Page 1

HP Archive

This vintage Hewlett Packard document was

preserved and distributed by

www.hparchive.com

Please

visit

us

on the web !

Scanned by on-line curator: Tony Gerbic

** For FREE Distribution Only ***

Page 2

HEWLETT-PACKARD

COMPANY

4.2A/4.4A

TRAVELING-VVAVE

AMPLIFIER

Page 3

)

)

)

00144·2

OPERATING

AND

SERVICE

MANUAL

MODEL

492A

AND

MODEL

494A

SERIALS

PREFIXED:

010-

TRAVELING-WAVE

AMPLIFIERS

Copy,;gh'

HEWLETT.'ACICA.D

COM'

ANY

1962

lS01

'AGE

MILL

ROAD,

'ALO

ALTO,

CALlFO.NIA,

U.S.A.

Printed:

JAN

1962

Page 4

Model

492Aj494A

Table

of Contents

ListsofIllustrations

and

Tables

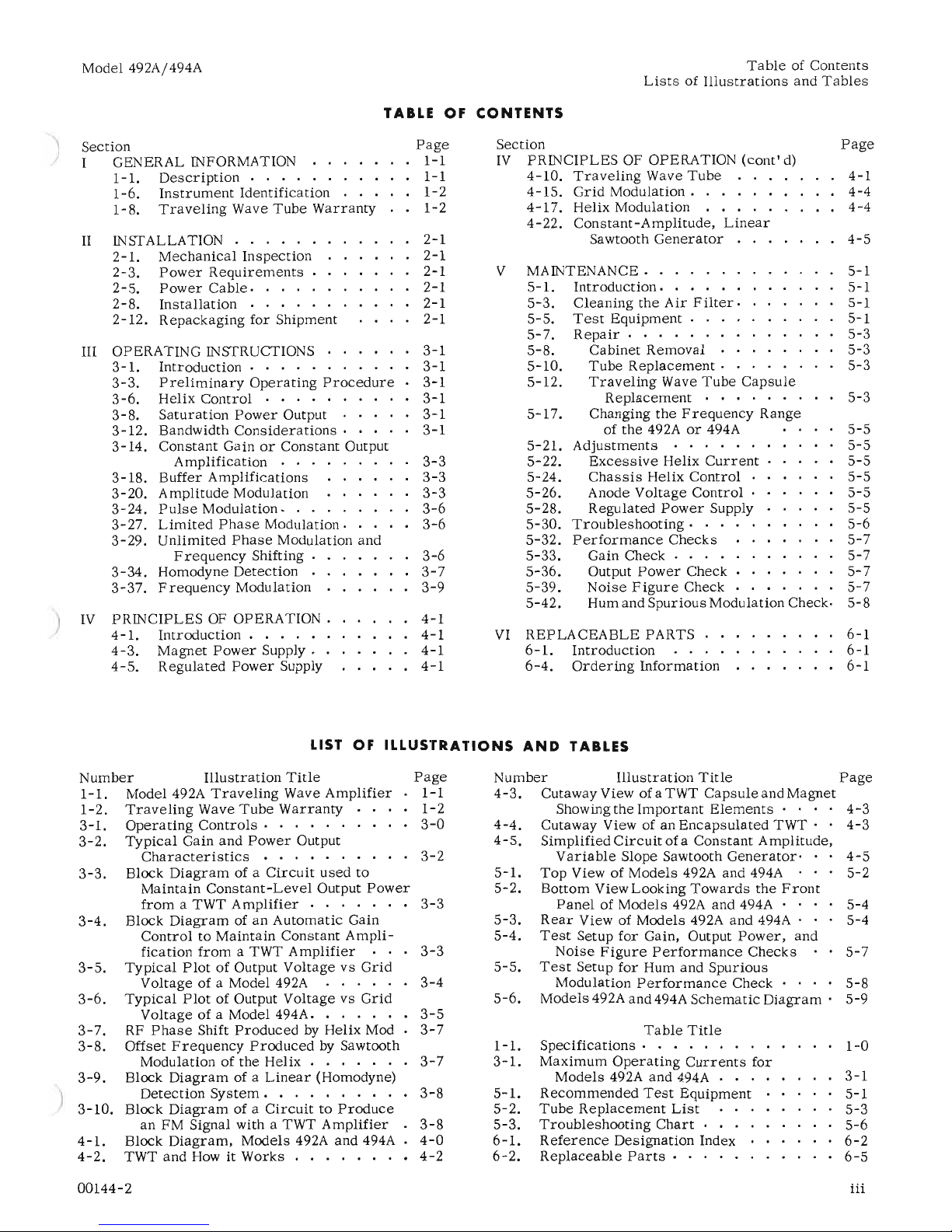

TABLE

OF

CONTENTS

Section

Page

Section

Page

I

GENERAL INFORMATION

1-1

IV

PRINCIPLES OF OPERATIO

(cont'd)

1-1.

Description

1-1

4-10.

Traveling

Wave

Tube

4-1

1-6.

Instrument

Identification

1-2

4-15.

Grid

Modulation.

4-4

1-8.

Traveling

Wave

Tube

Warranty

1-2

4-17.

Helix Modulation

·

.

4-4

4-22.

Constant-Amplitude,

Linear

II

INSTALLATION

2-1

Sawtooth

Generator

4-5

2-1.

Mechanical

Inspection

2-1

2-3.

Power

Requirements.

2-1

V

MAINTENANCE.

5-1

2-5.

Power

Cable.

2-1

5-1.

Introduction.

·

5-1

2-8.

Installation

2-1

5-3.

Cleaning

the

Air

Filter·

5-1

2-12.

Repackaging

for

Shipment

2-1

5-5.

Test

Equipment .

5-1

5-7.

Repair.

5-3

III

OPERATING INSTRUCTIONS

3-1

5-8.

Cabinet

Removal

5-3

3-1.

Introduction

.

3-1

5-10.

Tube

Replacement

.

.

5-3

3-3.

Preliminary

Operating

Procedure

3-1

5-12.

Traveling

Wave

Tube

Capsule

3-6.

Helix

Control

3-1

Replacement

5-3

3-8.

Saturation

Power

Output

3-1

5-17.

Changing

the

Frequency

Range

3-12.

Bandwidth

Considerations

.

3-1

of

the

492Aor494A

5-5

3-14.

Constant

GainorConstant

Output

5-21.

Adjustments

5-5

Amplification

3-3

5-22.

Excessive

Helix

Current

5-5

3-18.

Buffer

Amplifications

3-3

5-24.

Chassis

Helix

Control

5-5

3-20.

Amplitude

Modulation

3-3

5-26.

Anode Voltage

Control

.

5-5

3-24.

Pulse

Modulation.

3-6

5-28.

Regulated

Power

Supply

5-5

3-27.

Limited

Phase

Modulation.

3-6

5-30.

Troubleshooting.

·

5-6

3-29.

Unlimited

Phase

Modulation and

5-32.

Performance

Checks

5-7

Frequency

Shifting .

3-6

5-33.

Gain

Check.

5-7

3-34.

Homodyne

Detection

3-7

5-36.

Output

Power

Check

5-7

3-37.

Frequency

Modulation

3-9

5-39.

Noise

Figure

Check

5-7

5-42.

Hum and

Spurious

Modulation Check·

5-8

)

IV

PRINCIPLESOFOPERATION.

4-1

4-1.

Introduction

.

4-1

VI

REPLACEABLE

PARTS

.

6-1

4-3.

Magnet

Power

Supply.

4-1

6-1.

Introduction

6-1

4-5.

Regulated

Power

Supply

4-1

6-4.

Ordering

Information

6-1

LIST

OF

ILLUSTRATIONS

AND

TABLES

Number

Illustration

Title

Page

4-3.

CutawayView

ofaTWT

Capsule

andMagnet

Showing

the

Important

Elements·

. . .

4-3

4-4.

Cutaway View of an

Encapsulated

TWT·

.

4-3

4-5.

Simplified

Circuit

ofa

Constant

Amplitude,

Variable

Slope Sawtooth

Generator··

4-5

5-1.

Top

ViewofModels 492A and 494A

.,

5-2

5-2.

Bottom ViewLooking

Towards

the

Front

PanelofModels

492A and 494A .

..

5-4

5-3.

Rear

View of Models 492A

and

494A"

5-4

5-4.

Test

Setup

for

Gain, Output

Power,

and

Noise

Figure

Performance

Checks

5-7

5-5.

Test

Setup

for

Hum and

Spurious

Modulation

Performance

Check . .

5-8

5-6.

Models 492A and 494A

Schematic

Diagram'

5-9

Number

Illustration

Title

Page

1-1.

Model 492A

Traveling

Wave

Amplifier

1-1

1-2.

Traveling

Wave

Tube

Warranty

1-2

3-1.

Operating

Controls

.

3-0

3-2.

Typical

Gain

and

Power

Output

Characteristics

.

3-2

3-3.

Block

Diagram

of a

Circuit

used

to

Maintain

Constant-Level

Output

Power

fromaTWT

Amplifier

3-3

3-4.

Block

Diagramofan

Automatic

Gain

ControltoMaintain

Constant

Ampli-

fication

from

a TWT

Amplifier

3-3

3-5.

Typical

PlotofOutput VoltagevsGrid

Voltageofa Model 492A

3-4

3-6.

Typical

PlotofOutput VoltagevsGrid

Voltageofa Model 494A.

3-5

3-7.

RF

Phase

Shift

Produced

by Helix Mod

3-7

3-8.

Offset

Frequency

Produced

by Sawtooth

Modulationofthe

Helix .

3-7

3-9.

Block

Diagram

of a

Linear

(Homodyne)

)

Detection

System.

3-8

3-10.

Block

Diagram

of a

CircuittoProduce

an FM Signal with a

TWT

Amplifier

3-8

4-1.

Block

Diagram,

Models 492A and 494A

4-0

4-2.

TWT

and

HowitWorks

.

4-2

00144-2

1-1.

3-1.

5-1.

5-2.

5-3.

6-1.

6-2.

Table

Title

Specifications.

. . . . .

Maximum

Operating

Currents

for

Models

492A and 494A . . .

Recommended

Test

Equipment

Tube

Replacement

List

Troubleshooting

Chart

. . •

Reference

Designation Index

Replaceable

Parts·

. . . .

1-0

3-1

5-1

5-3

5-6

6-2

6-5

iii

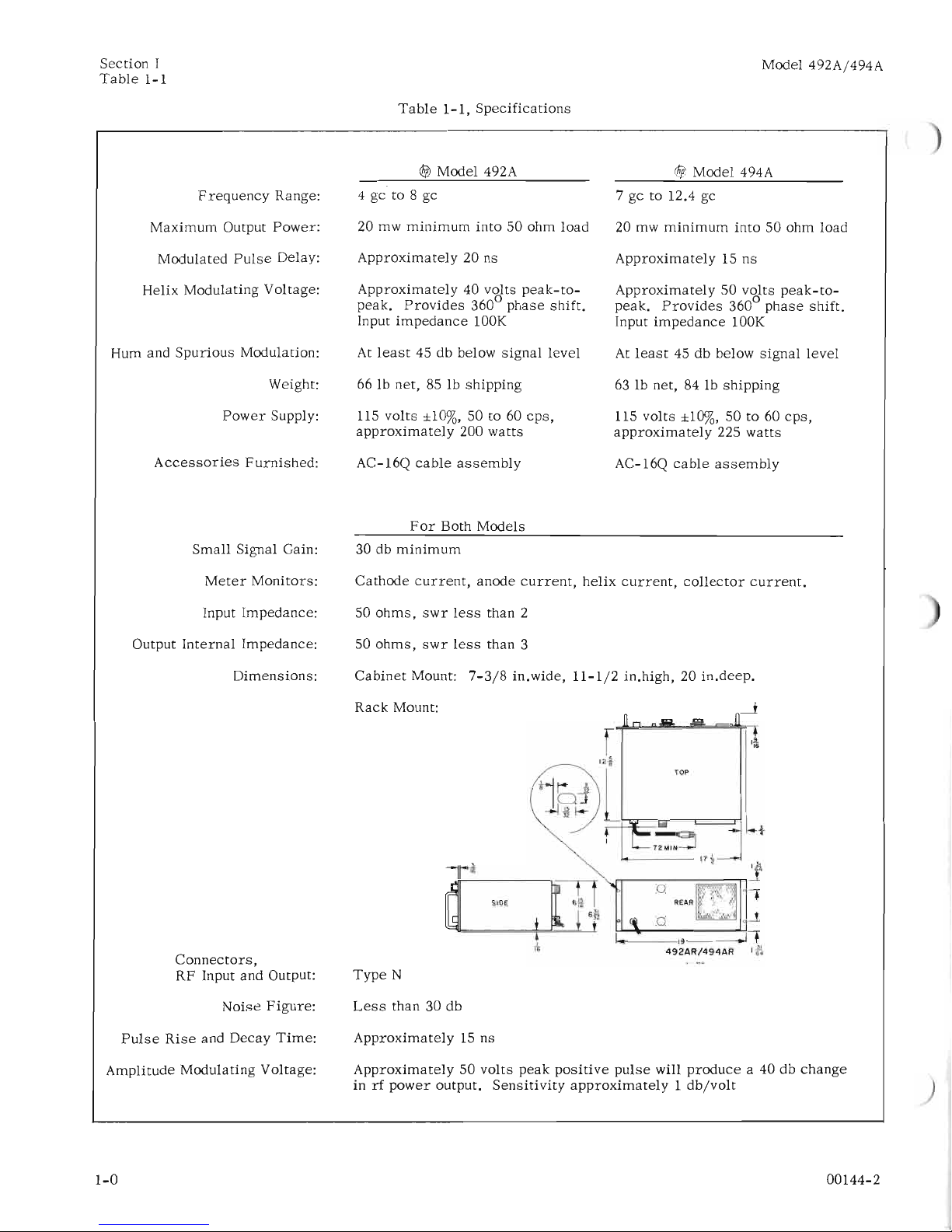

Page 5

Section I

Table

1-1

Model 492A/494A

Table

1-1,

Specifications

~ Model 492A

<Fj!

