Page 1

THIS IS A REPRINT, INCLUDING CHANGES 1 AND 2

*TB 9-6625-082-50

DEPARTMENT OF THE ARMY TECHNICAL BULLETIN

CALIBRATION PROCEDURE FOR

OSCILLOSCOPE, HEWLETT-PACKARD

MODELS 120A, 120AR, 120B. AND 120BR

Headquarters, Department of the Army, Washington, DC

14 January 1974

♦♦REPORTING OF ERRORS♦♦

You can help improve this publication by calling attention to errors and by

recommending improvements and stating your reasons for the recommendations.

Your letter or DA Form 2028, Recommended Changes to Publications, should be

mailed directly to Commander, U.S. Army Aviation and Missile Command,

ATTN: AMSAM-TMD-EP, Redstone Arsenal, AL 35898-5000. FAX to DSN 7882313 (commercial 256-842-2313). A reply will be furnished directly to you.

SECTION I. IDENTIFICATION AND DESCRIPTION

Test instrument identification .............................. 1 2

Calibration data card, DA Form 2416 .................. 2 2

Calibration description......................................... 3 3

II. EQUIPMENT REQUIREMENTS

Equipment required.............................................. 4 4

Accessories required ............................................. 5 5

III. PRELIMINARY OPERATIONS

Preliminary instructions....................................... 6 5

Equipment Setup.................................................. 7 6

IV. CALIBRATION PROCESS FOR MODELS

120A AND 120 AR

Intensity limit.................................................... 8 6

Vertical and horizontal amplifier dc balance..... 9 7

Triggering range and level................................. 10 9

Vertical and horizontal sensitivity and range ... 11 12

Calibrator........................................................... 12 13

Vertical amplifier frequency response and

attenuator compensation ................................... 13 13

Horizontal amplifier frequency response and

attenuator compensation ................................... 14 14

Amplifier phase shift.......................................... 15 16

Paragraph Page

__________

This bulletin supersedes TB 9-6625-082-50, 17 September 1970.

Page 2

TB 9-6625-082-50

V. CALIBRATION PROCESS FOR MODELS

Paragraph Page

Sweep timing...................................................... 16 16

Sweep magnifier................................................. 17 17

Power supply ...................................................... 18 18

Final procedure.................................................. 19 18

120B AND 120BR

Equipment setup................................................ 20 19

Intensity limit.................................................... 21 19

Vertical amplifier dc balance............................. 22 20

Triggering range and level................................. 23 21

Vertical and horizontal sensitivity and range ... 24 23

Calibrator........................................................... 25 24

Vertical amplifier frequency response and

attenuator compensation ................................... 26 24

Horizontal amplifier frequency response and

attenuator compensation ................................... 27 27

Amplifier phase shift.......................................... 28 28

Sweep timing...................................................... 29 28

Sweep magnifier................................................. 30 29

Power supply ...................................................... 31 30

Final procedure.................................................. 32 30

SECTION I

IDENTIFICATION AND DESCRIPTION

1. Test Instrument Identification. This bulletin provides instructions for the

calibration of Oscilloscope, Hewlett-Packard Models 120A, 120AR, 120B, and 120BR. The

manufacturer’s instruction manuals were used as the prime data source in compiling these

instructions. The oscilloscope will be referred to as the "TI" (test instrument) throughout

this bulletin.

a. Model Variations. Variations among models are described in text.

b. Time and Technique. The time required for this calibration is approximately 4

hours using the dc and low frequency technique.

2. Calibration Data Card, DA Form 2416

a. Forms, records, and reports required for calibration personnel at all levels are

prescribed by TM 38-750. DA Form 2416 must be annotated in accordance with TM 38-750

for each calibration performed.

b. Adjustments to be reported on DA Form 2416 are designated (R) at the end of the

sentence in which they appear. When adjustments are in tables, the (R) will follow the

designated adjustment. Report only those adjustments made and designated with (R).

2

Page 3

TB 9-6625-082-50

3. Calibration Description. TI parameters and performance specifications which

pertain to this calibration are listed in table 1.

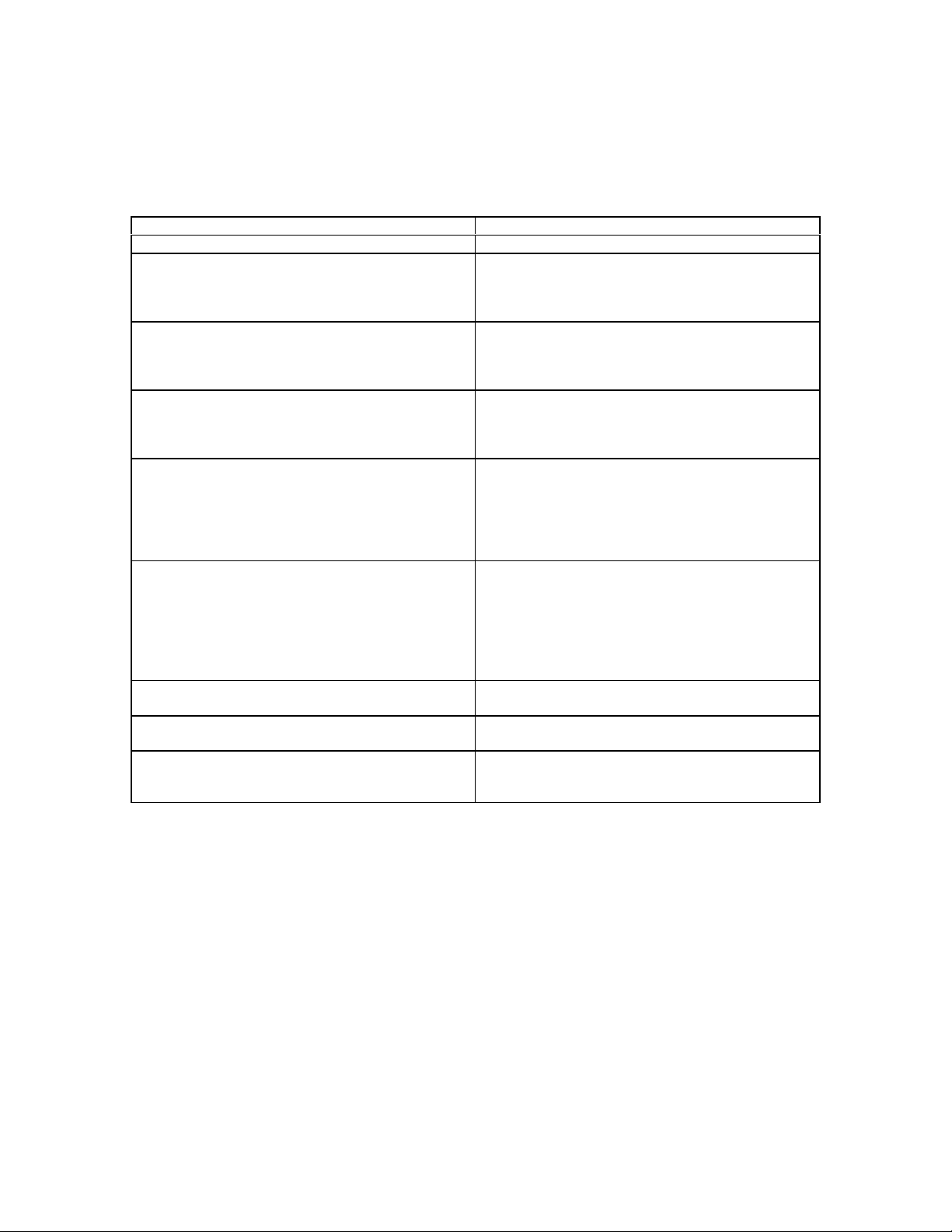

Table 1. Calibration Description

Test instrument parameters Performance specifications

Power input requirements

Vertical and horizontal amplifier bandwidth

(models 120 and 120AR):

Dc coupled

Ac coupled

Vertical amplifier bandwidth (models 120B and

120BR):

Dc coupled

Ac coupled

Horizontal amplifier bandwidth (models 120B and

120BR):

Dc coupled

Ac coupled

Horizontal sensitivity:

Range

Vernier

Accuracy

Vertical sensitivity:

Range

Vernier

Accuracy (models 120A and 120AR)

Accuracy (models 120B and 120BR)

Internal calibrator Calibrator signal automatically connected to

Common-mode rejection

Phase shift Vertical and horizontal amplifiers have same

See footnote at end of table.

