Page 1

Best practices for HP 10000 Series and HP 10000 G2

Series Racks

best practice

Abstract.............................................................................................................................................. 1

10000 G2 Series overview .................................................................................................................. 1

Product availability .............................................................................................................................. 3

Specifications...................................................................................................................................... 3

Dimensions...................................................................................................................................... 4

Additional Resources ........................................................................................................................ 6

Certification and regulatory compliance ................................................................................................. 6

Product certification.......................................................................................................................... 6

HP General Specification for Environment compliance.......................................................................... 6

Information Technology Equipment..................................................................................................... 6

Waste Electrical and Electronic Equipment directive ......................................................................... 6

Integration services and software........................................................................................................... 7

HP Factory Express........................................................................................................................... 7

Additional resources ..................................................................................................................... 7

HP eCo-Enterprise Configurator ......................................................................................................... 7

Additional resources ..................................................................................................................... 7

HP UPS Sizing Tool .......................................................................................................................... 7

Additional resources ..................................................................................................................... 7

Rack documentation CD.................................................................................................................... 8

Rack deployment considerations............................................................................................................ 8

Levels of rack security ....................................................................................................................... 8

HP 10000 G2 Series rack front doors ............................................................................................ 8

HP 10000 G2 Series rack rear doors ............................................................................................. 8

HP Side Panel Option Kit............................................................................................................... 8

Stabilization requirements ................................................................................................................. 8

Leveling feet................................................................................................................................. 8

HP 10000 Baying Kit ................................................................................................................... 9

HP 10000 Stabilizer Kit ................................................................................................................ 9

HP 10000 Ballast Option Kit ....................................................................................................... 10

Stabilization for seismic activity ....................................................................................................... 10

HP 10000 Series Plinth Option Kit ...............................................................................................11

Page 2

HP 10000 G2 Series Tie Down Option Kit.................................................................................... 11

Space and cable management requirements ..................................................................................... 11

Extension kits ............................................................................................................................. 11

Cable management kits............................................................................................................... 12

Thermal requirements ..................................................................................................................... 12

Additional resources....................................................................................................................... 13

Rack assembly guidelines ................................................................................................................... 13

Additional resources....................................................................................................................... 13

Installation and maintenance precautions ............................................................................................. 14

Moving racks with casters ........................................................................................................... 14

Connecting and disconnecting power to hot-pluggable power supplies............................................. 14

Rack-mountable products............................................................................................................. 15

Data Center planning and considerations ............................................................................................. 16

Environmental considerations .......................................................................................................... 16

Thermal considerations ............................................................................................................... 16

Third-party thermal considerations.................................................................................................... 18

Power considerations...................................................................................................................... 19

Power redundancy ..................................................................................................................... 19

Non-redundant........................................................................................................................... 19

High line voltage versus low line voltage.......................................................................................19

Grounding and Earth leakage current ........................................................................................... 20

Additional resources ................................................................................................................... 20

Equipment clearance and floor loading ................................................................................................ 20

Rack and accessory footprints.......................................................................................................... 21

Front door clearance .................................................................................................................. 22

Qualified shipping............................................................................................................................. 23

Qualification of rack components for shipping...................................................................................24

Rack shipping enclosures ................................................................................................................ 24

Standard shipping pallet ............................................................................................................. 24

CTO shock pallet........................................................................................................................ 24

Horizontal crate ......................................................................................................................... 25

Vertical crate for rack options ...................................................................................................... 25

Shipping specifications ............................................................................................................... 26

10000 and 10000 G2 Series Rack packing materials ....................................................................... 27

Preparation for shipment................................................................................................................. 27

Site preparation for receiving Integrated Racks.................................................................................. 28

General considerations (all shipments).............................................................................................. 28

Special shipping considerations....................................................................................................... 29

Door Height Clearances ................................................................................................................. 30

Modes of shipment......................................................................................................................... 30

Airfreight ...................................................................................................................................... 31

International Air Transport Association labeling ............................................................................. 31

Mode of receiving and delivery ....................................................................................................... 33

10000 and 10000 G2 Series Rack packing and shock pallet assembly............................................... 34

Dismounting a 10000 G2 Series Rack from a shock pallet.................................................................. 42

Installation service.............................................................................................................................. 43

Spares kits .................................................................................................................................... 43

Additional tools and equipment ....................................................................................................... 43

Battery decals and boxes ................................................................................................................ 43

Appendix a: glossary......................................................................................................................... 44

Appendix b: torque values.................................................................................................................. 45

Page 3

Abstract

This document outlines recommended practices for configuring, installing, transporting, and

establishing a work environment for the HP 10000 and HP 10000 Generation 2 (G2) Series Racks,

which includes the following models:

• 10000 Series rack models

– S10614

• 10000 G2 Series rack models

– 10622 G2

– 10636 G2

– 10642 G2

– 10647 G2

– 10842 G2

10000 G2 Series overview

10000 G2 Series racks (see Figure 1) provide an integrated platform for mounting computing

solutions and are designed for strength and durability.

Figure 1. 10000 G2 Series rack

1

Page 4

HP racks and rack accessories ease the centralization, protection, organization, and access to

hardware for servicing and upgrading. HP racks are flexible, secure, and designed to industry

standards. HP racks are designed be populated with the following HP products:

• HP ProLiant servers

• HP BladeSystem servers

• HP 9000 servers

• HP Integrity servers

• HP StorageWorks products

• HP rack mount power protection products

• HP rack mount switches

• HP rack mount monitors

The 10000 G2 Series racks are designed for greater ease-of-use. The 10000 G2 Series rack design

is based on the original 10000 Series racks.

Table 1 lists the key features of the 10000 G2 Series racks.

Table 1. 10000 G2 Series rack key features

Component Features

Front door

Rear doors

Side panels

Vertical ElA

mounting rails

Rear extension kit

Standard and

heavy-duty

stabilizers

The front door is designed to allow for air flow of 65 percent. The major

change in the front door is the look; the front door design has been

updated to reflect the evolving Industrial Design tastes of high value and

high volume customers. Based on the 10000 Series rack door, it maintains

the airflow capabilities of its predecessors, while the handle and closing

mechanisms have been improved and a new, modernized visual effect has

been implemented.

The rear doors have been modified to maximize the perforations supporting

airflow requirements. The rear door handle is designed to provide a more

ergonomically pleasing design.

The side panel design has been updated in favor of a lighter, easier to

install three-part solution.

These e-coated black rails with white U-markings provide greater contrast to

aid in the installation of product to the rails. The ESD grounding location

provides a more readily available solution.

An optional rear extension is available for Models 36U and 42U for

improved cable management,

New, improved standard and heavy duty stabilizers which also address

ease of installation.

Grounding kit

Rack tie-down kit

New universal grounding kit supports the 9000, 10000, and 10000 G2

Series racks.

For stability needs, the rack tie-down kit is available for the 10000 G2

Series racks.

2

Page 5

Product availability

The 10000 Series rack Model S10614 is available.

NOTE

The following 10000 Series rack models are discontinued:

• 10622

• 10636

• 10642

• 10647

•

10842

Specifications

The 10000 and 10000 G2 Series racks are graphite-metallic in color and are available in the rack

heights listed in Table 2. The racks are one-meter deep allowing more room for cable management

and for accommodating deeper server and storage equipment.

Additional cable management features are as follows:

• Wide (or 800-mm) rack models can accommodate network cabling on the sides of the rack.

• A cable egress in the top of the rack allows for overhead data center cabling.

• Split rear doors provide greater efficiency with respect to service access.

• A removable access panel on the rear door provides added flexibility for cable routing out the rear

and bottom of the rack.

• Velcro straps for bundling cables within the rack are included in the hardware kit and also

available as an option.

3

Page 6

Dimensions

Table 2 lists the dimensions of the 10000 and 10000 G2 Series rack models.

Table 2. 10000 and 10000 G2 Series rack dimensions

Rack model U height Width Depth

10000 Series rack models:

S10614 14U 600 mm /

10000 G2 Series rack models:

10622 G2 22U 600 mm /

10636 G2 36U 600 mm /

10636 G2

with rear extension

10642 G2 42U 600 mm /

10642 G2

with rear extension

10647 G2 47U 600 mm /

10842 G2 42U 800 mm /

23.62 in.

