Page 1

I nstallation,

Operation and

Models 3885,

Maintenance

Instructions

Owner’s Information

Model Number:

Serial Number:

Dealer:

Dealer’s Phone No.

Date of Purchase: Installation:

Current Readings at Startup:

Single Phase:

Three Phase – 1st Phase:

2nd Phase: 3rd Phase:

3886, 3887

Table of Contents

SUBJECT PAGE

Safety Instructions................................................................. 2

Description and Specifications ............................................. 2

Lifting of Pump ..................................................................... 2

Sliderail System .................................................................... 2

Piping..................................................................................... 2

Access Doors......................................................................... 3

Liquid Level Controls ........................................................... 3

Pump Motor Control Panels.................................................. 3

Wiring and Grounding ..........................................................3

Operation ............................................................................... 4

Maintenance ..........................................................................4

Disassembly/Assembly ......................................................... 5

Mechanical Seal Replacement .......................................... 5

Power Cable Replacement ................................................5

Start Capacitor Replacement............................................. 6

Motor Replacement ........................................................... 6

Engineering Data................................................................... 7

Sectional Assembly .............................................................. 8

Repair Parts and Materials of Construction.................... 9, 10

Typical 2" Slide Rail Installation........................................ 11

Typical Plumbing and Installation ...................................... 11

Trouble Shooting................................................................. 12

Goulds Pumps Limited Warranty .......................................12

IM059R02

Page 2

SAFETY INSTRUCTIONS

DESCRIPTION AND SPECIFICATIONS

TO AVOID SERIOUS OR FATAL PERSONAL

INJURY OR MAJOR PROPERTY DAMAGE, READ

AND FOLLOW ALL SAFETY INSTRUCTIONS IN

MANUAL AND ON PUMP.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE PUMP.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump or

in the manual, look for one of the following signal words and be alert to the

potential for personal injury or property

damage.

DANGER

Warns of hazards that WILL cause serious

personal injury, death or major property

damage.

WARNING

Warns of hazards that CAN cause serious

personal injury, death or major property

damage.

CAUTION

Warns of hazards that CAN cause personal

injury or property damage.

NOTICE:INDICATES SPECIAL INSTRUCTIONS

WHICH AREVERY IMPORTANT AND

MUST BE FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS

AND WARNINGS PRIOR TO PERFORMING ANY

WORK ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

WARNING

UNIT NOT DESIGNED FOR USE

WITH HAZARDOUS LIQUIDS OR

FLAMMABLE GASES. THESE

FLUIDS MAY BE PRESENT IN

CONTAINMENT AREAS.

Hazardous fluids

can cause fire,

burns or death.

NOTICE: INSPECT UNIT FOR DAMAGE AND

REPORT ALL DAMAGE TO THE CARRIER

OR DEALER IMMEDIATELY.

The Model 3885 is a 2" NPT discharge, 3⁄4" (19 mm) solids

handling, submersible effluent pump. The Model 3886 is

a 2" (50 mm) solids handling, submersible sewage pump.

The Model 3887 is a 2" flanged (standard) 3" flange

(optional) discharge, 2" (50 mm) solids handling,

submersible sewage pump.

Lifting of Pump

WARNING

Hazardous voltage

can shock, burn or

cause death.

• Lift the pump with an adequately sized chain or cable

attached to the lifting handle (458). DO NOT damage

electrical cables while raising and lowering unit.

DO NOT LIFT, CARRY OR HANG

PUMP BY THE ELECTRICAL

CABLES. DAMAGE TO THE

ELECTRICAL CABLES CAN CAUSE

SHOCK, BURNS OR DEATH.

Sliderail System

• The OPTIONAL Goulds Model A10-20 sliderail system is

recommended for proper installation.

NOTICE: FOLLOW THE INSTALLATION AND

OPERATION INSTRUCTIONS PROVIDED

WITH THE SLIDERAIL SYSTEM.

• Installation of the sliderail system should locate the pump

opposite the influent opening, preventing stagnate areas

where solids can settle.

• The pit floor MUST be flat under the sliderail base and

have sufficient loading capacity to support the entire

weight of the assembly, including the sliderail base,

sliderail guide, pump and all assorted piping.

Piping

• Discharge piping should be no smaller than 2" (51 mm)

diameter and kept as short as possible, avoiding

unnecessary fittings to minimize friction losses.

• Install an adequately sized check valve (suitable for

handling 3⁄4" (19 mm) solids for effluent applications and

2" (50 mm) solids for sewage applications) in the

discharge pipe to prevent backflow. Follow the check

valve manufacturer’s installation instructions.

• Install an adequately sized gate valve ABOVE the check

valve for pump, plumbing and check valve maintenance.

• To deter air locking, drill a 3⁄16" (4.8 mm) hole, 2"

(50.8 mm) beyond the pump discharge connection.

• All piping must be adequately supported, so as not to

impart any piping strain or loads on the pump.

2

Page 3

Access Doors

• Access doors can be single or double leaf design. Doors

should include a lifting handle and a lock provision for

tamper resistant operation. Standard and heavy duty steel

or aluminum doors are available.

• The pit access door must be of sufficient size to allow for

inspection, maintenance and crane or hoist service.

Liquid Level Controls

• Single float operation can be used on 1⁄3 and 1⁄2 HP models.

Mounting of the float switch must be checked by the

installer to insure proper turn on and turn off. The pump

may be plugged directly into the piggy back style plug

located on the cord of the float switch.

• The recommended float operation sequence used with a

control panel requires a three or four float system. In the

three float system, the floats are designated SW-1 for the

bottom float, SW-2 for the middle float and SW-3 for the

top float. In a four float system the fourth float is

designated SW-4.

• Simplex Control – The rising liquid level raises float

SW-2, turning on the pump. When the liquid level falls

sufficiently, SW-1 will turn the pump off. If the influent

is excessive, or if the pump fails to operate correctly,

SW-3 will activate an alarm, which will remain on until

manually reset.

• Duplex Control – The duplex control will alternate the

two pumps, causing the lead pump to change at each

system cycle. When equipped with three floats, the

system will cycle the same as the simplex control,

described above, except that the SW-1 will cause the

lead pump to alternate.

• If the influent is excessive, or if the lead pump fails to

operate correctly, the rising level will activate SW-3,

turning on the lag pump and the alarm. As before the

alarm must be manually reset.

• Four Float Control – The four float system operates the

same as the duplex control system, except that float

SW-3 will not turn on the alarm. In this system SW-4

turns on the alarm, which again must be manually reset.

• Several different float controls are available from the

Goulds Catalog.

NOTICE:POSITION THE FLOATS SO THAT THEY

DO NOT SNAG OR TANGLE ON THE PUMP,

DISCHARGE PIPING, OR OTHER

EQUIPMENT.

• The lower most float turns the unit off and should be set as

shown in the “TYPICAL PLUMBING and

INSTALLATION” drawing provided in this manual.

• Increasing the distance between the SW-1 and SW-2 floats

lengthens the running time. One (1) minute is the

minimum recommended pump cycle time.

NOTICE:DURING PUMP OPERATION, INSURE THAT

THE LIQUID LEVEL DOES NOT DROP

BELOW THE PUMP MOTOR FOR

EXTENDED PERIODS. THIS CAN CAUSE

THE PUMP MOTOR TO OVERHEAT,

CAUSING MOTOR DAMAGE AND

VOIDING THE WARRANTY.

Pump Motor Control Panels

• Control panels shall be in accordance with local and

National Electrical Code requirements.

• Single phase installations shall be equipped with a Goulds’

“SES” or “A” Series panel, or AS A MINIMUM, a

control panel with a properly sized magnetic contactor and

a disconnect switch.

• Three phase installations shall be equipped with a Goulds’

“SES” or “A” Series panel, or AS A MINIMUM with a 3

pole circuit breaker, an across the line magnetic starter

NEMA rated for the appropriate horsepower, ambient

compensated Quick Trip Class 10 overload relays.

Wiring and Grounding

• Use only stranded copper wire to motor and ground. The

ground wire must be at least as large as the wires to the

motor. Wires should be color coded for ease of

maintenance.

WARNING

Hazardous voltage

can shock, burn or

cause death.

Electrical supply MUST match pump’s nameplate

specifications. Incorrect voltage can cause fire,

damage motor and voids warranty.

Single phase motors are equipped with automatic

thermal protectors which open the motor’s

electrical circuit when an overload exists. This

can cause the pump to start unexpectedly and

without warning.

Some models are equipped with a 3-prong

grounded plug and MUST be used in a grounded

3-wire receptacle. DO NOT modify the plug or

remove the ground prong.

• Where cables must be spliced or connected to the motor

leads, splices MUST be water tight. Commercially

available potting or heat shrink kits may be used, if

allowed by local or federal regulations.

Install, ground and wire

according to local and National

Electrical Code requirements.

Install an all leg disconnect

switch near the pump.

Disconnect and lockout electrical

power before installing or

servicing pump.

3

Page 4

NOTICE: FOLLOW THE SPLICE KIT

MANUFACTURER’S INSTRUCTIONS.

• Where wire splices are used, follow one of these

procedures:

• Butt join the wires using properly sized and correctly

crimped Sta-Kon™, or equivalent, connectors. Insulate

and water proof each joint using heat shrink tubing

equipped with a self contained sealer. Apply heat

evenly from a torch until adequately sealed.

OR

• Use plastic insulators and a neoprene gasket sleeve set

with properly sized and correctly crimped Sta-Kon™

connectors. Place a cap and gasket on each wire end,

center insulator body over splice, insert the sleeve into

the body as far as possible, hand tighten caps.

• In the case of multiple conductors, stagger the joints.

WARNING

Hazardous

voltage

FAILURE TO PERMANENTLY

GROUND THE PUMP, MOTOR AND

CONTROLS BEFORE CONNECTING

TO ELECTRICAL POWER CAN

CAUSE SHOCK, BURNS OR DEATH.

• If the three phase motor(s) rotation is backwards, reverse

any two pump power cable leads at the pump control

panel.

WARNING

Hazardous

machinery

MOTOR OVERHEAT/OVER

CURRENT SENSING DEVICES

AUTOMATICALLY RESTART THE

MOTOR UNEXPECTEDLY AND

WITHOUT WARNING. THIS CAN

CAUSE SEVERE PERSONAL

INJURY.

• After installing the pump into the containment area, with

adequate submergence, open the discharge valve fully.

Start the unit using manual controls. If flow is appreciably

less than rated performance, pump may be air bound. To

expel trapped air, jog the unit several times, using the

manual controls.

• Have a qualified electrician take current measurements on

the single or all three phases. Record these readings in the

space provided in the “OWNER’S INFORMATION”

section of this manual for future reference.

• The unit is now ready for normal operation. Place the

controls in the automatic position.

Operation

• If the unit has been stored for an extended period, check

the oil level in the motor and seal chamber, to insure that

they are full, using the following procedures:

• Motor Cover – With the pump in the upright position,

remove the oil fill plug (358E), being careful that

nothing enters the motor. The oil level should be above

the top of the motor. With the correct oil fill as required.

DO NOT over fill.

• Cable Gland Assemblies – Re-torque both the power

and sensor cable glands to values given in step 10 of

“POWER CABLE REPLACEMENT”.

• Before lowering the pump(s) into the containment area,

three phase units should be jogged to insure correct

rotation. See the motor rotation arrow on the motor cover

(341). Check both pumps in a duplex operation.

NOTICE:MOTOR STARTUP TORQUE, “KICKBACK”,

WILL CAUSE THE MOTOR TO TWIST IN

THE DIRECTION OPPOSITE ROTATION.

INSURE THAT THE PUMP ASSEMBLY IS

ADEQUATELY RESTRAINED.

!

DANGER

DO NOT PLACE HANDS IN PUMP

SUCTION WHILE CHECKING

MOTOR ROTATION. TO DO SO

WILL CAUSE SEVERE PERSONAL

INJURY.

Maintenance

WARNING

Hazardous

voltage

WARNING

Biohazard can

cause serious

personal injury.

FAILURE TO DISCONNECT AND

LOCKOUT ELECTRICAL POWER

BEFORE ATTEMPTING ANY

MAINTENANCE CAN CAUSE

SHOCK, BURNS OR DEATH.

UNIT MUST BE FLUSHED AND

DISINFECTED, INSIDE AND OUT,

PRIOR TO SERVICING.

Periodic Maintenance

NOTICE:ROUTINE PERIODIC INSPECTIONS ARE

REQUIRED AND SHOULD FOLLOW THE

FREQUENCY AND MAINTENANCE

SCHEDULE PROVIDED.

FREQUENCY REQUIRED MAINTENANCE

MONTHLY • Duplex Units – Check for even

operating times. Uneven operation

times indicate a defective unit, float

switch or control.

Hazardous Machinery

NOTICE: DO NOT SWITCH PRIMARY POWER LEADS

COMING INTO A THREE PHASE DUPLEX

CONTROL PANEL, THIS WILL REVERSE

ROTATION OF BOTH PUMPS.

4

• Unimpeded float operation.

Page 5

Disassembly/Assembly

WARNING

Hazardous

voltage

NOTICE: FOLLOW ALL SAFETY AND LIFTING

• Following the slide rail instructions, remove the pumping

unit from the sewage containment area.

WARNING

Biohazard can

cause serious

personal injury.

MECHANICAL SEAL REPLACEMENT

1. Follow ALL instructions provided in the

“DISASSEMBLY” section of this manual.