Model 494A

Frequency

Range:

4

gc

to 8

gc

7gcto

12,4

gc

Maximum

Output

Power:

20 mw

minimum

into

50 ohm

load

20 mw

minimum

into

50 ohm load

Modulated

Pulse

Delay:

Approximately

20 ns

Approximately15ns

Helix Modulating Voltage:

Approximately40volts

peak-to-

peak.

Provides

3600phase

shift.

Input

impedance

lOOK

Approximately50volts

peak-to-

peak.

Provides

3600phase

shift.

Input

impedance

lOOK

Hum and

Spurious

Modulation:

At

least

45 db below

signal

level

At

least

45 db below

signal

level

Weight:

Power

Supply:

66

lb

net,

85 Ib shipping

US

volts

±10%, 50to60

cps,

approximately

200

watts

63 Ib net, 84 Ib

shipping

U5

volts

±10%, 50to60

cps,

approximately

225

watts

Accessories

Furnished:

AC-16Q

cable

assembly

AC-l6Q

cable

assembly

For

Both Models

Small

Signal Gain:

30 db

minimum

Meter

Monitors:

Cathode

current,

anode

current,

helix

current,

collector

current.

Input Impedance: 50

ohms,

swr

less

than 2

Output

Internal

Impedance: 50

ohms,

swr

less

than 3

Dimensions:

Cabinet

Mount:

7-3/8

in.wide,

U-l/2

in.high, 20

in.deep.

TypeN

Less

than 30 db

t

:0:

IU]

REAR

,~,,".

:0:

'.1&

1.----19---.,

492AR/494AR

Rack

Mount:

Noise

Figure:

Connectors,

RF

Input and Output:

Pulse

Rise

and Decay

Time:

Amplitude Modulating Voltage:

Approximately15ns

Approximately50volts

peak

positive

pulse

will

produce

a 40 db

change

inrfpower

output.

Sensitivity

approximately1db/volt

1-0

00144-2

Page 6

Model 492A/494A

SECTION

I

GENERAL

INFORMATION

Section I

Paragraphs

1-1to1-4

1-1.

DESCRIPTION.

1-2.

Thet$Models 492A and 494A

Traveling

Wave

Amplifiers

are

broadband,

linear

amplifiers

provid-

ing

adjustable

amplification

up toatleast

30 db,

be-

tween 4 and 12.4 gc, and

haveamaximum

power

out-

put ofatleast20milliwattstoan

external

load

of 50

ohms.

The

frequency

rangeofthet$Model 492A

is

4

to

8 gc; the

frequency

rangeofthe

Model 494A

is

7

to

12.4 gc.

These

traveling

wave tube (twt)

ampli-

fiers

are

designed

to be

used

alsoasbuffer

amplifiers

or

modulators

for

any

signal

within

their

frequency

range.

As

buffers,

their

input

impedances

remain

constant

with any

reasonable

load

changeatthe output

terminal;

the

attenuation between input andoutput

sig-

nalsisat

least

60 db,

minus

the

gain of

the

amplifier.

As

modulators,

they

can

be

usedtoamplitude,

fre-

quency,

pulse,

or

phase

modulate

the

signal

being

amplified

with no

interaction

on

the

signal

source.

The

gain and

power

output of

the

amplifiers

are

con-

tinuously

adjustablebythe

front

panelGRID BIAS

con-

trol.

Hum and

spurious

modulation

generated

within

the

amplifiers

areatleast

45 db below

the

output

sig-

nal

level

and

the

noise

figure

is

less

than 30

db.

1-3.

Thet$Models 492A and 494A

Traveling

Wave

Amplifiers,

amplify

any type ofrfsignal:

cw, swept,

sine-modulated,

pulsed,

multiple

signalsondifferent

frequencies,

etc.

A twt

amplifier

usedasa

modulator,

in conjunction with a

signal

generator,

canbeused

to

amplitude

modulate

anrfcarriertoapproximately

30%

with

less

than 2.5%

harmonic

distortion

and upto50%

with

less

than

5%

distortion.

Amplitude modulation

sensitivityisapproximately1db/volt.

Pulse

modula-

tion

is

excellent;

the

rise

timeisless

than15ns.

Phase

modulation up

to

3600with

less

than 1 db

amplitude

modulation

is

also

possible.

Wide-band

frequency

modulationissimulated

by a

step-wise

phase

modulation

describedinsection

Ill.

1-4.

The

front

panel

meterisprovided

for

checking

and

adjusting

electrode

currentsinthe

traveling-wave

tube.

The

meter

helpstoobtain

desired

operating

characteristics

during

normal

operationofthe

ampli-

fier

and

also

assists

with

preventive

maintenance

and

troubleshooting.

An

anode

voltage

adjustment

on the

instrument

chassis

prOVided

to

adjust

the

cathode

current

of the twt backtonormal

duetotube ageing.

)

00144-2

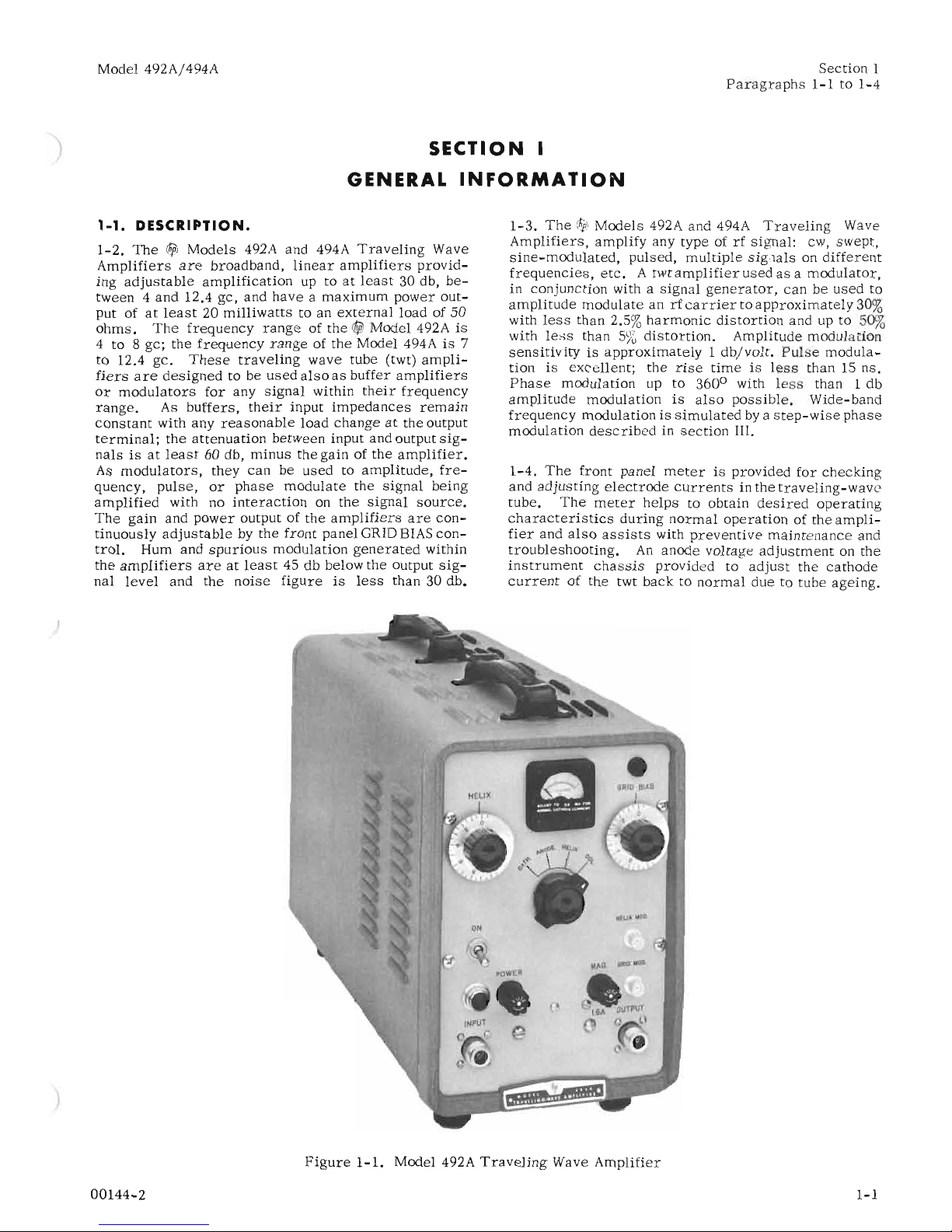

Figure

1-1.

Model 492A

Traveling

Wave

Amplifier

1-1

Page 7

Section

I

Paragraphs

1-5to1-9

1-5.

The~Model 492A and 494A

are

similarinthat

one

model

maybechangedtothe

other,byreplacing

the

twt,ascoveredinparagraph

5-17.

1-6.

INSTRUMENT

IDENTIFICATION.

1-7.

Hewlett-Packard

usesatwo-section

eight-digit

serial

number

(000-00000).

If

the

first

three

digits

of

the

serial

numberonyour

instrument

do not

agree

WA••ANTY

CLAIM

AND

ADJUITMINT

'IOCIDUU

Model 492A/494A

with

those

on

the

title

pageofthis

manual,

change

sheets

supplied

with

the

manual

will

define

differences

between

your

instrument

and

the

Model 492Aor494A

describedinthis

manual.

1-8.

TRAVELING

WAVE

TUBE

WARRANTY.

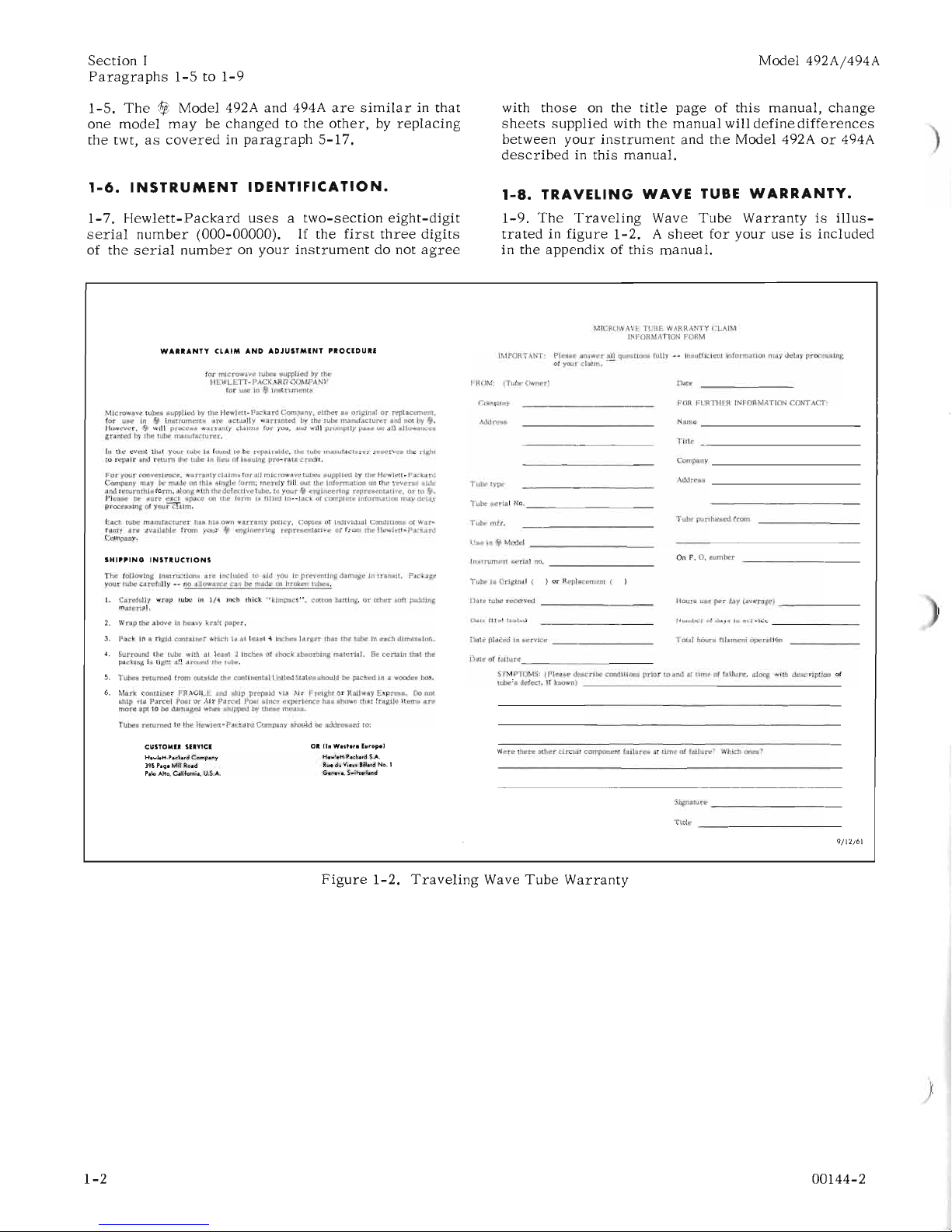

1-9.

