Page 1

Media Path for a Small, Low-Cost,

Color Thermal Inkjet Printer

The DeskJet 1200C media path is heated for media independence,

requiring development of a new grit drive roller and pinch wheel

combination. A new stepper motor was developed to attain the target

speed and accuracy. Media flatteners and precise gearing with an

antibacklash device contribute to accuracy.

by Damon W. Broder, David C. Burney, Shelley I. Moore, and Stephen B. Witte

The media path is the part of a printer that moves media

past the print cartridges, stopping and accurately locating

the media for printing. The media path also constrains the

media in a plane a fixed distance from the print cartridges. A

media path should advance media accurately and quickly, be

quiet, be inexpensive, hold the media flat, and keep the media

the correct distance from the print cartridges.

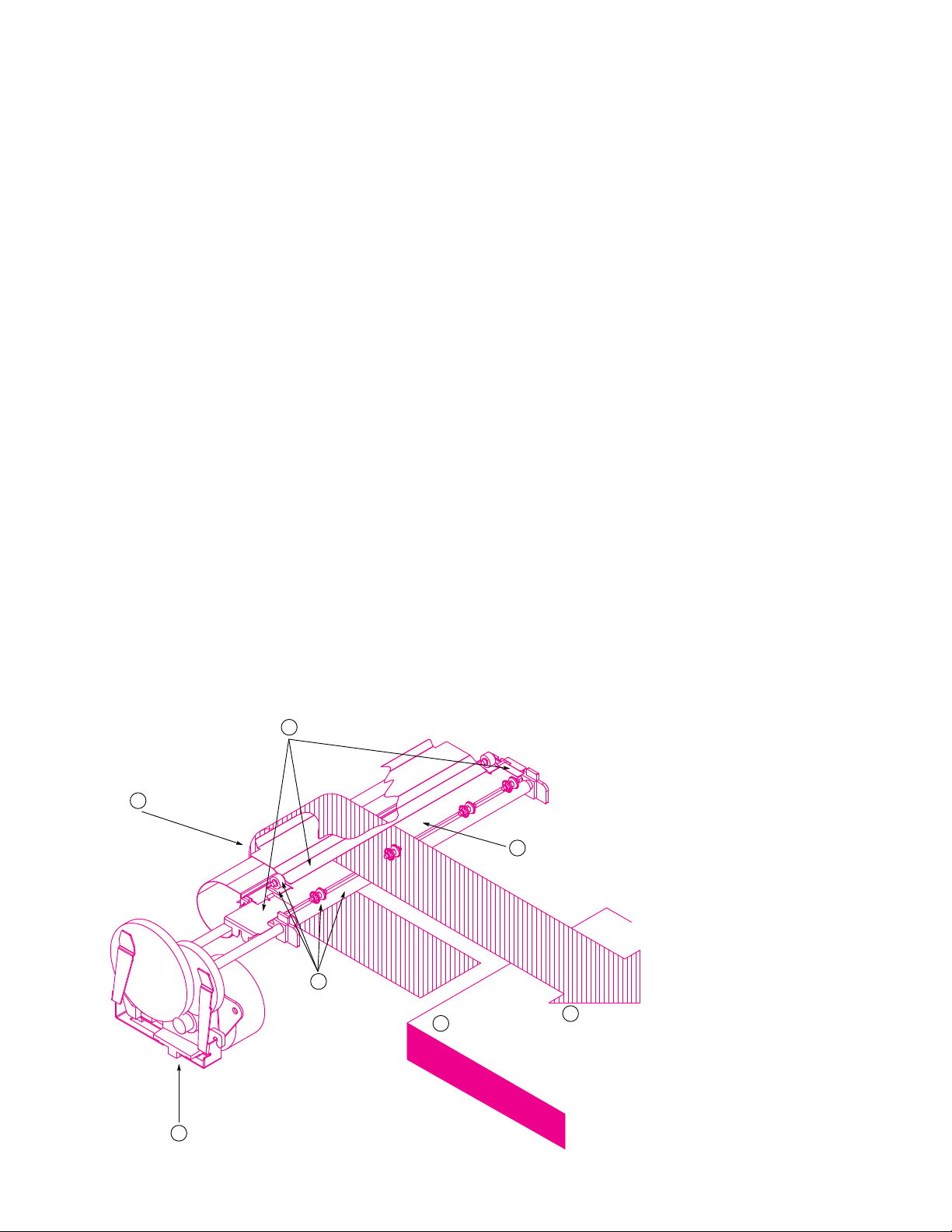

Fig. 1 shows an overview of the media path of the HP DeskJet 1200C printer. Media stacked in the input tray (1) is individually picked by a media pick roller (not shown) and

