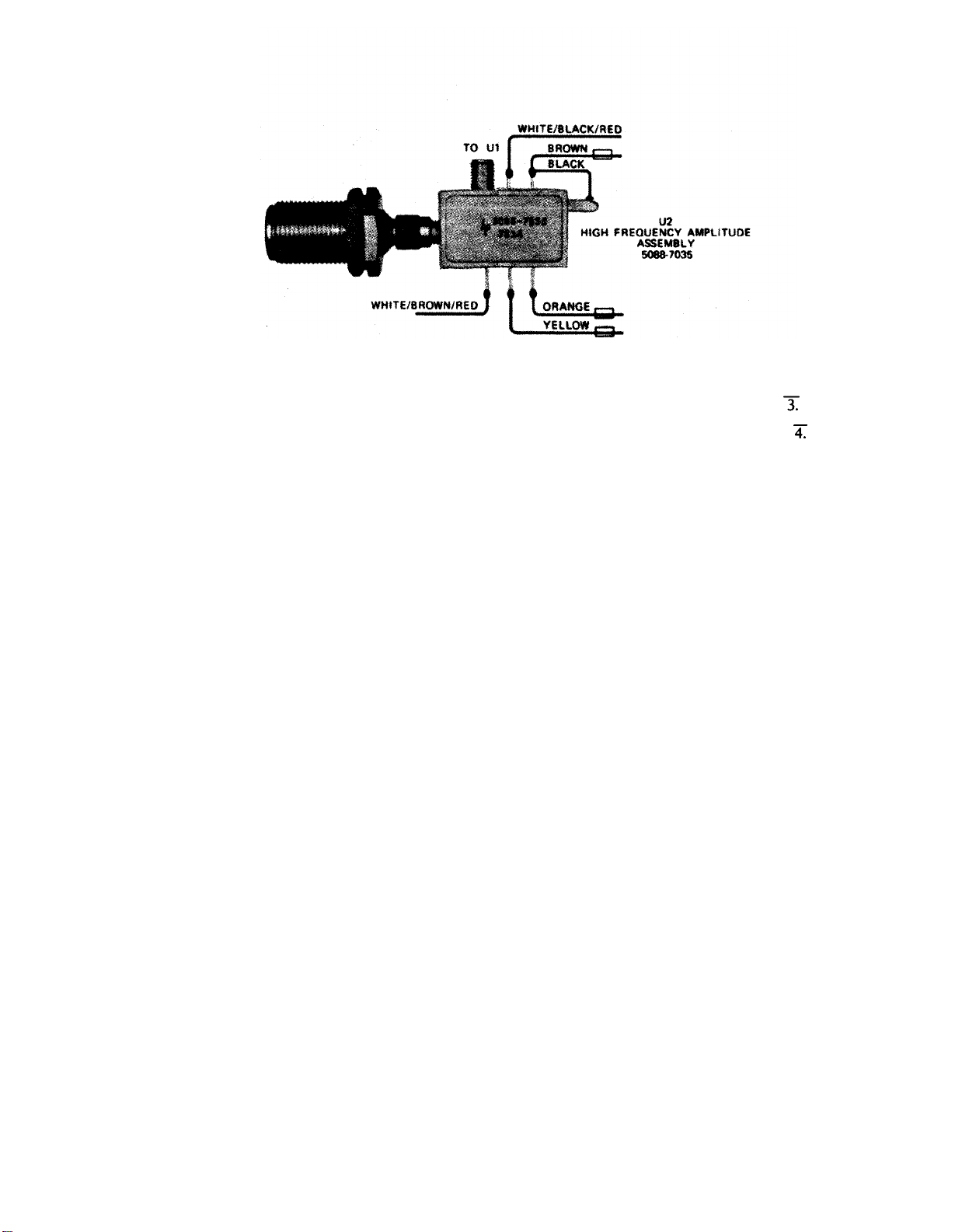

U2 High Frequency Amplitude Assembly (5088-7035)

A27 Low Frequency Amplitude Assembly . . . . . . . . . . . . . . . . . . 8-75

A16 Amplitude Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 003 Extended Dynamic Range

Option 004 Digital-to-Analog Conversion (DAC)

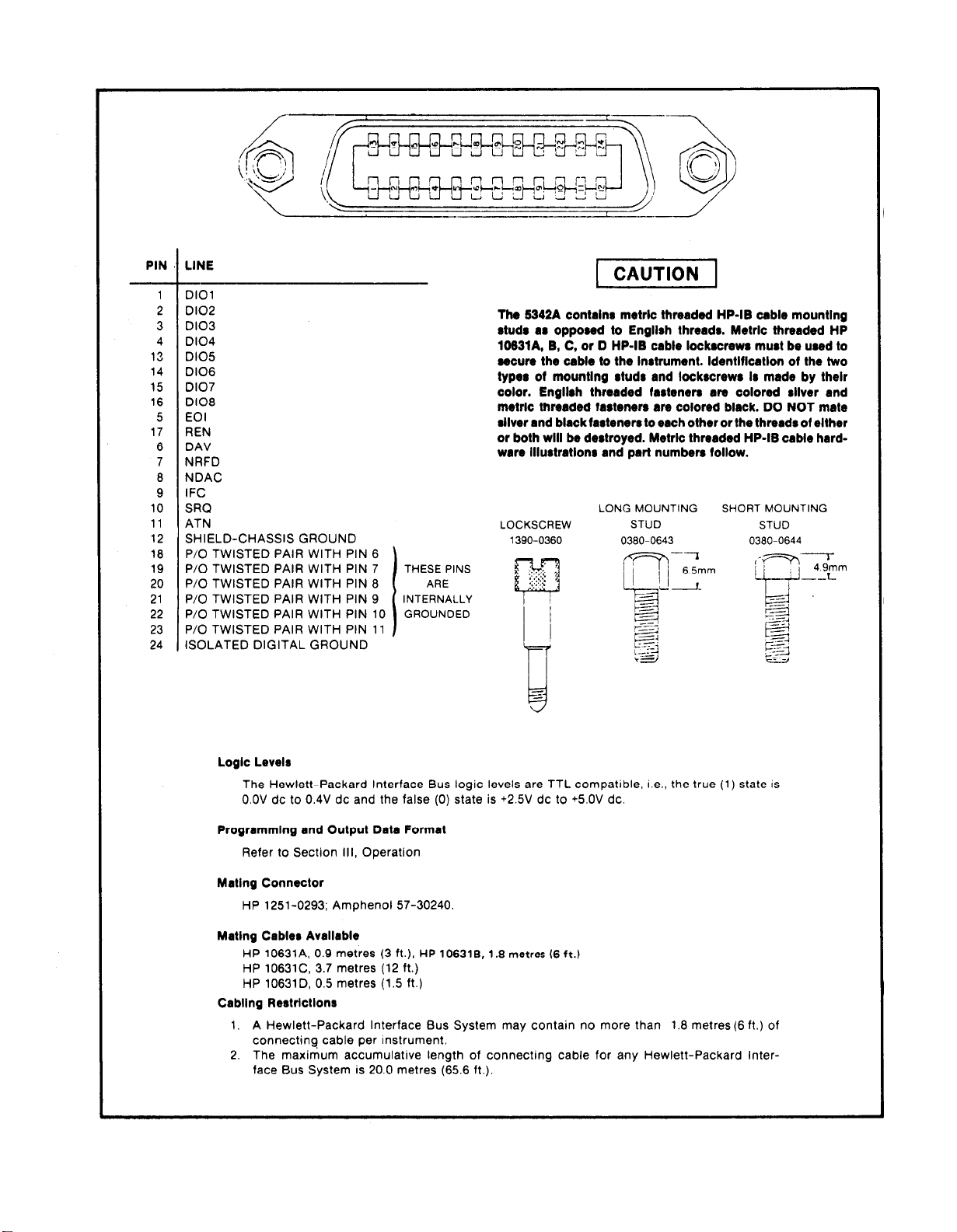

Option 011 Hewlett-Packard Interface Bus (HP-IB)

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interface Registers

Command Decoding ROM’s

Acceptor Handshake . . . . . . . . . . . . . . . . . . . . ..

Source Handshake

Assembly Locations

Troubleshooting to the Assembly Level (Standard Instrument) . . 8-84

Troubleshooting Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-73

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-60

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-72

. . . . . . . . . . . . . . . . . . . . . . . . 8-77

. . . .. . . . . . . . . . . ... . . 8-81

. . . . . . . . . . . . . . . . . . . . . 8-83

. . . . . . . . . 8-46

. . . . . . . . . . . . . 8-50

. . . . . . . . .

. . . . . . . . . 8-73

. . . . . . .

