Page 1

TM 11-6625-1614-15

DEPARTMENT OF THE ARMY TECHNICAL MANUAL

ORGANIZATIONAL, DS, GS,

AND DEPOT MAINTENANCE MANUAL

HEWLETT-PACKARD

ELECTRONIC VOLTMETER

MODEL 410C

This copy IS a reprint which includes current

pages from Change 1.

HEADQUARTERS, DEPARTMENT OF THE ARMY

AUGUST 1967

Page 2

TM 11-6625-1614-15

DANGEROUS VOLTAGES

EXIST IN THIS EQUIPMENT

Be careful when working on the power supplies

and their circuits, or on the 115- or 230-volt

ac line connections.

WARNING

DON’T TAKE CHANCES!

Page 3

This manual contains copyrighted material prepared by the Hewlett-Packard Co.

TM 11-6625-1614-15

TECHNICAL MANUAL

No. 11-6625-1614-15)

ORGANIZATIONAL, DS, GS, AND DEPOT MAINTENANCE MANUAL

HEWLETT–PACKARD ELECTRONIC VOLTMETER

Section

I

GENERAL

1-A.1.

1-A.2.

1-A.3.

1-A.4.

1-A.5.

1-A.6.

1-1.

1-4.

II INSTALLATION ----------------------------------------------------------------------------------------------------------

2-1.

2-3.

2-5.

2-9.

2-12.

2-14. Repackaging for Shipment ------------------------------------------------------------------------------

HEADQUARTERS

DEPARTMENT OF THE ARMY

W

ASHINGTON

, DC, 28 August 1967

MODEL 410C

(NSN 6625-00-969-4105)

Page

INFORMATION -------------------------------------------------------------------------------------------

Scope -------------------------------------------------------------------------------------------------------Index of Publications -----------------------------------------------------------------------------------Maintenance Forms, Records, and Reports --------------------------------------------------------Reporting Errors and Recommending Improvements -------------------------------------------Reporting Equipment Improvement Recommendations (EIR)--------------------------------Administrative Storage ---------------------------------------------------------------------------------Description ------------------------------------------------------------------------------------------------Accessories Available ------------------------------------------------------------------------------------

Inspection --------------------------------------------------------------------------------------------------Installation ------------------------------------------------------------------------------------------------Rack Mounting -------------------------------------------------------------------------------------------Three - Conductor Power Cable ---------------------------------------------------------------------Primary Power Requirements --------------------------------------------------------------------------

1-1

1-1

1-1

1-1

1-2

1-2

1-2

1-4

1-5

2-1

2-1

2-1

2-1

2-1

2-1

2-2

III OPERATION ---------------------------------------------------------------------------------------------------------------

IV

3-1.

3-3.

3-5.

3-7.

3-9.

3-11. DC Current Measurements (Figure 3-3)------------------------------------------------------3-13.

3-15. Precautions When Measuring AC Voltage ---------------------------------------------------3-28.

3-31. Measuring Resistance (Figure 3-7) -------------------------------------------------------------------3-33. Measuring DC Nano-Ampere Current (Figure 3-8) -----------------------------------------------

THEORY OF OPERATION --------------------------------------------------------------------------------------------4-1.

4-4.

4-5.

4-16.

4-23.

4-27.

V

MAINTENANCE ---------------------------------------------------------------------------------------------------------5-1.

5-3.

5-5.

Introduction -----------------------------------------------------------------------------------------------Adjustment of Mechanical Zero---------------------------------------------------------------------Front and Rear Panel Description ---------------------------------------------------------------------

Operating Procedures ------------------------------------------------------------------------------------

DC Voltage Measurements (Figure 3-2)-------------------------------------------------------

AC Voltage Measurements (Figure 3-4) -------------------------------------------------------

Negative Pulses --------------------------------------------------------------------------------------------

Overall Description --------------------------------------------------------------------------------------Circuit Description ---------------------------------------------------------------------------------------

Input Network ---------------------------------------------------------------------------------------

Modulator - Demodulator -----------------------------------------------------------------------The Feedback Network ---------------------------------------------------------------------------Power Supply ----------------------------------------------------------------------------------------

Introduction ----------------------------------------------------------------------------------------------Test Equipment Required ------------------------------------------------------------------------------Performance Checks -------------------------------------------------------------------------------------

3-1

3-1

3-1

3-1

3-1

3-1

3-1

3-1

3-1

3-4

3-4

3-4

4-1

4-1

4-1

4-1

4-1

4-2

4-2

5-1

5-1

5-1

5-1

Change

i

Page 4

TM 11-6625-1614-15

Section

Number

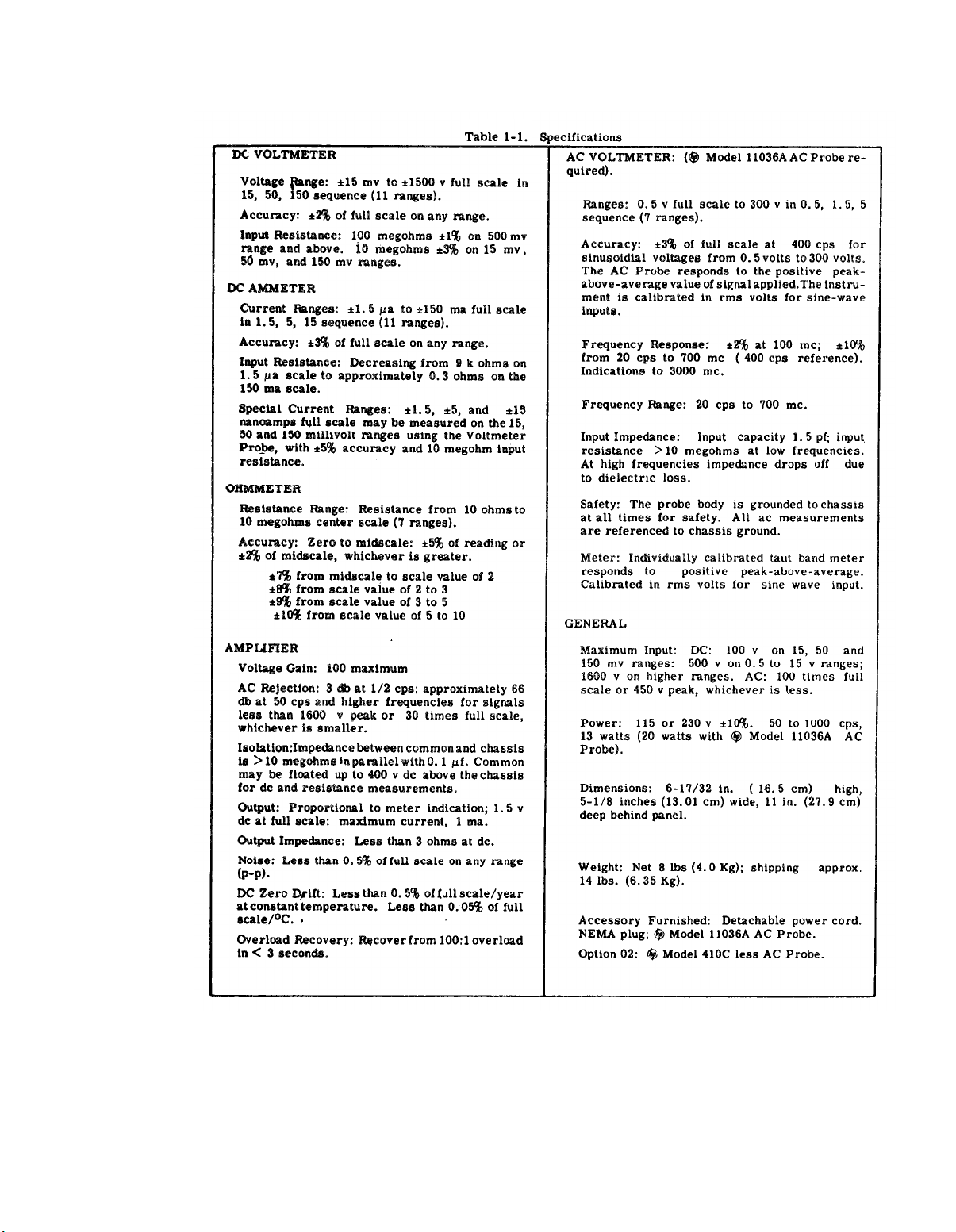

1-1.

3-1.

5-1.

5-2.

5-3.

5-4.

5-5.

5-6.

5-7.

5-8.

5-9.

5-10.

5-7.

5-9.

5-10.

5-13.

5-16.

5-17.

5-21.

5-22.

5-26.

5-28.

5-29.

5-30.

5-31.

5-33.

5-34.

5-35.

5-36.

5-45.

5-48.

Alternate Voltage Source -------------------------------------------------------------------------Mechanical Meter Zero ---------------------------------------------------------------------------DC Voltmeter OWration -------------------------------------------------------------------------DC Ammeter Operation --------------------------------------------------------------------------Ohmmeter Operation -----------------------------------------------------------------------------Amplifier Operation -------------------------------------------------------------------------------DC Amplifier Output Impedance Check ------------------------------------------------------AC Voltmeter Operation --------------------------------------------------------------------------

Adjustment and Calibration Prmedure --------------------------------------------------------------

Chopper Frequency Adjust ----------------------------------------------------------------------Power Supply Adjustment -----------------------------------------------------------------------DC Zero Adjustment and Bias ------------------------------------------------------------------DC Amplifier Output Adjust --------------------------------------------------------------------Ohms Adjust (R3)----------------------------------------------------------------------------------AC Zero Adjust ------------------------------------------------------------------------------------AC Full Scale Adjust (.5 V Range) --------------------------------------------------------------

Troubleshooting Procedure -----------------------------------------------------------------------------

Servicing Etched Circuit Boards ----------------------------------------------------------------Chopper, Assembly Installation -----------------------------------------------------------------

LIST OF TABLES

Specifications -----------------------------------------------------------------------------------------------------------Possible Eror When Measuring Voltage of Complex Waveforms ------------------------------------------Recommended Test Equipment ------------------------------------------------------------------------------------DCV Accuracy Test ---------------------------------------------------------------------------------------------------DCV Input Resistance Test ------------------------------------------------------------------------------------------DCA Accuracy Test ---------------------------------------------------------------------------------------------------Deleted

AC Accuracy Test -----------------------------------------------------------------------------------------------------Power Supply Test ----------------------------------------------------------------------------------------------------AC Full Scale Adjust -------------------------------------------------------------------------------------------------Front Panel Troubleshooting Prmedure --------------------------------------------------------------------------

Troubleshooting Prwedure ------------------------------------------------------------------------------------------

Page

5- 1

5-1

5-1

5-2

5-4

5-4

5-5

5-5

5-8

5-8

5-9

5-10

5-10

5-11

5-12

5-12

5-12

5-14

5-15

1-3

3-3

5-0

5-2

5-3

5-3

5-6

5-9

5-13

5-16

5-17

LIST OF ILLUSTRATIONS

Number

1-1.