2. To gain access to the pump impeller and mechanical seal

remove the four casing hex cap screws (372D). Remove

casing (100) and casing gasket (351); discard the gasket.

CAUTION

Hazardous pressure can

cause personal injury or

property damage.

3. Removal of the mechanical seal assembly (387) requires

draining the special insulating oil from the motor cover.

This is accomplished by removing the drain plug and

draining the oil into an adequately sized clean receptacle.

See “ENGINEERING DATA” section for required

volume.

4. To remove the impeller (101), it may be necessary to

heat the impeller and impeller locknut (304), three phase

motors only, with a torch. Use no more heat that is

necessary, as excess heat will damage the mechanical

seal. Secure the impeller from rotation, and remove

the impeller lock nut, by turning the lock nut

COUNTERCLOCKWISE. Remove the impeller

from the motor shaft by holding the motor shaft with a

screw driver and turning the impeller COUNTER-

CLOCKWISE.

FAILURE TO DISCONNECT AND

LOCKOUT ELECTRICAL POWER

BEFORE ATTEMPTING ANY

MAINTENANCE CAN CAUSE

SHOCK, BURNS OR DEATH.

INSTRUCTIONS PROVIDED IN THIS

MANUAL.

UNIT MUST BE FLUSHED AND

DISINFECTED, INSIDE AND OUT,

PRIOR TO SERVICING.

FAILURE TO REMOVE DRAIN

PLUG CAREFULLY CAN CAUSE

HOT OIL TO ERUPT FROM OIL

RESERVOIR CAUSING PERSONAL

INJURY OR PROPERTY DAMAGE

5. Remove and discard the mechanical seal and stationary

seat assembly. DO NOT damage the motor shaft or the

stationary seat bore.

6. Inspect and wipe clean the stationary seat bore.

7. To install the new stationary seat into the seal housing,

lubricate the stationary seat bore and motor shaft with

clean motor insulating oil. Using Goulds mechanical seal

installation tool (A02A013), slide the stationary seat

fully and squarely into the seal housing.

8. With a clean, lint free cloth, wipe the stationary face

clean of all lubricating oil or debris. DO NOT scratch or

otherwise damage the seal face.

9. Lubricate the inside of the rotary elastomer with clean

motor insulating oil. Using the Goulds installation tool,

slide the seal rotary assembly onto the motor shaft and

seat fully against the stationary seat. Remove the seal

installation tool.

10. Install the impeller onto the motor shaft by turning the

impeller on CLOCKWISE, tighten securely. Treat the

impeller with Loctite™ #271 and securely install. When

provided, securely install the impeller locknut.

11. Fill the motor cover with motor special insulating oil to

within 1⁄2" (13 mm) of the seal chamber housing. Tape

drain plug with Teflon™ tape and install plug securely.

12. Reassemble casing and new casing gasket to pump

assembly by installing the four casing hex cap screws,

torquing in sequence to 35 lbs ft (47 Ν m).

NOTICE:FOLLOW THE INSTRUCTIONS PROVIDED

IN THE “WIRING AND GROUNDING” AND

“OPERATION” SECTIONS OF THE

MANUAL AFTER UNIT DISASSEMBLY,

REASSEMBLY.

POWER CABLE REPLACEMENT

1. To gain access to the motor cover screws follow steps 1

through 6 in the “MECHANICAL SEAL

REPLACEMENT” section of this manual.

2. Remove the power cable strain relief (484B) assembly

from the motor cover and slide up the cable.

3. Remove the four bearing housing socket head screws

(371C). Carefully slide the motor cover from the motor

assembly. DO NOT damage the power cable.

4. Disconnect the power cable wires from the motor

assembly (338).

5. Remove cable from motor cover, inspect and replace as

required, following the procedures provided.

NOTICE: DISCARD STRAIN RELIEF ASSEMBLY.

THEY CAN NOT BE REUSED.

6. Install new motor cable strain relief assembly onto cable,

sliding the hex gland on first, then the washer and finally

the packing. Insert the cables into the motor cover hole.

Pull an appropriate amount of cable through the motor

cover to allow for connecting the cable leads. DO NOT

tighten the strain relief gland.

5

Page 6

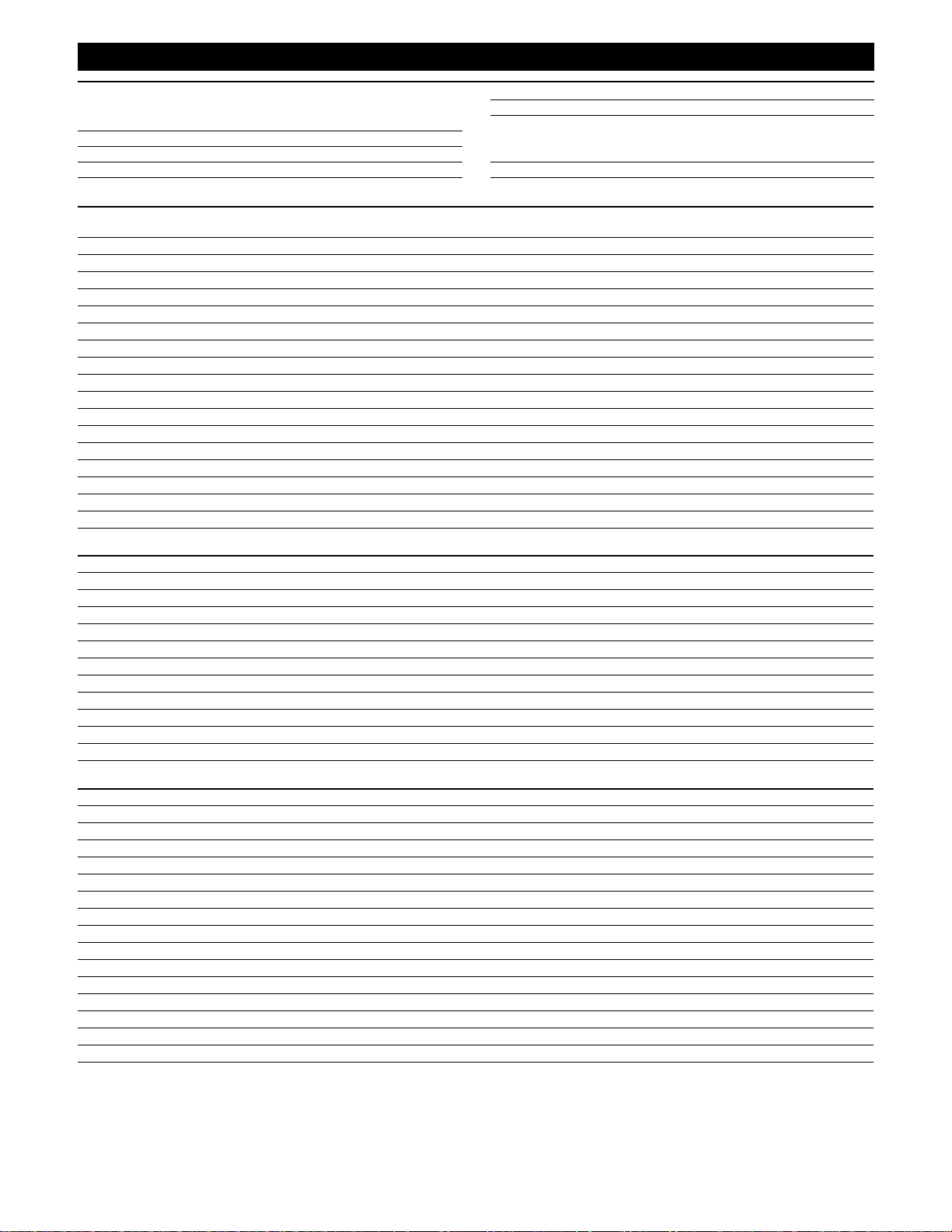

7. Connect the power cable leads to the motor assembly as

follows:

• Single Phase Motors – Connect the BLACK wire to

motor terminal L1. Connect the WHITE wire to

motor terminal L2. Connect the GREEN wire to the

motor ground.

• Three Phase Motors – See Figure 1.

WARNING

Hazardous

voltage

208-230 V 3/60

4

5

6

1

7

2

8

MOTOR LEADS

3

9

FAILURE TO CONNECT POWER

AND SENSOR WIRES TO

DESIGNATED WIRES CAN CAUSE

SHOCK, BURNS OR DEATH.

460 V 3/60

4

7

5

L

1

L

2

L

3

G

THREE PHASE MOTOR WIRING DIAGRAM

8

6

9

MOTOR LEADS

1

POWER CABLE LEADS

2

3

L

1

POWER CABLE LEADS

L

2

L

3

G

Figure 1

8. Wire tie the power cable to the motor assembly.

9. Slide the motor cover onto the motor assembly, while

carefully pulling the power cable out through the motor

cover hole. DO NOT damage cables. Install the four

seal housing socket head screws, torquing to 90 lbs in

(10 Ν m).

10. Install the power cable strain relief assembly torquing

the nylon bushing to 75 lbs in (8.5 Ν m) and the steel

bushing to 100 lbs in (11.3 Ν m).

11. Continue the assembly following steps 7 through 12 of

the “MECHANICAL SEAL REPLACEMENT”

section of this manual.

12. If the motor cover was replaced, it is necessary to

transfer the Goulds nameplate. Using two stainless steel

No. 2 round head metallic drive screws, install the

Goulds nameplate.

NOTICE: FOLLOW THE INSTRUCTIONS PROVIDED

IN THE “WIRING AND GROUNDING” AND

“OPERATION” SECTIONS OF THE

MANUAL AFTER UNIT DISASSEMBLY,

REASSEMBLY.

START CAPACITOR REPLACEMENT

1. On single phase motors only, to gain access to the motor

start capacitor (376), follow steps 1 through 5 in the

“POWER CABLE REPLACEMENT” section of this

manual.

NOTICE: DISCARD STRAIN RELIEF ASSEMBLY.

IT CAN NOT BE REUSED.

WARNING

Hazardous

voltage

FAILURE TO DRAIN CAPACITOR

OF STORED ELECTRICAL

CHARGE BEFORE SERVICE CAN

CAUSE A SEVERE SHOCK.

2. Remove the capacitor retaining screw and retaining

bracket from the motor assembly. Remove the two wires

from the capacitor. Discard the capacitor.

3. Connect the two motor wires to the new capacitor and

reassemble with the retaining bracket and retaining

screw, tightening securely.

4. Reassemble unit following steps 6 through 12 in the

“POWER CABLE REPLACEMENT” section of

this manual.

NOTICE: FOLLOW THE INSTRUCTIONS PROVIDED

IN THE “WIRING AND GROUNDING” AND

“OPERATION” SECTIONS OF THE

MANUAL AFTER UNIT DISASSEMBLY,

REASSEMBLY.

MOTOR REPLACEMENT

1. To gain access to the motor assembly, follow steps 1

through 5 in the “POWE R CABLE REPLACEMENT ”

section of this manual.

NOTICE: DISCARD STRAIN RELIEF ASSEMBLY.

IT CAN NOT BE REUSED.

2. Remove the four motor thru bolts and carefully pull

motor assembly from bearing housing. Further motor

service MUST be provided by a qualified motor repair

facility.

3. Insert the motor assembly into the bearing housing,

visually aligning the motor thru bolts through the lower

motor vent openings.

4. Install the four motor thru bolts, torquing to 35 lbs in

(4 Ν m).

5. To complete the assembly follow steps 6 through 12 in

the “POWER CABLE REPLACEMENT” section of

this manual.