23.62 in.

23.62 in.

36U 600 mm /

23.62 in.

23.62 in.

42U 600 mm /

23.62 in.

23.62 in.

31.49 in.

1,000 mm /

39.37 in.

1,000 mm /

39.37 in.

1,000 mm /

39.37 in.

1184.9 mm /

46.65 in.

1,000 mm /

39.37 in.

1184.9 mm /

46.65 in.

1,000 mm /

39.37 in.

1,000 mm /

39.37 in.

4

Page 7

Table 3 lists the 10000 G2 Series rack specification details.

Table 3. 10000 G2 Series rack specification details

Rack Details HP 10000 G2 Series racks

Rack Model 10622 G2 10636 G2 10642 G2 10647 G2 10842 G2

EIA-310 type Type D Type D Type D Type D Type D

1113.48 mm

Rack height max.

Rack U height 22U 36U 42U 47U 42U

D=1045#

Max. weight capacity

D=Dynamic/S=Static

Rack width: no side

panels

Rack width: with side

panels

Rack depth: front to

rear door

Front door percentage

open space

Nominal distance from

front mtg flange to

inside of rear door

Min. front equipment

opening width

Nominal Front

Equipment opening

width

S=1045#

597.3 mm

612.77 mm

1015 mm

63%

915.36 mm

451.3 mm

(per EIA)

452 mm

(per EIA)

1735.78 mm 2003.5 mm 2285 mm

D=1520#

S=2000#

597.3mm 597.3mm 597.3mm

604.3 mm 604.3 mm 604.3 mm

1015 mm 1015 mm 1015 mm

65% 65% 65%

915.36 mm 915.36 mm 915.36 mm

451.3 mm

(per EIA)

452 mm

(per EIA)

D=2000#

S=2000#

451.3 mm

(per EIA)

452 mm

(per EIA)

D=Not

applicable

S=2000#

451.3 mm

(per EIA)

452 mm

(per EIA)

2000 mm

(+/- 3 mm)

D=1000#

S=2000#

800mm

815.47mm

1015 mm

63%

915.36 mm

451.33 mm

(per EIA)

452mm

(per EIA)

Nom Ctr-to-ctr distance

for equipment

Std equipment

mounting hardware

for rack (example, clip

nuts)

Mounting hardware

size (example, M5)

Nominal front/back

mounting distance

Overall

rack/extension depth

Nominal distance from

front mtg flange to

inside of rear door

with extension

465 mm

(per EIA)

Cage nuts

M6 supplied;

M5&10-32

supported

742 mm

Not

applicable

Not

applicable

465 mm

(per EIA)

Cage nuts Cage nuts Cage nuts

M6 supplied;

M5&10-32

supported

742 mm 742 mm 742 mm

1184.9 mm/

46.65 in.

1060.87 mm 1060.87 mm

465 mm

(per EIA)

M6 supplied;

M5&10-32

supported

1184.9 mm/

46.65 in.

465 mm

(per EIA)

M6 supplied;

M5&10-32

supported

Not

applicable

Not

applicable

465mm

(per EIA)

Cage nuts

M6 supplied;

M5&10-32

supported

742 mm

Not

applicable

Not

applicable

5

Page 8

Additional Resources

Additional resources are available as follows:

• For a complete list of HP rack options and accessories, go to the main rack page at

www.hp.com/products/racks or to the main rack options page at www.hp.com/products/rackoptions.

• For a list of ProLiant servers and options, go to

• For a list of HP power products such as UPS and PDU, go to

• For a complete list of HP server storage equipment, go to

www.hp.com/products/proliant.

www.hp.com/products/ups.

www.hp.com/products/serverstorage.

Certification and regulatory compliance

Product certification

The10000 and 10000 G2 Series racks are defined as non-functional mechanical storage bays and

therefore, are not certified individually as a stand-alone product. The rack does not serve as an

overall safety or EMI rated enclosure nor does it carry any other Agency compliant rating. However,

any product intended for use in an HP rack should be individually certified as a stand-alone product.

For example, HP Power Distribution products, such as uninterruptible power supplies (UPSs) and

power distribution units (PDUs) are fully certified as stand-alone products.

Certain third-party products may not be fully certified as stand-alone products. Any product that does

not meet stand-alone certification is not included in any HP-specified rack configuration and should

not be installed in an HP rack.

HP General Specification for Environment compliance

HP General Specification for Environment (GSE) specifications prohibit or restrict the use of certain

chemical compounds in products or in the manufacture of products. HP complies with the GSE

specifications and restricts the use of these compounds in the development or manufacture of any HP

product (including third-party supplier product).

Information Technology Equipment

The 10000 and 10000 G2 Series racks are designed to comply with the applicable safety

requirements for Information Technology Equipment (ITE) when the rack is configured with properly

certified equipment. The 10000 and 10000 G2 Series racks are considered ITE compliant when the

following conditions are met:

• The rack is populated with individually certified products

• All installation guidelines and instructions are followed

Waste Electrical and Electronic Equipment directive

The directive on Waste Electrical and Electronic Equipment

(WEEE) requires manufacturers to finance the take back and

recovery of waste from electrical and electronic equipment at

the end of its useful life.

Any product or product packaging marked with the symbol

in Figure 2 must not be disposed of with other household

waste. The customer must dispose of the product by

delivering the product to a designated collection point for

the recycling of waste electrical and electronic equipment.

For more information about locations to drop off equipment

for recycling, please contact a local city office, the

Figure 2. WEEE disposal symbol

6

Page 9

household waste disposal service, or the business where the product was purchased.

Integration services and software

Several resources are available for planning rack configurations.

HP Factory Express

Factory Express is a robust portfolio of flexible, pre-priced, configured, customized and integrated

factory solutions and deployment services – supporting HP products from the desktop to the data

center with Windows®, Linux, and HP-UX 11i.

Additional resources

For specific information, please see the HP Factory Express link:

In addition to this available integration option, HP also provides information links and contacts for

problem solving of rack and product compatibility in support of Build to Order on site locations

through several venues. Please refer to the following resources:

• Frequently Asked Questions about Rack and Power products and interoperability

http://iss.tsgonline.hp.com/iss/workgroup/rackandpower/download/Rack 20System 20faqs.doc

• Contact your sales representative for the Interoperability guide to fit and HP ProLiant servers into HP

Rack System/E and 9000/10000 racks:

http://iss.tsgonline.hp.com/iss/workgroup/rackandpower/interoperability.asp

• To specifically request help on rack and power solutions:

http://iss.tsgonline.hp.com/iss/workgroup/rackandpower/requestform.asp

www.hp.com/go/factory-express.

HP eCo-Enterprise Configurator

If you require factory default racking for our HP hardware portfolio, you may still use the HP eCoEnterprise Configurator. If you require "custom" rack configuration capabilities, please contact the HP

Customer Business Center or an HP Authorized Partner for assistance.

Additional resources

For more information on the eCO Custom Builder tool, refer to the following HP websites:

• eCO-Enterprise Configurator:

• eCO-Enterprise Configurator features:

• Frequently asked questions

• What's new:

• Technical support:

http://h30099.www3.hp.com/configurator/about.asp

http://h30099.www3.hp.com/configurator/support.asp

http://h30099.www3.hp.com/configurator/

http://h30099.www3.hp.com/configurator/features.asp

: http://h30099.www3.hp.com/configurator/docs/eCo_FAQ.doc

HP UPS Sizing Tool

The UPS Sizing tool is an online tool that collects information on power consumption requirements and

then provides the correct UPS product for those requirements.

Additional resources

For additional information on the UPS Sizing tool, refer to

http://www.upssizer.com/selector.asp.

7

Page 10

Rack documentation CD

The Documentation CD shipped with the rack provides documentation for installing and optimizing

the rack.

Rack deployment considerations

The following sections describe the components and HP options available for the 10000 and 10000

G2 Series racks that may be necessary to achieve safety, regulatory compliance, or functionality

requirements.

Levels of rack security

Either of the following conditions may be necessary for compliance with certain safety certifications:

• Racks must be located in a restricted access area that is only accessible to trained personnel.

