Page 1

TM 11-6625-3068-24P

TECHNICAL MANUAL

ORGANIZATIONAL, DIRECT SUPPORT, AND GENERAL SUPPORT

MAINTENANCE REPAIR PARTS AND SPECIAL TOOLS LIST

FOR

UNIVERSAL FREQUENCY COUNTER 5335A (HP)

HEADQUARTERS, DEPARTMENT 0F THE ARMY

17 MAY 1985

Page 2

TM 11-6625-3068-24P

TECHNICAL MANUAL HEADQUARTERS

DEPARTMENT OF THE ARMY

No. 11-6625-3068-24P WASHINGTON, DC 17May 1985

ORGANIZATIONAL, DIRECT SUPPORT, AND GENERAL SUPPORT

MAINTENANCE REPAIR PARTS AND SPECIAL TOOLS LIST

(INCLUDING DEPOT MAINTENANCE REPAIR PARTS AND SPECIAL TOOLS)

FOR

UNIVERSAL FREQUENCY COUNTER 5335A (HP)

Current as of 1 January 1985

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS

You can help improve this manual. If you find any mistakes or if you know of a way to improve the

procedures, please let us know. Mail your letter, DA Form 2028 (Recommended Changes to Publications

and Blank Forms), or DA Form 2028-2 located in back of this manual direct to: Comm ander, US Army

Communications- Electronics Comm and and Fort Monm outh, ATTN: AMSEL- ME-MP, Fort Monmouth, NJ

07703-5007.

In either case, a reply will be furnished direct to you.

Table of Contents

Illus

Page Figure

SECTION I. Introduction .......................................................................................................................1

II. Repair Parts List............................................................................................................. 1-1

Group 00 Universal Frequency Counter 5335A (HP)..................................................................... 1-1 1

01 CCA, Power. Supply 05335-60001 (Al).......................................................................... 2-1 2

02 CCA, Amplifier 05335-60002 (A2) (No parts authorized)

03 CCA, Buffer Amplifier 05335-60003 (A3)....................................................................... 3-1 3

04 CCA, Main Logic 05335-60004 (A4).............................................................................. 4-1 4

05 CCA, Display 05335-60005 (A5).................................................................................... 5-1 5

06 CCA, HP- 1B Connector 05370-60005 (A 14)............................................................... 6-1 6

07 CCA, Channel C 05335-60009 (A9)............................................................................... 7-1 7

08 CCA, Amplifier 05335-60012 (A12) ............................................................................... 8-1 8

SECTION III. Special Tools List (Not applicable)

IV. National Stock Number and Part Number Index............................................................. I-1

Page 3

TM 11-6625-3068-24P

SECTION I

INTRODUCTION

1. Scope

This manual lists and authorizes spares and repair parts; special tools; special test, measurement, and diagnostic

equipment (TMDE); and other special support equipment r equired for perf ormance of organizational, direct sup- port, and

general support maintenance of the HP-5335A. It authorizes the requisitioning, issue, and disposition of spares, repair

parts and special tools as indicated by the source, maintenance and recoverability (SMR) codes.

2. General

This Repair Parts and Special Tools List is divided into the following sections:

a. Section H. RepairParts List. A list of spares and repair parts authorized by this RPSTL for use in the

performance of m aintenance. T he list als o includes parts which m ust be rem oved f or r eplacem ent of the authorized parts .

Parts lists are composed of functional groups in ascending numeric sequence, with the parts in each group listed in

ascending item number sequence. Figure numbers are listed directly beneath the group header.

b. Section III. Special Tools List. Not applicable.

c. Section IV. National Stock Num ber and Part Number Index . A list, in National item identification number ( NIIN)

sequence, of all National stock numbered items appearing in the listing, f ollowed by a list in alphameric sequence of all

part numbers appearing in the listings. National stock num bers and part num bers are cross -referenc ed to each illustration

figure and item number appearance.

3. Explanation of Columns (Section II and III)

a. Item No. (Column (1)). Indicates the number used to identify items called out in the illustration.