driven around the curved preheat zone (2) where it is preconditioned (moisture is driven off and the temperature is

raised). When the page reaches the pinch/drive rollers (3),

the main drive system (4) takes over from the pick roller

drive (not shown). Once in the print zone (5) the media is

heated further and ink is sprayed onto the page. The heating,

soaking, and drying causes the media to move out of its

Paper Control Shims

6

Preheat Zone

2

3

Pinch/Drive

Rollers

Main Drive System4

Input Tray

1

plane, but the media control shims (6) help hold it flat for

better print quality. The page is then incrementally advanced

and printed upon until the entire page has been printed.

Finally, the page is fed out into the output tray (7) and the

process is ready to repeat.

Design Approach

For the office printer market, the DeskJet 1200C is designed

to support a wide variety of plain papers, to be HP LaserJet

printer compatible, to print text very quickly, to print highquality graphics, and to be cost competitive. These characteristics forced the design team to face the following challenges:

• Constrain plain papers flat even though plain paper tends to

cockle and curl in various directions when ink is sprayed on

and heated.

• Print to 50-dot row margins for LaserJet compatibility, even

though such small margins allow very little control over

media flatness.

Fig. 1. Overview of the media

path of the HP DeskJet 1200C

printer. Media stacked in the input

tray (1) is individually picked by

a media pick roller (not shown)

and driven around the curved

Print Zone

5

Media Direction

7

Output Tray

preheat zone (2) where it is preconditioned (moisture is driven

off and the temperature is

raised). When the page reaches

the pinch/drive rollers (3), the

main drive system (4) takes over

from the pick roller drive (not

shown). Once in the print zone

(5) the media is heated further

and ink is sprayed onto the page.

The heating, soaking, and drying

causes the media to move out of

its plane, but the media control

shims (6) help hold it flat for better print quality. The page is then

incrementally advanced and

printed upon until the entire page

has been printed. Finally, the

page is fed out into the output

tray (7) and the process is ready

to repeat.

72 February 1994 Hewlett-Packard Journal

Page 2

• Move media very quickly through the print area while main-

taining high placement accuracy for good graphics print

quality.

• Keep the price low.

The parts of the media path (Fig. 1) that drive and meter the

media include the stepper motor, the drive pinions, the drive

gears, the antibacklash device, the shaft bushings, the adjustable plate, the drive rollers, and the pinch rollers. While

driving the media these components work together to ensure fast, accurate movement of the print media, which in

turn provides the best possible throughput.

The stepper motor provides the fastest response available in

an inexpensive motor. Although stepper motors aren’t always the most accurate type of motor, the accuracy of the

system can be optimized by designing the system so that the

motor always moves in multiples of four half steps. Moves

of four half steps cancel out all of the error caused by manufacturing variation except the locations of the stator teeth

which are formed out of the sheet-metal case of the motor.

Used in this way, the stepper motor can provide very fast

and accurate moves and is well-suited for driving the media

in an inkjet printer.

The gearing system in the DeskJet 1200C is designed to optimize the accuracy of the media drive. A single-reduction drive

is used because there are fewer components in the gear train,

so this type of drive is more accurate. However, accuracy is

not the only reason to use a single reduction. The size and

spacing of the drive rollers relative to the print cartridges and

heater also pushed the design towards a single-reduction

gear train. The DeskJet 1200C relies on a heated media path

to dry the ink as it is being printed. To make room for the

heater while maintaining control of the print media, the drive

rollers had to be much smaller than other inkjet printers had

typically used. By using smaller drive rollers, we were able

to use a single-reduction gear train.

The spacing of the drive rollers was a critical issue in the

design of the DeskJet 1200C. The spacing is constrained by

the size of the print cartridges and heater. Thus, we had to

trade off room for the heater and print cartridges against

control over the leading edge (the star wheels hold the media down against the output drive roller) and print quality in

the bottom margins (the main drive roller is more accurate

than the output drive roller). As the space between the rollers increases, there is a longer span of media at the top of

the page to control with the star wheels and a longer space

at the page bottom where the media is driven by the output

roller.

A major problem in reducing the shaft spacing was reducing

the size of the drive roller. Drive rollers in inkjet printers

have typically been rather large elastomer-coated shafts, 40

to 70 mm in diameter. To shrink the roller to a size we could

use (20 mm) we had to find a different process, one that

was new to inkjet printing. We decided to try the grit drive

system used in several HP plotters, which consists of a gritcoated metal drive wheel and an elastomer pinch wheel. By

using a grit system, we could minimize manufacturing errors

associated with the size and shape of elastomer rollers and

reduce the size to one we could use. Of course, we then faced

many problems adapting the grit drive system to a heated

media path system.