1

1

115 or 230 vac ±10%, 50 to 1000 Hz, 130 w

Dc to 200 kHz

2 Hz to 200 kHz

Dc to 450 kHz

2 Hz to 450 kHz

Dc to 300 kHz

2 Hz to 300 kHz

0.1 to 100 v/cm in 3 calibrated steps; .1, 1, and 10

v/cm

Continuously variable between steps and extends

10 v/cm step to at least 100 v/cm

±5%

10 mv/cm to 100 v/cm in 4 calibrated steps; 10 mv,

100 mv, 1 v, and 10 v/cm

Continuously variable between steps and extends

10 v/cm step to at least 100 v/cm

±5%

±3%

vertical amplifier; accuracy ±2%

At least 40 db. Common mode signal must not

exceed ±3 v peak

phase characteristics within ±2° to 100 kHz

when verniers are in CAL

3

Page 4

TB 9-6625-082-50

Table 1. Cable Description - Continued.

Test Instrument Parameters Performance Specifications

Sweep:

Sweep range

Vernier

Accuracy

Sweep expand

Automatic triggering (models 120A and 120AR):

Internal

External

Trigger point

Automatic triggering (models 120B and 120BR):

Internal

External

Trigger point

Selectable trigger level:

Models 120A and 120AR

Models 120B and 120BR

1

This specification is for information only and is not necessarily verified in this bulletin.

1

1 µsec to 0.5 sec/cm in 15 calibrated steps 1, 2, 5,

10, etc., sequence, 5 µsec/cm to 200 ms/cm

Continuously variable between ranges and

extends 200 ms/cm step to at least 0.5 sec/cm

±5%

X5 sweep expansion may be used on all ranges

and extends fastest sweep to 1 µsec/cm,

accuracy ±10%

From signals 50 Hz to 250 kHz causing 0.5 cm or

more vertical deflection; and from line voltage

At least 2.5 v p-p

Zero crossing, negative slope of external sync

signals; zero crossing, positive or negative slope

of vertical deflection signal

From signals 50 Hz to 450 kHz causing 0.5 cm or

more vertical deflection; and from line voltage

At least 1.5 v p-p

Zero crossing, negative slope of external sync

signals; zero crossing, positive or negative slope

of vertical signal

Screwdriver control overrides automatic

triggering and permits trigger point to be set

between -10 to +10 v

Front-panel control overrides automatic triggering

and permits trigger point to be set between -7 to

+7 v

SECTION II

EQUIPMENT REQUIREMENTS

4. Equipment Required. Table 2 identifies the specific equipment used in this

calibration procedure. This equipment is issued with secondary transfer calibration

standards set 4931-621-7877 and is to be used in performing this procedure. Alternate

items may be used by the calibrating activity when the equipment listed in table 2 is not

available. The items selected must be verified to perform satisfactorily prior to use and

must bear evidence of current calibration. The equipment must meet or exceed the

minimum use specifications listed in table 2. The accuracies listed in table 2 provide a fourto-one accuracy ratio between the standard and TI. Where the four-to-one ratio cannot be

met, the actual accuracy of the equipment selected is shown in parenthesis.

4

Page 5

TB 9-6625-082-50

5. Accessories Required. The accessories listed in table 3 are issued with secondary

transfer calibration standards set 4931-621-7877 and are to be used in this calibration

procedure. When necessary, these items may be substituted by equivalent items unless

specifically prohibited.

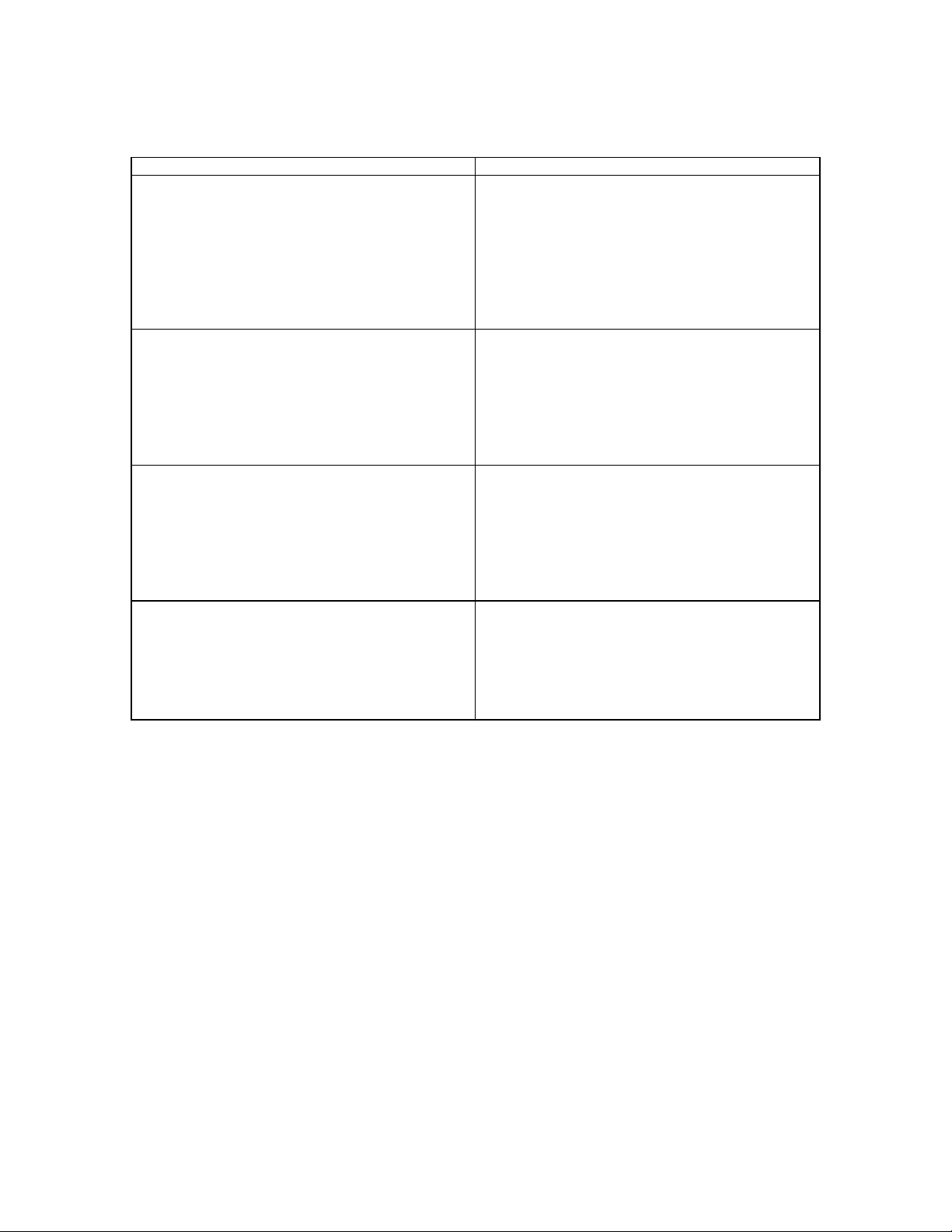

Table 2. Minimum Specifications of Equipment Required

Minimum use

Item Common name

A1 AC/DC VOLTMETER Range:-146 to -154 V dc;

Accuracy: ±..75%

A2 AUTOTRANSFORMER Range:105 to 125 V ac

Accuracy: ±1%

A3 DC VOLTMETER Range:-1235 to -2363 V

Accuracy: ±1.66%

A4 SIGNAL GENERATOR Frequency: 100 kHz

Voltage: 0.03 to 20 V rms

A5 SQUARE-WAVE

GENERATOR

A6 VOLTAGE

CALIBRATOR

A7 TEST OSCILLATOR Frequency: 10 Hz to 500 kHz

A8 TIME-MARK

GENERATOR

Frequency: 5 to 30 kHz

Voltage: 0.8 to 50 V p-p

Range:34.5825 mv rms to 37.2

Accuracy: ±..75%

Voltage: 0.03 to 2.9 v rms

Accuracy: ±.75%

Range:1 µsec to 50 ms

Accuracy: ±..75%

specifications

+33.58 to +37.12 V ac

v rms

Manufacturer and model

(part number)

Dana, Model 5703-S-2127

(7912606)

General Radio, Model

W10MT3AS3 (7910809)

Electrical Instruments Service,

Model ESV (MIS-10276)

Hewlett-Packard, Model 202CR

(8616395-2)

Tektronix, Type 106 (MIS-

10284)

Hewlett-Packard, Model 745A

(MIS-10342)

Preston, Model 134A (MIS-

10224)

Tektronix, Type 184MOD146B

(7912042-2)

Table 3. Accessories Required

Item Common Name Description and Part Number

B1 ADAPTER

B2 ADAPTER BNC jack to double banana plug (7907592)

B3 ADAPTER BNC T type, 2 jacks, 1 plug (MS35173-274)

B4 CABLE 30-in., RG-58/U; BNC plug terminations (7907467)

B5 CABLE

B6 CABLE

B7 LEAD 24-in., No. 18 AWG; single banana plug terminations (7907498)

B8 TERMINATION 50-ohm feed-through; BNC jack to BNC plug Hewlett-Packard,

1

Two required.