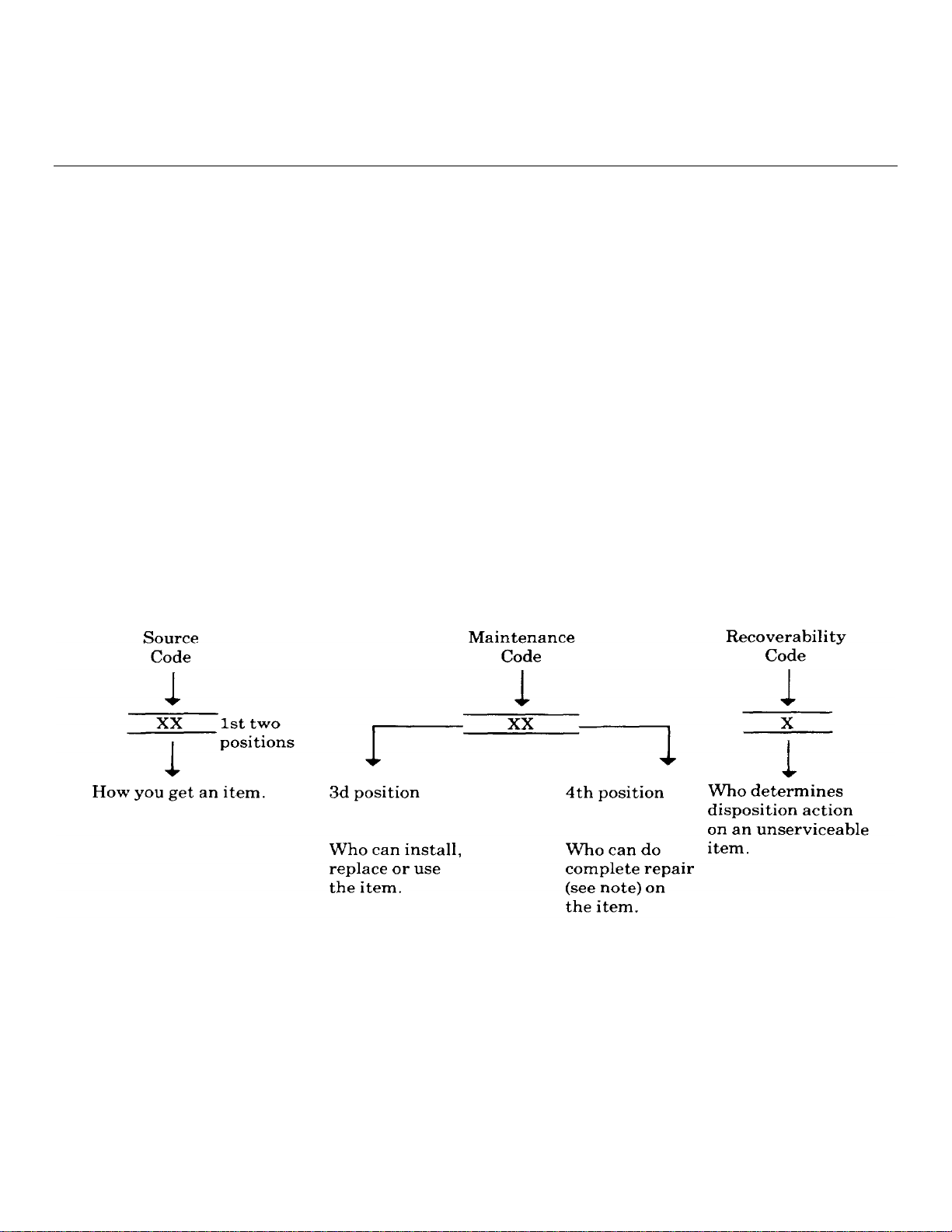

b. SMR Code (Column (2)). The source, maintenance, and recoverability (SMR) code is a five-position code

containing supply/requisitioning information, maintenance category authorization criteria, and disposition instruction, as

shown in the following breakout.

NOTE

Complete repair: Maintenance capacity, capability, and authority to perform all corrective maintenance

tasks of the "Repair" function in a use/user environment in order to restore serviceability to a failed item.