. . . . . . . . . . . . . . 8-79

. . . . . . . . . . . . 8-80

Page

8-47

8-49

8-51

8-53

8-56

8-57

8-57

8-60

8-65

8-67

8-68

8-68

8-69

8-71

8-71

8-71

8-71

8-73

8-73

8-73

8-75

8-80

8-80

8-82

8-84

8-84

8-85

Page 9

Model 5342A

Table of Contents

APPENDIX

TABLE OF CONTENTS

A

B

C

References .

Maintenance

Additional Authorization List . . . . . . . . C-1

(Continued)

. . . . . . . . . . ........ ...

Allocation . . . . . . . . . . . . . . . B-1

Page

A-1

vii

Page 10

Model 5342A

List of Tables

LIST OF TABLES

Table Title

1-1.

1-2.

1-3.

1-4.

3-1.

3-2

3-3.

3-4.

4-1.

4-2.

4-3.

4-4.

4-5.

5-1.

6-1.

6-2.

6-3.

6-4.

6-5.

6-6.

6-7.

6-8.

6-9.

Model 5342A Specifications . . . .

Equipment Supplied

Accessories Available

Recommended Test Equipment

HP-IB Interface Capability

5342A Bus Message Usage

Address Selection

Option 001 HP-IB Program Code Set

Operational Verification Record

Model 5342A Program

Model 9825A Program Description

Sample Printout

Performance Test Record

Adjustments

Exchange Assemblies

Abbreviations and Reference Designations

Replaceable Parts

Option 001 Replaceable Parts

Option 002 Replaceable Parts

Option 003 Replaceable Parts

Option 004 Replaceable Parts

Option 011 Replaceable Parts

Manufacturers Code List

Page

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2

1-3

1-4

1-5

3-19

3-20

3-21

3-22

4-9

4-10

4-13

4-15

4-32

5-2

6-1

6-2

6-5

6-37

6-38

6-41

6-42

6-44

6-45

7-1.

8-1.

8-2.

8-3.

8-4.

8-5.

8-6.

8-7.

8-8.

8-9.

8-10.

8-11.

8-12.

8-13.

8-14.

8-15.

8-16.

8-17.

8-18.

8-19.

8-20.

8-21.

8-21A.

8-21B.

8-21C.

Manual Backdating

Assembly Identification

Signal Names

10842A Kit Contents

Replaceable Parts for Extender Board 05342-60036 . . . . . . . . . . . . . . . . . . . . 8-18

Overall Troubleshooting

Assemblies Tested by Test Mode

Probable Failed Assemblies by Test Mode

Diagnostic Modes of the 5342A

A14 Microprocessor Troubleshooting

A19, A20, A21 Power Supply Troubleshooting

A1, A2 Keyboard/Display Troubleshooting

A3 Direct Count Amplifier Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 8-104

A13 Counter Troubleshooting

A17 Timing Generator Troubleshooting

A8, A9, A10 Main Loop Snythesizer Troubleshooting . . . . . . . . . . . . . . . . 8-113

A11, A12, A25, U1 IF Troubleshooting

A4, A6, A7 Offset Loop Synthesizer Troubleshooting . . . . . . . . . . . . . . . . . 8-122

A26 Sampler Driver Troubleshooting

A5 RF Multiplexer Troubleshooting

Option 002 Amplitude Measurement Troubleshooting

Option 001 HP-IB Troubleshooting

Acceptor Handshake (HP-IB)

Source Handshake (HP-IB)

U23, U26 ROM Table (HP-IB)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1

8-4

8-6

8-18

8-85

8-88

8-89

8-90

8-91

8-97

8-102

8-105

8-109

8-116

8-124

8-125

8-127

8-137

8-137

8-138

8-139

viii

Page 11

LIST OF FIGURES

Model 5342A

List of Figures

Figure

1-1.

2-1.

2-2.

2-3.

3-1.

3-2.

3-3.

3-4.

3-5.

8-1.

8-2.

8-3.

8-4.

8-5.

8-6.

8-7.

8-8.

8-9.

8-10.

8-11.

8-12.

8-13.

8-14.

8-15.

8-16.

8-17.

8-18.

8-19.

8-20.

8-21.

8-22.

8-23.

8-24.

8-25.

8-26.

8-27.

8-28.

8-29.

8-30.

8-31.

8-32.

8-33.

8-34.

8-35.

8-36.

8-37.

8-38.

Title

Model 5342A Microwave Frequency Counter

Line Voltage Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

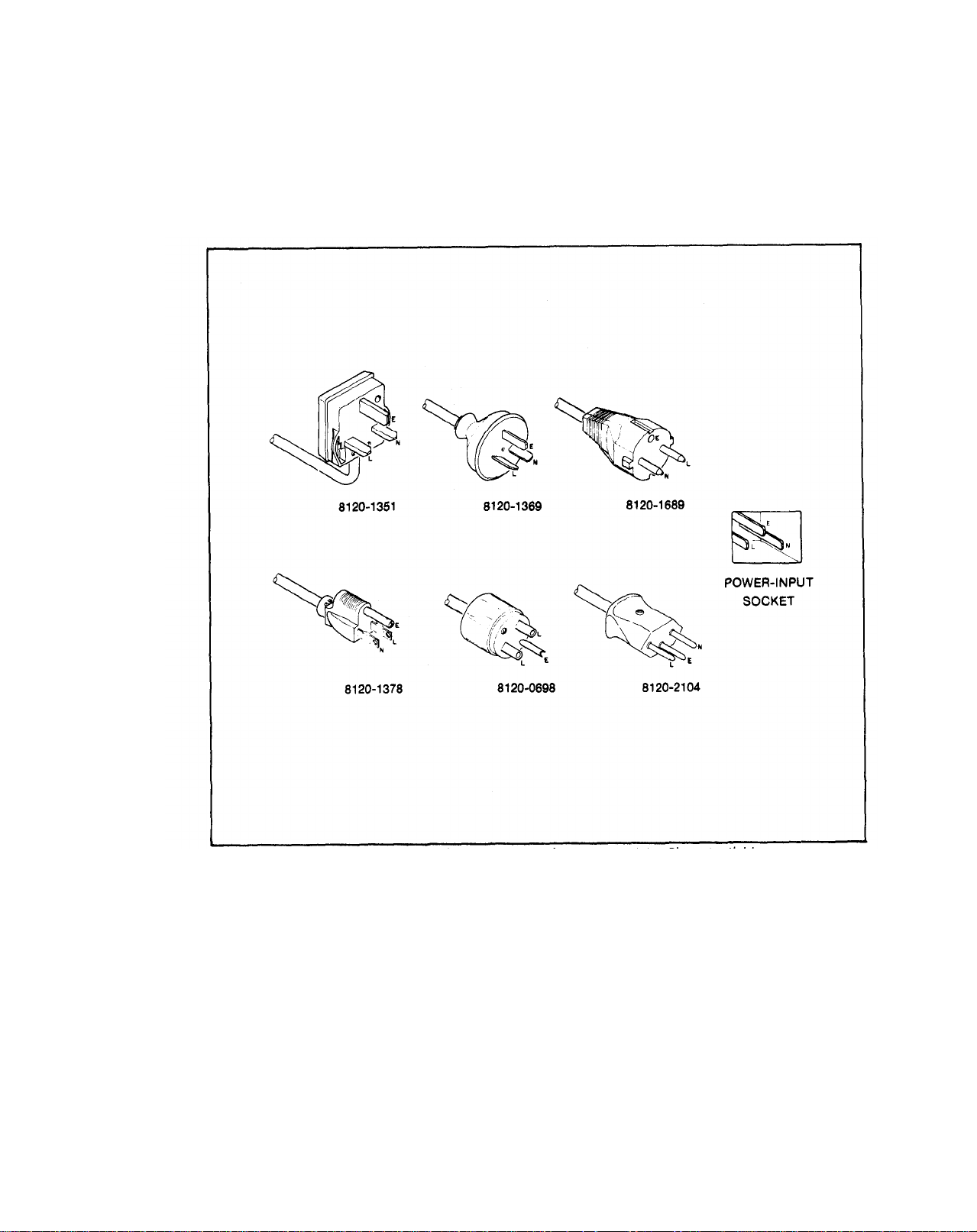

Power Cable HP Part Numbers versus Mains Plugs Available

Hewlett-Packard Interface Bus Connection . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Front Panel Controls and Indicators

Rear Panel Controls and Connectors

Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Amplitude Measurements (Option 002) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAC Operation (Option 004)

Schematic Diagram Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Frame, A25, A26, and U1 Removale

10842A Service Accessory Kit

Extender Board (05342-60036) Test Points R1, R2, and R3

Extender Board (05342-60036) Schematic Diagram . . . . . . . . . . . . . . . . . . . . . 8-21

Harmonic Heterodyne Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Frequency Relationships

HP 5342A Simplified Block Diagram

HP 5342A Block Diagram

Block Diagram of Synthesizer Section

Timing Diagram of A6 Search Generator Operation . . . . . . . . . . . . . . . . . .