1

1

1

Single banana jack to alligator clip (black) (7907560)

30-in., RG-58/U; double banana plug terminations (7907470)

36-in., RG-58/U; BNC plug and double banana plug terminations

(7907471)

Model 11048B (11048B)

SECTION III

PRELIMINARY OPERATIONS

6. Preliminary Instructions

a. The instructions outlined in this section are preparatory to the calibration process.

Personnel should become familiar with the entire bulletin before beginning the calibration.

5

Page 6

TB 9-6625-082-50

b. Items of equipment used in this procedure are referenced within the text by common

name and item identification number as listed in tables 2 and 3. For the identification of

equipment referenced by item numbers prefixed with A, see table 2, and for prefix B, see

table 3.

WARNING

HIGH VOLTAGE is used during the performance of this

calibration. DEATH ON CONTACT may result if personnel

fail to observe safety precautions.

7. Equipment Setup

a. Remove protective cover from TI.

b. Connect TI to autotransformer (A2).

c. Connect autotransformer to 115-volt ac source and adjust for 115 volts ac.

CAUTION

To prevent damage to crt, turn INTENSITY control fully

counterclockwise during warm-up.

d. Energize equipment and allow sufficient time for equipment to warm up and

stabilize.

SECTION IV

CALIBRATION PROCESS FOR MODELS 120A AND 120AR

NOTE

Unless otherwise specified, verify the results of each test and

take corrective action whenever the test requirement is not met

before continuing with the procedure.

NOTE

When indications specified in paragraphs 8 through 17 are not

within tolerance, perform the power supply check prior to

making adjustments. After adjustments are made, repeat

paragraphs 8 through 17. Do not perform power supply check

if all other parameters are within tolerance.

8. Intensity Limit

a. Performance Check

(1) Position TI controls as listed in (a) through (i) below:

6

Page 7

(a) TRIGGER LEVEL control to AUTO.

(b) INTENSITY control fully counterclockwise.

(c) Vertical AC-DC switch to AC.

(d) VERT. SENSITIVITY VERNIER control to CAL.

(e) VERT. SENSITIVITY switch to 1 VOLTS/CM.

(f) SWEEP EXPAND switch to X1.

(g) SWEEP TIME-HOR. SENS. switch to 1 MILLISECONDS/CM.

(h) SYNC switch to INT + (positive).

(i) HORIZ. POS. and VERT. POS. controls to midrange.

(2) Adjust INTENSITY and FOCUS controls for normal display. If normal display

cannot be obtained, perform b below.

b. Adjustments

(1) Position TI controls as listed in (a) through (c) below:

TB 9-6625-082-50

(a) SWEEP TIME-HOR. SENS. switch to 10 VOLTS/CM.

(b) FOCUS control for best focus.

(c) INTENSITY control index marker to 9 o'clock position.

(2) Adjust R316 (fig. 1) for a small round spot.

(3) Adjust R322 (fig. 1) until spot just disappears.

9. Vertical and Horizontal Amplifier Dc Balance

a. Performance Check

(1) Position TI controls as listed in (a) through (e) below:

(a) VERT SENSITIVITY switch to 10 VOLTS/CM.

(b) VERT SENSITIVITY VERNIER control fully counterclockwise.

(c) VERT POS. control to center spot on graticule.

(d) Vertical AC-DC switch to DC.

(e) SWEEP TIME-HOR SENS. switch to 10 VOLTS/CM.

7

Page 8

TB 9-6625-082-50

(2) Vary VERT. SENSITIVITY VERNIER control. If spot does not remain in center

of graticule, perform b(1) through (3) below.

(3) Turn VERT SENSITIVITY VERNIER control to CAL. VERT SENSITIVITY to

OFF, and SWEEP TIME HOR. SENS. switch to 10 V/CM.

(4) Repeat (1) and (2) above, using horizontal controls. If spot does not remain in

center of graticule, perform b(4) through (8) below.

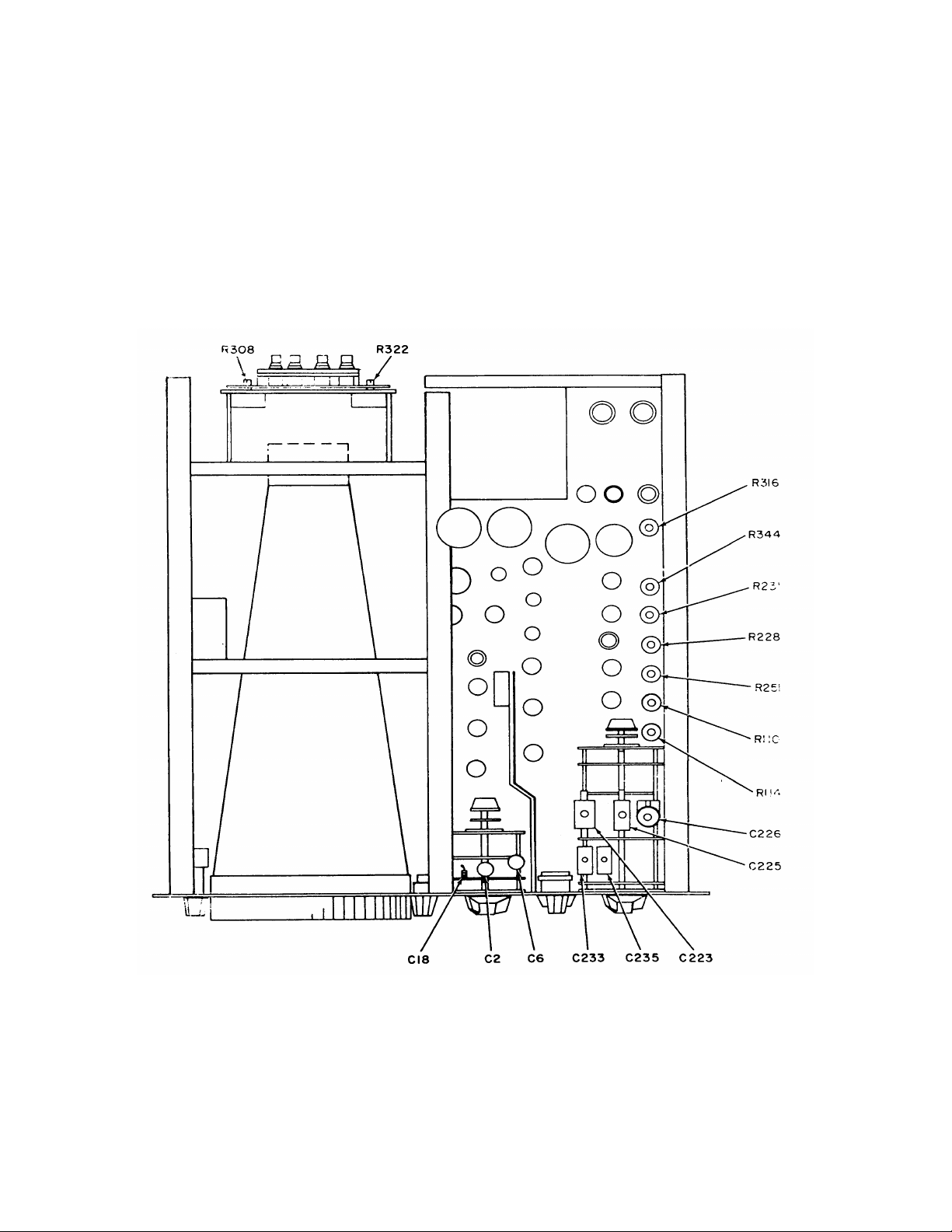

Figure 1. Oscilloscope - top view.

8

Page 9

b. Adjustments

(1) Turn VERT SENSITIVITY VERNIER control to midrange.

(2) Adjust VERT. DC BAL. control (front panel) to center spot on graticule.

(3) Vary VERT. SENSITIVITY VERNIER control and adjust VERT. DC BAL.

control until no spot shift is observed.

(4) Turn SWEEP TIME-HOR. SENS. VERNIER control fully counterclockwise.

