Page 1

7

Troubleshooting

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Troubleshooting process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Initial troubleshooting checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Troubleshooting flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Power-on checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Troubleshooting tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Information pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Menu map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Configuration page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Supplies status page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Embedded Web server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Gaining access to the embedded Web server. . . . . . . . . . . . . . . . . . 243

Information tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Settings tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Networking tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Other links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Printer Status and Alerts software. . . . . . . . . . . . . . . . . . . . . . . . . . . 245

To select status messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

To view status messages and information . . . . . . . . . . . . . . . . . . 246

Control-panel menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Using control-panel menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Resets submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Diagnostics menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Service menu (service PIN codes) . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Service ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Restoring the Service ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Converting the Service ID to an actual date. . . . . . . . . . . . . . . . . 250

Printer resets and power-on modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Cold reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

To perform a cold reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

NVRAM initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

To initialize NVRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Hard-disk initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

To initialize the hard disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Power-on bypass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Skip disk load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Self test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Test pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Engine test page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Formatter test page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Interface troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Communications checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

EIO troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Computer direct connect (parallel) test . . . . . . . . . . . . . . . . . . . . . . . 255

Q2431-90912 Chapter 7 Troubleshooting 227

Page 2

Display-message troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Status messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Warning messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Critical-error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Alphabetical printer messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Numerical printer messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Paper-path troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Paper-jam recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

To disable the paper-jam recovery . . . . . . . . . . . . . . . . . . . . . . . 296

Avoiding paper jams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Persistent jams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

Basic troubleshooting for persistent jams . . . . . . . . . . . . . . . . . . 298

Data collection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

General paper-path troubleshooting . . . . . . . . . . . . . . . . . . . . . . 299

Paper-path checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Paper-path test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

To perform a paper- test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Jams in tray 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Jams in tray 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Jams in tray 3 and/or tray 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Jams in the paper path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Media transport problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Multiple pages feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Paper is wrinkled or folded. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Paper is skewed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Image-formation troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Print quality problems associated with media. . . . . . . . . . . . . . . . . . 306

Overhead transparency defects . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Print quality problems associated with the environment. . . . . . . . . . 307

Print quality problems associated with jams. . . . . . . . . . . . . . . . . . . 307

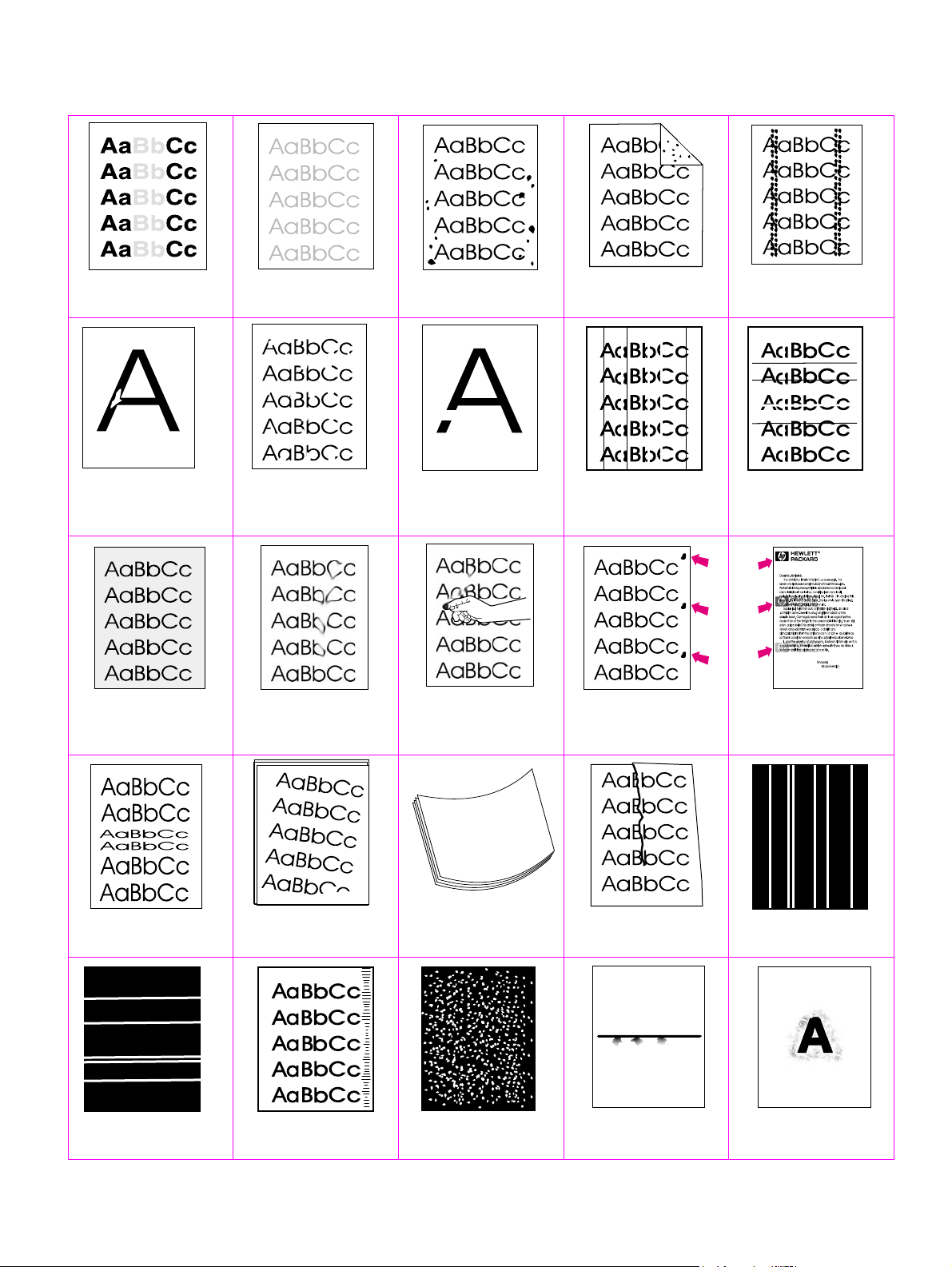

Image defects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Image quality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Check the print cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

EconoMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Half self-test functional check . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Drum rotation functional check . . . . . . . . . . . . . . . . . . . . . . . . . . 310

Image defect tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Repetitive defects troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 325

Troubleshooting the stacker and the stapler/stacker . . . . . . . . . . . . . . . 326

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

Initial checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

Jam errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

Stacker and stapler/stacker paper path. . . . . . . . . . . . . . . . . . . . 327

Stacker paper path test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

Stapler/stacker paper path test . . . . . . . . . . . . . . . . . . . . . . . . . . 328

Paper transport errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

Malfunction errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

Component errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

Printer component locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

Main printer parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

Printer switches and sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

Printer motors and fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 337

Printer PCAs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

228 Troubleshooting Q2431-90912

Page 3

Accessory component locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

500-sheet feeder main parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

500-sheet feeder switches, sensors, solenoids, and PCAs. . . . . . . . 340

1,500-sheet feeder main parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

1,500-sheet feeder switches, sensors, solenoids, and PCAs . . . . . . 343

Stapler/stacker stapler assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

Stacker and stapler/stacker motors and solenoids . . . . . . . . . . . . . . 346

Stacker and stapler/stacker PCAs. . . . . . . . . . . . . . . . . . . . . . . . . . . 347

Printer and accessory wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . 348

HP LaserJet 4200 wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

HP LaserJet 4300 wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

500-sheet feeder wiring diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

1,500-sheet feeder wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 351

Duplex accessory wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 352

Envelope feeder accessory wiring diagram. . . . . . . . . . . . . . . . . . . . 353

Stacker accessory wiring diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . 354

Stapler/stacker accessory wiring diagram. . . . . . . . . . . . . . . . . . . . . 355

DC controller connectors diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . 356

General timing diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

HP LaserJet 4200 general timing diagram . . . . . . . . . . . . . . . . . . . . 357

HP LaserJet 4300 general timing diagram . . . . . . . . . . . . . . . . . . . . 358

Q2431-90912 Chapter 7 Troubleshooting 229

Page 4

Introduction

In order to use the information in this chapter, you should have a basic understanding of the

LaserJet printing process. Explanations of each mechanical assembly, the printer systems, and

the basic theory of operation are contained in chapter 5 of this manual. Do not perform any of

these troubleshooting processes unless you understand the function of each printer component.

This chapter contains the following sections:

● Troubleshooting pro cess This section includes an initial troubleshooting checklist

and a troubleshooting flowchart. These contain information about common printer

errors that can inhibit proper operation or create print-quality problems. They also

include recommendations for resolving the cause of the problem. See

“Troubleshooting process” on page 231.

● Troubleshooting tools This section contains information that helps to isolate the

cause of printer failures. This section contains information about printing information

and test pages, resetting printer options, using the diagnostics and service menus,

and how to use the embedded Web server. See “Troubleshooting tools” on

page 239.

● Interface troubleshooting This section provides techniques for isolating the source

of communication problems to the printer hardware, the printer configuration, the

network configuration, or the software application. See “Interface troubleshooting”

on page 255.

● Display-message troubleshooting This section explains each control-panel-

display message and suggests recommendations for resolving the cause of each

message. When the printer message indicates a failure for which the root cause is

not obvious, use the printer error troubleshooting section and the troubleshooting

tools section found later in this chapter to solve the problem. See “Display-message

troubleshooting” on page 257.

● Paper-path troubleshooting This section provides information to help solve feed

problems. Including print media checks, jam troubleshooting checks, and information

about media-caused and printer-caused jams. See “Paper-path troubleshooting” on

page 295.

● Image-formation troubleshooting This section explains methods for solving

print-quality problems. See “Image-formation troubleshooting” on page 306.

● Stacker and stapler/stacker troubleshooting This section provides information

about solving stacker and stapler/stacker problems. See “Troubleshooting the

stacker and the stapler/stacker” on page 326.

● Printer and accessory components This section contains illustrations and tables

that list the printer and accessory internal components. See “Printer component

locations” on page 332 and “Accessory component locations” on page 339.

● Printer and accessory wiring diagrams This section contains wiring diagrams for

the printers and accessories. See “Printer and accessory wiring diagrams” on

page 348.

● General timing diagrams This section contains timing diagrams for the printer. See

“General timing diagrams” on page 357.

230 Troubleshooting Q2431-90912

Page 5

Troubleshooting process

When the printer malfunctions or encounters an unexpected situation, information on the printer

control panel alerts you to the situation. This section contains an initial troubleshooting checklist

that helps to eliminate many possible causes of the problem. The subsequent troubleshooting

flowchart helps you to diagnose the cause of the problem. The remainder of the chapter provides

steps for correcting the problems that have been identified.

● Use the initial troubleshooting checklist to evaluate the source of the problem and to

reduce the number of steps that are required to fix the problem.

● Use the troubleshooting flowchart to pinpoint the cause of malfunctions. The

flowchart lists the section within this chapter that provides steps for correcting the

malfunction.

Before beginning any troubleshooting procedure, check the following:

● Are supply items (for example, the print cartridge, fuser, and rollers) within their

rated life?

● Does the configuration page reveal any configuration problems? See “Configuration

page” on page 241.

Hint The customer is responsible for checking and maintaining supplies, and for using supplies that

are in good condition. The customer is responsible for media and print-cartridge supplies. The

customer is also responsible for replacing the fuser, transfer roller , and all paper pickup, feed, and

separation rollers (tray 1 has a separation pad instead of a roller) that are at or near the end of

their 200,000-page rated life.

Q2431-90912 Chapter 7 Troubleshooting 231

Page 6

Initial troubleshooting checklist

The following checklist contains basic questions that you can ask the customer to help define the

problem(s) quickly. For more information about printer and media specifications, see “Site

requirements” on page 5 and “Paper specifications” on page 9.