Data Transfer Timing in A10 Circuit

0Filter Timing on A12 IF Detector

A14U21 Expanded Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A19, A20, and A21 Power Supply Block Diagram . . . . . . . . . . . . . . . . . . . . . . 8-70

Option 002 Amplitude Measurement Block Diagram . . . . . . . . . . . . . . . . . . 8-74

Option 003 Extended Dynamic Range Block Daigram

5342A Front (A1 Display) View

5342A Rear View . . . . . . . . . . . . . . . . . . . . . . .

5342A Top View (Assembly Locations and Adjustments) . . . . . . . . . . . . . . 8-144

5342A Bottom View, Options Installed

5342A Detailed Block Diagram

A1 Display Assembly and A2 Display Drive Assembly . . . . . . . . . . . . . . . .

Option 004 Display Driver Additions on A2 Assembly . . . . . . . . . . . . . . . . 8-151

A3 Direct Count Amplifier Assembly

A4 Offset VCO Assembly . . . . . . . . . . . . . . . .

A5 RF Multiplexer Assembly

A6 Offset Loop Amp/Search Generator Assembly . . . . . . . . . . . . . . . . . . .

A7 Mixer/Search Control Assembly

A8 Main VCO Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A9 Main Loop Amplifier Assembly

A10 Divide-by-N Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A11 IF Limiter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A12 IF Detector Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A13 Counter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A14 Microprocessor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 011 A15 HP-IB Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-142

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . 2-2

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . 8-20

. . . . . . . . . . . . . . . . . 8-78

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

Page

1-1

2-1

3-5

3-8

3-12

8-3

8-14

8-19

8-37

8-38

8-39

8-44

8-45

8-51

8-54

8-58

8-61

8-64

8-143

8-145

8-147

8-149

8-153

8-155

8-157

8-159

8-161

8-163

8-165

8-167

8-169

8-171

8-173

8-175

8-177

ix

Page 12

Model 5342A

List of

Figures

LIST OF FIGURES (Continued)

Figure

8-39.

8-40.

8-41.

8-42.

8-43.

8-44.

8-45.

8-46.

Title

Option 002 A16 Amplitude Measurements,

A27 Low Frequency Amplifier, and

U2 High Frequency Amplifier Assemblies

Option 003 A16 Extended Dynamic Range Assembly . . . . . . . . . . . . . . . . .

A17 Timing Generator Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A18 Time Base Buffer Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A19, A20, A21, and A23 Power Supply Assembly . . . . . . . . . . . . . . . . . . . . .

A24 Oscillator Assemblies . . . . . . . . . . . .’ . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A25 Preamplifier Assembly

A26 Sampler Driver Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . ....

Page

8-179

8-181

8-183

8-185

8-187

8-189

8-191

8-193

x

Page 13

SECTION O

INSTRUCTIONS

TM 11-6625-3014-14

0-1.

SCOPE.

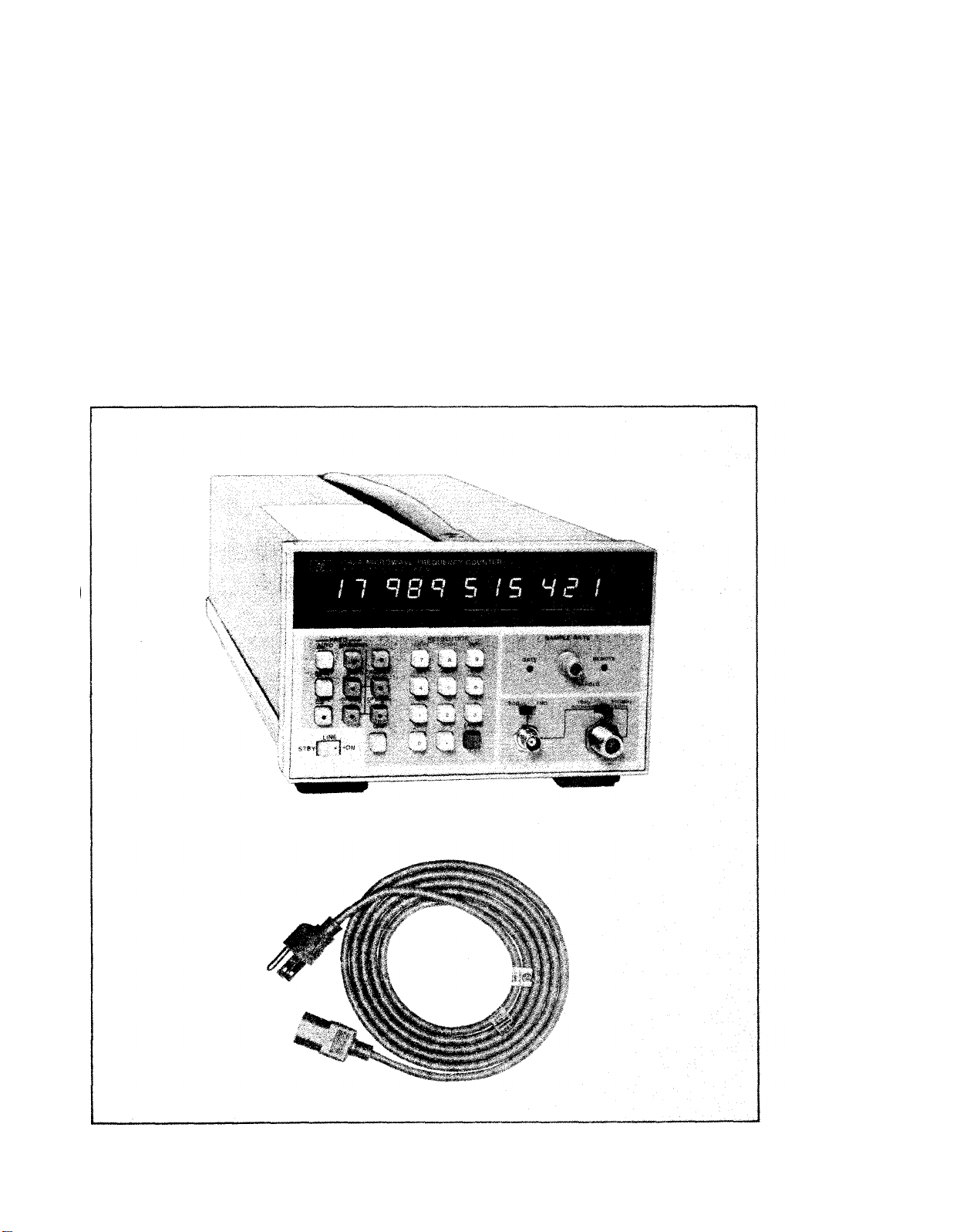

This manual describes Microwave Frequency Counter TD-1225A(V)l/U (fig. l-l)

and provides maintenance instructions. Throughout this manual, the TD-1225A(V)l/U

is refered to as the Hewlett-Packard (HP) Model 5342A.

0-2.

whether there are new

INDEXES OF PUBLICATIONS.

a.

DA Pam 310-4.

Refer to the latest issue of DA Pam 310-4 to determine

editions,

changes, or additional publications pertaining

to the equipment.

b.

DA Pam 310-7.

Refer to DA Pam 310-7 to determine whether there are

modification work orders (MWO’S) pertaining to the equipment.

0-3.

forms,

FORMS AND RECORDS.

a.

Reports of Maintenance and Unsatisfactory Equipment. Maintenance

records,

and reports which are used by maintenance personnel at all

levels of maintenance are listed in and prescribed by TM 38-750.

b.

Report of Packaging and Handling Deficiencies.

Fill out and forward

SF 364 (Report of Discrepancy (ROD))as prescribed in AR 735-11-2/DLAR

4140.55/NAVSUPINST 4610.33B/AFR 75-18/MCO p4610.19C and DLAR 4500.15.

c. Discrepancy in Shipment Report (DISREP) (SF 361). Fill out and

forward Discrepancy in Shipment Report (DISREP) (SF 361) as prescribed in

AR 55-38/NAVSUPINST 4610.33B/AFR 75-18/MCO P4610.19C and DLAR 4500.15.

0-4.

REPORTING OF EQUIPMENT IMPROVEMENT RECOMMENDATIONS (EIR).

EIR’s will be prepared using DA Form 2407, Maintenance Request.

Instructions for preparing EIR’s are provided in TM 38-750, The Army

Maintenance Management System.

EIR’s should be mailed directly to

Commander, US Army Communications and Electronics Materiel Readiness Command,

ATTN:

DRSEL-ME-MQ, Fort Monmouth, New Jersey 07703.

A reply will be

furnished directly to you.

0-5.

ADMINISTRATIVE STORAGE.