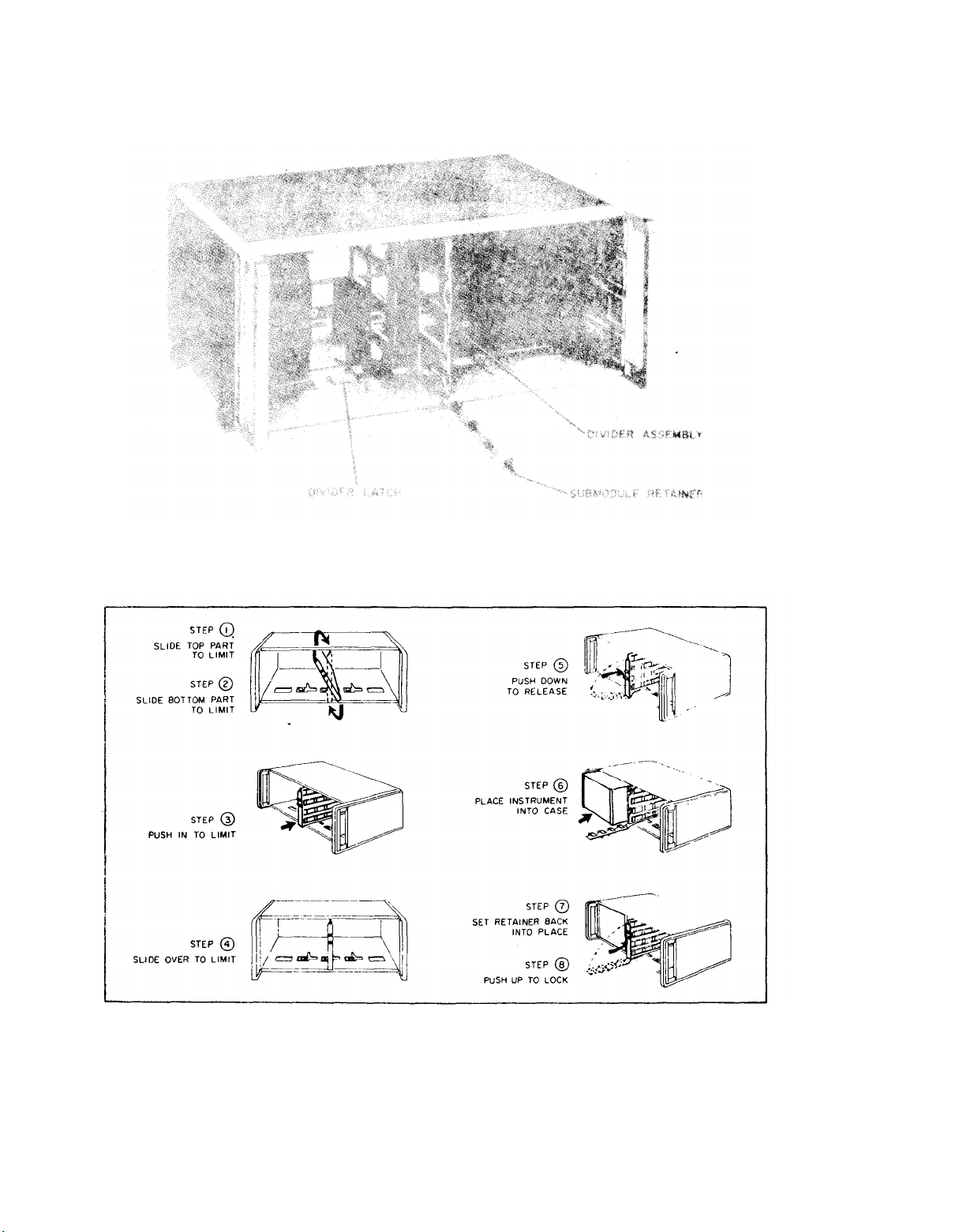

2-1.

2-2.

2-3.

2-4.

3-1.

3-2.

3-3.

3-4.

3-5.

3-6.

3-7.

3-8.

4-1.

4-2.

4-3.

Model 410C Electronic Voltmeter

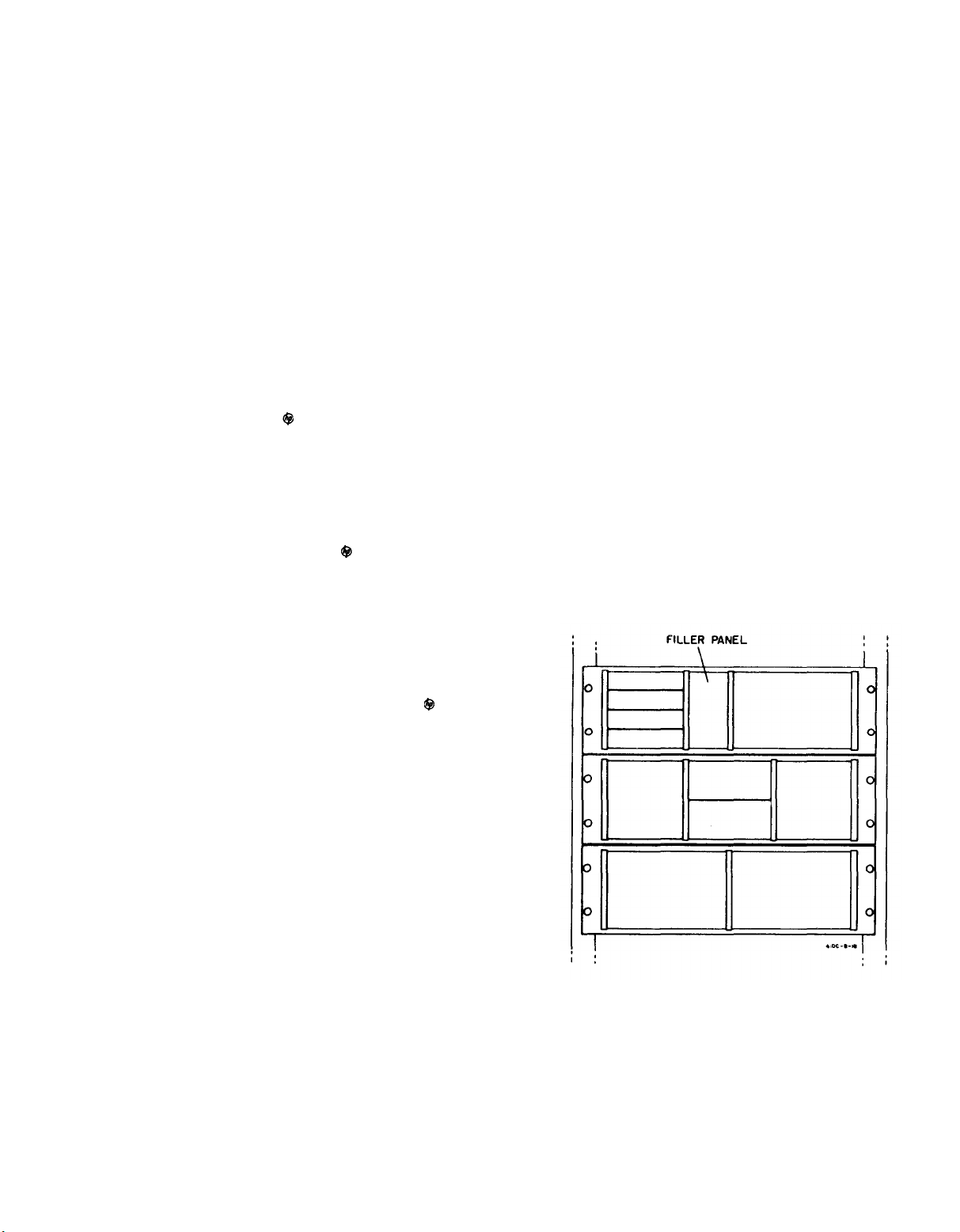

The

The Combining Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steps to Place Instrument in Combining Case--------------------------------------------------------------------

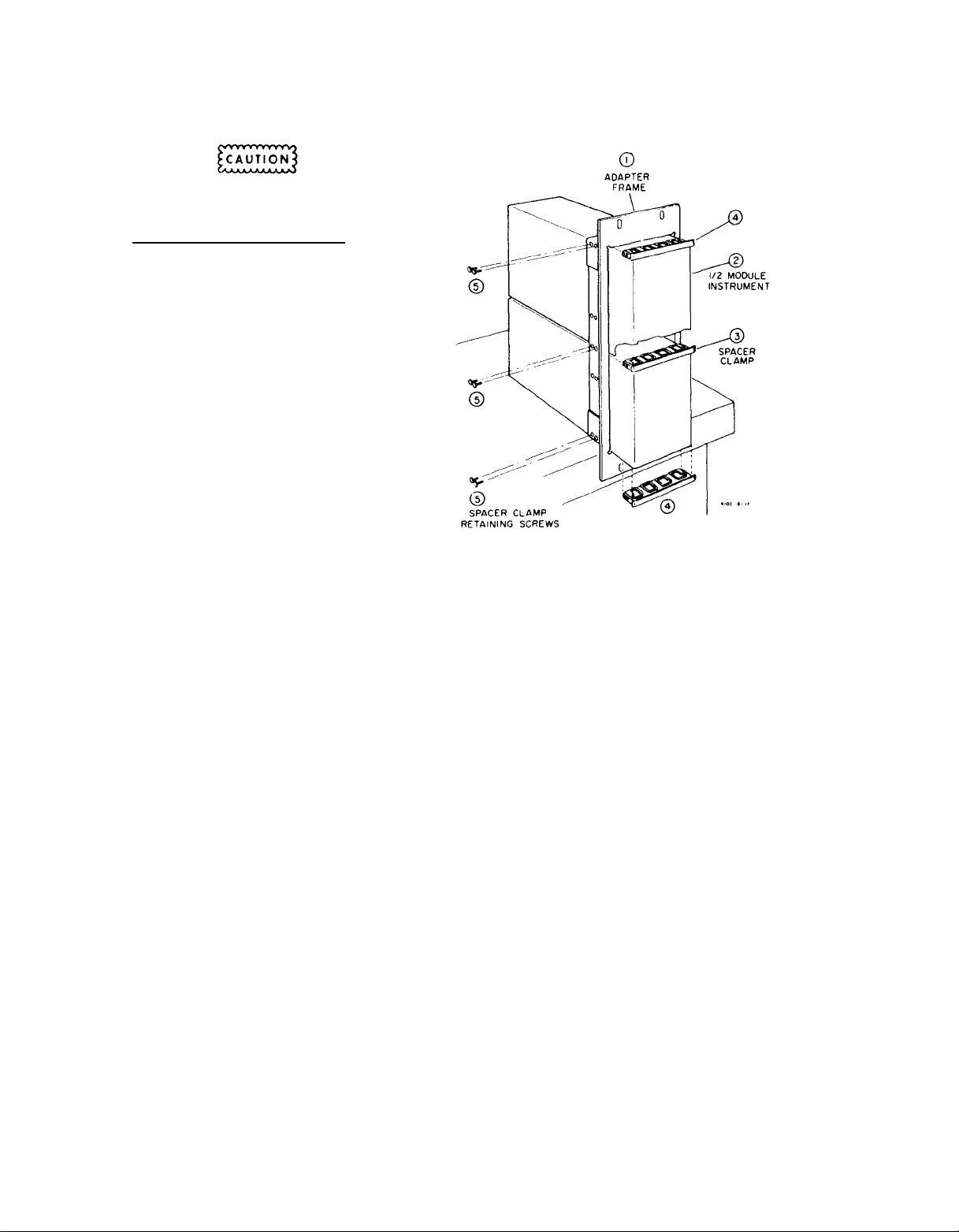

Adaptor Frame Instrument Combination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TWO Half Modules in Rack Adaptor ------------------------------------------------------------------------------Front and Rear Panel Controls --------------------------------------------------------------------------------------

DC Voltage Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Current Measurements

AD Voltage Measurements

Maximum AC Voltage Chart for 11036A Probe

Graph Used in Calculation of Pulse Voltage Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resistance Measurements

DC Nano-Ampere Current Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Diagram, Model 410C

Modulator - Demodulator Mechanical Analogy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Simplified Schematic, DC Current Measurement ---------------------------------------------------------------

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

.

