Page 1

October 1998 Edition

HP LaserJet Printer Family

Paper Specification Guide

Page 2

Page 3

HP LaserJet Printer Family

Paper Specification Guide ____

Page 4

© Copyright Hewlett-Packard

Company, 1998

All Rights Reserved.

Reproduction, adaptation, or

translation without prior written

permission is prohibited, except

as allowed under the copyright

laws.

Publication number: 5040-9072

First edition, October 1998

Warranty

The information contained in

this document is subject to

change without notice.

Hewlett-Packard makes no

warranty of any kind with

respect to this information.

HEWLETT-PACKARD

SPECIFICALLY DISCLAIMS

THE IMPLIED WARRANTY OF

MERCHANTABILITY AND

FITNESS FOR A PARTICULAR

PURPOSE.

Hewlett-Packard shall not be

liable for any direct, indirect,

incidental, consequential, or

other damage alleged in

connection with the furnishing or

use of this information.

Hewlett-Pack ard Company

11311 Chinden Boulevard

Boise, Idaho 83714 U.S.A.

Page 5

Contents

1 Introduction

About the HP LaserJet printer family. . . . . . . . . . . . . . . . . . . . . . . . . 7

Basic theory of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Supported HP LaserJet products . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Alternate sources of information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Guidelines and specifications for selecting media

Important notice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Recommendations to the customer. . . . . . . . . . . . . . . . . . . . . . . . . . 9

Buy media that meets specifications. . . . . . . . . . . . . . . . . . . . . 10

Test small amounts of media . . . . . . . . . . . . . . . . . . . . . . . . . . 10

General guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Quality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Basis weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Furnish (composition) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Curl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Finish (smoothness) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Felt side vs. wire side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Paper specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

U.S. paper grades: Basic sizes and basis weights . . . . . . . . . . . . . 16

Weight Equivalence Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Comparisons of paper smoothness. . . . . . . . . . . . . . . . . . . . . . . . . 18

Recycled paper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Archival paper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Colored paper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Paper with cutouts or perforations . . . . . . . . . . . . . . . . . . . . . . 20

Preprinted forms and letterhead . . . . . . . . . . . . . . . . . . . . . . . . 21

Envelope specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Envelope construction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Adhesive label specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Label stock facts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Overhead transparency specifications . . . . . . . . . . . . . . . . . . . . . . 30

Types of media to avoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

EN

3 Purchasing, shipping, and storing media

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Purchasing media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Overhead transparencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Shipping media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Contents 5

Page 6

Storing media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Environmental considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4 Troubleshooting

Factors contributing to print problems. . . . . . . . . . . . . . . . . . . . . . . 39

Two-sided printing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Automatic duplexing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Manual duplexing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Indications of paper problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

High rates of jams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

High rates of multiple feeds . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Post-image curl. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Indications of envelope problems . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Gray background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

High rates of jams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Wrinkling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

A Paper basis weights

B Postal customer recommendations statement

C Glossary

6 Contents

Index

EN

Page 7

1

Introduction

About the HP LaserJet printer family

HP LaserJet printers quietly produce documents of excellent print

quality at speeds ranging from four to seventeen pages per minute.

You can print on a variety of print media, including paper, envelopes,

labels, and overhead transparencies. (Envelopes and labels are not

supported on most HP Color LaserJet printers.) Many printer settings

are easily selectable from the printer control panel.

Basic theory of operation

HP LaserJet printers use laser and electrophotographic technologies.

In this process, a scanning laser beam writes an electrostatic image

onto a rotating photosensitive drum. As this image passes the

developing station, a dry, powdery toner is attracted to the imaged

areas. In an HP Color LaserJet printer, this process is repeated for

each of the four toner colors. The de veloped image then advances to

the transfer station where the drum contacts the media and the toner

image is electrostatically transferred onto the paper . After transf er , the

media passes through the fuser where heat is applied and the toner

fuses (melts) onto the media. The media is then delivered to the

output bin, ready for use.

EN

To create the printed image, the print media must be transported

through the printer, charged electrostatically, and heated. This is why

media properties such as electrical resistivity, caliper, finish, moisture

content, and stiffness can affect the print quality and media-handling

performance of your HP LaserJet printer.

Chapter 1 – Introduction

7

Page 8

Supported HP LaserJet products

This document provides useful guidelines for selecting media that will

give you the best performance with most HP LaserJet printers and

the HP LaserJet Companion.

This document does not support HP LaserJet 2686A, HP LaserJet

Plus, HP LaserJet 500, or HP LaserJet 2000 printers. See the user

guide for each printer for information about print media specifications.

Alternate sources of information

The media manufacturer and vendor can pro vide you with inf ormation

about the suitability of media for an HP LaserJet printer or the

HP LaserJet Companion.

If you hav e tried the suggestions outlined in this document and in your

user guide and you still need assistance, call the dealer from whom

you purchased your printer. You can also obtain support through the

worldwide network of HP Sales and Service Offices. (See the sales

and service listings located in any HP LaserJet printer user guide.)

In the United States, HP offers support through the Customer Care

Center. Call (208) 323-2551 from 6 am to 10 pm MST, Monday

through Friday, or from 9 am to 4 pm MST, Saturday.

8

Supported HP LaserJet products

EN

Page 9

Guidelines and

2

specifications for

selecting media

Important notice

Properties of media are subject to change by manufacturers.

Hewlett-Packard has no control over such changes. The customer

assumes all responsibility for the quality and performance of media.

Although testing media helps to characterize its performance,

long-term satisfaction requires process quality control by the

manufacturer and proper handling and storage by the customer.

Recommendations to the customer

HP LaserJet printers are designed to be flexible in the types of print

media they can use. Howe v er , it is advisable to use quality media and,

specifically, HP LaserJet or HP Multipurpose paper since it has been

designed to work with HP LaserJet printers. If HP paper is available in

your area, it is recommended that you use it.

Note HP recommends testing media prior to purchasing it in large quantities.

EN

Chapter 2 – Guidelines and specifications for selecting media

9

Page 10

Buy media that meets specifications

For best performance from your HP LaserJet printer, select

high-quality print media that meets the guidelines and specifications

in this document.

Test small amounts of media

If you are planning a large purchase of media, first print a small

quantity in your printing environment. Subject the media to the

temperature, humidity, and printing applications in which the media

will be operating. HP recommends that you ask your media v endor f or

a guarantee that their media will perform satisfactorily in your

HP LaserJet printer and that the vendor will assume responsibility for

the replacement of any media that will not print acceptably.

General guidelines

This section summarizes general guidelines for choosing print media.

Quality

HP LaserJet printers work best with high-quality media. Quality media

for HP LaserJet printers are characterized by uniform physical

properties, freedom from dust and lint, accurate cutting to size, and

proper packaging. Proper packaging protects media from moisture

and physical damage.

10

General guidelines

Avoid media with curled or bent edges , spots, dust or lint, wrinkling, or

inaccurate size. These characteristics can cause misfeeding,

jamming, premature wear of printer parts, or unsatisfactory print

quality in the printer.

Size

Table 2-1 lists the names and dimensions of the most commonly used

paper and envelopes. See the user documentation that came with

your printer for specific information on the media supported by your

HP LaserJet printer. Use only paper and envelopes that are

unsupported by your printer.

