Page 1

I.

:

HP

..

.

This vintage Hewlett Packard document was

preserved and distributed by

Archive

www.

'

Please visit us on the web

..

On-line curator: Tony Gerbic

hparchive.com

!

Page 2

Page 3

203210-

222-

@

1

1.

2

1

thru 3 01000

MANUAL

250-

317-00901 thru

CHANGES

MODEL 185B

OSCILLOSCOPE

Manual Serial Prefixed: 144-

Manual Printed: OCT 1962

1

thru 6

1

thru 8

432446-

525-

1

thru

thru 12

1

1

thru 14

11

230245-

1

thru 4 348-

1

thru 5 430-

1

thru 9

1

thru 10

534-

1

thru 13, 15

28 December 1965

Supplement A for

185B-901

Page 4

Serial Prefix Make

or Number Manual Changes

203210222230-

1

2

1.

1

thru 3

1

thru 4

Manual Changes Model 185B

Serial Prefix Make

or

Number Manual

,250-

317317-00901 thrul

01000

348-

I

Cbsnges

1

thru 6

lthru7

1

thru

8

1

thru9

Page

2/9

432446525534-

1

thru

11

1

thru 12

1

thru 14

1

thru 13, 15

245-

ERRATA Add the following:

(cont'd)

CHANGE

CHANGE 2

1

Reference

Desienation

C123

C160

L115

C425

C426

C427

C614

C615

C616

L608

1

thru 5

A302: HV Transformer Assembly: includes C309, C310, T301, V303, and V304;

Stock No. 185A-llA; Mfr. 28480; Mfr. Part No. 185A-llA; TQ

C309, C310: Same description and @ Stock No.

L603: Same description and

T301: HV Transformer;

130B-llB-1; TQ 1;

V303, V304: Tube electron: 5642; @Stock No. 1920-0001; Mfr. 28480; Mfr.

1920-0001; TQ 2; RS 2.

Section VI and schematic diagrams,

Add the following:

Value

0.05 pf

pi

0.005

360 ph

0.05

pf

8200 pf

0.05 pf

pf

0.05

0.05

pf

0.1

pf

100 ph

(Note: For instruments

under CHANGE 2 except Q209.)

Section VI and schematic diagrams,

C616: Delete.

QlOl, Ql02, Q103, Q209: Change to

Mfr. 01295; Mfr. Part No. 2N388A.

R611: Change to

28480; Mfr.

The Internal Graticule Cathode-Ray

Model 185B Oscilloscope. The CRT formerly supplied, without internal graticule,

is

still available

Figure

5-26,

Change wiring

430-

@

RS

1.

C: fxd,

and junction of R128 and +lOOV.

C: fxd,

and ground.

Coil: fxd, RF, 360 ph. (On+6.3VlinebetweenR107 andC110.

C:

pin 10 [+12. 6V] , and ground.)

C: fxd, cer, 8200 pf, 500VDCW. (Between

C-IOOVJ

C: fxd,

J1,

C: fxd, cer, 0.05

between

C: fxd,

between +12.6VF and ground.

C: fxd, cer, 0.1

between +12.6V [BRN wire]

Coil: fxd, RF, 100 ph.

this change] and C607 on -12.6V line.)

cer,

0.05

cer,

0.005

)

fxd, cer, 0.05

,

and ground

cer,

0.05 pf, +80% -20%, 1OOVDCW. (Between

pin 5 [-12.6V] , and ground.)

-

12.6V and ground.

cer,

0.05 pf, +80% -20%, 1OOVDCW.

serial

prefixed 222- and above, make

@

Stock No. 2100-0351;

Part

No. 2100-0351.

as

Option 05. This change obsoletes Option 03.

as

shown

in

1

thru 10

as

C312; change TQ column to 3.

@

Stock No.

Stock No. 130B-llB-1; Mfr. 28480; Mfr.

pf,

20%, 400VDCW. (Between ground

pf,

pf,

+80% -20%, 1OOVDCW. (Between

pf,

+80% -20%, 1OOVDCW. (On A602

pf,

+80% -20%, 50VDCW.

Tube

Figure

1.

as

L601, L602.

Description

)

500VDCW. (Between T103, pin 8,

J1,

pin 9

)

(On

A602

)

(On

S601A

,

and ground.)

(On

A602 between C614 [added by

all

component changes listed

@

Stock No. 1851-0024; Transistor 2N388A;

R:

var,

WW,

is

now supplied

4K ohms,

as

a

IO%,

standard part of the

1;

Part

J1,

RS

0.

No.

Part

@

1150-0052

0150-0014

9140-0038

0150-0096

0150-0082

0150-0096

0150-0096

0150-0096

0150-0121

9 140-0029

4W; Mfr.

($3

No.

Stock No

28 December 1965

Page 5

Manual Changes Model 185B Page 3/9

Serial Prefix Make

or Number Manual Changes

203210222230245-

CHANGE 2

(con t

'

d)

1

1.

2

1.thr1.1

1

1

r

thru 4

hru

I

I

-

3

5

7

I

I

I

1

I

I

Serial Prefix

or Number

250317-

317-00901 thru

O1OOO

348-

430-

L601

35UH

n

R613

IO

-

T

Make

Manual Changes

-

4

+

12.6VF

Serial

or Number Manual Changes

432446-

0603

Prefix

525-

534-

(k

Make

1

thru

11

1

thru

12

1

thru 14

1

thru 13.15

CHANGE 3

I

I

I

I

+12.6VF

I

Section

VI

and schematic diagrams,

Q209: Change to

Mfr. Part No. 2N2218.

Q603: Change to

Mfr. PartNo. 2N384.

R436: Change to

Mfr.

Part

R604:

R607: Change to

R610: Change to

Add the following:

Change to factory selected value.

Mfr. 01121; Mfr.

Mfr.

28480; Mfr. Part No. 0767-0011.

C134: C: fxd, elect, 20

Mfr. Part No. 40D-181-A2.

and R155.

reference designation corrections.

110

Figure

@

Stock No. 1854-0013; Transistor: silicon, 2N2218; Mfr. 04713;

@

Stock No. 1850-0041; Transistor: germanium, 2N384;

@

Stock No. 0819-0023; R: fxd,

No. 0819-0023.

$3

Stock No. 0683-3015; R: fxd, comp, 300 ohms, 5% 1/4W;

Part

@

Stock No. 0767-0011; R: fxd, metal film, 20K ohms, 5%, 3W;

)

Note: See Errata section of this manual change sheet concerning

i.

WW,

5 ohms, 5%, 55W; Mfr. 28480;

No. CB 3015.

pf,

25VDCW; @ Stock No. 0180-0076; Mfr. 56289;

(Connects between ground and junction of R154

Mfr.

02735;

28 December 1965

Page 6

Manual Changes Model 185B

Page

4/9

Prefix

Serial

or Number Manual Changes

203210222230245-

CHANGE

(cont'd)

3

Make Serial

1

1.

2

1

thru 3

1

thru 4

1

thru 5

C617: C: fxd,

Mfr. Part No. SM-62-N1500.

and R610.

5604: Connector: BNC; @ Stock No. 1250-0083;

UG-l094/U.

L116: Coil: fxd, RF, 1OO'ph;

3100-15-101.

R268: R: fxd, comp, 82K ohms,

Mfr. Part No. EB 8231.

or Number Manltal-€hm@s

Prefix

2 50317-

317-00901 thrul

01000

I

I

I

1

thru 6

1

thru

1

thru

1

thru 9

Make

7

8

432446-

525-

534-

1

1

1

1

E-kL-i

cer,

62

pf,

lo%,

SOOVDCW; @ Stock No. 0150-0087; Mfr. 91418;

(Connects between ground and junction of R607

)

Mfr.

(Insert in line between J601 and A602 [circuit board 185E65Pl

(Insert in line between SlOlA and junction of R154 and R155.)

@

Stock No. 9140-0029; Mfr. 99848; Mfr.

lo%,

1/2W; @ Stock No. 0687-8231; Mfr. 01121;

(Connect

a8

shown in Figure 2.)

91737; Mfr. Part No.

thru

11

thru 12

thn

14

th.ru

13,15

Part

No.

.

)

CHANGE 4

28 December 1965

Section

Figure

L

Figure 2.

VI

Add C244: C: fxd,

CR107, CR108, CR112, CR113, CR114: Change to

Add CR223: Diode: germanium;

QlKChange to @ Stock No. 1854-0003; Transistor: silicon; Mfr. 28480;

Q201: Change to

Q603: Change to

Disconnect R272 end which attaches to junction

and schematic diagrams,

cer,

0.1

pf,

40%

Mfr. 56289; Mfr. Part No. 33C41.

silicon; Mfr. 28480; Mfr. Part No. 1901-0040.

1910-0016. (Connects between R267 and S203A; anode side connects to S203A.

Note:

Do

not add CR223

Mfr. Part No. 1854-0003.

@

Mfr. Part No. 1850-0062.

Mfr.

Part

5-17,

to junction of R501 and S204.

Stock

@

Stock

No. 1850-0029.

if

instrument

No.

1850-0062; Transistor: germanium; Mfr. 28480;

No.

1850-0029; Transistor: germanium; Mfr. 28480;

-20% 50VDCW; @ Stock

(Connects in

@

Stock

No.

1910-0016; Mfr. 28480; Mfr.

serial

prefix

of

Q210 and R255B and reconnect

parallel

($3

Stock No. 1901-0040; Diode:

is

No.

0150-0084;

with

CR221.

250- or above.

)

Part

No.

)

