Page 1

5 Theory of operation

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Basic operation of the printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Printer operating sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Control system overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Pickup and feed system overview . . . . . . . . . . . . . . . . . . . . . . . . . 68

Laser/scanner system overview. . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Image formation system overview . . . . . . . . . . . . . . . . . . . . . . . . . 68

General descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

DC controller PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Motor and fan control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Power supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Fuser-control circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Fuser over-temperature protection. . . . . . . . . . . . . . . . . . . . . . . . . 72

High-voltage circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Low-voltage circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Overcurrent/overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . 75

Toner detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Cartridge detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Cartridge memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Laser/scanner assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Laser/scanner control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Paper pickup system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Paper pickup and feed block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Printing from tray 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Printing from tray 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Tray 2, 500-, 1,500-sheet feeder media size detection . . . . . . . . . 83

Lifter-driver operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Multiple feed prevention. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Media skew prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Fixing/delivery block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Printer jam detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Printer pickup delay jam from tray 1. . . . . . . . . . . . . . . . . . . . . . . . 87

Printer pickup delay jam from tray 2. . . . . . . . . . . . . . . . . . . . . . . . 87

Printer pickup stationary jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Printer delivery wrap jam when feeding regular media . . . . . . . . . 88

Printer delivery wrap jam when feeding non-regular media . . . . . . 88

Printer delivery delay jam. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Printer door open jam. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Printer residual media jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Printing from the 500-sheet feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

500-sheet feeder pickup and feeding. . . . . . . . . . . . . . . . . . . . . . . 90

Printing from the 1,500-sheet feeder. . . . . . . . . . . . . . . . . . . . . . . . . . 92

1,500-sheet feeder pickup and feeding . . . . . . . . . . . . . . . . . . . . . 92

1,500-sheet feeder lifting mechanism . . . . . . . . . . . . . . . . . . . . . . 94

Q2431-90912 Chapter 5 Theory of operation 65

Page 2

Envelope feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Envelope feeder pickup and feeding. . . . . . . . . . . . . . . . . . . . . . . 96

Envelope feeder jam detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Envelope feeder pickup delay jam . . . . . . . . . . . . . . . . . . . . . . . . 97

Envelope feeder pickup stationary jam . . . . . . . . . . . . . . . . . . . . . 97

Duplexer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Reversing and duplexer pickup. . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Duplexer jam detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Stacker and stapler/stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Stacker feed and delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Stacker jam detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Stacker feed jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Stacker feed stationary jam. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Stacker residual media jam. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Stapler/stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Stapler/stacker feed and delivery . . . . . . . . . . . . . . . . . . . . . . . . 107

Staple mode feed and delivery . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Stapler unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Stapler unit operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Staple level detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Stack mode feed and delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Stapler/stacker jam detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Stapler/stacker feed jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Stapler/stacker feed stationary jam. . . . . . . . . . . . . . . . . . . . . . . 117

Stapler/stacker delivery jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Stapler/stacker residual media jam . . . . . . . . . . . . . . . . . . . . . . . 117

Image-formation system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Electrostatic latent-image formation . . . . . . . . . . . . . . . . . . . . . . . . . 120

Primary charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Writing the image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Developing the image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Transferring the image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Fusing the image. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Cleaning the transfer charging roll er and photos en si tiv e drum . . 125

Print cartridge memory chip . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Formatter system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

PowerSave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Resolution Enhancement technology. . . . . . . . . . . . . . . . . . . . . . . . 127

EconoMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Input/output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Parallel interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Expanded I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Hard-disk accessory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

CPU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Printer memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Read-only memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Random-access memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

DIMM slots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Firmware DIMM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Nonvolatile memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Memory Enhancement technology . . . . . . . . . . . . . . . . . . . . . . . 129

PJL overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

PML . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

66 Theory of operation Q2431-90912

Page 3

Introduction

This chapter presents an overview of the relationships between major components in the printer.

It also provides a general description of the following:

● Basic operation of the printer

● Power supply

● Laser/scanner assembly

● Image formation

● Paper pickup and feeding

● 500-sheet feeder operation

● 1,500-sheet feeder operation

● Envelope feeder

● Duplexer

● Stacker and stapler/stacker

Basic operation of the printer

Printer operation can be divided into four systems. The control system (which includes the power

supply and DC controller PCA), the pickup and feed system (which consists of various rollers

and transports the media through the printer, the laser/scanner system (which forms the latent

image on a photosensitive drum), the image formation system (which transfers a toner image

onto the print media), and.

Printer operating sequence

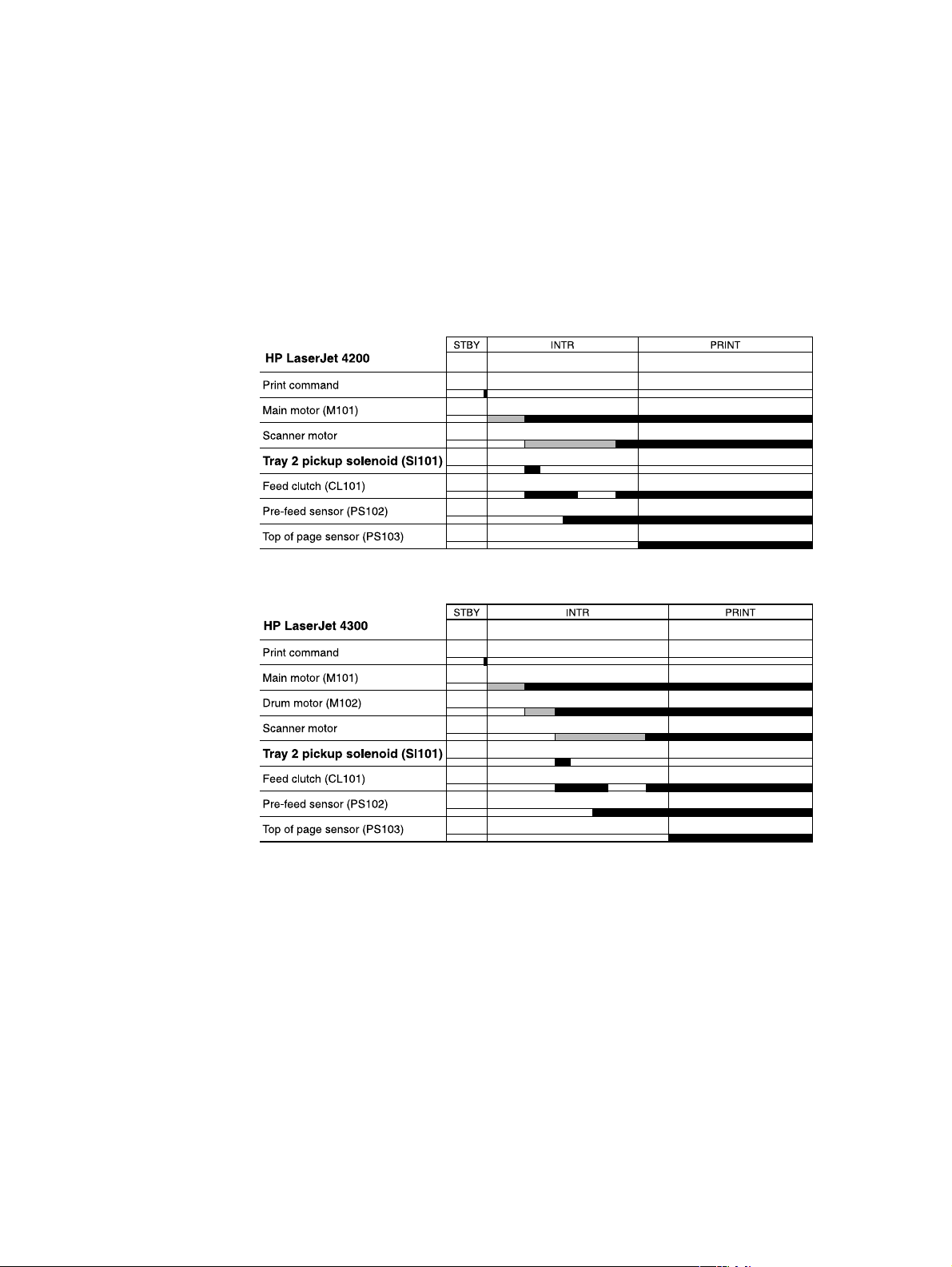

The operating sequence is controlled by a microprocessor on the DC controller PCA. The table

in this section describes the basic operating sequence from when the printer power is turned on

until the final printed page is delivered to an output bin. For information about the timing of the

basic operating sequence, see “HP LaserJet 4200 general timing diagram” on page 357 and

“HP LaserJet 4300 gene ral tim ing diagram” on page 358.

Table 30. Basic printer operating sequence

Period (sequence) Description

Waiting This is the period of time from when the printer power is turned on until the main

motor or drum motor (HPLaserJet 4300 only) begins to rotate. During this time

the transfer roller is cleaned and the microprocessor on the DC controller PCA

checks to determine if a print card ridge is installed in the printer.

Standby This is the period of time from the end of the waiting sequence until the print

command is input from the host computer, or from the end of the last rotation is

input from the sequence (described below) until a print command host computer,

or until the printer po wer is turned off. Th e m essa ge READY appears on th e control-

panel display.

Initial ro tation This is the period of time when th e photos ensit iv e drum is stab iliz ed to prepa re f or

printing.

Print This is the period of time from the initial rotation until control system detects the

page entering the printer (the p age is d etec ted by the top of pa ge sen so r (PS1 03).

Last rotation This is the period of time from the completion of the print job until the main motor

or drum motor (HP LaserJet 4300 only) stops. The final page of the job is

delivered to an output bin and the transfer roller is cleaned. If another print job is

immediately detected (sent by the host computer) the printer returns to the initial

rotation period. If no print jobs are waiting, then the printer returns to the standby

period.

Q2431-90912 Chapter 5 Theory of operation 67

Page 4

Control system overview

The control system consists of the power supply and the DC controller PCA. It controls the

pickup and feed, laser/scanner, and image formation systems. The microprocessor on the DC

controller PCA controls the operating sequence of the printer.

When the printer power is in the standby sequence (see table 30 on page 67), direct current

power (dc voltage) is supplied to the DC controller PCA by the power supply . When the printer is

in the standby sequence (see table 30 on page 67) the microprocessor on the DC controller PCA

sends signals to turn on and off various solenoids, motors, and other printer components needed

to process and print the image data input by the host computer.

Pickup and feed system overview

The pickup and feed system consists of a motor, various rollers, and sensors that detect the

presence of media, transport the media into and through the printer, and deliver the media to an

output bin.

If during the transport process, the media does not reach specific sensors in a specified time, the

microprocessor on the DC controller PCA halts the motor and a jam message appears on the

control-panel display.

Laser/scanner system ov erview

The laser/scanner system forms a latent (or potential) image on a photosensitive drum according

to signals sent from the microprocessor on the DC controller PCA.

The main components of the laser/scanner assembly are the laser driver PCA, the scanner

motor and a six-sided mirror. The DC controller PCA sends image data signals to the laser/

scanner assembly. The laser/scanner PCA converts these data signals into a laser beam of light.

The laser beam of light is reflected by the six-sided mirror onto a photosensitive drum (in the

print cartridge) and a latent image of the image to be printed is created.

Image formation system overview

The image formation system uses toner in the print cartridge to transfer the latent image on the

the photosensitive drum to the media. Heat and pressure (from the fuser) are used to

permanently bond the toner image to the media.

The photosensitive drum (in the print cartridge) receives a uniform negative primary charge that

will be exposed to the laser beam of light.

The photosensitive drum is exposed to the laser beam and an electrostatic latent image is

created on the drum (this image is invisible to your eye) by the laser neutralizing specific areas of

the drum’s surface. When the areas exposed to the laser beam come in contact with toner, the

toner is attracted to them (now the image can be seen on the drum).

The transfer roller applies a positive charge to the back of the media. As the media passes the

photosensitive drum the toner image is attracted to the media and transfers from the drum to the

media.

The media then passes through the fuser where heat and pressure are applied to permanently

bond the toner to the media.

68 Theory of operation Q2431-90912

Page 5

General descriptions

This section describes individual components found in the printer. Information is provided about

the following components.