EN

Page 11

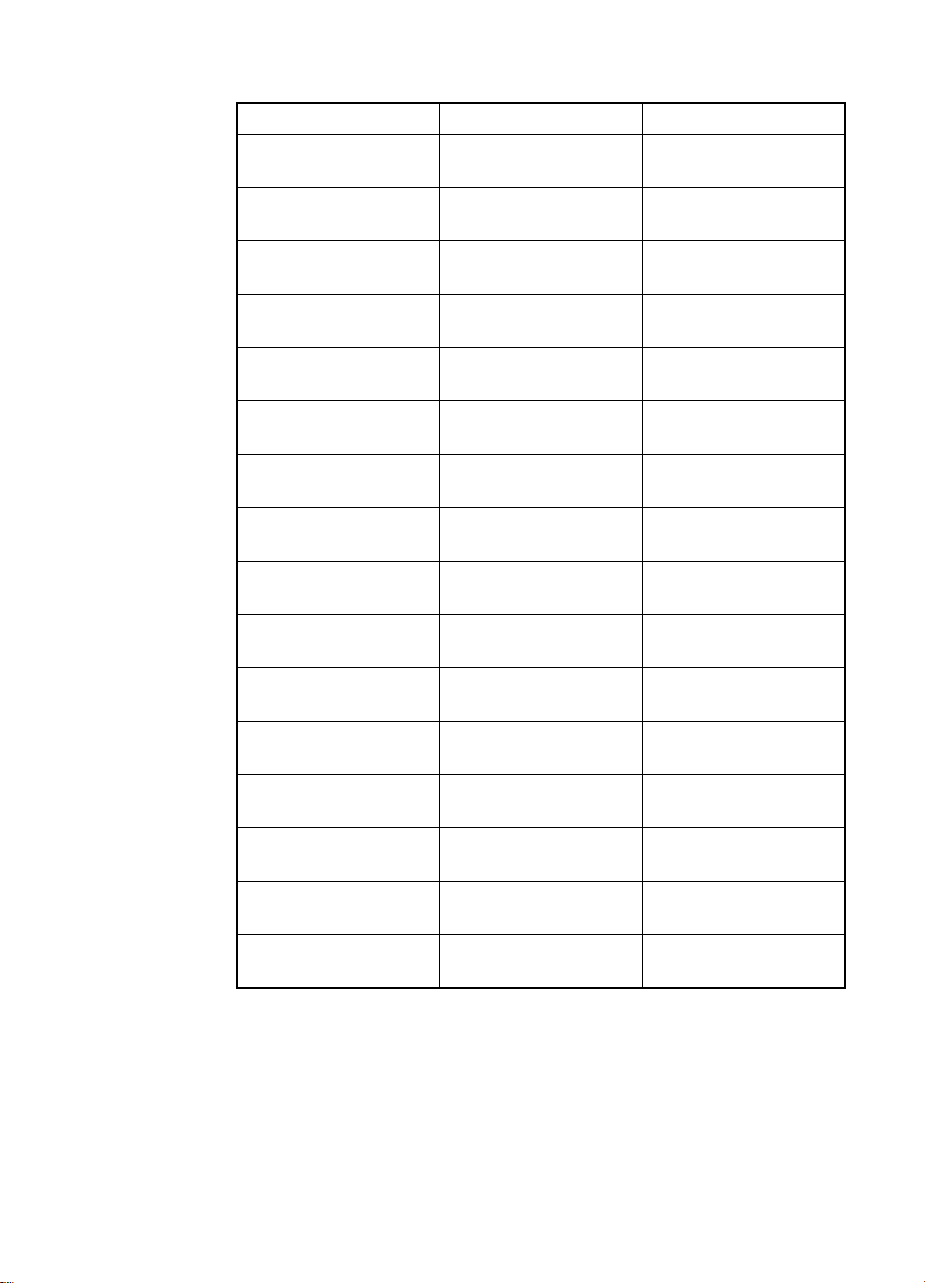

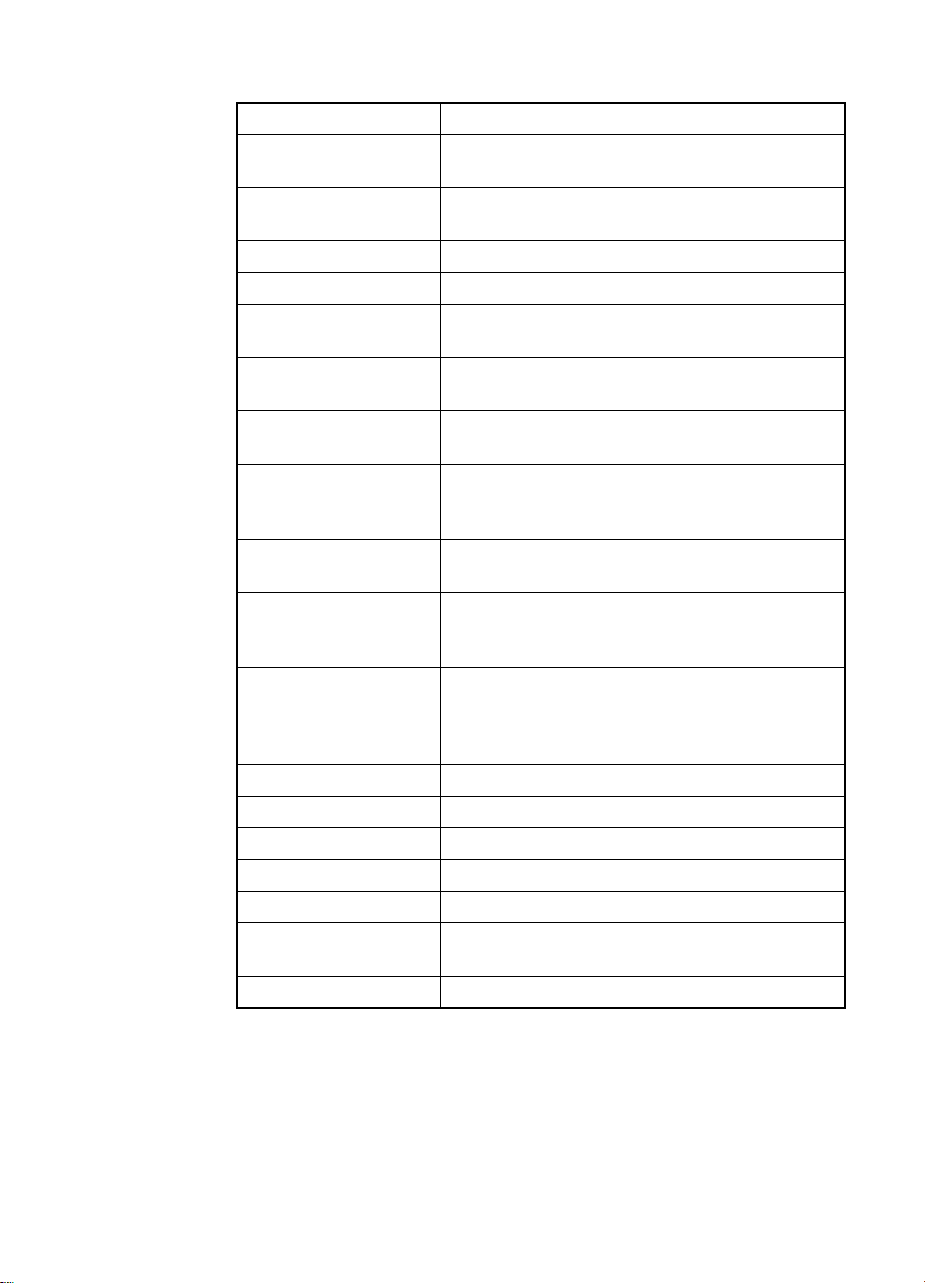

Table 2-1. Common paper and envelope sizes

Type of media Name Dimensions

Paper Letter 8.5 by 11 in

(216 by 279 mm)

Paper Legal 8.5 by 14 in

(216 by 356 mm)

Paper Executive 7.25 by 10.5 in

(184 by 267 mm)

Paper Tabloid/Ledger 11 by 17 in

(279 by 432 mm)

Paper A3 297 by 420 mm

(11.7 by 16.5 in)

Paper A4 210 by 297 mm

(8.3 by 11.7 in)

Paper A5 148 by 210 mm

(5.8 by 8.3 in)

Paper B4 (JIS) 257 by 364 mm

(10.1 by 14.3 in)

Paper B5 (JIS) 182 by 257 mm

(7.2 by 10 in)

Paper J Postcard (hagaki) 100 by 148 mm

(3.9 by 5.8 in)

Paper J Double Postcard

(oufuku hagaki)

Envelope Commercial #10 105 by 241 mm

Envelope #7 3/4 (Monarch) 98 by 191 mm

Envelope DL 110 by 220 mm

Envelope C5 162 by 229 mm

Envelope B5 176 by 250 mm

148 by 200 mm

(5.8 by 7.9 in)

(4.1 by 9.5 in)

(3.9 by 7.5 in)

(4.3 by 8.7 in)

(6.4 by 9.0 in)

(6.9 by 9.8 in)

EN

Chapter 2 – Guidelines and specifications for selecting media

11

Page 12

Basis weight

Basis weight (also called grammage) is an important characteristic of

paper. Paper that is too light or too heavy can cause misfeeds,

mis-stacking, paper jams, poor print quality, or excessive mechanical

wear in the printer.

CAUTION Avoid using extremely heavy paper. Use paper that falls within your

printer’s specified basis weight, as shown in appendix A or in the user

documentation that came with your printer.

Furnish (composition)

Furnish is the mixture of various materials used to make the paper

stock. For optimum performance of your HP LaserJet printer, use

paper made from 100 percent chemical wood pulp and/or cotton fiber.

Recycled paper, made with no more than 5 percent groundwood, is

also acceptable. To ensure that paper of a special fiber composition

will work correctly in your printer, test it before purchasing large

quantities. Other components in paper are sizing, fillers, and

pigments.

Note Avoid using coated paper or paper containing materials that melt,

vaporize, offset, discolor, or release hazardous emissions when

exposed to 205° C (401° F) for 0.1 second (0.2 second for

HP Color LaserJet printers).

12

General guidelines

Curl

Curl is curvature in a sheet of paper. It is typically measured by la ying

the sheet of paper on a flat surface, with the corners up, and

measuring the height of the corners. There are two types of curl:

In-ream curl is the amount of curl in a sheet of paper before

z

printing. In-ream curl results from the paper-manufacturing

process or from exposure to the environment. Paper with

excessive in-ream curl might lead to feeding and print-quality

problems.

Post-image curl is the amount of curl in a sheet of paper after

z

printing. Post-image curl results from exposure to the fusing

process and paper path in the printer. Paper with excessive

post-image curl may be difficult to handle or to use in

automatic-feed photocopiers.

EN

Page 13

Finish (smoothness)

Paper for laser printers should not have a heavy texture or a glossy

smoothness. Printed output on textured paper may have broken

character edges and show poor toner adhesion. On the HP Color

LaserJet printers, textured paper will cause inconsistent or blotchy

colors and may wrinkle in the fuser. Glossy-smooth paper tends to

highlight defects such as stra y toner particles, and may not hold toner .

For sharp resolution or detail, use a smooth paper.

Paper finish is typically measured using air leak methods. We

recommend a range for smoothness using the Sheffield method.

Equivalent values for other methods can be found in Figure 2-1 on

page 18.

Avoid using paper with embossed or raised surfaces because spotty

printing and misfeeding may occur. It is possible to print satisfactorily

on paper that has embossed areas in the leading edge, trailing edge,

or in areas where print will not appear on the paper; however,

misfeeding or jamming may occur.

Felt side vs. wire side

Some methods of manufacturing paper result in two-sided paper

properties. Along with other process variations, these properties can

make one side of the paper the preferred side on which to print. The

“top” side of the paper sheet, as it is formed, is known as the felt side.

The “bottom” is known as the wire side. Most manufacturers indicate

the preferred printing side on the package.

EN

Chapter 2 – Guidelines and specifications for selecting media

13

Page 14

Paper specifications

Use conventional white xerographic paper for most printing. The

paper should be high quality and free of cuts, tears, grease spots,

loose particles, dust, wrinkles, voids, and curled or bent edges.

Xerographic papers, also called photocopy or xerocopy papers, are

usually made from chemical wood pulp and are characterized by a

smooth surface, controlled electrical properties, heat stability, and

cleanliness. These characteristics ensure good image transfer, fusing

without excessive curl, and reliable printer operation.

Some printing applications may require a paper with a more

prestigious look or feel. Bond papers generally hav e a watermark and

often use cotton fiber. These papers tend to have a rougher surface

and their properties might not be controlled like those of xerographic

papers. Your HP LaserJet printer will print black satisfactorily on many

of these bond papers. Using this type of paper on HP Color LaserJet

printers can degrade color print quality. However, paper

manufacturers are now making laser-grade bond papers, which have

properties optimized for laser printing.

Note For paper specifications specific to Magnetic Ink Character Recognition

(MICR) printing applications, refer to the

HP part number 5091-3857.

HP MICR User’s Guide

,

One of the most important things you can do to ensure the best

performance from your HP LaserJet printer is to select high-quality

media. It is recommended that you use HP media. If you are not using

HP media, see Table 2-2, which summarizes the specifications of

paper that provide the best performance.

Note Paper ma y meet the general specifications listed in Table 2-5 and still

not print satisfactorily because of the printing environment or other

variables over which HP has no control.

14

Paper specifications

EN

Page 15

Table 2-2. Paper specifications

Description Specifications

Basis weight See appendix A or the user documentation for

your printer

Brightness 83% minimum. Recycled paper may not be as

bright

Caliper Depends on basis cut ranges

Curl In-ream: flat within 5 mm (0.2 in)

Cut edge

conditions

Electrical surface

resistivity

Electrical volume

resistivity

Finish 100 to 190 (Sheffield) for HP Color LaserJet

Finishing precision Cut sheet to within ±0.03 inch (± 0.8 mm) of

Furnish (fiber

composition)

Fusing compatibility Must not scorch, melt, offset, or release hazardous

Grain Long grain

Moisture content 4% to 6% by weight

Opacity 85% minimum

Packaging Polylaminated moisture-proof ream wrap

pH 5.5 pH minimum

Stiffness 1.6 minimum machine direction, 0.6 minimum

Wax pick 12 minimum (Dennison)

Cut with sharp blades with no visible fray and no

dust

2.0 to 15 by 10

10

ohms/in

2

(conditioned at 23° C and 50% RH)

1.2 to 15 by 10

(conditioned at 23

11

ohms/cm

°

C and 50% RH)

printers;

100 to 250 for all other HP LaserJet printers.

°

nominal and ± 0.2

square

100% chemical wood pulp and/or cotton fiber;

recycled paper with up to 5% groundwood may be

used

emissions when heated to 205° C (401° F) for

0.1 second (0.2 second for HP Color LaserJet

printers)

cross direction (Taber)

EN

Chapter 2 – Guidelines and specifications for selecting media

15

Page 16

U.S. paper grades: Basic sizes and basis weights

The U.S. paper grading system has evolved from custom and usage

rather than from a technical background, resulting in similar papers

having different stated weights. For example, a 24# bond paper is

exactly the same weight as a 60# book or a 60# text or a 33# cover.

This is because basis weight is defined as the weight of 500 sheets of

paper cut to basic size. The basic size for bond, book/text, cover,

index, bristol, and tag are all different so the given weights for these

paper grades may be diff erent although the ph ysical weight is virtually

identical. Table 2-3 will help clarify these differences. Note the

difference in basic size for each grade, which affects the weight of

500 sheets of that grade.