Page 7

Manual Changes Model 185B

Page 5/9

I

Serial Prefix Make

or

Number Manual Changes

250-

317-00901 thru

348430-

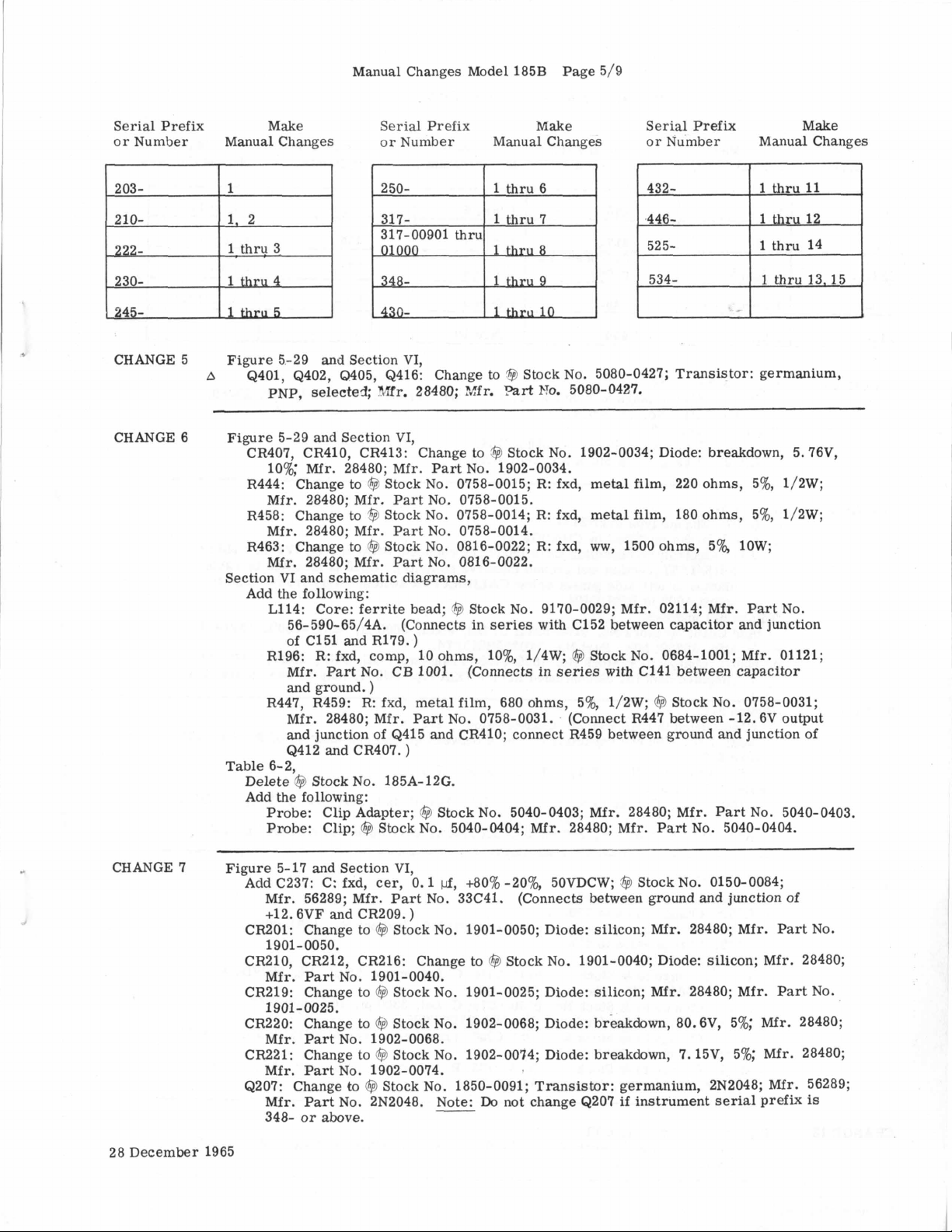

CHANGE 5 Figure 5-29 and Section

A

Q401, Q402,

9405,

Q416: Change to

PNP, selecte3 YTfr. 28480;

VI,

Yfr.

1

thru 6

1

thru 9

1

thru

10

’@

Stock No. 5080-0427; Transistor: germanium,

?art

FTo.

5080-0427.

432-

1

1

thru

11

thru 14

CHANGE 6 Figure 5-29 and Section VI,

to

‘$3

CR407, CR410, CR413: Change

Mfr.

10%;

R444: Change to

28480; Mfr. Part No. 1902-0034.

@

Stock No. 0758-0015;

Stock No. 1902-0034; Diode: breakdown, 5.76V,

R:

fxd, metal film, 220 ohms, 5%

1/2W;

Mfr. 28480; Mfr. Part No. 0758-0015.

R458: Change to

‘$3

Stock No. 0758-0014; R: fxd, metal film, 180 ohms, 5%, 1/2W;

Mfr. 28480; Mfr. Part No. 0758-0014.

R463: Change to

$3

Stock No. 0816-0022; R: fxd,

ww,

1500 ohms, 576 1OW;

Mfr. 28480; Mfr. Part No. 0816-0022.

Section

VI

and schematic diagrams,

Add the following:

L114: Core: ferrite bead;

56-590-65/4A.

(Connects in

of C151 and R179.

R196: R: fxd, comp, 10 ohms, 1096, 1/4W;

Mfr. Part No. CB 1001. (Connects in

and ground.

)

R447, R459: R: fxd, metal film, 680 ohms, 57% 1/2W;

Mfr. 28480; Mfr. Part No. 0758-0031.

‘$3

Stock No. 9170-0029; Mfr. 02114; Mfr.

series

)

with C152 between capacitor and junction

@

Stock No. 0684-1001; Mfr. 01121;

series

with C141 between capacitor

($3

Stock No. 0758-0031;

Part

No.

(Connect R447 between -12.6V output

and junction of Q415 and CR410; connect R459 between ground and junction of

Q412 and CR407.

)

Table 6-2,

Delete @ Stock No. 185A-12G.

Add the following:

Probe: Clip Adapter;

Probe: Clip;

@

9

Stock No. 5040-0403; Mfr. 28480; Mfr.

Stock No. 5040-0404; Mfr. 28480; Mfr.

Part

No. 5040-0404.

Part

No. 5040-0403.

CHANGE

7

Figure 5-17 and Section VI,

28 December 1965

pf,

40%

Add C237: C: fxd, cer, 0.1

Mfr. 56289; Mfr. Part No. 33C41.

+12.6VF and CR209.

CR201: Change to @ Stock

)

No.

-20%, 50VDCW; @ Stock No. 0150-0084;

(Connects between ground and junction

1901-0050; Diode: silicon; Mfr. 28480; Mfr.

of

Part

No.

1901-0050.

CR210, CR212, CR216: Change to

($3

Stock No. 1901-0040; Diode: silicon; Mfr. 28480;

Mfr. Part No. 1901-0040.

CR219: Change to

@I

Stock No. 1901-0025; Diode: silicon; Mfr. 28480; Mfr. Part

NO.

1901-0025.

CR220: Change to @ Stock No. 1902-0068; Diode: breakdown, 80.6V, 5%; Mfr. 28480;

Mfr.

Part

CR221: Change to

Mfr.

Q207: Change

Mfr.

348-

No. 1902-0068.

@

Part

No. 1902-0074.

to

($3

Part

or

above.

Stock No. 1850-0091; Transistor: germanium, 2N2048; Mfr. 56289;

No. 2N2048. Note:

Stock No. 1902-0074; Diode: breakdown, 7.15V, 5%; Mfr. 28480;

Do

not change Q207

if

instrument

serial

Prefix

is

Page 8

203210222-

1

2

1,

1.thru

Manual Changes Model 185B

250- lthru6

317-

317-00901

3

01000

1

thru

1

thru

thru

7

8

Page

6/9

432-

1

thru

1

thru 12

1

thru 14

11

23024 5-

CHANGE 8

CHANGE 9

CHANGE 10

1

thru 4

lthru5

Figure 5-29 and

Q418, Q419:

Mfr.

Section VI,

Change to

Part

No. 1850-0040.

$9

Stock No. 1850-0040; Transistor: 2N383; Mfr. 28480;

Tables 6-1 and 6-2,

C402: Change to

CR136: Change

$9

Stock No. 0180-0164.

to

@

Stock No. 1901-0050.

Figure 5-17,

A

Q207: Change type to 2N2635.

Figure 5-26 (as modified by CHANGE 2),

pf);

Add: electrolytic capacitor C618 (3000

R613/L607 junction and ground (observe polarity). C618

connects between +12.6VF

is

clamps to left-side gusset below CALIBRATOR switch. Wire from

board A602

is

BRN/ORN.

mounted

at

right of

by

+

lead to

cable

Tables 6-1 and 6-2,

Add C618:

Mfr. 56289; Mfr.

Q207: Change to @ Stock No. 1850-0158; Transistor: GE, PNP, 2N2635; Mfr 04713.

A

(Replacement for discontinued item.

($3

Stock No. 0180-0271; C: fxd, elect, 3000

Part

No. 34D308H015JT4.

)

(EIA

type 2N2048 may

pf,

-10% +loo% 15VDCW;

if

used

available.

Figure 5-13,

C160 (added in CHANGE 1): Change value to 2.2

pf.

Add: C161 (200 pf); capacitor connects between ground and junction of R147/CR137.

Figure 5-26,

to

2.2

C615 (added in CHANGE 1): Change value

fl.

Tables 6-1 and 6-2,

C160, C615: Change to

Mfr. 56289;

Mfr.

Add C161: C: fxd,

($3

Stock No. 0160-0128; C: fxd,

Part No. 5C15.

cer,

200 pf, 5%, 500VDCW; Mfr. 56289; Mfr.

cer,

2.2

1.4

20%, 25VDCW;

Part

No. 40C.

)

CHANGE

11

CHANGE 12

28 December 1965

Figure 5-13,

C130: Change value to 56 pf.

C159: Change value to 3300

Q102: Change transistor type

pf.

to

special 2N1310,

R142: Change value to 47K.

Tables

6-1 and 6-2,

C130: Change to

Mfr. 28480; Mfr.

C159: Change to

@

Stock No. 0140-0081;

Part

No. 0140-0081.

@

Stock No. 0150-0079; C: fxd, 3300

Mfr. 15450; Mfr. Part No. 811-000-Y5F0332K.

Q102: Change to

Mfr.

Part

R142: Change to

Mfr. 01121;

@

Stock No. 1851-0036; Transistor: special 2N1310; Mfr. 28480;

No. 1851-0036.

@

Stock No. 0686-4735; R: fxd, comp, 47K ohms, 5%, 1/2W;

Mfr.

Part

No. EB 4735.

Figure 5-29 and Section VI,

F405: Change to

@

Stock No. 2110-0067; Fuse: cartridge, 0.3 amp; Mfr. 28480;

Mfr. Part No. 2110-0067.

($3

C:

fxd, mica, 56

Stock No. 1851-0036.

pf,

18,

500VDCW;

pf,

IO%,

500vDCW;

Page 9

Manual Changes Model 185B Page 7/9

Circuit

1

1,

2

1

thru 3

1

thru 4

1

thru 5

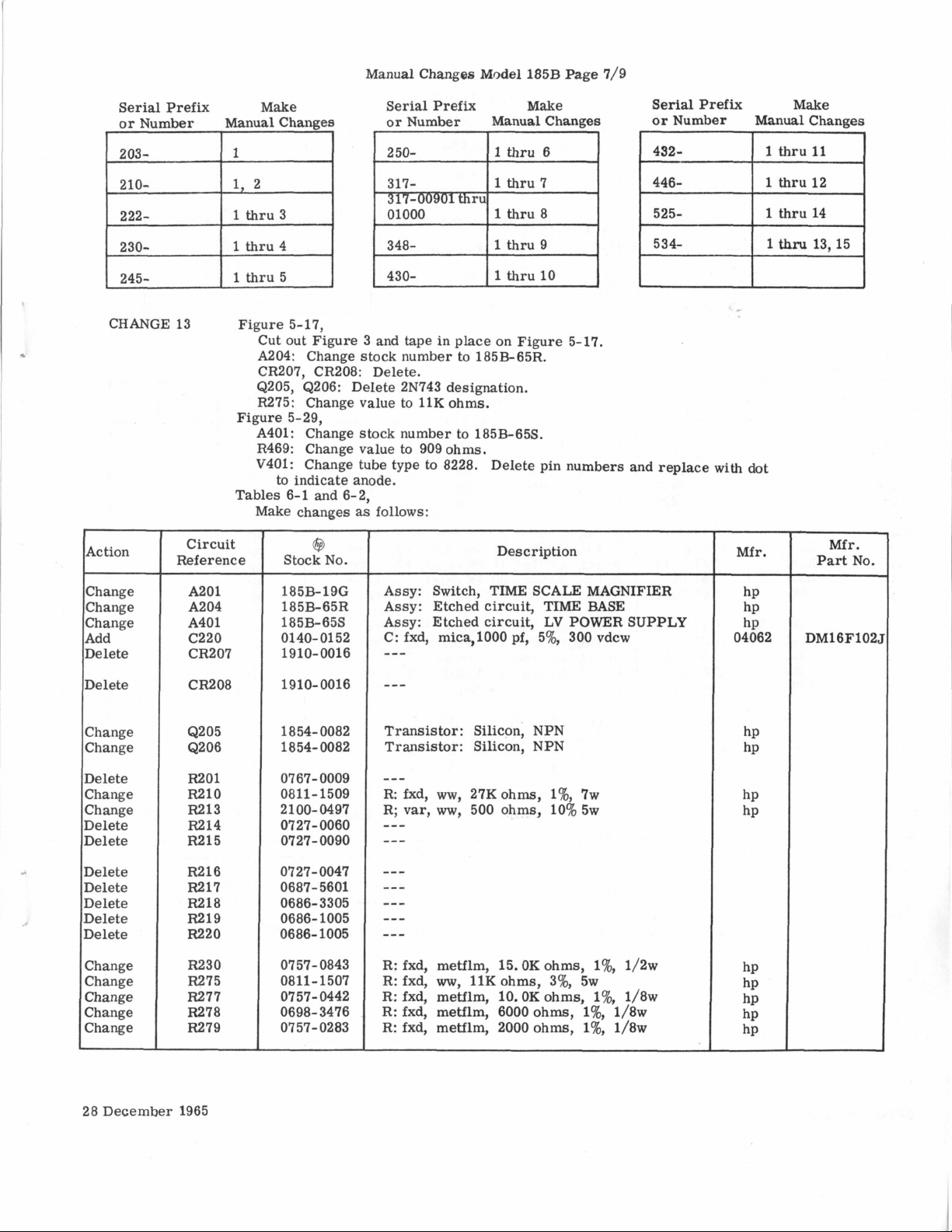

Cut out Figure

A204: Change stock number to 185B65R.