-Or-

• Racks must be configured with lockable hardware.

HP rack front doors, rear doors, and side panels support this locking requirement. Rear split doors are

standard on 10000 and 10000 G2 Series racks. (The 10000 Series rack Model S10614 is not

configured with split rear doors).

HP 10000 G2 Series rack front doors

All 10000 and 10000 G2 Series rack Models ship with front doors. The 42U and 36U front doors

(and necessary hardware) are available as option kits are backwards compatible with the 10000

Series racks of the same heights; this enables customers to have all racks standardized with the same

updated look, if desired.

NOTE

The front door option kit is not compatible with the 9000 Series racks.

HP 10000 G2 Series rack rear doors

All 10000 and 10000 G2 Series rack models ship with rear doors as part of the standard

configuration. The 10000 G2 rear door has been upgraded to provide a more ergonomically and

cosmetically pleasing handle.

HP Side Panel Option Kit

Side panels aid in providing proper front to rear airflow and a first level of security. 10000 Series

rack Models S10614 and 10622 ship with side panels installed. Side Panel Option kits are available

for all other rack models.

Stabilization requirements

Rack stability is of special concern when equipment is routinely installed, removed, or accessed within

the rack. Stability is addressed through the use of leveling feet, baying kits, fixed stabilizers, and/or

ballast.

Leveling feet

Leveling feet are adjustable stabilizers that provide leveling of the rack at the installation site and ship

installed to the racks. HP 10000 and 10000 G2 Series racks ship with leveling pads for stabilization;

these parts are found in the hardware kit – also shipped with each rack.

8

Page 11

HP 10000 Baying Kit

Baying kits are used to physically connect adjacent racks to create a row of two or more units. Racks

that are bayed together with a baying kit are more stable and reduce the potential tipping of the

rack. The same baying kit supports the 10000 and 10000 G2 Series Racks.

HP 10000 Stabilizer Kit

Fixed stabilizers are anti-tip feet (front and side) that provide stability and support when equipment is

installed, removed or accessed within the rack.

The following stabilizers are available:

• HP 10000 G2 600 mm Stabilizers

• HP 10000 G2 Heavy Duty 600-mm Stabilizer

• HP 10000 G2 800-mm Stabilizer

NOTE

The 600-mm and 800-mm stabilizer designs are different between the

10000 and 10000 G2 Series racks and have different part numbers.

If racks are secured together with baying kits, the side feet installed on each end of the row of racks

are considered optional.

Rack rows with four or more bayed racks do not need a stabilizer kit installed. Single racks or bays of

three racks, with no component exceeding 100 kg (220 lbs.), a standard 600-mm stabilizer is

required.

HP recommends that stabilizer option kits be used when one or more of the following situations occur:

• If a standard 600-mm (23.62-in.) or 800-mm (31.50-in.) front stabilizing foot is installed on a stand-

alone rack, the side feet, provided with the fixed stabilizer kit, should also be installed to stabilize

stand-alone racks from the side.

• A heavy duty 600-mm (23.62-in.) front stabilizer foot is required in either of the following

situations:

– A single rack-mountable component weighing 100 kg (220 lbs.) (or greater) is installed in a

stand-alone rack.

– A rack row of three or fewer racks are bayed together

– Side feet, which are included in the stabilizer kits, should also be installed to stabilize the rack

WARNING

To reduce the risk of personal injury or damage to the equipment, be sure

that:

• The leveling feet are extended to the floor.

• The full weight of the rack rests on the leveling feet.

• The stabilizing feet are attached to the rack if it is a single-rack

installation.

• The racks are coupled together in multiple-rack installations.

• Only one component is extended at a time or the rack may become

unstable.

9

Page 12

HP 10000 Ballast Option Kit

Ballast plates add weight to a rack and therefore improve side-to-side and front-to-back mechanical

stability for stand-alone racks or a row of three or fewer racks bayed together. Ballast plates fit in the

zero-U space at the interior sides of the rack and should be installed into the rack prior to installation

of any other equipment.

NOTE

The 10000 Ballast option kit is compatible with all 10000 and 10000 G2

Series racks.

Increasing rack weight

A rack with a light static load (less than 95 kg / 210 lbs.) should have ballast plates installed to

provide extra weight, thus reducing the possibility of the rack tipping over if a significant force where

to be applied to the rear or side of the rack. Racks with a heavier static load (greater than 95 kg /

210 lbs.), depending on the particular configuration involved, may not require ballasts.

Multiple Ballast kits may be necessary to provide sufficient weight. Each kit contains two 40-lb. (18kg) ballast plates. Ballast plates should be added to the rack until the total weight of components

installed into the rack is 210 lbs. (95 kg) (minimum).

For example, a lightly loaded rack configured with 50 lbs. (23 kg) of equipment requires two ballast

kits (four ballast plates). The total weight of four ballast plates is 160 lbs. (72 kg). Therefore, the total

installed weight of the rack components would be 210 lbs. (the minimum recommended rack installed

component weight):

Should any rack component weigh more than 100 lbs. (46 kg), there must be and additional 210 lbs.

(91 kg) of equipment weight in the rack (excluding the weight of the component) to provide balance

and maintain rack stability when the component is extended on its rails. In this instance, ballast plates

should be added until the total rack component weight is

300 lbs. (or greater).

Total weight of installed equipment + total weight of ballast plates = total rack component weight

WARNING

To reduce the risk of personal injury or damage to equipment, extend only

one component at a time. The rack may become unstable if more than one

component is extended.

Stabilization for seismic activity

Rack installations in geographical areas where there is a risk of seismic activity require special

considerations for stabilization of the rack.

IMPORTANT

The 10000 and 10000 G2 Series racks are not qualified as a Zone 4 or

OSHPOD solution.

An equipment integrator will need to determine the requirements for which, if any, ballast and

stabilizer kits are required. If the rack is bolted to the floor or to adjacent racks that have sufficient

combined weight, additional stabilization products may not be required.

10

Page 13

HP 10000 Series Plinth Option Kit

The Plinth Option kit provides a means for meeting building code guidelines to anchor a 10000

Series rack to the floor in geographical areas prone to seismic activity. This product provides a

solution to aid in avoiding damage or serious injury in the event of building or floor movement.

IMPORTANT

The Plinth option does not qualify the 10000 Series rack as a Zone 4

solution.

NOTE

The 10000 G2 Series racks do not support the Plinth option.

A technology brief entitled “Seismic anchoring of computing equipment using the HP Plinth kit” is

available at:

http://h20000.www2.hp.com/bc/docs/support/SupportManual/c00251418/c00251418.pdf.

HP 10000 G2 Series Tie Down Option Kit

The Rack Tie Down kit for 10000 G2 Series racks can be used to secure a rack to a data center

concrete floor to prevent racks from tipping in the event of building or floor movement.

IMPORTANT

The Rack Tie Down option does not qualify the 10000 G2 Series rack as a

Zone 4 solution.

NOTE

The Rack Tie Down kit supports the 10000 G2 Series racks only.

Space and cable management requirements

Extension kits

Cables and equipment can be damaged in use or in shipping if there is insufficient room in the rack.

Extensions can be used when additional room is required at the rear of the rack to provide adequate

room for equipment and associated cables. The extension kit provides approximately 6.0 inches (155

mm) of additional space at the rear of the rack.

NOTE

Extension kits are available as options. Due to pallet size, an Extension kit

cannot be installed at the factory and is not available for Configure to

Order racks. Use extended depth SKU for CTO orders.

Extension kits are compatible with the following 600-mm rack models:

• 36U Extension kit:

– HP 10000 Series Rack Model 10636

– HP 10000 G2 Series Rack Model 10636 G2

• 42U Extension kit:

– HP 10000 Series Rack Model 10642

– HP 10000 G2 Series Rack Model 10642 G2

11

Page 14

Cable management kits

Due to the dynamic nature of the rack environment, the cabling of systems has very few hard rules.

Cable management kits provide an easy way to organize and route cables within racks. Several kits

are available as options to assist with cabling requirements.

Additional information on cable management kits is available at

www.hp.com/products/rackoptions.