The

Traveling

Wave

Tube

Warranty

is

illus-

tratedinfigure

1-2.Asheet

for

your

useisincluded

in

the

appendixofthis

manual.

MICROWAVE

TUBE

WARRANTY CLAIM

INFORMATION FORM

IMPORT

ANT:

Please

ans

....erall

questions

fully--InsuHlclent Information may

delay

processing

of

your

claim.

-

for

microwave

tubes suppliedby[he

HEWLETT·

PACKARD

COMPANY

for

use

In*Instruments

Microwave

tubes

suppliedbythe

Hewlett-Packard

Company.

either88originalorreplacement.

for

use

in8instruments

are

actually

warrantedbythe

tube

manufaclUrer

and

not

by

9.

However, S

will

process

warranty

claims

for

you, and will

promptly

passonall

allowances

grantedbythe

tube

manufacturer.

In

the

event

that

your

tube Is (ound

toberepairable,

the tube

manufacturer

reserves

the

right

to

repair

and

return

the tube in lieu of

Issuing

pro--Tata

credil.

For

your

convenience,

warrantyclalms(orall

microwave

tubes

supplied

by the

Hewlett-Packard

Company

maybemade on

this

sIngle

form;

merely

fJII

out the

lnfonnallon

on the

reverse

side

and

rerurn

this

fonn.

along

....

lth

thedefectlve

rube.toyour8engineering

representallve.

or

tO~.

Pleasebesure

each

space

on the formisfilled

In··lackofcomplete

infonnation

may

delay

processingofyourcTiim.

Each

tube

manufacturer

has

his

own

warranty

policy.

Copies

of Individual Conditions of

War-

ranty

are

available

from

your*engineering

representativeorfrom Ihe He

....

len·Packard

Company.

SHIPPING

INSTIUCTIONS

FROM:

(rube

Owner)

Company

Address

Tube

type

Tube

serial

No.

_

Tube

mfr.

Use

in~Model _

Instrument

serial

no. _

Date

FOR FURTHER INFORMATION CONTACT:

Name

_

Title

_

Company _

Address

_

Tube

purchased

from

OnP.O.

number

The

following

instructions

are

includedtoaid youInpreventing

damageintransit.

Package

your

tube

carefully••no

allowance

canbemade on

broken

tubes.

TubeisOriginal ( )orReplacement

(

1.

Carefully

wrap

tube in

1/4

inch thick

"klmpack".

Cotton batting.orother

sofl

padding

material.

2. Wrap the

above

in heavy

kraft

paper.

3.

Pack

in a

rigid

container

....

hlch Isatleast4inches

larger

than the lube In

each

dimension.

4.

Surround

the

tube

withatleast2inches

of shock

absorbing

material.Becenaln

that the

packing Is tight

all

around

the tube.

Date

tube

received

_

Date

first

tested

Date

placedinservice

_

Dateoffailure

_

Hours

use

per

day

(average)

_

NumberofdaysInservice

_

Total

hours

filament

operation

5.

Tubes

returned

from

outside

the continental

UnltedSrates

shouldbepackedIna wooden box.

6.

Mark

container

FRAGILE and

ship

prepaid

via

Air

FreightorRailway

Expreu.Donot

ship

via

Parcel

POStorAJr

Parcel

POSt

since

experience

has

shown that

fragile

Items

are

more

apttobe

damaged

when

shippedbythese

means.

Tubes

returnedtothe

Hewlen·Packard

Company should be

addressed

to:

SYMPTOMS:

(Please

describe

conditions

priortoandattimeoffailure.

along with

description

of

lube's

defect,

If known) _

CUSTOMr.

snvlcr

H.~".,.d.rd

COfftpel'ly

]95

,.~

Mil

R_d

1'.

Alto. C.lifomi.,

U.S.A.

01

II.W....

,..I.r.,.J

H_lett·,.d.,dS.A.

kvedIiVifillli",dNo.l

G.I'l......S

...

itter!Mtd

Were

there

other

circuit

component

failuresattimeoffailure?

Which ones?

Signature

_

Title

9/12/61

1-2

Figure

1-2.

Traveling

Wave

Tube

Warranty

00144-2

)

Page 8

Model 492A/494A

SECTION

II

INSTALLATION

Section

II

Paragraphs

2-1to2-13

/

2-1.

MECHANICAL

INSPECTION.

2-2.

Unpack

the

instrument

upon

receipt

and

inspect

it

for

signs

of

phy

ical

damage

such

as

scratched

panel

surfaces,

broken

knobs,

etc.

If

thereisany

apparent

damage,

fileaclaim

with

the

carrier

and

refertothe

warranty

pageinthis

manual.

2-3.

POWER

REQUIREMENTS.

2-4.

The

Model 492A and Model 494A

requireapower

source

of

115

volts

± 10%,

single

phase,50to 60

cps,

which

can

deliver

approximately

225

watts.

2-5.

POWER

CABLE.

2-6.

For

the

protection

of

operating

personnel,

the

ational

Electrical

Manufacturers'

Association

(NEMA)

recommends

that

the

instrument

panel

and

cabinet

be

grounded.

This

instrument

is

equipped

with a

three-prong

conductor

power

cable

which, when

plugged

into

an

appropriate

receptacle,

grounds

the

instrument.

The

offset

pin on

the

power

cable

three-

prong

connectoristhe

ground

pin.

2-7.

To

preserve

the

protection

fearure

when

opera-

ting

the

instrument

fromatwo-contact

outlet,

use

a

three-prong

to

two-prong

adapter

and

connect

the

green

pigtailonthe

adaptertoground.

2-8.INST

ALLATION.

2-9.

The

only

special

precaution

necessary

for

in-

stalling

the

twt

amplifiers

is

that

they

should

not be

operated

closetovery

large

magnetic

fields,

such

as

60-cycle

fields,

unless

externally

shielded.

While

the

twt

amplifiers

are

shielded

within

the

cabinet,

complete

protection

against

large

low-frequency

fields

would

require

more

shielding

thanispracticaltoin-

cludeinthe

design.

2-10.

To

operate,

connect

the

instrument

to a

115-

voltacpower

source,

check

and

adjust

rube

operating

00144-2

currents

as

described

in

preliminary

operating

pro-

cedure,

section

1Il, and

connecttothe

external

equip-

ment

with

coaxial

cables

terminatedinstandard

UG-

21D/U,

type

connectors.

2-11.

In

section

V, beginning with

paragraph

5-32,

isalistofperformance

checks

for

this

instrument.

These

procedures

make

a good

testaspartofincom-

ing

quality-control

inspection

following

initial

rurn-on.

2-12.

REPACKAGING

FOR

SHIPMENT.

2-13.

The

following

listisa

general

guide

for

re-

packaging

an

instrument

for

shipment.

If you

have

any

questions,

contact

your

authorized

Hewlett-

Packard

sales

representative.

a.

If

possible,

use

the

original

container

designed

for

the

instrument,

b.

Wrap

the

instrument

in

heavy

paperorplastic

before

placingitin

the

shipping

container.

c.

Use

plentyofpacking

material

around

all

sides

of

the

instrument

and

protect

the

panel

with

card-

board

strips.

d.

Use

heavy

cardboard

carton

or

wooden box to

house

the

instrument

and

use

heavy

tape

or

metal

bandstoseal

the

container.

e.

Mark

the

packing

box with

"Fragile",

"Delicate

Instrument",

etc.

Note

If

the

instrumentistobeshippedtoHewlett-

Packard

Company

for

service

or

repair,

at-

tachtothe

instrumentatag

identifying

the

owner

and

indicating

the

service

or

repair

to

be

accomplished.

In

any

correspondence

be

sure

to

identify

the

instrument

by

model

number,

serial

prefix,

and

serial

number.

2-1

Page 9

Section

III

Figure

1-3

POWER

1.

Turns

on

all

circuits

of

the

amplifier

(allow

IS

minutes

warmup).

2.

Meter

selector

switchisused

for

selection

of

circuittobe

checkedonthe

front-panel

meter.

3.

Pin

jackisfor

measuring

grid

bias

(measures

E

k

;

grid

grounded).

4. GRID BIAS

controlisusedtoadjust

fordesired

tube

current.

Normal

cathode

currentisindi-

cated

on

the

meter

plate.

Do not

exceed

maxi-

mum

operating

currents,

refer

to

table

3-1.

Model 492A/494A

~-~--;3

MAG

C1RJD

Il100

8

7

L

S. HELIX

controlisusedtoadjust

for

best

broad-

band

response,

position

5,

or

for

maximum

gainatanyone

frequency.

6.

INPUTrfconnectoriswhere

therfsignaltobe

amplifiediscoupled

into

the

instrument.

7.

OUTPUTrfconnectoriswhere

the

amplified

rf

signaliscoupled

from

the

instrument.

8. GRID MOD.

connector

is

the

input

for

ampli-

tude

modulation

signals.

9. HELIX MOD.

connectoristhe

input

for

phase

and

frequency

modulation

signals.

3-0

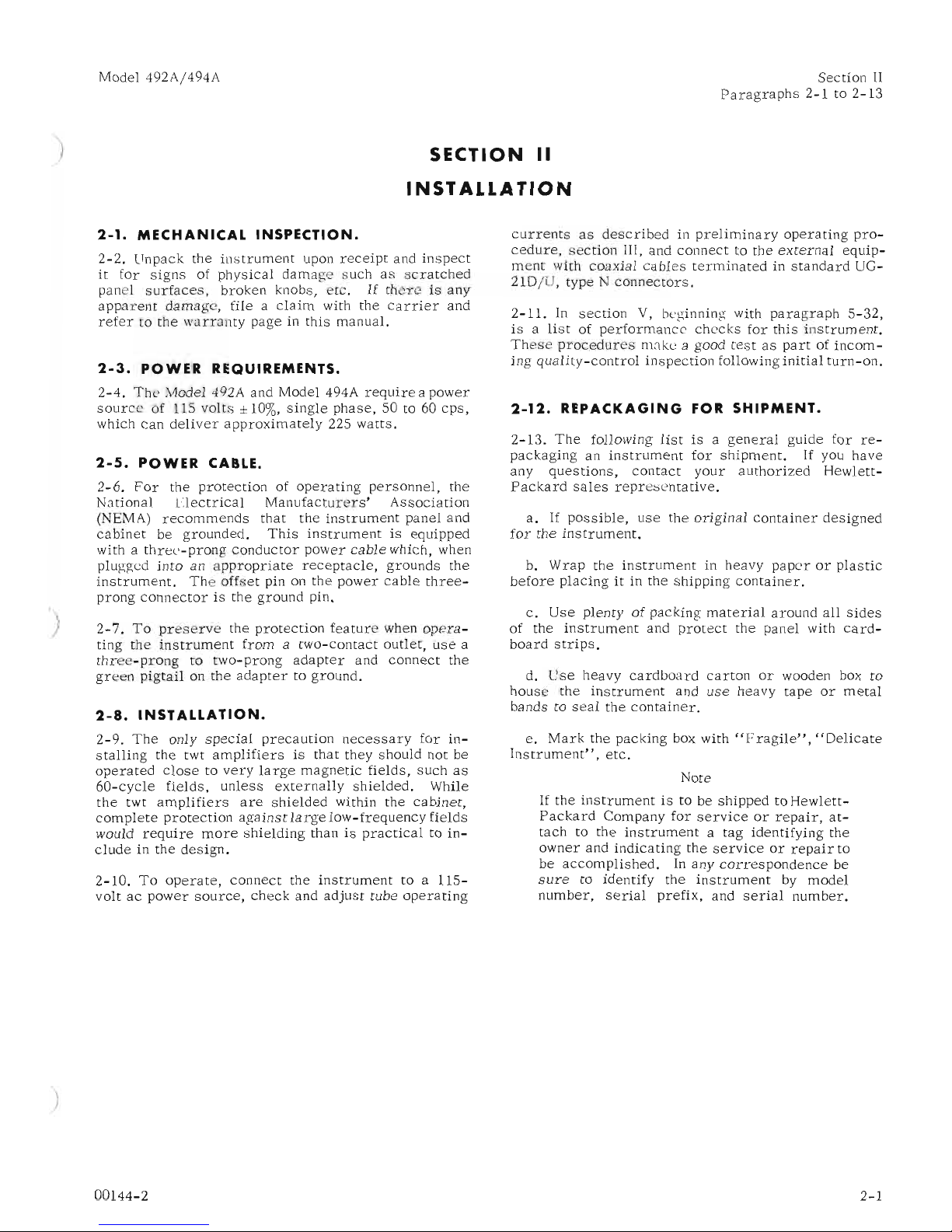

Figure

3-1.