CR207, CR208: Delete.

Q205, Q206: Delete 2N743 designation.

R275: Change value to 11K ohms.

Figure 5-29,

A401: Change stock number to 185B-65s.

R469: Change value to 909 ohms.

V401:

Tables 6-1 and 6-2,

Make changes

203210222230245-

CHANGE 13 Figure 5-17,

Action

Reference

Serial

or Number

430-

3

and tape in place on Figure 5-17.

Change tube type to 8228. Delete pin numbers and replace with dot

to

indicate anode.

as

follows:

Prefix

2

50-

317317-00901 thru

01000

348-

@

Stock No.

Make

Manual Changes

I

1

thru 6

I

1

thru

7

1

thru 8

1

thru 9

1

thru

10

Description

1

a

Serial

or

I

432-

I

446-

Prefix

Number Manual Changes

I

I

I

Mfr.

Make

1

thru

1

thru 12

1

thru 14

1

th~

11

13.15

Mfr

Part

.

No.

Change

Change

Change

Add

Delete

Delete

Change

Change

Delete

Change

Change

Delete

Delete

Delete

Delete

Delete

Delete

Delete

Change

Change

Change

Change

Change

A201

A204

A401

c220

CR207

CR208

Q205

Q206

R201

R210

R213

R214

R215

R216

R217

R218

R219

R220

R230

R275

R277

R278

R279

185B- 19G

18

5B- 6 5R

18 5

B- 6 5s

0140-01 52

1910- 001 6

1910- 0016

1854- 0082

1854- 0082

0767- 0009

0811-1509

2

100- 0497

0727-0060

0727-0090

0727-0047

0687- 5601

0686-3305

0686- 1005

0686-1005

0757-0843

0811- 1507

0757-0442

0698-3476

0757-0283

Assy: Switch, TIME SCALE MAGNIFIER

Assy: Etched circuit, TIME BASE

Assy: Etched circuit,

C: fxd, mica,lOOO pf, 5%, 300 vdcw

LV

POWER SUPPLY

---

---

Transistor: Silicon, NPN

Transistor: Silicon, NPN

---

R

fxd,

ww,

R; var,

27Kohms,

ww,

500 ohms, 10% 5w

176,

7w

---

---

R: fxd, mefflm, 15.OK ohms,

R: fxd,

R: fxd, mefflm, 10. OK ohms,

R: fxd, mefflm, 6000 ohms,

R: fxd, mefflm,

ww,

11K ohms, 3%, 5w

2000

ohms,

l%,

1%

176,

1%,

1/2w

1/8w

1/8w

1/8w

DM16F102;

28 December 1965

Page 10

1

thru

1

thru 4

Manual Changes Model 185B Page 8/9

Serial

Prefix

or Number Manual Changes

3

317-00901 thru

01000

348430-

Make

1

thru8

1

thru

1

thru 10

Serial Prefix Make

or Number Manual Changes

1

thru

11

1

thru 12

1

thru 14

1

thru

9

13,15

1

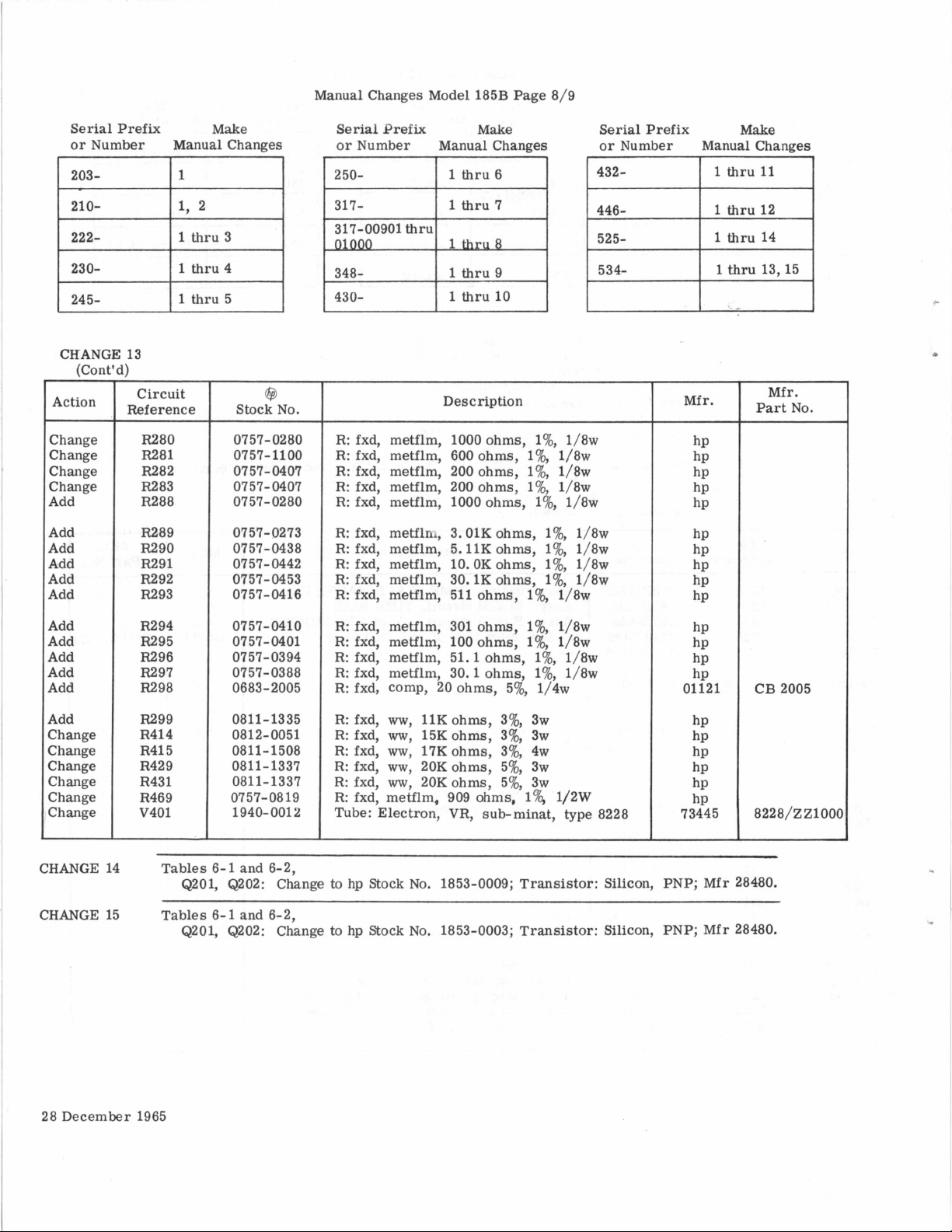

CHANGE 13

(Cont'd)

~~

Action

Change

Change

Change

Change

Add

Add

Add

Add

Add

Add

Add

Add

Add

Add

Add

Add

Change

Change

Change

Change

Change

Change

Circuit

Reference

R280

R281

R282

R283

R288

R289

R290

R291

R292

R293

R294

R295

R296

R297

R298

R299

R414

R415

R429

R431

R469

V401

@

Stock No.

0757-0280

0757-1100

0757-0407

0757-0407

0757-0280

0757- 0273

0757- 0438

0757- 0442

0'757-0453

0757-0416

0757-0410

0757-0401

0757- 03 94

0757-0388

0683-2005

081

1

-

13

35

0812-0051

0811- 1508

0811-1337

0811-1337

07

57- 08 19

1940-0012

Description

R: fxd, metflm, 1000 ohms,

R: fxd, metflm, 600 ohms,

R: fxd, metflm,

R: fxd, metflm,

R: fxd, metflm, 1000 ohms,

R: fxd, meffln,,

R: fxd, mefflm, 5.11K ohms,

R: fxd, metflm,

R: fxd, mefflm,

R: fxd, metflm, 511 ohms,

R:fxd, metflm, 301 ohms,

R: fxd, mefflm, 100 ohms,

R: fxd, mefflm, 51.1 ohms,

R: fxd, metflm, 30.1 ohms,

R: fxd, comp, ZOohms, 5%, 1/4w

R: fxd,

R: fxd,

R: fxd,

R: fxd,

R: fxd,

R: fxd, mefflm, 909 ohms,

Tube: Electron, VR, sub-minat, type 8228

ww,

ww,

ww,

ww,

ww,

200

ohms,

200

ohms,

3.01K ohms,

10. OK ohms,

30.1K ohms,

11K ohms, 3%, 3w

15K ohms, 3%, 3w

17Kohms,

20K ohms, 5%, 3w

ZOKohrns, 5%, 3w

1%,

1%,

1%,

I%,

I%,

l%,

1%,

17%

1%,

1%,

3%, 4w

17%

1/8w

1/8w

1/8w

1%,

1%,

1%,

I%,

1/8w

1/8w

1/8w

1/2W

1/8w

1/8w

1/8w

1/8w

1/8w

1/8w

1/8w

1/8w

Mfr.

Mfr.

Part No.

CB

2005

8228/ZZlOOO

.

CHANGE 14

CHANGE 15

28 December 1965

I

i

~

Tables 6-1 and 6-2,

Q201,

Q202:

Tables 6-1 and 6-2,

Q201, Q202: Change to hp Stock No. 1853-0003; Transistor: Silicon, PNP; Mfr 28480.

Change to hp Stock No. 1853-0009; Transistor: Silicon, PNP; Mfr 28480.

Page 11

Serial Prefix Make

or Number Manual Changes

222-

1

thru

3

25031

-1

01

7-

000

thri.

1

1

1

thru

thru

thru

6

7

8

Serial Prefix Make

or Number Manual Changes

1

thru

11

1

thru

12

1

thru

14

230245-

CHANGE

(Cont’d)

13

I

1

1

thru

thru

4

5

348- 1

430- 1

CUT 4LONG DOTTED LINE

1-

- - - - - - - - -

CUT 4LONG DOTTED LINE

thru

thru

- -

9

10

I

534-

1

1

thru

13 , 15

1

28

December

1965

Figure

3

I

I

I

I

I

I

I

-1

I

Page 12

OPERATING AND

SERVICE

MANUAL

MODEL

SERIALS

PREFIXED:.