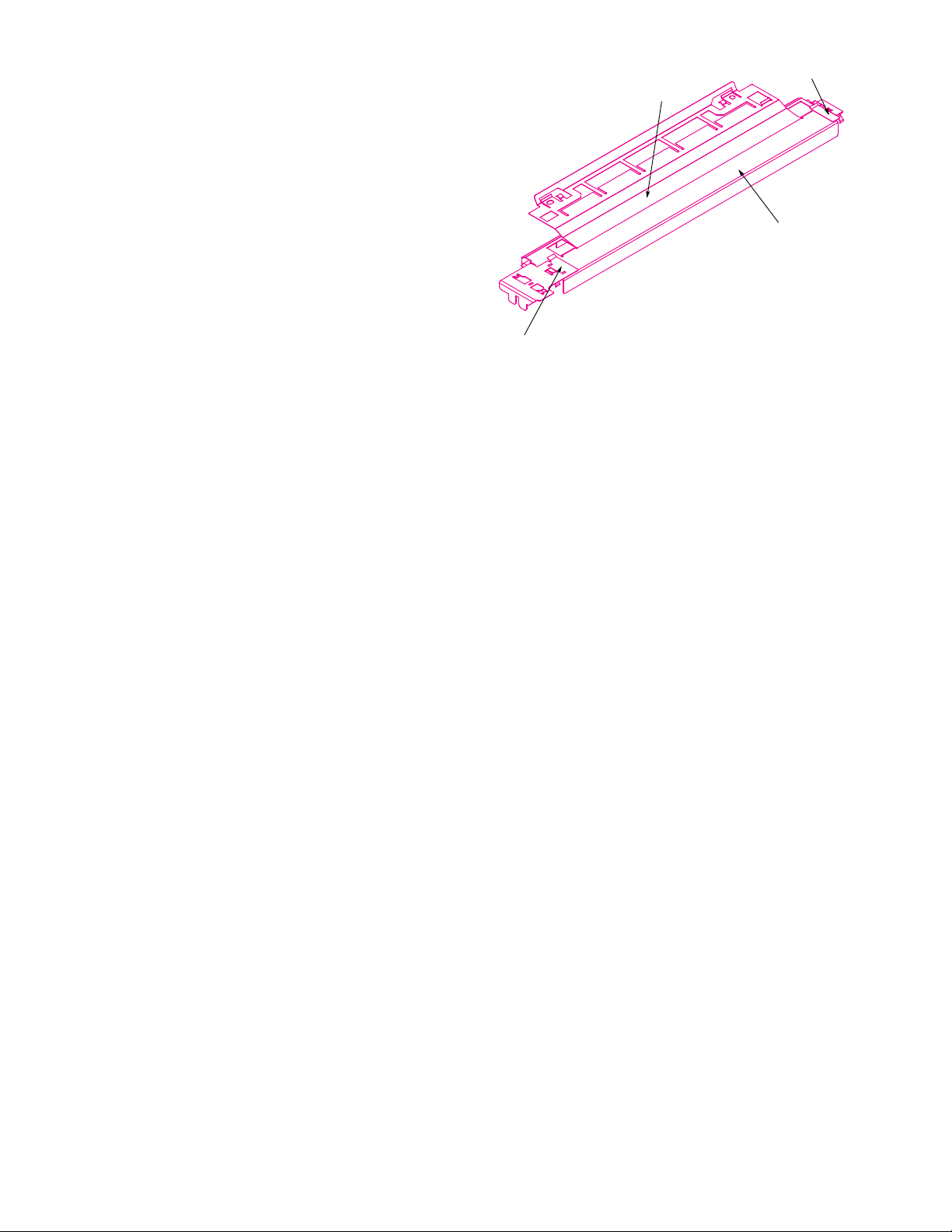

Right Shim

Center Shim

Grill

Left Shim

Fig. 2. A grill and three shims hold the media flat in the print zone.

The media path must also hold the print media flat. The environment in the print region is somewhat hostile to paper.

The ink soaks the paper, and the heater boils the water out

of the paper and dries it out. The DeskJet 1200C is intended

to print on any office paper with nearly equal print quality.

The heater and the ink design help achieve media independence, but at the same time, the heater and ink wreak havoc

with the fibers that make up the paper. The fibers, predominantly cellulose, swell with ink and the paper expands.