Table 2-3. Common paper grades and basis weights

Paper grade Basic size Basic area Factor Equivalent

Bond 432 by 559 mm

Text 635 by 965 mm

Book (coated

or uncoated)

Cover 508 by 660 mm

Bristol 571 by 724 mm

Index 648 by 775 mm

Tag 610 by 910 mm

Metric weight none none 3.76

(17 by 22 in)

(25 by 38 in)

635 by 965 mm

(25 by 38 in)

(20 by 26 in)

(22.5 by 28.5

in)

(25.5 by 30.5

in)

(24 by 36 in)

2

241 m

(374.0 sq. in)

2

613 m

(950.0 sq. in)

2

613 m

(950.0 sq. in)

2

335 m

(520.0 sq. in)

414 m2

(641.25 sq. in)

502 m2

(777.75 sq. in)

2

557 m

(864.0 sq. in)

1.00 24# bond

2.54 61# text

2.54 61# book

1.39 33# cover

1.71 41# bristol

2.08 50# index

2.31 55# tag

basis weights

(example)

2

90 g/m

(

16

U.S. paper grades: Basic sizes and basis weights

EN

Page 17

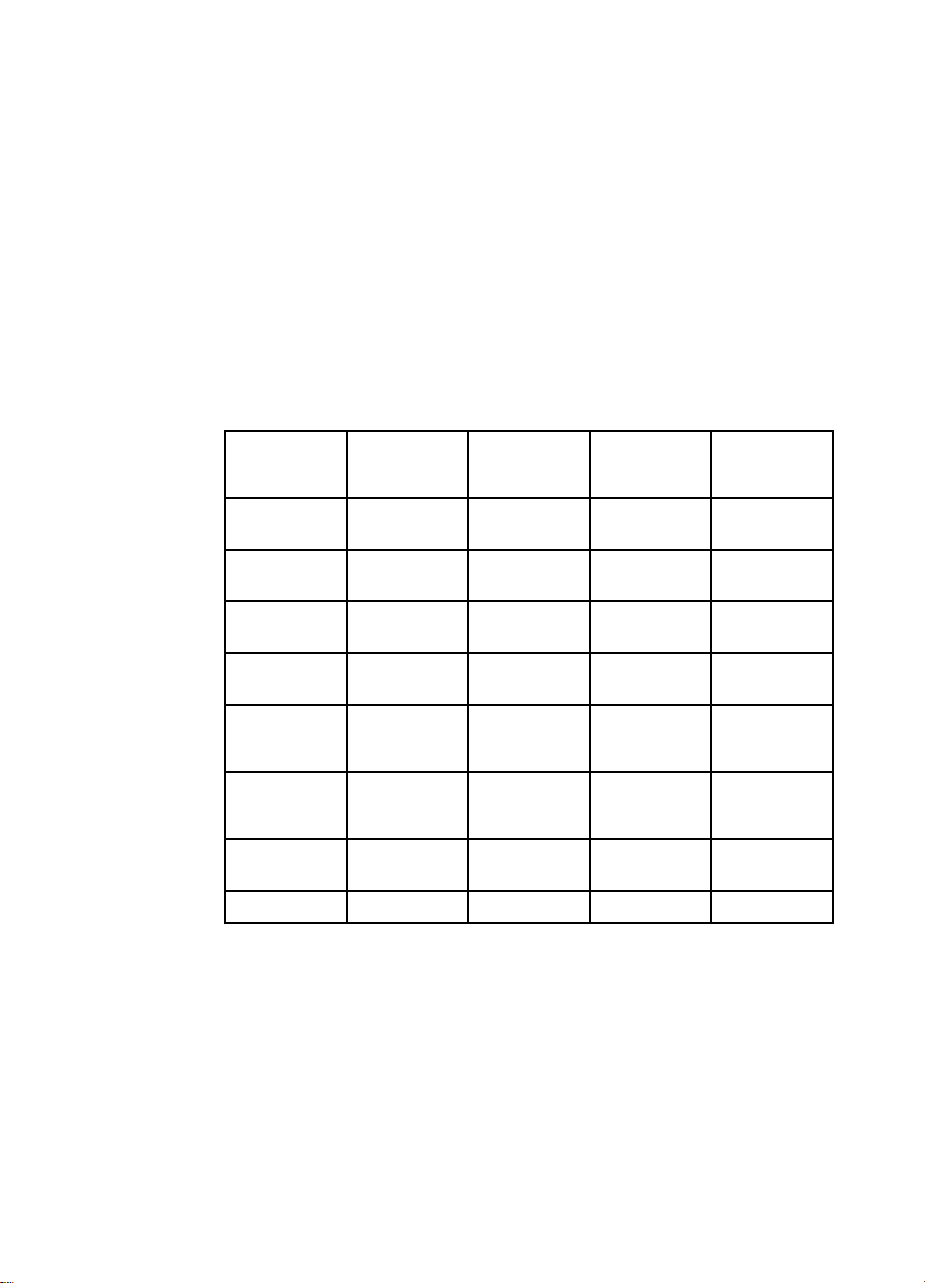

Weight Equivalence Table

Table 2-4 shows equivalent weights for different grades of paper.

Shaded boxes indicate a commonly a v ailab le standard weight for that

grade.

Table 2-4. Weight equivalence table

Bond wt.

(17 x 22)

16# 41# 22# 27# 33# 37#

17# 43# 24# 29# 35# 39#

20# 50# * 28# 34# 42# 46#

21# 54# 30# 36# 44# 49#

24# 60# * 33# 41# 50# 55#

27# 68# 37# 45# 55# 61#

28# 70# * 39# 49# 58# 65#

29# 74# 41# 50# 61# 68#

32# 80# * 44# 55# 67# 74#

36# 90# 50# 62# 75# 83#

39#

40# 101# 55# 68# 83# 92#

43# 110#

45# 115# 63# 77# 94# 104#

47# 119#

51# 128# 70# 86# 105# 117#

53# 134# 74# 90#

54# 137# 75# 93# 113#

58# 146#

65# 165#

66# 169# 92# 114# 138# 154#

67# 171# 94# 115#

70# 178# 98#

72# 183#

Text/

Book wt.

(25 x 38)

100# 55# 67# 82# 91#

Cover

wt.

(20 x 26)

60# 74# 90# 100#

65# 80# 97# 108#

80# 98# 120# 133#

90# 111# 135# 150#

100# 123# 150# 166#

Bristol wt.

(22.5 x 28.5)

120# 146# 162#

Index wt.

(25.5 x 30.5)

110# 122#

140# 155#

Tag wt.

(24 x 36) Metric wt.

125#

60 g/m

64 g/m

75 g/m

80 g/m

90 g/m

100 g/m

105 g/m

110 g/m

120 g/m

135 g/m

148 g/m

150 g/m

163 g/m

170 g/m

176 g/m

190 g/m

199 g/m

203 g/m

216 g/m

244 g/m

250 g/m

253 g/m

264 g/m

271 g/m

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Note T e xt and book grades marked with an * actually calculate out to 51, 61,

71, and 81, but are rounded to standard book/text weights of 50, 60,

70, and 80.