(5) Adjust R110 (fig. 1) to center spot on graticule.

(6) Turn SWEEP TIME-HOR. SENS. VERNIER control to CAL.

(7) Turn HORIZ. POS. control to center spot on graticule.

(8) Repeat (4) through (7) above until no shift is observed when varying SWEEP

TIME HOR. SENS. VERNIER control.

10. Triggering Range and Level

TB 9-6625-082-50

a. Performance Check

(1) Position TI controls as listed in (a) through (c) below:

(a) VERT SENSITIVITY switch to 1 VOLTS/CM.

(b) SWEEP TIME-HOR. SENS. switch to 5 MICROSECONDS/CM.

(c) SYNC switch to EXT.

(2) Observe that baseline is displayed on TI crt.

(3) Connect test oscillator (A7) to TI horizontal input connector, using cable and

termination (B6 and B8).

(4) Connect TI horizontal input connector to TI vertical input connector, using cable

(B5).

(5) Adjust test oscillator frequency to 250 kHz and amplitude for stable display on

TI.

(6) Slowly reduce test oscillator amplitude until TI display becomes unstable. If

test oscillator amplitude is not .70 volt rms or less, perform b(1) and (2) below.

(7) Turn SWEEP TIME-HOR. SENS. switch to 10 MILLISECONDS/CM.

9

Page 10

TB 9-6625-082-50

(8) Adjust test oscillator frequency to 50 Hz and amplitude for display on TI.

(9) Repeat (6) above.

NOTE

Some adjustment of TI TRIGGER LEVEL control may be

necessary at high frequencies.

(10) Turn SYNC switch to INT + (positive) and SWEEP TIME-HOR. SENS. switch to

50 MICROSECONDS/CM.

(11) Adjust test oscillator to 10 kHz and .8 centimeters of display on TI crt. If sweep

does not trigger on positive-going portion of display waveform, perform b(3) through (11)

below.

(12) Turn SYNC switch to INT-(negative). Observe that sweep triggers on negative

going part of waveform.

b. Adjustments

(1) Adjust test oscillator amplitude for stable display on TI.

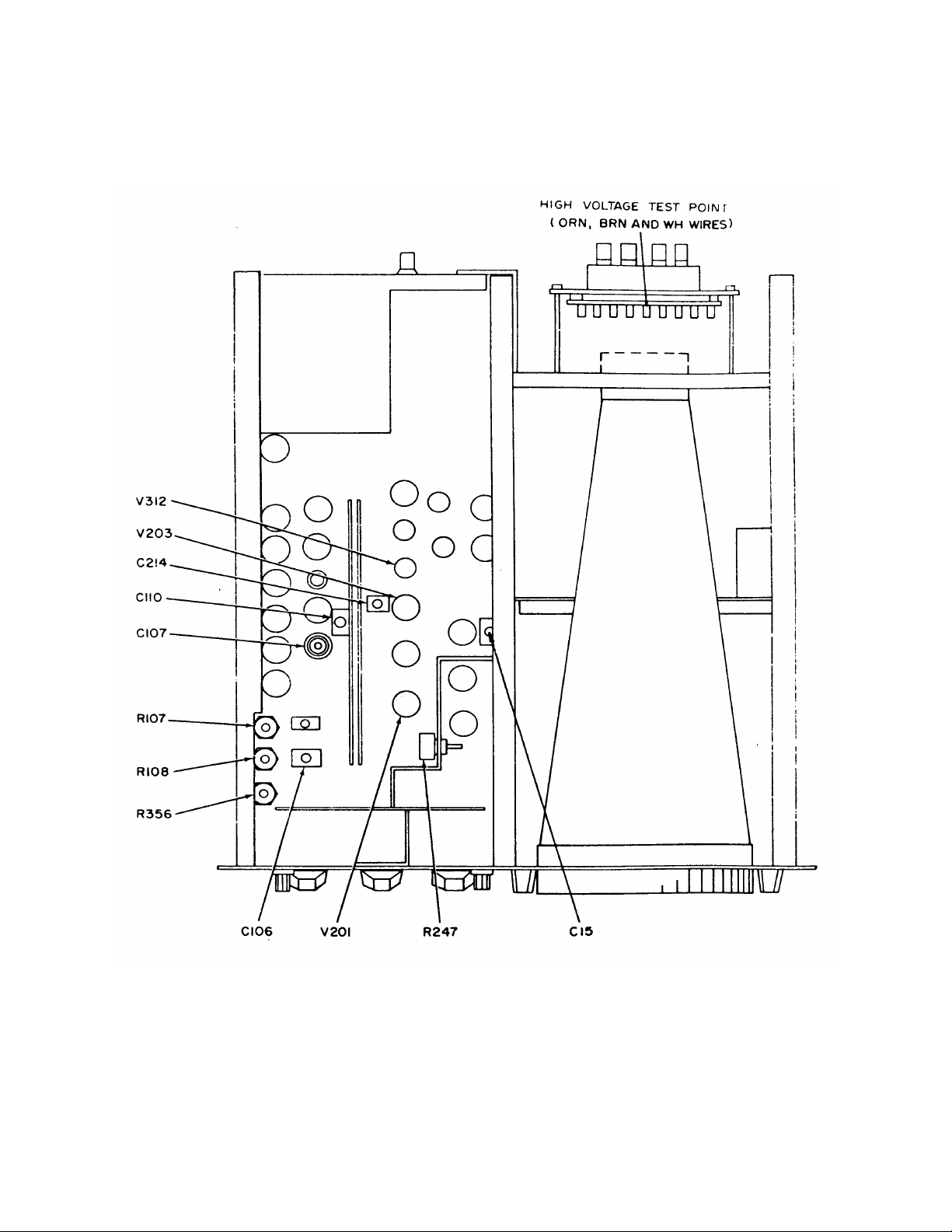

(2) Adjust R247 (fig. 2) while reducing test oscillator amplitude until triggering

becomes stable at minimum test oscillator amplitude (less than .70 volt rms).

(3) Turn TI VERT. SENSITIVITY VERNIER control to CAL.

(4) Connect ac/dc voltmeter (A1) between pin 8 of V203 (fig. 2) and chassis ground.

(5) If no trace is present on TI, perform adjustments (a) and (b) below:

(a) Adjust R228 (fig. 1) counterclockwise until trace appears.

(b) Turn R228 clockwise until trace just disappears.

(6) If trace is present, adjust R228 clockwise until trace just disappears.

(7) Record ac/dc voltmeter indication.

(8) Connect lead (B7) with two adapters (B1), between pin 1 of V201 (fig. 2) and

chassis ground.

(9) Slowly turn R228 counterclockwise until trace appears and then clockwise until

trace just disappears. Record ac/dc voltmeter indication.

above.

10

(10) Adjust R228 for indication of 2 volts more positive than value recorded in (9)

Page 11

(11) Remove lead connected in (8) above.

TB 9-6625-082-50

Figure 2. Oscilloscope - bottom view.

11

Page 12

TB 9-6625-082-50

11. Vertical and Horizontal Sensitivity and Range

a. Performance Check

(1) Position TI controls as listed in (a) through (d) below:

(a) SYNC switch to INT + (positive).

(b) SWEEP TIME-HOR. SENS. switch to 1 MILLISECOND/CM.

(c) VERT. SENSITIVITY switch to 100 MILLIVOLTS/CM.

(d) VERT. AC-DC switch to AC.

(2) Connect voltage calibrator (A6) to TI vertical input connector, using cable (B5).

Connect negative and ground vertical input connector together with ground strap.

(3) Adjust voltage calibrator for a 10-centimeter display amplitude on TI crt. If

voltage calibrator does not indicate between 335.825 and 371.175 millivolts rms, perform

b(1) and (2) below.

(4) Repeat (3) above, using settings listed in table 4. If voltage calibrator does not

indicate within limits specified, perform b(1) and (2) below to obtain best in-tolerance

compromise for all VERT. SENSITIVITY switch positions.

Table 4. Vertical and Horizontal Sensitivity and Range

Test instrument Voltage calibrator

VERT. SENSITIVITY indication (rms)

switch settings Min Max

10 mV/cm 33.5825 mV 37.1175 mV

1 V/cm 3.358 V 3.712 V

10 V/cm 33.58 V 37.12 V

(5) Connect voltage calibrator (A6) to horizontal input connectors of TI.

(6) Turn HORIZONTAL AC-DC switch to AC and SWEEP TIME-HOR. SENS.

switch to .1 VOLTS/CM.

(7) Adjust voltage calibrator for a 10-centimeter horizontal deflection on TI crt. If

voltage calibrator does not indicate between 335.825 and 371.175 millivolts rms, perform

b(3) and (4) below.