Then, as the paper is heated and dried, the fibers shrink and

the media contracts. None of the expansion and contraction

is uniform from one side of the media to the other, so the

media tends to move out-of-plane. To print with high quality,

the distance from the print nozzles to the print media must

be accurately maintained. We hold the media flat against a

grill (which covers the heater) with three shims—center,

left, and right, as shown in Fig. 2. The fixed right shim constrains the right edge of the media and acts as the zero reference point for printing. The adjustable left shim adjusts to A

and A4 sizes while constraining the left edge of the media.

The center shim helps keep the media flat against the grill

and helps keep the media from crashing into the print cartridge. The center shim also allows printing very near the

bottom edge of the media—as close as 5 mm.

As the paper advances out of the print region, we also hold

it down with the star wheels. These systems provide good

control over the media, keeping it constrained in a plane at a

fixed distance from the print nozzles.

Heated Media Path

The DeskJet 1200C was envisioned to support a broad range

of media: not just A and A4 sizes, but also glossy paper,

transparency film, and virtually any paper on the market (at

one point we were even printing on paper bags). With such a

wide range of media as the goal, and the added challenge of

fast throughput, it became evident that the DeskJet 1200C

would need a heated media path to meet these goals with

any kind of reasonable print quality.

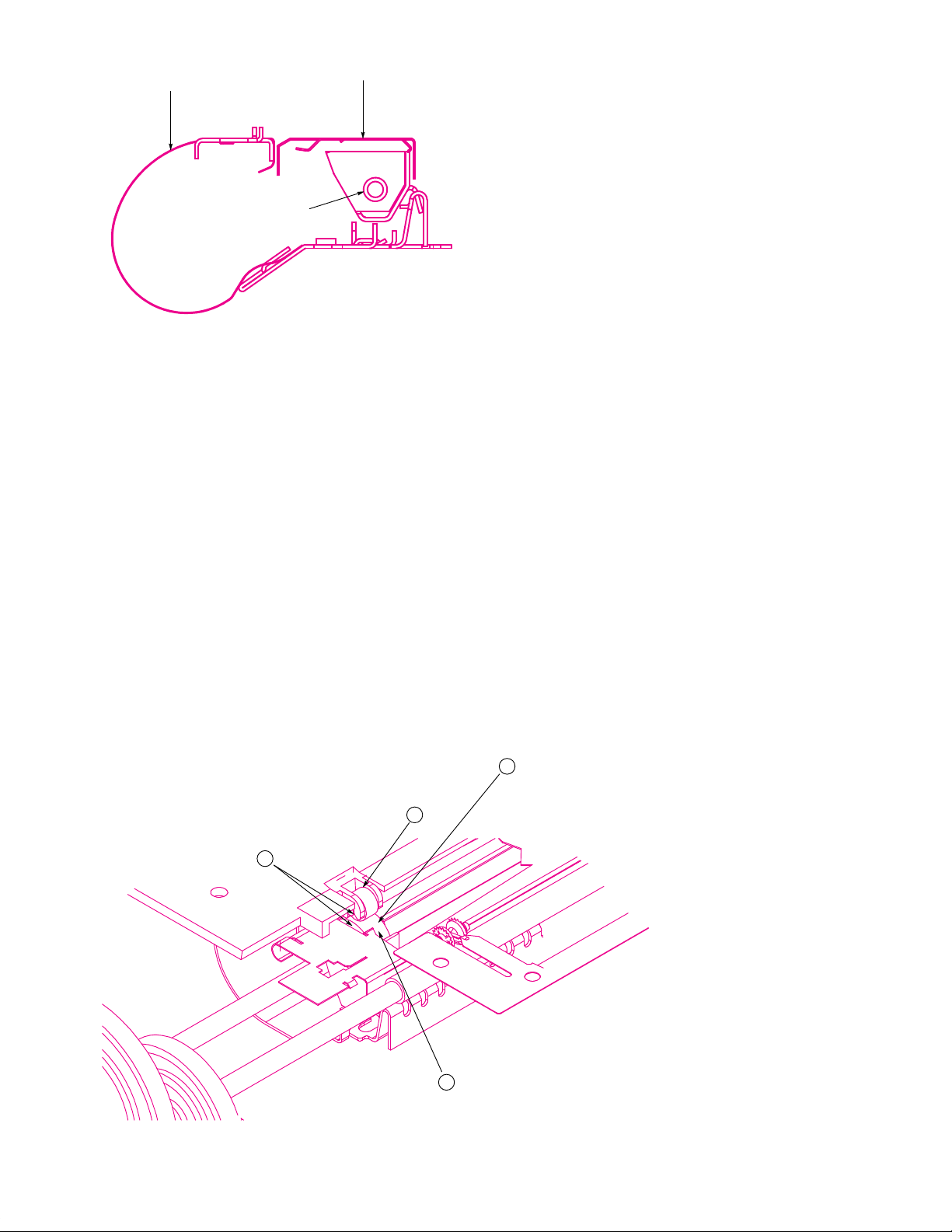

The heated media path of the DeskJet 1200C (see Fig. 3) is

composed of two main components: the preheater and the

main heater. The preheater is a flexible polyimide heater

that serves as the inner guide for the media. As the media is

February 1994 Hewlett-Packard Journal 73

Page 3

Preheater

Main Heater

Fig. 3. Heated media path.