Operating

Controls

00144-2

Page 10

)

Model 492A/494A

SECTION

III

OPERATING

INSTRUCTIONS

Section

III

Paragraphs

3-1to3-13

3-1.

INTRODUCTION.

3-2.

This

section

contains

operating

instructions

for

theModels

492A and 494A

Traveling

WaveTube

Ampli-

fiers.

Figure

3-1

gives

basic

operating

instructions.

The

remainder

of

this

section

supplements

these

in-

structions.

3-3.

PRELIMINARY

OPERATING

PROCEDURE.

3-4.

The

front

panel

controls,

indicator,

and

con-

nectors

for

the

492A and 494A

are

showninfigure

3-1.

This

figure

also

shows

the

uses

for

the

controls,

indi-

cator,

and

connectors.

Whenever

the

twtisturned

on,

use

the

front

panel

metertomeasure

the

current

to

each

electrode

in

the

traveling-wave

tube with

the

GRID BIAS

control

set

for

zero

bias.

The

safe

maxi-

mum

current

for

each

electrodeisshown in

table

3-1.

ormal

cathode

current

for

your

instrumentisindi-

cated

on

the

plate

attached

to

the

meter

face.

Cur-

rents

are

usuallyalittle

high when

the

instrument

is

first

turned

on, but

decreasetonormal

during

warm-

up. Allow IS

minutes

warmup

before

making

final

reading.

The

GRID BIAS

control

maybeusedtore-

duce

the

tube

currents

during

warmup.

Table

3-1.

Maximum

Operating

Currents

for

Models

492A and 494A.

Adjusting

the

HELIX

voltage

control

for

maximum

gainatthe

upper

frequency

limit

usually

produces

the

flattest

frequency

response

over

the

band.

Maximiz-

ing

the

gainatfrequencies

below

the

upper

frequency

limit

usually

resultsinadditional

gain

and

power

out-

put

over

that

obtained

when

adjusted

for

flattest

broad-

band

operation.

The

final

settingofthe

HELIX

con-

trol

is

independentofthe

typeofsignal

amplified.

3-8.

SATURATION

POWER

OUTPUT.

3-9.

Saturation

power

outputisthe

maximum

output

power

obtainable

with a

given

collector

current

and

optimized

helix

voltage.

As

the

input

signal

is

increased

from

the

noise

level,

the

output-vs-input

characteristic

is

linear

until

saturationisapproached

and

the

gain

beginstodecrease.

Eventually

the

output

reachesapeak

whichisthe

saturation

power

output

and any

further

increase

in

the

input

causes

the

outputtodecrease.Ifthe

collector

currentisreduced,

the

power

outputatwhich

saturation

occurs

will be

decreased.

The

primary

effects

which

lead

to

saturation

are:

1)

the

forces

between

the

electrons

in

the

beam

begin

to

limit

the

electron

density

in

the

bunches2)the

energy

transfer

from

the

electron

beamtothe

helix

causes

the

beam

velocitytodecrease

and

gradually

lose

synchronism

with

the

wave on

the

helix.

These

effects

become

more

pronounced

as

saturation

is

approached,

and

cause

the

gainofthe

twttodecrease.

3-6.

HELIX

CONTROL.

3-7.

The

HELIX

voltage

control

on

the

front

panel

maximizes

the

gain

and

power

outputofthe

twtata

selected

frequency

or

optimizes

the

gain

and

power

output

over

the

entire

band;

see

figures

3-2Aand

3-2B.

3-5.

If,

following

tube

replacement,

or

for

some

other

reason,

the

cathode

current

can

be

increased

with

the

GRID BIAS

controltoslightly

above

the

safe

maximum

current

(see

table

3-1),

readjust

the

anode

voltage

control,

paragraph

5-26.

The

anode

voltage

control

is

settolimit

the

twttoits

normal

cathode

current

when

the

bias

voltageonthe

twtiszero.

If

the

cathode

current

is

limitedtoits

normal

value,

but

the

currenttoanother

electrodeisexcessive,

the

amplifier

requires

service

or

adjustment,

see

para-

graphs

5-21or5-30.

)

CAUTION:

DO

NOT EXCEED:

Cathode

current

Helix

current

Collector

current.

Anode

current

3

ma

0.5

ma

3

ma

SO

/la

3-10.

Operating

the

492A

or

494A

near

saturation

power

output will

produce

second

harmonic

content

in

the

output.

To

obtain

maximum

power

output

from

the

twt without

excessive

second

harmonic

contentinthe

output,

increase

the

input

signal

level

until

satura-

tionisreached,

then

reduce

the

input until

the

out-

put

decreases

approximately

6 db (an

input

reduction

of

10

to

15 db).Ifsecond

harmonic

contentisun-

important,

operation

at

saturation

is

usually

very

satisfactory.

3-11.

One

advantageofoperating

the

twt

near

satura-

tionisthe

constant

output

characteristic

exhibited

by

a twt

at

saturation.

At

saturation

the

gain

of a twt

varies

inversely

with

the

input

level

and

input

varia-

tions

of

10 to 15 db

cause

the

outputtovary

only

4

to

6 db.Ifa

more

nearly

constant

outputisdesired,

see

paragraph

3-14.

3-12.

BANDWIDTH

CONSIDERATIONS.

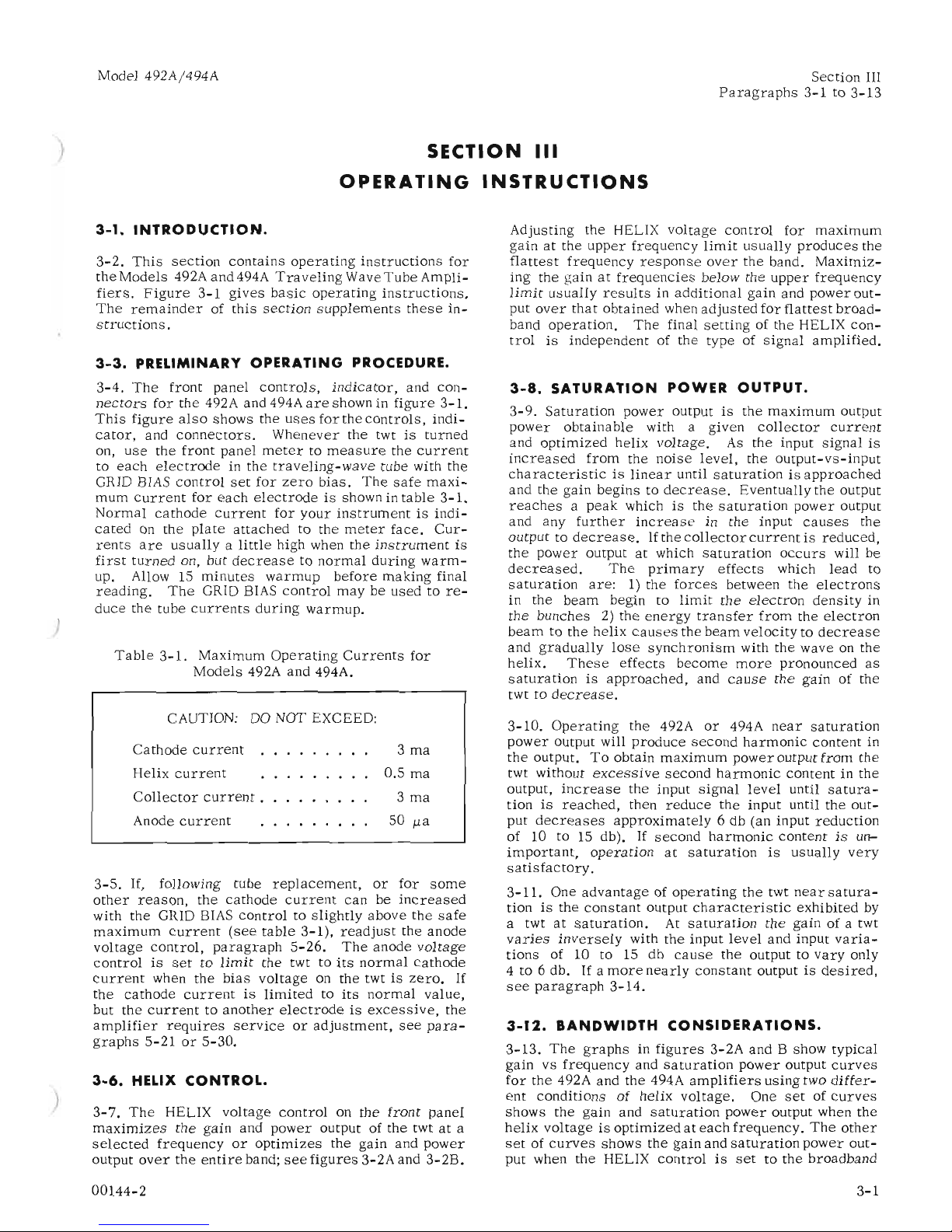

3-13.

The

graphsinfigures

3-2A

and B show

typical

gainvsfrequency

and

saturation

power

output

curves

for

the

492A and

the

494A

amplifiers

using

two

differ-

ent

conditions

of

helix

voltage.

One

setofcurves

shows

the

gain

and

saturation

power

output when

the

helix

voltageisoptimizedateach

frequency.

The

other

setofcurves

shows

the

gain

and

saturation

power

out-

put when

the

HELIX

controlissettothe

broadband

00144-2

3-1

Page 11

Section III

Figure

3-2

Model 492A/494A

GAIN:

GAIN AT

SATURATION

POWER

OUTPUT.

VHOPTIMIZED

AT EACH

FREQUENCY.

~

SMALL

SIGNAL

GAIN: VHOPTIMIZED

AT

EACH

FREQUENCY.

SIGNAL

GAIN;

VHOPTIMIZED

FOR

BROADBAND

OPERATION.

SATURATION

POWER

OUTPUT:

VHOPTIMIZED

AT

EACH

FREQUENCY

492A

-rr

a.

15

+-----+-----+-----+--------""'1-----+-----+-------1

50

30

A

V

H

:

HELIX

VOLTAGE

E

o

= 0

VOLTS

4

5

6 7

8

G-L-248

FREQUENCY

KMC

49'4

A

SMALL

SIGNAL

GAIN:

VHOPTIMIZED

AT

EACH

FREQUENCY.

VHOPTIMIZED

FOR

BROADBAND

OPERATION.

SATURATION

POWER

OUTPUT:

VHOPTIMIZED

AT

EACH

FREQUENCY,

GAIN:

GAIN

AT

SATURATION

POWER

OUTPUT

•

V

H

OPTIMIZED

AT

EACH

FREQUENCY.

rr

15

-1-----+-----+-----+-----+----""""""

......

-..---+-------1

25

45

.c

."

I

35

z

«

(9

B

V

H

:

HELIX

VOLTAGE

E

g

:

0

VOLTS

7 8

9 10

II

12

G-L-248

FREQUENCY

KMC

Figure

3-2.

Typical

Gain and

Power

Output

Characteristics

3-2

00144-2

Page 12

Model 492A/494A

Section

III

Paragraphs

3-14to3-22

is

developed

whichisthen

appliedtothe

twt

grid

to

hold

its

amplification

constant.

)

pOSltlOn.

To

obtain

the

most

nearly

constant

amplifier

gain

over

the

full

frequency

range

set

the

HELIX

con-

trol

to 5,

the

setting

which

yields

the

optimum

broad-

band

helix

voltage.

Since

noise

powerisdirectly

proportional

to bandwidth,

it

may

be

desirable

to

limit

the

bandwidth and

therefore

noisebymaximizing

the

gain

ataparticular

frequency

with

the

HELIX

control

and by

installing

suitable

filtersatthe output.

3-14.

CONSTANT

GAIN

OR

CONSTANT OUTPUT

AMPLIFICATION.

SIGNAL

GENERATOR

TRAVEL

ING

-WAVE

TUBE

ANPLIflER

TO

GRID

MOD

INPUT

) (

DIRECTIONAL

COUPLER

Rf

OUTPUT

":>--------o------=<o-----+--

OUT

LO-l-66

00

L=J-=-~/~

__

,"""",,---_--,

BALANCE

CONTROL

(SETTOOBTAIN0VOLTSTOTWT

GRID

MOD.

CONNECTOR,ATDESIRED

AMPLIfiCATION)

3-19.

The

492A and 494A

serve

as

very

effective

buffers

to

isolateamicrowave

signal

source

from

a

load.

Mismatches,

changesinexternal

circuitry,

or

the

introductionofmodulation

do not

affect

the

con-

stant

50-ohm

input

impedanceofthe

twt and

thus

will

not

affectasignal

source

connectedtothe

input.