NOTICE: FOLLOW THE INSTRUCTIONS PROVIDED

IN THE “WIRING AND GROUNDING” AND

“OPERATION” SECTIONS OF THE

MANUAL AFTER UNIT DISASSEMBLY,

REASSEMBLY

6

Page 7

Engineering Data

Maximum Diameter Solids

3885

3886 and 3887 2 in 50 mm

Minimum Casing Thickness

Casing Corrosion Allowance

3

⁄4 in 19 mm

5

⁄16 in 8 mm

1

⁄8 in 3 mm

Minimum Working Pressure 55 psi 380 kPa

Minimum Pump Submergence – Below Top of Motor Dome 6 in 152 mm

Minimum Number of Evenly Distributed Starts per Hour 6

Maximum Operating Temperature

Continuous Operation 40° C 104° F

Intermittent Operation 60° C 140° F

Motor Cover Oil Capacity 4.5 qts. 4.3 L

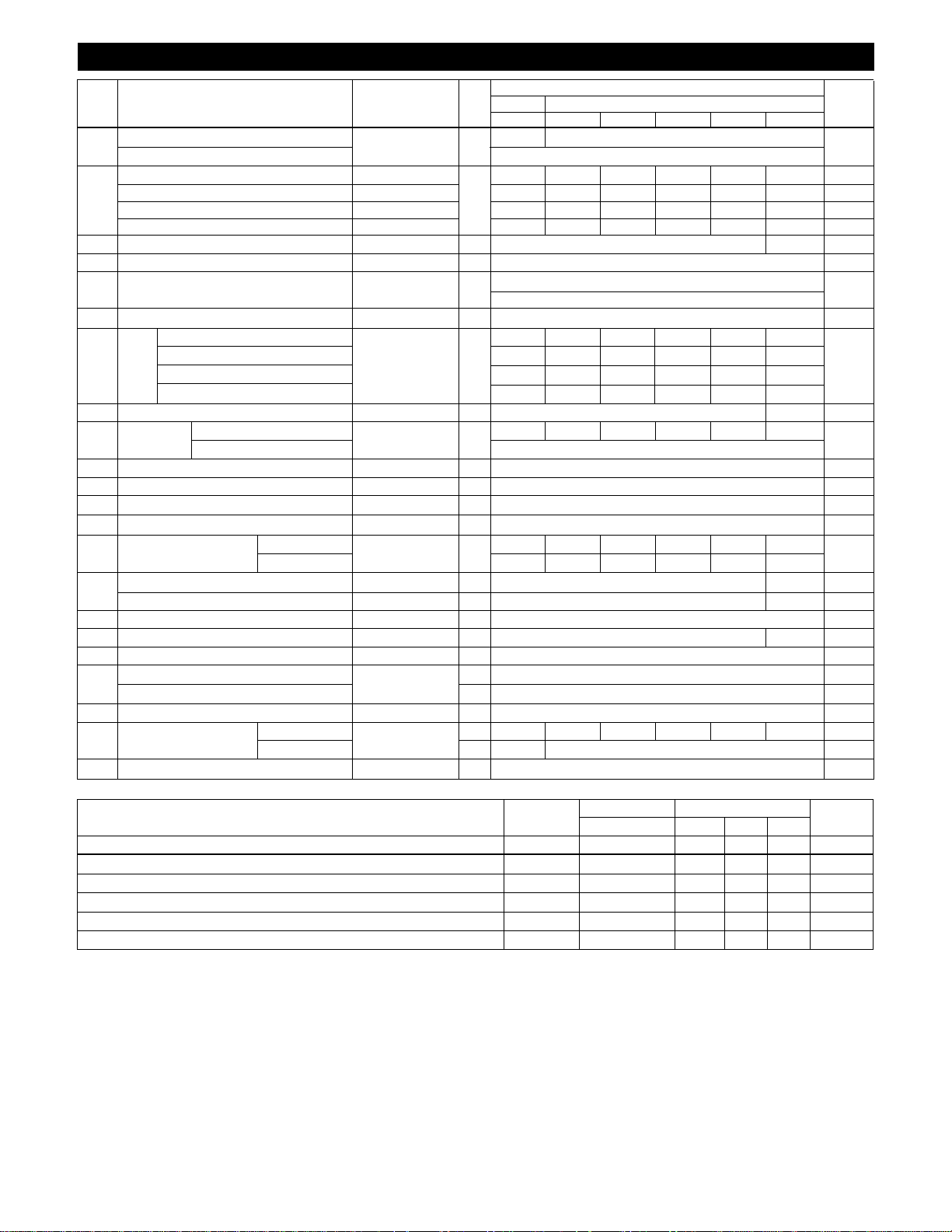

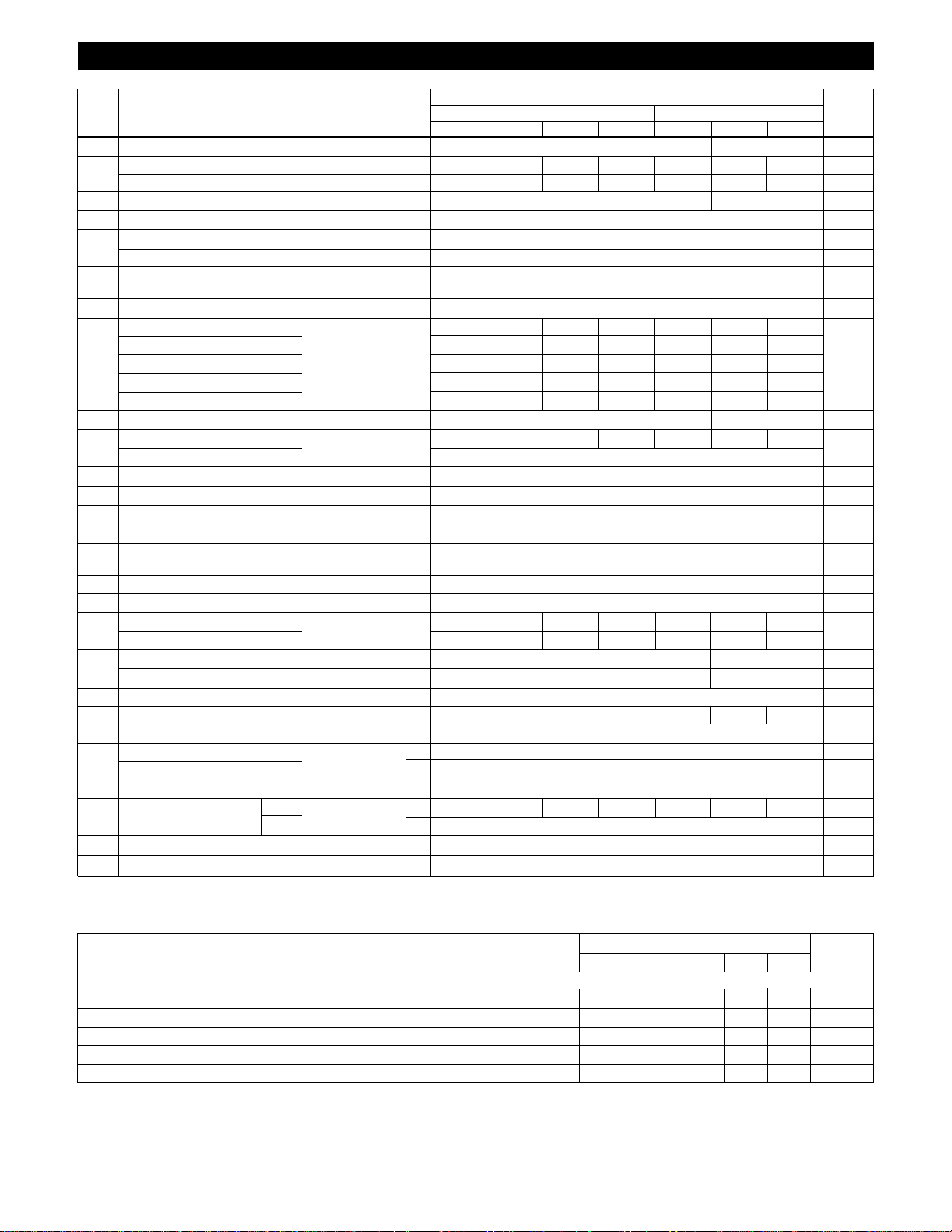

ELECTRICAL DATA 3885

HP RPM Voltage

1

⁄3 1725 115 1/60 9.4 M 1.92 16/3 15

1

⁄3 1725 230 1/60 4.7 N 7.58 16/3 10

1

⁄2 3450 115 1/60 14.5 M 1.00 16/3 20

1

⁄2 3450 230 1/60 7.3 M 4.03 16/3 10

1

⁄2 3450 200 3/60 3.9 R 3.8 14/4 10

1

⁄2 3450 230/460 3/60 3.4/1.7 R 5.81/23.24 14/4 10/10

3

⁄4 3450 230 1/60 10.0 J 2.99 14/3 15

3

⁄4 3450 200 3/60 6.2 L 5.7 14/4 10

3

⁄4 3450 230/460 3/60 5.4/2.7 L 4.04/16.15 14/4 10/10

Phase

/Hz Code Line to Line (Ohms) Cable AWG Breaker Amps

Amps

KVA Winding Resistance Power Fuse/Circuit

1 3450 230 1/60 12.5 J 2.09 14/3 20

1 3450 200 3/60 8.1 M 2.6 14/4 10

1 3450 230/460 3/60 7.0/3.5 L 4.04/16.15 14/4 10/10

11⁄2 3450 230 1/60 15.0 H 1.16 14/3 20

11⁄2 3450 200 3/60 10.6 K 1.9 14/4 15

11⁄2 3450 230/460 3/60 9.2/4.6 K 2.87/11.46 14/4 15/10

2 3450 230 1/60 18.0 F M-1.1/S-2.2 14/3 20

2 3450 200-230/460 3/60 12.0-11.6/5.8 K 1.66/6.62 14/4 15/10

ELECTRICAL DATA 3886 AND 3887BF

1

⁄3 1725 115 1/60 9.8 M 1.92 16/3 15

1

⁄3 1725 230 1/60 4.9 N 7.58 16/3 10

1

⁄2 1725 115 1/60 14.5 N 1.6 16/3 20

1

⁄2 1725 230 1/60 7.3 K 6.4 16/3 10

1

⁄2 1725 200 3/60 3.8 K 6.55 14/4 10

1

⁄2 1725 230/460 3/60 3.3/1.7 K 9.9/39.4 14/4 10/10

3

⁄4 1725 230 1/60 9.4 J 5.9 14/3 15

3

⁄4 1725 200 3/60 4.1 H 4.3 14/4 10

3

⁄4 1725 230/460 3/60 3.6/1.8 J 5.6/22.4 14/4 10/10

1 1725 230 1/60 12.3 H 2.6 14/3 20

1 1725 200 3/60 6.0 H 4.3 14/4 10

1 1725 230/460 3/60 5.8/2.9 J 5.6/22.4 14/4 10/10

ELECTRICAL DATA 3887BHF

1

⁄3 1725 115 1/60 12.4 M 1.00 16/3 15

1

⁄3 1725 230 1/60 6.2 M 4.03 16/3 10

1

⁄2 3450 115 1/60 14.5 M 1.00 16/3 20

1

⁄2 3450 230 1/60 7.6 M 4.03 16/3 10

1

⁄2 3450 200 3/60 4.1 R 3.8 14/4 10

1

⁄2 3450 230/460 3/60 3.6/1.8 R 5.81/23.24 14/4 10/10

3

⁄4 3450 230 1/60 9.4 J 2.99 14/3 15

3

⁄4 3450 200 3/60 6.2 L 5.7 14/4 10

3

⁄4 3450 230/460 3/60 5.4/2.7 L 4.04/16.15 14/4 10/10

1 3450 230 1/60 14.5 J 2.1 14/3 20

1 3450 200 3/60 8.6 M 2.6 14/4 10

1 3450 230/460 3/60 7.5/3.8 L 4.0/16.2 14/4 10/10

11⁄2 3450 230 1/60 18.0 F M-1.1/S-2.2 14/3 20

11⁄2 3450 200-230/460 3/60 10.0-9.6/4.8 K 1.66/6.62 14/4 15/10

2 3450 230 1/60 18.0 F M-1.1/S-2.2 14/3 20

2 3450 200-230/460 3/60 12.0-11.6/5.8 K 1.66/6.62 14/4 15/10

7

Page 8

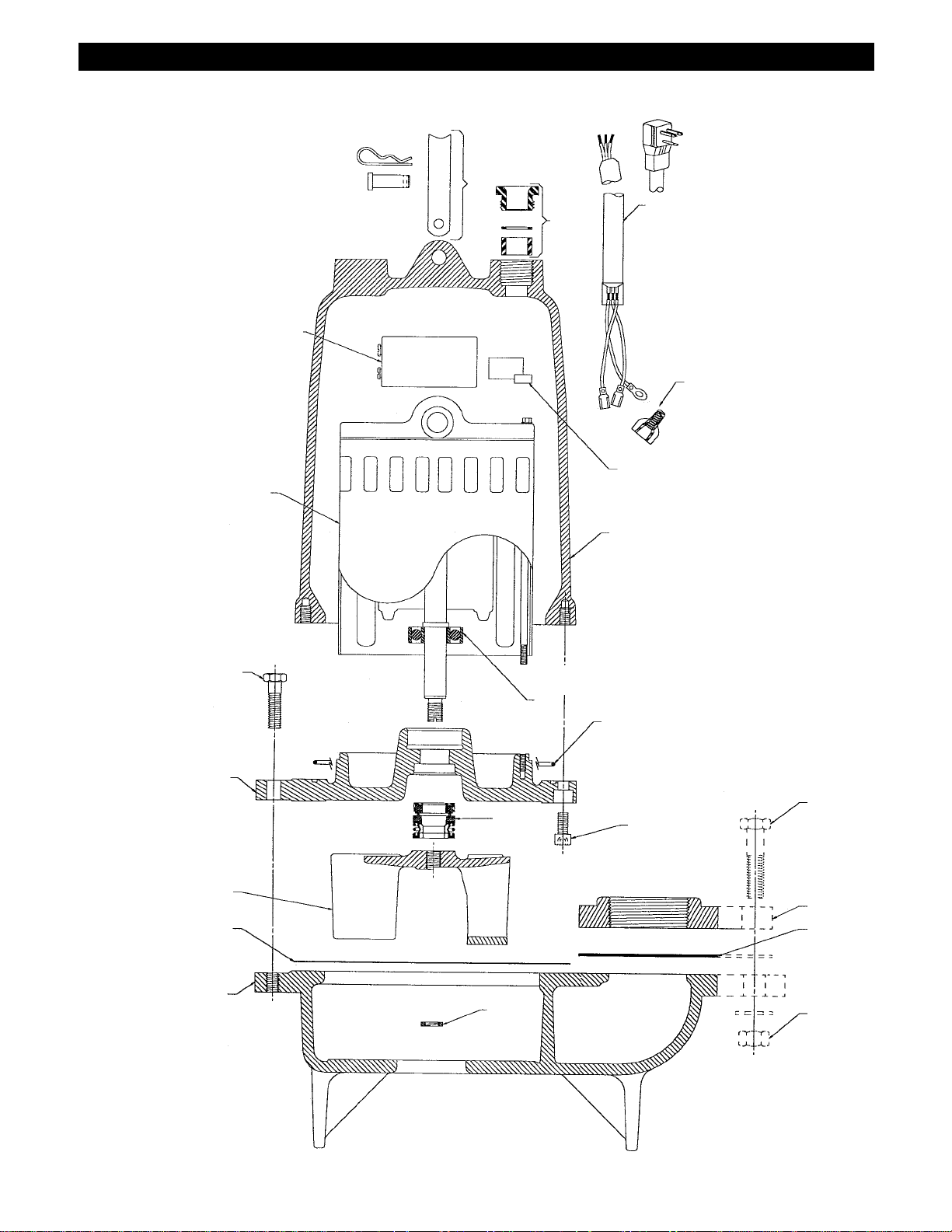

Repair Parts Diagram for Models 3885, 3886 and 3887

458

376

338

484B

456 GROUP

457

436

372D

340

101

351

387

341

112A

412M

Note: Models 3885 and 3886 are not flanged

and therefore do not require some of the

diagramed parts.