.

Page

1-0

2-0

2-0

2-1

2-2

3-2

.

3-5

3-6

3-7

3-8

3-9

3-10

3-11

4-0

4-0

4-3

ii

Page 5

TM 11-6625-1614-15

Number

4-4.

4-5.

4-6.

5-1.

5-2.

5-3.

5-4.

5-5.

5-6.

5-6.1

5-7.

5-8.

5-9.

5-10.

5-11.

5-12.

5-13.

5-14.

Page

Simplified Schematic, DC Voltage Measurements -------------------------------------------------------------Simplified Schematic, Resistance Measurement ----------------------------------------------------------------Simplified Schematic, AC Voltage Measurement --------------------------------------------------------------Alternate Voltage Source --------------------------------------------------------------------------------------------DC Ammeter Operation ---------------------------------------------------------------------------------------------High Frequency Response Test -------------------------------------------------------------------------------------Low Frequency Response Test --------------------------------------------------------------------------------------Troubleshooting Tree -------------------------------------------------------------------------------------------------A4 Chopper Assembly Installation --------------------------------------------------------------------------------Chopper Frequency Adjust Setup ----------------------------------------------------------------------------------Power Supply Measurements ---------------------------------------------------------------------------------------Power Supply Schematic ---------------------------------------------------------------------------------------------Typical Amplifier Waveforms --------------------------------------------------------------------------------------Amplifier Schematic---------------------------------------------------------------------------------------------------

11036A

Model

Model l1036A Probe Schematic -----------------------------------------------------------------------------------RANGE and FUNCTION Switching (Pictorial) ----------------------------------------------------------------Input RANGE and FUNCTION Switching Schematic ---------------------------------------------------------

AC Probe Exploded --------------------------------------------------------------------------------

4-4

4-5

4-6

5-1

5-3

5-5

5-6

5-14

5-15

5-16.1

5-17

5-19

5-20

5-21

5-22

5-22

5-23

5-24

iii

Page 6

1-0

TM 11-6625-1614-15

Model 410C

Figure 1-1.

Figure 1-1

Section I

Page 7

SECTION I

GENERAL INFORMATION

TM 11-6625-1614-15

1-A.1. Scope

a. This

instructions and covers operator’s, organizational,

direct support (DS), general support (GS), and depot

maintenance. It describes Hewlett-Packard (Federal

supply code 28480) Electronic Voltmeter Model 410C.

This manual applies to equipments with serial num-

bers prefixed by 433 and serial number 532-03701

and higher. If the first three digits on your instrument are 550, refer to figure 5-10, note 14 for the

change in equipments of this serial prefix.

b. A basic issue iterns list for this equipment is

not included as part of this manual.

manual includes installation and operation

1-A.2. Index of Publications

Refer to the latest issue of DA Pam 310-4 to determine whether there are new editions, changes, or additional publications pertaining to the equipment.

1-A.3. Maintenance Forms, Records,

and Reports

a. Reports of Maintenance and Unsatisfactory

Equipment. Department of the Army forms and

procedures used for equipment maintenance will be

those prescribed by TM 38-750, The Army Mainte-

nance Management System.

b. Report of Item and Packaging Discrepancies.

Fill out and forward SF 364 (Report of Discrepancy

(ROD) ) as prescribed in AR 735-1l-2/DLAR 4140.

55/NAVMATINST 4355.73/AFR 400.54/MCO

4430.3E.

c. Discrepancy in Shipment Report (DISREP)

(SF361). Fill out and forward Discrepancy in Ship-

ment Report (DISREP) (SF 361) as prescribed in AR

55-38/NAVSUPINST 4610.33B/AFR 75-18/MCO

P4610.19C and DLAR 4500.15.

1-A.4. Reporting Errors and Recoin.

mending Improvements

You can help improve this manual. If you find any

mistakes or if you know of a way to improve the procedures, please let us know. Mail your letter, DA

Form 2028 (Recommended Changes to Publications

and Blank Forms), direct to Commander, US Army

Communications and Electronics Materiel Readiness Command, ATTN: DRSEL-ME-MQ, Fort

Monmouth, NJ 07703. A reply will be furnished to

you.

1-A.5. Reporting Equipment Improve.

ment Recommendations (EIR)

If your Electronic Voltmeter needs improvement, let

us know. Send us and EIR. You, the user are the only

one who can tell us what you don’t like about your

equipment. Let us know why you don’t like the design. Tell us why a procedure is hard to perform. Put

it on an SF 368 (Quality Deficiency Report). Mail it

to Commander, US Army Communications and Electronics Materiel Readiness Command, ATTN: DRSEL-ME-MQ, Fort Monmouth, NJ 07703. We’ll

send you a reply.

1-A.6. Administrative Storage

Administrative storage of this equipment consists of

covering the equipment with heavy paper taped in a

way to prevent entry of dust particles. If environment

is humid, use bags of dessicant inside the paper

covering.

Change 1

1-1/ (1-2 Blank)

Page 8

Page 9

Section I

Table 1-1

Table 1-1.

TM

11-6625-1614-15

Model 410C

1-3

01556-2

Page 10

TM

11-6625-1614-15

Model 410C

1-1. DESCRIPTION.

1-2. The Hewlett-Packard Model 4l0C Electronic Voltmeter can be

used to measure DC voltage and DC current; AC voltage and

resistance. Positive and negative DC voltages from 10 millivolts

to 1500 volts and positive and negative DC currents from 1.5

microamperes to 150 milliamperes can be measured full scale.

Resistance from 10 ohms to 10 megohms full scale can be measured

with an accuracy of ±5% of reading at midscale; resistance from

0.2 ohms to 500 megohms can be measured with reduced accuracy.

The Model 410C Electronic Voltmeter is shown in Figure 1-1; the

specifications are given in Table 1-1.

1-3. With the Model 11036A detachable AC Probe, the Voltmeter

can be used to measure AC voltage from 20 cps to 700 Mc.

20 cps to 100 M

C

AC voltage from 0.5 to 300 volts can be measured;

)

From

from 100 Mc to 700 Mc, refer to Figure 3-5 for maximum AC voltage

that can be applied to the AC Probe. For additional information

on the AC Probe, refer to Paragraph 1-8.

1-4

Page 11

Model 410C

1-4. ACCESORIES AVAILABLE .

TM 11-6625-1614-15

1-5. MODEL 11036A AC PROBE.

Model 410C, permits AC voltage measurements from 0.5 volt rms

to 300 volts rms, full scale over a frequency range of 20 cps to

700 Mc.

is ±3% of full scale.

700 Mc, with indications obtainable to 3000 Mc. Frequency

response at 100 Mc is within ±2%. The Model 110364 responds to

the positive-peak-above-average value of the signal applied. The

Model 410C is calibrated to read in RMS volts, for sine wave

inputs .

Reference calibration accuracy at 400 cps (sinusoidal)

Frequency response is ±10% from 20 cps to

This accessory, when used with the

1-5

Page 12

TM 11-6625-1614-15

Section II

Figures 2-l and 2-2

Model 410C

Figure 2-1. The Combining Case

2-0

Figure 2-2. Steps to Place Instrument in Combining Case

01556-1

Page 13

Model 410C

SECTION II

INSTALLATION

TM 11-6625-1614-15

Paragraphs 2-1 to 2-13

Section II

2-1. INSPECTION.

2-2. ‘This

instrument was carefully inspected both

mechanically and electrically, before shipment. It

should be physically free of mars or scratches and in

perfect electrical order upon receipt. To confirm

this, the instrument should be inspected for physical

damage in transit. Also, check for supplied accessories, and test the electrical performance of the in-

.

strument using the procedure outlined in Paragraph

2-9. THREE-CONDUCTOR POWER CABLE.

To protect operating personnel, the National

2-10.

Electrical Manufacturers’ Association (NEMA) recommends that the instrument panel and cabinet be

grounded.

equipped with a three-conductor power cable

All Hewlett-Packard instruments

are

which

grounds the instrument when plugged into an appropri-

ate receptacle.

5-5 Performance Checks. If there is any

damage or deficiency, refer to

paragraph 1-A.3.

2-3. INSTALLATION.

2-4. The Model 410C is transistorized except for

one vacuum tube and requires no special cooling.

However, the instrument should not be operated where

the ambient temperature exceeds 55° C (140° F).

2-5. RACK MOUNTING.

2-6. The Model 410C is a submodular unit designed

for bench use. However, when used in combination

with other submodular units, it can be bench and/or

rack mounted.

The Combining Cases and Adapter

Frame are designed specifically for this purpose.

2-11. To preserve the protection feature when operating

ihe instrument from a two-contact outlet, use

three - prong to two - prong adapter and connect the

green pigtail on the adapter to ground.

2-12. PRIMARY POWER REQUIREMENTS.

2-13. The Modei 410C can be operated from either

115 or 230 volts, 50 to 1000 cps. The instrument can

be easily converted from i 15- to 230- volt operation.

The LINE VOLTAGE

switch located

the mode of AC operation. The line

switch, S4 a two-position slide

at the rear of the instrument, selects

voltage from

which the instrument is set to operate appears on the

siider of the switch. A 0.25-ampere, slo-blo fuse is

used for both 115- and 230-volt operation.

2-7. MODELS 1051A AND 1052A COMBINING CASES.

The Combining Cases are full-module unita which

accept various combinations of submodular

units.

Beinga full width unit, it can either be bench or rack

mounted. An illustration of the Combining Case is

shown in Figure 2-1. Instructions for installing the

Model 410C are shown in Figure 2-2.

2-8. RACK ADAPTER

FRAME ( Part No. 5060-

0797). The adapter frame is a rack mounting frame

that accepts various combinations of submodular

units. It can be rack mounted only.

An illustration

of the adapter frame is given in Figure 2-3. Instructions are given below.

a. Place the adapter frame on edge of bench as

shown in step 1, Figure 2-4.

b. Stack the submodular units in the frame as

shown instep 2, Figure 2-4. Place the spacer clamps

between instruments as shown in step 3, Figure 2-4.

c. Place spacer clamps on the two end instruments

(see step 4, Figure 2-4) and push the combination into

the frame.

d. Insert screws on either side of frame, and

tighten until submodular instruments are tight in the

frame.

e.

The compiete assembly is ready for rack

mounting.

01556-2

Figure 2-3. Adapter Frame Instrument Combination

2-1

Page 14

TM 11-6625-1614-15

Section II

Paragraph 2-14 to 2-15

DO NOT CHANGE THE SETTING OF THE

LINE VOLTAGE SWITCH WHEN THE VOLTMETER IS OPERATING.

2-14. REPACKAGING FOR SHIPMENT.

2-15. The following paragraphs contain a general

guide for repackaging of the instrument for shipment.

Refer to Paragraph 2-16 if the original container is

to be used: 2-17 if it is not.

2-16. If the original container is to be used, proceed as

follows:

a. Place instrument in original container if avai-

lable.