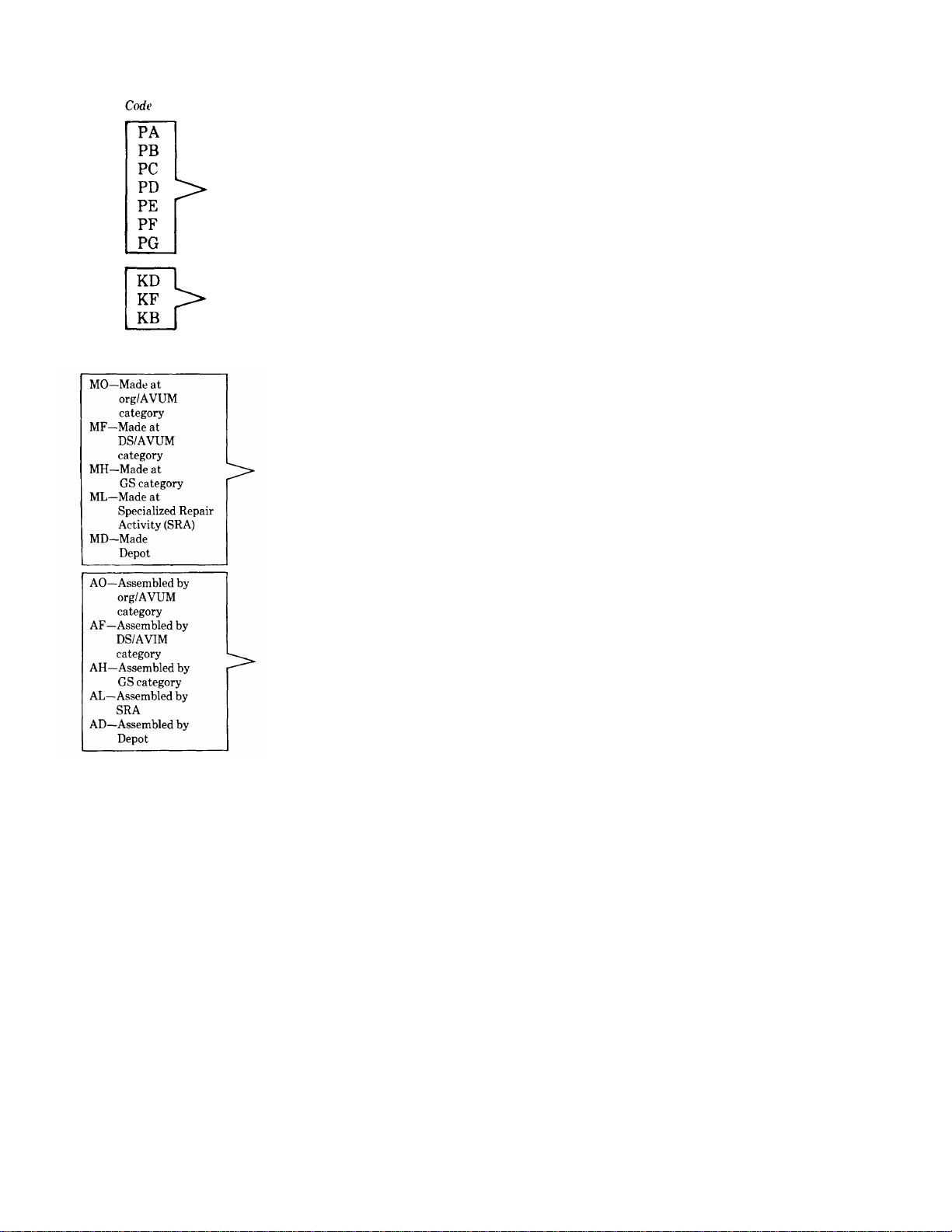

(1) Source code. The source code tells you how to get an item needed for maintenance, repair, or overhaul of an

end item/equipment. Explanations of source codes follows:

1

Page 4

TM 11-6625-3068-24P

Stocked items; use the applicable NSN to request/requisition items with these

source codes. They are authorized to the category indicated by the code entered in

the third position of the SMR code.

NOTE

Items coded PC are subject to deterioration.

Items with these codes are not to be requested/requisitioned individually. They are

part of a kit which is authorized to the maintenance category indicated in

the third position of the SMR code. The complete kit must be requisitioned

and applied.

Items with these codes are not to be requested/requisitioned individually. They must

be made from bulk material which is identified by the part number in the

description and usable on code (UOC) column and listed in the Bulk

Material group of the repair parts list. If the item is authorized to you by the

third position code of the SMR code, but the source code indicates it is

made at a higher category, order the item from the higher category of

maintenance.

Items with these codes are not to be requested/requisitioned individually. The parts

that make up the assembled item must be requisitioned or fabricated and

assembled at the category of maintenance indicated by the source code. If

the disposition code of the SMR code authorizes you to replace the item,

but the source code indicates the item is assembled at a higher category,

order the item, from the higher category of maintenance.

Explanation

Code Explanation

XA-Do not requisition an "XA" coded item. Order its next higher assembly.

XB-If an "XB" item is not available from salvage, order it using the FSCM and part number given.

XC-Installation drawing, diagram, instruction sheet, field service drawing, that is identified by manufacturers part number.

XD-Item is not stocked. Order an "XD" coded item through normal supply channels using the FSCM and part number

given, if no NSN is available.

NOTE

Cannibalization or controlled exchange, when authorized, may be used as a source of supply for item s

with the above source codes, except for those source coded "XA" or those aircraf t s upport items restricted

by requirements of AR 750-1.

Maintenance code

(2)

support items. The maintenance codes are entered in the third and fourth positions of the SMR code as follows:

(a) The maintenance code entered in the third position tells you the lowest maintenance category authorized

. Maintenance codes tell you the category of maintenance authorized to USE and REPAIR

2

Page 5

TM 11-6625-3068-24P

to remove, replace, and use an item. The maintenance code entered in the third position will indicate authorization

to one of the following categories of maintenance.

Code Applica tion/Explana tlon

C-Crew or operator maintenance done within organizational or aviation maintenance.

O-Organizational or aviation unit category can remove, replace, and use the item.

F-Direct support or aviation intermediate category can remove, replace, and use the item.

H-General support category can remove, replace, and use the item.

L--Specialized repair activity can remove, replace, and use the item.

D-Depot category can remove, replace, and use the item.

(b) The maintenance code entered in the fourth position tells whether or not the item is to be repaired and

identifies the lowest maintenance category with the capability to do complete repair (i.e., perform all authorized repair

functions). This position will contain one of the following maintenance codes.

NOTE

Some limited repair may be done on the item at a lower category of maintenanc e, if authorized by the

Maintenance Allocation Chart (MAC) and SMR codes.

Code Application/Explanation

O-Organizational or aviation unit is the lowest category that can do complete repair of the item.

F-Direct support or aviation intermediate is the lowest category that can do complete repair of the item.

H-General support is the lowest category that can do complete repair of the item.

L-Specialized repair activity (designate the specialized repair activity) is the lowest category that can do complete repair of

the item.

D-Depot is the lowest category that can do complete repair of the item.

Z-Nonreparable. No repair is authorized.

B-No repair is authorized. (No parts or special tools are authorized for the maintenance of a "B" coded item). However, the

item may be reconditioned by adjusting, lubricating, etc., at the user category.

Recoverability code

(3)

unserviceable items. The recoverability code is entered in the fifth position of the SMR Code as follows:

. Recoverability codes are assigned to items to indicate the disposition action on

Recoverability

Codes Applictation/Explanation

Z--Nonreparable Item. When unserviceable, condemn and dispose of the item at the category of maintenance shown in

the third position of SMR Code.

O-Reparable item. When uneconomically reparable, condemn and dispose of the item at organizational or aviation unit

category.

F-Reparable item. When uneconomically reparable, condemn and dispose of the item at direct support or aviation

intermediate category.

H-Reparable item. When uneconomically reparable, condemn and dispose of the item at general support category.

D-Reparable item. When beyond lower category repair capabillity, return to depot. Condemnation and disposal of item not

authorized below depot category.

L-Reparable item. Condemnation and disposal not authorized below specialized repair activity (SRA).

A-Item requires special handling or condemnation procedures because of specific reasons (e.g., precious metal content,

high dollar valve, critical material, or hazardous material). Refer to appropriate manuals/directives for specific

instructions.