HP general guidelines for cable management are as follows:

• Use eCo-Enterprise Configurator to fully plan the rack and server setup prior to installation.

• For good visual reference, do not install cabling until all equipment has been installed in the rack.

• Avoid dressing cabling tightly over sharp edges of railing or panels.

• Avoid pinching of cables between components.

• Avoid tight bend radii. Cables should never be bent tight enough to cause a crease in the

sheathing. Fiber cables must not violate their minimum bend radius – no exceptions.

• When securing cables inside the rack, the bundle should be dressed in such a way as to avoid

interference with installed components or rack side panels or rails.

• When possible, use all cable management arms included in component kits.

• For components that must be movable while Powered On, ensure a full range of motion is possible

without cable interference or disconnect. Cables dressed on management arms must be secured

enough to prevent movement into interference or pinch areas, yet not so tight as to cause binding to

the arm.

• Separate power and signal cables as much as possible. For example, dress all signal cables on the

Left side of the rack and all power cables on the Right side of the rack.

• Ensure that cabling does not impede the airflow to the rack-mountable servers or increase the

internal rack temperature beyond the specified maximum rating.

A list of available extension kits can be found at the main rack options product page at

www.hp.com/products/rackoptions.

Thermal requirements

Equipment that is exposed to excessive heat may not operate correctly and may experience

abnormally high failure rates. The 10000 and 10000 G2 Series rack air flows from the front to the

rear of the rack. HP recommends that rack components only be installed on the front rails for many

reasons including proper airflow. Roof-mounted Fan kits (available for 10000 and 10000 G2 Series

racks) may help meet additional thermal requirements of rack-mounted equipment and are used to

keep the ambient temperature inside the rack within the specified operational limits of the equipment.

NOTE

800-mm racks include vertical filler panels for thermal management.

12

Page 15

Additional resources

For information on options available for the 10000 Series Rack, refer to the Rack Options Catalogue

at

http://h18004.www1.hp.com/products/servers/proliantstorage/racks/10000series/documentation.html.

For information on deployment and configuration of multiple servers in a single rack, refer to the white

paper on high-density deployment on the HP 10000 Series Rack support and documentation section

at

http://h18004.www1.hp.com/products/servers/proliantstorage/racks/10000series/documentation.html.

For information on the HP Modular Cooling System refer to the HP Modular Cooling System Site

Preparation Guide and white papers available at

http://h20000.www2.hp.com/bizsupport/TechSupport/Home.jsp?lang=en&cc=us&prodTypeId=329290&prod

SeriesId=1155256.

Rack assembly guidelines

Table 4 lists guidelines to follow when physically placing components in a 10000 or 10000 G2

Series Rack.

Table 4. Rack assembly guidelines

Component Guideline

Weight Sort all components by weight, placing the heaviest components at the bottom of

the rack.

Keyboard/video/mouse

(KVM) switch box

Keyboard/integrated

keyboard monitor

Monitor Ergonomic considerations should drive the placement of a monitor in the rack,

Balance When baying racks to create a row, be sure to distribute the weight load among

Mount the switchbox either behind the keyboard or within a sidewall cavity to

provide a zero-U space solution.

When using any size rack, install the keyboard/integrated keyboard monitor at

a level that is in the correct ergonomic position where your shoulders and neck

are relaxed.

whether it is a CRT or Flat-panel design. It is recommended to arrange the screen

or rack-mountable flat panel monitor, a minimum of 4U’s above the keyboard

tray. Most customers prefer placement of the video system high in the rack,

especially in a full rack, to allow easier access to serviceability of other system

components below it. If you are using a 22U rack, place the monitor on top of

the rack frame.

the racks and place the heaviest components at the bottom of each rack. For

example, if you have several UPS units and several servers, do not put all of the

UPS units into one rack—distribute the weight evenly in the bottom positions of

each rack.

Additional resources

For further information regarding component placement, refer to the Important Safety Instructions that

are shipped with the rack and the Safety and Comfort Guide - Precautions for Server and Network

Products located at

www.hp.com (search for the safety and comfort guide).

13

Page 16

Installation and maintenance precautions

To reduce the risk of electric shock or damage to the equipment when installing, maintaining, or

servicing Enterprise products, observe the general precautions listed in Table 5.

Table 5. Rack installation and maintenance precautions

Precaution Description

Follow manufacturer instructions Always refer to the individual equipment installation instructions for any special

considerations when installing equipment in a rack.

Be aware of power voltages and use

trained personnel

Secure all equipment Unless the equipment is installed in a restricted access area, rack equipment

Provide overhead clearance for fire

sprinkler devices

Some Enterprise products are capable of producing hazardous voltages and

hazardous energy levels. The installation of internal options and routine

maintenance and service of these products should be performed only by

individuals who are knowledgeable with the procedures, precautions, and

hazards associated with this type of equipment. Refer to the documentation

included with each product to determine whether it belongs in this category.

should be operated only with all enclosures in place and properly secured.

Always refer to the equipment installation guide and observe all applicable

warnings and precautions.

A minimum clearance is required between the top of the rack and any fire

protection sprinkler devices. Check your local building codes for details.

Moving racks with casters

Racks with casters should be moved with care. Sudden stops, excessive force, and uneven surfaces

may cause the product to overturn. Both the 10000 and 10000 G2 Series Racks have casters which

are fixed in the front and swivel in the rear due to stability and safety concerns. Therefore, it is both

recommended and easier to move the rack with the back as the leading edge. For long, straight runs,

roll the rack with the front, fixed casters leading. For maneuverability when moving the rack into a

tight spot, it is better lead with the rear, swiveling casters. When rolling the rack, make sure to push

firmly on the front door frame and not the door mesh.

WARNING

To reduce the risk of personal injury or damage to the equipment, do not

attempt to move large equipment racks alone. Obtain adequate assistance

to stabilize the rack during movement or hire professional equipment

riggers.

CAUTION

To reduce the risk of damage to the casters, make sure that the full weight

of the rack rests on the leveling feet, and not on the casters. The casters are

designed only as an aid in moving the rack into position. They are not

designed to support the weight of the rack, and the casters may become

damaged if relied on to support the rack.

Connecting and disconnecting power to hot-pluggable power supplies

Observe the following guidelines when connecting and disconnecting power to the power supplies:

• Unplug the power cord before removing the power supply from the server.

• Install the power supply before connecting the power cord to the power supply.

• Do not overload the AC supply branch circuit that provides power to the rack. The total rack load

should not exceed 80 percent of the branch circuit rating.

14

Page 17

Rack-mountable products

Because computer components are stacked vertically in a rack, adhere to the following precautions to

ensure rack stability:

• Use the configuration you prepared with the HP eCo-Enterprise Configurator as a guideline for

installing the components.

• Load heavier components first and load the rack from the bottom up.

• When coupling or baying racks, be sure to balance the weight load between or among the racks,

placing the heaviest components at the bottom. For example, if you have several UPS units and

several servers, do not put all of the UPS units into one rack—distribute them evenly in the bottom

positions among the racks.

• Allow a minimum clearance of 30 in. (762 mm) at the back of the rack.

• Allow a minimum of 48 in. (1219.2 mm) clearance beyond the front of the rack to permit server

installation and removal. This applies to both individual rack installations as well as when aligning

rack rows so that the front doors are facing each other. See Figure 3.

• Use caution when pressing the component rail release latches and sliding a component into the

rack. The slide rails can pinch your fingers and cables.

• Components must be qualified prior to consideration for shipment within racks; this means the unit

has been successfully tested under common carrier simulations. HP recommends the use of padded

van carriers to avoid potential damaging handling scenarios. The qualification process is an ongoing effort to evaluate models as they are introduced. Prior to a successful qualification, a

component should be shipped in its individual shipping container; shipment of an unqualified

system in a rack, or any system without the proper shock pallet, will void the warranty. The listing of

qualified components is maintained on an internal HP database. If the reader is external to HP,

please contact your HP representative to arrange a review of the components intended for use.

Figure 3. Rack clearance (Minimum recommended front rack space)

15

Page 18

WARNING

To reduce the risk of personal injury or damage to the equipment, be sure that the rack is stabilized as follows:

• The leveling feet are extended to the floor.