Writing Zone

fed up into the main heater and the writing zone, it is

wrapped around the preheater. This contact allows the preheater to precondition the media so that when the media

reaches the writing zone it is much more dimensionally

stable. Much of the paper fiber shrinkage that occurs with

heating happens before the paper reaches the writing zone.

The main heater consists of a Kanthal wire and a quartz

tube. Current drawn through the wire causes it to heat up

and emit infrared radiation. The radiation and convective

heat from the bulb help evaporate the water from the ink in

the writing zone. This increase in the evaporation rate of the

ink allows increased throughput and improved print quality

over a much broader range of media.

Drive Roller Development

The DeskJet 1200C media advance is controlled by a highpressure nip concept (drive roller and pinch wheel) located

near the left and right media margins (Fig. 4). As mentioned

earlier, this gives a clear advantage in space conservation

and design simplicity over other inkjet products using largediameter drive rollers and low-pressure nip concepts.

A traction surface designed to tolerate thermal shock with a

low thermal expansion needed to be developed. The lowcost, high-quality advance mechanism goals also required a

reliable manufacturing process that would produce 100%

in-specification parts.

The traction surface characteristics were initially defined

from a customer satisfaction viewpoint:

• The combination of nip pressure and drive roller roughness

could not mar transparencies or leave tracks in plain paper.

• The traction surface had to push the media with no slippage.

• Banding had to be controlled much more tightly than before

to meet print quality expectations. This meant that the traction surface had to advance the media consistently a constant distance for a given arc of rotation, that is, the pitch

diameter had to be as tightly controlled as technology would

permit. The printer’s performance could not be adjusted to

compensate for poor control of this specification in manufacturing. Print quality swath banding has a 1:1 correlation

with this assembly.

• The cost had to be low and the process compatible with

high-volume manufacturing.

• The materials selected had to survive with no degradation

of their properties within the thermal operating environment

of the printer.

A fundamental design goal for the Deskjet 1200C drive roller

assembly was to develop a roller surface that would not slip

on any media type. This was approached from a mechanical

friction and traction point of view. Lab tooling adequate to

characterize the traction surface had to be developed quickly.

The reality of our schedule required high-risk decisions with

data lagging by several months.

Concurrent development was started for lab tools, prototypes, and metrics simultaneously. We had to allow the development of the drive roller assembly to slip out of phase

with the rest of the project and get convergence by the time

of the production build.

1

74 February 1994 Hewlett-Packard Journal

3

2

Fig. 4. Drive roller and pinch

wheel. (1) Nip area (drive roller

and pinch wheel), one of two in

the printer. (2) Pinch wheel. The

pinch wheel rolls on the media

above the drive roller to apply

normal loading of the media into

the traction surface of the drive

roller. (3) Drive roller. Rotary

motion of the drive train is converted to linear media motion.

The surface must not slip or leave

tracks in the media. (4) Pitch diameter is twice the radius from

4

the drive axle center of rotation

to the contact zone between the

media and the traction surfaces.

Page 4

Stepper Motor Simulation Model

The model used to simulate a permanent magnet stepper motor for the simulations

described in the accompanying article originated from a classic control systems

point of view. The model includes simple position and velocity feedback control

algorithms. Fig. 1 is a block diagram of the model.

A nonlinear block in the model allows the nonlinear characteristics of the stepper

to be included. This block makes the stepper torque output match the desired

torque for a given error signal.

The resultant nonlinear system was linearized by running it at a very high sample

rate of 40,000 samples per second. At this sample rate, speeds, positions and

currents are changing very slowly. Hence linear control systems analysis is valid.