FSCM (Column (3))

c.

to identify the manufacturer, distributor, or Government agency, etc., that supplies the item.

Part Number (Column (4))

d.

corporation, or Government activity), which controls the design and characteristics of the item by means of its engineering

drawings, specifications, standards, and inspection requirements to identify an item or range of items.

When you use a NSN to requisition an item, the item you receive may have a different part num ber from

the part ordered.

e. Description and Usable on Code (UOC) (Column (5)). This column includes the following information.

(1) The Federal item name and, when required, a minimum description to identify the item.

(2) The statement "END OF FIGURE" appears just below the last item desc ription in Column (5) for a given

figure in both section II and section III.

f. Qty (Column (6)). Indicates the quantity of the item used in the breakout shown on the illustration figure, which is

prepared for a functional group, subfunc tional group, or an assembly. A "V" appearing in this colum n in lieu of a quantity

indicates that the quantity is variable and the quantity may vary from application to application.

. The Federal Supply Code for Manufacturer (FSCM) is a 5-digit numeric code which is us ed

. Indicates the primary number used by the manuf acturer (individual, c ompany, firm,

NOTE

3

Page 6

TM 11-6625-3068-24P

4. Explanation of Columns (Section IV)

a. National Stock Number(NSN)Index.

(1) Stock number column. This colum n lists the NSN by National item identification number (NIIN) sequence.

The NIIN consists of the las t nine digits of the NSN. When using this c olumn to locate an item, ignore the f irs t f our digits of

the NSN. When requisitioning items use the complete NSN (13 digits).

(2) Fig. column. This column lists the number of the figure where the item is identified/located. The

illustrations are in numerical sequence in sections II and III.

(3) Item colum n. The item number identifies the item ass ociated with the figure listed in the adj acent Fig.

column. This item is also identified by the NSN listed on the same line.

b. Part NumberIndex. Part numbers in this index are listed by part number in ascending alphameric sequence.

(1) FSCM column. This column lists the Federal supply code for manufacturer (FSCM).

(2) Part number column. This column indicates the part number assigned to the item.

(3) Stock number column. This colum n lists the National stock num ber for the as sociated part number and

manufacturer identified in the part number and FSCM columns to the left.

(4) Fig. column. This column lists the num ber of the figure where the item is identified/located in s ections II

and III.

(5) Item colum n. The item number is that num ber assigned to the item as it appears in the figur e refer enced

in the adjacent figure number column.

5. Special Information

a. Short Form Repair Parts and Special Tools List (RPSTL). T his Repair Parts and Special Tools List is a short

form RPSTL. All repair parts will be listed in the next revision.

b. Associated Publications. The publication lis ted below pertains to the 5335A (HP) and its c omponents: TM 11-

6625-3068-14, Universal Frequency Counter 5335A (HP) (To be published.)

c. National Stock Number s. National stock numbers (NSN’s) that are miss ing from P source coded items have

been applied for and will be added to this TM by future change/revision when they are entered in the Army Master Data

File (AMDF). Until the NSN’s are established and published, submit exception requisitions to: Commander, US Army

Communications- Electronic s Com m and and Fort Monm outh, AT T N: AMSEL-MM, For t Monm outh, NJ 07703-5006 f or the

part required to support your equipment.

6. How to Locate Repair Parts

a. When National stock number or part number is not known.

(1) First. Using the table of contents, deter mine the ass embly group or subass embly group to which the item

belongs. This is necessary since figures are prepared for assembly groups and subassembly groups, and listings are

divided into the same groups.

(2) Second. Find the figure covering the assembly group or subassembly group to which the item belongs.

(3) Third. Identify the item on the figure and note the item number.

(4) Fourth. Refer to the Repair Parts List for the figure to f ind the part num ber f or the item number noted on

the figure.

(5) Fifth. Refer to the Part Number Index to find the NSN, if assigned.

b. When National stock number or part number is known.

(1) First. Using the index of National stock numbers and part numbers, find the pertinent National stock

number or part number. The NSN index is in National item identification number (NIIN) sequence (para 4a(1)). The part

numbers in the part num ber index are lis ted in as c ending alphanumeric sequence (para 4b). Both index es c r oss - ref er enc e

you to the illustration figure and item number of the item you are looking for.

(2) Second. After finding the figure and item number, verify that the item is the one you’re looking for, then

locate the item number in the repair parts list for the figure.

7. Abbreviations

Not applicable.