• The full weight of the rack rests on the leveling feet.

• The stabilizing feet are attached to the rack if it is a single-rack installation.

• The racks are coupled together in multiple-rack installations.

• Extend only one component at a time or the rack may become unstable.

Data Center planning and considerations

Environmental considerations

The data center must meet certain environmental conditions for the rack implementation.

Thermal considerations

The racks should be configured and arranged in a data center to ensure proper air flow.

Configuring a rack for proper air flow

The increasing power of new high-performance processor technology requires increased cooling

efficiency for rack-mounted servers. The 10000 Series Racks provide enhanced air flow for maximum

cooling, allowing these racks to be loaded with a maximum of 8–10 KW. For extreme cases, refer to

www.hp.com/go/mcs.

CAUTION

It is necessary to ensure that the components installed in the rack do not

exceed the Manufacturer's Maximum Recommended Ambient Operating

Temperature.

Rack openings and perforations

Slots, openings and perforations in the rack (especially in doors) provide ventilation, reliable

operation, and prevent overheating and, therefore, should never be blocked or covered. To provide

proper front-to-back air flow, any open "U" space in the front of a rack must be covered with a HP

10000 Series Universal Filler Panel.

CAUTION

Failure to cover open U spaces with blanking panels may result in improper

cooling that can lead to thermal damage.

Back-pressure air flow condition

Certain rack configurations, such as racks with extreme cable or server density, may cause a backpressure situation to occur. When a back-pressure situation occurs, heated exhaust air is forced

around the side of the server components and back into the server inlet. Contact an Authorized

Service Provider if you suspect a back-pressure situation is occurring in a rack.

16

Page 19

Configuring racks without air flow perforations

Older rack series, such as the Rack 7000 Series Racks and third-party racks with glass doors must

have the door removed to support the latest high-performance equipment. Components should not be

installed in a built-up enclosure unless the following conditions have been met:

• The enclosure is specifically designed to accommodate the component.

• There is proper ventilation for the component.

• All manufacturer instructions have been followed.

Rack placement and arrangement for proper air flow

Racks must be placed and arranged properly in the data center to provide sufficient air flow and

clearance for access to the rack.

In the front of the rack, a clearance of 48 in. (1219 mm) is required; this applies to individual rack

installations as well as when aligning rack rows so that the front doors are facing each other.

In the rear of the rack, a clearance of 30 in. (762 mm) is required to provide space for servicing the

rack.

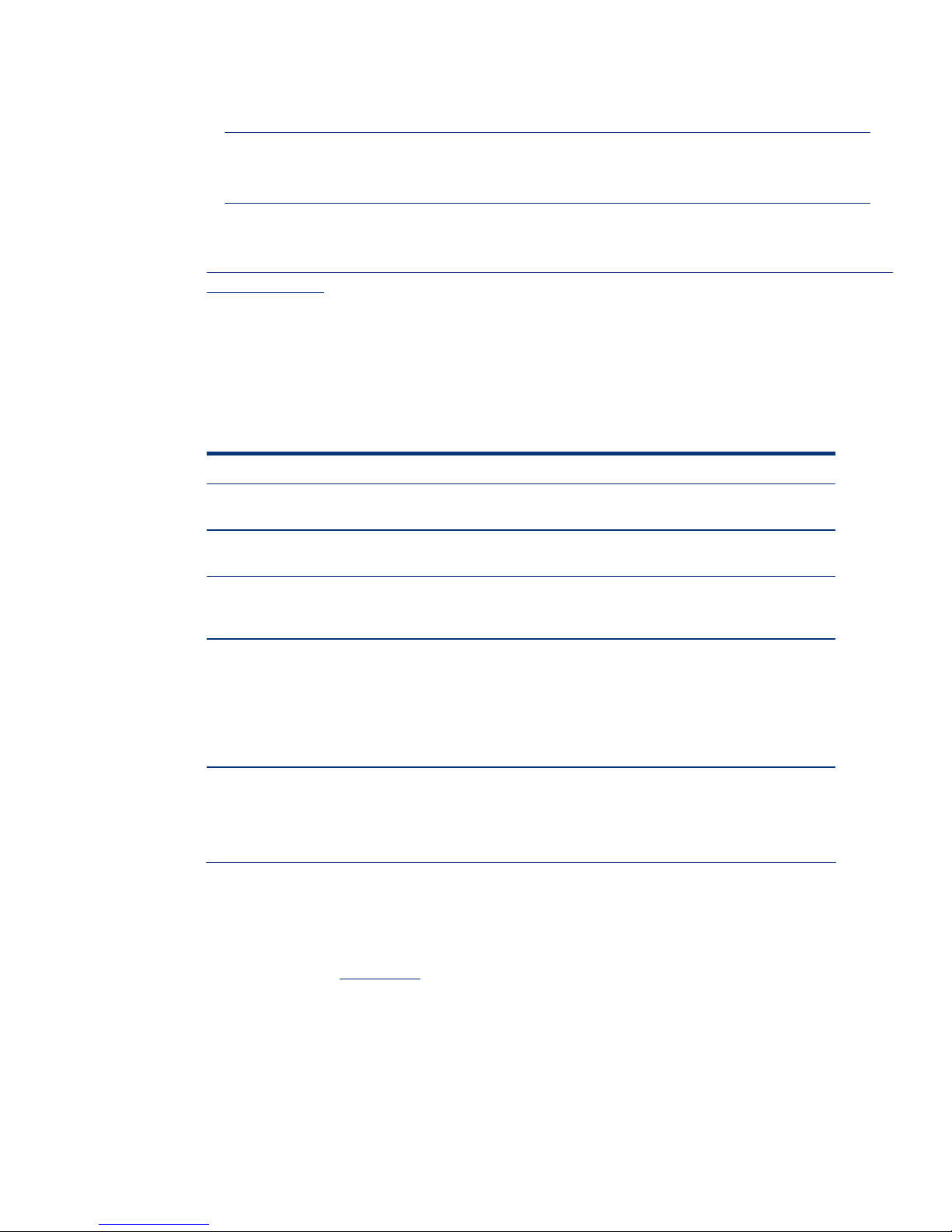

If a data center has multiple rows of racks, the rows of racks can be arranged to take advantage of

the front-to-back airflow, by arranging racks front-to-front and back-to-back. Additionally, conditioned

air registers may be oriented along the front aisles and the return air registers in the back aisles. Such

an arrangement will utilize the aisle space as air plenums and will increase the efficiency of the air

conditioning. See Figure 4.

Figure 4. Airflow diagram

17

Page 20

Data center temperature and humidity

The data center temperature and humidity should meet the guidelines listed in Table 6.

Table 6. Temperature and humidity specifications

Type Operating Non-operating

Temperature 50 to 90° F (10 to 35° C) at sea level -22 to 140° F (-30 to 60° C)

Humidity 10 to 90% non-condensing 5 to 90% non-condensing

NOTE

Altitude derating of 1o C for every 300 meters above sea level to a

maximum of 3,000 meters (1.8

of 10,000 feet). No direct sustained sunlight.

o

F per every 1,000 feet up to a maximum

Third-party thermal considerations

CAUTION

If a third-party rack is used, observe the following additional requirements

to ensure adequate airflow and to prevent damage to the equipment:

• Front and rear doors: If the 42U server rack includes closing front

and rear doors, allow 830 square inches (5,350 sq cm) of hole

evenly distributed from top to bottom to permit adequate airflow

(equivalent to the required 64 percent open area for ventilation). Be

sure that the option equipment does not impede airflow to the rackmountable servers or increase the internal rack temperature beyond

the specified maximum rating.

• Side: The clearance between the installed rack component and the

side panels of the rack must be a minimum of 2.75 inches (7 cm).

CAUTION

Always use blanking or filler panels to fill all remaining empty front panel

U-spaces in the rack. This arrangement ensures proper airflow. Using a

rack without installing blanking panels to fill empty U-spaces results in

improper cooling that can lead to thermal damage.

CAUTION

Be sure that the option equipment installed does not exceed the

Manufacturer’s Maximum Recommended Ambient Operating Temperature.