The

attenuation

between

the

output and

input

terminals

is

60 db

duetoattenuators

placed

along

the

helix.

How-

ever,

when

the

output

signalisreflected

fromamis-

matched

load

backtothe

input,

the

effective

signal

isolationisthe

60 db

minus

the

gainofthe

amplifier.

For

example:

withanamplifier

gain

of 25 db,anopen

or

short

circuitonthe

twt

output

can

result

in a

maxi-

mum

reflected

signal

35 db below

the

input

level

(approximately

1/56ofthe

input

signal),

which

corre-

spondstoa

swrofless

than 1.04.

Note

The

GRID MOD.

connectorisdirect-coupled

to

the

gridofthe

twt

amplifier.Ifadcpoten-

tial

accompaniesamodulating

voltage

applied

to

this

connector,

the

grid-bias

voltage

will

be

altered.

The

GRID BIAS

control

may

be

usedtocompensate

for

the

changeingrid

bias

voltage

due

to a

dc

componentatthe

input.

Figure

3-4.

Block

Diagram

of an

Automatic

Gain

ControltoMaintain

Constant

Amplifica-

tion

fromaTWT

Amplifier

3-18.

BUFFER

AMPLIFICATIONS.

3-20.

AMPLITUDE

MODULATION.

3-21.

To

amplitude

modulate

anrfsignal

applied

to

the

twt

amplifier

with a

minimumofenvelope

distor-

tion in

the

output

signal,

carefully

establish

the

opti-

mum

rf

drive,

grid

bias,

and

modulating

signal

amplitude

for

a given

setup.

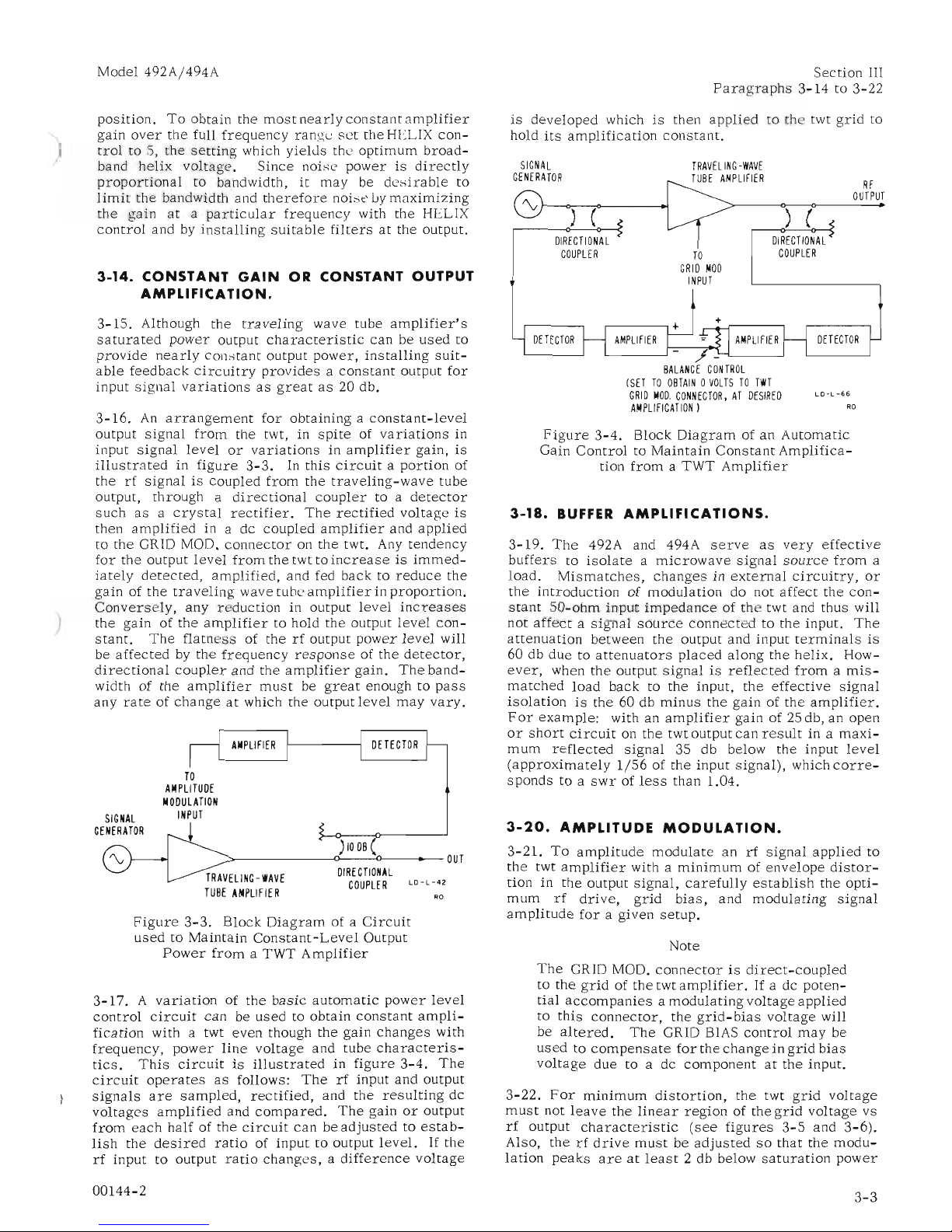

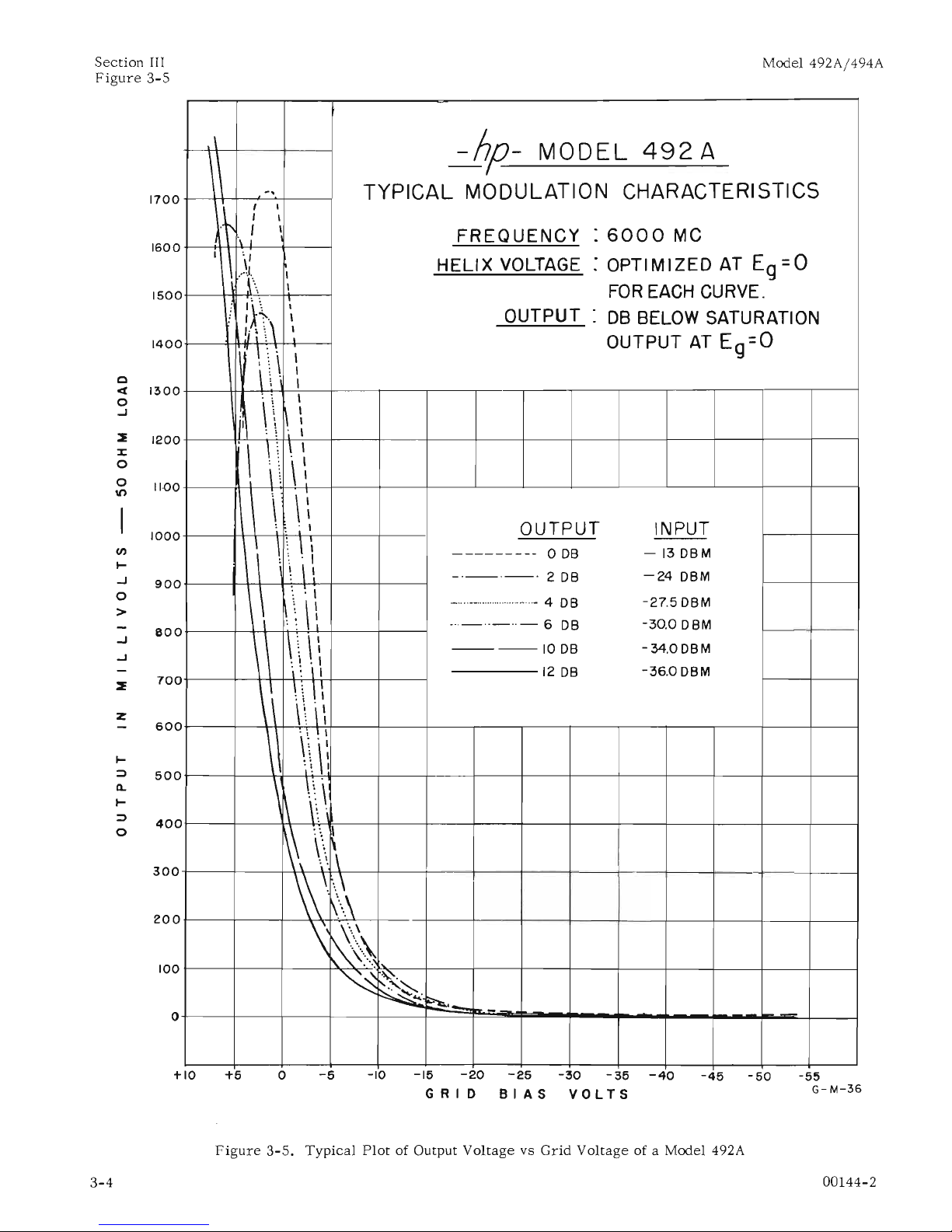

3-22.

For

minimum

distortion,

the

twt

grid

voltage

must

not

leave

the

linear

regionofthe

grid

voltage

vs

rf

output

characteristic

(see

figures

3-5

and

3-6).

Also,

therfdrive

mustbeadjustedsothat

the

modu-

lation

peaks

areatleast

2 db below

saturation

power

DIRECTIONAL

COUPLER

LO-L-'2

00

TRAVELING-WAVE

TUBE

AMPLIfiER

TO

AMPLITUDE

MODULATION

SIGNAL

INPUT

GENERATOR

!

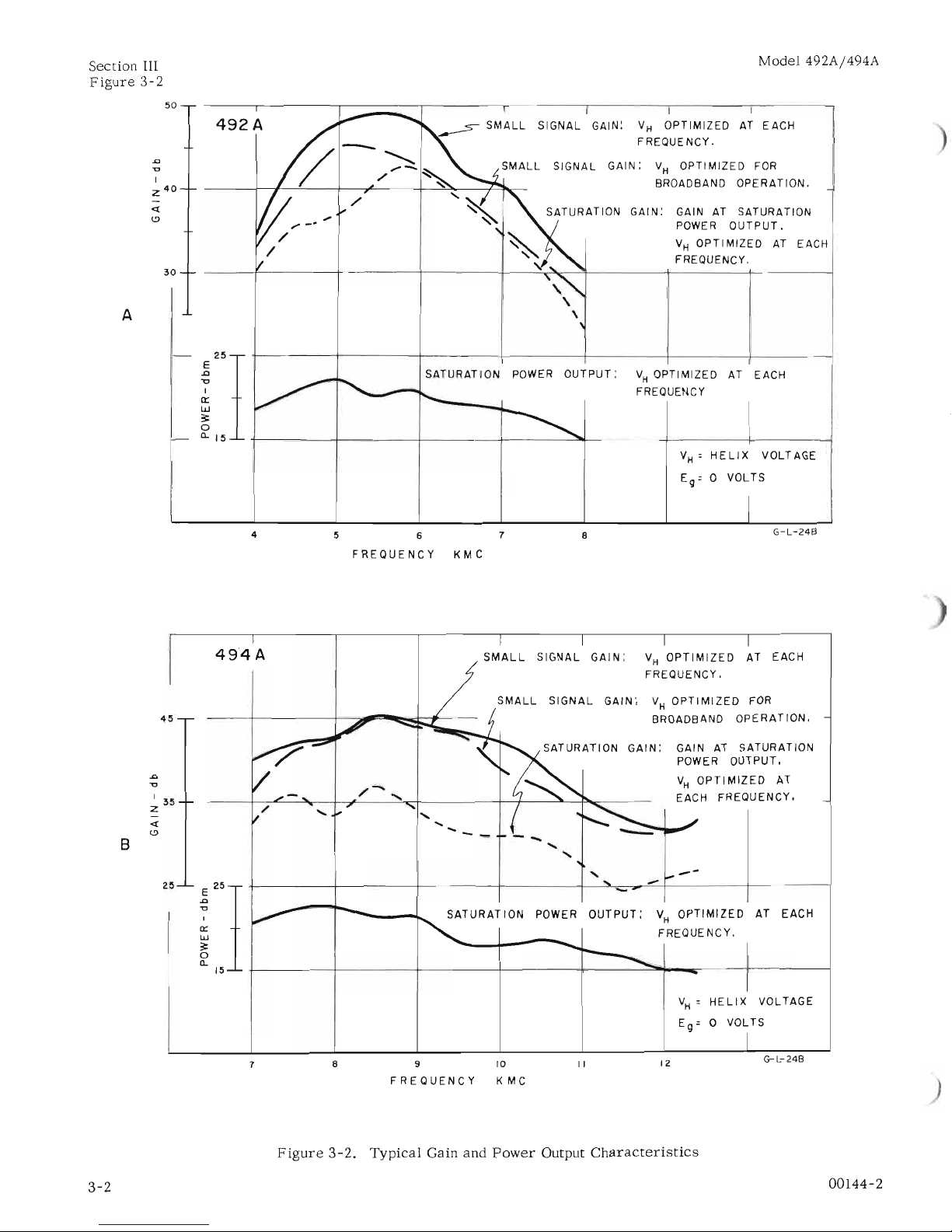

3-15.