4

Page 7

TM 11-6625-3068-24P

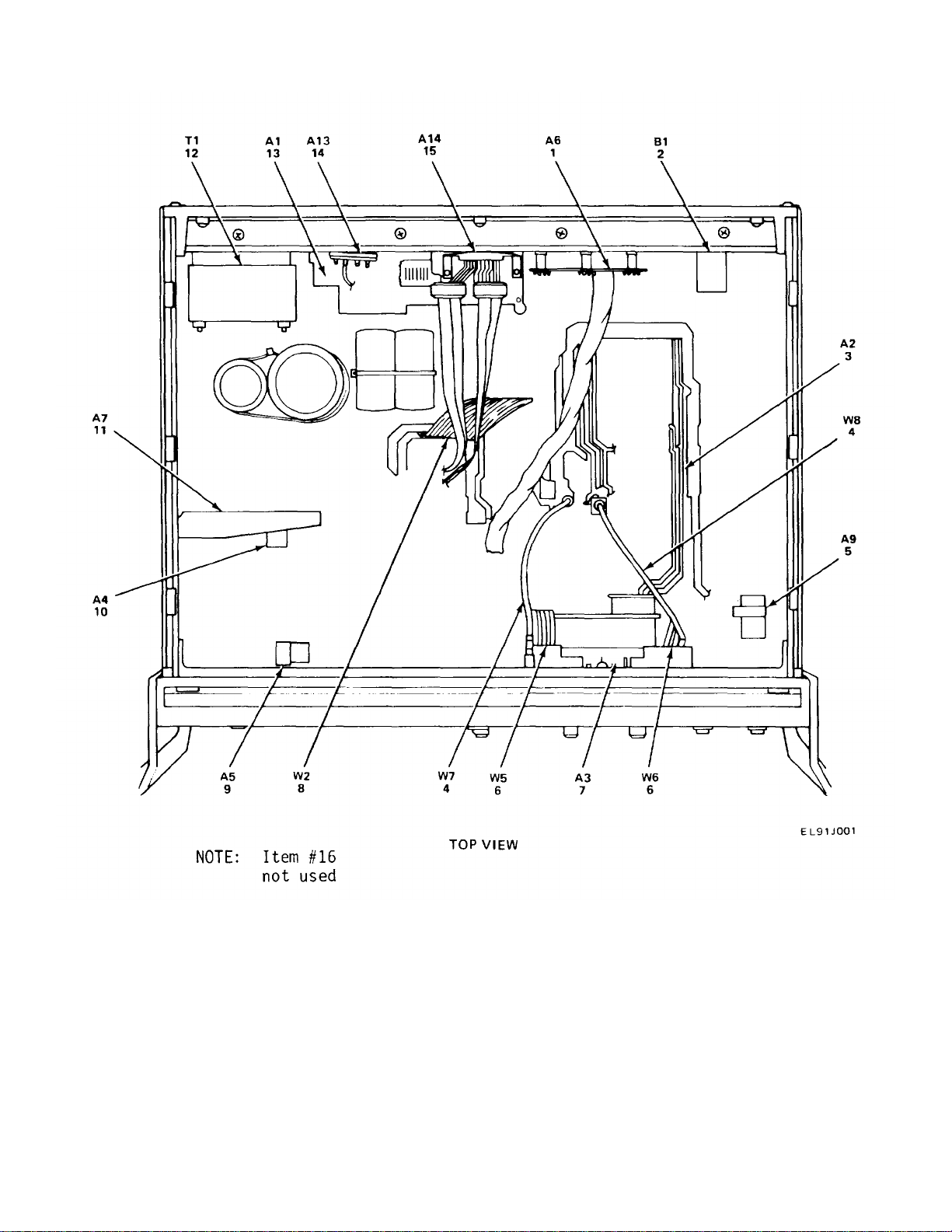

Figure 1. Frequency Counter, 5335A (Sheet 1 of 3)