Model 410C

Figure 2-4. Two Half Modules in Rack Adapter

b. Ensure that container is well sealed with strong

tape or metal bands.

2-17. If original container is not to be used, proceed

as follows:

a. Wrap instrument in heavy paper or

before placing in an inner container.

b. Place packing material around all sides of

instrument and protect panel face with cardboard d. Mark shipping container with "DELICATE

strips. INSTRUMENT”, “FRAGILE”, etc.

plastic

2-2

c. Place instrument and inner container in a heavy

carton or wooden box and seal with strong tape or

metal bands.

01556-1

Page 15

TM 11-6625-1614-15

Model 410C

Paragraph 3-1 to 3-18

Section III

SECTION III

OPERATION

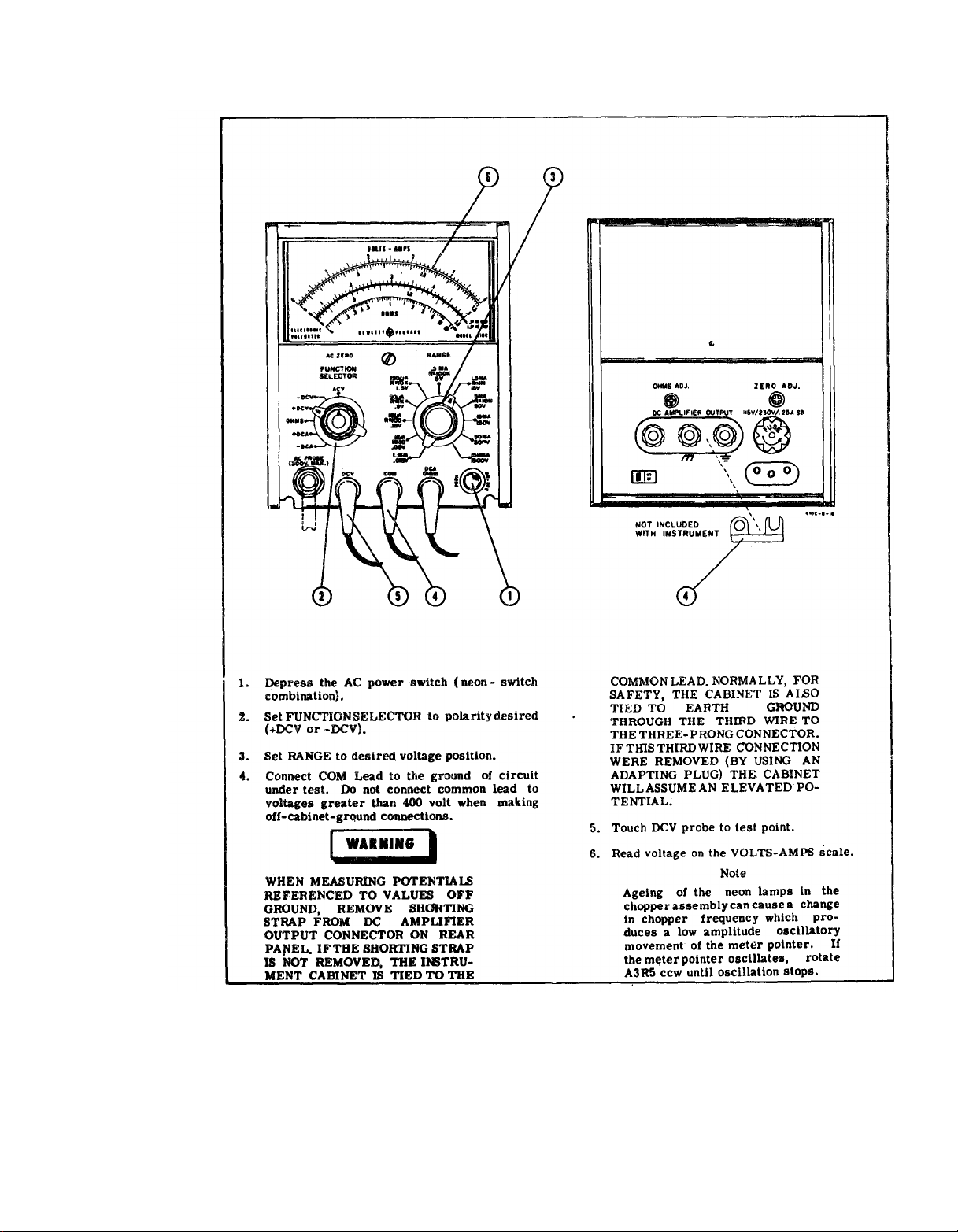

AC VOLTAGE MEASUREMENT (Figure 3-4).

3-1. INTRODUCTION.

3-2. The Model 410C is used to measure AC and DC

voltage, DC current, and resistance. All measure-

ment inputs are located on the front panel; a DC output connector is located on the rear panel. Front

panel controls and indicators are color coded. DC

voltage, DC current and resistance knobs and indi-

cators are in black; AC voltage controls and indicators are in red.

3-3. ADJUSTMENT OF MECHANICAL ZERO.

3-4. The procedure for adjustment of mechanical

zero is given in Section V.

3-5. FRONT AND REAR PANEL DESCRIPTION.

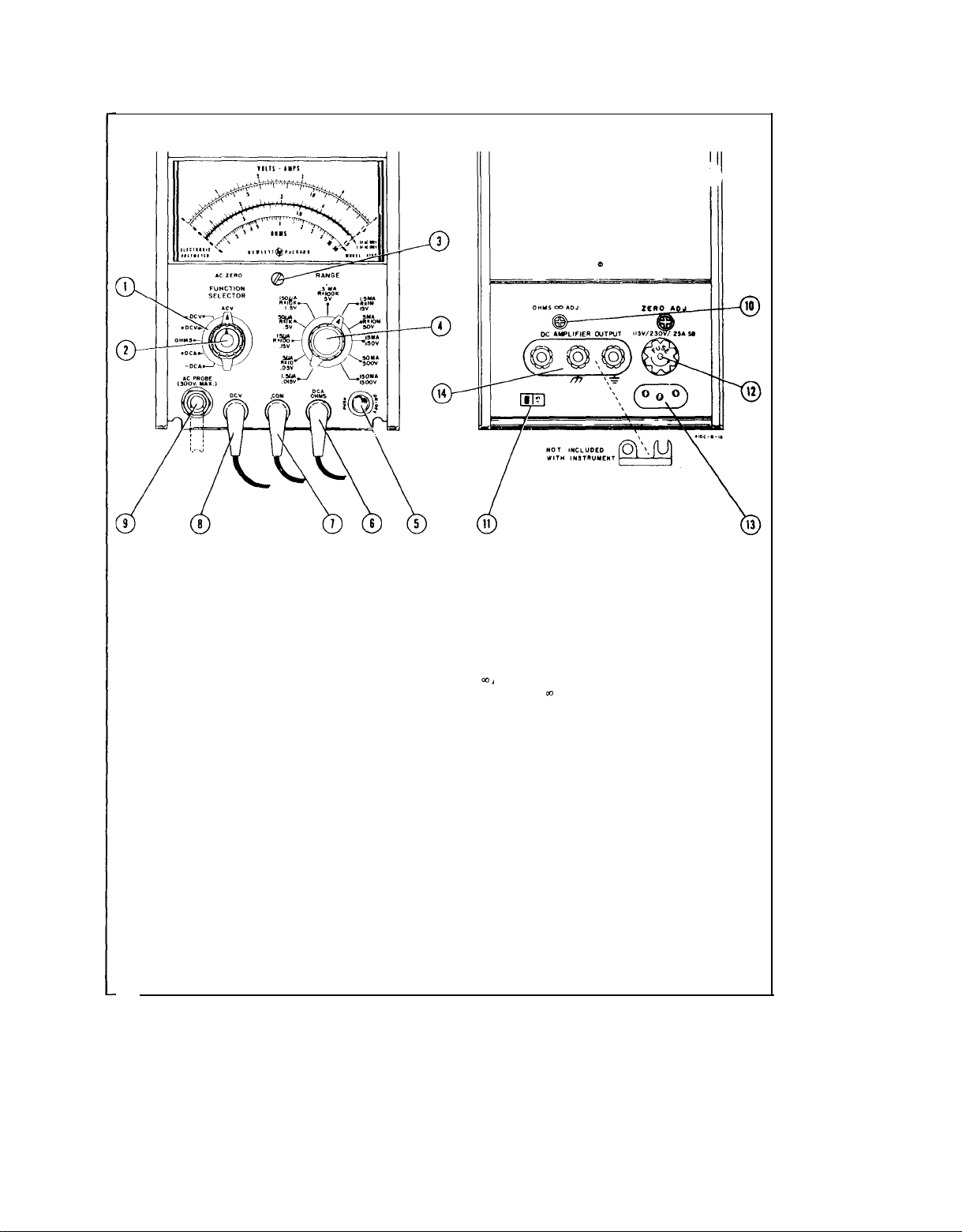

3-6. Figure 3-1 describes the function of all front

and rear panel controls, connectors and indicators .

The description of each control, connector and indi-

cator is keyed to a drawing which accompanies the

figure.

3-7. OPERATING PROCEDURES.

3-8. There are five operating procedures: DC Volt-

age Measurements, Figure 3-2; DC Current Measure-

ments, Figure 3-3; AC Voltage Measurements, Fig-

ure 3-4; Resistance Measurements, Figure 3-7; and

Measuring DC Current in Nano-amperes, Figure 3-8.

Note

Ageing of the neon tamps in the chopper

assembly can cause a change in chopper

frequency which produces a slight oscillatory movement of meter pointer. If

this oscillatory movement is observed,

rotate Oac Freq Adj A3R5 (see Paragragraph 5-28) in the ccw direction until

oscillation of pointer stops.

DC VOLTAGE MEASUREMENTS (Figure 3-2).

.

3-9.

3-10. The Model 410C is normally floating; however

a shorting bar can be connected at the DC AMPLIFIER

OUTPUT connector on the rear panel. When the instru-

ment is floating, the COM Lead should not be connected

to voltages greater than 400 volts.

3-11. DC CURRENT MEASUREMENTS (Figure 3-3).

3-13.

1

ONE SIDE OF ALMOST ALL POWER

DISTRIBUTION SYSTEMS IS GROUNDED.

EXTREME CAUTION MUST BE USED IF

DIRECT MEASUREMENT OF POWER

LINE VOLTAGES IS ATTEMPTED. IF

THE GROUND CLIP LEAD IS ACCIDENTALLY CONNECTED TO THE UNGROUNDEDSIDE OF THE LINE. SEVERE

DAMAGE TO THE 410C IS POSSIBLE

BECAUSE OF THE SHORT CIRCUIT

CREATED.

CAN BE SAFELY MEASURED BY USING

THE PROBE TIP ONLY. CONTACTING

THE GROUNDED POWER CONDUCTOR

WILL GIVE A READING OF 0 VOLTS

WHILE CONTACTING

GROUNDED LEAD WILL GIVE FULL

VOLTAGE READING.

3-14.

Although the Model 410C indicates a full scale

AC range of 500 volts, the optional Model 11036A AC

Probe should not be connected to AC voltages in excess of 300 volts RMS. AC voltage referenced to a

DC voltage may be measured, but the AC Probe clip

(alligator type) must be connected to the ground

of the circuit under test.

WHEN MEASURING AC REFERENCED

TO DC, THE PEAK AC VOLTAGE PLUS

DC VOLTAGE CONNECTED TO TRE

PROBE MUST NOT EXCEED 420 VOLTS.