Although

the

traveling

wave tube

amplifier's

saturated

power

output

characteristic

canbeused

to

provide

nearly

constant

output

power,

installing

suit-

able

feedback

circuitry

providesaconstant

output

for

input

signal

variationsasgreatas20 db.

Figure

3-3.

Block

Diagram

of a

Circuit

usedtoMaintain

Constant-Level

Output

Power

fromaTWT

Amplifier

3-16.

An

arrangement

for

obtainingaconstant-level

output

signal

from

the twt, in

spiteofvariations

in

input

signal

level

or

variationsinamplifier

gain,

is

illustrated

in

figure

3-3.

In

this

circuitaportion

of

therfsignaliscoupled

from

the

traveling-wave

tube

output,

throughadirectional

coupler

to a

detector

such

asacrystal

rectifier.

The

rectified

voltage

is

then

amplified

in a

dc

coupled

amplifier

and

applied

to

the

GRID MOD.

connectoronthe

twt. Any

tendency

for

the

output

level

from

the

twttoincreaseisimmed-

iately

detected,

amplified,

and fed

backtoreduce

the

gainofthe

traveling

wave tube

amplifierinproportion.

Conversely,

any

reduction

in output

level

increases

the

gainofthe

amplifiertohold

the

output

level

con-

stant.

The

flatnessoftherfoutput

power

level

will

be

affectedbythe

frequency

responseofthe

detector,

directional

coupler

and

the

amplifier

gain.

The

band-

width of the

amplifier

must

be

great

enoughtopass

any

rateofchangeatwhich

the

output

level

may

vary.

3-17.Avariation

of

the

basic

automatic

power

level

control

circuit

canbeusedtoobtain

constant

ampli-

fication

with a twt

even

though

the

gain

changes

with

frequency,

power

line

voltage

and tube

characteris-

tics.

This

circuit

is

illustrated

in

figure

3-4.

The

circuit

operates

as

follows:

Therfinput and output

signals

are

sampled,

rectified,

and

the

resulting

dc

voltages

amplified

and

compared.

The

gainoroutput

from

each

halfofthe

circuit

canbeadjustedtoestab-

lish

the

desired

ratioofinputtooutput

level.Ifthe

rf

input

to output

ratio

changes,adifference

voltage

)

)

00144-2

3-3

Page 13

Section

III

Figure

3-5

Model 492A/494A

\

\,

INPUT

-

13

DBM

-24DBM

-27.5DBM

-30.0DBM

-34.0DBM

-36.0DBM

:

6000

Me

:

OPTIMIZED

AT E

g

=0

FOR

EACH

CURVE.

DB

BELOW SATURATION

OUTPUT AT

Eg=O

OUTPUT

---------

0

DB

-'--'-'

2DB

-_..__

__..- 4

DB

-,,-,,-,,-6

DB

----IODB

----12

DB

OUTPUT

FREQUENCY

HELIX

VOLTAGE

dJp--

MODEL

492

A

TYPICAL

MODULATION

CHARACTERISTICS

\ • I I ,

\\

'\\

'!

I

: .,

\

\'

:

~

\

'\T\TT

\\\\

\\

\'

::

I'

\ !

\ \

~

:

.,

\; \ ,

\ \\\

~

. i ,

\

: ,

I \

1\

,

: ! . ,

"

.~k.

,

r···,

,

I ,

, ,

."

I ,

r,

I

1700

1600

I

1500

1400

0

et

1300

0

..J

~

1200

%:

0

0

11.00

\t)

1000

C/)

~

..J

900

0

>

..J

800

..J

~

700

z

600

~

::)

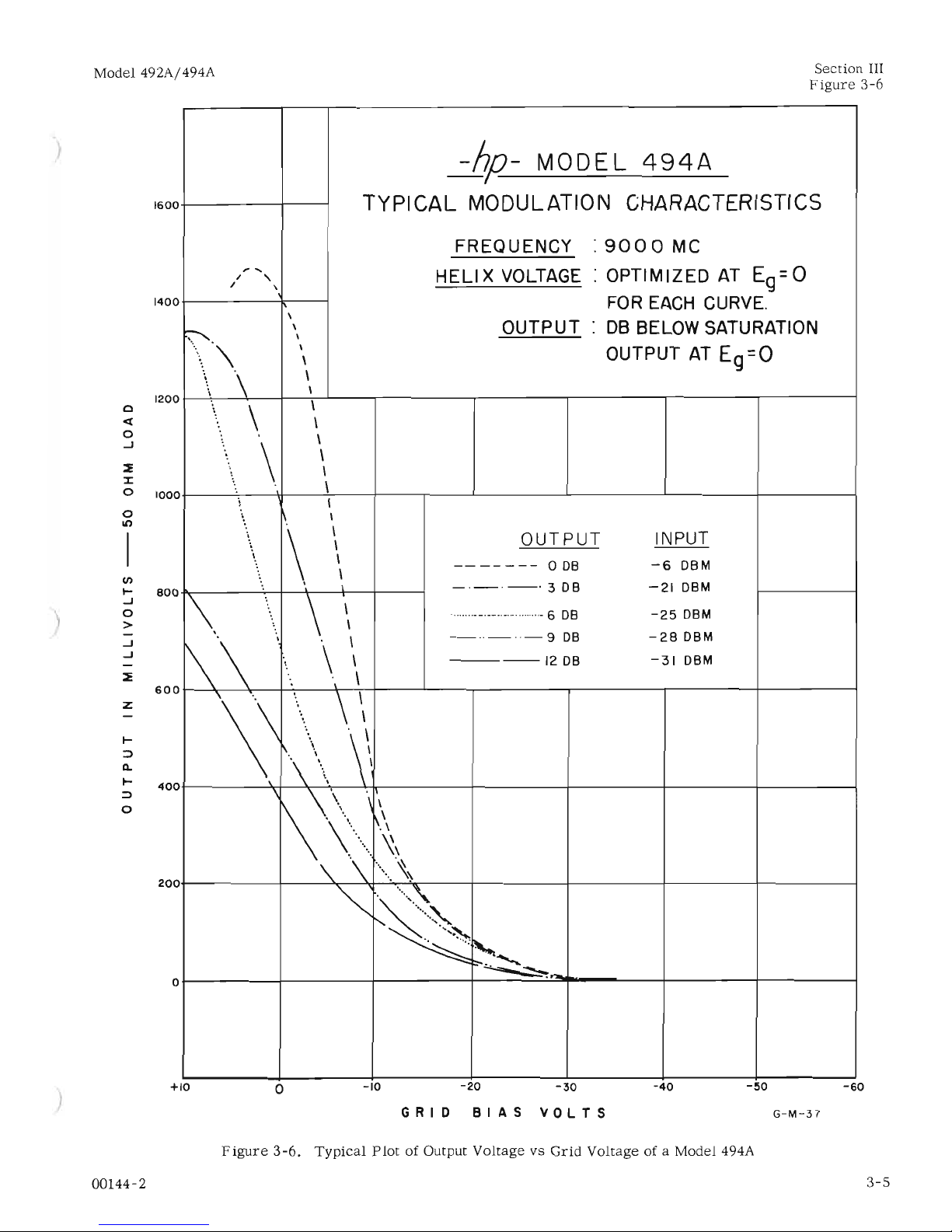

500

0.

~

::)

400

0

300

200

100

0

+10

+5

o

-5

-10

-15

-20 -25

-30

-35

-40

-45

-50

-55

G

RID

B I A S

VOL

T S

G-

M-36

Figure

3-5.

Typical

Plot

of Output

VoltagevsGrid

Voltageofa Model 492A

3-4

00144-2

Page 14

Model 492A/494A

Section III

Figure

3-6

)

1600+-----+-----1

-.::..bp--

MODEL

494A

TYPICAL

MODULATION

CHARACTERISTICS

INPUT

-6

OBM

-21

OBM

-250BM

-280BM

-31

OBM

OUTPUT

-------

0

DB

-'-'-'30B

............- _ 6

DB

-,,-,,-9

DB

----12

DB

FREQUENCY

:

9000

Me

HELIX

VOLTAGE:

OPTIMIZED

AT

Eg=O

FOR

EACH

CURVE.

OUTPUT:DB

BELOW SATURATION

OUTPUT

AT

E

g

=0

\

\

\

\

\

\

\

\

\

,

\

,

,

.

\

\.

\.

,.

.....

,.

,

,.

,

\ \

\

::::".

\'\

" \

\

\

\ \

800

-fI<--------t--\-----J'l---t---1

~\.\

',\

\

I \ \ \ \

6

00

+--4-~.____--+-.:,.-----4---;.-+-----l..-____,r----__r___---......,.....---_+---__l

'.'.

\ \

\>\\

\\

400+-------''rl-----T---'';---+-ir----1-----+-----+-----+----~

\

\.\

..•

',\

\\

.....

1\\

'.

'.

~~

\.

'\

\

..

\

200+------+------>,r-"""'d-....:...;-"""\r----11-----+-----+-----+----~

~~"

.•..

,~~

'~

"~

~

.............

~,.

~:.-.:.:..~

0~---_+_---_+_----1f_--==:..::.!!!~---_+_---_+---___l

1400+------+--~

1200

0

<

0

.J

:E

:I:

0

1000

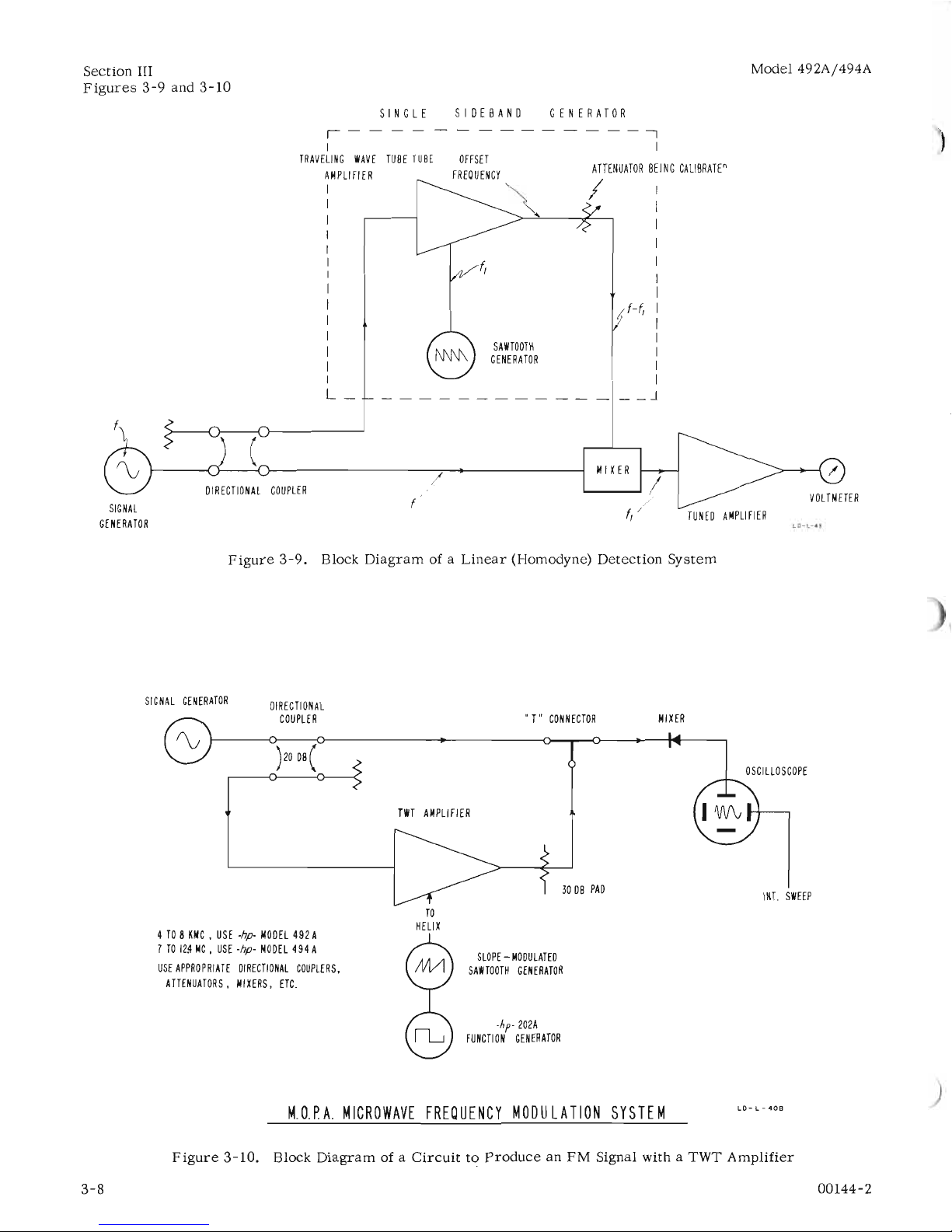

0

It)

z

V>

~

.J

o

>

.J

.J

)

+10

o

-10

GRID

-20

-30

BIAS

VOLTS

-40

-50

G-M-37

-60

Figure

3-6.