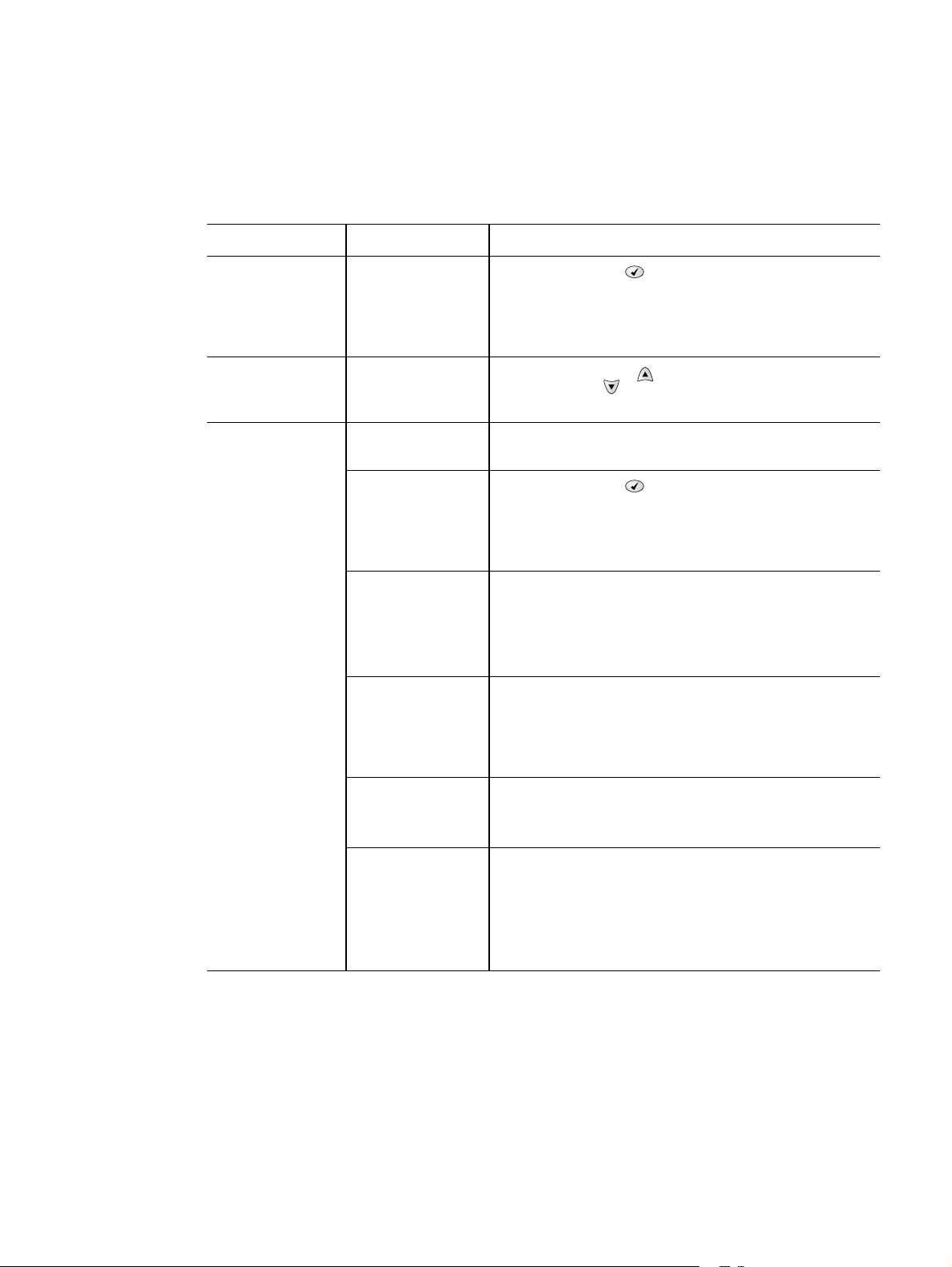

Table 37. Initial troubleshooting checklist

Environment

Media

● Is the printer installed in a suitable environment? See “Site

requirements” on page 5

● Is the printer installed on a solid, level surface?

● Is the supply voltage (from the wall receptacle) within ± 10

.

percent of the printer’s rated voltage (see “Site requirements” on

page 5

)?

● Is the power cord fully seated into both the printer and the wall

receptacle?

● Is the operating environment (for e x ampl e, the temper ature and

humidity levels) within the specified parameters that are listed in

chapter 1 (see “Site requirements” on page 5

● Is the printer exposed to ammonia gas, such as that produced

)?

by diazo copiers or office-cleaning materials?

● Is the printer exposed to direct sunlight?

● Is suitable media being used in the printer? See “Supported

sizes and w eights of media” on page 10

media” on page 14

● Does the customer use only supported print media?

● Is the media in good condition (no curls, folds, or other flaws)?

● Is the media stored correctly and within environmental limits?

● Is the correct side of the page printed on first?

● Is long-grain paper being used?

.

and “Supported types of

Input trays

Print cartridge

Fuser

Covers

Condensation

● Is the correct amount of media loaded in the tray (not stacked

above the arrows embossed in the t ray)?

● Is the media placed in the tray correctly?

● Are the paper guides aligned with the paper?

● Is the tray cassette installed correctly in the printer?

● Is the print cartridge installed correctly?

● Is the fuser installed correctly? See “Fuser” on page 162.

● Is the top cover closed?

● Does condensation occur following a temperature change

(particularly in winter following cold storage)? If so, wipe off the

affected parts or leave the printer on for 10 to 20 minutes and

then attempt to resume printing.

● Was a print cartridge opened soon after it was moved from a

cold room to a warm one? If so, allow the print cartridge and the

printer to acclimate to room temperature for one to two hours.

232 Troubleshooting Q2431-90912

Page 7

Table 37. Initial troubleshooting checklist (contin ued)

Miscellaneous

● Are any non-HP components installed? Check for any non-HP

components (print cartridges, memory modules, and EIO cards)

installed in the printer and remove them. Hewlett-Packard

recommends the use of HP components in its printers.

● Remove the printer from the network, and make sure that the

failure is associated with the printer before beginning

troubleshooting.

Q2431-90912 Chapter 7 Troubleshooting 233

Page 8

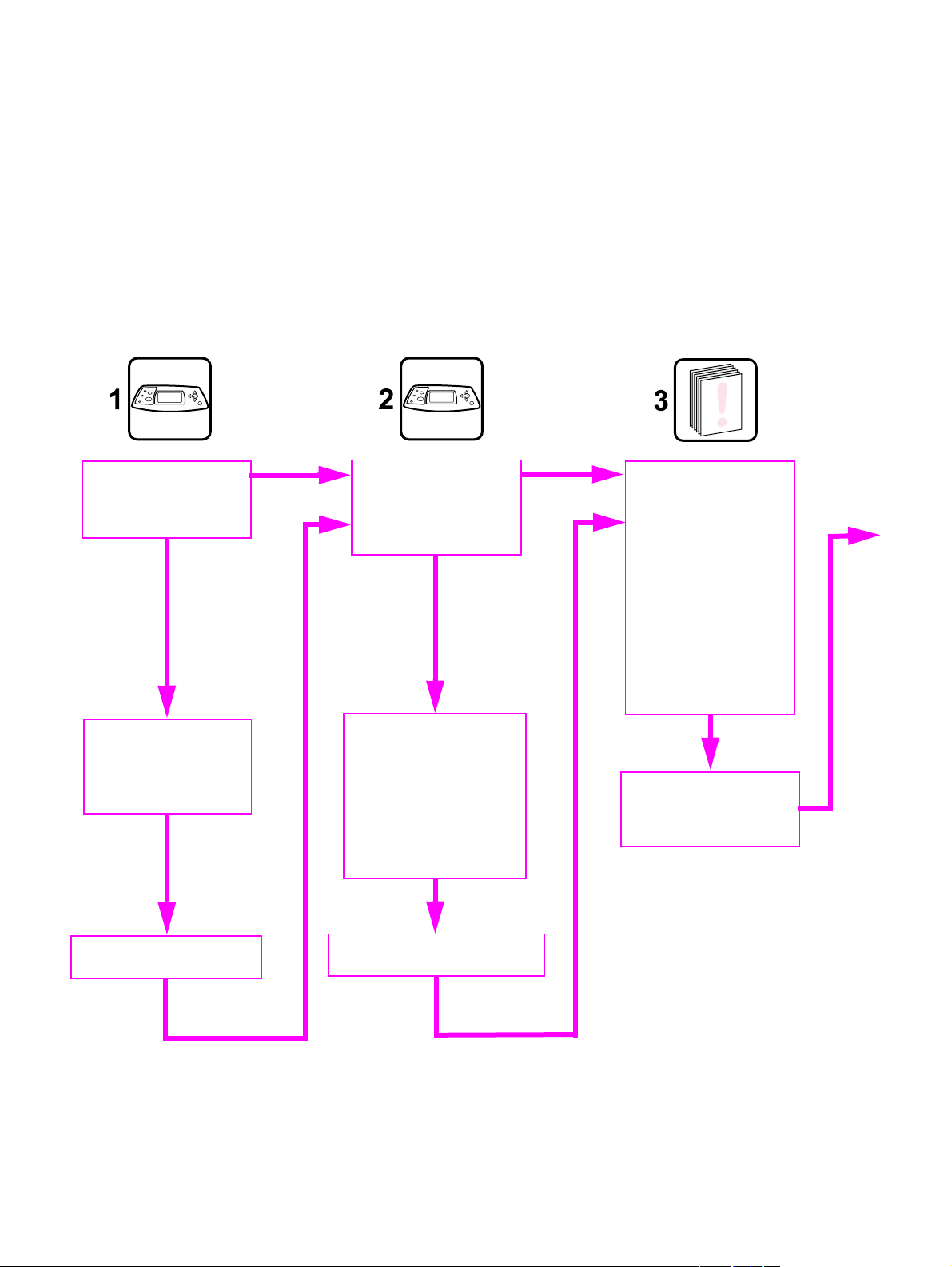

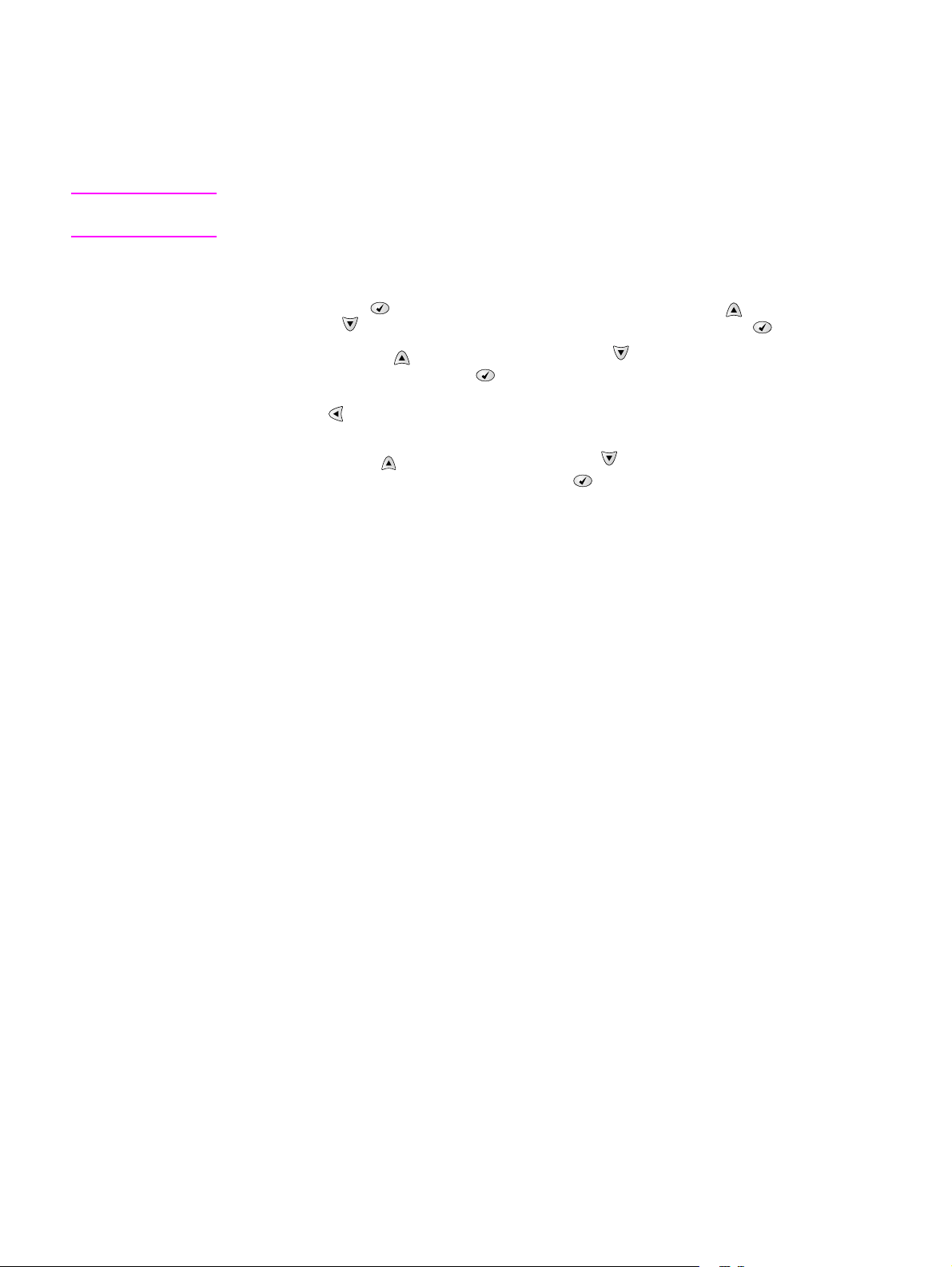

Troubleshooting flowchart

The flowchart on these two pages highlights the general processes you can use to isolate and

solve printer hardware problems quickly.

Each heading depicts a major troubleshooting step. A "yes" answer to a question allows you to

proceed to the next major step.

A "no" answer indicates that additional testing is needed. Proceed to the appropriate section in

this chapter, and follow the instructions there. After completing the instructions, proceed to the

next major step in this troubleshooting flowchart.

Power on

Is the printer on and does

a readable message

appear?