(8) Repeat technique of (6) above, 1 VOLT/CM and 10 VOLTS/CM settings listed in

table 4, and substituting HOR. SENS. switch for VERT SENSITIVITY switch. If voltage

calibrator does not indicate within specified limits, perform b(3) and (4) below to obtain best

in-tolerance compromise of error.

12

Page 13

TB 9-6625-082-50

b. Adjustments

(1) Adjust voltage calibrator for a .3535-volt rms output.

(2) Adjust VERT. GAIN control for 10 centimeters of display amplitude on TI crt.

(3) Adjust voltage calibrator output to .3535 volt rms.

(4) Adjust R114 (fig. 1) for 10 centimeters of horizontal display amplitude on TI crt.

(R)

12. Calibrator

a. Performance Check. Turn VERT. SENSITIVITY switch to CAL 6 CM and

SWEEP TIME-HOR. SENS. switch to 2 MILLISECONDS/CM. If display amplitude does

not indicate 6 centimeters, perform b below.

b. Adjustments. Adjust R356 (fig. 2) for display amplitude of 6 centimeters on crt.(R)

13. Vertical Amplifier Frequency Response and Attenuator Compensation

a. Performance Check

(1) Turn VERT. SENSITIVITY switch to 10 MILLIVOLTS/CM and SWEEP TIMEHOR. SENS. switch to 100 MILLISECONDS/CM.

(2) Connect test oscillator (A7) to TI vertical input connectors; using cable and

termination (B6 and B8).

(3) Adjust test oscillator for 10 Hz and for a display amplitude of 10 centimeters.

Note indication of test oscillator output meter.

(4) Maintain constant test oscillator output amplitude noted in (3) above, and

Increase test oscillator frequency until display amplitude is 8 centimeters. Test oscillator

frequency will be at least 200 kHz.

(5) Disconnect test oscillator and connect output of square-wave generator (A5) to

TI vertical input terminals, using cable and termination supplied with square-wave

generator, and adapter (B2).

(6) Turn SWEEP TIME-HOR. SENS. switch to 5 MICROSECONDS/CM.

(7) Adjust square-wave generator to 50 kHz and 8 centimeters of display amplitude

on TI crt. If square wave with maximum of 2 percent overshoot is not displayed; perform

b(1) below.

(8) Turn SWEEP TIME-HOR. SENS. switch to 200 MICROSECONDS/CM and

VERT. SENSITIVITY switch to 100 MILLIVOLTS.

13

Page 14

TB 9-6625-082-50

(9) Adjust square-wave generator to 5 kHz and 8 centimeters of amplitude display.

If flat-top square wave is not displayed, perform b(2) below.

(10) Turn VERT. SENSITIVITY switch to 1 VOLTS/CM and adjust square-wave

generator for 8 centimeters of display. If flat-top is not displayed, perform b(3) below.

b. Adjustments

(1) Adjust C15 (fig. 2) for best square-wave response.

(2) Adjust C6 (fig. 1) for flat-top square wave.

(3) Adjust C2 (fig. 1) for flat-top square wave.

14. Horizontal Amplifier Frequency Response and Attenuator Compensation

a. Performance Check

(1) Position TI controls as listed in (a) through (c) below:

(a) SWEEP TIME-HOR. SENS. switch to .1 VOLTS/CM.

(b) Horizontal AC-DC switch to DC.

(c) VERT. POS. control to center display.

(2) Connect test oscillator (A7) to TI horizontal input connectors, using cable and

termination (B6 and B8).

(3) Adjust test oscillator to 10 Hz and a 10-centimeter trace length. Note indication

of test oscillator level meter.

(4) Maintain constant test oscillator output amplitude of (3) above, and increase test

oscillator frequency until trace length is 8 centimeters. Test oscillator frequency will be at

least 200 kHz.

(5) Connect equipment as shown in figure 3.

(6) Adjust square-wave generator (A5) to 50 kHz and 8 centimeters of display

amplitude.

(7) Adjust test oscillator for approximately 5 kHz and stable display of 10

centimeters. Readjust test oscillator frequency for best display of square wave. If square

wave with flat top and maximum of 2 percent overshoot is not displayed; perform b(1)

below.

14

Page 15

TB 9-6625-082-50

Figure 3. Horizontal amplifier compensation - equipment setup.

(8) Turn SWEEP TIME-HOR. SENS. switch to 1 VOLTS/CM.

(9) Adjust square-wave generator to 5 kHz and 8 centimeters of display. Adjust test

oscillator to approximately 500 Hz and stable display of 8 centimeters. If flat-top square

wave is not displayed, perform b(2) below.

(10) Turn SWEEP TIME-HOR. SENS. switch to 10 VOLTS/CM. If flat-top square

wave is not displayed, perform b(3) below.

b. Adjustments

(1) Adjust C110 (fig. 2) for best square wave response. (R)

(2) Adjust C235 (fig. 1) for flat-top square wave. (R)

(3) Adjust C233 (fig. 1) for flat-top square wave. (R)

15

Page 16

TB 9-6625-082-50

15. Amplifier Phase Shift

a. Performance Check

(1) Position TI controls as listed in (a) through (c) below:

(a) SWEEP TIME-HOR. SENS. switch to .1 VOLTS/CM.

(b) VERT SENSITIVITY switch to 100 MILLIVOLTS/CM.

(c) Horizontal AC-DC switch to AC.

(2) Connect signal generator (A4) to TI vertical input connectors, using cable (B5).

(3) Connect TI vertical input connectors to horizontal input connectors, using cable

(B5).

(4) Adjust signal generator to 100 kHz and approximately 6 centimeters deflection

on TI crt. If pattern opening on crt is more than 0.2 centimeter, perform b(1) below.

(5) Turn SWEEP TIME-HOR. SENS. and VERT. SENSITIVITY switches to 10

VOLTS/CM.

(6) Increase signal generator output to obtain approximately same pattern as

before. If pattern opening on crt is more than 0.2 centimeter, perform b(2) below.

b. Adjustments

(1) Adjust C107 (fig. 2) for closed pattern on crt. (R)

(2) Adjust C18 (fig. 1) for closed pattern on crt. (R)

16. Sweep Timing

a. Performance Check

(1) Connect MARKER OUTPUT jack of time-mark generator (A8) to TI vertical

input connectors, using cable (B6).

(2) Turn SWEEP TIME-HOR. SENS. switch to 10 MILLISECONDS/CM and VERT.

SENSITIVITY switch to 1 VOLT.

(3) Set time-mark generator to 5 mS.

(4) Adjust HORIZ. POS. control to align third time marker with second vertical

graticule line. If nineteenth marker is not displayed within ± 0.5 centimeter of tenth

graticule line, and sweep length is not 10.5 centimeters; perform b below.

16

Page 17

TB 9-6625-082-50

(5) Turn SWEEP TIME-HOR. SENS. switch to 5 MICROSECONDS/CM. Adjust

time-mark generator for 5 µS output.

(6) Adjust HORIZ. POS. control to align second marker with second vertical

graticule line. Tenth time marker will be within 0.5 centimeter of tenth vertical graticule

line.

(7) Repeat technique of (5) and (6) above, using values listed in table 5. Perform

adjustments listed in the table as necessary for out-of-tolerance sweep timing.