Typical

PlotofOutput

VoltageVBGrid

Voltage

of a Model 494A

00144-2

3-5

Page 15

Section

III

Paragraphs

3-23to3-30

output.

The

linear

modulation

region

extends

from

approximately

+4

volts

(where

beam

de-focusing

occurs)toapproximately

-15

volts

(where

therfout-

put

becomes

an

exponential

function of the

grid

volt-

age).

This

linear

operating

region

permits

upto30%

modulation

with

less

than 2.5%

envelope

distortion

and upto50%

modulation

with

less

than5%distortion.

Envelope

distortion

increases

rapidly

above

50%

modu-

lation.

In

pulse

work

the

twt

maybebiased

near

or

below

cut-off

and

therfdrive

adjusted

for

saturation

outputatthe

peak

amplitudeofthe

modulating

pulse.

However,

the

grid

voltageatthe

peakofthe

modu-

lating

signal

must

not

cause

de-focusing

(approxi-

mately+4to

+ 8

volts)

nor

excessive

average

electrode

current,

see

table

3-1.

The

transient

responseofthe

492A

or

494A to a

step

function

appliedtothe

grid

is

approximately15nsec.

3-23.

Amplitude

modulationisaccompaniedbysome

incidental

phase

modul'btion of

therfsignal,

amount-

ingtoapproximately

90

phase

shiftoftherfcarrier

for

a 10 db

changeinthe

modulatedrfoutput

level.

In

practice

this

phase

modulationisunimportant

when

using

the

conventional

square-law

crystal

detectors,

butisimportantindetection

systems

where

the

out-

putisa functionoftherfcarrier

phase.

3-24.

PULSE

MODULATION.

3-25.

Thereisconsiderably

latitudeinthe

adjustment

of

modulation

characteristics

when

pulse

modulating

anrfsignal

using

the

492Aorthe

494A;

see

figures

3-5

and

3-6.

The

cw

input

level,

the

modulation-

pulse

amplitude,

and

the

grid

bias

determine

the

characteristics

of

the

rf

output

pulse

as

follows:

a.

The

cw

input

signal

primarily

determines

the

maximum

possible

leveloftherfoutput

pulse

and

whetherornot

the

twt

canbeoperated

into

saturation.

b.

The

peak-to-peak

amplitudeofthe

modulating

pulse

primarily

determines

the

on-off

ratioofthe

rf

output

pulse.

c.

The

grid

bias

level

primarily

determines

the

rf

output

levels

attained

during

the

pulse-on

and

pulse-

off

times

and

also,inconjunction

with

the

modulating

pulse,

determines

the

rf

input

level

necessary

to

saturate

the

twt.

The

GRID BIAS

control

always

should

be

set

so

that

the

twt

grid

will not

draw

cur-

rent

(approximately4volts

positive)

during

the

pulse-

on

period.

3-26.

To

pulse

modulate

therfsignal

being

amplified

in

the

492A

or

494A,

refer

to

figures

3-5or3-6

and

proceedasfollows:

a.

Determineifthe

twtisto be

driven

into

satura-

tion

andiftherfoutput

mustbeataspecific

level.

b.

Set

the

GRID BIAS

control

for

zero

bias.

c.

Connect

therfinput

signaltothe

twt and

adjust

its

leveltoproduce

the

desiredrfpulse

output

level.

d.

Determine

the

on-off

voltage

ratio

required

in

therfoutput

pulse.

3-6

Model 492A/494A

e.

Using

the

graph

in

figure

3-5

determine

the

magnitudeofmodulation

pulse

requiredtoproduce

the

desired

on-off

ratio.

f.

Set

the

GRID BIAS

controltoobtain

the

voltage

determined

in

step

e.,

Le.,

the

peak

voltageofthe

modulating

pulse.

The

bias

VOltage

maybemeasured

at

the

pin

jackonthe

front

panel.

g.

Connect

the

modulating

pulsetothe

GRID MOD.

connector

and

adjust

its

amplitudetothe

voltage

de-

terminedinstep

e to

produce

the

desired

on-off

ratio

in

therfoutput

pulse.

Since

the

gridofthe

twtiscon-

nected

directly

to

the

GRID MOD.

jack,adc

com-

ponent

in

the

modulating

signal

will

affect

the

grid

bias.

Also,ifcapacitive

couplingisused

the

modu-

lating

signal

will

drive

the

gridofthe

twt

above

and

below

the

dc

level

established

by

the

grid

bias,

an

amount

determined

by

the

duty

cycleofthe

modulating

signal.

The

GRID BIAS

control

mustbeadjusted

to

compensate

for

both of

these

effects.

h.

To

increase

the

on-off

ratiooftherfoutput

pulse,

increase

the

amplitudeofthe

modulation

pulse,

at

the

same

time

adjust

the

grid

biassothat

the

grid

will not be

driven

beyond 4

volts

positive,

see

the

Note

paragraph

3-21.

Note

Large

input

modulating

pulses,

above

15

volts,

tendtoshock-excite

the

helix,

produc-

ing

ringing

on

the

top of

therfoutput

pulse

and a slow

rise

time.Ifthe

traveling-wave

tubeisoperated

near

saturation

this

effect

is

minimized

and

better

pulse

characteristics

are

obtained.

3-27.

LIMITED

PHASE

MODULATION.

3-28.

The

signal

being

amplifiedinthe

492Aor494A

can

be

phase-modulated

by applying

voltagetothe

HELIX MOD.

connector.

This

voltage

varies

the

electron-beam

velocity

by

changing

the

potential

be-

tween

the

cathode

and

the

helix--a

positive

voltage

change

accelerates

the

electron

bunches

and

advances

the

phaseoftherfoutput

signal;anegative

change

slows

them

and

retards

the

phaseofthe

output

signal.

The

resultant

phase

deviationinthe

output

signal

is

directly

proportionaltothe

applied

voltage.

The

de-

gree

of

phase

deviation

producedislimited

by

the

range

of

helix

voltages

that

produces

amplification,

and

by

the

amountofincidental

amplitude

modulation

permissible

in

therfoutput.

Phase

deviation

of 360

0

is

possible

with

the

output

amplitude

heldtovariations

of

approximately

1-1/2

db andisobtained

with a

helix

voltage

variationofless

than 50

volts.

The

actual

voltage

required

foraphase

shiftof3600varies

with

the

operating

frequency

and

from

tube-to-tube.

3-29.

UNLIMITED

PHASE

MODULATION

AND

FREQUENCY

SHIFTING.

3-30.

Although

the

limited

phase

deviation

described

in

paragraph

3-27isusefulinsome

applications,

un-

limited

phase

deviation

hasamuch

wider

range

of

usage.

Itisparticularly

useful

because

the

frequency

00144-2

Page 16

Model 492A/494A

Section III

Paragraphs

3-31to3-36

G-l-7

TIM

E

DESIRED OUTPUT

(Ftl

FR

EQU

ENCY +-

__

-'---_----'

__

---A.

__

--L.._---l

--

---

---1---

INPUT FREQUENCY

(Fl

UNDESIRED OUTPUT ( F )

FREQUENCY

2

HIGH

Figure

3-8.

Offset

Frequency

Produced

by

Sawtooth Modulation of

the

Helix

LOW

SAWTOOTH MODULATION

APPLIED

TO

HELIX

3-31.Inpractical

applications,aconstant

amplitude

linear-slope

sawtooth

generator

is

used to

produce

the

sawtooth

waveforms.Ifthe

amplitude8fthe

saw-

tooth

voltageisadjustedtoproduce

a 360

shift,

one

cycle

of

the

cw

signal

will be addedorsubtracted

during

each

sawtooth, and

the

frequency

shift

pro-

duced in

the

output will be

equaltothe sawtooth

repe-

tition

rate.

Sawtooth

voltages

having

negative

slopes

(see

figure

3-7)

produceadecrease

in the output

fre-

quency (delay in

phase).

Conversely,

sawtooth

volt-

ages

of the

opposite

slope

causeanincreaseinoutput

frequency.

of the input

signal

canbeshifted

by a

predetermined

amount. Unlimited

phase

deviationiseffectively

sim-

ulated

by continuously

repeating

exact

3600phase

deviations.

Thisisaccomplished

by modulating

the

traveling

wave tube

helix

wiSh

a sawtooth

waveform,

each

sawtooth

producing

360

phase

shift,asshown

in

figure

3-7.

Anrfoutput

frequency

thatisshifted

in

relationtothe input

frequencyisthus produced,

as

shown in

figure

3-8.

O·

HIGH

SAWTOOTH

MODULATION

APPLIED

TO

HELIX

LOW

PHASE DIFFERENCE

BETWEEN

INPUT AND

OUTPUT WAVES

frequency

shift

with

its

relatively

small

power

content

would

be

rejected

by

most

narrow

band

circuits.

In

systems

where

the

undesired

frequency

shift

falls

within

the

pass

band of the

equipment

under

test,

a

negative

pulse

canbeappliedtothe

GRID MOD.

con-

nectortocut

off the twt

beam

current

during

the

fly-

back

time.

This

method

reduces

the

undesired

fre-

quency

shift

althoughitproduces

some

small

tran-

sients

and

leaves

small

time

intervals

during

which

thereisno

signal

output.

Practical

applications

of

offset

frequencies

include

the

measurement

of

ex-

tremely

high

swr's

accurate

calibrationofattenu-

ators

over

wide

amplitude

ranges

(paragraph

3-34),

frequency

shiftingofmicrowave

radio

relay

channels

for

retransmission,

productionofmixer

frequencies

for

radar

and

other

microwave

receivers,

etc.

G-l-I

TI

ME

..

3-34.

HOMODYNE

DETECTION.

Figure

3-7.

RF

Phase

Shift

Produced

by

Helix Modulation

3-32.

With sawtooth modulation,

the

desired

output

frequency

shift

(F

in

figure

3-8)

occurs

during

the

sawtooth

formatioJ

time,

andisproportional

to

the

rate

of

change

of voltage.

During

the sawtooth

fly-

back

time

the output

phaseisshifted

in the

opposite

direction

producinganundesired

frequency

shift(F2

in

figure

3-8).Ifthe

flyback

timeismade

extremely

short,

this

frequencyisfar

removed

from

the

desired

frequency

since

the

degreeoffrequency

shiftisin-

versely

proportionaltothe

flyback

time.

In

addition

to

being

far

removed

from

the

desired

frequency

the

powerinthe

undesired

frequencyisvery

small

since

itisproportionaltothe

ratio

of flyback

timetosaw-

tooth

time.

3-33.Ina

typical

case

involving a

desired

50-kc

fre-

quency

shift,

a

I-microsecond

flyback

time

would

produceaI-megacycle

frequency

shiftinthe

opposite

direction

and would

contain

only5%of

the

total

power

in

the

output wave.

In

practice,

this

undesired

3-35.

The

ability

of a twttoproduce

an

offset

fre-

quency

thatisstable

with

respecttothe

signal

source

makesitan

ideal

instrument

to

use

in a homodyne

(linear)

detection

system.

The

difference

frequency

will be dependent upon

the

stability

of the sawtooth

generator

usedtomodulate

the

twt helix, a

problem

ofnoconsequenceatthe

low modulating

frequencies

involved.

3-36.Atypical

linear

detector

system

suitable

for

calibrating

microwave

attenuators

is

illustrated

in

figure

3-9.

The

signal

generator

suppliesasignal

(f) both

toacrystal

mixer

andtoa

traveling

wave

tube

amplifier.

The

traveling

wave tube

amplifier

is

sawtooth modulated to

produce

an

offset

frequency

(f-f

) whichisapplied to

the

attenuatortobe

cali-

brated.

The

output

signal

from

the

attenuatoristhen

combined

with the

original

signal

(f) in

the

mixer

to

produceabeat

frequency

(f ) whose

amplitudeisdi-

rectly

proportional

to

the

ahtplitudeof(f-f

j

)

so

long

as

the

amplitudeof(f-f

j

)

remains

within

the

square-

law

region

of the

cryStal.

This

beat

frequency

is

amplified

by

the

tuned

amplifier

and

the

outputisin-

dicated

by an

ac

voltmeter.

The

lower

sensitivity

01144-2

3-7

Page 17

Section III

Figures

3-9

and

3-10

Model 492A/494A

SAWTOOTH

GENERATOR

f,

OFFSET

FREQUENCY

SINGLE

SIDEBAND

GENERATOR

-------------1

I

A

TTENUATORBEING

CALIBRATE"

/ I

I

I

I

I

I

I

f-f, I

I

I

I

I

I

_

_J

L_

I-

I

TRAVELING

WAVE

TUBE

TUBE

AMPLIFIER

SIGNAL

GENERATOR

COUPLER

/

f

VOLTMETER

TUNED

AMPLIFIER

LO-l-'"

Figure

3-9.

Block

Diagram

of a

Linear

(Homodyne)

Detection

System

INT.

SWEEP

OSCILLOSCOPE

MI

XER

30

DB

PAO

'T'

CONNECTOR

TWT

AMPLIFIER

)20OB(

DIRECTIONAL

COUPLER

SIGNAL

GENERATOR

4TO8

KNC0USE

-hp-

MODEL

492

A

7TO12.4

MC.