EN

Chapter 2 – Guidelines and specifications for selecting media

17

Page 18

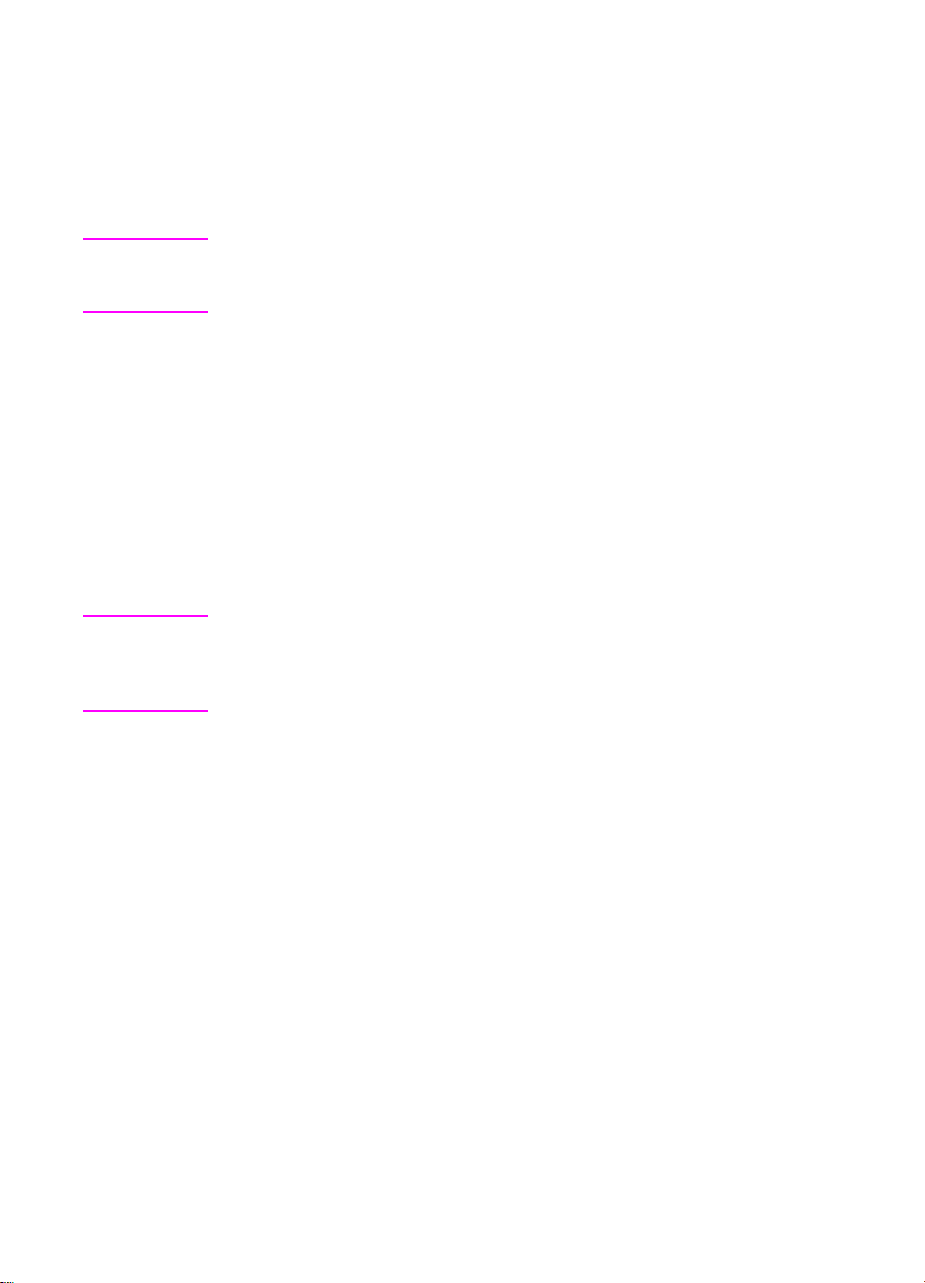

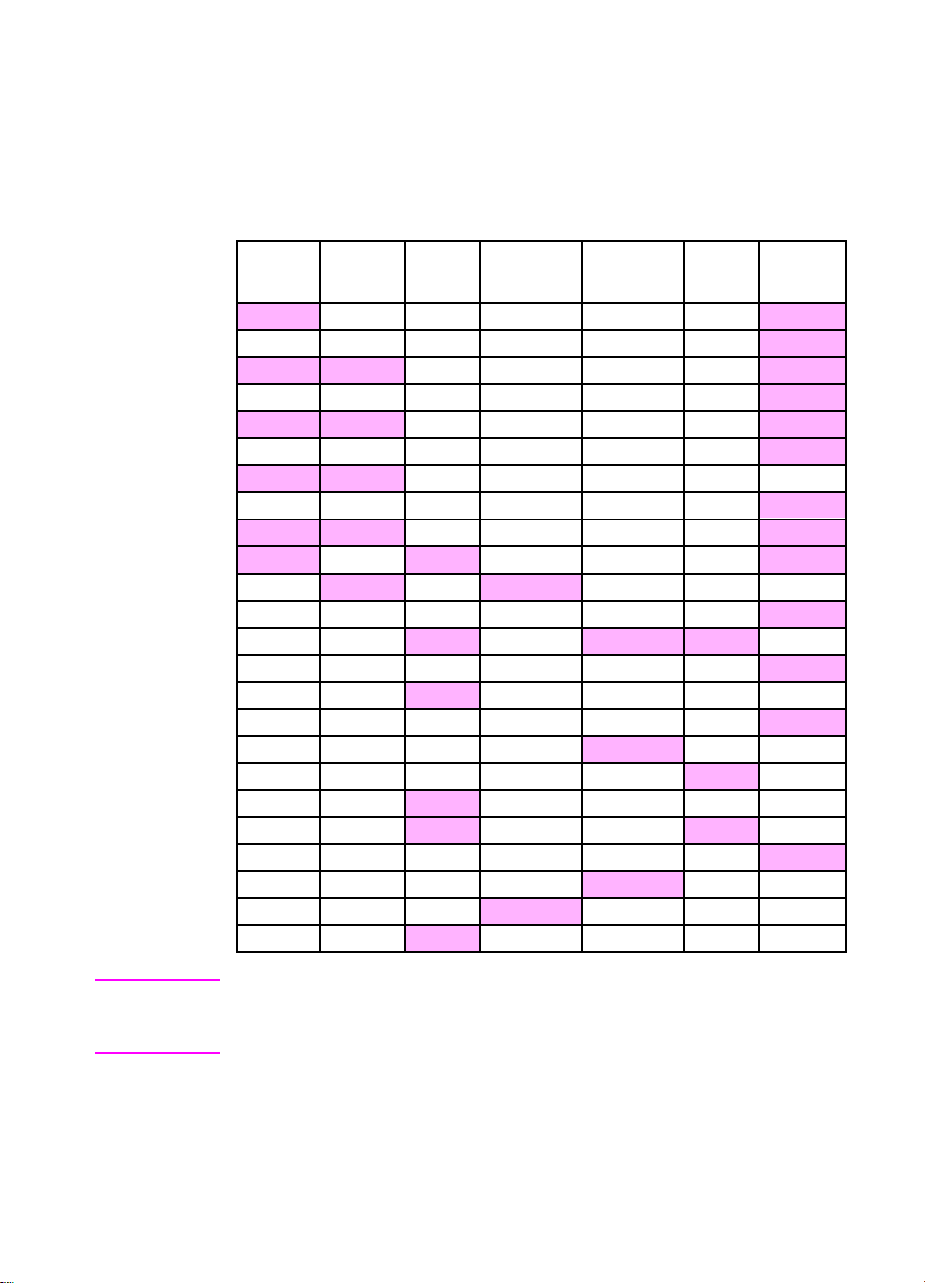

Comparisons of paper smoothness

Smoothness typically is expressed in terms of Sheffield, Gurley , Bekk,

or Bendtsen units. HP LaserJet printers generally require a

smoothness of between 100-250 Sheffield. Figure 2-1 compares the

different types of smoothness.

Sheffield Gurley S-P-S Bekk Bendtsen

(3 PSI) (1 KG/CM

(CC by 10-2/MIN) (SEC./100 CC) (SEC/10 CC) (CC/MIN)

Figure 2-1 Interrelation among methods of air-leak smoothness

2)

18

Comparisons of paper smoothness

EN

Page 19

Recycled paper

Recycled paper is a combination of printed waste paper, preconsumer waste, and post-consumer waste. Printed waste paper is

usually washed to remove most of the inks and other contaminants . A

recycled sheet of paper may contain dark specks or appear gray or

dirty. Choose recycled paper that meets the same specifications,

except brightness, as standard paper (see Table 2-2) and that has an

appearance suitable for your needs. HP recommends that recycled

paper contain no more than 5 percent groundwood.

Archival paper

Paper used for archiving must meet the same specifications as

standard paper; however, the pH should be no less than 7.0. Some

archival demands are more stringent than others, requiring a specific

degree of alkalinity and chemical stability. Toner is chemically stable

and should last as long as the paper does. Toner can be degraded by

petroleum-based solvents or plasticizers, such as those f ound in vin yl

folders.

Avoid folding archival documents across printed areas or handling

archival documents roughly. Discuss archival requirements with your

paper supplier.

Colored paper

You can use colored paper in your HP LaserJet printer as long as

the paper meets the same specifications as standard paper

(see Table 2-2).

The HP Color LaserJet printers are optimal for printing on white

paper. You also can use an HP Color LaserJet printer to print on

colored paper that meets all the specifications listed in this guide.

However, colored paper may change the printed colors. This is

because HP Color LaserJet printers create colors by printing a

pattern of dots, overlaying and varying their spacing to produce

various colors. When these colors are printed on colored media, the

shade or color of the media will vary the shades of your printed

colors. Since the printer cannot sense what color of paper you are

using, it cannot adjust the output colors for colored paper.

EN

Chapter 2 – Guidelines and specifications for selecting media

19

Page 20

Paper with cutouts or perforations

Using paper with cutouts or perforations could result in more feeding

and contamination problems with your printer.

Cutouts: A cutout is any portion of the paper that has been

removed, including binder holes, notches, and square cuts. Cutouts

can interact with paper position sensors in the printer or can result in

contamination by toner if printing at a cutout location.

Perforations: Perforations are a series of holes or slits punched

through the paper to aid in separating one piece of paper from

another. Perforations can create paper dust contamination or reduce

the stiffness of the paper so that paper buckles during feeding. These

papers often cause paper jams, misfeeds, and paper-handling

problems, and they may damage the printer.

If you must use papers with internal perforations or cutouts, follow

these guidelines:

Punch cutouts and perforations from the side to be printed on, so

z

that edge trimmings will not scratch the photosensitive drum.

Avoid printing at a cutout location or closer than 3 mm (0.125 in)

z

to the edge of a cutout. This will prevent toner from contaminating

the inside of the printer.

Cut cutouts and perforations cleanly (without burrs) to avoid

z

multiple feed, contaminants, or paper jam problems.

On most printers, avoid perforations that run across the page,

z

perpendicular to the paper path.

With an HP Color LaserJet printer, when printing on letter, A4,

z

and executive-size paper, avoid perforations that run down the

page because these paper sizes load long-edge first. When the

printer transfers paper from one set of rollers to the next, a

perforation can cause the page to bend downward and miss the

pickup point on the next roller.

20

Comparisons of paper smoothness

EN

Page 21

Preprinted forms and letterhead

To avoid multiple feed and jamming problems when using preprinted

forms, embossed paper, and letterhead paper, observe the following

guidelines:

Avoid using low-temperature inks (the kind used with some types

z

of thermography).

Use forms and letterhead paper printed by offset lithography or

z

engraving.

Print forms with heat-resistant inks that will not melt, vaporize, or

z

release hazardous emissions when heated to 205° C (401° F) for

0.1 second (0.2 second for the HP Color LaserJet printers).

Typically, oxidation-set or oil-based inks meet this requirement.

When the form is preprinted, be careful not to change the

z

moisture content of the paper, and do not use materials that

change the paper’s electrical or handling properties. Seal the

forms in moisture-proof wrap to prev ent moisture changes during

storage.

Avoid processing preprinted forms with a finish or coating.

z

Avoid using heavily embossed or raised letterhead papers.

z

Avoid papers with heavily textured surfaces.

z

EN

Chapter 2 – Guidelines and specifications for selecting media

21

Page 22

Envelope specifications

CAUTION Most HP Color LaserJet printers do not support envelopes. Printing

envelopes may damage the printer.

You can print many sizes and styles of envelopes on most

HP LaserJet printers by using manual feed, a multipurpose (MP) tra y,

an optional envelope tray, or an optional envelope feeder. Whichever

input method you use, envelopes should meet all specifications

discussed in this document. Your envelope vendor should pro vide you

with a satisfactory envelope that complies with the specifications

listed in Table 2-5.

See the user guide that came with your printer for detailed

instructions on printing envelopes.

Note Envelopes ma y meet the general specifications listed in Table 2-5 and

still not print satisfactorily because of the printing environment or other

variables over which HP has no control.

22

Envelope specifications

EN

Page 23

Table 2-5. Envelope specifications

Description Specifications

Basis weight • 60 to 90 g/m2 (16 to 24 lb), single thickness except

HP LaserJet 4P/4PJ and 5L printers.

• 75 to 90 g/m

HP LaserJet 4P/4PJ and 5L printers. Jamming might

result if 90 g/m

• 105 g/m

4000, 5000, 8000, and 8100 printers.

Caliper 0.084 to 0.14 mm (3.3 to 5.5 mils), single layer thickness

Curl Envelopes must lay flat, with no more than 6 mm (0.25 in)

curl across the entire surface

Finishing Avoid using envelopes with adhesive exposed to the

printer. Env elopes must be f olded accurately (± 0.04 in) so

that there are no more than two thicknesses of paper

anywhere along the leading edge. All folds must be well

scored and sharply creased, and construction must be

tight (not baggy). Avoid using envelopes that are stuck

together with excess seam gum.

Fusing

compatibility

All inks, adhesives, and other materials of the envelope

must be compatible with the heat and pressure of the

fusing process. Materials must not discolor, melt, offset, or

release hazardous emissions when heated to 205° C

(401° F) for 0.1 second.

Moisture content 4% to 6% by weight

Paper Paper used for envelope construction must meet the paper

specifications listed in Table 2-2. See the Caution

information that follows this table.

Smoothness 100 to 250 Sheffield

2

(20 to 24 lb), single thickness on the

2

2

(24 lb) is exceeded.

(28 lb), single thickness on HP LaserJet

CAUTION Envelopes containing windows, clasps, snaps, or synthetic materials

should not be used; these can cause severe printer damage.

See the printer user guide before using envelopes in your

HP LaserJet printer.

EN

Chapter 2 – Guidelines and specifications for selecting media

23

Page 24

Envelope construction

Because of their construction, some envelopes will not feed through

the printer dependably. Observe the following guidelines when

purchasing and using envelopes:

Make sure the envelope’s leading edge, which enters the printer,

z

is straight, with a sharp, well-creased fold with no more than two

thicknesses of paper. Envelope paper exceeding 90 g/m

basis weight may cause jamming.

Avoid using flimsy envelopes with thick or curved leading edges;

z

they will not feed reliably.

Envelopes should lay flat and should not be wrinkled, nicked, or

z

otherwise damaged.

Avoid envelopes with baggy construction; they might wrinkle

z

while going through the printer’s fuser assembly.

Make sure that the adhesives used in envelopes will not scorch,

z

melt, offset, or release hazardous emissions when heated to

205° C (401° F) for 0.1 second.

2

(24 lb)

24

Envelope specifications

EN

Page 25

Results of envelope tests

HP tests many types of envelopes to determine which ones print

acceptably in an HP LaserJet printer. Some of the test results are

listed below.

Commercial or Official envelopes (also called Business or

z

Regular), with diagonal seams and standard gummed flaps,

performed the most reliably.

Envelopes with double-side seam construction, which have

z

vertical seams at both ends of the envelope instead of diagonal

seams, tend to be more flimsy than diagonal-seam envelopes.

Double-side seam envelopes may tend to jam or wrinkle unless

the edges are thin and sharply creased. However, a variety of

double-side seam envelopes have performed acceptably during

testing.

Envelopes with a peel-off adhesive strip, or with more than one

z

flap that folds over for sealing, must use adhesives compatible

with the heat and pressure of the printer’s fusing process. Many

varieties of this type of envelope performed satisfactorily in HP

testing; however, the extra flaps and strips may result in

increased jamming or wrinkling.