371H

371C

195C

351A

100

304

357

8

Page 9

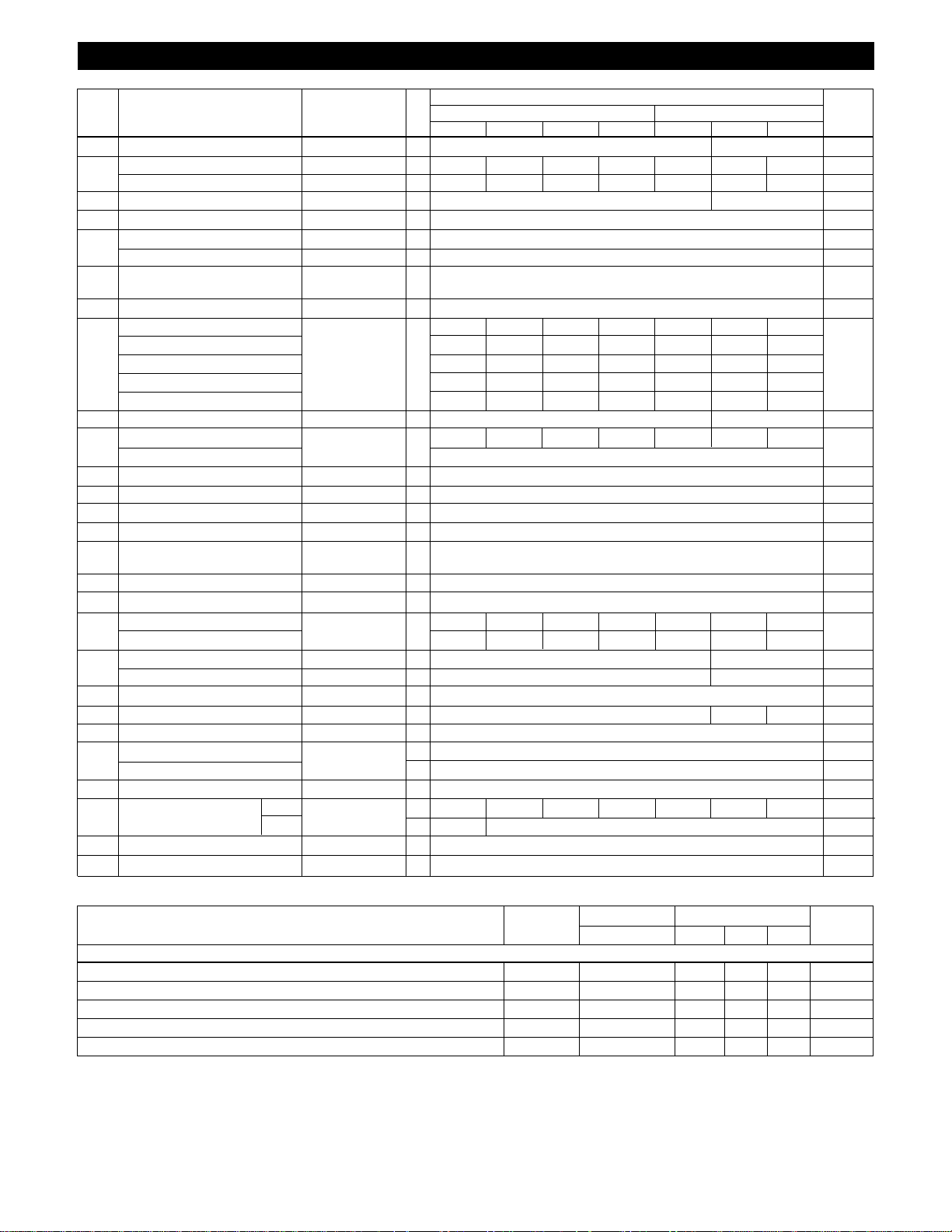

Model 3885 Repair Parts Table

Item

Part Name Material

No.

Casing – 1⁄3 HP “L” model only

100

Casing – all others 1K170

Cast Iron 1

Qty.

1725 RPM 3450 RPM

Reqd.

1

⁄3 HP1⁄2 HP

1K171 N/A

Repair Parts Order Number

3

⁄4 HP 1 HP 11⁄2 HP 2 HP

Max. Wt.

(lbs.)

13.0

Impeller Cast Iron 2K158 2K220 2K219 2K218 2K217 2K840 2.0

Impeller Bronze 2K271 2K272 2K273 2K274 2K275 2K841 2.5

101

Impeller – high head Cast Iron 1 N/A 2K225 HH N/A N/A 2K221HH N/A 3.5

Impeller – high head Bronze N/A 2K276 HH N/A N/A 2K277 HH N/A 4.0

112A Lower Ball Bearing Steel 1 4K132 4K384 –

112B Upper Ball Bearing Steel 1 4K132 –

Insulating Oil (gallon

218

Gallons required

)

Turbine Oil – Sunvis

932, Convis 150

4K432 (5 gallons)

1.2 gallons

7.5 lbs./

gal.

304 Impeller Locknut (3 PH only) AISI 300 series SS 1 13K6 –

1 Phase, 115V 118-121R 118-1222R N/A N/A N/A N/A

338 Motor

1 Phase, 230V 118-122R 118-1223R 118-1232R 118-1233R 118-1334R 120-845R

3 Phase, 230/460 V N/A 118-1321R 118-1322R 118-1323R 118-1324R 120-8425R

Stainless Steel

Short Ext.

1

13.0

to

24.0

3 Phase, 200 V N/A 118-1333R 118-1334R 118-1335R 118-1336R 120-8425R

340 Bearing Housing Cast Iron 1 1K167 1K332 10.0

341 Motor Cover

1 PH

3 PH 1K208

Cast Iron 1

1K207 1K207 1K208 1K208 1K208 1K208

23.0

351 Casing Gasket Composite 1 5K170 –

358E Plug – motor cover 3⁄8" NPT Steel 1 6K3 –

371C Skt. Hd. Screw – brg. housing to motor cover AISI 300 series SS 2 13K210 –

372D Hex Screw – seal housing to casing AISI 300 series SS 4 13K186 –

Start

376 Capacitor (1 PH only

Mechanical Seal – standard Silicon Carbide 1 10K63 (John Crane Type 6) 10K71 –

387

Mechanical Seal – optional Tungsten Carbide 1 10K30 (John Crane Type 21) 10K72 –

412M O-ring – motor cover

)

Run N/A N/A N/A N/A N/A 279342110

Varies 1

BUNA-N, AS 568A-166

1K197 9K197 9K197 9K197 9K197 275470130

1 4K252 –

–

436 Solid State Switch N/A 294811980

456 Power cable 1 See chart below –

Wire nut 3 PH, 200/230 V 4 9K145 –

457

(power cable) 3 PH, 460 V 6 9K145 –

Nylon Housing

458 Handle Assembly AISI 300 series SS 1 4K243 –

Strain Relief Assembly 1 PH

484B

(

power cable

)

3 PH 1 N/A 5K111 –

Varies

1 5K113 5K113 5K111 5K111 5K111 5K111 –

Loctite #271 1 AL271121 –

Model 3885 Power and Sensor Cables Description

Type and

AWG Size

Standard length* Optional Lengths

20' 30' 50' 100'

Wt.

(lbs./5 ft.)

Power Cables

1 PH: 1⁄3 and 1⁄2 HP, 115 V; standard with plug, optional with bare leads SJTOW – 16/3 9K165 9K214 9K215 N/A 0.5

1 PH: 1⁄3 and 1⁄2 HP, 230 V; standard with plug, optional with bare leads SJTOW – 16/3 9K164 9K214 9K215 N/A 0.5

1 PH: 3⁄4 – 11⁄2 HP, 230 V with bare leads STOW – 14/3 9K163 9K216 9K161 9K217 0.9

1 PH: 11⁄2 – 2 HP, 230 V with bare leads STOW – 14/3 9K266 9K267 9K268 9K269 0.9

3 PH: 1⁄2 – 2 HP, 208–230/460 V with bare leads STOW – 14/4 9K153 9K218 9K154 9K219 1.1

9

Page 10

Model 3886 and 3887 Repair Parts Table

Note: The 1K168 is the casing for the 3886 1⁄2 HP. The 1K178 is the casing for the 3887 1⁄3 – 1 HP.

Item

Part Name Material Qty.

No.

1

⁄3 HP

1

⁄2 HP

100 Casing Cast Iron 1 1K168 for NPT 3886 1K178 for flanged 3887 1K330 16.5

Impeller Cast Iron 1 2K268 2K239 2K240 2K241 2K242 2K800 2K798 3.0

101

Impeller Bronze 1 2K279 2K280 2K281 2K282 2K283 2K801 2K799 3.5

112A Lower Ball Bearing Steel 1 4K132 4K384 –

112B Upper Ball Bearing (Not Shown) Steel 1 4K132 –

Discharge Flange (2" NPT STD.) Cast Iron 1 6K76 1.5

195C

Discharge Flange (3" NPT OPT.) Cast Iron 1 A1-3 1.5

Motor Insulating Oil

218 Turbine Oil 1 4K432

(Approx. 1 Gallon Required)

304 Impeller Locknut (3 PH only) AISI 300 series SS 1 13K6 –

Motor – 1 Phase, 115V 118-121R 118-123R N/A N/A N/A N/A N/A

Motor – 1 Phase, 230V 118-122R 118-124R 118-1212R118-1213R118-1233R 120-844R 120-845R

338 Motor – 3 Phase, 230/460 V Stainless Steel 1 N/A 118-132R 118-1304R 118-134R 118-1323R N/A N/A

Motor – 3 Phase, 200 V N/A 118-1314R 118-1316R118-1316R118-1335R N/A N/A

Motor – 3 Phase, 200-230/460 V N/A N/A N/A N/A N/A 120-8425R 120-8425R

340 Bearing Housing Cast Iron 1 1K167 1K332 10.0

Motor Cover – 1 Phase 1K207 1K207 1K208 1K208 1K208 1K208 1K208

341

Motor Cover – 3 Phase 1K208

Cast Iron

1

351 Casing Gasket Composite 1 5K170 –

351A Discharge Flange Gasket Composite 1 5K150 –

357 Hex Nut –␣ discharge flange AISI 300 series SS 2 13K99

358E Plug – motor cover 3⁄8" NPT Steel 1 6K3 –

Skt. Hd. Screw – brg. housing to

371C

motor cover

371H

Hex Screw – discharge flange

372D

Hex Screw – bearing housing to casing

Capacitor (1 PH only

Capacitor (1 PH only

Mechanical Seal – standard Silicon Carbide 1 10K63 (John Crane Type 6) 10K71 –

387

Mechanical Seal – optional Tungsten Carbide 1 10K30 (John Crane Type 21) 10K72 –

) Start

) Run

412M O-ring – motor cover

AISI 300 series SS 4 13K210 –

AISI 300 series SS 2 13K153 –

AISI 300 series SS 4 13K186 –

Varies

Nitrile

9K197 9K197 9K235 9K235 9K197

1

N/A N/A N/A N/A N/A N/A

1 4K252 –

436 Solid State Switch (motor) – 1 N/A

456 Power Cable – 1 See chart below –

Wire Nut 3 PH, 200/230 V 4 9K145 –

457

Wire Nut 3 PH, 460 V 6 9K145 –

Nylon Housing

458 Handle Assembly AISI 300 series SS 1 4K243 –

Strain Relief Assembly

484B

(

power cable

)

1 PH 1 5K113 5K113 5K111 5K111 5K111 5K111 5K111 –

Varies

3 PH 1 N/A 5K111 –

528 Washer – discharge flange AISI 300 series SS 2 13K82 –

Loctite #271 – 1 AL27121 –

* Consult Factory

Repair Parts Order Number

1725 RPM 3450 RPM

3

⁄4 HP 1 HP 1 HP 11⁄2 HP 2 HP

275469128

294612982

Max. Wt.

lbs./gal.

275470130

279342110

294811980

(lbs.)

7.5

13.0

to

24.0

20.0

–376

–

Model 3887 Power Cables Description

Type and

AWG Size

Standard length* Optional Lengths

20' 30' 50' 100'

(lbs./5 ft.)