USE

·hp·

MODEL

494

A

USE

APPROPRIATE

DIRECTIONAL

COUPLERS.

ATTENUATORS.

MIXERS.

ETC.

TO

HELIX

SLOPE-MODULATED

SAWTOOTH

GENERATOR

.h

p

'

202A

FUNCTION

GENERATOR

M.O.P.A.

MICROWAVE

FREQUENCY

MODULATION

SYSTEM

LD-L-40B

Figure

3-10.

Block

Diagramofa

Circuit

tc?

ProduceanFM

Signal with a TWT

Amplifier

3-8

00144-2

Page 18

)

Model

492A/494A

limitisdetermined

by

the

crystal

and IF

amplifier

noise

andisapproximately

-100

dbm.

ote

When a

swr

indicator

(suchasthe

<[j)

Model

4158)

calibrated

for

use

with a

square-

law

detector

is

usedinplaceofthe

tuned

amplifier

and

voltmeter,

the

db

readings

mustbedoubled.

3-37.

FREQUENCY

MODULATION.

3-38.

Narrow-band

frequency

modulation

canbeob-

tained

by

applying

the

modulation

signal

directly

to

the

helixofthe

twt;

however,tofrequency

modulate

with an

appreciable

frequency

deviationitis

first

necessarytoproduceanoffset

frequencyasdescribed

in

paragraph

3-29.

The

deviationofthe

offset

fre-

quency

shouldbeslightly

greater

than

1/2

the

total

frequency

deviation

desired.

The

offset

frequency

is

then

varied

by

varying

the

slope

of

the

sawtooth.

3-39.Asawtooth

waveform

produced

by

the

special

generator

describedinparagraph

4-20

canbeslope-

00144-2

Section

1II

Paragraphs

3-37to3-40

modulated

by any

waveform

before

being

applied

to

the

traveling

wave

tube

helix.Inthis

manner

complex

signals

canbeusedtofrequency-modulate

the

signal

applied

to

the

twt and

the

center

of

the

output

fre-

quency

will

be

fixed by

the

sawtooth

repetition

rate

without

slope

modulation.

Innocase

should

the

p~ase

shift

duetoa

single

sawtooth

cycle

exceed

360

so

that

the

amplification

propertiesofthe

traveling

wave

tube

amplifier

will notbeadversely

affected

regard-

less

of

the

magnitudeofthe

apparent

phase

deviation

when

the

sawtooth

waveismodulated.

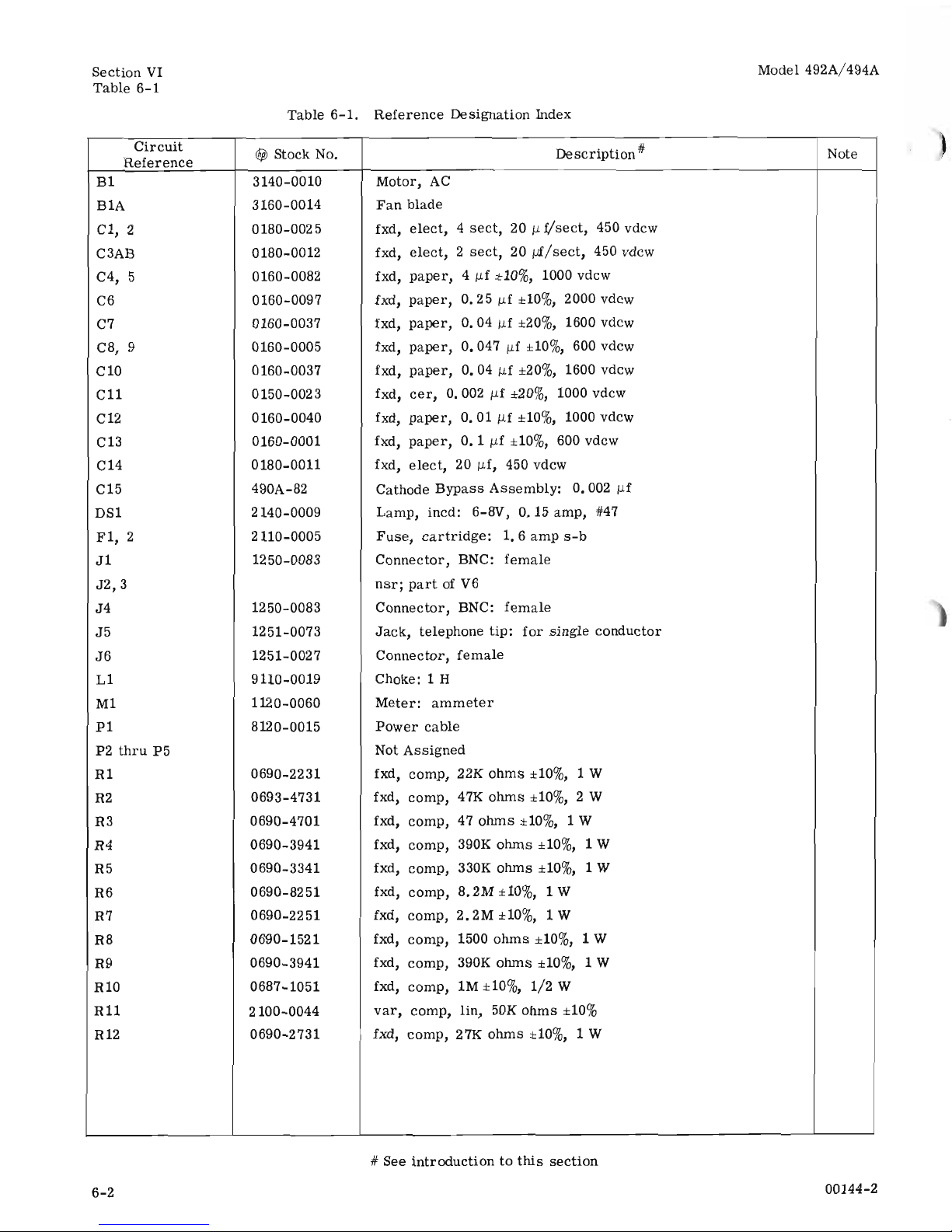

3-40.

Figure

3-10isa

block

diagram

of a

system

for

the

generationoffrequency-modulated

offset

signals.

In

this

arrangement,

the

slope-modulated

sawtooth

voltage

whichisappliedtothe

twt

helix

produces

an

offset

frequency,

the

instantaneous

frequencyofwhich

is

proportionaltothe

slopeofthe

sawtooth.

Varying

the

slopeofthe

sawtooth

voltage

varies

the

offset

fre-

quency.

Thus

the

output

signal

from

the

twtisan

fm

signal.

The

detected

fm

signal

(the

difference

between

the

signal

generator

frequency

and

the

fre-

quency-modulated

offset

frequency)

is

shown on

the

oscilloscope.

3-9

Page 19

"'"

,

o

'rjC/)

.....

CD

OQ

n

c:

~.

'i

0

CD

::s

"'"-

,<

......

3::

8.

CD

>-

"'"

'Cl

N

;>

-....

"'"

'Cl

"'"

;>

J4

rG'iiiDl

l!QQJ

J5

PIN

JACK

ON

FRONT

PANEL

FOR

MEASURING

BIAS

J2mD

J3m

(

~Jll

HELlXI

MOO.

Figure

4-1.

Block

Diagram

~

Models

492A and 494A

~

-

SRI

HALF

WAVE

RECTIFI

ER

+

SR2

~

VI

V5A

SR3

SERIES

HELIX

VOLTAGE

REGULATOR

MODULATOR

I

DOUBLER

6BQ6

V4

1126BQ7A

REFERENCE

ew

I

-

VOLTAGE

I

HELIX

~

0

OA2

STRAY

CAPACITY

'--c.--

T1

V2

V5B

..,-

,,'

-",

CONTROL

DISCHARGE

I I

POWER

TUBE

TUBE

,

,

I

i

~

TRANSFORMER

6AU6

1

12

6BQ7A

IWI

~

I

I

elY

-

:

~

u

> <

@

HELIX

e>

elY

I

-

--

I

""

ANODE

\~.J

~

, "

'--

""

~

<

V3

~o

I

GRID

BIAS

I

<:>

BIAS

eIY~

REGULATOR

OB2

80-

L-44B

JF1

I.SA

F2

1.6

A

~

SR4

~

TIT

MAGNET

SI

SUPPLY

L----J

L-

o

o

......

"'"

"'"

,

N

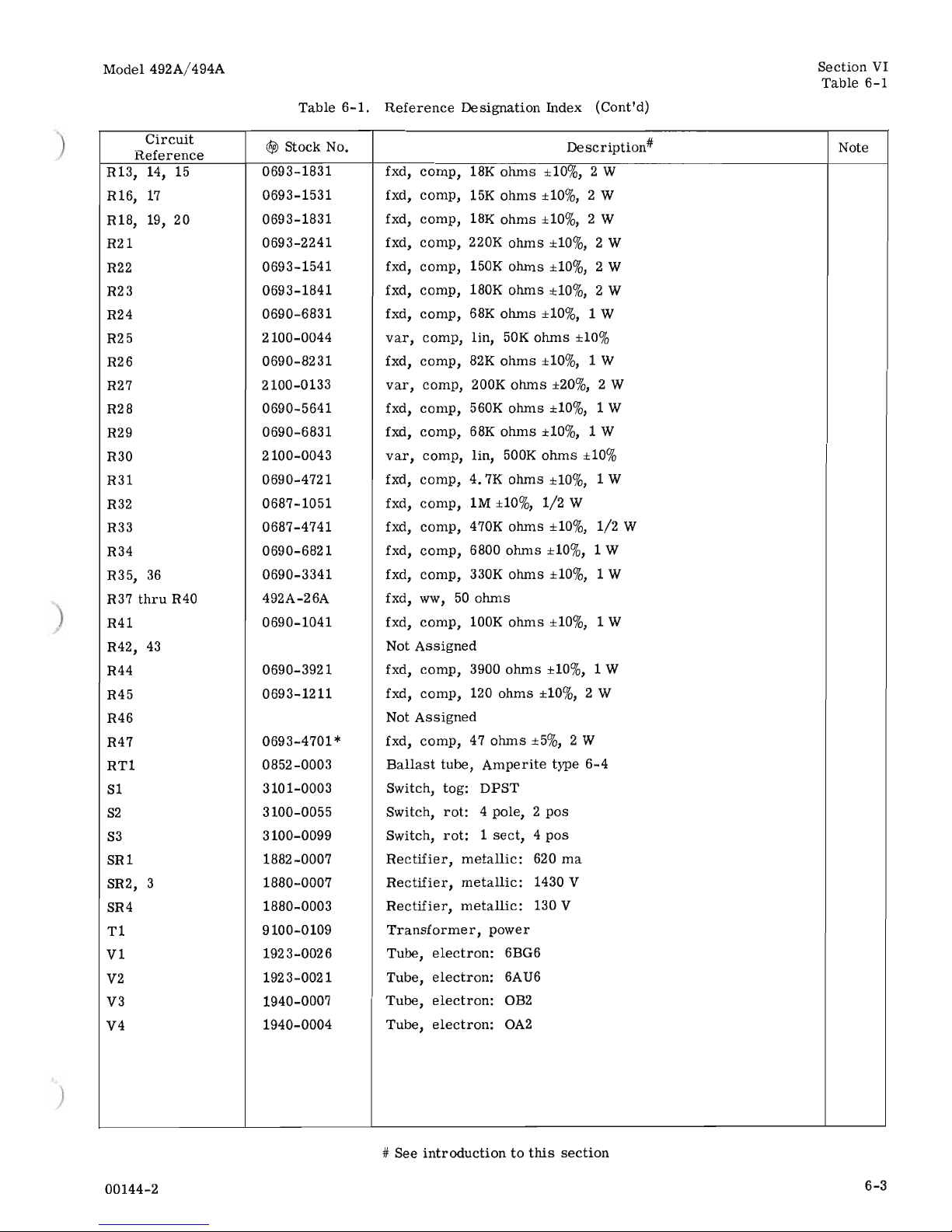

Page 20

)

Model 492A/494A

SECTION

IV

PRINCIPLES

OF

OPERATION

Section

IV

Paragraphs

4-1to4-13

)

)

4-1.

INTRODUCTION.

4-2.

The

twt

amplifier

contains

very little

signal

cir-

cuitry

external

to

the

twt

itself.

The

electrical

cir-

cuitsinthe

instrument

provide

the

operating

voltages

and

the

means

for

modulating

the

twt,asshown in

the

block

diagram,

figure

4-1.

4-3.

MAGNET

POWER

SUPPLY.

4-4.

The

492A and 494A

utilizea400-gauss

electro-

magnet

(surrounding

the

traveling

wave tube

capsule)

to hold

the

emitted

electrons

in a

very

narrow

beam.

The

power

supply

for

the

magnet

consists

of a

full-

wave

selenium

bridge

rectifier

connected

directly

across

the

US-volt

line

andacapacitive-input

filter,

and

supplies

approximately

0.7

ampere

at

an output

voltage

of 120

voltsdcwith

less