NOTE

For additional information, refer to the Setup and Installation Guide or the

Documentation CD provided with the server, or to the server documentation

located in the Support section at the following URL:

www.hp.com/servers/proliantdl380

.

For additional information on data center best practices, see the “Powering the data center efficiently”

available at:

http://h20000.www2.hp.com/bc/docs/support/SupportManual/c00099859/c00099859.pdf.

18

Page 21

Power considerations

Power is best managed within the rack by the use of a power distribution unit (PDU). Depending on

the configuration, it may be necessary or desirable to use multiple PDUs to connect all devices inside

the rack.

Each PDU should be connected to a dedicated (unshared) branch circuit that is suitably rated for the

continuous load of all the equipment connected to it. The total power load for a PDU should not

exceed 80 percent of the branch circuit rating.

If a PDU is not used, each piece of equipment within the rack should be connected to a dedicated

branch circuit.

Power redundancy

High-availability Information Technology equipment such as servers and storage devices can be

configured with backup or redundant power sources and power supplies in either of the following

configurations:

• 1+1 design: Two power supplies can be provided where either power supply is capable of

sustaining the associated equipment’s power demand.

• N+1 design: Typically three power supplies are provided, requiring at least two to handle the

equipment’s power demand. If one fails, the other two remain on line with enough capacity to meet

the power demand.

It is important that the wiring and branch circuitry to each installation be suitably rated for the power

demand of the connected equipment. Routing the power through separate branch circuits, breaker

panels and PDUs is also recommended to provide additional redundancy.

Non-redundant

For equipment provided with a single source of power, all components should be connected to the

same power distribution device (PDU or UPS). The power distribution device should be suitably rated

for the connected load. If the total load exceeds the rating of the power distribution device, obtain a

suitably rated device or add a second power distribution device and divide the load equally between

the devices.

High line voltage versus low line voltage

HP recommends that rack-optimized equipment is installed for operating at high line voltage (200240V AC).

All HP products that are optimized for rack mounting have wide-range power supply inputs designed

to operate at a voltage range of 100--240V.

Benefits that support high line voltage operation of an installation are as follows:

• Power supplies run more efficiently and waste less power when operating at 200--240V, thus

saving electrical power.

• Greater power capacity in a single rack. For the same size circuit, almost twice the power can be

delivered to a rack at high line versus low line. For example, an 115V 30A branch circuit can

deliver 3450VA to a rack, while a 230V 30A branch can deliver 6900 VA to a rack.

• Some products require 200-240V input power to operate at their full-rated capacity.

• Power supplies run cooler at higher input voltages and therefore will last longer and improve

overall availability. Also, because they run cooler, they produce less waste heat contributing to

lower cooling costs.

• Keeping input currents lower allows the use of smaller, more standardized power connections.

19

Page 22

Grounding and Earth leakage current

For proper operation and safety, rack components must be properly grounded in accordance with

any local and regional building codes. Furthermore, make sure that all power distribution devices

used in the installation, such as branch wiring and receptacles, are Listed or Certified grounding-type

devices.

Because of the high ground-leakage currents associated with multiple servers connected to the same

power source, a reliable grounded (earthed) connection is essential. HP recommends the use of a

PDU that is either permanently wired to the building’s branch circuit or is provided with a nondetachable cord that is wired to an industrial style plug. National Electrical Manufacturers Association

(NEMA) locking-style plugs or those complying with International Electro technical Commission (IEC)

60309 are considered suitable for this purpose. HP does not recommend using common power outlet

strips for this equipment.

Observe the following limits when connecting the product to AC power distribution devices:

• For UPS products and PDUs that have permanently attached AC power cords or are directly wired

to the building power, the total combined leakage current should not exceed 5 percent of the total

input current required for the connected products.

• For UPS products and PDUs that have detachable AC power cords, the total combined leakage

current should not exceed 3.5 mA per PDU or UPS.

Additional resources

A power calculator is available at

Catalog.xls.

http://h30099.www3.hp.com/configurator/calc/Power Calculator

Also available is a ProLiant Rack/Site Installation Utility for purposes of reviewing the server loading

to determine the number of power supplies for the power supplies to be redundant and approximate

the electrical and heating load per server for facilities planning. The ProLiant Rack/Site Installation

Utility is available at

http://h30099.www3.hp.com/configurator/calc/Site Preparation Utility.xls.

There is also a quick reference power cord matrix available at

ftp://ftp.compaq.com/pub/products/servers/proliantstorage/power-protection/powercordmatrix.pdf.

Equipment clearance and floor loading

A clearance of 48 inches in front of a configured rack and 30 inches to the rear of a configured rack

is recommended. All buildings and raised computer room floors are engineered to provide a specific

floor loading.

WARNING

When configuring a solution, make sure that the floor loading

specifications are followed. Failure to do so may result in physical injury or

damage to the equipment and the facility.

20

Page 23

Figures 5 and 6 illustrate the foot print of a standard10000 Series Rack.

Figure 5. 10000 and 10000 G2 Series

Rack foot print (600-mm wide)

Figure 6. 10000 Series Rack

foot print (800-mm wide)

Rack and accessory footprints

When accessories such as extensions and stabilizing kits are added to a particular rack, the footprint

of the rack will extend into rack rear row and infringe upon necessary clearances. See Figures 7 -- 9.

Figure 7. Foot print for a 600-mm rack

configuration with an extension kit installed

(598-mm wide x 1184.9-mm deep)

Figure 8. Footprint for a 600-mm rack

configuration with an extension and standard

stabilizer kit installed (1001.5-mm wide x

1390.0-mm deep)

Figures 9. Footprint for a 600-mm rack

configuration with an extension and heavy

duty stabilizer kit installed (1001.5-mm

wide x 1414.7-mm deep)

21

Page 24

Front door clearance

When racks are bayed together, the design of the front door limits the extent to which the rack door

on the right may open. If there is insufficient space to allow for the necessary work, open the door on

the Left side or remove the door from the rack receiving service. There are slight differences between

the opening allowances of the 10000 and 10000 G2 Series Racks due to the different geometries

and construction of the doors.