NO

Power-on Checks

Follow the power-on

troubleshooti ng ch ecks.

See “Po w e r-on ch ecks”

on page 236.

YES

Control-Panel display

Does the message

READY, OFFLINE, or

POWERSAVE appear on

the control-panel display?

NO

Error messages appears

Use the error-message

tables in this chapter to

understand the message

and correct the problem.

See “Alphabetical printer

messages” on page 258

and “Numerical printer

messages” on page 274.

YES

Event log

Print an event lo g. If error

messages appear on the

control-panel display

when you try to see or

print the event log, see

“Alphabetical printer

messages” on page258

and “Numerical printer

messages” on page274.

If the event log does not

print, see “Engine test

page” on page 254.

Evualuate the event log

After evalu ating the event

log, go to step 4. See

figure 200 on page 235.

Display panel is functional

Proceed to step 2.

Errors have been corrected

Proceed to step 3.

Figure 199. Troubleshooting flowchart (1 of 2)

234 Troubleshooting Q2431-90912

Page 9

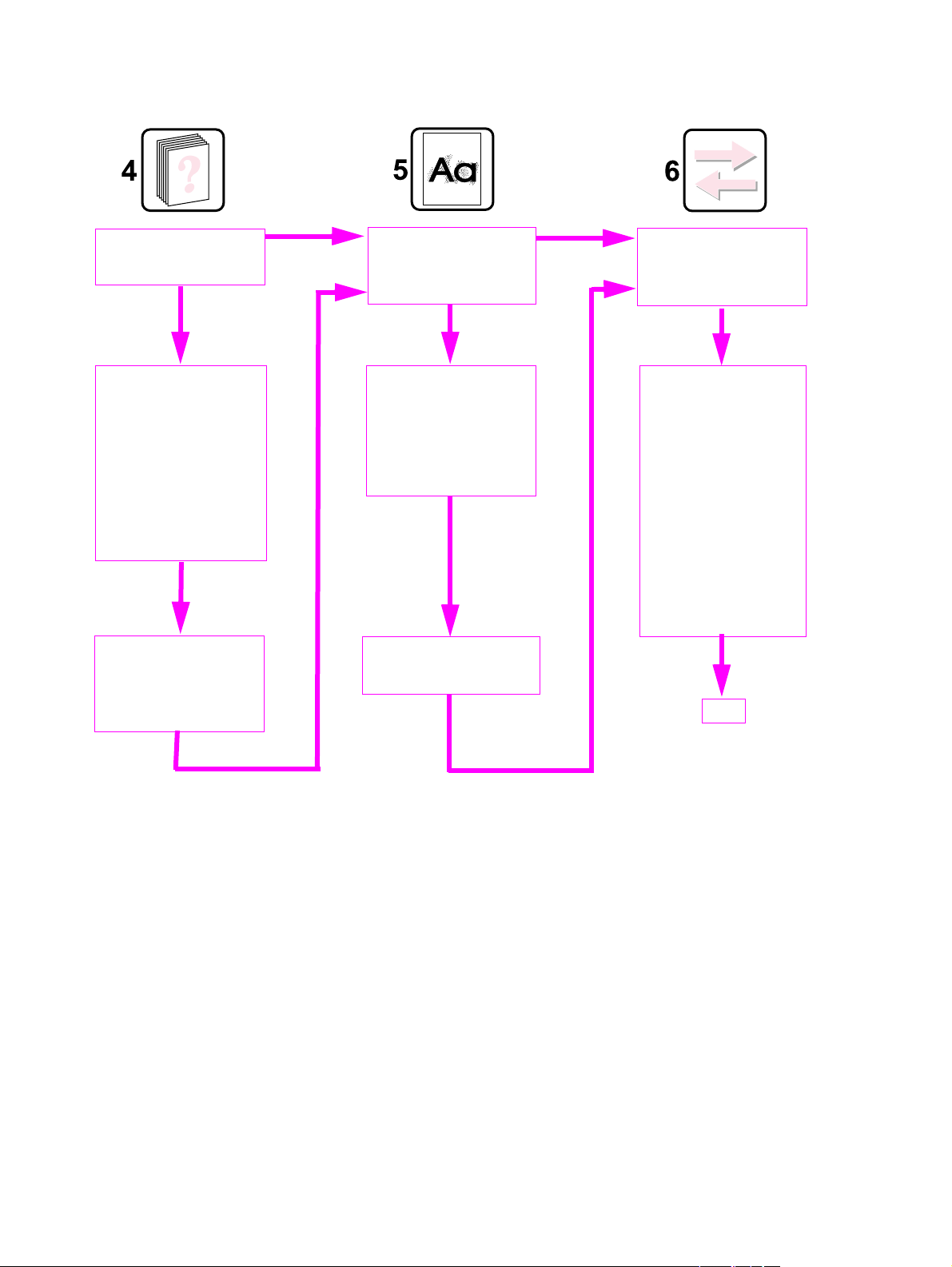

Troubleshooting flowchart (continued)

Information pages

Can you print a

configuration page?

NO

Configuration page

Print an eve nt log. I f error

messages appear on the

control-panel display

when you try to see or

print the configuration

page, see “Alphabetical

printer messages” on

page 258 and “Numerical

printer messages” on

page 274.

Evaluate th e

configuration page

After evaluating the

configuration page, go to

step 5.

YES

Image quality

Does the print quality

meet customer

requirements?

NO

Image defects

Compare the images with

the sample def e cts i n th e

image defect tables. See

“Image-formation

troubleshooting” on

page 306.

Image defects correcte d

After meeting print quality

requirements, go to step 6.

YES

Interface

Can the customer print

successfully from t he host

computer?

NO

Perform corrective

actions

Repeat control-panel

error message actions

and image defect

corrective act ions un til all

errors and image defects

are corrected.

See “Alphabetical printer

messages” on page 258

and/or “Numerical p rinter

messages” on page 274

and/or “Image-formation

troubleshooting” on

page 306.

YES

END

Figure 200. Troubleshooting flowchart (2 of 2)

Q2431-90912 Chapter 7 Troubleshooting 235

Page 10

Power-on checks

The basic printer functions should start up as soon as the printer is plugged into an electrical wall

receptacle and the power switch is pushed to the on position.

Overview

Turn on the printer power. If the control-panel display remains blank, random patterns appear, or

asterisks remain on the display, perform power-on checks to locate the cause of the problem.

During normal printer operation, the main cooling fan begins to spin briefly after the printer power

is turned on. Place your hand over the holes in the left-side cover. If the fan is operating, you will

feel a slight vibration and feel air passing into the printer. You can also lean close to the printer

and hear the fan operating. When this fan is operational, the dc side of the power supply is

properly functioning.

After the fan is operating, the main motor turns on (unless the top cover is open, or a jam

condition is sensed, or the paper path sensors are damaged). You should be able to visually and

audibly determine if the main motor is turned on.

If the fan and main motor are operating properly, the next troubleshooting step is to separate

print engine, formatter, and control-panel problems. Perform an engine test (see “Engine test

page” on page 254). If the formatter is damaged, it might interfere with the engine test. If the

engine test page does not print, try removing the formatter and performing the engine test again.

If the engine test is then successful, the problem is almost certainly with the formatter, the control

panel, or the cable that connects them.

If the printer control panel is blank when you turn on the printer, check the following items.

1. Make sure that the printer is plugged into an active electrical outlet that delivers the correct

voltage.

2. Make sure that the on/off switch is in the on position.

3. Make sure that the fan runs briefly, which indicates that the power supply is operational.

4. Make sure that the control panel display wire-harness is connected. See the hint in the

procedure for “Top cover” on page 146.

5. Make sure that the firmware DIMM and the formatter are seated and operating properly . See

“Firm ware DIMM” on page 160.

6. Remove any HP Jetdirect or other EIO cards, and then try to turn the printer on again.

Note If the printer control-panel display is blank, but the main cooling fan runs briefly after the printer

power is turned on, try printing an engine test page to determine whether the problem is with the

control-panel display, formatter, or other printer components. See “Engine test page” on

page 254.

If the main cooling fan is not operating, check the following items.

7. Check the fuse on the power supply (location FU2; near the power switch) to make sure that

it is not open.

8. If necessary, replace the power supply. See “Power supply” on page 188.

9. If necessary, replace the DC controller PCA. See “DC controller PCA” on page 181.

Note It is important to have the printer control panel functional as soon as possible in the troubleshooting

process so that the control-panel display can be used to help locate printer errors.

236 Troubleshooting Q2431-90912

Page 11

Table 38. Power-on defect or blank display

Problem Action

The power cord is not plugged into the wall

receptacle and connected to the printer.

Make sure that the power cord is firmly plugged into the

wall receptacle and connected to the printer.

Proper power is not available. Measure the voltage at the outlet. If necessary, plug the

power cord into another circuit outlet.

The power switch is off. Set the switch to the on position. You should hear the

switch toggle. If the front right-side cover has been

remove d rece ntly, make sure that the rod conne cting the

power supply switch moves as you toggle the switch.

See the reinstall note in “Right-side cover” on page 149.

If the printer still does not turn on, the power switch

might be defective.

1. Remove the power supply.

2. Measure the resistance between the two terminals

of the power switch (SW1) by applying the tester

probes to the terminals. The resistance must be low

(under 1 KΩ) when the pow er i s t urned on, an d h igh

(over 6 MΩ) when the switch is turned off.

3. Replace the power supply, if necessary.

The overcurrent/overvoltage detection circuit is

activated.

Wait f or mo re than tw o min utes bef ore turning the pri nter

back on.

A fuse is blown. 1. Check the fuses (FU1 and FU2) on the power

supply.

2. Replace the power supply if necessary.

The main cooling fan (located on the left side of

the printer) does not turn on when the printer is

started.

An operational fan indicates the following:

● AC power is present in the printer.

● DC power supply is functional (24V, 5V, and 3.3V are

being generated).

● The DC controller’s microprocessor is functional.

If the fan is not working:

1. Turn the printer off and remove the formatter.

Disconnect the optional accessories.

2. Turn the printer on and check the fan again.

If the fan is still not working:

1. Verify that the fan is connected to the power supply.

2. Replace the f an. S ee “Mai n cooling fa n (left side )” on

page 168.

3. Replace the power supply assembly. See

“Power

supply” on page 188.

4. Replace the DC controller. See “DC controller PCA”

on page 181

Note:

The fan only operat es during the initi al startup and whil e

printing, and when the temperature inside the printer is

too high. If the temperature is too high, the fan turns on

to cool the inside of the printer.

Q2431-90912 Chapter 7 Troubleshooting 237

Page 12

Table 38. Power-on defect or blank display (continued)

Problem Action

The fan works, but the control-panel display is

blank.

1. Print an engine test. “Engine test page” on page254

2. If the engine test is successful, perform the following

steps in order.

● Reseat the control panel and formatter c onnec tor. See

“Control-panel assembly” on page157 and “Formatter

assembly” on page 161.

● Replace the control panel cable. See “Control-panel

assembly” on page 157.

● Replace the control panel assembly. See

“Control-panel assembly” on page157.

● Replace the firmware DIMM. See “Firmware DI MM” on

page 160.

● Replace the formatter. See “Formatter assembly” on

page 161.

3. If the engine test is not successful, remove the

formatter and attempt to perf orm the engine test aga in. If

the engine test is succes sful with t he fo rmatter remov ed,

replace the formatter. See “Formatter assembly” on

page 161. If the test is not successful with the formatter

removed, replace the DC controller PCA. See

“DC controller PCA” on page 181.

238 Troubleshooting Q2431-90912

Page 13

Troubleshooting tools

Press the SELECT ( ) button to open the menus. Use the UP ARROW ( ) button or the DOWN

A

RROW ( ) button to scroll through the menus that appear. For more information about control

panel menus, see “Control-panel menus” on page 39. The high-level menus appear in the

following order:

● RETRIEVE JOB ● INFORMATION

● PAPER HANDLING ● CONFIGURE DEVICE

● DIAGNOSTICS ● SERVICE

Information pages

1. Press the SELECT ( ) button to open the MENUS.

2. Press the D

3. Press the S

4. Press the D

OWN ARROW button to scroll to INFORMATION.

ELECT ( ) button to select INFORMATION.

OWN ARROW ( ) button to scroll to a listed information page. The following

pages are available:

● Menu map

● Configuration

● Supplies status

● File directory

● Usage page

● PCL and PS font list

5. Press the S

ELECT ( ) button to select and print the selected information page.

The informational pages for the printer are also available in the embedded Web server. Not all

information pages are discussed in detail in this manual. For more information, see the

HP LaserJet 4200/4300 Use Guide. The information pages include the following.

● Menu map: A menu map shows how individual items are configured within the

high-level (user-set values) menus. The last page of the menu map series describes

instructions about how to use the control-panel buttons. Print a menu map before

changing printer settings or before replacing the formatter assembly.

● Configuration page: The configuration page lists printer configuration information.

For example, the printer serial number and tray size settings appear on the

configuration page. Print a configuration page before servicing the printer to help

restore values after servicing the printer.

● Supplies status: This page shows the levels of the printer supplies, a calculation of

the number of pages that can be printed before the supplies are replaced, and

cartridge-usage information.