1856

144-

OSCILLOSCOPE

Copirieht

1501

?AOE

WEWlE??-?ACKAID COHPANY

MI11

ROAD.

PA10 AllO. CALIFORNIA,

1961

U.S.A.

Page 13

Table of Contents

Model

185B

TAB18

Section Page

I GENERAL INFORMATION

1.1

.

Introduction

1.3

.

Options

1.6

.

Instrument Identification

1.8

.

Description

1.14

.

Cathode-Ray Tube Warranty

II

PREPARATION FOR USE

.

Incoming Inspection

2.1

2.2

.

2.4

.

2.6

.

2.8

.

2.10

.

2.12

.

Installation

.

2.13

.

2.16

2.18

.

2.20

.

Associated Equipment Available

2.22

.

Reshipment

III

OPERATINGINSTRUCTIONS

Introduction

3.1

.

Front Panel Controlsand Connectors

3.4

.

Rear PanelConnectors

3.6

.

The Principle of the Sampling

3.8

.

Triggering the Model

3.13

.

3.14

.

General

3.17

3.27

3.30

3.31

3.35

3.37

IV

PRINCIPLESOFOPERATION

4-

4.4

4.5

4.7

4.9

4.13

4.17

4.19

4.21

4.23

4.26

4.31

4.32

4.34

4.36

Triggering Methods

.

Effects of FM and Jitter

.

.

Pulse

.

Observation of Intermittent Pulses

.

Examining Pulse Irregularities

.

Operating Instructions

1

.

Introduction

.

BlockDiagram Description

.

General

.

Input Circuits

.

Ramp-GateGenerator

.

Time-Base Circuits

.

Calibrator

.

Vertical Amplifier

.

Horizontal Amplifier

.

Time.BaseDetermination

.

TunnelDiode Operation

.

Triggering Circuits

.

General

.

Trigger Input

.

Ramp-Gate Generator Circuits

.............

MechanicalInspection

Power Requirements

230-Volt Operation

Three-Conductor Power Cable

Operational Check

Cooling

Cabinet Mount

Rack Mount

Oscilloscope

Electronic Switch

............

............

Analysis

............

............

........

...........

.....

...........

....

........

........

.....

......

.......

.......

...........

.........

..........

...........

...........

..........

..........

...........

.........

...........

.........

......

......

185B

....

......

......

......

......

....

.....

......

arid

.......

......

.....

......

.......

.

.

. .

.

.

.

OF

1-1

1-1

1-1

1-1

1-1

1-3

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-2

2-2

3-1

3-1

3-1

3-3

3 -4

3-4

3-4

3-5

3-6

3-6

3-6

3-6

3-6

4-1

4-1

4-1

4-1

4-1

4-1

4-1

4-2

4 -2

4-2

4-2

4-2

4-3

4-3

4-3

4-4

CONTENTS

Section Page

IV PRINCIPLES OF OPERATION (Cont'd)

4.46

.

Ramp-Gate Extender

Voltage Generator Circuits

4.54

.

Time-Base Circuits

4.56

.

Comparator

.

4.66

4.71

4.77

4.81

4.87

4.95

4.96

4.101

4-103.High-Voltage

4.106

V

MAINTENANCE

5.1

5.3

5.5

5.6

5.8

5.10

5- 12

5.15

5.17

5 . 30

5.31

5.34

5.37

5.41

5.43

5.45

5.47

5.51

5.53

5.57

5.59

5.67

5.68

5.69

5.70

5.72

5.73

5.75

VI

REPLACEABLE PARTS

6.1

6.4

Time Scale/Time Scale

Relationship

.

Delay Circuits

.

Comparator Blocking Oscillator

.

Horizontal-Scancircuits

.

Calibrator

.

Vertical Amplifier

.

General Operation

.

Transients

.

Low-Voltage Power Supplies

.

Introduction

.

Test InstrumentsRequired

.

Periodic

.

Cleaning

.

General Maintenance

.

Cabinet Removal

.

Troubleshooting

.

System Troubleshooting

.

SectionalTroubleshooting

.

Repair

Access

.

and Fan Motor

.

Replacement of Semiconductors

.

Servicing Etched Circuit Boards

.

CRT Replacement

Adjustment Following Repair

.

.

Adjustments

Low-Voltage

.

.

High-Voltage

.

Vertical Amplifier

.

Sync Circuit

.

Time Base

.

Performance Check

.

Time Calibrator

.

Sync Pulse

.

Amplitude Calibrator

.

Time Scale

.

Minimum Delay

.

Trigger Sensitivity

.

Introduction

.

Ordering Information

..........

.............

..........

Plower

............

...........

Maintenance

the

Air

.............

to Power Transistors

..........

Power

Power

..........

...........

...........

..........

...........

and

Ramp-

.......

.........

Magnifier

.........

.....

........

.......

Supply

....

...

....

.......

Filter

.....

......

........

.........

....

....

........

......

...

'Supplies

Supply

...

...

.......

.......

........

......

........

.......

.........

.......

.

.

.

.

.

4-6

4-7

4-7

4-8

4-9

4-9

4-10

4-12

4-12

4-12

4-13

4-13

4-13

5-1

5-1

5-1

5-1

5-1

5-1

5-1

5-1

5-1

5-1

5-4

5-4

5-4

5-5

5-5

5-6

5-6

5-6

5-7

5-7

5-7

5-7

5.16

5-10

5-10

5-10

5-10

5-10

5-10

6-1

6-1

6-1

~

ii

01255-1

Page 14

Model

185B

LIST

Of

ILLUSTRATIONS

List

of

List of Tables

Illustrations

Number Title Page

1.1

.

1.2

2.1

2.2

3.1

3.2

3.3

3.4

3.5

3.6

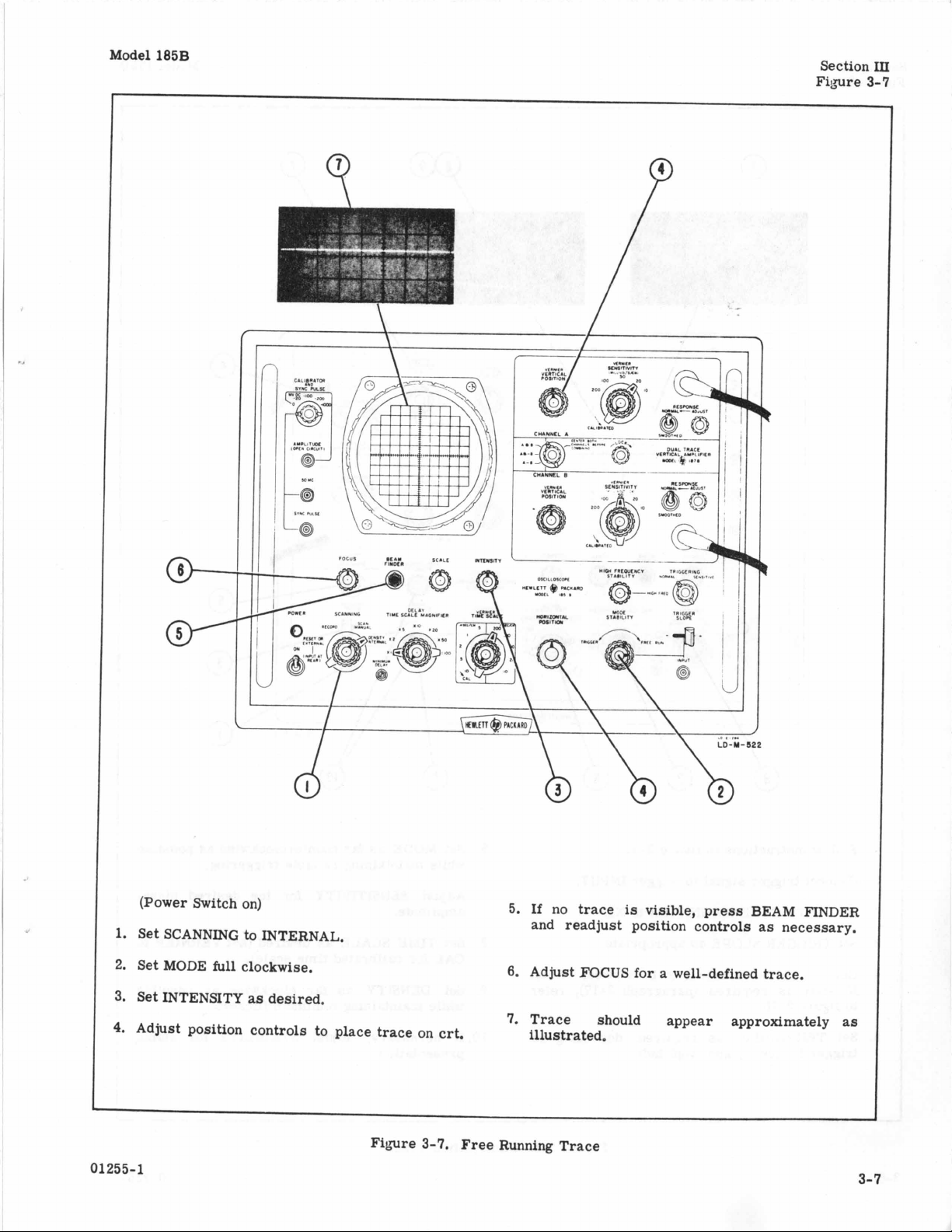

3.7

3.8

3.9

3.10

3.11

3.12

3.13

3.14

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

4.10

4.11

4.12

Model

.

Cathode-Ray Tube Warranty

.

Associated

.

Dimensions for

.

Operating Controls and Connectors

.

Rear Panel Controls

.

Viewing Signals Above

.

Viewing Signals Below

.

Viewing Signals Below

.

Viewing Signals Below

.

Free Running Trace

.

Unmagnified Trace

.

Magnified Trace

.

Viewing Delayed Signal

.

Using Delayed Trigger

.

Delayed Sync Pulse

.

External Scan

.

Recording the Signal

.

Overall BlockDiagram

.

Time-Base Determination

.

Tunnel-Diode Operation

.

Triggering-Circuit Block Diagram

.

Tunnel-Diode Count-Down Circuit

Ramp Generator

.

.

Time-Base BlockDiagram

.

Ramp Voltage vs Time

.

Effects of Delay

.

Staircase Generator

.

Vertical Amplifier Block Diagram

.

High-Voltage Power Supply

185B

Oscilloscope

Dual-Trace Vertical Plug-In

($9

Equipment Available

Rear

with

Support

.........

10

kc

10

kc by Using

Delayed Trigger

SYWC

PULSE OUT

Circuit under Test

Block Diagram

...........

10

kc by Using

..........

10

kc when the

..........

.........

..........

...........

........

........

..........

............

.........

.....

....

....

........

.....

........

......

.......

Model

187B

Unit

.

.

1-0

......

...

.....

...

......

...

...

...

...

...

...

...

...

...

...

...

...

...

1-3

2-0

2-3

3-0

3-2

3-5

3-5

3-5

3-5

3-7

3-8

3-9

3-10

3-11

3-12

3-13

3-13

4-0

4-2

4-3

4-4

4-5

4-6

4-8

4-a

4-10

4-11

4-13

4-13

Number Title Page

5.1

.

Driving the Trigger Circuit

.

Trigger Circuit Waveforms

5.2

Disassembly for Power Transistor

.

5.3

Replacement

.