3-15. PRECAUTION WHEN MEASURING AC VOLT-

AGE.

3-16. Special considerations must be kept in mind

when making AC voltage measurements. These considerations are discussed in the following paragraphs.

3-17. GENERAL CONSIDERATION OF COMPLEX

WAVEFORMS.

harmonics or spurious voltages will introduce error

in the meter indication since the meter has been calibrated to read RMS values of true sine waves while

the Model 11036A Probe is a peak-above-average

responding device.. The magnitude of error that may

be expected when harmonics are present on the mea-

sured waveform is indicated in Table 3-1.

POWER LINE’ VOLTAGES

THE UN-

Waveforms containing appreciable

3-12. General instructions for the measurement of

DC current are the same as those given for DC volt-

age measurements, Paragraph 3-9.

01556-2

3-18. VOLTAGE MEASUREMENTS AT FREQUENCIES BELOW 50 CYCLES/SECOND. Voltage measurements at frequencies as low as 10 cycles per

3-1

Page 16

TM 11-6625-1614-15

Section III

Figure 3-1

Model 410C

1.

FUNCTION SELECTOR: This control is used for

selecting type of measurement to be made. They

are: ±DC Voltage, ±DC Current, AC Voltage,

and resistance measurements.

2.

AC ZERO: This control provides adjustment for

zero-setting the meter before making AC voltage measurements.

3.

MECHANICAL ZERO ADJUST: This adjustment

mechanically zero-sets the meter prior to turn-

ing on Voltmeter.

4.

RANGE:

meter range.

5.

AC POWER SWITCH: This push button - lamp

combination, when depressed, turns the instrument power on or off. The push button glows

when the Voltmeter power is on,

6.

DCA-OHMS: This lead is used in conjunction

with the COM Lead to measure DC current or

ohms. The FUNCTION SELECTOR determines

which measurement is made.

7.

COM: This lead is used with the input leads for

DC voltage current, AC voltage, and resistance

measurements. The COM Lead is normally

floating; however, a shorting bar can be connected from the floating ground terminal to the

chassis ground terminal on the DC AMPLIFIER

OUTPUT connector. If a shorting bar is not

used, the COM Lead is floating except when the

FUNCTION SELECTOR is set to ACV.

3-2

This control selects the full scale

Figure 3-1. Front and Rear Panel Controls

DCV: This lead is used in conjunction with the

8.

COM Lead to measure ±DC voltage.

9.

AC PROBE (300V MAX): Receptacle for telephone-type plug of Model 11036A

With probe connected the Voltmeter may be

used to make AC voltage measurements.

ADJUST: This control is used to set meter

10.

pointer to before resistance measurements

are made. Only periodic adjustment

screwdriver adjustment is necessary.

11.

LINE VOLTAGE: This two-position slide switch

sets the instrument to accept either 115 or 230

volt AC primary power.

FUSEHOLDER: The fuseholder contains a 0. 25

12.

ampere slow-blow fuse for both 115 vac and

230 vac modes of operation.

13.

AC POW ERCONNECTOR: Accepts power cable

supplied with the instrument.

14.

DC AMPLIFIER OUTPUT: Provides DC voltage output proportional to meter indication for

driving external recorder. 1.5 volts DC output for full scale meter deflection.

AC Probe.

this

of

01556-2

Page 17

Model 410C

second maY be made without loss of accuracy by removing the. plastic nose on the Model 11036A and using

in its place a 0.25 microfarad blocking capacitor in

series with the exposed contact of the probe.

THE GRAY INSULATING MATERIAL

AROUND THE AC PROBE IS POLY-

STYRENE, A LOW-MELTING POINT

MATERIAL. IT IS NOT POSSIBLE TO

SOLDER TO THE CONTACT WHICH IS

EXPOSED WITH THE PROBE NOSE IS

REMOVED WITHOUT

DESTROYING

THE POLYSTYRENE.

Table 3-1.

% Harmonic

o

10% 2nd

20% 2nd

50% 2nd

l0% 3rd

20% 3rd

50% 3rd

Possible Error When Measuring Voltage

of Complex Waveforms

,

True RMS Value

100

100.5

102

112

100.5

102

112

Voltmeter Indication

100

90 to 110

80 to 120

75 to 150

90 to 110

87 to 120

106 to 150

3-19. VOLTAGE MEASUREMENT AT HIGH FREQUENCIES. At frequencies above 100 megacycles

the distance between the point of voltage measurement and anode of the probe diode must be made as

short as possible. If feasible, substitute a small disc

type capacitor of approximately 50 picofarsds for the

removable tip on the probe. Solder one terminal of

the button capacitor to the measurement point in the

circuit and not to the probe contact. The probe contact ( with tip removed ) can then contact the other

terminal of the capacitor for the measurement.

3-20. At frequencies above 100 megacycles considerable voltage may be built up across ground leads

and along various part of

a grounding piane.

Consequently, to avoid erroneous readings when measuring medium and high frequency circuits, use the

ground clip lead on the shell of the probe to connect

the circuit ground. In some cases at the higher frequencies it maybe necessary to shorten the grounding

lead on the probe.

3-21. For all measurements at higher frequencies,

hold the molded nose of the probe as far from the external ground piane or from object at ground potential

as can conveniently be done. Under typical conditions,

this practice will keep the input capacitance several

tenths of a picofarad lower than otherwise.

3-22. For measurements above approximately 250

megacycles it is almost mandatory that measurements

be made on voltages which are confined to coaxial

transmission iine circuits. For applications of this

type, the Model 11036A Probe is particularly suitable

because the physical configuration of the diode and

probe is that of a concentric line, and with a few precautions it can be connected to typical coaxial transmission line circuits with little difficulty.

01556-2

TM 11-6625-1614-15

Paragraphs 3-19 to 3-27 and Table 3-1

3-23. T

O connect the probe into an existing coaxial

transmission line, cut the line away so the center conductor of the line is exposed through a hole large

enough to clear the body of the probe. The nose of the

probe should be removed for this type of measurement.

Connect one terminal of a button-type capacitor of approximately 50 picofarads to the center conductor of

the coaxial line so that the other terminal of the oapacitor will contact the anode connection of the probe.

A close-fitting metal shield or bushing should be ar-

ranged to ground the outer cylinder of the probe to the

outer conductor of the transmission line.

connection is likely to cause some increase in the

standing wave ratio of the line at higher frequencies.

The Model 11042A Probe T Connector is designed to

do this job with SWR or less than 1.1 at 500 Mc (see

Paragraph 1-11).

3-24. EFFECT OF PARASITIC ON VOLTAGE

READINGS .

At frequencies above 500 megacycles,

leads or portions of circuits often resonate at frequencies two, three, or four times the fundamental

Of the voltage being measured. These harmonics may

cause serious errors in the meter reading. Owning to

the resonant rise in the probe circuit at frequencies

above 1000 megacycles, the meter may be more sensitive to the harmonics than to the fundamental. To

make dependable measurements at these frequencies,

the circuits being measured must be free of ail parasitics.

3-25. EFFECT OF DC PRESENT WITH AC SIGNAL.

When measuring an AC signal at a point where there

is a high DC potential, such as at the plate of a vacuum

tube, the high DC potential may cause small leakage

current through the blocking capacitor in the tip of the

Model 11036A AC Probe. When the AC signal under

measurement is small, the error introduced into the

reading can bes significant. To avoid leakage, an additional capacitor with a dielectric such as mylar or

polystyrene which has high resistance to leakage is

required. (Use 5 picofarads or higher, and insert the

capacitor between the point of measurement and the

probe tip.)

3-26. PULSE MEASUREMENTS

3-27. POSITIVE PULSES. The Model 11036A AC Probe

is peak-above-average responding and clamps the

positive peak value of the applied voltage. This permits the probe to be used to measure the positivevoltage amplitude of a pulse, provided the reading obtained is multiplied by a factor determined from the

following expression:

t

is the duration of the positive portion of the

1

voltage in microseconds.

t

is the duration of the negative portion of the

2

voltage in microseconds.

K

is a factor determined from the

t

o/

1 and the graph shown as

R

where R

generator in kilohms, and t

the positive portion of the pulse in microseconds.

o is the source impedance of the pulse

l

Section III

This type of

expression

Figure 3-6,

is the duration of

3-3

Page 18

TM 11-6625-1614-15

Section III

Paragraphs 3-28 to 3-34

PRF is the pulse repetition frequency in pulses per

second (pps).

Suppose, for example:

t

10 microseconds

=

1

t

=

990 microseconds

2

K=

0.55

PRF =

To find K, assuming/= 2 kilohms and

seconds:

X axis of the graph shown as Figure 3-6, and reading

K where X and Y axes intersect the unmarked curve. If

the ratio of

X and Y axes by 10, and use the curve marked ”R

t

1 and K each X10”.

Solving the expression for the multiplying factor,

1000 pps

t

l=10micro-

Ro/tl = 2 10° = 0.2. Location 0.2 on the

Ro/tl were greater than 1, multiply the

3-28. NEGATIVE PULSES.

3-29. In the case of a 10 microsecond negative pulse

(t2) and a pulse repetition frequency (PRF) of 1000 pps,

t

l would be 990 microseconds. Thus To/t1 would be

approximately 0, and from the graph it is seen that

K is approximately 0. The expression would then

reduce to

3-30. It can be seen that in the case of negative pulses

of short duration much smaller readings will be obtained for an equivalent positive pulse. As a result,

large multiplying factors must be used and unless the

pulse voltage is large, these measurements may be

impractical.

3-31. MEASURING RESISTANCE (Figure 3-7).

/

o

3-32. Before making resistance measurements, power

must be removed f rom the circuit to be tested. Also,

make sure capacitors are discharged to eliminate any

residual voltage.

3-33. MEASURING DC NANO-AMPERE CURRENT

(Figure 3-8).

3-34. The Model 410C can be used to measure nano-

ampere leakage current in transistors and diodes. The

three most sensitive DC voltage measurement ranges

are used to measure DC nano-ampere currents.

Model 410C

3-4

.

.

Page 19

Model 410C

TM 11-6625-1614-15

Section III

Figure 3-2

01556-2

Figure 3-2. DC Voltage Measurements

3-5

Page 20

TM 11-6625-1614-15

Section III

Figure 3-3

Model 410C

3-6

Figure 3-3. DC Current Measurements

01556-3

Page 21

Model 410C

TM 11-6625-1614-15

Section III

Model 410C

01556-3

Figure 3-4. AC Voltage Measurements

3-7

Page 22

3-8

TM 11-6625-1614-15

Section III

Figure 3-5

01556-2

Figure 3-5.

Model 410C

Page 23

Model 410C

TM 11-6625-1614-15

Section III

Figure 3-6

01556-2

Figure 3-6. Graph Used in Calculation of Pulse Voltage Readings

3-9

Page 24

TM 11-6625-1614-15

Section III Model 410C

Figure 3-7

3-10

Figure 3-7.

Resistance Measurements

01556-2

Page 25

Model 410C

TM 11-6625-1614-15

Section III

Figure 3-8

01556-3

Figure 3-8.

DC Nano-Amoere Current Measurements

3-11

Page 26

TM 11-6625-1614-15

Section IV

Figure 4-1 and 4-2

Model 410C

4-0

Figure 4-1. Block Diagram, Model 410C

Figure 4-2. Modulator-Demodulator Mechanical Analogy

01556-2

Page 27

Model 410C

SECTION IV

THEORY OF OPERATION

TM 11-6625-1614-15

Paragraph 4-1 to 4-18

Section IV

4-1.