● DC controller PCA ● 500-sheet feeder

● Power supply assembly ● 1,500-sheet feeder

● Pickup and feed assembly ● envelope feeder

● Laser/scanner assembly ● Duplexer

● Image formation system ● Stacker and stapler/stacker

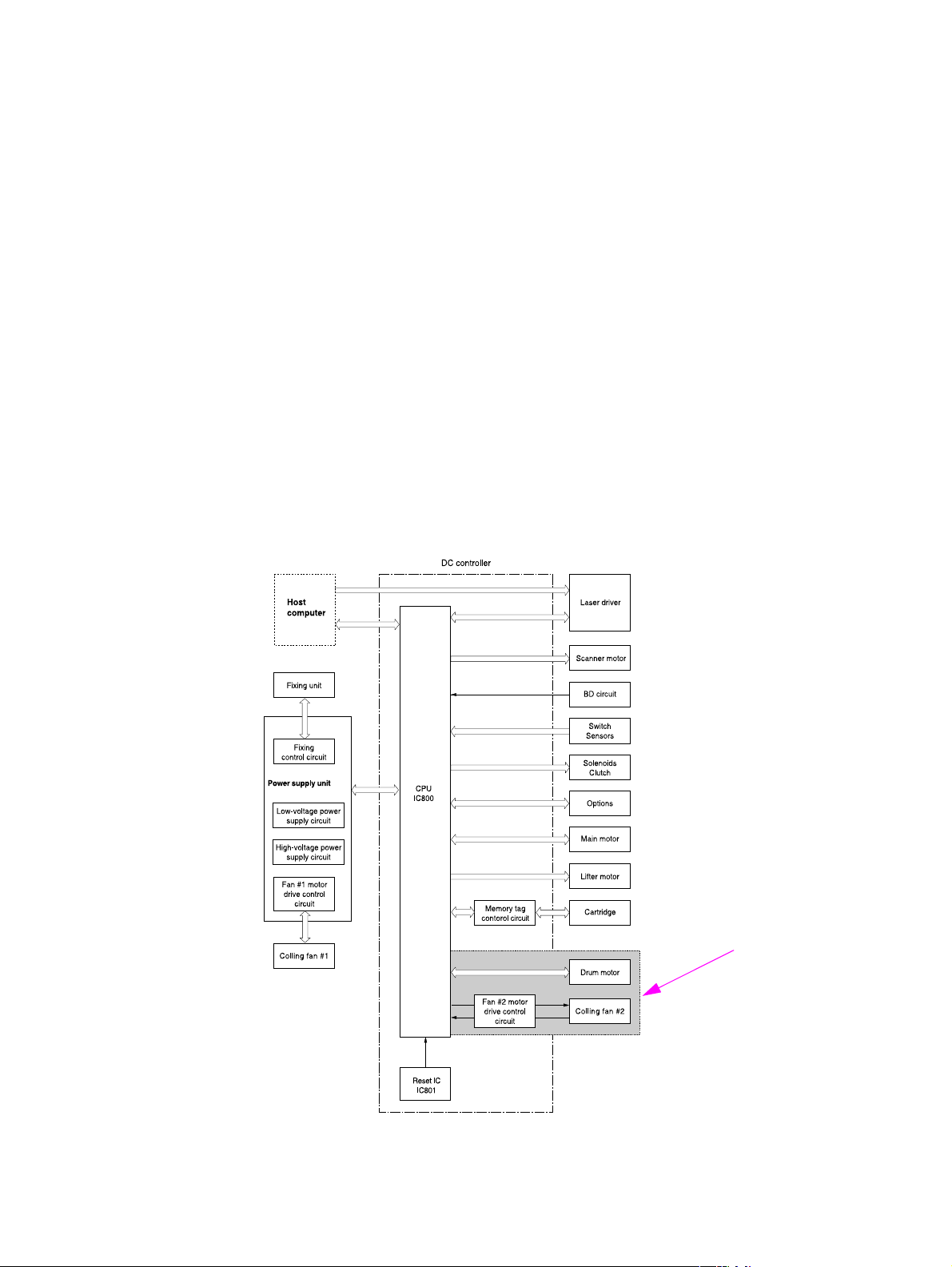

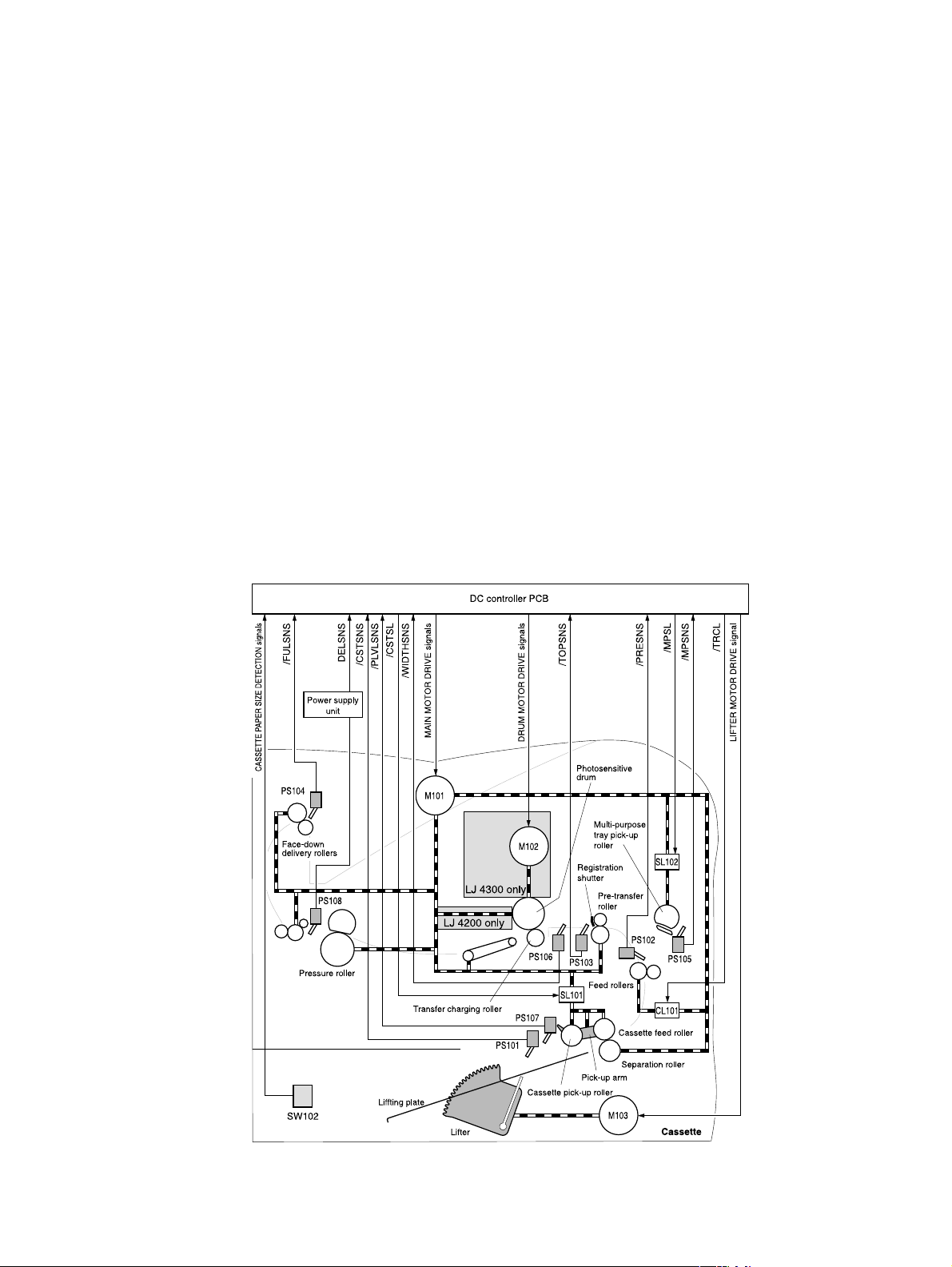

DC controller PCA

The DC controller PCA controls the operation of the printer and its components. The DC

controller PCA starts printer operation when the printer power is turned on and the power supply

sends dc voltage to the DC controller PCA. After the printer enters the standby sequence (see

table 30 on page 67. the DC controller PCA sends out various signals to operate motors,

solenoids and other printer components based on the print command and image data sent by the

host computer. For a list of DC controller PCA connectors, see figure 233 on page 356.

HP LaserJet 4300 only

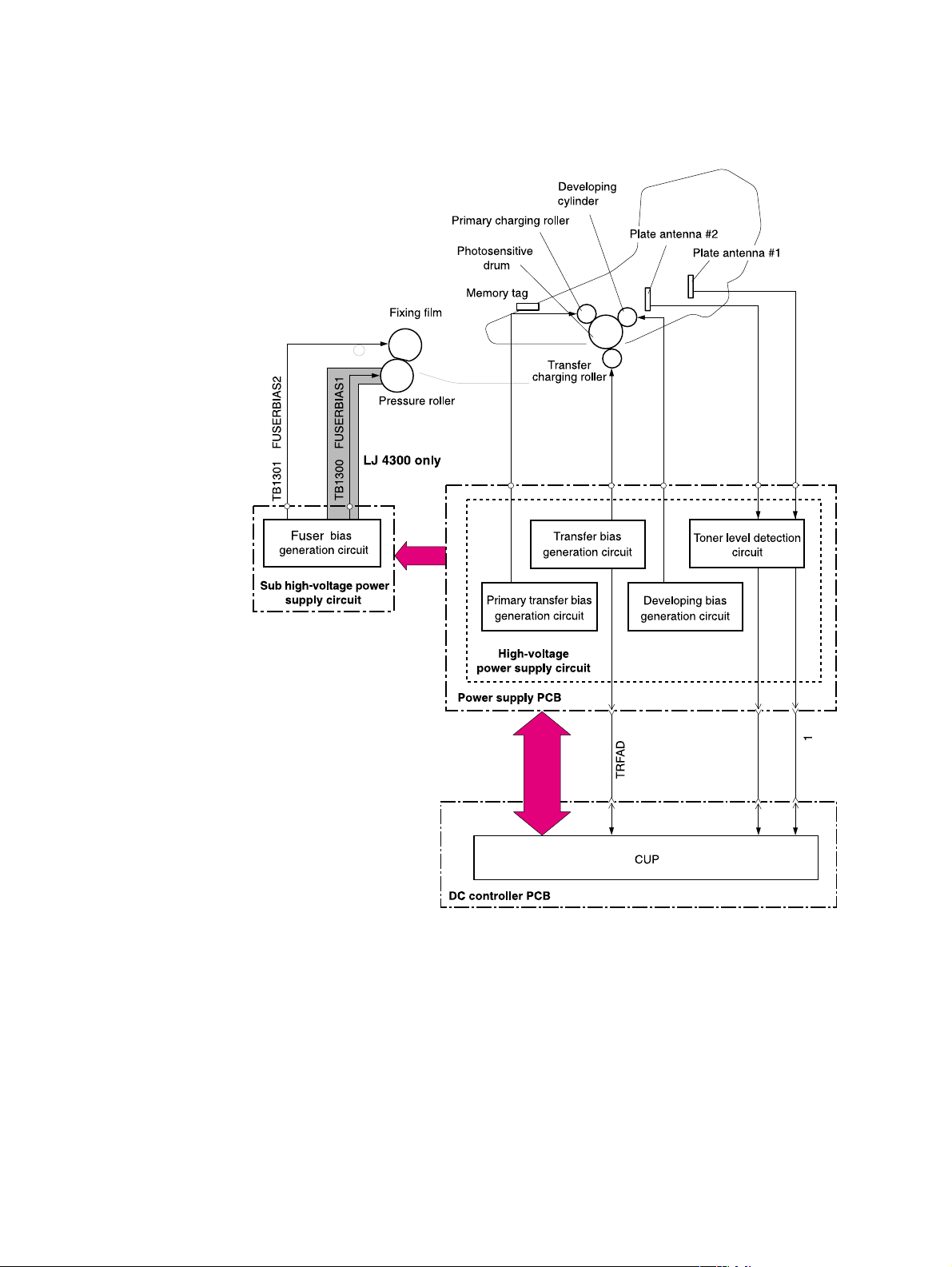

Figure 6. DC controller PCA block diagram

Q2431-90912 Chapter 5 Theory of operation 69

Page 6

Motor and fan control

The HP LaserJet 4200 printer has three dc brushless motors. The main motor, the lifter driver

motor (inside of the lifter driver assembly), and a fan motor. The main motor is used for image

formation (rotating the photosensitive drum in the print cartridge) and paper pickup and feed.

The lifter motor raises the plate in the tray cassette. The fan motor rotates the fan blades.

The HP LaserJet 4300 printer has five dc brushless motors. The main motor, the print cartridge

motor, the lifter motor, and two fan motors. the main motor is used for paper pickup and feed.

The print cartridge motor rotates the photo sensitive drum (the photosensitive drum used in the

larger HP LaserJet 4300 print cartridge is heavier than the one used in the HP LaserJet 4200

printer). The lifter motor raises the plate in the tray cassette. Two fan motors rotate the left- and

right-side fans.

The DC controller PCA controls the operation of the motors and fans.

Table 31. Printer fans and motors

Motor names Purpose Type Rotation Speed Failure

detection

Motor Main motor (M101)

HP LaserJet 4200

Main motor (M101)

HP LaserJet 4300

Print cartridge

motor (M102)

HP LaserJet 4300

Lifter motor (M103)

HP LaserJet 4200

HP LaserJet 4300

Fan Left-side cooling

fan (FN101)

HP LaserJet 4200

HP LaserJet 4300

Drives the tray cassette

pickup roller, feed /

separation roller, tray 1

pickup roller, pretransfer roller,

photosensitive drum,

developing cylinder,

pressure roller, and

output delivery roller

Drives the tray cassette

pickup roller, feed /

separation roller, tray 1

pickup roller pretransfer rol ler , pres sure

roller, and output

delivery roller.

Drives the transfer

charging roller,

photosensitive drum,

and developing

cylinder.

Moves the tray cassette

lifting plate up and

down.