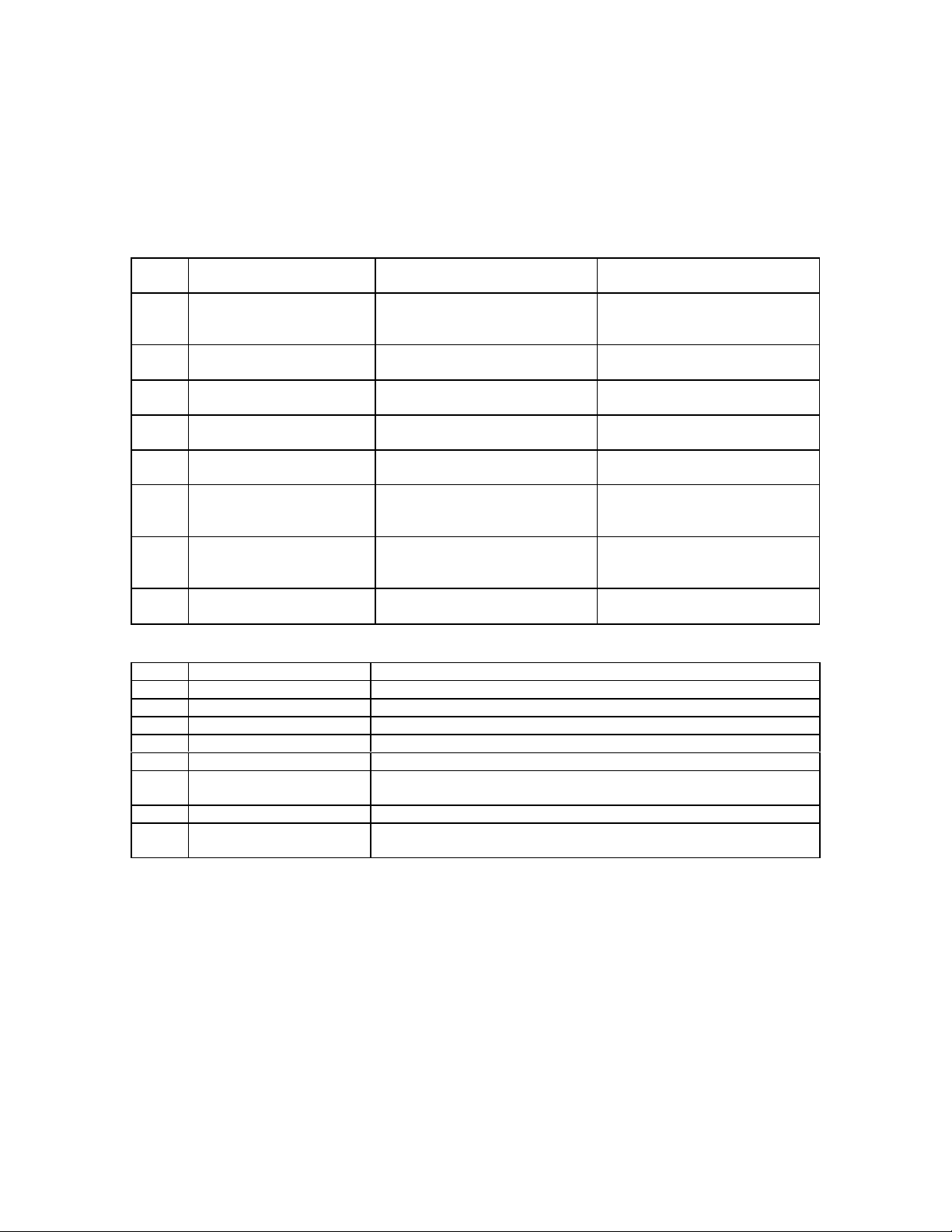

Table 5. Sweep Timing

Test instrument Time-mark

SWEEP TIME-HOR. generator Time mark/

SENS. switch output cm Adjustments

10 MICROSECONDS/CM

20 MICROSECONDS/CM 10 µs 2 - - -

50 MICROSECONDS/CM 50 µs 1 C225 (fig. 1) (R)

100 MICROSECONDS/CM 0.1 ms 1 - - 200 MICROSECONDS/CM 0.1 ms 2 - - -

.5 MILLISECONDS/CM 0.5 ms 1 C223 (fig. 1) (R)

1 MILLISECONDS/CM 1 ms 1 - - 2 MILLISECONDS/CM 1 ms 2 - - 5 MILLISECONDS/CM 5 ms 1 - - -

20 MILLISECONDS/CM 10 ms 2 - - 50 MILLISECONDS/CM 50 ms 1 R251 (fig. 1) (R)

1

Adjust C226 until last five markers coincide with last five major graticule divisions (one marker per cm). (R)

2

Adjust C214 until first five markers coincide with first five major graticule divisions (one marker per cm). (R)

10 µs

1 C2261 (fig. 1) (R)

C2142 (fig. 2) (R)

b. Adjustments. Adjust R107 (R) (fig. 2) for one marker per centimeter and R231 (R)

(fig. 1) for sweep length of 10.5 centimeters.

17. Sweep Magnifier

a. Performance Check

(1) Turn SWEEP TIME-HOR. SENS. switch to 10 MILLISECONDS/CM and

SWEEP EXPAND switch to X5.

(2) Set time-mark generator (A8) to 10 mS.

NOTE

Adjust TI TRIGGER LEVEL control for stable display, if

necessary.

(3) Adjust HORIZ. POS. control to align first time marker with left-hand graticule

edge. If one marker per 5 centimeters is not displayed, perform b(1) below.

17

Page 18

TB 9-6625-082-50

(4) Turn SWEEP TIME-HOR. SENS. switch to 20 MICROSECONDS/CM.

(5) Set time-mark generator to 1 µS.

(6) Adjust HORIZ. POS. control to align fifth time marker with second vertical

graticule line. If thirty-seventh time marker is not within I centimeter of 10th vertical

graticule line, perform b(2) below.

b. Adjustments

(1) Adjust R108 (fig. 2) for one marker per five centimeters. (R)

(2) Adjust C106 (fig. 2) for equal spacing of markers on first portion of sweep (four

markers per centimeter).(R)

18. Power Supply

NOTE

Do not perform power supply check if all other parameters are

within tolerance.

a. Performance Check

(1) Connect ac/dc voltmeter (A1) between pin 2 of V312 (fig. 2) and chassis ground.

If ac/dc voltmeter does not indicate between -146 and -154 volts dc, perform b(1) below.

Record ac/dc voltmeter indication.

(2) Adjust autotransformer (A2) from 105 to 125 volts and back to 115 volts. Ac/dc

voltmeter will indicate within ±1 percent of indication recorded in (1) above.

(3) Connect positive lead of dc voltmeter (A3) to chassis ground and negative lead to

HIGH VOLTAGE TEST POINT (fig. 2). If dc voltmeter does not indicate between -2137

and -2363 volts, perform b(2) below.

b. Adjustments

(1) Adjust R344 (fig. 1) for indication of -150 volts dc on ac/dc voltmeter. (R)

(2) Adjust R308 (fig. 1) for indication of -2250 volts dc on dc voltmeter. (R)

19. Final Procedure

a. Deenergize and disconnect all equipment and reinstall protective covers on TI.

b. In accordance with TM 38-750, annotate and affix DA Label 80 (U.S. Army

Calibration System). When the TI cannot be adjusted within tolerance, annotate, and affix

DA Form 2417 (Unserviceable or Limited Use tag).

18

Page 19

TB 9-6625-082-50

SECTION V

CALIBRATION PROCESS FOR MODELS 120B AND 120BR

NOTE

Unless otherwise specified, verify the results of each test and

take corrective action whenever the test requirement is not met

before continuing with the procedure.

NOTE

When indications specified in paragraphs 21 through 30 are

not within tolerance, perform the power supply check prior to

making adjustments. After adjustments are made, repeat

paragraphs 21 through 30. Do not perform power supply check

if all other parameters are within tolerance.

20. Equipment Setup

a. Remove protective cover from TI.

b. Connect TI to autotransformer (A2) and connect autotransformer to 115-volt ac

source, and adjust for 115 volts ac.

c. Energize TI by turning INTENSITY and POWER control to ON and allow 20

minutes for equipment to warm up and stabilize.

21. Intensity Limit

a. Performance Check

(1) Position TI controls as listed in (a) through (i) below:

(a) TRIGGER SOURCE switch to INT + (Positive).

(b) TRIGGER SOURCE/LEVEL control to AUTO

(c) INTENSITY control fully counter. clockwise, but not to OFF.

(d) Vertical AC/DC switch to AC.

(e) VERTICAL SENSITIVITY/VERNIER control to CAL.

(f) VERTICAL SENSITIVITY switch to 1 VOLTS/CM.

(g) SWEEP MAGNIFIER switch to X1.

(h) HORIZONTAL DISPLAY switch to 1 MILLISECONDS/CM.

19

Page 20

TB 9-6625-082-50

(i) Horizontal POSITION and vertical POSITION controls to midrange.

To prevent damage to the crt, turn INTENSITY control of TI

back to position of normal viewing brightness immediately

after performing (2) below.

(2) Adjust INTENSITY and FOCUS controls for normal display. If normal display

cannot be obtained, perform b below.

b. Adjustments

(1) Position TI controls as listed in (a) through (c) below:

(a) HORIZONTAL DISPLAY switch to 10 VOLTS/CM.

(b) FOCUS control for best focus.

(c) INTENSITY control index marker to 9 o'clock position.

(2) Adjust R316 (fig. 4) for a small round spot.

CAUTION

(3) Adjust R320 (fig. 4) until spot disappears.

22. Vertical Amplifier Dc Balance

a. Performance Check

(1) Position TI controls as listed in (a) through (e) below:

(a) HORIZONTAL DISPLAY switch to 10 VOLTS/CM.