● File directory: This page provides information about files on the ramdisk or installed

EIO disk drives and flash DIMMs if those memory accessories are installed.

● Usage page: The usage page is only available if an optional hard disk is installed. It

provides useful accounting information (for example, the number of pages of various

paper sizes that have been used and data that can be used to calculate toner

usage).

● PS or PCL font list: This page lists the fonts that are installed in the printer

memory. This page also lists fonts on an optional hard-disk accessory or flash DIMM

if those me mory accessories are installed.

Q2431-90912 Chapter 7 Troubleshooting 239

Page 14

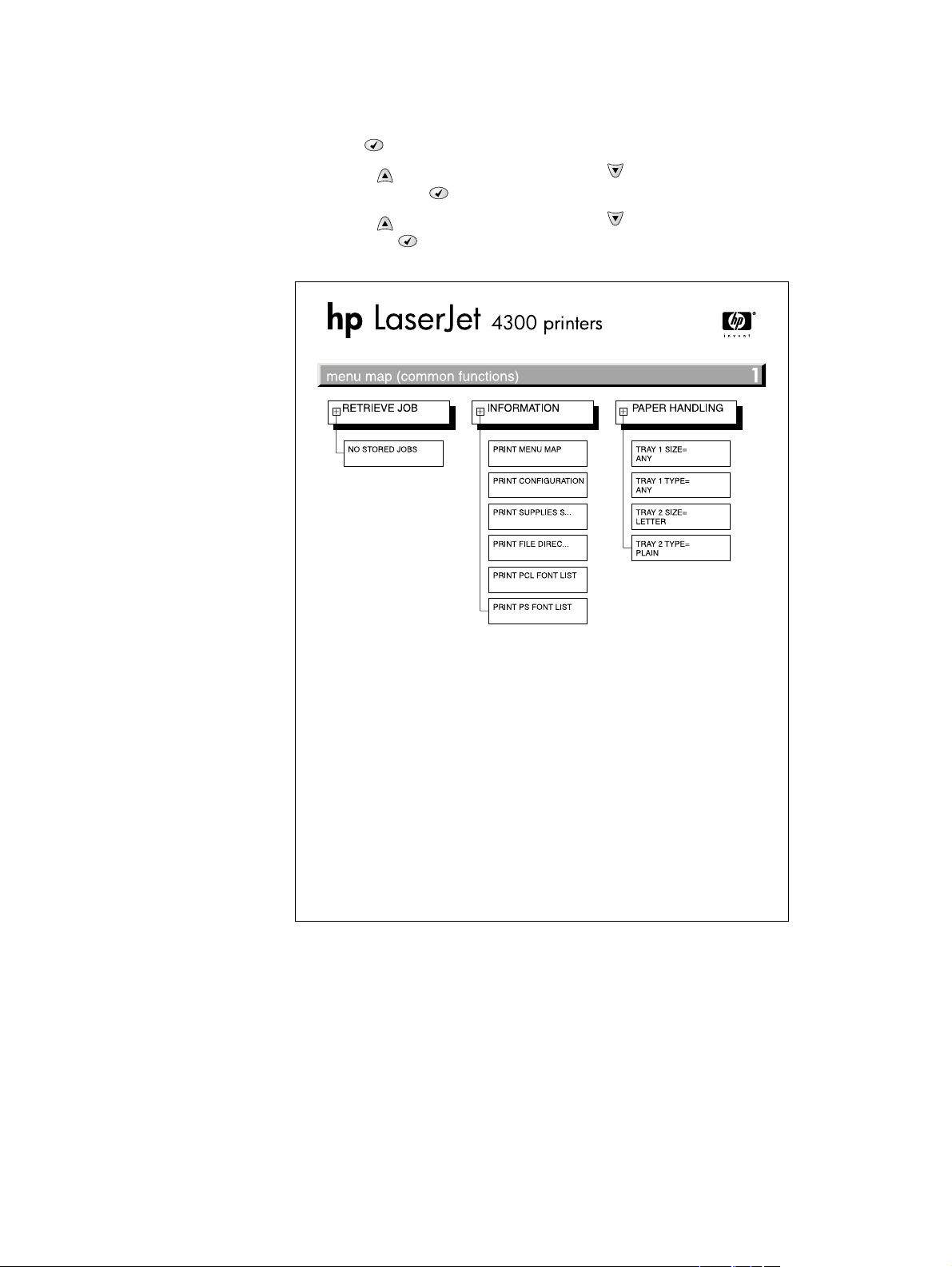

Menu map

Use the menu map to help navigate the printer submenus and select configuration settings.

Printing a menu map is very helpful when you are changing numerous printer settings.

1. Press the S

2. Use the U

P ARROW ( ) button or the DOWN ARROW ( ) button to scroll to INFORMATION,

and then press the S

3. Use the U

P ARROW ( ) button or the DOWN ARROW ( ) button to scroll to MENU MAP, and

then press the S

ELECT ( ) button to open the menus.

ELECT ( ) button.

ELECT ( ) button.

Figure 201. Sample menu map page

240 Troubleshooting Q2431-90912

Page 15

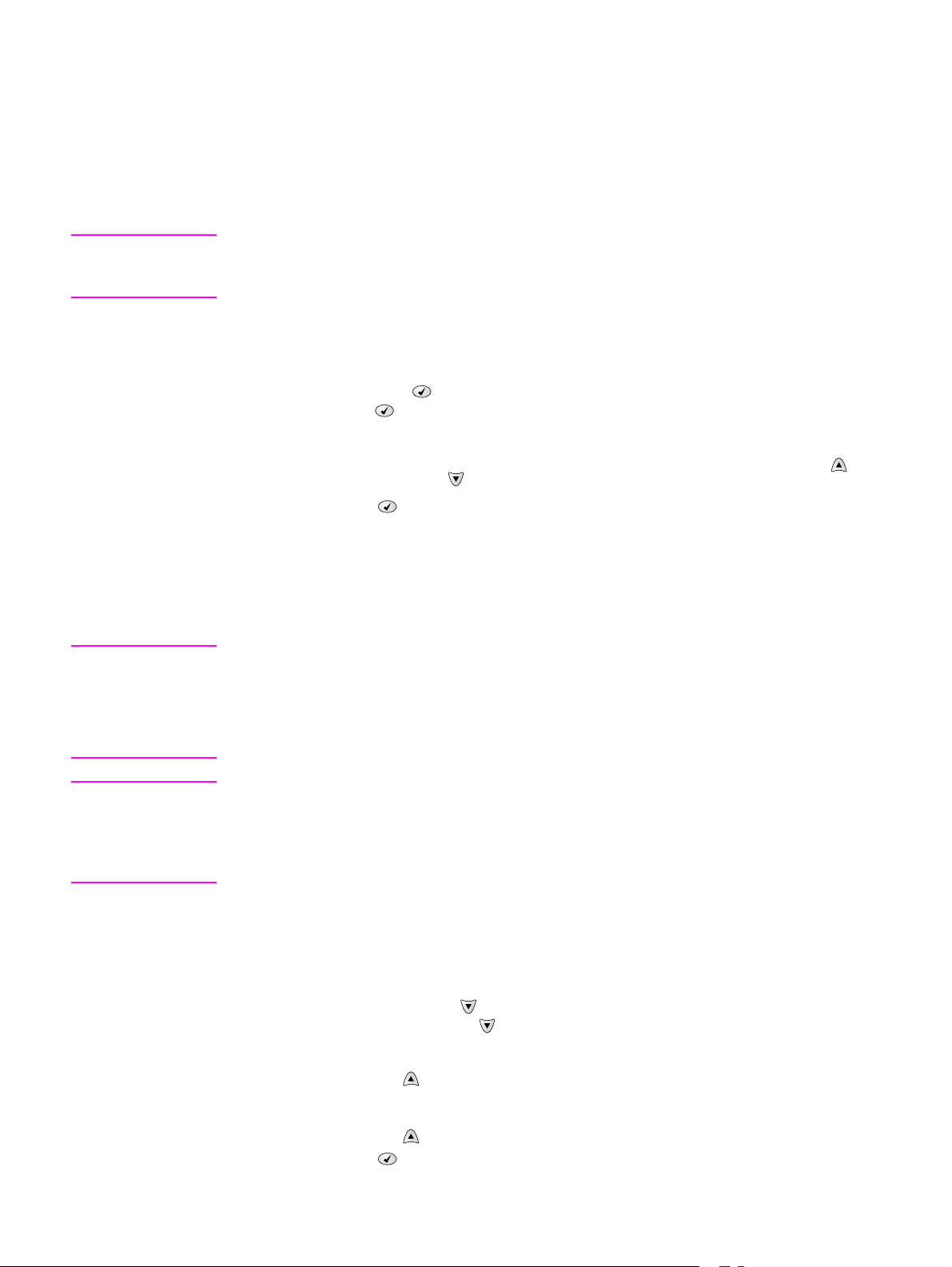

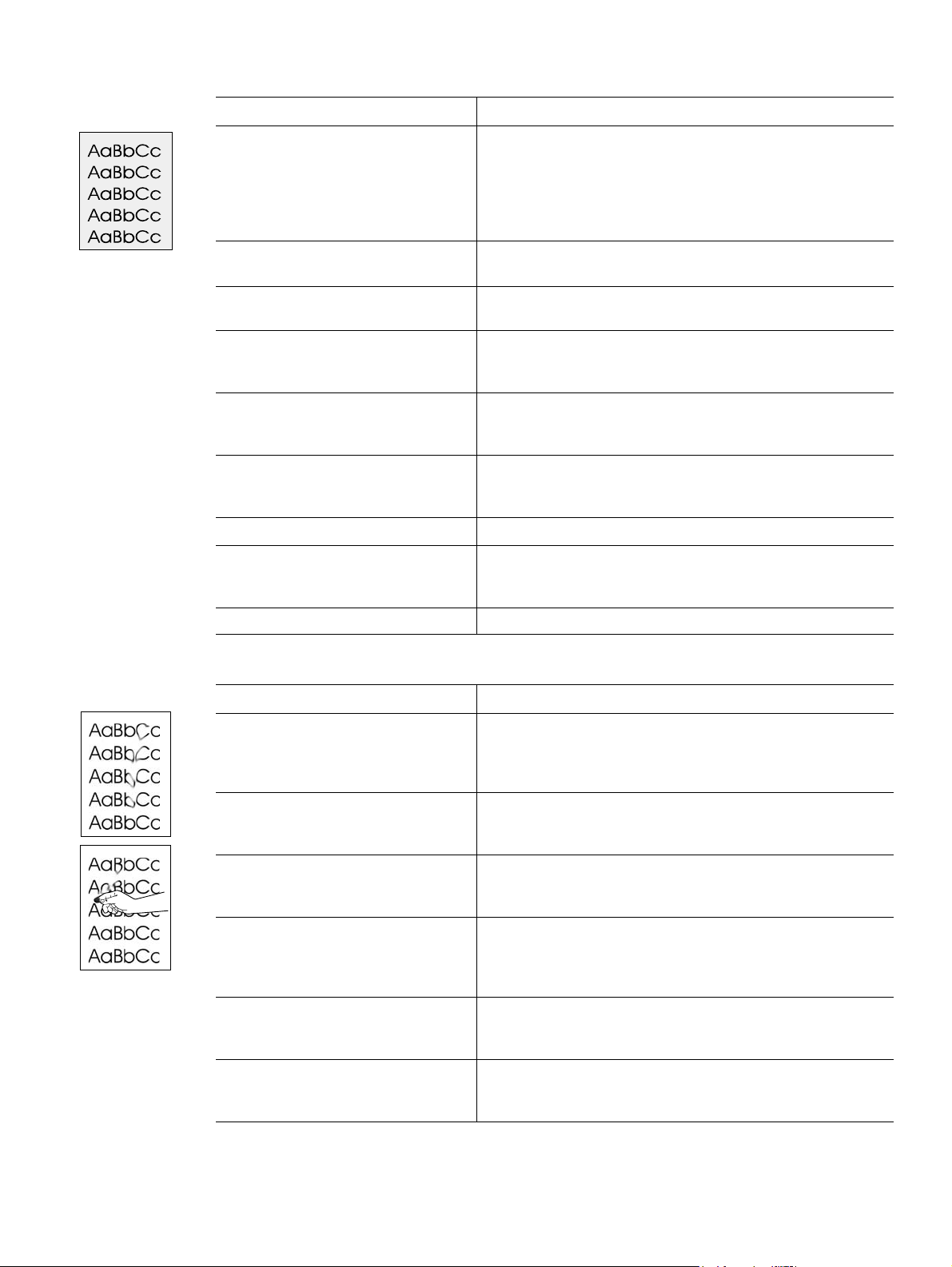

Configuration page

Use the configuration page to view current printer settings, to help troubleshoot printer problems,

or to verify installation of optional accessories, such as memory (DIMMs), trays, and printer

languages. The content of the configuration page varies, depending on the options currently

installed in the printer. To decode the service identification information on the configuration page,

see “Converting the Service ID to an actual date” on page 250.