Power Cables

1 PH: 1⁄3 and 1⁄2 HP, 115 V; standard with plug, optional length with bare leads SJTOW – 16/3 9K165 9K214 9K215 N/A 0.5

1 PH: 1⁄3 and 1⁄2 HP, 230 V; standard with plug, optional length with bare leads SJTOW – 16/3 9K164 9K214 9K215 N/A 0.5

1 PH: 3⁄4 – 1HP, 230 V with bare leads STOW – 14/3 9K163 9K216 9K161 9K217 0.9

1 PH: 11⁄2 – 2 HP, 230 V with bare leads STOW – 14/3 9K266 9K267 9K268 9K269 0.9

3 PH: 1⁄2 – 2 HP, 208–230/460 V with bare leads STOW – 14/4 9K153 9K218 9K154 9K219 1.1

9K197 REF#615996 1 or 624751 1 MFD 110 VAC

9K235 REF#615996 2 189/227 MFD 110 VAC

10

Wt.

Page 11

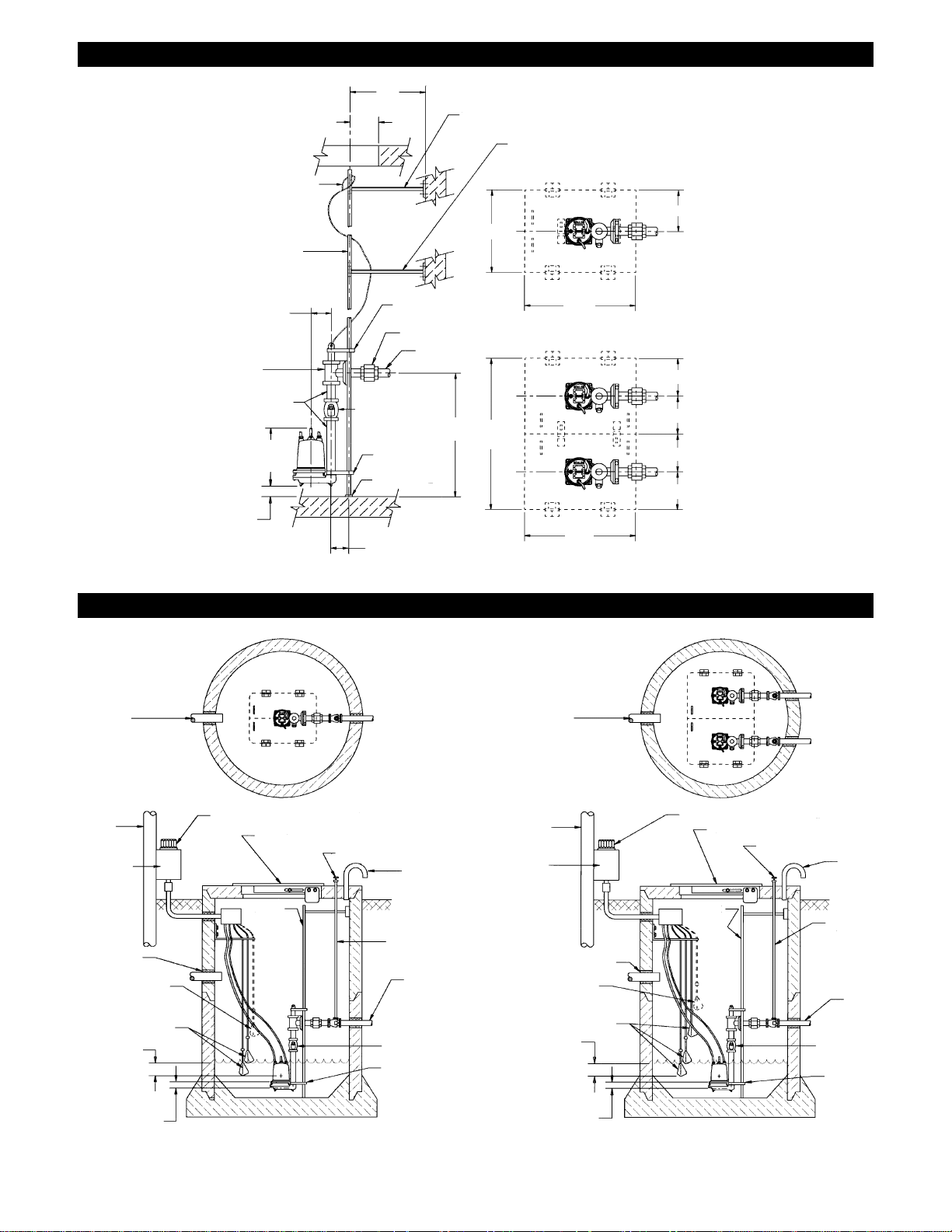

Typical 2" Slide Rail Installation

LIFTING CABLE

GUIDE RAILS

1" DIA. PIPE

81⁄4"

13"

WALL BRACKET

INTERMEDIARY WALL BRACKET FOR

WET WELLS OVER 96" DEEP.

12"

24" MIN.

61⁄4"

MAX.

QUICK

DISCONNECT

VERTICAL PIPE

NIPPLES

221⁄2"

MAX.

31⁄16"

MIN.

Typical Plumbing and Installation

INFLUENT

TOP PUMP

BRACKET

COUPLING

CHECK VALVE

BOTTOM PUMP

BRACKET

BASE PLATE

51⁄8"

DISCHARGE

36"

44"

MIN.

32"

MIN.

SIMPLEX

11"

11"

11"

11"

32"

MIN.

DUPLEX

INFLUENT

SERVICE

POLE

CONTROL

PANEL

GROUT SEAL

HIGH LEVEL ALARM

(OPTIONAL)

FLOAT SWITCH

6" NORMAL

OPERATION

3" MIN. SUBMERGENCE

(MAINTENANCE ONLY)

ALARM LIGHT (OPTIONAL)

HINGED ACCESS DOOR

SLIDE

RAIL

WRENCH OPERATED VALVE

VENT

VALVE

OPERATING

ROD

DISCHARGE

CHECK VALVE

SLIDE RAIL GUIDE

SERVICE

POLE

CONTROL

PANEL

GROUT SEAL

HIGH LEVEL ALARM

(OPTIONAL)

FLOAT SWITCH

6" NORMAL

OPERATION

3" MIN. SUBMERGENCE

(MAINTENANCE ONLY)

ALARM LIGHT (OPTIONAL)

HINGED ACCESS DOOR

WRENCH OPERATED

VALVE

SLIDE

RAIL

DUPLEXSIMPLEX

VENT

VALVE

OPERATING

ROD

DISCHARGE

CHECK

VALVE

SLIDE

RAIL

GUIDE

11

Page 12

Trouble Shooting

WARNING

Hazardous

voltage

FAILURE TO DISCONNECT AND LOCKOUT ELECTRICAL

POWER BEFORE ATTEMPTING ANY SERVICE CAN CAUSE

SHOCK, BURNS OR DEATH.

SYMPTOM PROBABLE CAUSE RECOMMENDED ACTION

MOTOR NOT RUNNING Motor thermal protector tripped. Allow motor to cool. Insure minimum pump submergence. Clear

NOTE: If circuit breaker “OPENS”

repeatedly, DO NOT reset. Call

qualified electrician.

a)Manual operation Power cable is damaged. Resistance between power leads must read as shown in

b) Automatic operation Inadequate electrical connection Inspect control panel wiring. Call a qualified electrician.

in control panel.

NOTE: Check the pump in manual

mode first to confirm operation. If

pump operates, the automatic

controls are at fault. If pump does

not operate, see above.

PUMP WILL NOT Liquid level cords tangled. Untangle cords and insure free operation.

TURN OFF

LITTLE OR NO LIQUID Check valve installed backwards, Check flow arrow on valve and check valve operation.

DELIVERED BY PUMP plugged or stuck closed.

PUMP CYCLES CONSTANTLY Discharge check valve inoperative. Inspect, repair or replace as required.

Open circuit breaker or blown fuse. Determine cause, call a qualified electrician.

Pump impeller binding or jammed. Check motor amp draw. If two or more times higher

Defective liquid level switch. With switch disconnected, check continuity while activating

Insufficient liquid level to Allow liquid level to rise 3" to 4" (76 mm - 101 mm)

activate controls. above turn-on level.

Liquid level cords tangled. Untangle cords and insure free operation.

Pump is air locked. Shut off pump for approximately one minute, then restart. Repeat

Influent flow is matching pump’s Larger pump may be required.

discharge capacity.

Excessive system head. Consult with dealer.

Pump inlet plugged. Inspect and clear as required.

Improper voltage or wired Check pump rotation, voltage and wiring.

incorrectly. Consult with qualified electrician.

Pump is air locked. See recommended action, above.

Impeller is worn or damaged. Inspect impeller, replace as required.

Liquid level controls defective Inspect, readjust or replace as required.

or improperly positioned.

Sewage containment area too small. Consult with dealer.

Liquid level controls defective or Inspect, readjust or replace as required.

improperly positioned.

Influent excessive for this size pump. Consult with dealer.

debris from casing and impeller.

than listed in the “DESCRIPTION AND SPECIFICATIONS”

section, impeller is locked, motor bearings or shaft is damaged.

Clear debris from casing and impeller, consult with dealer.

“ENGINEERING DATA”. Resistance between power leads and

ground should read infinity. If any reading is incorrect, call a

qualified electrician.

liquid level switch. Replace switch, as required.

until air lock clears. If air locking persists in a system with a check

valve pipe, a 0.188" (5 mm) hole may be drilled in the discharge pipe

approximately 2" (51 mm) beyond the discharge connection.

This warranty applies to all water systems pumps manufactured by Goulds Pumps.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty period shall exist for a

period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Goulds Pumps distributor from whom the pump was purchased and furnish complete details

regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Goulds Pumps Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Goulds Pumps and the dealer in purchases,

consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corporation, limited liability

company, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

12

GOULDS PUMPS LIMITED WARRANTY

Page 13

Instrucciones

de instalación,

Modelos

operación y

mantenimiento

Información del propietario

Número de Modelo:

Número de Serie:

Agente:

No. telefónico del agente

Fecha de compra: Instalación:

Lecturas actuales en la puesta en marcha:

Monofásica:

Trifásica - primera fase:

Segunda fase: Tercera fase:

3885, 3886,

3887

Índice

TÓPICO PÁGINA

Instrucciones de seguridad .................................................... 14

Descripción y especificaciones ............................................. 14

Levantamiento de la bomba .................................................. 14

Sistema de riel corredizo....................................................... 14

Tuberías................................................................................ 14

Puertas de acceso .................................................................. 15

Controles de nivel de líquido ................................................ 15

Paneles de control de motores de las bombas ........................ 15

Alambrado y conexión a tierra .............................................. 15

Operación ............................................................................. 16

Mantenimiento ..................................................................... 16

Desmontaje/Reensamblaje.................................................... 1 7

Reemplazo del sello mecánico .........................................17

Reemplazo del cable de alimentación............................... 17

Reemplazo del condensador de arranque.......................... 18

Reemplazo del motor ....................................................... 18

Datos de ingeniería ............................................................... 19

Montaje seccional ................................................................. 20

Partes de repuesto y materiales de construcción .............. 21, 22

Instalación típica de riel corredizo de 2 pulg. ........................ 23

Plomería e instalación típica ................................................. 23

Identificación y resolución de problemas .............................. 24

Garantía limitada de Goulds Pumps ...................................... 24

13

Page 14

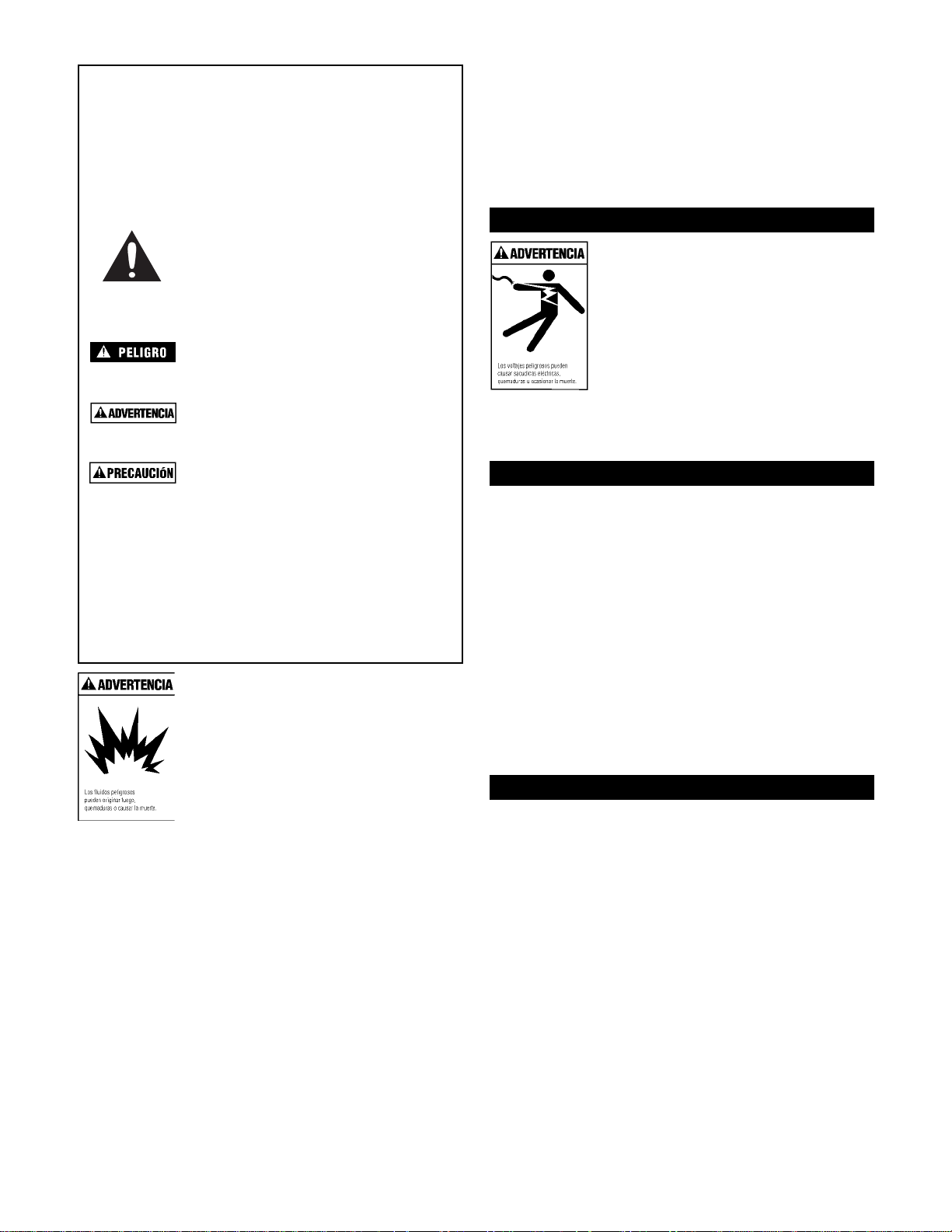

INSTRUCCIONES DE SEGURIDAD

DESCRIPCIÓN Y ESPECIFICACIONES

PARA EVITAR LESIONES PERSONALES GRAVES

O AÚN FATALES Y SERIOS DAÑOS MATERIALES,

LEA Y SIGA TODAS LAS INSTRUCCIONES DE

SEGURIDAD EN EL MANUAL Y EN LA BOMBA.