OVERALL DESCRIPTION.

4-2.

The Model 410C includes

modulator - amplifier- demodulator, and a

circuit. A block diagram of the Model 410C is shown

in Figure 4-1.

4-3. Signals to be measured are applied through the

appropriate input lead to the input network. AC volt-

ages are detected in the AC probe, and therefore all

signals to the input network are DC. The input network attenuates the DC signal to a level determined

by RANGE and FUNCTION SELECTOR settings. The

attenuated DC voltage is applied to the modulator which

converts the DC to AC for amplification. The amplified AC signal is converted back to DC voltage inthe

demodulator and coupled to cathode follower VIB. The

cathode follower output to the DC AMPLIFIER OUTPUT connector and meter circuit is a DC voltage

proportional to the amplitude of the signal applied to

the input. A portion of the voltage to the meter circuit

is returned to the modulator as feedback. When the

feedback voltage and attenuated DC voltage are nearly

equal, the meter stabilizes.

4-4. CIRCUIT DESCRIPTION.

4-5. INPUT NETWORK.

4-6. The input network includes a precision voltage

divider, which by means of the FUNCTION SELECTOR

and RANGE switches, providesa maximum of 15 millivolts at the modulator input regardless of the range

set and signal applied. The ± DCA, ±DCV, OHMS, and

ACV modes of operation are discussed below.

4-7. DC CURRENT MEASUREMENTS: Refer to Figure 4-3, throughout this explanation. The purpose of

the input network is to provide proper attenuation of

currents applied.

full scale are applied with input impedance decreasing

from 9K ohms on the 1.5 µa range to approximately

0.3 ohms on the 150 ma range.

4-6. Tbe change in input impedance is varied by using

DC current shunts in conjunction with RANGE switch

A2S2. The DC voltage developed across these shunt

resistors, when applied through the modulator-am-

plifier-demodulator network to the meter, provide a

deflection on the meter proportional to the DC current

being measured.

4-9. DC VOLTAGE MEASUREMENTS. Refer to

Figure 4-4 throughout this explanation. The purpose

of the input network is to accurately attenuate the input signal to a maximum of 15 millivolts at the modu-

01556-2

Currents from 1.5 µa to 150 ma

an input network, a

meter

later input. The network presents an input impedance

of 10 megohms on the three most sensitive ranges and

100 megohms on all other ranges.

4-10. The resistor R1 (located in the DCV probe) in

conjunction with resistors A2R10 through A2R26, provides the 10 megohm input impedance required for the

three most sensitive DCV ranges. Resistors A2R4

and A3R30 are shunted out of the circuit by the RANGE

switch on the three most sensitive DCV ranges.

4-11. When using the eight less sensitive ranges,

A2R4 and A3R30 are placed in series with Rl and

A2R10 through A2R26 to present more than 100 meg-

ohm impedance to the input.

4-12. A3R30 is used to calibrate full scale on the

1500 volt range. (See Paragraph 5-35. )

4-13. RESISTANCE MEASUREMENTS. The purpose

of the input network shown in Figure 4-5 is to place

approximately 0. 6 volt DC source in series with a

known (reference) resistance. The resistance to be

measured is ptaced in parallel with the known resistance, which changes the voltage proportionally. The

maximum changes in voltage applied to the modulator

is 15 mv because of attenuation provided by A2R4,

A3R30, and A1R2.

4-14. A DC current of approximately 60 ma is

supplied at the junction of A2R22 and A2R23 through

A7R10, R2, A2R2 and A2R1 to the input network. The

OHMS ADJ.,

Resistor A2R1 is shorted out in the XIM position of

the RANGE switch; resistors A2R1 and A2R2 are

shorted out in the X10M range. The resistors A2R2

and/or A2R1 are electrically removed from the circuit to increase the voltage at the junction of A2R22

and A2R23. This is done to compensate for tbe loading of the attenuator (A2R4, A3R30, and A1R2) on

these ranges.

4-15.

Figure 4-6 throughout this explanation. Voltage at

the AC probe is converted to DC and applied to the input network. The input signal is attenuated to produce

a maximum of about 15 millivolts at the modulator in-

AC zero adjustment of meter pointer is made

put .

with the AC ‘ZERO control.

4-16. MODULATOR-DEMODULATOR.

4-17. Refer to the Amplifier Schematic, Figure 5-10 ,

and to the Mechanical Analogy Schematic,

4-2 throughout this explanation.

4-18. The input network applies approximately 15

millivolts DC, for full scale meter deflection (posi-

tive or negative, depending on the polarity of the

R3, sets the meter for full scale

AC VOLTAGE MEASUREMENTS. Refer to

Figure

4-1

Page 28

TM 11-6625-1614-15

Section IV

Paragraphs 4-19 to 4-31

voltage or current being measured) to the neon-photoconductor chopper. Also applied to the opposite side

of the chopper is the amplifier feedback voltage, which

is of the same polarity and approximately 5 microvolts lower in amplitude than the input voltage. The

modulator-chopper consists of two photoconductors,

A4V1 and A4V2, which are alternately illuminated by

two neon lamps, A4DS1 and A4DS2, respectively. The

neon lamps are part of a relaxation oscillator, whose

frequency is controlled by A3R5. The oscillator frequency is nominally set to 100 cps for operation from

60 cps power line, or to 85 cps for 50 cps line. This

frequency is selected so that it is not harmonically

related to the power line frequency, precluding pos-

sible beat indications on the meter.

4-19. As the photoconductors are alternately illuminated by the neona, their respective resistances are

low (conductive ) when illuminated and high (non-conductive) when darkened. Therefore the input voltage

and feedback voltage are alternately applied to the

input amplifier. The amplitude of the resultant signal

to the amplifier is the voltage difference between the

input and feedback voltages.

4-20. The chopped DC signal is amplified by a three

stage RC amplifier, consisting of A3V1A, A3Q1 and

A3Q2. The amplified signal to the input of the demodulator-chopper is 180° out of phase with the output of the modulator-chopper.

4-21.

The demodulator - chopper consists of two

photoconductors, A4V3 and A4V4, which are alternately

illuminated by neon tamps A4DS1 and A4DS2, respectively. Approximately 150 millivolts square-wave is

applied to the demodulator from the amplifier. Since

the same neon lamps illuminate both the modulator

and demodulator photoconductors, operation of the two

chopper is synchronous. Therefore, when A4V1 is

sampling the input voltage, A4V3 is clamping the

amplified and inverted difference voltage to ground.

Alternately, when A4V2 is sampling the feedback vol-

tage, A4V4 is charging capacitors A3C13 and A3C14

to the peak value of the square-wave. These capacitors maintain this charge so long as the input voltage

remains constant by virtue of having no discharge

path and because they are being repetitively recharged

by the demodulator.

4-22. Therefore, a DC potential, proportional to the

difference between the input and feedback voltages, is

applied to the grid of the cathode follower and subsequently to meter circuit and DC AMPLIFIER OUTPUT

connector. A portion of the meter circuit voltage is

fed back to the modulator. The meter stabilizes when

the feedback voltage and input voltages are nearly

equal.

4-23. THE FEEDBACK NETWORK.

4-24. The feedback network drives the meter and

determines the DC gain of the amplifier. The feedback is varied depending on the position of the FUNCTION and RANGE selectors. The different feedback

configurations are discussed below.

Model 410C

4-25.

FEEDBACK NETWORK FOR ±DCA. OHMS,

AND ±DCV. Figures 4-3, 4-4 and 4-5 show the feed-

back configuration for ail positions of the FUNCTION

SELECTOR except ACV. The meter is electrically

inverted for ±DCV and ±DCA modes of operation. The

DC OUTPUT ADJ., A6R20 sets the output voltage. The

DC pot, A6R18 determines the amount of feedback to

the modulator. The resistor A2R30 is in the circuit

in the ± .015 DCV and ±1.5 µa modes of operation, to

decrease feedback and thus increase amplifier gain to

compensate for the decrease in input signal to the

modulator on these ranges.

4-26. FEEDBACK CIRCUIT FORAC VOLTAGE

SUREMENTS: Figure 4-6 shows the feedback confi-

guration for the ACV position of the FUNCTION SEL-

ECTOR switch, A2S2. The resistors that are placed

in the circuit by the RANGE switch program the amplifier gain to compensate for the non-linear response

of the AC probe. A6R16 and A6CR1 compensate the

non-linear response of the AC probe to the linear

calibration of the upper meter scale on the 5 volt

range.

4-27. POWER SUPPLY.

4-28. PRIMARY POWER. Either 115 or 230 volt ac

power is connected through fuse R1 (0.25 amp slo-blo)

and switch S3 to the primary of power transformer

T1. Switch S4 connects T1 primaries in parallel for

l15 volt operation of in series for 230 voit operation.

4-29.

UNREGULATED AND ZENER REGULATED

POWER SUPPLY. Full wave rectifier CR1 and CR2

produces unregulated +270 volts, which is used to

drive the photochopper neons. Unregulated +175 volts

and +140 volts are tapped off and are used to provide

B+ to the plates of A4V1B and A4V1A, respectively.

Zener regulators A7CR6 and CR7 provide regulated

+38 volts and -9 volts to bias A3Ql and A3Q2. Filtering

of the outputs is provided by the RC network consisting

of A7R1 through A7R3 and C5A through C5D.

4-30. SERIES REGULATED POWER SUPPLY. The

output of the full wave rectifier CR3 and CR4 is re-

gulatedbytransistor Ql, which is connected in series

with the output. Zener diode A7CR8 provides reference

voltage to the base of Q1. Regulated +6 volts is supplied

to the filaments of A3VlA/B and the AC Probe diode

+0.6 volts is provided through A7R10 to R3,

A6V1.

the OHMS ADJ, control. Filtering of the outputs is

provided by C6A and C6B.

4-31. STANDBY FILAMENT SUPPLY. The filament

tap (Tl, Pins 1 and 2) provides 6.0 volts actothe

filament of the AC probe diode, A8V1, so that the

filament remains warm when the Modei 410C is being

used in modes of operation other than ACV. When

FUNCTION selector A1S1 is switched to ACV, 6.0

volts AC is removed from the filament and 6 volts DC

is applied. Therefore, the ACV mode is ready for

imrnediate use,

warm up.

without waiting for the filament to

MEA-

4-2

01556-2

Page 29

01556-2

Model 410C

4-3

Figure 4-3.

TM 11-6625-1614-15

Figure 4-3

Section IV

Page 30

4-4

Section IV

TM 11-6625-1614-15

Figure 4-4

01556-2

Model 410C

Figure 4-4.

Page 31

01556-2

4-5

Figure 4-5.

TM 11-6625-1614-15

Figure 4-5

Section IV

Page 32

TM 11-6625-1614-15

Section IV

4-6

Figure 4-6

01556-2

Model 410C

Figure 4-6.