The model was used to compute velocity profiles with several different motor

resistances, inductances, and so on. The lowest-resistance motor available in a

permanent magnet motor at this time was an 8-ohm motor. Fig. 2* shows that the

Nonlinear Stepper Simulator:

Reference

Generator

Reference

Position

Error

(Torque

+

Desired)

–

Coil Resistance and Inductance

Current Level Maximum

Holding Torque Maximum

Back EMF Feedback

Optimum Switching Time to Match Desired Torque

Half-Stepping and Full-Stepping Modes

simulated velocity clearly does not reach the desired 1400 steps per second. This

motor fails and stalls in the real system. In Fig. 3,* the simulated velocity of a

2-ohm motor is shown. In this successful run, it appears that the motor has no

trouble reaching the desired 1400 steps per second. This motor was built and is

now the motor being used in the DeskJet 1200C printer.

The curre n t s i n a failing stepper motor are shown in Fig. 4* and the currents in a

stable, running stepper motor are shown in Fig. 5.* In the failing stepper motor, the

currents do not even reach their normal operating levels before they are switched

again. The characteristic hook in the graph of these currents reflects reality very

well for the case of insufficient voltage used to drive the motor.

Stephen B. Witte

Development Engineer

San Diego Printer Division

Torque

Delivered

Linear Plant Differential Equations:

Moment of Inertia of Motor and Gears

Acceleration and Velocity of Rotor

Friction

Digital Filter:

Position and

Velocity

Feedback

Sample Time 25 Microseconds

Position

Response

Fig. 1. Block diagram of the theoretical stepper motor model.

The term traction was used to define media slippage with the

drive surface to avoid preconceptions of friction behavior.

(Paper has a composite surface of fibers and fillers that cause

its frictional characteristics to be nonlinear with normal

forces beyond a relatively low surface shear stress.)

The characterization efforts revealed interactions with printer

components not previously considered. Affected components

were redesigned and the traction surface successfully developed in concert with these components. Analytical tools to

measure system and component performance were developed or enhanced by this project. This greatly improved correlation of print quality goals with measured performance

and design specifications.

High-volume processes at multiple suppliers for this assembly

were characterized with proven process margins. Supplier

inspection processes were improved to fit part requirements

and inspection metrics.

Media Motor and Antibacklash Device

The goal for selecting the Deskjet 1200C media axis drive

was to design a motor and gearing system that is simple and

compact and has better speed and accuracy than we had

* See top of next page for Figs. 2, 3, 4, and 5.

ever achieved before. Not only did this new gear drive system

have to have improved performance, but it also had to be

less expensive.

One key element of the media drive system is the motor

selection. The HP PaintJet, PaintJet XL, and PaintJet XL 300

printers use a hybrid stepper motor to drive gear trains that

control two roller media drive systems. These systems have

relatively high inertia and are limited in speed. They also

have multiple idler gears for the purpose of transferring

position control to a different location in the machine. For

the HP DeskJet 1200C printer, a decision was made to use a

double-pinion approach to eliminate the idler gears.

For low cost, we believed that a permanent magnet stepper

combined with an antibacklash device would be as accurate

as the hybrid stepper system. The key issues were: How do

we design a low-cost anti-backlash device? and, How do we

get the speed and torque that we need out of this low-cost

stepper motor?

To determine whether the permanent magnet stepper would

work, a theoretical model was developed that allows the

simulation of the motion of a stepper motor from a standing

February 1994 Hewlett-Packard Journal 75

Page 5

1600

1400

1200

1000

800

600

Velocity (steps/s)

400

200

0

–200

0 0.005 0.01 0.015 0.02 0.025

Time (seconds)

0.8

0.6

0.4

0.2

0

–0.2

Current (amperes)

–0.4

–0.6

–0.8

0 5 10 15 20 25

Time (ms)

30

Fig. 2. Simulated velocity profile of a failing motor (8-ohm).

1600

1400

1200

1000

800

600

Velocity (steps/s)

400

200

0

–200

0 0.005 0.01 0.015 0.02 0.025

Time (seconds)

Fig. 3. Simulated velocity profile of a good (2-ohm) motor.

start through high speed and back down to a stop (see

“Stepper Motor Simulation Model” on page 75). This model

includes the motor, system inertia, inductance, motor resistance, and friction. It also dynamically calculates backEMFs and motor currents.

This simulation predicted that a motor with a resistance of

one or two ohms could run significantly faster than previous

DeskJet motors. Speeds of 2000 full steps per second (2500

r/min) were predicted as possible high-end speeds where

older permanent magnet motors had not been run much

faster then 600 to 1000 steps per second.

A motor vendor was located that would be willing to wind

the motor coils with a heavy-gauge wire and prototype

motors were assembled. These motors performed at the

predicted speeds and astounded the motor R&D engineers

themselves! They previously had not built permanent magnet steppers with this kind of speed capability. This vendor

developed manufacturing processes to produce these lowresistance coils in production and ultimately won the contract to provide HP with these motors for the Deskjet 1200C

printer.