Generally, feeding problems increase with envelope size. Larger

z

envelope sizes (C5, B5) cannot have a basis weight greater than

105 g/m

2

(28 lb).

EN

Chapter 2 – Guidelines and specifications for selecting media

25

Page 26

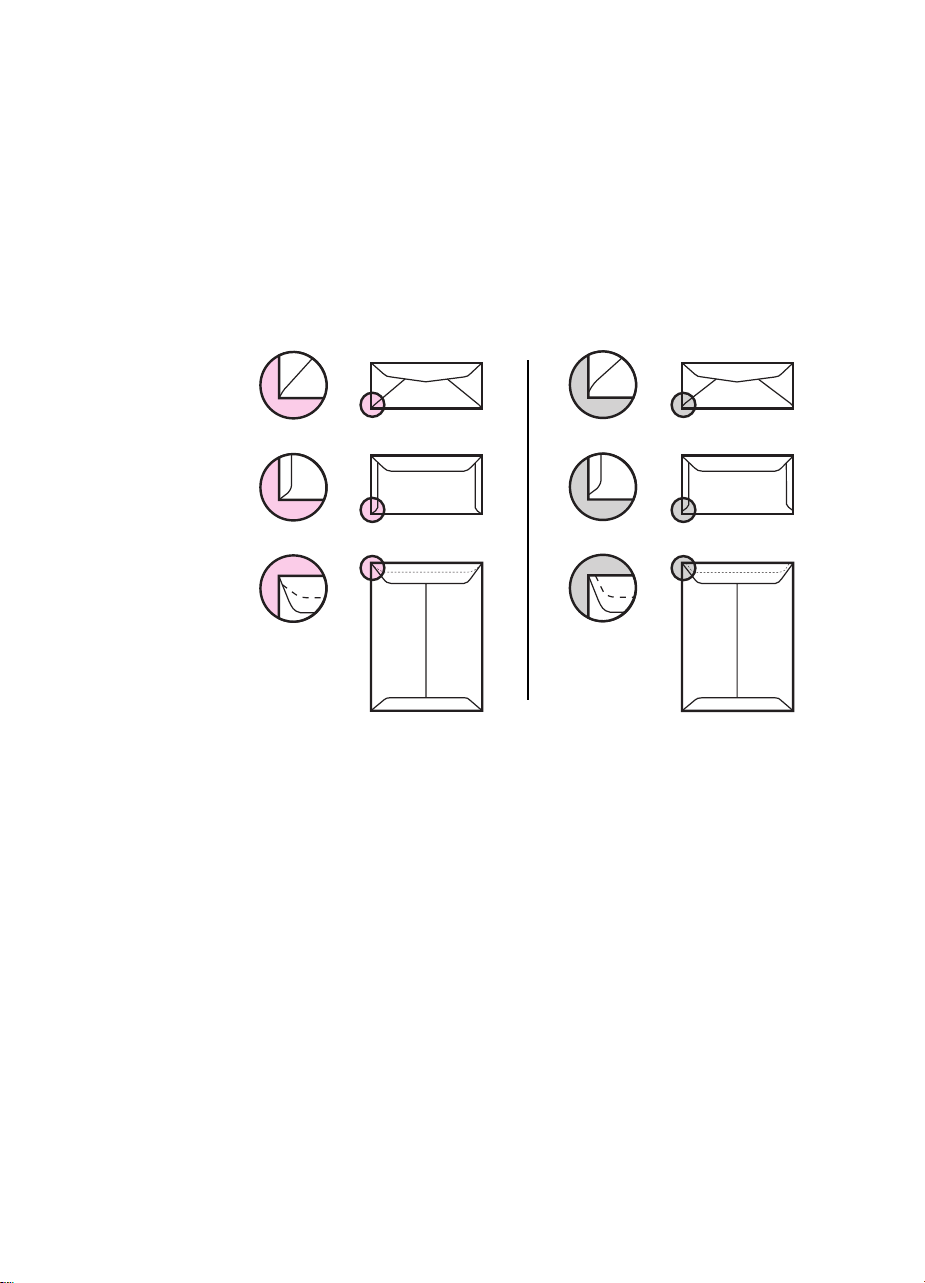

Unacceptable envelope construction

Many envelopes will feed through your HP LaserJet printer without

problems. However, some envelope constructions (as shown in

Figure 2-2) will not feed reliably. Problems may occur when the

envelopes are folded smaller than normal, causing a thick leading

edge near a corner. Folding inconsistencies at the manufacturer may

cause some envelopes to feed well and others to jam. Purchase

envelopes with the quality and consistency that you require.

Good construction Poor construction

Figure 2-2 Envelope construction

26

Envelope specifications

EN

Page 27

Adhesive label specifications

CAUTION Not all HP Color LaserJet printers support labels. Refer to your user

guide to see if your HP Color LaserJet printer prints on labels.

Most labels are coated with pressure-sensitive adhesive. Label stock

includes the top or face sheet, the adhesive, and the liner or carrier

sheet (also referred to as the backing). See your HP LaserJet printer

user guide for detailed instructions on printing on labels.

Label stock facts

Consider the information in this section when choosing label stock.

Top or face sheets

The top sheet, which is the printing surface, is usually composed of

xerographic paper. The top sheets of the labels must provide good

toner adhesion.

Carrier sheets

The carrier sheet must be compatible with the temperatures and

pressure of the fusing process and must be coated for easy release of

the top sheet.

CAUTION Avoid removing labels from the carrier sheet and then printing on the

remaining labels. If you must remove labels, remove them from the

bottom of the carrier sheet, continuing toward the top.

Adhesives

The adhesive must withstand the 205° C (401° F) temperatures

encountered for 0.1 second in the printer’s fusing process. It also

must not produce emissions that exceed e xposure le v els or threshold

limits established by OSHA and other safety agencies. Adhesives

must not come in direct contact with any part of the printer. No

adhesive should be pressed out of the edges or between die-cuts (the

cuts between individual labels).

EN

Chapter 2 – Guidelines and specifications for selecting media

27

Page 28

Label construction

Labels must be designed specifically for use with a laser printer . They

should have sufficient tack to the carrier sheet so they do not peel

during pickup and feeding. Also , the materials used for the label sheet

should be compatible with the heat and pressure of fusing and should

not contaminate the printer with adhesives or other substances.

CAUTION Labels that peel or contaminate components with adhesives can

severely damage y our printer. Make sure that any labels used in your

laser printer are specifically designed for laser printers.

Labels can be arranged on the sheet in a variety of configurations.

Corners of labels typically have a radius at each corner to prevent

peeling while being printed. If individual labels are surrounded by the

carrier sheet (matrix removed), it is recommended that they are

separated by no more than 2.5 mm (0.1 in).

Regularly inspect your labels after printing for any indications of label

edges lifting or adhesive contaminating the printed surface. If either of

these problems are observed, it is recommended that use of that box

or lot number of labels be discontinued and the problem discussed

with your label vendor.

Note Labels may meet the general specifications listed in Table 2-6 and still

not print satisfactorily because of the printing environment or other

variables over which HP has no control.

See “Purchasing media” in chapter 3 for information about ordering

HP labels.

28

Adhesive label specifications

EN

Page 29

Table 2-6. Label stock specifications

Description Specifications

Adhesive Must not be on any external surfaces of the label

before, during, or after printing. Label construction

and die-cutting must not allow labels to peel off during

transport, printing, or fusing.

Caliper Must not exceed 0.18 mm (0.007 in)

Curl In-ream: flat within 13 mm (0.5 in)

10

Electrical surface

resistivity

Electrical volume

resistivity

Finishing precision Cut sheet to within ±0.8 mm (0.03 in) of nominal and

Fusing compatibility All adhesives, carrier sheets, top sheets, and other

Packaging Moisture-proof wrap to preserve properties

Shelf life One year minimum, stored at 22° C (72° F) and 50%

2.0 to 15 by 10

1.2 to 15 by 1011 ohms/cm

±0.2° square

materials used in label construction must be

compatible with the heat and pressure of the fusing

process. Materials must not discolor, melt, offset, or

release hazardous emissions when heated to

205° C (401° F) for 0.1 second.

relative humidity (R.H.)

ohms/in

2

EN

The following actions ma y cause labels to peel off, possibly damaging

the inside of your printer:

Using labels in the lower tray of noncompatible HP LaserJet

z

printers. See the user documentation for your printer for more

information.

Printing on labels while the printer is in duplex (two-sided printing)

z

mode

Removing individual labels from the carrier sheet and then

z

printing on the remaining labels

Chapter 2 – Guidelines and specifications for selecting media

29

Page 30

Overhead transparency specifications

Overhead transparencies used in HP LaserJet printers must

withstand the 205° C (401° F) temperature encountered in the

printer’s fusing process for 0.1 second (1.2 seconds for HP Color

LaserJet printers). See your HP LaserJet printer user guide for

detailed instructions on using overhead transparencies. Table 2-7 lists

specifications for overhead transparencies.

Table 2-7. Overhead transparency specifications

Description Specifications

Caliper 0.12 to 0.132 mm (4.8 to 5.2 mils) for

HP Color LaserJet printers.

0.100 to 0.110 mm (3.9 to 4.3 mils) for all

others.

Cutting angle 90° ± 0.2°

10

Electrical surface resistivity 2.0 to 15 by 10

Finishing precision Cut sheet to within ± 0.8 mm (0.03 in) of

nominal and ± 0.2° square

Fusing compatibility Overhead transparency materials must be

compatible with the heat and pressure of the

fusing process. Materials must not discolor,

melt, offset, or release hazardous emissions

when heated to 205° C (401° F) for

0.1 second (1.2 seconds for HPColor

LaserJet printers). For HP LaserJet 500

printers: 200

ohms/in

°

C (392° F

2

).

See “Purchasing media” in chapter 3 for information about ordering

HP transparencies.

30

Overhead transparency specifications

EN

Page 31

Types of media to avoid

HP recommends against using media with any of the following

characteristics:

paper that is extremely shiny or glossy

z

media that is very rough, highly textured, or embossed

z

media with multipart forms

z

media, media coatings, dyes, or inks that produce hazardous

z

emissions or melt that when exposed to a fusing temperature of

205° C (401° F) for 0.1 second (0.2 second for HP Color LaserJet

printers)

media that offsets or discolors

z

media that is damaged, curled, wrinkled, or irregularly shaped

z

envelopes or labels that are noncompatible with HP Color

z

LaserJet printers

envelopes that have an open flap with the adhesive exposed so

z

that closing the flap seals the envelope

envelopes with clasps, snaps, tie strings, windows, or synthetic

z

materials. These may severely damage the printer.

envelopes that are not square, straight, or constructed correctly

z

(see “Unacceptable envelope construction

envelopes with a basis weight less than 60 g/m

z

than 105 g/m

envelopes with baggy construction or folds that are not sharply

z

creased

media that was already printed on or was already fed through a

z

photocopier or an HP LaserJet printer. Do not refeed media.

2

(28 lb)

in chapter 2)

”

2

(16 lb) or greater

EN

Chapter 2 – Guidelines and specifications for selecting media

31

Page 32

32

Types of media to avoid

EN

Page 33

Purchasing, shipping,

3

and storing media

Introduction

The performance of HP LaserJet printers depends on the condition of

the print media used. This section contains recommendations for

purchasing, shipping, handling, and storing media, and it provides

information on the environmental effects on media.

Purchasing media

In the United States, you can purchase HP media (paper, overhead

transparencies, and labels) through the HP Direct Marketing Division.