Administrative storage of equipment issued to and used by Army activities

shall be in accordance with TM 740-90-1.

0-6.

DESTRUCTION OF ARMY ELECTRONICS MATERIEL.

Destruction of Army electronics materiel to prevent enemy use shall be in

accordance with TM 750-244-2.

0-1

Page 14

Model 5342A

General Information

SECTION I

GENERAL INFORMATION

1-1. INTRODUCTION

1-1. This manual provides operating and service information for the Hewlett-Packard Model

5342A Microwave Frequency Counter, shown in Figure 1-1.

1-3. SPECIFICATIONS

1-4. Specifications of the 5342A are listed in Table 1-1.

Figure 1-1. Model 5342A Microwave Frequency

Counter

1-1

Page 15

Model 5342A

General Information

INPUT 1:

Frequency range: 500 MHz to 18 GHz

Sensitivity:

500 MHz to 12.4 GHz -25 dBm

12.4 GHz to 18 GHz

Maximum input: +5 dBm (see Options 002,003

for higher level).

Dynamic range:

500 MHz to 12.4 GHz 30 dB

12.4 GHz to 18 GHz

Impedance: 50 ohms, nominal

Connector:

Damage level: +25 dBm, peak

Coupling:

SWR:

<2:1, 500 MHz—10 GHz

<3:1, 10 GHz—18 GHz

FM tolerance:

FM

(wide):

CW

(normal): 20 MHz p-p worst case.

For modulation rates from dc to 10 MHz.

AM

tolerance:

the minimum signal level is not less than the

sensitivity specification.

Automatic amplitude discrimination: Automati-

cally measures the largest of all signals present, providing that signal is 6 dB above any

signal within 500 MHz; 20dB above any signal,

500 MHz—18 GHz.

Modes of operation:

Automatic:

and displays highest level signal within sensitivity range.

Manual:

±50 MHz to true value.

Acquisition time:

Automatic mode: Normal FM 530 ms worst

case; wide FM 2.4 s worst case.

Manual mode:

INPUT 2:

Frequency range:

Count.

Sensitivity:

50 10 Hz to 520 MHz 25 mV rms,

1 M 10 Hz to 25 MHz 50 mV rms.

Impedance:

nominal.

Coupling: ac

Connector: Type BNC female.

Maximum input:

dc fuse protected; 1 MW 200V dc +5.0V rms.

Crystal frequency: 10 MHz

Stability:

Aging rate: <1 X 10-

Short term:

50°C.

Line variation:

nominal.

(TTL compatible); 1.5V peak-to-peak into

50W available from rear panel BNC.

Table 1-1. Model 5342A Specifications

INPUT CHARACTERISTICS

-20 dBm

25 dB

Precision Type N female

dc to load, ac to instrument.

Switch selectable (rear panel)

50 MHz p-p worst case.

Any modulation index provided

Counter automatically acquires

Center frequency entered to within

80

ms after frequency entered.

10 Hz to 520 MHz Direct

Selectable: 1 MW, <50 pF or 50W

50Ω

3.5V rms (+24 dBm) or 5V

TIME BASE

7

per month.

External time base:

Requires 10 MHz, 2.0V peakto-peak sine wave or square wave into 1 KW

via rear panel BNC connector.

Switch

selects either internal or external time base.

OPTIONAL TIME BASE

(OPTION 001)

Option 001 provides an oven-controlled crystal

oscillator time base, 10544A (see separate data

sheet), that results in better accuracy and longer

periods between calibration.

Crystal frequency: 10 MHz

Stability:

Aging rate:

up.

Temperature:

50°C.

Short term:

Line variation:

nominal.

Warm-up:

after turn-on, at 25°C.

AMPLITUDE MEASUREMENT

(OPTION 002)

Option 002 provides the capability of measuring

the amplitude of the incoming sine wave signal,

and simultaneously displaying its frequency (MHz)

and level (dBm). The maximum operating level

and the top end of dynamic range are increased to

+20 dBm. Amplitude offset to 0.1 dB resolution

may be selected from front panel pushbuttons.

INPUT 1:

Frequency range: 500 MHz—18 GHz,

Dynamic range (frequency and level):

-22 dBm to +20 dBm 500 MHz to 12.4 GHz

-15 dBm to +20 dBm 12.4 GHz to 18 GHz

Maximum operating level: +20 dBm

Damage level: +25 dBm, peak

Resolution: 0.1 dB

Accuracy:

±1.5 dB (excluding mismatch

uncertainty).

SWR:

<2:1 (amplitude measurement).

<5:1 (frequency measurement).

Measurement time: 100 ms + frequency mea-

surement time.

Display:

Simultaneously displays frequency to 1

MHz resolution and input level. (Option 011

provides full frequency resolution on HP-IB

output.)

INPUT 2:

(500 impedance only)

Frequency range: 10 MHz—520 MHz

Dynamic range (frequency and level):

-17 dBm to +20 dBm.

Damage level: +24 dBm, peak

Resolution: 0.1 dBm.

Accuracy:

1.5 dB (excluding mismatch

uncertainty).

SWR:

<1.8:1

Measurement time: 100 ms + frequency mea-

surement time.

Display:

Simultaneously displays frequency to 1

MHz resolution and input level.

1-2

Page 16

Model 5342A

General Information

Table 1-1.

Model 5342A Specifications (Continued)

EXTENDED DYNAMIC RANGE

(OPTION 003)

Option 003 provides an attenuator that automatically extends the dynamic range of operation for

input 1.

INPUT 1:

Frequency range:

500

MHz to

18

GHz

Sensitivity:

500 MHz to 12.4 GHz -22 dB

12.4 GHz to 18 GHz

Maximum operating level:

-15 dBm

+20

dBm.

Dynamic range:

500 MHz to 12.4 GHz 42 dB

12.4 GHz to 18 GHz

Damage level:

SWR:

<5:1

+25

dBm, peak

35 dB

DIGITAL-TO-ANALOG CONVERTER

(OPTION 004)

Option 004 provides the ability to convert any

three consecutive displayed digits into an analog

voltage output. A display of

put; 999 produces 9.99V full scale.

∅∅∅

produces ∅ V out-

Accuracy: ±5 mV, ±0.3 mV/°C (from 25°C)

Conversion Speed:

reading.

Resolution:

10 mV

Output: 5 mA. Impedance <1.0 ohm.

Connector: Type BNC female on rear panel.

Accuracy: ±1 count ± time base error.

GENERAL

Resolution:

1 MHz.

Residual stability:

common time base or counter uses external

higher stability time base, <4 X 10-

typcial.

Front panel pushbuttons select 1 Hz to

When counter and source use

11

rms

Display: 11-digit LED display, sectionalized to

read GHz, MHz, kHz, and Hz.

Self-check:

buttons. Measures 75 MHz for resolution

chosen.

Selected from front panel push-

Frequency offset: Selected from front panel

pushbuttons. Displayed frequency is offset by

entered value to 1 Hz resolution.

Sample rate: Variable from less than 20 ms be-

tween measurements to HOLD which holds

display indefinitely.

IF out: Rear panel BNC connector provides 25

MHz to 125 MHz output of down-converted

microwave signal.

Operating temperature:

Power requirements: 100/120/220/240V rms, +5%,

-10%, 48—66 Hz; 100 VA max.

Accessories furnished:

Size: 133 mm H X 213 mm W X 498 mm D

0°C

Power

to

50°C.

cord,

229

cm

(7½

ft.)

Weight: Net 9.1 kg (20 Ibs.).

Shipping 12.7 kg (28 Ibs.).

1-5. SAFETY CONSIDERATIONS

1-6. This product is a Safety Class I instrument (provided with a protective earth terminal). Safety

information pertinent to the operation and servicing of this instrument is included in appropriate

sections of this manual.

1-7. INSTRUMENT IDENTIFICATION

1-8. Hewlett-Packard instruments have a 2-section, 10-character serial number (0000A00000),

which is located on the rear panel.

The four-digit serial prefix identifies instrument changes. If

the serial prefix of your instrument differs from that listed on the title page of this manual, there

are differences between this manual and your instrument. Instruments having higher serial

prefixes are covered with a “Manual Changes” sheet included with this manual. If the change

sheet is missing, contact the nearest Hewlett-Packard Sales and Service Office listed at the back of

this manual. Instruments having a lower serial prefix than that listed on the title page, are covered

in Section

VII.

1-9. ACCESSORIES

1-10. Table 1-2 lists accessory equipment supplied and Table 1-3 lists accessories available.

Table 1-2. Equipment Supplied

DESCRIPTION HP PART NUMBER

Detachable Power Cord 229 cm (7½ feet long)

8120-1378

1-3

Page 17

Model 5342A

General Information

Table 1-3. Accessories Available

DESCRIPTION

Bail Handle Kit 5061-2002

Rack Mounting Adapter Kit (Option 908) 5061-0057

Rack Mounting Adapter Kit with slot for access

to front connectors from rear.