Cools the inside of the

printer

dc

Counter

motor

clockwise

dc

Counter

motor

clockwise

dc

Counter

motor

clockwise

dc

Counter

motor

clockwise

dc

NA 2-speed

motor

2-speed

(full and half)

2-speed

(full and half)

2-speed

(full and half)

1-speed Yes

(full and half)

Yes

Yes

Yes

Yes

Right-side cooling

fan (FN102)

HP LaserJet 4300

Cools the inside of the

printer.

dc

NA 1-speed Yes

motor

70 Theory of operation Q2431-90912

Page 7

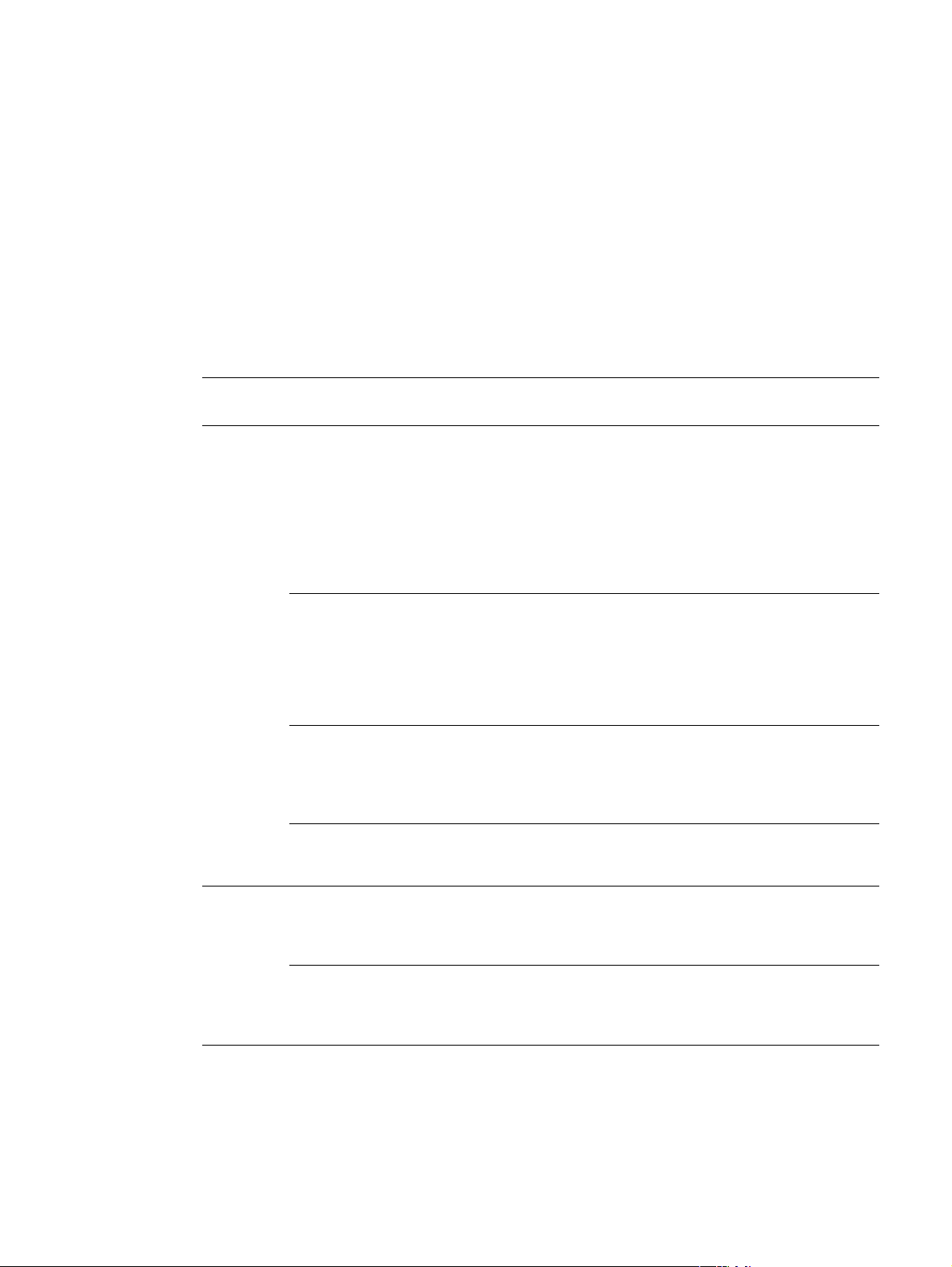

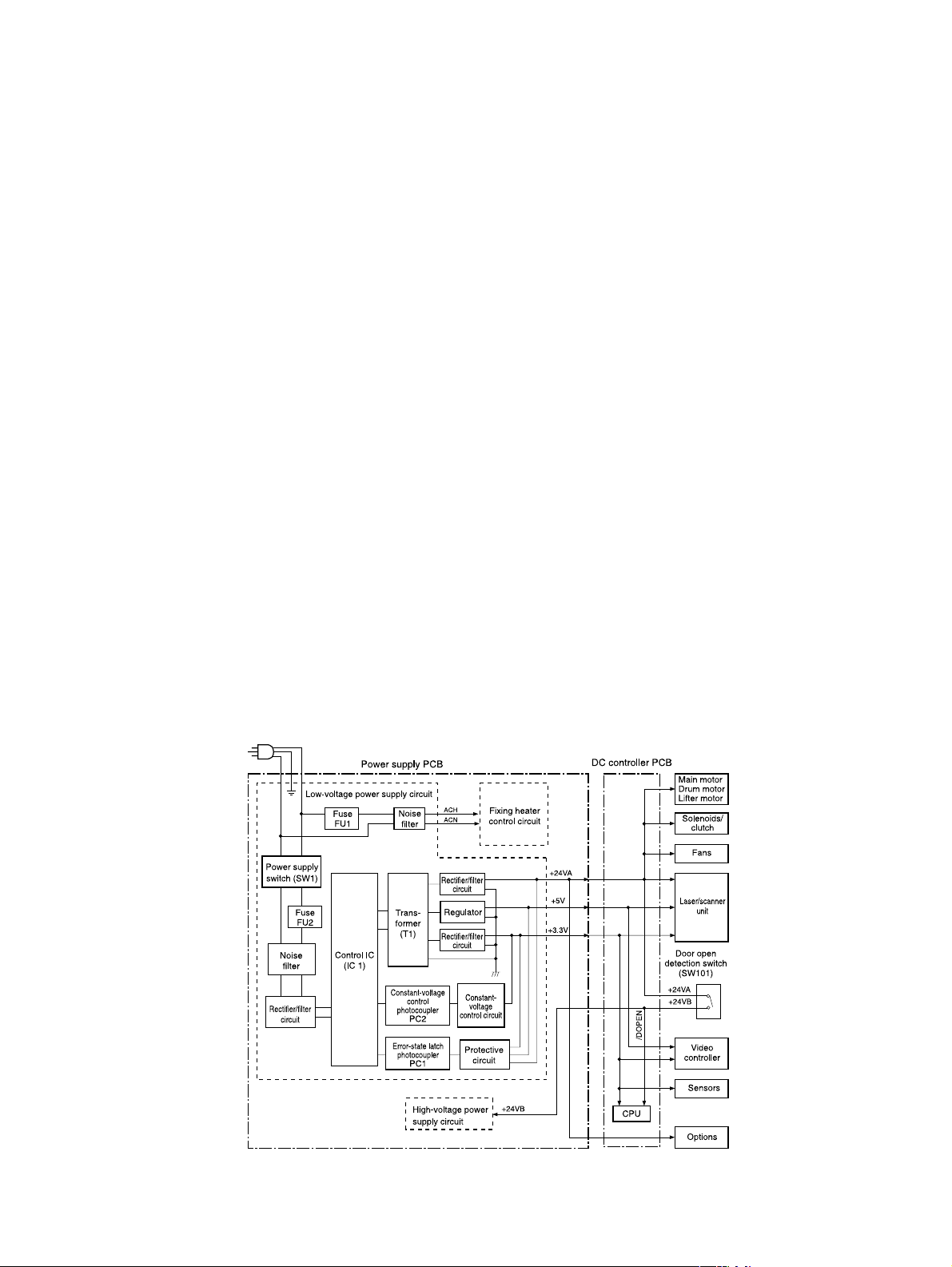

Po wer supply

The power supply consists of the fuser-control circuit, the high-voltage circuit, and the lowvoltage circuit. The fuser-control and high-voltage circuits control the temperature of the fuser

and generate high-voltage according to signals from the DC controller PCA. The low-voltage

circuit generates the dc voltages used by other components in the printer (for example the DC

controller PCA, the motors, and fans).

Figure 7. Power supply block diagram

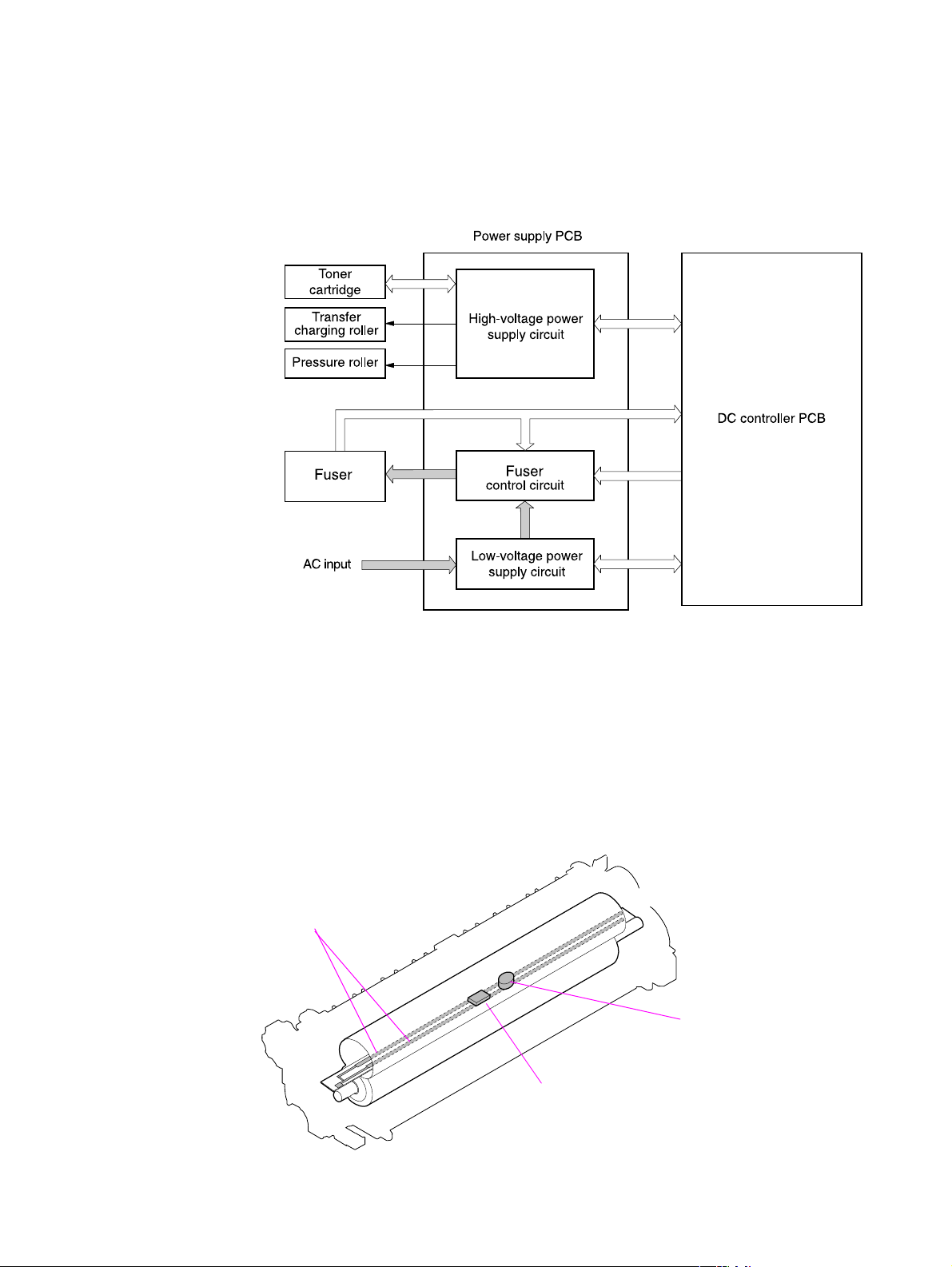

Fuser-control circuit

The fuser-control ci rcuit c ontro ls the f user ’s components. The two fuser heaters provide the high

temperatures which cause the toner to be permanently bonded to the media. The fuser

thermistor is used to monitor the fuser temperatures. The thermal switch detects abnormally high

fuser temperatures and interrupts the supply of voltage to the fuser if the temperature is

determined to be too high.

Fuser heaters

Fuser thermal switch

Fuser thermistor

Figure 8. Fuser components

Q2431-90912 Chapter 5 Theory of operation 71

Page 8

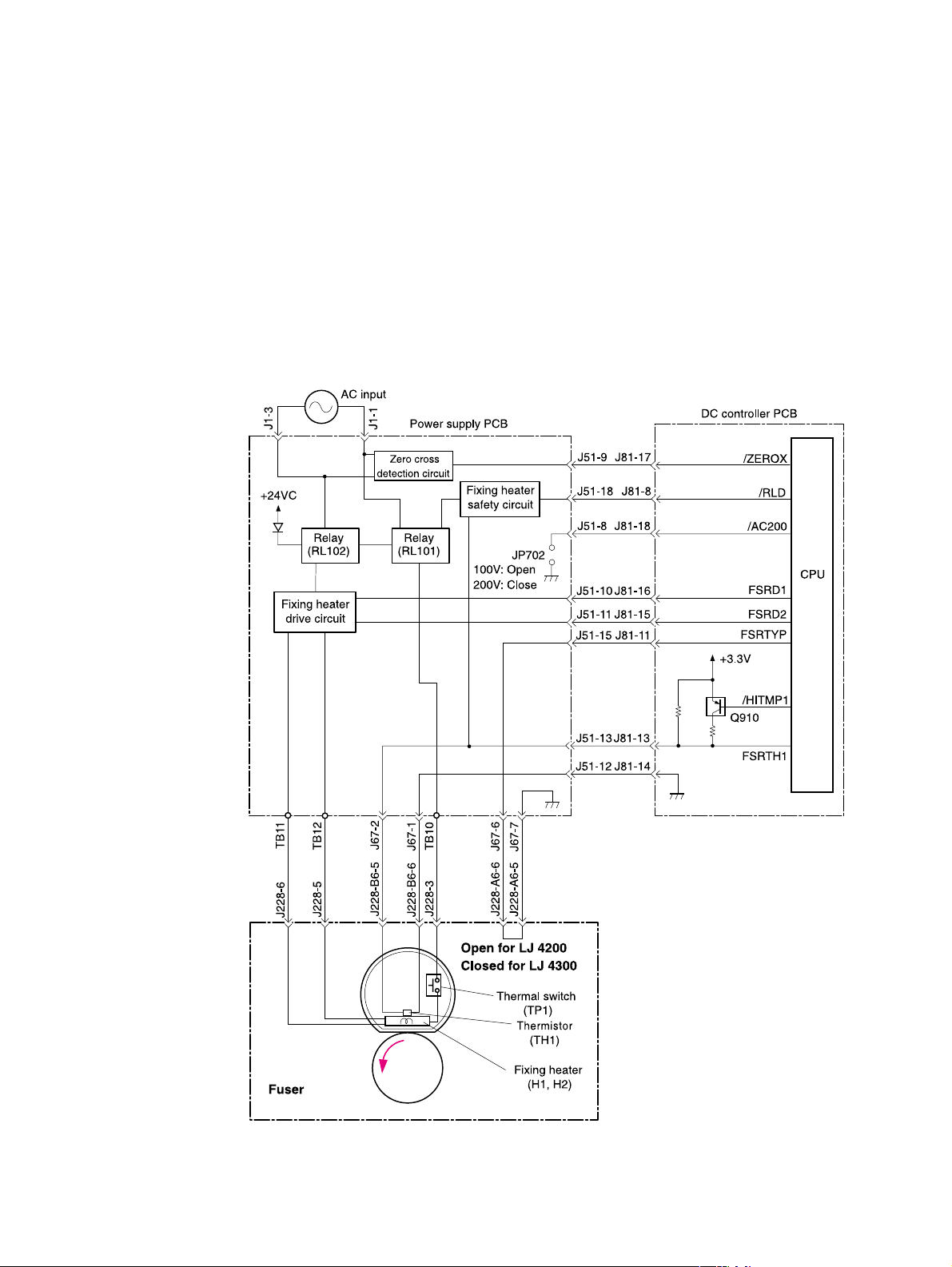

Fuser over-temperature protection

The fusing heater safety circuit is located on the power supply and constantly monitors the fusing

temperature.