To order from HP Direct Marketing, call (800) 538-8787 and specify

the HP part number listed in the tables that follow. To order paper

outside of the U.S., contact your local HP sales office.

EN

Chapter 3 – Purchasing, shipping, and storing media

33

Page 34

Paper

In the U.S., use the part numbers listed in Table 3-1 to order paper

from the HP Direct Marketing Division (800) 538-8787. Outside of the

U.S., contact your local HP sales office.

You can also purchase acceptable paper from your local paper

supplier. Ask your vendor to verify that the paper will work correctly

with an HP LaserJet printer.

Table 3-1. LaserJet printer paper part numbers

HP Multipurpose paper HP part number

500 sheets letter-size

216 by 279 mm (8.5 by 11 in)

250 sheets letter-size

216 by 279 mm (8.5 by 11 in)

500 sheets three-hole, letter-size

216 by 279 mm (8.5 by 11 in)

500 sheets legal-size

216 by 356 mm (8.5 by 14 in)

500 sheets tabloid-size

279 by 432 mm (11 by 17 in)

500 sheets recycled

216 by 279 mm (8.5 by 11 in)

HPM1120

HP25011

HPM113H

HPM1420

HPM1720

HPR1120

HP LaserJet paper HP part number

500 sheets letter-size

216 by 279 mm (8.5 by 11 in)

200 sheets letter-size

216 by 279 mm (8.5 by 11 in)

500 sheets three-hole, letter-size

216 by 279 mm (8.5 by 11 in)

HPJ1124

HPJ200C

HPJ113H

34

Purchasing media

(continued on the following page)

EN

Page 35

HP Office paper HP part number

500 sheets letter-size

216 by 279 mm (8.5 by 11 in)

500 sheets, three-hole, letter-size

216 by 279 mm (8.5 by 11 in)

500 sheets legal-size

216 by 356 mm (8.5 by 14 in)

500 sheets tabloid-size

279 by 432 mm (11 by 17 in)

HP Soft Gloss paper (For HP Color LJ

4500 and 8500 printers only)

200 sheets letter-size

216 by 279 mm (8.5 by 11 in)

200 sheets A4 size

216 by 279 mm (8.5 by 11 in)

HPC8511

HPC3HP

HPC8514

HPC1117

HP part number

HPJ200C

HPJ113H

EN

Chapter 3 – Purchasing, shipping, and storing media

35

Page 36

Overhead transparencies

In the U.S., use the HP part numbers in Table 3-2 to order

transparencies from the HP Direct Marketing Division

(800) 538-8787. To order transparencies outside of the U.S., contact

your local HP sales office. Each box contains 50 overhead

transparencies.

Table 3-2. HP LaserJet printer transparency part numbers

Transparency size HP part number

Letter – 216 by 279 mm (8.5 by 11 in) 92296T

A4 – by 297 mm (8.3 by 11.7 in) 92296U

Letter – HP Color LaserJet C2934A

A4 – HP Color LaserJet C2936A

Labels

In the U.S., use the HP part numbers in Table 3-3 to order labels from

the HP Direct Marketing Division (800) 538-8787. To order labels

outside of the U.S., contact your local HP sales office. Each box

contains 100 sheets, 216 by 279 mm (8 ¾ by 11 in), except where

otherwise noted.

36

Purchasing media

Table 3-3. HP LaserJet printer labels part numbers

Label size

(height by width)

25½ by 67 mm (1 by 2 5/8 in) 30 92296A

25½ by 102 mm (1 1/3 by 4 in) 14 92296B

25½ by 102 mm (1 by 4 in) 20 92296C

51 by 102 mm (2 by 4 in) 10 92296D

85 by 102 mm (3 1/3 by 4 in) 6 92296E

13 by 45 mm (½ by 1¾ in) 25 92296F

18 by 88 mm (2/3 by 3 7/16 in) 25 92296G

70 by 70 mm (2¾ by 2¾ in) 9 92296H*

39 by 102 mm (1½ by 4 in) 12 92296J*

215 by 279 mm (8½ by 11 in) 1 92296K

*Contains 70 sheets, 216 by 279 mm (8 1/2 by 11 in)

Number

per sheet

HP

part number

EN

Page 37

Shipping media

When shipping print media through different environments, use

plastic wrap to wrap all cartons on the shipping pallet. When shipping

media across bodies of water, also wrap individual cartons.

Packaging must protect the media from physical damage.

Storing media

Follow these guidelines when stacking and storing print media:

z DO NOT store cartons or reams directly on the floor; place

cartons on a pallet or on shelves.

z DO NOT store individual reams in a manner that will result in

curling or warping.

Rewrap partially used packages of media before storing.

z

z DO NOT stack more than six cartons on top of each other.

Stack each carton squarely on top of the one underneath.

z

Stack each carton upright.

z

z DO NOT place anything on top of media, regardless of whether

the paper is packaged or unpackaged.

Store envelopes in a protective box to avoid damaging the

z

envelope edges.

Keep stored media away from temperature and humidity

z

extremes.

z DO NOT store printed documents in vinyl folders (which may

contain plasticizers) and do not expose the documents to

petroleum-based solvents.

EN

Chapter 3 – Purchasing, shipping, and storing media

37

Page 38

Environmental considerations

HP LaserJet printers are designed to operate in a wide range of

environmental conditions. For best perf ormance, store and use media

at 20° to 24° C (68° to 75° F), with a relative humidity of 45 to 55

percent. Follow these guidelines when media is used in an

environment outside those temperature and humidity ranges:

z DO NOT expose the media to humidity or temperature extremes.

If media is left unwrapped or in the printer input tray, extreme

changes in the environment will cause the media to take on

unwanted characteristics.

In the case of humidity extremes, keep paper and envelopes

z

tightly wrapped in plastic.

If a significant temperature difference occurs between the media

z

storage area and the printer’s operating environment, before

unwrapping the media, allow it time to adjust to the temperature

in the printer’s operating environment. The greater the

temperature difference and the greater the amount of media to

acclimate, the longer this time period should be. Allow one day f or

every 10° C (20° F) difference in temperature between storage

environment and printing environment.

38

Environmental considerations

EN

Page 39

4

Troubleshooting

Factors contributing to print problems

Print-quality problems usually result from media that does not meet

the specifications in this guide, has been stored improperly, or is not

in good condition. Ask the following questions to determine if the

media you are using is causing print-quality problems:

Does your media meet the specifications outlined in this

z

document?

Is the media in good condition? Is the media bent, wrinkled, or

z

“dog-eared?”

Are you using the printing procedures outlined in the printer user

z

guide?

Are you observing correct practices when handling media? (See

z

the guidelines in your printer user guide for loading media.)

Are your print-quality problems isolated to a specific type of

z

media?

Are you using media that has already been run through the

z

printer?

Did you check these aspects of the environment in which the

z

printer operates?

• temperature

• humidity

• exposure to sunlight

• cleanliness

EN

Chapter 4 – Troubleshooting

39

Page 40

If you cannot determine the cause of your print defects, try the

following procedures:

1 Print with media from another lot or from a different manufacturer.

2 Flip the paper over in the tray, or turn it from front to rear (both, if

necessary).

3 If you have an envelope print-quality problem, print a sheet of

paper to determine if the problem is caused by the variable

thickness of your envelope.

• If the paper’s print quality is good, re-examine your envelope

and the envelope specifications in this guide.

• If the paper’s print quality is poor, you may have a printer

problem.

4 Read the rest of this chapter for troubleshooting information,

perform the maintenance procedures recommended in your

printer user guide, or see the troubleshooting section in your

printer user guide.

5 Call your authorized HP dealer for assistance.

Two-sided printing

Two-sided printing, also known as duplex printing, means printing on

both sides of a sheet. Duplex printing can be either an automatic or a

manual process.

40

Two-sided printing

Automatic duplexing

Automatic duplexing requires an HP LaserJet printer designed

especially for duplex printing.

Manual duplexing

Manual duplex printing, in which sheets that already have been

printed on are re-fed into the printer, requires both operator and

software intervention. (See the software application user guide for

more information.) Hewlett-Pac kard recommends manually re-feeding

sheets only through the manual feed slot or the MP tray. Do not

re-feed sheets from the paper cassette trays. Using the paper

cassette trays can cause jams, misfeeds, and print-quality problems.

EN

Page 41

Indications of paper problems

This section provides information on conditions that may indicate

paper problems. These conditions include high rates of jams, high

rates of multiple feeds, and post-image curl.

High rates of jams

Problem

Paper is too stiff or heavy. Heavy or stiff paper may not be able to

negotiate the paper path or be picked up from the paper tray.

Solution

• Make sure the paper does not exceed the basis weight listed f or

your printer as specified in appendix A or in the user

documentation for your printer.

• Manually feed the paper into the printer.

• Use the correct output bin, as shown in your printer user guide.

• Use a lighter-weight paper.

Problem

EN

Paper is too moist, resulting in waviness and curl.

Solution

Try another ream of paper.

Problem

Paper is too smooth or too rough.

Solution

Change the paper type or manually feed the paper into the printer.

See your printer user guide for the correct output tray selection.

Problem

Paper is not cut to specification. This can cause poor print alignment,

mis-stacking, improper fit in the paper tray, or difficulties for the paper

sensors.

Solution

Change the paper type or try another ream of paper.

Chapter 4 – Troubleshooting

41

Page 42

Problem

Paper has excessive curling.

Solution

Flip the paper stack over, try another ream, or change the type of

paper. You may need to acclimate the paper to your environment to

diminish differences in heat and moisture.

Problem

Paper is too light or too flimsy.

Solution

Make sure the paper meets the specifications listed in appendix A for

basis weight.

Problem

Paper adjustments are set incorrectly in the printer.

Solution

Make sure all paper adjustments have been set correctly. See the

user documentation for your printer for more information.

Recovering from paper jams

To recover from a paper jam, follow the directions listed in your

HP LaserJet printer user guide. DO NOT reuse the jammed

paper—even if it appears undamaged!

High rates of multiple feeds

Problem

Paper is added in small amounts to the paper tray.

Solution

Add only large amounts of paper to the paper tray, and avoid mixing

paper types in the paper tray.

Problem

Paper is too dry, not moist enough. (Insufficient moisture makes

paper less conductive and creates static buildup.)

Solution

Try another ream of paper or change the paper type.

42

Indications of paper problems

EN

Page 43

Problem

Paper is too light or too thin.

Solution

Change the paper type.

Problem

Paper is too smooth or too rough. Surfaces tend to interlock or stick

together.

Solution

Change the paper type.

Problem

Paper is embossed or has raised letterhead.

Solution

Change the paper type.

Problem

Paper adjustments are set incorrectly.

Solution

EN

Make sure all paper adjustments have been set correctly. See the

user documentation for your printer for more information.

Problem

Paper sticks together at the edges (edgeweld).

Solution

Edgeweld is caused by the use of dull cutting blades during the

manufacturing process. Bend the paper to break the weld. Try a

different ream of paper or try a different paper manufacturer.

Chapter 4 – Troubleshooting

43

Page 44

Post-image curl

When a sheet of paper is printed on by an HP LaserJet printer, the

sheet develops a curvature called post-image curl. Generally, the

higher the moisture content of the paper, the greater the curl. Higher

weight equals higher curl.

Both the paper and the printer affect the amount of post-image curl. In

the papermaking process, stresses that can cause curl are

manufactured into the paper, so different papers will have differing

amounts of post-image curl. In the printing process, the paper is

subjected to the heat and pressure of the fusing assembly as well as

to the contours of the paper path.

The following suggestions may help to reduce post-image curl:

Print to the face-up output bin. (This option is not available with

z

some printers.)

Turn the paper stack over or turn it around in the input tray to

z

reverse the direction of the paper.