Note If an HP Jetdirect print server is installed, an HP Jetdirect configuration page prints as well.

HP LaserJet 4200n/tn/dtn/dtns/dtnsL and 4300n/tn/dtn/dtns/dtnsL printers come with an

HP Jetdirect printer server installed.

1. Press the S

2. Use the

then press S

3. Use the

ELECT ( ) button to open the menus.

UP ARROW ( ) button or the DOWN ARROW ( ) button to scroll to INFORMATION, and

ELECT ().

UP ARROW ( ) button or the DOWN ARROW ( ) button to scroll to PRINT

CONFIGURATION, and then press the S

A

B

C

ELECT ( ) button.

D

E

F

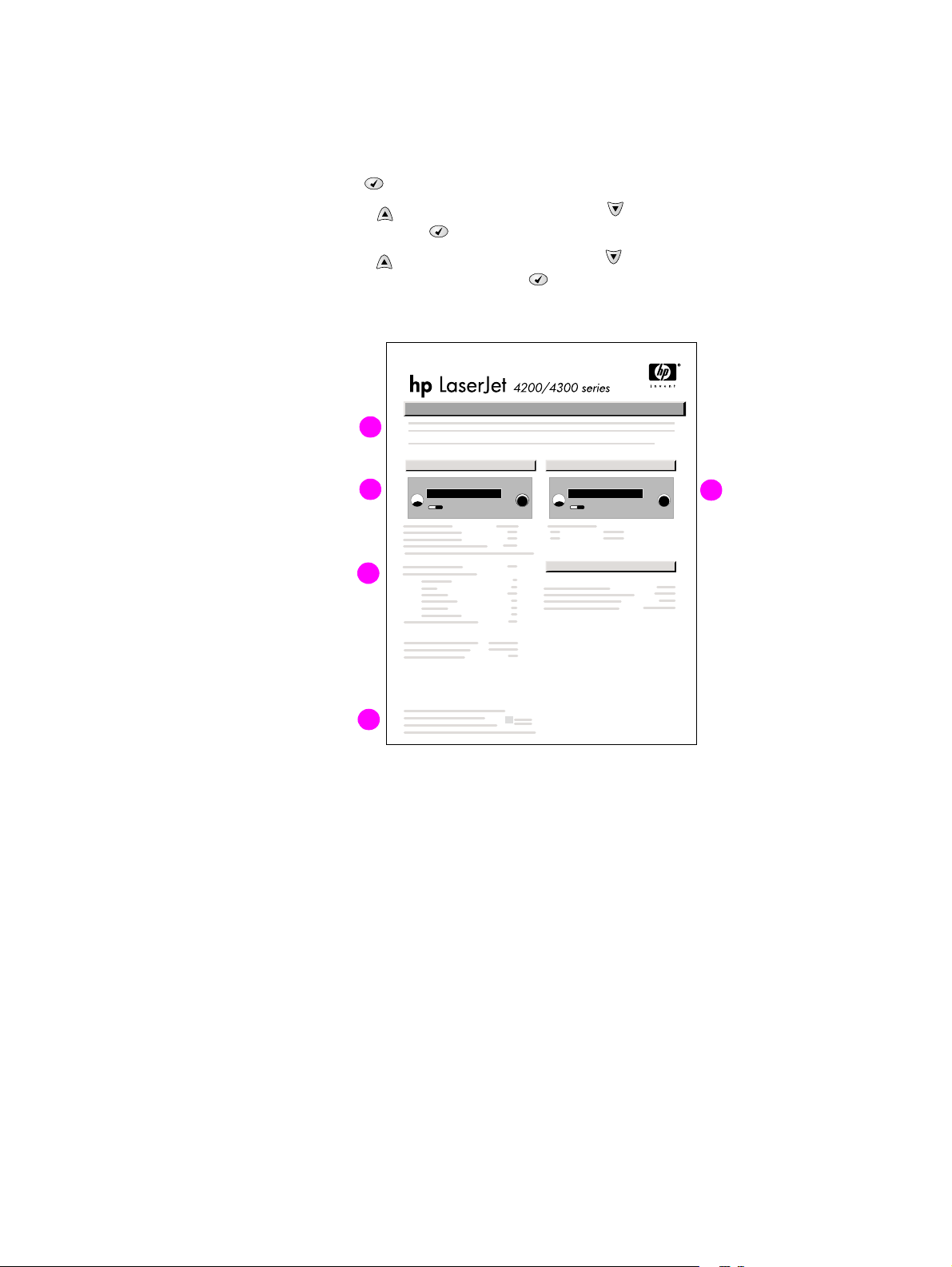

Figure 202. Configuration page

A. Printer Information Lists the serial number, page counts, printer number

(DC controller revision), service ID (see “Service ID” on

page 250), and other printer information

B. Event log Lists the three most recent event log entries (numeric codes for

printer events)

C. Personalities and options Lists installed personalities and options (such as PS and PCL

languages) and installed optional DIMM(s) or EIO accessories

D. Memory Lists the printer memory and I/O buffering and resource saving

information

E. Security Lists the status of the control-panel lock, control-panel

password, and any disk drives

F. Paper trays and options Lists the size and type settings for all trays and lists optional

paper-handling accessories that are installed

Q2431-90912 Chapter 7 Troubleshooting 241

Page 16

Supplies status page

Use the supplies status page to obtain information about the print cartridge installed in the

printer, the amount of life left in the print cartridge, and the number of pages and jobs that have

been processed. The page also lets you know when you should perform the next preventative

maintenance.

1. Press the S

2. Use the U

and then press the S

3. Use the U

ELECT ( ) button to open the menus.

P ARROW ( ) button or the DOWN ARROW ( ) button to scroll to INFORMATION,

ELECT ( ) button.

P ARROW ( ) button or the DOWN ARROW ( ) button to scroll to PRINT SUPPLIES

STATUS PAGE, and then press the S

A

B

C

ELECT ( ) button.

E

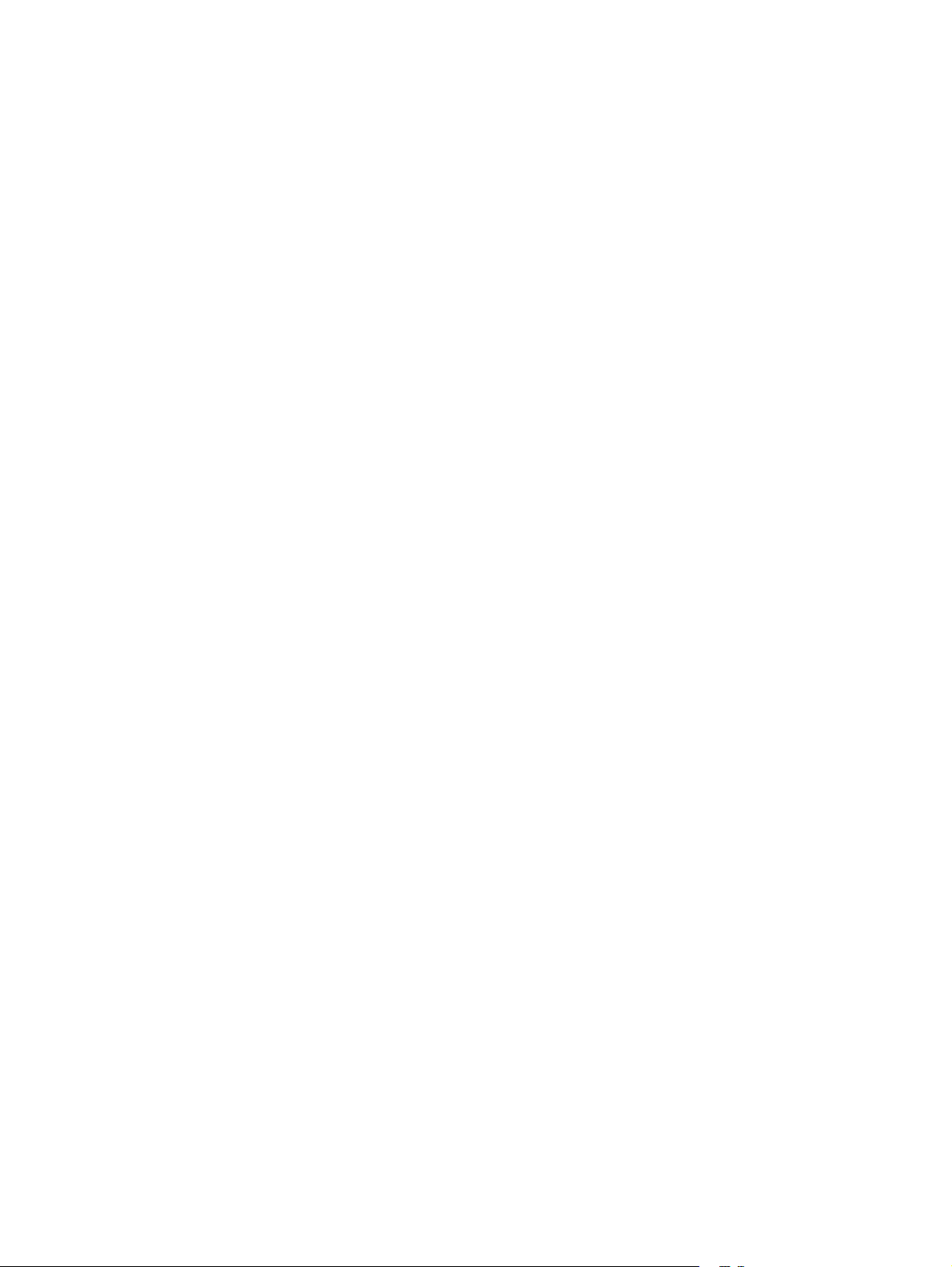

Figure 203. Supplies status page

A. Supplies website Lists the website for ordering supplies over the Internet

B. Cartridge information Provides information about the amount of toner available in the

C. Printing statistics Lists statistics about the total number of pages and jobs that

D. Recycle website Lists the website for information about returning used HP print

E. Maintenance kit gauge Shows a gauge to let you know the remaining life of the

D

print cartridge, and shows the print-cartridge part number and

estimated pages that can be printed for the amount of toner in

the cartridge

have been processed using this print cartridge, the first and last

use date for the cartridge, and the print cartridge serial number

cartridges

maintenance kit components

242 Troubleshooting Q2431-90912

Page 17

Embedded Web server

When the printer is directly connected to a computer, the embedded Web server is supported for

Windows 95 and later. In order to use the embedded Web server with a direct connection, you

must choose the Custom installation option when you install the printer driver. Select the option

to load Printer Status and Alerts. The proxy server is installed as part of the Printer Status and

Alerts software.

When the printer is connected to the network (by using a HP Jetdirect print server EIO card), the

embedded Web server is automatically available.

Use the embedded Web server to view printer and network status and to manage printing

functions from your computer instead of from the printer control panel. The following are

examples of what you can do through the embedded Web server:

● view printer status information

● specify the type of paper that is loaded in each tray

● determine the remaining life for all supplies and order new supplies

● view and change tray configurations

● view and change the printer control panel menu configurations

● view and print internal pages

● receive notification of printer and supplies events

● view and change the network configuration

To use the embedded Web server, you must have Microsoft Internet Explorer 4 and later or

Netscape Navigator 4 and later. The embedded Web server works when the printer is connected

to an IP-based network. The embedded Web server does not support IPX-based printer

connections. You do not have to have Internet access to open and use the

embedded Web server.

Gaining access to the embedded Web server

In a supported Web browser on your computer, type the IP address for the printer. (To find the

IP address, print a configuration page.)

Note After you navigate to the URL, you can bookmark it so that you can return to it quickly in the future.

The embedded Web server has three tabs that contain settings for and information about the

printer: the Information tab, the Settings tab, and the Network tab. Click the tab that you want

to view. See the following sections for more information about each tab.

Q2431-90912 Chapter 7 Troubleshooting 243

Page 18

Informa tion tab

The Information tab contains the following pages.

● Device Status. Shows the printer status and the life that remains in HP supplies

(0 percent represents that a supply is empty). This page also shows the type and

size of print media set for each tray. To change the default settings, click Change

Settings.

● Configuration page. Shows the information that is contained on the printer

Configuration page.

● Supplies Status. Shows the life that remains in HP supplies (0 percent represents

that a supply is empty). This page also provides supplies part numbers. To order

new supplies, click Order Supplies in the Other Links area on the left side of the

window. To visit this or any website, you must have Internet access.

● Event log. Shows a list of all printer events and errors.

● Usage page. Shows a summary of the number of pages the printer has printed,

grouped by size and type (this page is only available if an optional hard disk is

installed).

● Device Information. Shows the printer network name, address, and model

information. To change these entries, click Device Information on the Settings tab.

Settings tab

Use the Settings tab to configure the printer from your computer. The Settings tab can be

password protected. If the printer is on a network, always consult with the network administrator

before changing settings on this tab.

The Settings tab contains the following pages.

● Configure Device. Use this page to configure all the printer settings. This page

contains the traditional printer menus: Information, Paper Handling, Configure

Device, and Diagnostics.

● Alerts. (On networks only.) Use this page to establish e-mail alerts for various

printer and supplies events.