Transit Case 9211-2682

Service

Accessory Kit (refer to paragraph

Microwave Attenuators

Signature Analyzer

1-16)

HP PART NUMBER

K70-59992A

Model 10842A

Model 8491B, 8494/5/6H

Model 5004A

1-11. DESCRIPTION

1-12. The 5342A Microwave Frequency Counter measures the frequency of signals in the range

of 10 Hz to 18 GHz, with a basic sensitivity of -25 dBm. Signals in the frequency range of 10 Hz to

500 MHz are measured by the direct count method. Signals in the frequency range of 500 MHz to

18 GHz are down-converted to an IF by a heterodyne conversion technique for application to the

counter circuits. The unique conversion technique employed results in high sensitivity and FM

tolerance in addition to automatic amplitude discrimination. The counted IF is added to the local

oscillator frequency to determine the unknown frequency for display.

1-13. OPTIONS

1-14. Options available with the 5342A are described in Table 1-1 and paragraph 3-57. If an

option is included in the initial order, it will be installed at the factory and ready for operation

upon receipt. If an option is ordered

for field installation it will be supplied as a retrofit kit. Refer

to Section II for kit part numbers and installation instructions.

1-15. SERVICE EQUIPMENT AVAILABLE

1-16. Extender boards are available for servicing printed circuit assemblies while extended from

the instrument. The extender boards allow assemblies to be extended from their plug-in con-

nectors for monitoring with appropriate test equipment. Extender boards for each assembly are

supplied in Service Accessory Kit 10842A as described in paragraph 8-46.

1-17. RECOMMENDED TEST EQUIPMENT

1-18. The test equipment listed in Table 1-4 is recommended for use during performance tests,

adjustments, and troubleshooting. Substitute test equipment may be used if it meets the required

characteristics listed in the table.

1-4

Page 18

Table 1-4 Recommended Test Equipment

Model 5342A

General Information

INSTRUMENT

Oscilloscope

Signal Generator

Spectrum Analyzer RF inputs from 1 MHz—500 MHz T,A,P

DC Voltmeter 20V Range, 0.05V Resolution T,A

AC Voltmeter 10 MHz-350 MHz T,A

AC Voltmeter 100 kHz, 1% accuracy

Logic State Analyzer HP 1740A compatibility

Signature Analyzer 5342A compatibility T

Power Splitter DC—18 GHz

Logic Pulser

Current Tracer

Logic Probe

Step Attenuator

AP Clips (4) Clip for 14 pin/16 pin IC’s

Isolation Transformer 120V IN — Isolated 120V OUT

Extender Boards 2 X 10 pin

REQUIRED

CHARACTERISTICS

100 MHz bandwidth

10 Hz—10 MHz

10 MHz—2.4 GHz

2 GHz—18 GHz

USE*

T,A,OV,P

T,A,OV,P HP 651B

A (Opt. 002)

OV,P

TTL compatibility

1 mA—1 A range

TTL compatibility

DC—18 GHz 10 dB steps

2 X 12 pin

2 X 15 pin HP P/N 05342-60032

2 X 18 pin (2)

OV,P

2 X 22 pin (2)

X 24 pin

2

A 14 Extender

A15 Extender

Power Meter

Power Sensor

50Ω Termination

Microwave Amplifier 1 GHz, >+20 dBm Output

Signal Generator

Signal Generator

Swept Frequency Analyzer

15 MHz—18GHz Modulator HP 8755B compatibility

15 MHz-18 GHz Detectors 0.1—18 GHz

(2 required)

Oscilloscope Mainframe HP 8755B compatibility

Directional Coupler 2—18 GHz

Directional Coupler 100—500 MHz

Signal Generator (Two Microwave sources needed

Mainframe

Bus System Analyzer

*T = Troubleshooting

A = Adjustments

OV = Operational Verification

P = Full Performance Testing

10 MHz—18 GHz

10 MHz—18 GHz

-30 dBm to +20 dBm

DC—18 GHz

100 MHz, +20 dBm

>100 MHz,

100 MHz—18 GHz

for automatic amplitude

discrimination test — see

paragraph 4-35)

Control HP-IB lines T (Opt. 011) HP 59401A

>+20 dBm

A,OV,P HP 436A

A,OV,P HP 8481A

P (Opt.

A (Opt. 002) HP 8601A

P,OV,

(Option 002)

RECOMMENDED

MODEL

HP 1740A

HP 8620C/86222A

HP 8620C/86290A

HP 141T/8552A/8554B

HP 3465A

HP 3406A

HP 3400A

T HP 1607A (use

T HP 546A

T HP 547A

T HP 545A

T HP P/N 1400-0734

T Allied Electronics

T

P

with HP 1740A)

HP 5004A

HP 11667A

HP 8495B

P/N 705-0048

HP P/N 05342-60030

HP P/N 05342-60031

HP

P/N 05342-60033

HP P/N 05342-60034

HP P/N 05342-60035

HP P/N 05342-60036

HP

P/N 05342-60039

HP 909A

(Option 012)

002) HP 489A

HP 3312A

P

P

P

P

P

P

P

HP 8755B

HP 11665B

HP 11664A

HP 182T

HP 11692D

HP 778D

HP 8620C Mainframe

1-5

Page 19

Model 5342A

Installation

SECTION II

INSTALLATION

2-1. INTRODUCTION

2-2. This section contains information for unpacking, inspection, storage, and installation.

2-3. UNPACKING AND INSPECTION

2-4. If the shipping carton is damaged, inspect the instrument for visible damage (scratches,

dents, etc.). If the instrument is damaged, notify the carrier and the nearest Hewlett-Packard

Sales and Service Office immediately (offices are listed at the back of this manual). Keep the

shipping carton and packing material for the carrier’s inspection. The Hewlett-Packard Sales

and Service Office will arrange for repair or replacement of your instrument without waiting for

the claim against the carrier to be settled.

2-5. INSTALLATION REQUIREMENTS

CAUTION

Before connecting the instrument to ac power lines,

be sure that the voltage selector is properly

positioned as described below.

2-6.