MinimumDelay Measurement

5.4

5.5

.

Calibrator Instrument Setup

.

Top View, Model

5.6

5.7

.

Left Side

5.8

.

Right Side View, Model

5.9

.

Bottom View, Model

.

5.10

5 .ll

5.13

5.14

5.15

5.16

5.17

5.18

5.19

5.20

5.21

5.22 . A602

5.23

5.24

5-25

5.26

5.27

5.28

5.29

5 .30

5.31

5.32 . A302

5.33

A103

.

Waveforms

5.12

.

Parts Location, Switch Assemblies

.

Trigger Circuit, Schematic Diagram

.

A204

.

Waveforms

.

Parts Location, Switch Assemblies

.

Time-Base Circuit, Schematic Diagram

.

A1

.

Waveforms

.

Assembly Location

.

Main Vertical Amplifier,

Schematic Diagram

.

Waveforms

.

Assembly Location

.

Parts Location, Calibrator and Sync Pulse

Switch,

.

Calibrator and Sync Pulse Generator,

Schematic Diagram

.

A401

.

Assembly Location

.

Low-Voltage Power Supply,

Schematic Diagram

.

A301

.

Assembly Location

.

High-Voltage Power Supply,

Schematic Diagram

View,

Component Location

Component Location

and

A2

Component Location

Component Location

S601,

and

A402

Component Location

High-Voltage Rectifier Assembly

............

185B

Model

185B

.............

.............

.............

..........

.............

..........

with Amp1 . Conn

.........

Component Location

..........

.........

..........

......

......

.....

......

........

185B

......

185B

......

.......

.......

...

.

.

.......

...

.....

........

.......

.

5603 . 5-23

.

.

.......

.

........

5-3

5-3

5-5

5-8

5-8

5-11

5-12

5-12

5-13

5-16

5 . 16

5-17

5-17

5-18

5-18

5-18

5-19

5-20

5-20

5-21

5-21

5-22

5-22

5-23

5-23

5-24

5-24

5-25

5-26

5-26

5-26

5-27

LIST

Number Title Page

1.1

.

Specifications

2.1

.

Associated Equipment Available

.

3.1

5.1

5.2

5.3

5.4

01255-1

Methods of Triggering

.

Recommended Test Equipment

.

System Troubleshooting

.

Resistance to Ground

.

Adjustments Following Tube, Transistor,

and

Diode Replacement

............

....

........

.....

........

.........

.......

1-1

2-2

3-4

5-0

5-2

5-4

5-6

Of

TABLES

Number Title Page

5.5

.

Time Scale Adjustments

5.6

.

Condensed Test and Adjustment

Procedure

5.7

.

Amplitude Calibrator Accuracy

.

Time Scale Calibration Check

5.8

6.1

.

Reference DesignationIndex

.

Replaceable Parts

6.2

.............

.......

....

.....

.....

..........

5-8

5-9

5-10

5-10

6-2

6-24

iii

Page 15

Section

Figure

I

1-1

Model

185B

Y

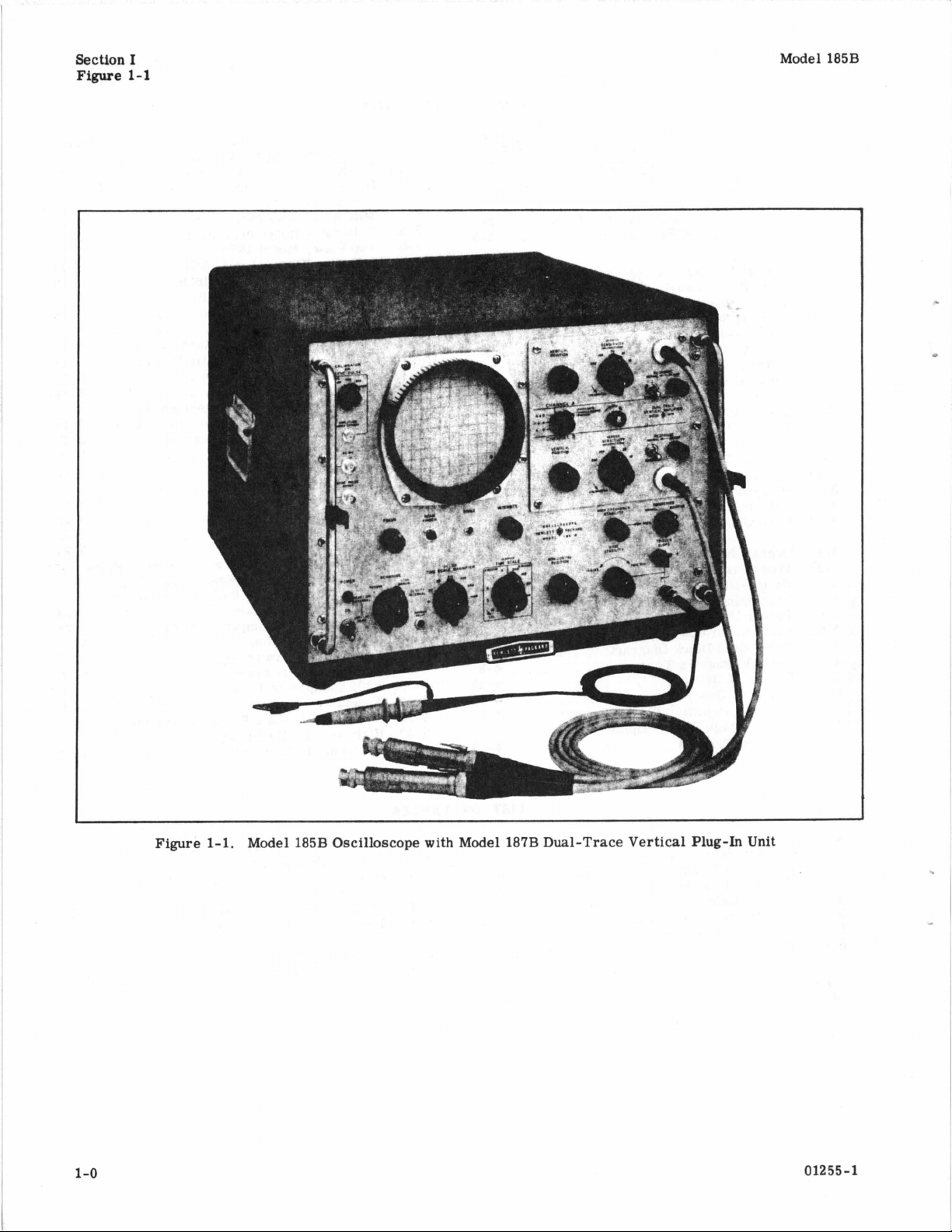

Figure 1-1. Model 185B Oscilloscope with Model 187B Dual-Trace Vertical Plug-In Unit

1-0

~

01255-1

Page 16

Model

185B

Paragraphs

Section I

1-1

to

1-10

SECTION

GENERAL INFORMATION

1-1.

INTRODUCTION.

1-2.

This manual gives operation and maintenance

information for the

An operational check

operation

performance check

specifications during incoming inspection

paragraph

1-3.

1-4.

P2

phosphor with external graticule.

options, however, are available:

a.

b. Option

c. Option

d:

e.

1-5.

option

differences in crt persistence, color, and oscilloscope

photography techniques, instruments with or without

option

are, however,

(see section VI).

in this manual apply to all options unless otherwise indicated.

is

given in paragraph

5-67.

OPTIONS.

The

Model

Option

Option

Option

1.

P1

Internal graticule in cathode ray

3.

7.

P7 phosphor

11.

P11

31.

P31 phosphor

Option

31

1

is

available only with option

3

are operationally interchangeable. There

some differences in component parts

@

Model

to

185B

assure basic instrument

2-10.

that

may be used for verifying

185B

is

normally supplied with

phosphor

phosphor

is

not available with option

All

references to the Model

Oscilloscope.

A

complete

is

given in

The following

tube

3,

3.

Other than

and

185B

I

1-6.

INSTRUMENT IDENTIFICATION.

1-7.

Hewlett-Packard Company uses a two-section

eight-digit serial number (e.g.

first

three digits of the serial number onyour instru-

ment are not

with

this manual which define differences between

your instrument and

sheets are missing, your Hewlett-Packard engineering representative can supply you with the necessary

information.

144-,

change sheets have been supplied

this

a

1-8.

DCSCRl?TlON.

1-9.

GENERAL. The

provides

ena

will

below

spaced.

signal

operate reliably.

above

obtain jitter-free presentation.

1-10.

high speed characteristics

nique. Using this system the entire signal under examination

taken on different occurrences of the input at slightly

later points along the waveform.

a

with repetition rates to

visual display of very high-speed phenom-

present a steady display of pulse repetition rates

100

kc even when the signals are randomly

For frequencies above

is

divided down

100

kc, more uniform spacing

PRESENTATION. The Model

is

scanned, with each succeeding sample

@

Model

so

that the input circuitry will

As

the input frequency increases

by

000-00000).

manual. If

1000

mc. The instrument

100

185B

kc,

is

these

Oscilloscope

the

185B

using the sampling tech-

Each time such a

If the

change

incoming

required

obtains

to

it8

I

HORIZONTAL

Sweep Speeds:

10 ranges,

within

between ranges and increases fastestunmaanified

sweep speedto

sweep

the exception of time represented by

of

the unmagnified sweep.

Magnification:

7

calibrated ranges

and

X100.

speed to

sweep speed

Intensity and sample density are not affected by

magnification.

Delay Control:

Three-turn

when using magnified sweep. Permits any

tion of unmagnified trace

10

nsec/cm

Vernier gives continuous adjustment

&5%.

4

is

maintained at all magnifier settings with

Increases maximum calibrated sweep

0.1

nsec/cm; with vernier, maximum

is

further extended to

variable delay control

to

10

psec/cm, accuracy

nsec/cm. Accuracy of the basic

X1,

X2,

X5,

X10, X20, X50,

0.04

is

to

be

viewed on screen.

01255-1

Table

first

nsec/cm.

available

1/4

por-

1-1.

Specifications

cm

Minimum Delay (input trigger

Less than

faster. On slower sweep

lay increases to

5

psec on the lO-psec/cm range.

Sample

Continuously adjustable from approximately 70

samples per trace

Scanning Functions:

Internal

for normal viewing.

Record

approximately

Manual

knob.

External

approximately

input impedance greater than

120

Density:

-

X

-

X

-

X

-

nsec at

a

maximum of approximately

to

axis

driven

axis driven by internal slow ramp;

60

seconds for one trace.

axis driven by manual scan control

X

axis

driven

12

volts for 10-cm deflection,

to

start

100

nsec/cm sweep and

speeds,

1000

by

by

minimum de-

samples per trace.

internal staircase

external voltage;

25,000

Specifications cont'd

of trace):

ohms.

1-1

Page 17

Section

Table

I

1-1

(cont‘d)

1-1.

Table

“RIGGER FUNCTIONS

Normal-External Trigger

to

Amplitude: 450 mv

volts rms or 100 volts peak will not damage

input circuit.

Width: 5 nsec at minimum amplitude.

Rate:

50 cps to 1 mc

speed setting. Maximum

100 mc on the 200 nsec/cm

Jitter:

Input Impedance: 50 ohms nominal

Sensitive-External Trigger

Amplitude: *15

Width:

Rate: Same as normal

Jitter:

Input Impedance: 50

High Frequency

Input Frequency: 50 to

Sensitivity: 200 mvpeak-to-peak. Operates from

Jitter: 4% of cycle from 50 to 400 mc;

Signal at Input Connector: Less than 15 mvpeak-

Input Impedance: 50 ohms nominal, ac coupled.