Page 8

TM 11-6625-3068-24P

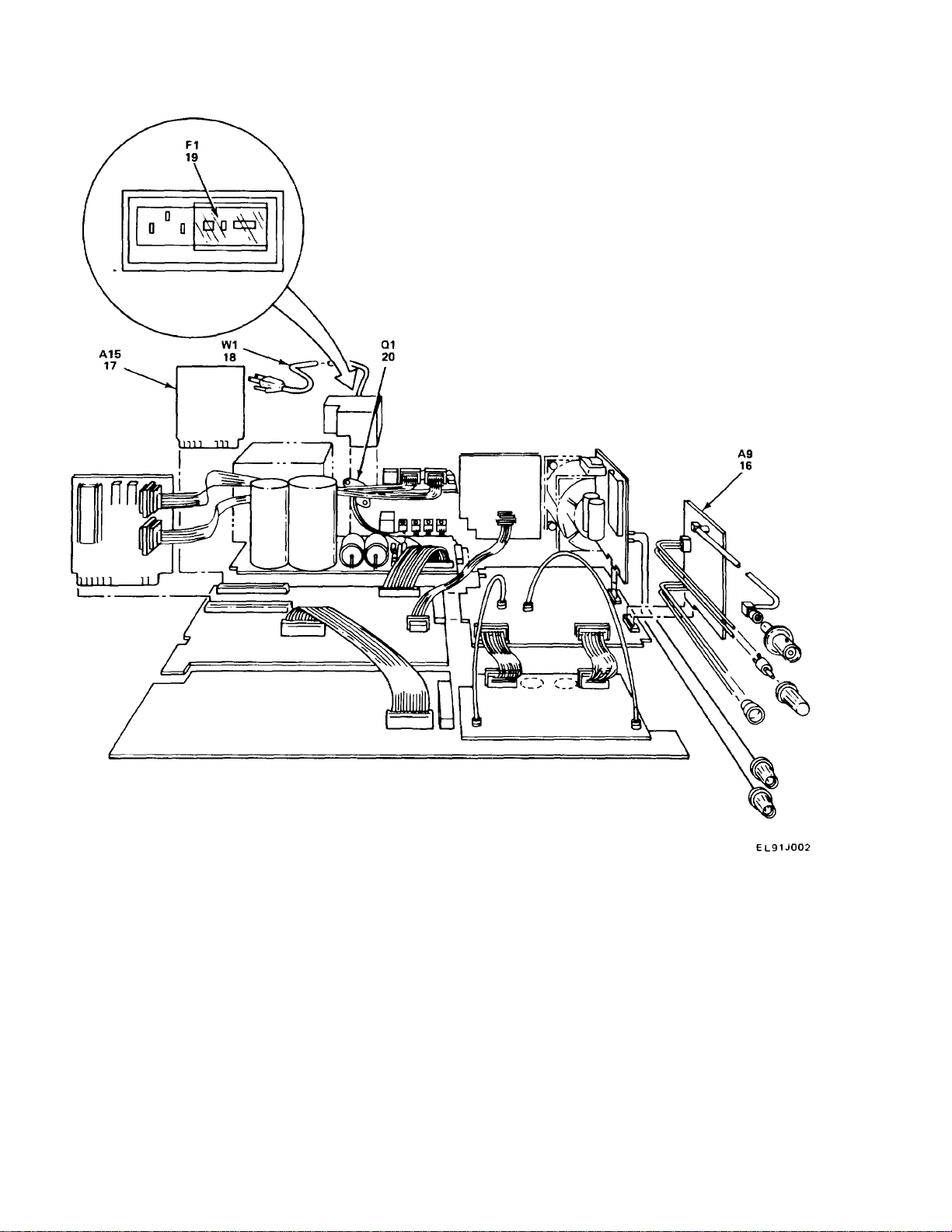

Figure 1. Frequency Counter, 5335A (Sheet 2 of 3)

Page 9

TM 11-6625-3068-24P

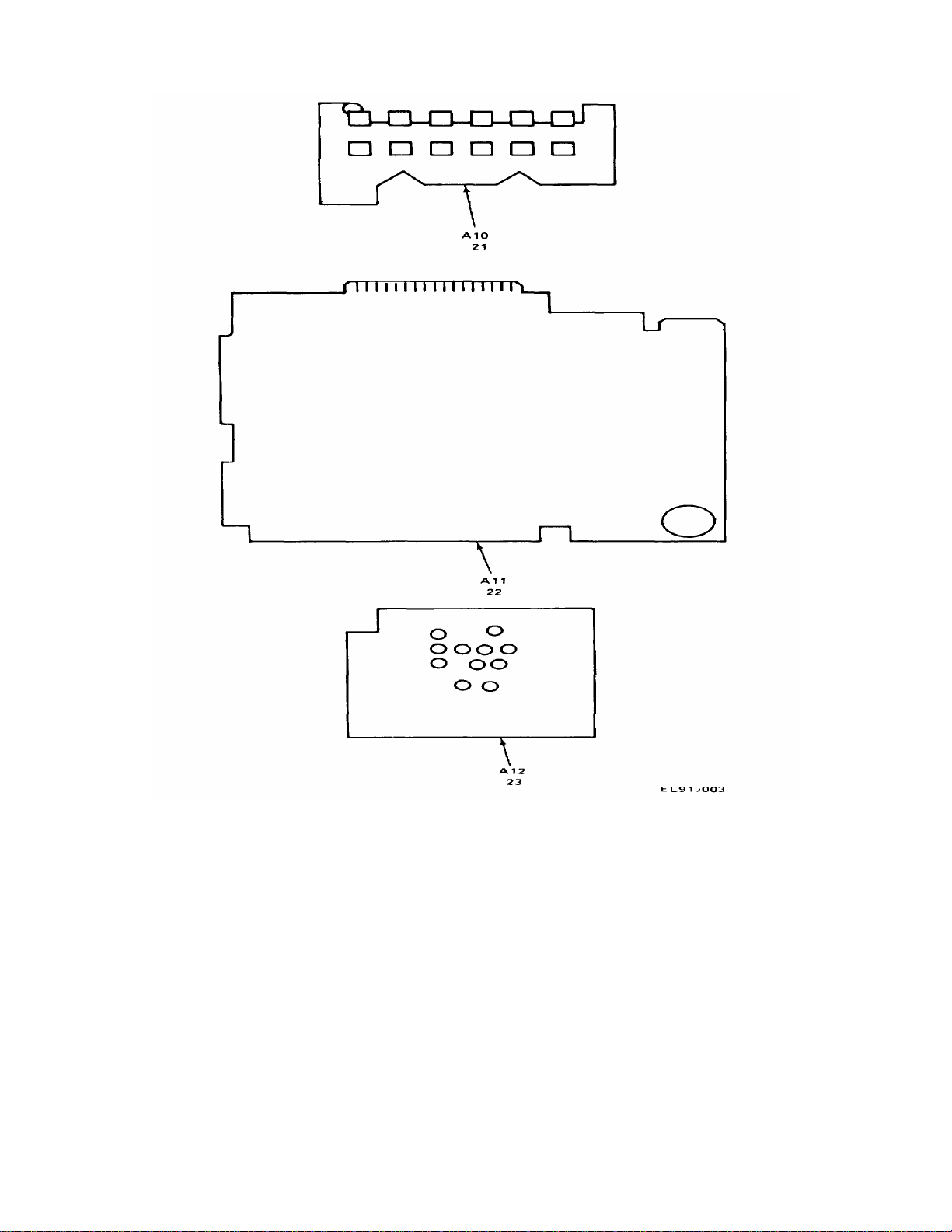

Figure 1. Frequency Counter, 5335A (Sheet 3 of 3)

Page 10

SECTION II TM 11-6625-3068-24P

(1) (2) (3) (4) (5) (6)

ITEM SMR PART

NO CODE FSCM NUMBER DESCRIPTION AND USABLE ON CODES (UOC) QTY

GROUP 00 UNIVERSAL FREQUENCY COUNTER

5335A (HP)