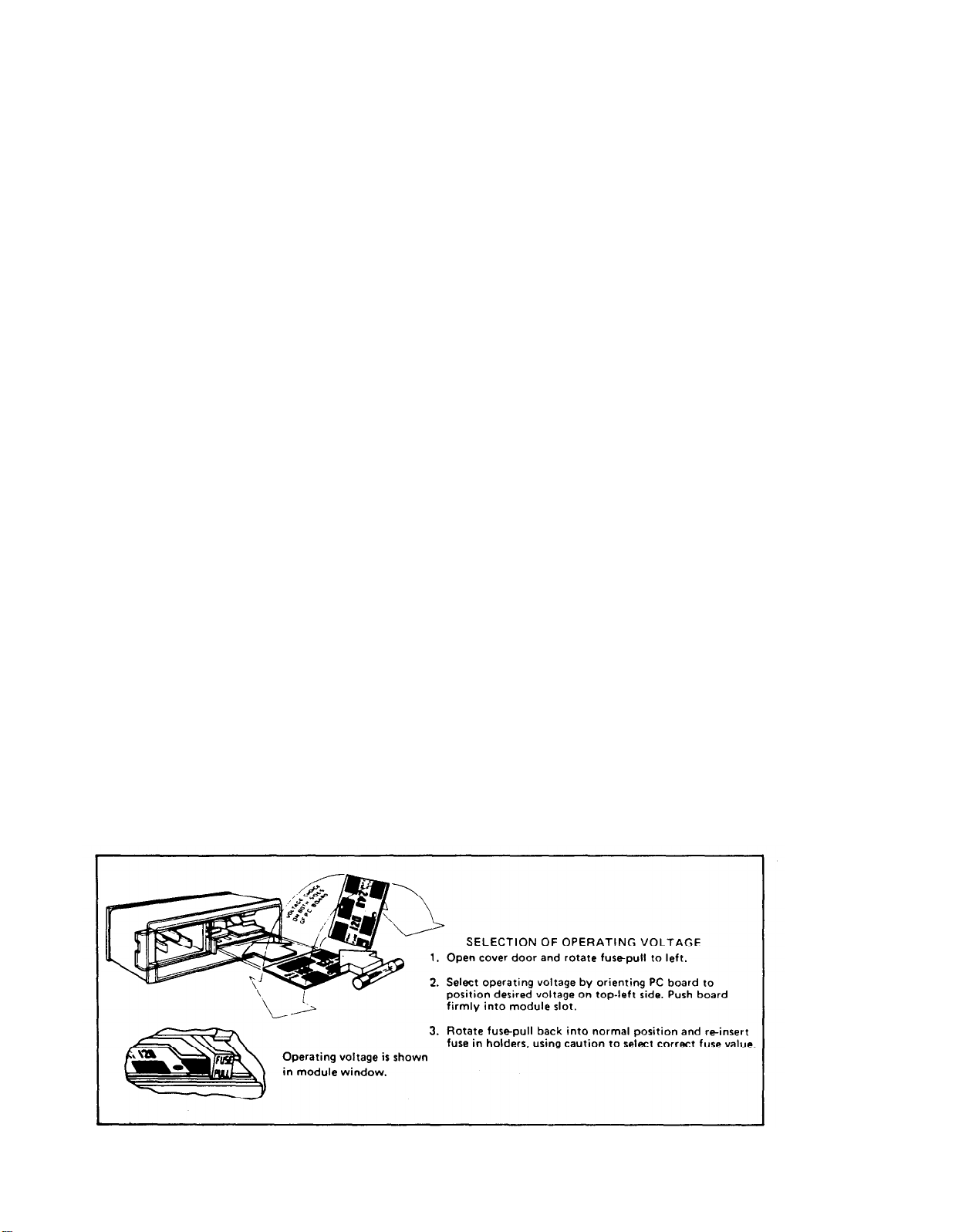

LINE VOLTAGE REQUIREMENTS. The 5342A is equipped with a power module that con-

tains a printed-circuit line voltage selector to select 100- 120-, 220-, or 240-volt ac operation.

Before applying power, the pc selector must be set to the correct position and the correct fuse

must be installed as described

2-7. Power line connections are selected by the position of the plug-in circuit card in the

module. When the card is plugged into the module, the only visible markings on the card indicate the line voltage to be used. The correct value of line fuse, with a 250-voIt rating, must be

installed after the card is inserted. This instrument uses a 0.75A fuse (HP Part No. 2110-0360) for

100/120-volt operation; a 0.375A fuse (HP Part No. 2110-0421) for 220/240-volt operation.

2-8. To convert from one line voltage to another, the power cord must be disconnected from

the power module before the sliding window covering the fuse and card compartment can be

moved to expose the fuse and circuit card. See

below.

Figure 2-1.

Figure 2-1. Line Voltage Selection

2-1

Page 20

Model 5342A

Installation

2-9. Power Cable

2-10. The 5342A is shipped with a three-wire power cable. When the cable is connected to an appropriate ac power source, this cable connects the chassis to earth ground. The type of power cable plug shipped with each instrument depends on the country of destination. Refer to Figure 2-2 for the part numbers of the power cable and plug configurations available.

2-2

Figure 2-2. Power Cable HP Part Numbers versus Mains Plugs Available

WARNING

BEFORE SWITCHING ON THIS INSTRUMENT, THE

PROTECTIVE EARTH TERMINALS OF THIS INSTRU-

MENT MUST BE CONNECTED TO THE PROTECTIVE

CONDUCTOR OF THE (MAINS) POWER CORD. THE

MAINS PLUG SHALL ONLY BE INSERTED IN A

SOCKET OUTLET PROVIDED WITH A PROTECTIVE

EARTH CONTACT, THE PROTECTIVE ACTION MUST

NOT BE NEGATED BY THE USE OF AN EXTENSION

CORD (POWER CABLE) WITHOUT A PROTECTIVE

CONDUCTOR (GROUNDING).

Page 21

Model 5342A

Installation

2-11. Operating Environment

2-12. TEMPERATURE. The 5342A may be operated in temperatures from 0°C to +55°C.

2-13. HUMIDITY. The 5342A may be operated in environments with humidity up to 95%. However, it should be protected from temperature extremes which cause condensation in the

instrument.

2-14. ALTITUDE. The 5342A may be operated at altitudes

2-15. STORAGE AND SHIPMENT

2-16. Environment

2-17. The instrument may be stored or shipped in environments within the following limits:

TEMPERATURE . . . . . . . . . . . . . . . . . -40°C to +75°C

HUMIDITY . . . . . . . . . . . . . . . . . . . . . . . . . .

ALTITUDE . . . . . . . . . . . . .

2-18. The instrument should also be protected from temperature extremes which cause

condensation within the instrument.

2-19. Packaging

2-20. ORIGINAL PACKAGING. Containers and materials identical to those used in factory

packaging are available through Hewlett-Packard offices. If the instrument is being returned to

Hewlett-Packard for servicing, attach a tag indicating the type of service required, return address,

model number, and full serial number. Also, mark the container FRAGILE to ensure careful

handling. In any correspondence, refer to the instrument by model number and full serial

number.

2-21. OTHER PACKAGING. The following general instructions should be used for repacking

with commercially available materials:

7,620 metres (25,000 feet)

up to 4,600 metres (15,000 feet).

Up to 95%

Wrap instrument in heavy paper or plastic. (If shipping to Hewlett-Packard office or

a.

service center, attach tag indicating type of service required, return address, model

number, and full serial number.)

b. Use strong shipping container. A double-wall carton made of 350-pound test material is

adequate.

c.

Use a layer of shock-absorbing material 70 to 100 mm (3-to 4-inch) thick around all sides

of the instrument to provide firm cushioning and prevent movement inside container.

Protect control panel with cardboard.

d. Seal shipping container securely.

Mark shipping container FRAGILE to ensure careful handling.

e.

f. In any correspondence, refer to instrument by model number

2-22. FIELD INSTALLATION OF

2-23. Procedures for field installation of Options 001,002,003,004, and 011 are described in the

OPTIONS

and full serial number.

following paragraphs.

2-3

Page 22

Model 5342A

Installation

2-24. Part Numbers for Ordering Option Kits

2-25. To obtain the necessary parts for installation of an option, order by part number as listed

below (refer to Section VI for ordering information):

Option

001

002

003

*004

001

If the instrument in which Option 004 is to be installed

has a series number 1812 or lower, the U7 ROM on

A14 Microprocessor will have to be replaced. Order

U7 ROM Part Number 1818-0706 to replace the old

U7 ROM (1818-0331).

2-26. Installation of 10 MHz Oscillator Option 001

2-27. Option 001 consists of oven-controlled crystal oscillator time base 10544A, which has a pc

card connector. Option 001 is installed in the same connector on the motherboard as the standard oscillator (A24). See Figure 8-44. To install Option 001, proceed as follows:

High Stability Time Base HP Model 10544A

Amplitude Measurement

Extended Dynamic Range 05342-60201 (Kit)

Digital-to-Analog Converter

HP-IB I/O 05342-60019 (HP-IB Assy.)

Name Part Number

05342-60200 (Kit)

05342-60202 (Kit)

05342-60029 (HP-IB Input Assy.)

*NOTE

a.

Remove the standard oscillator from A24 connector.

b. Install Option 001 oscillator into A24 connector.

Attach Option 001 oscillator to the motherboard by means of two 6/32X5/16 pan head

c.

screws. Install the screws from the bottom of the motherboard using star washers.

d. Perform Option 001 oscillator adjustment as described in paragraph 5-32.

2-28. Installation of Amplitude Measurement Option 002

2-29. Option 002 consists of U2 High Frequency Amplitude assembly and A27 Low Frequency

Amplitude Assembly modules and the A16 Amplitude Assembly pc board. U2 is connected to the

high frequency input of the 5342A, A27 is connected to the low frequency input and both of the

modules are connected to the A16 board by the coax wires supplied. See photo of installed

option, Figure 8-22, and schematic diagram, Figure 8-39. To install the components proceed as

follows:

NOTE

The parts that comprise this option are listed in Table 6-5.

a.

Remove the top and bottom covers and top plate from instrument.

b. Place instrument top down.

c.

At inside front panel, disconnect cables from A1J1,J1J3,J25J1 (IF OUT lNT), and A25J2 (IF

OUT EXT).

d. Solder one end of the white/red/green 14-inch wire (8120-0483) to AT1 feedthrough

capacitor terminal on A25 Preamplifier assembly.

2-4

Page 23

Install coax assembly 8120-2268 through A22 motherboard from top of instrument at A16

e .

slot. Place the wires through the holes as shown below:

NOTE

Model 5342A

Installation

Prior to installing A27 Low Frequency

Amplitude Assembly, connect the wires as

described below.

f.

Solder one

capacitor terminal on A27.

Place heat shrinkable tubing (0890-0983) over connection at C7,

g.

h.

Place heat shrinkable tubing (0890-0983) over three of the coax wires (red, blue, and

green) that were installed in step e. and solder

Coax

Red

Blue

Green

Apply heat to shrink the tubing at the connections made in step g and h.

i.

Remove attaching nut from front panel N-type input connector and disconnect rigid

j.

coax W1 from J1 on U1 Sampler. Remove W1 from instrument.

Mount A27 Low Frequency Amplitude Assembly in the recessed angle of the casting

k.

behind front frame, see Figure 8-22. Attach A27 to casting with two pan head screws

supplied. Place a star washer under the other screw.