Fig. 5 shows the complete motor, gears, and backlash system.

Fig. 4. Simulated currents in a failing motor.

1.5

1

0.5

0

Current (amperes)

–0.5

–1

–1.5

0 5 10 15 20 25

Time (ms)

Fig. 5. Simulated currents in a stable, running stepper motor.

Fig. 5. The complete motor, gears, and backlash system.

30

76 February 1994 Hewlett-Packard Journal

Page 6

Reducing Stepper Noise. Once we had the speed that we

needed, we had several more hurdles to pass. It was necessary to control the motor and make it start and stop precisely without the noises that normally come from stepper

motors. When the first DeskJet 1200C lab prototypes were

built, people were very concerned about the stepper noise.

Hardware was developed that allows the dynamic response

of both the motor and the gear-driven shaft to be measured.

This hardware was combined with personal-computer-based

software that makes the process of smoothing out the step

profile of the motor relatively easy. Because the designers

had been clever enough to make it easy to download step

times to the printer, it was possible to try out different combinations of step times quickly and observe the response of

the motor and drive shaft visually (in addition to hearing it).

The dynamic response was successfully smoothed out and

the system became much quieter. At the same time, we were

also anticipating problems with overshoot.

Controlling Backlash. Fig. 6 shows the function of the antibacklash device. The purpose of this sheet-metal spring is to

keep the teeth of the gears meshed tightly even if the motor

backs up slightly. If the gears were to become unmeshed,

the resultant accuracy error would be twice as much as all

other error sources combined.

The DeskJet 1200C media axis completes a 1/3-inch swath

advance in under 58 milliseconds. (For comparison, the

PaintJet XL300 completes a 1/6-inch swath advance in about

200 milliseconds.) Hence, it was expected that it would be

difficult or impossible to prevent gear backlash. However,

we came up with a way to reduce this backlash. The idea is

to use a piece of sheet-metal steel that pinches the gears,

adding friction so that when the motor stops and backs up,

the gears follow it backwards. This steel antibacklash device

has three springs built into one component. The first spring

applies a controlled pinch force on the gear. The second

spring is stretched forward every time the motor moves forward and provides the restoring force or antibacklash function. The third spring provides a thrust load that keeps the

plastic gears pushed against the motor mounting plate.

Motor Pinions. One of the most difficult challenges on the HP

DeskJet 1200C printer was to achieve an overall accuracy

goal that was as good as the PaintJet XL300 over twice the

distance of that printer. It turns out that one of the key components in the DeskJet 1200C mechanism is the quality of

the motor pinions. We chose to hob the pinions instead of

molding them because their relatively small size makes hobbing relatively low in cost. Also, hobbing is substantially

more accurate. Gear accuracy is commonly measured in the

industry, and the key measurement is called total composite

error or TCE. This measurement is very similar to runout

and essentially behaves the same way as runout. However,

while it is easy to measure runout on a motor-driven smooth

shaft, it is difficult to measure the TCE of a pinion after it

has been mounted on the motor shaft, especially with a stepper motor. To measure the TCE of a pinion after it has been

mounted on the motor shaft, it is necessary to turn the motor

very smoothly and slowly at only a few r/min. So, first we

designed the stepper motor (which is by nature very oscillatory) to go extremely fast, and then we tried to drive it at

very slow speeds. We were only able to make the motor

move at slow speeds by using two function generators constrained in a phase-locked loop to be 90 degrees out of phase,

then connecting their amplified outputs to the phases of the

motor. Effectively, this became a sine-wave drive for the

stepper, and it did successfully drive the permanent magnet

Anti-Backlash Spring

The Function of the Anti-Backlash Spring

Motor Moves Forward

Motor Slows Down, but

Still Moving Forward

Anti-Backlash

Spring Working

Motor backs up slightly and stops.

Teeth stay tightly meshed because the

backlash device pulls the big gear

backwards against the small gear.

Fig. 6. Controlling the backlash. The large drawing at the top shows

the function of the antibacklash device. The purpose of the backlash

sheet-metal spring is to keep the teeth of the gears meshed tightly

even if the motor backs up slightly. If the gears were to become unmeshed, the resultant accuracy error would be twice as much as all

other error sources combined. The middle drawings show the motor

moving forward and the motor slowing down but still moving forward. The two drawings on the bottom show the backlash spring

working (left) and the backlash spring not working (right).

Motor backs up slightly and stops. Teeth

have become unmeshed because the big

gear continued to move forward while the

motor was backing up. This is a failure.