● E-mail. (On networks only.) Use this page in conjunction with the Alerts page to set

up incoming and outgoing e-mail, as well as to establish e-mail alerts.

● Security. Use this page to set a password that must be typed to gain access to the

Settings and Networking tabs. Also use it to enable and disable certain features of

the embedded Web server.

● Other Links. Use this page to add or customize a link to another website. The link

you establish appears in the Other Links area on all embedded Web server pages.

The following permanent links always appear in the Other Li nks area: HP Instant

Support™, Order Supplies, and Product Support.

● Device Information . Use this page to name the printer and assign an asset number

to it. Use the name and e-mail address for the primary contact who will receive

information about the printer.

● Language. Use this page to specify the language in which the

embedded Web server information appears.

Networking tab

The network administrator uses this tab to control network-related settings for the printer when it

is connected to an IP-based network. This tab does not appear if the printer is directly connected

to a computer, or if the printer is connected to a network with anything other than an HP Jetdirect

print server card.

244 Troubleshooting Q2431-90912

Page 19

Other links

This section of the embedded Web server contains links that connect you to the Internet. You

must have Internet access in order to use any of these links. If you use a dial-up connection and

did not connect when you first opened the embedded Web server, you must connect before you

can visit these Web sites. Connecting to the Internet might require that you close your Web

browser and reopen it.

● HP Instant Support™ connects to the HP website to help you find solutions. This

service analyzes your printer error log and configuration information to provide

diagnostic and support information that is specific to your printer.

● Order Supplies connects to the HP website so you can order genuine HP supplies,

such as print cartridges and paper.

● Product Support connects to the support site for the HP LaserJet 4200/4300

printer, where you can search for help regarding general topics.

Printer Status and Alerts software

Printer Status and Alerts is supported only for Windows 95 and later versions.

The Printer Status and Alerts software is available to users of both networked and directly

connected printers. To use Printer Status and Alerts software with a directly connected

computer, you must select the Custom installation option when you install the printer driver, and

then select the option to install Printer Status and Alerts. For network connections, Printer Status

and Alerts is installed automatically with the Typical software installation option.

Use this software to view the embedded Web server information for a particular printer. Printer

Status and Alerts also generates messages on the computer that explain the status of the printer

and print jobs. Depending on how the printer is connected, you can receive different messages.

● Networked printers. You can receive regular job status messages that appear

every time a print job is sent to the printer or every time the print job is complete.

You can also receive alert messages. These messages appear when you are

printing to a particular printer if that printer experiences a problem. In some cases,

the printer can continue to print (such as when a tray that is not being used is open,

or a print cartridge is low). In other cases, a problem might prevent the printer from

printing (such as when paper is out, or a print cartridge is empty).

● Directly connected printers. You can receive alert messages that appear when the

printer experiences a problem but can continue printing or a problem that prevents it

from printing. You can also receive messages that indicate that the print cartridge is

low.

You can set alert options for a single printer that supports Printer Status and Alerts, or you can

set alert options for all printers that support Printer Status and Alerts. For networked printers,

these alerts only appear for your jobs.

Even if you set alert options for all printers, not all of the selected options will apply to all printers.

For example, when you select the option to notify you when the print cartridges are low, directly

connected printers that support Printer Status and Alerts generate a message when the print

cartridges are low. However, none of the networked printers generate this message unless the

alert affects a user-specific job.

Q2431-90912 Chapter 7 Troubleshooting 245

Page 20

To select status messages

1. Open Printer Status and Alerts in one of these ways:

• Double-click the Printer Status and Alerts tray icon, which is near the clock in the Tray

Manager.

• On the Start menu, point to Programs, point to Printer Status and Alerts, and click

Printer Status and Alerts.

2. Click the Options icon on the left side of the window.

3. In the For field, select the printer driver for this printer, or select All Printers.

4. Clear the options for the messages that you do not want to appear, and select the options for

the messages that you do want to appear.

5. In Status check rate, select how frequently you want the software to update the

printer-status information that the software uses to generate the messages. The status

check rate might not be available if the network administrator has restricted the rights to this

function.

To view status messages and informat ion

On the left side of the window, select the printer for which you want to see information. The

information that is provided includes status messages, supplies status, and printer capabilities.

You can also click the job history (clock) icon at the top of the window to view a list of previous

jobs that were sent to the printer from your computer.

246 Troubleshooting Q2431-90912

Page 21

Control-panel menus

Use the control-panel menus to control various printer functions. For example, you can use the

Resets submenu to quickly reset and restore most of the factory default printer settings. Not all

of the available menus are described in this manual. For more information about control-panel

menus, see “Control-panel menus” on page 39.

Using control-panel menus

1. Press the SELECT ( ) button to open the menus.

2. Use the U

you want, and then press the S

3. Some menus might have several submenus. Use the U

D

OWN ARROW ( ) button to scroll to the submenu item that you want, and then press the

S

ELECT ( ) button.

4. Use the U

then press the S

P ARROW ( ) button or the DOWN ARROW ( ) button to scroll to the menu that

ELECT ( ) button.

P ARROW ( ) button or the

P ARROW ( ) button or the DOWN ARROW ( ) button to scroll to the setting, and

ELECT ( ) button. An asterisk (*) appears next to the selection on the

display, indicating that it is now the default. Some settings change rapidly if the

U

P ARROW ( ) button or the DOWN ARROW ( ) button is held down.

5. Press P

AUSE/RESUME to close the menu.

Resets submenu

To find the Resets submenu, use the control panel to open the Configure Device menu (see

“Control-panel buttons” on page 37 and “Configure Device menu” on page 44). Items on the

Resets submenu are used to return settings to the defaults and to change settings such as

PowerSave.

The following section lists the settings and their possible values in the Resets submenu. The

default value for each setting is the one that has an asterisk (*) next to it.

Table 39. Resets submenu

Item Values Explanation

RESTORE FACTORY

SETTINGS

POWERSAVE OFF

No values

available.

*ON

Performs a simple reset and restores most of the factory

(default) settings. This item also clears the input buffer for

the activeI/O. Restorin g f actory setting s does not aff ect the

network parameter settings on the optional HPJetdirect

print server.

CAUTION

Restoring memory during a print job cancels the print job.

Turns the PowerSave mode on or off. The PowerSave

mode affects the printer in two ways:

● minimizes the amount of power that the printer consumes

when it is idle

● reduces wear on the electronic components in the printer

(for ex ample , it turns off the displa y bac klight, alth ough the

display can still be read)

The printer automatically leaves the PowerSave mode

when you send a print job, press a printer control panel

button, open a tray, or open the top cover.

You can set the amount of time t hat the printer re mains idle

before it enters the PowerSave mode. For more

information see “System Setup submenu” on page 49.

Q2431-90912 Chapter 7 Troubleshooting 247

Page 22

Diagnostics menu

Administrators can use this menu to isolate parts and to troubleshoot jam and print-quality

issues.

The following section lists the settings and their possible values in the Diagnostics menu. The

default value for each setting is the one that has an asterisk (*) next to it.

Table 40. Diagnostics menu

Item Values Explanation

PRINT EVENT LOG No values

available.

SHOW EVENT LOG No values

available.

PAPER PATH TEST

● PRINT TEST

PAGE

● SOURCE

● DESTINATION

● DUPLEX

● COPIES

No values

available.

● PRINT TEST PAGE Press the SELECT () button to start the paper-path test

● SOURCE

ALL TRAYS

TRAY 1

*TRAY 2

TRAY [N]

● DESTINATION

ALL BINS

*STANDARD OUTPUT

OPTIONAL BIN 1

Press the SELECT () button to generate a list of the

50 most recent entries in the event log. The printed event

log shows the error number, page count, error c ode, and

description or personality that was in use when the event

occurred.

the UP ARROW ( ) button or the

Use

DOWN ARROW ( ) button to scroll through the event log

contents.

Generate a test page which is useful for testing the paper-

handling features of the printer.

using the source (tray), destination (output bin), duplex,

and number o f copies settings that you set in the other

items on the Paper Path Test menu. Set the other items

before choosin g PRINT TEST PAGE.

Select the tray f or the pap er path tha t y ou wa nt to test. You

can select any tray that is installed. Select ALL TRAYS to

test the paper path for eve ry tra y. (Paper must be lo aded i n

the selected tray s.)

Select the output bin for the paper path that you want to

test. You can select any output bin that is installed.

Optional bins (stacker or stapler/stacker bin) must also be

correctly configured. Select ALL BINS to test the paper

path for every bin.

● DUPLEX

*OFF

ON

● COPIES

*1

10

50

Determine whether or not the paper goes through the

duplexer during the paper path test. This item is available

only if the duplexer is installed.

Set how many sheets of paper are used from each tray

during the paper-path test. If you are testing the stapling

function of the optional stapler/stacker (DESTINATION item

OPTIONAL BIN 1), you must select 10 copies.

100

500

248 Troubleshooting Q2431-90912

Page 23

Service menu (service PIN codes)

Authorized HP service technicians can use this menu to gain access to printer settings that are

reserved for service personnel. The service menu is protected by use of a personal identification

number (PIN). When you select SERVICE from the list of menus, you are prompted to type an

eight-digit PIN code.

Note The printer automatically exits the service menu after about one minute if no menu items are

selected or changed.

Use the PIN code 11420002 for the HP LaserJet 4200 product and the PIN code 11430002

for the HP LaserJet 4300 product.

1. Press the Select ( ) button to open the menus. Use the Up Arrow ( ) button or the

Down Arrow ( ) button to scroll to SERVICE, and then press the Select ( ) button.

2. Press the Up Arrow ( ) button or the Down Arrow ( ) button until the first digit of the PIN

code appears. Press the Select ( ) button to save that digit. Repeat this selection

procedure until you have typed the entire eight-digit PIN code. You can use the

Left Arrow ( ) button to return to a PIN digit. When the last digit is saved, the service

submenu appears on the control-panel display.

3. Use the Up Arrow ( ) button or the Down Arrow ( ) button to scroll to the service-menu

item that you want, and then press the Select ( ) button.

● Clear event log. Select this item to clear (resets to zero) the internal event log.

● Total page count. Select this item to set the total number of pages that have been

printed to-date. Typically this is only required when a new formatter is installed.

● Maintenance count. Select this item to set the number of pages that have been

printed since the last maintenance kit was installed or the total number of pages that

have been printed on this printer if a maintenance kit has not yet been installed

(during the first 200,000 pa ges ) .

● Maintenance interval. Select this item to specify the number of pages that can be

printed before a maintenance-kit-required message appears on the control-panel

display to indicate that a maintenance kit is required.

● Serial number. Select this item to update the serial number if you replace the

formatter.

● Service ID. Select this item to specify the date when the printer was first used,

rather than the date when a replacement formatter is installed. See “Restoring the

Service ID” on page 250.

● Cold reset. Select this item to reset the default paper size when you replace the

formatter.

factory settings (see “R e se ts sub menu ” on page 247). Use this item to restore the

initial default factory settings for the paper size. When you replace a formatter in a

country/region that uses A4 as the standard paper size, use this item to reset the

default paper size to A4. Letter and A4 are the only cold reset values available.

When you perform a cold reset (see “Cold reset” on page 251) or restore

Q2431-90912 Chapter 7 Troubleshooting 249

Page 24

Service ID

This information appears on the configuration page (see “Configuration page” on page 241),

which eliminates the need for customers to keep paper receipts for proof of the warranty.

Because the printer does not have an internal clock, the availability of the service ID date

depends on the printer being connected to a source that can provide the date, in this case a time

server on the same network as the printer. When the printer is not connected to a date source,

the service ID is not available, and 00000 appears on the configuration page.

Restoring the Service ID

If you replace the formatter, the date is lost. Use this menu item to reset the value to the date that

the printer was first used. The date format is YYDDD. Use the following procedure to calculate

the date.

1. To calculate YY, subtract 1990 from the calendar year. For instance, if the printer was first

used in 2002, calculate YY as follows: 2002 – 1990 = 12 (YY = 12).

2. To calculate DDD, use the following formula:

30 (calendar month – 1) + calendar day = DDD. If the calendar day is 31, use 30 instead.

For instance, if the printer was first used on October 17, calculate DDD as follows:

a. Subtract 1 from 10 (October is the tenth month of the year): 10 – 1=9.

b. Multiply 9 by 30: 9 x 30 = 270.

c. Add 17 to 270: 270 + 17 = 287 (DDD = 287).

Converting the Service ID to an actual date

You can use the printer’s Service ID number to determine whether the printer is still under

warranty. Use the following procedure to convert the Service ID into the installation date.

1. Add 1990 to YY to determine the actual year that the printer was installed.

2. Divide DDD by 30 and add 1 to the remainder. The total is the month.

3. The remainder from the calculation in step 2 is the day of the month.

Using the Service ID 12287 as an example, the date conversion is as follows:

● 12 + 1990 = 2002, so the year is 2002.

● 287 divided by 30 = 9 with a remainder of 17. Add 1 to 9 to get 10 so the month is

October.

● The remainder (from the above calculation) is 17, so that is the day of the month.