The wire previously soldered to A27C10 has a black ground wire attached. Solder the end

l.

of this black wire to the ground lug installed in preceding step.

end of the black/white/blue 14-inch wire (8120-0471) to C7 feedthrough

these wires to the terminals listed below:

Terminal

A27C10

A27C9

A27C8

Solder the free end of white/red/green wire (other end connected to A25AT1 in step d)

m.

to A22 motherboard at XA16B, pin 3 (ATT).

NOTE

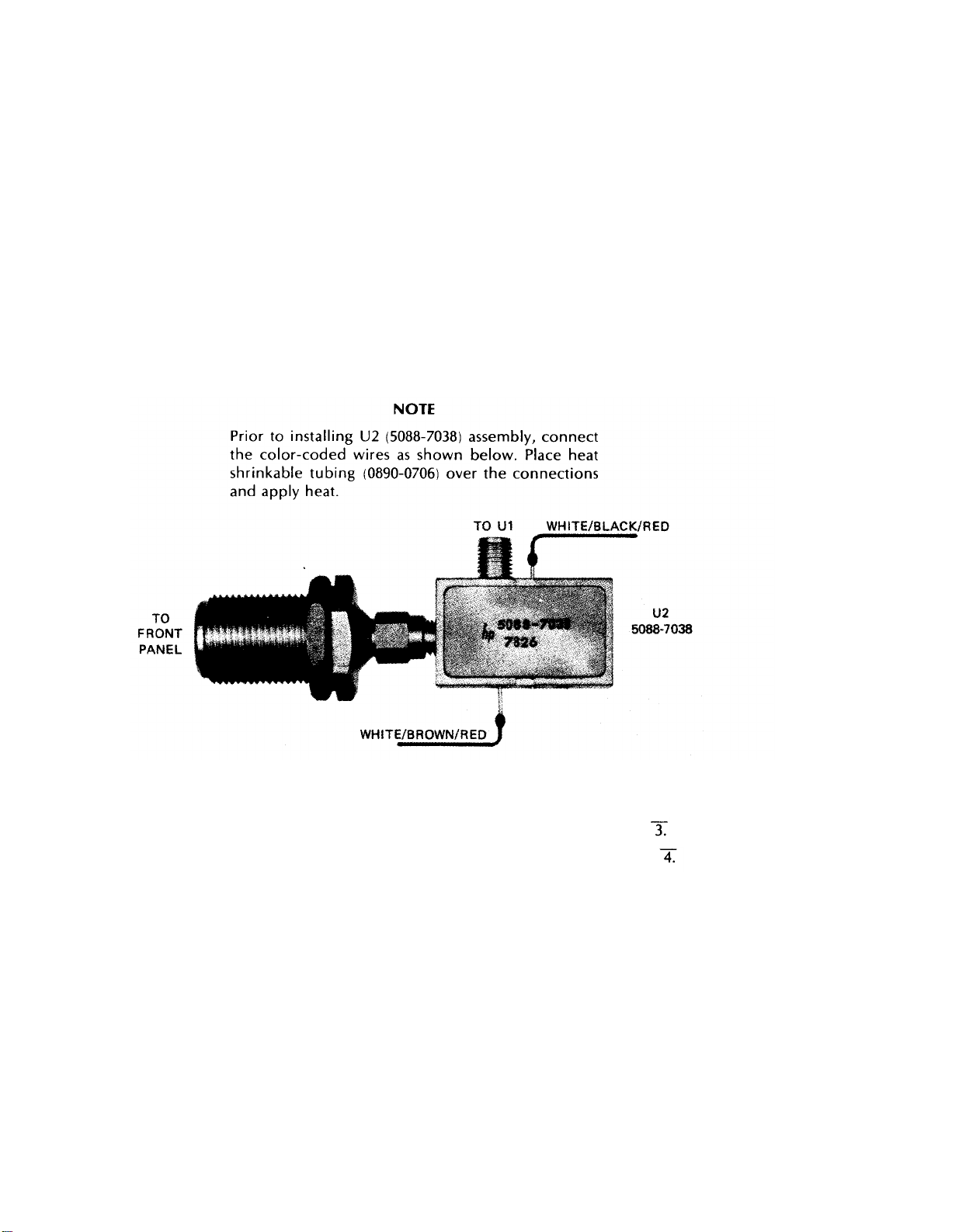

Prior to installing U2 High Frequency Amplitude

Assembly, connect the color-coded wires as shown

below. Place heat shrinkable tubing (0890-0983 for

coax and 0890-0706 for single wires) over all connections to U2.

2-5

Page 24

Model 5342A

Installation

n.

o.

p.

q.

r.

s.

Connect rigid coax (8120-2516) from U2 High Frequency Amplitude Assembly to J1 on

Sampler U1. Install U2 input connector through front panel. Fasten with attaching nut.

Solder white/black/red wire (from U2) to A22 motherboard XA16B, pin

Solder white/brown/red wire (from U2) to A22 motherboard XA16B, pin

Harness the coax cables and wires with tie wraps supplied.

Connect cable 05342-60119 from A27J1 to A1J3.

Connect cable A1J3/A27J2 to A27J2.

Reconnect A1J1,J1 (IF OUT INT) and J2 (IF OUT EXT) and harness with tie wrap.

t.

Harness the white cables with tie wraps supplied.

u.

NOTE

The ROM and U2 High Frequency Amplitude

Assembly are supplied as a matched pair and are

included

(05342-80005).

v.

Install the ROM (supplied with option) into U3 socket on A16 (05342-60038) board.

Replace resistor R2 on A16 board with a resistor of the value labeled on U2 assembly.

w.

Insert the plug of 8120-2268 cable into mating socket on A16 board (05342-60038) and

x.

install A16 into connector XA16.

Perform the Option 002 adjustments listed under paragraph 5-33 through 5-39 of this

y.

manual.

Perform the operational verification procedures in paragraphs 4-14, 4-15, and 4-17

z.

of this manual.

under one replaceable part number

NOTE

If the instrument does not meet the specified

accuracy of ±1.5 dB as described in paragraph 4-14,

perform the following procedures.

Replace resistor R6 from the A27 Low Frequency Amplitude Assembly and replace with a

resistor of a higher or lower value as shown below. For lower power readings increase the

value and for higher power readings decrease the value of resistor R6 as follows:

2-6

dB Change

0.2

0.4

0.6

0.8

1.0

R6 Changes

(ohms)

10

20

30

40

50

Page 25

Model 5342A

Installation

2-30.

Installation of Extended Dynamic Range Option 003

2-31. Option 003 consists of A16 Extended Dynamic Range Assembly (05342-60037) and U2

Attenuator Assembly (5088-7038). See Figure 8-22 for location of U2 (Option 002 or 003).

NOTE

The parts that comprise this option are listed at the

end of Table 6-6.

Remove the top and bottom covers and top plate from instrument.

a.

Place instrument top down.

b.

At inside front panel, disconnect cable from A1J1,A1J3,A25J1 (IF OUT INT), and A25J2

c.

(IF OUT EXT).

Solder one end of the white/red/green 14-inch wire (8120-0483) to AT1 feedthrough

d.

capacitor terminal on A25 Preamplifier Assembly.

Solder free end of white/red/green wire (other end connected to A25AT1 in step d) to

e.

A22 Motherboard at XA16B, pin 3 (ATT).

Solder white/bIack/red wire (from U2) to A22 Motherboard XA16B, pin

f.

Solder white/brown/red wire (from U2) to A22 Motherboard XA16B, pin

g.

h.

Remove the N-type input connector from front panel and replace with U2 (5088-7038).

Connect rigid coax (supplied) from U2 to J1 on Sampler U1.

i.

Install A16 board (05342-60037) into XA16 connector.

j.

Perform the operational verification procedures in paragraphs 4-13 and 4-16

k.

of this manual.

2-32.

Installation of Digital-to-Analog Conversion (DAC) Option 004

2-33. Option 004 consists of an A2 Display Driver Assembly (05342-60028) that contains DAC

circuitry added to the standard A2 circuit. Interconnecting wires are included with the Option

004 retrofit kit (05342-60202). Procedures for installation of Option 004 are as follows:

2-7

Page 26

Model 5342A

Installation

a.

b.

Remove top and bottom covers, front frame and A1-A2 assemblies. Refer to disassembly

procedures, paragraph 8-22.

Replace the original A2 board (05342-60002) with Option 004 A2 board (05342-60028) and

reassemble unit.

If the series number of the instrument is

c.

1812 or lower, the U7 ROM, 1818-0331 on the

A14 Microprocessor board will have to be replaced with U7 ROM, 1818-0706 as described

in step d. If instrument has the

1818-0706 ROM, proceed to step e.