To protect the fuser from excessive temperatures, the printer has the following three protective

functions:

● The CPU monitors the voltage of the thermistor. If the fuser temperature reaches

240° C (464° F) or higher, the CPU turns off the relay (RL101) to interrupt the power

to the fusing heater.

● If the temperature of the fusing heater continues to rise abnormally and the

temperature of the thermistor (TH1) exceeds about 250° C (482° F), the relay 1

(RL101) opens up to cut off the power supply to the fusing heater.

● When the temperature of the heater exceeds about 250° C (482° F), the thermal

switch (TP1) is turned off to cut off the power supply to the fusing heater

.

Figure 9. Fuser over-temperature protection circuit block diagram

72 Theory of operation Q2431-90912

Page 9

High-voltage circuit

The high-voltage circuit produces the voltage biases that are applied to the primary charging

roller, the developing cylinder, the transfer charging roller, and the pressure roller.

Figure 10. High-voltage circuit block diagram

The primary charging voltage (bias) applies a uniform negative charge to the photosensitive

drum in the print cartridge. There are two types of primary charging biases. The primary charging

dc negative voltage and the primary charging ac bias. Both biases are generated by the highvoltage circuit on the power supply. These biases are superimposed on one another and then

applied to the primary charging roller which will transfer the biases to the drum. The laser/

scanner assembly generates the electrostatic image on the primary charged photosensitive

drum. See “Image formation system overview” on page 68. The electrostatic image cannot be

seen until toner is deposited on the drum.

Q2431-90912 Chapter 5 Theory of operation 73

Page 10

The developing voltage (bias) causes the toner to adhere to the electrostatic image that the

laser/scanner assembly created on the photosensitive drum. There are two types of developing

biases. The developing dc negative bias and the developing ac bias. Both biases are generated

by the high-voltage circuit on the power supply. These biases are superimposed on one another

and then applied to the primary charging roller which will transfer the biases to the drum. The

biased developing cylinder picks up toner particles and deposits them onto the electrostatic

image on the photosensitive drum. The image is now visible on the drum.

The transfer voltage (bias) allows the toner image on the photosensitive drum to transfer to the

media. There are two types of developing biases. The transfer dc positive bias and the dc

negative bias. Both biases are generated by the high-voltage circuit on the power supply.

Transfer dc positive bias is applied to the transfer roller during the toner transfer process.

Transfer dc positive bias is applied to the transfer roller during the transfer roller cleaning

process. The dc positive bias attracts the toner to the media (this transfers the toner image on

the photosensitive drum to the media). The dc negative bias is used to clean residual toner off of

the transfer roller.

The fuser voltage (bias) prevents toner on the media from sticking to the fuser’s pressure roller.

For the HP LaserJet 4200 there is one type of fuser bias. A dc positive bias is generated by the

sub high-voltage circuit on the power supply . The dc positive bias is applied to the pressure roller

in the fuser.

For the HP LaserJet 4300 there are two types of fuser biases. The fuser dc positive bias and a

dc negative bias. Both biases are generated by the sub high-voltage circuit on the power supply .

The dc positive bias is applied to the pressure roller in the fuser. The dc negative bias is applied

to the fixing film in the fuser.

Low-voltage circuit

The low-voltage circuit converts the ac power from the power source (the wall receptacle the

printer’s power cord is plugged into) into the direct current voltage (vdc) used by printer

components (like the motors and fans). The ac voltage is converted into +24 vdc, +5 vdc, and

+3.3 vdc. The +24 vdc voltage is supplied to printer components like the main motor, laser/

scanner assembly motor, solenoids and clutches. The +5 vdc voltage is supplied to the laser/

scanner assembly. The +3.3 vdc is supplied to the sensors and the DC controller PCA.

Figure 11. Low-voltage circuit block diagram

74 Theory of operation Q2431-90912

Page 11

Overcurrent/overvoltage protection

If a short-circuit or other problem on the load side causes an excessive current flow or generates

abnormal voltage, the overcurrent/overvoltage protection systems automatically cut off the

output voltage to protect the power supply circuit.

If the overcurrent or overvoltage protection system are activated and the power supply circuit

does not generate dc voltage, it is necessary to turn the power off, correct the problem, and then

turn the printer on again.

The circuit has two fuses (FU1, FU2), which break and cut off the output voltage if overcurrent

flows through the ac line.

Toner detection

To monitor the toner level, the printer uses two plate antennas and a toner level circuit in the

high-voltage power supply circuit (see figure 10 on page 73). Toner level detection is performed

by the DC controller PCA which monitors the output signal of this circuit. The signal is fed back to

the DC controller PCA from the antennas during the wait and standby operating periods (see

table 30 on page 67). The DC controller PCA detects toner level from 1 percent to 100 percent. If

the toner is detected as being low, a message will appear on the control-panel display (see

“Alphabetical prin ter mess ag es ” on page 258).

Cartridge detection

The presence of the cartridge is detected using information stored in plate antenna 2 and the

print cartridge memory tag (see “High-voltage circuit block diagram” on page 73). The DC

controller PCA detects the presence (or lack of) the print cartridge during the wait operating

sequence ((see table 30 on page 67).

Cartridge memory

This memory is built-in EEPROM in the cartridge, so that the printer is capable of detecting the

cartridge conditions.

Read/write of the cartridge memory is performed by the memory controller board through the

antenna unit. The cartridge information read by the memory controller is updated by the DC

controller PCA and written to the memory. The read/write of the memory is implemented when

the memory controller board receives a command from the DC controller PCA. The DC controller

PCA instructs the memory controller to perform read/write at the following timing.

Reading timing

● When the power is turned on

● When the door is closed

● When the DC controller PCA receives a command from the formatter

Writing timing

● When printing is completed

● When the DC controller PCA receives a command from the formatter

The memory data sent from the memory controller also contains the error status that has

occurred during read/write operation. When error status is sent, the DC controller PCA attempts

to read the operation four times. If the error status is not cleared after the operation, the DC

controller PCA determines one of the following error conditions: sub-CPU failure, memory data

abnormality, or memory access abnormality.

Do not remove the toner cartridge when the top cover interlock is overridden. Cartridge memory

will be disabled.

Q2431-90912 Chapter 5 Theory of operation 75

Page 12

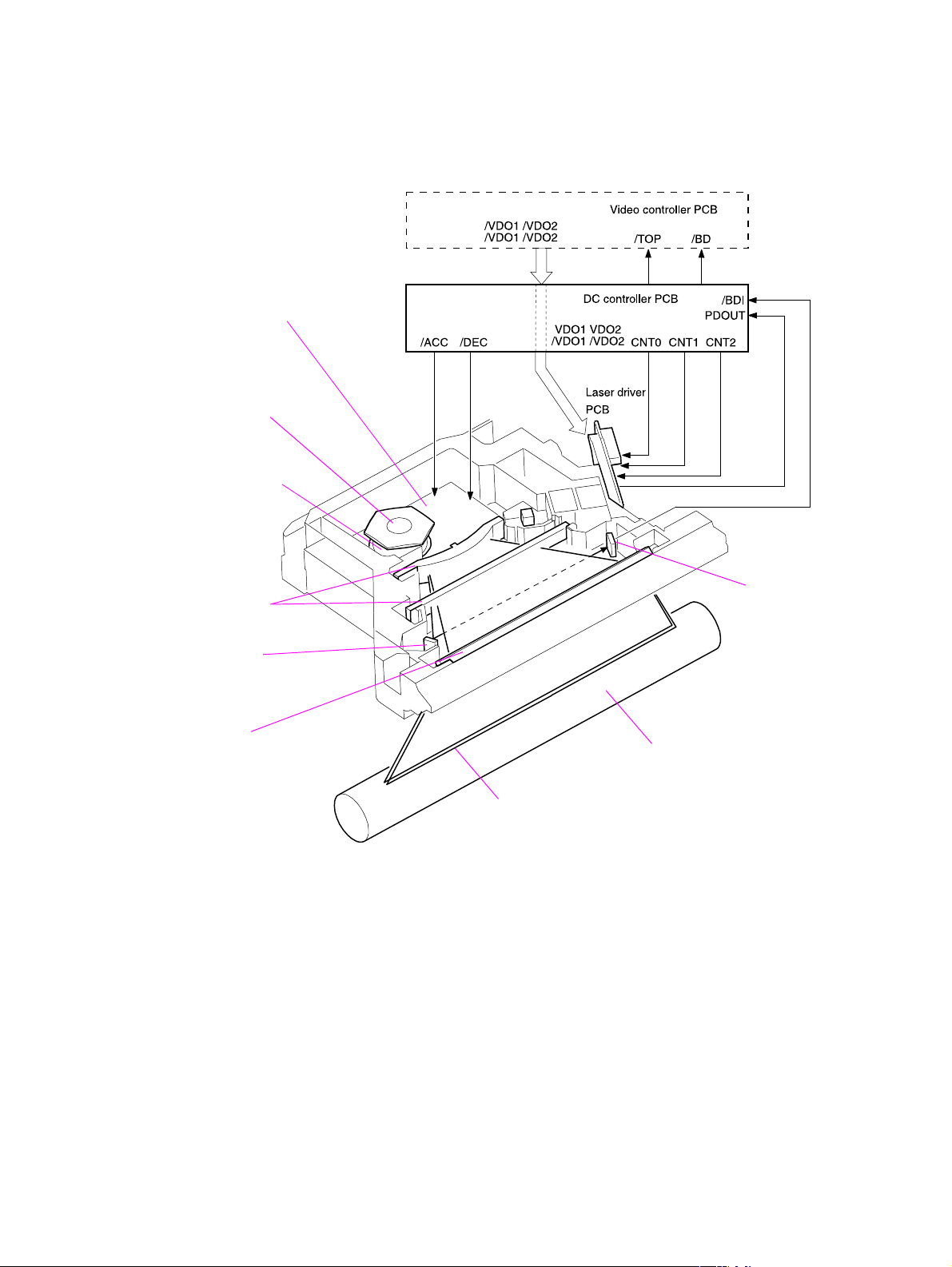

Laser/scanner assembl y

The laser/scanner produces the latent electrostatic image on the photosensitive drum in the print

cartridge.The main components of the laser/scanner assembly are the laser driver PCA, the

scanner motor, various mirrors, and the focusing lenses.

Scanner motor PCA

Scanner motor

Scanner mirror

Focusing lens

BD mirror

Mirror

Figure 12. Laser/scanner assembly

The laser scanner uses two laser diodes to scan two lines simultaneously producing high speed

laser scanning. After receiving the print command from the host computer, the DC controller

PCA activates the scanner motor which rotates the six-sided scanner mirror. The laser driver

PCA emits light from the two laser diodes according to signals from the DC controller PCA. The

two laser beams strike the six-sided scanning mirror and are directed through the focusing

lenses and down onto the photosensitive drum. The modulated laser beams generate the latent

electrostatic image on the photosensitive drum according to the image data signals received

from the DC controller PCA.

BD PCA

Photosensitive drum

(inside the print cartridge)

Laser beams

76 Theory of operation Q2431-90912

Page 13

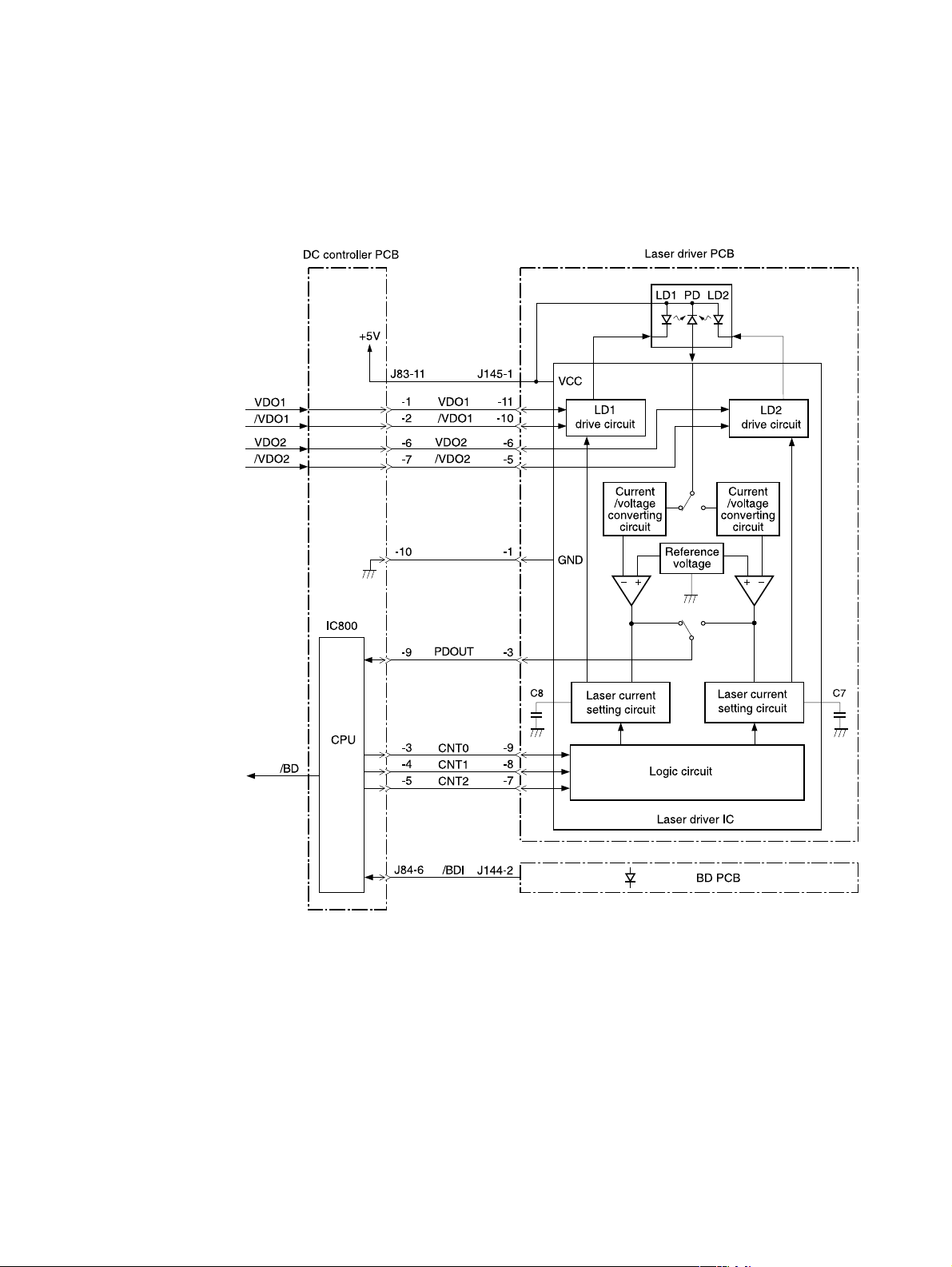

Laser/scanner control

The laser/scanner control circuit on the laser driver PCA turns the laser diodes on an off

according to image data signals received from the DC controller PCA. The DC controller PCA

sends image data signals VD01/VD01,VD02, and /VD02 and the laser control signals CNT0,