● The complete date is 17-October-2002.

A 6-day grace period is built into the date system.

250 Troubleshooting Q2431-90912

Page 25

Printer resets and power-on modes

Cold reset

A cold reset unlocks menus that have been previously locked and sets all control panel menu

items (including EIO settings) back to the factory defaults. However, it does not clear the values

in the service menu (such as the serial number and page counts).

Note Before performing a cold reset, print a menu map and a configuration page (see “Menu map” on

page 240 and “Configuration page” on page 241). Use the information on the configuration page

to reset any customer-set printer configuration values that the cold reset procedure changes.

To perform a cold reset

1. Turn the printer power off.

2. Hold down the S

down the S

ELECT ( ) button, and then turn the printer power on. Continue holding

ELECT ( ) button until all three printer control-panel lights flash once and then

remain on. This might take up to 10 seconds.

3. After the message SELECT LANGUAGE appears on the display, press the U

button or the D

4. Press the S

OWN ARROW ( ) button until COLD RESET is highlighted.

ELECT ( ) button. The printer performs a cold reset and then continues its

P ARROW ()

power-on sequence.

5. Check all I/O settings and reset any customer-set printer configuration values.

NVRAM initializatio n

CAUTION Initializing the NVRAM resets the serial number, the event log, the page counts, and the EIO card

(Initializing the NVRAM will reset service menu values to factory defaults). Use the service menu

to restore the serial number and page counts. Also reconfigure any computers that print to this

printer so that the computers can recognize the printer. Initialize the NVRAM only when absolutely

necessary. In most situations, use a cold reset rather than a NVRAM initialization to reset printer

settings (this will retain the values in the service menu).

Note Before performing a NVRAM initialization, print a menu map and a configuration page (see “Menu

map” on page 240 and “Configuration page” on page 241). Use the information on the

configuration page to reset any customer- s et pri nte r co nfi guration values that the NVRAM

initialization procedure changes. Take special note of the total page count, maintenance count,

and the serial number.

To initialize NVRAM

1. Remove any installed accessories (for example, a stapler/stacker).

2. Turn the printer power off.

3. Hold down the D

holding down the D

once and then remain on. This might take up to 10 seconds.

4. Press the U

5. Press the P

6. Press the U

7. Press the S

power-on sequence.

Q2431-90912 Chapter 7 Troubleshooting 251

OWN ARROW ( ) button, and then turn the printer power on. Continue

OWN ARROW ( ) button until all three printer control panel lights flash

P ARROW ( ) button.

AUSE/RESUME button. The display should show SKIP DISK LOAD.

P ARROW ( ) button until NVRAM INIT is highlighted.

ELECT ( ) button. The printer initializes NVRAM and then continues its

Page 26

Hard-disk initialization

CAUTION A hard-disk initialization erases and reformats the printer hard disk. Perform a hard disk

initialization only if an error code on the control panel indicates an EIO disk error. Always try

initializing the hard disk before replacing it.

Note Before performing a hard-disk initialization, print a menu map and a configuration page (see “Menu

map” on page 240 and “Configuration page” on page 241). Use the information on the

configuration page to reset any customer-set printer configuration values that the hard disk

initialization procedure changes.

To initialize the hard disk

1. Turn the printer power off.

2. Hold down the P

down the P

AUSE/RESUME button, and then turn the printer power on. Continue holding

AUSE/RESUME button until all three printer control panel lights flash once and then

remain on. This might take up to 10 seconds.

3. Press the B

4. Press the S

ACK ARROW ( ) button. The display should show INITIALIZE DISK.

ELECT ( ) button. The printer initializes the hard disk and continues its power-on

sequence.

Power-on bypass

When the power is turned on the printer begins the power-on sequence. By performing a

power-on bypass, you can cause the printer to resume the power-on sequence but not to

recognize any installed EIO hard disk (skip disk load procedure). This can be helpful in isolating

EIO hard-disk errors.

You can also resume the power-on sequence but make the printer continuously print

configuration pages until the Pause/Resume button is pressed (self test procedure). This can be

helpful if you need to verify the printer components that are installed by reviewing the information

found on the configuration page, but the you cannot open the menus to print a configuration

page.

Skip disk load

1. Turn the printer power off.

2. Hold down the D

holding down the D

OWN ARROW ( ) button, and then turn the printer power on. Continue

OWN ARROW ( ) button until all three printer control panel lights flash

once and then remain on. This might take up to 10 seconds.

3. Press the U

4. Press the U

P ARROW ( ) button followed by the Pause/Resume button.

P ARROW ( ) button or the DOWN ARROW ( ) button until SKIP DISK LOAD is

highlighted.

5. Press the S

ELECT ( ) button. The printer continues the power-on sequence but ignores an

installed EIO hard disk.

252 Troubleshooting Q2431-90912

Page 27

Self test

1. Turn the printer power off.

2. Hold down the S

down the S

ELECT ( ) button, and then turn the printer power on. Continue holding

ELECT ( ) button until all three printer control panel lights flash once and then

remain on. This might take up to 10 seconds.

3. Press the U

P ARROW ( ) button or the DOWN ARROW ( ) button until SELF TEST is

highlighted.

4. Press the S

ELECT ( ) button. The printer continues the power-on sequence and begins to

continuously printing configuration pages.

5. Press the Pause/Resume button to exit the self test.

Q2431-90912 Chapter 7 Troubleshooting 253

Page 28

Test pages

Printing test pages helps you determine whether or not the printer engine and the formatter are

functioning.

Engine test page

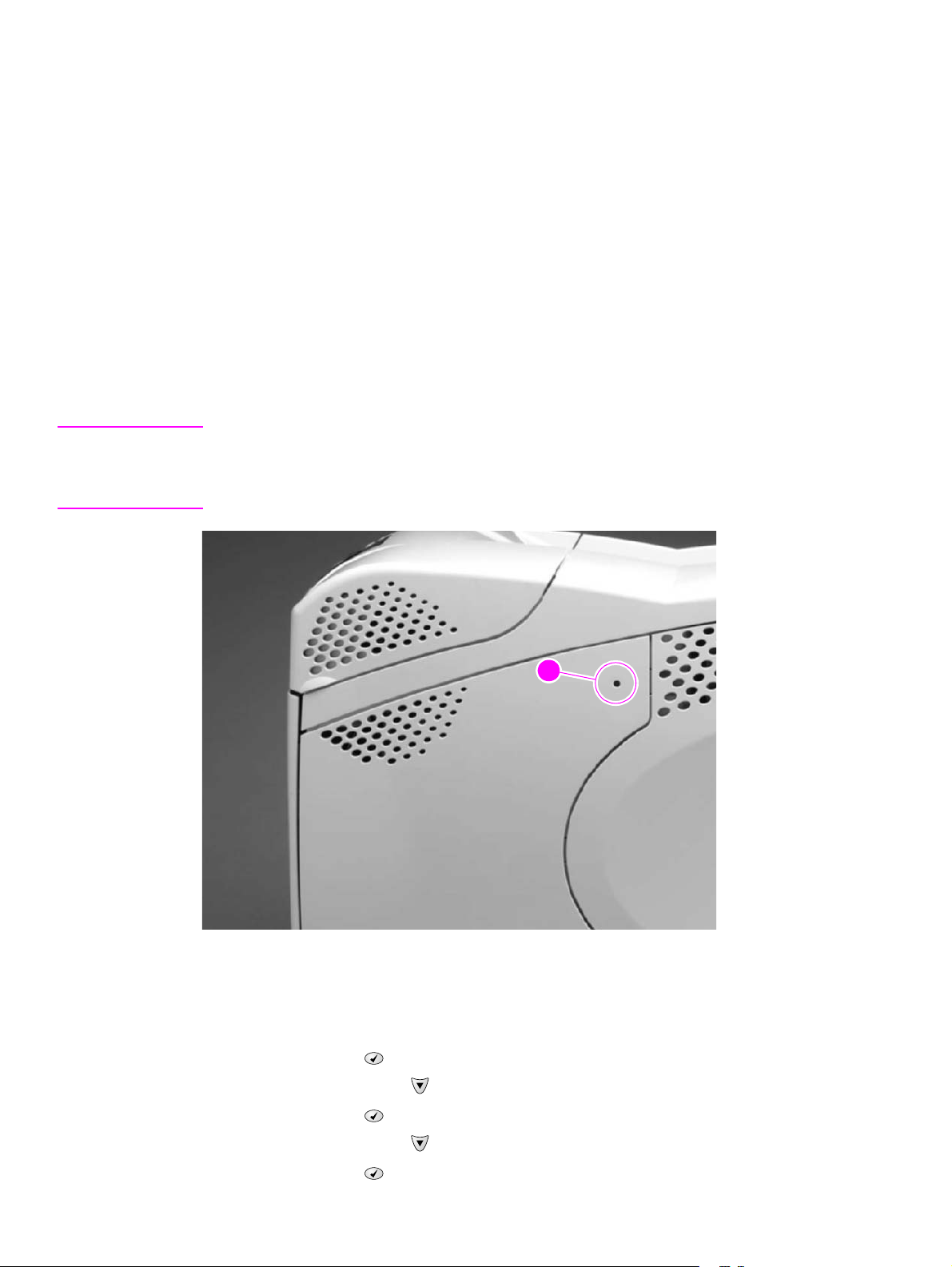

To verify that the printer engine (all printer components except the formatter, formatter DIMMs,

EIO products, and the stacker or stapler/stacker) is functioning, print an engine test page. Use a

small, non-metallic, pointed object to depress the test-page switch, which is located on the right

side of the printer (callout 1).

The test page should have a series of vertical lines. The test page will print from the last tray you

printed from. However, if the printer has been turned off and then back on since the most recent

print job, the page will print from tray 2. The printer will continuously print test pages as long as

the test-page switch is depressed. The printer will not print a test page if it is in PowerSave

mode.

Hint A damaged formatter might interfere with the engine test. If the engine test page does not print,

try removing the formatter and performing the engine test again. If the engine test is then

successful, the problem is almost certainly with the formatter, the control panel, or the cable that

connects them.

Figure 204. Engine test-page switch

Formatter test page

To verify that the formatter is functioning, print a configuration.

1. Press the S

2. Press the D

3. Press the S

ELECT ( ) button to open the MENUS.

OWN ARROW ( ) button to scroll to INFORMATION.

ELECT ( ) button to select INFORMATION.

11

4. Press the D

5. Press the S

254 Troubleshooting Q2431-90912

OWN ARROW ( ) button to scroll to PRINT CONFIGURATION.

ELECT ( ) button to select PRINT CONFIGURATION.

Page 29

Interface troubleshooting

Communications checks

Note Communication problems are normally the customer’s responsibility. Time spent attempting to

resolve these problems might not be covered by the Hewlett-Packard product warranty.

Refer the customer to the network administrator for assistance in troubleshooting network

problems.

If the printer is not connected directly to a Windows or MS-DOS-based host, see “EIO

troubleshooting” on page 255.

CAUTION HP LaserJet printers are not designed to work with mechanical switch-box products without

proper surge protection. These devices generate high transient voltages that cause permanent

damage to the formatter PCA. This circumstance is not covered by the Hewlett-Packard product

warranty.

Computer direct connect (parallel) test

After the printer is installed, verify communications by bypassing the Windows driver between

the printer and the IBM-compatible computer. Type the following at the MS-DOS prompt:

C:\DIR>LPT1 Enter (for printing to parallel port #1)

The printer should print a directory listing of the C: \ directory. You might need to press [G

the control panel to print the data in the buffer.

O] on

EIO troubleshooting

If the printer contains an optional HP Jetdirect print server, and you cannot communicate with the

printer over the network, verify that the print server is operating. Print a configuration page (see

“Configuration page” on page 241). If the Jetdirect card does not appear under “Installed

personalities and options” on the configuration page, reseat or replace the Jetdirect EIO card.

See the troubleshooting section of the HP Jetdirect Print Server Software Administrators Guide.

When the HP Jetdirect print server is installed correctly, print a Jetdirect page (this page

automatically prints when a Jetdirect print server is installed and a configuration page is printed).

See “Jetdirect page” on page 256. The Jetdirect page contains valuable network related

information about the printer.

If the host system and printer are still not communicating, replace the formatter PCA and the

EIO card and reconfigure the printer.