ESTE MANUAL HA SIDO CREADO COMO UNA

GUÍA PARA LA INSTALACIÓN Y OPERACIÓN DE

LA UNIDAD Y SE DEBE CONSERVAR JUNTO A

LA BOMBA.

Este es un SÍMBOLO DE ALERTA DE

SEGURIDAD. Cuando vea este símbolo en

la bomba o en el manual, busque una de las

siguientes palabras de señal y esté alerta a las

lesiones corporales potenciales o daños a la

propiedad.

Advierte los peligros que CAUSARÁN

serias lesiones corporales, la muerte o daños

mayores a la propiedad.

Advierte los peligros que PUEDEN causar

serias lesiones corporales, la muerte o daños

mayores a la propiedad.

Advierte los peligros que PUEDEN causar

lesiones corporales o daños a la propiedad.

AVISO: INDICA INSTRUCCIONES ESPECIALES

QUE SON MUY IMPORTANTES Y QUE SE

DEBEN SEGUIR.

EXAMINE BIEN TODAS LAS INSTRUCCIONES Y

ADVERTENCIAS ANTES DE REALIZAR

CUALQUIER TRABAJO EN ESTA BOMBA.

MANTENGA TODAS LAS CALCOMANÍAS DE

SEGURIDAD.

ESTA UNIDAD NO ESTÁ DISEÑADA

PARA EL USO CON LÍQUIDOS

PELIGROSOS O GASES

INFLAMABLES. ESTOS FLUIDOS

PODRÍAN ESTAR PRESENTES EN

LAS ÁREAS DE CONTENCIÓN.

AVISO: INSPECCIONE LA UNIDAD PARA VER SI

TIENE DAÑOS Y AVISE INMEDIATAMENTE

TODO DAÑO AL TRANSPORTISTA

O AL AGENTE.

El Modelo 3885 es una bomba de efluentes sumergible de

manejo de sólidos de 3⁄4 de pulgada (19 mm), de descarga de 2

pulgadas NPT. El Modelo 3886 es una bomba de aguas negras

sumergible de manejo de sólidos de 2 pulgadas (50 mm).

El Modelo 3887 es una bomba de aguas negras sumergible de

manejo de sólidos de 2 pulgadas (50 mm), de descarga bridada

de 2 pulgadas (estándar) y de 3 pulgadas (opcional).

Levantamiento de la bomba

NO LEVANTE NI TRANSPORTE NI

CUELGUE LA BOMBA DE LOS

CABLES ELÉCTRICOS. EL DAÑO A

LOS CABLES ELÉCTRICOS PUEDE

CAUSAR CHOQUES, QUEMADURAS

O LA MUERTE.

• Levante la bomba con una cadena o cable de tamaño

adecuado conectado a la manija de levantamiento (458).

NO dañe los cables eléctricos al levantar o bajar la unidad.

Sistema de riel corredizo

• Para una instalación apropiada, se recomienda el sistema

de riel corredizo Goulds Modelo A10-20 OPCIONAL.

AVISO: SIGA LAS INSTRUCCIONES DE

INSTALACIÓN Y OPERACIÓN

SUMINISTRADAS CON EL SISTEMA DE RIEL

CORREDIZO.

• La instalación del sistema de riel corredizo debe situar la

bomba opuesta al orificio de entrada, evitando las áreas

estancadas donde puedan asentarse sólidos.

• El piso de la fosa DEBE ser plano debajo de la base del

riel corredizo y tener suficiente capacidad de carga para

soportar el peso completo del conjunto, incluyendo la base

del riel corredizo, la guía del riel corredizo, la bomba y las

diferentes tuberías.

Tuberías

• La tubería de descarga no debe ser de menos de 2 pulgadas

(51 mm) de diámetro y debe mantenerse lo más corta

posible, evitando los accesorios innecesarios para reducir

al mínimo las pérdidas por fricción.

• Instale una válvula de retención de tamaño adecuado

(apropiada para manejar sólidos de 3⁄4 de pulgada (19 mm)

para aplicaciones de efluentes y sólidos de 2 pulgadas (50

mm) para aplicaciones de aguas negras) en la tubería de

descarga para evitar el contraflujo. Siga las instrucciones

de instalación del fabricante de la válvula de retención.

14

• Instale una válvula de compuerta de tamaño adecuado

SOBRE la válvula de retención para el mantenimiento

de la bomba, la plomería y la válvula de retención.

• Para evitar la obturación por aire, perfore un agujero de 3⁄16

de pulgada (4,8 mm), a 2 pulgadas (50,8 mm) al otro lado

de la conexión de descarga de la bomba.

• Todas las tuberías deben apoyarse adecuadamente,

de modo de no deformar la tubería y no aplicar cargas

sobre la bomba.

Page 15

Puertas de acceso

• Las puertas de acceso pueden ser de una o dos hojas. Las

puertas deben incluir una manija de levantamiento y un

dispositivo de traba para permitir una operación resistente

a las manipulaciones indebidas. Se ofrecen puertas de

acero o aluminio estándar o reforzado.

• La puerta de acceso a la fosa debe ser de tamaño suficiente

para permitir la inspección y el mantenimiento y para el

servicio de grúa o montacargas.

Controles del nivel de líquido

• En los modelos de 1⁄3 y 1⁄2 HP puede utilizarse una

operación de flotador único. El instalador debe revisar el

montaje del interruptor de flotador para asegurar su

encendido y apagado apropiados. La bomba debe

enchufarse directamente al enchufe estilo “en hombros”

situado sobre el cordón del interruptor de flotador.

• La secuencia de operación del flotador recomendada para

usarse con un panel de control requiere un sistema de tres

o cuatro flotadores. En el sistema de tres flotadores, estos

se designan SW-1 para el flotador inferior, SW-2 para el

flotador intermedio y SW-3 para el flotador superior. En

un sistema de cuatro flotadores, el cuarto flotador se

designa SW-4.

• Control simple – El nivel de líquido ascendente levanta

el flotador SW-2, encendiendo la bomba. Cuando

el nivel de líquido disminuye lo suficiente, SW-1 apaga

la bomba. Si el afluente es excesivo, o si la bomba no

funciona correctamente, SW-3 activará una alarma,

la cual se mantendrá activada hasta que sea

reposicionada en forma manual.

• Control doble – El control doble alternará las dos

bombas, haciendo que la bomba principal cambie en

cada ciclo del sistema. Cuando está equipado con tres

flotadores, el sistema ciclará igual que el control simple,

descrito arriba, excepto que SW-1 hará que la bomba

principal alterne.

• Si el afluente es excesivo, o si la bomba principal no

funciona correctamente, el nivel ascendente activará

SW-3, encendiendo la bomba secundaria y la alarma.

Al igual que antes, la alarma debe reposicionarse en

forma manual.

• Control con cuatro flotadores – El sistema de cuatro

flotadores funciona igual que el sistema de control

doble, excepto que el flotador SW-3 no activará la

alarma. En este sistema, SW-4 activa la alarma,

la cual también debe reposicionarse en forma manual.

• Se ofrecen varios controles de flotadores diferentes en el

Catálogo Goulds.

AVISO: POSICIONE LOS FLOTADORES DE MODO

QUE NO SE ENGANCHEN NI SE ENREDEN

EN LA BOMBA, LA TUBERÍA DE DESCARGA

U OTRO EQUIPO.

• El flotador más inferior apaga la unidad y debe ajustarse

tal como se indica en el dibujo de “PLOMERÍA E

INSTALACIÓN TÍPICA” incluido en este manual.

• Aumentando al distancia entre los flotadores SW-1 y SW-2

alarga el tiempo de operación. Un (1) minuto es el tiempo

de ciclo mínimo recomendado para la bomba.

AVISO: DURANTE LA OPERACIÓN DE LA BOMBA,

ASEGURE QUE EL NIVEL DE LÍQUIDO NO

DISMINUYA POR DEBAJO DEL MOTOR DE

LA BOMBA DURANTE PERÍODOS

PROLONGADOS. ESTO PUEDE CAUSAR

RECALENTAMIENTO DEL MOTOR DE

LA BOMBA, PRODUCIENDO DAÑO AL

MOTOR Y ANULANDO LA GARANTÍA.

Paneles de control del motor de la bomba

• Los paneles de control deben cumplir con los requerimientos

del Código Eléctrico Nacional y local.

• Las instalaciones monofásicas deben estar equipadas con un

panel Serie “SES” o “A” de Goulds o, COMO MÍNIMO,

con un panel de control con un contactador magnético e

interruptor de desconexión de tamaño apropiado.

• Las instalaciones trifásicas deben estar equipadas con un

panel Serie “SES” o “A” de Goulds o, COMO MÍNIMO,

con un cortacircuitos tripolar, un arrancador magnético de

línea clasificado por NEMA para la potencia adecuada y relés

de sobrecarga Quick Trip de Clase 10 de compensación

ambiental.

Alambrado y conexión a tierra

• Utilice solamente alambre de cobre trenzado, al motor y

a tierra. El alambre a tierra debe ser por lo menos del

tamaño de los alambres al motor. Los alambres deben

tener los colores de código para facilitar el mantenimiento.

Instale, conecte a tierra y alambre

de acuerdo con los requerimientos

del Código Eléctrico Nacional y

local.

Instale un desconectador de todos

los circuitos, cerca de la bomba.

Desconecte y bloquee la corriente

eléctrica antes de instalar o dar

servicio a la bomba.

El suministro eléctrico DEBE ser conforme a las

especificaciones de la placa del fabricante de la

bomba. La tensión incorrecta puede causar

incendios, daños al motor y anular la garantía.

Los motores monofásicos están equipados con

protectores térmicos automáticos que abren el

circuito eléctrico del motor cuando existe una

sobrecarga térmica. Esto puede causar que la bomba

arranque inesperadamente y sin advertencia.

Algunos modelos están equipados con un enchufe de

tres clavijas conectado a tierra y DEBE usarse en un

receptáculo de tres alambres conectado a tierra. NO

modifique el enchufe ni quite la clavija de tierra.

• Cuando haya que empalmar o conectar cables a los

conductores del motor, los empalmes DEBEN ser

herméticos al agua. Pueden usarse juegos de encapsulación

o tubos de contracción por calor comercialmente

disponibles, si los reglamentos locales o federales lo

permiten.

15

Page 16

AVISO: SIGA LAS INSTRUCCIONES DEL

!

Maquinaria Peligrosa

PELIGRO

FABRICANTE DEL JUEGO DE EMPALME.

• Cuando se utilicen empalmes de alambres, siga uno de

estos procedimientos:

• Una a tope los alambres con conectores Sta-Kon™, o

equivalentes, del tamaño adecuado y correctamente

plegados. Aísle e impermeabilice cada junta con tubo de

contracción por calor con un sellador autocontenido.

Aplique calor en forma uniforme con un soplete hasta

sellar adecuadamente.

O

• Utilice aisladores plásticos y una camisa de

empaquetadura de neopreno con conectores Sta-Kon™

de tamaño adecuado y plegados correctamente. Coloque

una tapa y empaquetadura en cada extremo del alambre,

centre la caja del aislador sobre el empalme, inserte la

camisa en la caja lo más posible, apriete las tapas con

la mano.

• En el caso de conductores múltiples, escalone las juntas.

ADVERTENCIA

Tensión

Peligrosa

LA FALLA DE CONECTAR A TIERRA

PERMANENTEMENTE LA BOMBA,

EL MOTOR Y LOS CONTROLES,

ANTES DE CONECTAR LA

CORRIENTE ELÉCTRICA, PUEDE

CAUSAR CHOQUES, QUEMADURAS

O LA MUERTE.