When the printer is not in use for long periods, remove paper from

z

the paper tray and rewrap it.

Change to a different type or brand of paper.

z

Follow the storage and handling specifications in this document.

z

On HP Color LaserJet printers, reduce toner coverage by using

z

dither patterns rather than solid fill.

The grain of the paper can effect the curl of the media. Theref ore,

z

if you are feeding the paper landscape mode (horizontally) and

experiencing curl, try feeding the paper portrait mode (vertically).

44

Indications of paper problems

EN

Page 45

Indications of envelope problems

Gray backg rounds and high r ates of jams may indicate problems with

envelopes.

Gray background

For best print quality, avoid printing over seams or other multiple la y er

areas. On some printers, you can reduce background (gray shading

in non-imaged areas) by adjusting the density of the print. If a gray

background appears on your envelopes, adjust the print density

setting on your printer to a darker setting. (See your printer user guide

for instructions about how to adjust print density.)

High rates of jams

Overfilling the env elope tray and misadjusting its guides are the most

common causes of jams. However, if the envelope tray is properly

loaded, the envelopes may be causing the problems.

Envelopes with the following characteristics can lead to jams:

Problem

Poorly manufactured envelopes.

EN

The leading edge must be straight, with a sharp, well-creased fold.

The envelope must not have more than two thicknesses of paper

along any leading edge. The folded layers of paper should form a

point at the leading-edge corners (as shown in Figure 2-2).

Solution

Purchase envelopes that are manufactured correctly, or run a pen or

pencil over the envelope edges to flatten them.

Problem

Envelopes are not creased sufficiently to have sharp edges.

Solution

Crease the leading edge of the envelope with a pen or pencil, or

change to a different type or brand.

Chapter 4 – Troubleshooting

45

Page 46

Problem

Envelopes are wrinkled, “dog-eared,” or curled.

Solution

Use envelopes with edges that are thin and sharply creased.

Problem

Envelopes are too stiff or heavy. Stiff or heavy envelopes cannot

negotiate the paper path or be picked up from the envelope tray.

Solution

Use a lighter-weight envelope. Do not exceed 105 g/m

Problem

Envelopes are too smooth (not enough friction for transport) or too

rough.

Solution

Change to a different type of envelope.

Problem

Envelope is inserted too far into the manual feed slot.

2

(28 lb).

Solution

Insert the envelope only until you feel a slight resistance.

Recovering from envelope jams

To recover from an envelope jam, follow the directions listed in your

HP LaserJet printer user guide. DO NOT reuse the jammed

envelope—even if it appears undamaged!

Wrinkling

Wrinkles that form in envelopes after printing usually are caused by

the following envelope conditions:

loose envelope construction

z

folds that are not sharply creased

z

high moisture content

z

low weight/low strength paper used in envelope construction

z

See Figure 2-2 for characteristics of good envelope construction.

46

Indications of envelope problems

EN

Page 47

A

Paper basis weights

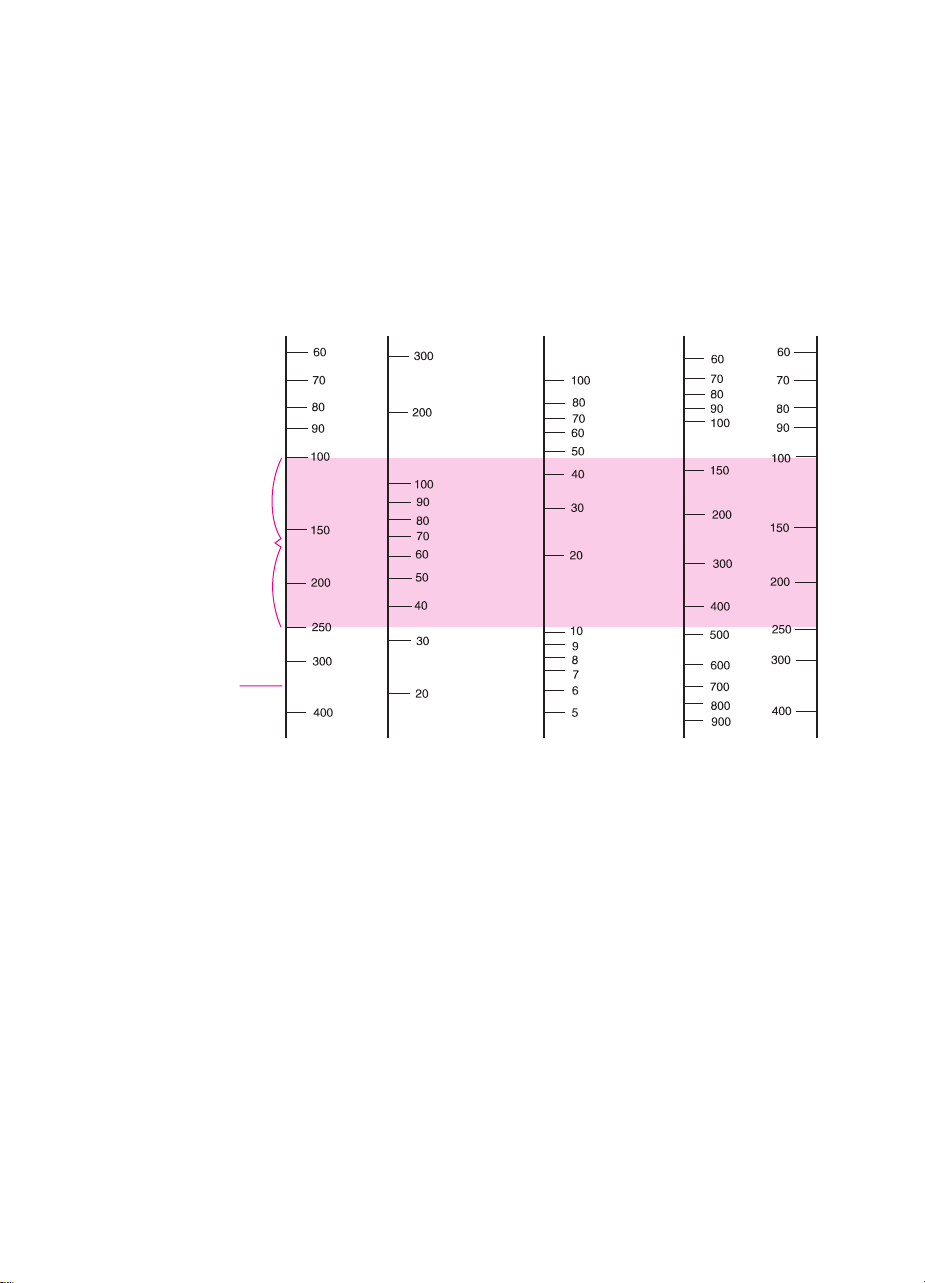

Table A-1. Paper basis weights

Printer Source Basis Weight

HP LaserJet 1100/1100A Front input slot

Paper output bin

Scanner input bin

HP LaserJet 8100 Tray 1 (MP tray)

60 to 105 g/m2

(16 to 28 lb)

60 to 157 g/m

(16 to 43 lb)

60 to 157 g/m

(16 to 42 lb)

60 to 199 g/m

(16 to 53 lb)

2

2

2

EN

Tray 2

(Optional 500-sheet)

Tray 3, Tray 4, and Tray 5

Optional 2000-sheet

Standard output bin

Appendix A – Paper basis weights

60 to 105 g/m2

(16 to 28 lb)

60 to 105 g/m

(16 to 28 lb)

60 to 105 g/m

(16 to 28 lb)

60 to 105 g/m

(16 to 28 lb)

2

2

2

47

Page 48

Table A-1. Paper basis weights (continued)

HP Color LaserJet 8500 Tray 1*

Tray 2 and Tray 3*

Tray 4 (Optional)*

Mailboxes

Left (face-up output bin)

Duplexer

*Limit to media-fill mark on

the media width guides

HP Color LaserJet 4500 Tray 1*

*Tray 1 can support paper

weights between 16 and 47

lb bond if the width of the

media is less than or equal

to 148 mm. Tray 1 can

support paper weights

between 16 and 36 lb bond

if the width of the media is

wider than 148 mm.

Tray 2, Tray 3

60 to 216 g/m

2

(16 to 58 lb)

60 to 105 g/m

2

(16 to 28 lb)

60 to 105 g/m

2*

(16 to 28 lb)

60 to 105 g/m

2

(16 to 28 lb)

60 to 216 g/m

2*

(16 to 58 lb)

60 to 105 g/m

2

(16 to 28 lb)

Single-sided:

60 to 159 g/m

2

(16 to 42 lb)

If less than or equal to 148

mm width:

60 to 176 g/m

2

(16 to 47lb)

If more than or equal to 148

mm width:

60 to 176 g/m

2

(16 to 36 lb)

HP LaserJet 3100 Printer product input bin

48

Appendix A – Paper basis weights

Duplexer

Front paper output slot

Scanner product bin

60 to 105 g/m

2

(16 to 28 lb)

64 to 105 g/m

2

(17 to 28 lb)

60 to 105 g/m

2

(16 to 28 lb)

60 to 163 g/m

2

(16 to 43lb)

44 to 252 g/m

2*

(12 to 67 lb)

*using special media lever

EN

Page 49

Table A-1. Paper basis weights (continued)

Printer Source Basis Weight

HP LaserJet 8000 series Tray 1

60 to 199 g/m

(16 to 53 lb)

2

Tray 2, Tray 3, 2 x 500sheet input tray, and

60 to 105 g/m

(16 to 28 lb)

optional 2000-sheet input

tray

HP LaserJet 5000 series Tray 1

60 to 199 g/m

(16 to 53 lb)

250-sheet tray and

optional 500-sheet tray

Duplexer

60 to 105 g/m

(16 to 28 lb)

60 to 105 g/m

(16 to 28 lb)

HP LaserJet Companion Paper input slot 60 to 105 g/m

(16 to 28 lb)

HP LaserJet 4000/4000N/

4000T/4000TN

Tray 1

250-sheet tray and

optional 500-sheet tray

Duplexer

60 to 199 g/m

(16 to 53 lb)

60 to 105 g/m

(16 to 28 lb)

60 to 105 g/m

(16 to 28 lb)

HP LaserJet 6L/5L Paper input bin

60 to 105 g/m

(16 to 28 lb)

Front paper output slot

60 to 163 g/m

(16 to 43 lb)

HP LaserJet 5Si Mopier

and 5Si/5Si MX

Tray 1

60 to 199 g/m

(16 to 53 lb)

2

2

2

2

2

2

2

2

2

2

2

EN

Tray 2, Tray 3, Tray 4, and

Duplexer

HP LaserJet 6P/6MP Tray 1 (Multipurpose tray)

Tray 2 (Paper cassette)

Appendix A – Paper basis weights

60 to 105 g/m

(16 to 28 lb)

60 to 163 g/m

(16 to 43 lb)

60 to 105 g/m

(16 to 28 lb)

2

2

2

49

Page 50

Table A-1. Paper basis weights (continued)

Printer Source Basis Weight

HP LaserJet 5P/5MP Tray 1 (Multipurpose tray)

60 to 158 g/m

(16 to 42 lb)

2

Tray 2 (Paper cassette)

HP LaserJet 4V/4MV Multipurpose tray

Paper cassette

Optional lower cassette

HP LaserJet 4P/4PJ

Paper cassette

and 4L

Manual feed

HP LaserJet 4P/4PJ

HP Color LaserJet and

Manual feed

Front input tray

Color LaserJet 5/5M

Optional rear tray

Manual feed

HP LaserJet 5, 4 Plus,

(Tray 1) Multipurpose tray

and 4

60 to 105 g/m

2

(16 to 28 lb)