FIG. 1

1 PAHDD 28480 05335-61006 REAR BD ASSY........................................................... 1

2 PADZZ 23936 8500C FAN,TUBEAXIAL ......................................................... 1

3 PAHDD 28480 J5335-60002 BD ASSY,AMP SUPP .................................................. 1

4 XBHZZ 28480 05335-60112 CABLE ASSY............................................................... 2

5 PAHDD 28480 05335-60009 BD ASSY,CHAN,OPT030 (A9) ................................... 1

6 XBHZZ 28480 8120-2867 CABLE ASSY .............................................................. 1

7 PAHDD 28480 05335-60003 BD ASSY,AMP BUFFER ............................................. 1

8 XBHZZ 28480 05335-60101 CABLE ASSY .............................................................. 1

9 PAHDD 28480 05335-60005 BD ASSY,DISPLAY (A5)............................................. 1

10 PAHDD 28480 05335-60004 BD ASSY,MAIN LOGIC................................................ 1

11 PADZZ 28480 05335-60007 BD ASSY,HP-IB........................................................... 1

12 PADZZ 28480 9100-4113 TRANSFORMER ..................... ................................... 1

13 PAHDD 28480 05335-60001 BD ASSY,PWR SPLY ................................................. 1

14 PADZZ 28480 0960-0443 TEST SET SUBASSEMBL........................................... 1

15 PAHDD 28480 05370-60005 CIRCUIT CARD ASSEMB (HP-1B

CONNECTOR PCB A14) ............................................ 1

17 PADZZ 28480 10544-60011 OSCILLATOR,NONCRYST......................................... 1

18 XBHZZ 28480 8120-1378 CABLE ASSEMBLY,POWE......................................... 1

19 PAOZZ 75915 313001 FUSE............................................................................ 1

20 PADZZ 04713 2N6055 TRANSISTOR ............................................................. 1

21 PAHDD 28480 05335-60010 SW PNL CCA,OPT040 ................................................ 1

22 PAHDD 28480 05335-60011 AMPL BD ASSY,OPT040 (All) .................................... 1

23 PAHDD 28480 05335-60012 AMPL BD ASSY,OPT040 (A12) .................................. 1

END OF FIGURE

1-1

Page 11

TM 11-6625-3068-24P

Figure 2. CCA, Power Supply, 05335-60001, A1

Page 12

SECTION II TM 11-6625-3068-24P

(1) (2) (3) (4) (5) (6)

ITEM SMR PART

NO CODE FSCM NUMBER DESCRIPTION AND USABLE ON CODES (UOC) QTY

GROUP 01 CCA, POWER SUPPLY

05335-60001 Al

FIG. 2

1 PADZZ 28480 0490-1172 RELAY.......................................................................... 1

2 PADZZ 28480 2110-0043 FUSE .......................................................................... 2

3 PADZZ 28480 1251-0600 CONNECTOR,RECEPTACL ....................................... 9

4 PADZZ 28480 1251-6608 CONNECTOR.............................................................. 1

5 PADZZ 75915 312005 FUSE ........................................................................... 1

6 PADZZ 28480 2110-0083 FUSE ........................................................................... 1

END OF FIGURE

2-1

Page 13

TM 11-6625-3068-24P

Figure 3. CCA, Buffer Amplifier, 05335-60003, A3

Page 14

SECTION II TM 11-6625-3068-24P

(1) (2) (3) (4) (5) (6)

ITEM SMR PART

NO CODE FSCM NUMBER DESCRIPTION AND USABLE ON CODES (UOC) QTY

GROUP 02 CCA, BUFFER AMPLIFIER

05335-60003 A3

FIG. 3

1 PADZZ 28480 5082-4584 LENS,LIGHT................................................................ 2

2 PADZZ 28480 3101-2498 SWITCH,PB................................................................. 11

3 PADZZ 28480 1250-1671 CONNECTOR.............................................................. 2

4 PADZZ 28480 1200-0614 CONNECTOR.............................................................. 2

5 PADZZ 28480 0490-0508 RELAY.......................................................................... 1

6 PADZZ 28480 1250-0835 CONNECTOR,RECEPTACL ....................................... 2

END OF FIGURE

3-1

Page 15

TM 11-6625-3068-24P

Figure 4. CCA, Main Logic, 05335-60004, A4

Page 16

SECTION II TM 11-6625-3068-24P

(1) (2) (3) (4) (5) (6)

ITEM SMR PART

NO CODE FSCM NUMBER DESCRIPTION AND USABLE ON CODES (UOC) QTY

GROUP 03 CCA, MAIN LOGIC

05335-60004 A4

FIG. 4

1 PADZZ 28480 1251-3076 CONNECTOR.............................................................. 1

2 PADZZ 28480 1251-6608 CONNECTOR ............................................................. 2

3 PADZZ 28480 1990-0627 LENS,LIGHT................................................................ 1

4 PADZZ 28480 3101-0680 SWITCH,PB................................................................. 1

5 PADZZ 28480 1251-2035 CONNECTOR,RECEPTACL ....................................... 1

6 PADZZ 28480 1251-2026 CONNECTOR,RECEPTACL ....................................... 1

END OF FIGURE

4-1

Page 17

TM 11-6625-3068-24P

Figure 5. CCA, Display, 05335-60005, A5

Page 18

SECTION II TM 11-6625-3068-24P

(1) (2) (3) (4) (5) (6)

ITEM SMR PART

NO CODE FSCM NUMBER DESCRIPTION AND USABLE ON CODES (UOC) QTY

GROUP 04 CCA, DISPLAY

05335-60005 A5

FIG. 5

1 PADZZ 28480 5082-4684 LENS,LIGHT................................................................ 10

2 PADZZ 28480 5082-7651 LFNS,LIGHT ................................................................ 13

END OF FIGURE

5-1

Page 19

TM 11-6625-3068-24P

Figure 6. CCA, HP-1B Connector, 05370-60005, A14

Page 20

SECTION II TM 11-6625-3068-24P

(1) (2) (3) (4) (5) (6)