Page 33

Page 34

TM 11-6625-1614-15

Section V

Table 5-1

Table 5-1. Recommended Test Equipment

Instrument

Type

Voltmeter Calibrator

Required

Range: .015 to

Frequency: DC and

Accuracy:

DC

Power

Supp Iy

DC Voltmeter

Range: O to 10 v continuous

Range: 10

Accuracy:

Frequency Response Frequency: 20 cps to 10

Test

Set with

Output: 2 v into 50 ohms

Characteristics

+0. 370 AC

*O.

v

+0. 2%

external oscillator

300 v

2%0

Model 410C

Recommended Model

@

Model 738BR Volt-

meter Calibrator

400

cps

AC

and DC

Checks and

Use

Accuracy

Calibration

Adjustments

DC

DC Ammeter Accuracy

Checks supply

Accumcy Checks; Power

Supply

Measurements;

@Model

@

723A DC

Model 3440A/3442A

Digital

Voltmeter

Power

I

i

Troubleshooting

Frequency Response

Mc

Test@ Model

uency Response

739AR Freq-

Test

.

Set

Oscillator

Frequency: 20 cps to 10

output :

RF Signal

Generator

Frequency: 10 Mc to

output: 1.0

Power

Meter

Frequency: 10Mc to700

Range: 1.0

VHF Signal

AC Voltmeter

Electronic

Generator

Frequency:

Range:

Counter Frequency Range: to at

least 102

DC

Standard output:

Accuracy:

Ohmmeter Range:

Accuracy:

Thermistor Mount

Frequency: 10 Mc to 700Mc

Impedance: 50

Pr~be-T-Connector For

use with 50

mission line

10 KC Filter

High pass fi 1 ter

10 kc

Connector

Connector Adapter

Adapter

Male

Type N male to

Resistors:

10

M!l

5 MQ

4,5Mfl

500 K

56 K

10 K

9K

1.5K

56

ohms

10

ohms

Accuracy:

Accuracy:

Accuracy:

Accuracy:

Accuracy:

Accuracy:

Accuracy:

Accuracy:

Accuracy:

Accuracy: *170

2.0 v

480 Mc to

115 V

cps

1000 v

+0. 2%

100 Mf2

+5%

re]ection

BNC

to male

*1%

+1%

+1%

+1%

*1%

+1%

*I?o

*1%

+1%

v

v

ohm

capable

BNC

480 Mc

700Mc

match

ohm trans-

of

BNC

female

Frequency Response

Mc

Frequency Response

Frequency Response

Mc

Frequency Response

Power

Supply

Measure-

ments (ripple)

Chopper Frequency Adjust@ Model

DC

Adjust

Troubleshooting

Frequency Response

Frequency Response

Frequency Response

Frequency Response

Frequency

Performance

Performance

Performance

Performance

Performance

Performance

Performance

Performance

Performance

Performance Checks

Response

Checks &

Checks

Checks

Checks

Checks

Checks

Checks

Checks

Checks

Test@ Model

651A Test

Oscillator

Test@ Model

608C

RFSigmal

Generator

Test@ Model

431B

Power

Meter

Test@ Model

Signal

@

Model

612A

VHF

Generator

3400A RMS

Voltmeter

521C Electronic

Counter

@

Model

740A DC

Standard

@

Model

412A

DC VTVM

@?

Model

478A

Test

Thermistor

Test@ Model

Coaxial

Mount

11042A Probe-

T-Connector

Test@ Model K02-411A

10 KC Filter

Test@

Test@

Part No.

Part No.

Part No.

@ Part No.

1250-0216

1250-0067

0730-0168

0730-0125

@ Part No. 0730 -015’7

@ Part

No. 0721-0011

@ Part

No. 0730-0053

@ Part

No. 0727-0157

@ Part No.

0730-0026

@ Part No. 0730 -001’7

@ Part

No.

@ Part No. 0727-0335

0811-0341

5-0

01556-2

Page 35

Model 410C

TM 11-6625-1614-15

Section V

Paragraphs 5-1 to 5-11

SECTION V

MAINTENANCE

5-1. INTRODUCTION.

5-2. This section contains maintenance procedures

for the Model 410C Electronic Voltmeter.

5-3. TEST EQUIPMENT REQUIRED.

5-4. The test equipment required to maintain and

adjust the Model 410C is listed in Table 5-1. Equipment having similar characteristics may be substi-

tuted for items listed.

5-5. PERFORMANCE CHECKS.

5-6. The performance checks presented in this

section are front panel operations designed to com-

pare the Model 410C with it’s published specifications.

These operations may be incorporated in periodic

maintenance, post repair and incoming quality control

checks. These operations should be conducted before

any attempt is made at instrument calibration or

adjustment. During performance checks, periodically

vary the line voltage to the Model 410C, ± 10% on either

115v or 230 v operation. A 1/2 hour warm-up period

should be allowed before these tests are conducted.

5-7. ALTERNATE VOLTAGE SOURCE.

5-6. Should it be necessary to use the

Voltmeter Calibrator to conduct these Performance

Checks, the arrangement described in Figure 5-1 will

provide the necessary voltage values required. How-

ever; the Model 738BR Voltmeter Calibrator is the

preferred instrument for these operations.

Model 738AR

5-9. Mechanical METER ZERO.

a. Turn instrument on.

minute warm-up period.

b. Turn voltmeter off, and allow 30 seconds for

all capacitors to discharge.

c. Rotate mechanical zero-adjustment screw on

front panel clockwise until pointer reaches zero,

moving up scale.

d. If for some reason the pointer should overshoot zero, repeat step c until desired results

are obtained.

e. When pointer has been positioned at zero,

rotate zero-adjust screw slightly counterclock-

wise to free it. If meter pointer moves to the

left during this action, repeat steps c and e.

5-10. DC VOLTMETER OPERATION.

5-11. ACCURACY CHECK (DCV).

a. Set the Model 410C FUNCTION SELECTOR

to the +DCV position; RANGE switch to. 015 V .

Connect Model 410C DCV and COM cables to the

Voltmeter Calibrator

terminals.

Allow at least a 20

Model 738BR) output

01556-2

Figure 5-1. Alternate Voltage Source

5-1

Page 36

TM 11-6625-1614-15

Section V

Paragraphs 5-12 to 5-15

Table 5-2

Model 410C

Range Settings

.015V

.05V

.15V

.5V

1.5V

5V

15 V

50 V

150V

500 V

1500

Table 5-2. DCV Accuracy Test

Voltmeter Calibrator

Model 738B

Settings

Range

1. 5-5

1. 5-5

1. 5-5

1. 5-5

1. 5-5

1. 5-5

1. 5-5

1. 5-5

1.5-5

1-3

1-3

Voltage

.015

.05

.15

.5

1.5

5

15

50

150

300

300

Model 410C

Model 410C

Meter Readings

.01.47 to .0153 V

.049 to .051 V

.147 to .153 V

.49 to .51 V

1.47 to l.53 V

4.9 to 5.l V

14.7 to 15.3 V

49 to 51 V

147 to 153 V

290 to 310 V

270 to 330 V

b. Adjust Voltmeter Calibrator to provide a

+.015 v dc voltage.

c. Model 410C should read between 0. 0147 and

0.0153 v.

d. Readjust Model 410C and Voltmeter Cali-

brator (,) settings listed in Table 5-2. Note

Model 410C meter readings. If Model 410C fails

to meet pecifications, refer to Paragraph, 5-30

and

5−32 for proper adjustment procedure.

5-12

INPUT RESISTANCE CHECK (DCV).

a. Connect an external resistor, Rx, of lO M

ohms ±1% ( Part No. 0370-0168) in series

between the voltmeter calibrator and the DCV

cable of the Model 410C.

b. Set Model 410C FUNCTION selector to +DCV;

RANGE to .015 V.

c. Adjust voltmeter calibrator for +.015v DC

output.

d. Model 410C should read .0075 v, verifying

R

of 10 M ohms.

in

e. Table 5-3 provides settings required to

verify Model 410C R

on RANGES specified.

in

5-13.

5-14. ACCURACY CHECK (DCA).

a. Figure 5-2 describes the test arrangement

required for this operation.

The following

additional equipment will also be required:

DC Power Supply Model 723A)

DC Voltmeter Model 3440A/3442A)

10 K, 1%, 1 w resistor Part No. 0727-0157)

56 K, 1%, 1 w resistor Part No. 0730-0053)

10 , 1%, 1 w resistor Part No. 0727-0335)

56 , 1%, 1/2 w resistor Part No. 0811-0341)

b. Connect the Model 410C as shown in Figure

5-2; FUNCTION SELECTOR to +DCA; RANGE

to 150 MA.

c. Use 56 ohm resistor for R1 and 10 ohm

resistor for R2.

d. Adjust dc power supply to obtain 1.4v reading

on system voltmeter.

e. Model 410C should read between 135.5 and

144.5 ma.

f. Adjust dc power supply for System voltmeter

readings listed in Table 5-4. Note Model 410C

meter readings.

5-15. INPUT RESISTANCE CHECK (DCA).

a. Figure 5-2 describes the test arrangement

required for this operation.

R2 with a 10 ohm ±1% resistor Part No.

Replace R1 and

0727-0335).

b. Set Model 410C FUNCTION SELECTOR to

+DCA: RANGE to 150 MA.

5-2

Change 1

01556-2

Page 37

Model 410C

TM 11-6625-1614-15

Section V

Tables 5-3 and 5-4

Figure 5-2

Figure 5-2. DC Ammeter Operation

Table 5-3. DCV Input Resistance Test

01556-2

Table 5-4. DCA Accuracy Test

5-3

Page 38

TM 11-6625-1614-15

Section V

Paragraphs 5-16 to 5-19

Table 5-5

c. Adjust dc power supply to provide system

voltmeter reading of 1.50 v.

e. Model 410C should read approximately

150 ma.

mately 0.3 ohms, where

f. Set Model 410C RANGE to 1.5 µa.

g.

h. Adjust dc power supply to provide system

voltmeter reading of 13.5 mv.

j.

µa. This will verify R

range.

OHMMETER OPERATION.

5-16.

a. A 10 ohm ±l% resistor Part No. 0727-

0335) and a 10M resistor Part No. 0730-

0168) will be required for this test.

b. Set Model 410C FUNCTION SELECTOR to

OHMS; RANGE to RX10.

c. Set pointer to using rear panel adjust-

ment (OHMS ADJ) if required.

d. Connect COM and DCA OHMS cables across

10 ohm resistor.

e. Meter should read 1 (±5%), indicating 10

ohms.

f. Reset Model 410C RANGE to RX10M. Re-

place 10 ohm resistor with 10 M ohm resistor.

g. Meter should read 1 (+5%), indicating 10 M

ohms.

This will verify a R

RXI

-

I

410C

410C

R

410C=Etotal

Replace Rx with a 9 K ohm ±1% resistor

Part No. 0730-0026).

Model 410C should read approximately 1.5

of 9 K on 1.5 µa

in

of approxi-

in

Table 5-5. DC Voltage

Deleted

h. If both of these ranges function properly, it

can be assumed that the remainder will also .

If meter does not function properly, refer to

Paragraph 5-31 for adjustment procedure.

5-17. AMPLIFIER OPERATION.

Deleted

see paras 5-19 and 5-24

5-19. AMPLIFIER GAIN CHECK.

a. Connect Voltmeter

738BR) output to Model 410C DCV and

cables.

b. Connect DC Voltmeter Model

3442A) to DC AMPLIFIER OUTPUT on rear

panel of Model 410C. Set DC Voltmeter RANGE

to 10 v.

Output Test

Calibrator Model

Model 410C

COM

3440A/

5-4

Change

1

01556-2

Page 39

TM 11-6625-1614-15

Model 410C

Parsgraphs 5-20 to 5-23

.