6

4 to 105 g/m

(17 to 28 lb)

64 to 105 g/m

(17 to 28 lb)

64 to 105 g/m

(17 to 28 lb)

6

0 to 105 g/m

(16 to 28 lb)

60 to 135 g/m

(16 to 36 lb)

136 to 157 g/m

(37 to 42 lb)

100 to 180 Sheffield

75 to 90 g/m

2

2

2

2

2

2

2

(20 to 24 lb)

75 to 90 g/m

2

(20 to 24 lb)

75 to 90 g/m

2

(20 to 24 lb)

60 to 135 g/m

2

(16 to 36 lb)

HP LaserJet 4Si and III Si Upper and lower bin:

HP LaserJet IIIP, IIP Plus,

and IIP

50

Appendix A – Paper basis weights

(Tray 2) Paper cassette

(Tray 3) Lower cassette

Duplexer (LJ4 Plus and 5

only)

Cassette and manual feed

Duplexer

Multipurpose tray and

paper cassettes

60 to 105 g/m

(16 to 28 lb)

60 to 90 g/m

(16 to 24 lb)

60 to 90 g/m

(16 to 24 lb)

60 to 105 g/m

(16 to 28 lb)

60 to 90 g/m

(16 to 24 lb)

60 to 105 g/m

(16 to 28 lb)

2

2

2

2

2

2

EN

Page 51

Table A-1. Paper basis weights (continued)

Printer Source Basis Weight

HP LaserJet IIID and IID Upper bin:

Cassette and manual feed

60 to 135 g/m

(16 to 36 lb)

2

Lower bin:

Cassette and manual feed

Duplexer

60 to 90 g/m

(16 to 24 lb)

60 to 90 g/m

(16 to 24 lb)

HP LaserJet III and II Cassette and manual feed 60 to 135 g/m

(16 to 36 lb)

2

2

2

EN

Appendix A – Paper basis weights

51

Page 52

Table A-2. Paper and envelope sizes

Printer Source Minimum Size Maximum Size

HP LaserJet 1100/

1100A

Paper input bin

76 by 127 mm

(3 by 5 in)

216 by 356 mm

(8.5 by 14 in)

Scanner input bin

HP LaserJet 8100 Tray 1 (MP tray)

Tray 2

(Optional 500-sheet)

Tray 3, Tray 4, and

Tray 5

(Optional 2000sheet)

Envelope feeder

Duplexer

HP Color LaserJet

8500

Tray 1*

Tray 2*

Tray 3*

Tray 4 (Optional

2000-sheet)*

51 by 89 mm

(2 by 3.5 in)

76 by 127 mm

(3 by 5 in)

98 by 191 mm

(3.9 by 7.5 in)

98 by 191 mm

(3.9 by 7.5 in)

98 by 191 mm

(3.9 by 7.5 in)

90 by 160 mm

(3.5 by 6.3 in)

127by 191 mm

(5 by 7.5in)

98 by 191 mm

(3.9 by 7.5 in)

184 by 267 mm

(7.25 by 10.5 in)

184 by 267 mm

(7.25 by 10.5 in)

216 by 279 mm

(8.5 by 11 in

216 by 362

(8.5 by 30)

297 by 450 mm

(11.7 by 17.7 in)

216 by 762 mm

(8.5 by 30 in)

297 by 450 mm

(11.7 by 17.7 in)

279 by 432 mm

(11 by 17 in)

178 by 254 mm

(7 by 10 in)

279 by 432 mm

(11 by 17 in)

304 by 469 mm

(12 by 18.5 in)

216 by 256 mm

(8.5 by 14 in)

279 by 432 mm

(11 by 17 in)

279 by 432 mm

(11 by 17 in)

HP Color LaserJet

4500

HP LaserJet 3100 Paper input bin 76.2 by 127 mm

52

Appendix A – Paper basis weights

Duplexer

*Limit to media-fill

mark on the media

width guides

Tray 1*

Tra y 2, Tray 3

Duplexer

184 by 267 mm

(7.25 by 10.5 in)

76 by 127 mm

(3 by 5 in)

216 by 279 mm

(8.5 by 11 in)

216 by 279 mm

(8.5 by 11 in

(3 by 5 in)

279 by 432 mm

(11 by 17 in)

216 by 356 mm

(8.5 by 19)

182 by 257 mm

(7.2 by 10 in)

182 by 257 mm

(7.2 by 10 in)

310 by 470 mm

(12.2 by 18.5 in)

EN

Page 53

Table A-2. Paper and envelope sizes (continued)

HP LaserJet 8000 Tray 1 (MP tray)

Tray 2 and Optional

500-sheet

Tray 3

Optional 2000-sheet

Envelope feeder

Duplexer

HP LaserJet 5000 Tray 1

Tray 2

(Optional 250-sheet)

Tray 3

(Optional 500-sheet)

HP LaserJet

Companion

HP LaserJet 4000/

4000N

Paper Input Slot 51 by 89 mm

Tray 1

93 by 191 mm

(3.67 by 7.5 in)

216 by 279 mm

(8.5 by 11 in)

216 by 279 mm

(8.5 by 11 in)

216 by 279 mm

(8.5 by 11 in)

98 by 191 mm

(3.1 by 7.5 in)

216 by 279

(8.5 by 11 in)

76 by 127 mm

(3 by 5 in)

148 by 210 mm

(5.8 by 8.2 in)

148 by 210 mm

(5.8 by 8.2 in)

(2 by 3.5 in)

76 by 127 mm

(3 by 5 in)

297 by 450 mm

(11.7 by 17.7 in)

257 by 364 mm

(10.1 by 14.3 in)

279 by 432 mm

(11 by 17 in)

279 by 432 mm

(11 by 17 in)

176 by 250 mm

(7 by 9.9 in)

279 by 432 mm

(11 by 17 in)

312 by 470 mm

(12.28 by 18.5 in)

279 by 432 mm

(11 by 17 in)

297 by 437 mm

(11.7 by17 in)

216 by 762 mm

(8.5 by 30 in)

216 by 356 mm

(8.5 by14 in)

EN

250-sheet tray

Envelope feeder

HP LaserJet 4000T/

4000TN

HP LaserJet 6L/5L Paper input bin 76.2 by 127 mm

Tray 1

250-sheet tray

500-sheet tray

Envelope feeder

216 by 279 mm

(8.5 by 11 in)

90 by 160 mm

(3.5 by 6.3 in)

76 by 127 mm

(3 by 5 in)

191 by 267 mm

(7.3 by 10.5 in)

90 by 160 mm

(3.5 by 6.3 in)

(3 by 5 in)

Appendix A – Paper basis weights

216 by 356 mm

(8.5 by 14 in)

178 by 254 mm

(7 by 10 in)

216 by 356 mm

(8.5 by 14 in)

216 by 356 mm

(8.5 by 14 in)

178 by 254 mm

(7 by 10 in)

216 by 356 mm

(8.5 by 14 in)

53

Page 54

Table A-2. Paper and envelope sizes (continued)

Printer Source Minimum Size Maximum Size

HP LaserJet

5Si Mopier and

5Si/5Si MX

Tray 1

Tray 2

100 by 191 mm

(3.9 by 7.5 in)

216 by 279 mm

(A4 /Letter)

(8.5 by 11 in)

297 by 450 mm

(11.7 by 17.7 in)

257 by 364 mm

(JIS B4)

(10.12 by 14.33 in)

HP LaserJet 6P and

5P

HP LaserJet

5/5M/5N

Tray 3

Tray 4

Envelope feeder

Tray 1 (MP tray)

Tray 2

(Paper cassette)

Tray 1

Tray 2

Tray 3

216 by 279 mm

(Letter)

(8.5 by 11 in)

216 by 279 mm

(Letter)

(8.5 by 11 in)

100 by 191 mm

(3.9 by 7.5 in)

76 by 127 mm

(3 by 5 in)

184 by 267 mm

(7.25 by 10.5 in)

(Executive)

90 by 160 mm

(3.5 by 6.3 in)

184 by 267 mm

(7.25 by 10.5 in)

(Executive)

184 by 267 mm

(7.25 by 10.5 in)

(Executive)

279 by 432 mm

(11 by 17 in)

279 by 432 mm

(11 by 17 in)

163 by 241 mm

(6.4 by 9.5 in)

216 by 356 mm

(8.5 by 14 in)

216 by 356 mm

(8.5 by 14 in)

216 by 356 mm

(8.5 by 14 in)

216 by 356 mm

(8.5 by 14 in)

216 by 356 mm

(8.5 by 14 in)

HP Color LaserJet

and HP Color

LaserJet 5/5M

54

Appendix A – Paper basis weights

Envelope feeder

Front input tray

Optional rear tray

Manual feed

100 by 191 mm

(3.9 by 7.5 in)

184 by 267 mm

(7.25 by 10.5 in)

184 by 267 mm

(7.25 by 10.5 in)

184 by 267 mm

(7.25 by 10.5 in)

163 by 241 mm

(6.4 by 9.5 in)

279 by 432 mm

(11 by 17 in)

210 by 297 mm

(8.3 by 11.7 in)

279 by 432 mm

(11 by 17 in)

EN

Page 55

Table A-2. Paper and envelope sizes (continued)

Printer Source Minimum Size Maximum Size

HP LaserJet 4V/

4MV

Multipurpose tray*

98.4 by 148 mm

(3.9 by 5.8 in)

297 by 450 mm

(11.7 by 17.7 in)

HP LaserJet 4P/4PJ

HP LaserJet 4L

HP LaserJet 4 Plus

and 4

HP LaserJet 4Si

and IIISi

HP LaserJet IIIP,

IIP Plus, and IIP

HP LaserJet IIID and

IID

Paper cassette

and optional lower

cassette

Manual feed*

Manual feed*

Multipurpose tray*

Envelope feeder

Manual feed*

Envelope feeder

Multipurpose tray*

Envelope cassette

Manual feed*

Envelope cassette

216 by 279 mm

(8.5 by 11 in)

76 by 127 mm

(3 by 5 in)

76 by 190 mm

(3 by 7.75 in)

90 by 160 mm

(3.5 by 6.3 in)

90 by 160 mm

(3.9 by 6.3 in)

98.4 by 216 mm

(3.8 by 8.5 in)

98.4 by 190 mm

(3.9 by 7.5 in)

96.4 by 170 mm

(3.8 by 6.7 in)

96.4 by 188 mm

(3.8 by 7.4 in)

90 by 190 mm

(3.5 by 7.5 in)

90 by 190 mm

(3.5 by 7.5 in)

297 by 432 mm

(11 by 17 in)

216 by 356 mm

(8.5 by 14 in)

216 by 356 mm

(8.5 by 14 in)

216 by 356 mm

(8.5 by 14 in)

176 by 250 mm

(7.0 by 9.9 in)

216 by 356 mm

(8.5 by 14 in)

110 by 241 mm

(4.3 by 9.5 in)

216 by 356 mm

(8.5 by 14 in)

164 by 255 mm

(6.5 by 10 in)

216 by 356 mm

(8.5 by 14 in)

183 by 257 mm

(7.2 by 10.1 in)

EN

Envelope feeder

HP LaserJet III

and II

* Multipurpose trays and manual feed slots accept paper, envelopes, labels, and

overhead transparencies.

Manual feed*

Envelope cassette

90 by 190 mm

(3.5 by 7.5 in)

90 by 190 mm

(3.5 by 7.5 in)

90 by 190 mm

(3.5 by 7.5 in)

120 by 257 mm

(4.7 by 10.1 in)

216 by 356 mm

(8.5 by 14 in)

183 by 257 mm

(7.2 by 10.1 in)