SYNC PROBE

The 185B-21A (use with any trigger function) in-

creases input impedance to more than 7500

ac coupled; reduces sensitivity by approximately

4:l at 10 mc and higher and by approximately 20:l

at

low frequencies.

SYNC PULSE OUTPUT

Amplitude: Positive; at least 1.5 v into 50 ohms

Rise Time: Less than 2 nsec

Width: Approximately 5 psec

Recurrence: One pulse per sample

CALIBRATOR

Voltage:

20 mv, 100 mv,

Time:

Approximately 5 psec burst of 50 mc sinewave.

Frequency accuracy

Less than 0.03 nsec or 0.02% of the time

represented

ever

is

approximately 5:l in the “smoothed” response

position.

Reflection from step of

by

greater (fast rise Signals). Reduced

to

rms or 10 volts peak

circuit.

5 nsec at minimum amplitude

Same as normal

of 200 nsec/cm

smaller signals at some increase in jitter. Up

to 5 volts rms or 15 volts peak will not damage

input circuit.

from 400 to 1000 mc

to-peak, approximately 10 mc

Reflection from step of

less than 8%.

i2 volts peak. Up

on

the lO-Fsec/cm sweep

rate

increases

and

faster

the

unmagnified speed, which-

1/2

nsec

is

*200 mv peak. Up to 5 volts

will

not damage input

ohms

nominal, dc coupled

1000

mc forsweepspeeds

and

faster

1/2

nsec rise time

200

mv, and 1000 mv;

dc

less

8%

rangee.

coupled.

than

of Cycle

*2%.

Specifications (cont’d)

X-Y

RECORDER OUTPUT

X-

and

to

5

to

8%.

is

ohms,

&

minals in all positions of the scanning control. In

the

MANUAL and RECORD positions the voltage

can

be

ventional

Horizontal Output: Approximately

of sweep

v/cm).

Vertical Output: Approximately

graticule,

impedance approximately 1,000 ohms.

GENERAL

Cathode Ray

5AQ mono accelerator with P2 phosphor normally supplied. 2900-volt accelerating potential,

External Graticule (standard):

Edge lighted with controlled illumination, 10 cm

by

axes have 2-millimeter subdivisions.

Power: 115 or 230 volts

approximately

Dimensions:

Cabinet Mount: 14-5/8 inches high, 19 inches

wide, 22-1/8 inches deep

Rack Mount: 12-1/4 inches high, 19 inches

wide, 21 inches deep behind panel

Weight:

Cabinet Mount: Net 65 lb

Accessories Furnished: 185B-21A Sync Probe

Accessories Available:

185A-39A Plug-In Extender

185A-21C Resistive Divider Probe, 5:l division,

185A-21D Resistive Divider Probe,

185A-21E Resistive Divider Probe, 50:l divi-

185A-21F Resistive Divider Probe,

AC-16W 3-ft RG-55 cable for 185A-21C,D,E,F

Associated Instruments:

187B Dual Trace Vertical Amplifier

187B accessories available:

187A-76A BNC Adapter

187A-76B Type

187B-76C 10:

187A-76D Blocking Capacitor

187B-76E 50-ohm T Connector

Model

Model 908A 50-ohm Coaxial Termination

187B-76F Adapters

187B-76G Probe Socket

Model 213A Pulse Generator,

Model 185B

Y-axis

used to make pen recordings with a con-

signals are available at rear

X-Y

recorder.

to

+13 volts at end of sweep (1.2

Source

impedance approx. 20,000 ohms.

-1

volt at bottom (0.2 v/cm), Source

0

volt

+1

volt at top of

at

ter-

start

Tube:

P1,

P7, and

10 cm, marked in centimeter squares. Major

300

250 ohms

sion, 500 ohms

sion, 2500 ohms

sion, 5000 ohms

llOOA

nsec

rise

time k350 mv amplitude

P11

watts

N

Adapter

1

Divider

Delay Line

phosphors available.

*IO%,

50 to

less

60

1O:l

divi-

1OO:l

divi-

than 0.5

cp8,

A.

1-2

01255-1

Page 18

Model

185B

Paragraphs

Section I

1-11

to

1-15

sample

is

taken, the

“spot"

on the

crtis

moved hori-

zontally along the waveform. Thus, a complete pic-

ture of

a

repetitive high speed signal

is

synthesized

by a buildup of image-retaining “dots” on the oscilloscope face

1-11.

The Model

ranging from

nanoseconds per centimeter depending on the

of the TIME SCALE switch. Any part

time scale can

by adjusting the TIME SCALE MAGNIFIER

as

a graph

185B

10

microseconds per centimeter

be

expanded without loss

is

provides

plotted point by point,

10

basic

time

scales

setting

of

this

of

calibration,

switch.

to

10

basic

Built-in time and amplitude calibrators provide a

convenient means

vertical calibration. Intensity of

pendent of duty cycle, and vertical deflection may

adjusted up

185B

to

provides output signals for

of

checking

10

centimeters. In addition, the Model

both

horizontal and

the

trace

X-Y

recorders and

is

inde-

be

provides means for controlling the display either manually or externally.

1-12.

VERTICAL AMPLIFIER. The vertical system

of the Model

such as the Model

185B

includes aplug-in vertical amplifier

187B.

It

is

this amplifier which

determines vertical characteristics such as bandpass,

sensitivity, etc. The vertical plug-in unit

of

the

basic

1-13.

F’igure

185B-21A

Model

Sync Probe shown in

185B

Oscilloscope.

1-1

illustrates the Model

the

figure

with the oscilloscope. The Model

Vertical Amplifier

plug-in unit

Table

1-1

1-14.

CATWODLRAY

1-15.

The cathode-ray tube supplied with the Model

185B

is

is

lists

guaranteed against electrical failure for one

year from the date

Company. The cathode-ray

trated in figure

in the appendix of

is

shown installed, although the

not part of the basic oscilloscope.

the specifications for the Model

TUBE

WARRANTY.

of

sale

by

the

tube

warranty

1-2.

A

sheet

for your use

this

manual.

is

not part

187B

185B.

is

Dual Trace

The

supplied

185B.

Hewlett-Packard

is

illus-

is

included

IEWLETT-PACKARD

01255-1

CO.

PAOC

MILL

ROAD.

PAL0

Figure

ALTO. CALIF.

1-2.

U.S.A.

Cathode-Ray

Tube

Warranty

1-3

Page 19

se~tian

Figure

n

2-1

Model

185B

MODEL

DUAL TRACE

I

CAL AMPL I F I ER

VERT

1878

MODEL 196A/B

OSCILLOSCOPE

CAMERA

MODEL IlOOA

DELAY LINE

MODEL

DELAY

2-0

I

I

I

00A-76

LINE LOAD

A

Figure

2-1.

CONNECTING

Aellociated

@

Equipment

Available

MODEL l85A-76A

SYNC TAKE-OFF

UP

-Y-93

01255-1

Page 20

Model 185B

Section

Paragraphs 2-1

to

II

2-19

SECTION

PREPARATION

2-1.

INCOMING INSPLCTION.

2-2. MECHANICAL INSPECTION.

2-3. Upon receipt of your Model 185B, check the

contents against the packing

strument for any obvious damage received in transit.

If

damage

(Refer

ditional information.)

all re-usable packing material until an operational

check

2-4. POWER REQUIREMENTS.

2-5. The Model 185B requires

115 or 230 volts

which can deliver approximately

2-6. 230-VOLT OPERATION.

2-7.

operated switch

ment. The existing fuse should

2-ampere slow-blow fuse.

Be

erly for the line voltage

power supplies may

switch

2-8. THREE-CONDUCTOR POWER CABLE,

2-9. To protect operating personnel, the National

Electrical Manufacturers' Association (NEMA)

ommends

grounded. This instrument

conductor power cable which, when plugged into an

appropriate receptacle, grounds the instrument. The

offset pin on the power cable three-prong connector

is

the ground pin. To preserve the protection feature

when operating the instrument from

outlet, use

connect the green pigtail to ground.

2-10. OPERATIONAL CHECK.

2-11. The following procedure

for checking basic operation

controls mentioned in the following procedure

shown in figure 3-1. A complete check-out procedure

to

verify specifications

a.

Install the vertical plug-in unit.

gain

to

b.

Turn INTENSITY

c.

Set

100 NSEC/CM,

is

evident, file claim with the carrier.

to

the

warranty sheet in

To

has

been successfully completed.

*lo%,

If

.230-volt operation

is

provided on the rear of the instru-

CAUTION

sure

to

set

the 115-230 volt switch prop-

is

set

to the wrong position.

that

the instrument panel and cabinet

a

three-prong to two-prong adapter and

approximately 50 mv/cm.

full

SCANNING to INTERNAL, TIME SCALE to

DENSITY full clockwise, MODE

list

and inspect the in-

this

facilitate reshipment, keep

single phase,

is

desired, a screwdriver-

be

is

equipped with a three-

of

is

given in paragraph 5-67.

counterclockwise.

manual for ad-

a

power

300

be

to

be

damaged

is

given

the Model 185B. All

source

50

to

watts.

replaced with

used. The

a

60 cps,

if

this

two-contact

as

a

means

Set

vertical

of

rec-

be

are

to

II

FOR

FREE RUN, TIME SCALE MAGNIFIER and CALIBRATOR AND SYNC PULSE OUTPUT switches full

counterclockwise.

d. Center HORIZONTAL POSITION and VERTICAL

POSITION controls.

e.

minutes

vertical plug-in input

f.

pears.

and readjust HORIZONTAL POSITION and VERTICAL

POSITION controls as necessary.

g.

h

mately five cycles of

2-12.

a

2-13. COOLING.

2-14. The Model 185B uses

tem

within the cabinet. The air intake and filter

cated on

ment, choose

of clearance around rear and sides of cabinet..

2-15.

the

be

coated with a

No.

filter

cooling. Refer to paragraph

procedures.

2-16. CABINET MOUNT.

2-17. The Model 185B cabinet mount

instrument.

ated with

plane.

ment to a better viewing angle. Be sure to maintain

clearance required for proper cooling mentioned in

paragraph 2-14.

2-18. RACK MOUNT.

2-19. The standard rack model

rear-support pins and bushings. The bushings

installed on rear flanges. The pins are for use in

mounting the instrument

tended to mate with bushings when instrument

stalled. Do not mount the instrument with only frontpanel screws, particularly

to

any

support pins

securing front panel to rack are not supplied. Install

instrument

USE

Turn the Model 185B on and allow about

for

the instrument

to

Rotate INTENSITY clockwise until a

If

the crt remains

Adjust FOCUS for a

resultant presentation should

The

a

INSTALLATION.

to

maintain tolerable operating temperatures

rear

of instrument. When mounting instru-

a

site

that provides

AIR

air

FILTER. Before operating the Model 185B,

filter,

3

from Research Products Co. In addition, the

should

A

vibration or shock.

located at rear of instrument, should

filter

be

cleaned periodically to insure proper

The instrument

its

front panel in a verticalor near-vertical

bail

is

provided for raising front of instru-

are

shown in figure 2-2. Screws for

as

follows:

to

the 50-mc connector.