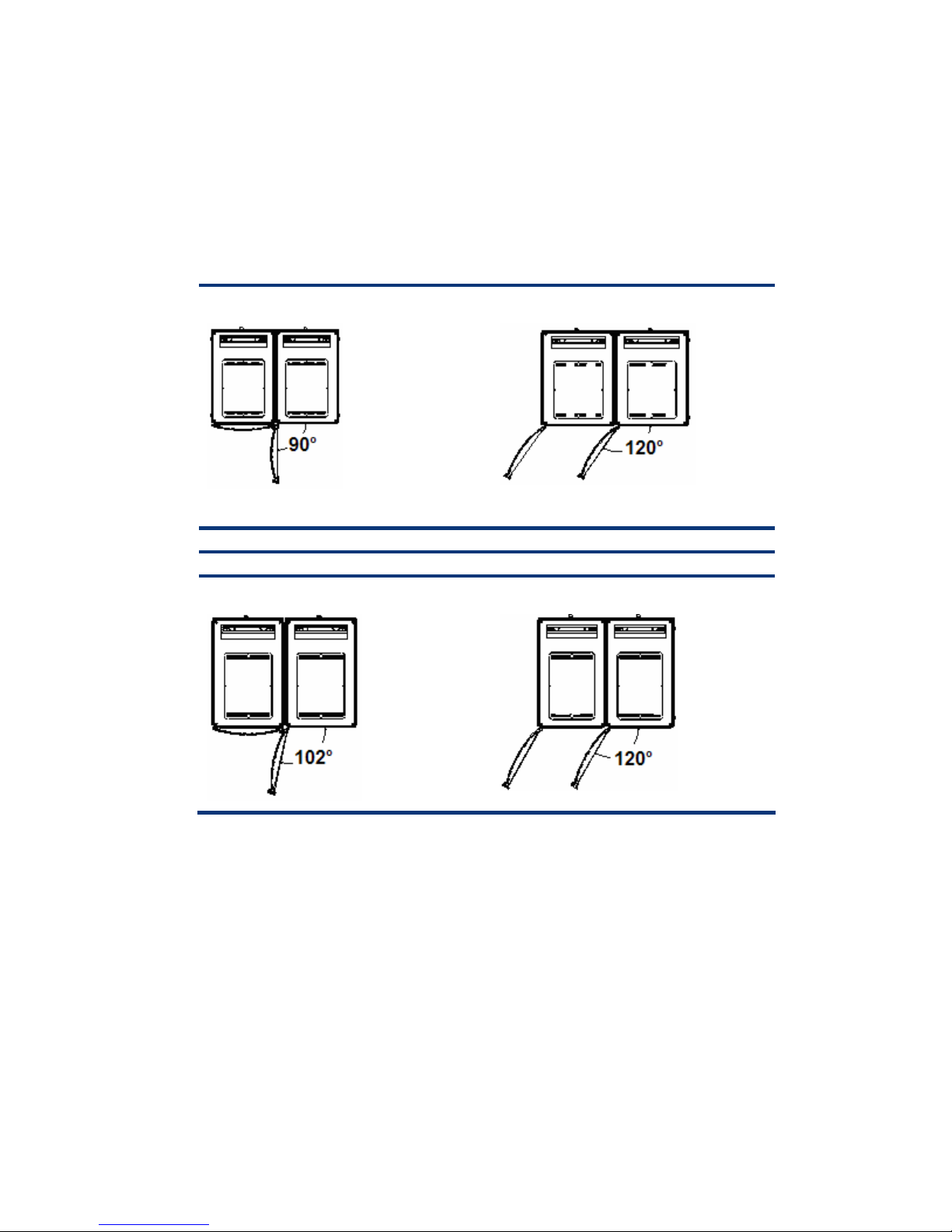

Figures 10 -- 13 illustrate the front door clearance for 10000 Series Racks.

Front door clearance for 10000 Series Racks configured with 600-mm baying brackets:

Figure 10. 90° access with one door closed Figure 11. 120° access with both doors

open

Front door clearance for 10000 Series Racks configured with 24-inch baying brackets:

Figure 12. 102° access with one door closed Figure 13. 120° access with both doors

open

22

Page 25

Figures 14 - 17 illustrate the front door clearance for 10000 G2 Series Racks.

Front door clearance for 10000 Series Racks configured with 600-mm baying brackets:

Figure 14. 95° access with one door closed Figure 15. 118° access with both doors

open

10000 G2 Series Racks configured with 24-inch baying brackets:

Figure 16. 108° access with one door closed Figure 17. 118° access with both doors

open

Qualified shipping

All 10000 Series 42U, 36U, and 22U 600-mm wide racks can be shipped in three standard

shipping configurations, depending on the shipping environment and configuration. Shipment of

empty racks is typically done on a standard wooden pallet, but a horizontal shipping crate is also

available where severe distribution environments are anticipated

Ensure all of the following conditions are met when shipping a configured rack:

• All configured racks must be shipped on a shock pallet.

• Designated hardware must be configured in the rack.

• Shipping recommendations of this document must be followed.

• The configured rack must be shipped in an upright position.

Contact the HP Rack Configuration Center for special shipment situations requirement additional

protection.

The above information applies to the both 10642 G2 and 10636 G2 Series Racks. Both the 10000

G2 42U and 36U Series Racks are available in all three shipping configurations: standard pallet,

Configure to Order (CTO) shock pallet, horizontal crate.

23

Page 26

Some specialized racks are limited on shipment options:

• The 10647 rack is available as a standard pallet and crate.

• The 10842 is available as a standard pallet and shock pallet.

• The S10614 is available only on the shock pallet.

Qualification of rack components for shipping

A component is a term used in this document to mean a physical device intended to be mounted in

the rack. Examples of components include, but are not limited to:

• Slide- or rail-mounted devices such as server or storage units

• Shelved devices such as keyboards and displays

• Side-mounted zero-U PDUs

• Fan kits that mount to the rack roof

Components must be qualified prior to consideration for shipment within racks; this means the

component has been successfully tested under common carrier simulations. HP recommends the use of

padded van carriers to avoid some potential damage handling scenarios. The qualification process is

an on-going effort to evaluate components as they are introduced.

Prior to a successful qualification, a component should be shipped in its individual shipping container;

shipment of an unqualified system in a rack or any system without the proper shock pallet will void the

warranty.

Rack shipping enclosures

Standard shipping pallet

10000 and 10000 G2 Series Racks ship on a standard wooden pallet with plastic shrink-wrap

around the rack. Component installation must occur on the customer site. This pallet and rack

configuration is designed for shipping an empty rack. It does not support any component-shipping

configuration.

NOTE

Wooden components of the pallets have been properly treated to comply

with the pest-free certifications required by foreign countries.

CTO shock pallet

10000 and 10000 G2 Series Racks ship on a CTO shock pallet. The shock pallet is designed to

allow the rack to be shipped while fully loaded and configured with components. The shock pallet

ensures that the rack is capable of handling the weight of the installed components during shipment

without damaging the rack or the equipment within.

With each rack on a shock pallet, a pallet ramp is included to support the dismount of the rack from

the pallet.

24

Page 27

NOTE

Each of the packing and unpacking procedures takes less than one-half

hour and requires at least two people to complete.

NOTE

The 10000 and 10000 G2 Series Racks use different shock pallets. If a

rear extension is installed on the 10000 G2 Series Rack, a specific shock

pallet is required to accommodate the dimensions of the rack and attached

rear extension. The 10000 Series Rack with extension is not supported in

the CTO shipping environment.

An HP shock pallet spares kit is recommended and can be obtained when moving a data center or

relocating pre-configured racks. Contact your local HP reseller for information on spares kits.

NOTE

The 10000 Series Rack Model 10647 is not available on a shock pallet

due to safety and stability concerns.

NOTE

All wood components of these pallets have been properly treated to comply

with the pest-free certifications required by foreign countries.

Horizontal crate

10000 and 10000 G2 Series Racks ship in an enclosed horizontal crate. The enclosed horizontal

crate provides greater protection for the empty rack during airfreight transport and other rugged

transportation modes.

NOTE

Horizontally crated racks do NOT support configured racks.

NOTE

The 10000 Series Rack Models S10614 and 10842 are not available for

shipment in a horizontally crate.

Vertical crate for rack options

If specially ordered, 10000 G2 Series 42U and 36U racks can be shipped in a vertical crate. The

rack must include factory installed option in the customer order to qualify for shipment in the vertical

crate. The rack ships on a CTO shock pallet and is enclosed in a wooden crate. The vertical crate

provides greater protection for the configured rack during airfreight transport and other rugged

transportation modes.

NOTE

All wood components of these pallets have been properly treated to comply

with the pest-free certifications required by foreign countries.

25

Page 28

Shipping specifications

Table 7 list the rack shipping specifications

Table 7. Rack shipping specifications

Rack model Shipping

dimensions

10622 52.25 x 48x 36 in. /

1,327.15 x 1,219.2 x

812.8 mm

10636 75.25 x 48 x 36 in. /

1,911 x 1,219.2 x 812.8

mm

10642 86.22 x 48 x 36 in. /

2,190 x 1,219.2 x 812.8

mm

10647 95.37 x 48 x 36 in. /

2,425 x 1,219.2 x 812.8

mm

10842 86.22 x 48 x 43.5 in. /

2,190 x 1,219.2 x

1,104.9 mm

Shipping

weight

225 lbs. /

102.13 kg

272 lbs. /

123 kg

284 lbs. /

129 kg

296 lbs. /

134 kg

335 lbs. /

151.95 kg

Dynamic

load

capacity

(gross)*

474.00 kg

/

1,045 lbs.

689.46 kg

/

1,520 lbs.

907.18 kg

/

2,000 lbs.

N/A *** 907.18 kg

453.59 kg

/

1,000 lbs.

Static

load

capacity

474.00 kg

/

1,045 lbs.

907.18 kg

/

2,000 lbs.

907.18 kg

/

2,000 lbs.

/

2,000 lbs.

907.18 kg

/

2,000 lbs.