Section V

Figure 5-3

Figure 5-3.

c. Set Model 410C FUNCTION SELECTOR to

+DCV ; RANGE to .015 V.

d. Adjust voltmeter calibrator for +. 015 VDC

output.

e. The dc voltmeter should read +1.5 v. This

will vertfy a gain of 100, when the gain /A/

E

equals

5-20. AMPLIFTER NOfSE CHECK.

a. Leave the dc voltmeter connected to the DC

AMPLIFIER OUTPUT as in Paragraph 5-19.

b. Set the Model 410C RANGE to 1500 V;

5-21.

DC out/E410C.

FUNCTION SELECTOR to +DCV.

c. Short the Model 410C DCV and COM cables.

Note dc voltmeter readings.

should be less than 7.5 millivolts .

d. Reset Model 410C RANGE to 1.5 V. DC

Voltmeter should read less than 7.5 mv.

DC AMPLIFTER OUTPUT

CHECK.

a. Connect an external DC Voltmeter Model

3440A/3442A) to Model 410C DC AMPLIFIER

OUTPUT terminals on rear panel.

b. Set Model 410C FUNCTION SELECTOR to

OHMS position.

High Frequency Response Test

reading

This

IMPEDANCE

c. Record voltage indicated on external dc

voltmeter for use as a reference.

d. Connect a 1.5 k ohm ±1% resistor Part

No. 0730-0017) across Model 410C DC AMPLI -

FIER OUTPUT terminals. DC voltage recorded

in step c above should not change more than

3 mv, indicating that dc amplifier output impedance is within the 3 ohm specification at dc.

5-22. AC VOLTMETER OPERATION.

5-23. 11036A

a. Figure 5-3 describes the test arrangement

Model 410C AC Probe in T-Connector at this

point.

b. Adjust signal generator for a 0.7 volt (rms)

AC PROBE ACCURACY CHECK.

required for this operation. Do not

output at 1000 cps.

c. Connect Model 11036A AC Probe to signal

generator and read output on Model 410C Volt-

meter (meter should read 0.7 volts).

d. Remove probe tip from Model 11036A and

connect the ac probe as shown in Figure 5-4.

e. Turn signal generator to 50 Mc and adjust

signal generator for a power reading of 9.8

dbm (0.7 volts) on the power meter.

f. The difference between reading on Model

410C meter and 0.7 volt reference is the ac

probe error at that frequency.

g. Repeat steps f and g every 100 Mc from 50

to 700 Mc.

place

01556-2

5-5

Page 40

TM 11-6625-1614-15

Section V

Parsgraphs 5-24 to 5-25

Figure 5-4, Table 5-6

Figure 5-4. Low Frequency Response Test

AC VOLTMETER ACCURACY CHECK.

a. A Voltmeter Calibrator Model 738BR)

will be required for this operation.

b. Adjust voltmeter calibrator for 400 cps-

rms output.

c. Set Model 410C FUNCTION SELECTOR to

ACV; RANGE to 500 V.

d. Adjust the voltmeter calibrator to settings

listed in Table 5-6. Model 410C should indicate

readings within limits specified. If not, refer

Model 410C

5-25. AC VOLTMETER FREQUENCY RESPONSE

CHECK.

a. A Frequency Response Test Set Model

739AR), a Test Oscillator Model 651A), an

RF Signal Generator Model 608 C), a Power

Meter Model 431 B), a Thermistor

Model 478A), a Probe - T - Connector

Model 11042A), a VHF Signal Generator

Model 612A) and a 10 KC Filter Model K02411A) will be required for this operation. Figure 5-3 and 5-4 describe the arrangement to be

Mount

5-6

Change 1

Table 5-6. AC Accuracy Test

01556-2

Page 41

Model 410C

b. Connect the Model 410C as shown in Figure 5-4. Set Model

410C FUNCTION SELECTOR toACV; RANGE to 1.5 V.

Set frequency response test set to EXTERNAL.

c.

Adjust test oscillator output AMPLITUDE to provide Model

d.

410C reading of 1.4 V; FREQUENCY to 400 cps.

Set frequency response test set METER SET to convenient

e.

SET LEVEL.

Vary test oscillator frequency from 20 cps to 10 Mc. Model

f.

410C should read between 1.25 and 1.55 v at all frequencies.

When checking the frequency response from 20 cps to 50 cps,

disconnect the 11042A from the test set up in figure 5-4. Replace

the probe tip on the Model 11036A and connect directly through a

50-ohm load to the output of the Frequency Response Test Set.

Connect the output of the Test Oscillator directly to the input

TM 11-6625-1614-15

of the Frequency Response Test Set.

the entire operation.

If frequency response test set deflection varies from preset

g.

SET LEVEL, adjust test oscillator output amplitude to return

pointer to original position.

To check Model 410C frequency response from 10 Mc to 480 Mc,

h.

use arrangement described in Figure 5-3.

Set Model 410C FUNCTION SELECTOR to ACV; RANGE to .5 V.

i.

Adjust RF signal generator to provide Model 410C reading

j.

of 0.45 V at 10 Mc. Note power meter reading; mark for future

reference.

Observe step g

throughout

5-7

Page 42

TM 11-6625-1614-15

k. Vary RF signal generator frequency from 10 Mc to 480 Mc.

Model 410C should read between 0.40 to 0.50 v at all frequencies.

If power meter pointer varies from reference determined in

l.

above, readjust RF signal generator OUTPUT LEVEL to return

step j

pointer to reference deflection.

To check Model 410C frequency response from 480 Mc to 700

m.

Mc, replace RF signal generator with VHF Signal Generator (H-P

Model 410C

Model 612A) and repeat steps i

should not vary more than ±10% from reference.

5-26. ADJUSTMENT AND CALIBRATION PROCEDURE.

5-27. The following is a complete adjustment and calibration

procedurE for the Model 410C.

only if it has previously been established by Performance Checks,

Paragraph 5-5, that the Model 410C is out of adjustment.

Indiscriminate adjustment of the internal controls to “refine”

settings may actually cause more difficulty.

outlined do not rectify any discrepancy that may exist, and all

connections and settings have been rechecked, refer to Paragraph

5-36, Troubleshooting, for possible cause and recommended corrective

action.

5-28. CHOPPER

a. A Voltmeter Calibrator (H-P Model 738BR) and an Electronic

FREQUENCY ADJUST.

through m above. Model 410C

These operations should be conducted

If the procedures

Counter (H-P Model 52lC) and an AC Voltmeter (H-P Model 3400A)

will be required.

5-8

Page 43

TM 11-6625-1614-15

b. Use ac voltmeter to verify Model 410C line

voltage of 115 v. Chopper frequency will vary with

line voltage variations.

c. Connect 410C, electronic counter, and

voltmeter as ahown in Figure 5-6.1.

d. Set Model 410C FUNCTION SELECTOR to

+DCV; RANGE to 1.5 V.

e. Adjust voltmeter calibrator to supply + 5 V dc

to the Model 410C (DCV and COM cables).

Table 5-7, Power Supply Test

voltage

+ 175 v

+38V

+6V

V

–9.1

Location on A7

Wht/blk and Orange

Junction of CR6 and R4

Cathode of CR8

Anode of CR7

f. Observe counter, and adjust A3R5 for a chop-

per frequency of 100 cps ( ±2 cps).

5-29. Power Supply Adjustment

a. Refer to Table 5-7 for Power Supply check

points and typical voltage values. Measure dc

voltages between common and designated location

on Al.

b. Set Model 410C FUNCTION to ACV. Short

ACV and COM cable.

Tolerance

±30V

±8.0 V

±0.6 V

+1.8V

c. Measure + 175 volt ac ripple with ac voltmeter

(H-P Model 3400A). RMS value of ripple should not

exceed 2.5 mv.

5-30. DC Zero Adjustment and Bias

a. Set Model 410C Function Selector to + DCV

and Range Switch to .5 V.

b. Short DCV Cable to COM Cable.

c. Adjust A3R21 fully counterclockwise, and

then rotate about 20° clockwise.

d. Adjust ZERO ADJ pot on rear panel for zero

meter deflection. Switch to – DCV. If any deflection

is observed, adjust ZERO ADJ pot to return meter

pointer halfway back to zero. Check zero setting on

all ranges for both + DCV and – DCV. Zero offset

should not exceed 1070 in any case.

5-31. DC Amplifier Output Adjust

a. Set the Model 410C FUNCTION SELECTOR

to ACV; RANGE to 5 V.

b. Connect a DC Voltmeter (H-P Model 3440A/

3442A) to the dc amplifier OUTPUT on the Model

410C rear panel. Set dc voltmeter RANGE to 10 v.

c. Connect Model 410C AC Probe to voltmeter

calibrator output. Adjust voltmeter calibrator to provide a 5 v, 400 cps signal.

d. Model 410C should read full scale (5 v). The

dc voltmeter should indicate 1.5 V. If it does not, adjust A6R20 for 1.5 v reading.

5-32. Full Scale DC Adjustment

a. Set Model 410C. FUNCTION SELECTOR to

+ DCV; RANGE to .015 V.

Change 1

5-9/(5-10 Blank)

Page 44

Page 45

Model 410C

b. Adjust DC Standard (H-P Model 740A) to apply .015 to Model

410C .

TM 11-6625-1614-15

Model 410C should read full scale.

c.

for proper pointer deflection.

Reset Model 410C RANGE to 1500 v. Adjust dc standard for

d.

1000 v output.

Adjust A3R30 for Model 410C reading of 985 v (1% low).

e.

If an error greater than ±2% of full scale exists on any

f.

range between 0.5 v and 1500 v Inclusive, select new setting for

A3R30 to yield best results over these ranges. If error greater

than ±2% of full scale still exists on any of the above ranges,

readjust A6R18 to reduce error.

If error greater than ±2% of full scale exists on any

g.

range between 15 mv and 150 mv inclusive, select new setting for

A6R18 to yield best results on these ranges. If error greater

than ±2% of full scale still exists on any of the above ranges,

readjust A3R30 to reduce error.

If not, adjust A6R18

If error greater than ±2% of full scale exists on both 15

h.

mv to 150 mv and 0.5 v to 1500 v ranges,

A6R18 to correct 15 mv and 150 mv range.

specification, proceed to readjust A3R30

1500 v range error.

5-33. OHMS ADJUST (R3).

Set Model 410C FUNCTION SELECTOR to ORMS; RANGE to RX10M.

a.

start by readjusting

Once they are within

to correct 0.5 v to

5-11

Page 46

TM 11-6625-1614-15

Short OHMS and COM cables. Model 410C should read zero.

b.

Vary Model 410C RANGE switch through remainder of OHMS

c.

settings. Meter should read zero, except at RX10 when meter

should read about 0.1 ohm (resistance of leads).

Disconnect OHMS and COM cables. Model 410C meter should

d.

read . If not, set OHMS ADJ (rear panel) for reading.

Checks reading on all OHMS RANGE settings.

5-34. AC ZERO ADJUST.

Set Model 410C FUNCTION SELECTOR to ACV; RANGE to .5 V.

a.

Set AC ZERO vernier on front panel to center of rotation.

b.

Short Model 410C ac Probe and ac probe common (short lead).

c.

Adjust R1 for Model 410C zero deflection.

d.

5-35. AC FULL SCALE ADJUST (.5 V RANGE).

Connect Model 410C ac probe to voltmeter calibrator output

a.

Model 410C