50-mc sine wave.

adhesive such

stabilize. Connect the

blank,

press BEAM FINDER

thin,

well-defined

a

forced-air cooling

at

least three inches

as

5-6

for proper cleaning

be

is

is

intended

is

at

installation and are in-

if

installation

Location dimensions for

to

supplied with

trace

approxi-

Filter

a

portable

be

is

two

ap-

trace.

sys-

are

lo-

Coat

oper-

two

are

is

in-

subject

01255-1

2-

1

Page 21

Section

Paragraphs

II

2-20

to

Model 185B

2-23

(9-1

196A/B

Oscilloscope Camera

187B

Dual

Trace Amplifier

1

lOOA

Delay

Line

Sync Take-Off

11OOA-76A

Delay Line

Resistive Dividers

185A-21C

185A-21D

185A-21E

185A-21F

AC-16W

Cable

Load

Use

A

High quality camera for use in

permanently recording oscilloscope

presentations

~~ ~~

A dual-channel vertical amplifier

(plug-in) for Model 185B (shown

installed in figure

Overcomes inherent oscilloscope delay,

allowing

rate

Inserted

line

sumdied

~~

Termination for

(normally suppliedwith Model

system)

~

These dividers provide a means for

obtaining

capacitance input

Delay

(All

cable terminated in 50 ohms)

Connecting

Dividers

rise

pulses

to

to

between

permit sync

with

a

high-impedance, low-

Line

or other 50-Ohm systems.

dividers must

cable

1-1)

times of slow repetition

be

viewed

signal

Model

llOOA

for 185A-21C/F

line

take-off

llOOA

Delay Line

to

Model llOOA

be

used with

and delay

(normally

system)

llOOA

Features

Image

to

object ratio:

(1:

1

available)

Model 196B allows oscilloscope

photograph on either internal

external

I

Sensitivity 4 mv/cm

Badwidth:

1000 mc

Input

2 pf nominal

Rise Time: 0.25

Delay:

Insertion

6

db for both

Termination Resistance: 50

graticule oscilloscopes

DC

to

Impedance:

120

ne

Loss:

channels

l:O.

9

to

200 mv/cm

800mc ueable

lOOK shunted

M

ohma

or

1

to

by

c

3

Division

Input Res.

250 5:

a

500

2500 50:

5000

Ratio

10:

100:

Max

Inpl

VRMS

1

1

1

1

10

15

35

50

J

186A

Switching Time Tester

I

a.

Fabricate a bracket for rear support pins and

fasten pins

b.

c.

port

2-20.

2-21.

is

available from Hewlett-Packard Company

crease the usefulness of your Model 185B. Additional

equipment

in unit. Refer to the manual for operating information

regarding your particular plug-in or contact your

nearest

this

information.

2-2

in

place.

Install

Lift instrument into place, engaging rear-sup-

pins, and secure front panel firmly to rack.

bracket at

ASSOCIATED EQUIPMENT

Figure

2-1 and

is

available for use with the vertical plug-

@

representative and he

rear

table

Measures switching time of transistors,

diodes and tunnel diodes. Teste pulse

response of active and passive net-

works. Triggers Model 185B in

vance of pulse output. Accessory

universal adapter available.

of rack.

AVAILABLE.

2-1 show equipment

will

supply you with

to

that

in-

to

Pulse output: 0.1

Pulse Rise Time:

Pulse Repetition

ad-

2-22.

2-23.

dent, repack the instrument using the following procedure

shipping container, taking

in their original positions. (If

was discarded, more may

Hewle

able,

RESHIPMENT.

If,

after

as

a

a.

If

possible, repack the Model 185B in

tt-

Packard Engine e r ing Representative.)

b.

If

the original packaging material

proceed as follows:

(1) Wrap instrument in heavy paper or plastic.

(2)

Use

around

panel

continuously variable

Collector Supply:

Base

Supply:

I

incoming inspection, damage

guide.

care

be

plenty of packing

all

sides of instrument and protect

with

cardboard strips.

material

20 volts peak

LRss

than 1 nsec

Rate:

5 kc

to

50 kc,

0

to

*SO volts

0

to

+lo

volts

is

its

(at

is

least

original

all

material

not avail-

01255-1

to

replace

the

packing

obtained from your

evi-

pads

4

in.)

I

Page 22

Model

185B

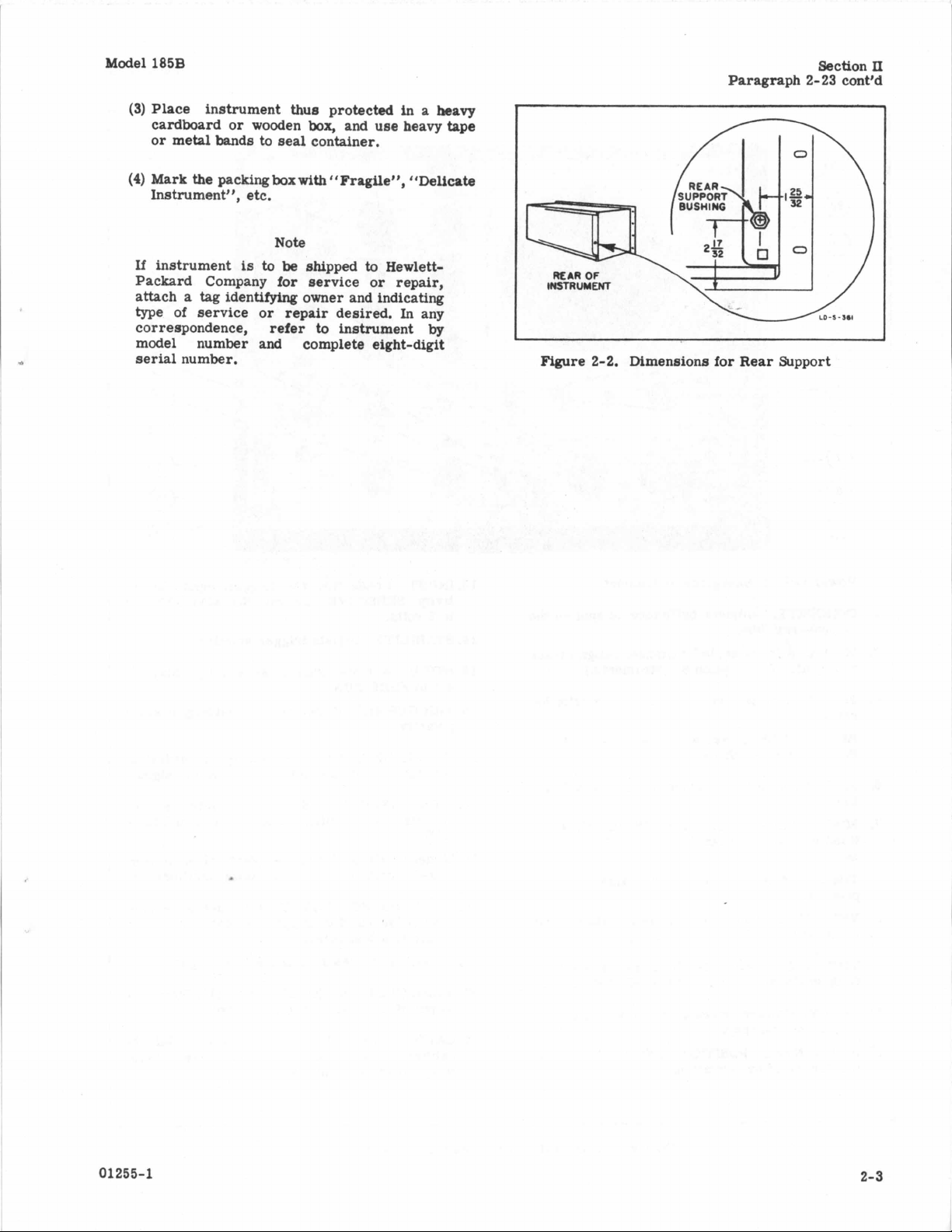

(3)

Place

cardboard

or metal

(4)

Mark the

Instrument”,

instrument thus protected

or wooden

bands

to

packing

seal

box

box,

container.

with

‘‘

Fragile”,

and use heavy tape

etc.

Note

If

instrument

Packard Company for service or repair,

attach

type of service or repair

correspondence,

model number

serial number.

a

is

to

be

shipped

tag

identifying owner and indicating

refer

and

to instrument by

complete eight-digit

to

desired.

in a heavy

“Delicate

Hewlett-

In

any

REAR

OF

INSTRUMENT

Figure

Paragraph

Dimensions for Rear Support

2-2.

Section

2-23

II

Cmt’d

01255-1

2-3

Page 23

Section

Figure

111

3-1

Model 185B

1.

Power switch. Energizes instrument.

2. INTENSITY. Adjusts brilliance of spot on the

cathode-ray

3.

SCALE. Adjusts

with graticule on option 3 instruments.)

4.

FOCUS. Adjusts focus of spot on the cathoderay

tube.

5. BEAM FINDER. Helps locate a presentation

that

is

6.

SCANNING. Adjusts mode of horizontal deflection.

7. SCAN (MANUAL) or DENSITY (INTERNAL).

Used

to

density.

8. TIME SCALE. Adjusts basic time scale of

presentation.

9.

VERNIER. Provides continuously variable time

scale between TIME SCALE ranges.

10.

TIME SCALE MAGNIFIER. Expands

time

scale

11.

DELAY. Enables operator

magnified presentation.

12. HORIZONTAL POSITION. Adjusts horizontal

positioning of presentation.

tube.

scale

brilliance. (Aligns trace

deflected

manually scan display or

off

selected

the

crt.

by

TIME SCALE control.

to

to

adjust scan

the

basic

view any part of

13.

INPUT. Connection for trigger input. Sensitivity: SENSITIVE i200 mv; NORMAL i200 mv

to 2 volts.

14.

STABILITY. Adjusts trigger stability.

15. MODE. Adjusts trigger sensitivity. May

set

to

FREE RUN.

16. TRIGGER SLOPE. Selects desired trigger slope

polarity.

17.TRIGGERING. Set

frequency and amplitude

18. HIGH FREQUENCY STABILITY.

ger stability on HIGH FREQ. position of TRIGGERING.

19.Model 187B

plug-in unit. Not part of

20.SYNC. PULSE OUTPUT. Provides

sync pulse out for triggering

to use as a

21.50 MC. Provides a pulsed 50-mc output.

22. AMPLITUDE DC (OPEN CLRCUIT). Provides

output of four calibrated dc voltages.

23,CALIBRATOR AND SYNC PULSE. Selects

calibrated

to appropriate connectors.

Dual

test

dc

this

switch according

of

trigger signal.

Adjusts

Channel Vertical Amplifier

basic

oscilloscope.

a

test

circuits, or

pulse.

voltages or sync pulse outputs

be

to

trig-

delayed

~~

Figure

3-0 01255-1

3-1.

Operating Controls and Connectors

Page 24

Model 185B

Paragraphs 3-1

Section

to

111

3-5

SECTION

0

P

ERATI

3-1.

INTRODUCTION.

3-2.

This

tion of all controls in the Model 185B Oscilloscope.

If

more theoretical information

Section

3-3. The vertical amplifier system for the Model

185B includes

for operating the plug-in unit are contained in the in-

struction manual for

3-4.