ITEM SMR PART

NO CODE FSCM NUMBER DESCRIPTION AND USABLE ON CODES (UOC) QTY

GROUP 05 CCA, HP-1B CONNECTOR

05370-60005 A14

FIG. 6

1 PADZZ 28480 1251-3283 CONNECTOR.............................................................. 1

2 PADZZ 28480 1200-0519 CONNECTOR.............................................................. 2

3 PADZZ 28480 3101-1973 SWITCH ASSEMBLY................................................... 1

END OF FIGURE

6-1

Page 21

TM 11-6625-3068-24P

Figure 7. CCA, Channel, 05335-60009, A9

Page 22

SECTION II TM 11-6625-3068-24P

(1) (2) (3) (4) (5) (6)

ITEM SMR PART

NO CODE FSCM NUMBER DESCRIPTION AND USABLE ON CODES (UOC) QTY

GROUP 06 CCA, CHANNEL C

05335-60009 A9

FIG. 7

1 PADZZ 28480 1250-0835 CONNECTOR,RECEPTACL ....................................... 1

2 PADZZ 28480 1251-4275 CONNECTOR.............................................................. 1

3 PADZZ 28480 2110-0301 FUSE,CARTRIDGE ..................................................... 1

END OF FIGURE

7-1

Page 23

TM 11-6625-3068-24P

Figure 8. CCA, Amplifier, 05335-60012, A12

Page 24

SECTION II TM 11-6625-3068-24P

(1) (2) (3) (4) (5) (6)

ITEM SMR PART

NO CODE FSCM NUMBER DESCRIPTION AND USABLE ON CODES (UOC) QTY

GROUP 07 CCA,AMPLIFIER

05335-60012 A12

FIG. 8

1 PADZZ 28480 5082-4584 LENS,LIGHT................................................................ 2

2 PADZZ 28480 0490-0508 RELAY.......................................................................... 9

3 PADZZ 28480 1250-1671 CONNECTOR.............................................................. 2

END OF FIGURE

8-1

Page 25

SECTION IV TM11-6625-3068-24P

NATIONAL STOCK NUMBER AND PART NUMBER INDEX

NATIONAL STOCK NUMBER INDEX

STOCK NUMBER FIG. ITEM STOCK NUMBER FIG. ITEM

4140-00-004-9000 1 2

5920-00-050-4953 2 2

5935-00-068-3546 3 6

71

6625-00-169-8770 1 14

5961-00-264-4875 1 20

5920-00-296-1519 2 5

5935-00-446-8768 4 6

5955-01-013-4821 1 17

5961-01-049-6786 3 1

81

5930-01-057-8425 6 3

5920-01-073-1231 7 3

5935-01-082-1966 2 3

5935-01-087-8437 4 5

6625-01-141-1096 1 15

5930-01-169-7864 3 2

I-1

Page 26

SECTION IV TM11-6625-3068-24P

NATIONAL STOCK NUMBER AND PART NUMBER INDEX

PART NUMBER INDEX

FSCM PART NUMBER STOCK NUMBER FIG. ITEM

28480 0490-0508 3 5

82

28480 0490-1172 2 1

28480 05335-60001 1 13

28480 05335-60002 1 3

28480 05335-60003 1 7

28480 05335-60004 1 10

28480 05335-60005 1 9

28480 05335-60007 1 11

28480 05335-60009 1 5

28480 05335-60010 1 21

28480 05335-60011 1 22

28480 05335-60012 1 23

28480 05335-60101 1 8

28480 05335-60112 1 4

28480 05335-61006 1 1

28480 05370-60005 6625-01-141-1096 1 15

28480 0960-0443 6625-00-169-8770 1 14

28480 10544-60011 5955-01-013-4821 1 17

28480 1200-0519 6 2

28480 1200-0614 3 4

28480 1250-0835 5935-00-068-3546 3 6

71

28480 1250-1671 3 3

83

28480 1251-0600 5935-01-082-1966 2 3

28480 1251-2026 5935-00-446-8768 4 6

28480 1251-2035 5935-01-087-8437 4 5

28480 1251-3076 4 1

28480 1251-3283 6 1

28480 1251-4275 7 2

28480 1251-6608 2 4

42

28480 1990-0627 4 3

04713 2N6055 5961-00-264-4875 1 20

28480 2110-0043 5920-00-050-4953 2 2

28480 2110-0083 2 6

28480 2110-0301 5920-01-073-1231 7 3

28480 3101-0680 4 4

28480 3101-1973 5930-01-057-8425 6 3

28480 3101-2498 5930-01-169-7864 3 2

75915 312005 5920-00-296-1519 2 5

75915 313001 119

28480 5082-4584 5961-01-049-6786 3 1

81

28480 5082-4684 5 1

28480 5082-7651 5 2

28480 8120-1378 1 18

28480 8120-2867 1 6

23936 8500C 4140-00-004-9000 1 2

28480 9100-4113 1 12

I-2

Page 27

By Order of the Secretary of the Army:

Official:

DONALD J. DELANDRO

Brigadier General, United States Army

The Adjutant General

Distribution:

To be distributed in accordance with special list.

JOHN A. WICKHAM JR.

General, United States Army

Chief of Staff

*U.S. GOVERNMENT PRINTING OFFICE, 1985-515-085i20045

Page 28

Page 29

PIN: 057871-000

Loading...

Loading...