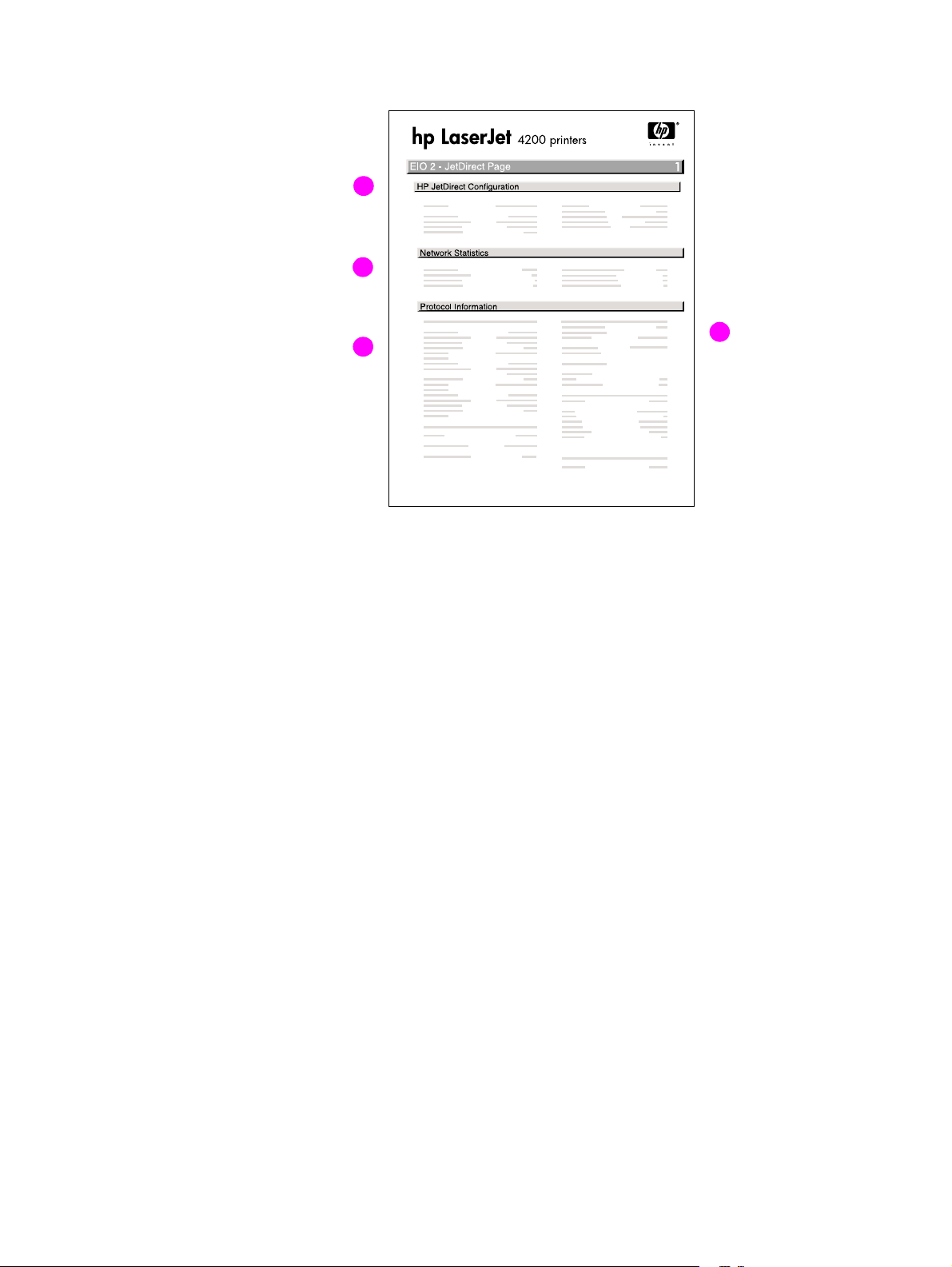

The following illustration shows the contents of the Jetdirect page.

Q2431-90912 Chapter 7 Troubleshooting 255

Page 30

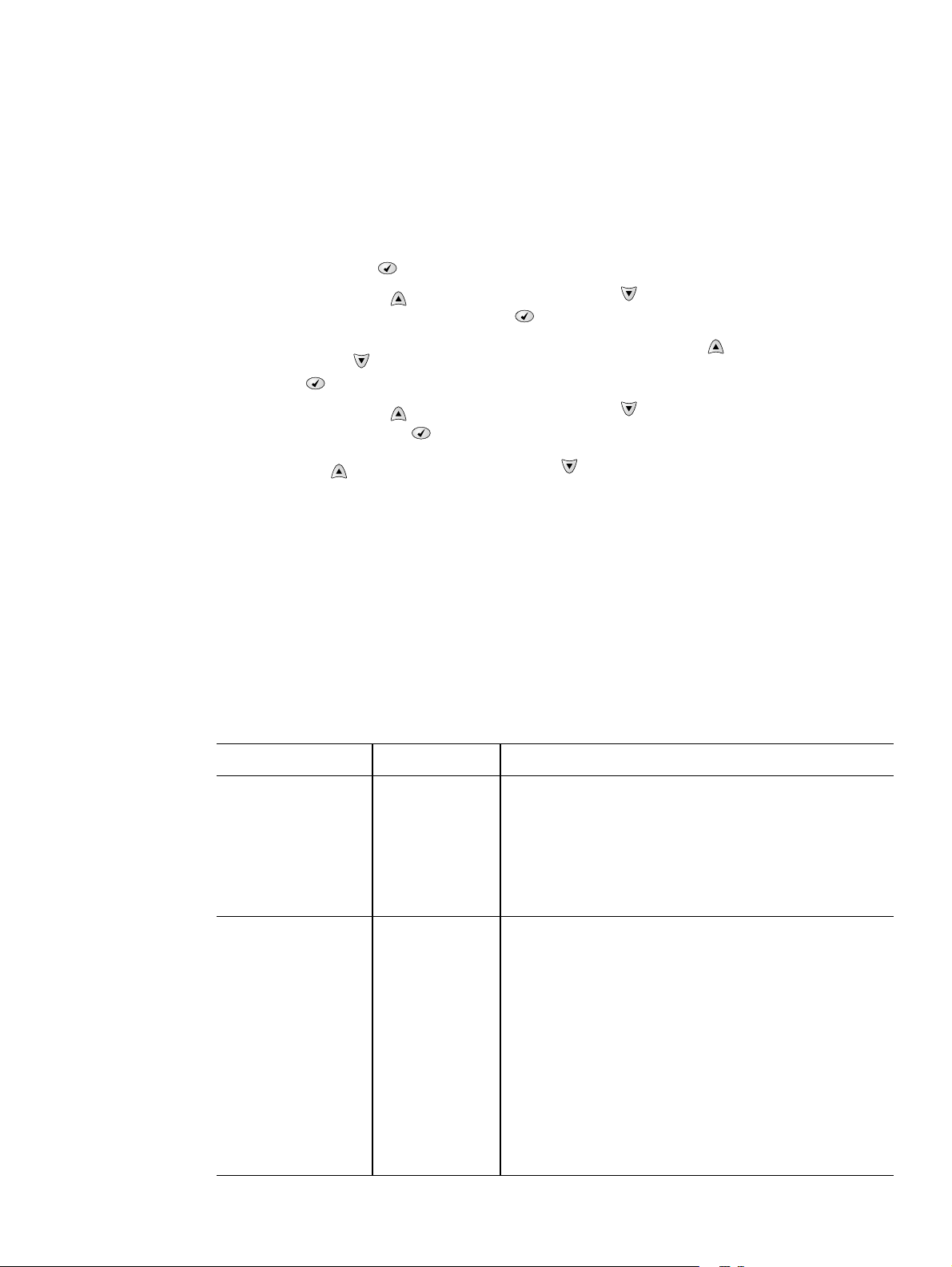

Jetdirect page

A

B

Figure 205. Jetdirect page

A. HP Jetdirect Configuration

B. Network Statistics This block indicates that network activity has been occurring. Bad

C

D

If the EIO Jetdirect card properly installed and th e printer c ompletes its

internal diagnostics, the I/O CARD READY status message prints. If

communication is lost, an I/O NOT READY status message prints,

followed by a two-digit error code. See the

HP Jetdirect Network Interface ConfigurationGuide for further details

and recommended action.

packets, framing errors, unsendable packets, and collisions should be

minimal. If a high percentage (greater than one percent) of these

occur, contact the network administrator. All of the statistics are set to

zero when the printer is turned off.

C. TCP/IP In this block, the default IP address is “192.0.0.192.” you can operate

the printer with this default address. The error message ARP

DUPLICATE ADDRESS might appear in this block. This is also an

acceptable error code if the TCP/IP protocol is not being used. Check

with the network administrator to determine the correct IP address for

the printer. To configure the printer’s IPaddress, go to the control

panel EIO menu, select CFG NETWORK=YES, select CFG TCP/IP=YES,

and then select BOOTP=NO.

D. Novell/NetWare This block should state the name of the Novell printer server to which

the printer is connected. If the node name reads“NPIxxxxxx” (where

xxxxxx = the last six digit s of the EIO’s LAN address), the EIO card has

not been configured for a Novell server. This could indicate that the

card is operating under protocol other than Novell. Check with the

network administrator to determine what node name might be

appropriate.

256 Troubleshooting Q2431-90912

Page 31

Display-message troubleshooting

The following tables explain the messages that might appear on the control-panel display or in

the event log. Alphabetical printer messages and their meanings are listed in “Alphabetical

printer messages” on page 258, and numerical printer messages are listed in “Numerical printer

messages” on page 274.

Note Not all messages are described in the tables; the messages that are not listed are self-explanatory.

Status messages

Status messages reflect the current state of the printer. They inform you of normal printer

operation and require no interaction to clear them. They change as the state of the printer

changes. Whenever the printer is ready, is not busy, and has no pending warning messages, the

status message READY

Warning messages

Warning messages inform you of data and print errors. These messages typically alternate with

READY

or with status messages and continue to appear until the SELECT ( ) bu tto n i s pr es se d. I f

CLEARABLE

when the next print job is sent to the printer.

WARNING is set to JOB in the printer’s configuration menu, these messages are cleared

appears if the printer is online.

Error messages

Error messages inform you that an action must be performed, such as adding paper or clearing a

paper jam.

Some error messages are auto-continuable (these are not critical errors and the printer will

continue to function). If the printer setting AUTO CONTINUE=ON is used, the error message will

continue to appear for about 10 seconds and then the printer will resume printing.

Note Pressing any button while an auto-continuable error message appears on the control-panel

display overrides the auto-continue feature, and the button’s function will take precedence. For

example, pressing the CANCEL JOB button will cancel the job.

Critical-error messages

Critical-error messages inform you of a device failure. Some of these messages can be cleared

by turning the printer off and then on. These messages are not affected by the auto-continue

setting. If a critical error persists, then service is required.

Q2431-90912 Chapter 7 Troubleshooting 257

Page 32

Alphabetical printer messages

Note Not all messages are described in the tables; the messages that are not listed are self-explanatory .

Table 41. Alphabetical printer messages

Message Description Action

ACCESS DENIED

MENUS LOCKED

BAD DUPLEXER CONNECTION The duplexer is not functioning. 1. Turn off the printer.

BAD ENVELOPE FEEDER CONNECTION The envelope feeder is not

An attempt has been made to

modify a printer menu item, but

the network systems

administrator has enabled the

control-panel security

mechanism. The message will

disappear shortly, and the printer

will return to the ready state.

functioning.

Contact the network systems

administrator to change settings.

2. Remove and then reinstall

the accessory.

3. Turn on the printer.

4. Check the rear accessory

power connector.

5. If the error persists, replace

the duplexer.

1. Turn off the printer .

2. Remove, and then reinstall

the accessory.

3. Turn on the printer.

4. Check the front accessory

power connector.

5. If the problem persists,

replace the envelope feeder.

CANNOT DUPLEX Check rear bin

or

CANNOT DUPLEX Check paper

CARTRIDGE FAILURE

For help press

alternates with

RETURN FOR REPLACEMENT

For help press

CHOSEN PERSONALITY NOT

AVAILABLE

For help press

alternates with

CHOSEN PERSONALITY NOT

AVAILABLE

To continue press

The printer cannot perform the

duplex function.

The print cartridge contains part

of the sealing tape.

The printer job language

(PJL) encountered a request for a

personality that did not e xist in the

printer. The job is aborted and no

pages print.

1. Close the face-up bin before

sending a duplex print job.

2. Replace the duplexer.

3. Replace the

DC controller PCA.

See “DC controller PCA” on

page 181.

1. Try to remove the sealing

tape.

2. If the sealing tape cannot be

removed, insert a new print

cartridge and return the faulty

print cartridge for

replacement.

1. Press the H

detailed information.

2. Press the U

button and the

D

OWN ARROW ( ) button to

step through the instructions.

ELP ( ) button for

P ARROW ()

258 Troubleshooting Q2431-90912

Page 33

Table 41. Alphabetical printer messages (continued)

Message Description Action

CLOSE TOP COVER

For help press

DATA RECEIVED

To print last page press

DETECTABLE SIZE

IN TRAY XX

For help press

alternates with

DETECTABLE SIZE IN TRAY XX

Recommend move

switch to STANDARD

DISK DEVICE

FAILURE

alternates with

READY

For menus press

The top cover is open or the top

cover s witc h (SW101) is defectiv e .

The printer received data and is

waiting for a form feed. When the

printer receives another file, the

message should disappear.

A tray has been loaded with

media that is a standard size and

the switch in the tray is set to

“custom.”

A device failure has occurred on

the specified drive.

1. Press the HELP ( ) button for

information.

2. Close the top cover.

3. Replace the top cover

switch (SW101). See figure

212 on page 335.

Press the S

ELECT ( ) button to

continue.

1. Press the HELP ( ) the for

detailed information.

2. Press the U

P ARROW ()

button and the

D