Operación

• Si la unidad ha estado almacenada durante un período

prolongado, verifique el nivel de aceite en el motor y en la

cámara de sello para asegurar que estén llenos, utilizando los

siguientes procedimientos:

• Cubierta del motor – Con la bomba en la posición vertical,

quite el tapón de llenado de aceite (358E), teniendo

cuidado de que no entre nada al motor. El nivel de aceite

debe estar por encima del extremo superior del motor, con

el llenado de aceite correcto en la forma requerida. NO

llene demasiado.

NO PONGA LAS MANOS EN LA

SUCCIÓN DE LA BOMBA MIENTRAS

VERIFICA LA ROTACIÓN DEL

MOTOR. EL HACERLO PODRÍA

CAUSAR GRAVES LESIONES

PERSONALES.

AVISO: NO CAMBIE LOS CONDUCTORES DE

POTENCIA PRIMARIA QUE LLEGAN A UN

PANEL DE CONTROL DOBLE TRIFÁSICO.

ESTO INVERTIRÁ LA ROTACIÓN DE

AMBAS BOMBAS.

• Si la rotación del (de los) motor(es) trifásico(s) es al revés,

invierta los dos conductores del cable de alimentación en

el panel de control de la bomba.

ADVERTENCIA

Maquinaria

Peligrosa

LOS DISPOSITIVOS DE DETECCIÓN

DE RECALENTAMIENTO/

SOBRECORRIENTE DEL MOTOR

REARRANCAN

AUTOMÁTICAMENTE EL MOTOR

EN FORMA INESPERADA Y SIN

ADVERTENCIA. ESTO PUEDE

PRODUCIR GRAVES LESIONES

PERSONALES.

• Después de instalar la bomba en el área de contención, con

inmersión adecuada, abra completamente la válvula de

descarga. Arranque la unidad utilizando los controles

manuales. Si el flujo es apreciablemente menor que el

rendimiento nominal, la bomba podría estar obturada con

aire. Para expulsar el aire atrapado, avance lentamente la

unidad varias veces, empleando los controles manuales.

• Haga que un electricista calificado mida la corriente en

la fase única o en las tres fases. Anote estas lecturas en

el espacio incluido en la sección de “INFORMACIÓN DEL

PROPIETARIO” de este manual para referencia futura.

• Ahora la unidad está lista para la operación normal. Coloque

los controles en la posición automática.

• Conjuntos de casquillos para el paso de cables - Retorsione

los casquillos de los cables de potencia y de los sensores a

los valores dados en el paso 11 de la sección de

“REEMPLAZO DEL CABLE DE

ALIMENTACIÓN”.

• Antes de bajar la(s) bomba(s) al área de contención, las

unidades trifásicas deben hacerse avanzar poco a poco para

verificar la rotación correcta. Ver la flecha de rotación del

motor en la cubierta del mismo (341). Revise ambas bombas

en operación doble.

AVISO: LA TORSIÓN DE PUESTA EN MARCHA

DEL MOTOR, EL “CONTRAGOLPE”,

CAUSARÁ QUE EL MOTOR GIRE EN

LA DIRECCIÓN OPUESTA A LA ROTACIÓN.

ASEGURE QUE LA BOMBA ESTÉ

ADECUADAMENTE RESTRINGIDA.

16

Mantenimiento

ADVERTENCIA

Tensión

Peligrosa

ADVERTENCIA

Peligro biológico –

puede causar graves

lesiones personales.

LA FALLA DE DESCONECTAR Y

BLOQUEAR LA CORRIENTE

ELÉCTRICA ANTES DE INTENTAR

CUALQUIER MANTENIMIENTO,

PUEDE CAUSAR CHOQUES,

QUEMADURAS O LA MUERTE.

LA UNIDAD DEBE LAVARSE Y

DESINFECTARSE POR DENTRO Y

POR FUERA, ANTES DE DARLE

SERVICIO.

Page 17

Mantenimiento periódico

AVISO: SE REQUIEREN INSPECCIONES PERIÓDICAS

DE RUTINA Y DEBEN REALIZARSE DE

ACUERDO CON LA FRECUENCIA Y EL

PROGRAMA DE MANTENIMIENTO

SUMINISTRADOS.

FRECUENCIA MANTENIMIENTO REQUERIDO

UNA VEZ AL MES • Unidades dobles – Verifique los

tiempos de operación uniformes. Los

tiempos de operación no uniformes

indican una unidad, flotador, interruptor

o control defectuoso.

• Operación del flotador sin obstrucción.

Desmontaje/Reensamblaje

ADVERTENCIA

Tensión

Peligrosa

AVISO: SIGA TODAS LAS INSTRUCCIONES DE

• Siguiendo las instrucciones del riel corredizo, retire la unidad

de bombeo del área de contención de aguas negras.

ADVERTENCIA

LA FALLA DE DESCONECTAR Y

BLOQUEAR LA CORRIENTE

ELÉCTRICA ANTES DE INTENTAR

CUALQUIER MANTENIMIENTO,

PUEDE CAUSAR CHOQUES,

QUEMADURAS O LA MUERTE.

SEGURIDAD Y DE LEVANTAMIENTO

PRESENTADAS EN ESTE MANUAL.

LA UNIDAD DEBE LAVARSE Y

DESINFECTARSE POR DENTRO Y

POR FUERA, ANTES DE DARLE

SERVICIO.

4. Para retirar el impulsor (101), podría ser necesario calentar

con un soplete el impulsor y la contratuerca del impulsor

(304), motores trifásicos únicamente. No use más calor que

el necesario, ya que el exceso de calor dañará el sello

mecánico. Bloquee el impulsor para que no gire y retire

la contratuerca girándola EN SENTIDO CONTRARIO A

LAS MANECILLAS DEL RELOJ. Retire el impulsor

del eje del motor sujetando el eje con un destornillador y

girando el impulsor EN SENTIDO CONTRARIO A

LAS MANECILLAS DEL RELOJ.

5. Retire y deseche el conjunto del sello mecánico y asiento

estacionario. NO dañe el eje del motor o el agujero del

asiento.

6. Inspeccione y limpie con un paño el agujero del asiento

estacionario.

7. Para instalar el nuevo asiento estacionario en la caja del

sello, lubrique el agujero del sello estacionario y el eje del

motor con aceite aislante para motores limpio. Empleando

la herramienta de instalación de sello mecánico Goulds

(A02A013), deslice el asiento estacionario en forma

completa y encuadrada en la caja del sello.

8. Con un paño limpio y sin pelusas, quite todo el aceite

lubricante o residuos de la cara estacionaria. NO raye ni

dañe la cara del sello.

9. Lubrique el interior del elastómero rotatorio con aceite

aislante para motores limpio. Empleando la herramienta

de instalación Goulds, deslice el conjunto rotatorio del sello

en el eje del motor y asiéntelo totalmente contra el asiento

estacionario. Retire la herramienta de instalación del sello.

10. Instale el impulsor sobre el eje del motor girando el

impulsor EN EL SENTIDO DE LAS MANECILLAS

DEL RELOJ. Apriete bien. Trate el impulsor con

Loctite™ #271 e instálelo firmemente. Cuando se

suministre, instale firmemente la contratuerca del impulsor.

Peligro biológico –

puede causar graves

lesiones personales.

REEMPLAZO DEL SELLO MECÁNICO

1. Siga TODAS las instrucciones incluidas en la sección

de “DESMONTAJE” de este manual.

2. Para tener acceso al impulsor y al sello mecánico de

la bomba, quite los cuatro tornillos de cabeza hexagonal

de la carcasa (372D). Quite la carcasa (100) y

la empaquetadura de la carcasa (351); deseche

la empaquetadura.

PRECAUCIÓN

LA FALLA DE QUITAR

CUIDADOSAMENTE EL TAPÓN DE

DRENAJE, PUEDE CAUSAR LA

ERUPCIÓN DE ACEITE CALIENTE

DEL TANQUE DE ACEITE Y CAUSAR

LESIONES PERSONALES O DAÑOS A

Presión Peligrosa – puede

causar lesiones personales

o daños a la propiedad.

LA PROPIEDAD

3. El retiro del conjunto del sello mecánico (387) requiere

drenar el aceite aislante especial de la cubierta del motor.

Esto se logra quitando el tapón de drenaje y drenando

el aceite en un colector limpio de tamaño adecuado.

Consulte la sección de “DATOS DE INGENIERÍA” para

obtener información sobre el volumen requerido.

11. Llene la cubierta del motor con aceite aislante especial para

motores hasta menos de 1⁄2 pulgada (13 mm) de la caja de

la cámara del sello. Encinte el tapón de drenaje con cinta

Teflon™ e instale firmemente el tapón.

12. Reensamble la carcasa y la nueva empaquetadura de

la carcasa en el conjunto de la bomba instalando los cuatro

tornillos de cabeza hexagonal de la carcasa y apretándolos

en secuencia a 35 lbs.-pies (47 N-m).

AVISO: SIGA LAS INSTRUCCIONES INCLUIDAS EN

LAS SECCIONES DE “ALAMBRADO Y

CONEXIÓN A TIERRA” Y “OPERACIÓN”

DEL MANUAL DESPUÉS DE DESMONTAR O

REENSAMBLAR LA UNIDAD.

REEMPLAZO DEL CABLE DE ALIMENTACIÓN

1. Para tener acceso a los tornillos de la cubierta del motor,

siga los pasos 1 a 6 en la sección de “REEMPLAZO DEL

SELLO MECÁNICO” de este manual.

2. Retire el protector contra tirones (484B) del cable de

alimentación de la tapa del motor y deslice el cable hacia

arriba.

3. Retire los cuatro tornillos de cabeza hueca (371C). Deslice

cuidadosamente la cubierta y retírela del motor. NO dañe el

cable de alimentación.

4. Desconecte los alambres del cable de alimentación

del motor (338).

17

Page 18

5. Retire el cable de la cubierta del motor, inspecciónelo y

reemplácelo, según sea requerido, siguiendo los

procedimientos suministrados.

AVISO: DESECHE EL PROTECTOR CONTRA

TIRONES, YA QUE NO PUEDE VOLVER A

USARSE.

6. Instale un nuevo protector contra tirones en el cable,

deslizando el casquillo hexagonal primero, luego la

arandela y finalmente el empaque. Inserte los cables en el

agujero de la cubierta del motor. Pase una cantidad

apropiada de cable por la cubierta del motor para permitir

conectar los conductores del cable. NO apriete el casquillo

del protector contra tirones.

7. Conecte los conductores del cable de alimentación al

conjunto del motor, de la siguiente manera:

• Motores monofásicos – Conecte el alambre NEGRO

al terminal L1 del motor. Conecte el alambre

BLANCO al terminal L2 del motor. Conecte el

alambre VERDE a la conexión a tierra del motor.

• Motores trifásicos – Ver la Figura 1.

ADVERTENCIA

Tensión

Peligrosa

LA FALLA DE CONECTAR LOS

ALAMBRES DE ALIMENTACIÓN Y

DE LOS SENSORES A LOS

ALAMBRES INDICADOS, PUEDE

CAUSAR CHOQUES, QUEMADURAS

O LA MUERTE.

208-230 V 3/60

4

5

6

1

7

2

8

3

CONDUCTORES DEL MOTOR

9

DIAGRAMA DE CABLEADO DE MOTOR TRIFÁSICO

L

1

L

2

L

3

CONDUCTORES DEL CABLE DE ALIMENTACIÓN

G

460 V 3/60

4

7

5

8

6

9

1

CONDUCTORES DEL MOTOR

2

3

L

1

L

2

L

3

CONDUCTORES DEL CABLE DE ALIMENTACIÓN

G

Figura 1

8. Amarre el cable de alimentación al motor.

9. Deslice la cubierta sobre el motor, mientras hala

cuidadosamente el cable de alimentación hacia afuera por el

agujero de la cubierta del motor. NO dañe los cables.

Instale los cuatro tornillos de cabeza hueca de la caja del

sello, apretándolos a 90 lbs.-pulg. (10 N-m).

10. Instale el protector contra tirones en el cable de

alimentación, apretando el manguito de nilón a 75 lbs.-pulg.

(8.5 N-m) y el manguito de acero a 100 lbs.-pulg.

(11.3 N-m).

11. Continúe el reensamblaje siguiendo los pasos 7 a 13 de la

sección de “REEMPLAZO DEL SELLO MECÁNICO”

de este manual.

12. Si se reemplazó la cubierta del motor, es necesario

transferir la placa de identificación Goulds. Instale la placa

de identificación Goulds con dos tornillos metálicos de

cabeza redonda No. 2 de acero inoxidable.

AVISO: SIGA LAS INSTRUCCIONES INCLUIDAS EN

LAS SECCIONES DE “ALAMBRADO Y

CONEXIÓN A TIERRA” Y “OPERACIÓN” DEL

MANUAL DESPUÉS DE DESMONTAR O

REENSAMBLAR LA UNIDAD.

REEMPLAZO DEL CONDENSADOR DE ARRANQUE

1. En los motores monofásicos únicamente, para tener acceso

al condensador de arranque (376) del motor, signa los pasos

1 a 5 en la sección de “REEMPLAZO DEL CABLE DE

ALIMENTACIÓN” de este manual.

AVISO:DESECHE EL PROTECTOR CONTRA TIRONES,

YA QUE NO PUEDE VOLVER A USARSE.

ADVERTENCIA

Tensión

Peligrosa

LA FALLA DE DRENAR LA CARGA

ELÉCTRICA ALMACENADA EN EL

CONDENSADOR ANTES DE DARLE

SERVICIO, PUEDE PRODUCIR UN

CHOQUE SERIO.