CNT1, and CNT2 to the logic circuit on the laser driver PCA. The laser control signals control

laser emission, automatic power control (APC), horizontal synchronization control, and image

mask control.

Figure 13. Laser control circuit block diagram

Laser emission control is simply turning the laser diodes on and off. Automatic power control is

used to limit the amount of light that is emitted from the laser diodes. Horizontal synchronization

control is used to determine the starting position for the images horizontal direction. Image mask

control is used to avoid laser beam emission on the non-imaging areas of the drum (about 5mm

down the vertical edges and 8mm at the top and bottom)

Q2431-90912 Chapter 5 Theory of operation 77

Page 14

Paper pickup system

The paper pickup and feed system consists of various kinds of pickup and feed rollers that are

driven by the printer’s motor(s). The printer uses tray 1 (the manual feeding tray) and a cassette

in tray 2 as media sources. The printed media is delivered to either the rear output bin (straight

through printing) or the top output bin (the default destination). Two additional 500-sheet feeders

and one 1,500-sheet feeder can be added to the printer. These accessories are discussed

further along in this chapter.

Media is detected in tray 1 by the tray 1 paper sensor (on the tray 1 pickup assembly; PS105).

The media is detected in tray 2 by the tray 2 paper sensor (PS101). The paper size sensor

(PS106) and the paper size switch (SW102) detect the media that is loaded in the tray 2

cassette.

All of the rollers in the printer are driven by two motors, a clutch, and a solenoid which are

controlled by the DC controller PCA (for the HP LaserJet 4300 has three motors). See “Motor

and fan control” on page 70.

The pre-feed, top of page, and fuser assembly delivery sensor (PS102, PS103, PS108) detect

arrival and passing of media along the paper path. If the paper does not reach or pass these

sensors within a specific amount of time the microprocessor on the DC controller PCA halts the

printer functions and a jam error message will appear on the control-panel display. See

“Alphabetical printer messages” on page 258 and “Numerical prin ter mess ag es ” on page 274.

For information about the location of printer switches, sensors, and motors see “Printer switches

and sensors” on page 336 and “Printer motors and fans” on page 337.

Figure 14. Printer paper pickup and feed block diagram

78 Theory of operation Q2431-90912

Page 15

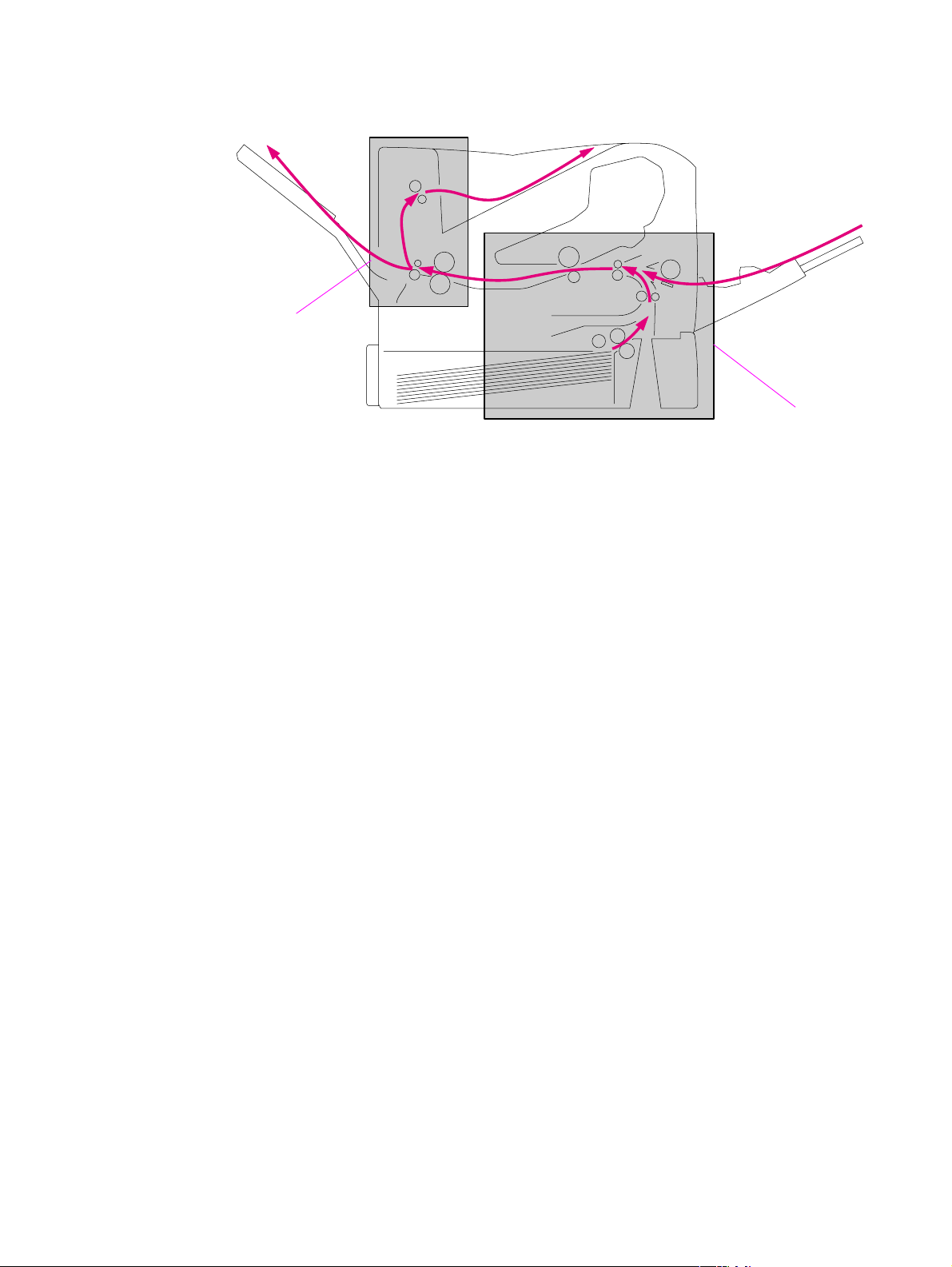

The paper pickup and feed system is divided into two blocks. The paper pickup/feed block, and

the fuser/delivery block.

Fuser/delivery block

Figure 15. Paper pickup/feed and fuser/delivery block diagram

Paper pickup and feed block

Paper pickup/feed block

The printer functions that take place in the pickup/feed block are cassette media size and

presence detection, media entering the paper path from tray 1 or tray 2, Lifting of the tray 2

paper plate, multiple feed prevention, and page skew correction. For information about the

locations of switches, sensors, and motors in the pickup/feed block, see “Printer switches and

sensors” on page 336 and “Printer motors and fans” on page 337.

When the print command is received from the host computer by the DC controller PCA it turns

the main motor (M101) power on. This motor will drive the tray 2 pickup, feed, and separation

rollers to rotate. For the HP LaserJet 4300, the print cartridge motor power also is turned on. The

laser/scanner motor power is turned on.

The DC controller PCA then activates the feed clutch (CL101) to rotate the feed roller. The tra y 2

pickup solenoid is activated (SL101) and the pickup arm descends. The pickup roller touches the

media and a sheet is fed into the printer. The separation roller prevents multi-sheets of media

from being fed all at one time.

As the pre-feed sensor (PS102) detects the media, the DC controller PCA turns off the clutch

which stops the media. When the DC controller PCA detects that the laser/scanner is ready it

activates the feed clutch again. The feed roller moves the media further into the printer. Page

skew is corrected by the registration shutter and the media is transported to the fuser/delivery

block (feed belt, fuser, and delivery output bin).

For information about the timing of these operations, see “HP LaserJet 4200 general timin g

diagram” on page 357 and “HP LaserJet 4300 general timing diagram” on page 358.

Q2431-90912 Chapter 5 Theory of operation 79

Page 16

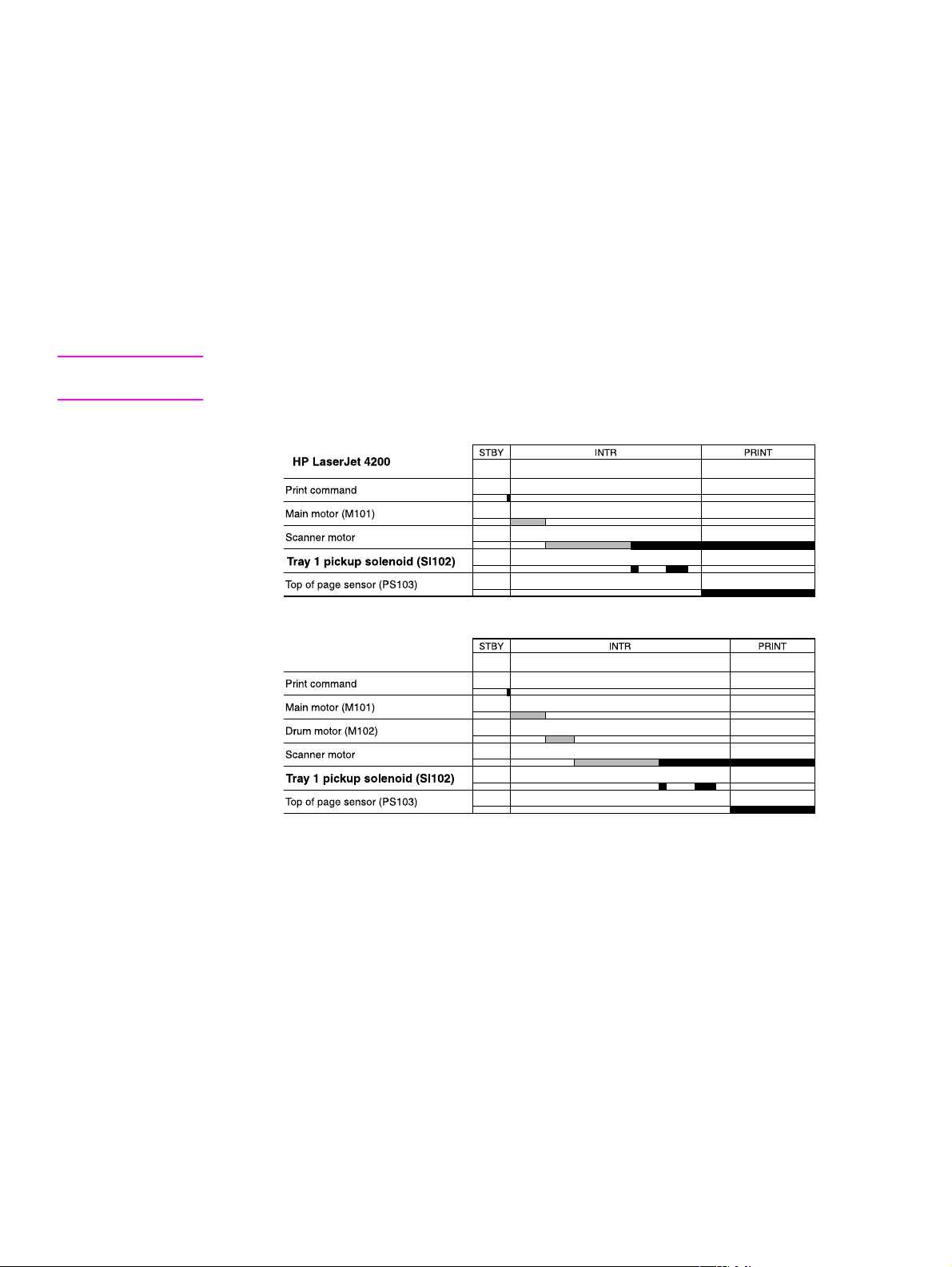

Printing from tray 1

The presence of paper in tray 1 is detected by the tray 1 paper sensor (PS105).

When the DC controller PCA receives the print command, the printer starts the initial rotation

phase. (This consists of main motor warm-up, scanner motor warm-up, high-voltage control

sequence and fuser warm-up.) When the initial rotation phase ends, the tray 1 pickup solenoid

(SL102) is activated.