Shipping options

Standard shipping

pallet

CTO shock pallet**

Horizontal crate

Standard shipping

pallet

CTO shock pallet**

Horizontal crate

Standard shipping

pallet

CTO shock pallet**

Horizontal crate

Standard shipping

pallet***

Horizontal crate

Standard shipping

pallet

CTO shock pallet**

S10614 44 x 35 x 30.5 in. /

1,117.6 x 889 x 774.7

mm

10636 G2 47.9 x 36 x 85 in. 378 lbs. 689.46 kg

10636 G2

with rear

extension

10642 G2 47.9 x 36 x 85 in. 378 lbs. 907.18 kg

10642 G2

with rear

extension

*Dynamic load amounts are based on the use of a CTO shock pallet

**Shipping dimensions apply to this shipping option

***Due to safety and stability factors, the 10000 Series Rack Model 10647 cannot ship with equipment installed.

54 x 36 x 85 in. 497 lbs. 689.46 kg

54 x 36 x 85 in. 497 lbs. 907.18 kg

200 lbs. /

90.91 kg

227.00 kg

/

500 lbs.

/

1,520 lbs.

/

1,520 lbs.

/

2,000 lbs.

/

2,000 lbs.

270 kg /

600 lbs.

907.18 kg

/

2,000 lbs.

907.18 kg

/

2,000 lbs.

907.18 kg

/

2,000 lbs.

907.18 kg

/

2,000 lbs.

CTO shock pallet**

Standard shipping

pallet

CTO shock pallet**

Horizontal crate

CTO shock pallet**

Standard shipping

pallet

CTO shock pallet**

Horizontal crate

CTO shock pallet**

26

Page 29

10000 and 10000 G2 Series Rack packing materials

Figure 18 shows the typical packaging material shipped with the empty rack upon arriving at the

customer configuration site.

Refer to the Bill of Materials for shipment of the various racks, sorted by rack height.

Figure 18. HP Rack on Shock Pallet

4

4

3

2

2

5

1

2

2

3

Packaging material shipped with the empty rack includes the following:

1. Ramps (ramps are placed vertically on the side of the rack during shipment, typically held in place

with the stretch wrap.)

2. Corner posts

3. Corrugated sheets

4. Cap

5. Antistatic bag

6. Stretch wrap (not shown)

7. Banding (not shown)

8. Corroclips (not shown)

9. IATA labels (not shown)

10. CTO shock pallet

Preparation for shipment

All racks require some preparation for shipment, regardless if qualified components are used. A

qualified component has been tested for common carrier shipment conditions, often with the aid of

specific hardware. This hardware, if required, is included in the accessories shipped with the product.

If a component is being shipped that has not been qualified, additional preparation may be required.

27

Page 30

Site preparation for receiving Integrated Racks

To determine if a configured rack is suitable for shipment, be sure to examine the receiving facility site

conditions. Circumstances requiring special handling of the rack, such as inadequate door height

clearance or having to move the rack in a horizontal orientation, may justify a decision to install

components after the moving process.

The specialized, air-ride, padded-van carriers usually have the ability to perform site surveys.

Among other elements, the site survey should address the following in general terms:

• What are the hours the facility is open for deliveries? Can delivery be done during the day during

normal business hours?

• Are appointments required?

• Does the receiving dock require union labor? Is there a site contact?

• Are there any security or building access issues? Is there a site contact?

• Does the facility have a dock? Is the delivery dock a standard raised dock? Can a 48-foot trailer

gain access? Are there any restrictions on the size, length, width or height, of the truck permitted?

• On what floor in building will the equipment be installed? This information is in consideration of

height and width clearances along the way: doors, light fixtures, cable trays, sprinkler heads,

elevators, etc.

• What are the door height clearances (width and height) for freight elevators, doorways, or other

obstacles?

• If equipment is not going on the first floor, is there an elevator? If yes, what is the weight capacity

of the elevator?

• Is the path from the loading dock to the computer room robust enough to support the weight of the

configured rack?

• Is there a delivery/unpacking/staging area? Does the customer allow cardboard boxes and/or

other packing material in the computer room? Does the customer have a detrash requirement, for

example is complete trash removal 1 or 2 days after install required?

• Is there a raised floor or are there any thresholds of concern? If there is a raised floor, how deep? Is

there a ramp? What sort of equipment maneuvering is required to gain access? Are there special

equipment needs, for example, will any stair walkers, lifters, cranes, ramps, steel plates or floor

covers be required to place the equipment in the computer room?

NOTE

HP does not advocate tipping loaded racks to navigate height restricted

doorways.

• Will the rack be removed from the pallet at a location other than the final installation location?

• Is movement across rough surfaces likely?

General considerations (all shipments)

Before beginning these procedures, please understand and follow these precautions.

28

Page 31

WARNING

To reduce the risk of personal injury or damage to the equipment, prior to

shipping, remove all non-rack-mounted equipment, including any

component that is not mechanically fastened to the rack structure.

The following are the minimum requirements for qualifying components for shipment in a HP 10000

and 10000 G2 Racks mounted on a CTO shock pallet:

• The shock pallet is a 1-way pallet and should not be reused. Reuse of a cushioned pallet may not

protect the rack and server components in transit. If a datacenter or loaded rack move is being

scheduled, it is strongly recommended that the shock pallet spares kit is purchased as well as all

safety considerations be addressed. For a complete list of HP rack options and accessories, refer to

the main rack page at

www.hp.com/products/rackoptions.

www.hp.com/products/racks or to the main rack options page at

• Use a torque wrench to tighten all front panel mounting hardware and rail/slide connections to 20

in-lb. (2.2594 N-m). Use provided mounting hardware to secure any spring-loaded slide assemblies

to the mounting rails.

• Use the shipping hardware or additional clamping or hold-down brackets provided with each

component. This hardware is typically found in the accessory box. The Server Immobilization Bolt

(SIB) is a large orange thumbscrew and is easily installed from the rear of the rack.

• Dress and secure all data and power cables. Cables and cable management arms should be tie-

wrapped to prevent movement of cables that may place a load on connector assemblies or that

may cause fraying due to friction. Wire-formed cable management clamps are provided with each

rack for this purpose. Some components provide sheet metal cable management extensions or

spring loaded cable retention reels that should be utilized in all cases. Firmly close front and rear

doors.

• Reuse any packaging materials that were initially provided with the rack.

• Check to ensure the rack mounting brackets are properly secured to the pallet. The bracket with

keyhole cutouts should be at an angle to the pallet deck and should not be loose. The front hold

downs for 10000 G2 Series Racks are right-angled and sit flush to the pallet and frame. Ensure that

the bolt securing the bracket to the pallet is torqued to 150 in-lb (16.9 N-m).

• All racks should be secured in the trailer/truck to prevent the rack from potentially falling on its side

during vehicle turns.

NOTE

Since most common carriers are not accustomed nor equipped to perform

this function, this detail is particularly important, even if the configuration is

common carrier qualified.

Special shipping considerations

Additional requirements for nonqualified components for shipment in a HP 10000 and 10000 G2

Series Rack that is mounted on a shock pallet are listed below:

• Replace any wing nuts with hex- or square-head nuts and appropriate locking hardware.

• Inspect the rack for unsupported mechanical structures. Look for any cantilevered chassis with little

or no rear support or any large chassis with rails mounted to the extreme top or bottom of the

chassis. Be especially attentive to any free movement of the component while mounted in the rack.

In some cases, it may be beneficial to use supplemental packaging materials to brace these

29

Page 32

components. The white foam from the shipping containers of the components works well in these

situations.

• Do not ship backup media in either tape drives or in tape library units.

• HP UPS systems have been qualified for rack CTO with the exception of the R12000 which has

unique shipping provisions due to its size. Each of these UPS systems may be shipped in a rack

provided the system is electrically disconnected from the battery during shipment; each unit comes

equipped with the appropriate isolators to comply with this requirement.

• Some shipping regulations require specific identification of the batteries enclosed with the package.

For example, the US Department of Transportation requires a pack enclosing a UPS battery be

marked to indicate a spill proof lead acid battery was enclosed. For CTO Rack shipments destined

for Europe, specific markings of all battery systems are required, including the real-time clock

batteries found in each server.

To comply with these requirements, HP provides a family of decals that may be applied to the

shipping carton.

WARNING