Anti-Backlash Spring

Not Working

February 1994 Hewlett-Packard Journal 77

Page 7

stepper at slow speeds. For the first time we could measure

pinion quality after the gears had been mounted on the motor

shaft. With this measurement ability, we were able to work

with the vendor and resolve tricky problems such as damaging the pinions and bending the motor shafts while mounting

the gears on the shafts. The resultant print quality of the HP

DeskJet 1200C printer is good enough that few swath advance accuracy problems have occurred in production.

Media Drive Accuracy

The media advance accuracy is an important metric of the

performance of the media drive system. As media moves

through the printing region it is stopped, printed on, and

then advanced to the next printing location. The distance it

moves each time depends upon the print mode and what is

being printed. Print quality for both text and graphics depends on advance accuracy. However, graphics print quality

is more dependent on advance accuracy because there is no

blank space in which to hide the advance error. Every advance made during graphics printing has the potential to

show a print quality error, whereas during text printing it is

possible to avoid splitting text between advances and

thereby avoid showing advance error.

In the early stages of development the design team needed

an estimate of the drive accuracy of the printer. A mathematical model was constructed that simulates an advance

made by the worst-case components in the worst possible

orientation. This model provided a good guide to what sort

of tolerances we needed in our manufacturing processes, but

was too conservative to simulate what we expected most

advances to look like. The next model built was a Monte

Carlo model that chooses components from simulated distributions and orients the parts randomly, much like a manufacturing process. When this model is run for a large number

of cases, a good approximation of the expected mean and

standard deviation of an advance is produced. Once the

mean and standard deviation are known, process control of

advances is possible. The goal of the modeling effort was to

simulate advances and establish tolerance limits on advance

accuracy. This goal was achieved and the process limits

were confirmed by measuring drive components, building

machines, and measuring their swath advances.

The DeskJet 1200C project was able to use tools previously

developed for media advance measurement for other printers. The best tool we found is an optical vision system which,

when given a specific plot, measures a series of advances

and reports the data. For our purposes, predominantly

graphics print quality, measuring 32 nozzle advances provides all the information we need about the drive system.

The 32-nozzle advance data can easily be extrapolated to the

other advance distances we are interested in.

Fig. 7 shows media advance measurements down the length

of a page. This data was processed to find the mean and

Mean + 3s

0.1080

0.1075

0.1070

0.1065

0.1060

0.1055

0.1050

Paper Advance Distance (inches)

Fig. 7. The measured media advance down the length of one page

of a single machine is shown along with the predicted accuracy calculated with measurements of the drive components as inputs to the

model, which is shown as a distribution. The actual output of the

model is the mean and standard deviation for a given machine.

Mean – 3s

Predicted

Distribution

Measured

standard deviation, which were compared with the model.

First, components were measured and used to build a set of

machines. Then the swath advance of the machines built

with these components was measured. Finally, the statistics

of the measured swath advance were compared with the

results from the model with the measured components as

inputs. Fig. 7 also shows the results of the simulation: the

distribution of swath advances predicted by the model. As

can be seen, the measured advance fits within the predicted

distribution and the mean and standard deviation of the predicted distribution agree well with the measured mean and

standard deviation. Thus, we confirmed the accuracy of our

fabrication processes, the simulation model, and the printers

we manufacture.

Acknowledgments

As with any large development effort, there are innumerable

people without whose contributions this product would not

exist or function as smoothly as it does. We would like to

thank Gerold Firl, Mike Green, Joe Milkovits, Tim Zantow,

and Tom Halpenny for their contributions to the media path.

We would like to thank Ron Kaplan for his valuable assistance in the early characterization and tooling development,

Frank Nasworthy for his expertise in designing the pinch

wheel, Steve Witte for his assistance with the hardware connectivity and programming skills, Damon Broder for his

overall support of the paper advance system, Jeff Wilson

and Dennis Culver for their design and fabricating assistance in tooling design, and our staff of lab technicians—Tau

Ngo, Nhuong Nguyen, Robert Schmidt, Damon Johnson, and

Danny Zepeda—for their many long hours of testing. Thanks

also to Steve Gaddi for his support of paper advance testing.

HP-UX is based on and is compatible with UNIX System Laboratories’ UNIX* operating system.

It also complies with X/Open’s* XPG3, POSIX 1003.1 and SVID2 interface specifications.

UNIX is a registered trademark of UNIX System Laboratories Inc. in the U.S.A. and other countries.

X/Open is a trademark of X/Open Company Limited in the UK and other countries.

78 February 1994 Hewlett-Packard Journal

Loading...

Loading...