The cam rotates, the paper tray lifter rises, and the media comes in contact with the tray 1 pickup

roller. At the same time, the tray 1 pickup roller rotates twice and a sheet of media in tray 1 is

picked up. The separation pad prevents unnecessary sheets from feeding with the first sheet.

The sheet then reaches the registration assembly, where its skew is corrected. Then it goes

through transfer, separation, and fusing stages; passes through the delivery unit; and is

delivered to the output bin.

Note If paper is removed from tray 1 just before it is picked, the tray 1 pickup roller might continue to

rotate up to six times and a jam will be detected.

Figure 16. Tray 1 timing diagrams

80 Theory of operation Q2431-90912

Page 17

Separation pad

Tra y 1 pic kup roller

Tra y 1 pic kup solenoid

Cam

Lifter

Figure 17. Tray 1 pickup

Q2431-90912 Chapter 5 Theory of operation 81

Page 18

Printing from tray 2

When the DC controller PCA receives print command, the main motor (M101) and scanner

motor start rotation. When the main motor reaches its prescribed speed, the feed roller clutch

(CL101) and tray 2 pickup solenoid (SL101) are activated. (The tray 2 pickup roller, tray 2 feed

roller, tray 2 separation roller, and paper feed rollers are driven by the main motor rotation.)

The tray 2 pickup roller, activated by the pickup solenoid, rotates once and picks up the media in

the tray. The unnecessary sheets are removed by the separation roller and the media is fed to

the pre-feed sensor (PS102).

The sheet then reaches the registration assembly, where its skew is corrected. Then it goes

through transfer, separation, and fusing stages; passes through the delivery unit; and is

delivered to the output bin.

Figure 18. Tray 2 timing diagrams

82 Theory of operation Q2431-90912

Page 19

Tray 2, 500-, 1,500-sheet feeder media size detection

Media size in the cassette are detected by three switches. The switches are active after the

cassette is placed in the tray 2 feeder. (this also applies to the optional 500- and 1,500-sheet

feeder). The DC controller PCA microprocessor detects the size and presence of the media by

the combinations of the switches.

Table 32. Tray 2 and 500-sheet feeder media size switch settings

Paper size Media size switch setting

Upper Center Lower

No cassette installed

A4

LTR

B5

A5

EXE

LGL

UNV

Off Off Off

Off Off On

Off On Off

Off On On

On Off Off

On Off On

On On Off

On On On

Table 33. 1,500-sheet feeder media size switch settings

Paper size Media size switch setting

Upper Center Lower

No cassette installed

A4

LTR

LGL

Off Off Off

On Off On

Off On On

On On Off

The tray 2 cassette can detect the media size using the switches describe above, however the

user can define the media size for the tray using the control-panel (see “Paper Handling menu”

on page 42). In this case the printer may not correctly detect the media size if the user’s defined

size does not match the tray settings.

To prevent a false size detection, the printer measures the time it takes for the media to pass

from its leading edge to its trailing edge and determines the media size that was fed from the

tray. When the measured size differs from the user’s defined size or from the media size

switches, a message will appear on the control-panel display (see “Alphabetical printer

messages” on page 258).

Q2431-90912 Chapter 5 Theory of operation 83

Page 20

Lifter-driver operation

The lifter driver keeps the media stack surface at a specific level in order to have a stabilized

pickup operation regardless of the size of the media in the tray 2 cassette. The DC controller

PCA operates the lifter driver motor (M103) for 50 seconds. The motor stops when the paper

stack position sensor (PS107) detects the media. If the paper stack position sensor does not

detect any media within 8 seconds after the lifting operation has begun, the DC controller PCA

determines there has been a lifter driver motor failure and a message appears on the controlpanel display (see “Alphabetical printer messages” on page 258 or “Numeric al printer

messages” on page 274). The DC controller PCA stops the lifting operation if the paper stack

position sensor detects the absence of the tray 2 cassette.

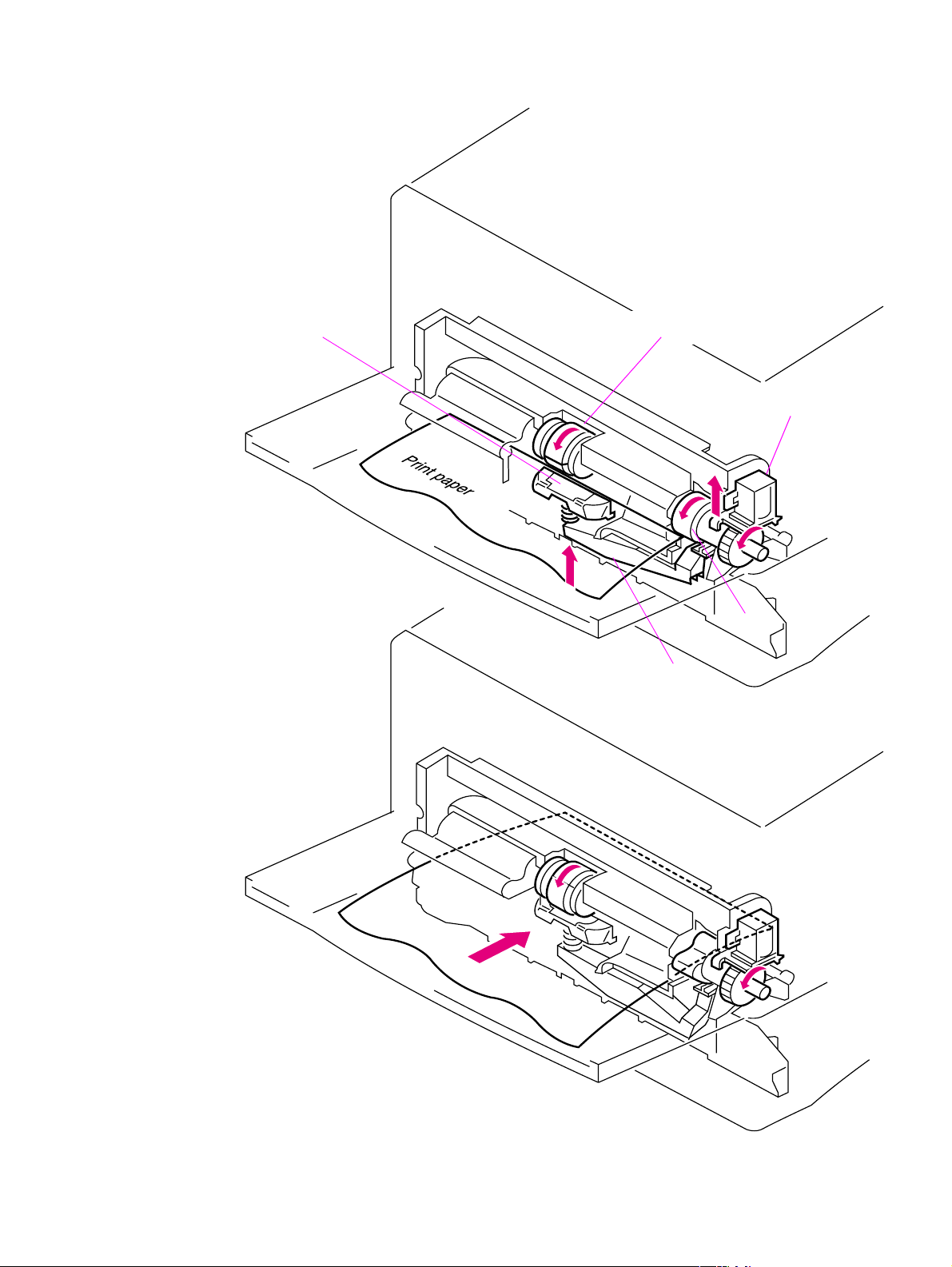

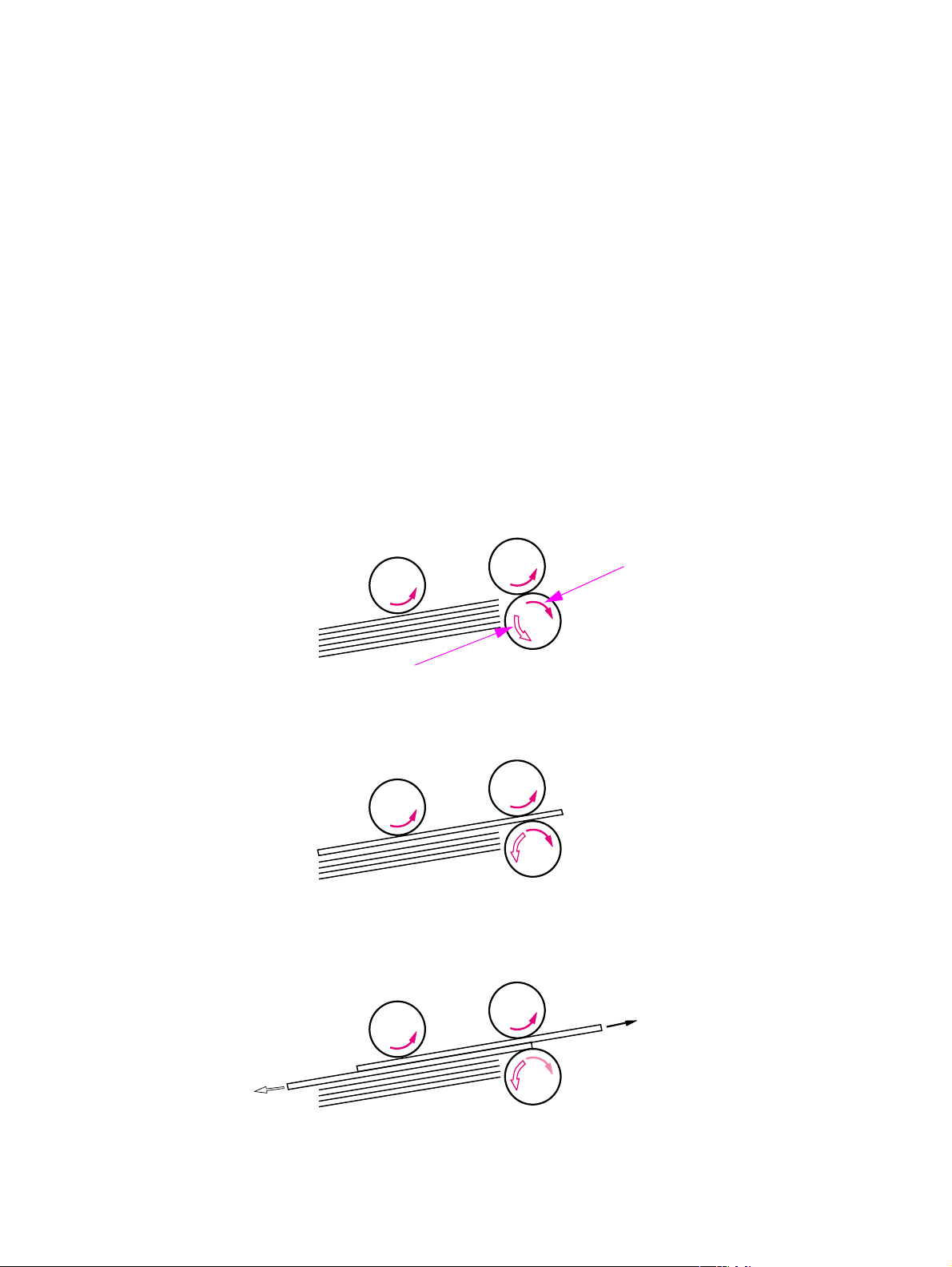

Multiple feed prevention

The printer uses the separation roller in tray 2 to prevent multiple-feeding. Normally, the

separation roller rotates in the same direction as the feed roller. The separation roller is equipped

with a torque limiter, but because the force of the feed roller exceeds that of the torque limiter, the

separation roller is actually driven by the feed roller.

If multiple sheets of media are picked up, however, the low friction force between the sheets

weakens the rotational force from the feed roller to the separation roller. Consequently, the

torque limiter takes control of the separation roller, and rotates the separation roller in the reverse

direction, which removes the extra sheets.

Feed roller

Pickup roller

Media

Normal

Driving force transmitted from the feed roller

Separation roller

Driving force transmitted from the motor through the torque limiter

Multiple feed

Figure 19. Multiple feed prevention

84 Theory of operation Q2431-90912

Page 21

Media skew prevention

The printer uses a registration shutter on the registration assembly to prevent media from

entering the printer skewed (without decreasing the throughput speed). When media is fed to the

registration assembly its leading edge contacts the registration shutter, but does not yet open the

shutter. The feed roller continues to rotate and the media begins to sag. The sagging papers

leading edge comes in full contact with the shutter (skew is corrected at this point) and raises the

registration shutter. With the shutter out of the way, the media can continue into the printer paper

path.

Registration assem bly shutter

Leading edge contacts

the shutter

Media sags and the

entire leading edge

contacts the shutter

Skew is corrected and

the shutter rais es up . The

media can contin ue along

the paper path.

Figure 20. Correcting skewed media pages

Q2431-90912 Chapter 5 Theory of operation 85

Page 22

Fixing/delivery block

The paper pickup and feed system is divided into two blocks. The paper pickup tray to the fuser

block, and the fuser to output bin block.

Fuser/delivery block

Figure 21. Paper pickup/feed and fuser/delivery block diagram

The fuser/delivery block consists of the various rollers, sensors, the fuser, and the output

delivery assembly. The rollers transport the media through the fuser/delivery block paper path.

The fuser applies heat and pressure to the media to permanently bond the toner image (which

was transferred to the media from the photosensitive drum in the print cartridge) to the media.

The output delivery assembly sends the printed media either to the rear output bin (if the rear

output door is open) or to the top output bin (the default output delivery bin). Sensors along the

paper path detect the movement of the media, jams if they occur, and when the top output bin is

full.

Paper pickup/feed block

86 Theory of operation Q2431-90912

Page 23

Printer jam detection

The printer uses the following sensors to detect the presence of media and to verify if the media

is being fed properly or has jammed. For information about the location of these sensors, see

“Printer switches and sensors” on page 336.