3-5. Figure 3-1 shows

trols and gives a short description of theiruse. Num-

bers

ure

3-1

dicate operational procedure. More detailed information related to

a. BEAM FINDER. Pressing the BEAM FINDER

reduces gain of horizontal and vertical amplifiers to

a point where a “lost” presentation may

adjusted

HORIZONTAL POSITION and VERTICAL POSITION

controls.

b. SCALE. The SCALE control adjusts intensity

of graticule on those instruments provided withanexternal graticule. On internal graticule instruments,

SCALE aligns trace with graticule.

c. INPUT. This connector

chronizing circuits. These circuits insure an exact

time relationship between input signal and moment of

sampling. To operate properly, the sampling oscilloscope

nal that

supply

step

i).

d. TRIGGERING. The TRIGGERING switch may

be

set to SENSITIVE, NORMAL or HIGH FREQ.

pending on amplitude and frequency of trigger signal.

SENSITIVE position

200 millivolts with a frequency below 100 mc. Do not

exceed 10 volts peak input on SENSITIVE position.

NORMAL position

nals (200 mv to

position should be used for trigger signals of

plitudes above 100 mc. The input circuits on HIGH

FREQ. position

1000 mc

circuits.

Do

peak to INPUT when TRIGGERING

SITIVE. Doing

section contains information on the func-

is

desired, refer

IV,

Principles of Operation.

a

plug-in unit. Detailed instructions

that

particular unit.

FRONT PANEL CONTROLS AND

CONNECTORS.

all

front panel operatingcon-

in figure 3-1 are given

to the photograph and do not necessarily in-

these

to

center of cathode-ray tube using the

either

must

be

is

time-related to the input signal, or must

a

sync pulse to trigger circuit under

is

is

2

volts) below 100 mc. HIGH FREQ.

will

so

they may

not connect any voltage exceeding 10 volts

divide down signals

be

CAUTION

so

may damage inputcircuits.

to

relate the

controls

is

accurately triggered by a sig-

used for trigger signals below

used for higher amplitude sig-

used

to

is

listed

be

the input

operate synchronizing

is

on SEN-

N G I

text

in fig-

below:

found and

to

the syn-

test

all

as

high as

to

(see

de-

am-

111

NSTRU

adjusts frequency of count-down oscillator, enabling

it

either positive-going or negative-going slope

signal.

of input circuits

same point on input signal.

full

sync circuits will

at a 100-kc rate.

quency above

near 100

of the input signal.

triggering stability for repetition

by

PUT connector provides

is

With sync pulse from SYNC PULSE OUTPUT connected

in Model 185B

delaying input signal for the purpose of examining

fast

wave output, synchronized with pulse from SYNC

PULSE OUTPUT. Frequency of sine wave

cycles. This signal

reference on the cathode ray tube, or for checking

time

nector provides dc voltages selected by CALIBRATOR

AND SYNC PULSE switch for calibration of vertical

amplifier in oscilloscope. Voltages selected are accurate to within i3$~ of selected value.

when in

sync pulse output and pulsed 50-mc output to appropriate jacks. On other positions of this switch,

voltage

CUIT) connector

mines time

time calibration of

fications when VERNIER control

clockwise.

fine adjustment between any

TIME SCALE switch, resulting in continuous variation

of time scale from

CTI

0

NS

e.

HIGH FREQUENCY STABILITY. This control

to

lock

in

at a submultiple of input trigger frequency.

f.

TRIGGER SLOPE. The TRIGGER SLOPE switch

may

be

used

to

synchronize Model 185B circuits

of

g. MODE. The MODE control adjusts sensitivity

clockwise

kc

h. STABILITY. The STABILITY control adjusts

varying hold-off time in triggering circuits.

i.

SYNC

PULSE OUTPUT. The SYNC PULSE OUT-

delayed 130 nanoseconds from trigger initiation.

to

circuit under

rise

time.

MC. This connector provides

j.

50

scales

k. AMPLITUDE (DC OPEN CIRCUIT). This con-

m. CALIBRATOR AND SYNC PULSE. This switch,

full

is

supplied to AMPLITUDE (DC OPEN CIR-

n. TIME SCALE. The TIME SCALE switch deter-

p. VERNIER. The VERNIER control provides

so

they

will

trigger reliably

If

MODE control

to

FREE RUN position, Model 1858

free

run,

i.e.

sample automatically

If

they

are

triggered withafre-

100

kc,

they

will

but

will

synchronize with a submultiple

test,

is

overcome. The effect

is

valuable for setting up a time

on oscilloscope.

counterclockwise position, connects both

as

explained in step

scale

in nsec or p sec per centimeter. The

this

switch

operate

a

fast

inherent delay (0.1 psec)

is

two

IO

psec/cm to 3 nsec/cm

at

a

frequency

rates

above 100

rise

time pulse

is

similar

a

pulsed sine

is

50 mega-

k.

correct within speci-

is

full Counter-

steps selected

on

trigger

at

the

is

set

kc

that

to

a

dc

by

a

01255-1

3-1

Page 25

Section

Figure

III

3-2

Model

185B

1.

Regulated dc output connector

instruments.

2.

Channel A vertical output voltage

deflection present on

187B). Sensitivity 0.2 volt/cm, Graticule

Center:

3.

Channel B vertical

as

item

0

2.

volt.

For

output.

this

use

for

use with future

for

connector (with Model

with

X-Y

Same

characteristics

vertical

recorder.

-

4. OUTPUT TIME BASE SCAN. Horizontaldrive

voltage

with

Sweep

5. INPUT EXT SCAN. Connect

drive

volts/cm, Input Range:

6.

115-230 Volt Switch.

used.

volt operation, 2-ampere slow-blow fuse

230-volt operation (see section

is

available at

X-Y

recorder. Sensitivity:

Start:

0

volt.

signal

to

this

connector. Sensitivity:

0

Use

4-ampere slow-blow fuse

Set

this

connector.

external

to

12

volts.

to

line voltagebeing

VI).

1.2

volb/cm,

horizontal

for

POWER

CORD

For

use

1.2

115-

for

3-

Figure

2

3-2.

Rear-Panel Controls

01255-1

Page 26

Model

185B

Paragraphs

Section

3-6

to

111

3-7

.

q.

TIME SCALE MAGNIFIER. The TIME SCALE

MAGNIFIER switch

selected by TIME SCALE switch

by TIME SCALE MAGNIFIER switch.

r.

DELAY. The DELAY control selects any part

of unmagnified presentation for magnification;

with delay control you effectively slide cathode-ray

tube along expanded presentation

divides

the value

by

number selected

to

view portion you

that

has

been

i.e.,

want

8.

SCANNING. The SCANNING switch determines

type

of horizontal deflection

point

it

should

beam across the face of the cathode-ray tube

relation

The beam may

of the tube and yet the time

ample,

185B

deflection; they

to

50

provides a choice

(1)

INTERNAL. The time

setting of TIME SCALE and TIME SCALE

MAGNIFIER switches. On INTERNAL, the

beam

of the tube

DENSITY control and sampling frequency.

(2)

MANUAL. On MANUAL position, scanning

accomplished

DENSITY (INTERNAL) control. Manual operation may

sweep

the only visible portion of trace

illuminated by setting of MANUAL SCAN control. The time scale in seconds per centimeter

is

determined again

MAGNIF'IER and TIME SCALE switches. Man-

ual scan

it

is

e.g., when

RECORD. On RECORD position, operation

exactly the same as on MANUAL except

in

very slowly across

time scale determined by setting

SCALE MAGNIFIER and TIME SCALE switches.

RESET OR EXTERNAL. The RESET OR EXTERNAL position

vides a means for resetting scan when oper-

ating on RECORD position,

a

means of scanning with an external signal.

An input connector, INPUT EXTERNAL SCAN,

is

horizontal input,

t.

SCAN (MANUAL) - DENSITY (INTERNAL), The

function of this control depends on setting of SCANNING switch.

NAL, the SCAN (MANUAL)

control adjusts number of samples per centimeter

and hence the density of sample dots

viewer. Reducing scan density

ing up the physical speed of horizontal sweep,

be

emphasized

its

time scale in seconds per centimeter.

take

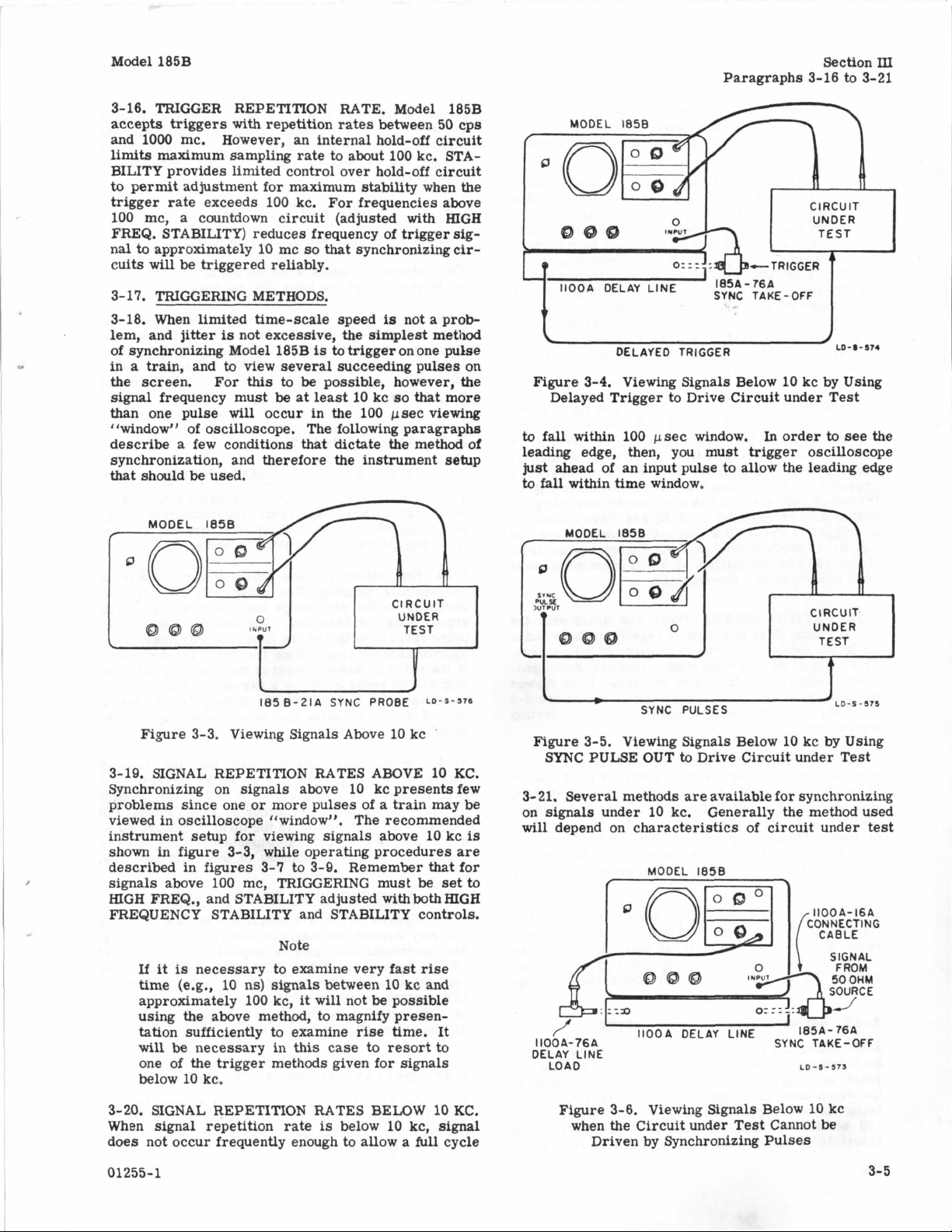

10

nanoseconds per centimeter. The