2. Retire el tornillo de retención del condensador y el soporte

de retención del motor. Retire los dos alambres del

condensador. Deseche el condensador.

3. Conecte los dos alambres del motor al nuevo condensador y

reensámblelo con el soporte de retención y el tornillo de

retención, apretando firmemente.

4. Reensamble la unidad siguiendo los pasos 6 a 12 en

la sección “REEMPLAZO DEL CABLE DE

ALIMENTACIÓN” de este manual.

AVISO: SIGA LAS INSTRUCCIONES INCLUIDAS EN

LAS SECCIONES DE “ALAMBRADO Y

CONEXIÓN A TIERRA” Y “OPERACIÓN” DEL

MANUAL DESPUÉS DE DESMONTAR O

REENSAMBLAR LA UNIDAD.

REEMPLAZO DEL MOTOR

1. Para tener acceso al conjunto del motor, siga los pasos 1 a 5

en la sección de “REEMPLAZO DEL CABLE DE

ALIMENTACIÓN” de este manual.

AVISO: DESECHE EL PROTECTOR CONTRA

TIRONES, YA QUE NO PUEDE VOLVER

A USARSE.

2. Retire los cuatro pernos pasantes del motor y quite

cuidadosamente el conjunto del motor de la caja de

cojinetes. El servicio adicional del motor DEBE ser

realizado por una instalación capacitada en reparación

de motores.

3. Inserte el conjunto del motor en la caja de cojinetes,

alineando visualmente los pernos pasantes del motor con

los orificios de ventilación en la sección inferior del motor.

4. Instale los cuatro pernos pasantes del motor, apretando a

35 lbs.-pulg. (4 N-m).

5. Para concluir el reensamblaje, siga los pasos 6 a 12 en

la sección de “REEMPLAZO DEL CABLE DE

ALIMENTACIÓN” de este manual.

AVISO: SIGA LAS INSTRUCCIONES INCLUIDAS EN

LAS SECCIONES DE “ALAMBRADO Y

CONEXIÓN A TIERRA” Y “OPERACIÓN” DEL

MANUAL DESPUÉS DE DESMONTAR O

REENSAMBLAR LA UNIDAD.

18

Page 19

Datos de ingeniería

Sólidos de diámetro máximo

3885

3

⁄4 pulg. 19 mm

3886 y 3887 2 pulg. 50 mm

Espesor máximo de la carcasa

Corrosión permitida de la carcasa

5

⁄16 pulg. 8 mm

1

⁄8 pulg. 3 mm

Presión mínima de trabajo 55 psi 380 kPa

Inmersión mínima de la bomba – Por debajo 6 pulg. 152 mm

del extremo superior de la cúpula del motor

Número mínimo de arranques de distribución uniforme por hora 6

Temperatura máxima de operación

Operación continua 40° C 104° F

Operación intermitente 60° C 140° F

Capacidad de aceite de la cubierta del motor 4,5 cuartos 4,3 L

DATOS ELÉCTRICOS – 3885

HP RPM Tensión Fase Amperios Código Resistencia del devanado Cable de – Amperios fusible/

1

⁄3 1725 115 1/60 9,4 M 1,92 16/3 15

1

⁄3 1725 230 1/60 4,7 N 7,58 16/3 10

1

⁄2 3450 115 1/60 14,5 M 1,00 16/3 20

1

⁄2 3450 230 1/60 7,3 M 4,03 16/3 10

1

⁄2 3450 200 3/60 3,9 R 3,8 14/4 10

1

⁄2 3450 230/460 3/60 3,4/1,7 R 5,81/23,24 14/4 10/10

3

⁄4 3450 230 1/60 10,0 J 2,99 14/3 15

3

⁄4 3450 200 3/60 6,2 L 5,7 14/4 10

3

⁄4 3450 230/460 3/60 5,4/2,7 L 4,04/16,15 14/4 10/10

1 3450 230 1/60 12,5 J 2,09 14/3 20

1 3450 200 3/60 8,1 M 2,6 14/4 10

1 3450 230/460 3/60 7,0/3,5 L 4,04/16,15 14/4 10/10

11⁄2 3450 230 1/60 15,0 H 1,16 14/3 20

11⁄2 3450 200 3/60 10,6 K 1,9 14/4 15

11⁄2 3450 230/460 3/60 9,2/4,6 K 2,87/11,46 14/4 15/10

2 3450 230 1/60 18,0 F M-1,1/S-2,2 14/3 15/10

2 3450 200-230/460 3/60 12,0-11,6/5,8 K 1,66/6,62 14/4 15/10

/Hz KVA – fase a fase (ohmios) alimentación AWG cortacircuitos

DATOS ELÉCTRICOS 3886 Y 3887

1

⁄3 1725 115 1/60 9,8 M 1,92 16/3 15

1

⁄3 1725 230 1/60 4,9 N 7,58 16/3 10

1

⁄2 1725 115 1/60 14,5 N 1,6 16/3 20

1

⁄2 1725 230 1/60 7,3 K 6,4 16/3 10

1

⁄2 1725 200 3/60 3,8 K 6,55 14/4 10

1

⁄2 1725 230/460 3/60 3,3/1,7 K 9,9/39,4 14/4 10/10

3

⁄4 1725 230 1/60 9,4 J 5,9 14/3 15

3

⁄4 1725 200 3/60 4,1 H 4,3 14/4 10

3

⁄4 1725 230/460 3/60 3,6/1,8 J 5,6/22,4 14/4 10/10

1 1725 230 1/60 12,3 H 2,6 14/3 20

1 1725 200 3/60 6,0 H 4,3 14/4 10

1 1725 230/460 3/60 5,8/2,9 J 5,6/22,4 14/4 10/10

DATOS ELÉCTRICOS 38867BHF

1

⁄3 1725 115 1/60 12,4 M 1,00 16/3 15

1

⁄3 1725 230 1/60 6,2 M 4,03 16/3 10

1

⁄2 3450 115 1/60 14,5 M 1,00 16/3 20

1

⁄2 3450 230 1/60 7,6 M 4,03 16/3 10

1

⁄2 3450 200 3/60 4,1 R 3,8 14/4 10

1

⁄2 3450 230/460 3/60 3,6/1,8 R 5,81/23,24 14/4 10/10

3

⁄4 3450 230 1/60 9,4 J 2,99 14/3 15

3

⁄4 3450 200 3/60 6,2 L 5,7 14/4 10

3

⁄4 3450 230/460 3/60 5,4/2,7 L 4,04/16,15 14/4 10/10

1 3450 230 1/60 14,5 J 2,1 14/3 20

1 3450 200 3/60 8,6 M 2,6 14/4 10

1 3450 230/460 3/60 7,5/3,8 L 4,0/16,2 14/4 10/10

11⁄2 3450 230 1/60 18,0 F M-1,1/S-2,2 14/3 20

11⁄2 3450 200-230/460 3/60 10,0-9,6/4,8 K 1,66/6,62 14/4 15/10

2 3450 230 1/60 18,0 F M-1,1/S-2,2 14/3 20

2 3450 200-230/460 3/60 12,0-11,6/5,8 K 1,66/6,62 14/4 15/10

19

Page 20

Diagrama de repuestos para los Modelos 3885, 3886 y 3887

458

376

338

484B

GRUPO 456

457

436

372D

340

101

351

387

341

112A

412M

Nota: los Modelos 3885 y 3886 no son

bridados y, por lo tanto, no requieren algunas

de las partes incluidas en el diagrama.

371H

371C

195C

351A

20

100

304

357

Page 21

Tabla de repuestos para el Modelo 3885

Artículo

Nombre de la parte Material

No.

Carcasa – 1⁄3 HP, modelo “L” únicamente

100

Carcasa – todos los demás 1K170

Hierro fundido 1

1725 RPM 3450 RPM

Cant.

1

⁄3 HP1⁄2 HP

1K171 N/A

Número de pedido de repuestos

3

⁄4 HP 1 HP 11⁄2 HP 2 HP

(lbs.)

Impulsor Hierro fundido 2K158 2K220 2K219 2K218 2K217 2K840 2,0

Impulsor Bronce 2K271 2K272 2K273 2K274 2K275 2K841 2,5

101

Impulsor – carga alta Hierro fundido 1 N/A 2K225 HH N/A N/A 2K221HH N/A 3,5

Impulsor – carga alta Bronce N/A 2K276 HH N/A N/A 2K277 HH N/A 4,0

112A Rodamiento inferior Acero 1 4K132 4K384 –

112B Rodamiento superior Acero 1 4K132 –

Aceite aislante (galón) –

218

galones requeridos

Aceite para turbinas –

Sunvis 932, Convis 150

4K432 (5 galones)

1,2 galones

7,5 lbs./

galón

304 Contractuerca del impulsor (trifásico únicamente) AI Serie AISI 300 1 13K6 –

monofásico, 115V 118-121R 118-1222R N/A N/A N/A N/A

338 Motor

monofásico, 230V 118-122R 118-1223R 118-1232R 118-1233R 118-1334R 120-845R

trifásico, 230/460 V N/A 118-1321R 118-1322R 118-1323R 118-1324R 120-8425R

Acero inoxidable –

ext. corta.

1

trifásico, 200 V N/A 118-1333R 118-1334R 118-1335R 118-1336R 120-8425R

340 Caja del cojinete Hierro fundido 1 1K167 1K332 10,0

341

Cubierta del

motor

1 PH

3 PH 1K208

Hierro fundido 1

1K207 1K207 1K208 1K208 1K208 1K208

351 Empaquetadura de la carcasa Compuesto 1 5K170 –

358E Tapón – cubierta del motor 3⁄8* NPT Acero 1 6K3 –

371C Tornillo de cabeza hueca – caja del cojinete Acero inoxidable

a la cubierta del motor Serie AISI 300

2 13K210 –

372D Tornillo hexagonal – caja del sello a la carcasa AI Serie AISI 300 4 13K186 –

Condensador arrangue

376

(monofásico únicamente) operación N/A N/A N/A N/A N/A 279342110

Sello mecánico – estándar Carburo de silicio 1 10K63 (John Crane Tipo 6) 10K71 –

387

Sello mecánico – opcional Carburo de tungsteno 1 10K30 (John Crane Tipo 21) 10K72 –

412M Aro tórico – cubierta del motor

varía 1

BUNA-N, AS 568A-166

1K197 9K197 9K197 9K197 9K197 275470130

1 4K252 –

436 Interruptor electrónico N/A 294811980

456 Cable de alimentación 1 Ver la tabla de abajo –

Tuerca para alambre trifásico, 200/230 V 4 9K145 –

457

(cable de alimentación) trifásico, 460 V 6 9K145 –

Caja de nilón

458 Conjunto de la manija Acero inox. AISI 300 1 4K243 –

Conjunto de protección contra tirones Monofásico

484B

(

cable de alimentación

)

Trifásico 1 N/A 5K111 –

varía

1 5K113 5K113 5K111 5K111 5K111 5K111 –

Loctite #271 1 AL271121 –

Peso

máx.

13,0

13,0

to

24,0

23,0

–

Modelo 3885 – descripción de cables de alimentación y de sensores

Tipo y

tamaño AWG

Longitud estándar*

20' 30' 50' 100'

Longitudes opcionales

Peso (lbs./

5 pies)

Cables de alimentación

Monofásicos: 1⁄3 y 1⁄2 HP, 115 V; con enchufe estándar, con conductores

expuestos opcional

Monofásicos: 1⁄3 y 1⁄2 HP, 230 V; con enchufe estándar, con conductores

expuestos opcional

SJTOW – 16/3 9K165 9K214 9K215 N/A 0,5

SJTOW – 16/3 9K164 9K214 9K215 N/A 0,5

Monofásicos: 3⁄4 – 11⁄2 HP, 230 V con conductores expuestos STOW – 14/3 9K163 9K216 9K161 9K217 0,9

Monofásicos: 11⁄2 – 2 HP, 230 V con conductores expuestos STOW – 14/3 9K266 9K267 9K268 9K269 0,9

Trifásicos: 1⁄2 – 2 HP, 208–230/460 V con conductores expuestos STOW – 14/4 9K153 9K218 9K154 9K219 1,1

21

Page 22

Tabla de repuestos para los Modelos 3886 y 3887

Nota: 1K168 es la carcasa para el modelo 3886 de 1⁄2 HP. 1K178 es la carcasa para el modelo 3887 de 1⁄3 - 1 HP.

Artículo

Nombre de la parte Material

No.

Cant.

1

⁄3 HP

100 Carcasa Hierro fundido 1 1K168 para 3886 NPT 1K178 para 3887 bridado 1K330 16,5

Impulsor Hierro fundido 1 2K268 2K239 2K240 2K241 2K242 2K800 2K798 3,0

101

Impulsor Bronce 1 2K279 2K280 2K281 2K282 2K283 2K801 2K799 3,5

112A Rodamiento inferior Acero 1 4K132 4K384 –

112B

Rodamiento superior (no se muestra)

Brida de descarga (2 pulg. NPT est.) Hierro fundido 1 6K76 1,5

195C

Brida de descarga (3 pulg. NPT op.) Hierro fundido 1 A1-3 1,5

Aceite aislante del motor

218 Aceite para Turbina 1 4K432

(se requiere aprox. 1 galón)

Acero 1 4K132 –

304 Contratuerca del impulsor (trifás únic.) AI serie AISI 300 1 13K6 –