● Pre-fed sensor (PS102)

● Top of page sensor (PS103)

● Fuser delivery sensor (PS108)

The microprocessor on the DC controller PCA checks for media jamming by timing the passing

of the media as it moves past these sensors. If the media does not pass the sensor in a specific

period of time, the transport process is stopped (motors are turned off and the rollers no longer

rotate) and a jam message appears on the control-panel display.

Printer pickup delay jam from tray 1

If the top of page sensor (PS103) does not detect the leading edge of the media within a specific

time after the media is picked up the microprocessor on the DC controller PCA determines there

is a pickup jam.

Note The printer attempts to re-pickup the media several times before determining there is a pickup

jam. The number of re-pickup tries depends on the pickup source (for example, the re-pickup is

tried 4 times if tray 1 is the pickup source).

The transport process is stopped and a 13.XX.YY JAM message appears on the control-panel

display. For more information about jam messages, see “Alphabetical printer messages” on

page 258 and “Numeri c al printer messages” on page 274.

Printer pickup delay jam from tray 2

If the pre-feed sensor (PS102) does not detect the leading edge of the media within a specific

time after the media is picked up the microprocessor on the DC controller PCA determines there

is a pickup jam.

Note The printer attempts to re-pickup the media several times before determining there is a pickup

jam. The number of re-pickup tries depends on the pickup source (for example, the re-pickup is

tried 4 times if tray 1 is the pickup source).

The transport process is stopped and a 13.XX.YY JAM message appears on the control-panel

display. For more information about jam messages, see “Alphabetical printer messages” on

page 258 and “Numeri c al printer messages” on page 274.

Printer pickup stationary jam

If the top of page sensor (PS103) does not detect the trailing edge of the media within a specific

time after the media is picked up the microprocessor on the DC controller PCA determines there

is a pickup jam.

The transport process is stopped and a 13.XX.YY JAM message appears on the control-panel

display. For more information about jam messages, see “Alphabetical printer messages” on

page 258 and “Numeri c al printer messages” on page 274.

Q2431-90912 Chapter 5 Theory of operation 87

Page 24

Printer delivery wrap jam when feeding regular media

Regular size media is defined as A4, letter, legal, B5, executive or A5.

If the fuser delivery sensor (PS108) does not detect the trailing edge of the media after a

specified fusing time the microprocessor on the DC controller PCA determines there is a fuser

wrap jam.

The transport process is stopped and a 13.XX.YY JAM message appears on the control-panel

display. For more information about jam messages, see “Alphabetical printer messages” on

page 258 and “Numerical printer messages” on page 274.

Printer delivery wrap jam when feeding non-regular media

Non-regular media is defined as media that is less than 200mm (7.9 inches) in length.

If the fuser delivery sensor (PS108) does not detect the trailing edge of the media within a

specified time after a fuser wrapping jam is detected, the microprocessor on the DC controller

PCA determines there is a fuser wrap jam.

Or If the fuser delivery sensor (PS108) does not detect the trailing edge of the media within a

specified time after it has detected the leading edge of the media the microprocessor on the DC

controller PCA determines there is a fuser wrap jam.

The transport process is stopped and a 13.XX.YY JAM message appears on the control-panel

display. For more information about jam messages, see “Alphabetical printer messages” on

page 258 and “Numerical printer messages” on page 274.

Printer delivery delay jam

If the fuser delivery sensor (PS108) does not detect the trailing edge of the media within a

specific time after detecting the leading edge of the media, the microprocessor on the DC

controller PCA determines there is a fuser stationary jam.

The transport process is stopped and a 13.XX.YY JAM message appears on the control-panel

display. For more information about jam messages, see “Alphabetical printer messages” on

page 258 and “Numerical printer messages” on page 274.

If the fuser delivery sensor (PS108) detects the trailing edge (paper out) of the media within a

specified time, after it has detected the leading edge of the media the microprocessor on the DC

controller PCA determines there is a delivery jam.

However, if the paper length detected by the top of page sensor (PS103) does not match the

media size that the printer expects from the pickup source, this jam is ignored. The top of page

sensor (PS103) determines the length of the page by measuring the tim it takes between the

passing of the leading and trailing edges of the page.

The transport process is stopped and a 13.XX.YY JAM message appears on the control-panel

display. For more information about jam messages, see “Alphabetical printer messages” on

page 258 and “Numerical printer messages” on page 274.

Note This jam cannot be detected for pages that are less than 200mm (7.9 inches) in length.

88 Theory of operation Q2431-90912

Page 25

Printer door open jam

If the top door is opened (this will activate the top door open switch; SW101) during a print

operation, the microprocessor on the DC controller PCA determines there is door open jam.

The transport process is stopped and a 13.XX.YY JAM message appears on the control-panel

display. For more information about jam messages, see “Alphabetical printer messages” on

page 258 and “Numeri c al printer messages” on page 274.

Printer residual media jam

If either the top of the page sensor (PS103) or the fuser delivery sensor (PS108) does not detect

the leading edge of the media at the start of initial rotation (see table 30 on page 67) the

microprocessor on the DC controller PCA determines there is residual media jam.

Q2431-90912 Chapter 5 Theory of operation 89

Page 26

Printing from the 500-sheet feeder

Note The HP LaserJet 4200/4300 series printers support up to two optional 500-sheet feeders.

The paper-feeder driver controls the operation sequences of the 500-sheet feeder. An 8-bit

microprocessor in the paper-feeder driver controls the 500-sheet feeder sequences and the

communication with the DC controller PCA.

The paper-feeder driver drives the solenoid in response to the pickup command. The paperfeeder driver also returns the status of the paper feeder to the DC controller PCA.

The printer delivers a charge of +24 vdc to the paper feeder, which then generates +3.3 v for the

integrated circuits.

Figure 22. 500-sheet feeder I/O block diagram

500-sheet feeder pic k up and f ee ding

Three switches on the paper-feeder driver detect the media size and the presence of the 500sheet tray. The relationship between the switch combinations and the paper sizes is the same as

for the printer. See table 32 on page 83.

The main motor (M101) of the printer drives the paper feeder. When the DC controller PCA

sends a print command to the paper feeder, the main motor of the printer begins to rotate. When

the scanner motor reaches its prescribed speed, the paper-feeder driver receives the pickup

command from the DC controller PCA and activates the paper-feeder pickup solenoid. (The

main motor drives the pickup roller, feed roller, and separation roller.)

90 Theory of operation Q2431-90912

Page 27

The pickup roller, activated by the solenoid, rotates once, picking up the media inside the 500sheet tray. The separation roller removes any unnecessary sheets and the media travels to the

pre-feed sensor (PS102).

The sheet then reaches the registration assembly, where its skew is corrected. Then it goes

through transfer, separation, and fusing stages; passes through the delivery unit; and is

delivered to the output bin.

Note The 500-sheet feeder detects pickup and feed jams in the same way as the printer. See “Printer

jam detection” on page 87.

Figure 23. 500-sheet feeder pickup and feed diagram

Q2431-90912 Chapter 5 Theory of operation 91

Page 28

Printing from the 1,500-sheet fe eder

The paper-feeder driver controls the operation sequences of the 1,500-sheet feeder. An 8-bit

microprocessor in the paper-feeder driver controls the 1,500-sheet feeder sequences and the

communication with the DC controller PCA.

The paper-feeder driver drives the solenoid in response to the pickup command. The paperfeeder driver also returns the status of the paper feeder to the DC controller PCA.

The printer delivers a charge of +24 vdc to the 1,500-sheet feeder, which then generates +3.3 v

for the integrated circuits.

Figure 24. 1,500-sheet feeder I/O block diagram

1,500-sheet feeder pickup and feeding

Three switches on the paper-feeder driver detect the media size and the presence of the 1,500sheet tray. The relationship between the switch combinations and the paper sizes is the same as

for the printer. See table 32 on page 83

The main motor (M101) of the printer drives the paper feeder. When the DC controller PCA

sends a print command the main motor of the printer begins to rotate. When the scanner motor

reaches its prescribed speed, the paper-feeder driver receives the pickup command from the DC

controller PCA and activates the paper pickup solenoid. (The main motor drives the pickup roller,

feed roller, and separation roller.)

The pickup roller, activated by the solenoid, rotates once, picking up the media inside the

1,500-sheet tray. The separation roller removes any unnecessary sheets and the media travels

to the pre-feed sensor (PS102).

The sheet then reaches the registration assembly, where its skew is corrected. Then it goes

through transfer, separation, and fusing stages; passes through the delivery unit; and is

delivered to the output bin.

Note The 1,500-sheet feeder detects pickup and feed jams in the same way as the printer. See“Printer

jam detection” on page 87.

92 Theory of operation Q2431-90912

Page 29

Figure 25. 1,500-sheet feeder pickup and feed diagram

Q2431-90912 Chapter 5 Theory of operation 93

Page 30

1,500-sheet feeder lifting mechanism

The lifting mechanism maintains the media stack surface at a specific position inside the 1,500sheet feeder. This allows the feeder to perform a stabilized pickup operation regardless of the

size of the media loaded in the feeder. The lift plate inside of the feeder is lifted by two wire

cables. A motor (M1) winds these wires up using pulleys in the feeder. When the front door of the

feeder is opened, the pulley gears and the motor gear are disengaged and the lift plate lowers

under its own weight. The lifting mechanism is active (the plate is in the raised position) when it

is signaled by the DC controller PCA, the front door is closed, or during the print operation. The

1,500-sheet feeder control PCA driver stops the motor (M1) when the 1,500-sheet feeder paper

stack position sensor (SR2) detects media.

If the 1,500-sheet feeder paper stack position sensor (SR2) does not detect media within about

30 seconds after the start of the lift operation, the paper-deck driver PCA detects a lifter motor

failure and sends a signal to the DC controller PCA. An error message appears on the controlpanel display.

Figure 26. 1,500-sheet feeder lifting mechani sm

94 Theory of operation Q2431-90912

Page 31

Envelope feeder

The envelope-feeder driver controls the operation sequences of the envelope feeder. An 8-bit

microprocessor in the envelope feeder driver controls the envelope-feeder sequence and the

communication with the DC controller PCA.

The DC controller PCA sends the pickup command to the envelope-feeder driver with the

necessary timing. The envelope-feeder driver activates the solenoid in response to the

command.

The printer delivers a charge of +24 vdc to the envelope feeder, which then generates +5 v for

the integrated circuits.

Figure 27. Envelope feeder I/O block diagram

Q2431-90912 Chapter 5 Theory of operation 95

Page 32

Envelope feeder pickup and feeding

In the envelope feeder, the env elope sensor (PS901) detects the presence of envelopes and the

envelope-size sensor (PS903) detects the width of the envelope. The envelope pickup motor

(M901) drives all of the rollers in the envelope feeder.

When the DC controller PCA sends a print command the main motor (M101) in the printer begins

to rotate. After the main motor initial rotation phase is completed, the scanner motor begins to

rotate. As the scanner motor rotates, the envelope pick-up motor (M901) begins to rotate to drive

the pickup roller, feed roller, and separation roller, and an envelope is picked up.

The separation roller removes any unnecessary envelopes and the envelope travels to the

printer. The registration assembly corrects any skew. The envelope travels through the printer

paper path and is delivered to the output bin.

Figure 28. Envelope feeder pickup and feed diagram

96 Theory of operation Q2431-90912

Page 33

Envelope feeder jam detection

The envelope feeder uses the envelope multiple feed sensor (PS902) along with sensors in the

printer to detect the presence of media and to determine whether the media is feeding properly

or is jamming.

If a jam occurs in the envelope feeder, the error message 13.XX.YY appears on the control-panel

display. For more information see “Numerical printer messages” on page 274.

Envelope feeder pickup delay jam

If the pickup sensor (PS103) does not detect the leading edge of the envelope within a specific

time after the envelope is picked up, it attempts to pick up the media several times before

determining that a pickup jam has occurred.

If the pre-fed sensor inside of the printer (PS102) does not detect the leading edge of the

envelope within a specific amount of time after the re-pick operation stops, the microprocessor

on the DC controller PCA determines that a jam has occurred.

The transport process stops and a 13.XX.YY message appears on the control-panel display. For

more information about jam messages, see “Numerical printer messages” on page 274.

Envelope feeder pickup stationary jam

If the envelope multiple feed sensor (PS902) detects multiple fed envelopes after the pickup

operation begins The transport process stops and a 13.XX.YY message appears on the controlpanel display. For more information about jam messages, see “Numerica l pr in ter mess ag es ” on

page 274.

Q2431-90912 Chapter 5 Theory of operation 97

Page 34

Duplexer

The duplexer driver controls the operation of the duplexer. An 8-bit microprocessor in the

duplexer driver controls the duplexer sequence and the communication with the DC controller

PCA.

The duplexer driver drives the solenoid, motors, and fan according to commands that the DC

controller PCA sends to the duplexer. The duplexer also communicates its status to the DC

controller PCA.

The printer delivers a charge of +24 vdc to the duplexer, which then generates +5 v for the

integrated circuits.

Figure 29. Duplexer I/O block diagram

98 Theory of operation Q2431-90912

Page 35

Reversing and duplexer pickup

The duplexer has two stepping motors: the reversing motor (M701) and the duplex feed motor

(M702). The duplexer driver controls forward and reverse rotations of the motor.

The face-up output tray diverter, which is controlled by the duplexer solenoid, feeds print media

to the duplexer.

Note The duplexer cannot be used if the face-up tray is open,.

When the trailing edge of the media passes the reverse sensor (PS703), the reversing motor

changes direction. The oblique roller and feed roller then move the media so that its edge makes

contact with the left panel to correct skew.

Figure 30. Duplexer pickup and reversing diagram

Q2431-90912 Chapter 5 Theory of operation 99

Page 36

Duplexer jam detection

The following paper sensors detect whether or not the print media is present and is feeding

normally.

● Tray 2 paper sensor (PS101)

● Pre-feed sensor (PS102)

● Top-of-page sensor (PS103)

● Face-down tray paper-full sensor (PS104)

● Tray 1 (multipurpose tray) paper sensor (PS105)

● Paper width sensor (PS106)

● Fuser delivery sensor 1 (PS108)

The microprocessor on the DC controller PCA detects a jam by using the sensor to check for

media presence at a specific timing that is stored in the memory.