(b) VERTICAL SENSITIVITY switch to 10 VOLTS/CM.

(c) VERTICAL SENSITIVITY/VERNIER control fully counterclockwise.

(d) VERTICAL POSITION control to center spot on graticule.

(e) Vertical AC-DC switch to DC.

(2) Vary VERTICAL SENSITIVITY/VERNIER control and observe that spot

remains in center of graticule. If spot moves, perform b below.

b. Adjustments

20

(1) Turn VERTICAL SENSITIVITY/VERNIER control fully counterclockwise.

Page 21

TB 9-6625-082-50

Figure 4. Oscilloscope - top view.

(2) Adjust BAL control (front panel) to center spot on TI crt graticule.

(3) Vary VERT. SENSITIVITY VERNIER control and adjust BAL control until no

spot shift is observed.

23. Triggering Range and Level

a. Performance Check

(1) Position TI controls as listed in (a) through (d) below:

(a) VERTICAL SENSITIVITY VERNIER control to CAL.

(b) VERTICAL SENSITIVITY switch to 1 VOLTS/CM.

21

Page 22

TB 9-6625-082-50

(c) HORIZONTAL DISPLAY switch to 5 µSEC/CM.

(d) TRIGGER SOURCE switch to EXT.

(2) Observe that baseline is displayed on TI crt.

(3) Connect test oscillator (A7) to TI horizontal input connector, using cable and

termination (B6 and B8).

(4) Connect TI horizontal input connector to TI vertical input connector, using cable

(B6).

(5) Adjust test oscillator frequency to 450 kHz and output amplitude for a stable

display on TI crt.

(6) Slowly reduce test oscillator amplitude until TI display becomes unstable. If

test oscillator amplitude does not indicate 0.5 volt rms or less, perform b(1) and (2) below.

(7) Turn HORIZONTAL DISPLAY switch to 10 MILLISECONDS/CM.

(8) Adjust test oscillator frequency to 50 Hz and amplitude output for a stable

display on TI crt.

(9) Repeat (6) above.

NOTE

Some adjustment of TI TRIGGER SOURCE/ LEVEL control

may be necessary at high frequency.

(10) Turn TRIGGER SOURCE switch to INT + (positive) and HORIZONTAL

DISPLAY switch to 50 µSEC/CM.

(11) Adjust test oscillator to 10 kHz and an 8-centimeter display on TI crt.

(12) Adjust HORIZONTAL DISPLAY switch for several cycles of display. If sweep

does not trigger on positive-going portion of displayed waveform, perform b(3) through (6)

below.

(13) Turn TI TRIGGER SOURCE switch to INT - (negative). Observe that sweep

triggers on negative-going part of display.

b. Adjustments

(1) Adjust test oscillator amplitude output to 0.53 volt rms.

(2) Adjust R203 (fig. 4) until triggering becomes stable.

22

Page 23

(3) Position TI controls as listed in (a) through (d) below:

(a) VERTICAL SENSITIVITY switch to CAL.

(b) HORIZONTAL DISPLAY switch to .5 MILLISECONDS/CM.

(c) TRIGGER SOURCE switch to INT + (positive).

(d) TRIGGER SOURCE/LEVEL control just out of AUTO.

(4) Connect ac/dc voltmeter (A1) between pin 2 of V202 (fig. 4) and chassis ground.

(5) Adjust R258 (fig. 4) clockwise until sweep free-runs and then counterclockwise

until sweep trace just disappears. Record ac/dc voltmeter indication.

(6) Adjust R258 (fig. 4) for indication of 3 volts more positive than the value

recorded in (5) above.

24. Vertical and Horizontal Sensitivity and Range

a. Performance Check

(1) Position TI controls as listed in (a) through (c) below:

TB 9-6625-082-50

(a) HORIZONTAL DISPLAY switch to 1 MILLISECONDS/CM

(b) VERTICAL AC-DC switch to AC.

(c) VERTICAL SENSITIVITY switch to 100 MILLIVOLTS/CM.

(2) Connect voltage calibrator (A6) to TI vertical input connector, using cable (B5).

Connect negative and ground vertical input connector together using ground strap.

(3) Adjust voltage calibrator for a 10-centimeter amplitude display on TI crt. If

voltage calibrator does not indicate between 335.825 and 371.175 millivolts rms, perform

b(1) and (2) below.

(4) Repeat (3) above, using settings listed in table 6. Voltage calibrator will indicate

within limits specified.

Table 6. Vertical and Horizontal Sensitivity

Test instrument Voltage calibrator or Ac/dc

VERTICAL voltmeter indication (rms)

SENSITIVITY Min Max

switch settings Vert Horiz Vert Horiz

10 MV/CM 33.5825 mv - - - 37.1175 mv - - -

1 VOLTS/CM 3.429 v 3.358 v 3.641 v 3.712 v

10 VOLTS/CM 34.29 v 33.58 v 36.41 v 37.12 v

23

Page 24

TB 9-6625-082-50

(5) Connect voltage calibrator (A6) to horizontal input of TI, using cable (B6).

(6) Turn HORIZONTAL DISPLAY switch to .1 VOLTS/CM.

(7) Adjust voltage calibrator for a 10 centimeter horizontal deflection on crt. If

voltage calibrator does not indicate between 335.825 and 371.175 millivolts rms, perform

b(3) and (4) below.

(8) Repeat technique of (7) above at 1 VOLT/CM and 10 VOLTS/CM settings listed

in table 6 for HORIZONTAL DISPLAY. Indications will be within limits specified.

b. Adjustments

(1) Adjust voltage calibrator for a 353.5 millivolt rms output.

(2) Adjust CAL control for a 10-centimeter display amplitude on TI crt.

(3) Adjust voltage calibrator output for a 353.5-millivolt rms output.

(4) Adjust R104 (fig. 4) for a 10-centimeter horizontal display amplitude on TI crt.

(R)

25. Calibrator

a. Performance Check. Turn VERT. SENSITIVITY switch to CAL (6 CM) and

HORIZONTAL DISPLAY switch to 1 MILLISECONDS/CM. If display amplitude is not 6

centimeters, perform b below.

b. Adjustments. Adjust R51 (fig. 4) for display amplitude of 6 centimeters on TI crt.

(R)

26. Vertical Amplifier Frequency Response and Attenuator Compensation

a. Performance Check

(1) Turn VERTICAL SENSITIVITY switch to 10 MILLIVOLTS/CM and

HORIZONTAL DISPLAY switch to 100 MILLISECONDS/CM.

(2) Connect test oscillator (A7) to TI vertical input, using cable and termination (B6

and B8).

(3) Adjust test oscillator for a 10-Hz output and for display height of 10 centimeters.

Note indication of test oscillator level meter.

(4) Maintain constant test oscillator output amplitude of (3) above, and increase test

oscillator frequency until display amplitude is 7 centimeters. Test oscillator frequency will

be at least 450 kHz.

24

Page 25

TB 9-6625-082-50

(5) Disconnect test oscillator and connect output of square-wave generator (A5) to

TI vertical input terminals, using cable and termination supplied with square-wave

generator, and adapter (B2).

(6) Position TI controls as listed in (a) through (c) below:

(a) VERTICAL SENSITIVITY switch to 100 MILLIVOLTS/CM.

(b) VERTICAL SENSITIVITY/VERNIER control fully counterclockwise.

(c) HORIZONTAL DISPLAY switch to 0.5 MILLISECONDS/CM.

(7) Adjust square-wave generator to 1 kHz and an 8-centimeter amplitude display

on TI crt. If an optimum square wave is not displayed, perform b(1) below.

(8) Turn VERTICAL SENSITIVITY/VERNIER control to CAL and adjust squarewave generator for an 8-centimeter amplitude display. If an optimum square wave is not

displayed, perform b(2) and (3) below.

(9) Turn VERTICAL SENSITIVITY switch to 1 VOLTS/CM. Adjust square-wave

generator for an 8-centimeter amplitude display. If an optimum square wave is not

displayed, perform b(4) below.

(10) Turn VERTICAL SENSITIVITY switch to 10 VOLTS/CM and adjust squarewave generator for maximum output. If an optimum square wave is not displayed, perform

b(5) below.

(11) Position TI controls as listed in (a) through (c) below:

(a) VERTICAL SENSITIVITY switch to 10 MILLIVOLTS/CM.

(b) VERTICAL SENSITIVITY/VERNIER control fully counterclockwise.

(c) HORIZONTAL DISPLAY switch to 5 µSEC/CM.