CAUTION

ROM U7 is a large-scale MOS IC. Its inputs are

susceptible to damage by high voltage and by static

charges. Particular care should be exercised when

servicing this IC or handling it under conditions

where static charges can build up.

Remove top plate from 5342A. Remove A14 Microprocessor and replace ROM U7 part

d.

number 1818-0331 with part number 1818-0706. Install A14.

At bottom of 5342A connect coax cable to the connector at the bottom rear of A2 board

e.

labeled D/A OUTP. Solder the other end of this cable to the DAC OUT connector on the

rear paneI.

f.

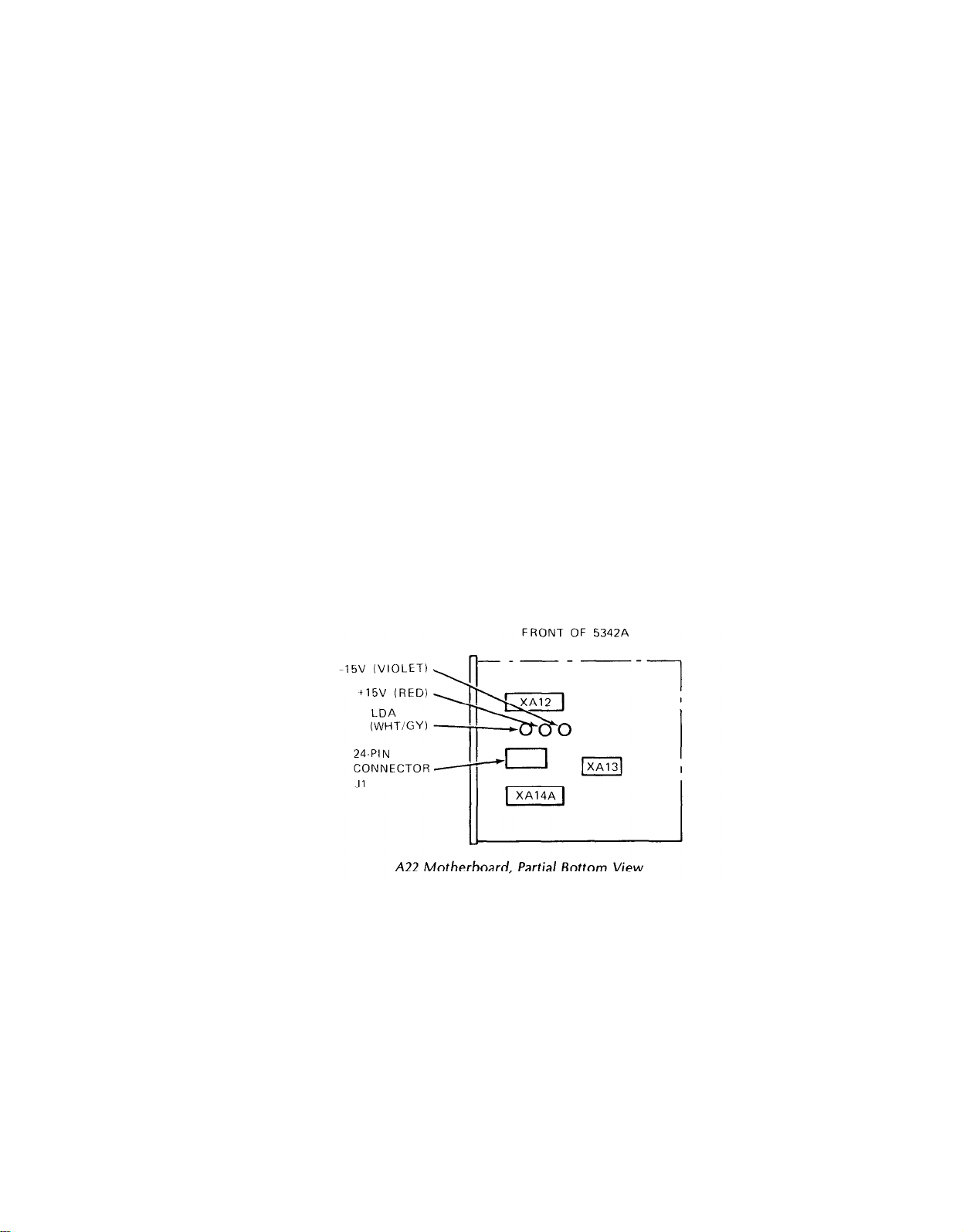

Connect the white/gray wire to the pin (push-on) labeled LDA at bottom rear of A2

Display Driver board. Solder other end of wire to LDA terminal on A22 Motherboard as

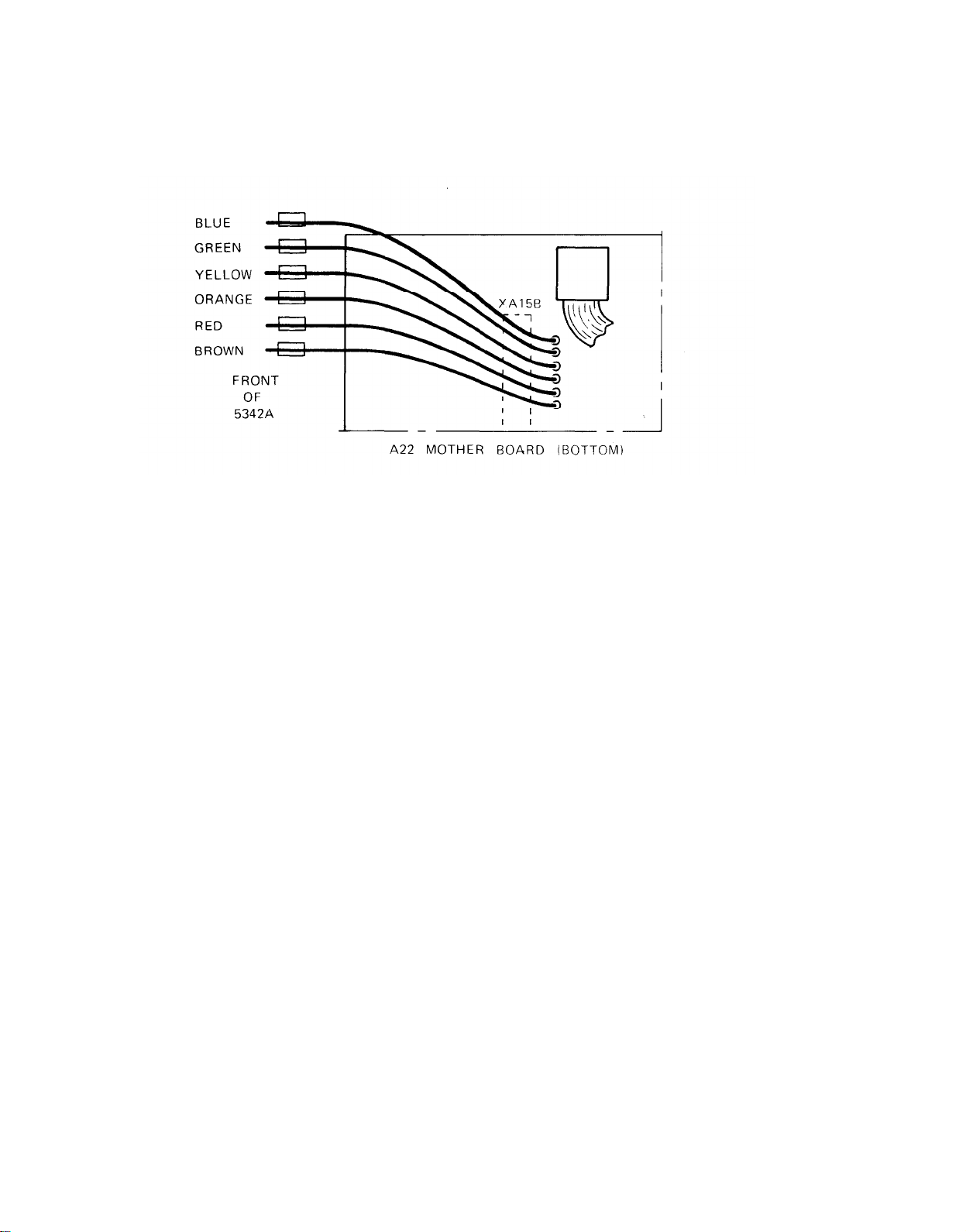

shown in figure below.

Connect red wire (+15V) and violet wire (-15V) to the proper terminals (push-on pins) on

g.

A2 Display Driver board (see

Figure 8-25, component locator for location). Connect

other end of these wires to terminals on A22 Motherboard as shown in figure below.

2-8

h.

Reassemble instrument and perform operational verification procedures in para-

graph 4-27 of this manual.

2-34.

2-35.

Installation of HP-IB Option 011