If the DC controller PCA detects that a jam has occurred, it stops print operation and an error

message appears on the control-panel display. See “Alphabetical printer messages” on

page 258 and “Numerical printer messages” on page 274.

100 Theory of operation Q2431-90912

Page 37

Stacker and stapler/stacker

The stacker delivers media from the printer to the stacker delivery bin. The stapler/stacker

staples the media together, and then delivers it to the stapler/stacker delivery bin. The DC

controller PCA controls the stacker and stapler/stacker. When the stacker or stapler/stacker

feeds, the DC controller PCA sends page information (for example, the paper size or whether the

page is the first or last page of the job) to the stacker or stapler/stacker.

Stacker

Figure 31. Stacker and stapler/stacker paper path

Stapler/stacker

Q2431-90912 Chapter 5 Theory of operation 101

Page 38

The following diagram illustrates the power-on sequence for the stacker and stapler stacker.

Figure 32. Power-on sequence for the stacker and stapler/stacker

102 Theory of operation Q2431-90912

Page 39

Stacker

The DC controller PCA controls the stacker and sends signals to the stacker driver PCA. The

stacker driver PCA then controls the operation of the stacker components like the stacker motor,

solenoid, and sensors. When the printer power is turned on, dc power from the printer’s lowvoltage supply circuit is supplied to the stacker. The stacker performs the power-on sequence

(see figure 32 on page 102) and enters the standby mode. When it receives a signal from the DC

controller PCA, the stacker driver PCA activates the motors and solenoids as needed to perform

the stack operation.

Figure 33. Stacker driver PCA block diagram

Q2431-90912 Chapter 5 Theory of operation 103

Page 40

Stacker feed and delivery

The stacker feed and delivery system consists of several feed rollers and guides that the stacker

motor and solenoids drive. Sensors along the stacker paper path detect the arrival and passing

of media and confirm the position of the jogger guide. The jogger guide helps to align the pages

before placing them in the delivery bin.

Table 34. Stacker components

Component Purpose

Motor Feed motor (M103) Rotates the feed and delivery roller

Solenoid Deflector solenoid (SL1101) Operates the delivery deflector

Sensor Paper inlet sensor (PS1101) Used for jam detection

Paper delivery sensor (PS1102) Used for jam detection

Delivery paper full sensor (PS1106) Detects that the delivery bin is full

Switch Door open switch (SW1101) Detects an open door

After the leading edge of the media reaches the fixing delivery sensor (PS108) in the printer, the

DC controller PCA sends a signal to the stacker driver PCA. The stacker driver PCA activates

the deflector solenoid (SL101) for a specific amount of time to move the delivery deflector into

place in the printer which routes the media to the stacker rather than to the printer’s top output

bin. The stacker driver PCA also activates the stacker motor (at the same speed as the printer’s

main motor) to rotate the feed and delivery rollers).

The feed roller moves the media into the stacker. If the DC controller PCA sends a

following-page signal (which means there is another page in the job), the stacker driver PCA

activates the deflector solenoid (SL101) again. The delivery roller moves the media into the

delivery bin.

Delivery bin

Delivery

Feed roller

Deflector

Figure 34. Stacker feed delivery diagram

104 Theory of operation Q2431-90912

Page 41

Stacker jam detection

The stacker uses the following sensors to detect the presence of media and to verify whether the

media is feeding correctly or is jamming. For information about the location of these sensors, see

“Stacker and stapler/stacker switches and sensors” on page 345.

● Paper inlet sensor (PS1101)

● Paper delivery sensor (PS102)

Stacker feed jam

If the paper inlet sensor (PS1101) does not detect the leading edge of the media within a specific

time after the stacker driver has received the paper delivery signal, the DC controller PCA

determines that a stacker feed delay jam has occurred.

The transport process stops and a 13.XX.YY JAM message appears on the control-panel

display. For more information about jam messages, see “Alphabetical printer messages” on

page 258 and “Numeri c al printer messages” on page 274.

Stacker feed stationary jam

If the paper inlet sensor (PS1101) does not detect the trailing edge of the media within a specific

time after the paper inlet sensor (PS1101) detected the leading edge of the media, the DC

controller PCA determines that a stacker feed delay jam has occurred.

The transport process stops and a 13.XX.YY JAM message appears on the control-panel

display. For more information about jam messages, see “Alphabetical printer messages” on

page 258 and “Numeri c al printer messages” on page 274.

Stacker residual media jam

If the paper inlet sensor (PS1101) or the paper delivery sensor (PS1102) detects media during

the initial drive period, the DC controller PCA determines that a stacker feed delay jam has

occurred.

The transport process stops and a 13.XX.YY JAM message appears on the control-panel

display. For more information about jam messages, see “Alphabetical printer messages” on

page 258 and “Numeri c al printer messages” on page 274.

Note This jam only occurs if the paper delivery sensor (PS1102) detects media at the start of the initial

drive.

Q2431-90912 Chapter 5 Theory of operation 105

Page 42

Stapler/stacker

The DC controller PCA controls the stapler stacker by sending signals to the stapler/stacker

driver PCA. The stapler/stacker PCA controls the stapler/stacker motor, solenoids, sensors, and

the stapler unit. When the printer power is turned on dc power from the printer’s low-voltage

supply circuit is supplied to the stapler/stacker. The stapler/stacker performs the power on

sequence (see figure 32 on page 102) and enters the standby mode. When the DC controller

PCA sends a signal, the stapler/stacker driver PCA activates the motors and solenoids as

needed to perform the staple and stack operation.

Figure 35. Stapler/stacker driver PCA block diagram

106 Theory of operation Q2431-90912

Page 43

Stapler/stacker feed and delivery

The stapler/stacker feed and delivery system consists of several feed rollers and guides that are

driven by the stapler/stacker motors and solenoids. Sensors along the stapler/stacker paper path

detect the arrival and passage of media and confirm the position of the jogger guide. The jogger

guide helps to align the pages before stapling and dropping them into the delivery bin.

The stapler/stacker has two modes. The staple mode staples media together and drops them

into the delivery bin. The stack mode drops the media directly into the delivery bin without

stapling them together.

Table 35. Stapler/stacker components

Component Purpose

Motor Paddle motor (M1101) ● Rotates the paddle (clockwise)

● Disengages the delivery roller (counterclockwise)

Jogger motor (M1102) Shifts the jogger guide.

● Widens the jogger guide (clockwise)

● Narrows the jogger guide (counterclockwise)

Feed motor (M103) Rotates the feed and delivery roller

Stapler motor (M1104) Rotates the staple cam

Solenoid Deflector solenoid (SL1101) Operates the delivery deflector

Clamp solenoid (SL1102) Operates the stapler clamp

Sensor Paper inlet sensor (PS1101) Detects jams

Paper delivery sensor (PS1102) Detects jams

Paddle home sensor (PS1103) Detects if the paddle is in the home position

Delivery roller disengaging sensor

(PS1104)

Jogger home position sensor

(PS1105)

Delivery paper full se ns or (PS11 06) Detects a full delivery bin

Switch Door open switch (SW1101) Detects an open door

Staple presence switch (SW1102) Detects the presence of staples in the stapler cartridge

Staple home position sw i tch

(SW1103)

Detects the disengaging the delivery roller

Determines if the jogger guide is in the home position

Determines if the stapler cam is in the home position

Q2431-90912 Chapter 5 Theory of operation 107

Page 44

Figure 36. Stapler/stacker motors, solenoids, and sensors block diagram

108 Theory of operation Q2431-90912

Page 45

Staple mode feed and delivery

In this mode, two to fifteen pages of media are stapled into one set and the stacks are then

delivered to the delivery bin.

After the leading edge of the media reaches the fixing delivery sensor (PS108) in the printer the

DC controller PCA sends a signal to the stapler/stacker driver PCA. The stapler/stacker driver

PCA activates the deflector solenoid (SL101) for a specific amount of time to move the delivery

deflector into place, which routes the media to the stapler/stacker rather than the printer’s top

output bin.

The stapler/stacker driver PCA activates the paddle motor (M1101) to rotate (counterclockwise)

the upper and lower delivery rollers to disengage them. It also activates the stacker motor (which

rotates at the same speed as the printer’s main motor) to rotate the feed and delivery rollers.

Upper delivery roller

Lower delivery roller

Stapler/stacker

Printer

Delivery

deflector

Fuser

delivery

sensor

Media path

Figure 37. Staple mode feed and delivery diagram (1 of 6)

Q2431-90912 Chapter 5 Theory of operation 109

Page 46

The jogger guide motor (M1101) moves the jogger guides to the waiting position, and the stapler/

stacker driver PCA again activates the paddle motor (M1101) counterclockwise to engage the

upper and lower delivery rollers.

Jogger guides

Upper

delivery

roller

Lower

delivery

roller

Stapler/stacker

Printer

Media

Figure 38. Staple mode feed and delivery diagram (2 of 6)

At a specific time after the paper inlet sensor (PS1101) detects the leading edge of the media,

the stapler/stacker PCA changes the speed of the feed motor (M1103) to synchronize the feed

rollers with the speeds of the other stapler/stacker motors and rollers. The stapler/stacker PCA

then activates the paddle motor (M1101) counterclockwise to again disengage the upper and

lower delivery rollers. The delivery deflector returns to its normal position.

Upper

delivery

roller

Lower

delivery

roller

Waiting position

Turn-out position

Jogger guides

Stapler/stacker

PS1101

Waiting position

Printer

Delivery deflector

Figure 39. Staple mode feed and delivery diagram (3 of 6)

110 Theory of operation Q2431-90912

Page 47

At a specific time after the paper inlet sensor (PS1101) detects the trailing edge of the media, the

stapler/stacker driver PCA activates the clamp solenoid (SL1102). The clamp keeps the page

from being pushed out of position by the pages that follow.

Upper

delivery

roller

SL1102

PS1101

Lower

delivery

roller

Figure 40. Staple mode feed and delivery diagram (4 of 6)

Jogger guides

Waiting position

The stapler/stacker now operates according to the following conditions.

● Is this the last page in the staple job

• No. The feed motor (M1101) changes speed and another page enters the stapler/

stacker. The stapler/stacker driver PCA activates the jogger motor and the jogger

guide moves to align the media stack horizontally. The stapler/stacker driver PCA

activates the paddle motor and the paddle pushes the page up against a guide to

align the media stack vertically. The delivery deflector moves into position to allow

the next page to enter the stapler/stacker.

• Yes. The feed motor (M1101) turns off. The stapler/stacker driver PCA activates the

jogger motor and the jogger guides move inward to align the media stack

horizontally. The stapler/stacker driver PCA activates the paddle motor and the

paddle pushes the page up against a guide to align the media stack vertically. Then

the pages are stapled.

Jogger guide

Media

Paddle

Lower

delivery

roller

Jogger guide

authentically

aligns the

media stack

Paddle vertically

aligns the media

stack

Staple

Figure 41. Staple mode feed and delivery diagram (5 of 6)

Q2431-90912 Chapter 5 Theory of operation 111

Page 48

After the pages are stapled, the stapler/stacker driver PCA activates the feed motor (M1103;

counterclockwise) to again engage the upper and lower delivery rollers. The stapled stack is

moved all of the way out onto the jogger guides. The stapler/stacker driver PCA activates the

jogger motor (M1102) to move the jogger guide into the turn-out position and allow the stack to

drop into the delivery bin.

Jogger guide

Jogger guide

Stapled media

Drop

moves into the

turn-out position

Figure 42. Staple mode feed and delivery diagram (6 of 6)

Figure 43. Staple mode timing diagram

112 Theory of operation Q2431-90912

Page 49

Stapler unit

The major components of the stapler unit are the stapler motor (M104), the staple cartridge, the

staple-detection switch, and the staple-module home-position switch. The staple cartridge holds

a maximum of 1,000 staples. The stapler/stacker driver PCA controls the stapler unit.

Stapler unit

Figure 44. Stapler unit I/O block diagram

Stapler/stacker

Q2431-90912 Chapter 5 Theory of operation 113

Page 50

Stapler unit operation

The stapler unit uses the stapler unit motor (M104), staple cam, staple press head plates, staple

arm, and support base to staple media together. The staple mode is enabled by using the

printer’s settings (see “Stapler/s tacker subme nu” on page 51). The stapling procedure begins

when media enters the staple guide and the DC controller PCA sends the end-of-job signal to

the stapler/stacker driver PCA.

Stapler unit

Staples

Staple press

head plates

Staple motor (M104)

Figure 45. Stapler unit

After the paddle and jogger guides align the edges of the media, the stapler/stacker PCA

activates the stapler unit motor (M104). The two staple cams begin to rotate.

Side view

Staple cam 2

Support base

Media

Staples

Staple press

head plate 2

Staple press

head plate 1

Staple cam 1

Staple cams

Staple press

head plate2

Staple press

head plate 1

Staple cam 1

Front view

Figure 46. Staple operation (1 of 3)

114 Theory of operation Q2431-90912

Page 51

As staple cam 1 rotates, it raises the staple press head plate 1. This forms the flat staple into a

“u” shape. While this is happening, the staple arm raises the swing guide.

Staple

Side view

Figure 47. Staple operation (2 of 3)

As staple cam 2 rotates, it raises staple press head plate 2. This pushes the staple up and

through the media. The staple arm raises the back end of the support base, bringing its front end

in contact with the staple legs that protrude through the media and folding them to complete the

staple operation.

Side view

Figure 48. Staple operation (3 of 3)

Front view

Front view

Q2431-90912 Chapter 5 Theory of operation 115

Page 52

Staple level detection

The stapler/stacker driver PCA uses the staple-detection switch to detect the presence and

number of staples in the stapler unit. A spring on the staple-detection switch holds the stapledetection flag in the raised position. When this flag is fully raised, the switch is open.

There is a slot cutout in the bottom of the staple cartridge. If the staple cartridge is mostly full of

staples, the staples block the staple-detection flag’s movement so that it cannot move to its

raised position. The staple-detection switch is closed, and the stapler/stacker driver PCA

determines that there are at least 70 staples in the cartridge. When less than 70 staples are left