(12) Adjust square-wave generator to 100 kHz and 8 centimeters of display

amplitude. If an optimum square wave is not displayed on TI crt, perform b(6) below.

(13) Disconnect cable from square-wave generator OUTPUT, and connect to squarewave generator +OUTPUT.

(14) Turn VERTICAL SENSITIVITY/VERNIER control to CAL and adjust squarewave generator for an 8-centimeter amplitude display. If an optimum square wave is not

displayed on TI crt, perform b(7) below.

25

Page 26

TB 9-6625-082-50

b. Adjustments

(1) Adjust C6 (fig. 5) for best square-wave pattern on TI crt.(R)

Figure 5. Vertical sensitivity switch - location of adjustments.

(2) Adjust C9 (fig. 6) for best square-wave pattern on TI crt. (R)

Figure 6. Oscillator - right-side view (panel removed).

26

Page 27

TB 9-6625-082-50

(3) Repeat (1) and (2) above for best results.

(4) Adjust C4 (fig. 5) for best square-wave pattern on TI crt. (R)

(5) Adjust C2 (fig. 5) for best square-wave pattern on TI crt. (R)

(6) Adjust C12 (R) and C13 (R) (fig. 4) for best square-wave pattern on TI crt.

(7) Adjust C10 (R) and C11 (R) (fig. 4) for best square wave on TI crt.

27. Horizontal Amplifier Frequency Response and Attenuator Compensation

a. Performance Check

(1) Position TI controls as listed in (a) and (b) below:

(a) VERTICAL SENSITIVITY switch to 1 VOLTS/CM.

(b) HORIZONTAL DISPLAY switch to .1 VOLTS/CM.

(2) Connect test oscillator (A7) to TI horizontal input connectors, using cable and

termination (B6 and B8).

(3) Adjust test oscillator frequency to 10 Hz and a 10-centimeter trace length. Note

test oscillator output level.

(4) Maintain constant test oscillator output amplitude of (3) above, and increase test

oscillator frequency until display amplitude is 7 centimeters. Test oscillator frequency will

be at least 300 kHz.

(5) Connect equipment as shown in figure 3.

(6) Adjust square-wave generator (A5) to 100 kHz and 8 centimeters of amplitude

display.

(7) Adjust test oscillator to approximately 8 kHz and stable display of 10

centimeters. If an optimum square wave is not displayed, perform b(1) below.

(8) Turn HORIZONTAL DISPLAY switch to 1 VOLTS/CM.

(9) Adjust square-wave generator to 1 kHz and an 8-centimeter display. Adjust

HORIZONTAL POSITION control as required.

(10) Adjust test oscillator to approximately 800 Hz and stable display of 8

centimeters. If flat-top square wave is not displayed, perform b(2) below.

(11) Turn HORIZONTAL DISPLAY switch to 10 VOLTS/CM. If flat-top square wave

is not displayed, perform b(3) below.

27

Page 28

TB 9-6625-082-50

b. Adjustments

(1) Adjust C103 and C104 (fig. 4) for flat-top square wave.(R)

(2) Adjust C235 (fig. 4) for a flat-top square wave. (R)

(3) Adjust C233 (fig. 4) for a flat-top square wave.(R)

28. Amplifier Phase Shift

a. Performance Check

(1) Position TI controls as listed in (a) through (c) below:

(a) HORIZONTAL DISPLAY switch to .1 VOLTS/CM.

(b) VERTICAL SENSITIVITY switch to 100 MILLIVOLTS/CM.

(c) Horizontal AC-DC switch to AC.

(2) Connect signal generator (A4) to TI vertical input connector, using cable. (B5).

(3) Connect TI vertical input to horizontal input, using cable (B5).

(4) Adjust signal generator to 100 kHz and approximately 6 centimeters of

deflection on TI crt. Pattern opening on crt will be less than 0.2 centimeter.

(5) Turn HORIZONTAL DISPLAY switch to 1 VOLTS/CM and VERTICAL

SENSITIVITY switches to 1 VOLTS/CM.

(6) Increase signal generator output to obtain approximately same pattern as

before. Pattern opening will be less than 0.2 centimeter.

b. Adjustments. Adjustments in paragraph 27b above interact with pattern openings

checked above. If necessary, repeat paragraph 27a(1) through (7) and b(1) above.

29. Sweep Timing

a. Performance Check

(1) Connect time-mark generator (A8) MARKER OUTPUT to TI vertical input,

using cable (B6).

(2) Turn HORIZONTAL DISPLAY switch to 20 MILLISECONDS/CM.

28

(3) Set time-mark generator to 10 mS.

Page 29

TB 9-6625-082-50

(4) Adjust horizontal POSITION control to align third marker behind second

vertical graticule line. If nineteenth marker is not displayed within ±0.5 centimeter of 10th

vertical graticule line and sweep length is not 10.75 centimeters, perform b(1) below.

(5) Turn HORIZONTAL DISPLAY switch to 5 µSEC/CM and set time-mark

generator to 5 µS.

(6) Adjust HORIZ. POS. control to align second time marker with second vertical

graticule line. If 10th time marker is not within ±0.5 centimeter of 10th vertical graticule

line, perform b(2) below.

(7) Repeat technique of (5) and (6) above, using values listed in table 7. Perform

adjustments (b(3) below) as necessary for out-of-tolerance sweep timing.

Table 7. Sweep Timing

Test instrument Time-mark

HORIZONTAL DISPLAY generator Adjustments

switch output Time mark/cm (fig. 4)

10 µSEC/CM 10 µS

20 µSEC/CM 10 µS

50 µSEC/CM 50 µS

100 µSEC/CM

200 µSEC/CM

.5 MILLISECONDS/CM .5 ms 1 C223 (R)

1 MILLISECONDS/CM 1 ms 1 - - 2 MILLISECONDS/CM 1 ms 2 C233 (R)

10 MILLISECONDS/CM 10 ms 1 - - 20 MILLISECONDS/CM 10 ms 2 - - -

50 MILLISECONDS/CM 50 ms 1 R247 (R)

100 MILLISECONDS/CM 50 ms 2 - - 200 MILLISECONDS/CM .1 s 2 - - -

.1 ms 1 - - .1 ms 2 - - -

1 - - 2 - - 1 C225 (R)

b. Adjustments

(1) Adjust R267 (R) (fig. 4) for 2 markers per centimeter and adjust R254 (R) (fig. 4)

for sweep length of 10.75 centimeters.

(2) Adjust C227 (fig. 4) for 1 marker per centimeter.(R)

(3) Perform appropriate adjustments in table 7.

30. Sweep Magnifier

a. Performance Check

(1) Turn HORIZONTAL DISPLAY switch to 5 MILLISECONDS/CM and SWEEP

MAGNIFIER switch to X5.

29

Page 30

TB 9-6625-082-50

(2) Set time-mark generator (A8) to 5 mS.

(3) Adjust HORIZONTAL POSITION control to align first time marker with first

vertical graticule line. One marker per 5 centimeters will be displayed ±0.5 centimeter.

b. Adjustments. No adjustments can be made.

31. Power Supply

NOTE

Do not perform power supply check if all other parameters are

within tolerance.

a. Performance Check

(1) Connect ac/dc voltmeter (A1) between pin 2 of V311 (fig. 4) and chassis ground.

If ac/dc voltmeter does not indicate between -145.5 and -154.5 volts dc, perform b(1) below.

(2) Connect positive lead of dc voltmeter (A3) to chassis ground and negative lead to

terminal 17 of T302 (fig. 4). If dc voltmeter does not indicate between -2375 and -2625

volts, perform b(2) below.

b. Adjustments

(1) Adjust R352 (fig. 4) for indication of -150 volts dc on ac/dc voltmeter. (R)

(2) Adjust R308 (fig. 4) for indication of -2500 volts on dc voltmeter.(R)

32. Final Procedure

a. Deenergize and disconnect all equipment and replace TI within protective cover.

b. In accordance with TM 38-750, annotate and affix DA Label 80 (U.S. Army

Calibration System). When the TI cannot be adjusted within tolerance, annotate and affix

DA Form 2417 (Unserviceable or Limited Use tag).

30

Page 31

TB 9-6625-082-50

By Order of the Secretary of the Army:

CREIGHTON W. ABRAMS

General, United States Army

Chief of Staff

Official:

VERNE L. BOWERS

Major General, United States Army

The Adjutant General

Distribution:

To be distributed in accordance with DA Form 12-34, Section II (qty rqr block No. 75),

requirements for calibration procedures publications.

US GOVERNMENT PRINTING OFFICE: 1981 - 740-031/2007

PIN: 010316-000

Loading...

Loading...